Patents

Literature

57results about How to "Satisfy the viscosity requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slurry disperse dye and preparation method and appliance

The invention discloses a slurry disperse dye and a preparation method and an appliance, wherein the slurry disperse dye comprises liquid disperse dyes, functional prepolymers and synthetic thickeners, the synthetic thickeners and functional additives are added into the slurry disperse dye to prepare trace printing paste, and can complete printings of polyester fabrics on a common rotary screen printing machine or a screen printing machine, then printed polyester fabrics are prepared through a heat-setting stenter in 180 DEG C-210 DEG C for 45-120s. The slurry disperse dye has the advantages of short printing process when being used for polyester fabric printings, is soft in fabric handing, does not need post process, saves a lot of water and energy consumption, nearly does not have discharge amount of waste water, uses common equipment as process equipment, and is a green printing process technology.

Owner:SUZHOU UNIV

Streptococcus thermophilus and application thereof

InactiveCN105886434AWell organizedImprove textural properties such as tissue stateMilk preparationBacteriaFlavorImmunologic Competence

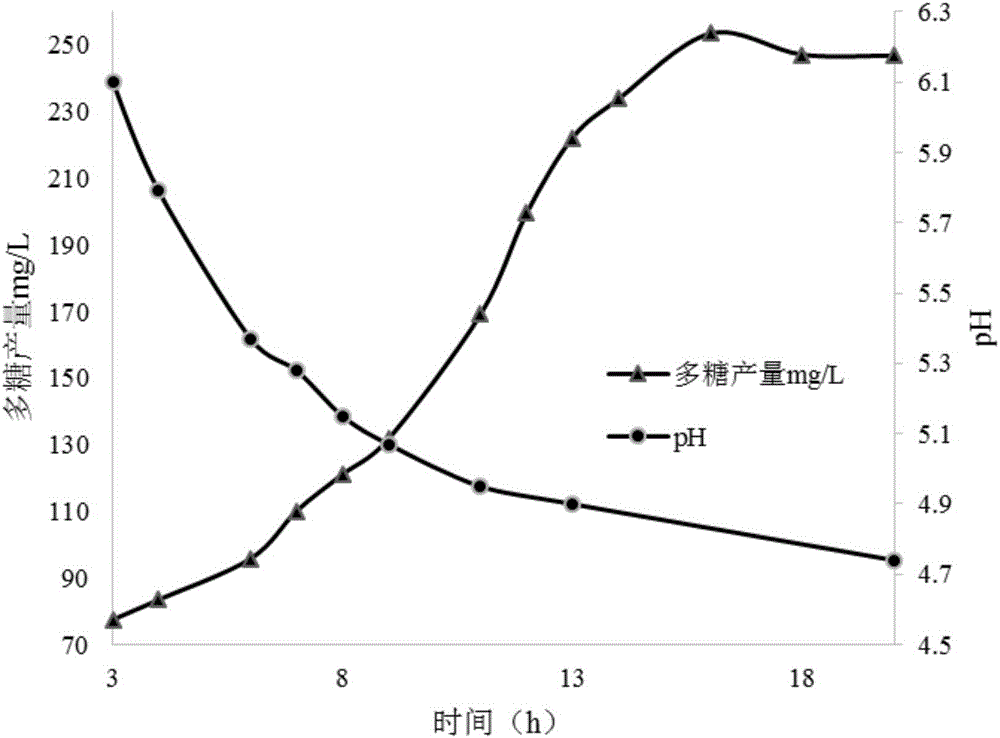

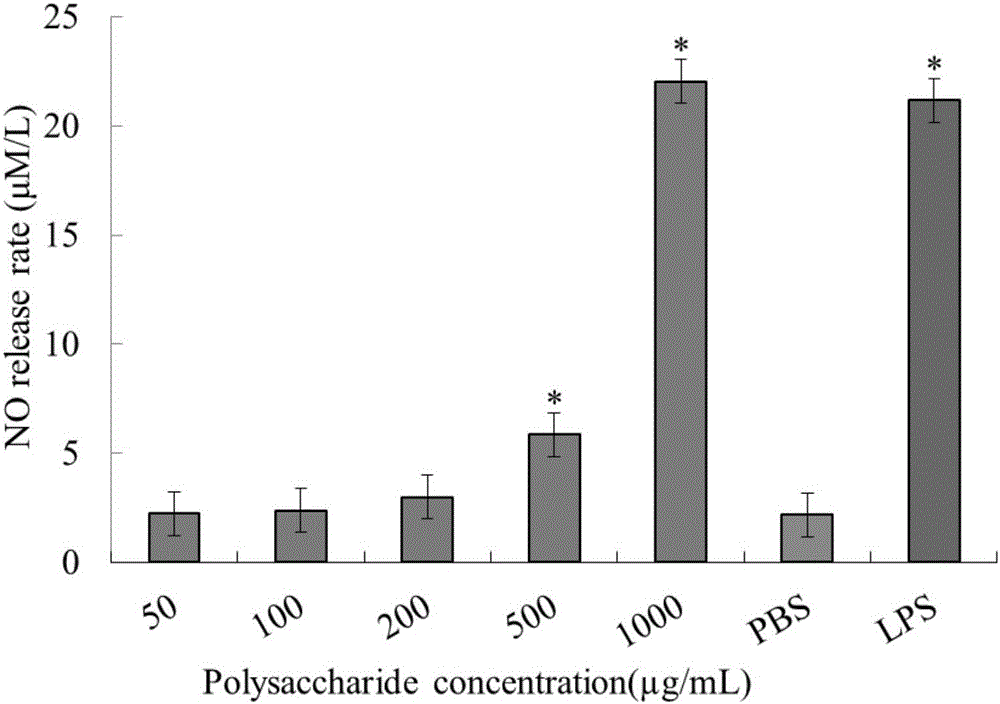

The invention provides a streptococcus thermophilus AR-333 strain and application thereof. The streptococcus thermophilus AR-333 strain is obtained through being separated from naturally fermented milk, and the collection number of the strain is CGMCC 10262. The streptococcus thermophilus AR-333 is fermented for 16h under the condition of 40 DEG C by skimmed milk; the yield of extracellular mucopolysaccharide reaches 256.97 mg / L; meanwhile, the streptococcus thermophilus is used as a yoghourt fermenting agent; the viscosity of yoghourt can be obviously improved; the tissue state of the yoghourt can be improved; good flavor is realized; the generated extracellular mucopolysaccharide has an immunologic competence regulating function; macrophages RAW264.7 can be simulated to release NO.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

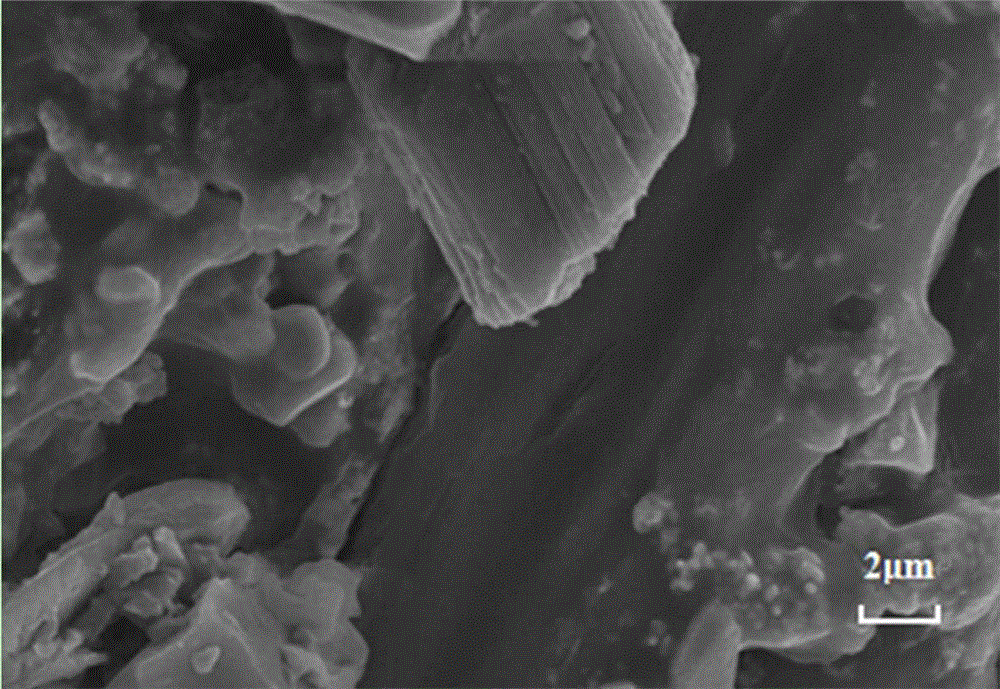

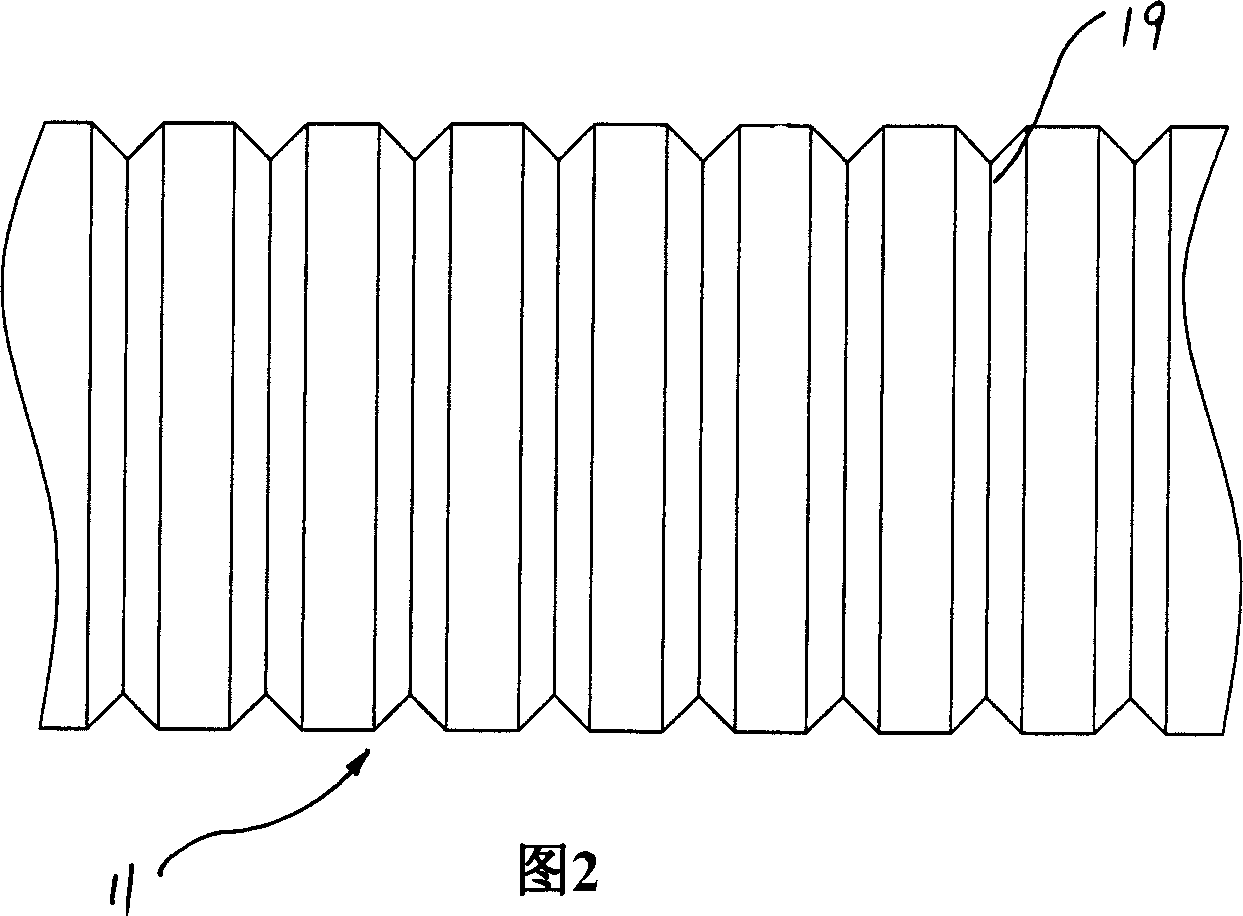

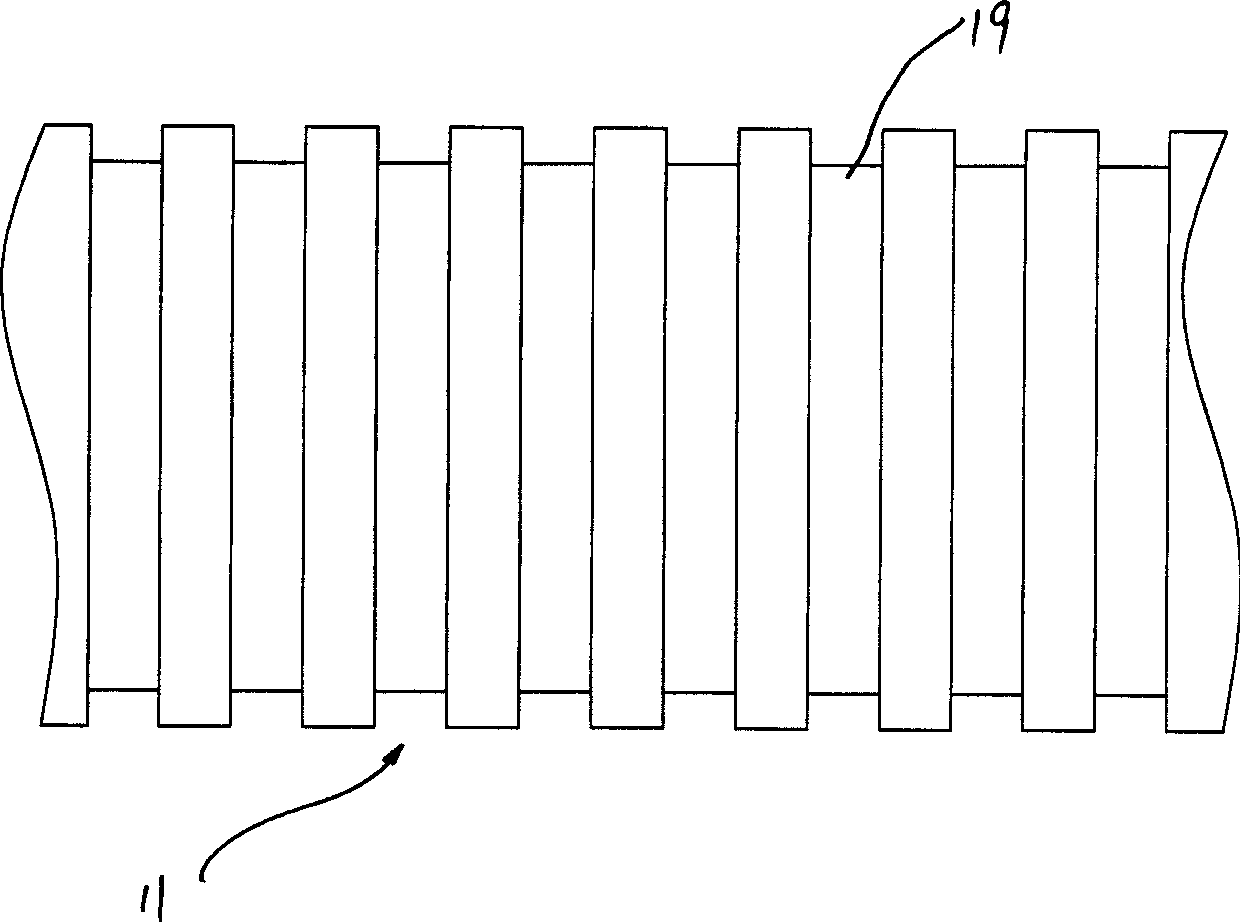

Preparing method for multi-scale nano particle interlayer toughening composite material

