Method and device for preparing polystyrene thin film

A polystyrene film and preparation device technology, which is applied to flat products, household utensils, and other household utensils, can solve the problems of low pass rate, poor repeatability, and low reliability of the film, so as to prolong the preparation time and reduce thickness deviation , the effect of reducing the volatilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

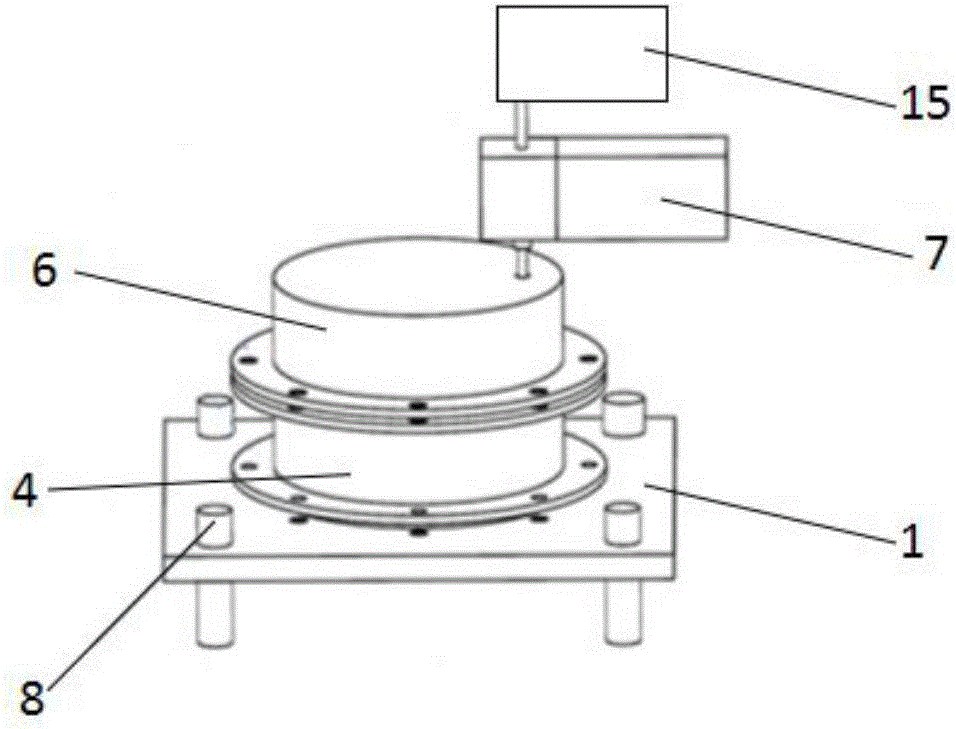

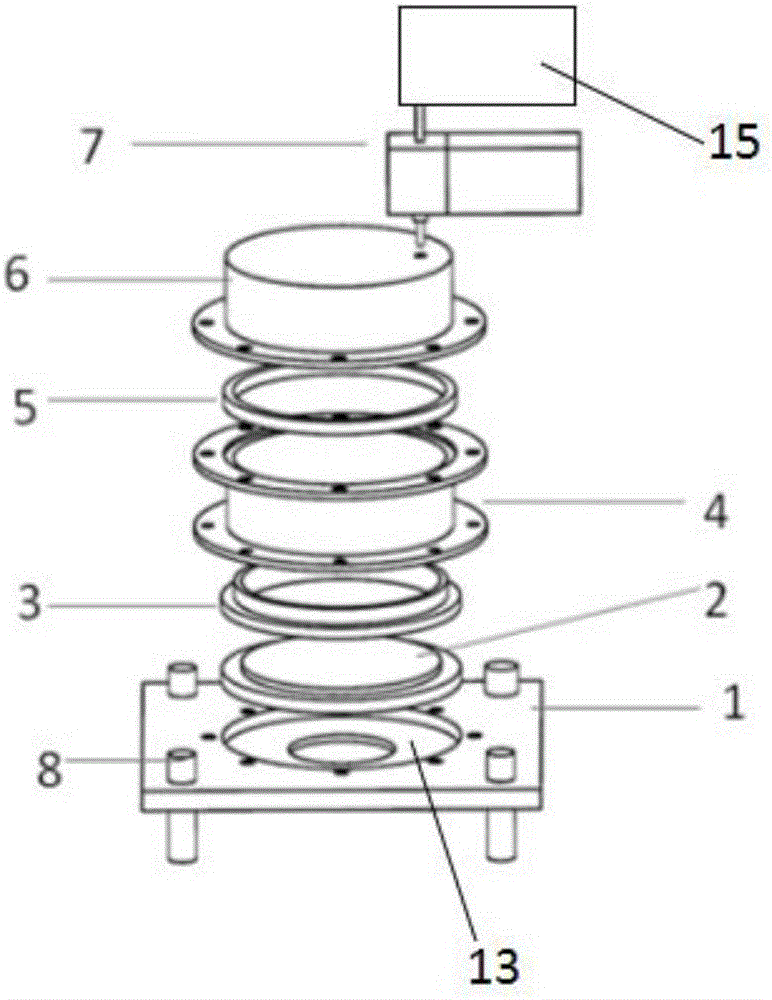

[0039] Figure 1~2 A preparation device for a polystyrene film is shown, including: a base 1, on which a leveling bolt 8 and a mold placement groove 13 are connected;

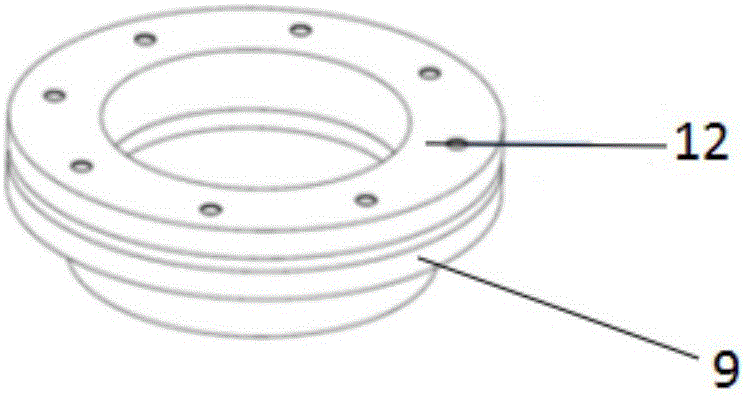

[0040] A casting mold for containing polystyrene solution, which includes a casting template 2 arranged in a mold placement groove 13, an L-shaped sealing ring 3 matching the casting template 2, and a detachable connection on the base 1 and sleeved on the casting mold The middle cylinder 4 outside the template 2; the casting template 2 is a circular copper plate with a boss, the diameter of the boss is consistent with the inner diameter of the L-shaped sealing ring, the height of the boss is lower than the height of the L-shaped sealing ring, and the upper edge of the L-shaped sealing ring The height to the upper surface of the boss is the maximum height of the casting liquid level, and the outer diameter of the L-shaped sealing ring is consistent with the diameter of the casting template;

[0041] The upper c...

Embodiment 1

[0049] A method for preparing a polystyrene film using the above-mentioned polystyrene film preparation device, comprising the following steps:

[0050] Step 1, calculate the quality of polystyrene required for preparing the polystyrene film of target thickness according to the inner diameter of L-shaped sealing ring; adopt the following formula to calculate:

[0051] m PS = ρ PS ·π·r 2 ·t×10 -4

[0052] Among them, m PS is the mass of polystyrene g; t theoretical film thickness μm; ρ PS is the density of polystyrene g / cm 3 ; r is the effective radius of the casting template, that is, the inner diameter radius cm of the L-shaped sealing ring;

[0053] Then prepare and filter the polystyrene solution; use an electronic level to test the levelness of the casting template 2, and adjust the leveling bolt 8 on the base to make the casting template 2 reach the level; pour the filtered polystyrene solution into the casting mold template 2, and place the casting mold in an ope...

Embodiment 2

[0058] A method for preparing a polystyrene film using the above-mentioned polystyrene film preparation device, comprising the following steps:

[0059] Step 1, using polystyrene with a weight-average molecular weight of 250,000 as the raw material for film preparation; calculating the mass of polystyrene required for a film with a target thickness of 10um to be 0.1394g according to the inner diameter of the L-shaped sealing ring being 6.5cm;

[0060] Add 0.1394g of polystyrene and 15mL of chloroform into the reagent bottle, put a stirring bar in the reagent bottle, cover the seal cap, turn on the magnetic stirrer, the room temperature is 25°C, the stirring speed is 50rpm, and the time is 0.5h, obtain polystyrene solution; Adopt the needle filter that diameter is 25mm and PTFE filter membrane aperture is 0.22 micron to filter polystyrene solution;

[0061] Combine the casting formwork 2, L-shaped sealing ring 3, middle cylinder 4 and base 1 through bolts to form a casting mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com