Patents

Literature

35results about How to "Improve printing success rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

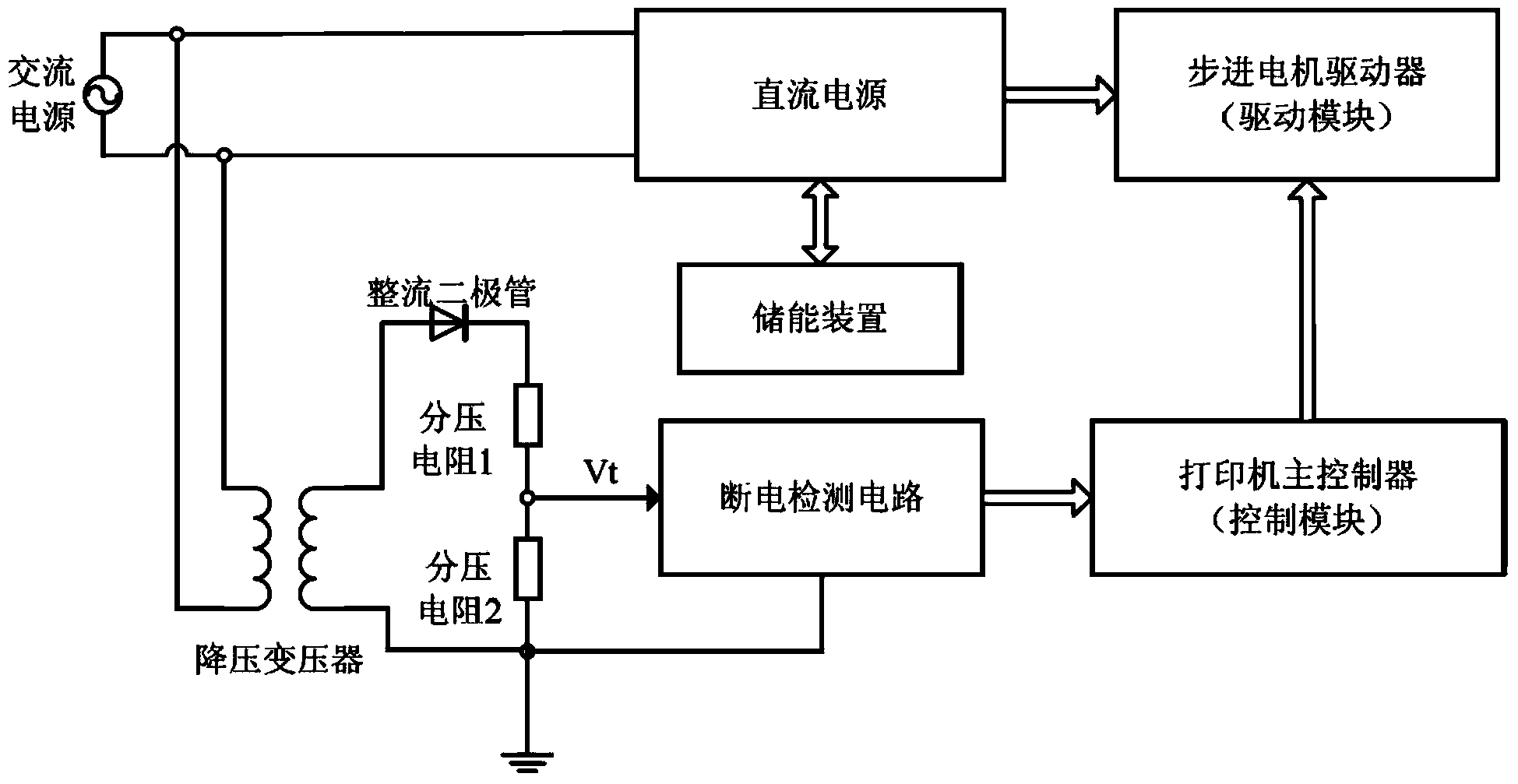

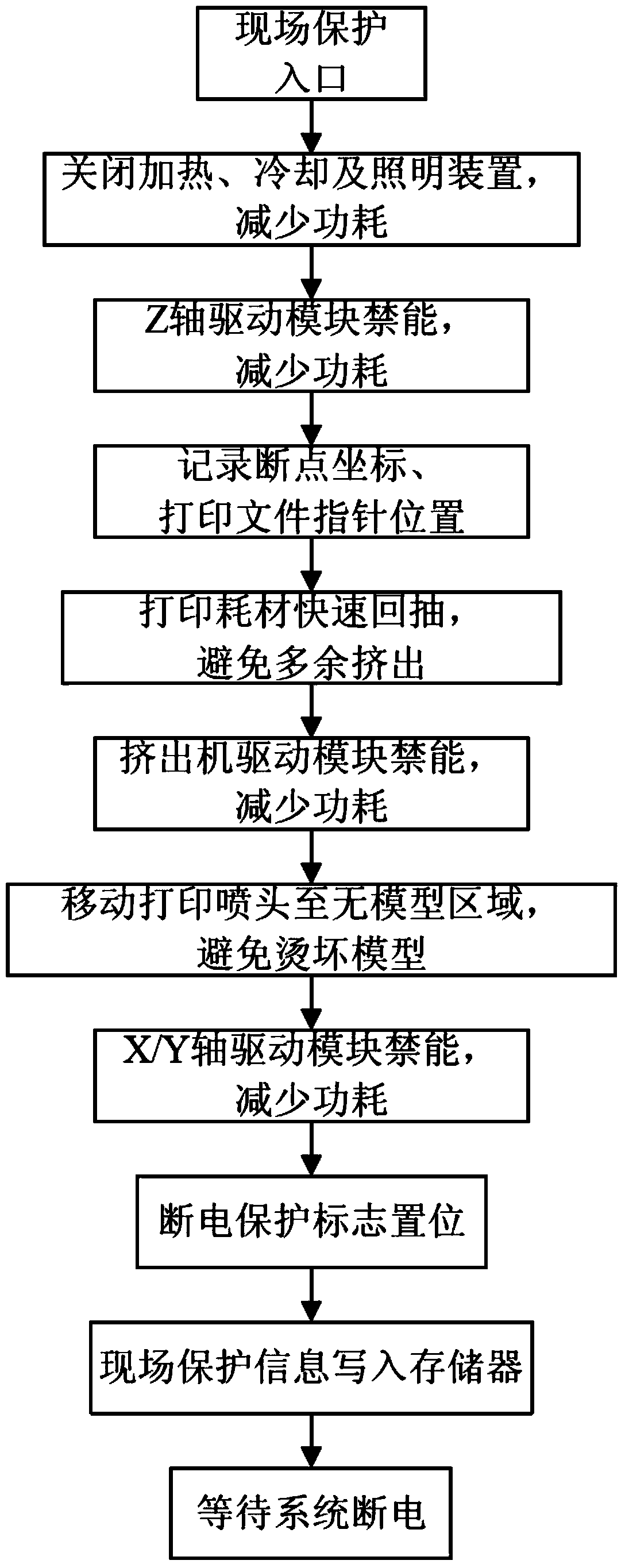

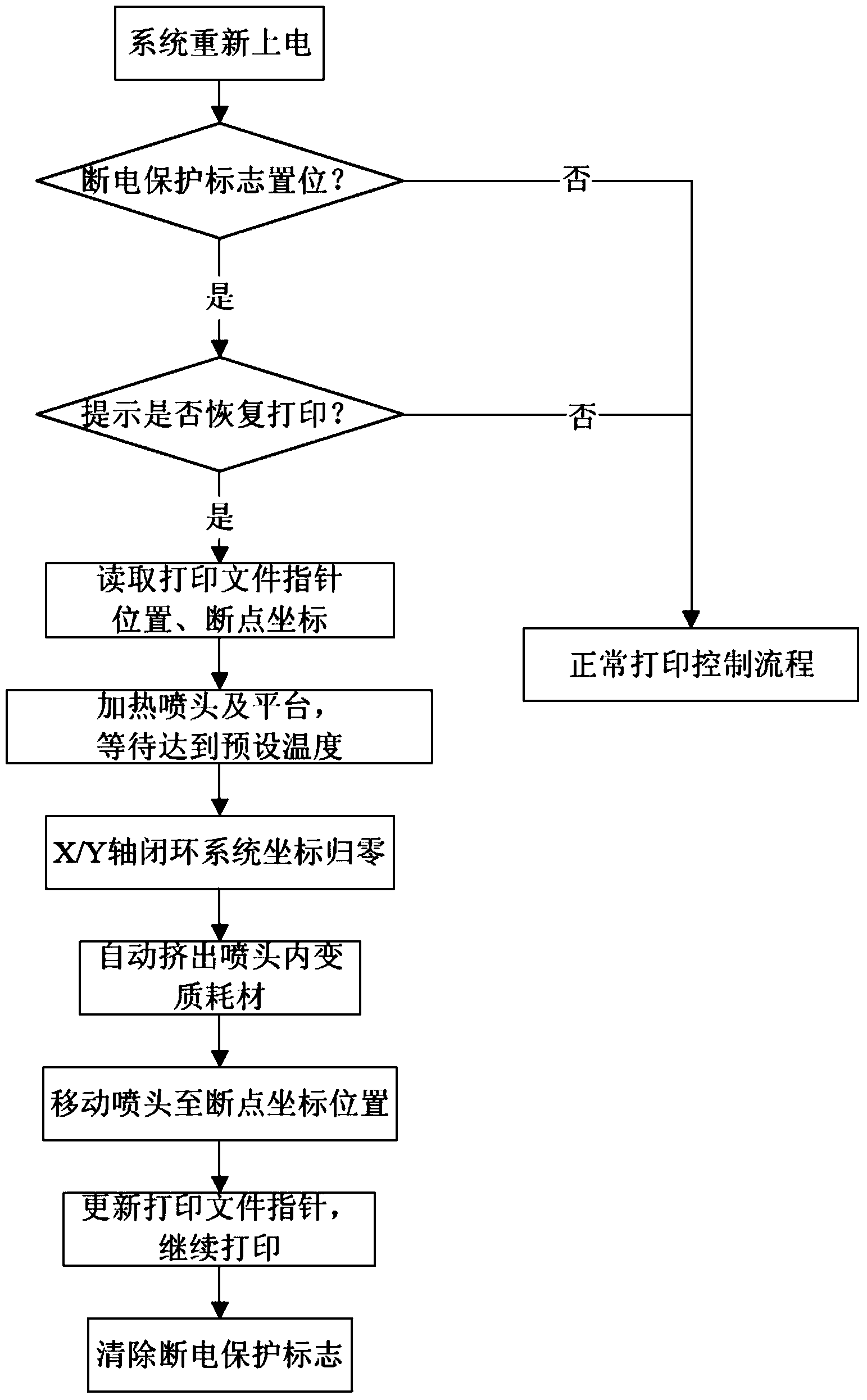

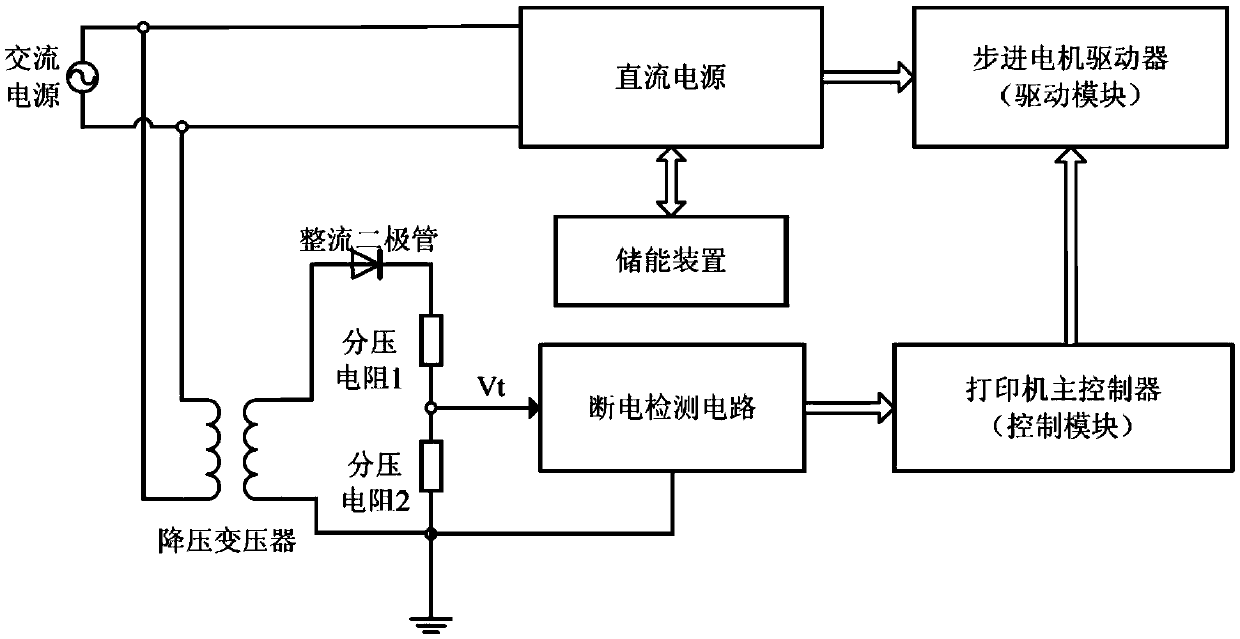

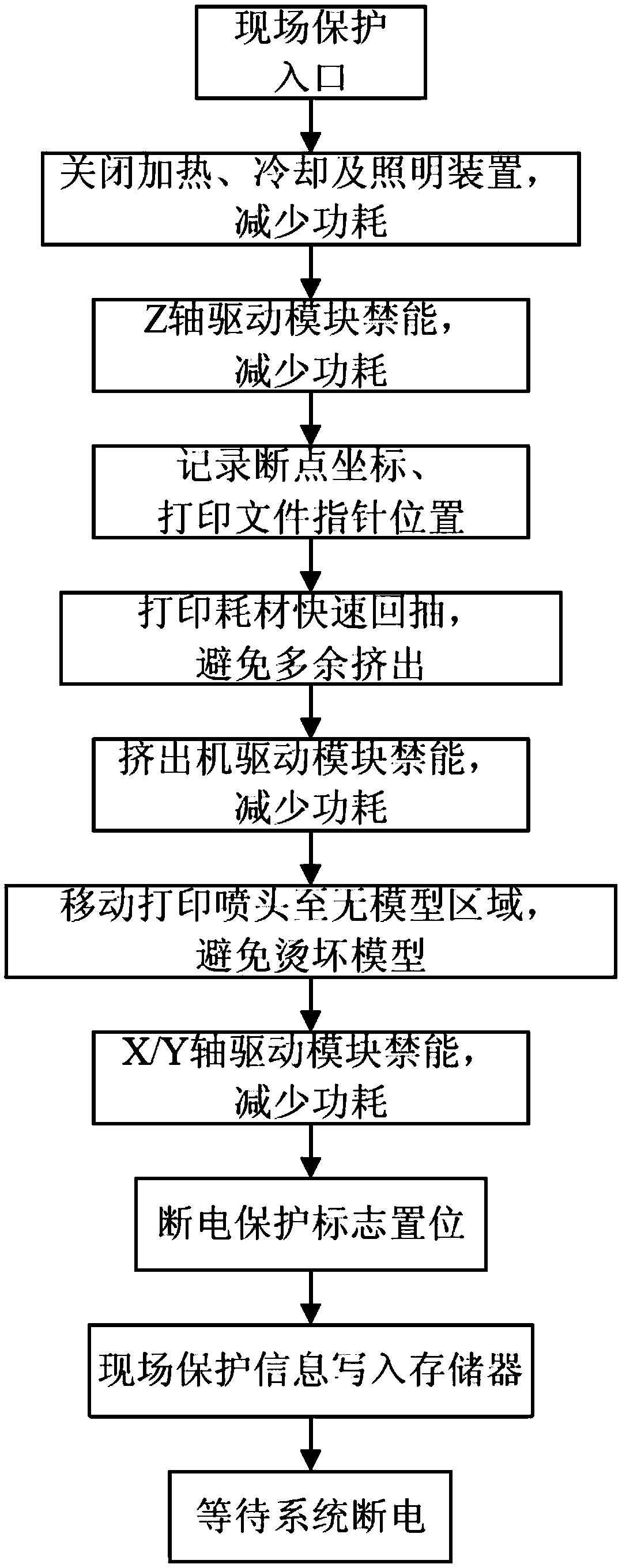

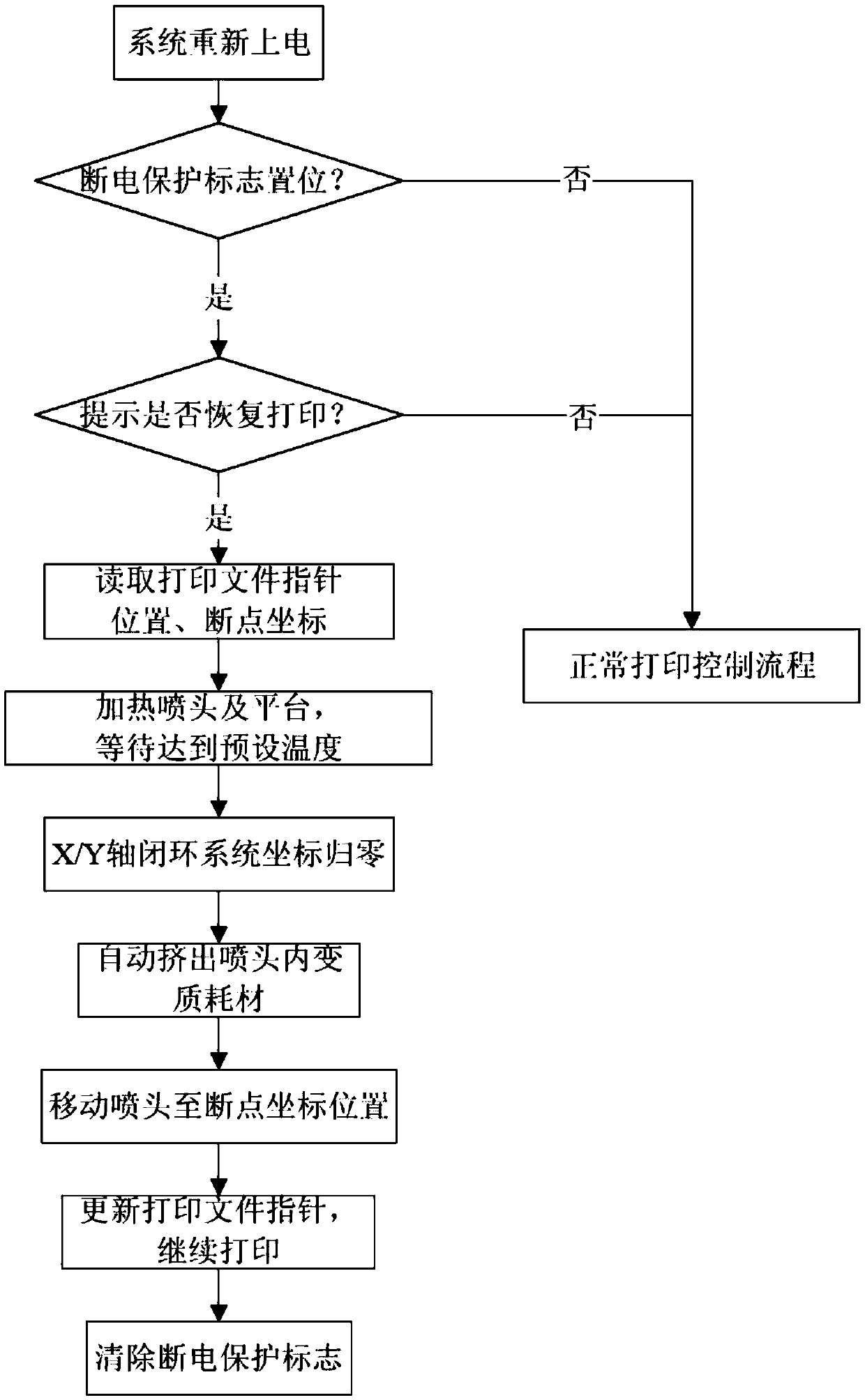

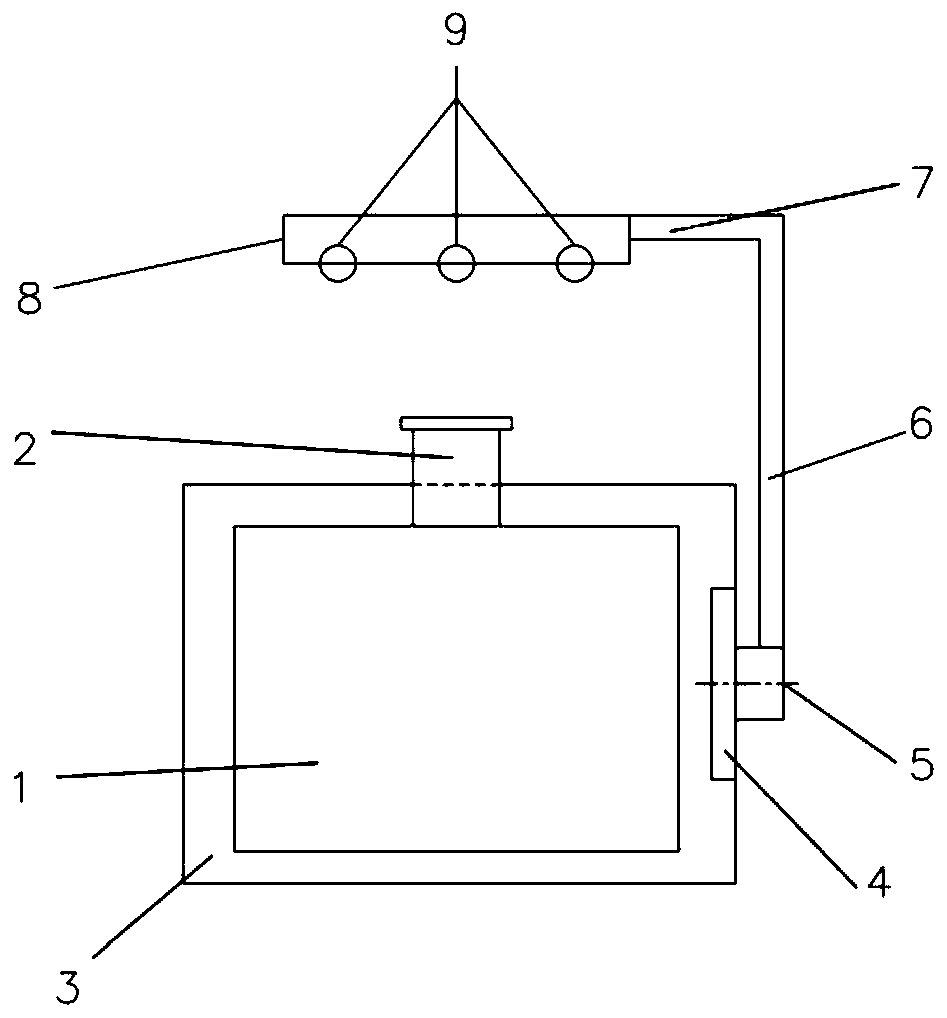

3D printer capable of printing continuously at outage and method for controlling 3D printer to continue printing at outage

The invention relates to a 3D printer capable of printing continuously at an outage and a method for controlling the 3D printer to continue printing at the outage and belongs to the technical field of 3D printing. The 3D printer comprises a power module capable of storing electric energy, an outage detection module used for detecting the power supply state of an external power source, and a control module which controls all components of the printer to switch between the power supply state and the outage state. By means of the method, the printer can use the stored electric energy to record the work state at the outage, and all the components are set to be in the outage state; when power supply is recovered, the printer can be controlled to return to the previous state and continue last work; as a result, reprinting is avoided, consumable items are effectively saved, and the success rate of printing is increased substantially; furthermore, closed-loop control is achieved in cooperation with a displacement detection module, and the accuracy of continuous printing at the outage is further improved. Moreover, the 3D printer capable of printing continuously at the outage is simple in structure, the method for controlling the 3D printer to continue printing at the outage is easy and convenient to implement, and the application range is rather wide.

