A three-dimensional printing structure, printer and printing method of a discontinuous columnar curved surface

A 3D printing and columnar technology, applied in the field of 3D printing, can solve the problems of fixed and non-adjustable spacing between printing heads, low printing efficiency, and a small number of printing heads, etc., to simplify the printing of curved surfaces, improve printing efficiency, and save printing materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

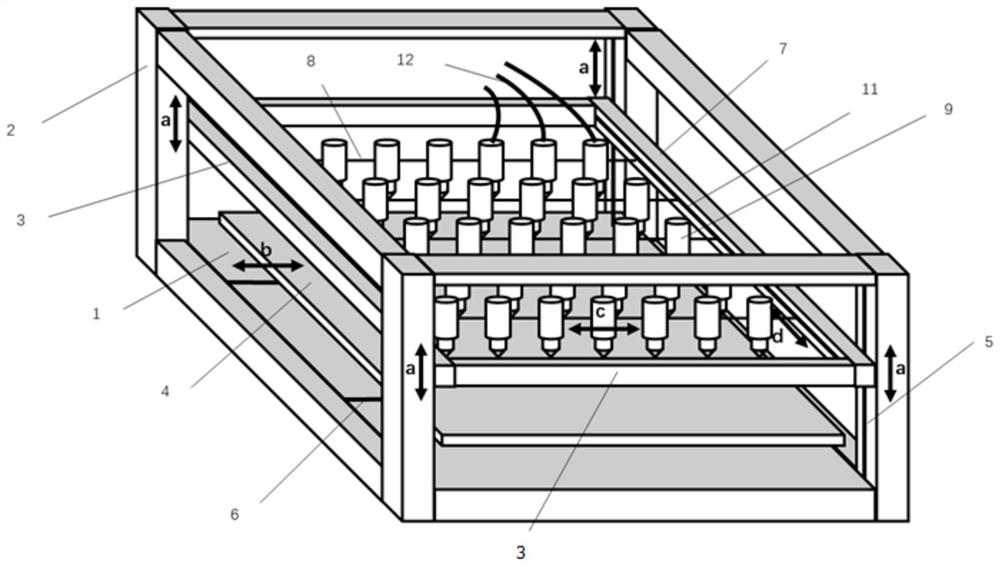

[0024] A discontinuous columnar surface 3D printing structure, such as figure 1 As shown, it includes a rectangular base 1, four vertical rods of equal length are drawn perpendicular to the base 1 at the four corners of the base 1, and three horizontal rods parallel to the base 1 are connected between two adjacent rods. The three transverse bars between adjacent vertical bars are parallel to each other. These rod bodies form a frame-shaped integral frame 2 . The base 1 is located on the bottom surface of the overall frame 2 . In the middle position of the overall frame 2 in the vertical direction, a printing frame 3 is arranged, and the printing frame 3 is set as a rectangular plate whose outline matches the overall frame 2. A plurality of print heads 9 are arranged on the printing frame 3, and printing The discharge port of the head 9 is arranged towards the base 4 . Printhead 9 top is provided with feed pipe 12, as figure 1 As shown, all the print heads 9 are connected w...

Embodiment 2

[0034] A printer with the three-dimensional printing structure of a discontinuous columnar surface as described in Embodiment 1.

Embodiment 3

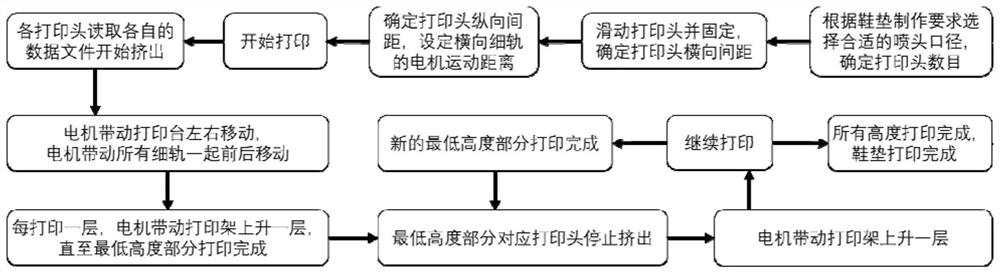

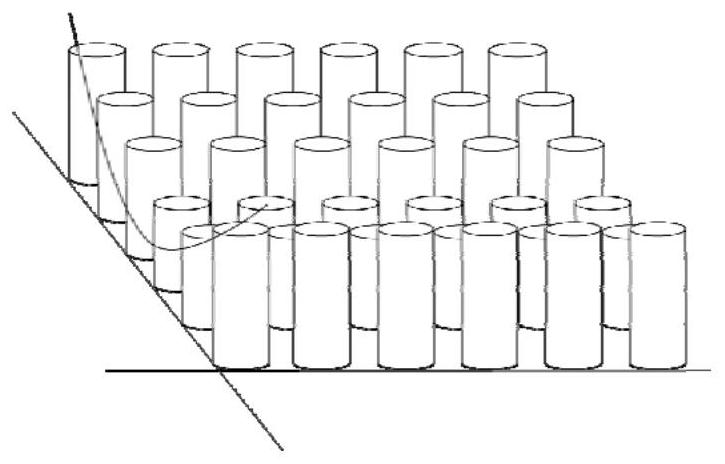

[0036] A three-dimensional printing method for a discontinuous columnar curved surface. The printing device can be used to print discontinuous cylindrical curved surface objects, which can be applied to two scenarios. The discontinuous cylindrical surface shape of .

[0037] If you choose the first printing method to print the surface shape of discontinuous columns with equal intervals, the printing steps are as follows:

[0038]A) First, select the corresponding print head 9 according to the needs of the printed object, determine the number of the selected print head 9, replace the print nozzle with a suitable caliber, and then slide the selected print head 9 on each horizontal thin rail 8, refer to the horizontal thin rail 8 The scale on the rail 8 adjusts the position of the print head 9 to an equal distance and fixes it; then slide the two ends of each horizontal thin rail 8 on the longitudinal slide rail 11, and adjust the horizontal thin rail 8 to each horizontal thin ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com