Patents

Literature

198results about How to "Facilitate large-scale industrial application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LiNixCoyMn2O2 modified material and preparation method and application thereof

ActiveCN104134790AImprove overcharge resistanceAvoid structural collapseCell electrodesSecondary cellsLithium-ion batteryMetal

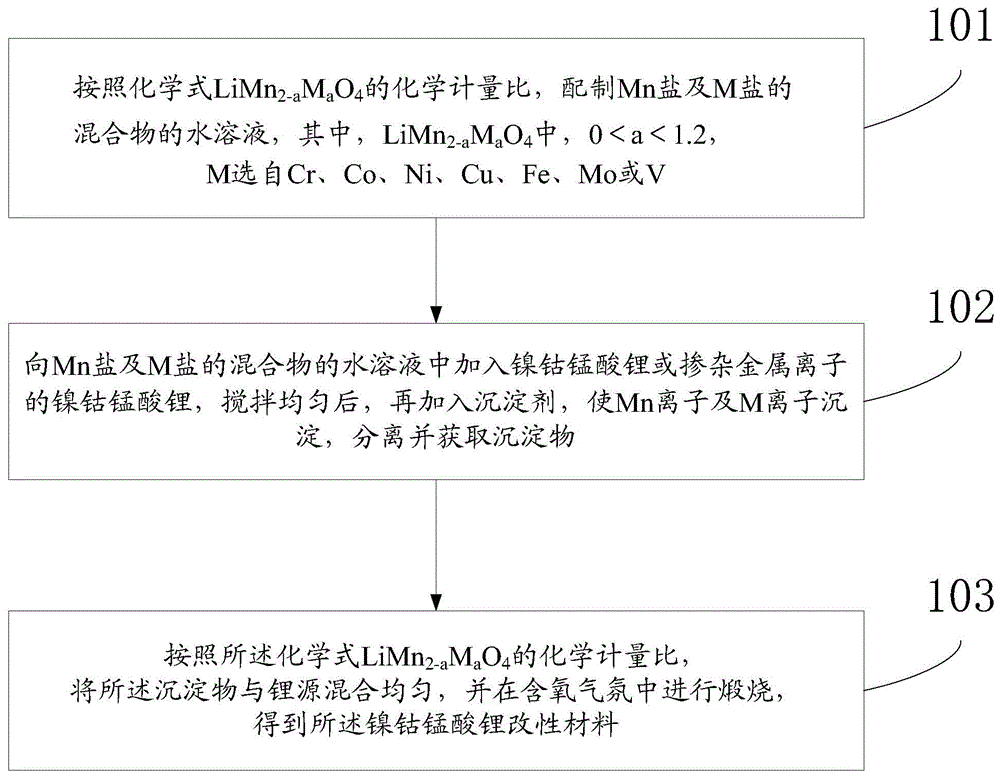

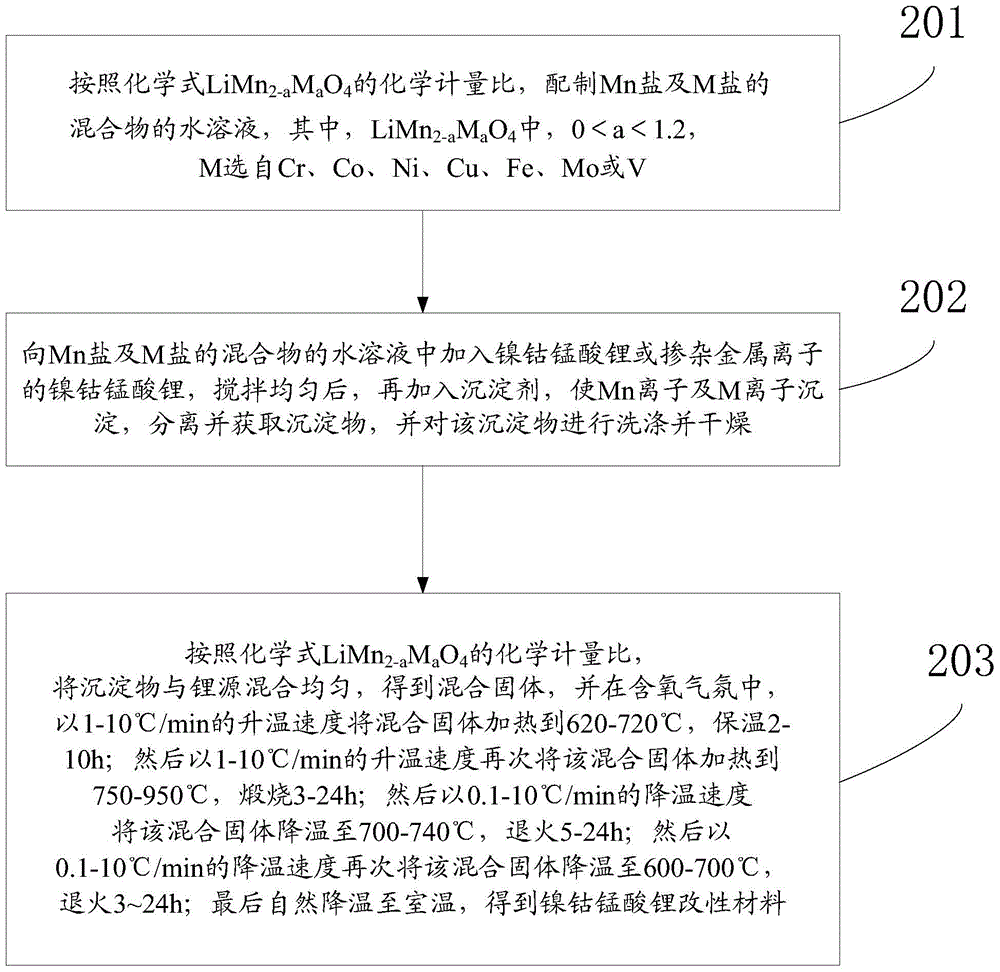

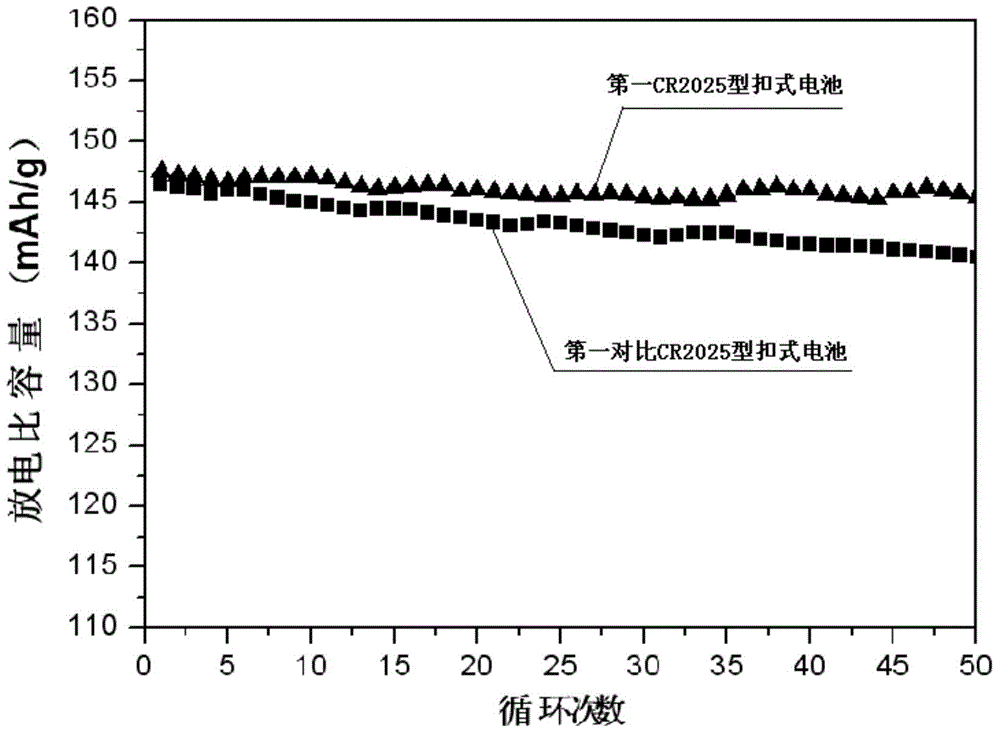

The invention discloses a LiNixCoyMn2O2 modified material and a preparation method and application thereof, belonging to the field of an anode material for a lithium ion battery. The LiNixCoyMn2O2 modified material comprises LiNixCoyMn2O2 or LiNixCoyMn2O2 doped with metal ions and LiMn<2-a>MaO4 coating the surface of the LiNixCoyMn2O2 or the LiNixCoyMn2O2 doped with the metal ions, wherein in the LiMn<2-a>MaO4, a is more than zero and less than 1.2, and M is selected from Cr, Co, Ni, Cu, Fe, Mo or V. By using the LiMn<2-a>MaO4 as a coating layer, the overcharging performance of the LiNixCoyMn2O2 during charging and discharging is enhanced, a structure of the LiNixCoyMn2O2 is prevented from being collapsed, the stability of the LiNixCoyMn2O2 is improved, moreover, the charging cut-off voltage of the LiNixCoyMn2O2 is increased, the energy density of a LiNixCoyMn2O2 battery is improved, and the LiNixCoyMn2O2 material has the advantages of favorable cycle performance, rate capability and safety performance.

Owner:CHERY AUTOMOBILE CO LTD

Streptococcus thermophilus and application thereof

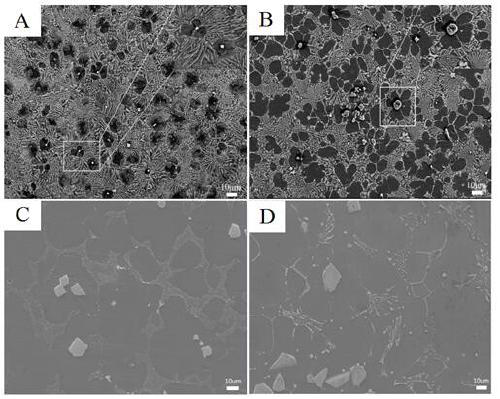

InactiveCN105886434AWell organizedImprove textural properties such as tissue stateMilk preparationBacteriaFlavorImmunologic Competence

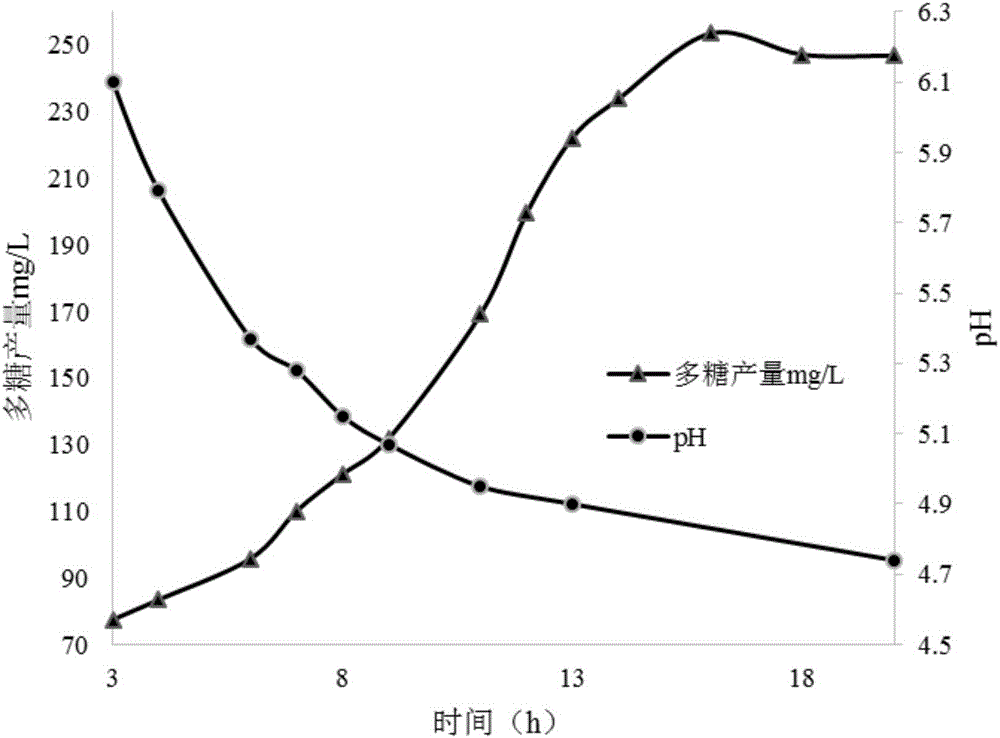

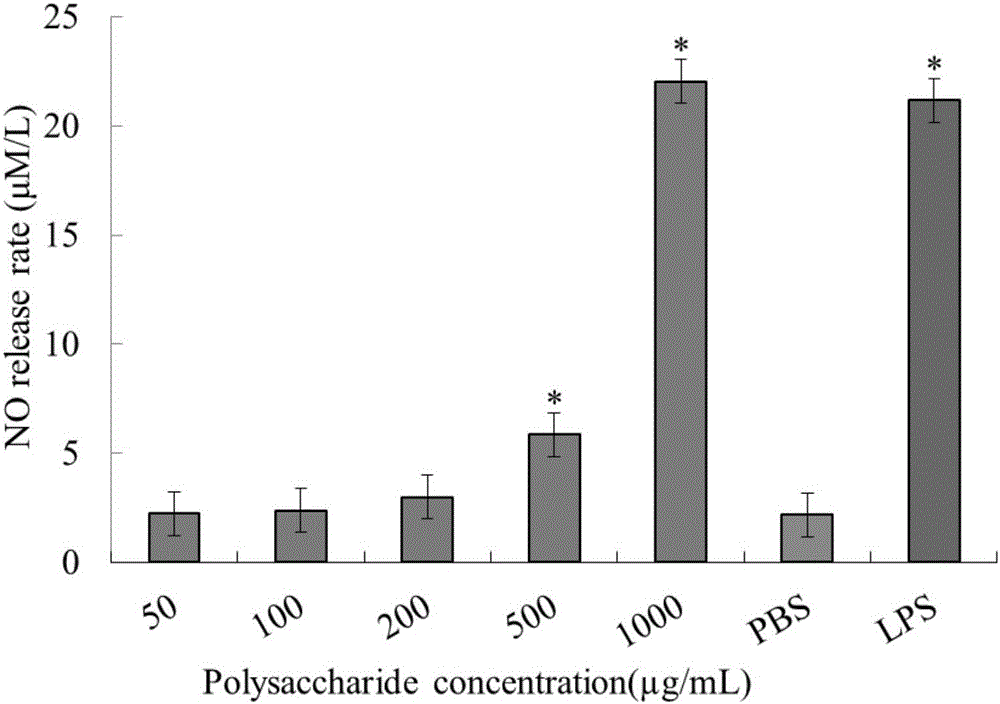

The invention provides a streptococcus thermophilus AR-333 strain and application thereof. The streptococcus thermophilus AR-333 strain is obtained through being separated from naturally fermented milk, and the collection number of the strain is CGMCC 10262. The streptococcus thermophilus AR-333 is fermented for 16h under the condition of 40 DEG C by skimmed milk; the yield of extracellular mucopolysaccharide reaches 256.97 mg / L; meanwhile, the streptococcus thermophilus is used as a yoghourt fermenting agent; the viscosity of yoghourt can be obviously improved; the tissue state of the yoghourt can be improved; good flavor is realized; the generated extracellular mucopolysaccharide has an immunologic competence regulating function; macrophages RAW264.7 can be simulated to release NO.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