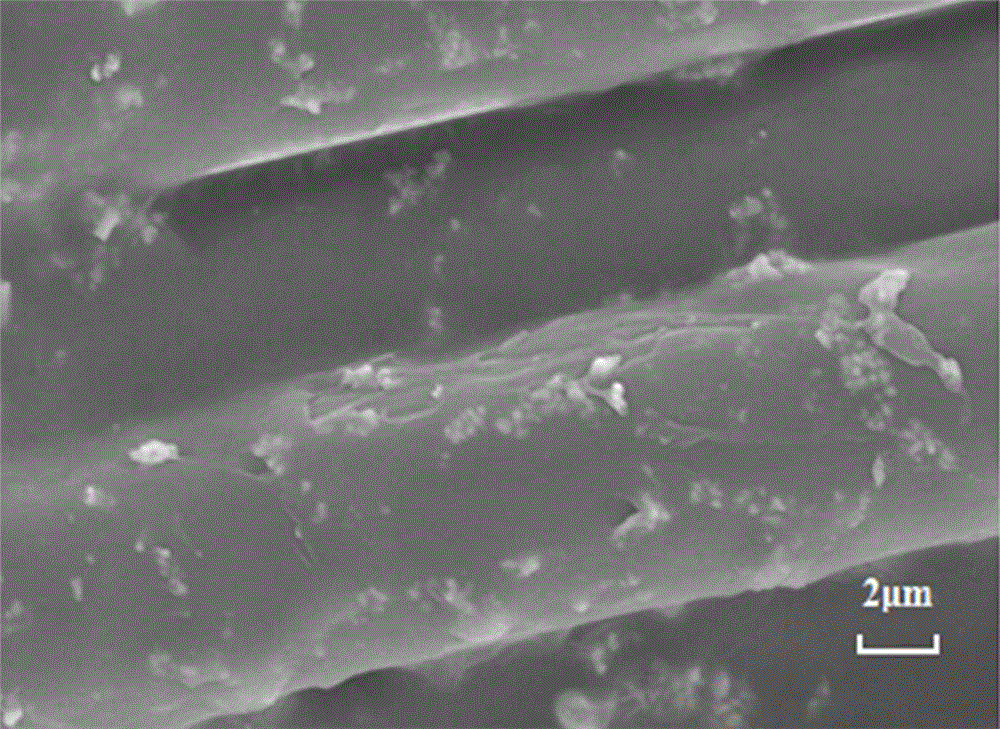

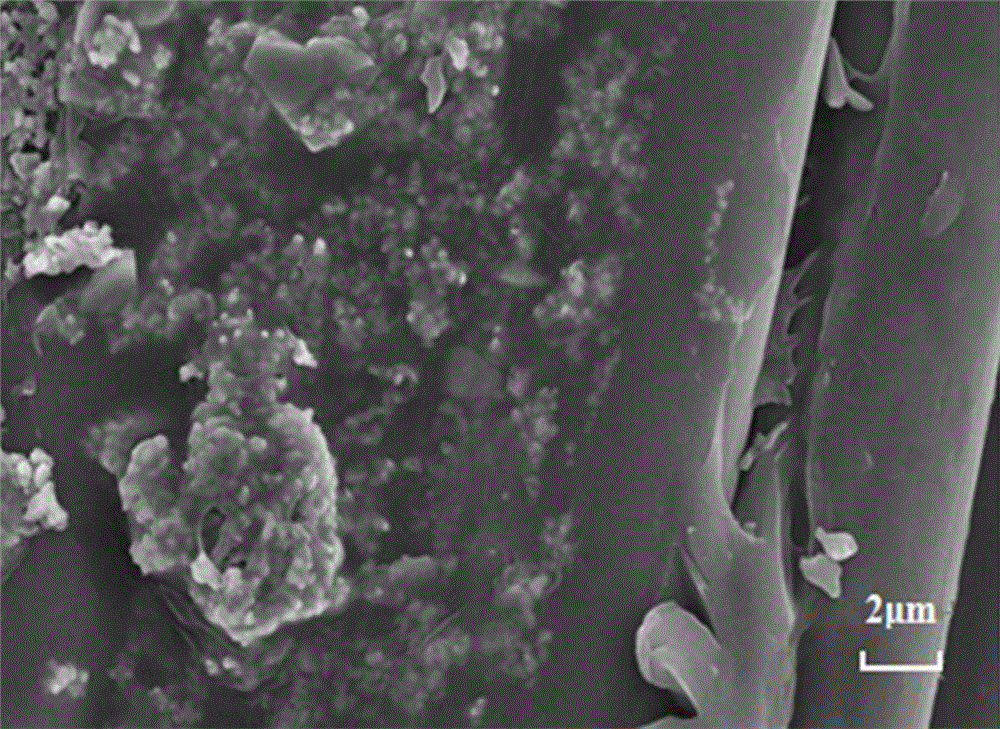

ActiveCN104945852ASatisfy the requirement of viscosityThe modification principle is simpleFiberHigh intensity

The invention relates to the technical field of composite materials, in particular to a preparing method for a multi-scale nano particle interlayer toughening composite material. Modified micron particles and nano particles exist at a composite material interlayer at the same time, so that a toughening composite material is coordinated. Compared with the prior art, the preparing method for the multi-scale nano particle interlayer toughening composite material has the advantages that the viscosity of a matrix resin is not changed, the requirement for low resin viscosity by a RTM forming technology is met, and meanwhile the modified particles can be in linkage with fibers in a high strength mode through chemical crosslinking. The modified principle for raw materials is simple, the technology is mature, the prepared composite material cannot lose the thermal property, the mechanical property is good, the interlayer fracture toughness is greatly improved, and the requirement for high-performance composite material by the modern industry can be met. The preparing method is simple, environmentally protected, low in cost, and wide in application prospect.

Owner:ZHONGBEI UNIV

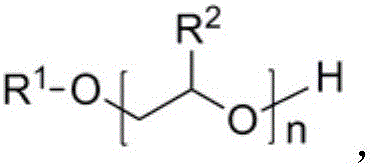

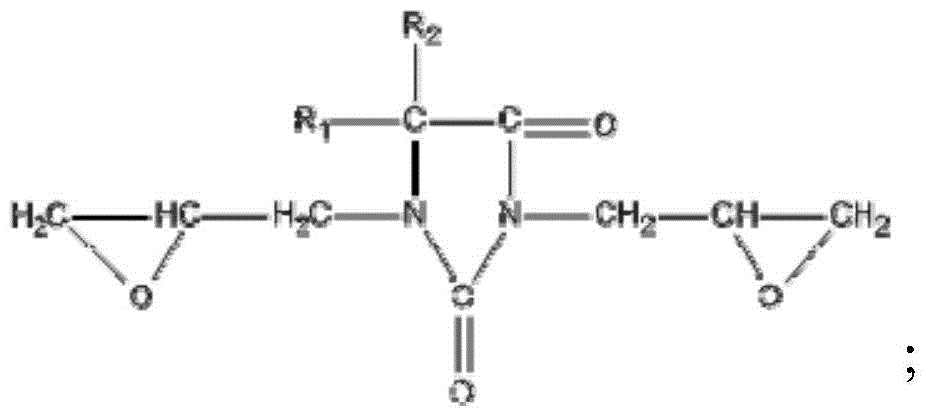

Quantum dot ink and preparation method thereof

The invention is applicable to the technical field of quantum dot light emission, and provides a quantum dot ink and a preparation method thereof. The quantum dot ink comprises the following components in percentage by weight: 0.01-20.0% of quantum dot, 0.01-40.0% of viscosity modifier and 40.0-95.0% of solvent. The viscosity modifier is compounds disclosed in the specification, wherein R1 and R2 are independently selected from hydrogen, alkyl, aryl or hetetoaryl, and n is 2-20.

Owner:TCL CORPORATION

Trace amount of printing paste and preparation method and application thereof

ActiveCN105113284AReduce water consumptionReduce sewage dischargeDyeing processPrepolymerEnergy consumption

The invention discloses a trace amount of printing paste and a preparation method and application thereof. The printing paste is composed of liquid disperse dyes, a function prepolymer, a synthetic thickener, a functional addition agent and water. The trace amount of prepared printing paste can finish printing of a polyester fabric on a conventional rotary screen printing machine or a screen printing machine; high-temperature processing is performed through a tentering heat setting machine, the temperature is 180-210 DEG C, the time is 45-120 seconds, and a polyester printing fabric is prepared. The printing paste is used for printing and is characterized in that the printing process is short, the fabric is soft in touch, afttertreatment is not needed, plenty of water resources are saved, plenty of energy consumption is reduced, and there is almost no waste water emission. Processing devices are all conventional devices, and the preparation method is a green printing processing technology.

Owner:SUZHOU UNIV

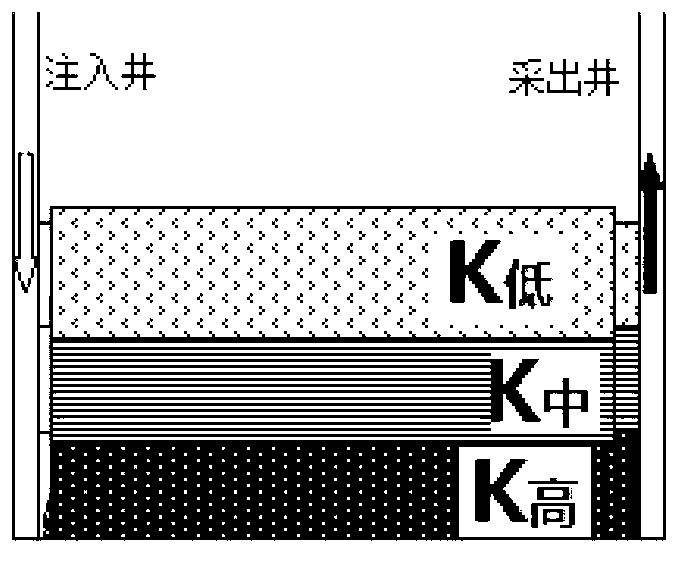

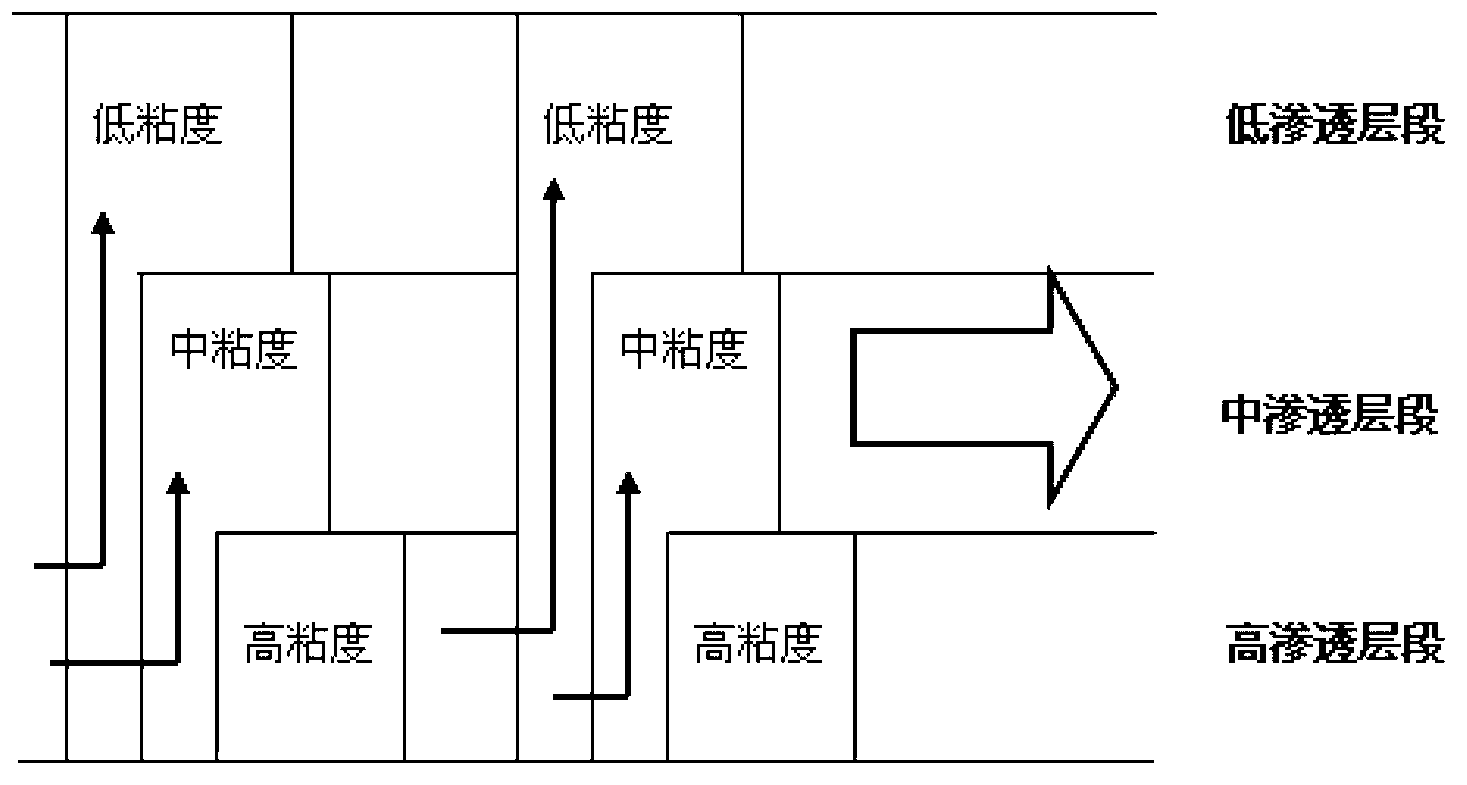

Heavy oil displacement method using wedged vicious slug

The invention relates to a heavy oil displacement method using a wedged vicious slug. The method includes the steps of 1, dividing a nonhomogeneous reservoir into a plurality of layers according to water absorbing capacities, and acquiring permeability Ki of each reservoir; 2, designing three slugs, namely a pre-slug, a main wedged slug and a trailed slug, according to the permeabilities Ki and the physical properties in heavy oil and reservoirs; 3, alternately injecting the heavy oil reservoir with the pre-slug which is prepared with low-concentration B III-type poly-surfactant and which enters a high permeability layer to emulsify crude oil; 4, injecting the reservoirs with the main wedged slug for multiple rounds; and 5, injecting the trailed slug with low-concentration B III-type poly-surfactant or fresh water generally. In each round, the main wedged slug is divided into three small slugs; the small slugs in each round are combined by regulating the corresponding concentrations by the B III-type poly-surfactant according to formation permeability. According to the method, the nonhomogeneous heavy oil reservoirs are emulsified to reduce viscosity, the wedged equivalent vicious slug is used for equi-fluidity displacement, and swept volume is increased; accordingly, recovery efficiency of heavy oil can be further increased, investment can be reduced and operation can be simplified.

