Patents

Literature

262results about How to "Improve dressing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

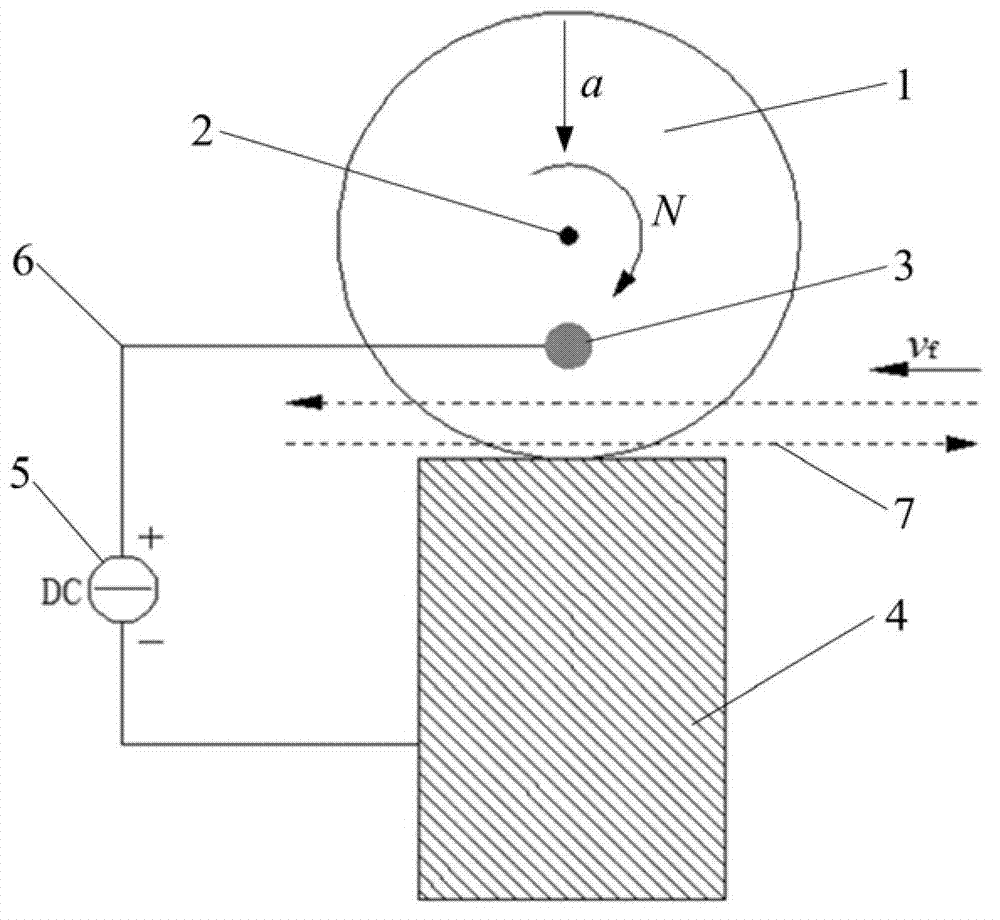

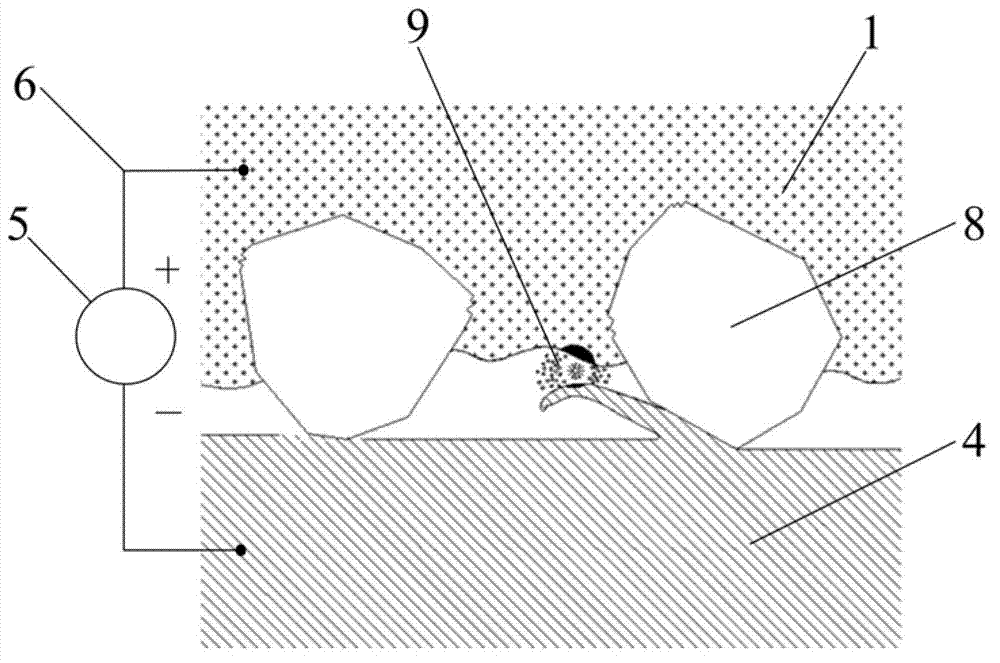

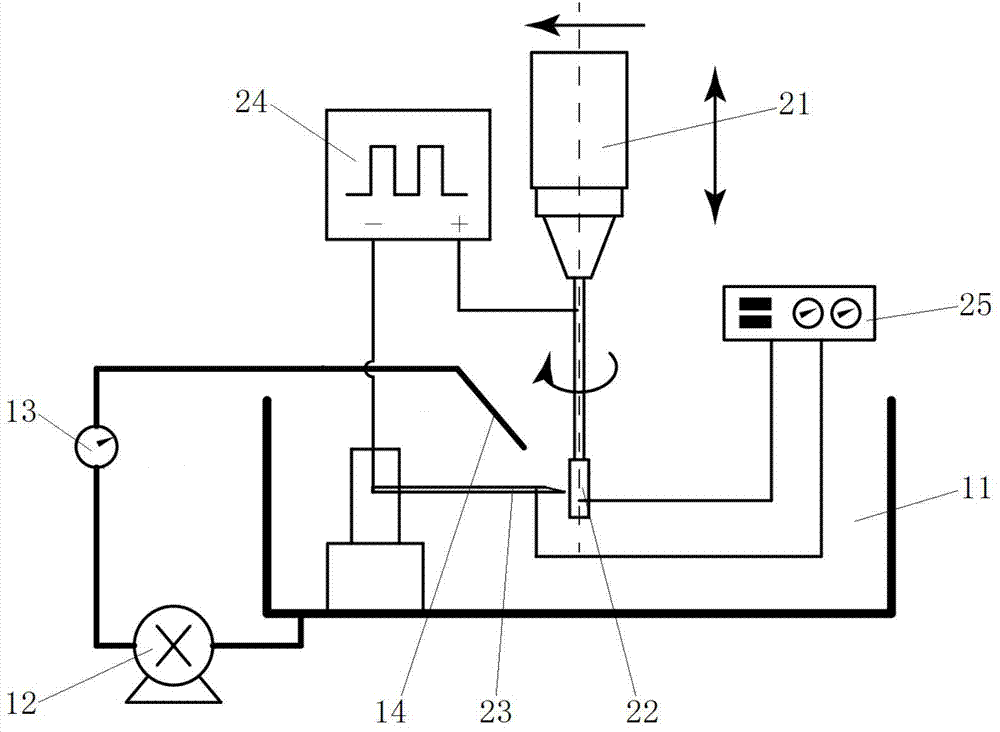

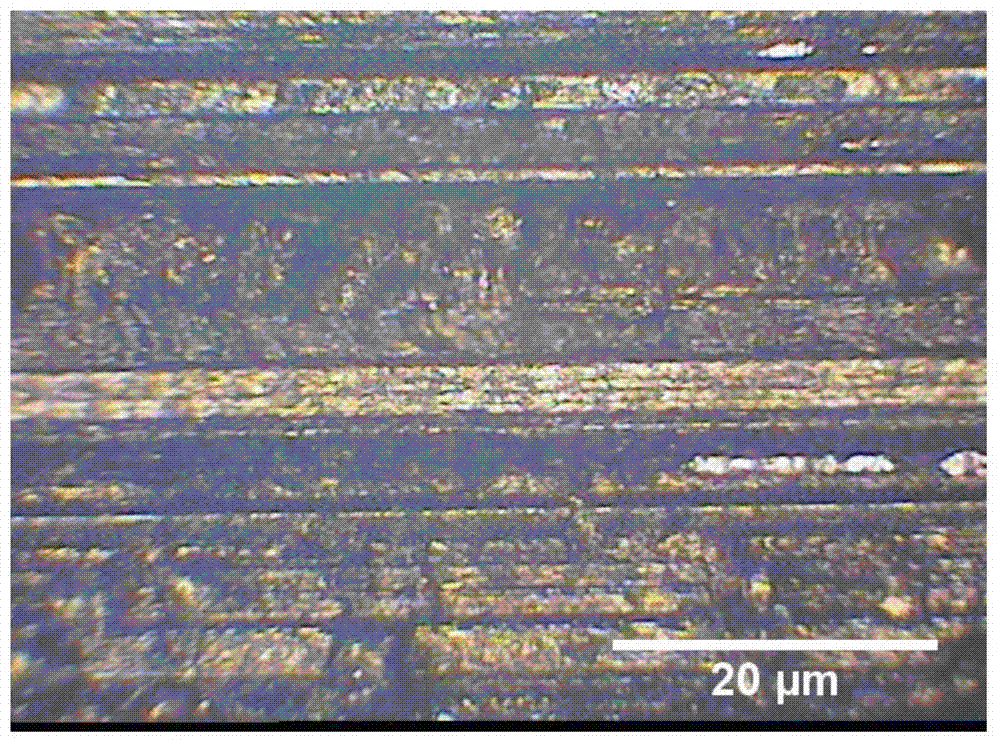

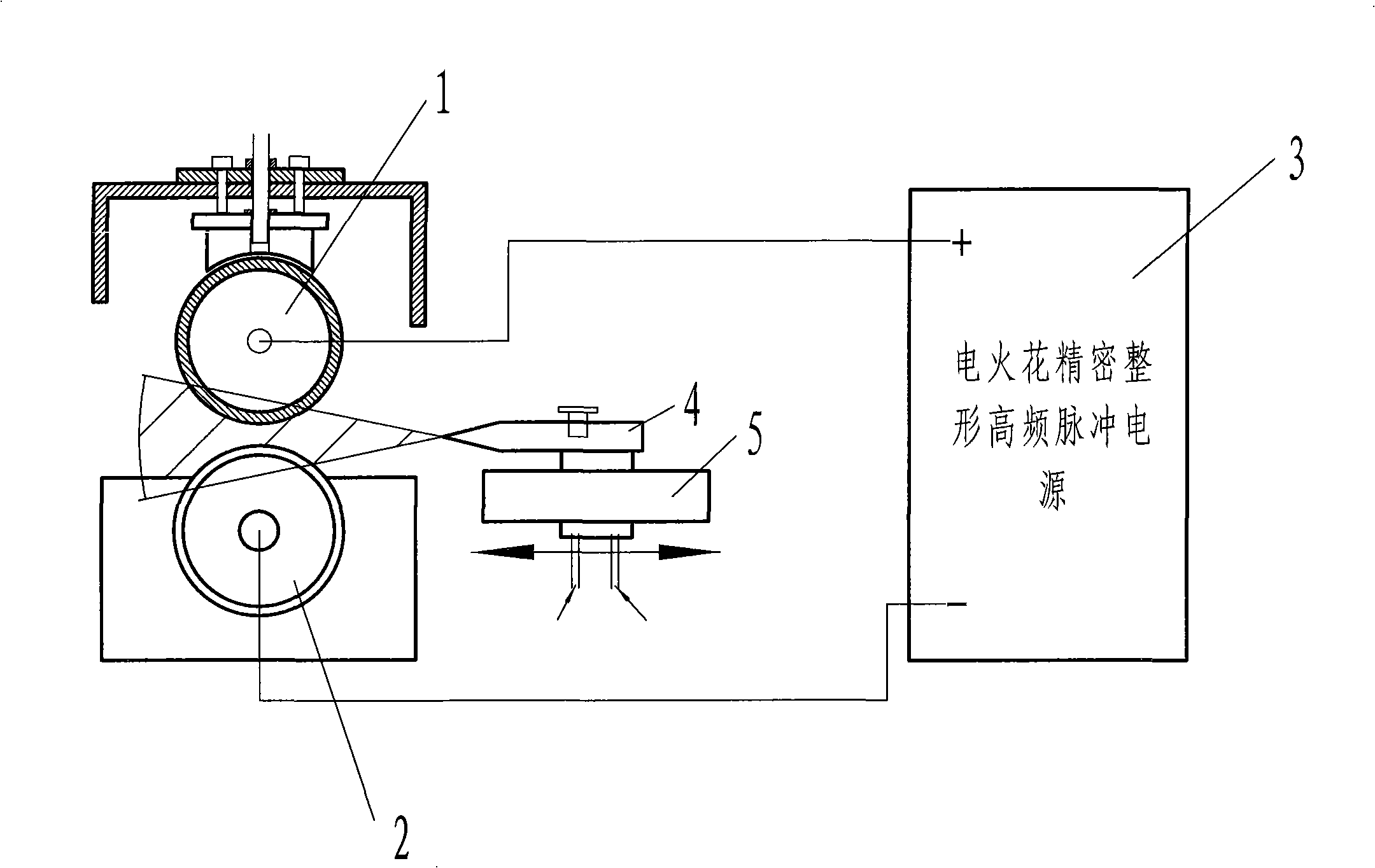

In-gas discharge dressing and truing method for large-particle diamond grinding wheel

ActiveCN103395002AWon't burnAvoid arcingAbrasive surface conditioning devicesWear particleCopper electrode

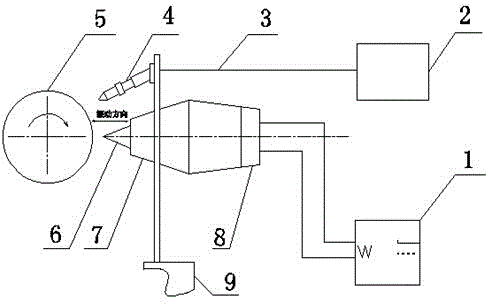

The invention discloses an in-gas discharge dressing and truing method for a large-particle diamond grinding wheel. The method includes: fixing the diamond grinding wheel on a grinding wheel shaft, and fixing a conducting electrode on the horizontal plane; connecting the diamond grinding wheel, the electrode, a graphite brush, a power source and a wire to form a discharge circuit; connecting a positive pole of the power source to the grinding wheel, and connecting a negative pole of the power source to the electrode. When rotating, the diamond grinding wheel linearly reciprocates on the surface of the electrode; metal bond is removed by pulse sparks generated between the electrode and the metal bond of the grinding wheel, so that diamond abrasive particles are edged from the surface of the grinding wheel; spark discharge occurs between the metal bond and whirling conducting chips generated when the edged diamond abrasive particles cut the copper electrode, generated instant high temperature is transmitted to cutting edges of the diamond abrasive particles in contact cutting through the chips, the tips of the cutting edges are pneumatically dressed, and accordingly micro edging, dressing and truing of the grinding wheel are achieved, more effective abrasive particles are generated and efficient grinding of smooth mirrors is achieved.

Owner:SOUTH CHINA UNIV OF TECH

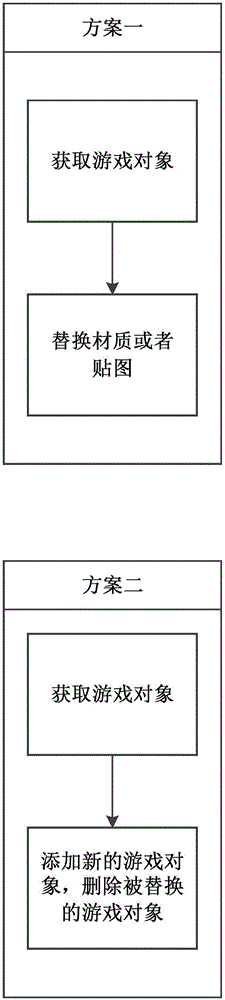

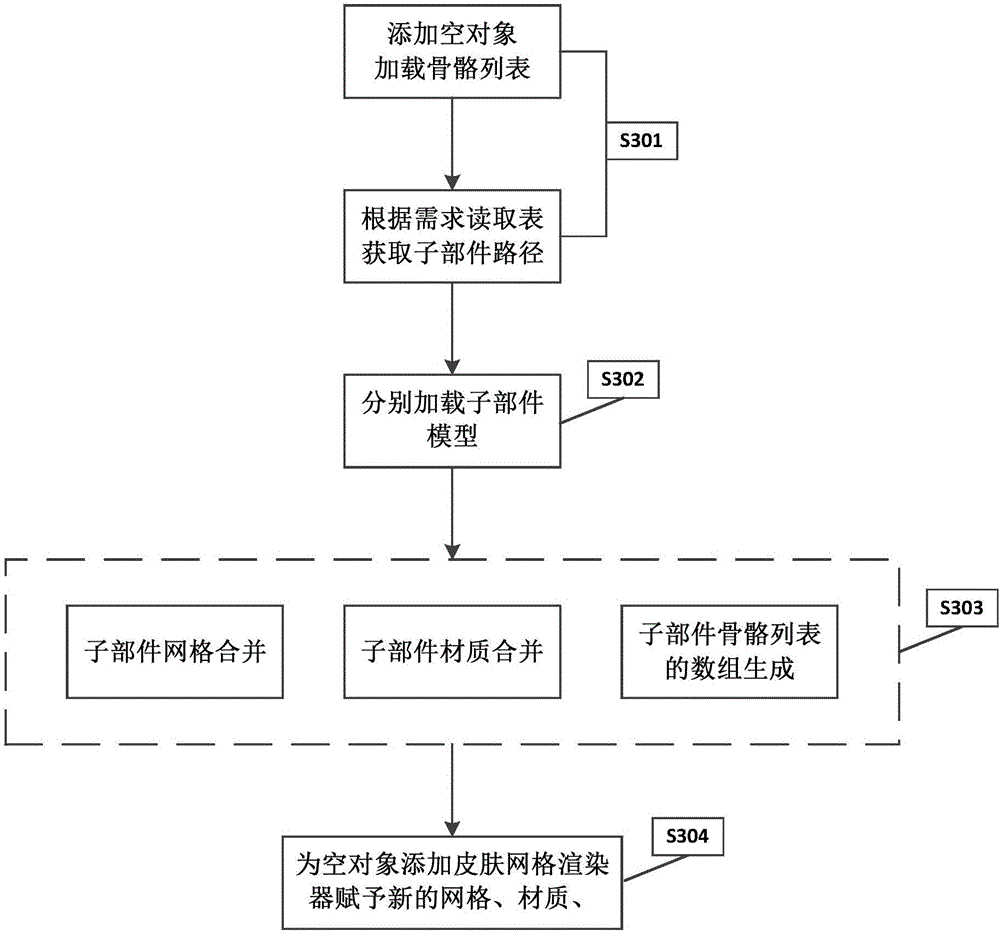

Game dress-up system and method

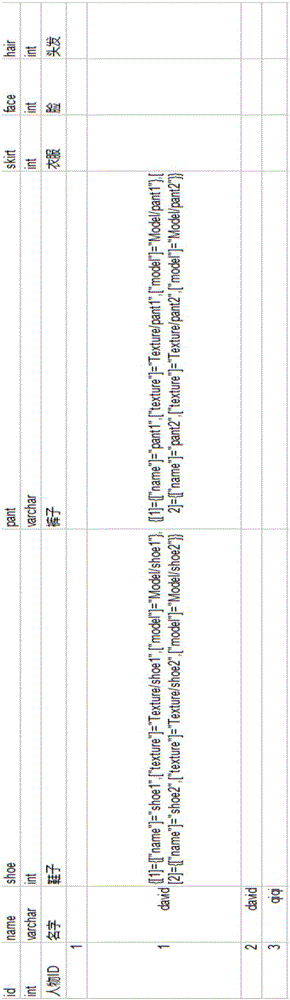

The technical scheme of the invention provides a game dress-up system and a game dress-up method. The game dress-up method comprises the following steps: saving a game role body part and to-be-dressed information, and establishing a corresponding null object role; acquiring command information, a data table of to-be-dressed body part of the game role, and calling information of a corresponding to-be-dressed body part under a storage path of the data table; traversing the game role body part information, acquiring a game role part model mesh, a part model skeleton list and a part model map, and performing merging; and rendering the null object role by using a skin mesh renderer. The game dress-up system and method have the beneficial effects that the drawing efficiency can be improved by adopting a skin mesh renderer after mesh merging; and the number of drawcall can be reduced after materials are merged, so that the dress-up efficiency is improved, and application and extension of skeletal animation are conveniently combined.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

