Patents

Literature

1288results about How to "Improve printing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

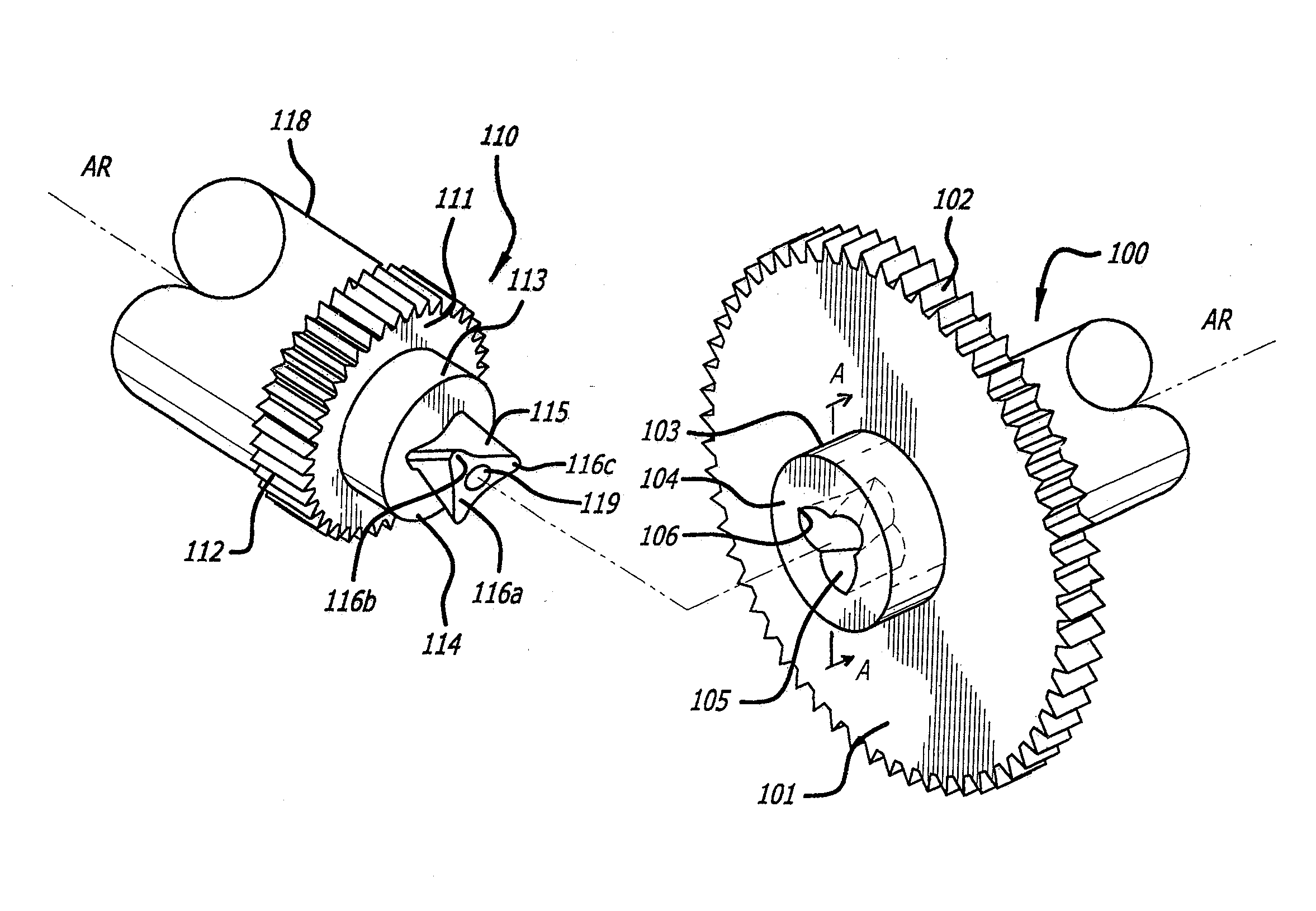

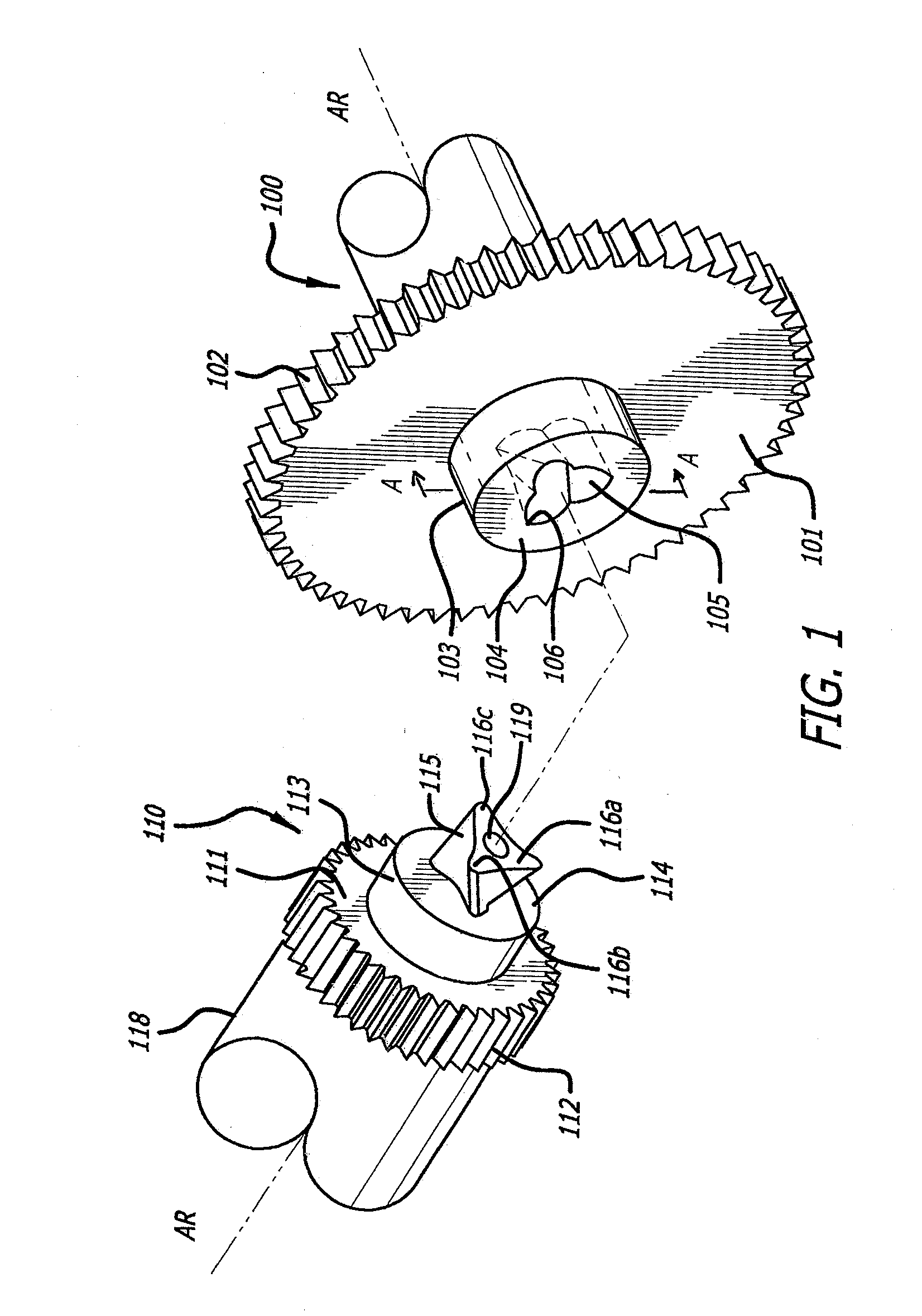

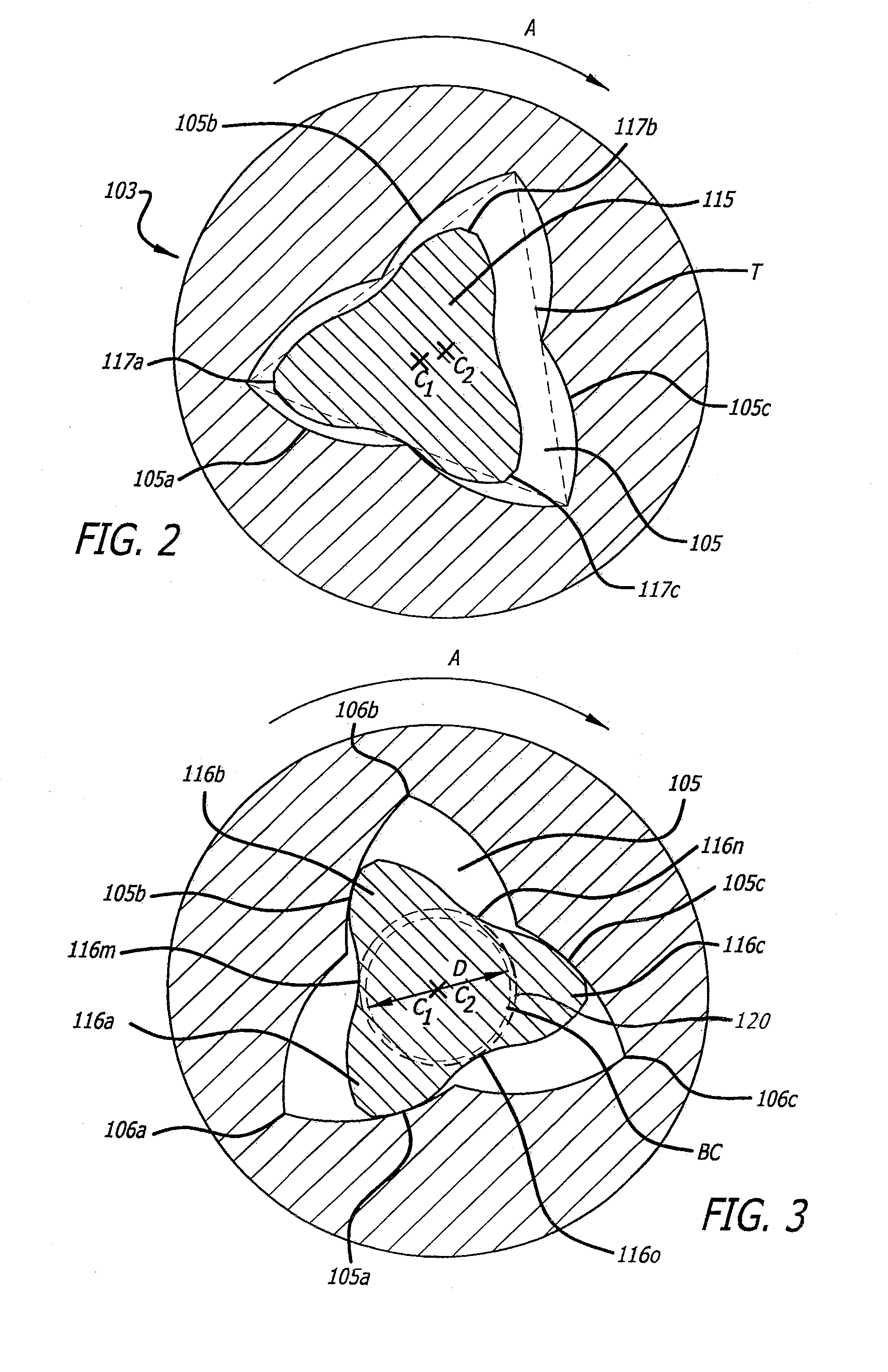

Rotating Drive Shaft Coupling

ActiveUS20130058710A1Reduce maintenanceLower manufacturing requirementsCouplings for rigid shaftsElectrographic processDrive shaftCoupling

A rotatable coupling is used with a replaceable developer cartridge and electrostatographic image devices. The coupling has a driven portion and a driving portion. The driven portion has a shaft with a connecting portion that has a plurality of helical involute teeth extending outwardly. The driving portion has an end with a gear shaft and a twisted petaline recess in the gear shaft. The sides of the recess are engageable with the helical involute teeth so that the driving portion drives the driven portion and transmit torque.

Owner:RAINBOW TECH INT LTD

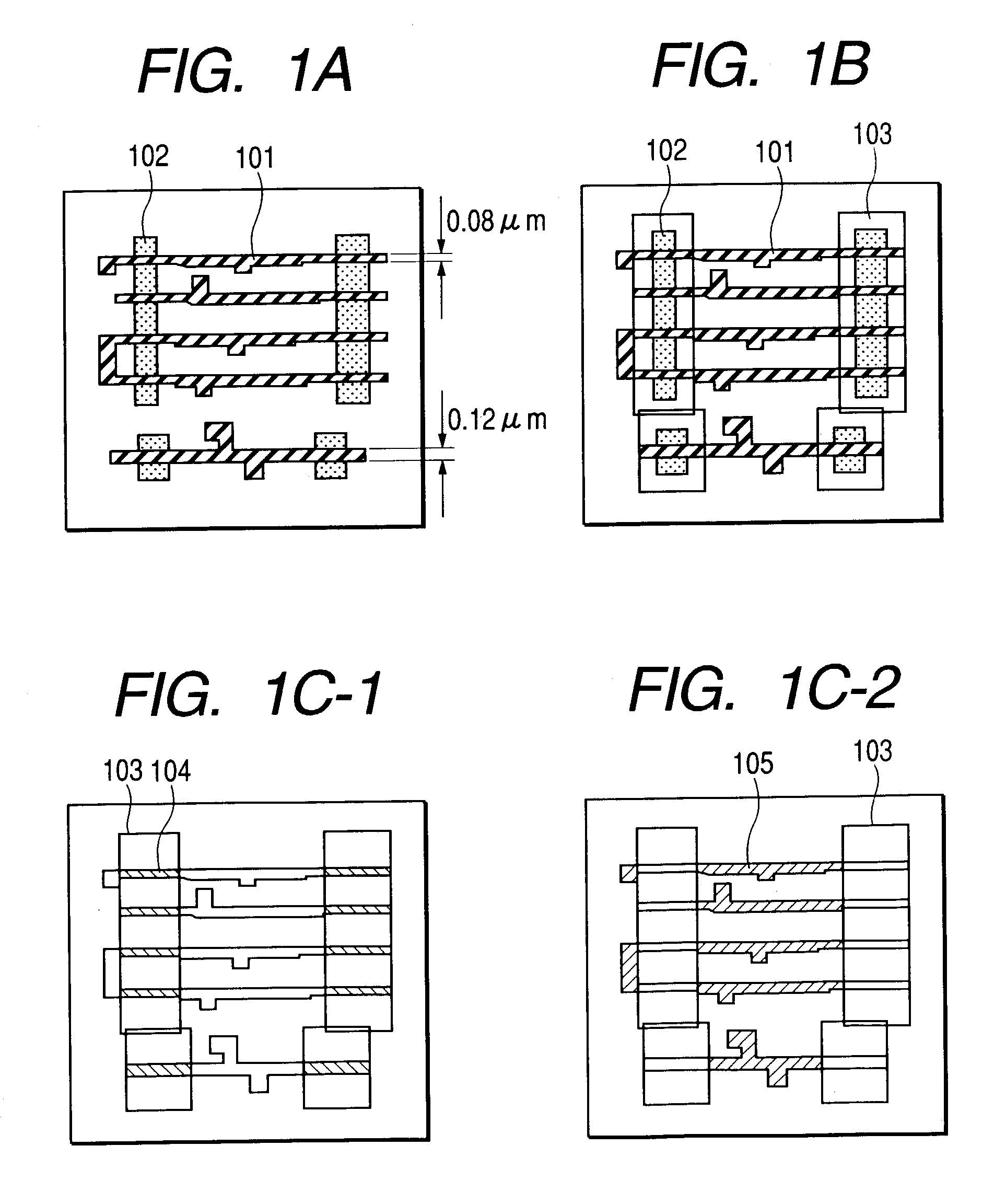

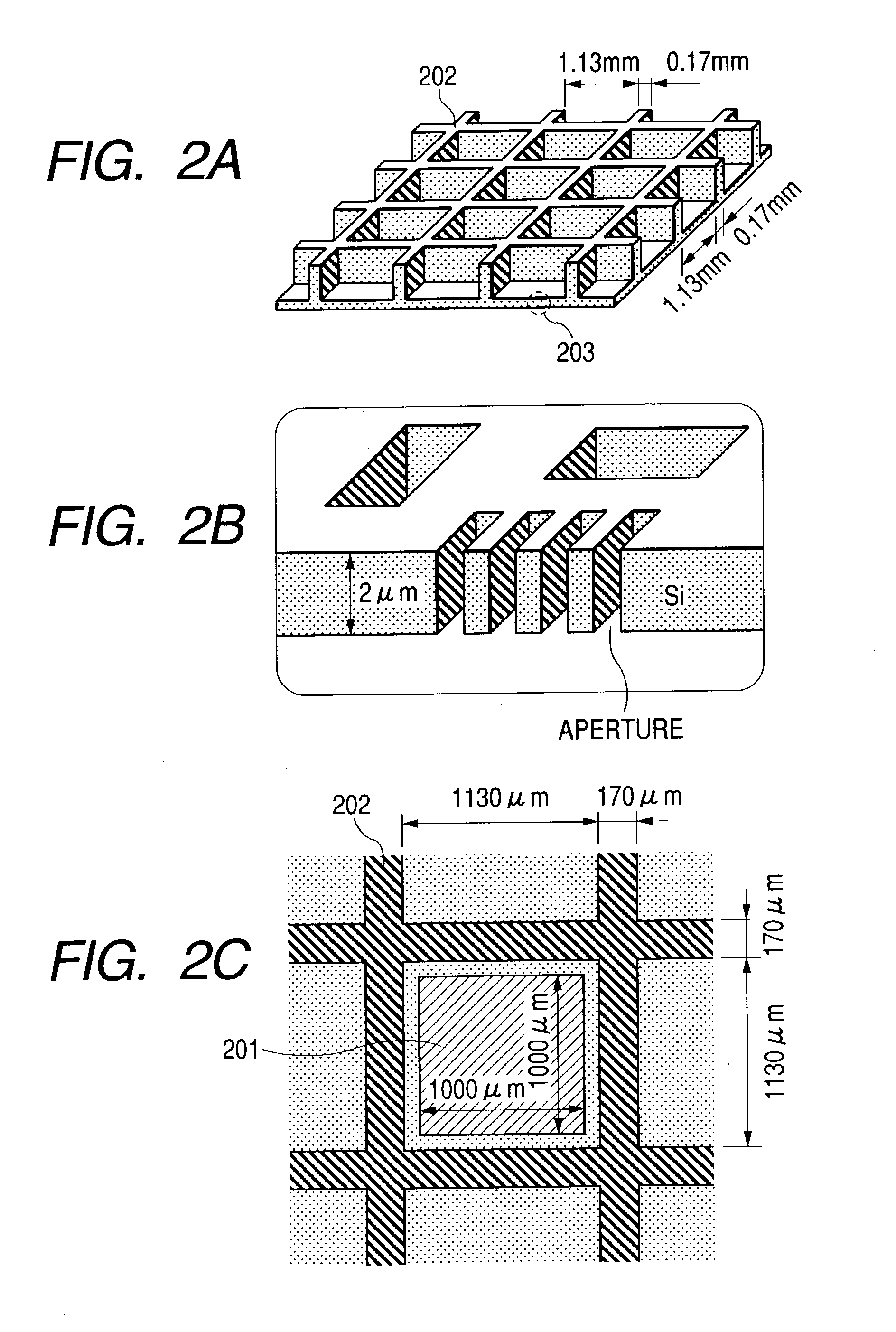

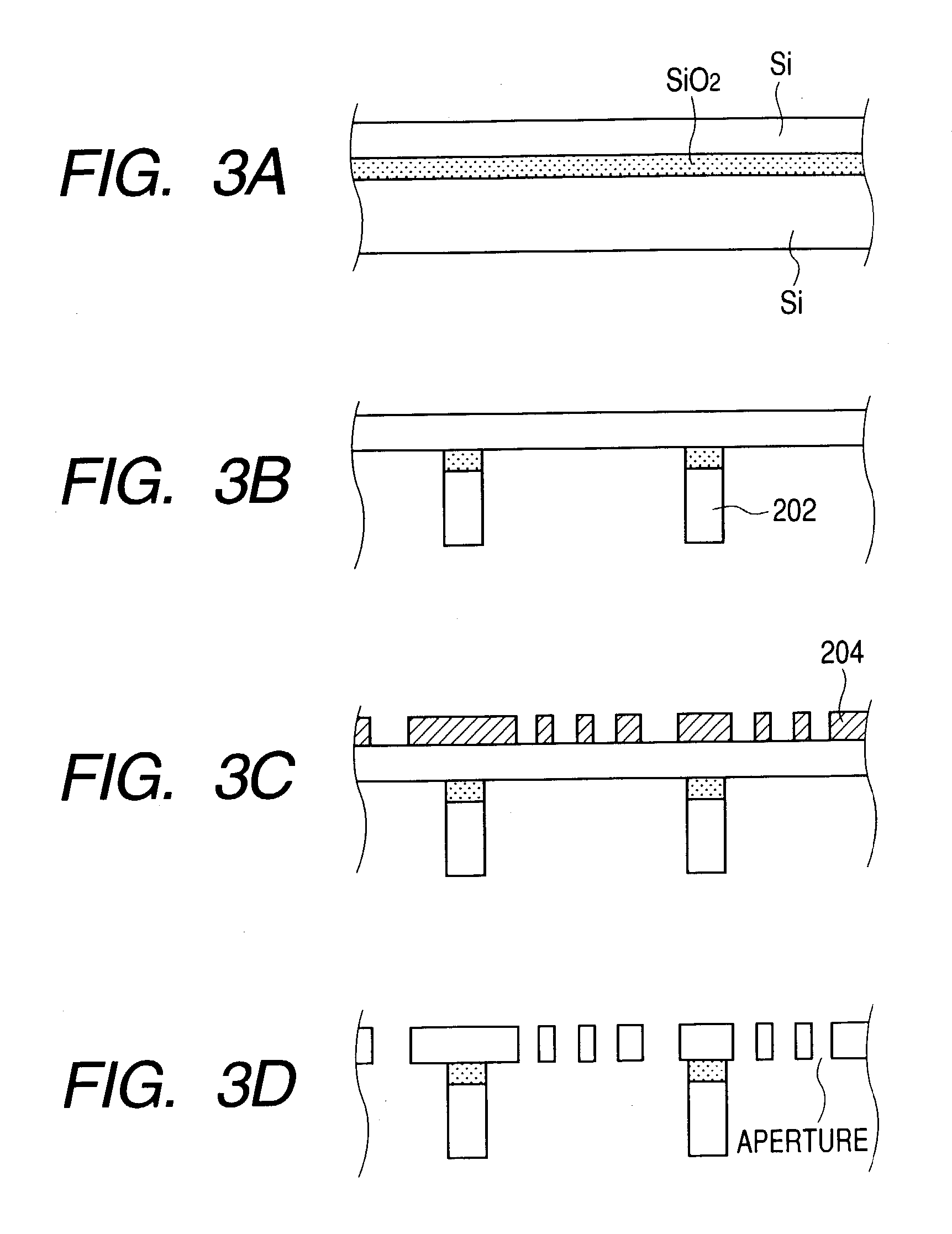

Semiconductor device and manufacturing method thereof

InactiveUS6964832B2Beam blur is preventedImprove accuracyElectric discharge tubesRadiation applicationsHigh dimensionalSemiconductor

A method is provided for solving a problem that the fine processing property is degraded by an increase of a current applied to complementarily divided masks in an electron beam projection process. In the method, the complementarily divided masks used for electron projection are used whereby one mask is used for patterns requiring high dimensional accuracy and another is used for other patterns. Consequently, it is possible to lower the current applied to the patterns requiring high dimensional accuracy to realize high printing accuracy. In addition, the highly accurate patterns can be formed at a high throughput.

