Process for treating benzohydroxamic acid production wastewater through ozone iron-carbon micro-electrolysis

A benzhydroxamic acid, iron-carbon micro-electrolysis technology, applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of difficult to remove organic substances in water, increase waste water Deal with problems such as difficulty to achieve the effect of high COD removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

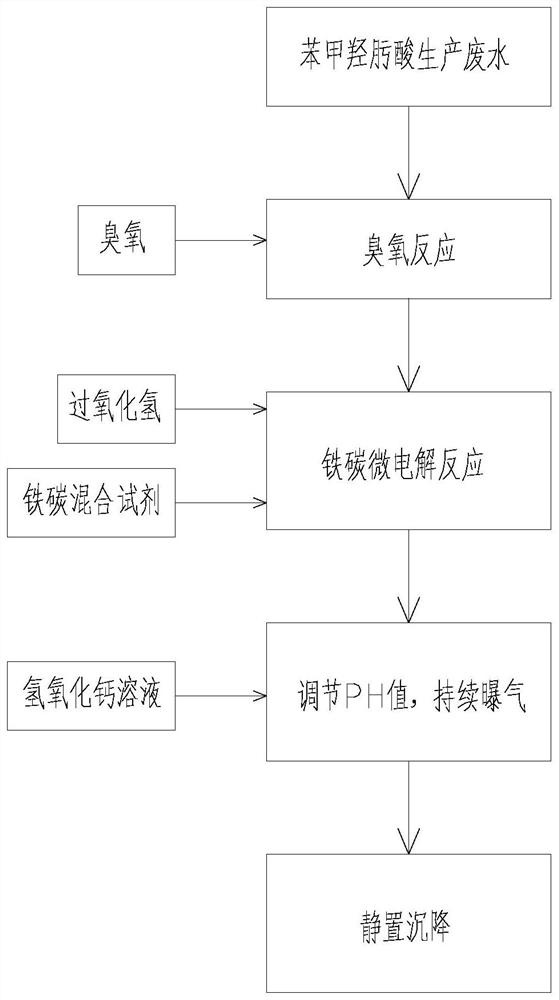

[0028] see figure 1 , the embodiment of the present invention is solely directed at the treatment of benzohydroxamic acid production wastewater, provides a kind of ozone iron carbon micro-electrolysis process benzohydroxamic acid production wastewater process, specifically comprises the following steps:

[0029] S01, pass ozone to the benzohydroxamic acid production wastewater, and continue to carry out the ozone reaction;

[0030] S02. Add hydrogen peroxide and iron-carbon mixed reagent, stir evenly, and continue the iron-carbon micro-electrolysis reaction;

[0031] S03, add calcium hydroxide solution to adjust the pH value, and then continue to aerate;

[0032] S04, set aside to settle, so that ferrous hydroxide and ferric hydroxide obtained from the iron-carbon micro-electrolysis reaction are precipitated.

[0033] The technical feature of the present invention is that it adopts a joint treatment process of ozone first and then iron-carbon micro-electrolysis. Its process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com