Patents

Literature

44 results about "Benzohydroxamic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

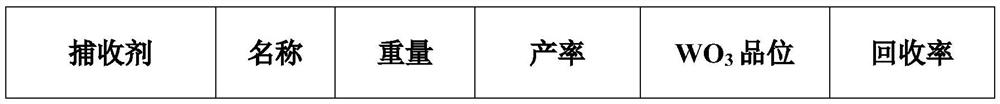

Beneficiation method of black and white tungsten mineral

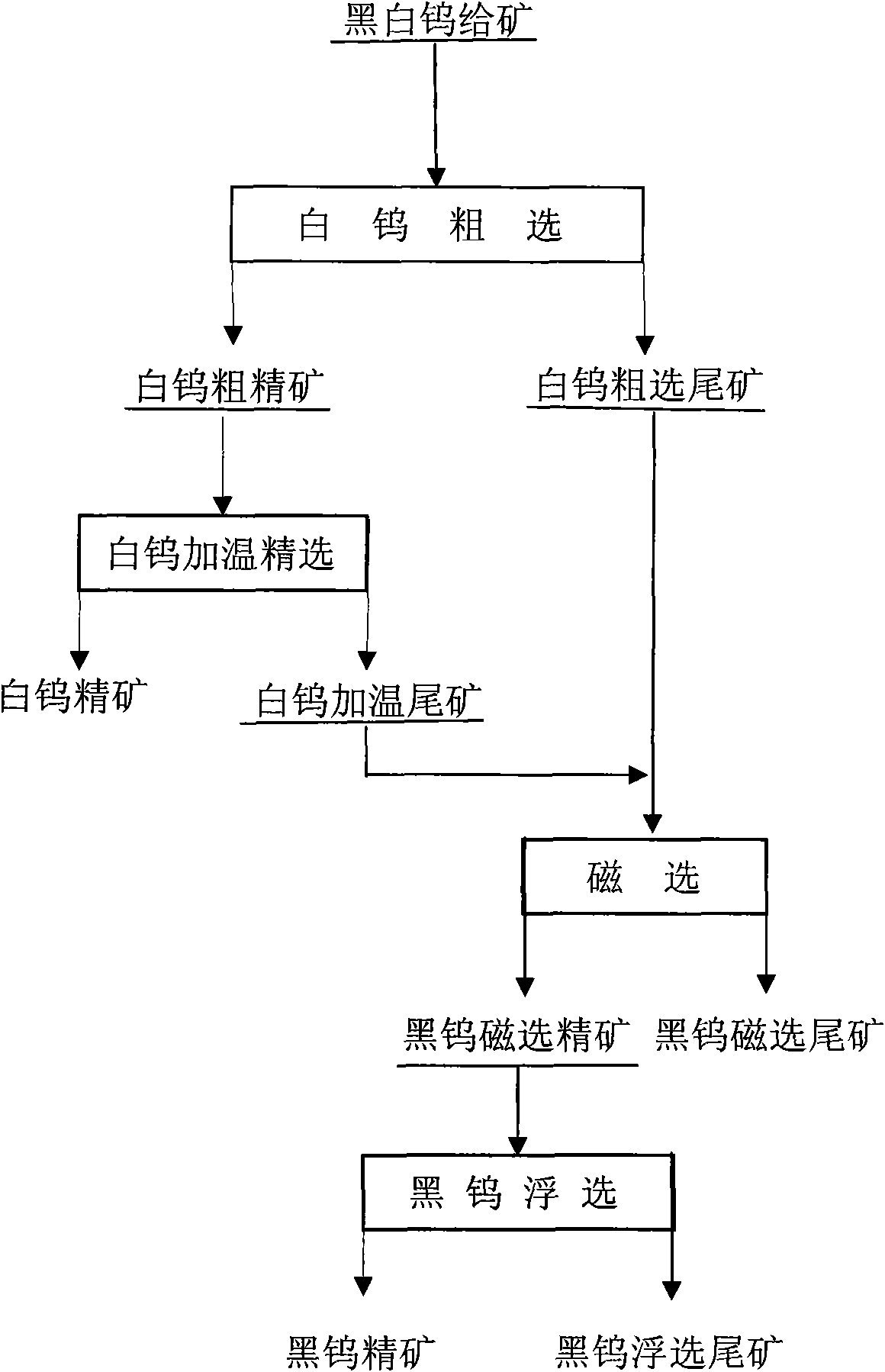

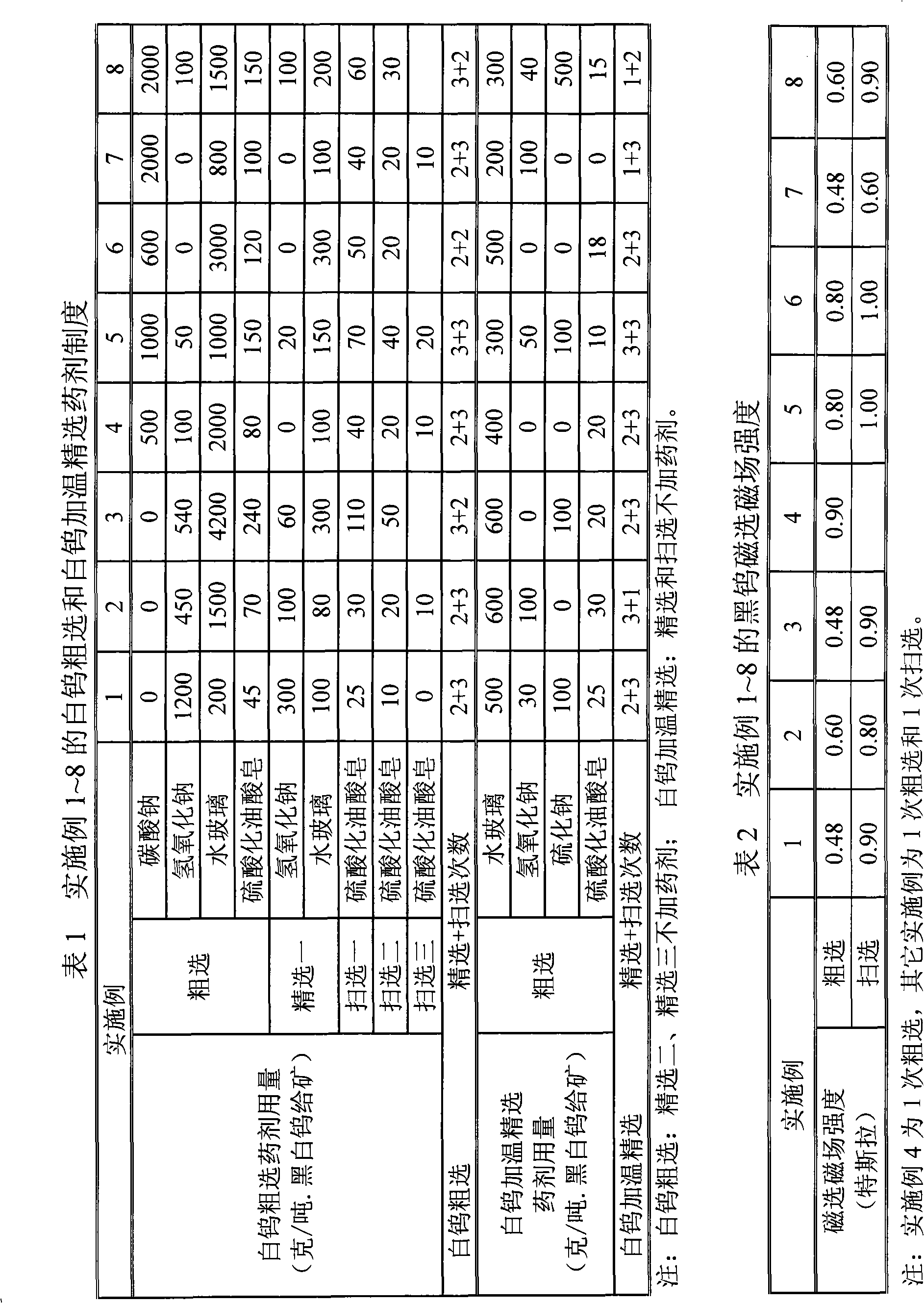

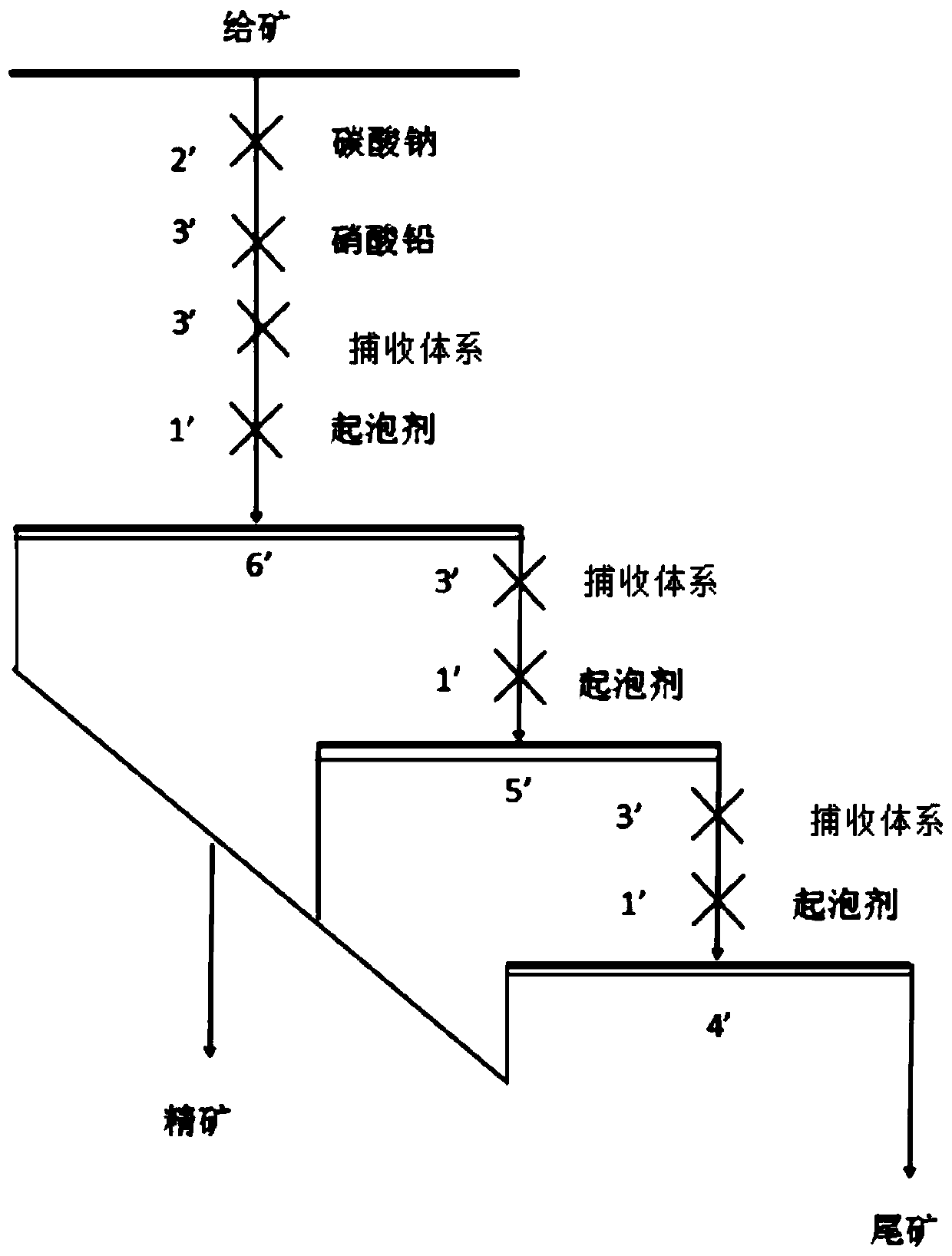

The invention relates to a beneficiation method of black and white tungsten mineral.The method is characterized in that: black and white tungsten mineral through sulfide floatation and magnetic separation deferrization is added with sodium hydroxide, sodium carbonate, sodium silicate and sulphated nascent soap for white tungsten roughing, so as to obtain white tungsten rough concentrate and white tungsten rougher tailings; the white tungsten rough concentrate is added with sodium silicate, sodium hydroxide, sodium sulfide and sulphated nascent soap for white tungsten warming cleaning, so as to obtain white tungsten concentrate and white tungsten warming tailings; the white tungsten rougher tailings and the white tungsten warming tailings are mixed for magnetic separation, so as to obtain black tungsten magnetic separation concentrate and black tungsten magnetic separation tailings; the black tungsten magnetic separation concentrate is added with sodium carbonate, sodium silicate, aluminum sulfate, lead nitrate, sodium fluosilicate, benzohydroxamic acid, sulphated nascent soap and karaffin oil for black tungsten flotation, so as to obtain black tungsten concentrate and black tungsten flotation tailings. The method of the invention is simple in recovery technology, steady in process, high in tungsten recovery rate and low in reagent cost, the used beneficiation reagent does not pollute the environment, and tailings water can meet emission requirement. The invention is applicable to black and white tungsten mineral with WO3 content of .15-2.0% and black and white tungsten proportion of 1:9 to 9:1.

