Supporting device for three-dimensional printing and three-dimensional printing method

A support device and 3D printing technology, applied in the direction of additive processing, etc., can solve the problem of waste of silk materials, achieve the effect of saving printing materials, optimizing algorithm structure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

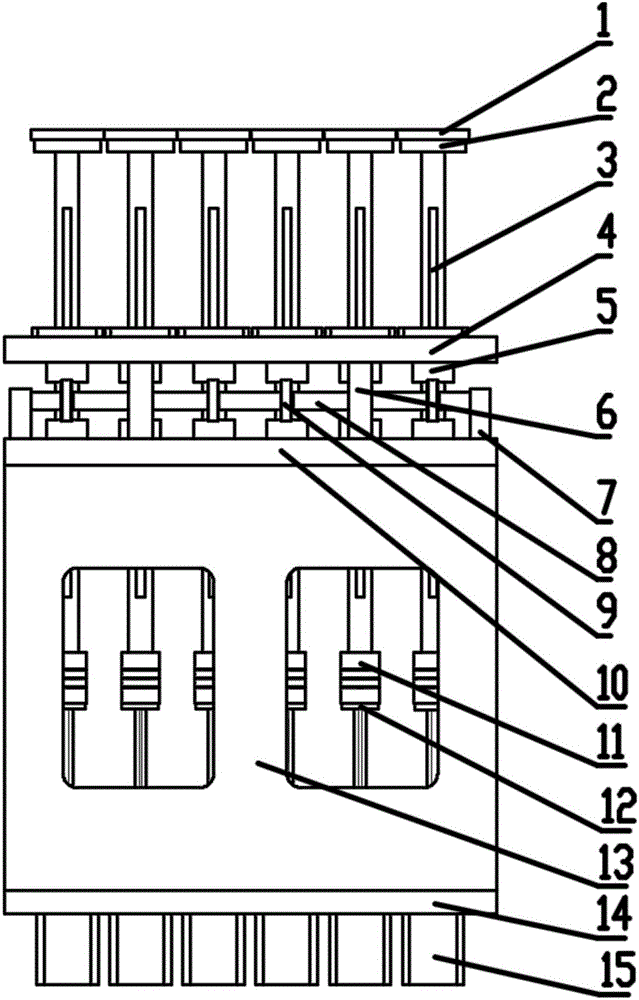

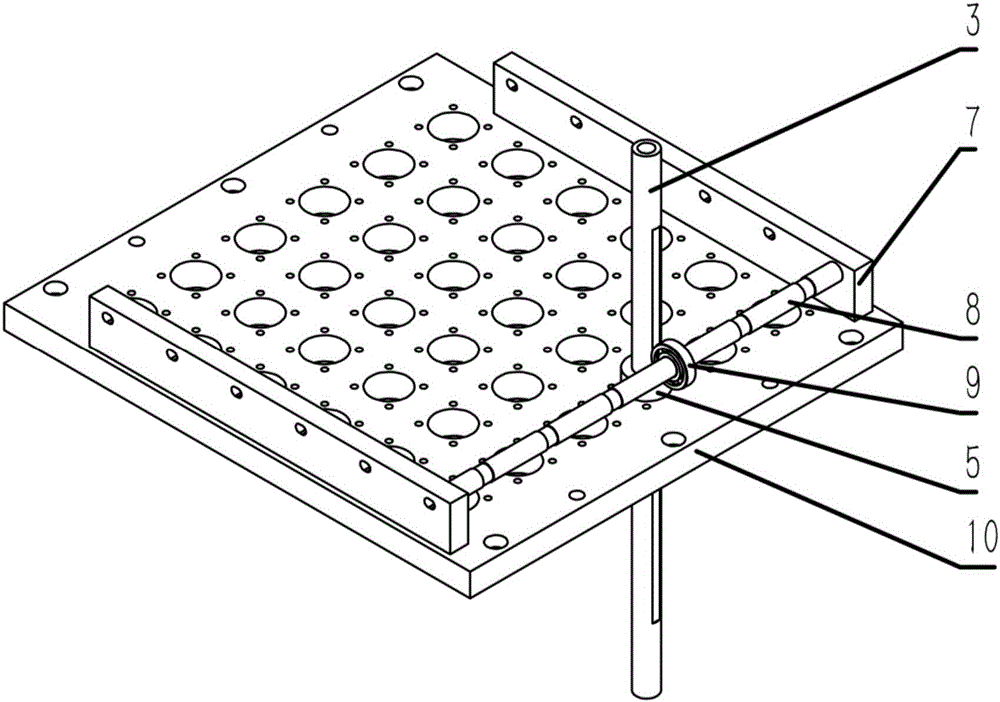

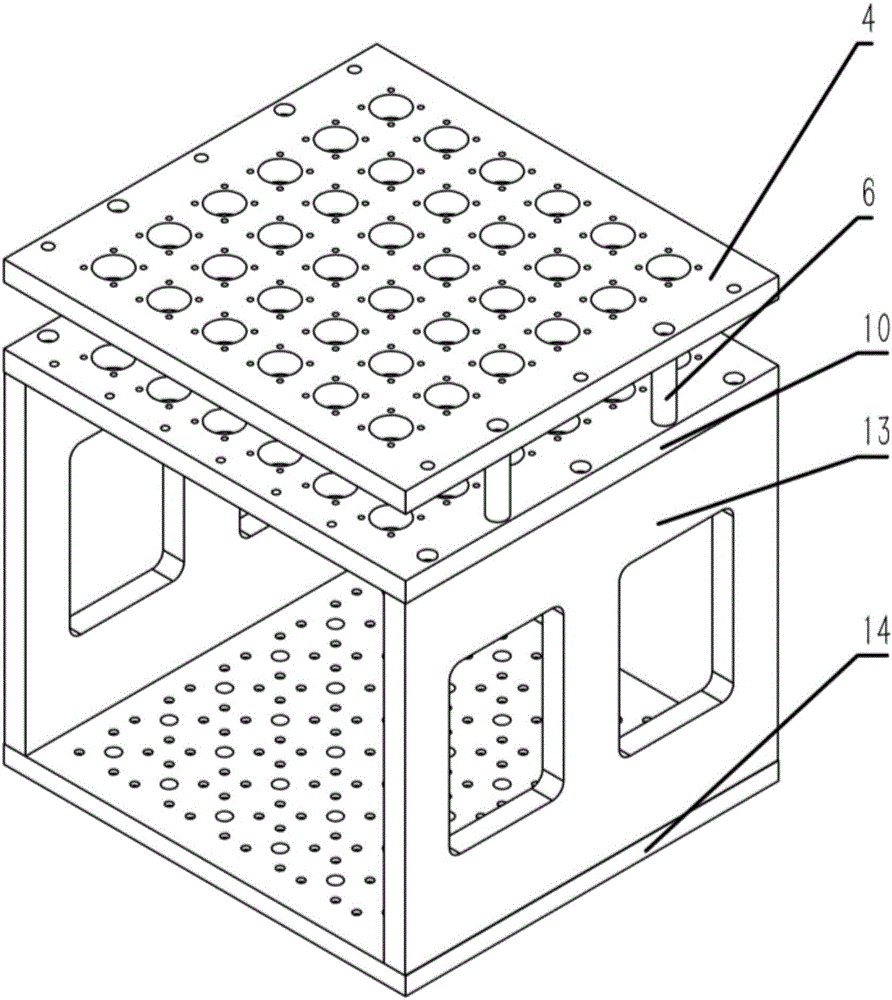

[0048] Such as Figure 1~3 As shown, the supporting device of the present invention includes a movable top block panel 1, a movable top block bottom plate 2, a lifting rod 3, an upper limit plate 4, a limit flange 5, a connecting column 6, a bearing pressing seat 7, and a bearing installation shaft 8 , rolling bearing 9, lower limit plate 10, polished rod nut coupling 11, motor nut 12, connecting bearing plate 13, motor mounting seat plate 14 and linear stepper motor 15.

[0049] Such as figure 1 As shown, as the power source of the lifting unit, the linear stepper motor 15 is screwed and fixedly connected with the motor mounting seat plate 14 through the screw holes on its end face. The support unit includes a plurality of support plates spliced into a complete printing range. The support plate is composed of a movable top block panel 1 and a movable top block bottom plate 2. In this embodiment, the support plates are installed in the frame in a 6×6 square matrix, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com