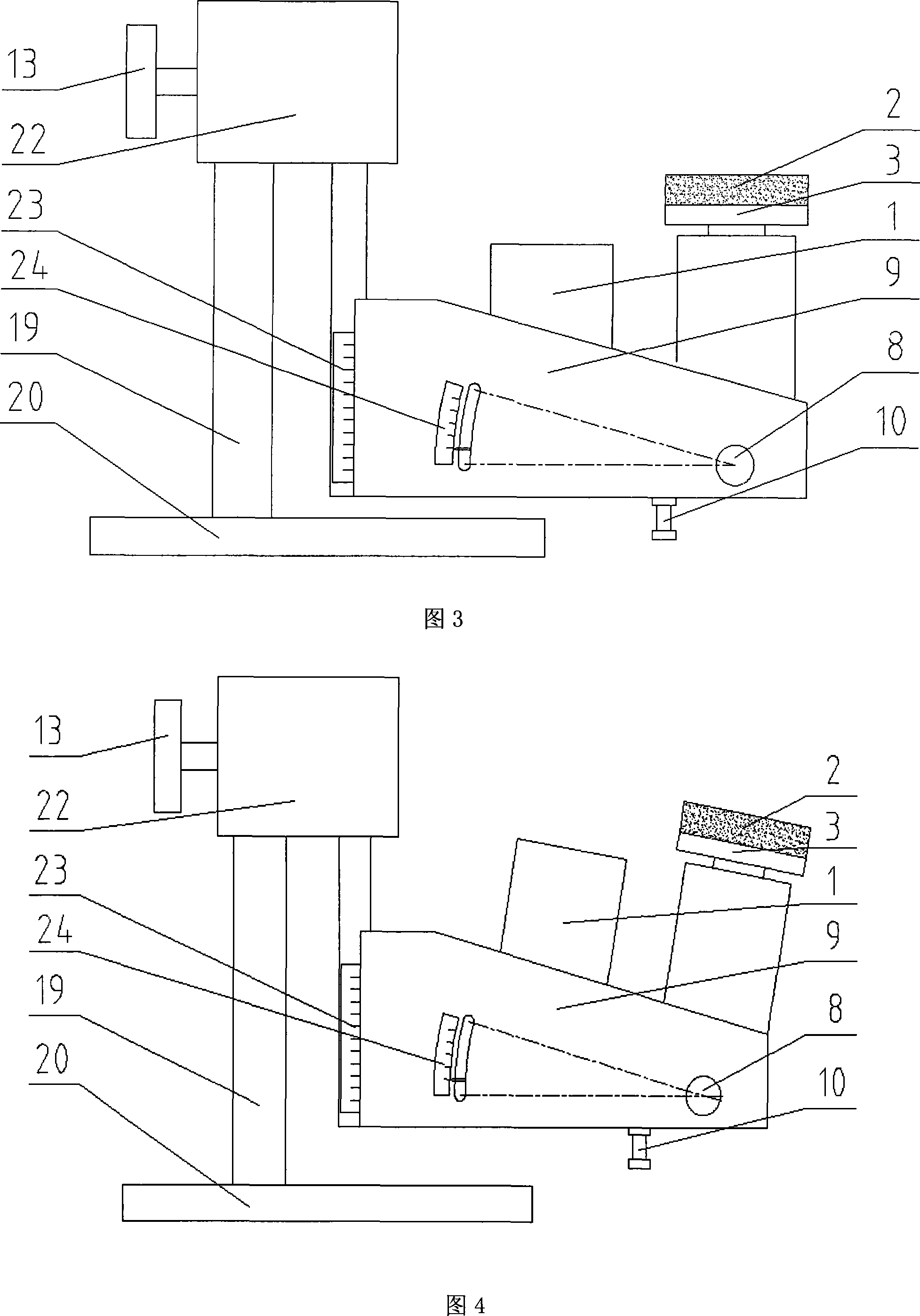

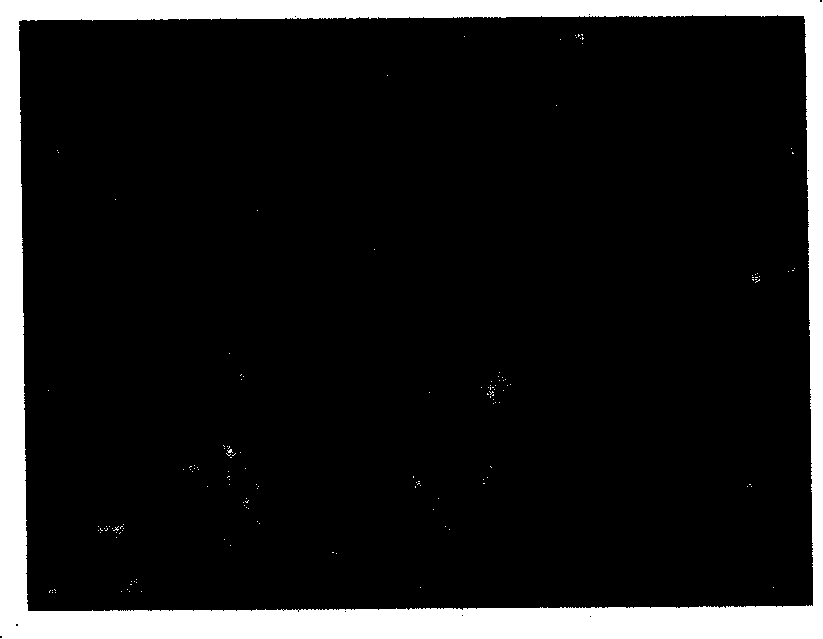

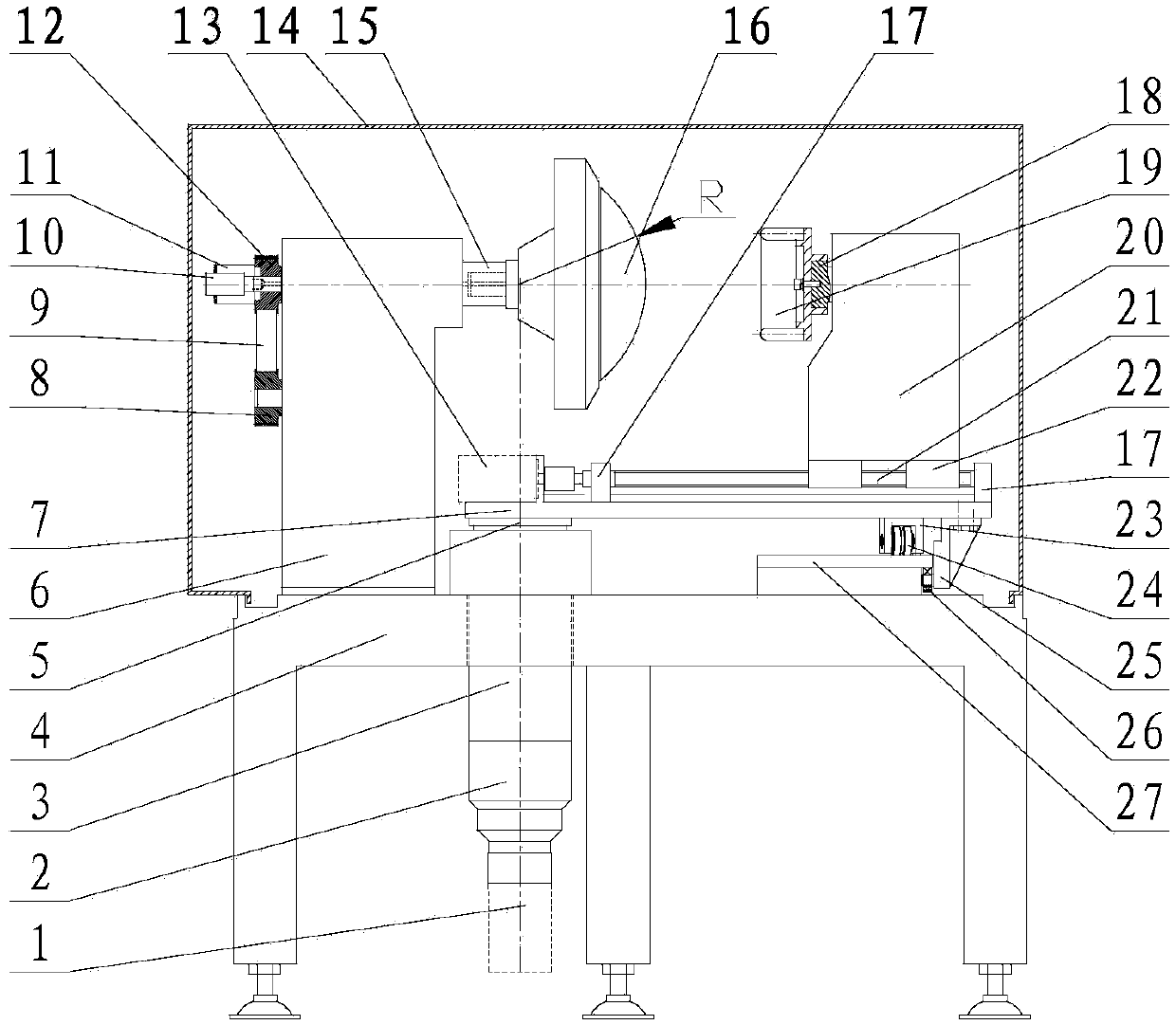

Device and method for modifying profile curvature of skylight glass

ActiveCN102336515AReduce labor intensityAvoid it happening againGlass reforming apparatusProgrammable logic controllerEngineering

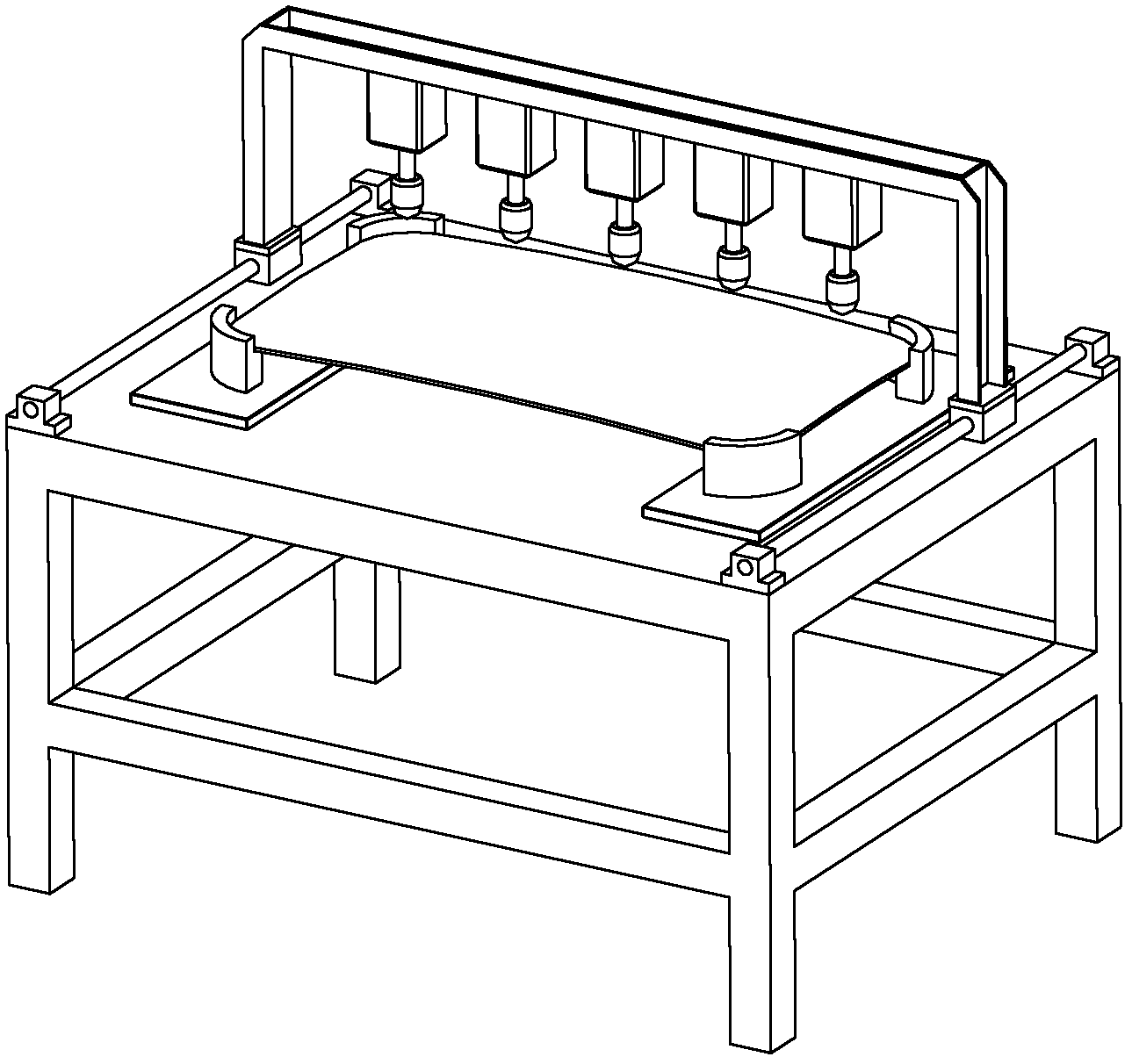

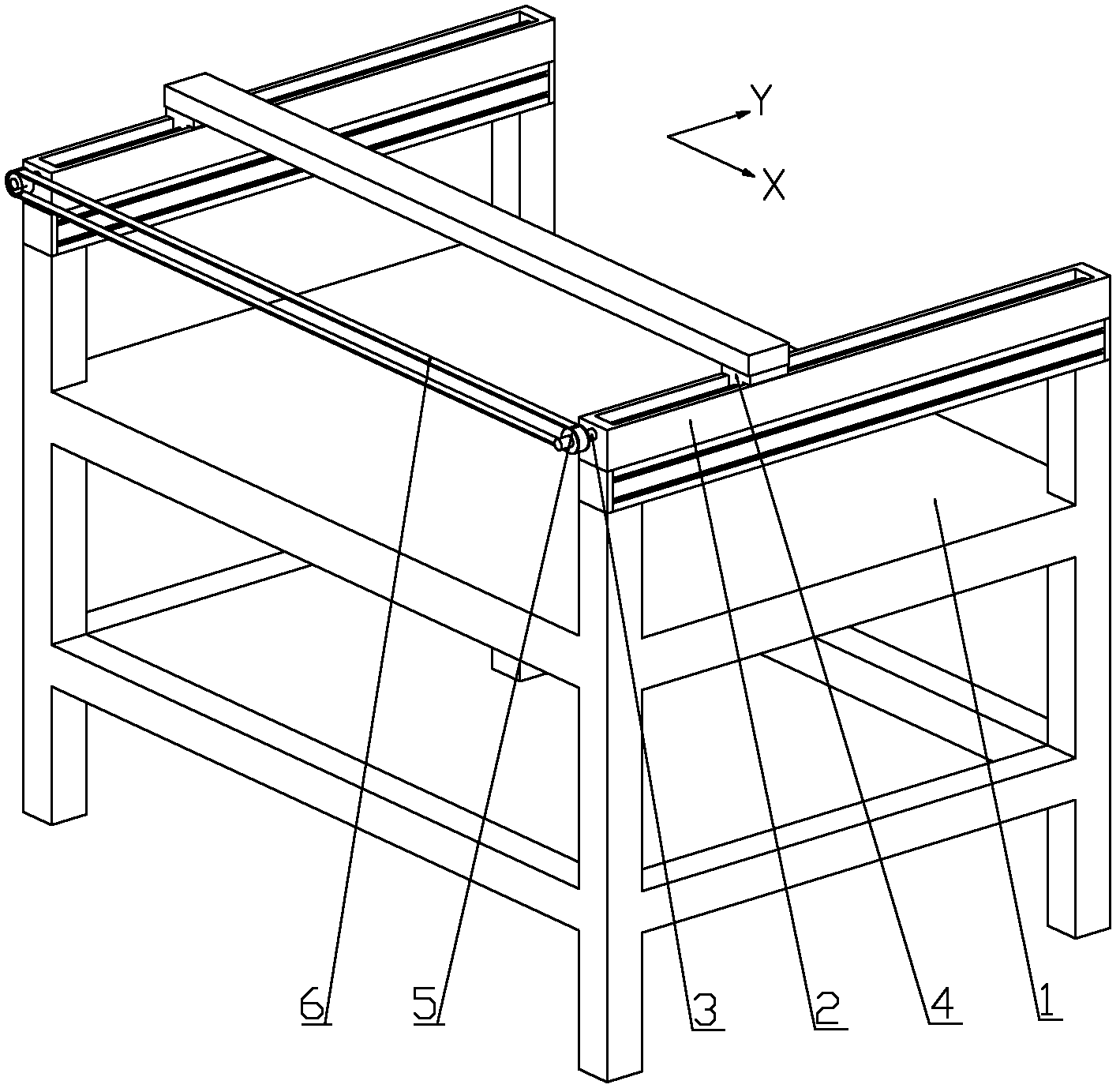

The invention discloses a device and a method for modifying profile curvature of skylight glass, which relate to the filed of glass reshaping. The device comprises a frame, a glass locating device, a cross beam and a press-down modification device, and further comprises translational slip mechanisms for realizing horizontal translational motion of the cross beam along the axis Y, a glass longitudinal compressing device, a roof modification device, a glass profile size detection device and a PLC (Programmable Logic Controller) control device; a left end and a right end of the cross beam are fixed on nut slide blocks of the translational slip mechanisms located at the left end and the right end of the frame; the glass profile size detection device is fixed under the cross beam through a connection plate, and the glass profile size detection device measures at an appointed position and feeds back the measured data by a position sensor, calculates an offset value between a real-time measured value and a standard value and adjusts the press-down speed or ejection speed, the strength of force and the pressing degree or the ejection degree of a pressure head so as to modify the glass. The method and the device realize semi-automation modification for the glass profile, are suitable for profile modification of various glasses, and simultaneously, improve modification efficiency, greatly.

Owner:FUYAO GLASS IND GROUP CO LTD +1

Device for measuring wall or ground flatness by lasers

ActiveCN103925892AConvenient flatness measurementConvenient flatness inspection and measurementUsing optical meansLaser transmitterBall bearing

The invention discloses a device for measuring the wall or ground flatness by lasers. The device comprises a base and a laser transmitter, the lower portion of the base is supported on a standard supporting face, the standard supporting face is the plane which is locally leveled and ground, and has the qualified flatness, the laser transmitting point of the laser transmitter is arranged in the plane of the standard supporting face, a stepped shaft is arranged in the middle of the upper portion of the base, a thrust ball bearing is arranged at the position of a small shaft of the stepped shaft, a boss is arranged on the upper portion of the laser transmitter, a stepped hole is formed in the boss, the position of a large hole of the stepped hole is matched with the thrust ball bearing, and the laser transmitter rotates around the axis of the stepped shaft through the thrust ball bearing. The device is simple and compact in laser, a constructor can conveniently conduct wall or ground flatness measurement in the construction process, meanwhile, an inspector can conveniently check and measure the flatness in the inspection and acceptance process, the measured face can be rapidly and accurately measured, and the measuring and repairing efficiency can be improved.