Owner:广东省资源综合利用研究所

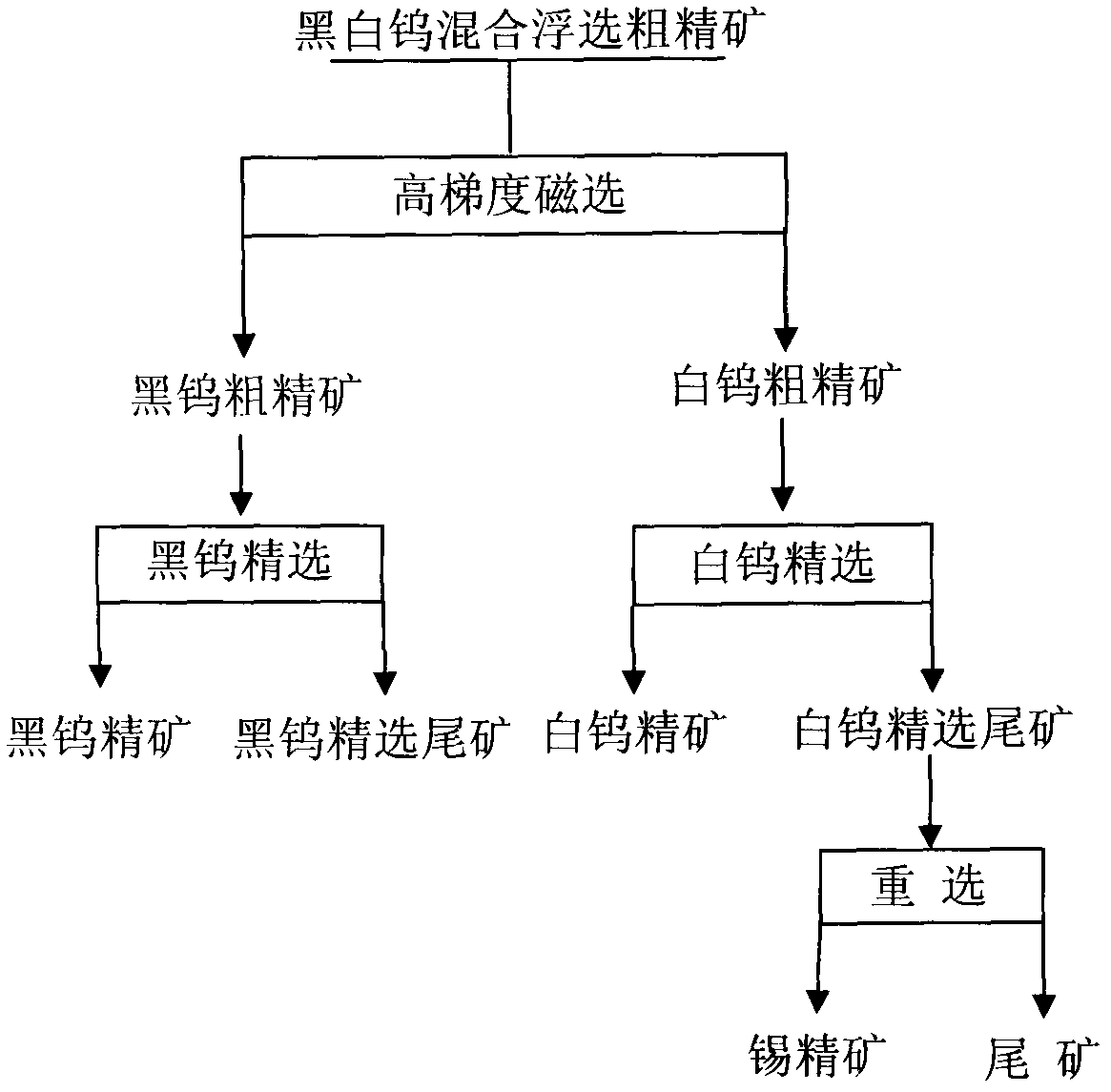

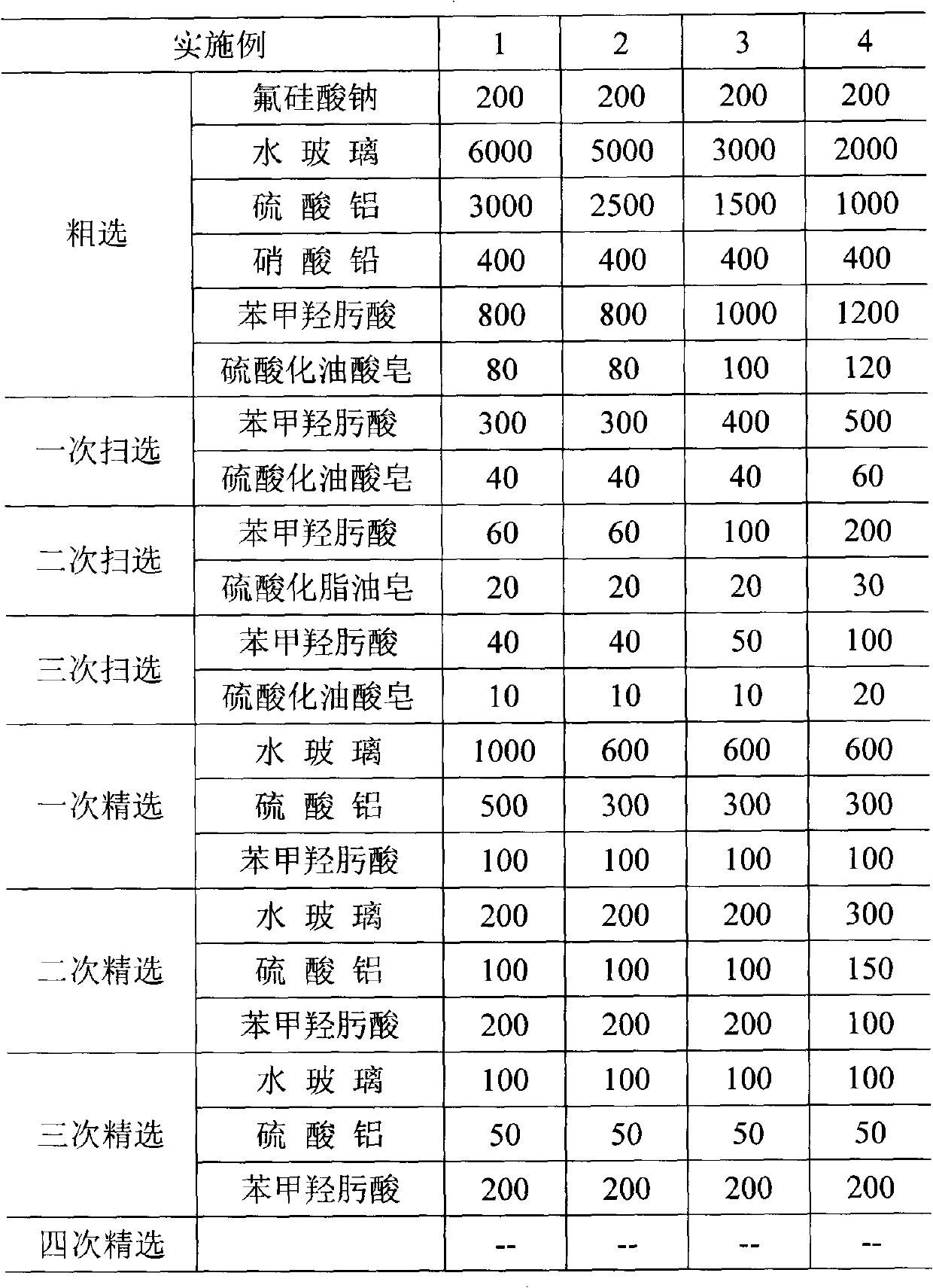

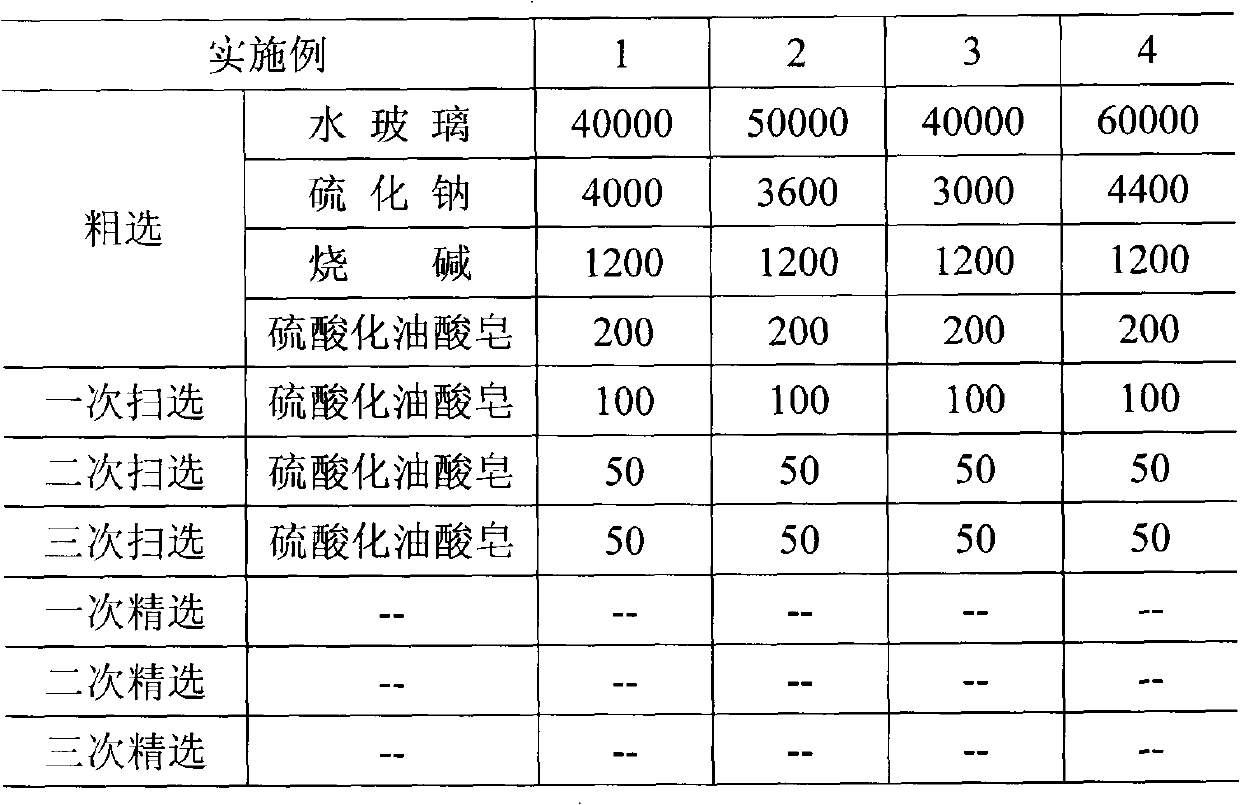

Method for separating black and white tungsten bulk flotation rough concentrates

ActiveCN102211053AHigh recovery rateReduce mutual interferenceGlass recyclingWet separationLead nitrateFatty acid

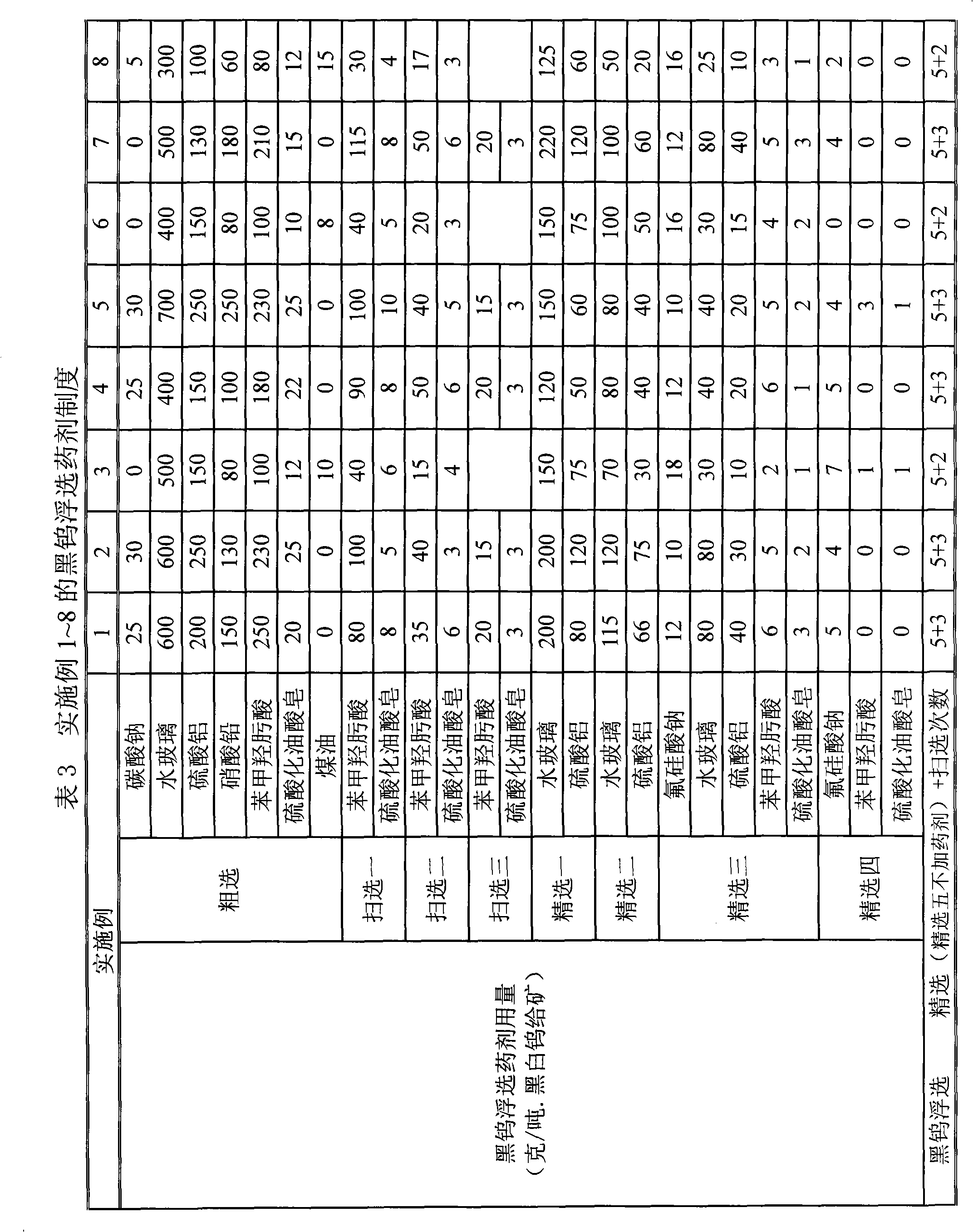

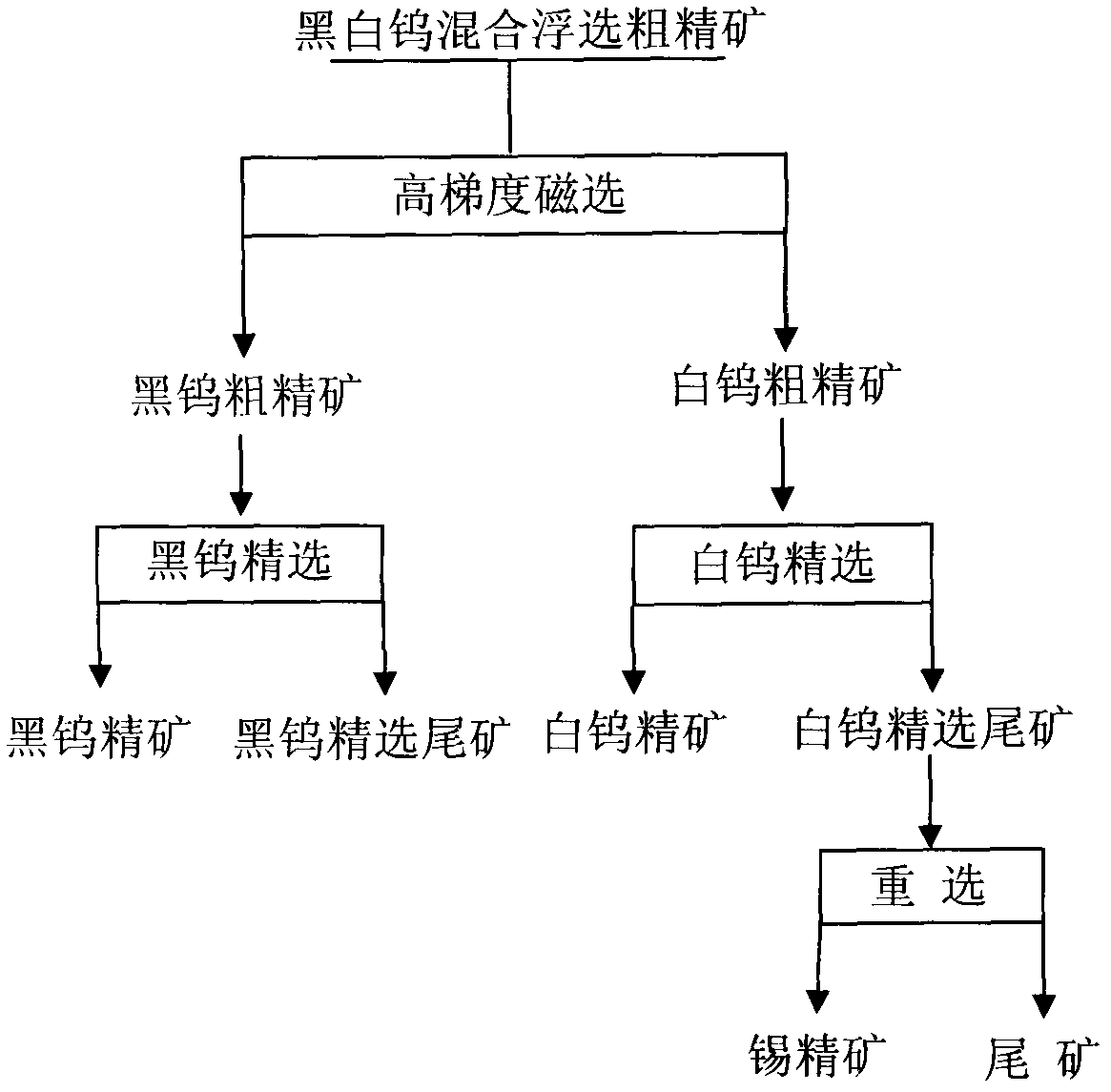

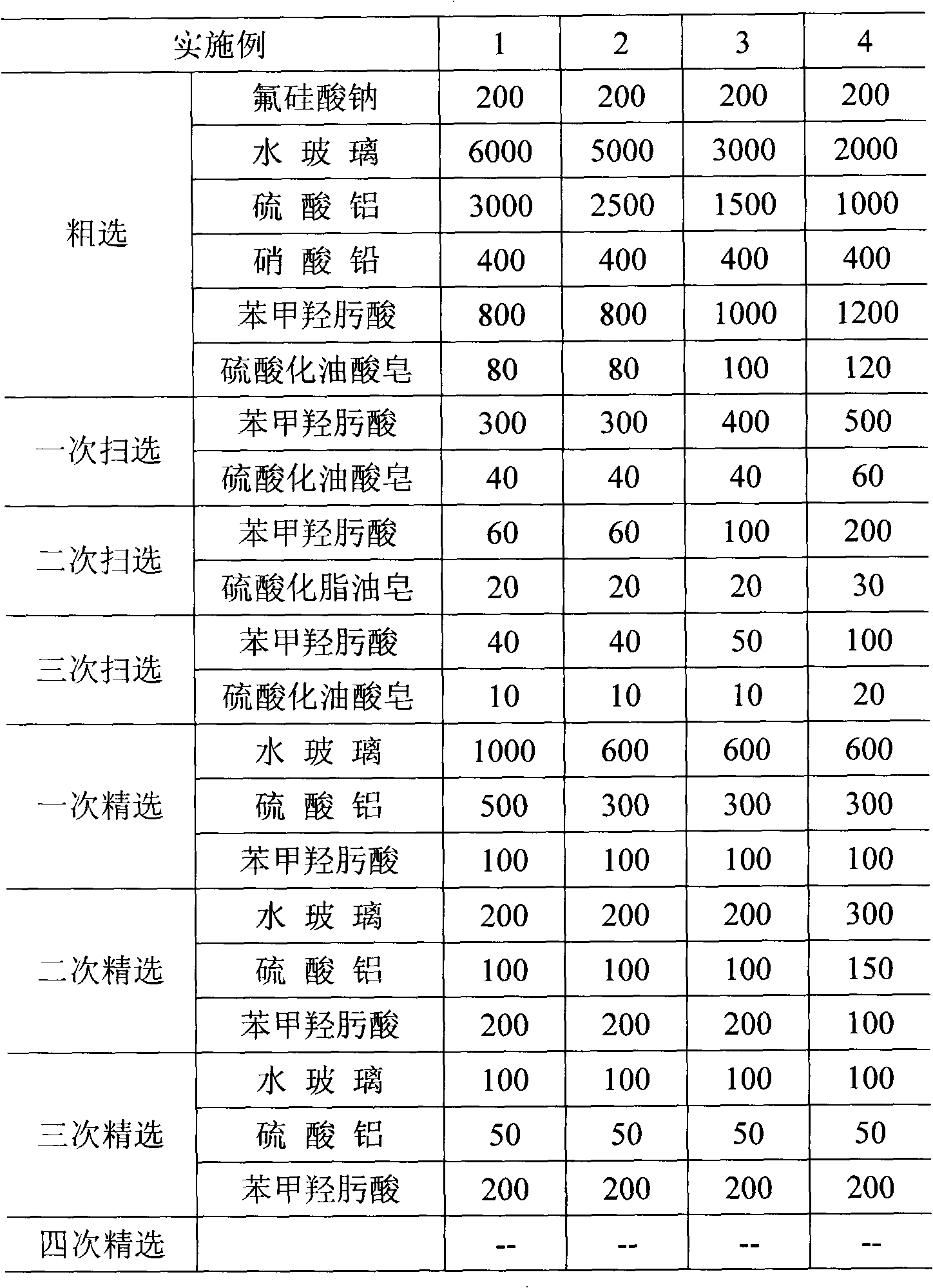

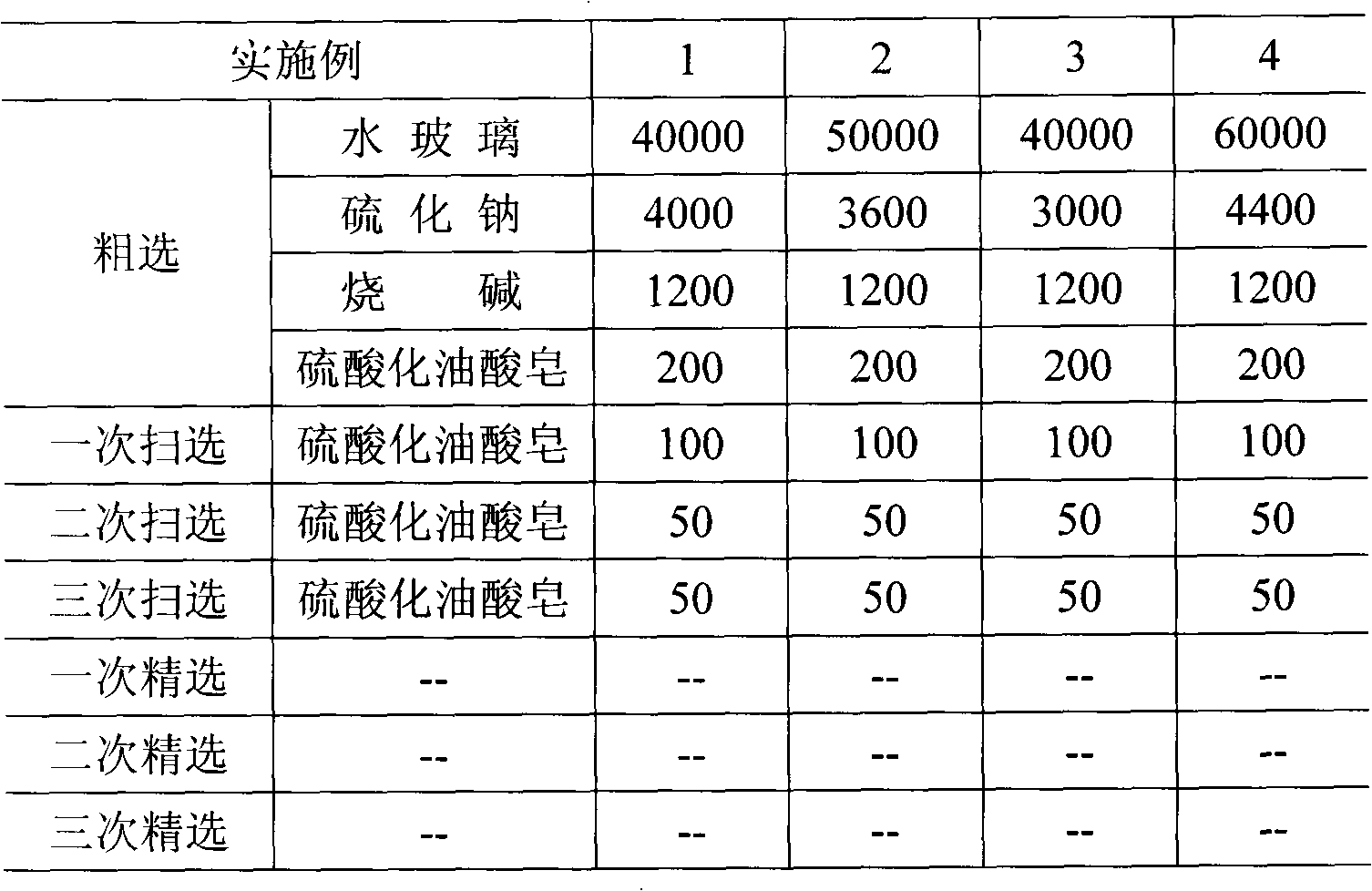

The invention relates to a method for separating black and white tungsten bulk flotation rough concentrates. The method is characterized in that a black tungsten rough concentrate and a white tungsten rough concentrate are obtained by virtue of high-gradient magnetic separation, roughing or roughing and scavenging; black tungsten concentrates and black tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and four-time concentrating on the black tungsten rough concentrate by utilizing sodium fluosilicate, sodium silicate, aluminum sulfate, lead nitrate, benzohydroxamic acid and sulfated nascent soap; white tungsten concentrates and white tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and three-time concentrating on the white tungsten rough concentrate after the white tungsten rough concentrate is heated up and stirred by utilizing sulfated fatty acid soap, sodium silicate, caustic soda and sodium sulfide; cassiterites in the white tungsten cleaner tailings are recovered by a table concentrator. The method related by the invention has the advantages of small mutual interference of black tungsten ore and white tungsten ore in the black and white tungsten bulk flotation rough concentrates, high recovery ratio of black tungsten ore and high and stable quality of the black tungsten ore; and the method is suitable for the black and white tungsten bulk flotation rough concentrates containing 5-40% of WO3.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

Benefication method for concentrating fine tungsten ore in tailings by warming scheelite