Owner:DAQING DAHUA HONGYE PETROLEUM ENG TECH

Function prepolymer and preparation method and application thereof

The invention discloses a function prepolymer and a preparation method and application thereof. The function prepolymer is a butyl acrylate polymer and prepared from a monomer, modified matter and an emulsifying agent through emulsion polymerization. A synthetic thickener, liquid disperse dye and the function prepolymer are mixed with water and evenly stirred to obtain printing paste; printing and drying of a polyester fabric are achieved through the obtained printing paste on a rotary screen printing machine or a mobile screen printing machine, then high-temperature processing is carried out on a tentering heat setting machine, and a printed polyester fabric is obtained. According to the technical scheme, the printing process is short, the hand feeling of the fabric is soft, postprocessing is not needed, a large amount of water and energy are saved, almost no wastewater is drained, processing equipment is conventional, and the printing processing technology is environmentally friendly.

Owner:SUZHOU UNIV

Water polyurethane elastic thin-wall products preparation

A process for preparing the elastic thin-wall product of water polyurethane includews such steps as adding thickneing agent in water polyurethane emulsion, immersing the mould of thin-wall product in it, taking it out, drying and demoulding.

Owner:SICHUAN UNIV

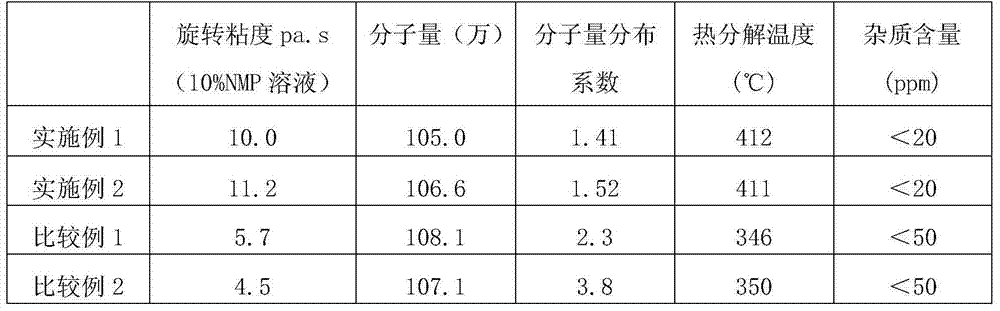

Soap-free emulsion polymerization method of polyvinylidene fluoride for lithium battery electrode binding agent

The invention relates to a soap-free emulsion polymerization method of polyvinylidene fluoride for a lithium battery electrode binding agent. The polymerization method takes a fluorocarbon solvent as a cosolvent, takes water as a dispersion medium, takes inorganic persulfate as an inhibitor and takes an ester as an adjusting agent; a polymerization reaction is carried out at the temperature of 84-86 DEG C and the pressure of 2.0-2.2MPa; the inhibitor and the adjusting agent are continuously added. The method has a moderate polymerization condition; a polymerized product does not contain any emulsifying agent and less impurity content; the size of the molecular weight is moderate and the distribution coefficient is narrow; the product has good thermal chemical stability, moderate viscosity and good processability.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

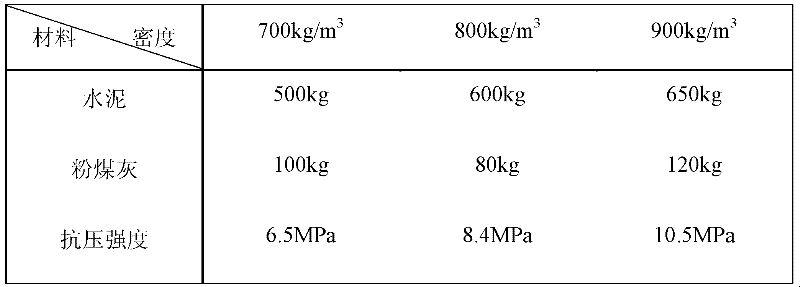

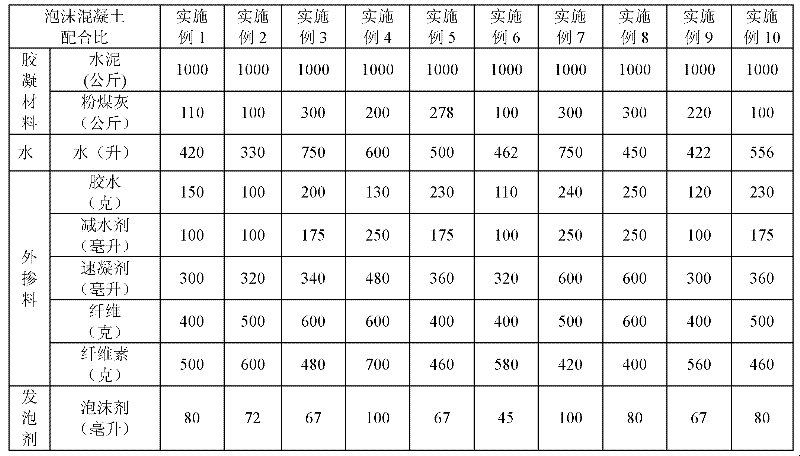

Foam concrete for wet-spraying support of coal mine and preparation method thereof

The invention relates to foam concrete for wet-spraying support of a coal mine and a preparation method. The foam concrete comprises a cementing material, water, an admixture and a foaming agent, wherein the cementing material is prepared from cement and fly ash, and the admixture comprises glue, a water reducing agent, an accelerating agent, fiber and cellulose. The invention can produce the foam concrete which not only has light weight and the functions of fire resistance, crack resistance, dynamic pressure resistance and the like, but also has great viscosity, and is particularly suitable for concrete spraying support operation of the coal mines and underground works. The formula can overcome the shortcomings of high rebound degree, large dust, incapability of ensuring spraying strength and the like during construction of a dry spraying method; and the problems of too fast solidification, pipe blockage and the like of an existing wet spraying method are also solved.

Owner:SHANDONG UNIV +2

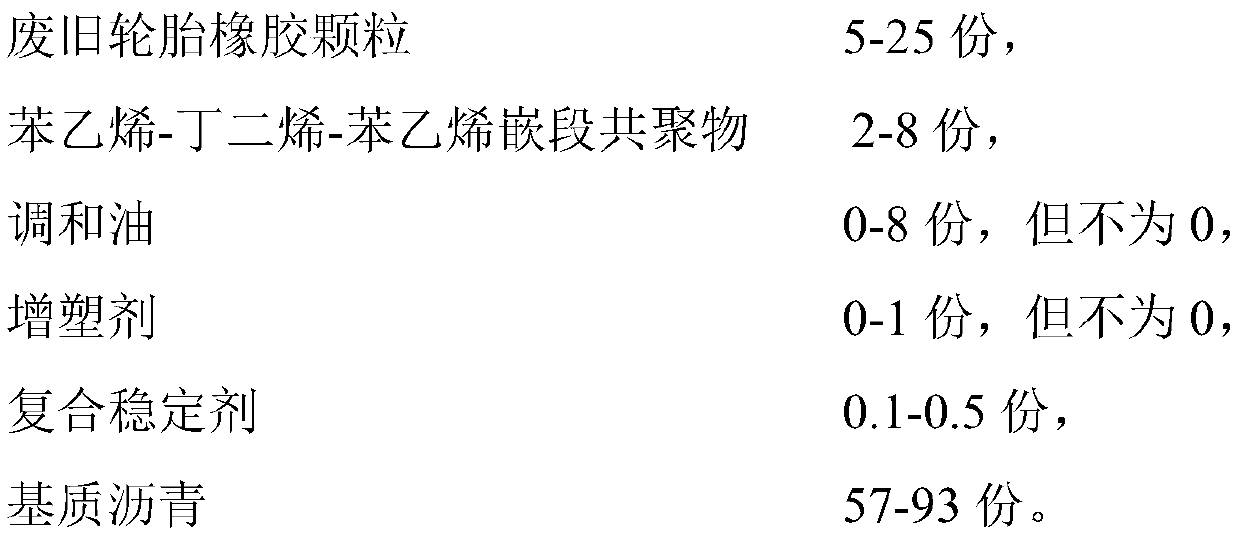

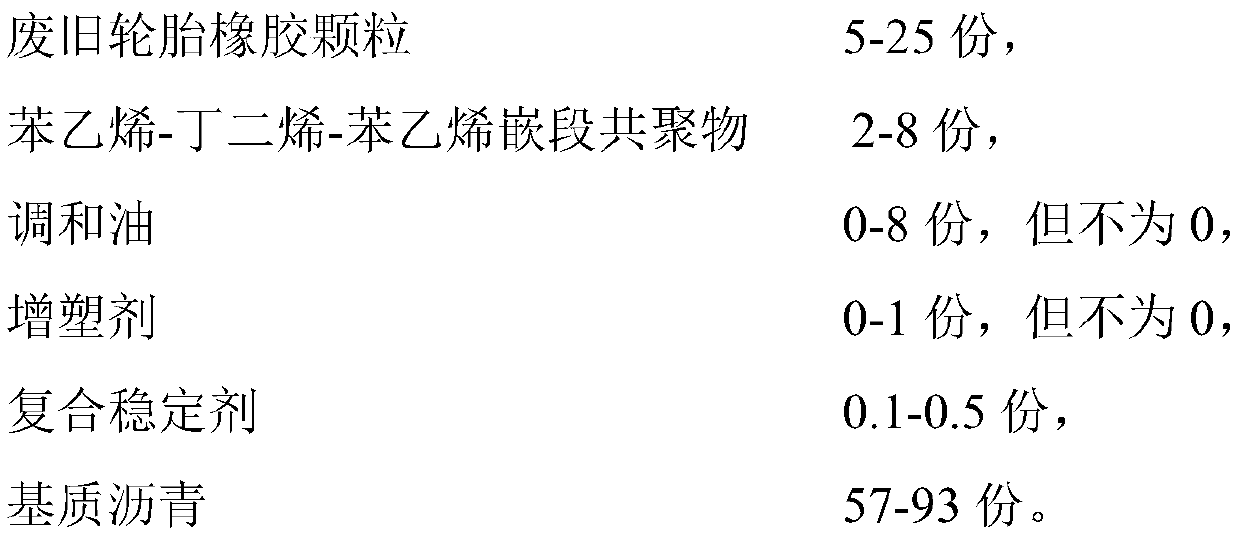

Compounded high-viscosity high-elasticity asphalt material and preparation method therefor

InactiveCN110452550AHigh viscosityIncreasing the thicknessBuilding insulationsPlasticizerBituminous materials

The invention relates to a compounded high-viscosity high-elasticity asphalt material and a preparation method therefor. The asphalt material is prepared from the following ingredients in parts by weight: 5-25 parts of waste tire rubber granules, 2-8 parts of styrene-butadiene-styrene block copolymer, 0-8 (but 0 is exclusive) parts of blend oil, 0-1 (but 0 is exclusive) part of plasticizer, 0.1-0.5 part of composite stabilizer and 57-93 parts of matrix asphalt. Compared with the prior art, the asphalt material prepared by the method has the advantages that the kinetic viscosity at the temperature of 60 DEG C is not smaller than 20,000Pa.s, the recovery of elasticity at the temperature of 25 DEG C is not smaller than 90%, the storage stability at the temperature of 180 DEG C is not greaterthan 4.0 DEG C, the asphalt material has good mechanical properties and storage stability, the high-temperature rut resistance of pervious asphalt concrete can be improved, the low-temperature frost heave resistance of the pervious asphalt concrete can also be improved, the durability of the pervious asphalt concrete is remarkably improved, and the service life of the pervious concrete is prolonged.

