Patents

Literature

398 results about "Dressing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This method uses the body's own enzymes and moisture beneath a dressing, and non-viable tissue becomes liquefied. Maintaining a balance in moisture is important. Dressing frequency and absorbency. Dressing types commonly used are hydrocolloids, hydrogels, and transparent films (semi-occlusive and occlusive).

Polishing apparatus and dressing method for polishing tool

InactiveUS6899592B1Easy to dressReduce the binding forceGrinding drivesAbrasive surface conditioning devicesIrradiationBond Force

In a polishing apparatus, a polishing tool including abrasive particles and a binder for bonding together the abrasive particles is pressed against a substrate to polish the substrate. The polishing apparatus has a light source for irradiating a polishing surface with light rays for weakening a bond force of the binder for bonding together the abrasive particles, and a waste matter removing mechanism for forcefully removing waste matter produced by polishing or waste matter produced by irradiation. By irradiating the polishing surface with the light rays, dressing of the polishing surface is performed, and products resulting from dressing and the like are removed. The polishing apparatus supplies abrasive particles to the polishing surface stably by dressing and allows high-speed polishing of the substrate.

Owner:EBARA CORP

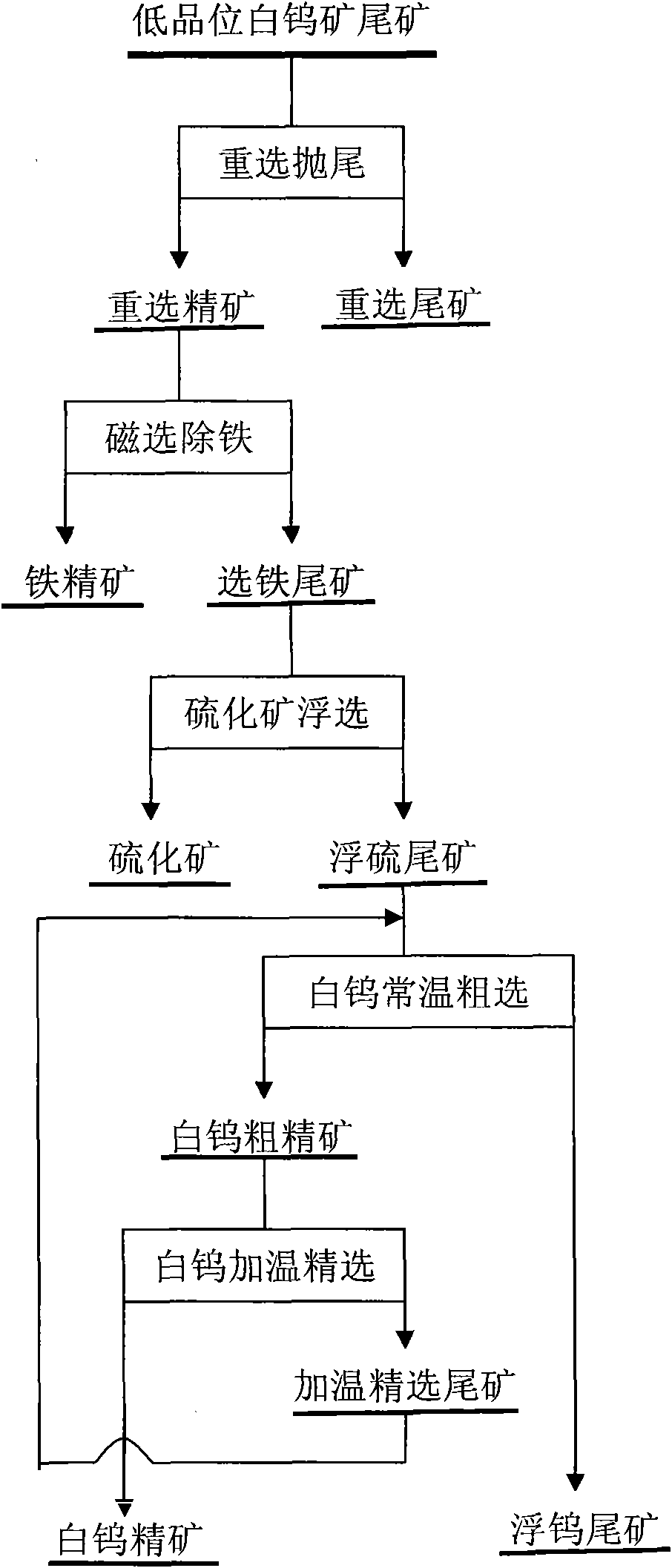

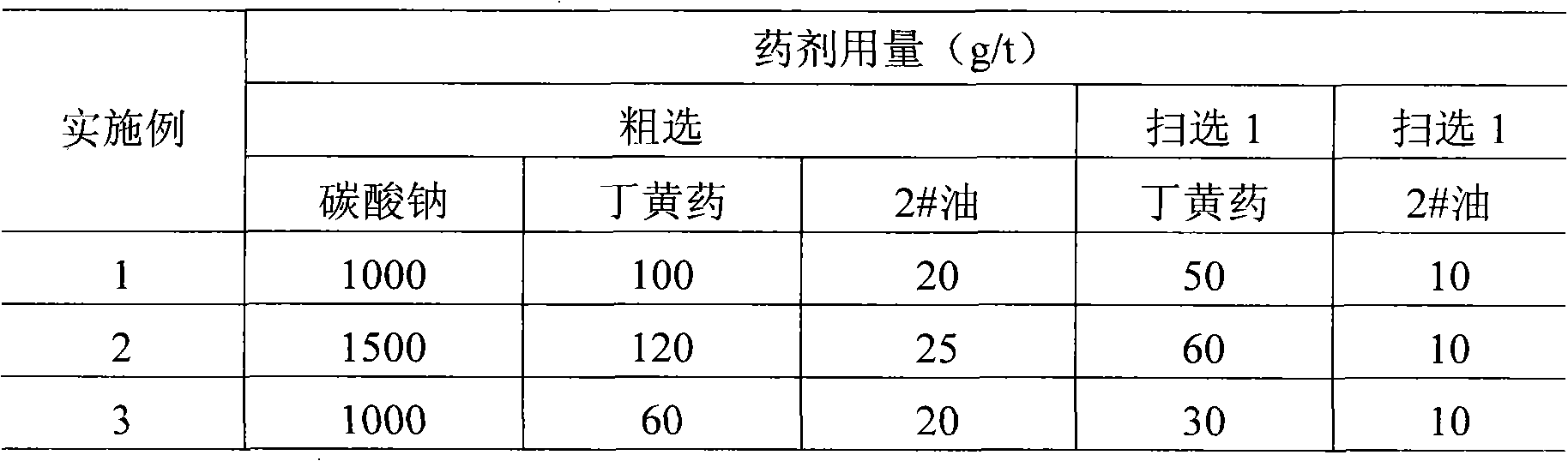

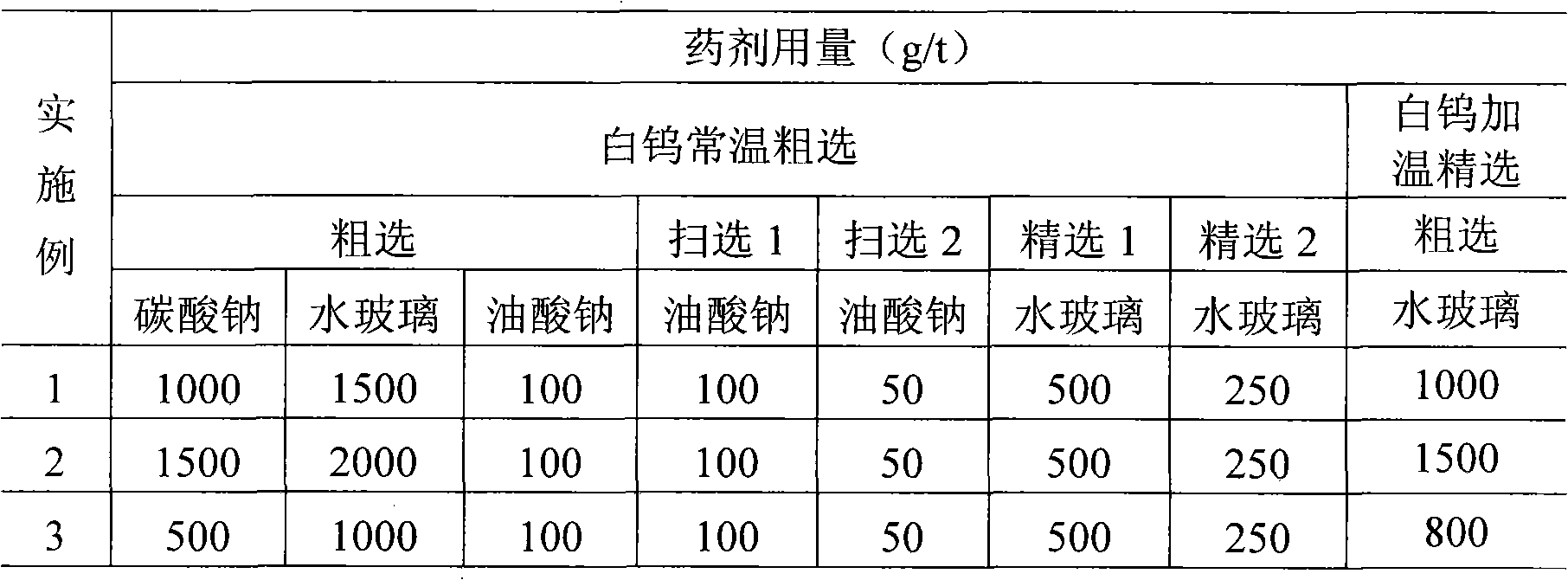

Ore dressing method of low-grade scheelite

InactiveCN101869876AImprove sorting indexImprove the quality of selectionFlotationIron removalLower grade

The invention relates to an ore dressing method of a low-grade scheelite, which is characterized by comprising the following steps: 1. tailing discard by gravity concentration; 2. iron removal by magnetic separation; 3. sulfide ore flotation; 4. normal-temperature rougher flotation of scheelite; and 5. heating concentration of the scheelite. The invention provides a lower-cost ore dressing method for dressing scheelite concentrates from the tailings of the low-grade scheelite. The invention has the characteristics that the comprehensive recovery cost is saved, the beneficiation feed grade of the scheelite is improved, the flotation feed ore quantity is reduced, the dosage of a flotation reagent is reduced, the used ore dressing reagent is more friendly to the environment, and secondary pollution can not be caused. The method of the invention is applicable for low-grade scheelite resources with 0.03 to 0.15 percent of WO3.

Owner:广东省资源综合利用研究所

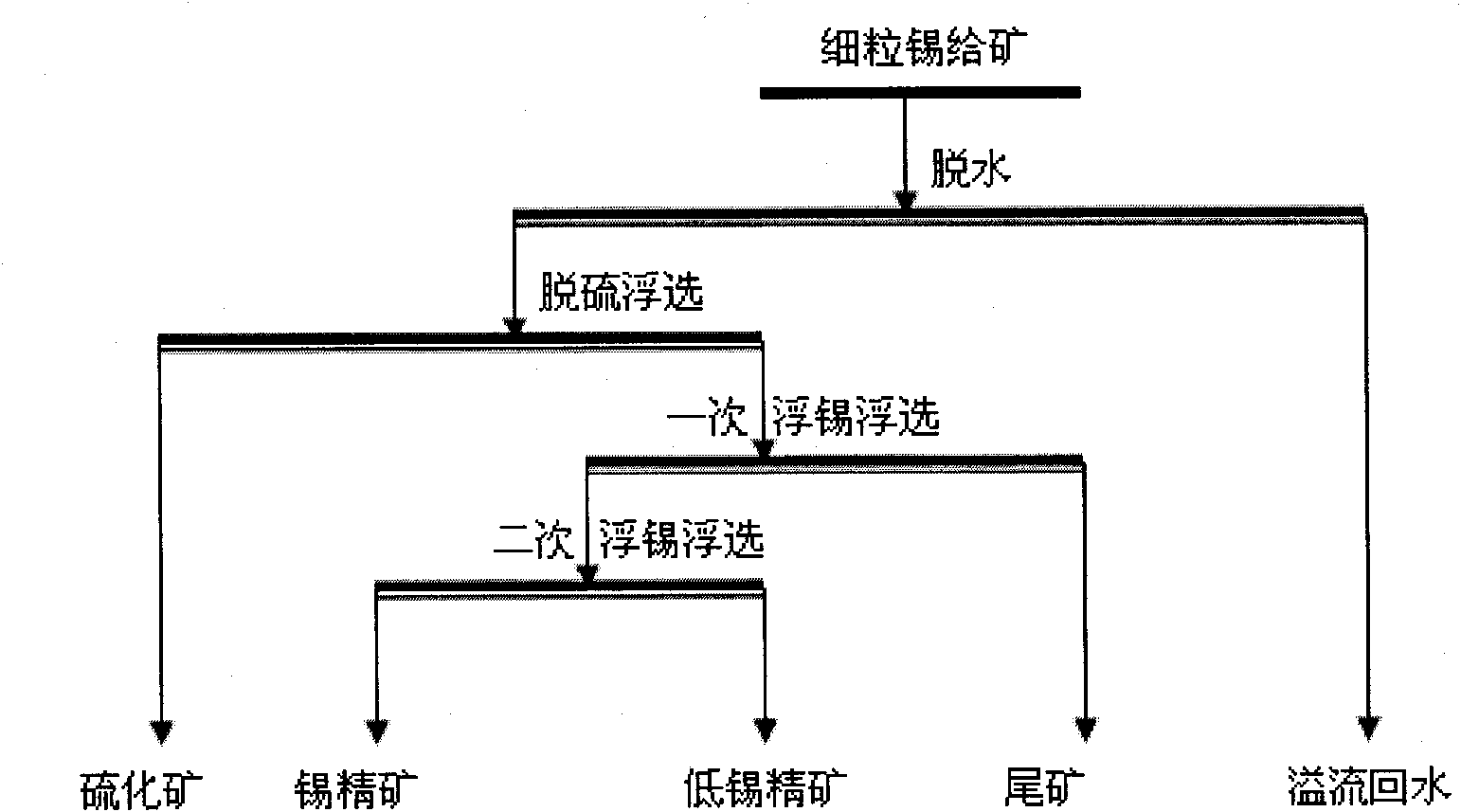

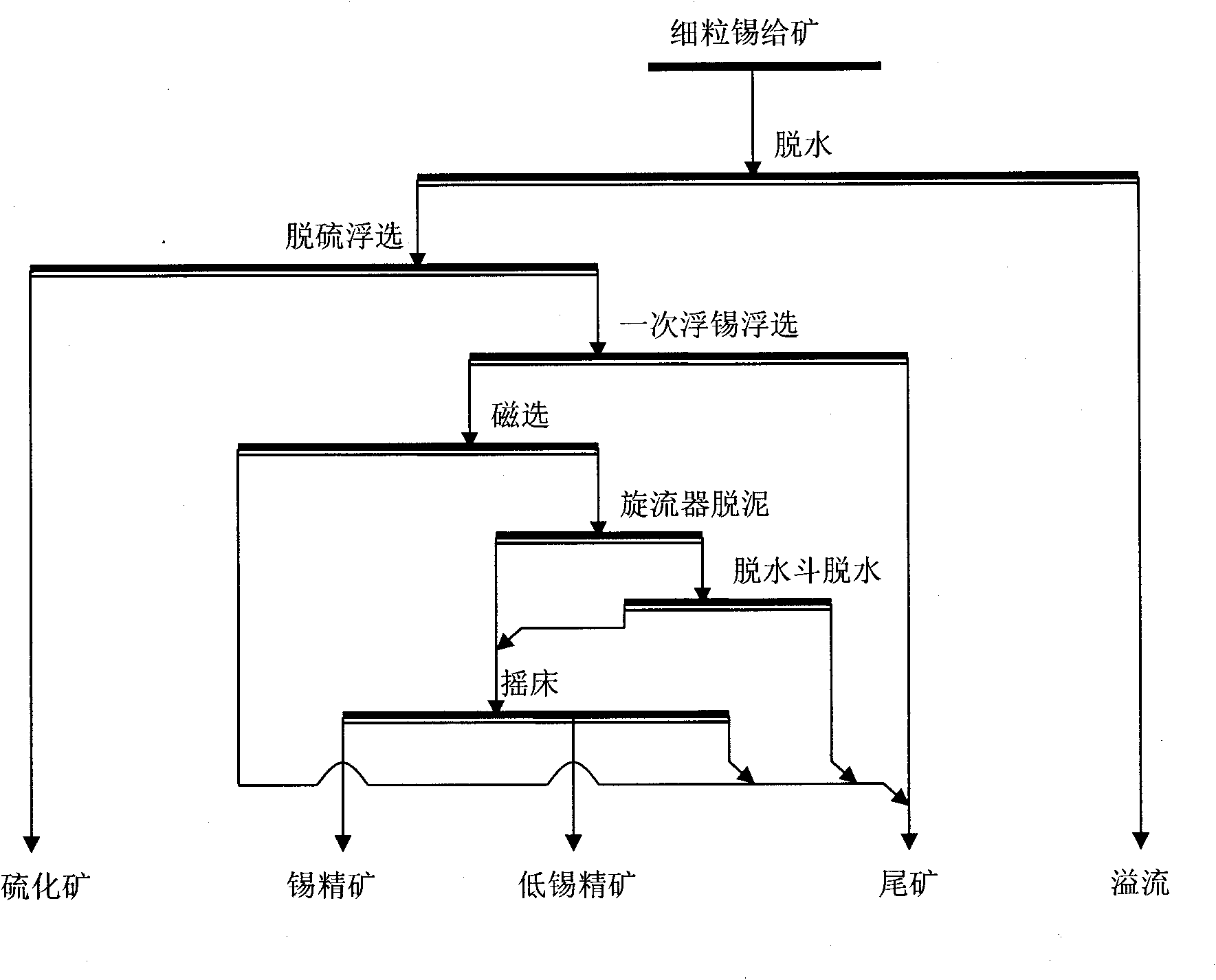

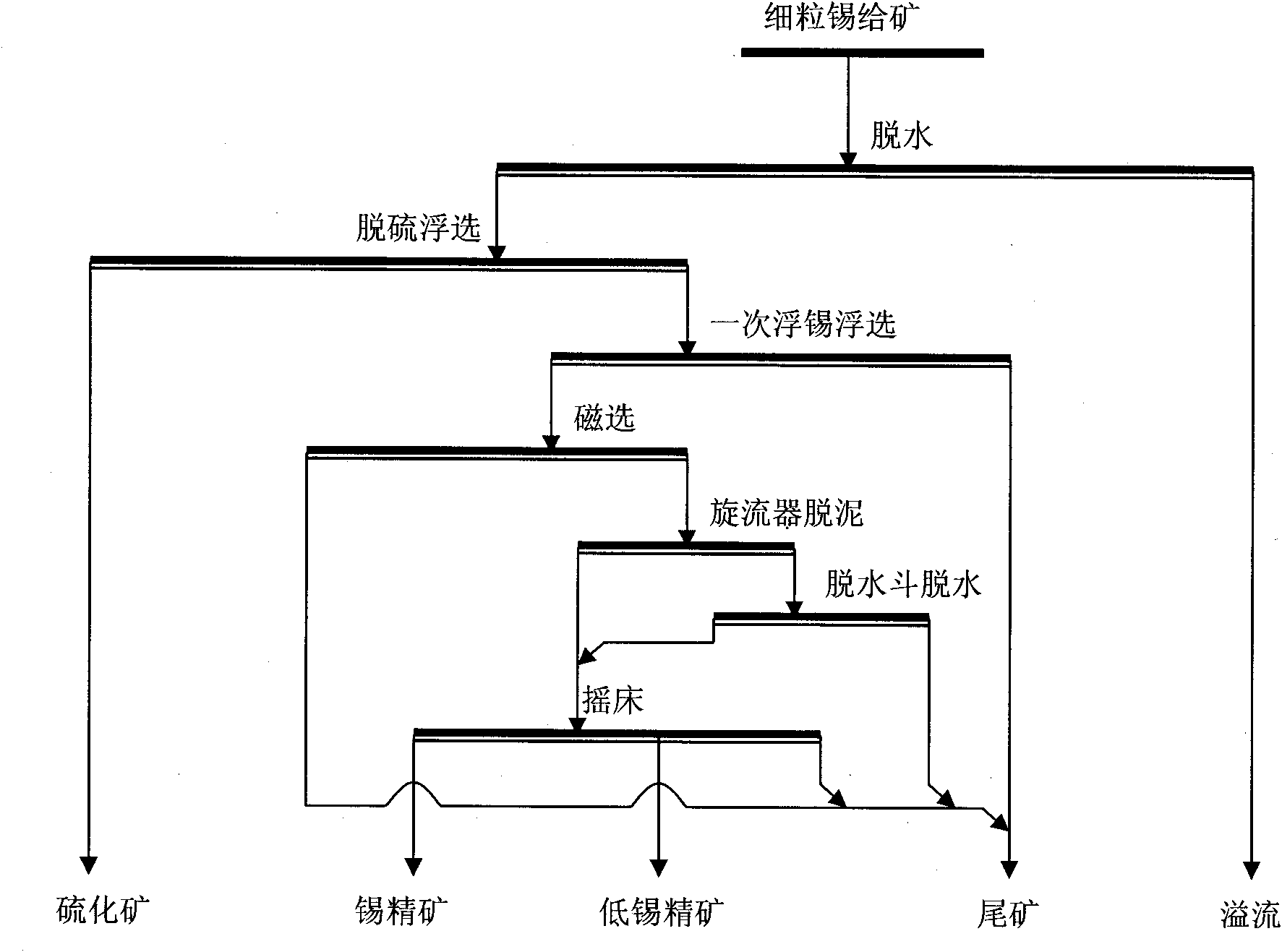

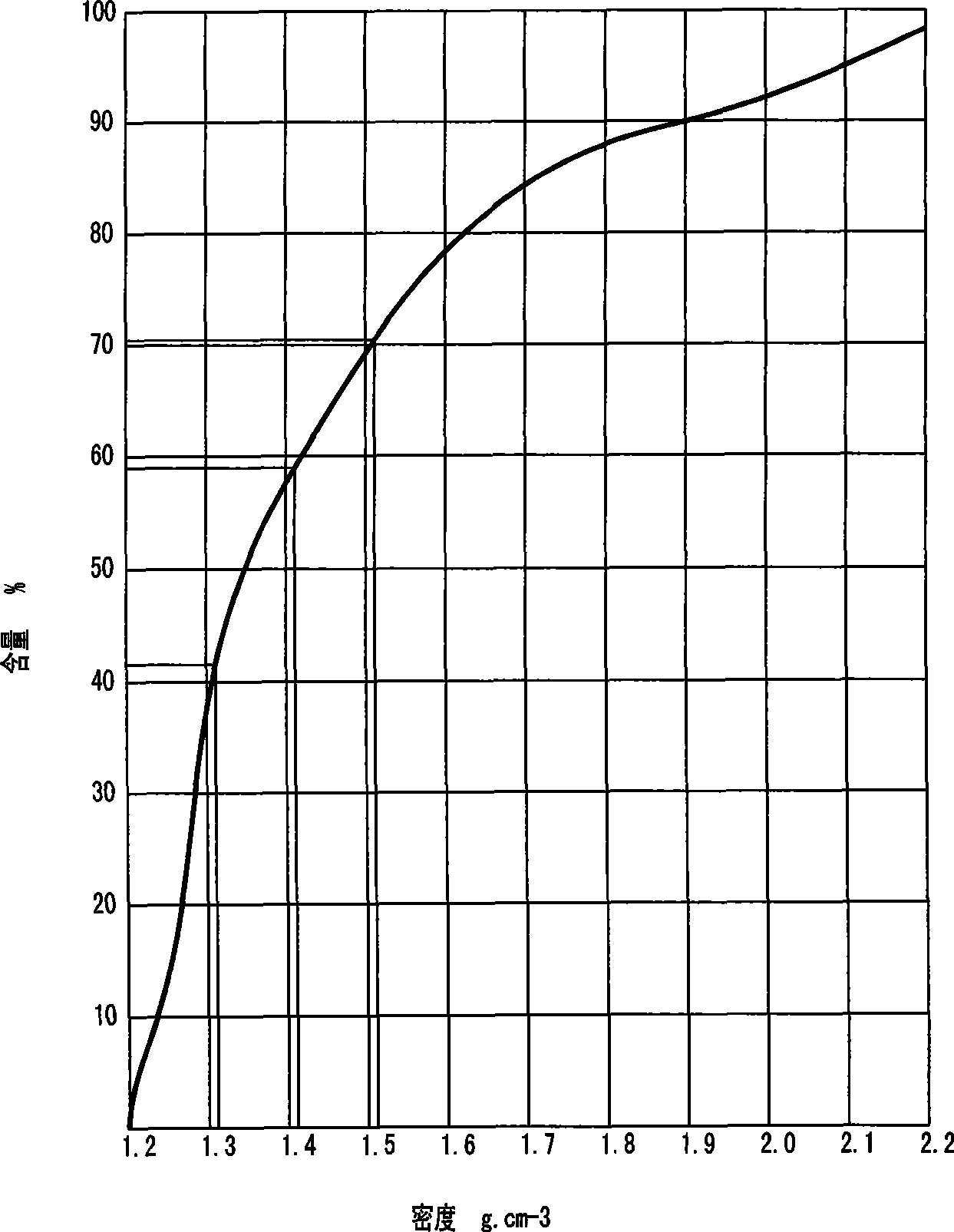

Combined mineral dressing technology of fine grain and micro grain cassiterite

ActiveCN101884951AAchieve separationAvoid interferenceFlotationWet separationNiobiumConcentration ratio

The invention relates to a combined mineral dressing method of fine grain and micro grain cassiterite, which gives up the single mineral dressing method of fine grain and micro grain cassiterite for years. The invention adopts the effective combination of two-time flotation operation, magnetic separation operation, desliming and dewatering operation and reselection operation, provides a new mineral dressing model for selecting grain and micro grain cassiterite which has the size of 10-37 micrometers and has complex mineral property, high impurity content and big mineral dressing difficulty, and improves the cassiterite concentration ratio and cassiterite operation recovery rate; cassiterite concentration ratio can reach 5-10, the cassiterite operation recovery rate can be above 70%, and the tin-containing grade of tin concentrate products can be above 50%. The method also can be used for the mineral dressing of fine grains and micro grains of non-ferrous metal, such as tungsten, molybdenum, tantalum, niobium and the like and has favorable economic benefit and social benefit.

Owner:广西华锡矿业有限公司铜坑矿业分公司

Liquid seed dressing method for dressing small quantities of seed

A method of dressing seeds is disclosed. The method utilizes a seed treatment slurry which is applied to seed by subjecting the seed and seed treatment slurry to a dual asymmetrical centrifugal mixing motion. The method provides uniformly dressed seeds and is suitable for dressing small seed lots.