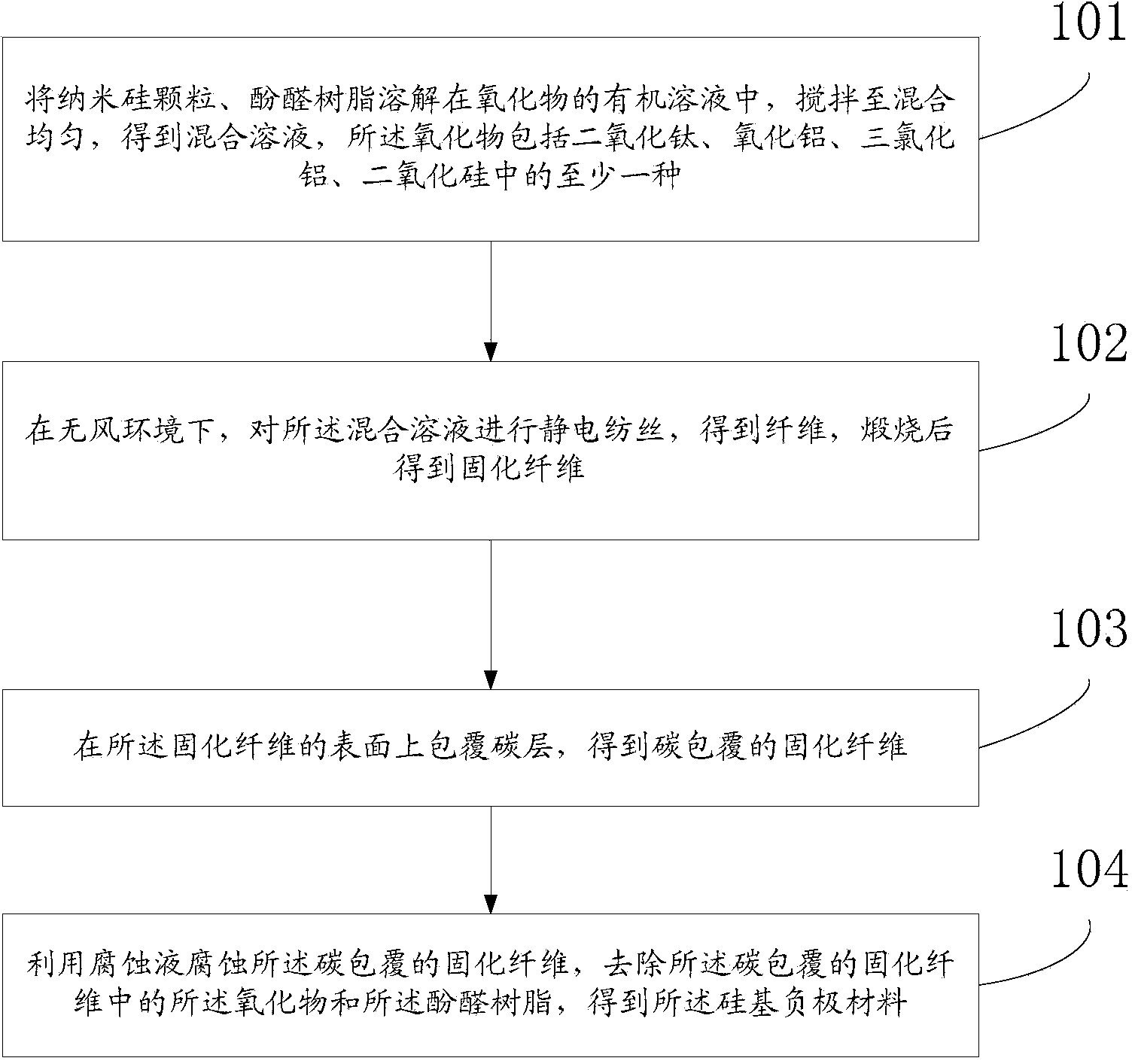

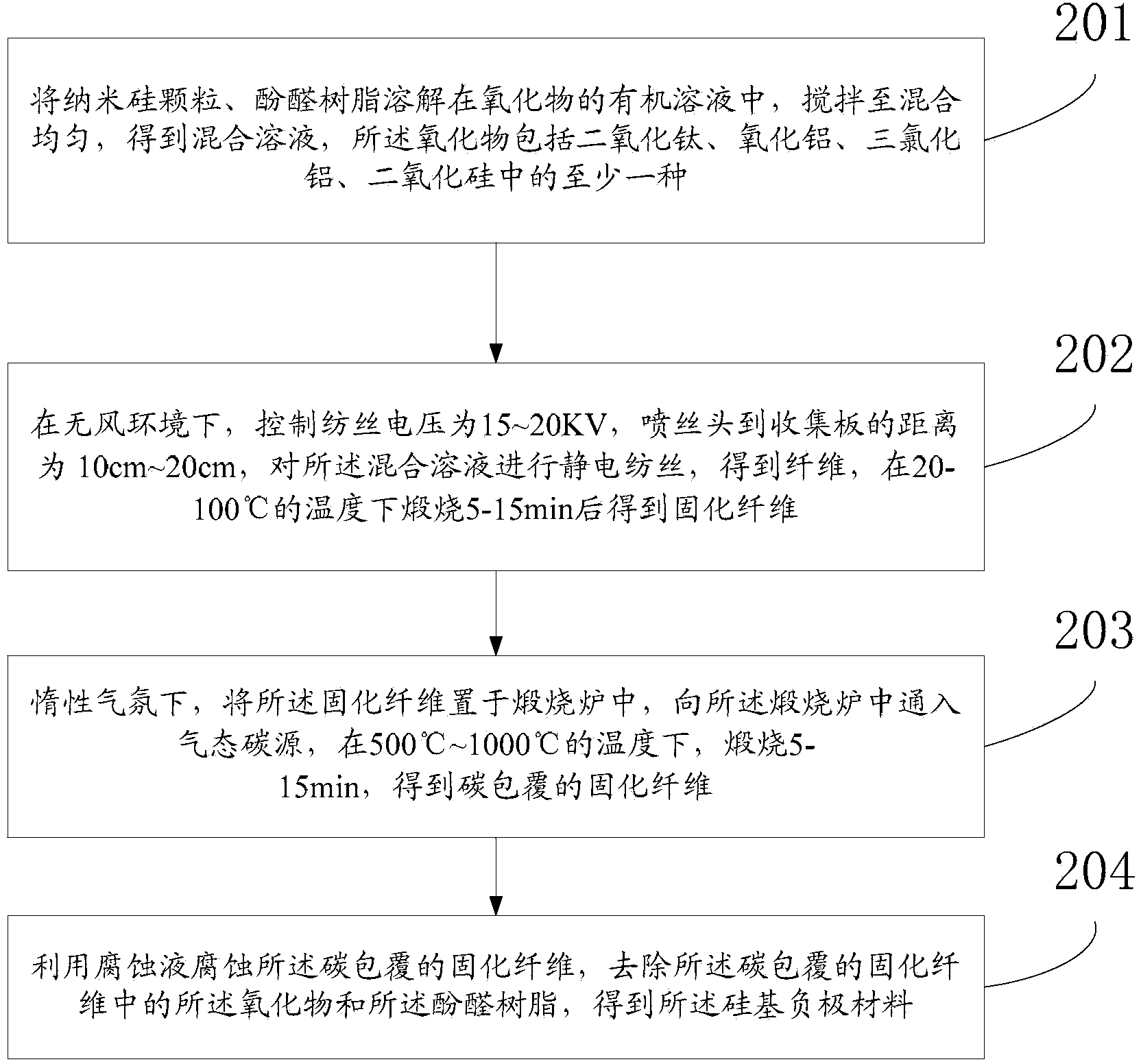

Silicon-based negative electrode material and method thereof

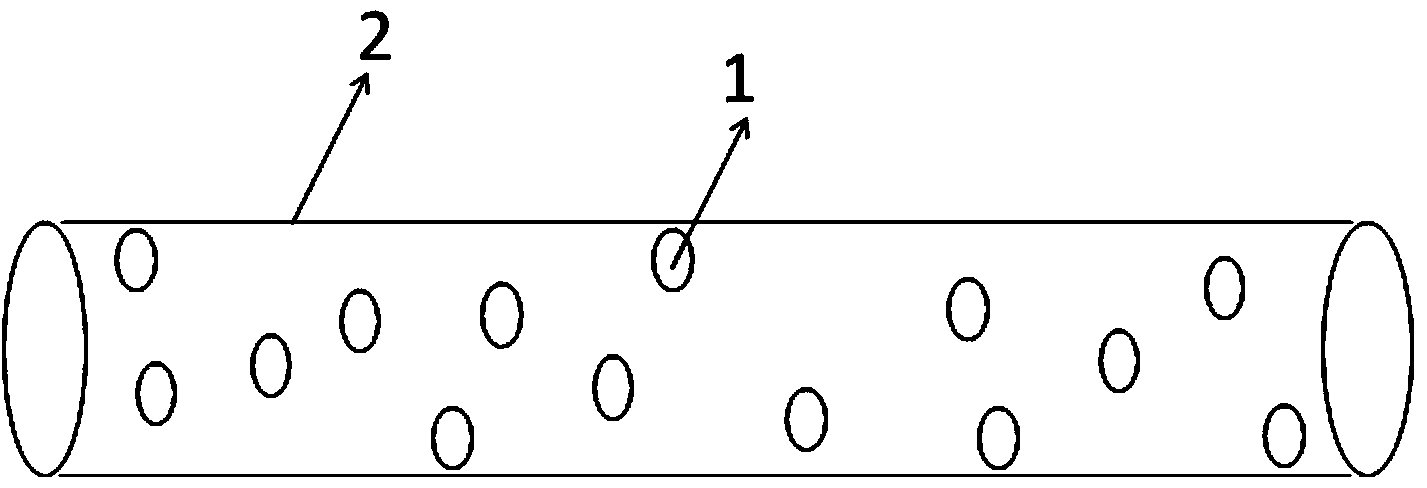

ActiveCN104112847AAvoid thickeningIncrease capacity and cycle performanceCell electrodesSecondary cellsSilicon particleElectrical battery

The invention discloses a silicon-based negative electrode material and a preparation method thereof, belonging to the field of negative electrode materials of lithium ion batteries. The silicon-based negative electrode material comprises a carbon tube and nanometer silicon particles in the carbon tube. Since gaps exist in the carbon tube, the silicon particles can be fixed in the limited space in the carbon tube, which enables volume expansion or shrinkage of the silicon particles to be in the limited space; thus, influence on electron transport performance between an active material and a current collector is avoided, thickening of an SEI membrane is prevented, and the capacity and cycle performance of a lithium battery are improved.

Owner:CHERY AUTOMOBILE CO LTD

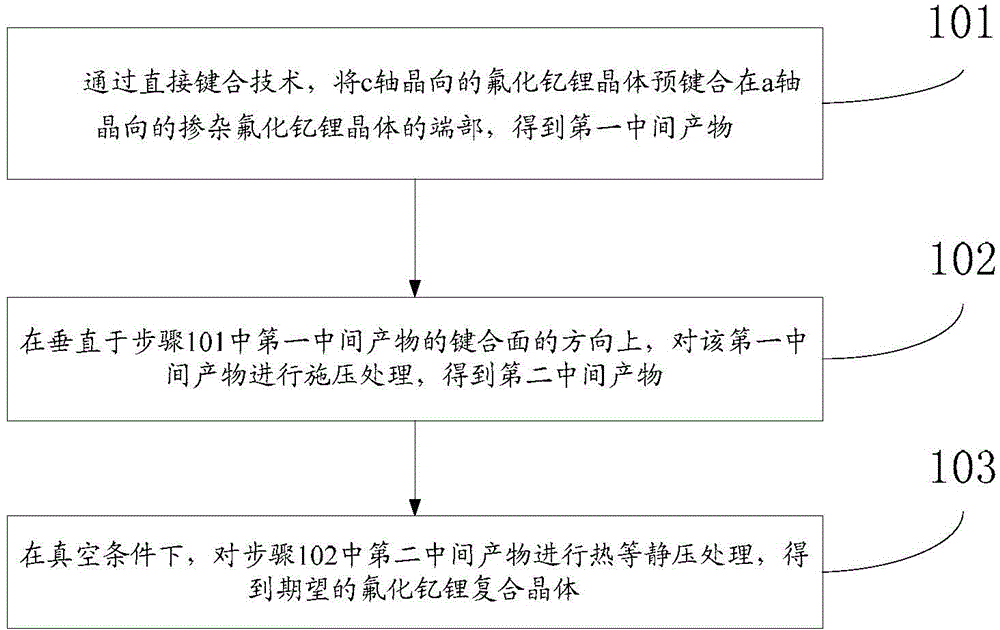

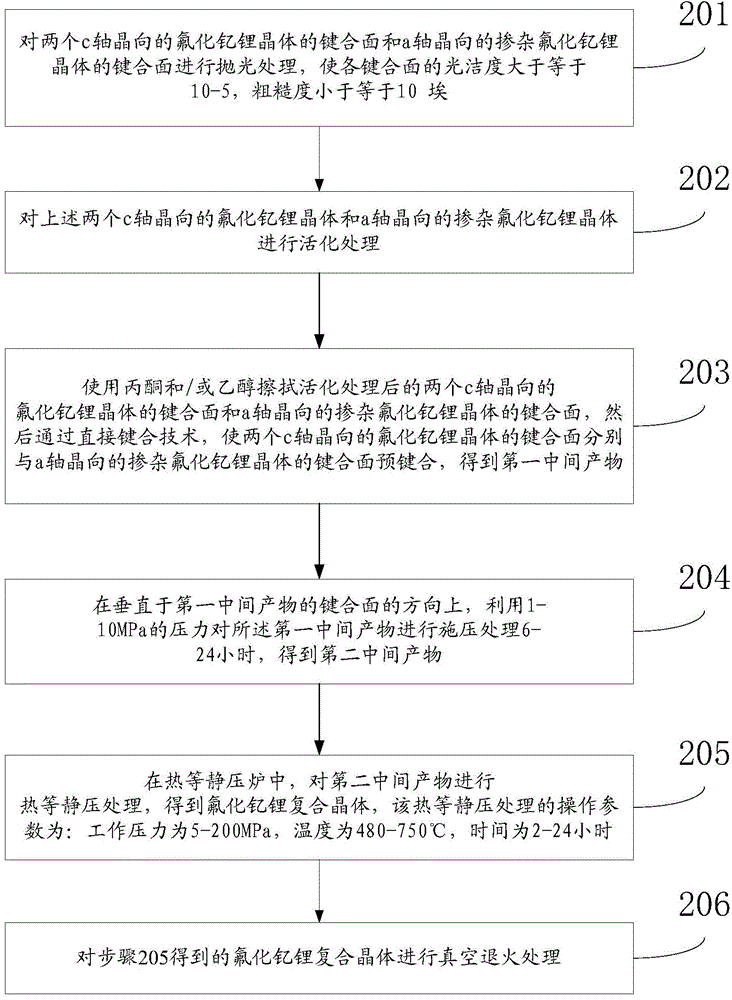

Yttrium lithium fluoride composite crystal and preparation method thereof

ActiveCN104099665AReduce lossImprove output efficiencyPolycrystalline material growthAfter-treatment detailsPhysical chemistryCrystal orientation

The invention discloses an yttrium lithium fluoride composite crystal and a preparation method thereof, and belongs to the technical field of laser crystal preparation. According to the method, an yttrium lithium fluoride crystal on a c-axis crystal orientation is pre-boned at the end part of a doped yttrium lithium fluoride crystal on an a-axis crystal orientation with a direct bonding technology, and a first intermediate product is obtained; the intermediate product is subjected to pressure treatment in the direction perpendicular to the bonding surface of the first intermediate product, and a second intermediate product is obtained; and finally, under the vacuum condition, the second intermediate product is subjected to hot isostatic pressure treatment, and the yttrium lithium fluoride composite crystal is obtained. The prepared yttrium lithium fluoride composite crystal doesn't have the axial matching problem and has a low heat effect, thermally induced depolarization loss of the crystal is reduced, and the output power and the beam quality of a laser are improved.

Owner:北京雷生强式科技有限责任公司 +1

Method for removing low-concentration heavy metal in waste water by sludge absorption

InactiveCN101514037ALow costWide variety of sourcesSludge treatmentOther chemical processesSorbentMunicipal sewage

A method for removing low-concentration heavy metal in waste water by sludge absorption relates to an isolation technology of heavy metal in waste water. Waste water and sludge of sewage factories are dried at the temperature of 45 to 60 DEG C, crushed to below 0.45 mm, mixed and reacted with low-concentration heavy metal waste water, and the pH is controlled between 3 to 6. After solid-liquid separation, the heavy metal in waste water is purified. The surface radicals of sludge has absorption ability for heavy metal and the remaining sludge of city sewage factories is selected as non-living biomass absorbent to treat waste water so that the method has the advantages of low cost, wide source, simple device, convenient operation and few secondary pollution. The method is particularly applicable to treatment of large-capacity and low-construction heavy metal in waste water, and also can be used for isolating heavy metal as pretreatment working procedure of various biological water treatment technologies. The waste is controlled by waste while high-efficiently isolating heavy metal, therefore, a new way is provided for city sludge resource recycle, ,and the method also has very great potential at the aspect of industrial extension and great economic, social and environmental benefits.

