Patents

Literature

37results about How to "Save printing materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

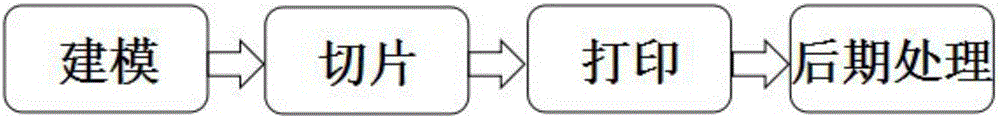

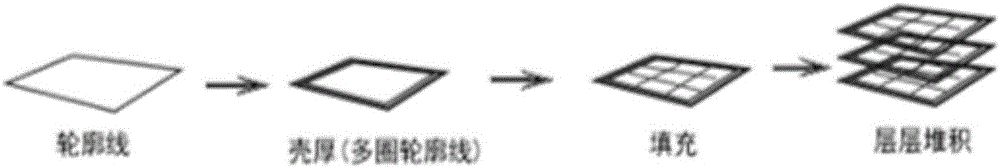

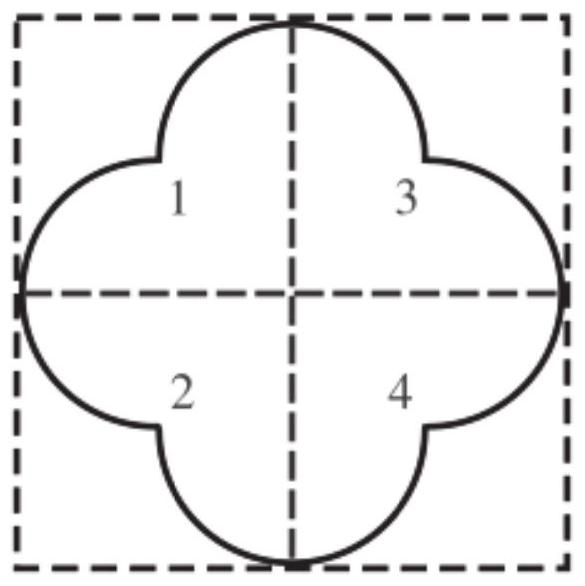

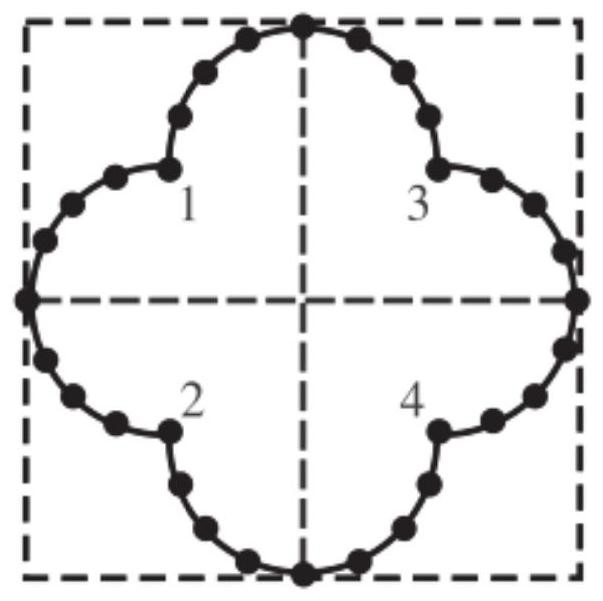

Model area change rate-based adaptive hierarchical processing method

InactiveCN106202687ASolve molding accuracySolve molding speedGeometric CADAdditive manufacturing apparatusRoundingLayer thickness

The invention discloses a model area change rate-based adaptive hierarchical processing method. The method comprises the following steps of importing an STL model and establishing a model topological structure; performing uniform hierarchical slicing on the model with the highest precision, obtaining a two-dimensional polygon contour layer and calculating an area of each layer of a polygon after slicing; performing derivation on the area of each layer of the polygon to obtain an area change rate of the model; comparing the calculated area change rate with a threshold according to a relationship between the area change rate of the model and the printing precision, and obtaining a printing precision distribution situation of the model in a printing direction; calculating hierarchical layer thickness data required for model printing, and performing processing by using a rounding-off method to generate adaptive hierarchical layer thickness data; and reading the hierarchical layer thickness data by a slicing engine, and performing adaptive layer thickness slicing on the model to obtain a gcode file required for printing. According to the method, while the detail characteristics of the model are ensured, the forming speed of the model is increased, and the printing time is effectively shortened.

Owner:HOHAI UNIV CHANGZHOU

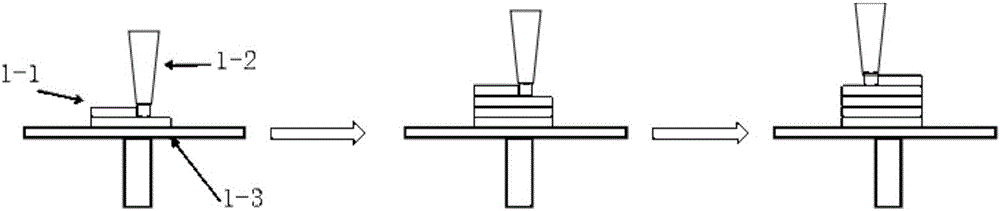

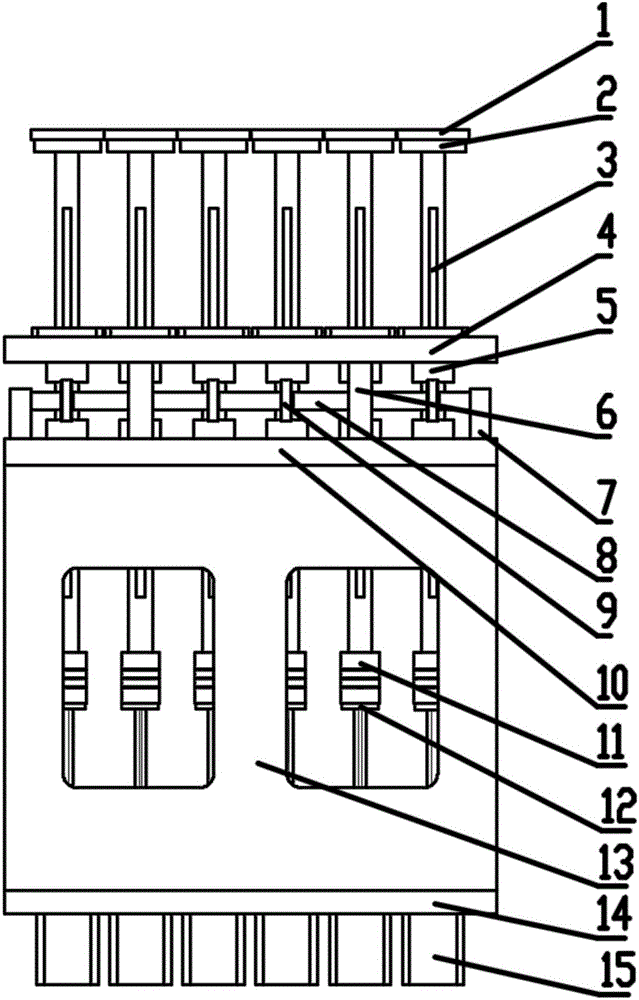

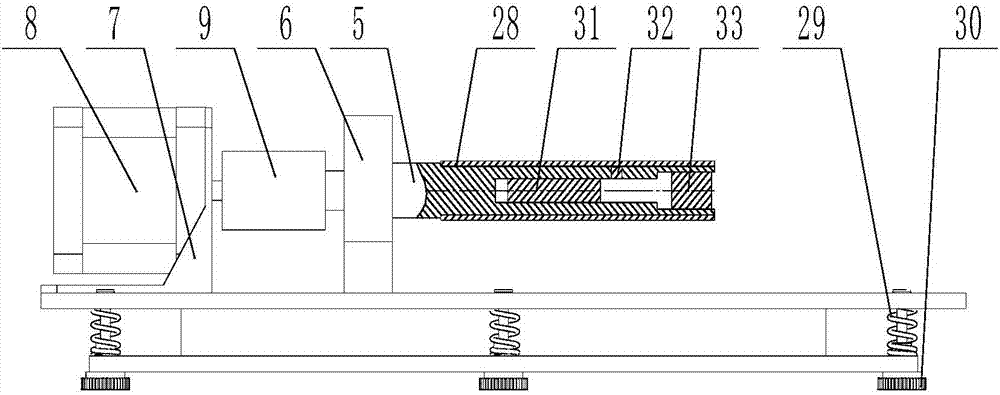

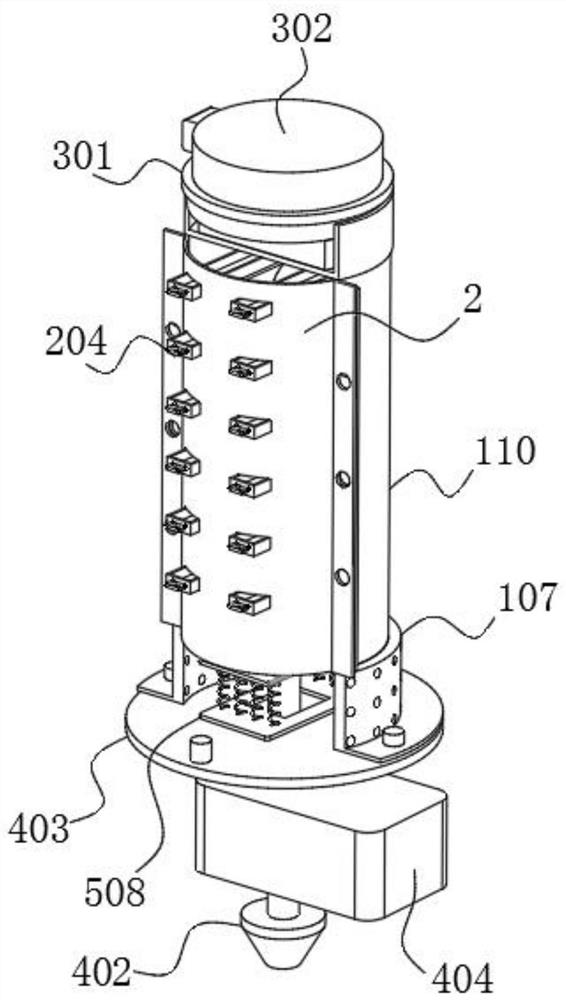

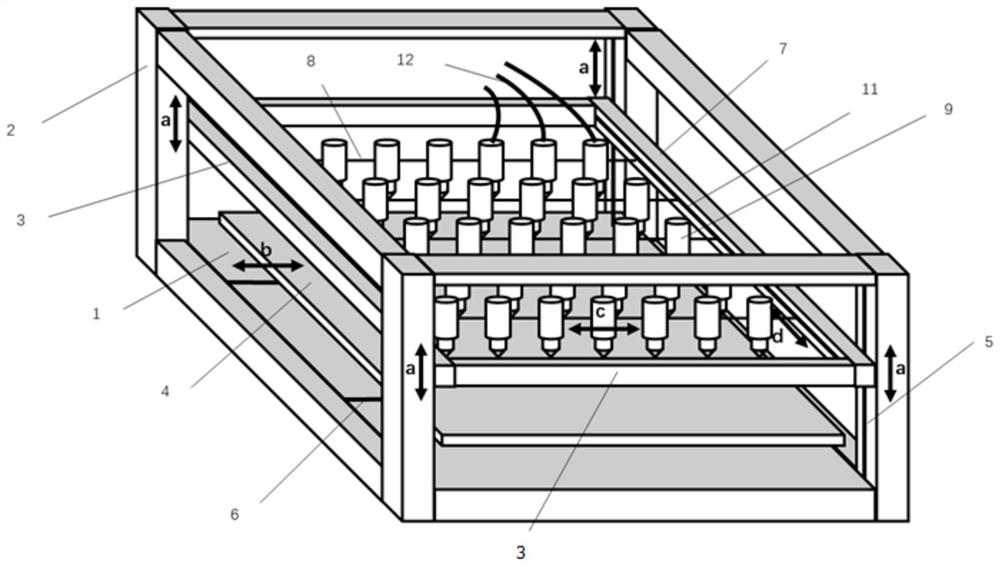

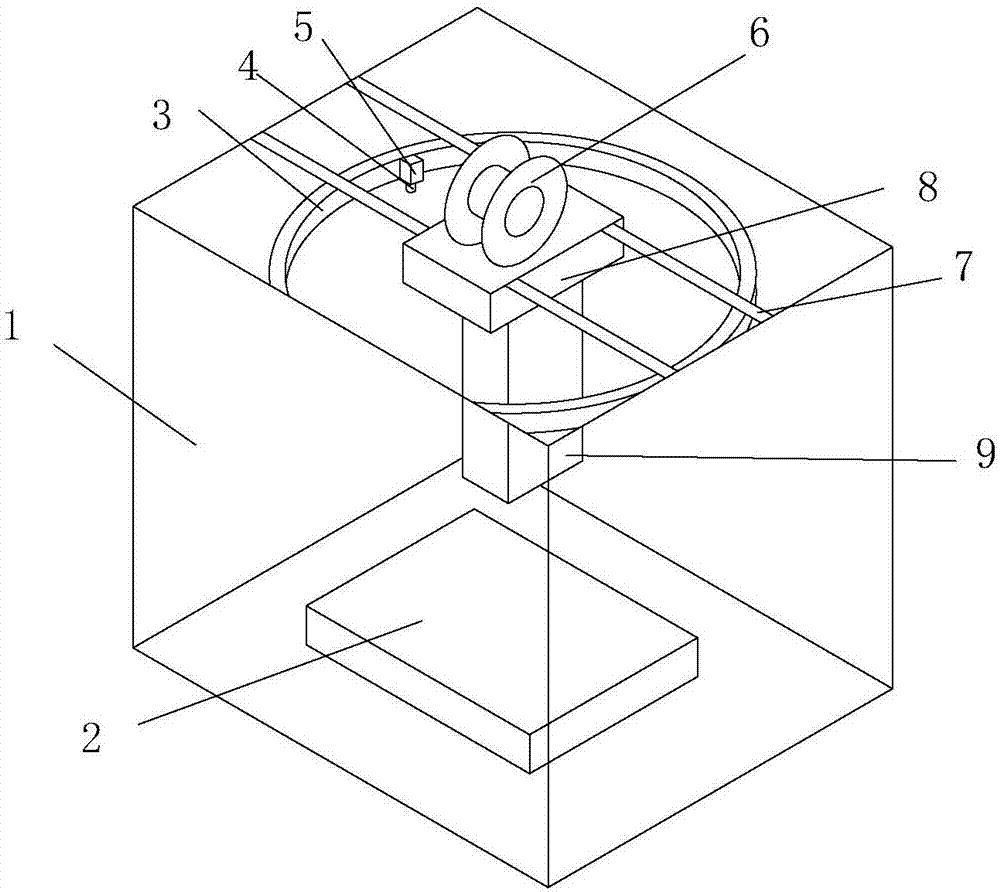

Supporting device for three-dimensional printing and three-dimensional printing method

ActiveCN105711095ASolve wasteSimple procedureAdditive manufacturing apparatusEngineeringControllability

The invention discloses a supporting device for three-dimensional printing. The supporting device for three-dimensional printing comprises a rack, a supporting unit and a lifting unit, wherein the supporting unit is spliced by multiple supporting plates and arranged just under a three-dimensional forming region of a three-dimensional printer; and the lifting unit is installed on the rack and is used for driving the supporting plates to move to required supporting positions to support a three-dimensional model to be printed. The invention also discloses a three-dimensional printing method. The original supporting modules needing to be printed and separated are replaced with the liftable supporting plates of the supporting device disclosed by the invention, and thus saving materials and improving the printing efficiency. Meanwhile, according to the device and the method, a supporting part is replaced by external machinery, so that the original printer algorithm structure is optimized, and the controllability is good.

