Green and pollution-free environment-friendly aluminum paste production system

A production system, pollution-free technology, applied in the direction of grain processing, etc., can solve the problems of water dripping and loss, equipment defects, lack of screening, etc., to prevent high-temperature oxidation of the output, reduce use and waste, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

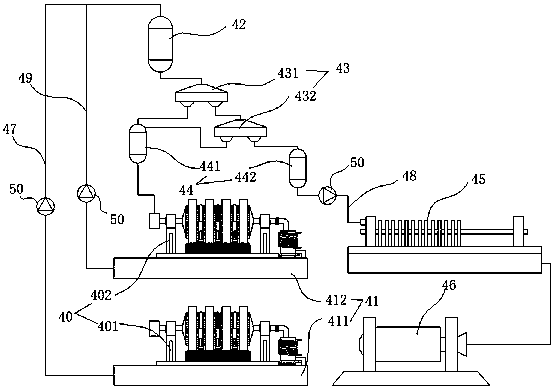

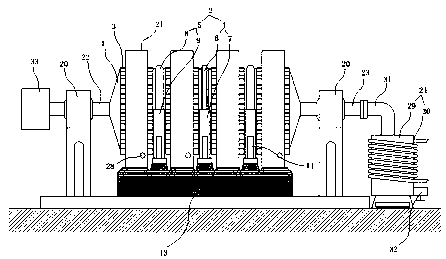

[0028] A green and pollution-free environment-friendly aluminum powder slurry production system, comprising a ball mill 40, a slurry tank 41, a material storage tank 42, a slurry filter screen 43, a middle tank 44, a filter press 45 and a kneader 46, is characterized in that, The number of the ball mill 40 is 2, divided into a primary ball mill 401 and a secondary ball mill 402, the number of the slurry filter 43 is 2, divided into a primary slurry filter 431 and a secondary slurry filter Sieve 432, the number of the slurry pool 41 is 2, divided into a primary slurry pool 411 and a seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com