Patents

Literature

546 results about "Surface mass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

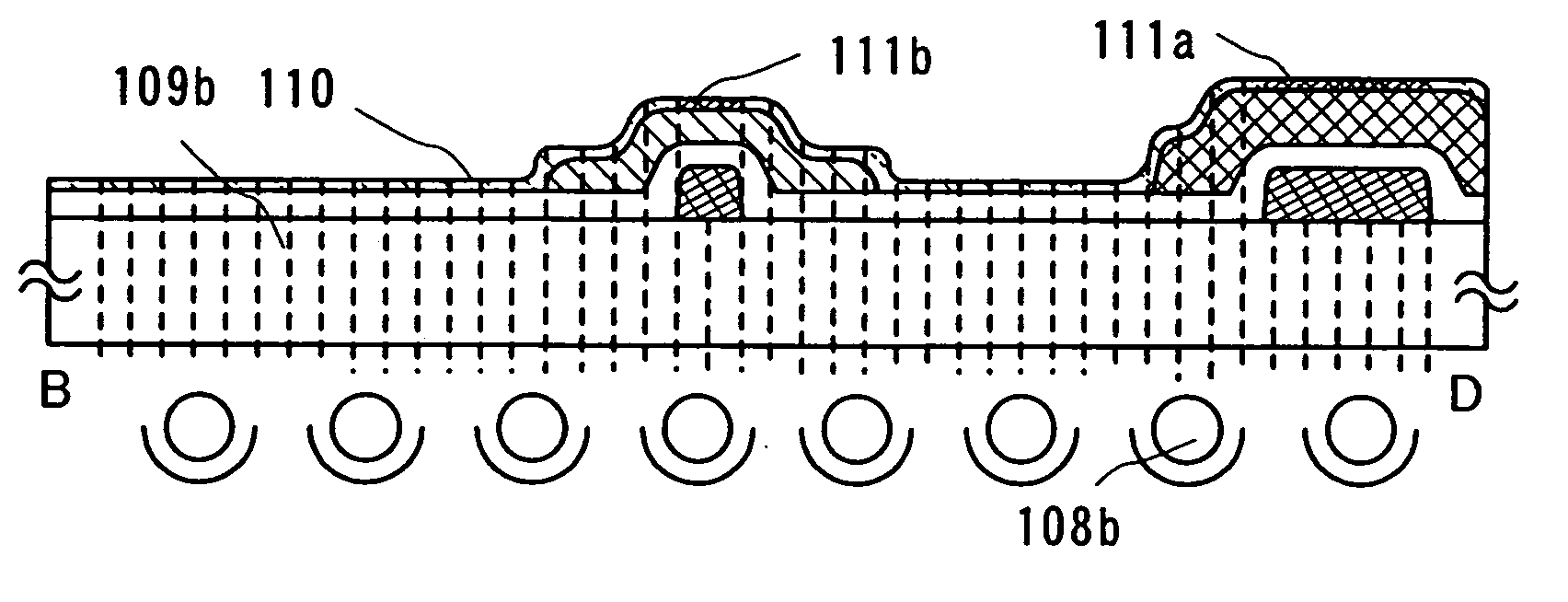

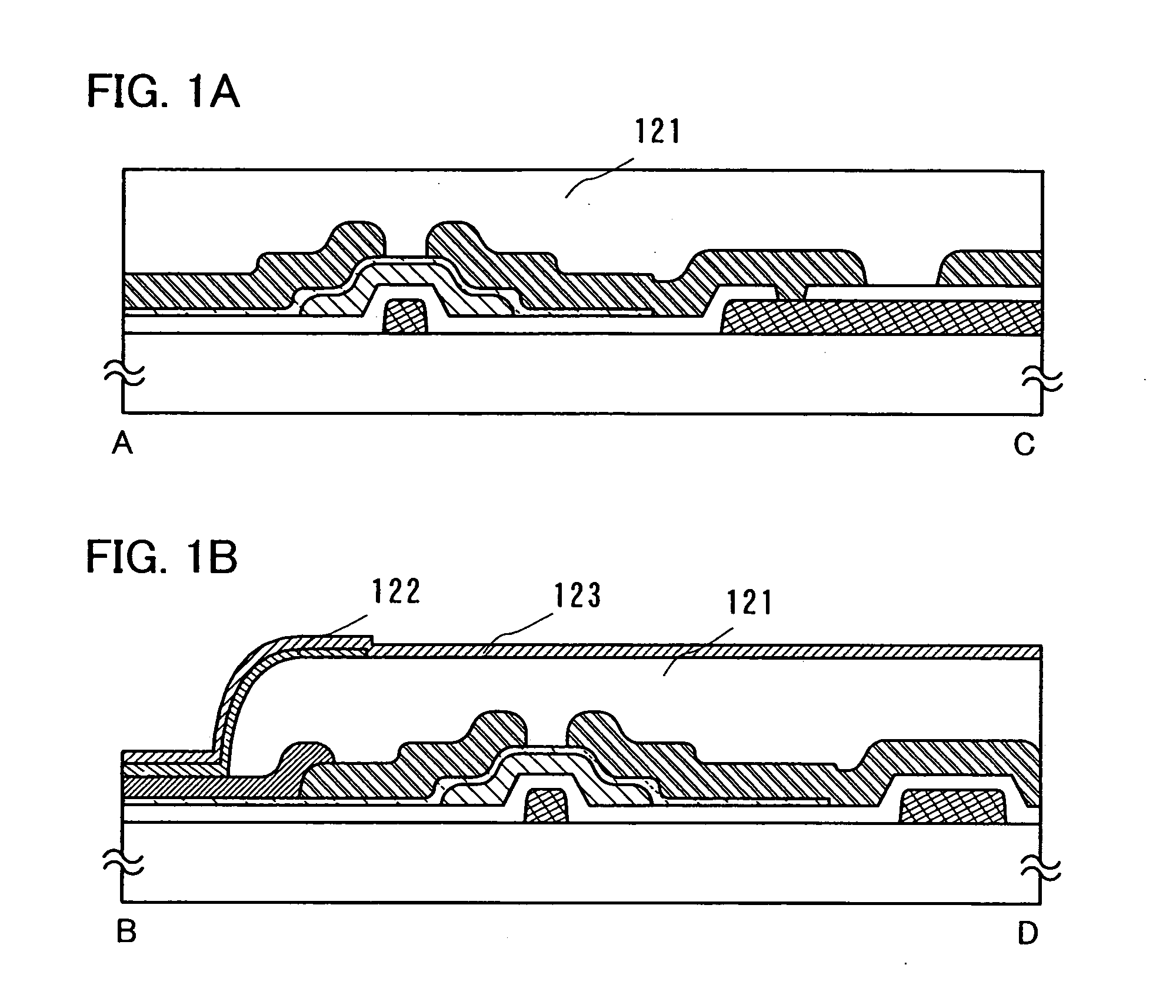

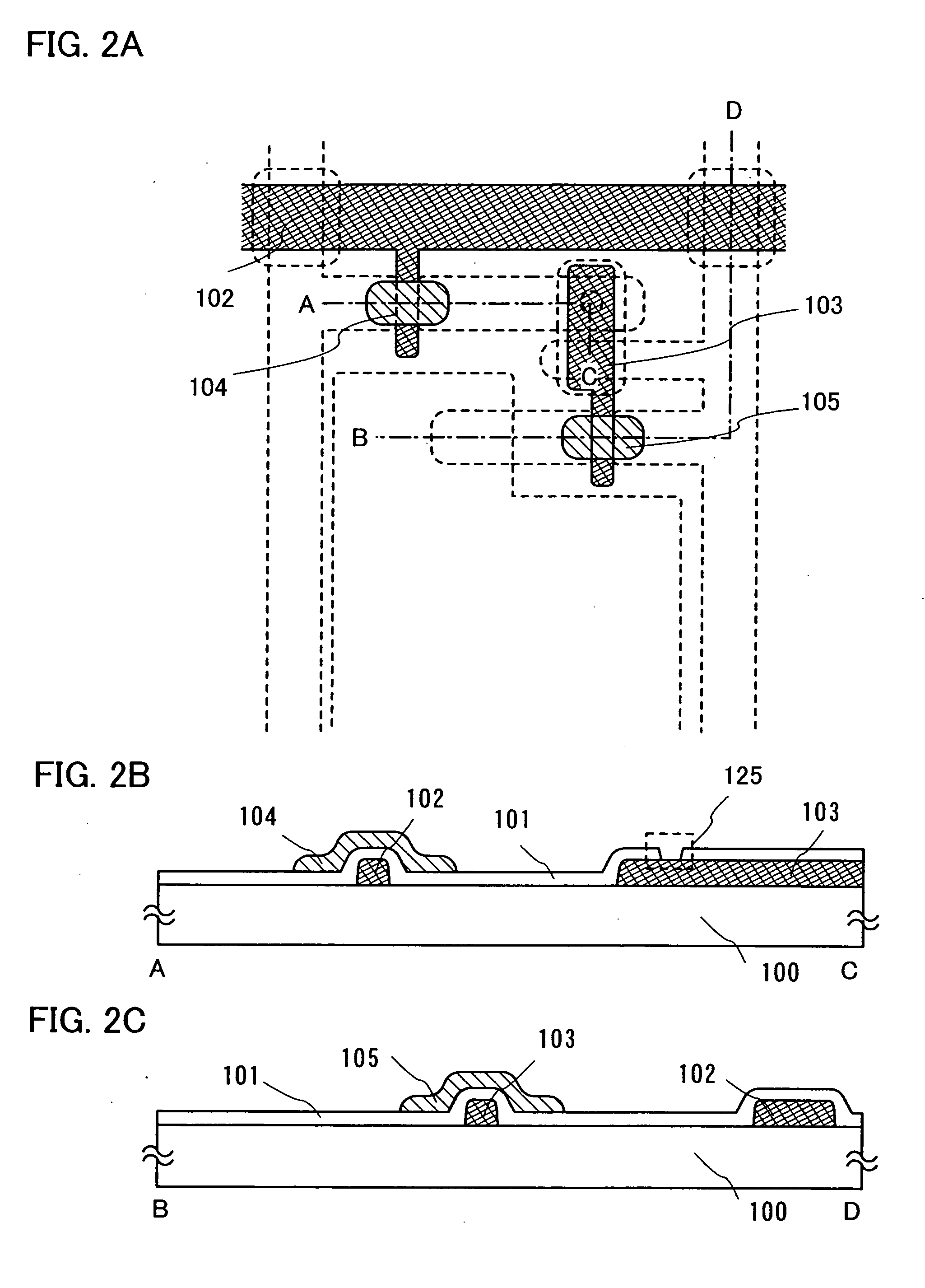

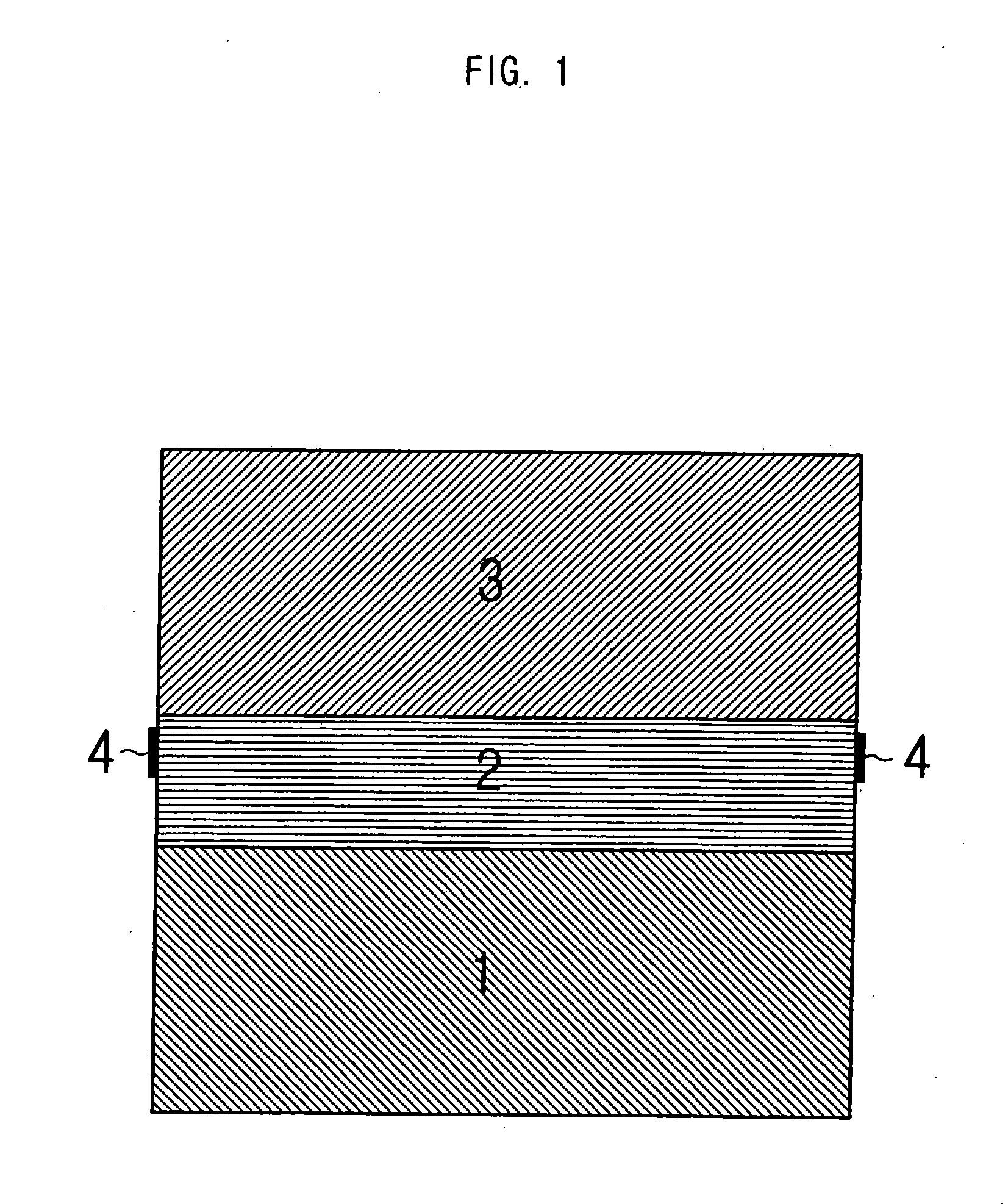

Method for manufacturing display device

InactiveUS20060121745A1Improve controllabilityLow costSolid-state devicesSemiconductor/solid-state device manufacturingLight irradiationDisplay device

The present invention, the quality of the surface of a substrate is improved and the wettability thereof is controlled by light irradiation from the reverse side with respect to the substrate having the conductive layer. A conductive material or an insulating material is adhered on the modified surface by discharging it (including jetting, etc.), or the like to form a conductive layer and an insulating layer. The processing efficiency by the light can be enhanced by function of the light absorption and energy radiation of the photocatalytic substance. Furthermore, the mask layer is formed selectively on the conductive layer and the wettability of the region on the conductive layer that is a non-irradiation region is also controlled.

Owner:SEMICON ENERGY LAB CO LTD

Method of sheet billet continuously casting and rolling to produce thin strip steel coil

ActiveCN101108394AShort production processSave construction investmentMetal rolling arrangementsProduction lineStrip mill

A method of using thin plate adobe continuous casting and rolling to producing thin band steel coil is provided, which belongs to rolling metal at once after continuous casting, in particular relating to thin standard band steel production method. The invention is characterized in that: a conticaster, a swing shear, a roller-hearth type heating furnace, a scale breaker, a vertical miller, 7 mill groups, laminar flow cooling device and reeling machine are connected to a CSP produce line, the produce line adopts reasonable temperature system, rolling equipment, rolling way and combining with cooling after rolling, the molten steel after continuous casting is a casting adobe of 50 to 70mm thick and 900 to 1300 wide, after cutting, heating, scale breaking, proceed continuous rolling to form a thin band of 1.2 to 1.5mm thick and 900 to 1300 wide, then after cooling to reel steel coil. The production flow is short, the equipment is few, the investment is less and the running expense is low; The technics and equipment is reasonable and high efficient, double locomotive and double flow casting, heating by two furnaces, seven rolling machines roll continuously, the production is smooth and saves energy with high production efficiency; the product performance is even and stable, the board shape is regular with high accuracy and good surface quality.

Owner:MAANSHAN IRON & STEEL CO LTD

Coating for lost foam cast iron

InactiveCN101569918AStrong ability to absorb EPSExempt from cleanupFoundry mouldsFoundry coresSodium BentoniteHigh surface

The invention belongs to the technical field of coatings for lost foam, in particular to a coating for lost foam cast iron. The invention provides the coating for the lost foam cast iron, which comprises the following components (calculated as the weight): 70 portions of bauxite, 30 portions of quartz powder, 2 to 5 portions of bentonite, 0.5 to 2 portions of white latex, 0.5 to 1.0 portion of sodium carboxymethyl cellulose, 2 to 3 portions of water soluble phenolic resin, 0.5 to 2 portions of attapulgite, 2 to 5 portions of spodumene powder, 0.01 to 0.03 portion of surfactant, and 0.01 to 0.02 portion of defoaming agent. The coating has thin and even coatings and good air permeability; the surfaces of castings are smooth, clean, and level and easy to peel off, and black defects are eliminated; and the castings have level surfaces and high surface quality.

Owner:山东醴泉机械科技有限公司

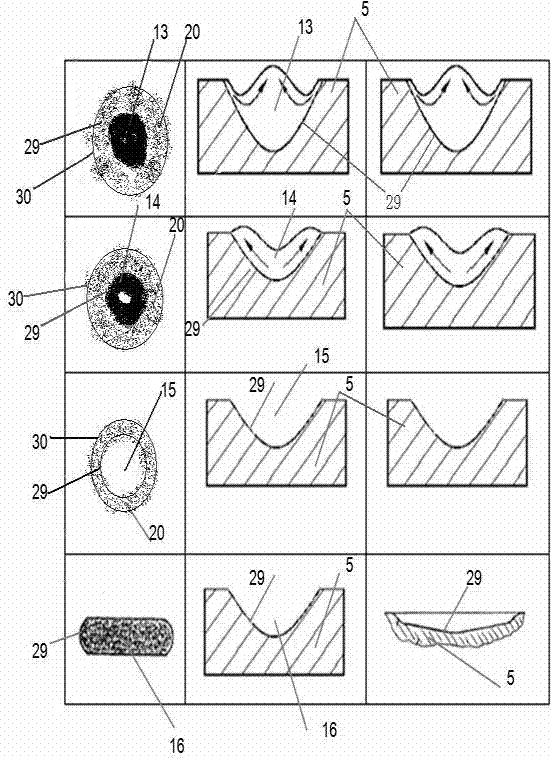

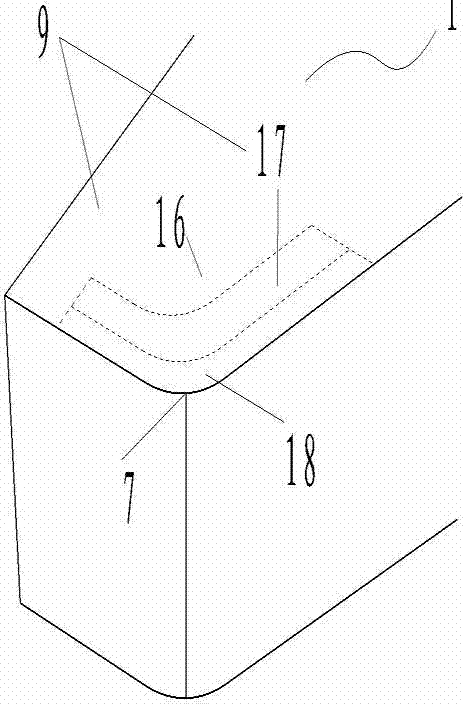

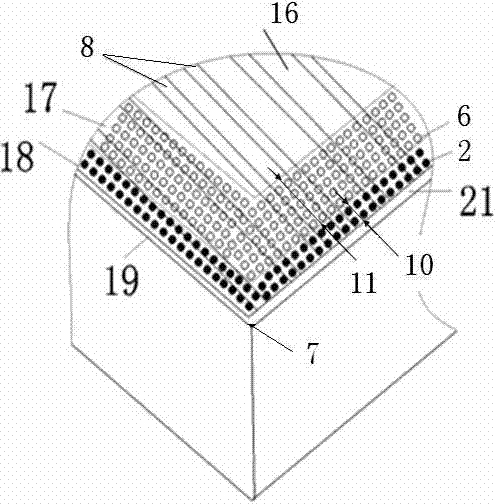

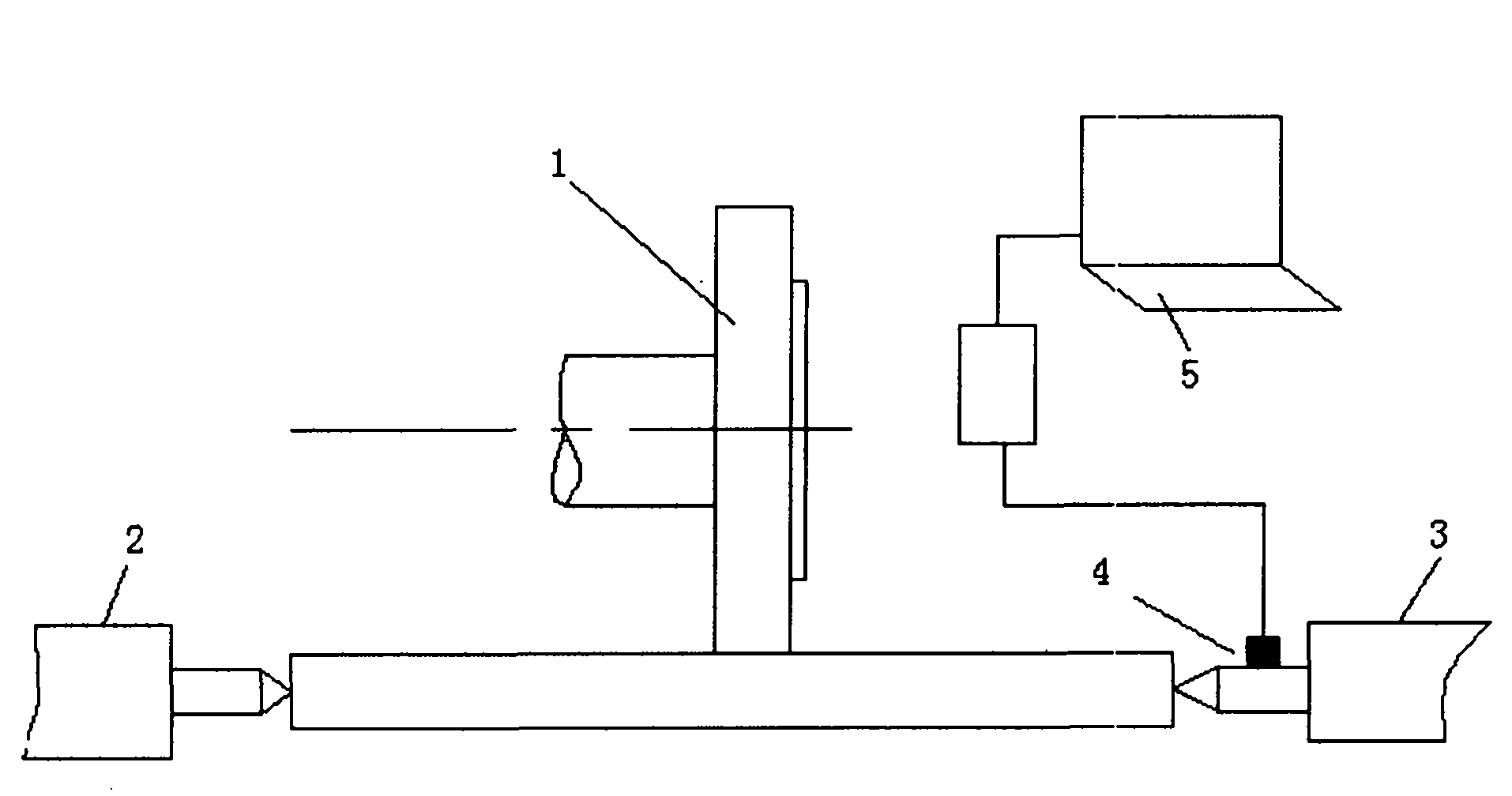

Compound model processing method and device for cutter

ActiveCN102962656AReduce wearImprove performanceMeasurement/indication equipmentsLaser beam welding apparatusNumerical controlHigh energy

The invention provides a compound model processing method and device for a cutter, relating to the active processing of microtexture compound morphologies on the main friction and abrasion surfaces of the cutter, and belonging to the field of machinery manufacture. Three microstructural models, namely micro concave cavities, fused bulges and micro grooves respectively, are processed at the main friction and abrasion parts of the cutter through high energy laser beams or high energy electron beams. With the adoption of the compound model processing method and device for the cutter, the continuous service life of the cutter is prolonged, the cutting quality of the cutter is improved, the surface quality and the cutting and cooling performances after the processing of a workpiece are improved, and the machining cost of metal cutting is lowered. The invention also discloses the processing device for applying the compound mould processing method; and the device is integrated with a high energy technique and a numerical control technique, so that predetermined compound microstructural morphologies and distributions thereof can be processed on the main cutting working face of the cutter efficiently and stably. Processing objects for the method and the device thereof provided by the invention are various cutters during the cutting processing.

