Environmental protection type tin printing ink solidified by ultraviolet light

A technology of printing iron ink and ultraviolet light, which is applied in the field of coatings, can solve the problems of high cost and achieve the effect of reducing production cost, reducing cost and speeding up printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

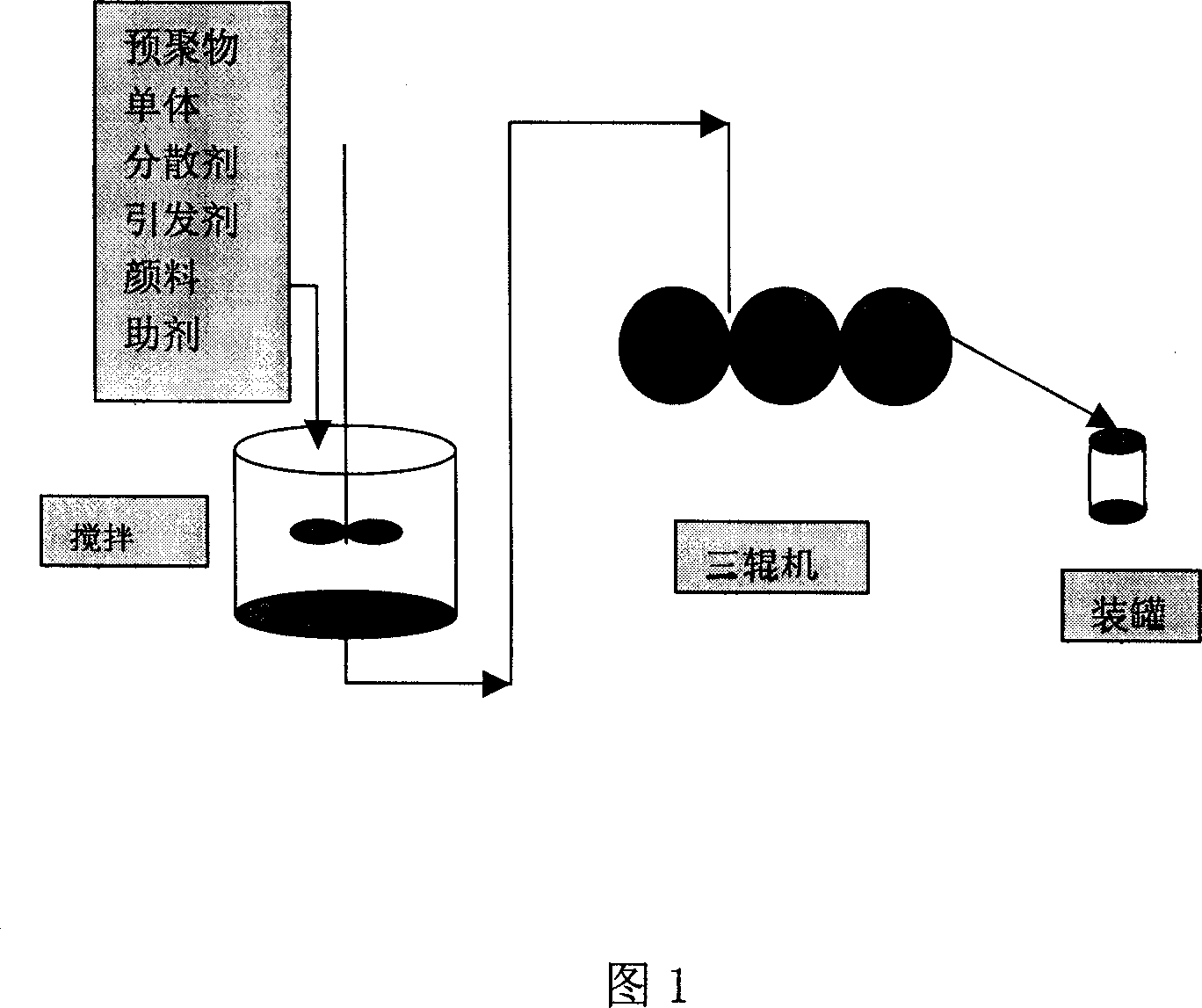

[0023] The environment-friendly ultraviolet light curing iron printing ink mainly includes prepolymer, monomer, dispersant, initiator, pigment and auxiliary agent. The specific raw material components (parts by weight) are: acrylic prepolymer 60%, acrylic acid 12% monomer, 8% initiator, 14% pigment, 6% dispersant and other additives.

[0024] Among them, the acrylic prepolymer is epoxy acrylate and polyester acrylate; the acrylic monomer is tripropylene glycol diacrylate; the dispersant is the polymer pigment dispersant K-SPERSE which is suitable for UV-curable ink Pigment dispersant; polymer pigment dispersant K-SPERSE is commercially available, such as this type of product produced and sold by King’s Industries in the United States; pigments are titanium dioxide, permanent yellow, phthalocyanine blue, carbon black and golden red, etc.; As the agent, 1-hydroxy-cyclohexyl phenone and 2-methyl (4-methylsulfonylphenyl)-2-morpholine-1-acetone and the like are used.

[0025] As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com