Owner:ZHEJIANG UNIV

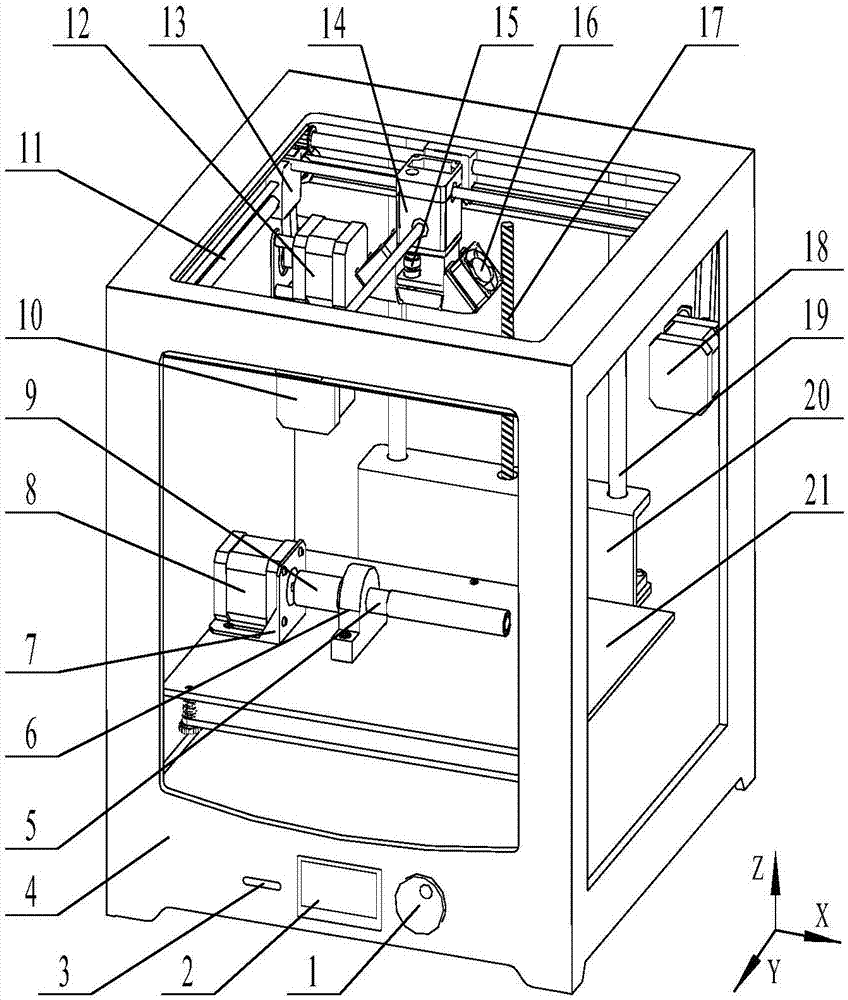

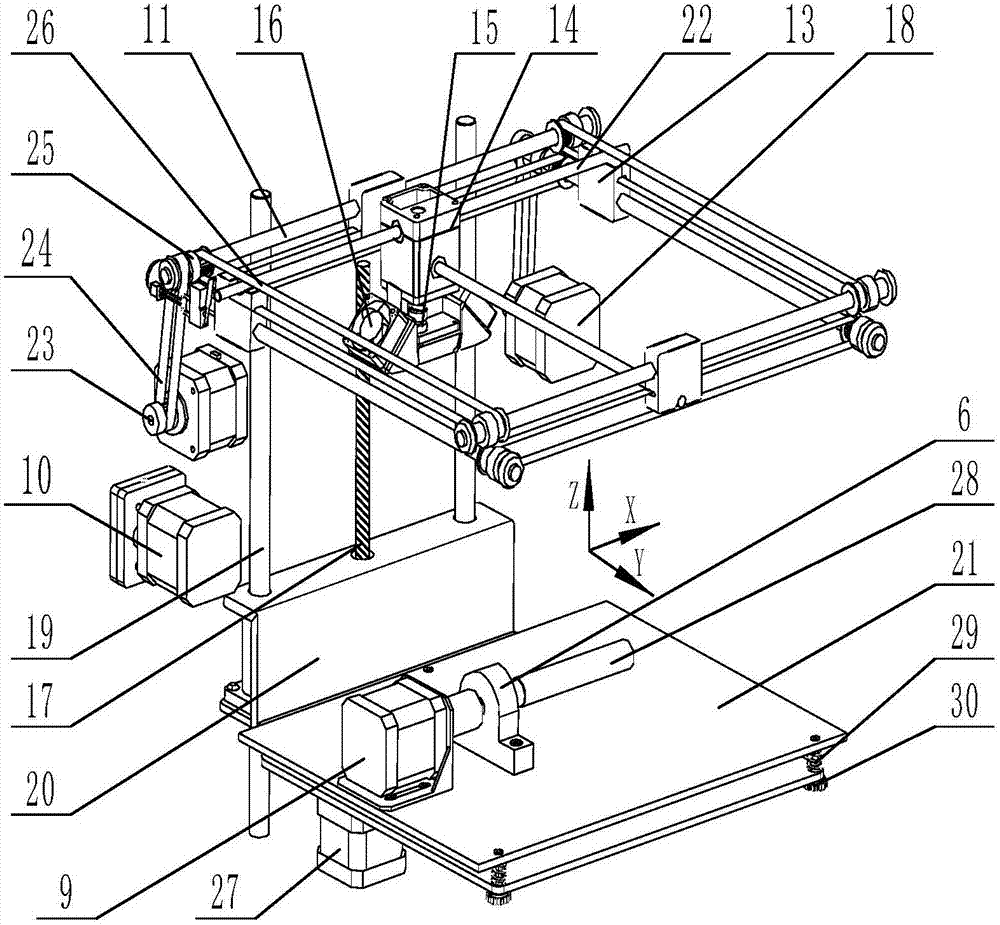

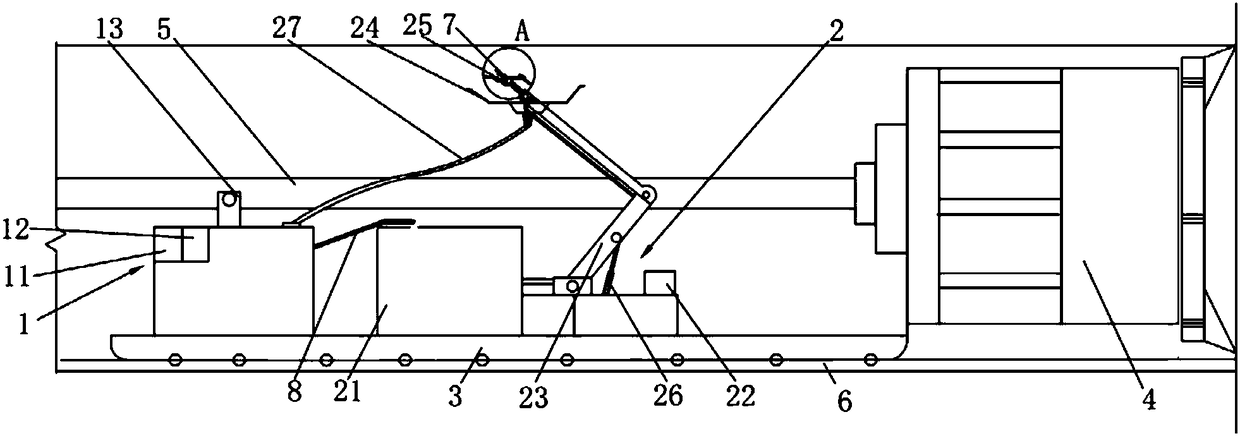

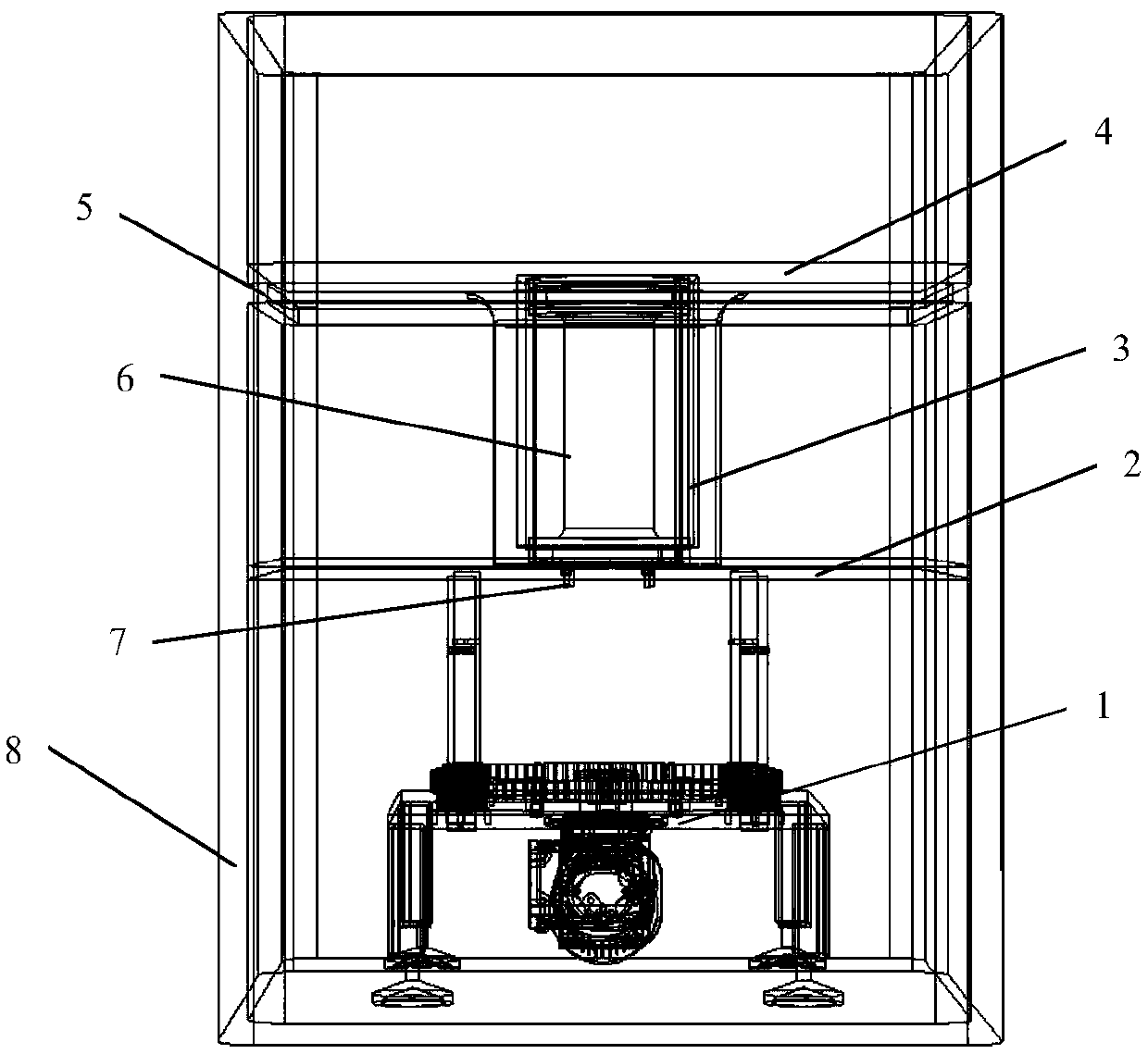

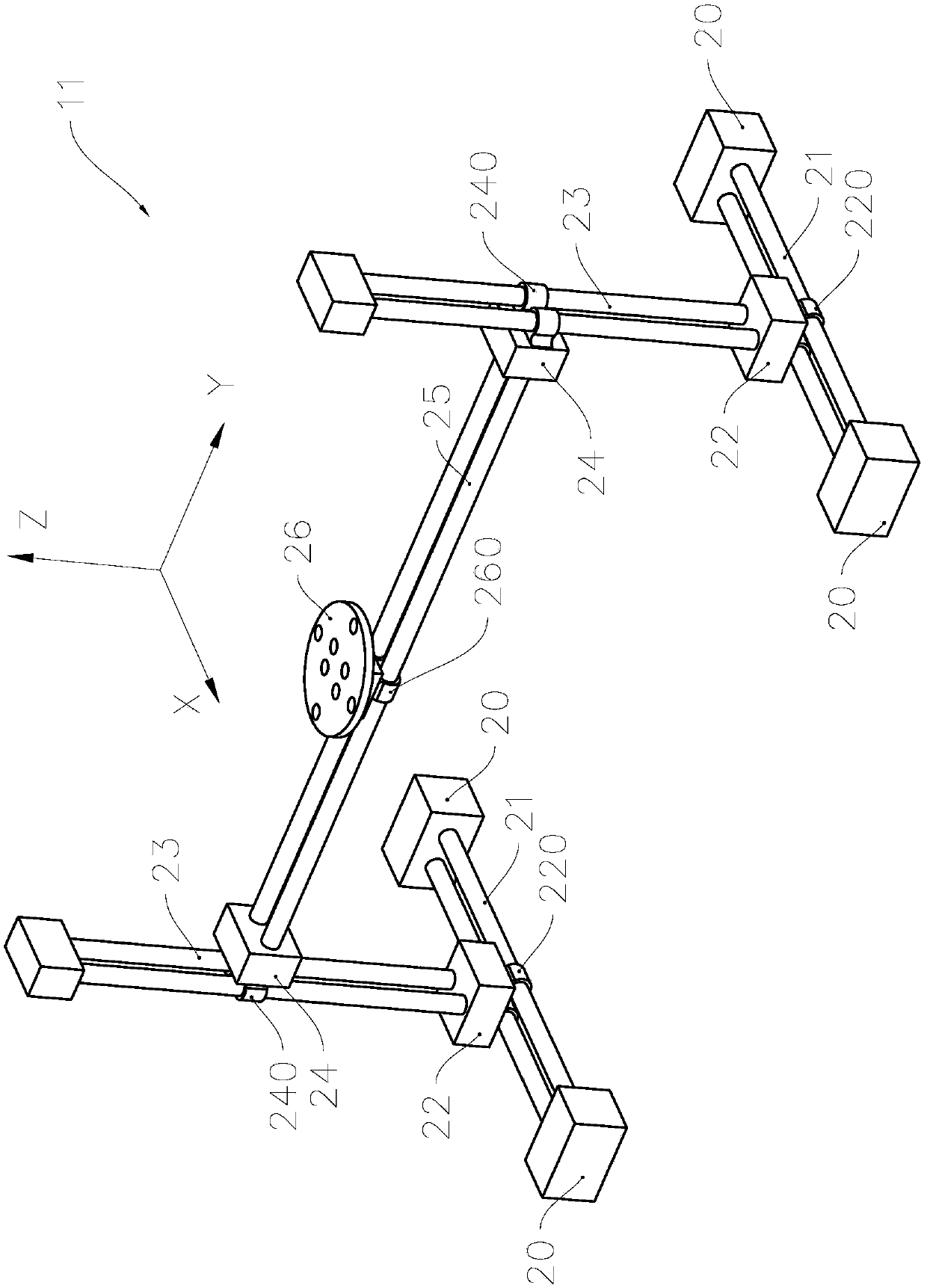

Four-axis linkage 3D printing device based on fusion deposition principle

InactiveCN106985379AEasy to manufactureImprove molding rateManufacturing driving means3D object support structuresSprayerSurface mass

The invention discloses a four-axis linkage 3D printing device based on the fusion deposition principle, belongs to the field of 3D printing and manufacturing, and relates to the four-axis linkage 3D printing device based on the fusion deposition principle. The printing device is composed of a rack, a printing sprayer assembly, a control assembly, an X-axis drive assembly, a Y-axis drive assembly, a Z-axis drive assembly and an A-axis drive assembly. A shaft sleeve of the A-axis drive assembly can be detached and replaced, a series of shaft sleeves the same in inner diameter but different in outer diameter can be selected, and forming and manufacturing of pipe-shaped structure models different in inner diameter are conveniently achieved. By means of the printing device, a thin-wall pipe net-shaped structure can be conveniently prepared, any auxiliary supporting structure does not need to be additionally arranged in the printing process, the posttreatment and other complex operation processes are simplified, printing materials are saved, and the forming rate and surface quality of test piece printing are effectively improved. The A-axis drive assembly is flexible in control and easy and convenient to mount and dismount, a series of inner diameter test pieces can be formed by replacing the shaft sleeves of different outer diameters, and the four-axis linkage 3D printing device is simple, practical and easy to operate and popularize.

Owner:DALIAN UNIV OF TECH

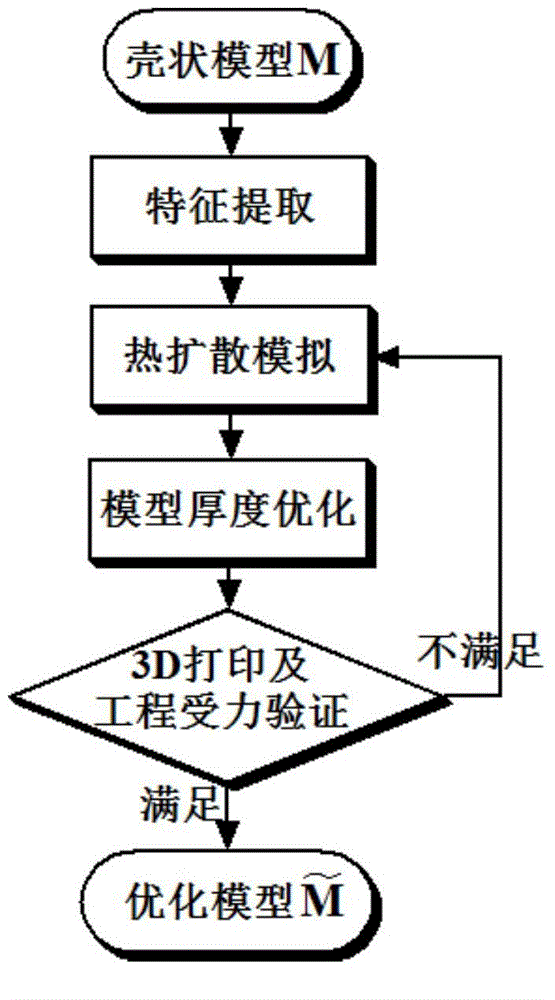

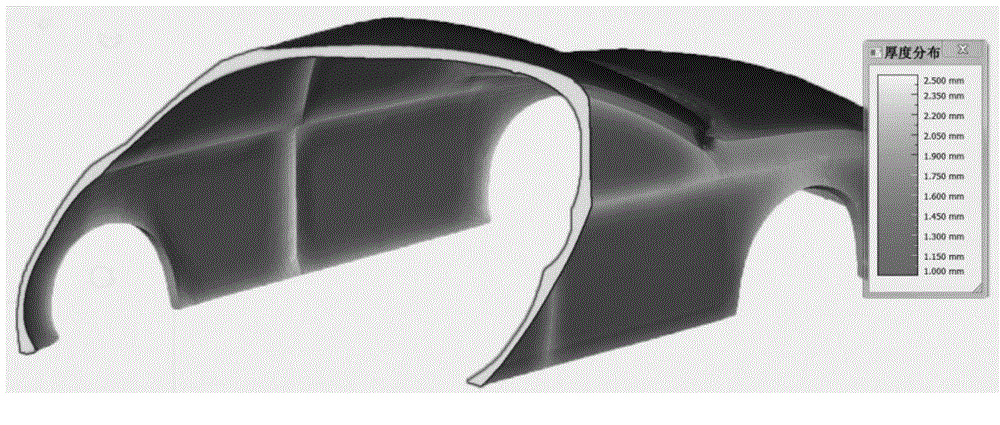

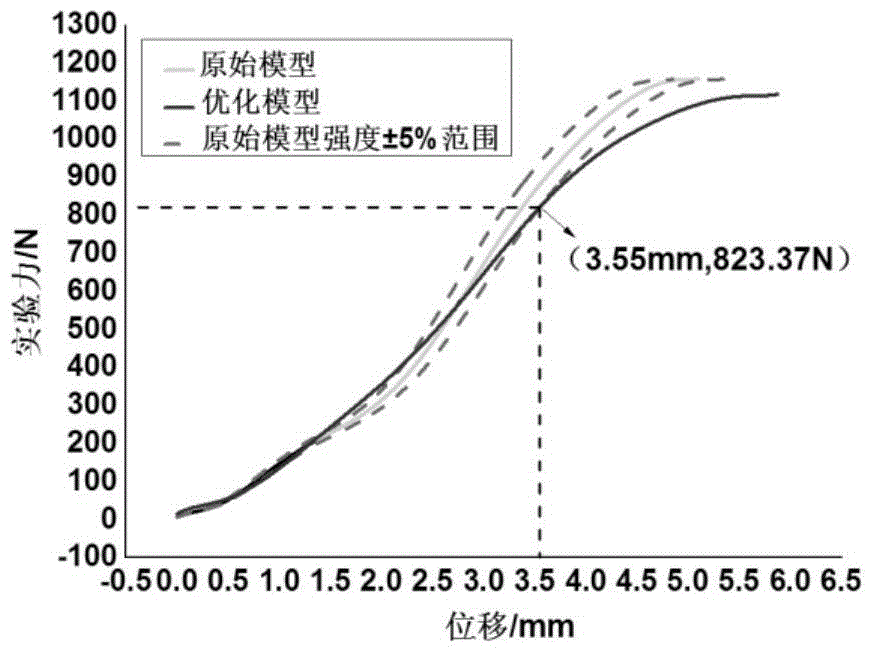

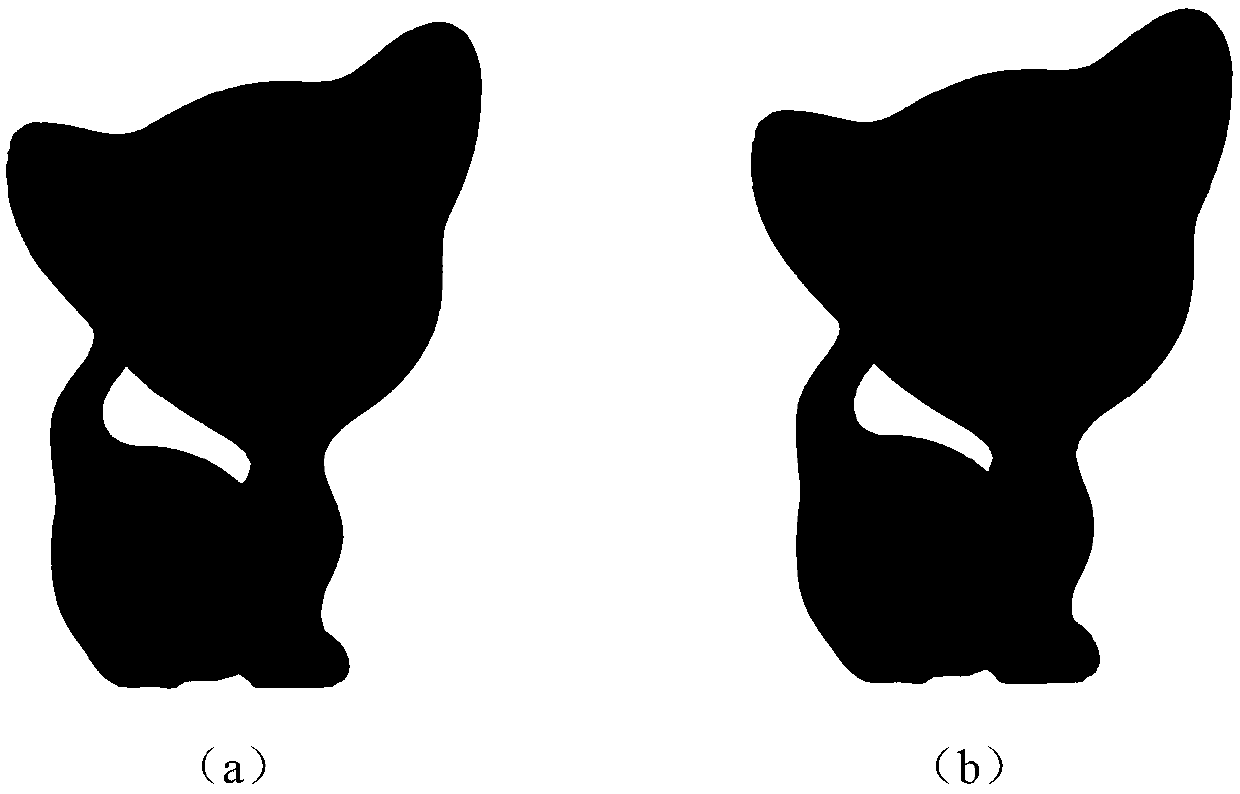

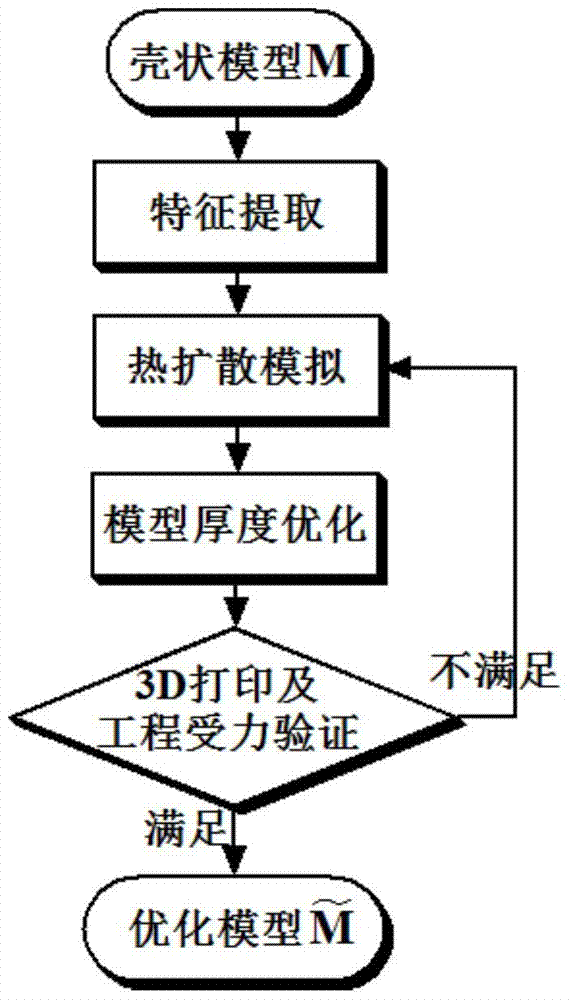

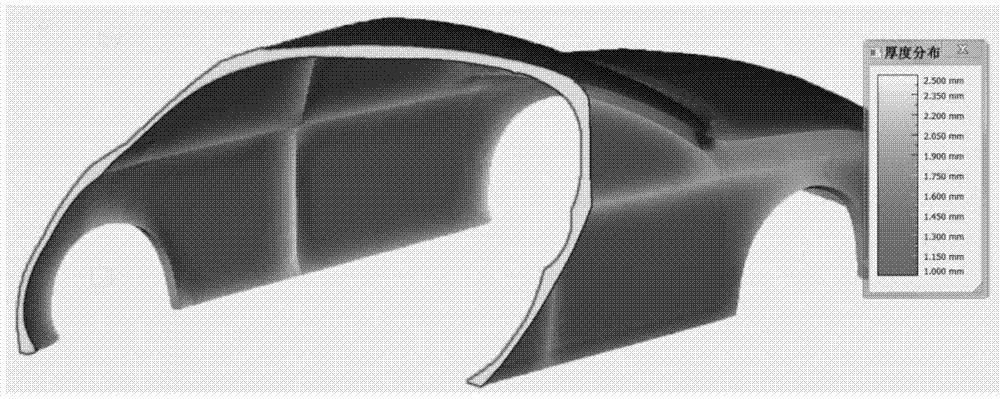

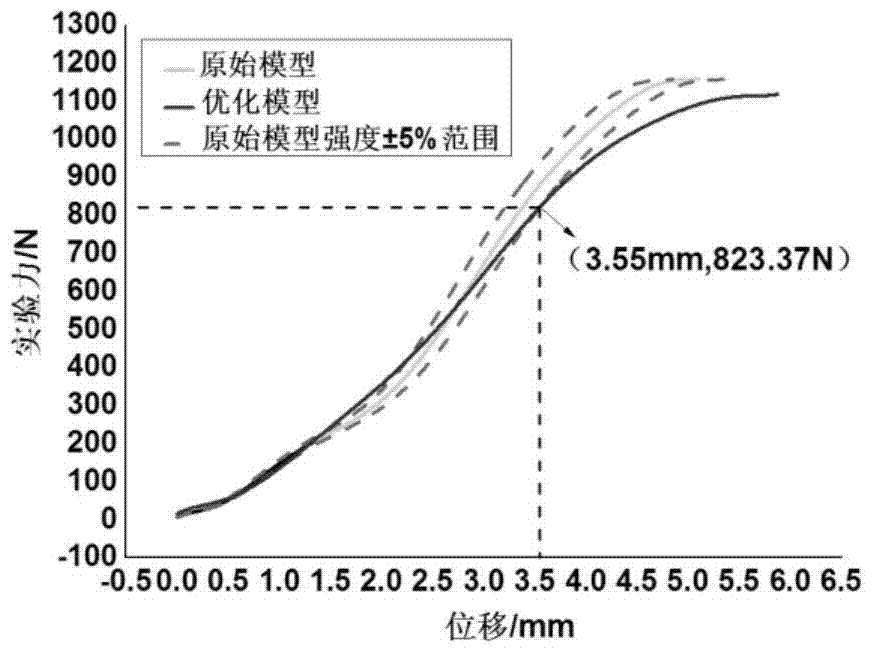

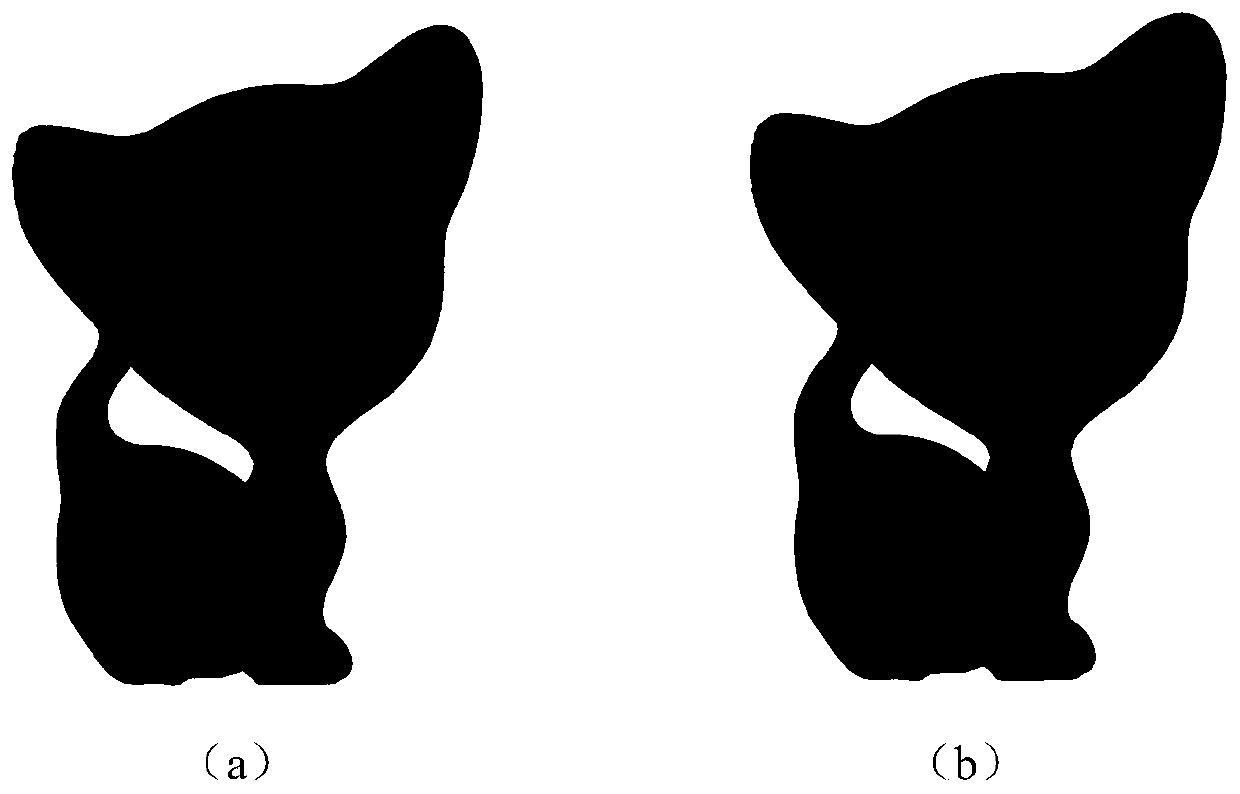

Shell-shaped component light modeling system for 3D (three-dimensional) printing

InactiveCN104881514AHigh speedAchieve lightweightSpecial data processing applications3D modellingStress distributionDiffusion

The invention provides a shell-shaped component light modeling system for 3D (three-dimensional) printing, and belongs to the field of computer aided design and industrial design manufacturing. According to the shell-shaped component light modeling system for 3D printing, stress distribution of a model is simulated through thermal diffusion under the conditions that characteristic constraints and stress working conditions are given, and a simulating numerical value corresponds to the thickness of the model to obtain an initially optimized model; an entity experiment model is obtained through 3D printing and is subjected to engineering stress verification; furthermore, thermal diffusion degree is adjusted through diffusion parameters according to engineering verification conditions, so that the thickness of the optimized model is close to actual stress requirements; and a weight optimized model which meets stress requirements is obtained through a circular iteration process.