Owner:JIANGSU UNIV

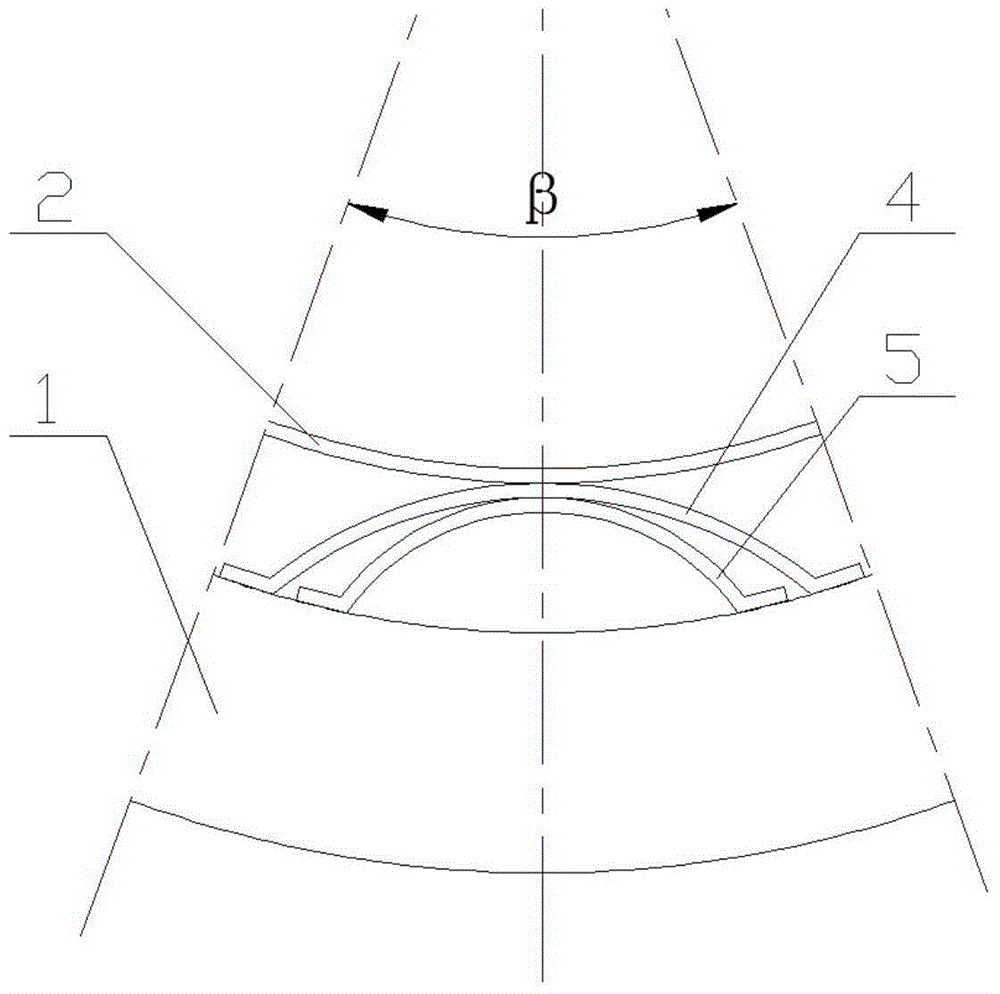

Method for polishing inner concave surface of optical elements as well as device

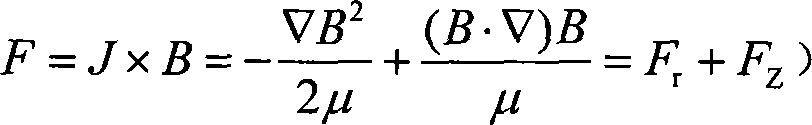

InactiveCN101352826AImprove controllabilityHigh utility valueOptical surface grinding machinesPolishing compositions with abrasivesMagnetic polesHigh surface

The invention belongs to the technical field of precision optical polish finish, in particular to a polishing method of the inner concave surface of optical elements and a polishing device. A core mould with a tank circuit and inosculating with the shape of the inner concave surface to be processed is fixed below the inner concave surface of a work piece to be processed, and the work piece rotates around the own rotary shaft, keeps a micro clearance from the core mould and applies magnetic fields to processing regions by an external magnetic pole tool head and an internal magnetic pole exciting coil. When magneto-rheological fluids with polishing abrasives flow through the processing region along the tank circuit, a flexible polishing head is formed under the action of magnetic field and absorbed on the inner concave surface and polishing effects are generated. The polishing method and the device can realize the inner concave surface polishing of conformal optical elements with small curvature radiuses or deep cavity structure and other cyclically symmetric high gradient aspheric surfaces, and can remove distribution by utilizing computer-controlled polishing, and besides the polishing method and the device have the polishing surface shape control ability and both the advantages of high precision and high surface quality.

Owner:TSINGHUA UNIV

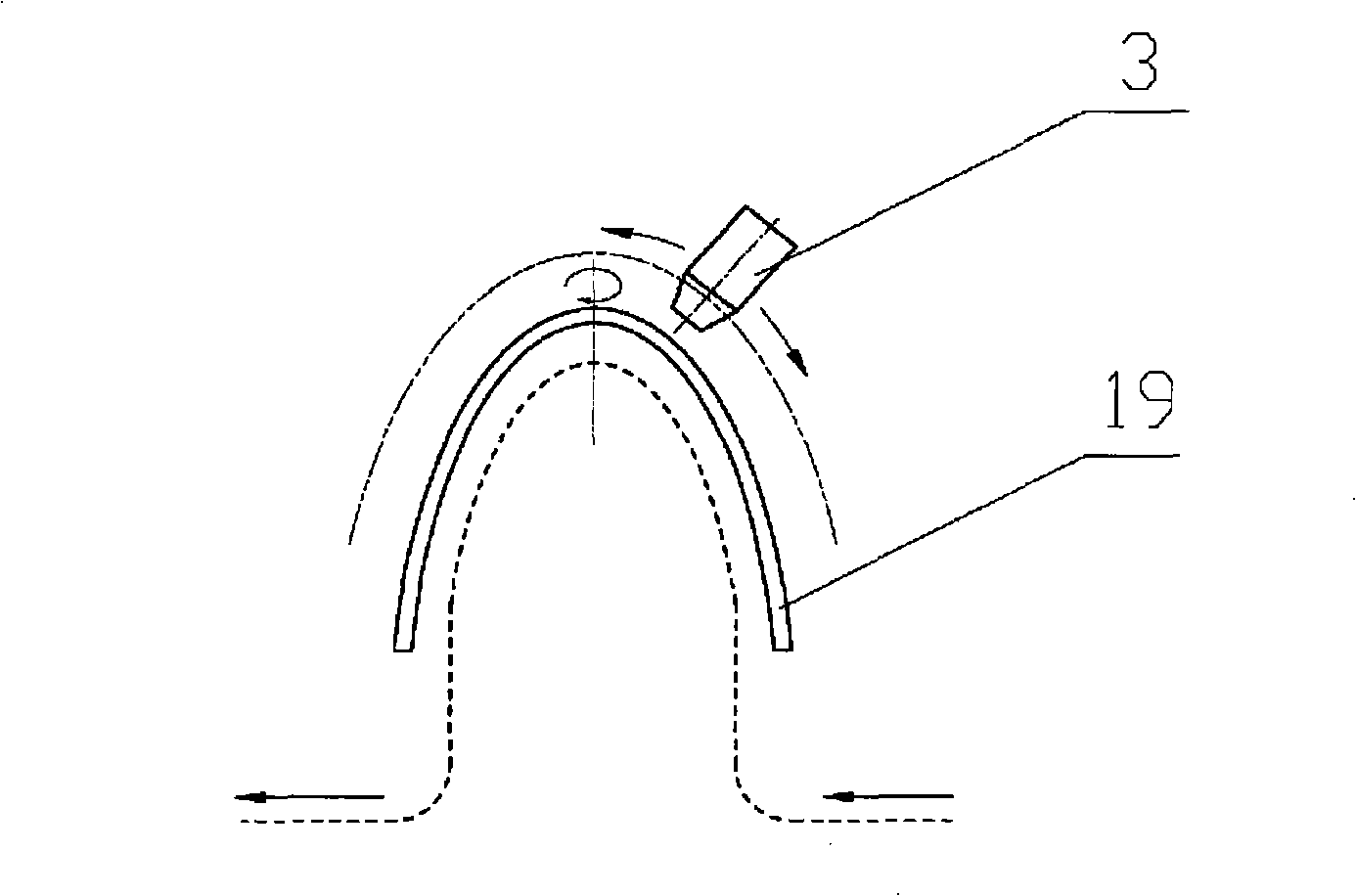

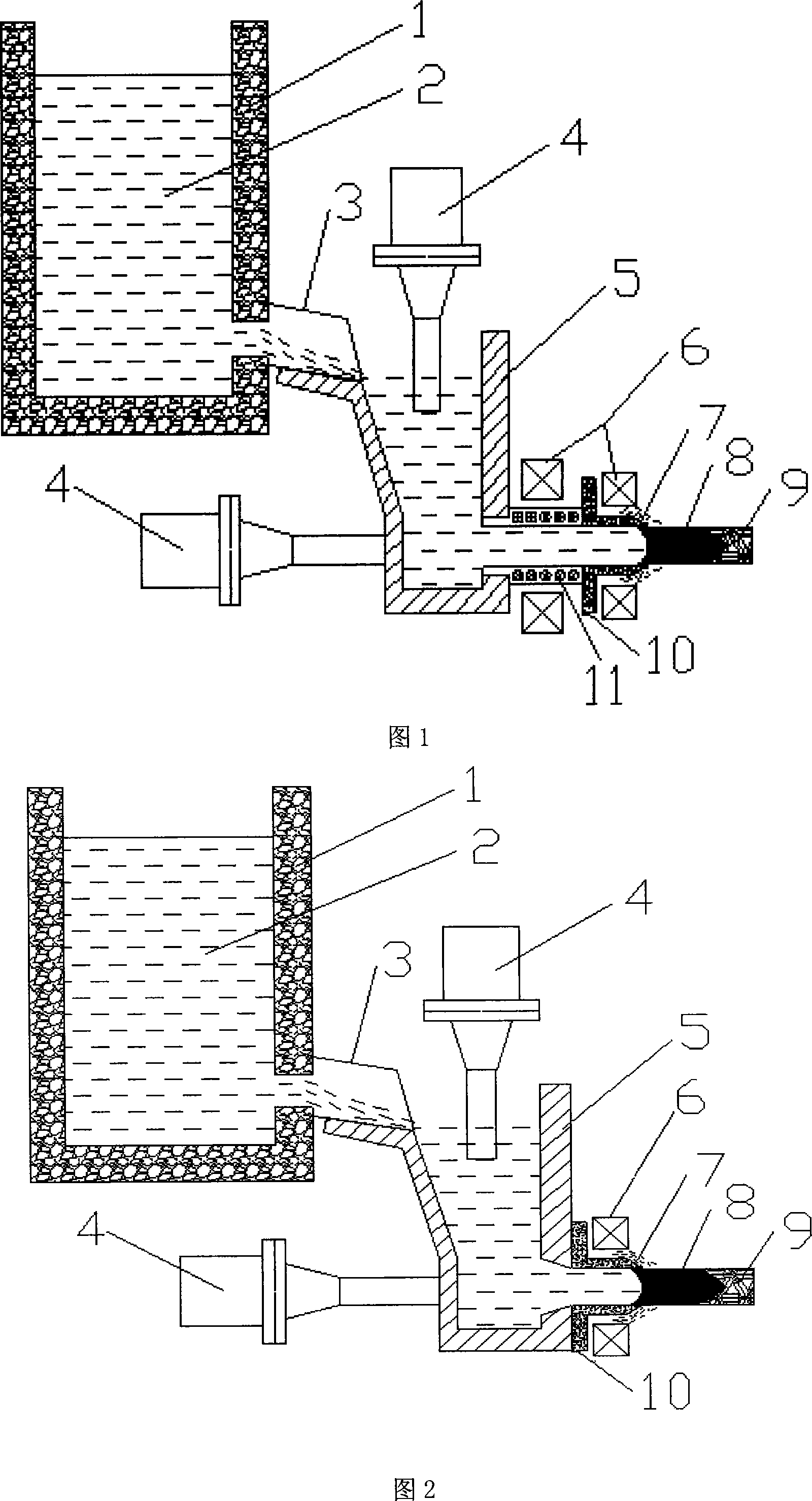

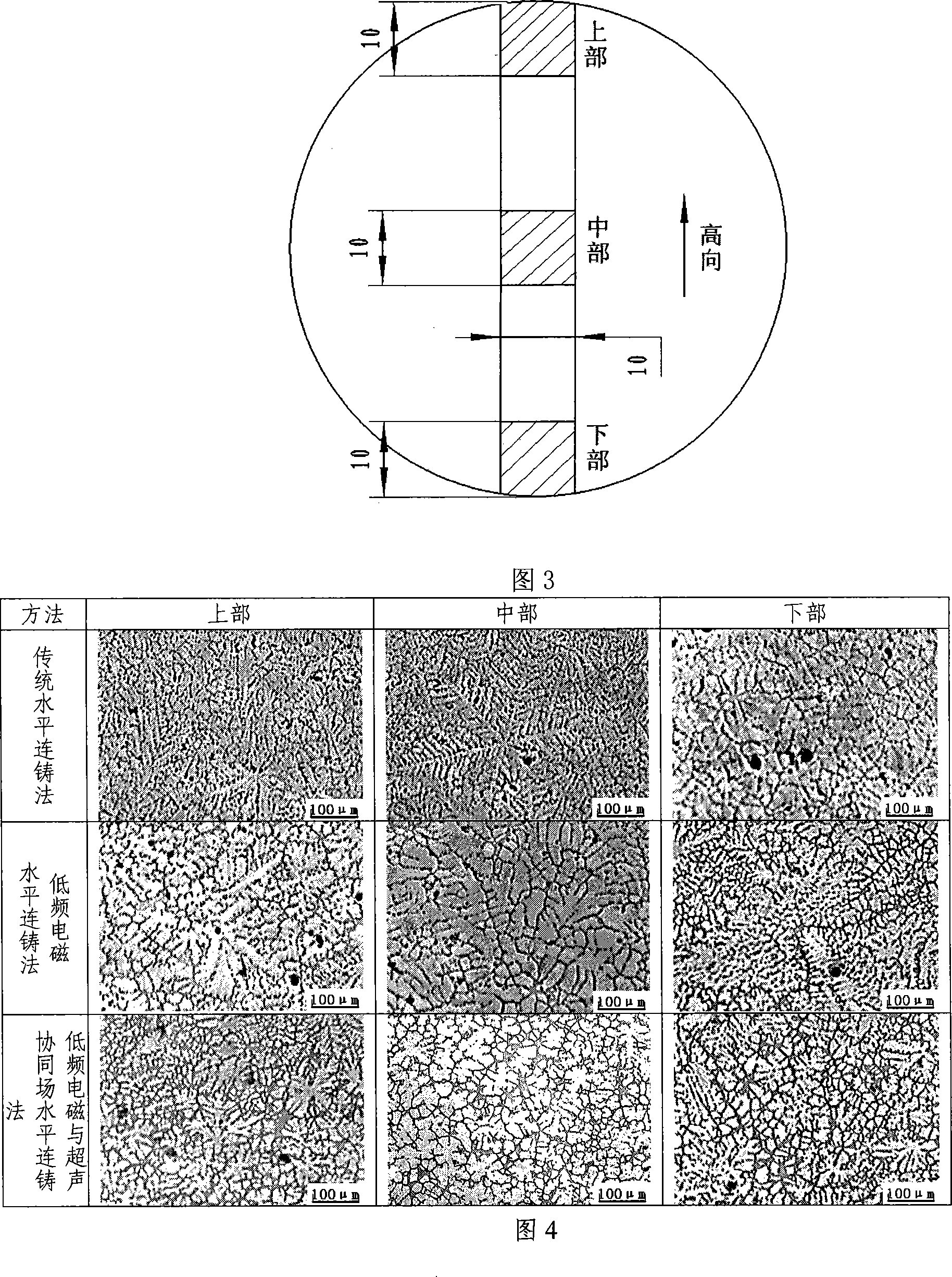

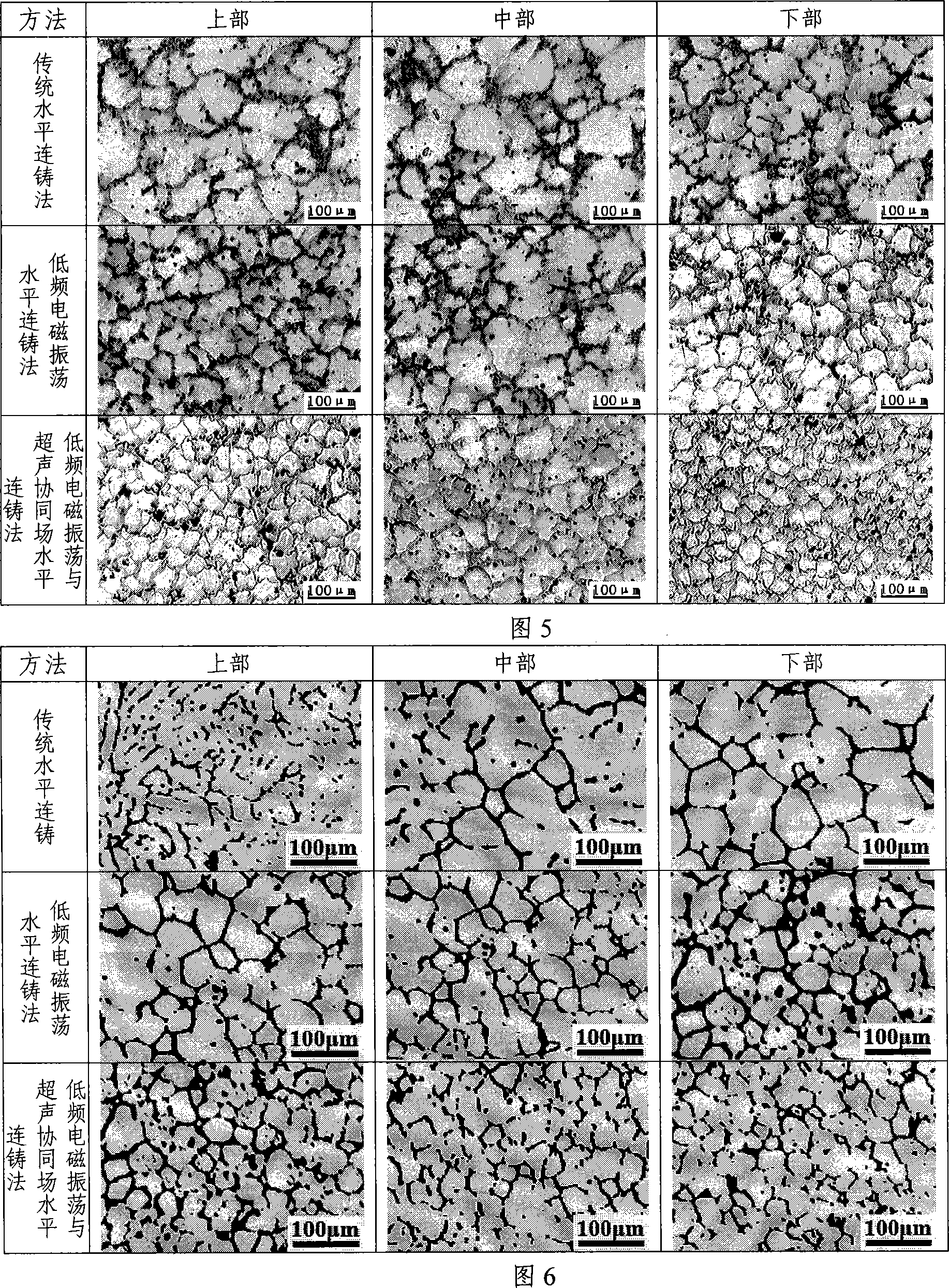

Horizontal continuous light alloy casting process and apparatus with cooperation of power ultrasound wave and low frequency electromagnetic wave

The present invention is horizontal continuous light alloy casting process and apparatus with cooperation of power ultrasonic wave and low frequency electromagnetic wave. In the continuous casting apparatus, one set of exciting windings is set inside the water jacket and applied with AC power to produce low frequency electromagnetic field, or one set of exciting windings is set inside the water jacket while one other set of exciting windings is set between the crystallizer and the pouring basket to produce electromagnetic fields. At the same time, one ultrasonic rod is inserted into the crystallizer to apply power ultrasonic field during casting. The present invention can reduce the temperature gradient in casting blank solidification, alter liquid hole shape, raise the homogeneity of the casting blank and raise casting blank quality.

Owner:NORTHEASTERN UNIV

Precision numerical control milling method for thin-wall parts

InactiveCN101602122AReduce stiffnessGuaranteed machining accuracyMilling equipment detailsNumerical controlEngineering

The invention discloses a precision numerical control milling method for thin-wall parts, and provides a processing method for reducing the milling deformation of the thin-wall parts and improving processing precision and surface quality. When a thin-wall part is finished by fine processing through end milling, the machining allowances of the side wall and a web plate are larger than those of the prior process, and are between 2 and 5mm respectively; when the side wall is processed, the axial depth ap is between 0.2 and 0.8mm, and the radial cutting width is 60 to 80 percent of the diameter of a cutting tool; and when the web plate is processed, the axial depth ap is between 2 and 5mm, and the radial cutting width ae is 10 to 20 percent of the diameter of the cutting tool. The processing method effectively slows down the reduction of the self-rigidity of workpieces and control the cutting force in the thin-wall direction when the processing efficiency is ensured, thereby effectively reducing and controlling the processing deformation of the thin-wall parts, and ensuring the processing precision and surface quality of the parts.

Owner:TIANJIN UNIV OF COMMERCE

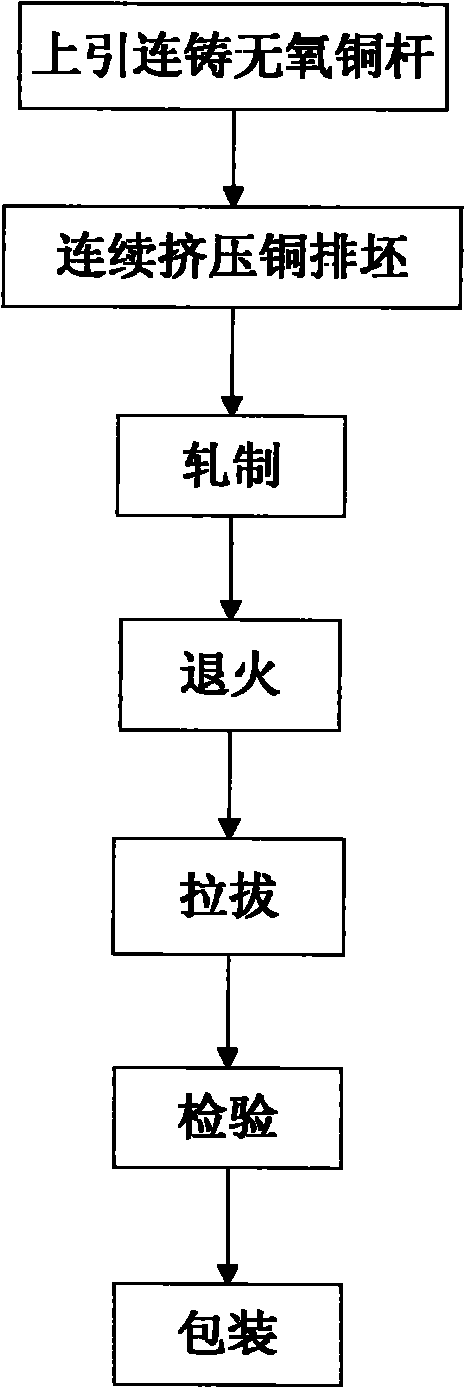

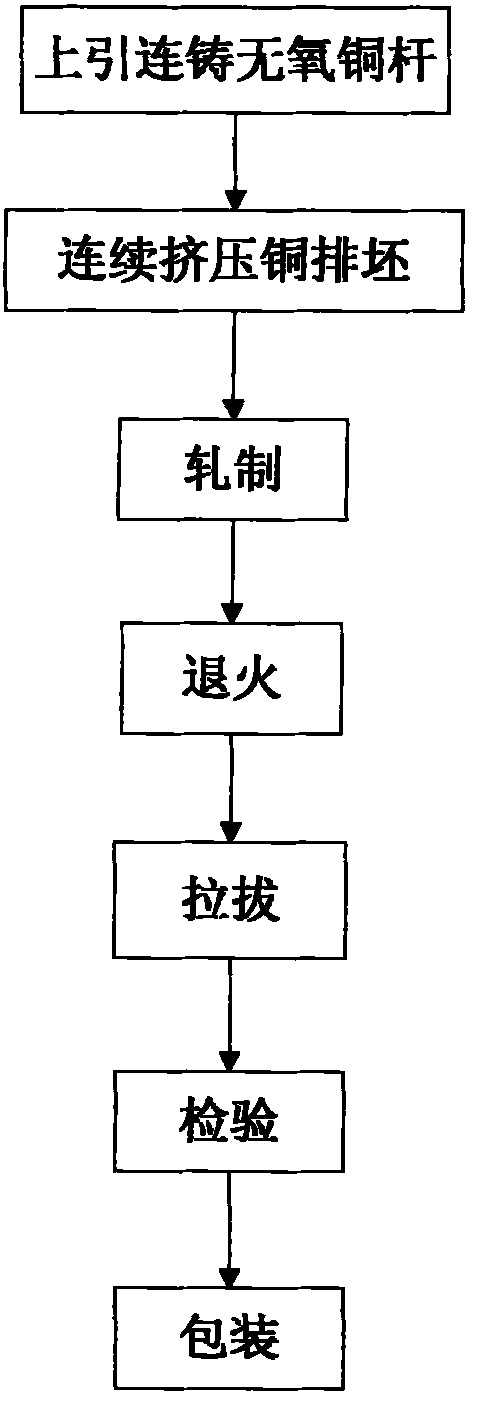

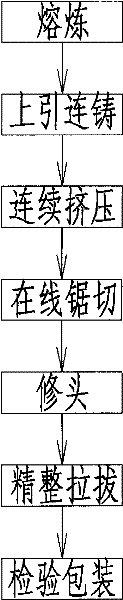

Production method of conducting copper bars for bus duct with large flakiness ratio

InactiveCN101916624AAvoid picklingImprove working environmentOpen bus-bar installationsCable/conductor manufactureLow oxygenHigh conductivity

The invention discloses a production method of conducting copper bars for a bus duct with a large flakiness ratio, belonging to the technical field of processing of non-ferrous metals. The production method is characterized by comprising the following steps of: upward continuously casting oxygen-free copper bars, continuously extruding copper bar billets, rolling, annealing, drawing, checking and packaging. By adopting the continuous extrusion technology to produce the copper bar billets, the continuous production can be realized, and the weight of each roll of copper bar billets can reach more than 3 tons. Moreover, because the copper bar billets are produced in a roll shape, the defect of cutting the head and the tail of each copper bar in the traditional production process is avoided, and the yield of the product reaches more than 90%. Meanwhile, by reasonably setting continuous extrusion process parameters, rolling rate and the like, the invention effectively improves the quality of the product and has the advantages of high purity, low oxygen content, high conductivity, excellent surface quality and the like. The product is detected to show that the content of Cu and Ag is greater than or equal to 99.97%, the content of O is less than or equal to 10ppm, and the conductivity is 98-101% according to the IACS.

