3D printing method suitable for cylindrical parts

A 3D printing and 3D printer technology, applied in the field of 3D printing, can solve the problems of curve contour distortion, large vibration of printing head, affecting printing accuracy and printing speed, etc., and achieve the effect of increasing printing speed, increasing strength and improving printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

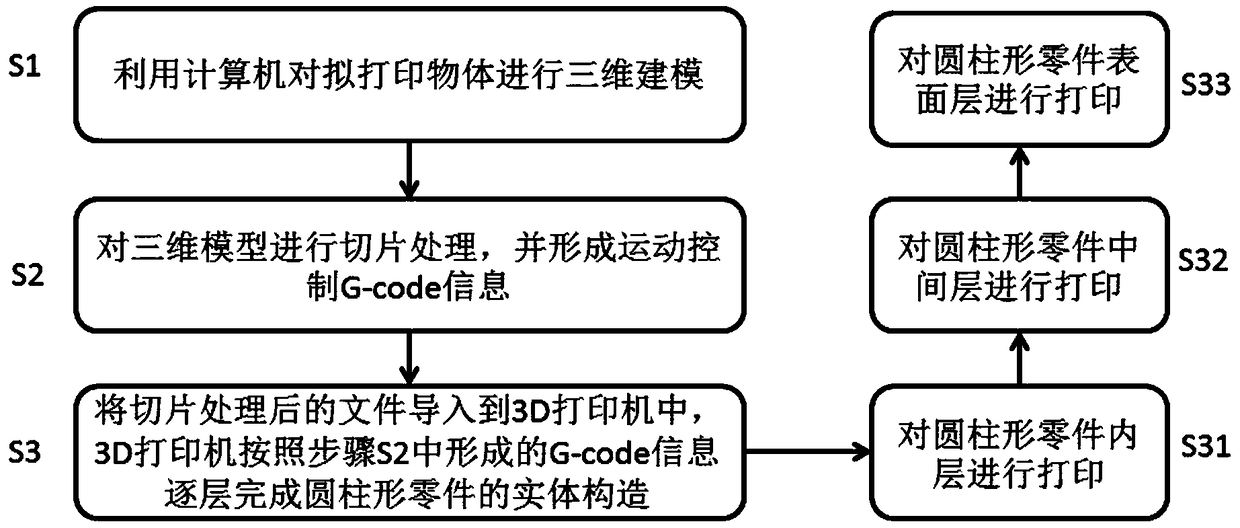

[0026] Such as figure 1 As shown, the present invention provides a kind of 3D printing method that is suitable for cylindrical part, and this method comprises the following steps:

[0027] Step S1: use computer design software to carry out three-dimensional modeling of the cylindrical part to be printed.