InactiveCN101579653ASimple recycling processThe beneficiation process is stableFlotationWet separationLead nitrateSoluble glass

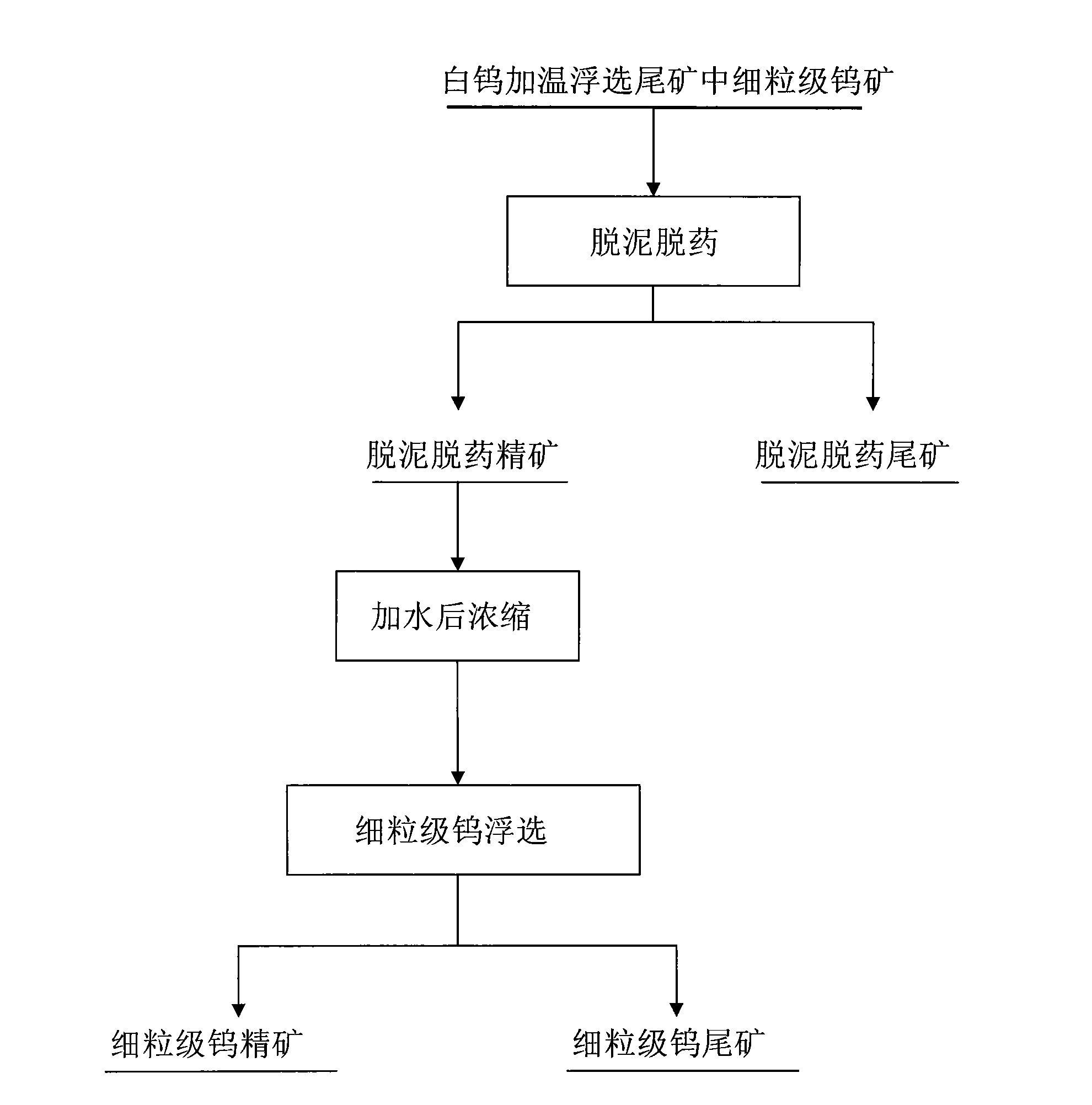

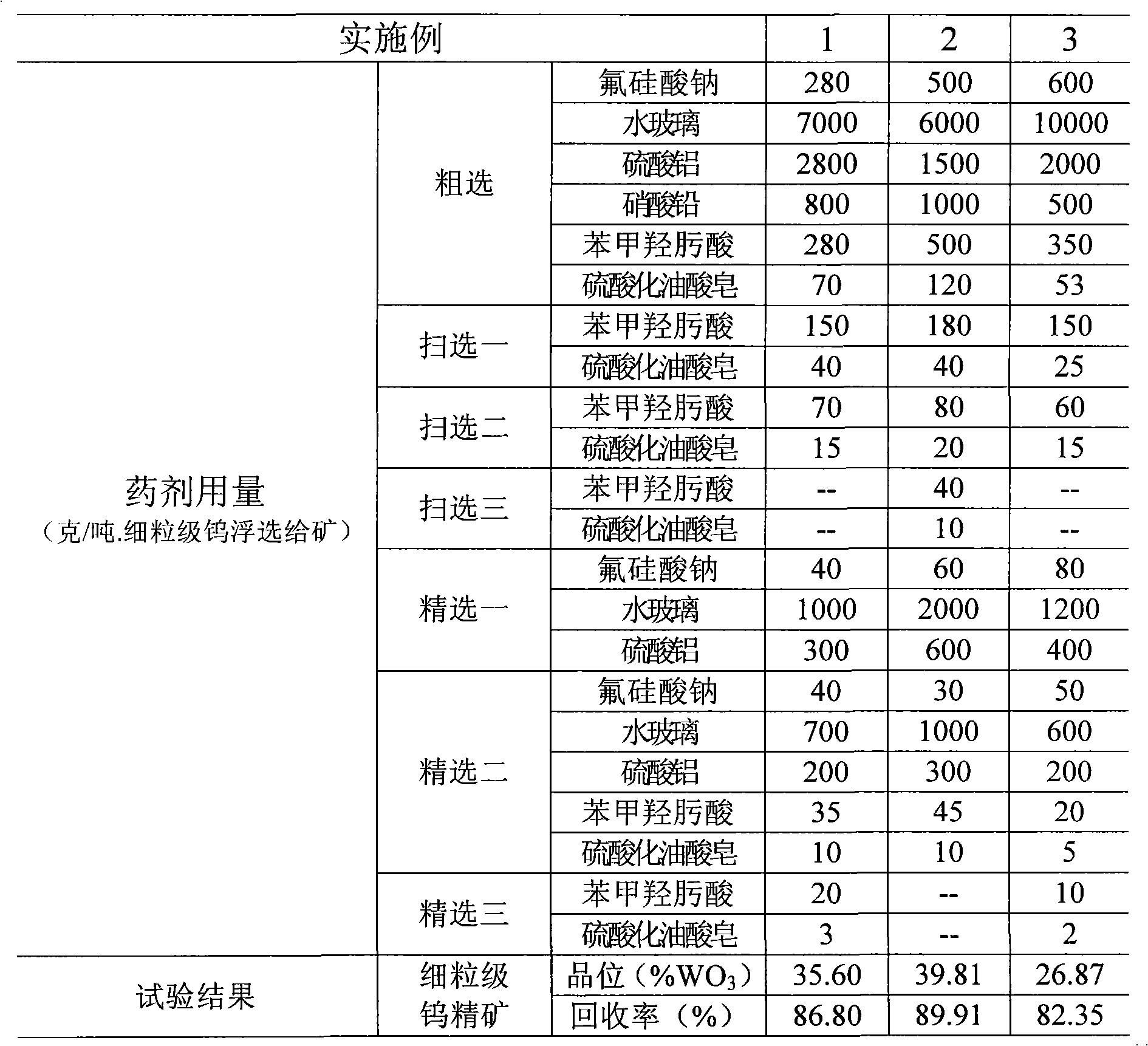

The invention discloses a benefication method for concentrating fine tungsten ore in tailings by warming scheelite, which is characterized by comprising the following steps in turn: performing desliming and reagent removal; condensing concentrate after desliming and reagent removal, which is added with water, into 26 to 44 percent of pulp density, and controlling the pH of pulp at about 8.5; performing floatation on the fine tungsten ore; adding regulators of sodium fluosilicate, soluble glass, aluminium sulphate and lead nitrate; and adding collecting agents of benzohydroxamic acid and sulfated oleate soap, and performing rough concentration, concentration and scavenging to obtain the fine tungsten ore concentration and fine tungsten tailings. The method has simple recovery process flow, stable benefication process, high tungsten recovery rate, and low cost of reagents; the used benefication reagents do not pollute environment; and tailing water can meet the emission requirement. The method is suitable for the fine tungsten ore, of which the WO3 content is 0.95 to 5.10 percent, the ratio of peanut ore to the scheelite is between 1:9 to 9:1, and the occupancy rate of WO3 metal smaller than 30 microns is more than or equal to 60 percent, and which is subjected to concentration of the tailings by warming the scheelite and then reconcentration of the tailings by a shaker.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

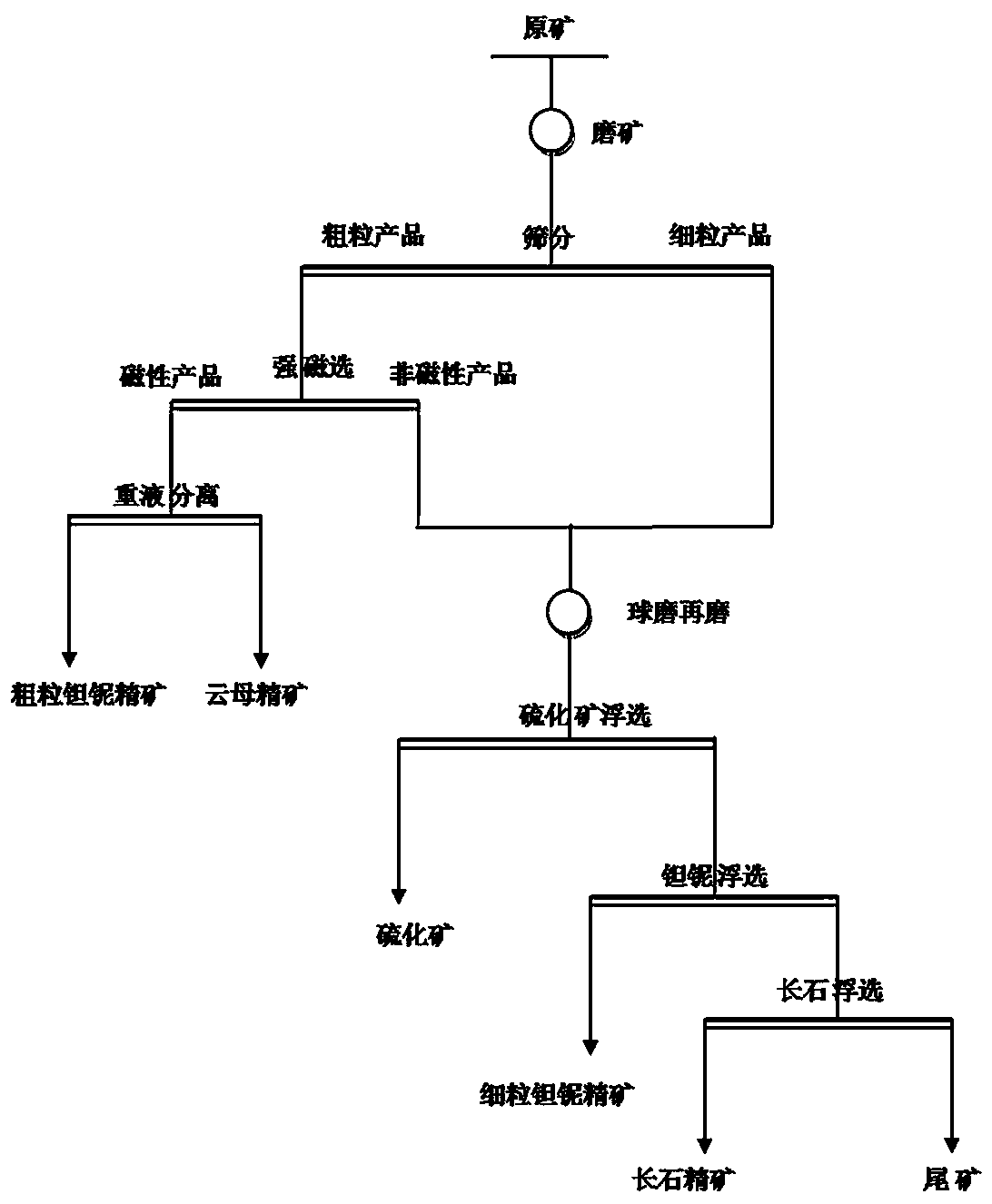

Comprehensive recycling process for associated tantalum-niobium ores

ActiveCN105126993AReduce circulation lossImprove overall recoveryFlotationWet separationImpurityMaterials science

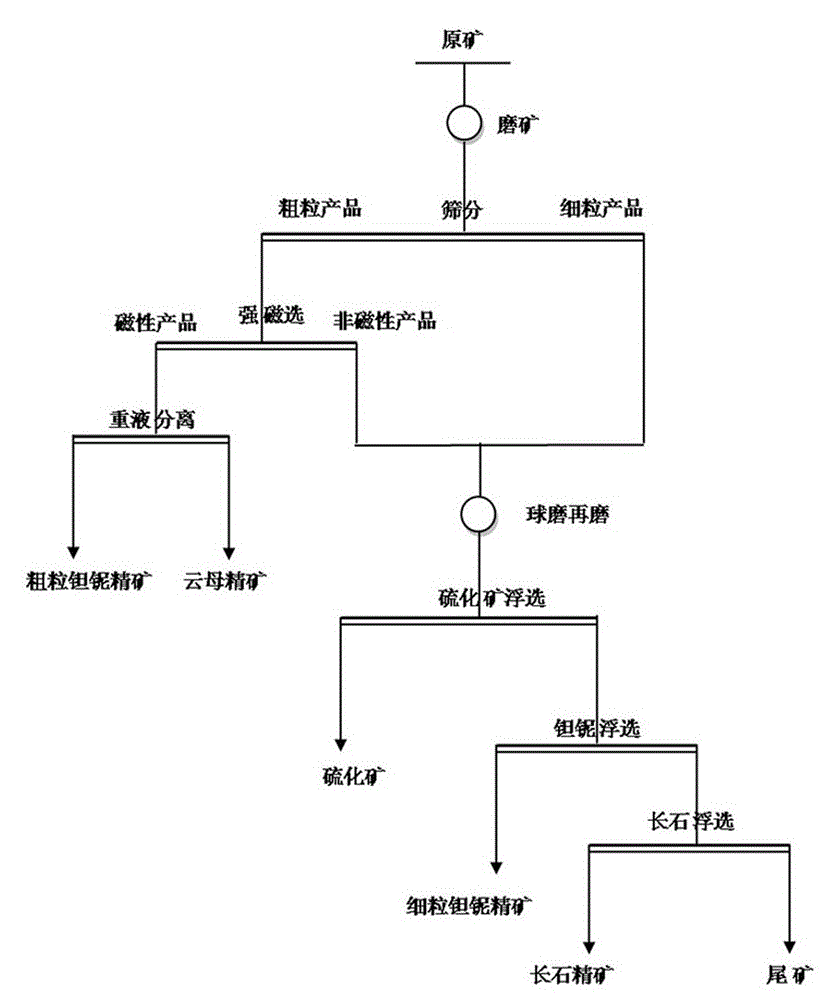

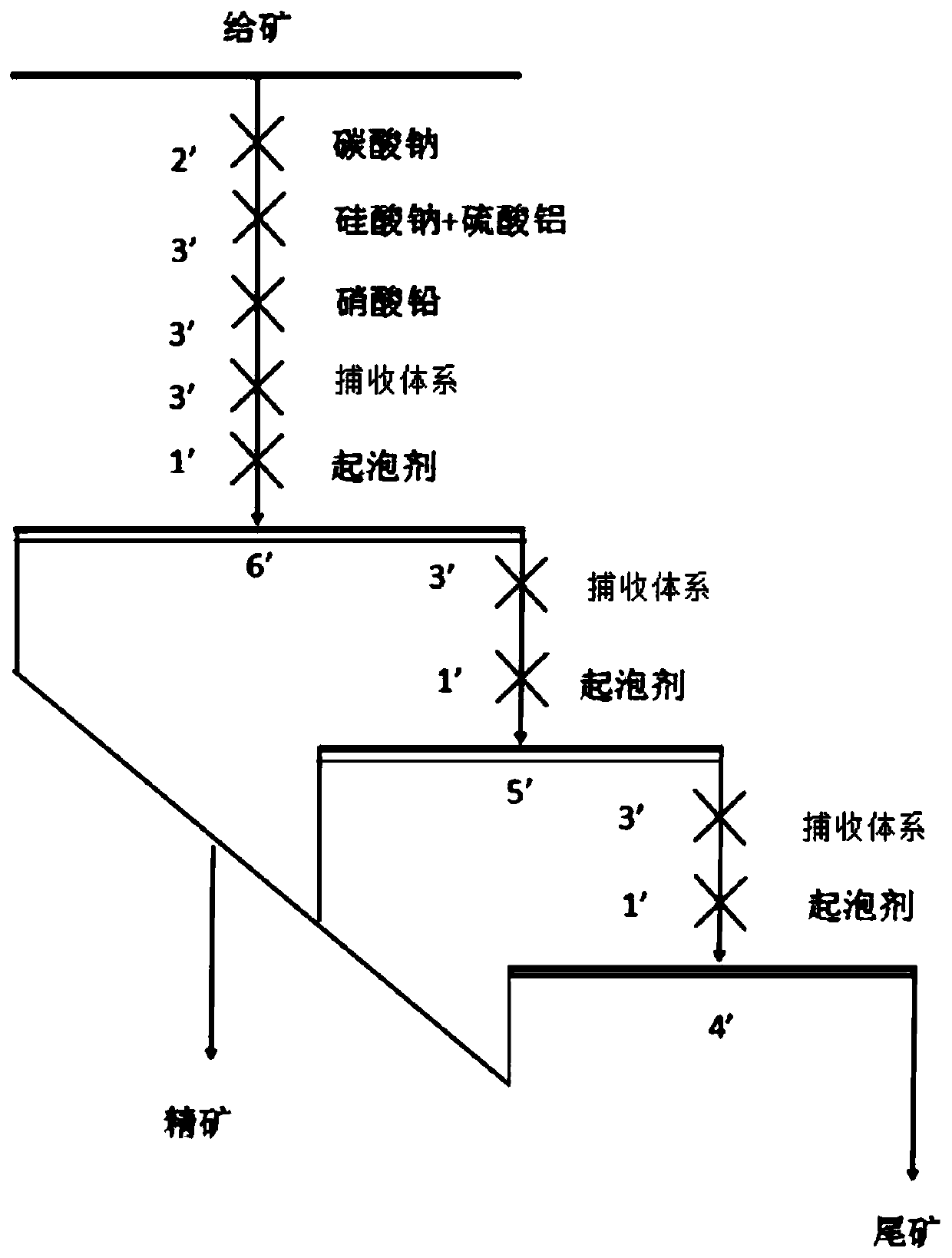

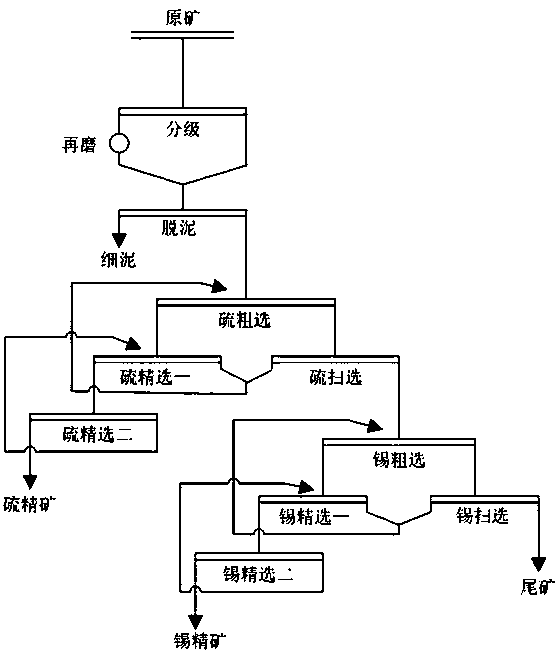

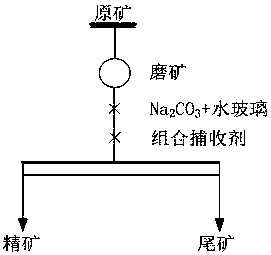

The invention provides a comprehensive recycling process for associated tantalum-niobium ores. Mainly, classification is conducted after raw ores are rough ground; rough grain tantalum-niobium minerals and mica minerals rich in rare metal are recycled from rough grain products on a sieve through a high-gradient magnetic separation-heavy fluid separation method; fine fraction tantalum-niobium minerals and feldspar minerals rich in rare metal are recycled through a floatation method after sulphide ore floatation and impurity removal are conducted on products below the sieve; a combined collecting agent which includes diphosphonic acid, benzohydroxamic acid and soybean oil acid flotation and is high in tantalum-niobium mineral selectivity and collecting capacity is added during tantalum-niobium flotation so that tantalum and niobium can be obtained through floatation. By means of the process, tantalum-niobium minerals good in index are obtained, and other associated rare metal in the minerals is comprehensively recycled.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

