Ore dressing method of micro-fine particle tantalum-niobium ores

A beneficiation method and technology for tantalum-niobium ore, which are applied in chemical instruments and methods, wet separation, planer/intercalation bed, etc., can solve the problems of non-recovery, low recovery rate, and low recovery rate of fine-grained tantalum-niobium ore.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

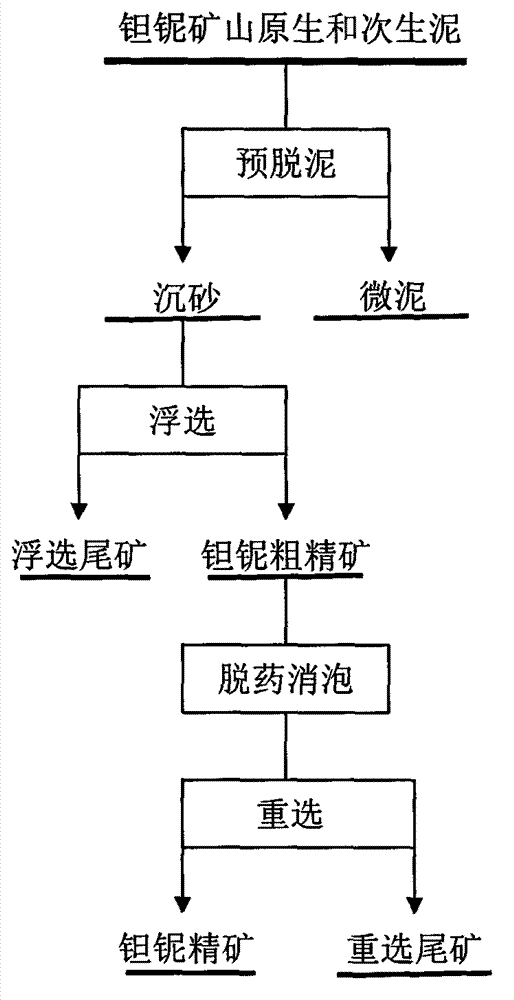

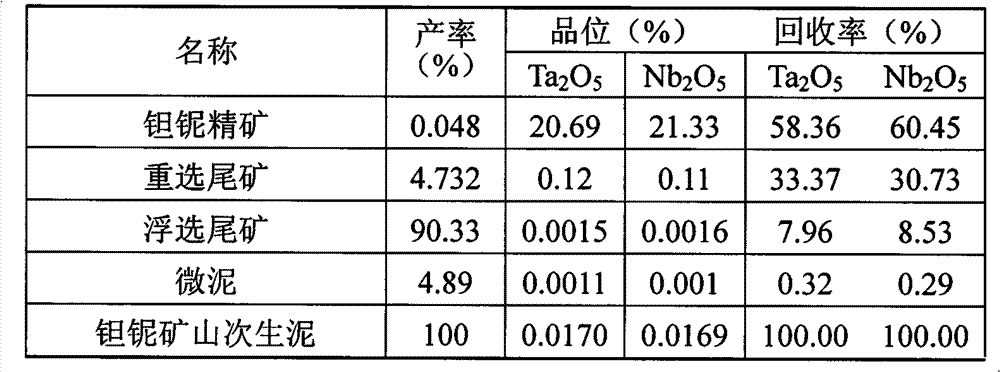

[0016] Ta content in secondary mud of a tantalum-niobium mine in Jiangxi 2 o 5 0.017%, Nb 2 o 5 0.0169%, -0.037mm accounts for 98%.

[0017] Desliming pretreatment: use a hydrocyclone to pre-desilt to obtain sand and micro-sludge, remove 4.89% of the micro-sludge, Ta 2 o 5 and Nb 2 o 5 Losses of 0.32% and 0.29%;