Owner:DALIAN UNIV OF TECH

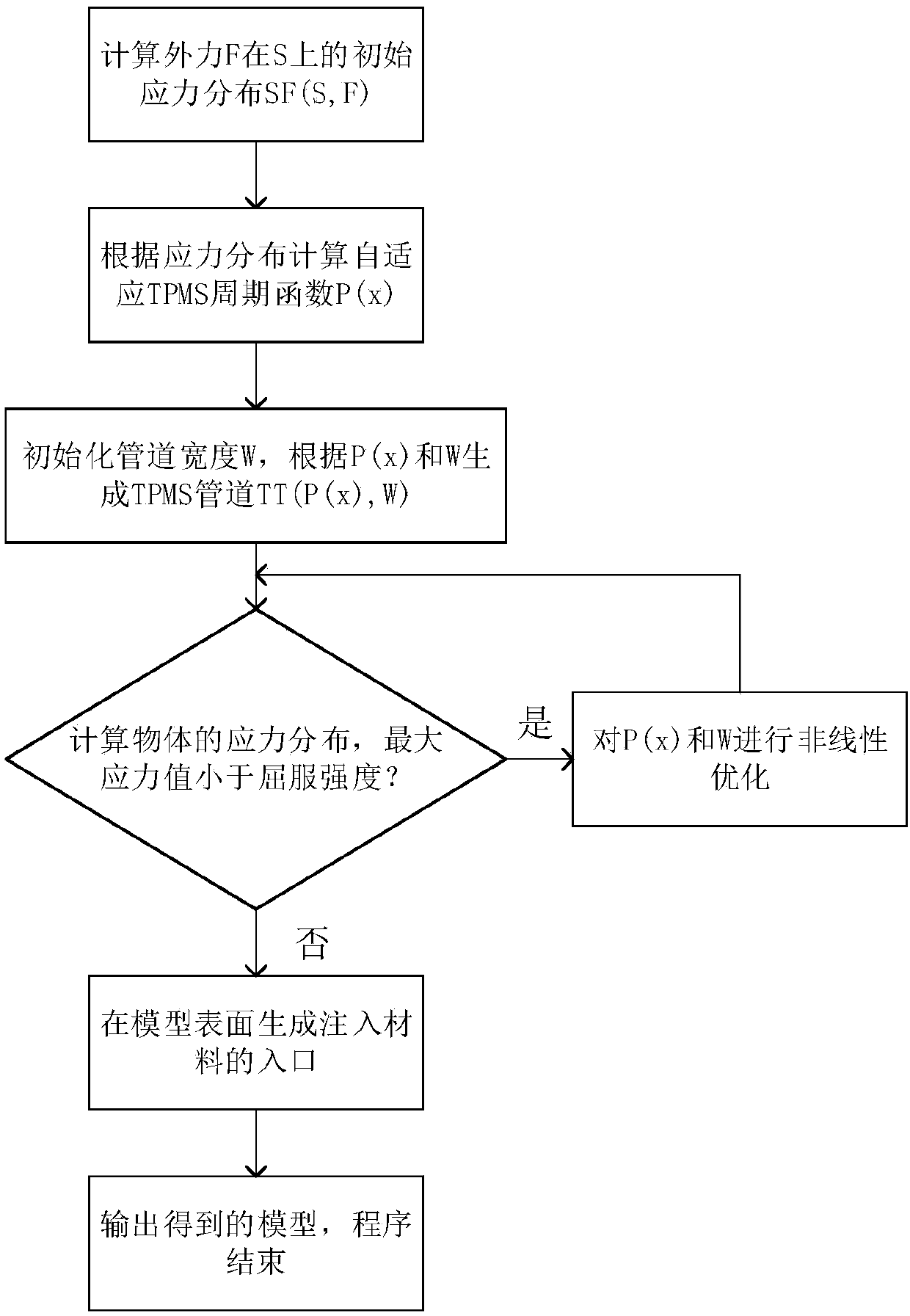

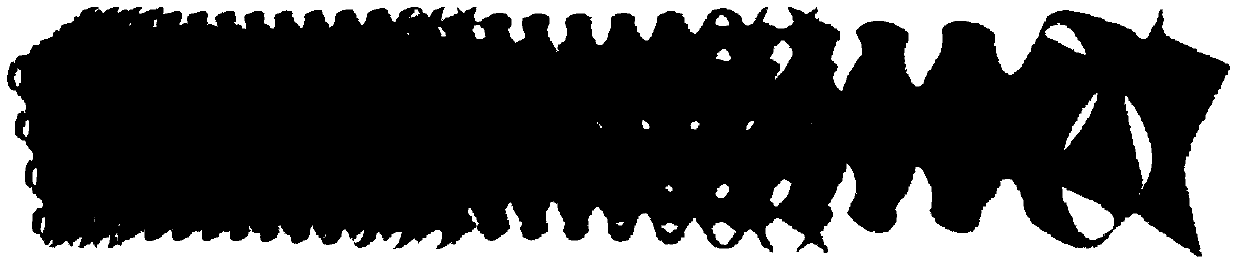

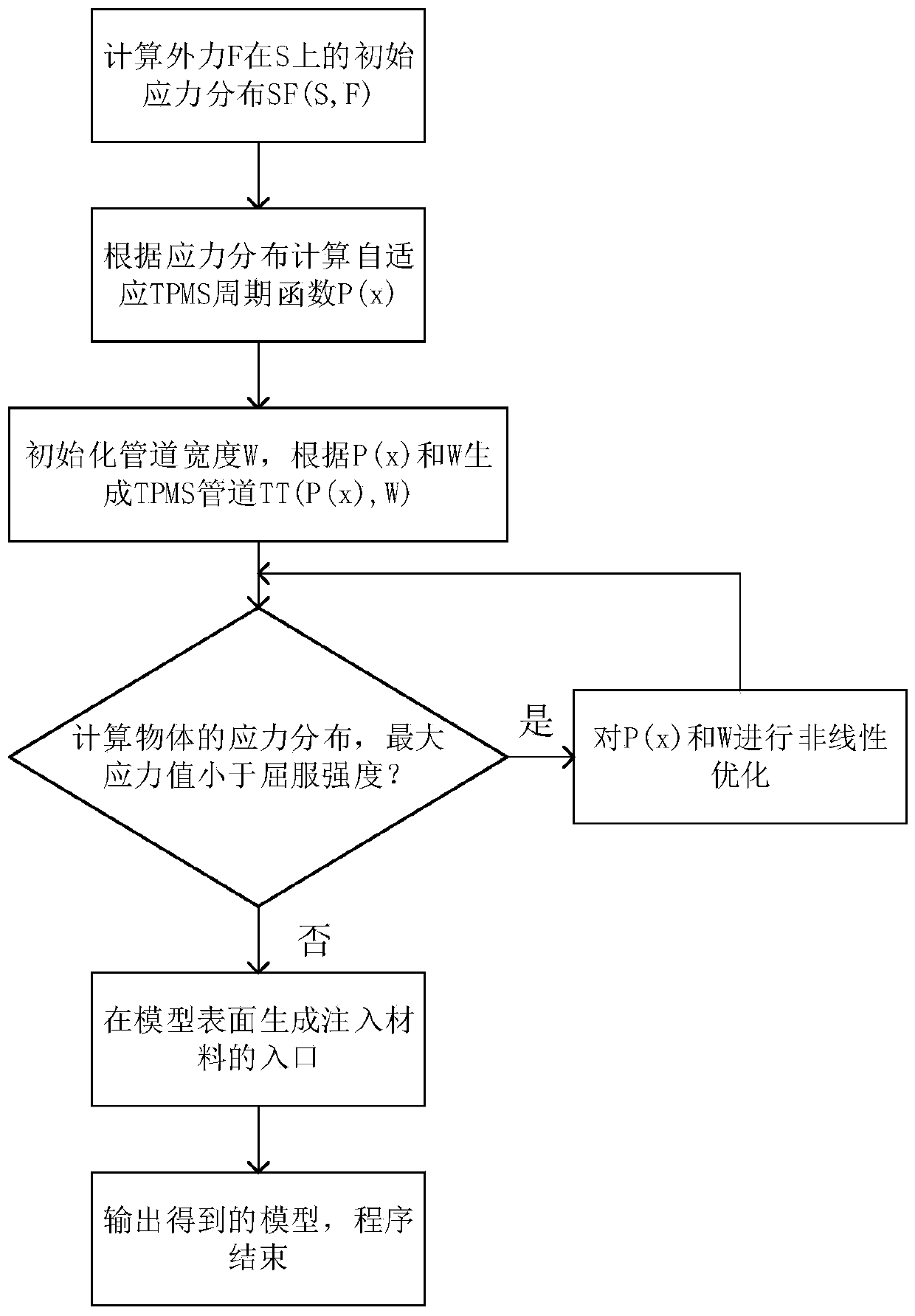

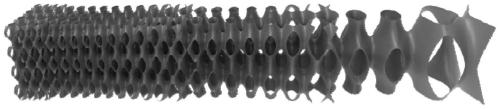

TPMS-based model structure optimization method and device for 3D printing

ActiveCN108846148ARealize support-freeSave printing materialsDesign optimisation/simulationSpecial data processing applicationsElement analysisStress distribution

The invention discloses a TPMS-based model structure optimization method and device for 3D printing. The method comprises a step of performing finite element analysis on a given model to obtain a stress distribution of the model, a step of defining an adaptive TPMS periodic function according to the geometrical shape of the given model and the stress distribution, a step of initializing a pipelinewidth, generating an internal pipeline according to the TPMS periodic function and the pipeline width, a step of recalculating the stress distribution of the model and judging whether a force requirement is satisfied or not, and generating an entry point on the surface of the model to be an inlet for injecting a material into the pipeline if so, otherwise, optimizing the TPMS periodic function and the pipe width according to a new stress distribution, generating an internal pipeline according to the optimized TPMS periodic function and the pipe width, and performing the step repeatedly untilthe stress distribution satisfies the force requirements. According to a structure optimized by using the method of the invention, only printing an outer casing and the inner pipeline of the model isneeded, and the effects of save a printing material and saving a printing time are achieved.

Owner:SHINING 3D TECH CO LTD

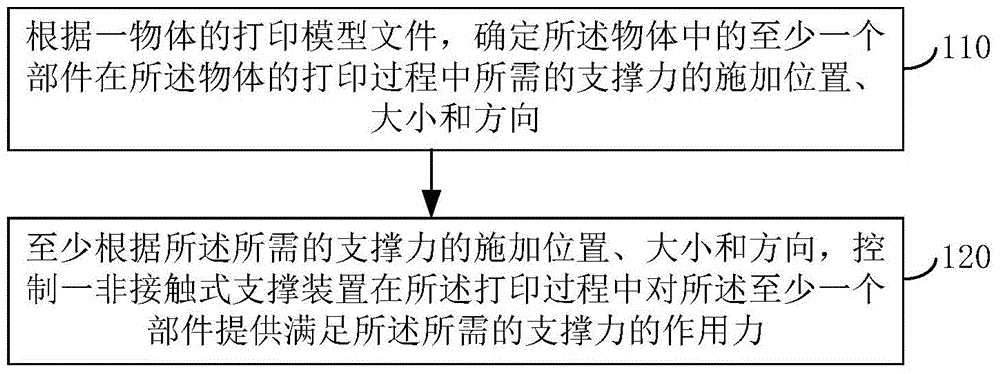

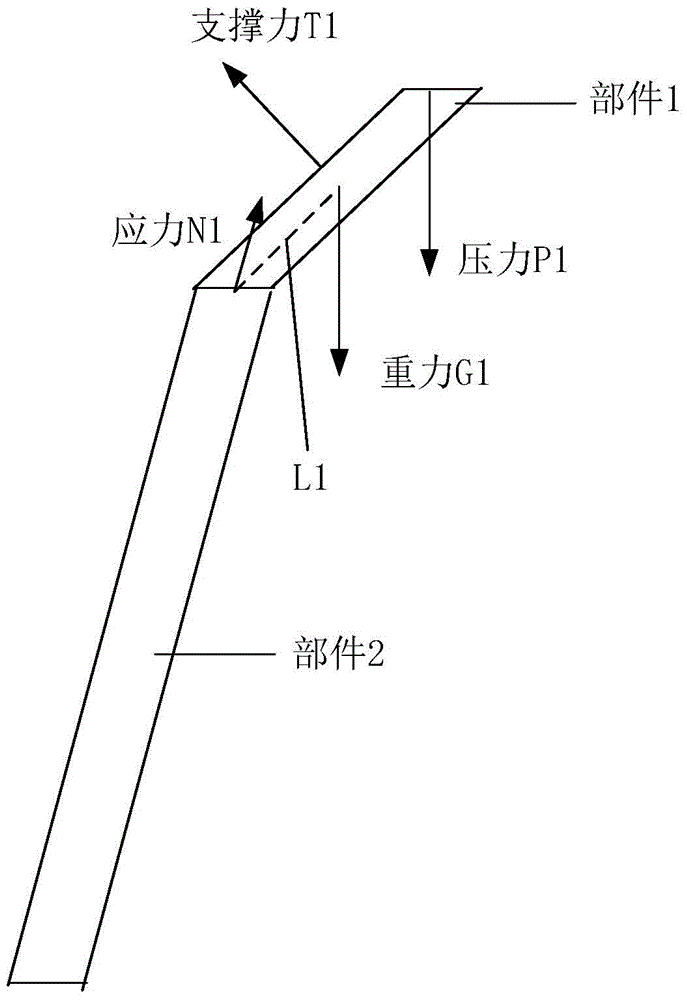

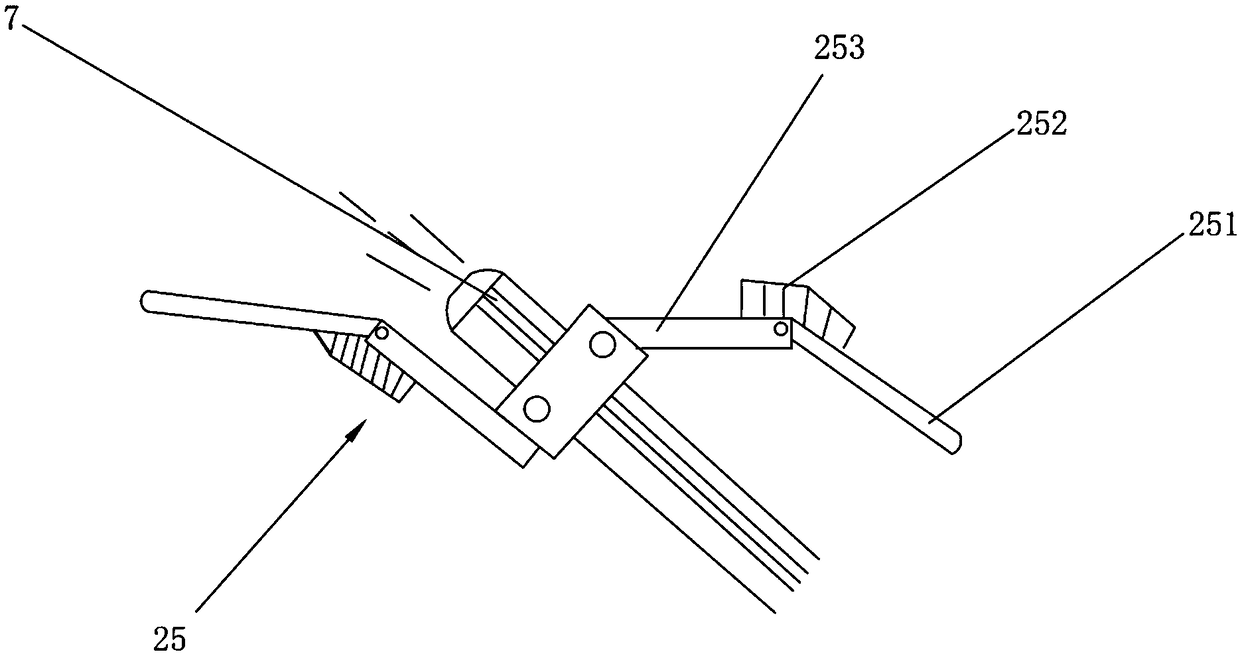

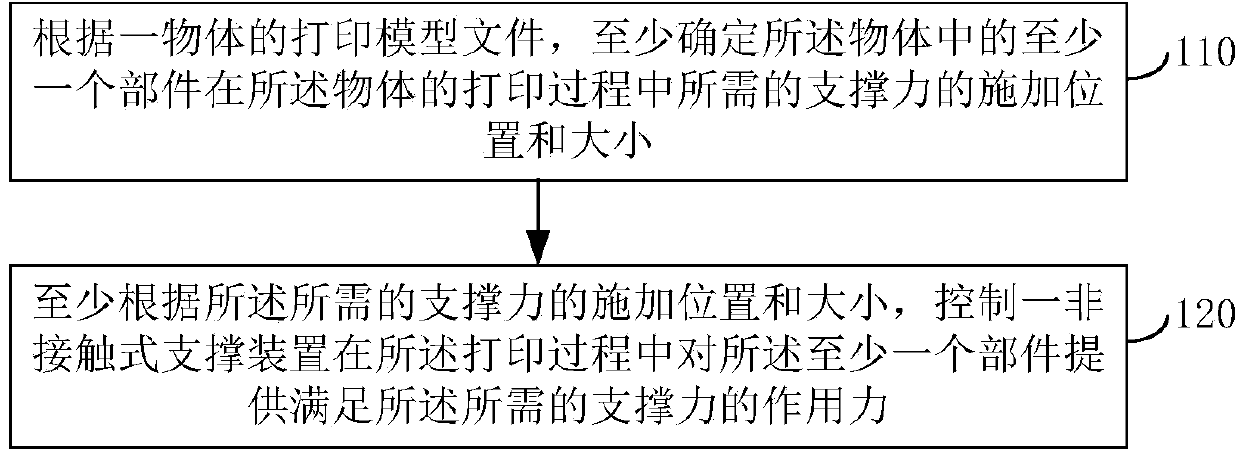

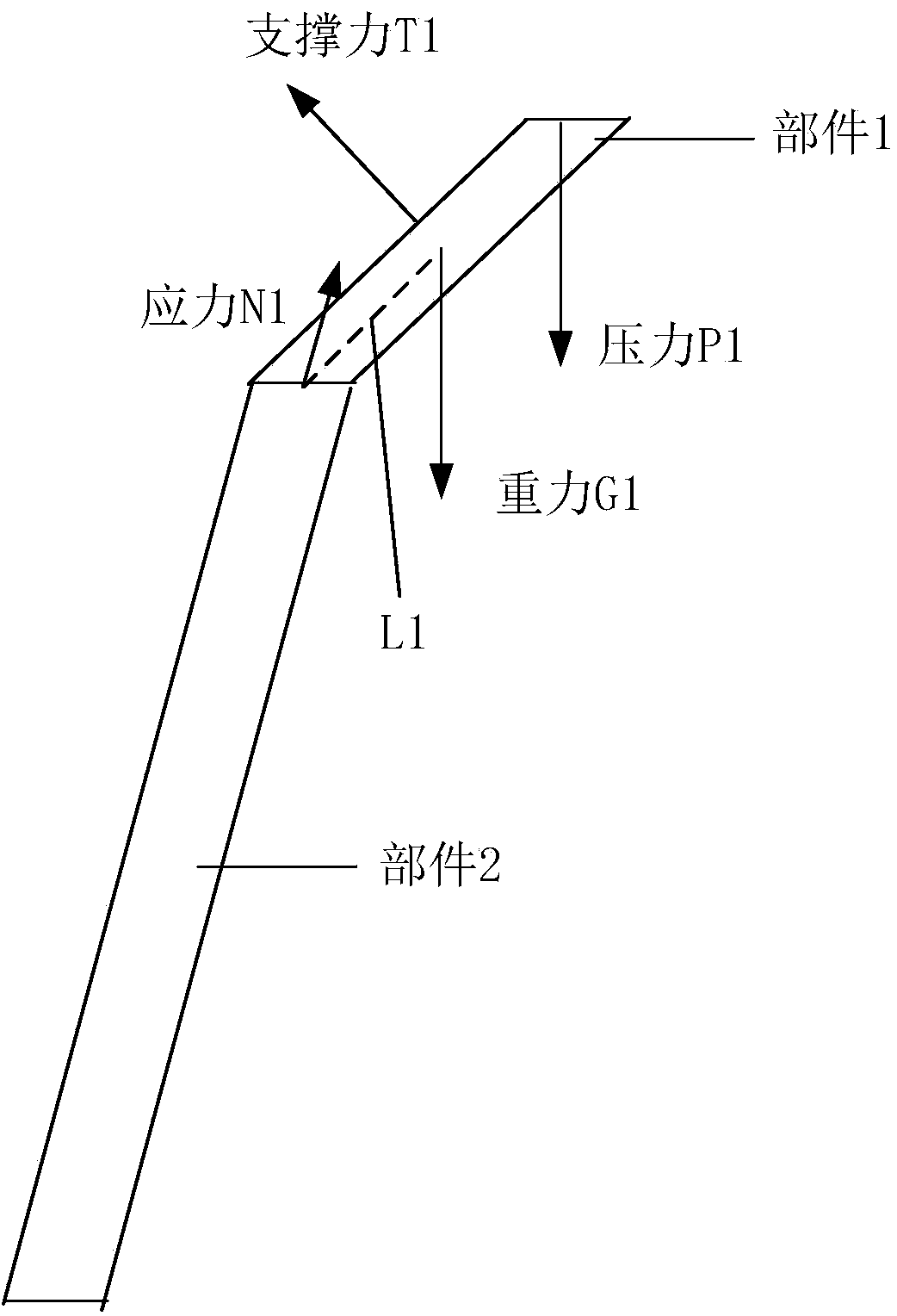

Method and device assisted for 3D printing and 3D printer

Owner:BEIJING ZHIGU TECH SERVICE

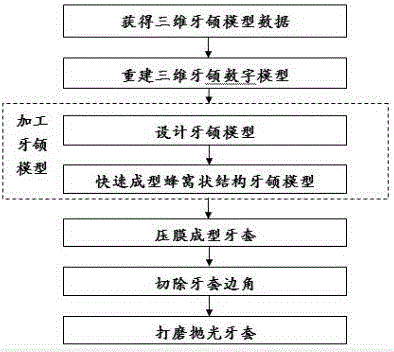

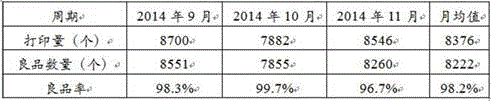

Processing method of invisible braces

The invention discloses a method for processing invisible braces, which includes a step of processing a dental model, the step of processing a dental model includes: (1) designing a dental model, using three-dimensional graphics processing software to design a target dental model, and the tooth The interior of the jaw model is with an internal support structure; (2) Rapidly forming a dental model with an internal support structure, using 3D printing equipment to rapidly form the dental model with an internal support structure. The processing method of the invisible braces of the present invention improves the processing technology of the invisible braces, and substitutes the support structure inside the jaw model, which saves a large amount of raw materials for printing and reduces the production cost; The processing accuracy is improved, the time required for the entire braces production process is shortened, and the processing efficiency is improved; the weight of the honeycomb tooth and jaw model involved in the present invention is greatly reduced, which is beneficial to saving transportation costs in the production process.