Owner:TONGJI UNIV

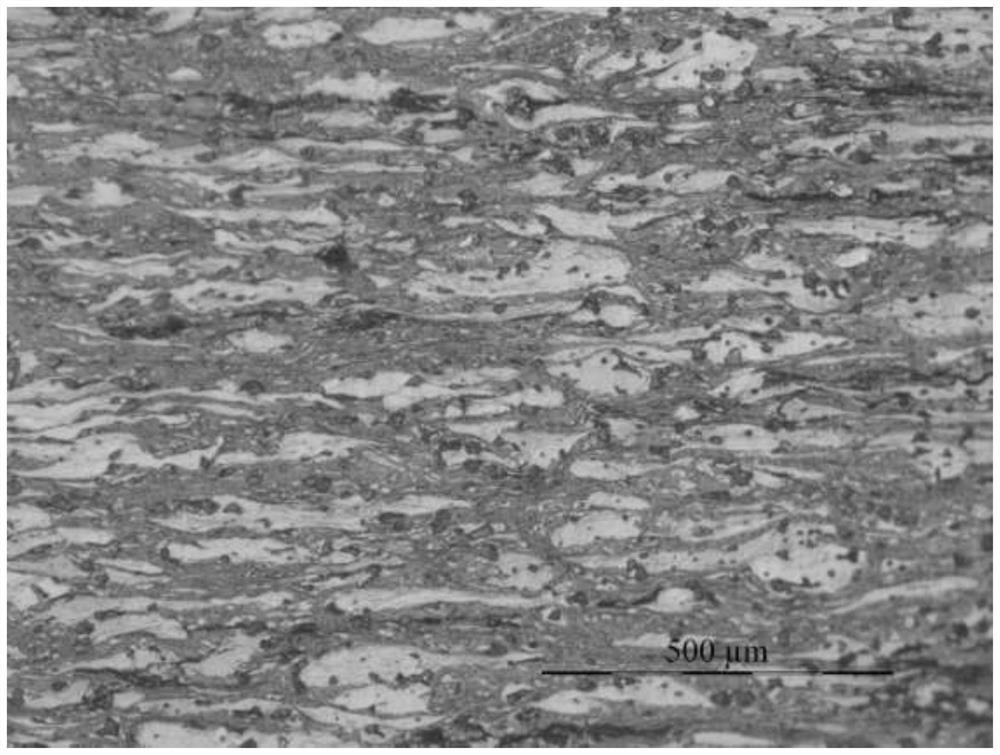

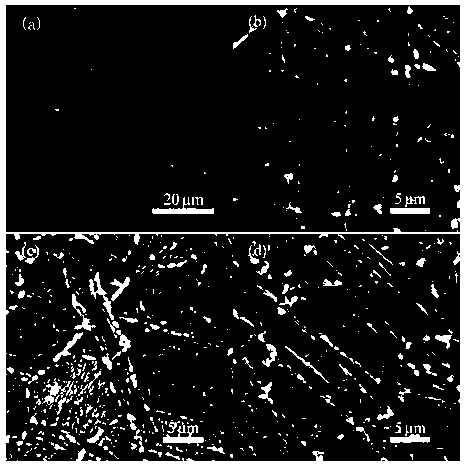

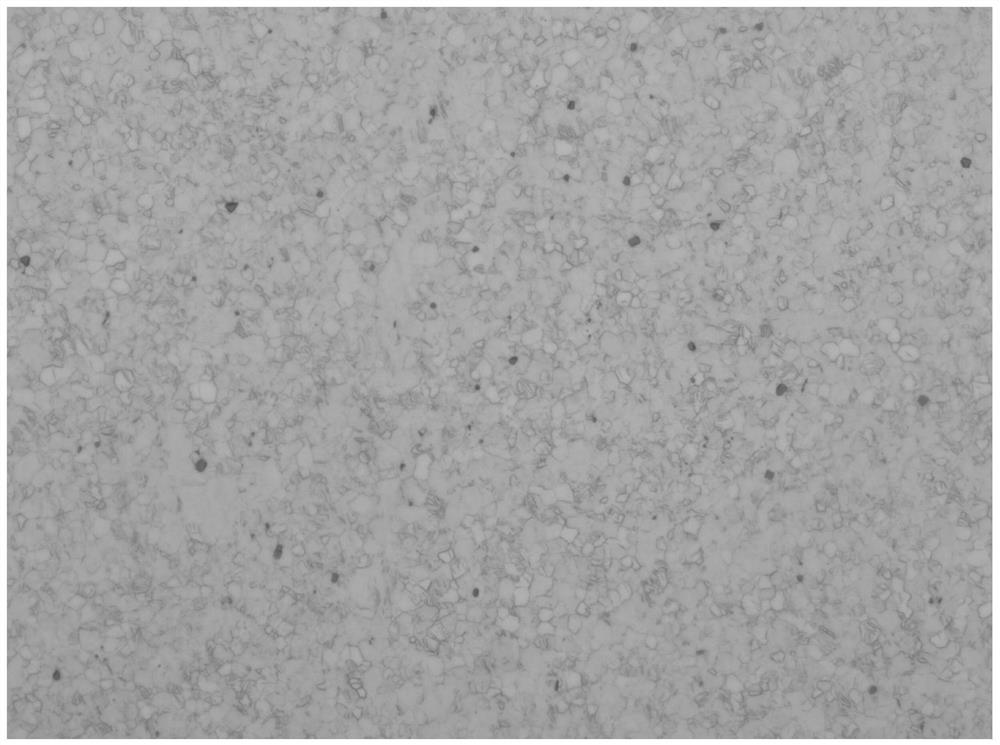

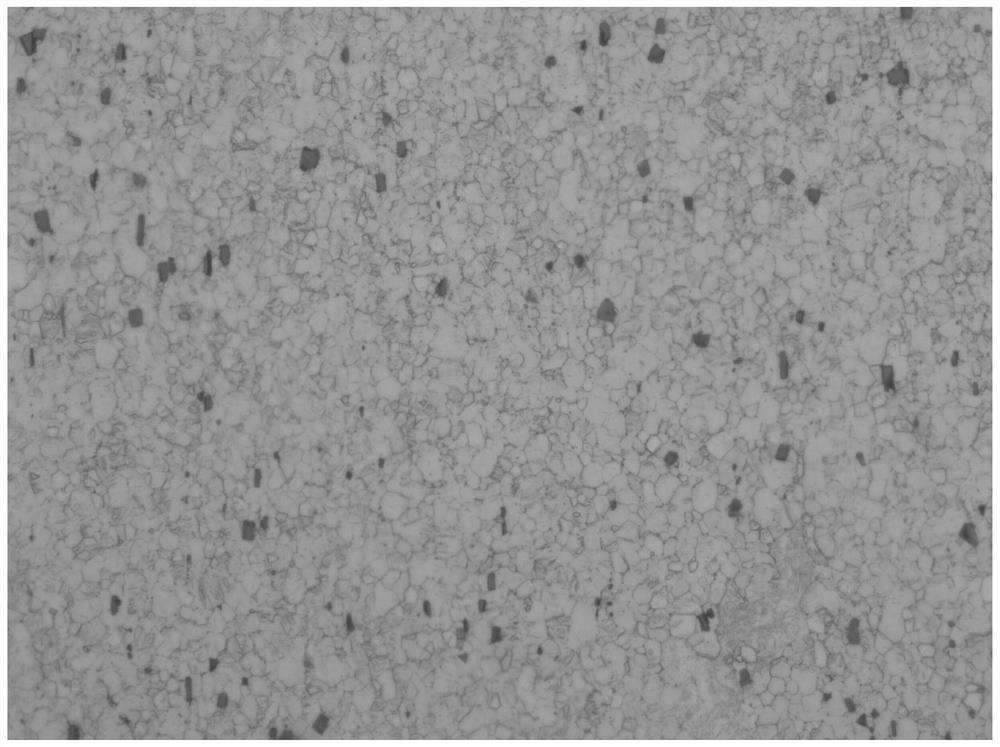

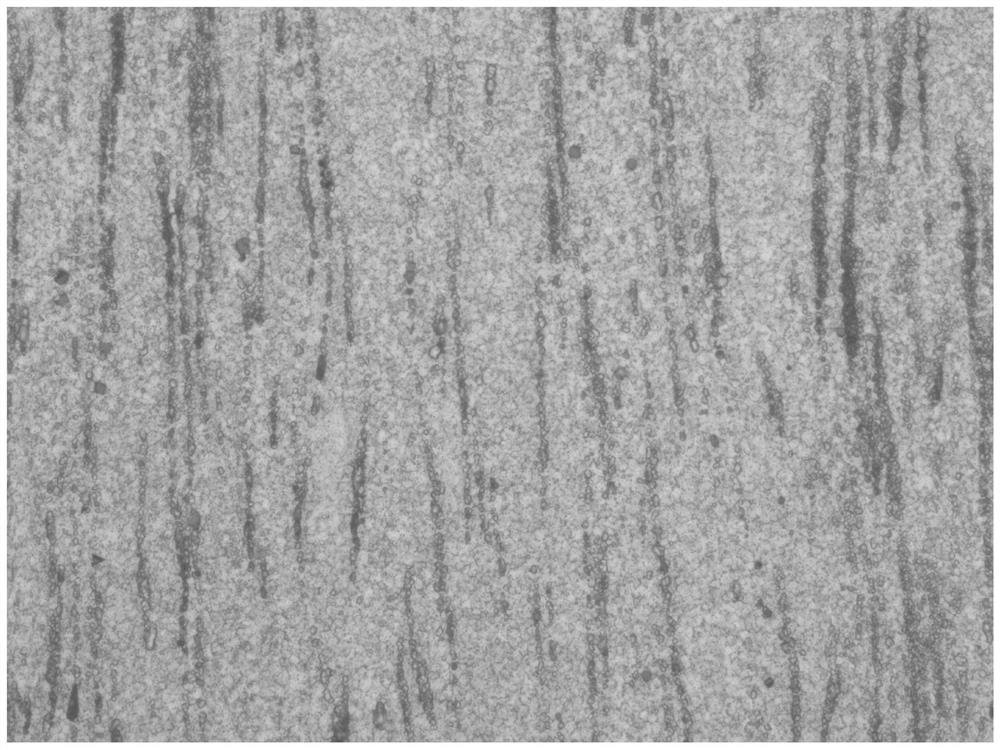

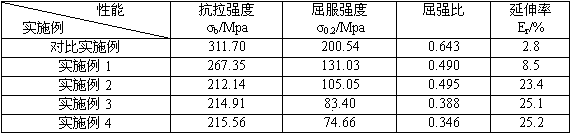

High-performance deformed rare earth-magnesium-lithium alloy based on island-shaped beta1 nanometer precipitated phase strengthening

ActiveCN112111682AImprove mechanical propertiesStrong precipitation strengtheningSolution treatmentMetallic materials

The invention discloses a high-performance deformed rare earth-magnesium-lithium alloy based on island-shaped beta1 nanometer precipitated phase strengthening, and belongs to the technical field of metal materials. The rare earth-magnesium-lithium alloy comprises Mg, Gd, Y, Zn and Li elements, wherein an alloy matrix is composed of alpha-Mg or alpha-Mg plus beta-Li, and a large number of nanoscaleisland-shaped beta1 precipitated phases which are densely and discretely distributed exist in the alpha-Mg matrix. The island-shaped beta1 nanometer precipitated phases generated through a dynamic precipitation mechanism in thermal deformation, and the strength of a magnesium-lithium alloy can be effectively improved through the precipitation strengthening effect. A preparation process comprisesthe steps that the magnesium-lithium alloy is cast under the protection of fused salt and an inert atmosphere, and the rare earth-magnesium-lithium alloy is obtained through extrusion molding after solution treatment. Compared with the prior art, the production efficiency, yield strength, tensile strength and elongation of the alloy are all improved in a breakthrough mode.