Owner:TONGJI UNIV +1

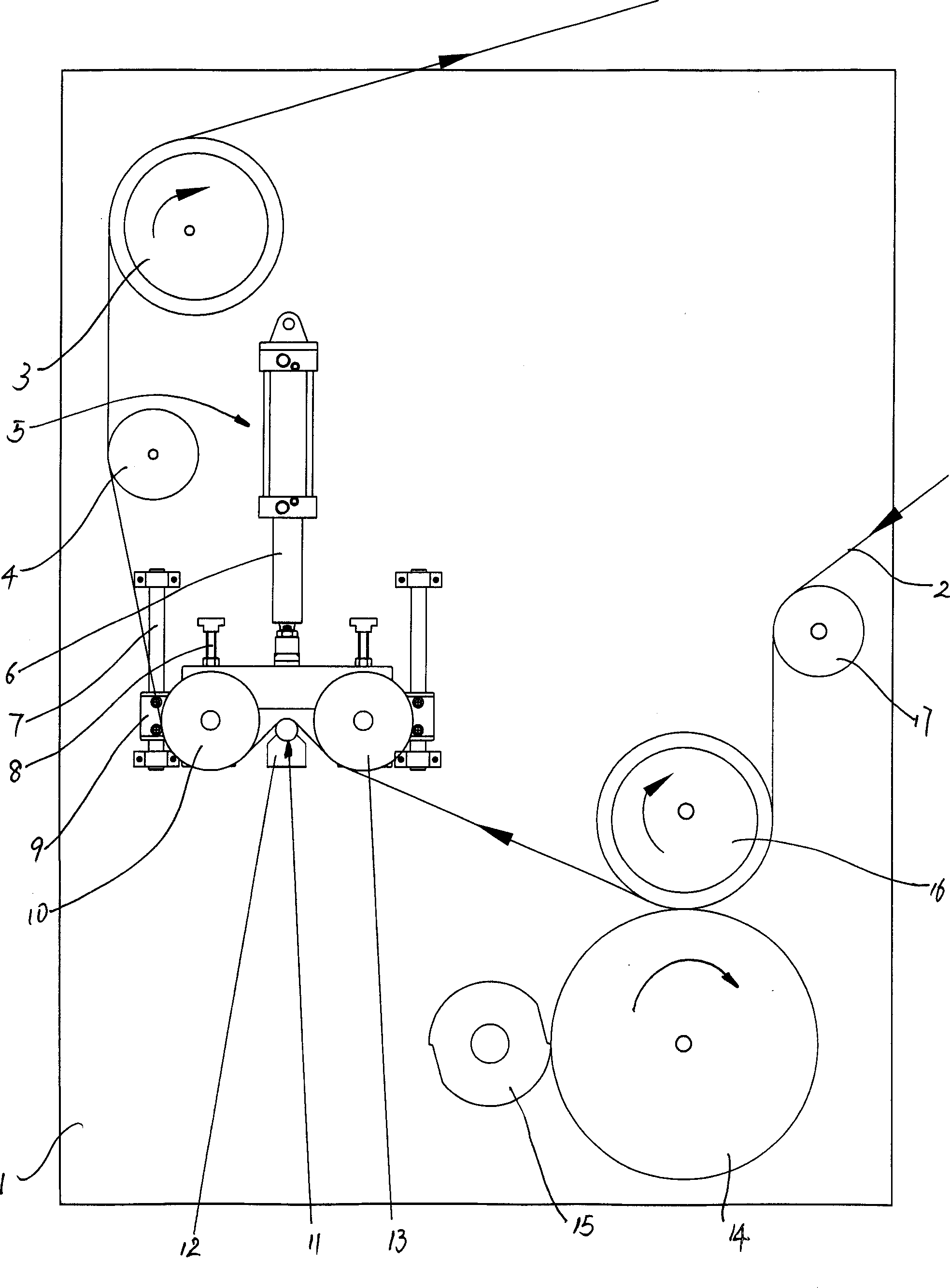

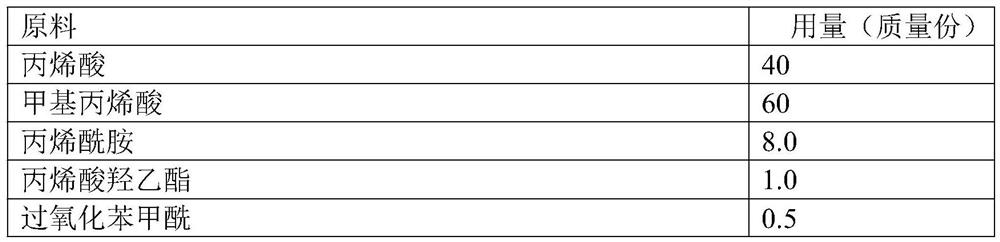

Glue smearing device for coating machine

InactiveCN1861272AUniform coating streaksGood transparencyLiquid surface applicatorsCoatingsAdhesive glueEngineering

A scraper unit for coater is arranged on the coating head between the adhesive applying wheel and baking oven. It is composed of supporting frame, pressing mechanism and adhesive scraping roller on said supporting frame. The coated substrate passes through the gap between said adhesive scraping roller and pressing mechanism for squeezing the adhesive from convex position to concave position, so ensuring sufficient adhesion with less consumption of adhesive.

Owner:林峻

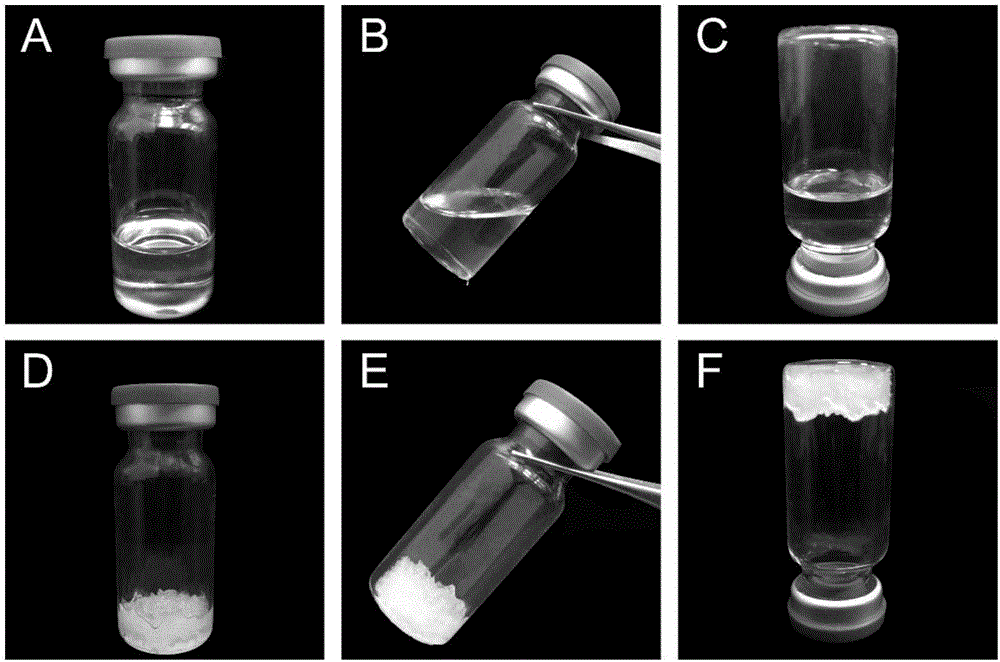

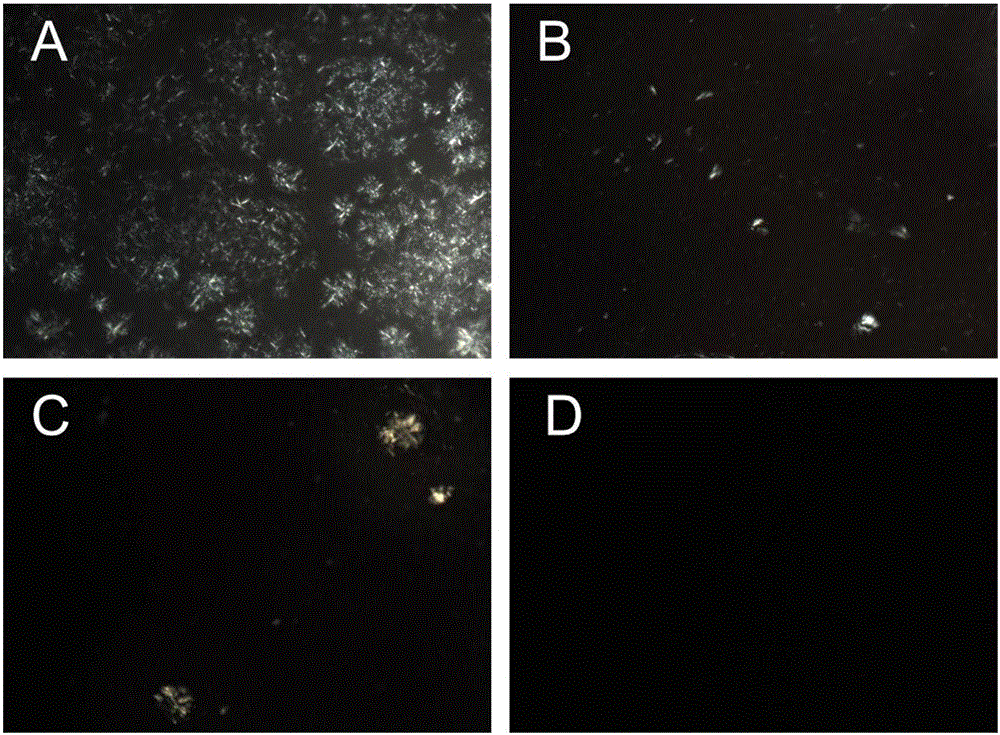

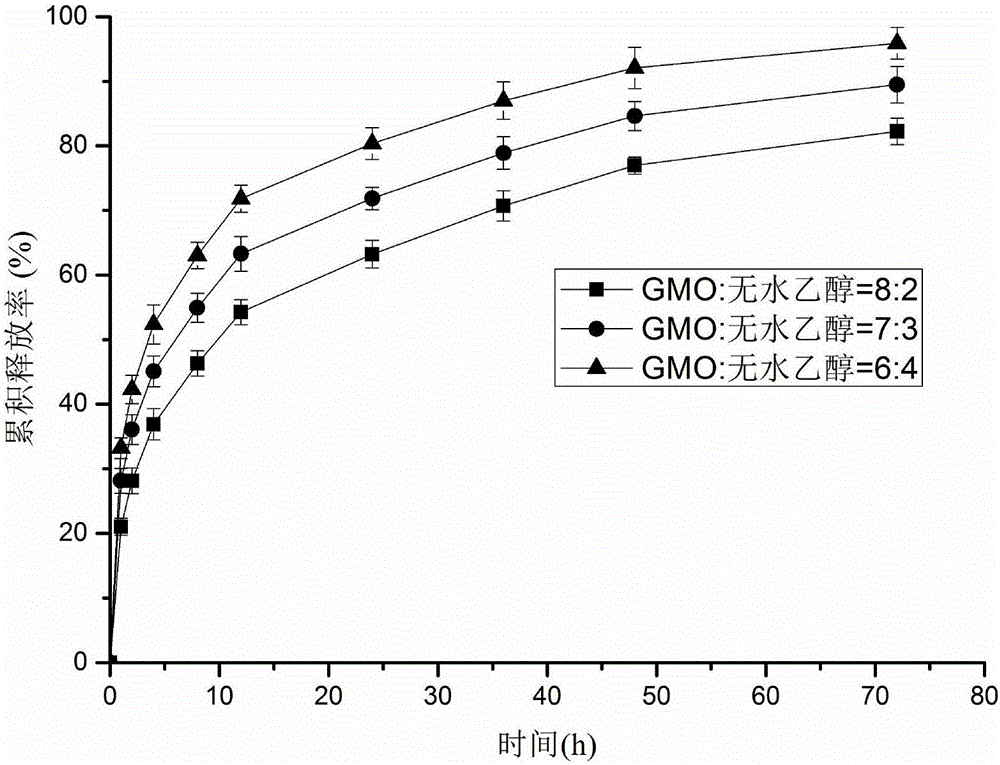

Cubic liquid crystal in-situ gel injection of local anesthetic, and preparation method of injection

ActiveCN106491519AAvoid breedingImprove stabilityAerosol deliveryOintment deliveryMass ratioAmide local anesthetics

The invention relates to cubic liquid crystal in-situ gel injection of local anesthetic, and a preparation method of the injection. The injection is prepared from the local anesthetic, a liquid crystal material and an organic solvent and / or a release regulator; the local anesthetic is amide local anesthetic and the mass concentration of the local anesthetic is 0.1 to 8 w / w%; the organic solvent is an organic solvent which is mutually soluble with water, the liquid crystal material is mono-oleic acid glycerolipid, and the mass ratio of the liquid crystal material to the organic solvent is (1-9):1; and the release regulator is selected from at least one of medium chain triglyceride, oleic acid, tocopherol and tocopheryl acetate, and the mass concentration of the release regulator is 0 to 30 w / w%. The cubic liquid crystal in-situ gel injection of the local anesthetic has very good long-acting sustained release effect, low sudden release raten high compliance and small adverse effect, can reduce administration times and can avoid the peak valley phenomenon.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD

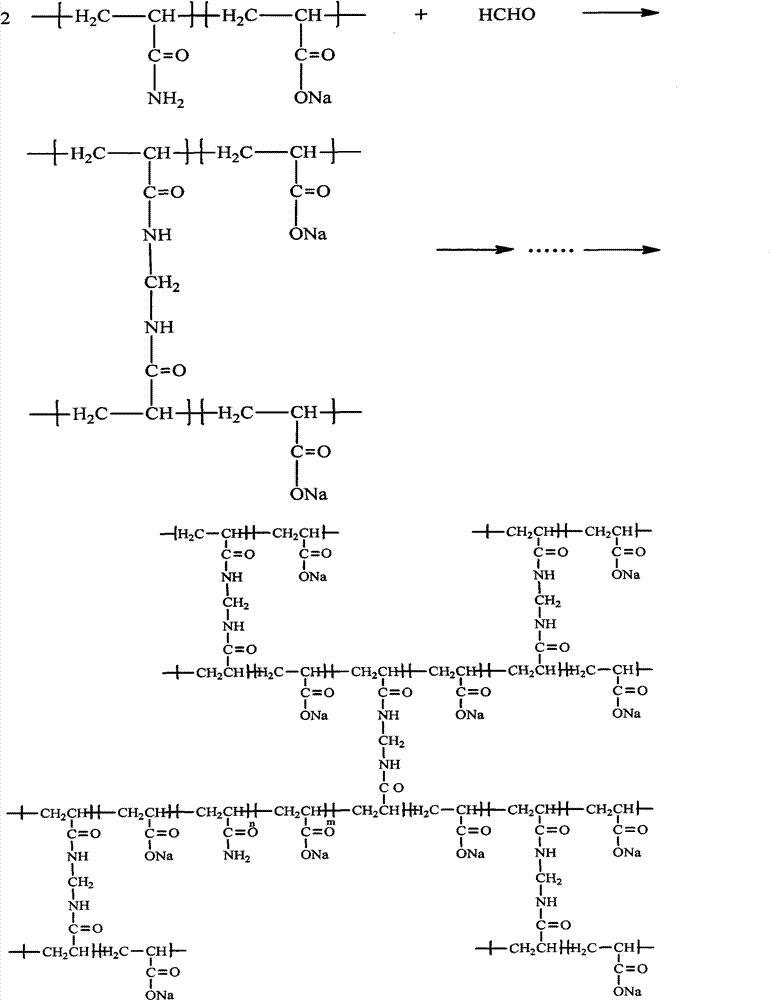

Acryiic acid copolymer/montmorillonite nanocomposite thickener, preparation method and application

InactiveCN106243267ASatisfy the viscosity requirementGood compatibilityVegetal fibresPolyesterSulfite salt

The invention discloses an acryiic acid copolymer / montmorillonite nanocomposite thickener, a preparation method and application. The thickener is prepared from, by weight, 33-67 parts of acrylic acid, 33-67 parts of acrylamide, 8.8-17.8 parts of sodium hydroxide, 3-4 parts of sodium base montmorillonite clay(Na-MMT), 46-60 parts of deionized water, 3 parts of 0.5% ammonium persulfate solution, 1-3 parts of 0.5% anhydrous sodium sulfite solution. The preparation method comprises the steps that 1, raw materials are prepared; 2, instantaneous polymerization is performed; 3, a post treatment is performed. The thickener is a white particle, and is readily soluble in water, 2% of aqueous solution is translucent, the pH is 6-6.5, and the viscosity is 8.1-9.8 s (textile 3 # cup), the viscosity stability is 100%(under the conditions of 1%, 95 DEG C and 2 hours ). The thickener can be used for warp sizing, meets the slurry viscosity requirement of polyester sizing agent for the sizing of staple fibre yarn, and is good in the bubbleless property of the slurry.