Owner:SHANGHAI SMARTEE DENTI TECH CO LTD

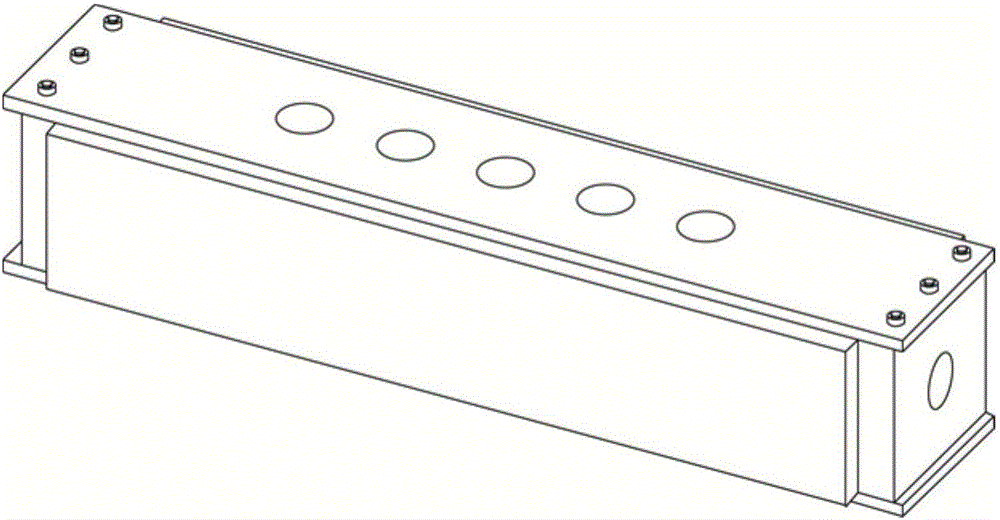

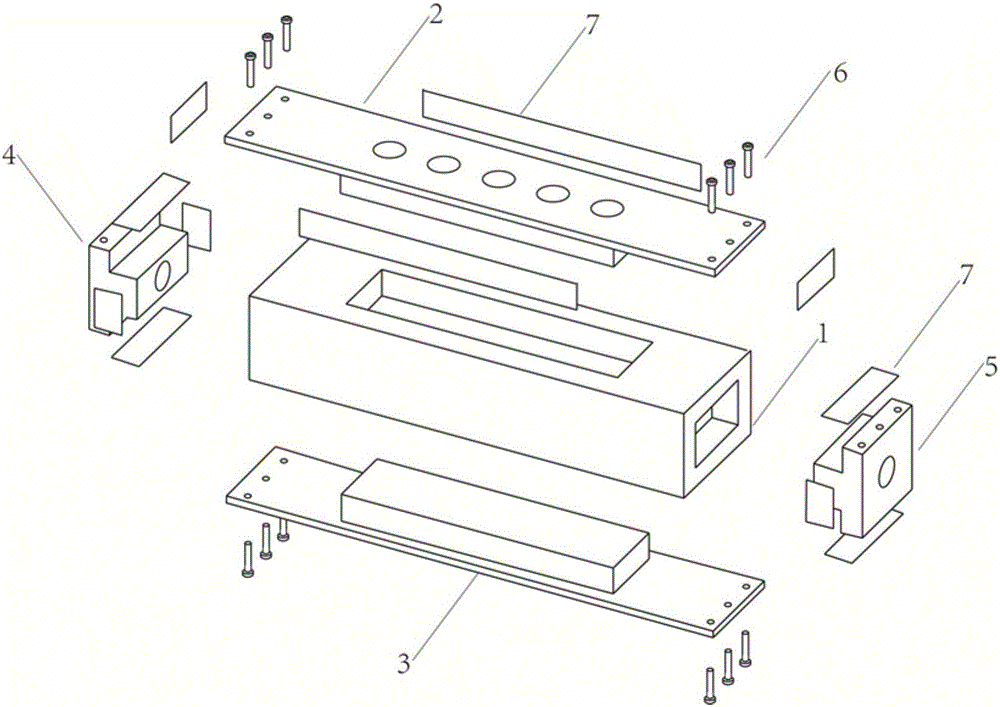

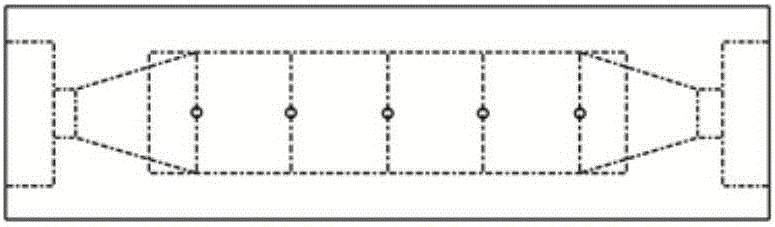

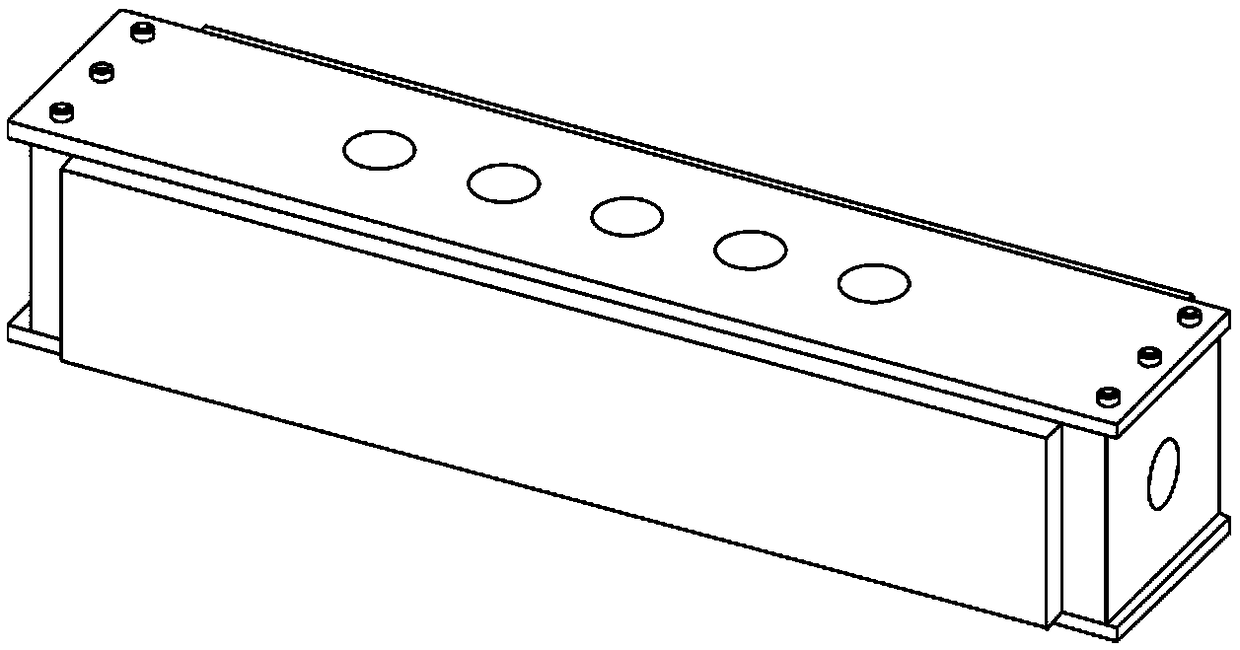

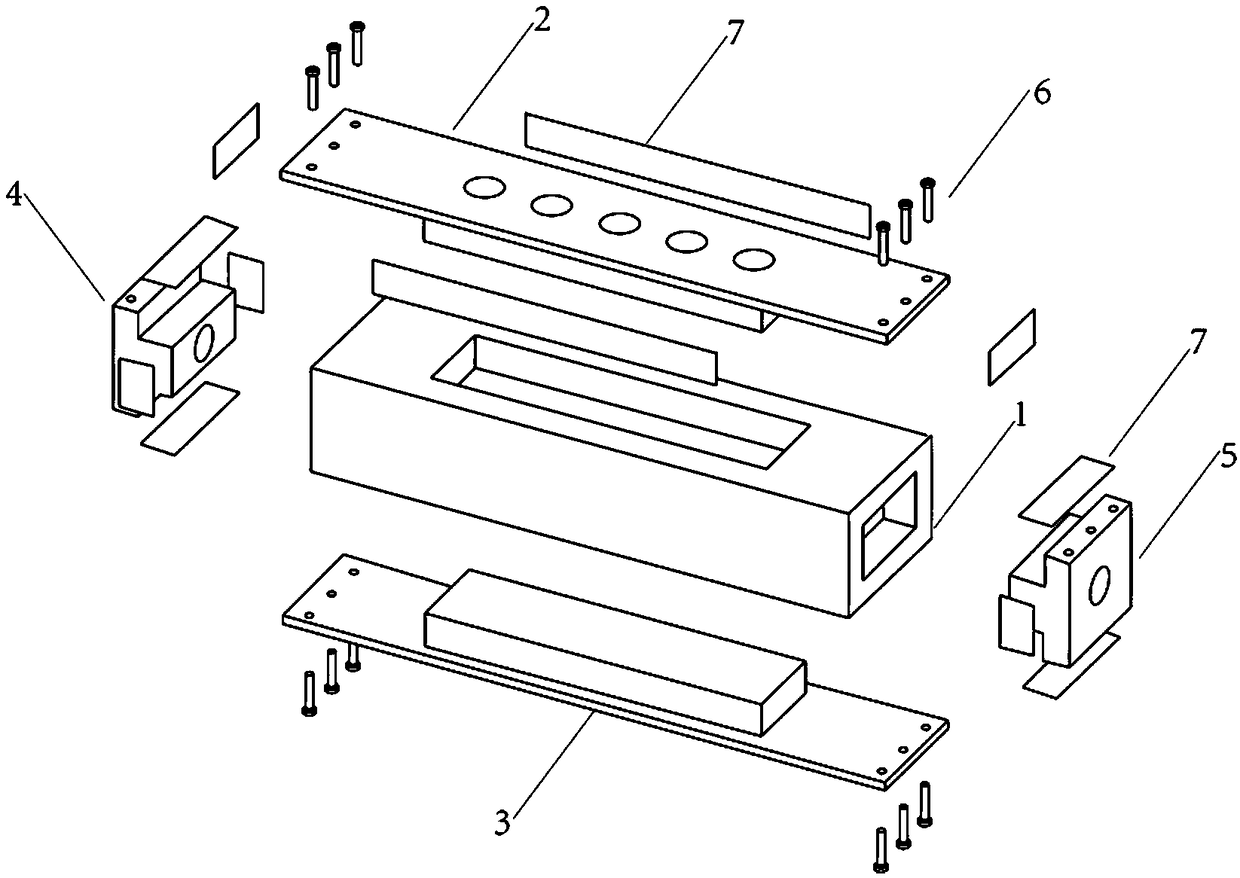

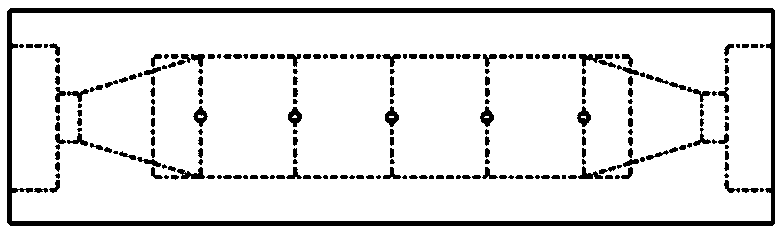

Rock coarse fracture seepage simulation model and making method

ActiveCN106353233AReduce intensityOvercome the disadvantage of low strengthPermeability/surface area analysisEngineeringWater pressure

The invention discloses a rock coarse fracture seepage simulation model and a making method. The rock coarse fracture seepage simulation model comprises a fracture main board, a left mounting board, a right mounting board, an upper mounting board and a lower mounting board, the fracture main board is of a cuboid structure, a hydrophobic area is arranged on one side of the cuboid structure, a water gathering area is arranged on the other opposite side, the hydrophobic area is communicated with the water gathering area, the outer side of the hydrophobic area is matched with the left mounting board, and the outer side of the water gathering area is matched with the right mounting board; the upper surface and the lower surface of the cuboid structure are respectively matched with the upper mounting board and the lower mounting board, and a pressure measuring hole communicated with a communicating area between the hydrophobic area and the water gathering area is formed in the upper mounting board. 3D printing technology is adopted to manufacture the fracture main board which is fixed through the upper, lower, left and right mounting boards, and a bolt or a water pressure sensor is mounted on each mounting board, so that the making method of the rock coarse fracture seepage simulation model is simple to make, convenient to experiment and capable of reflecting rock fracture seepage characteristics more really and more accurately.

Owner:SHANDONG UNIV

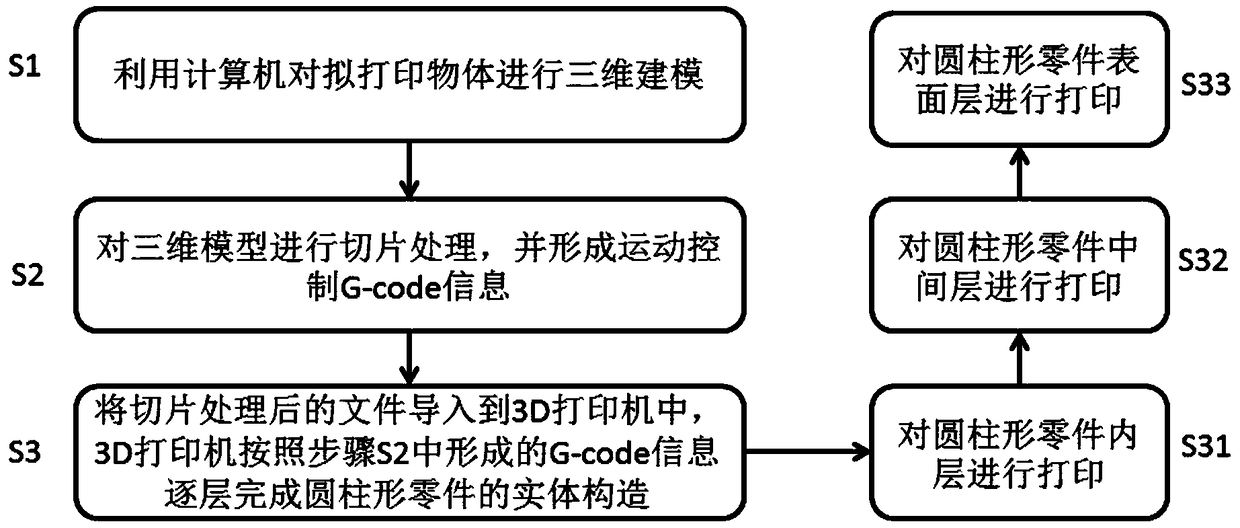

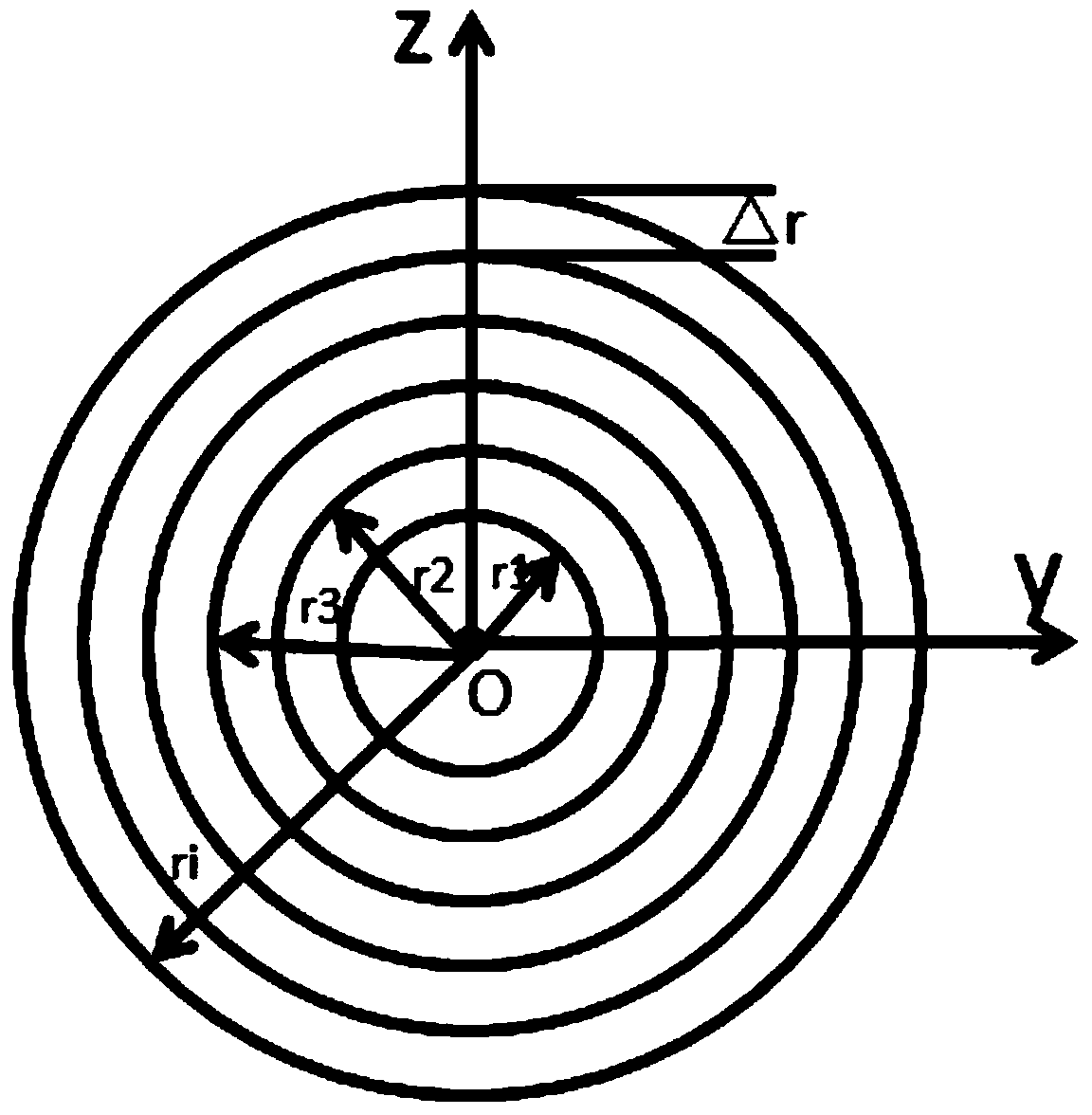

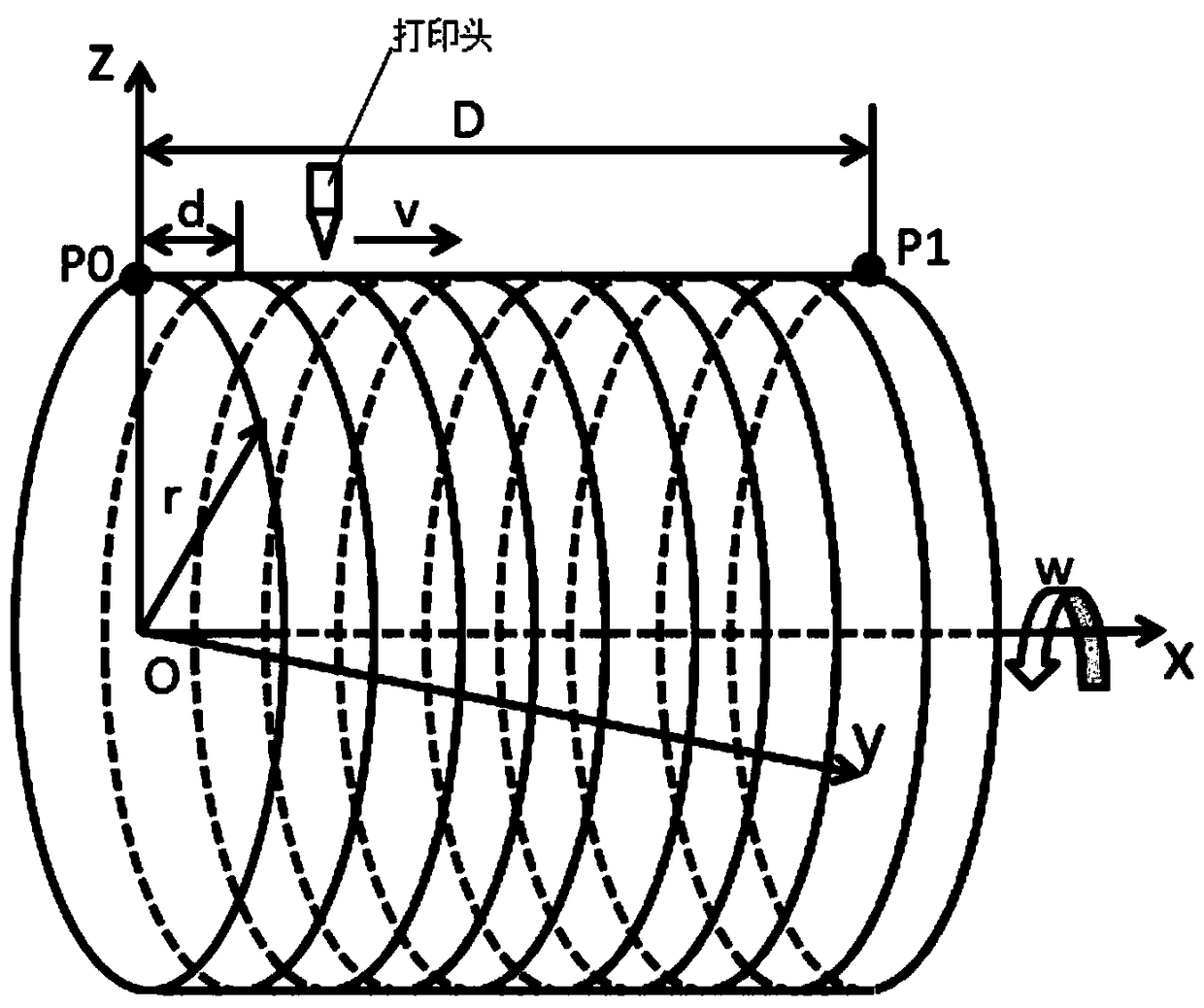

3D printing method suitable for cylindrical parts

ActiveCN109177174AIncrease printing speedAvoid vibrationAdditive manufacturing apparatusManufacturing data aquisition/processingEngineeringDimensional modeling

The invention discloses a 3D printing method suitable for cylindrical parts. The 3D printing method suitable for the cylindrical parts comprises the following steps that S1, the to-be-printed cylindrical parts are subjected to three-dimensional modeling through computer design software; S2, a three-dimensional model is subjected to slicing processing through a slicing method of cylindrical face pieces, and movement control G-code information is formed; and S3, files subjected to slicing processing enter a 3D printer, the 3D printer finishes solid construction of the cylindrical parts layer bylayer from inside to outside according to the G-code information formed in the step 2, the 3D printer adopts a printing tube arranged in the X direction as a printed piece adhesion platform, the printing tube can rotate along the central axis, and a printing head is arranged over the printing tube and can horizontally move in the length direction of the printing tube and move vertically in the Z direction. The 3D printing method suitable for the cylindrical parts avoids shape distortion caused when a straight line replaces a curved line during slicing of the parts with curved section profiles.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Grout spraying equipment for tunnel roof-supporting shield

PendingCN108756907AReduce pollutionReduce construction costsUnderground chambersTunnel liningAgricultural engineeringResidual soils

The invention relates to the technical field of tunnel engineering, in particular to grout spraying equipment for a tunnel roof-supporting shield. The grout spraying equipment comprises a walking track, a shield platform located on the walking track and a shield machine head arranged at the front end of the shield platform, and further comprises an automatic mixing device, residual soil 3D printing equipment, a spray head and an automatic conveying device, wherein a residual soil conveying pipe is connected to the shield machine head; the automatic mixing device is fixedly installed on the shield platform, and communicates with the residual soil conveying pipe, the residual soil 3D printing equipment is fixedly installed on the shield platform and is adjacent to the automatic mixing device; the automatic conveying device is arranged between the automatic mixing device and the residual soil 3D printing equipment, and the spray head is connected to the residual soil 3D printing equipment. According to the grout spraying equipment for the tunnel roof-supporting shield, zero worker participation in the primary lining process of the tunnel shield is realized, and the residue soil produced by the shield is recycled, so that the cost is reduced, the environmental pollution is reduced, and the efficient construction is realized.

Owner:BEIJING CHONGJIAN ENG

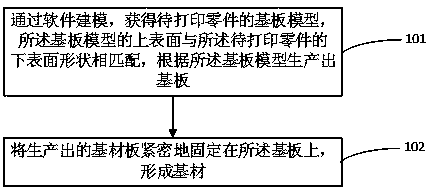

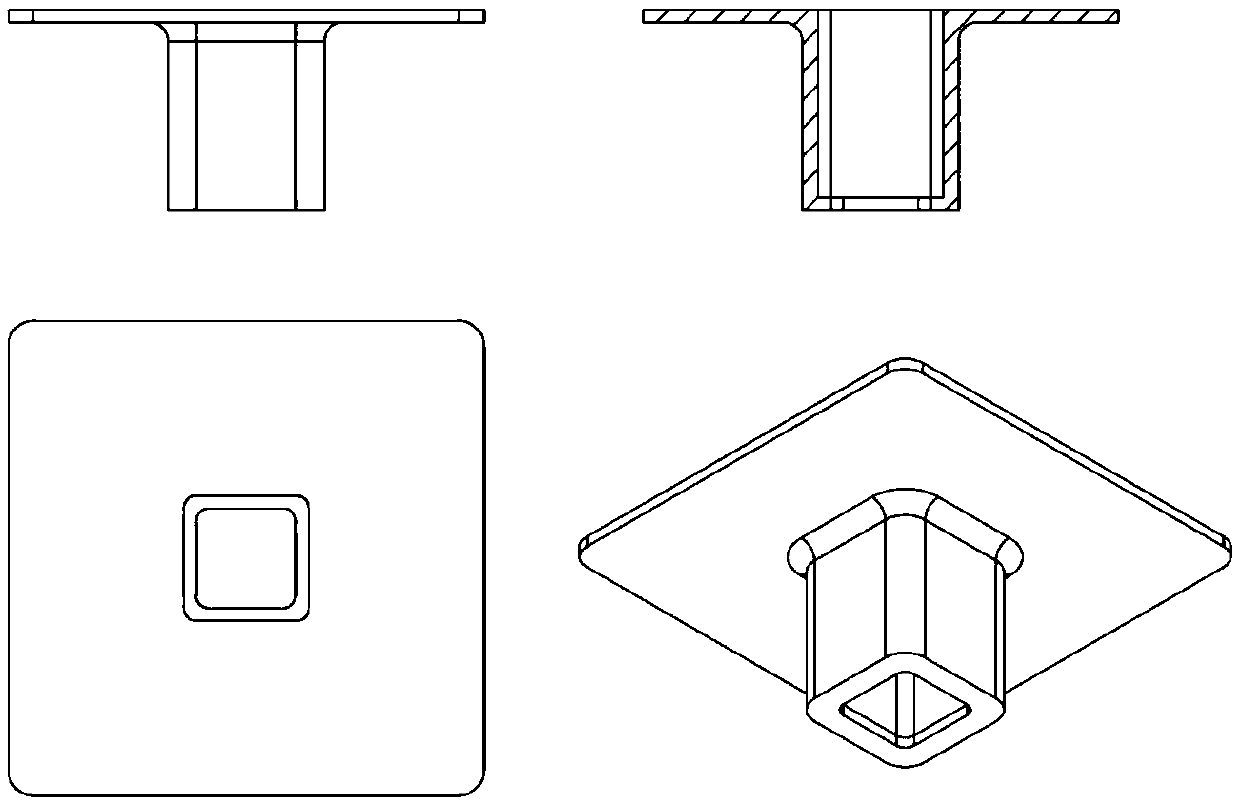

Method of preparing base material and base material

PendingCN108582791AReduce printing timeSave printing materialsManufacturing platforms/substratesManufacturing data aquisition/processingMetallurgyDirect printing

The invention discloses a method of preparing base material and a base material. The method of preparing the base material includes the steps that through software modeling, a base plate model of a to-be-printed part is obtained; the shape of the upper surface of the base plate model is matched with the shape of the lower surface of the to-be-printed part, and a base plate is produced according tothe base plate model; and a produced base material plate is tightly fixed to the base plate to form the base material. According to he base material obtained through the method, the shape of the upper surface of the base material is matched with the shape of the lower surface of the to-be-printed part; when the parts are printed, the needed parts can be directly printed without printing a solid support and printing time is saved and printing materials are saved.