Owner:BEIJING UNIV OF TECH

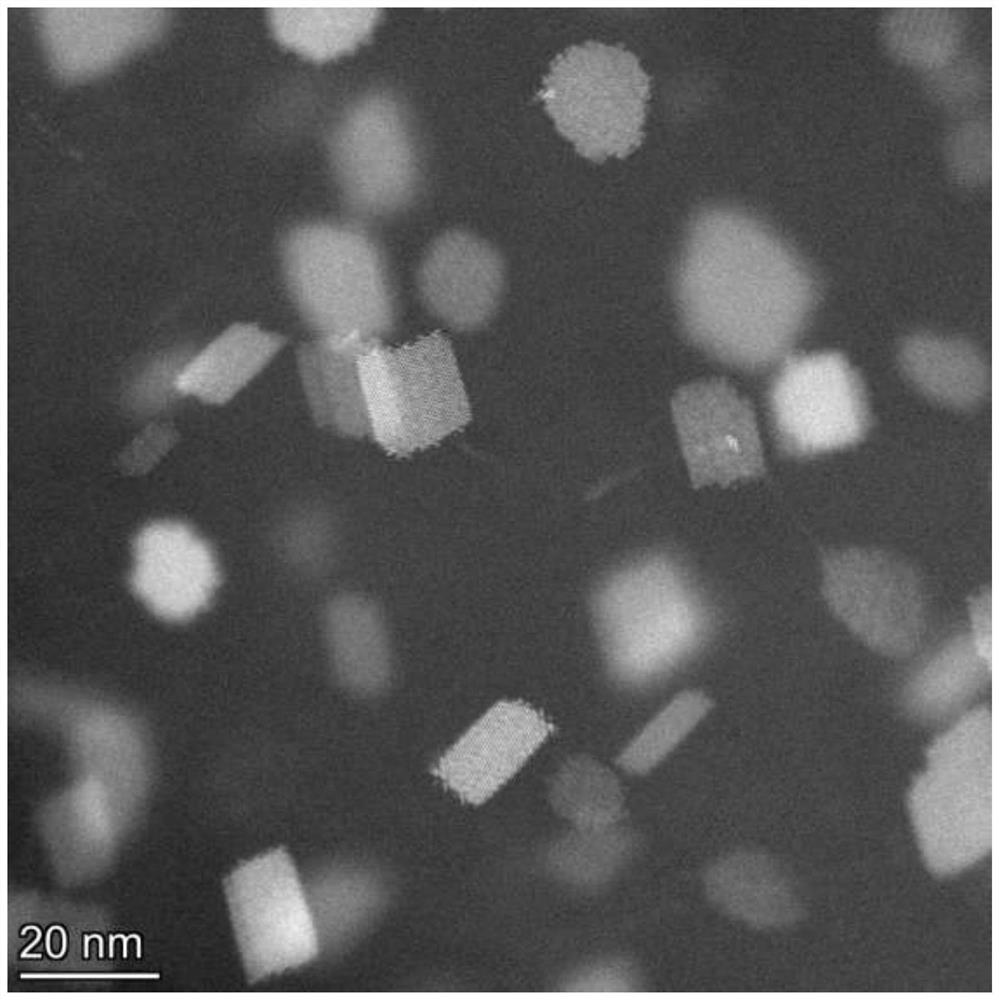

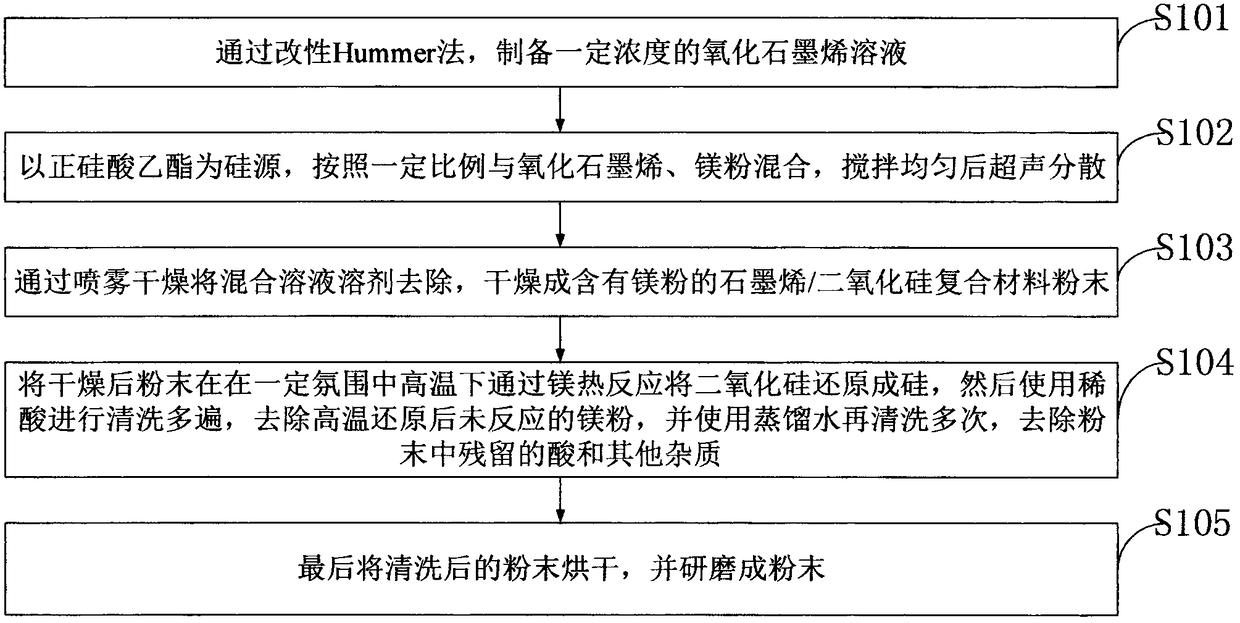

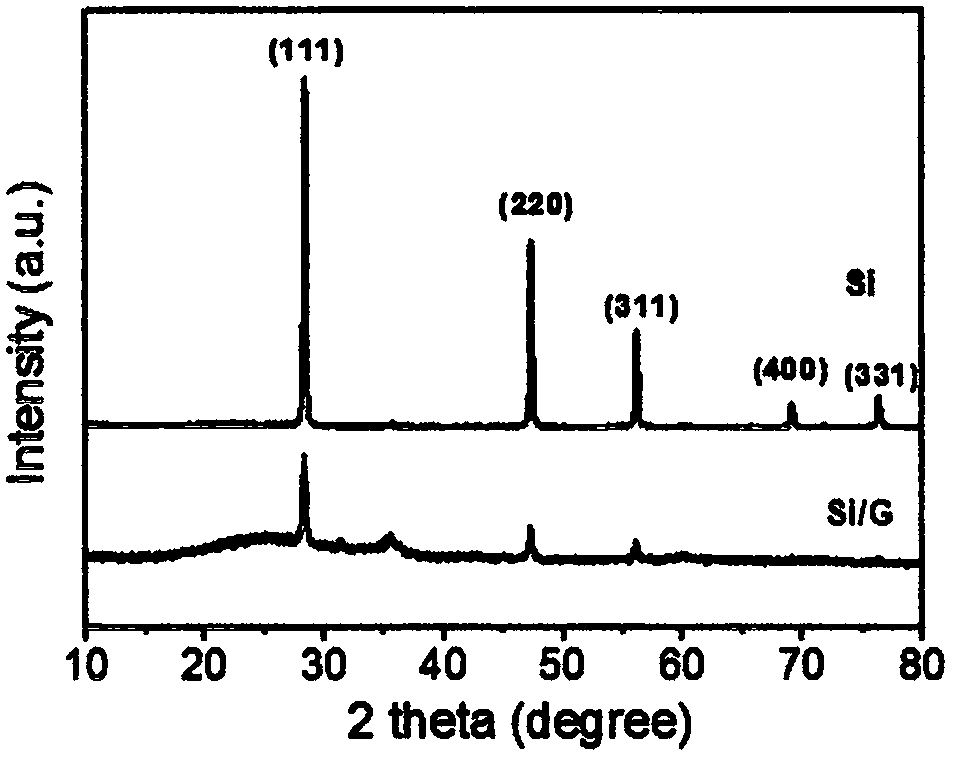

High-capacity graphene/ silicone composite negative electrode material and preparation method

The invention belongs to the field of preparation of negative electrode materials of lithium ion cells, and discloses a high-capacity graphene / silicone composite negative electrode material and a preparation method. The method specifically comprises the following steps: preparing certain graphene oxide solution by a modified Hummer method; preparing tetraethoxysilane as a silicone source; uniformly mixing the silicone source with the graphene oxide and magnesium powder based on certain ratio; ultrasonically dispersing; drying the mixed solution into powder through a spraying drying device; reducing under high temperature in certain atmosphere; washing with diluted acid and distilled water in a plurality of times; drying; and grinding powder with certain fineness. According to the method,tetraethoxysilane is used as the silicone source which is high in compatibility; the reaction time is controllable; and moreover, silicone can be effectively wrapped with graphene, so that the electricity conductivity of the silicone can be improved; and meanwhile, the silicone expansion in charging and discharging process can be avoided. Therefore, the circulating performance and the multiplyingpower of the cell with the silicone negative electrode material can be improved.

Owner:厦门紫阳科技产业发展有限公司

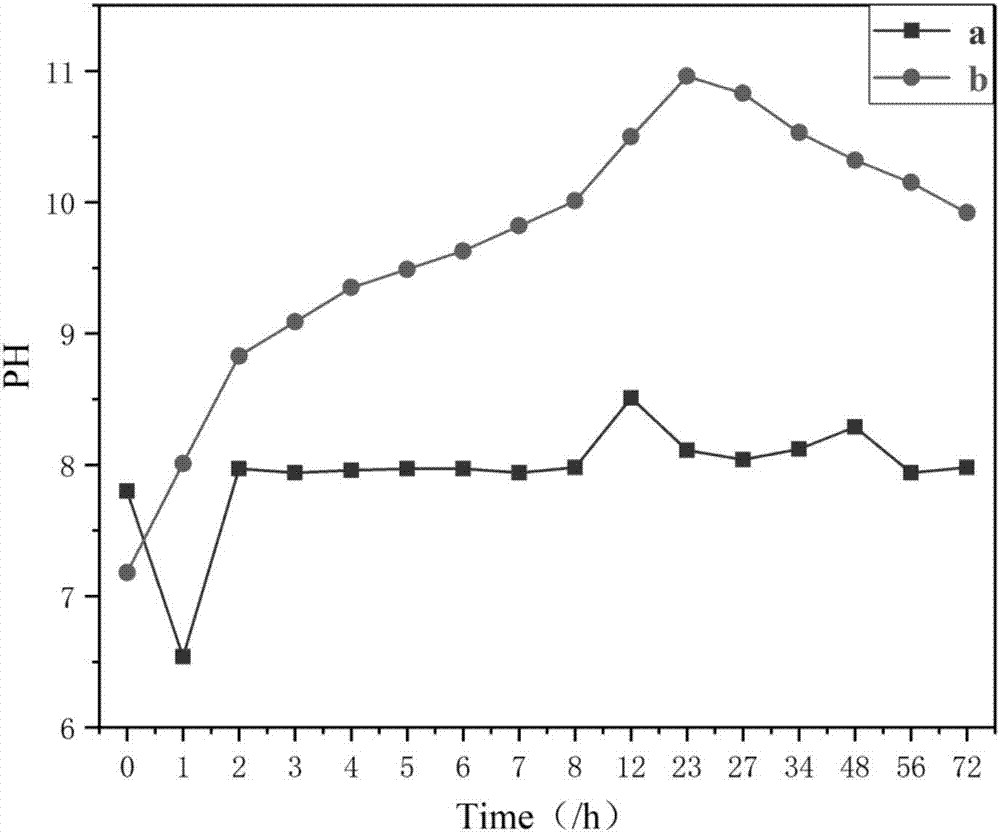

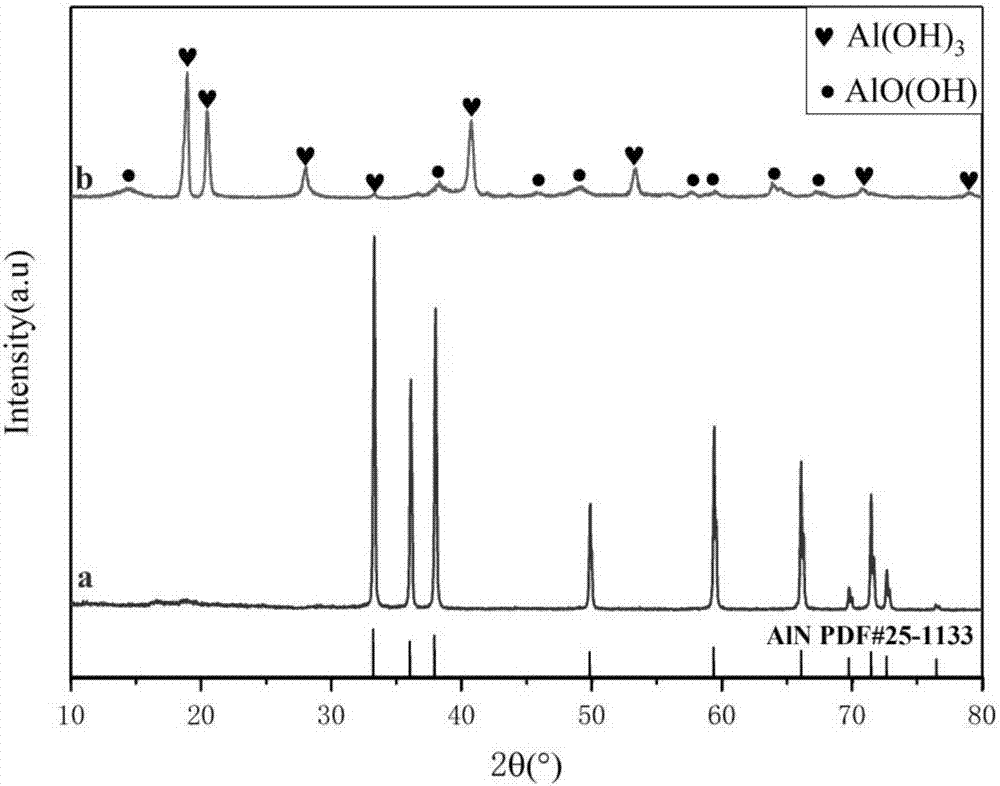

Hydrolysis-resisting aluminum nitride powder and preparation method thereof

ActiveCN107954725AExcellent hydrolysis resistanceSolve storage and application challengesOrganic acidRoom temperature

The invention discloses hydrolysis-resisting aluminum nitride powder and a preparation method thereof. The hydrolysis-resisting aluminum nitride powder is prepared by carrying out covering treatment on surfaces of aluminum nitride powder particles through an organic acid and a coupling agent, wherein the content of the organic acid is 1 to 15 weight percent, and the content of the coupling agent is 0.5 to 20 weight percent. An experiment proves that at room temperature, the aluminum nitride powder prepared by the preparation method is immersed into water and can keep unhydrolyzed for one weekor longer than one week; at 80 DEG C, the hydrolysis-resisting aluminum nitride powder prepared by the preparation method can stably exist in water for at least 72h without any hydrolysis. The problemthat aluminum nitride powder is not easy to store and apply, caused by the fact that the aluminum nitride powder is easy to hydrolyze, is effectively solved. Furthermore, the advantages of simple technological operation, low raw material price, low production cost, wide application range, easiness for realizing industrial production and the like are also achieved; the industrial application valueis remarkable, and large-scale industrial application of aluminum nitride is facilitated.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH +1

High-modulus magnesium alloy and preparation method thereof

The invention discloses a high-modulus magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components in percentage by weight: 0-19.5wt% of Y, 0-13wt% of Gd,0-2wt% of Zn, 0-3.0wt% of Ni, 4-6wt% of Al, 3-6wt% of Li, 0.3-0.6wt% of Zr, 0-2wt% of Ag, and the balance of Mg and inevitable impurities, wherein the total amount of the impurities is less than 0.12wt%. In the alloy system, aluminum and lithium e added to generate an equilibrium precipitated phase AlLi during solidification, which can greatly increase the elastic modulus of the alloy; in addition to the phase, zirconium reacts with aluminum to generate an Al3Zr phase, and rare earth elements Y and Gd generate a large amount of second phase in the alloy, which all increase the elastic modulus of the alloy to some extent. In addition, after solid solution aging, more precipitated phase AlLi isprecipitated in the alloy to further increase the elastic modulus of the alloy, and the elastic modulus is up to 52-55 Gpa, which can meet the requirements of the engineering field for lightweight high-modulus magnesium alloy materials. The high-modulus magnesium alloy has a good application prospect in the aerospace field.

Owner:CHONGQING UNIV

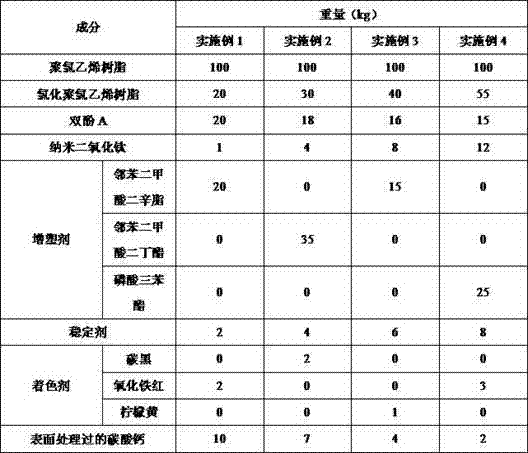

High-strength and high-stability modified PVC and preparation method thereof

The invention discloses high-strength and high-stability modified PVC (polyvinyl chloride) which comprises the following components in parts by weight: 100 parts of PVC resin, 20-55 parts of CPVC (chlorinated polyvinyl chloride) resin, 15-20 parts of phenolic antioxidant, 1-12 parts of titanium dioxide, 15-35 parts of plasticizer, 2-8 parts of stabilizer, 0-3 parts of colorant, and 2-10 parts of filling. The high-strength and high-stability modified PVC has the benefits that: the modified PVC has good mechanical property, high strength, good balance of stiffness and toughness, heat resistance, light resistance, corrosion resistance, and high stability; the service life of a product is ensured; in addition, the preparation method is good in repeatability; the process is controllable; the manufacturing cost is low; and the industrial large-scale application is facilitated.

Owner:SUZHOU SUNWAY POLYMER

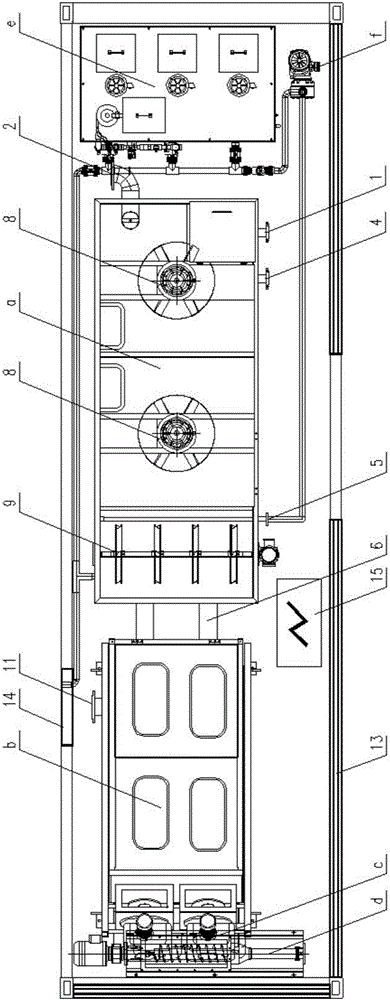

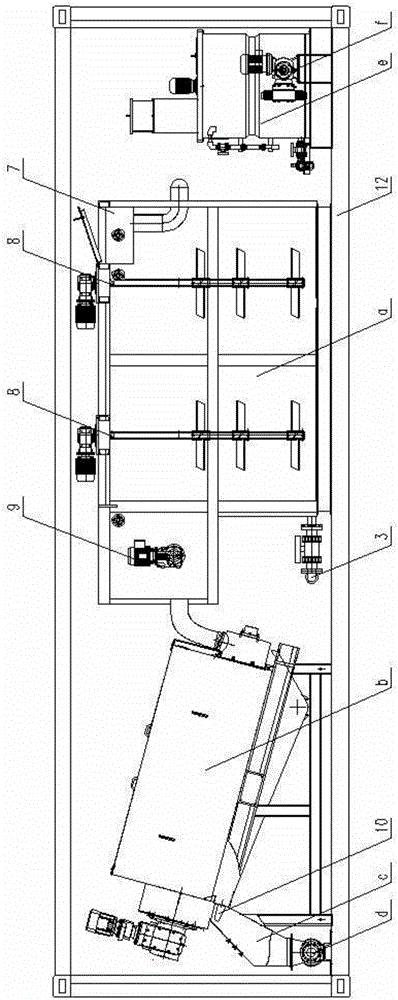

Skid-mounted type building mud treatment device and process

ActiveCN105731762AHigh level of integrationImprove environmental performanceSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesRetention timeElectrical control

The invention discloses a skid-mounted type building mud treatment device and process. The treatment device comprises a mud homogenizing tank, a screw overlapped type sludge dehydrator, a sludge storage tank, a sludge conveying pump, an agent preparation system, an agent adding pump and an electrical control cabinet which are installed on an overall base or in a container. The mud homogenizing tank comprises mud homogenizing stirring tanks and a mud and agent mixing stirring tank. The mud homogenizing tank is longer in retention time after being improved, and mud is mixed more uniformly and is not prone to settle. The screw pitch is in special reducing design after a screw shaft of the screw overlapped type sludge dehydrator is improved, the spiral angle is gentler, and an abrasion-resistant layer is thicker. Through special structural design, the building mud is rapidly dehydrated on the overall base or in the container, a whole system is high in integration degree, the occupied place is small, the mass is low, the size is small, mobility, environmental protection performance and dehydration speed are high, the effect is good, outward transport disposal cost is reduced, and treated soil can be directly modified and resourcefully utilized.

