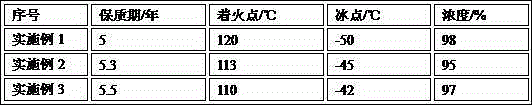

Patents

Literature

459 results about "Benzole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the United Kingdom, benzole or benzol is a coal-tar product consisting mainly of benzene and toluene. It was originally used as a 'motor spirit', as was petroleum spirits. Benzole was also blended with petrol and sold as a motor fuel under trade names including "National Benzole Mixture" and "Regent Benzole Mixture".

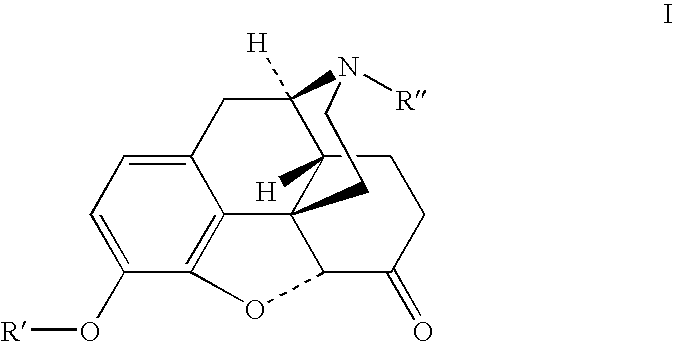

Preparation of opioid analgesics by a one-pot process

A one-pot process for preparing opioid analgesics such as hydrocodone, hydromorphone, and analogues thereof by reacting codeine, morphine, and analogues thereof with hydrogen in a solvent system of benzophenone and neutral solvent in the presence of a metal catalyst followed by oxidation in the presence of potassium tert-alkylate.

Owner:ACURA PHARMA

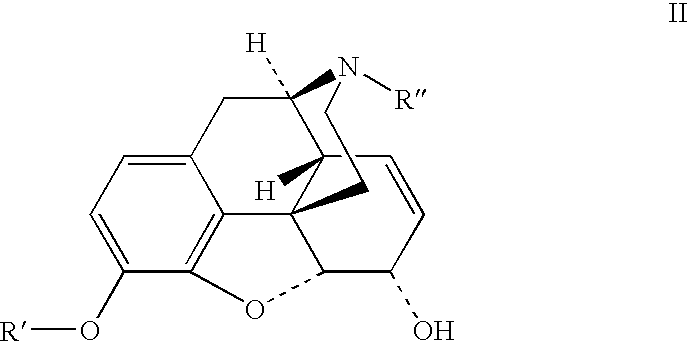

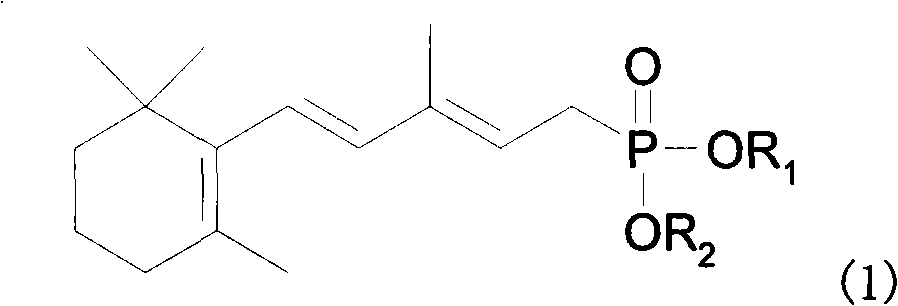

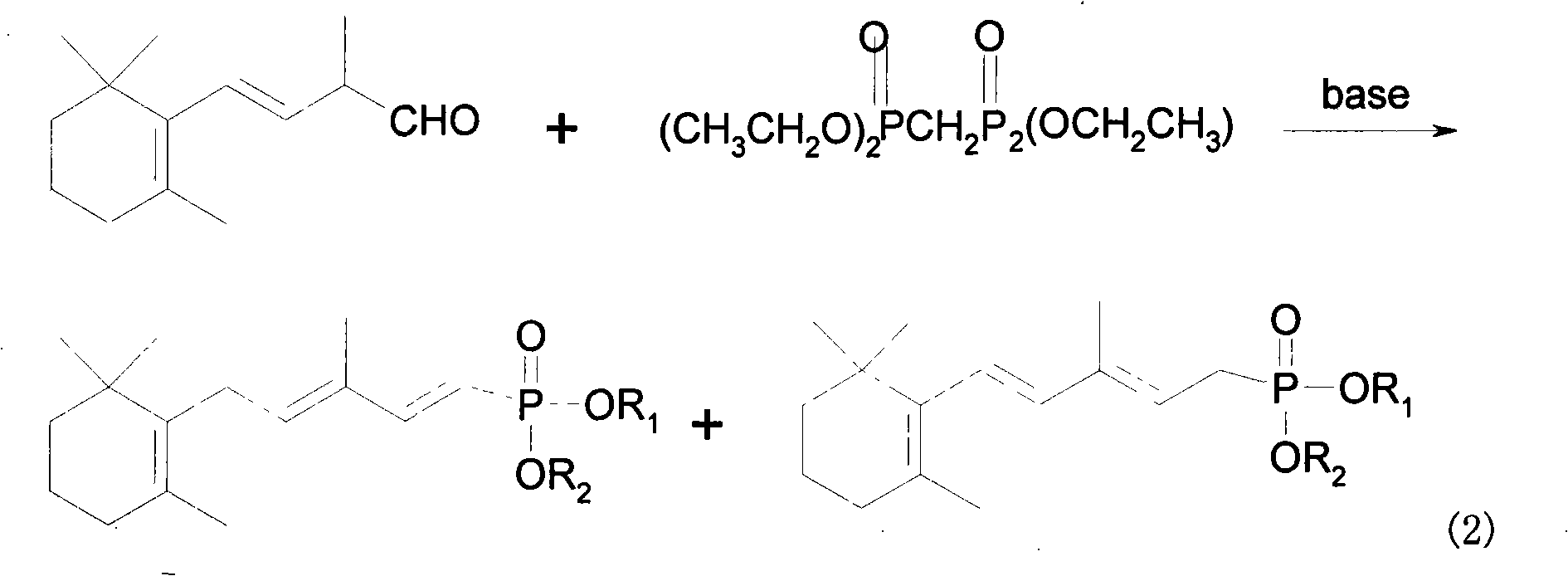

Method for preparing 3-methyl-5-(2,6,6-trimethyl-1-cyclohexene-1-base)-2, 4-pentadiene-dialkyl phosphoric ester

InactiveCN101318975AReduce energy consumption and difficulty of production operationsConducive to industrial productionGroup 5/15 element organic compoundsTolueneCyclohexenes

The invention provides a method for preparing 1, 3-methyl-5-(2, 6, 6-trimethyl-1- cyclohexene-1-yl)-2, 4-pentadiene methyl phosphonate. In the method, a benzophenone compound preventing transposition is added in the process of generating the 1, 3-methyl-5-(2,6,6-trimethyl-1-cyclohexene-1-yl)-2,4-pentadiene methyl phosphonate by the reaction of methylene diphosphate four alkyl and C14 aldehyde in a mixed solvent of methylbenzene and tetrahydrofuran, thereby inhibiting the generation of a target product isomer in order that the content of the target product in a final product reaches up to 97 percent.

Owner:GUANGZHOU WISDOM BIO TECH

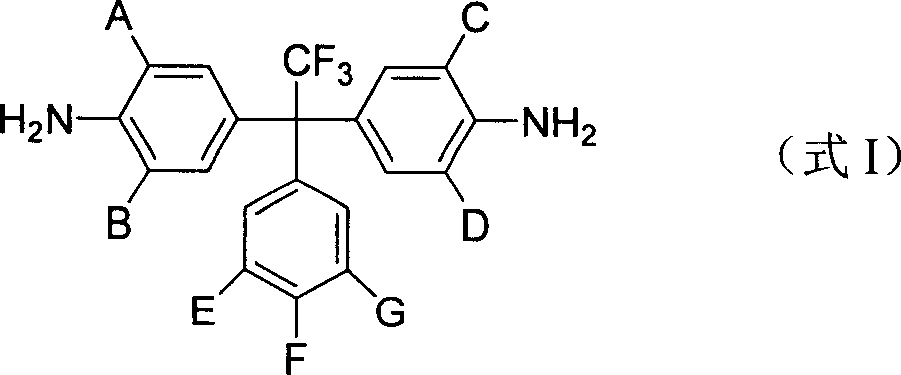

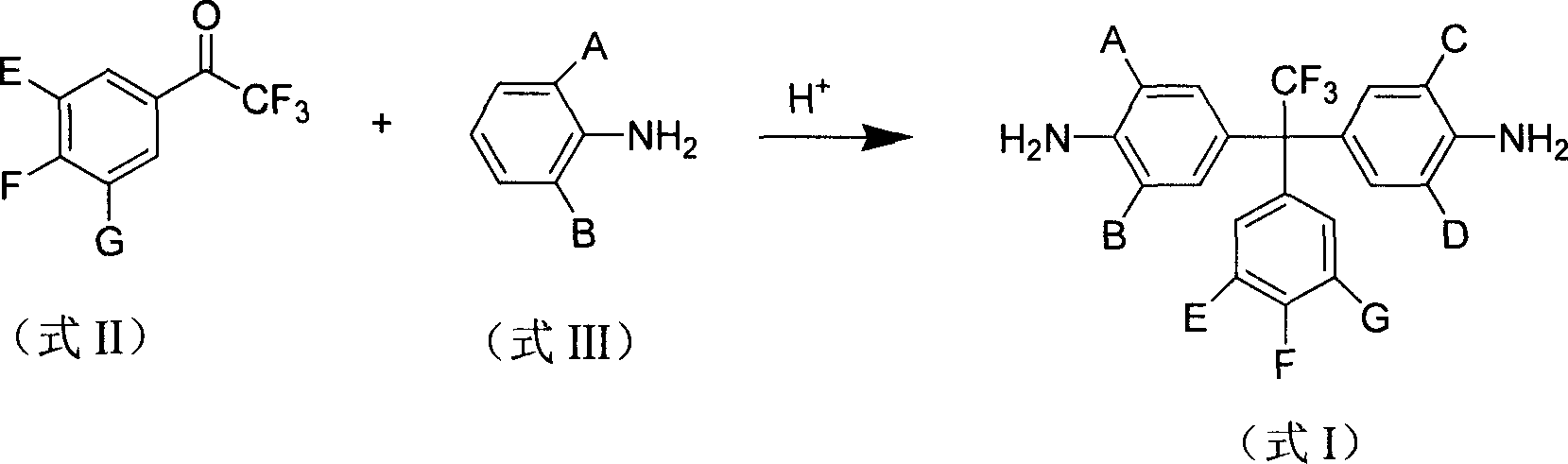

Intrinsical fluorinated photosensitive polyimide resin and its preparation method

The invention discloses an intrinsic-typed photoactive polyimide resin and making method, which is polycondensated by 3,3',4,4' -benzophenone pyromellitic dianhydride 40 with polyalkyl substituted aromatic methane diamine 20-42 as fluorine aromatic lateral group, wherein the carbon atom number of A, B, C and D in the formula I is 1-10; E, F, G is H atom or trifluoromethyl. The invention possesses superior solubility, which can be reserved for half year under indoor temperature and 18 months under 4 deg.c.

Owner:INST OF CHEM CHINESE ACAD OF SCI

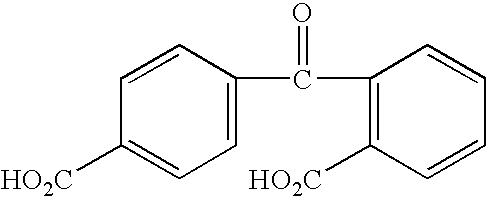

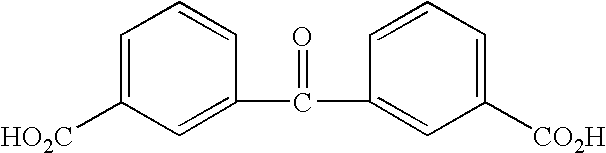

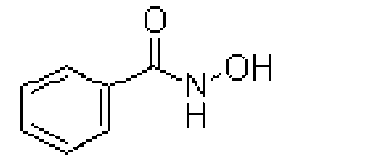

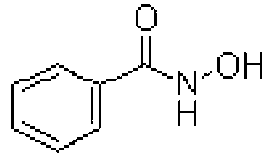

Benzophenone or benzoic acid anilide derivatives containing carboxyl groups as enzyme stabilizers

InactiveUS7968508B2Favorable inhibition constantReduce capacity requirementsSoap detergents with inorganic compounding agentsBiochemical fibre treatmentBenzoic acidBenzole

Washing and cleaning agents containing benzophenone or benzole anilide derivatives containing carboxyl groups, which function as protease inhibitors and are suitable as enzyme stabilizers. Additional subjects are the use of such compounds as reversible inhibitors of a protease and consequently for a washing or cleaning agent formulation, and additional methods and uses relating thereto.