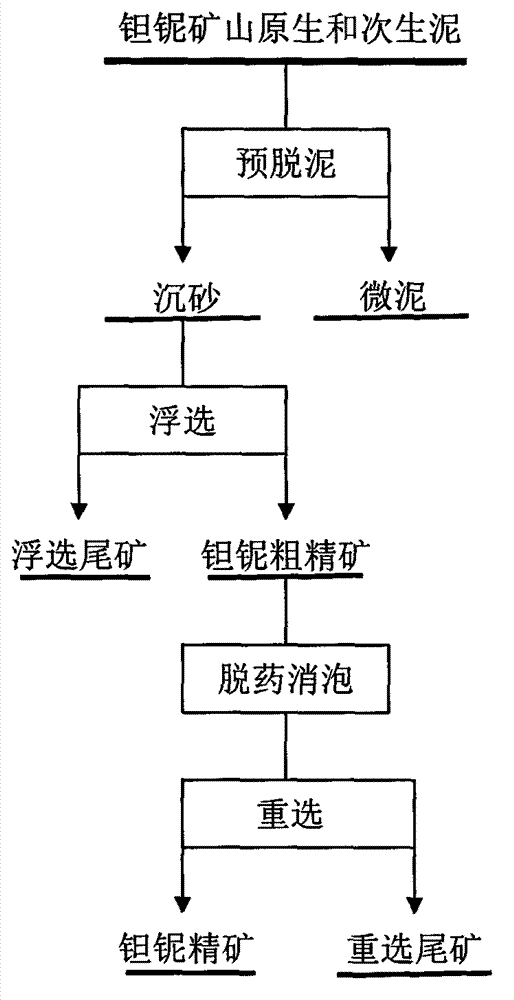

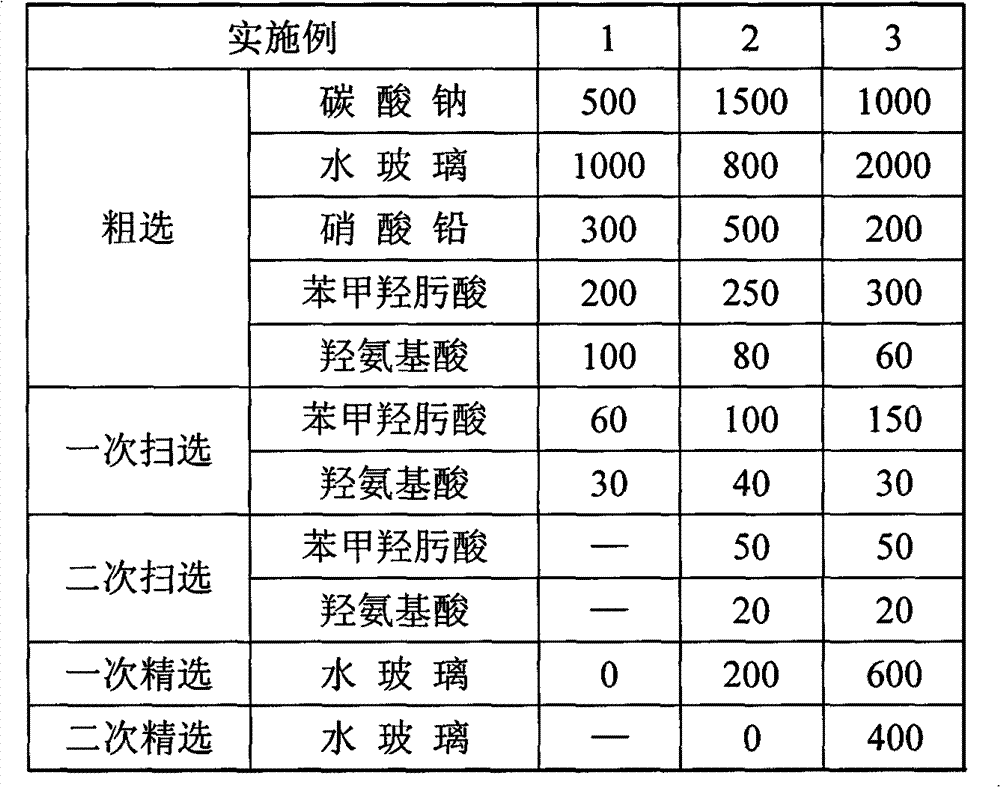

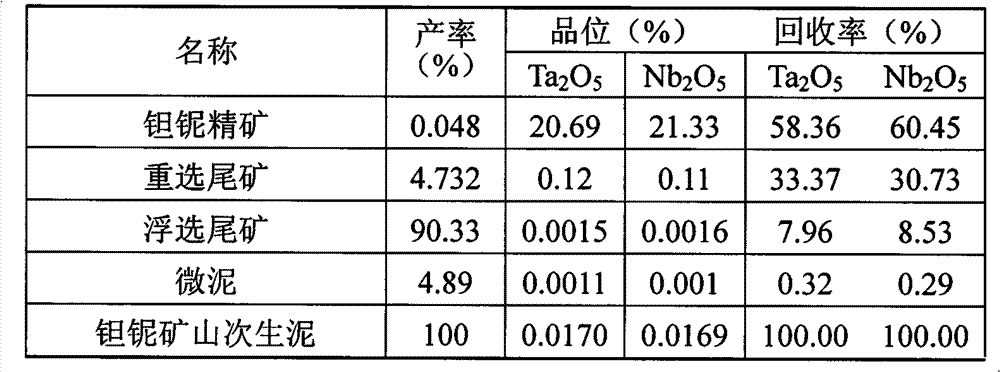

Ore dressing method of micro-fine particle tantalum-niobium ores

InactiveCN102861662AEliminate selection noiseImprove flotation recoveryPlaning/slotting machinesWet separationBenzohydroxamic acidLead nitrate

Disclosed is an ore dressing method of micro-fine particle tantalum-niobium ores. The ore dressing method is characterized by including steps of firstly, performing desliming pre-treatment to obtain set sand and micro-mud; secondly, adding an adjusting agent of sodium carbonate, an inhibiting agent of water glass, an activating agent of lead nitrate and collectors of benzohydroxamic acid and hydroxyamino acid to the set sand for once roughing; adding the benzohydroxamic acid and the hydroxyamino acid for once or twice scavenging; adding the water glass for once or twice concentration or blank concentration to obtain tantalum-niobium rough concentrates and flotation tailings; thirdly, performing de-reagent and de-foaming: adding sulfuric acid to the tantalum-niobium rough concentrates, and stirring the mixture until foams are disappeared; and fourthly, performing gravity concentration: subjecting the tantalum-niobium rough concentrates to de-reagent and de-foaming, and subjecting the tantalum-niobium rough concentrates to gravity concentration to obtain tantalum-niobium concentrates and gravity concentration tailings. According to the ore dressing method of the micro-fine particle tantalum-niobium ores, the recovery rate of the micro-fine particle tantalum-niobium ores is increased by over 30%, and the ore dressing method is applicable to primary mud and secondary mud with sizes of -0.037mm in tantalum-niobium ores.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

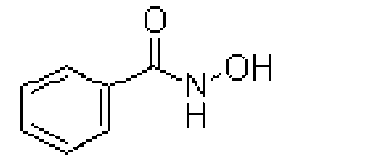

Floating and collecting agent of bertrandite beryllium ores and application thereof

InactiveCN101716559ALarge molecular sizeEfficient flotation collectionFlotationBenzohydroxamic acidBenzyl group

The invention relates to a floating and collecting agent of bertrandite beryllium ores and application thereof. In the invention, benzohydroxamic acid is used as an organic compound collecting agent, and after benzyl is introduced to hydroximic acid, the selective collecting capacity to beryllium ores of hydroximic acid medicaments is improved. The floating and collecting agent is used for the flotation of the bertrandite beryllium ores, has excellent selective collecting property and is a high-efficiency floating and collecting agent for the beryllium ores.

Owner:CENT SOUTH UNIV

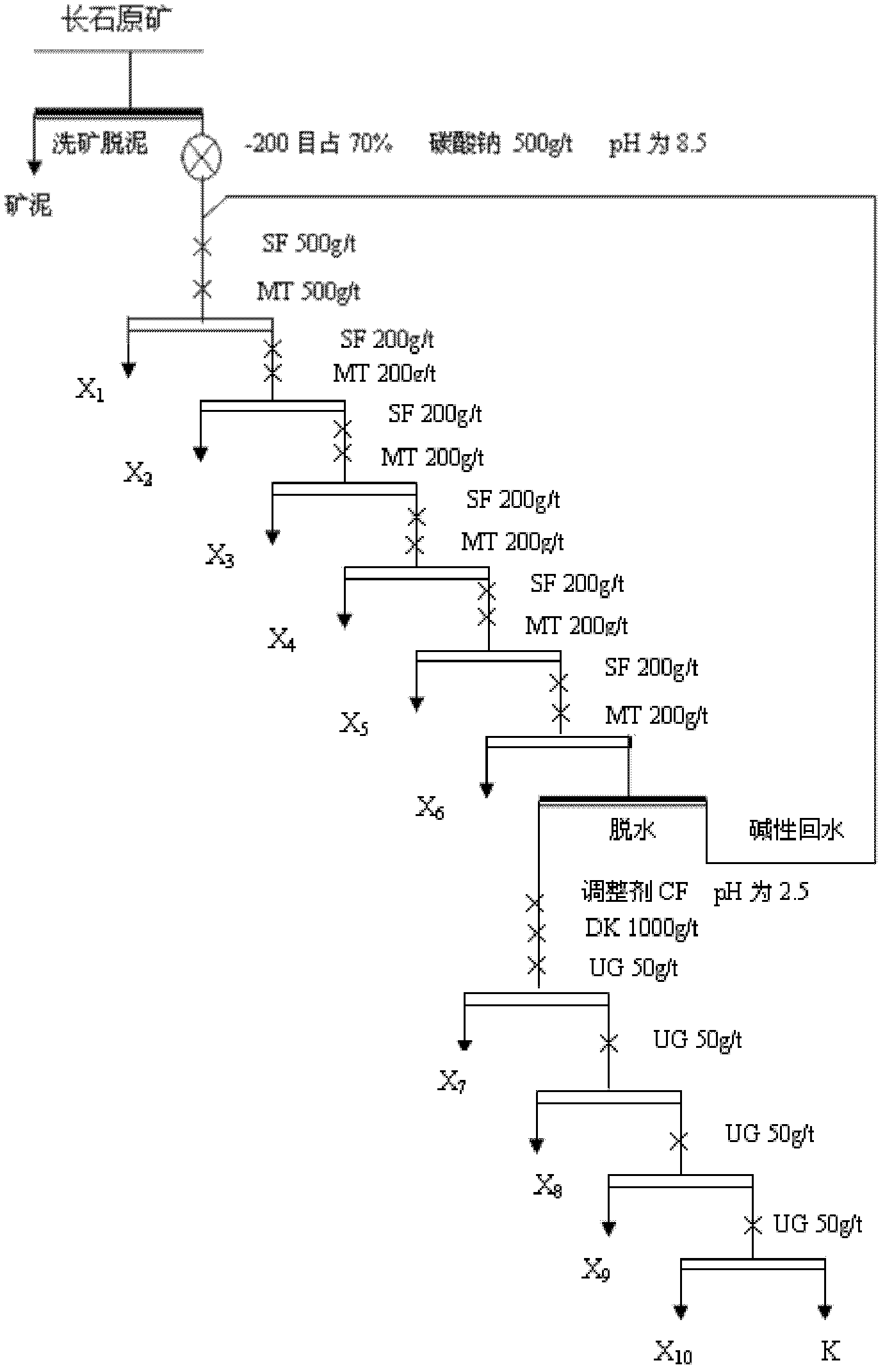

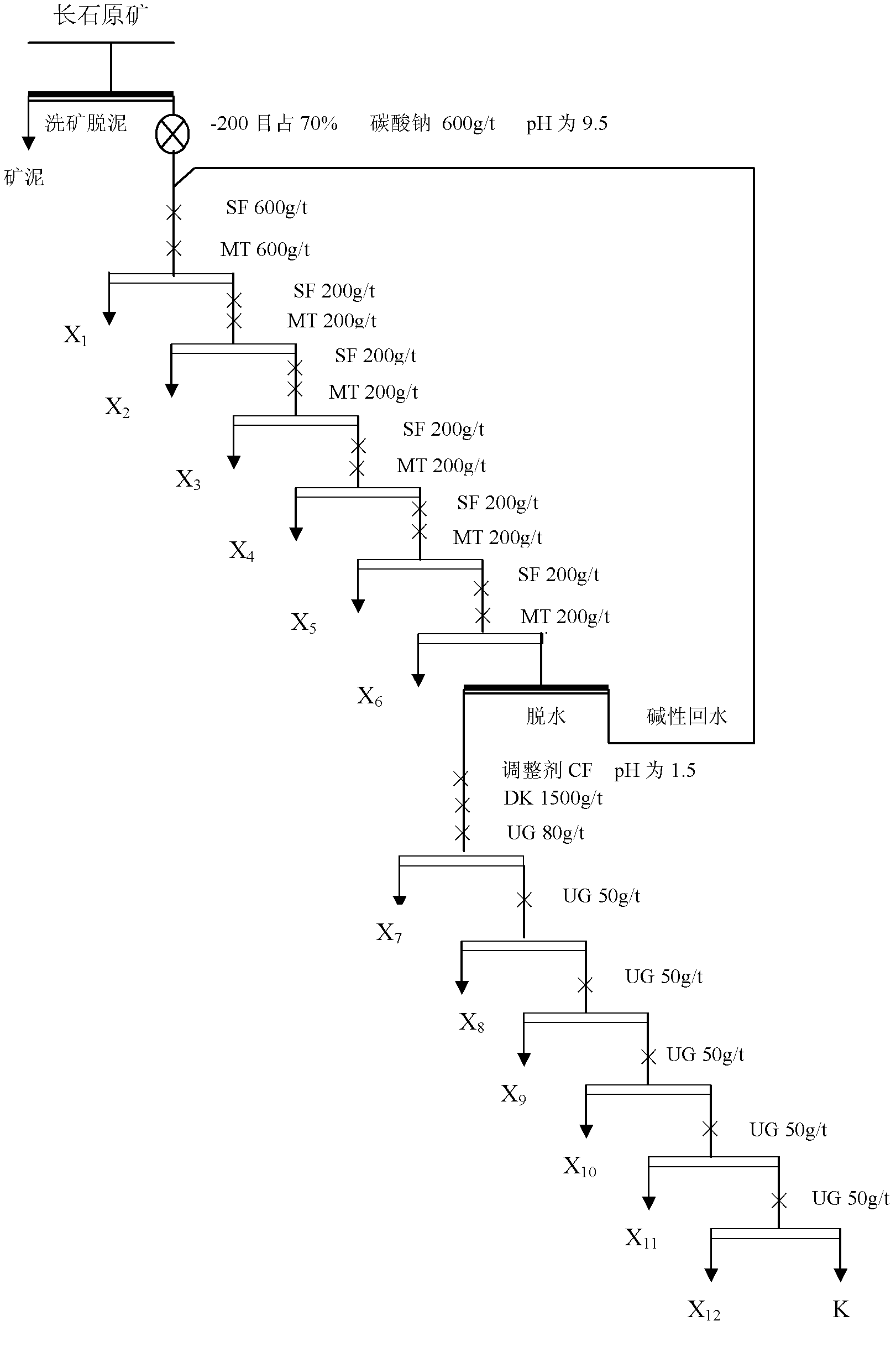

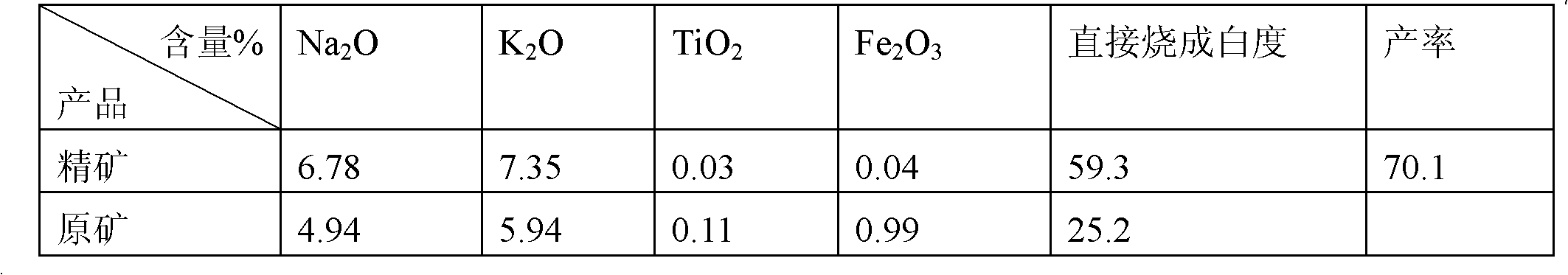

A high-efficiency beneficiation and impurity removal process and combined agent for complex and refractory potassium albite ore

ActiveCN102284352AImprove qualityGood workmanshipFlotationWet separationWater useMethyl isobutyl carbinol

The invention relates to an efficient ore dressing and impurity removal process for potassium and sodium feldspar ores which are complex and difficult to process and a combined medicament thereof. The process comprises the following steps of: desliming and regulating the pH value of ore pulp to 8 to 10 in the phases of desliming by ore washing and grading by ore grinding; adding 1,000 to 2,000 g / t of saponification oleic acid and 1,000 to 2,000 g / t of benzohydroxamic acid in the alkaline flotation phase of reverse flotation impurity removal to perform collection and floatation on iron and titanium minerals by anions, wherein in the saponification oleic acid, a mass ratio of the oleic acid to sodium carbonate is 1:(0.3-0.5); and after dehydrating, regulating the pH value of the ore pulp to2 to 3 in the acidic floatation phase, adding 800 to 1,500 g / t of sodium chloride and 800 to 1,500 g / t of potassium chloride to inhibit potassium and sodium feldspar, and adding 200 to 400 g / t of dodecanaminium and 200 to 400 g / t of methyl isobutyl carbinol (MIBC) which serve as emulsified cation collecting agents to perform the floatation impurities with colors. By the process, feldspar concentrates in which the content of Fe2O3 and TiO2 is below 0.1 percent, and the content of Na2O and K2O is over 14 percent can be obtained, and the whiteness of the directly-sintered feldspar concentrates can reach over 55, so the feldspar concentrates can be used as super high-quality ceramic raw materials, and other products can be used for firing bricks. In addition, return water used in the process in the moisture phase is recycled, namely water dehydrated after alkaline flotation and return water of acidic tailings can return to the process to be recycled, so the process is high in comprehensive recovery efficiency, economic, practical, energy-saving and environment-friendly.

