Patents

Literature

128results about How to "Small thickness deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

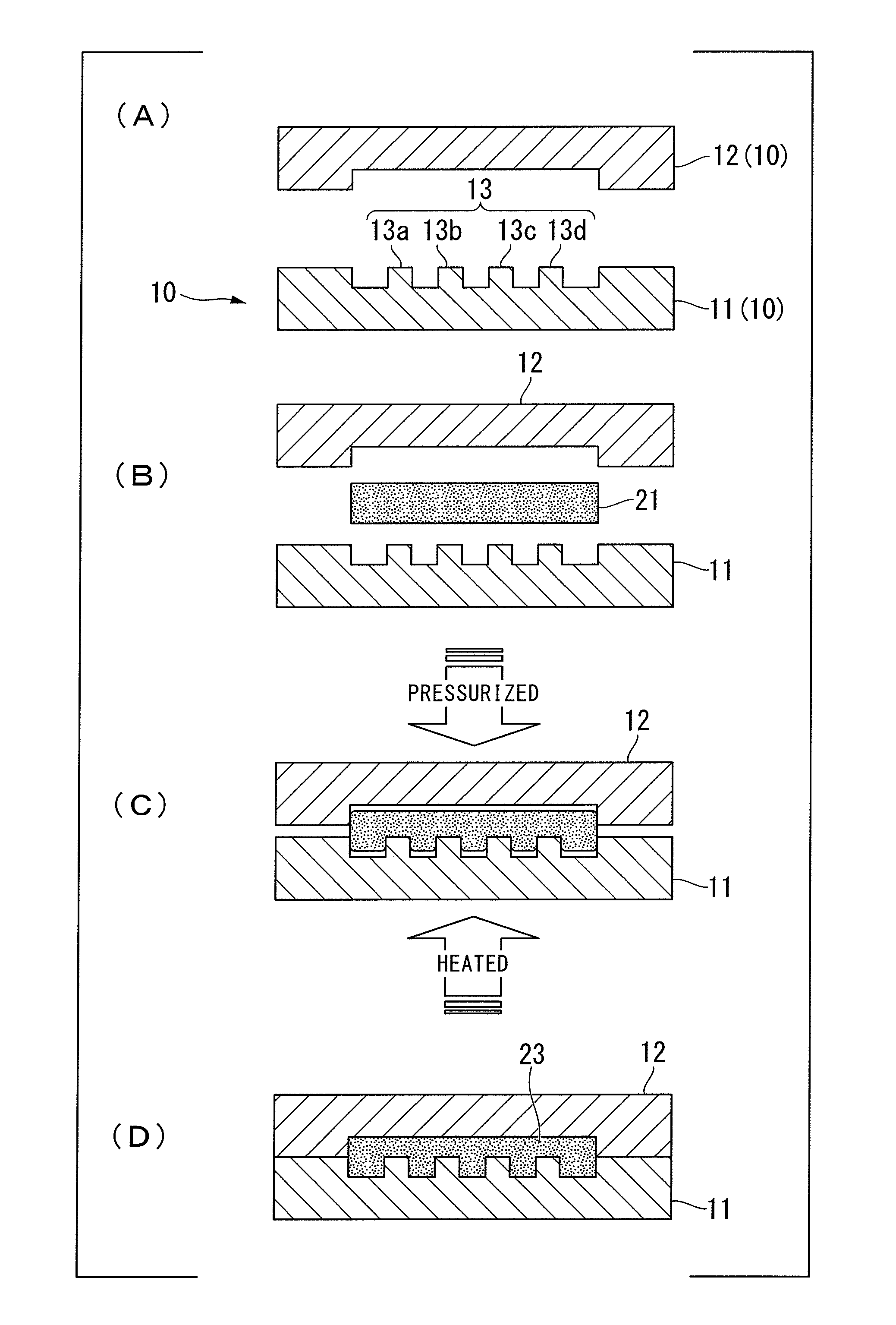

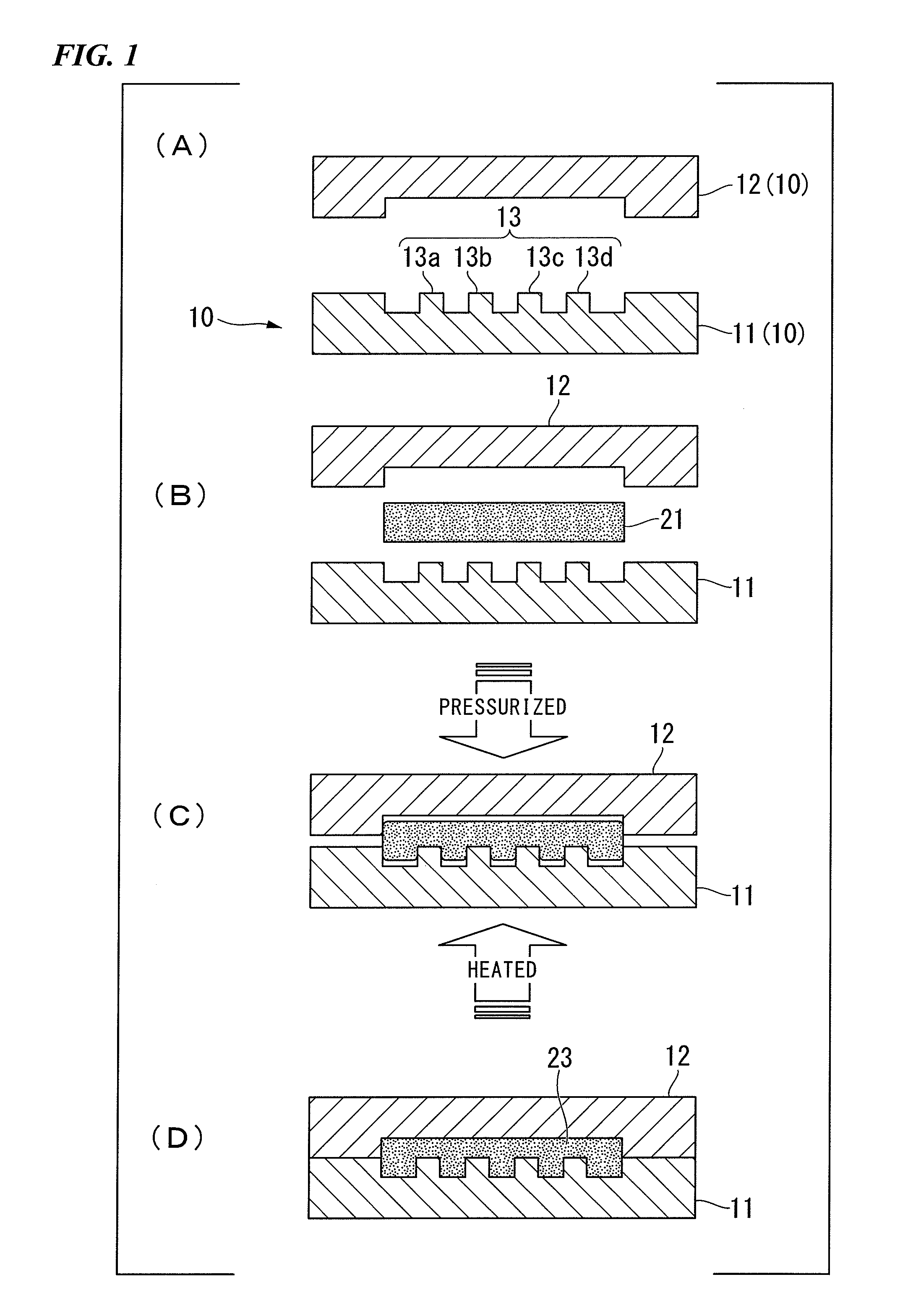

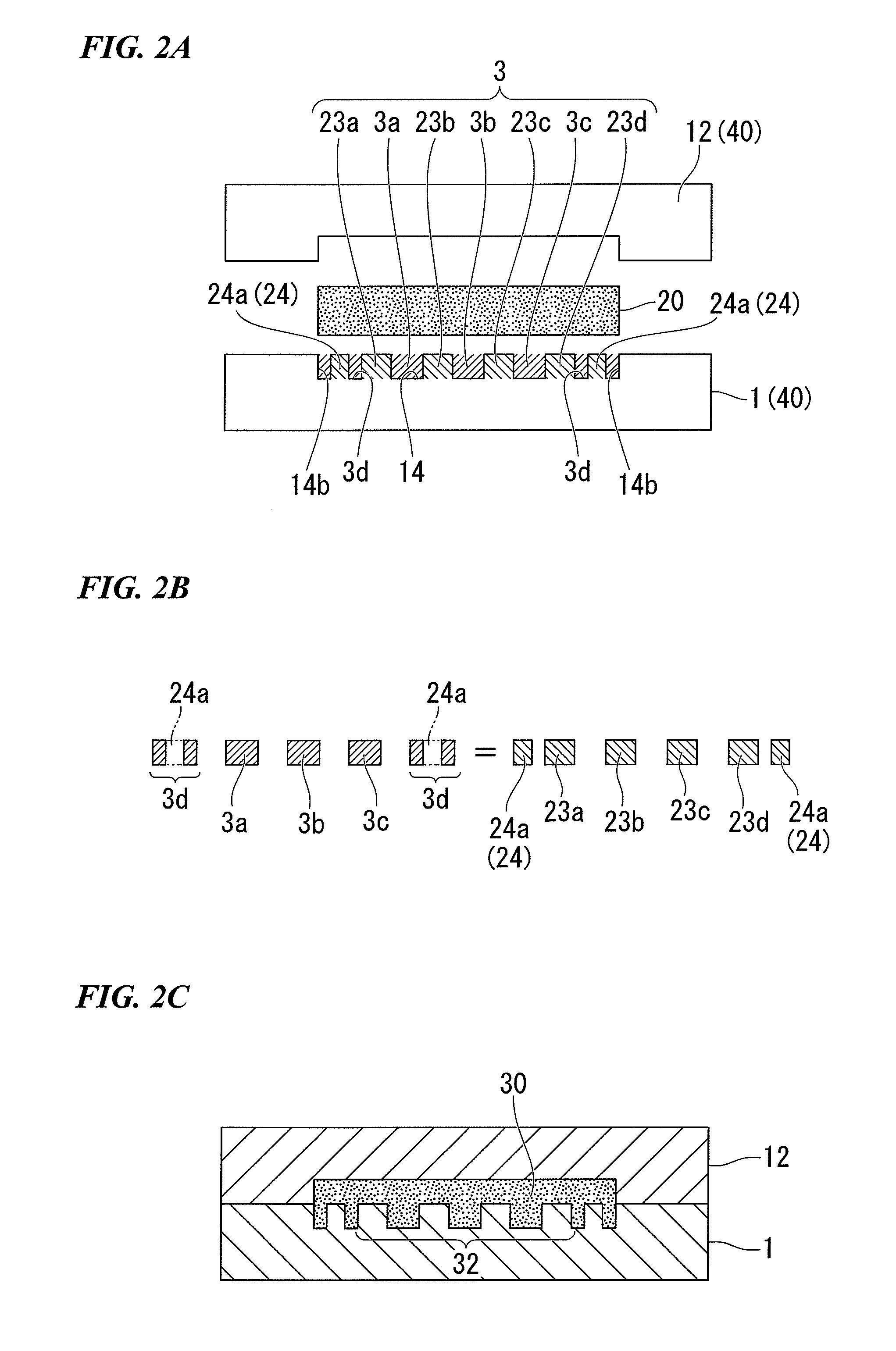

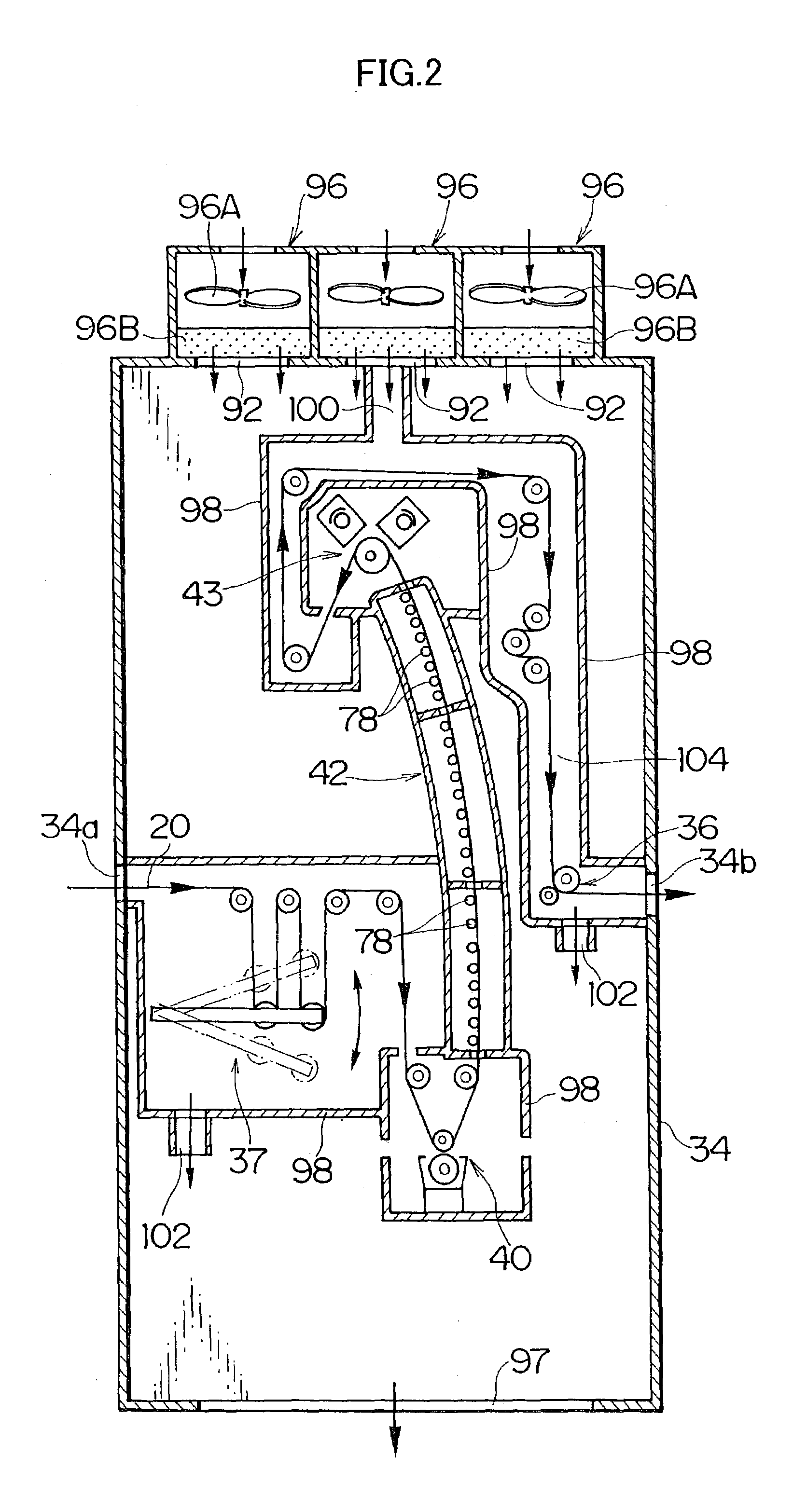

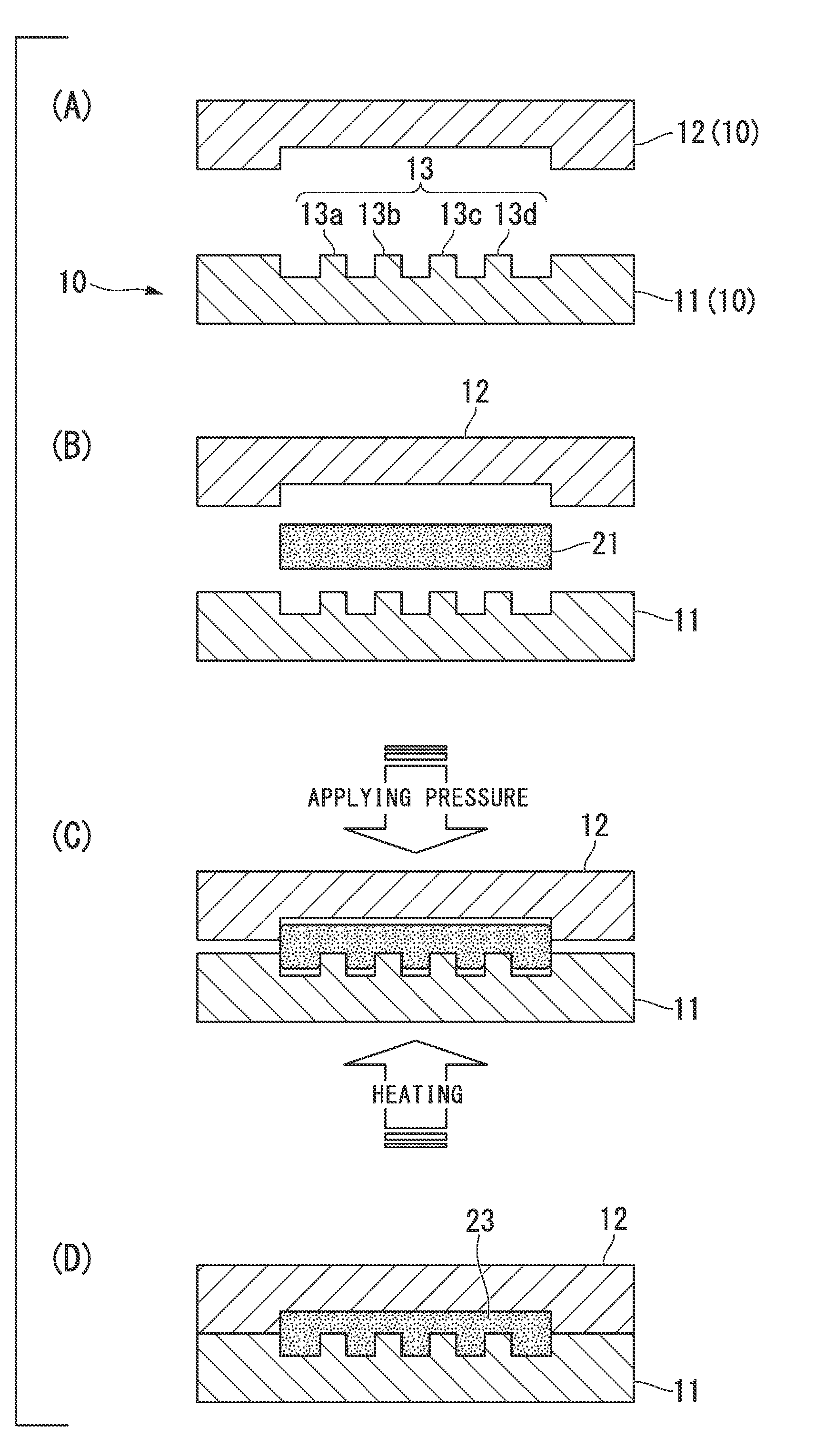

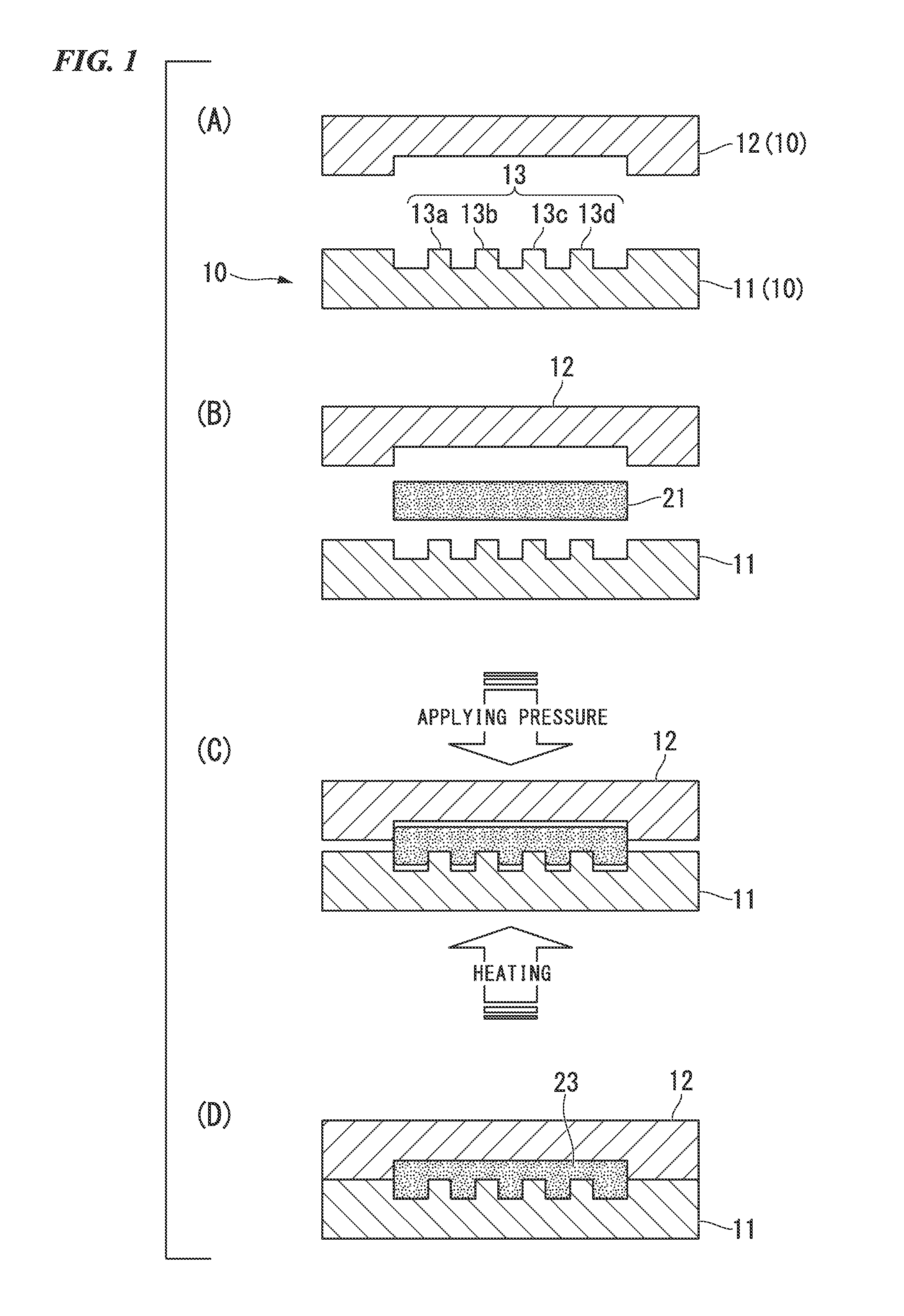

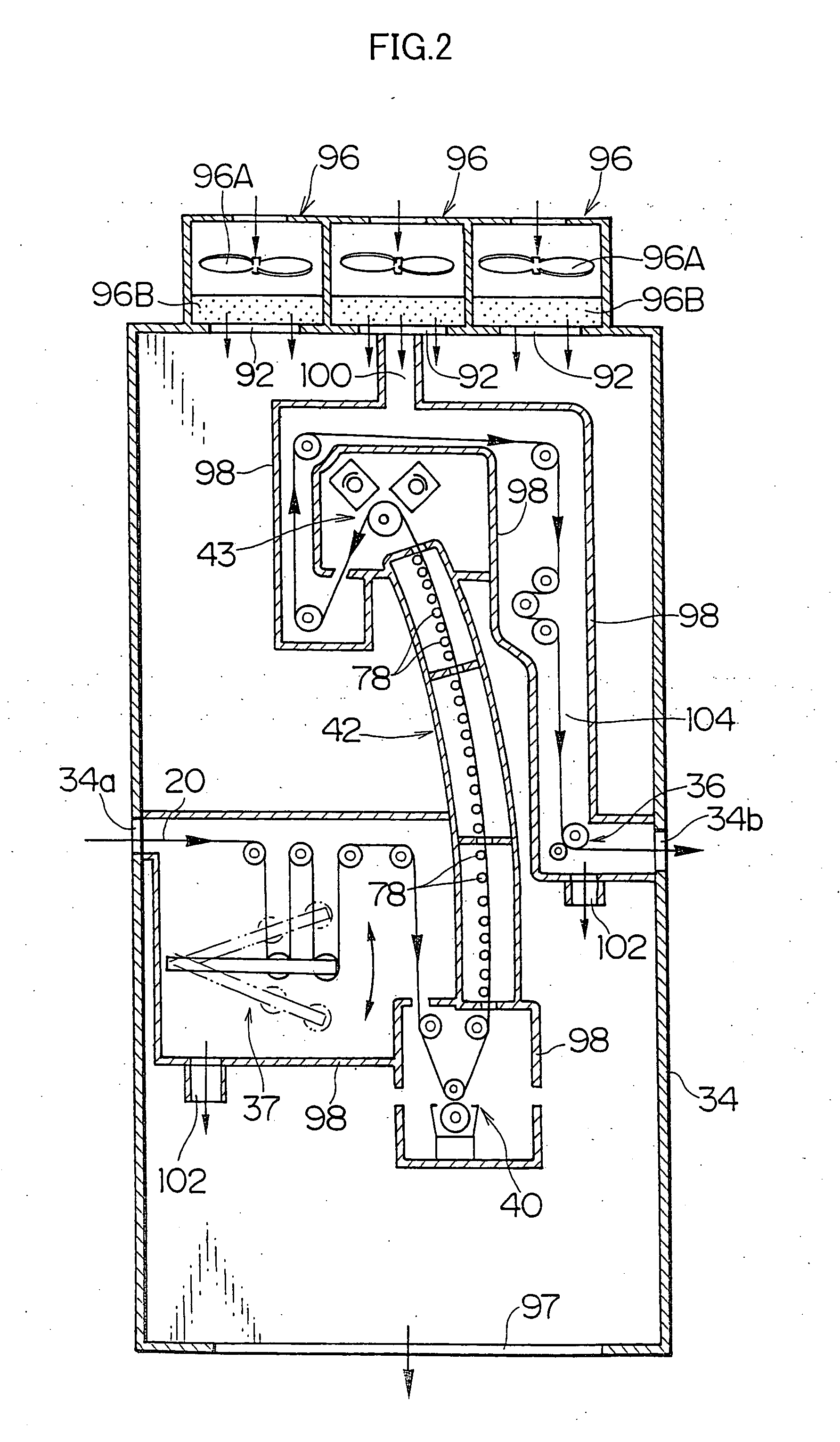

Sheet press molding method and method of manufacturing fuel cell separator

InactiveUS20120025420A1Speed up the flowSmall thickness deviationFinal product manufactureCeramic shaping apparatusFuel cellsEngineering

Owner:SHOWA DENKO KK

Low-temperature radiation electrothermal film and preparation method thereof

InactiveCN103305051AHigh peel strengthImprove adhesion strengthInksOhmic-resistance heatingPolyesterRadiant heater

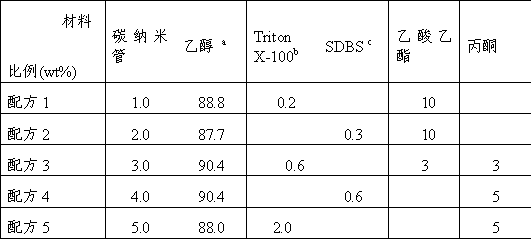

The invention discloses a low-temperature radiation electrothermal film and a preparation method thereof. The carbon nanometer conductive ink comprises the following components in mass percent: 1 to 5% of carbon nano tube, 94 to 98% of solvent, and 0.2 to 2% of surface active agent. The preparation method comprises the following steps: manufacturing a hot melt adhesive layer on a polyester film; printing a carbon nanometer conductive ink layer onto the hot melt adhesive layer; printing a generating and heating ink layer on the ink layer; manufacturing an electrode; and then hot-processing and compounding the polyester film through a hot melt adhesive film. The low-temperature electric radiant heater film has the characteristics that the peeling strength is high and the electro thermal power can be flexibly adjusted.