Owner:STATE GRID CORP OF CHINA +1

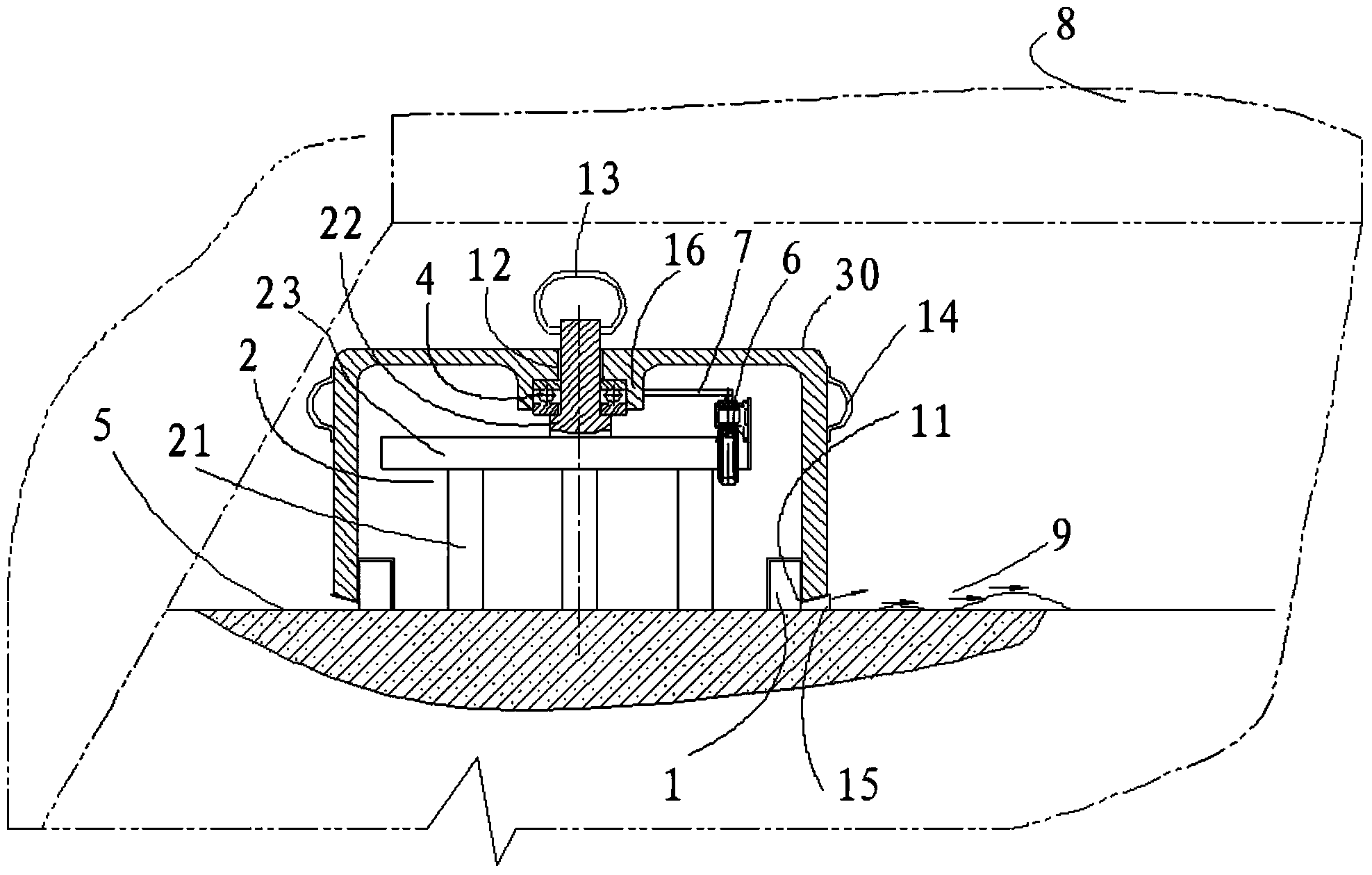

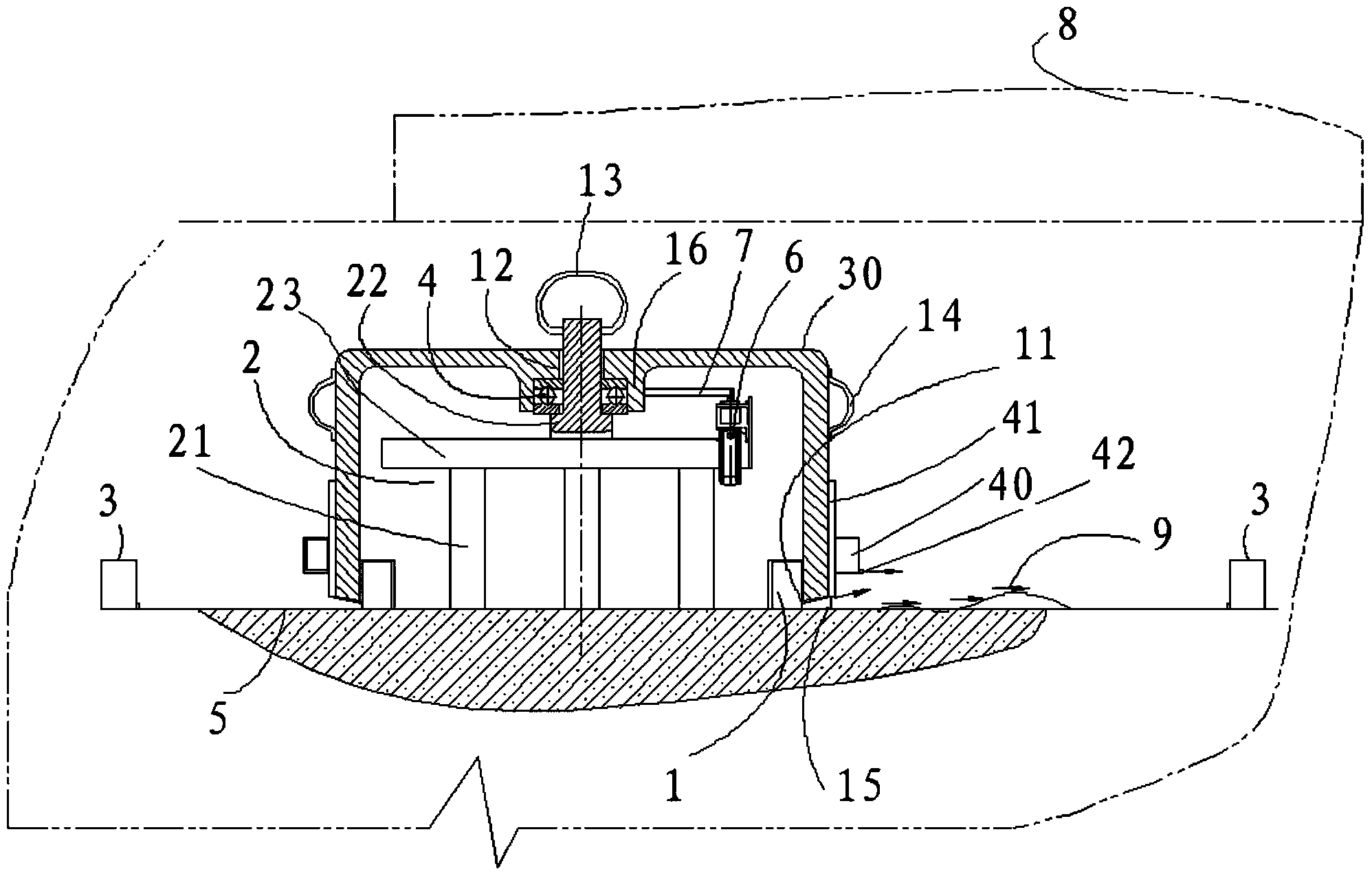

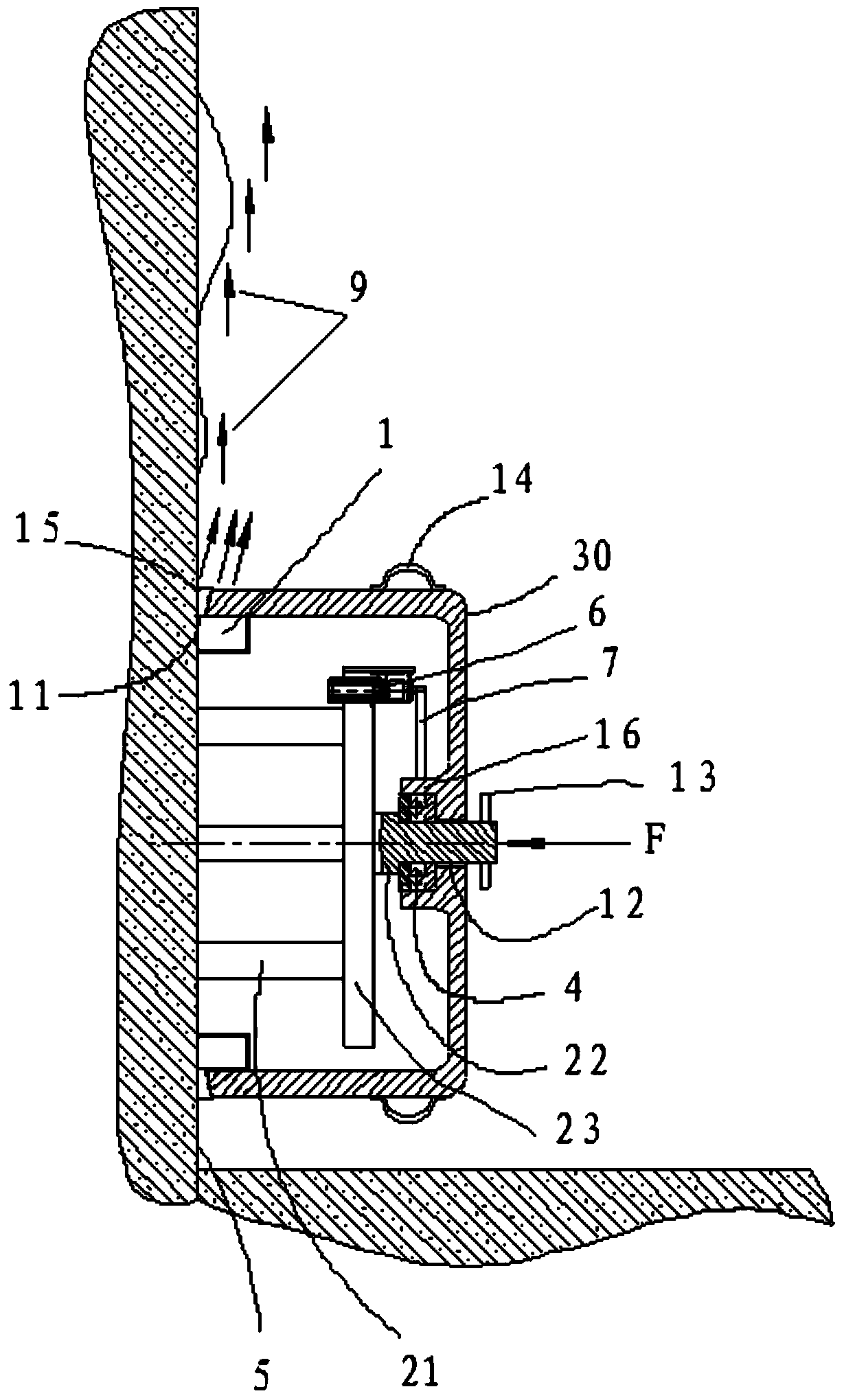

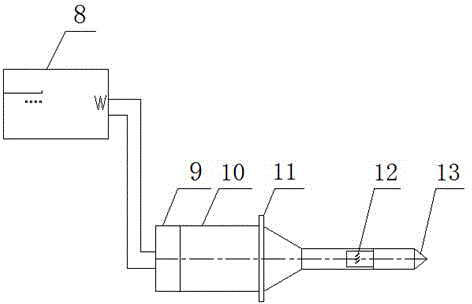

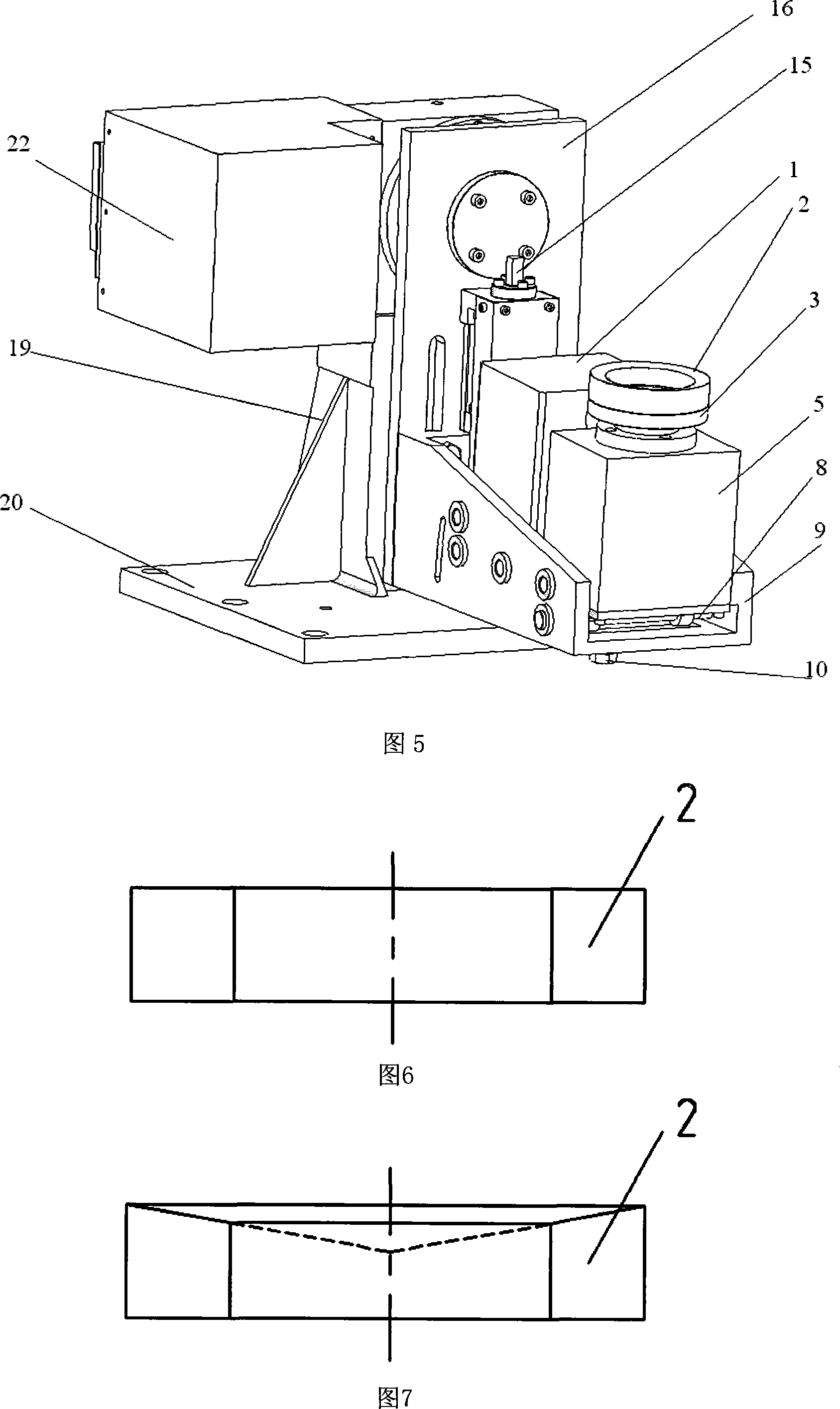

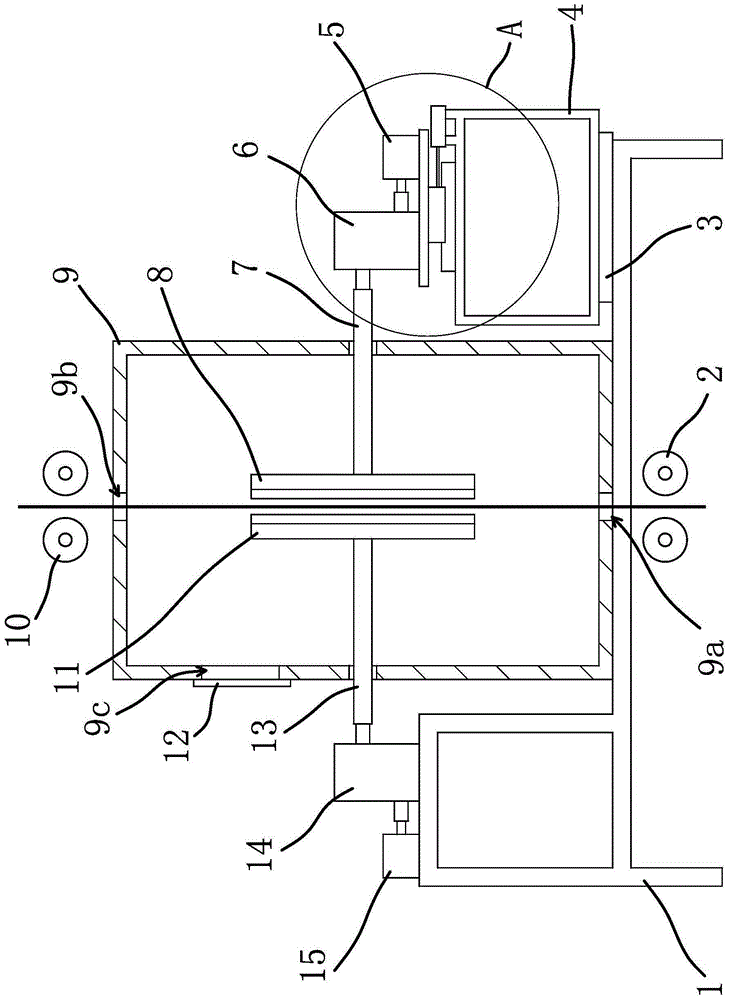

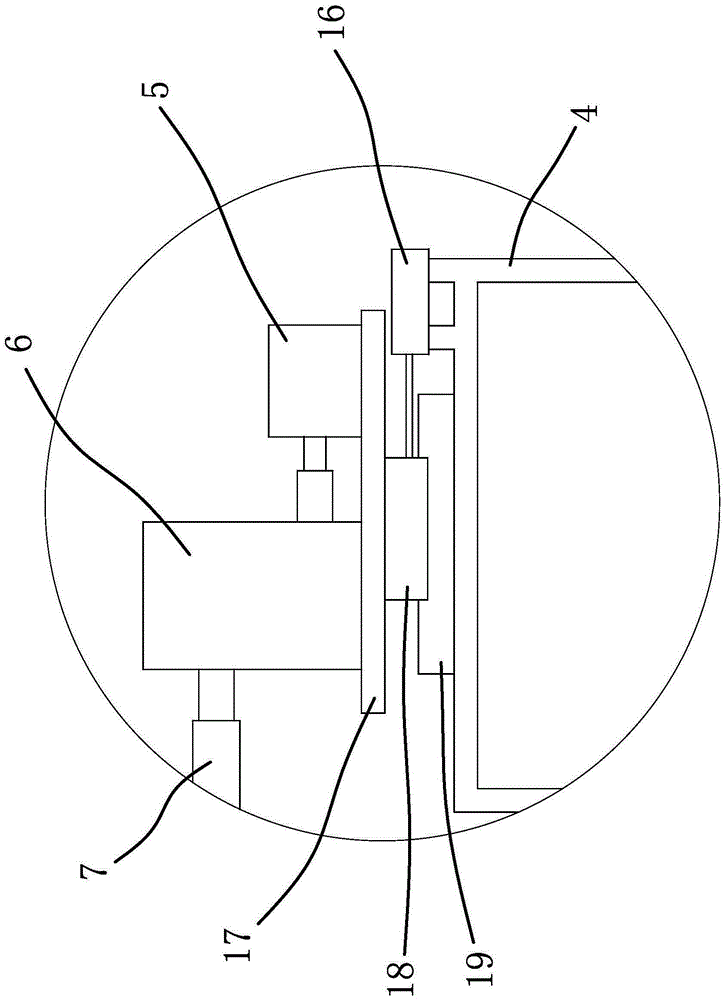

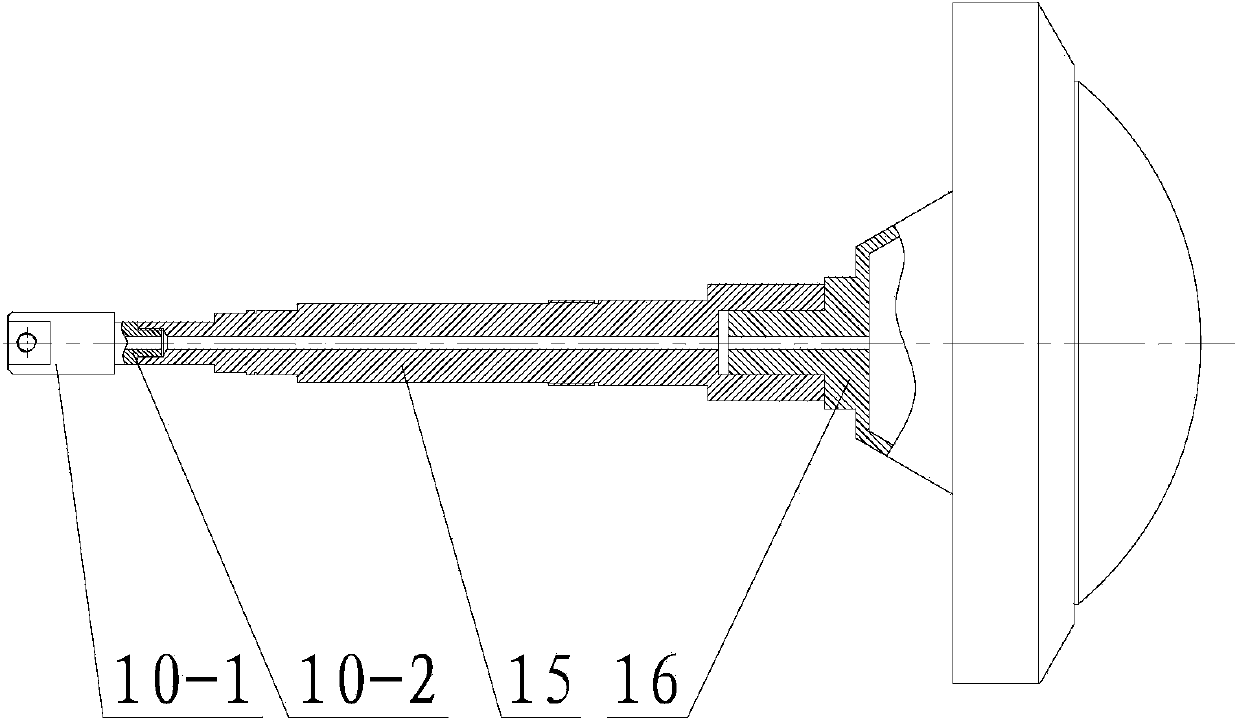

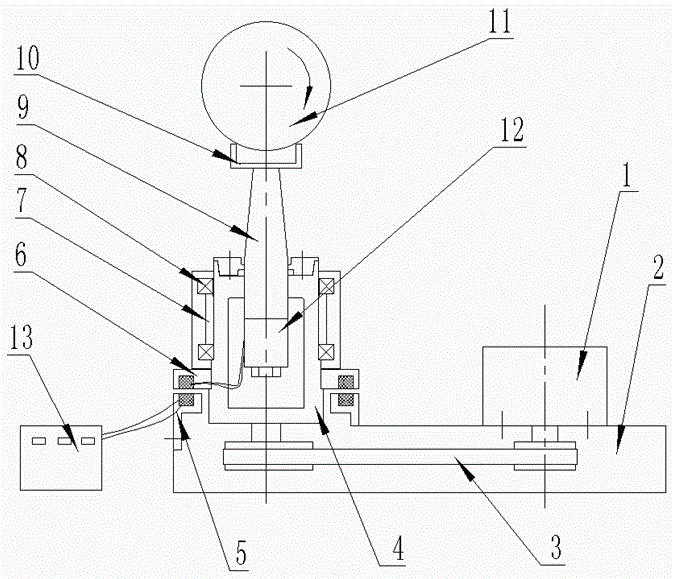

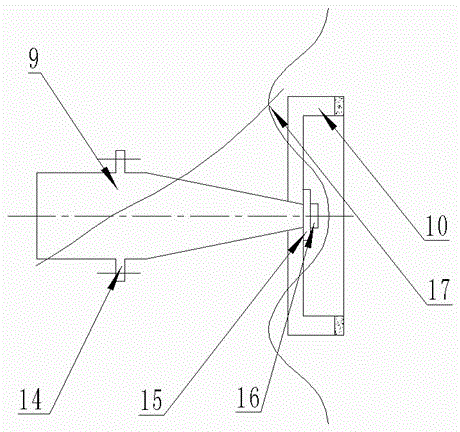

Ultrasonic laser composite dressing device for superabrasive grinding wheel

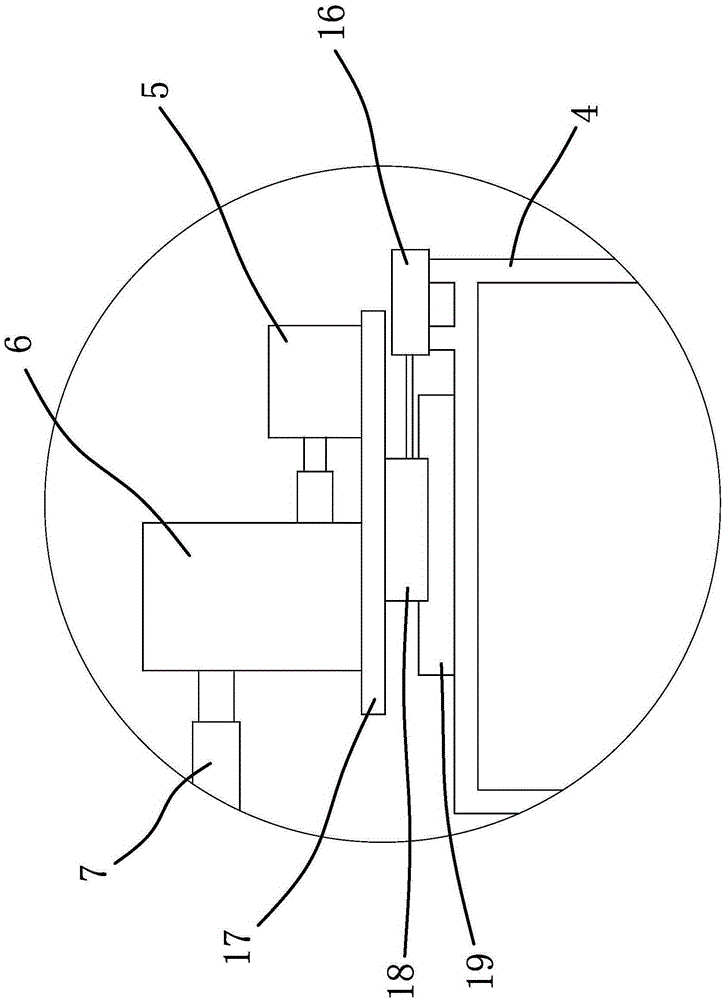

InactiveCN104440559AEasy outflowReduce wearAbrasive surface conditioning devicesLaser transmitterCutting force

The invention discloses an ultrasonic laser composite dressing device for a superabrasive grinding wheel. The ultrasonic laser composite dressing device is mainly formed by an ultrasonic vibration dressing system, a laser transmitting system and a lathe bed. A laser transmitter transmits energy to a laser focusing head with a focusing head fixing and adjusting device through optical fibers, laser beams are focused during work to heat the rotating grinding wheel in front of a dressing point at proper energy density for proper heating time, an ultrasonic generator transmits an ultrasonic frequency signal to an ultrasonic transducer, the ultrasonic frequency signal is converted into mechanical vibration through the transducer to be transmitted to an amplitude-change pole, waves, generating longitudinal vibration, of the amplitude-change pole will be decomposed at the position, where a diamond slot is formed, of the small end, the vibration type involves longitudinal vibration and bending vibration, composite elliptical ultrasonic vibration is formed at the point of a diamond dressing stylus for dressing, and after the dressing stylus completely disengages from the grinding wheel, the dressing stylus will be moved to the position where dressing is started for the next time and starts dressing for the next round. In the dressing process, under the recombination action of ultrasonic vibration and laser auxiliary heating, removal of partial materials of the grinding wheel is changed from brittle removal into plastic removal, cutting force is reduced, abrasion to the dressing stylus is reduced, and the dressing efficiency and dressing result are improved.

Owner:HENAN POLYTECHNIC UNIV

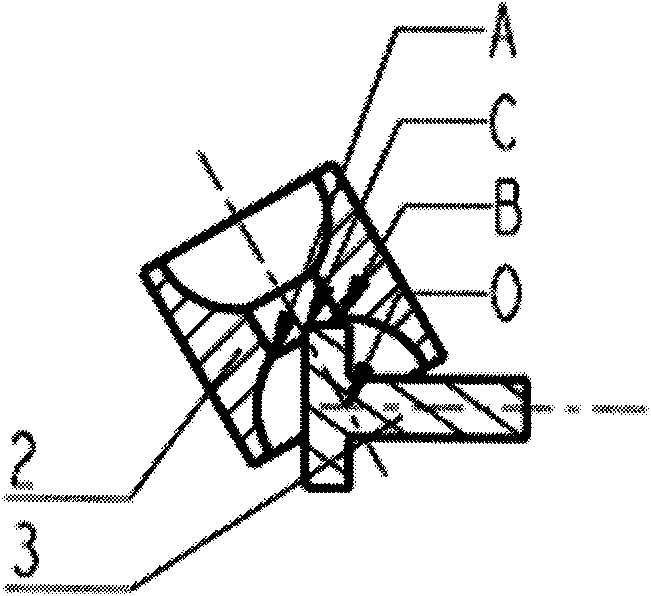

Method for roughly trimming diamond grinding wheel

InactiveCN103042468AReduce the gripQuick removalGrinding feed controlAbrasive surface conditioning devicesMicrometerPulsed laser beam

The invention provides a method for roughly trimming a diamond grinding wheel. The method includes steps of A, scanning the surface of the diamond grinding wheel, acquiring the highest point of the surface of the grinding wheel and determining the position of the highest point in radial, axial and generating line directions; B, emitting a focused pulse laser beam along the inner normal direction of the surface of the grinding wheel and enabling the position of a focal spot of the focused pulse laser beam to be coincided with the position of the highest point of the grinding wheel in the radial, axial and generating line directions; C, erecting a silicon carbide roller at a position opposite to a generating line of the grinding wheel and setting the cutting depth as 0.005mm; and D, repeating the steps once after the grinding wheel is trimmed for 3 to 5 minutes until a circle run-out error of the grinding wheel is not larger than 20 micrometers. The method has the advantages that diamond grains are ablated and directly removed by the focused pulse laser beam, remaining diamond grains are removed by the silicon carbide roller, deteriorative layers of surfaces of the grains which are ablated by laser, grains without holding force and the like are mechanically peeled off, and the method is applicable to efficiently roughly trimming diamond grinding wheels with large grains.