Owner:CENT SOUTH UNIV

Preparation method for trapping agent for bauxite flotation

The invention relates to a preparation method for a trapping agent for bauxite flotation. The method is characterized by comprising the following steps of: undergoing a hydroxyl oximation reaction on a caustic soda solution, a hydroxylamine sulfate solution and methyl benzoate serving as raw materials to obtain a mixed solution containing sodium benzohydroxamic acid, sodium sulfate, methanol and water; and diluting the obtained mixed solution with water. The KL trapping agent prepared with the method has the advantages of high trapping capability, small using amount, good separating effect, effective reduction in chloride ions which are introduced into an alumina production flow, and effective reduction in corrosion of stainless steel equipment in ore dressing and the alumina production flow.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

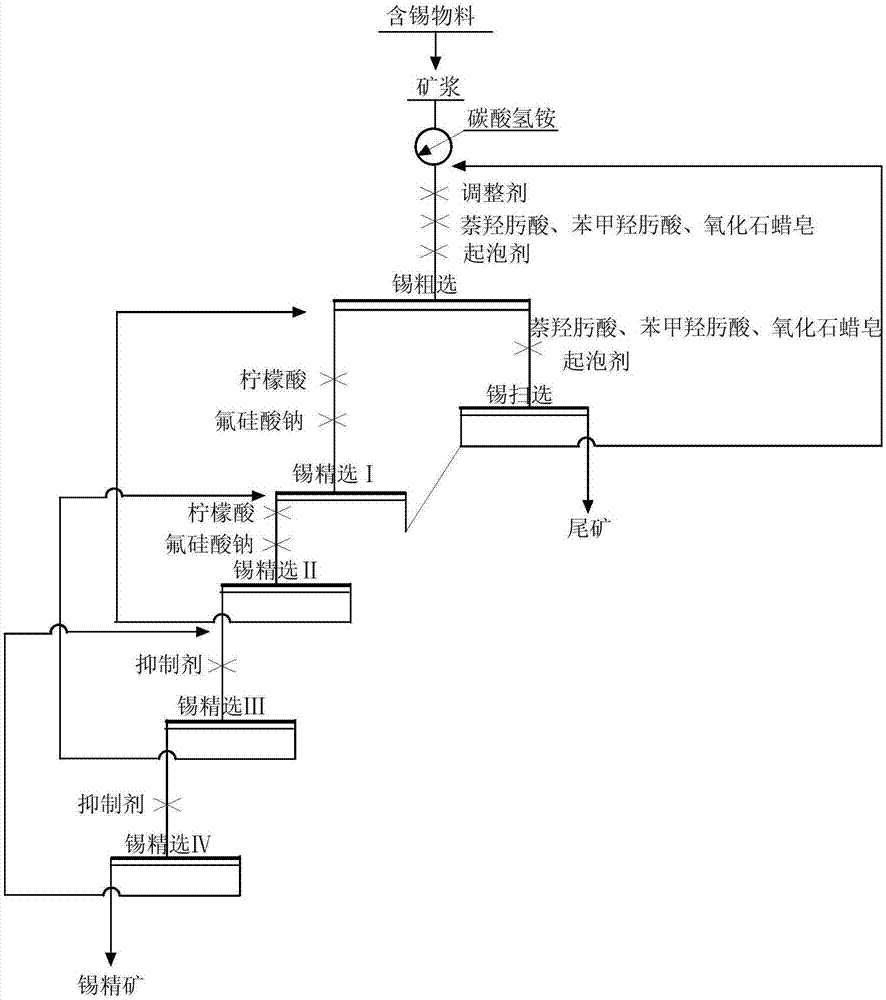

Micro-fine particle cassiterite flotation method

The invention relates to a micro-fine particle cassiterite flotation method. The micro-fine particle cassiterite flotation method comprises the steps that tin-containing materials are prepared into pulp, and ammonium bicarbonate is added in the pulp; then an adjusting agent, collecting agents and a foaming agent are added, wherein the collecting agents comprise naphthalene hydroximic acid, benzohydroxamic acid and oxidized paraffin wax soap; and the pulp is subjected to roughing, and then citric acid and sodium fluosilicate are added into tin rough concentrate for choiceness to obtain cassiterite concentrate. The problems that the micro-fine particle cassiterite flotation recovery rate is low, the concentrate grade is unsatisfactory, and the impurity content is high are solved, and the tin concentrate with the Sn content being larger than or equal to 35% and the recovery rate being larger than or equal to 90% can be obtained; and compared with the prior art, the thin concentrate recovery rate is increased by 15-20%, and the tin concentrate grade is improved by 10-15%. The low-carbon, environment-friendly, economical and efficient method for micro-fine particle cassiterite recovery through flotation is simple in technique, has the advantages that the material adaptability is high, using is safe and stable, the reagent dosage is few, and pollution is little, and has good application prospects.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

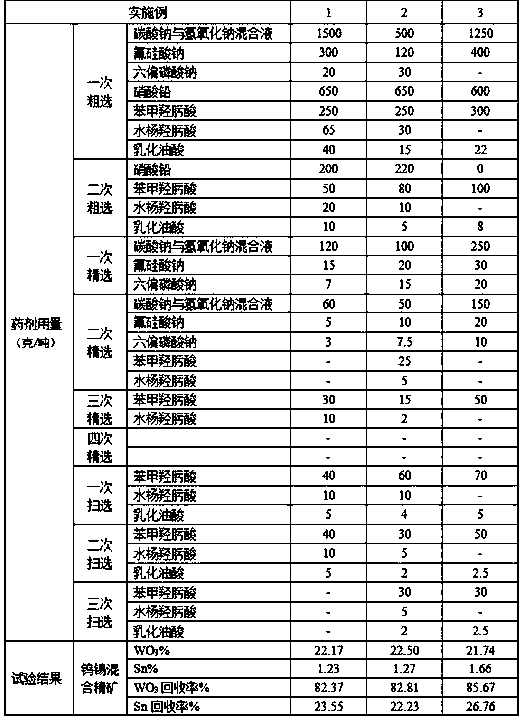

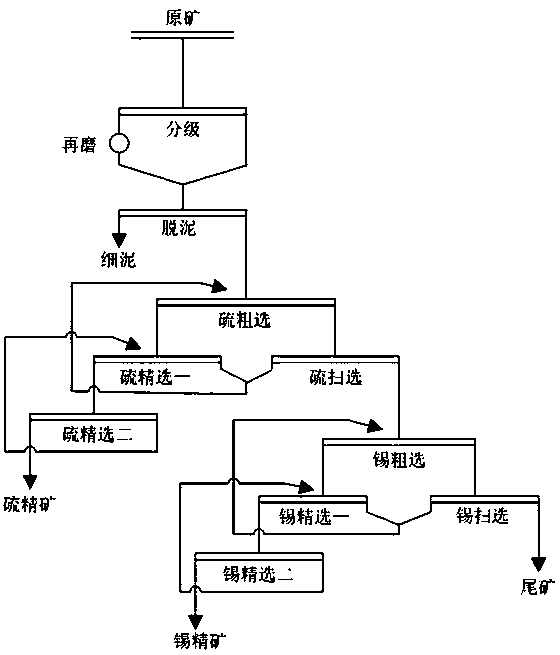

Tungsten tin mineral beneficiation method

ActiveCN109127120ASolve the problem of high mineral processing costIncrease profitFlotationLead nitrateHydroxamic acid

The invention discloses a tungsten tin mineral beneficiation method; and tungsten tin minerals are tungsten tin fed ores as sulfide ores flotation tailings obtained after grinding of multimetal ores of tungsten associated cassiterite, removal of magnetite by magnetic separation and removal of sulfur concentrates by sulfide ore flotation. Mixed liquid of sodium carbonate and sodium hydroxide, sodium fluosilicate, sodium hexametaphosphate and lead nitrate are added in the tungsten tin fed ores for pulping; then, collecting agents-benzohydroxamic acid, hydroxamic acid and emulsified oleic acid are added for tungsten tin mixed flotation; and tungsten tin mixed concentrates with WO3 of not less than 20% and Sn of not less than 1% are obtained by 2 times of roughing, 3-4 times of selection and 2-3 times of scavenging. The method has the following characteristics: the beneficiation method of tungsten tin mixed flotation is used for the tungsten tin fed ores; and when tungsten minerals are recovered by floatation, tin minerals are enriched in tungsten concentrates to achieve the purpose of synchronously recovering the tin minerals. The method is simple in recovery process flow, stable in beneficiation process and suitable for beneficiation of the tungsten tin fed ores with WO3 of 0.2-0.5%, Sn of not more than 0.2%, CaF2 of not more than 25%, CaCO3 of not more than 10% and the black andwhite tungsten ratio of 2: 8-8: 2.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

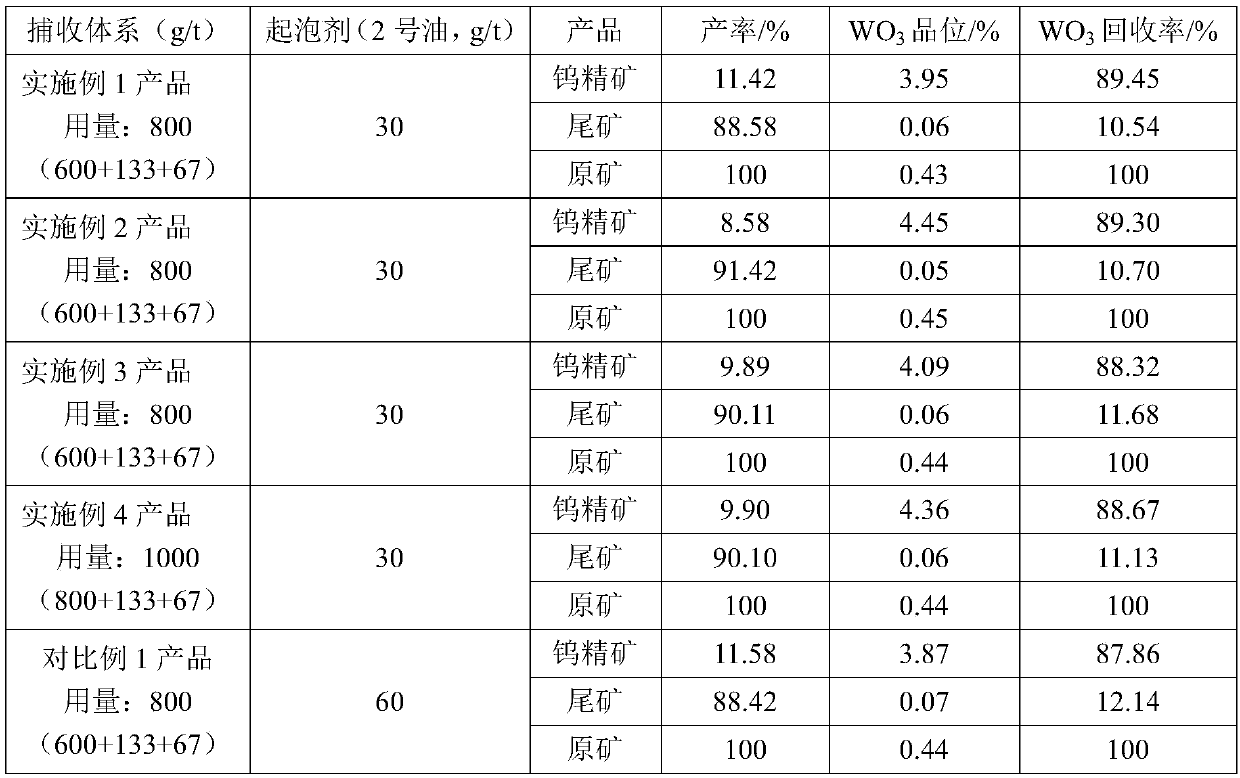

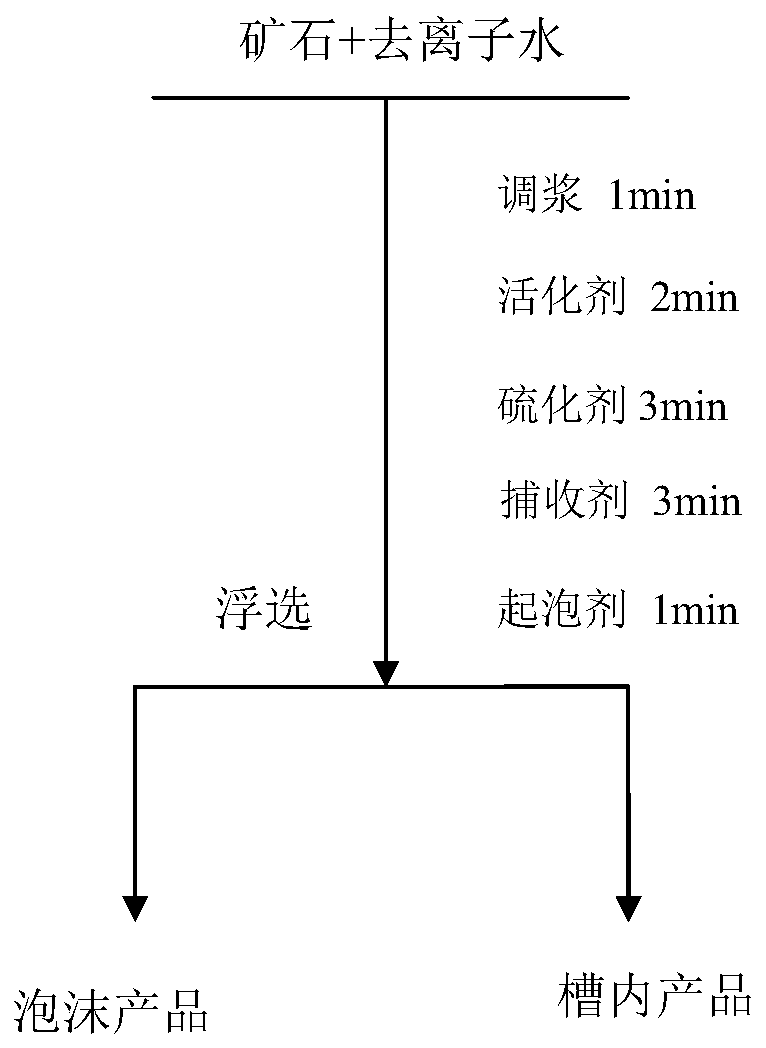

Collecting system prepared from W/O/W multiphase emulsion as well as preparation method and application thereof

ActiveCN110142143ADisadvantages of preventing low utilizationIncreased solubilization benefitFlotationHydroxylamineHydroxylamine Hydrochloride

The invention relates to a collecting system prepared from W / O / W multiphase emulsion as well as a preparation method and application thereof. The method comprises the following steps: adding a hydroxylamine water solution into a methyl benzoate and surfactant system; after the system is uniformly dispersed to form water-in-oil microemulsion, adding alkali and neutralizing to form the water-in-oil-in-water W / O / W multiphase emulsion; carrying out oximation reaction; then dropwise adding concentrated sulfuric acid to obtain the collecting system. The collecting system provided by the invention selects water as a solvent and is green and environmentally friendly; the W / O / W multiphase emulsion is constructed so that the utilization rate of hydroxylamine is improved and the reaction of the hydroxylamine is accelerated; and the yield of benzohydroxamic acid is high and the energy consumption is low. The collecting system prepared by the method contains the benzohydroxamic acid, a surfactant and other impurity components; the surfactant can have a foaming effect and can be used for reducing the dosage of a foaming agent when being applied to mineral dressing engineering; and in a floatation process, the cost of medicaments is reduced and the collecting effect is relatively good.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

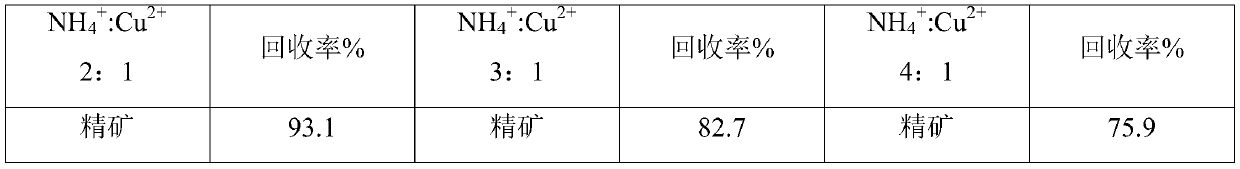

Copper-ammonia complex ion sulfuration activator and application thereof

ActiveCN110394240AImprove flotation effectImprove flotation recoveryCopper oxides/halidesCopper ammonia complexesBenzohydroxamic acidCopper oxide

Owner:HUNAN RES INST FOR NONFERROUS METALS

Halogenated benzohydroxamic acid collecting agent and application thereof in mineral flotation

PendingCN113385305AEnhanced harvesting capacityStrong harvesting abilityFlotationBenzohydroxamic acidMining engineering

The invention relates to the technical field of mineral flotation, and particularly discloses a halogenated benzohydroxamic acid collecting agent and application thereof in mineral flotation. The halogenated benzohydroxamic acid collecting agent provided by the invention comprises at least one of compounds shown in the formula (I). According to the halogenated benzohydroxamic acid provided by the invention, after the benzohydroxamic acid is subjected to halogen modification, a hydrophobic parameter logP of a molecule is positively responded, and the contribution rate of the unit molecule to the hydrophobic property of the mineral surface is remarkably improved by changing the logP of the molecule; meanwhile, compared with benzohydroxamic acid, halogenated benzohydroxamic acid can change the chelating capacity of the compound on positioning ions on the surfaces of all minerals, chelating groups in molecules generate a new chelating relation on the positioning ions on the surfaces of the minerals, then the separation efficiency in the mineral flotation process is improved, and the separation effect of a flotation system is improved.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Mixed collector of cassiterite and preparation method and application thereof

InactiveCN109967260AConducive to flotationFully dissociatedFlotationWet separationBenzohydroxamic acidCassiterite

The invention discloses a mixed collector of cassiterite and a preparation method and application thereof. The mixed collector of the cassiterite is formed by mixing salicylhydroxamic acid, benzohydroxamic acid and styrene phosphonic acid. By means of the mixed collector, the agent cost is reduced, the viscosity of bubbles in the floatation process is reduced, the floatation indexes of tin are increased, low-grade tin tailings are classified in advance, coarse fraction products are fully disaggregated, recovery of the tin is facilitated, the classified products are deslimed, the influences offine silt on following tin floatation are reduced, the consumption of the fine silt on agents is reduced, and the tin grade and the tin recovery rate are increased while the production cost is reduced.

Owner:KUNMING UNIV OF SCI & TECH

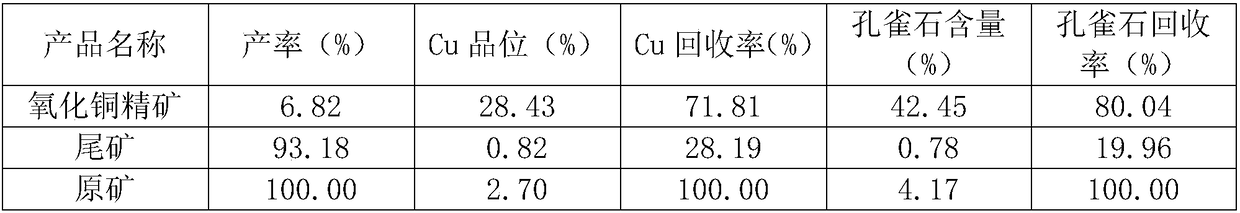

Combined collector in flotation of copper oxide ores and using method thereof

InactiveCN108212541AReduce dosageDoes not affect subsequent separation operationsFlotationBenzohydroxamic acidEconomic benefits

The invention belongs to the technical field of beneficiation collectors, in particular to a combined collector in flotation of copper oxide ores and a using method thereof. The combined collector isformed by mixing benzohydroxamic acid, proxan sodium and fatty alcohol-polyoxyethylene ether according to the weight ratio of 75:22:3. The combined collector in flotation of the copper oxide ores andthe using method thereof have the advantages that the problem that the grade and the recovery rate of copper oxide concentrates are low in a conventional method can be solved, higher efficiency for collecting malachite-oriented and chrysocolla-oriented copper oxide minerals by using the combined collector can be achieved, the combined collector can be reduced, the technological process is simple,meanwhile, better qualified products of the copper oxide concentrates can be obtained, and the economic benefits of enterprises can be improved.