Owner:KMT纳米科技(香港)有限公司

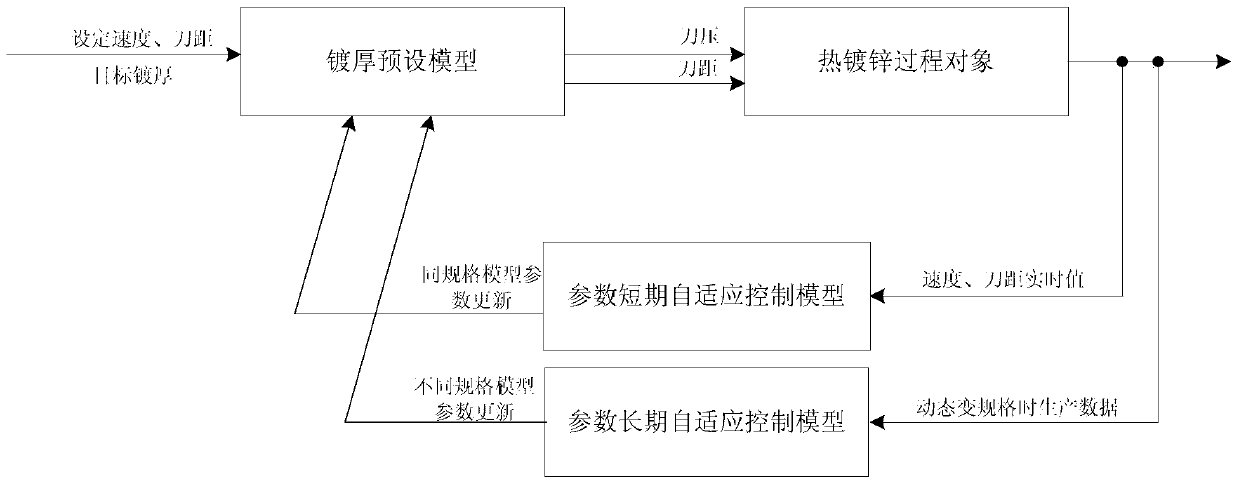

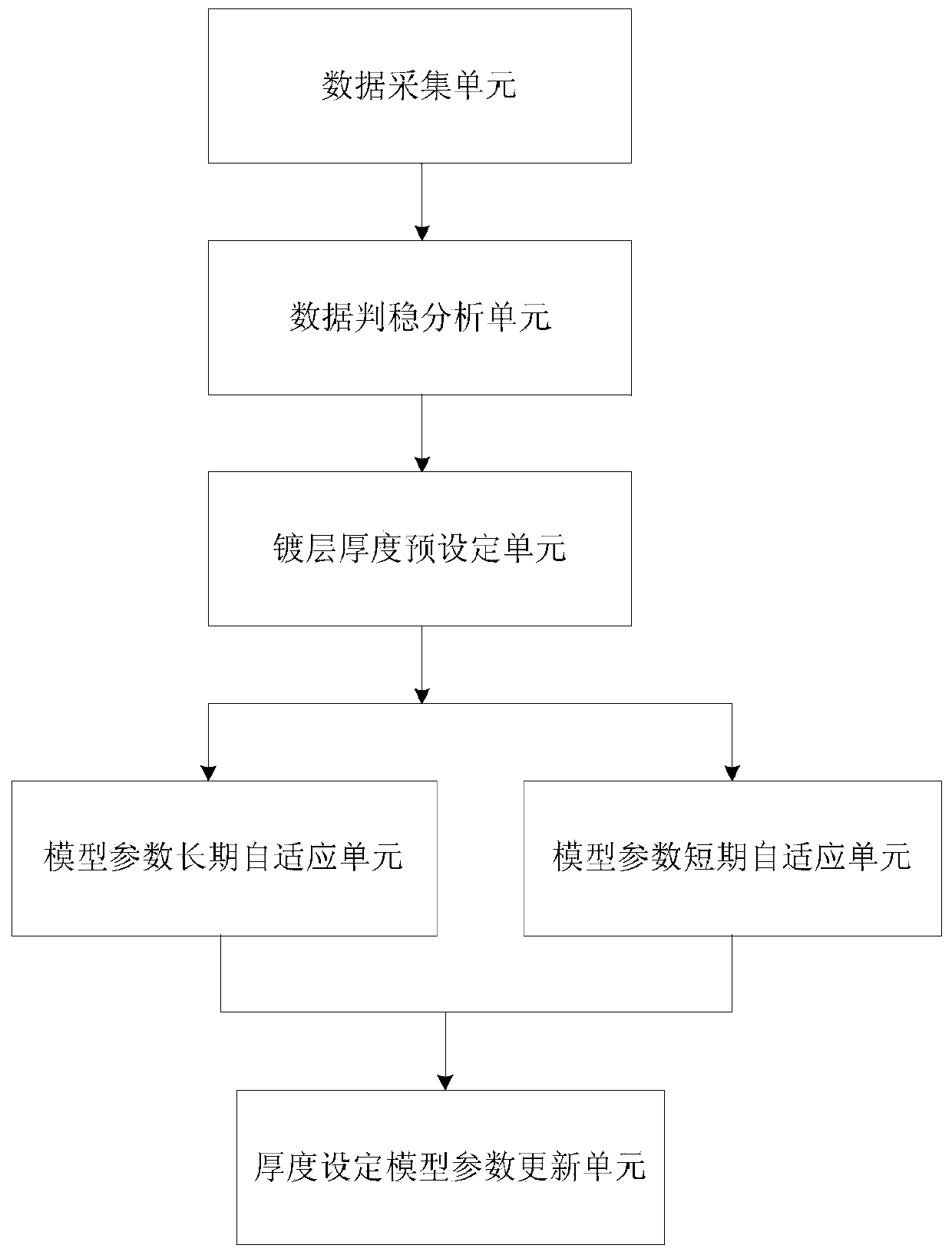

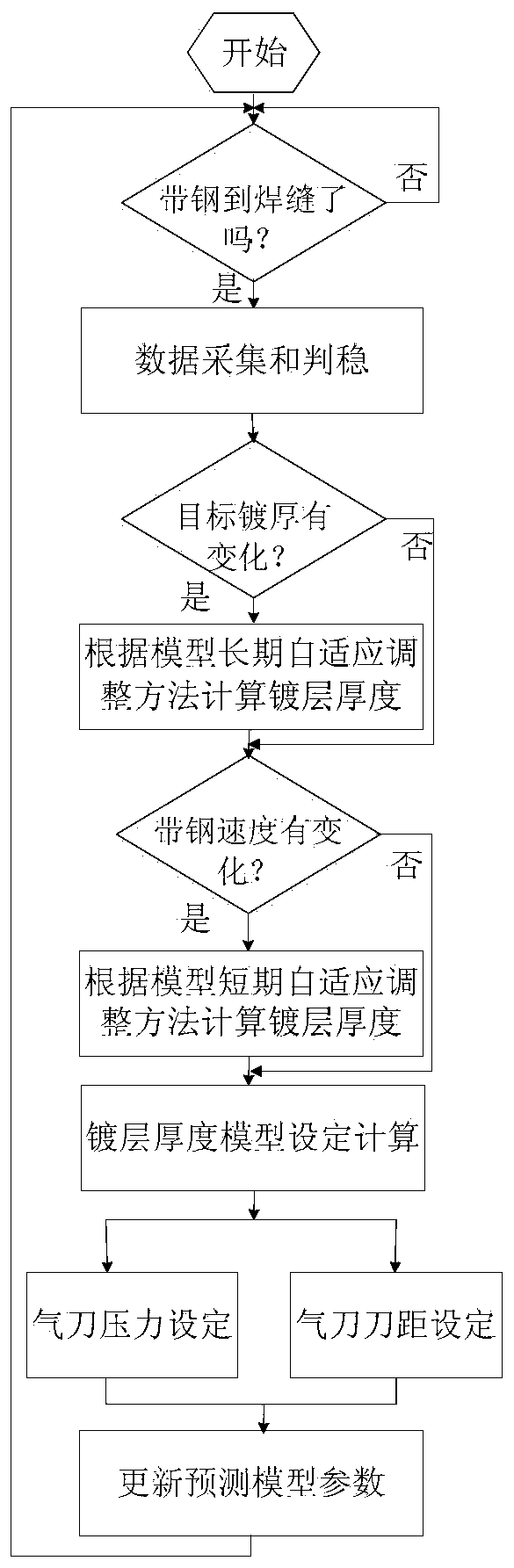

Preset control method for thickness flying gauge change of hot-dip zinc coating

ActiveCN103469137AInhibition effectImprove uniformityHot-dipping/immersion processesAir knifeModel parameters

The invention provides a preset control method for a thickness flying gauge change of a hot-dip zinc coating. The method comprises the following steps: with a strip steel speed, air knife pressure, and a distance between an air knife and the surface of strip steel as main influence factors and by applying a principal component analysis method, building a thickness preset model of the coating by using a least-square fitting algorithm of a log-log space; carrying out long-term self-adaption adjustment and short-term self-adaption adjustment on the thickness of the coating aiming at the effects of a variable speed, a target thickness and a strip steel substrate thickness on the thickness of the coating existing in the flying gauge change process; and carrying out online updating calculation on thickness model parameters of the coating by using a Kalman filtering algorithm and a smooth filtering algorithm in thickness control, so as to improve the preset accuracy of the model parameters. By adopting the preset control method, the control problems of overlarge thickness deviation of the coating and coating thickness detection lag caused by changes of the target thickness of the coating, the strip steel substrate thickness and the strip steel speed are solved; automatic preset control of the thickness of the zinc coating is achieved; the thickness deviation of the zinc coating is reduced; the thickness control accuracy of the zinc coating is improved; zinc consumption is reduced; the galvanization cost is also saved.

Owner:ANGANG STEEL CO LTD

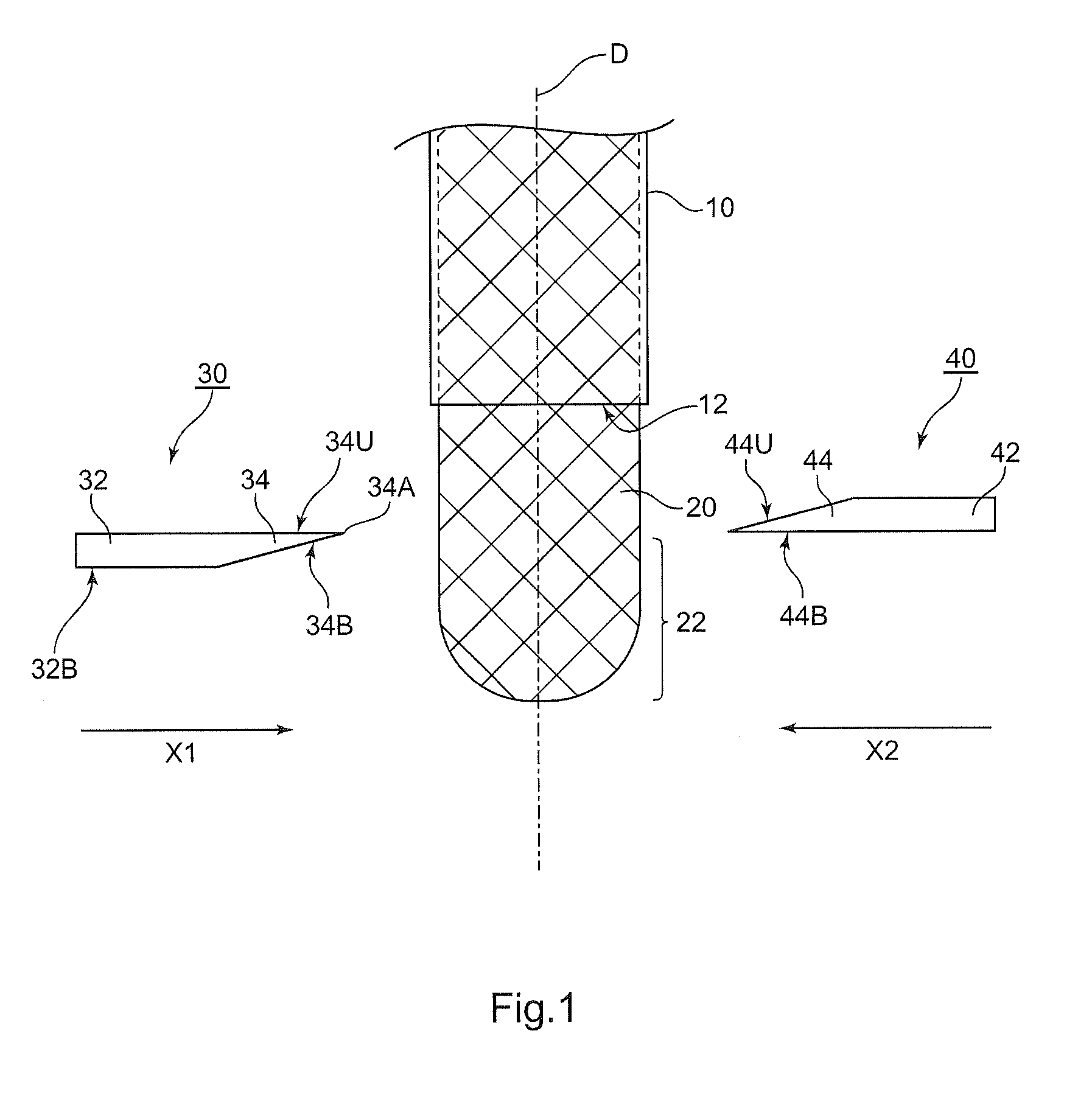

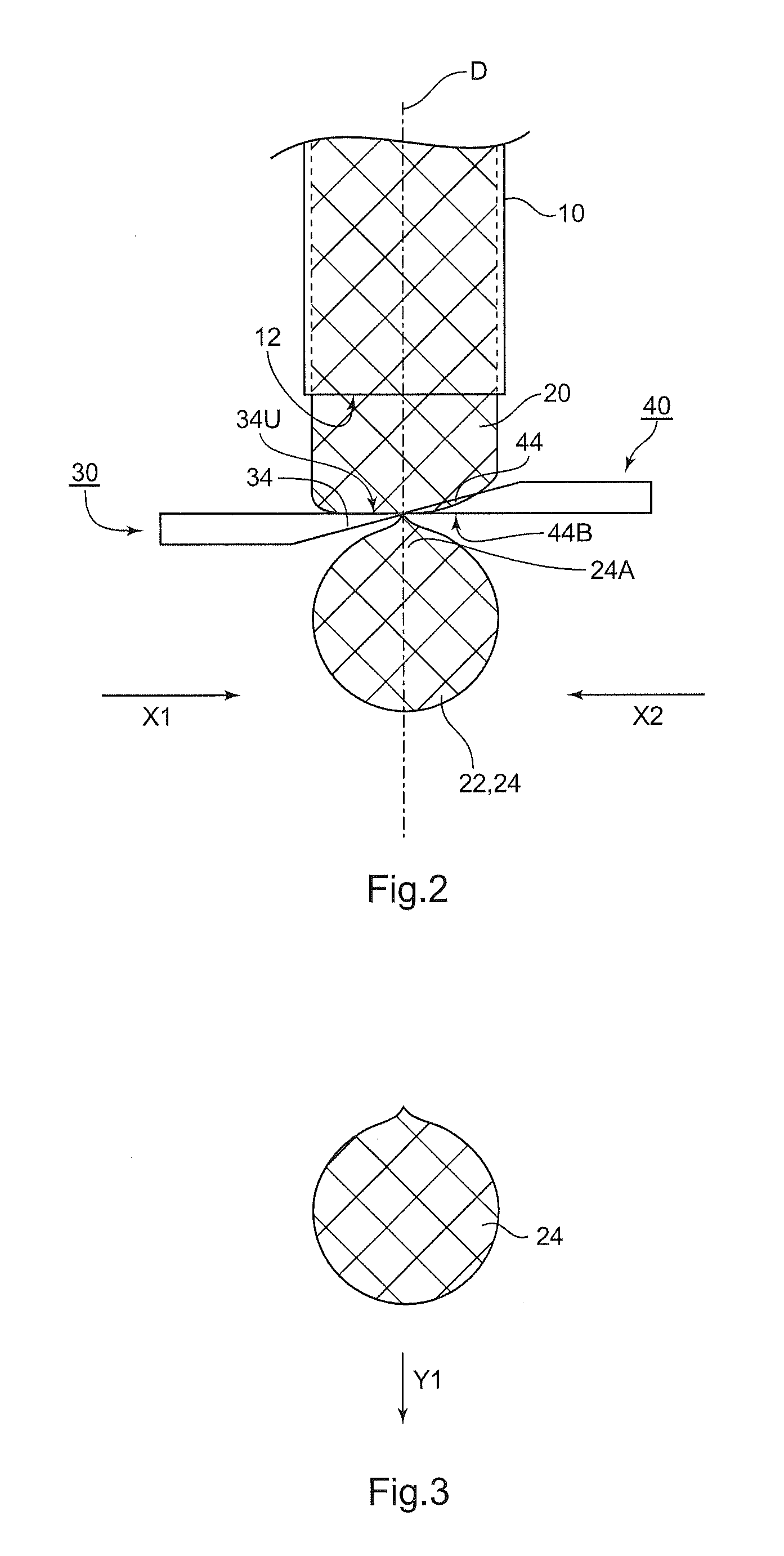

Manufacturing method of glass blank for magnetic recording glass substrate, manufacturing method of magnetic recording glass substrate and manufacturing method of magnetic recording medium

InactiveUS20110277508A1Improve flatnessLittle crack defectGlass drawing apparatusGlass forming apparatusVitrificationFlat glass

Provided is a method of manufacturing a glass blank for a magnetic recording medium glass substrate, including: manufacturing a glass blank by at least press molding a falling molten glass gob with a pair of press molds both so as to face each other in a direction perpendicular to a direction in which the molten glass gob falls, in which: the molten glass gob is formed of a glass material having a glass transition temperature of 600° C. or more; and when the press molding is carried out so that the molten glass gob is completely extended by pressure and molded into a flat glass between press-molding surfaces of the pair of press molds, at least a region in contact with the flat glass in each of the press-molding surfaces of the pair of press molds forms a substantially flat surface. Also provided are a method of manufacturing a magnetic recording medium glass substrate and a method of manufacturing a magnetic recording medium each using the method of manufacturing a glass blank for a magnetic recording medium glass substrate.

Owner:HOYA CORP

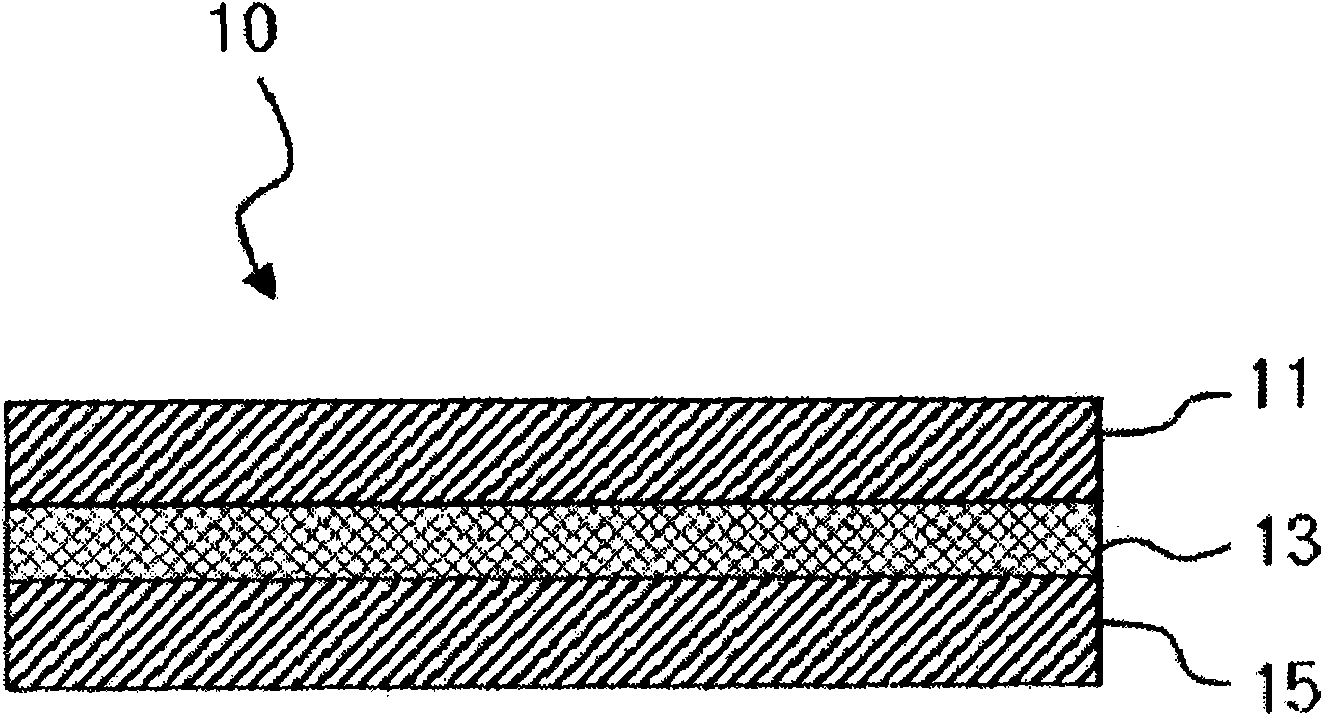

Polymer power cell anode-cathode film

ActiveCN101179122AImprove liquiditySmall thickness deviationOrganic electrolyte cellsActive material electrodesPolyesterPolymer science

The invention relates to a cathode and anode film of a polymer battery. A cathode and anode film of a polymer battery, which is prepared by using active materials, adding a conductive agent, a pore-forming agent, a solvent and a binder to make a slurry, and then coating it on a polyester film. It is characterized in that: The agent is a mixture of two different molecules of copolymerized vinylidene fluoride-hexafluoropropylene. The present invention mixes two kinds of PVDF with different characteristics as the binder in the film-making process, controls the viscosity of the slurry in a certain range, and effectively improves the fluidity of the slurry in the film-making process; the direct coating method is used to make the film , the process is convenient to operate, the thickness deviation of the cathode and anode films produced is small, the yield is high, and the cost is low, making it possible to commercialize lithium-ion batteries on a large scale.

Owner:WANXIANG 123 CO LTD

High-precision tungsten piece preparation method

ActiveCN1621199AImproved uniformity of heatingSmall thickness deviationFurnace typesOther manufacturing equipments/toolsEmulsionSurface roughness

The high precision tungsten plate producing process is especially suitable for producing high precision shielding tungsten plate for CT machine. The production process includes coating the blank tungsten plate with graphite emulsion of 15-20 wt% concentration, rolling after homogeneous heating, electrolytic polishing and pressurizing flattening. The said process is suitable for production of high precision tungsten plate with thickness deviation within 0.01 mm, flatness within 0.005 mm, lower surface roughness and sizes 0.203x146.05x257.05 mm.

Owner:WESTERN METAL MATERIAL

Method of manufacturing acrylic film, and acrylic film

InactiveUS20120121881A1Small thickness deviationHigh thickness accuracySynthetic resin layered productsFlat articlesUltraviolet lightsElectronic component

The present invention relates to a method for manufacturing an acrylic film and to an acrylic film manufactured by same, the method comprising: a first step of coating an acryl-based resin syrup; and a second step of hardening the acryl-based resin syrup coated in the first step by irradiating ultraviolet light. According to the present invention, an excellent film having low thickness deviation and thickness precision may be provided. In addition, defects in the film such as fish eyes and uneven distribution of physical properties in the vertical and horizontal directions may be kept to a minimum. Consequently, the film according to the present invention can be applied to various industrial sheets such as protective films for various semiconductor processes, pressure-sensitive adhesives or adhesives for optical products and pressure-sensitive adhesives or adhesives for electronic components, or to laminated products.

Owner:LG HAUSYS LTD

Photochromic films and method for manufacturing the same

ActiveCN101784591AHigh transparencyIncreased durabilityGlass/slag layered productsOptical elementsPhotochromismAcrylate

The present invention provides a photochromic film which is formed by curing a photochromic composition and includes a multifunctional (metha)acrylate-based monomer that has two or more functional groups, and a photochromic dye, a product including the same, and a method for producing the photochromic film.