Owner:浙江力博实业股份有限公司

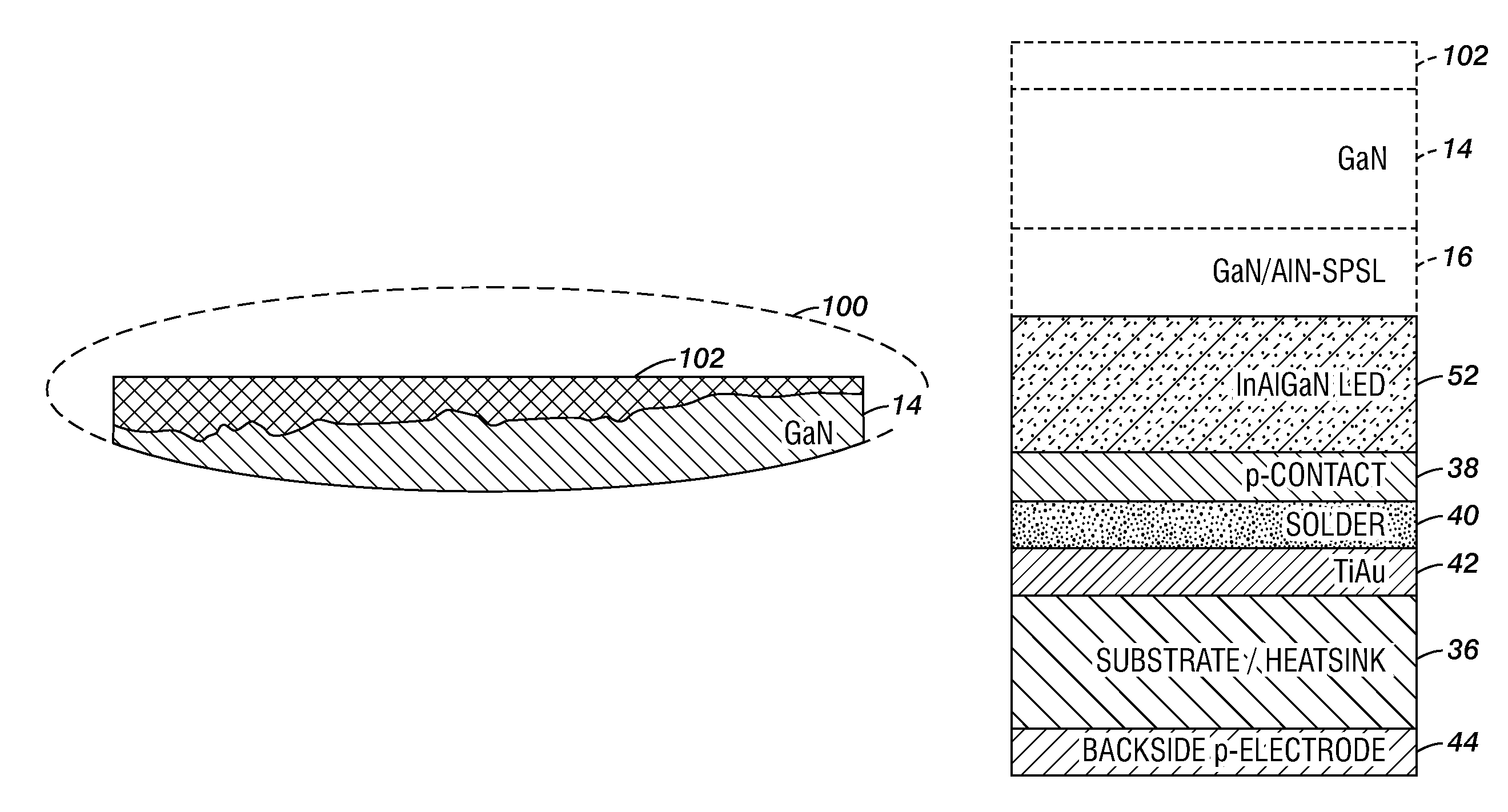

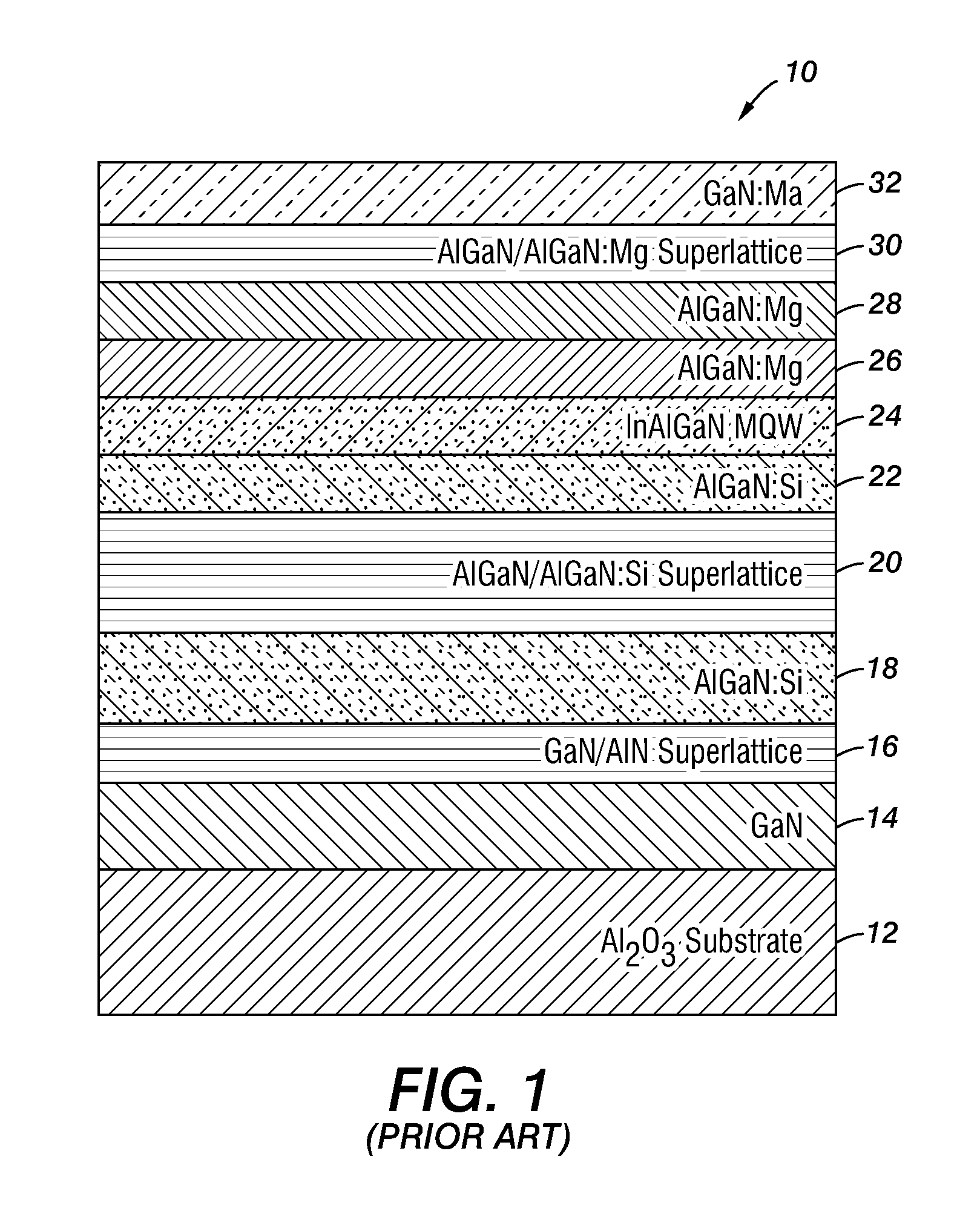

Method for controlling the structure and surface qualities of a thin film and product produced thereby

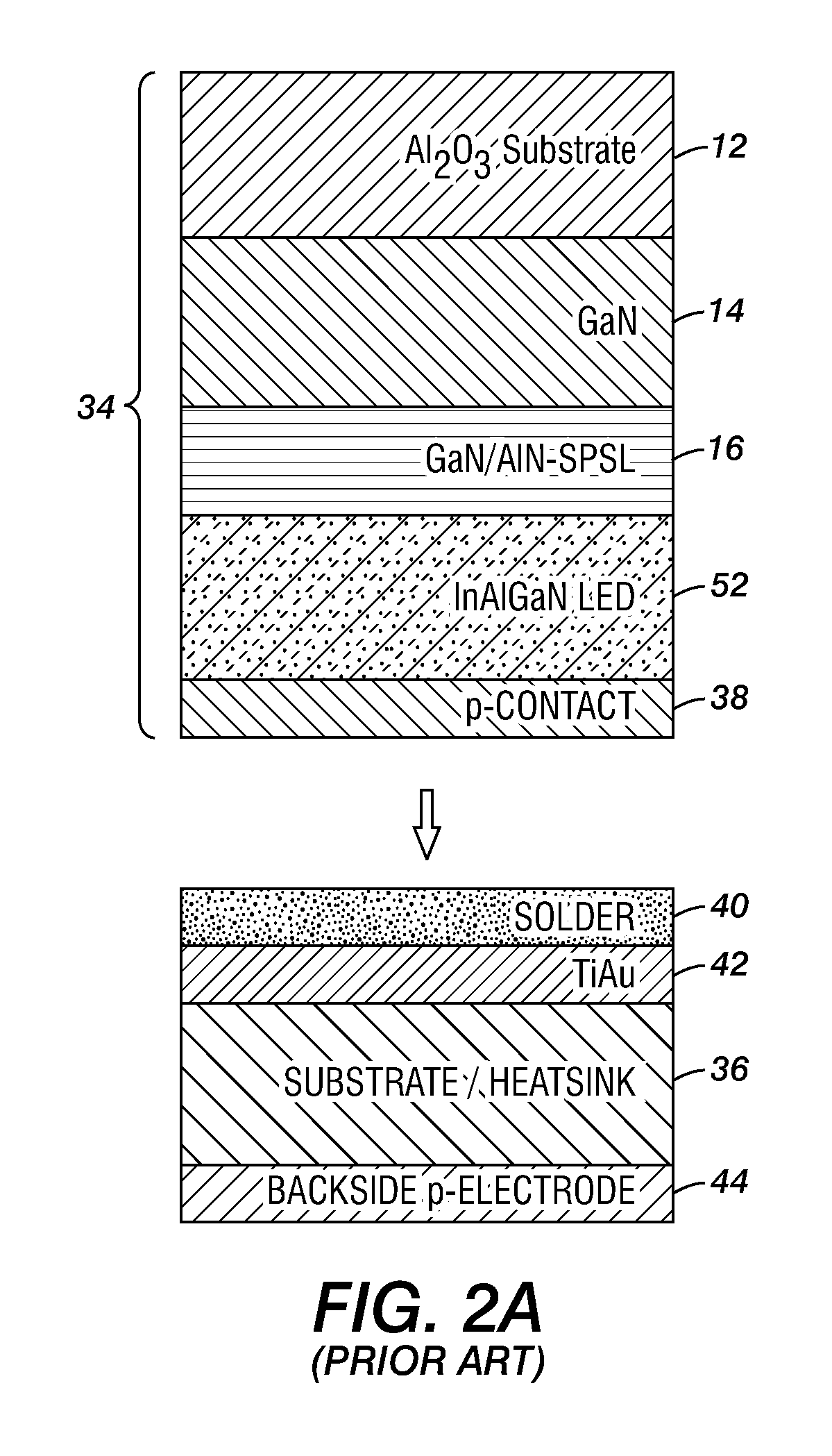

InactiveUS7501299B2Improve structural qualityDevice performance and longevitySemiconductor/solid-state device manufacturingNanoopticsSemiconductor structureQuantum well

A system and method for providing improved surface quality following removal of a substrate and template layers from a semiconductor structure provides an improved surface quality for a layer (such as a quantum well heterostructure active region) prior to bonding a heat sink / conductive substrate to the structure. Following the physical removal of a sapphire substrate, a sacrificial coating such as a spin-coat polymer photoresist is applied to an exposed GaN surface. This sacrificial coating provides a planar surface, generally parallel to the planes of the interfaces of the underlying layers. The sacrificial coating and etching conditions are selected such that the etch rate of the sacrificial coating approximately matches the etch rate of GaN and the underlying layers, so that the physical surface profile during etching approximates the physical surface profile of the sacrificial coating prior to etching. Following etching, a substrate is bonded to the exposed surface which acts as a heat sink and may be conductive providing for backside electrical contact to the active region.

Owner:PALO ALTO RES CENT INC

Physical/Biochemical Sensor Using Piezoelectric Microcantilever And Manufacturing Method Thereof

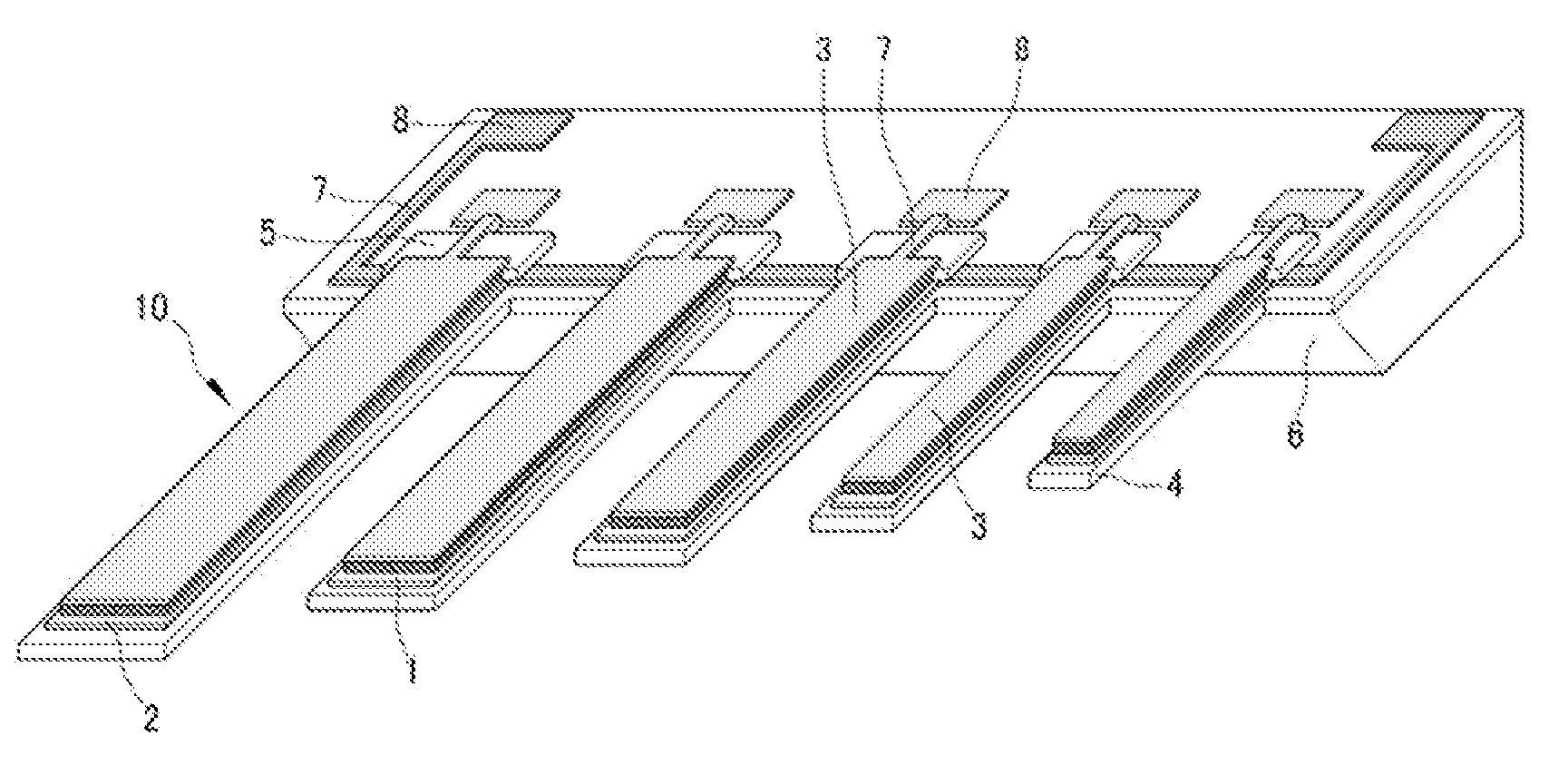

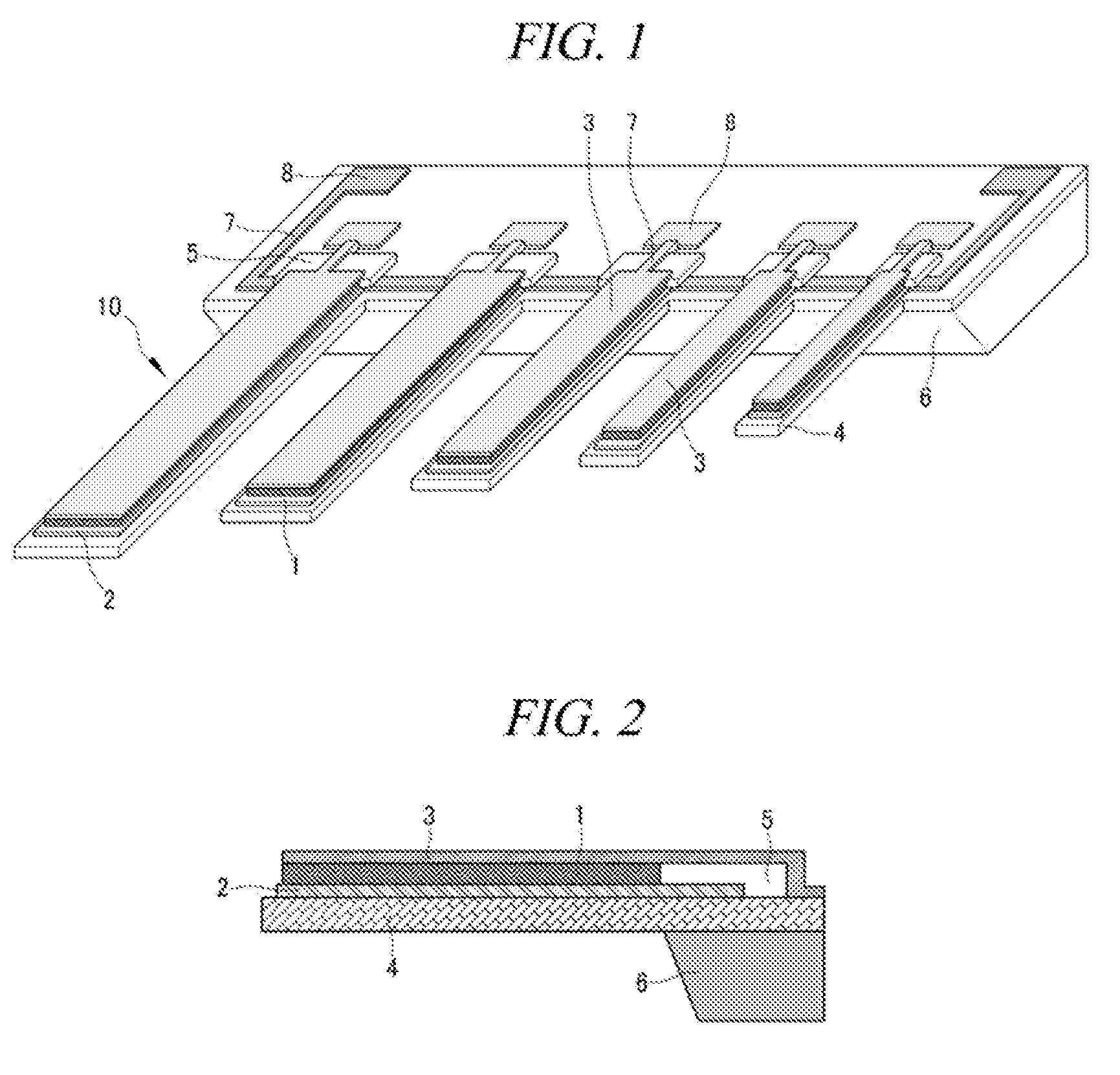

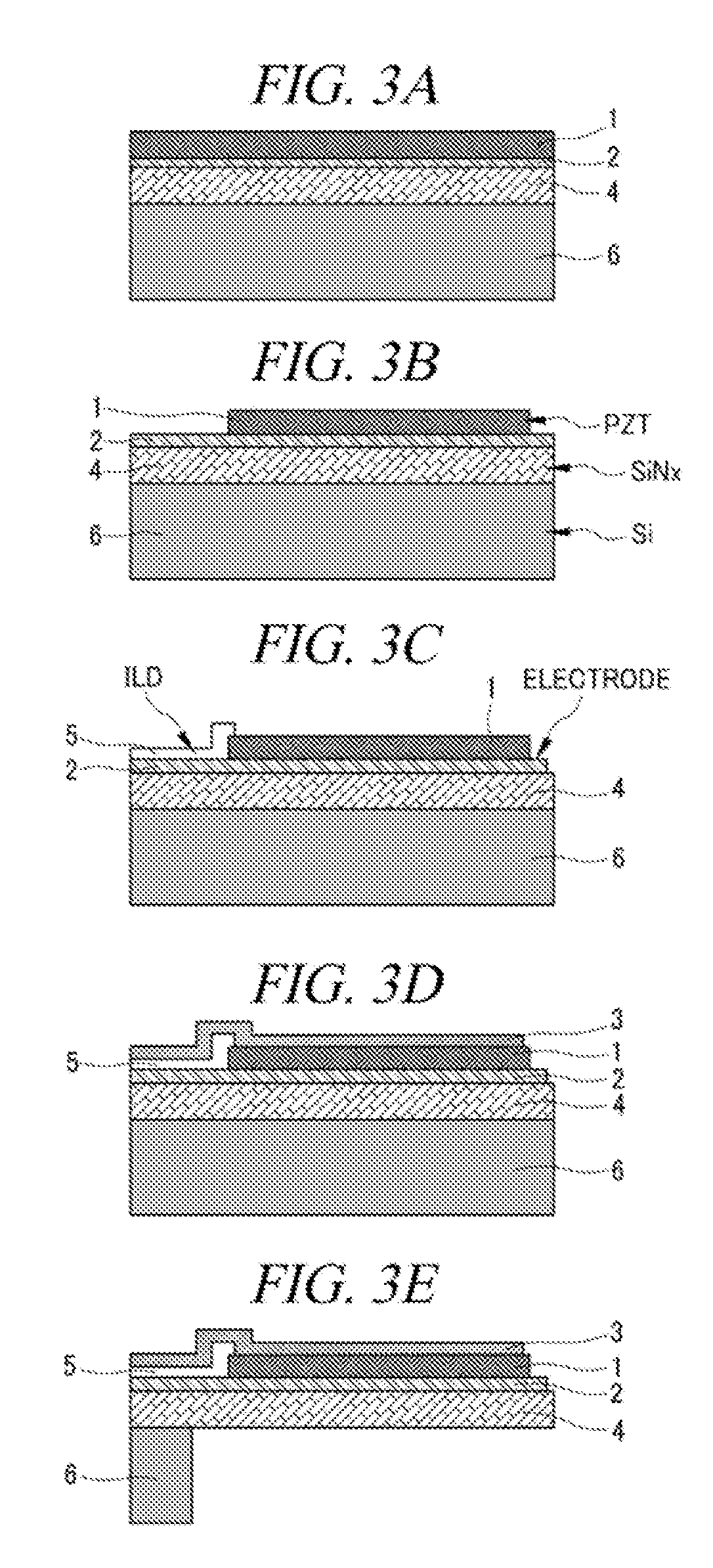

ActiveUS20100033058A1Accurate informationQuick responseMaterial analysis using sonic/ultrasonic/infrasonic wavesPiezoelectric/electrostriction/magnetostriction machinesSurface stressMass loading

The present invention discloses a physical / biochemical sensor using a multisized piezoelectric microcantilever resonator array which enables to quantitatively and simultaneously analyze a mass loading effect and a surface stress change effect and a manufacturing method thereof. In the physical / biochemical sensor using the multisized piezoelectric microcantilever resonator array, a plurality of piezoelectric micro-cantilever resonators having different sizes is arrayed so as to quantitatively and discriminately analyze a surface stress change as well as a sensor surface mass change induced by an adsorbed sensing-target material occurring in a sensing process. Thus, the mass loading effect and the surface stress change effect can be quantitatively and simultaneously analyzed.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