Owner:HENKEL KGAA

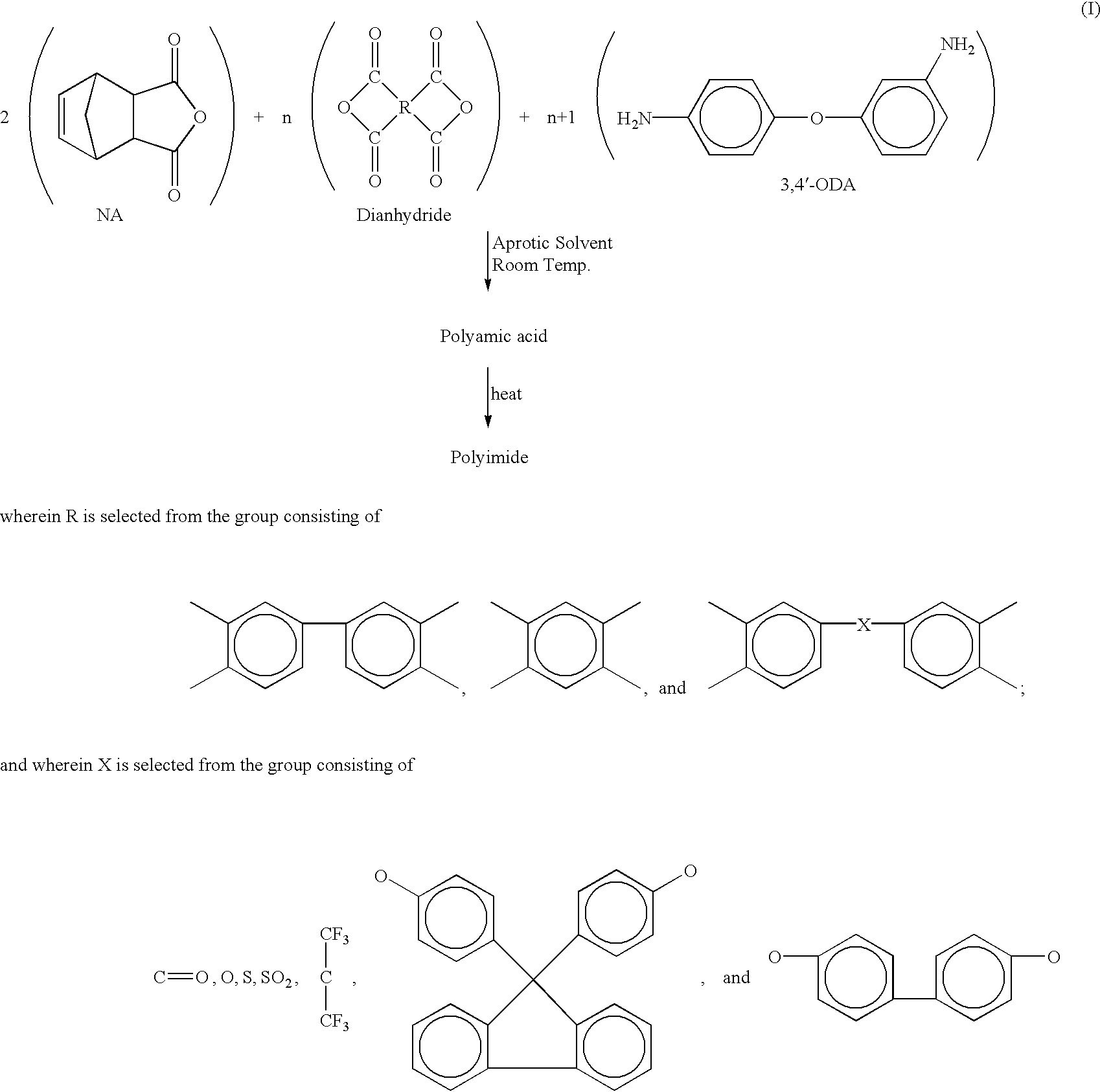

Heat, moisture, and chemical resistant polyimide compositions and methods for making and using them

InactiveUS6777525B2Improve mechanical propertiesGood thermal propertiesEngine sealsSynthetic resin layered productsDiaminodiphenyl etherBoiling point

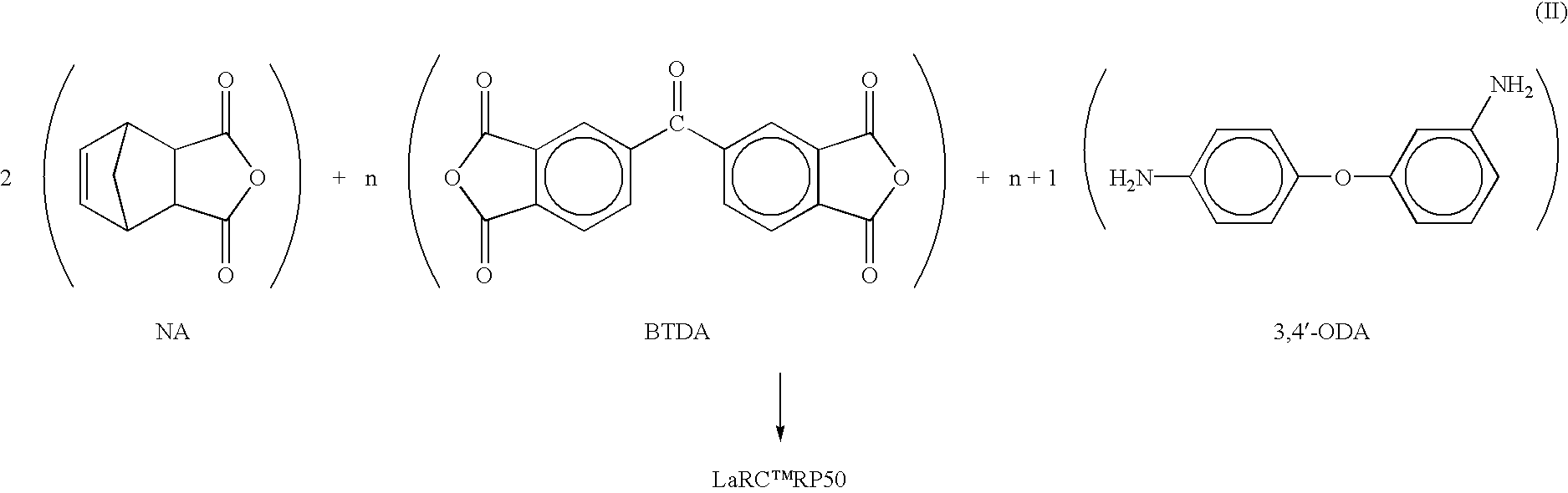

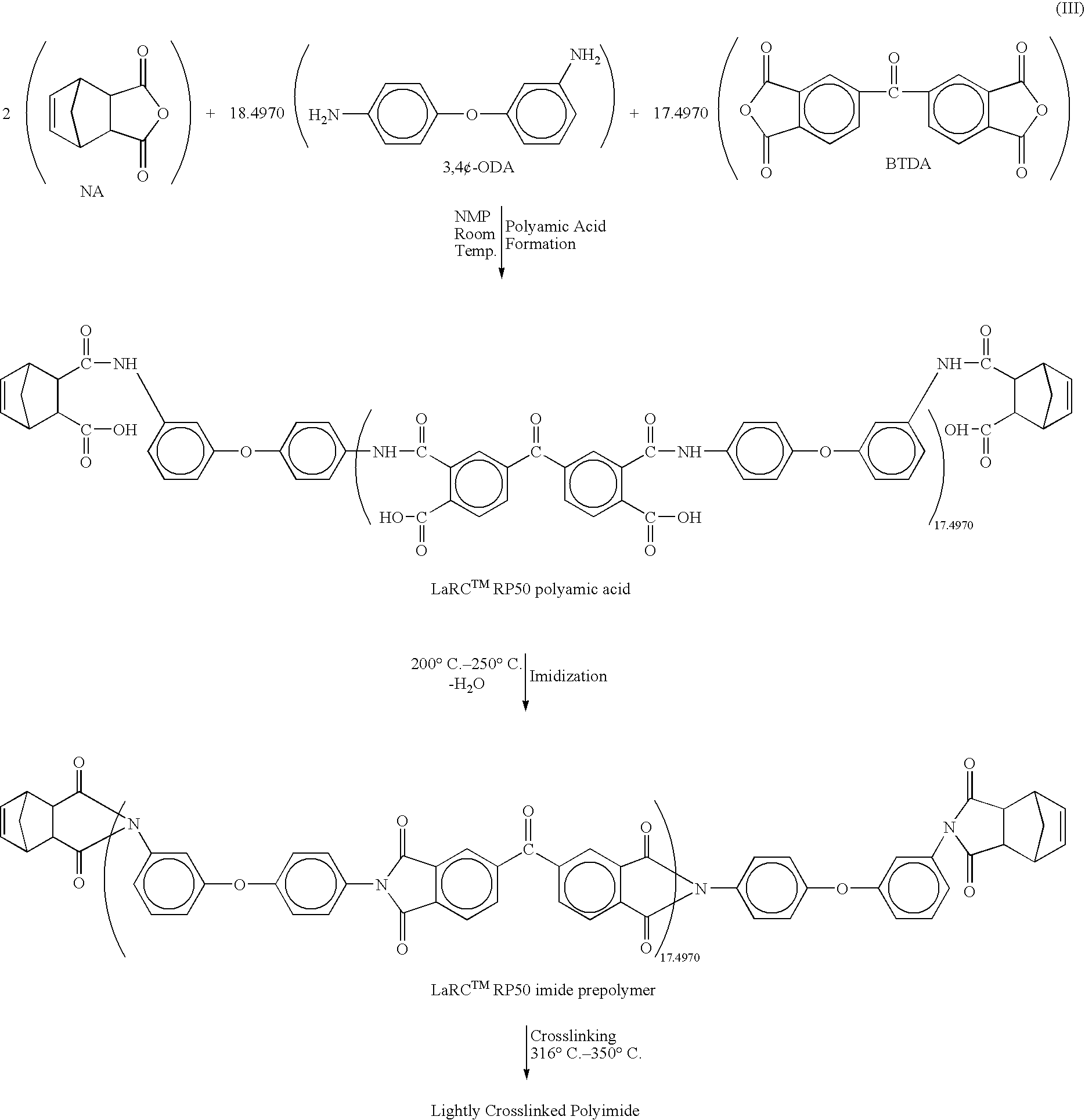

Polyimides having a desired combination of high thermo-oxidative stability, low moisture absorption and excellent chemical and corrosion resistance are prepared by reacting a mixture of compounds including (a) 3,3',4,4'-benzophenonetetracarboxylic dianhydride (BTDA), (b) 3,4'-oxydianiline (3,4'-ODA), and (c) 5-norbornene-2,3-dicarboxylic anhydride (NA) in a high boiling, aprotic solvent to give 5 to 35% by weight of polyamic acid solution. The ratio of (a), (b), and (c) is selected to afford a family of polyimides having different molecular weights and properties. The mixture first forms a polyamic acid precursor. Upon heating at or above 300° C., the polyamic acids form polyimides, which are particularly suitable for use as a high temperature coating, adhesive, thin film, or composite matrix resin.

Owner:NASA

Preparation method and application of PTFE and polyester-based composite film for preventing wind turbine blades from icing

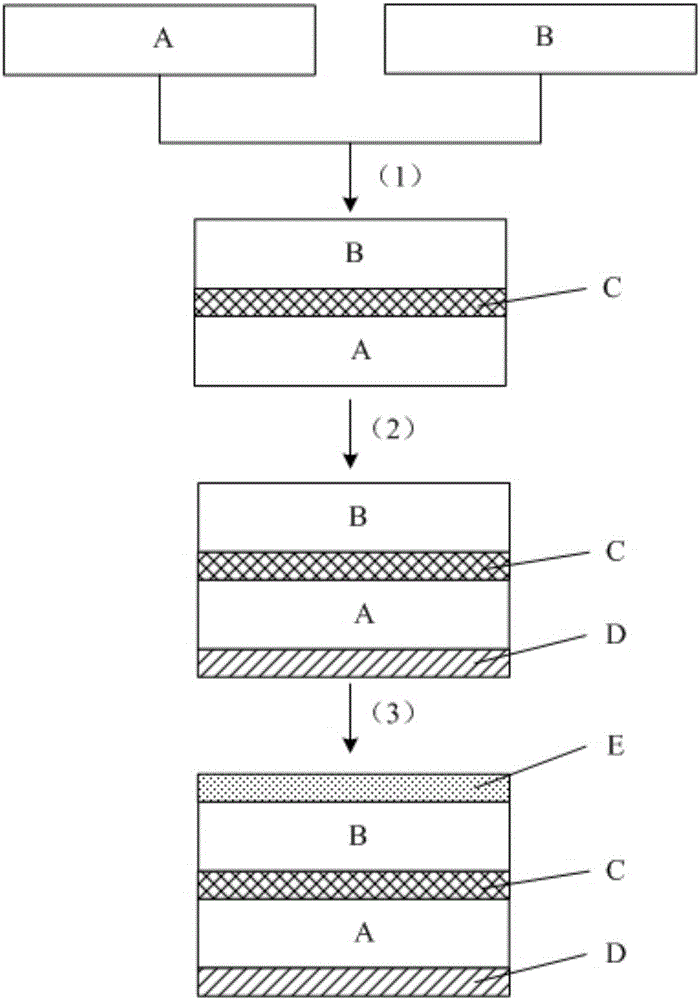

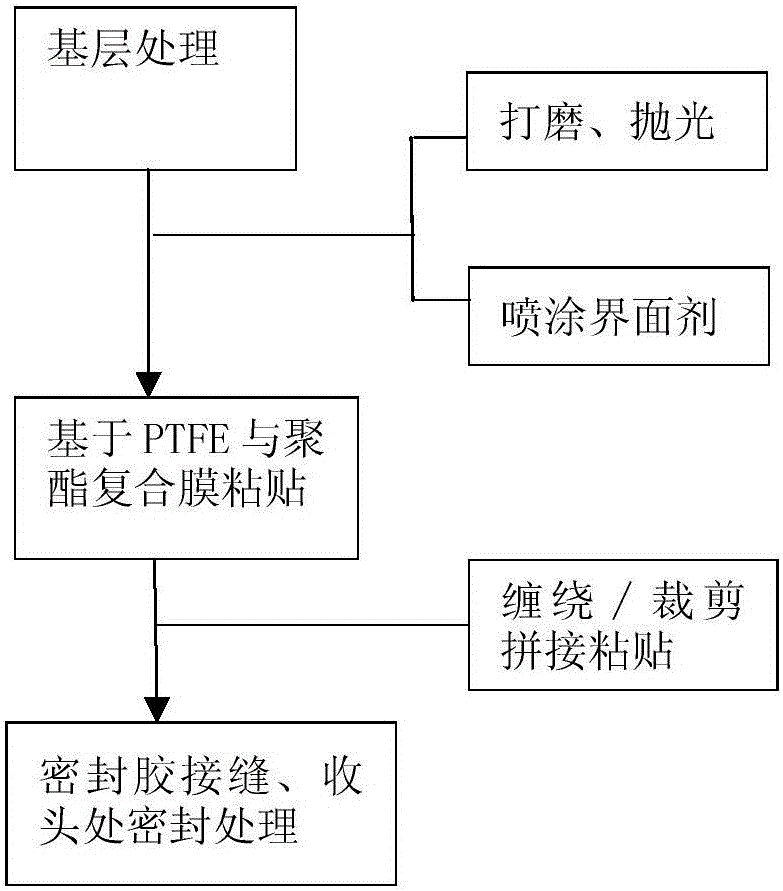

ActiveCN106313812AHigh peel strengthHigh bonding strengthNon-macromolecular adhesive additivesSynthetic resin layered productsPolyesterBenzoyl peroxide