Owner:同臣环保装备科技(苏州)有限公司

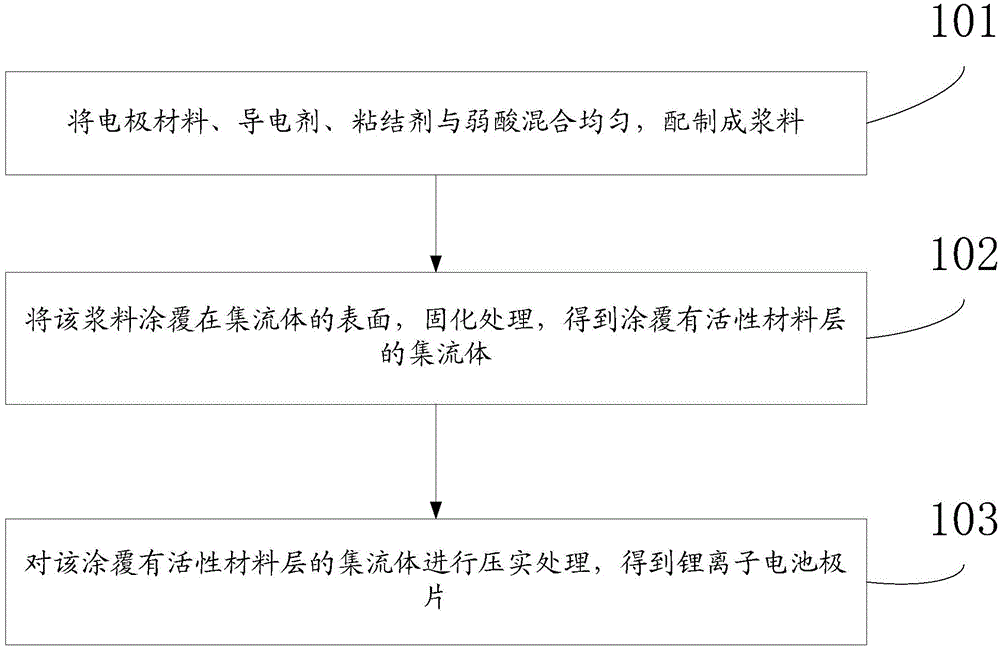

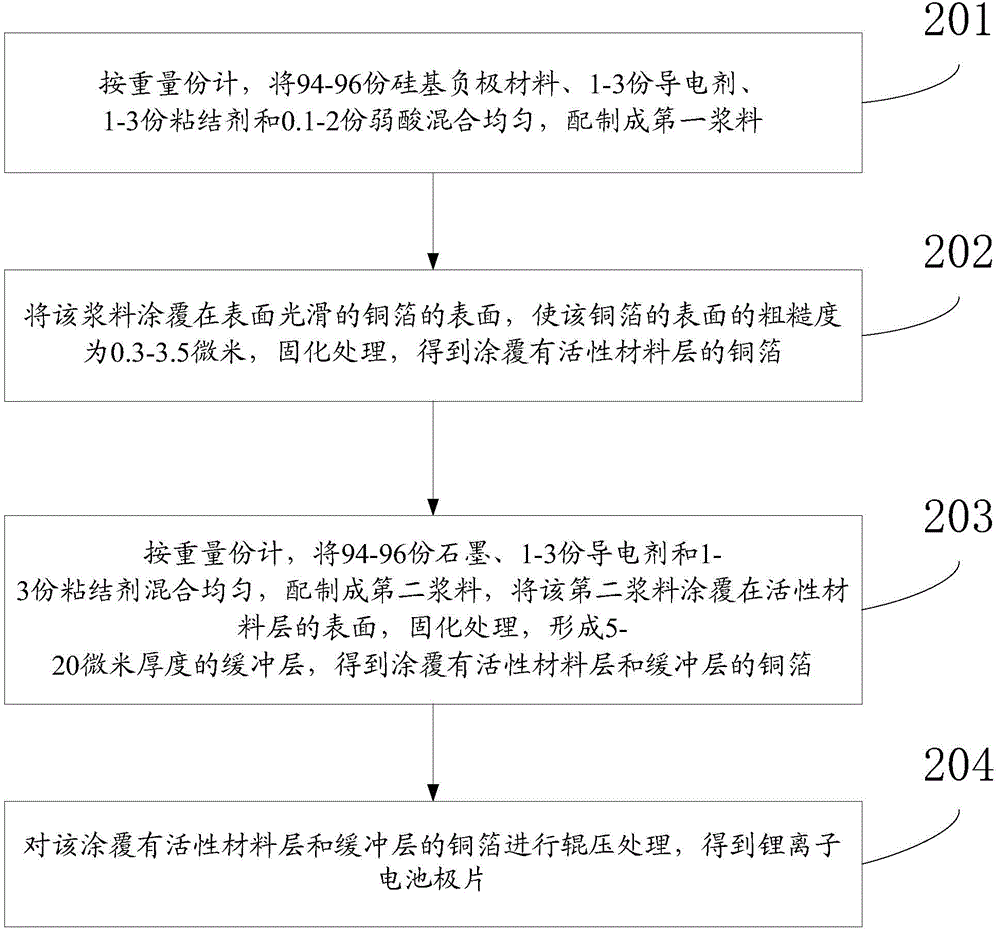

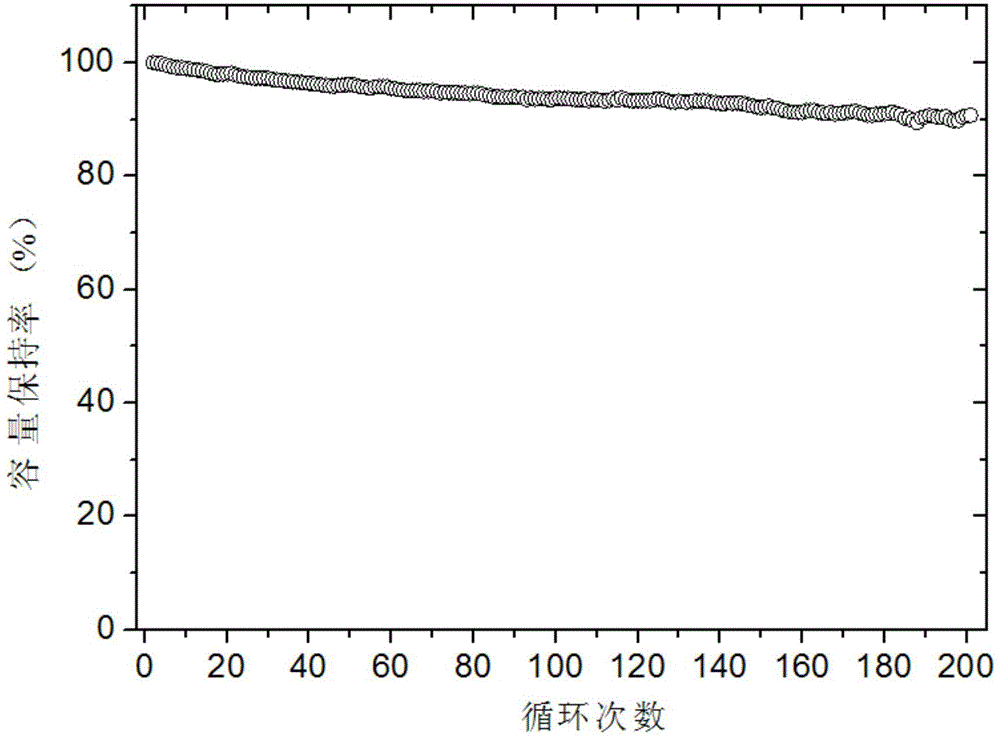

Lithium ion battery pole piece and preparation method thereof

InactiveCN104134780AImprove circulation stabilityInhibit sheddingElectrode carriers/collectorsElectrode collector coatingRough surfaceElectrical battery

The invention discloses a lithium ion battery pole piece and a preparation method thereof, and belongs to the field of battery pole pieces. The lithium ion battery pole piece comprises a current collector and an active material layer coated on the surface of the current collector. The surface of the current collector is a rough surface with the roughness of 0.3-3.5 micrometers, so that a bonding effect of the active material layer and the current collector is improved, an active material is prevented from falling out of the current collector, and the cycling stability of a lithium ion battery can be improved.

Owner:CHERY AUTOMOBILE CO LTD

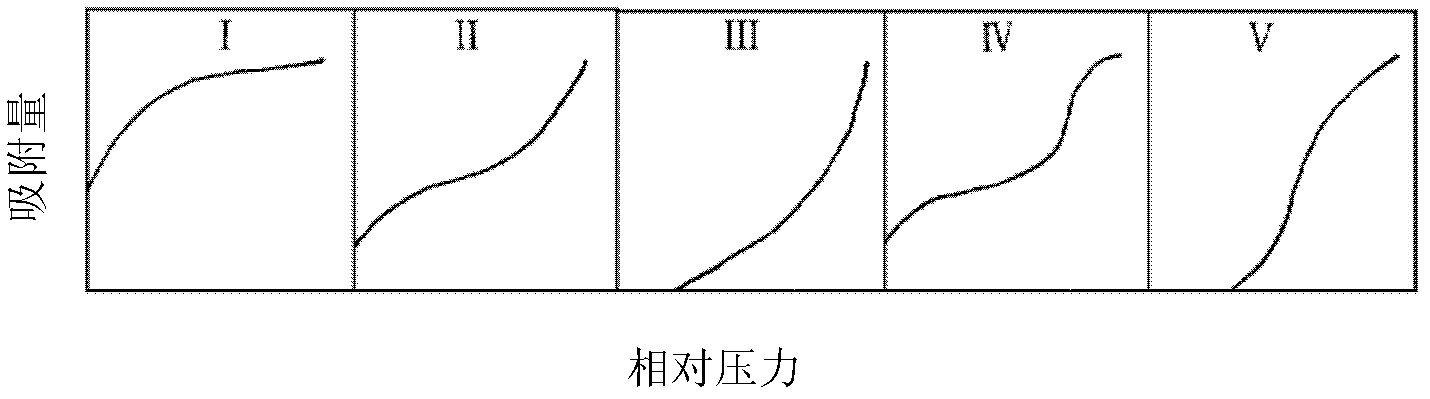

Active carbon absorbent for removing mercury in flue gas

InactiveCN105056885AImprove adsorption capacityIncrease the number ofOther chemical processesDispersed particle separationActivated carbonFlue gas

The invention aims to provide an active carbon absorbent for removing heavy metals especially mercury in flue gas and a preparation method thereof. By improving the preparation method of active carbon, the ratio of mesoporous pore canals in active carbon is increased, thus the oxidant load capacity and dispersion degree of active carbon are both improved; the performance of active carbon on absorbing mercury is enhanced, thus the mercury can be removed more easily, and moreover, the provided method has little pollution and can be applied to the industry.

Owner:QINGDAO JINZHI HIGH NEW TECH

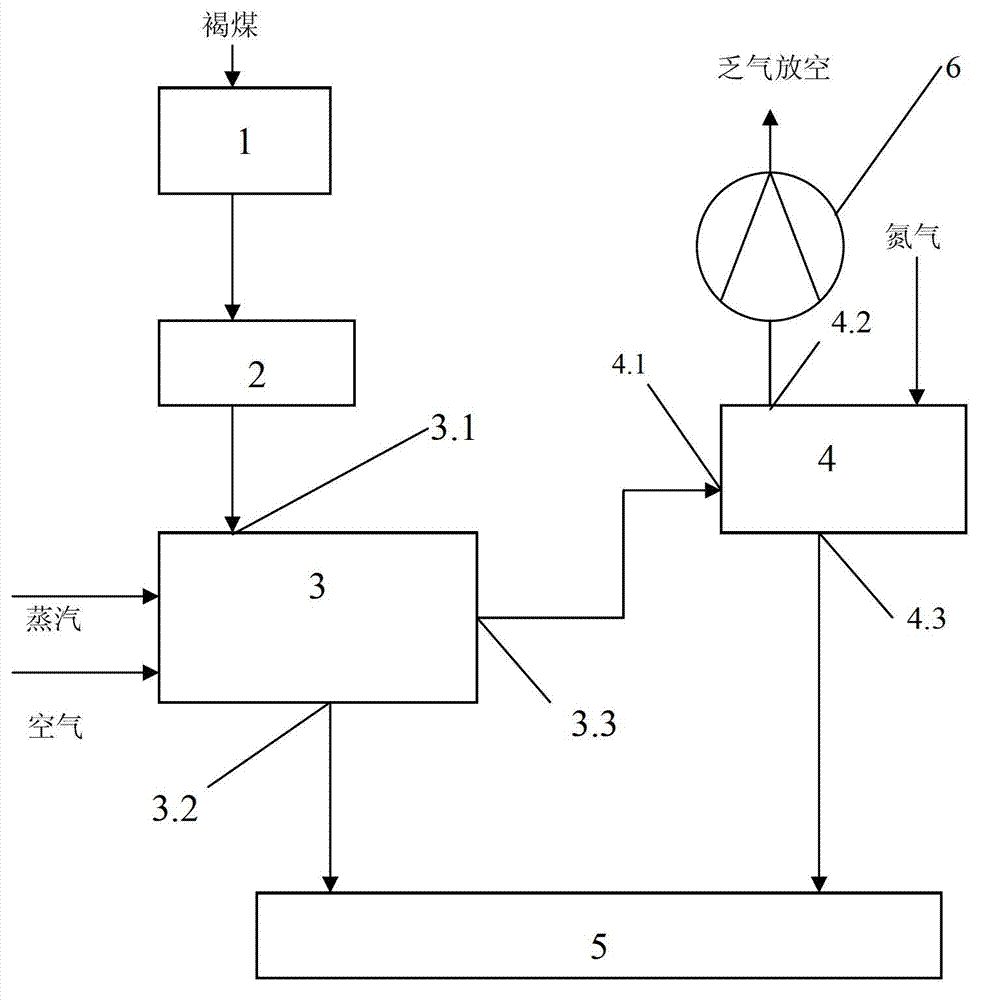

Lignite pre-drying process and lignite pre-drying device

InactiveCN103047836AImprove efficiencyReduce moisture contentDrying gas arrangementsDrying machines with non-progressive movementsGranularityProcess engineering

The invention discloses a lignite pre-drying process and a lignite pre-drying device which solve the problems of poor 'dewatering' and dedusting effects and no large-scale industrial application caused by direct-contact heat transfer of the prior art. The technical scheme includes that the process includes that lignite with the granularity smaller than 13mm is fed into a drying tube of a tube drier via a lignite inlet of the tube drier, and meanwhile, a heat source serving as a drying medium is fed to the outside of the drying tube of the tube drier, so that lignite in the drying tube and the heat source outside the drying tube are subjected to indirect heat exchange, and dried lignite is discharged via a lignite outlet; and exhaust with dust and generated by feeding of the lignite in the drying tube is mixed with steam generated after lignite drying to form tail gas, the tail gas enters a bag filter via a tail gas outlet to be filtered and separated, lignite dust collected after separation is discharged via a dust outlet of the bag filter, and the tail gas is discharge by an induced draft fan via a tail gas outlet of the bag filter. The lignite pre-drying process is simple, good in dewatering effect, safe, reliable and suitable for large-scale industrial application, and tail gas emission reaches the standards.