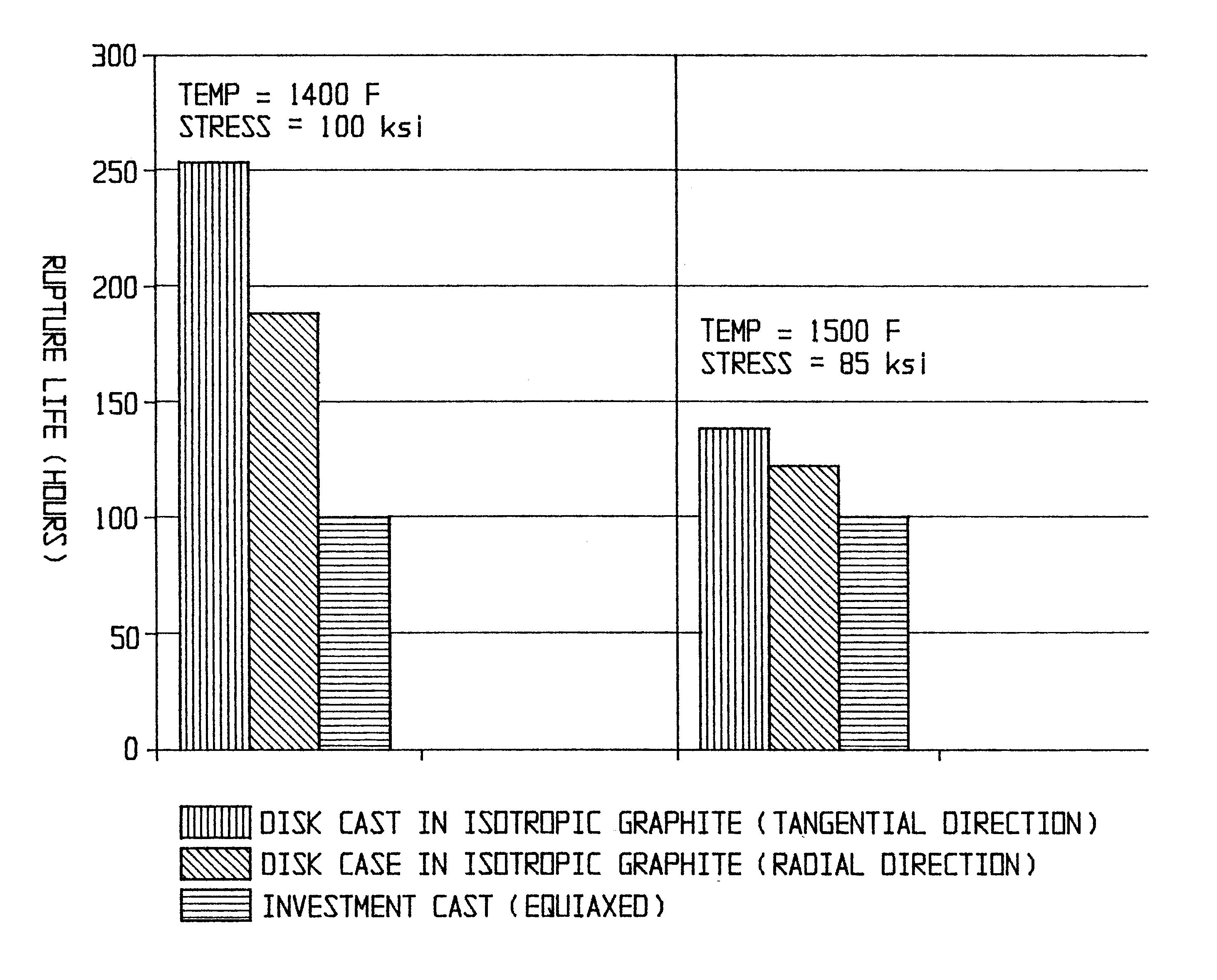

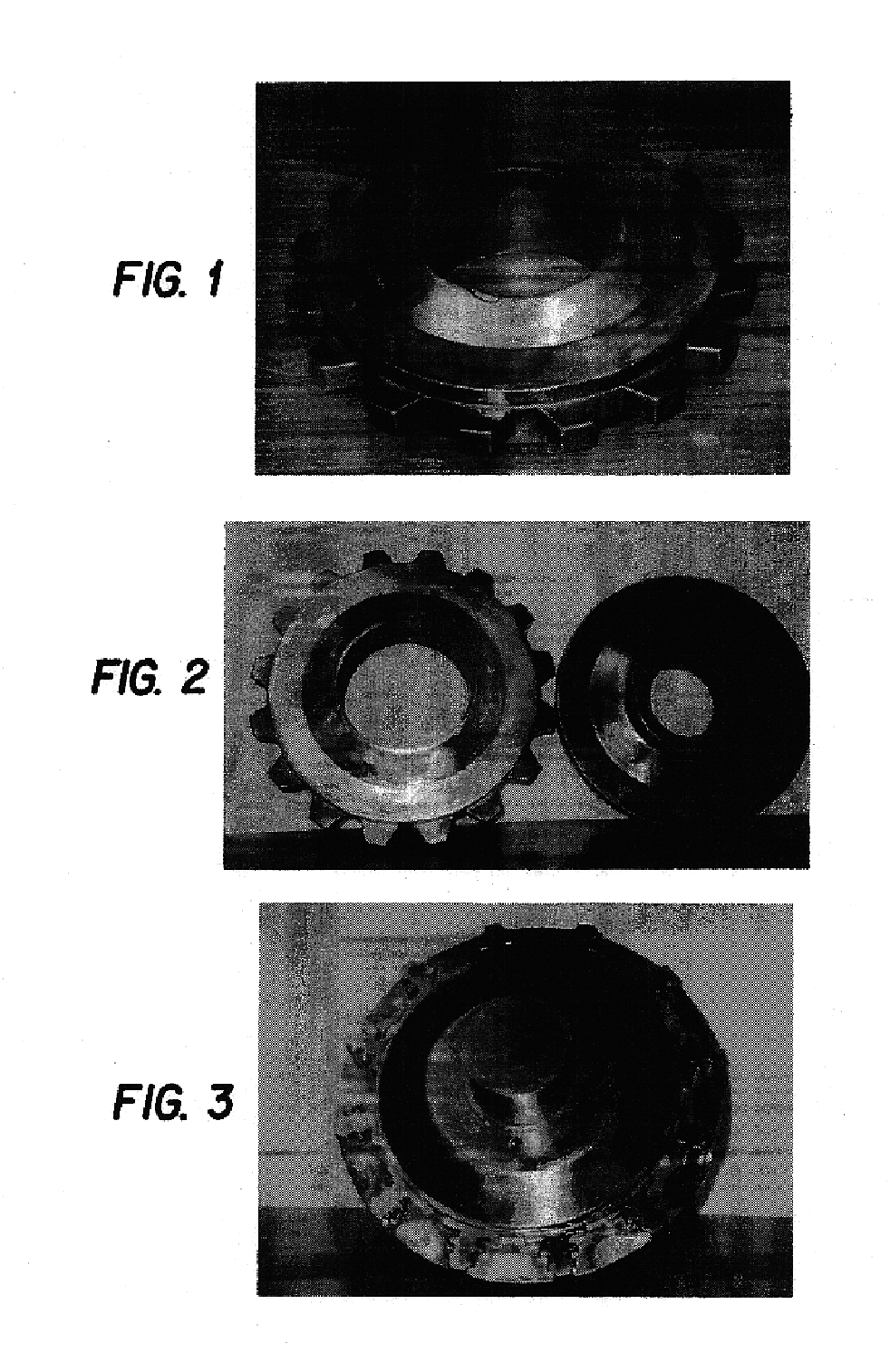

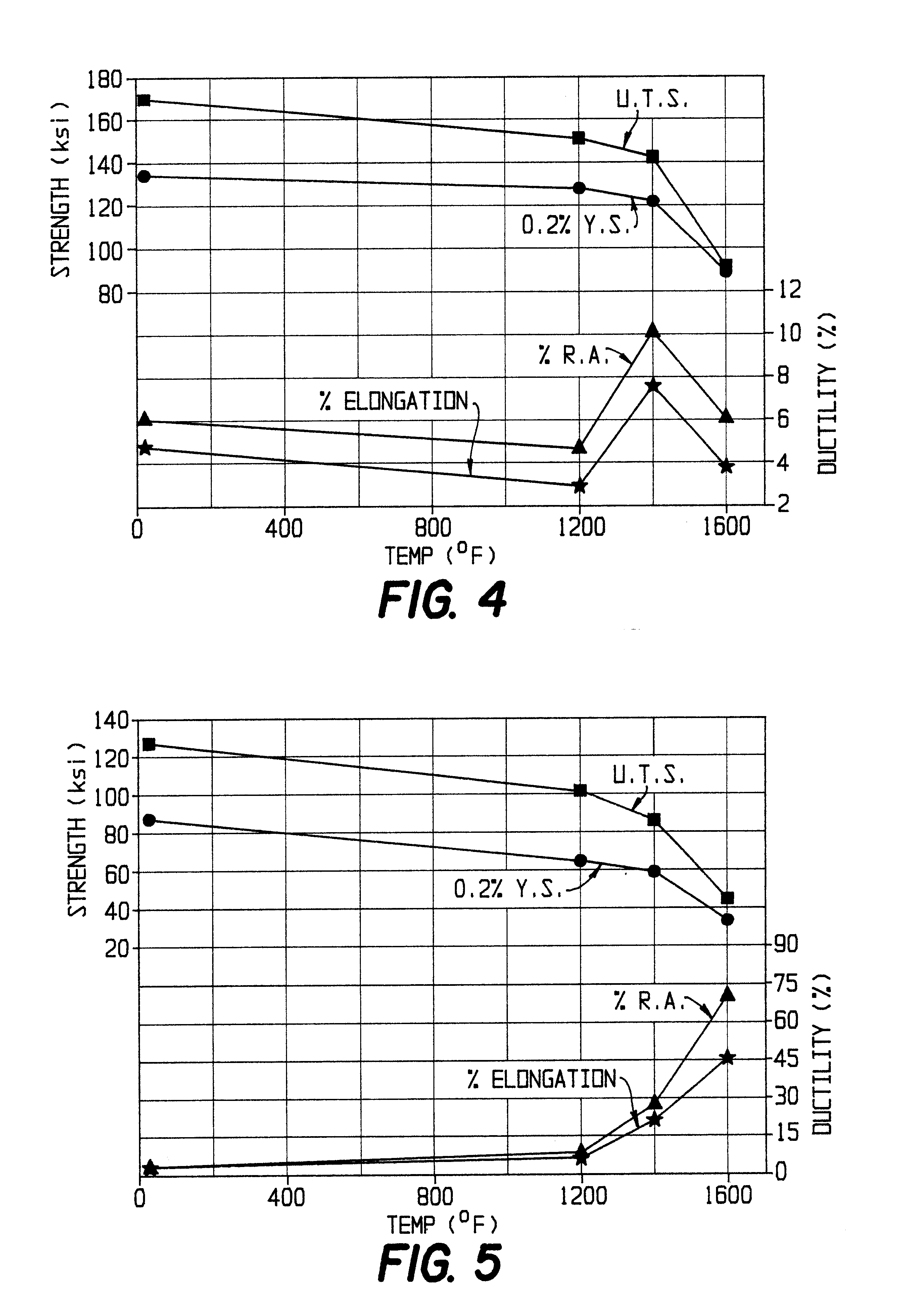

Castings of metallic alloys with improved surface quality, structural integrity and mechanical properties fabricated in finegrained isotropic graphite molds under vacuum

InactiveUS6799626B2Quality improvementImprove mechanical propertiesFoundry mouldsPretreated surfacesSuperalloyCobalt

Methods for making various metallic alloys such as nickel, cobalt and / or iron based superalloys, stainless steel alloys, titanium alloys and titanium aluminide alloys into engineering components by melting of the alloys in a vacuum or under a low partial pressure of inert gas and subsequent casting of the melt in the graphite molds under vacuum or low partial pressure of inert gas are provided, the molds having been fabricated by machining high density, high strength ultrafine grained isotropic graphite, wherein the graphite has been made by isostatic pressing or vibrational molding.

Owner:SANTOKU CORP

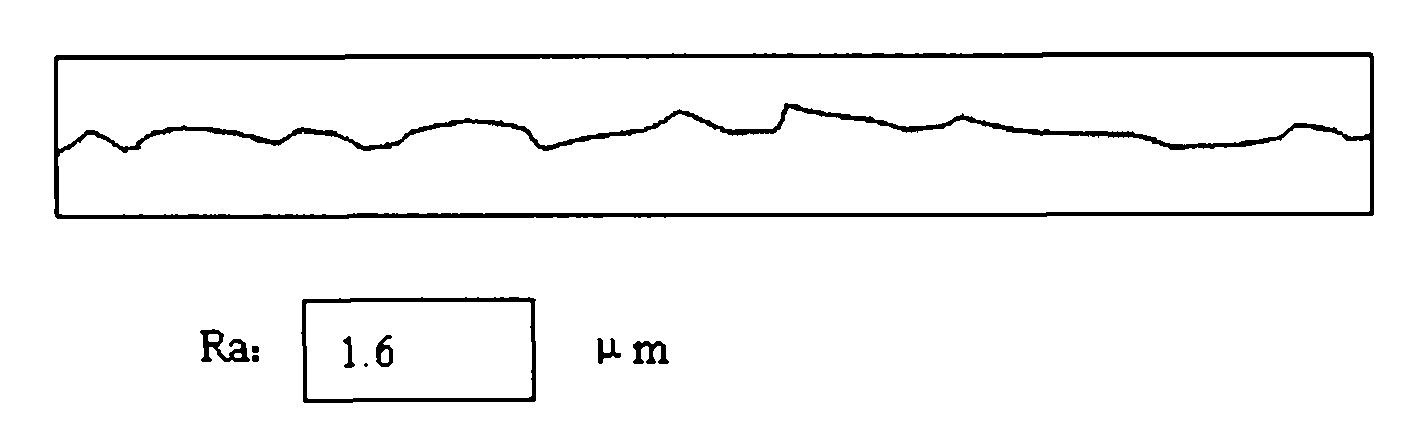

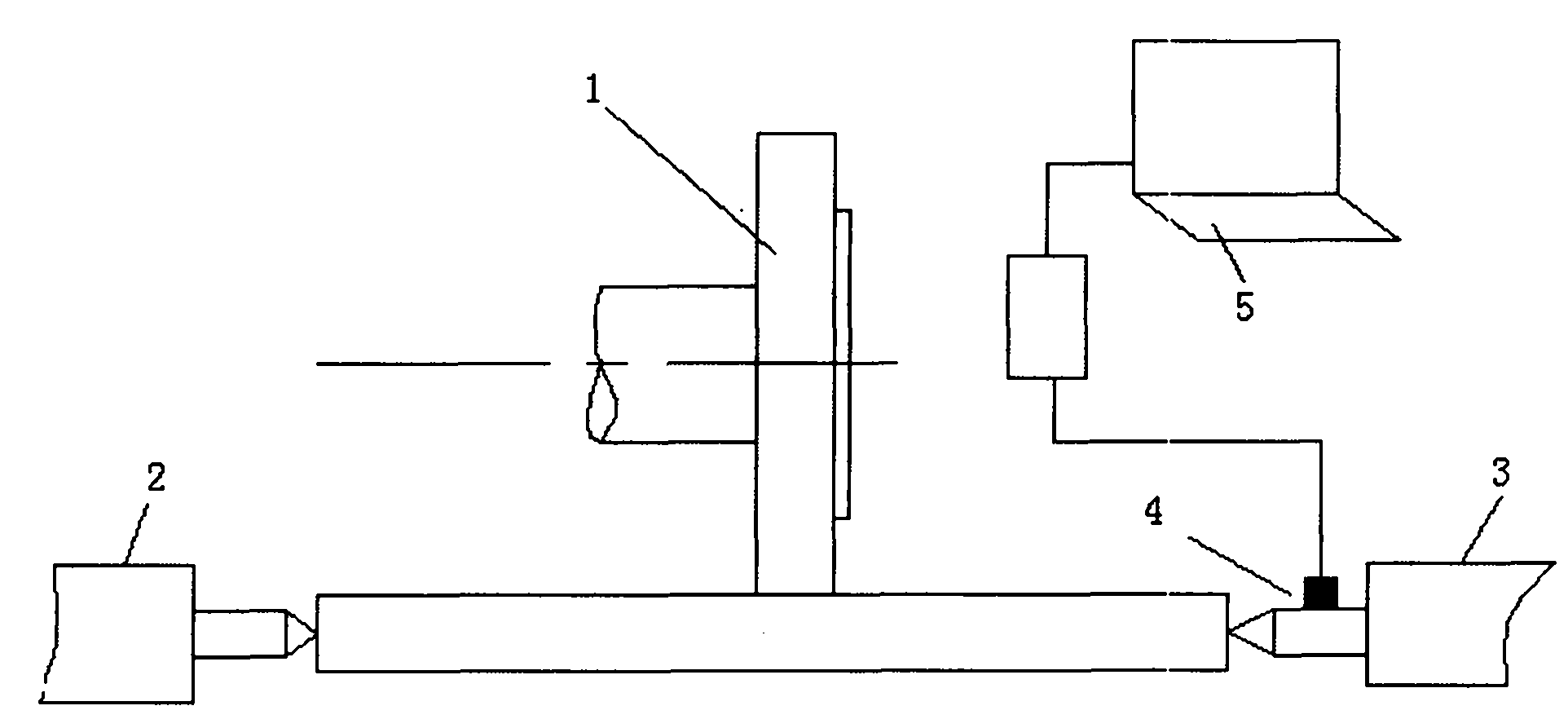

Outer circle grinding workpiece surface quality visualization real-time monitoring method

InactiveCN101829951ARealize visual real-time monitoringImprove grinding efficiencyRevolution surface grinding machinesGrinding feed controlAcoustic emissionData acquisition

The invention relates to an outer circle grinding workpiece surface quality visualization real-time monitoring method, which comprises the following steps of: 1, arranging an acoustic emission sensor and acquiring data; 2, preprocessing an acoustic emission signal; 3, establishing a roughness relationship model between the root mean square (RMS) of the acoustic emission signal and the workpiece surface; and 4, realizing the visualization of the workpiece surface quality in the grinding process. The outer circle grinding workpiece surface quality visualization real-time monitoring method can realize the visual real-time monitoring of the workpiece grinding quality by using the acoustic emission signal, provides help for guiding a grinding machine operator to select technological parameters, and has significance for improving the grinding efficiency and the grinding quality.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

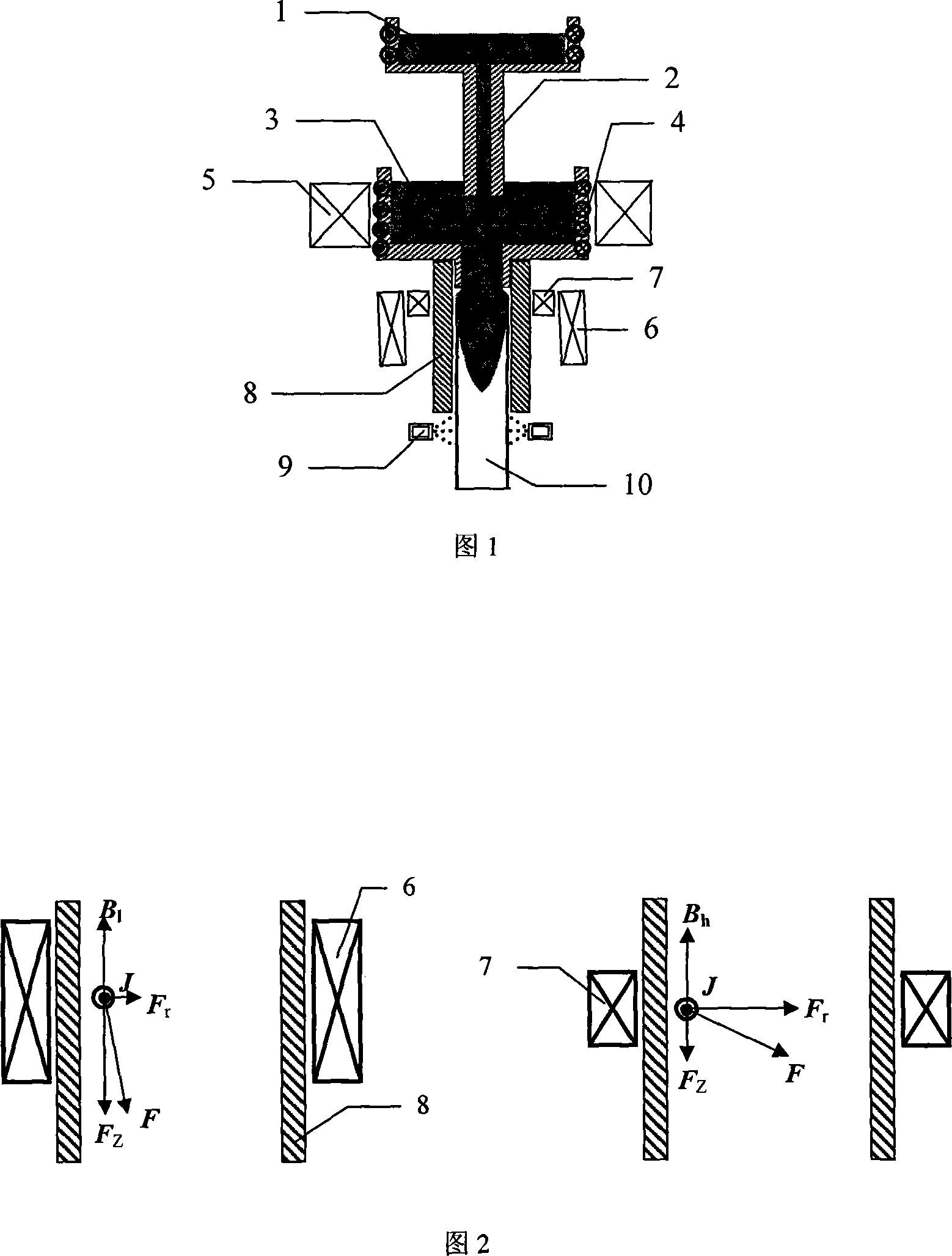

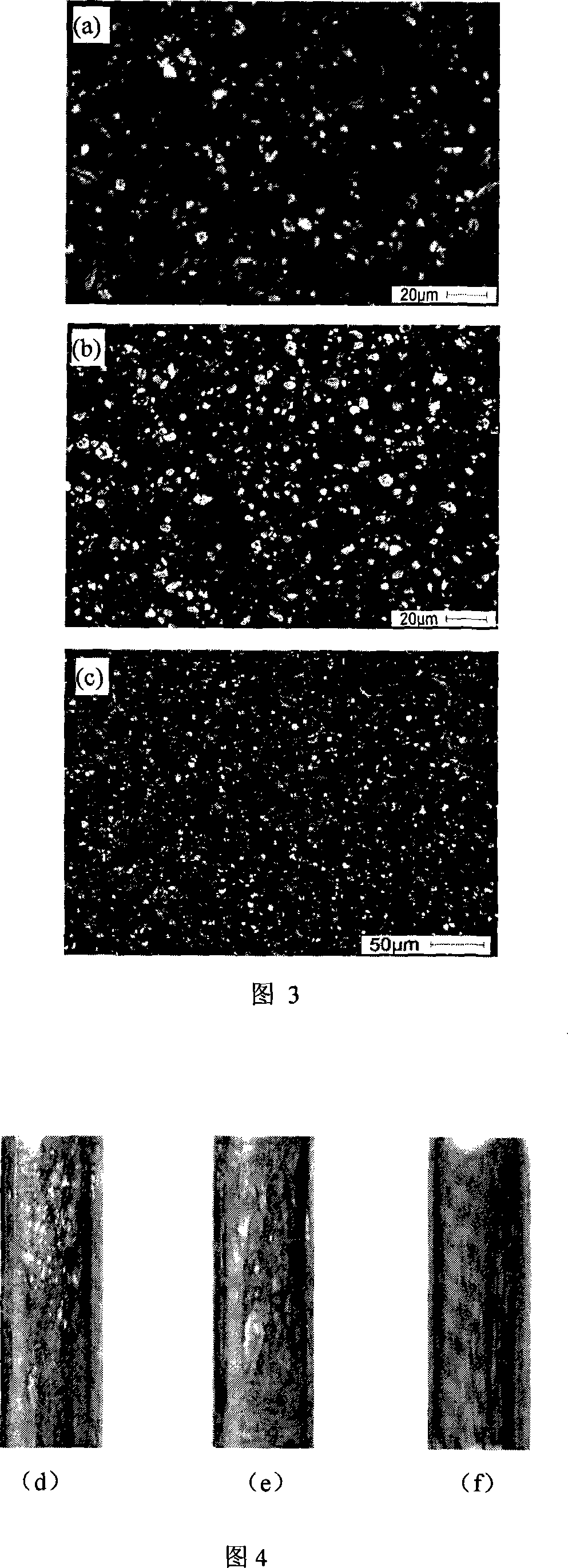

Method of continuous casting particulate reinforced metal matrix composites on different frequency multi-electromagnetic field

Disclosed is a method of particle reinforced metal matrix composite continuous casting in compound magnetic field at different frequency, relating to material processing technology field; in the process of the preparation of the composites melt, low-frequency alternating magnetic field is applied: the frequency is from 5 to 50 Hz, the power range is from 5 to 60 kW; electromagnetic stirring is carried out, making the particles to be fined and evenly distributed; in the process of continuous casting, low-frequency alternating magnetic field is applied to the crystallizer zone: the frequency is from 5 to 50 Hz, the power range is from 5 to 20 kW; electromagnetic stirring is carried out to improve the internal quality; meanwhile, the high-frequency alternating magnetic field is applied in initial solidification zone in crystallizer: the frequency is from10 to 50 kHz, the power range is from 20 to 100Kw, soft contact is applied to improve the surface quality of casting billet. The composites article reinforcement prepared by the method are evenly distributed and fined, the internal organization is compact without any structural defects such as rarefaction or shrinkage hole, the casting billet has high surface finish without any defects.

Owner:JIANGSU UNIV

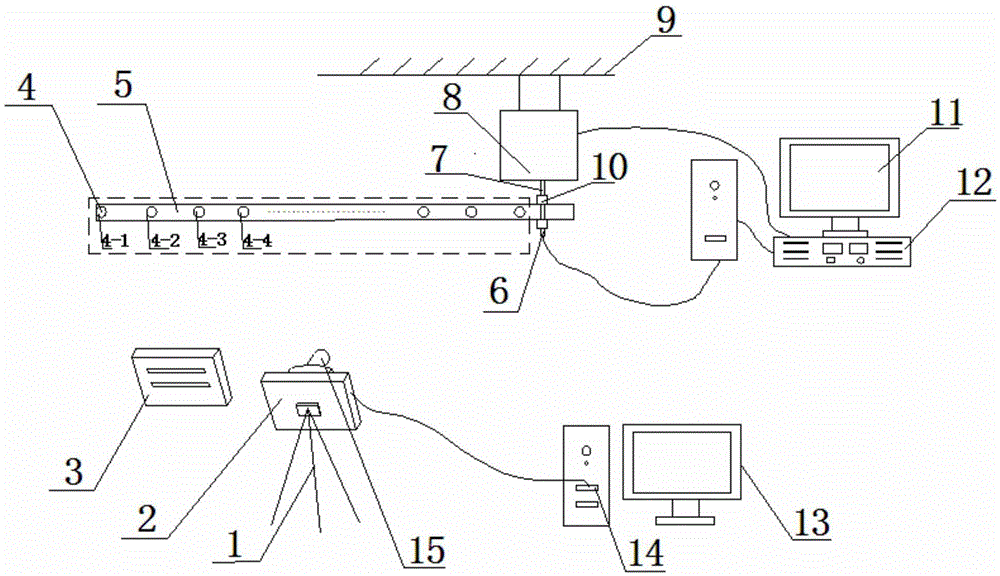

Method and system for thin-wall part modal testing based on machine vision

ActiveCN105424350AGuaranteed accuracyImprove spatial resolutionMachine part testingSubsonic/sonic/ultrasonic wave measurementModal testingConstant frequency

The invention discloses a method and system for thin-wall part modal testing based on machine vision. The method for the thin-wall part modal testing comprises the steps that a to-be-tested thin-wall part is fixed on an excitation head of an exciter and the to-be-tested thin-wall part is driven to perform equal-frequency vibration; meanwhile, a CCD industrial camera is used to continuously collect images of a vibration course of the thin-wall part; image processing is carried out to acquired sequence images so as to obtain an inherent frequency; the constant-frequency vibration of the thin-wall part is carried out under the inherent frequency; the continuous sequence images under the constant-frequency vibration are acquired; the image processing is carried out to the acquired continuous sequence images; and further a modal shape under the inherent frequency is obtained. The system disclosed by the invention has the advantages of a flexible structure; a complicated debugging course is not required; only low requirements are proposed for surface quality of the thin-wall part; non-contact measurement is carried out; vibration characteristics of a tested object are not changed; and the system has the advantages of high measurement precision and high efficiency, etc.