Owner:CORTEVA AGRISCIENCE LLC

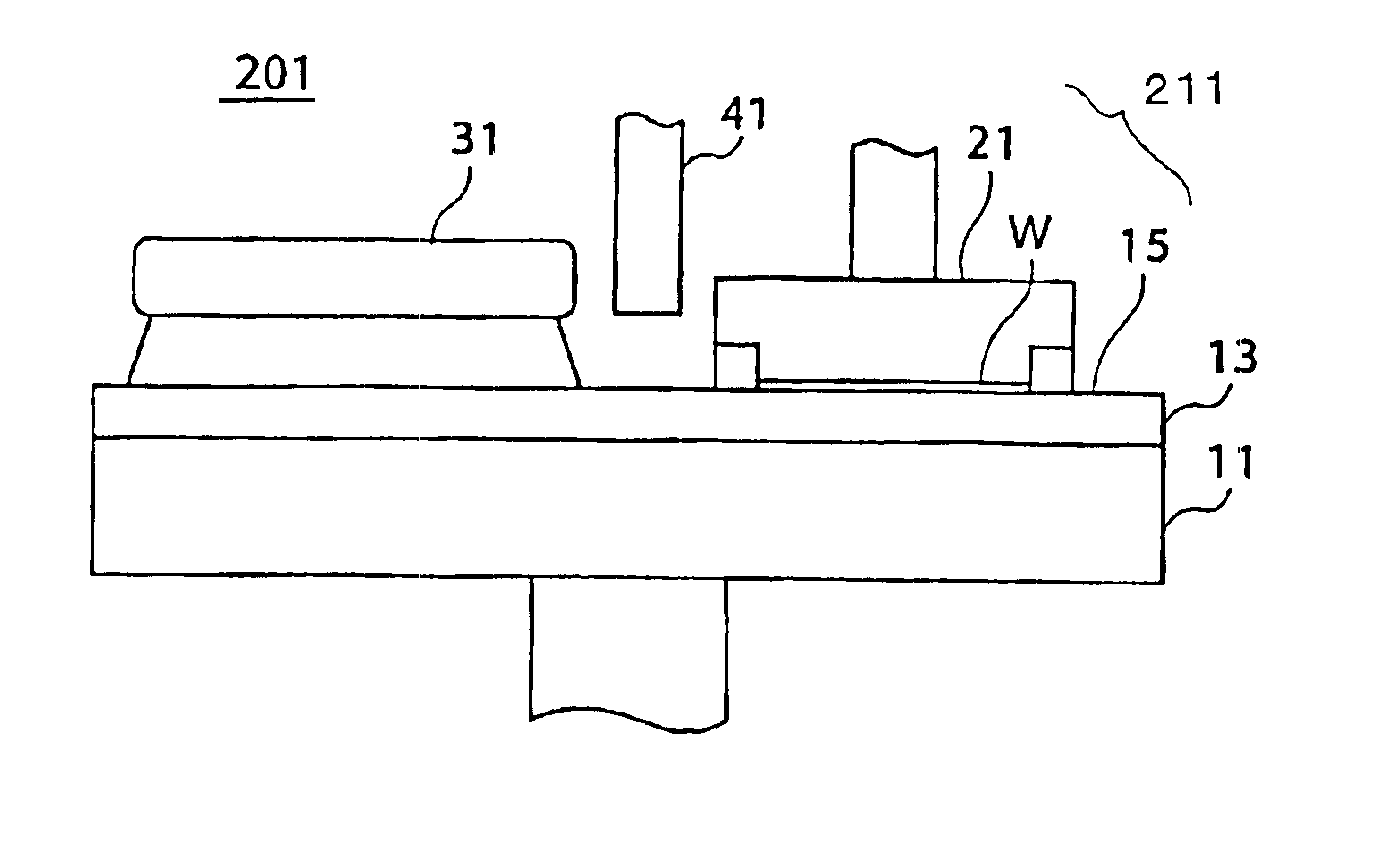

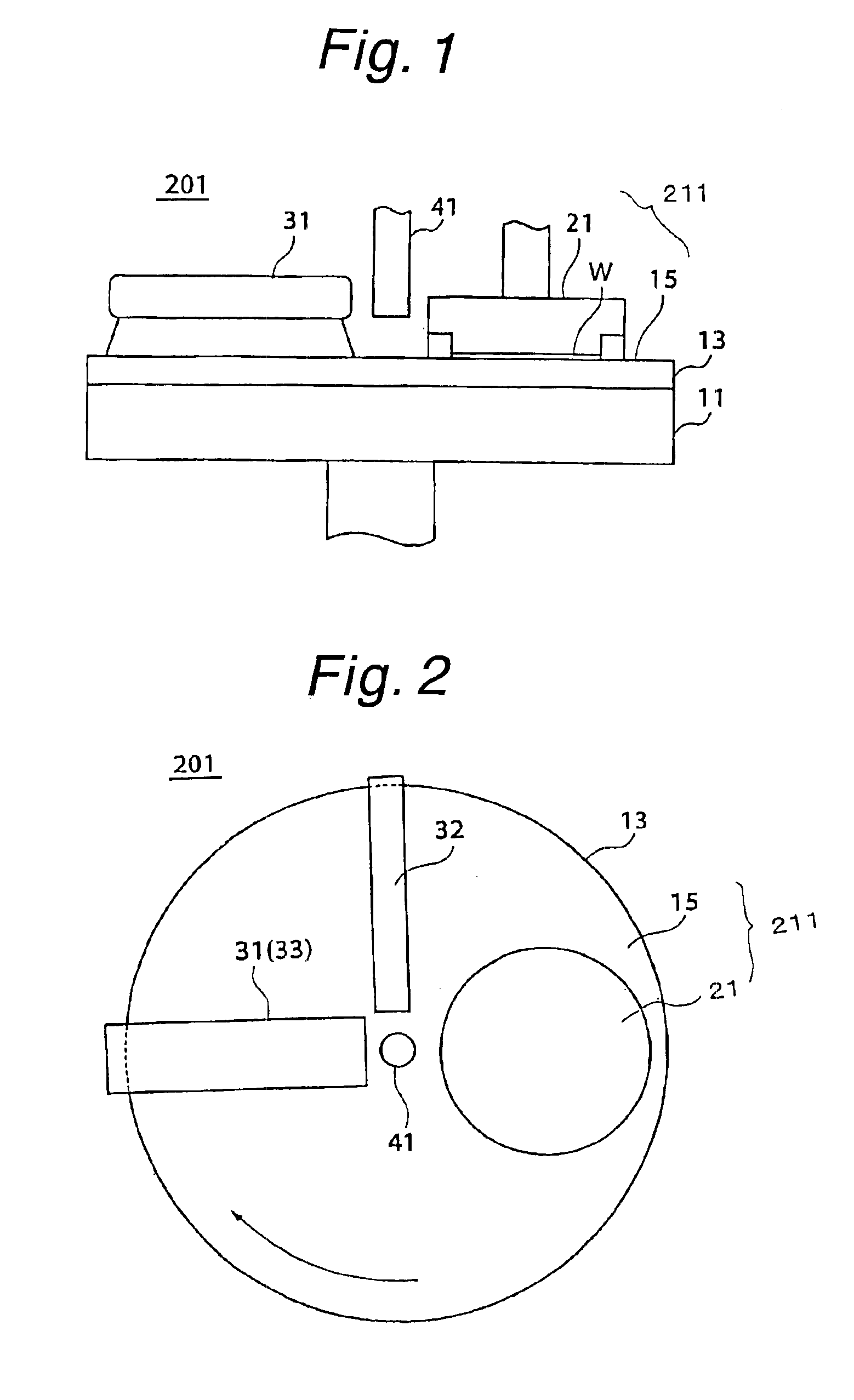

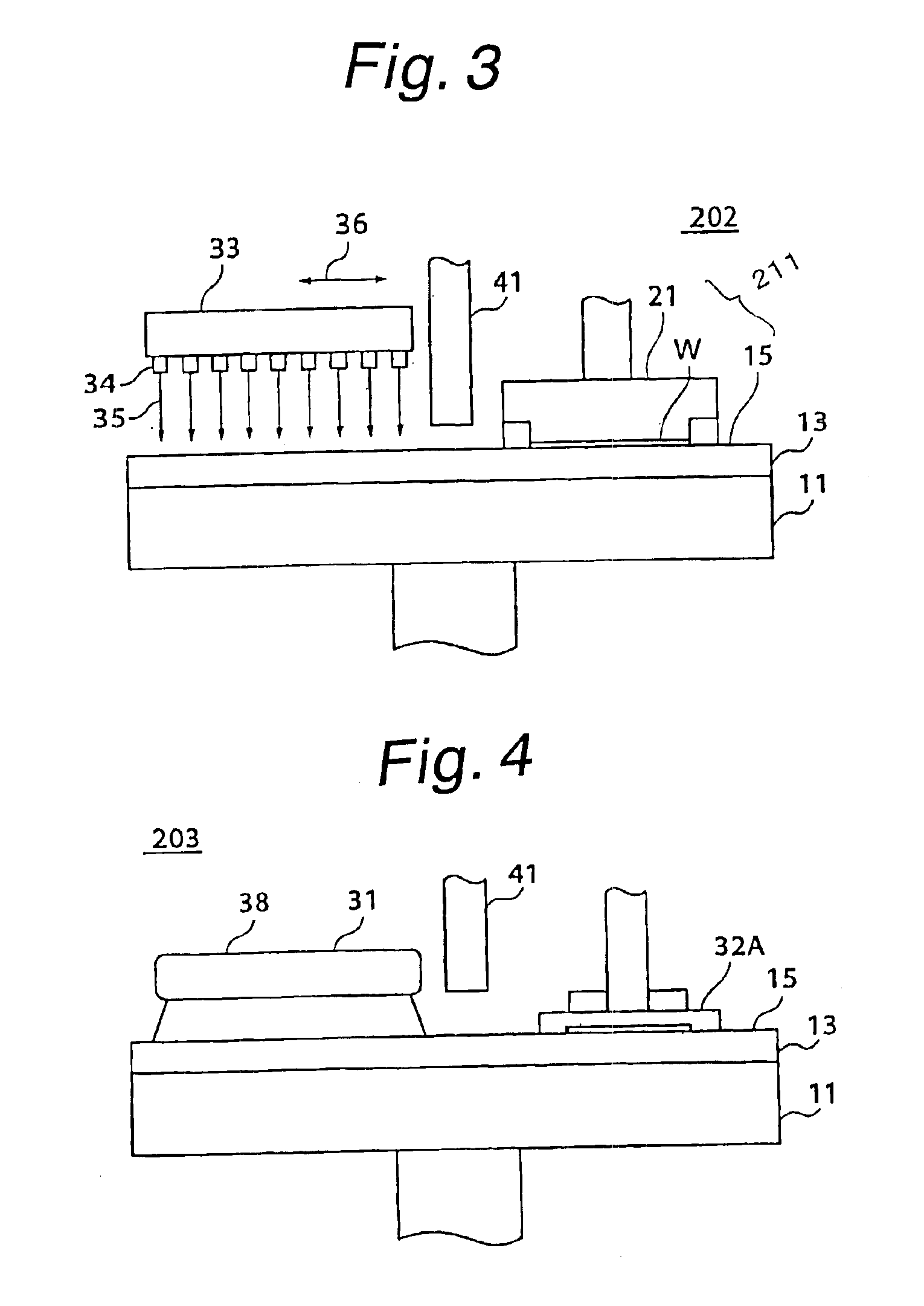

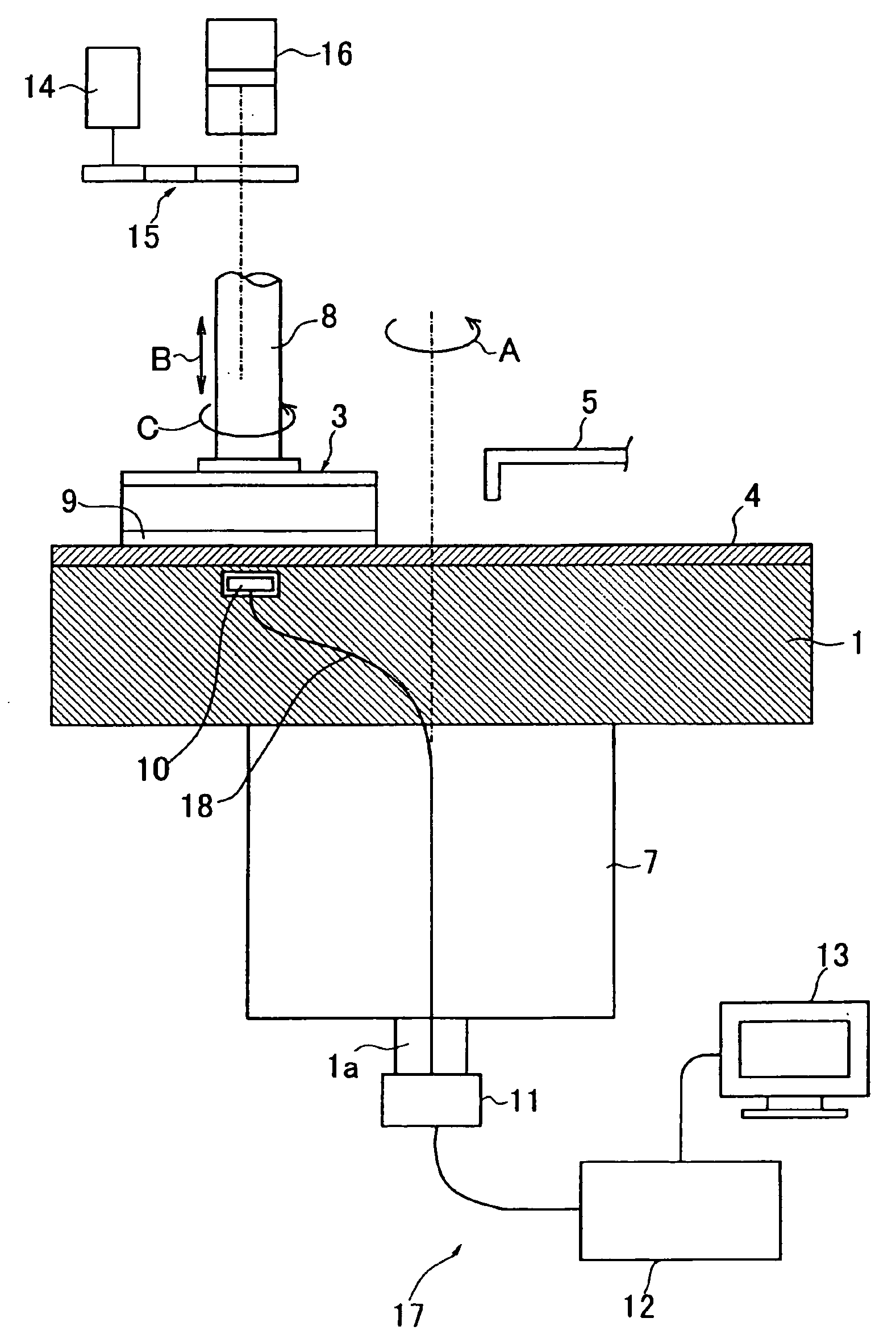

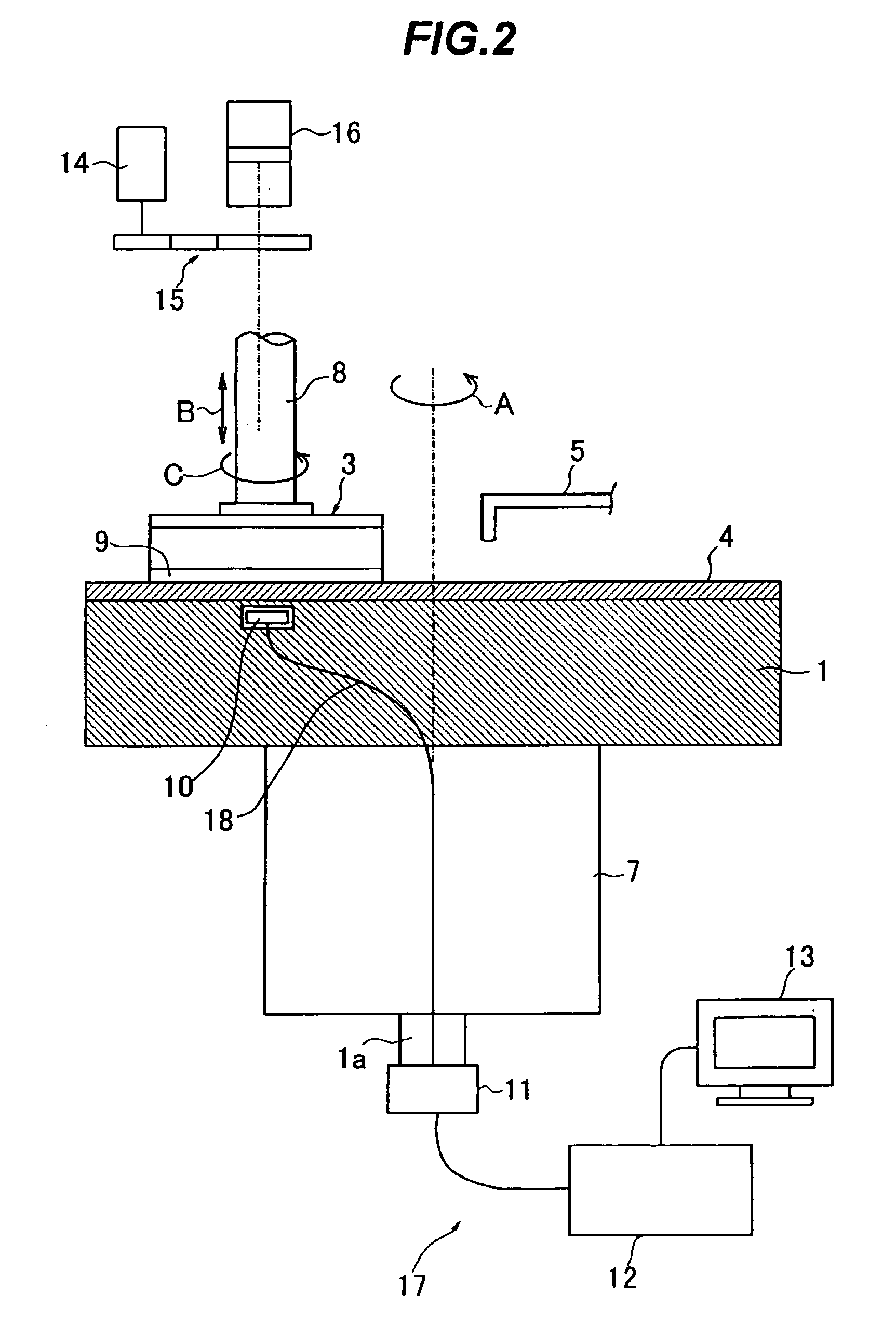

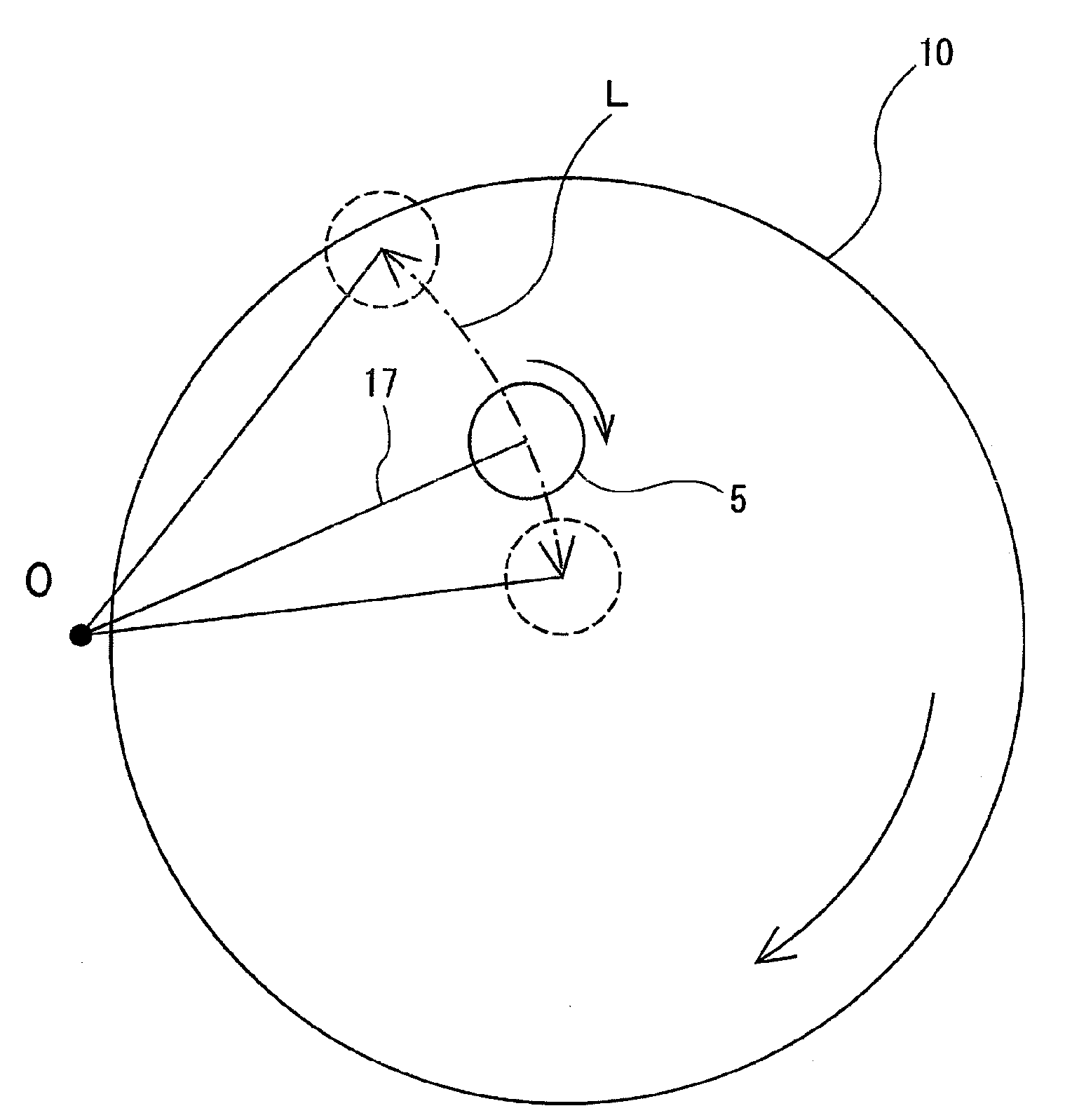

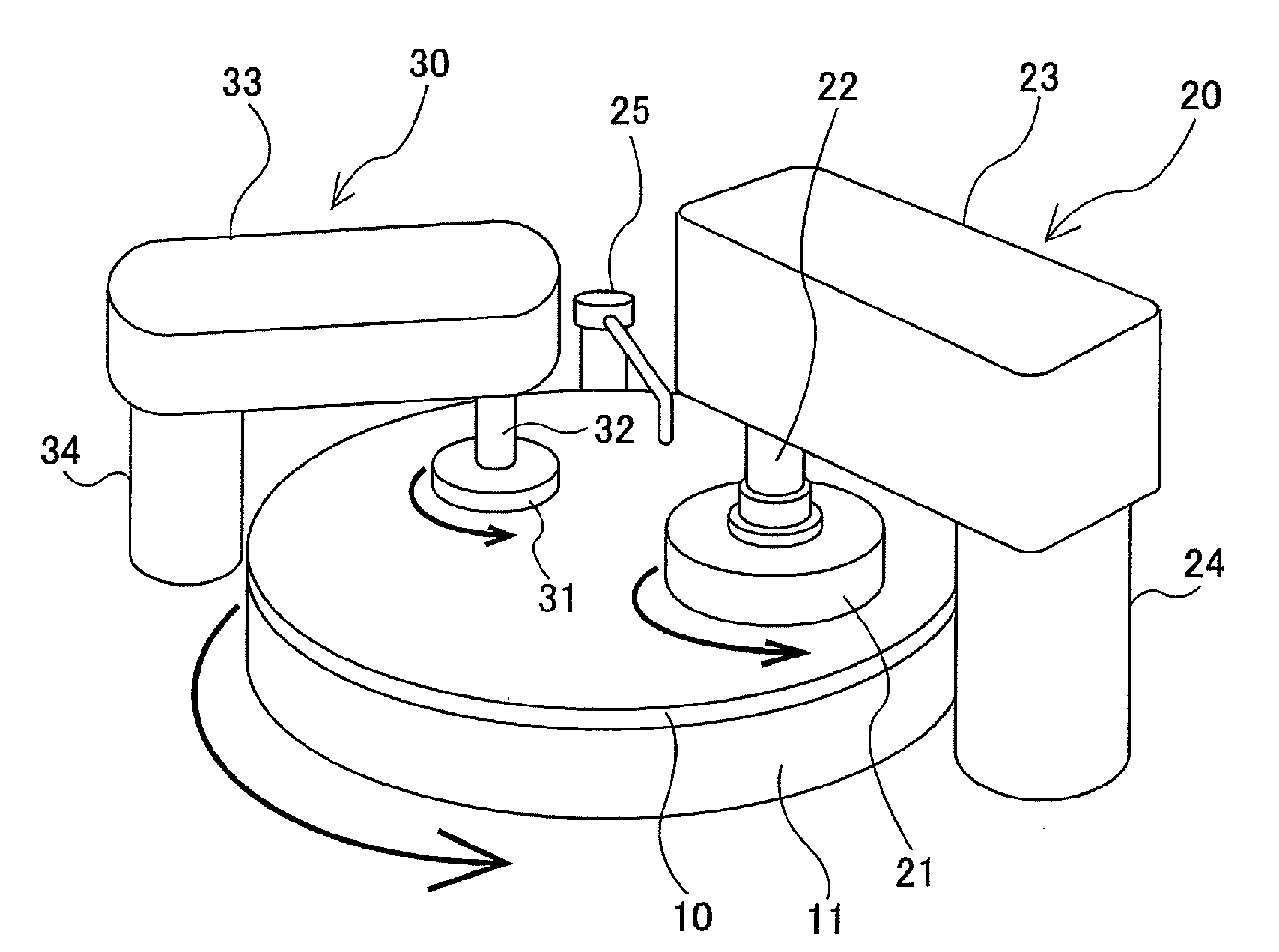

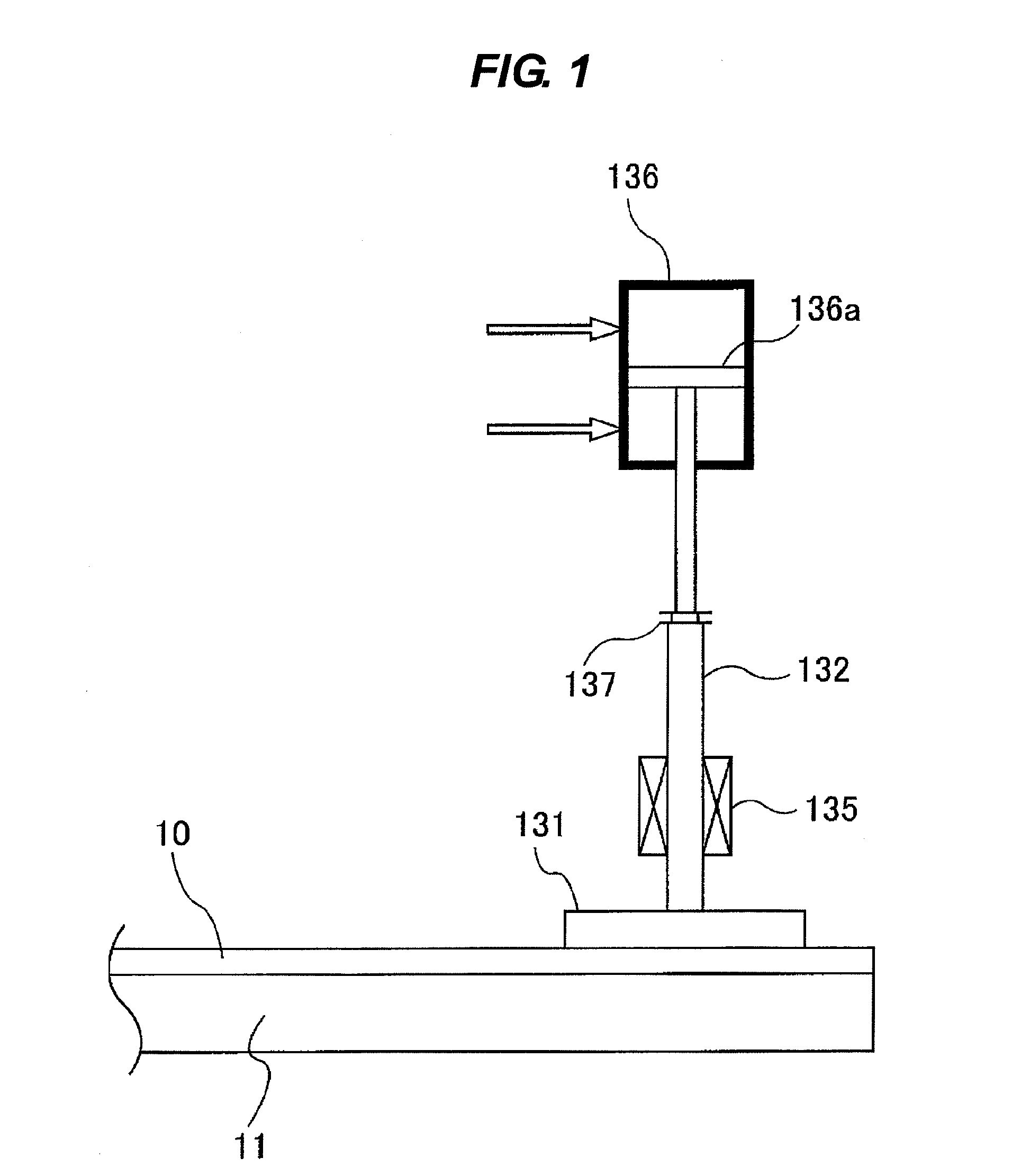

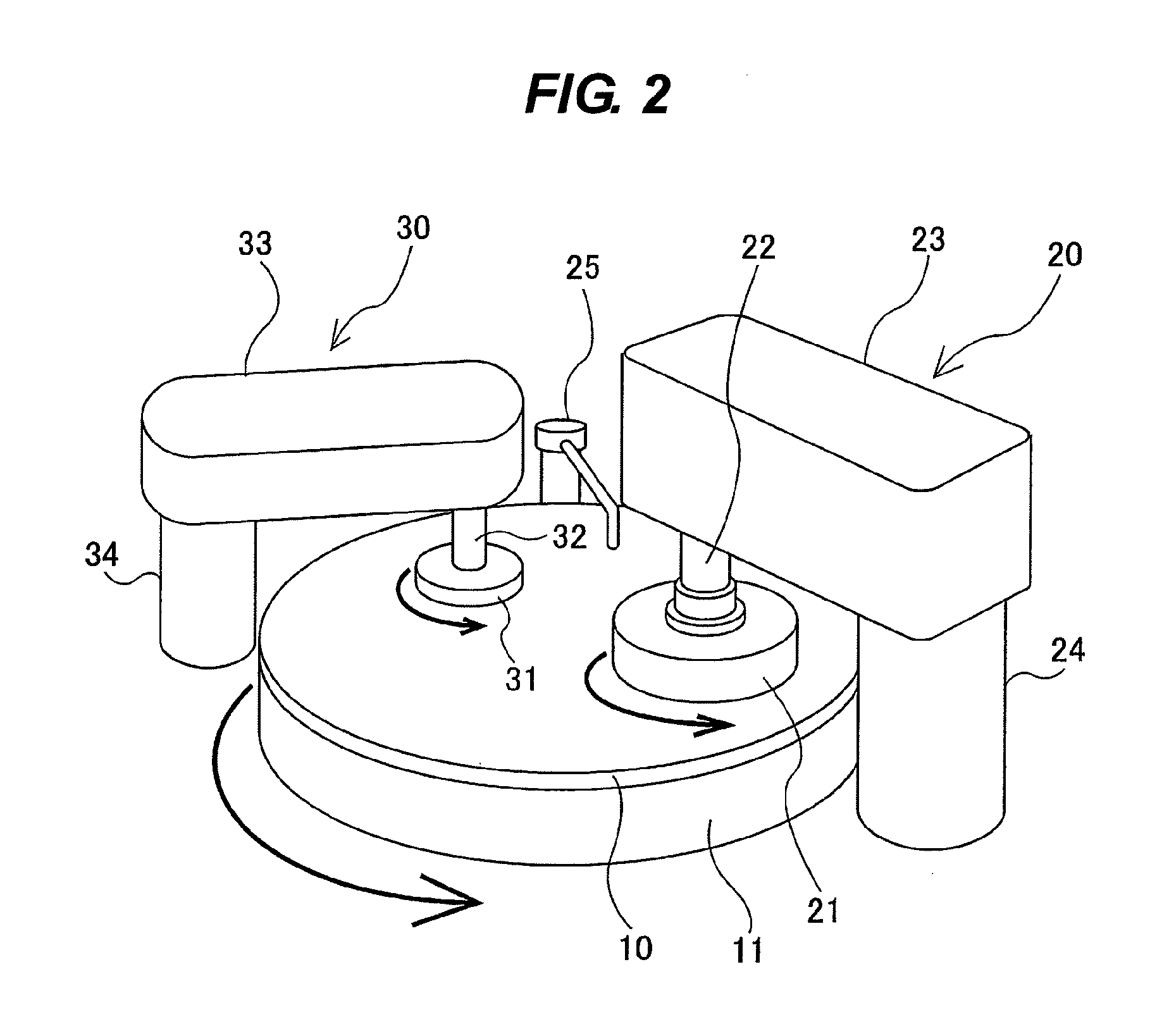

Method and apparatus for dressing polishing pad, profile measuring method, substrate polishing apparatus, and substrate polishing method

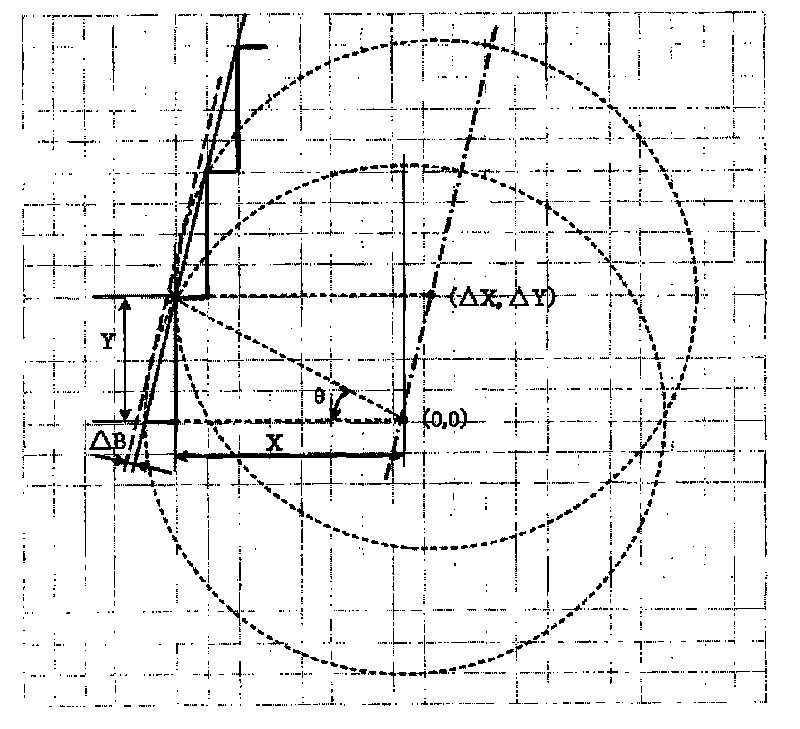

ActiveUS20090137190A1Constant cutting rateWithout adversely affectingPolishing machinesRevolution surface grinding machinesEngineeringDressing method

The present invention provides a dressing method of dressing a polishing pad used in a polishing apparatus for polishing a substrate. This method includes repetitively moving the dresser on an upper surface of the polishing pad in a radial direction of the polishing pad so as to perform a dressing process on the polishing pad, during the dressing process, measuring a height of an upper surface of the polishing pad at a predetermined point in one of plural zones on the polishing surface, and repeating the repetitive moving of the dresser and the measuring of the height of the upper surface of the polishing pad so as to measure the height of the upper surface of the polishing pad in all of the plural zones.

Owner:EBARA CORP

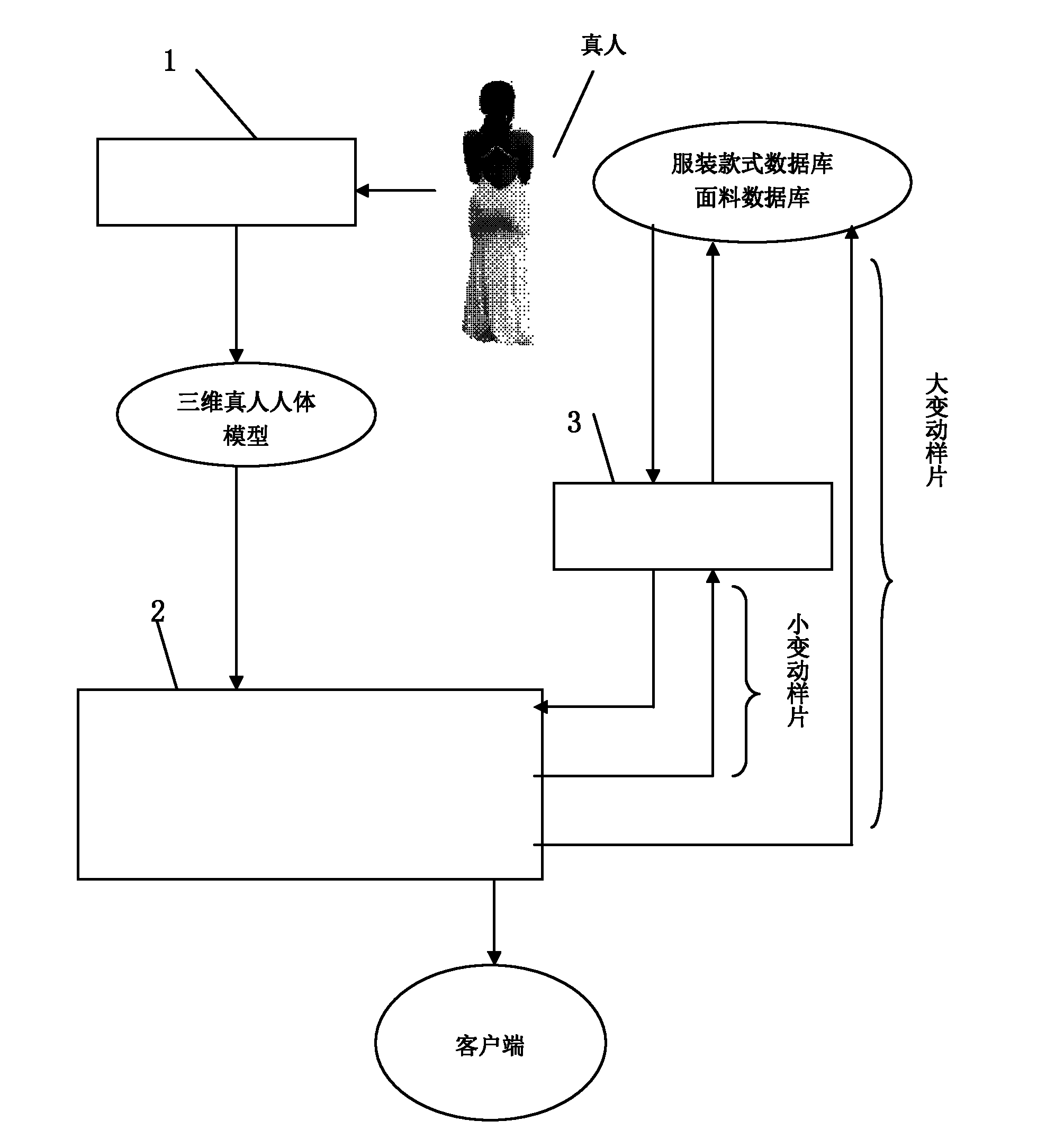

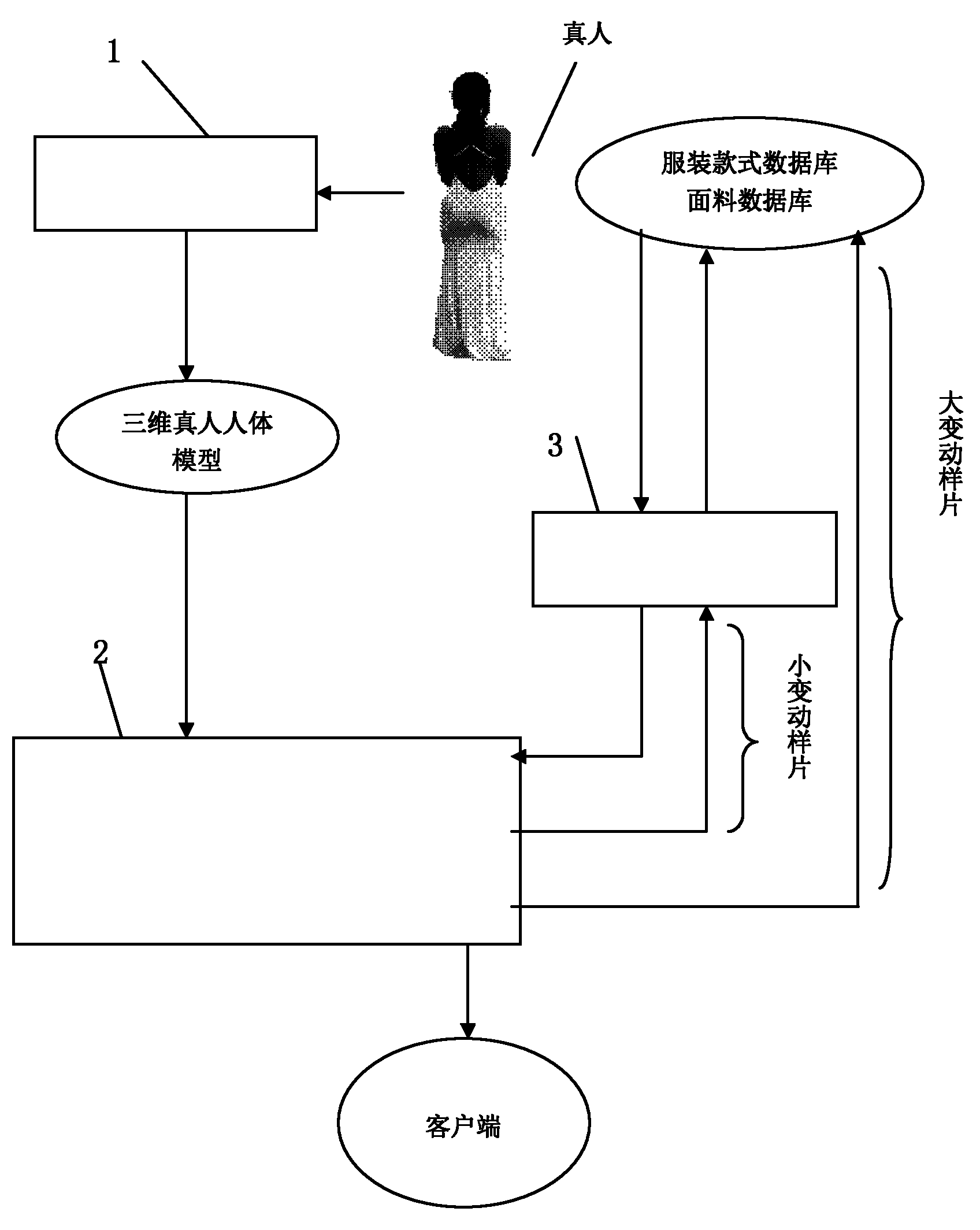

Three-dimensional virtual dressing method of clothes for real person

InactiveCN102044038AImprove the design levelImprove design efficiencyCommercePersonalizationBody measure

The invention relates to a three-dimensional virtual dressing method of clothes for a real person, relating to the technical fields of digital clothing design. The system is characterized in that an object of the three-dimensional virtual dressing of the clothes is three-dimensional real-person body model structured according to the three-dimensional measuring data of the real person. A three-dimensional body measuring system measures the data of the real-person body of a consumer, the figure curve