Owner:LG CHEM LTD

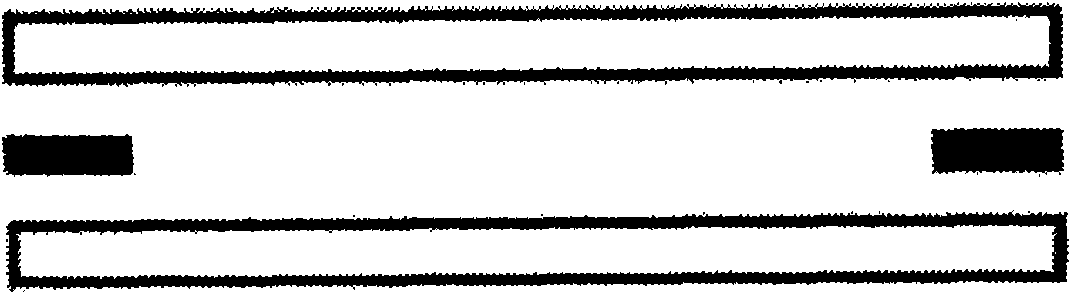

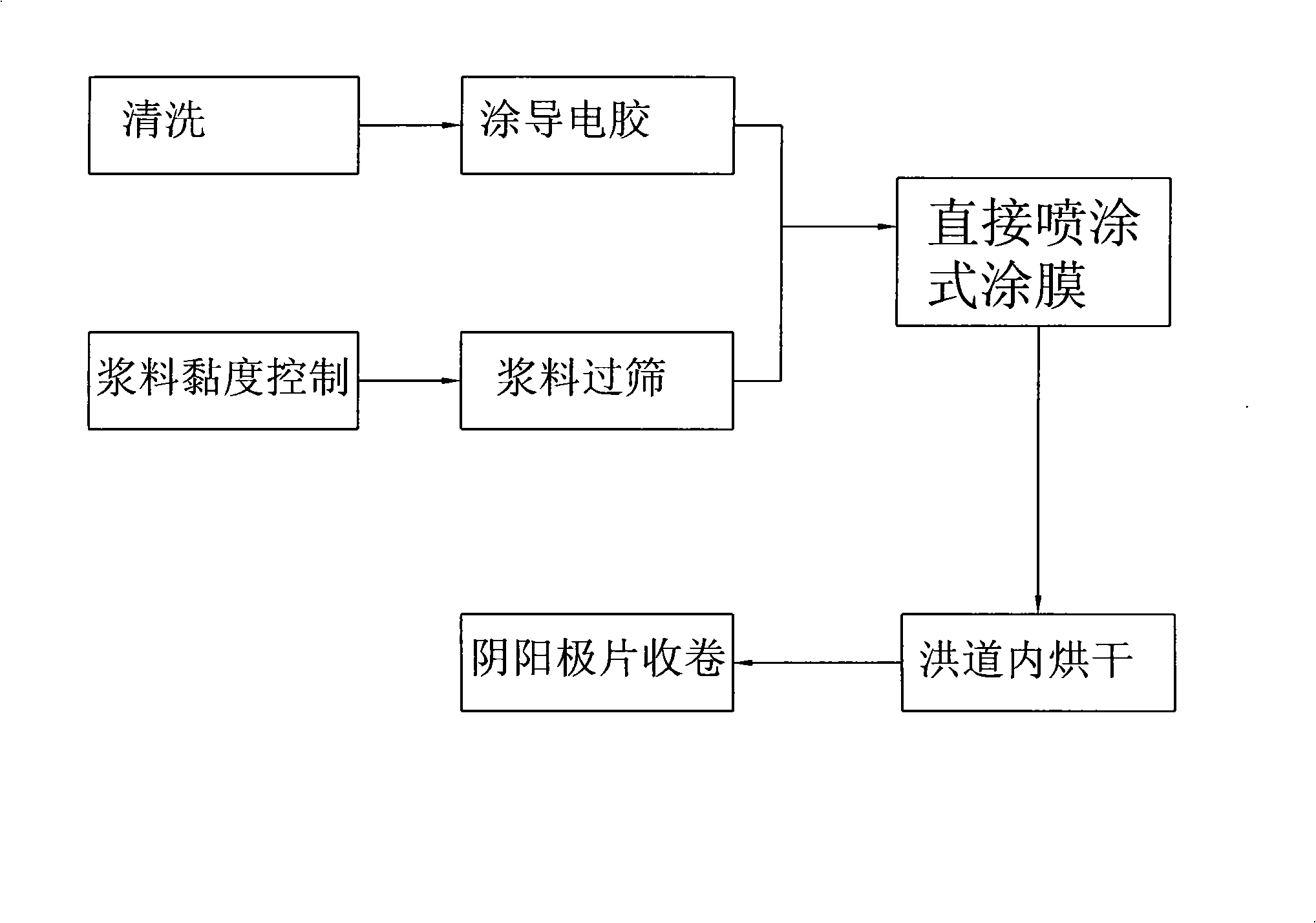

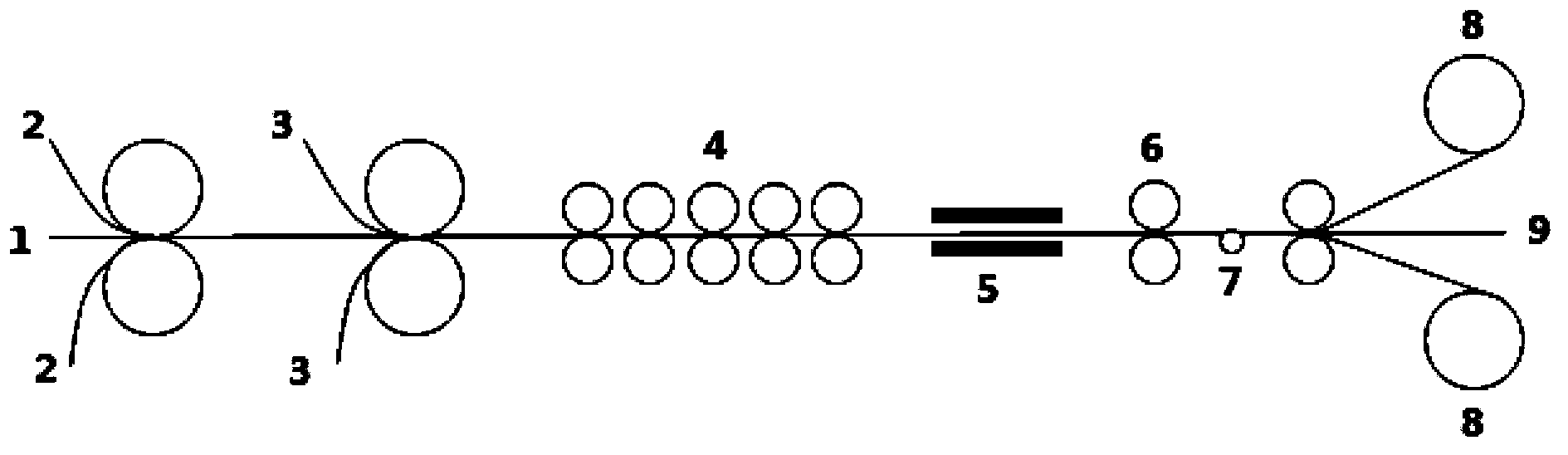

Production technology for polymer lithium battery anode and cathode slice

ActiveCN101262054ASmall thickness deviationEasy to operateElectrode manufacturing processesElectrode carriers/collectorsAdhesiveSlurry

The invention relates to a production technique of cathode and anode flakes of a lithium polymer battery, solving the disadvantages of large deviation of membrane weight and membrane thickness in the process of preparing cathode and anode flakes in the prior art. The production technique is characterized by comprising the following steps: a. a current collector is washed with acid base or alkali acid, and then fully rinsed with clean water; b. the washed current collector is coated with a layer of conductive adhesive and fully dried; c. cathode and anode flake slurry with proper stickiness is prepared and removed of large particles inside by screening; d. the current collector is unreeled on an unreeling guiding rail and directly sprayed with the cathode and anode flake slurry and fully dried; e. reeling. A nozzle is directly used for spraying, which ensures that the cathode and anode membranes are light with small thickness deviation, simple operation technique and less production procedures of the cathode and anode flakes, thereby improving the rate of finished products with low cost and realizing continuous and automatic mass production of the lithium ion battery.

Owner:WANXIANG 123 CO LTD

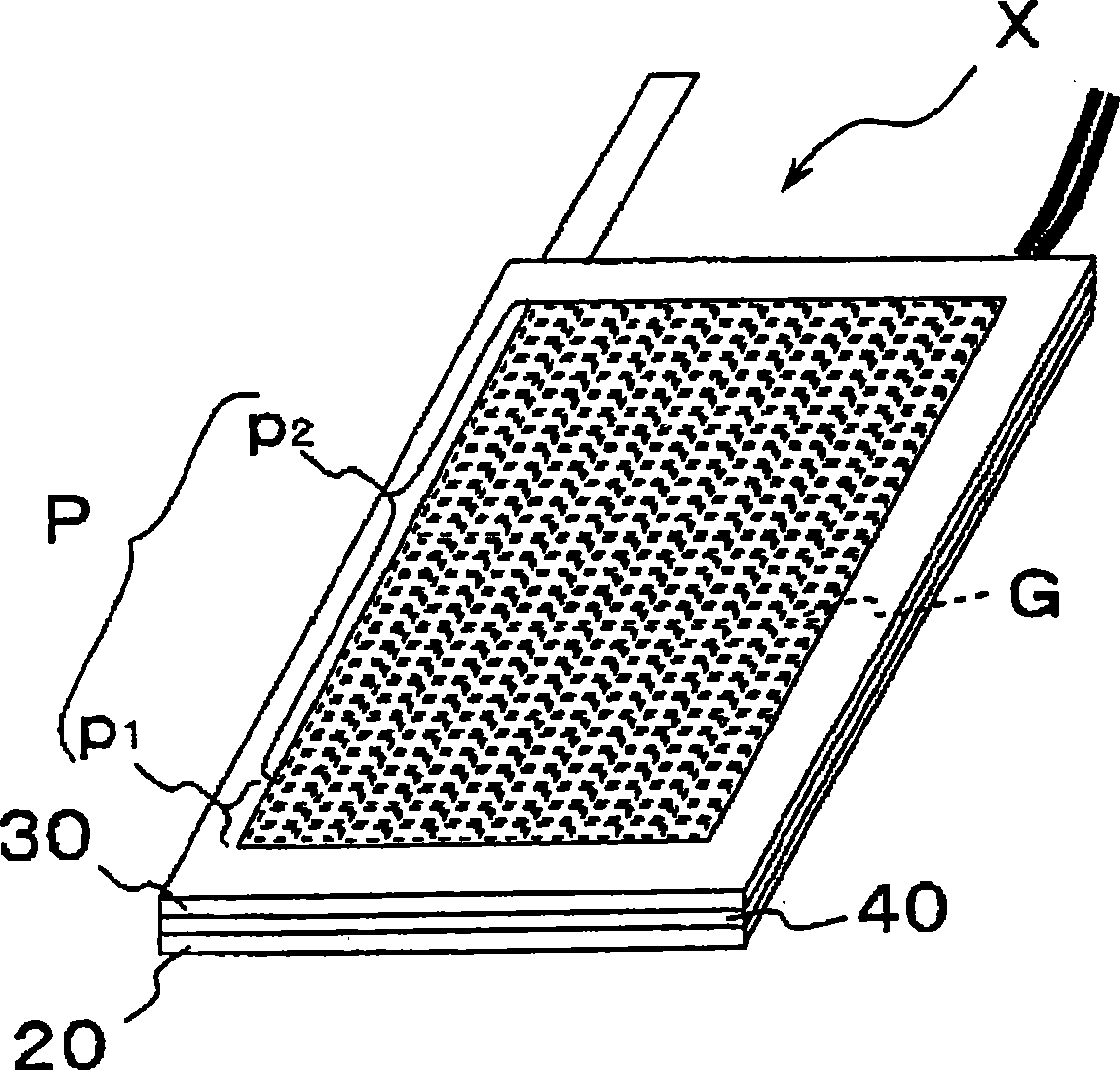

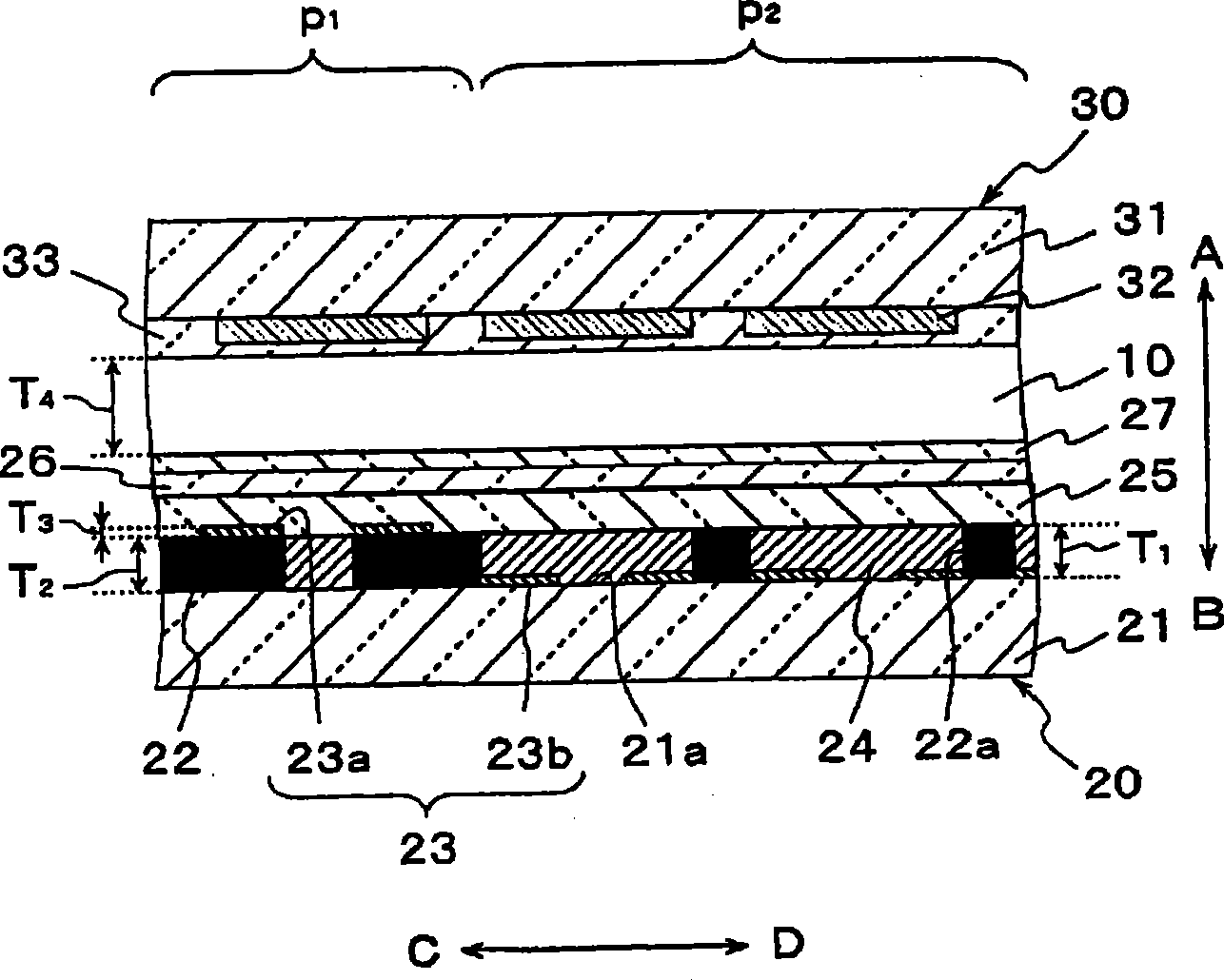

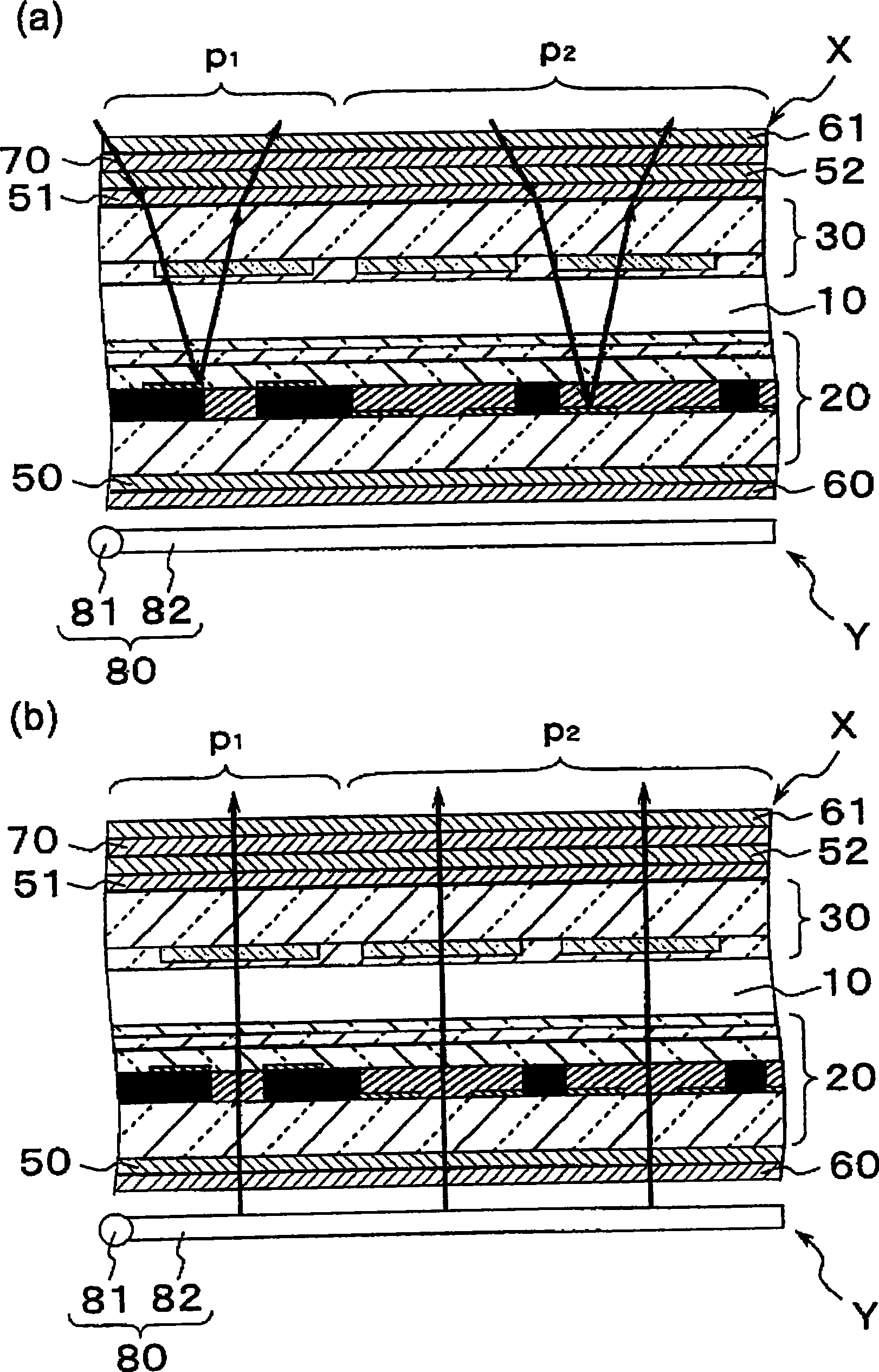

Liquid crystal display panel, liquid crystal display device and method for manufacturing liquid crystal display panel

InactiveCN101460886AIncreasing the thicknessHigh color purityNon-linear opticsLiquid-crystal displayHigh color

A liquid crystal display panel, a liquid crystal display device and a manufacturing method of a liquid crystal display, which have excellent display properties and achieve high color purity in a transmissive display mode and high display brightness in monochrome display in a reflective display mode, are provided. A liquid crystal display panel X according to one of the present invention includes: a first base (20) having a display-area portion p 1 that includes a transparent substrate (21), a light shielding film (22) formed on a main surface of the transparent substrate (21) and having through holes, a light reflecting film (23) formed on the light shielding film (22), a color filter (24) formed on the main surface of the transparent substrate (21) exposed in the through holes of the light shielding film (22), and a transparent electrode (26) formed on the main surface of the transparent substrate (21); a second base (30) that includes a transparent substrate (31), and a transparent electrode (32) formed on a main surface of the transparent substrate (31); and a sealing member (40) for sealing liquid crystal between the first base (20) and the second base (30).

Owner:KYOCERA CORP

Laminated extruded resin sheet

InactiveUS6908670B1Small thickness deviationLamination ancillary operationsSynthetic resin layered productsThermoformingPolyresin

The present invention provides a laminated extruded resin sheet comprising a methyl methacrylate resin produced by laminating resin layers (B) on both surfaces of a resin layer (A) by a multilayer-extrusion molding method, the resin layer (A) being made by dispersing uniformly 0 to 50 parts by weight of rubber-like polymer into 100 parts by weight of a methyl methacrylate resin, and the resin layer (B) being made by dispersing uniformly 1 to 50 parts by weight of an insoluble methyl methacrylate resin particle having a weight-average particles size of 1 to 100 um into 100 parts by weight of a base resin comprising 100 parts by weight of a methyl methacrylate resin and 0 to 70 parts by weight of rubber-like polymer. The laminated extruded resin sheet of the present invention provides a molder article having smaller bias of thickness in secondary thermoforming.

Owner:SUMITOMO CHEM CO LTD

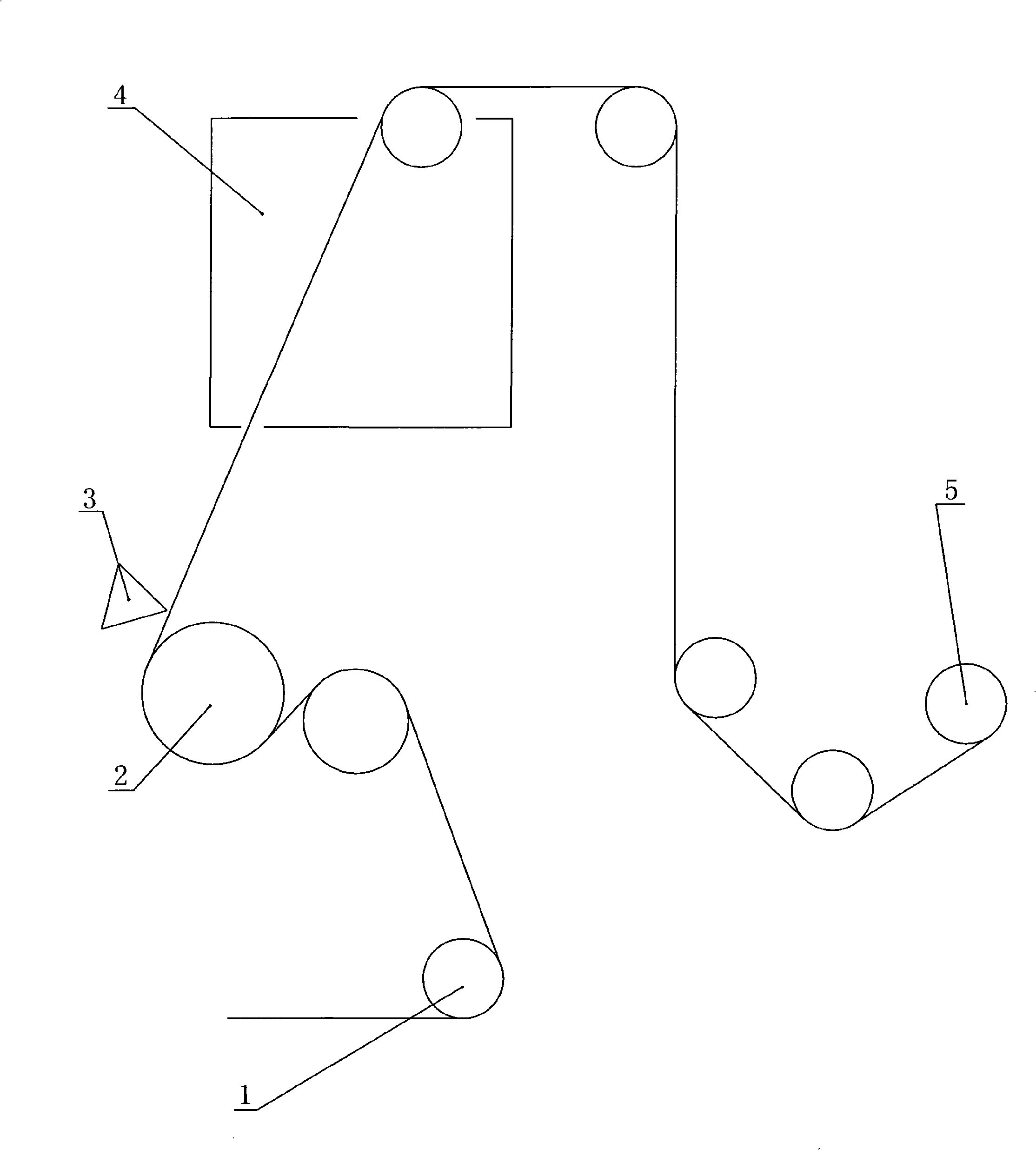

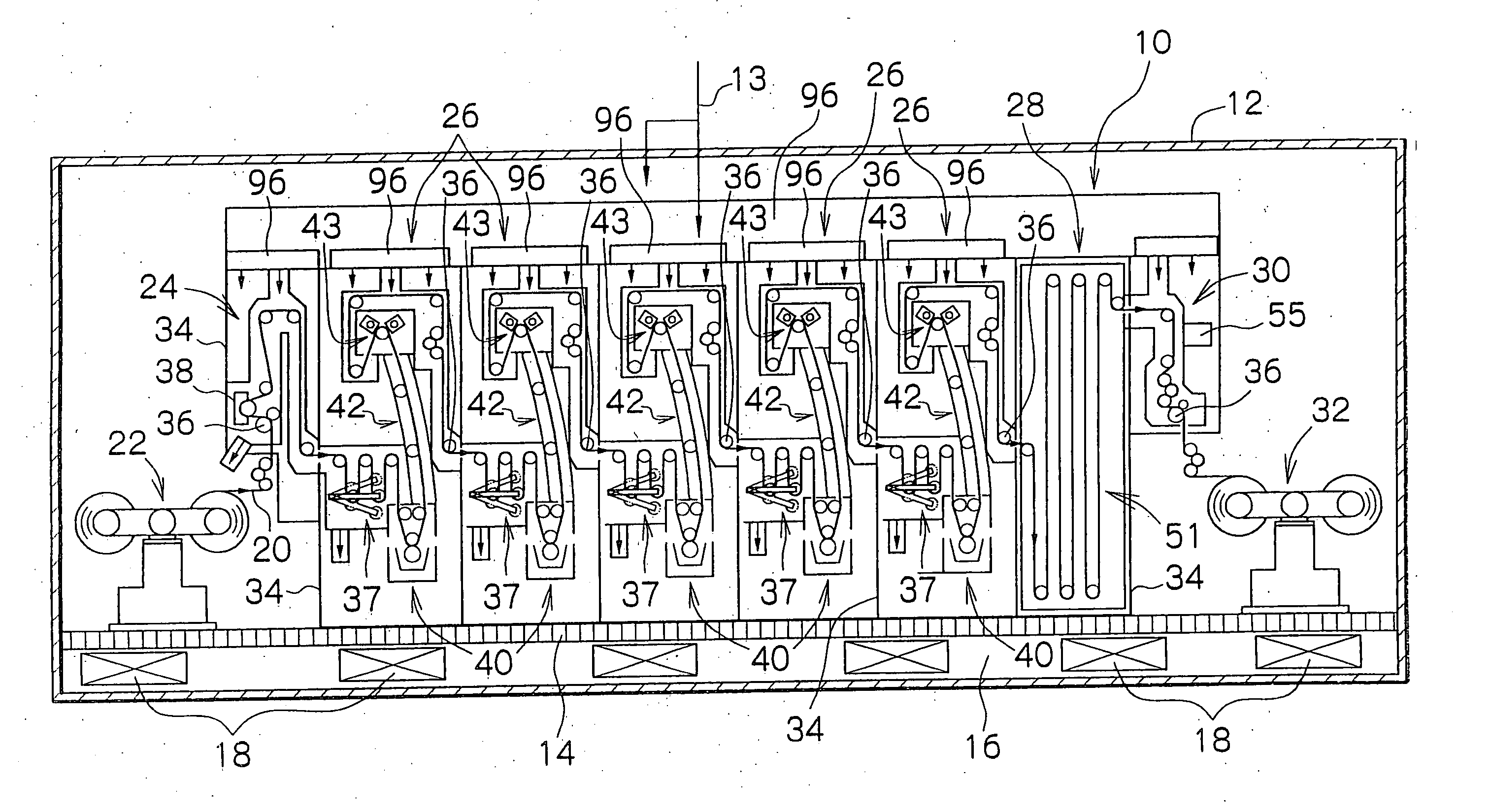

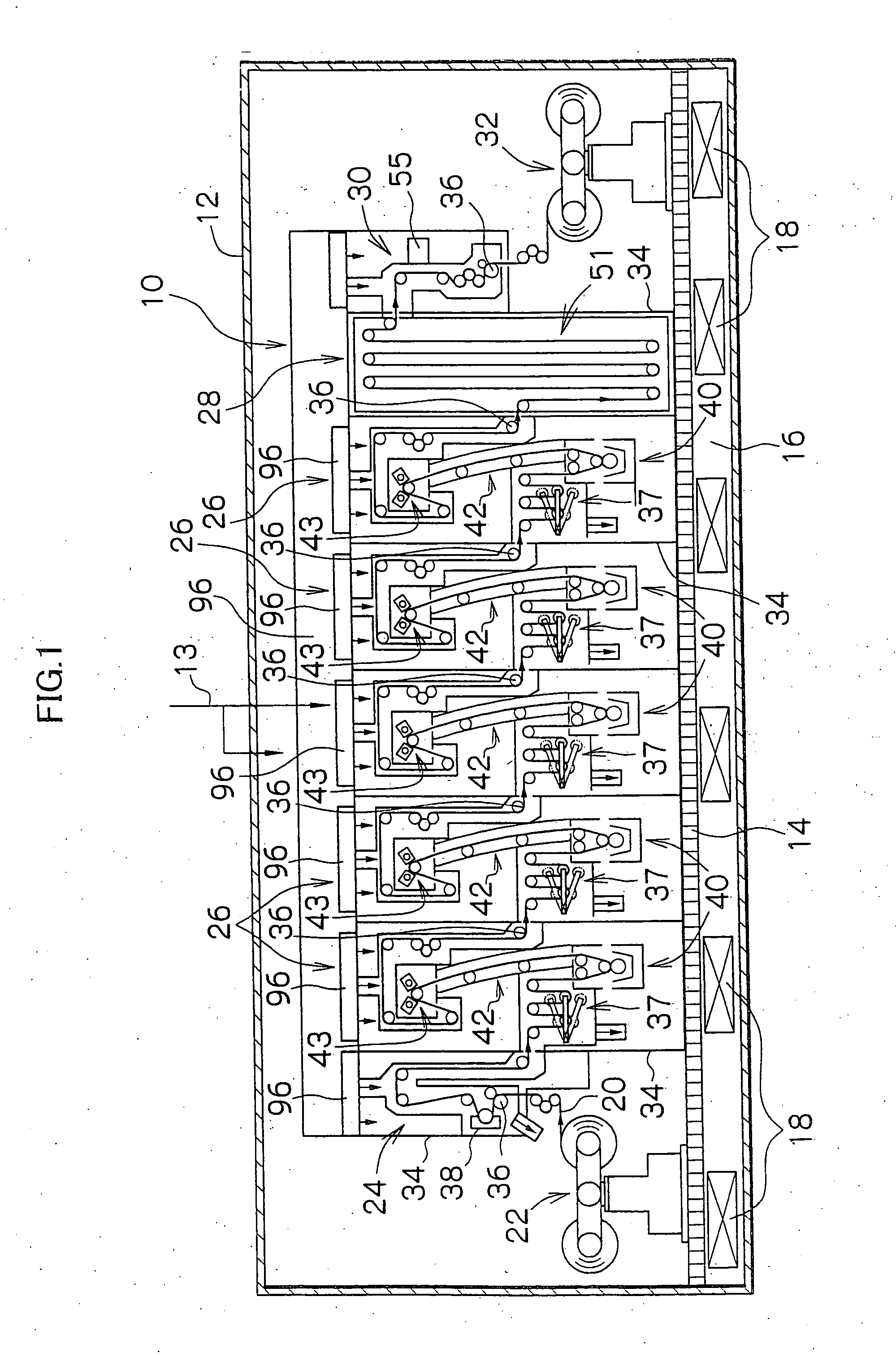

Production apparatus of multilayer coating film

InactiveUS7182813B2Easy constructionSmall thickness deviationLiquid surface applicatorsDrying machines with progressive movementsCoated surfaceEngineering