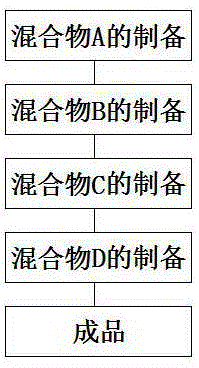

The invention discloses a preparation method and application of a PTFE and polyester-based composite film for preventing wind turbine blades from icing. The method includes the steps that a bonding composite agent is adopted for lamination complexing, an interface adhesive is applied, and a pressure-sensitive adhesive is adopted for photo-initiated pressure-sensitive adhesive application. The bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, benzoyl peroxide and (4)ethoxylated bisphenol A dimethacrylate; the photo-initiated pressure-sensitive adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, butyl acrylate, (4)ethoxylated bisphenol A dimethacrylate, 4,4'-bis(diethylamino)benzophenone and dimethylformamide. The method and the composite film solve the non-adhesion technical problem that a PTFE film can not be pasted on the surfaces of wind turbine blades with an adhesive directly, the bonding peel strength is improved, and the composite film is suitable for wind turbine blades of various models.

Owner:NANJING HAOHUI HI TECH CO LTD

Preparation process of benzoyl chloride

ActiveCN103787874AReduce pollutionSave resourcesPreparation from carboxylic acid halideOrganic compound preparationBenzoic acidPtru catalyst

The invention discloses a preparation process of benzoyl chloride. The preparation process comprises the following steps of synthesis of benzotrichloride: carrying out temperature reaction on methylbenzene and chlorine under the catalytic action of a catalyst to synthetize a crude benzotrichloride product; synthesis of the benzoyl chloride: continuously stirring and heating the crude benzotrichloride product and benzoic acid to prepare a crude benzoyl chloride product after adding the catalyst; refining of the benzoyl chloride: carrying out reduced pressure distillation on the crude benzoyl chloride product to prepare a refined benzoyl chloride product; recovering benzoyl chloride raffinate, adding water to the benzoyl chloride raffinate which is subjected to the reduced pressure distillation, heating and stirring to transform the benzoyl chloride contained in the raffinate into the benzoic acid, cooling, then separating out benzoic acid. The preparation process disclosed by the invention is easy to safe to operate, effectively shortens the reaction time, achieves the purity of the prepared benzoyl chloride by 99.5%, reduces the environmental pollution by recycling residues, saves the resources, reduces the cost, meets the requirements of pharmaceutical chemicals and can carry out massive industrial production.

Owner:YIDU YOUYUAN IND CO LTD

Floating and collecting agent of bertrandite beryllium ores and application thereof

InactiveCN101716559ALarge molecular sizeEfficient flotation collectionFlotationBenzohydroxamic acidBenzyl group

The invention relates to a floating and collecting agent of bertrandite beryllium ores and application thereof. In the invention, benzohydroxamic acid is used as an organic compound collecting agent, and after benzyl is introduced to hydroximic acid, the selective collecting capacity to beryllium ores of hydroximic acid medicaments is improved. The floating and collecting agent is used for the flotation of the bertrandite beryllium ores, has excellent selective collecting property and is a high-efficiency floating and collecting agent for the beryllium ores.

Owner:CENT SOUTH UNIV

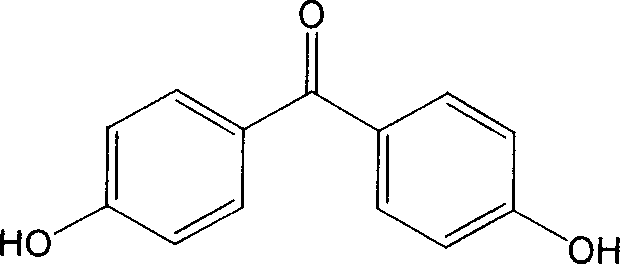

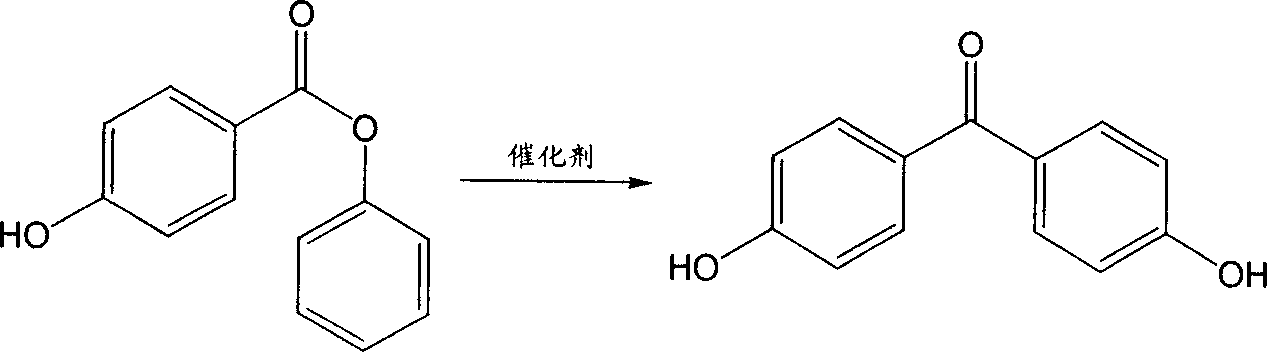

Method for preparing 4,4'-dihydroxy benzophenone

InactiveCN1696094AOvercoming a large amountIntractableOrganic compound preparationCarbonyl compound preparationOrganic solventPhosphoric acid

A process for preparing the 4,4'-bihydroxybiphenyl methaneone includes mixing phenyl p-hydroxybenzoate with catalyst in organic solvent, heating while stirring, reaction, separating the resultant and recrystallizing.