Owner:TSC LASER TECH DEV BEIJING CO LTD

3D printing assisting method and device as well as 3D printer

Owner:BEIJING ZHIGU TECH SERVICE

Rotating nozzle device, 3D printer and printing method

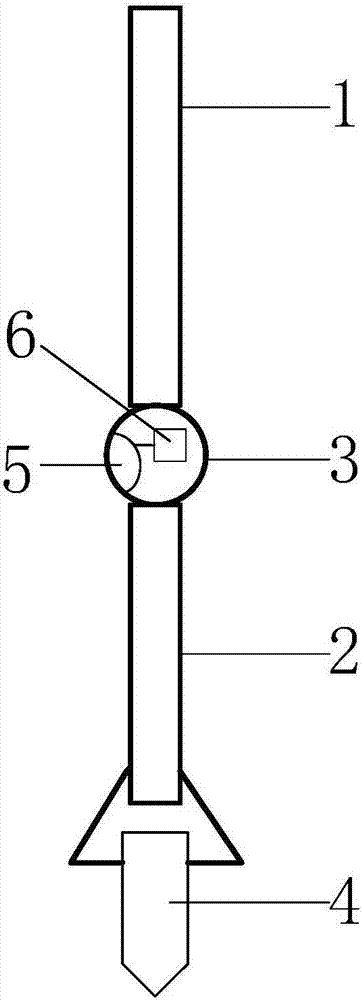

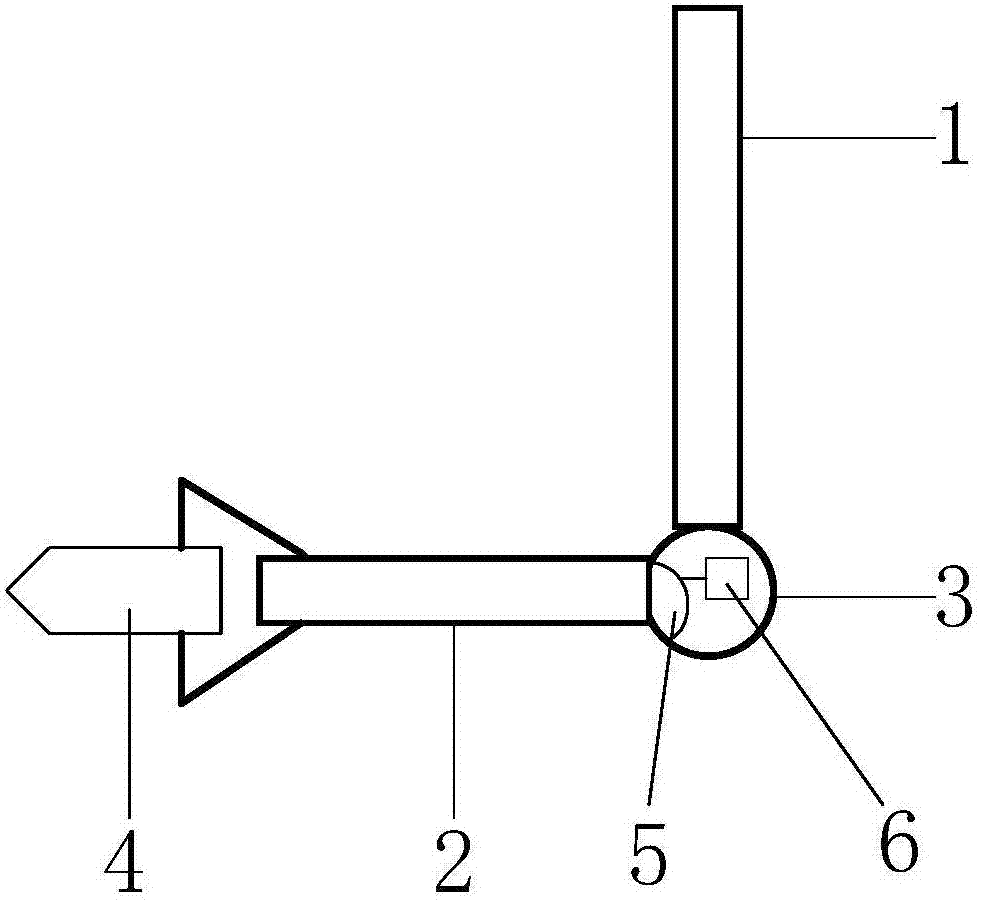

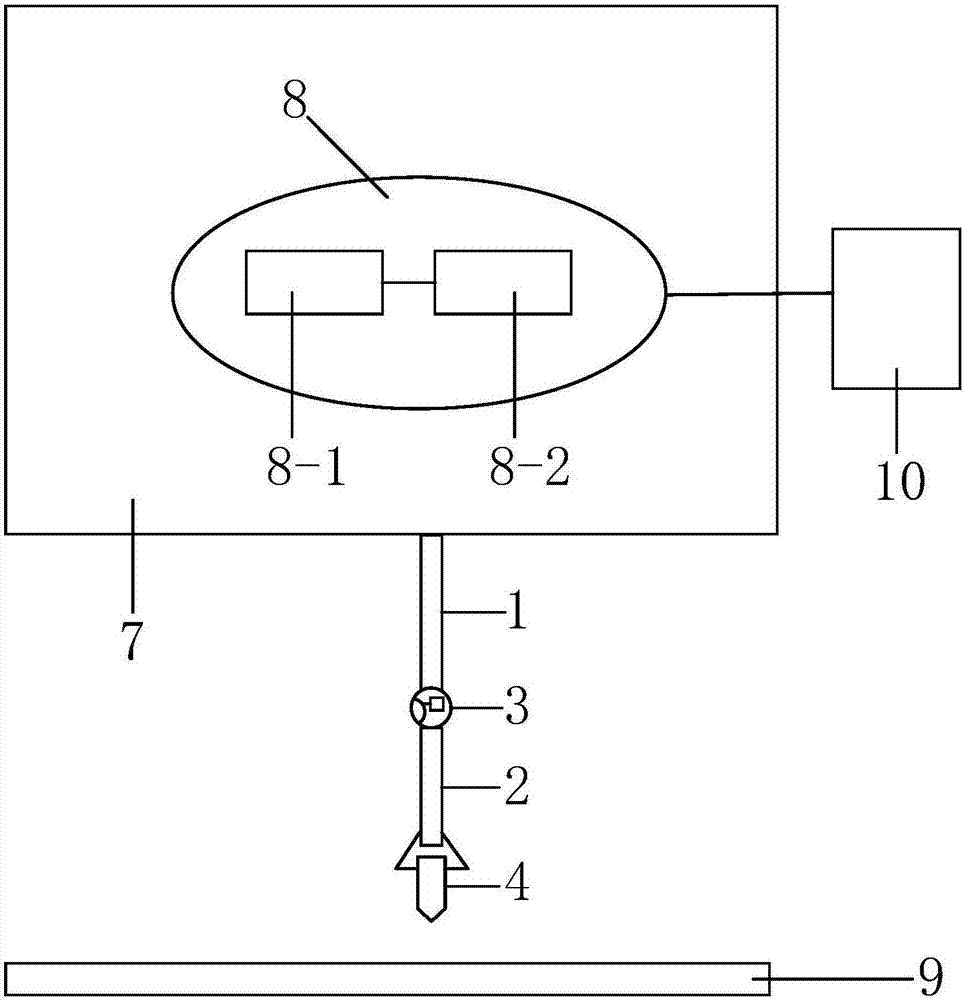

ActiveCN105773978ABreaking through the traditional form and structureIntegrity guaranteedAdditive manufacturing apparatusRotational axisEngineering

The invention discloses a rotating nozzle device, a 3D printer and a printing method. The rotating nozzle device comprises a supporting shaft, a rotating shaft and a nozzle. The supporting shaft is mounted at the bottom of the body of the 3D printer. One end of the rotating shaft is connected with the supporting shaft through a rotating joint, and the other end of the rotating shaft is provided with the nozzle. A driver and a sensor are arranged inside the rotating joint. The sensor is connected with a processor and the driver of the 3D printer. The driver is connected with the rotating joint. According to the rotating nozzle device, the 3D printer and the printing method, the traditional morphological structure of the printing nozzle is broken through, and the problem that the side protruding part of a printed model needs to be supported is solved; printing materials are reduced, printing efficiency is improved, and the integrity of the finally-printed model is guaranteed; convenience is brought to switching of the nozzle directions in the printing process, and the flexibility of the rotating nozzle for printing the 3D model is improved.

Owner:SHANGHAI SUNGLOW PACKAGING TECHNOLOGY CO LTD

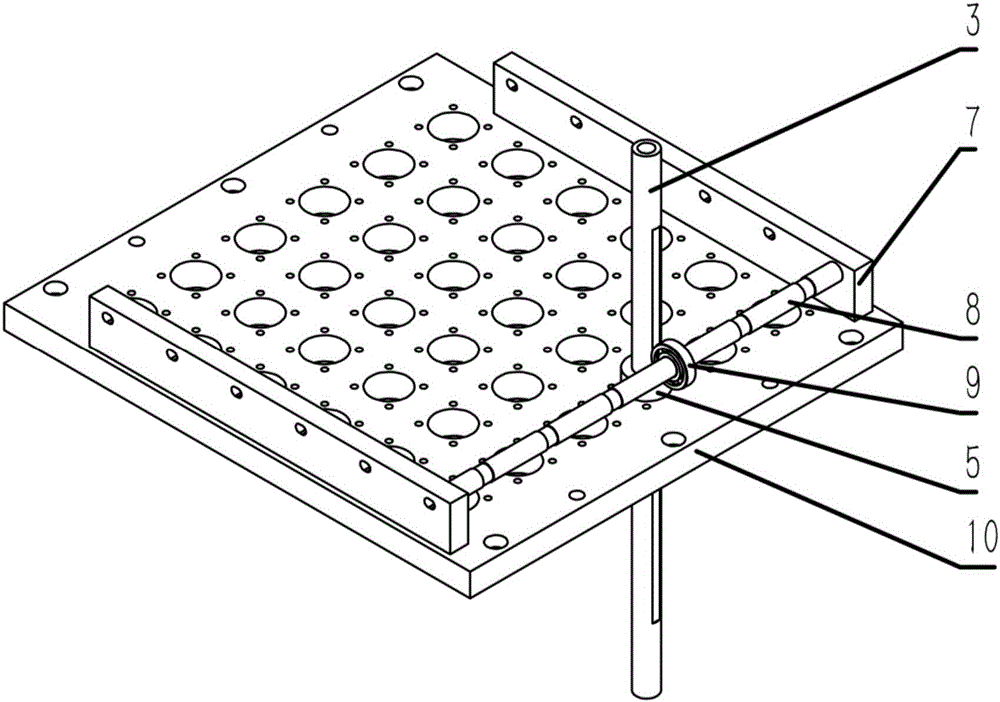

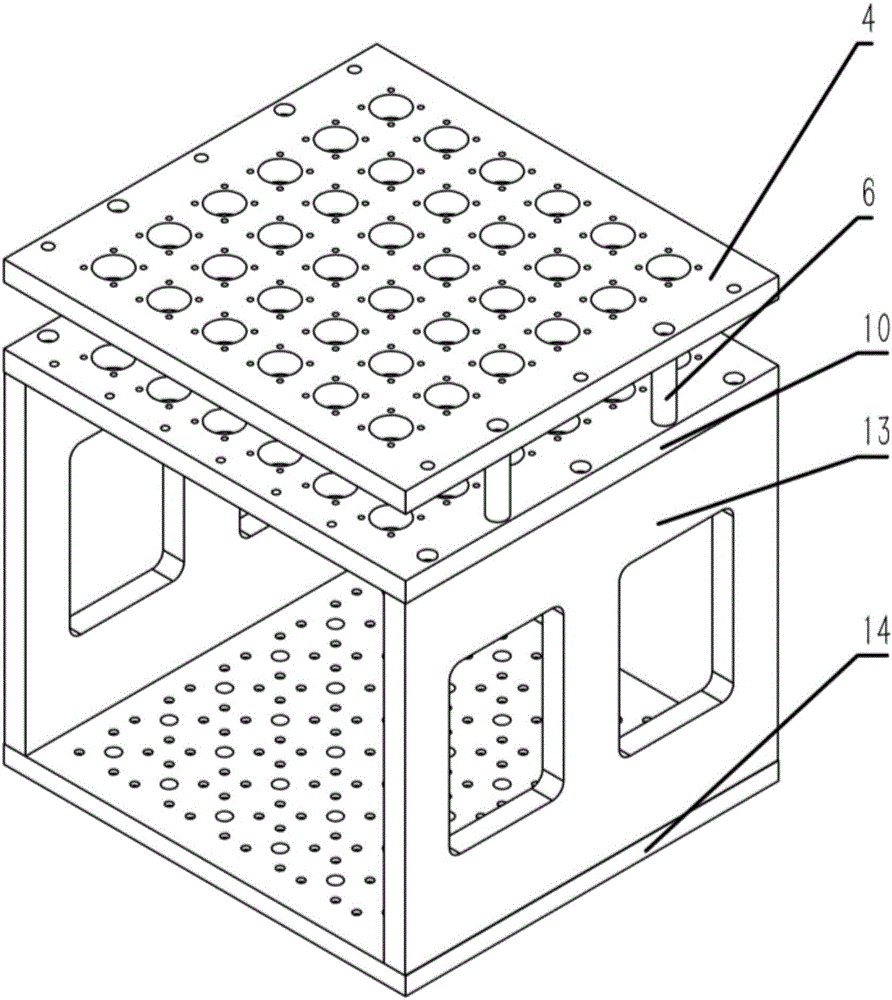

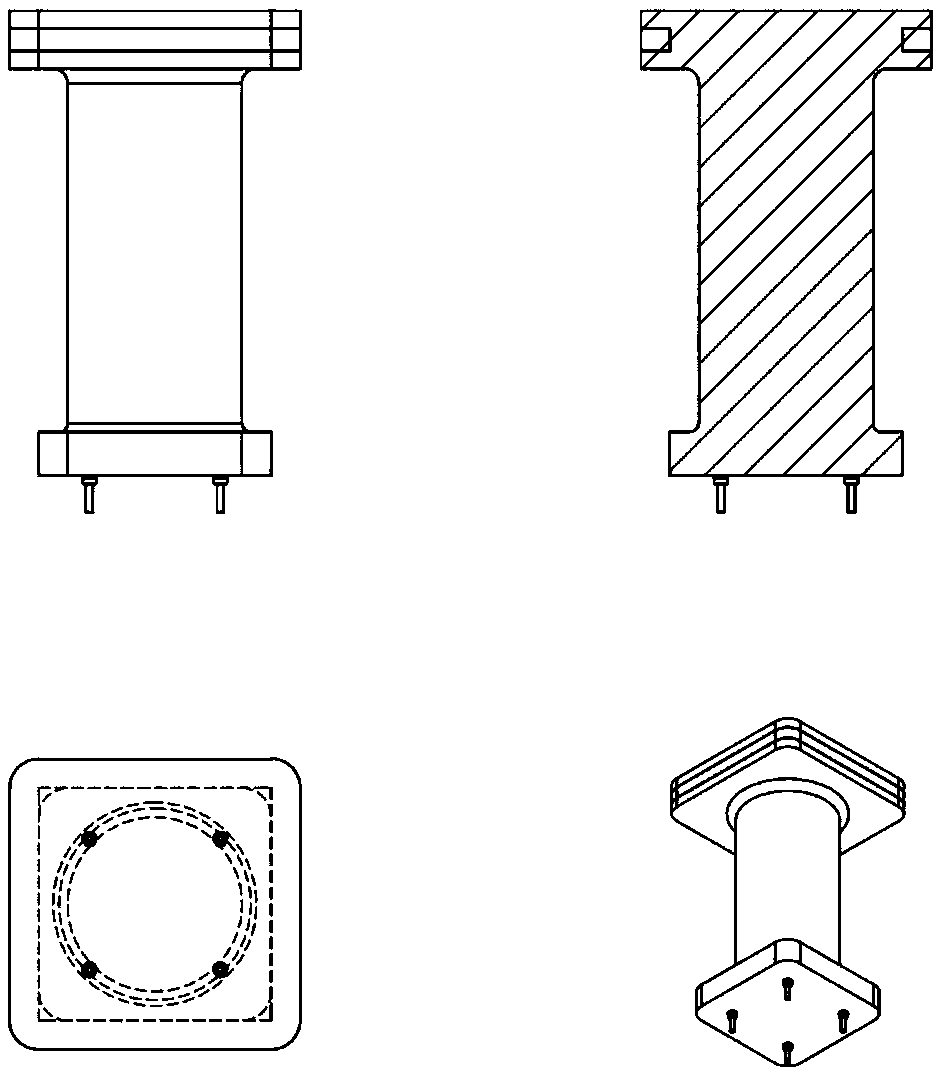

Powder bed 3D printing equipment size adjustable and controllable platform

InactiveCN109624315AImprove printing efficiencySave printing materialsManufacturing platforms/substratesAdditive manufacturing with solidsEngineeringWorkbench

The invention discloses a powder bed 3D printing equipment size adjustable and controllable platform for solving the technical problem about the poor compatibility of an existing powder bed 3D printing platform. According to the technical scheme, a power system, a printing workbench, a circular sleeve or square sleeve, a fixed circular inner cavity workbench or fixed square inner cavity workbench,a boss structure, a movable circular workbench or movable square workbench and a printing equipment outer cylinder are included. The printing workbench is connected with the bottom of the movable circular or movable square workbench through a connection hole. The boss structure is designed in the printing equipment outer cylinder. The fixed circular inner cavity workbench or fixed square inner cavity workbench is arranged on the boss structure, and the movable circular workbench or movable square workbench is connected with the printing workbench. Due to existence of the fixed workbench, themovable workbench and the sleeve, the proper printing platform can be selected according to the specific printing piece size and number, the printing efficiency is improved, printing materials are saved, and the printing cost is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

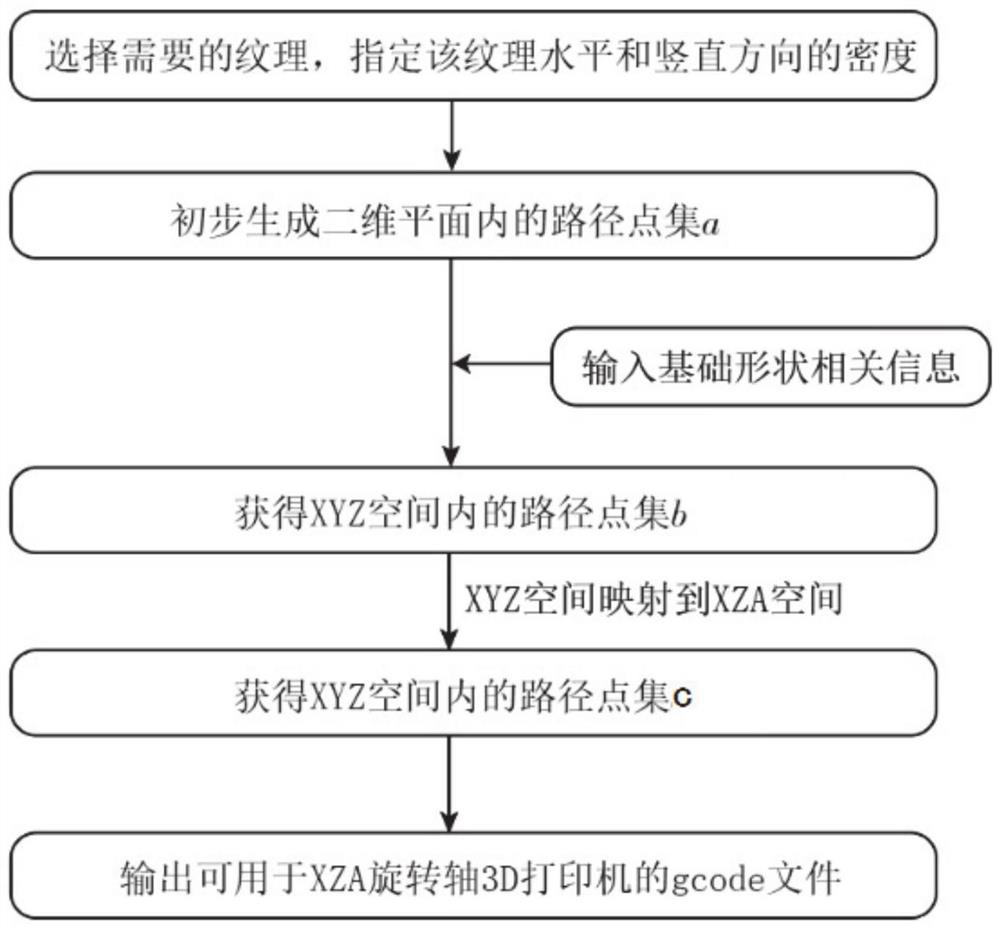

Hollowed-out ceramic 3D printing method of XZA rotating shaft 3D printer and control method

ActiveCN113459241AReduces the effects of slow dryingIncrease success rateAdditive manufacturing apparatusCeramic shaping apparatusComputer printingControl system

The invention provides a hollowed-out ceramic 3D printing method of an XZA rotating shaft 3D printer and a control system. The hollowed-out ceramic 3D printing method comprises the steps that texture, texture density and related printing information are determined; according to the texture density, path planning is performed in a two-dimensional plane, and a path point set a in the two-dimensional plane is preliminarily generated; basic shape information is read, a basic shape is parameterized into a rectangular area determined according to the texture density, the path point set a is mapped to an XYZ space, and a path point set b of the XYZ space is obtained; the path point set b is mapped to the XZA space, and a path point set c of the XZA space is obtained; and a printable G-code file is determined according to the path point set c, and the printable G-code file is output for printing. Continuous-path hollow ceramic 3D printing is realized, the influence caused by the gravity of clay and the low drying speed of the clay can be reduced, the success rate of hollow ceramic 3D printing is increased, and the quality of hollow ceramic 3D printing is improved.

Owner:SHANDONG UNIV

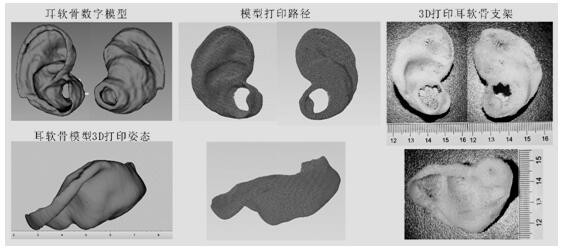

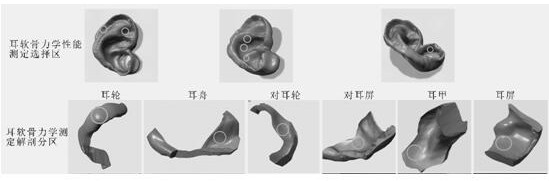

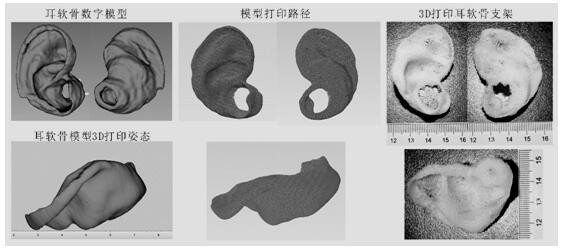

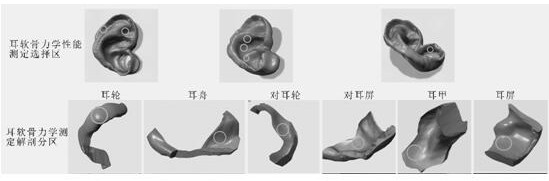

3D printed mechanical bionic auricle cartilage tissue engineering scaffold and manufacturing method thereof

ActiveCN112354017AMechanical bionics haveGood biocompatibilityAdditive manufacturing apparatusTissue regeneration3d printPoly dl lactide

The invention relates to a 3D printed mechanical bionic auricle cartilage tissue engineering scaffold and a manufacturing method thereof. A personalized auricle cartilage scaffold is printed accordingto an individual auricle cartilage structure model of a patient through a 3D printing technology, and the tissue engineering scaffold is formed by printing a biodegradable composite material (PLCL-PCL) of Poly-L-lactide-caprolactone (PLCL) and polycaprolactone (PCL) capable of being subjected to 3D printing disclosed in CN201910139657.9. The frameless, porous and pore-through auricle cartilage tissue engineering scaffold is good in biocompatibility, degradability and thermal stability, has a fine and complex three-dimensional structure of auricle cartilage, has the mechanical property characteristic similar to that of a corresponding anatomical region of natural human auricle cartilage tissue, is adaptive to the mechanical property of the natural auricle cartilage, and can be applied to construction of personalized tissue engineering auricle cartilage.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

A simulation model of seepage in rough cracks of rock mass and its manufacturing method

ActiveCN106353233BReduce intensityOvercome the disadvantage of low strengthPermeability/surface area analysisEngineeringMotherboard

The invention discloses a rock coarse fracture seepage simulation model and a making method. The rock coarse fracture seepage simulation model comprises a fracture main board, a left mounting board, a right mounting board, an upper mounting board and a lower mounting board, the fracture main board is of a cuboid structure, a hydrophobic area is arranged on one side of the cuboid structure, a water gathering area is arranged on the other opposite side, the hydrophobic area is communicated with the water gathering area, the outer side of the hydrophobic area is matched with the left mounting board, and the outer side of the water gathering area is matched with the right mounting board; the upper surface and the lower surface of the cuboid structure are respectively matched with the upper mounting board and the lower mounting board, and a pressure measuring hole communicated with a communicating area between the hydrophobic area and the water gathering area is formed in the upper mounting board. 3D printing technology is adopted to manufacture the fracture main board which is fixed through the upper, lower, left and right mounting boards, and a bolt or a water pressure sensor is mounted on each mounting board, so that the making method of the rock coarse fracture seepage simulation model is simple to make, convenient to experiment and capable of reflecting rock fracture seepage characteristics more really and more accurately.