The coating construction has flexibility corresponding to the number of layers of multiple coating layers, by which a multilayer coating film can be produced with small film thickness without adherence of dust to a film surface, a drying fault such as unevenness induced by drying-wind on the film surface, or a coating fault such as a level variation and a streak. The multilayer coating film has a coating surface state of high quality with coating thickness deviation of 3% or less. A coating device is constructed in which at least a feed roller, a coater and a dryer are integrally incorporated in a casing, and the coating device is given a function as an independent device, whereby the production apparatus of the multilayer coating film can be constructed by only appropriately placing as many coating devices as the number corresponding to the number of layers of the multiple coating layers formed on a web between a delivery device and a winder.

Owner:FUJIFILM HLDG CORP +1

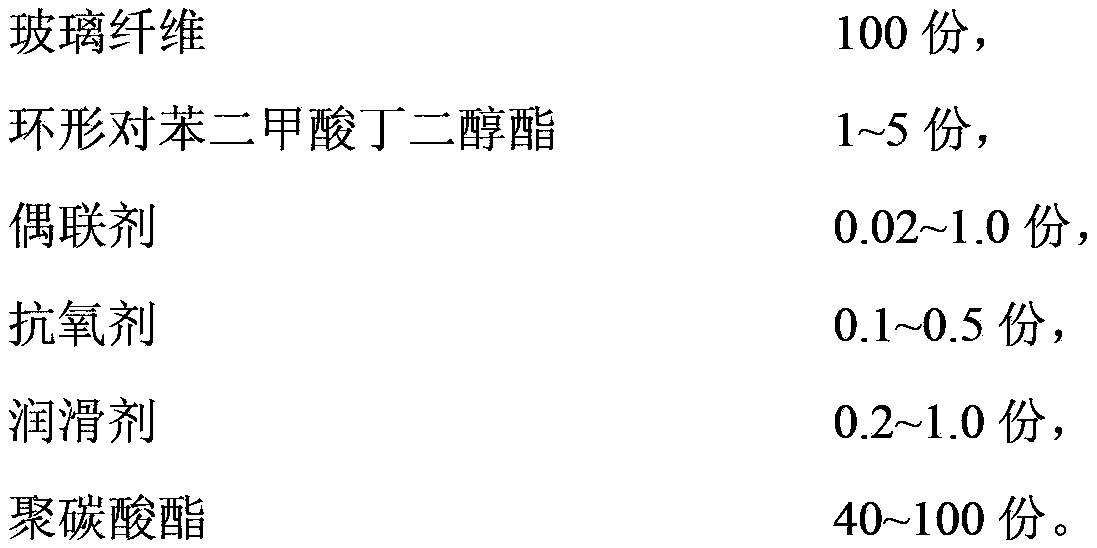

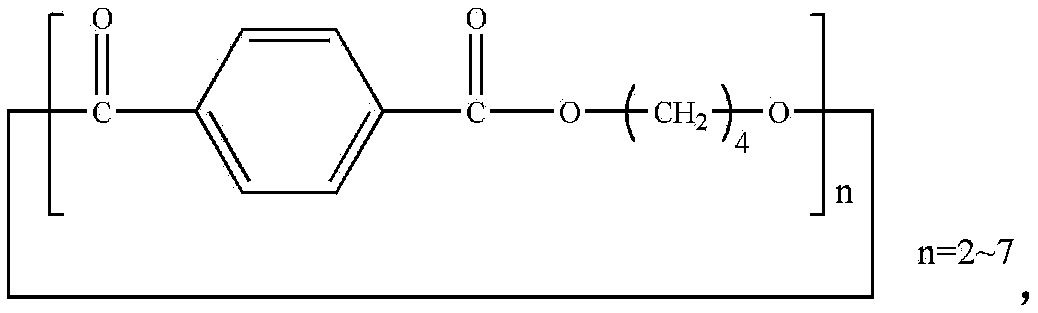

A continuous-glass-fibre-reinforced polycarbonate composite material and a preparing method thereof

The invention belongs to the technical field of polymer composite materials and relates to a continuous-glass-fibre-reinforced polycarbonate composite material and a preparing method thereof. The composite material is prepared from following components by weight: 100 parts of glass fibre, 1-5 parts of cyclic butylene terephthalate, 0.02-1.0 part of a coupling agent, 0.1-0.5 part of an antioxidant, 0.2-1.0 part of a lubricant and 40-100 parts of polycarbonate. The composite material has high strength and modulus. The composite material is mainly used for high-grade mobile phones, laptops, and other electronic products. In addition, a proper amount of the cyclic butylene terephthalate is added to blend and modify the polycarbonate, and the compatibility between the cyclic butylene terephthalate and the polycarbonate is good, and therefore the fluidity of the polycarbonate is largely improved only by an extremely little amount of addition of the cyclic butylene terephthalate and mechanical properties of the material are hardly influenced.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