Owner:HUNAN UNIV OF SCI & TECH

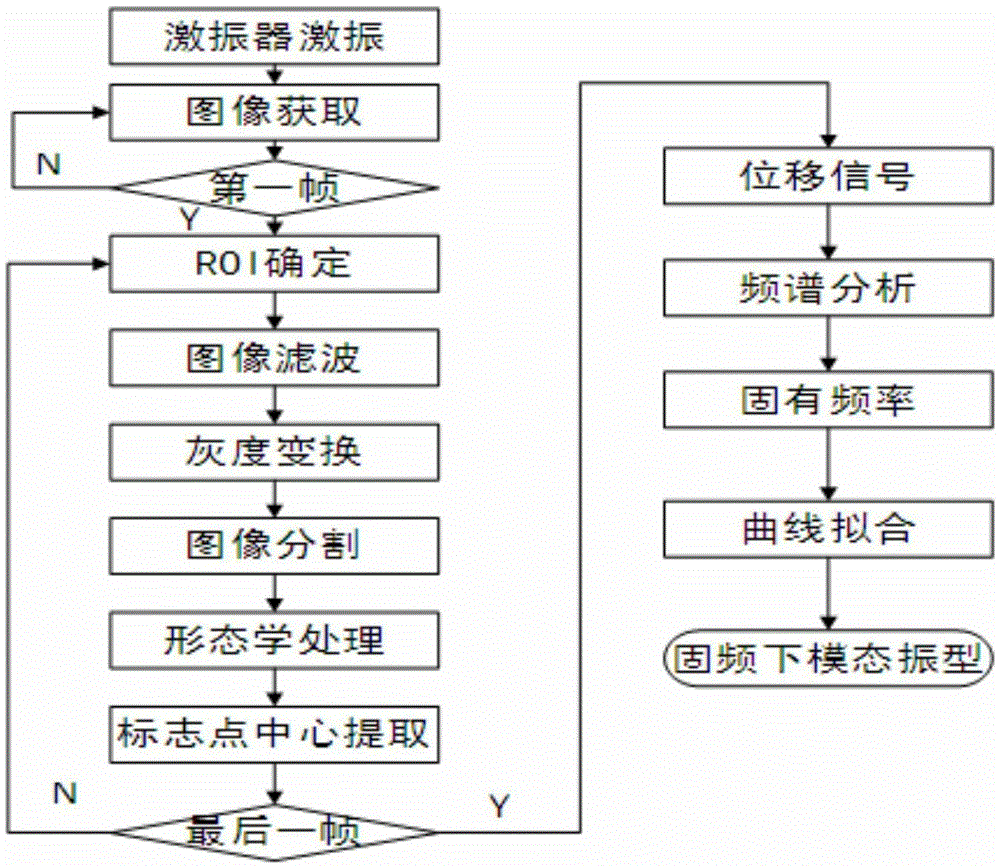

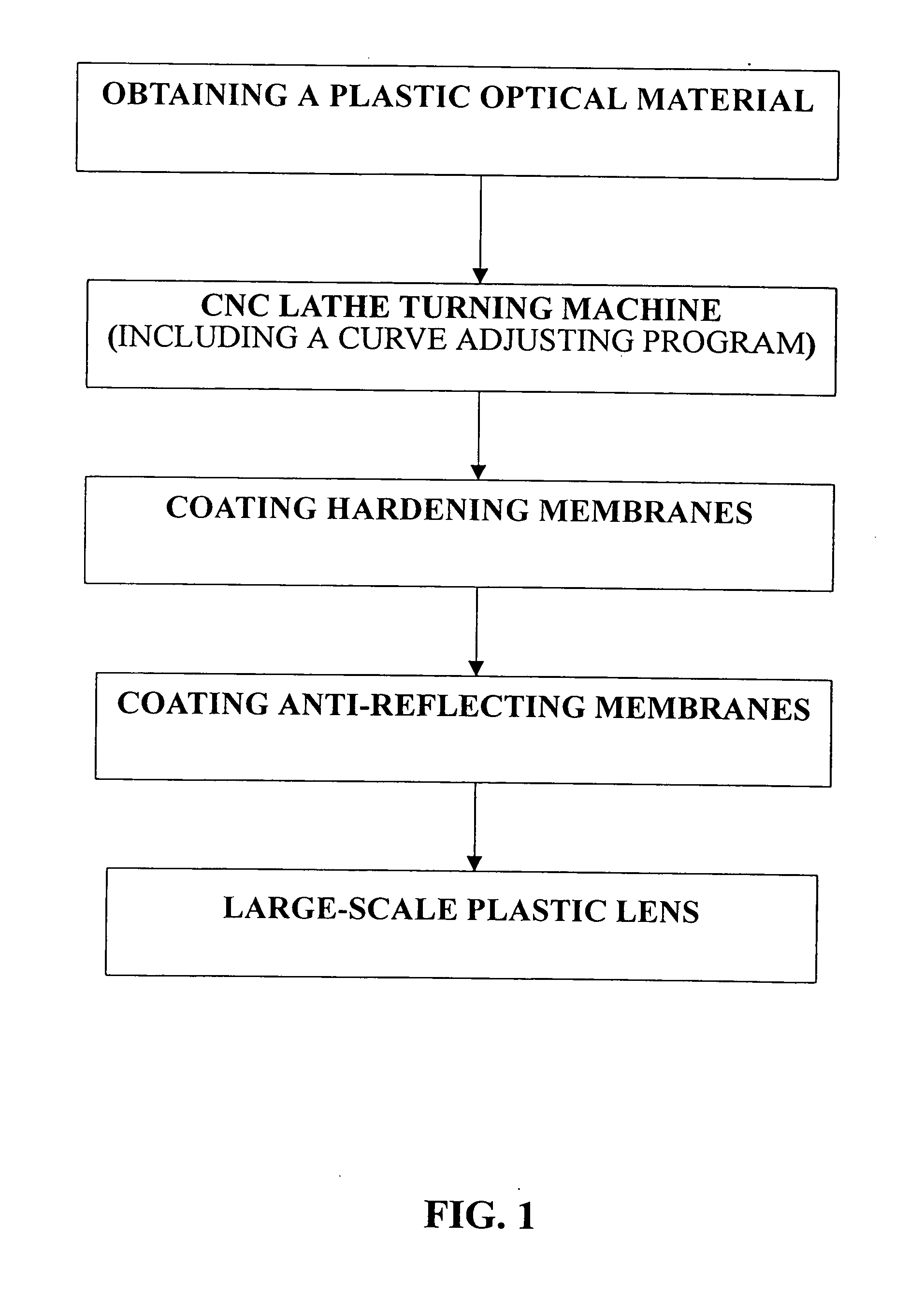

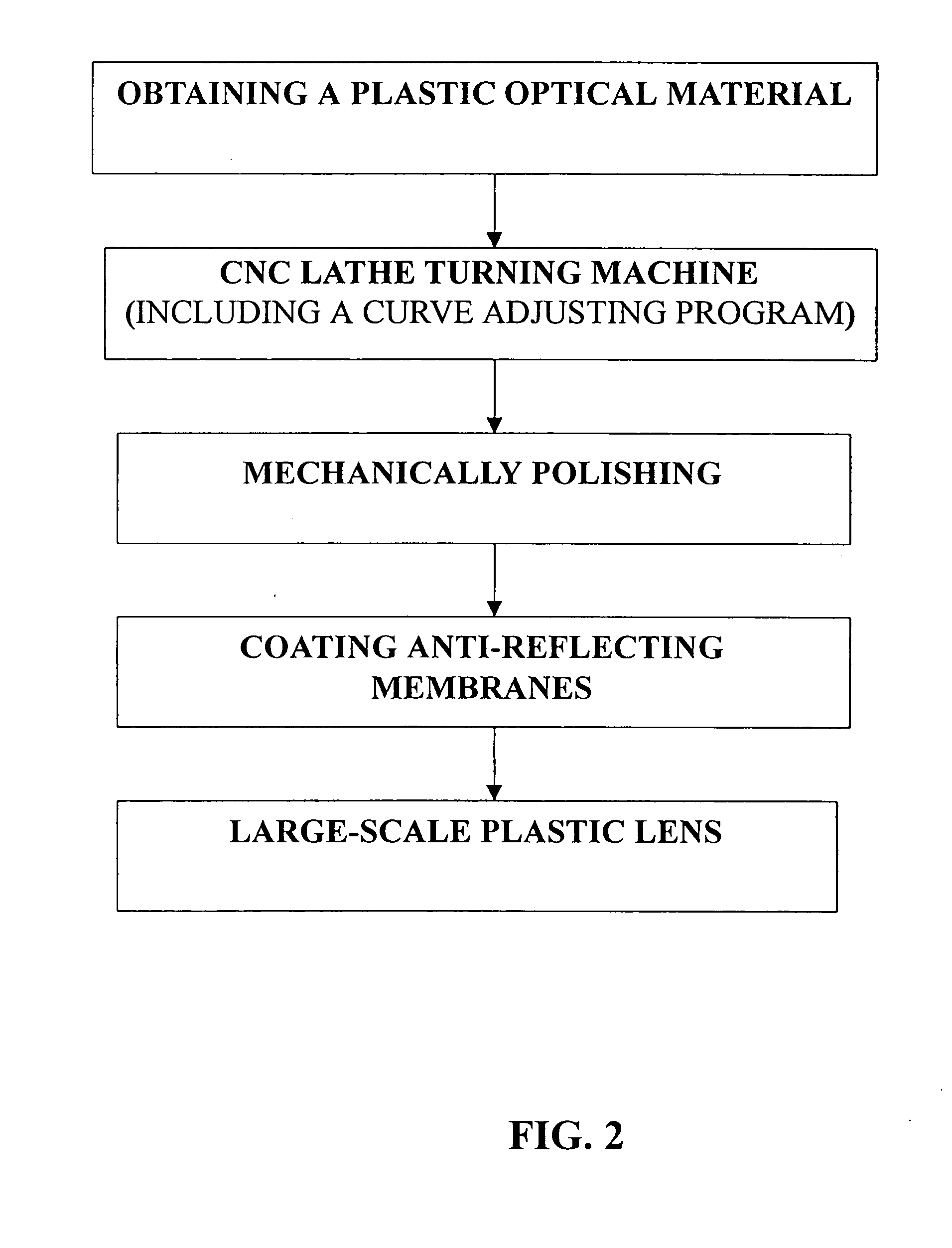

Methods for manufacturing large-scale plastic lenses

InactiveUS20050260343A1The production process is simpleReduce manufacturing costOptical surface grinding machinesOptical articlesAspheric lensMembrane configuration

Methods for manufacturing large-scale plastic lenses that cut a plastic optical material piece into a non-spherical lens by use of an accurate CNC lathe turning machine cooperating with a curve adjusting program to correct variations caused in the following steps. After cutting, the non-spherical lens is coated with hardening membranes or / and selectively polished to improve surface quality of surfaces of the non-spherical lens. Lastly, anti-reflecting membranes coat on the hardening membranes to achieve a large-scale plastic lens. By the methods, manufacturing procedures of the large-scale plastic lens are simplified to save time and to reduce manufacturing costs.

Owner:I STRONG SYST

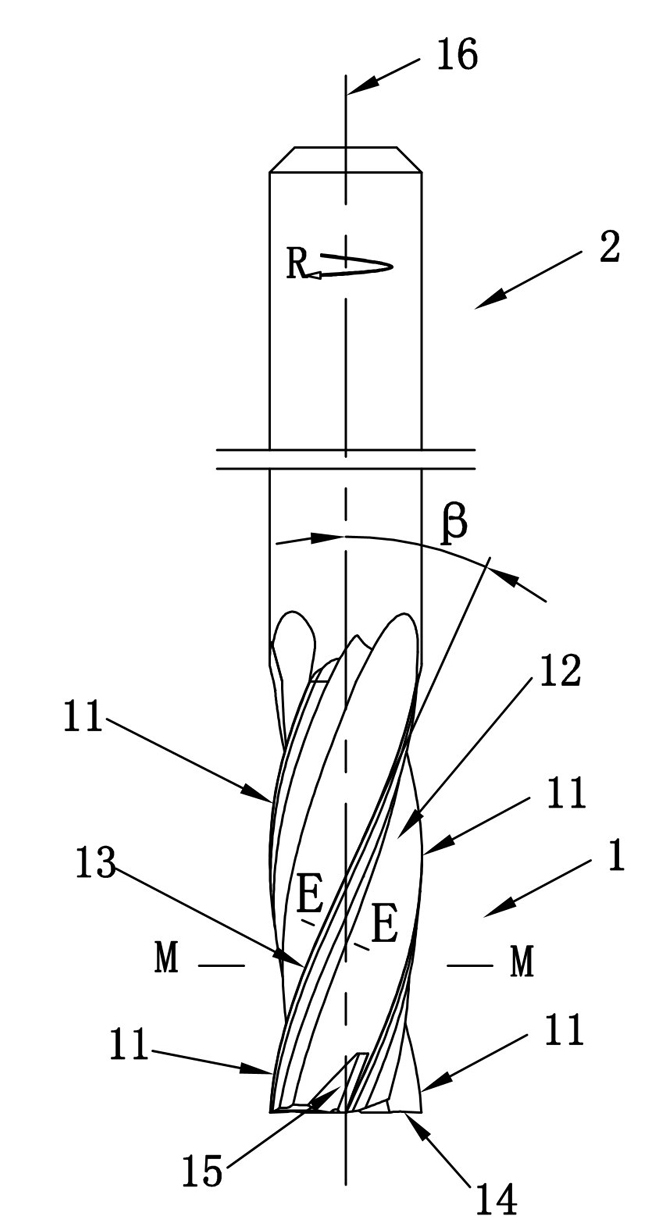

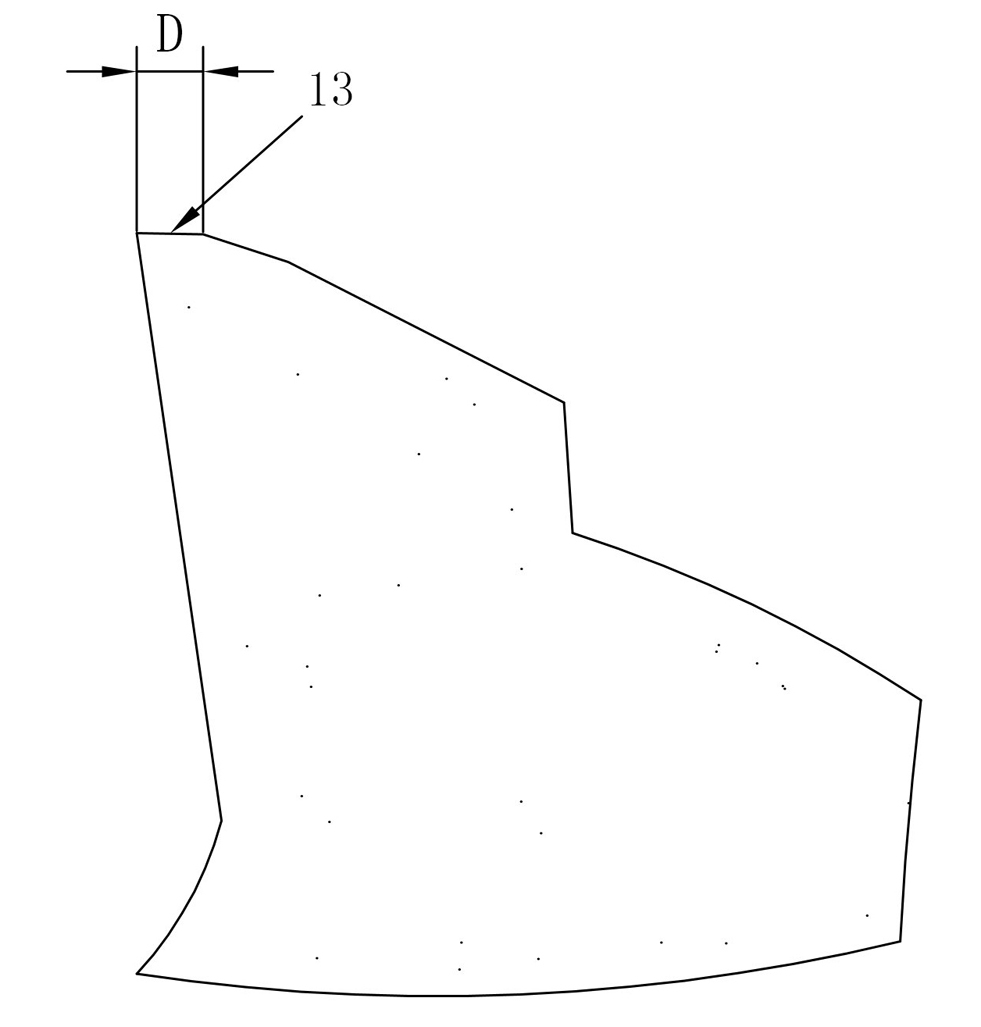

End milling cutter for processing nonferrous metal

InactiveCN102009216AImprove surface qualityReduce residual depthMilling cuttersRadial planeNonferrous metal

The present invention discloses an end milling cutter for processing nonferrous metal, comprising a cutting part and a handle part, wherein the whole cutting part is provided with a plurality of peripheral cutting edges spirally extending from a bottom end to the handle part; a spiral chip removal slot is disposed between two adjacent peripheral cutting edges; in the radial plane of the cutting part, two included angles formed by a connecting line from each peripheral cutting edge to a rotation centre of the end milling cutter and a connecting line from two adjacent peripheral cutting edges to the rotation centre of the end milling cutter are not dimensionally identical; the difference of the two included angles is [alpha], wherein the absolute value of [alpha] is greater than 0 degree but less than or equal to 30 degrees. The end milling cutter for processing nonferrous metal has the advantages that the structure is simple, resonances generated during cutting process can be avoided, the resonance trend during the cutting is reduced, and the surface quality of processed workpieces is improved.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Thermoplastic resin-laminated structure, method for preparation and use thereof

InactiveUS20080063847A1Maintain good propertiesReduce usageLayered product treatmentSynthetic resin layered productsElectricityElectrical resistance and conductance

Systems and methods consistent with the present invention provide a thermoplastic resin-laminated structure having an exterior layer, a base layer, and a binding layer that is placed between the exterior layer and the base layer. The exterior, base and binding layers include at least one material selected from a group consisting of electric resistance-heat generating materials and heat-conductive materials, and has at least one connection terminal at a certain region for supplying at least one of electricity or heat. The resin-laminated structure has excellent properties such as adhesive strength between a base layer and an exterior layer, and recycling utility as well as surface quality in feeling, thermal durability, acoustic absorptivity, heat-shielding property, and impulse-durability. Therefore, it can be used for interior automotive trims, acoustic absorptive members, heat-insulating members, lagging members, protective coating members, anti-vibration members, and sound-blocking members for civil engineering and construction, anti-vibration and sound-blocking members for sewage and water pipe, soundproofing members for hot-water “ondol”, plastic furniture, various multi-layer mats, handles, sofas, chairs, various toys, middle soles of shoes, and golf bags. A method for preparing the resin-laminated structure is also provided.

Owner:CHANG HONG GEUN

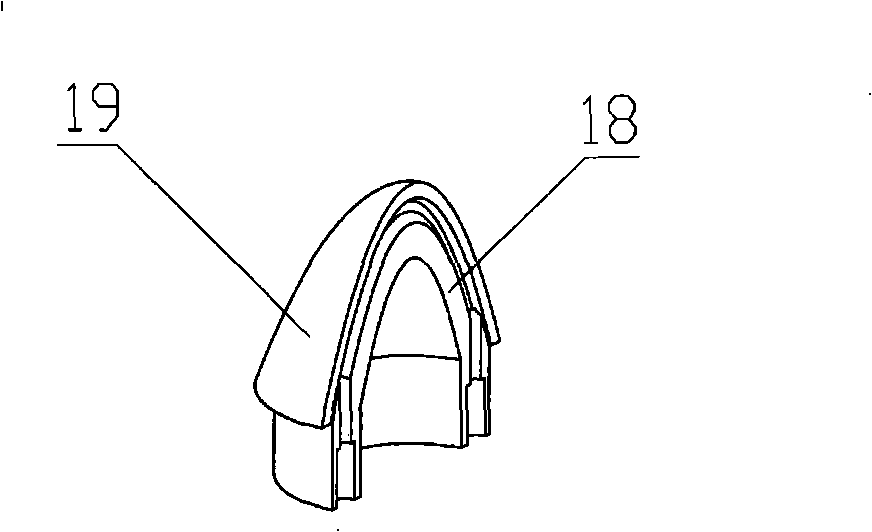

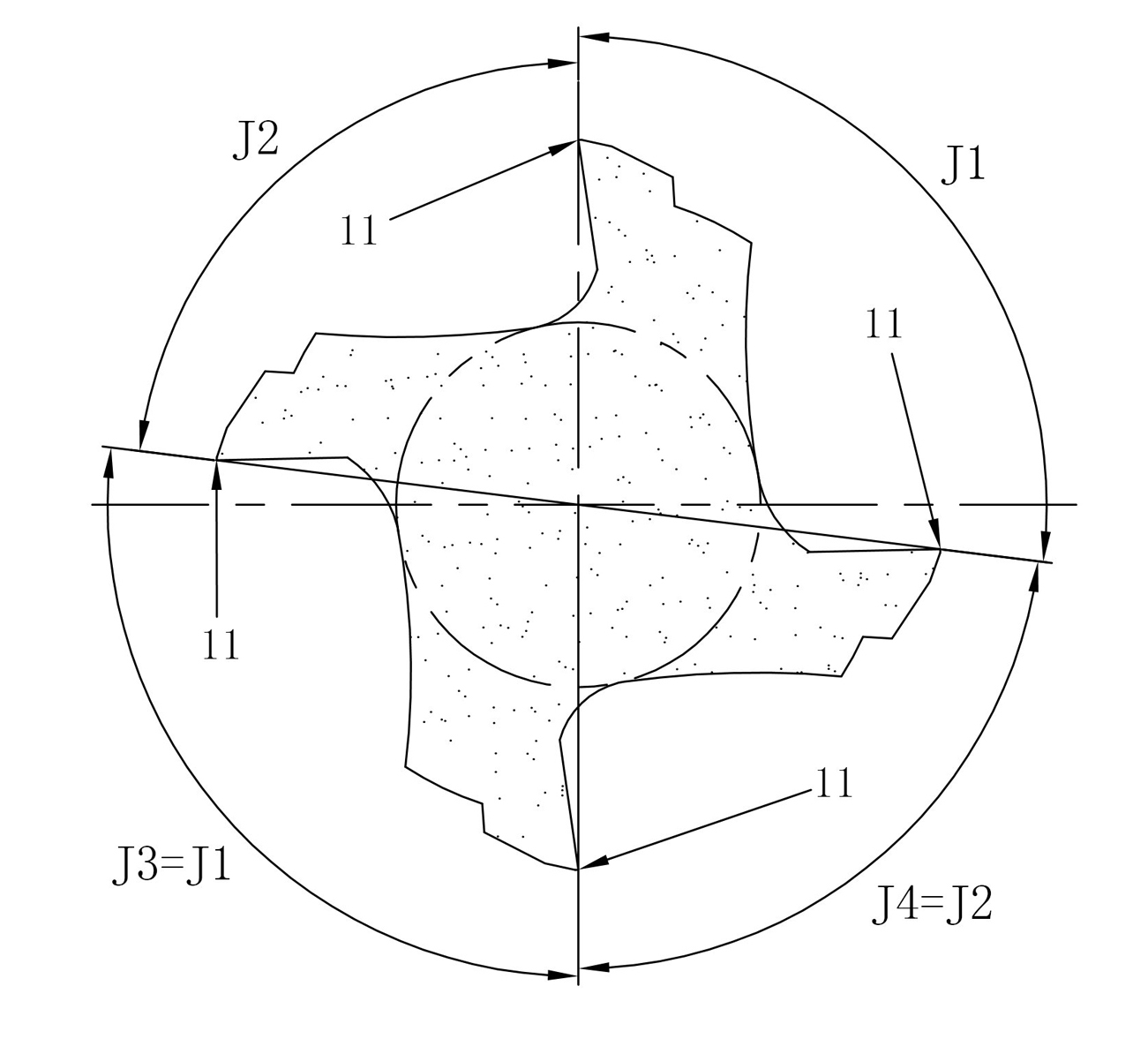

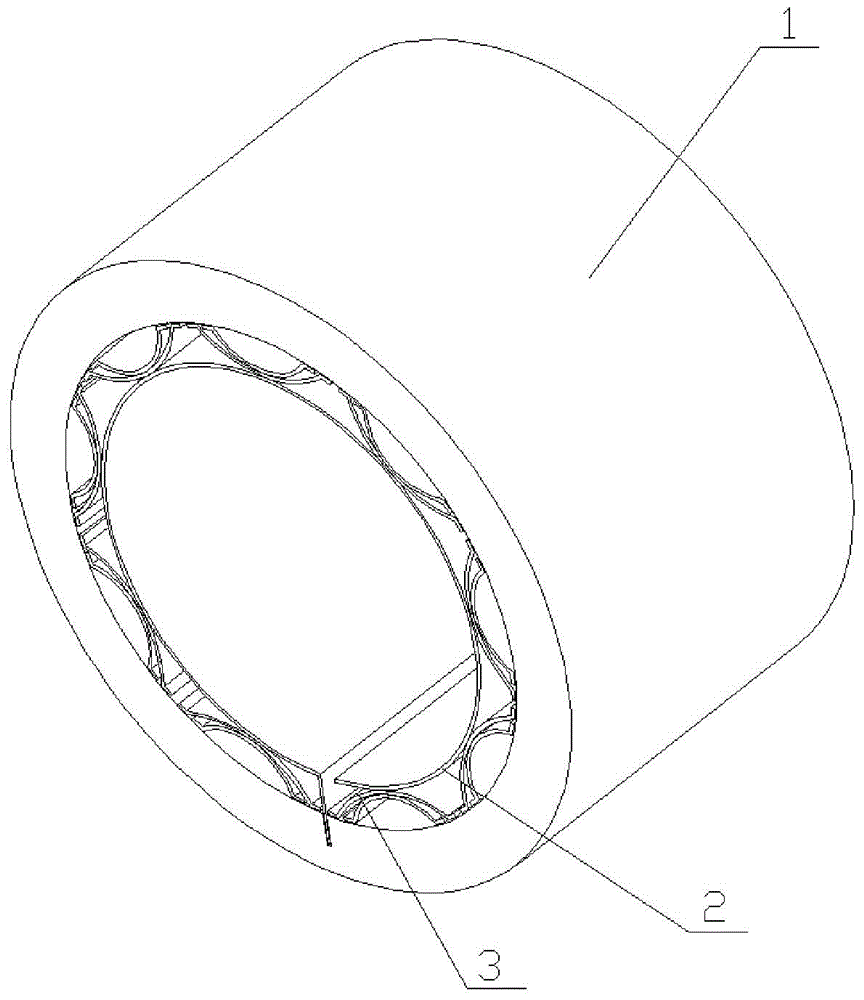

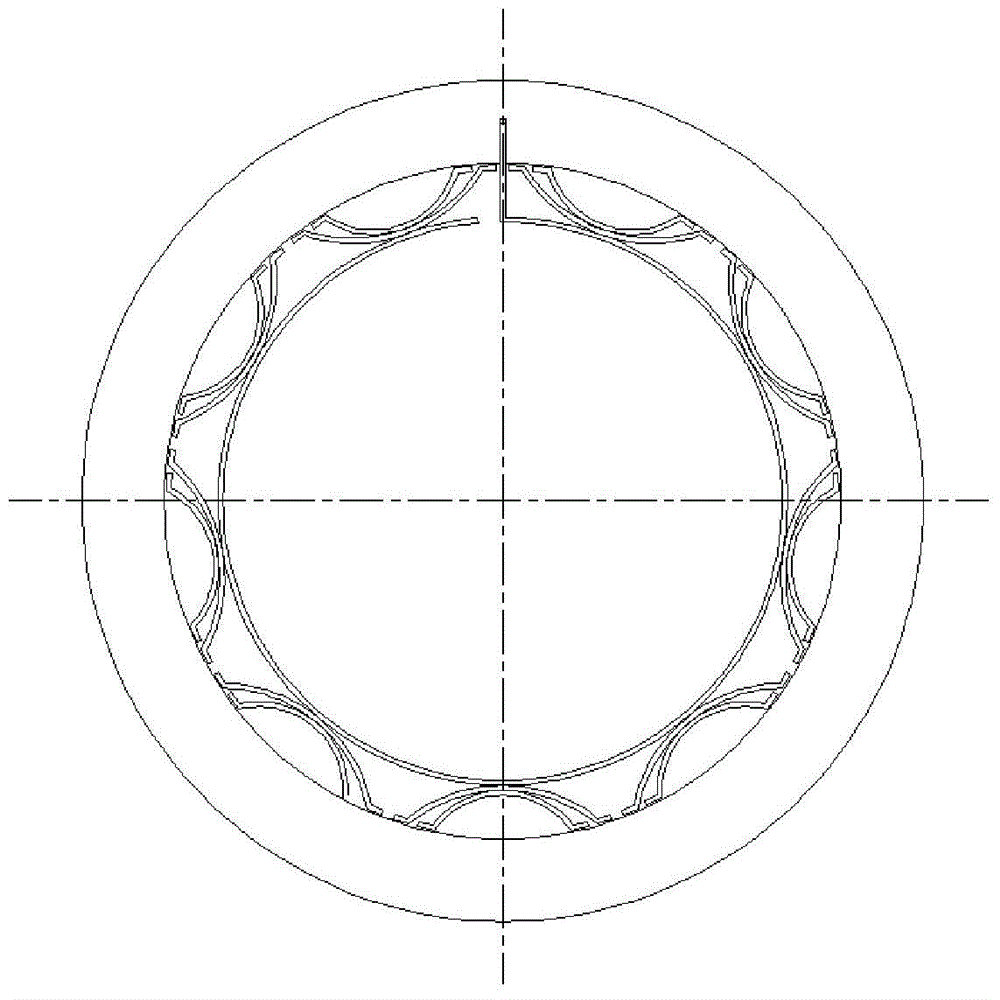

Minitype foil aerodynamic pressure bearing

InactiveCN104632871AQuality improvementImprove performance parametersSliding contact bearingsCushioningEngineering

The invention discloses a minitype foil aerodynamic pressure bearing. The minitype foil aerodynamic pressure bearing comprises a bearing body, a top layer foil and a composite elastic wave foil structure, wherein the composite elastic wave foil structure is connected with the top layer foil for circumferential location, the composite elastic wave foil structure comprises an outer elastic wave foil and an inner elastic wave foil, the convex surface of the inner side of the composite elastic wave foil structure is connected with the tangent position of the outer surface of the top layer foil, the convex surface of the outer side of the composite elastic wave foil structure is contacted with the inner surface of the bearing body, and the bearing body has mounting, protecting and supporting actions; and a matching surface of the bearing and a rotating shaft is formed on the inner surface of the top layer foil. According to the minitype foil aerodynamic pressure bearing, the surface quality and the performance parameters of the wave foil are improved, the bearing damping and stiffness characteristics are improved, the bearing capacity and the impact vibration cushioning capability of the bearing are improved remarkably, and the life and the stability of the bearing are prolonged and improved.

