Four-axis linkage 3D printing device based on fusion deposition principle

A four-axis linkage and fused deposition technology, which is applied in processing drive devices, 3D object support structures, additive manufacturing, etc., can solve problems such as reduced molding efficiency, reduced surface quality and dimensional accuracy, and cumbersome processes to improve work efficiency. Effects of improving molding rate and surface quality and simplifying complicated operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail through specific embodiments in conjunction with the accompanying drawings and technical solutions.

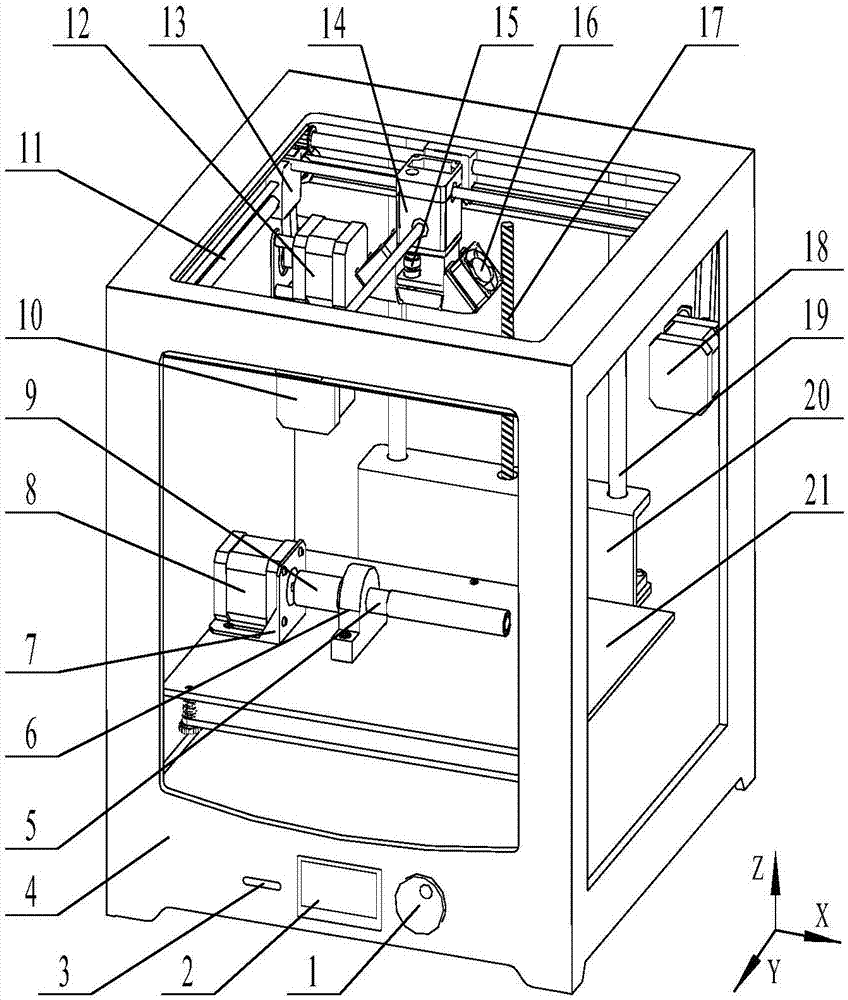

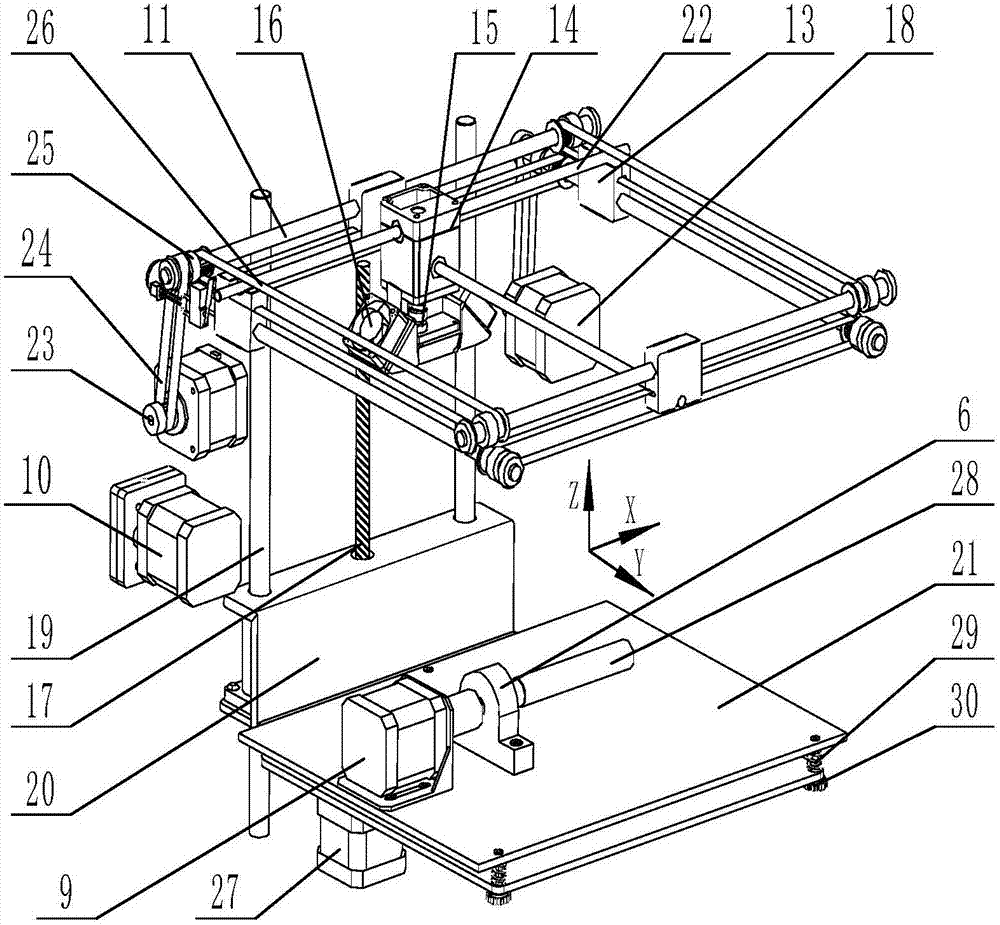

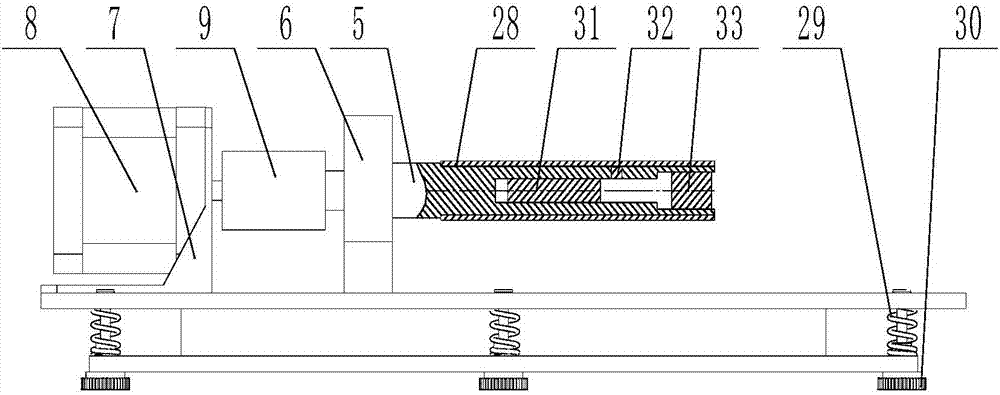

[0015] attached figure 1 , attached figure 2 It is a schematic diagram of the overall structure of the 3D printing device, with image 3 It is a schematic diagram of the structure of the A-axis device of the 3D printing device. As shown in the figure, the printing device is composed of a frame, a printing nozzle assembly, a control assembly, an X-axis drive assembly, a Y-axis drive assembly, a Z-axis drive assembly, and an A-axis drive assembly; the control assembly coordinates and controls the X-axis, Y-axis, Z-axis The axis drives the movement of the assembly, so as to realize the horizontal movement of the print head assembly in the X and Y directions and the up and down movement in the Z direction. The surface of the A-axis can be used as a printing working platform to achieve continuous rotation in the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com