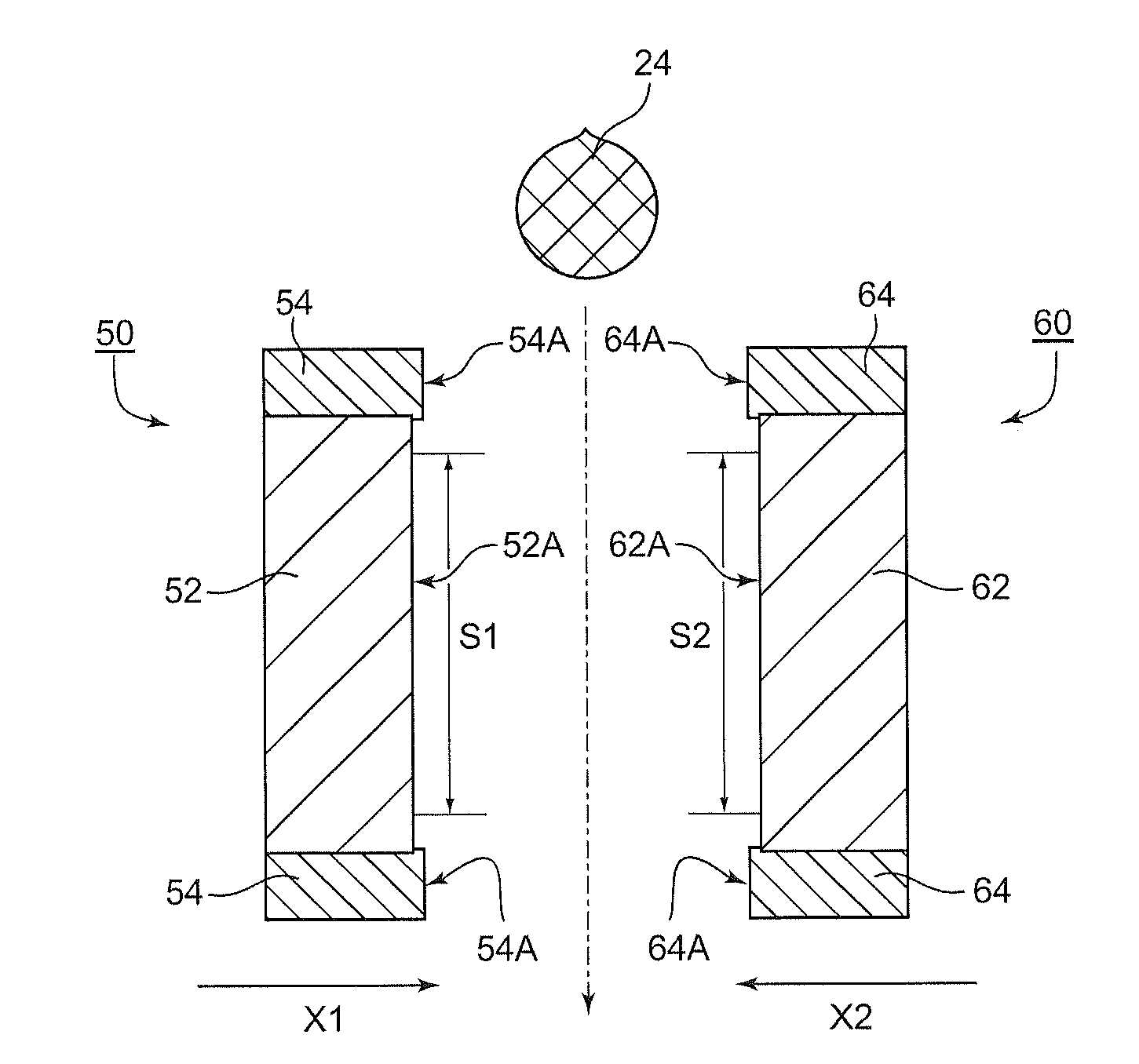

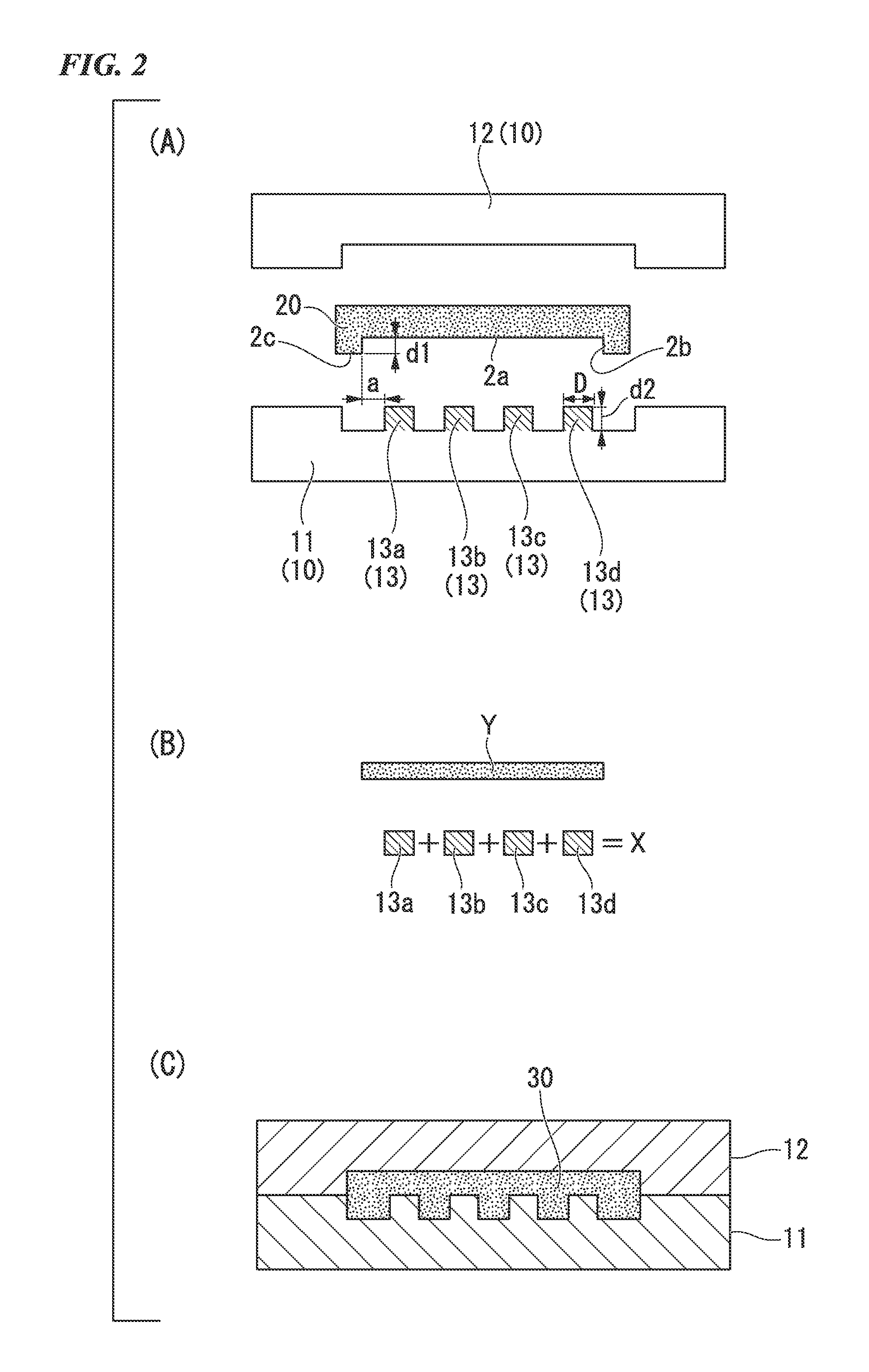

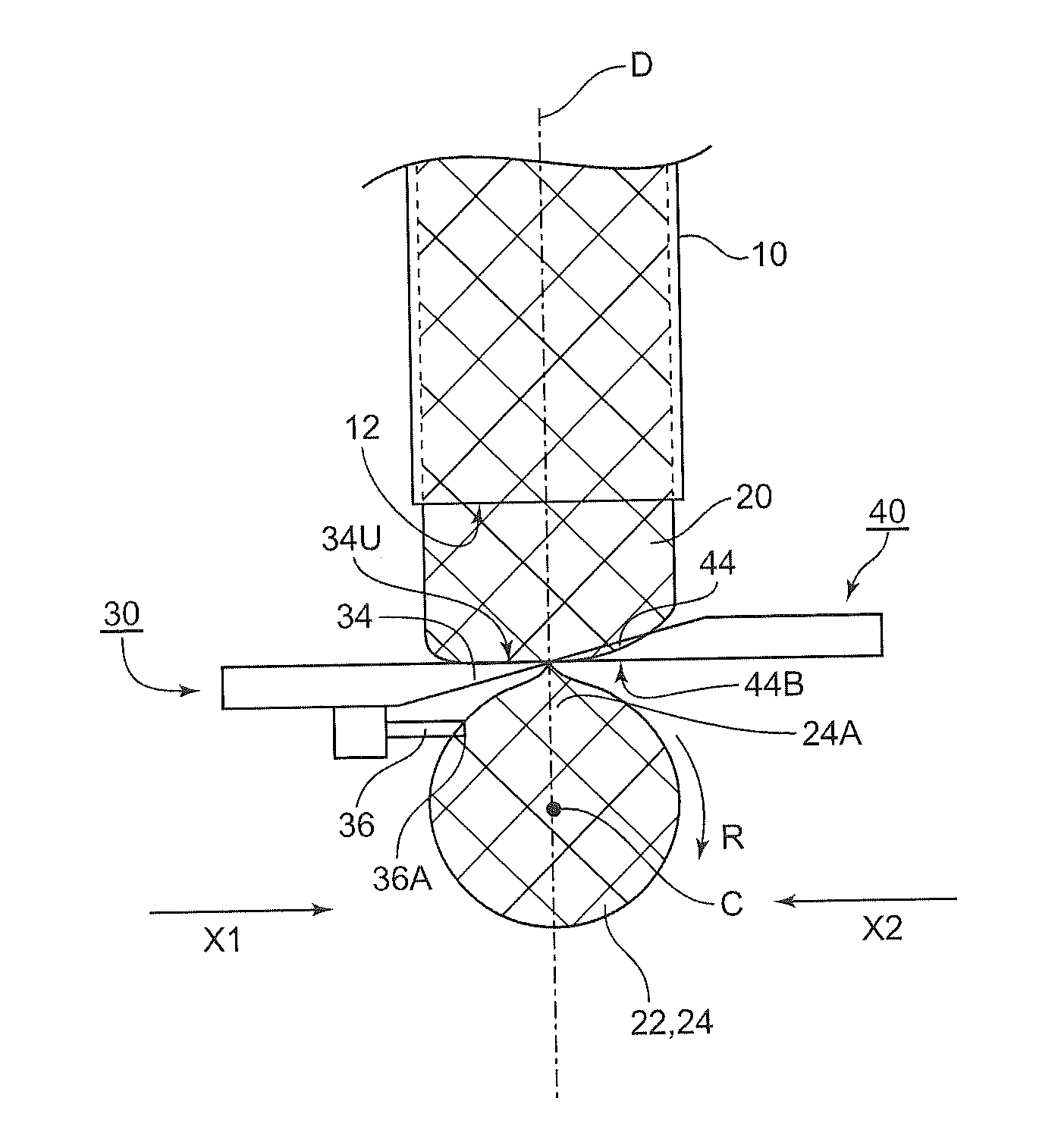

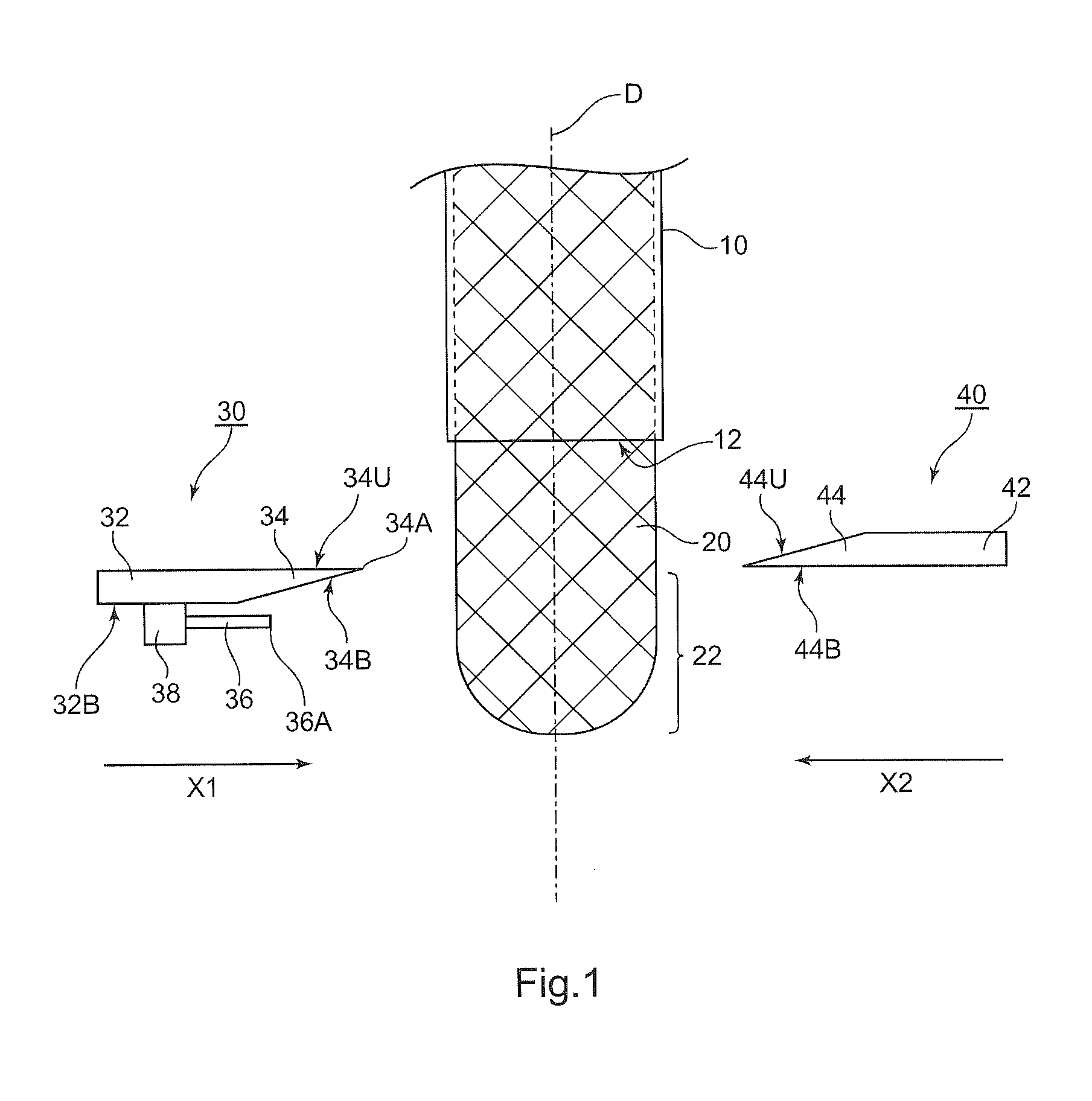

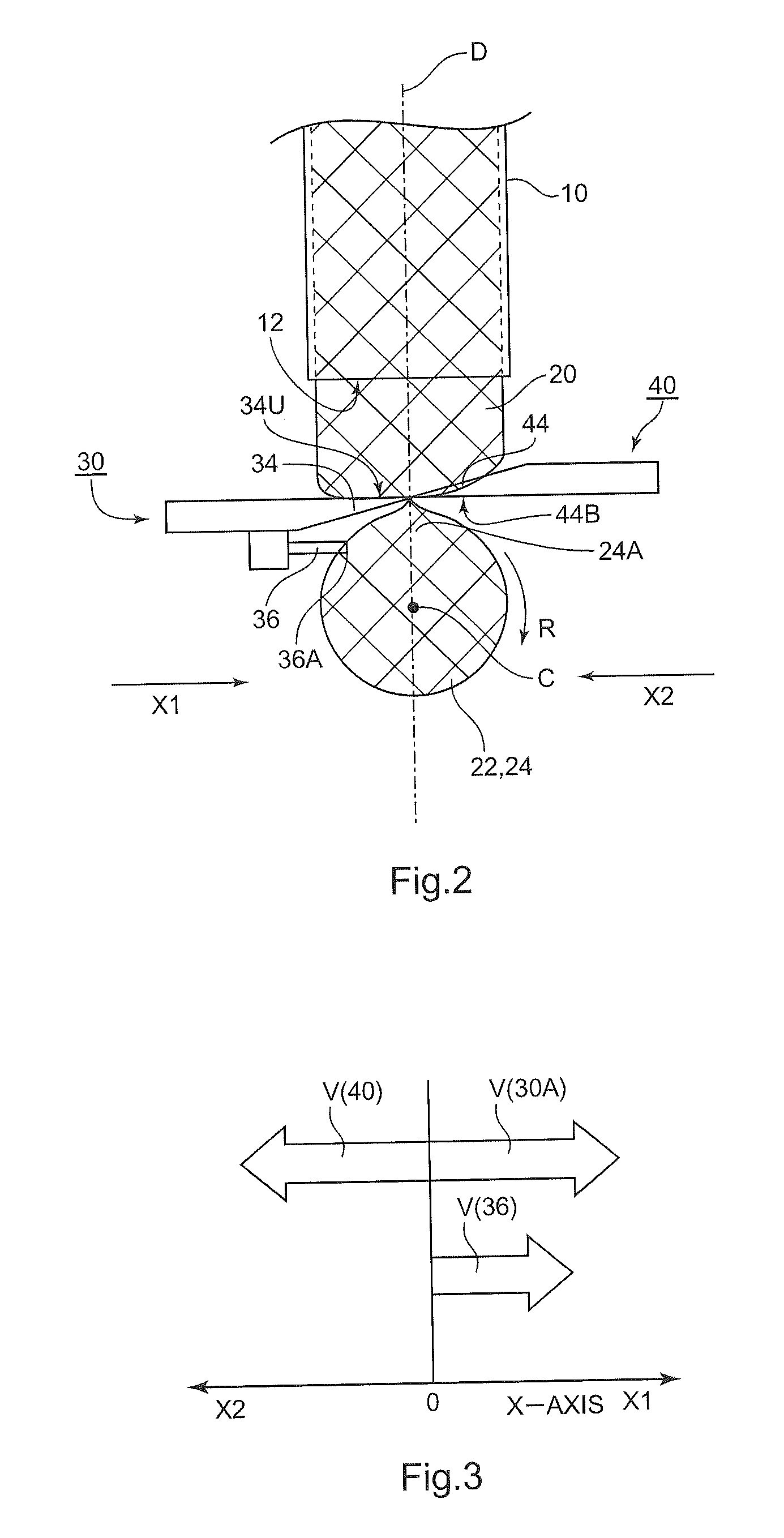

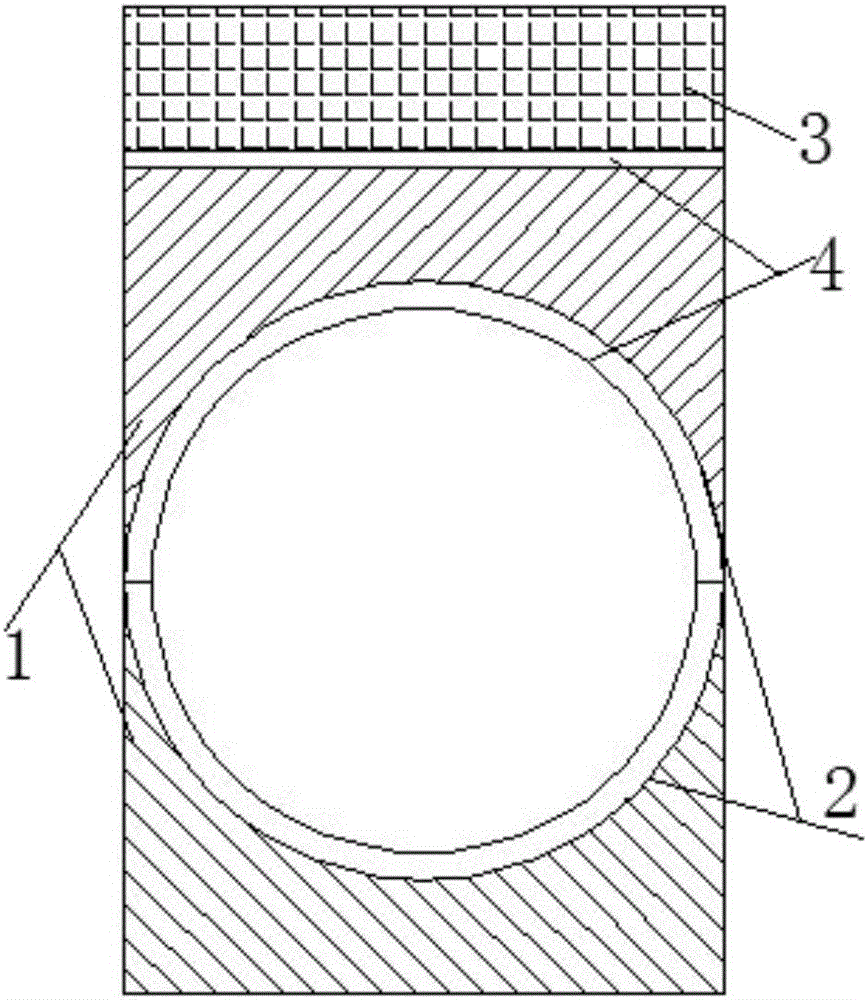

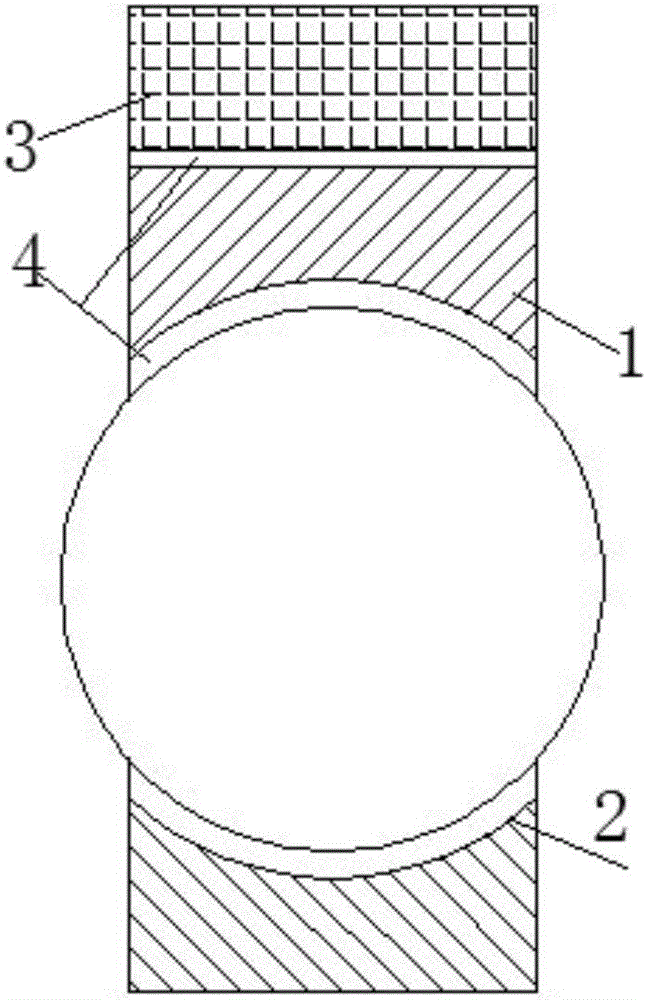

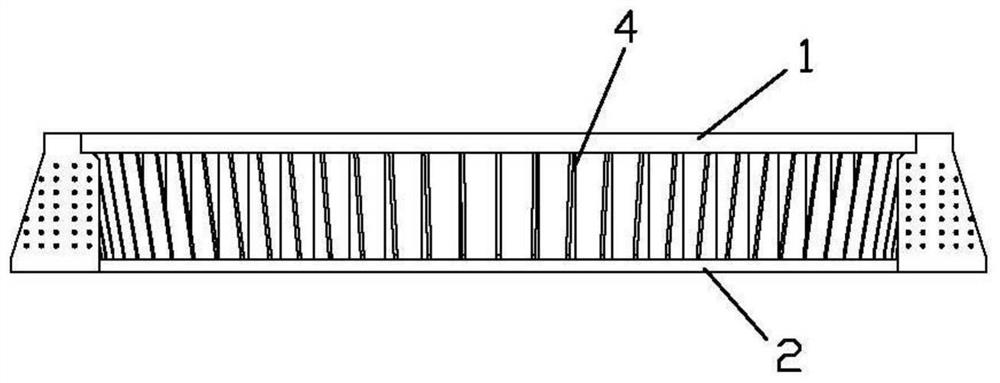

Sheet press molding method and method of producing fuel cell separator

InactiveUS20120018914A1Thin thicknessImprove conductivityFinal product manufactureDomestic articlesFuel cellsEngineering

Provided is a sheet press molding method that can create molded articles having low thickness deviation. In this method, a molded article (30) is formed by applying pressure to a sheet material (20) using a pair of dies (10), at least one of which has a prescribed recess-projection pattern (13) comprising recess and projection portions. The method includes: a sheet-forming process in which a recessed portion (2a) having volume equal to the total volume of the projection is formed in the surface of the sheet material (20), which includes a resin composite and 60-95% filler by volume; and a pressing process wherein the recessed portion (2a) in the sheet material (20) is placed facing the recess-projection pattern (13) on the dies (10) and pressure is applied to the dies (10), thereby forming a molded article (30) to which the recess-projection pattern (13) is transferred.

Owner:SHOWA DENKO KK

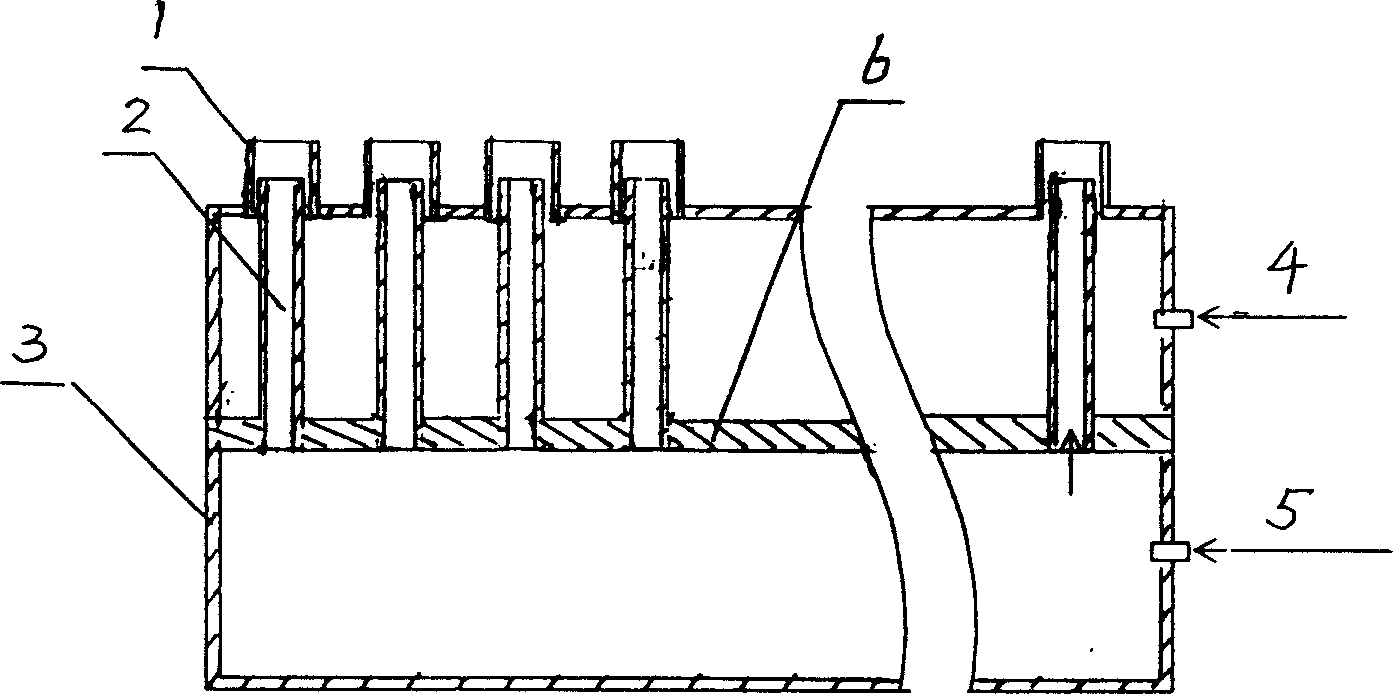

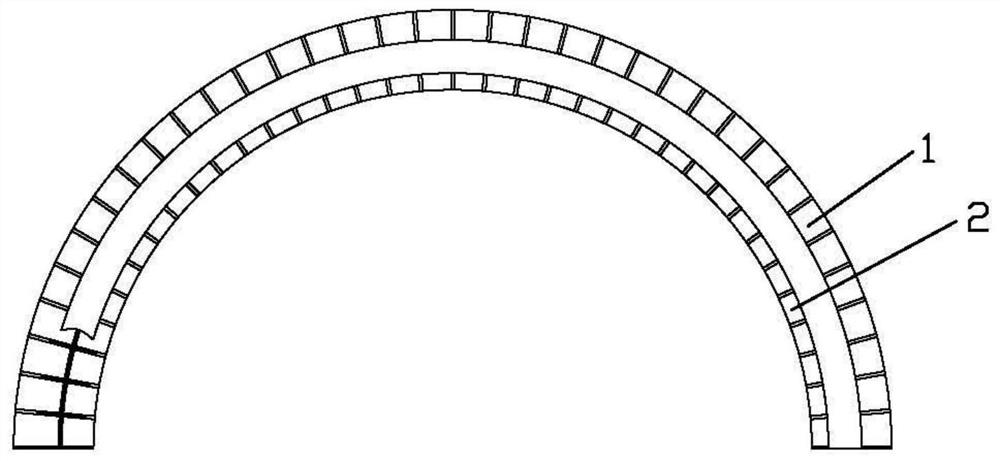

A heating furnace used for drawing willow glass by secondary melting method

ActiveCN104310766APlay a homogenizing roleSmall thickness deviationGlass reforming apparatusHeating furnaceDirect radiation

A heating furnace used for drawing willow glass by a secondary melting method is provided. The heating furnace comprises a furnace body having a rectangular cross section and heating devices disposed in the furnace body. The middle of the furnace body is provided with a heating path along the width direction. The heating furnace is characterized in that: the heating devices are divided into a high temperature zone and an annealing zone from top to bottom; the high temperature zone and the annealing zone are separated by a light thermal-insulating thin plate; the temperature of each zone can be controlled individually according to needs; heat homogenizing plates have functions of homogenizing heat distribution, allow temperature distribution in the heating path to be more uniform than temperature distribution by adoption of direct radiation heating with heating rods, and allow temperature fluctuations to be smaller; the willow glass having a thickness of 0.03-0.2 mm, a width of 20-2000 mm and a length longer than 5 m and having good flexibility can be drawn; and the willow glass is low in thickness deviation and good in flatness.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

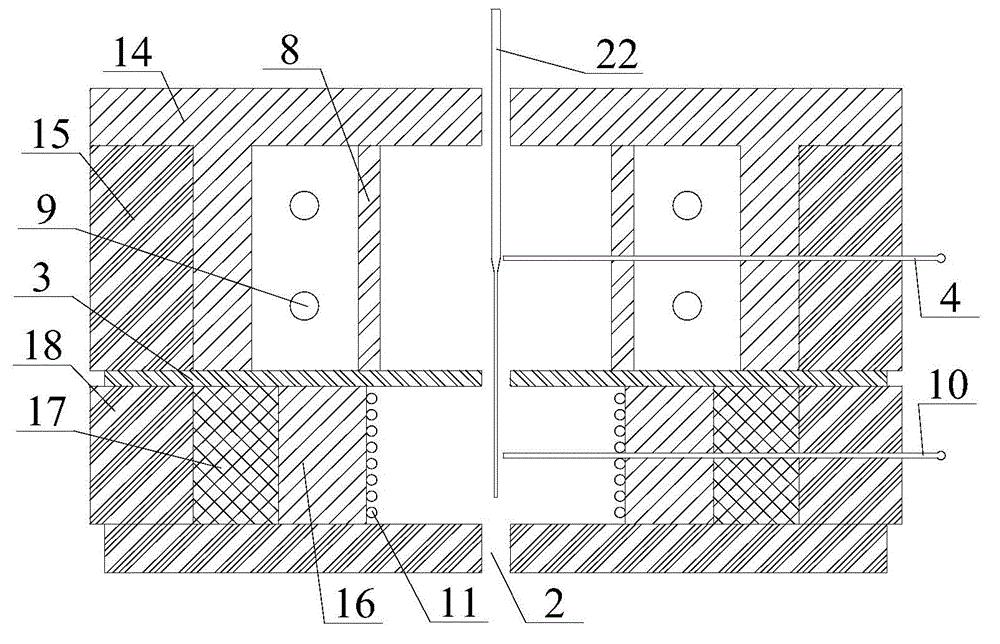

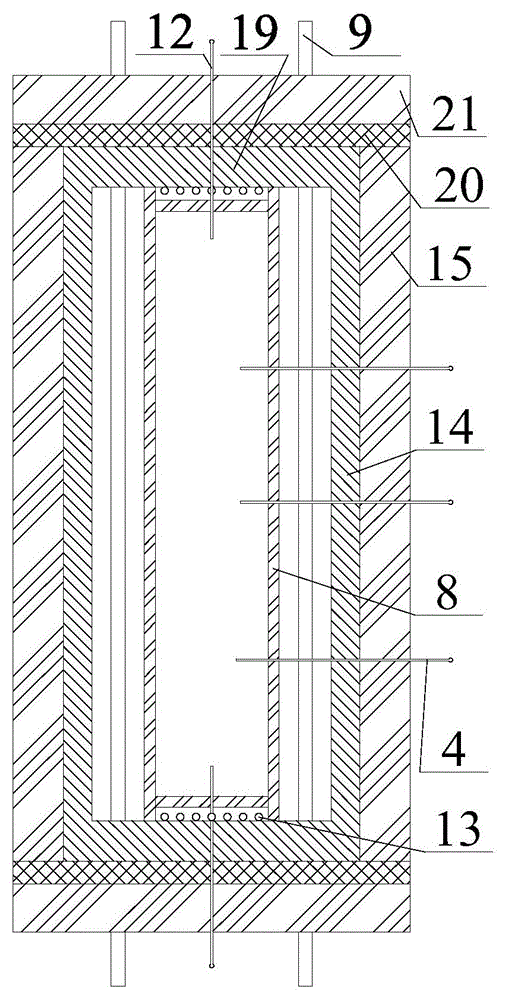

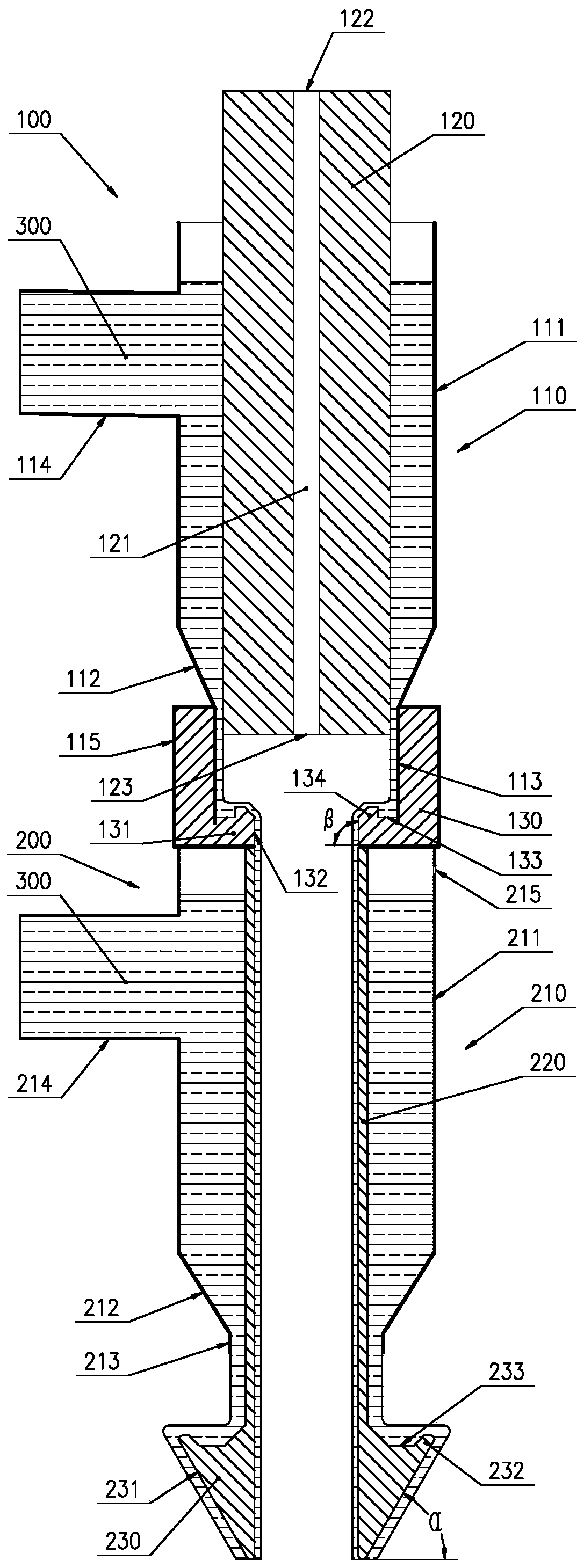

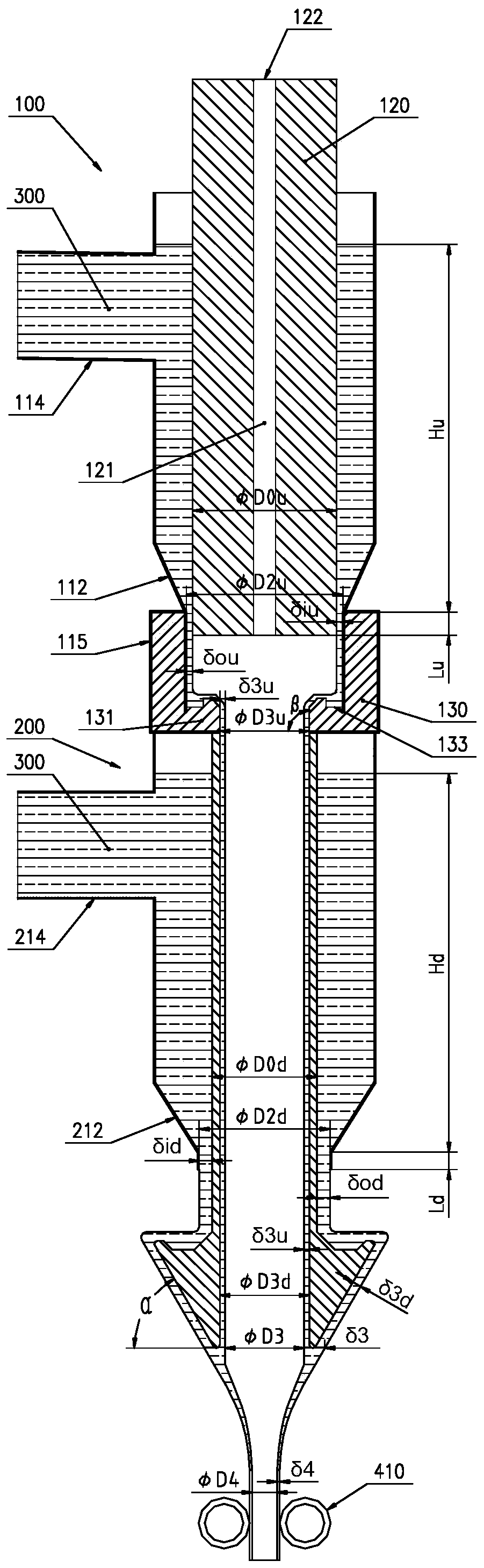

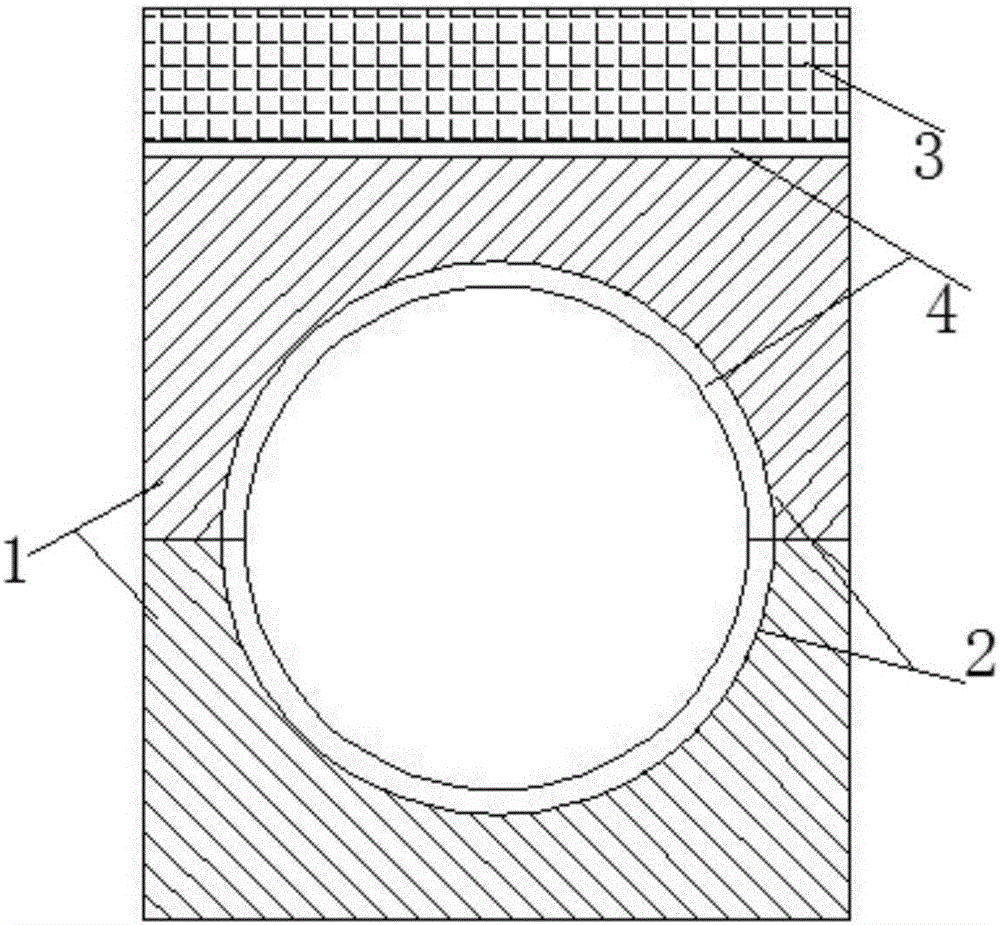

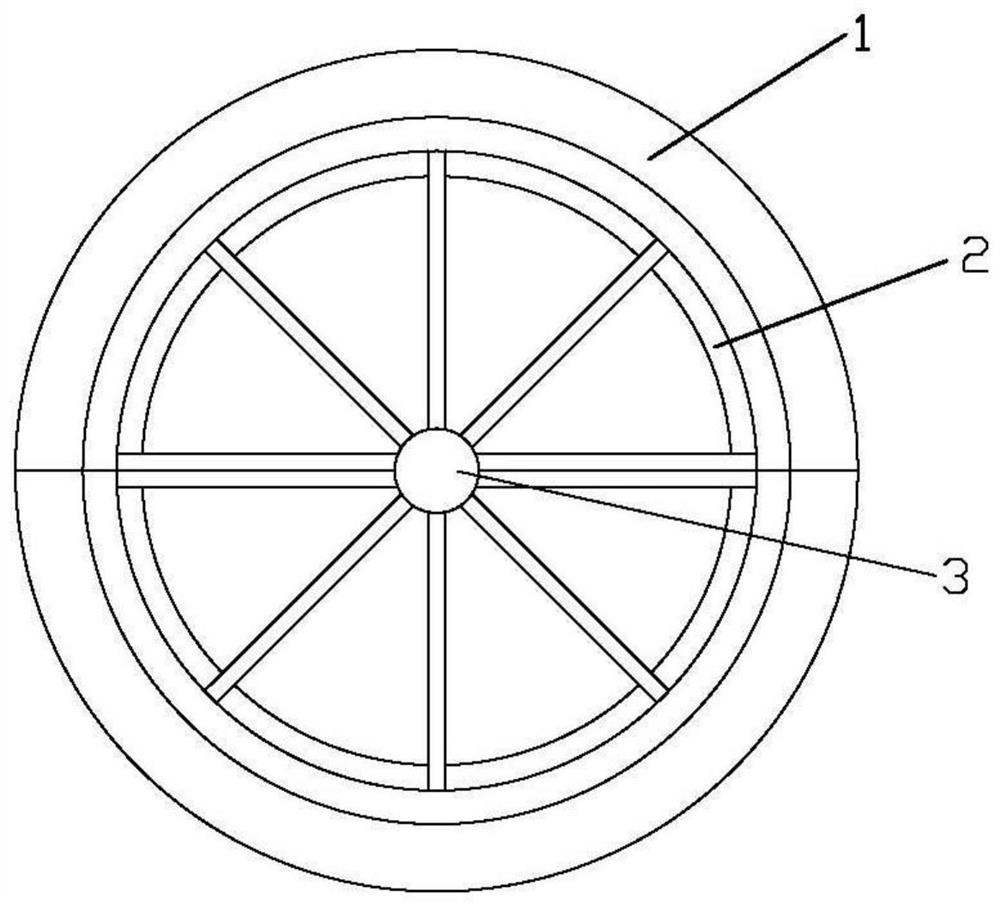

Equipment for inner overflow and outer overflow down-draw molding of glass pipe, and design method thereof

ActiveCN110255865AEvenly distributedImprove internal and external surface qualityGlass forming apparatusDesign optimisation/simulationEngineeringMaterial supply

The invention belongs to the technical field of glass pipe manufacturing, and particularly discloses equipment for inner overflow and outer overflow down-draw molding of a glass pipe, and a design method thereof. A purpose of the present invention is to solve the problem of how to produce a glass pipe with excellent surface quality and small thickness deviation. The equipment comprises an inner overflow device and an outer overflow device, wherein the inner overflow device comprises a first annular material supply barrel, a cylindrical core part and an inner overflow disc, and the outer overflow device comprises a second annular material supply barrel, a cylindrical core part and an outer overflow disc. According to the present invention, the flow rate of the glass liquid outflowing from the outlet can be uniformly distributed through the first narrow channel formed in the inner overflow device, the overflow is performed by using the inner overflow disc, the flow rate of the glass liquid outflowing from the outlet can be uniformly distributed through the second narrow channel formed in the outer overflow device, and the glass liquid is subjected to overflow by using the outer overflow disc, such that the good surface characteristic is formed so as to mold the glass pipe with excellent inner and outer surface quality and small thickness deviation.