Owner:SHANDONG UNIV

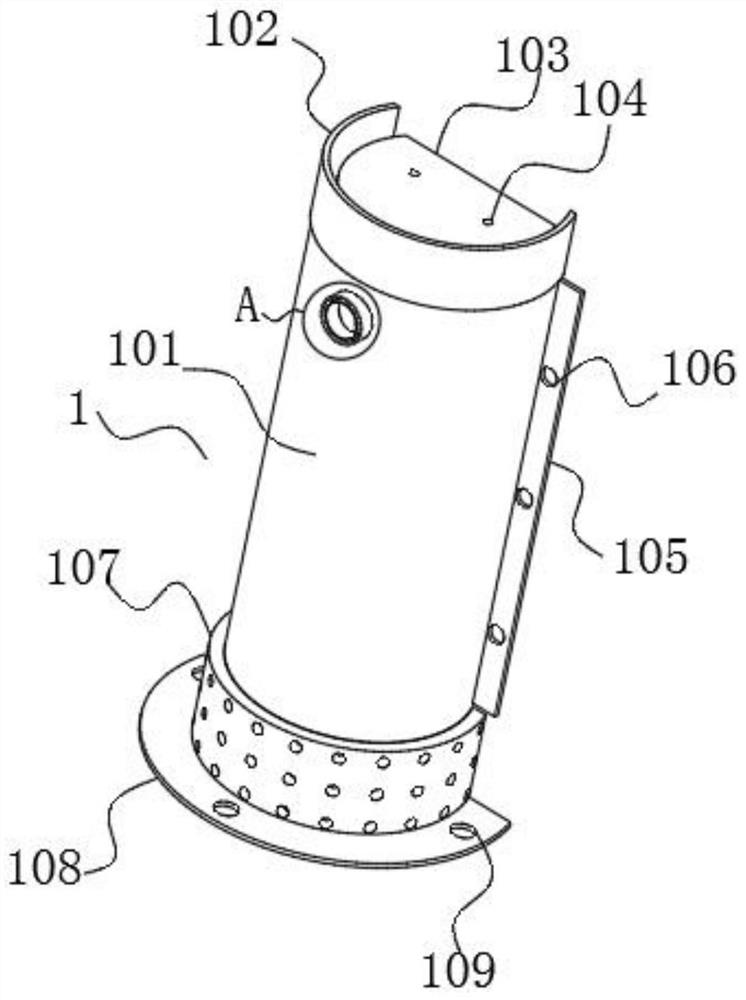

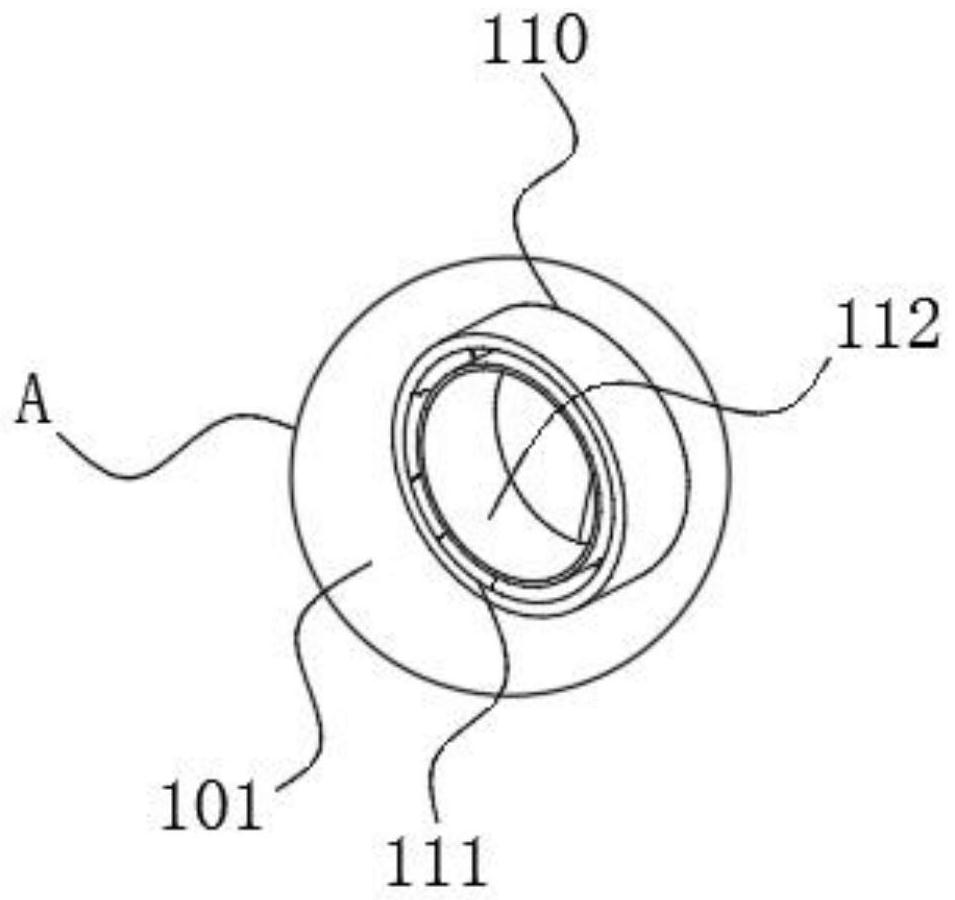

Heat dissipation mechanism for 3D printer spray head

ActiveCN113103579ASave printing materialsImprove printing efficiencyManufacturing heating elementsManufacturing auxillary operationsProcess engineeringWater pipe

The invention discloses a heat dissipation mechanism for a 3D printer spray head, and relates to the technical field of 3D printers. The heat dissipation mechanism comprises a heat insulation barrel assembly, a mounting face plate, a refrigeration suite and a spray head unit; the refrigeration suite and the heat insulation barrel assembly are in threaded rotation, and the spray head unit is matched with the heat insulation barrel assembly in a sleeving mode; and condensation assemblies are matched with insertion holes in an inserted mode, volute-shaped water pipes are fixedly connected between wave-shaped water pipes, the other ends of the wave-shaped water pipes are fixedly connected with water storage tanks; and micro water pumps are arranged inside the water storage tanks. According to the heat dissipation mechanism for the 3D printer spray head, the spray head unit is arranged in the heat insulation barrel assembly, the refrigeration suite is started, and heat exchange is carried out on the interior of a heat insulation barrel through the condensation assemblies, so that a low-temperature environment is kept inside the heat insulation barrel, and the situation that blockage is caused due to the fact that printing materials start to be softened on the upper portion of an L-shaped feeding pipe due to the fact that the feeding pipe is heated due to long-time heating of a heater is avoided, the printing materials are saved, and the printing efficiency is improved; and after printing is finished, water collecting boxes are pulled out from the mounting face plate, and condensate water is poured out.

Owner:XIAMEN RONGTA TECH

A lightweight modeling system for shell-like parts oriented to 3D printing

InactiveCN104881514BHigh speedAchieve lightweightSpecial data processing applications3D modellingComputer Aided DesignEngineering

The invention provides a 3D printing-oriented lightweight modeling system for shell-like components, which belongs to the fields of computer-aided design and industrial design and manufacturing. The lightweight modeling system for shell-like parts oriented to 3D printing simulates the force distribution of the model through thermal diffusion under the given feature constraints and stress conditions, and corresponds the simulated value to the thickness of the model to obtain a preliminary optimization Model. Then, the physical experimental model was obtained by 3D printing, and the engineering force verification of the experimental model was carried out. Furthermore, according to the engineering verification, the degree of thermal diffusion is adjusted through the diffusion parameters, so that the thickness of the optimized model is closer to the actual force requirements. Finally, through the above-mentioned cyclic iteration process, a weight optimization model that meets the force requirements is obtained.

Owner:DALIAN UNIV OF TECH

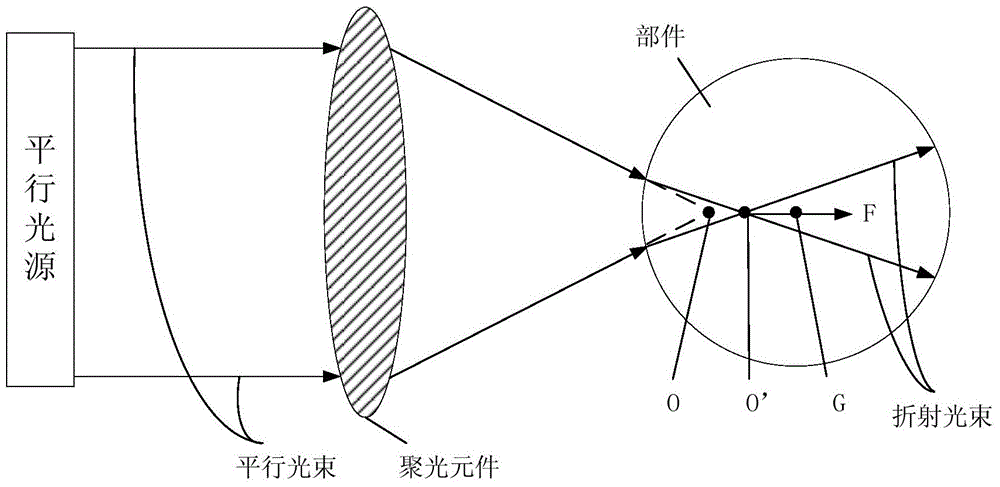

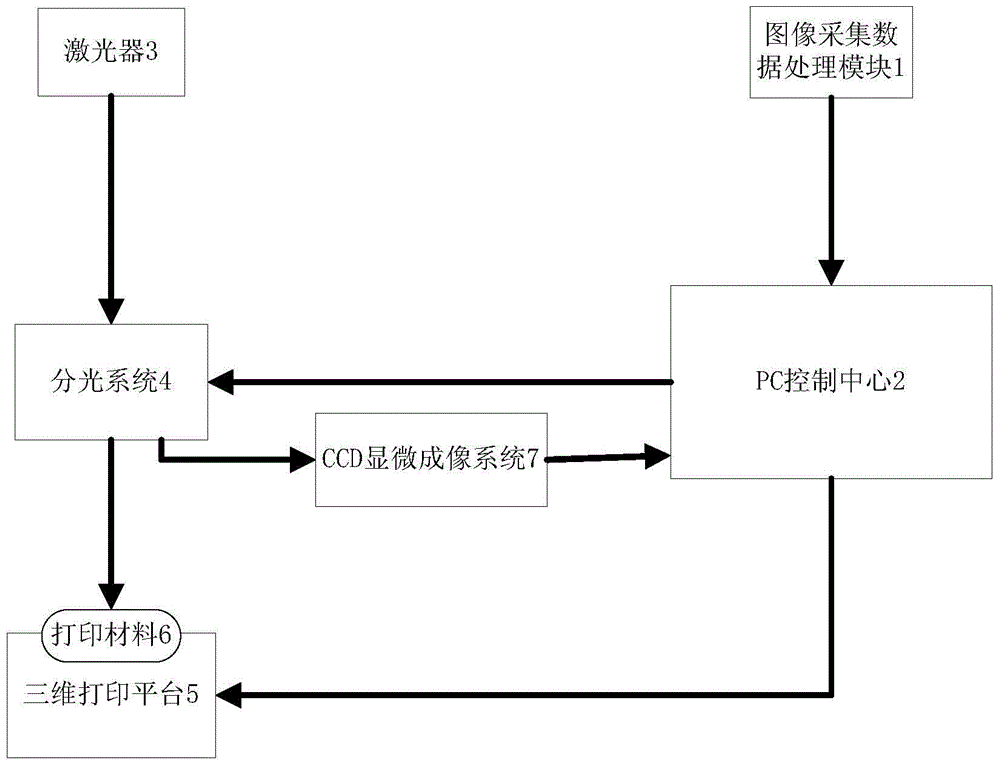

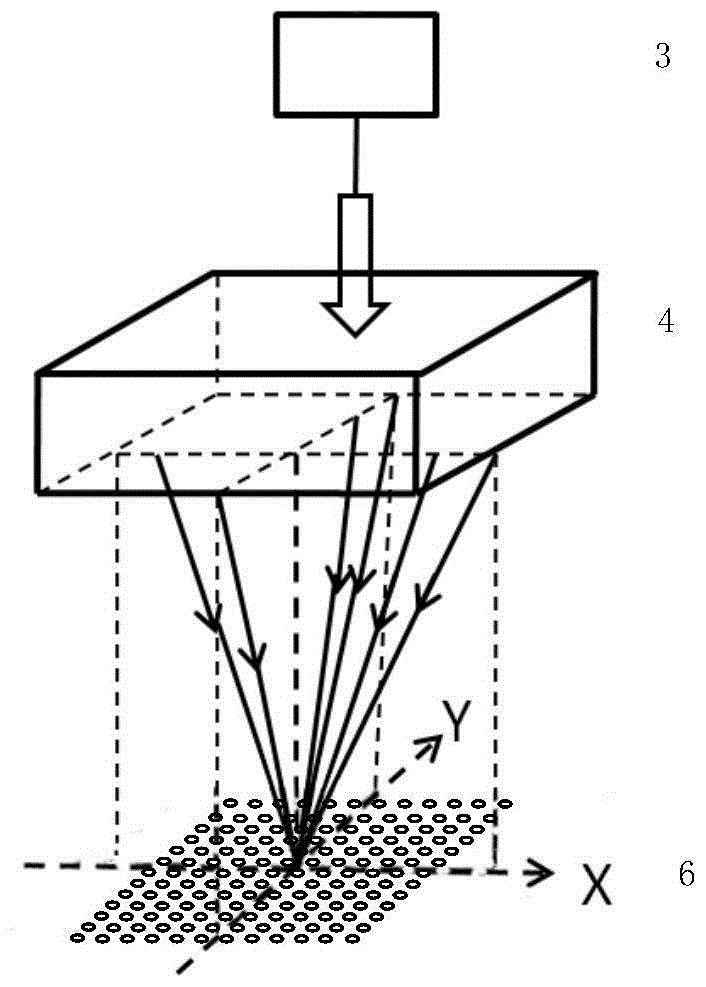

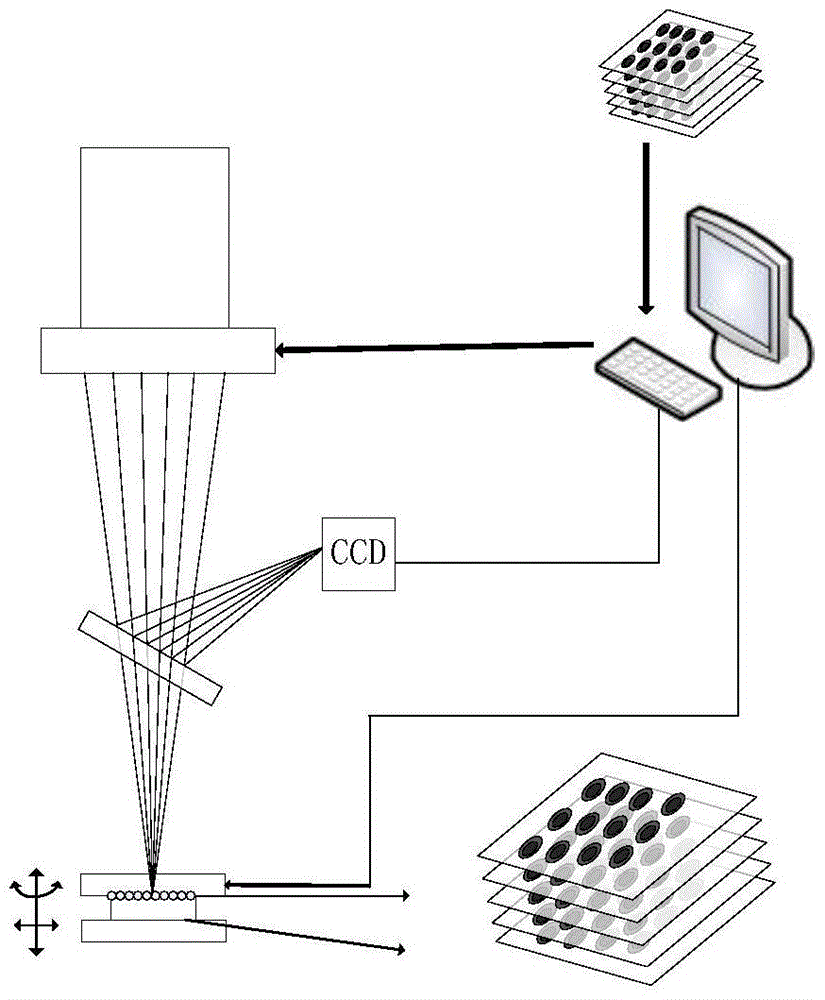

A multi-beam laser interference cross-scale 3D printing system and method

ActiveCN104999670BLarge exposure field areaImprove efficiencyAdditive manufacturing apparatus3D object support structuresMicro nanoBeam splitting

Owner:CHANGCHUN UNIV OF SCI & TECH

A tpms-based model structure optimization method and device for 3D printing

ActiveCN108846148BRealize support-freeSave printing materialsDesign optimisation/simulationSpecial data processing applicationsStress distributionAlgorithm

Owner:SHINING 3D TECH CO LTD

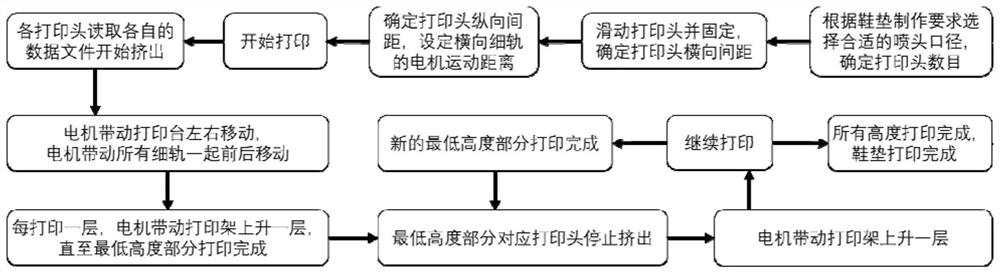

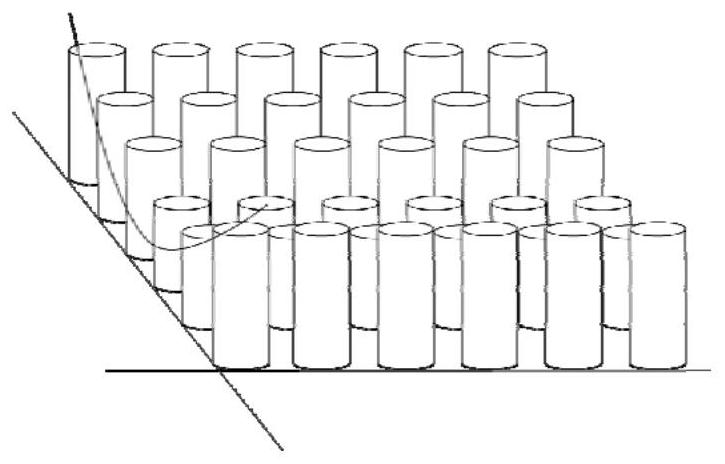

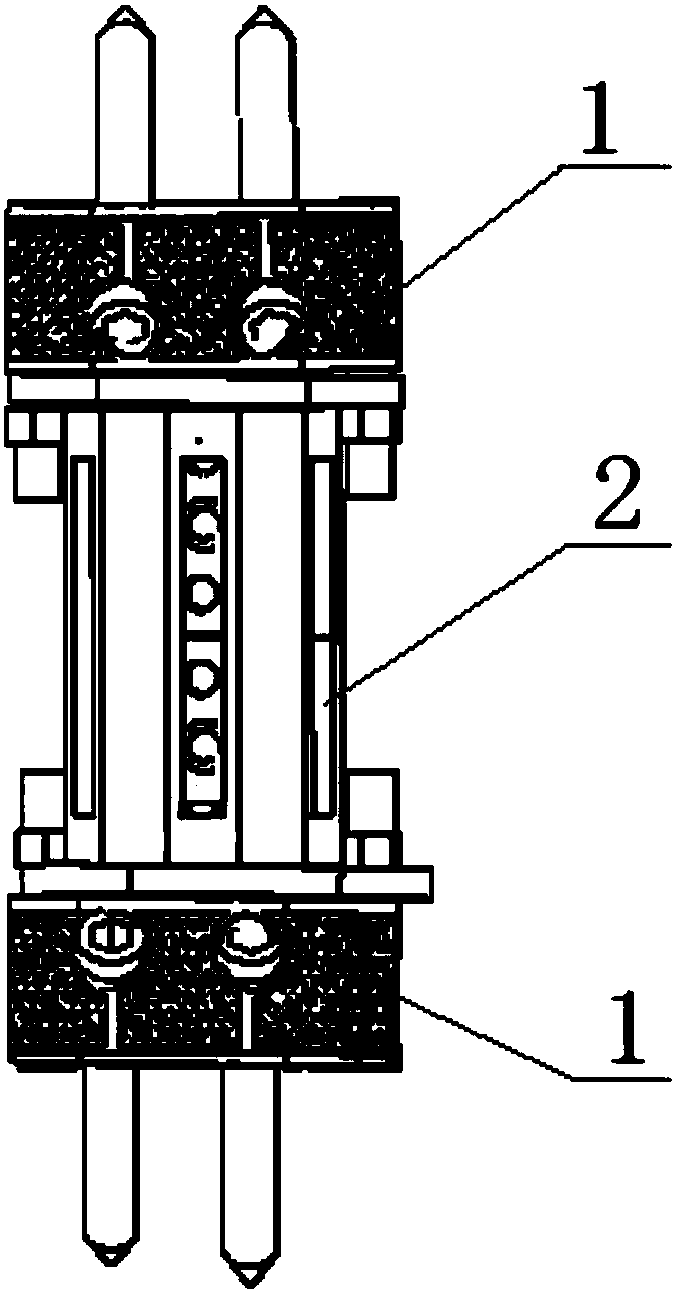

A three-dimensional printing structure, printer and printing method of a discontinuous columnar curved surface

ActiveCN111421806BAdjustable vertical spacingSimplify printing jobsAdditive manufacturing with liquidsDomestic articlesComputer printingStructural engineering

The invention discloses a three-dimensional printing structure of a discontinuous columnar curved surface, which comprises an integral frame, a printing frame arranged on the integral frame, a plurality of printing heads are arranged on the printing frame, and a height adjustment component, The horizontal moving assembly and the vertical moving assembly; the height adjustment assembly includes longitudinal guide rails arranged on the overall frame, the horizontal moving assembly includes horizontal guide rails, the bottom of the overall frame is provided with a base, and the horizontal guide rails are attached to the base and parallel to the horizontal thin rail, perpendicular to the longitudinal rail. The vertical moving component includes a vertical slide rail set on the printing frame, and a horizontal thin rail is slidingly connected in the vertical sliding rail, and the print head is mounted on the horizontal thin rail; the printing frame, the printing table, and the horizontal thin rail are equipped with independent driven by the motor. The print frame is a rectangular frame, the longitudinal slide rails are attached to the long sides of the print frame, and the horizontal thin rails are always parallel to the short sides of the print frame. The horizontal thin rails are independent of each other, and the print heads on the same horizontal thin rail are independent of each other.

Owner:JIANGNAN UNIV

3D printer with monitoring device

InactiveCN107009625AMonitor work statusMeet consumer demandAdditive manufacturing apparatusManufacturing auxillary operationsEngineering3d printer

The invention discloses a 3D printer with a monitoring device, which comprises a main body, a printing platform is arranged at the bottom of the main body, a guide rod is arranged on the top of the main body, a nozzle base is arranged on the guide rod, and a nozzle base is installed on the bottom of the nozzle base. There is a spray head, the top of the base of the spray head is provided with a wire pulley, a slide rail is provided around the top of the main body and on the lower side of the guide rod, a slide block is provided on the slide rail, and a probe is provided at the bottom of the slide block. By setting the probe inside the printer, the working condition of the printer can be monitored in real time, and problems can be dealt with in time, improving the printing quality and precision, saving printing time and printing materials, and the present invention is simple and compact in structure and small in size , low production cost, and meet today's increasing consumer demand for 3D printers.