Owner:CHANGCHUN GOLD RES INST

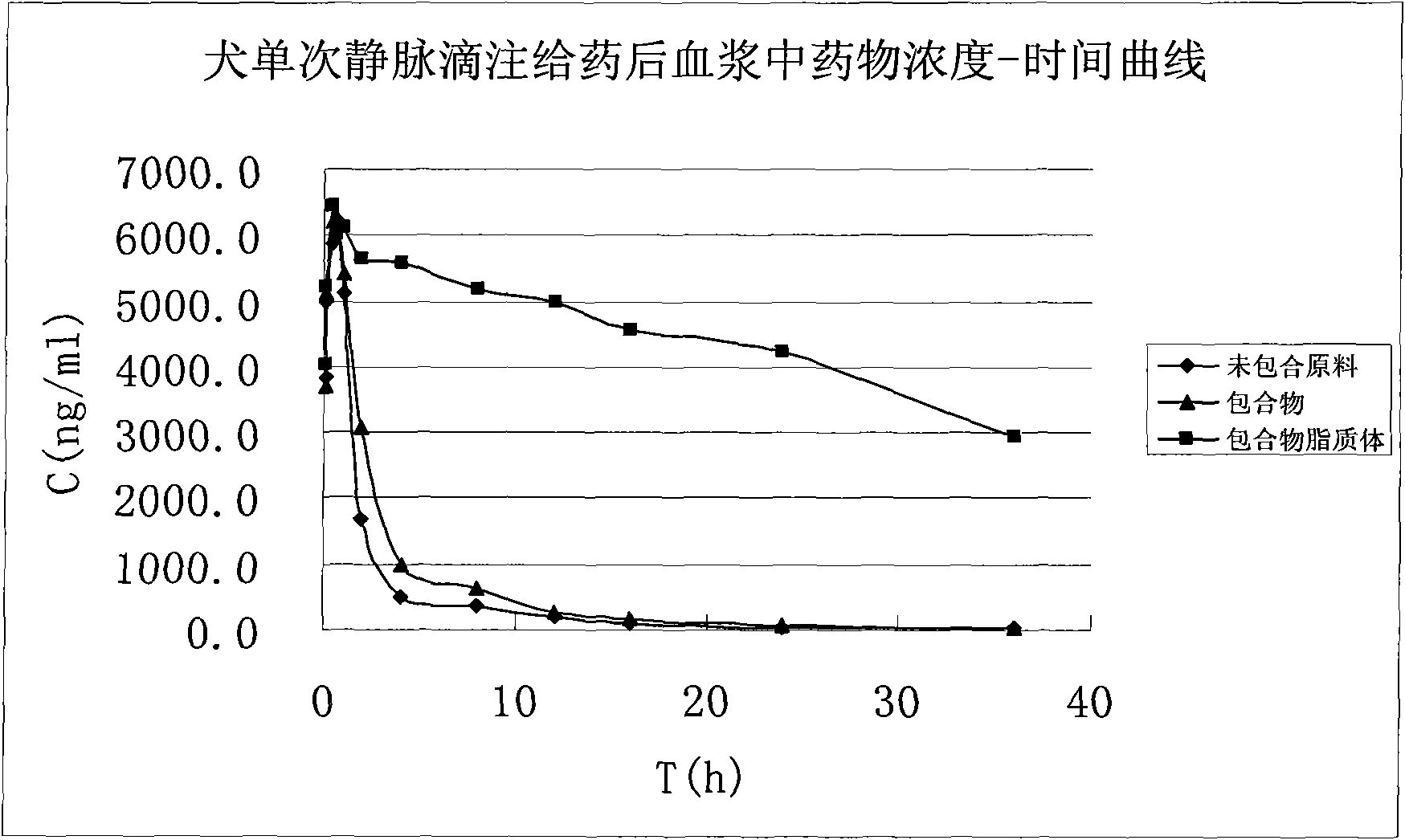

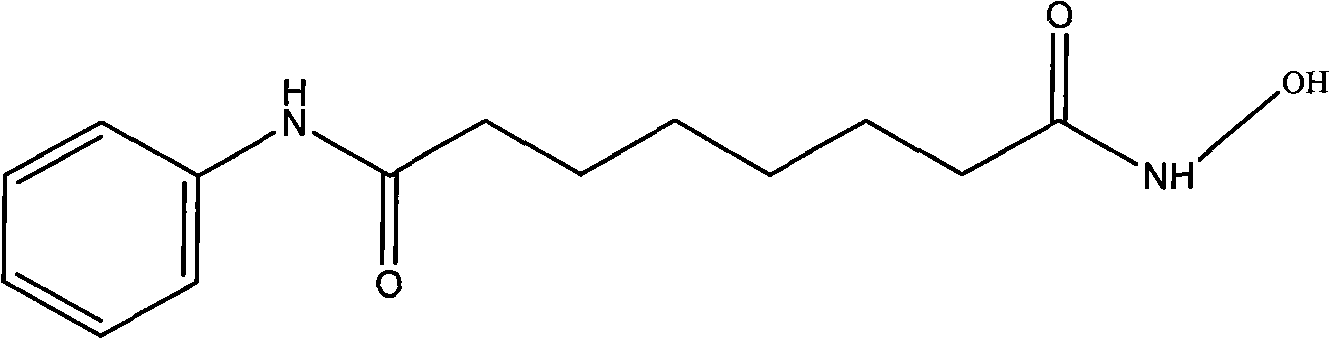

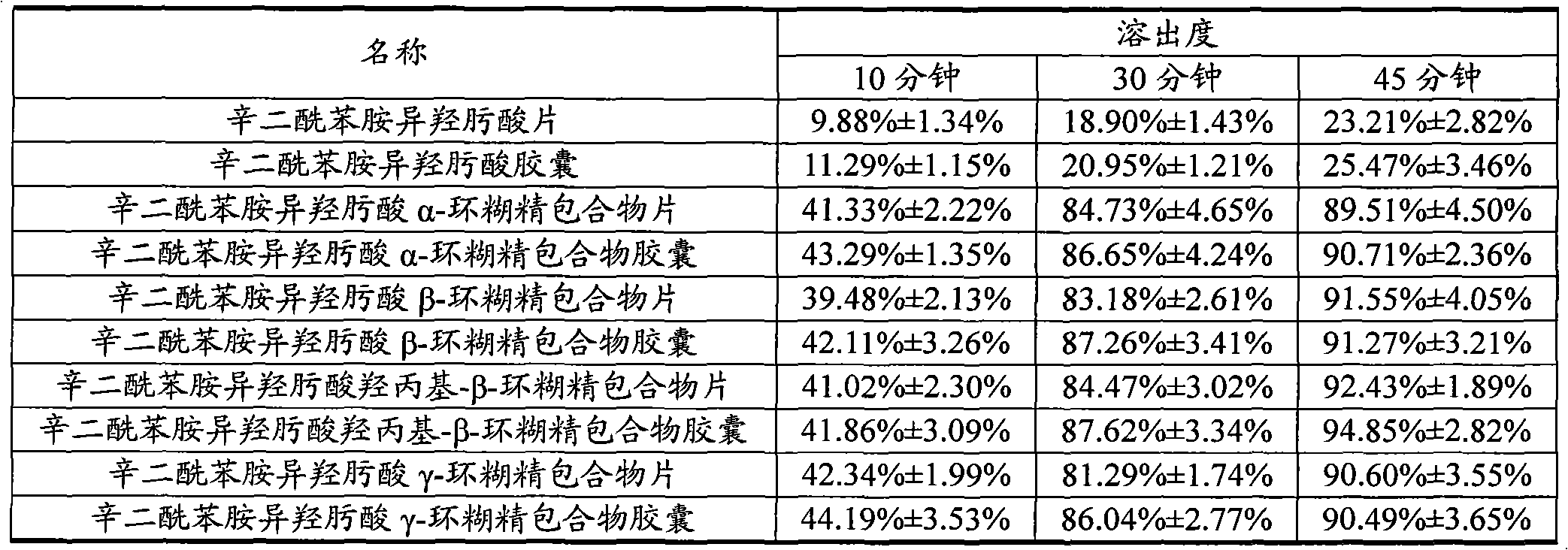

Octanedioyl benzohydroxamic acid cyclodextrin clathrate liposome

InactiveCN102397248AImprove stabilityReduce releaseOrganic active ingredientsPharmaceutical non-active ingredientsBenzohydroxamic acidCholesterol

The invention relates to a novel octanedioyl benzohydroxamic acid cyclodextrin clathrate liposome, a preparation method thereof, and an application thereof in medicine preparations. The octanedioyl benzohydroxamic acid cyclodextrin clathrate liposome provided by the invention is composed of an active component octanedioyl benzohydroxamic acid, a cyclodextrin clathration agent, and a phospholipid material. Preferably, the octanedioyl benzohydroxamic acid cyclodextrin clathrate liposome comprises cholesterol. The invention also provides a method for preparing the octanedioyl benzohydroxamic acid cyclodextrin clathrate liposome, and an octanedioyl benzohydroxamic acid intravenous infusion composition. The octanedioyl benzohydroxamic acid cyclodextrin clathrate liposome provided by the invention is advantaged in good stability, and provides functions of medicine releasing delaying, toxicity reducing, treatment effect improving, and the like.

Owner:EVERYTHING BEIJING MEDICAL TECH DEV

Combined reagent for microfine-particle cassiterite flotation and application method thereof

InactiveCN108393198AReduce consumptionEnhanced harvesting capacityFlotationBenzohydroxamic acidCassiterite

The invention discloses a combined reagent for microfine-particle cassiterite flotation and an application method thereof, and belongs to the field of mineral flotation reagents. The combined reagentcomprises the following raw materials in percentage by mass: 10-50 wt% of tributyl phosphate, 10-50 wt% of benzohydroxamic acid, 10-50 wt% of pyruvic acid, and 2-10 wt% of terpenic oil. The combined reagent is mixed according to a certain ratio; through a cooperative effect of the reagent, the cassiterite capturing capacity is improved, and better selectivity is achieved; and compared with a single cassiterite floatation collecting agent, the advantages of low reagent consumption, low cost, normal-temperature dissolution, no poison, high efficiency and environmental protection are achieved, inparticular, the better effect on floatation of microfine-particle cassiterite with particle sizes of 2-38 microns is achieved, and important significance on recycling of tin ore resources is improved.

Owner:KUNMING UNIV OF SCI & TECH

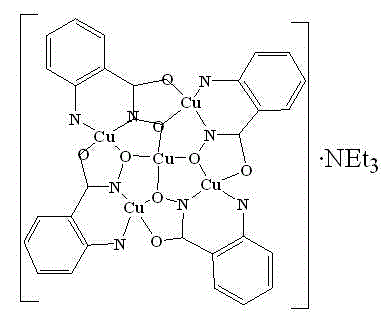

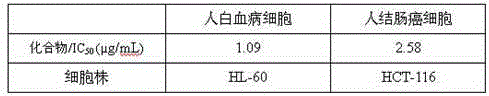

O-amino benzohydroxamic acid copper compound, preparation method and applications thereof

InactiveCN104817576AHigh anticancer activityIncrease fat solubilityCopper organic compoundsAntineoplastic agentsLeukemiaCoordination complex

The present invention discloses an o-amino benzohydroxamic acid copper compound. The preparation method comprises: mixing and dissolving o-amino benzohydroxamic acid and Cu(OAc)2.H2O in a methanol solution, stirring at a room temperature, adding triethylamine, continuously stirring, filtering to obtain a deep green solution, natural evaporating the filtrate, and obtaining the dark green crystal after three weeks. According to the present invention, the copper compound has a high anticancer activity and can be adopted as the raw material to prepare drugs for treatment of human promyelocytic leukemia and human colon cancer; and compared with the widely-used platinum anticancer drugs, the copper coordination compound of the present invention has characteristics of high anticancer activity, good liposolubility, low cost, simple preparation method, and the like, and provides the new way for development of anticancer drugs.

Owner:LIAOCHENG UNIV

Scheelite flotation collecting agent

InactiveCN111495607AIncreased floatabilityImprove stabilityFlotationBenzohydroxamic acidEconomic benefits

The invention provides a scheelite flotation collecting agent and a preparation method thereof. The scheelite flotation collecting agent is prepared from, by weight, 25%-50% of benzohydroxamic acid, 50%-75% of modified fatty acid and 0.5%-2% of water glass. The scheelite flotation collecting agent is used for scheelite flotation, is good in low temperature resistance, good in selectivity and highin collecting capacity, and can obtain scheelite rough concentrate with the high grade and the high recovery rate. The preparation method of the scheelite flotation collecting agent is wide in sourceof the raw materials and simple in preparation process, the produced scheelite flotation collecting agent is good in dissolving performance, strong in collecting force, high in selectivity and good inlow temperature resistance, the fine scheelite grade can be effectively improved after all the components cooperate, the beneficiation technical index is effectively improved, economic benefits are remarkable, and good market popularization prospects are achieved.

Owner:河南天鸿选矿科技有限公司

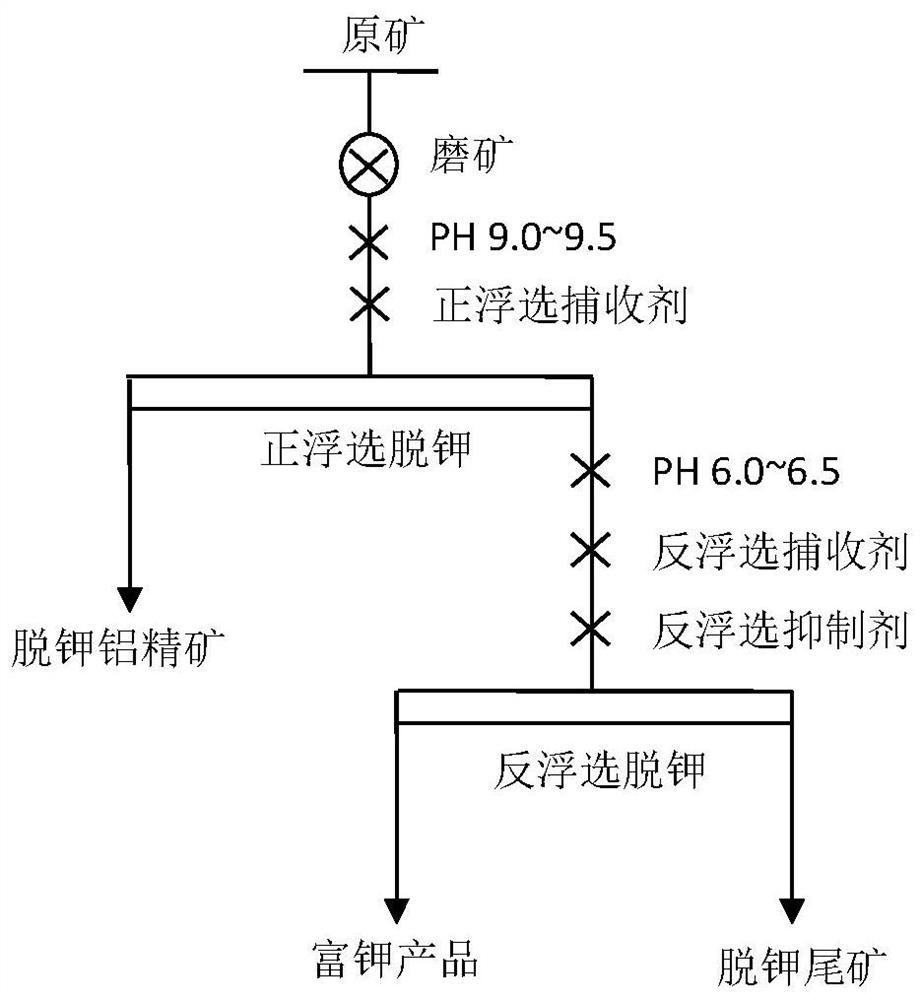

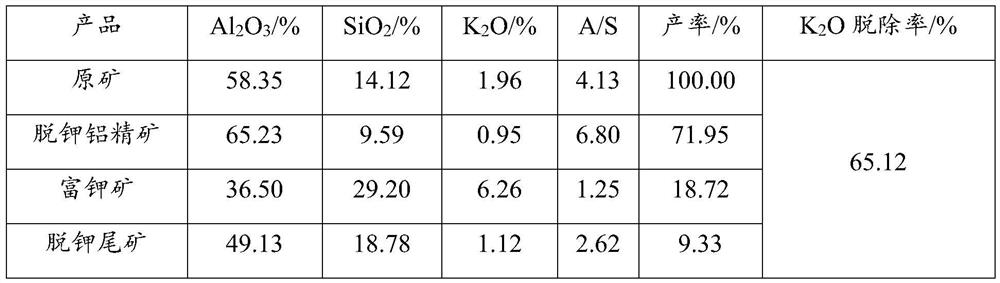

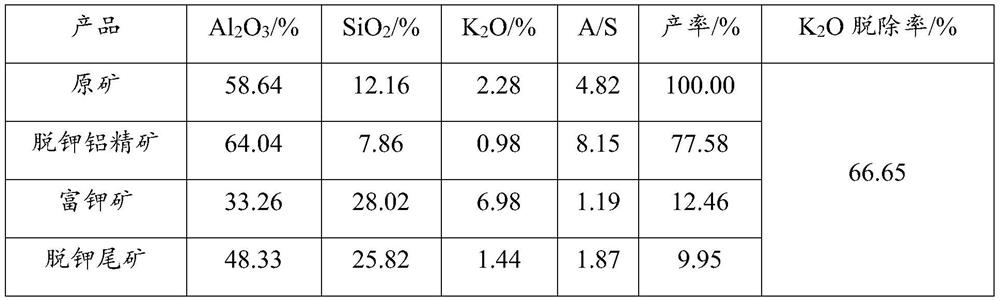

Flotation method for removing potassium from potassium-containing bauxite

The invention discloses a flotation method for removing potassium from potassium-containing bauxite. The flotation method comprises the following steps: (1) grinding the potassium-containing bauxite until the potassium-containing bauxite with the fineness of-0.074 mm accounts for 85-95% of the total mass; (2) performing direct flotation on the potassium-containing bauxite obtained in the step (1)to remove potassium; (3) carrying out reverse flotation potassium removal on the direct flotation underflow obtained by the direct flotation potassium removal in the step (2); in the direct flotationpotassium removal process, the adopted direct flotation potassium removal collecting agent is selected from one or more than two of sodium oleate, benzohydroxamic acid or oxidized paraffin soap; in the reverse flotation potassium removal process, the adopted reverse flotation potassium removal collecting agent is selected from one or more than two of dodecyl trimethyl ammonium chloride, dodecyl dimethyl benzyl ammonium chloride or hexadecyl trimethyl ammonium bromide; in the reverse flotation potassium removal process, a reverse flotation inhibitor is adopted, and the reverse flotation inhibitor is selected from starch and / or dextrin. According to the flotation method for removing potassium from potassium-containing bauxite, the potassium oxide removal rate is remarkably increased.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for separating black and white tungsten bulk flotation rough concentrates

ActiveCN102211053BHigh recovery rateReduce mutual interferenceGlass recyclingWet separationLead nitrateFatty acid

The invention relates to a method for separating black and white tungsten bulk flotation rough concentrates. The method is characterized in that a black tungsten rough concentrate and a white tungsten rough concentrate are obtained by virtue of high-gradient magnetic separation, roughing or roughing and scavenging; black tungsten concentrates and black tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and four-time concentrating on the black tungsten rough concentrate by utilizing sodium fluosilicate, sodium silicate, aluminum sulfate, lead nitrate, benzohydroxamic acid and sulfated nascent soap; white tungsten concentrates and white tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and three-time concentrating on the white tungsten rough concentrate after the white tungsten rough concentrate is heated up and stirred by utilizing sulfated fatty acid soap, sodium silicate, caustic soda and sodium sulfide; cassiterites in the white tungsten cleaner tailings are recovered by a table concentrator. The method related by the invention has the advantages of small mutual interference of black tungsten ore and white tungsten ore in the black and white tungsten bulk flotation rough concentrates, high recovery ratio of black tungsten ore and high and stable quality of the black tungsten ore; and the method is suitable for the black and white tungsten bulk flotation rough concentrates containing 5-40% of WO3.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

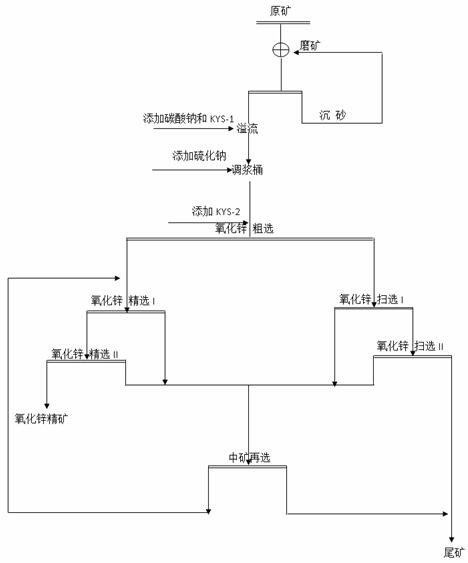

Low-temperature-resistant zinc oxide ore flotation composite reagent and preparation method and application thereof