characteristic and the face characteristic, and guides the data into a three-dimensional dressing system; the original standard body model of the three-dimensional dressing system is corrected according to the data of the real person in the three-dimensional dressing system, and the three-dimensional real-person body model is showed virtually so as to lead the virtual body model to embody the figure characteristic and the face characteristic of the real person; the consumer and a designer decide the style, the fabric and the color design data by two-way selection, guide the data into a tailor-making system, complete the design of clothes and generate individual clothes sample pieces automatically; ready-made clothes are sewn virtually, and when the clothes are worn on the three-dimensional real-person body model, the individual dressing effect is intuitively displayed; and the design level and design efficiency of clothes are greatly improved.

Owner:SHANGHAI UNIV OF ENG SCI

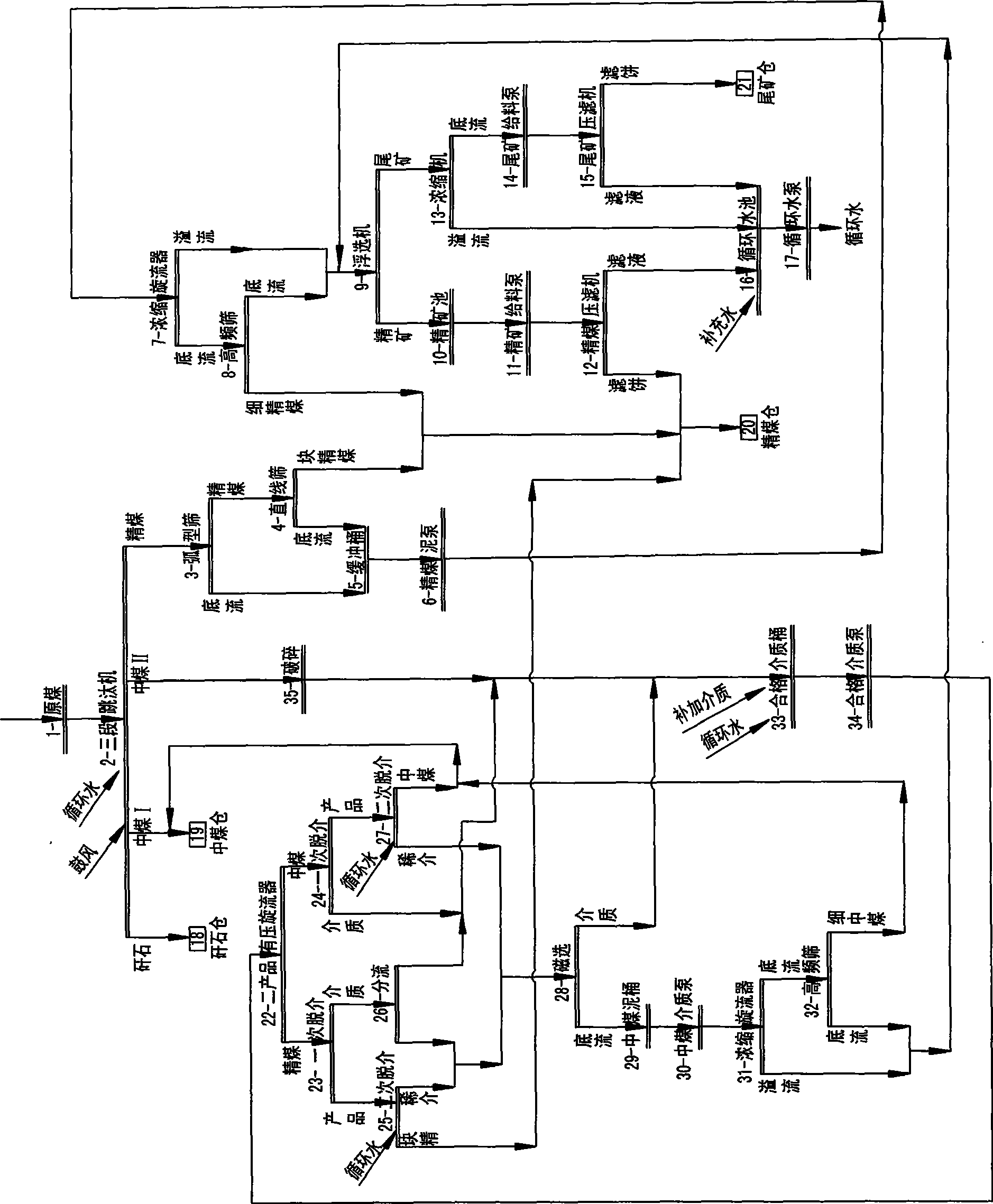

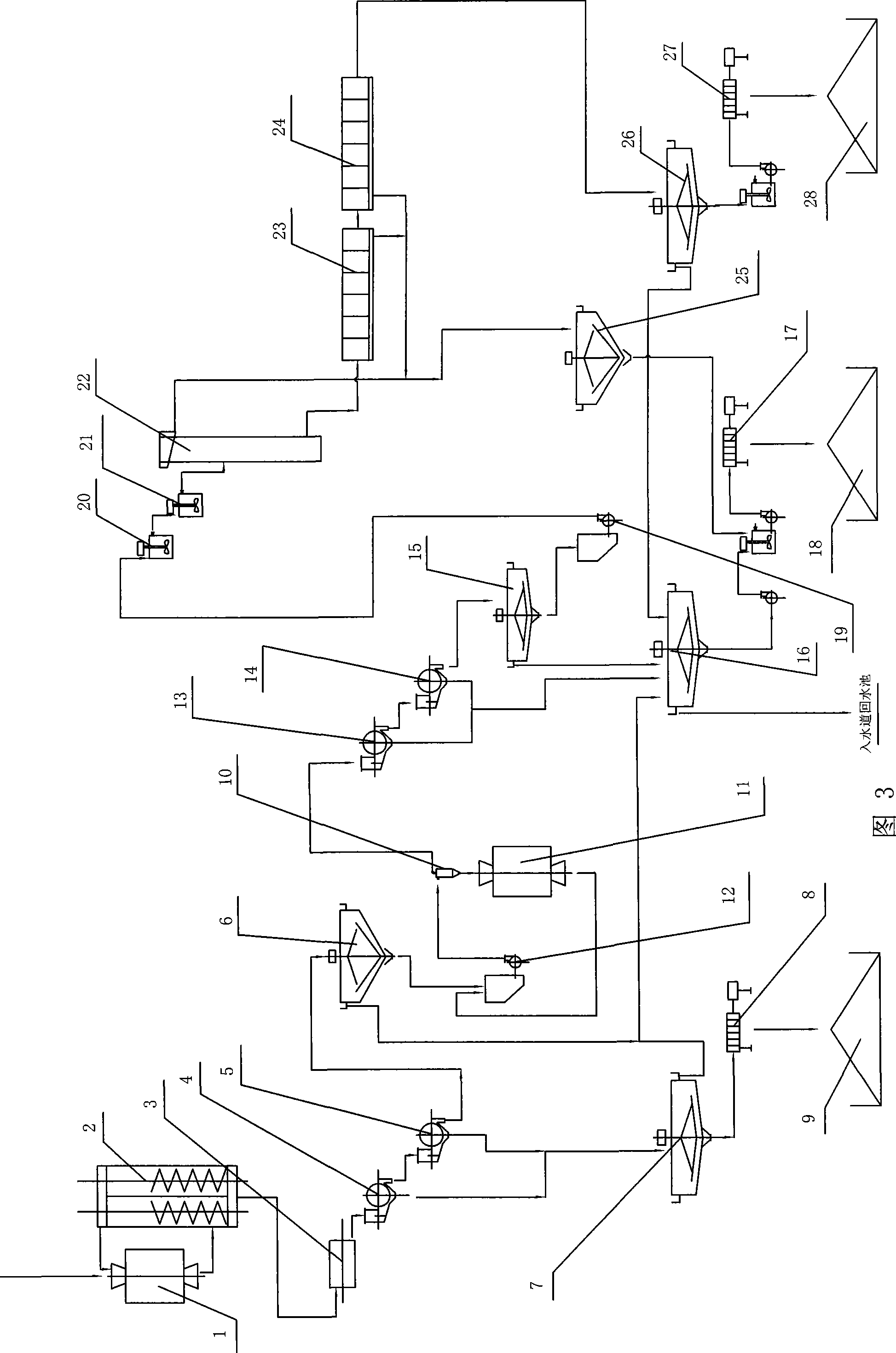

A coal dressing method and system of four-product jigging primary cleaning, secondary head coal small simplified heavy medium reelecting

ActiveCN101530824AReduce investmentLow operating costSievingScreeningTotal investmentSeparation technology

The invention discloses a coal dressing method and system of four-product jigging primary cleaning and secondary head coal small simplified heavy medium reelecting. The invention is a coal dressing method and system that selects the secondary head coal product through the four-product jigging technique and then reelects the secondary head coal with small simplify heavy medium separation technology. The adoption of the invention to select coal is characterized by less total investment, simpler system and lower operational expense, which can improve the stability of the system, reduce the powerconsumption, simplify the managing and maintaining work. The method can be easily realized with present technical merits, which is beneficial to be popularized in the middle and small coal washeries where the management level is low and if the method is used in oversize coal washeries, the cost for washing is lower.