Owner:HITACHI LTD

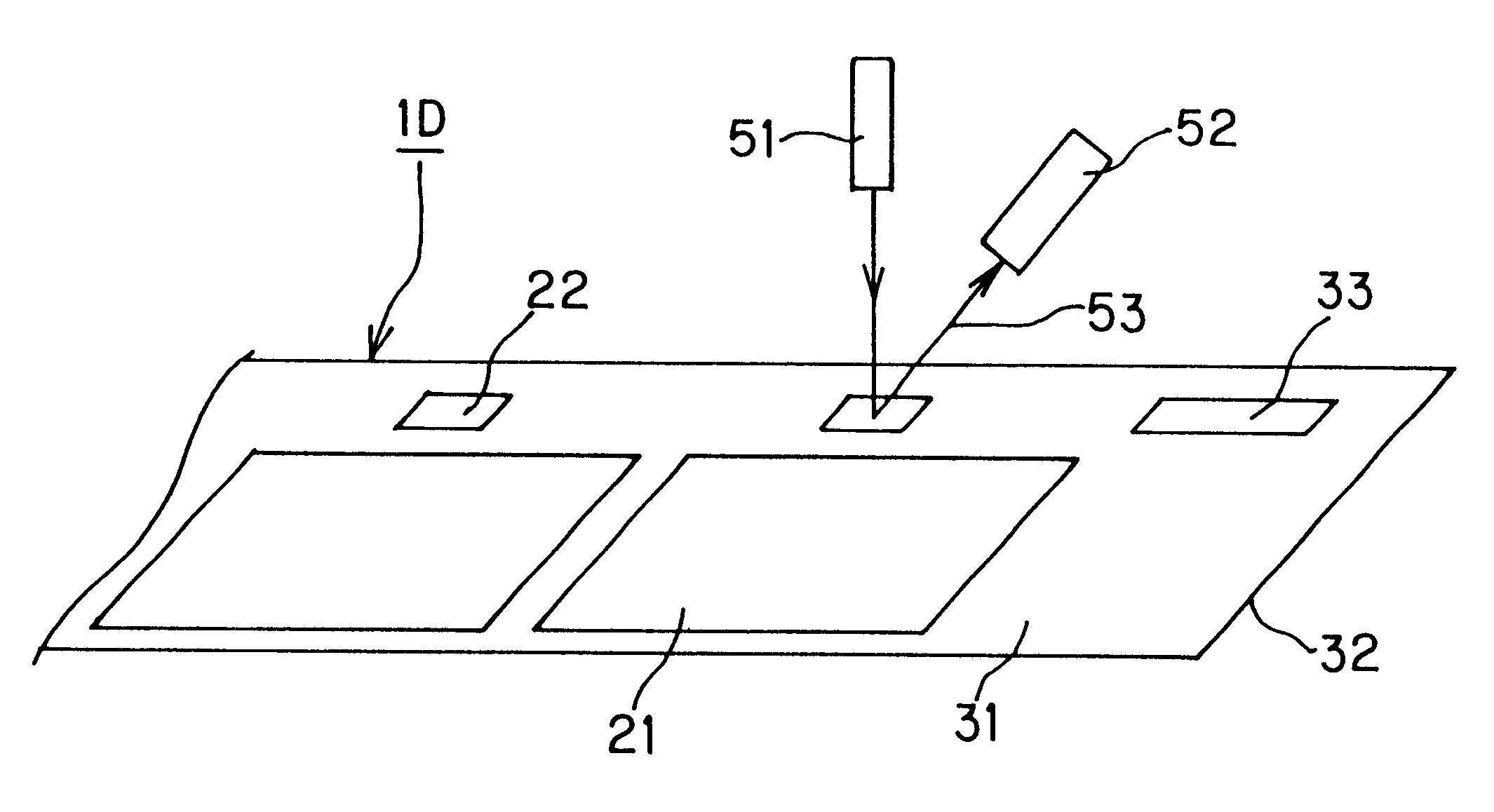

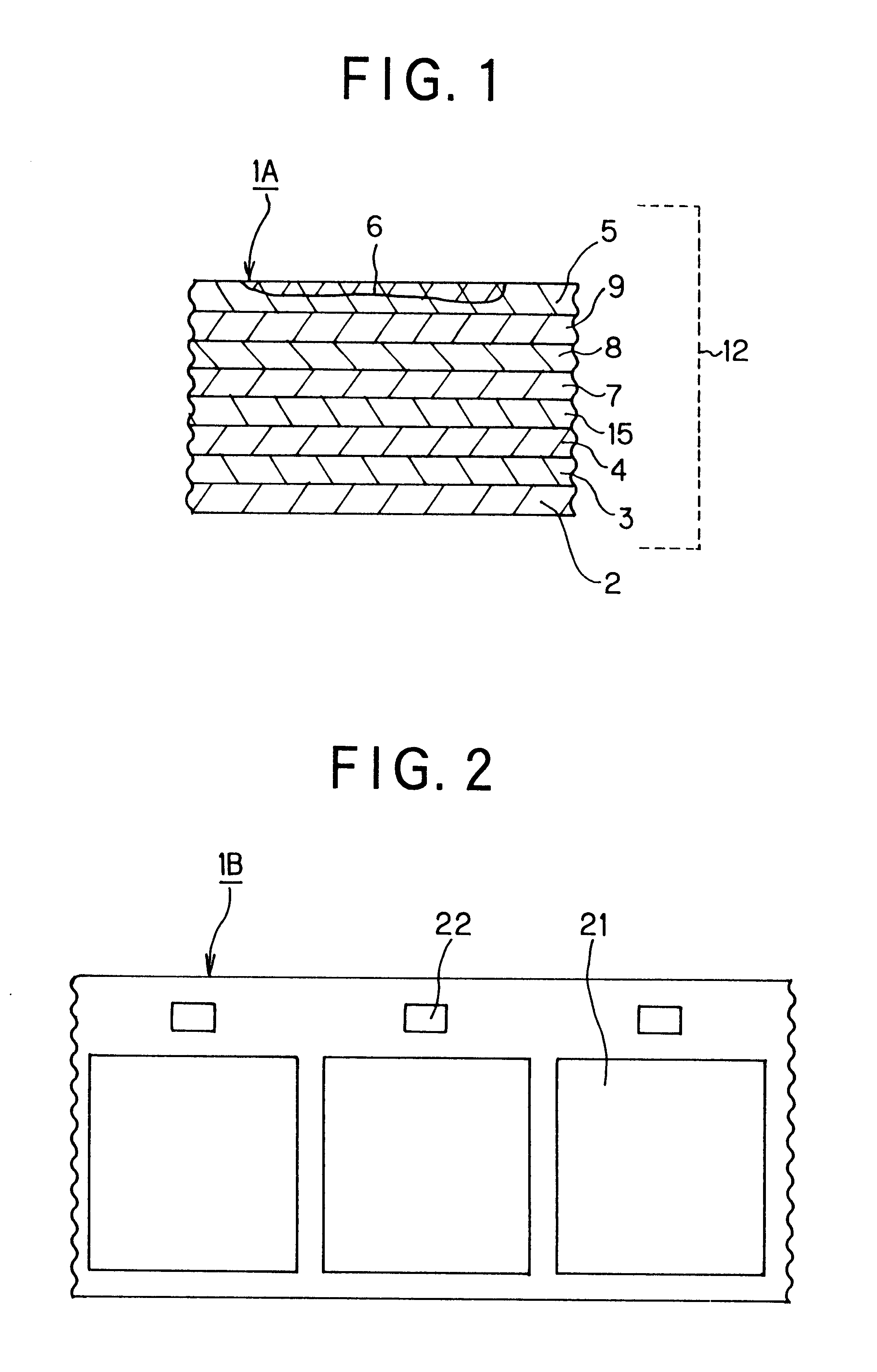

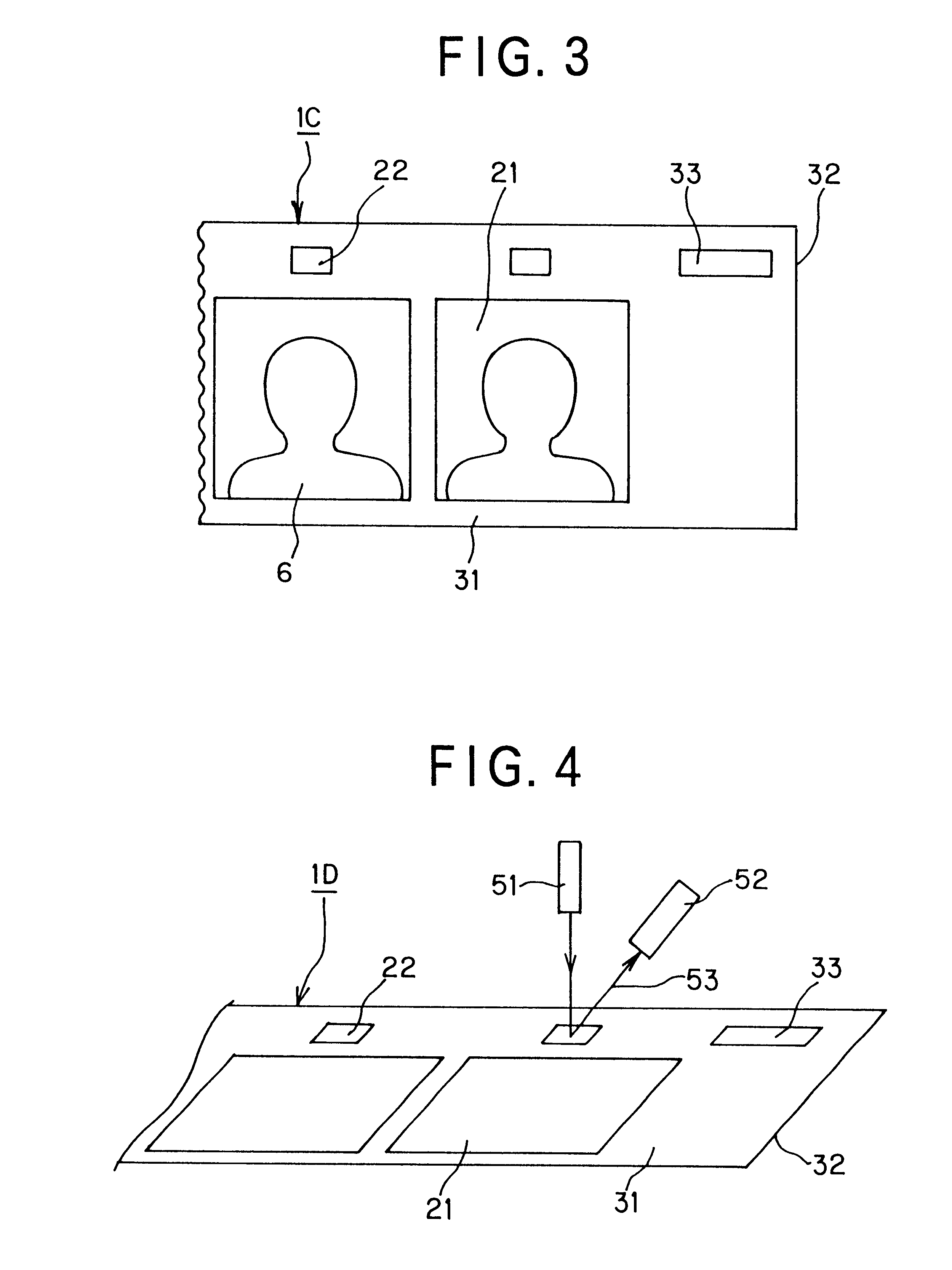

Intermediate transfer recording medium, method of forming print, and print

InactiveUS6308630B1Quality improvementSimple formatCylinder pressesPlaten pressesComputer scienceRecording media

An intermediate transfer recording medium is comprised by providing a transfer portion having a receptor layer on a substrate film. The transfer portion is printed with the image and thereafter transferred on a surface of a transfer-receiving material. In the first aspect of the intermediate transfer recording medium, the transfer portion is provided with plural hologram patterns 21 with a hologram mark 22 allocated to each the hologram pattern. According to the first aspect of the invention, since an image is formed on the receptor layer through positioning process using the hologram mark and then the transfer portion is transferred to the surface of the transfer-receiving material, no joint of a print plate appears in the hologram pattern and accuracy of transfer is remarkably excellent. On the other hand, In the second aspect of the intermediate transfer recording medium, peeling strength required to peel the transfer portion from the substrate film at the time when transferring the transfer portion to the transfer-receiving material is controlled in the range of 10 to 150 gf / inch. According to the second aspect of the invention, any transfer failure such as tail-extension or chip of the transfer portion is not caused.

Owner:DAI NIPPON PRINTING CO LTD

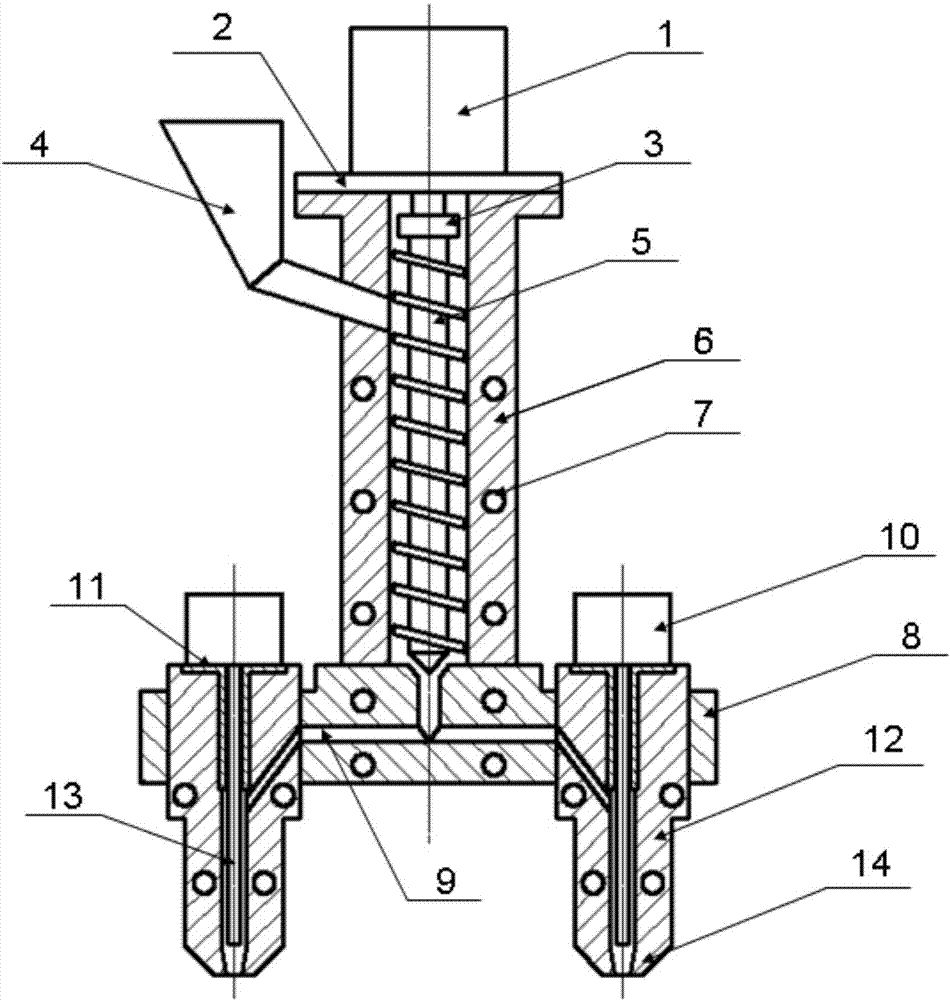

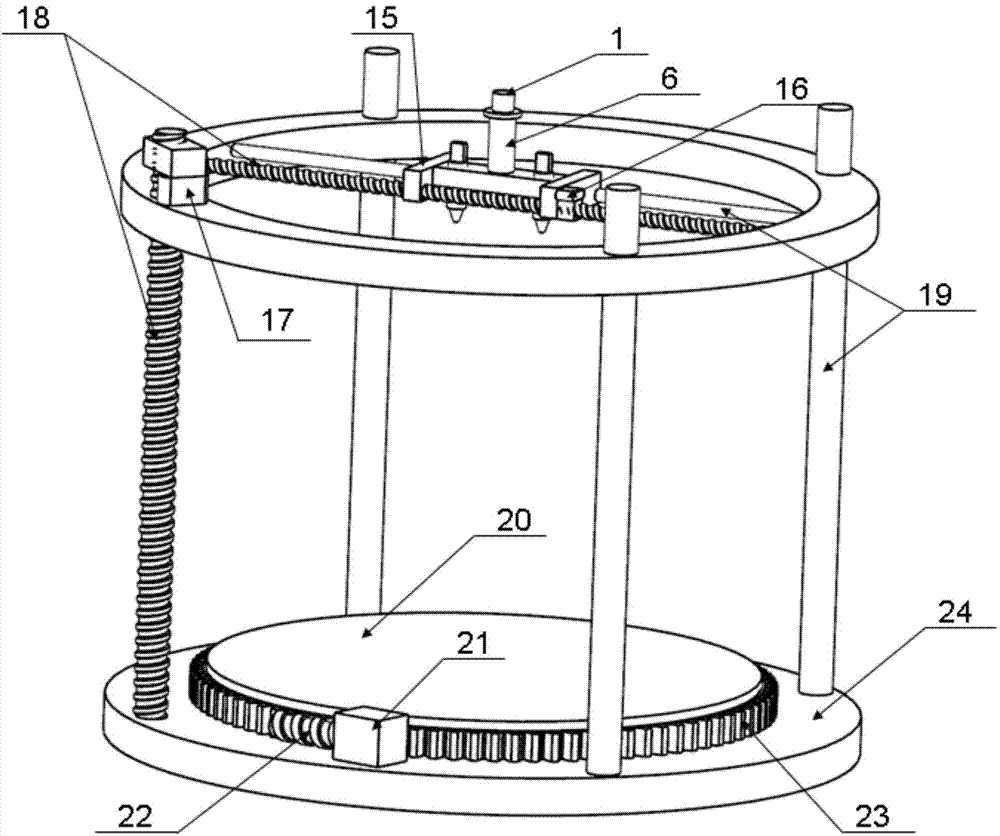

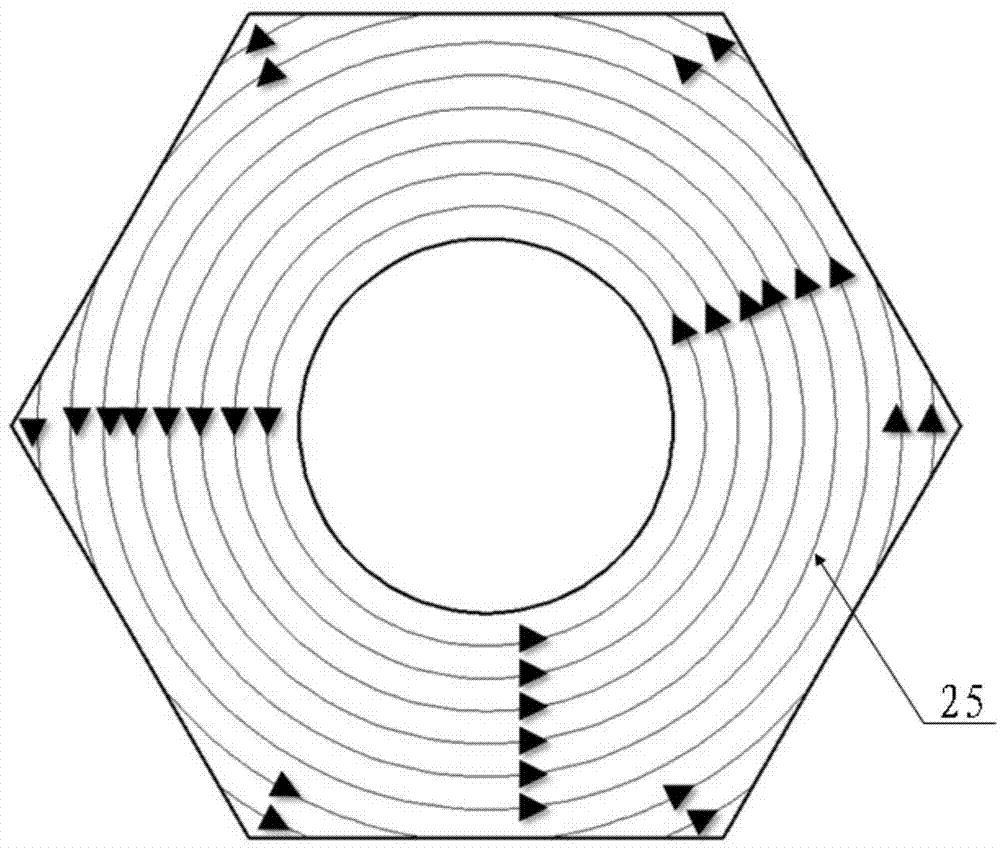

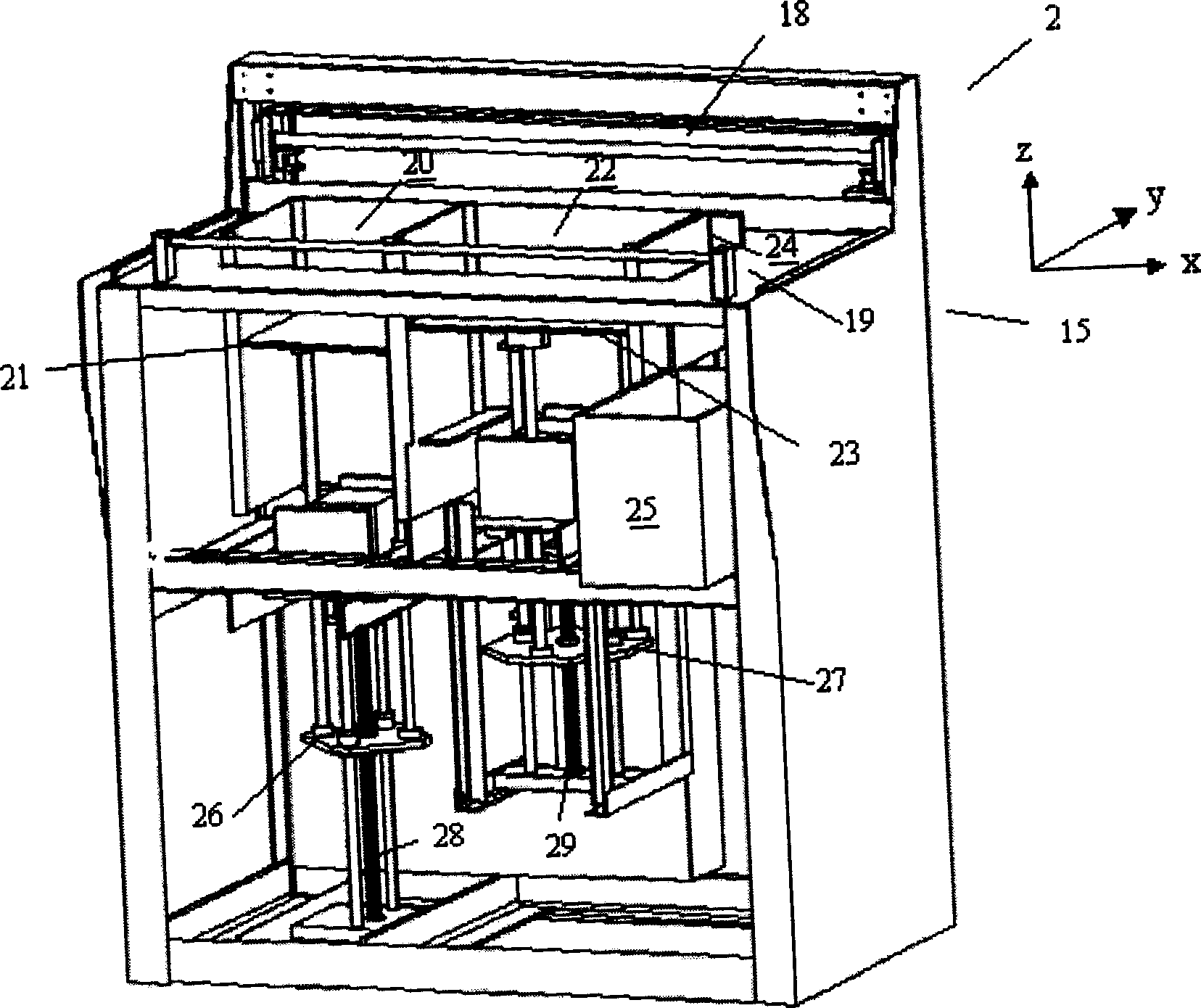

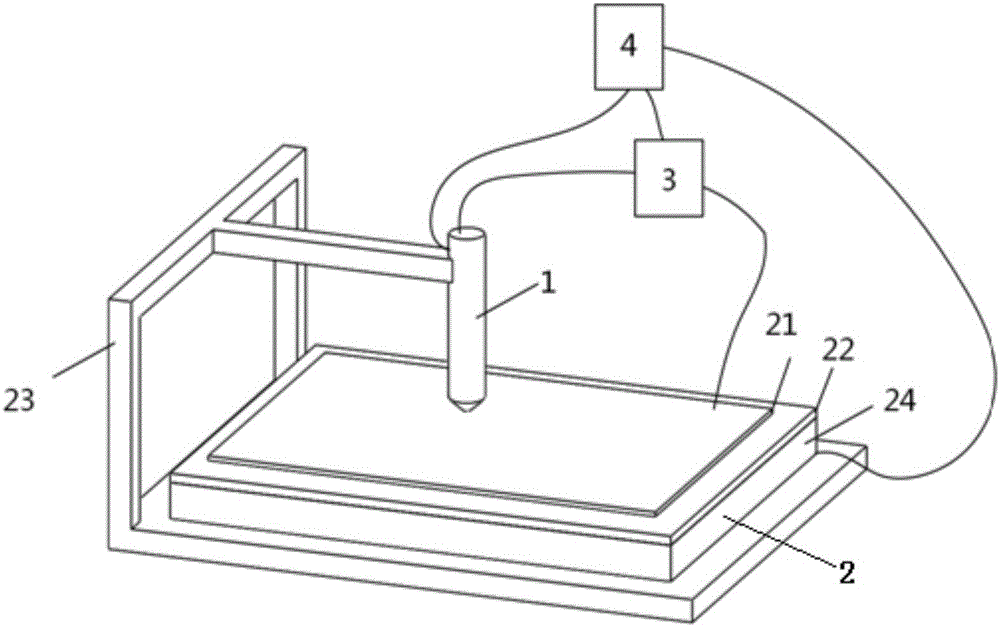

Melt differential three-dimensional printer

ActiveCN103692653ABurn out preventionConvenient Quantitative ManagementManufacturing driving meansAdditive manufacturing with liquidsHot runnerMotor drive

The invention discloses a melt differential three-dimensional printer. The melt differential three-dimensional printer mainly comprises a material melting unit, a micro-droplet jetting unit, a cylindrical-coordinate system molding unit and a rack, wherein a servo motor drives a screw rod to rotate in the material melting unit; a heater, which is fixedly arranged inside a machine cylinder, ensures that granules are entirely plastified through temperature regulation; a molten material is transmitted by the screw rod to the micro-droplet jetting unit; in the micro-droplet jetting unit, the molten material is transmitted into a valve body through a hot runner in a runner plate; a linear servo motor drives a valve needle to do reciprocating motion in the valve body so as to quantitatively and intermittently squeeze the molten material out of a nozzle to form melt micro-droplets; in the cylindrical-coordinate system molding unit, the molten micro-droplets are injected to a bearing table for cooling and deposition molding; the servo motors in the left-right direction and in the vertical direction are respectively engaged with the corresponding screw rod to rotate so as to drive the material melting unit and the micro-droplet jetting unit to move along the left-right direction and the vertical direction; a circumference servo motor drives the bearing table with a worm gear to rotate through a worm rod so as to realize three-dimensional movement under a cylindrical-coordinate system.

