Patents

Literature

38results about How to "Little change in composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

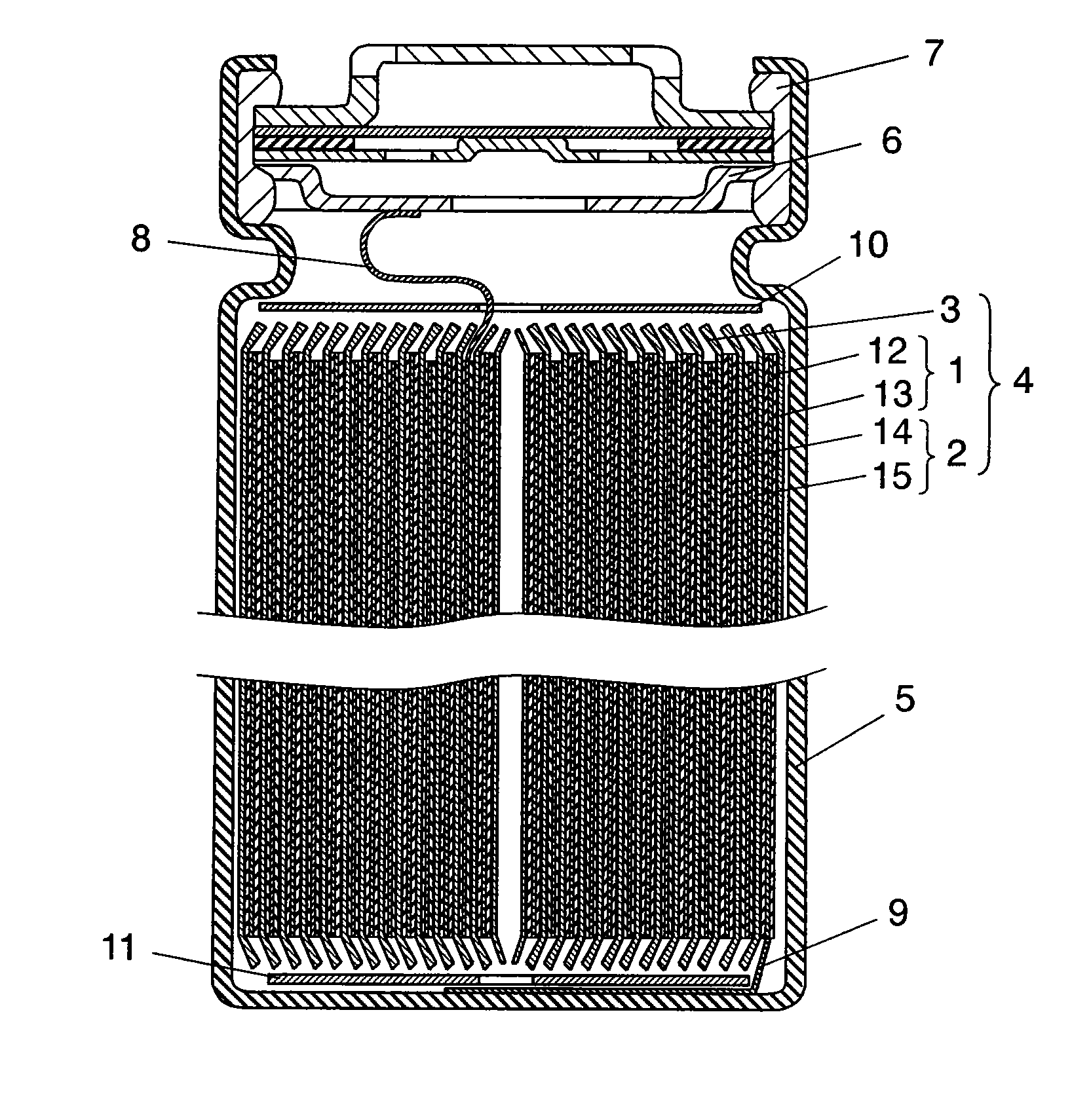

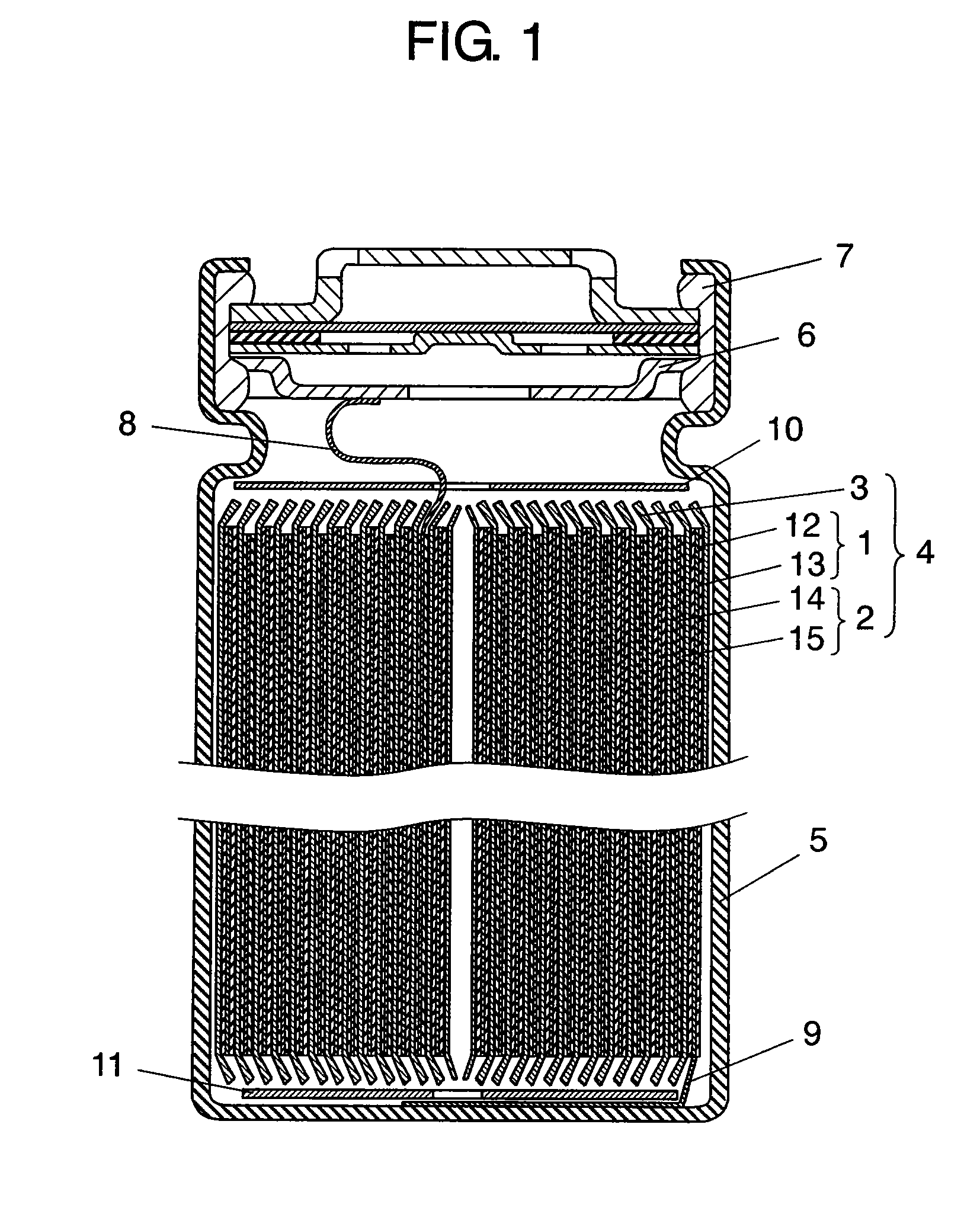

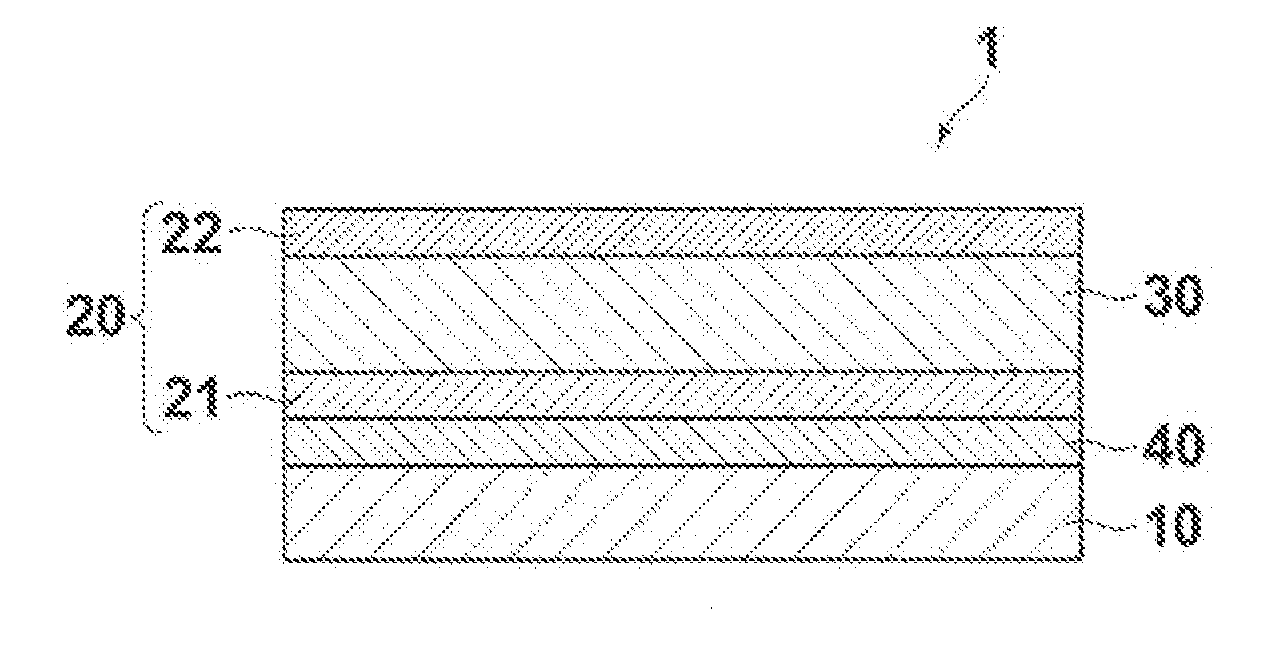

Method and apparatus for manufacturing member for secondary battery and secondary battery using the same

InactiveUS20100190063A1Stable productionUniform thicknessFinal product manufactureSecondary cells manufacturePhysical chemistryBattery cell

At least (i) dispersing and mixing inorganic oxide filler, solvent and binder so as to produce a coating paint; (ii) supplying the coating paint to a gravure coater; and (iii) coating the coating paint to member via a gravure roll are included. The (i) or (ii) includes allowing the coating paint to stand still and removing an aggregate and a precipitate of inorganic oxide filler.