Owner:JINYITONG SCI ANDTECH BEIJING CO LTD

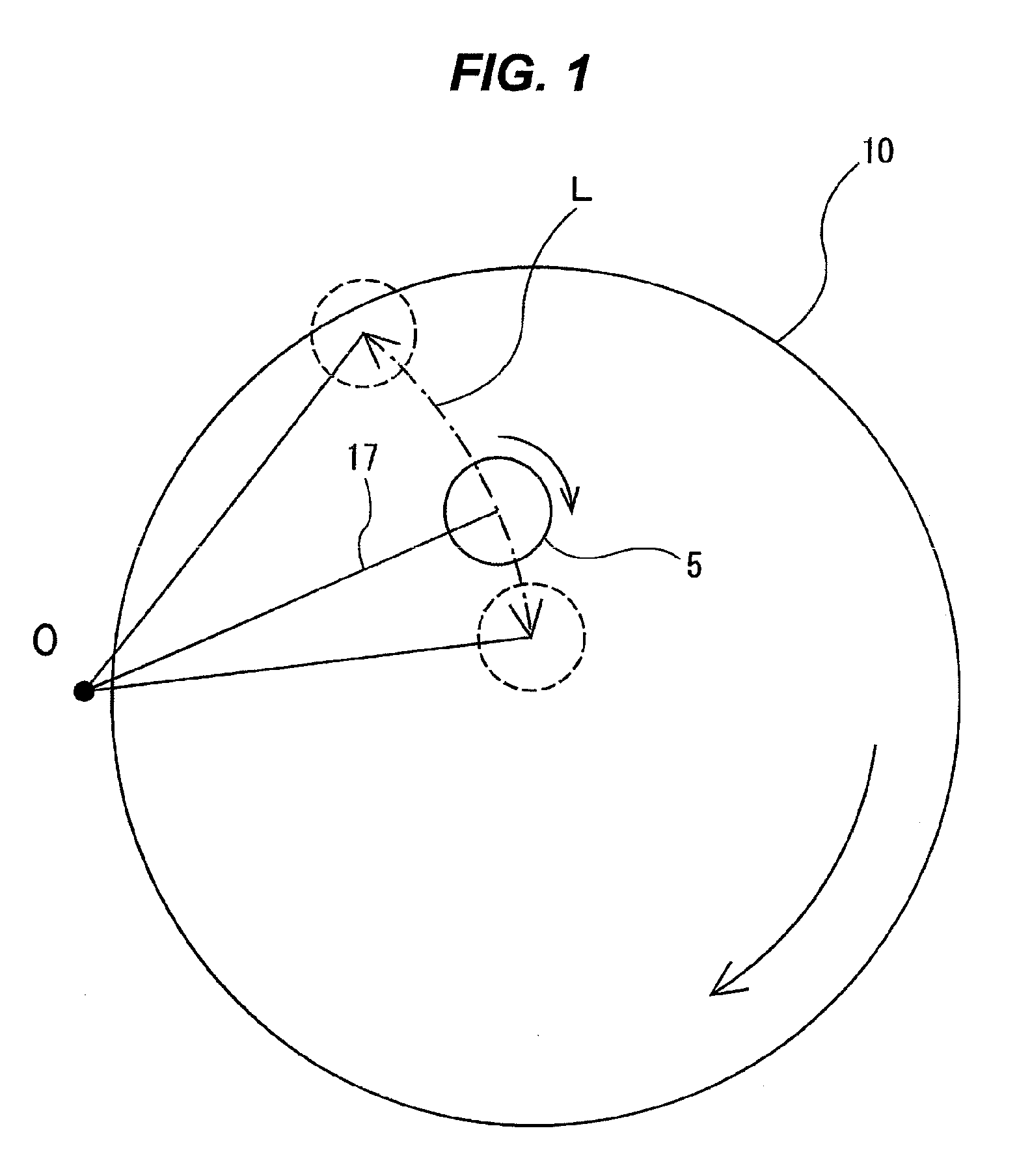

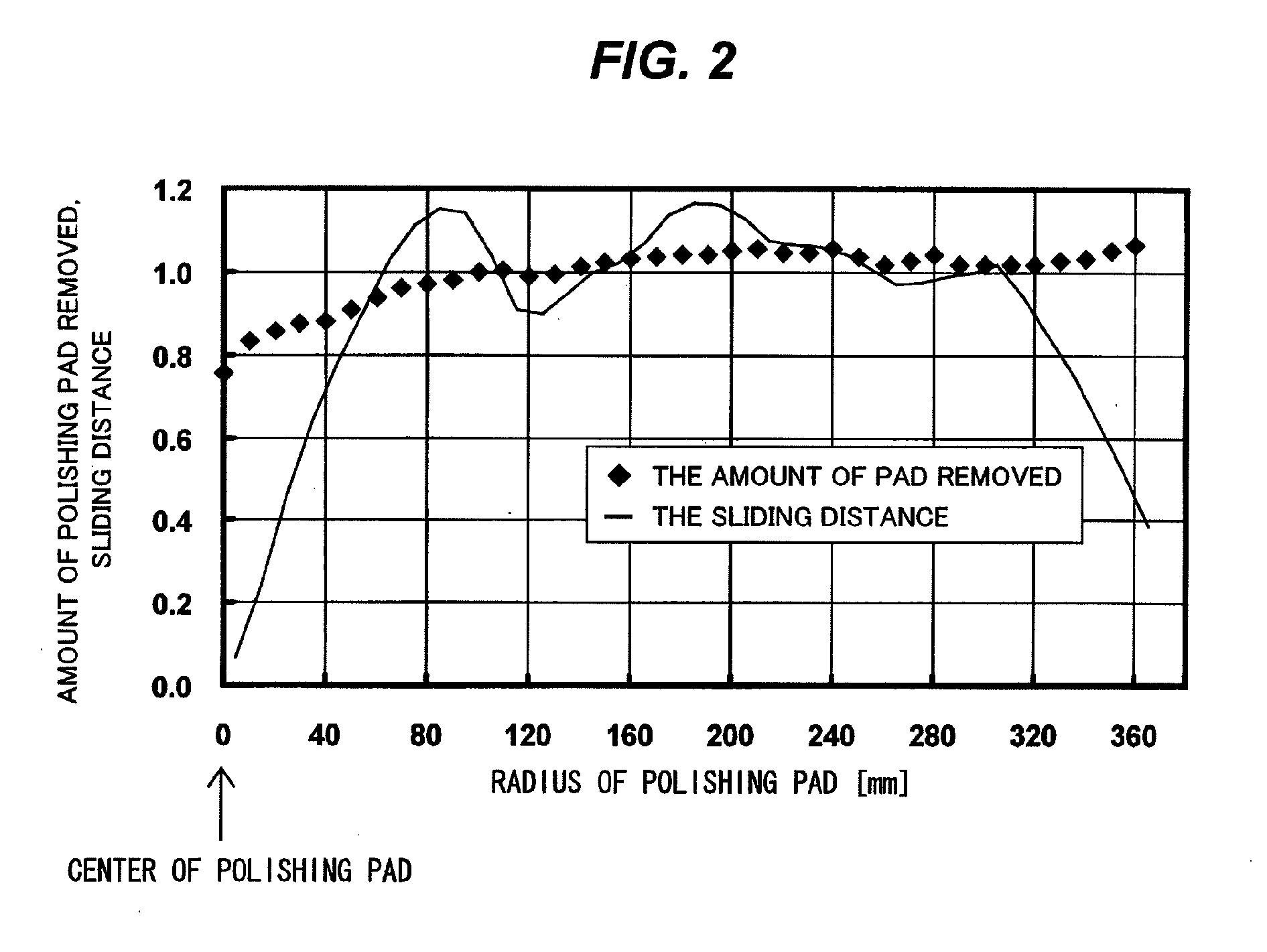

Dressing method, method of determining dressing conditions, program for determining dressing conditions, and polishing apparatus

ActiveUS20100081361A1Simulation is accurateSimulation results are accurateGrinding drivesBelt grinding machinesMaterials scienceA diamond

A method of dressing a polishing member with a diamond dresser having diamond particles arranged on a surface thereof is provided. The method includes determining dressing conditions by performing a simulation of a distribution of a sliding distance of the diamond dresser on a surface of the polishing member, and dressing the polishing member with the diamond dresser under the dressing conditions determined. The simulation includes calculation of the sliding distance corrected in accordance with a depth of the diamond particles thrusting into the polishing member.

Owner:EBARA CORP

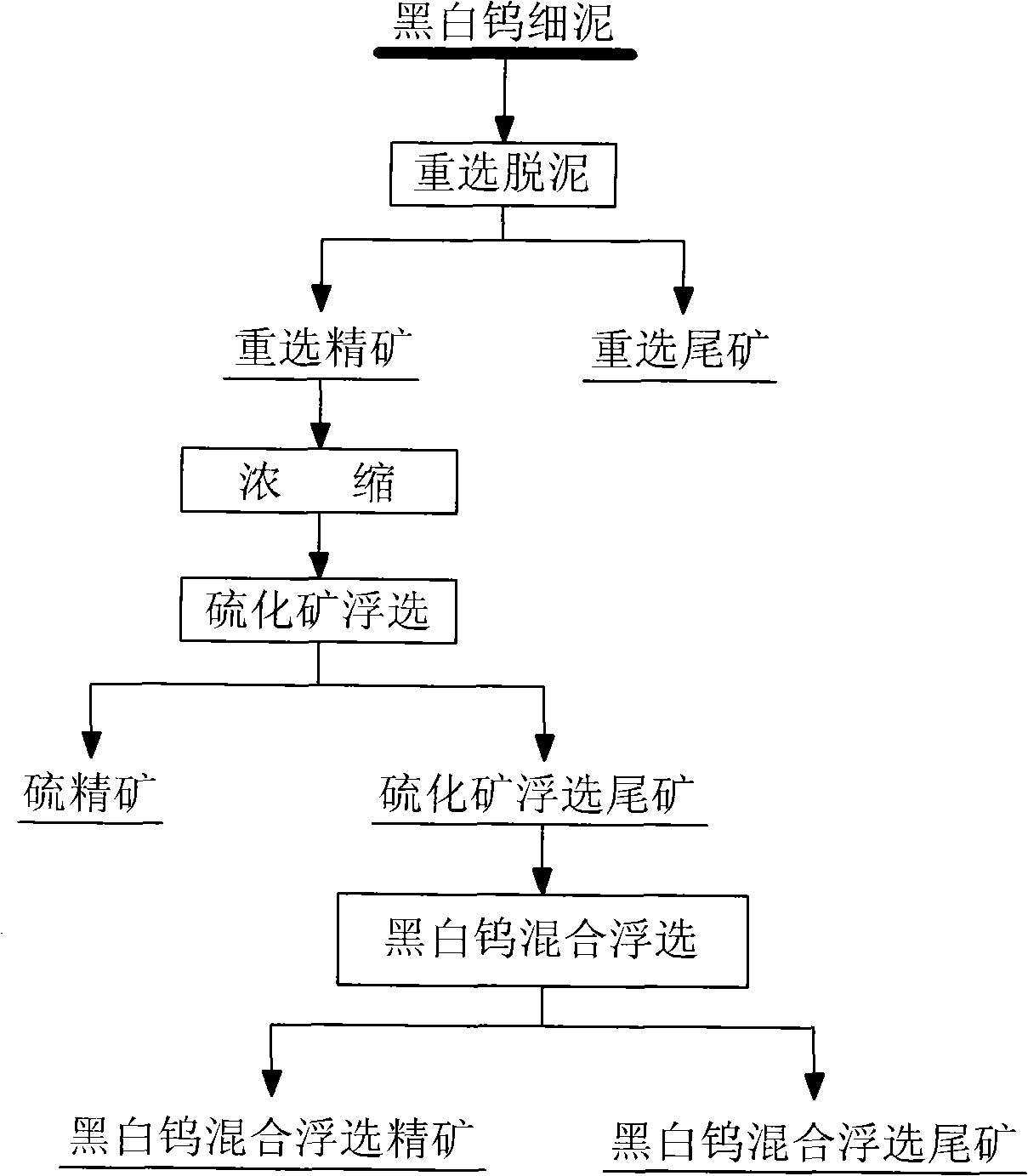

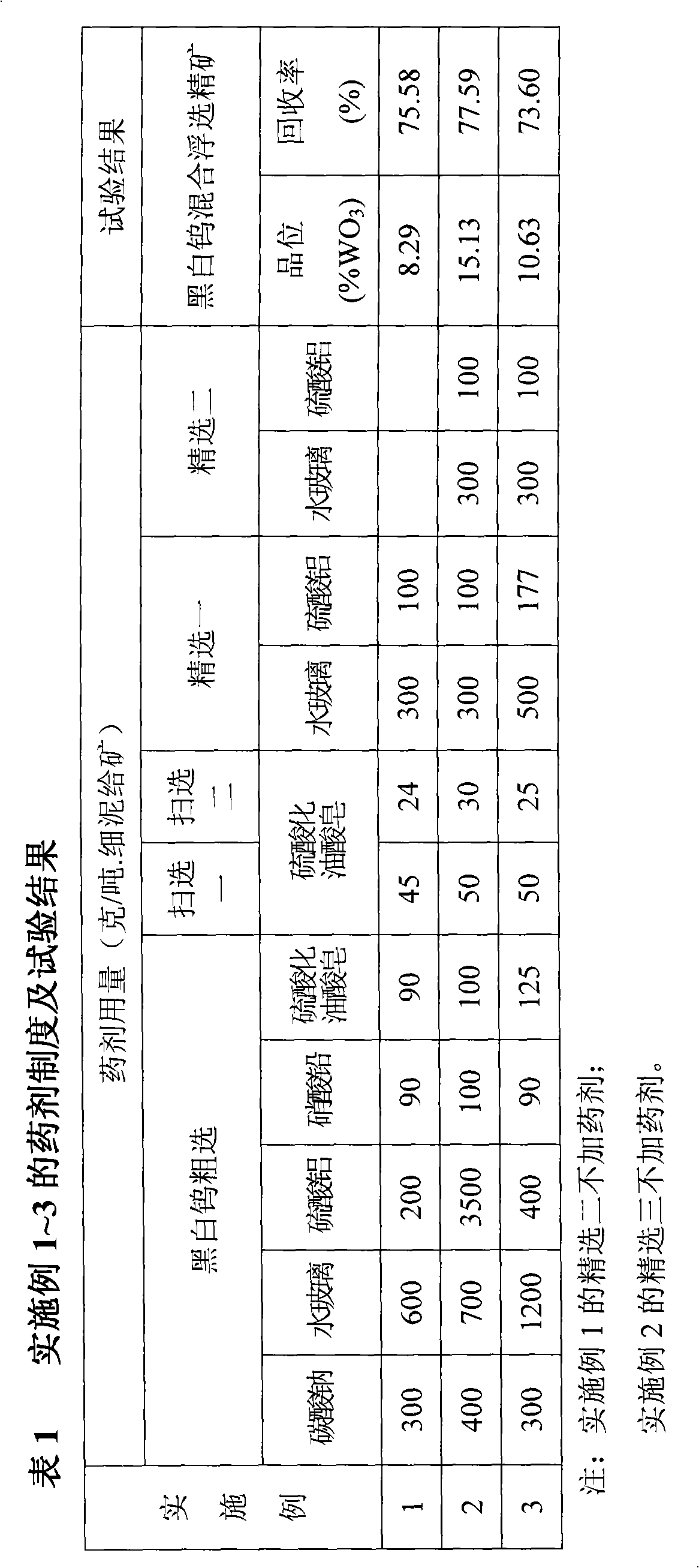

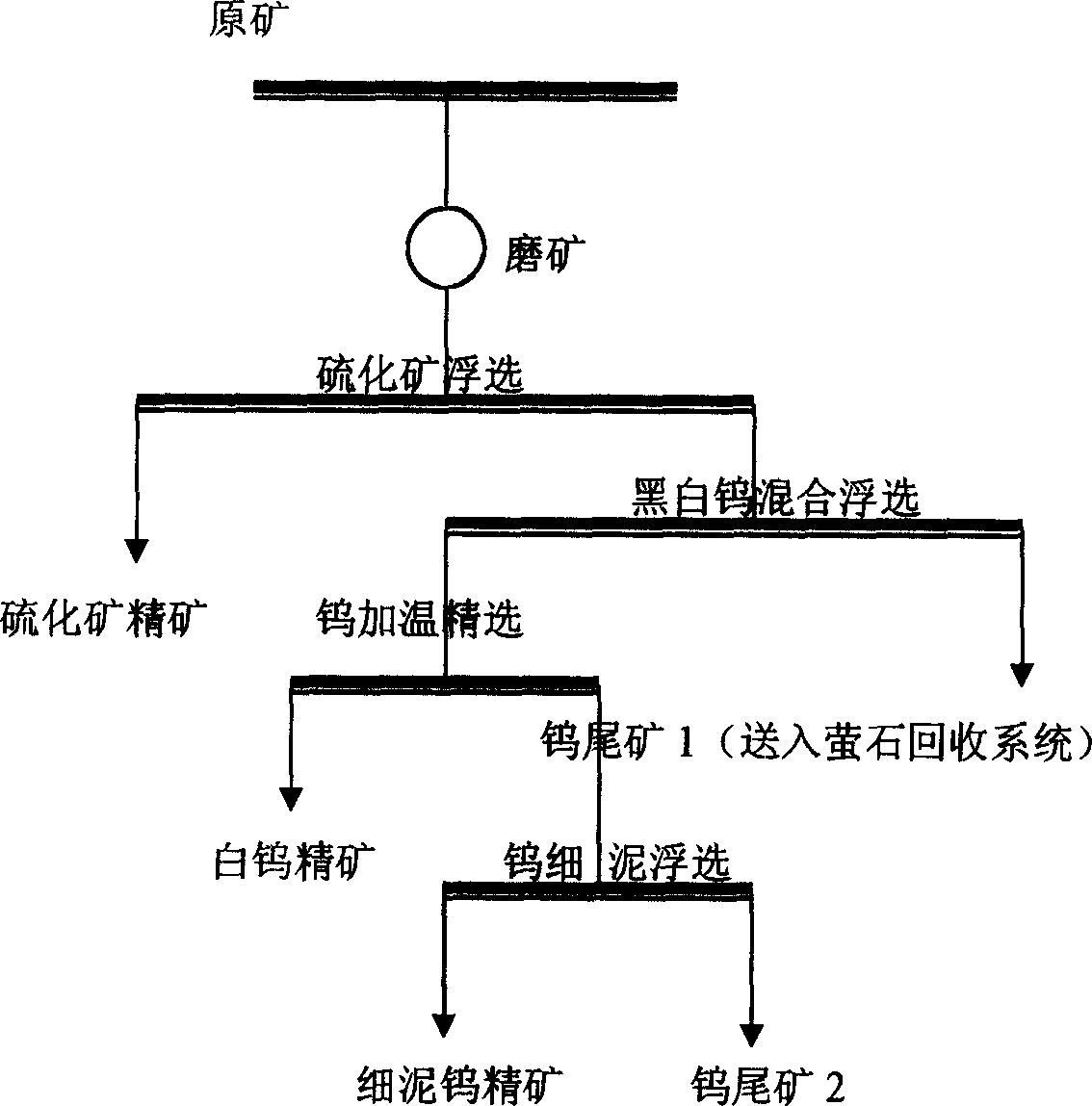

Beneficiation method for black and white tungsten fine deposit

The invention relates to an ore dressing method for black-and-white tungsten fine deposit. The method is characterized in that: (1) gravity concentrate and gravity tailings are obtained by gravity desliming; (2) sulphide concentrate and sulphide ore flotation tailing are obtained by sulphide flotation; (3) the mixed flotation of black-and-white tungsten is performed, the sulphide ore flotation tailing is added with a regulator such as sodium carbonate, sodium silicate, aluminum sulfate, and lead nitrate, and is also added with a collector such as sulfating nascent soap; black-and-white tungsten mixed flotation concentrate and black-and-white mixed flotation tailing are obtained after one-time rough flotation, two or three times of fine flotation and two or three times of scavenging. The method provided by the invention is characterized in that the recovery process of the black-and-white tungsten fine deposit is simple, the flotation process of mixed black-and-white tungsten is stable, the recovery rate of tungsten is high and the cost of the dose is low. The method is suitable for the black-and-white tungsten fine deposit of which the content WO3 ranges from 0.10 to 0.50 percent, the WO3 is less than 30 micrometers and metals account for no less than 60 percent.

Owner:广东省资源综合利用研究所

Mineral dressing method for black and white tungsten minerals

A technology for dressing the mixture of wolframite and scheelite incldues magnetic separation to remove iron, floatation for removing sulfide ore, adding water glass, aluminium sulfate and lead nitrate for regulating sludge, adding benzhdroxyoximic acid, sulfated oleic soap and kerosene, and combined floatation.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

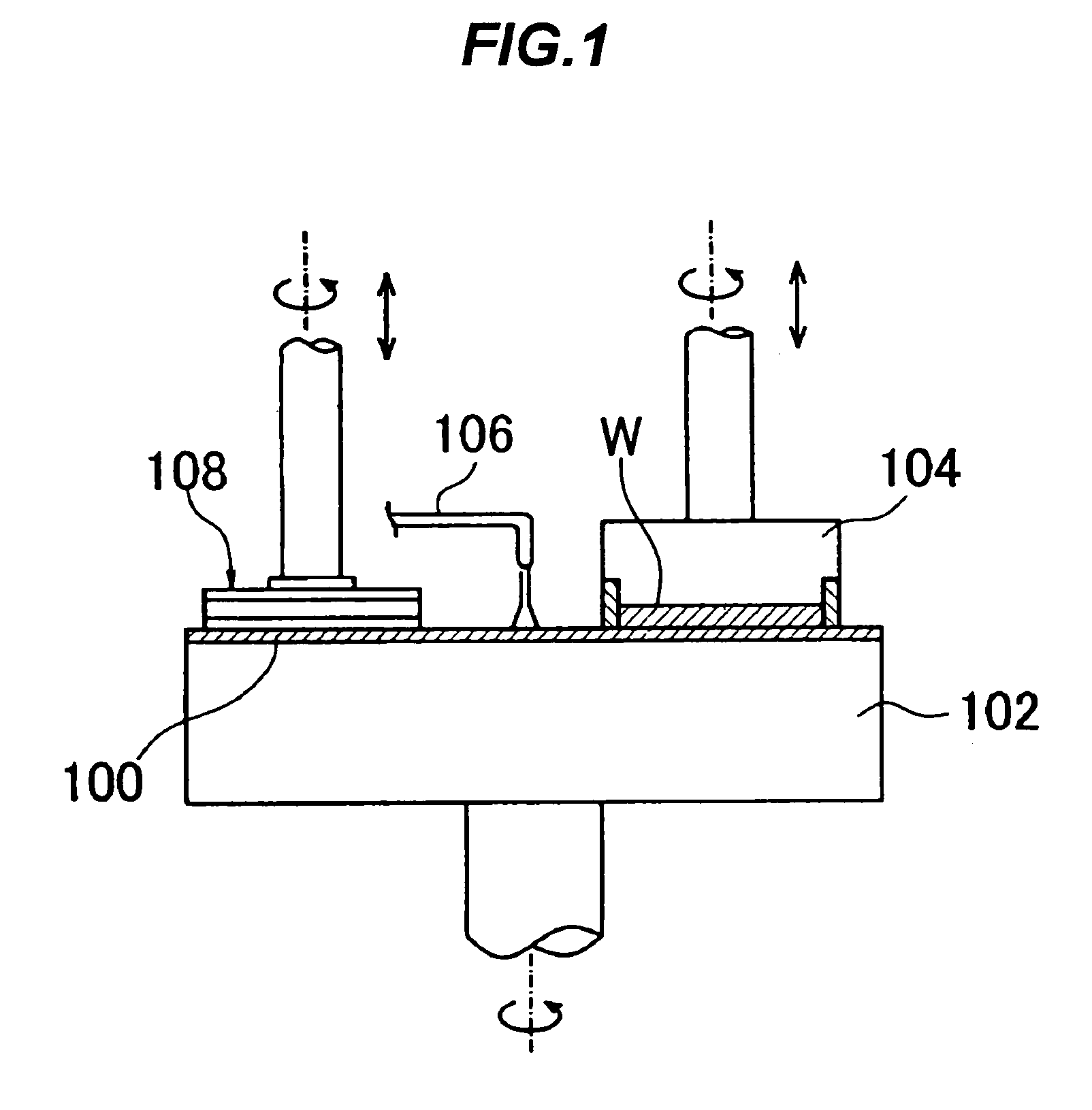

Dressing apparatus, dressing method, and polishing apparatus

ActiveUS20100311309A1Stably producing low pressing force of dresser diskImprove operating rateRevolution surface grinding machinesGrinding drivesDrive shaftEngineering

A dressing apparatus for use in a polishing apparatus for polishing a substrate to planarize a surface of the substrate is disclosed. The dressing apparatus includes a dresser disk, a dresser drive shaft coupled to the dresser disk, a pneumatic cylinder configured to press the dresser disk against the polishing pad through the dresser drive shaft, a pressure-measuring device configured to measure pressure of the gas supplied to the pneumatic cylinder, a load-measuring device configured to measure a load acting on the dresser drive shaft, and a pressure controller configured to control the pressure of the gas supplied to the pneumatic cylinder. The pressure controller is configured to establish a relationship between the pressure of the gas and a pressing force of the dresser disk against the polishing pad, based on measurement values of the pressure-measuring device and the load-measuring device.