ActiveCN111940146ALow costTo promote floatingFlotationProcess efficiency improvementAcetic acidBenzohydroxamic acid

Owner:云南省地质矿产勘查开发局中心实验室

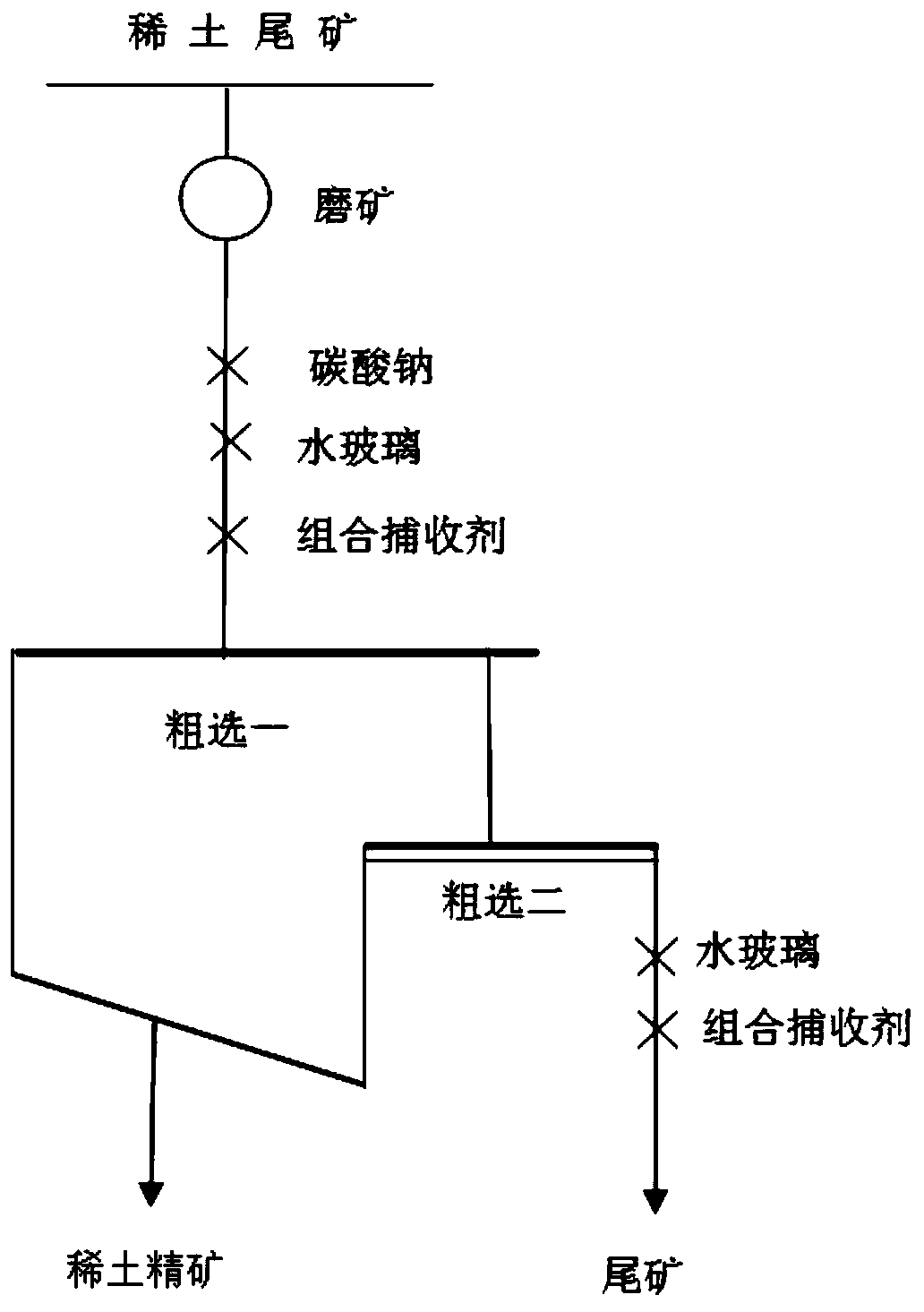

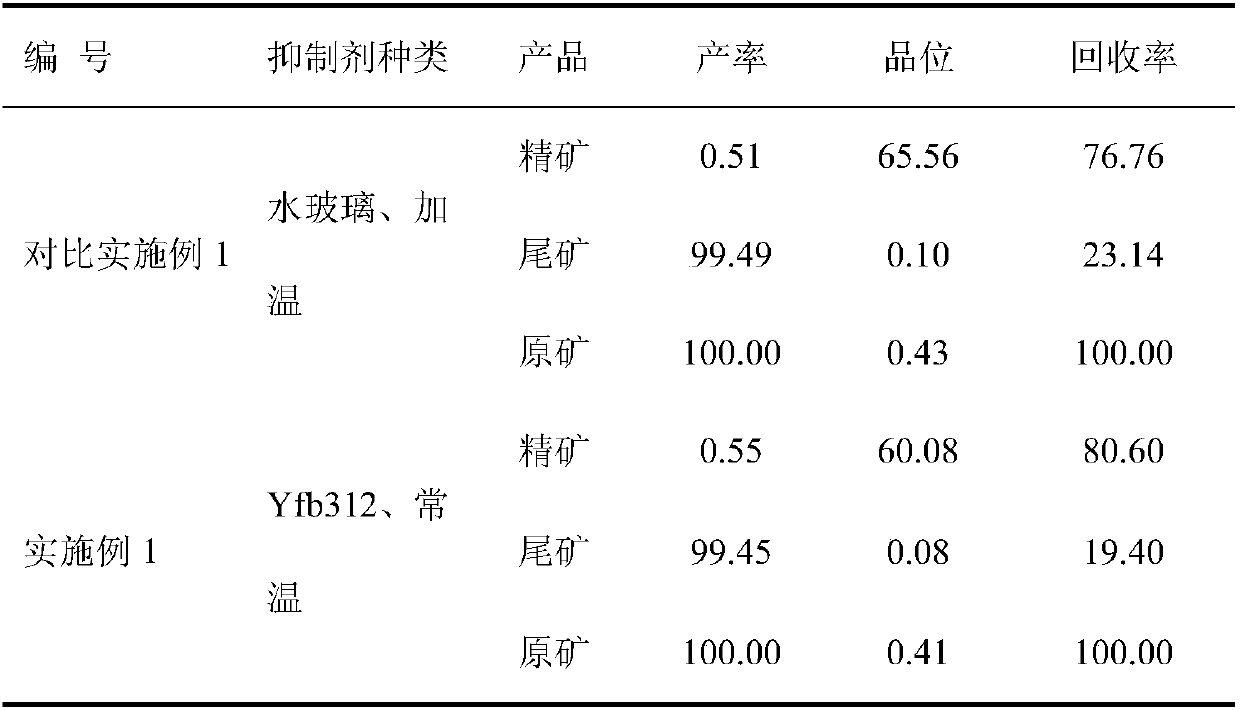

Combined reagent and flotation method for flotation of ultra-low grade rare earth ore and application of combined reagent

The invention belongs to the technical field of mineral resource recycling and utilization and in particular relates to a combined reagent and a flotation method for flotation of an ultra-low grade rare earth ore and application of the combined reagent. The combined reagent is composed of two chemicals, namely benzohydroxamic acid and octyl hydroxamic acid in a mass ratio of (2:1)-(4:1). The invention further provides application of the combined reagent. Under identical flotation conditions, the combined reagent is capable of remarkably increasing the grade of the ultra-low grade rare earth ore, the use amount of the reagent is small, the cost can be reduced, resources can be saved, and the application range of rare earth ores can be widened.

Owner:CENT SOUTH UNIV

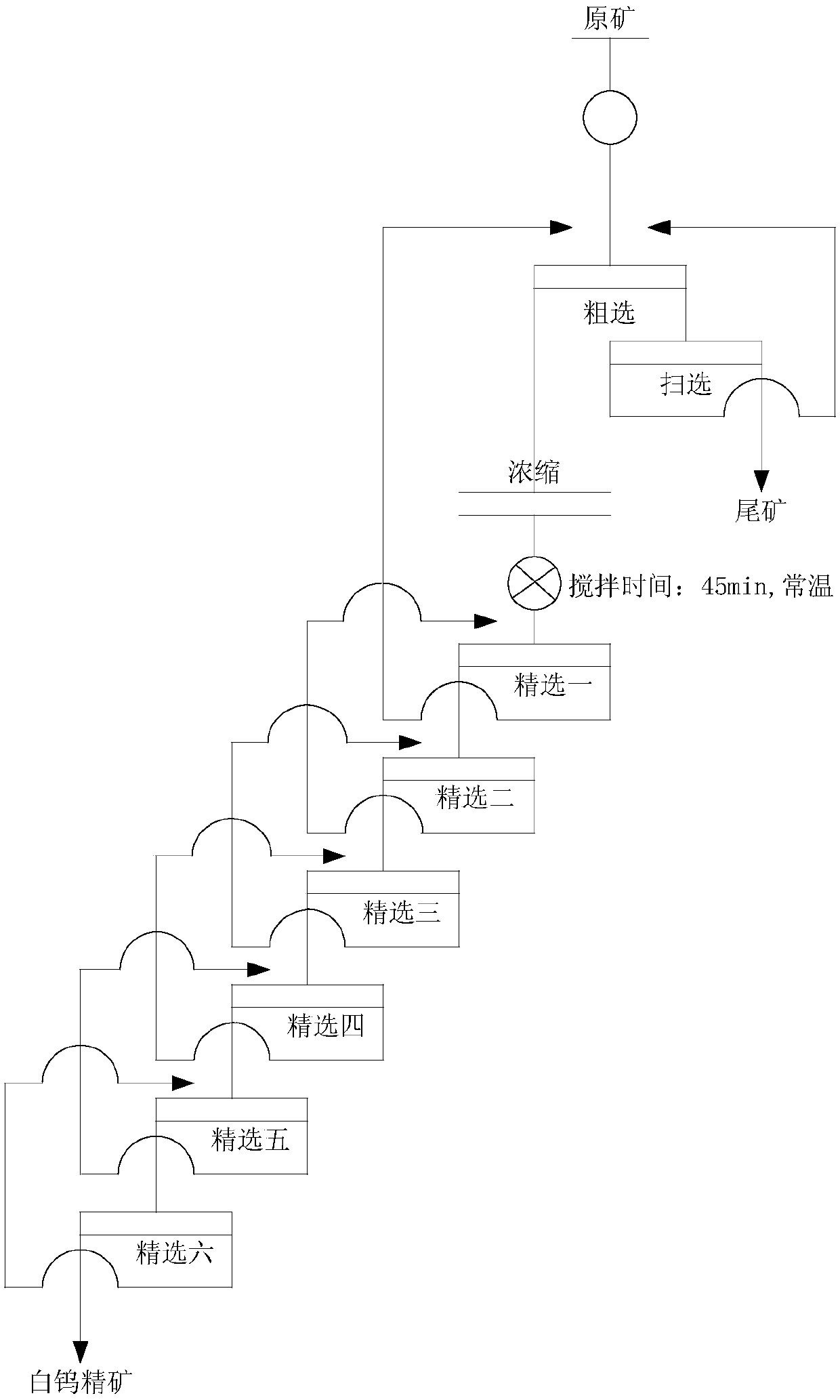

A method for beneficiating scheelite at normal temperature

The invention discloses a method for selecting scheelite at normal temperature. The method comprises the following steps: (1) pulping: a raw ore is milled and classified to prepare pulp with a concentration of 30-35%; the pulp is injected in a flotation machine; and the pH of the pulp is adjusted within 7-9; (2) roughing: a water glass and sodium humate combined inhibiting agent is adopted to inhibit a calcium-contained gangue mineral; and a sodium oleate and benzohydroxamic acid combined capturing agent is added for roughing and scavenging to obtain a scheelite concentrate; (3) the concentration of the scheelite concentrate is condensed to 60%; and the water glass and sodium humate combined inhibiting agent is added for strongly stirring by above 30 m under the effect of a normal-temperature magnetic field to dilute to the mass concentration of 30%; and (4) six times of blank selection are performed for the scheelite concentrate treated in the step (3) to obtain the scheelite concentrate.