Owner:PANASONIC CORP

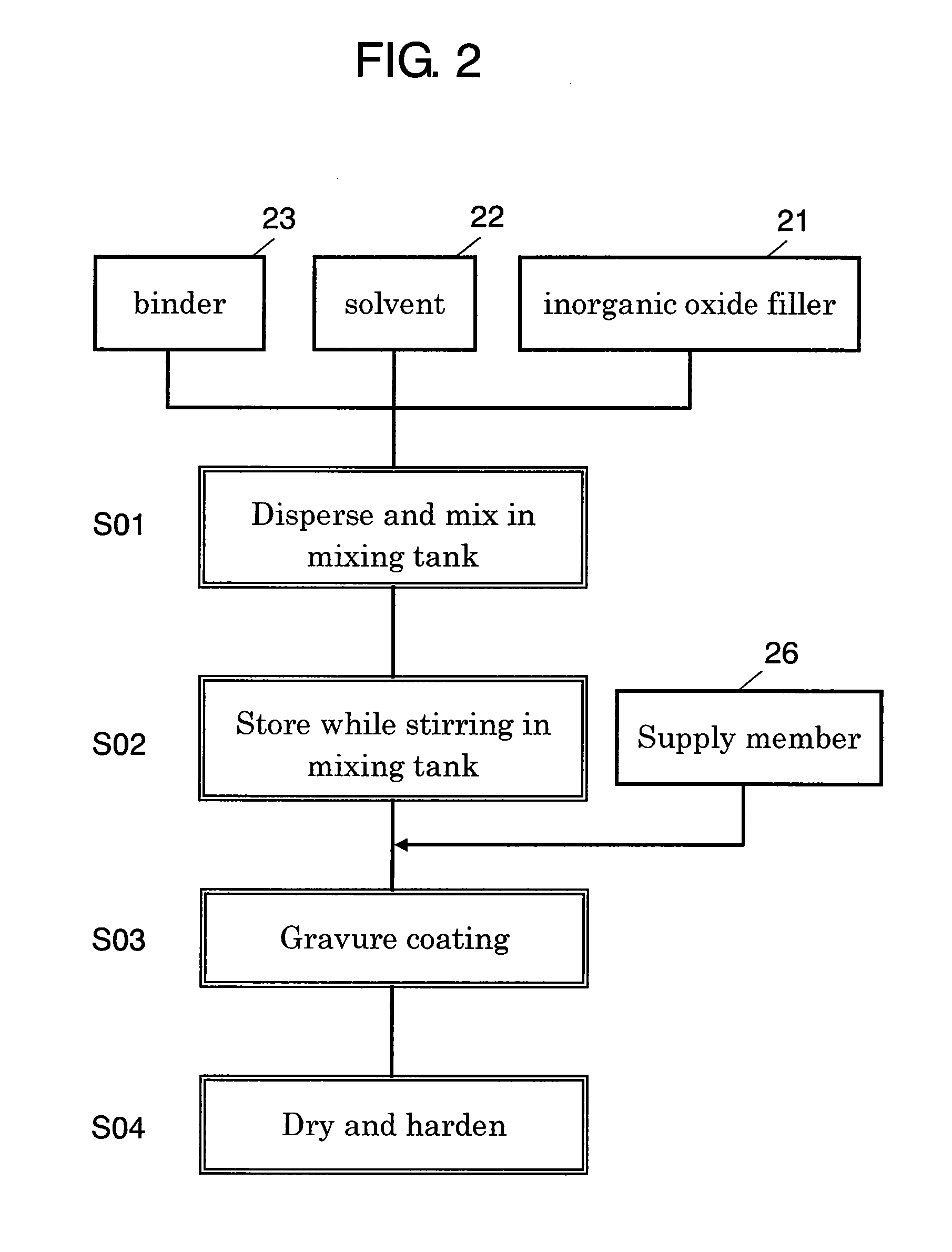

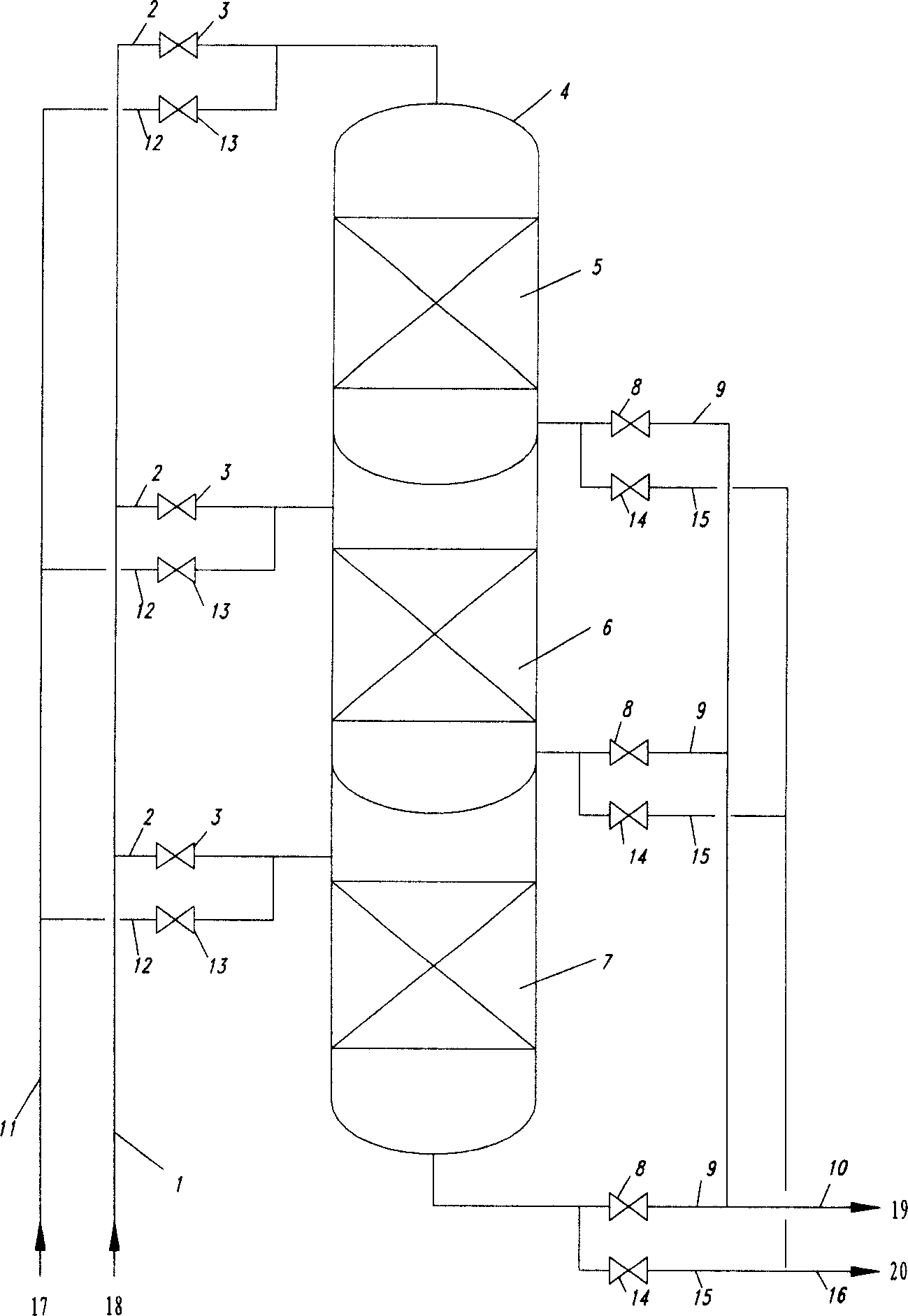

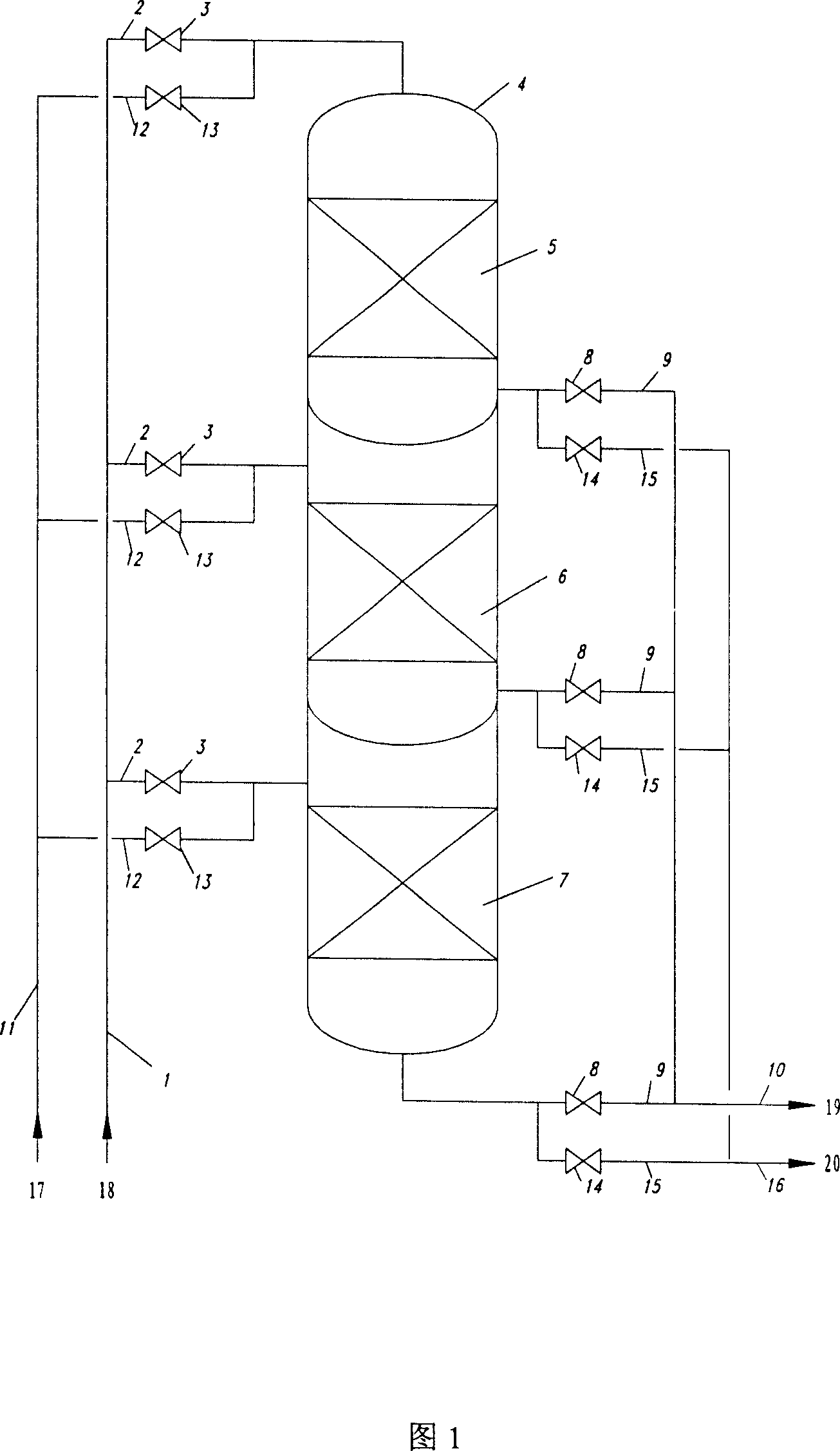

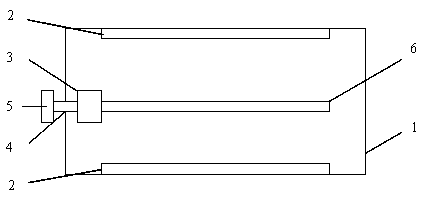

Method for producing propylene continuously in switch mode

ActiveCN1915928ALittle change in compositionImprove product qualityHydrocarbon by hydrocarbon crackingBiochemical engineeringFixed bed

This invention relates to a changeover method for continuously manufacturing propylene by C4+ alkenes catalytic cracking. The method adopts a reactor with a set of parallel fixed beds. Each fixed bed is operated according to a certain interval, and the products of all fixed bed are mixed and sent to the next process so that the reactant of the next process has stable composition. The method solves the problems of low catalyst activity and large change of product composition at the beginning and end of reaction, which leads to difficulties in stable quality and next process. The method can be used in propylene industrial manufacture by C4+ alkenes catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

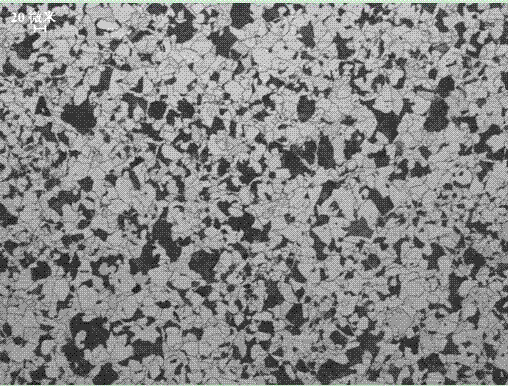

Production method of heavy-gauge large-single-weight low-alloy high-strength structural steel plates

InactiveCN102732674AReduce the process of forging billet openingReduce processProcess efficiency improvementElectric furnaceElectro-slag remeltingHeat treated

The invention provides a production method of heavy-gauge large-single-weight low-alloy high-strength structural steel plates. The method comprises the steps of smelting, casting, electroslag remelting, electroslag ingot cleaning, heating, rolling, water cooling, hydrogen diffusion treatment, supersonic wave flaw detection, normalization, examination and warehousing. The largest thickness of the steel plates produced through the method of the invention can reach 410mm. The method allows the isotropy, the impact toughness and the Z-directional performances of the heavy-gauge steel plates to be realized through adopting large slab electroslag remelting treatment and a reasonable controlled rolling and heat treatment technology, the production cost to be reduced, the time of delivery to be substantially shortened and the specification range to be wide, and is used for satisfying continuously increased market application amount demands; and the steel plates can completely substitute import products to satisfy various requirements of heavy-gauge large-single-weight steel plates applied to water power, wind power and large building structures.

Owner:WUYANG IRON & STEEL +1

Method for producing large-thickness lamination-crack-resistant tempered high-strength steel plate

The invention discloses a method for producing a large-thickness lamination-crack-resistant tempered high-strength steel plate. The method is characterized by comprising the steps: smelting, performing continuous casting, performing electroslag remelting, heating, rolling, annealing and performing heat treatment. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.18 percent of C, 0.20-0.50 percent of Si, 0.95-1.25 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.80-1.15 percent of Ni, 0.40-0.60 percent of Cr, 0.40-0.60 percent of Mo, 0.020-0.050 percent of Nb, 0.010-0.030 percent of Ti, 0.020-0.045 percent of TAl, and the balance of Fe and inevitable impurities. According to the method, electroslag remelting treatment is adopted, good overall performance of the large-thickness steel plate with the diameter of 30mm can be met due to the reasonable controlled rolling and heat treatment process, and the production cost is reduced; and the specification range is wide. The method adopts the steps of electric furnace smelting, continuous casting and electroslag remelting smelting, the contents of P and S in the obtained tempered high-strength steel plate are low, and the steel is pure; and moreover, a large-slab electroslag remelting technology is adopted, the round ingot hammer cogging process during electroslag remelting is reduced, the production period is shortened, and the cost is obviously reduced.

Owner:WUYANG IRON & STEEL

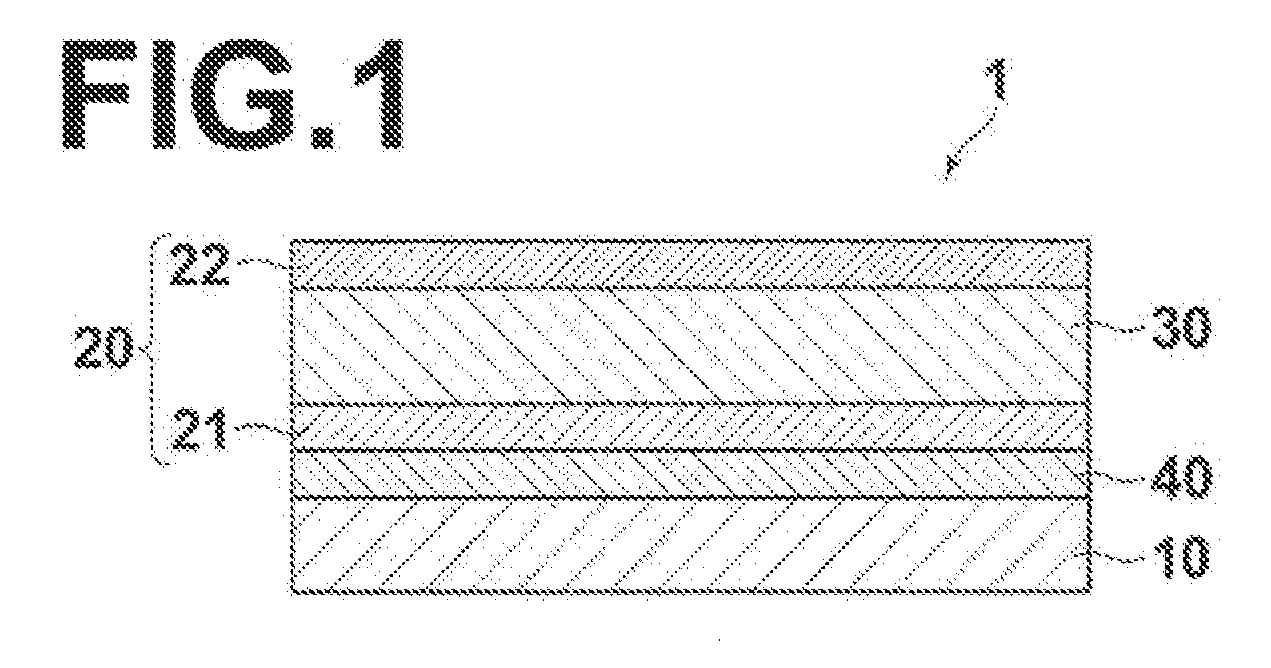

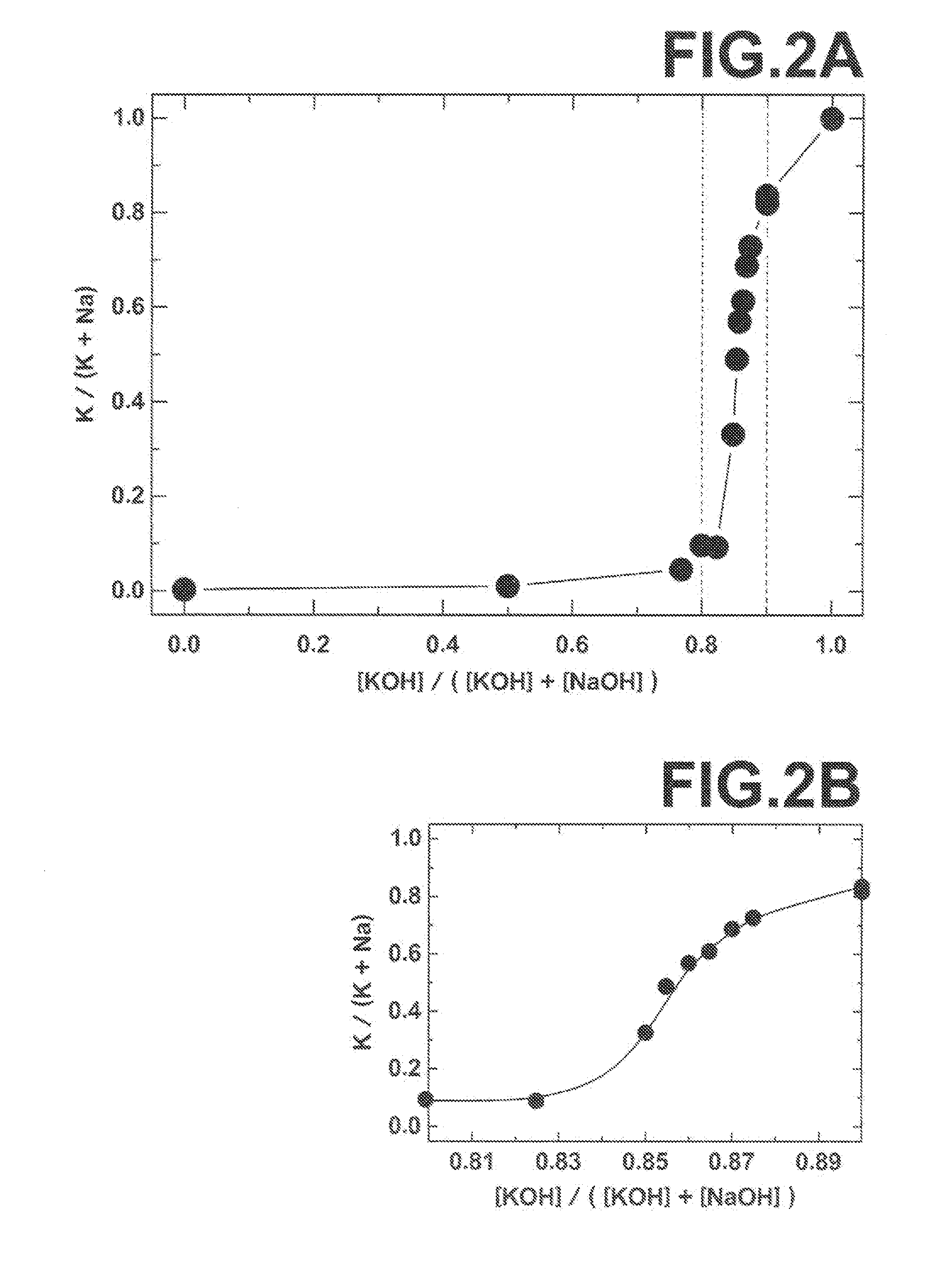

Perovskite oxide film and ferroelectric film using the same, ferroelectric device, and method for manufacturing perovskite oxide film

ActiveUS20130234564A1Little composition shiftGood crystallinityMolten spray coatingPiezoelectric/electrostriction/magnetostriction machinesIonOxide

A perovskite oxide film is formed on a substrate, in which the perovskite oxide film has an average film thickness of not less than 5 μm and includes a perovskite oxide represented by a general formula (P) given below:(K1−w−x, Aw, Bx)(Nb1−y−z, Cy, Dz)O3 - - - (P),where: 0<w<1.0, 0≦x≦0.2, 0≦y<1.0, 0≦z≦0.2, 0<w+x<1.0, A is an A-site element having an ionic valence of 1 other than K, B is an A-site element, C is a B-site element having an ionic valence of 5, D is a B-site element, each of A to D is one kind or a plurality of kinds of metal elements.