Owner:PANOWIN TECH

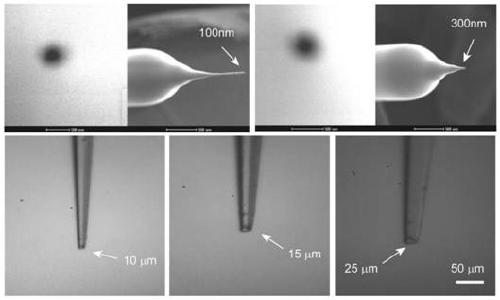

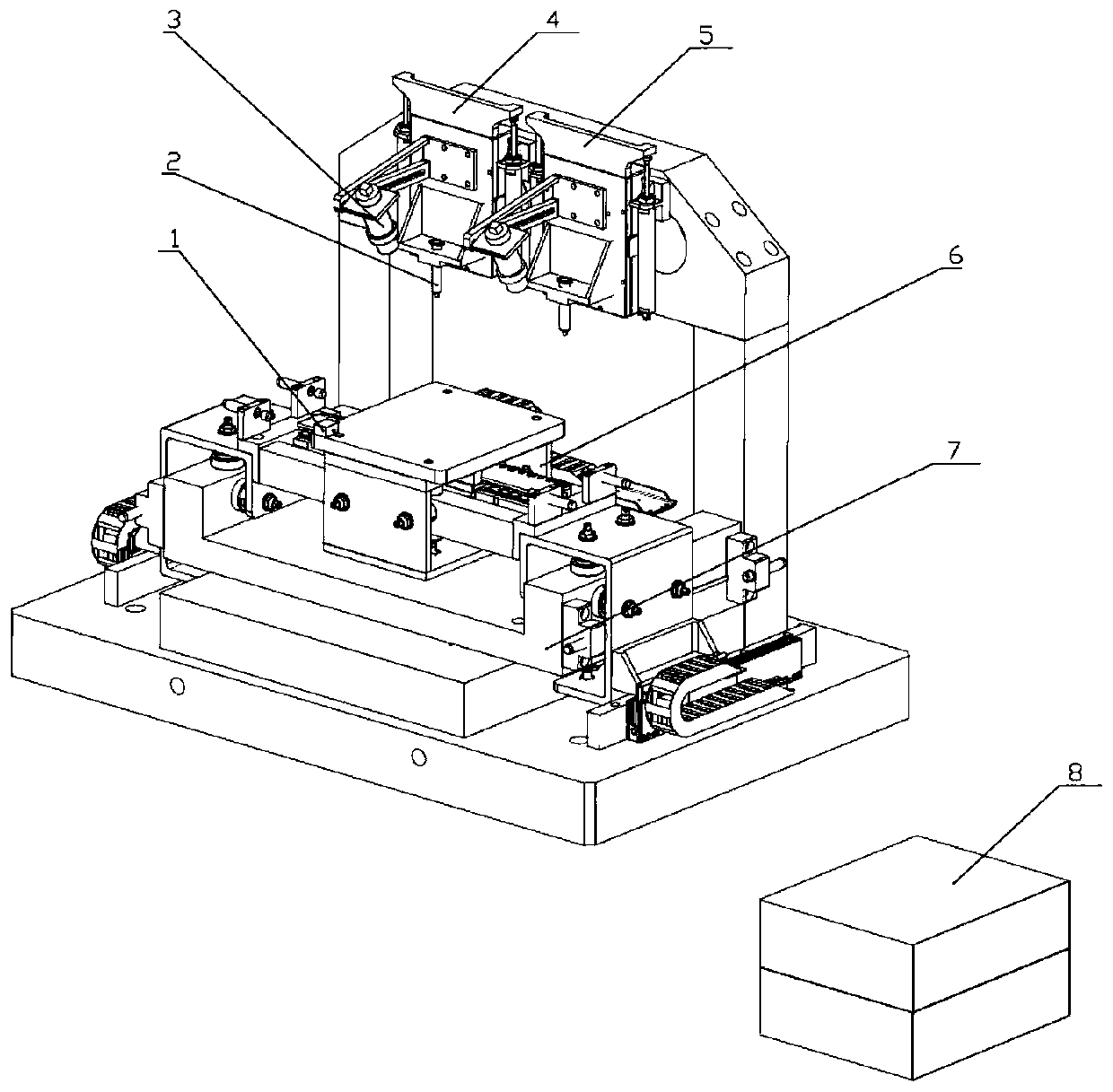

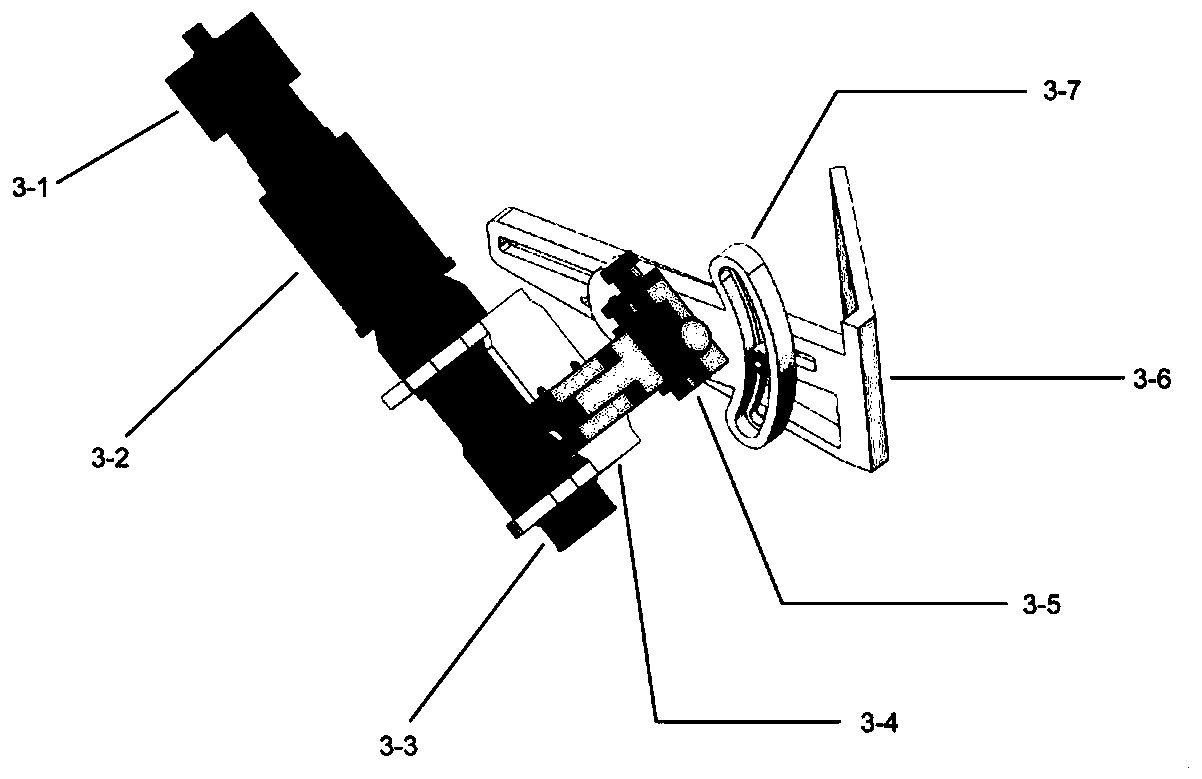

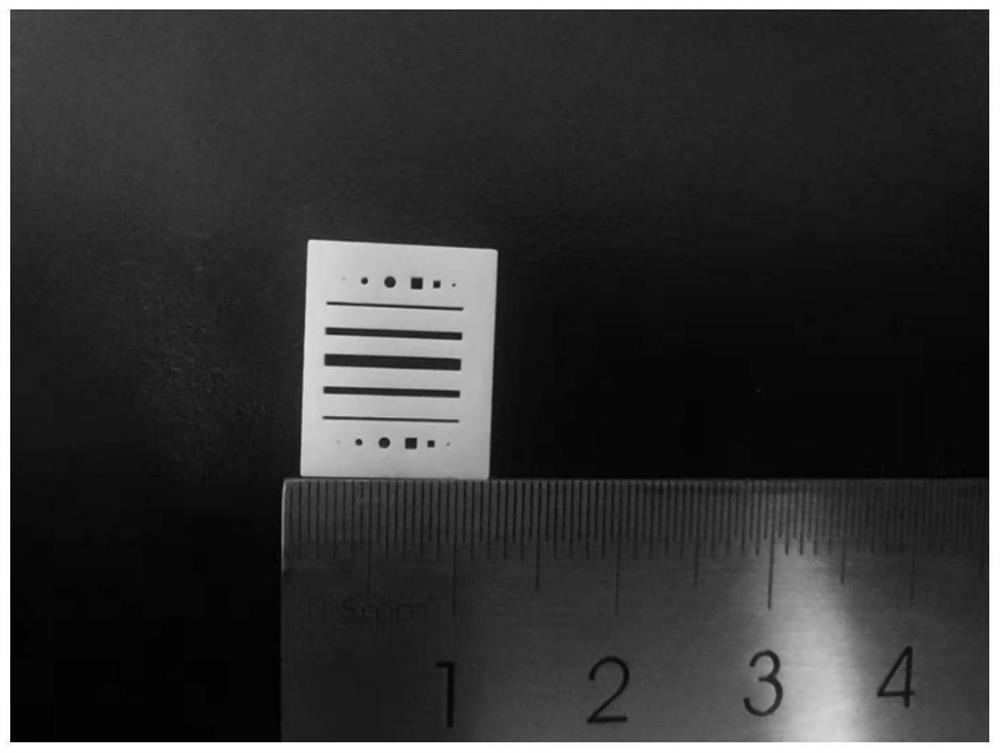

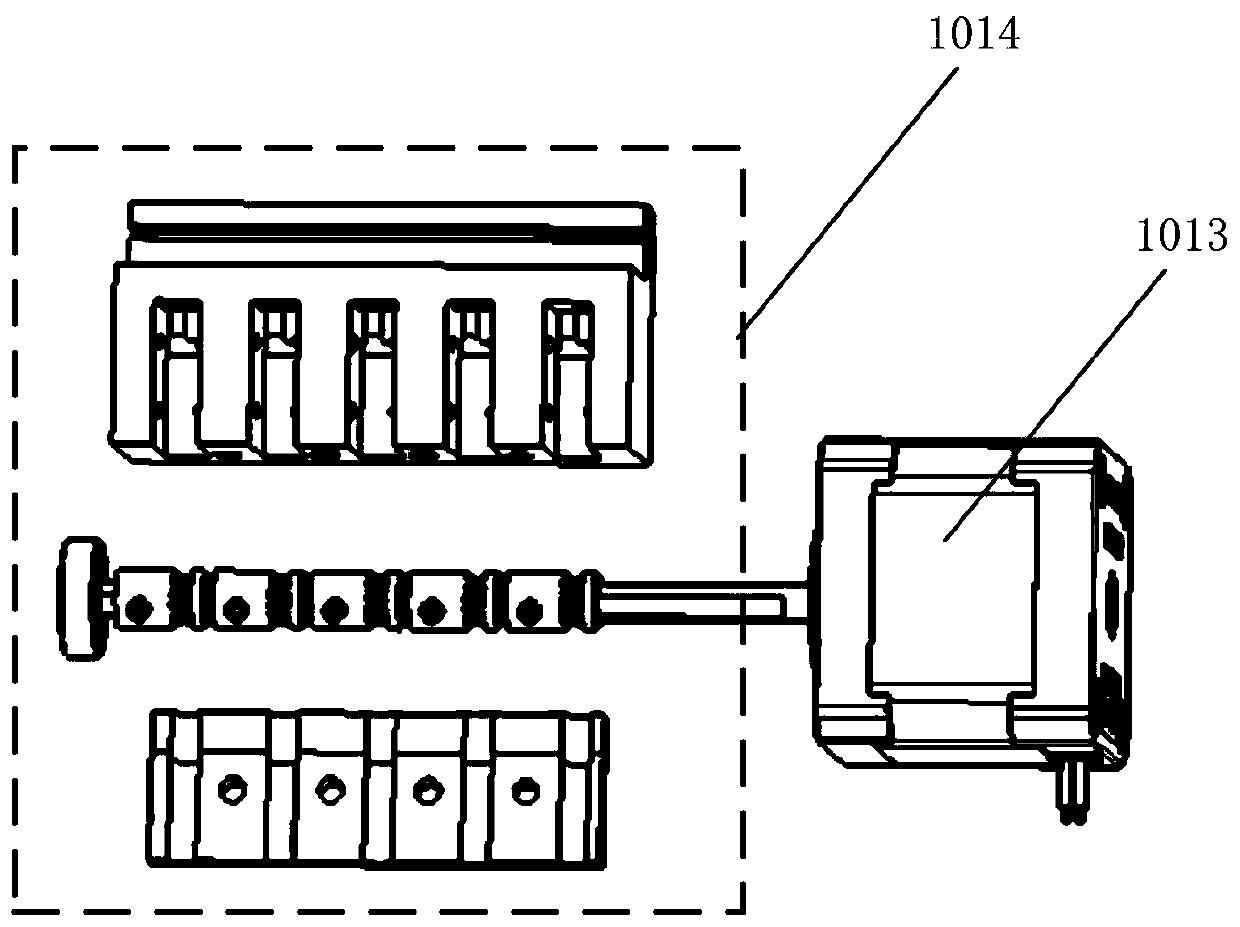

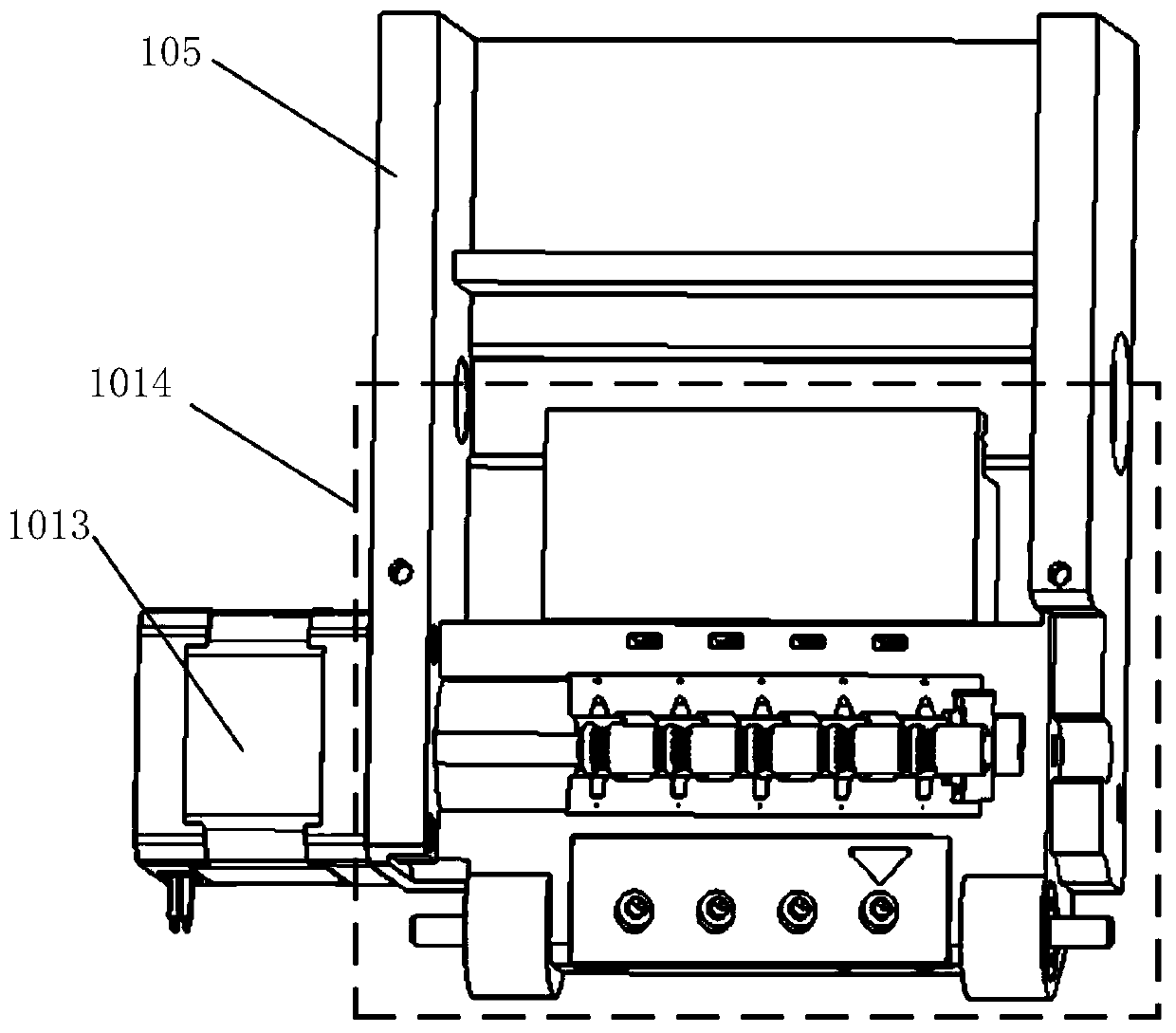

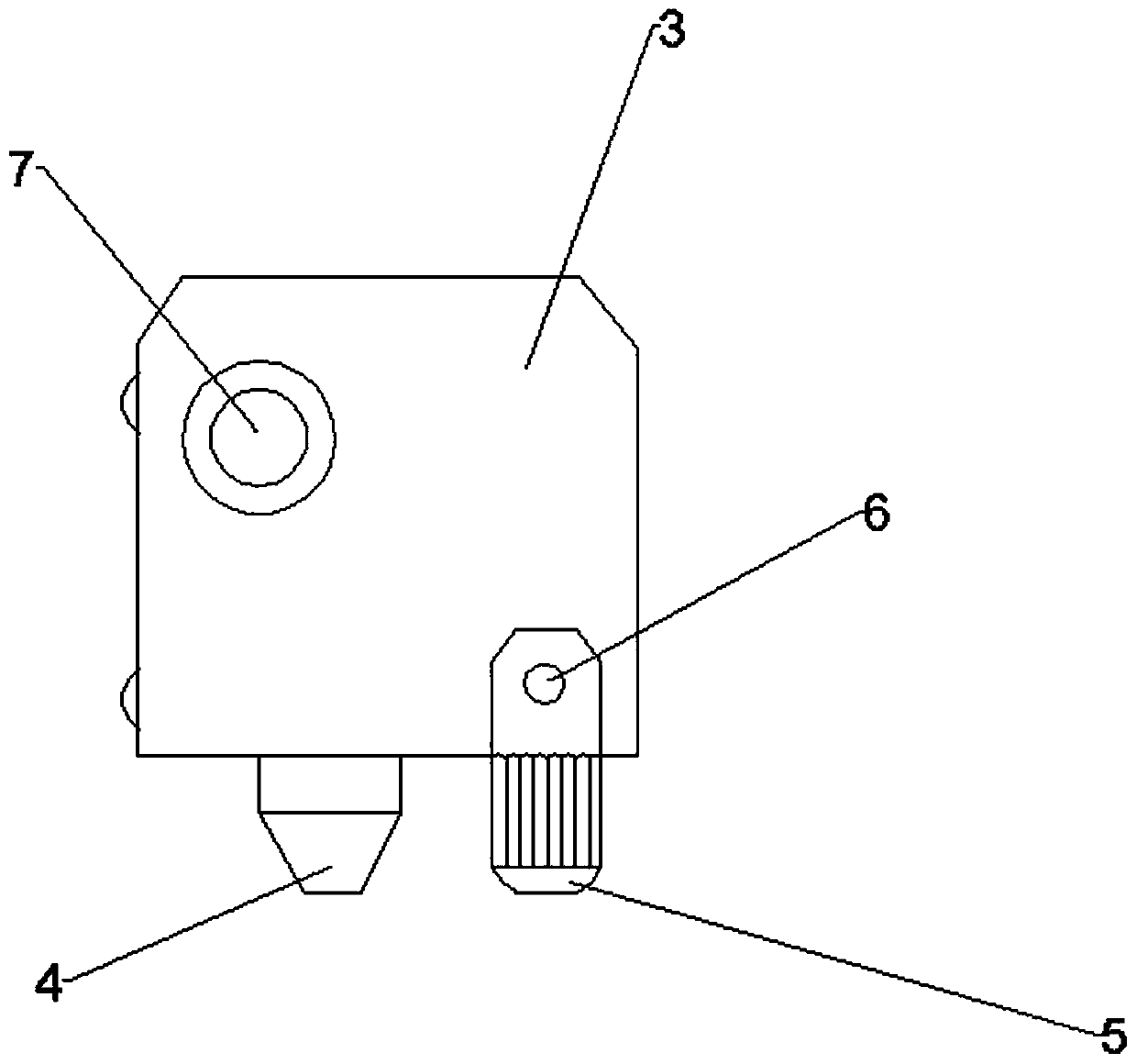

Submicron-precision multi-pin direct writing type 3D printer

PendingCN111070665ARealize motion controlRealize real-time observationManufacturing platforms/substratesAdditive manufacturing with liquidsCMOSComputer printing

The invention provides a submicron-precision multi-pin direct writing type 3D printer comprising material cylinders, a nanoscale-locating-precision three-axis platform, a glue dispensing machine and aprinting platform. Print pins are arranged at the front ends of the material cylinders. The glue dispensing machine is connected with the material cylinders through gas pipes. The nanoscale-locating-precision three-axis platform comprises a X-axis displacement platform, a Y-axis displacement platform and Z-axis displacement platforms. The X-axis displacement platform and the Y-axis displacementplatform are used for adjusting the position of a print platform. The material cylinders are installed on the Z-axis displacement platforms and can move up and down along with the Z axis. Imaging systems following the filament discharging process and printing process of submicron-scale printing pins are arranged above the material cylinders on the Z-axis displacement platforms. Each imaging systemcomprises a CMOS camera, a telecentric lens and an objective lens. Compared with the prior art, the submicron-precision multi-pin direct writing type 3D printer adopts capillary glass micro-pins as printing pins and combines the nanoscale-precision locating platform, the multi-material-cylinder structure, a laser calibrator and the imaging systems, so that high-precision multi-material printing can be achieved.

Owner:WESTLAKE UNIV

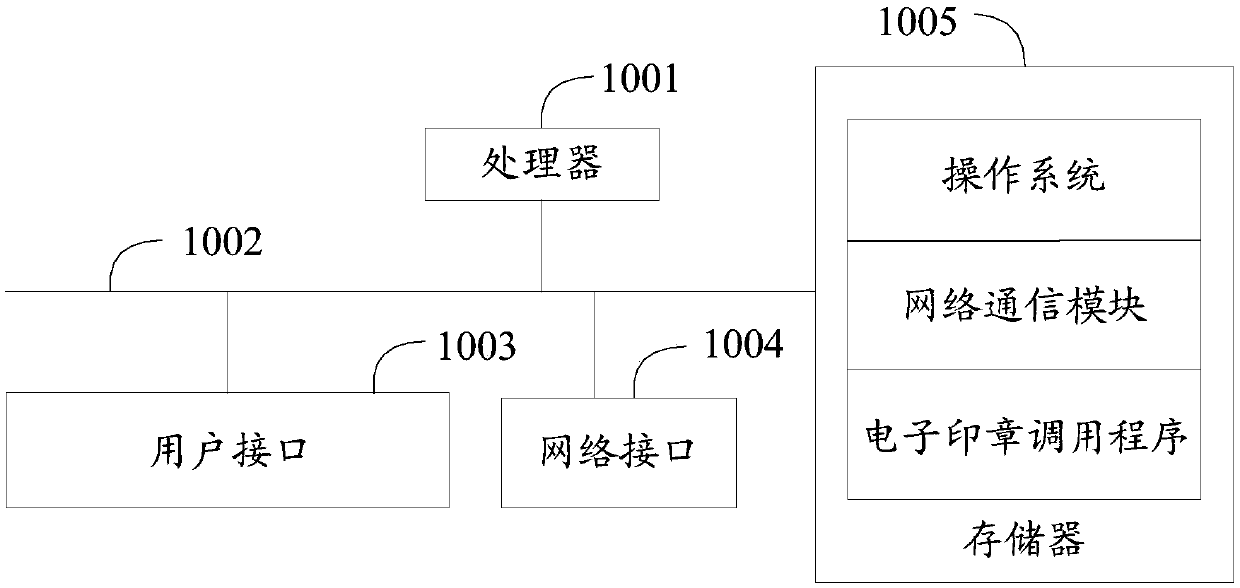

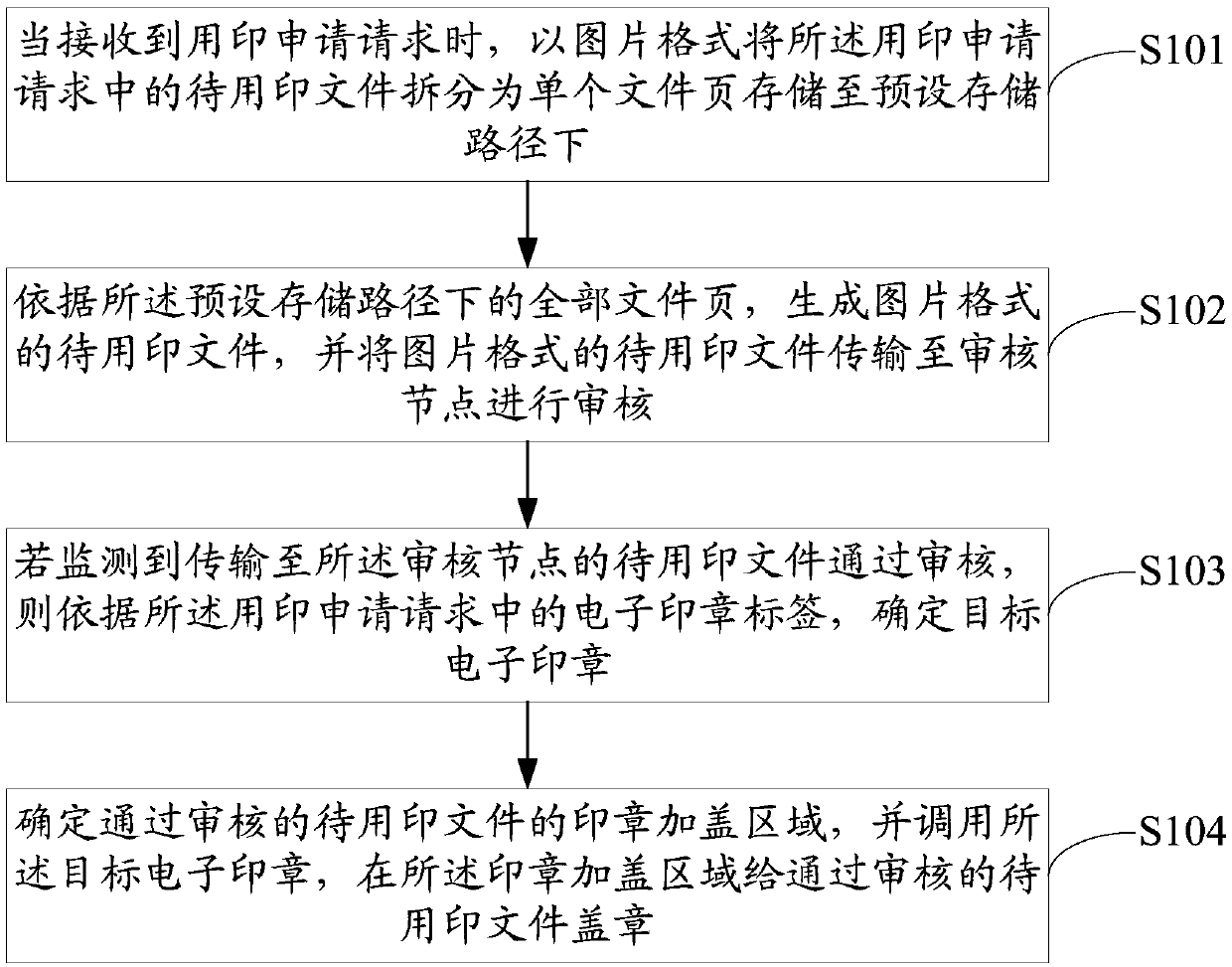

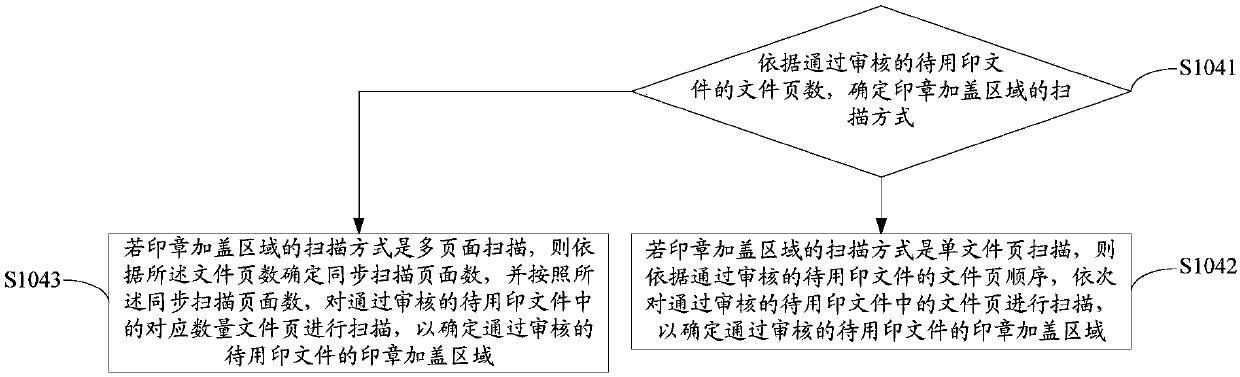

Electronic seal calling method and device, equipment and readable storage medium

PendingCN109947699AImprove printing success rateImprove the efficiency of stampingOffice automationFile system administrationFile transmissionDatabase

