3D printer capable of printing continuously at outage and method for controlling 3D printer to continue printing at outage

A 3D printer, power-off and continuous printing technology, applied in the field of 3D printing, can solve the problems of waste of consumables and reduce the success rate of printing large-scale models.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

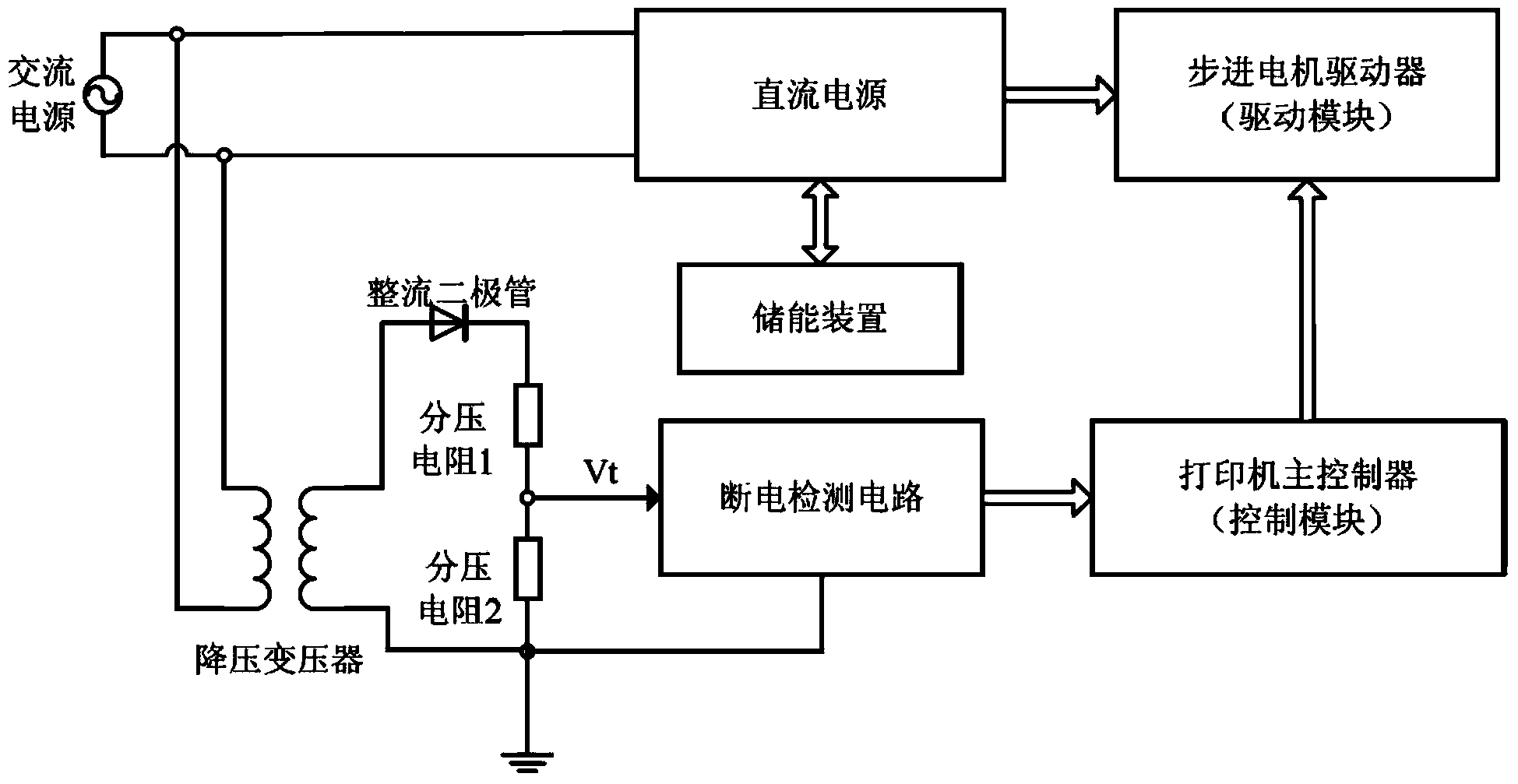

[0047] see figure 1 As shown, it is a schematic structural diagram of the 3D printer with the function of continuous printing after power failure of the present invention.