Owner:BEIJING UNIV OF CHEM TECH

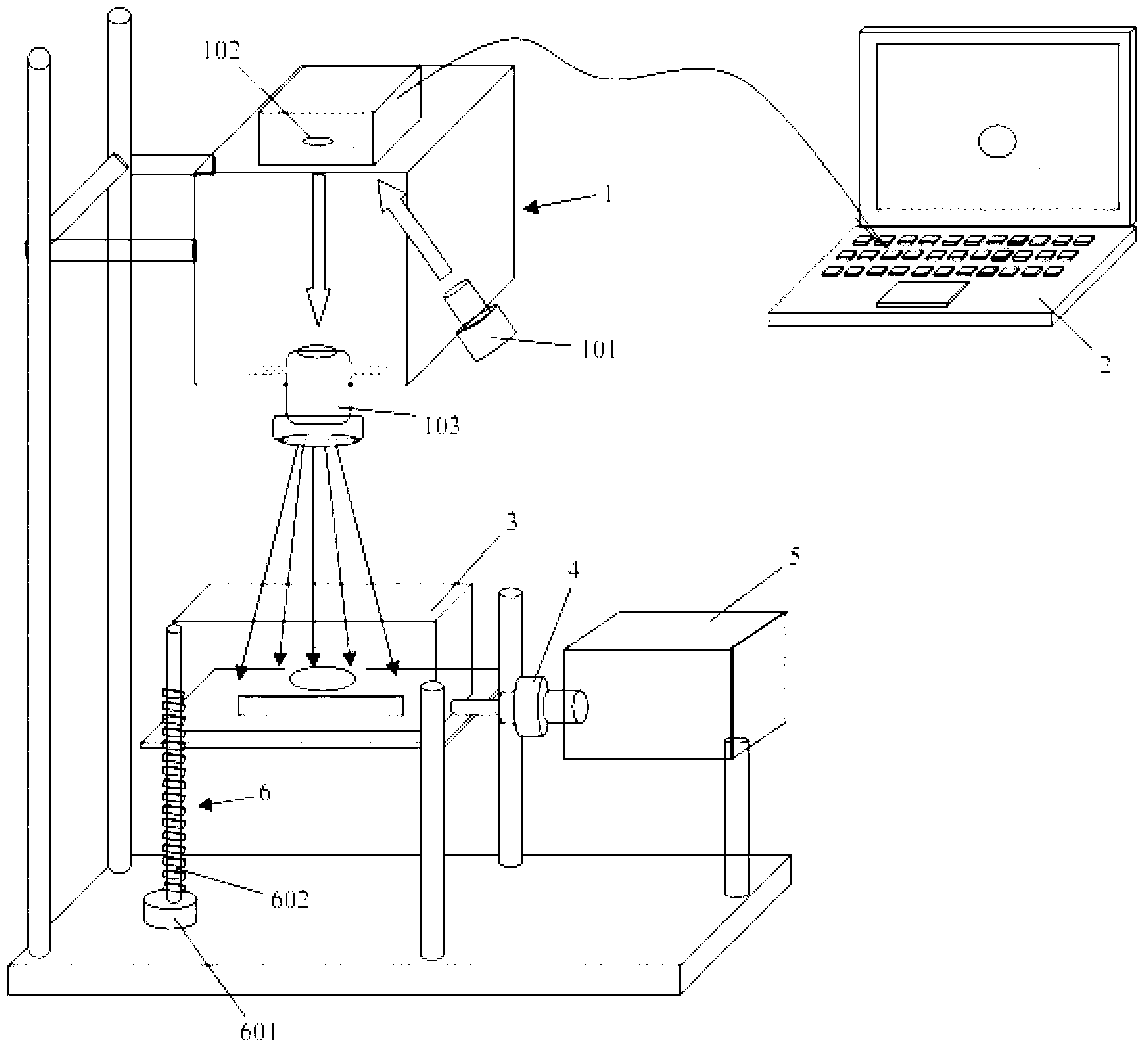

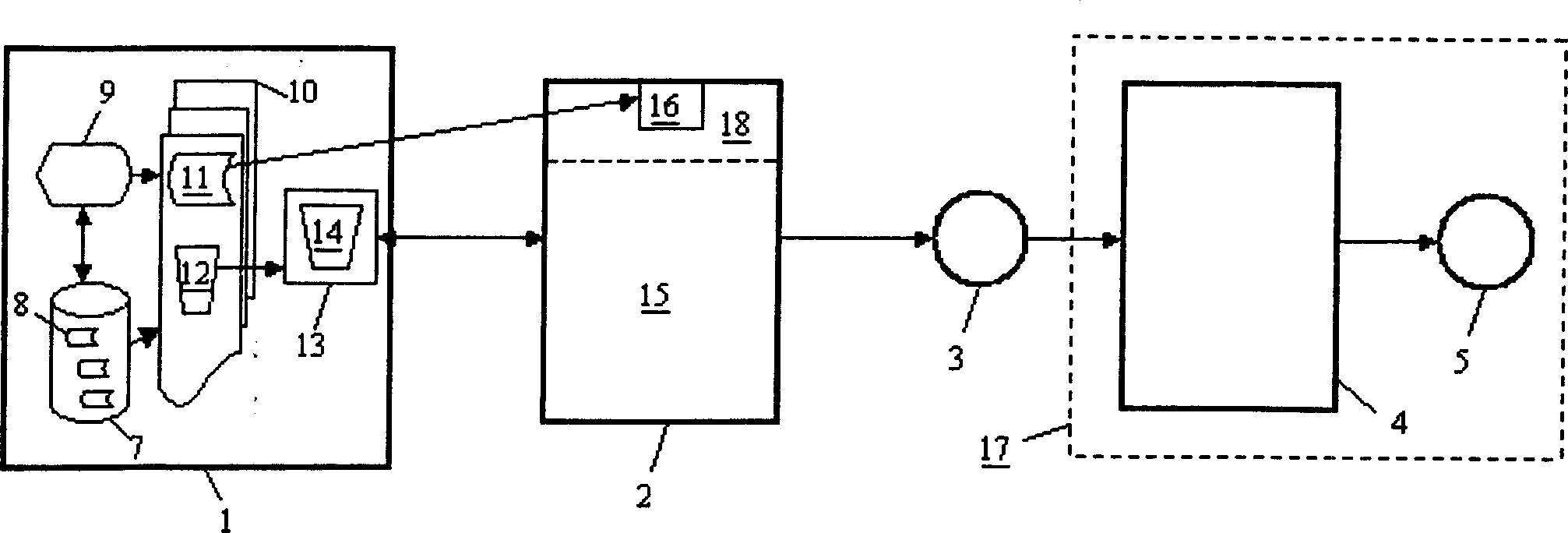

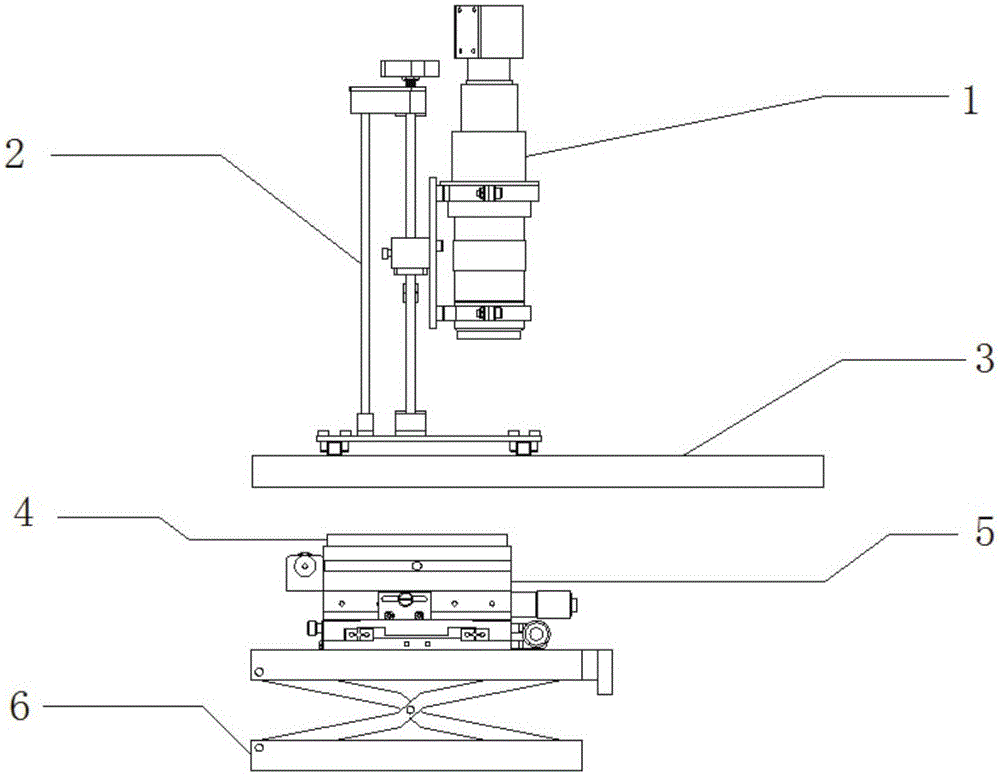

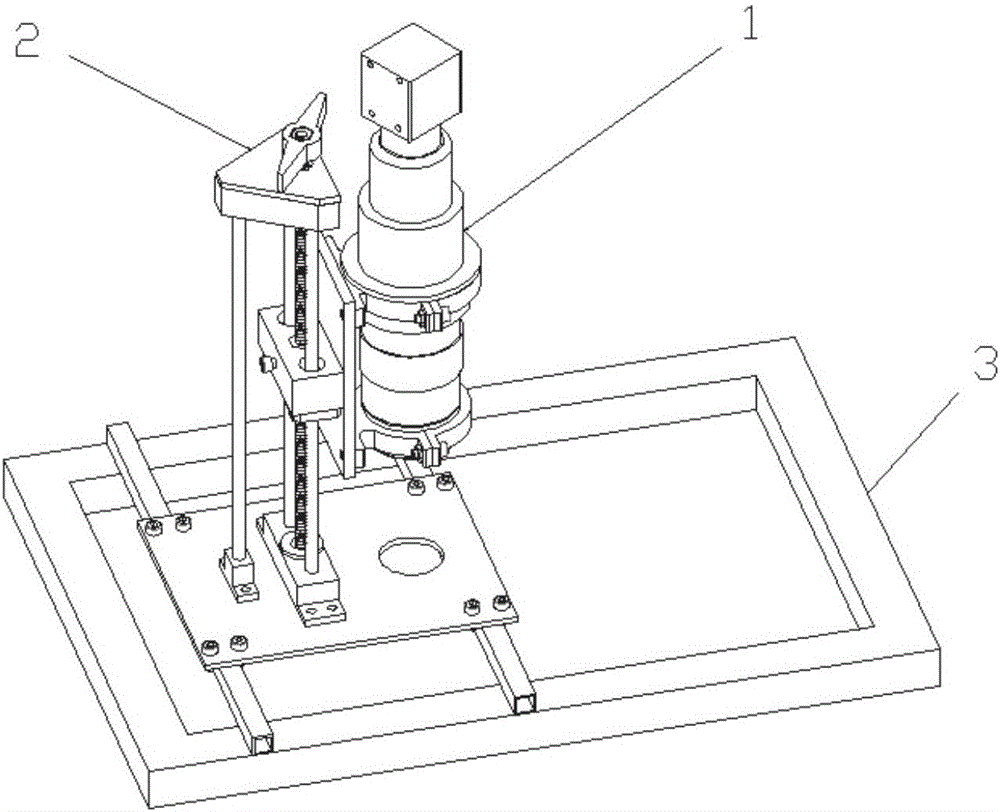

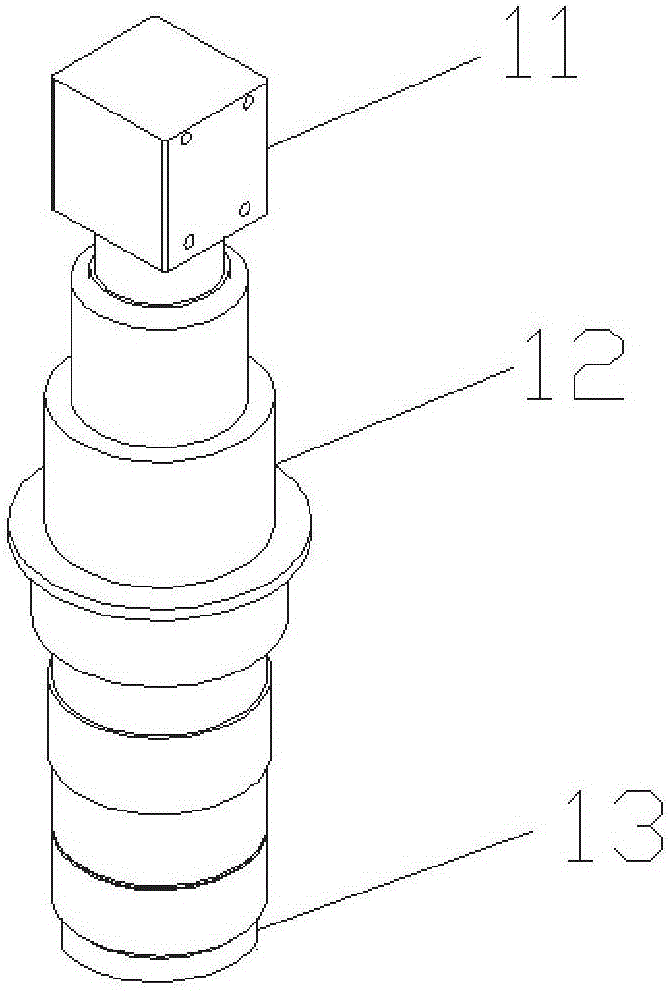

Light-curing three-dimensional printer based on digital light processing (DLP) projection

The invention discloses a light-curing three-dimensional printer based on digital light processing (DLP) projection, which comprises a computer system (2), an automatic control system, a DLP projection system (1), a molding work pool (3), a feeding system (4) and a lifting system. Compared with the three-dimensional printer in the prior art, the light-curing three-dimensional printer has the advantages of high molding speed and high printing precision, and the surface of a molded product is continuous and is not layered; moreover, the DLP projection-based light-curing three-dimensional printer can be applied to performing light curing on light-sensitive materials with various strengths and made from different raw materials.

Owner:王健犀

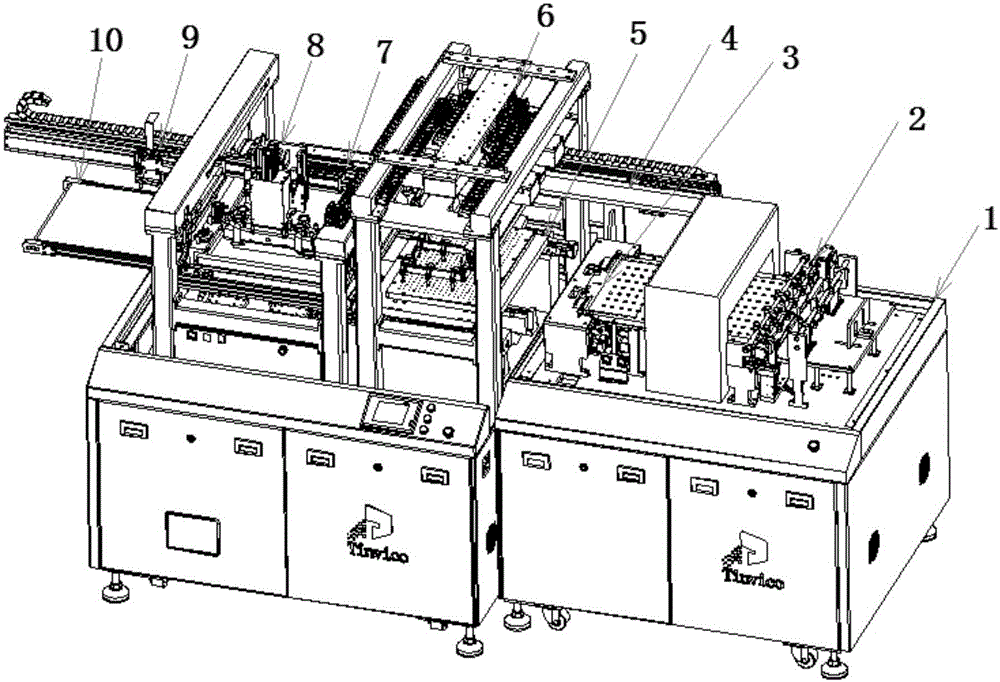

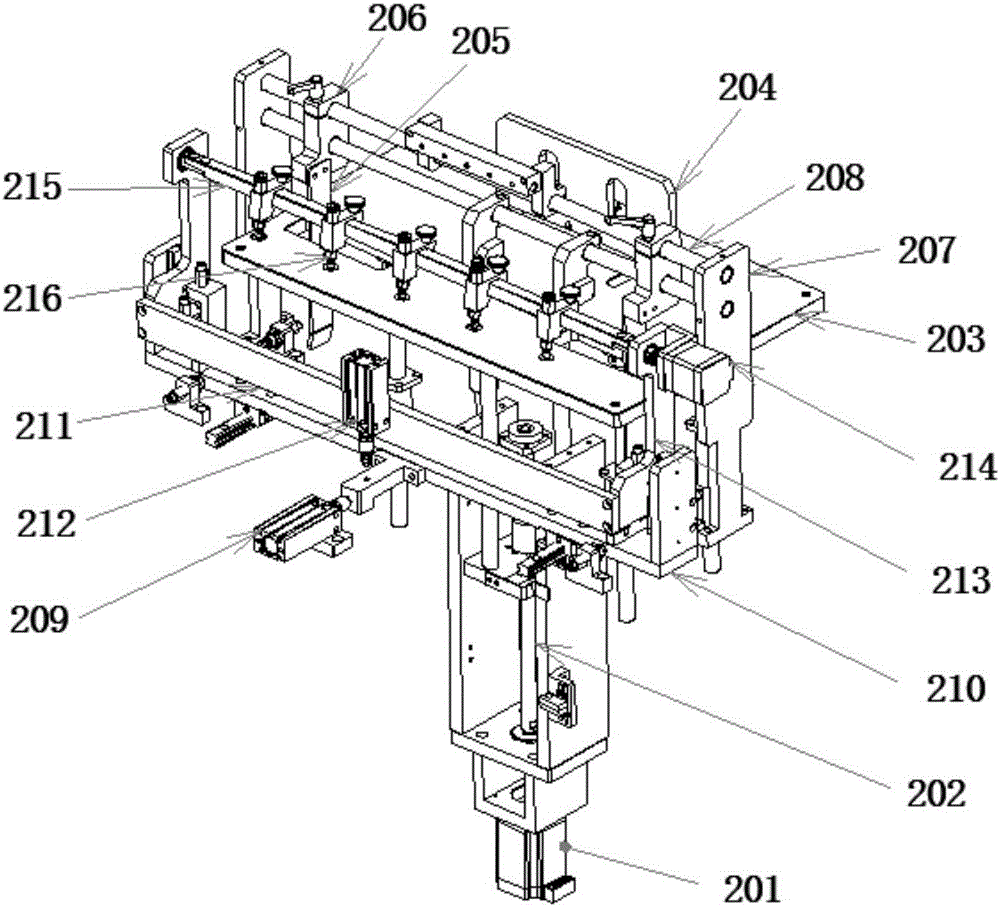

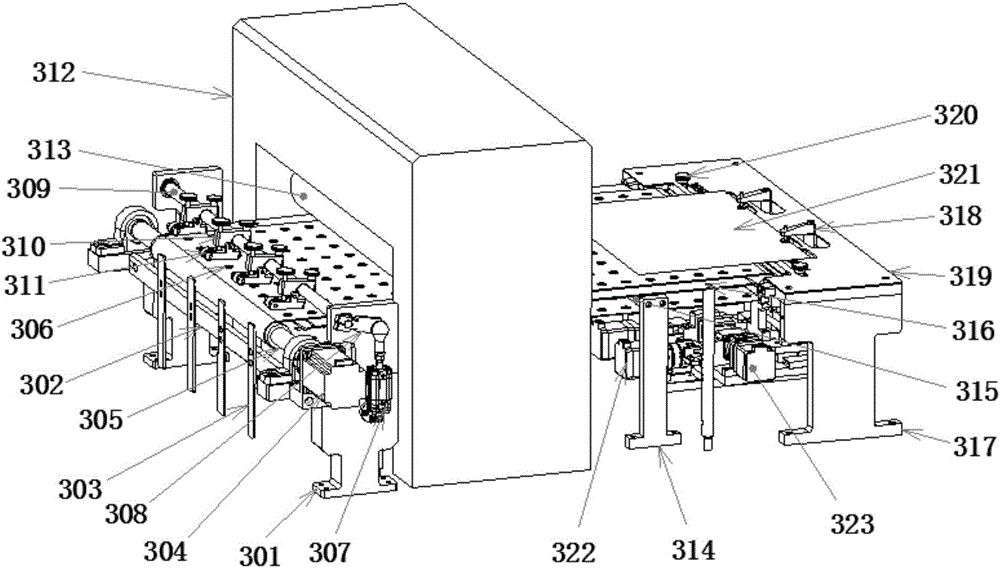

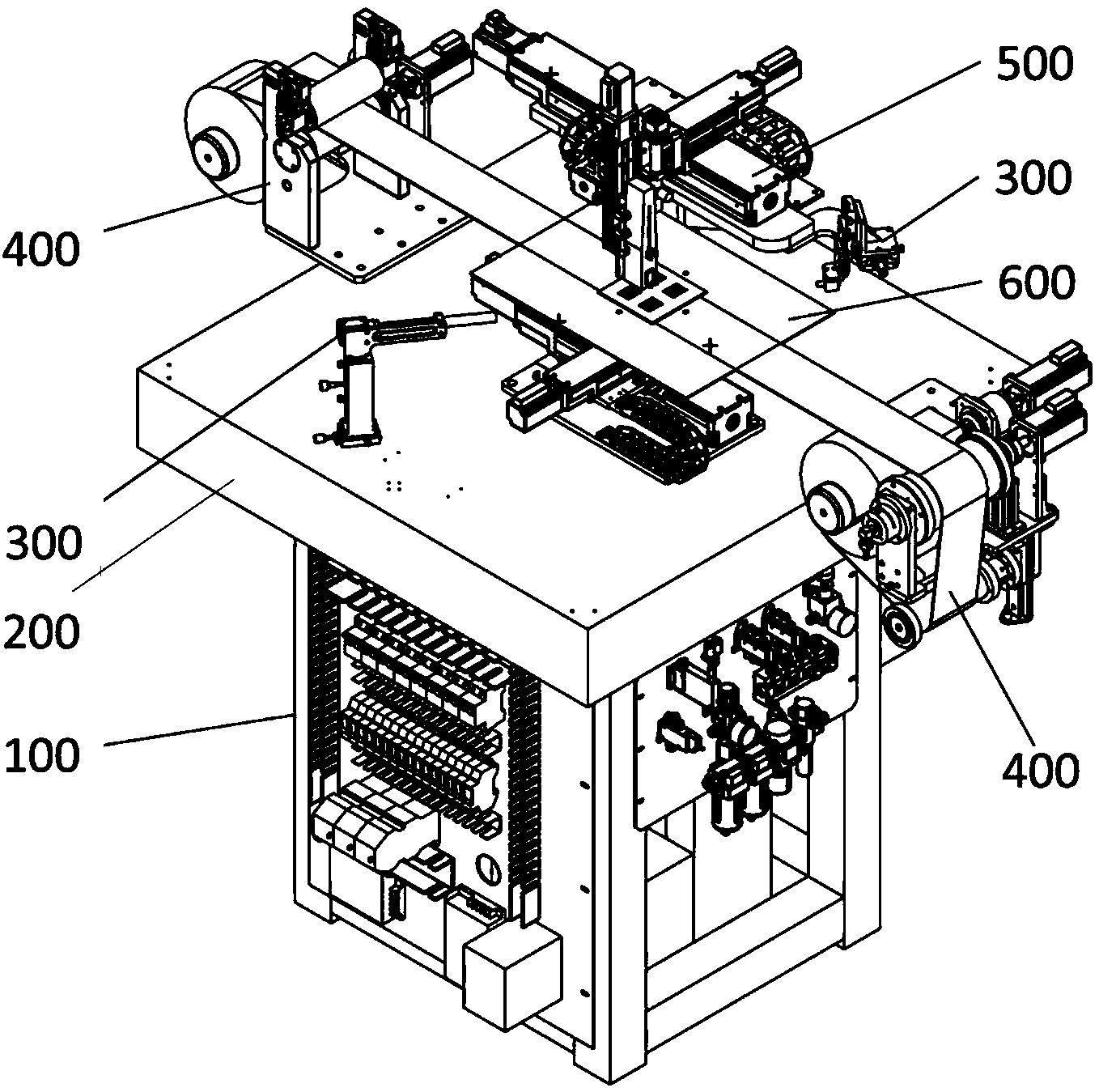

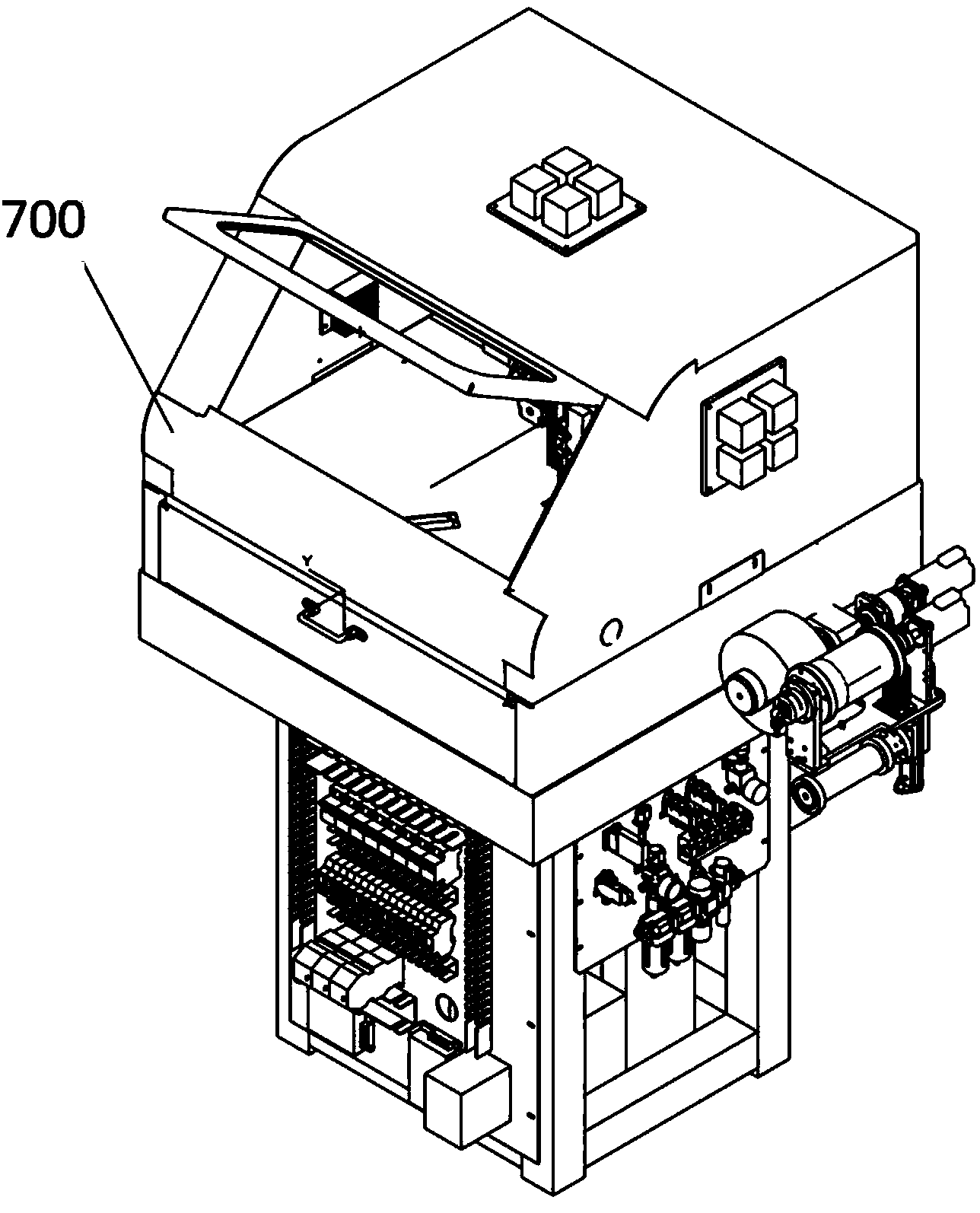

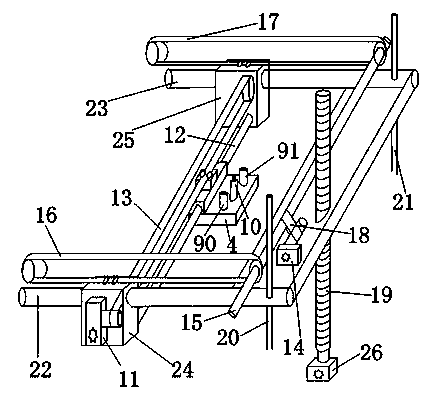

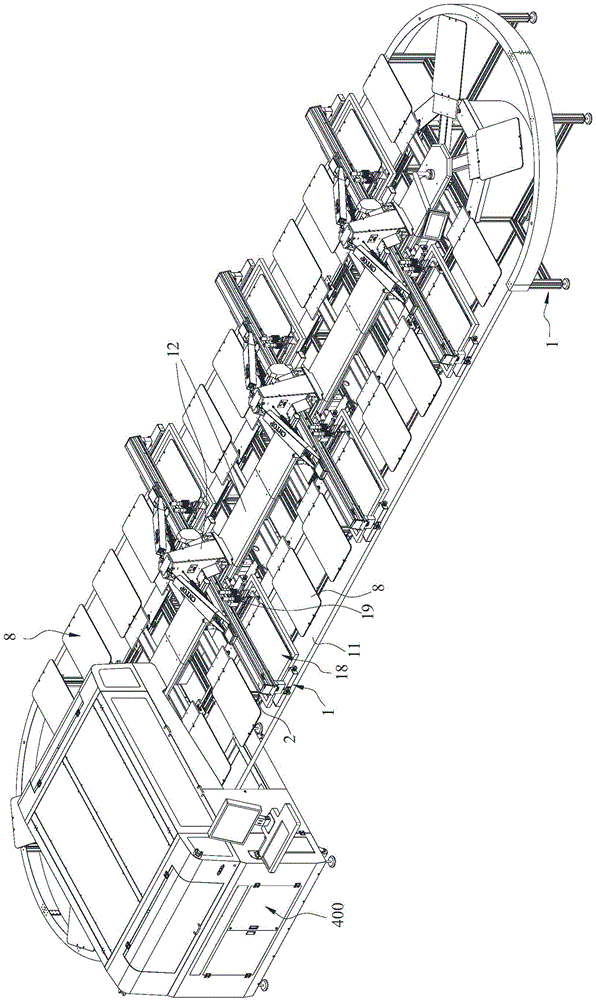

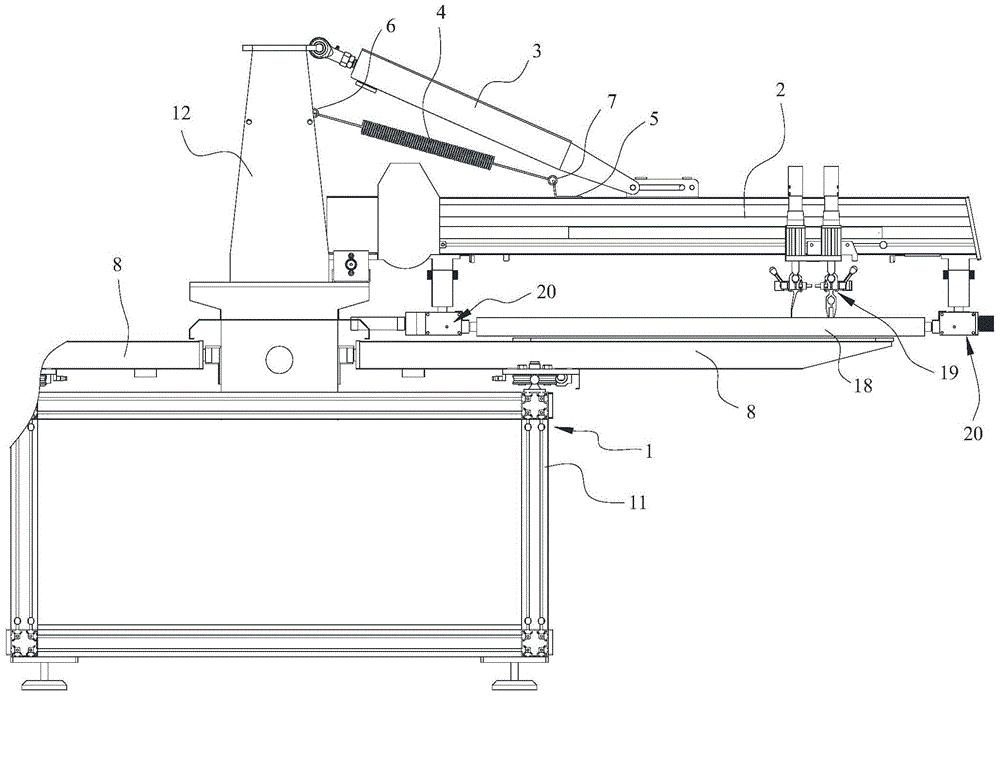

Full-automatic high-precision double-printing-platform screen printing machine

InactiveCN106671579ASolve the problem of manual loading and unloadingReasonable layoutScreen printersConveyor partsEngineeringPrinting press

