An adjustable external support device for 3D printing

A support device, 3D printing technology, applied in the direction of 3D object support structure, metal processing equipment, manufacturing tools, etc., can solve the problems of destroying the surface quality of the formed parts, affecting the printing efficiency and printing cost, etc., to improve the printing speed and quality, The effect of reducing use and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

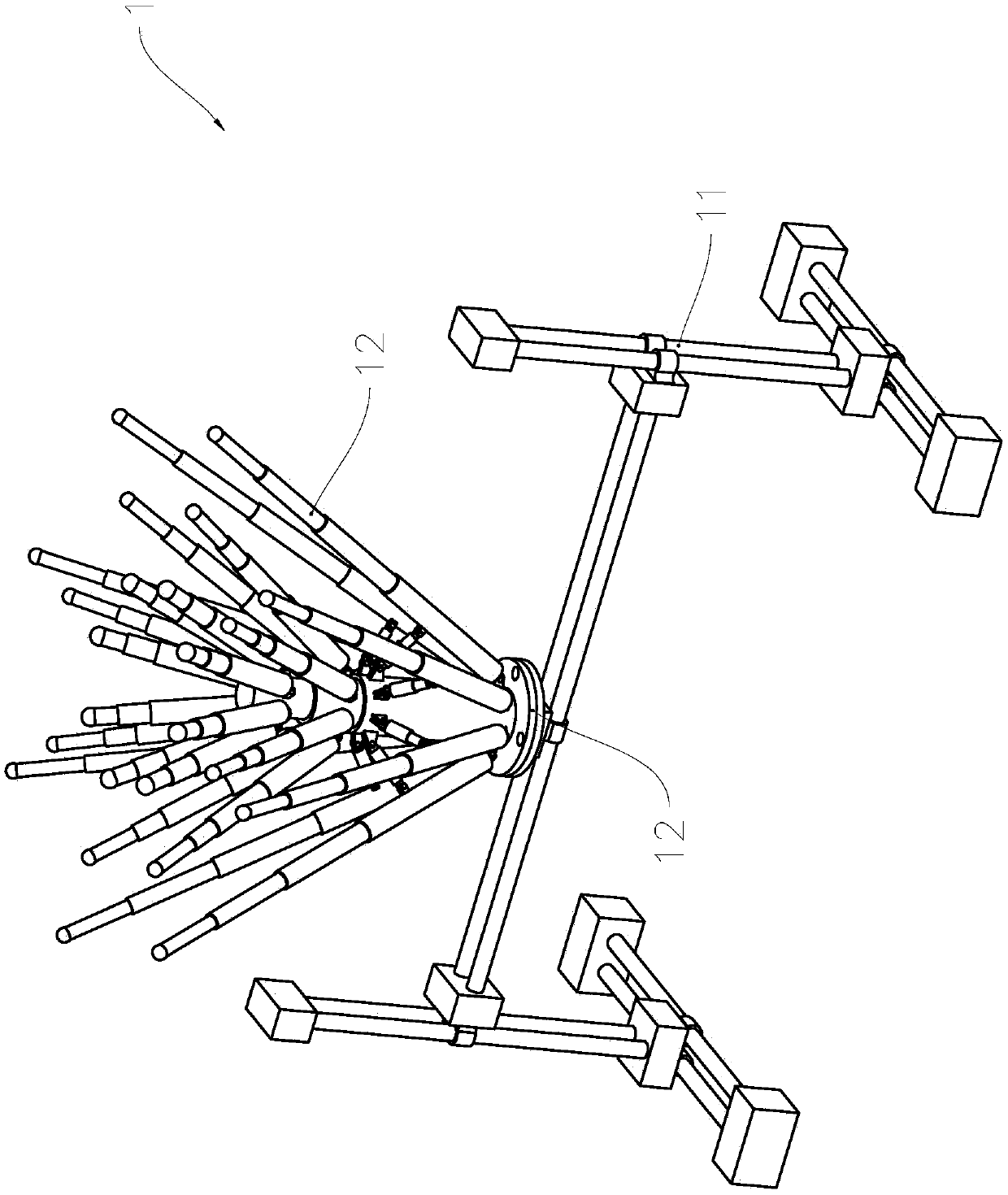

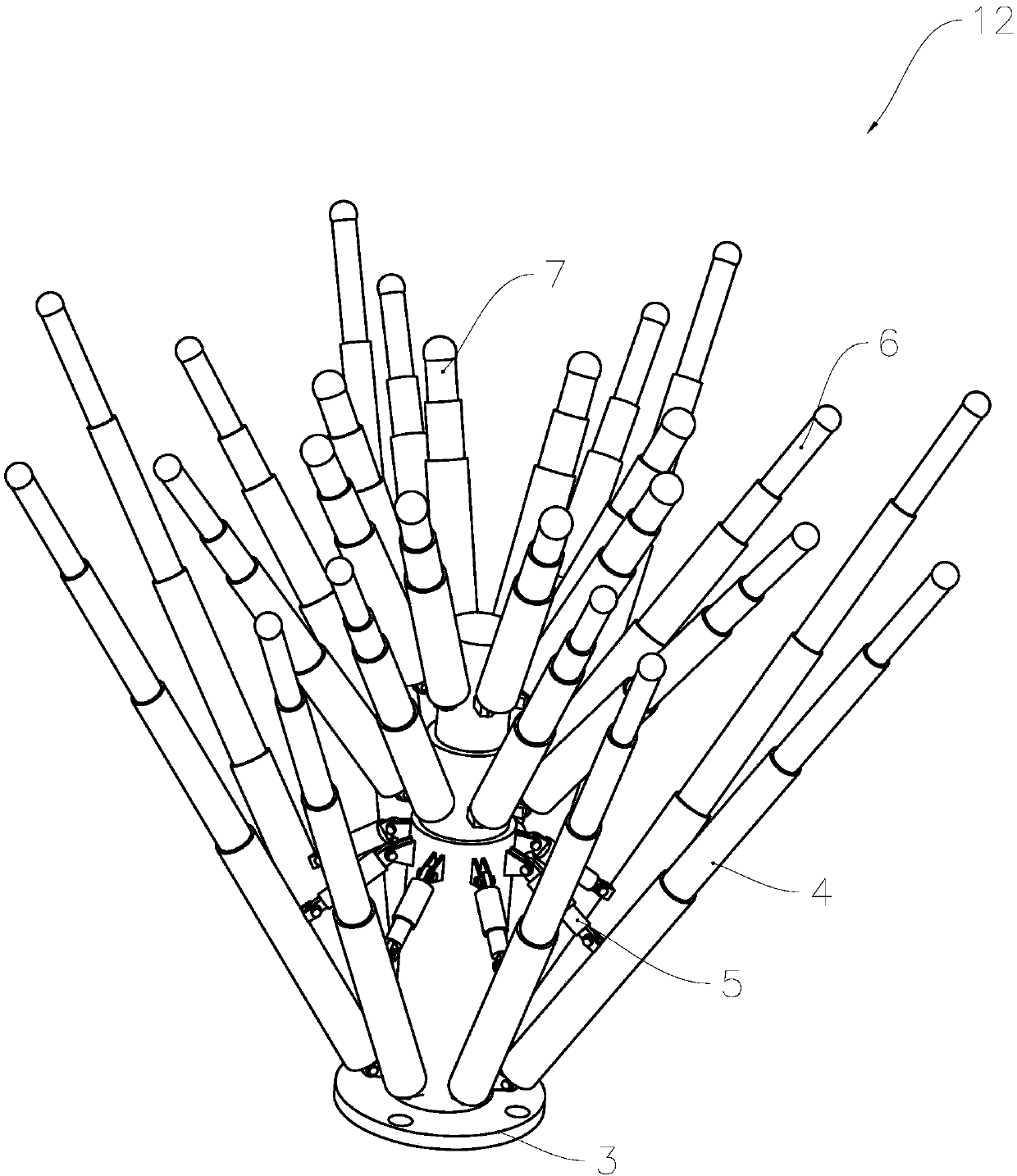

[0032] see figure 1 , the adjustable external support device 1 of the present invention includes a control unit, a lift and traverse unit 11 and a support unit 12 controlled by the control unit, and the support unit 12 is installed on the displacement output end 26 of the lift and traverse unit 11 .

