A mass production method of long-range ordered mesoporous carbon materials with high nitrogen content and ultra-high specific surface area

A technology with ultra-high specific surface area and high nitrogen content, applied in the field of nanomaterials, it can solve the problems of low doping content and no way to flexibly change nitrogen doping, etc., and achieve the effects of large specific surface area, stable structure and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a method for mass production of long-range ordered mesoporous carbon materials with high nitrogen content and ultra-high specific surface area, which includes the following steps:

[0037] (a) Heat and stir phenolic resin, tetraethyl orthosilicate, F127 and 0.1 mol / L hydrochloric acid in ethanol solution for 3-5 hours at room temperature, the mass ratio is 1:2:1, and the temperature is 40°C;

[0038] (b) Casting the stirred solution onto roll-to-roll blades, using a PET substrate for roll-to-roll coating at a coating speed of 1 mm / min;

[0039] (c) Pass the film obtained in step (b) through a 40-60°C gradient oven (gradient temperature rise in the range of 40-60°C) using roll-to-roll equipment, and let it stand for 6-12 hours with a temperature gradient of 0.1°C / cm;

[0040](d) Pass the film obtained in step (c) through a 90-100°C gradient oven (gradient temperature rise in the range of 90-100°C) using roll-to-roll equipment, and let it stand ...

Embodiment 2

[0047] This embodiment provides a mass production method for long-range ordered mesoporous carbon materials with high nitrogen content and ultra-high specific surface area, which is basically the same as that in Example 1, except that in step (f), melamine and pre-sintering The mass ratio of the product is 0.5:1.

Embodiment 3

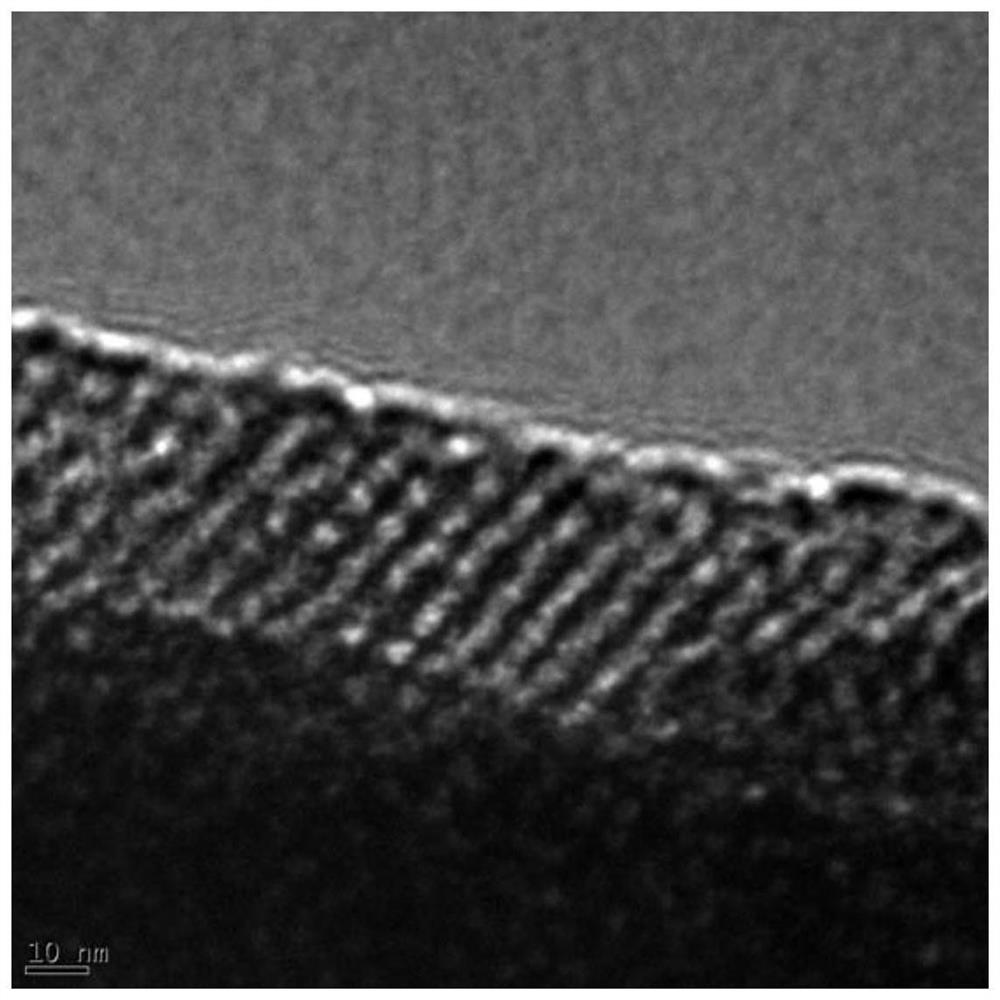

[0049] This embodiment provides a mass production method for long-range ordered mesoporous carbon materials with high nitrogen content and ultra-high specific surface area, which is basically the same as that in Example 1, except that in step (f), melamine and pre-sintering The mass ratio of the product is 1:1; the transmission electron microscope shows figure 1 It can be seen from the figure that the material contains an ordered cylindrical pore structure, and the structure is regularly arranged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com