Owner:渭南高新区金石为开咨询有限公司

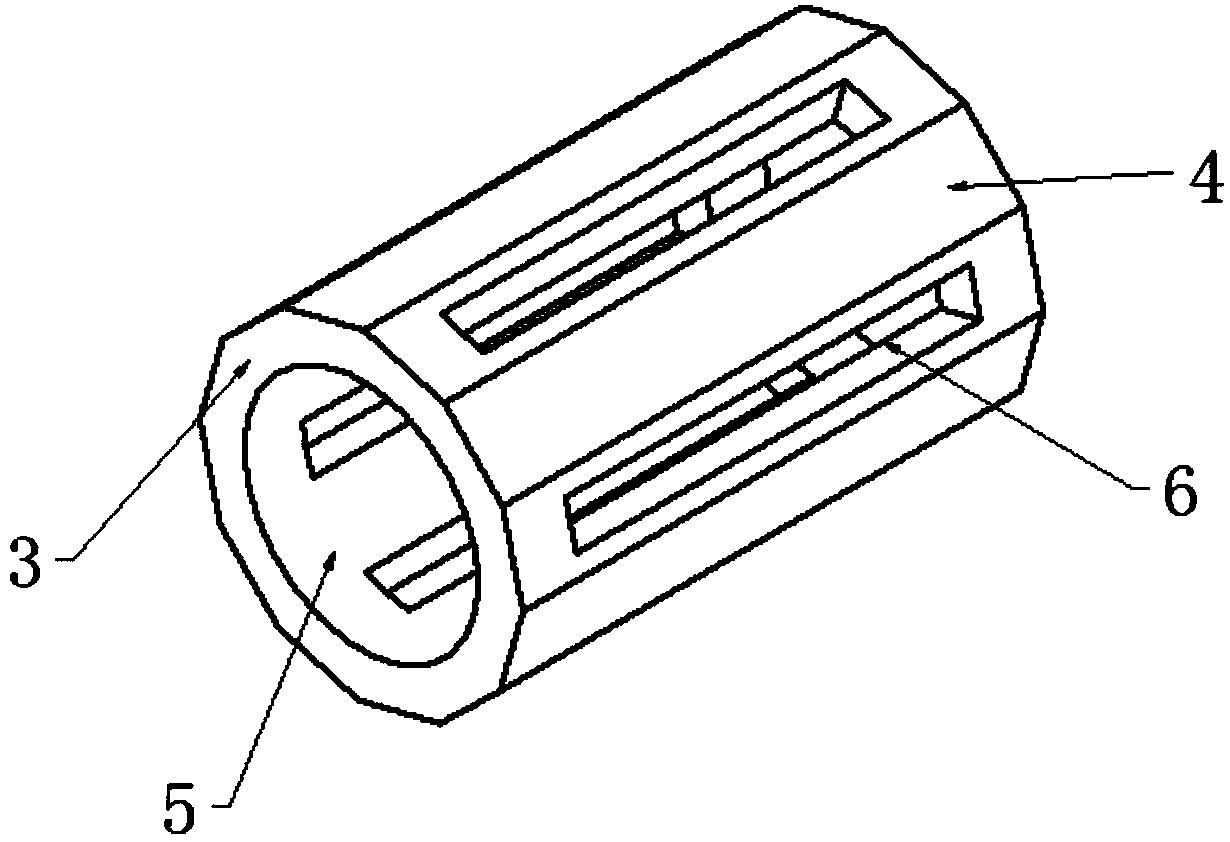

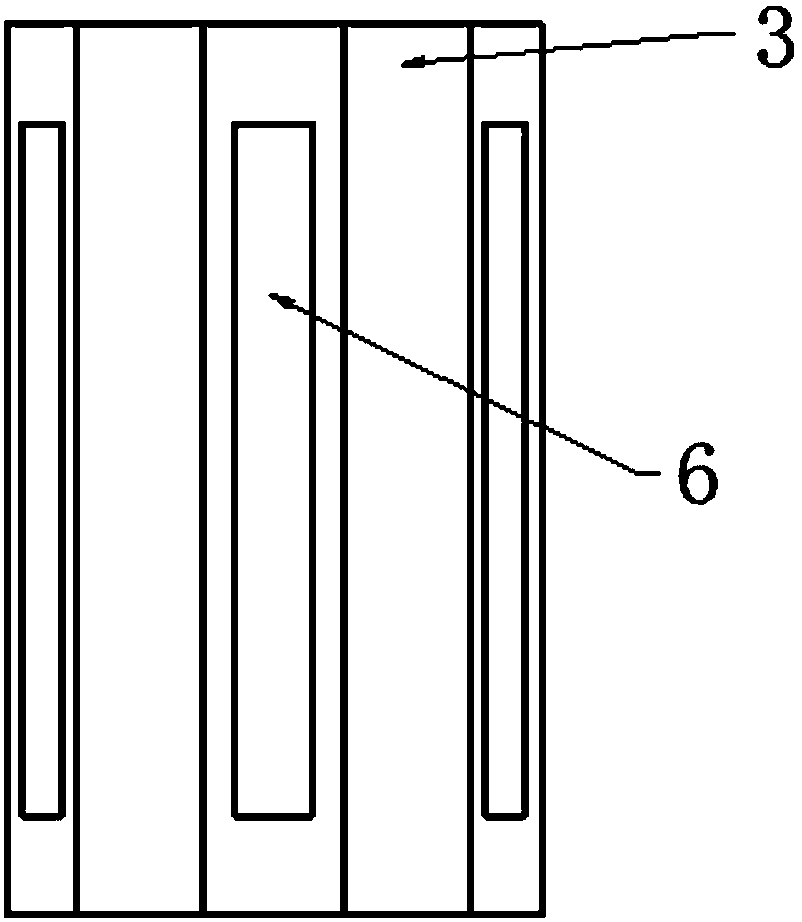

3D-printed manual vertebral body interior fixing device

The invention relates to a vertebral column stabilizer and particularly relates to a 3D-printed artificial vertebral body interior fixing device. The 3D-printed artificial vertebral body interior fixing device comprises a prolongable member and 3D-printed members located at the two ends of the prolongable member, wherein the prolongable member comprises an outer sleeve and supporting platforms which are separately located at the two ends of the outer sleeve, and the 3D-printed members are located at outer sides of the supporting platforms and are fixedly connected with the supporting platforms; a sleeve wall of the outer sleeve comprises a sleeve outer wall and a sleeve inner wall, the sleeve outer wall is polygonal, the sleeve inner wall is provided with a thread, and a plurality of long-strip holes are uniformly formed in the sleeve wall of the outer sleeve in a spaced manner and are formed symmetrically relative to the axis of the outer sleeve. According to the device, 3D-printed member modules and non-3D-printed member modules are assembled, a simple prolongable mode with stable mechanics is developed, both 3D-printed parts and non-3D-printed parts have different models, and the different models can be modularly assembled, so that the saving of printing materials is facilitated, the printing time is shortened, the flexibility of operating is improved, a slit of a artificialvertebral body and a bone interface is reduced, fusion is promoted, and the forward stability is facilitated.

Owner:李建民

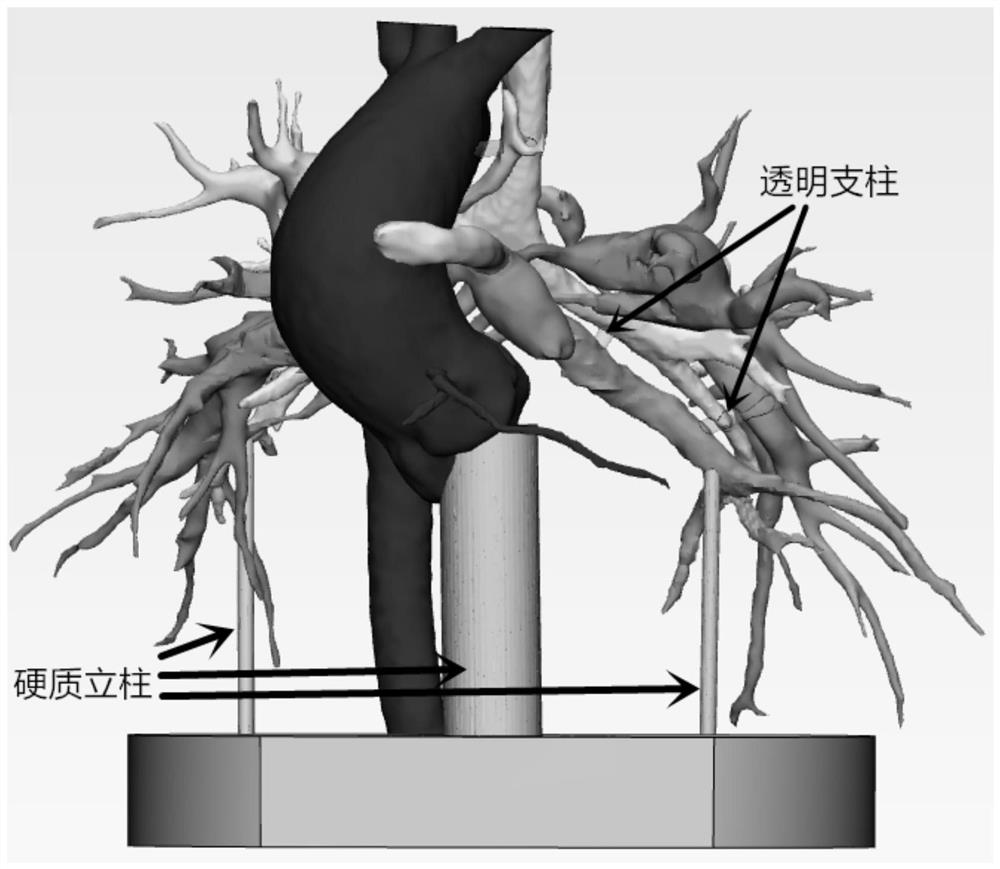

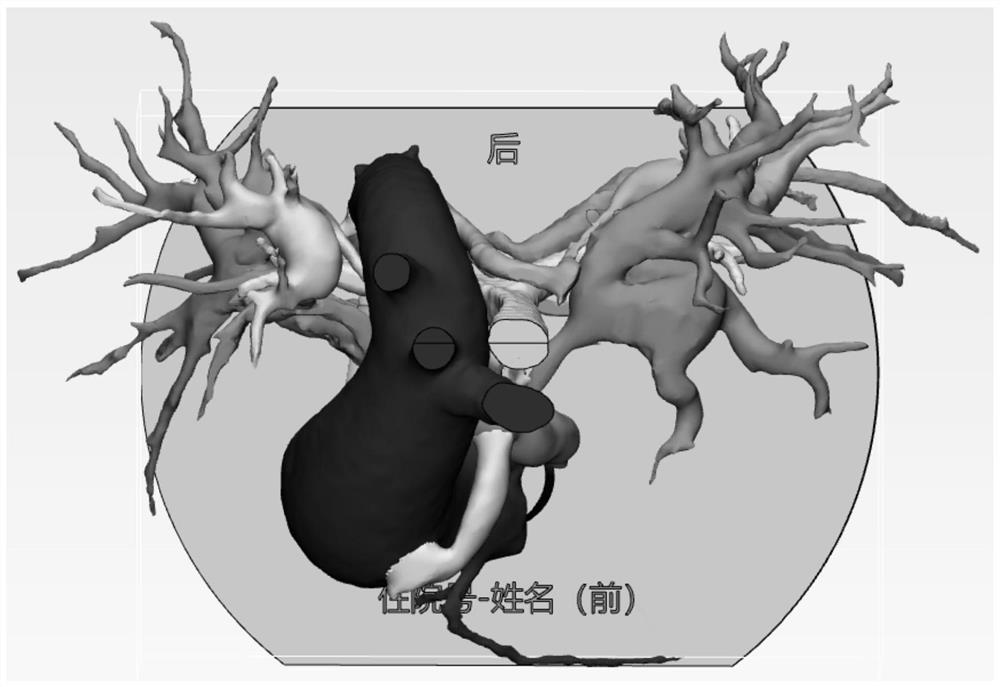

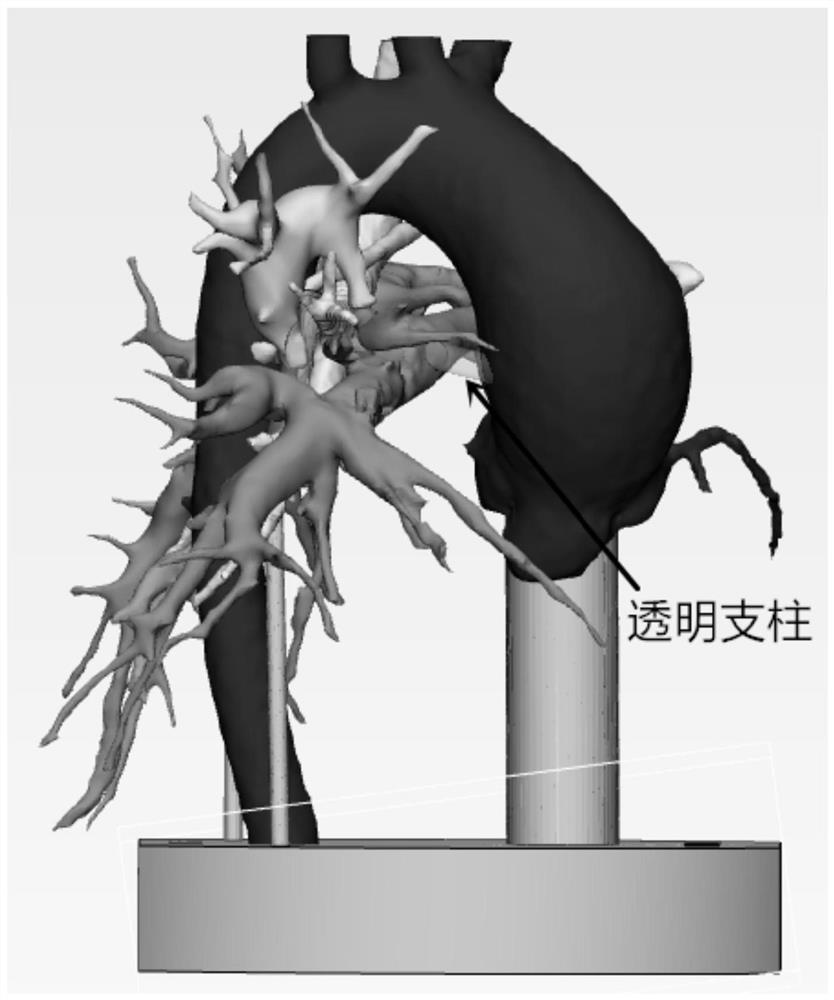

Pulmonary artery atresia combined large main pulmonary collateral vessel model manufacturing method

InactiveCN113910613AShorten production timeReduce printing workloadAdditive manufacturing apparatusEducational modelsComputer printingDigital mockup

The invention discloses a pulmonary artery atresia combined large main pulmonary collateral vessel model manufacturing method. The manufacturing method comprises the following steps: acquiring heart enhanced CT data through CT scanning; segmenting and reconstructing the CT data through Mimics software to obtain a 3D digital model; selecting and reserving parts of an aorta, an upper body branch artery, a bronchus, a collateral vessel and a pulmonary artery in the 3D digital model; arranging supporting columns among the parts of the aorta, the upper body branch artery, the bronchus, the collateral vessel and the pulmonary artery, additionally arranging a chassis at the bottom, and forming a to-be-printed model; and inputting to-be-printed model data into a 3D printer, and manufacturing a solid model. Key organs such as the aorta, the upper body branch artery, the bronchus, the collateral vessel and the pulmonary artery for evaluating the illness state of patients with pulmonary artery atresia combined with ventricular septal defect and thick main lung collateral vessel are selected from the 3D digital model, data of other secondary structures are removed, the printing workload is reduced, printing materials are saved, the model manufacturing time is shortened, and the efficiency is improved.

Owner:GUANGDONG GENERAL HOSPITAL +1

A 3D-printed mechanical bionic auricular cartilage tissue engineering scaffold and its manufacturing method

ActiveCN112354017BGood biocompatibilityPromote degradationAdditive manufacturing apparatusTissue regenerationAuricular cartilagePoly dl lactide

The invention relates to a 3D printed mechanical bionic auricular cartilage tissue engineering scaffold and a manufacturing method thereof. It uses 3D printing technology to print a personalized auricular cartilage scaffold based on the patient's individual auricular cartilage structure model. Lactone (PLCL) and polycaprolactone (PCL) biodegradable composite material (PLCL-PCL) is printed, the auricular cartilage tissue engineering scaffold without borders, porous and through-holes of the present invention is biocompatible and degradable It has good stability and thermal stability, has a fine and complex three-dimensional structure of auricular cartilage, and has similar mechanical properties to the corresponding anatomical regions of natural human auricular cartilage tissue. It is suitable for the mechanical properties of natural auricular cartilage and can be applied Construction of personalized tissue-engineered auricular cartilage.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