Owner:EBARA CORP

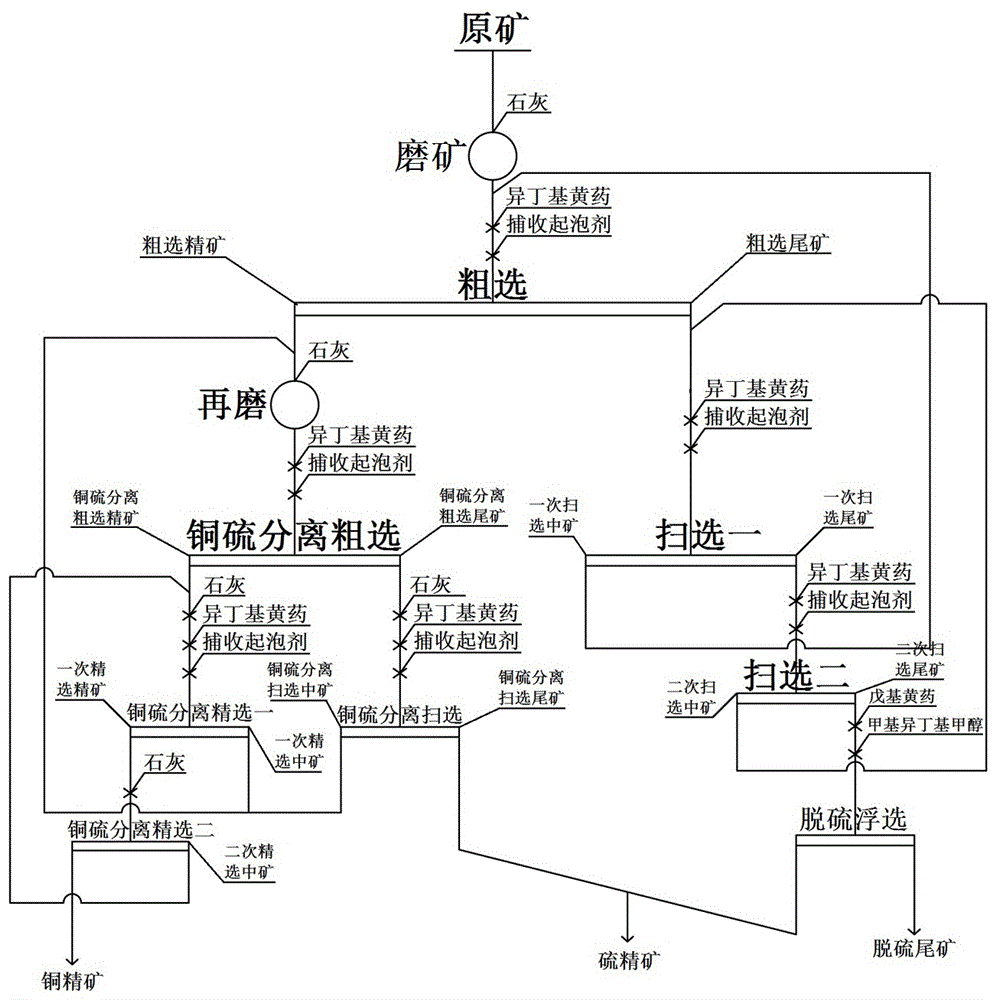

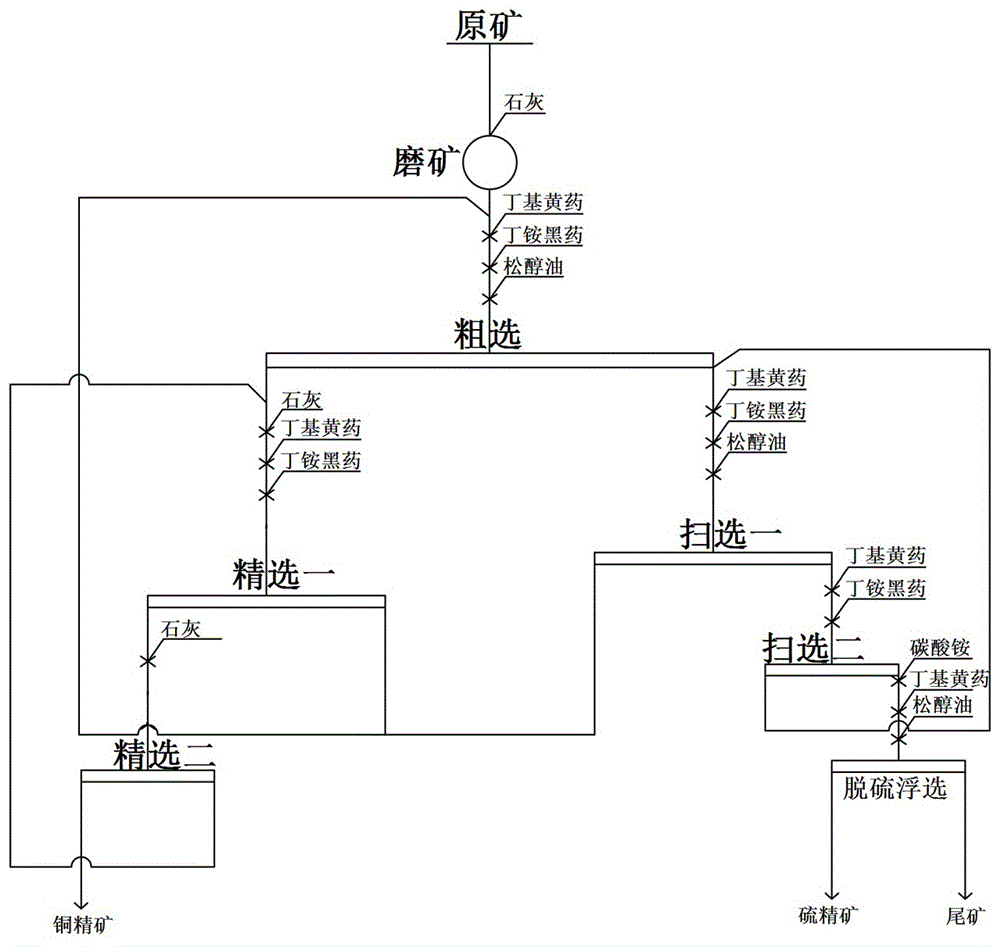

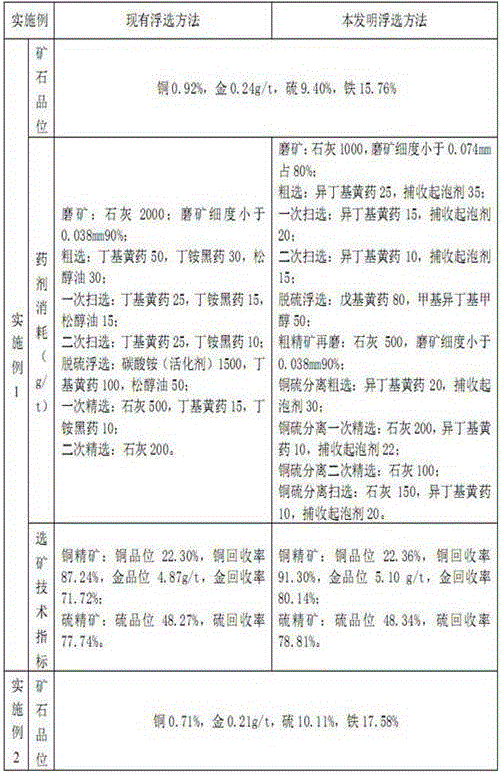

Floating method for finely disseminated copper sulfide ores

The invention discloses a floating method for finely disseminated copper sulfide ores. The floating method specifically comprises steps such as ore grinding, roughing, roughed concentrate re-grinding, roughed concentrate copper-sulfur separating and floating and roughened tailing scavenging, wherein multi-time concentrating and multi-time scavenging are performed on roughened concentrate and roughened tailings, cyclic ore dressing is performed on ores, and different ore dressing reagents are matched, so that the recovery rate of raw ores is increased. The floating method has the advantages that: by optimizing an ore grinding process and reasonably adding a collecting agent and a collecting-foaming agent, surface characteristics of ores are improved, selective adsorption, on copper sulfide ore particle surfaces such as fine-grained copper pyrite and chalcocite, of the collecting agent is strengthened, and hydrophobic agglomeration is formed, so that the recovery rate of copper concentrate is increased by 3-6% in comparison with that of an existing ore dressing method.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

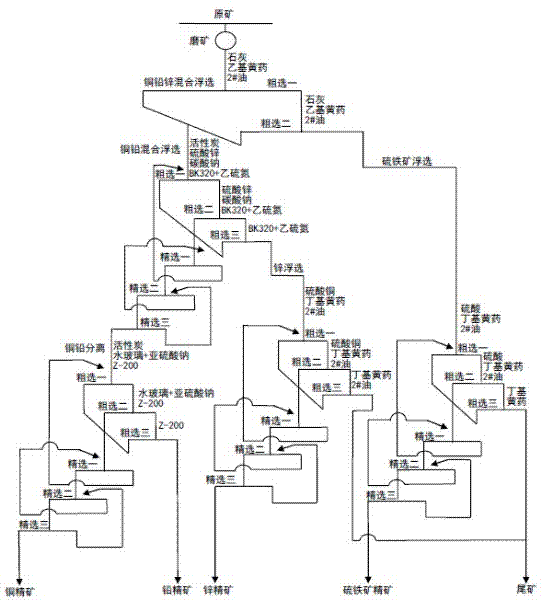

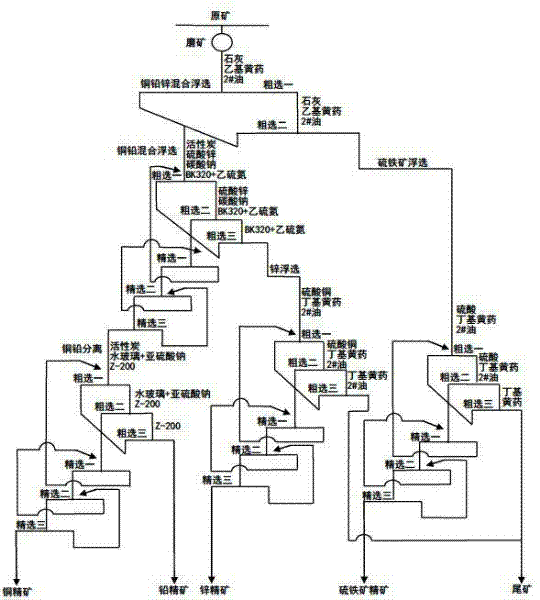

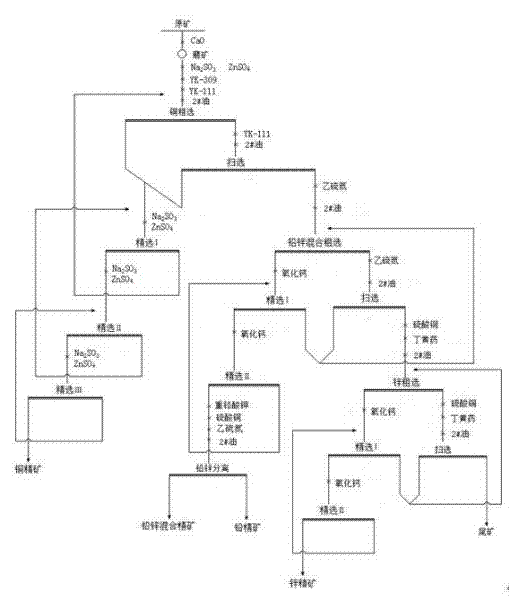

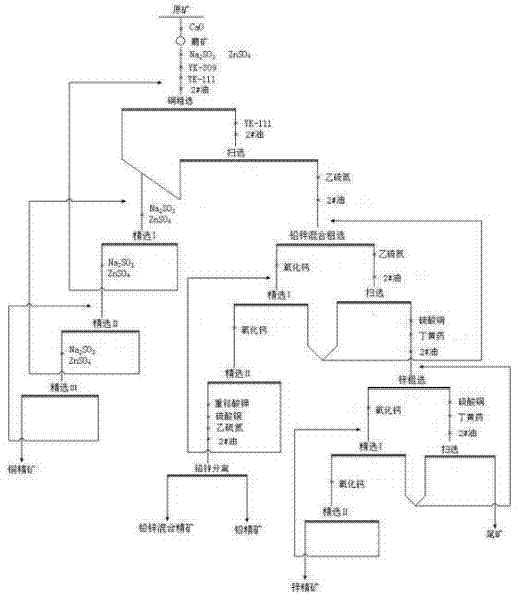

Mineral dressing method for separating Cu-Pb-Zn-Fe multi-metal sulfide mineral

The invention discloses a mineral dressing method for separating a Cu-Pb-Zn-Fe multi-metal sulfide mineral, which comprises the following steps: selecting a raw mineral, grinding the mineral, carrying out mixed flotation to Cu, Pb and Zn, carrying out mixed flotation to Cu and Pb, separating Cu and Pb, carrying out Zn flotation and pyrite flotation, and finally obtaining a Cu, Pb, Zn and pyrite concentrate. The method has the advantages of good metal sulfide mineral effect and high metal recovery rate, is simple to operate and is suitable to popularize and apply.

Owner:KUNMING UNIV OF SCI & TECH

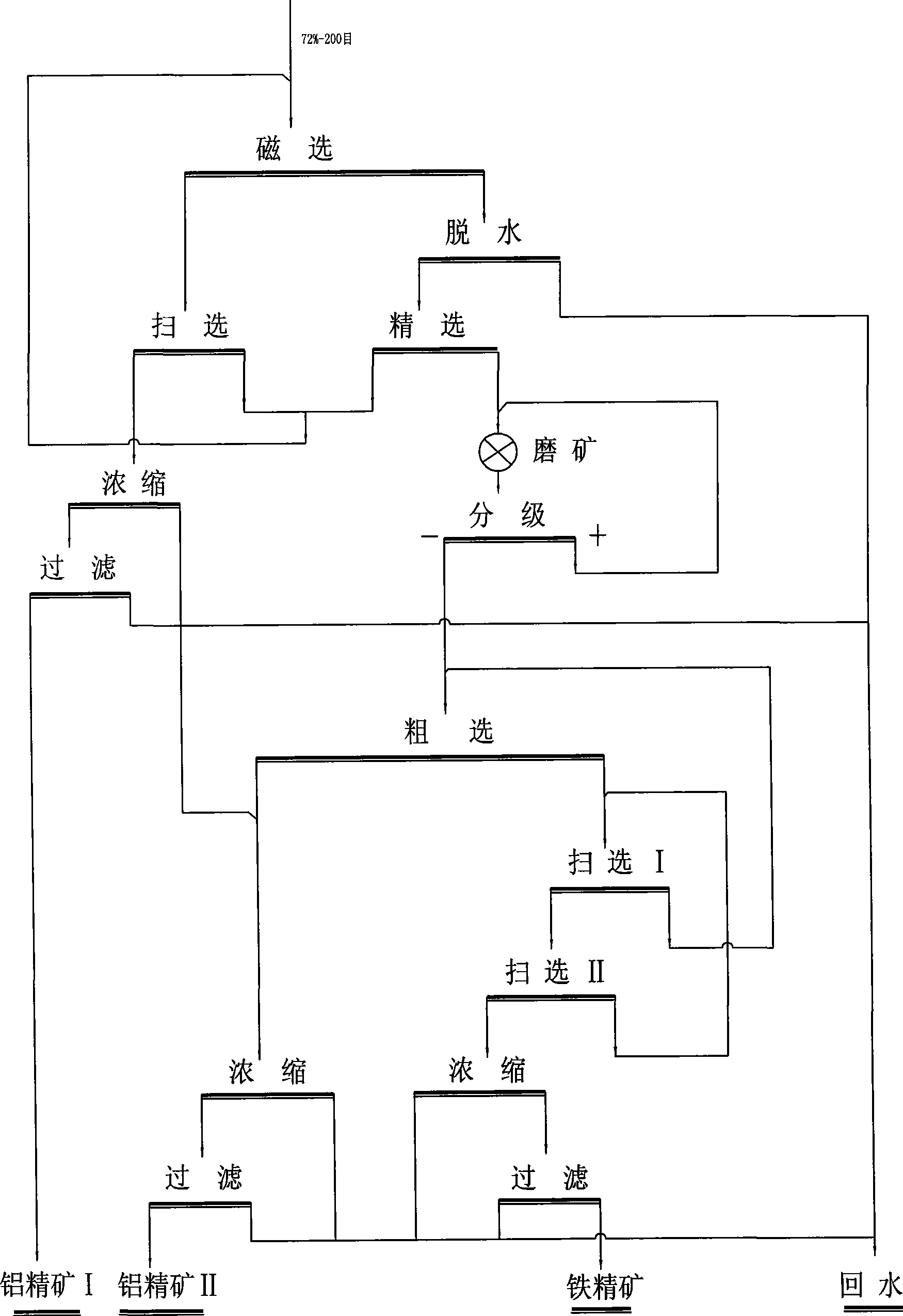

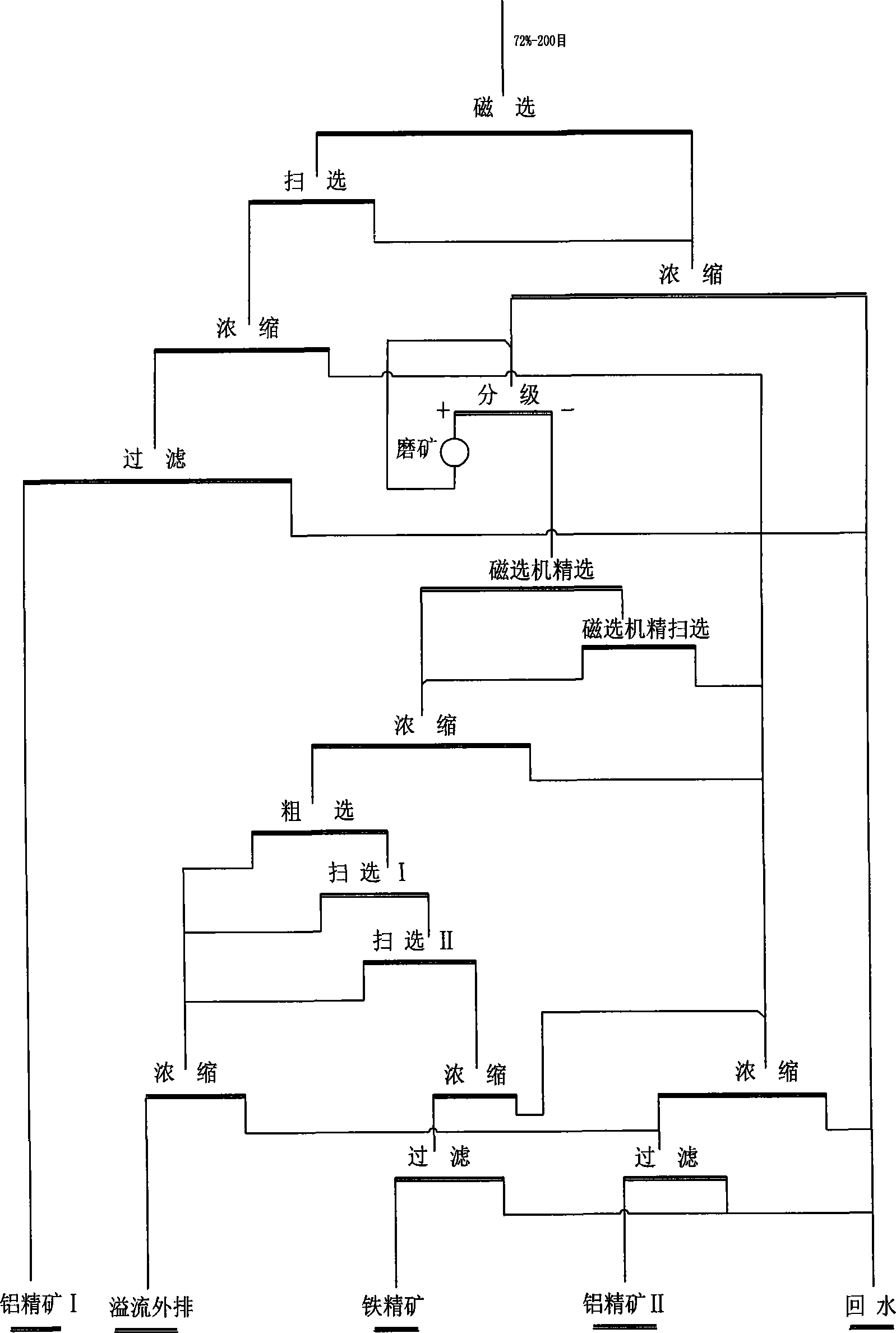

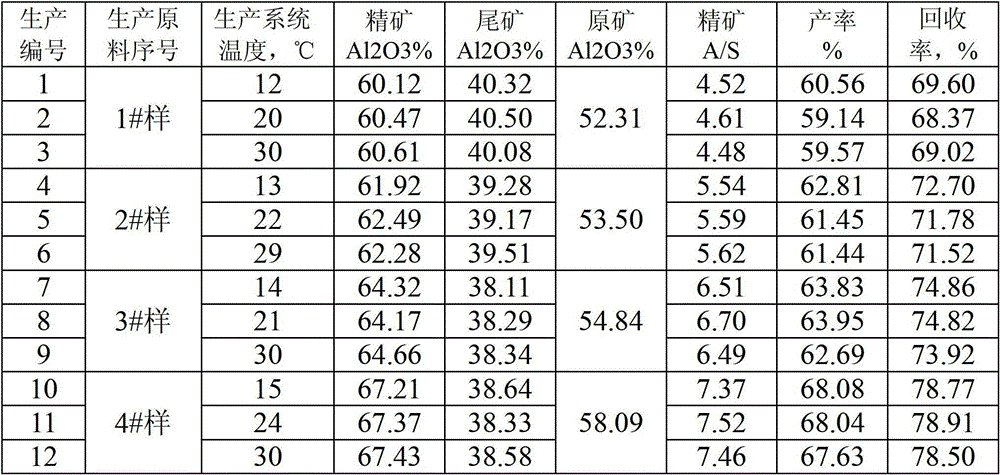

High iron bauxite dressing method

ActiveCN101417260AQuality improvementLower iron contentHigh gradient magnetic separatorsFlotationProduction rateReverse flotation

The invention provides a beneficiation method for high iron bauxite. The invention adopts strengthening magnetic separating-anionic reverse flotation flow, stage grinding and stage magnetic separating. Under the condition of ensuring the magnetic separating iron concentrate recovery rate, strengthening magnetic separating has the priority to obtain higher quality aluminum concentrate one and high grade iron rough concentrate, thus improving the selection grade of the reverse flotation and opening circuit fully in the reverse flotation process, a reverse flotation rougher flotation device adopts a flotation column with large charge and fine even bubbles, thus obtaining iron concentrate with higher quality. In addition, the beneficiation method optimizes and reduces the production rate of material entering reverse flotation operation, and achieving the purposes of energy saving and consumption reducing.

Owner:中铝国际南方工程有限公司

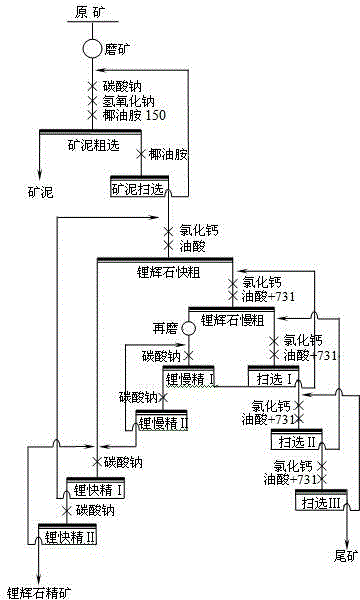

Ore dressing method of spodumene quarry

ActiveCN102909136AImprove sorting effectExtended flotation timeFlotationControllabilityMaterials science

The invention discloses an ore dressing method of a spodumene quarry, which comprises the following steps: raw ore grinding, slime floating, spodumene fast roughing, spodumene fast selecting, spodumene slow roughing, spodumene slow selecting and other steps, and a spodumene concentrate is finally obtained. The spodumene quarry separated by adopting the ore dressing method has good separation index, and the grade and the recovery rate of the spodumene concentrate are high. The ore dressing method is a new spodumene flotation process with the advantages of economy, applicability, simplicity, cleanness, strong controllability and good separation effect and is suitable for popularization and application.