Owner:HUNAN UNIV

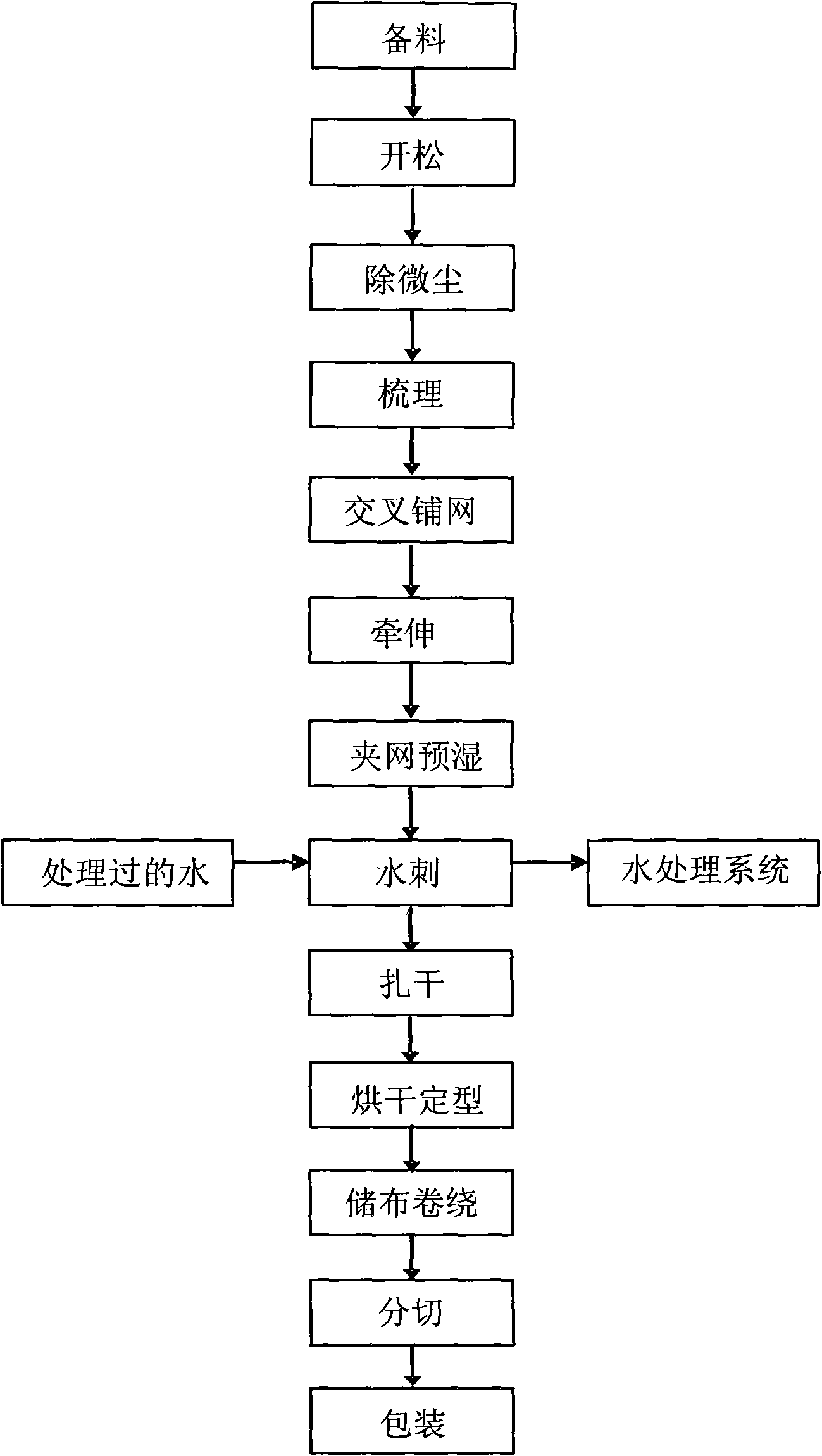

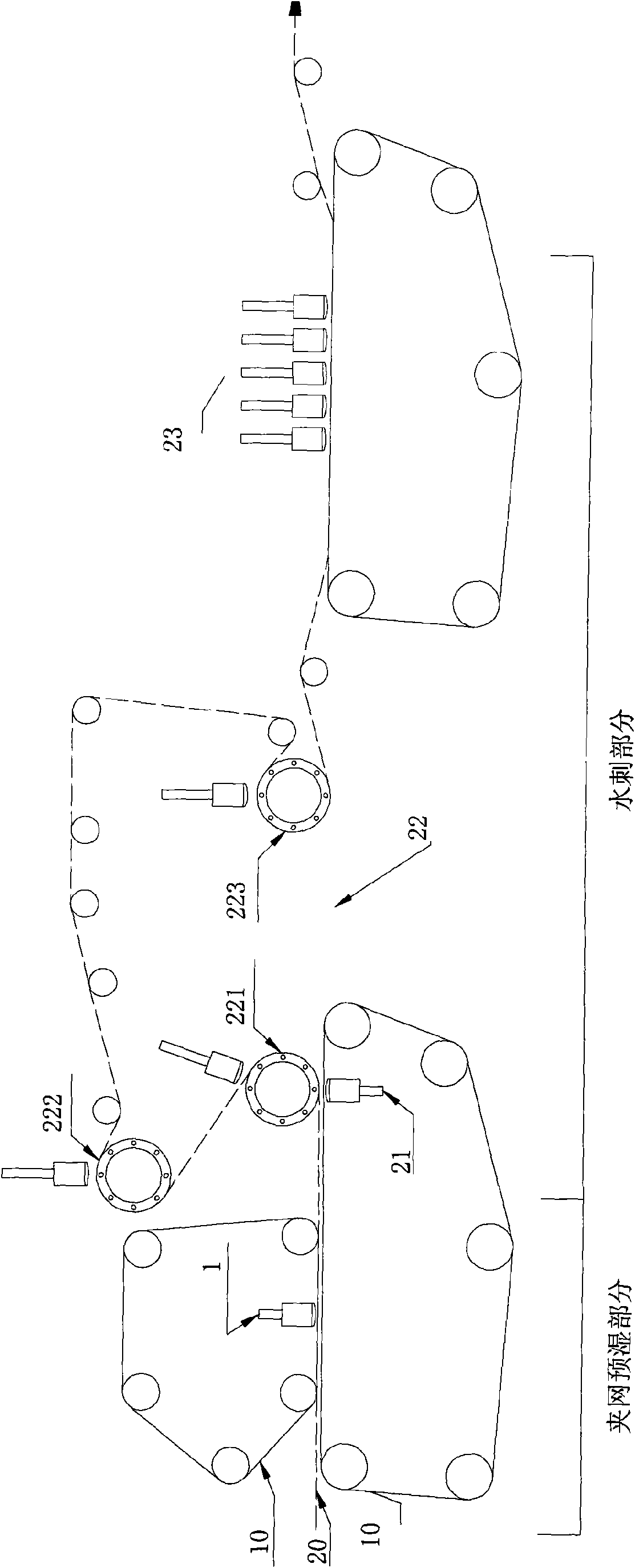

Production technique of pure cotton non-woven fabrics and device

InactiveCN101624755AReduce tensionImprove uniformityNon-woven fabricsPulp and paper industryNonwoven fabric

The invention discloses a production technique of pure cotton non-woven fabrics and a device. The technique comprises the following steps: cross lapping: spreading a fibre screen evenly and alternately in a reciprocating way; extending: regulating the arrangement of fibre at different extension speeds; clipping screen and prewetting: performing pre-wetting processing to the fibre screen; performing once flat-screen water thrust: snarling the fibre screen for parallel movement with water jet; performing drum water thrust: snarling the fibre screen for circular movement with water jet; and performing twice flat screen water thrust: snarling the fibre screen for parallel movement with water jet again. By adopting the production technique, the device and the water thrust process of using the manner combining the flat screen and the drum, the invention can maximize favorable factors and minimize unfavorable ones to develop respective advantages, improves the physical performances of producing ratio, product tension, evenness, flexibility and surface mass, saves materials, reduces pollution to circulating water, reduces the maintenance amount of device, prolongs the service period of the device and achieves the aim of reducing cost and saving energy.

Owner:AOMEI MEDICAL SUPPLIES CO LTD

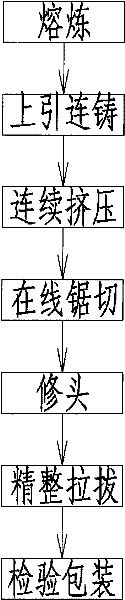

Large-section oxygen-free copper busbar and preparation method thereof

InactiveCN102262924AHigh purityImprove conductivitySingle bars/rods/wires/strips conductorsMetal/alloy conductorsBusbarOxygen content

The invention relates to an oxygen-free copper busbar and a preparation method thereof, in particular to a large-section oxygen-free copper busbar and a preparation method thereof, belonging to the technical field of nonferrous metal processing. The technological process of the present invention is: smelting→upward continuous casting→continuous extrusion→online sawing→head trimming→drawing→inspection and packaging. The invention solves the shortcomings of the traditional process of large-section copper bus bars, provides a production technology with short process flow, high degree of automation, low oxygen content, excellent product quality, environmental protection and pollution-free, and effectively improves the quality and performance of products , has the advantages of high purity, low oxygen content, high electrical conductivity, and excellent surface quality.

Owner:SHANDONG ZHONGJIA NEW MATERIALS

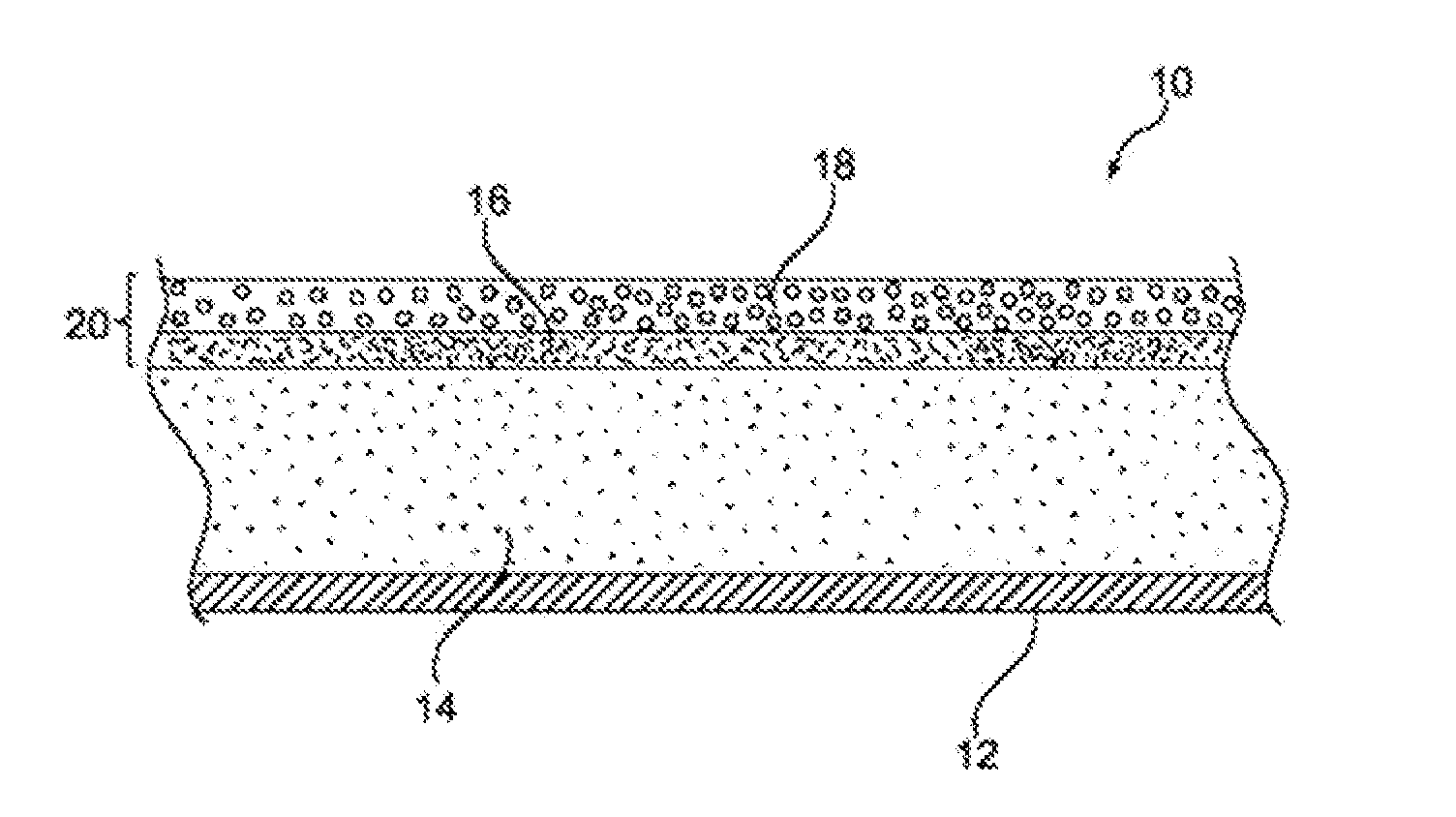

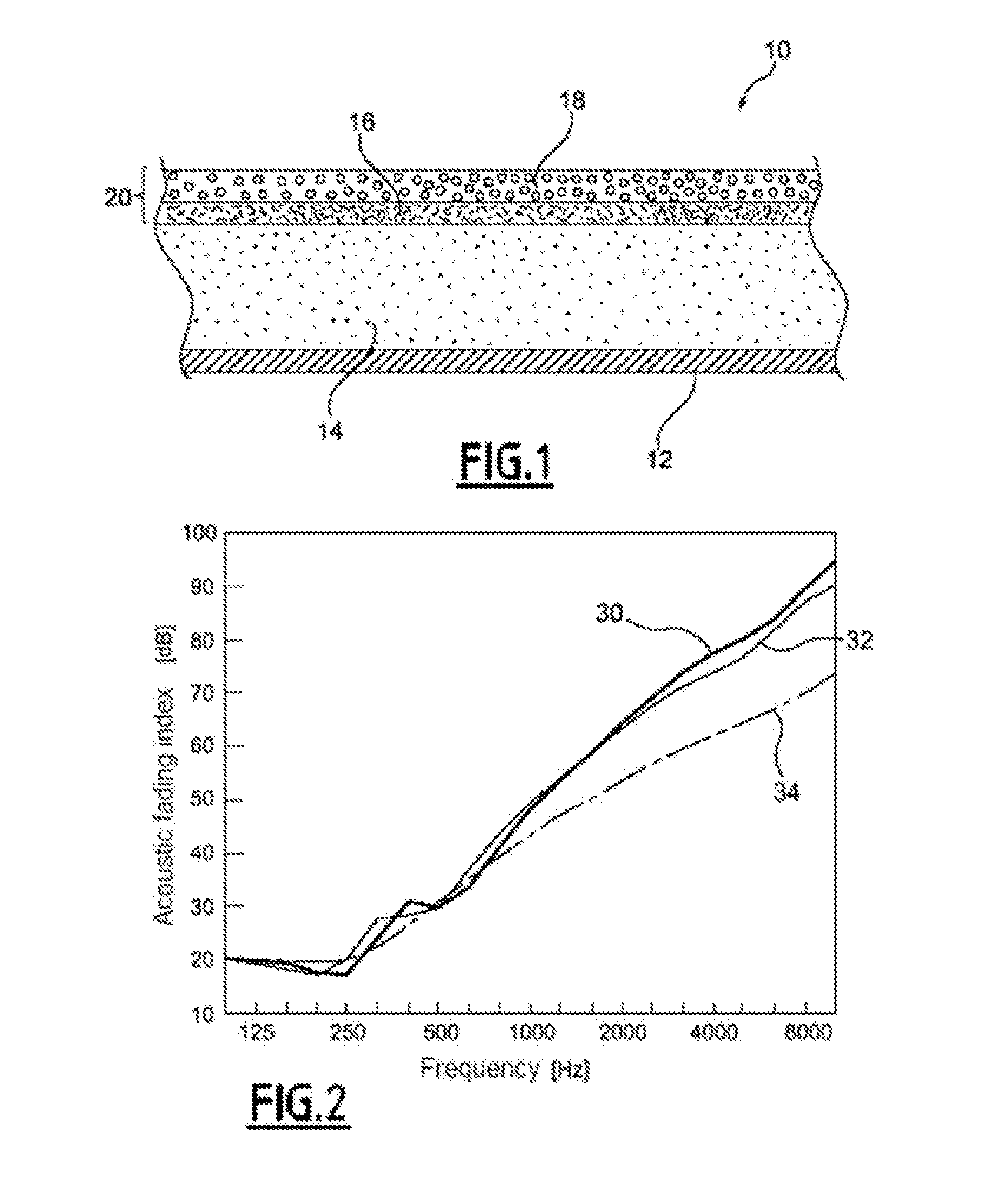

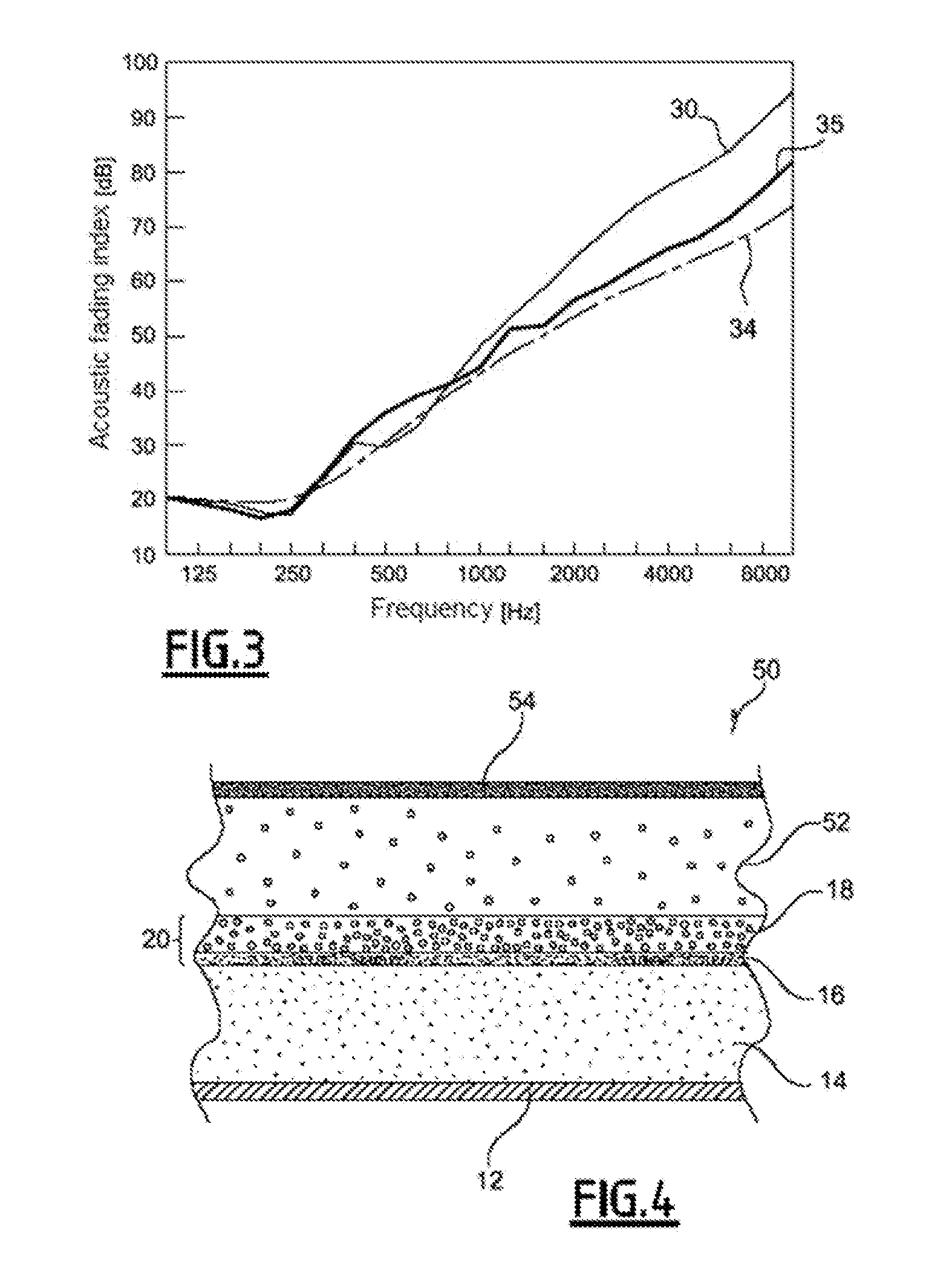

Soundproofing assembly, in particular for a motor vehicle

ActiveUS9133615B2Good attenuation indexLowering indexSynthetic resin layered productsMachines/enginesInsulation layerEngineering

This assembly includes an elastic and porous base spring layer intended to be placed facing a surface, in particular of an automobile vehicle, and an intermediate insulation layer impervious to the passage of air, the intermediate layer being positioned on the base spring layer. The airproof intermediate layer has a surface mass density of less than 500 g / m2, the sound proofing assembly including a porous stiffening layer, positioned in contact with the impervious intermediate layer. The porous stiffening layer has a smaller thickness than the thickness of the base spring layer and a flexural stiffness, reduced to a unit width, of more than 0.01 N.m.