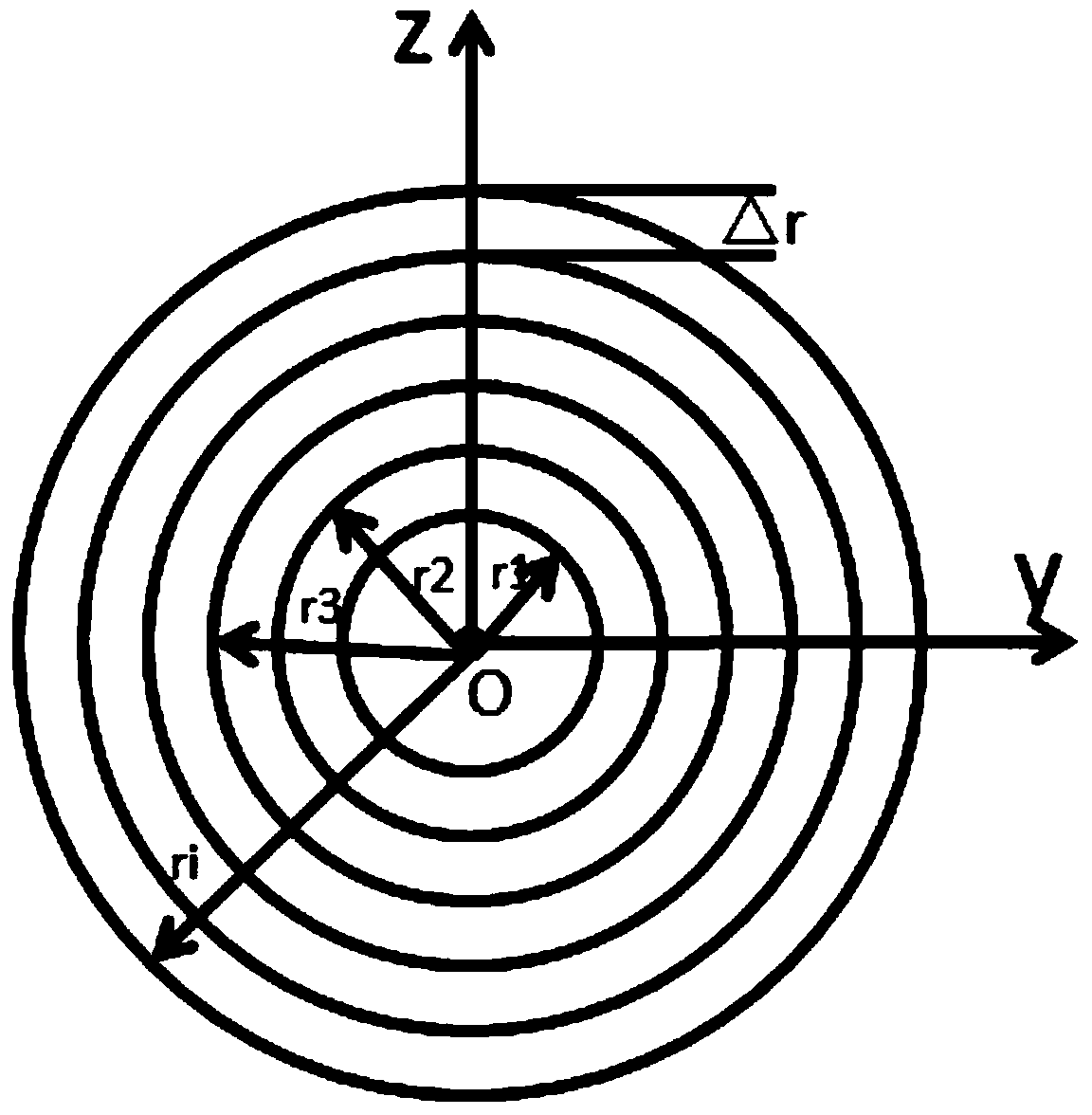

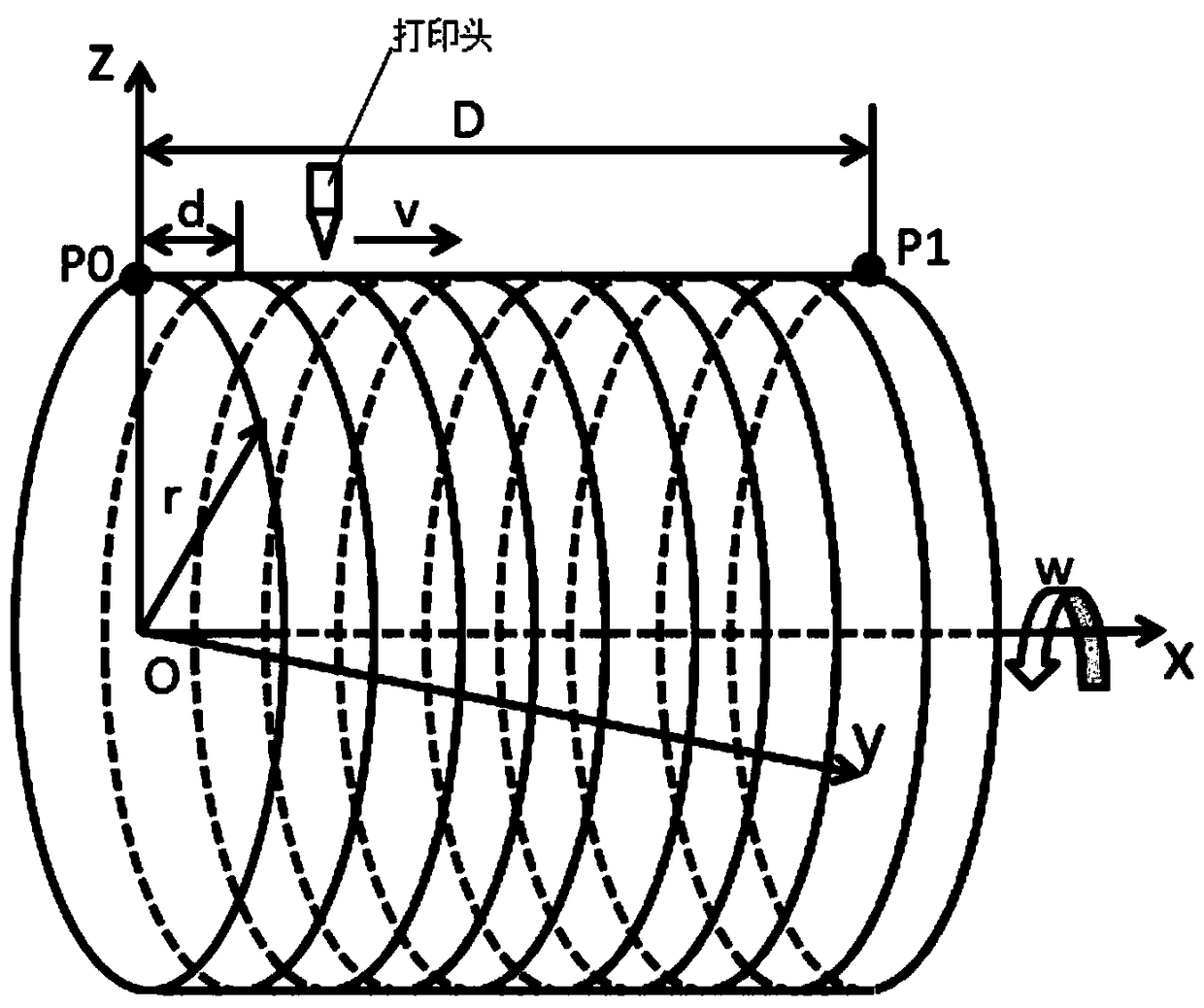

[0028] Step S2: Perform slice processing on the 3D model, and form motion control G-code information. The specific operation of slicing the 3D model is as follows: figure 2 As shown, along the central axis of the cylindrical part, use the cylindrical surface to slice the cylindrical part, and divide the cylindrical part into several layers with a thickness that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com