Owner:WUHAN UNIV

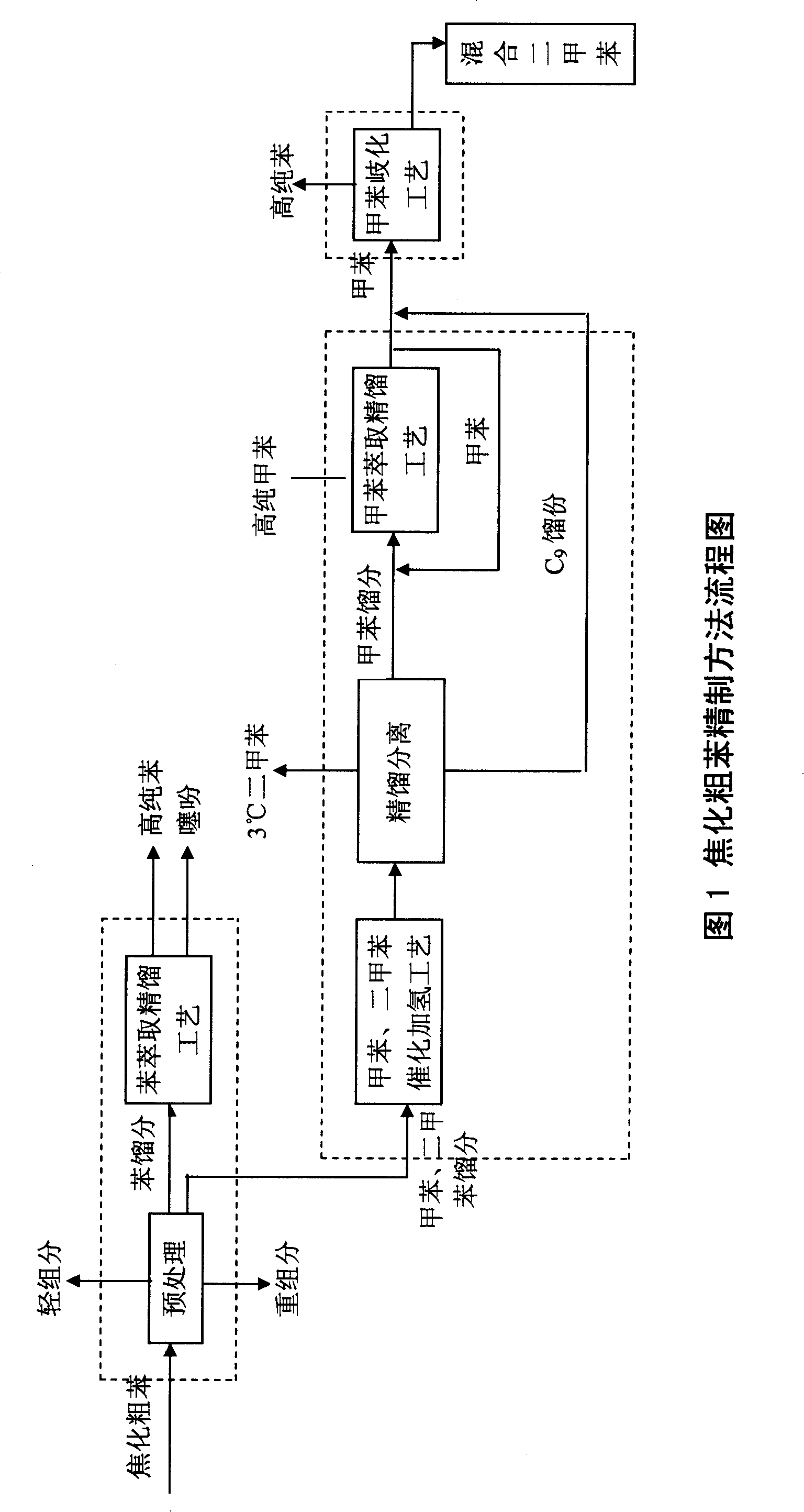

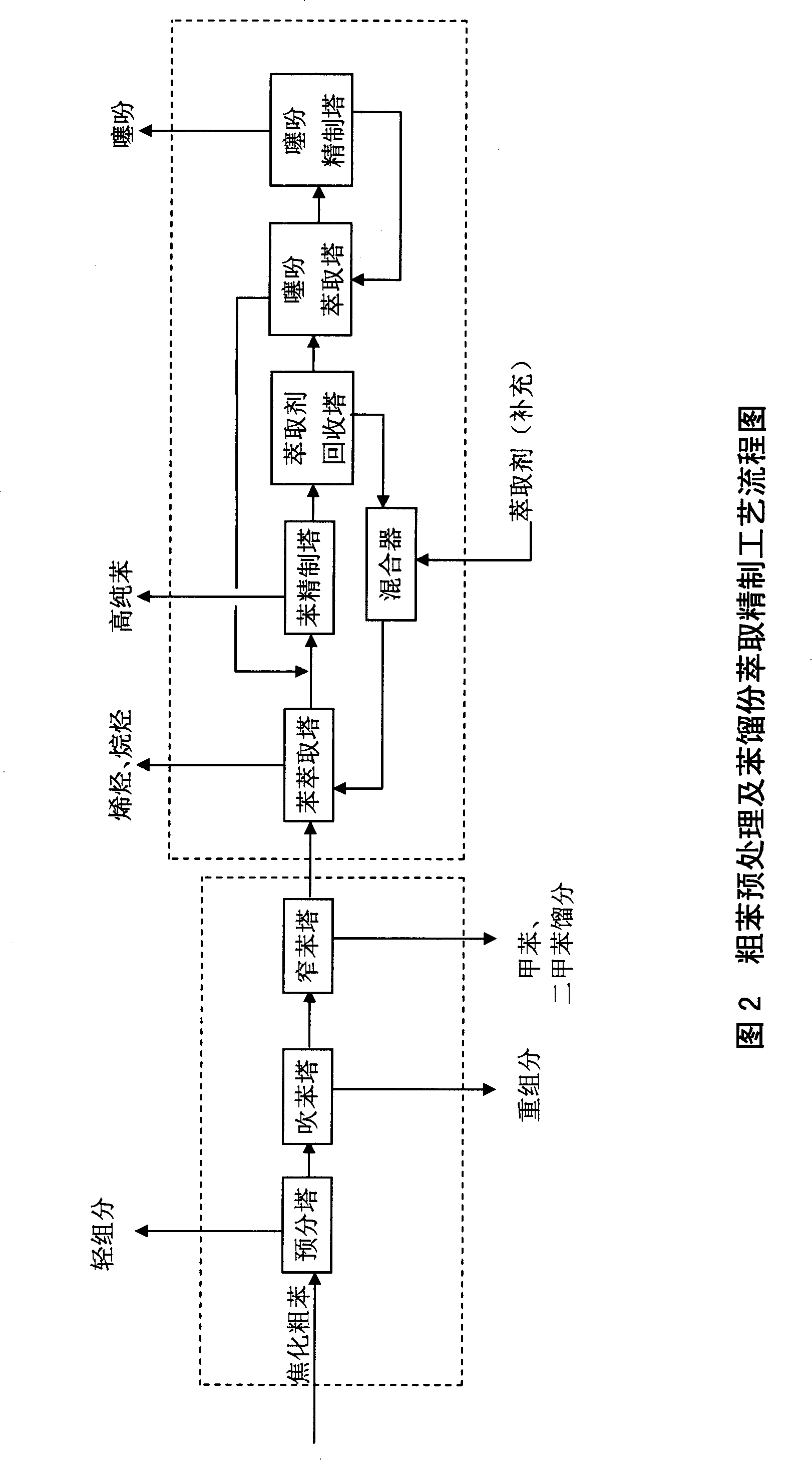

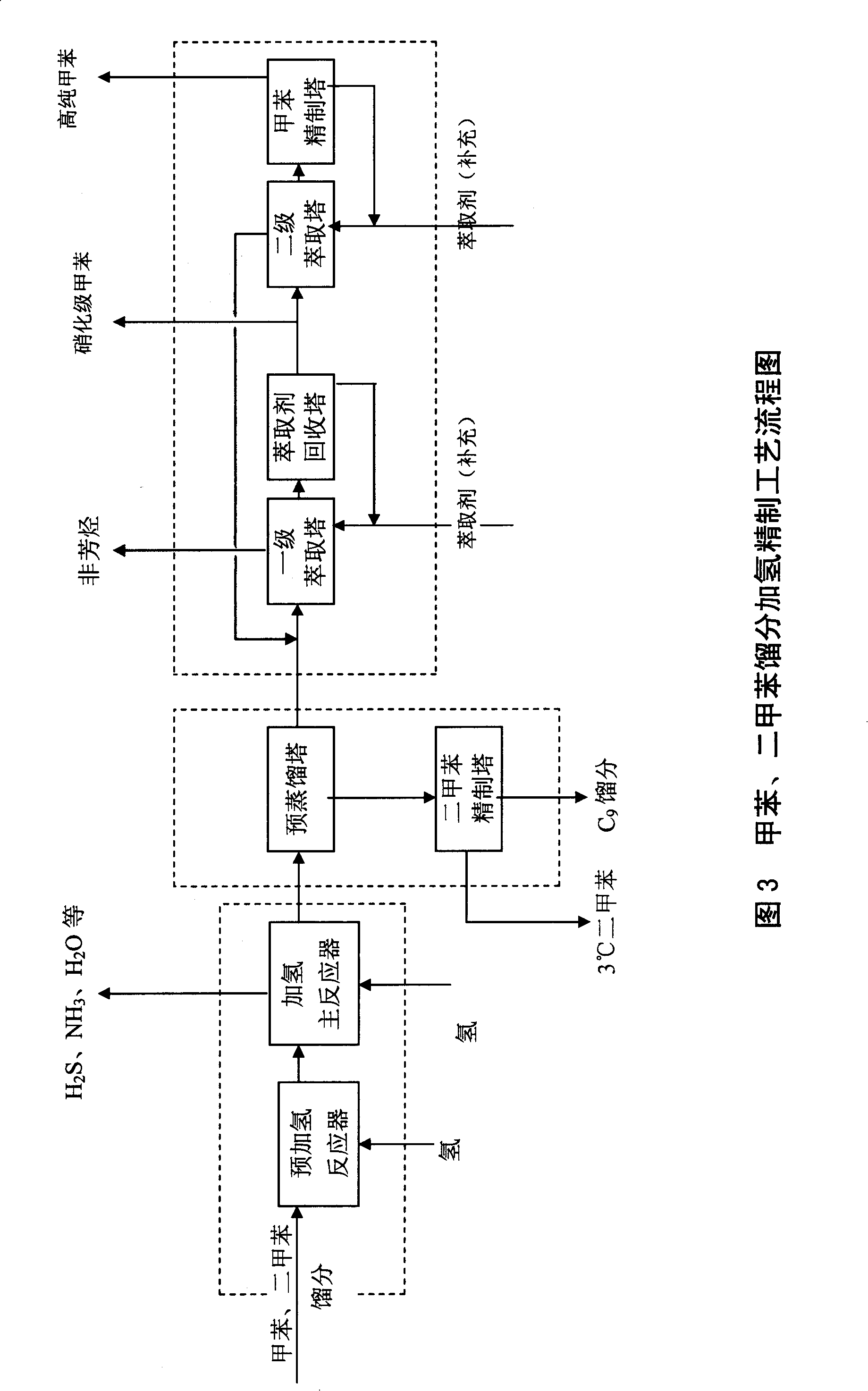

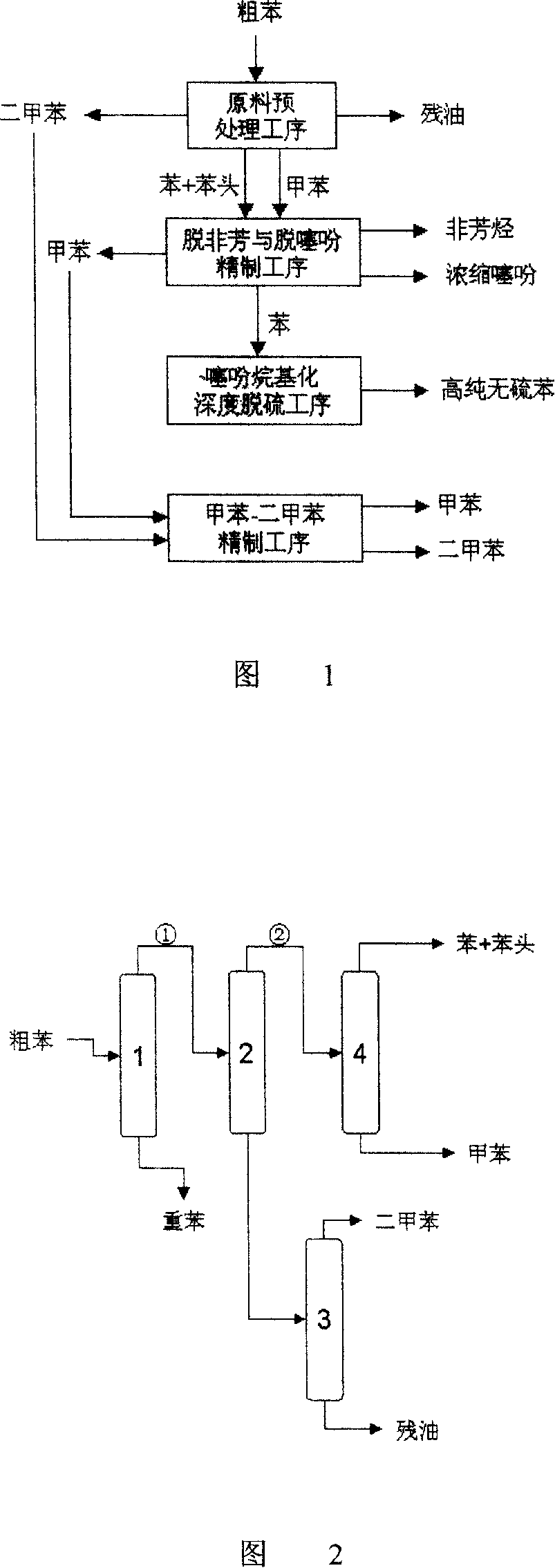

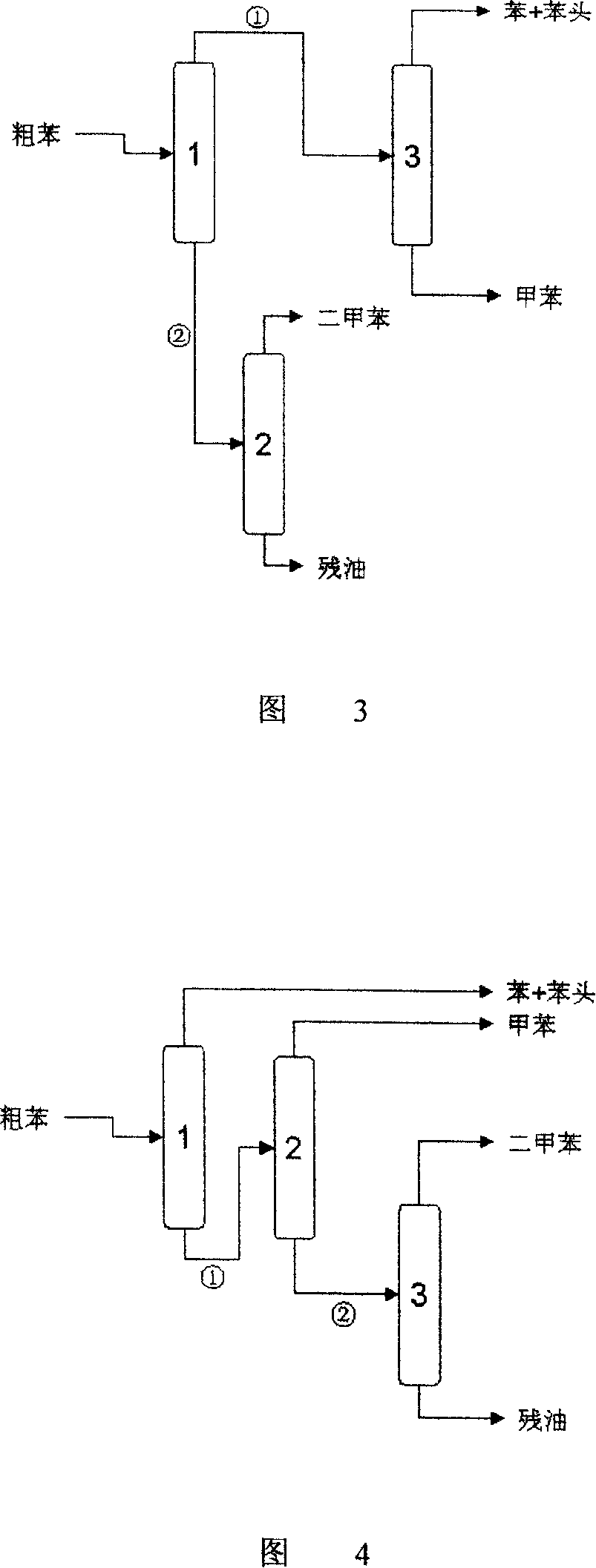

Method for refining carbonization crude benzole

ActiveCN101219918AHigh purityIncrease added valueDistillation purification/separationExtractive distillationCarbonization

The invention relates to a method for refining coking benzol, consisting of a process of benzol pretreatment and benzene extractive distillation, a hydrofining process of toluol, xylene distillation and a toluene disproportionation process. The invention has the advantages of that high-purity and high-quality product of the benzene, toluol and / or thiophen can be obtained; device investment is reduced by times; processing cost is also greatly reduced without environmental pollution; product proportion can be regulated according to market requirement.

Owner:山西侨友化工股份有限公司

Anticorrosive environment-friendly spray paint formula

InactiveCN105199580ABright colorGood light fastnessAnti-corrosive paintsPolyurea/polyurethane coatingsDiacetone alcoholChemical industry

The invention discloses an anticorrosive environment-friendly spray paint formula, and relates to the field of chemical industries. The anticorrosive environment-friendly spray paint formula comprises the following components in parts by weight: 28 to 35 parts of glacial acetic acid, 3 to 7 parts of organic fluorine epoxy resin, 7 to 12 parts of epoxy modified organic silicon resin, 2 to 6 parts of glycol monomethyl ether, 6 to 9 parts of dimethyl sulfoxide, 8 to 13 parts of zinc phosphate, 8 to 13 parts of barium chromate, 1 to 4 parts of ethanol, 2 to 7 parts of polyacrylate, 1 to 4 parts of alcohol soluble resin, 7 to 13 parts of diacetone alcohol, 6 to 9 parts of zinc oxide, 8 to 13 parts of toluene diisocynate, 3 to 7 parts of n-butyl acetate, 12 to 16 parts of benzophenone, 9 to 13 parts of triethanolamine and 3 to 7 parts of diphenyl polysiloxane. The paint is bright in color and good in air-curing resisting effect, can substitute medium chrome yellow in inorganic pigment, is applicable to the outer wall paint, and has no harm of heavy metals, no harmful substances, good environment protection effect, little odor, no peculiar smell after being smeared on the wall, good mechanical performance, excellent electric insulation performance, dampness and water resistance, rust and cold resistance and ozone aging resistance.

