Patents

Literature

180results about How to "Low volatile content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-odor low-VOC (volatile organic compound)-content styrene polymer composition and preparation method thereof

ActiveCN103044793AOvercome the shortcomings of not being able to directly add to raw materialsWon't overflowPolymer scienceAntioxidant

The invention discloses a low-odor low-VOC (volatile organic compound)-content styrene polymer composition and a preparation method thereof. The composition is prepared from the following components in percentage by weight: 70-99% of styrene polymer, 0.5-29% of strippant master batch and 0.01-1% of antioxidant. The preparation method comprises the following steps: preparing a strippant master batch, mixing the components in a high-speed mixer, adding the mixture into a screw extruder, carrying out melt extrusion, and granulating. The invention has the advantages of simple production technique and lower production cost, and effectively lowers the order and VOC content of the styrene polymer; and the prepared styrene polymer composition can be used in the field of materials with strict environmental requirements in packaging materials, daily necessities, home appliances, OA, toys, sports equipment, shoe materials, cables, instruments and meters, electronic components and equipment, construction materials and automobile materials.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

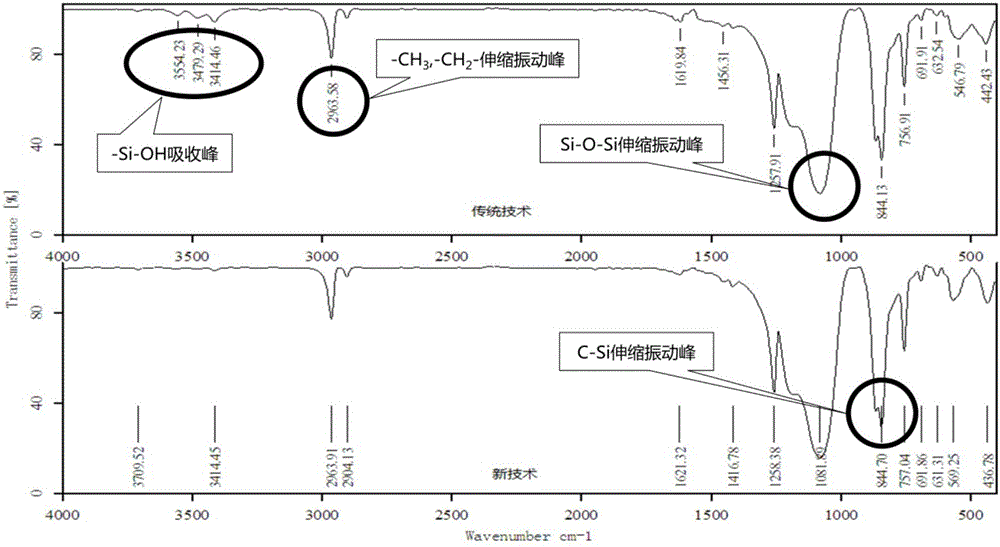

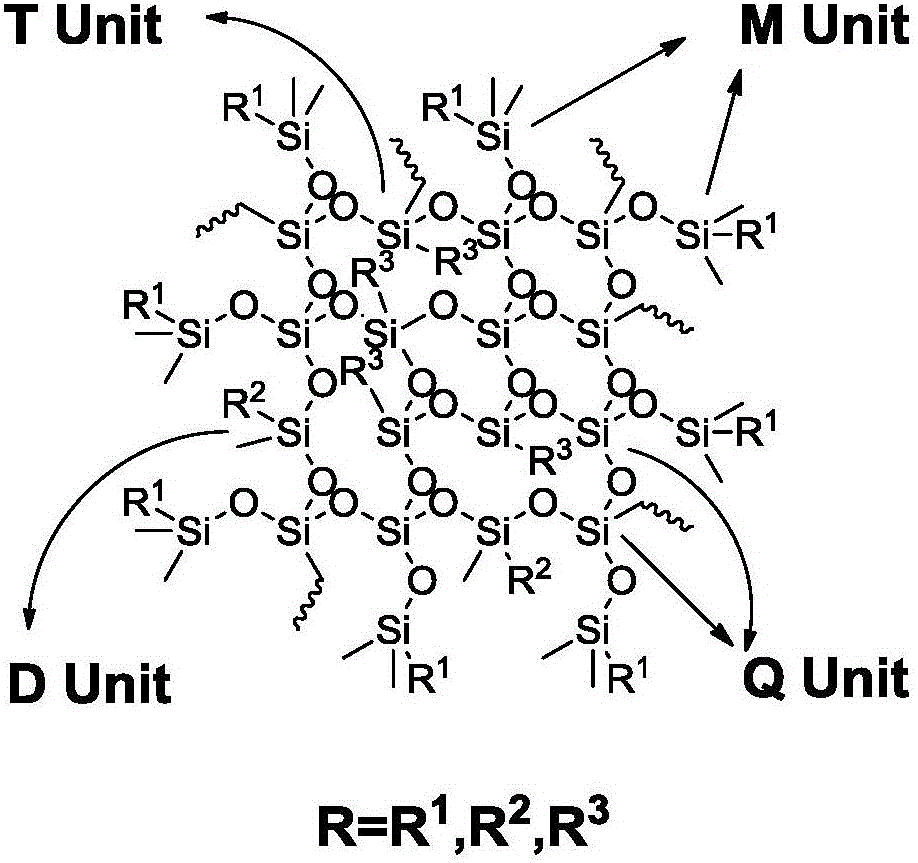

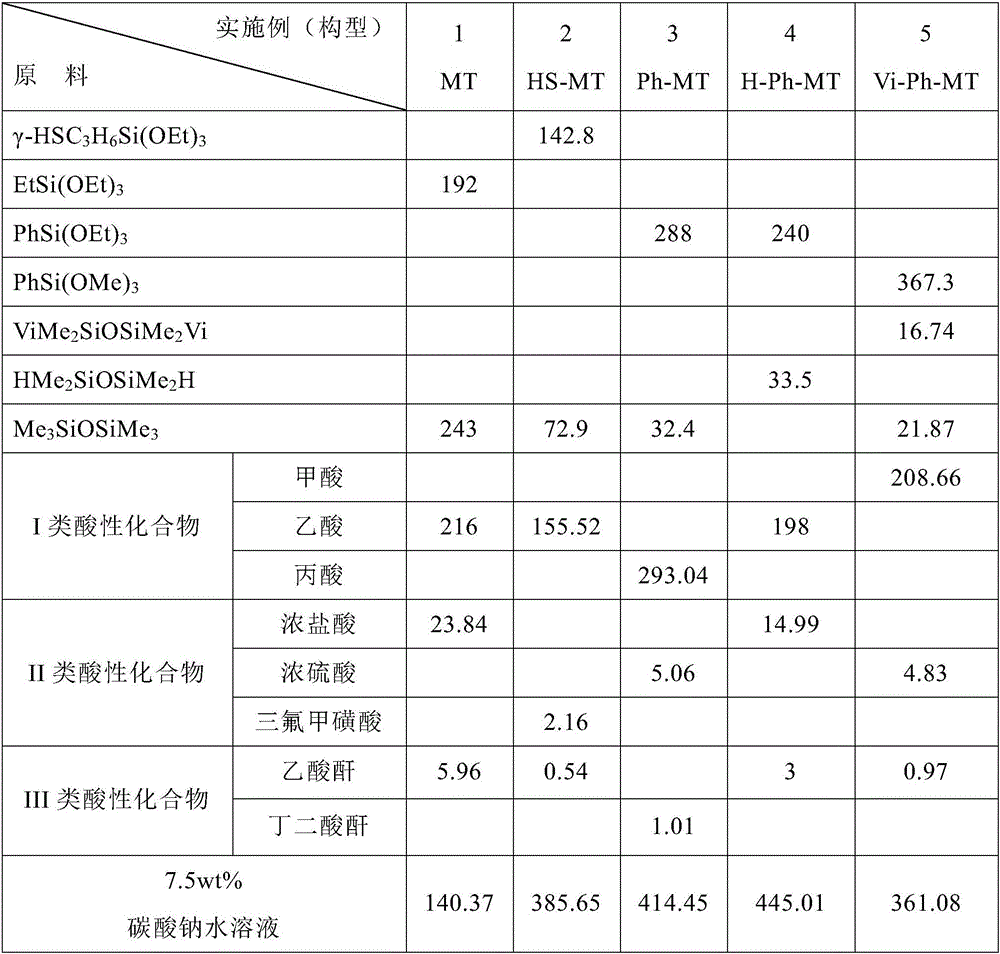

Preparation method of organopolysiloxane resin

The invention discloses a preparation method of organopolysiloxane resin. The preparation method includes the steps of (1), taking alkoxyorganosilane, an end-capping reagent and an acidic compound as preparation raw materials; (2), feeding the preparation raw materials with uniform stirring, wherein the feeding molar ratio of the end-capping reagent to the alkoxyorganosilane to the acidic compound is (0-40):1:(0.2-5); (3), adjusting the temperature at 40-150 DEG C at which condensation polymerization reaction is conducted for 2-20 hours; (4), terminating the condensation polymerization reaction, adjusting a reaction mixture to be neutral, and purifying a reaction product so as to obtain the organopolysiloxane resin. The preparation method of the organopolysiloxane resin has the advantages of environmental protection and no pollution during production, low energy consumption, short period, high product yield and the like and is more excellent in performance.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD

Process for producing propylene terpolymer

InactiveUS20160312018A1Lower melting temperatureReduce volatilityPolymer scienceZiegler–Natta catalyst

Owner:BOREALIS AG

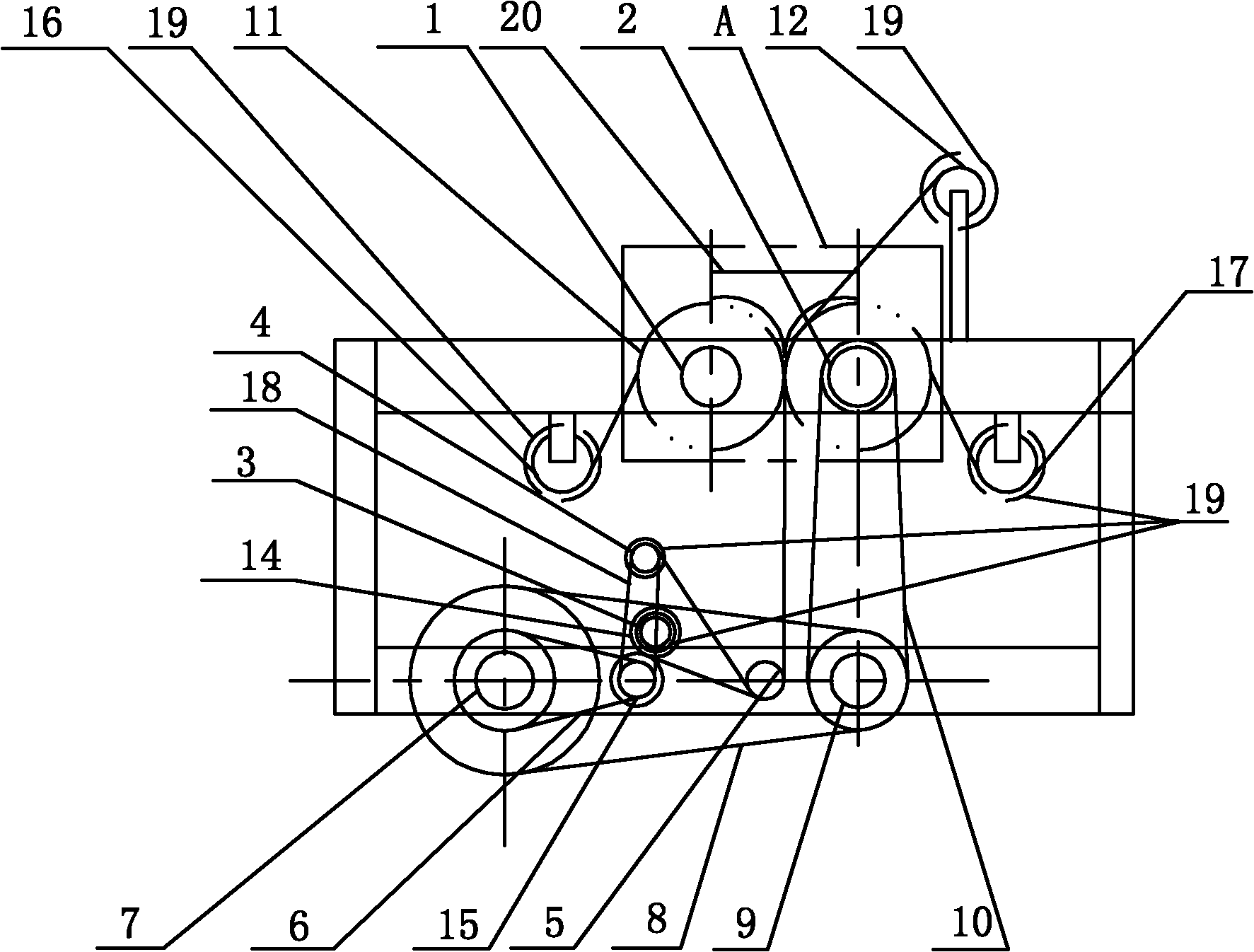

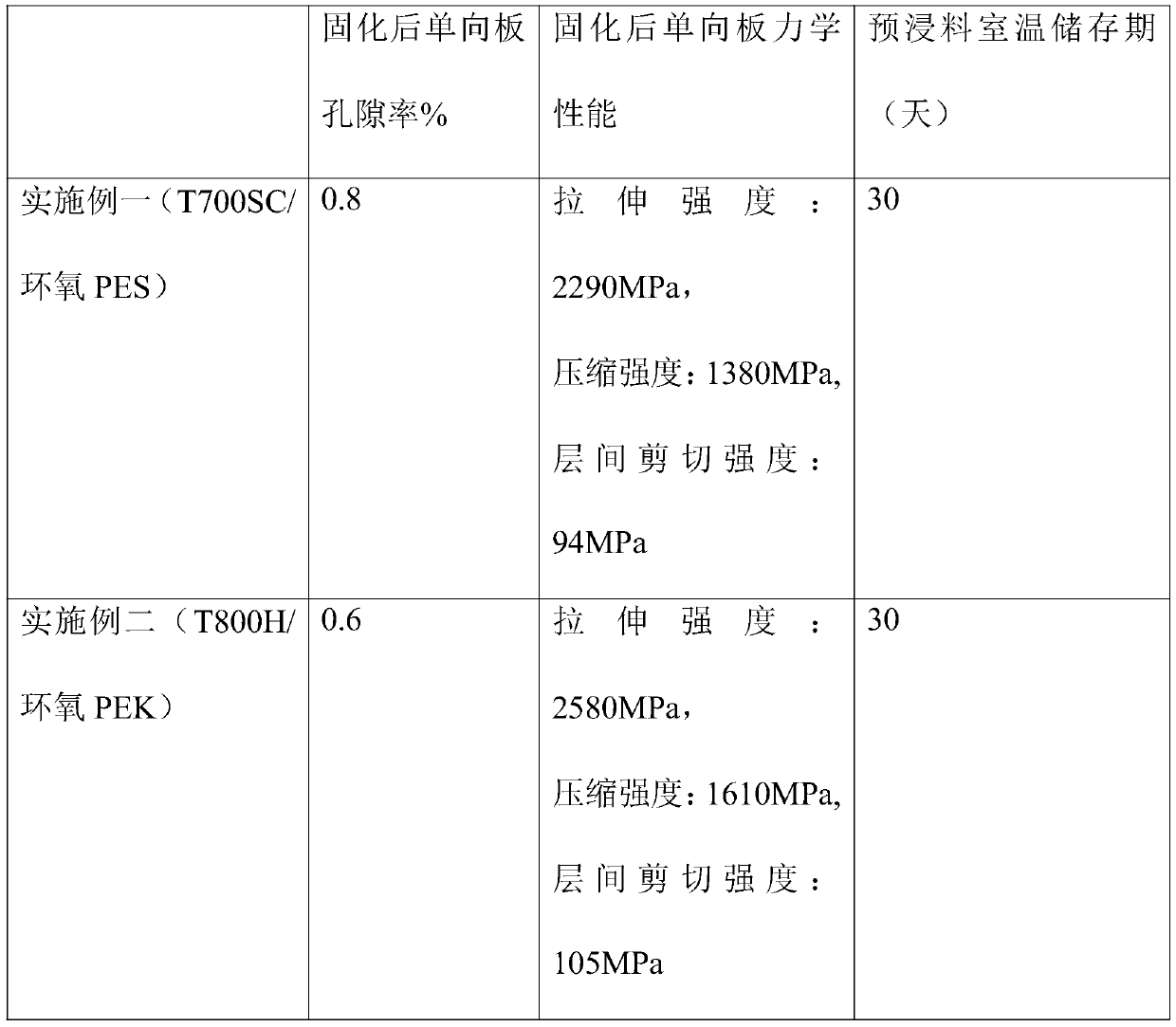

Epoxy matrix resin and prepreg and preparation method thereof and device for preparation thereof