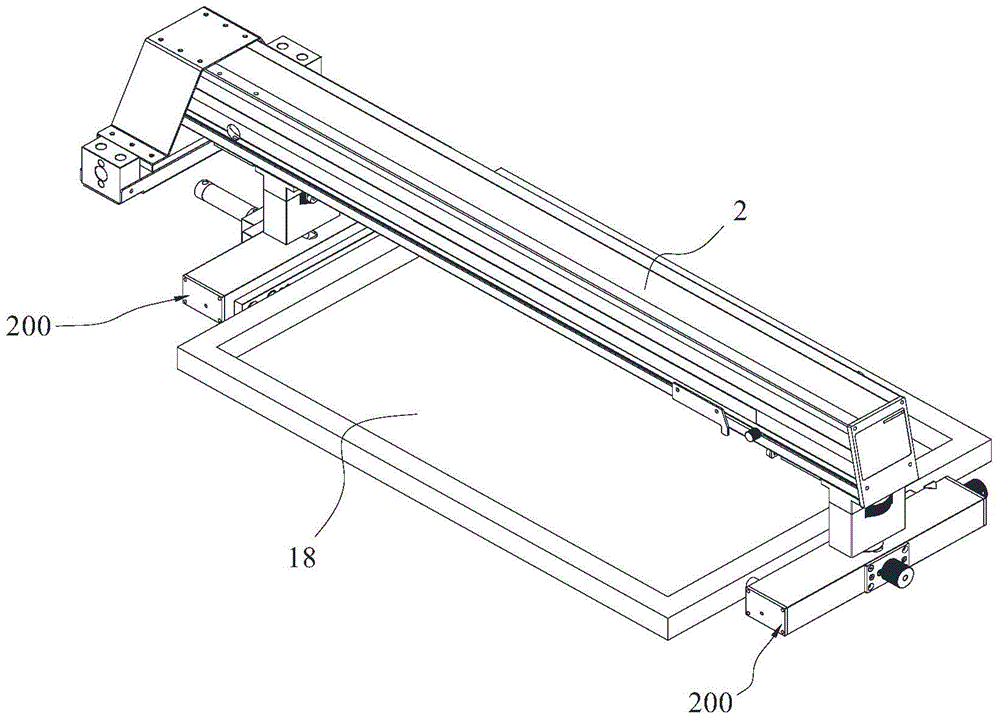

The invention discloses a full-automatic high-precision double-printing-platform screen printing machine. The full-automatic high-precision double-printing-platform screen printing machine comprises a machine frame, material conveying mechanism, a screen printing plate mounting and alignment mechanism and a screen printing mechanism and further comprises a double-printing-platform transfer assembly located on the machine frame, wherein the material conveying mechanism is located on the machine frame; the double-printing-platform transfer assembly comprises a positioning position, a printing position, a lifting printing platform and a printing platform, the lifting printing platform and the printing platform are located in the positioning position or the printing position alternately and switched between the positioning position or the printing position; the material conveying mechanism is used for conveying to-be-printed materials to the positioning position; and the screen printing plate mounting and alignment mechanism and the screen printing mechanism are arranged above the printing position for printing the to-be-printed materials located in the printing position. By means of the full-automatic high-precision double-printing-platform screen printing machine, while one to-be-printed material is printed, another to-be-printed material is automatically fed onto the printing platform and photographed and positioned, and the technical problems that most of existing full-automatic flexible-plate screen printing machine adopts single-platform linear material conveying, and consequently the system efficiency is low are solved.

Owner:SHENZHEN TINVICO TECH CO LTD

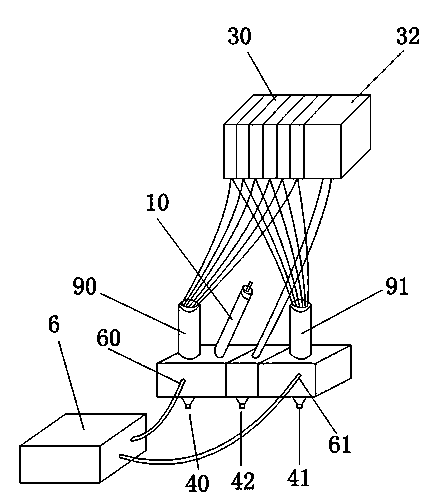

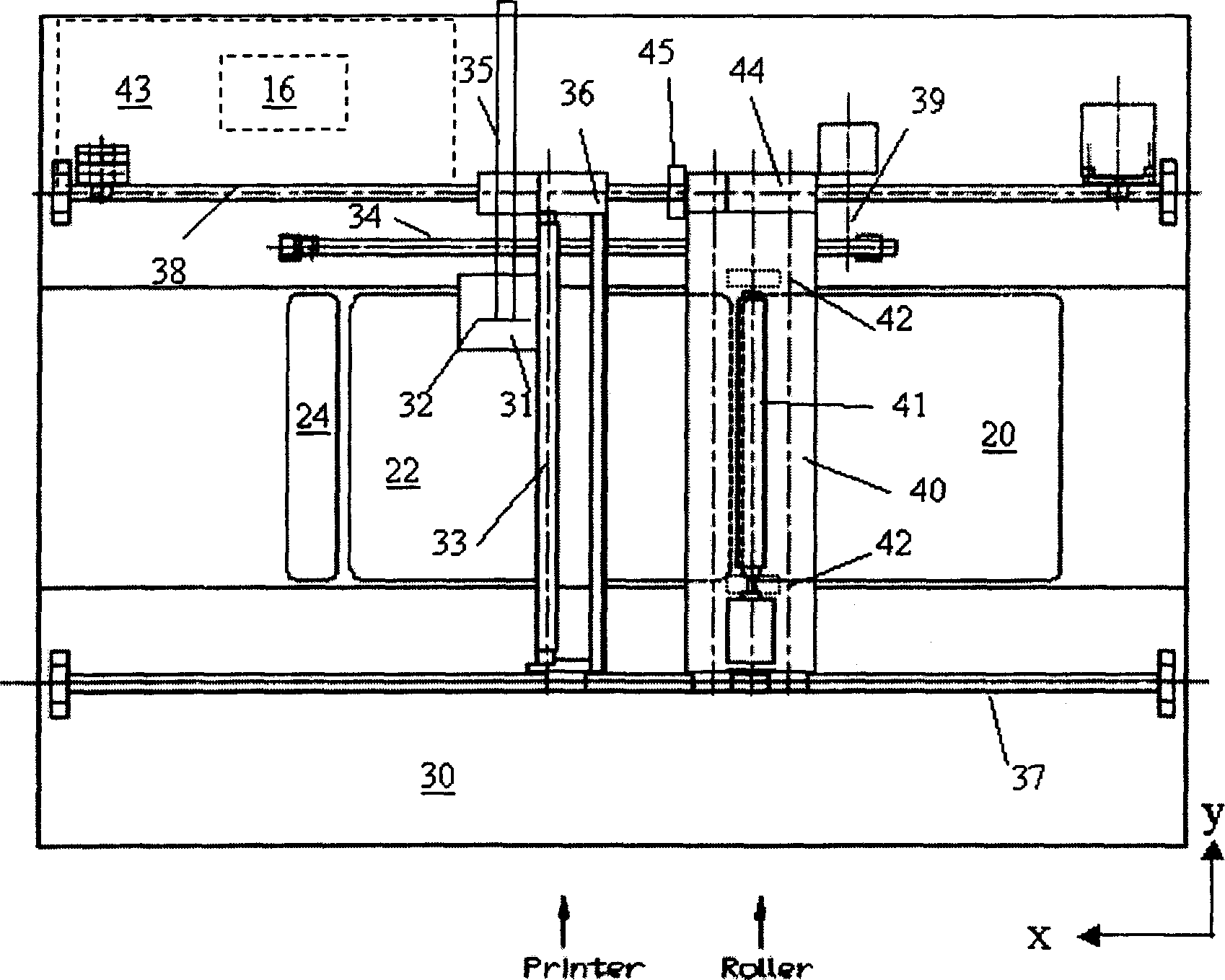

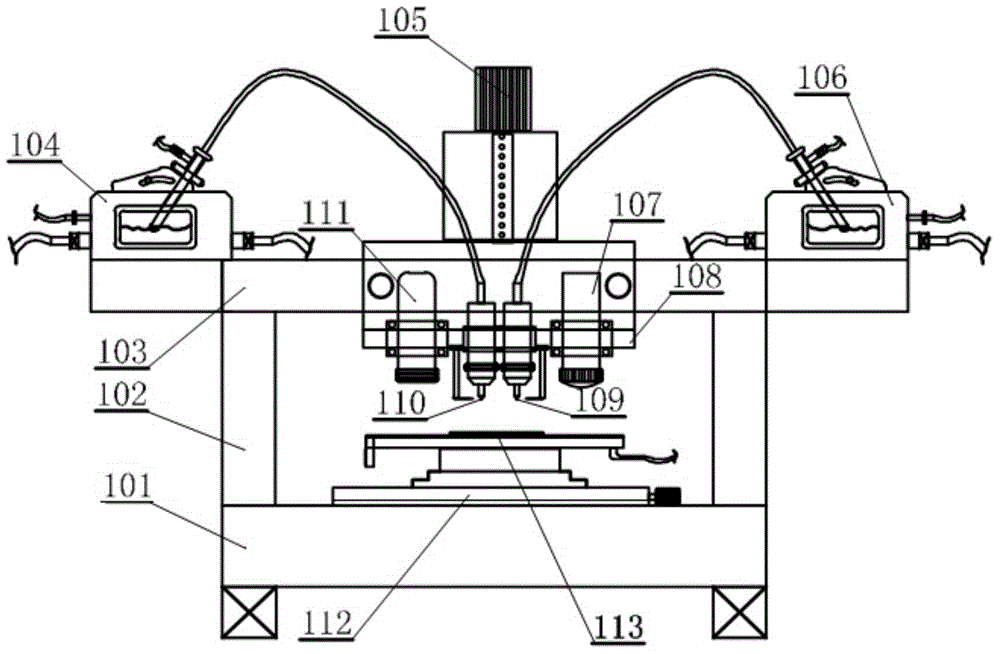

System and method for multifunctional electric fluid ink-jet printing

ActiveCN103895345ADiameter has little effectSimple structureTypewritersPower drive mechanismsMicro environmentControl unit

The invention discloses a system and method for multifunctional high-resolution electric fluid ink-jet printing. The system comprises a control unit, a hard substrate bearing and moving module, a jet printing module, a roll-to-roll thin film substrate conveying module, a jet visual inspection module and a micro-environment control unit defined by a shell box body, wherein the temperature and the humidity of the micro-environment control unit are adjustable. The jet printing module comprises a movement platform controlling a nozzle to move and the nozzle, adjustment and control in three jet printing modes are achieved, and meanwhile a visual system used for observation of patterns on a substrate is arranged. The hard substrate bearing and moving module is used for bearing and fixing a hard printing medium substrate and enabling the substrate to move relative to the nozzle. The roll-to-roll thin film substrate conveying module is used for feeding and adsorbing a flexible substrate and guaranteeing that the surface of the flexible substrate is smooth and the flexible substrate is free of sliding in movement. The jet visual inspection module is used for inspecting a space flight track of a drop. A temperature and humidity control module is used for controlling the temperature and the humidity inside a printing cavity and guaranteeing the printing stability.

Owner:WUHAN GUOCHUANGKE OPTOELECTRONIC EQUIP CO LTD

Three-dimensional color printing device and method

ActiveCN105500700AImprove printing accuracyFast molding speedAdditive manufacturing apparatusAutomatic controlControl system

The invention discloses a three-dimensional color printing device and method. The three-dimensional color printing device comprises a print area, a feeding system, a nozzle group, a moving mechanism and an automatic control system, wherein the print area is provided with a forming plate and a forming work pool, and the forming plate is provided with a lifting mechanism which is used for drawing a workpiece curing layer; the feeding system comprises a support material feeding box and a solid material feeding box and is used for supplying print raw materials for the nozzle group; the nozzle group comprises at least one solid material nozzle and a support material nozzle, the solid material nozzle is connected with the solid material feeding box of the feeding system through a premixer, and the support material nozzle is connected with the support material feeding box of the feeding system; andthe moving mechanism is provided with motors and guide posts / rods on the X-axis direction, the Y-axis direction and the Z-axis direction and is used for driving the nozzle group for performing mobile printing on the three-dimensional direction. The three-dimensional color printing device has the characteristics of being high in print accuracy and smooth and clean in surface of formed products and can realize color printing and printing of different photosensitive materials.

Owner:QINGDAO ACADEMY OF INTELLIGENT IND

Fast shaping device for making body from image of computer and with printing machine

InactiveCN1911635AImprove stabilityImprove printing accuracyCoatingsPrintingEngineeringRapid prototyping

The present invention is one fast forming apparatus, in which the virtual image stored in the memory of computer is tomographically treated and the tomographical treatment obtained contours are jet printed one layer by one layer with fluid onto the powder in the constituting platform for combining with powder so as to form stereo real object. The fast forming apparatus includes the jet printing mechanism and firmware interfaces of a printer or a plotter, one work platform with tomographically operating software and jet printing control firmware, and one computer with memory with stored virtual image.

Owner:赖维祥 +1

Liquid metal printing device

ActiveCN105855540ARealize spatial 3D printingReduce surface tensionAdditive manufacturing apparatusVoltage pulseLiquid state

The invention discloses a liquid metal printing device. The device comprises a liquid metal printing mechanism, a substrate movement mechanism connected with the liquid metal printing mechanism, a voltage pulse regulating and controlling mechanism connected with the liquid metal printing mechanism and the substrate movement mechanism, and a control device connected with the liquid metal printing mechanism, the substrate movement mechanism and the voltage pulse regulating and controlling mechanism. The liquid metal printing device is used for liquid metal ink which is low in viscosity and high in surface tension, and not only are the printing precision of liquid metal patterns and wettability between liquid metal and a base improved, but also plane printing and space 3D printing can be achieved.

Owner:BEIJING DREAM INK TECH CO LTD

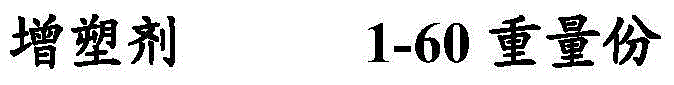

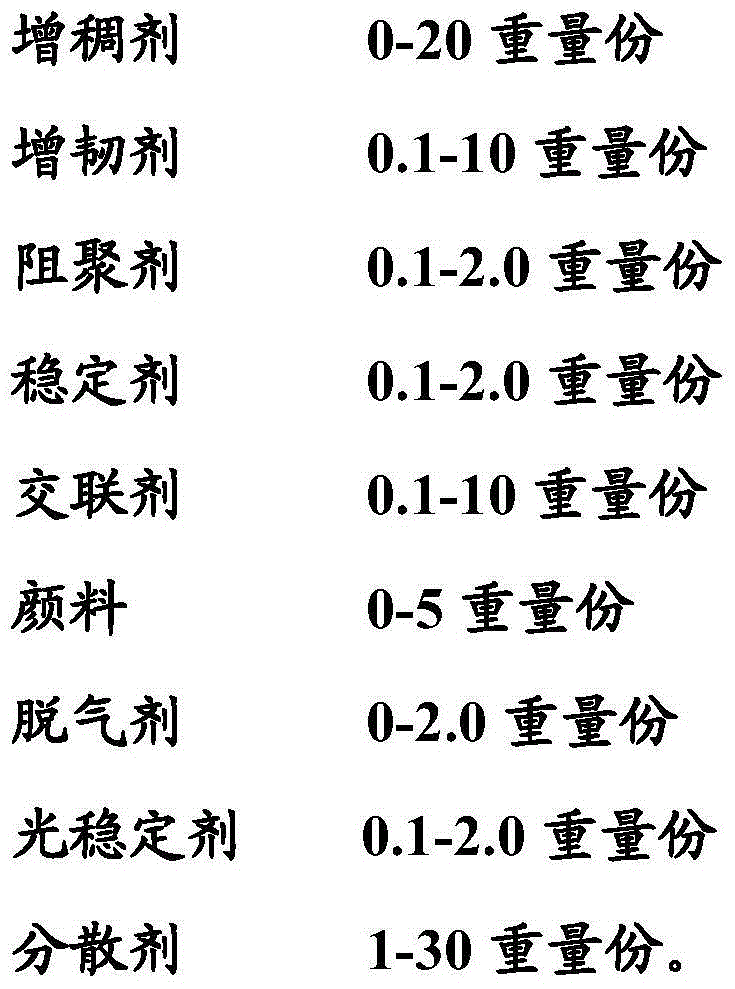

3D printing composition, preparation and application methods and product thereof

The invention discloses a 3D printing composition, its preparation and application methods and a product thereof. According to the material, cyanoacrylate and a powder material are used as main bodies; a solvent is added to adjust fluidity of the material; and simultaneously, certain amounts of a plasticizer, a thickener, a flexibilizer, a stabilizer, a cross-linking agent, a pigment, a degassing agent and the like are contained to raise stability of the material and mechanical property of a printing product. As the material is a liquid and solidification process of the material is controlled by controlling conditions such as environment humidity, temperature and the like during printing, an ink-jet printing head which has been developed comparatively mature at present can be used for printing. The composition provided by the invention has characteristics of high printing precision, fast forming speed and low cost. Meanwhile, a printing product has high mechanical strength. The composition is a novel green 3D printing material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

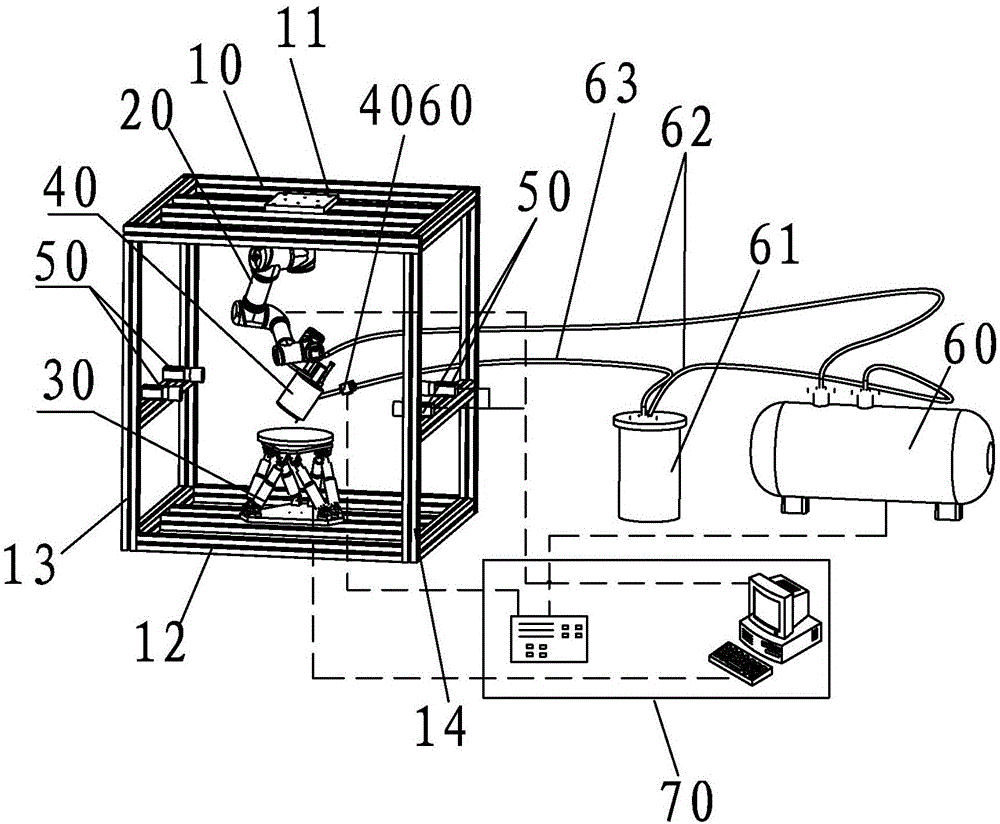

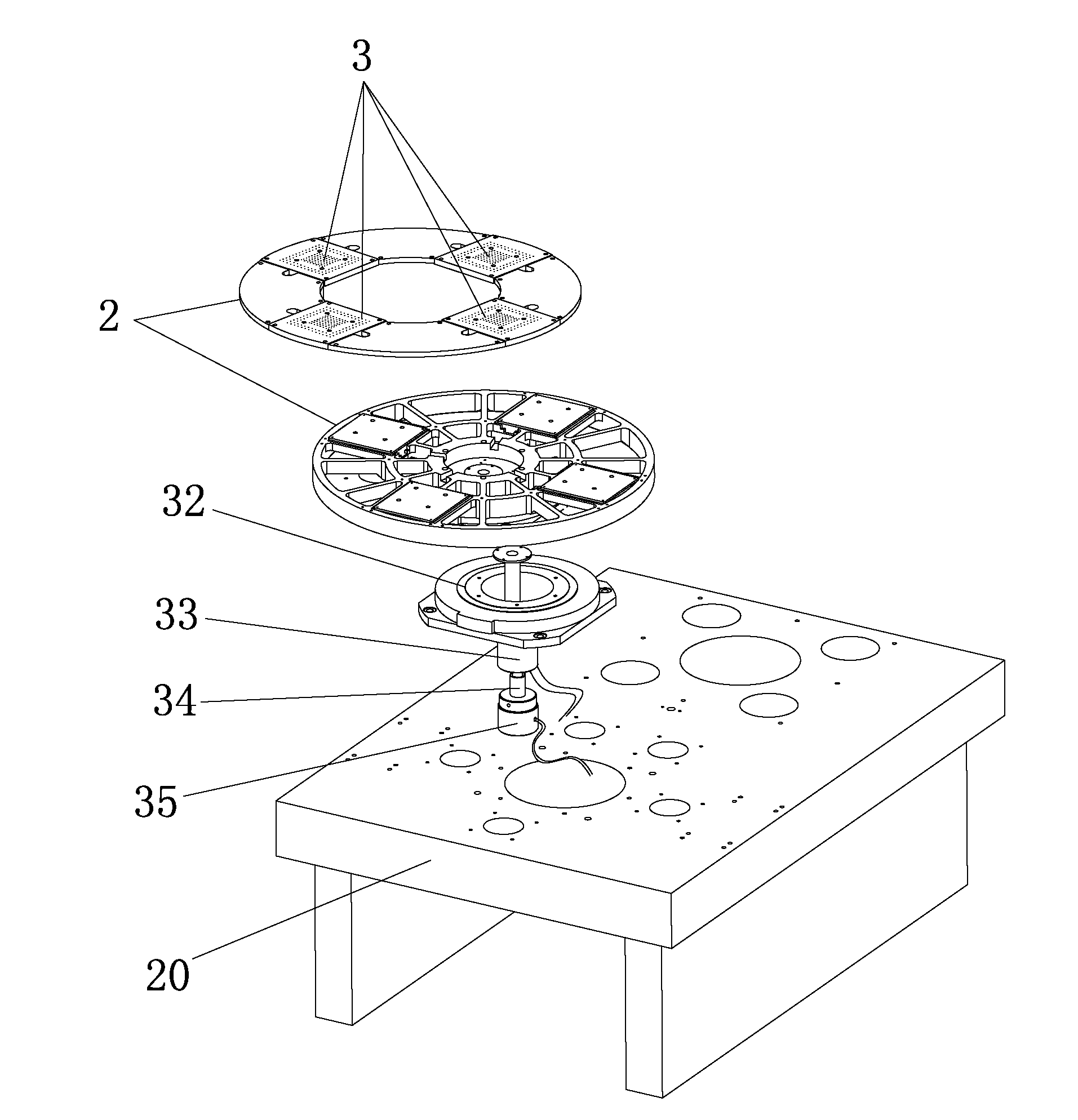

3D printing system based on multi-axis linkage control and machine vision measurement

ActiveCN106264796ARealize 3D patterned printingSimple structureManufacturing driving meansBone implantMachine visionControl system

The invention relates to a 3D printing system based on multi-axis linkage control and machine vision measurement. The 3D printing system comprises a rack, a workbench for placing an artificial bone scaffold, a printing device arranged above the workbench, a material conveying device for conveying a printing material, an image collection camera, a drive mechanism for adjusting the direction of the printing device and a control system, wherein the printing device, the material conveying device, the image collection device and the drive mechanism are all connected with the control system; the workbench is a six-degree-of-freedom parallel platform connected with the rack; the drive mechanism is a six-axis mechanical arm; and the printing device is connected with the six-axis mechanical arm. When in use, the artificial bone scaffold is put on the six-degree-of-freedom parallel platform, and the position of the printing device is controlled by the six-axis mechanical arm; and through the cooperation between the six-degree-of-freedom parallel platform and the six-axis mechanical arm, accurate control on the spatial position of a printing nozzle of the printing device is realized, and three-dimensional pattern printing is realized on a complicated tiny artificial bone surface and the internal surface of a porous structure.