Owner:CDGM OPTICAL GLASS

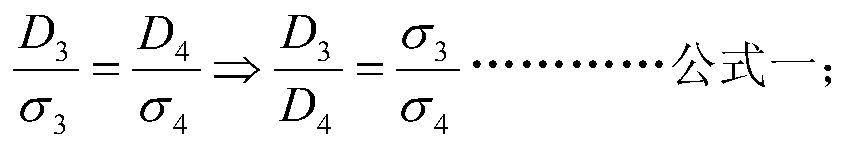

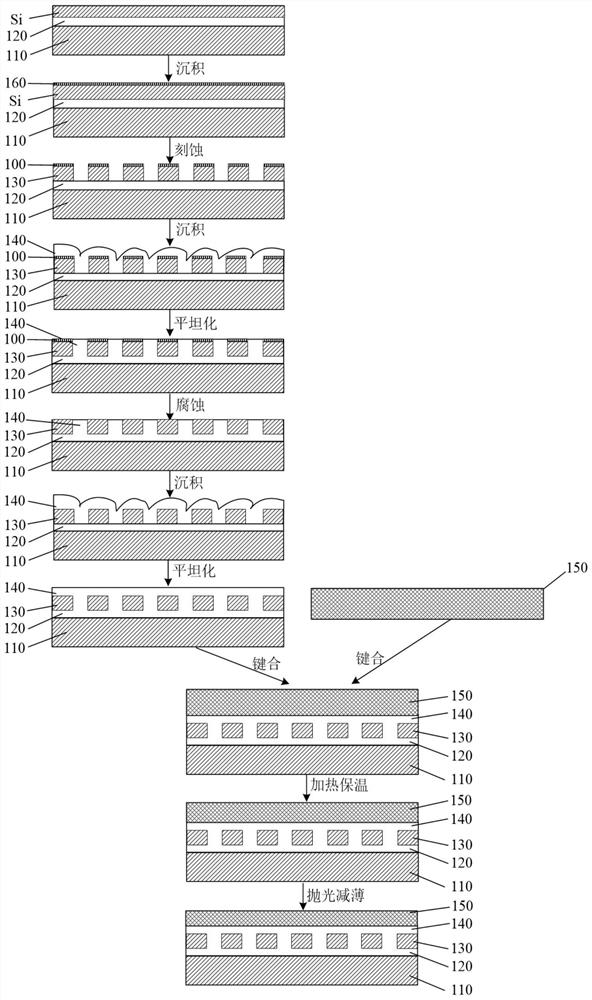

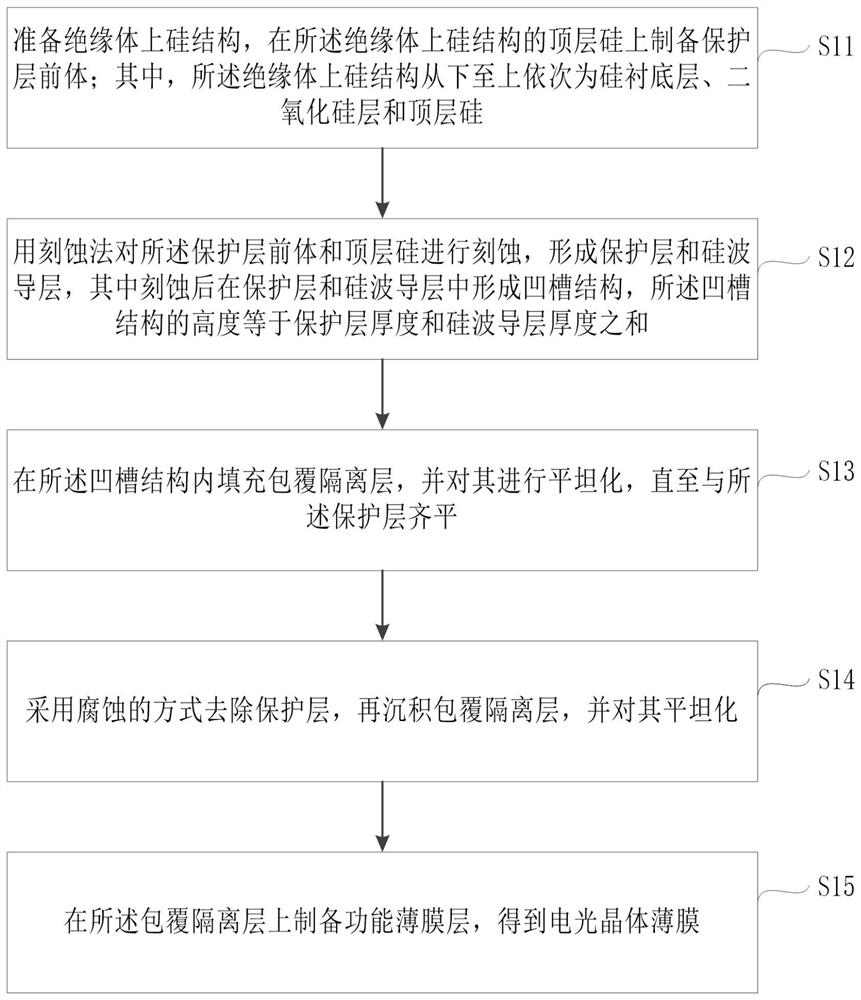

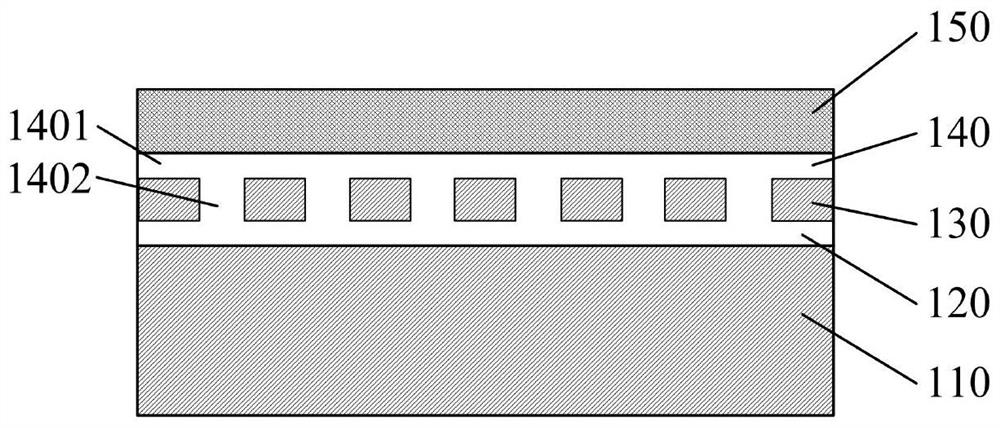

Preparation method of electro-optical crystal film, electro-optical crystal film and electro-optical modulator

PendingCN111965857AImprove consistencyReduce lossOptical light guidesNon-linear opticsIsolation layerThin membrane

The invention provides a preparation method of an electro-optical crystal thin film, the electro-optical crystal thin film and an electro-optical modulator, and the preparation method of the electro-optical crystal thin film comprises the following steps: preparing a silicon-on-insulator structure, and preparing a protective layer precursor on top silicon of the silicon-on-insulator structure; etching the protective layer precursor and the top silicon layer by using an etching method to form a protective layer and a silicon waveguide layer, forming a groove structure in the protective layer and the silicon waveguide layer after etching, and enabling the height of the groove structure to be equal to the sum of the thickness of the protective layer and the thickness of the silicon waveguidelayer; filling and coating an isolation layer in the groove structure, and flattening the isolation layer until the isolation layer is flush with the protection layer; removing the protective layer ina corrosion manner, depositing and coating the isolation layer, and flattening the isolation layer; and finally, preparing a functional film layer on the coating isolation layer to obtain the electro-optic crystal film. By adopting the scheme, the silicon waveguide layer is protected by the protective layer, the thickness of the coated isolation layer is controllable, the surface is smooth, the coated isolation layer is bonded with the functional film layer, and the propagation of optical signals is not influenced.

Owner:JINAN JINGZHENG ELECTRONICS

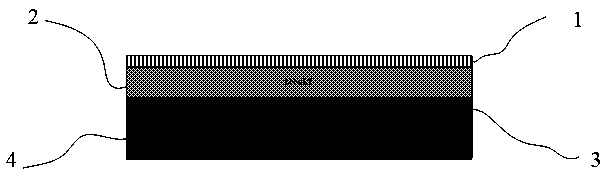

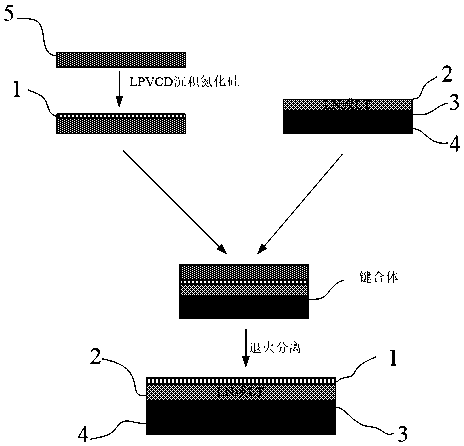

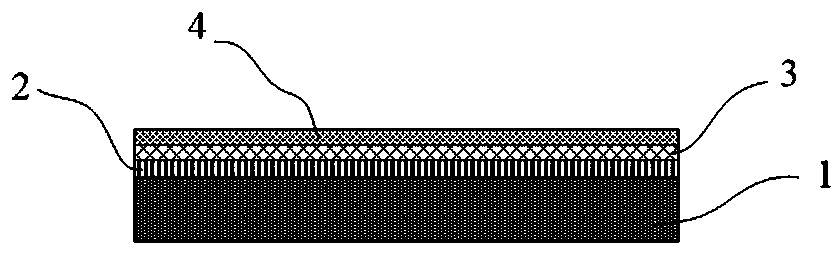

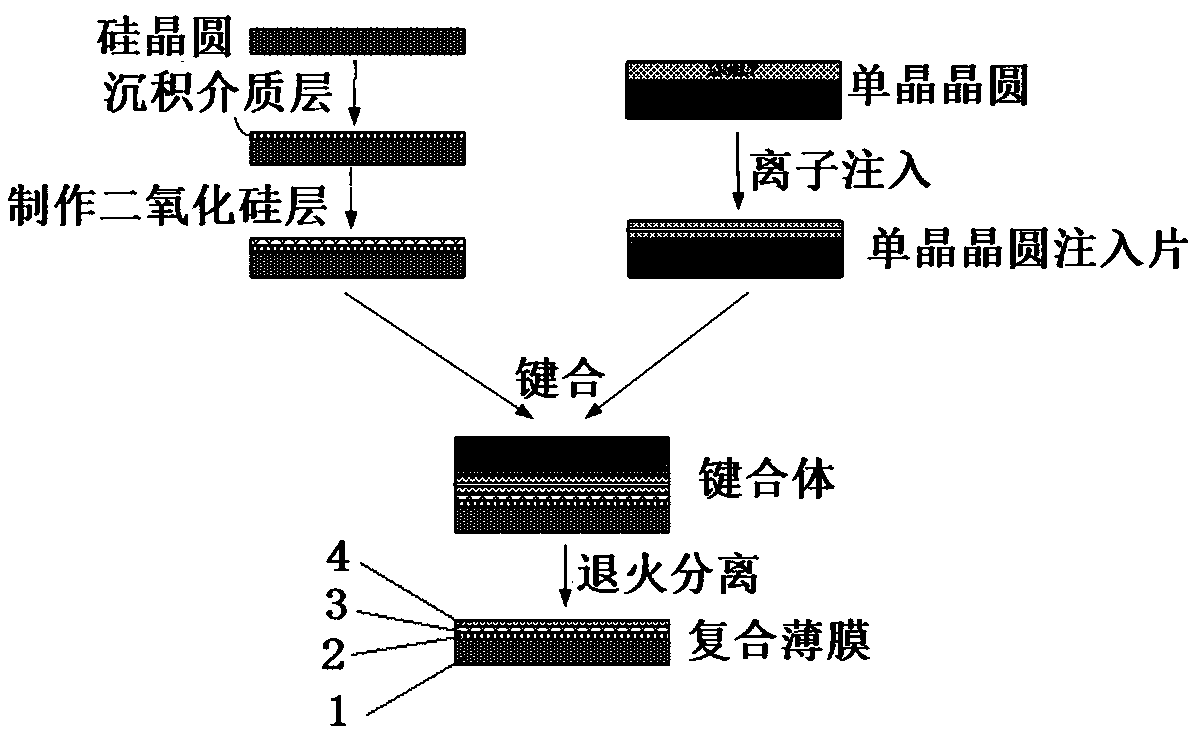

Single crystal film with silicon nitride layer and preparation method thereof

ActiveCN110618488AImprove insulation performanceMeet performance requirementsOptical waveguide light guideSilicon oxideSingle crystal

The present invention discloses a single crystal film with a silicon nitride layer and a preparation method thereof. The single crystal film with the silicon nitride layer comprises a silicon nitridelayer, a lithium niobate film layer, a silicon oxide layer and a silicon substrate layer from top to bottom. The single crystal film with the silicon nitride layer of the invention has better compatibility with the lithium niobate film, high mode limitation, low propagation loss and high power processing capacity as an optical waveguide transmission layer since silicon nitride has a good insulation effect and a wide optical transmission window. With the preparation method of the single crystal film with the silicon nitride layer in the invention, the silicon nitride waveguide is prepared by LPVCD deposition and integrated with a lithium niobate modulator, and a waveguide device with high integration level, wide bandwidth and low loss can be obtained. The preparation method of the inventionis suitable for industrial production and has a high yield.

Owner:JINAN JINGZHENG ELECTRONICS

Method for manufacturing glass blank, method for manufacturing magnetic recording medium substrate and method for manufacturing magnetic recording medium

InactiveUS20110283739A1Small thickness deviationImprove flatnessGlass drawing apparatusGlass forming apparatusMolten glassRecording media

Provided are a method of manufacturing a glass blank, the method including press-molding a molten glass gob under a state in which a separation mark formed on an upper surface of the molten glass gob faces at least one of the molding surface sides of a pair of press molds arranged facing each other in a horizontal direction, when the molten glass gob falls into a space between the pair of press molds, and a method of manufacturing a magnetic recording medium substrate and a method of manufacturing a magnetic recording medium, both using the glass blank.

Owner:HOYA CORP

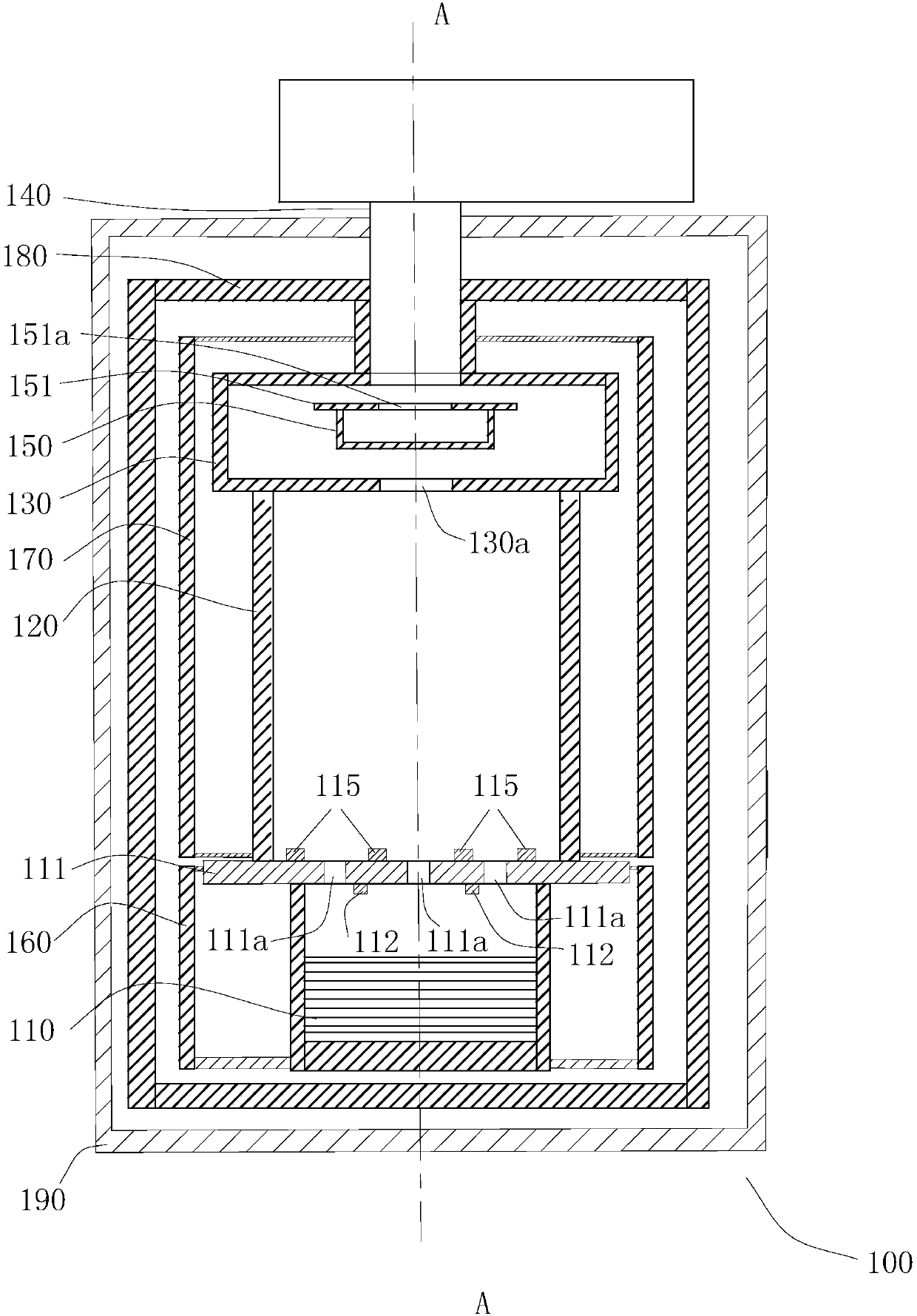

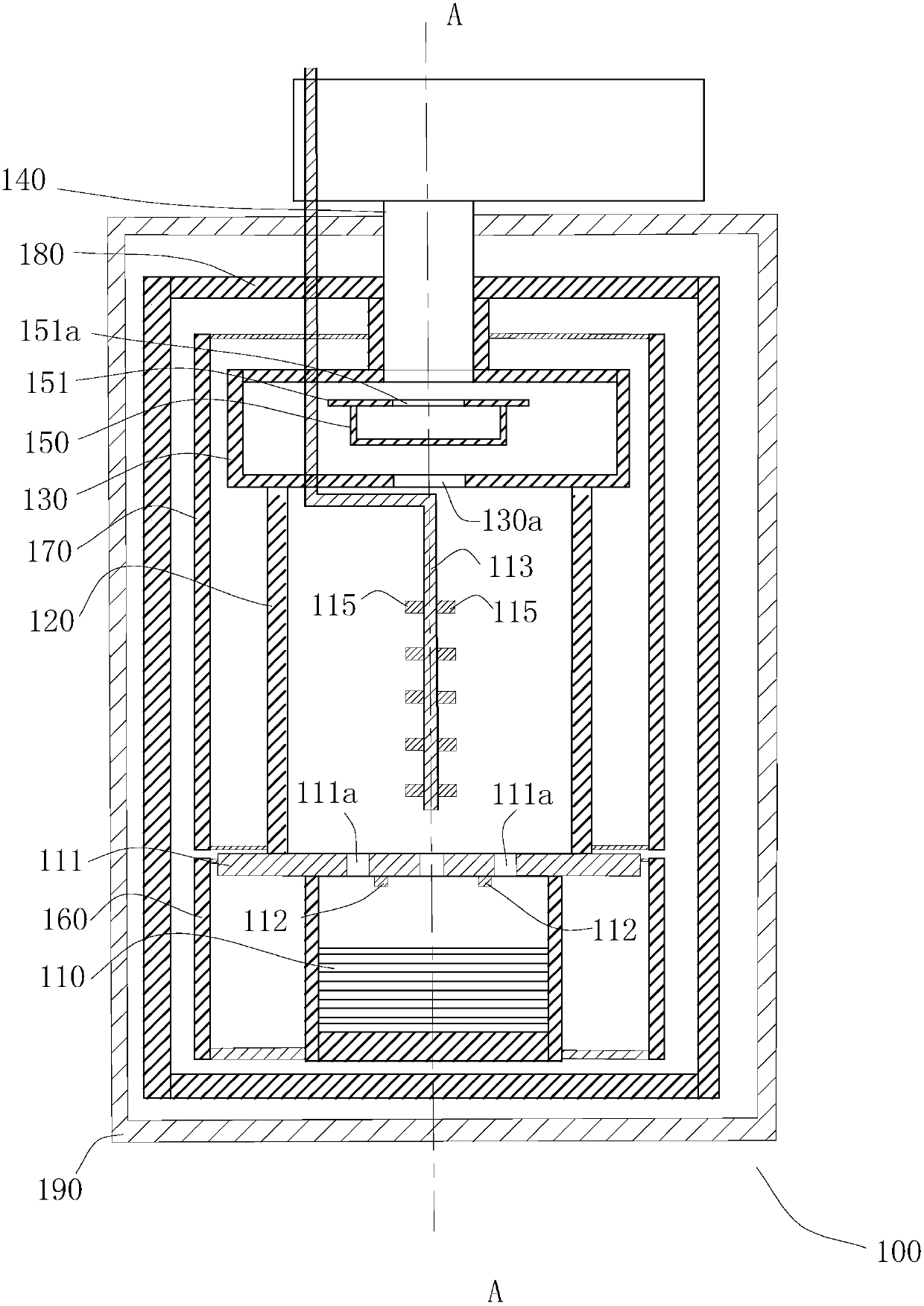

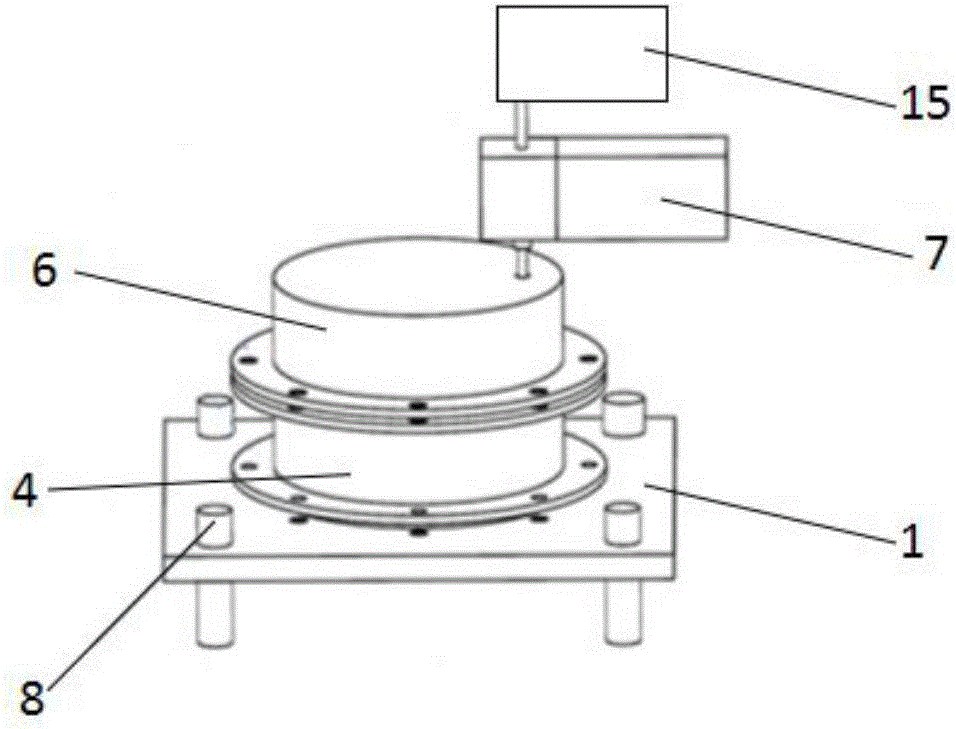

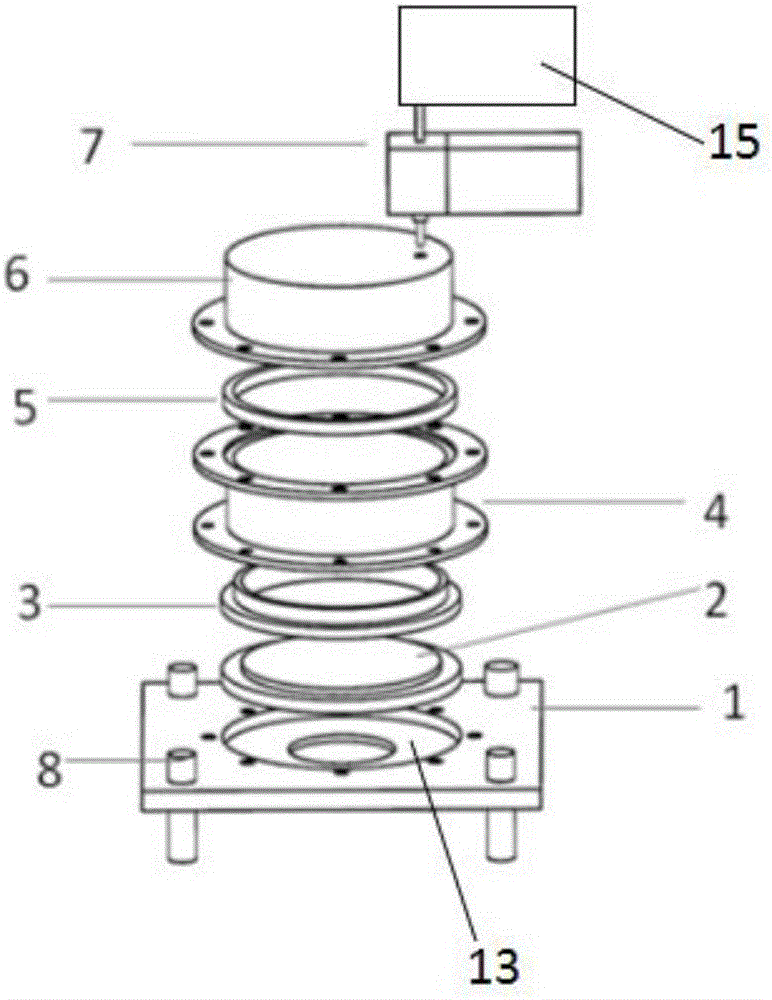

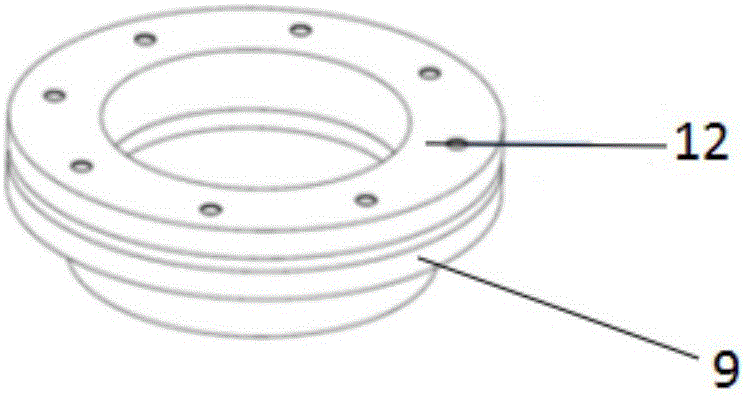

Chemical vapor deposition furnace

ActiveCN107604340ASmall thickness deviationReasonable structureFinal product manufactureChemical vapor deposition coatingCrucibleChemical vapor deposition

The invention relates to a chemical vapor deposition furnace. The chemical vapor deposition furnace comprises a crucible used for containing raw materials, a crucible cover used in cooperation with the crucible, a deposition chamber, a material collecting box and a gas guide tube, wherein the crucible, the crucible cover, the deposition chamber, the material collecting box and the gas guide tube are assembled from bottom to top; a plurality of first through holes making the crucible and the deposition chamber communicate are formed in the crucible cover, and a second through hole making the deposition chamber and the material collecting box communicate is formed in the material collecting box; and the chemical vapor deposition furnace further comprises a first heater used for heating the crucible, a dust collecting chamber and a dust collecting chamber cover plate covering the dust collecting chamber are arranged inside the material collecting box, and a third through hole making the dust collecting chamber and the material collecting box communicate is formed in the dust collecting chamber cover plate. The chemical vapor deposition furnace is reasonable in structure, multi-stage collection is carried out on zinc sulfide products, defects such as fog spots, fog layers and patterns do not exist in the prepared zinc sulfide, the overall thickness deviation of the zinc sulfide products is small, and the product conversion rate is high.