Owner:JIANGXI UNIV OF SCI & TECH

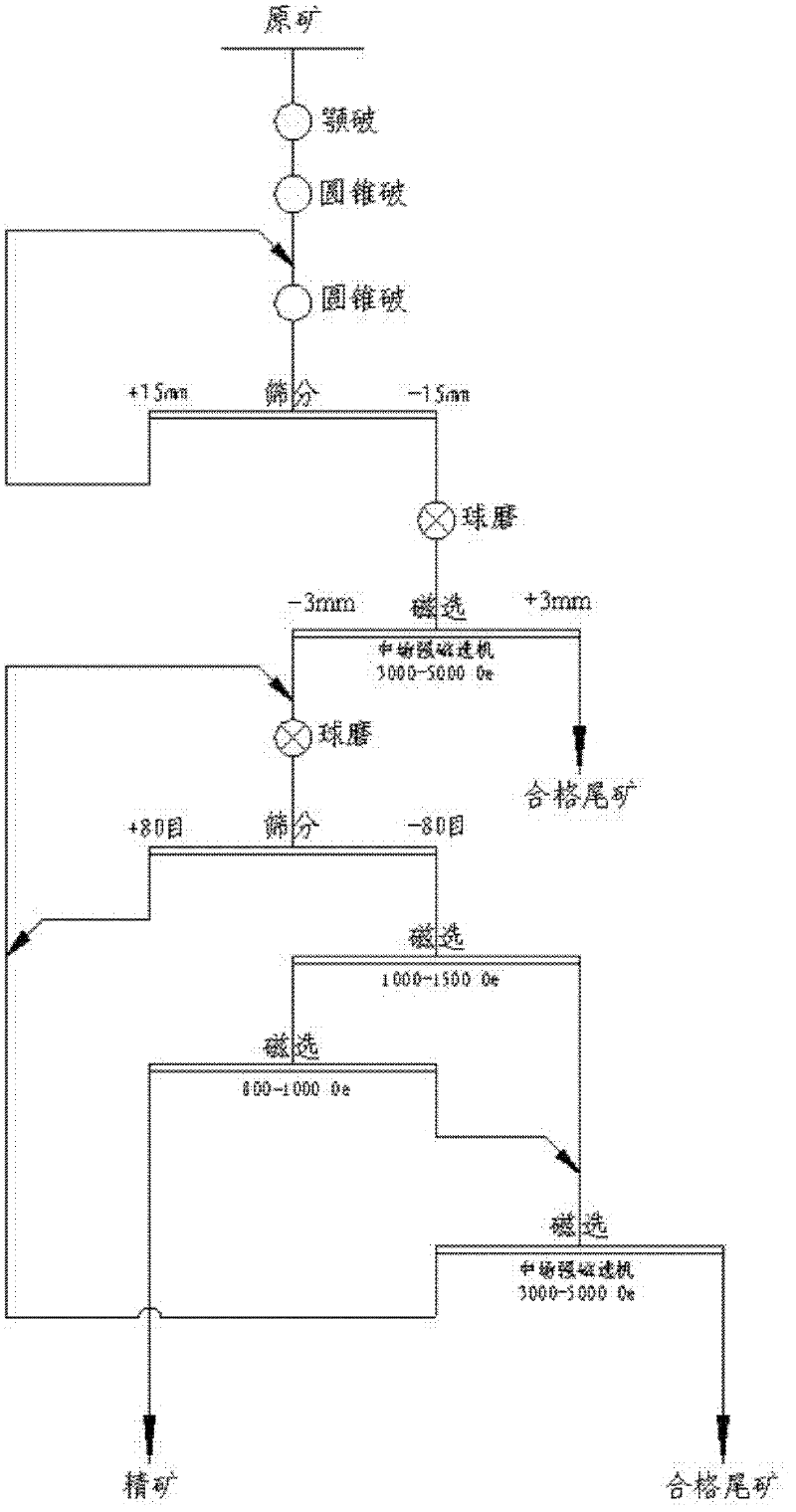

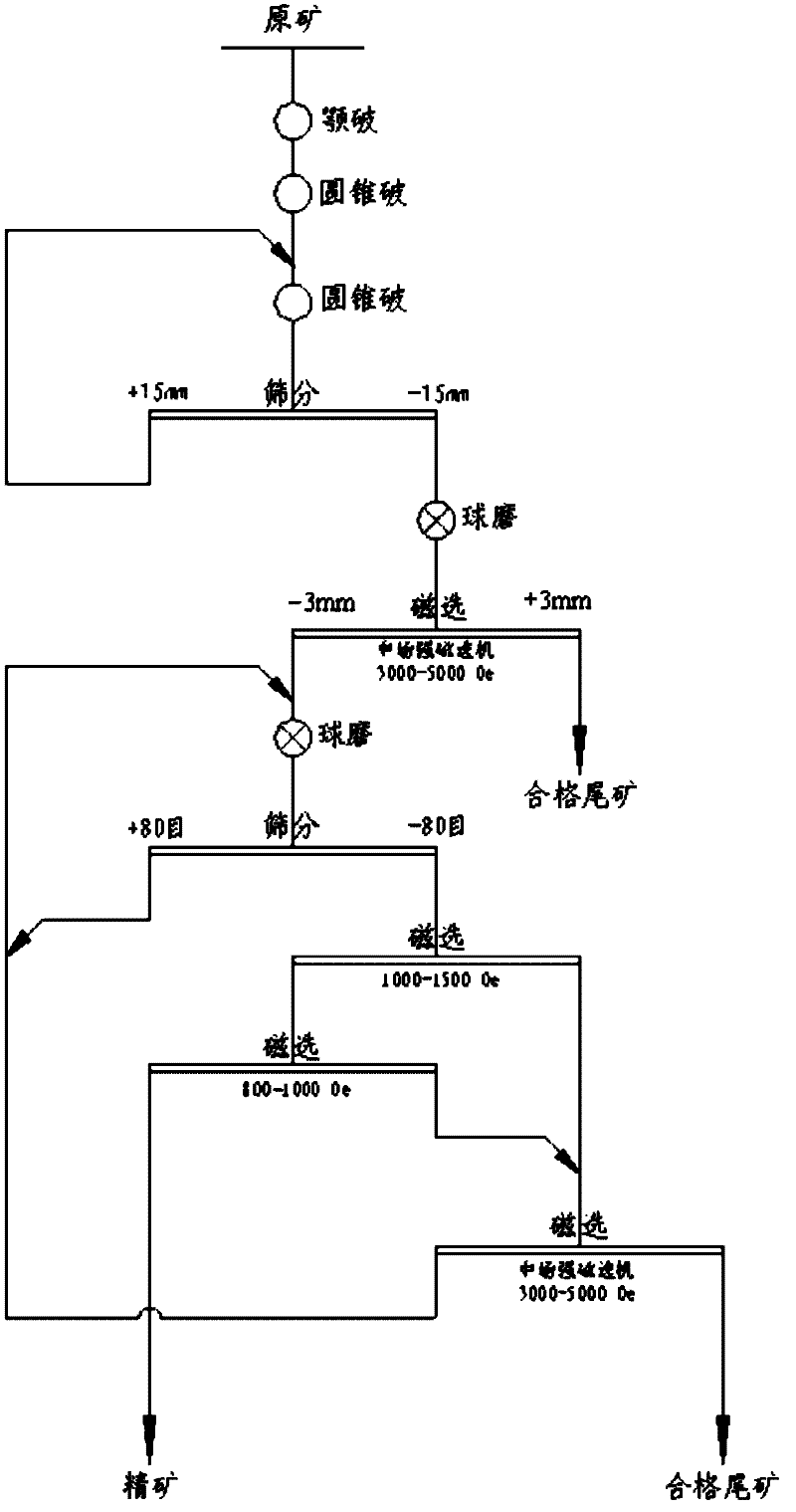

Ore dressing method of vanadium titanium magnetite

The invention discloses an ore dressing method of a vanadium titanium magnetite and belongs to the field of magnetic separation of vanadium titanium magnetite. The invention provides an ore dressing method of a vanadium titanium magnetite. The method has low costs and simple operations, and comprises the following processing steps of: a. crushing and screening vanadium titanium magnetic iron ore,carrying out fine grinding to have a granularity no more than 3mm, then carrying out magnetic separation under a field intensity of 3000-5000 Oe to obtain a rough concentrate and a mine tailing; b. grinding the rough concentrate to 80 mesh and carrying out magnetic separation by a magnet separator with a field intensity of 1000-1500 Oe; c. then carrying out magnetic separation by a magnet separator with a field intensity of 800-1000 Oe to obtain a qualified iron ore concentrate and a mine tailing. According to the invention, after coarse grain tailings discarding, low-grade raw ore vanadium titanium magnetite, which needs no repeated grinding, can reach concentrate grade with TFe equal to 59% and recovery rate reaching about 80%. In the technology, repeated grinding and grading are not needed after coarse grain tailings discarding, therefore magnetic separation costs are lowered substantially.

Owner:PANZHIHUA LIYU MINING

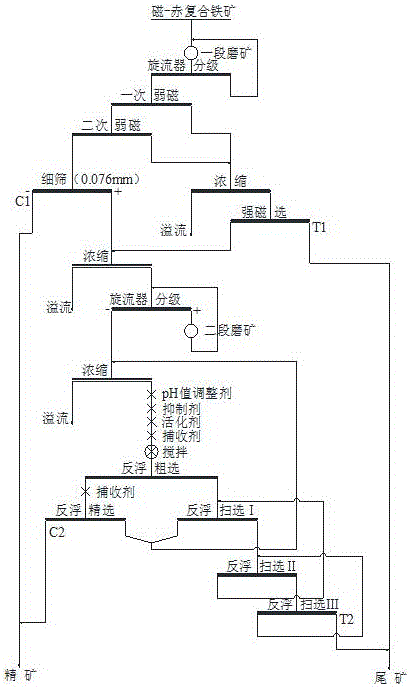

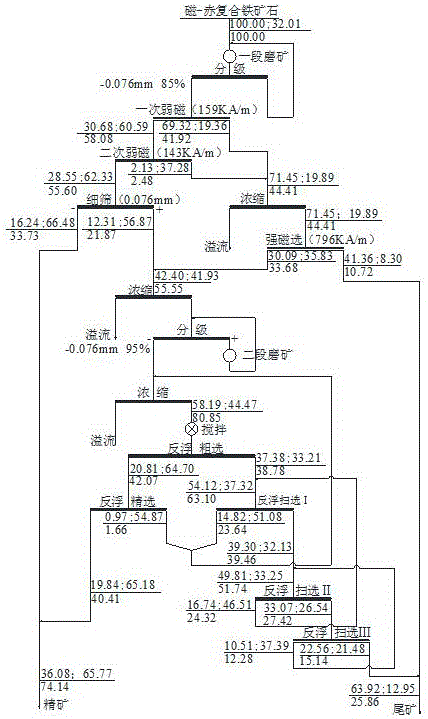

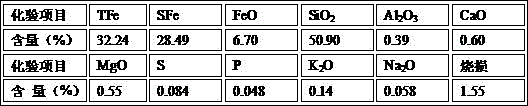

Compound maghemite ore dressing method

ActiveCN106076606AAdvantages of beneficiation methodIndicators are stableWet separationMaghemiteHigh intensity

The invention discloses a compound maghemite ore dressing method. The compound maghemite ore dressing method comprises the following steps: feeding compound maghemite ore into an ore grinding-grading-low-intensity magnetic separation operation segment to obtain low intensity magnetic separation concentrate and low-intensity magnetic separation tailings; feeding the low-intensity magnetic separation concentrate into a fine sieving operation segment to obtain finely-sieved concentrate C1; feeding the low-intensity magnetic separation tailings into a high-intensity magnetic separation operation segment, and throwing out high-intensity magnetic separation tailings T1 to obtain high-intensity magnetic separation concentrate; combining coarse fraction low-intensity magnetic separation concentrate with the high-intensity magnetic separation concentrate, and feeding the mixture into a pre-grading-two-stage ore grinding-reverse flotation operation segment to obtain reverse flotation concentrate C2, and throwing out reverse flotation concentrate T2. In the method, staged ore grinding and high-intensity tailing throwing are adopted, so that discarding as soon as possible is realized; the low-intensity magnetic separation concentrate is obtained by fine sieving, so that collection as soon as possible is realized; oversize finely-sieved and high-intensity coarse concentrate is ground, so that the amount of ore ground at a second segment is lowered greatly, and energy-saving and consumption lowering are facilitated; an oversize finely-sieved product is reground and floated, so that the flotation grade is raised, and the adaptability of negative ion reverse floatation to ore characteristic fluctuation is improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

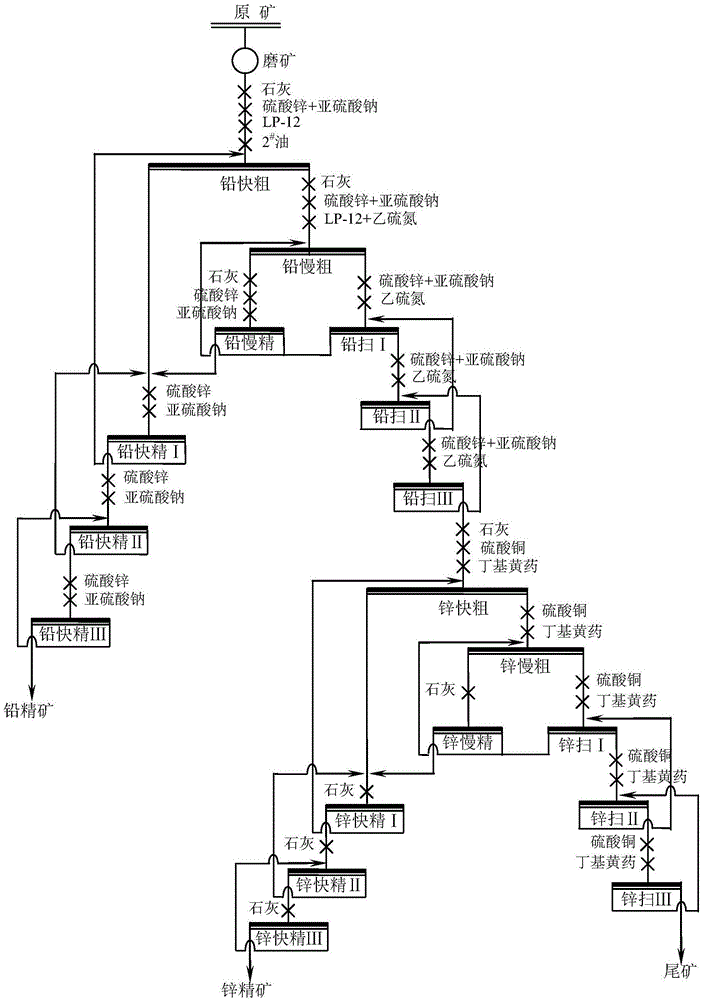

Ore dressing method for lead-zinc-silver poly-metallic ores

The invention provides an ore dressing method for lead-zinc-silver poly-metallic ores. Lead-silver concentrates and zinc concentrates are finally obtained through the steps of raw ore grinding, lead fast roughing, lead slow roughing, lead scavenging, lead fast concentration, lead slow concentration, zinc fast roughing, zinc slow roughing, zinc scavenging, zinc fast concentration and zinc slow concentration. The lead-zinc-silver poly-metallic ores sorted by the ore dressing method provided by the invention are good in sorting index and high in separation efficiency; the ore dressing method is a lead-zinc-silver ore dressing method which is stable, efficient, strong in adaptive capacity, good in sorting effect, high in comprehensive recovery index and low in production cost and is suitable for popularization and application.

Owner:DONGSHENGMIAO MINING LLC +2

Ore-dressing method for separating copper, lead and zinc multi-metal complex ore embedded with fine grains

InactiveCN102225369AImprove sorting indexNo pollution in the processFlotationCopperEnergy consumption

The invention discloses an ore-dressing method for separating a copper, lead and zinc multi-metal complex ore embedded with fine grains. The method comprises the following steps: firstly, preferentially separating copper by utilizing a selective collecting agent; separating a lead-zinc mixed ore with excellent flotability according to the flotability of lead and zinc minerals, and then separating lead concentrate from lead-zinc mixed concentrate by restraining lead mineral; and lastly activating the separated zinc concentrate with inferior flotability. The ore-dressing method can be used for acquiring following four products: copper concentrate, lead concentrate, zinc concentrate and lead-zinc mixed concentrate. The ore-dressing method has the advantages that selecting index is high, copper is excellently separated from zinc and lead, energy consumption is saved, no environmental pollution exists, and the like. The ore-dressing method is especially fit for separating the minerals of the copper, lead and zinc complex ore which is embedded with more than two minerals, has superfine particle size, is wrapped by minerals and is difficult to be separated.

Owner:河南省岩石矿物测试中心

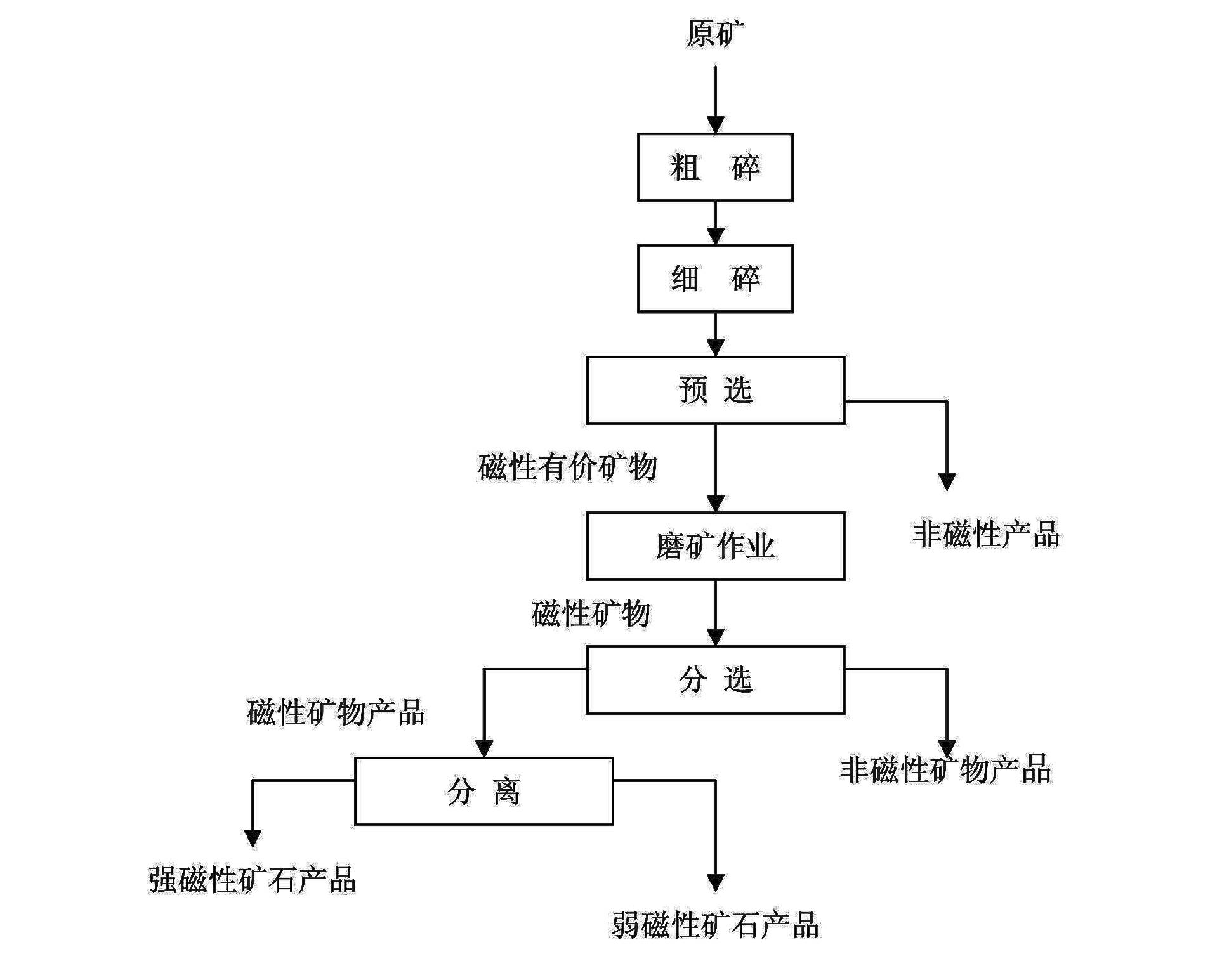

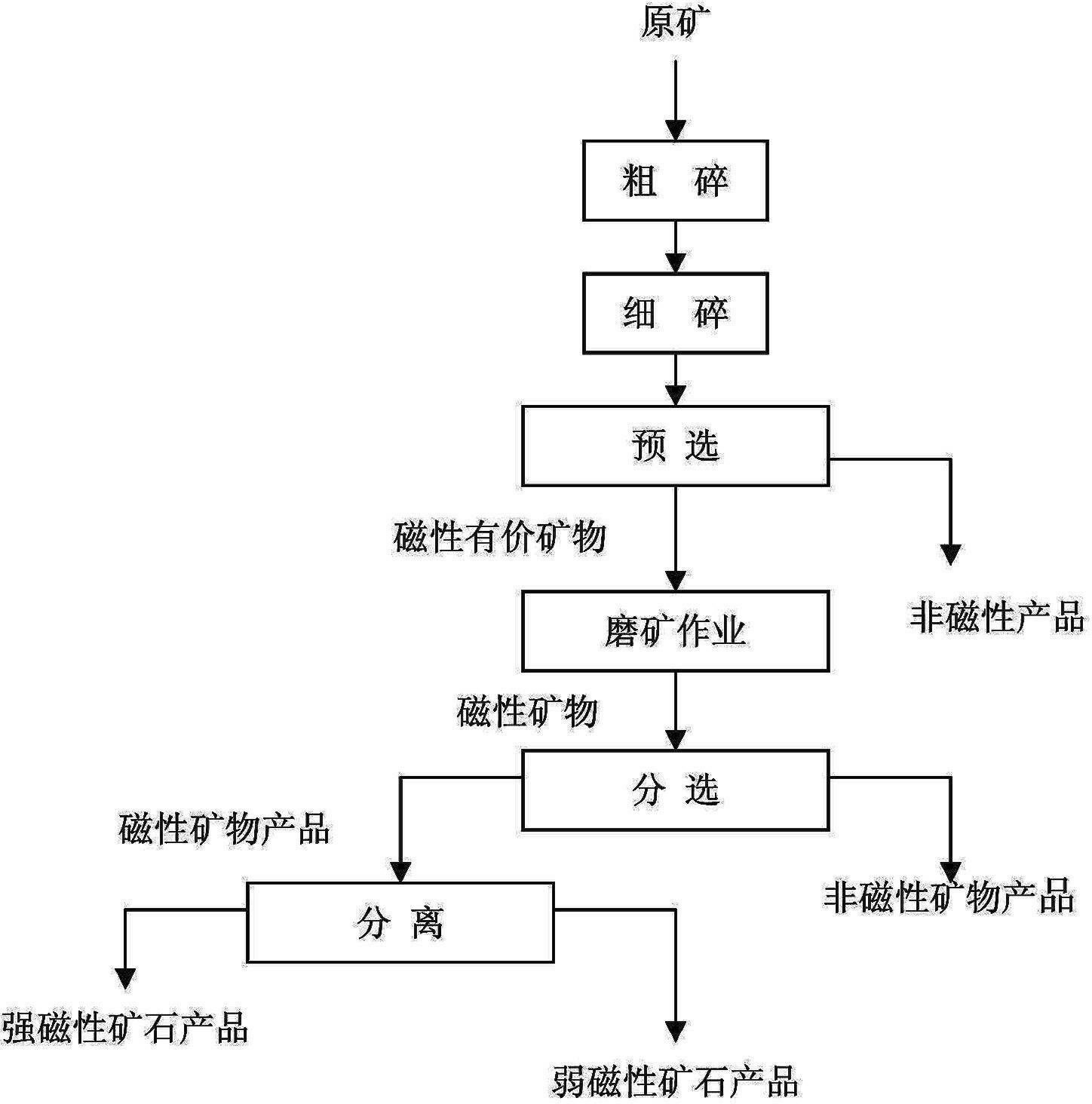

Magnetic ore dressing method

ActiveCN102527504AReduce difficultyReduce grinding amountMagnetic separationMagnetic separatorMaterials science

The invention provides a magnetic ore dressing method. The magnetic ore dressing method comprises the steps of raw core coarse crushing, fine crushing, ZCLA presorting, ore grinding, ZCLA sorting, and strong magnetic flow and weak magnetic flow implementing of ore concentrate subjected to ZCLA sorting. Compared with the general magnetic core dressing process, the magnetic ore dressing method has the advantages that by a section of sorting operation, valuable ores with different magnetic differences and wider particle size range in the magnetic ores can be gathered and sorted, and before the low-magnetic ores are sorted by a strong magnetic separator, the iron does not need to be removed in advance, the sorted particle range is wide, the whole sorting process is simple and the sorting effect is good.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