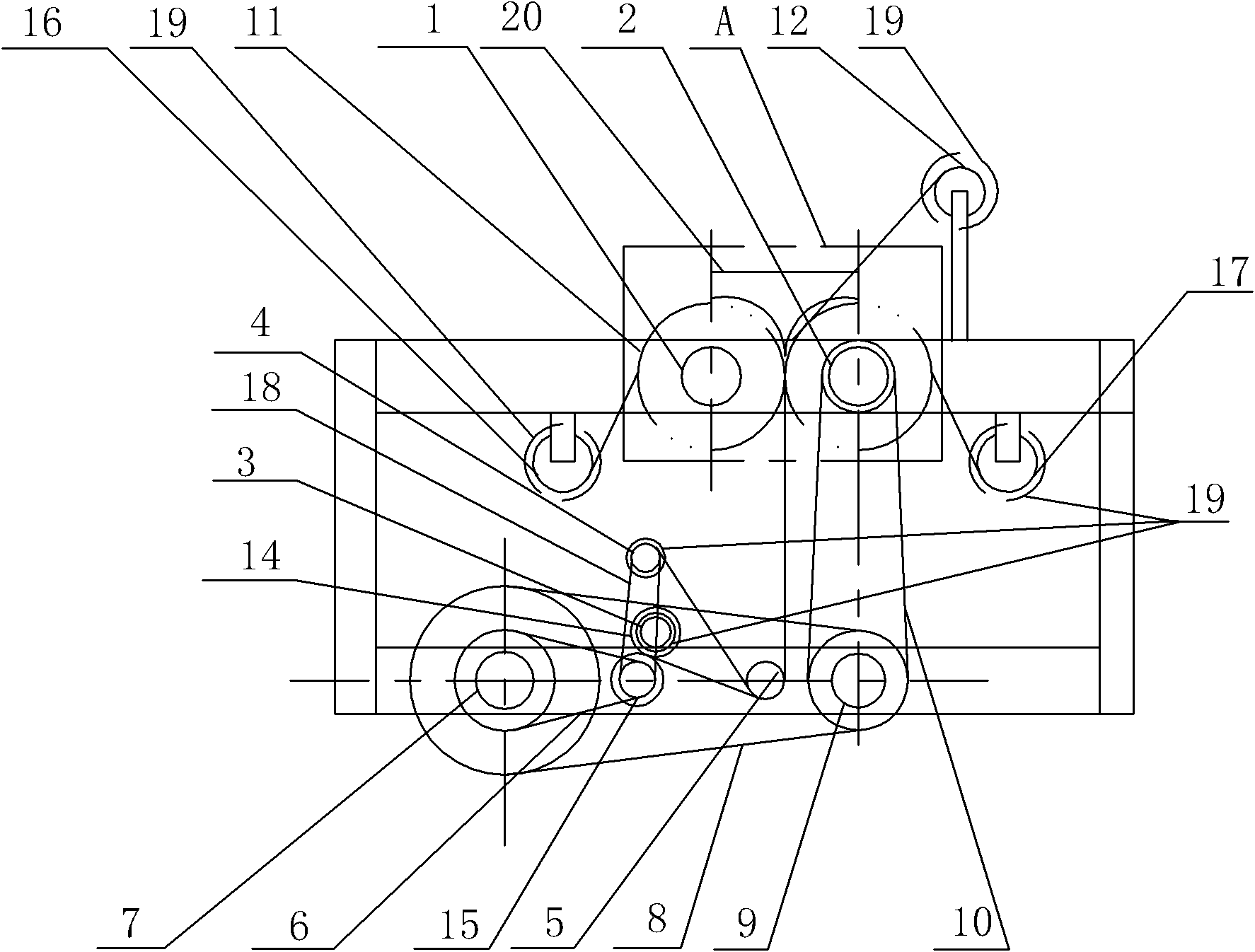

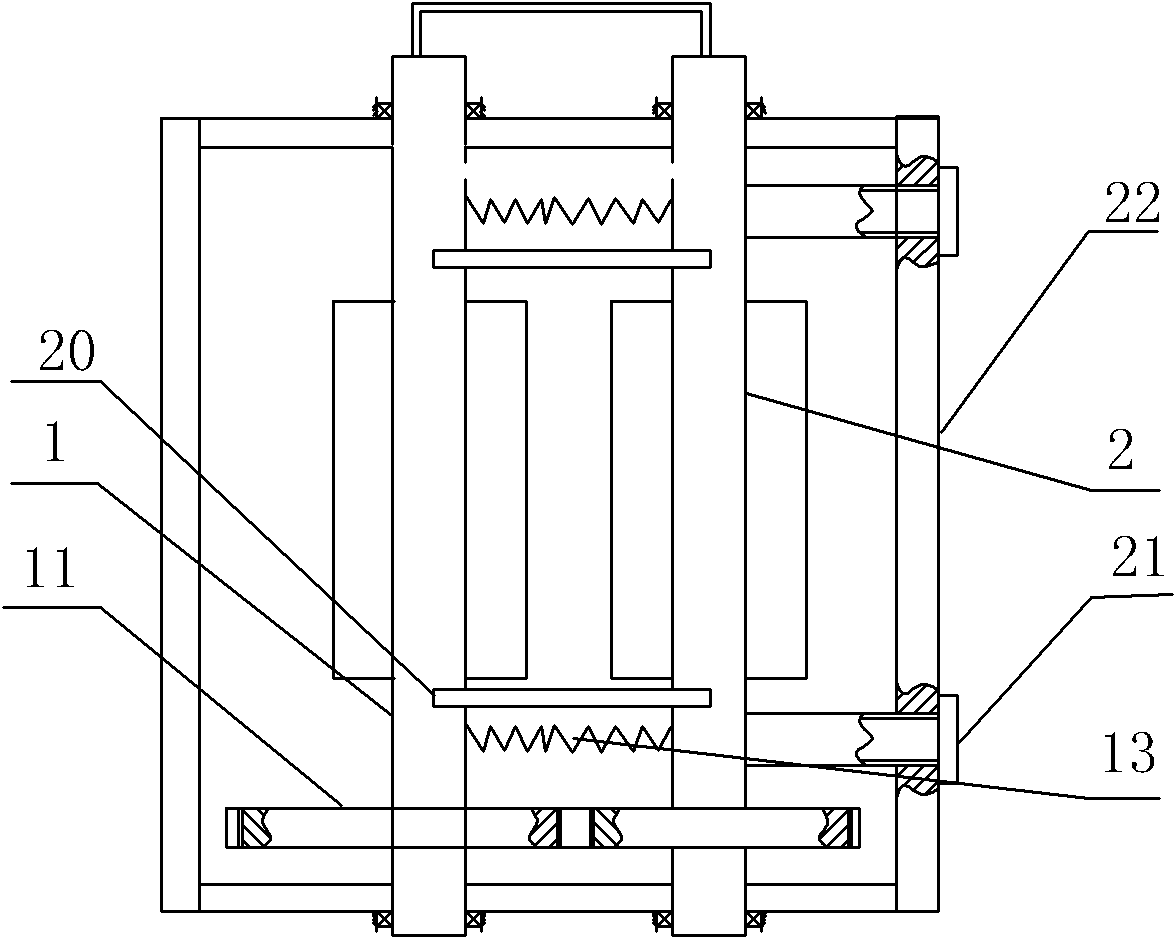

The invention discloses an epoxy matrix resin, a prepreg, a preparation method of the prepreg and a device for preparation of the prepreg, in order to solve the problem of poor performance of an epoxy matrix resin curing substance caused by uneven toughening phase state even no phase separation in the traditional epoxy matrix resin curing product, the problem of complex technique of the traditional preparation method of the prepreg and relatively imprecise control on the resin content in the prepreg, and the problem of high manufacturing cost of the traditional device for preparing the prepreg. The epoxy matrix resin is prepared from a phenolic epoxy resin, a bisphenol A epoxy resin, a core shell polymer, a curing agent and a curing accelerator; the prepreg is prepared from the epoxy matrix resin and fiber woven cloth; and the prepreg is prepared through the device for producing the prepreg by a heat fusion method. After and before the resin is cured, the toughening phase state is not changed and is uniformly dispersed; and the toughening phase state effect is good and stable. The mechanical property of the composite material obtained by curing with the prepreg is high.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Single-component, high-solid-content and low-volatility organic compound and environment-friendly type varnish composition and preparation method and application of varnish composition

The invention discloses a single-component, high-solid-content and low-volatility organic compound (VOC) and environment-friendly type varnish composition. The varnish composition comprises at least one polymer with a hyper-branched or tree-shaped structure, at least one hydroxyl acrylic resin or hydroxyl methacrylic resin, at least one cross-linking curing agent, at least one acid catalyst, at least one rheology control agent and at least one auxiliary agent. With the adoption of the varnish composition and application of the varnish composition, disclosed by the invention, the viscosity of a varnish coating system can be effectively reduced, and the solid content of the construction can be easily improved to be 58 percent or above; construction VOC emission is reduced to be smaller than or equal to 420g / L; varnish film shrinkage caused in a curing process can also be effectively reduced and a cured multi-coating varnish film has better appearance effect; particularly, the effect in a wet-on-wet process, a three-coating and one-drying process of curing three coatings together or an IPP system of primers, paints and varnishes is obvious.