Owner:HUNAN UNIV

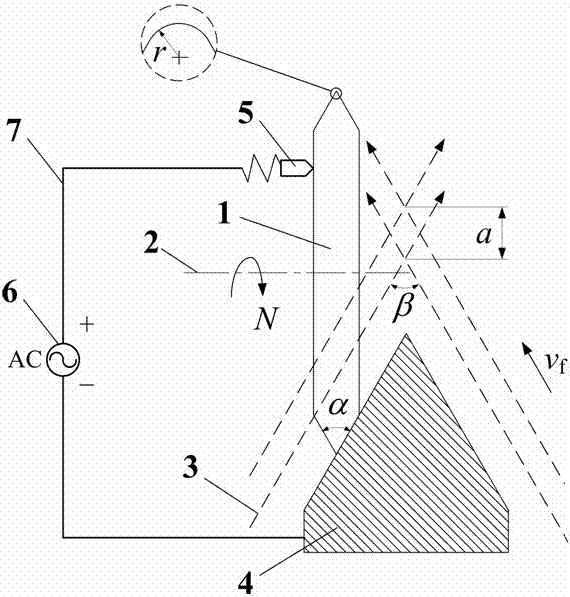

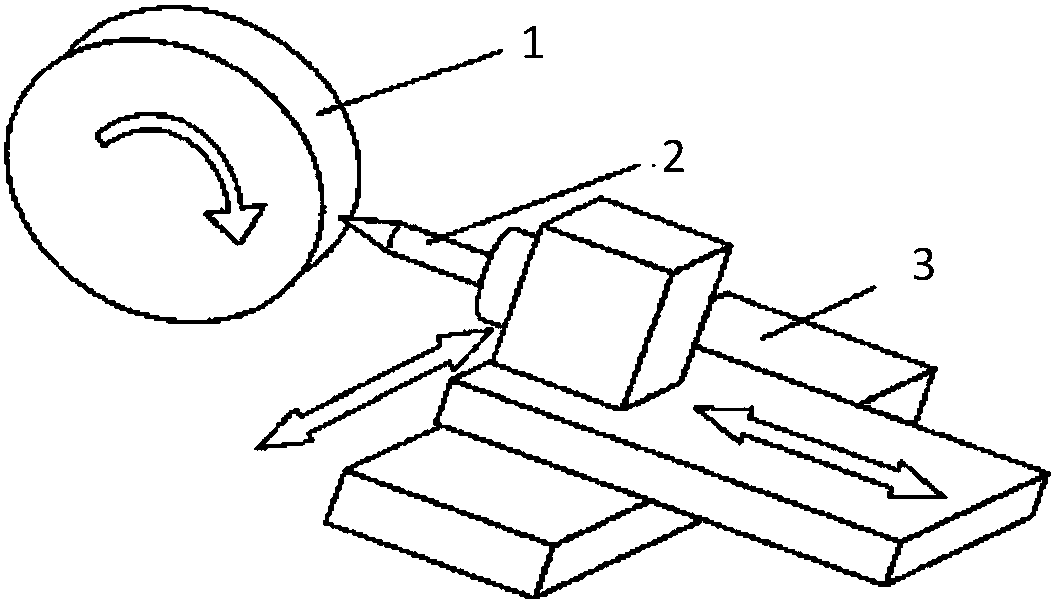

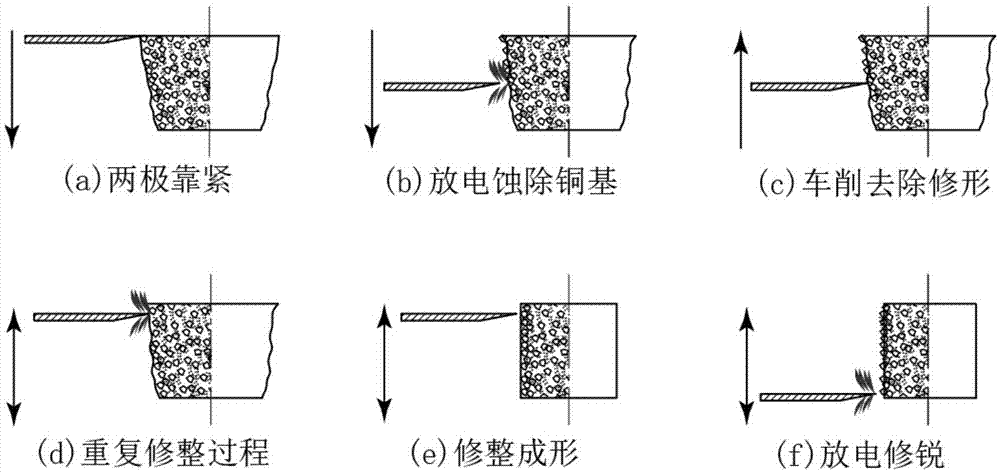

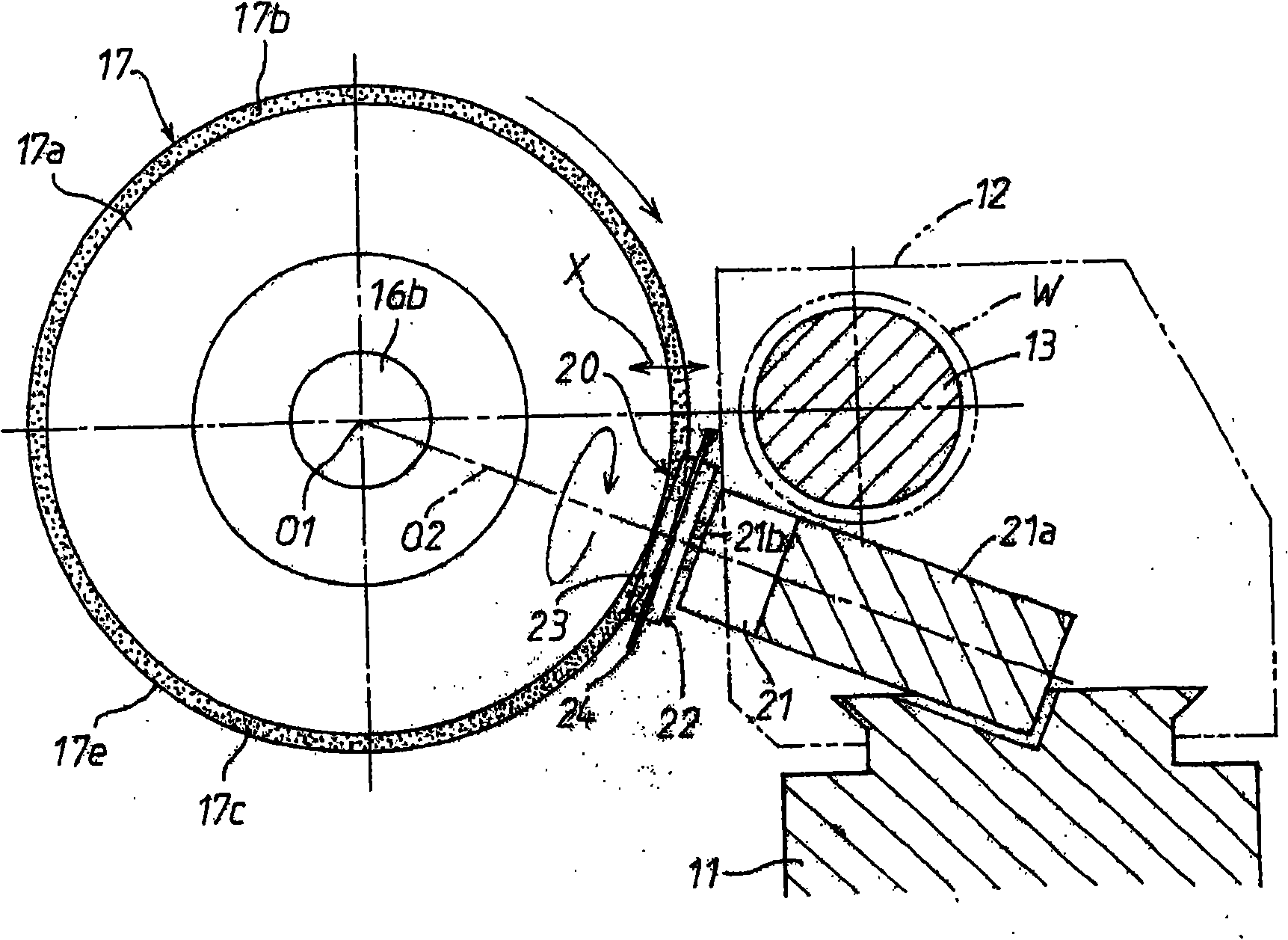

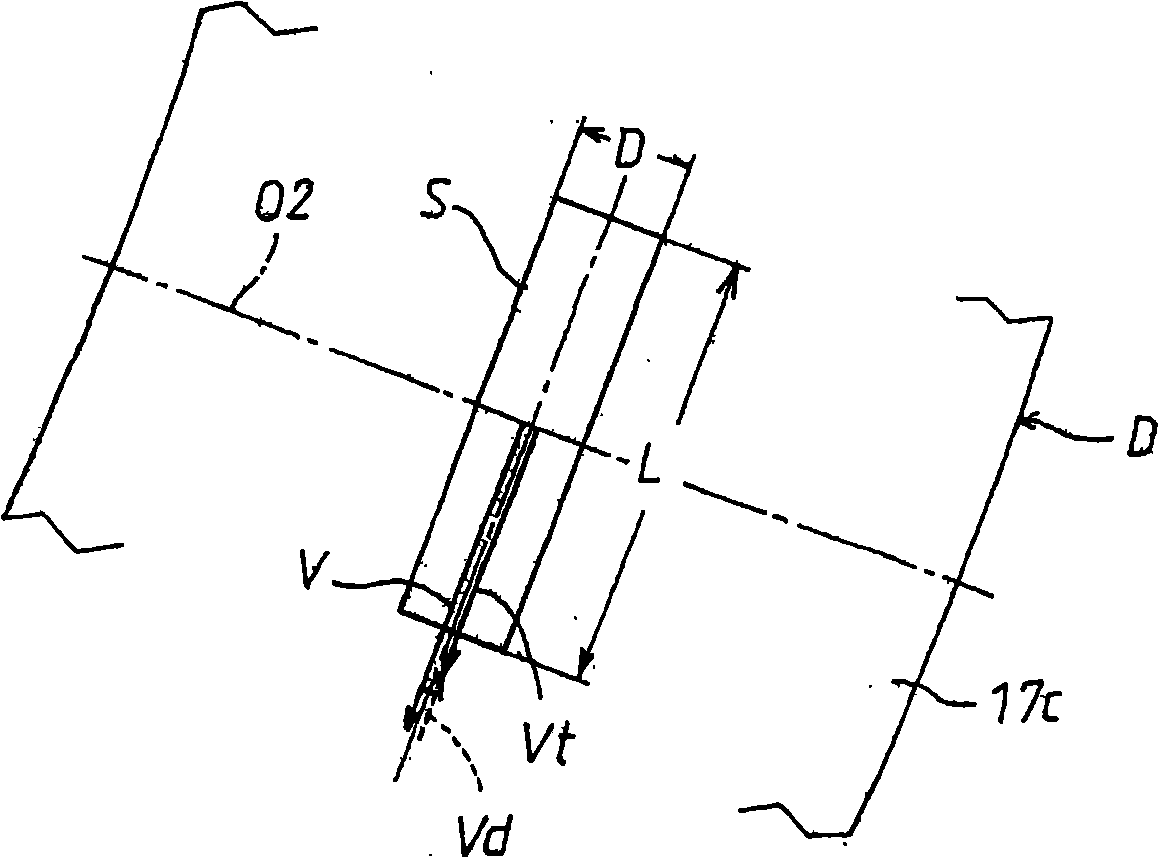

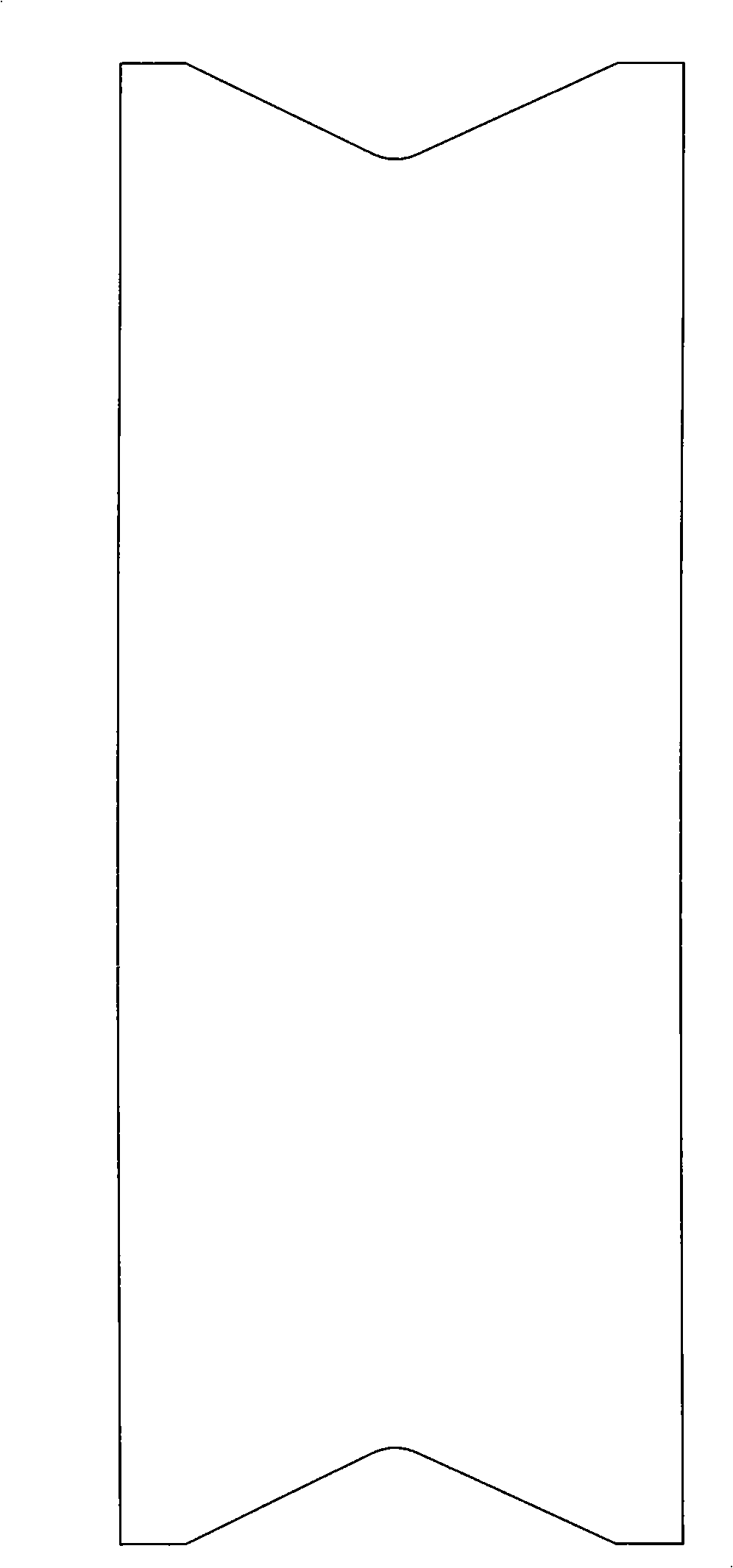

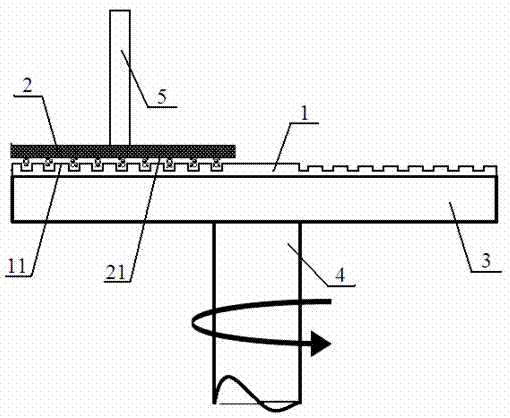

Method for finishing V-shaped sharp angle of metal-base diamond grinding wheel by electrical discharge grinding in gas

InactiveCN102490121AImprove dressing efficiencyImprove protectionAbrasive surface conditioning devicesVertical planeSharp angle

The invention discloses a method for finishing a V-shaped sharp angle of a metal-base diamond grinding wheel by electrical discharge grinding in gas. The method for finishing the V-shaped sharp angle of the metal-base diamond grinding wheel by electrical discharge grinding in gas comprises steps of: fixing a diamond grinding wheel tool on a grinding wheel shaft, fixing electrodes on a horizontal plane, and forming a discharging loop by using a lead, a pulse power supply, an electrographite brush and the diamond grinding wheel tool; performing contact discharge grinding in gas to the right side of the diamond grinding wheel tool, wherein the diamond grinding wheel tool moves from left to right along the axial direction of the grinding shaft while moving from bottom up along with the grinding wheel shaft in a vertical plane perpendicular to the horizontal plane so as to form a V-shaped traveling path with a left side which inclines upwards; and switching the direction of the diamond grinding wheel tool, wherein grinding wheel tool moves from right to left along the axial direction of the grinding shaft while moving from bottom up along with the grinding shaft so as to form a V-shaped traveling path with a right side which inclines upwards, and performing contact discharge grinding in gas to the left side of the diamond grinding wheel tool. According to the method for finishing the V-shaped sharp angle of the metal-base diamond grinding wheel by electrical discharge grinding in gas, the finishing ratio of the V-shaped sharp angle of the superhard metal-base diamond grinding wheel can be greatly improved, and no cooling liquid difficult to treat is needed.

Owner:SOUTH CHINA UNIV OF TECH

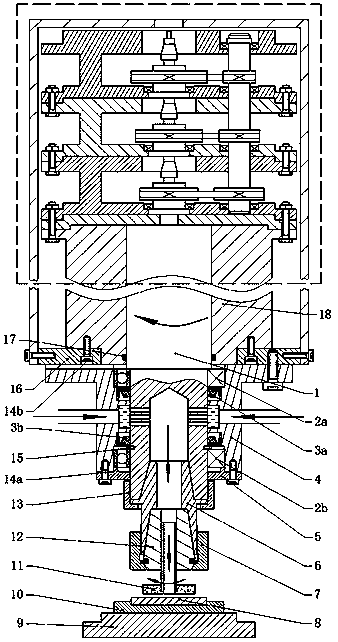

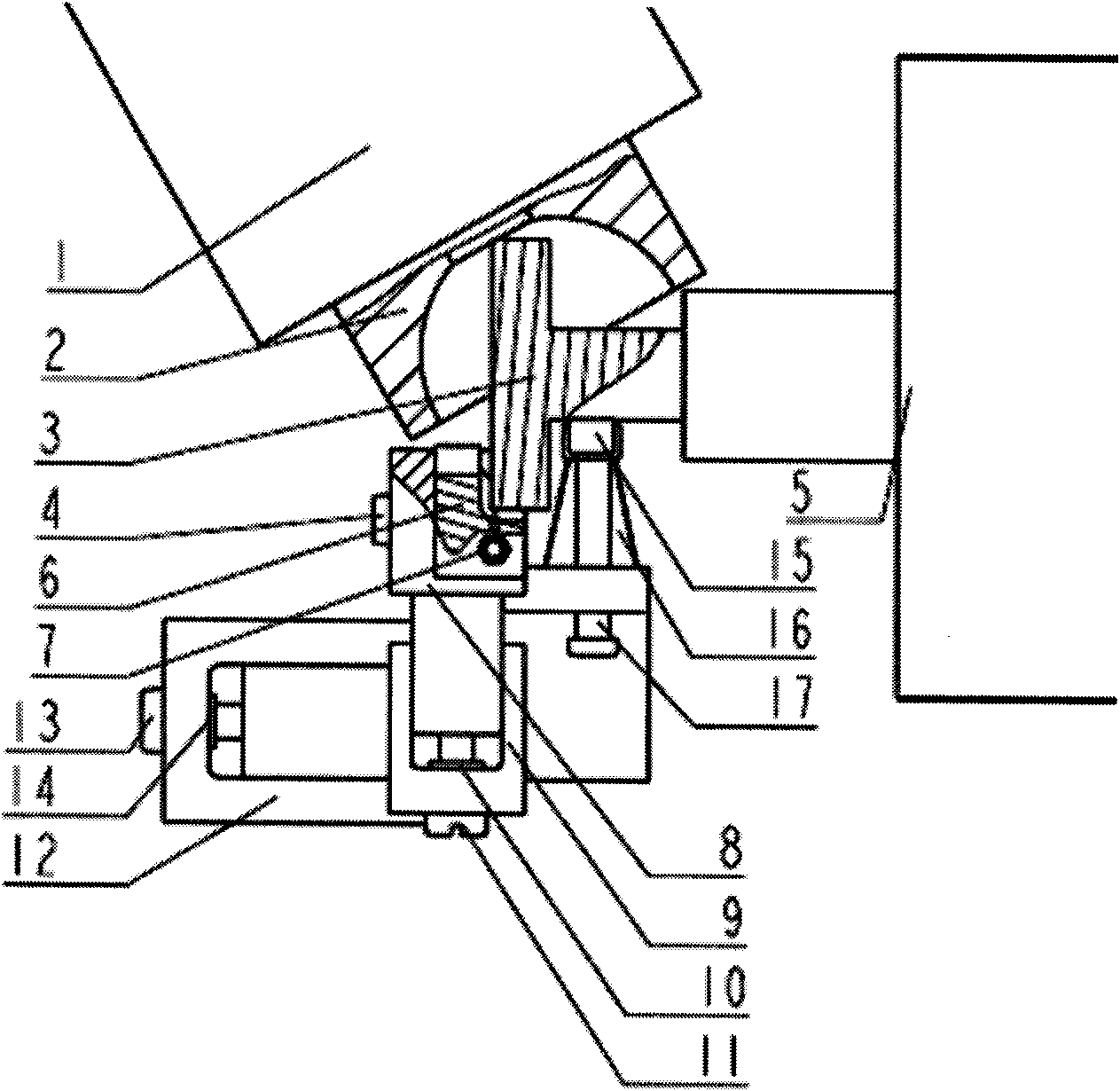

Cup type grinding wheel trimming device

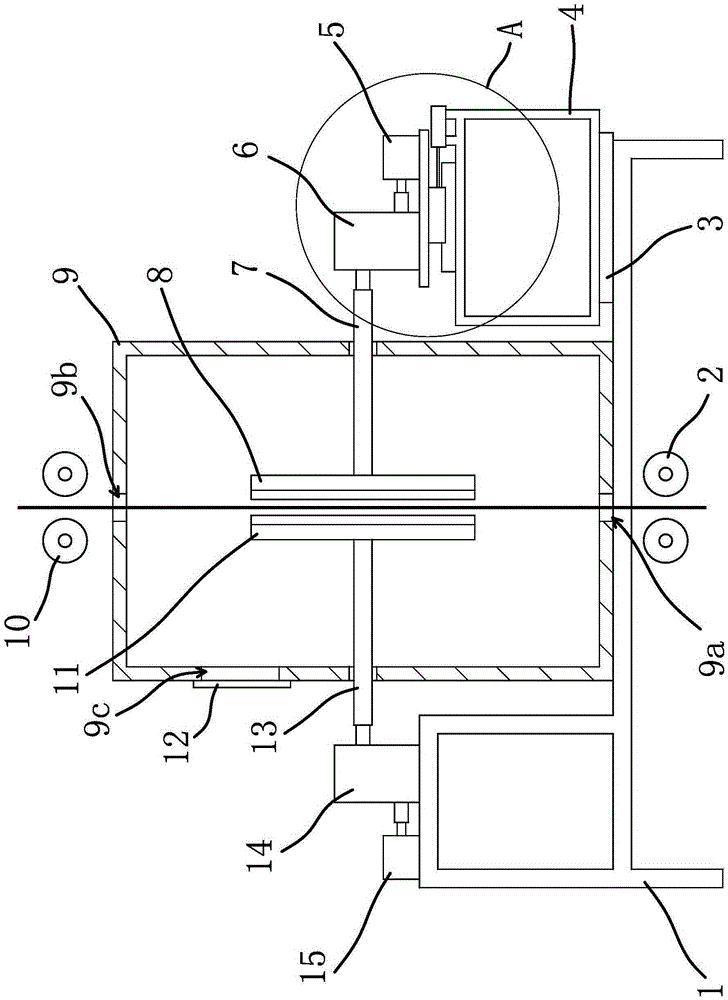

InactiveCN101121250APrecise TrimmingTrim powerfulAbrasive surface conditioning devicesControl systemEngineering

A cup-shaped wheel dresser relates to a non-sphere processing grinding wheel; the wheel dresser provides a cup-shaped wheel dresser; the height and inclination of the wheel dresser are adjustable and the wheel dresser has the oscillating function. The wheel dresser is equipped with a base, an oscillating arm support saddle, an oscillating arm rotary shaft, a dressing grinding wheel, a grinding wheel panel, a main shaft, a main shaft band wheel box, servo motors, transmission mechanisms, a screw, a bolt, a supporting round stick, a triangle support saddle, runners and a numerically controlled system. The oscillating arm is equipped on the base and the oscillating arm base is connected with the oscillating arm rotary shaft. The grinding wheel is connected with the main shaft and the grinding wheel is installed on the main shaft; the main shaft is connected with the main shaft band wheel box; the first servo motor is connected with the main shaft by the first transmission mechanism and the second servo motor is connected with the oscillating arm rotary shaft by the second transmission mechanism. The bottom of the main shaft band wheel box is connected with the triangle support saddle and fixed on the triangle supported saddle; the bolt is equipped under the triangle support saddle and the triangle support saddle is connected with the oscillating arm; the screw is equipped on the oscillating arm and the triangle support saddle is linked with the lower end of the screw; the triangle support saddle and the oscillating arm are equipped with runners and the numerically controlled system is connected with the servo motors.

Owner:XIAMEN UNIV

Method for finishing resin binding agent diamond abrasive wheel by combining laser and machinery

InactiveCN101190503AImprove dressing efficiencyGood terrainAbrasive surface conditioning devicesComposition processSingle crystal

The invention provides a laser and mechanical composition finishing resin binder diamond grinding wheel method, comprising: adopting high power density pulse laser, focusing a laser beam by focusing lens and irradiating vertically to the grinding surface of the grinding wheel, rotating a grinding wheel, measuring the fluctuation of the grinding wheel round, adjusting the focus position of the laser to lead the focus to be dropped at the maximum position of the fluctuation of the round, adjusting the parameter of the laser in order to lead the maximum position of the fluctuation of the grinding wheel round to reach the value, axially and repeatedly feeding and rotating the grinding wheel till diamond grinding grain part close to the maximum position of the fluctuation round is wholly removed or partly and slightly removed or partly lost with holding force owning to the removal of the bonder through a plurality of finishing, shaping the grinding wheel by using a single-crystal diamond pen or a carborundum idler wheel with definite tip, removing the grinding grain which loses the holding force and the grinding grain metamorphosing layer burned by laser, and repeatedly carrying out the composition processes till required round fluctuation and topography and geomorphology are reached. The invention obviously improves the finishing efficiency of the grinding wheel and leads the cutting surface of the grinding wheel to obtain excellent topography and geomorphology.

