Chiral nano film and preparation method and application thereof

A nano-film and chiral technology, applied in the field of nano-materials, can solve the problems of long-range disorder of chiral nano-materials, limit practical applications, weak optical activity, etc., and achieve the effect of controllable structure, simple method and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

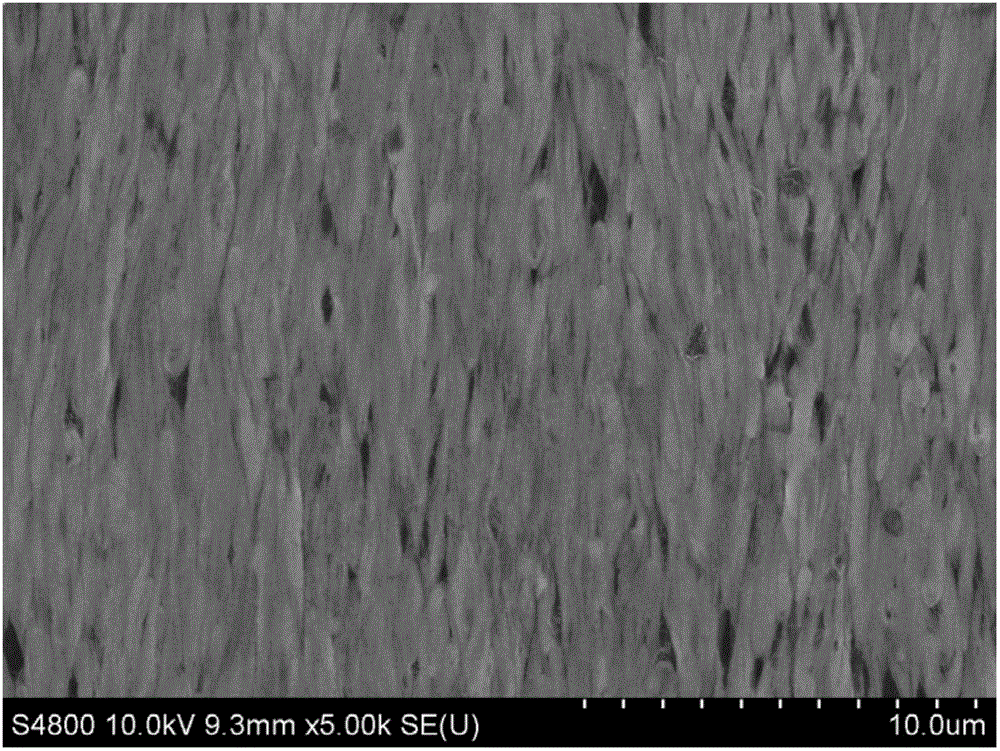

[0046] (1) Preparation of ultrafine gold nanowires:

[0047] Add 40 mg of chloroauric acid (HAuCl 4 4H 2 (0), then add 40mL hexane and 1.358mL oleylamine successively, after the chloroauric acid is completely dissolved, add 1.886mL triisopropylsilane (TIPS). After mixing evenly, place it in a water bath at 30°C for 24 hours. After the reaction was completed, ethanol was added at a volume ratio of 1 / 2 of ethanol / hexane, centrifuged at 4500 rpm for 15 minutes, and the precipitate was dispersed in 1 mL of chloroform to obtain a colloidal solution of gold nanowires.

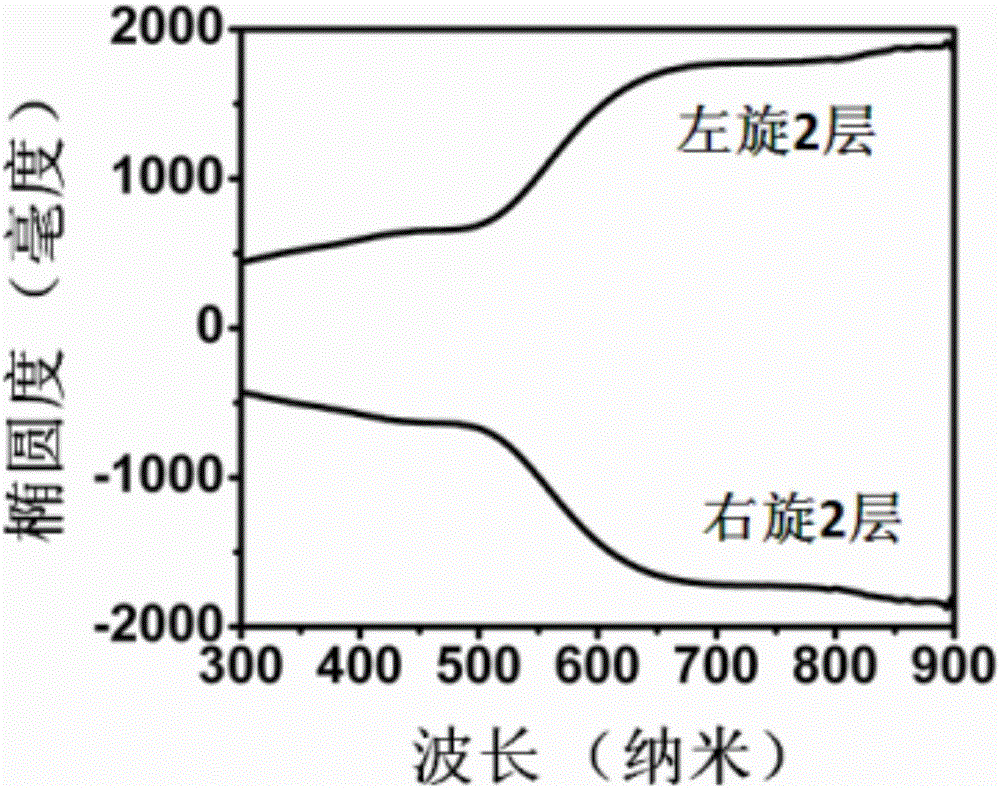

[0048] (2) Preparation of chiral thin film:

[0049] Add ethylene glycol into the Langmuir-Blodgett tank (LB tank) until the liquid level is about 2 mm above the edge of the tank, and spread the gold nanowire colloid solution obtained in step (1) onto the surface of ethylene glycol with a 50 μL microsyringe , The sample drop position is selected in the center of the LB tank. After dripping the sample, let it sta...

Embodiment 2

[0055] (1) Preparation of ultrafine tungsten oxide nanowires

[0056] Add 200 mg of WCl to 15 mL of benzyl alcohol with stirring 6 , after the solution turned blue, 1 mL of oleylamine was added. Stirring was continued for 30min, and then the solution was transferred to a 50mL polytetrafluoroethylene reactor. React at 180°C for 24h. Then cool to room temperature, centrifuge at 8000 rpm for 5 min to collect the precipitate, and then wash twice with acetone, chloroform and ethanol respectively. Finally, 16 mL of chloroform and 4 mL of oleylamine were added to the precipitate, and the solution was sonicated for 2 h until it became a transparent solution. Finally, it was washed three times with chloroform and ethanol, and finally dispersed in 20 mL of chloroform to obtain a colloidal solution of tungsten oxide nanowires.

[0057] (2) Preparation of chiral thin film:

[0058] Add ethylene glycol to the LB tank until the liquid level is about 2 mm above the edge of the tank, use...

Embodiment 3

[0061] (1) Preparation of ultrafine nickel molybdate nanowires

[0062] Mix 6mL ethanol, 2mL oleylamine and 1mL oleic acid in a 20mL polytetrafluoroethylene reactor under stirring, then add 0.3mL 1M NiCl 2 aqueous solution and 0.3 mL of 1M NaMoO 4 Aqueous solution, continued to stir for 10min, and then reacted at 140°C for 4h. After cooling to room temperature, the product was dispersed in 10 mL of hexane, then added to 20 mL of ethanol for precipitation, and centrifuged at 8000 rpm for 5 min. Finally, the precipitate was dispersed in 20mL of hexane to obtain a nickel acid nanowire colloidal solution;

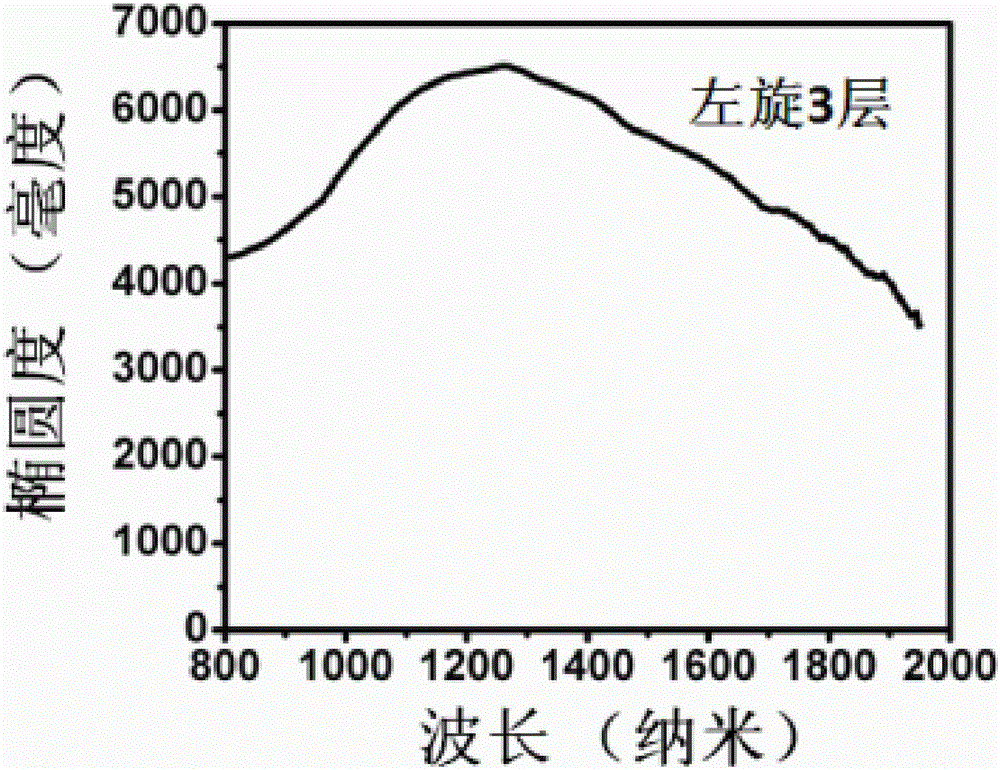

[0063] (2) Preparation of nickel molybdate nanowire chiral thin film

[0064] Add ethylene glycol into the LB tank until the liquid level is about 2 mm above the edge of the tank, take 100 μL of the nickel molybdate nanowire colloid solution obtained in step (1) twice with a 50 μL micro-syringe and spread it on the surface of ethylene glycol, drop The sample position is sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com