Powder laying device suitable for metal selective laser melting forming equipment

A technology of laser selective melting and forming equipment, applied in the direction of additive manufacturing, additive processing, etc., can solve the problems of warping or undulation of the current layer scanning plane, unfavorable cost control and timely delivery, easy wear and tear of bristles, etc., to reduce defects. Cost and time cost, improve the quality of powder spreading, and reduce the effect of equipment use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

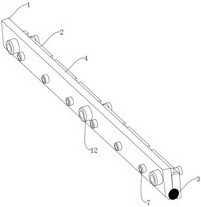

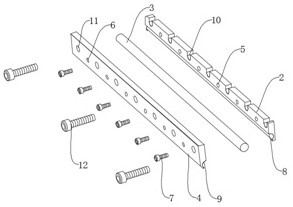

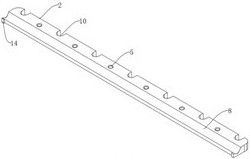

[0027] The present invention provides such Figure 1-6 The shown powder spreading device suitable for metal laser selective melting and forming equipment includes a device body 1, the device body 1 is composed of a scraper bottom plate 2, a rubber strip 3 and a scraper cover plate 4, and the outside of the scraper bottom plate 2 is set There are a plurality of first threaded holes 5 distributed in a linear array, and the surface of the scraper cover plate 4 is provided with a plurality of second threaded holes 6 distributed in a linear array. The first fastening screw 7 is provided, and the scraper bottom plate 2 and the scraper cover plate 4 are fixedly connected by the first fastening screw 7, and the bottom ends of the adjacent side of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com