Owner:SICHUAN UNIV

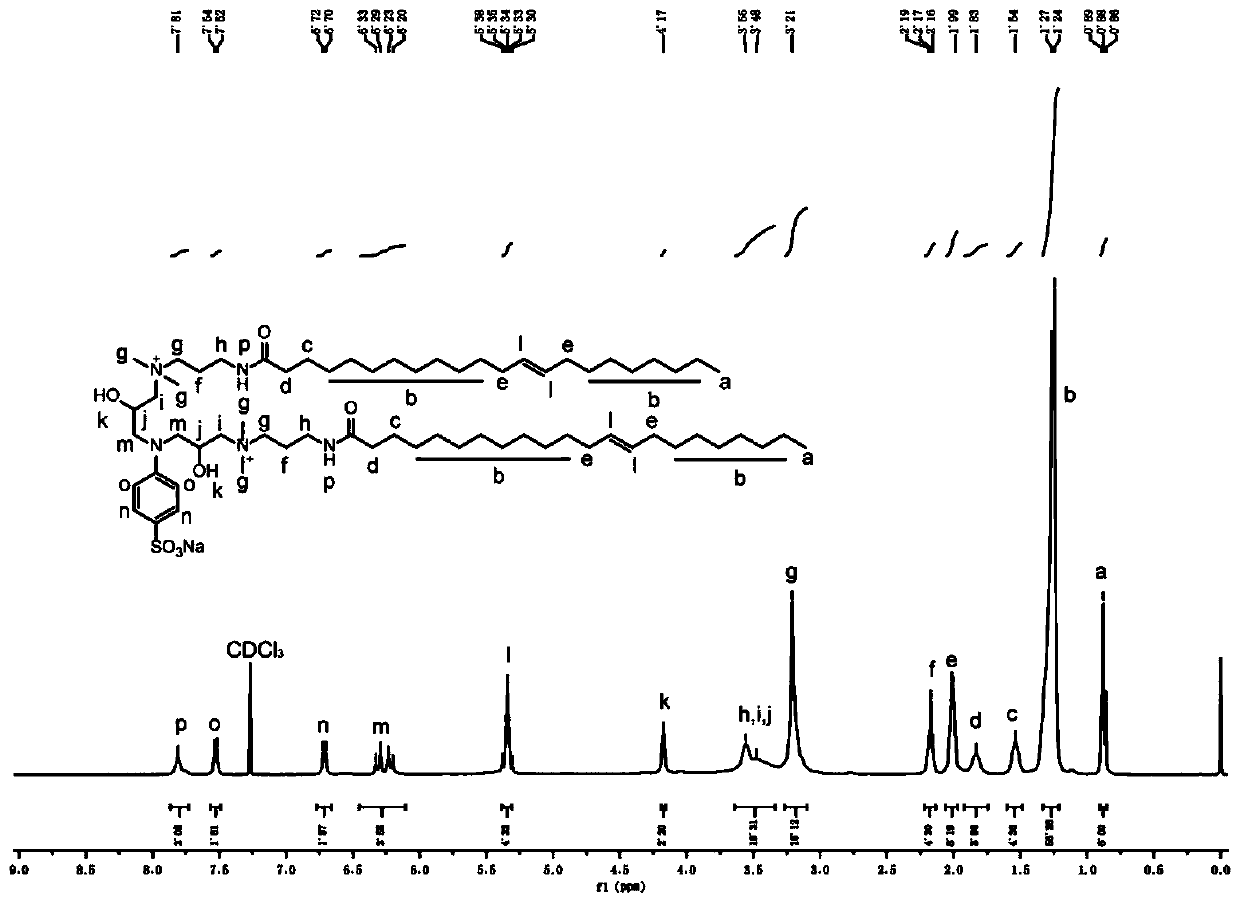

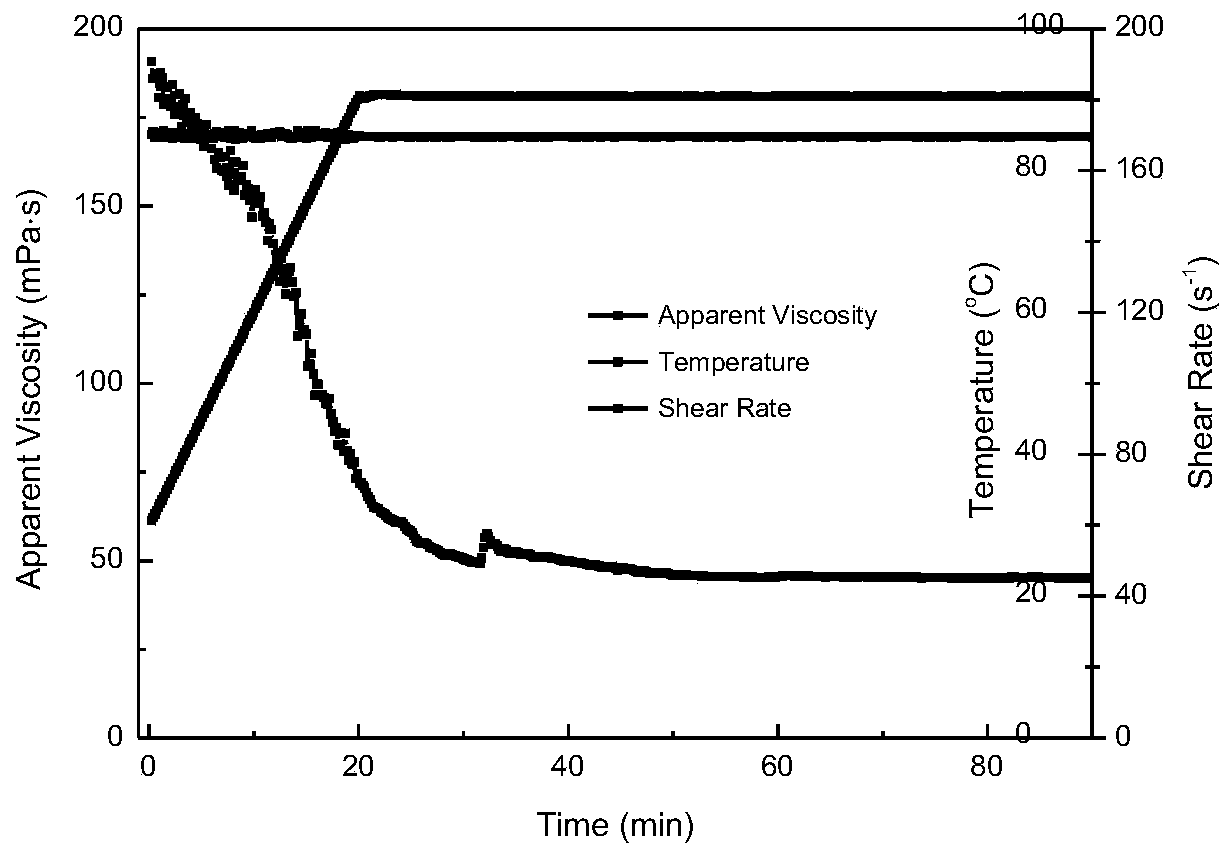

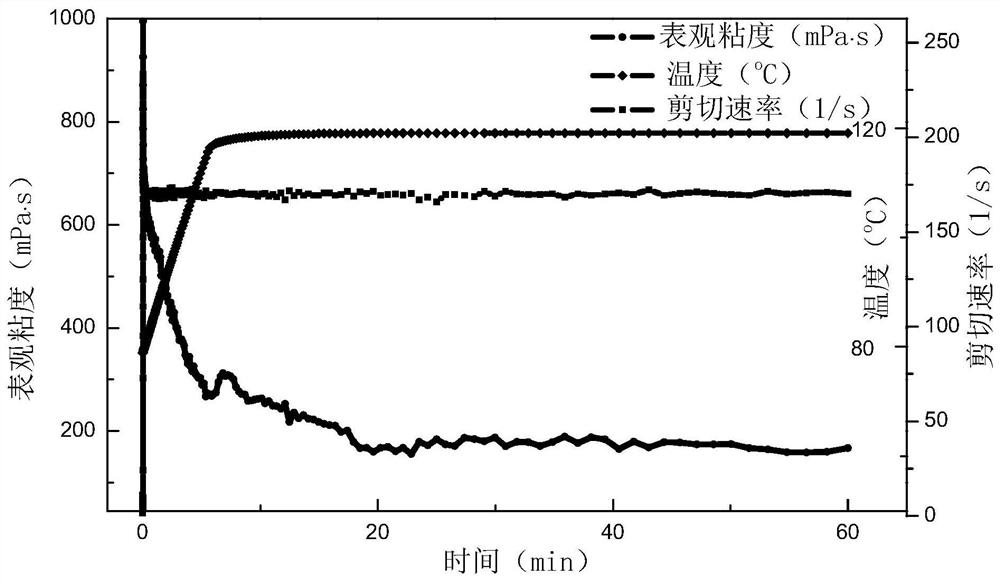

Preparation of sulfonic acid amphoteric double-ion viscoelastic surfactant and application in fracturing fluid

InactiveCN110665431ASatisfy the viscosity requirementGood temperature and shear resistanceTransportation and packagingSulfonic acids salts preparationActive agentFracturing fluid

The invention discloses preparation of a sulfonic acid amphoteric double-ion viscoelastic surfactant and application in fracturing fluid. The preparation method includes: firstly subjecting long-chainaliphatic tertiary amine and epichlorohydrin to quaternization reaction on obtain an intermediate DNPC; and then reacting the DNPC with sodium sulfanilate to obtain the sulfonic acid amphoteric double-ion surfactant VBS. The preparation method disclosed by the invention has the characteristics of high yield, no industrial waste residue and environmental friendliness. In addition, the sulfonic acid amphoteric double-ion viscoelastic surfactant VBS is compounded with an inorganic salt counter ion to obtain a clean fracturing fluid system with excellent rheological properties. The system has theadvantages of strong sand suspending performance, simple on-site preparation, automatic gel breaking and small stratum damage. After 90min of shearing at 90DEG C and under 170s<-1>, the 10mmol / L VBSfracturing fluid system can maintain the viscosity at about 50mPa.S, and can meet the viscosity requirement of site construction for clean fracturing fluid.

Owner:SOUTHWEST PETROLEUM UNIV

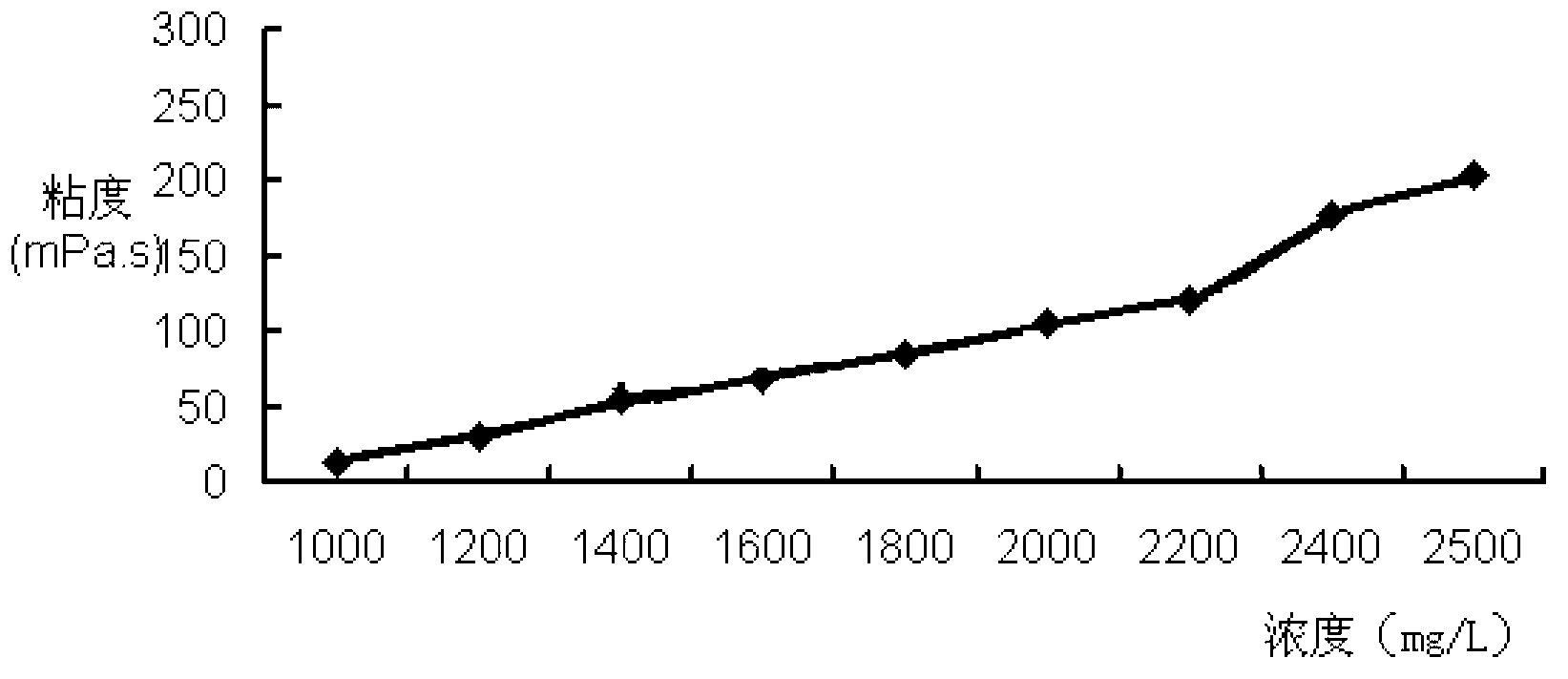

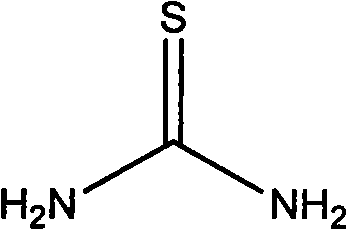

Method for improving viscosity stability of oil field polymer flooding

ActiveCN102952532AOvercoming the problem of excessive dosageReduce loss from oxidative degradationDrilling compositionPolymer scienceThiourea

The invention provides a method for improving the viscosity stability of oil field polymer flooding. With the method, a problem of polymer viscosity reduction under high-temperature and oxygen-containing conditions is solved. The invention adopts anionic polyacrylamide, hexamethylenetetramine, and thiourea. Thiourea is dosed before polymerization, and hexamethylenetetramine is dosed after polymerization, such that polymer solution viscosity stability is greatly improved. With the invention provided by the invention, displacing fluid viscosity stability is greatly improved, and polyacrylamide high-temperature resistance and oxidation resistance are improved. The process is simple, the cost is low, and the material is easy to transport and to store.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing oil-based magneto-rheological hydraulic drive medium

InactiveCN102031187AImprove control effectWide viscosity rangeLubricant compositionEngineeringMagneto rheological

The invention relates to a method for preparing an oil-based magneto-rheological hydraulic drive medium, which comprises the following steps of: sequentially adding 50 to 65 percent of mineral oil, 30 to 40 percent of magnetic particles and 1 to 10 percent of additive according to the proportion, and stirring and mixing to obtain the oil-based magneto-rheological hydraulic drive medium. The oil-based magneto-rheological hydraulic drive medium can realize the movement of a valve core with a few relative sliding pairs or without the relative sliding pair, improves the control performance of a hydraulic element and a hydraulic system, and can meet the requirement of most hydraulic systems on viscosity and the using requirement of the drive medium in the hydraulic system.