Owner:FUJIFILM CORP +1

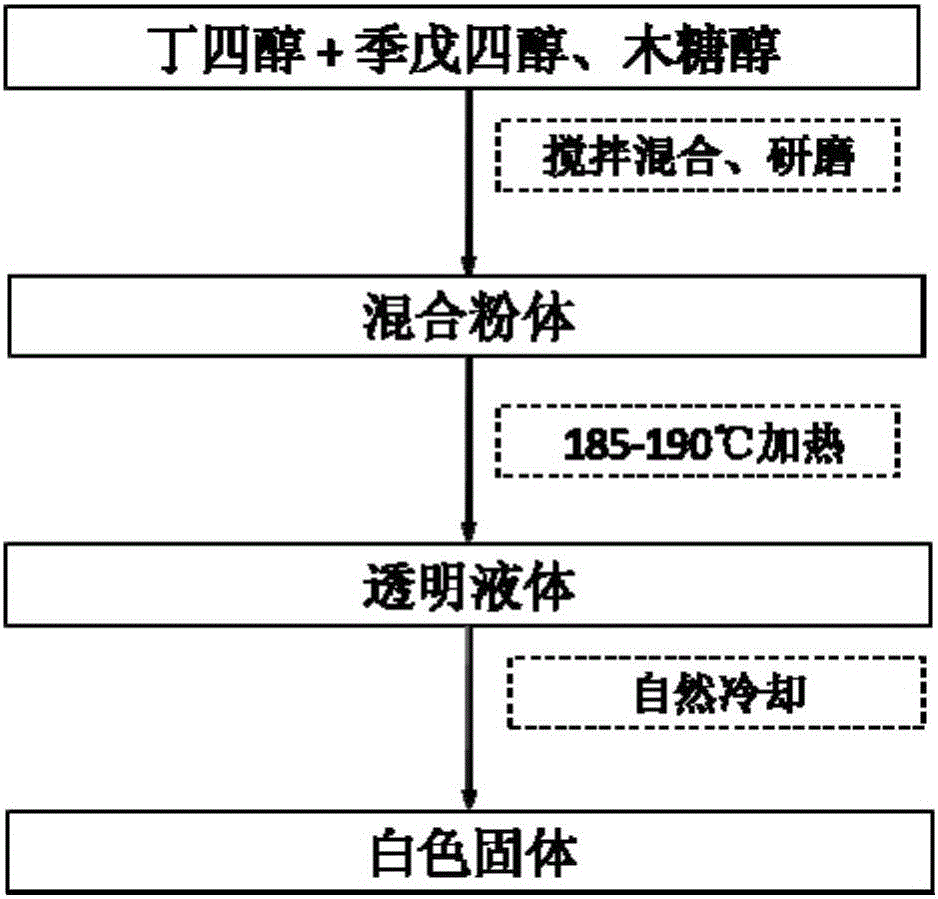

Polylol compound phase-change material and preparation method thereof

ActiveCN106281235AIncrease enthalpyHigh phase change enthalpyHeat-exchange elementsThermal energyPhase change enthalpy

The invention relates to a polylol compound phase-change material and a preparation method thereof. The compound phase-change material takes butantetraol, pentaerythrotol and xylitol powder as raw materials and is prepared through the following steps: carrying out manual grinding, ball milling or sand milling on a mixture of the butantetraol, the pentaerythrotol and the xylitol for 1h to 3h; then heating the mixture at 185 DEG C to 190 DEG C for 3h to 6h until all the powder is completely melted to form transparent liquid; finally, naturally cooling the transparent liquid to form the white and solid polylol compound phase-change material, wherein the mass percent content of the butantetraol is 60 percent to 75 percent, the mass percent content of the pentaerythrotol is 24 percent to 35 percent and the mass percent content of the xylitol is 1 percent to 5 percent. The polylol compound phase-change material has the advantages of high phase-change enthalpy value, small super-cooling degree, stable melting point and the like, and can be used in the fields of solar heat energy storage, industrial residual heat recycling and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

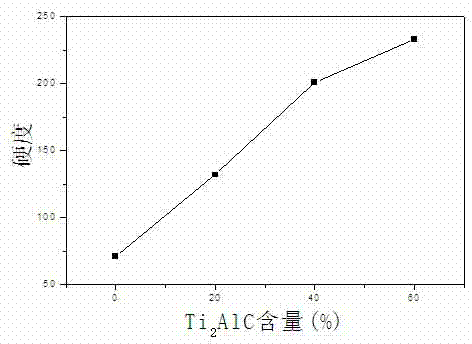

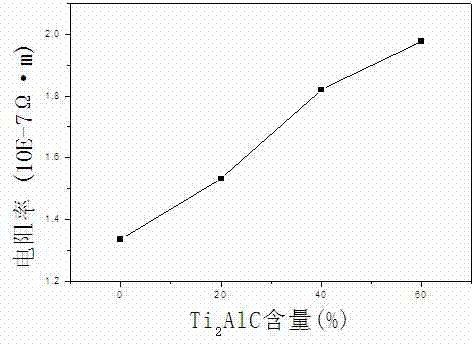

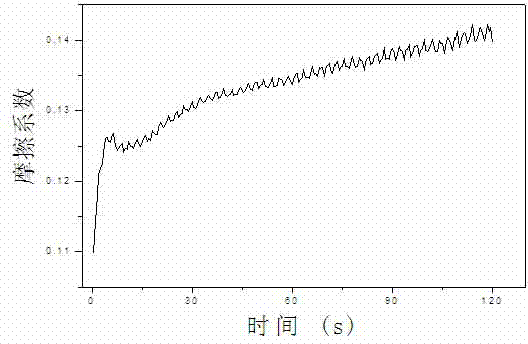

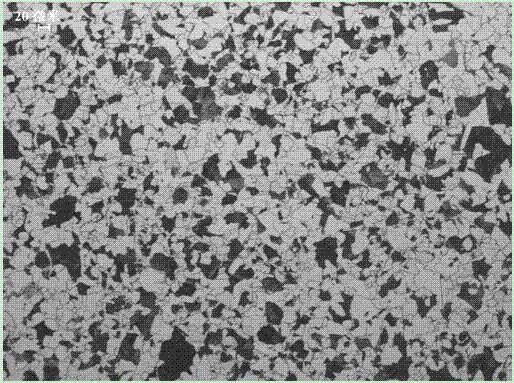

Cu-Ti2 AlC functionally gradient material and preparation method thereof

InactiveCN103085395AAdvantages and Notable ImprovementsImprove thermal shock resistanceCeramic layered productsMetal layered productsAdditive ingredientGradient material

The invention relates to a preparation method of a Cu-Ti2 AlC functionally gradient material. The preparation method is characterized in that a composite material which contains pure Cu or main ingredient Cu is formed at one side of the prepared gradient material; the compound which contains pure Ti2AlC or main ingredient Ti2AlC is arranged at the other side of the prepared gradient material; 1-4 interlayers are arranged; the contents of Cu and Ti2AlC change in gradient along with the thickness direction, and gradually change along with the performance; the hardness and strength of the material are obviously improved along with the direction from Cu to enriched Ti2AlC; the oxidation resistance and the anti-high temperature performance are improved; the wear-resisting property and the elastic modulus are gradually improved; and the toughness, the electric conductivity and the thermal conductivity are obviously improved along the direction from Ti2AlC to enriched Cu. The material has significance as to a special environment which has different operational performances as to different contact surfaces; the material is prepared from Cu and Ti2AlC powder used as raw materials in a manner of hot-pressed sintering under certain atmosphere after evenly mixing and layered charging, wherein the sintering temperature is 800-1000 DEG C; the heating rate is 8-20 DEG C / min; the pressure is 20-40 MPa; and heat preservation time is 0.5-3 hours. By adopting a hot-pressed sintering method, the prepared gradient material is high in compactness, excellent in performance, and good in industrialized prospect.

Owner:HUBEI UNIV OF TECH

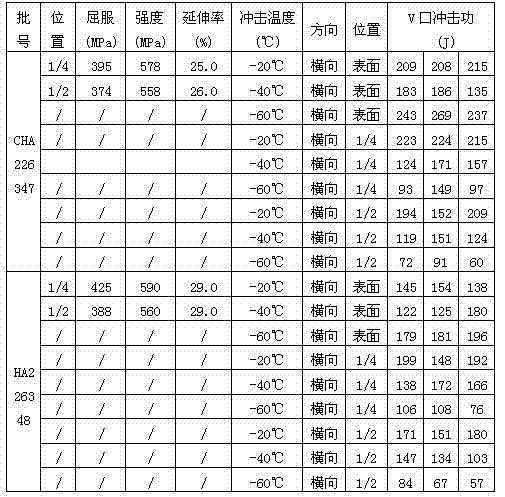

F-grade large-thickness weldable steel plate with high pureness and high low-temperature toughness and production method thereof

The invention discloses an F-grade large-thickness weldable steel plate with high pureness and high low-temperature toughness and a production method thereof. The steel plate consists of the following components in percentage by mass: 0.10-0.20% of C, 0.15-0.55% of Si, 0.90-1.80% of Mn, P not higher than 0.03%, S not higher than 0.03%, 0.020-0.040% of Nb, 0.010-0.080% of Al, 0.035-0.085% of V, Ti not higher than 0.020%, and the balance of Fe and inevitable impurities. The method performs the production through an electroslag remelting process; the largest thickness of the steel plate can reach 500 mm; the high pureness is realized after the remelting; the interior structure of the steel plate is compact; the low-power defect control is lower; the low-power structure of the steel plate has no such defects as cracks and air holes; the looseness and segregation grades are not higher than 1.0 grade; the ultrasonic flaw detection is performed to satisfy the I-grade requirement of GB / T2970; the steel plate has the following excellent comprehensive performances: the transverse stretching, the longitudinal stretching and the impact performance are basically consistent, and the isotropy and the Z-direction performance are better; the steel plate has higher low-temperature toughness; -60 DEG C of impacting energy reaches above 27 J; and after the remelting, the variation of the main components in the steel is little, and the components are more uniform.

Owner:WUYANG IRON & STEEL

Extremely-thick low alloy steel plate for E-level high purity ocean platform and production method thereof

The invention discloses an extremely-thick low alloy steel plate for an E-level high purity ocean platform and further relates to a production method of the steel plate. The steel plate comprises, by weight, 0.10%-0.18% of C, 0.15%-0.35% of Si, 0.90%-1.60% of Mn, 0-0.02% of P, 0-0.005% of S, 0.020%-0.030% of Nb, 0.010%-0.080% of Al, 0.035%-0.065% of V, 0-0.025% of Ti, and the balance Fe and inevitable impurities. The production method of the steel plate includes the following steps of electric furnace smelting, LF / VD refining, continuous casting, electroslag remelting, steel ingot heating, rolling, water cooling after rolling, heat stacking, heat treatment and finished product obtaining. The maximum thickness of the steel plate obtained through the method can reach 350 mm, and the characteristics of being good in welding property, excellent in low temperature impact toughness and good in thickness directional property are achieved. Meanwhile, steel is clean, performance evenness is good, high flaw detection and performance requirements can be met, and a wide application prospect is achieved.