Owner:HUNAN UNIV

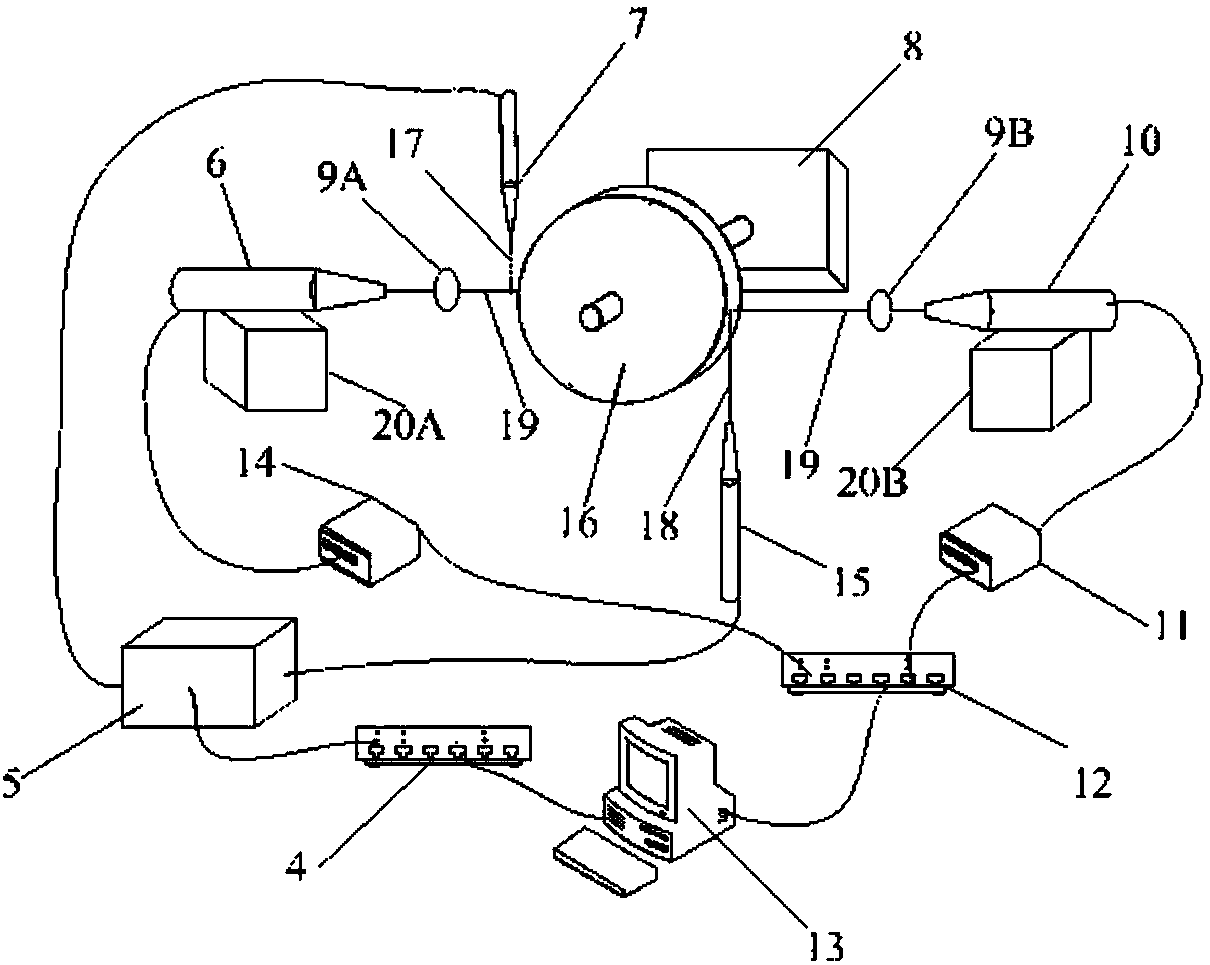

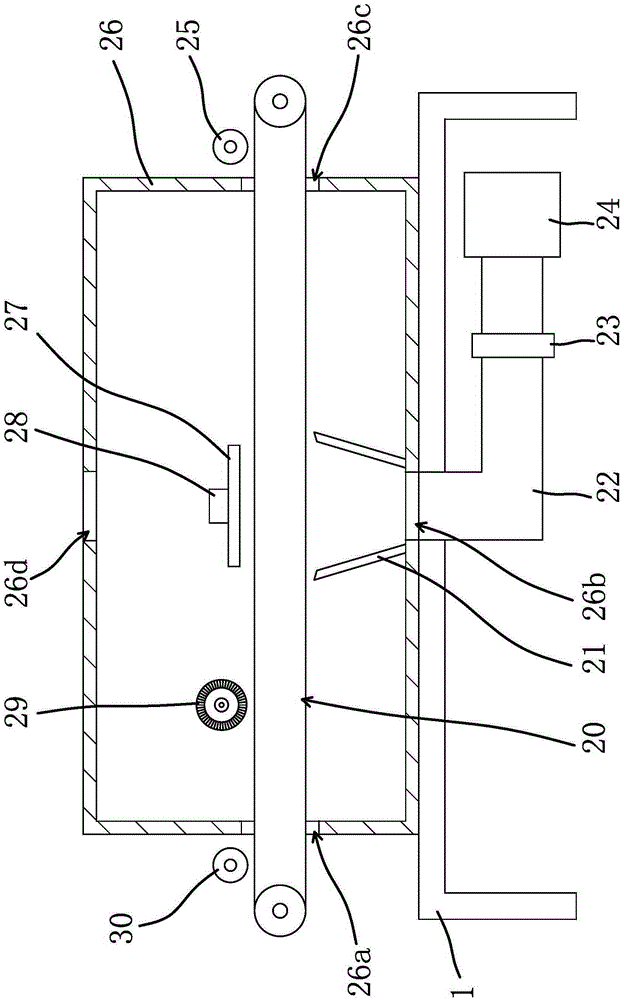

Gas-liquid parallel tube type grinding wheel double laser trimming device and method

ActiveCN108081137AReduced chip spaceAvoid Coulomb ExplosionsAbrasive surface conditioning devicesAutomatic grinding controlPicosecond laserFemto second laser

The invention discloses a gas-liquid parallel tube type grinding wheel double laser trimming device. The gas-liquid parallel tube type grinding wheel double laser trimming device comprises gas-liquidcontrol equipment, a gas-liquid control operating platform, a picosecond laser ablation head, a gas-guide flexible pipe, a grinding machine, focusing lenses, a femtosecond laser ablation head, a femtosecond laser device, a laser device control operating platform, control equipment, a picosecond laser device, a fine water-guide pipe, a superhard grinding-material grinding wheel, a gas column flow,a liquid column flow, laser beams and three-dimensional moving platforms. By means of the gas-liquid parallel tube type grinding wheel double laser trimming device and method, the auxiliary gas-liquidparallel tube type grinding wheel double laser trimming device is provided, the situations that diamond grinding particle chip tolerance space of the grinding wheel is reduced and the height of highlighted binder is not enough caused by plasma particles and phase explosion effect are avoided, and the defects of microcracks, graphite metamorphic layers and the like generated by peripheral heat accumulation during diamond grinding are overcome; and by means of the gas-liquid parallel tube type grinding wheel double laser trimming device and the method, the generation of coulomb explosion can beavoided, the surface grating and micro-cone structure of the grinding wheel are reduced, the utilization efficiency of laser energy is improved, and the grinding wheel trimming efficiency and the trimming surface quality are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

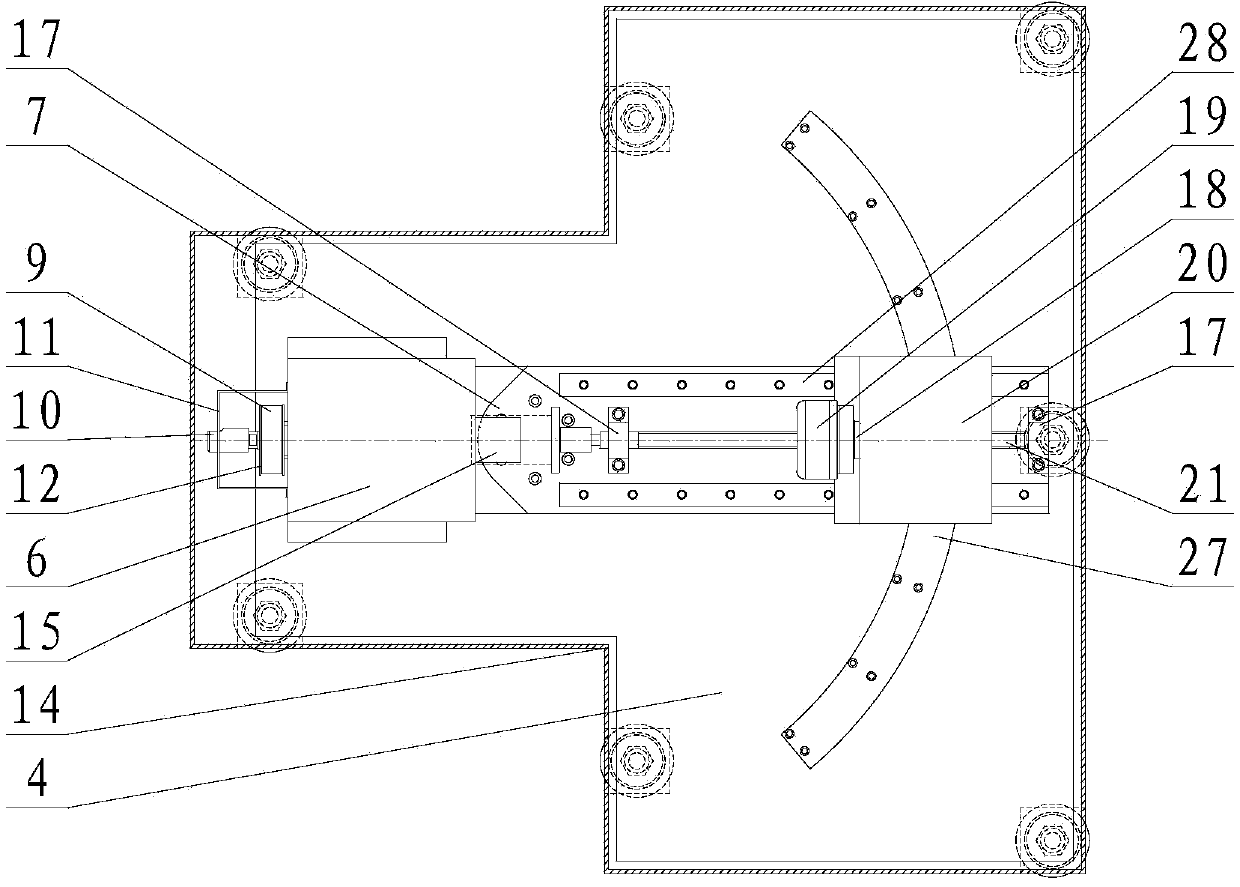

Diamond rotation body grinding wheel line electrode discharging and turning compound dressing method and device

ActiveCN104493719AGood removal effectFast preparationAbrasive surface conditioning devicesReciprocating motionEngineering

The invention discloses a diamond rotation body grinding wheel line electrode discharging and turning compound dressing method and device, and belongs to the field of machining. The dressing method includes the steps: S1, setting a tool, switching on a pulse power supply, controlling a diamond grinding wheel to rotate, reciprocating movement and feed movement of the diamond grinding wheel relative to a tool line electrode, and continuing feeding after a discharge current signal is monitored; S2, softening metal-based materials of a projection of the diamond grinding wheel and corroding parts of the metal-based materials under the discharge action; S3, turning and peeling exposed diamond particles by the aid of the relative reciprocating movement of the diamond grinding wheel and the tool line electrode; S4, repeating the steps S2 and S3; S5, judging shape modification conditions according to discharge waveforms; S6, stopping approaching movement of the diamond grinding wheel and the tool line electrode, and dressing the diamond grinding wheel under the discharge action. Line electrode discharge and turning are synchronously performed, the diamond grinding wheel with low circular run-out and a sharp surface is rapidly prepared, and machining efficiency and accuracy are high.

Owner:CHANGZHOU INST OF TECH

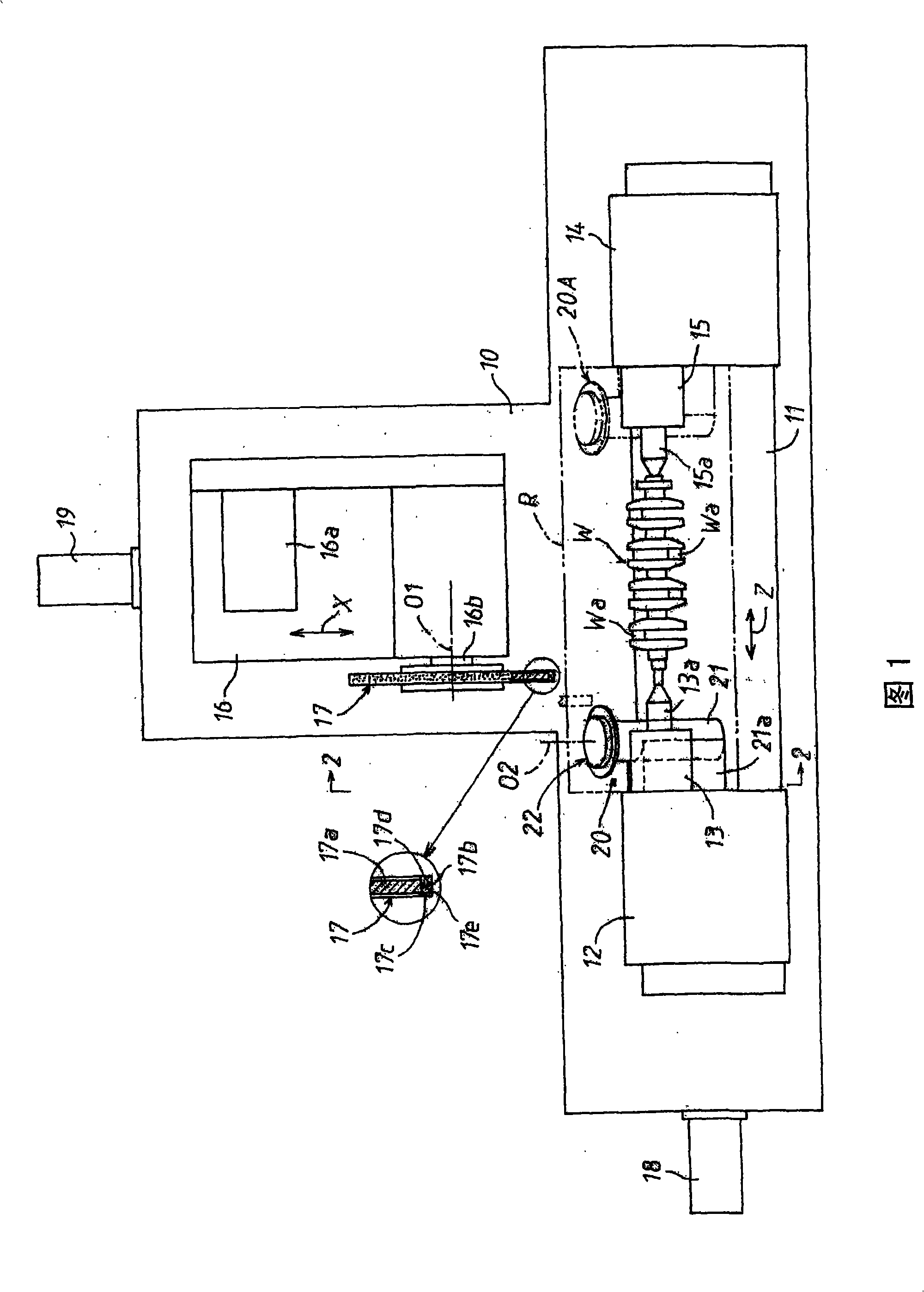

Wheel truing device

InactiveCN101341003AImprove dressing efficiencyChange directionRevolution surface grinding machinesAbrasive surface conditioning devicesCylindrical grindingMechanical engineering

A wheel truing apparatus adapted for use in a cylindrical grinding machine wherein a work head with a work spindle for support of a workpiece and a wheel head with a grinding wheel for grinding the workpiece are mounted on a bed for relative movement in a Z-axis direction parallel with the rotation axis of the work spindle and in an X-axis direction crossing the Z-axis direction, characterized in that the wheel truing apparatus comprises a rotary drive portion mounted on the work head or a member united therewith, and a wheel truing tool supported on the rotary drive portion for rotation therewith, the wheel truing tool being provided at its outer periphery with a truing portion for truing a grinding surface of the wheel brought into contact therewith, wherein the rotary drive portion is placed in a position adjacent to said work head in a tooling area defined by a stroke of the relative movements of said wheel head and said work head in the Z-axis direction and apart from said work spindle radially outward and is arranged in such a manner that the rotation axis line of said truing tool is oriented toward the rotation axis line of said grinding wheel in a condition where said truing portion is retained in contact with the grinding surface of said wheel, whereby the truing portion of said tool is brought into contact with the grinding surface of said wheel by relative movement of said wheel head to said work head for truing the grinding surface.

Owner:JTEKT CORP

Velvet fabric and production method thereof

ActiveCN105178043AAdjust the clearanceImprove general performanceMechanical cleaningPressure cleaningAntioxidantEngineering

The invention provides a velvet fabric and a production method thereof, and is used for solving the technical problems that the existing velvet fabric is too simple, has no characteristic such as abrasion resistance, electrostatic resistance, high-low temperature resistance and the like, is single in function, has no production method and the like. The velvet fabric comprises a velvet layer, and is characterized in that a reinforcing layer is fixed on the velvet layer, and the reinforcing layer consists of the following components in parts by weight: 25 to 30 parts of polytetrafluoroethylene, 1.2 to 1.6 parts of antioxidant, 2 to 3 parts of cross-linking agent, 2 to 4 parts of catalyst and 30 to 50 parts of water. The invention also provides a production method of the velvet fabric. The velvet fabric has advantages of high functionality and simple process.

Owner:HAINING JBL TEXTILE

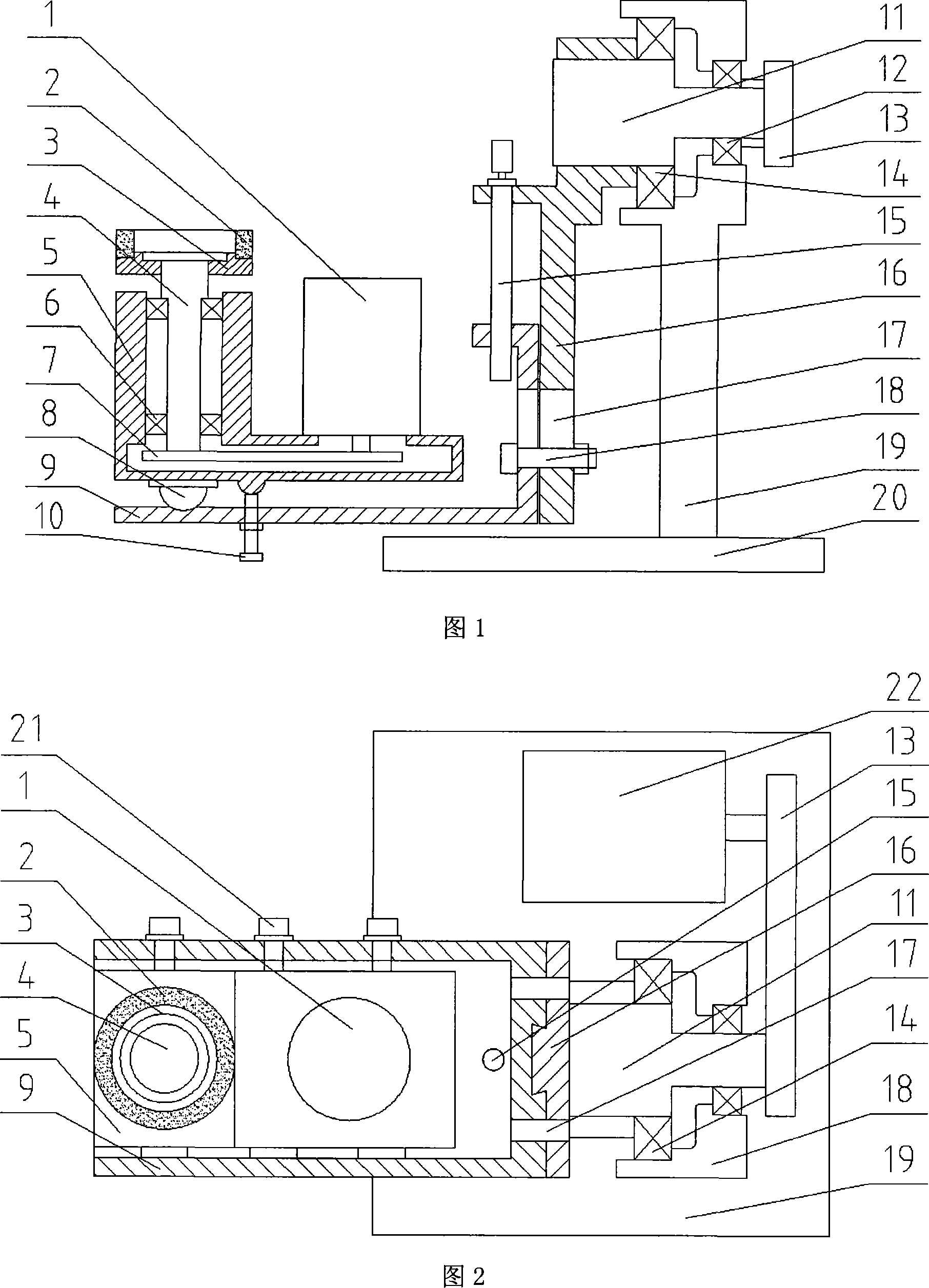

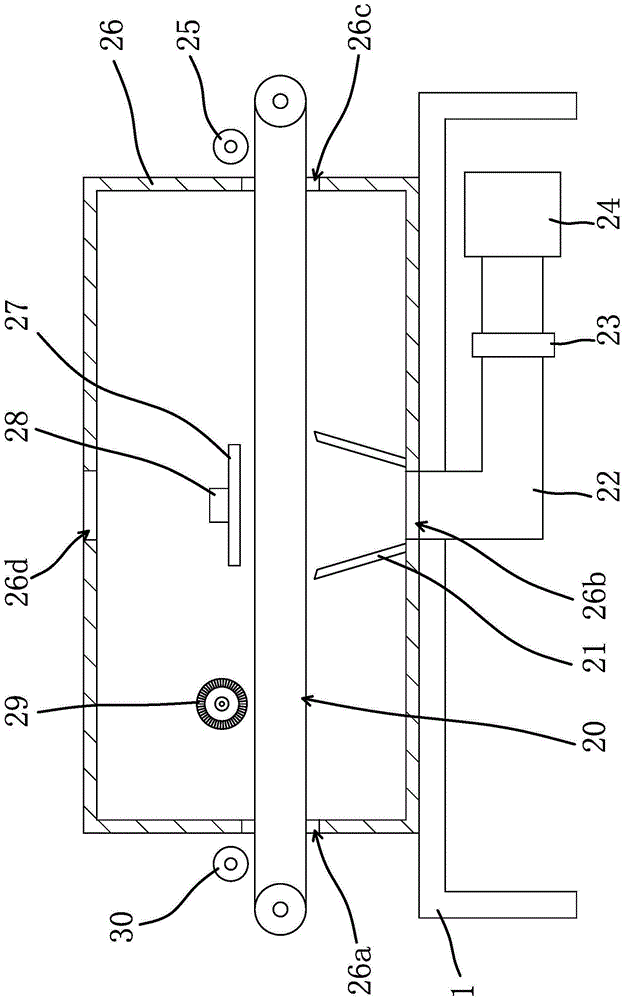

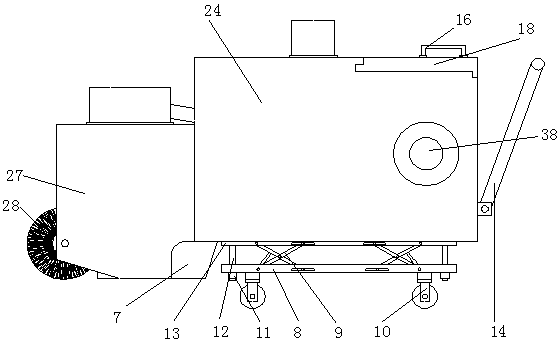

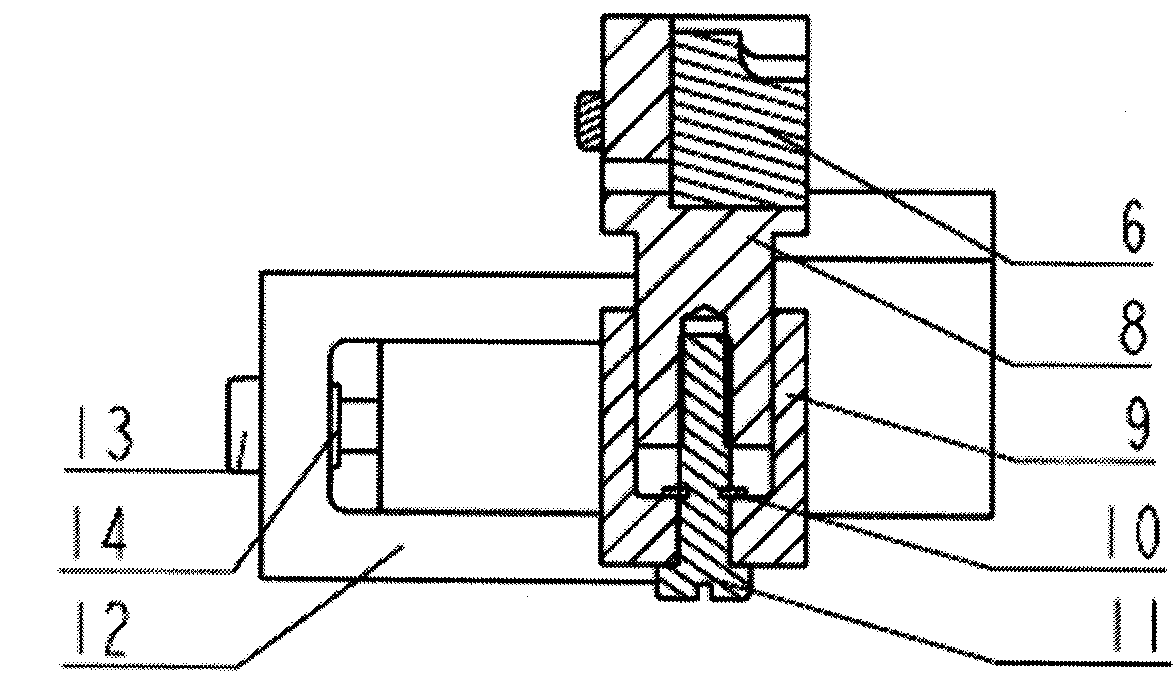

Off-line-type gas bag polishing tool finisher

ActiveCN103586775AWill not affect normal workImprove work efficiencyAbrasive surface conditioning devicesDrive wheelReducer

The invention discloses an off-line-type gas bag polishing tool finisher, and relates to a gas bag polishing device. The off-line-type gas bag polishing tool finisher is high in efficiency, low in cost, easy to operate and high in reliability. The off-line-type gas bag polishing tool finisher is provided with a swing motor, a planetary reducer, a swing main shaft box, a base, a swing shaft, a gas bag main shaft box, a swing arm, a driving wheel, a belt, a rotary connector, a rotary connector support, a driven wheel, a feeding motor, a protective cover, a gas bag main shaft, a gas bag tool, a lead screw support, a grinding wheel main shaft, a finishing grinding wheel, a grinding wheel main shaft box, a lead screw, a sliding block, a swing arm supporting base, a supporting bearing, a barb frame, a barb bearing, an arc guide rail, a guide rail, a gas bag driving motor and a grinding wheel driving motor. The off-line-type gas bag polishing tool finisher can effectively improve the working efficiency of a gas bag polishing machine and meanwhile has obvious effects in the aspects of improving the finishing efficiency of the gas bag tool, improving the reliability of the finishing process, reducing the cost and the size of finishing equipment and the like.