The invention provides an electronic seal calling method which comprises the following steps: when a seal application request is received, splitting a file to be sealed in the seal application requestinto single file pages in a picture format, and storing the single file pages in a preset storage path; Generating a to-be-stamped file in a picture format according to all file pages under the preset storage path, and transmitting the to-be-stamped file in the picture format to an auditing node for auditing; If it is monitored that the file to be stamped transmitted to the auditing node passes auditing, determining a target electronic stamp according to an electronic stamp tag in the stamping application request; And determining a seal stamping area of the audited file to be stamped, callingthe target electronic seal, and stamping the audited file to be stamped in the seal stamping area. The invention further provides an electronic seal calling device and equipment and a readable storage medium. According to the invention, the seal use success rate and the seal use sealing efficiency of the electronic seal can be effectively improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

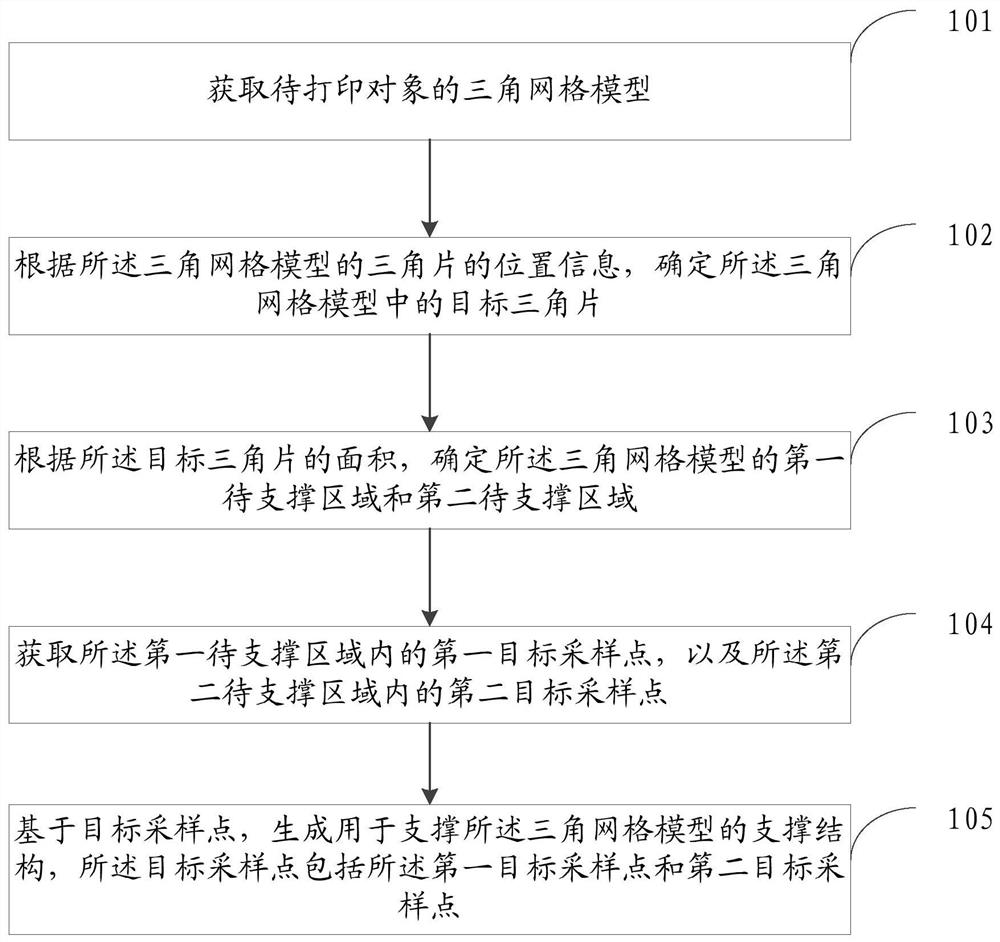

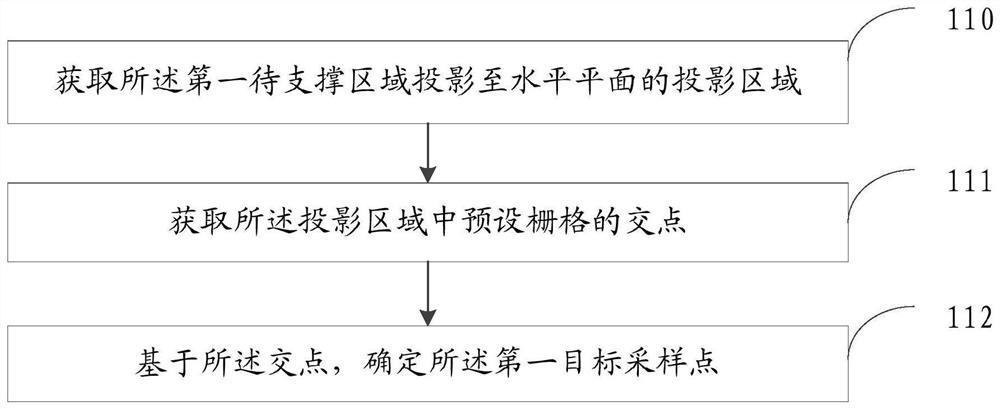

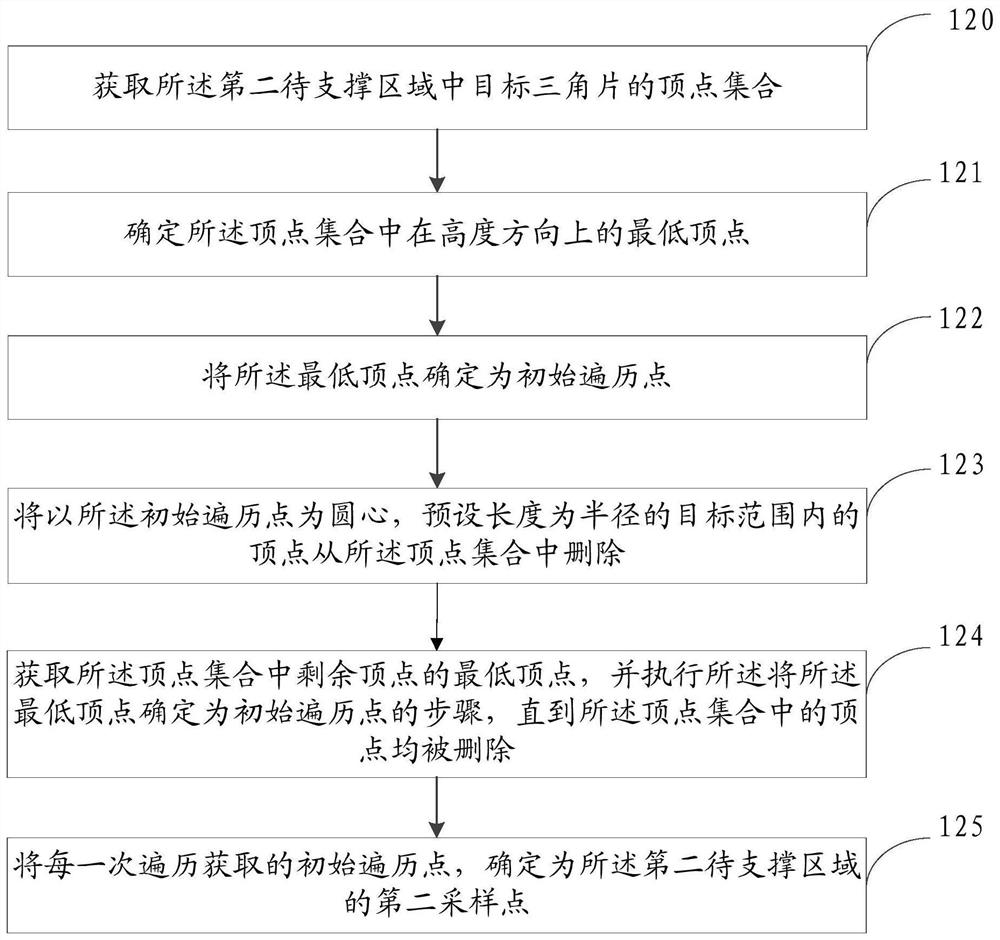

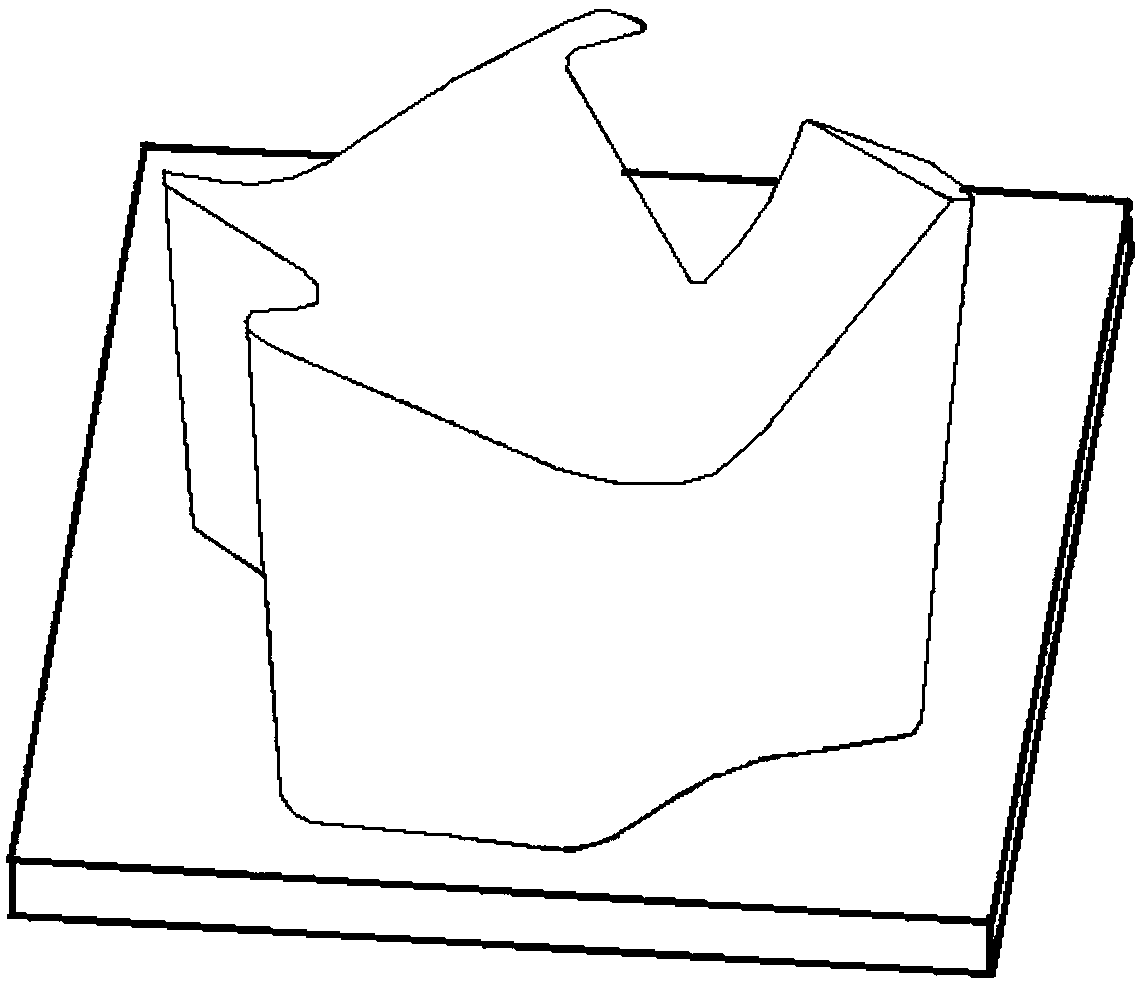

Support structure generation method and device, electronic equipment and storage medium

PendingCN111859488AEvenly distributedAvoid missing detectionGeometric CADDetails involving 3D image dataProcess engineeringStructure generation

The invention discloses a supporting structure generation method and device, electronic equipment and a storage medium, and relates to the technical field of printing. According to the invention, thespecific implementation scheme is that the method comprises the steps: acquiring a triangular mesh model of a to-be-printed object; determining a target triangular plate in the triangular mesh model according to the position information of the triangular plate of the triangular mesh model; determining a first to-be-supported area and a second to-be-supported area of the triangular mesh model according to the area of the target triangular plate; obtaining a first target sampling point in the first to-be-supported area and a second target sampling point in the second to-be-supported area; and generating a support structure for supporting the triangular mesh model based on the target sampling point. Since the target sampling points are obtained separately according to the area of the target triangular plate, the target sampling points can be distributed uniformly, the possibility of missing detection of a tiny support area in the model is avoided, and the printing success rate is improved.

Owner:SHENZHEN ANYCUBIC TECH CO LTD

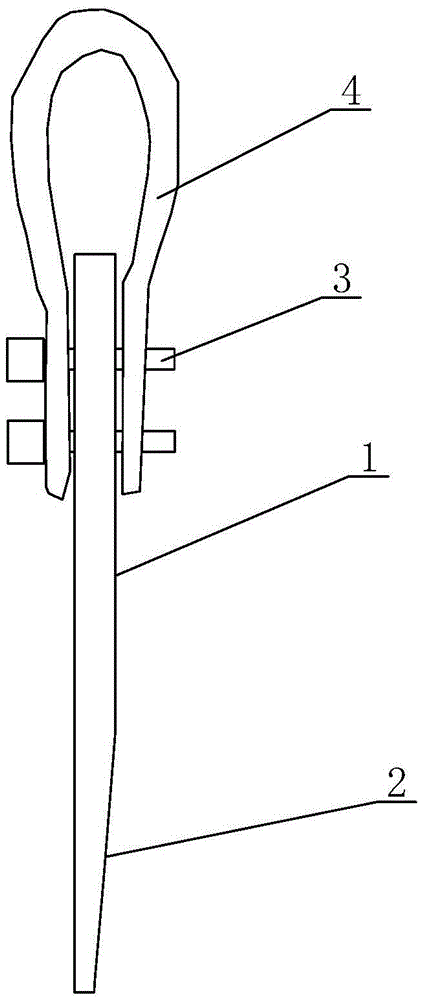

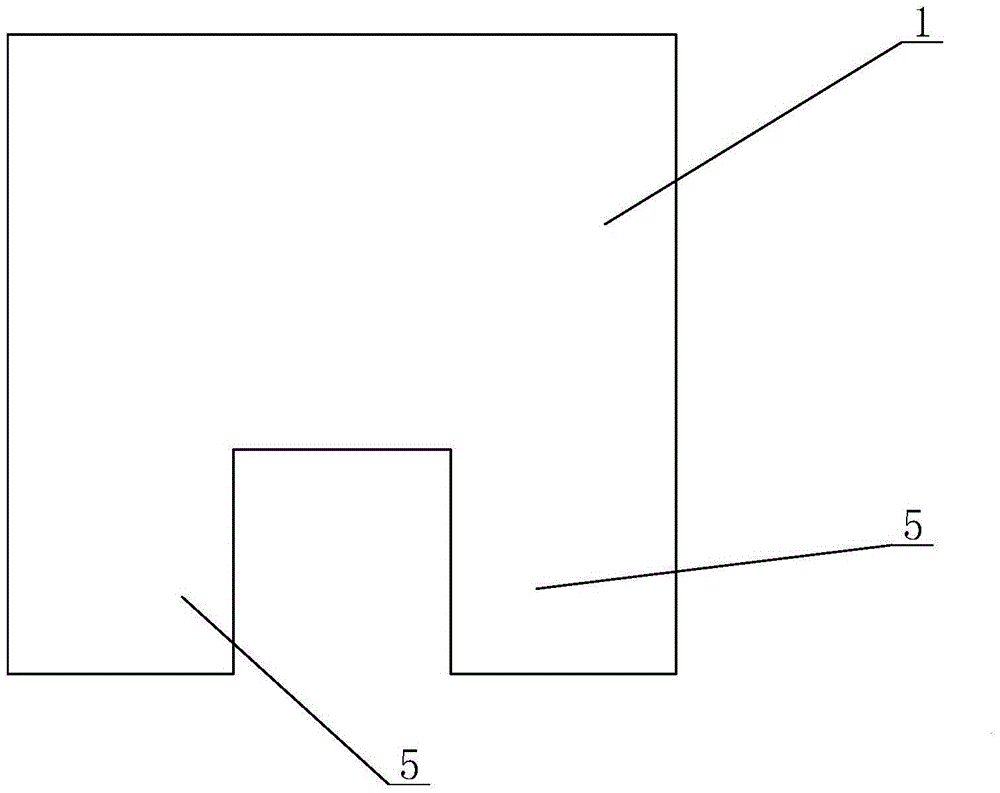

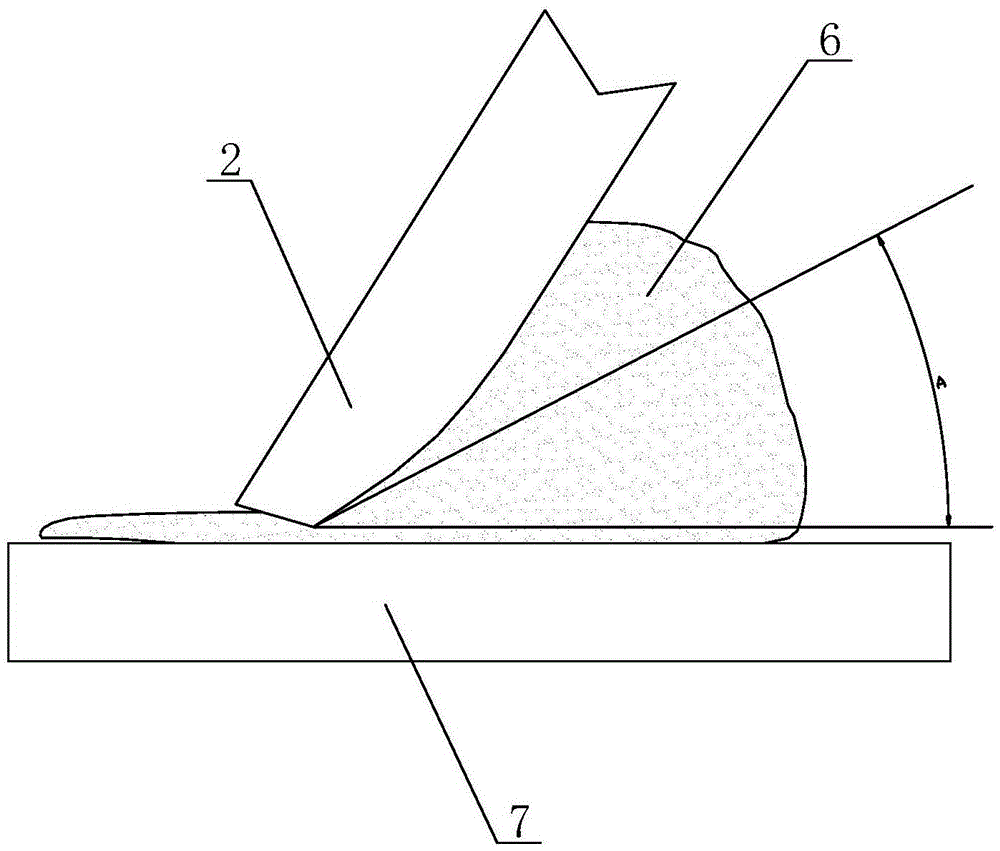

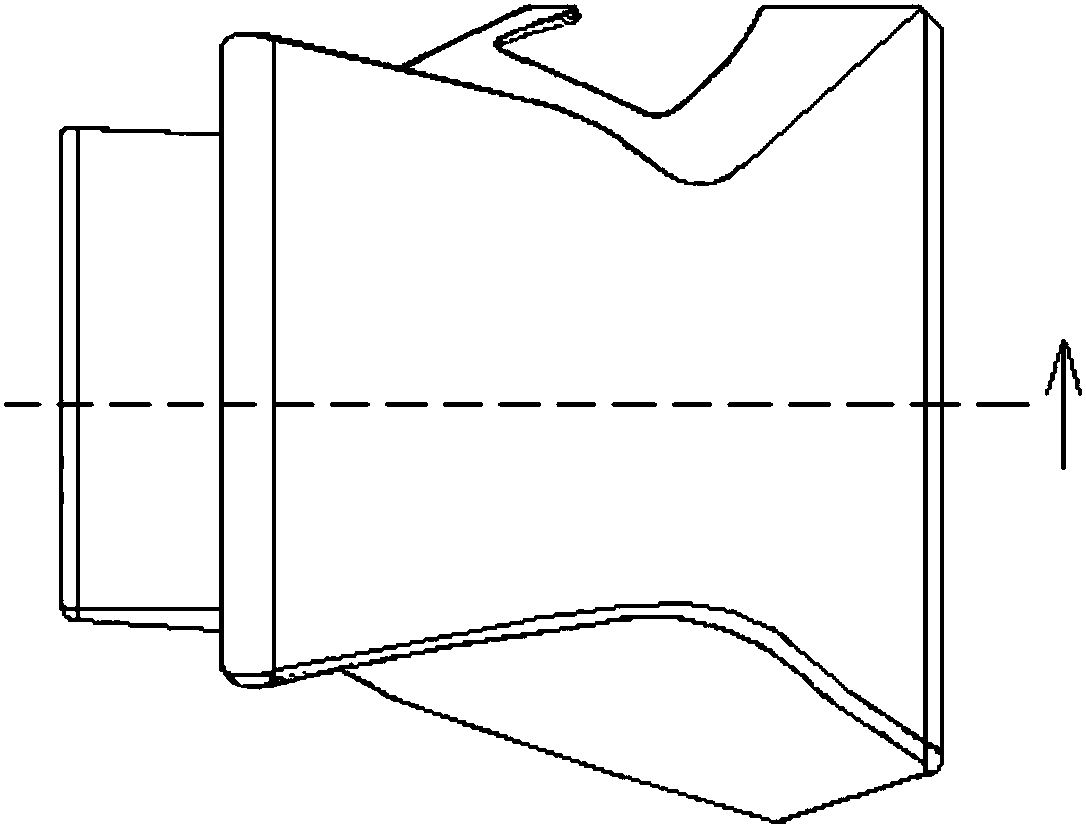

Scraper structure and glue application method

InactiveCN105107686AReduce adhesionImprove the detachment effectLiquid surface applicatorsCoatingsStencil printingRelative motion

The invention discloses a scraper structure and a glue application method. The scraper structure comprises a body and a head. One end of the body is provided with a fastening handle, and the other end thereof is provided with the head. The width of the section of the head gradually decreases. In the glue application method, the head and a printing plate form an entry angle 10-40 degrees and a separating angle 10-40 degrees. In the scraper structure and the glue application method, the head of the scraper is designed a manner wherein the width of the section gradually decreases, so that the bottom of the scraper forms small gathering entry angle and separating angle 10-30 degrees, glue scraping and glue coating processes are smooth and meet hydromechanics principle, scraping thickness non-uniformity and bubbles caused by abrupt changes in sectional area of relative motion of the scraper and glue in conventional metal stencil printing are decreased, printing success rate and controllability are improved, printing quality can be improved, glue waste can be decreased, printing resistance is decreased, and production process convenience is improved.