Owner:WUYANG IRON & STEEL

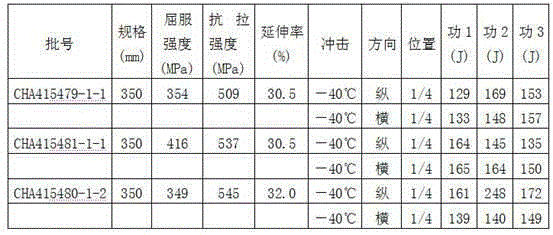

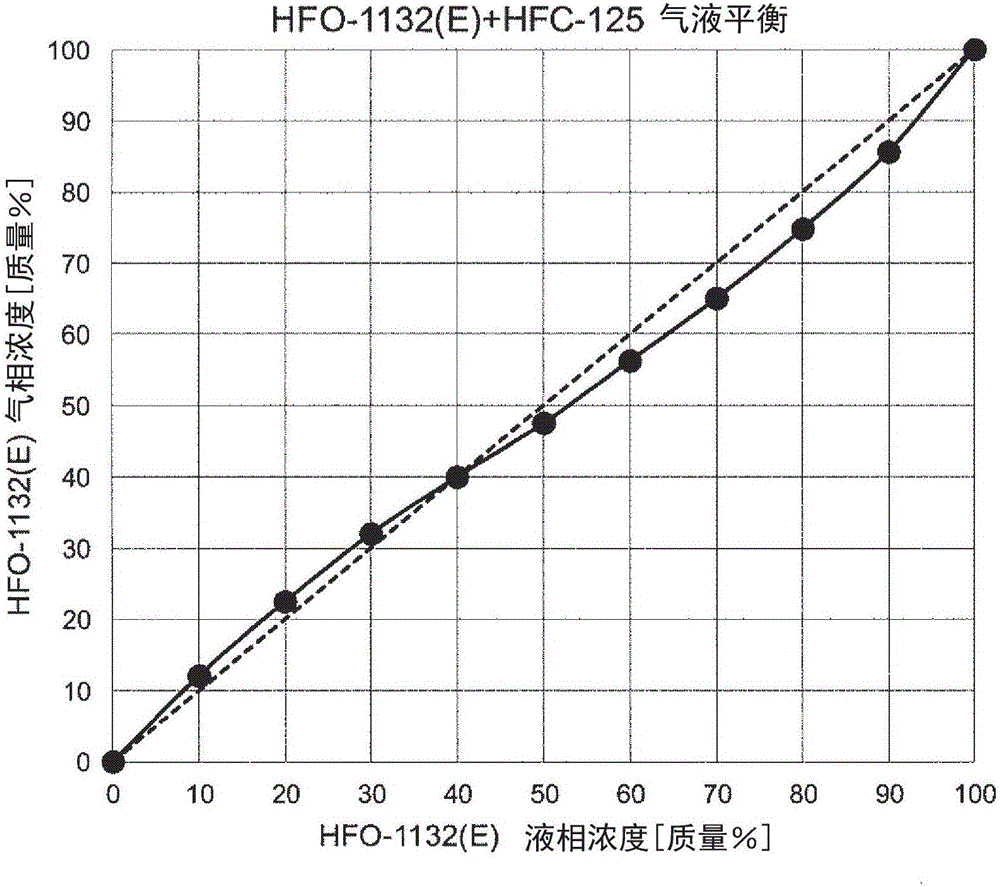

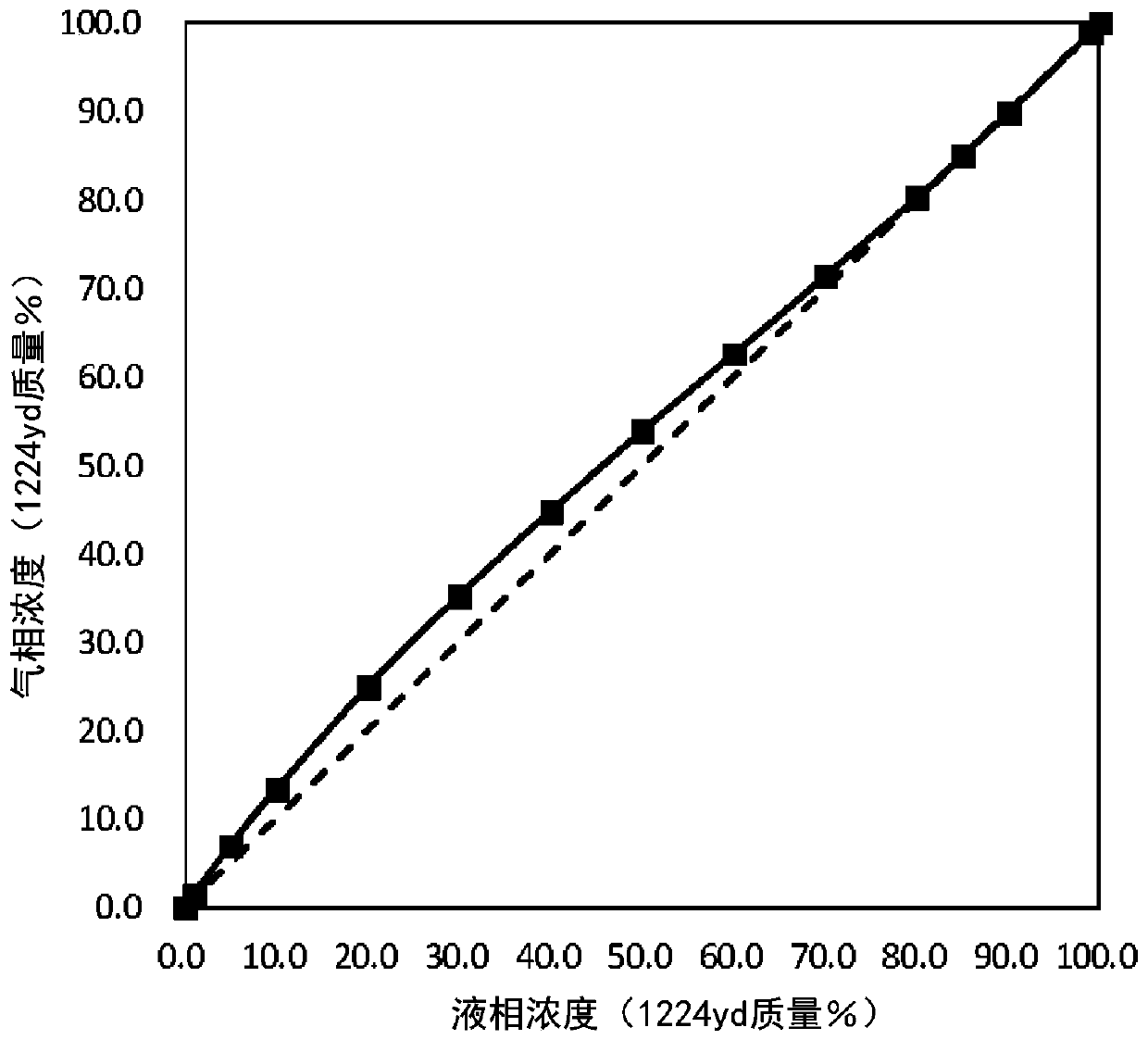

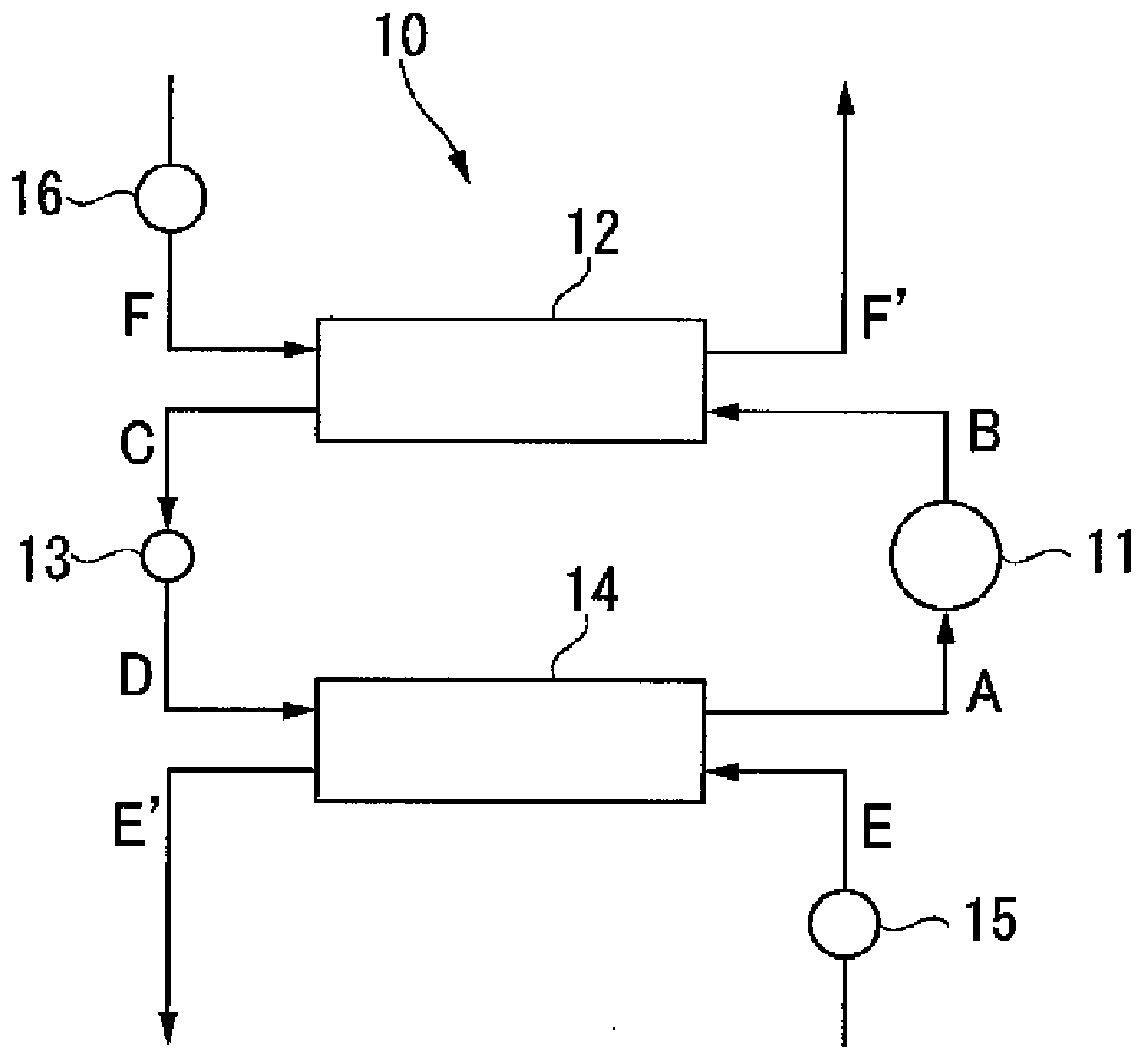

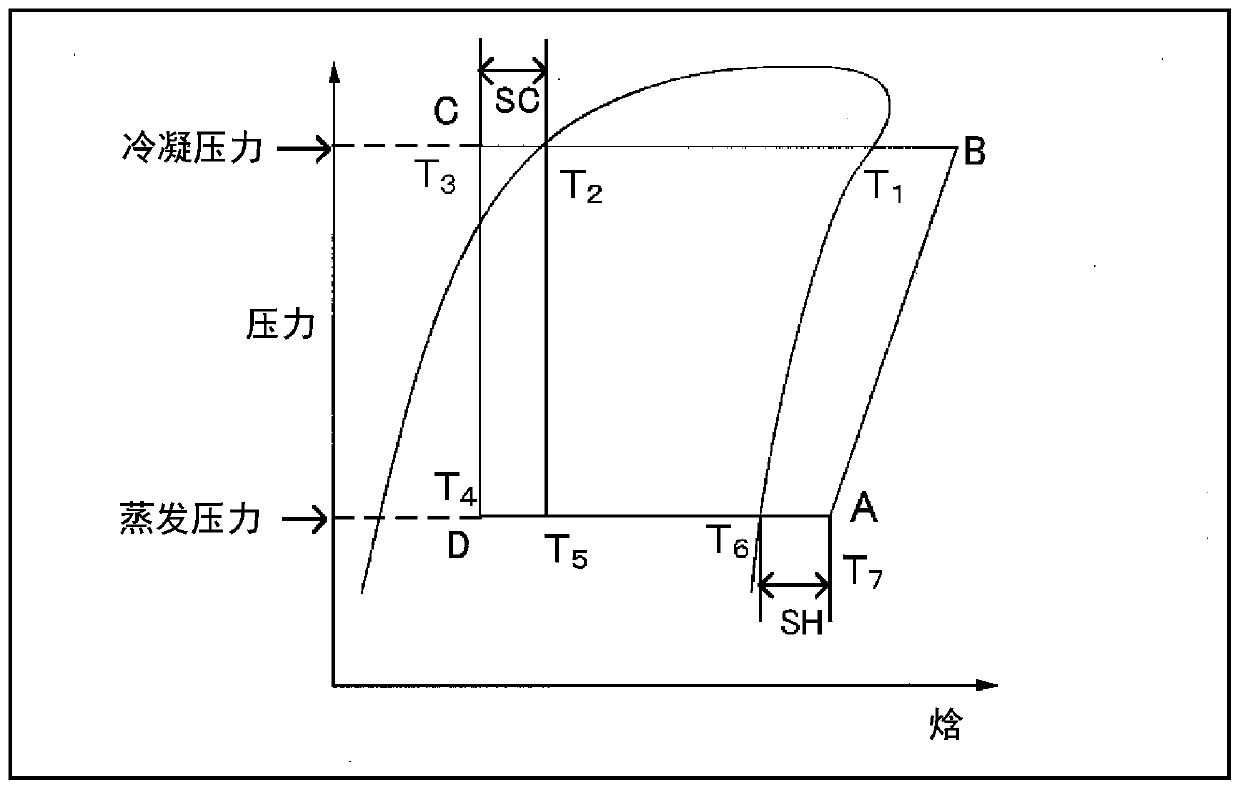

Working medium for heat cycle, composition for heat cycle system, and heat cycle system

InactiveCN106414655ALittle change in compositionReduce temperature gradientCompression machines with non-reversible cycleHeat-exchange elementsMass ratioDouble bond

Provided are: a working medium for a heat cycle, said working medium containing 1,2-difluoroethylene and exhibiting high stability, reduced environmental impact, and cycle performance that can replace that of R410A (a pseudo-azeotropic mixed refrigerant including difluoromethane and pentafluoroethane at a mass ratio of 1:1) and 1,1,1,2-tetrafluoroethane; a composition for heat cycle system, said composition using the medium; and a heat cycle system using the composition. The working medium for a heat cycle is characterized by the inclusion of 1,2-difluoroethylene and at least two types of hydrofluorocarbon selected from the group of hydrofluorocarbons that include a carbon-carbon double bond other than a saturated hydrofluorocarbon and 1,2-difluoroethylene.