Owner:WUHUAN ENG

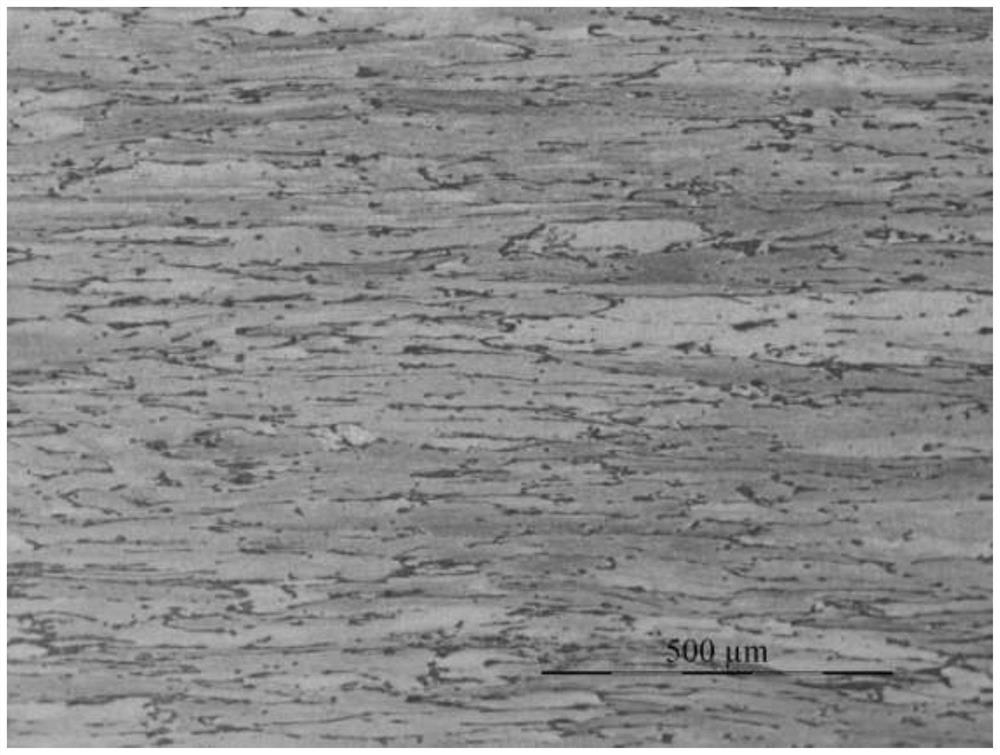

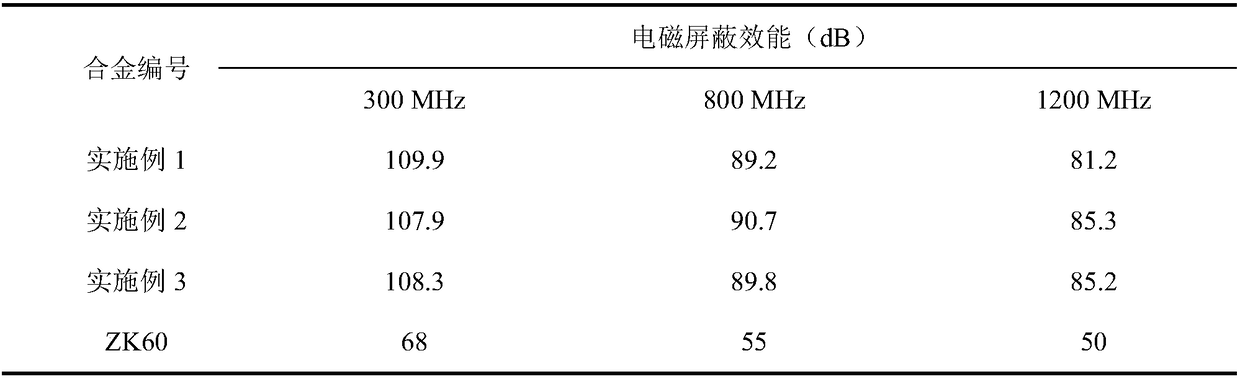

High electromagnetic shielding effectiveness magnesium alloy and preparation method thereof

ActiveCN108165853AGood electromagnetic shieldingHigh electromagnetic shieldingProcess equipmentCerium

The invention provides a high electromagnetic shielding effectiveness magnesium alloy and a preparation method thereof. Components of the alloy comprise, by weight percentage, 1-5 wt.% of Zn, 1-5 wt.%of Sn, 0.1-0.5 wt.% of Ca, 0.1-0.5 wt.% of Ce and the balance Mg and inevitable impurities. By adding alloy elements (Mg, Zn, Sn, Ca and Ce) in the magnesium alloy to be matched to hot rolling and hot treatment, the high electromagnetic shielding effectiveness magnesium alloy is achieved. The method includes the specific process steps of smelting, homogenizing, hot rolling and solid solution aging. Adding of a small amount of calcium and cerium alloy elements, forming and precipitating of a second phase are promoted, and the conductivity and the shielding performance of the alloy are improved; meanwhile, due to precipitating of the high-density second phase, electromagnetic waves can also be effectively reflected; besides, in combination of refined crystal strengthening, precipitating strengthening and the like, the alloy has high strength while good electromagnetic shielding performance is achieved. Process equipment related to the high electromagnetic shielding effectiveness magnesium alloy and the preparation method thereof is universal equipment, cost is low, operation is easy, and industrial achievement is easy.

Owner:CHONGQING UNIV

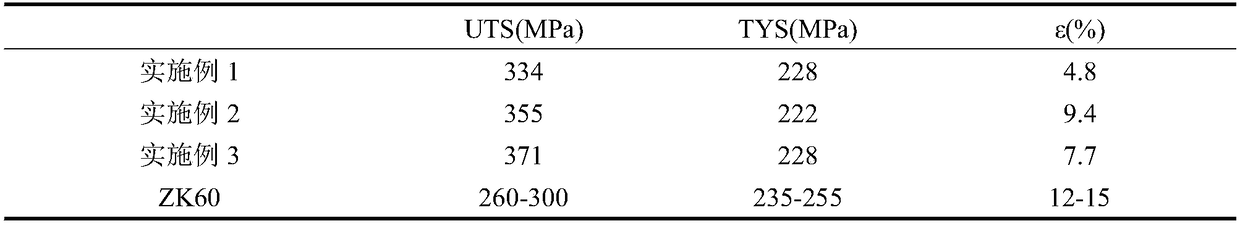

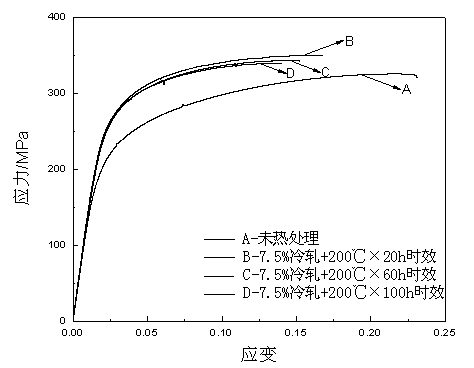

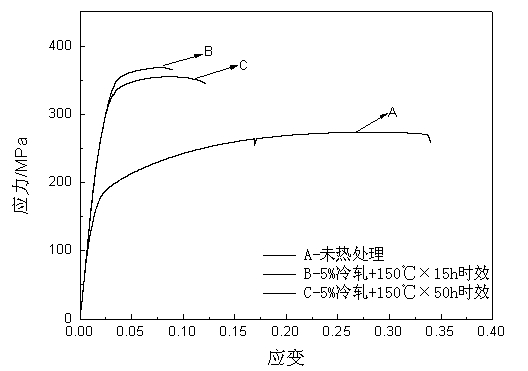

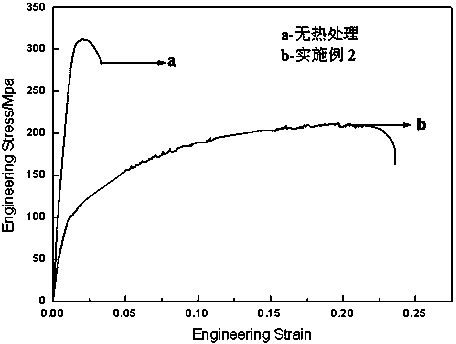

Thermal treatment process for improving deformed magnesium alloy strength

The invention provides a thermal treatment process for improving deformed magnesium alloy strength, which is used for achieving the purpose of remarkably improving the magnesium alloy strength through small-deformation cold rolling and different-time artificial ageing. The thermal treatment process specifically comprises the following steps of: (1), carrying out cold rolling on magnesium alloy under the room temperature, wherein the cold-rolling deformation is 5%-7.5%; and (2), heating up the cold-rolled and pre-deformed magnesium alloy to 150 DEG C to 200 DEG C for ageing, preserving the heat for 15 hours to 100 hours, and cooling in the air to the room temperature. The thermal treatment process can be used for remarkably improving the strength of the magnesium alloy. Moreover, relative to the normal ageing process, the thermal treatment process further can be used for remarkably improving the aging velocity of the magnesium alloy. Besides, the used process equipment is normal common equipment which is easy to operate, lower in cost and easy to industrialize.

Owner:CHONGQING UNIV

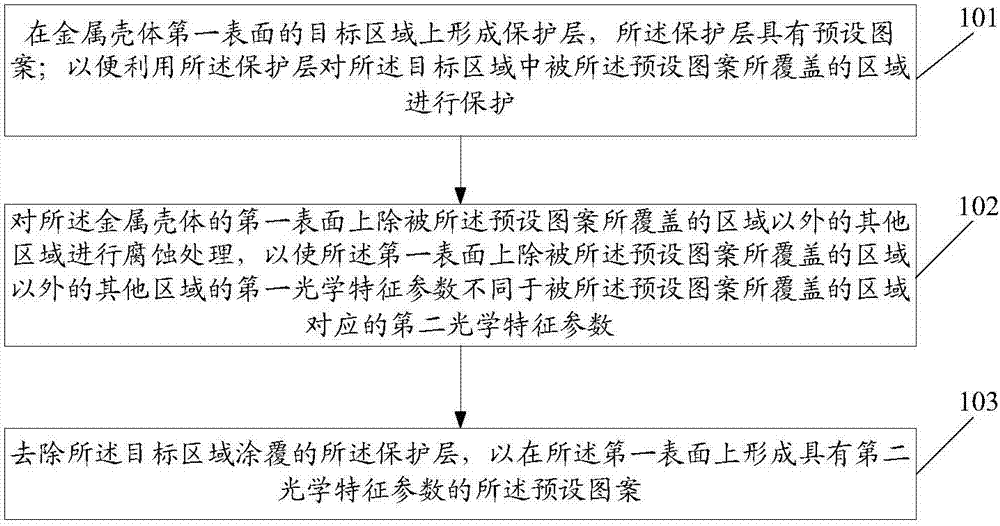

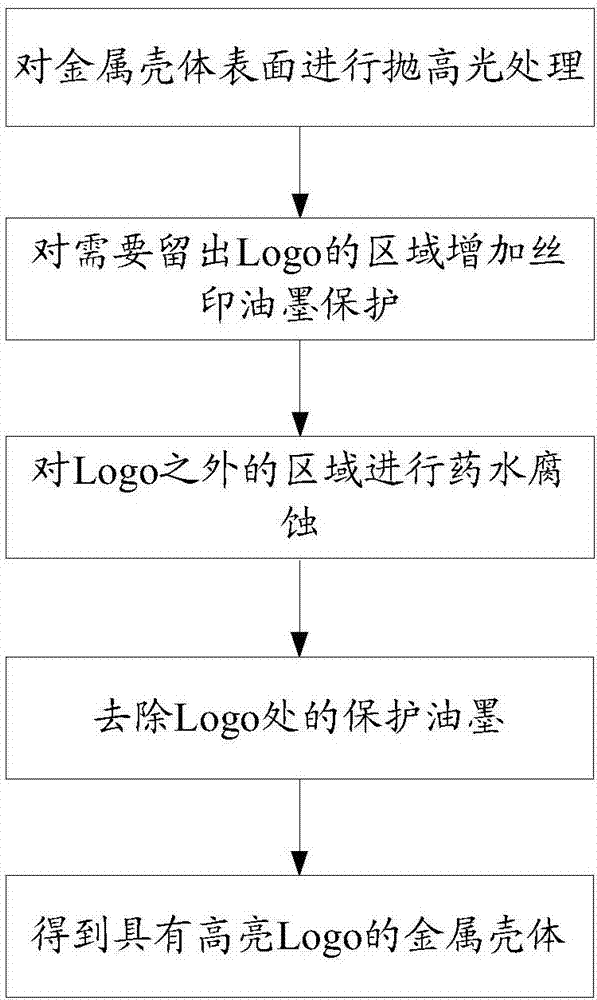

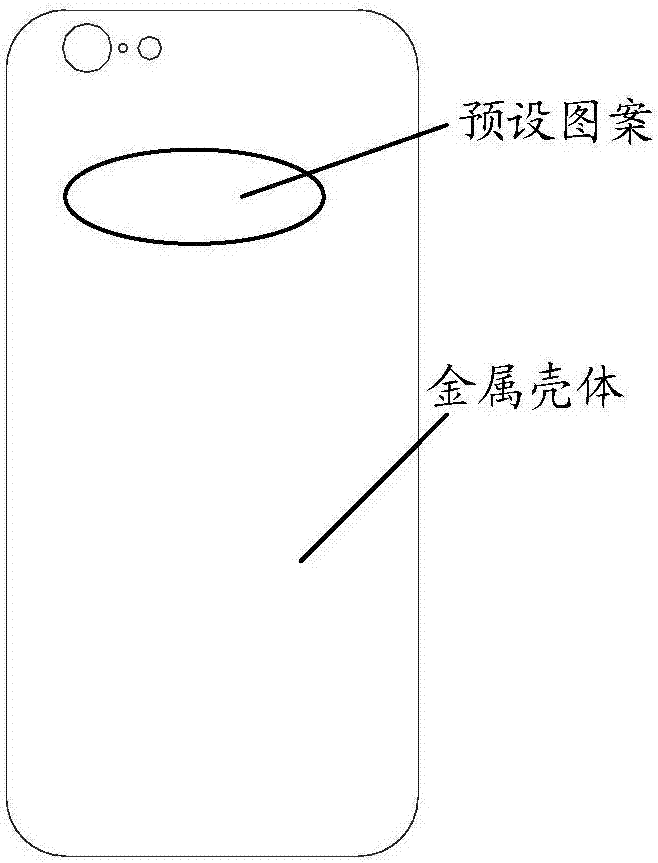

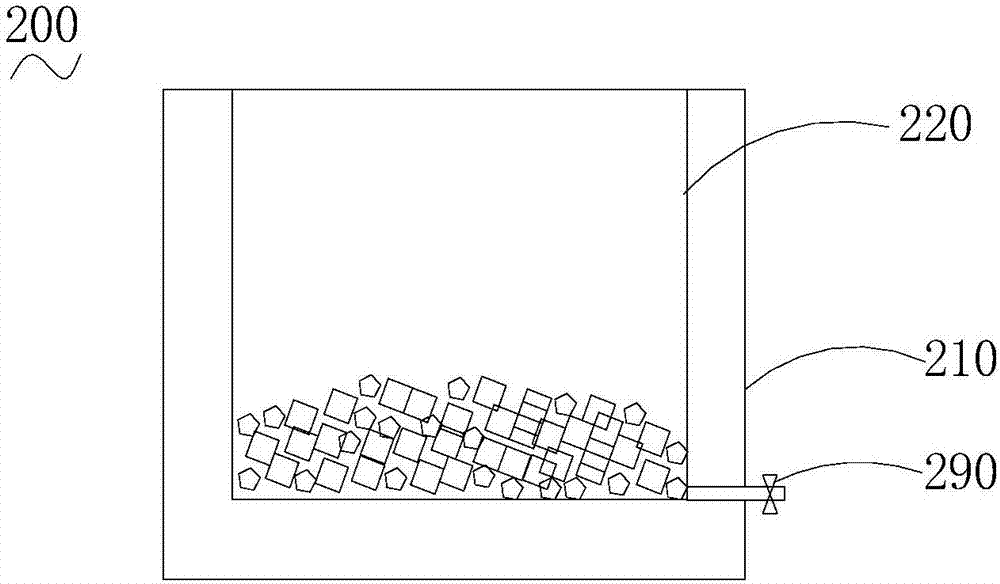

Pattern preparation method and electronic equipment

InactiveCN107116949ASimple processFacilitate large-scale industrial applicationDecorative surface effectsCasings/cabinets/drawers detailsProtection layerFeature parameter

The embodiment of the invention discloses a pattern preparation method which comprises the following steps: enabling a protection layer to be formed in a target region of a first surface of a metal shell, wherein the protection layer is provided with a predesigned pattern, and the protection layer is utilized to protect the area, covered with the predesigned pattern, in the target region; performing corrosion treatment on the other areas, excluding the area covered with the predesigned pattern, on the first surface of the metal shell, so as to enable the first optical characteristic parameter of the other areas, excluding the area covered with the predesigned pattern, on the first surface to be different from the second optical characteristic parameter corresponding to the area covered with the predesigned pattern; and removing the protection layer covering the target region, and enabling the predesigned pattern with the second optical characteristic parameter to be formed on the first surface. The embodiment of the invention further discloses electronic equipment.

Owner:LENOVO (BEIJING) LTD

High-strength and high-toughness magnesium-lithium alloy capable of achieving rapid age hardening and preparation method thereof

ActiveCN113355574AEnhanced age hardening responseShorten aging timeSolution treatmentMetallic materials

The invention discloses a high-strength and high-toughness magnesium-lithium alloy capable of achieving rapid age hardening and a preparation method thereof, and belongs to the technical field of metal materials. 0.1-3 wt% of element Li is added into a Mg-Gd alloy. An alloy matrix comprises an alpha-Mg phase, and a large amount of dense and discretely distributed nanoprecipitates exist in the alpha-Mg matrix. Under the aging condition of 200 DEG C, the peak aging time of the alloy is less than or equal to 12 hours. During peak aging, the yield strength of the alloy reaches 302 MPa; the tensile strength reaches 343 MPa; and the elongation reaches 17.5%. The preparation process of the magnesium-lithium alloy comprises the steps of casting under the protection of molten salt and inert atmosphere, and performing solution treatment, extrusion forming and aging heat treatment to obtain the magnesium-lithium alloy. Compared with the prior art, by simply controlling the content of element Li, the high-strength and high-toughness magnesium-lithium alloy capable of achieving rapid age hardening and the preparation method thereof can significantly enhance an age hardening reaction of the alloy, significantly improve the mechanical properties of the magnesium-lithium alloy, and shorten the peak hardening time.