Owner:无锡佰利兄弟能源科技有限公司

Zirconia ceramic paste and preparation method thereof

PendingCN112759386AImprove stabilityAvoid flowAdditive manufacturing apparatusPhotoinitiatorSolid content

The invention discloses a preparation method of zirconium oxide ceramic paste and the zirconium oxide ceramic paste thereof. The preparation method of the zirconium oxide ceramic paste comprises the following steps: (1) uniformly mixing and stirring zirconium oxide powder, a macromolecular dispersant and ethanol, and then performing ball-milling, sieving, drying and crushing to obtain mixed powder; (2) mixing and stirring the mixed powder, photosensitive resin and a photoinitiator to obtain zirconia ceramic paste; (3) adding a thixotropic agent into the zirconia ceramic paste in a stirring state, and performing grinding and refining to obtain zirconia ceramic paste, wherein the volume percent of the zirconia powder in the zirconia ceramic paste is 50-70%, and the zirconia ceramic paste prepared by the method has high solid content, high thixotropic property and relatively high stability.

Owner:DONGGUAN UNIV OF TECH +3

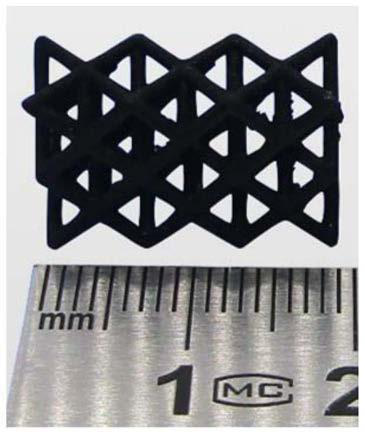

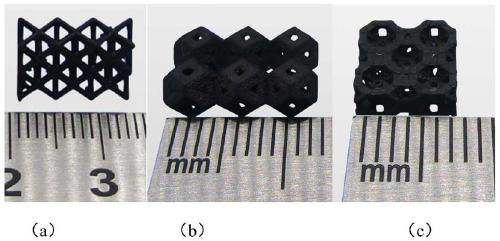

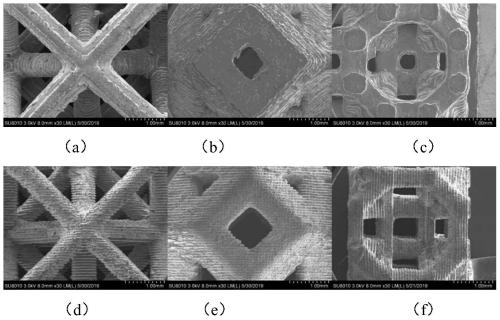

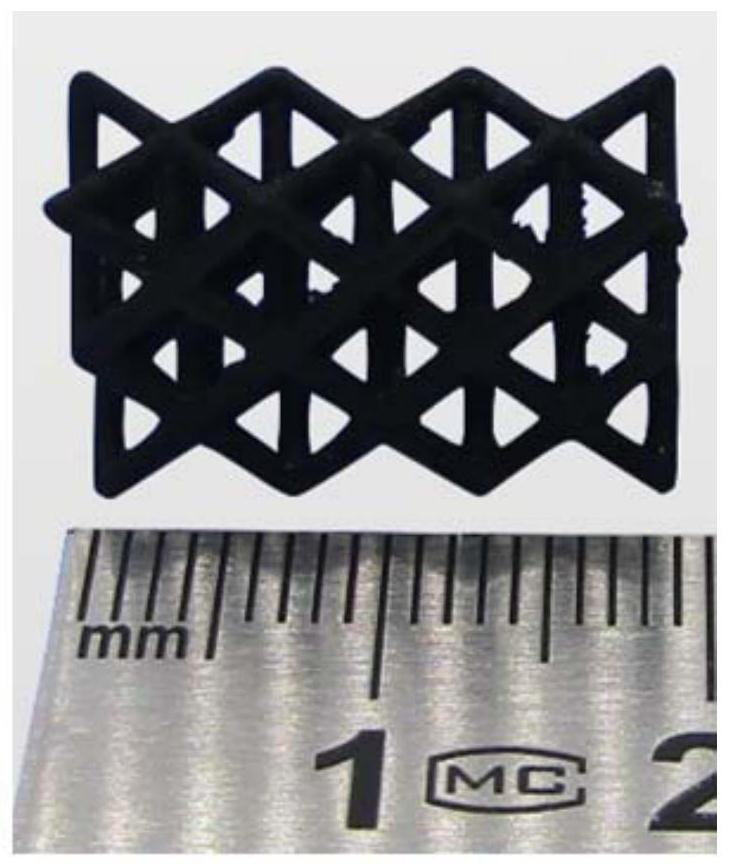

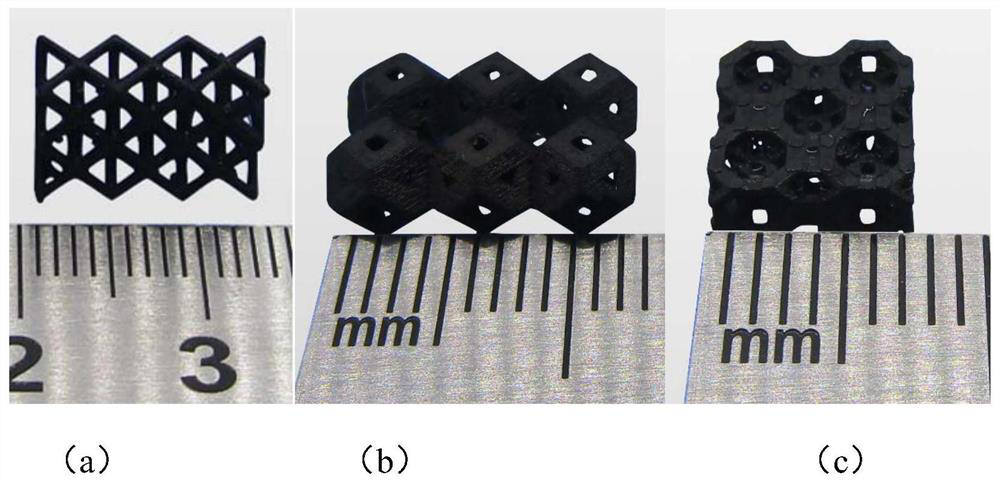

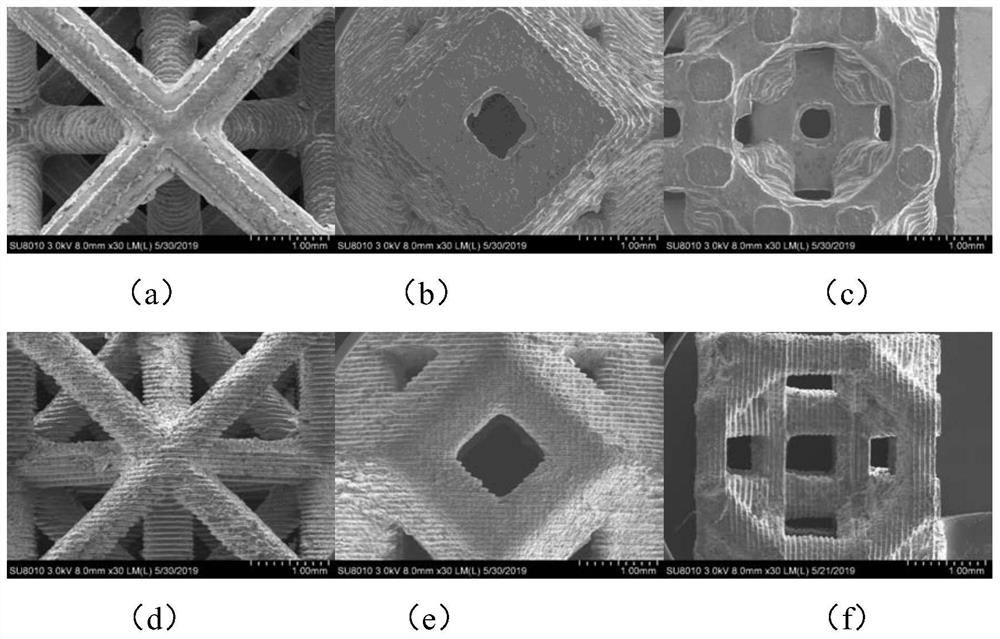

Photocuring 3D printing SiCN ceramic precursor material and application thereof

ActiveCN110451986ALow viscosityImprove green toughnessAdditive manufacturing apparatusCeramic shaping apparatusSolid componentCarbon nanotube

The invention provides a photocuring 3D printing SiCN ceramic precursor material. The precursor material comprises, by weight percentage, 40-75% of a prepared liquid precursor, 20-65% of acrylic active monomers, 0.1-5% of a photoinitiator, 0.1-1% of a light absorber, 0.1-2% of a leveling agent and 0.1-2% of a defoaming agent, wherein the light absorber is a carbon nanotube. A method of applying the precursor material in photocuring 3D printing to obtain a SiCN ceramic material is also provided. According to a formula, it is not needed to add solid components such as ceramic powder and clay. Aproduct has no impurity elements, the ceramic yield is high, and the precursor material is suitable for rapidly preparing SiCN ceramic products of high-precision special-shaped structures and periodiccomplex structures.

Owner:NAT UNIV OF DEFENSE TECH

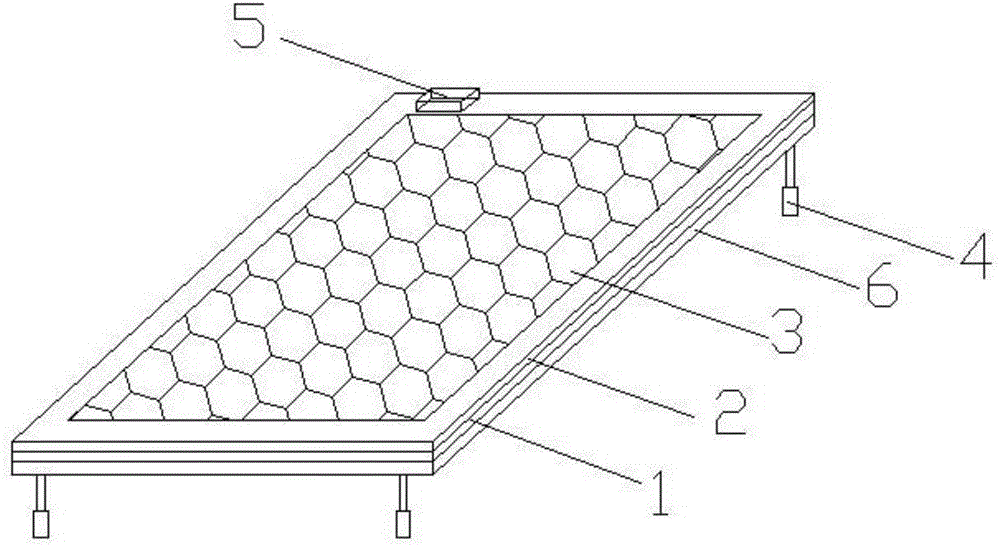

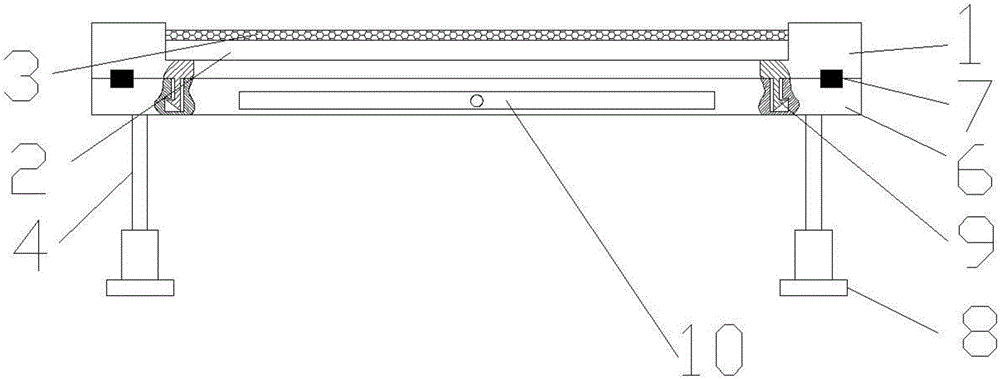

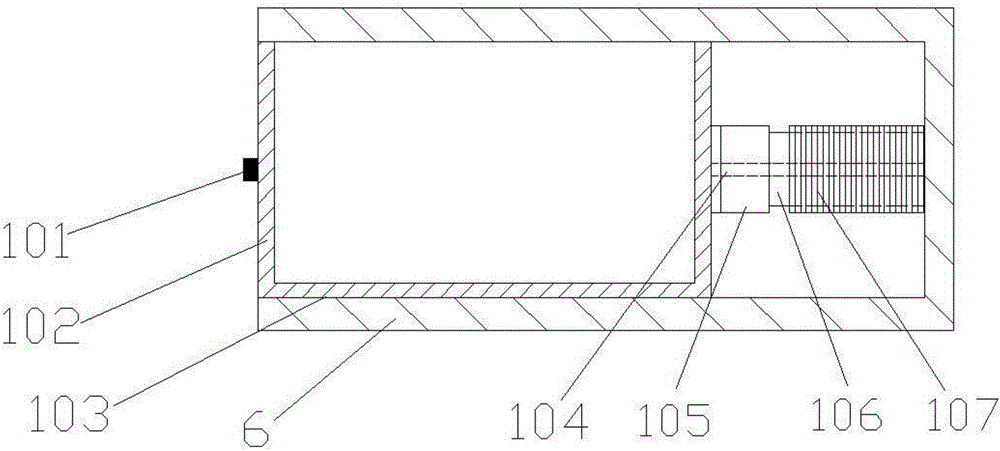

Baseplate of 3D printer

InactiveCN107521105ASimple structureEffectively stickManufacturing platforms/substrates3d printCopper wire

The invention discloses a baseplate of a 3D printer. The baseplate of the 3D printer comprises a connecting plate, a PC plate, a hot melting adhesive layer, an anti-bonding pattern, hydraulic extension rods, a level and an automatic drawer device; the PC plate is a main body of the baseplate, and is provided with a buckle on the lower surface; the connecting plate is arranged on the lower surface of the PC plate; magnets are respectively arranged on the connecting plate and the PC plate; the hot melting adhesive layer is arranged on the upper surface of the PC plate; the anti-bonding plate is arranged on the surface of the hot melting adhesive layer; four hydraulic extension rods are provided and in threaded connection with the connecting plate, and antiskid pads are arranged at the lower ends; the level is positioned on the left side of the upper end of the PC plate; the automatic drawer device comprises a switch button, a drawer and an extension mechanism; the extension mechanism comprises a shell, a magnet, an iron core and a copper wire; the magnet and the iron core are arranged in the shell; and the copper wire is wound on the iron core. The baseplate of the 3D printer can perform printing without needing heating, is easy to bond a printing material, is convenient to take parts, simple in structure, safe and environment-friendly, and can effectively increase the printing success rate.

Owner:江苏天泽教育咨询有限公司

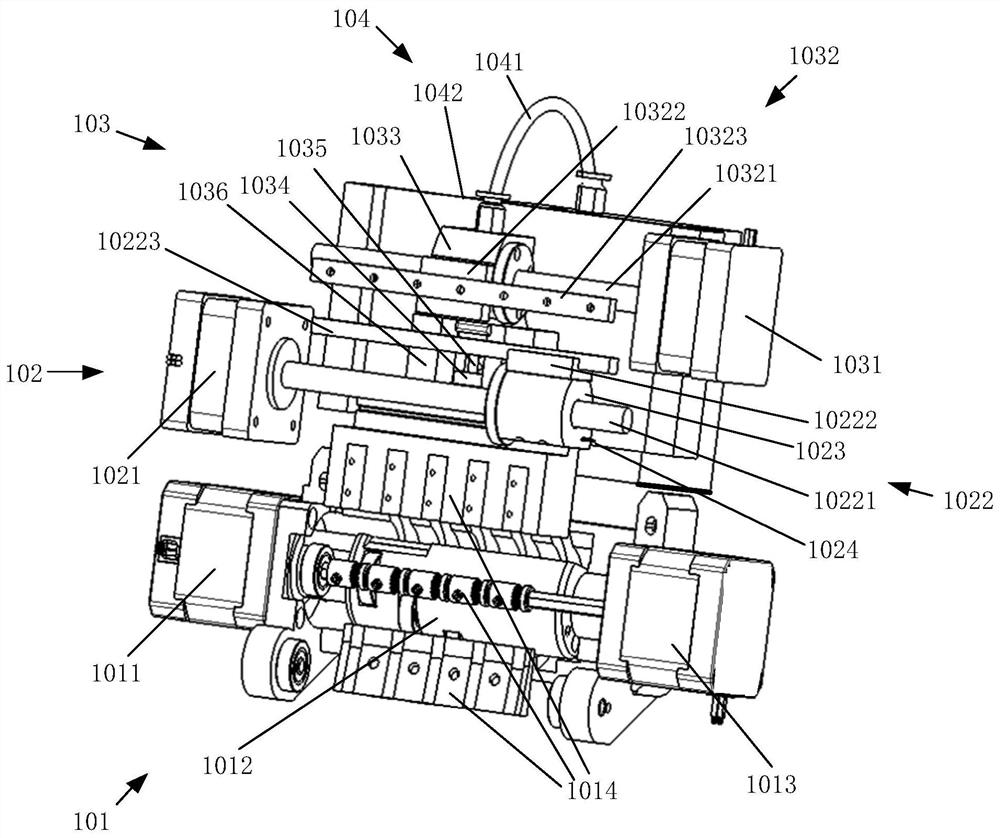

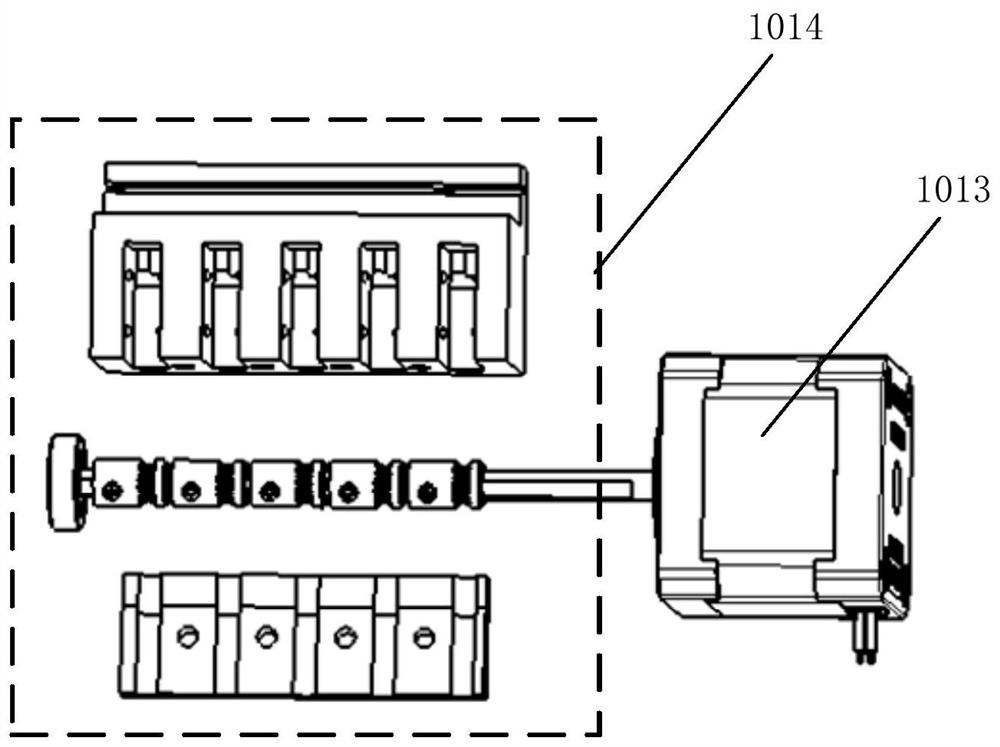

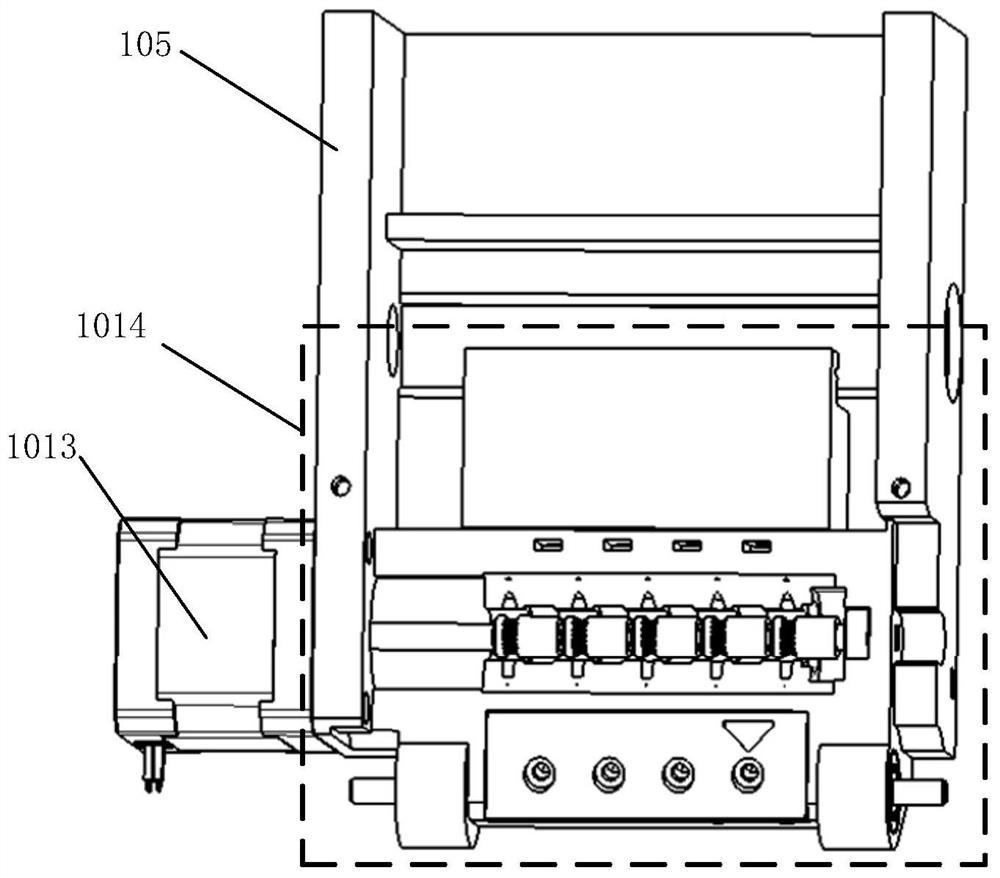

Printing color separation equipment, 3D printing system and 3D printing method

ActiveCN110561751AGuaranteed stabilityGuaranteed printing accuracy3D object support structuresManufacturing data aquisition/processingMulti materialOutput device

The invention relates to printing color separation equipment, a 3D printing system and a 3D printing method. The printing color separation equipment comprises a main control device, a feeding device,a consumable cutting device, a consumable melting device and a consumable output device; the main control device analyzes consumable information obtained beforehand to generate consumable control information; the feeding device conveys corresponding initial consumables based on material color selecting instructions and feeding instructions; if the main control device detects that the conveying quantity of the initial consumables reaches a consumable quantity, the consumable cutting device is controlled to move a consumable position to cut the initial consumables to obtain cut consumables; theconsumable melting device is controlled to move to the consumable position; the cut consumables are fed in a consumable channel, and are molten with the consumables retained at the last time to obtainmolten consumables; and the consumable output device processes the molten consumables to generate multi-color consumables. A single-nozzle 3D printer can realize multi-color and multi-material 3D printing by using the multi-color consumables corresponding to models to be printed; and the multi-color and multi-material 3D printing precision and stability are guaranteed.

Owner:郑尚

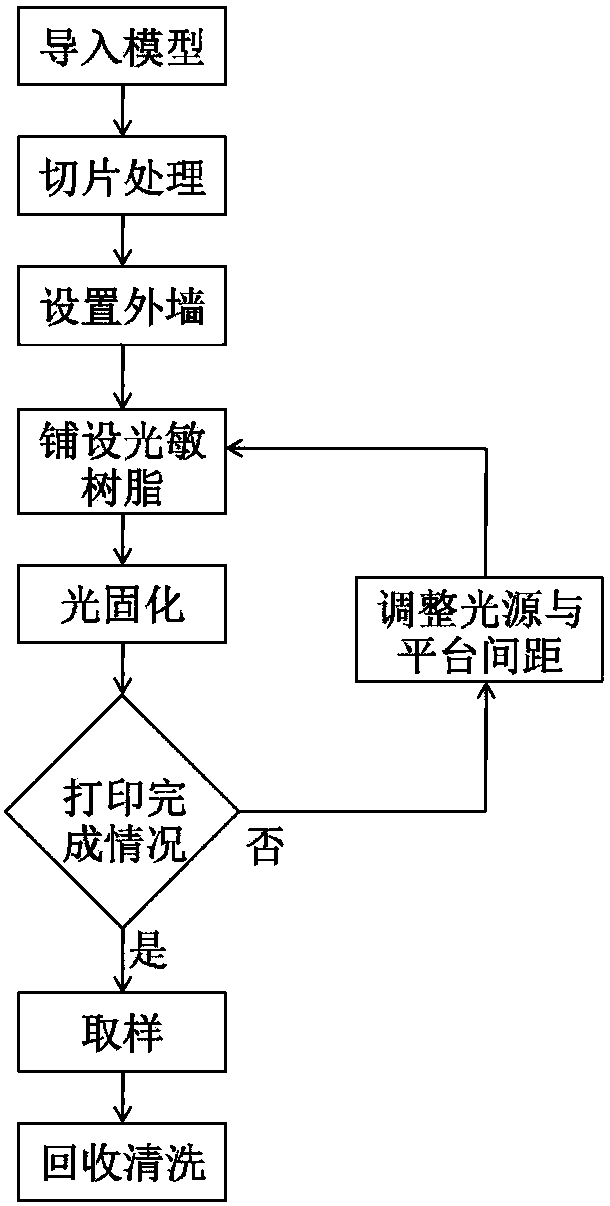

Photosensitive resin printing method without solid supporting

InactiveCN108582766AImprove molding qualityGood surface treatmentAdditive manufacturing apparatus3D object support structuresLiquid stateEngineering

The invention discloses a photosensitive resin printing method without solid supporting. Continuous closed outer walls are synchronously cured at the outer peripheries of workpieces, so that liquid-state photosensitive resins not cured in the outer walls fixedly wrap the cured workpieces, solid support pieces in the traditional printing process are omitted, the printing process is simplified, theproduction efficiency is improved, the workpiece forming quality is high, and the surface treatment is convenient; the liquid-state photosensitive resins are fully dispersed and refined before use, sothat the stability of resin layers is guaranteed, reliable supporting can be provided for the cured workpieces, the printing success rate is high, and the support removing workload after printing isreduced; and meanwhile, wastes are not generated in the whole printing process, and the photosensitive resins not cured can be recycled, so that the production raw material cost is prominently reduced.