Owner:王海平

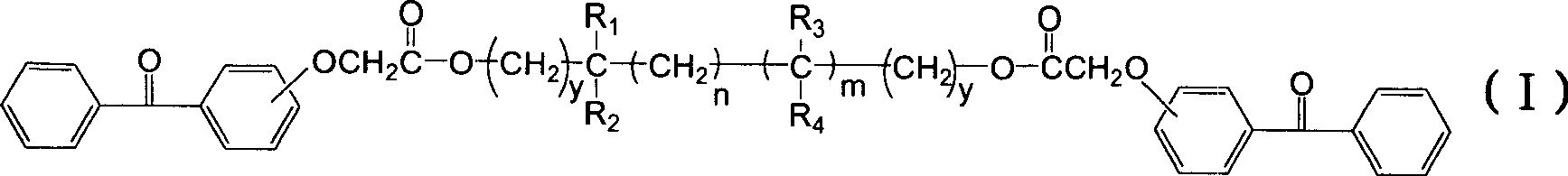

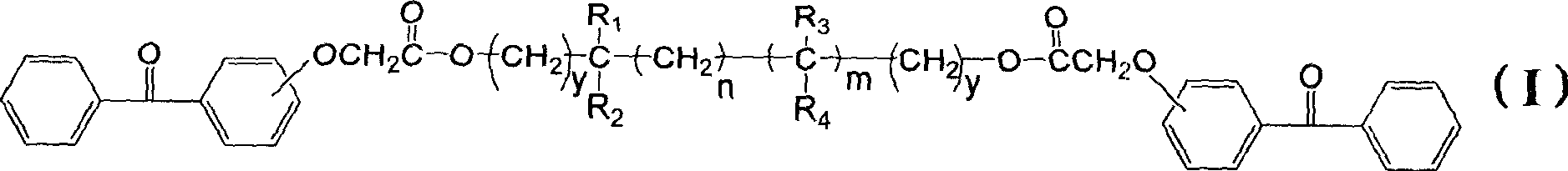

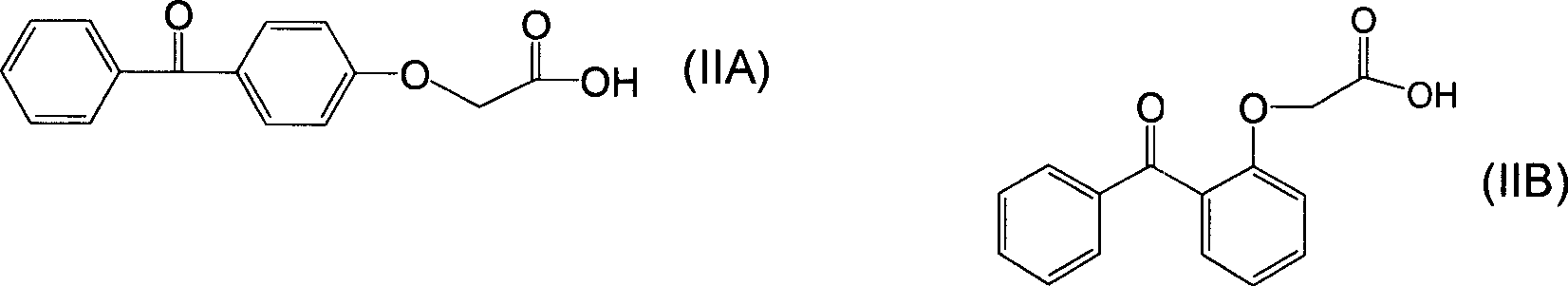

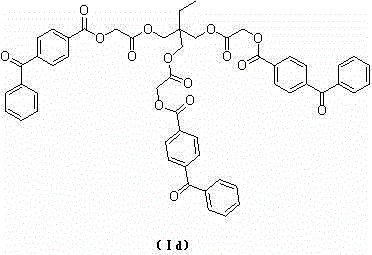

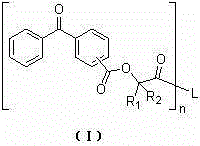

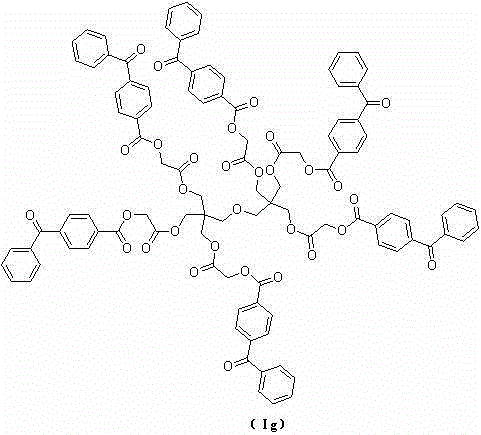

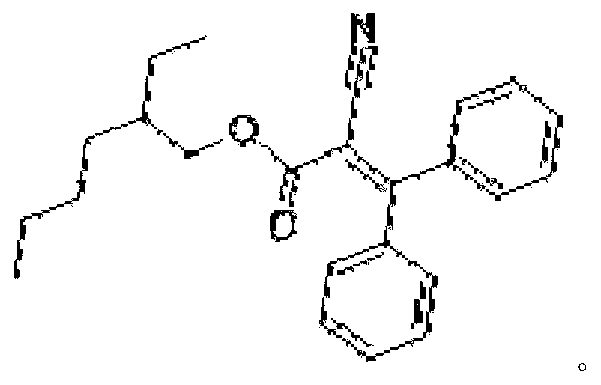

Polyfunctional benzophenone derivates and uses as photoinitiators thereof

ActiveCN101434543AAvoid defectsSmall smellOrganic chemistryCoatingsBenzophenoneCombinatorial chemistry

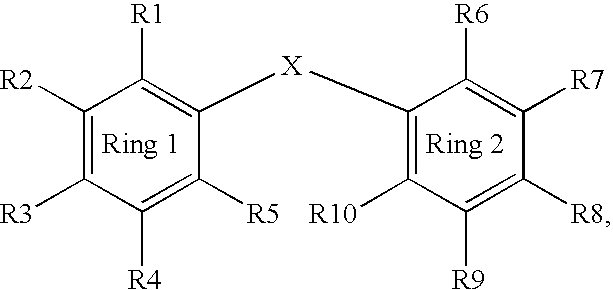

The invention discloses a compound and a composition of two or over two of the compound displayed in a formula (1), wherein, m is 0 or 1; n is an integer of 0-4; y is each independently selected from 1 or 2; R1, R2, R3, R4 are each independently selected from H, -CH3 or -CH2CH3, but not H simultaneously. The compound or composition can be functioned as light trigger in light-cured liquid composition. The invention discloses a multi-functional benzophenone derivative and the application as light trigger thereof.

Owner:INSIGHT HIGH TECH (BEIJING) CO LTD

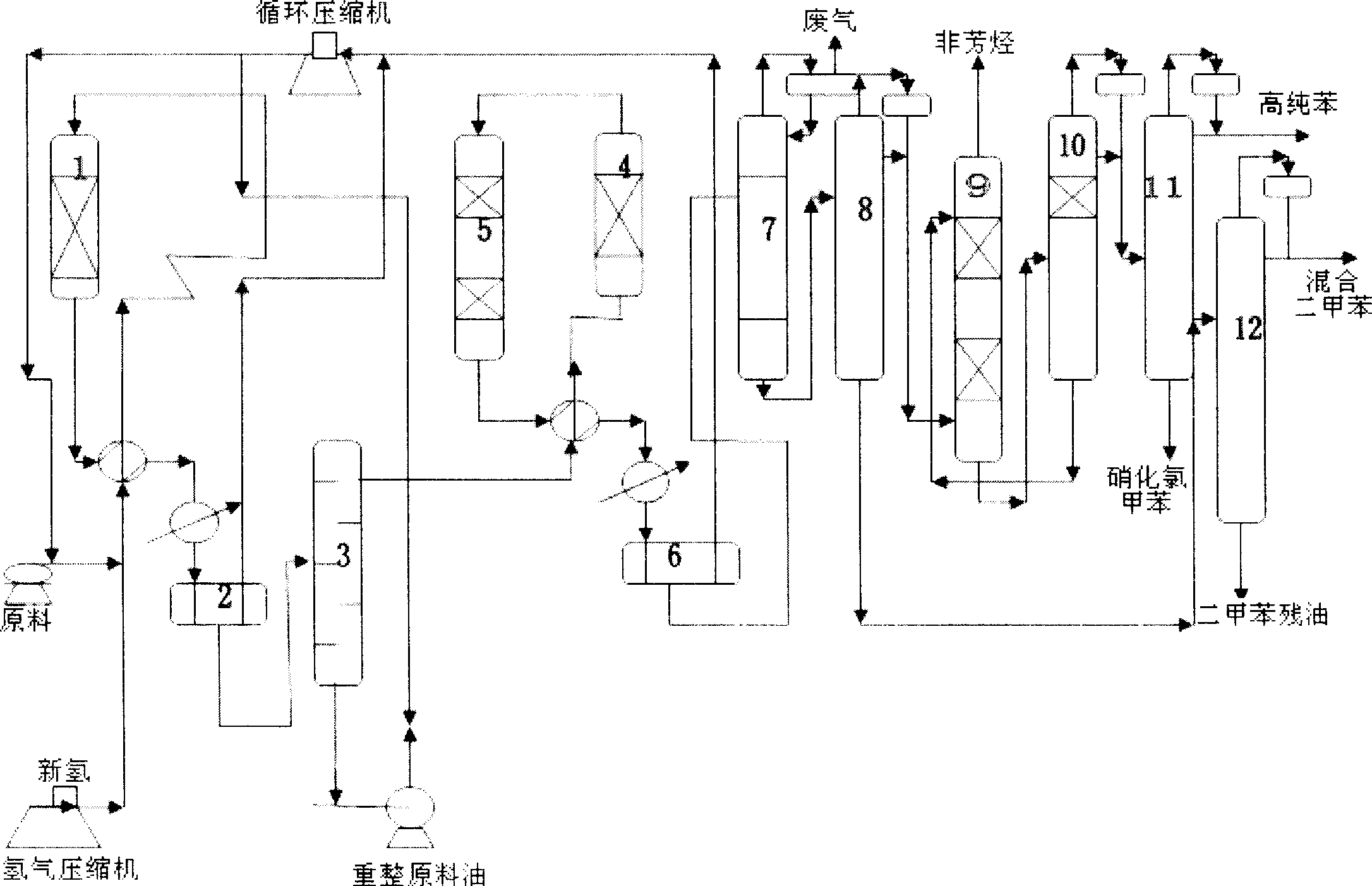

Method for producing benzene aromatic hydrocarbon from crude benzole

ActiveCN1900032ALess investmentLong cycle operationDistillation purification/separationMetal/metal-oxides/metal-hydroxide catalystsBenzoleSolvent

The present invention relates to process of producing benzene series arene with crude benzole. Whole fraction crude benzole and other hydrocarbon oil are mixed, and the mixed oil is produced into high purity benzene, toluene and xylene through the process including hydrorefining, reforming, solvent extracting, distilling, rectifying and other steps. The present invention has the features of no arene loss, total arene yield over 100 %, high purity of arene products over 99.9 %, low S and N impurity content in arene products less than 1 ppm and long operation period of the processing apparatus. The present invention is especially suitable for use in refinery possessing hydrogenation equipment and reforming equipment.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

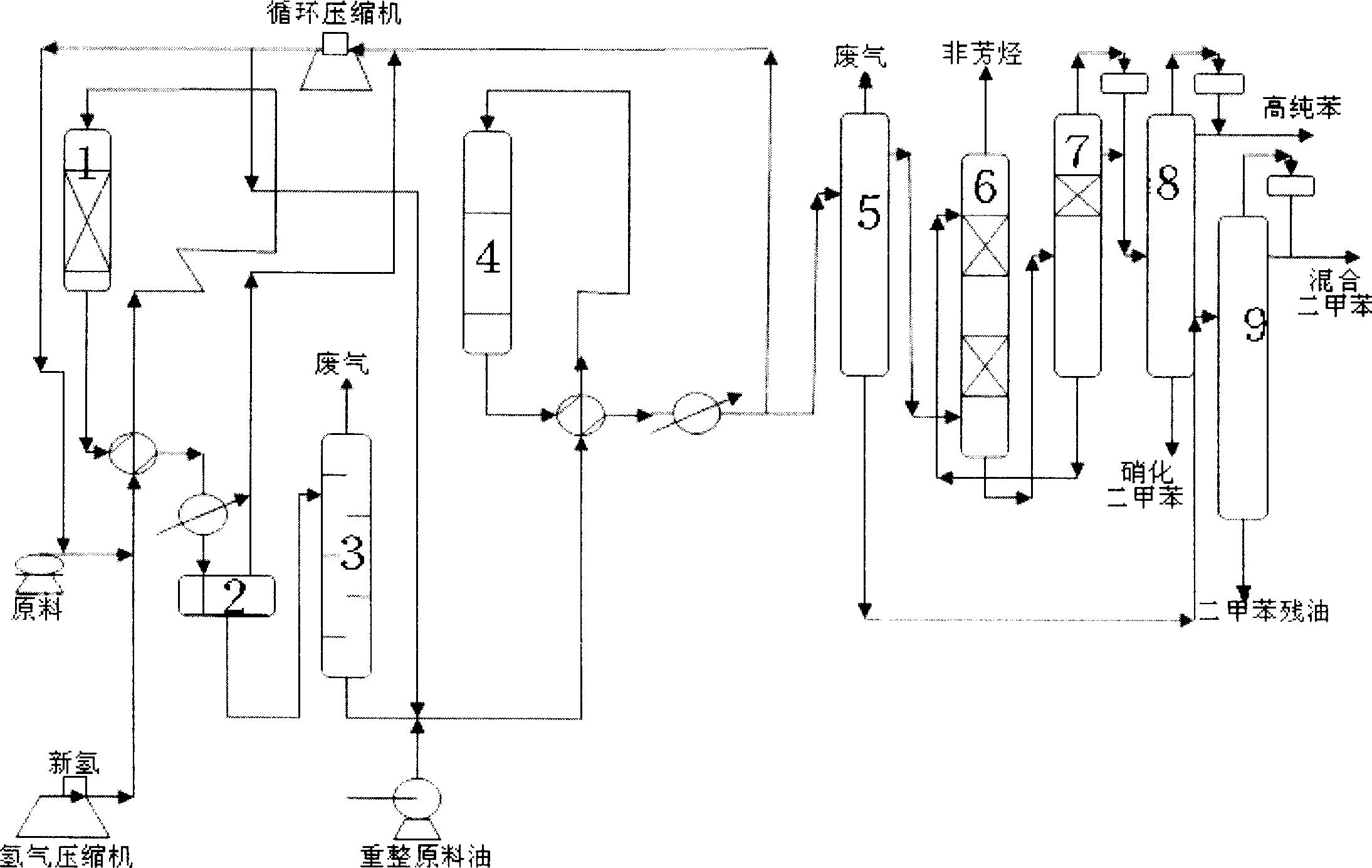

Method for producing benzene aromatic hydrocarbon from crude benzole

InactiveCN1900033AAdaptableLittle change in operating conditionsDistillation purification/separationHydrocarbonsBenzoleSolvent

The present invention discloses process of producing benzene series arene with crude benzole. Whole fraction crude benzole is produced into high purity benzene, toluene and xylene through the process including hydrorefining, solvent extracting, distilling, rectifying and other steps. The present invention has the features of high purity of arene products over 99.9 %, and low S and N impurity content in arene products less than 1 ppm. The present invention is especially suitable for use in refinery possessing hydrogenation equipment and reforming equipment to deep process crude benzole.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Benzophenone macromolecular photoinitiator and preparation method thereof