Owner:KUNMING UNIV OF SCI & TECH

Winding epoxy resin composition, preparation method thereof and use thereof

InactiveCN101948611AHigh strength, high toughness and impact resistanceImprove high temperature resistanceEpoxyConductor Coil

The invention relates to a winding epoxy resin composition, a preparation method thereof and use thereof, which are used for solving the problems of high viscosity or low toughness and the like of the conventional epoxy resin for use in a winding forming process. The winding epoxy resin composition consists of 100 mass parts of epoxy resin, 30 to 50 mass parts of amine curing agent and 0.5 to 5.0 mass parts of micro molecular compounds having epoxy groups. The wound products have high-strength and high-toughness impact resistance and are improved in manufacturability and flexibility.

Owner:BLUESTAR BEIJING CHEM MACHINERY

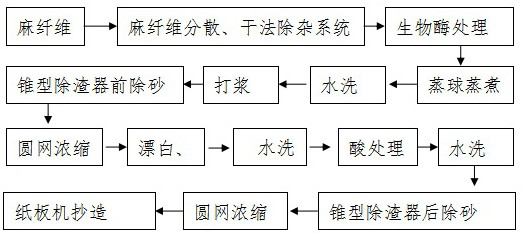

Method for preparing pulp for viscose fiber from hemp for seeds

ActiveCN113062138AReduce COD contentHigh fiber contentPulp bleachingPulping with inorganic basesPolymer sciencePolymer chemistry

The invention discloses a method for preparing pulp for viscose fibers from hemp for seeds. The pulp for viscose fibers has the following indexes: the moisture content is 8-10%; the content of ash is less than or equal to 0.12%; the polymerization degree is 500 to 550; the content of methylcellulose is greater than 92.5%; the content of iron is less than or equal to 30 ppm; the whiteness is greater than or equal to 80%; and the content of small dust is less than or equal to 160 mm<2> / kg. By adopting the scheme, the permeability of the fibers can be improved, and the fibers can be leveled, so that the reaction performance of the fibers can be improved favourably.

Owner:山东银鹰股份有限公司

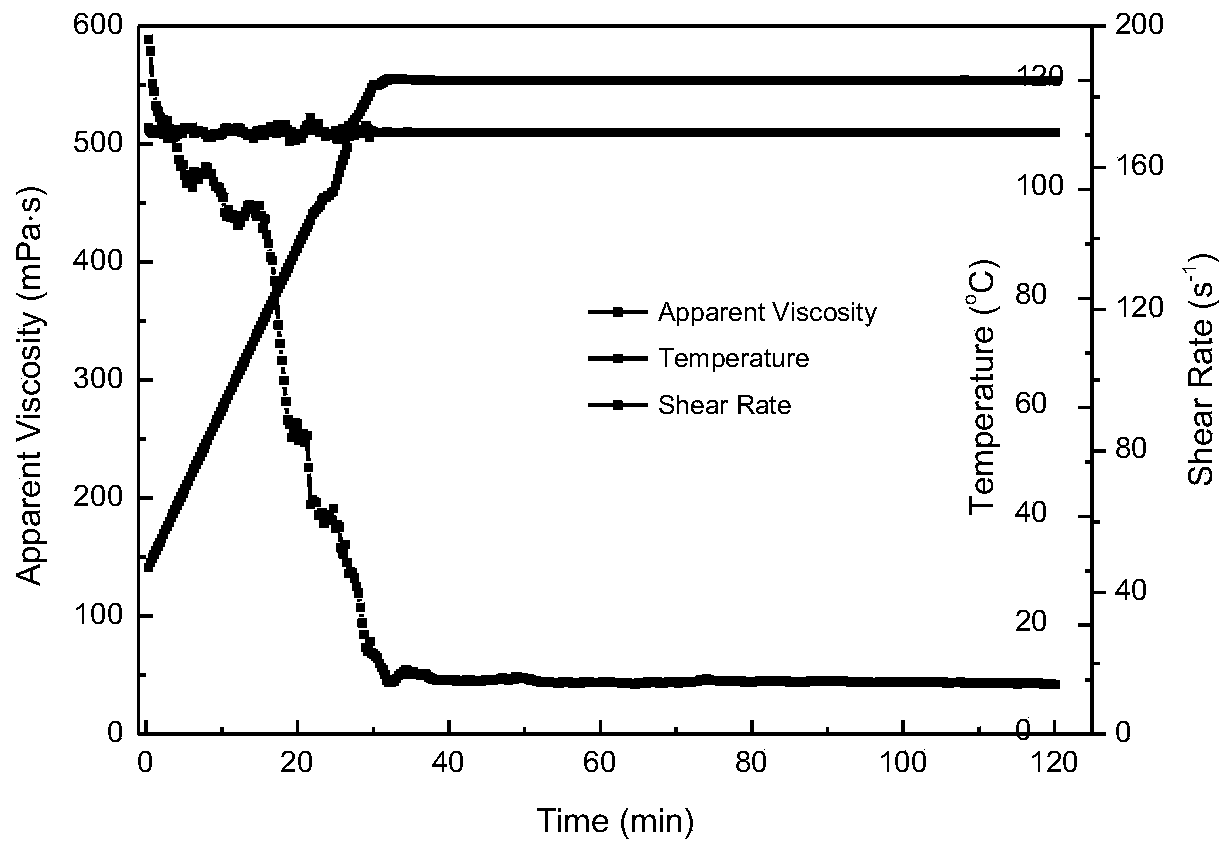

Beta-CD gemini viscoelastic surfactant, preparation method and temperature-resistant and salt-resistant clean fracturing fluid

PendingCN113600095ALow critical micelle concentrationReduce usageTransportation and packagingMixingCritical micelle concentrationInorganic salts

The invention discloses a beta-CD gemini viscoelastic surfactant, a preparation method and a temperature-resistant salt-resistant clean fracturing fluid. The beta-CD gemini viscoelastic surfactant is prepared from a cyclodextrin group, long-chain tertiary amine and epichlorohydrin, the critical micelle concentration of the surfactant is 2-3 orders of magnitude lower than that of a common surfactant, and the prepared surfactant serves as a thickening agent to be used for preparing the clean fracturing fluid. The clean fracturing fluid prepared by compounding the surfactant and counter ion salt or inorganic salt is low in usage amount, the viscosity can be maintained at about 150mPa.s after 60 minutes at the temperature of 120 DEG C and 170s<-1>, the viscosity requirement of on-site construction on the clean fracturing fluid is met, and the clean fracturing fluid has excellent temperature resistance, shearing resistance, viscoelasticity and suspension supporting effect and can be used for fracturing yield increase transformation of high-temperature oil and gas reservoirs.

Owner:SOUTHWEST PETROLEUM UNIV

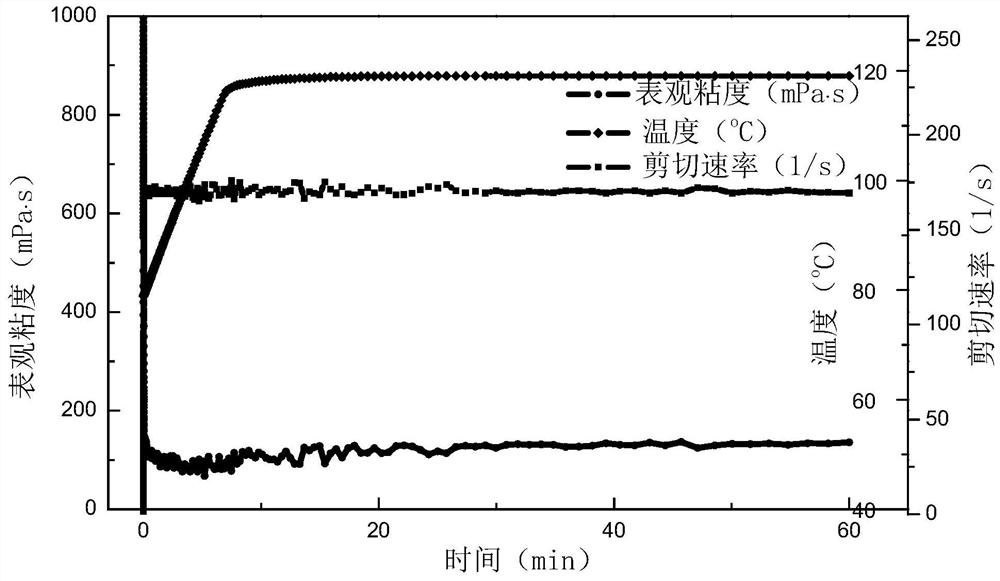

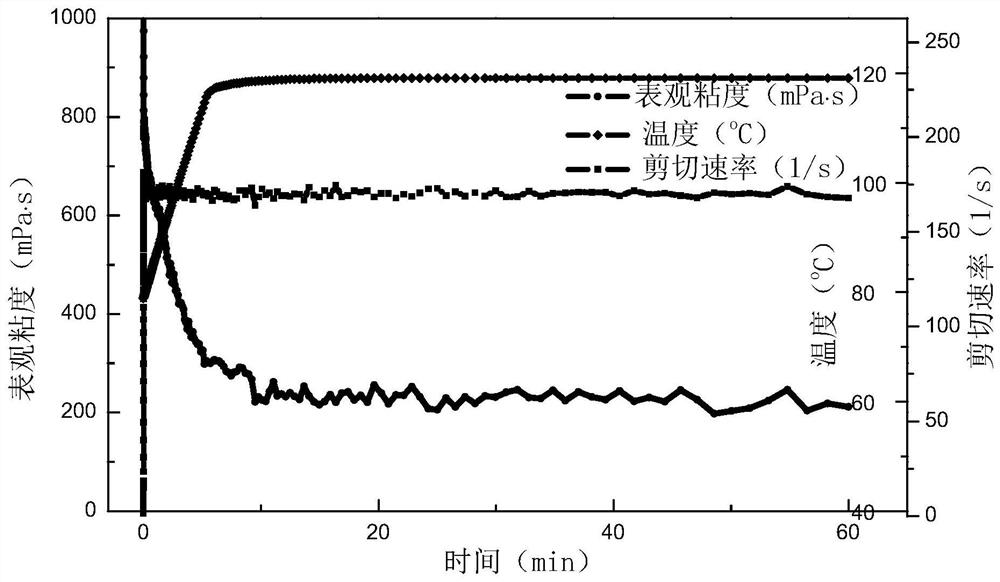

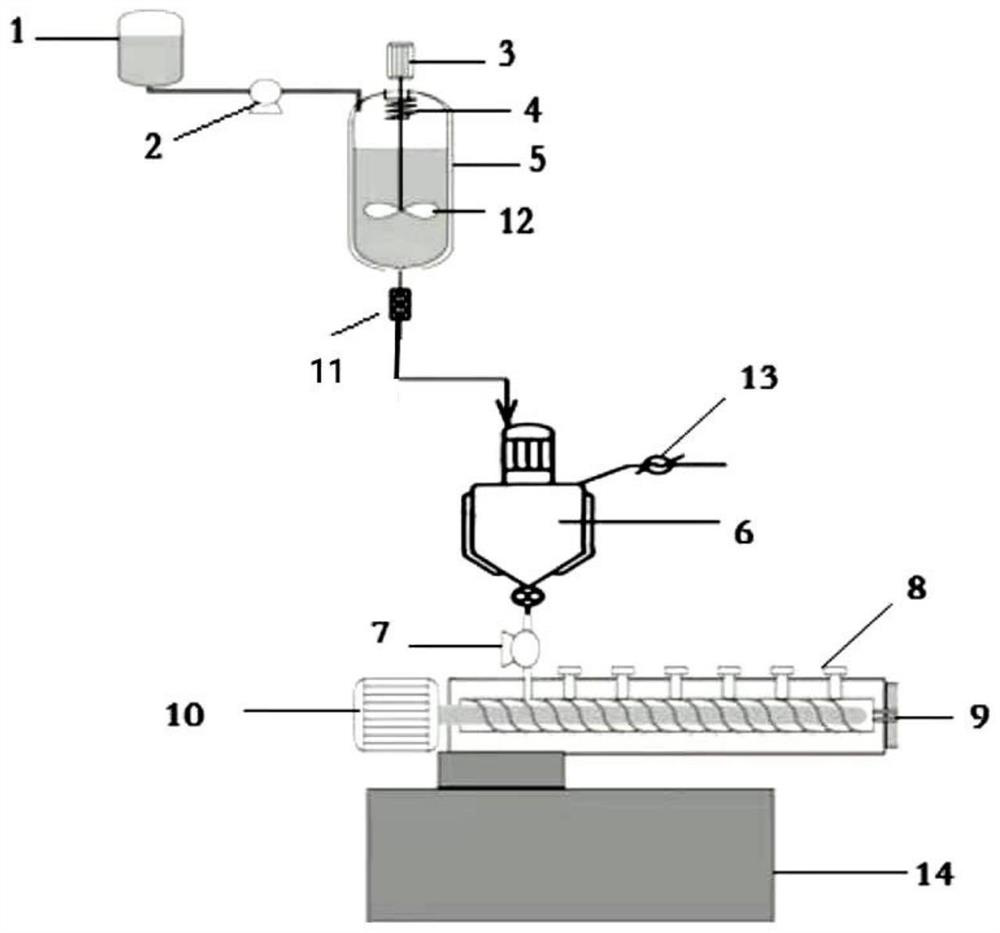

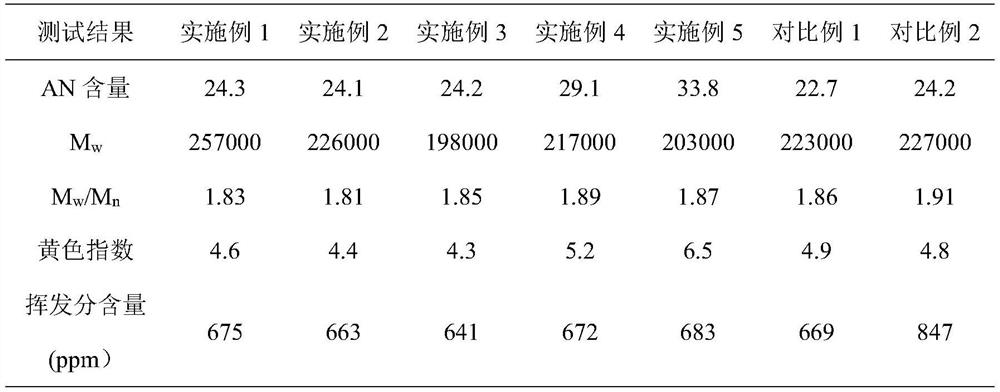

Device and method for preparing SAN resin with stable composition and low volatile components