Owner:AGC INC

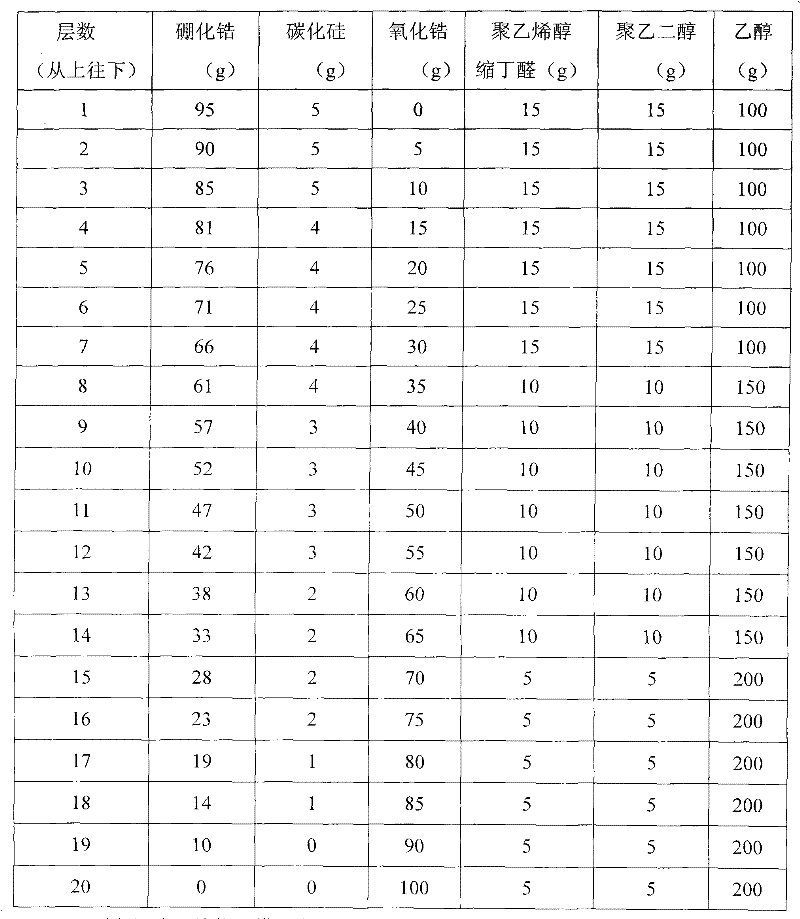

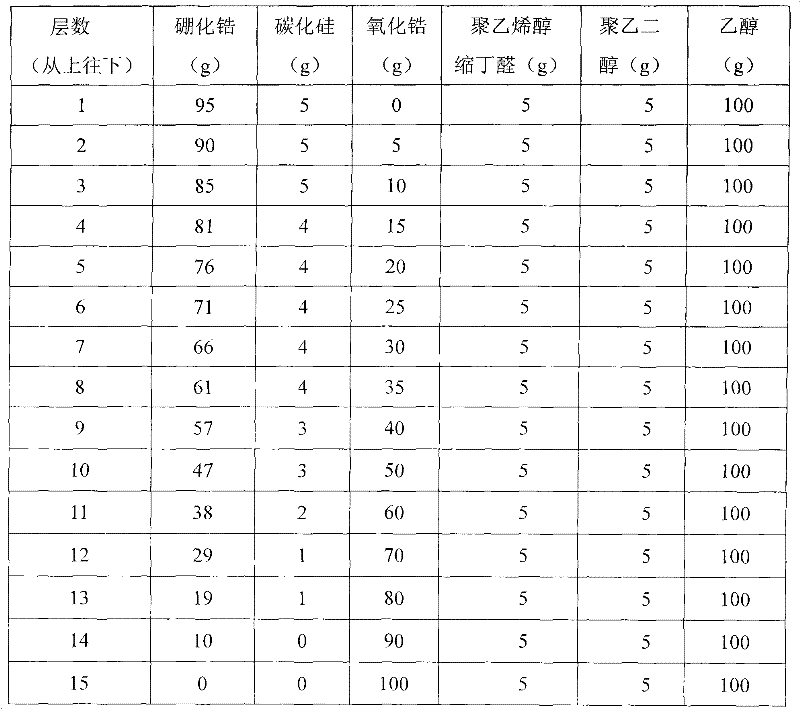

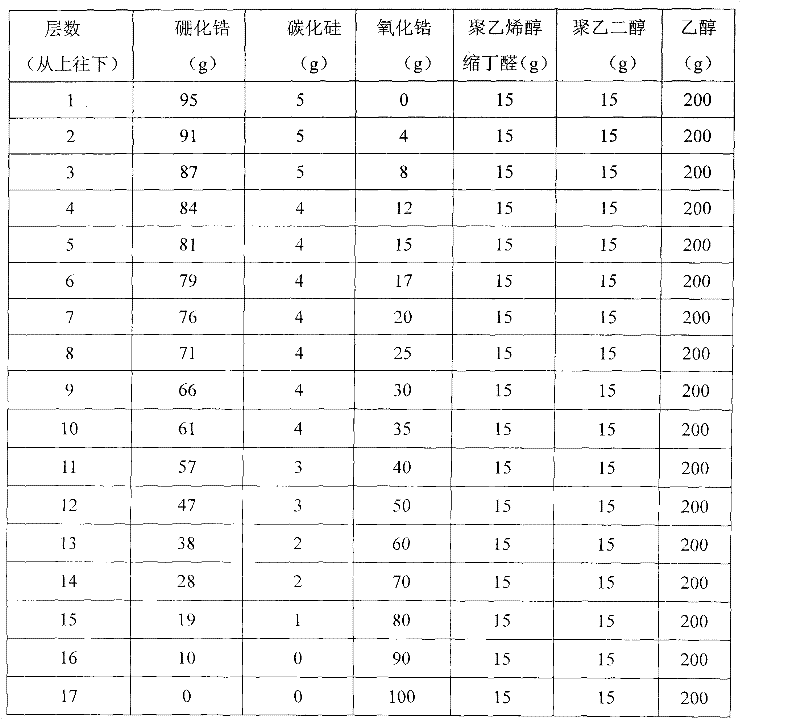

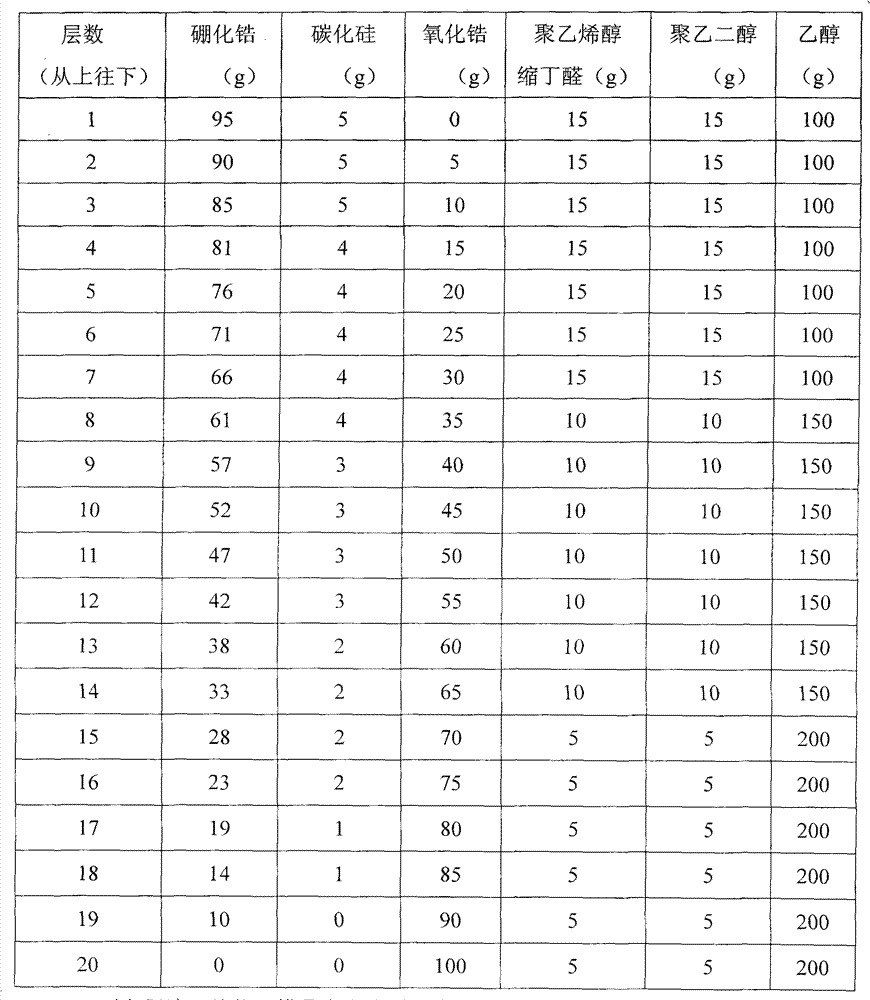

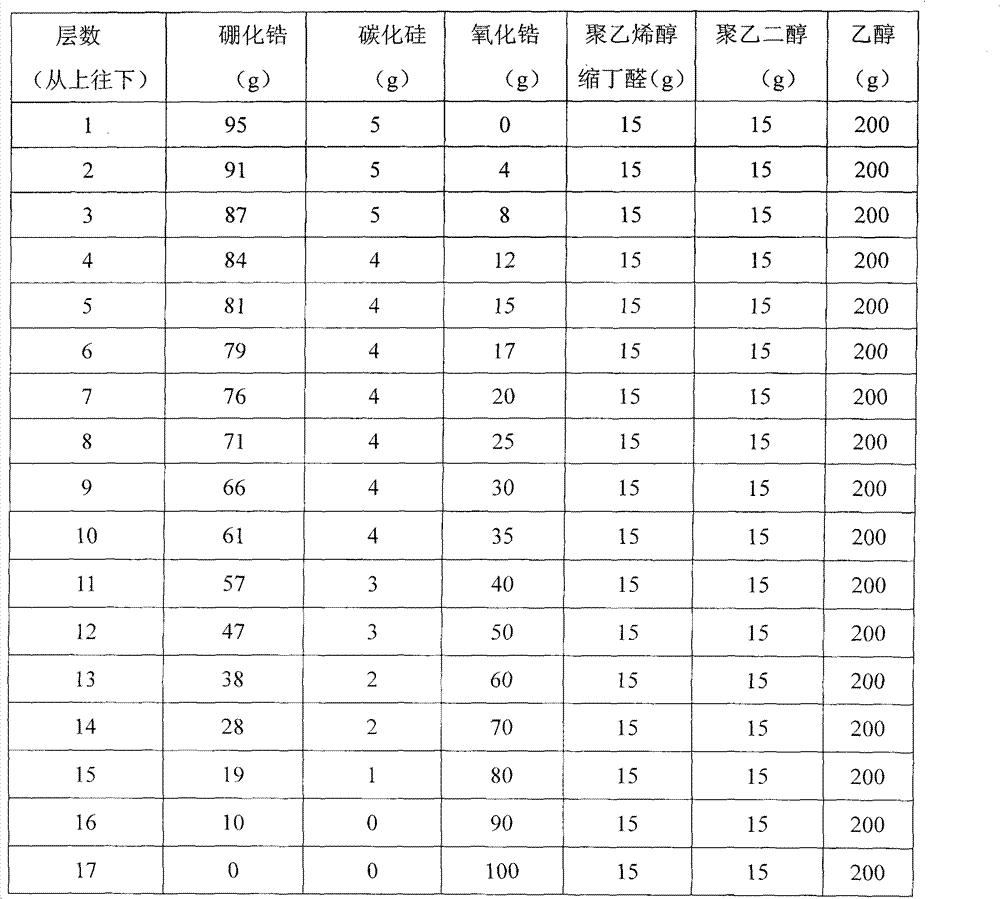

Preparation method of gradient zirconium boride ultrahigh-temperature ceramic

InactiveCN102173809ALittle change in compositionSmall residual thermal stressZirconium hydrideBoride

The invention provides a preparation method of gradient zirconium boride ultrahigh-temperature ceramic. The preparation method is characterized by comprising the following steps of: 1) preparing casting sheets with different components respectively by a casting method, namely adding a binder and a plasticizer into a solvent to stir uniformly, adding zirconium boride ceramic powder respectively tostir uniformly to form casting materials, and performing casting forming; 2) slicing; 3) overlapping the slices sequentially according to the component size of the zirconium boride, placing the slices into a graphite grinding apparatus, and then performing vacuum degreasing, wherein the layer number is more than 15; the mass percentage of the zirconium boride in the zirconium boride ceramic powder of each layer of casting slice is reduced sequentially; the mass percentage of silicon carbide is not changed or is reduced; the mass percentage of zirconium oxide is increased sequentially; and themass percentage sum of three components in the zirconium boride ceramic powder of each casting slice is 100 percent; and 4) performing hot pressed sintering to prepare the gradient zirconium boride ultrahigh-temperature ceramic with a heat insulation function. The preparation process is simple and the cost is low. By the preparation method, an ultrathin ceramic part can be prepared and has fracture toughness of up to 8 MPa.m1 / 2.

Owner:SHANDONG UNIV OF TECH

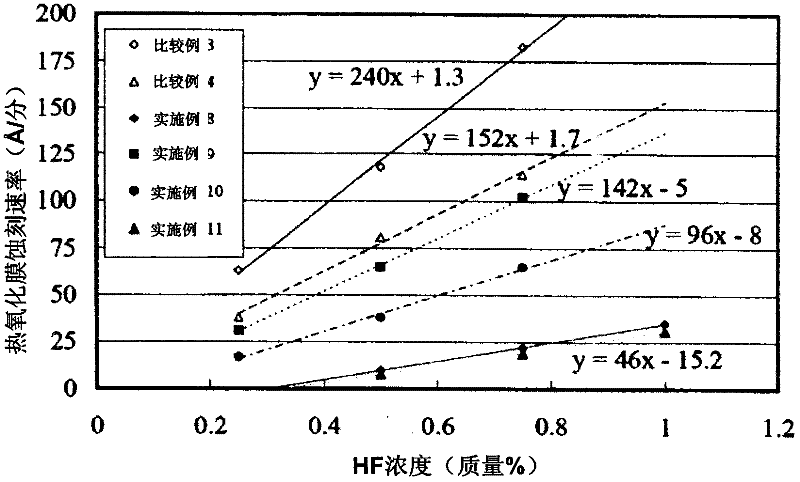

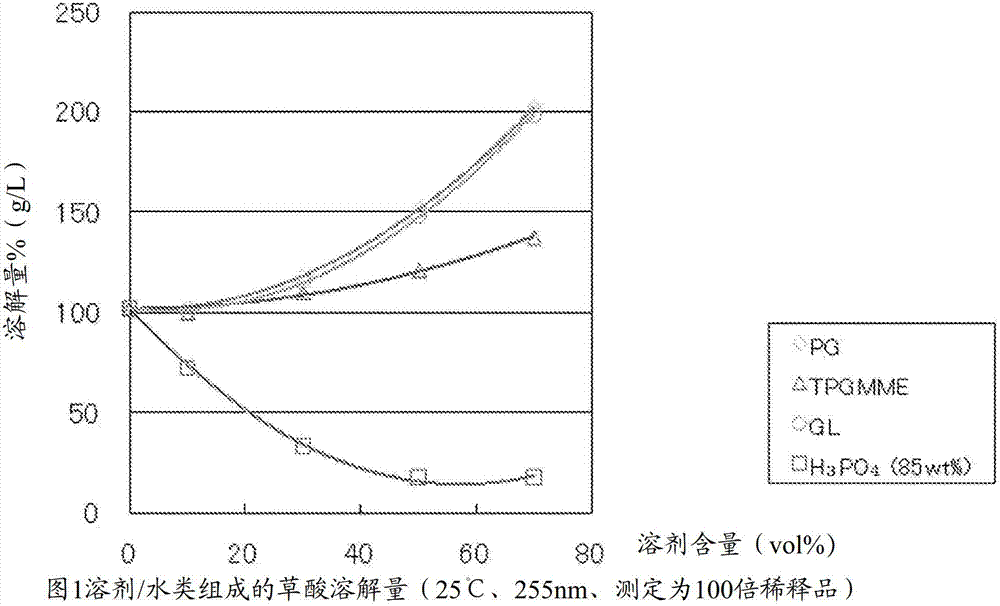

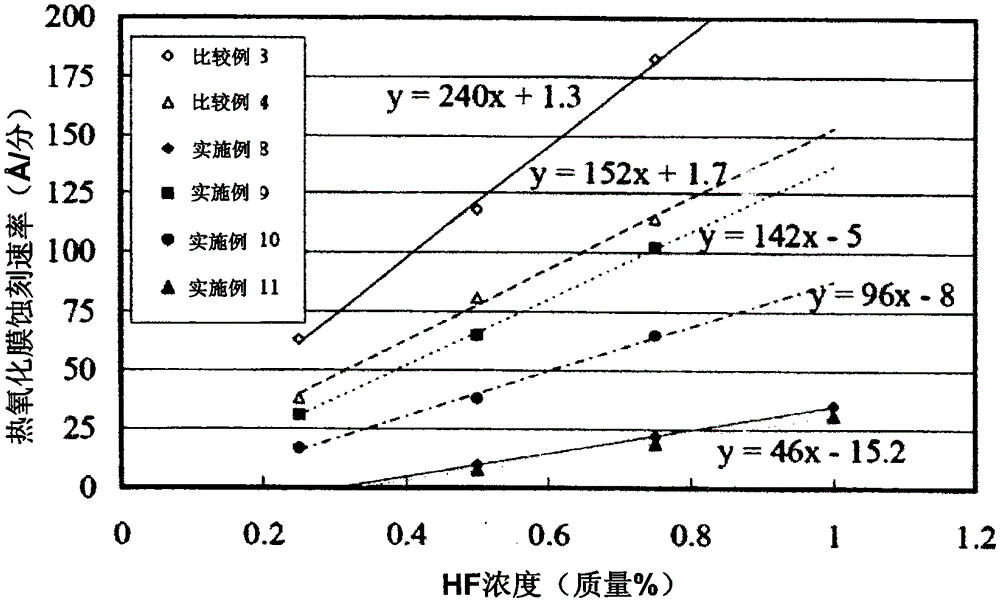

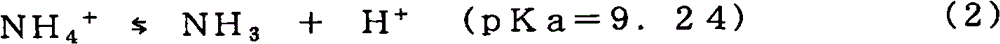

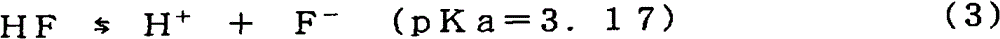

Etching liquid

ActiveCN102379028ALittle change in compositionReduce exchange frequencySemiconductor/solid-state device manufacturingSurface treatment compositionsAmmoniumNuclear chemistry

Provided is an etching liquid that contains: hydrofluoric acid (A); ammonium fluoride (B); a salt (C) that comprises an acid (C1) having a higher pKa than hydrofluoric acid (which has a pKa of 3.17) and a base (C2) having higher pKa than ammonium (which has a pKa of 9.24); and water (D). As a result, the liquid chemical does not change much in composition upon evaporation and the like, has a low exchange frequency, and can etch silicon dioxide films with uniformity over time as well.

Owner:DAIKIN IND LTD

Azeotrope or azeotropic composition, working medium for heat cycle, and heat cycle system

InactiveCN110869461AReduce environmental loadPromote circulationHeat-exchange elementsMechanical engineeringHeat cycling

Provided are: an azeotropic composition that provides a working medium that is for a heat cycle and that undergoes little compositional change, has a small temperature gradient, and has excellent cycle performance; a working medium that is for a heat cycle and uses the azeotropic composition; and a heat cycle system. An azeotrope or an azeotropic composition that comprises 1-chloro-2,3,3,3-tetrafluoropropene and (E)-1-chloro-3,3,3-trifluoropropene. A working medium that is for a heat cycle and includes the azeotrope or azeotropic composition.