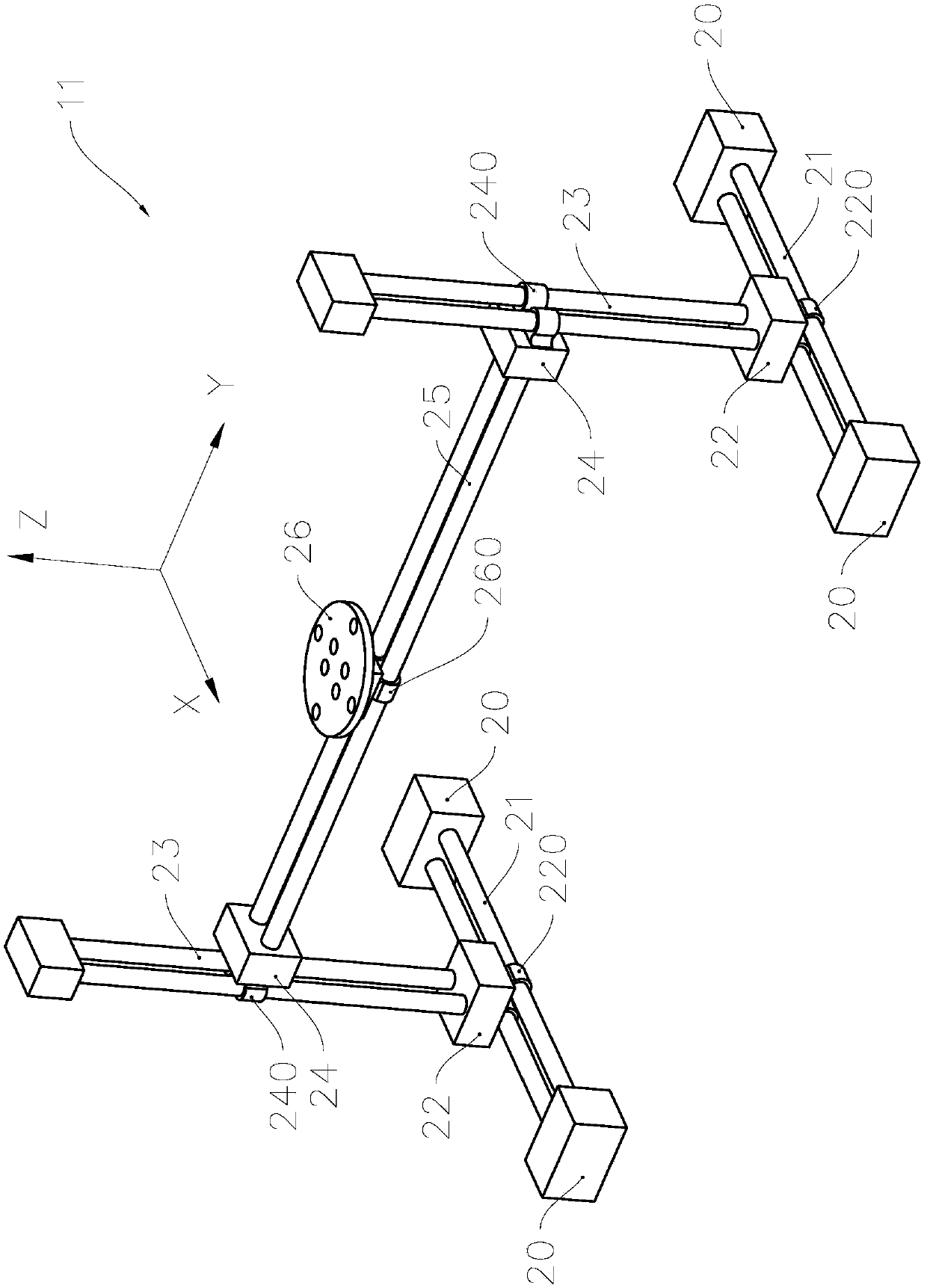

[0033] see figure 2 The lifting and traversing unit 11 is a three-dimensional drive unit, which is used to drive the support unit 12 to perform three-dimensional movement in three-dimensional space, so as to move to the right below the supporting area of the three-dimensional object to be printed to support the suspended part of the three-dimensional object.

[0034] The lifting and traversing unit 11 includes a first traversing mechanism, a lifting mechanism, a second traversing mechanism, and four support seats 20 for supporting the whole supporting unit 11 on the printing platform or other fixed positions.

[0035] The first traversing mechanism includes two groups of supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com