Ink droplet droppoint deviation compensation method in bidirectional printing of inkjet printer

An inkjet printer, bidirectional printing technology, applied in printing and other directions, can solve the problems of affecting the speed of the carriage, consuming computing time, and difficult to continue to improve the printing speed, so as to improve printing efficiency, improve printing quality, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

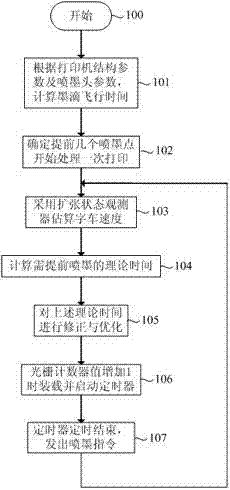

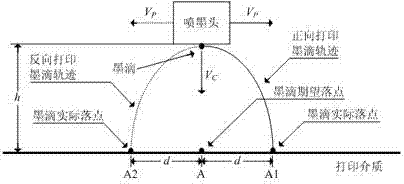

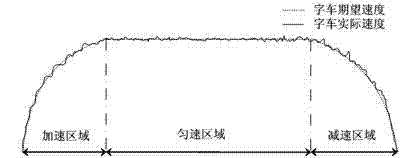

[0031] In the bidirectional printing process of wide-format inkjet printers, whenever ink droplets are ejected from the inkjet head in a direction perpendicular to the printing medium, there is a certain distance between the inkjet head and the printing medium, so the ink drops fall to the It takes a certain amount of time to print the medium; and due to inertia, the ink drop has the same horizontal speed as the character carriage when it is ejected, so the actual trajectory of the ink drop is as follows: figure 2 shown. Depend on figure 2 It can be seen that in the bidirectional printing process, due to the reciprocating motion of the character carriage, the actual landing point and the expected landing point of the ink droplets ejected at the same grid point will appear. The deviation reduces the printing quality of high-speed and high-precision inkjet printers. At the same time, the actual running curve of the word car is also as follows: image 3 As shown, there is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com