Owner:AGC INC

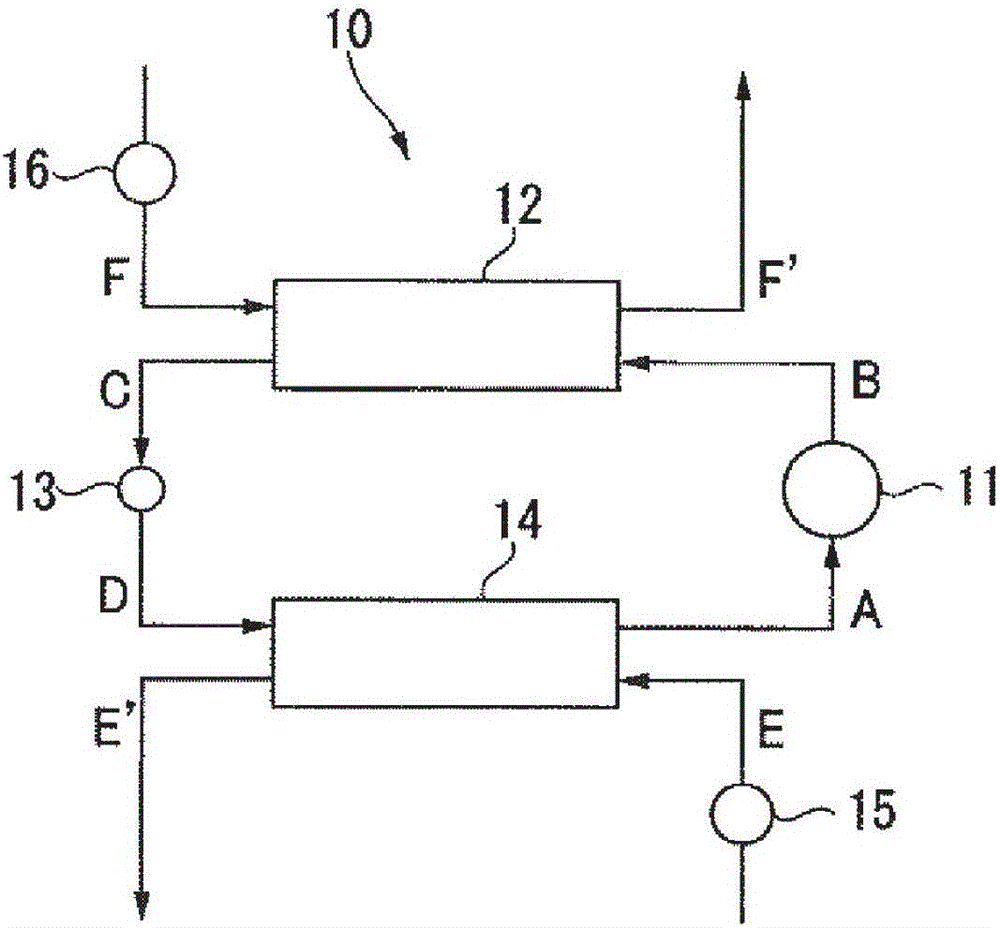

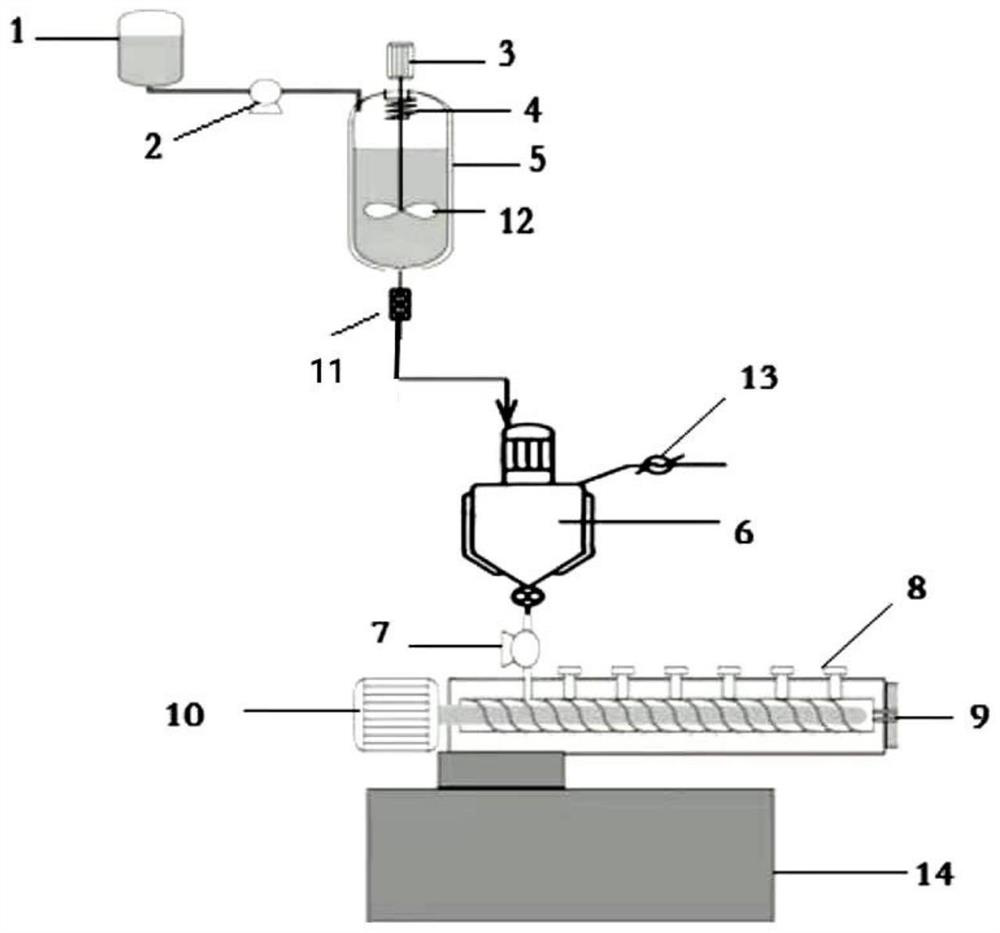

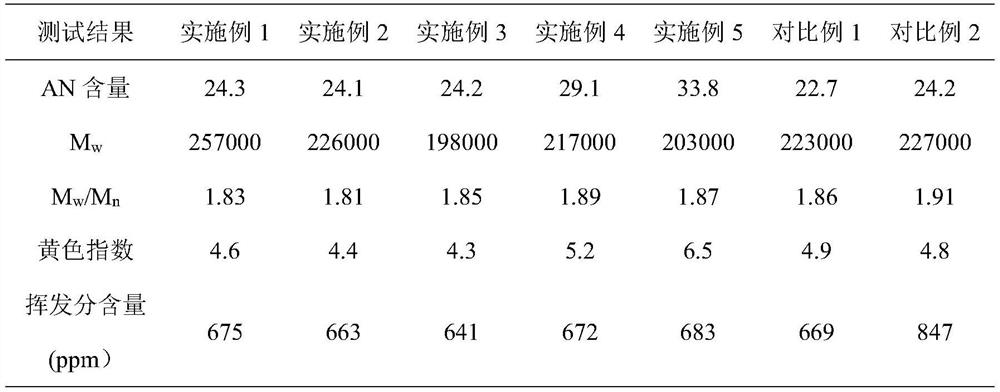

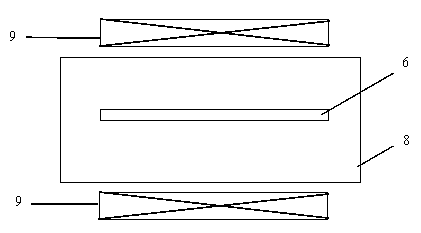

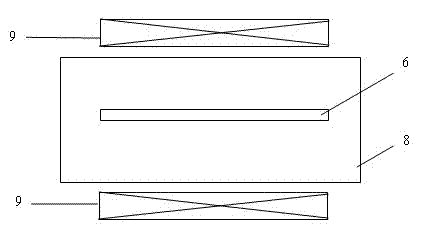

Device and method for preparing SAN resin with stable composition and low volatile components

InactiveCN113877498AEnsure controllabilityLittle change in compositionDistillation separationChemical/physical/physico-chemical stationary reactorsPolymer scienceBulk polymerization

The invention provides a device and a method for preparing SAN resin with stable composition and low volatile components, and belongs to the field of high polymer material preparation methods. According to the method, the SAN resin is prepared by adopting continuous bulk polymerization of thermal-initiated free radicals, acrylonitrile steam is controlled to instantaneously condense and flow back to a reaction kettle to participate in polymerization at the top of the kettle through a built-in condensing coil at the top of the polymerization kettle, and stable composition of styrene and acrylonitrile monomers and the final SAN resin in a reaction system is ensured. A two-stage devolatilization mode in which two static flash tanks are connected in series in the conventional SAN resin preparation process is optimized into a one-stage flash tank static devolatilization and two-stage double-screw devolatilization extruder dynamic devolatilization mode, so that the thermal degradation risk of the SAN resin at the high temperature of the two-stage devolatilization device is effectively reduced, and the mechanical property, transparency and appearance quality of the SAN resin are improved. Meanwhile, compared with the devolatilization effect of a two-stage series static flash tank, the volatile component content of the SAN resin obtained by the process is lower and can reach 600-700ppm.

Owner:CHANGCHUN UNIV OF TECH

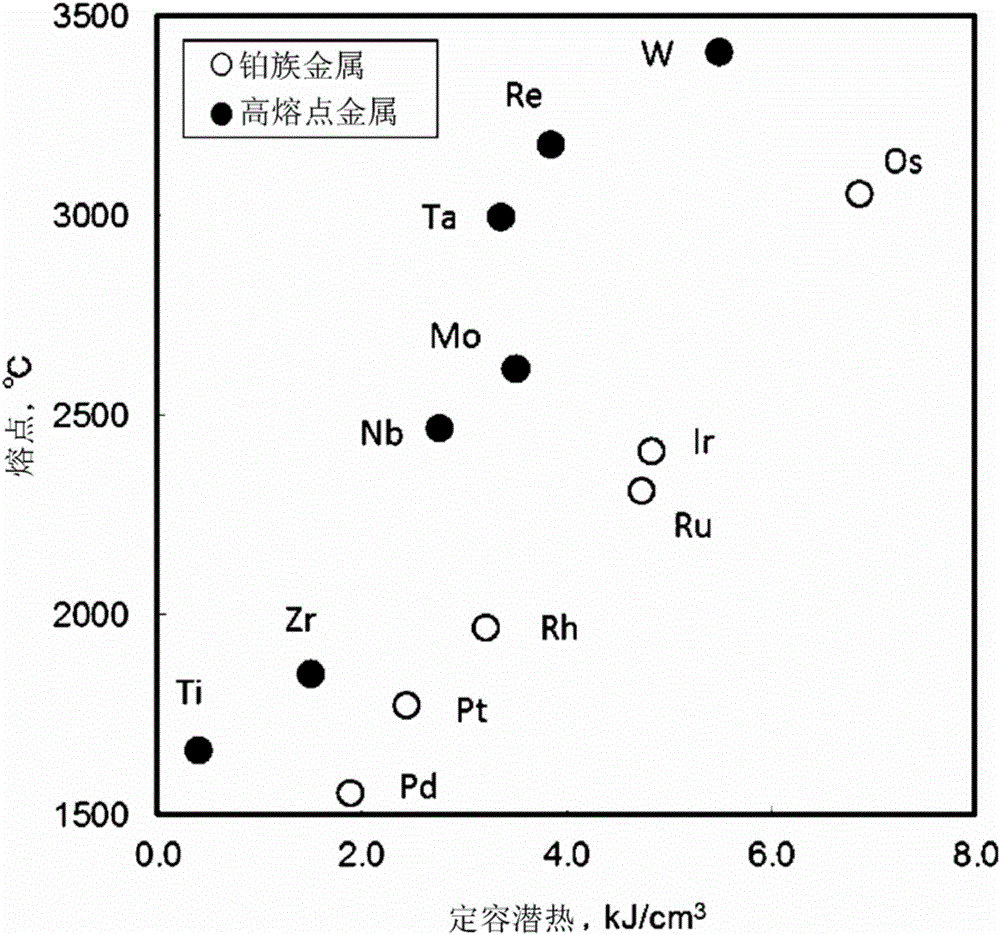

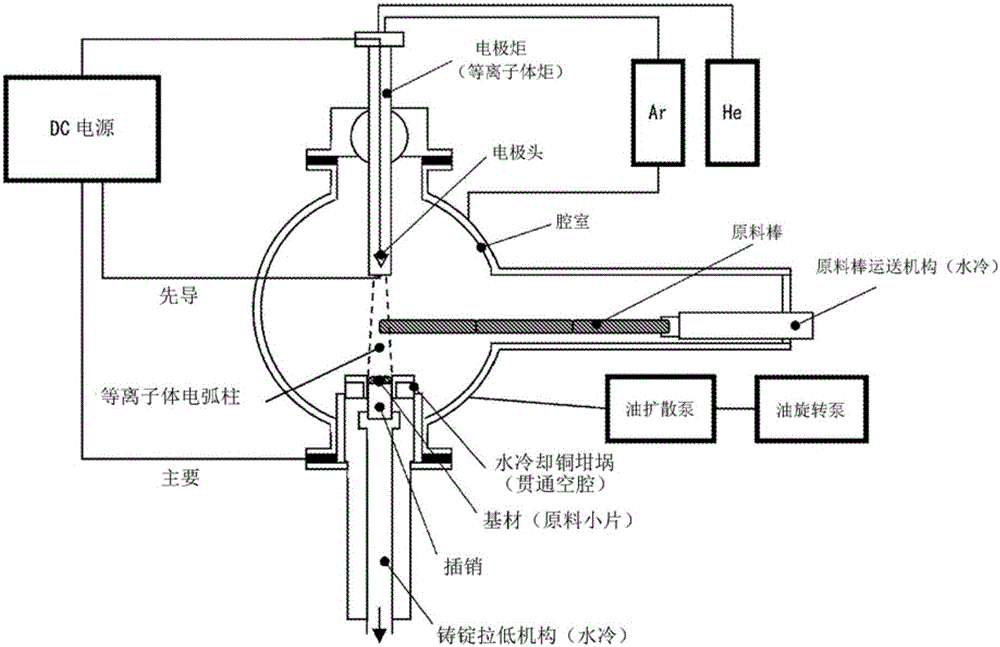

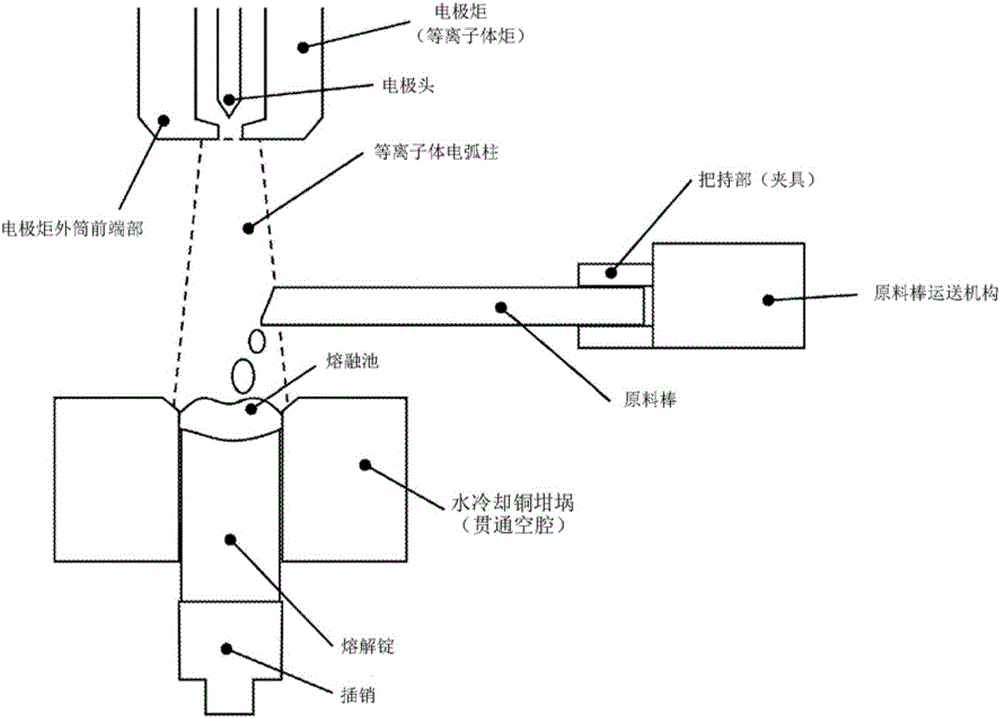

Platinum group alloy manufacturing method

The present invention is a continuous founding-type melt ingot manufacturing process in which used is a plasma arc melting furnace in which a plasma arc column is formed between an electrode torch disposed inside and at an upper part of a vacuum chamber and a water-cooled copper crucible which is provided with a cavity having a cross sectional area S1 and which is disposed inside and at a lower part of the chamber. While the end portion of a raw material rod formed of a platinum group alloy is inserted into the plasma arc column and melted, the melted material is caused to drip onto a base material inside of the water-cooled copper crucible and form a molten pool. While the height of the liquid surface of the molten pool is maintained at a constant height by lowering the base material, the bottom portion of the molten pool is caused to solidify. The horizontal cross-sectional area S (mm2) and the length L (mm) of the melt ingot satisfy S1>=S>500, L>4 radical sign (S / Pi), the internal pressure of the chamber at the time of melting is at least 0.8atm, and the lowering speed is no more than 10mm / min.