Owner:BEIJING UNIV OF TECH

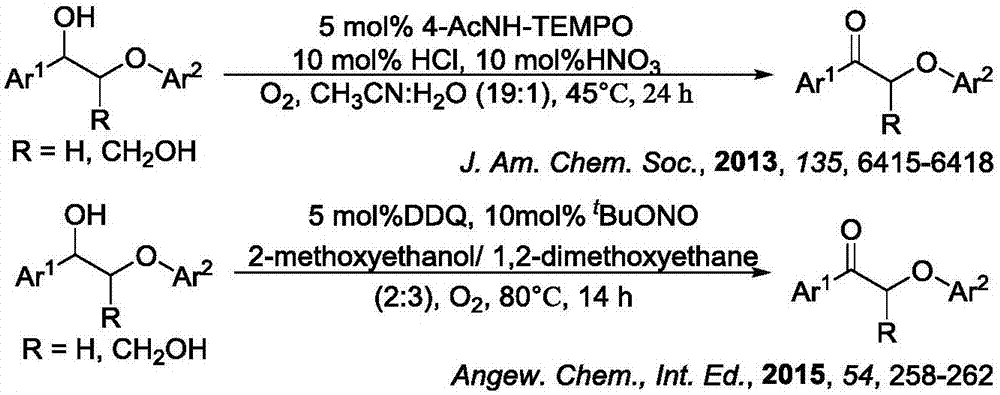

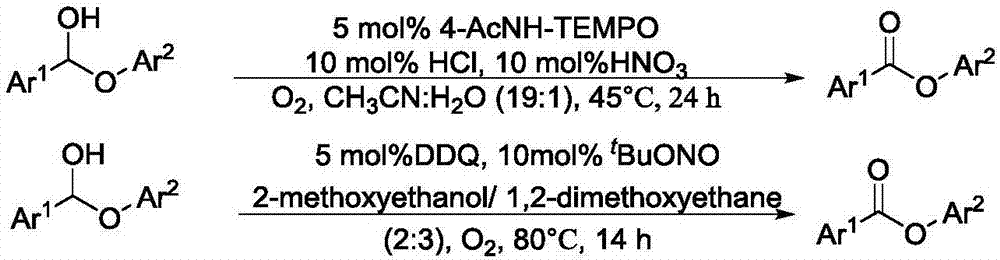

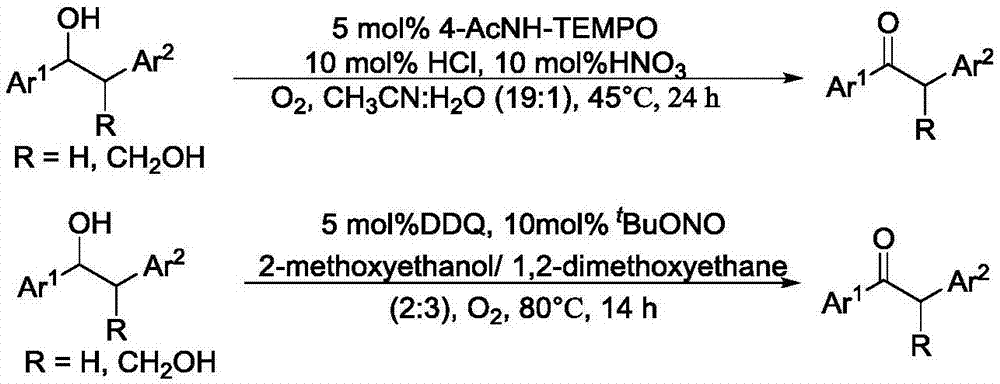

Method for degrading oxidation lignin into small molecular aromatic compound

InactiveCN106928053AMild reaction conditionsImprove conversion rateOxygen-containing compound preparationOrganic compound preparationBenzoic acidBiomass degradation

Belonging to the technical field of biomass degradation, the invention relates to a method for degrading oxidation lignin into a small molecular aromatic compound, and in particular relates to a method of breaking C-C bond by nontransition metal catalysis to degrade oxidation lignin into a small molecular aromatic compound. The method includes: firstly oxidizing oxidation lignin in an organic solvent with an oxidizing agent, then subjecting the obtained intermediate product to alcoholysis or hydrolysis under the action of a catalyst so as to obtain a small molecular aromatic compound, like methoxy substituted benzoic acid, methoxy substituted phenol, methoxy substituted benzoate and chain alcohol, etc. The method provided by the invention has the advantages of simple steps, mild reaction conditions, high conversion rate (up to 100%), no need for transition metals and the like, has effect on multiple connection modes of oxidation lignin, can reach the purpose of high selectivity and efficient degradation of lignin, and is conducive to large-scale industrial application.

Owner:JILIN UNIV

Thermal treatment method for improving plasticity of aluminum alloy plate material

The invention provides a thermal treatment method for improving the plasticity of an aluminum alloy plate material. The method mainly comprises the following steps: keeping the temperature of a 5052 aluminum alloy cast ingot in a cast state for 10-25 hours at the temperature of 400 DEG C to 500 DEG C; cooling to room temperature through water quenching; subsequently rolling the aluminum alloy treated through the abovementioned technical scheme at room temperature to realize different deformation rates within 15%-90%; afterwards, annealing the rolled aluminum alloy at the temperature of 150 DEG C to 400 DEG C; keeping the temperature for 2-10 hours; and air-cooling to room temperature. The aluminum alloy treated through the thermal treatment process disclosed by the invention is high in formability and remarkable in effect, can provide important foundation for subsequently obtaining a high-quality aluminum alloy plate material and is in favor of fully exploiting the usability potential of the material. In addition, processing equipment used in the thermal treatment method is universal equipment which is low in cost, easy to operate and easy to implement industrially.

Owner:CHONGQING UNIV

Preparation method of chemical crosslinking sand fixing material suitable for wind prevention and sand fixation of desert road

InactiveCN110003916ASimple manufacturing processPromote growthAgriculture tools and machinesOther chemical processesSuper absorbentOrganic fertilizer

The invention provides a preparation method of chemical crosslinking sand fixing material suitable for wind prevention and sand fixation of a desert road. The chemical sand fixing material is preparedfrom the following raw materials in parts by weight: 0.5-1 part of organic and inorganic composite super absorbent resin, 2-6 parts of a cellulose derivative, 5-10 parts of desert cement, 15-25 partsof black humic acid, 25-35 parts of inorganic nanoparticles, 10-20 parts of an organic fertilizer and 15-25 parts of a plant straw powder. The chemical sand fixing material has relatively strong sandfixing, crusting and crush-resisting and wind erosion-resisting performance, and can form a stable sand layer crust quickly on the surface of the sand to achieve a purpose of quick wind prevention and sand fixation.Moreover, the chemical sand fixing material also can play water retaining and warm keeping roles to provide nutritional conditions to wind prevention and sand fixation plants of the desert road. A sand fixer is primarily prepared from a natural raw material, is green and environment-friendly, is free of secondary pollution and is classified as a wind prevention and sand fixation material which is excellent in performance.

Owner:刘 志勇 +1

Alpha and beta two-phase magnesium lithium alloy with excellent casting performance and heat transfer performance

The invention discloses a dual-phase α+β magnesium-lithium alloy with excellent casting performance and heat transfer performance and a processing technology thereof. According to weight percentage, the composition of the alloy is: Li: 8.0‑10.0wt.%, Ge: 0.2‑0.8wt.%, Cd: 0.6‑0.8wt.%, Bi: 0.2‑0.5wt.%, Zr: 0.4‑ 0.8wt.%, Pd: 0.1‑0.2wt.%, Cu: 0.3‑0.5wt.%, Al: 1.8‑3.4wt.%, Fe: 0.2‑0.5wt.%, Mn: 0.1‑0.4wt.%, The balance is magnesium. The magnesium-lithium alloy for die-casting has high thermal conductivity that traditional magnesium-lithium alloys do not possess. This enables the alloy to have further specific applications in the occasions where the heat generation is large and the weight of the device is required, and it is convenient for large-scale industrial application.

Owner:GUANGZHOU YUZHI TECH CO LTD

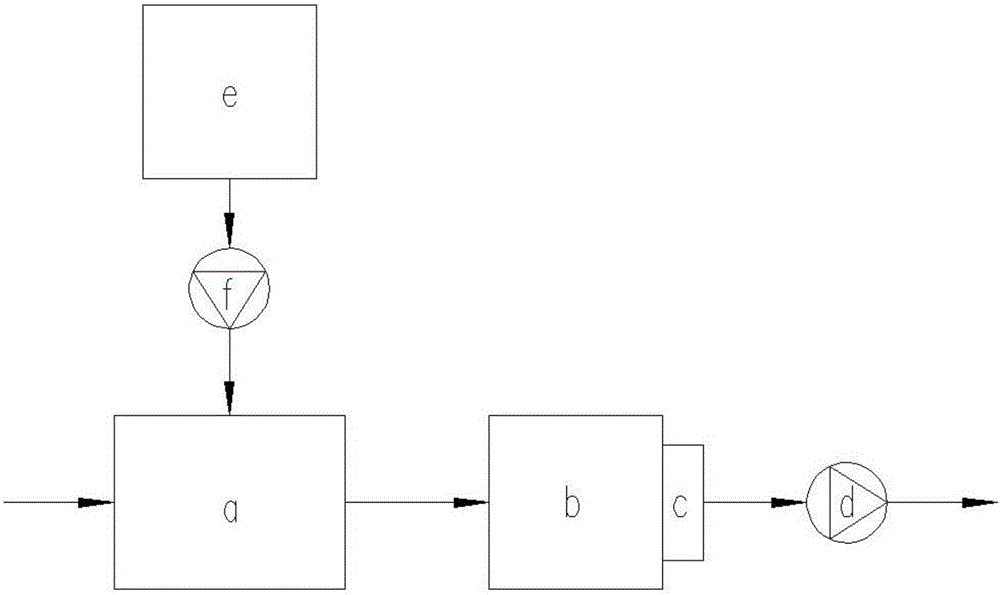

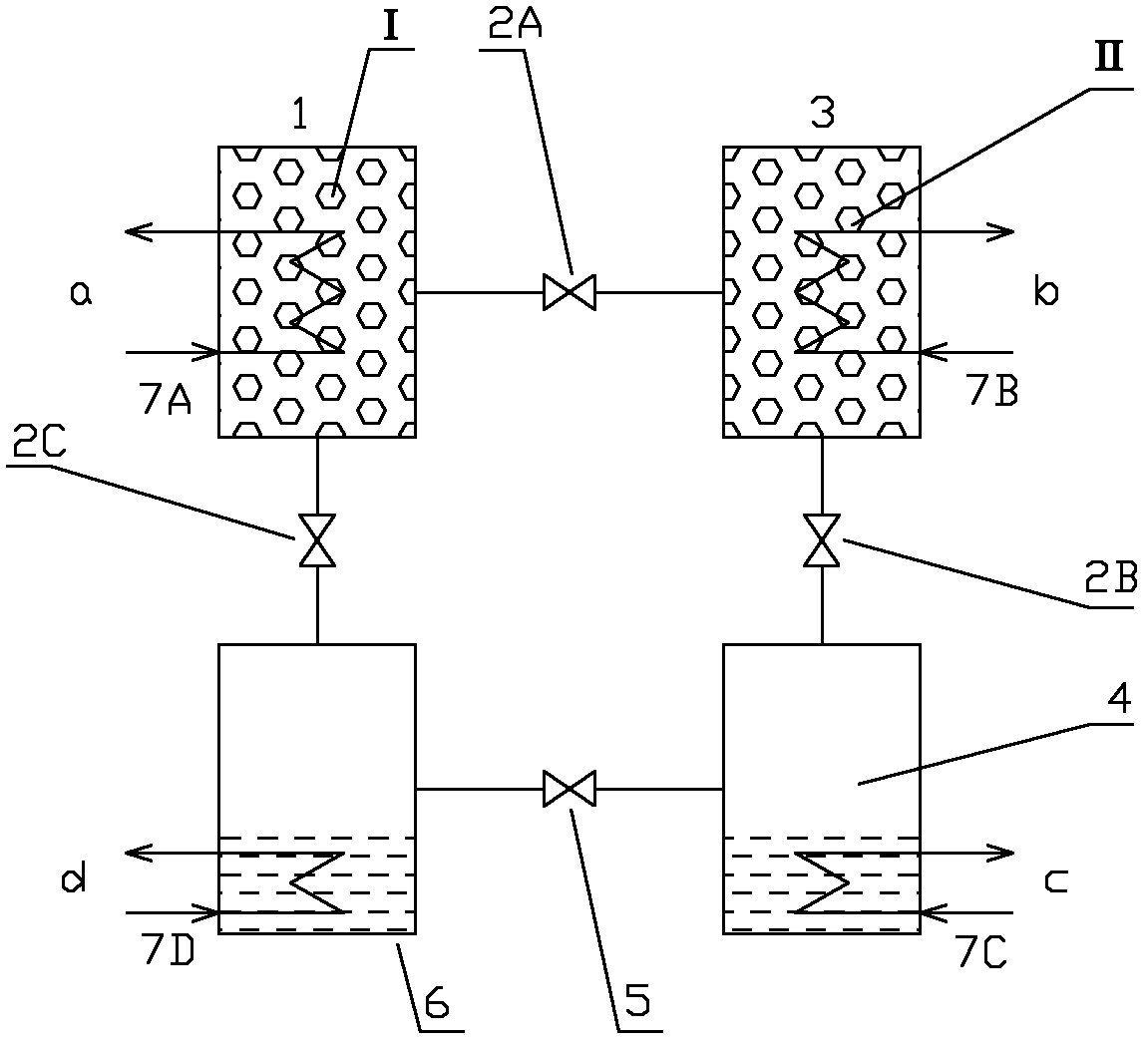

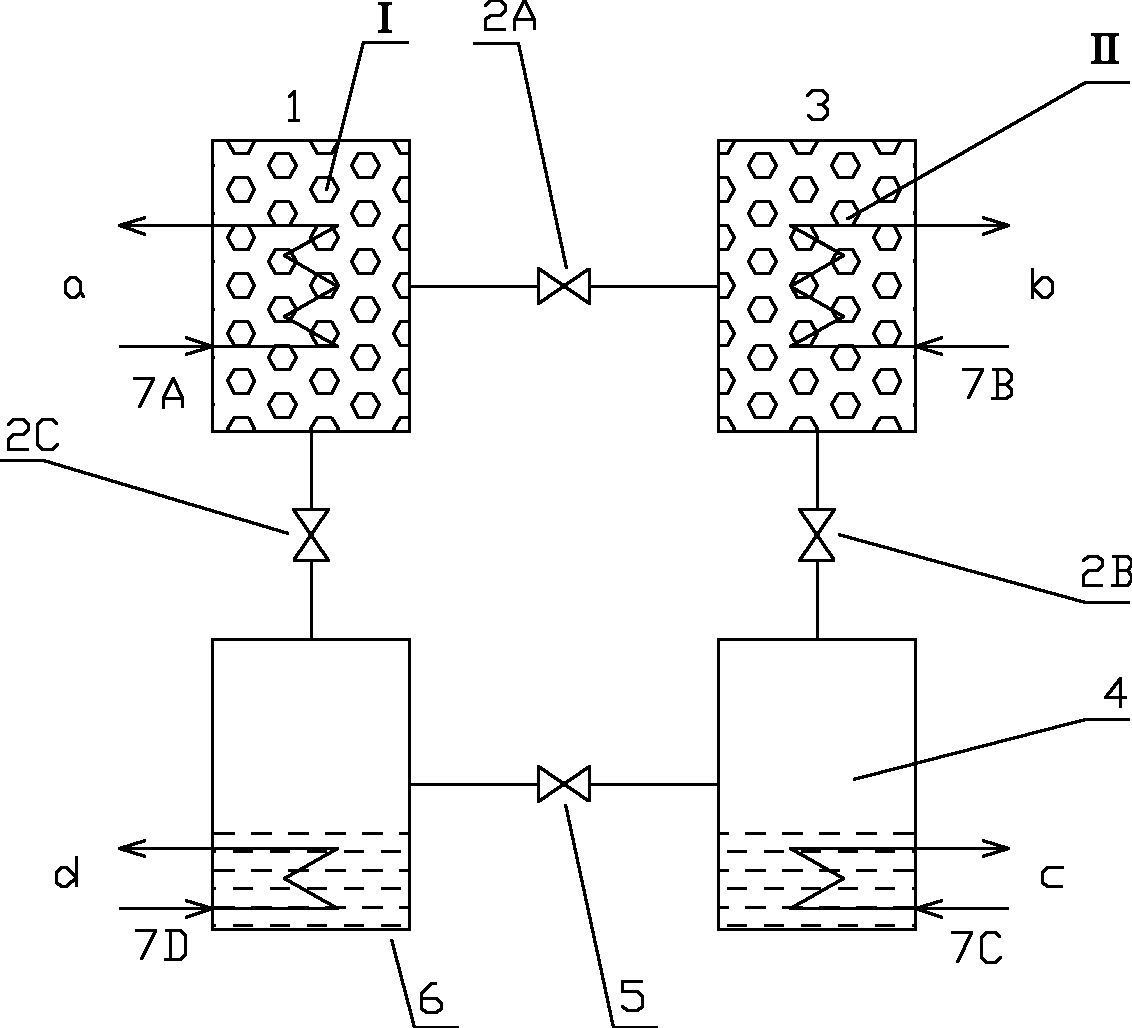

Double-stage adsorption refrigerating recycling system

InactiveCN102679616ALow desorption temperatureEase of large-scale industrial applicationEnergy efficient heating/coolingClimate change adaptationActivated carbonMolecular sieve

The invention relates to a double-stage adsorption refrigerating recycling system which is characterized by consisting of a primary adsorption bed, a secondary adsorption bed, a condenser, an evaporator, a heat exchange tube, a valve and an auxiliary pipeline. Heteroatom SAPO-34 molecular sieves are filled in the primary adsorption bed; and hydrophobic silica gel, activated carbon, pure silicon molecular sieves and at least one of MCM (mesoporous crystalline material) series mesoporous silica materials are filled in the secondary adsorption bed. A desorption process of the primary adsorption bed can be greatly improved by an adsorption effect of the secondary adsorption bed of the double-stage adsorption refrigerating recycling system, and the temperature of a driving heat source of the primary adsorption bed is reduced. The double-stage adsorption refrigerating recycling system has the advantages of low desorption temperature and high adsorbent recycling adsorption quantity, reduction of the size of the system is facilitated, and the efficiency of the adsorption refrigerating system is improved.