Owner:QUANZHOU INST OF EQUIP MFG

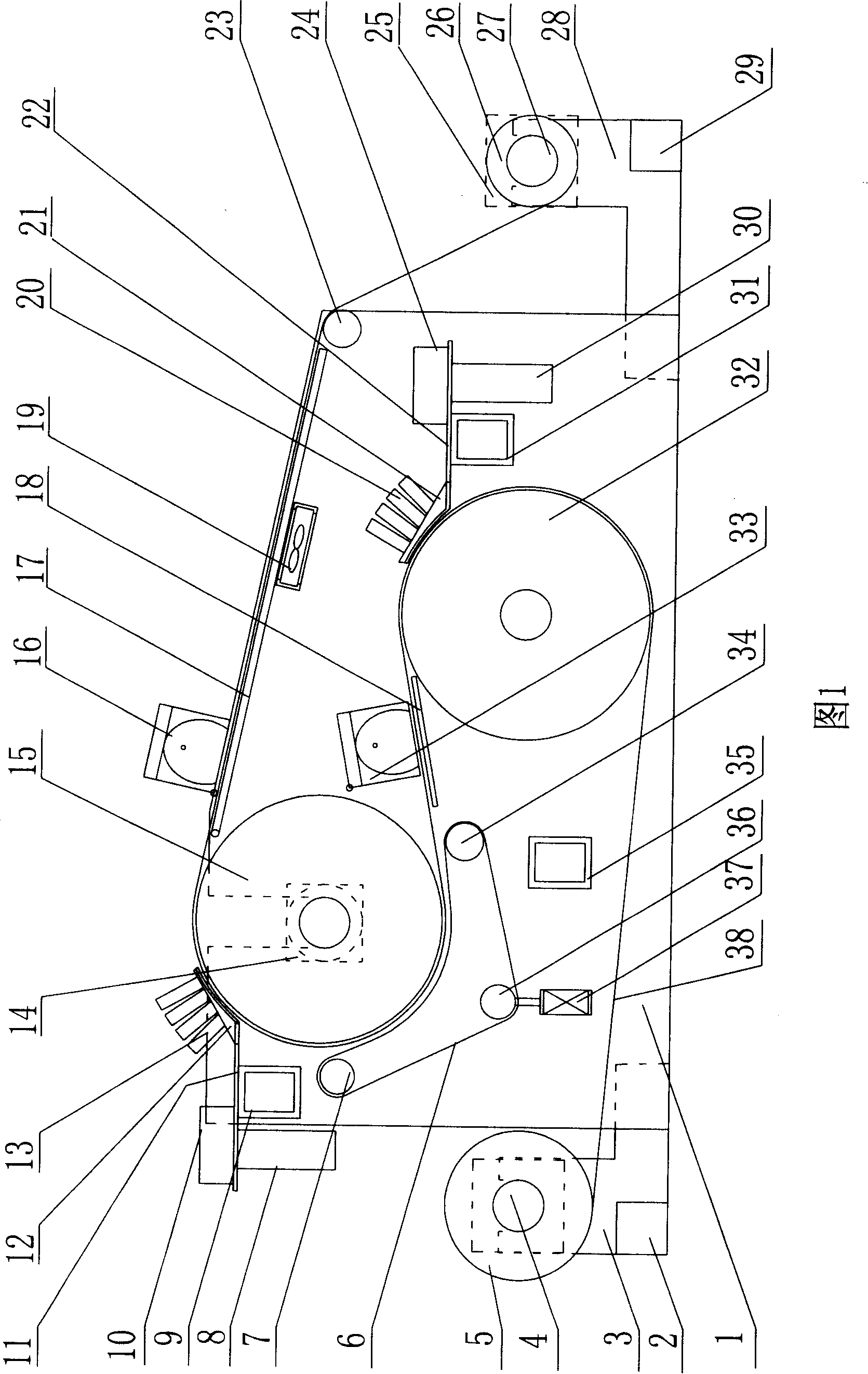

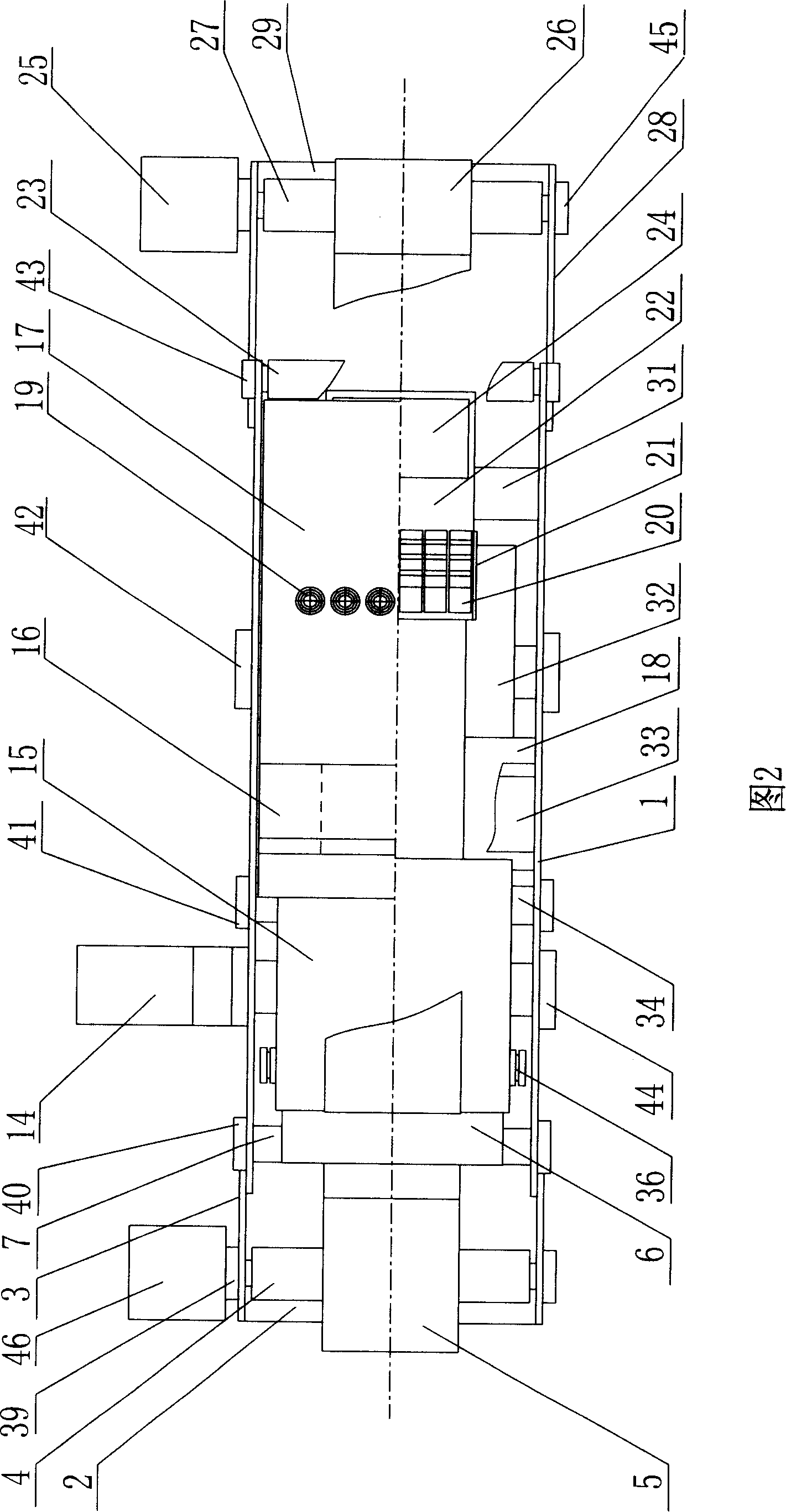

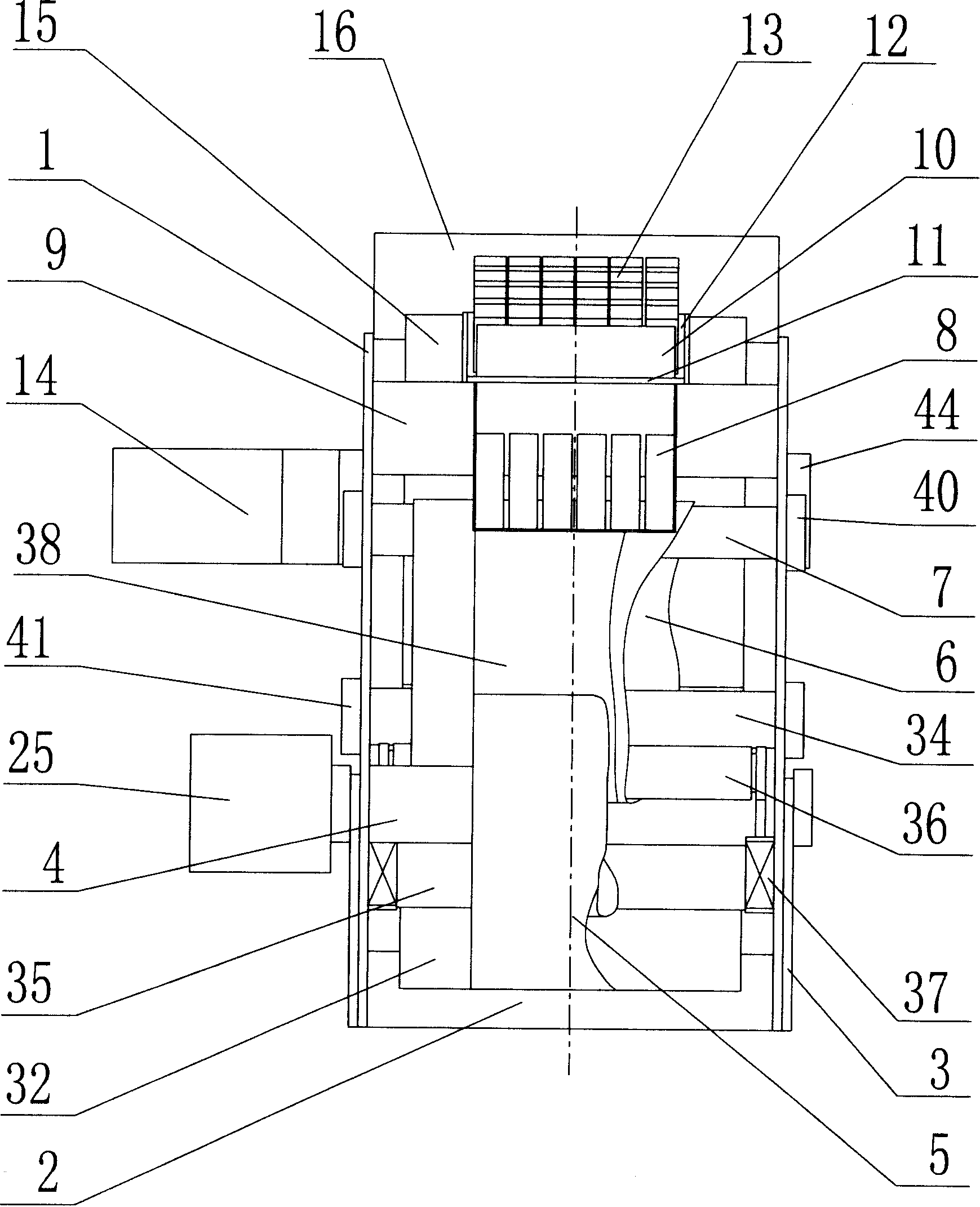

Photovoltaic solar printer

ActiveCN101961947APrecise positioningImprove printing effectFinal product manufactureScreen printersPhotovoltaic solar energyEngineering

The invention relates to the technical field of photovoltaic equipment, in particular to a photovoltaic solar silicon chip printer. The photovoltaic solar printer comprises a framework, an industrial control device and an operating disk mechanism, a transport mechanism, a carrier plate mechanism, a vacuum suction plate mechanism, a steel screen seat mechanism, a screen pressing and regulating mechanism, a scraper mechanism and a vision system device, wherein the operating disk mechanism, the transport mechanism, the carrier plate mechanism, the vacuum suction plate mechanism, the steel screen seat mechanism, the screen pressing and regulating mechanism, the scraper mechanism and the vision system device are connected with the industrial control device. The photovoltaic solar silicon chip printer has the advantages of accurate positioning, good printing effect, high printing accuracy and high production efficiency.

Owner:FOLUNGWIN AUTOMATIC EQUIP CO LTD

Synchronous double-side digital printer

InactiveCN101164791AWon't wrinkleImprove printing accuracyTypewritersOther printing apparatusDigital printingDigital ink

The present invention relates to a printing machine. In the concrete, it relates to a printing machine capable of making personalized synchronous double-sided digital ink jet on the flexible rolled materials, such as paper, plastics and fabrics, etc. Said printing machine includes wall boards and feeding device, receiving device and guide device which are mounted on the wall boards, between wall boards, a front face printing drum and a back face printing drum are placed. The spray-printing material on the feeding device can be winded on the back face printing drum by adopting rubbing contact mode, and the back-printing face of back-printed spray-printing material can be winded on the front face printing drum by adopting rubbing contact mode, then the double-face printed spray-printing material can be passed through the described guide device and can be winded on the receiving end of receiving device.

Owner:梁健

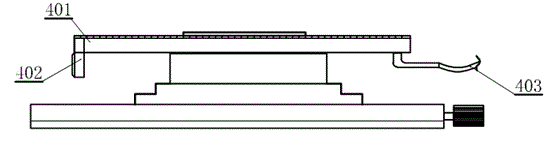

System and method for aligning silk-screen printing

InactiveCN104999776AEasy to install and removeSimple structureScreen printersSemiconductor/solid-state device manufacturingMicro motionPrinting press

The invention relates to the technical field of silk-screen printing equipment, particularly to a system and method for aligning silk-screen printing. A silk screen plate and a lifting table are arranged on a silk-screen printing machine, a fixture is arranged on the silk screen plate, an XYR micro-motion platform is arranged on the lifting table, a vacuum chuck is arranged on the XYR micro-motion platform, the vacuum chuck is used for adsorbing a printing stock, and the printing stock corresponds to a position under the silk screen plate; a first positioning mark is arranged on the silk screen plate, and a second corresponding positioning mark is arranged on the print stock; the fixture is used for regulating the height and the two-dimension plane coordinates, which are relative to those of the silk screen plate, of an imaging and amplifying camera, the XYR micro-motion platform is used for regulating the two-dimension plane coordinates of the print stock and rotating the print stock, the lifting table is used for regulating the height of the printing stock, the first positioning mark on the silk screen plate and the second corresponding positioning mark on the print stock are collected by the imaging and amplifying camera, and the position and the direction of the printing stock are regulated through the XYR micro-motion platform and the lifting table, so that the first positioning mark and the second positioning mark are accurately aligned, and the effect that a blanking region of the printing stock and a pattern on the silk screen plate are accurately aligned is achieved.

Owner:XIAMEN UNIV

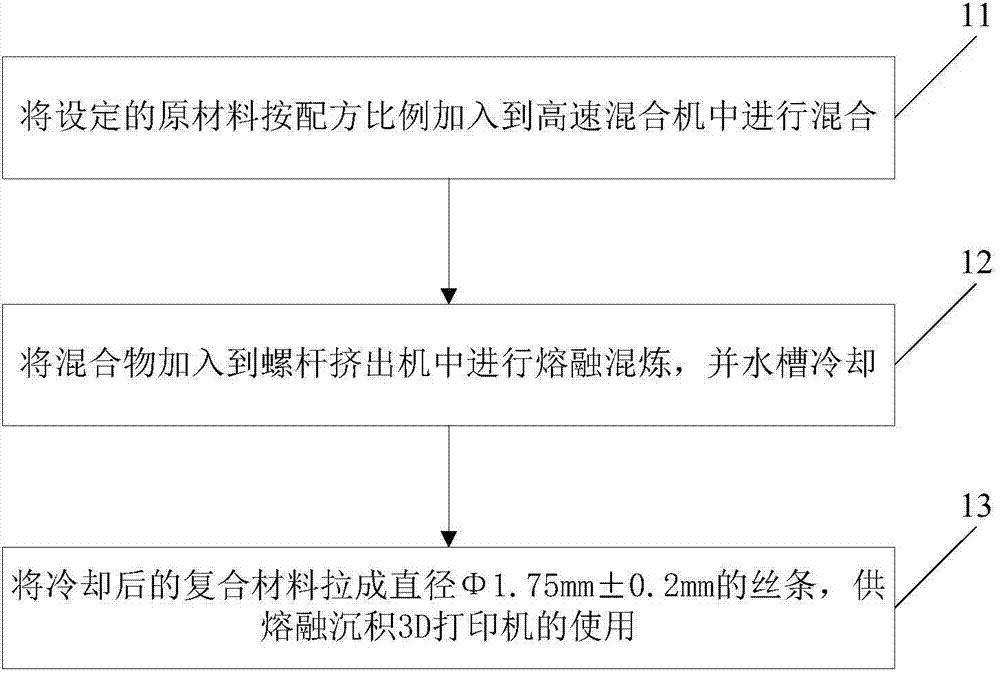

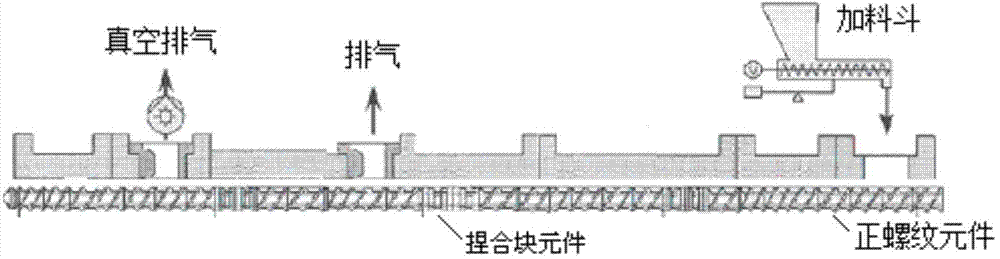

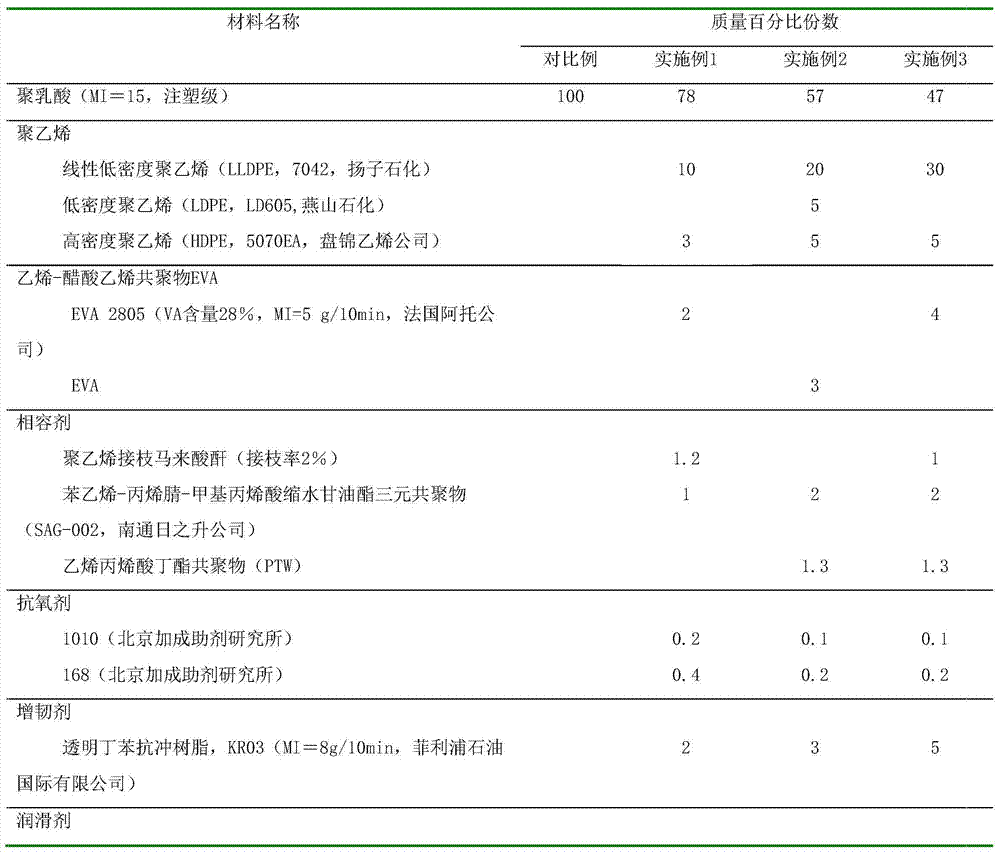

Preparation method of polylactic acid composite material for hot-melt 3D printing

InactiveCN104725802AImprove liquidityRapid crystallinityAdditive manufacturing apparatusPolymer scienceAntioxidant

The invention discloses a preparation method of a polylactic acid composite material for hot-melt 3D printing. The preparation method comprises the following steps: mixing set raw materials in a high-speed mixer according to formula proportions, wherein the raw materials comprise the following components in percentage by mass: 45-75% of polylactic acid, 10-40% of polyethylene, 5-10% of ethylene-vinyl acetate copolymer (EVA), 1-5% of a compatilizer, 0.3-0.6% of an antioxidant, 1-5% of a toughening agent, 0.5-2% of a lubricating agent, 0.1-1% of a nucleating agent and 0.5-2% of a plasticizer; adding the mixture into a screw extruder to perform melting mixing, and cooling in a water tank; and drawing the cooled composite material into slivers with the diameter phi of 1.75+ / 0.2mm. The composite material has high fluidity, fast crystallinity and high toughness, has the characteristics of low shrinkage ratio and high printing accuracy, and is suitable for rapid prototyping of melt deposition 3D printing.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