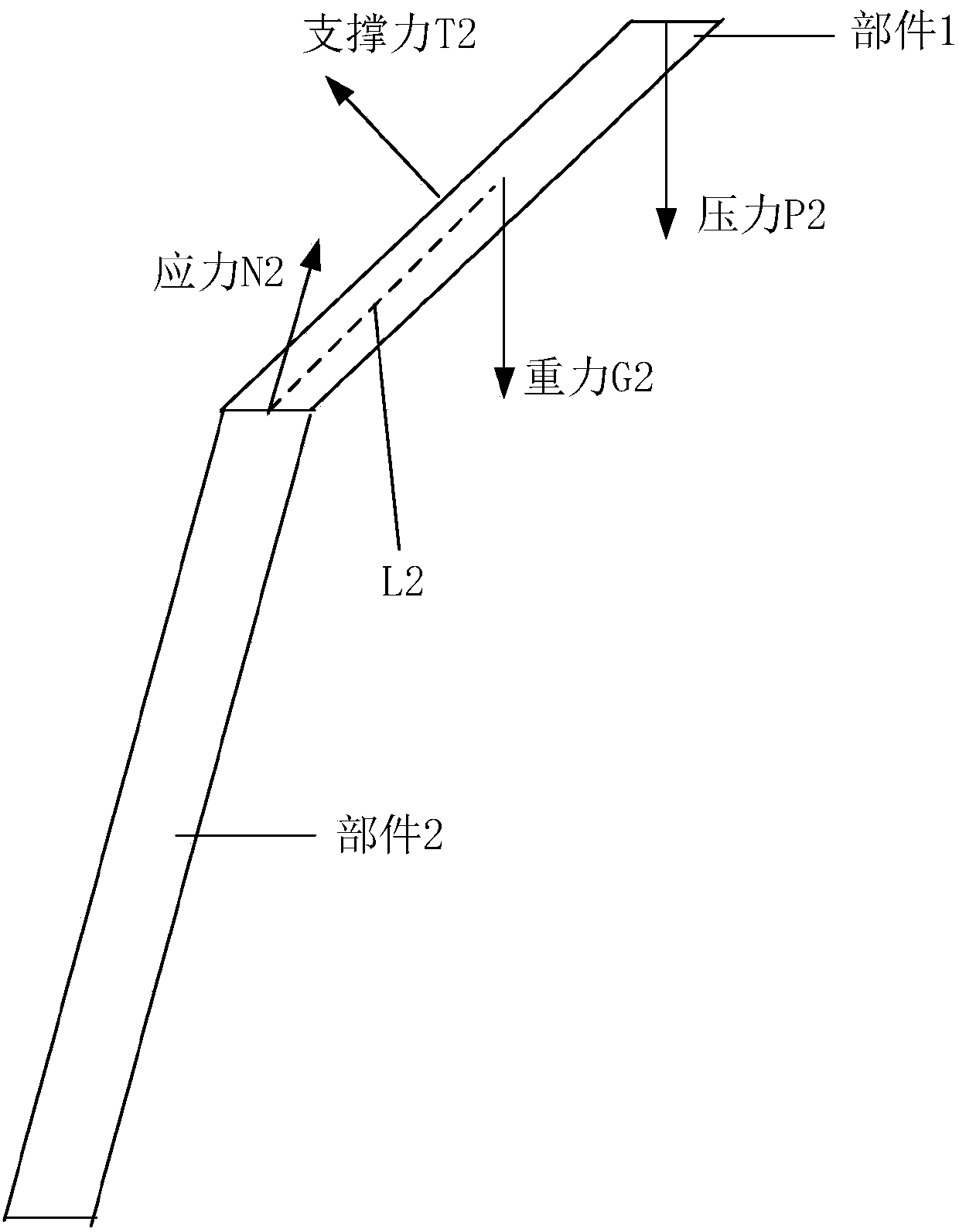

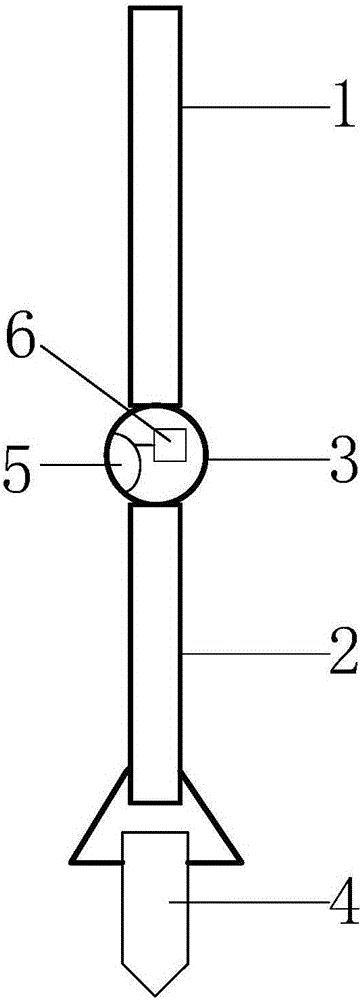

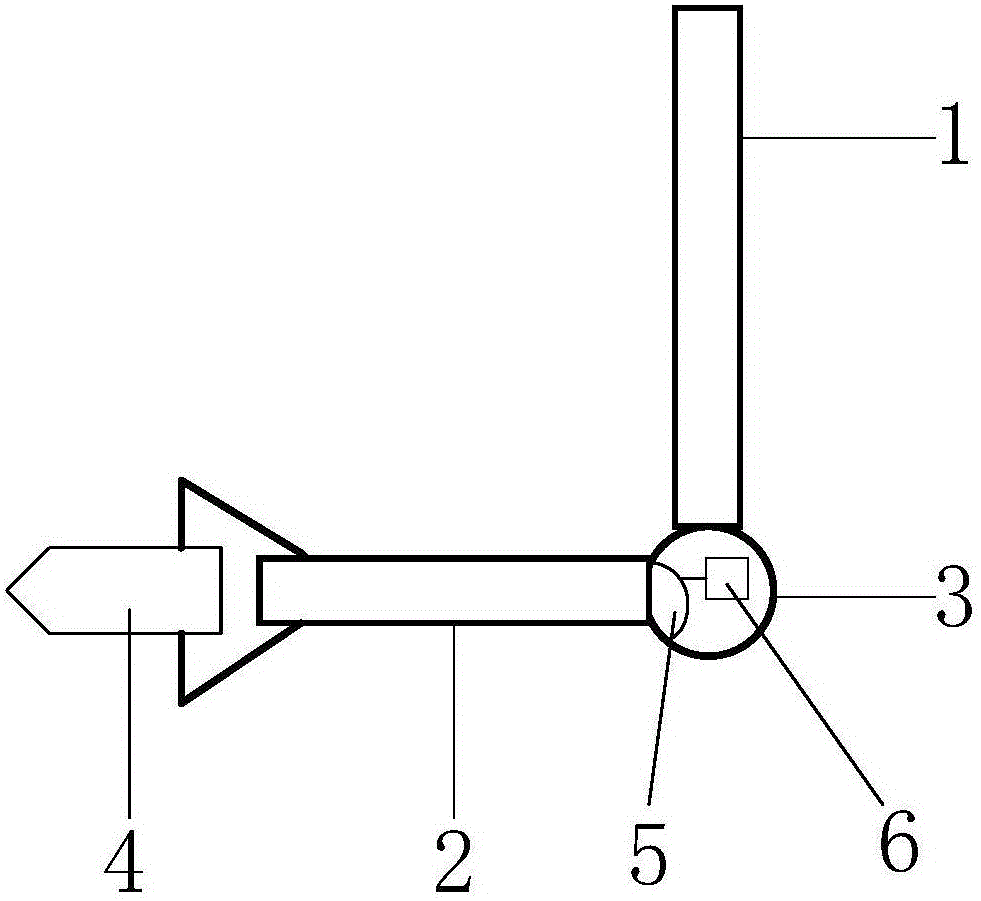

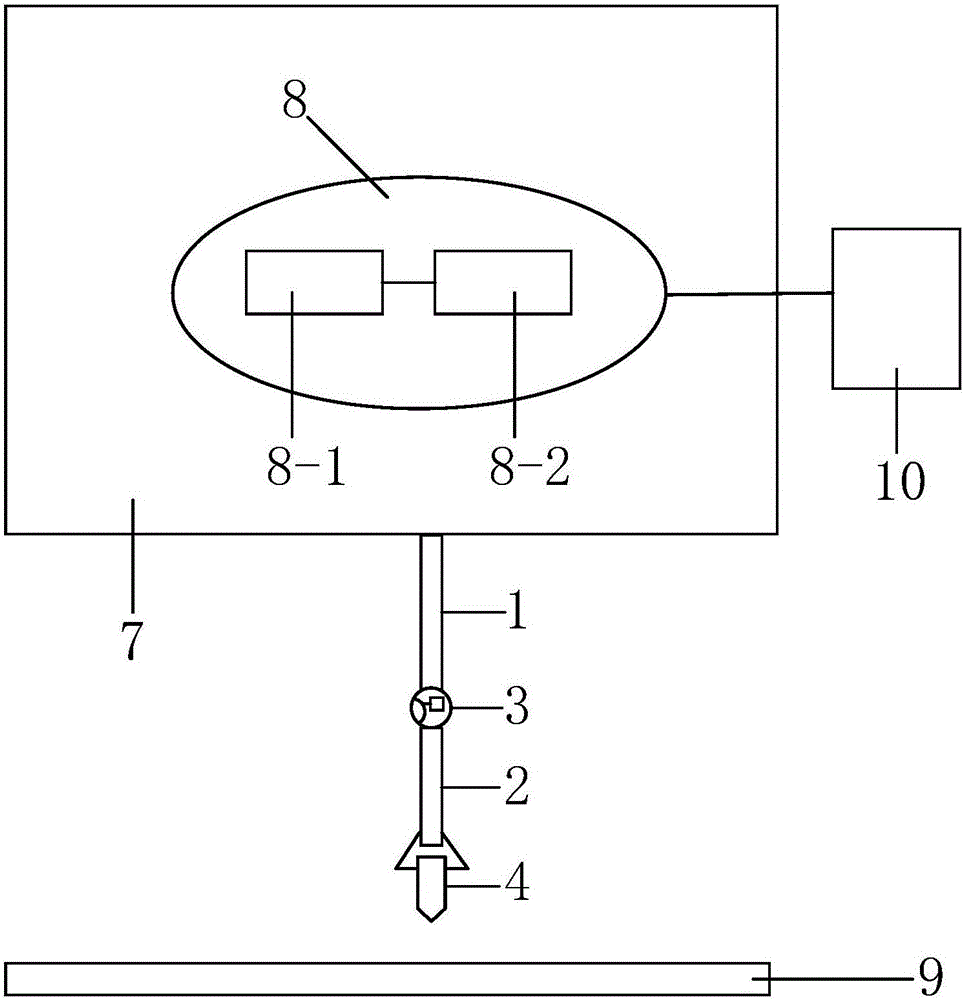

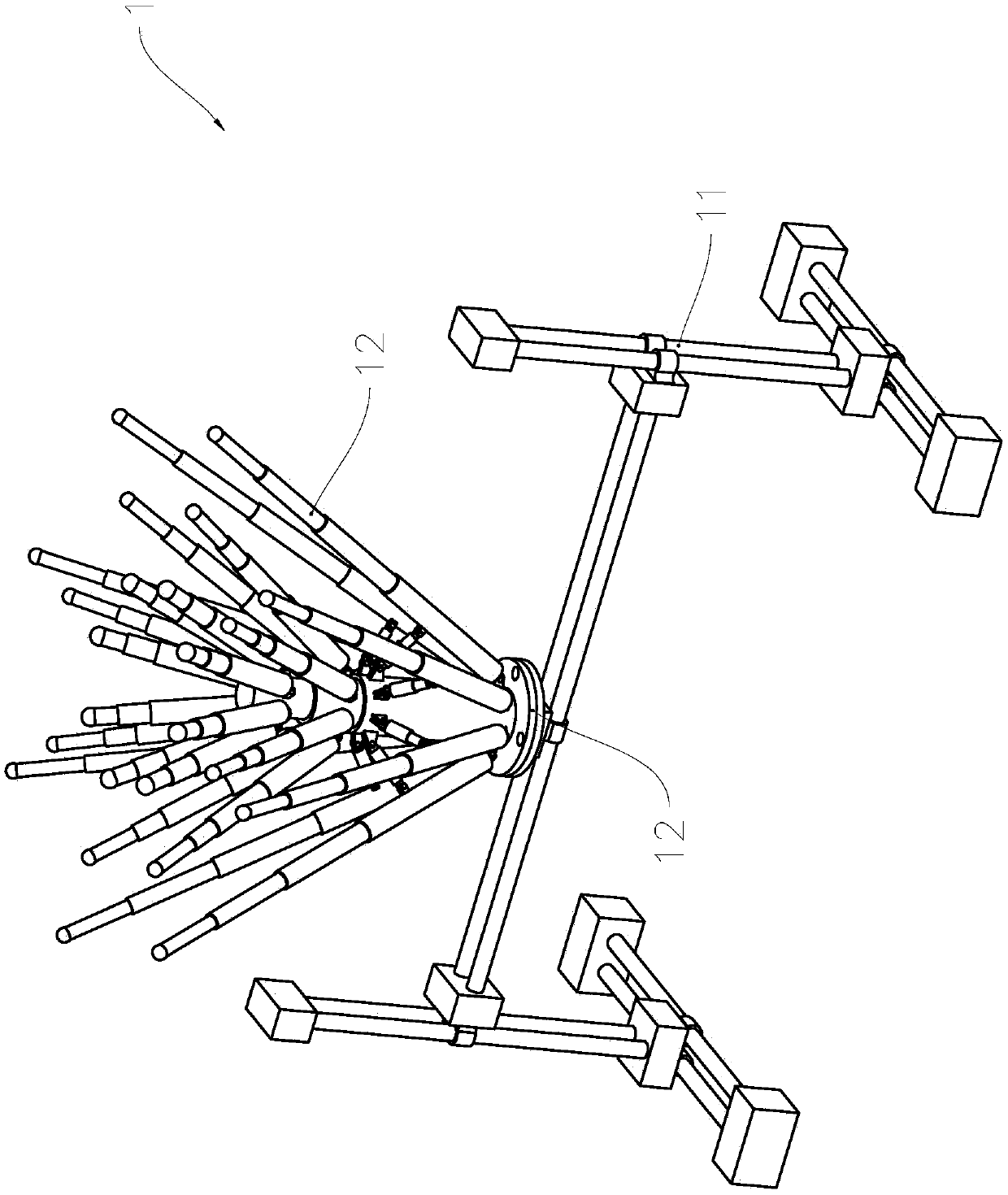

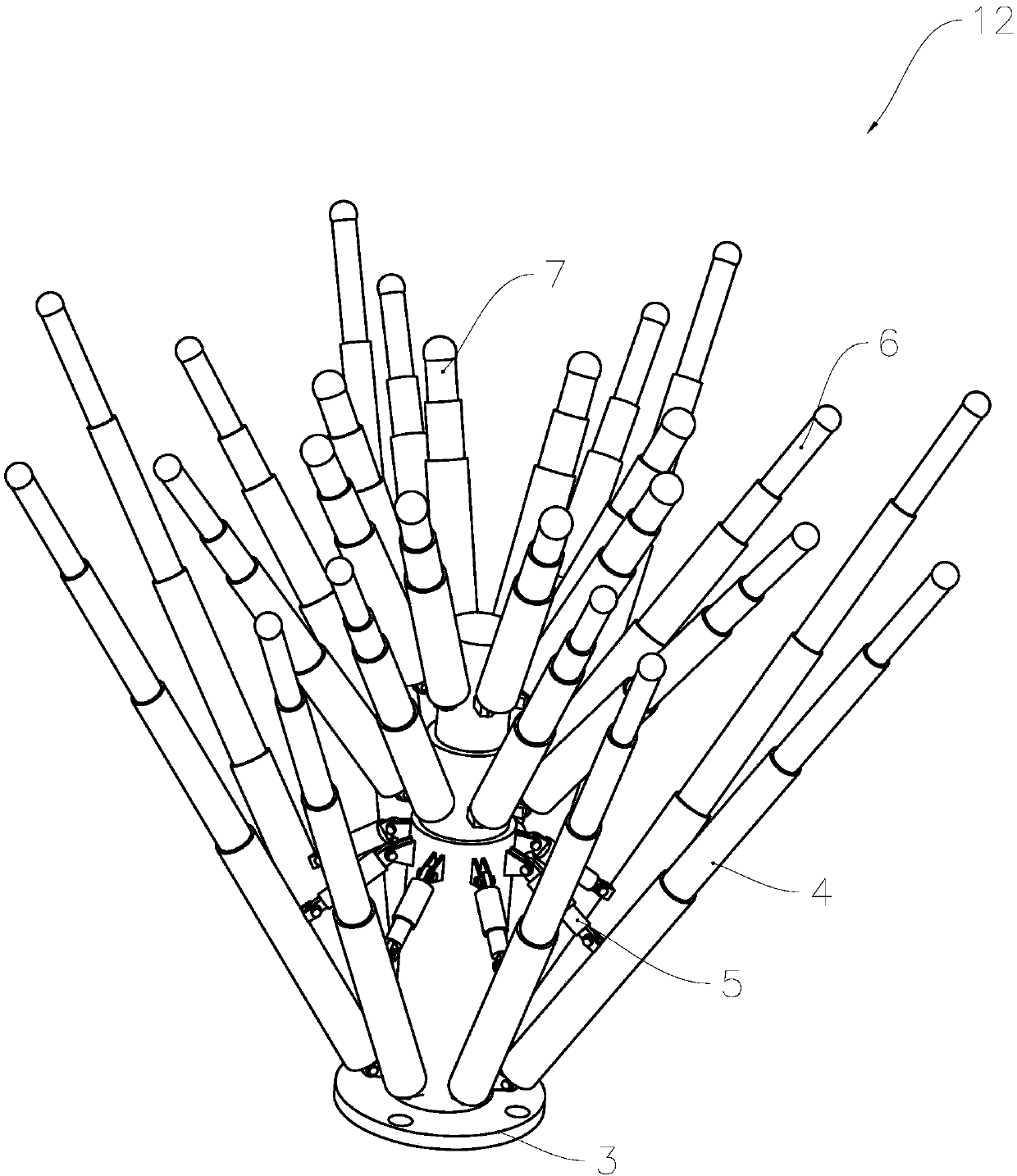

An adjustable external support device for 3D printing

ActiveCN107498875BImprove printing speed and qualityReduce use and wasteAdditive manufacturing apparatus3D object support structuresEngineering3 dimensional printing

The invention relates to an adjustable external supporting device for 3D printing, and belongs to the technical field of quick formation. The supporting device comprises a control unit, a lifting and transverse moving unit and a supporting unit, wherein the lifting and transverse moving unit and the supporting unit are controlled through the control unit; the supporting unit is mounted an output end of the lifting and transverse moving unit and comprises a support, and a telescopic supporting rod which extends to a position to be supported in order to support a suspension part of a three-dimensional object; the lower end of the supporting rod is fixedly connected to the support through a swinging driving device which is used for controlling a swinging angle of the supporting rod relative to the support. According to the device, the supporting unit is pushed to be below an area to be supported during the three-dimensional printing process, and then the swinging angle and the telescoping length of the supporting rod are controlled, so as to support the suspension part of the three-dimensional object. Therefore, the quantity of printing materials for printing a supporting structure can be decreased, and meanwhile, the three-dimensional object printing speed and quality can be effectively improved; and the device can be widely applicable to the technical field of quick formation.

Owner:ZHEJIANG UNIV

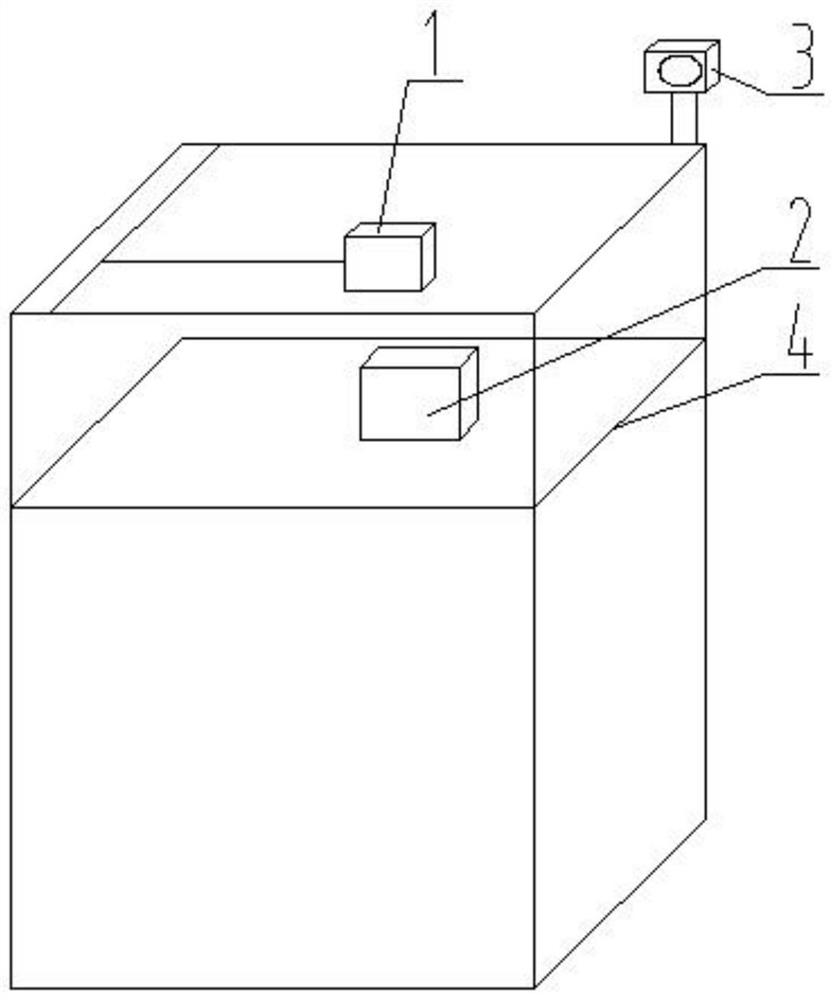

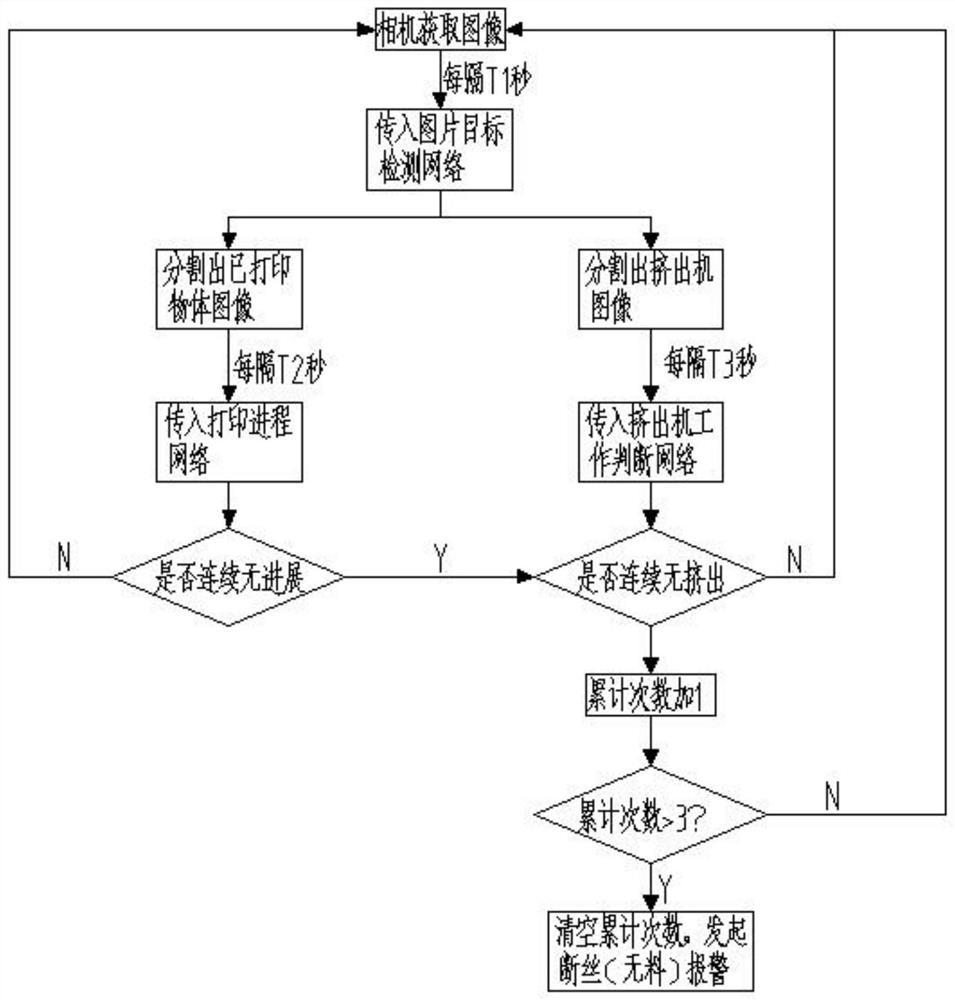

A machine vision-based 3D printer wire break alarm device and alarm method

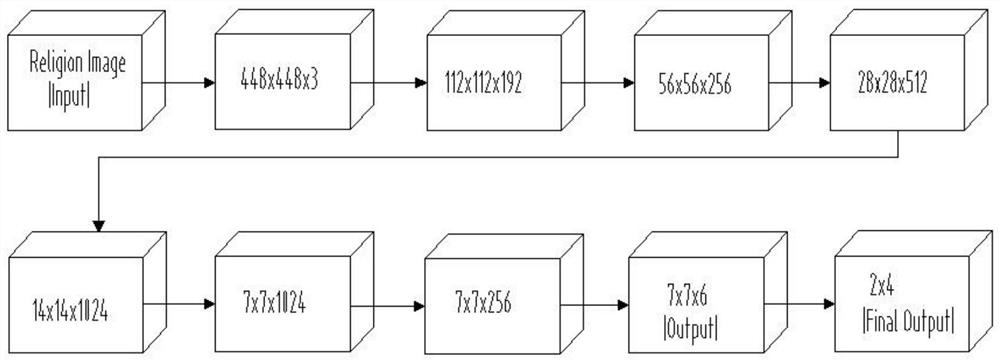

ActiveCN111674048BSave printing materialsGuaranteed to workAdditive manufacturing apparatusManufacturing data aquisition/processingMachine visionComputer printing

The present invention provides a machine vision-based 3D printer broken wire alarm device and alarm method. The 3D printer includes an extruder and a lifting platform. The produced model is set on the lifting platform and below the extruder, and the machine vision-based 3D printer broken wire alarm device includes a camera, and the camera is set on the side of the extruder nozzle. The invention overcomes the need to make changes to the hardware, starts from the idea of software, and detects the broken wire (no material) of the 3D printer based on the principle of machine vision, so as to issue an alarm and suspend printing, so as to remind the staff, save printing materials and promote printing. Purpose of work progress.

Owner:GUANGDONG UNIV OF TECH

Rotary nozzle device, 3D printer and printing method

ActiveCN105773978BBreaking through the traditional form and structureIntegrity guaranteedAdditive manufacturing with liquidsApplying layer meansEngineering3d printer

Owner:SHANGHAI SUNGLOW PACKAGING TECHNOLOGY CO LTD

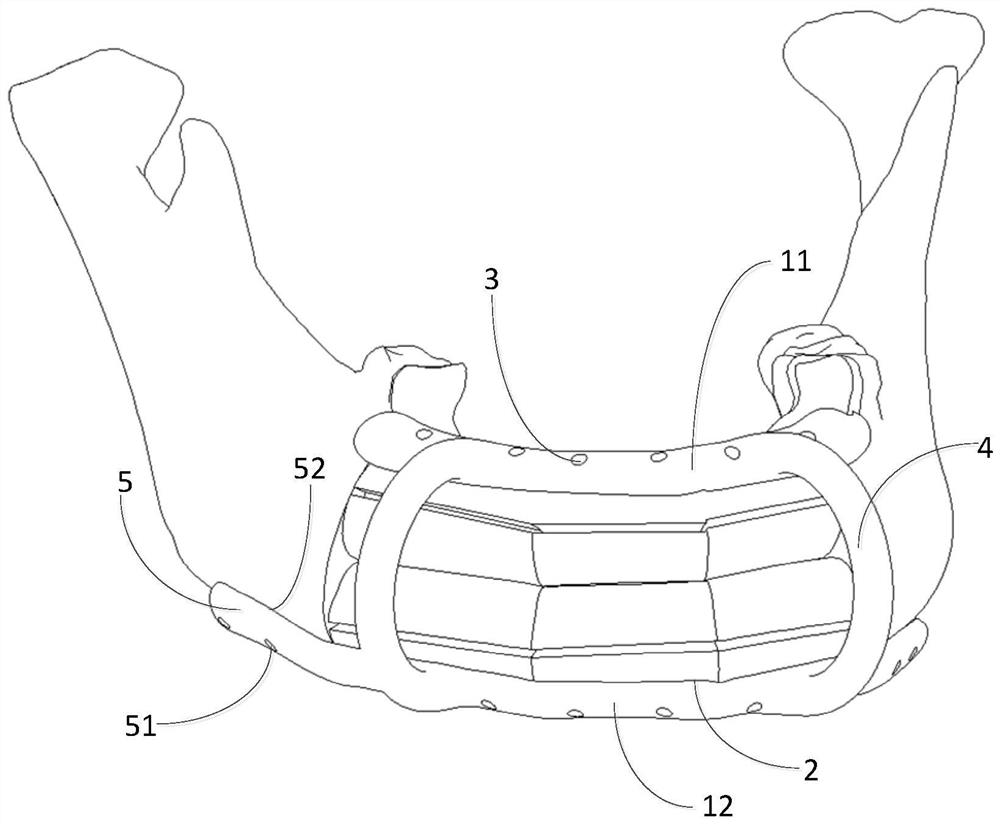

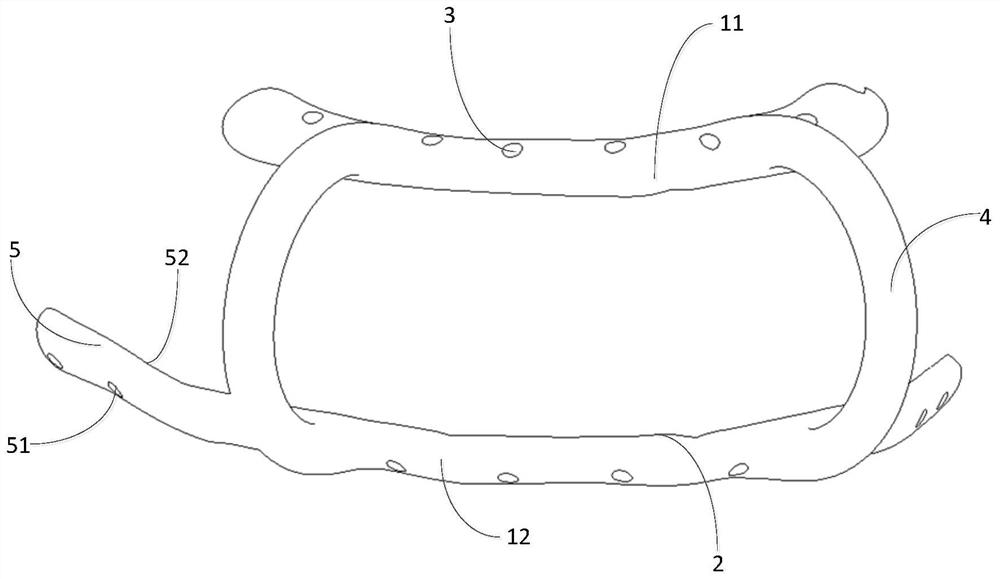

An in-place guide plate applied to multi-segment fibula double stack reconstruction of mandible

ActiveCN110313994BAvoid wanderingGuaranteed accuracyDiagnosticsSurgeryMaxillofacial oral surgeryPost transplant

The invention relates to the technical field of medical instruments for oral and maxillofacial surgery, in particular to an in-place guide plate applied to multi-segment fibula double-stacked reconstruction of mandible, aiming at solving the problem that the height of the fibula of a single-layer segment after transplantation in the prior art may not be sufficient The technical point of helping the patient to restore the occlusal and masticatory function on the basis of restoring the appearance and appearance in the future is to include a first guide plate and a second guide plate, the first guide plate is located above the second guide plate, and the first guide plate is located above the second guide plate. The inner side of the plate and the second guide plate is provided with an arc-shaped groove for the fibula cut section to be placed after double stacking, the arc-shaped groove is closely fitted with the surface of the fibula, and the first guide plate and the second guide plate are symmetrically arranged There are retaining holes. The present invention completes the mandibular reconstruction operation through the digitally designed guide plate, which is more perfect in appearance and more ideal in function.

Owner:JIANGSU OURING THREE DIMENSIONAL SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com