Owner:无锡映型三维数字技术有限公司

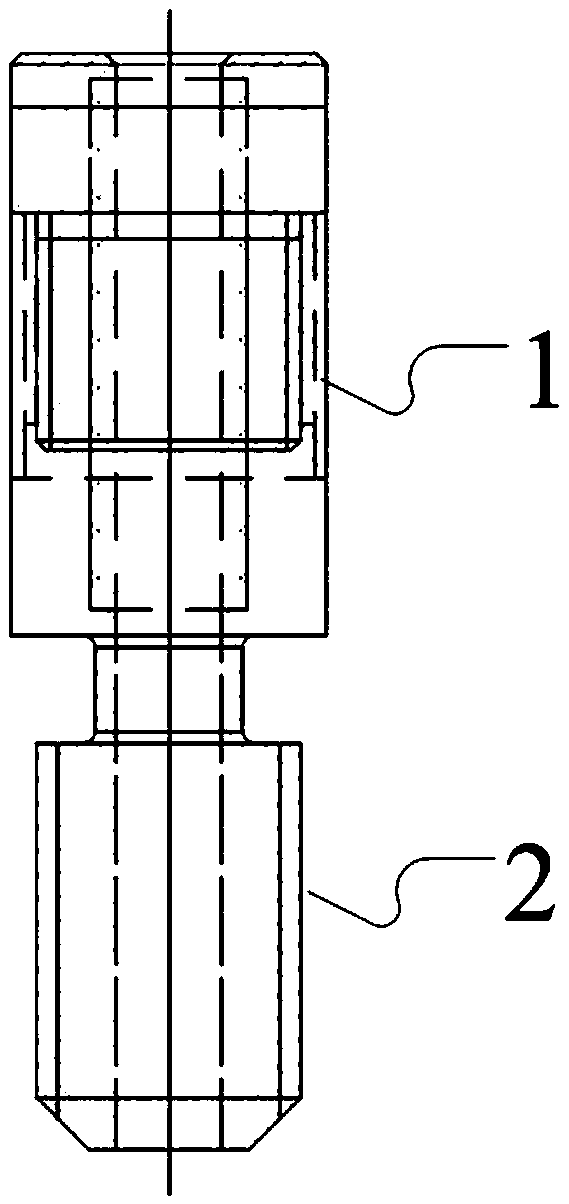

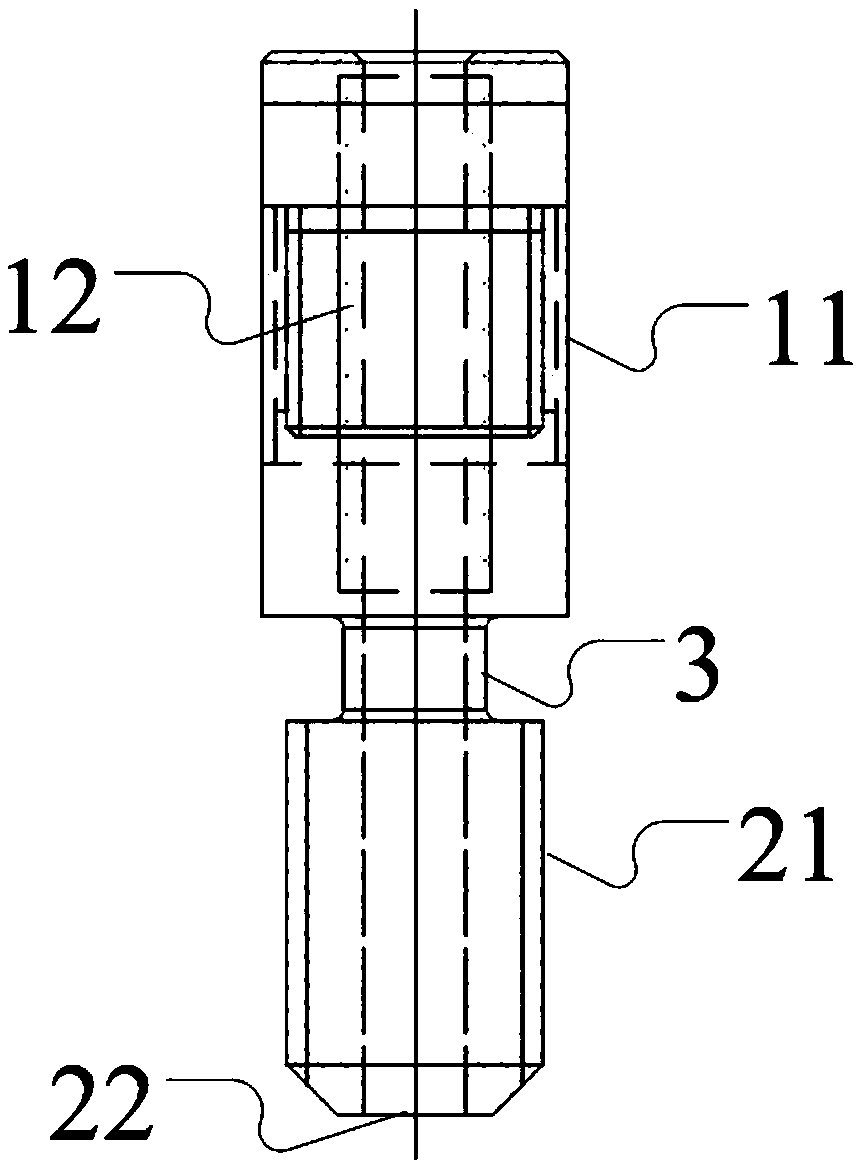

Throat pipe structure for 3D printer, nozzle device and desktop grade 3D printer

PendingCN109514860AControl the amount of extrusionControl feedManufacturing heating elements3D object support structures3d printTitanium

The invention discloses a throat pipe structure for a 3D printer, a nozzle device and a desktop grade 3D printer. The throat pipe structure comprises a heat dissipating cold area and a heating hot area. The heat dissipating cold area comprises a titanium throat pipe outer pipe body and a polytetrafluoroethylene throat pipe inner pipe body. The polytetrafluoroethylene throat pipe inner pipe body issleeved with the titanium throat pipe outer pipe body. The heating hot area comprises a heating block connecting area and a nozzle connecting area. The heating block connecting area is located on theouter side of the heating hot area. The nozzle connecting area is located below the heating hot area. The heating hot area further comprises a heat insulating area connected with the titanium throatpipe outer pipe body so that the range of the heating hot area in the throat pipe structure can be reduced and the extrusion amount of printing materials can be controlled. The throat pipe structure solves the technical problem that the printing effect is poor. The 3D printer is simple in structure, convenient to install, high in precision and stable in quality.

Owner:SHANGHAI FUSION TECH CO LTD

3d printing method for manufacturing metal part or ceramic part through resin

PendingCN112439901AIncrease contentHigh viscosityAdditive manufacturing apparatusTransportation and packagingSlurryCeramic particle

The invention discloses a 3d printing method for manufacturing a metal part or a ceramic part through resin. The 3d printing method comprises the following steps that S1, a photosensitive resin preparation process is conducted; S2, nano metal particles can be pretreated or not pretreated, and nano ceramic particles must be pretreated; S3, slurry is prepared; S4, FDM printing is carried out; S5, the printed object is cleaned; S6, supports are removed, wherein redundant supports on the printed object are removed; S7, degreasing is carried out; S8, sintering is conducted, wherein some metals needto be sintered in a specific atmosphere or vacuum. As an FDM method needs high-viscosity resin, the sedimentation problem of particles does not need to be considered. Compared with the prior art, a resin material with metal particles or ceramic particles having a volume fraction of 60%-95% can be prepared.

Owner:杜晖

Device for detecting and adjusting hot bed platform in printing process of 3D printer

PendingCN109703026AEasy to detectImprove the level ofManufacturing platforms/substratesManufacturing recyclingSpray nozzleEconomic benefits

The invention discloses a device for detecting and adjusting a hot bed platform in the printing process of a 3D printer. The device for detecting and adjusting the hot bed platform in the printing process of the 3D printer comprises a fixed shell, a sliding rod, a material storage bin, a discharging spray nozzle, a distance measuring sensor, a fixing nut, a through hole, signal transmission lines,the hot bed platform, a servo spiral push rod, a collecting baffle and a motor box. The device for detecting and adjusting the hot bed platform in the printing process of the 3D printer has the beneficial effects that the material storage bin and the sliding rod are located on the same horizontal plane, so that assembly and disassembly of the device are convenient; the distance measuring sensor is provided with infrared interaction, the distance between the hot bed platform and the spray nozzle is accurately measured, so that detection and leveling of the hot bed platform are convenient; thesignal transmission lines are connected between the device and a control host, so that signals of the sensors can be accurately transmitted to the control host, and it is avoided that the sensor and other work portions of the printer interfere mutually; the top end of the servo spiral push rod is connected with the hot bed platform, and automatic vertical adjustment of the hot bed platform is achieved; the four corners of the collecting baffle are provided with flaky protrusions, so that redundant materials sprayed by a printing spray nozzle can be conveniently collected, cost is saved, and economic benefits are improved.

Owner:HENAN ZHUCHENG ELECTRONICS TECH CO LTD

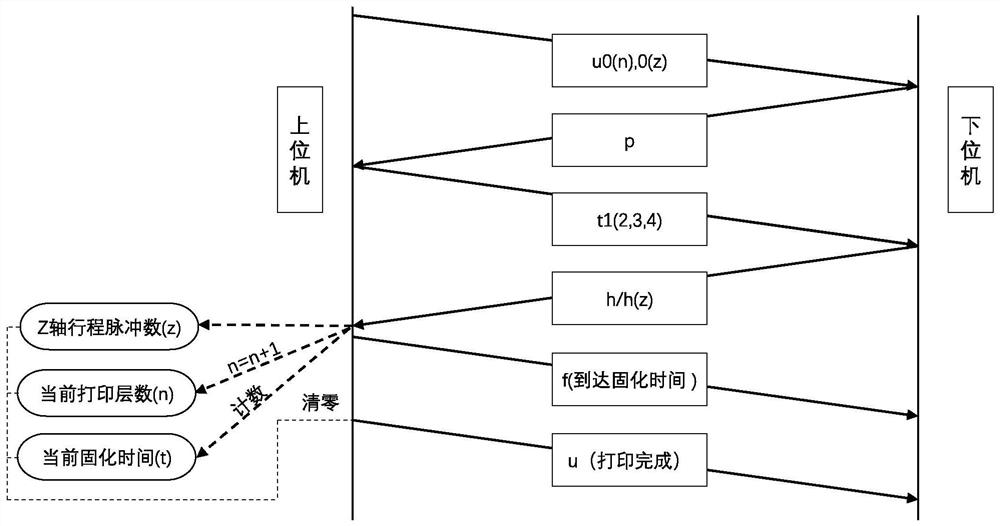

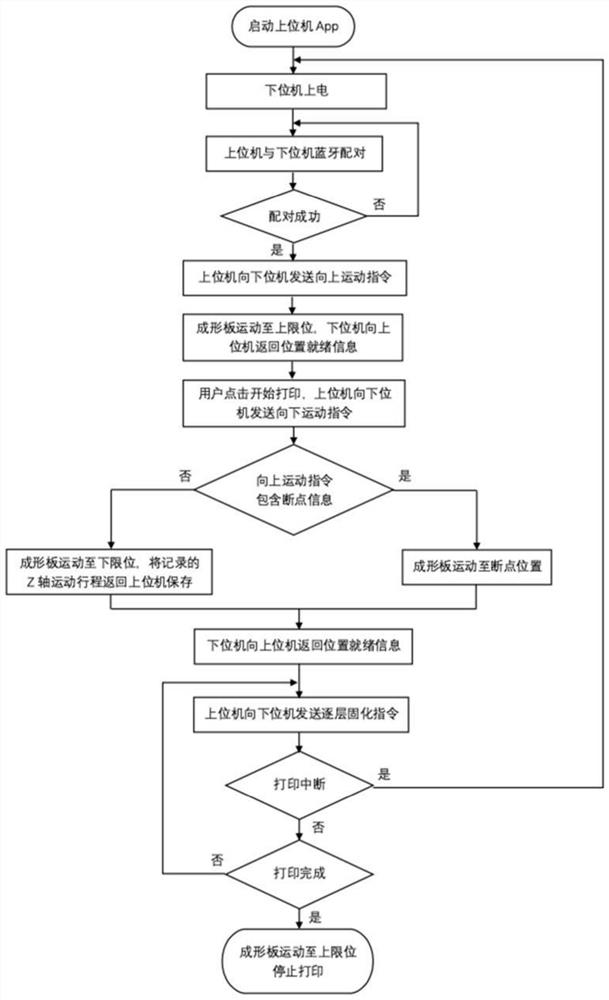

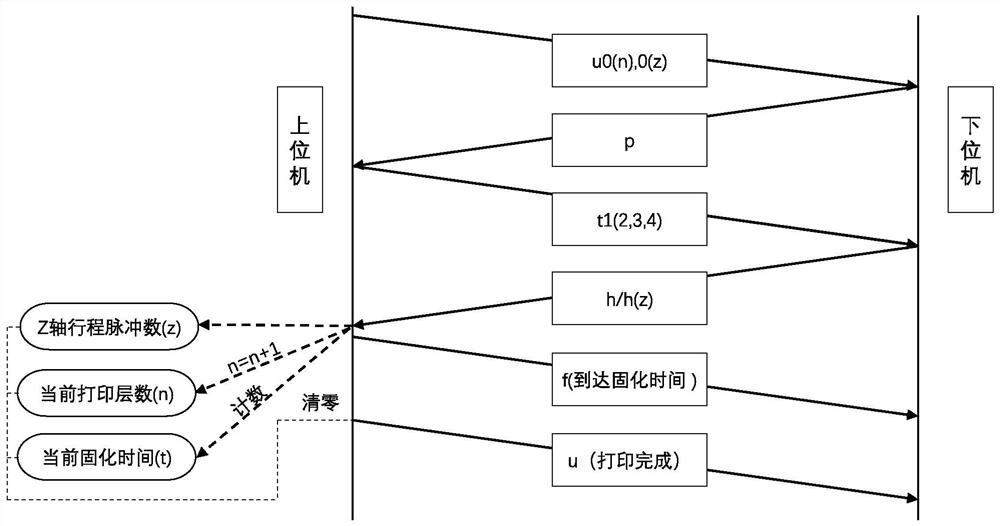

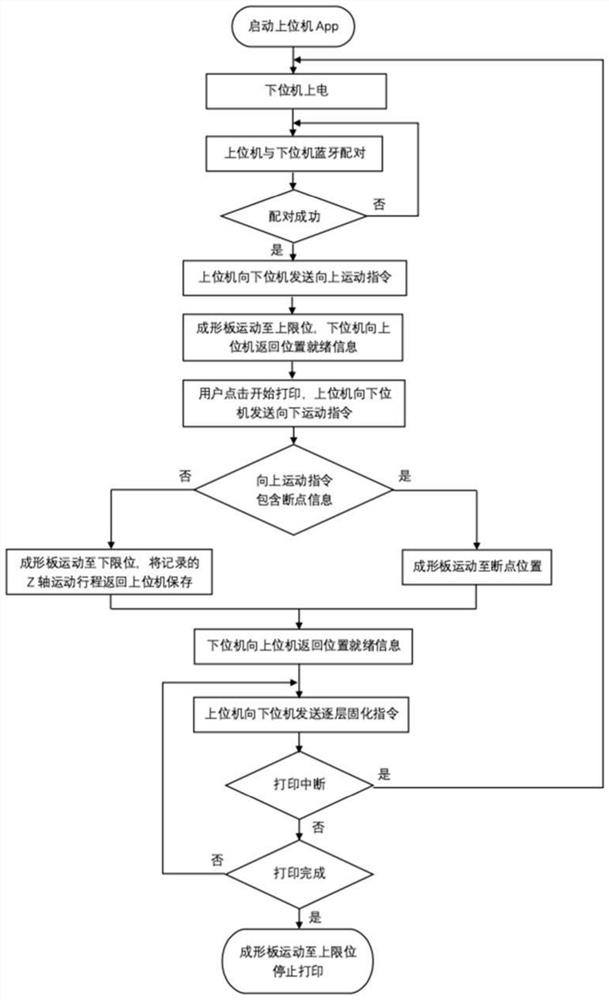

Breakpoint continuous printing method of surface exposure 3D printing equipment

ActiveCN112622261AImprove curing effectLow costAdditive manufacturing apparatus3D object support structuresPersonalizationProcess engineering

The invention discloses a breakpoint continuous printing method of surface exposure 3D printing equipment. The method integrates the breakpoint continuous printing method into a control method of the equipment, and adds the operation required for realizing breakpoint continuous printing into the operation of the whole system according to the interactive logic relationship between an upper computer and a lower computer. The breakpoint continuous printing function is achieved for the surface exposure technology, and the implementation method is simple and reliable. Compared with surface exposure printing equipment without a breakpoint continuous printing function, the breakpoint continuous printing function can significantly improve the printing success rate and save the printing cost; the upper computer is used for recording the Z-axis stroke, and personalized customization is achieved according to different conditions of each equipment; and according to the method, the medium-fault printing state is judged, whether the layer needs to be cured again or not is judged according to the irradiation time of the current layer when printing is interrupted, so that the printing quality of a breakpoint layer is improved, and the possibility of layer staggering during breakpoint continuous printing is reduced.

Owner:XI AN JIAOTONG UNIV

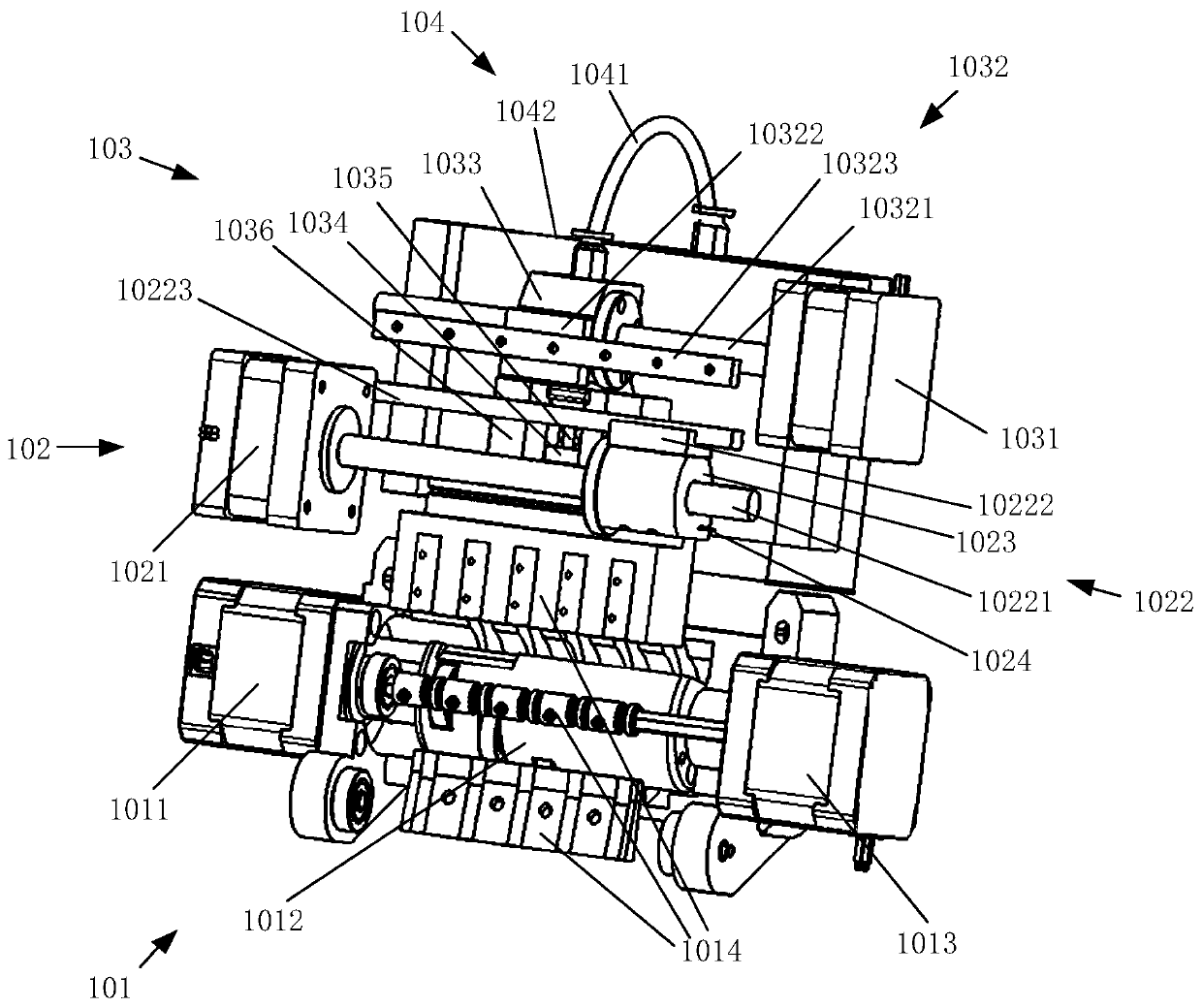

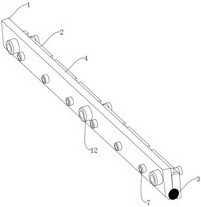

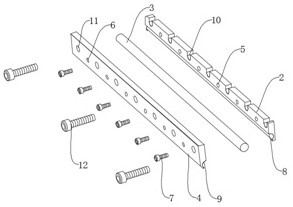

Powder laying device suitable for metal selective laser melting forming equipment

InactiveCN112372000ARealize fast installationStable supportAdditive manufacturing apparatusSelective laser meltingEngineering

The invention discloses a powder laying device suitable for metal selective laser melting forming equipment. The powder laying device suitable for the metal selective laser melting forming equipment comprises a device body, the device body is composed of a scraper bottom plate, an adhesive tape and a scraper cover plate, and a plurality of first threaded holes distributed in a linear array mode are formed in the outer side of the scraper bottom plate. A plurality of second threaded holes distributed in a linear array mode are formed in the surface of the scraper cover plate, and first fastening screws are arranged between the interiors of the first threaded holes and the interiors of the second threaded holes. According to the powder laying device suitable for the metal selective laser melting forming equipment, the device body is fixed to an equipment material boot through second fastening screws, under cooperation of a bottom plate concave groove, a cover plate concave groove and a boss, it is guaranteed that through holes have good supporting performance on the adhesive tape, a deformation tolerance space is reserved, it is guaranteed that a production task is smoothly completedunder the condition of local deformation, and stable and uniform powder laying operation is facilitated; and the powder laying device is provided with a rubber soft scraper between a hard scraper anda brush scraper, and the printing success rate is increased on the premise that the forming quality is guaranteed.