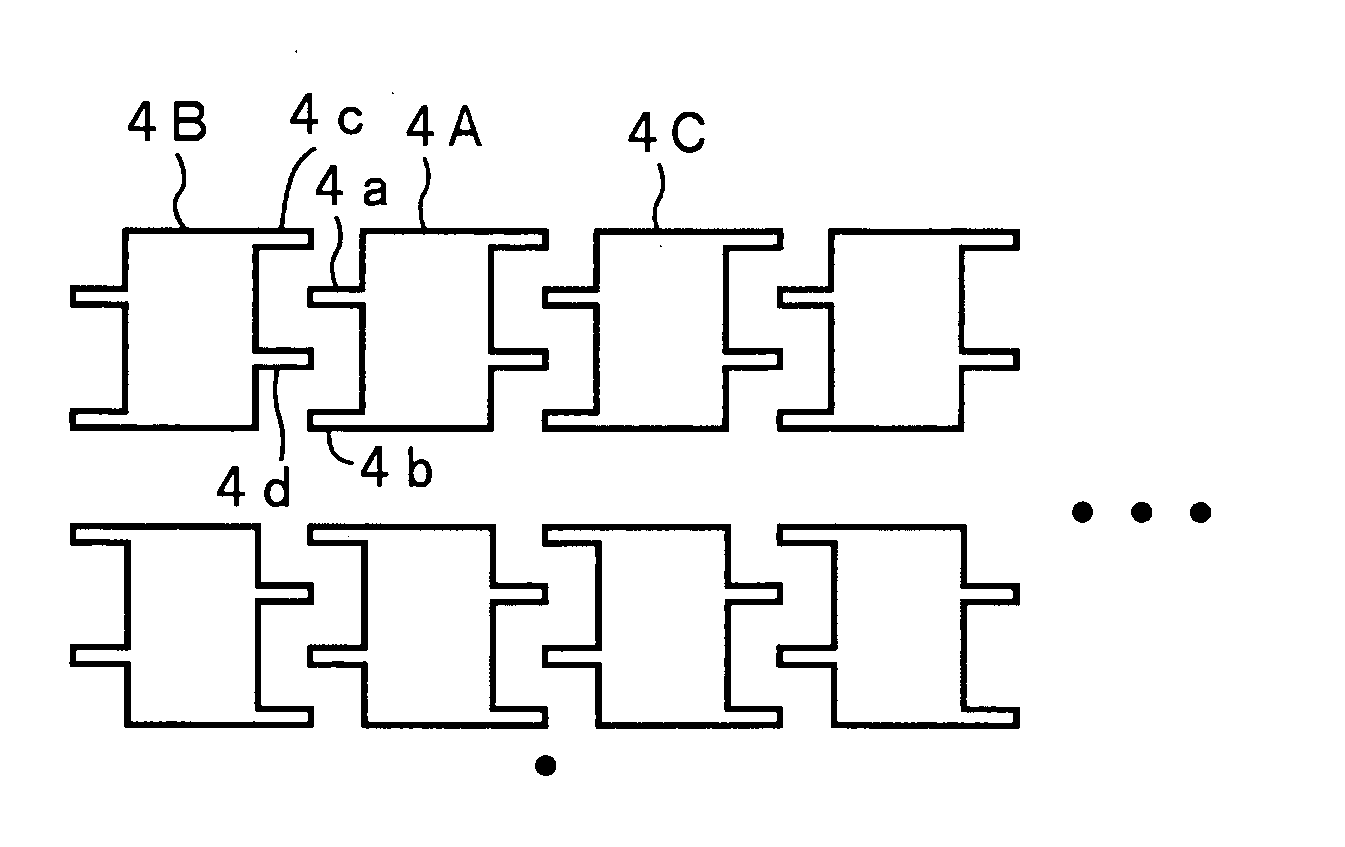

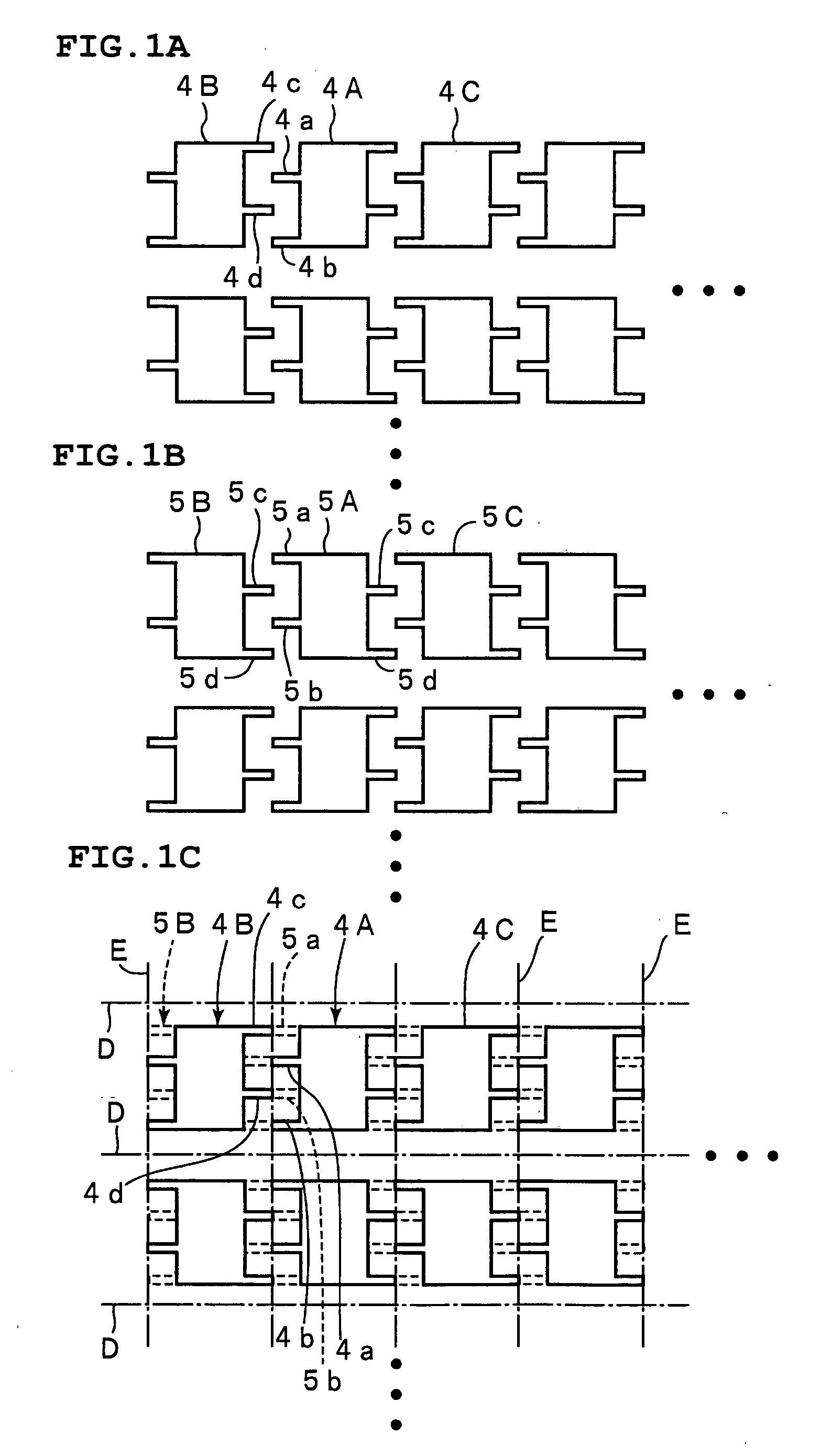

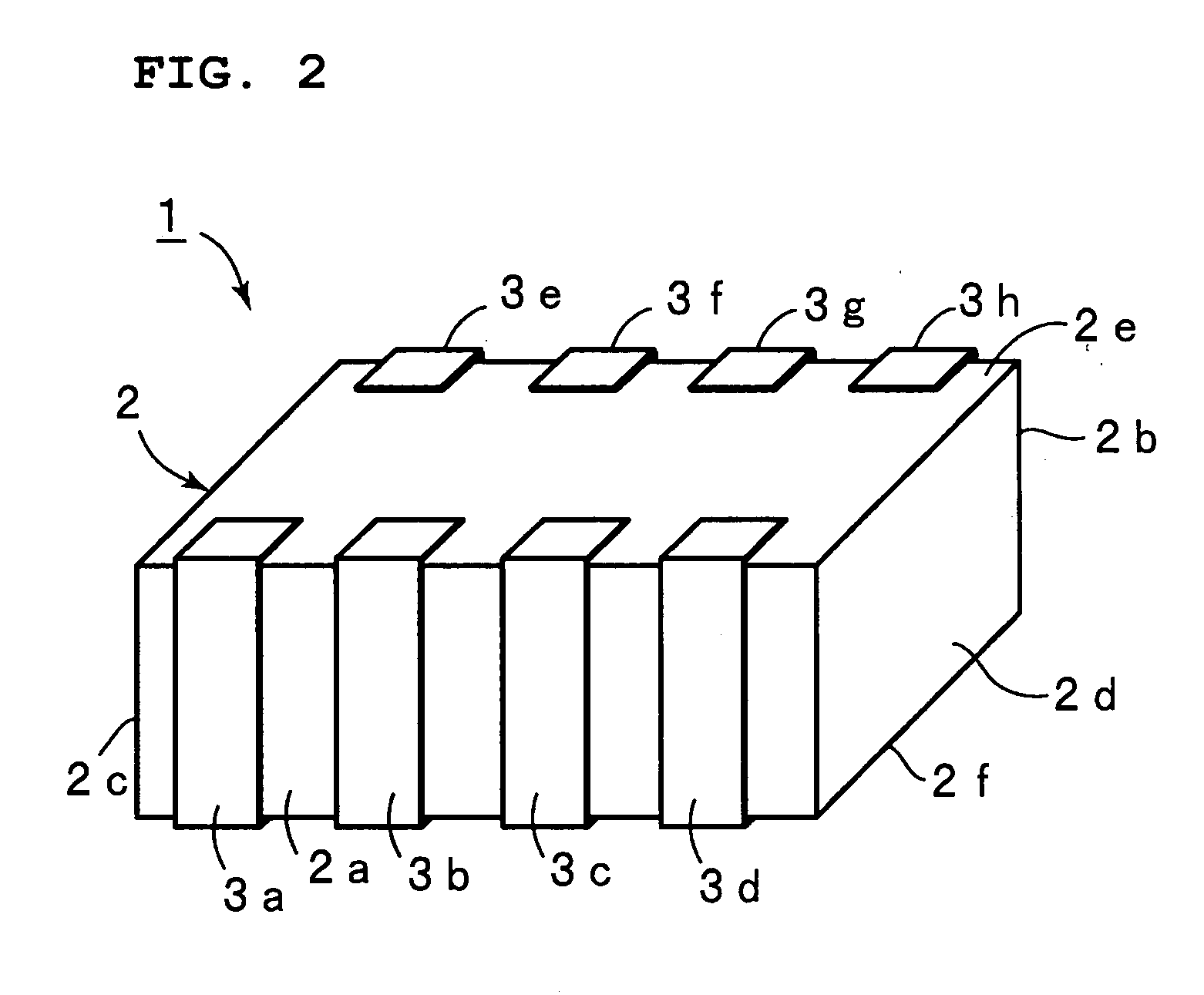

Method of producing multi-terminal type laminated ceramic electronic component

ActiveUS20050067086A1Improve accuracyImprove printing accuracyMultiple fixed capacitorsFixed capacitor dielectricElectronic componentMaterials science

In a method of producing a multi-terminal type laminated ceramic electronic component in which internal electrodes are embedded in a sintered ceramic member, and the internal electrodes have plural first lead-out electrodes led out to a first side surface and plural second lead-out electrodes led out to a second side surface, the plural second lead-out electrodes of one of the adjacent internal electrodes in each internal electrode pattern are not continuous with the plural first lead-out electrodes of the other of the adjacent internal electrodes, and the plural second lead-out electrodes and the plural first lead-out electrodes are alternately arranged in a direction that is substantially perpendicular to the direction of a line connecting the first and second side surfaces.

Owner:MURATA MFG CO LTD

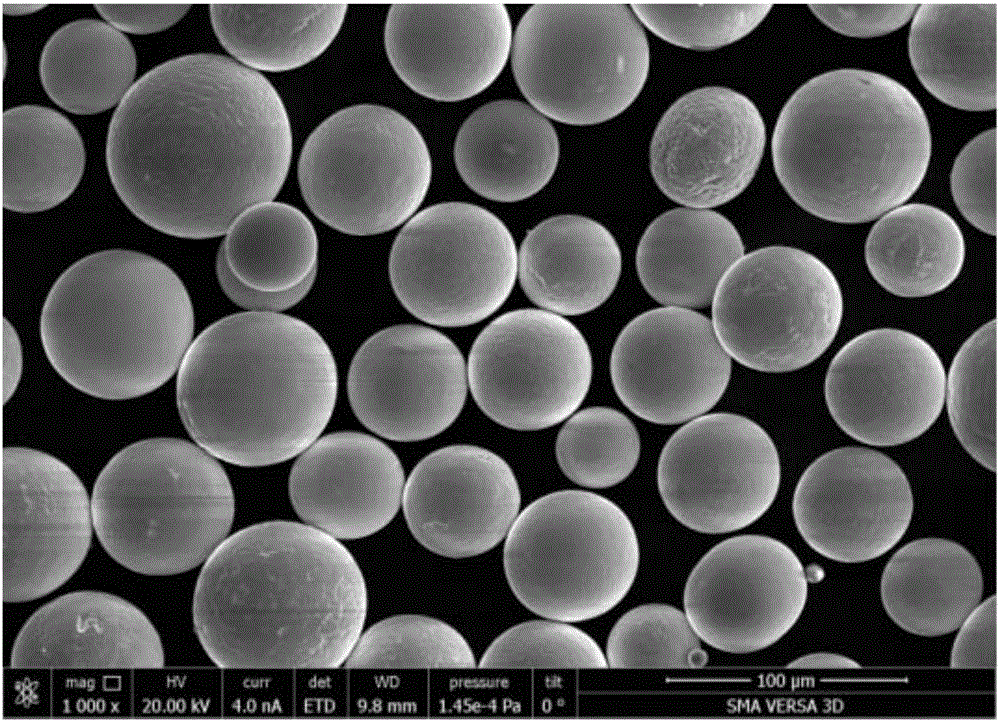

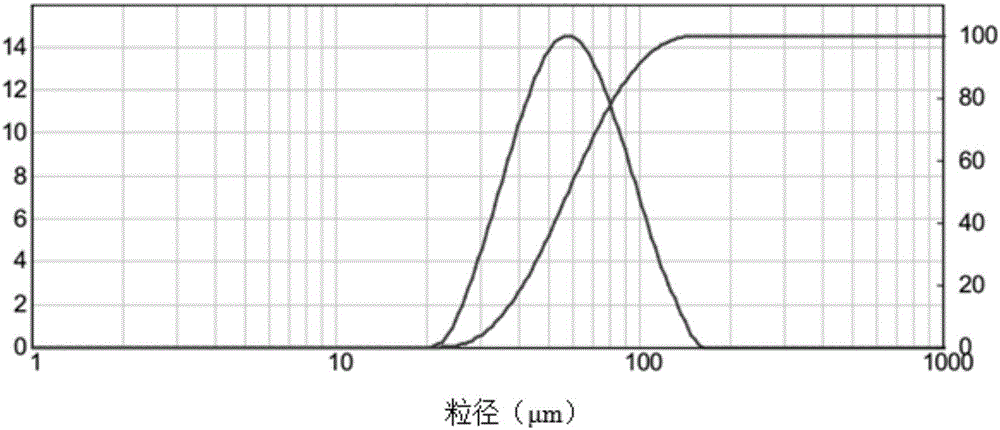

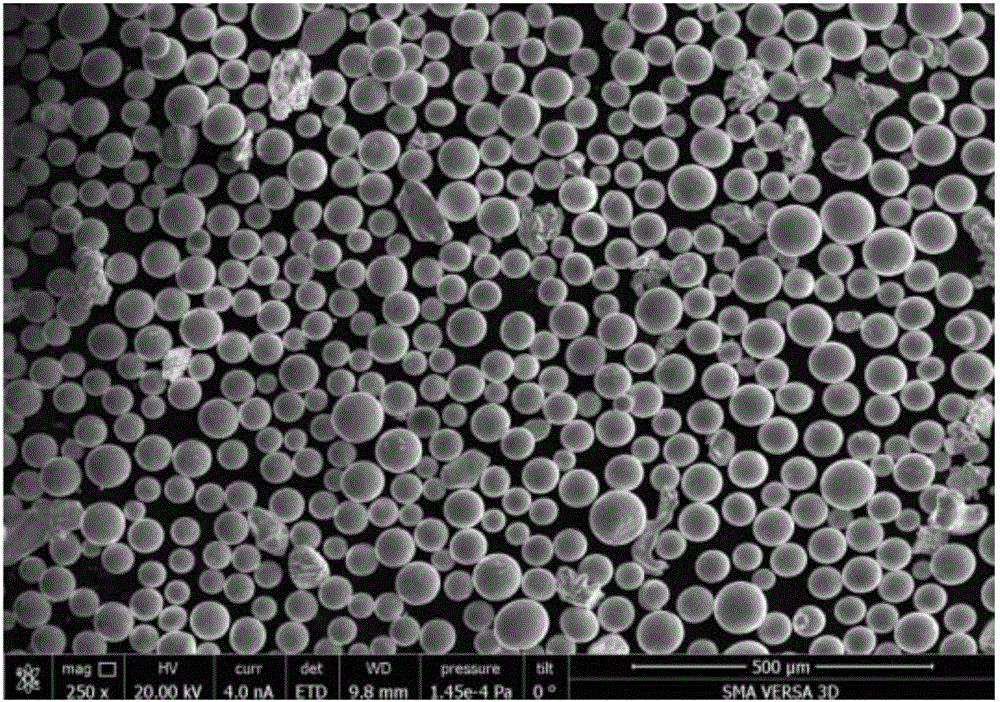

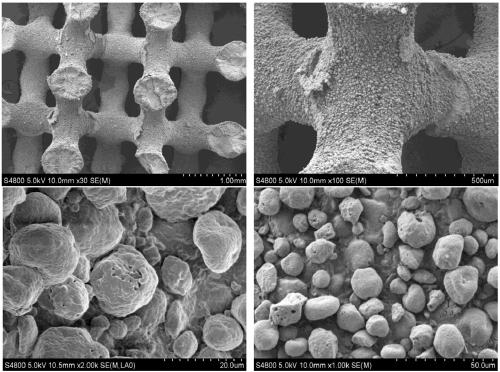

Preparation method of spherical titanium-alloy powder for 3D printing

InactiveCN106493350AUniform particle sizeImprove liquidityAdditive manufacturing apparatusTransportation and packagingHydrogenMicrometer

The invention provides a preparation method of spherical titanium-alloy powder for 3D printing, relates to a method for manufacturing 3D printing consumables, and aims at solving the technical problems that existing Ti-6Al-4V alloy powder is nonuniform in particle size and irregular in shape, and cannot meet the usage requirement of 3D printing. The method comprises the steps that Ti powder and alloy powder of contained elements are added into a ball mill for ball milling according to components of titanium alloy, and titanium-alloy powder is obtained; and the titanium-alloy powder is screened and conveyed to thermal plasma spheroidizing equipment for plasma spheroidizing in hydrogen-containing gas, and the spherical titanium-alloy powder for 3D printing is obtained. According to the spherical titanium-alloy powder, the particle size is smaller than or equal to 100 micrometers, the spheroidization degree is larger than 95%, and the spherical titanium-alloy powder can be applied to the field of 3D printing manufacturing.

Owner:HEILONGJIANG HEIKE TECH CO LTD

Rapid prototyping SLA 3D printer and printing method thereof

The invention relates to the technical field of 3D printers and printing methods, in particular to a rapid prototyping SLA 3D printer. The rapid prototyping SLA 3D printer comprises an SLA 3D printer body, wherein the SLA 3D printer body comprises a hollow cabinet body and a support which extends upwards along one side surface of the cabinet body, wherein a laser scanning device is arranged at the front end of the bottom surface of the cabinet body, a reflecting mirror is arranged at the center of the bottom surface of the cabinet body, a resin trough is arranged right above the reflecting mirror, the bottom surface of the resin trough is fixedly provided with a piece of high-transparency quartz glass, the high-transparency quartz glass is fixedly arranged on an iron plate, the iron plate is fixedly connected with a motor on the bottom surface of the cabinet body, a lifting platform is arranged right above the resin trough, the support is provided with a vertical slide rail, and the lifting platform can slide up and down along the vertical slide rail. The invention also discloses a printing method of the rapid prototyping SLA 3D printer. Compared with the prior art, the rapid prototyping SLA 3D printer has the advantages that the prototyping speed is high; since a downward-pulling mechanical structure for eliminating the vacuum force is arranged, the rate of finished products is greatly increased, the precision is high, and the printer is particularly suitable for producing a prototype with high precision requirement and a complicated structure; the structure is simple, the operation is convenient, and the production cost is greatly reduced; therefore, the rapid prototyping SLA 3D printer can be widely popularized and used.