Owner:LANGFANG NIPPON PAINT

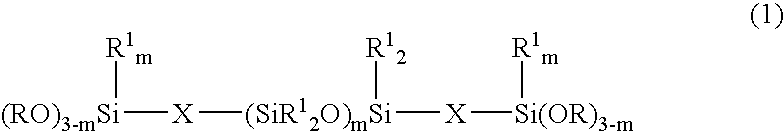

Room temperature-curable organopolysiloxane composition

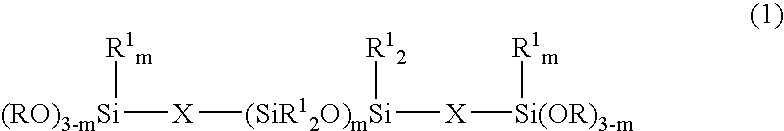

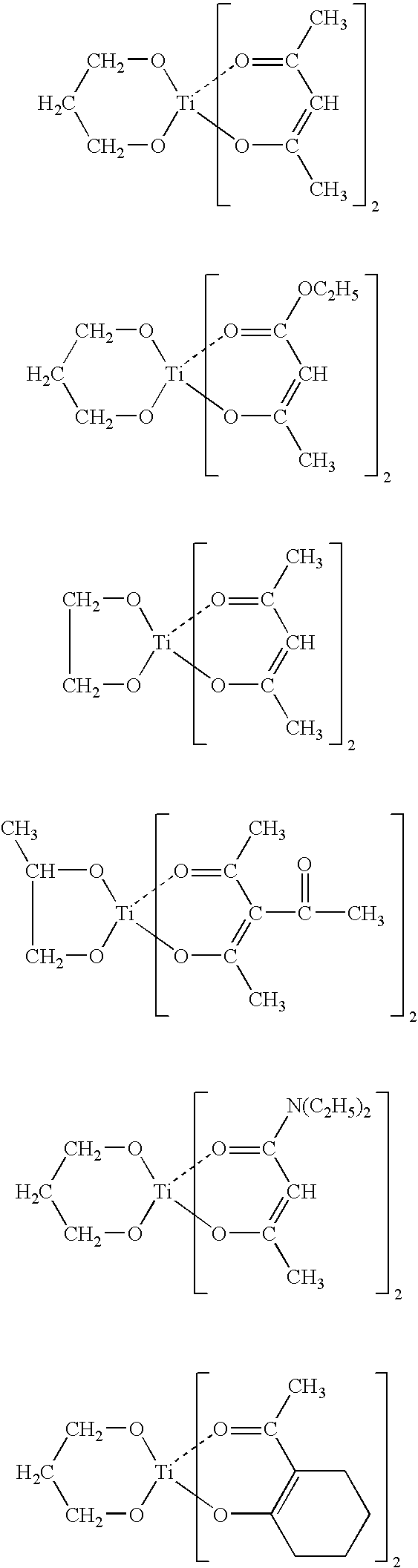

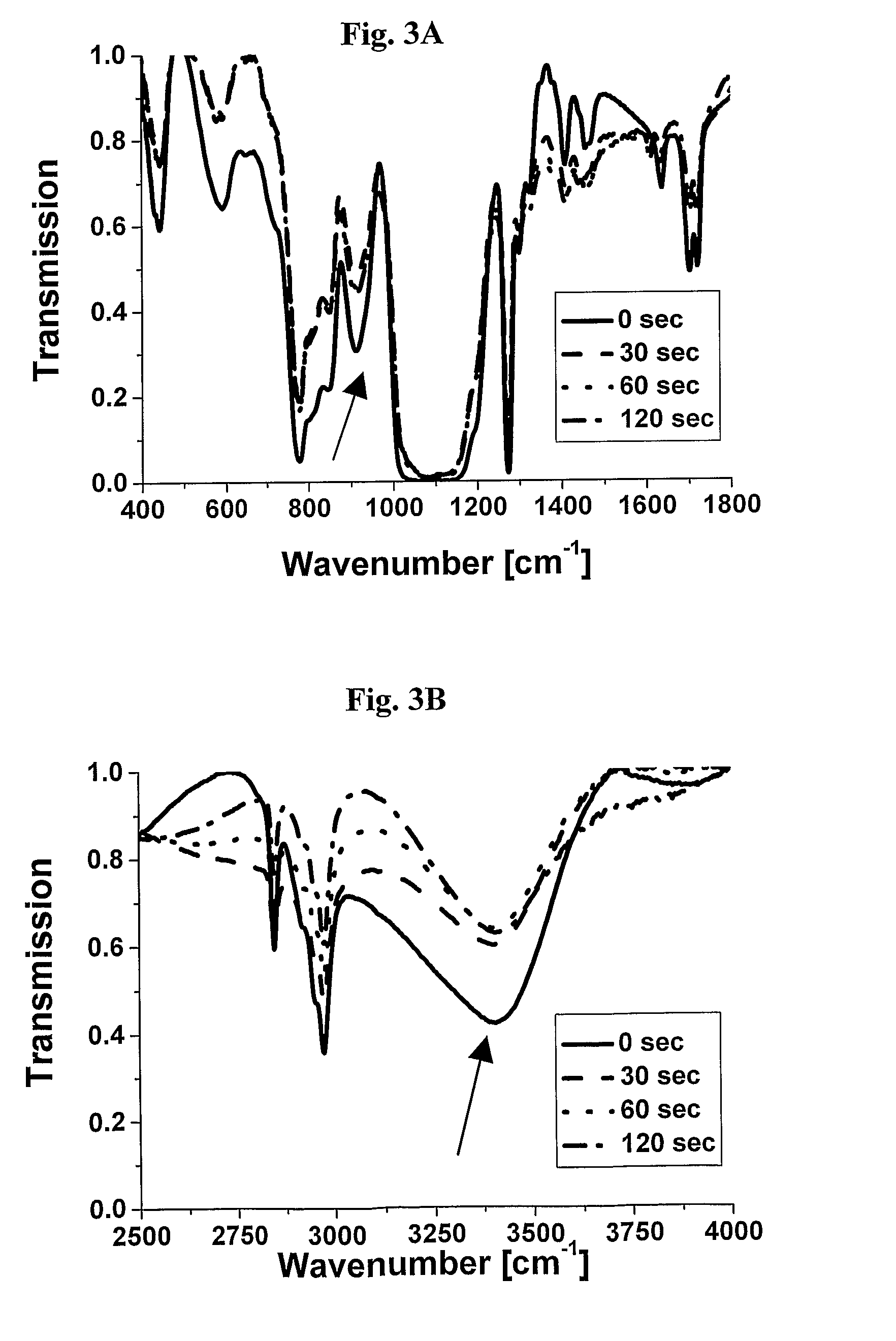

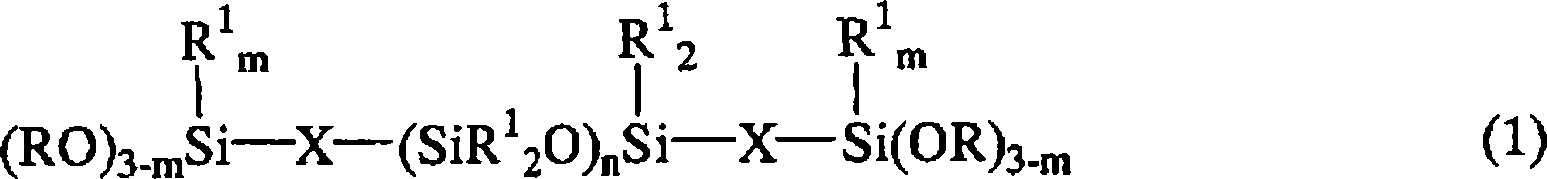

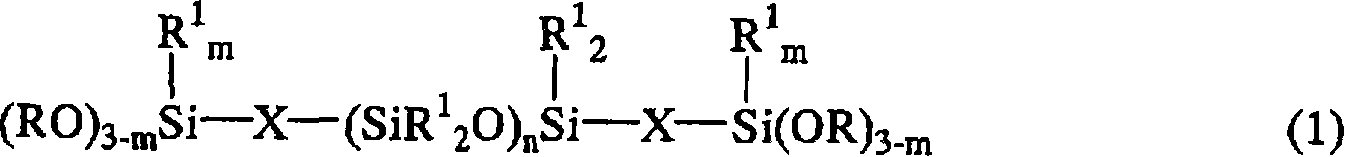

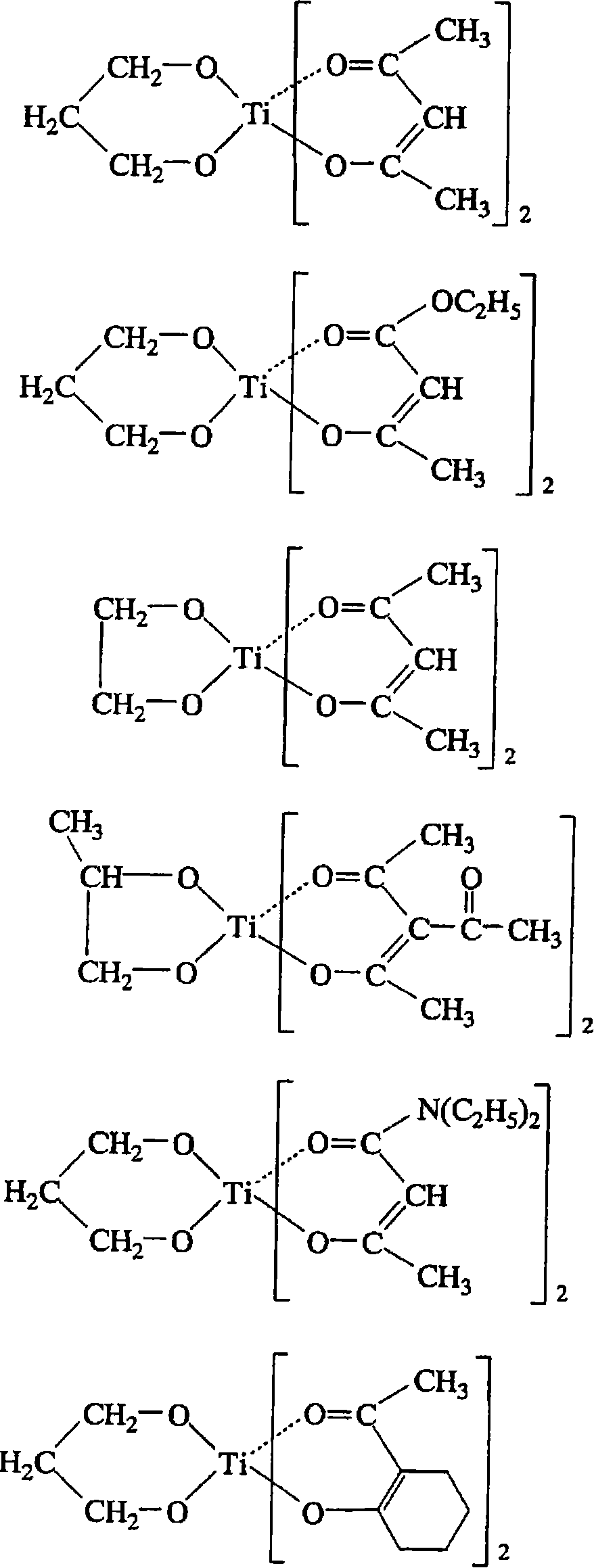

A room temperature-curable polyorganosiloxane composition is provided. The composition comprises(A) 100 parts by weight of a polyorganosiloxane represented by the following general formula (1):wherein R is a monovalent hydrocarbon group containing 1 to 5 carbon atoms, R1 is independently a substituted or unsubstituted monovalent hydrocarbon group containing 1 to 10 carbon atoms; n is an integer of at least 10; X is oxygen atom or an alkylene group containing 2 to 5 carbon atoms, and m is independently an integer of 0 or 1; or a mixture of such polyorganosiloxane,(B) 0.1 to 50 parts by weight of a partial hydrolysate of an organosilicon compound having at least 3 hydrolyzable groups bonded to silicon atom in one molecule;(C) 1 to 500 parts by weight of at least one filler,(D) 0.01 to 10 parts by weight of a curing catalyst, and(E) 0.1 to 10 parts by weight of a silane coupling agent.The present invention is capable of forming a rubber elastomer which exhibits excellent adhesion to resins whose adhesion has been difficult, for example, polyimide resin.

Owner:SHIN ETSU CHEM IND CO LTD

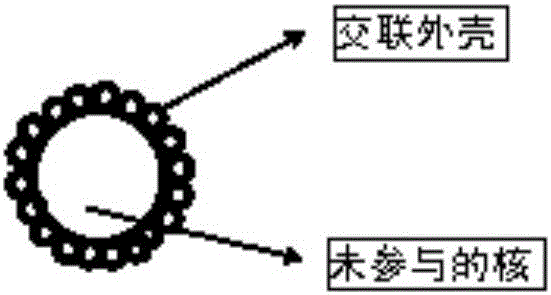

Multifunctional environment-friendly emulsion as well as preparation method and application thereof

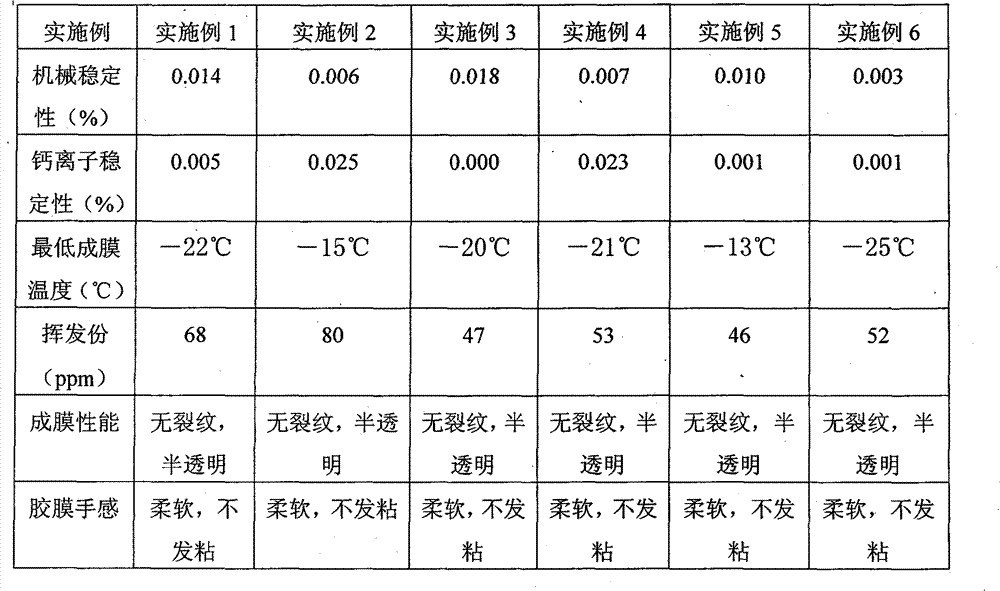

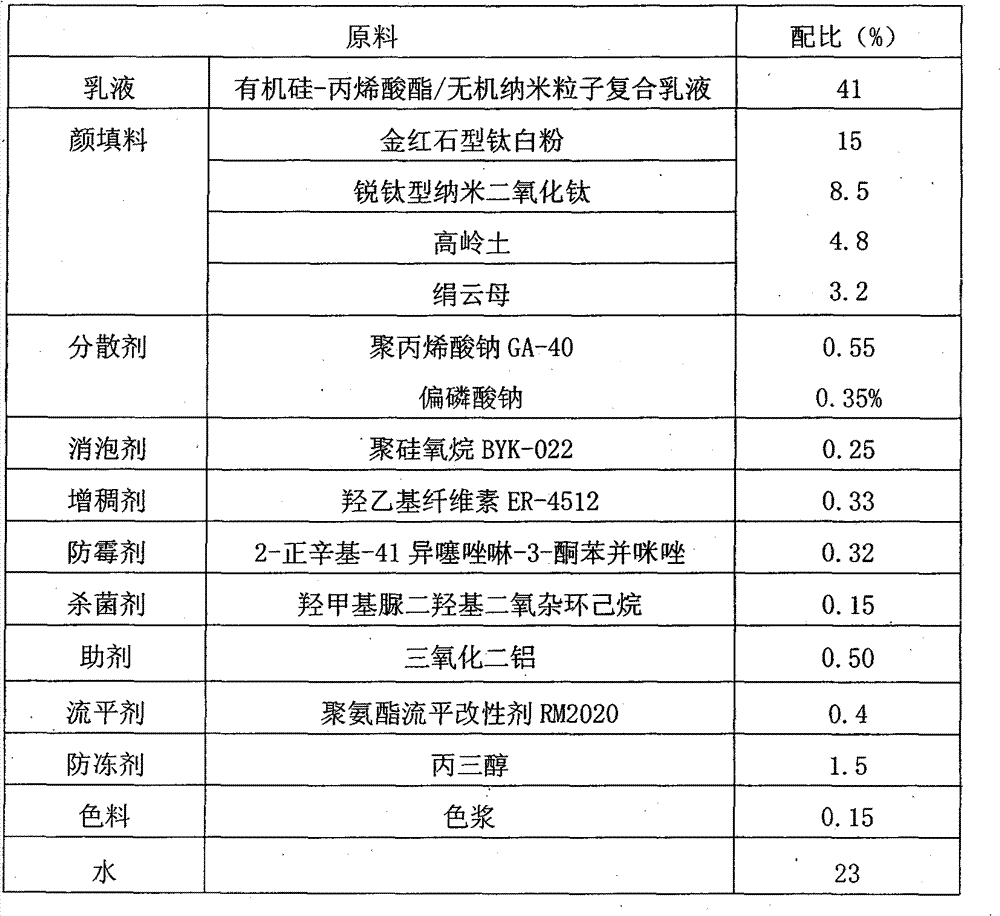

ActiveCN102964527AHigh solid contentImprove stabilityAntifouling/underwater paintsPaints with biocidesSurface finishEmulsion

The invention discloses organosilicon-acrylate ester / inorganic nanometer composite emulsion as well as a preparation method and application of the composite emulsion. The composite emulsion consists of 4.0-8.0(wt)% of inorganic nanometer grains and 92-96.0(wt)% of organosilicon-acrylate ester polymers. The preparation method comprises the following steps of (1) preparing polymer-coated inorganic nanometer grain emulsion; (2) adding an acrylate ester monomer to prepare a shell polymer; (3) adding unsaturated organosilicon monomer to obtain organosilicon modified composite emulsion; (4) carrying out chemical degassing; and (5) removing residual monomers and neutralizing to obtain target products. The prepared organosilicon-acrylate ester / inorganic nanometer composite emulsion has good stability and excellent film-forming performance, modifies the thixotropy of a coating system and also has excellent settlement resistance. Water-borne coating prepared by the composite emulsion disclosed by the invention has the advantages of high adhesion force, paint film washing resistance, alkali resistance, paint film strength, surface cleanness and paint film covering force; and the volatile matter content of the coating is very low; the water-borne coating is green and environment-friendly and also has anti-bacterial property and bactericidal property.

Owner:NANTONG TENGLONG CHEM TECH CO LTD

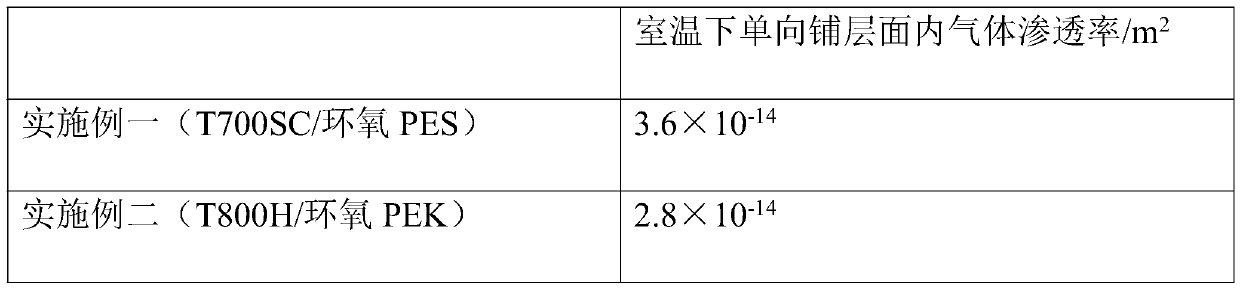

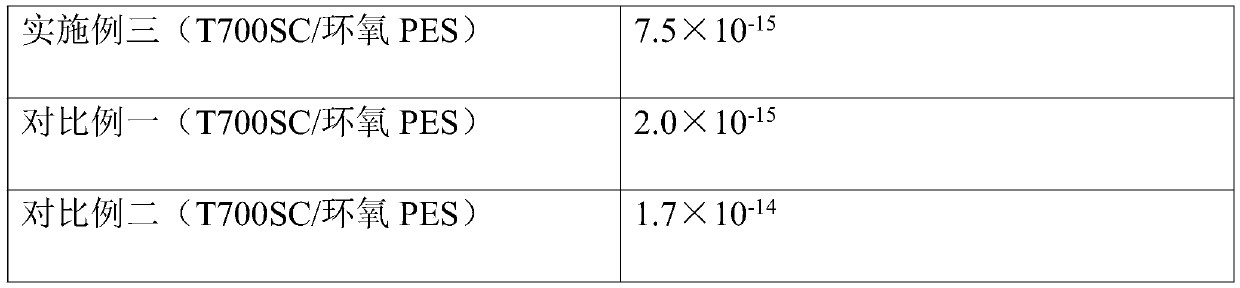

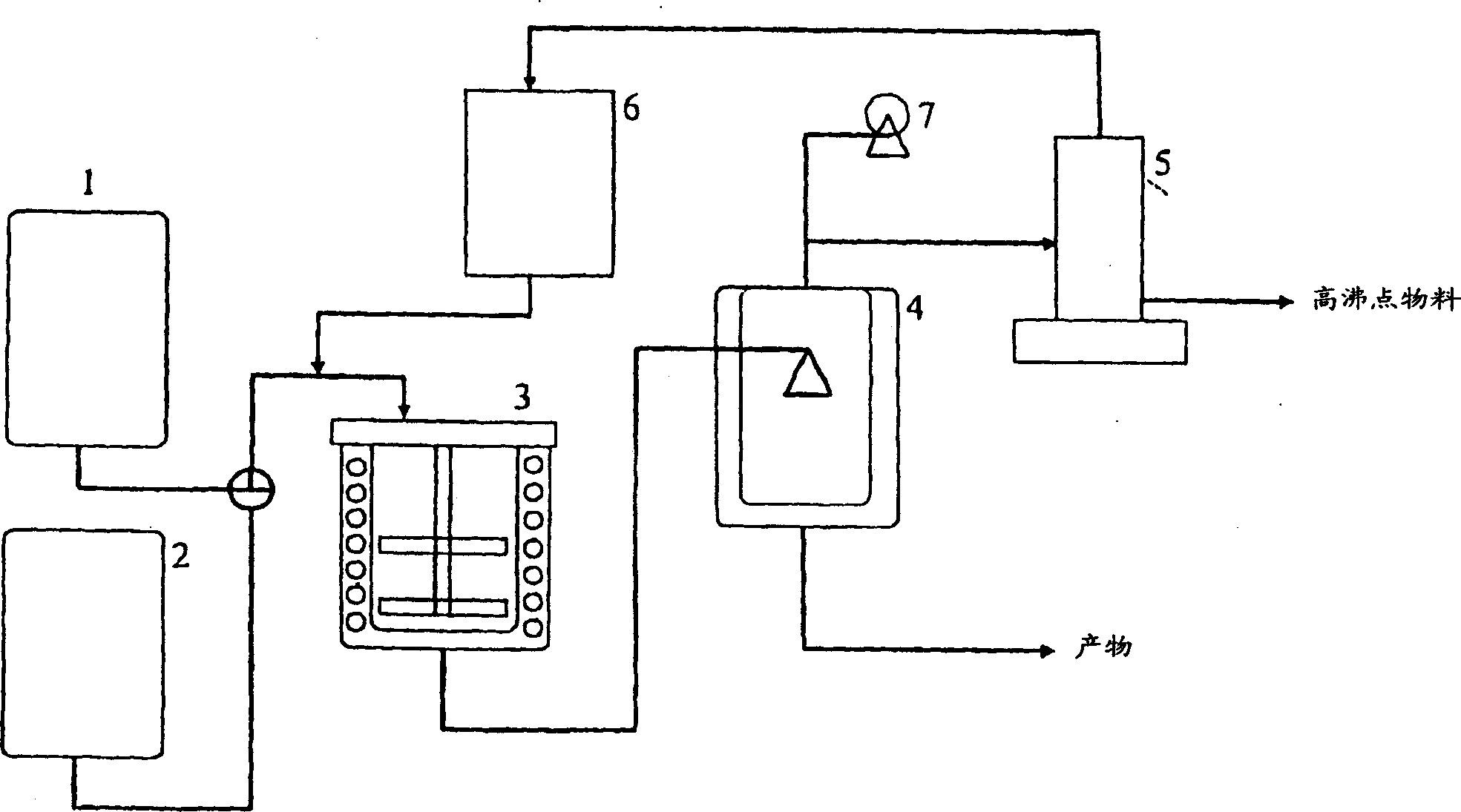

Preparation method of carbon fiber/toughened epoxy resin prepreg for vacuum bag forming process

The invention discloses a preparation method of a carbon fiber / toughened epoxy resin prepreg for a non-autoclave vacuum bag forming process. According to the method, the dissolution degree and the particle size of a curing agent and a toughening agent in epoxy resin are controlled by controlling a resin formula, the particle sizes of the curing agent and the toughening agent and process conditionsfor resin system configuration, and meanwhile, two modification effects are achieved: 1, the resin system is toughened; and 2, the requirements of a non-autoclave process on the viscosity of the resin in the prepreg and a room-temperature storage period are met. The prepared epoxy resin system is prepared into a rubber film, the carbon fiber / epoxy resin prepreg is further prepared by adopting a rubber film calendering method, and the semi-impregnated prepreg (unsaturated impregnated prepreg) is obtained by controlling the pressure and temperature during compounding of the rubber film and carbon fibers.