Owner:FAURECIA AUTOMOTIVE IND

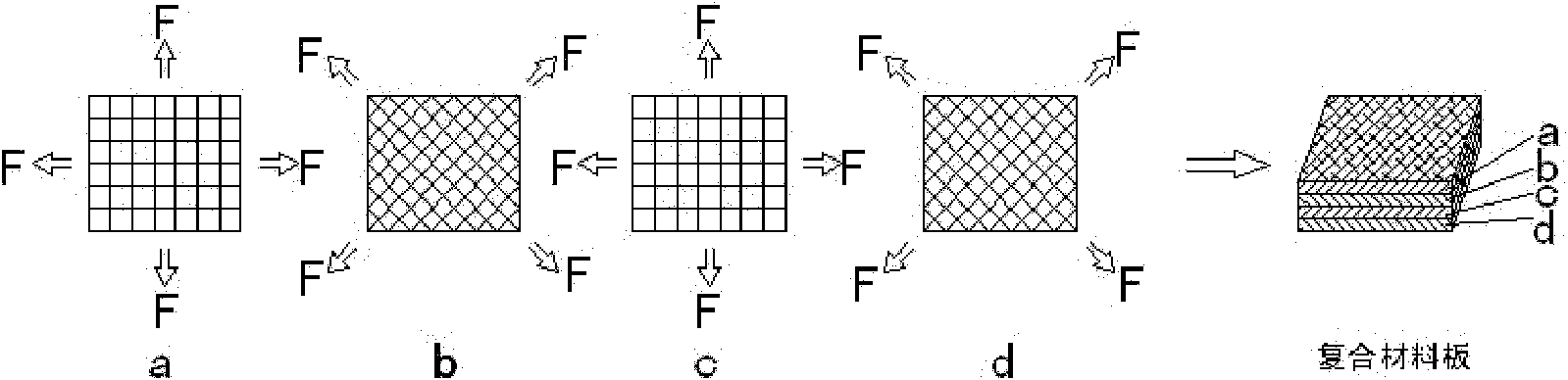

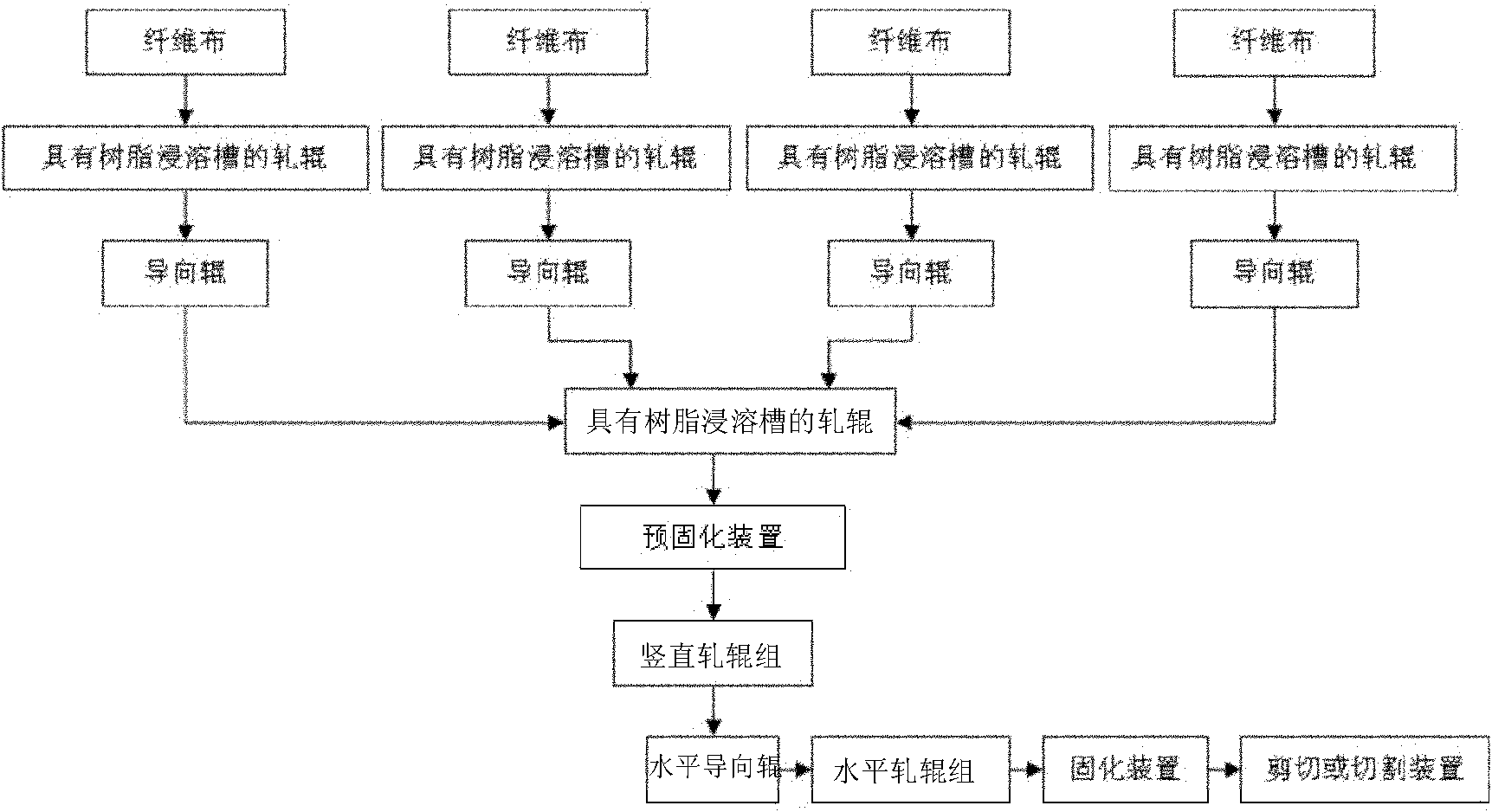

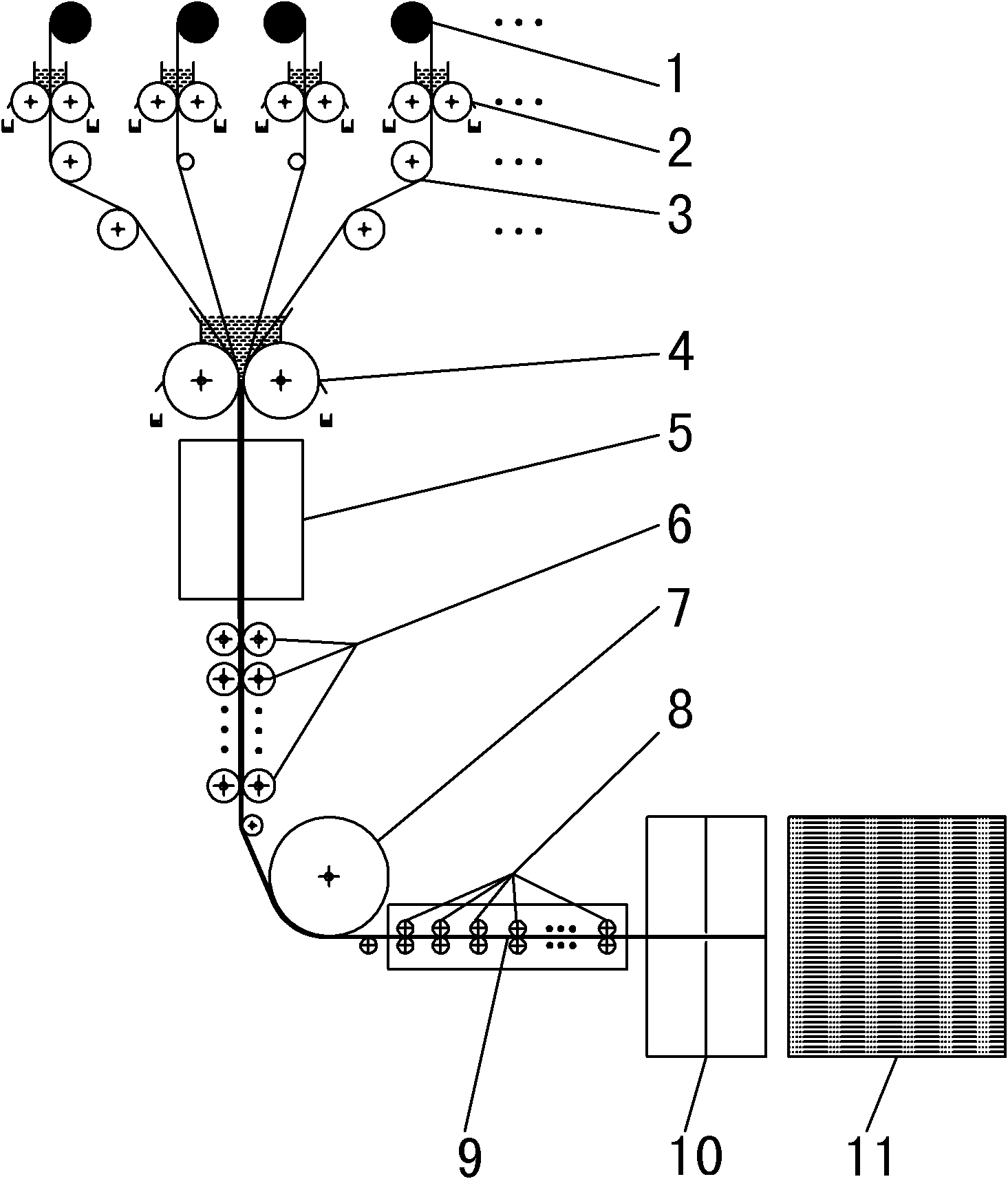

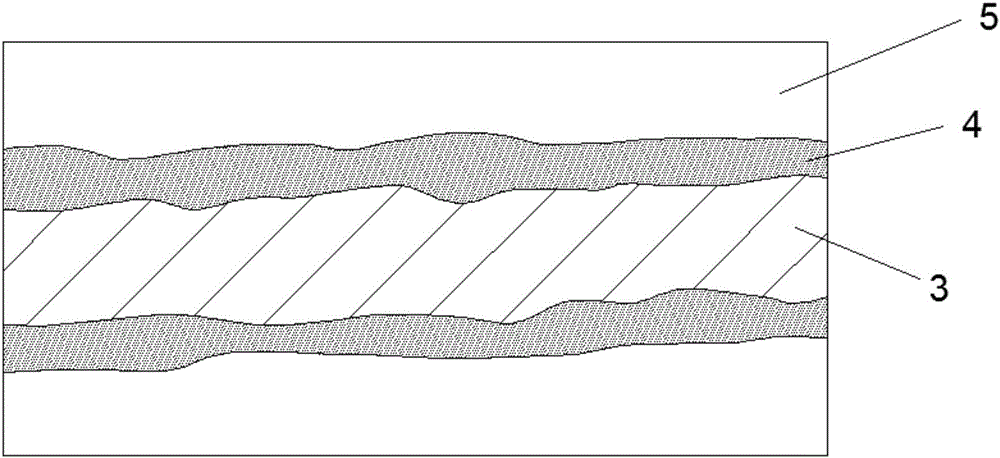

Method and device for rolling and molding fiber reinforced composite board

InactiveCN101913253AUniform directional mechanical propertiesHigh strengthLiquid/gas/vapor textile treatmentPorosityFiber-reinforced composite

The invention discloses a method and a device for rolling and molding a fiber reinforced composite board. The molding method can obtain the composite board which has the advantages of uniform mechanical properties in all directions on the board plane, high strength, high surface quality and high precision by using fiber cloth with different texture directions as a reinforcing material. The method makes resin on both sides of each layer of fiber cloth uniformly distributed in a form of two-time resin impregnation and rolling so as to obviously reduce the phenomenon of bubbles inside the molded composite board and ensure good properties of the composite board. In addition, the fiber cloth moves along the vertical direction in the process of resin impregnation to make the resin uniformly distributed on both sides of the fiber cloth. The molded fiber reinforced composite board is continuously rolled through multi-rolling, and has compact material texture and low board porosity. The device is easy to control the thickness and the size of the fiber reinforced composite board and only needs to increase and decrease the number of fiber cloth racks, resin impregnation tanks and rollers, and the gap between two rollers.

Owner:XI AN JIAOTONG UNIV

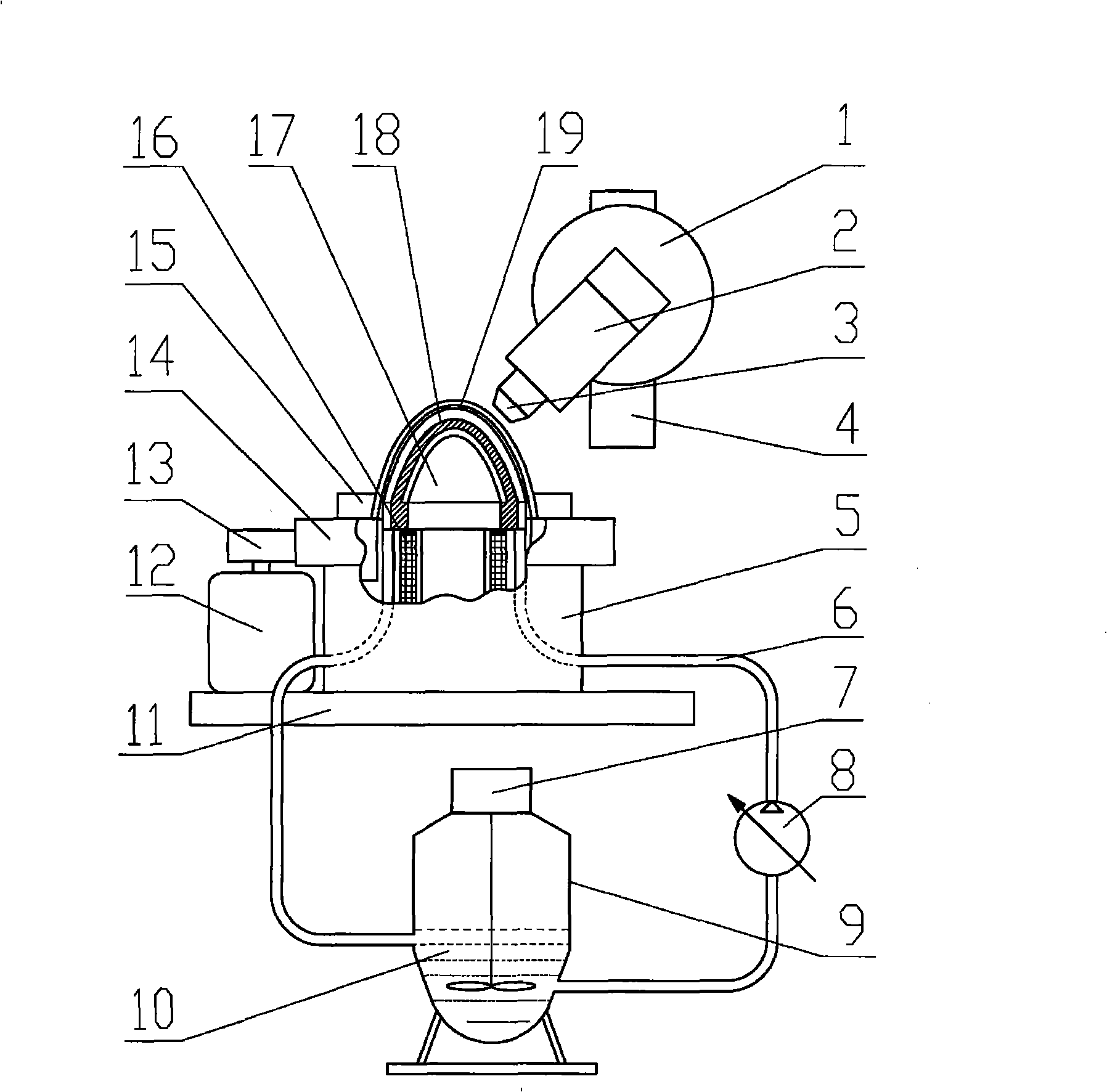

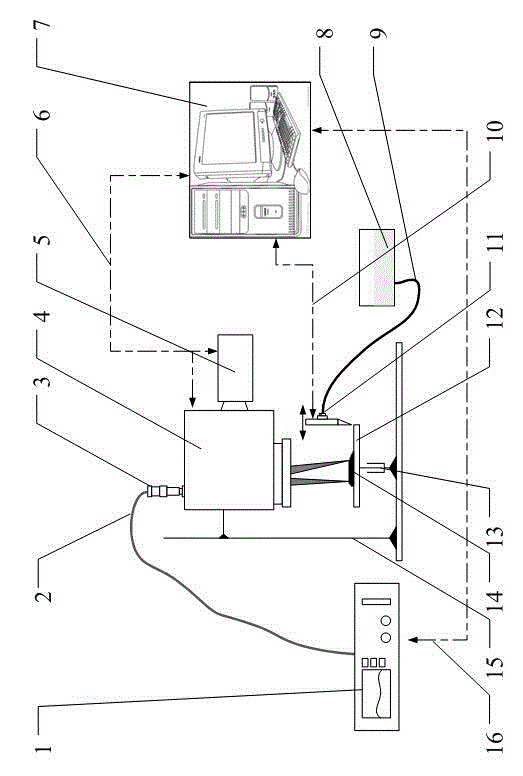

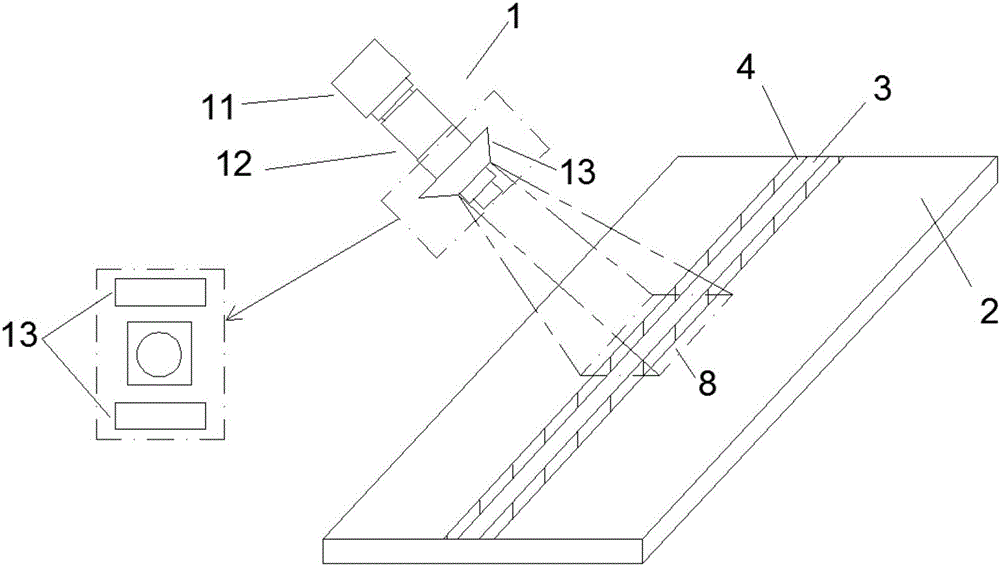

Nanopowder laser selective melting additive manufacturing system and method

ActiveCN104890240AAchieve surface treatmentDeoxidizingAdditive manufacturing apparatusIncreasing energy efficiencySelective laser sinteringControl line

The invention relates to a nanopowder laser selective melting additive manufacturing system and method. The selective melting additive manufacturing system comprises a single mode fiber laser, an output optical fiber, a QBH connector, a scanning galvanometer, a CCD camera, a scanning control line, a control computer, a coating cavity, a conveying pipeline, a coating movement control device, a coating cutter, a workbench base body, a lifting device, a support and a laser control line. In terms of the nanopowder laser selective melting additive manufacturing method, nanopowder is dispersed in solvent through a nanometer dispersion technology, a dispersed solution containing the nanopowder is arranged on the surface of the base body in a coating mode through the coating cutter, and a material is sintered through the selective melting additive manufacturing system. According to the invention, due to the fact that the nanometer material is used as a selective laser sintering material, the selective laser sintering performance and the surface quality can be improved, and surface treatment of the base material can be achieved. Due to the fact that the nanopowder is dispersed in a nanometer dispersion liquid mode, the solvent has oxidation resistance, and sintering can be conducted in the air.

Owner:HARBIN INST OF TECH

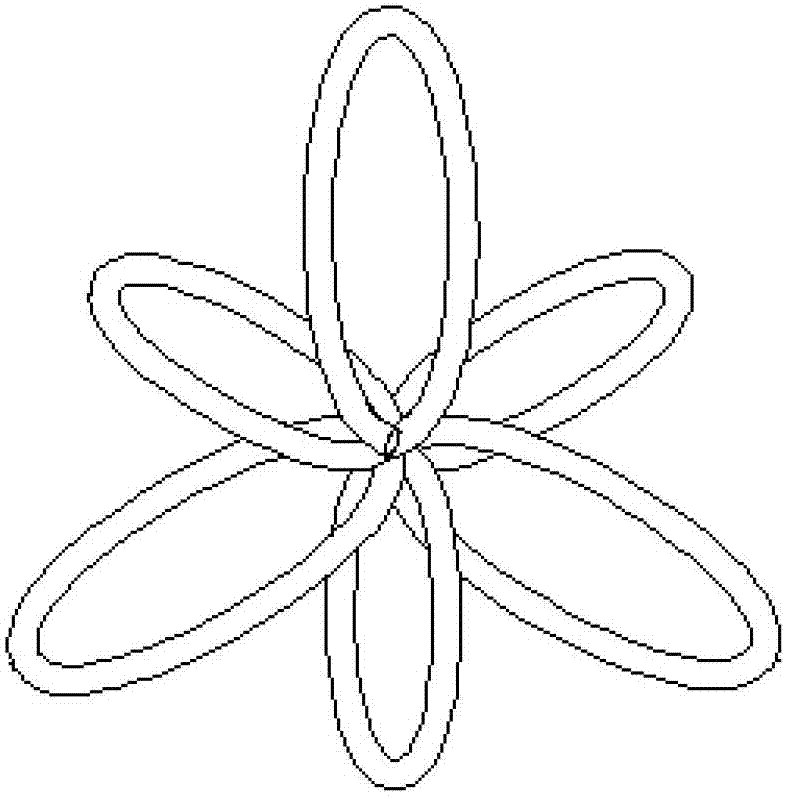

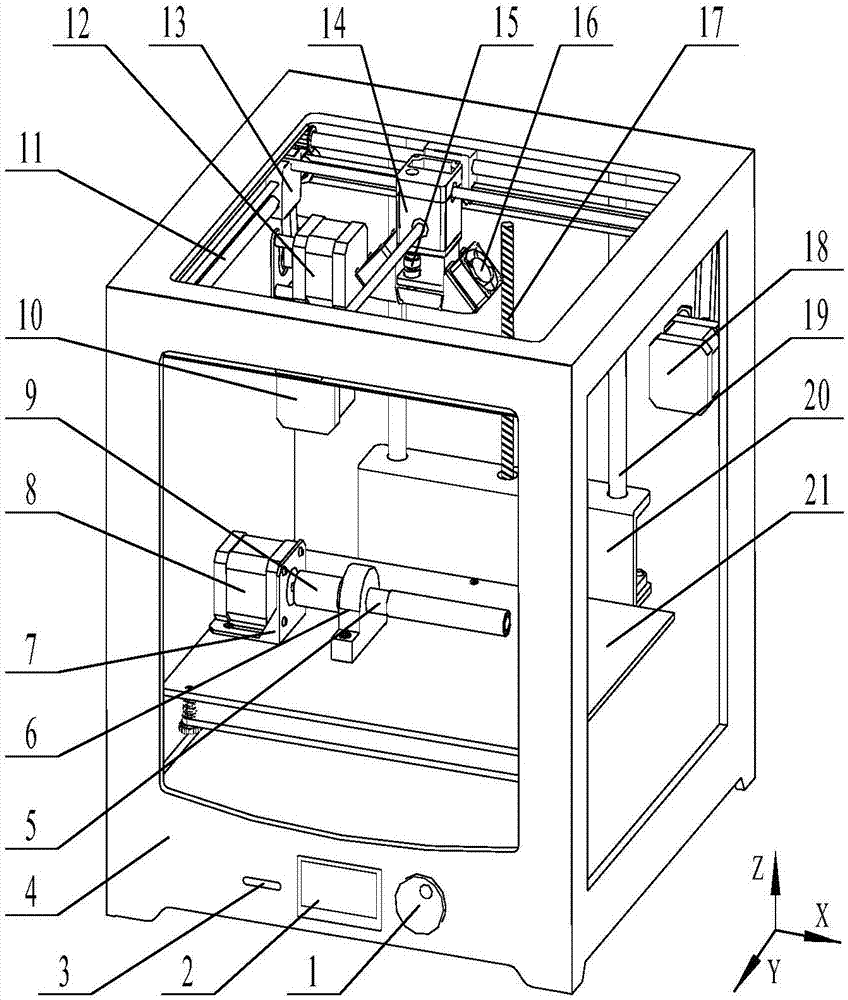

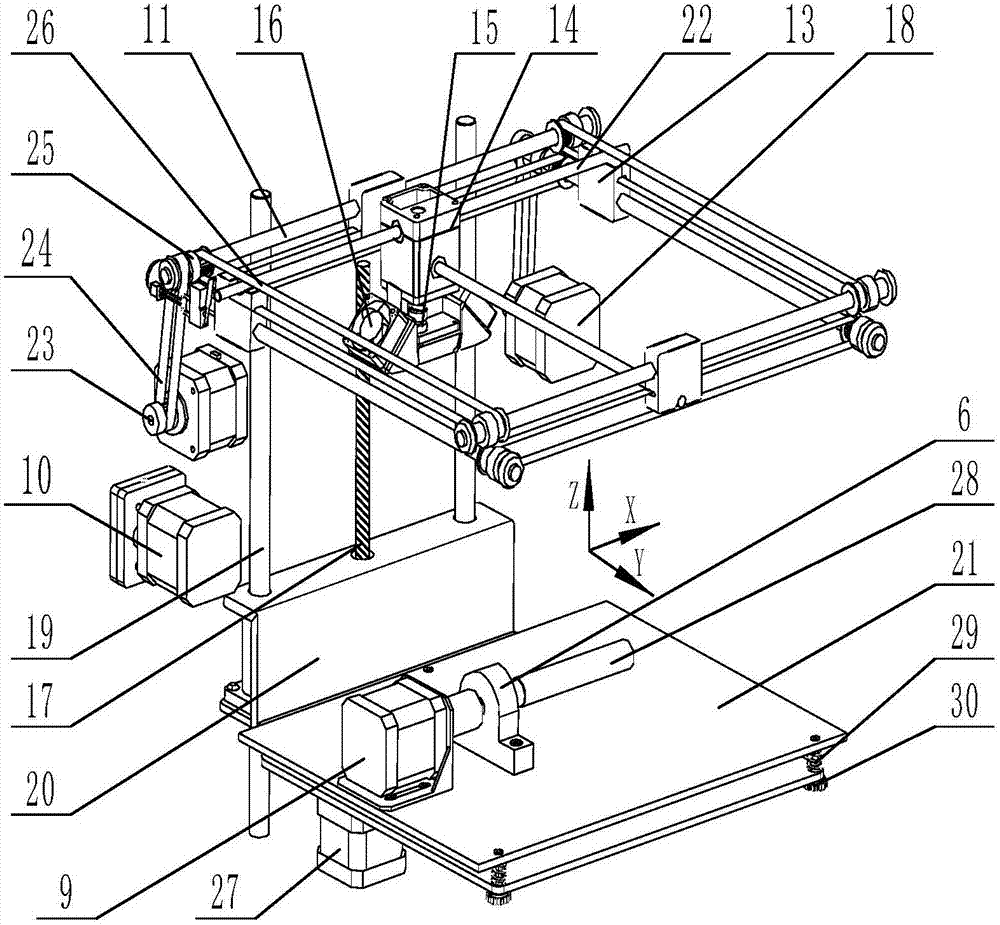

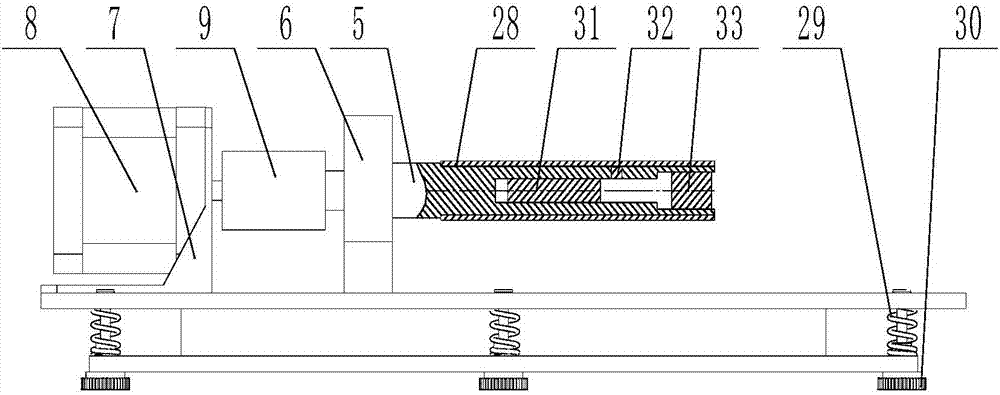

3D printer based on polar coordinates

ActiveCN105291439AImproved Surface Dimensional AccuracyEasy to moveAdditive manufacturing apparatusRectangular coordinatesEngineering

The invention provides a 3D printer based on polar coordinates. The 3D printer comprises a bottom plate, a workbench arranged on the bottom plate and capable of moving in a plane according to the polar coordinates, and a printing head having an adjustable distance with the workbench. The 3D printer provided by the invention realizes the completion of printing of the printing head for any curve and straight line in a working stroke under a coordinate system through the workbench, and has the advantages that the printing speed is fast, the curved surface dimensional accuracy of the printed parts is high, and the surface quality is also greatly improved; and meanwhile, the 3D printer provided by the invention is simple in structure, small in size and large in working range, the movement amounts of the printing head and the workbench during curved surface printing are much smaller than those under a rectangular coordinate system, the noise is also greatly reduced, and the service life is longer.

Owner:四川康铭智能装备科技有限公司

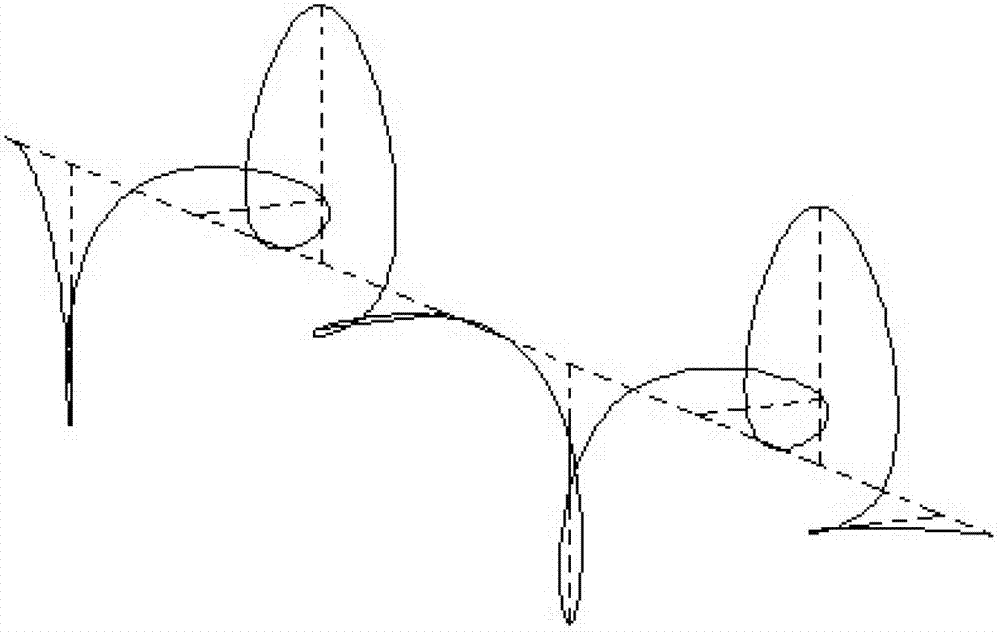

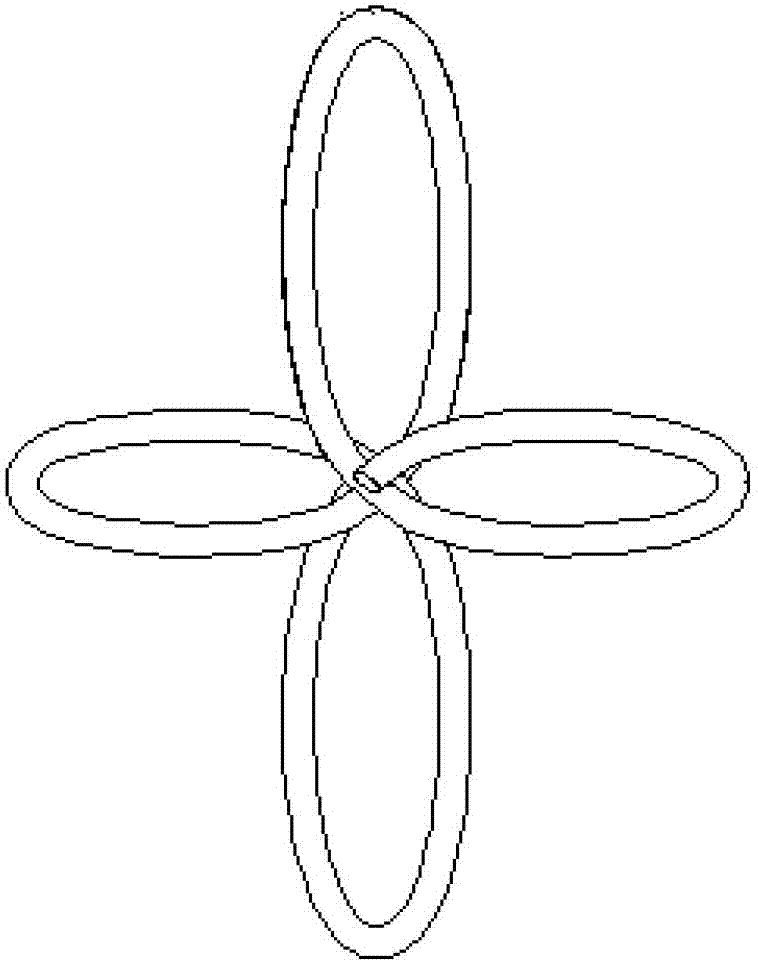

Metal cutting wire with spiral wave-shaped rotary bending parts

The invention discloses a metal cutting wire with spiral wave-shaped rotary bending parts. The metal cutting wire is provided with a plurality of spiral wave-shaped rotary bending parts along a central axis. According to the metal cutting wire with the spiral wave-shaped rotary bending parts, better capability of carrying mortar grinding materials in the hard material cutting process can be provided through a three-dimensional structure, and the grinding materials are unlikely to strip from the cutting wire so that the production speed in the cutting and fragmenting process of silicon, jewel and the like is greatly increased, the production efficiency in the cutting and fragmenting process of silicon, jewel and the like is greatly improved, and the surface quality of the fragmented materials also can be effectively improved at the same time. The speed of the grinding materials in the abrasion cutting process of hard materials is reduced relative to that of the metal cutting wire, so that the abrasion degree of the metal cutting wire is reduced.