Owner:安徽光智科技有限公司

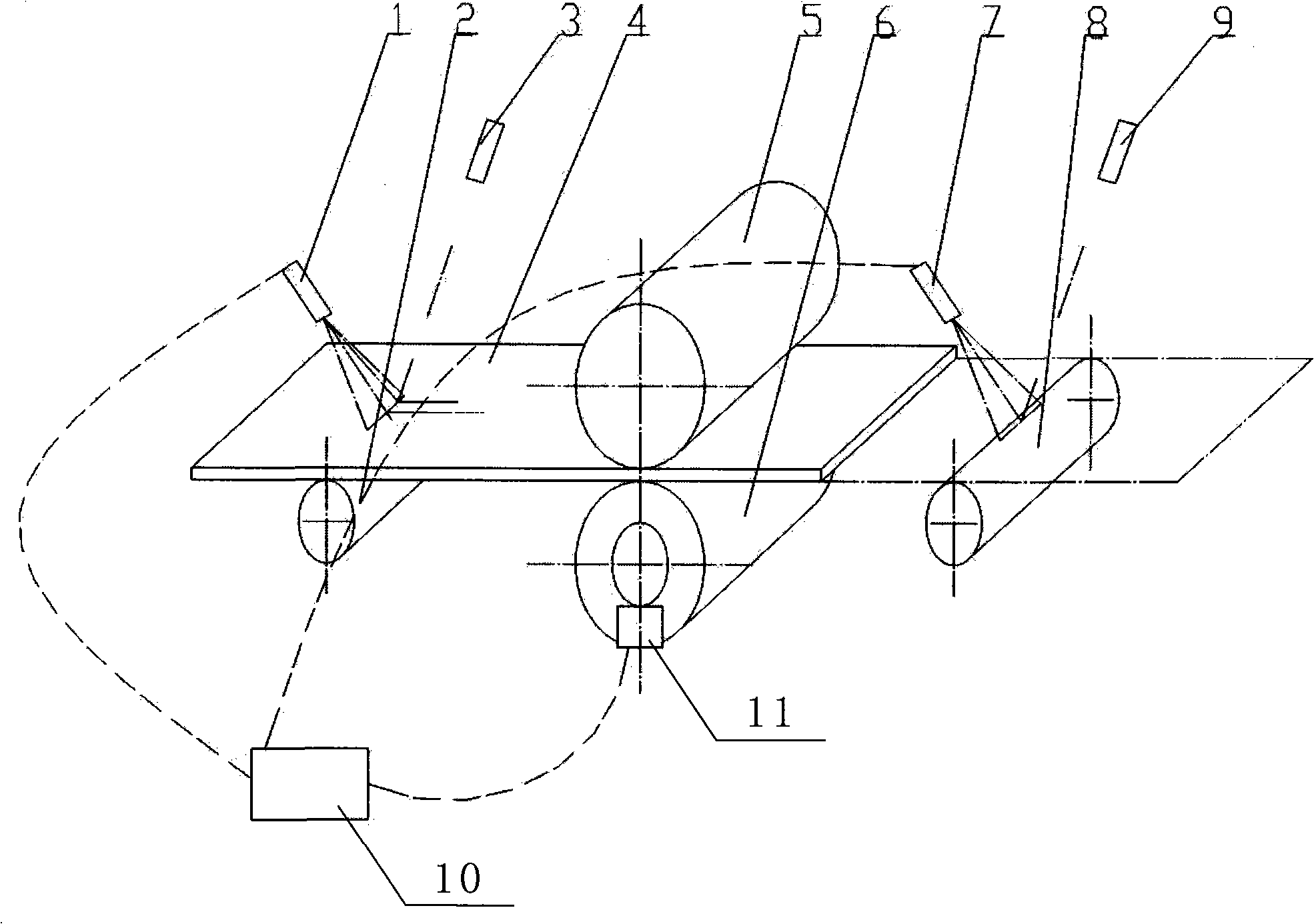

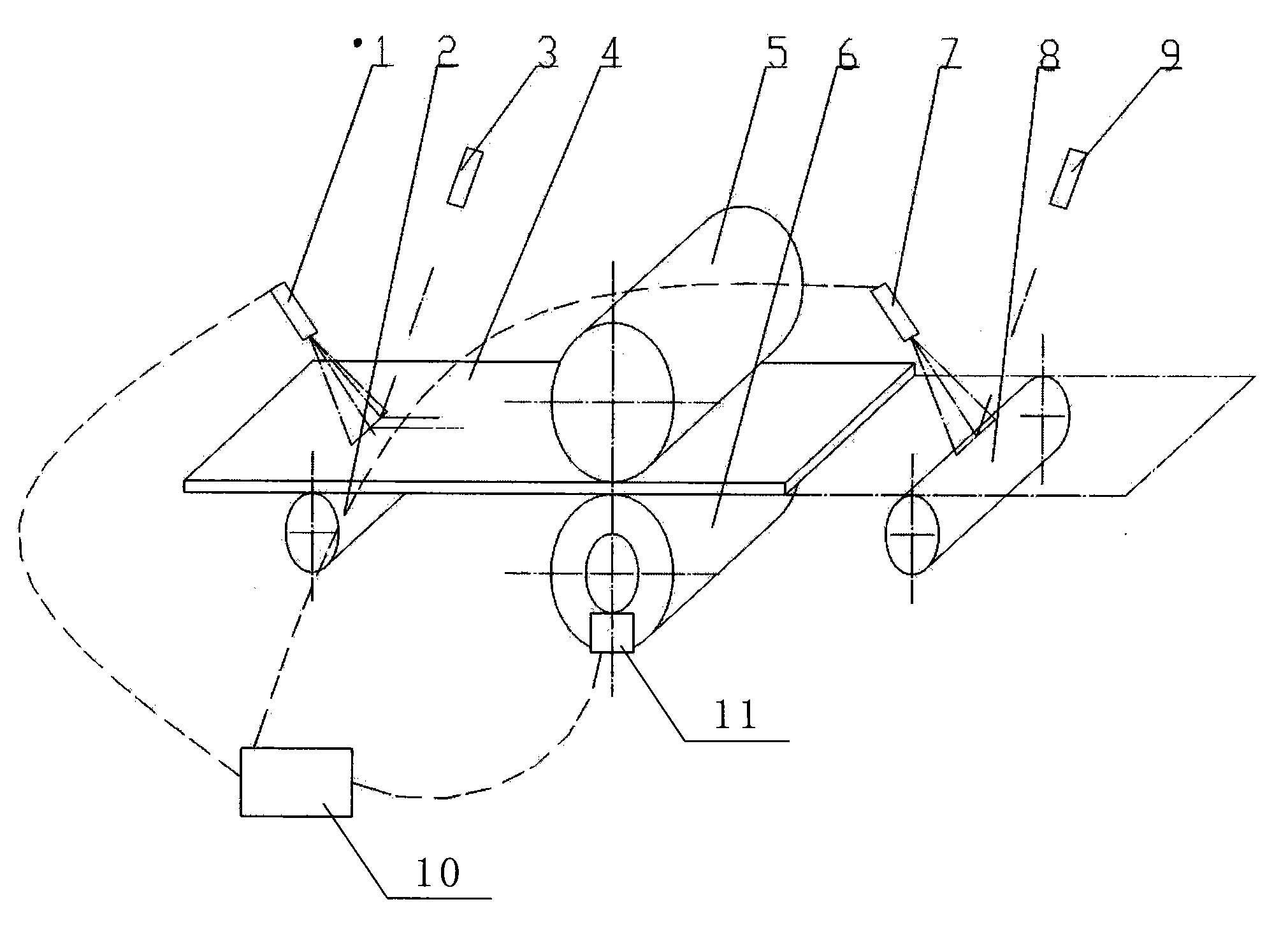

Semiconductor monocrystalline silicon multi-wire cutting clamping device and method

InactiveCN106079126AReduced slice thickness variationSolve the uneven thickness of silicon waferWorking accessoriesFine working devicesWire cuttingSlice thickness

The invention discloses a semiconductor monocrystalline silicon multi-wire cutting clamping device. The device comprises a set of clamping plates. Each clamping plate is provided with an arc-shaped groove. The surface of each groove is provided with adhesives. A fixture is connected to any one clamping plate through the adhesives and located at the end, away from the groove, of the clamping plate. According to the semiconductor monocrystalline silicon multi-wire cutting clamping device, the shape of a monocrystalline silicon rod to be cut is changed by using the clamping plates; meanwhile, the difference between the impact state of mortar and the aggregation state of the mortar on side faces during cutting is changed, and the purpose that cutting states in all positions in the vertical direction are equivalent during cutting is achieved; and the thickness deviation of slices can be effectively reduced, the problem of uneven thicknesses of silicon slices is solved, and the device has good application value.

Owner:XIAN ZHONGJING SEMICON MATERIALS CO LTD

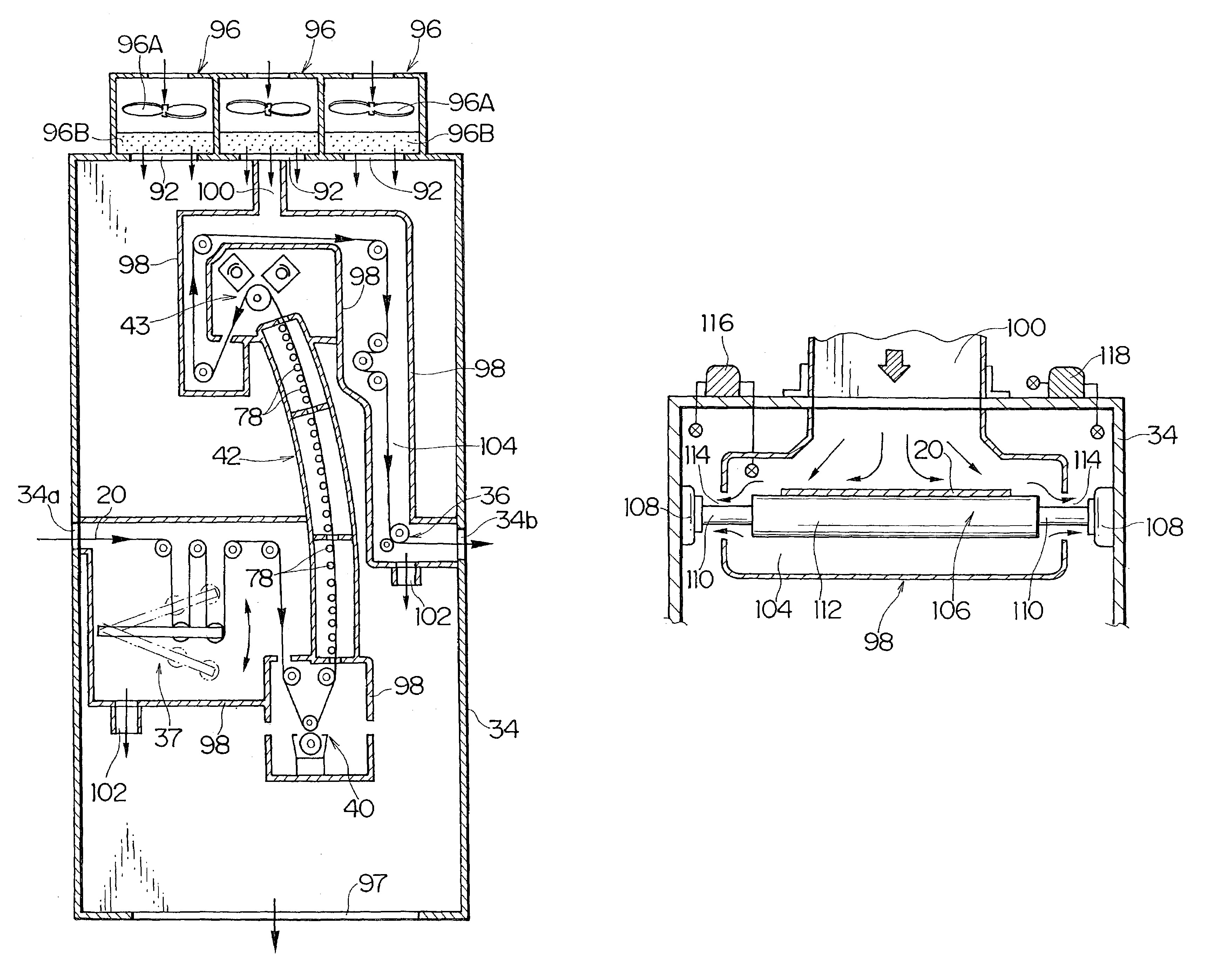

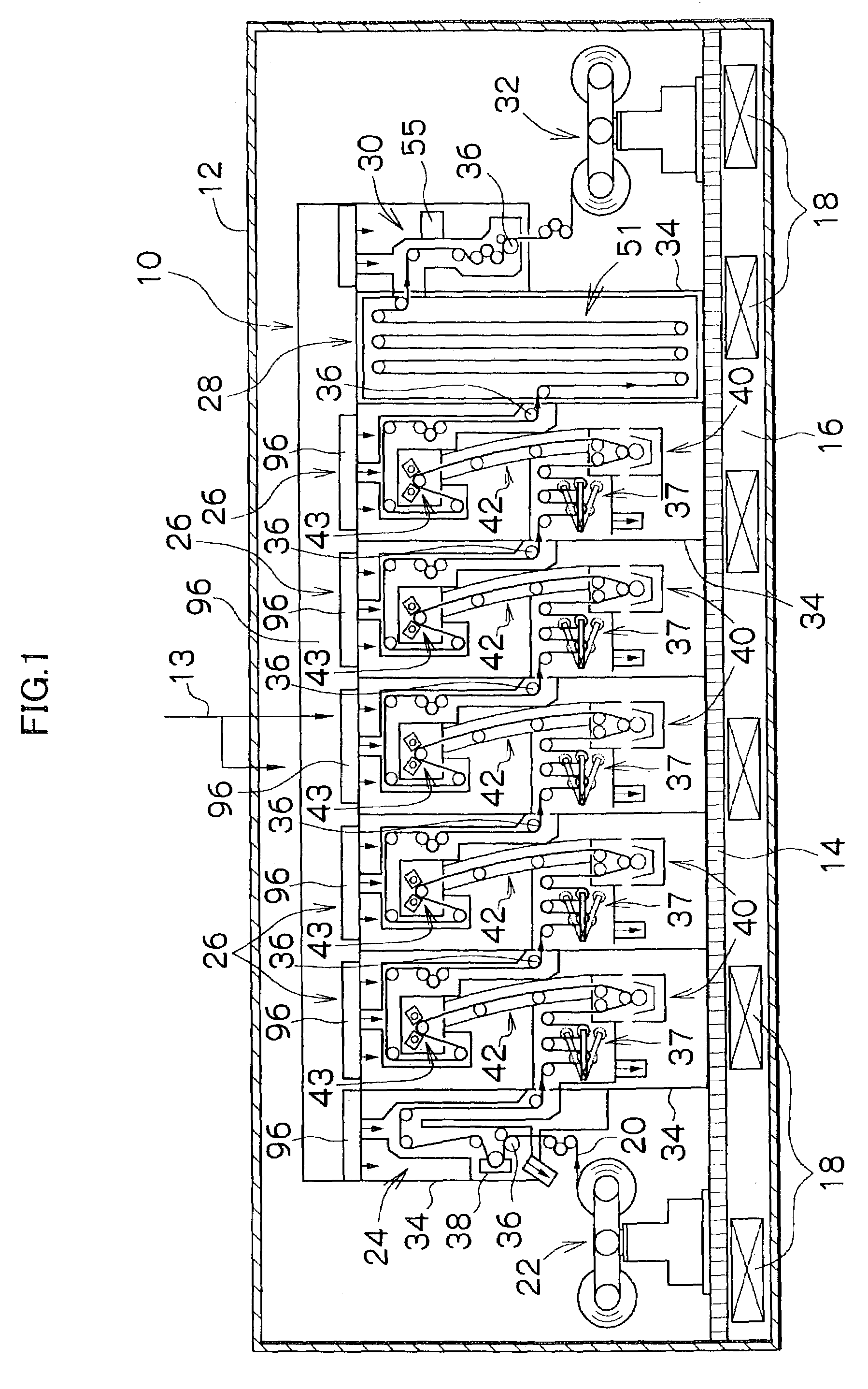

Production apparatus of multilayer coating film

InactiveUS20060121202A1Improve cleanlinessReduce air volumePretreated surfacesDrying machines with progressive movementsMembrane surfaceThin membrane

A method for forming multiple coating layers produces a coating construction that has flexibility corresponding to the number of layers of multiple coating layers, by which a multilayer coating film can be produced with small film thickness without adherence of dust to a film surface, a drying fault such as unevenness induced by drying-wind on the film surface, or a coating fault such as a level variation and a streak. The multilayer coating film has a coating surface state of high quality with coating thickness deviation of 3% or less. In the method, a belt-like substrate is continuously fed. A coating / drying step follows, with multiple steps performed in a single unit. A plurality of coating layers are formed by sequentially performing the coating / drying step by multiple units. Finally, the belt-like substrate with the multiple coatings is continuously wound.

Owner:FUJIFILM HLDG CORP +1

Single crystal single domain piezoelectric film and preparation method thereof

ActiveCN110581212AWith pyroelectric effectSimple processPiezoelectric/electrostrictive/magnetostrictive devicesElectromechanical coupling coefficientAmorphous silicon

The invention discloses a single crystal single domain piezoelectric film and a preparation method thereof. The single crystal single domain piezoelectric film sequentially comprises a single crystalfilm layer, a silicon dioxide layer, a dielectric layer and a single crystal silicon layer. The material of the single crystal film layer is single crystal lithium niobate or single crystal lithium tantalate. The dielectric layer is a damaged layer of monocrystalline silicon, amorphous silicon or polycrystalline silicon. The piezoelectric coefficient of the single crystal single domain piezoelectric film is 98-100% of that of the body material, while the piezoelectric coefficient in the prior art is 10-90% of that of the body material. The single domain single crystal film has stable piezoelectric performance in use, the electromechanical coupling coefficient does not decrease, the device bandwidth is wide, the loss is low and the consistency is good. The preparation method of the single crystal single domain piezoelectric film has low cost, low energy consumption and high efficiency and is suitable for industrial production and has high yield. The silicon dioxide layer of tens of nanometers in the obtained film can achieve the effects of controllable thickness, small thickness deviation, flat surface and good uniformity, thus the obtained device has good consistency.

Owner:JINAN JINGZHENG ELECTRONICS

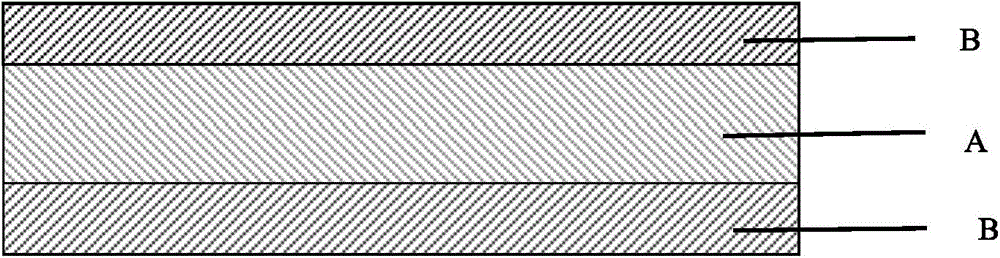

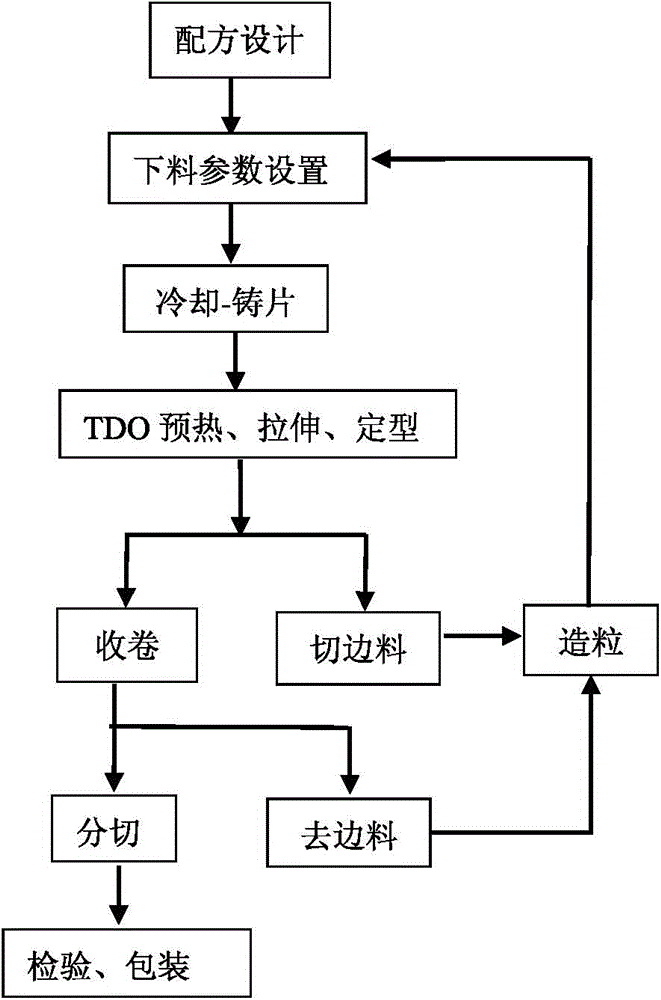

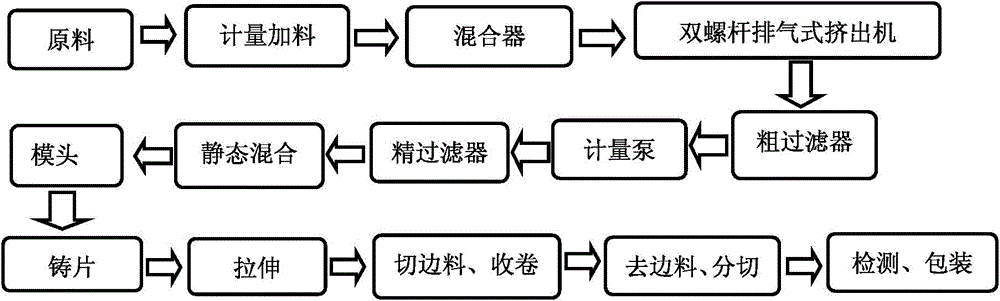

Environmentally friendly degradable heat-shrinkable film formed by tape casting and manufacturing method thereof

ActiveCN103625061BWith surface roughnessGood printabilitySynthetic resin layered productsLaminationSurface layerStatic mixer

The invention relates to the field of processing and manufacturing of heat-shrink films, and in particular relates to a tape-casting environment-friendly degradable heat-shrink film and a manufacturing method thereof. The environment-friendly degradable heat-shrink film is of a three-layer (B / A / B) structure, wherein A is a base material core layer, and B is a printable surface layer; each printable surface layer comprises degradable poly lactic acid (PLA) resin, nano-silicon dioxide and processing aids. Materials of the base material core layer and the printable surface layers are put into a mold head through a double-screw exhaust type extruder, a coarse filter, a metering pump, a fine filter and a static mixer respectively, converge at the mold head and are extruded; the extruded materials are attached to a quenching roller and are quickly cooled to form a casting sheet; the casting sheet is preheated in transverse stretching equipment, and is transversely and uniformly stretched for four times, set and cooled to obtain the degradable heat-shrink film.