Owner:吉凯恩(丹阳)工业有限公司

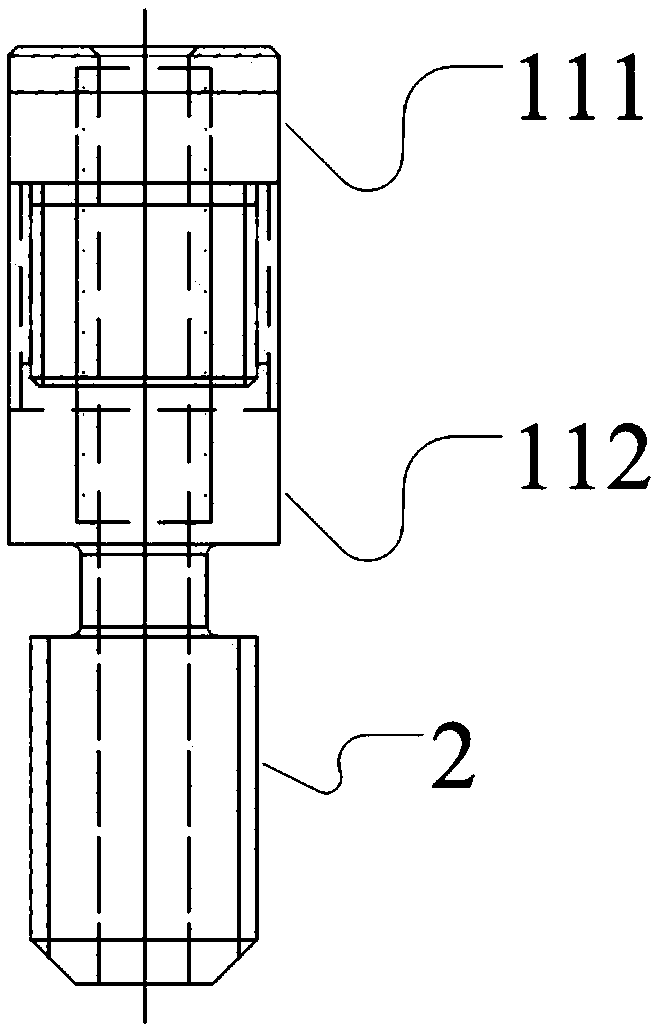

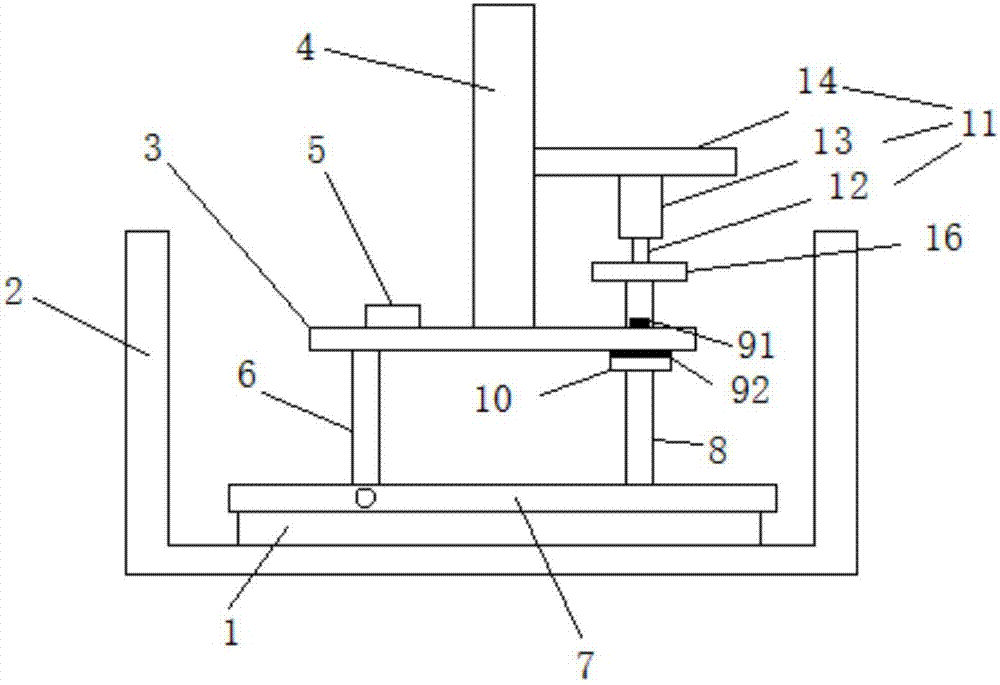

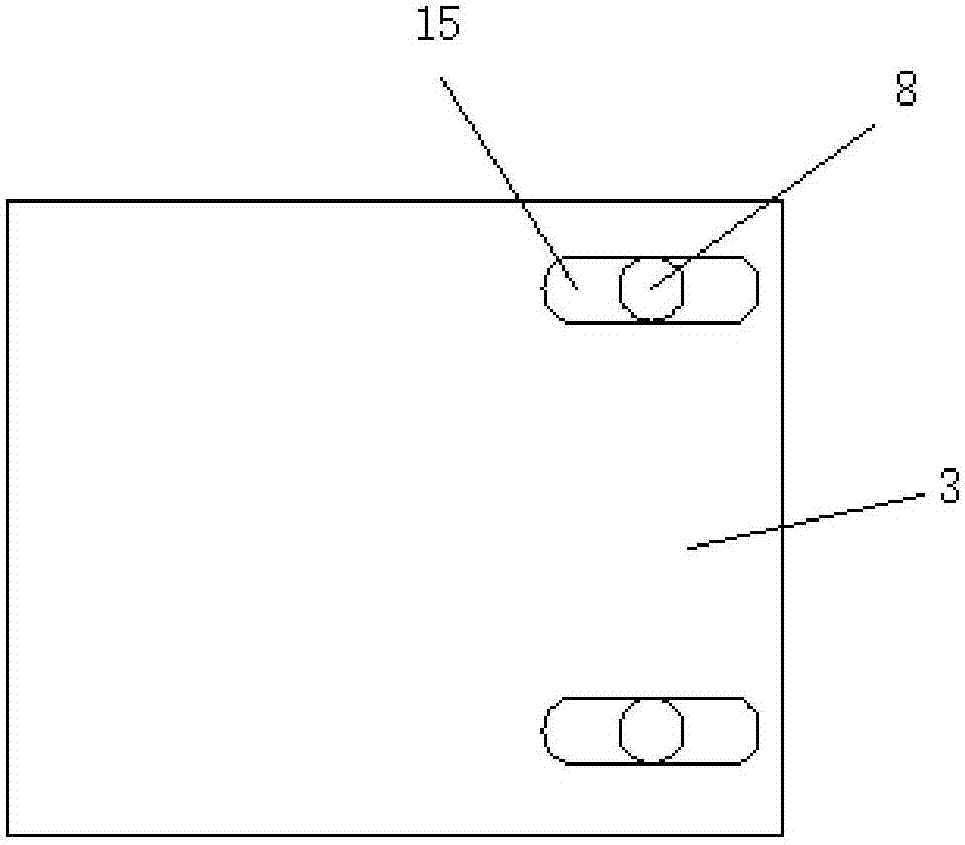

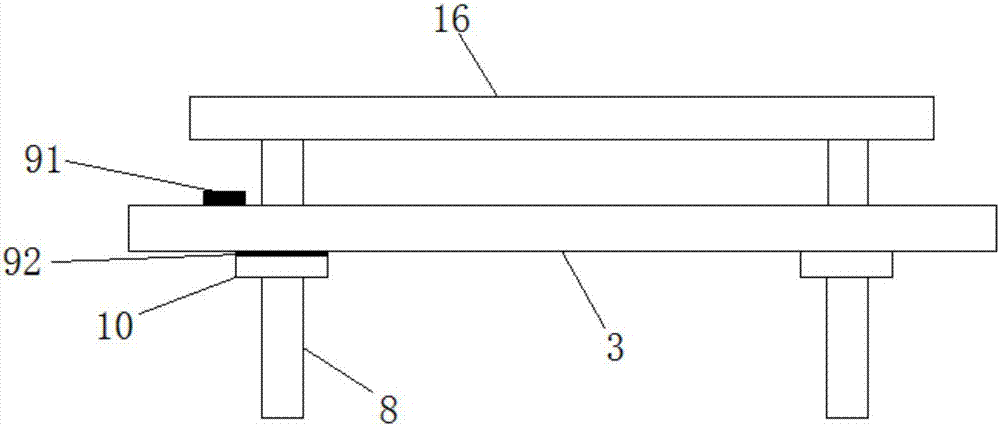

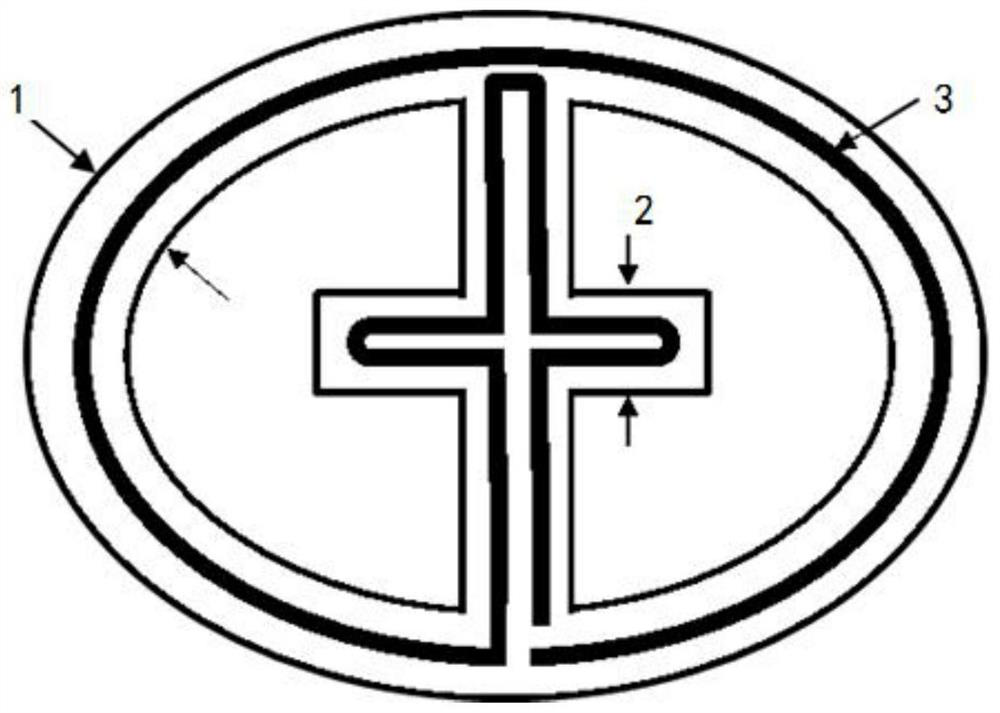

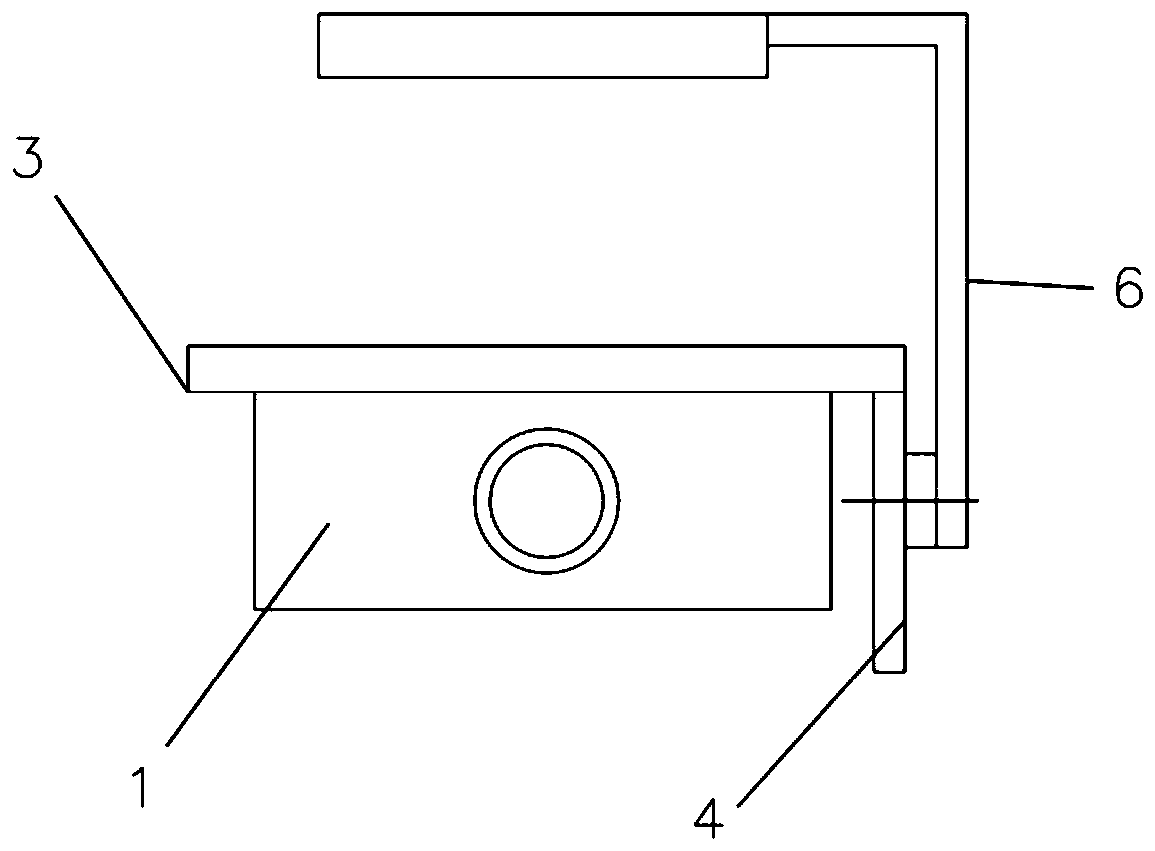

Release mechanism of 3D printer

InactiveCN106863777AImprove printing success rateGood effectManufacturing platforms/substrates3D object support structuresEngineering3d printer

Owner:CHENGDU FEIHANG PEIPENG TECH CO LTD

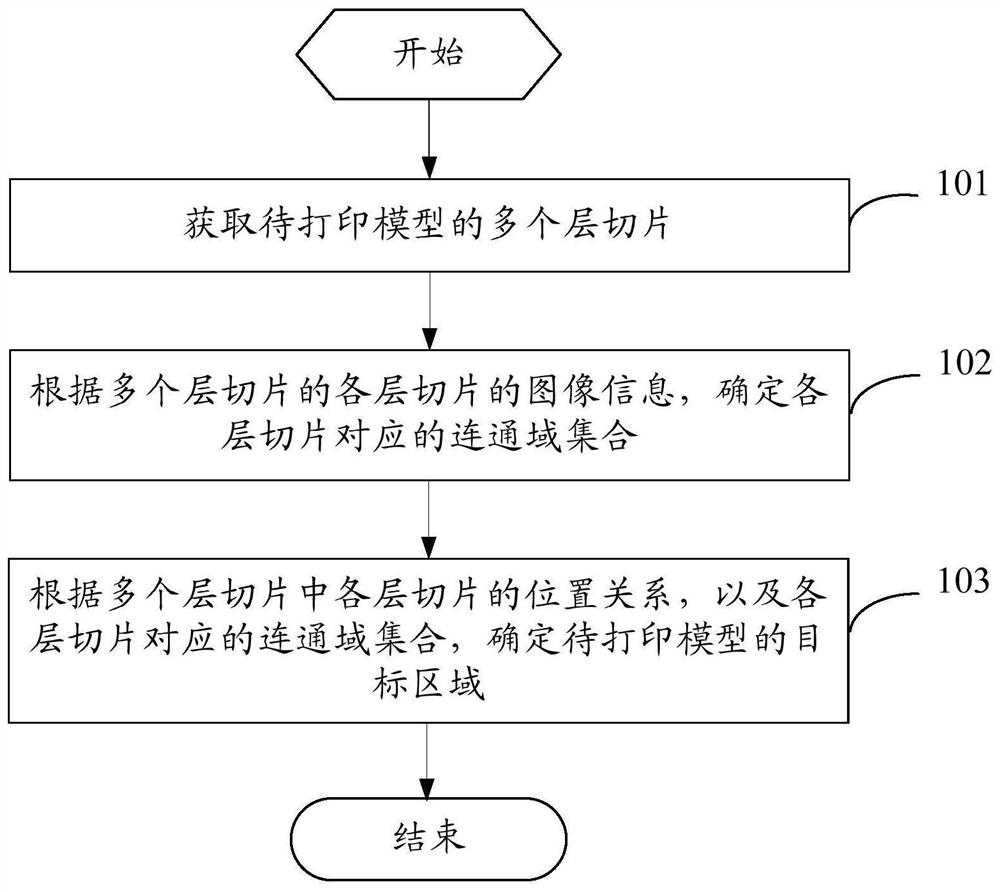

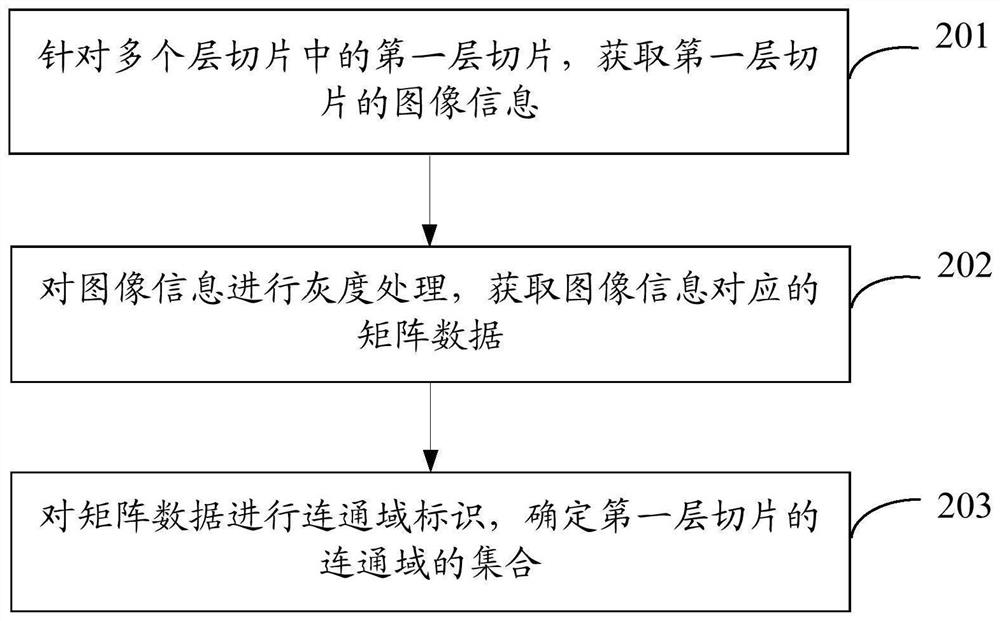

Printing processing method and device, electronic equipment and storage medium

PendingCN112348946APrint smoothlyImprove printing success rateAdditive manufacturing apparatusManufacturing data aquisition/processingEngineeringComputer science

The invention discloses a printing processing method and device, electronic equipment and a storage medium, and relates to the technical field of printing. The printing processing method comprises thesteps: acquiring multiple layer slices of a to-be-printed model; determining a connected domain set corresponding to each layer slice according to the image information of each layer slice of the plurality of layer slices; determining a target area of the to-be-printed model according to the position relationship of each layer of slice in the plurality of layers of slices and the connected domainset corresponding to each layer of slice; wherein the target area is an area with defects in the to-be-printed model. In this way, a user can be helped to discover and correct defects in the slice intime, the model to be printed can be printed smoothly, and the printing success rate of printing equipment is increased.

Owner:SHENZHEN ANYCUBIC TECH CO LTD

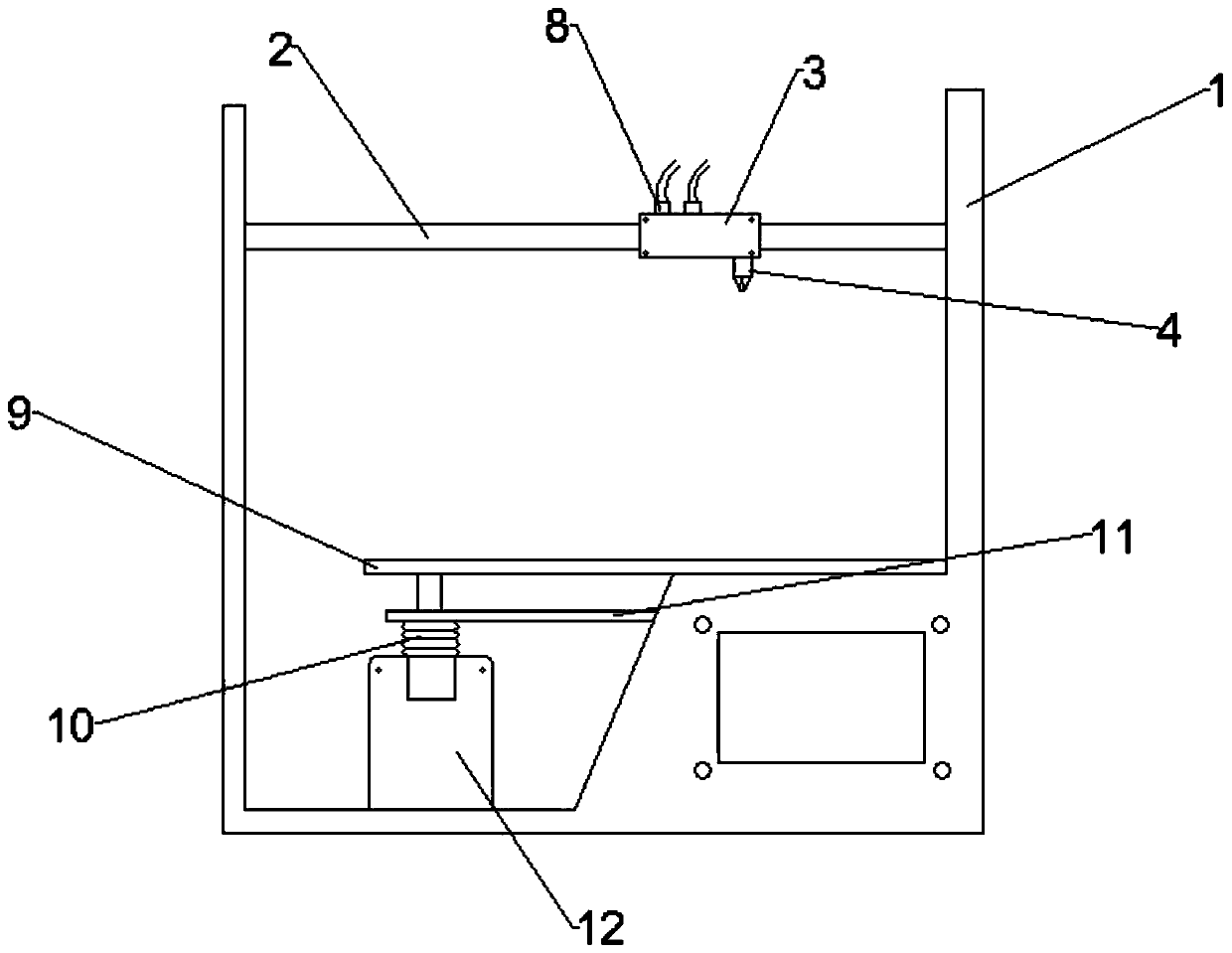

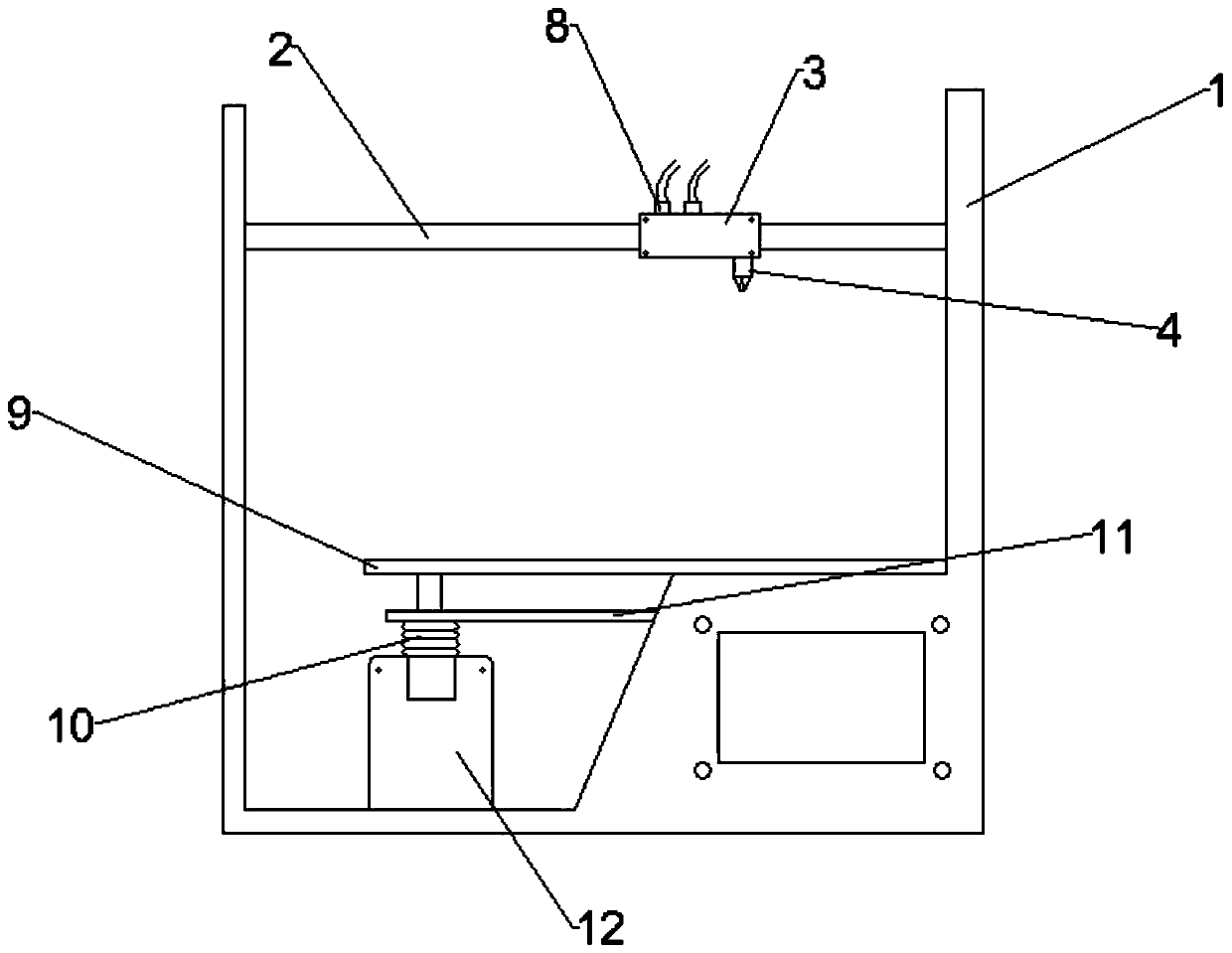

3D printer with function of continuous printing after power failure and control method of continuous printing after power failure

The invention relates to a 3D printer capable of printing continuously at an outage and a method for controlling the 3D printer to continue printing at the outage and belongs to the technical field of 3D printing. The 3D printer comprises a power module capable of storing electric energy, an outage detection module used for detecting the power supply state of an external power source, and a control module which controls all components of the printer to switch between the power supply state and the outage state. By means of the method, the printer can use the stored electric energy to record the work state at the outage, and all the components are set to be in the outage state; when power supply is recovered, the printer can be controlled to return to the previous state and continue last work; as a result, reprinting is avoided, consumable items are effectively saved, and the success rate of printing is increased substantially; furthermore, closed-loop control is achieved in cooperation with a displacement detection module, and the accuracy of continuous printing at the outage is further improved. Moreover, the 3D printer capable of printing continuously at the outage is simple in structure, the method for controlling the 3D printer to continue printing at the outage is easy and convenient to implement, and the application range is rather wide.