Owner:BEIHANG UNIV

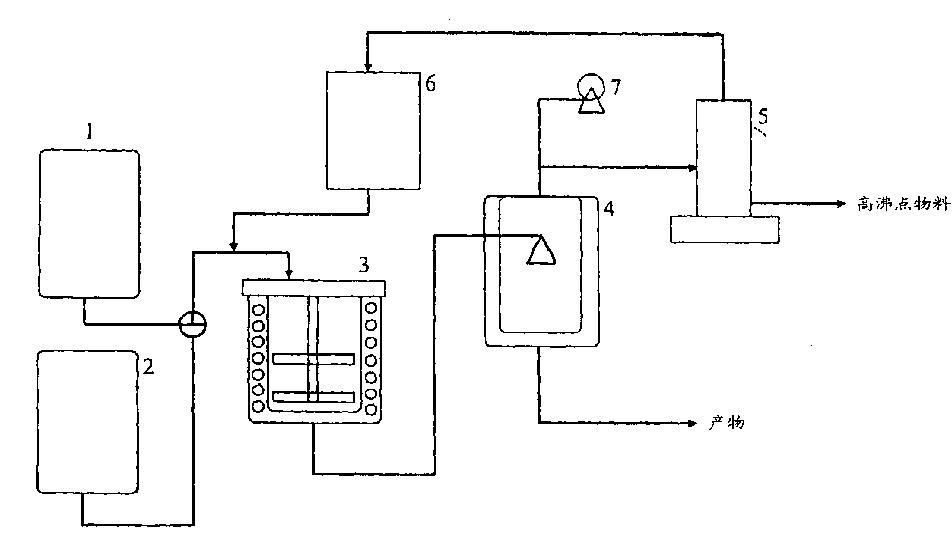

Process for preparing water-soluble styrenelacrylic resins by continuous bulk polymerization

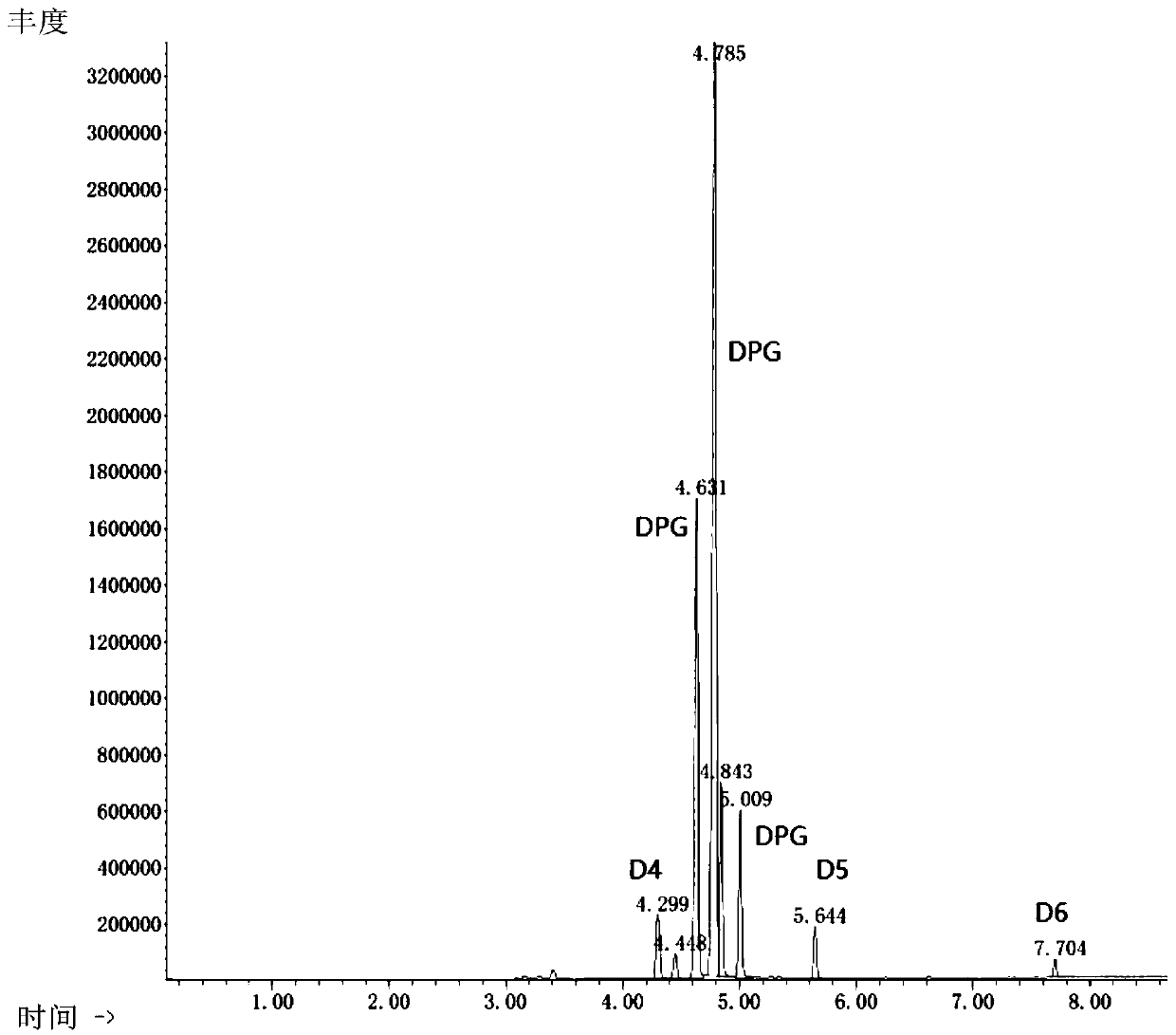

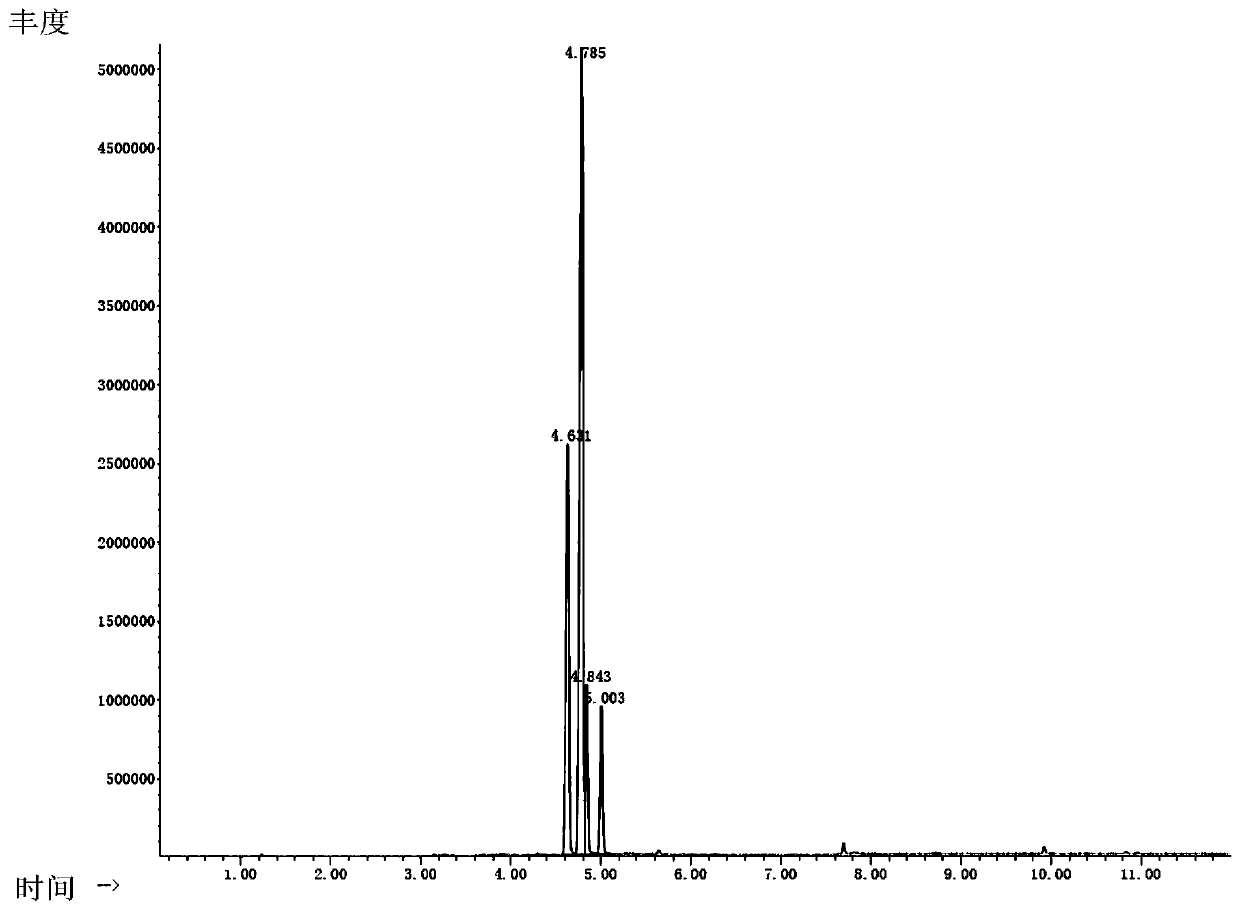

The invention relates to a bulk polymerization process for preparing water-soluble styrene / acrylic resins, in which styrene and acryl monomers are polymerized in a solvent mixture of dipropylene glycol methyl ether and water in a temperature-controllable reactor equipped externally with an oil jacket containing a cooling coil therein and the resulting polymers are deprived of volatile contents in a falling-strand type devolatilizer. The water-soluble styrene / acrylic resins take industrial advantages over conventional resins because the resins, if polymerized at lower temperatures, show lower molecular weights, narrower molecular weight distributions, higher acid values and lower volatile content.

Owner:HANWHA CHEMICAL CORPORATION

High-heat-resistance high-rigidity environmentally-friendly polystyrene resin composition and preparation method thereof

The invention discloses a high-heat-resistance high-rigidity environmentally-friendly polystyrene resin composition and a preparation method thereof. The polystyrene resin composition contains the following components in percentage by weight: 59-99 percent of polystyrene resin, 0.5-30 percent of SMA (Styrene-Maleic Anhydride) resin, 0-10 percent of stripping agent master batch and 0.01-1 percent of antioxidant, wherein the stripping agent master batch consists of a matrix and a stripping agent. The preparation method has the advantages of simple production process, reduced production cost and capabilities of effectively improving heat resistance and rigidity of polystyrene resin without reducing mechanical property thereof and meanwhile reducing smell and VOC (Volatile Organic Compound) content of the polystyrene resin; and the prepared polystyrene resin composition can be used in the fields of materials with strict requirements on heat resistance and environmental friendliness in packaging materials, daily articles, household appliances, OA (Office Automation), toys, electronic parts and components and equipment, building materials and automobile materials.