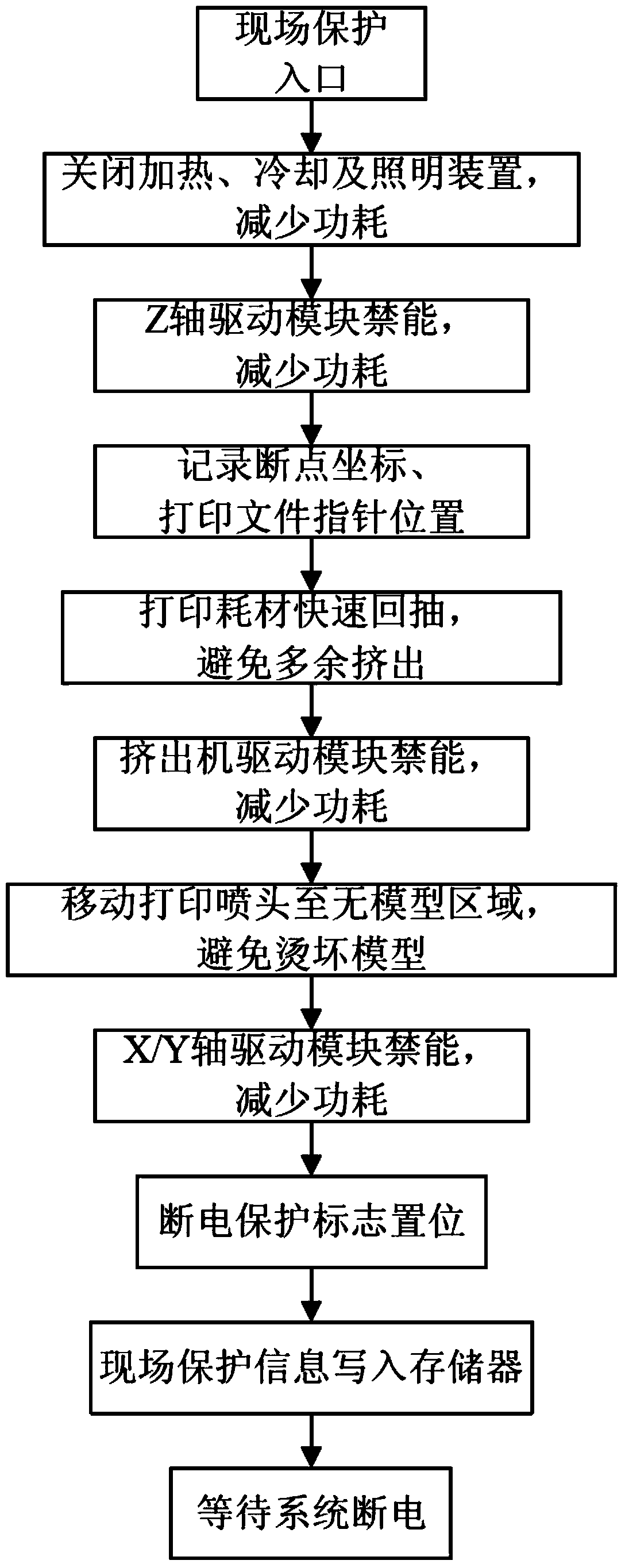

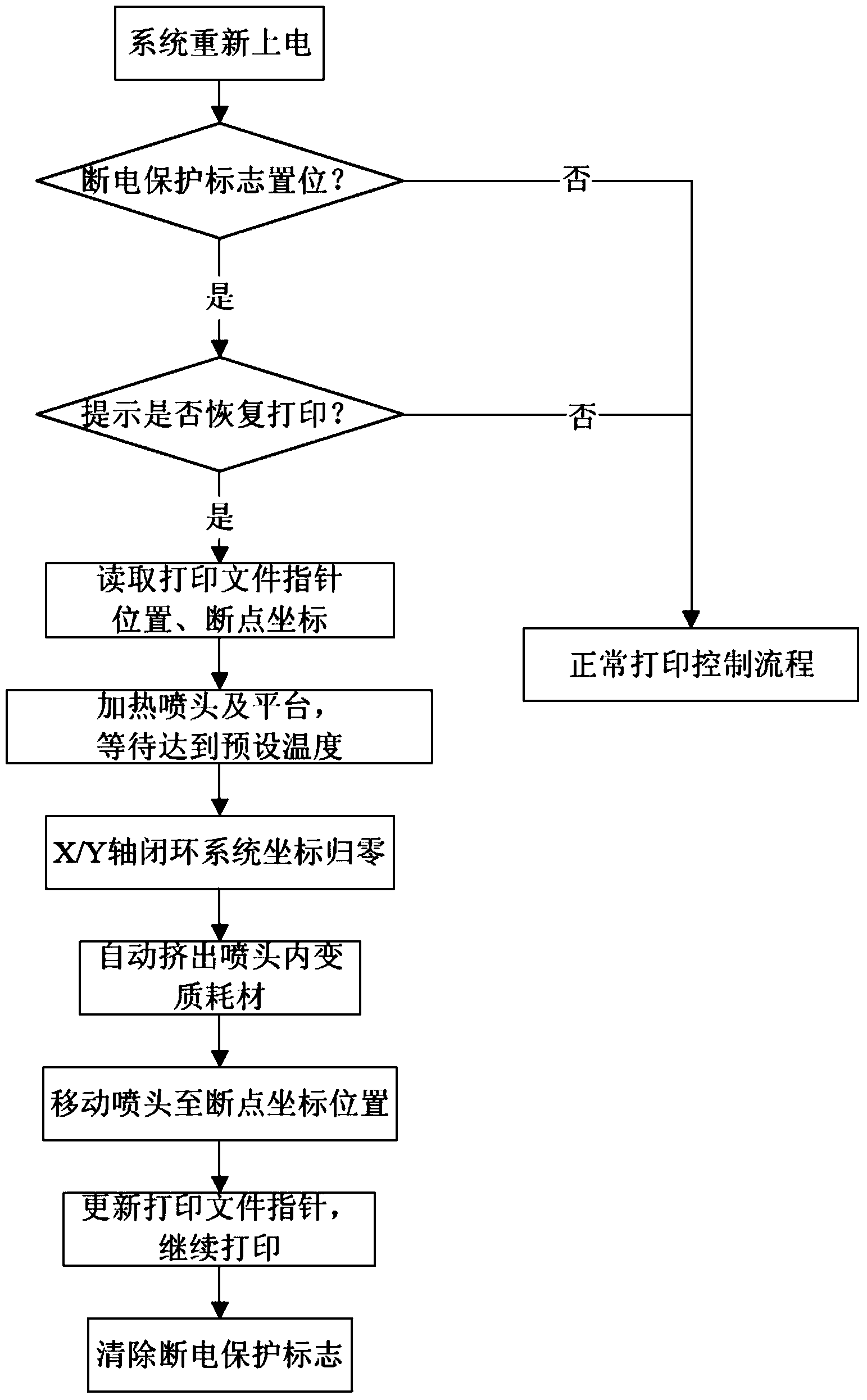

[0048] In one embodiment, the 3D printer with the function of continuous printing after power failure includes a machine frame, a printing running mechanism connected to the machine frame, an extrusion nozzle connected to the printing running mechanism, connected and driven The drive module of the printing running mechanism described above; also includes a power supply module, a power failure detection module and a control module. Wherein, the power supply module is connected between the external power supply and the printing running mechanism, and is used to obtain electric energy from the external power supply, supply power to the drive module, and store electric energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com