Owner:DONGGUAN JINGJIZHE DIGITAL TECH

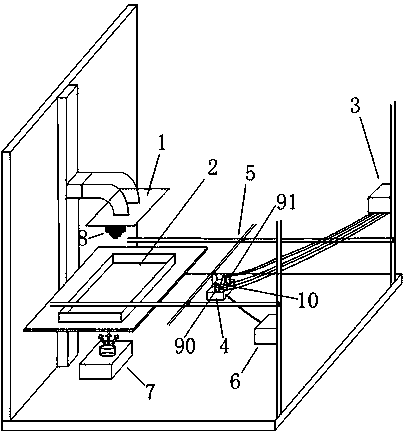

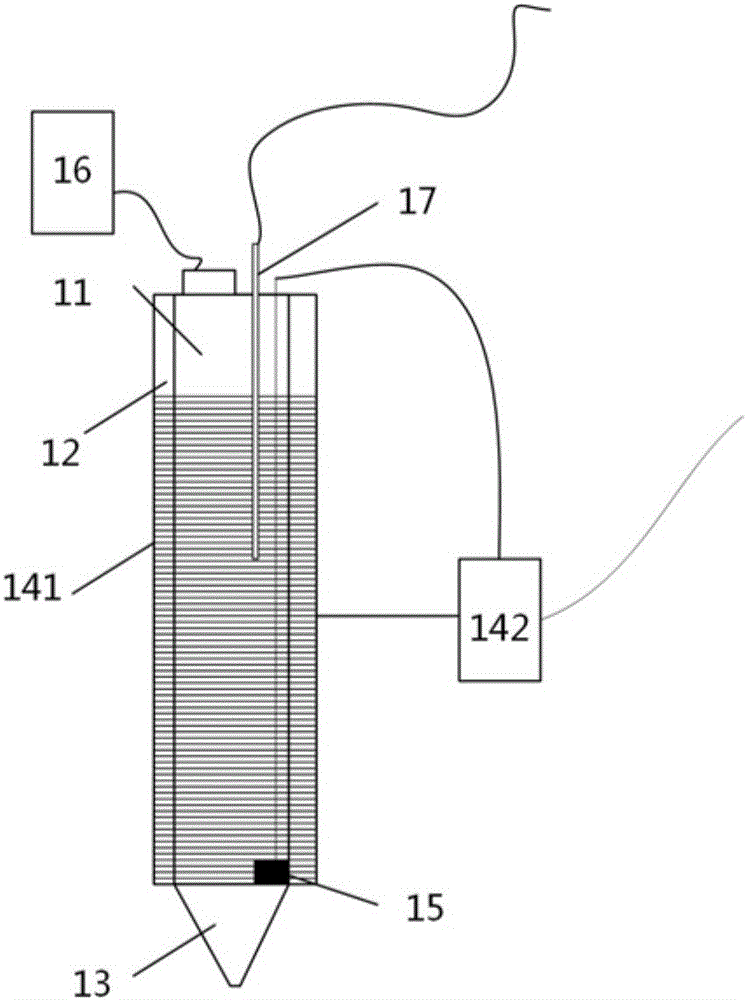

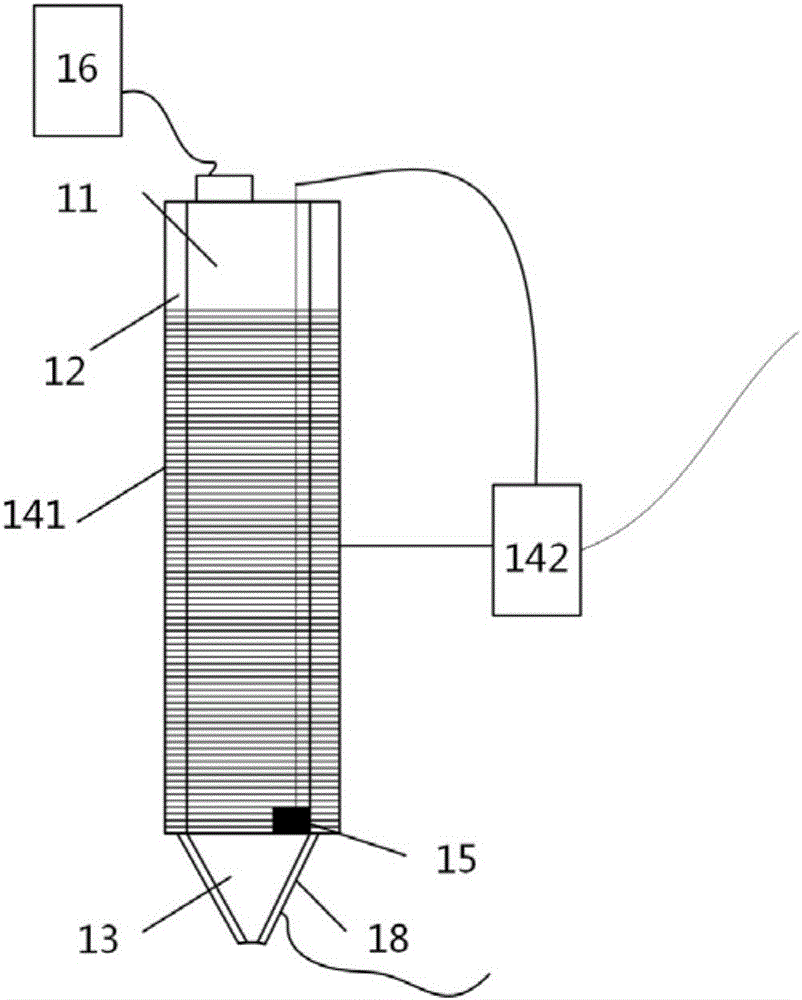

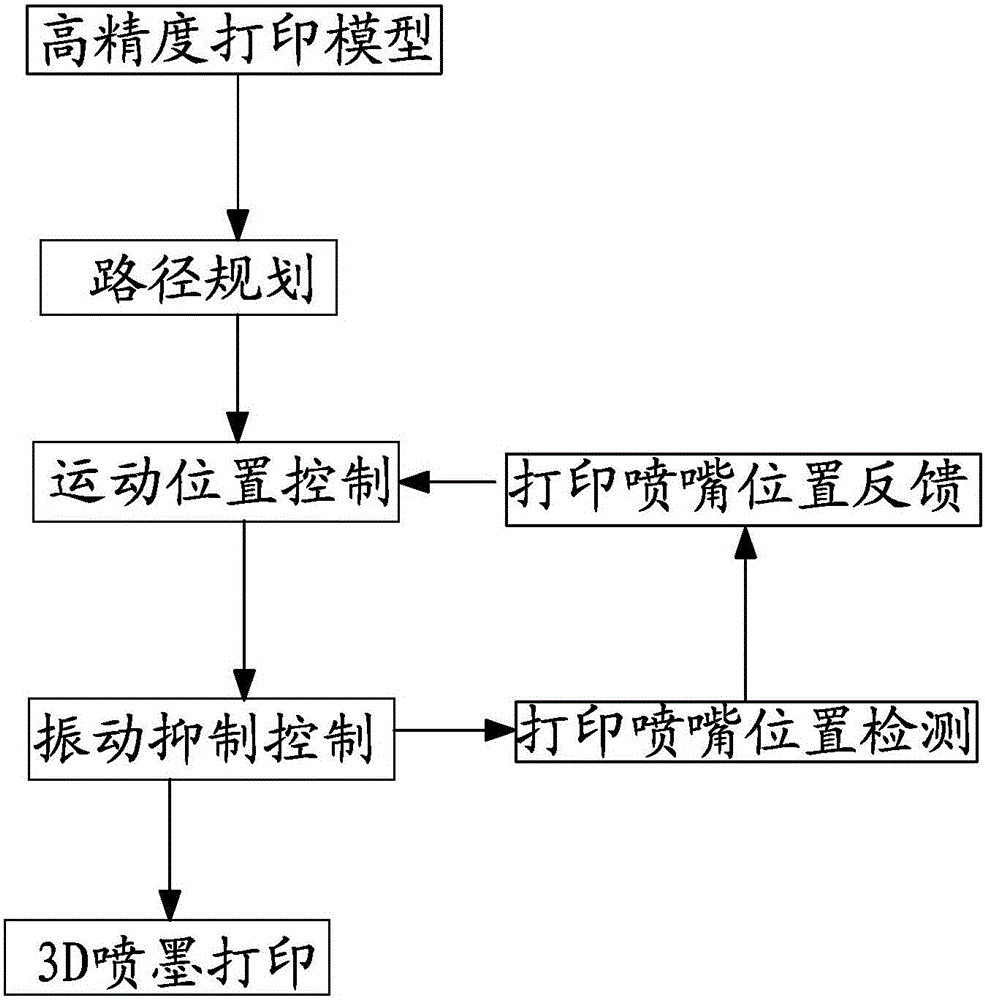

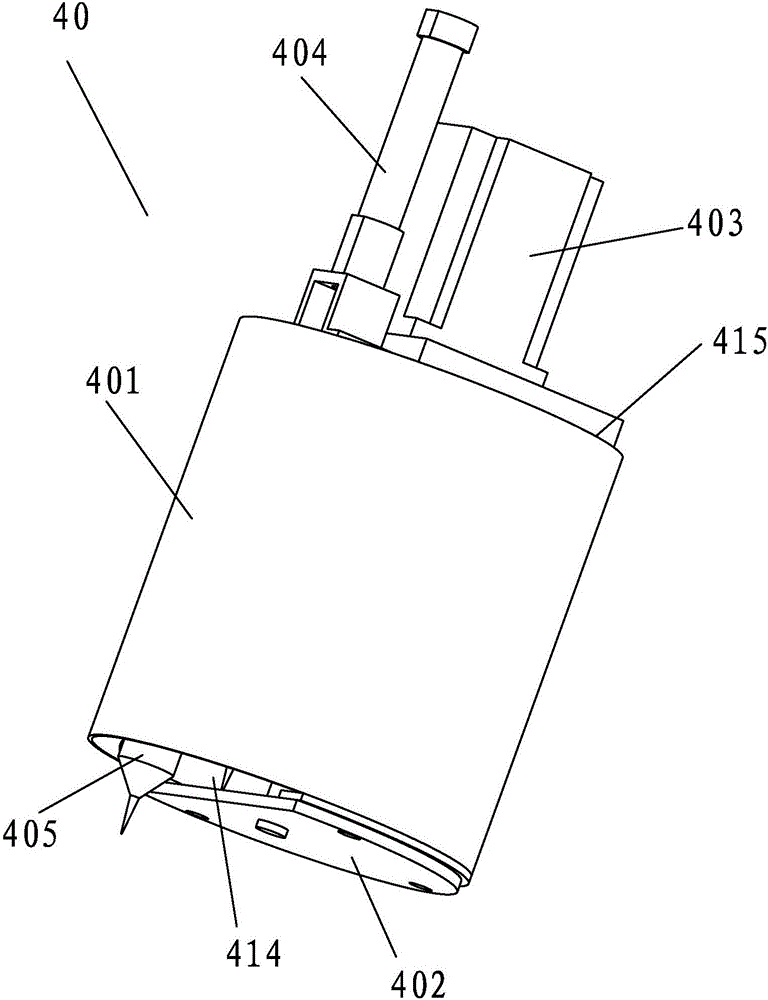

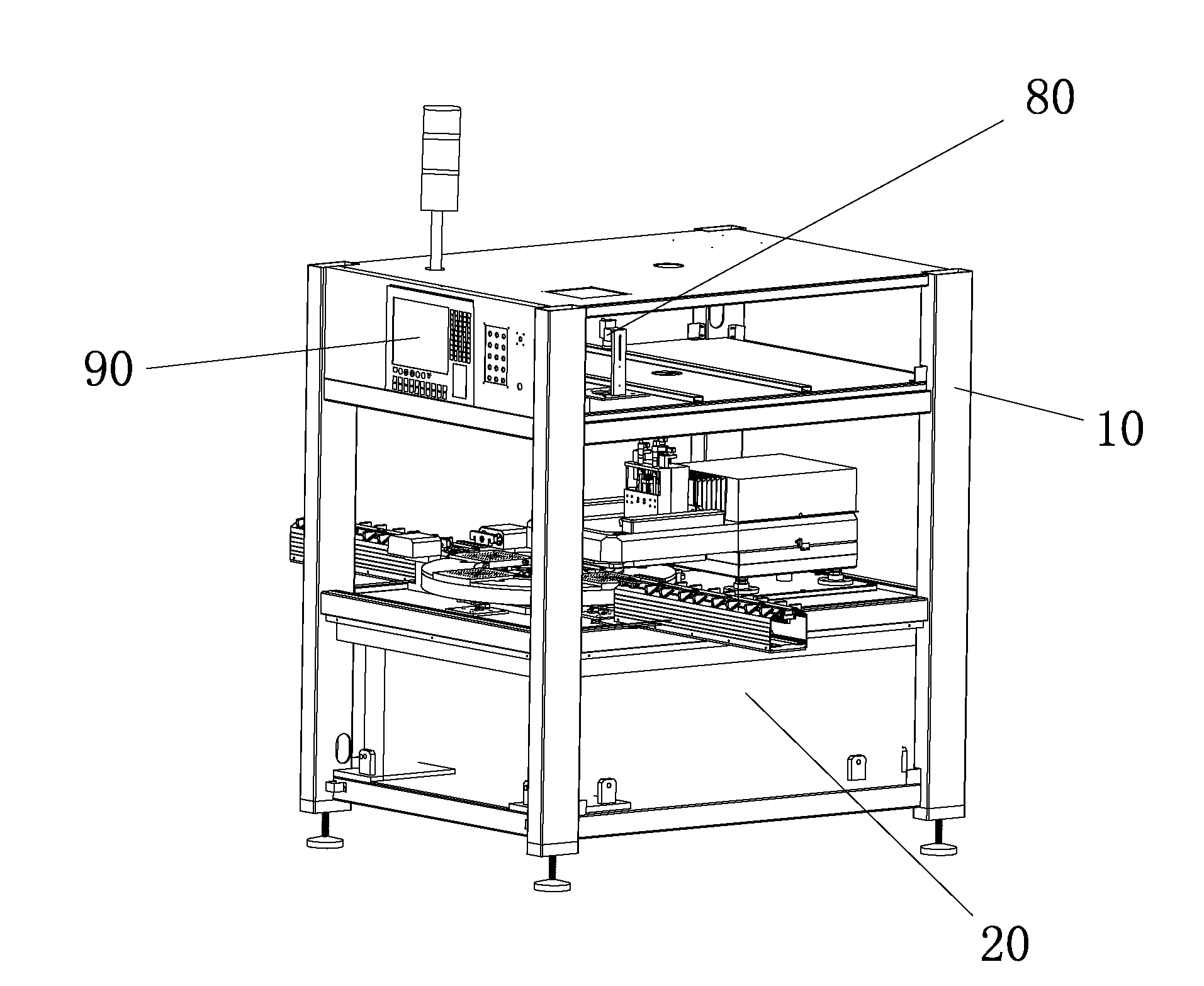

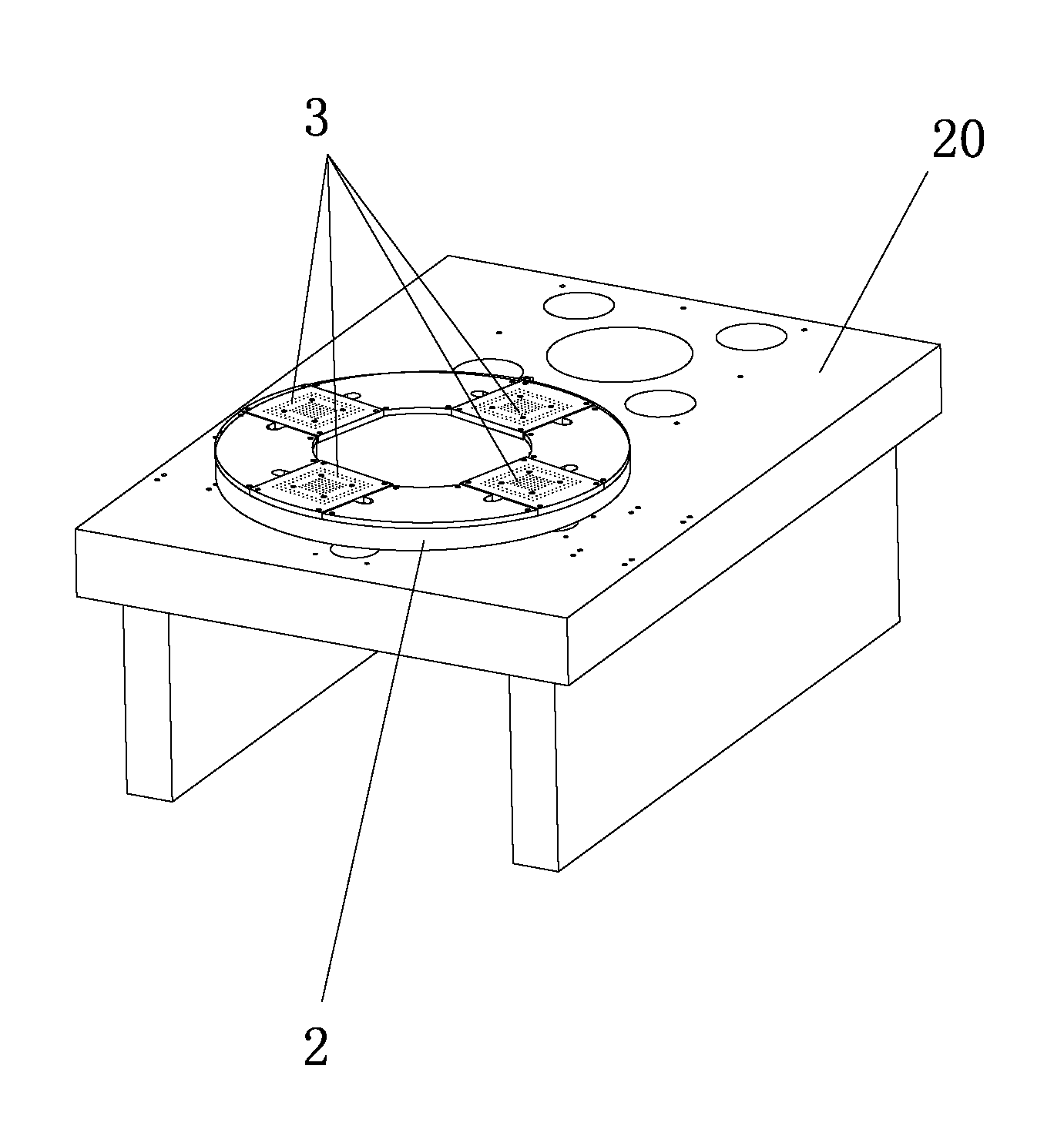

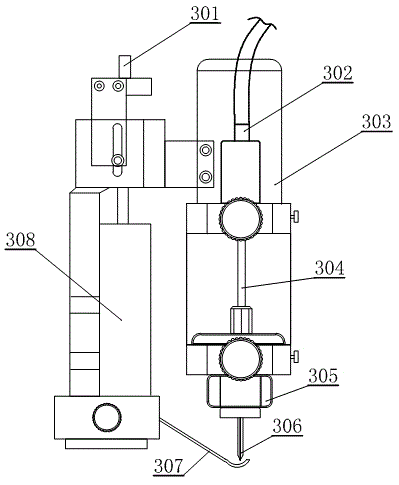

High-precision electric field driven spray deposition 3D printer and working method thereof

PendingCN107932894AHigh frequencyContinuous and stable feedingAdditive manufacturing apparatus3D object support structuresComputer printingImage resolution

The invention discloses a high-precision electric field driven spray deposition 3D printer and a working method thereof, and solves the problems of a traditional 3D printer on multiple aspects of resolution, stability and controllability; high-precision printing of multilayer structures can be realized; the printing process is observed and monitored in real time; and high-precision pattern printing is performed on insulation substrates through electric conducting materials. The high-precision electric field driven spray deposition 3D printer comprises a mounting baseplate; a Y-axle worktable is arranged on the mounting baseplate; a vacuum absorption platform is fixed on the Y-axle worktable; a printing substrate is absorbed on the vacuum absorption platform; a printing nozzle and a vertical observation camera are correspondingly arranged above the printing substrate, and are connected to a Z-axle worktable; the Z-axle worktable is fixed on an X-axle worktable; a squint observation camera is correspondingly arranged on one side of the printing nozzle; an LED light source and a far infrared curing light source are correspondingly arranged on the other side of the printing nozzle; theprinting nozzle communicates with a storage bottle; and the storage bottle is arranged on a lifting table.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

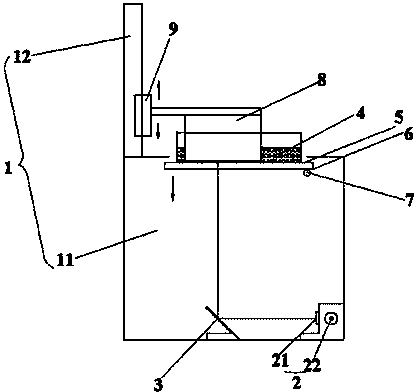

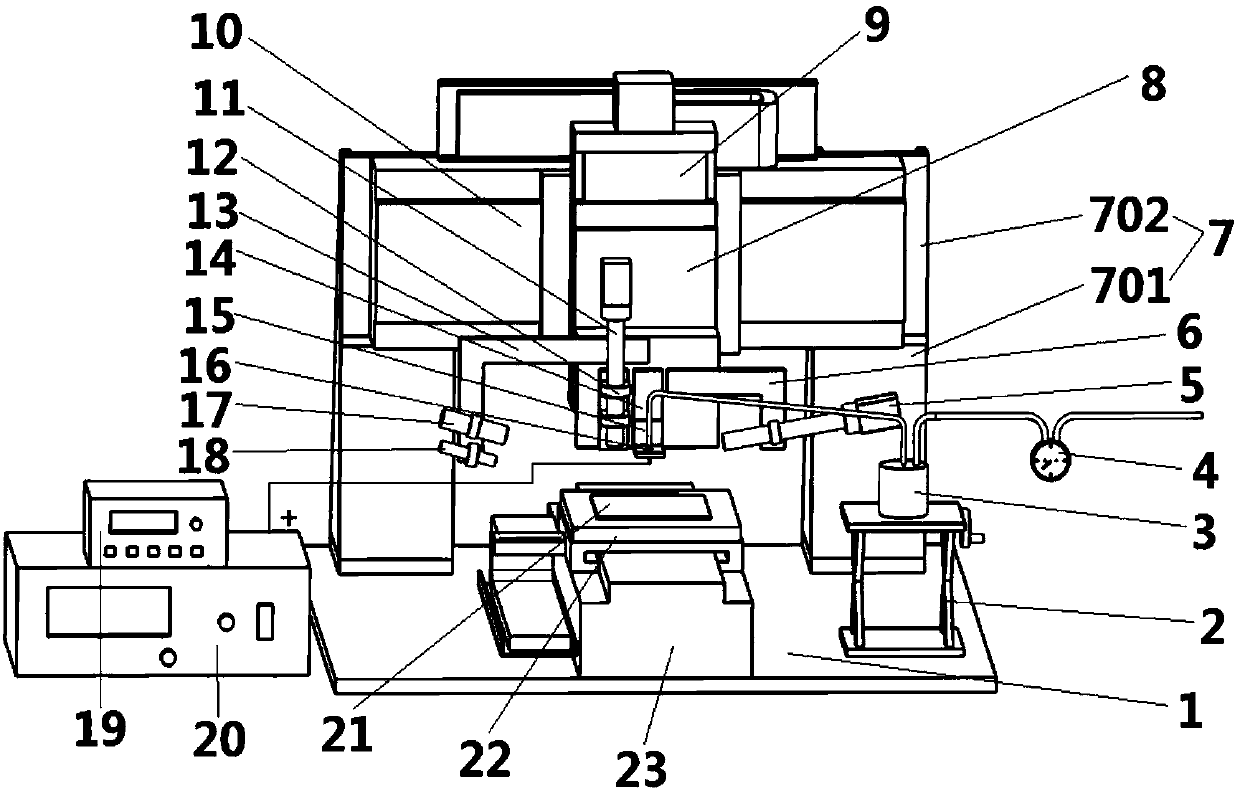

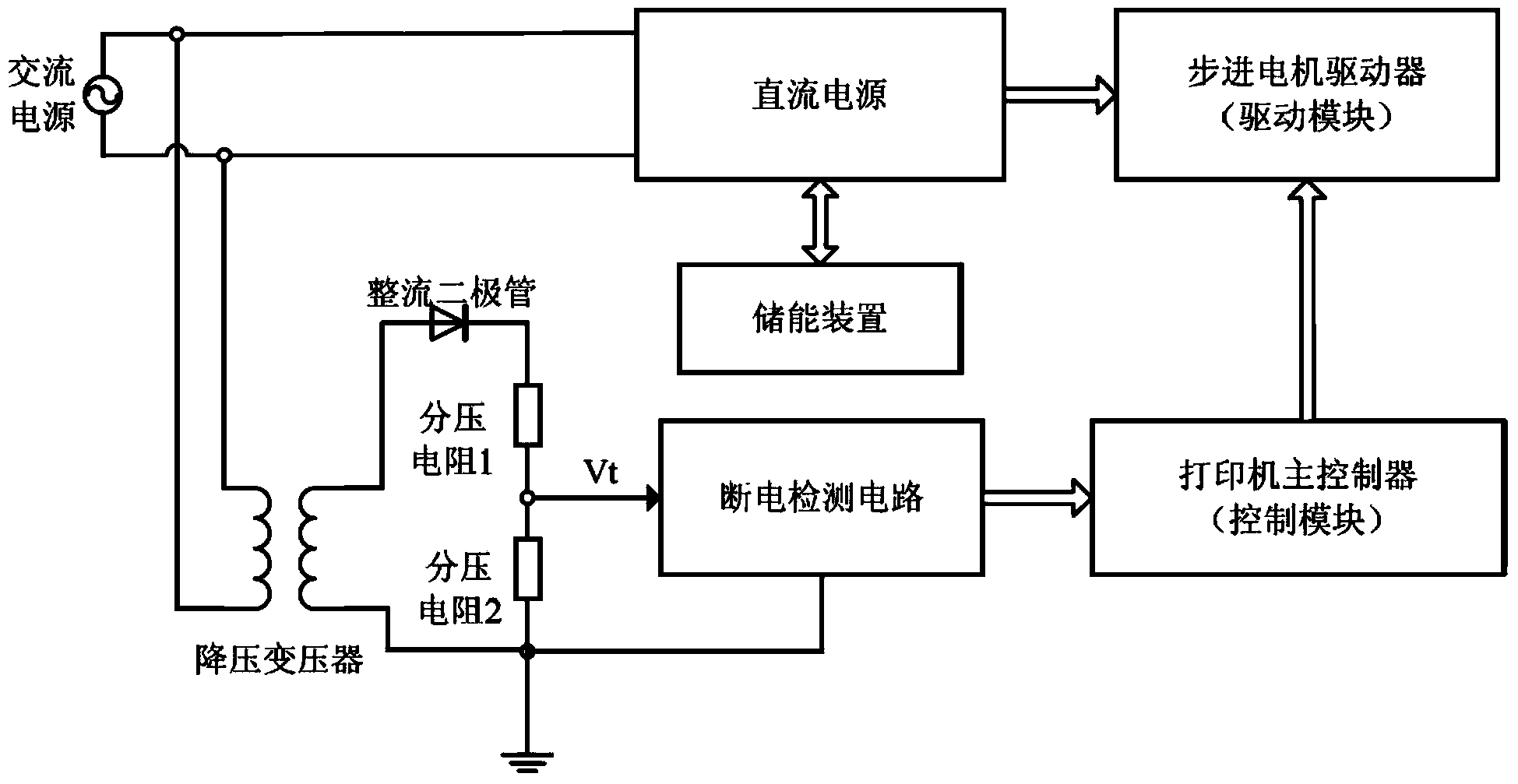

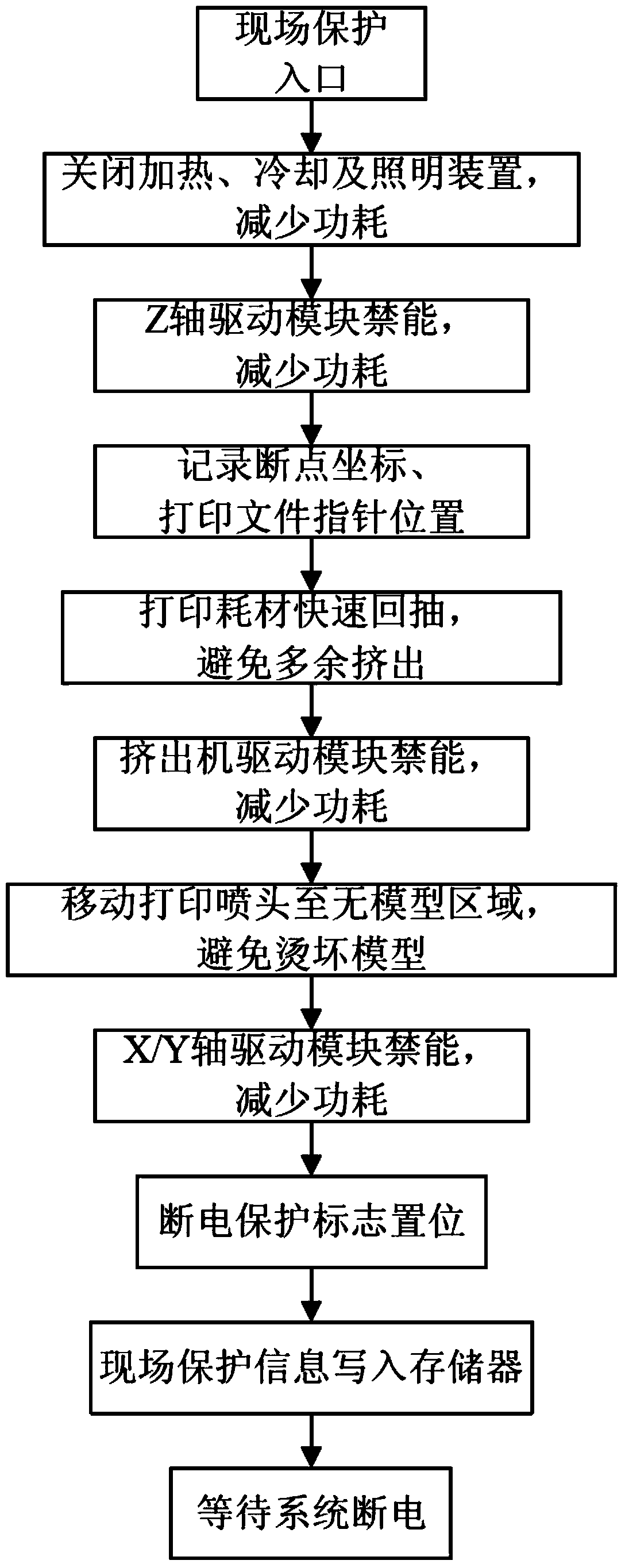

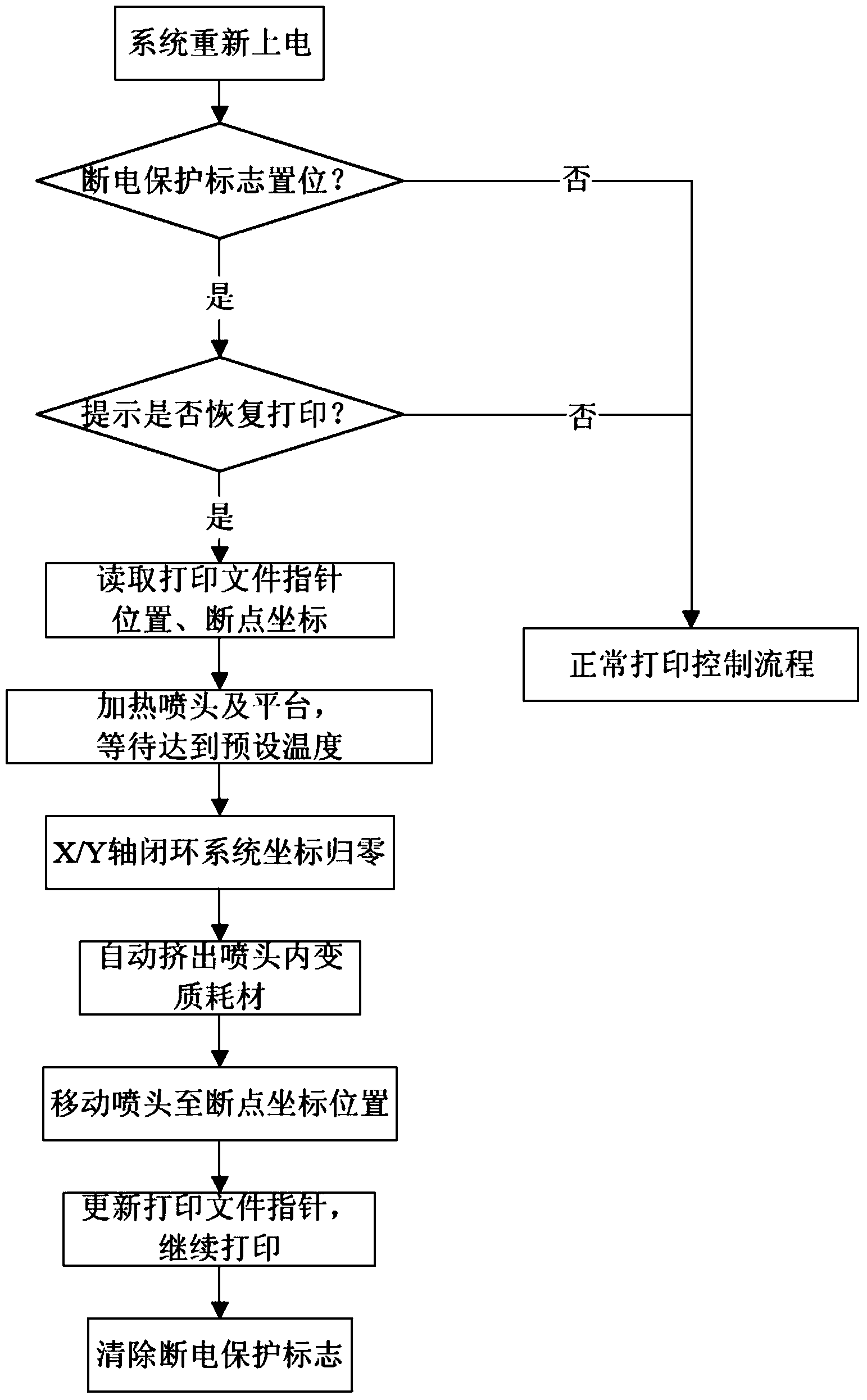

3D printer capable of printing continuously at outage and method for controlling 3D printer to continue printing at outage

The invention relates to a 3D printer capable of printing continuously at an outage and a method for controlling the 3D printer to continue printing at the outage and belongs to the technical field of 3D printing. The 3D printer comprises a power module capable of storing electric energy, an outage detection module used for detecting the power supply state of an external power source, and a control module which controls all components of the printer to switch between the power supply state and the outage state. By means of the method, the printer can use the stored electric energy to record the work state at the outage, and all the components are set to be in the outage state; when power supply is recovered, the printer can be controlled to return to the previous state and continue last work; as a result, reprinting is avoided, consumable items are effectively saved, and the success rate of printing is increased substantially; furthermore, closed-loop control is achieved in cooperation with a displacement detection module, and the accuracy of continuous printing at the outage is further improved. Moreover, the 3D printer capable of printing continuously at the outage is simple in structure, the method for controlling the 3D printer to continue printing at the outage is easy and convenient to implement, and the application range is rather wide.

Owner:PANOWIN TECH

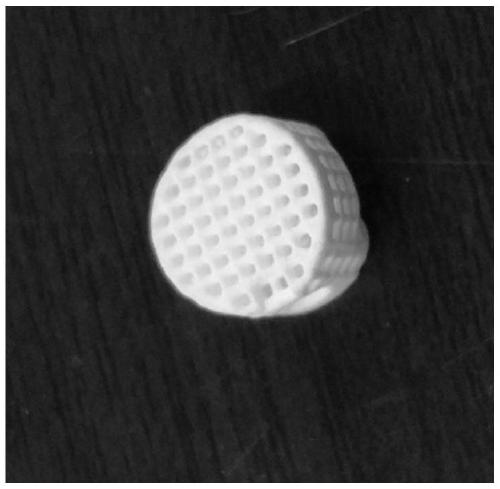

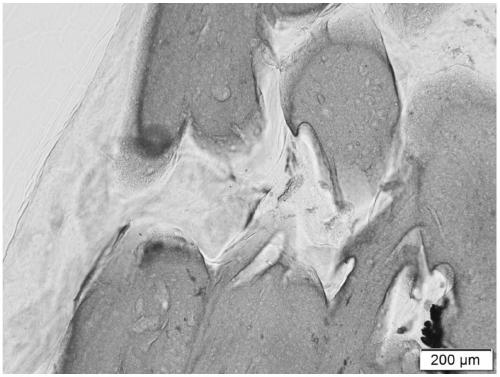

Calcium phosphate bone induction biological ceramic stent based on photocuring 3D printing technology and preparation method thereof

PendingCN109650909AHigh solid contentLow viscosityAdditive manufacturing apparatusCeramic shaping apparatusCalcium biphosphateDispersity

The invention discloses a calcium phosphate bone induction biological ceramic stent based on a photocuring 3D printing technology and a preparation method thereof, and belongs to the field of biomedical materials. Through the method, ceramic paste which is high in content of solid, low in viscosity and good in dispersity and fluidity can be effectively prepared. Through the photocuring 3D printingtechnology and follow-up degreasing sintering, the bone induction porous calcium phosphate ceramic stent with an internal penetrating pore structure can be prepared, wherein the shape, size, porosityand macroscopic morphology of the bone induction porous calcium phosphate ceramic stent can be accurately controlled, and the bone induction porous calcium phosphate ceramic stent is used for bone tissue repairing and filling and individualized repairing.

Owner:SICHUAN UNIV

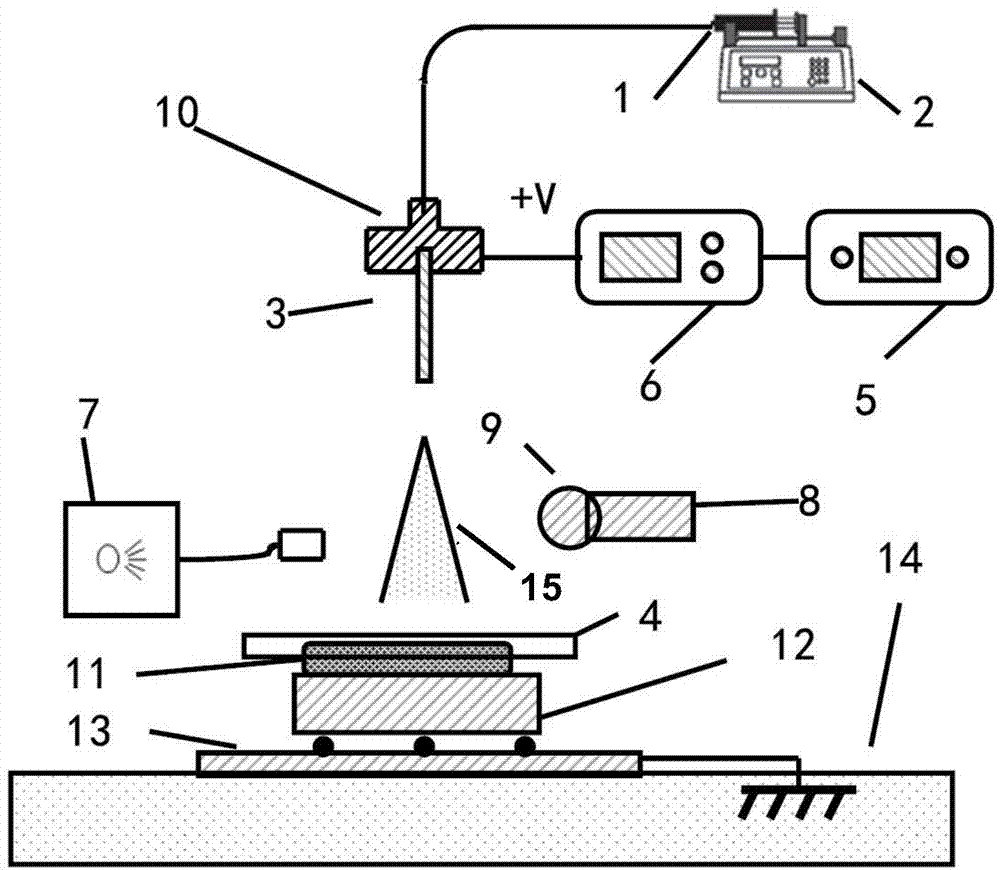

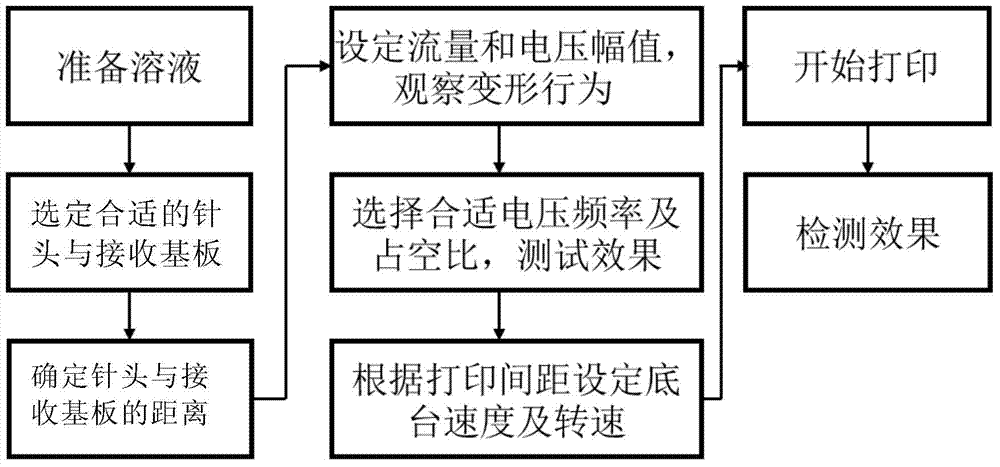

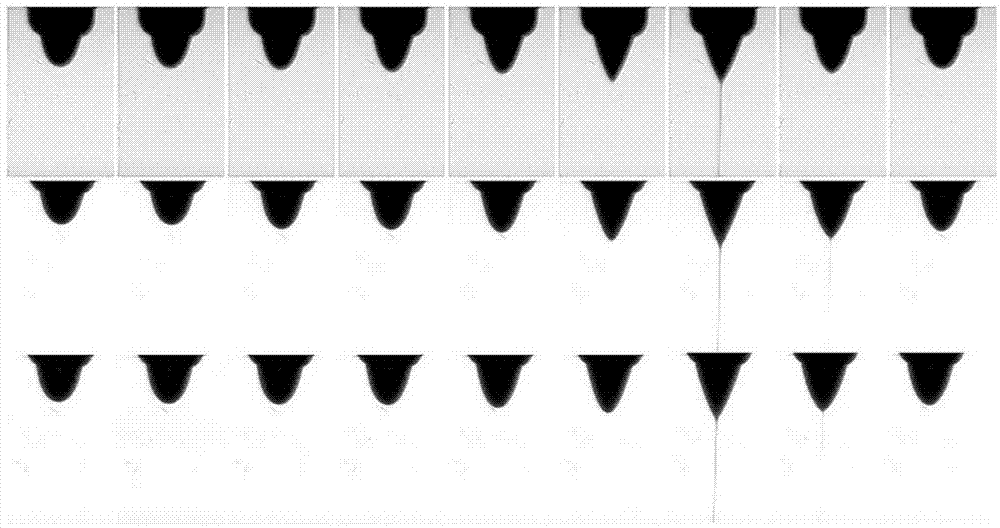

Electro hydrodynamic preparation device and method for batch micro-droplets and micro-structures

The invention provides an electro hydrodynamic preparation device and method for batch micro-droplets and micro-structures. The preparation device comprises a liquid conveying system, an injection receiving system, a voltage control system, a high-speed photographing system and a bottom platform movement control device. The preparation method includes the steps that a micro-injection pump is utilized to push liquid to a needle head tip from an injector according to a certain flow; fluid is gathered at the needle head tip; under the effect of an electric field, the liquid gathered at the needle head forms a Taylor cone, linear liquid ejected from the tip of the Taylor cone falls onto a receiving substrate, and finally deposited droplets are formed. Bottom platform moves to be matched with continuous ejection of the linear liquid, so batch micro-droplets or micro-structures of certain modes can be prepared.