Owner:WUHAN JINFA TECH CO LTD

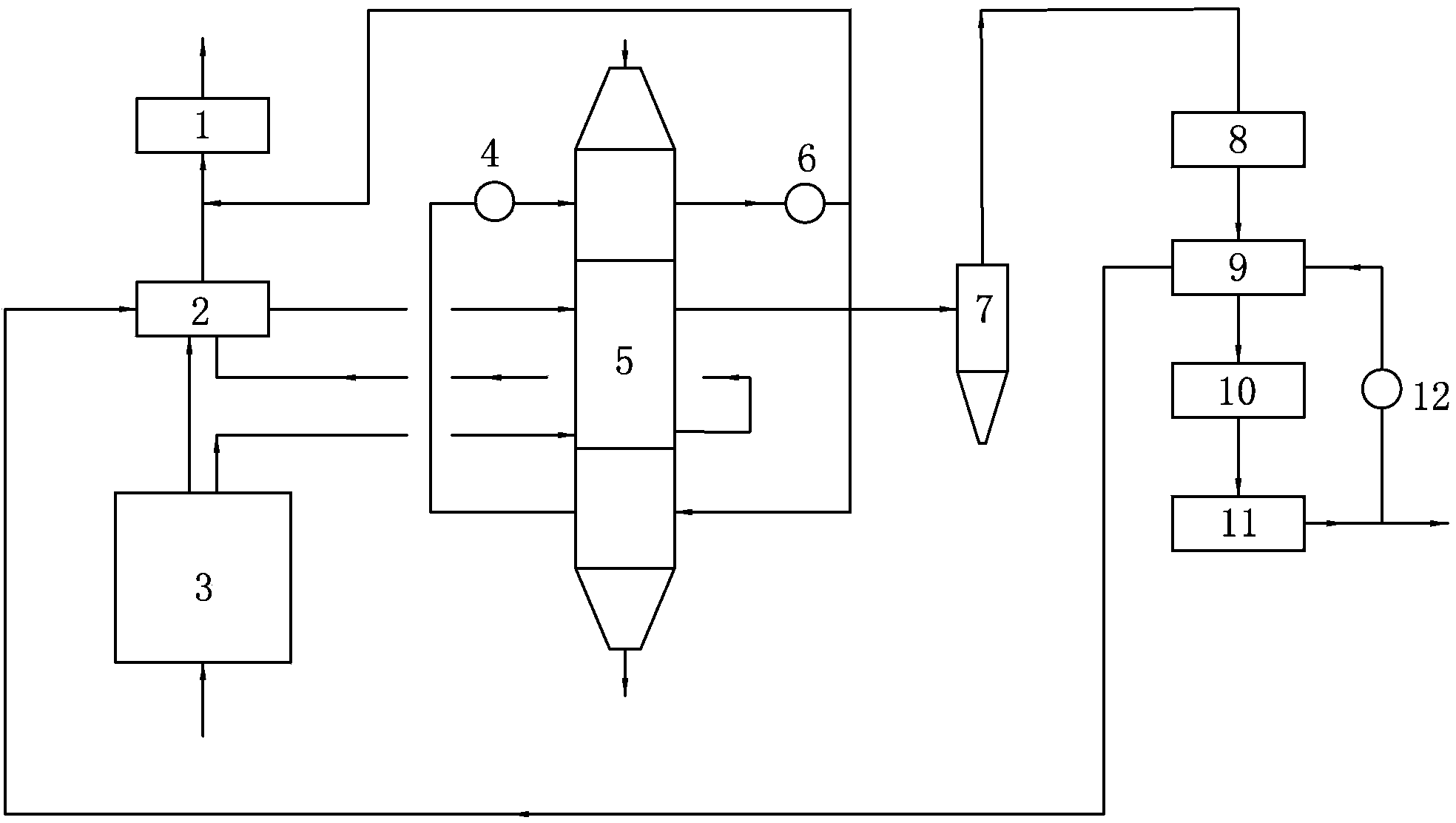

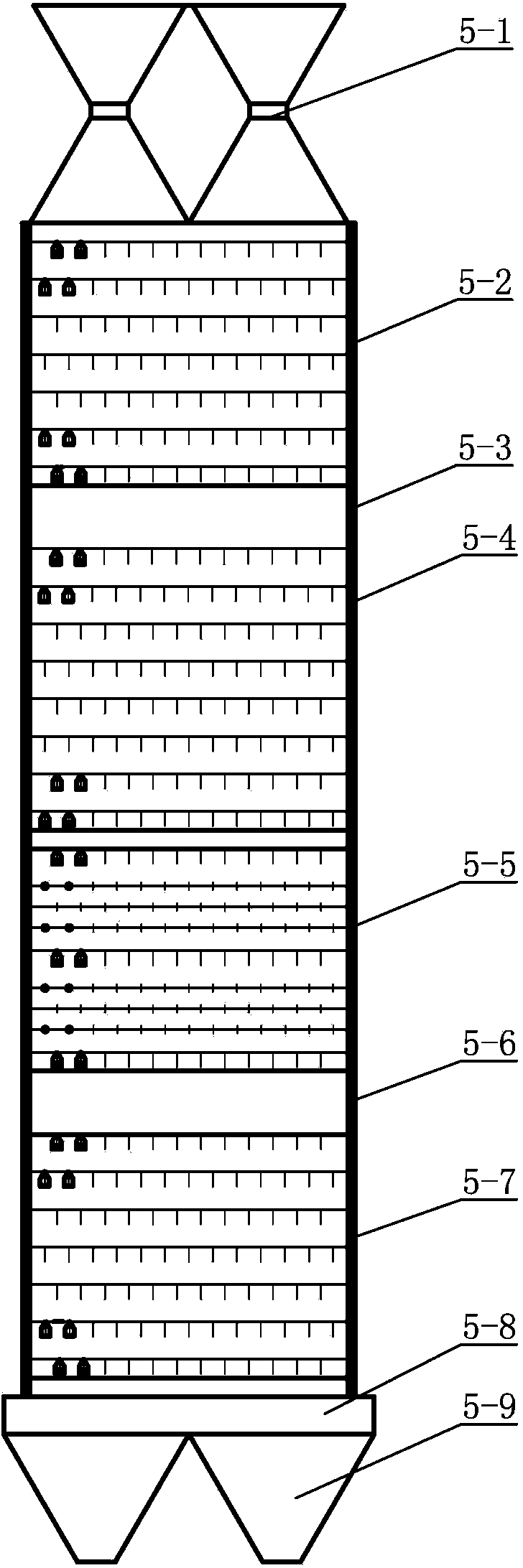

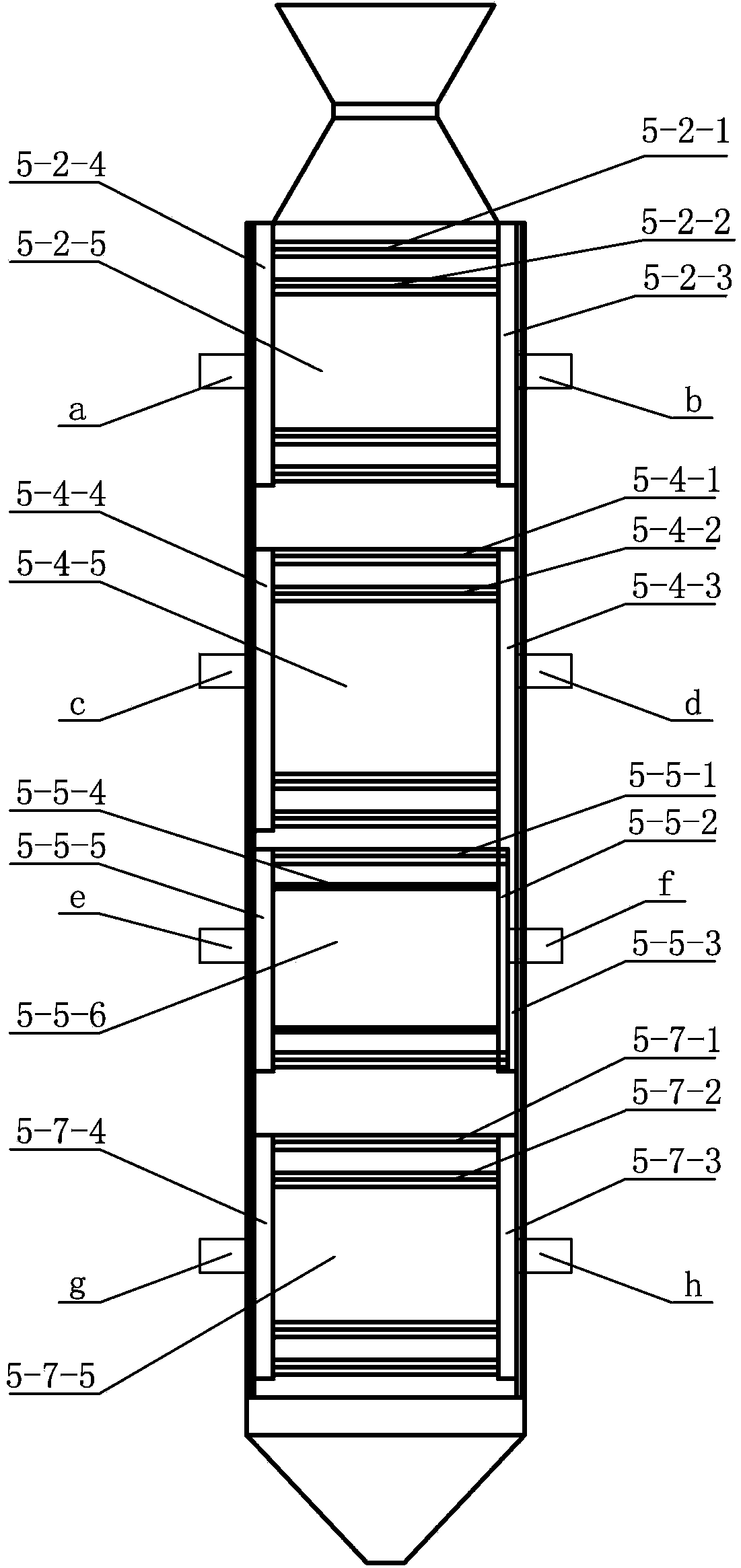

Device and method for pyrolyzing pea coal by utilizing internally heated vertical furnace

ActiveCN103468292AAvoid secondary crackingHigh yieldIndirect and direct heating destructive distillationCycloneRecuperator

The invention relates to a device and method for pyrolyzing pea coal by utilizing an internally heated vertical furnace. The device comprises an internally heated vertical furnace, wherein a feed hopper, a drying section, a first transition section, a pyrolysis section I, a pyrolysis section II, a second transition section, a cooling section, a discharge valve and a discharge hopper are arranged on the internally heated vertical furnace sequentially from top to bottom, wherein the drying section is communicated with a dry steam circulating fan and a high-temperature steam circulating fan; the dry steam circulating fan is communicated with the cooling section; the pyrolysis section I is communicated with a coal gas heat exchanger and a micro-cyclone dust collector; the micro-cyclone dust collector is communicated with a quencher; the quencher is communicated with a raw gas heat exchanger; the raw gas heat exchanger is communicated with a coal gas heat exchanger and a horizontal water-tube cooler; the horizontal water-tube cooler is communicated with an electrical tar precipitator; the pyrolysis section II is communicated with a combustion furnace and the micro-cyclone dust collector; the combustion furnace is communicated with the coal gas heat exchanger. The device and method are easy to operate, high in heat efficiency, environment-friendly and high in carbocoal quality, and the coal gas can be recycled.

Owner:陕西凯德利能源科技有限公司

Polymeric pigment dispersant utilized as a grind resin for pigments in solventborne pigment dispersions and method of preparing the same

InactiveUS7005473B2Good color travelEnough timeTransportation and packagingOrganic dyesPolyesterCarbamate

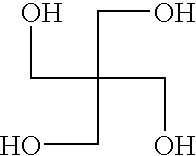

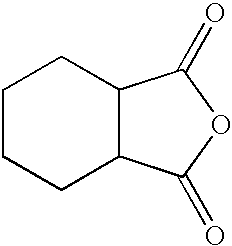

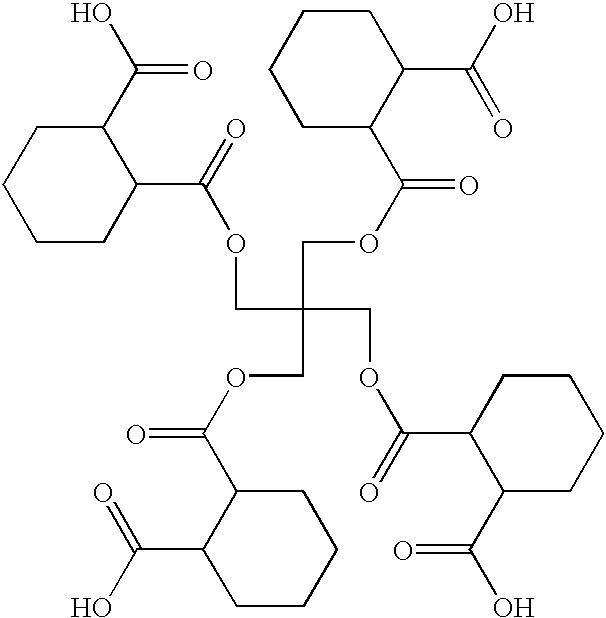

The present invention is directed to a polyester polycarbamate polymeric pigment dispersant to be used as a grind resin to incorporate pigment into pigment dispersions for coating compositions. The pigment dispersant is the reaction product of a first compound having a plurality of hydroxyl groups, a carboxylic acid anhydride, a second compound having at least one epoxy group, and a carbamate compound. The present invention is also directed to a method of preparing the pigment dispersant.

Owner:BASF CORP

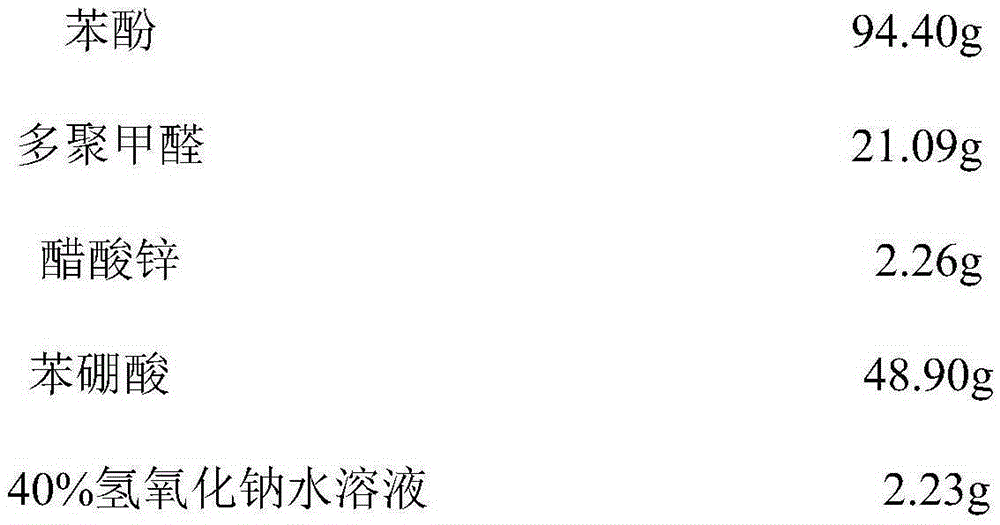

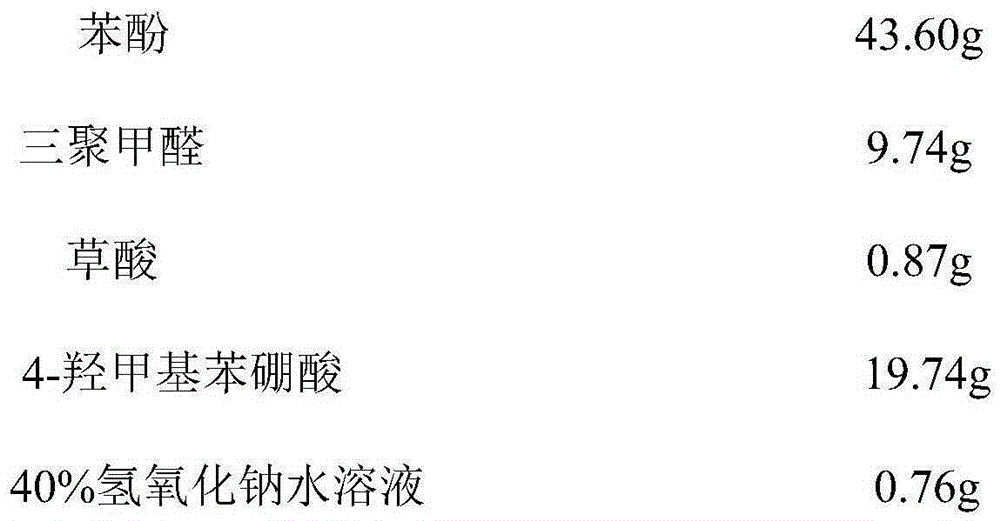

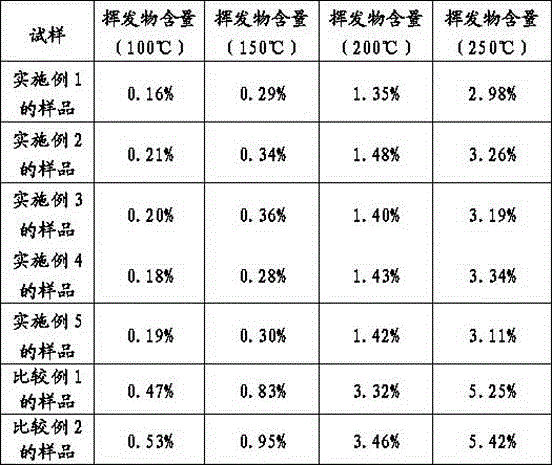

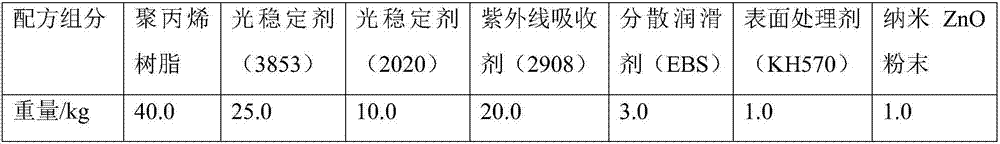

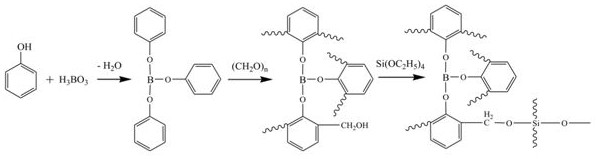

Preparing method for ablation-resisting boron-modified thermoplastic phenolic resin

The invention relates to a preparing method for ablation-resisting boron-modified thermoplastic phenolic resin. For solving the problems that at present, boron-modified phenolic resin is complex in production process and pollutes environment, and an obtained composite material product is high in porosity, solvent is not used in the synthetic process, an effective catalyst is adopted to make a boron-containing compound react fully, a resin structure is connected in a copolymerization mode, the suitable reaction temperature and the suitable time are controlled, and the boron-containing thermoplastic phenolic resin which is high in molecular weight, low in volatile content and low in curing volume shrinkage rate is synthesized, wherein the composite material of the resin is high in ablation performance and mechanical property. While the good heat resistance and ablation resistance of the boron-containing compound are brought into full play, the manufacturability and the mechanical property of the boron-containing phenolic resin are improved, and it is the research core to meet the requirement of aerospace development with the thermoplastic phenolic resin having a high carbon yield, a suitable softening point and good manufacturability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Ultraviolet light curing glue with low volatile content

ActiveCN105733493ALow volatile contentImprove performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses ultraviolet light curing glue with low volatile content. The ultraviolet light curing glue consists of the following raw materials in percentage by weight: 30-60% of polyester type urethane acrylate, 5-15% of hyperbranched urethane acrylate, 5-15% of thiol, 25-40% of an acrylate monomer and 1-7% of a photoinitiator. The ultraviolet light curing glue has relatively low volatile content, can be used in situations with low volatile content requirements, and is excellent in curing property and high in adhesion reliability and wide in application range.

Owner:YANTAI DARBOND TECH

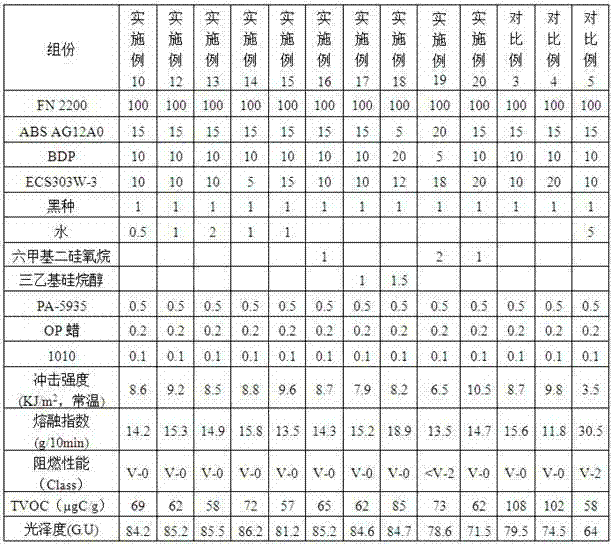

High-gloss and low-volatility flame retardant polycarbonate composition as well as preparation method and application thereof

The invention discloses a high-gloss and low-volatility flame retardant polycarbonate composition as well as a preparation method and application thereof. The polycarbonate composition consists of the following components: 100 parts of PC resin, 5-30 parts of acrylonitrile butadiene styrene (ABS) resin, 5-20 parts of a phosphate fire retardant, 0-20 parts of glass fiber, 0.5-2 parts of a high-gloss additive, 0.5-2 parts of fennelflower, 0.3-1 part of an anti-dropping agent and 0.1-2 parts of an additive. The preparation method comprises the steps of mixing the PC resin, the ABS resin, the high-gloss additive, the anti-dropping agent, the fennelflower and the additive in a high-speed mixer for 1-2min to obtain a premix; melting and extruding the premix through a dual-screw extruder; laterally feeding the phosphate fire retardant and the glass fiber, and implementing secondary vacuum pelleting to obtain a finished product. The flame retardant polycarbonate composition disclosed by the invention, through the high-gloss additive, improves gloss thereof, and simultaneously avoids remarkable change in mechanical performance, flowing property and flame retardant performance; the prepared flame retardant polycarbonate composition is high in gloss, good in fluidity, low in volatile content and excellent in mechanical performance, and is applicable to such electronic appliances as television and computer frame as well as products having requirement on high gloss such as automobile.