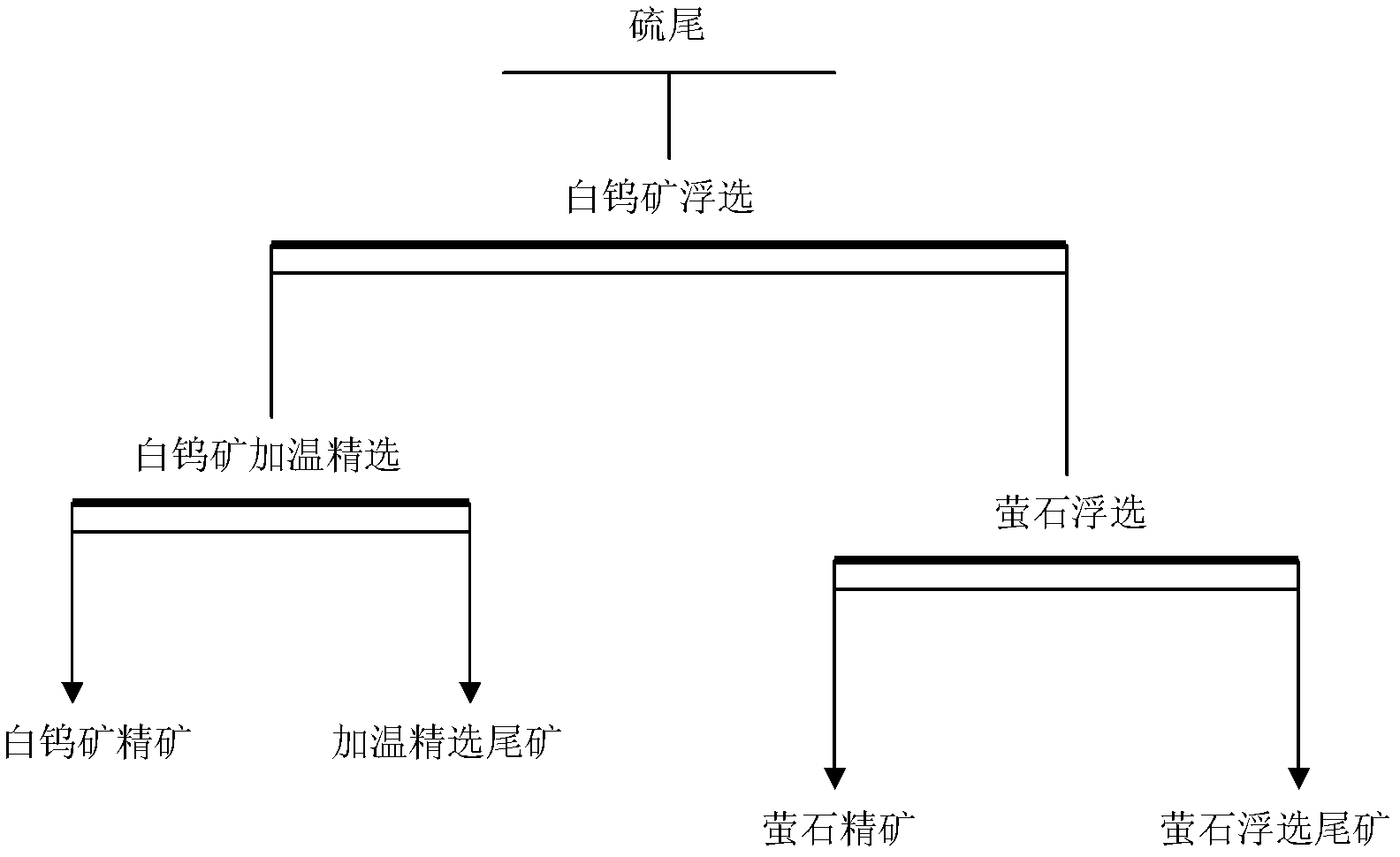

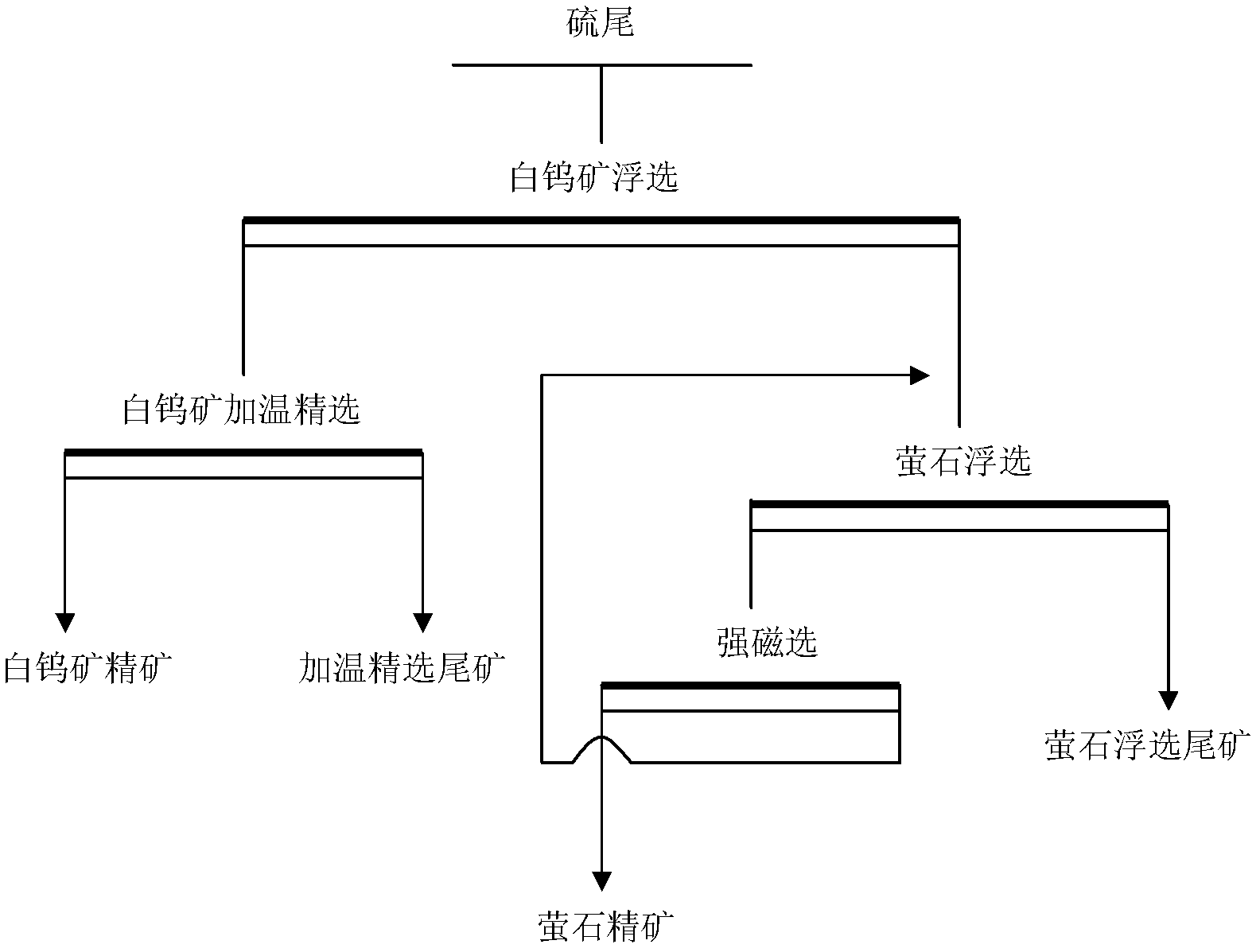

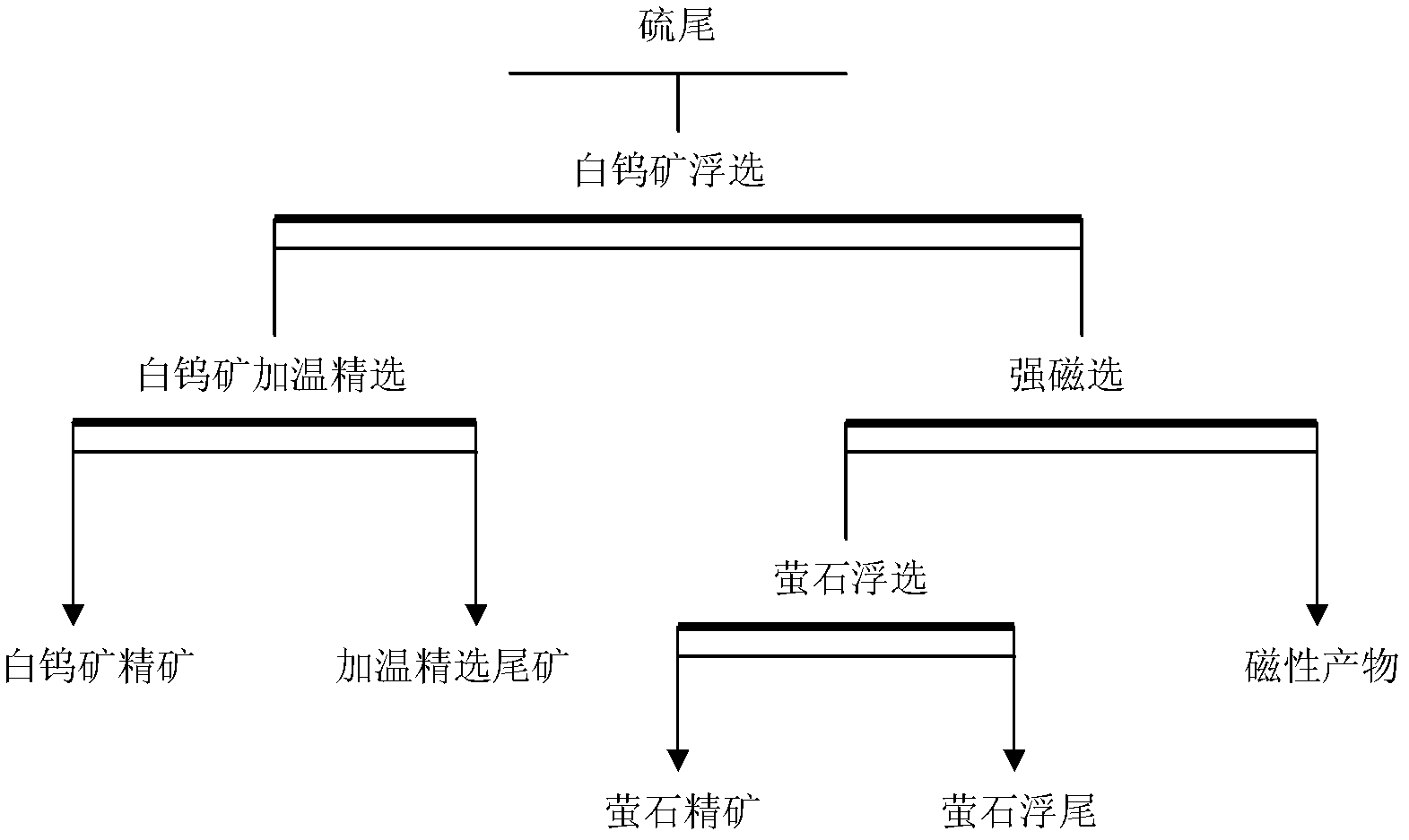

Ore dressing method for separation and recovery of scheelite and fluorite from sulfur flotation tailings of polymetallic ore

InactiveCN102489393AReduce acid consumptionReduce drug consumptionGlass recyclingSolid separationSulfurMaceral

The invention discloses an ore dressing method for separation and recovery of scheelite and fluorite from sulfur flotation tailings of polymetallic ore. The ore dressing method can eliminate the shortcomings caused by a preferential flotation process in the prior art by simultaneously performing bulk flotation on the scheelite and the fluorite and further separating the scheelite from the fluorite, further significantly improve the recovery rate of the scheelite and the fluorite and realize high-efficient recovery of two minerals, namely the scheelite and the fluorite in the polymetallic ore.Furthermore, the scheelite and the fluorite are dressed through a rough concentration bulk flotation and fine concentration separation two-stage process, so that indexes in various stages of operations are convenient to stipulate and control, and quantification of the indexes of the ore dressing process of the scheelite and the fluorite and operation management can be effectively realized.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

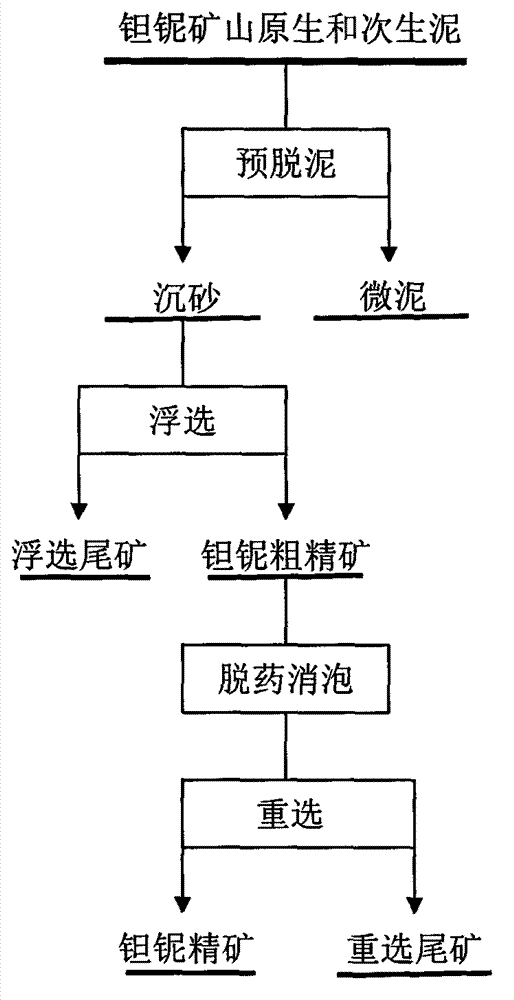

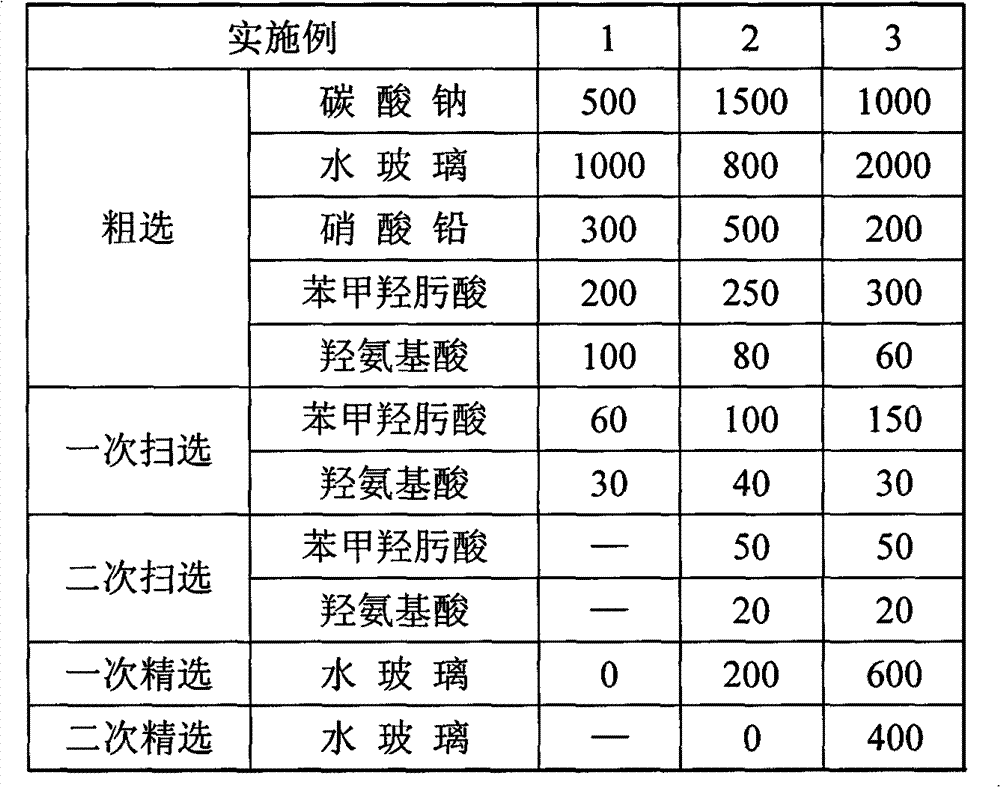

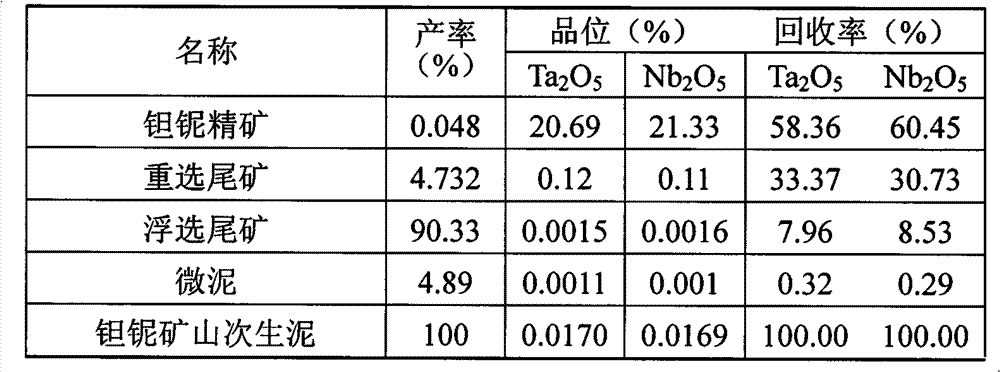

Ore dressing method of micro-fine particle tantalum-niobium ores

InactiveCN102861662AEliminate selection noiseImprove flotation recoveryPlaning/slotting machinesWet separationBenzohydroxamic acidLead nitrate

Disclosed is an ore dressing method of micro-fine particle tantalum-niobium ores. The ore dressing method is characterized by including steps of firstly, performing desliming pre-treatment to obtain set sand and micro-mud; secondly, adding an adjusting agent of sodium carbonate, an inhibiting agent of water glass, an activating agent of lead nitrate and collectors of benzohydroxamic acid and hydroxyamino acid to the set sand for once roughing; adding the benzohydroxamic acid and the hydroxyamino acid for once or twice scavenging; adding the water glass for once or twice concentration or blank concentration to obtain tantalum-niobium rough concentrates and flotation tailings; thirdly, performing de-reagent and de-foaming: adding sulfuric acid to the tantalum-niobium rough concentrates, and stirring the mixture until foams are disappeared; and fourthly, performing gravity concentration: subjecting the tantalum-niobium rough concentrates to de-reagent and de-foaming, and subjecting the tantalum-niobium rough concentrates to gravity concentration to obtain tantalum-niobium concentrates and gravity concentration tailings. According to the ore dressing method of the micro-fine particle tantalum-niobium ores, the recovery rate of the micro-fine particle tantalum-niobium ores is increased by over 30%, and the ore dressing method is applicable to primary mud and secondary mud with sizes of -0.037mm in tantalum-niobium ores.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

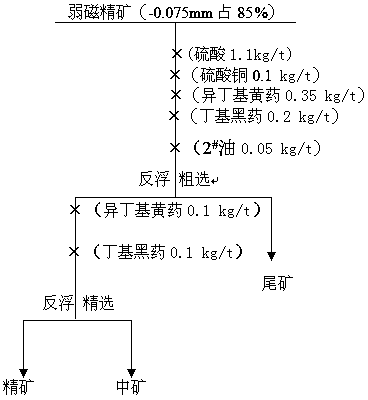

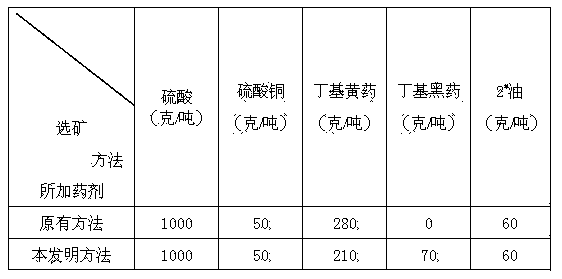

Ore dressing method for removing pyrrhotite from iron ore

InactiveCN104069937AEnhanced harvesting capacityGood beneficiation effectFlotationWet separationChemical mixturesIronstone

The invention discloses an ore dressing method for removing pyrrhotite from iron ore. The ore dressing method for removing the pyrrhotite from the iron ore includes that performing crushing, ore grinding, grading and low intensity magnetic separation techniques to obtain low intensity magnetic concentrate, wherein the TFE grade of the low intensity magnetic concentrate is more than or equal to 65.0%, and the low intensity magnetic concentrate comprises 0.5-1.4% of S; carrying out reverse flotation roughing and reverse flotation selection on the low intensity magnetic concentrate to obtain low-pyrite concentrate with less than 0.15% of S. Weighted by the dry ore amount for the reverse flotation, the reverse flotation roughing chemical comprises (1) pH regulating agent, to be specific, 800-1200 g / t of sulfuric acid; (2) activating agent, to be specific, 80-150 g / t of copper sulfate; (3) collecting agent, to be specific, 250-400 g / t of iso-butyl xanthate and 150-250 g / t of butyl dithiophosphate; (4) foaming agent, to be specific, 30-70 g / t of 2# oil. The ore dressing method for removing the pyrrhotite from the iron ore uses the butyl dithiophosphate and butyl xanthate or iso-butyl xanthate to form sulfur content reducing chemical mixture, the molecular arrangement between the chemical micelles is improved to form a synergistic effect, the chemical is good for mineralizing and adsorbing, the hydrophobicity and the floating speed are properly reinforced, and the sulfur content of the iron concentrate is reduced to less than or equal to 0.03-0.15%. The ore dressing method for removing the pyrrhotite from the iron ore is especially suitable for removing the pyrrhotite from the iron ore with pyrrhotite through reverse flotation.

Owner:马钢集团设计研究院有限责任公司 +1

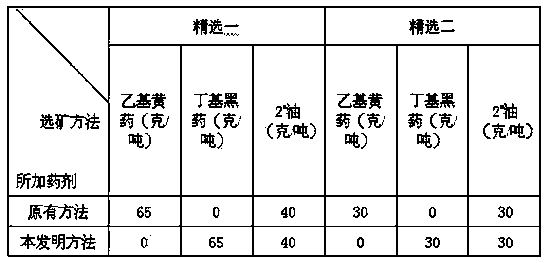

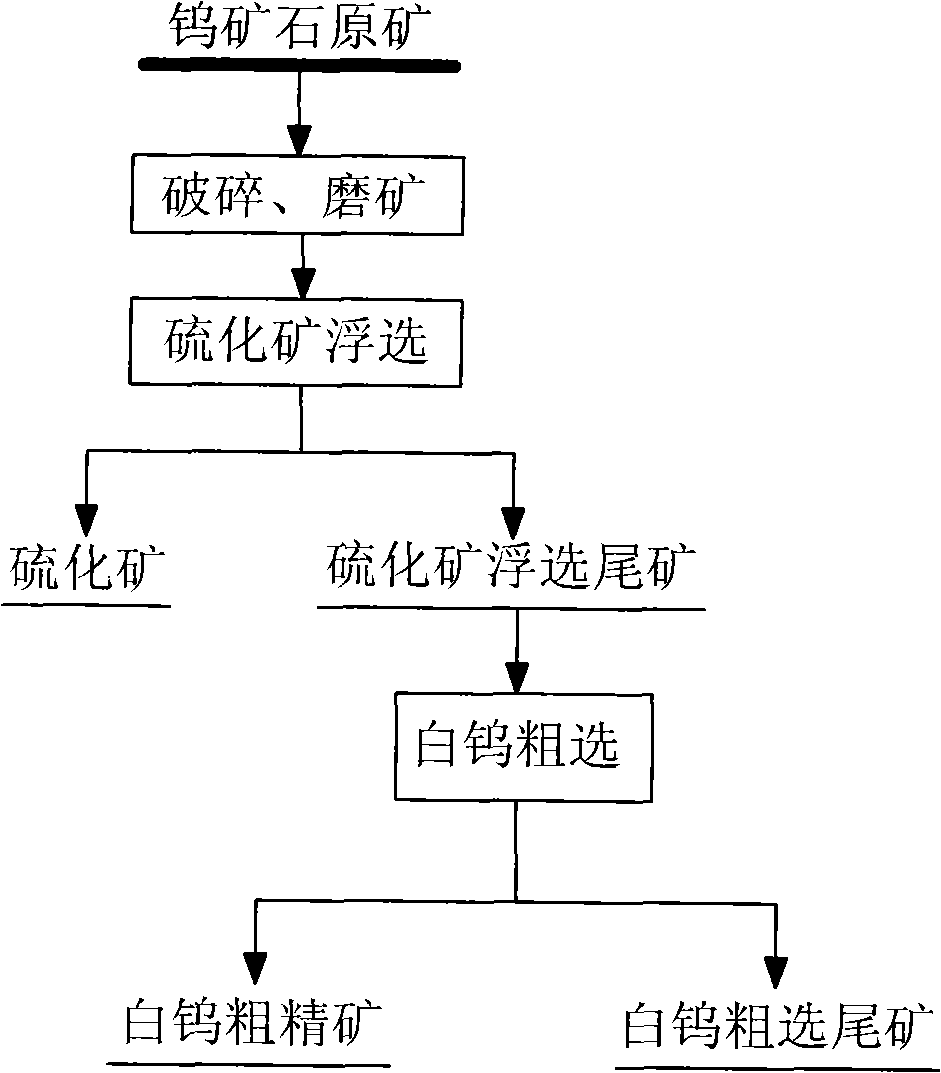

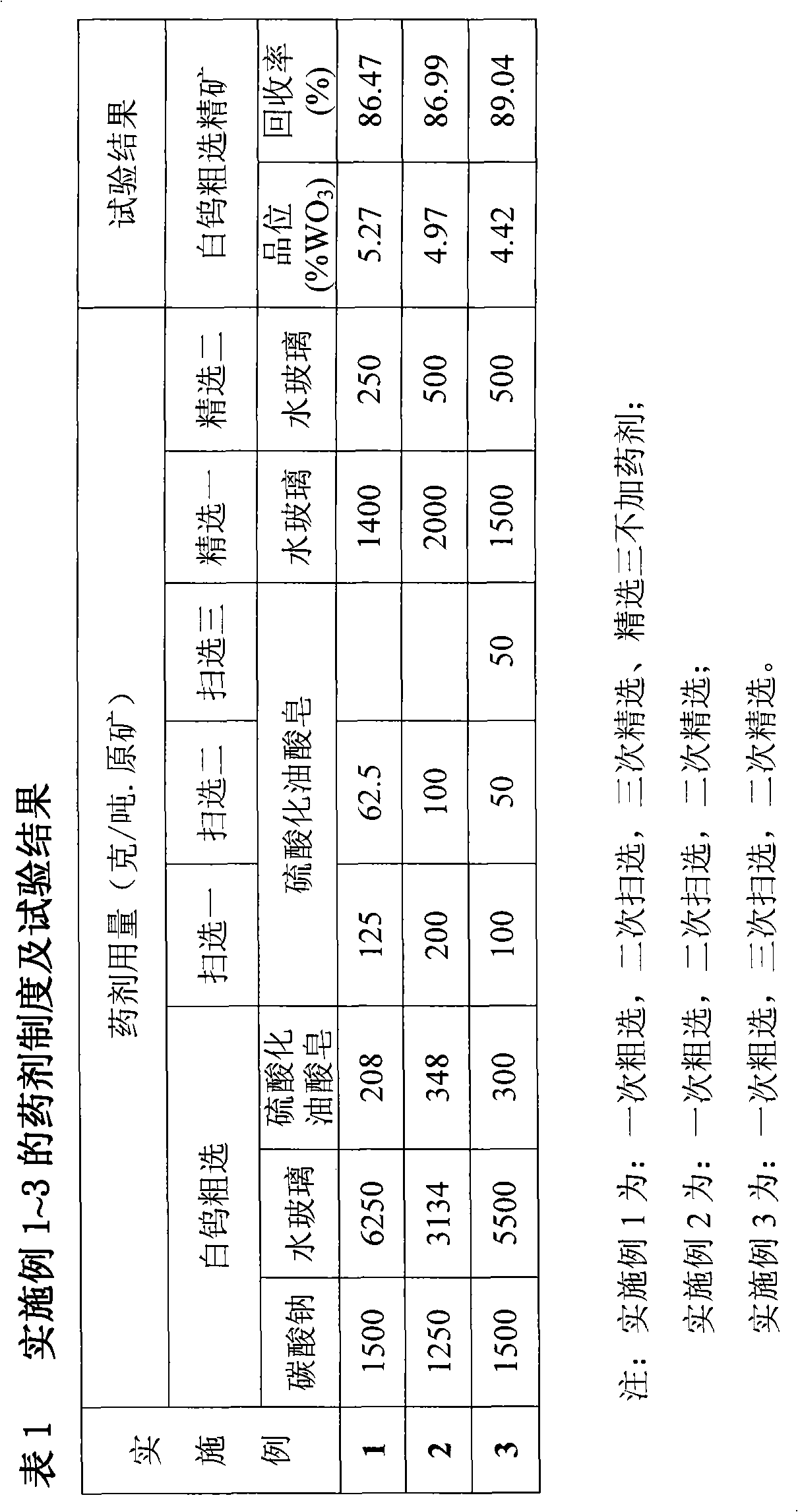

Beneficiation method for recycling scheelite from tungsten ore rich in mispickel

InactiveCN101269353AReduce dosageImprove rough selection indexFlotationSodium silicateMaterials science

The invention relates to an ore dressing method for recycling scheelite from tungsten ore which is rich in arsenopyrite. The method is characterized in that: (1) the flotation of sulphide ore is performed: the tungsten ore is crushed, ground and floated so as to obtain the sulphide ore and sulphide ore flotation tailing which are mainly composed of arsenopyrite; (2) the rough flotation of scheelite is performed: the sulphide ore flotation tailing is mixed with sodium carbonate and sodium silicate, then is added with a collector, namely, sulfating nascent soap; the scheelite concentrate and the coarse ore and the scheelite coarse flotation tailing are obtained by stirring, rough flotation, fine flotation and scavenging. The method provided by the invention is characterized in that the process is simple, the beneficiation reagent has low cost, the recovery rate of tungsten is high, and scheelite concentrate and coarse ore with the recovery rate of tungsten ranging from 80 to 90 percent and containing WO3 which accounts for 4 to 10 percent is obtained.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

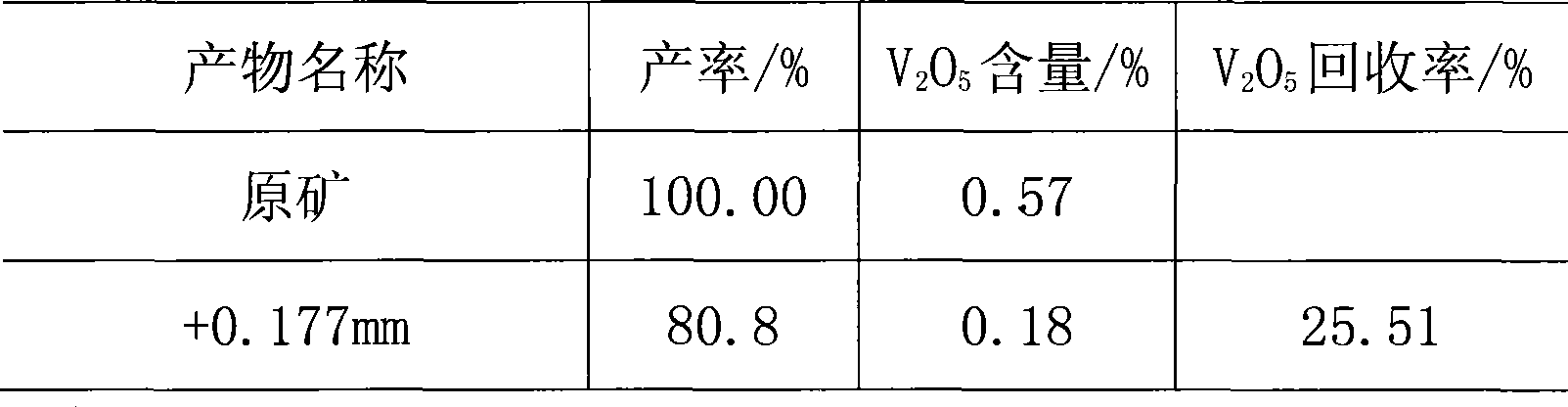

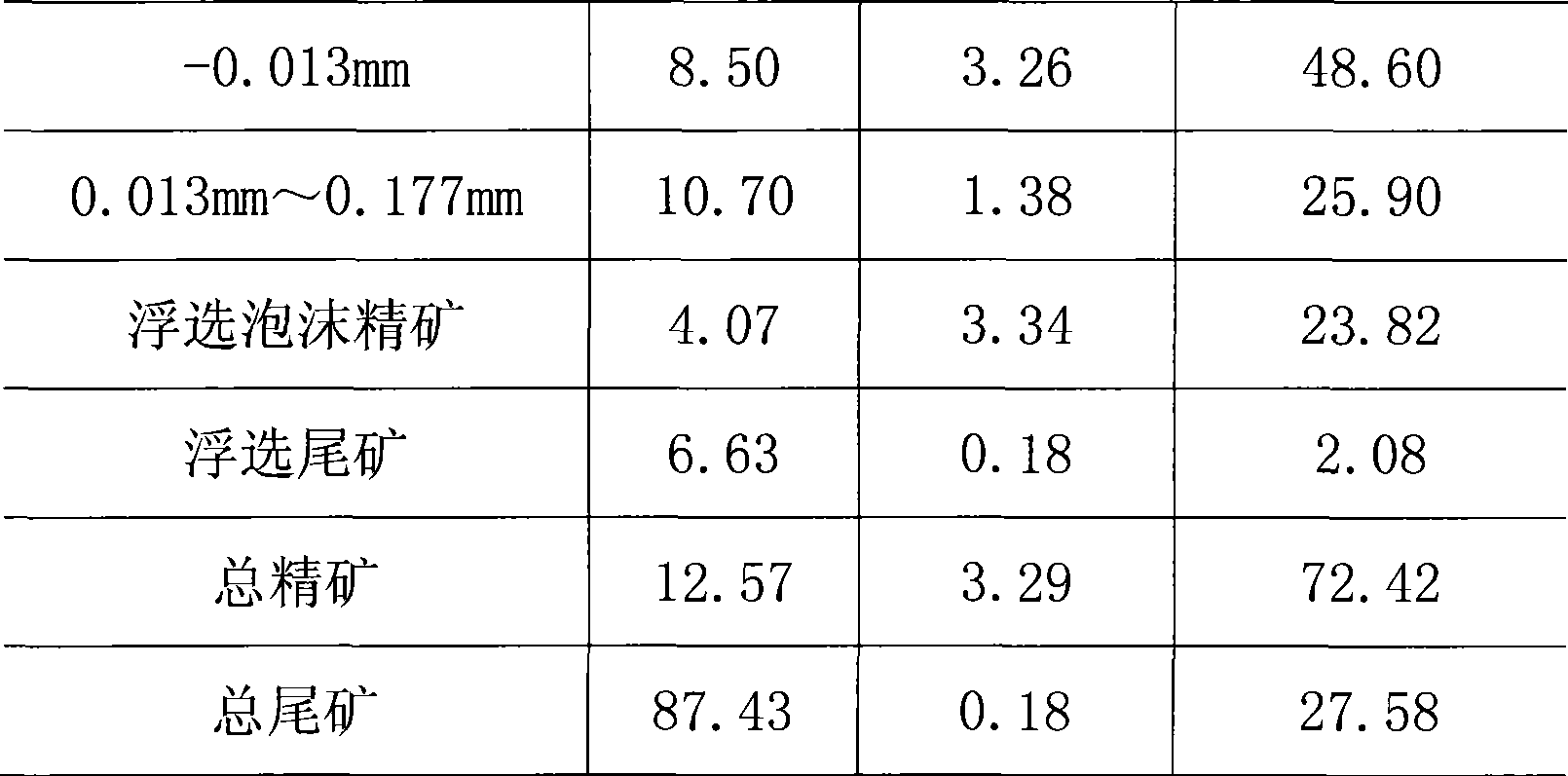

Stone-like coal navajoite physical mineral dressing method

The invention relates to a method of preparation, in particular to a method for realizing the vanadium enrichment by the physical method of preparation before the chemical vanadium extracting process of the stone coal vanadium ore. The technical proposal comprises the following: step one, choosing the stone coal vanadium ore and crushing equipment, and crushing the stone coal vanadium ore by the crushing equipment; step two; finishing the first gradation, and separating out the coarse fraction ore and discarding ore tailings; step three; finishing the second gradation, and separating out finefraction ore and directly obtaining the refined ore; and step four, enriching vanadium in the middle-level ore obtained from two gradations by the selective grinding-floatation method so as to obtainthe floatation foam refined ore and the in-slot ore tailings. The method has the advantages of 1, reducing the investment cost for building a vanadium extracting factory and the production cost for vanadium extraction; 2, reducing the consumption of the materials and the tailings needed for extracting each ton of vanadium, and further reducing the 'three wastes' pollution during the vanadium extraction; and 3, facilitating the use of the environmental protection process with high investment which replaces the conventional sodium method roasting process in the stone coal vanadium extraction industry, and fundamentally solving the problem of the 'three wastes' pollution.

