Ultrasonic vibration cup-shaped grinding wheel dresser for dressing super-hard abrasive grinding wheel

A grinding wheel dresser and super-hard abrasive technology, applied in the field of precision grinding, can solve the problems of small processing force, low processing temperature, surface damage and small residual stress, so as to improve life, reduce grinding heat and power consumption , the effect of improving the microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

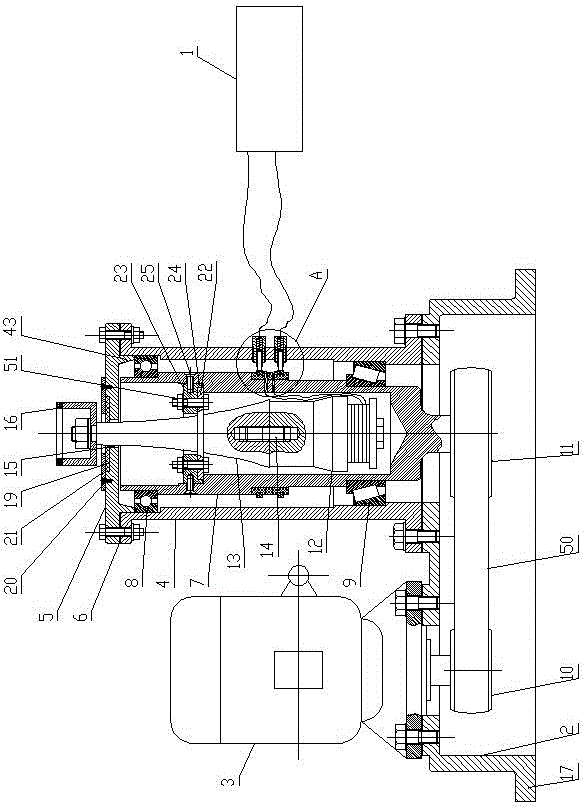

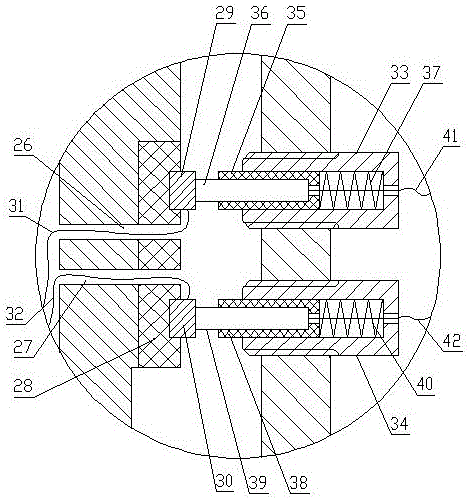

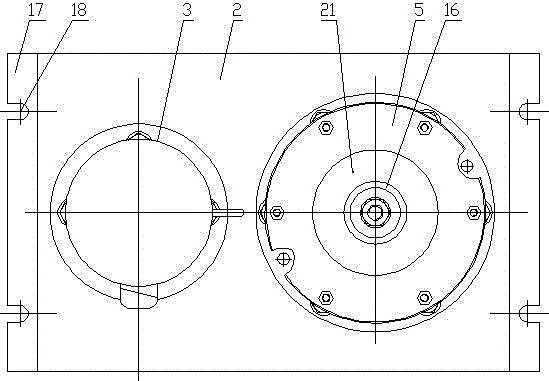

[0026] like figure 1 , figure 2 and image 3 As shown, the ultrasonic vibrating cup-type grinding wheel dresser for dressing superabrasive grinding wheels of the present invention includes an ultrasonic generator 1 and a base 2 with a hollow structure inside; The cylindrical body 4 on the side, the centerline of the cylindrical body 4 is set along the vertical direction, the lower end flange of the cylindrical body 4 is connected to the base 2, and the upper end flange of the cylindrical body 4 is connected with a cover plate 5, and the cover plate 5 is connected to the circle A sealing gasket 6 is provided between the cylinders 4; a hollow shaft 7 with an open upper end and a blocked lower end is arranged coaxially inside the cylindrical body 4, and there is a gap between the upper end of the hollow shaft 7 and the lower surface of the cover plate 5,

[0027] The upper part between the inner wall of the cylindrical body 4 and the outer wall of the hollow shaft 7 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com