Owner:KINGFA SCI & TECH CO LTD

Paint with color change additive and method of application and painted substrate

InactiveUS20070100035A1Improve stabilityKeep for a long timeNon-fibrous pulp additionLayered productsColor changesChemistry

The present invention relates to a latex paint and more particularly to a paint containing a color change additive. The present invention in one or more embodiments provides for a latex paint including a pH sensitive color change additive, which changes the color of the paint in a certain period of time after application to allow painters to see where they have painted. One or more embodiments of these paint formulations of the present invention are formulated at pH values which allow for greater stability of the color change additive, improved shelf stability of the formulation, longer color change times after application, lower volatile content and odor, and use with existing packaging. The present invention is further directed to a method of applying a paint and painting a substrate white. The painted substrates have a multicolored surface while drying.

Owner:GLIDDEN

Preparation method of hydroxyl blocking polydimethylsiloxane

The invention discloses a preparation method of manufacturing hydroxyl blocking polydimethylsiloxane with low volatile content. Firstly, the hydroxyl blocking polydimethylsiloxane with low viscosity is refined to obtain intermediate products with the content of volatile less than 0.03%. Then, a condensation reaction is done. The water is removed through nitrogen to control the viscosity. Finally, the high viscosity hydroxyl blocking polydimethylsiloxane with the content of volatile less than 0.03% is obtained. The preparation method of manufacturing the hydroxyl blocking polydimethylsiloxane has the advantages that the preparation method and the technology are simple and non-pollution, volatile components of products are small, the quality is stable and good and the like.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

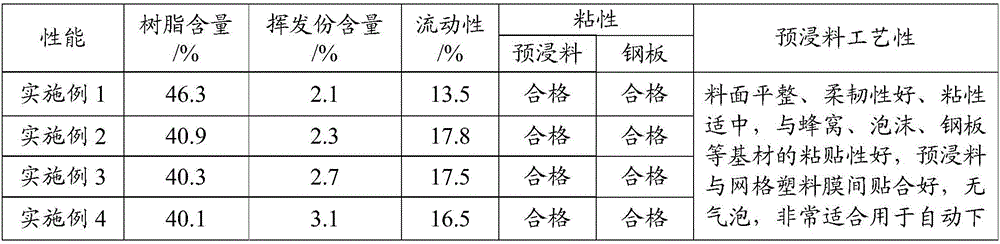

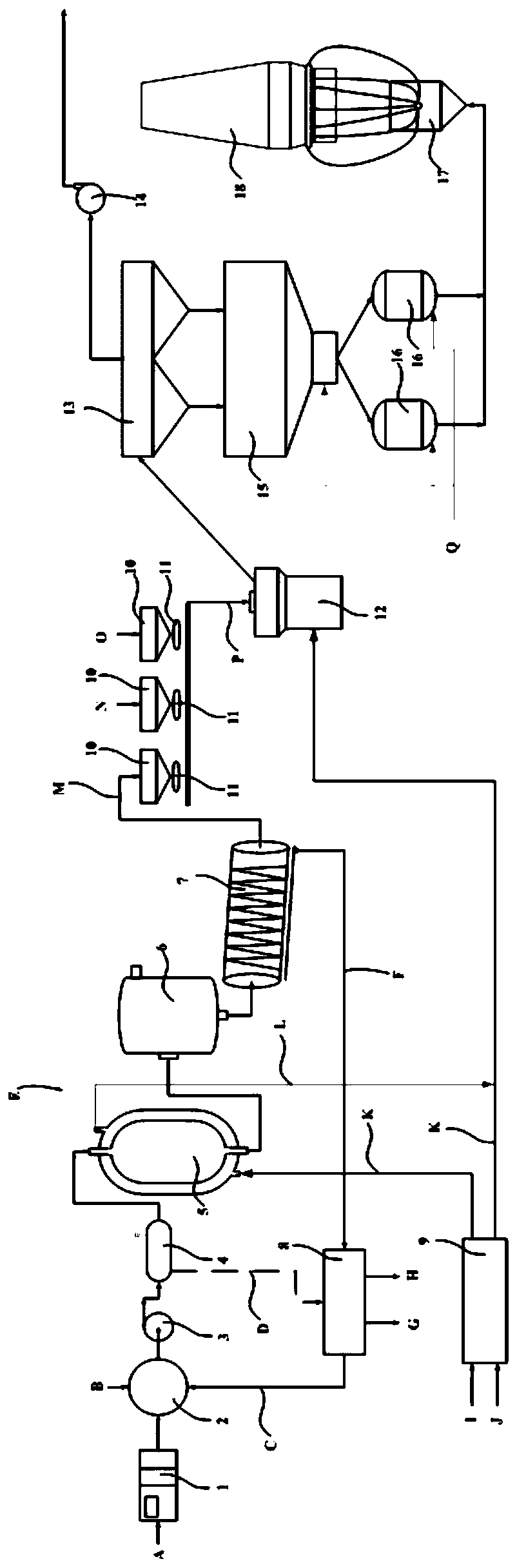

Method using coating technology to prepare solution-method phenolic aldehyde prepreg

ActiveCN105882077AImprove performanceIncrease flexibilitySynthetic resin layered productsLaminationFiberFiltration

The invention relates to a method using the coating technology to prepare solution-method phenolic aldehyde prepreg. The method includes: performing suction filtration pretreatment on a phenolic resin solution to discharge the solvent in the phenolic resin solution; using a coating machine to evenly coat a high-temperature-resistant plastic film with resin after pretreatment, and thermally drying to form a resin film; covering the upper surface and the lower surface of fiber fabric with the resin film through continuous operations, and performing rolling compaction to obtain the phenolic aldehyde prepreg. The method has the advantages that the phenolic aldehyde prepreg prepared by the method is excellent in comprehensive performance, the resin content and the volatile matter content, lower than 1.5%, of the prepared phenolic aldehyde prepreg are easy to control as compared with those of traditional solution-method prepreg, the viscosity and process operability of the prepared phenolic aldehyde prepreg are equivalent to those of prepreg prepared by a hot-melt method, the whole cloth surface is smooth and flat, fit, free of bubbles and the like, and the prepared prepreg is especially applicable to an automatic discharge machine; in addition, the equipment cost of the used coating machine is 1 / 3-1 / 2 of that of an impregnator used in the hot-melt method, production energy consumption of the method is greatly lower than that of a solution method, high production efficiency is achieved, and accordingly the production cost of the finished product can be lowered evidently.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

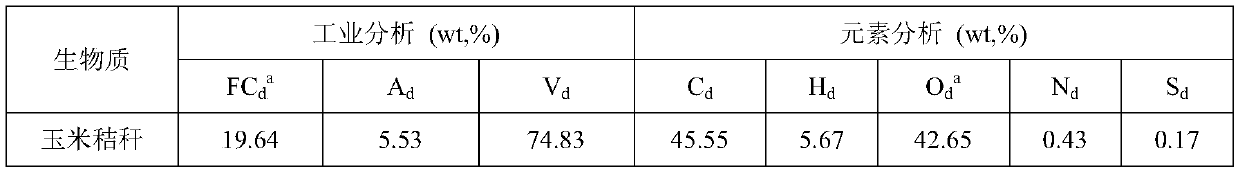

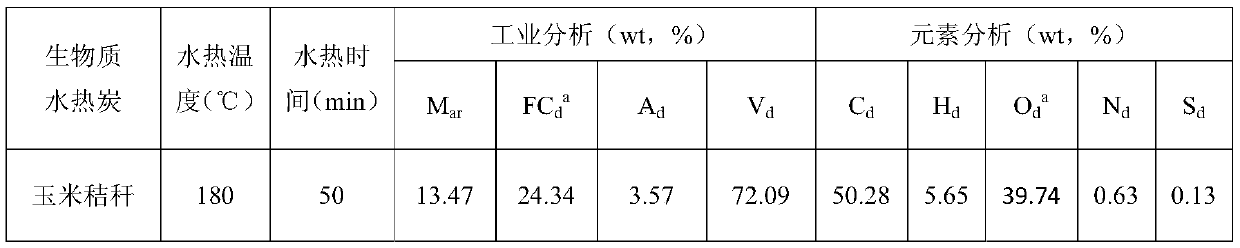

Method for carrying out blast furnace blowing on biomass hydrothermal carbon

ActiveCN110218826AImprove milling performanceEasy to transportBiofuelsSolid fuelsMetallurgyWaste rubber

The invention belongs to the technical field of blast furnace ironmaking, and particularly discloses a method for carrying out blast furnace blowing on biomass hydrothermal carbon. The method solves the problem that an optimal utilization method of biomass resources in blast furnace blowing process. The method can also be used for heat treatment of waste plastics, waste rubbers and other municipalcombustible solid waste water to prepare the hydrothermal carbon and the method can be efficiently applied to determination of a blast furnace blowing scheme. Under the condition that the influencesof biomass hydrothermal carbonization treatment, biomass hydrothermal carbon powder preparing, conveying and blowing on blast furnace smelting key process parameters are considered, the optimal utilization method for carrying out blast furnace blowing on biomass hydrothermal carbon is formed. According to the method, the system is analyzed by aiming at different biomass hydrothermal carbon, important assessment index of the blast furnace smelting downstream behavior is adopted, and the safe and efficient blast furnace blowing on the biomass hydrothermal carbon is realized, so that the comprehensive utilization efficiency of biomass resources is improved, and the emission of CO2 produced by the ironmaking is reduced.

Owner:UNIV OF SCI & TECH BEIJING

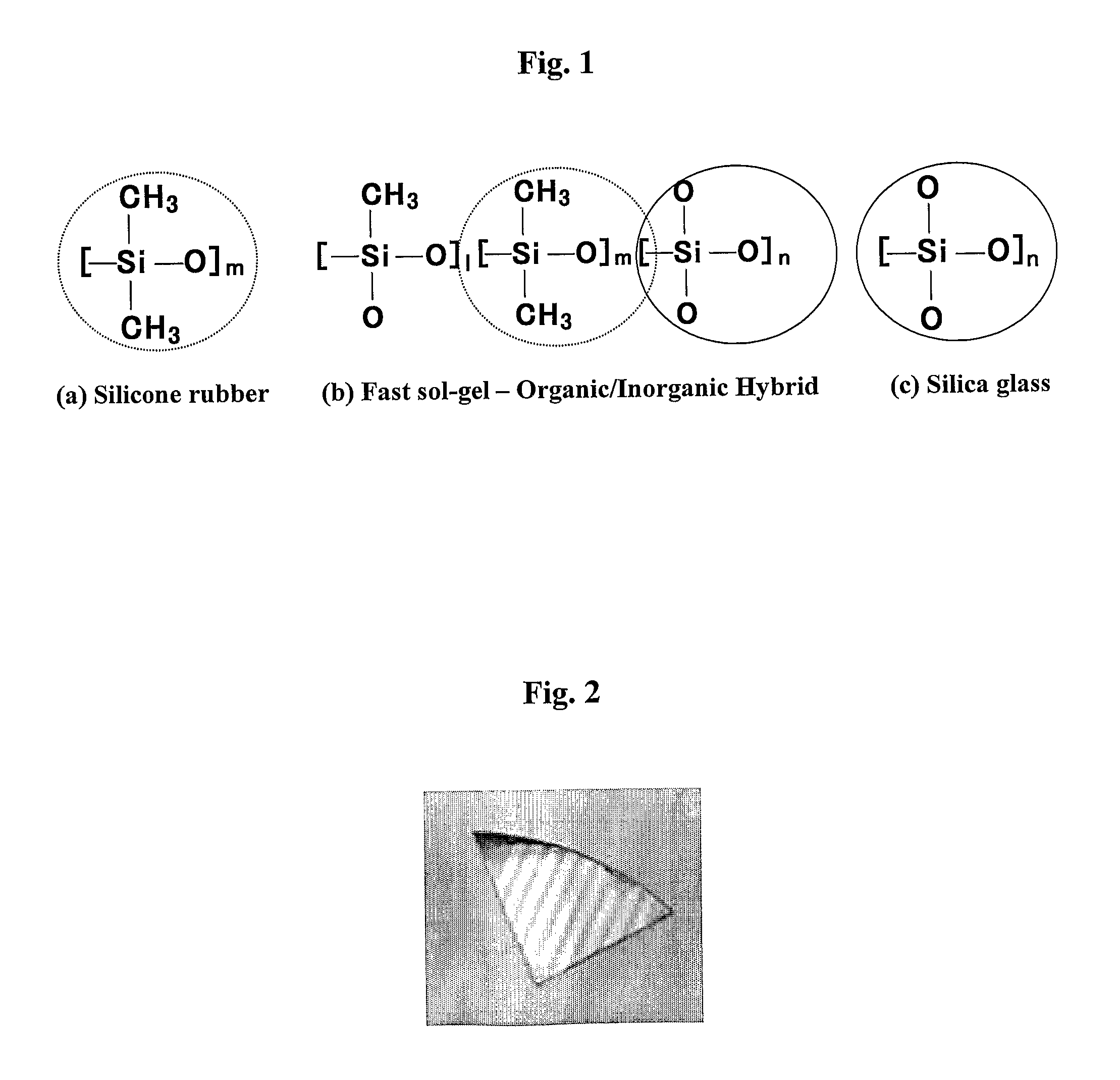

Uv-curable inorganic-organic hybrid resin and method for preparation thereof

ActiveUS20110244695A1Low volatile contentImprove thermal stabilitySemiconductor/solid-state device detailsSolid-state devicesCrack freeUltraviolet

Owner:STATE OF ISRAEL - SOREQ NUCLEAR RES CENT

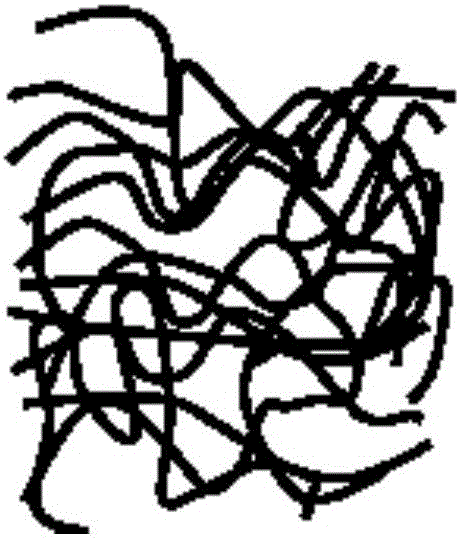

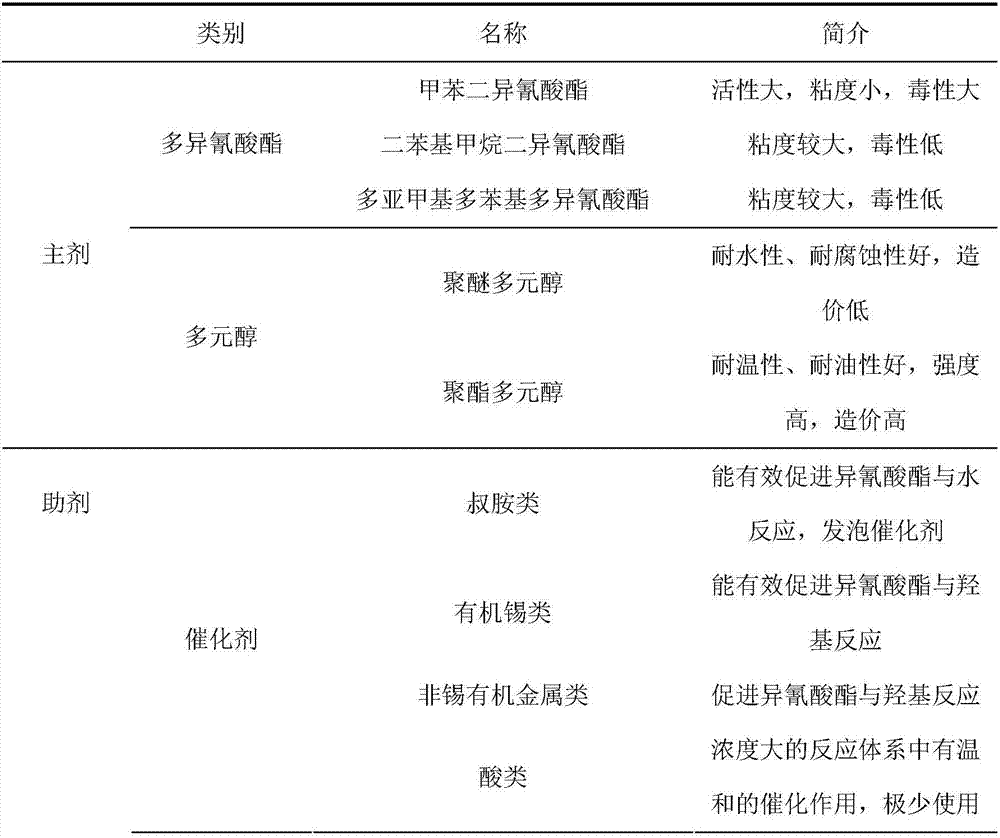

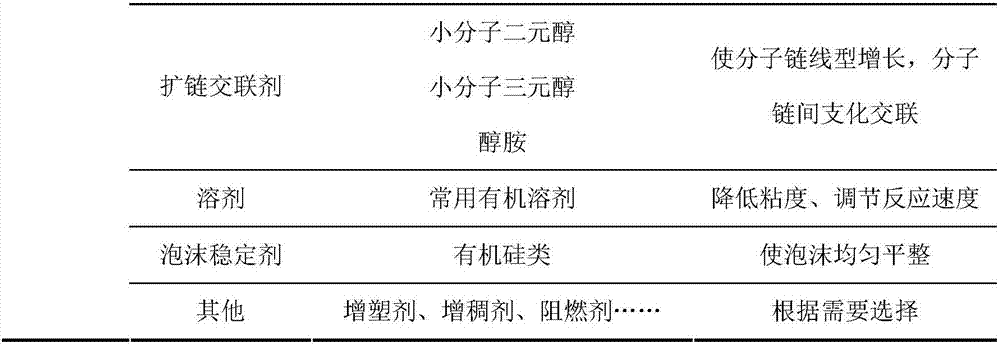

Polyurethane grouting material and preparation method thereof

The invention discloses a polyurethane grouting material and a preparation method thereof. The polyurethane grouting material comprises polyhydric alcohols, polyisocyanates, an organic amine catalyst, an organic tin catalyst, a chain extender and a foam stabilizer. The content of the components is as follows: 1 part of polyhydric alcohols and 1 part of polyisocyanates are contained; the content of the organic amine catalyst is 0.3% of the mass of the polyhydric alcohols; the content of the organic tin catalyst is 1.6% of the mass of the polyhydric alcohols; the content of the chain extender is 0.6% of the mass of the polyhydric alcohols; the content of the foam stabilizer is 1.0% of the mass of the polyhydric alcohols. The preparation method comprises the following steps: dividing the raw materials into two components, wherein the component A includes polyisocyanates and the component B includes the polyhydric alcohols and the additives; adding a defined amount of water into the component B; mixing the components A and B and quickly and fully stirring. The polyurethane grouting material prepared according to the preparation method has the advantages of low toxicity, low pollution, excellent grouting performance, low cost, convenience in construction, and the like, and meets national relevant standard and requirement for water plugging construction in China.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Aqueous metal antirust agent and preparation method thereof