InactiveCN113877498AEnsure controllabilityLittle change in compositionDistillation separationChemical/physical/physico-chemical stationary reactorsPolymer scienceBulk polymerization

The invention provides a device and a method for preparing SAN resin with stable composition and low volatile components, and belongs to the field of high polymer material preparation methods. According to the method, the SAN resin is prepared by adopting continuous bulk polymerization of thermal-initiated free radicals, acrylonitrile steam is controlled to instantaneously condense and flow back to a reaction kettle to participate in polymerization at the top of the kettle through a built-in condensing coil at the top of the polymerization kettle, and stable composition of styrene and acrylonitrile monomers and the final SAN resin in a reaction system is ensured. A two-stage devolatilization mode in which two static flash tanks are connected in series in the conventional SAN resin preparation process is optimized into a one-stage flash tank static devolatilization and two-stage double-screw devolatilization extruder dynamic devolatilization mode, so that the thermal degradation risk of the SAN resin at the high temperature of the two-stage devolatilization device is effectively reduced, and the mechanical property, transparency and appearance quality of the SAN resin are improved. Meanwhile, compared with the devolatilization effect of a two-stage series static flash tank, the volatile component content of the SAN resin obtained by the process is lower and can reach 600-700ppm.

Owner:CHANGCHUN UNIV OF TECH

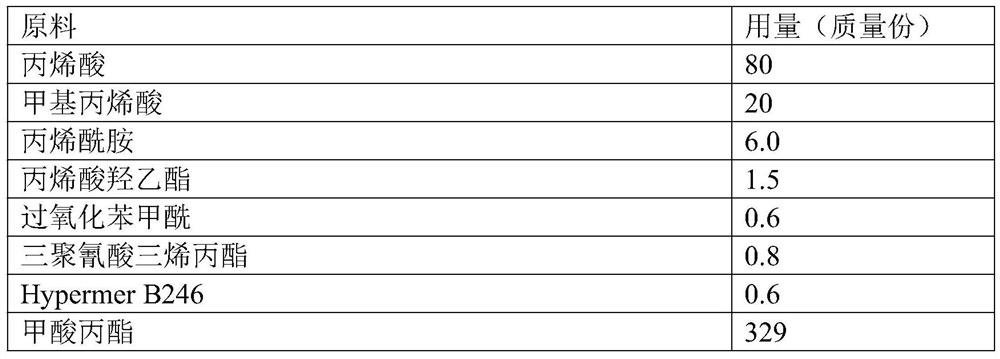

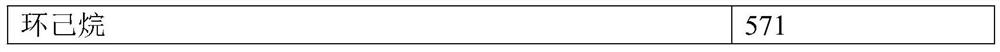

Carbomer and preparation method thereof

The invention relates to the technical field of thickeners, in particular to carbomer and a preparation method thereof. The carbomer disclosed by the invention is prepared from the following raw materials in parts by mass: 100 parts of an acrylic monomer, 5.0 to 8.0 parts of acrylamide, 0.5 to 2.0 parts of hydroxyethyl acrylate, 0.4 to 0.6 part of an initiator, 0.6 to 1.4 parts of a cross-linking agent, 0.4 to 1.0 part of a stabilizer and 800 to 1000 parts of a mixed solvent. The method specifically comprises the following steps: uniformly mixing a mixed solvent, adding the mixed solvent into a reaction kettle, starting stirring, and heating to 80-85 DEG C; uniformly mixing the mixed monomer, the cross-linking agent, the initiator and the stabilizer, and adding the mixture into the reaction kettle for 2-2.5 hours; continuously keeping the temperature and reacting for 3-5 hours after dropwise adding; and filtering, washing and drying the obtained product to obtain the product. The prepared carbomer is prepared into an aqueous solution with the mass fraction of 0.5%, the wetting time is only 55-178 s, after the pH value is adjusted to 6.8-7.5 through a NaOH solution with the mass fraction of 15%, the viscosity is 5000-80000 mPa.s, and the carbomer can swell in an ethanol aqueous solution with the volume fraction of 80%.

Owner:湖北新德晟材料科技有限公司

Glue smearing device for coating machine

InactiveCN100450642CSatisfy the viscosity requirementGuaranteed thicknessLiquid surface applicatorsCoatingsAdhesive glueEngineering

A scraper unit for coater is arranged on the coating head between the adhesive applying wheel and baking oven. It is composed of supporting frame, pressing mechanism and adhesive scraping roller on said supporting frame. The coated substrate passes through the gap between said adhesive scraping roller and pressing mechanism for squeezing the adhesive from convex position to concave position, so ensuring sufficient adhesion with less consumption of adhesive.

Owner:林峻

Coating of ink jet paper and method of manufacturing the same

InactiveCN1995540AImprove foldabilityFast absorptionNon-fibrous pulp additionPotassiumPollutant emissions

The invention relates to a dope for ink-jet paper and the manufacturing method. the basic component of dope is that 93. 8-96. 8% of 10% gelatin aqueous solution, 2. 95-6. 15% of 20% copolymer water solution of acrylic salt and acrylamide, and 0.05-0.25% of water-soluble assistant sodium benzoate. The acrylic salt is the one or the mixture of two kinds or three kinds of sodium acrylate, potassium acrylate, or ammonium acrylate. Manufacturing procedures are that (1) preparing 10% gelatin aqueous solution, (2) preparing 20% copolymer water solution of acrylic salt and acrylamide, (3) preparing the dope for ink-jet paper. The dope in invention is even transparent solution and there is no insoluble matter of solid color packing in it. The rigidity of dope can not be improved so as to maintain the folding performance of paper. The copolymer of acrylic salt and acrylamide prepared by special process is used as absorbing water agent. It is provided with simple manufacturing method, no contamination discharge, low producing cost, poisonless and harmless, easily natural degradation and convenience recovery of printing paper to use.

Owner:HEBEI UNIV OF TECH

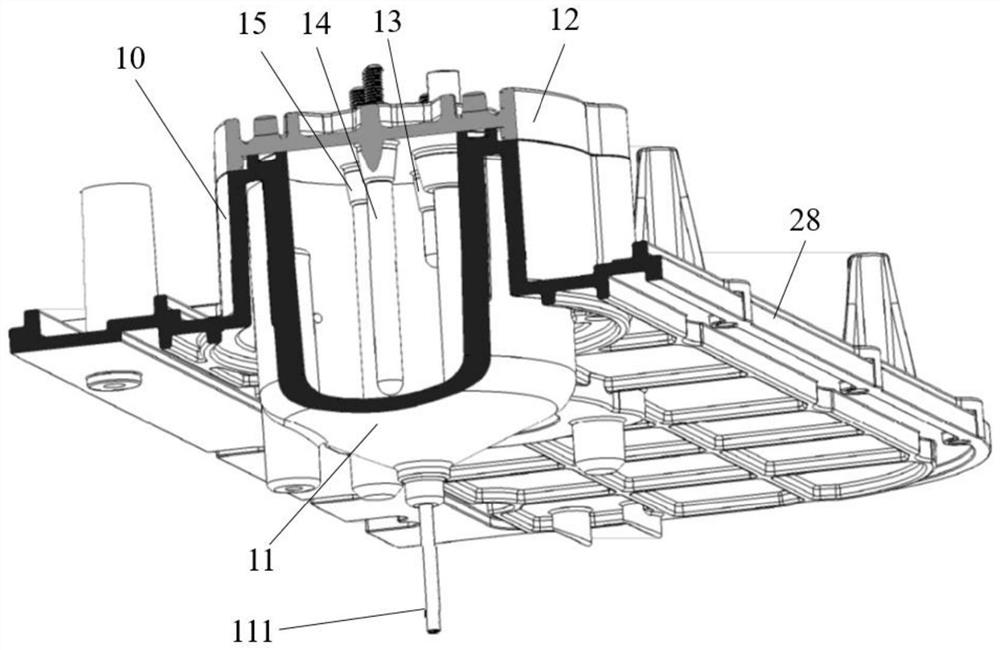

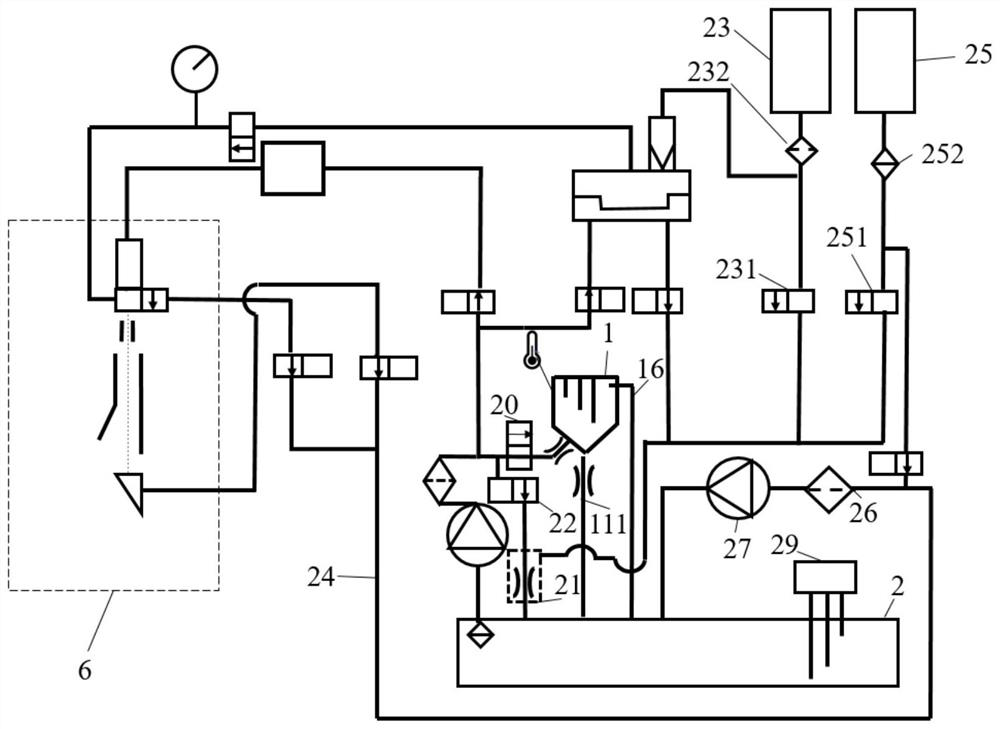

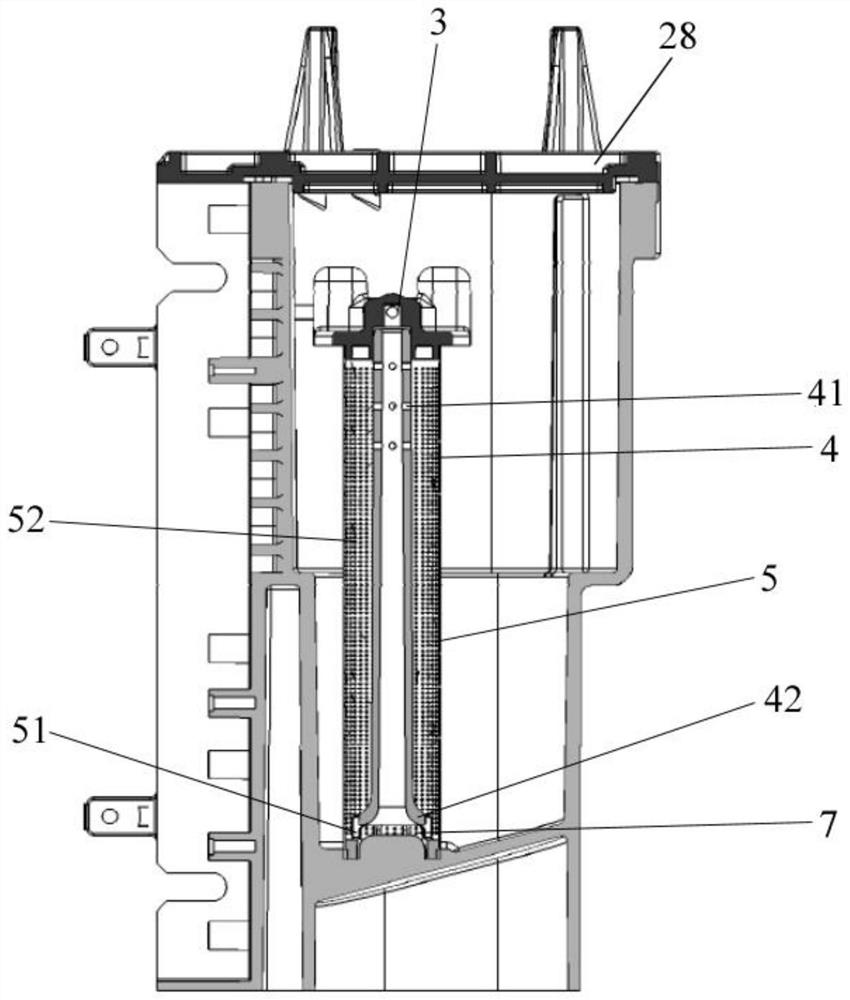

Viscometer and ink supply system

The invention discloses a viscometer and an ink supply system, and relates to the field of printers. The viscometer comprises a containing part; a base formed by extending outwards along one end of the containing part, wherein the base is conical, an ink injection port is formed in the side wall of the base, and an ink discharging pipe is further arranged at the bottom of the base; a top cover arranged opposite to the base and fixed to the other end of the containing part; and an electrode assembly fixed to the top cover and located in the containing part, and wherein the electrode assembly is used for determining the time required for emptying the ink with the preset capacity in the containing part. According to the viscometer and the ink supply system, the viscosity of the ink can be detected, and meanwhile the ink can be fully mixed and stirred.