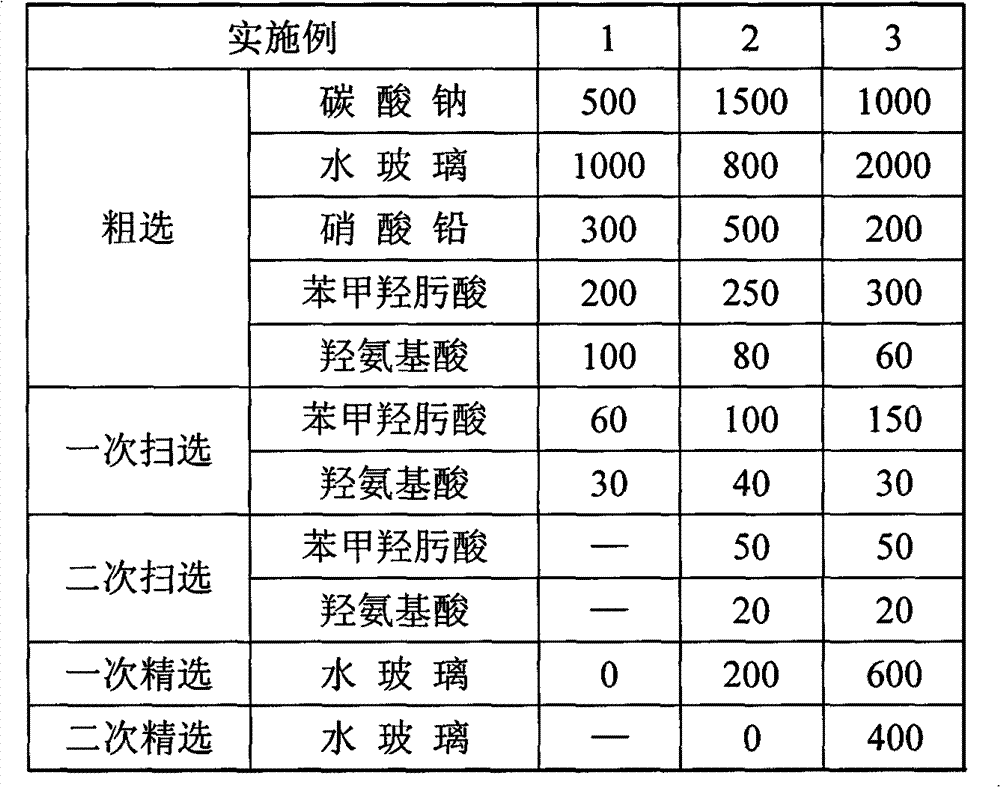

[0018] Flotation: Carry out flotation for grit settling according to the amount of chemicals listed in Table 1, one roughing, one sweeping, one blank concentration to obtain tantalum-niobium coarse concentrate and flotation tailings;

[0019] Drug removal and defoaming: Add sulfuric acid at 300g / t to the rough concentrate of tantalum and niobium, and stir until the foam disappears;

[0020] Gravity separation: The tantalum-niobium rough concentrate after de-drug and defoaming is subjected to a centrifugal concentrator, and undergoes a rough separation, two sweeping separations, and a single concentration to obtain tantalum-niobium concentrate and gravity sepa...

Embodiment 2

[0024] Ta content in primary mud of a tantalum-niobium mine in Yunnan 2 o 5 0.0169%, Nb 2 o 5 0.0162%, -0.037mm accounted for 95.96%.

[0025] Desliming pretreatment: use a hydrocyclone to pre-desilt to obtain sand and micro-sludge, remove 5.50% of the micro-sludge, Ta 2 o 5 and Nb 2 o 5 Losses of 0.42% and 0.47%;

[0026] Flotation: carry out flotation on the grit according to the amount of chemicals listed in Table 1, one roughing, two sweepings, one beneficiation and one blank beneficiation to obtain tantalum-niobium rough concentrate and flotation tailings;

[0027] Drug removal and defoaming: Add sulfuric acid at 500g / t to the rough concentrate of tantalum and niobium, and stir until the foam disappears;

[0028] Gravity separation: The tantalum-niobium rough concentrate after de-drug and defoaming is subjected to a centrifugal concentrator, and undergoes a rough separation, two sweeping separations, and a single concentration to obtain tantalum-niobium concentrat...

Embodiment 3

[0032] Ta content in primary and secondary mud of a tantalum-niobium mine in Yunnan, Fujian 2 o 5 0.0165%, Nb 2 o 5 0.0169%, -0.037mm accounts for 98..87%;

[0033] Desliming pretreatment: use a hydrocyclone to pre-desilt to obtain sand and micro-sludge, remove 5.33% of the micro-sludge, Ta 2 o 5 and Nb 2 o 5 Losses of 0.42% and 0.44%;

[0034] Flotation: Carry out flotation on the grit according to the dosage of reagents listed in Table 1, one roughing, two sweepings, two beneficiaries to obtain tantalum-niobium coarse concentrate and flotation tailings;

[0035] Drug removal and defoaming: Add sulfuric acid at 200g / t to the rough concentrate of tantalum and niobium, and stir until the foam disappears;

[0036] Gravity separation: The tantalum-niobium rough concentrate after de-drug and defoaming is subjected to a centrifugal concentrator, and undergoes a rough separation, two sweeping separations, and a single concentration to obtain tantalum-niobium concentrate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com