InactiveCN103409743AEvenly dispersedGood dispersionMetallic material coating processesToluidineHuman health

The invention discloses an aqueous metal antirust agent and a preparation method thereof. The aqueous metal antirust agent is prepared from following raw materials by weight: 10-20 parts of dodecylbenzenesulfonic acid, 20-30 parts of pentaerythritol tetraoleate, 40-45 parts of butyl oleate, 10-15 parts of o-toluidine, 7-15 parts of sodium sulfate, 10-20 parts of sodium hydroxide, 10-15 parts of sodium silicate and 40-50 parts of water. The aqueous metal antirust agent can be uniformly dispersed in water without impurities such as suspended solids, etc. and has good dispersity. The content of volatile organic compounds is 0.3-0.5 ppm. The content of harmful volatile compounds is low, thus having no harm to human health, and therefore the aqueous metal antirust agent is environment friendly and healthy.

Owner:JIANGXI GRESS TECH CORP

Room temperature-curable organopolysiloxane composition

A room temperature-curable polyorganosiloxane composition is provided. The composition comprises (A) 100 parts by weight of a polyorganosiloxane represented by the following general formula (1): wherein R is a monovalent hydrocarbon group containing 1 to 5 carbon atoms, R<1 >is independently a substituted or unsubstituted monovalent hydrocarbon group containing 1 to 10 carbon atoms; n is an integer of at least 10; X is oxygen atom or an alkylene group containing 2 to 5 carbon atoms, and m is independently an integer of 0 or 1; or a mixture of such polyorganosiloxane, (B) 0.1 to 50 parts by weight of a partial hydrolysate of an organosilicon compound having at least 3 hydrolyzable groups bonded to silicon atom in one molecule; (C) 1 to 500 parts by weight of at least one filler, (D) 0.01 to 10 parts by weight of a curing catalyst, and (E) 0.1 to 10 parts by weight of a silane coupling agent. The present invention is capable of forming a rubber elastomer which exhibits excellent adhesion to resins whose adhesion has been difficult, for example, polyimide resin.

Owner:SHIN ETSU CHEM CO LTD

Organosilicon surfactant and application thereof in preparation of polyurethane flexible foam

The invention provides an organosilicon surfactant. The organosilicon surfactant has the following general formula: MDxD'yD ''zM, wherein M is selected from any one of (CH3) 3SiO1 / 2 and (CH3) 2RSiO1 / 2, D is (CH3) 2SiO2 / 2, D'is (CH3) 2 (R) SiO2 / 2, D ''is (CH3) 2 (R') SiO2 / 2, x + y + z is 70-100, x is 68-98, y is 1-16, and z is 1-16. The invention also provides an application of the organic siliconsurfactant in polyurethane flexible foam. Alkynediol polyether, high-molecular-weight hydrogen-containing silicone oil and at least one alkynediol polyether are introduced, and a high-molecular organosilicon copolymer surfactant is formed through hydrosilylation. The preparation method is used for preparing the polyurethane flexible foam, and the rebound resilience of the polyurethane flexible foam can be improved.

Owner:JIANGXI MENHOVER CHEM TECH CO LTD

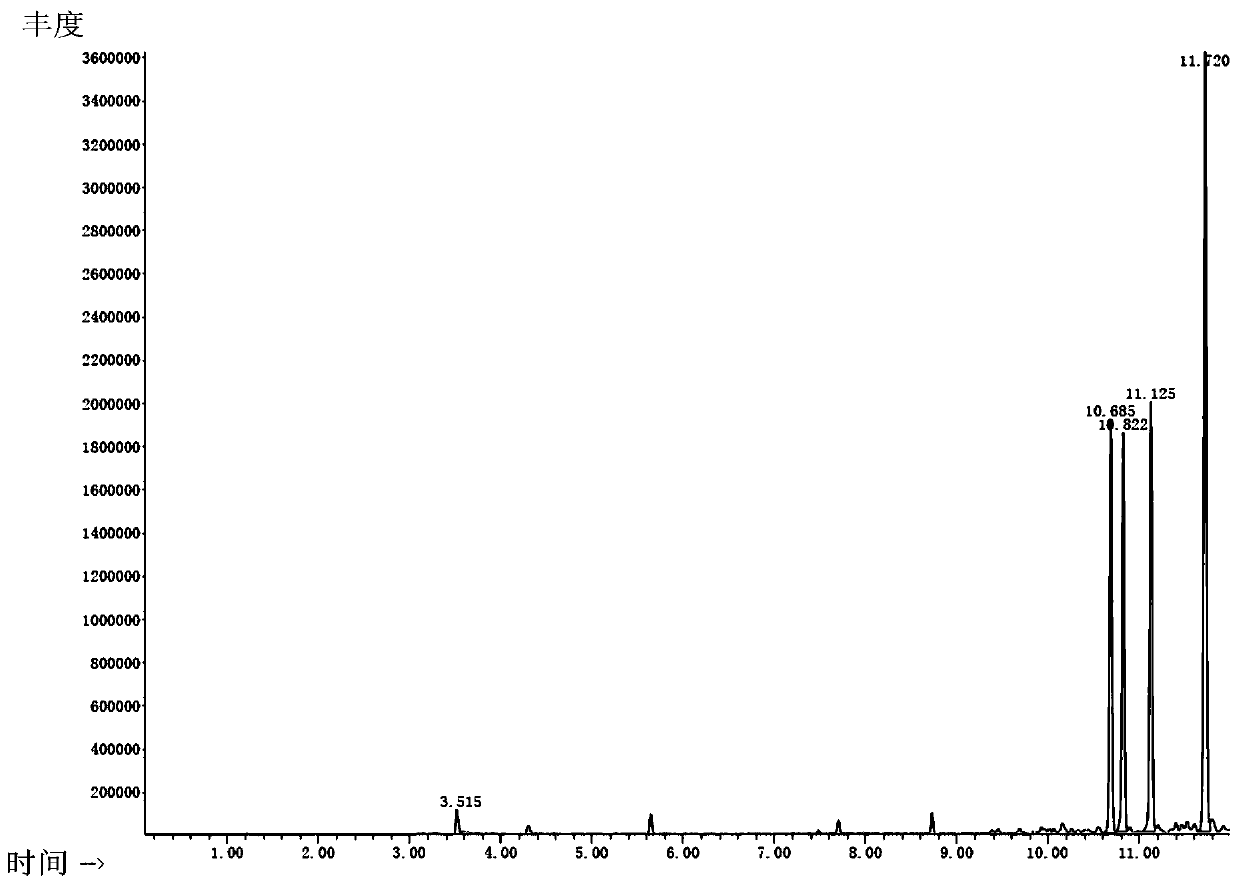

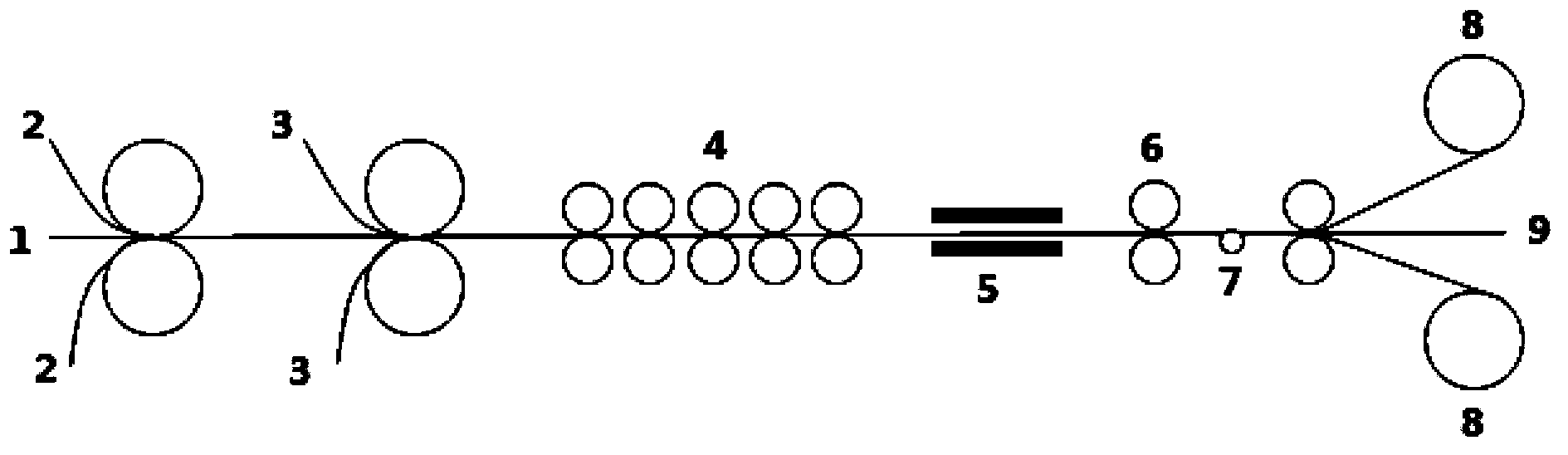

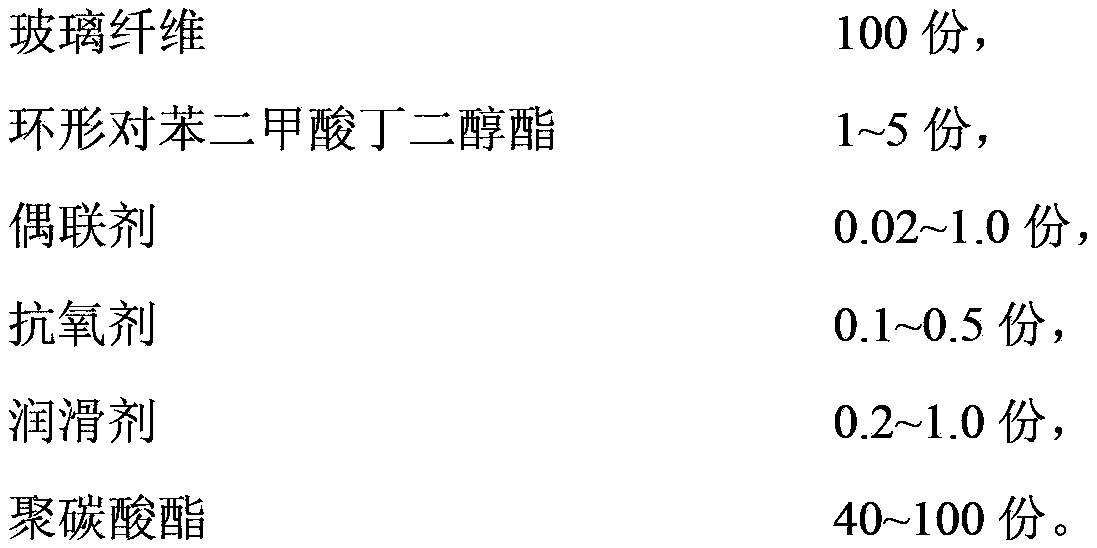

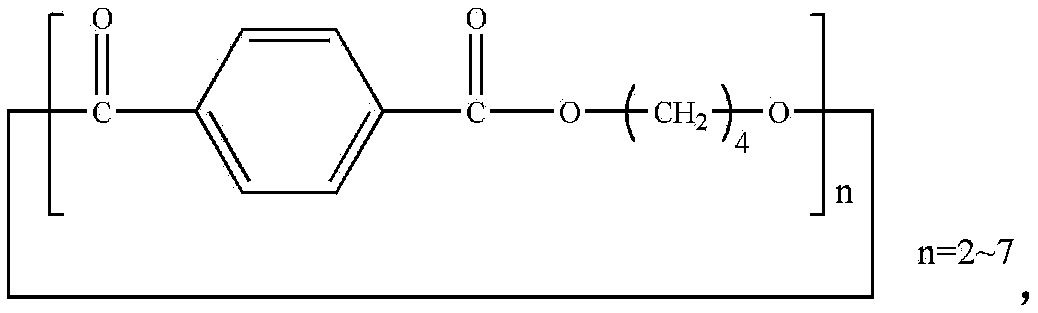

A continuous-glass-fibre-reinforced polycarbonate composite material and a preparing method thereof

The invention belongs to the technical field of polymer composite materials and relates to a continuous-glass-fibre-reinforced polycarbonate composite material and a preparing method thereof. The composite material is prepared from following components by weight: 100 parts of glass fibre, 1-5 parts of cyclic butylene terephthalate, 0.02-1.0 part of a coupling agent, 0.1-0.5 part of an antioxidant, 0.2-1.0 part of a lubricant and 40-100 parts of polycarbonate. The composite material has high strength and modulus. The composite material is mainly used for high-grade mobile phones, laptops, and other electronic products. In addition, a proper amount of the cyclic butylene terephthalate is added to blend and modify the polycarbonate, and the compatibility between the cyclic butylene terephthalate and the polycarbonate is good, and therefore the fluidity of the polycarbonate is largely improved only by an extremely little amount of addition of the cyclic butylene terephthalate and mechanical properties of the material are hardly influenced.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

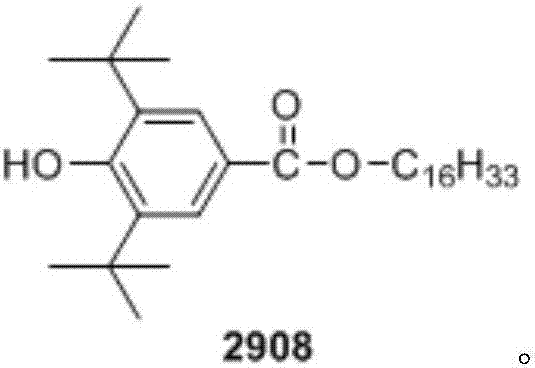

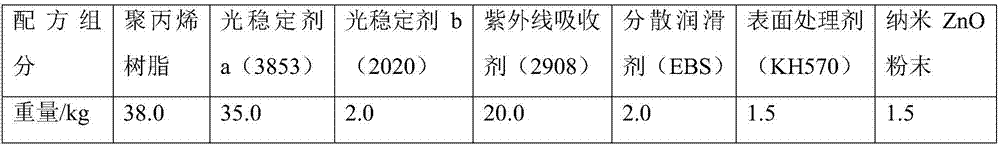

Special low-volatility migration-resistant nano composite anti-aging master batch for polypropylene and preparation method

ActiveCN106977811AEfficient Shielding CapabilityLong-term shielding abilityUltraviolet lightsZno nanoparticles

The invention discloses a special low-volatility migration-resistant nano composite anti-aging master batch for polypropylene. The master batch comprises the following components in parts by weight: 35 to 45 parts of carrier resin polypropylene, 35 to 45 parts of light stabilizer a, 0 to 10 parts of light stabilizer b, 20 to 30 parts of ultraviolet light absorber, 1 to 2 parts of nano zinc oxide, 0.5 to 2 parts of dispersed lubricant and 0.5 to 5 parts of surface treating agent. In the master batch disclosed by the invention, a broadband as well as efficient and long-acting ultraviolet screening capacity of the nano zinc oxide are used to take a synergistic effect with the organic light stabilizer, so that weather resistance of a target product is greatly improved; a universal formula is adopted, and by an ultrahigh adsorption effect brought by a high specific surface area of the nano zinc oxide, content of volatile matter in the master batch and a subsequent plastic product is effectively reduced, the low VOC (Volatile Organic Compound) requirement on the product is met, and the master batch accords with the national standard.

