A continuous-glass-fibre-reinforced polycarbonate composite material and a preparing method thereof

A polycarbonate and glass fiber technology, which is applied in the field of continuous glass fiber reinforced polycarbonate composite materials and its preparation, can solve the problems of poor interlayer interface bonding of composite materials, poor overall performance of composite materials, and poor glass fiber wettability, etc. problems, to achieve the effect of improving mechanical properties, low volatile content, and uniform resin distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

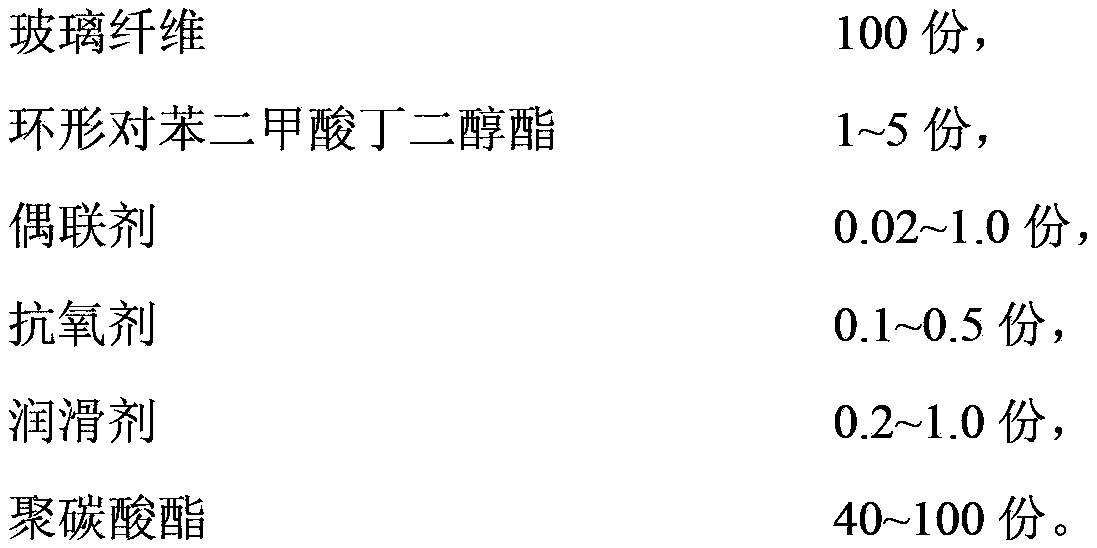

[0041] Take the raw material according to the following parts by weight:

[0042]

[0043] Glass fiber reinforced polycarbonate composites were prepared by the following steps:

[0044] (1) Polycarbonate film is prepared by hot melt casting method:

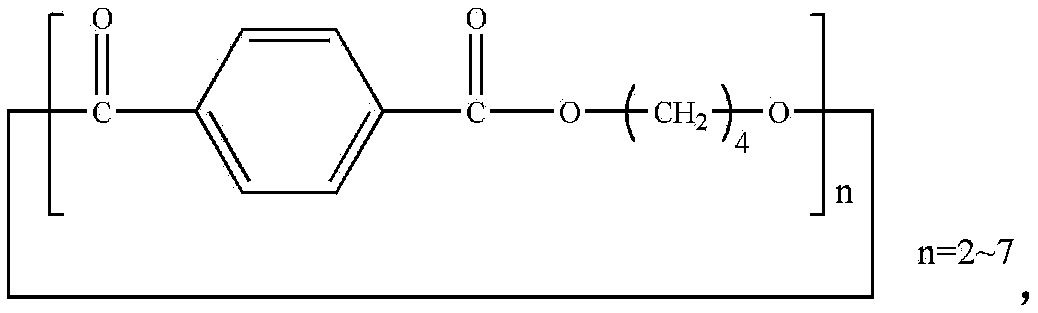

[0045] Will contain 40 parts of polycarbonate, 1 part of cyclic butylene terephthalate CBT100, 0.02 parts of coupling agent 3-aminopropyltriethoxysilane (KH550), 0.1 part of antioxidant 1010 and 0.2 parts The combination material of lubricant silicone powder is prepared into a thin film, and the thickness of the thin film is 0.070mm;