Owner:XIAMEN UNIV

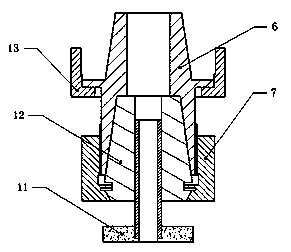

Electrolytic grinding device capable of realizing rotary solution feeding and working method thereof

InactiveCN103447640AReduce pressure requirementsReduce traffic requirementsEngineeringGrinding wheel

The invention provides an electrolytic grinding device capable of realizing rotary solution feeding and a working method thereof. The electrolytic grinding device comprises a motorized spindle stator and a motorized spindle rotor. A blind hole is formed inside the end, extending outside, of the motorized spindle rotor, the lower end of the motorized spindle rotor is connected with a conductive grinding wheel through a clamping device, a plurality of through holes are formed in the radial direction of the motorized spindle rotor, and a first sealing ring and a second sealing ring are arranged above and below the through holes respectively for sealing the same. An outer cover is arranged on the outer side of the motorized spindle rotor, and middle holes are formed in positions, corresponding to the through holes, of the outer cover. A first bearing and a second bearing are arranged between the motorized spindle rotor and the outer cover. An electrolyte solution passes through the middle holes of the outer cover, enters the inside blind hole from the through holes of the end, extending outside, of the motorized spindle rotor, and then passes a center hole of the clamping device to outflow around from clearances of the conductive grinding wheel and a workpiece. The electrolytic grinding device is low in requirement on pressure and flow of the electrolyte solution, good in solution feeding effect, and particularly suitable for electrolytic grinding of workpieces such as inner holes and inner cavities in special geometrical shapes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

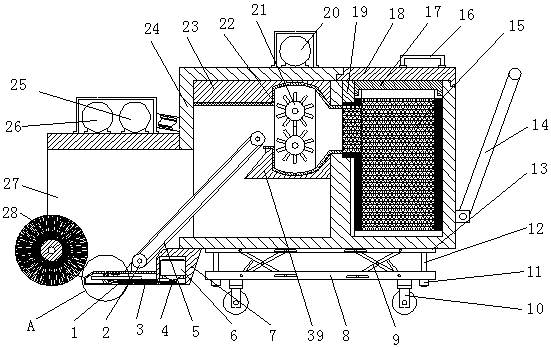

Mechanical device for automatic lawn trimming

ActiveCN108243707AReduce space consumptionNo need for manual cleaningMowersElectric machineryMechanical equipment

The invention discloses a mechanical device for automatic lawn trimming. The mechanical device comprises a main box body and a push rod, wherein the push rod is arranged on the right side of the mainbox body, a mobile lifting mechanism is arranged at the lower end of the main box body, and a guide block is arranged at the upper end of a cutting mechanism; a auxiliary box body is disposed on the left side of the main box body, the cutting mechanism is disposed on the left side of the lower end of the main box body, and a conveying mechanism is obliquely disposed inside the main box body and the auxiliary box body. A cleaning disc is driven to rotate through a belt and a belt pulley by a cleaning motor which is arranged in the mechanical device for automatic lawn trimming, so that grass isswept towards a cutting knife so as to facilitate cutting, and cut grass can be swept onto the conveyor belt in the auxiliary box body; the mechanical device has reasonable structural design and highcutting efficiency, and by cutting the grass through an arranged crushing mechanism, occupied space of the grass is reduced, so that storage is facilitated, no manual cleaning of grass clippings is needed, and the labor cost is reduced; meanwhile, the device has high trimming efficiency and more abundant functions.

Owner:TAIZHOU ZHONGGANG CHEM & CONSTR CO LTD

Method for processing complex surface knife tool

InactiveCN101298122AFully sharpenedInhibit excessive electrolysisAbrasive surface conditioning devicesEngineeringAlloy

The invention provides a processing method of a cutter with complex profile, comprising the steps as follows: (1) a dressing electrode is designed according to the structure and size requirement of the cutter to be processed, the design theory of the cutter and the processing principle of the profile modeling method; (2) the profile of a grinding wheel is dressed by the dressing electrode; (3) the dressing electrode is grinded and processed by the grinding wheel with profile dressed; and (4) no-pressure rolling grinding and impact polishing of the surface of the workpiece which is online electrolyzed, dressed and grinded are carried out to gain the hard alloy cutter. The invention provides the processing method for the cutter with complex profile, which has high dressing efficiency and low cost.

Owner:ZHEJIANG UNIV OF TECH

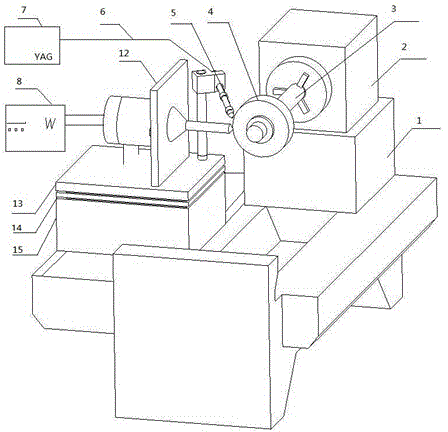

Ultrasonic laser composite dressing method for grinding wheel

InactiveCN104440558AEasy outflowReduce wearAbrasive surface conditioning devicesLaser transmitterCutting force

The invention belongs to composite dressing method types of grinding wheels and particularly relates to an ultrasonic laser composite dressing method for a grinding wheel. The ultrasonic laser composite dressing method is characterized in that a laser transmitter transmits energy to a focusing head with a focusing head fixing device through optical fibers, laser beams are focused to heat the rotating grinding wheel in front of a dressing point at proper energy density for proper heating time, an ultrasonic generator transmits an ultrasonic frequency signal to an ultrasonic transducer, the ultrasonic frequency signal is converted into mechanical vibration through the transducer to be transmitted to an amplitude-change pole, waves, generating longitudinal vibration, of the amplitude-change pole will be decomposed at the position, where a chute is formed, of the small end, the vibration type involves longitudinal vibration and bending vibration, and composite elliptical ultrasonic vibration is formed at the point of a diamond dressing stylus for dressing. The auxiliary heating effect of lasers is recombined during ultrasonic vibration dressing, removal of partial materials of the grinding wheel is changed from brittle removal into plastic removal, cutting force is reduced, abrasion to the dressing stylus is reduced, and dressing efficiency and dressing precision are improved.

Owner:HENAN POLYTECHNIC UNIV

Jacquard weave cut velvet and processing method thereof

ActiveCN105421095AVersatileEasy to combMechanical cleaningPressure cleaningAntistatic agentEngineering

The invention provides jacquard weave cut velvet and a processing method thereof and solves the technical problems that existing velvet does not have the characteristics of washing resistance, mildew resistance and the like, the service life of the existing velvet is greatly shortened, the service life is short, and no processing method exists. The jacquard weave cut velvet comprises a velvet layer and is characterized in that a protective layer is fixed to the velvet layer, and the protective layer is prepared from, by weight, 35-50 parts of polyurethane resin, 5-8 parts of an antistatic agent, 0.6-1.8 parts of mildew inhibitor, 0.5-2 parts of a washing-resistant agent, 2-4 parts of a cross-linking agent and 20-25 parts of methylbenzene. The jacquard weave cut velvet and the processing method thereof have the advantages of being long in service life and high in processing speed.

Owner:HAINING JBL TEXTILE

A polishing finisher

InactiveCN105364715ASolve the shedding of abrasive particlesImprove efficiencyAbrasive surface conditioning devicesSapphireMicrostructure

The invention provides a polishing finisher comprising a base and a sapphire grinding pad. The sapphire grinding pad comprises root portion and a grinding layer, wherein the root portion is fixed on the base and the grinding layer comprises a plurality of projections and a plurality of recesses. The surface of at least one of each projection and each recess is provided with a microstructure with a surface roughness between 0.1-5 microns. The grinding layer and the root portion of the polishing finisher are formed integrally, so that the problem of falling-off of grinding particles of conventional finishers is radically solved; the microstructures at the surface of the grinding layer improves the polishing pad finishing efficiency.

Owner:CRYSTALWISE TECH

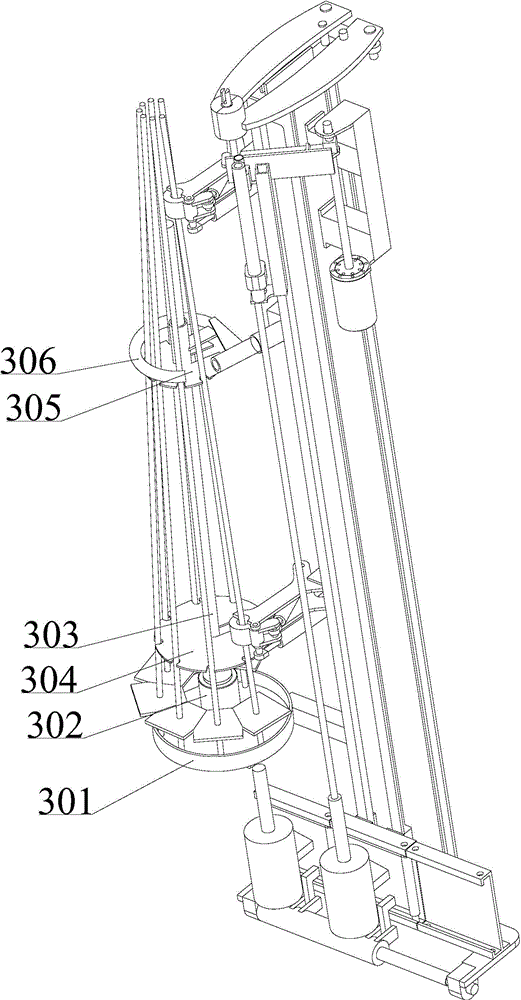

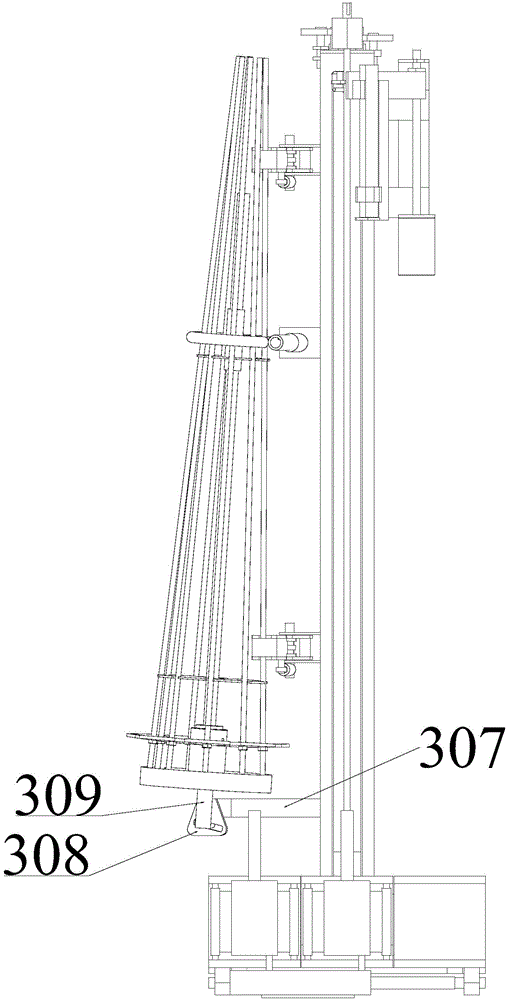

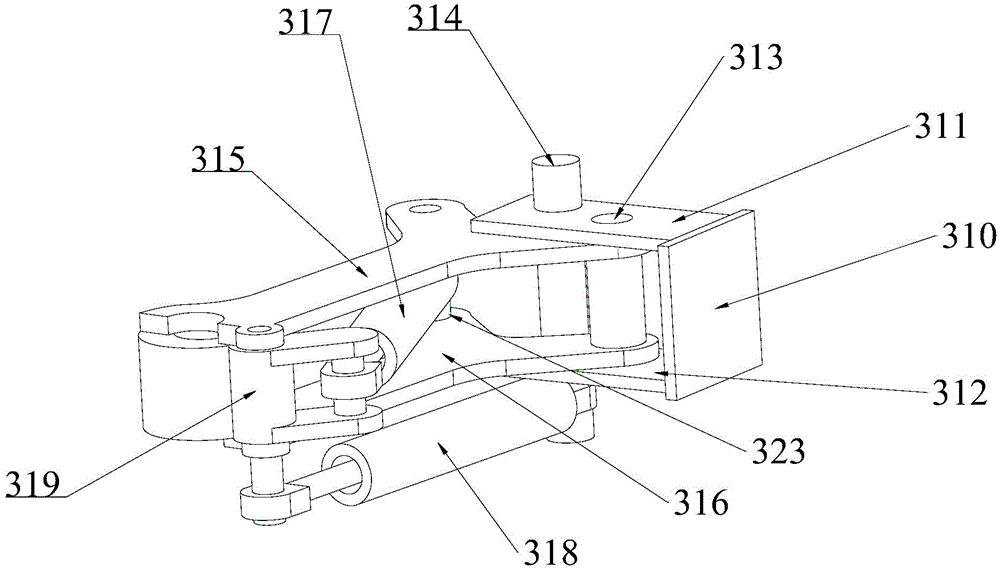

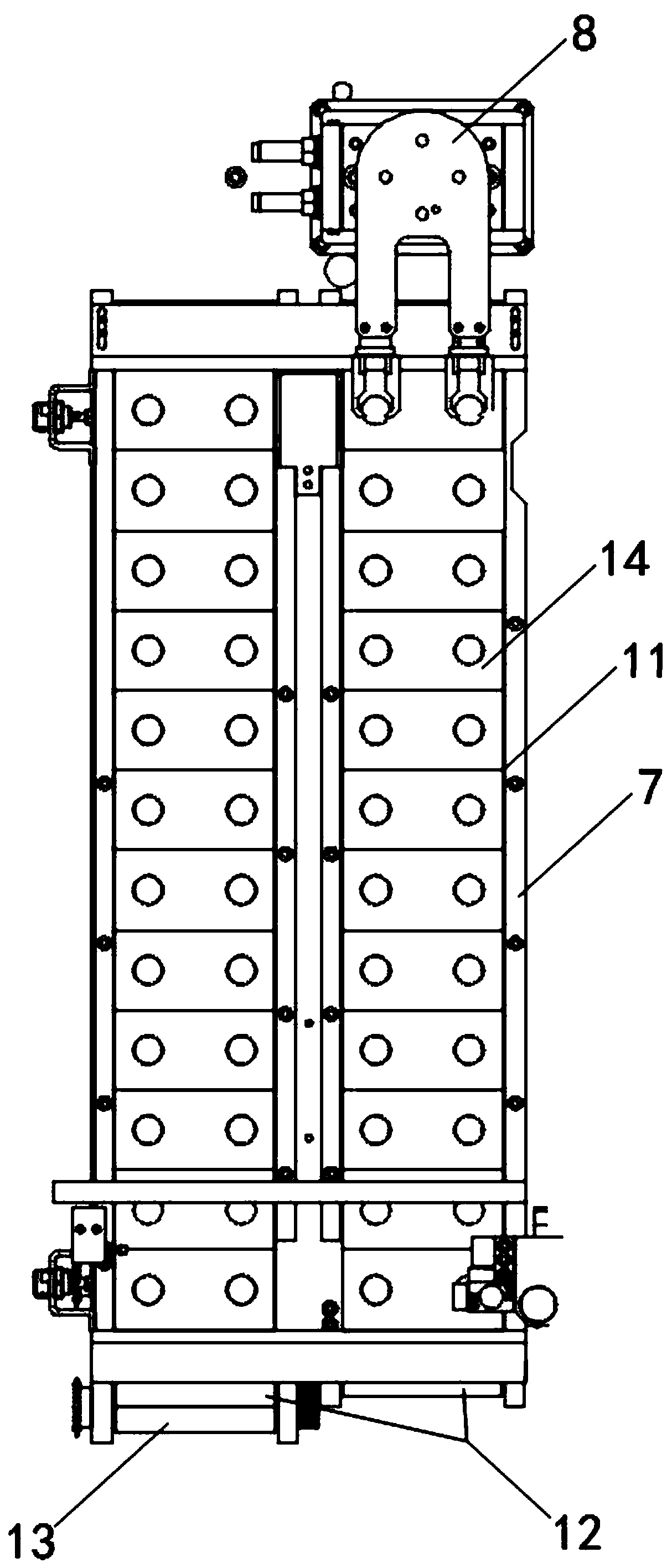

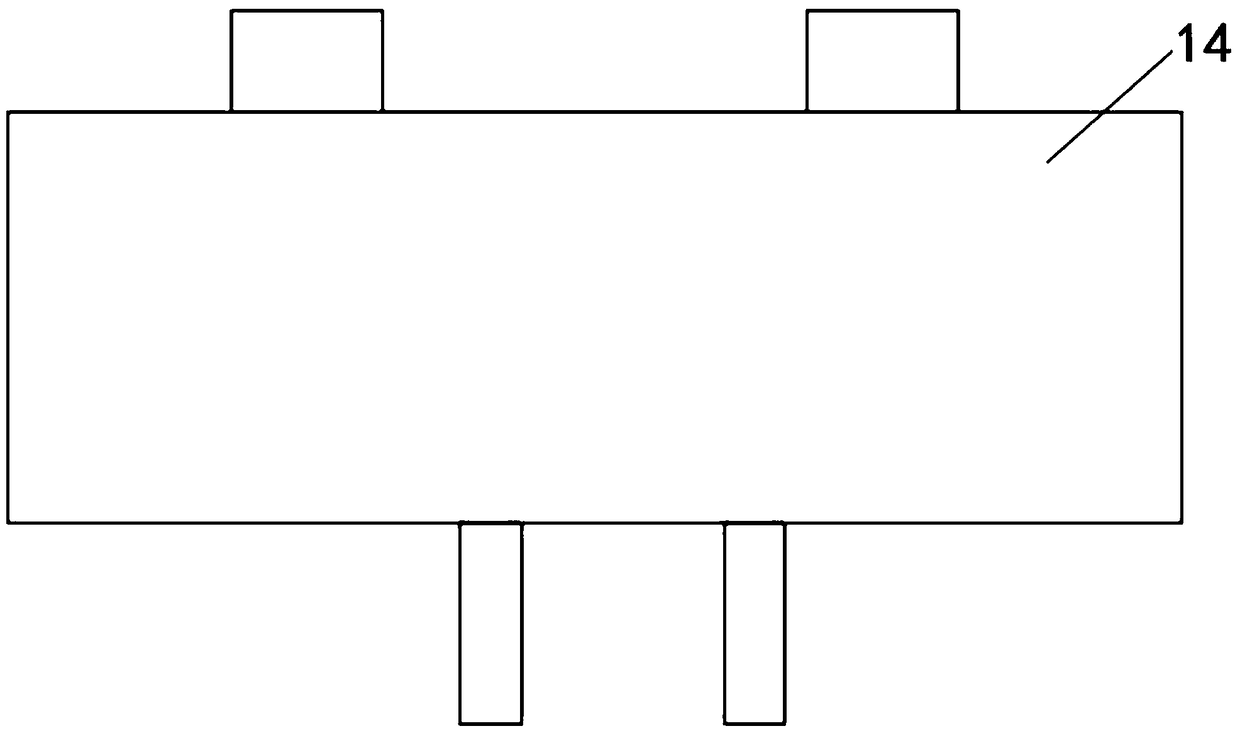

Automatic rod feeding device for mine anchor rod drilling machine

InactiveCN104806277AAutomate operationsImprove dressing efficiencyAnchoring boltsEngineeringRock bolt

The invention discloses an automatic rod feeding device for a mine anchor rod drilling machine. The device comprises an anchor rod storing mechanism, a first manipulator, a second manipulator and a fixing seat. According to the device, an anchor rod is stored into semicircular grooves in an upper index plate and a lower index plate through the anchor rod storing mechanism; the anchor rod is grasped, conveyed and positioned through the first manipulator and the second manipulator; therefore, automatic conveying of the anchor rod is achieved; the replacing efficiency of the anchor rod and a drilling rod can be increased; the time of supporting the tunnel is reduced; the risk of collapse of the tunnel is reduced.

Owner:王发秀

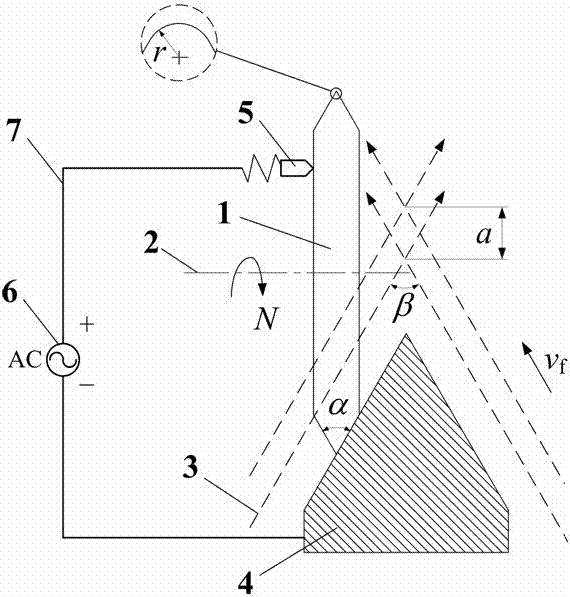

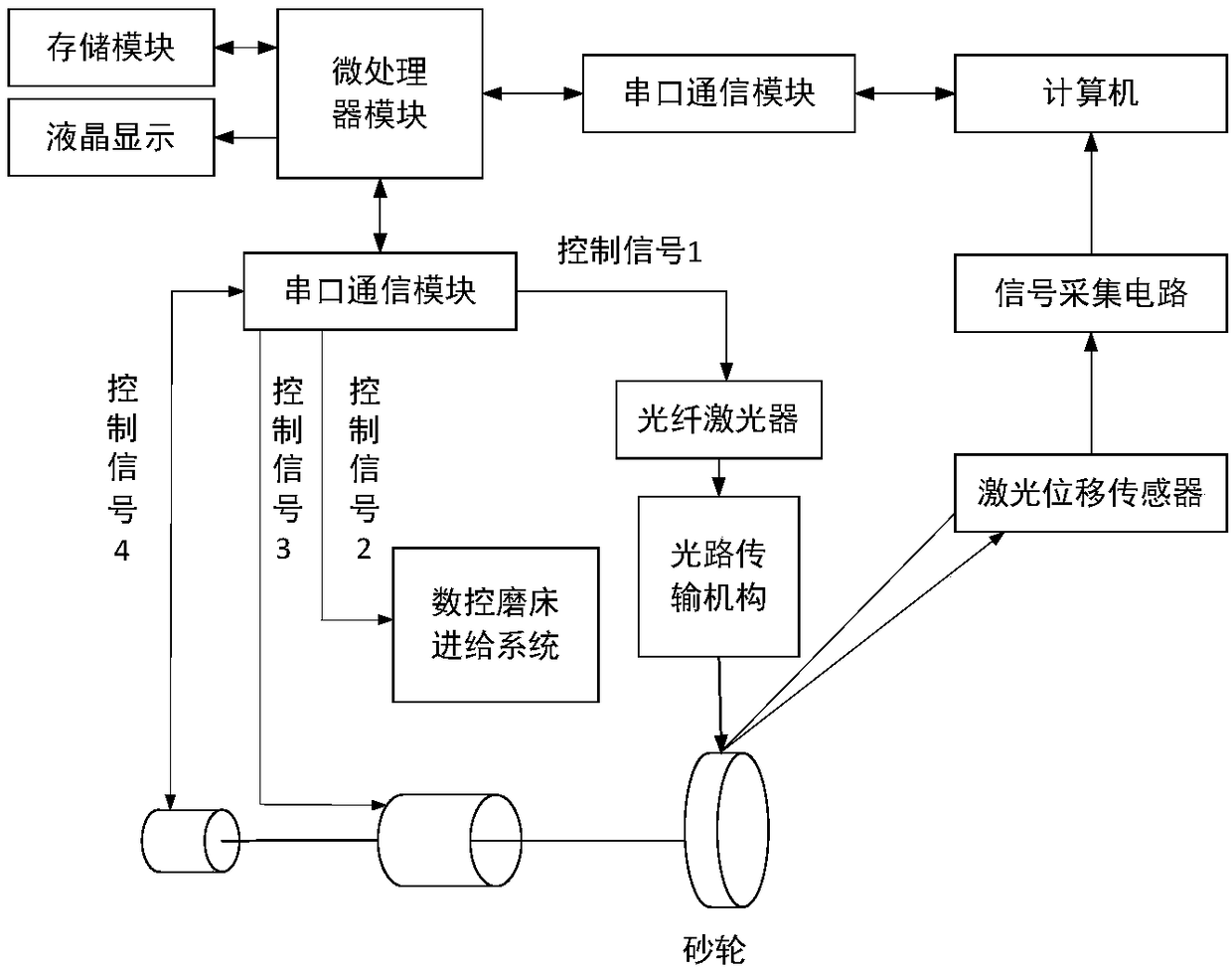

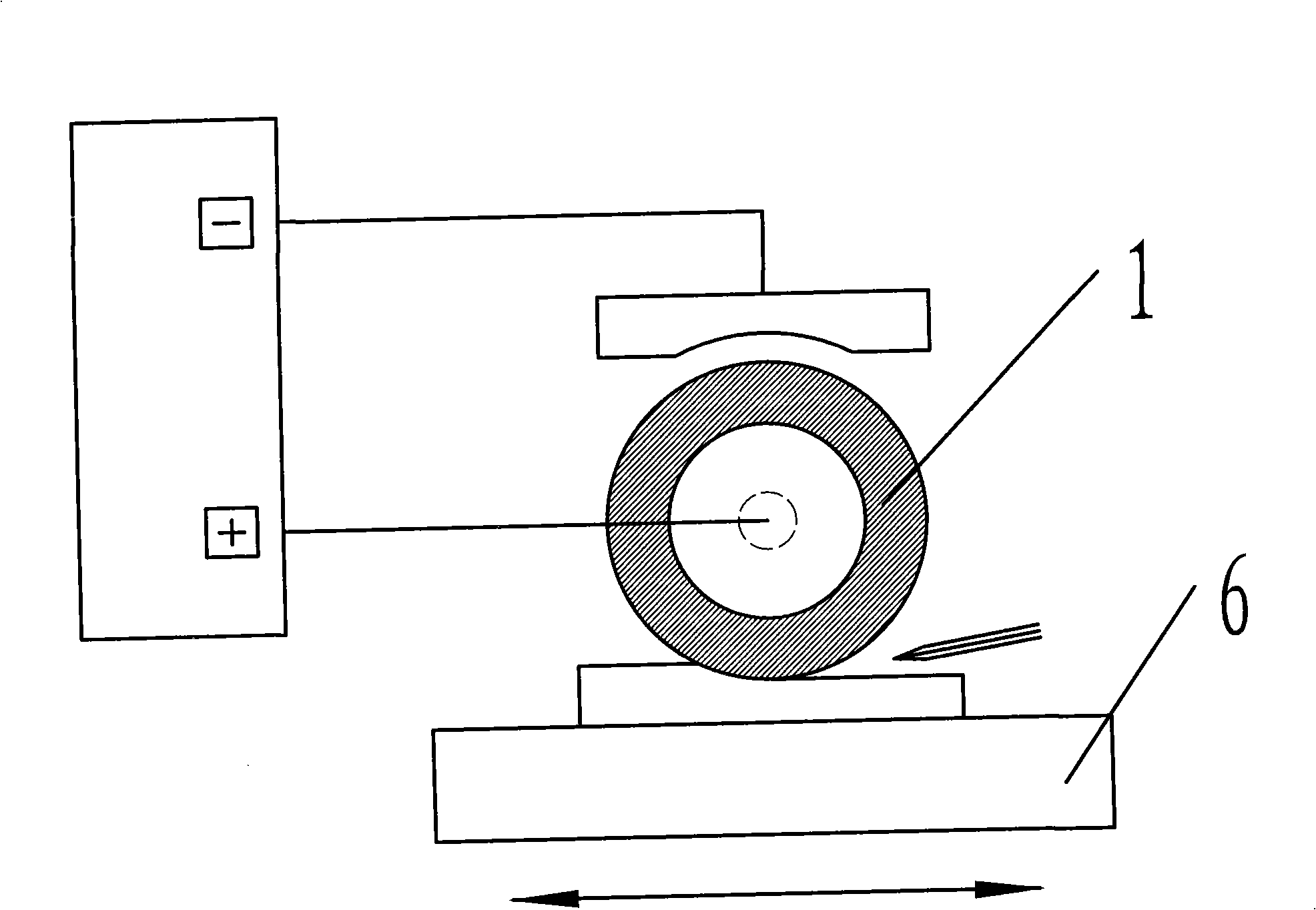

Method for assisting on-line trimming diamond grinding wheel based on discharging in air

InactiveCN1557608ADressing force reducedReduce wearAbrasive surface conditioning devicesEngineeringCooling fluid

The present invention is air discharge method for auxiliary in-situ trimming of grinding diamond wheel and belongs to the field of precise machining technology. The present invention includes three steps of establishing spark discharge temperature field in air, trimming with diamond pen under air discharge and controlling the sustained air discharge. In the first step, the discharge between electrode and grinding wheel in the air establishes temperature field to soften adhering metal material in grinding diamond wheel; in the second step, the grinding wheel rotates and the trimming diamond pen reciprocates in the surface of the grinding wheel to trim the softened binding agent material mechanically; and in the third step, the measuring link, control link and executing link complete the control for sustained discharge. The present invention realizes the in-situ trimming of grinding diamond wheel at high efficiency, high precision and low cost.