Owner:LEADJET LOGO TECH WUHAN

One-part anti-aging epoxy resin composition for rtm molding

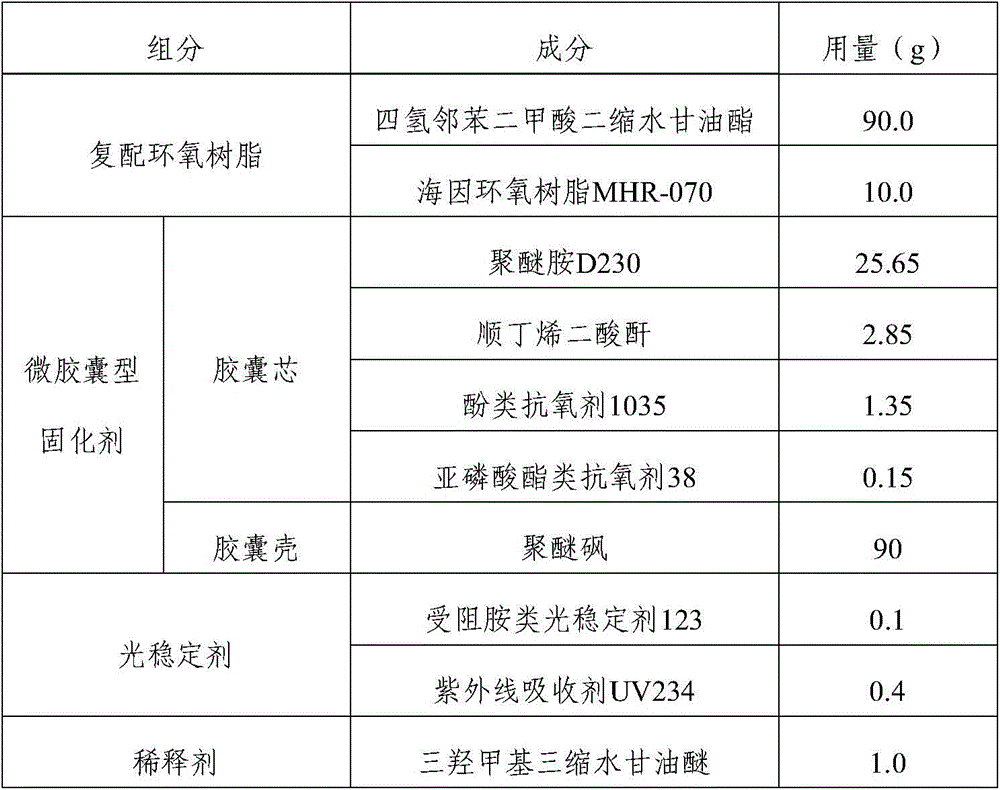

The invention relates to a one-component RTM (Resin Transfer Molding) anti-aging epoxy resin composition which comprises the following components in parts by weight: 100 parts of compound epoxy resin, 90-150 parts of a microcapsule-type curing agent, 0.5-5 parts of a compound light stabilizer and 1-10 parts of a diluent, wherein the microcapsule-type curing agent is composed of a capsule core and a capsule shell at the mass ratio of 1: (2-3), and the capsule core contains 80-95 percent by mass of a compound curing agent and 5-20 percent by mass of a compound antioxidant. The invention further protects molding epoxy resin prepared by taking the composition as a raw material.

Owner:CHINA NAT BLUESTAR (GRP) CO LTD +1

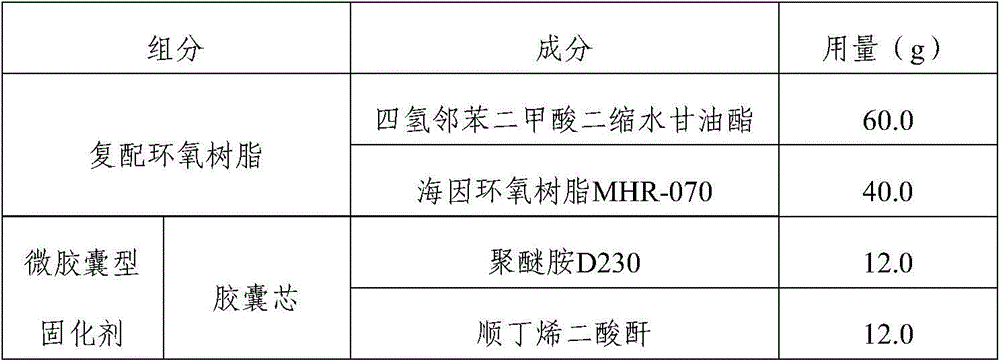

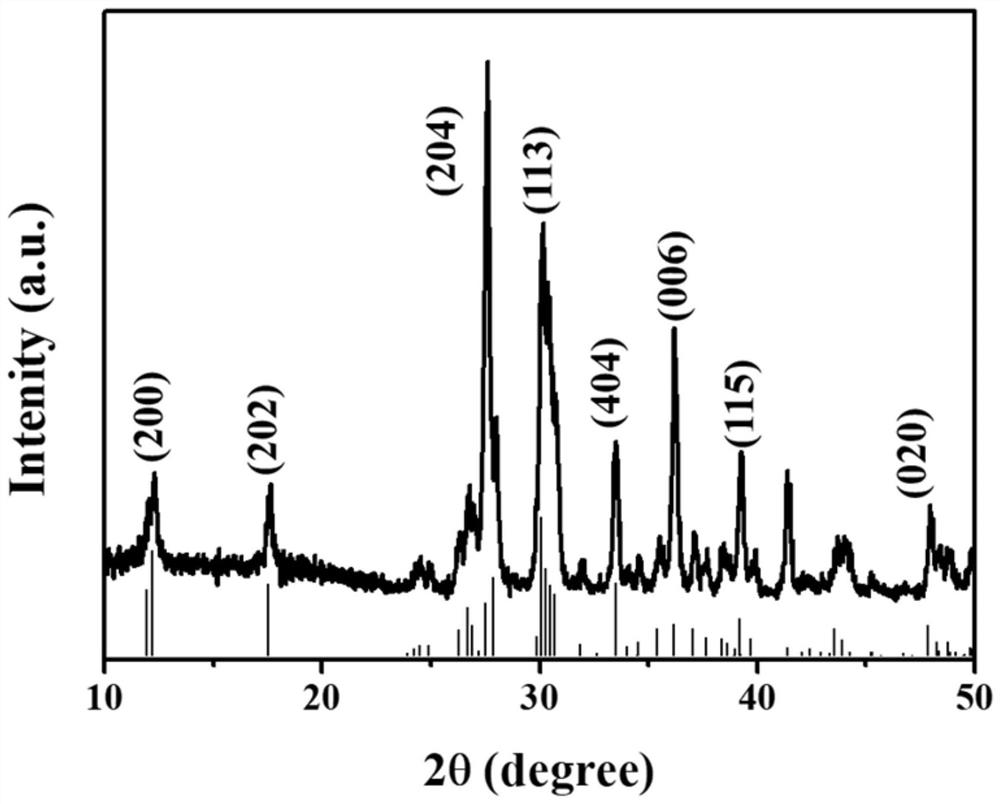

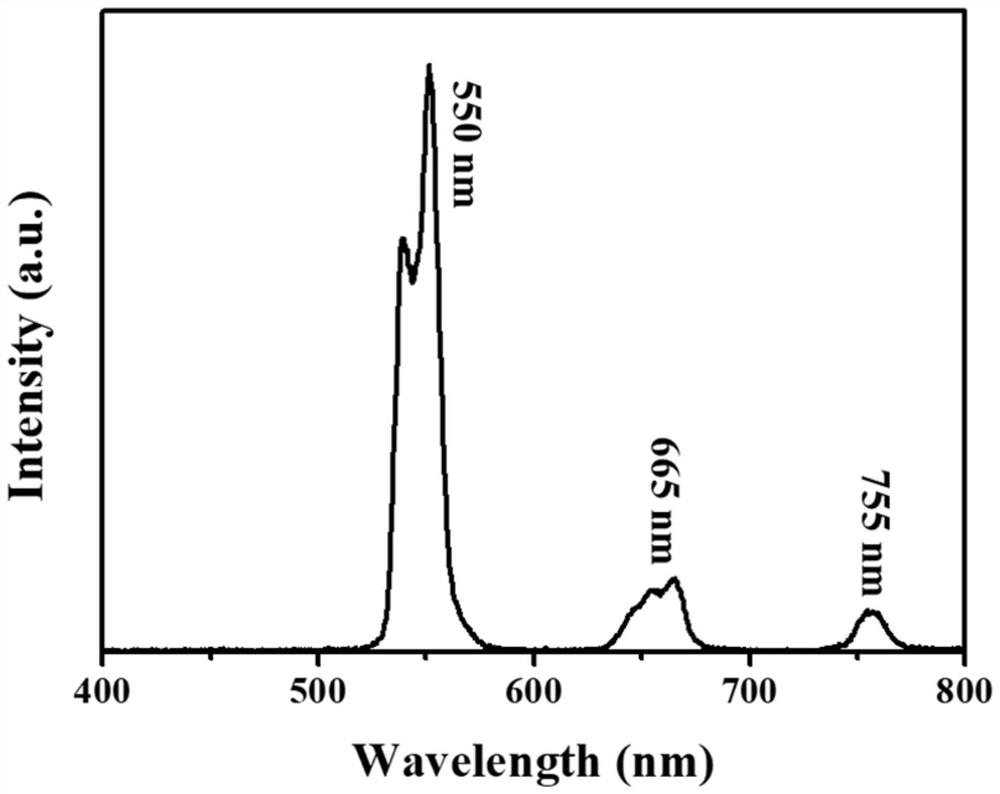

Rare earth doped Bi2Ti4O11 high-purity green nanofiber and preparation method and application thereof

InactiveCN112176456ANot hydrolyzedImprove luminosityElectroconductive/antistatic filament manufactureInorganic material artificial filamentsSpinningPyrrolidinones

The invention discloses a rare earth doped Bi2Ti4O11 high-purity green nanofiber and a preparation method and application thereof. Glacial acetic acid and N,N-dimethylformamide are used as solvents, tetrabutyl titanate, bismuth nitrate, ytterbium nitrate and holmium nitrate are used as experimental raw materials, a proper amount of polyvinylpyrrolidone is added to improve the viscosity and conductivity of a solution, and after an electrostatic spinning precursor solution is prepared, the electrostatic spinning precursor solution is moved into an electrostatic spinning device; high pressure isapplied, the precursor solution forms a Taylor cone at a needle tip under the combined action of electric field force and surface tension, and filaments are sprayed to a collecting plate; then materials on the collecting plate are moved into a muffle furnace, heat treatment is carried out, and pure one-dimensional Bi2Ti4O11:Yb3+, Ho3+ nano materials can be obtained; and finally, under excitation of a 980nm laser device, a sample shows the excellent green up-conversion luminescence property, the luminescence intensity is decreased along with increase of the temperature, and the excellent temperature sensing property is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

Method for increasing viscosity of polyester bottle flakes

InactiveCN103614784AViscosity value increasesSatisfy the viscosity requirementFilament forming substance formingSpinning head liquid feederYarnPolyester

The invention discloses a method for increasing the viscosity of polyester bottle flakes. The method includes stirring phenol / tetrachloroethane mixed liquor with the concentration of 0.010g / ml (a weight ratio of 3:2) and enabling the phenol / tetrachloroethane mixed liquor to react under the conditions that the vacuum degree ranges from 40Pa to 71Pa and the temperature ranges from 200 DEG C to 250 DEG C by means of vertical condensation polymerization so as to obtain melts with an increased viscosity value of 0.820+ / -0.001dl / g; stirring phenol / tetrachloroethane mixed liquor with the concentration of 0.010g / ml (a weight ratio of 5:3) and enabling the phenol / tetrachloroethane mixed liquor to react under the conditions that the vacuum degree ranges from 20Pa to 40Pa and the temperature ranges from 279 DEG C to 280 DEG C by means of horizontal condensation polymerization so as to obtain melts with an increased viscosity value of 0.900+ / -0.001dl / g on the basis of the melts obtained in the previous step. The method has the advantages that condensation polymerization is carried out on polyester bottle flake solution twice, so that the viscosity of the polyester bottle flakes can be increased and reaches 0.900+ / -0.001dl / g, high requirements on the viscosity of industrial yarns can be met, and the spinning quality and the spinning efficiency can be balanced by the aid of the method; switchable dual rough filter devices and switchable dual fine filter devices are implemented in the method, a working procedure is continuous, and accordingly the work efficiency is high.

Owner:盐城市华普轻纺机械有限公司

High-temperature-resistant synthetic leather slurry with high bonding strength and preparation method thereof

The invention discloses high-temperature-resistant synthetic leather slurry with high bonding strength and a preparation method thereof. The high-temperature-resistant synthetic leather slurry is prepared from the following raw materials in parts by weight: 120-150 parts of polyurethane resin, 10-12 parts of zinc oxide, 3-4 parts of stearic acid, 2-4 parts of cellulose acetate, 1-2 parts of polypropylene, 2-3 parts of lauryl sodium sulfate, 1-3 parts of magnesium stearate, 4-6 parts of polyamide wax micropowder, 20-25 parts of soldering iron ore sands, 40-50 parts of barium sulfate packing, 12-15 parts of peanut leaves, 0.5-1.5 parts of monoethanolamine, 0.2-0.4 part of para aminobenzoic acid, 0.5-1.0 part of phosphotriester, 2-4 parts of glass wool, 6-7 parts of phenyl trichlorosilane and 65-80 parts of acetone. The slurry disclosed by the invention is simple in preparation process, low in cost and excellent in performance, has good viscidity, still can satisfy the viscidity requirement at high temperatures and has good wear resistance. By modifying the peanut leaves, the viscidity of the peanut leaves can be improved, the vicidity of the slurry is enhanced and the stable performance of the slurry is improved.

Owner:HEFEI ANSHAN COATING FABRICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com