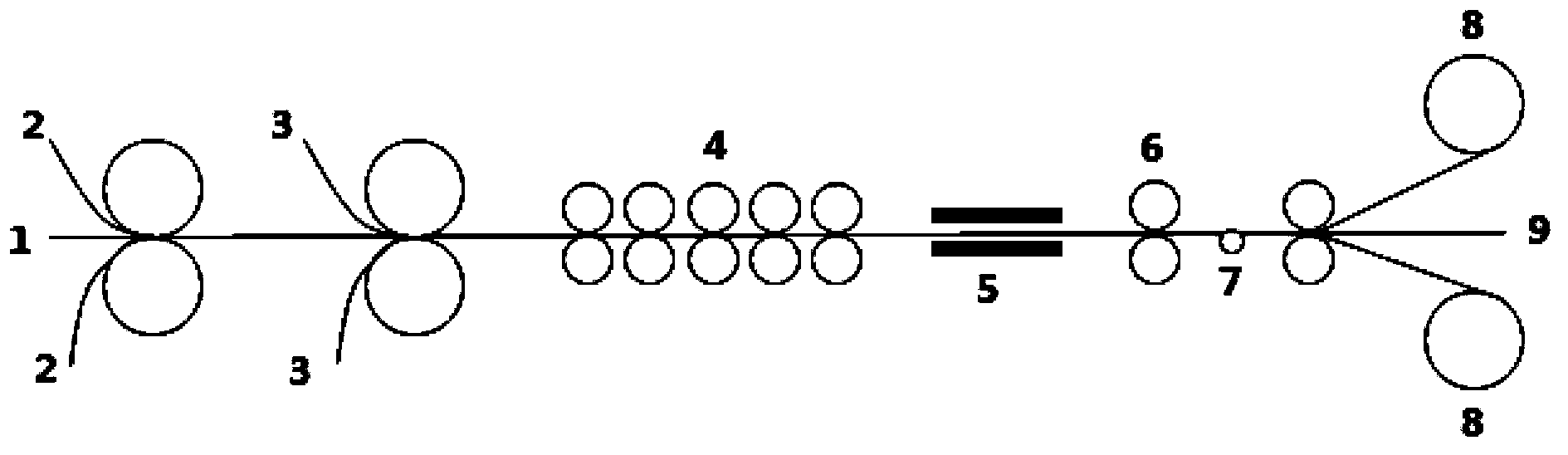

[0046] (2) According to figure 1 Schematic diagram of the production process of continuous glass fiber reinforced polycarbonate prepreg tape, 100 parts of glass fiber cloth 1 is superimposed on the middle of two layers of polycarbonate film 2, and then superimposed on the middle of two layers of release paper 3, and passed through a hot pressing roller 4. The temperature of the hot pressing ro...

Embodiment 2

[0050] Take the raw material according to the following parts by weight:

[0051]

[0052] Glass fiber reinforced polycarbonate composites were prepared by the following steps:

[0053] (1) Polycarbonate film made by blow molding:

[0054] Will contain 55 parts of polycarbonate, 2 parts of cyclic butylene terephthalate CBT100, 0.1 part of coupling agent 3-glycidyl ether oxypropyl trimethoxysilane (KH560), 0.2 parts of antioxidant 168 and 0.4 parts of lubricant TAF (modified ethylene bis fatty acid amide, Suzhou Xingtai Photochemical Auxiliary Co., Ltd.) is prepared into a film, and the thickness of the film is 0.094mm;

[0055] (2) According to figure 1 Schematic diagram of the production process of continuous glass fiber reinforced polycarbonate prepreg tape, 100 parts of glass fiber cloth 1 is superimposed on the middle of two layers of polycarbonate film 2, and then superimposed on the middle of two layers of release paper 3, and passed through a hot pressing roller 4. ...

Embodiment 3

[0059] Take the raw material according to the following parts by weight:

[0060]

[0061]

[0062] Glass fiber reinforced polycarbonate composites were prepared by the following steps:

[0063] (1) Polycarbonate film is made by hot melt casting or blow molding:

[0064] Will contain 70 parts of polycarbonate, 3 parts of cyclic butylene terephthalate CBT100, 0.3 parts of coupling agent 3-(methacryloyloxy)propyl trimethoxysilane (KH570), 0.3 parts of antioxidant ( Antioxidant 1010 and antioxidant 168 (the ratio by weight is 2:1) and 0.6 parts of lubricant RH-313 (pentaerythritol stearate, Dongguan Jianxing Plastic Products Co., Ltd.) are mixed to form a film, and the thickness of the film is 0.120mm;

[0065] (2) According to figure 1 Schematic diagram of the production process of continuous glass fiber reinforced polycarbonate prepreg tape, 100 parts of glass fiber cloth 1 is superimposed on the middle of two layers of polycarbonate film 2, and then superimposed on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com