Owner:SHANGHAI JIAO TONG UNIV +1

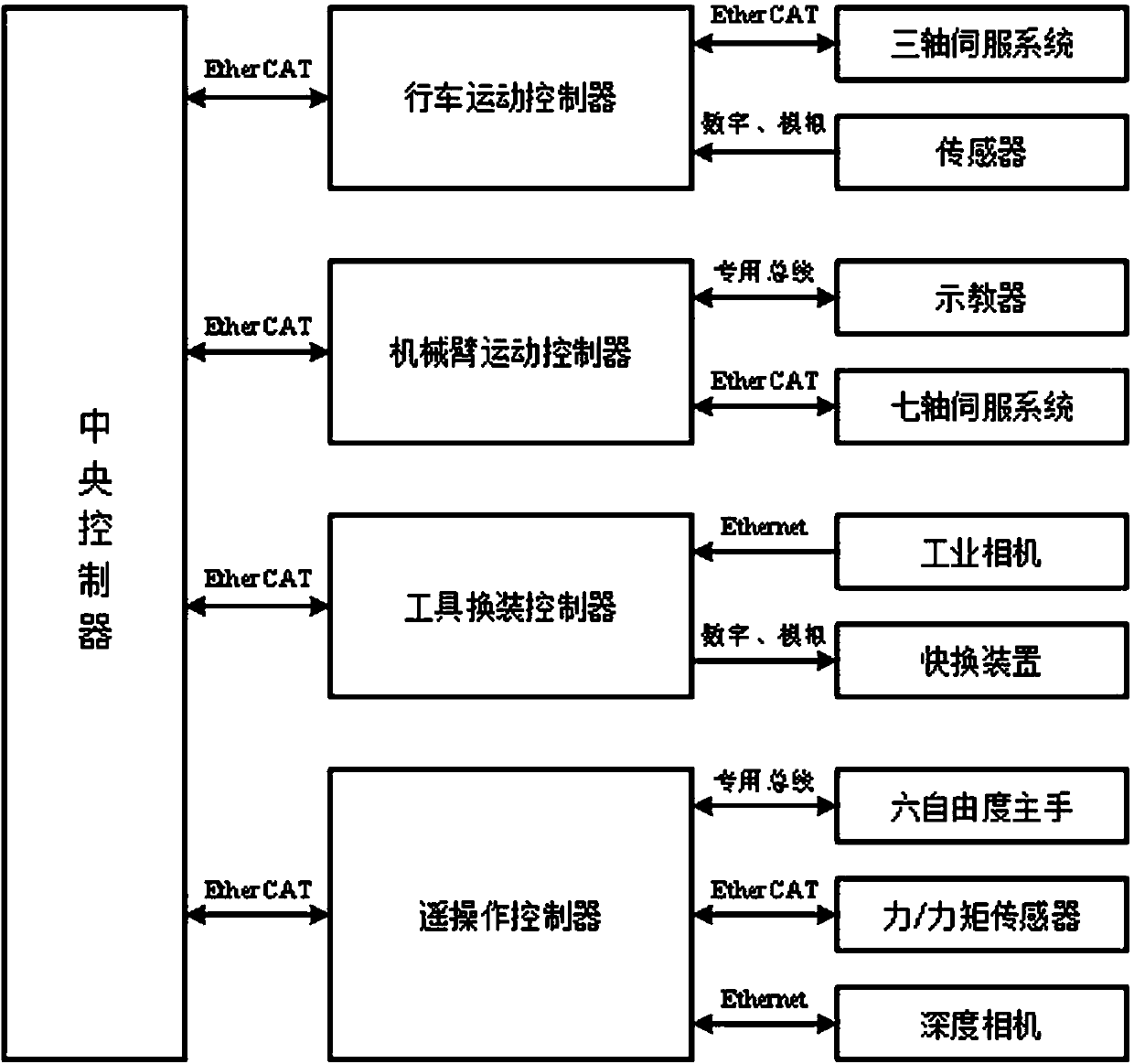

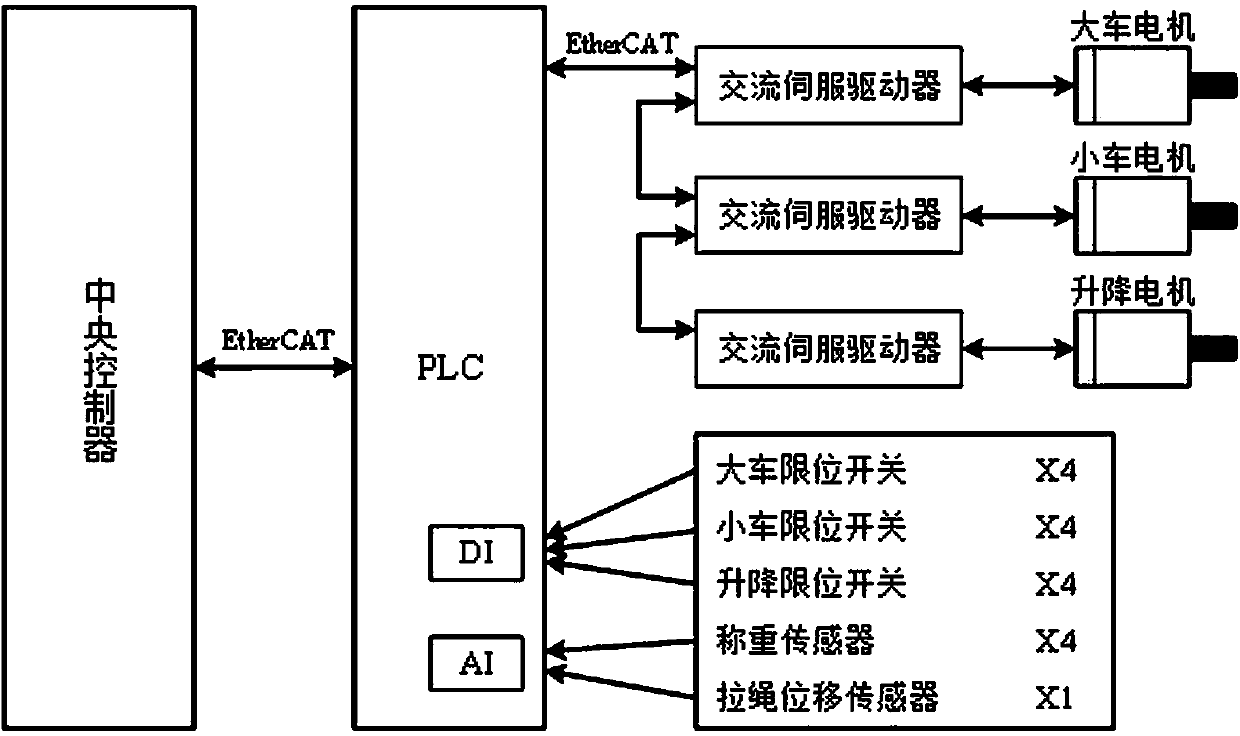

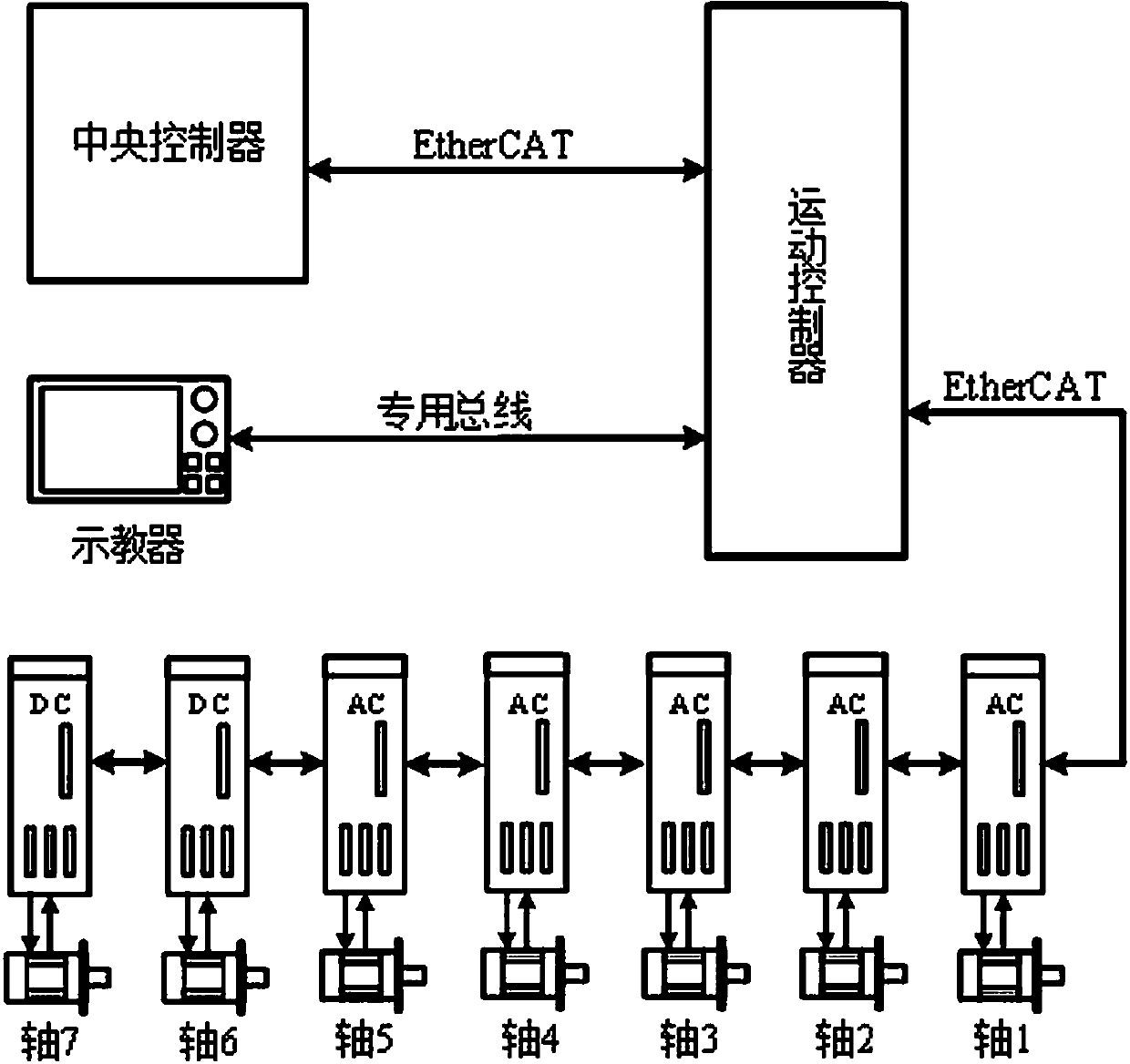

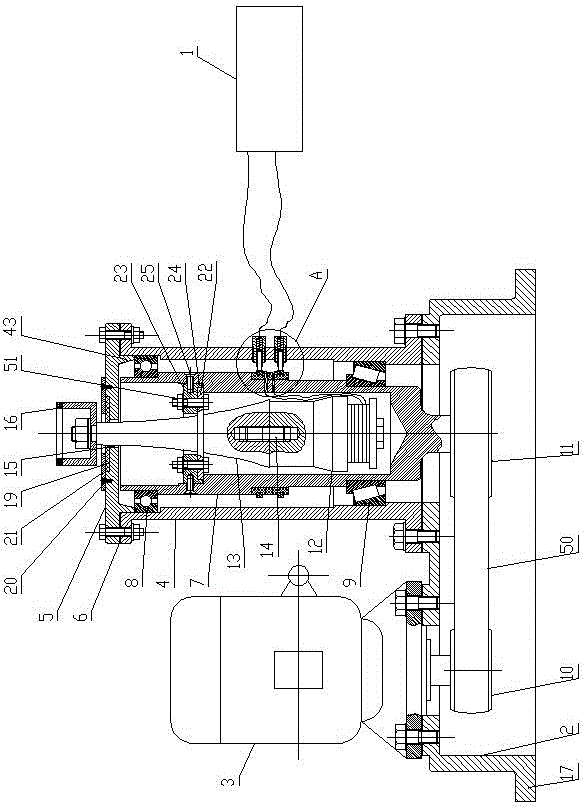

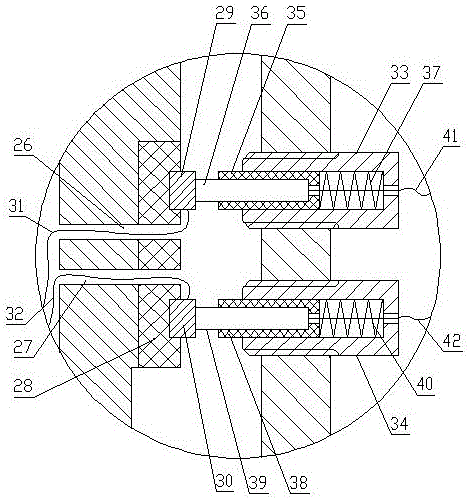

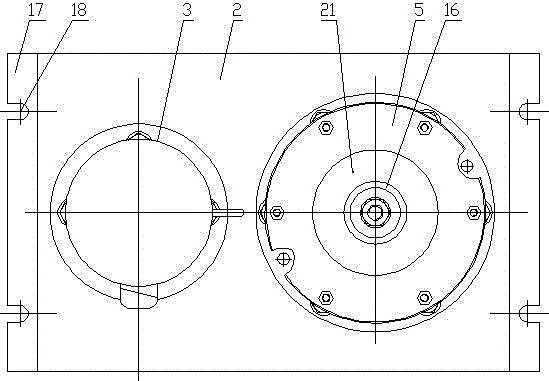

Radiation-resistant power manipulator control system

InactiveCN107662210AImprove control efficiencyImprove work presenceProgramme-controlled manipulatorMovement controlControl mode

The invention discloses a radiation-resistant power manipulator control system. The system includes a central controller and a sub control system, the sub control system includes a vehicle movement control system, a mechanical-arm movement control system, a tool replacement control system and a remote operation control system, and the central control system is connected with the sub control systemthrough communication; the vehicle movement control system includes a vehicle controller, a servo system and a sensor system; the mechanical-arm movement control system includes a mechanical-arm controller, a teaching machine and a mechanical-arm servo system; the tool replacement control system includes a tool replacement controller, an industrial camera and a quick replacement device; the remote operation control system includes a remote operation controller, master manipulator sensor and a depth camera; such control mode as 'centralized management and decentralized control effectively achieves radiation-resistant power manipulator control.

Owner:中国东方电气集团有限公司

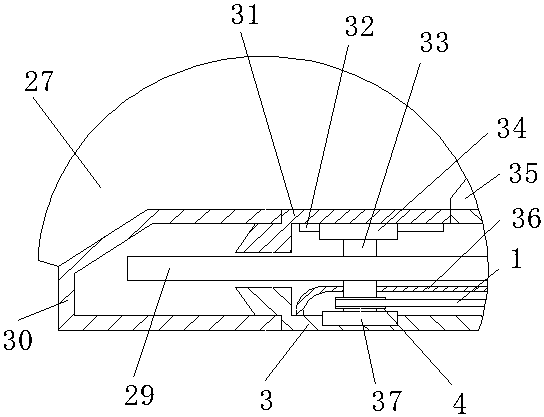

Ultrasonic vibration cup-shaped grinding wheel dresser for dressing super-hard abrasive grinding wheel

ActiveCN105643463ASimple structureReduce maintenance workAbrasive surface conditioning devicesUltrasonic generatorMicrostructure

The invention relates to an ultrasonic vibration cup-shaped grinding wheel dresser for dressing a super-hard abrasive grinding wheel. The grinding wheel dresser comprises an ultrasonic generator and a base, wherein a variable-frequency motor and a cylinder body are arranged on the base, the central line of the cylinder body is arranged in a vertical direction, and a cover plate is connected to the upper end of the cylinder body through a flange; a hollow shaft with an open upper-end and a plugged lower-end is coaxially arranged in the cylinder body, a bearing is arranged between the inner wall of the cylinder body and the outer wall of the hollow shaft, and the variable-frequency motor is in transmission connection with the lower end of the hollow shaft; an ultrasonic transducer and an amplitude-change pole are arranged in the hollow haft, the outside of the amplitude-change pole is fixedly arranged on the hollow shaft through a detachable connection structure, and the upper end of the amplitude-change pole is upward and penetrates the cover plate, and a top-opened cup-shaped grinding wheel is fixedly coaxially arranged at the upper end of the amplitude-change pole. The grinding wheel dresser provides ultrasonic vibration in the axial direction, therefore, the microstructure of the dressed grinding wheel can be well improved, dressing of abrasive particles is completed while shaping is completed, grinding heat and power consumption are beneficially reduced, blockage to the grinding wheel and dressing burns are avoided, and the service life of the external circular grinding wheel is prolonged.