Owner:河南银金达新材料股份有限公司

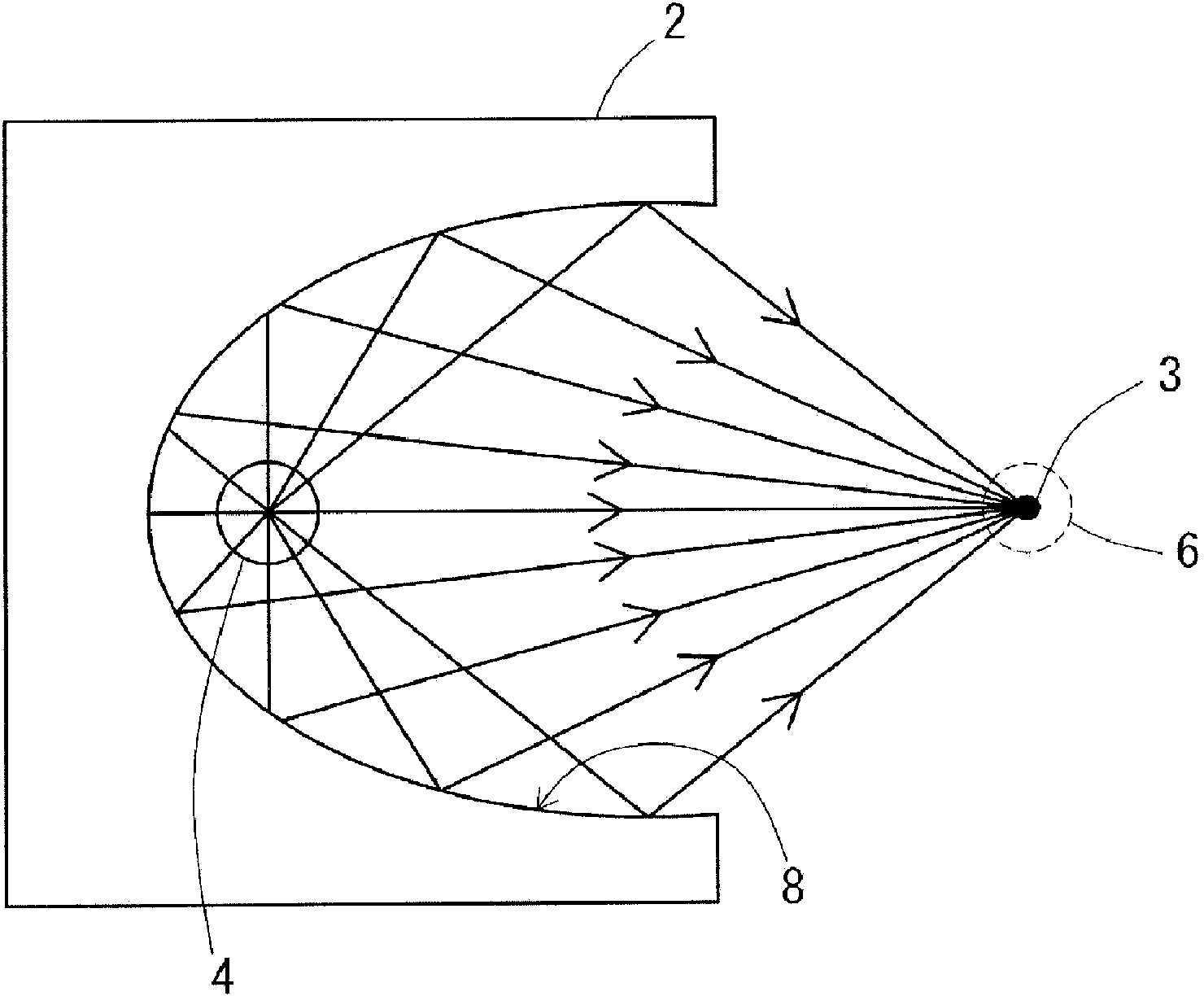

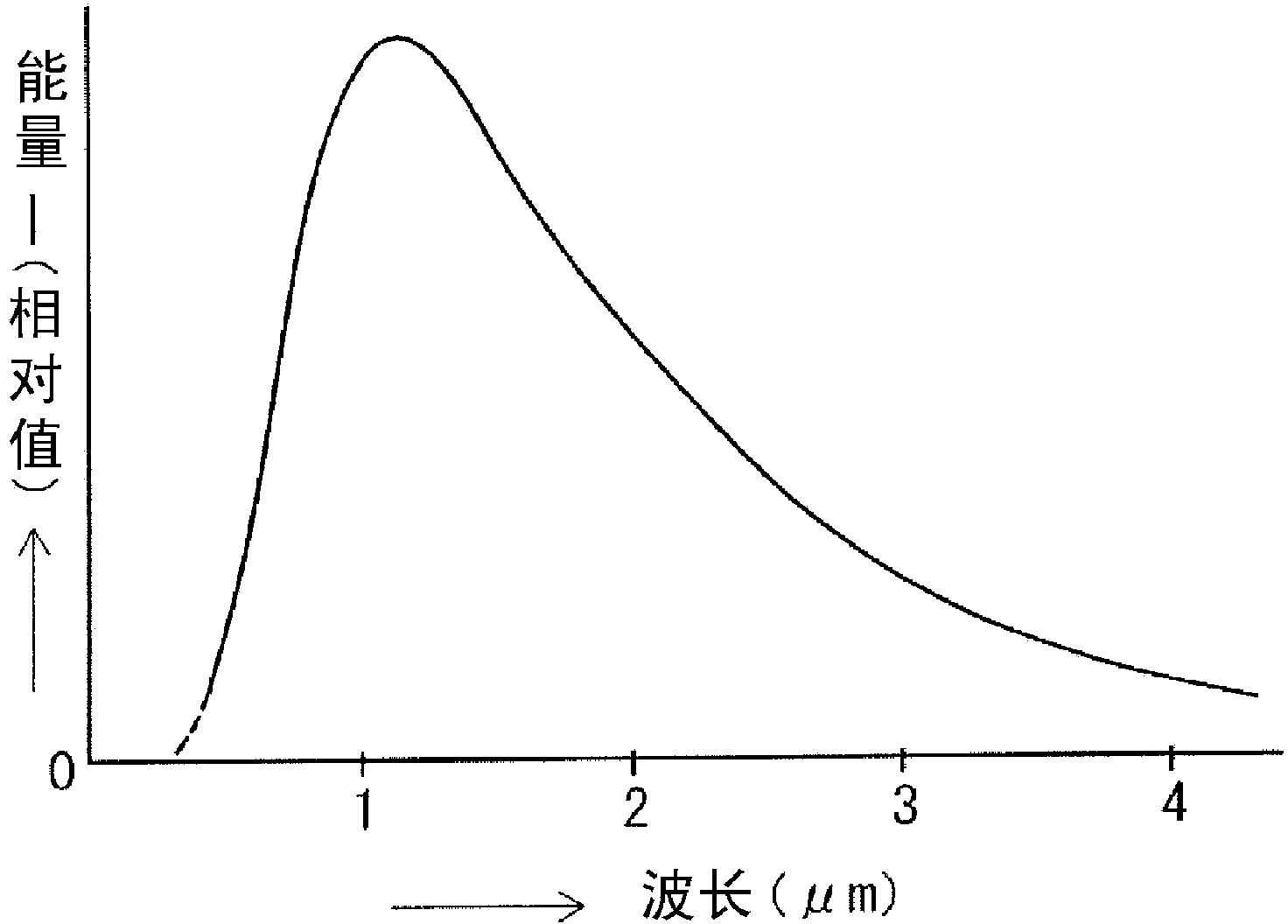

Adhesive composition for resin-bonded wire saw and method for producing resin-bonded wire saw

InactiveCN104379695AEfficient uneven thicknessSmall variation in thicknessNon-macromolecular adhesive additivesMetal sawing tool makingSolventSilane coupling

[Problem] To provide: a method for efficiently producing a resin-bonded wire saw that stabilizes the step of cutting an ingot and that obtains a smooth wafer in which the thickness of a damaged layer on the wafer surface caused by cutting is small; and an adhesive composition for resin-bonded wire saws that is suitable for said method. [Solution] This method for producing a resin-bonded wire saw comprises: a step of applying, to the surface of a metal core wire, a paste including an adhesive composition, abrasive grains, and a solvent for dissolving the adhesive composition, said adhesive composition being used for producing resin-bonded wire saws in which abrasive grains are firmly fixed to the surface of a metal core wire by means of a resin bond, said adhesive composition for resin-bonded wire saws including, as essential components, 100 parts by weight of a novolac-type phenolic resin, 10-30 parts by weight of a resol-type phenolic resin, and 0.1-5 parts by weight of an amine-based silane coupling agent; and a heating step of heating the applied paste with infrared rays including near-infrared rays, and causing said adhesive composition to undergo a cross-linking reaction.

Owner:TKX

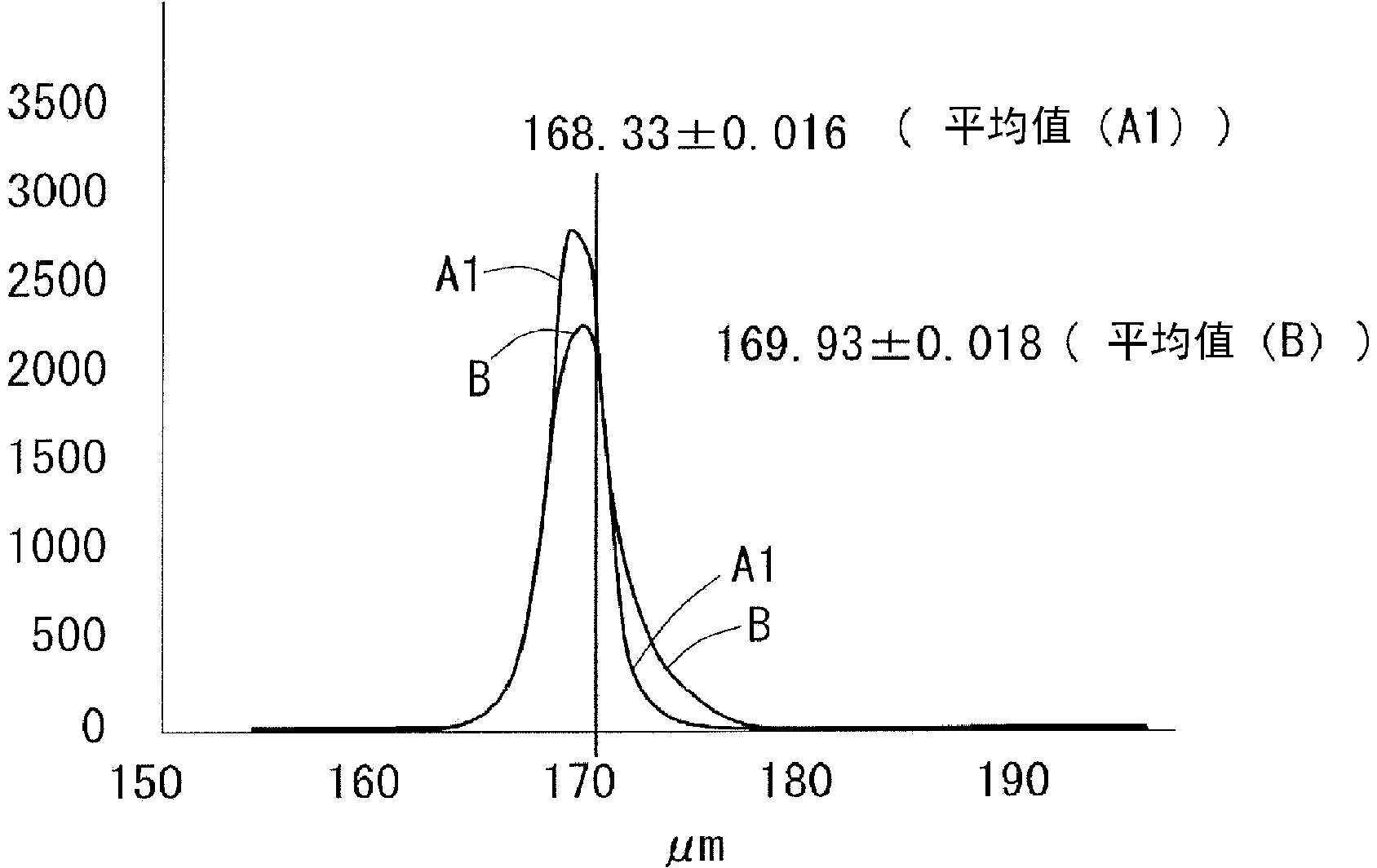

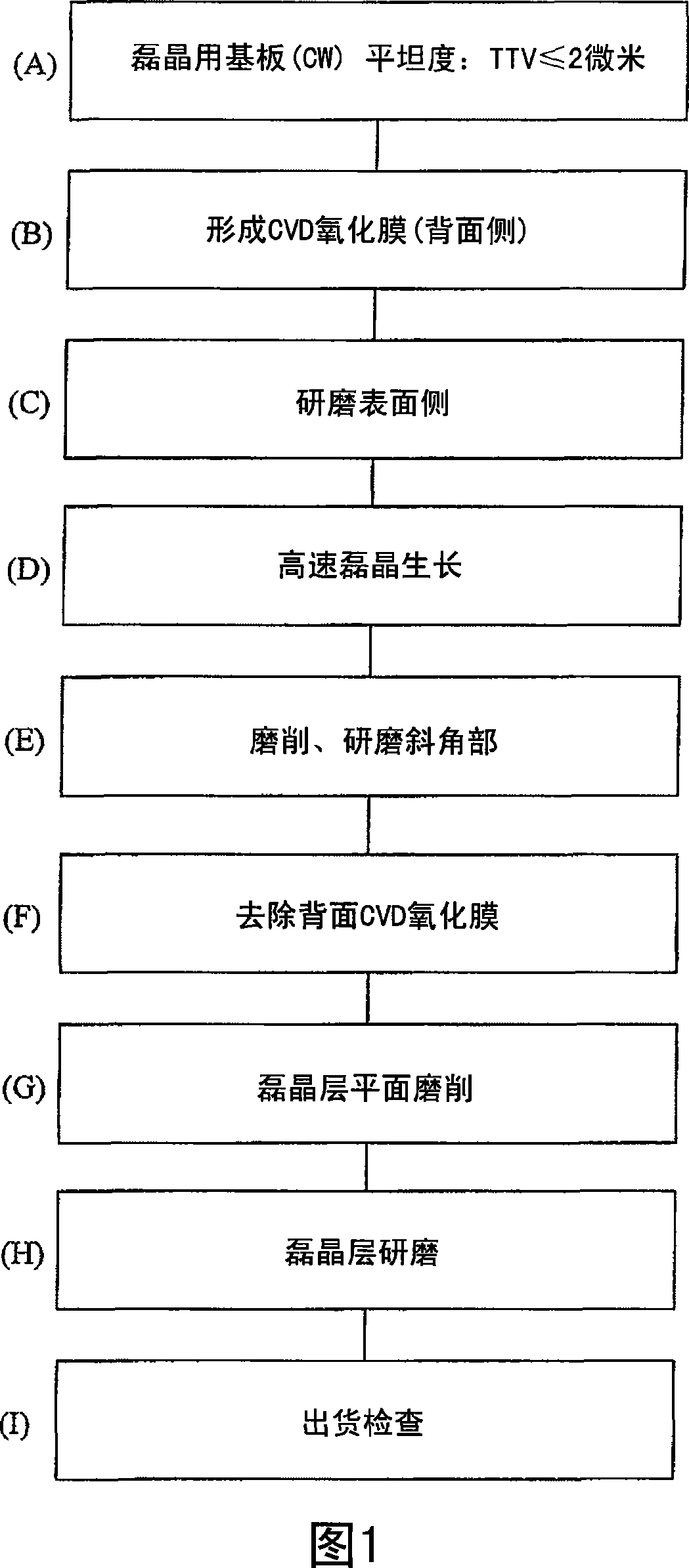

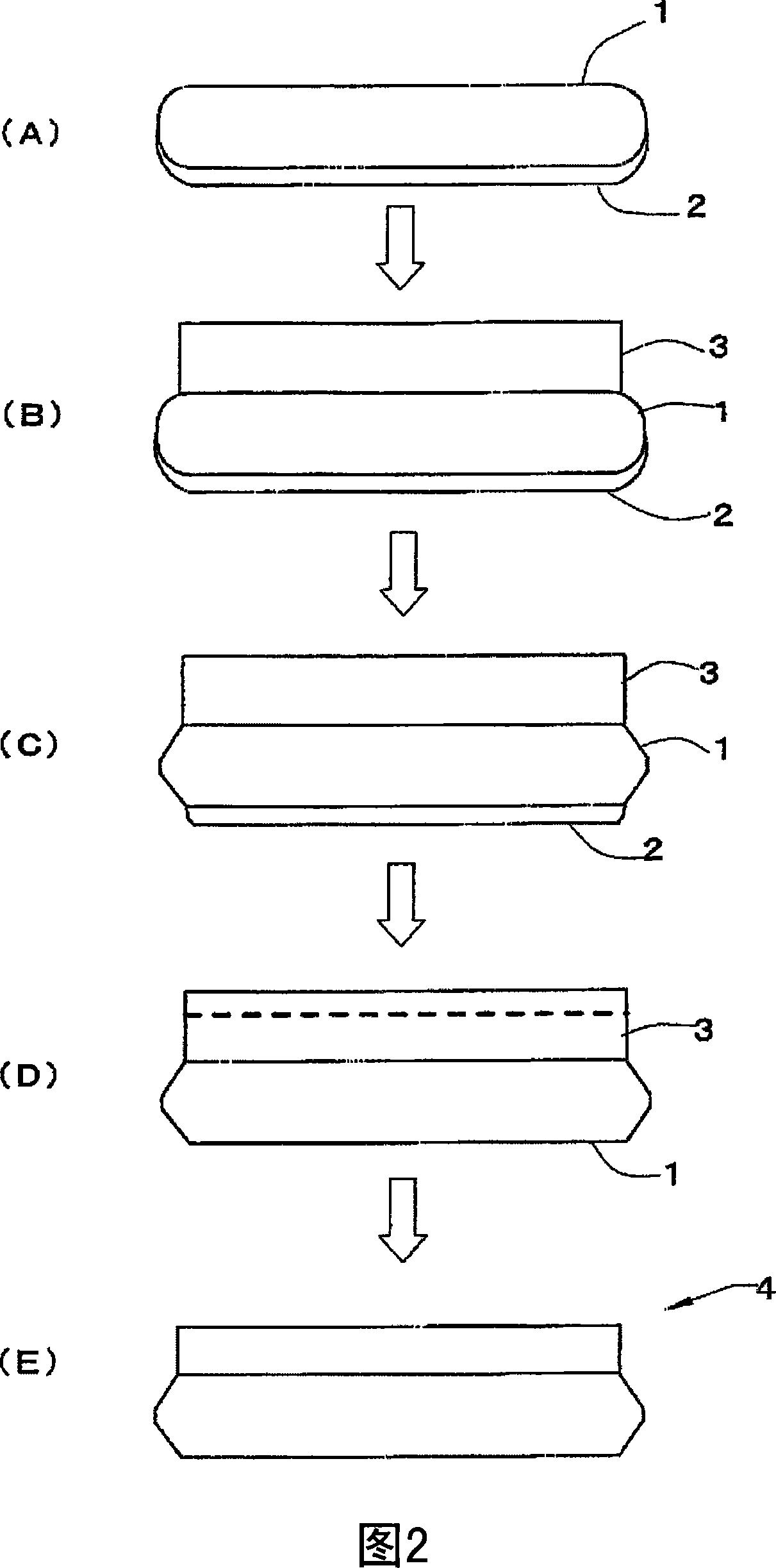

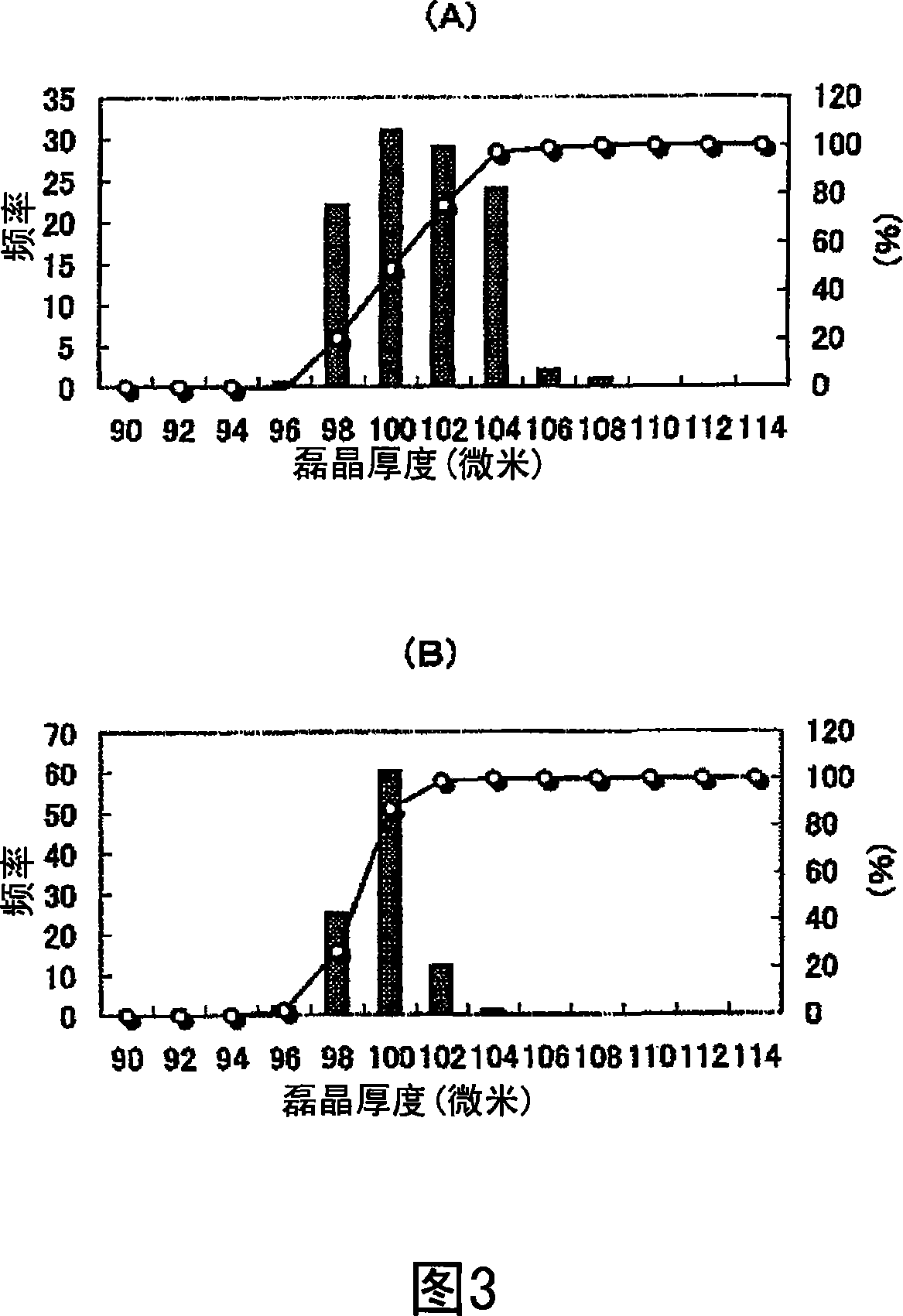

Epitaxial wafer manufacturing method and epitaxial wafer

InactiveCN101091237AIncrease production capacityLow costSemiconductor/solid-state device manufacturingWaferingOptoelectronics

An epitaxial wafer manufacturing method at least includes a process (D) of growing an epitaxial layer thicker than a final target epitaxial layer on an epitaxial wafer having an initial thickness; a process (G) of planarizing the grown epitaxial layer by planarizing polishing; and a process (H) of polishing the epitaxial layer after the planarizing polishing. Preferably, a wafer having a TTV, which indicates planarity, of 2[mu]m or less is used as the epitaxial wafer, and further, the method includes an process (E) of grinding the chamfered part of the wafer and the process (E) of polishing the ground chamfered part. Thus, a technology of manufacturing the epitaxial wafer having excellent thickness uniformity of the epitaxial layer at a high productivity and low cost is provided, even when the epitaxial wafer is provided with the thick epitaxial layer.

Owner:SHIN-ETSU HANDOTAI CO LTD

Manufacturing method of large-diameter thick-wall flange cylinder

ActiveCN111715986ASmall thickness deviationReduce welding distortionMetal working apparatusWelding accessoriesProduct inspectionWeld seam

The invention relates to a manufacturing method of a large-diameter thick-wall flange cylinder. The manufacturing method of the large-diameter thick-wall flange cylinder can effectively solve the problems of large plate thickness deviation, welding deformation and large error caused by shrinkage of different degrees in a welding process in an existing manufacturing method. The technical solution of the manufacturing method of the large-diameter thick-wall flange cylinder is that the large-diameter thick-wall flange cylinder is of an annular structure, the welding method comprises the followingsteps of 1) blanking; 2) platform laying; 3) installing and welding parts; 4) assembling; 5) welding; 6) assembling a reinforcing rib plate; and 7) product inspection. According to the manufacturingmethod of the large-diameter thick-wall flange cylinder, joints of upper and lower circular seams of the large-diameter thick-wall flange cylinder and a cylinder body are full-penetration first-stagewelding seams, a workpiece is of an annular structure, the height-width ratio is 6.6, the thickness deviation is small, the welding deformation is small, the error is small, the service life and the using effect are greatly prolonged, and the manufacturing method of the large-diameter thick-wall flange cylinder is a great innovation.

Owner:ZHENGZHOU NO 9 METALLURGICAL SANWEI CHEM MACHINERY +1

Online thickness measurement and control method for metal alloy sheet strip hot rolling mill

ActiveCN101543844BPrecise control of final rolling thicknessSave manpower and material resourcesRoll force/gap control deviceMeasuring devicesWork rollOptical scanners

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Cover tape raw paper, manufacturing method of cover tape raw paper and cover tape

ActiveCN106480784AGuaranteed tensile strengthGuaranteed brightnessFlexible coversWrappersFiberSurface layer

The invention discloses cover tape raw paper, a manufacturing method of the cover tape raw paper and a cover tape. The cover tape raw paper comprises a surface layer, a bottom surface layer and a middle layer located between the surface layer and the bottom surface layer, wherein the surface layer is a high molecular resin layer; a raw material of the middle layer is long-fiber wood pulp; the bottom surface layer is a high molecular resin layer. The cover tape raw paper disclosed by the invention has the following advantages that 1, the tensile strength and brightness of the raw paper are guaranteed by using bleached long-fiber wood pulp with high strength; 2, the transverse shrinkage rate of the raw paper under a high-temperature condition is reduced through adding an auxiliary material into the middle long-fiber wood pulp layer and the uniformity of wood pulp fibers is improved; 3, the transparency of the raw paper is improved through improving the beating degree of paper pulp and the tightness of the raw paper; 4, the thickness uniformity of the raw paper is improved by adopting a relatively low net application concentration and the auxiliary material and the thickness tolerance is reduced.

Owner:浙江洁美电子信息材料有限公司

Method and device for preparing polystyrene thin film

InactiveCN106738539AImprove surface qualityImprove thickness uniformityFlat articlesSolvent vaporSurface layer

The invention discloses a method and device for preparing a polystyrene thin film. According to the method, the volatilization rate of solvent is decreased through the mode of controlling the discharging speed of solvent vapor, and the corrugated degree of the surface of the thin film due to the 'skinning' effect is lowered. Meanwhile, a solvent vapor fumigation levelling technology of high-viscosity fluid is adopted, and thus preparation time cannot be excessively prolonged. A high-viscosity fluid body is weak in mobility, and the surface layer of the high-viscosity fluid body can be re-dissolved under the fumigation action of the solvent vapor, so that the viscosity is lowered, the mobility is slightly enhanced and short-range migration can happen. By means of long-term dynamic rebalancing, surface quality of the thin film can be improved. By the adoption of a heat treatment clamp which is designed and processed in a matched mode, the heat treatment effect is improved, and the surface quality of the thin film is further improved. By the aid of the method, thickness uniformity of the thin film is effectively improved, and thickness deviation is reduced. The polystyrene thin film with the thickness being 10-100 microns, the thickness uniformity reaching 80% or above and the thickness deviation being smaller than + / -20% is successfully prepared through the method.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com