Owner:ISHIFUKU METAL IND CO LTD

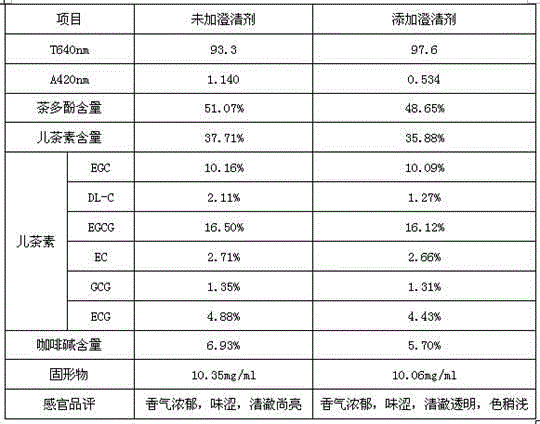

Green tea juice clarification method

InactiveCN105613847AGood clarificationSoup is clear and translucentTeaEpigallo-catechin gallateGreen tea

The present invention relates to a green tea juice clarification method and belongs to the processing field of drink and especially green tea drink. The green tea juice clarification method comprises the following steps: green tea leaves are taken and cleaned, deionized water of 10-12 times of the weight of the tea leaves at a temperature of 95 DEG C is added, the tea leaves are subjected to temperature constant water bath at a constant temperature of 90 DEG C for 15 min, then the treated tea leaves are filtered using a 200 mesh filtering cloth, the filtrate is cooled to obtain a tea juice, then at room temperature, a clarifying agent is added into the tea juice, and the mixture is stirred and filtered after 60 min to obtain clarified green tea juice. The prepared green tea juice by the green tea juice clarification method is good in clarification effects and the light transmission is more than 97.6%. Besides, the green tea juice has no big differences in tastes and fragrance compared to the control. The main ingredients of the prepared green tea are less in changes and the soup color is more clarified and translucent.

Owner:SHAANXI QIYUAN TECH DEV

Production method of heavy-gauge large-single-weight low-alloy high-strength structural steel plates

InactiveCN102732674BImprovement ingredientsUniform compositionElectric furnaceProcess efficiency improvementElectro-slag remeltingHeat treated

The invention provides a production method of heavy-gauge large-single-weight low-alloy high-strength structural steel plates. The method comprises the steps of smelting, casting, electroslag remelting, electroslag ingot cleaning, heating, rolling, water cooling, hydrogen diffusion treatment, supersonic wave flaw detection, normalization, examination and warehousing. The largest thickness of the steel plates produced through the method of the invention can reach 410mm. The method allows the isotropy, the impact toughness and the Z-directional performances of the heavy-gauge steel plates to be realized through adopting large slab electroslag remelting treatment and a reasonable controlled rolling and heat treatment technology, the production cost to be reduced, the time of delivery to be substantially shortened and the specification range to be wide, and is used for satisfying continuously increased market application amount demands; and the steel plates can completely substitute import products to satisfy various requirements of heavy-gauge large-single-weight steel plates applied to water power, wind power and large building structures.

Owner:WUYANG IRON & STEEL +1

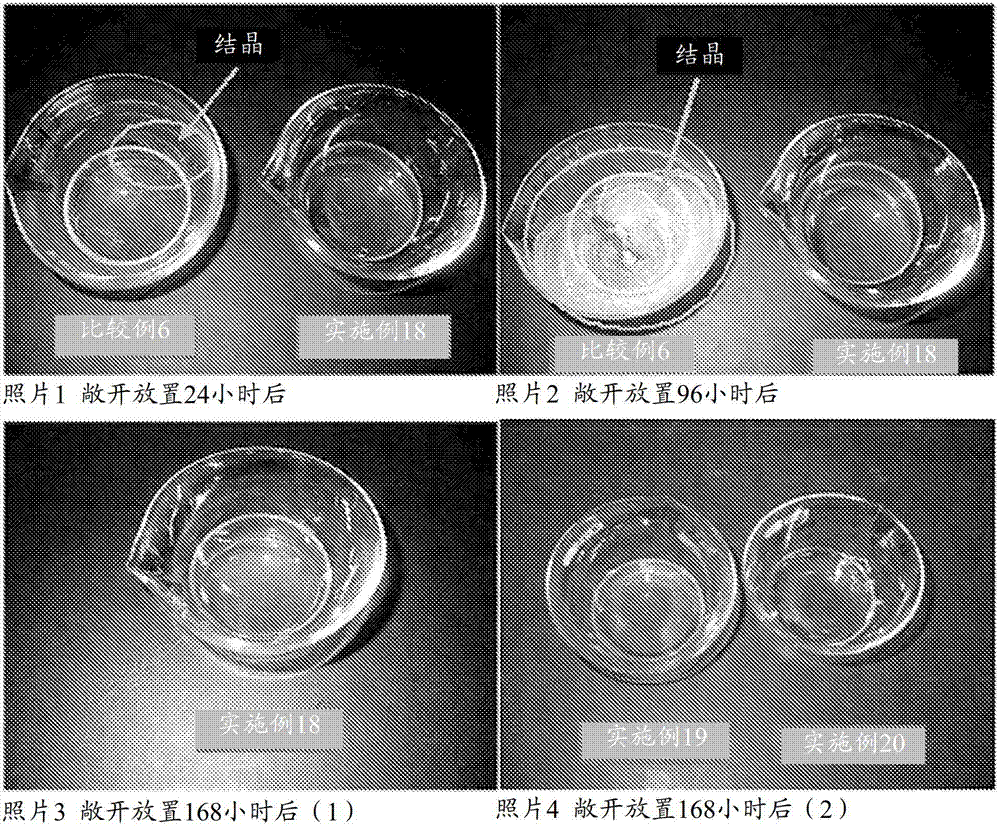

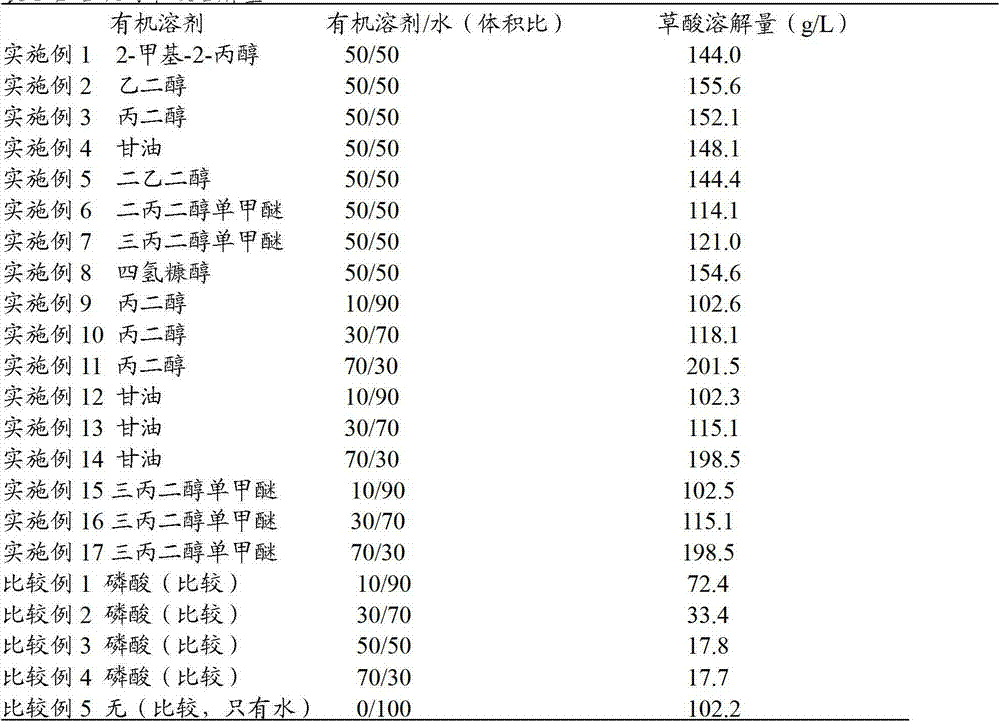

Photoresist residue and polymer residue removing liquid composition

InactiveCN103080845AInhibition of recrystallizationImprove work efficiencyDetergent mixture composition preparationSemiconductor/solid-state device manufacturingResistEvaporation

Provided are a photoresist residue and polymer residue removing liquid composition, and a method of removing the residue used therewith, for removing photoresist residue and polymer residue produced during a process of manufacturing a semiconductor circuit element having metallic wiring. Specifically, the composition does not contain nitrogen-containing organic hydroxyl compounds, ammonia or fluorine compounds, and contains an aliphatic polycarboxylic acid having a melting point of 25 DEG C or higher with an excellent residue removing property and having a metallic oxide main component as the residue removing component. The photoresist residue and polymer residue removing liquid composition, and the method of removing the residue used therewith, is capable of preventing the aliphatic polycarboxylic acid from being recrystallized by evaporation of water after a solution has adhered around a cleaning device liquid ejecting nozzle or a cleaning tank and a chamber. In the photoresist residue and polymer residue removing liquid composition containing the aliphatic polycarboxylic acid with a melting point of 25 DEG C or higher, the removing liquid contains an organic solvent that is miscible with water and has a vapor pressure of 17 mm Hg or less at 20 DEG C and a hydroxyl group within the structure.

Owner:KANTO CHEM CO INC

Wet tissue with bacteriostasis function and manufacturing method thereof

ActiveCN108904380AReduce dosageImprove spraying efficiencyCosmetic preparationsToilet preparationsEmulsionPhosphate

The invention relates to the field of wet tissue manufacturing, and provides a wet tissue with the bacteriostasis function and a manufacturing method thereof to improve the bacteriostasis effect of wet tissues. The wet tissue with the bacteriostasis function and the manufacturing method thereof comprise a basic material and wet tissue emulsion. The basic material is loaded with the wet tissue emulsion. The wet tissue emulsion comprises, by mass, 1-2 parts of glycerinum, 3-6 parts of hyaluronic acid, 2-4 parts ofsodium hexadecyl polyoxyethylene ether phosphate, 4-6 parts of Chinese medicinal extract, 0.2-0.5 part of EDTA disodium, and 60-70 deionized water. Growth of bacteria can be effectively inhibited by adding the Chinese traditional medicine extract to the wet tissue, and irritation toskin is little.

Owner:亚美利加(辽宁)药业有限公司

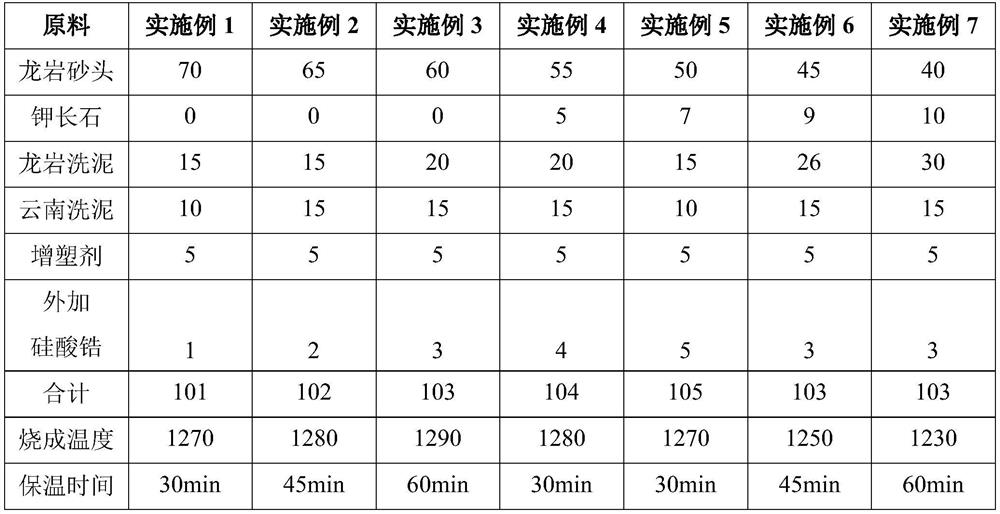

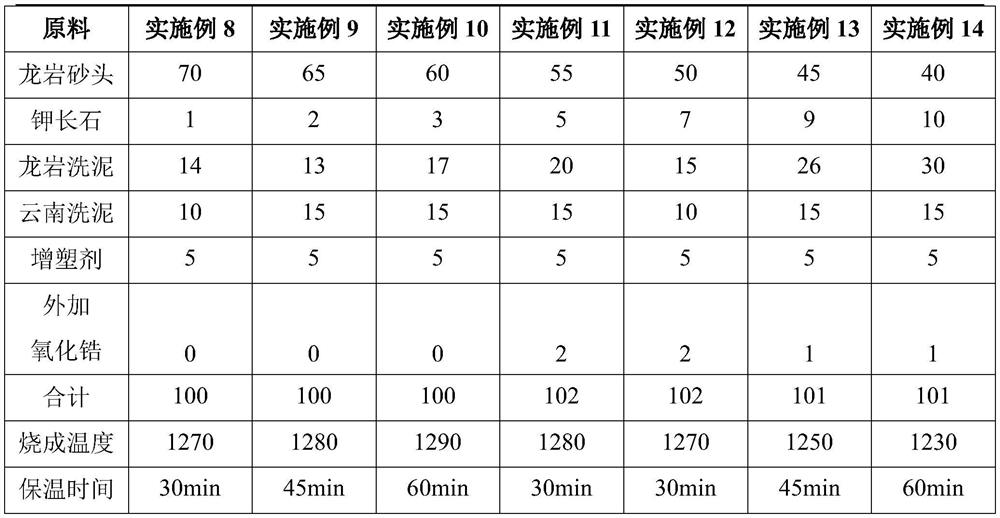

High-silicon daily reinforced porcelain and preparation method thereof

The invention relates to daily high-silicon reinforced porcelain and a preparation method thereof, in particular to high-silicon daily reinforced porcelain prepared by taking Longyan sand head as a main raw material, and belongs to the field of daily reinforced porcelain. The porcelain body is mainly composed of the following components in percentage by mass: 40 to 70% of Longyan sand head, 0 to 10% of feldspar mineral, and 25 to 50% of clay mineral. According to the method, feldspar and quartz can be completely provided by the Longyan sand head, a large amount of high-quality feldspar and quartz resources are saved, waste sand head resources are fully utilized, and the method has huge social, economic and technical values.