Owner:KEYIZHAN INTELLIGENT EQUIP CO LTD +1

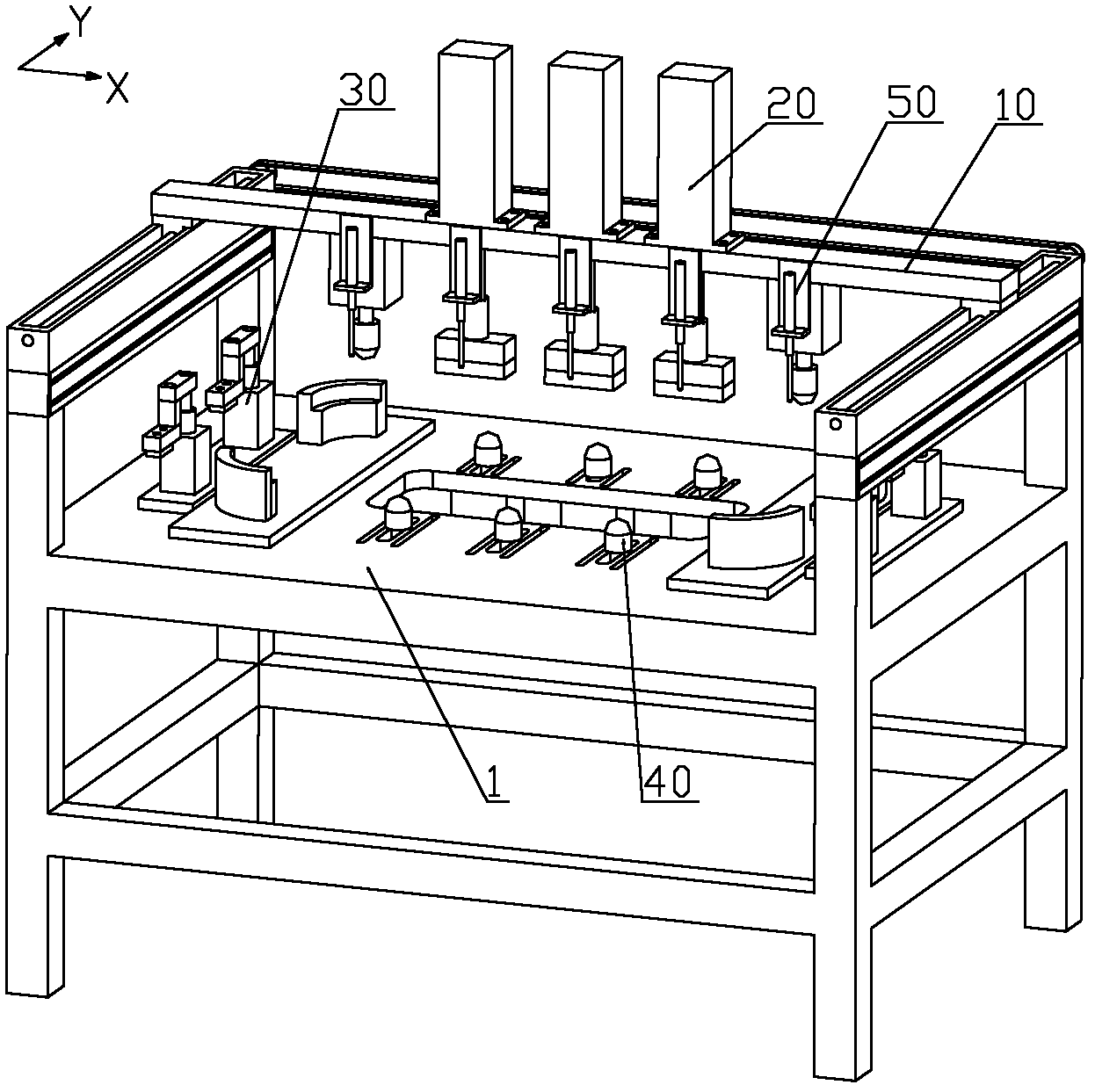

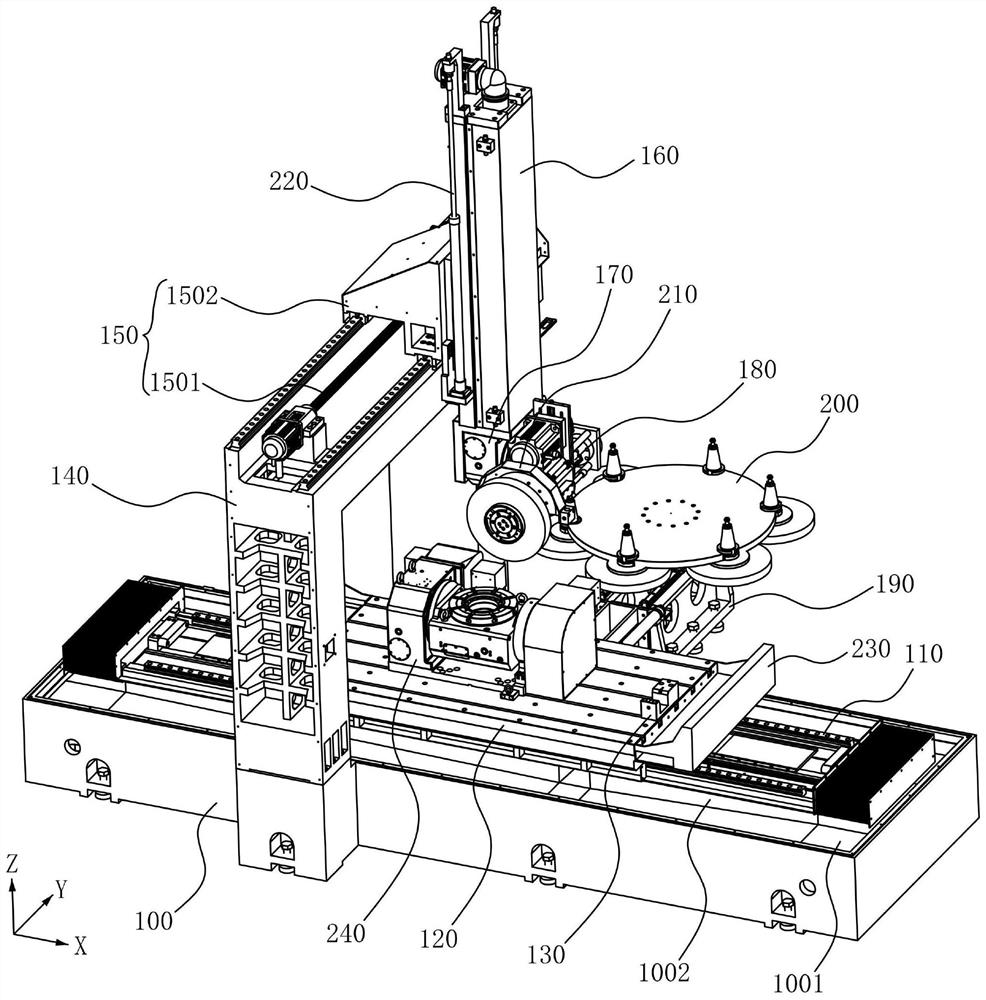

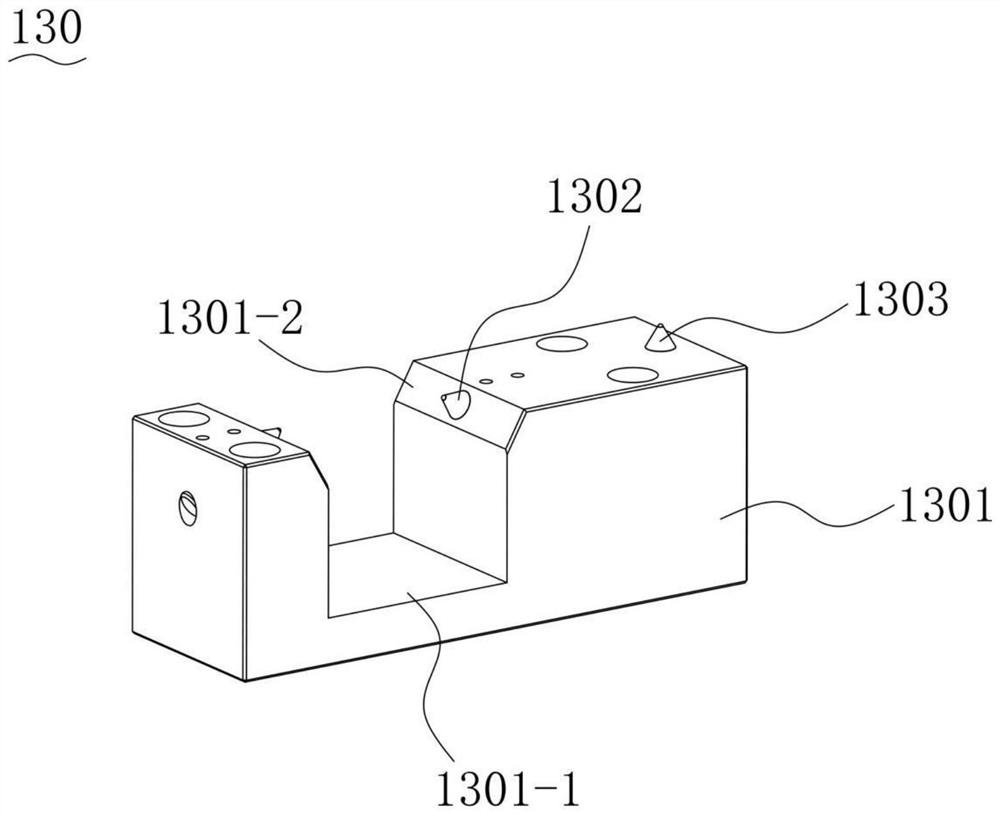

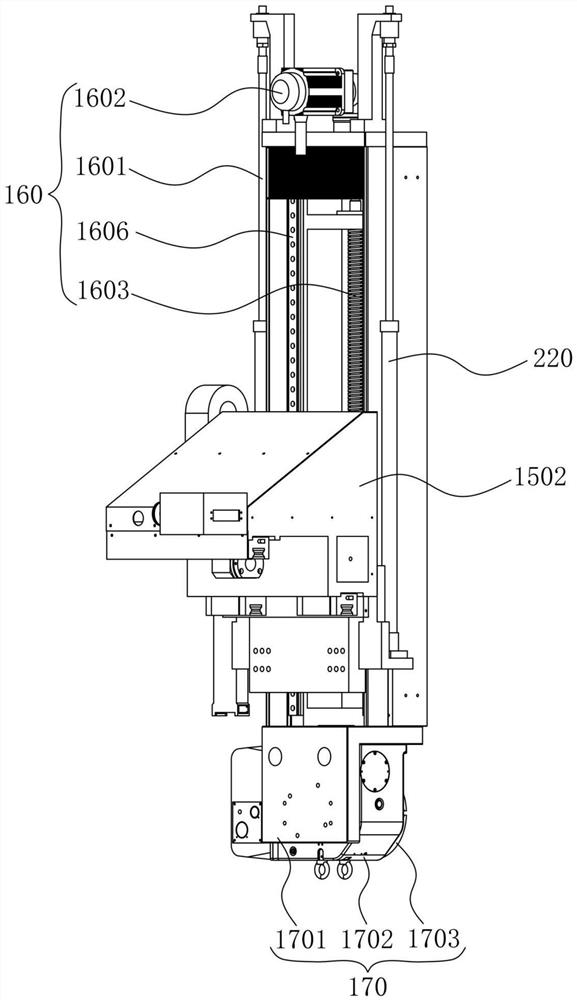

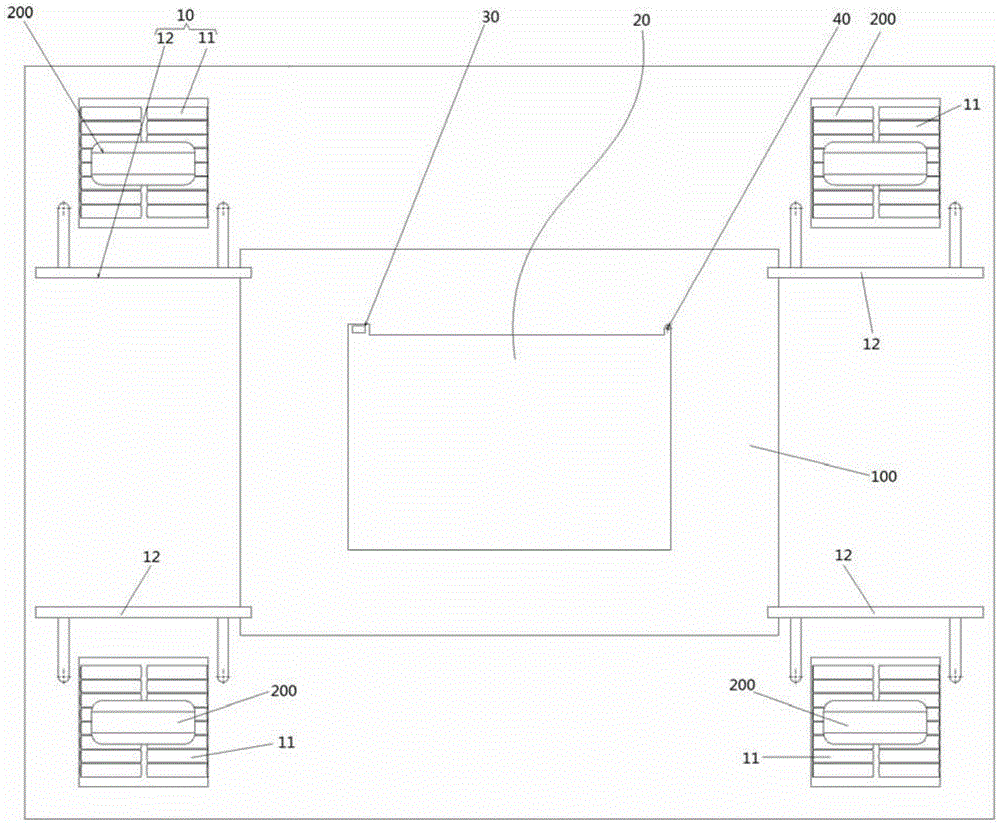

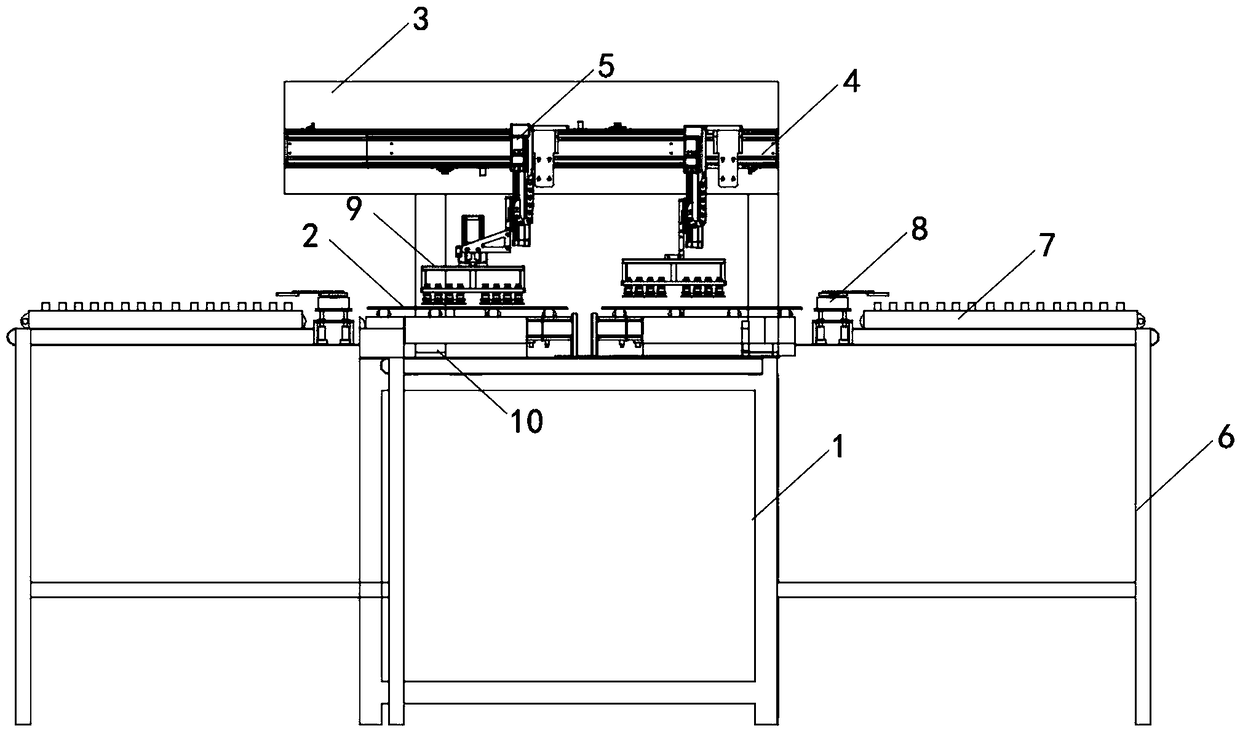

Plane contour grinding center of door-shaped vertical mill

PendingCN112775739AEasy to useImprove dressing efficiencyGrinding wheel securing apparatusGrinding carriagesEngineeringGrinding wheel

The invention provides a plane contour grinding center of a door-shaped vertical mill. The plane contour grinding center comprises a lathe bed, an X-axis feeding device, a workbench, a sand finishing device, a portal frame, a Y-axis feeding device, a Z-axis feeding device, an automatic angle adjusting device, an automatic tool changing electric spindle, a Y-axis driving device and a grinding wheel tool magazine. The X-axis feeding device is mounted on the lathe bed; the workbench is installed on the X-axis feeding device, the sand finishing device is installed on the workbench, the portal frame is installed on the lathe bed, the Y-axis feeding device is installed on the portal frame, the Z-axis feeding device is installed on the Y-axis feeding device, the automatic angle adjusting device is installed on the Z-axis feeding device, and the automatic tool changing electric spindle is installed on the automatic angle adjusting device; and the Y-axis driving device is installed on one side of the lathe bed in the Y-axis direction, and the grinding wheel tool magazine is installed on the Y-axis driving device. The plane contour grinding center can automatically complete grinding wheel replacement work, is convenient to use, can also automatically complete grinding wheel dressing work, and is high in dressing efficiency.

Owner:豪特曼智能装备信阳有限公司

Replacing and installing device for taking electric car battery and method for replacing and installing battery through replacing and installing device

ActiveCN105416248AEnsure safetyImprove dressing efficiencyElectric propulsion mountingVehicle servicing/repairingWork safetyElectrical and Electronics engineering

The invention provides a replacing and installing device for a taking electric car battery and a method for replacing and installing the battery through the replacing and installing device. The replacing and installing device comprises a support, positioning structures and a battery replacing and installing part. The positioning structures comprise the first positioning structures and the second positioning structures. The first positioning structures are used for supporting a taking electric car and positioning the taking electric car in the advancing direction of the taking electric car, and the second positioning structures are arranged on the support. The battery replacing and installing part is arranged on the support and connected with the second positioning structures in a following manner. The second positioning structures control the battery replacing and installing part to adjust the relative position between the battery replacing and installing part and the battery in the direction perpendicular to the advancing direction. The part of the battery replacing and installing part is used for dismounting and mounting the battery in the vertical direction. According to the technical scheme, the problems that in the prior art, the work safety of workers is threatened during battery replacing and installing work, and consequently the replacing and installing efficiency of dismounting and mounting the battery is low can be solved.

Owner:BEIJING ELECTRIC VEHICLE

High-efficiency trimming device for aero titanium alloy support seat

The invention discloses a high-efficiency trimming device for an aero titanium alloy support seat. The high-efficiency trimming device for the aero titanium alloy support seat comprises a working table, two rotary plates, trimming frames, a seat conveying table and a swinging and feeding frame, wherein the two rotary plates are symmetrically arranged on two sides of the upper end surface of the working table; a perpendicular L-shaped installation plate is arranged on the upper part of the middle part of the working table; a rail plate is horizontally arranged above the installation plate; andthe trimming frames matched with the rotary plates are arranged at two ends of the rail plate. The high-efficiency trimming device for the aero titanium alloy support seat provided by the invention has the beneficial effects that cross-shaped rotary frames on the rotary plates rotate to drive multiple rotary trimming seats to rotate anticlockwise so as to trim a seat body, so that the efficiency on trimming the seat body through the device is improved; the rotary plates and the rotary frames are matched in different rotation direction so as to carry out trimming operation, so that the probability of contacting the rotary trimming seats and grinding sheets on the rotary frames is increased, and the device can be used for sufficiently and comprehensively trimming the seat body; and a sleeveplate is used for clamping, stopping and sleeving a hydraulic rod, so that the hydraulic rod moves up and down stably and firmly, and the seat body is ensured to be stable when being swung, fed and moved.

Owner:GLOBAL ADVANCED TECH GRP

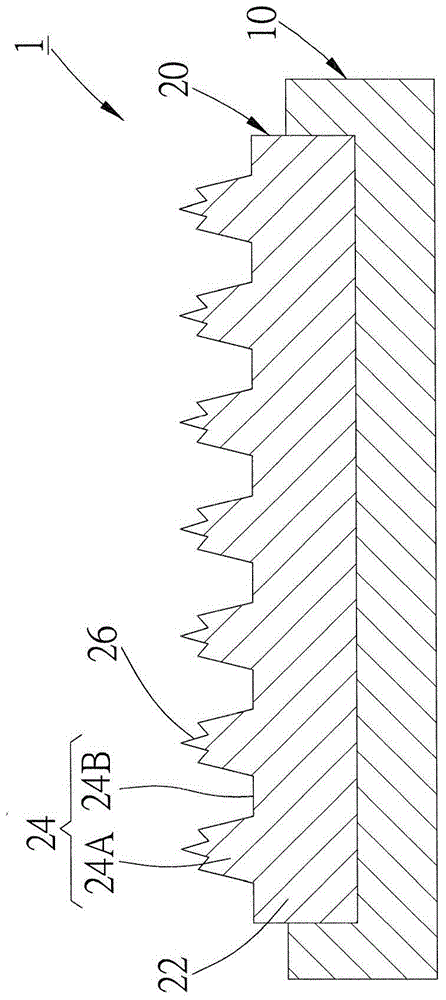

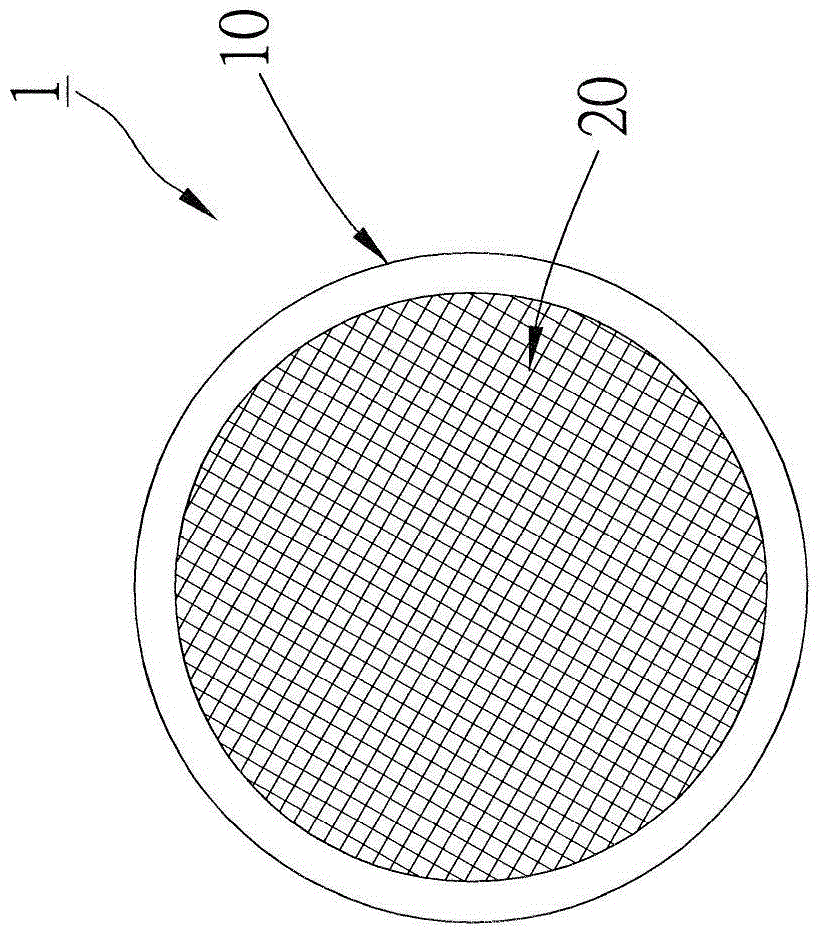

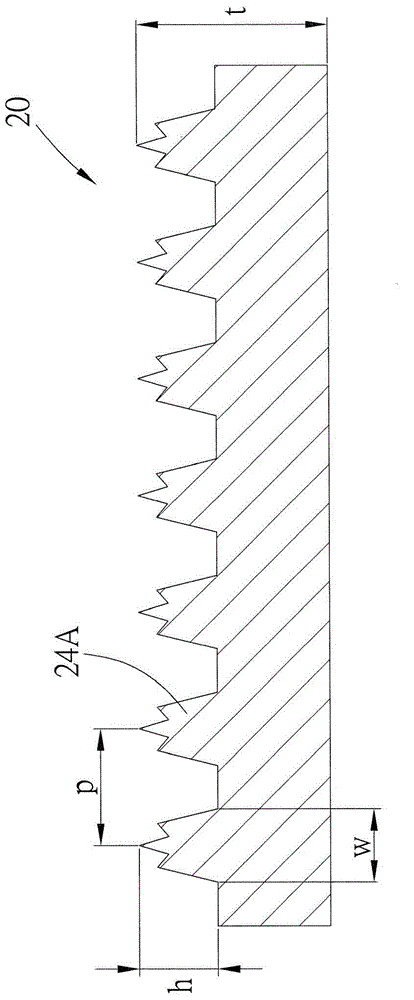

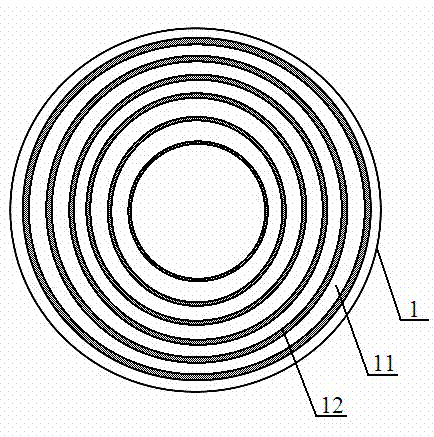

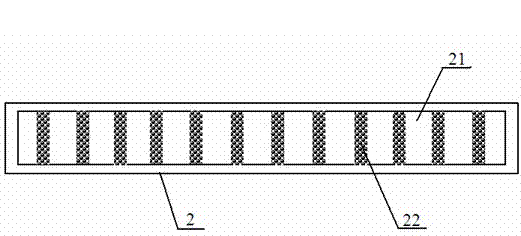

Chemical mechanical polishing (CMP) grinding pad finishing structure

ActiveCN102862121ASimple structureEasy to manufactureAbrasive surface conditioning devicesEngineering

The invention provides a chemical mechanical polishing (CMP) grinding pad finishing structure, which comprises a finishing device and a grinding pad, wherein the finishing device comprises a finishing surface, the finishing surface is arranged above the upper surface of the finishing pad, the upper surface of the grinding pad is of a circular shape, the upper surface of the grinding pad is provided with a plurality of circular grooves, the finishing surface of the finishing device is provided with a plurality of strip-shaped grinding bands, the width of each strip-shaped grinding band is smaller than or equal to the width of each circular groove on the upper surface of the grinding pad, and the interval among the strip-shaped grinding bands is equal to that among the circular grooves on the upper surface of the grinding pad. The CMP grinding pad finishing structure has advantages of simpleness in structure and convenience in production. The grinding pad finishing efficiency can be well improved, and the service life of the grinding pad can be prolonged.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Composite dressing device

ActiveCN105563332AReduce wearSolve efficiency problemsMechanical vibrations separationAbrasive surface conditioning devicesUltrasonic vibrationEngineering

The invention discloses a composite dressing device. The composite dressing device comprises a machine base, a cup-shaped grinding wheel and a spindle. The spindle is rotatably assembled on the machine base around the axis extending in the vertical direction. The composite dressing device further comprises an ultrasonic vibration system which is used for driving abrasive particles in the cup-shaped grinding wheel to vibrate at a high frequency. The ultrasonic vibration system is connected with the cup-shaped grinding wheel, so that longitudinal and radial coupled vibration, mainly radial vibration, of the cup-shaped grinding wheel is generated; by the adoption of the vibration form, the impacting and grinding effect of the abrasive particles is improved, and the area of the cup-shaped grinding wheel and the area of the grinding wheel to be dressed are increased. Under the action of the ultrasonic vibration, the impacting and grinding force of the abrasive particles to the grinding wheel to be dressed is improved, and the grinding progress is accelerated; the dressing efficiency of the grinding wheel to be dressed is improved in the way of combining ultrasonic dressing with cup-shaped grinding wheel dressing, and the problems that in the prior art, the dressing efficiency of a superhard grinding wheel is low, and the loss of a dressing tool is large are solved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Electrolytic in-process dressing device of concave spherical surface of spherical coupling

ActiveCN101856800AAchieve grindingSolve the difficult problem of ELID grindingGrinding drivesSpherical surface grinding machinesElectricityElectrolysis

The invention provides an electrolytic in-process dressing device of a concave spherical surface of a spherical coupling, comprising a workpiece spindle, a grinding wheel, an electric spindle, a dressing electrode, a gap regulation device and a brushgear. A ball bowl workpiece is fixed on the workpiece spindle and is driven by the workpiece spindle to rotate at a low speed; the grinding wheel is fixed on the electric spindle and is driven by the electric spindle to rotate at a high speed; the rotation axes of the workpiece spindle and the electric spindle are in the same plane and lead rotating movement tracks of the ball bowl workpiece and the grinding wheel are enveloped to a spherical surface; the gap regulation device can regulate axial gaps and radial gaps between the dressing electrode and the grinding wheel; the dressing electrode is provided with a pipe joint; grinding liquid is sprayed on the grinding wheel through the pipe joint and small holes formed inside the dressing electrode; and the brushgear is fixed on a gap regulation piece and supplies electricity for the grinding wheel. The device of the invention has simple structure and convenient use, and solves the difficult problem that the grinding wheel is difficult to be dressed when the electrolytic in-process dressing is carried out on the concave spherical surface of the spherical coupling.

Owner:北京航天兴华科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com