Rolling digital printing device

A digital printing and optical device technology, applied in printing devices, printing, typewriters, etc., can solve the problems of dust or substrate nozzle contact, incompatibility of printing ink, and high demand for substrates, so as to improve the printing speed and quality, The effect of stable product quality and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

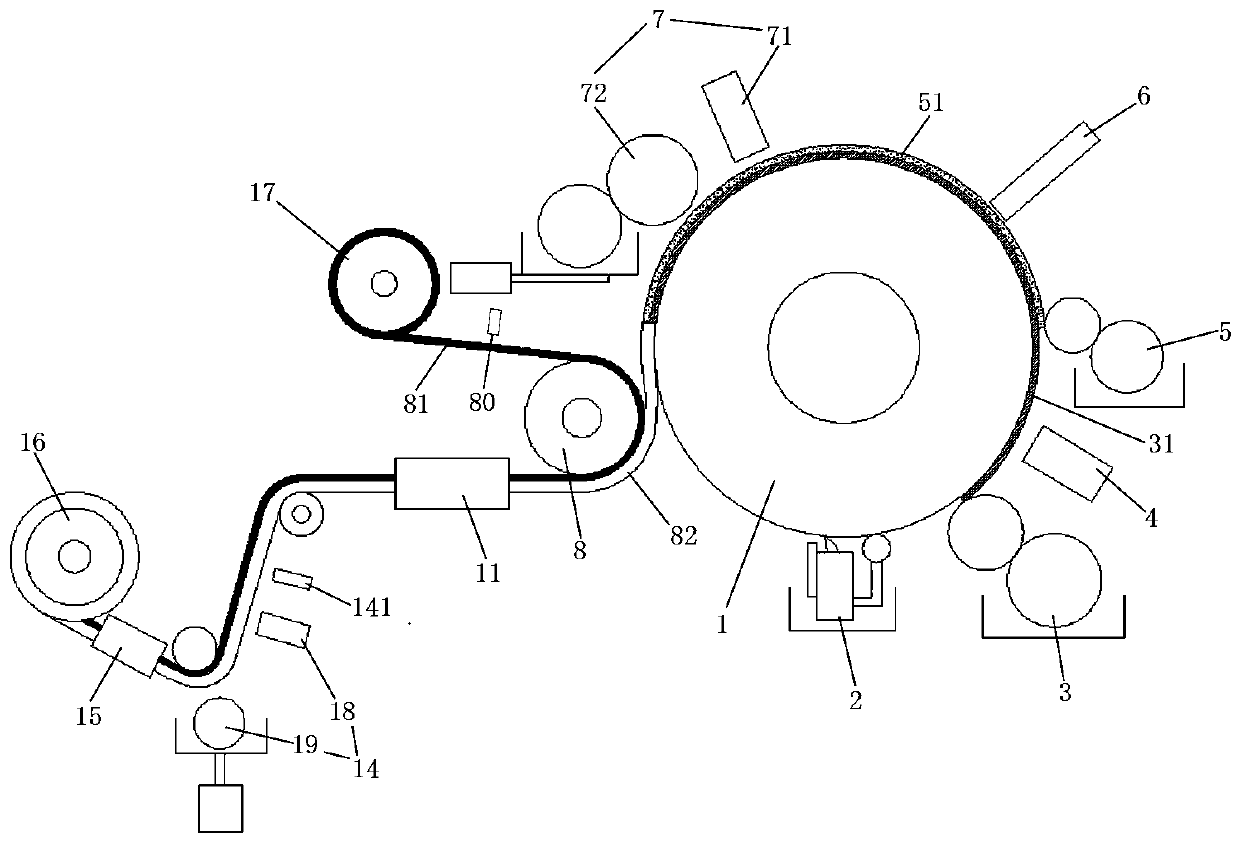

[0016] see figure 1 As shown, it is a structural schematic diagram of a preferred embodiment of the present invention. The present invention is a rolling digital printing device. The printing method is as follows: the cylinder 1 is continuously rotated, and the cleaning device 2 first cleans the surface of the cylinder 1, and then The coating and drying device 4 forms a separation layer 31, and then coats the separation layer 31 to form an adaptation layer 51, the combination of the separation layer 31 and the adaptation layer 51 forms a transfer layer 82, and then sprays on the adaptation layer by the spray printing device 6, A printing layer with a printed pattern is formed, then glued, and then bonded with the substrate 81 to form a comprehensive layer. The comprehensive layer will be peeled off the cylinder 1, and the cylinder will re-enter a new round of film coating after being cleaned by the cleaning station. Superimposition and compounding, and a series of processes su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com