Owner:GUANGDONG SITONG GROUP

Preparation method of gradient zirconium boride ultrahigh-temperature ceramic

InactiveCN102173809BLittle change in compositionSmall residual thermal stressZirconium hydrideBoride

The invention provides a preparation method of gradient zirconium boride ultrahigh-temperature ceramic. The preparation method is characterized by comprising the following steps of: 1) preparing casting sheets with different components respectively by a casting method, namely adding a binder and a plasticizer into a solvent to stir uniformly, adding zirconium boride ceramic powder respectively tostir uniformly to form casting materials, and performing casting forming; 2) slicing; 3) overlapping the slices sequentially according to the component size of the zirconium boride, placing the slices into a graphite grinding apparatus, and then performing vacuum degreasing, wherein the layer number is more than 15; the mass percentage of the zirconium boride in the zirconium boride ceramic powder of each layer of casting slice is reduced sequentially; the mass percentage of silicon carbide is not changed or is reduced; the mass percentage of zirconium oxide is increased sequentially; and themass percentage sum of three components in the zirconium boride ceramic powder of each casting slice is 100 percent; and 4) performing hot pressed sintering to prepare the gradient zirconium boride ultrahigh-temperature ceramic with a heat insulation function. The preparation process is simple and the cost is low. By the preparation method, an ultrathin ceramic part can be prepared and has fracture toughness of up to 8 MPa.m1 / 2.

Owner:SHANDONG UNIV OF TECH

Sputtering Target Comprising Ni-P Alloy or Ni-Pt-P Alloy and Production Method Therefor

ActiveUS20170121811A1Excellent propertyHigh densityElectric discharge tubesVacuum evaporation coatingAlloySmall deviations

A method of producing a Ni—P alloy sputtering target, wherein a Ni—P alloy having a P content of 15 to 21 wt % and remainder being Ni and unavoidable impurities is melted and atomized to prepare a Ni—P alloy atomized powder having an average grain size of 100 μm or less, the Ni—P alloy atomized powder is mixed with a pure Ni atomized powder, and the obtained mixed powder is hot pressed. An object of the present invention is to provide a method of producing a Ni—P alloy sputtering target which achieves a small deviation from an intended composition.

Owner:JX NIPPON MINING & METALS CORP

Method for producing propylene continuously in switch mode

ActiveCN100368358CLittle change in compositionImprove product qualityHydrocarbon by hydrocarbon crackingBiochemical engineeringFixed bed

This invention relates to a changeover method for continuously manufacturing propylene by C4+ alkenes catalytic cracking. The method adopts a reactor with a set of parallel fixed beds. Each fixed bed is operated according to a certain interval, and the products of all fixed bed are mixed and sent to the next process so that the reactant of the next process has stable composition. The method solves the problems of low catalyst activity and large change of product composition at the beginning and end of reaction, which leads to difficulties in stable quality and next process. The method can be used in propylene industrial manufacture by C4+ alkenes catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing vertical anisotropic iron base soft magnetic film

InactiveCN1252754CStrong adhesionUniform thicknessCathode sputtering applicationMagnetic materialsPerpendicular anisotropyRadio frequency magnetron sputtering

A preparation method for a vertical anisotropy iron-base soft-magnetic film is to prepare an iron-base soft-magnetic film on a chip with a RF magnet-control spraying method then to anneal it under spraying method then to anneal it under suitable temperature after the preparation and to cool it without extra outer magnetic field or in the outer magnetic field vertical to the film face to get a vertical anisotropy iron-base soft-magnetic film, among which, the chip is a carrier chip or a silicon chip and the target material is an iron -base soft magnetic alloy.

Owner:EAST CHINA NORMAL UNIV

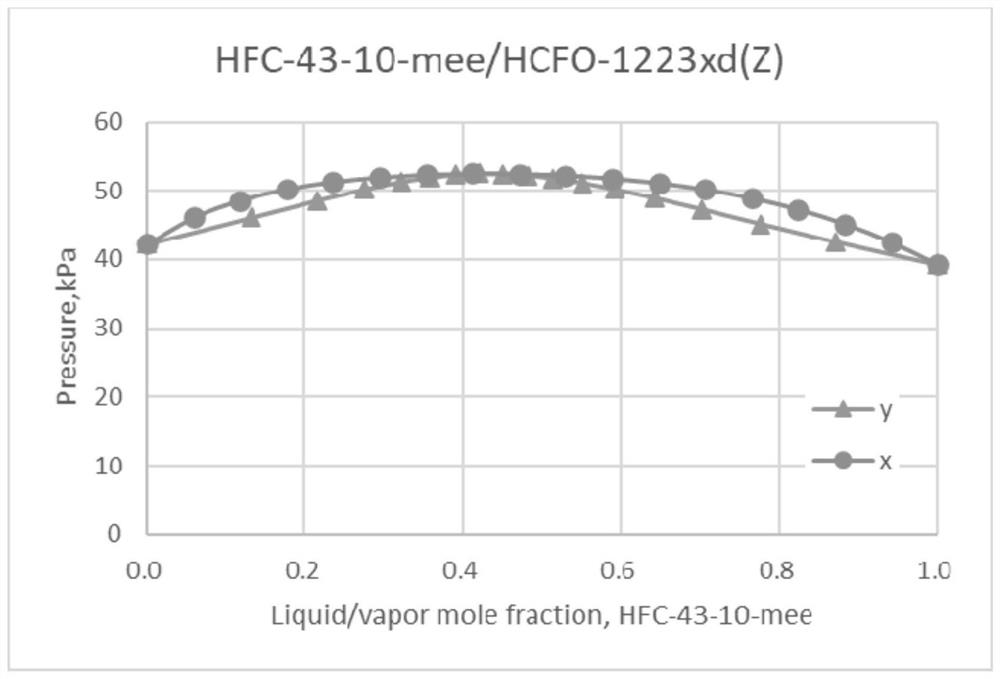

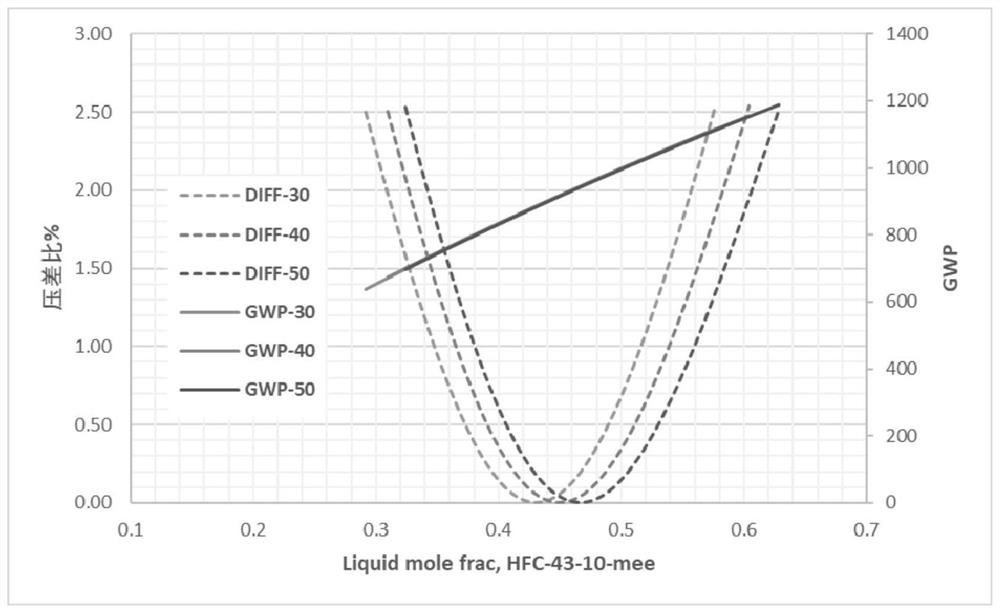

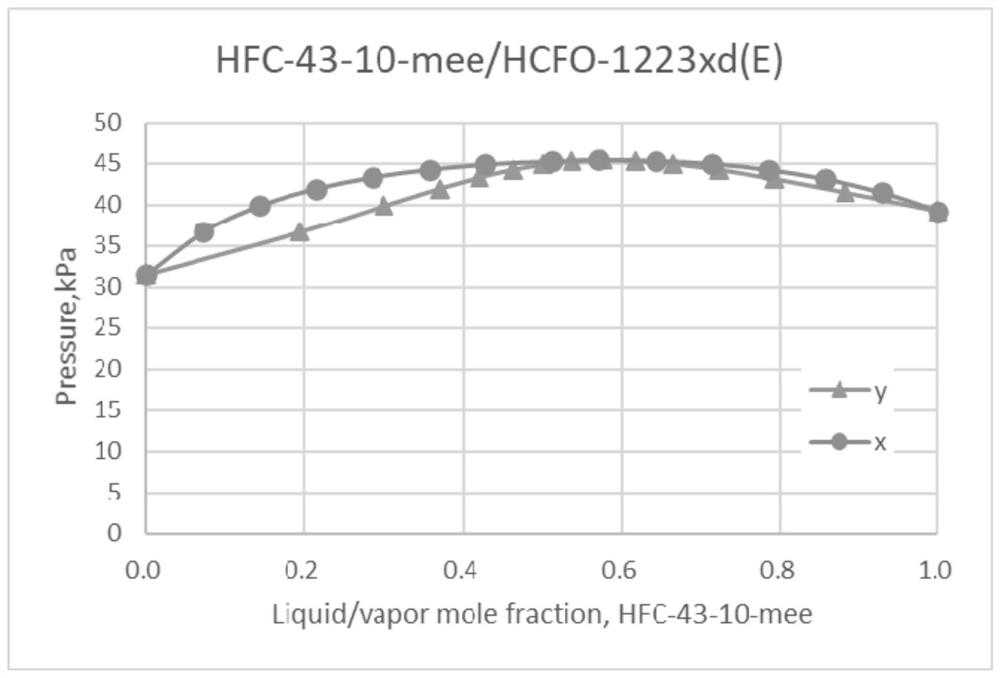

Azeotropic or azeotrope-like composition and preparation method thereof

ActiveCN114149790ALittle change in compositionSmall temperature glideBiocideTransportation and packagingZeotropic mixtureCombinatorial chemistry

The present invention discloses an azeotropic or azeotrope-like composition comprising a first component 1, 1, 1, 2, 2, 3, 4, 5, 5, 5-decafluoropentane and a second component selected from the group consisting of Z-1, 2-dichloro-3, 3, 3-trifluoropropene or E-1, 2-dichloro-3, 3, 3-trifluoropropene wherein the second component is present in an amount effective to form an azeotropic or azeotrope-like mixture with 1, 1, 1, 2, 2, 3, 4, 5, 5, 5-decafluoropentane. The invention also discloses a preparation method of the azeotropic or azeotrope-like composition. The composition provided by the invention has the advantages of low GWP, environmental protection and small temperature slip.

Owner:ZHEJIANG JUHUA NEW MATERIALS RES INST CO LTD

Polysulfone dialysis membrane, and production method and application thereof

ActiveCN107149884APromote formationGood compatibilityMembranesSemi-permeable membranesDialysis membranesWater baths

The invention provides a polysulfone dialysis membrane, and a production method and an application thereof. A polysulfone-polyethylene glycol block copolymer in the production method is used as a pore forming agent. The production method comprises the following steps: dissolving 10-25 parts by weight of polysulfone and 1-25 parts by weight of the polysulfone-polyethylene glycol block copolymer in 60-100 parts by weight of an organic solvent, and mixing above materials and the organic solvent to prepare a membrane casting solution; and cooling and defoaming the membrane casting solution, pouring the obtained solution onto a substrate, scraping a membrane, volatilizing the organic solvent in the membrane casting solution, placing the volatilized solution, solidifying the solution to form a membrane, and immersing the formed membrane in water to completely displace the organic solvent in the membrane in order to obtain the polysulfone dialysis membrane. The polysulfone-polyethylene glycol block copolymer used as the pore forming agent promotes the formation of membrane pores, so the pore forming agent is firmly anchored to the surface of the polysulfone base membrane, the loss problem of a hydrophilic pore forming agent is solved, and the membrane is endowed with a permanent hydrophilic property; and the polysulfone dialysis membrane also has the advantages of high membrane flux, high flux recovery rate and good stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

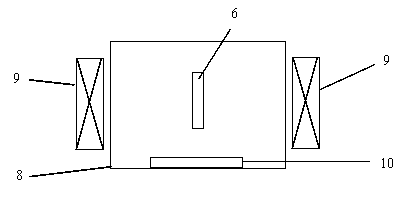

Electroplating production method and device for copper/aluminum composite conducting bar

InactiveCN102418128BImprove ionic phase distribution differencesLittle changeCellsMegasonic cleaningAluminum composites

The invention relates to a conducting bar for power transmission, in particular to an electroplating production method and a device for a copper / aluminum composite conducting bar under the action of ultrasound and an electric magnetic field. The electroplating production method and the device are characterized in that the less change for a traditional process of a copper / aluminum composite conducting bar is carried out; no special requirements for a substrate material and the state of the substrate material are needed; in the traditional method for producing the copper / aluminum composite conducting bar: firstly, ultrasonic wave cleaning is applied in the cleaning process, so that the aluminum bar can be better cleaned; and secondly, the electric magnetic filed is applied in the main plating process for carrying out electromagnetic stirring on an electroplating liquid and improving the distribution of electroplating ions in the electroplating liquid; the electromagnetic stirring realizes non-contact stirring, so that the pollution to the electroplating liquid is avoided; and in addition, the stirring strength is easily and accurately controlled and the goals of low production cost and uniform and compact coating of the copper / aluminum composite conducting bar are achieved.

Owner:JIANGSU UNIV

Electroplating production method and device for copper/aluminum composite conducting bar

InactiveCN102418128AImprove ionic phase distribution differencesLittle changeCellsMegasonic cleaningAluminum composites

The invention relates to a conducting bar for power transmission, in particular to an electroplating production method and a device for a copper / aluminum composite conducting bar under the action of ultrasound and an electric magnetic field. The electroplating production method and the device are characterized in that the less change for a traditional process of a copper / aluminum composite conducting bar is carried out; no special requirements for a substrate material and the state of the substrate material are needed; in the traditional method for producing the copper / aluminum composite conducting bar: firstly, ultrasonic wave cleaning is applied in the cleaning process, so that the aluminum bar can be better cleaned; and secondly, the electric magnetic filed is applied in the main plating process for carrying out electromagnetic stirring on an electroplating liquid and improving the distribution of electroplating ions in the electroplating liquid; the electromagnetic stirring realizes non-contact stirring, so that the pollution to the electroplating liquid is avoided; and in addition, the stirring strength is easily and accurately controlled and the goals of low production cost and uniform and compact coating of the copper / aluminum composite conducting bar are achieved.

Owner:JIANGSU UNIV

etchant

ActiveCN102379028BReduce exchange frequencyUniform etchingSemiconductor/solid-state device manufacturingSurface treatment compositionsHydrofluoric acidEvaporation

The present invention provides a kind of etchant, it contains hydrofluoric acid (A), ammonium fluoride (B), by the acid (C1) that has higher pKa than hydrofluoric acid (pKa=3.17) and has higher than ammonia ( The salt (C) and water (D) obtained from the base (C2) of pKa (pKa=9.24) have little change in composition due to the evaporation of the chemical solution, and the exchange frequency of the chemical solution is low, and can be uniform even over a long period of time. to etch the silicon oxide film.

Owner:DAIKIN IND LTD

A kind of polysulfone dialysis membrane and its preparation method and application

ActiveCN107149884BGuaranteed Curl WindingPromote formationSemi-permeable membranesMembranesDialysis membranesPolymer science

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com