Owner:PANOWIN TECH

Photocuring 3D printing SiCN ceramic precursor material and its application

ActiveCN110451986BLow viscosityImprove green toughnessAdditive manufacturing apparatusCeramic shaping apparatusSolid componentCarbon nanotube

The present invention provides a light-curing 3D printing SiCN ceramic precursor material, which comprises the following components in weight percentage: modulated liquid precursor 40-75%, acrylic acid active monomer 20-65%, photoinitiator 0.1-5% , 0.1-1% of the light absorber, 0.1-2% of the leveling agent, and 0.1-2% of the defoamer, wherein the light absorber is carbon nanotube. It also provides a method for obtaining SiCN ceramic materials by using it for photocuring 3D printing. The formula of the present invention does not need to add solid components such as ceramic powder and clay. There are no impurity elements in the product, and the ceramic yield is high, which is suitable for the rapid preparation of SiCN ceramic products with high-precision special-shaped structures and periodic complex structures.

Owner:NAT UNIV OF DEFENSE TECH

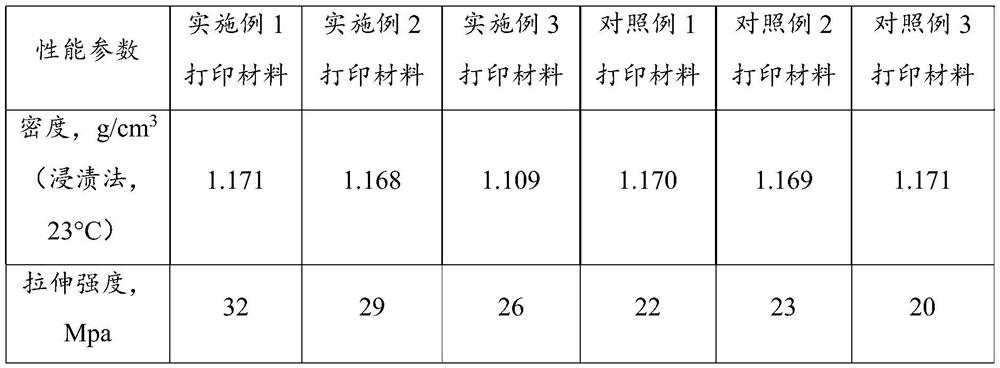

Three-dimensional printing method and system

ActiveCN106738854BImprove printing success rateImprove printing qualityAdditive manufacturing apparatusAdditive manufacturing processesUltimate tensile strengthMultiple layer

The invention provides a three-dimensional printing method and system. The method comprises the steps that mapping relation between the supporting degrees of all layers of slices to upper layer slices and various packing densities is established; a three-dimensional printing object model is subjected to slicing processing, and the multiple layers of slices are obtained; the degrees of all the layers of slices supporting the upper layer slices are obtained, and the packing densities of all the layers of slices are determined according to the mapping relation; and all the layers of slices are subjected to three-dimensional printing through the determined packing densities. According to the three-dimensional printing method balancing printing supplies and the object strength, a judgment standard is added, the proper packing densities are selected according to the supporting relation of all the layers of slices and slices of the upper and lower layers, printing materials are not wasted, the printing quality can be improved, the printing time is controlled in a reasonable range, and the printing success probability is increased, so that the three-dimensional printing cost is lowered.

Owner:INVENTECSHANGHAI TECH +2

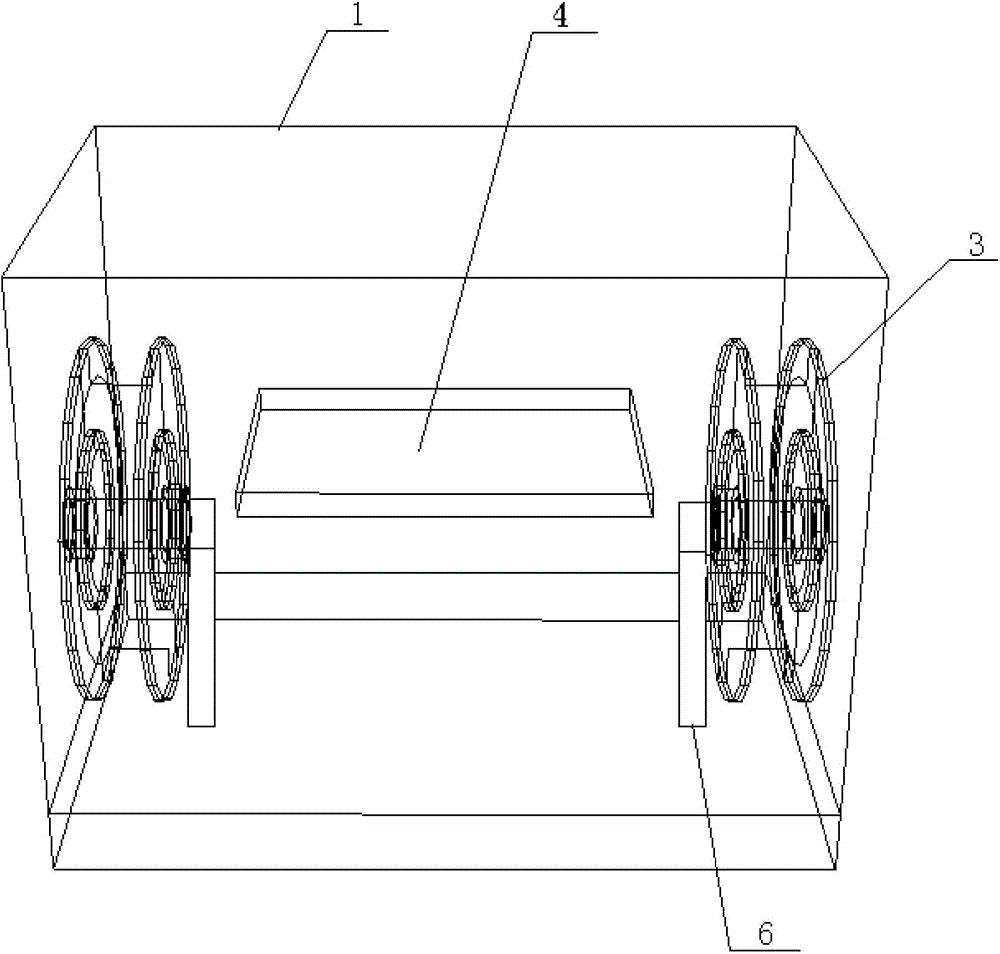

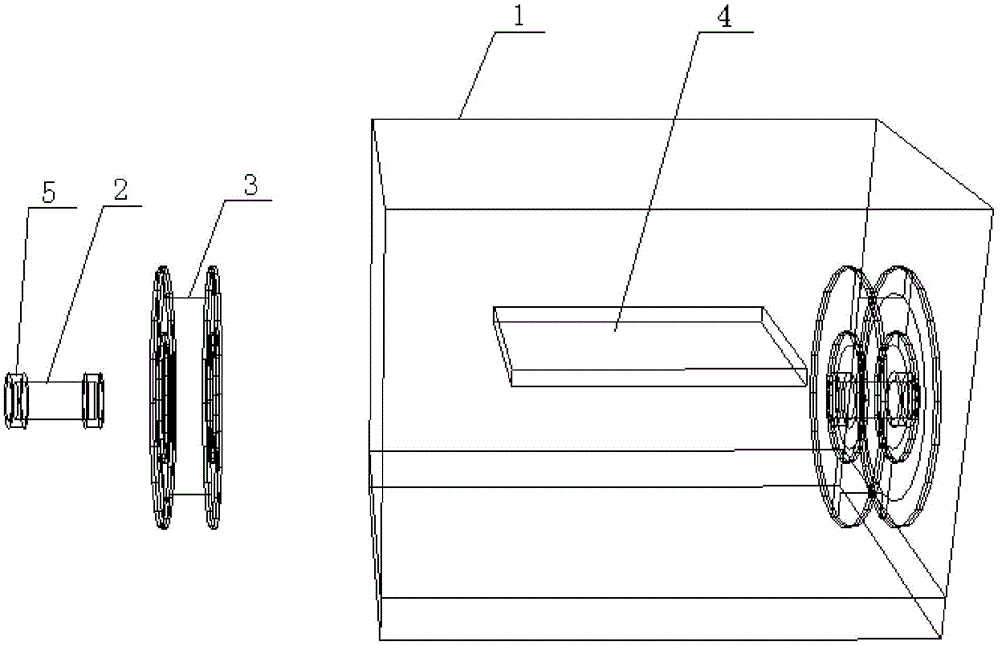

3D (third-dimensional) printer with built-in raw material

InactiveCN104827669ASave spaceImprove printing success rateAdditive manufacturing apparatusEngineeringRaw material

The invention relates to the technical field of printers, and in particular relates to a 3D (third-dimensional) printer with a built-in raw material. The 3D printer comprises a machine shell, wherein rolling shafts are symmetrically arranged on two opposite inner walls in the machine shell; H-shaped wheels sleeve the rolling shafts; the raw material winds the H-shaped wheels; a printing platform is arranged between the H-shaped wheels; and the height from the axis of each rolling shaft to the bottom of the machine shell is greater than the maximal radius of each H-shaped wheel. The 3D printer with the built-in raw material has the beneficial effects that by virtue of the built-in raw material, the space can be saved; the printing success rate can also be improved; the printer is relatively integral and beautiful; the overall printer is hung in the air through upward movement of the raw material; and due to the design, the printer can be applicable to packaging materials with various sizes in the market.

Owner:常州新艺叁迪打印技术有限公司

A method for continuous printing of surface exposure 3D printing equipment

ActiveCN112622261BImprove curing effectLow costAdditive manufacturing apparatus3D object support structuresProcess engineeringBreak point

The invention discloses a continuous printing method of a surface exposure 3D printing device. The method integrates the continuous printing method of the equipment into the control method of the equipment. According to the interactive logic relationship between the upper computer and the lower computer, the interrupted Click Continue to play the required operations to join the operation of the entire system. The present invention realizes the breakpoint continuous printing function for the surface exposure technology, and the realization method is simple and reliable. Compared with the surface exposure printing equipment without breakpoint continuous printing function, the breakpoint continuous printing function can significantly improve the printing success rate and save printing costs; use the host computer to record the Z-axis travel, and realize individuality according to the different conditions of each device Customization; judging the printing status of the interrupted layer, and judging whether the layer needs to be re-cured according to the irradiation time of the current layer when printing is interrupted, which improves the printing quality of the interrupted layer and reduces the possibility of wrong layers when the interrupted continuous printing occurs .

Owner:XI AN JIAOTONG UNIV

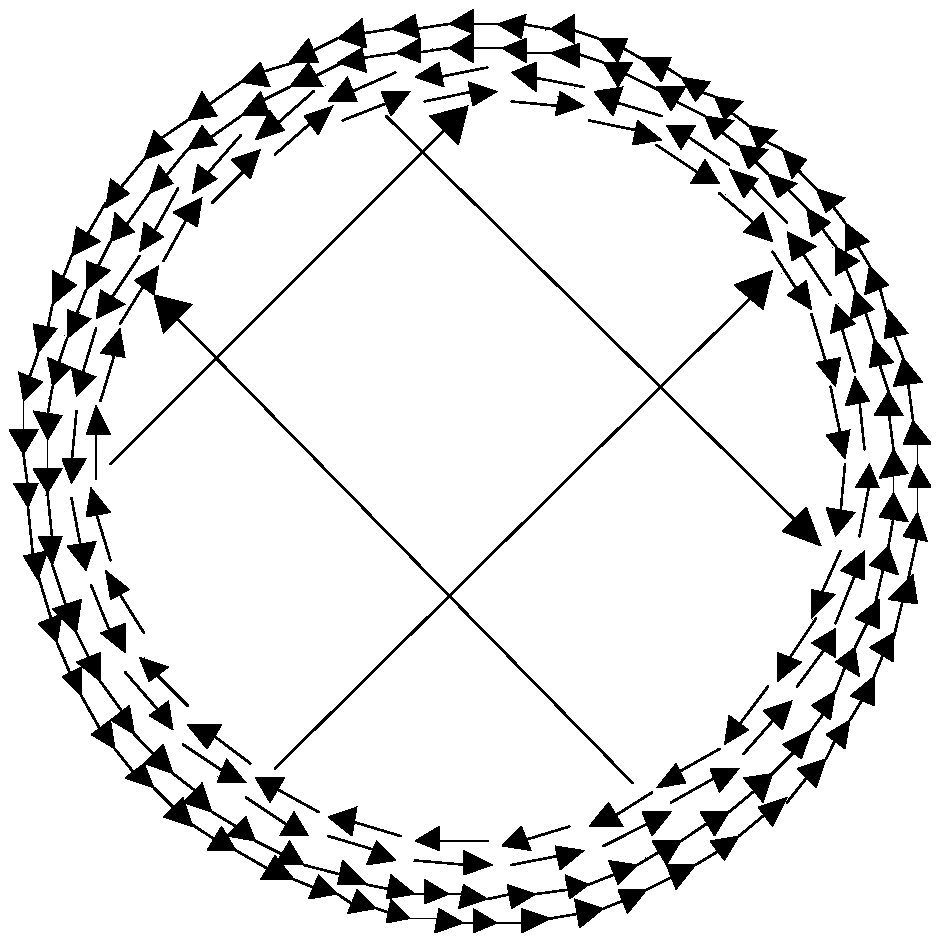

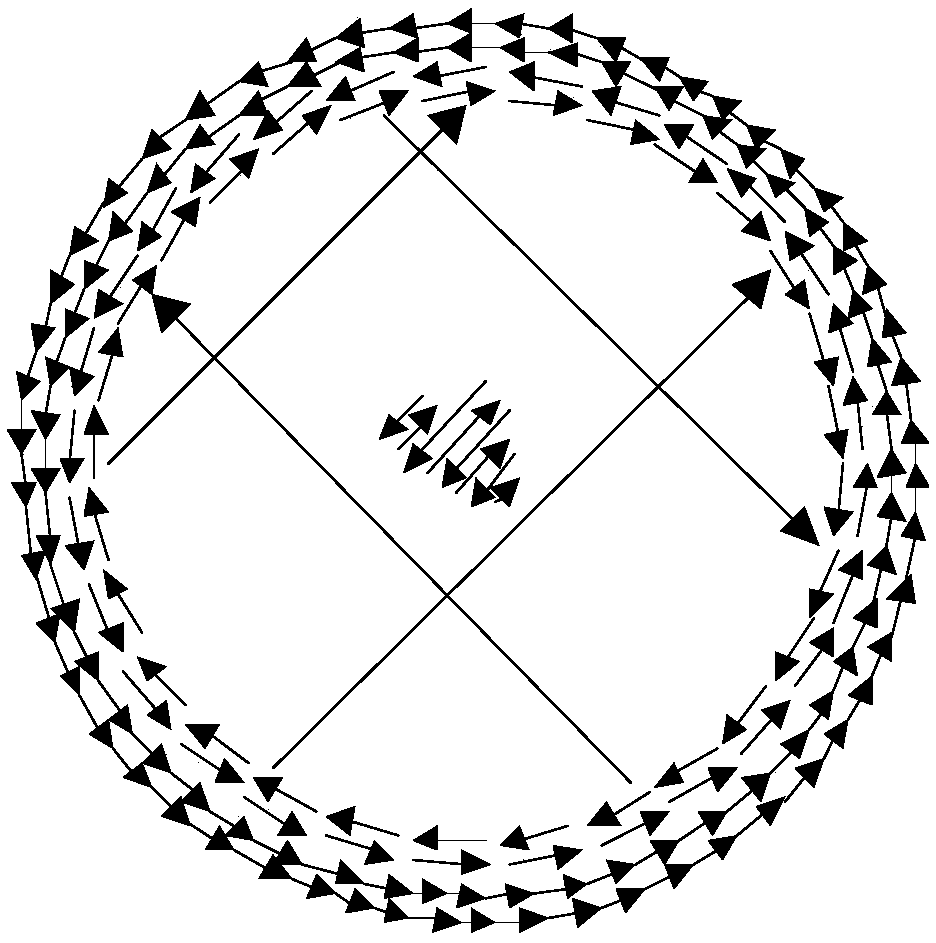

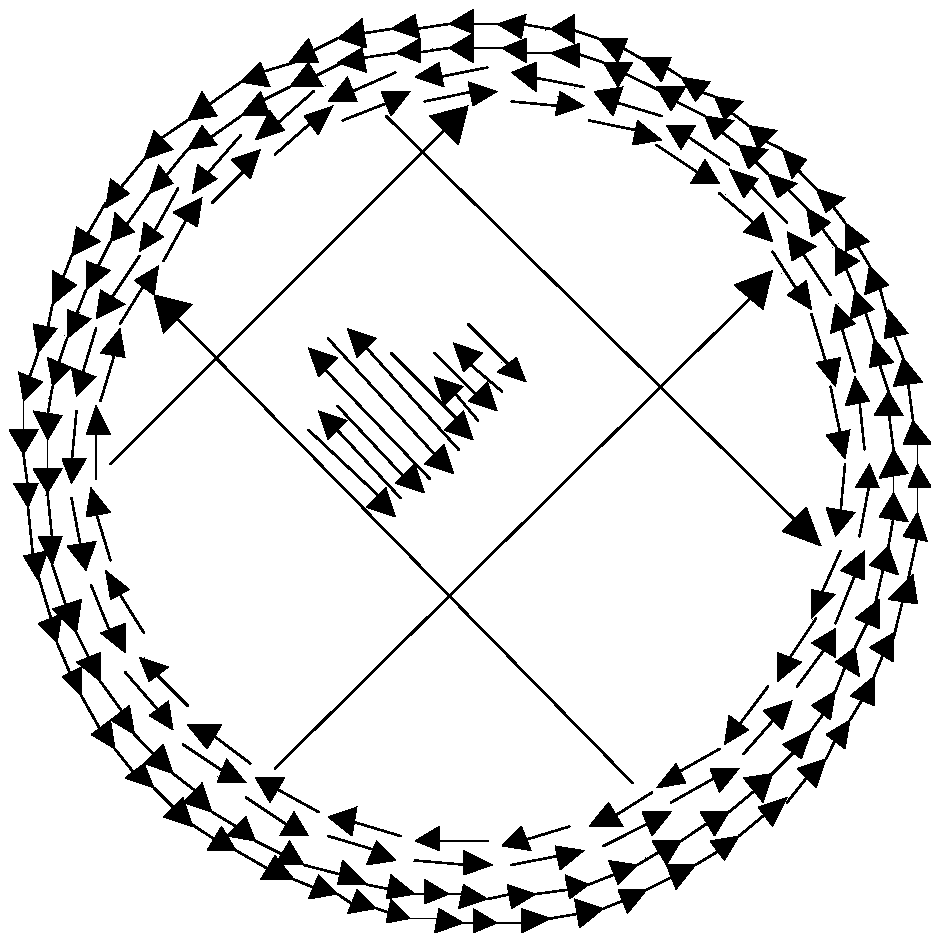

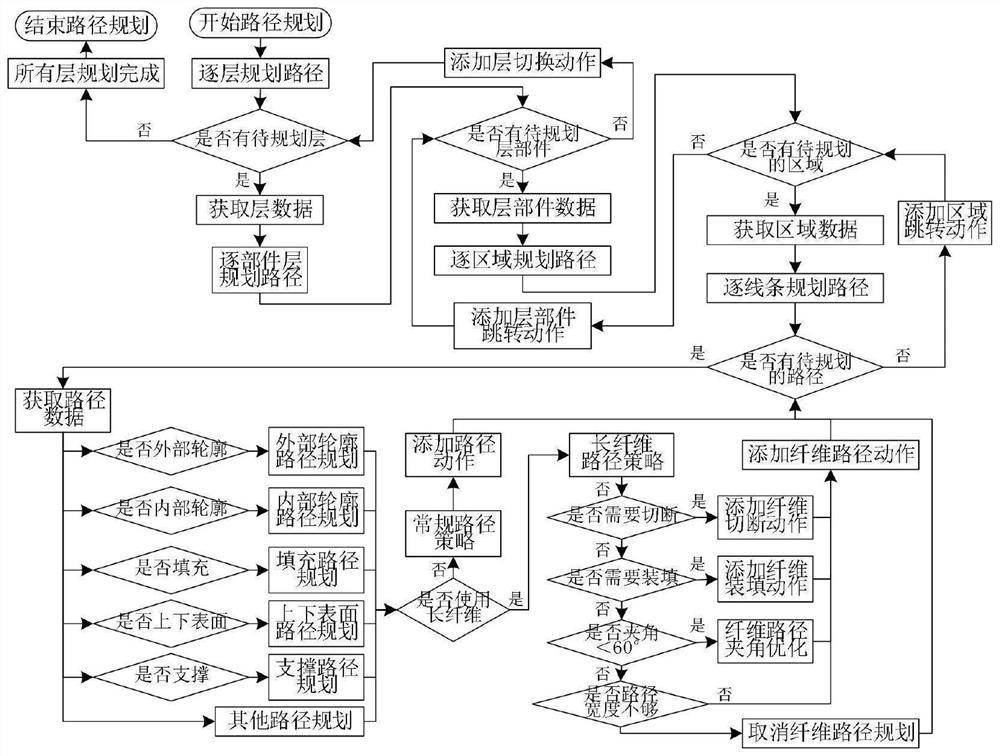

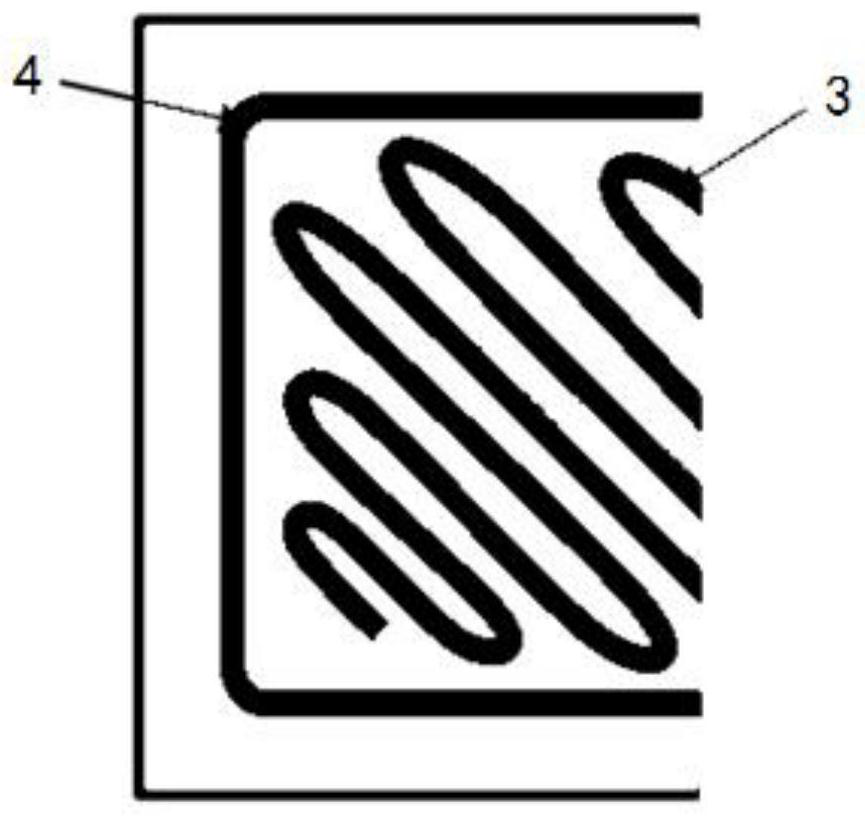

Continuous fiber path generation method for multi-nozzle 3D printing and storage medium

PendingCN114393820AAchieving controllable additionReduce cutting actionAdditive manufacturing apparatus3D object support structures3d printFiber

The invention discloses a continuous fiber path generation method for multi-nozzle 3D printing and a storage medium, and relates to the technical field of 3D printing. The method comprises the following specific steps: checking the integrity of a model file, and determining the minimum size information of a model; 3D printing path planning is carried out based on the minimum size information of the model; and performing path filling according to the path planning. According to the continuous fiber 3D printing process characteristics, the continuous fiber path generation method and the filling strategy of the 3D printing continuous fiber / resin composite material are provided by considering that the continuous fiber wire material printing path needs to be cut off, and the continuous fiber path generation method and the filling strategy are verified through a 3D printing experiment. The rapid forming method is provided for preparation of the continuous fiber / resin composite material component, controllable adding of continuous fibers can be achieved by freely designing the fiber laying path, the rapid forming method has great advantages especially for personalized customization of some composite material structures in complex geometrical shapes, and the printing efficiency is improved.