ActiveCN104987435AMild reaction conditionsEasy to operateOrganic compound preparationCarboxylic acid esters preparationArylPolymer science

The invention relates to a preparation method of benzophenone macromolecular photoinitiator. The benzophenone macromolecular photoinitiator is a compound with the structural formula (I) shown in the specifications, wherein carboxylic ester substituent groups of benzophenone can be 2-position carboxylic ester substituent groups or 3-position carboxylic ester substituent groups or 4-position carboxylic ester substituent groups, each R1 and each R2 are independently selected from hydrogen, optionally substituted alkyl groups and optionally substituted aryl groups, n is an integer from 1 to 6, and L is residues of polyhydric alcohols. The preparation method has the advantages that reaction conditions are mild, operation is easy, the yield is high, and the cost is low; the preparation method is suitable for industrial production.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

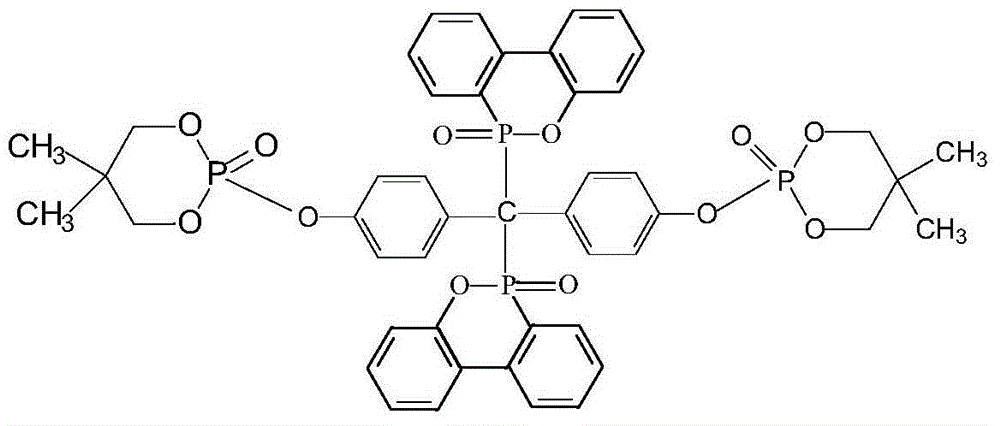

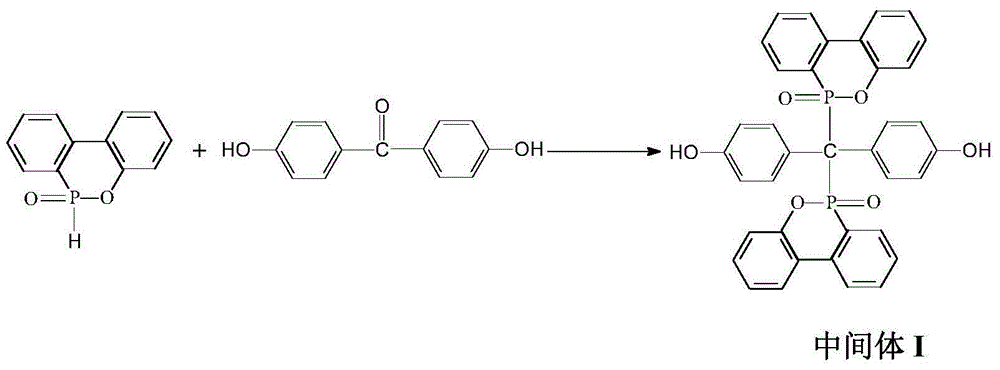

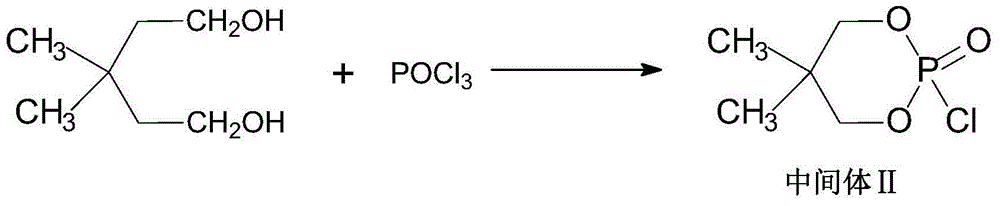

DOPO-containing cyclic phosphate flame retardant as well as preparation method and application thereof

InactiveCN104558683AEasy to operateAdvanced technologyGroup 5/15 element organic compoundsPhosphateFire retardant

The invention discloses a DOPO-containing cyclic phosphate flame retardant. The flame retardant is prepared by the following steps: reacting 4,4 / -dihydroxy benaophenonel and DOPO so as to obtain an intermediate I; preparing an intermediate II from neopentyl glycol and phosphorus oxychloride under the action of chloroform; and reacting the intermediate I and the intermediate II in an organic solvent, thereby obtaining the flame retardant. The flame retardant is white in appearance, high in thermal stability and high in flame retardant rate and has the purity of 98.6 percent. According to the flame retardant, the DOPO, benzophenone oxygroup structural units are introduced into the phosphate, and the flame retardant has high phosphorus content, high heat resistance and high-temperature char yield, can serve as a reactive flame retardant, also can serve as an additive flame retardant and is wide in application prospects.

Owner:CHINA THREE GORGES UNIV

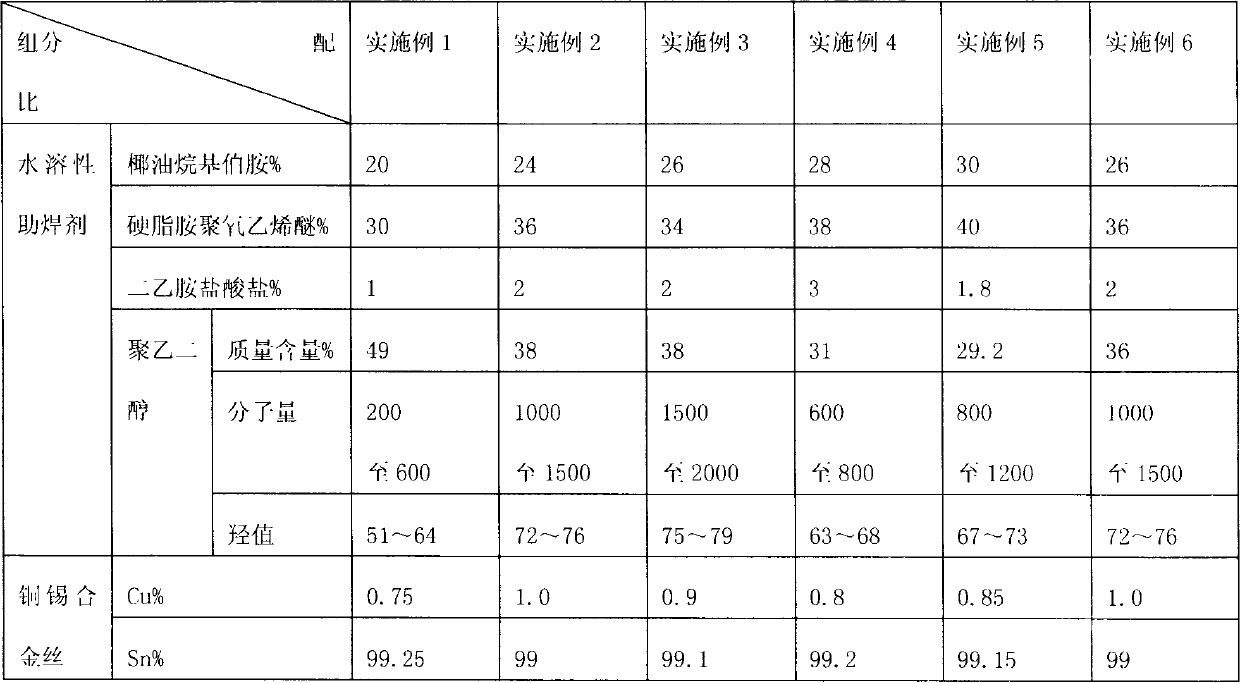

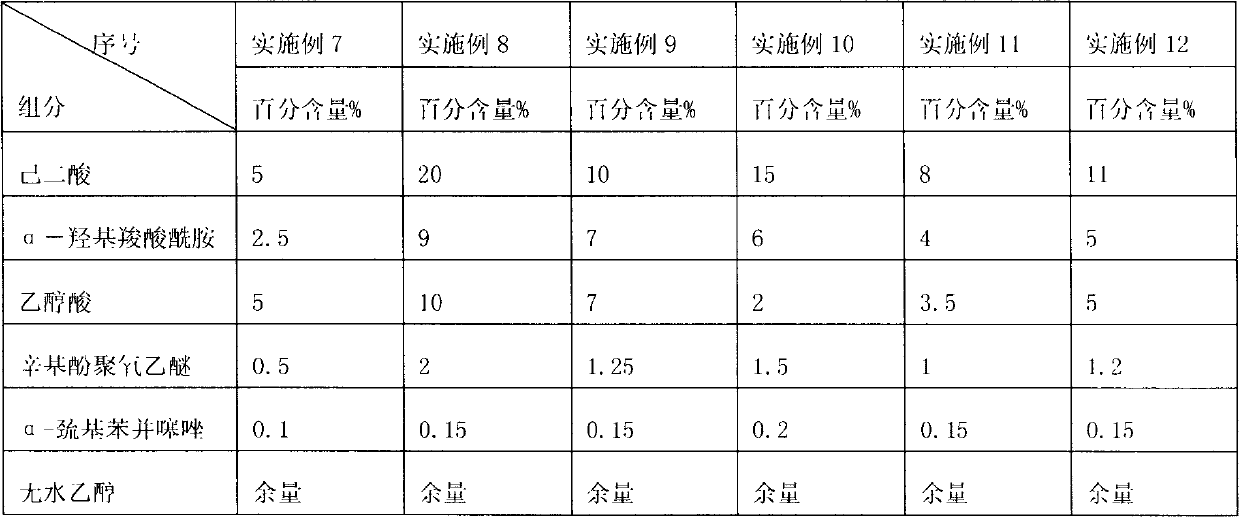

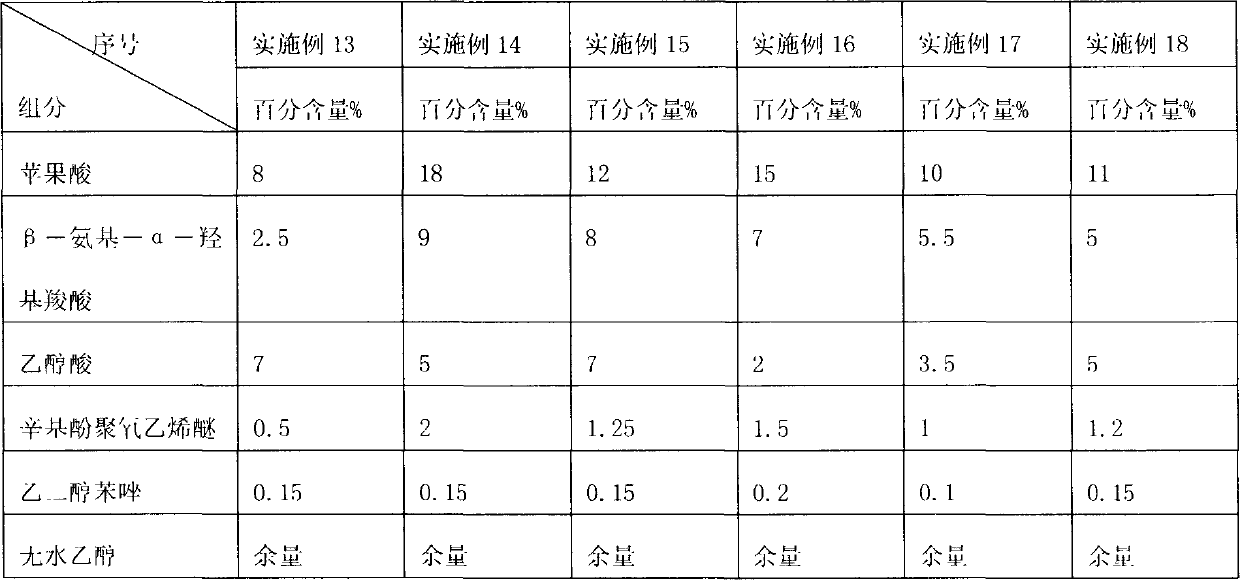

Halogen-free soldering flux

ActiveCN102166692APrevent oxidationReduce pollutionWelding/cutting media/materialsSoldering mediaOrganic acidChemistry

The invention discloses a halogen-free soldering flux, which comprises the following components in percentage by mass: 5 to 20 percent of organic acid, 2.5 to 10 percent of hydroxamino carboxylic acid, 2 to 10 percent of glycollic acid, 0.5 to 2 percent of surfactant, 0.1 to 0.2 percent of corrosion inhibitor and the balance of organic solvent, wherein the organic acid is succinic acid, adipic acid or malic acid; the hydroxamino carboxylic acid is beta-amino-alpha-hydroxy carboxylic acid; the surfactant is alkylphenol polyoxyethylene ether or octylphenol polyoxyethylene ether; the corrosion inhibitor is benzotriazole, alpha-mercaptobenzothiazole or glycol benzole; and the organic solvent is absolute ethanol. The halogen-free soldering flux has the advantages of no halogen or lead and higher wettability.

