Device and method for preparing SAN resin with stable composition and low volatile components

A low-volatile, resin-based technology, applied in the field of polymer material preparation, can solve the problems of wide distribution of monomer material composition, high concentration of unreacted monomer and solvent, etc., to improve mechanical properties, reduce the risk of thermal degradation, and stabilize the composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

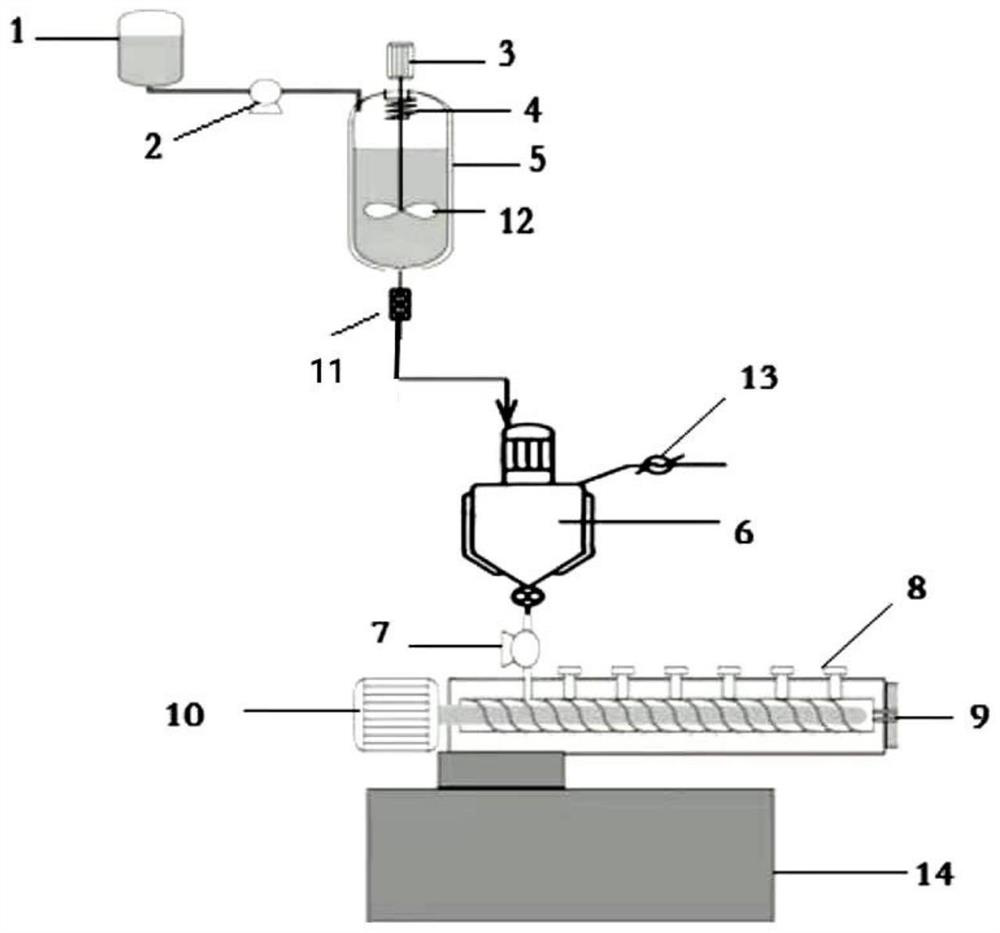

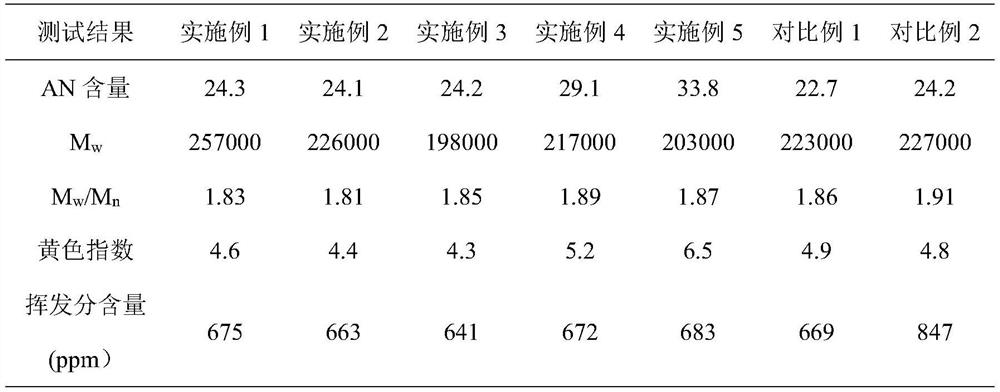

[0052] The styrene monomer of 75 parts by weight, the acrylonitrile monomer of 25 parts by weight, the toluene accounting for 25% by weight of the monomer, and the chain transfer agent n-dodecyl mercaptan accounting for 0.15% by weight of the monomer are in the feed tank After being mixed evenly, it is continuously injected into the reaction kettle through the feeding pump, and the polymerization reaction is carried out at 150°C for 3 hours to obtain the reaction mixture; the built-in cooling coil in the reaction kettle controls the acrylonitrile vapor to condense instantly at the top of the kettle and return to the reaction kettle to participate in polymerization. Ensure that the composition of styrene and acrylonitrile monomers and the final SAN resin in the reaction system is stable;

[0053] Start the discharge gear pump, the flash tank devolatilizer, and the twin-screw devolatilization extruder for devolatilization, and at the same time start the feeding pump, adjust the s...

Embodiment 2

[0056] The styrene monomer of 75 parts by weight, the acrylonitrile monomer of 25 parts by weight, the toluene that accounts for 25% by weight of the monomer, the chain transfer agent n-dodecyl mercaptan that accounts for 0.15% by weight of the monomer in the batching tank After mixing evenly in the medium, it was continuously injected into the reaction kettle through the feeding pump, and the polymerization reaction was carried out at 160°C for 2.5 hours. Other processes are the same as in Example 1. The performance test results of the product are shown in Table 1.

Embodiment 3

[0058] The styrene monomer of 75 parts by weight, the acrylonitrile monomer of 25 parts by weight, the toluene that accounts for 25% by weight of the monomer, the chain transfer agent n-dodecyl mercaptan that accounts for 0.15% by weight of the monomer in the batching tank After mixing evenly in the mixture, it was continuously injected into the reaction kettle through the feeding pump, and the polymerization reaction was carried out at 170°C for 2 hours. Other processes are the same as in Example 1. The performance test results of the product are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com