Owner:宿迁联盛科技股份有限公司

Low-chlorine value biomass briquette fuel and production method thereof

The invention discloses a low-chlorine value biomass briquette fuel. According to the invention, the pretreated corn straws are taken as a raw material for anaerobic fermentation for 10-20 days, so that mechanical endurance of the briquette fuel is increased, magnesium carbonate is taken as an anti-slagging agent, during a combustion process, the Mg element and elements such as Si, K, and Na which are inherent in the corn straws and are capable of slagging are subjected to a reaction, a novel compound K2Mg(SO4)2 is generated and provides anti-slagging performance to the briquette fuel, and the produced briquette fuel has the advantages of low chlorine value and high combustion value, no harmful gas is discharged after combustion is carried out, and a boiler is not easily corroded.

Owner:蚌埠华东石膏有限公司

Boron-silicon phenolic resin suitable for hot-melt preimpregnation process, composite material and preparation methods of boron-silicon phenolic resin and composite material

ActiveCN112194765ALow volatile contentThe content is easy to controlSynthetic resin layered productsFiberPhenol formaldehyde resin

The invention provides boron-silicon phenolic resin suitable for a hot-melt preimpregnation process, a composite material and preparation methods of the boron-silicon phenolic resin and the compositematerial, wherein the boron-silicon phenolic resin comprises the following preparation raw materials in parts by mole: 50-150 parts of phenol, 50-200 parts of aldehyde, 2-150 parts of a boron-containing compound and 1-80 parts of silicate ester; raw materials for preparing the borosilicate phenolic resin further comprise a modifier and a flexibilizer. the dosage relationship among the modifier, the toughening agent and the phenol comprises 100 parts by weight of the phenol, 0-50 parts by weight of the modifier and 0-50 parts by weight of the toughening agent. Compared with a boron-silicon phenolic resin solution, the boron-silicon phenolic resin suitable for the hot-melt preimpregnation process has the advantages of good storage stability, good fiber adhesion, low porosity of a composite material, high mechanical strength and good ablation resistance, and compared with the boron-silicon phenolic resin, Si-O bonds with high bond energy are introduced, so the heat resistance of the boron-silicon phenolic resin is further improved, and the interlayer strength and ablation scouring performance of the composite material product taking the boron-silicon phenolic resin as a base materialare greatly improved.

Owner:北京玻钢院复合材料有限公司

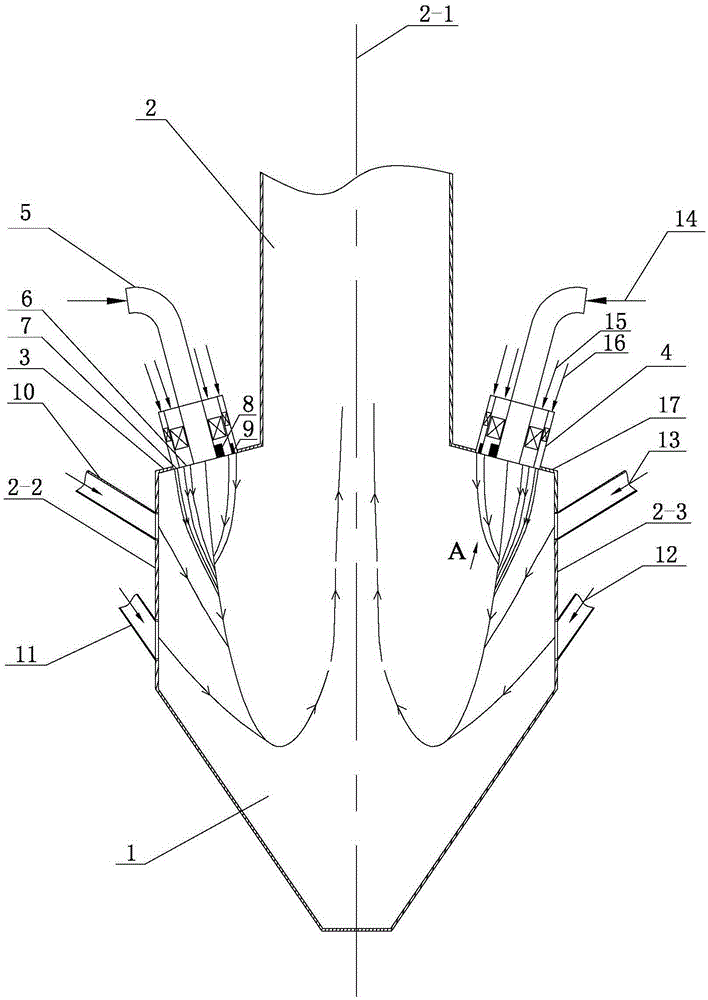

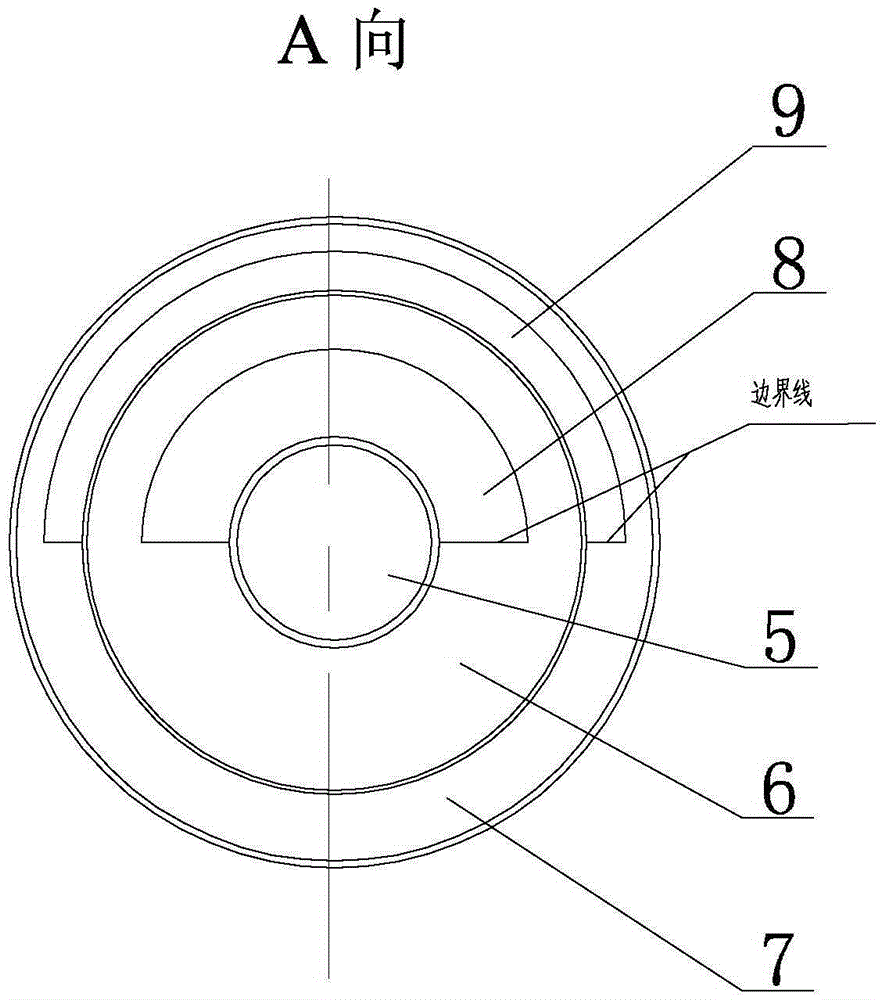

Secondary air offset whirl pulverized coal burner for W flame boiler

ActiveCN105423294AGood for early ignitionImprove flame stabilityPulverulent fuel combustion burnersCombustion apparatusCombustion chamberSlag

Disclosed is a secondary air offset whirl pulverized coal burner for a W flame boiler. The problems of high NOx discharge amount, high fly ash combustible matter content, slag-bonding to water walls of front and back walls of a lower combustion chamber and high temperature corrosion of the W flame boiler which is provided with an existing whirl pulverized coal burner on an arch are solved. A circular ring inner secondary air stop block in the circumferential direction is added in inner secondary air on a dividing cylinder of primary air and inner secondary air of the whirl pulverized coal burner; the angle of the circular ring inner secondary air stop block in the circumferential direction is 180 degrees; a circular ring outer secondary air stop block in the circumferential direction is added in outer secondary air on a dividing cylinder of the inner secondary air and the outer secondary air; the angle of the circular ring outer secondary air stop block in the circumferential direction is 180 degrees; the boundary line in the diameter direction of the circular ring inner secondary air stop block and the circular ring outer secondary air stop block is parallel to the front and back walls of the boiler; the circular ring inner secondary air stop block and the circular ring outer secondary air stop block are mounted on one side close to the center of a combustion chamber. The secondary air offset whirl pulverized coal burner is used for the W flame boiler.

Owner:HARBIN INST OF TECH

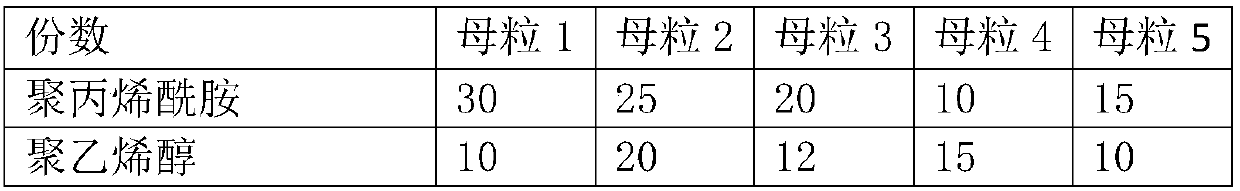

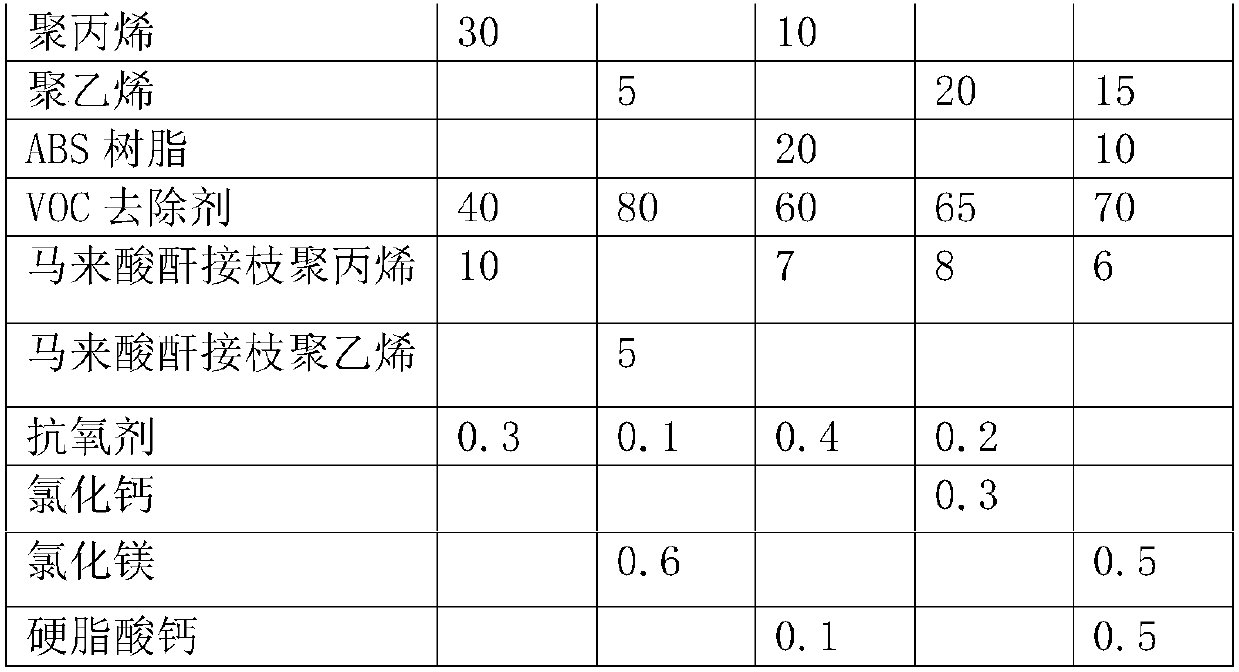

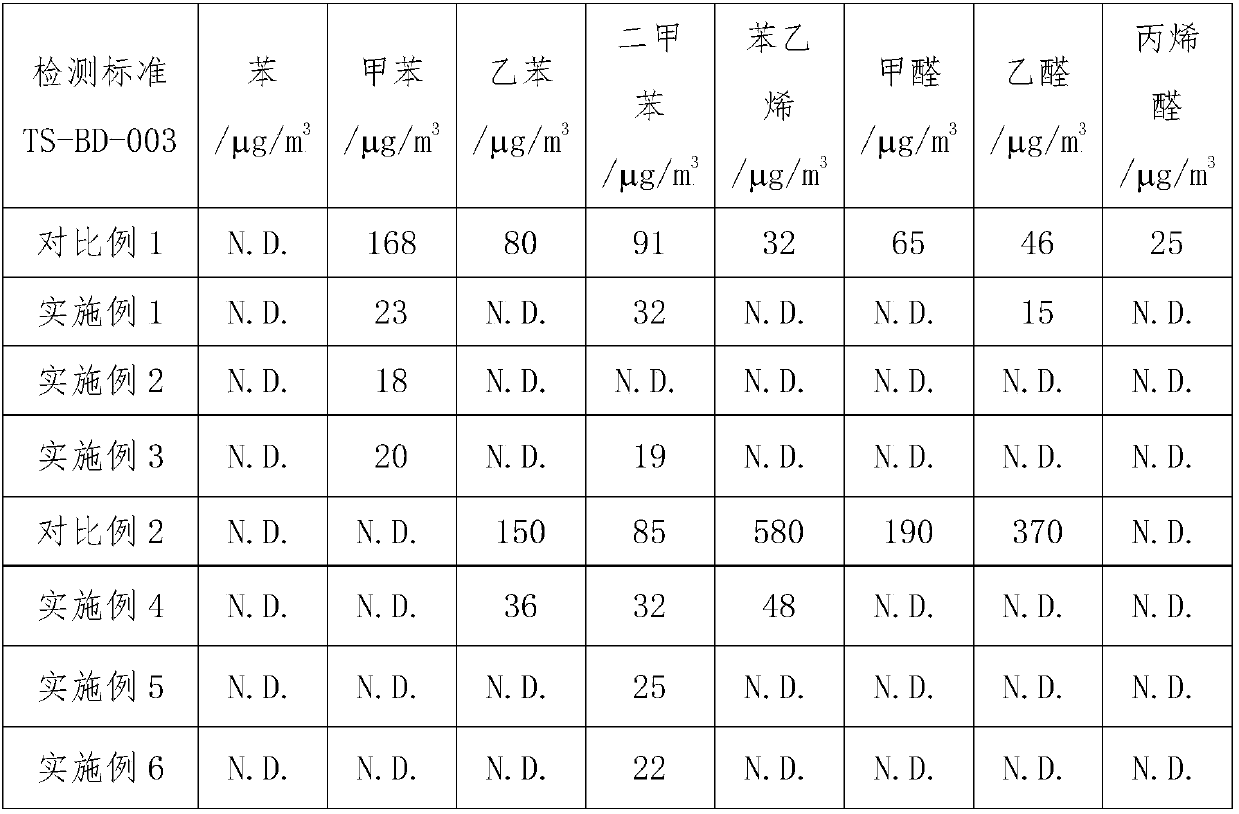

Vehicle interior decoration material VOC removal master batch and preparation method thereof

The invention discloses a vehicle interior decoration material VOC removal master batch and a preparation method thereof, and belongs to the technical field of materials. The vehicle interior decoration material VOC removal master batch comprises, by weight, 10-30 parts of polyacrylamide, 10-20 parts of polyvinyl alcohol, 40-80 parts of a VOC remover, 5-30 parts of polyolefin, 0-20 parts of ABS resin, 5-10 parts of a compatibilizer and 0.3-1.0 part of an assistant. The invention also discloses a preparation method of the vehicle interior decoration material VOC removal master batch. The masterbatch uses the VOC volatile matter remover as a main component, the VOC volatile matter remover interacts with VOC volatile components in the interior decoration in the processing process to extractthe volatile components from a polymer melt, and the volatile components are removed by using vacuum negative pressure, so the content of the VOC volatile components in the vehicle interior decorationmaterial is effectively reduced, and the air quality in the vehicle is improved.

Owner:NANJING JULONG SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com