Owner:SHANDONG UNIV +1

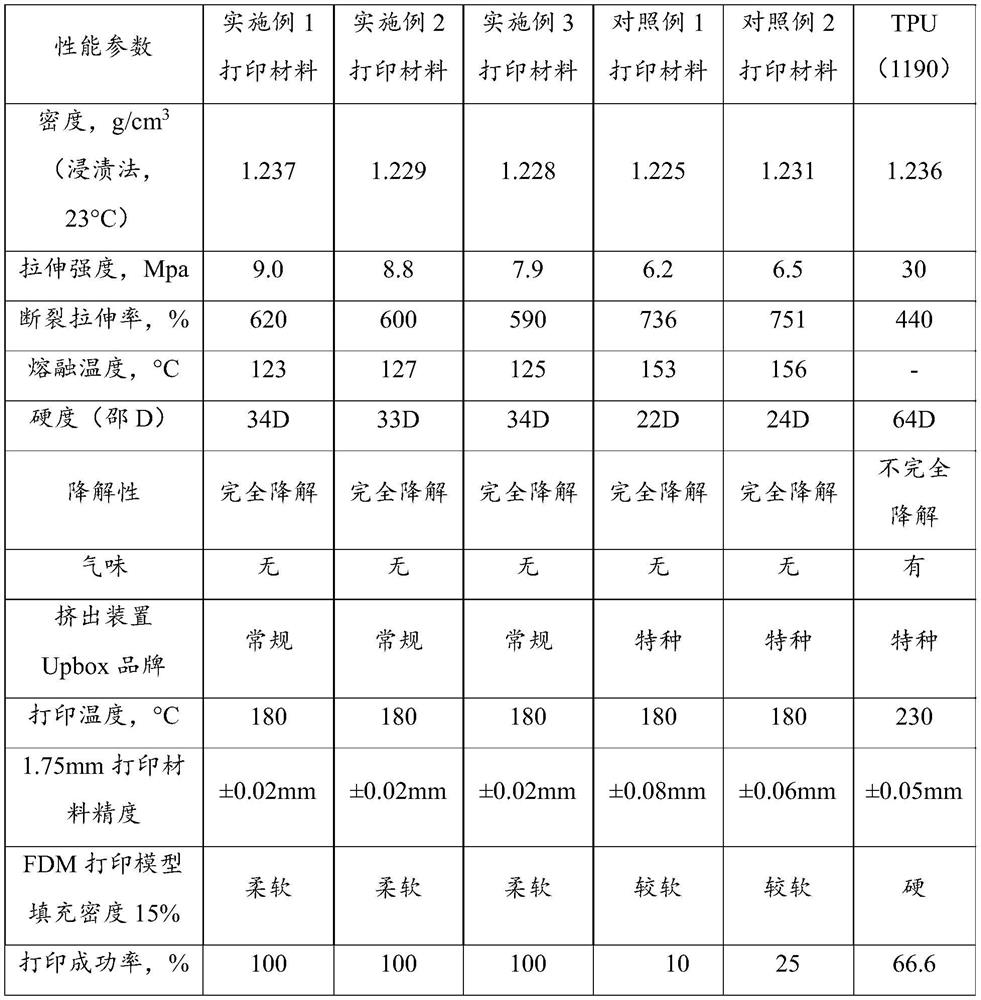

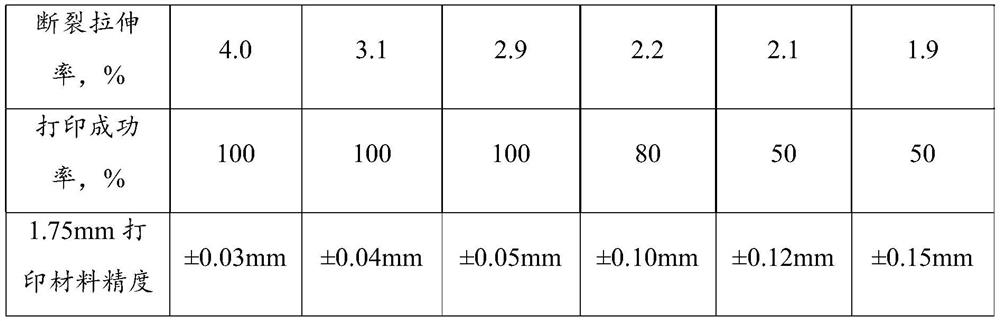

Degradable flexible 3D printing material as well as preparation method and application thereof

ActiveCN113150510AReduce swelling ratioInhibition of crystallinityAdditive manufacturing apparatusPolymer sciencePolymer chemistry

The invention provides a degradable flexible 3D printing material as well as a preparation method and application thereof. The degradable flexible 3D printing material is prepared from the following raw materials in parts by weight: 40 to 90 parts of PBAT, 5 to 15 parts of polylactic acid, 3 to 8 parts of polycaprolactone, 5 to 15 parts of modified starch, 0.1 to 2 parts of maleic anhydride grafted polylactic acid, 3 to 5 parts of PEG and 1 to 3 parts of compatibilizer. The flexible 3D printing material has the advantages of being capable of being completely degraded, good in compatibility, low in thermal expansion rate, good in flexibility and the like, the printing temperature is low and the printing precision and the printing success rate are high during 3D printing, the 3D printing requirements of FDM equipment can be well met, printed products have good flexibility and rebound resilience, and the application range is wide.

Owner:张晓军

Preparation method of high-adhesion ceramic slurry for DLP photocuring 3D printing

The invention relates to the technical field of ceramic 3D printing, in particular to a preparation method of high-adhesion ceramic slurry for DLP photocuring 3D printing, which comprises the following steps: proportionally preparing UV photocuring monomers containing large-volume side chains or ethyoxyl groups into a UV photocuring premixed solution, and uniformly stirring; a dispersing agent is added into the UV photocuring premixed liquid, then ceramic powder is added, and ceramic slurry is obtained; carrying out ball milling on the ceramic slurry; and carrying out vacuum defoaming on the ball-milled ceramic slurry. According to the preparation method, by adding the UV photocuring monomer containing a large-volume side chain or an ethyoxyl group, the shrinkage rate in the photocuring process is reduced, the adhesion performance of the ceramic slurry to a printing platform base material in the DLP photocuring 3D printing process is improved, and the printing stability and efficiency are greatly improved; the printing success rate is increased by 80% or above compared with that of a traditional UV photocuring slurry system, and application and popularization of the DLP ceramic photocuring 3D printing technology are promoted.

Owner:WUHAN UNIV OF TECH

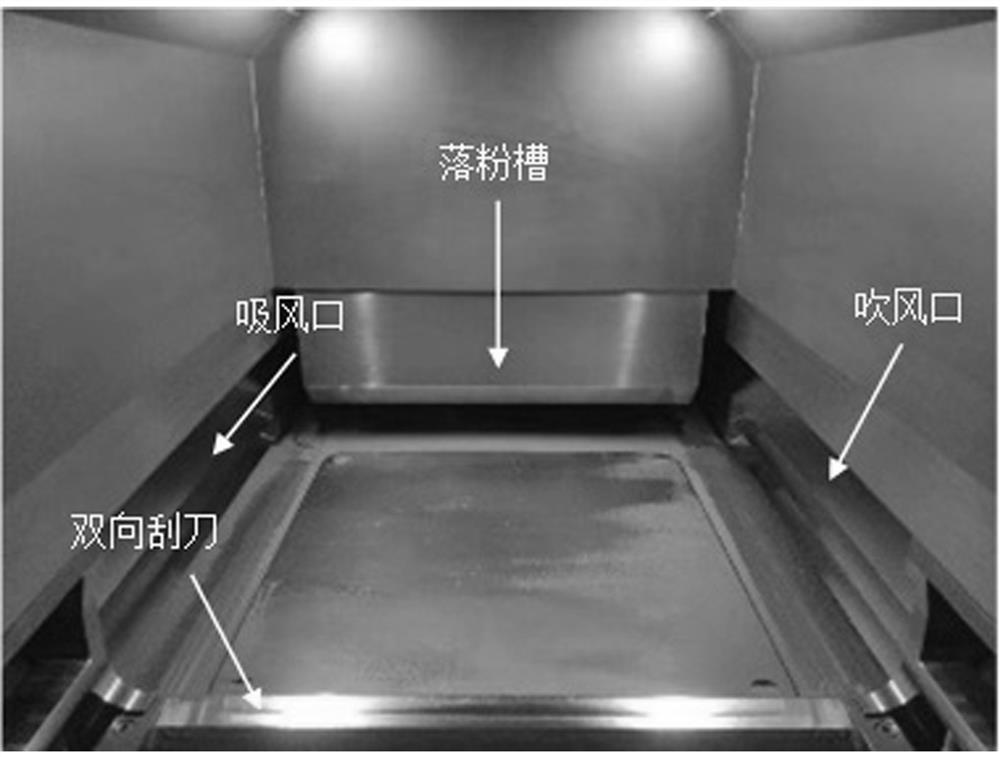

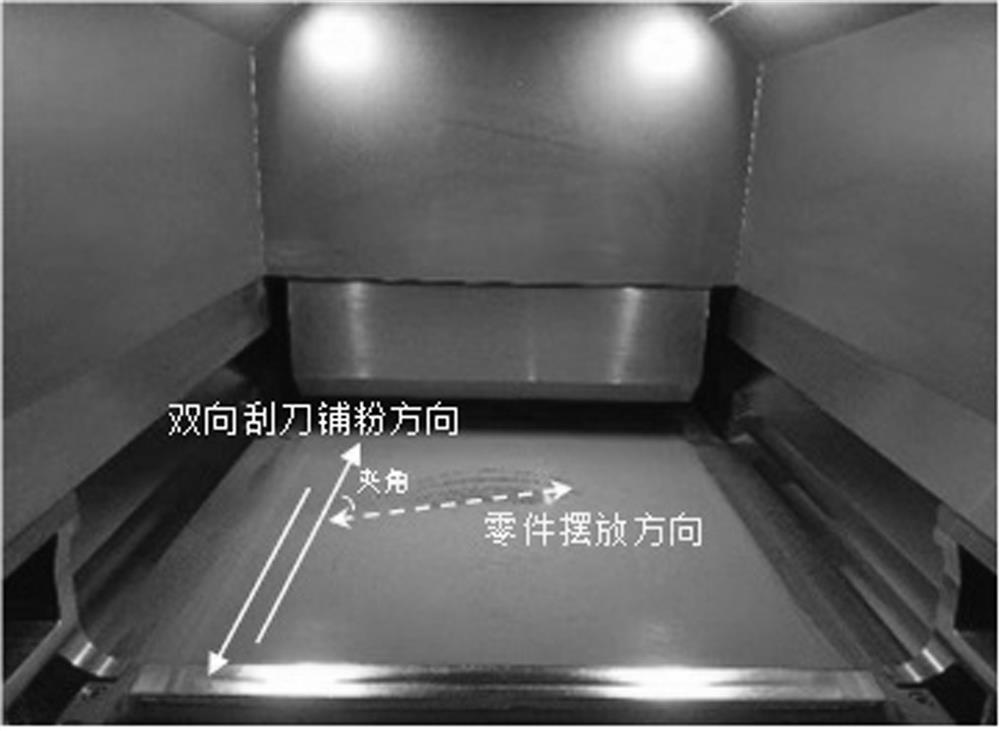

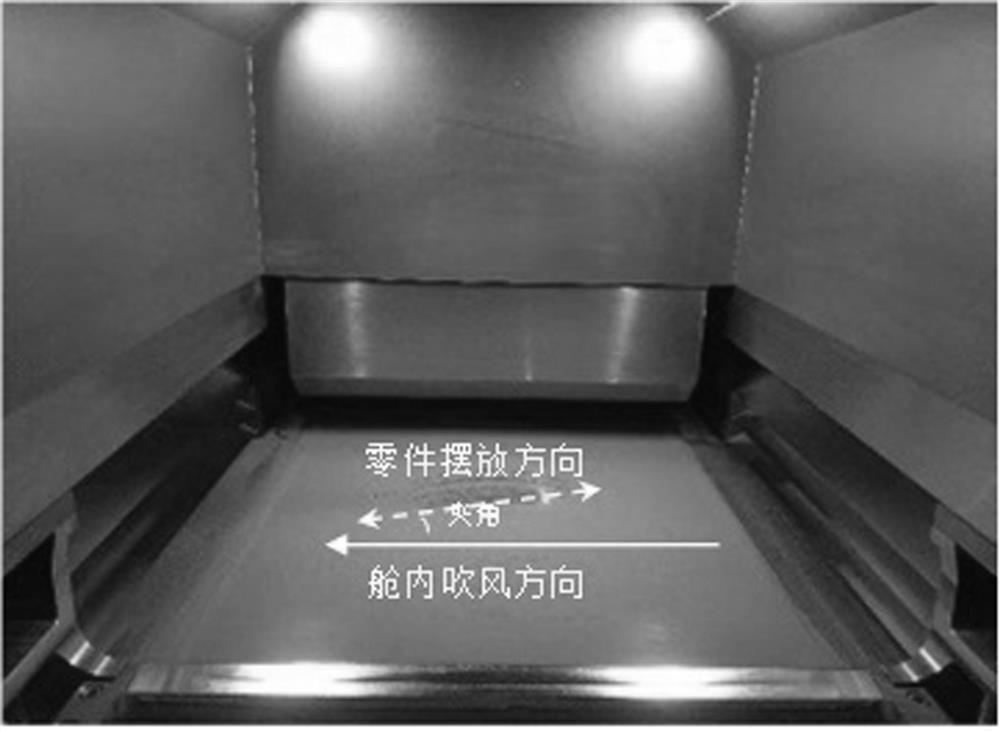

A method to improve the success rate of 3D printing thin-walled metal components

ActiveCN111299581BImprove printing success rateMake full use of the print size correction functionAdditive manufacturing apparatusIncreasing energy efficiency3d printData pack

The invention discloses a method for improving the success rate of 3D printing thin-walled metal components, which includes the following steps: 1) performing early software processing on the digital model of the thin-walled metal components, adjusting the position of the thin-walled metal components in the equipment forming cabin, ensuring Thin-walled metal components can be printed; 2) Place and optimize the digital models of thin-walled metal components that meet the above requirements; 3D printing equipment, preparatory work for printing equipment in the early stage, and start printing through 3D printing technology after the preparation work is completed; 4) After printing is completed, take out the thin-walled metal components for subsequent processing, and finally complete the delivery of thin-walled metal components. The present invention can give full play to the printing size correction function of the scraper through the secondary optimization of the placement position of the thin-walled metal components required by the basic placement, reduce the risk of scraper jamming, and improve the printing success rate of the thin-walled metal components.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

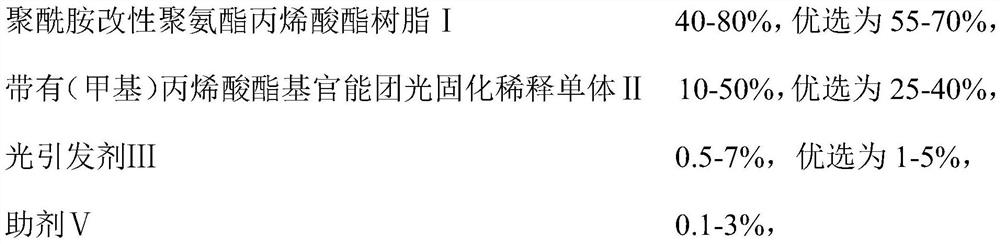

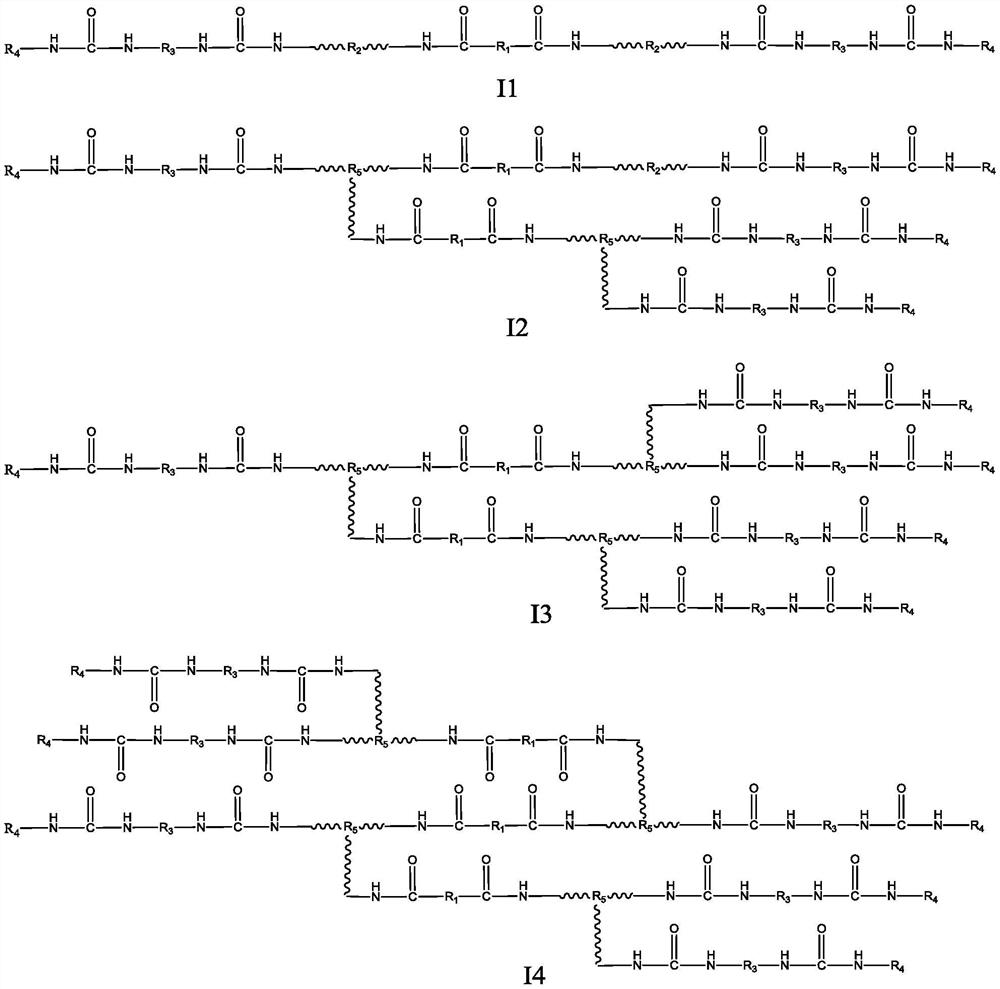

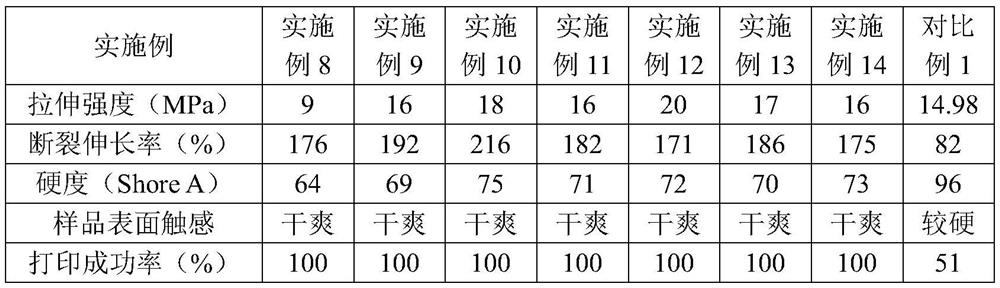

A kind of 3D printing soft elastic photosensitive resin composition and preparation method thereof

ActiveCN112876616BGood flexibilityIncrease elasticityAdditive manufacturing apparatusMethacrylatePolymer science

The invention provides a 3D printing soft elastic photosensitive resin composition and a preparation method thereof. The composition contains polyamide modified urethane acrylate resin, photocurable diluting monomer with (meth)acrylate functional group, photoinitiator and auxiliary agent. The polyamide modified polyurethane acrylate resin is obtained by reacting polyisocyanate, active hydrogen polymer, polybasic acid and amino acrylate compound. The soft elastic photosensitive resin of the invention has high tensile strength, large elongation at break, low shrinkage rate, low viscosity, easy printing, and can meet the market performance requirements of soft elastic wearing such as wristbands and shoe materials.

Owner:WANHUA CHEM GRP CO LTD

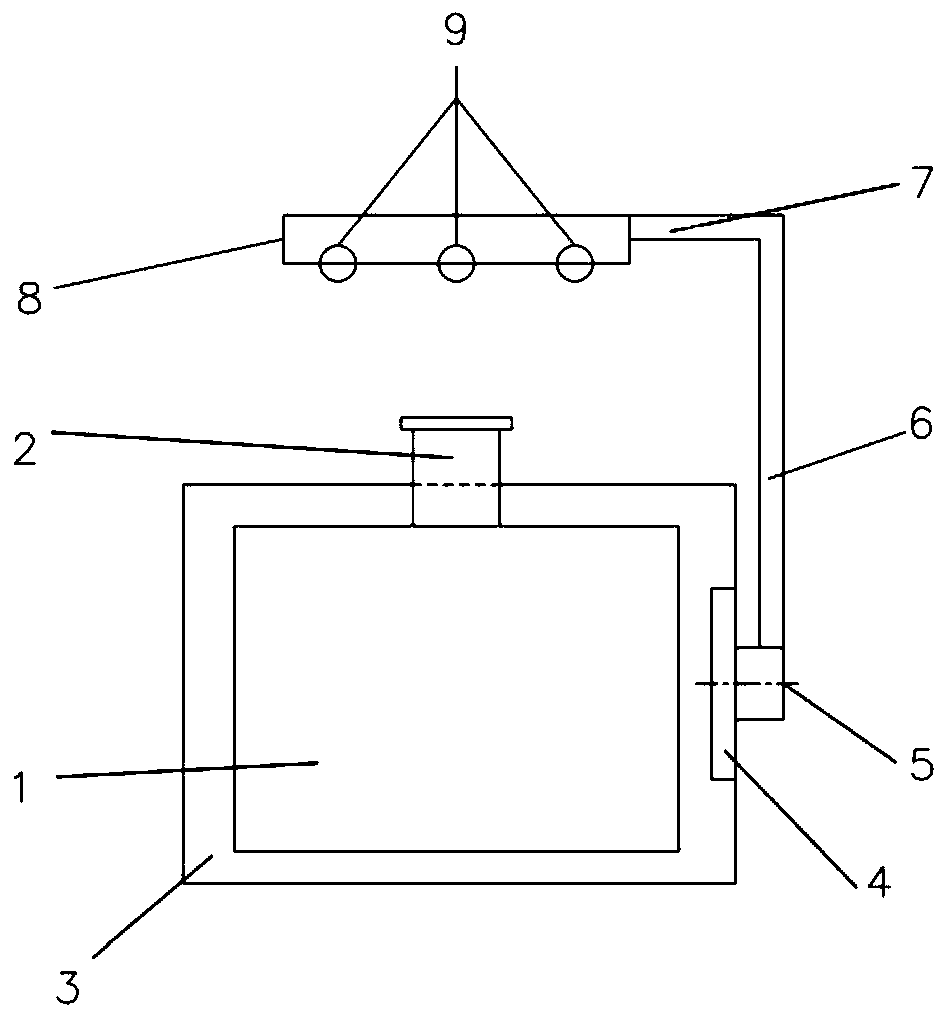

Automatic detecting and correcting device for light intensity of optical projector

PendingCN109910305AAccurate measurementExtended service lifeAdditive manufacturing apparatus3D object support structuresPower flowUltimate tensile strength

The invention discloses an automatic detecting and correcting device for the light intensity of an optical projector. The automatic detecting and correcting device comprises the optical projector, anda light outlet is formed in the top of the optical projector; and an optical projector rear cover plate of the optical projector is provided with an optical projector mechanism fixing plate towards the side face of the optical projector in an extending mode. The automatic detecting and correcting device is characterized in that a rotating shaft is arranged on the optical projector mechanism fixing plate; a measuring mechanism is fixedly connected to the rotating shaft, and the other end of the measuring mechanism is connected with a working panel through a rotating connecting rod; when working, the working panel is rotated into an illumination area above the light outlet by the rotating shaft and rotated to a non-illumination area by the rotating shaft when in a non-working state; and a plurality of induction devices are distributed on the lower surface of the working panel in a dotted mode. The automatic detecting and correcting device automatically measures the light intensity of the optical projector after the optical projector is started, the actual illumination intensity can be effectively measured, and the illumination intensity of the optical projector is adjusted to meet the demands by changing the current magnitude of the optical projector; and when an optical path of the optical projector is damaged, a worker is reminded to conduct timely processing, operation is convenient, and the service life of the optical projector is effectively prolonged.

Owner:福建国锐中科光电有限公司

Composite 3D printing material containing coffee grounds as well as preparation method and application of composite 3D printing material

ActiveCN113321907ALow moisture absorptionEvenly dispersedAdditive manufacturing apparatusBio-packagingPolyesterPolycaprolactone

The invention provides a composite 3D printing material containing coffee grounds as well as a preparation method and application of the composite 3D printing material. The composite 3D printing material is prepared from the following raw materials in parts by weight: 10 to 55 parts of modified coffee grounds, 45 to 90 parts of polylactic acid, 1 to 5 parts of polycaprolactone, 10 to 30 parts of polyhydroxyalkanoate and 1 to 3 parts of plasticizer, wherein the modified coffee grounds are obtained by modifying coffee grounds raw materials with a mixed solution containing water-soluble polyester and a coupling agent. According to the method, high-value utilization of the waste coffee grounds can be achieved, environment protection is facilitated, meanwhile, the cost of consumables is greatly reduced, and remarkable social benefits and economic benefits are achieved; and in addition, the composite 3D printing material containing the coffee grounds can well meet the functional requirements of daily 3D printing, the comprehensive performance of printed products is excellent, and the application range is wide.

Owner:张晓军

Printing color separation device, 3D printing system and 3D printing method

ActiveCN110561751BGuaranteed stabilityGuaranteed printing accuracy3D object support structuresManufacturing data aquisition/processingComputer printingProcess engineering

The invention relates to a printing color separation device, a 3D printing system and a 3D printing method. The printing color separation device includes a main control device, a feeding device, a consumable material cutting device, a consumable material welding device and a consumable material output device; the main control device analyzes the pre-acquired Consumables information to generate consumables control information; the feeding device transmits the corresponding initial consumables based on material color selection instructions and feeding instructions; if the main control device detects that the initial consumables transmission volume reaches the consumables volume, it controls the consumables cutting device to move to the consumables position for cutting The initial consumables are obtained to obtain cutting consumables; the consumables welding device is controlled to move to the consumables position, so that the cutting consumables enter the consumables channel, and the cutting consumables are welded with the consumables left over from the last time to obtain welding consumables; the consumables output device processes the welding consumables to generate multi-color consumables. Using the multi-material and color consumables corresponding to the generated model to be printed can enable the single-nozzle 3D printer to achieve multi-color and multi-material 3D printing, ensuring the accuracy and stability of multi-color and multi-material 3D printing.

Owner:郑尚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com