Owner:HUNAN HUAQI RESOURCES ENVIRONMENT SCI & TECH DEV CO LTD

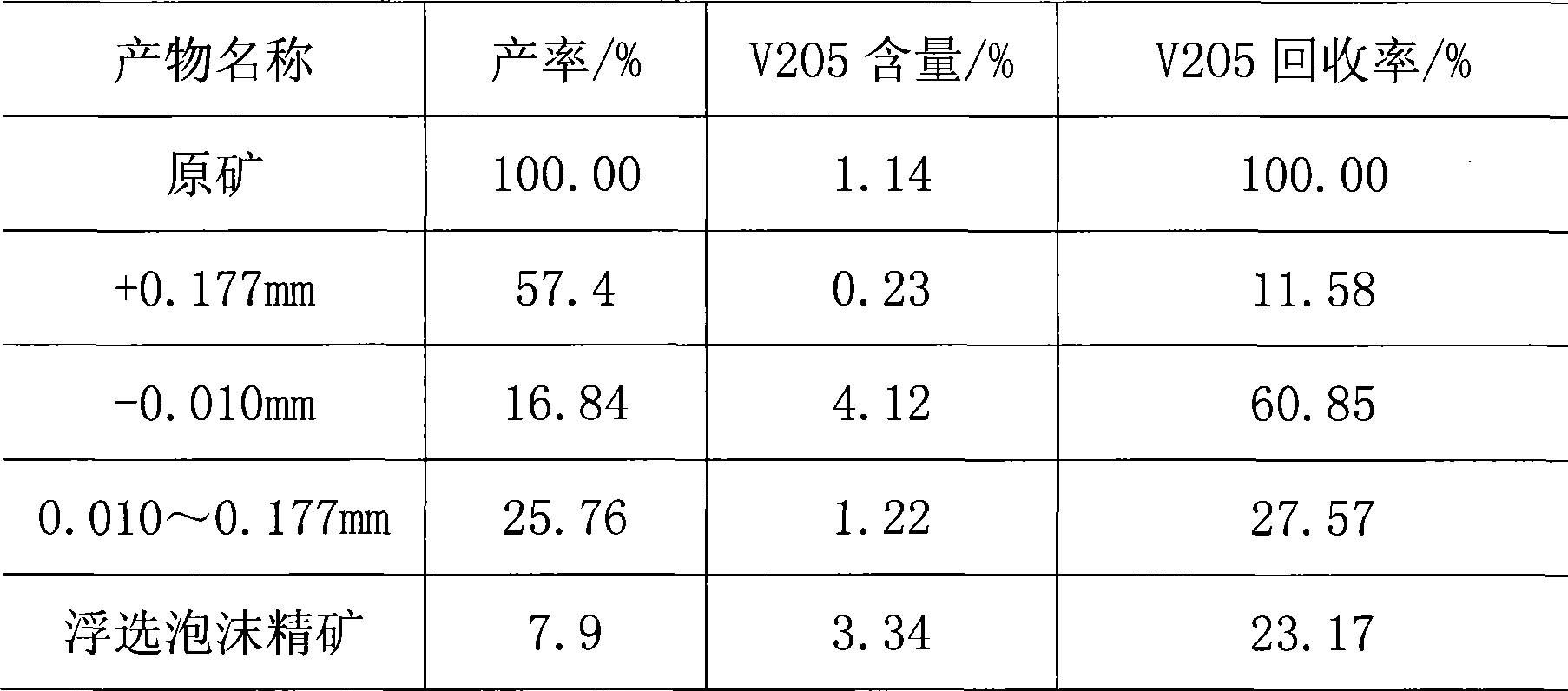

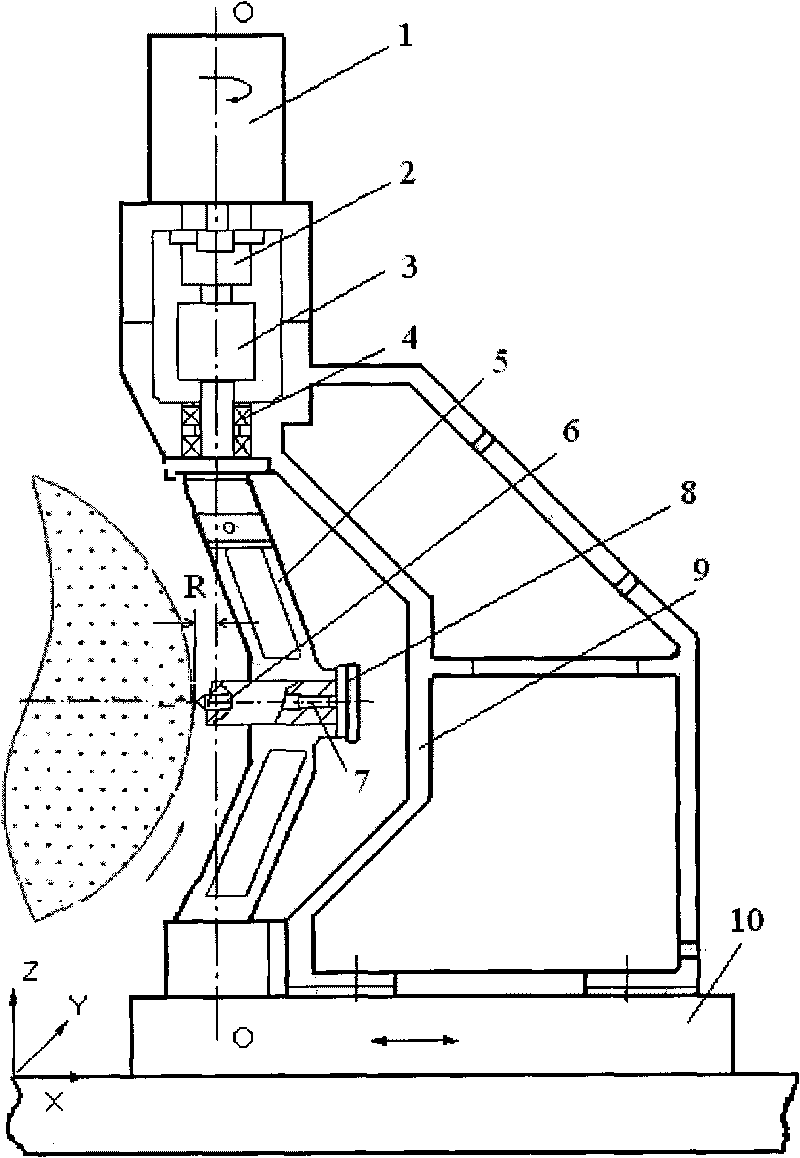

Precise dressing method of molding grinding wheel of grinding big-diameter bearing and flexible device thereof

InactiveCN101704220AImprove trimming accuracyAvoid restrictionsAbrasive surface conditioning devicesMotor driveElectric machinery

The invention relates to a precise dressing method of molding grinding wheel of a grinding big-diameter bearing and a flexible device thereof. The precise dressing method of the molding grinding wheel is that the dressing motion track of a diamond pen (6) is synthetized through the interpolating and feeding movement along the axial direction (X shaft) and the radial direction (Y shaft) of the grinding wheel. The flexible device is mainly composed of a servo driving motor (1), a harmonicwave reducer (2), a coupler (3), a bearing (4), a spindle (5), an adjusting screw rod (7), a dial (8) and a support base (9), wherein the diamond pen (6) is installed on the spindle (5) and the distance (R) of the diamond pen point opposite to the swing center of the spindle (O-O) is adjusted via driving the adjusting screw rod (7) by the dial (8); namely, the swing radius of the diamond pen is formed and the servo motor drives the spindle (5) to drive the diamond pen to swing along the Z shaft; and the flexible device is installed on the workbench (10) and is driven by the workbench to realize the interpolating and feeding movement along the X shaft and Y shaft, and the synthesizing movement of the X, Y and Z shafts are controlled by PLC. The invention can solve the problems of low dressing precision of the grind wheel, low matching of the dresser of the grind wheel in prior art.

Owner:DONGHUA UNIV +1

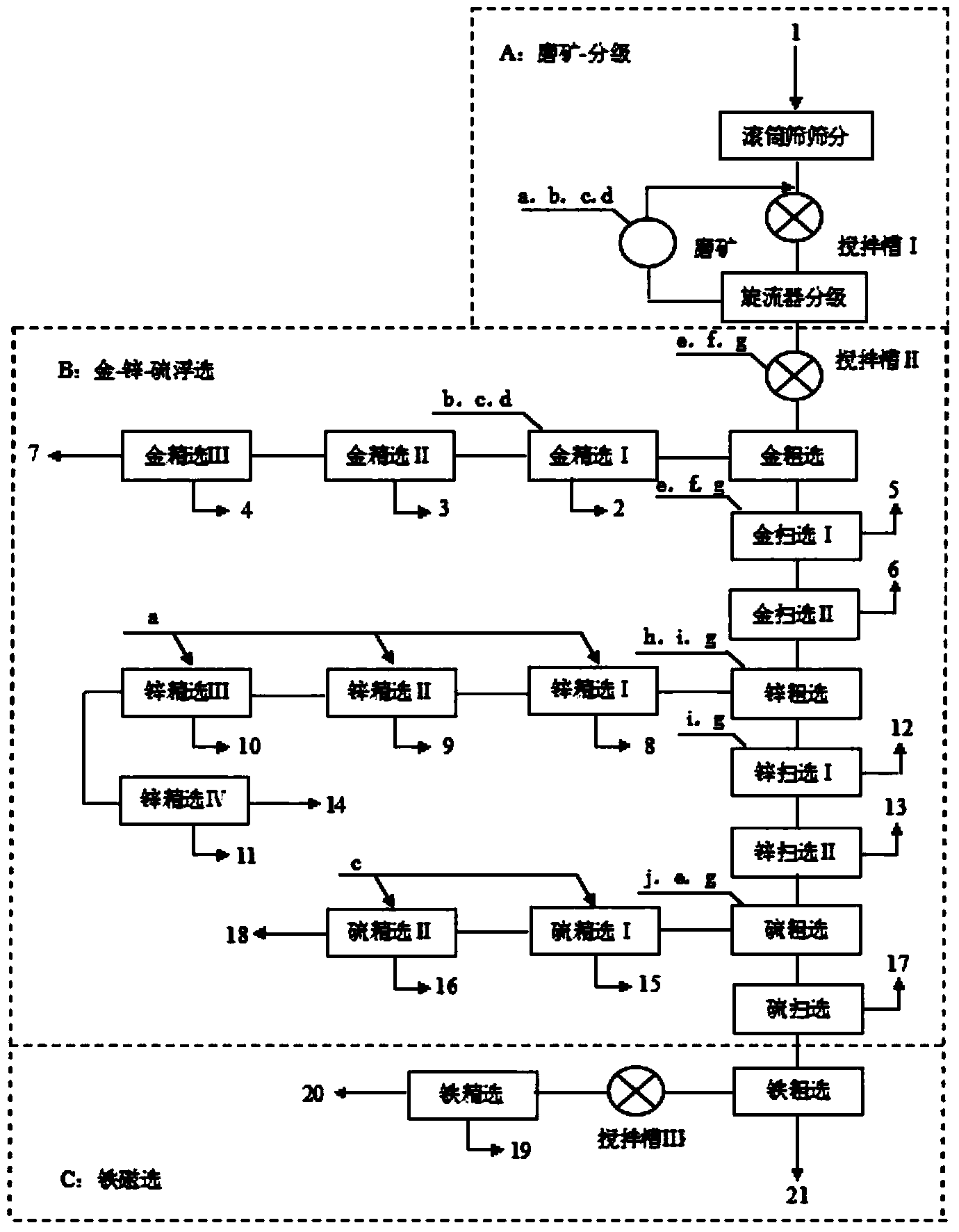

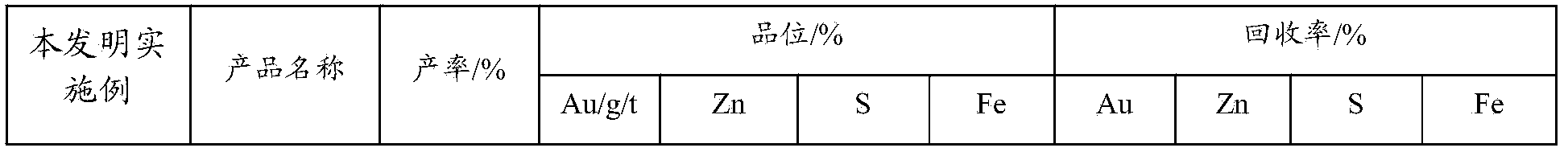

Ore dressing method for comprehensively recovering gold, zinc, sulfur and iron from abandoned tailing

ActiveCN104226461AEfficient separation and extractionSolve the problem of growing oxide film and poor flotation activityFlotationGrain treatmentsCarbonateMonomer

The invention relates to an ore dressing method for comprehensively recovering gold, zinc, sulfur and iron from abandoned tailings. By grinding the abandoned tailings, useful mineral monomer dissociation is realized, and simultaneously mineral surface oxide films are stripped off to improve mineral floatation activity; by jointly using water glass and sodium hexametaphoshpate to effectively inhibit iron gangue, silicon gangue and carbonate gangue, fine silt can be better dispersed and the adverse influence of mineral silt on floatation can be eliminated; through the high-efficiency combination and reasonable matching of inhibitors, collectors and activators, the sequentially prior floatation of gold, zinc and sulfur is realized, then iron is recovered by adopting a low-intensity magnetic separation process, and thus gold concentrate, zinc concentrate, sulfur concentrate and iron concentrate are obtained. Through mineral grinding activation and floatation and reasonable fitting and matching of floatation chemicals, the method solves the problem that the floatation activity is poor due to the oxide film on surfaces of useful minerals in the abandoned tailings, and can be used for effectively separating and extracting gold, zinc and sulfur components in the abandoned tailings.

Owner:ZIJIN MINING GROUP

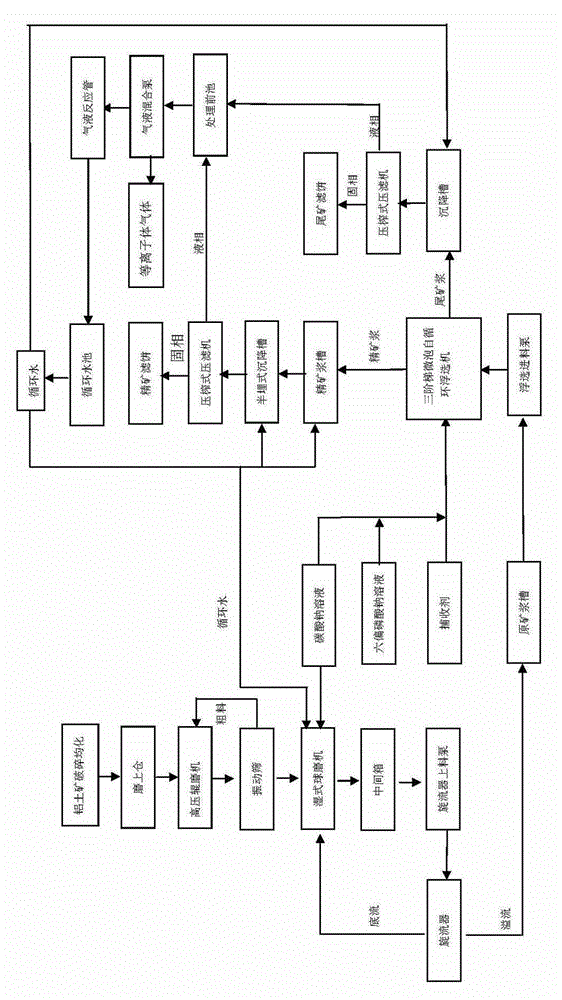

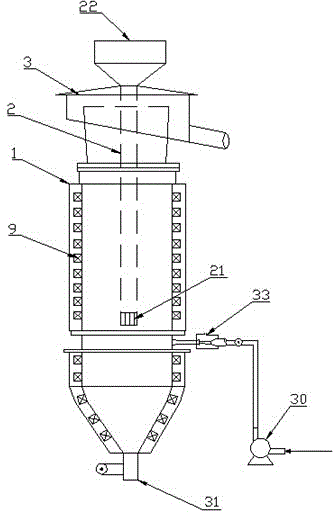

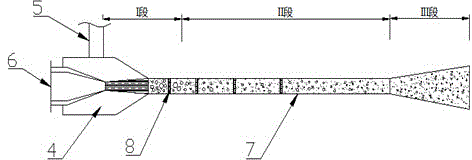

Ore-dressing method for low-grade bauxite

The invention relates to an ore-dressing method for low-grade bauxite, and the method can be used for efficiently solving the problems of incomplete ore dissociation, difficult equipment maintenance, high energy consumption, and no self-contained water system existing in the method in the prior art. The technical scheme of the invention is realized via the following steps of: (1) breaking and homogenizing the bauxite; (2) selectively dissociating the bauxite; (3) floating by virtue of micro-bubbles; (4) discharging a combined-type concentrate; (5) discharging combined-type tailings; and (6) treating and circulating water. The method disclosed by the invention is easily-met in condition, less in power consumption, high in yield, low in pollution, energy-saving and environmentally-friendly;and by utilizing the circulated water, the water consumption is reduced, thus greatly decreasing the production cost.

Owner:HENAN DONGDA TECH CO LTD

Quality improvement and impurity reduction ore dressing method of ferromagnetic minerals

InactiveCN104888959AImprove featured performanceEfficient selection effectFlotationMagnetic separationGranularityWater flow

The invention provides a quality improvement and impurity reduction ore dressing method of ferromagnetic minerals. The method is characterized in that the ferromagnetic minerals are cleaned, and the cleaning process comprises the following steps: 1, adding a flotation agent to crude concentrates, and carrying out size mixing, wherein the weight of ores with the granularity of 0.07-4mm in the crude concentrates is 80-90% of the total weight of the crude concentrates, and the flotation agent comprises a collector and an inhibitor; and 2, adding a material obtained in step 1 into a floating agglomeration electromagnetic cleaning device, and controlling the magnetic field intensity of the floating agglomeration electromagnetic cleaning device to be 11.94-63.69kA / m, the magnetic field transformation period to be 2-6s and the rising water flow speed to be 2-6cm / s. The method allows high-quality ferromagnetic mineral products to be obtained, greatly reduces the content of impurities, greatly shortens the ore dressing process of the ferromagnetic minerals, and has huge market economic benefit.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

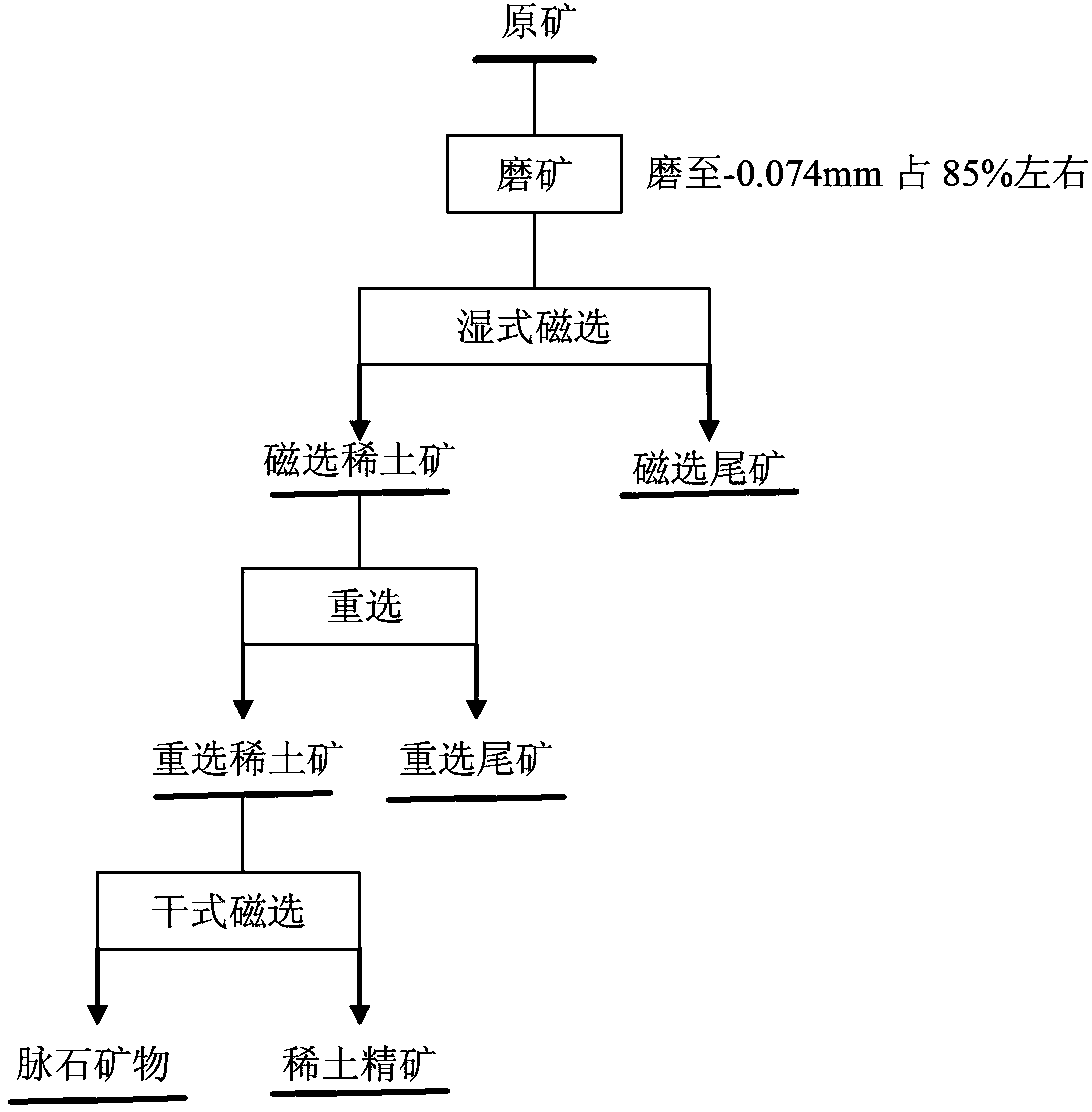

Ore dressing method for low-grade rare earth ore

The invention discloses an ore dressing method for low-grade rare earth ore. The method is characterized by comprising the following steps: (1) ore grinding: crushing and grinding raw ore till -0.074 millimeter to obtain ore accounting for about 85 percent; (2) wet magnetic separation: performing magnetic separation under the magnetic field strength of 800-1000MT to obtain magnetic separation rare earth ore and magnetic separation tailings; (3) re-separation: re-separating the magnetic separation rare earth ore to obtain re-separated rare earth ore and re-separated tailings; and (4) dry magnetic separation: filtering and drying the re-separated rare earth ore, and performing magnetic separation under the magnetic field strength of 400-500MT to obtain gangue minerals and rare earth ore concentrate. The method belongs to physical mineral separation, does not involve addition of any chemical additive, and is a low-cost, environment-friendly and efficient ore dressing method. The method is suitable for raw ore of which the rare earth grade is lower than 0.1 percent.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com