Owner:JIANGXI UNIV OF SCI & TECH

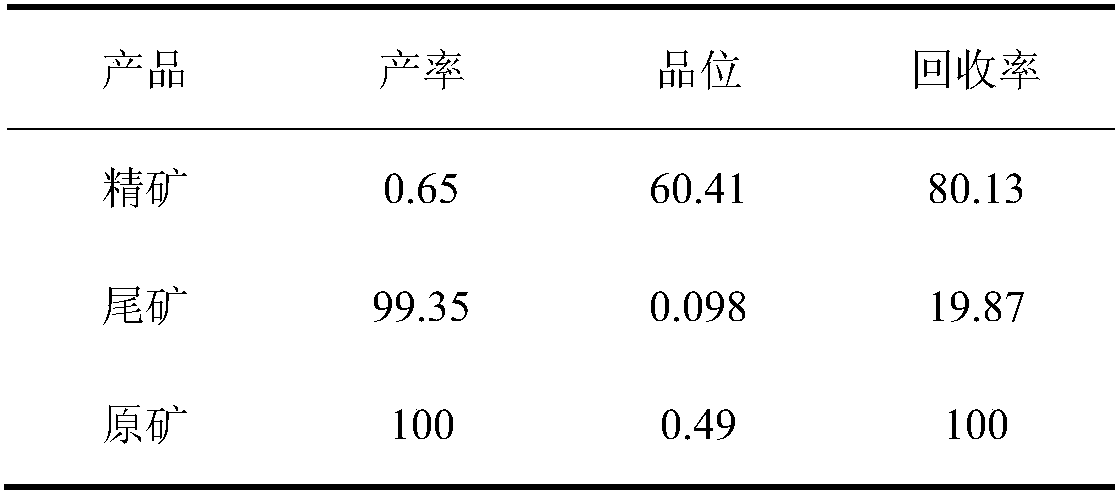

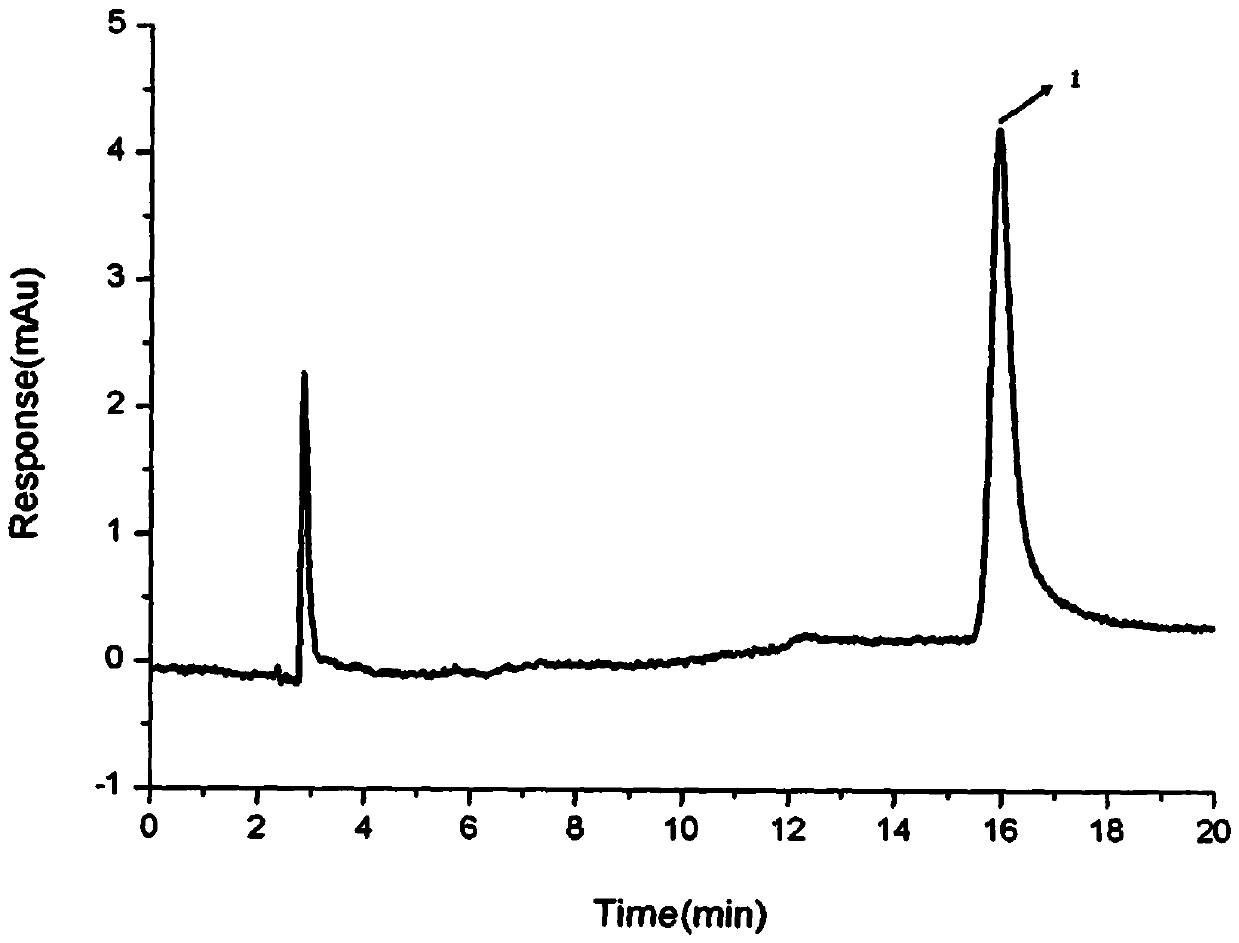

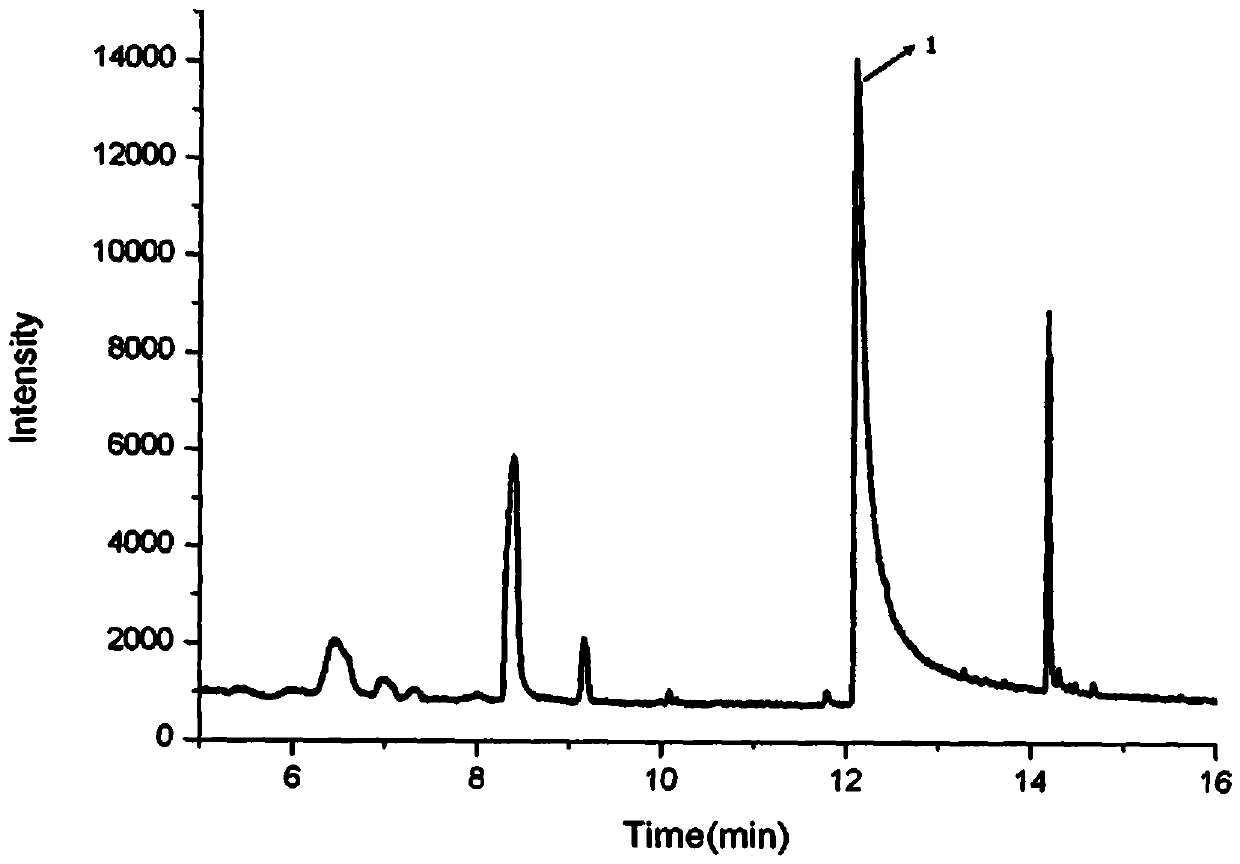

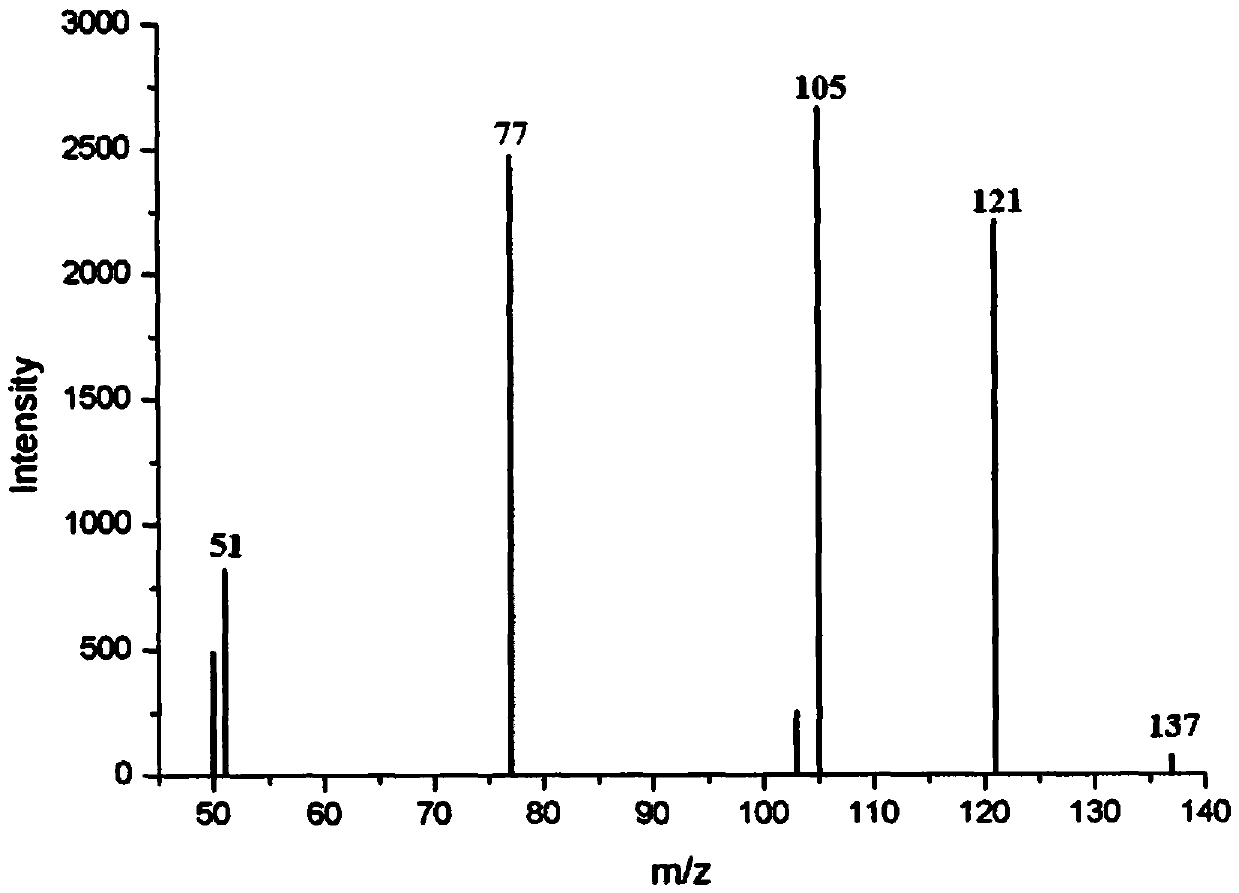

Method for detecting benzohydroxamic acid in flour and flour improver

ActiveCN111398472AGuaranteed to be accurateImprove solubilityComponent separationBiotechnologyBenzohydroxamic acid

The invention belongs to the technical field of analytical chemistry, and relates to a method for detecting benzohydroxamic acid in flour and a flour improver. Liquid chromatography quantification andgas chromatography-mass spectrometry assists qualitation. The method for determining the content of benzohydroxamic acid is simple, quick, quantitative and accurate in qualitative detection, has higher recovery rate and precision, and can meet the detection requirements of flour and flour improver samples.

Owner:宁波谱尼测试技术有限公司

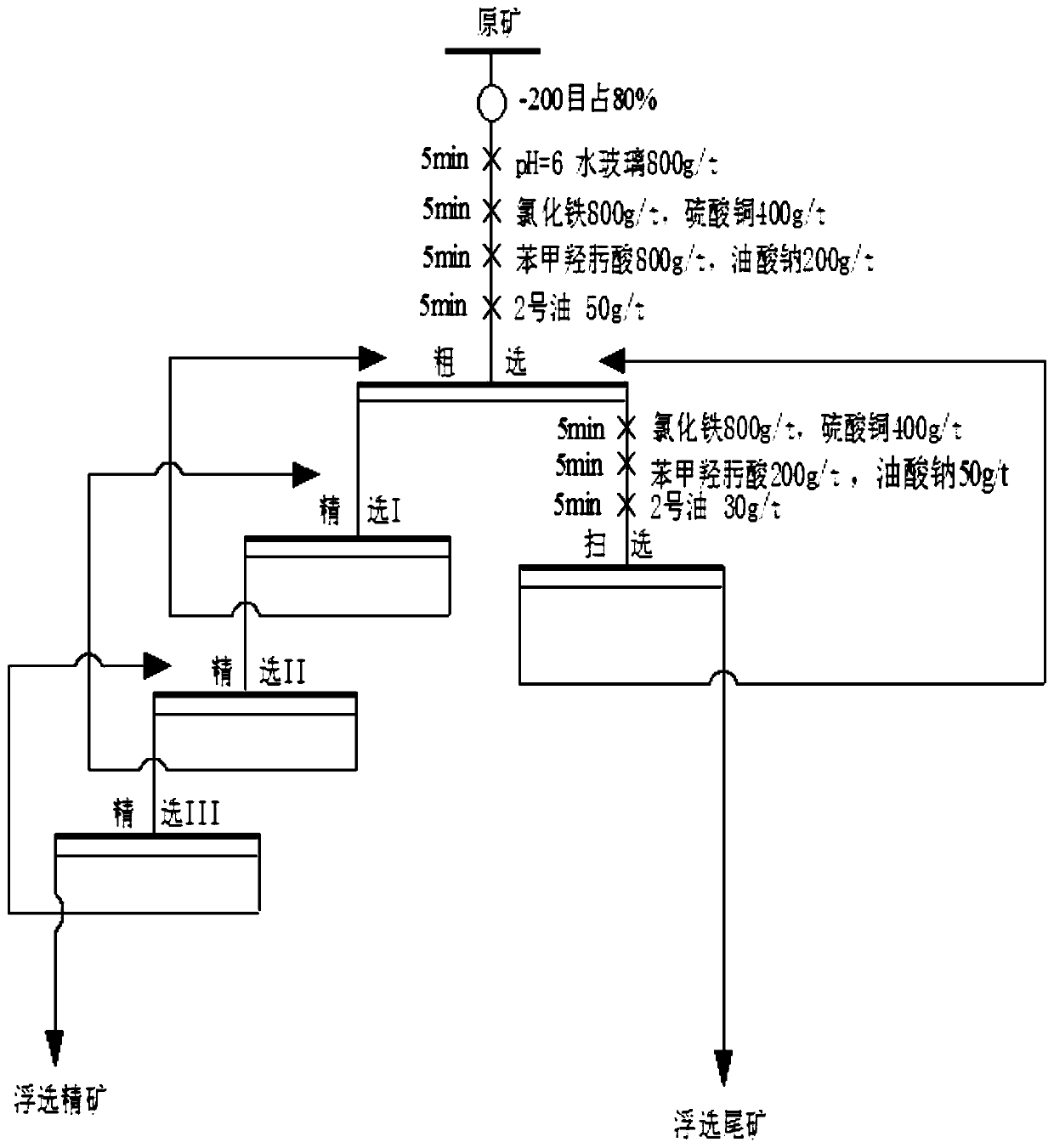

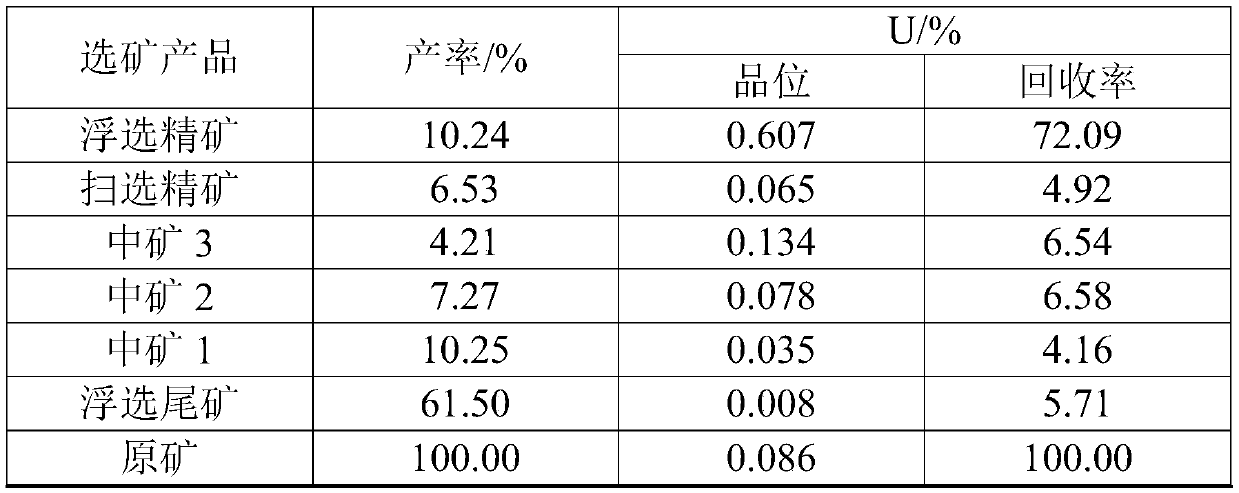

Flotation method of crystalline uranium ore

ActiveCN111530635ARaise the gradeEfficient HarvestingFlotationProcess efficiency improvementBenzohydroxamic acidNiobium

The invention belongs to the technical field of beneficiation, and particularly relates to a flotation method for crystalline uranium ore. The method comprises: crushing and grinding ore, adjusting the concentration of ore pulp until the mass fraction of the ore accounts for 10%-40%, transferring the ore pulp into a flotation tank, adjusting the pH value of the ore pulp to 4-6.5 by using sulfuricacid, adding water glass into the ore pulp, stirring, adding ferric chloride and copper sulfate into the ore pulp, stirring so that the crystalline uranium ore is in full contact and combination withFe<3+> and Cu<2+>, adding benzohydroxamic acid and sodium oleate into the ore pulp, stirring, adding No.2 oil, stirring, performing air flotation on the niobium-titanium-uranium ore to obtain roughingconcentrate and roughing tailings, adding ferric chloride and copper sulfate into the obtained roughing tailings, stirring, adding benzohydroxamic acid and sodium oleate, stirring, scavenging to obtain scavenged concentrate and flotation tailings, and returning the scavenged concentrate to the previous stage of roughing for recleaning, carrying out concentration on the obtained roughing concentrate for multiple times, and returning the concentrated tailings to the previous stage for flotation till an ideal flotation index is achieved. The flotation concentrate with a high uranium grade and arecovery rate can be obtained.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

A comprehensive recovery process of associated tantalum-niobium ore

ActiveCN105126993BReduce circulation lossImprove overall recoveryFlotationWet separationNiobiumMineral flotation

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

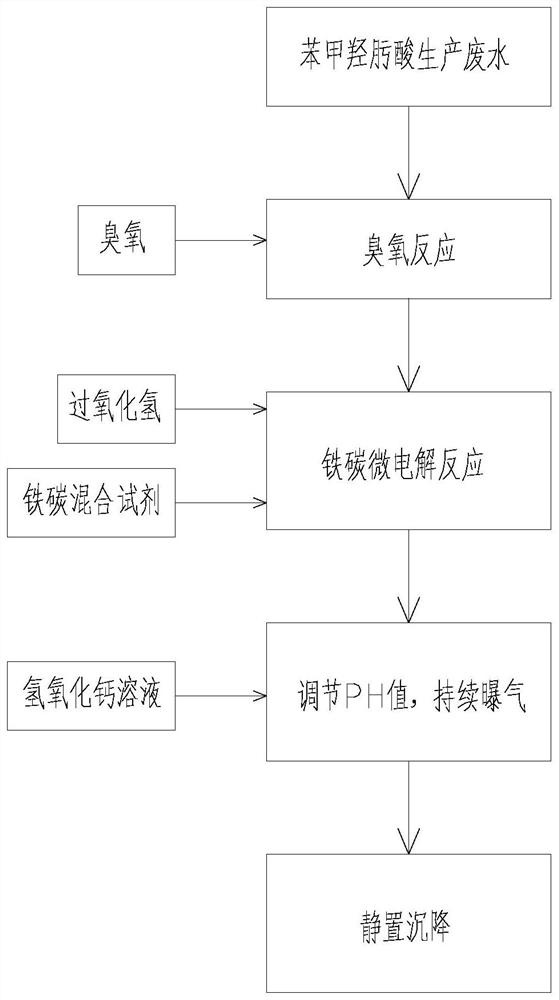

Process for treating benzohydroxamic acid production wastewater through ozone iron-carbon micro-electrolysis

PendingCN114291943AHigh removal rateEasy to handleMultistage water/sewage treatmentNature of treatment waterFerric hydroxideElectrolysis

The invention provides a process for treating benzohydroxamic acid production wastewater by ozone iron-carbon micro-electrolysis, which comprises the following steps: S01, introducing ozone into benzohydroxamic acid production wastewater, and continuously carrying out ozone reaction; s02, adding hydrogen peroxide and an iron-carbon mixed reagent, uniformly stirring, and continuously carrying out iron-carbon micro-electrolysis reaction; s03, adding a calcium hydroxide solution to adjust the pH value, and then continuously aerating; and S04, standing and settling are conducted, and ferrous hydroxide and ferric hydroxide obtained through the iron-carbon micro-electrolysis reaction are precipitated. Efficient wastewater treatment is completed through ozone and iron-carbon micro-electrolysis reaction and optimal test data research.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Resourceful treatment method of benzohydroxamic acid production wastewater

PendingCN113800719AReduce processing costsEasy to handleSpecific water treatment objectivesWater contaminantsBenzohydroxamic acidEnvironmental engineering

The invention belongs to the technical field of wastewater treatment and utilization, and particularly discloses a resourceful treatment method of benzohydroxamic acid production wastewater. The resourceful treatment method of the benzohydroxamic acid production wastewater provided by the invention comprises the following steps: firstly, adding alkaline resin into the benzohydroxamic acid production wastewater, and carrying out sufficient adsorption to obtain loaded resin and a residual water phase; desorbing the loaded resin by using an eluent, and fully desorbing to obtain regenerated resin and a benzohydroxamic acid enriched solution. The obtained benzohydroxamic acid enriched solution is compounded to prepare the collecting agent which can be used for flotation of scheelite. According to the method disclosed by the invention, resource utilization of the benzohydroxamic acid production wastewater is realized, and the wastewater treatment cost is reduced.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

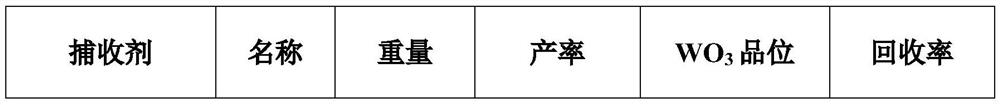

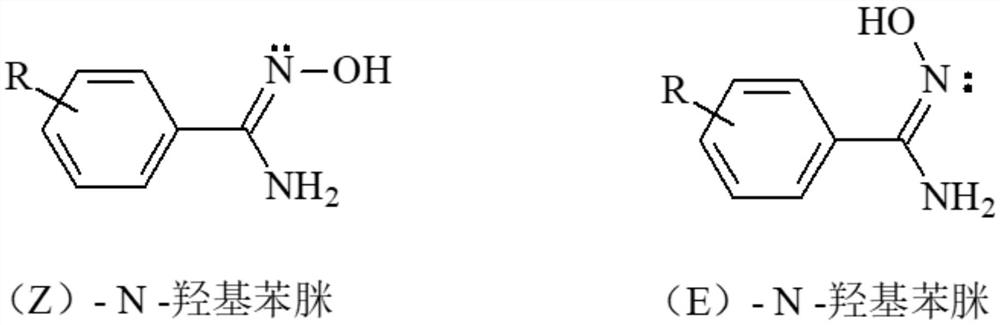

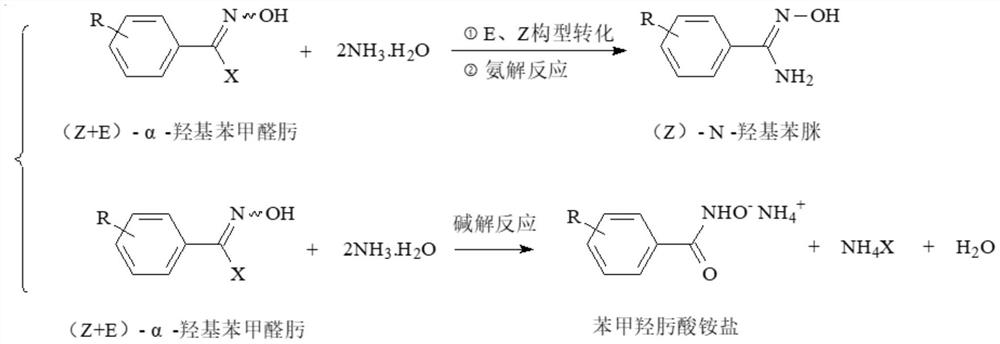

Method for preparing (Z)-N-hydroxyphenylamidine by ammonolysis method

ActiveCN112174853ALess alkaline hydrolysis side reactionImprove conversion rateOrganic chemistryBulk chemical productionBenzohydroxamic acidAlkaline hydrolysis

The invention discloses a method for preparing(Z)-N-hydroxyphenylamidine by ammonolysis, which comprises the following steps: 1, completely or partially dissolving alpha-halogenated benzaldoxime compounds simultaneously containing E and Z two configurations by using a first solvent to obtain a solution A; 2, adding an anhydrous sodium salt or potassium salt of a benzohydroxamic acid compound, andstirring to fully convert the (E)-alpha-halogenated benzaldoxime compound into (Z) type to obtain a solution B; 3, adding an anhydrous ammonia source, and carrying out an ammonolysis reaction to generate (Z)-N-hydroxybenzamidine so as to obtain a solution C; 4, concentrating the solution C, and adding water and a second solvent to dissolve most of solids; filtering and separating liquid; and carrying out post-treatment to obtain the high-purity (Z)-N-hydroxyphenylamidine. According to the method disclosed by the invention, the E configuration in the raw material can be fully converted into theZ configuration, the problem that more alkaline hydrolysis side reactions occur during E and Z configuration conversion reaction and ammonolysis reaction is also avoided, and the yield of the purified target product is increased to 95% or above.

Owner:HUNAN JINGSHI NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com