Owner:NANJING UNIV OF TECH

Coal flotation and desulfuration combined inhibitor and application thereof

ActiveCN105331421AReasonable designFacilitate large-scale industrial applicationSolid fuelsEthyl acetateBULK ACTIVE INGREDIENT

The invention relates to a coal flotation and desulfuration combined inhibitor and an application thereof, and belongs to the technical field of coal washing and dressing. The coal flotation and desulfuration combined inhibitor is prepared from, by mass, 60% to 80% of active ingredient, 10% to 20% of accelerant and 10% to 20% of organic solvent. The active ingredient is selected from at least one of carboxymethylcellulose, humic acid, humate and tannin. The accelerant is selected from at least one of sulfuric acid, muriatic acid and nitric acid. The organic solvent is selected from at least one of acetic acid, ethanol, ethyl acetate and acetone. According to the designed desulfuration inhibitor, after flotation and desulfuration are carried out on sulphur coal, the vast majority of inorganic sulfur and part of organic sulfur can be removed, so that the total sulphur content of obtained clean coal products is below 1%. The desulfuration inhibitor is reasonable in ingredient design, and large-scale industrial application is facilitated.

Owner:SHENZHEN RUICHENG SHIDAI IND CO LTD

Iron-based high-damping alloy with high thermal conductivity and preparation method thereof

ActiveCN106756595AWith mechanical propertiesWith damping propertiesVibration attenuationMechanical property

The invention discloses an iron-based high-damping alloy with high thermal conductivity and a preparation method thereof. The iron-based high-damping alloy comprises the following components in percentage by weight: 6-8% of Cr, 1-2% of Si, 4-6% of Al, 1.5-2.5% of Hf, 4-9% of Cu, 1-2% of B, 2.5-4.5% of Sn, 2-3% of Co and the balance of Fe. The iron-based high-damping alloy with high thermal conductivity has the mechanical property and damping capacity of the traditional iron-based high-damping alloy: the tensile strength is 540-550 MPa, the elasticity modulus is 80-85 GPa, the yield strength is 240-280 MPa, the elongation is 24-32%, and the SDC is 30-34%. On the basis of ensuring the damping capacity and mechanical property of the existing iron-based high-damping alloy for deformation, the thermal conductivity of the alloy is increased to 110-150 W / m.K from about 60-90 W / m.K and the alloy can be applied to occasions of higher temperature and vibration attenuation on a large scale.

Owner:NINGBO SYRNMA METAL MATERIALS CO LTD

Lead recycling method and device for perovskite battery

ActiveCN107513618AAvoid pollutionImprove effective usePhotography auxillary processesWaste accumulators reclaimingOrganic solventWaste material

The invention relates to a lead recycling method for a perovskite battery. The lead recycling method comprises the following steps that the perovskite battery is smashed to form fragments; the fragments are soaked in a soaking solution and subjected to solid-liquid separation, and thus a leady separation solution is obtained; the soaking solution comprises an organic solvent which can dissolve perovskite materials; and chemical precipitation operation or electrolysis operation is conducted on the leady separation solution so as to obtain a leady solid body. According to the lead recycling method for the perovskite battery, on one hand, lead is recycled, therefore lead pollution is avoided, and the environment is protected; on the other hand, the recycled lead can be changed into valuable matter from a waste material, and thus the effective utilization of resources is improved. In addition, the lead recycling method for the perovskite battery is simple and practicable, and beneficial for application to a mass industry. The invention further provides a lead recycling device for the perovskite battery.

Owner:KUNSHAN GCL OPTOELECTRONIC MATERIAL CO LTD

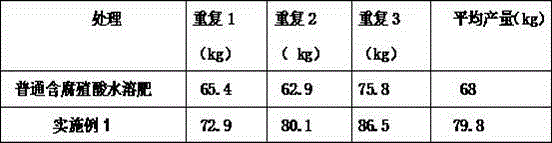

Method for co-producing humic acid containing water-soluble fertilizer by utilizing seaweed extract

InactiveCN105801206APrevent intrusionIncrease contact areaAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDistillationBULK ACTIVE INGREDIENT

The invention relates to a method for co-producing a humic acid containing water-soluble fertilizer by utilizing a seaweed extract. The method comprises the following steps: washing fresh or dried seaweeds, adding the fresh or dried seaweeds to a reaction kettle containing a mixture of a certain mass of water and organic solvents according to a certain mass ratio, stirring the materials at a high speed for pulping (the dried seaweeds need to be soaked to swell and then are pulped), adding a certain mass of wetting and penetrating agents after pulping, soaking and extracting, recovering part of the organic solvents through low temperature and low pressure distillation after soaking at a certain temperature for a period of time, finally obtaining seaweed residues and the seaweed extract through filter pressing, mixing the seaweed extract with macroelement fertilizers and humic acid containing organic matters, heating and stirring the materials until the macroelement fertilizers and the humic acid containing organic matters are completely dissolved and carrying out spray drying, thus obtaining the product. The method has the beneficial technical effects that combining the fertilizers with active ingredients of the seaweeds, the product has obvious effects on improvement of the stress resistance and disease resistance of crops; and besides, being fully water-soluble, the product can meet the requirements of modern agriculture.

Owner:刘彬

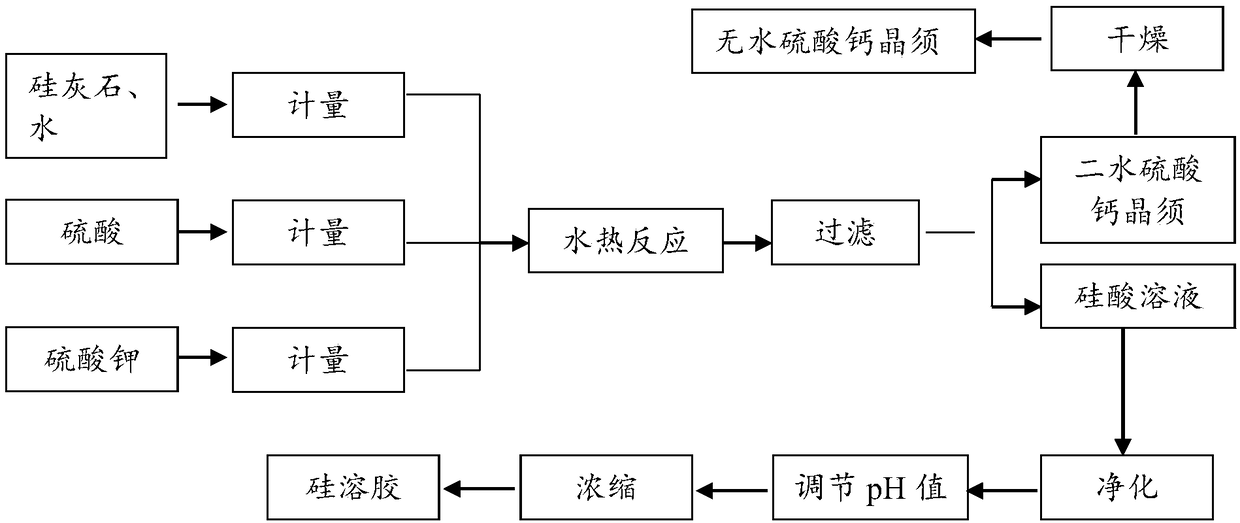

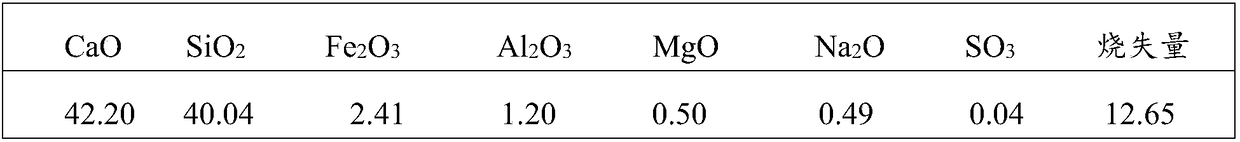

Method for preparing calcium sulfate whiskers and silica sol from low-grade wollastonite

InactiveCN108411356AEfficient use ofIncrease added valuePolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateSilicic acid

The invention provides a method for preparing calcium sulfate whiskers and silica sol from low-grade wollastonite. The method includes steps of carrying out smashing, to be more specific, smashing low-grade wollastonite fine ore with a sedimentation value lower than 60 to obtain wollastonite powder, and measuring the content of CaO in the wollastonite powder; carrying out hydrothermal reaction, tobe more specific, adding the wollastonite powder and water into a reaction kettle, adding sulfuric acid into the reaction kettle after the stirring rotational speeds are stable, uniformly stirring the wollastonite powder, the water and the sulfuric acid, adding potassium sulfate into the reaction kettle, carrying out reaction for 75 min, stopping stirring and carrying out filtering to obtain calcium sulfate dihydrate whiskers and silicic acid solution; preparing the calcium sulfate whiskers, and to be more specific, drying the calcium sulfate dihydrate whiskers to obtain the anhydrous calciumsulfate whiskers; preparing the silica sol, to be more specific, purifying the silicic acid solution, regulating the pH (potential of hydrogen) value of the silicic acid solution and concentrating the silicic acid solution to allow the solution density to reach 1.12 g / cm<3> so as to obtain the silica sol. The method has the advantages that the low-grade wollastonite is used as a raw material, thecalcium sulfate whiskers and the silica sol can be prepared by means of low-temperature hydrothermal reaction, accordingly, the added value can be greatly increased, application markets can be expanded, and the method is simple and is easy to operate.

Owner:黄石海纳新材料科技股份有限公司

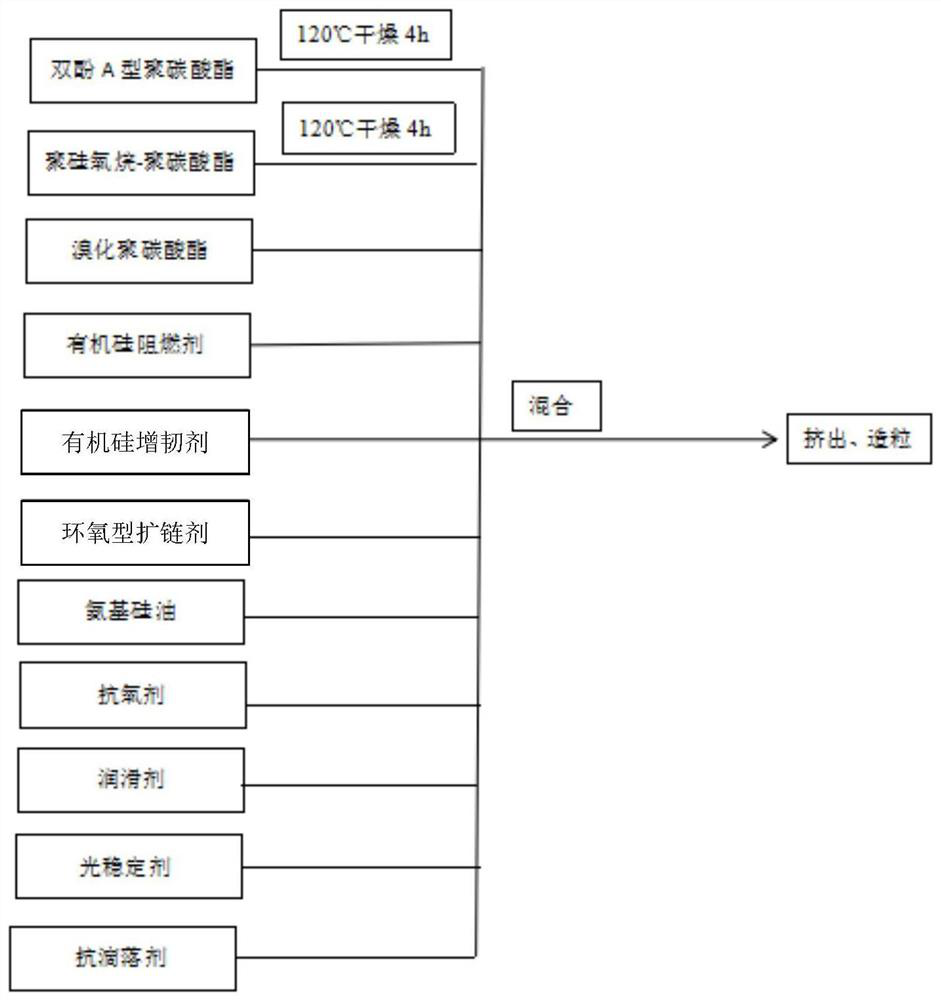

Damp-heat aging resistant polycarbonate composition and preparation method thereof

The invention relates to a damp-heat aging resistant polycarbonate composition and a preparation method thereof. The polycarbonate composition is prepared from the following raw materials, by weight:polycarbonate, polysiloxane-polycarbonate, a flame retardant, a flexibilizer, a chain extender, amino silicone oil, an antioxidant, a lubricant, a light stabilizer and an anti-dripping agent. The chain extender is an epoxy type chain extender; and the toughening agent is an organic silicon toughening agent. The polycarbonate composition disclosed by the invention has very good damp-heat aging resistance, and has good flame retardance and mechanical properties.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Mg-Li-Sn alloy with flame retardance and machining process thereof

The invention discloses a Mg-Li-Sn alloy with flame retardance and a machining process thereof, and unshielded melting of the Mg-Li-Sn alloy under the atmospheric condition can be achieved. The alloyis composed of, by weight, 10.0-12.0% of Li, 2.0-9.0% of Sn, 4.0-6.0% of Sr, 0.2-0.8% of Mn, 0.1-0.2% of Dy, 0.2-0.3% of Ho, 0.8-1.2% of S, 0.2-0.4% of B, and the balance Mg. The solution of a novel material is provided specific to the current situation that a Mg-Li alloy needs shielded melting during melting under high temperature currently. The Mg-Li-Sn flame-retardant alloy with the excellent flame retardance is obtained by an alloying method, and unshielded melting of the Mg-Li alloy under the atmospheric condition is achieved. When the alloy is exposed in the atmosphere under high temperature, an oxide layer and a nitride film are formed on the surface of the alloy. The films are compact in structure and high in spreadability, and the films are solid and not prone to volatilizing under high temperature and can provide excellent protection so that a magnesium alloy melt can be prevented from being further oxidized. The obtained Mg-Li alloy material has the mechanical performance asa traditional Mg-Li alloy under the room temperature, and further has the high heat transfer coefficient which is not possessed by the traditional Mg-Li alloy, specifically, the heat transfer coefficient of the obtained Mg-Li alloy material is 110-120 W / m.K and the heat conductivity coefficient of the traditional material is about 80 W / m.K.

Owner:GUANGZHOU YUZHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com