Owner:ZHENJIANG NAISI ADVANCE MATERIALS

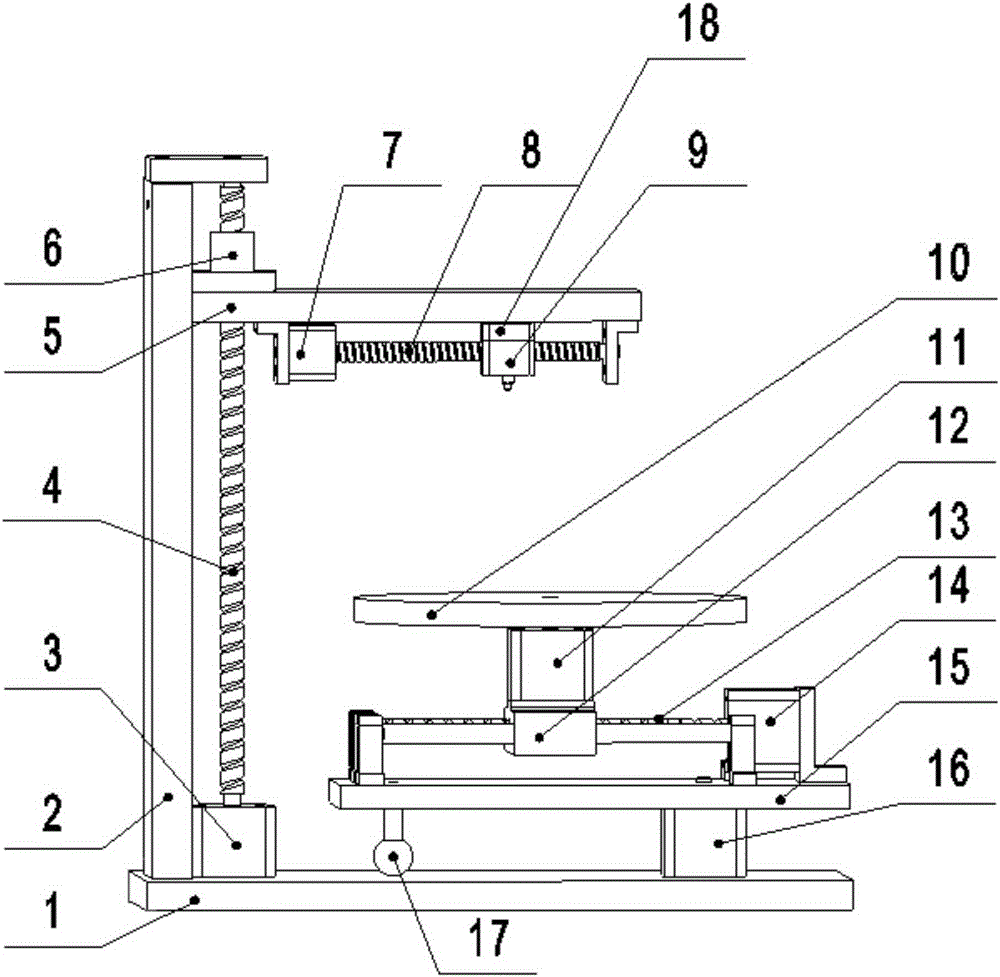

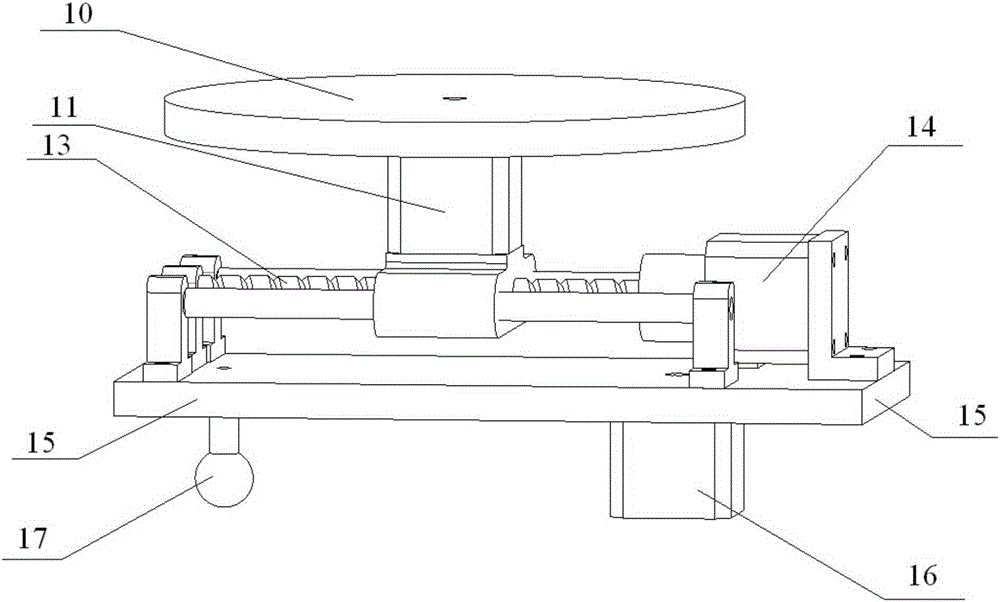

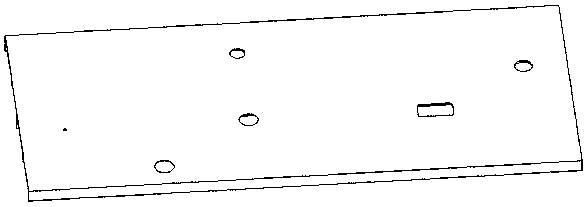

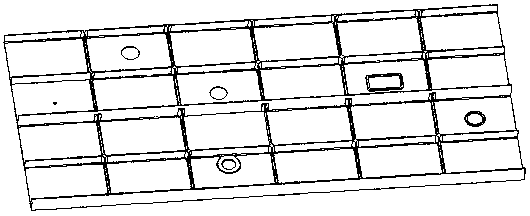

Four-axis linkage 3D printing device based on fusion deposition principle

InactiveCN106985379AEasy to manufactureImprove molding rateManufacturing driving means3D object support structuresSprayerSurface mass

The invention discloses a four-axis linkage 3D printing device based on the fusion deposition principle, belongs to the field of 3D printing and manufacturing, and relates to the four-axis linkage 3D printing device based on the fusion deposition principle. The printing device is composed of a rack, a printing sprayer assembly, a control assembly, an X-axis drive assembly, a Y-axis drive assembly, a Z-axis drive assembly and an A-axis drive assembly. A shaft sleeve of the A-axis drive assembly can be detached and replaced, a series of shaft sleeves the same in inner diameter but different in outer diameter can be selected, and forming and manufacturing of pipe-shaped structure models different in inner diameter are conveniently achieved. By means of the printing device, a thin-wall pipe net-shaped structure can be conveniently prepared, any auxiliary supporting structure does not need to be additionally arranged in the printing process, the posttreatment and other complex operation processes are simplified, printing materials are saved, and the forming rate and surface quality of test piece printing are effectively improved. The A-axis drive assembly is flexible in control and easy and convenient to mount and dismount, a series of inner diameter test pieces can be formed by replacing the shaft sleeves of different outer diameters, and the four-axis linkage 3D printing device is simple, practical and easy to operate and popularize.

Owner:DALIAN UNIV OF TECH

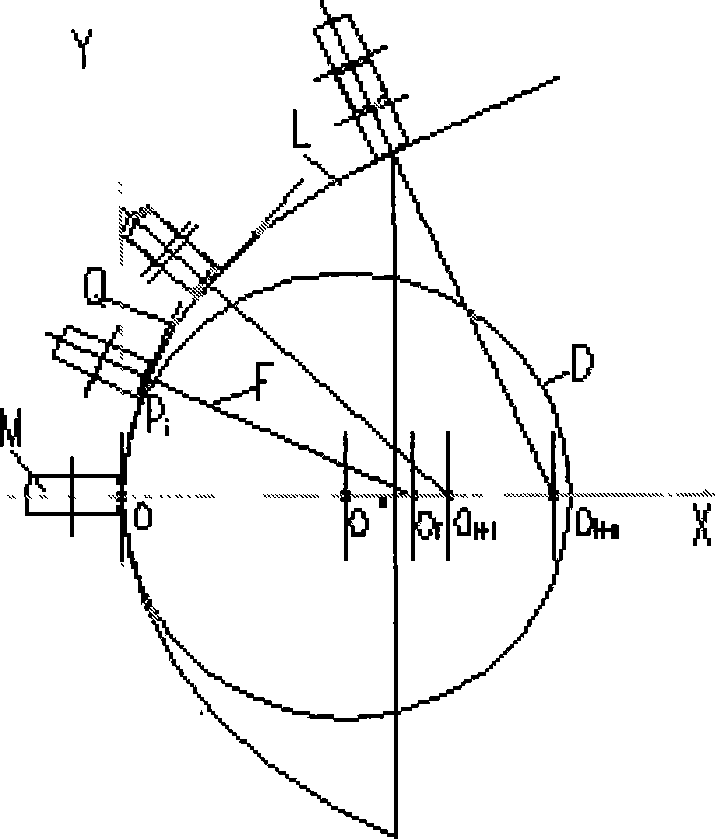

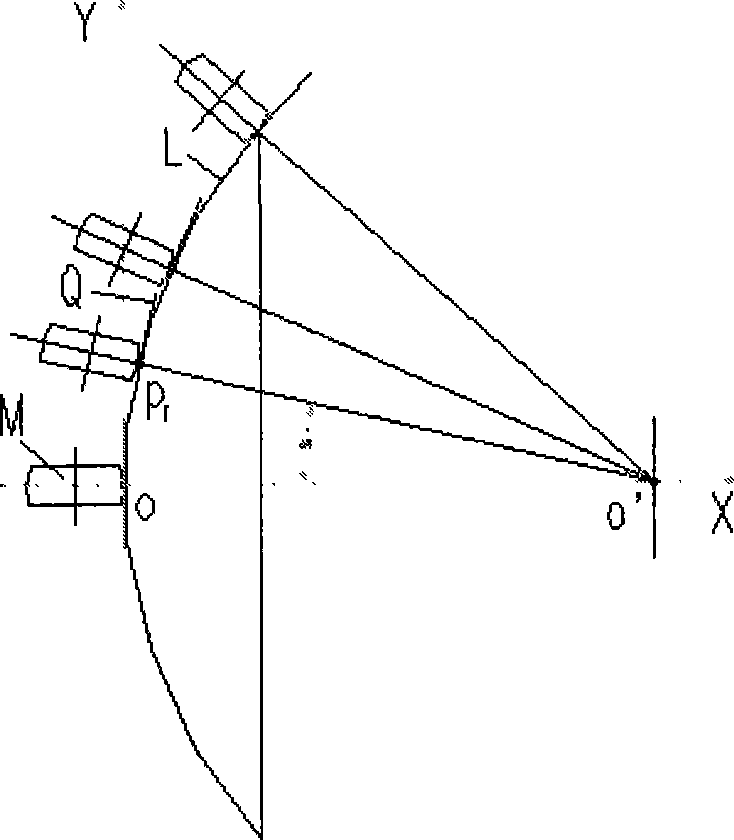

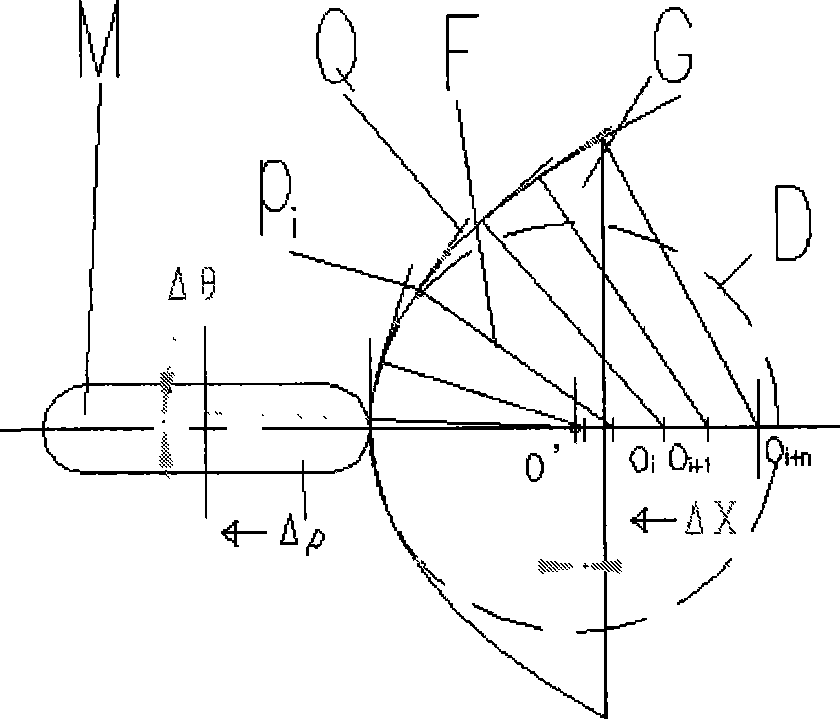

Processing method and device for forming aspheric surface part by numerical control tangent line turning method

InactiveCN101376229ARequirements to ensure surface accuracyEasy to ensure surface accuracy requirementsLensNumerical controlSurface roughness

The invention provides a non-spherical surface element shaping and processing method by using a numerical control tangent revolution method and a device thereof, and relates to an optical element processing technique. The processing method and the device can always conduct the tangent point processing for the meridional profile curve of any designed and given axisymmetrical non-spherical surface (including higher order and quadric spherical surface) and spherical surface element, so as to obtain a theoretical continuous smooth high precision surface without corrugation. The tangent point processing of the non-spherical surface is realized through the rotation of a workpiece and an abrasive wheel, and the numerical control linkage of an oscillating shaft, a workpiece shat and an abrasive axle. The tangent point processing of the spherical surface is realized through the rotation of the workpiece and the abrasive wheel, the oscillation of the oscillating shaft and the fixation of the abrasive axle at a certain distance. The processing technique has the advantages of good commonality, high precision and processing efficiency, easily ensured surface roughness and surface texture, low processing cost and the like.

Owner:CHANGCHUN UNIV OF SCI & TECH +2

Detection method for identifying surface quality of continuous laser seam of metal workpiece online

ActiveCN106442543AOnline discrimination is accurateFast online discriminationOptically investigating flaws/contaminationAnti jammingMetallic materials

The invention provides a detection method for identifying the surface quality of a continuous laser seam of a metal workpiece online, wherein the method comprises the following steps: using a high resolution color area array camera, a high magnification micro lens and double LED illuminating systems to acquire an image of the surface of the seam; afterwards, when dividing a seam region and calculating the characteristic value, translating or rotating the workpiece to shoot an image for other positions of the seam, continuously shooting the image of the seam and completing real-time calculation until reaching a seam welding end or an overlapping point; finally integrating the calculation results of the images, and completing online judgement on the size, the position and the surface defect of the continuous seam. The method is used to complete online detection of the quality of a laser straight welded joint, a curve welding seam or a space welding seam of various ferrous metals and nonferrous metals, and belongs to the category of non-contact visual inspection; a device is simple and compact, high in response speed and strong in anti-jamming capability, has the characteristics of stability, reliability and convenience, and can be widely applied to the field of laser welding of metal materials.

Owner:龚新林 +5

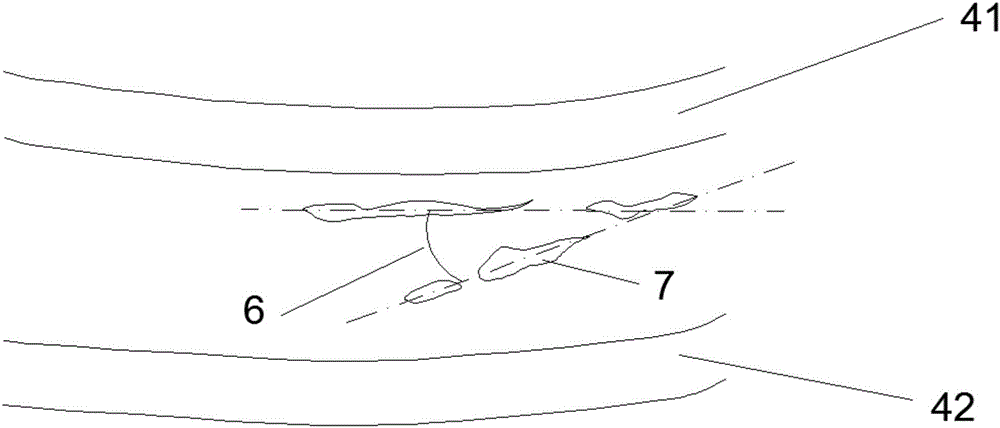

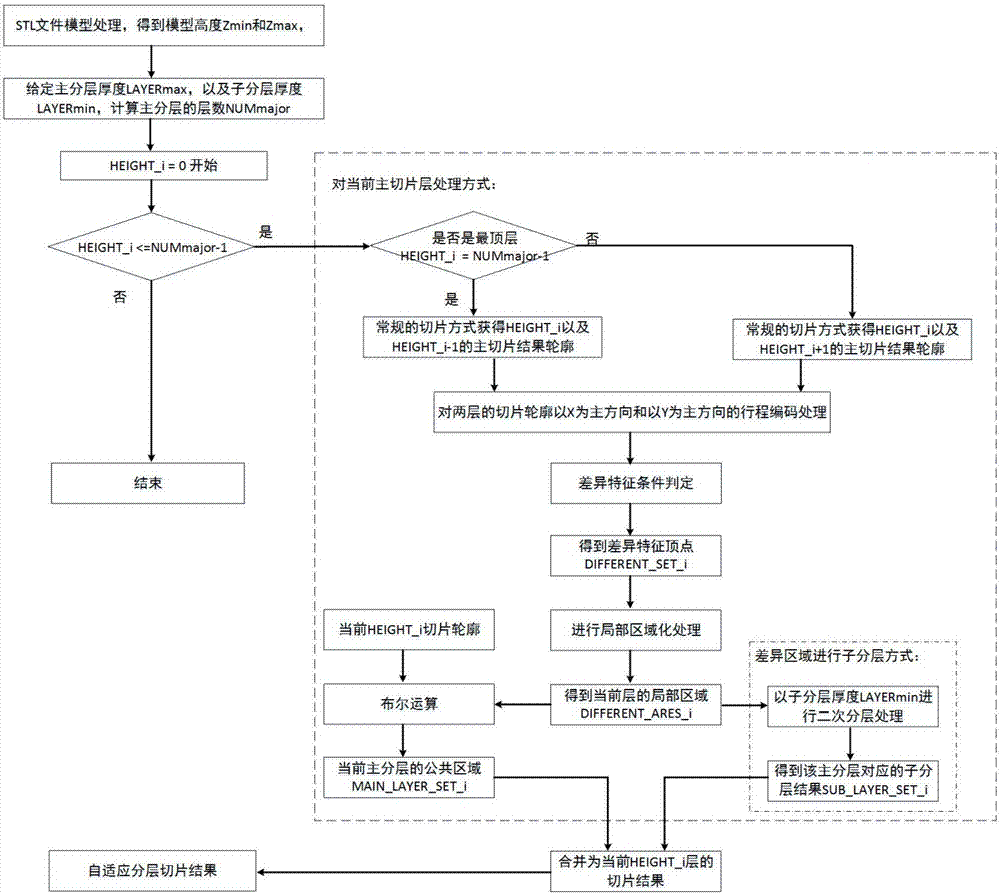

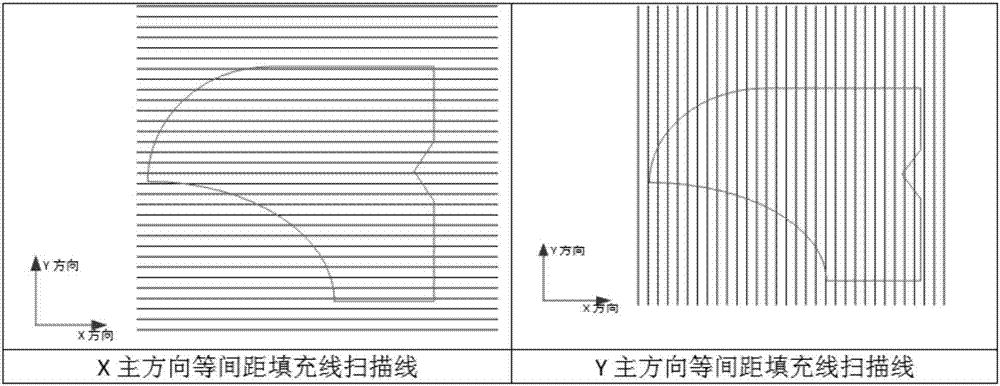

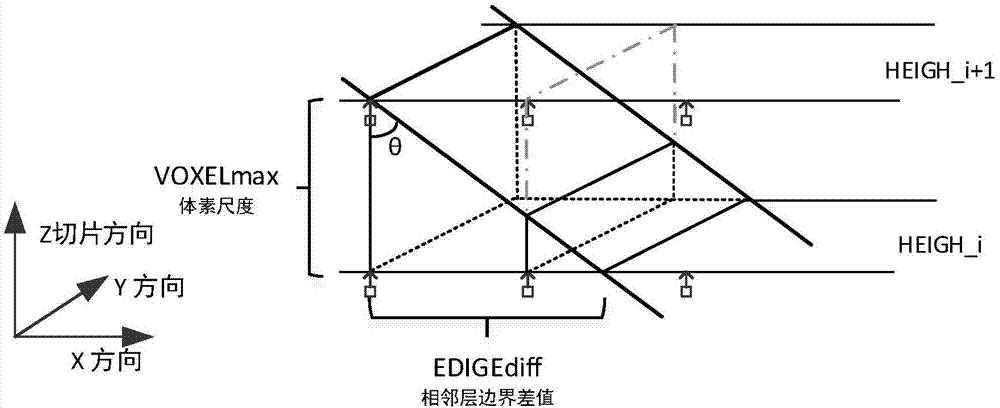

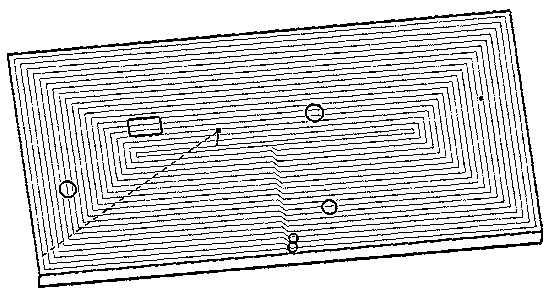

Adaptive layering type additive manufacturing method

ActiveCN107571506AJudgment is fast and effectiveGuaranteed Feature AccuracyAdditive manufacturing apparatusManufacturing data aquisition/processingLayer thicknessSelf adaptive

The invention belongs to the field of additive manufacturing and discloses an adaptive layering type additive manufacturing method. The method comprises the following steps that (a), primary slicing treatment is conducted on a to-be-treated model file, and multiple main slice layers and the profile loop and data of each main slice layer are obtained; (b), points on the main slice layer profile loops are divided into difference feature vertexes and public feature vertexes; (C), local regionalization treatment is conducted on the difference feature vertexes, new local regions are generated, secondary slicing treatment is conducted on the new local regions according to the preset minimum layer thickness, and multiple sub-slice layers and profile data of the sub-slice layers are generated; and(d), 3D printing is conducted according to the profile data of the main slice layers and the sub-slice layers, and in this way, additive manufacturing is completed. By means of the adaptive layeringtype additive manufacturing method, the overall morphology of the model and the local features in the slice layers are taken into account, fine sub-layering treatment of the local regions in the slicelayers is realized, the inherent staircase effect of the slices is lowered, the layering slicing efficiency is improved, and the surface quality of finally-printed products is guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

Milling method of high-precision suspended web

ActiveCN108746782ACut evenlyEven by forceWorkpiecesMilling equipment detailsWeb structureEngineering

The invention discloses a milling method of a high-precision suspended web. The milling method is used for efficient and stable milling of a large-size suspended web structure and comprises the stepsthat the glossy face of a part is subjected to rough milling, and the technical allowance is reserved; a frame face is subjected to rough milling, the technical allowance is reserved, and a pluralityof false bosses are reserved according to the structural characteristics, so that the structural rigidity of the part is improved; the frame face is pressed in an unstressed mode, a positioning datumface is corrected, and thus the situation that the machining error is caused by part deformation is prevented; a glossy face web is subjected to semi-fine milling, and the small allowance is reserved;and the glossy face web is subjected to finish machining in place in modes of a small-diameter tool in small cutting quantity and back-and-forth feed, and thus the situations that cutter back-off deformation is caused by the large cutting quantity, and the surface quality of a part becomes poor due to trajectory change and acceleration and deceleration of a machine tool are prevented. The millingstability of the large-size suspended web structure is effectively improved, the part machining efficiency and the surface quality integrity are improved, and reworking polishing of a bench worker isreduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com