Owner:浙江强力控股有限公司

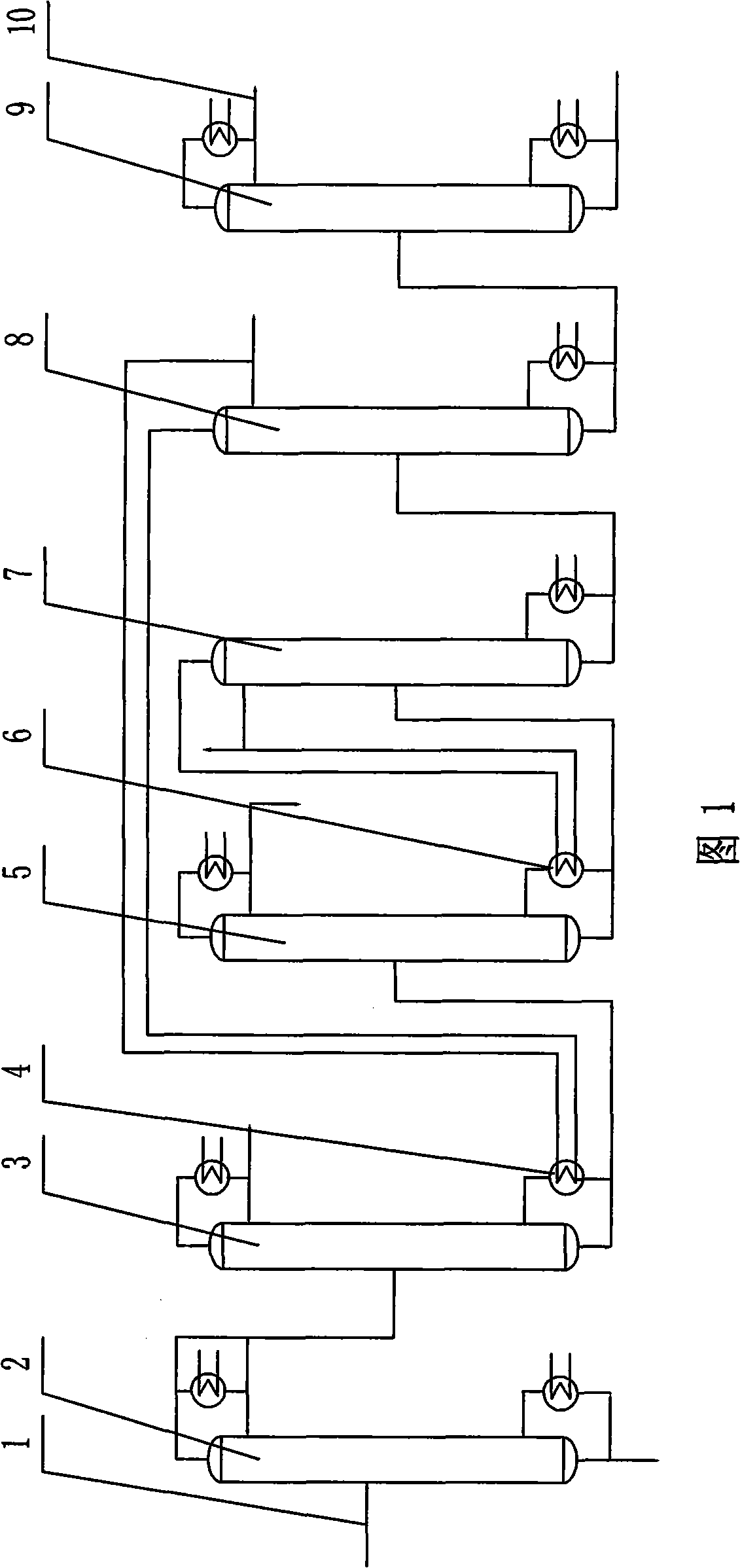

Fine purification system and method for carbonization crude benzol

InactiveCN101270027ALess investmentReduce energy consumptionDistillation purification/separationBenzene vaporReboiler

The present invention relates to a refining system of coked crude benzole and a refining method thereof. The basic equipment consists of two benzene towers, a primary tower, a first pure benzene tower, a second pure benzene tower, a toluene tower and a xylene tower. The heat of the reboiler of the primary tower comes from toluene vapor on the top of the toluene tower; the heat of the reboiler of the first pure benzene tower comes from the pure benzene vapor on the top of the second pure benzene tower. The refining method comprises pre-distillation, refining of the pure benzene and separation of the toluene and the xylene. The method not only saves energy but also reduces the cost of investment. The process is simplified. Compared with the traditional sulfuric acid washing process, the method eliminates the acid-alkali washing and benzene blowing processes. The whole process generates no waste acid, acid residue, caustic dross or waste water, which can cause serious damage to the environment. Compared with the catalytic hydrogenation, the method has the advantages of simplifying the process, lowering the energy consumption, reducing the cost of investment and production, and improving the benefit of production, and thus being an excellent method for steel enterprises and coking enterprises to further process and make use of by-products.

Owner:天津凯赛特科技有限公司

Method for synthesizing methyl 3-(trifluoromethyl)benzoate

InactiveCN102351704AImprove controllabilityEfficient use ofOrganic compound preparationCarboxylic acid esters preparationSide chainWater chlorination

The invention provides a new method for synthesizing methyl 3-(trifluoromethyl)benzoate, which comprises side-chain chlorination reaction, fluorination reaction and esterification reaction. The method is environment-friendly and high in reaction yield; and the selected raw materials, namely chlorine, m-methylbenzoyl chloride, anhydrous hydrofluoric acid, methanol, light calcium carbonate and the like are cheap and readily available in industry. The related three reactions are high in controllability and easy to operate, and an intermediate product is not required to be purified and can undergo the next reaction. Byproducts generated in the reactions can be effectively utilized, and the industrial feasibility of the method is improved.

Owner:ZHEJIANG WEIHUA CHEMICAL CO LTD

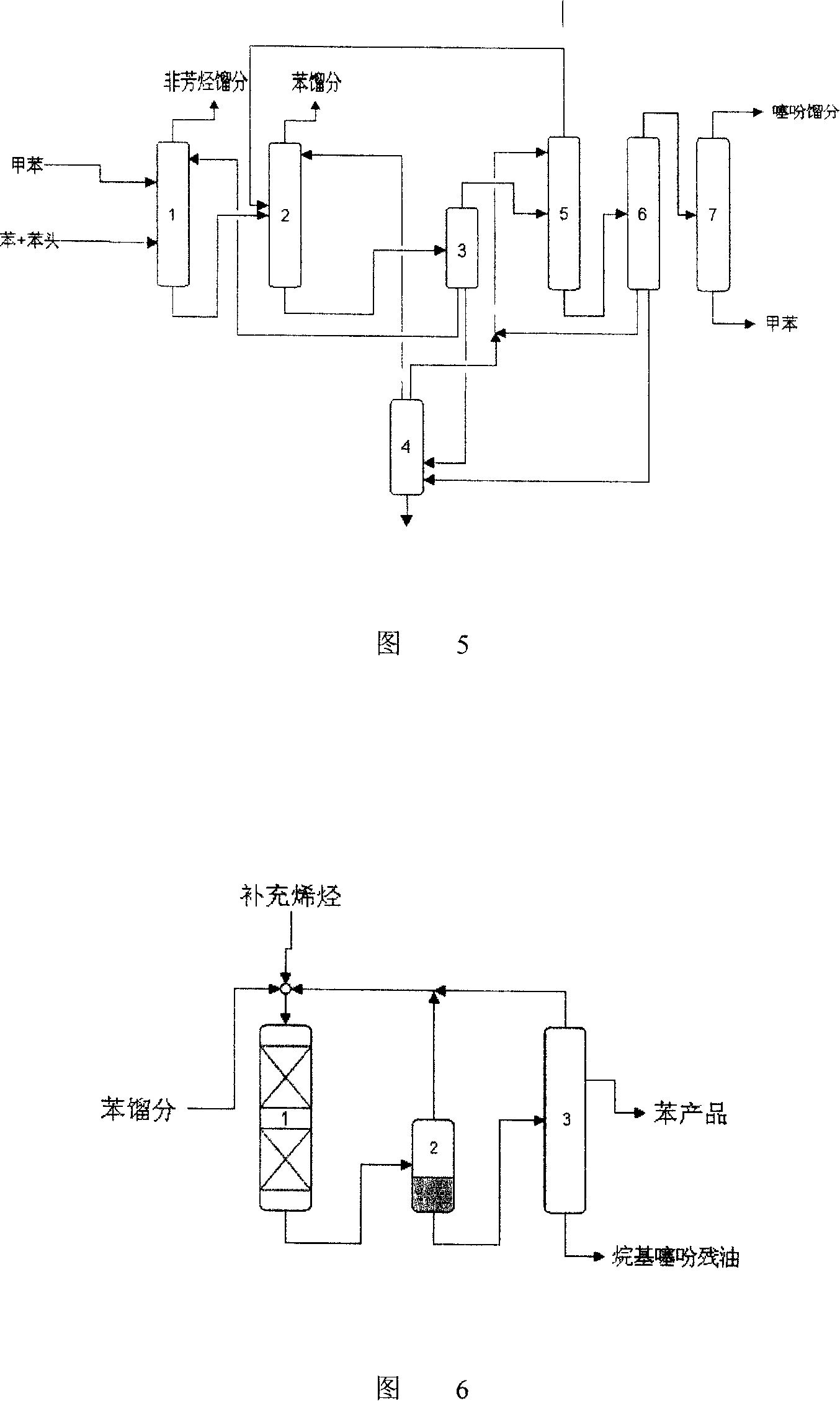

Method for refining carbonization crude benzole

InactiveCN101152994AAvoid sulfonation lossHigh recovery rateDistillation purification/separationCarbonizationBenzole

The present invention relates to a refining method of coking crude benzol. The method has four following sequential steps as follows: thepretreatment process of raw materials, the refining process of doffing non-arene and doffing othiophene, the deep desulfurization process of thiophene alkyl, and the refining process of toluene and xylene. The products of high-purity sulfur-free benzene, toluene and xylene can be made. The detailed technological process can be referred to the specification munual. Compared with the traditional pickling method, the present invention has the following advantages: the whole process has no production of acid tar, no serious pollution to the environment and no serious corrosion of equipment; at the same time, the present invention avoids sulfonate loss of arene, effectively improves the reclamation rate of arene and belongs to an environmental friendly technology. Besides, the products of coking benzene category are obviously superior in quality to the traditional pickling. Compared with the catalytic hydrogenation process, the process is simple and not only can save a substantial amount of investment costs, but also the operation cost of device is low. The quality of benzene products is equivalent to hydrogenated benzene. The present invention provides an environmentally protective and economical process for the reasonable development and utilization of coking benzene resources, and has quite broad application prospects.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

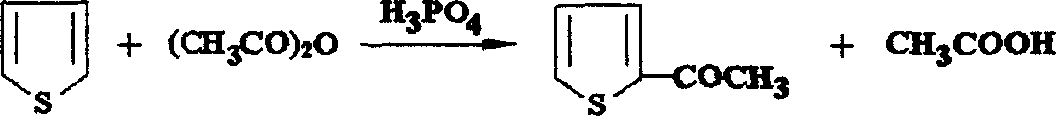

2-acetyl thiophene synthetic method using thiophene in crude benzene as material

The invention provides a process for synthesizing 2- acetyl thiophene pharmaceutical intermediate compound by using thiophene in crude benzole through selective acetylation reaction, wherein an extraction and distillation method is adopted to condensate the thiophene in carbonized crude benzole, and to further prepare acetyl thiophene pharmaceutical intermediate compound from the thiophene concentrate through catalytic conversion.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