Owner:SHANGHAI JIAO TONG UNIV

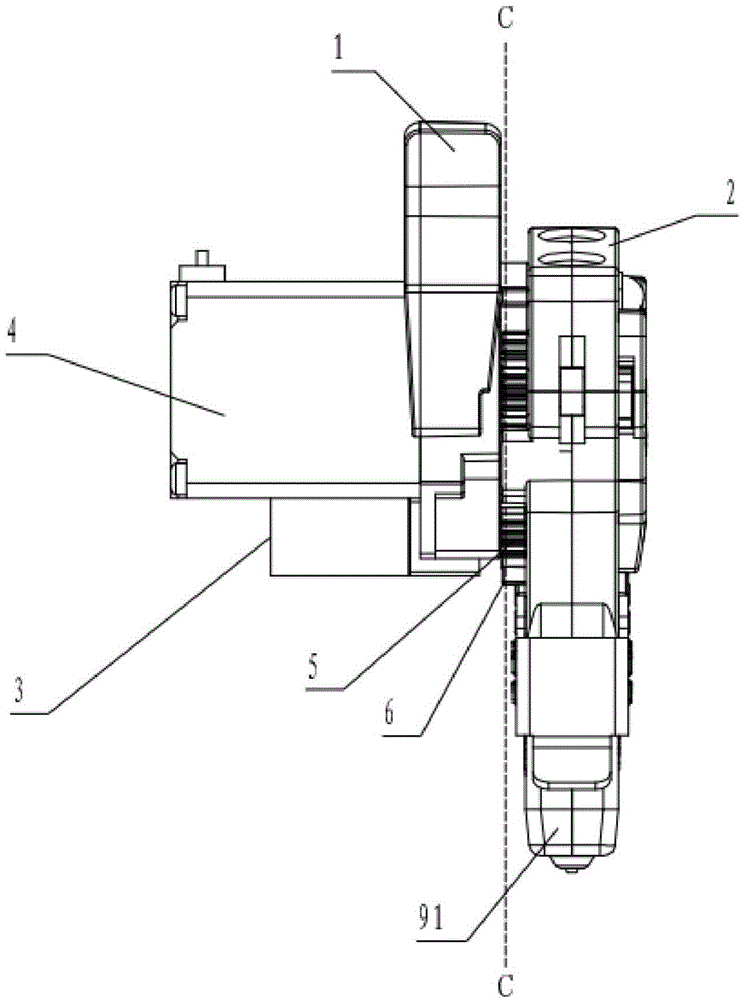

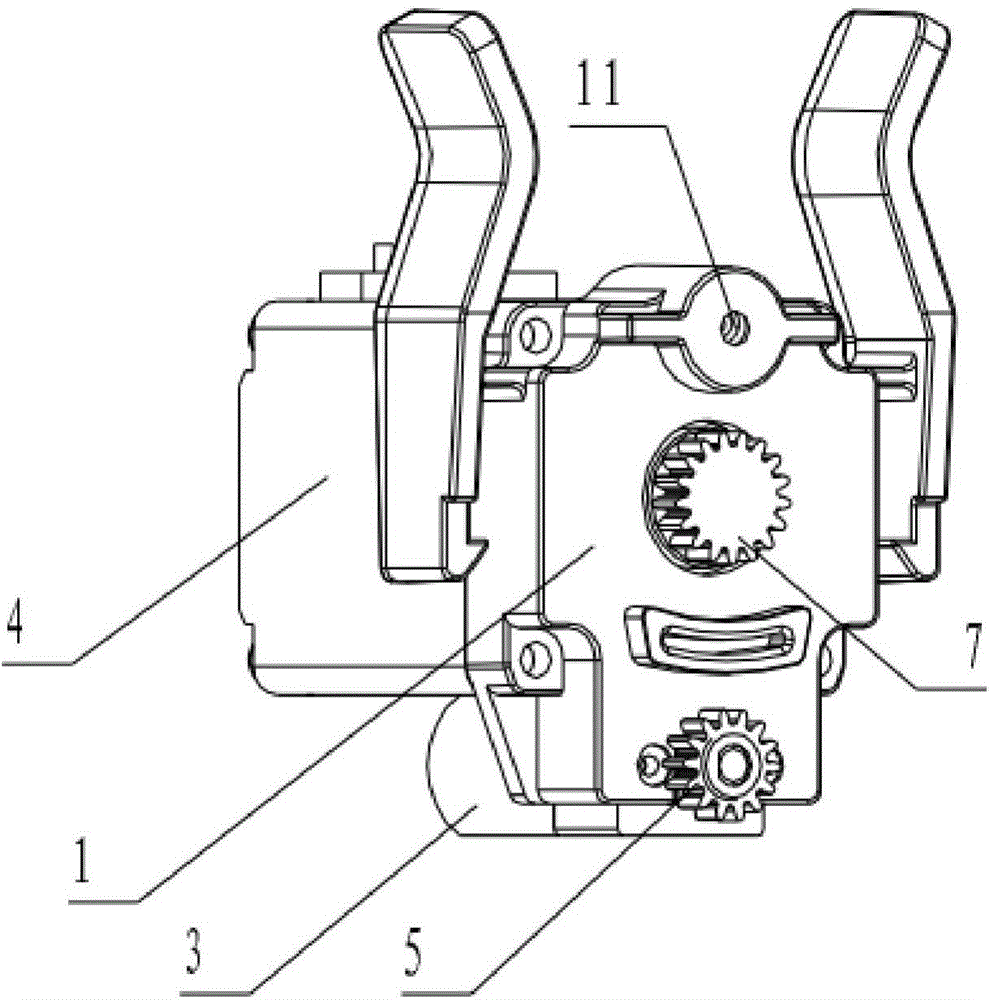

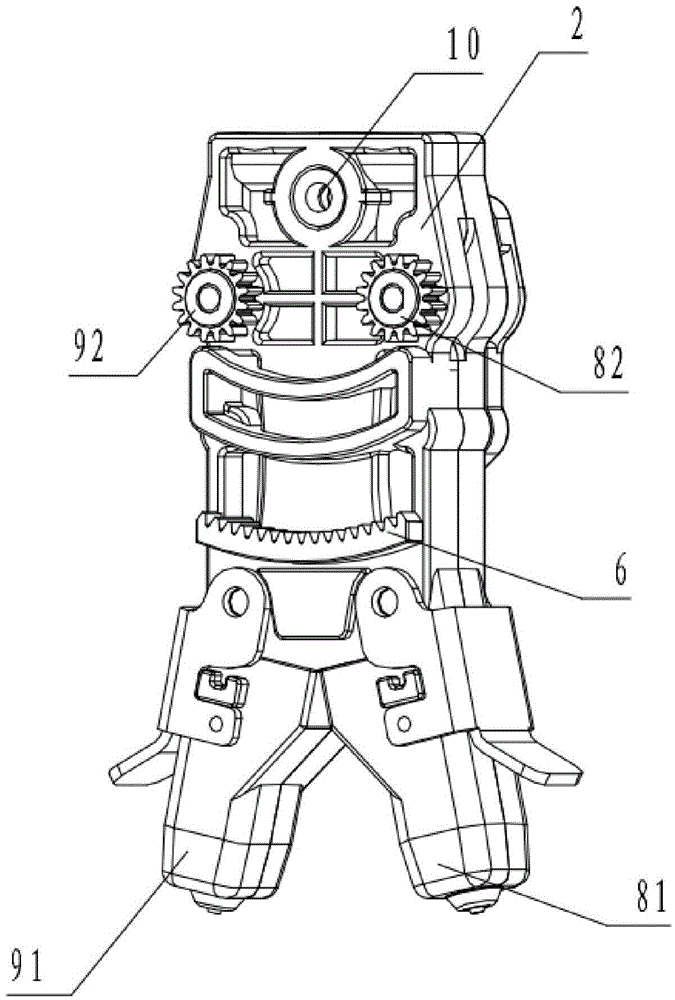

Rotary type double-nozzle switching device for 3D printing

The invention discloses a rotary type double-nozzle switching device for 3D printing. The rotary type double-nozzle switching device comprises a steering motor and a wire feeding motor which are arranged on a first bracket; a second bracket is provided with a first nozzle mounting groove, a second nozzle mounting groove, a first wire feeding gear and a second wire feeding gear which correspond to the first nozzle mounting groove and the second nozzle mounting groove, and a first driven wheel and a second driven wheel which are coaxially connected with the first wire feeding gear and the second wire feeding gear; the second bracket is rotationally arranged on the first bracket; a steering gear is connected with the steering motor in a driving manner and is engaged with an arc-shaped rack on the second bracket; under the transmission of the steering gear, the arc-shaped rack enables the second bracket to swing on the first bracket by taking the circle center of the arc-shaped rack as the circle center; a wire feeding driving wheel is in driving connection with the wire feeding motor; when the second bracket swings to the right side, the second bracket is engaged with the first driven wheel; and when the second bracket swings to the left side, the second bracket is engaged with the second driven wheel. By virtue of the rotary type double-nozzle switching device for the 3D printing, the effective printing space is effectively improved when a 3D printer adopts double nozzles, and the mutual influences between the nozzles is higher; and the practicability is high and the usability is good.

Owner:JIANGSU HAOYU ELECTRONICS TECH

Novel decorating machine

The invention discloses a novel decorating machine. The novel decorating machine comprises a table rack, a printing arm, a cylinder, an extension spring, an elastic table plate, a screen frame, a scraper, and a screen frame fixing device, wherein the table rack comprises a rack leg and a fixed arm fixed on the rack leg, the fixed arm is linear, the rack leg wounds the periphery of the fixed arm, one end of the printing arm is hinged to the lower portion of the fixed arm, a piston rod of the cylinder extends out of one end of a cylinder body of the cylinder to be hinged to the upper end of the fixed arm, the other end of the cylinder body of the cylinder is hinged to the middle of the printing arm and is in sliding match with the printing arm in the direction of the length of the printing arm, one end of the extension spring is connected with the middle of the fixed arm, the other end of the extension spring is connected with the printing arm through a sliding plate, the sliding plate is in sliding match with the printing arm, and the bottom of the elastic table plate is in sliding match with the rack leg. The novel decorating machine is capable of buffering the action performed by the cylinder to lift or press the printing arm, greatly reducing vibration by the aid of an elastic force produced by the elastic table plate, and improving register accuracy.

Owner:SHENZHEN CNTOP DIGITAL EQUIP CO LTD

PLA modified material applied to 3D printing of large casting molds, and method of PLA modified material

InactiveCN106009572AEasy to degradeNon-irritatingAdditive manufacturing apparatusEnvironmental resistancePolymer science

The invention relates to the technical field of high polymer materials, the technical field of 3D printing, and the field of 3D casting, in particular to a PLA modified material applied to 3D printing of large casting molds, and a method of the PLA modified material. The invention provides the PLA modified material applied to 3D printing of large casting molds, and the PLA modified material comprises the following components: polylactic resin, an inorganic filler, a plasticizer, a flexibilizer, a coupling agent, a chain extender, an antioxidant, an anti-hydrolysis agent, a compatilizer, and a lubricant. To overcome defects in the prior art, the invention creatively develops the PLA modified material specially applied to 3D printing of large casting molds, and the PLA modified material has the advantages of being low in shrinking percentage, good in dimensional stability, high in strength, not liable to be affected with damp, low in price, easy to degrade, environment-friendly, non-toxic, non-irritant, non-pollution and the like.

Owner:NINGXIA KOCEL MOLD

3D ink-jet printer for printing electronic circuit board through ultrasonic atomization nanometer suspending liquid

InactiveCN104014790ATroubleshoot direct printing issuesSafe and convenient man-machine operationEvaporationEngineering

The invention discloses a 3D ink-jet printer for printing an electronic circuit board through ultrasonic atomization nanometer suspending liquid. The 3D ink-jet printer comprises an ultrasonic atomization nanometer suspending liquid device, a nanometer fine ink-jet printing device, an industrial positioning camera, a video monitor, an infrared laser micro-fusion-covering device, a heatable vacuum absorption workbench, a three-coordinate movable sliding table and a control portion. According to the 3D ink-jet printer, the nanometer suspending liquid to be printed is atomized based on an ultrasonic double-cavity atomization method, the nanometer suspending liquid is sent to a controllable nanometer fine ink-jet printing device through a guide pipe under the action of auxiliary gas and is directly printed on a substrate in a non-contact mode through a fine ceramic nozzle, the printed nanometer sizing agent is solidified and dried through the method of bottom plate heating or infrared laser micro fusion covering, evaporation of the solvent in the sizing agent, gasification of an organic clad layer and fusion of nanometer particles are accelerated, and therefore the electronic circuit board with high conductivity and micron-size line width is formed. The 3D ink-jet printer can directly print a conducting layer, an insulating layer, a protective layer and a solder mask and can print semiconductor components and parts.

Owner:张远明

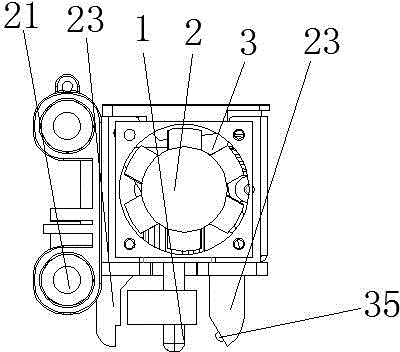

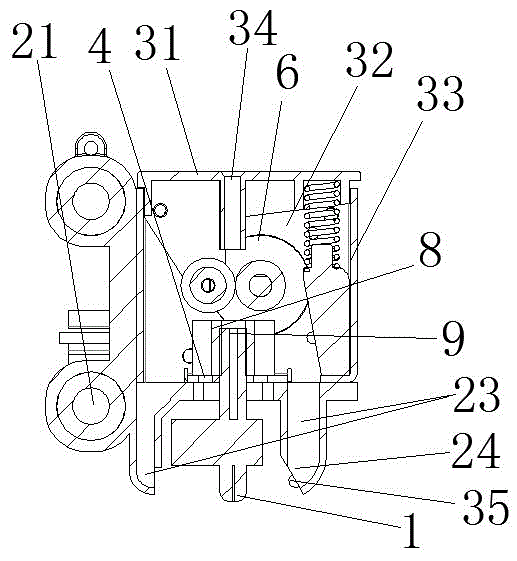

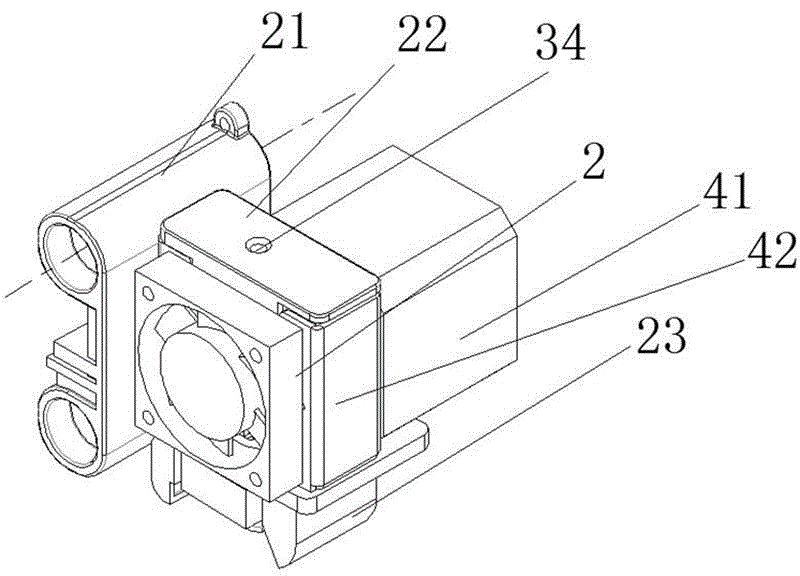

Air-cooling device for printing head of 3D (three-dimensional) printing machine

InactiveCN104786510AHigh efficiency of active coolingSmall footprintManufacturing platforms/substratesAdditive manufacturing with liquids3d printerWorking space

The invention discloses an air-cooling device for a printing head of a 3D (three-dimensional) printing machine. The printing head is arranged at a slide rod of the printing machine in a sleeving manner by lug rings and axially slides; the air-cooling device is integrated on the printing head; a wire conveying mechanism is arranged in a seat housing cavity body of the printing head; a cooling fan aligned to the wire conveying mechanism is arranged on one axial side of the seat housing cavity body; a printing head nozzle is formed in the lower part of the seat housing cavity body; the seat housing cavity body is provided with air guide pipelines leading to the printing head nozzle. The air-cooling device improves heat dissipation of the printing head of the printing machine and enables occupied working space of the printing head to be further reduced, thereby being favorable for improving the portability of the folding-type 3D printing machine.

Owner:FUZHOU ZHANXU ELECTRONICS

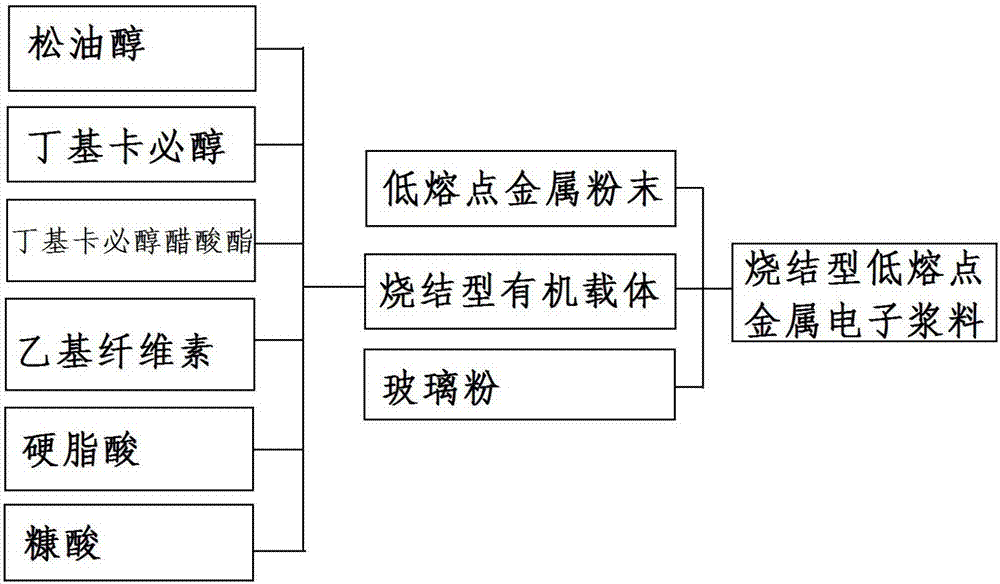

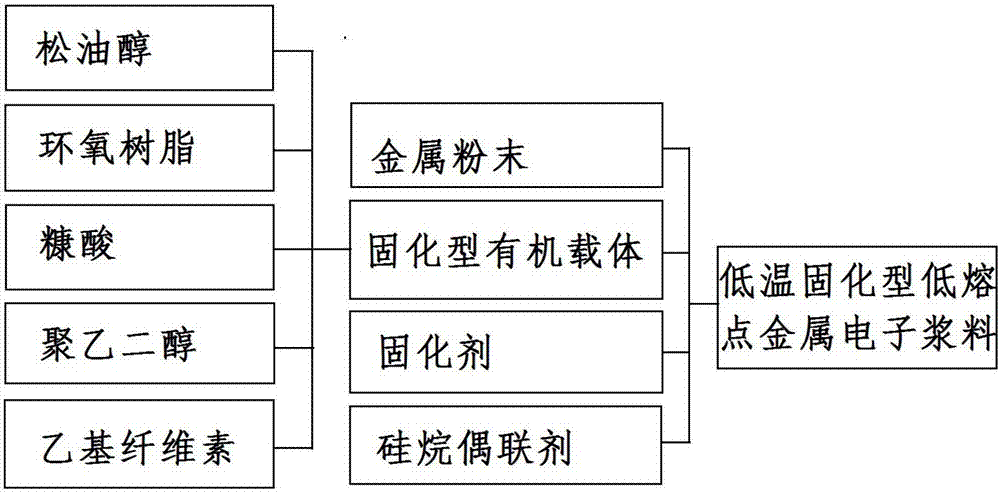

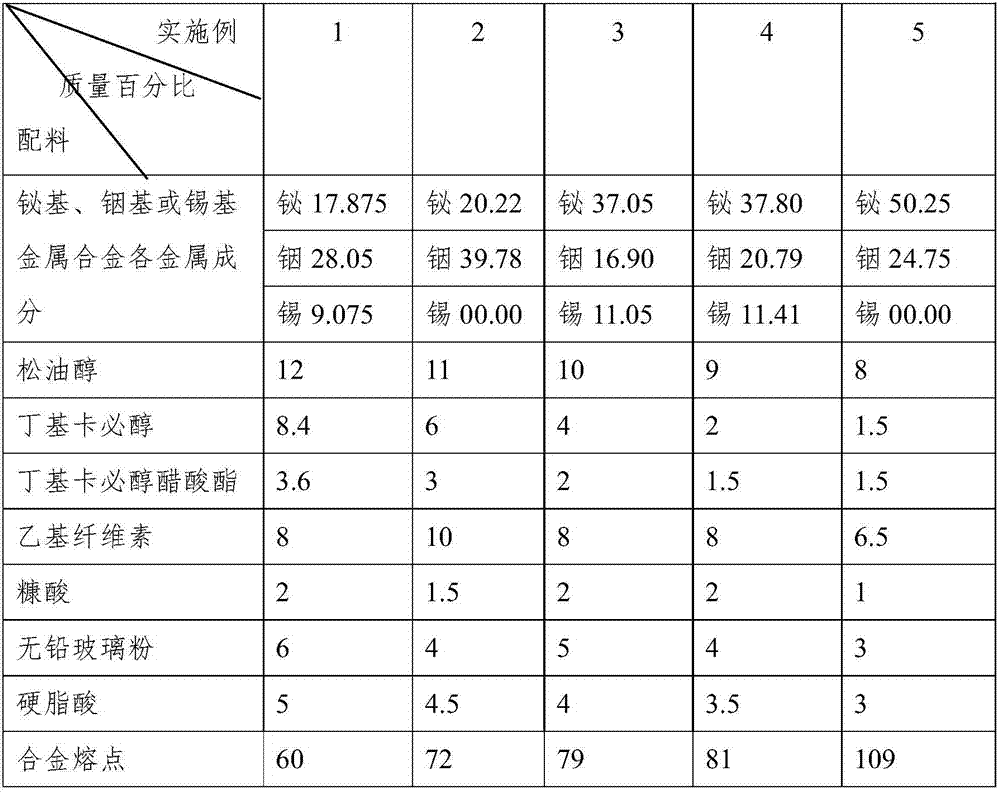

Electronic paste based on low-melting-point metal micro-nano powders and manufacture method thereof

ActiveCN107274965AImprove printing accuracyLower sintering temperatureNon-conductive material with dispersed conductive materialCable/conductor manufactureElectrical resistance and conductanceScreen printing

The invention provides an electronic paste based on low-melting-point metal micro-nano powders. The electronic paste is composed of low-melting-point metal micro-nano powders, a binder, a solvent and an auxiliary agent. The mass proportion of the low-melting-point metal micro-nano powders in the electronic paste is 45 to 90%. The melting point of low-melting-point metal is -78 to 232 degree centigrade. The electronic paste is suitable for traditional printing methods such as silk screen printing and can be widely used in printing electronic industry, such as front and back electrodes of solar panels, RFID tags, cell phone antennas, non-contact IC card antenna lines, and the like. The electronic paste has the advantages of high printing precision, low sintering temperature, no diffusion after sintering, low breaking rate, small contact resistance and low cost.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

Pretreatment liquid for direct injection of polyester fiber through dispersive ink and direct injection digital printing process

The invention discloses a pretreatment liquid for direct injection of polyester fiber through dispersive ink and a direct injection digital printing process. The pretreatment liquid comprises, by mass, 0.2-5 parts of thickener, 1-10 parts of dispersion promoter, 2-5 parts of sodium chloride and 76-95 parts of water. The pretreatment liquid is semi-thick liquid, polyester fabric after going through impregnation or padding treatment liquid is dried, injection printing of dispersive dye ink is performed, high-temperature steaming baking is performed for color fixing after drying, water washing is performed, and then drying is performed to obtain a printing finished product. The pretreatment liquid is simple to prepare, convenient to use and suitable for direct injection process digital printing of all fabric high in polyester content, and the pretreatment liquid is easy to wash away after printing, so that hand feel of fabric is unaffected. Conventional heat transfer printing is replaced by the dispersive direct injection process, and transfer printing paper is not used, so that the direct injection digital printing process is environment-friendly. The pretreatment liquid can effectively prevent ink from spreading around on the polyester fabric, so that patters are ensured to be exquisite and lines are ensured to be clear after printing; color yield rate is high, printing is saturated and bright in color, and visual three-dimensional sense is high.

Owner:深圳市墨库图文技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com