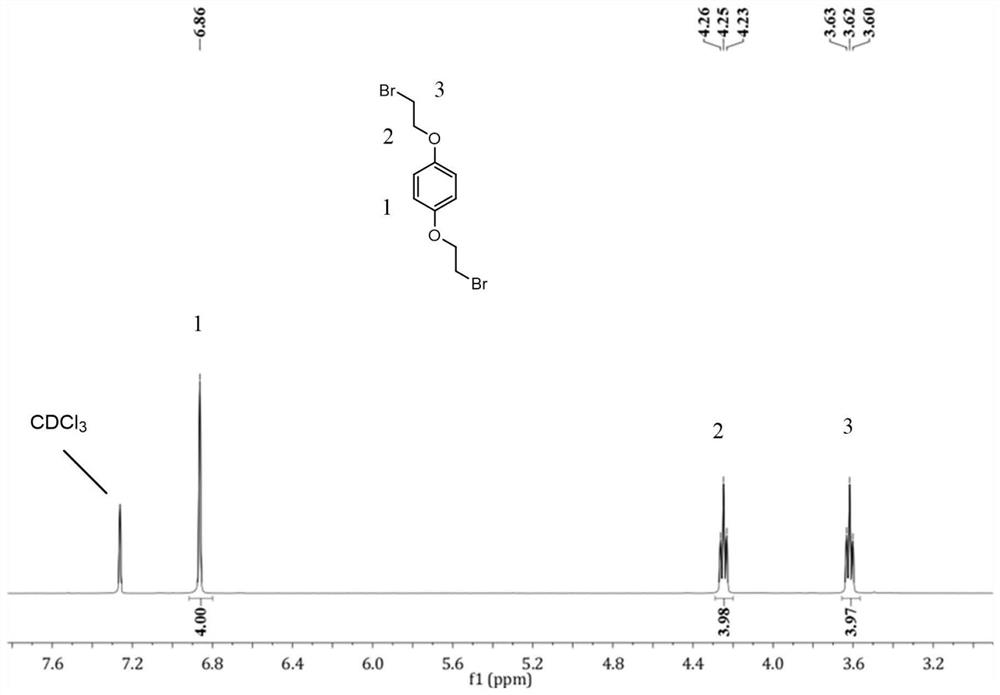

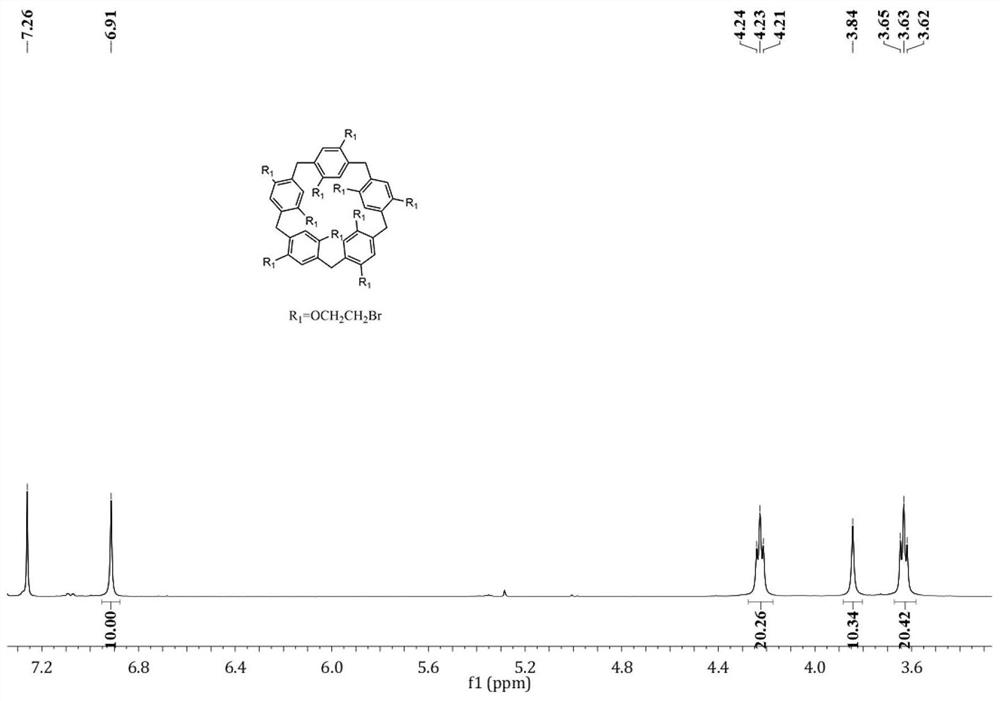

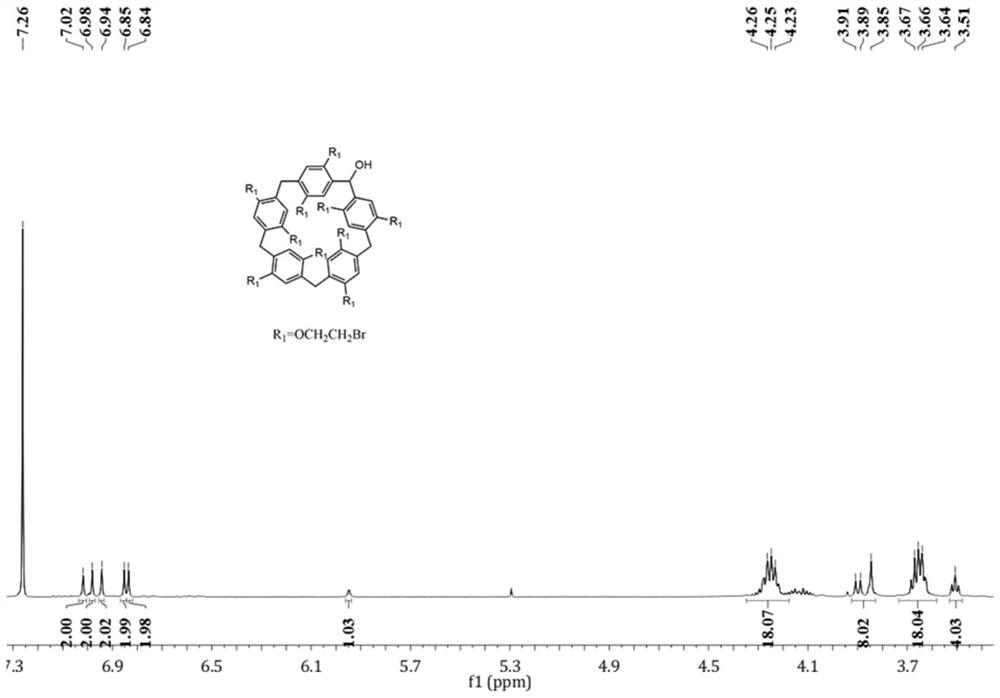

Pillar aromatic hydrocarbon and pillar aromatic hydrocarbo-like compound with aggregation-induced emission effect as well as preparation method and application thereof

ActiveCN112079684AExcellent aggregation-induced luminescence effectHigh quantum yieldOrganic non-active ingredientsHydrocarbonsImidePharmaceutical drug

The invention provides a pillar aromatic hydrocarbon and pillar aromatic hydrocarbon-like compound with an aggregation-induced emission effect as well as a preparation method and application thereof.The pillar aromatic hydrocarbon and the pillar aromatic hydrocarbon-like compound have the following structural general formula, or in the structural general formula, R1 is equal to OCH2CH2Br or H; and R2 is equal to OCH2CH2Br or H. The preparation method comprises the following steps: reacting a compound 1 with N-bromo succinimide to obtain a compound 2; then carrying out oxidation reaction to obtain a compound 3, and reacting the compound 3 with benzophenone to obtain the pillar aromatic hydrocarbon and pillar aromatic hydrocarbon-like compound 4 shown in a formula (a); and if the compound 3reacts, obtaining a compound 5 shown as a formula (b). The obtained pillar aromatic hydrocarbon and pillar aromatic hydrocarbon-like compound has an excellent AIE effect, contains a plurality of recognition sites and an electricity-rich cavity, can realize accurate fluorescence regulation and control by utilizing the AIE effect and supramolecular assembly of the pillar aromatic hydrocarbon and pillar aromatic hydrocarbon-like compound, and has wide application in the fields of nano-drug delivery, diagnosis and treatment and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

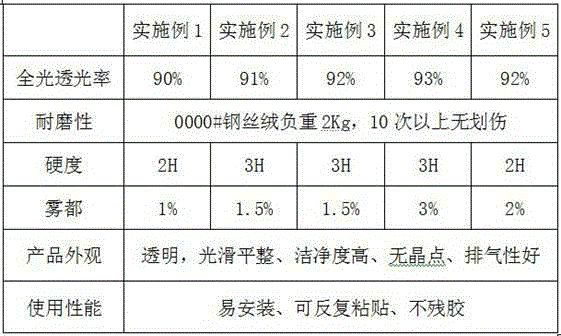

Hardening coating and easily torn and located protective film prepared by utilizing hardening coating

ActiveCN104152006ASimple recipeImprove curing effectFilm/foil adhesivesSynthetic resin layered productsPolymer scienceMethacrylate methyl

The invention relates to the technical field of optical protective films, and in particular relates to a hardening coating and an easily torn and located protective film prepared by utilizing the hardening coating. The hardening coating disclosed by the invention comprises the following raw materials by weight percent: 50-70% of epoxy acrylate, 5-10% of urethane acrylate, 5-10% of methyl methacrylate, 5-12% of butyl acrylate, 5-10% of hydroxyethyl acrylate, 2-5% of benzoin ethyl ether, 0.5-3% of benzophenone, 0.1-2% of triethanolamine, 0.1-2% of a polysiloxane-polyether copolymer, and 0.5-5% of EDAB. The easily torn and located protective film prepared by utilizing the hardening coating has the characteristics of uniform colour and lustre and low newton ring; furthermore, the easily torn and located protective film is simple to operate and is torn and located easily and can be well pasted in place once; and the easily torn and located protective film is easy to install, rapid to exhaust, repetitive to paste, free from residual glue and the like and can be widely applied to protecting various liquid crystal display screens.

Owner:NALI OPTICAL MATERIAL DONGGUAN

Formula and preparation method of anti-ultraviolet ray quartz stone plate

The present invention discloses a formula and a preparation method of an anti-ultraviolet ray quartz stone plate. The anti-ultraviolet ray quartz stone plate comprises, by weight, 65-75 parts of quartz sand, 15-25 parts of quartz powder, 8-10 parts of an unsaturated resin, 0.5-1 part of titanium dioxide powder, 0.1-0.3 part of an anti-ultraviolet ray agent, 0.5-1.5 parts of a silane coupling agent, 0.2-0.4 part of tert-butyl peroxy-2-ethylhexanoate, and 0.2-0.3 part of cobalt naphthenate, wherein the particle size of the quartz sand is 10-300 mesh, the particle size of the quartz powder is 325 mesh, and the anti-ultraviolet ray agent is benzophenone or benzotriazole or iron oxide red or zinc oxide. The preparation method comprises: completely stirring the materials, uniformly distributing the material, pumping vacuum, carrying out high pressure pressing molding, baking for 4-6 h with a baking oven, and carrying out thicknessing polishing. The variable quartz stone plate has advantages of ultraviolet ray resistance, color change resistance, aging resistance and the like.

Owner:ZAOZHUANG KEJIA PHOTOELECTRIC TECH CO LTD

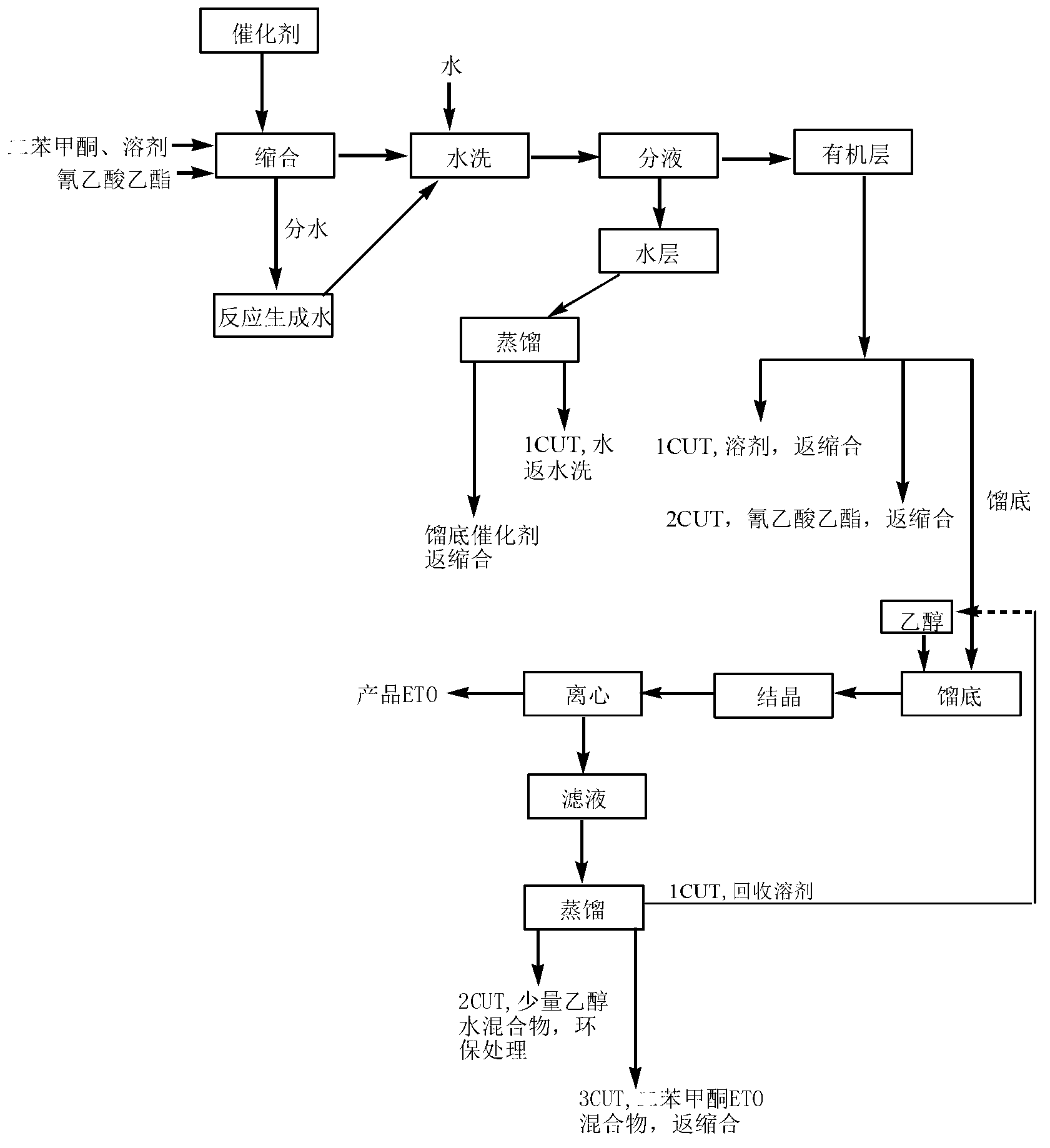

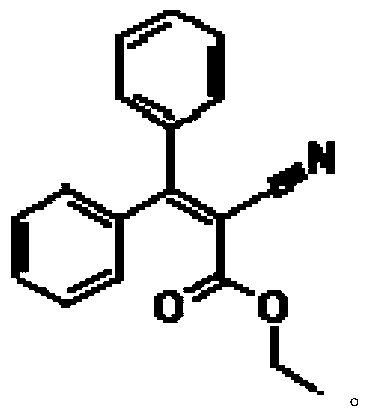

Preparation method of ultraviolet absorbent intermediate etocrilene (ETO)

ActiveCN103242197AHarm reductionReduce manufacturing costCarboxylic acid nitrile preparationOrganic compound preparationDistillationEthyl cyanoacetate

The invention relates to a preparation method of an ultraviolet absorbent intermediate etocrilene (ETO). The preparation method comprises the following steps of: 1, adding benzophenone, ethyl cyanoacetate, a catalyst and a water-insoluble solvent into a condensation reaction kettle, carrying out backflow water distribution reaction for 12-15h, and then, cooling to 50-55 DEG C, wherein the excessive equivalent of the ethyl cyanoacetate relative to the benzophenone is 0.2-5; 2, washing the reaction liquid by using water, and separating the liquid to respectively obtain a water layer and an organic layer; distilling the recycled water at the water layer at normal pressure, dissolving distillation tailings by using a solvent same as the solvent used in the step 1, and then, replenishing a proper quantity of catalyst to obtain a product, wherein the distilled recycled water is used in the step 2, and the product is used in the step 1; and distilling the recycled solvent at the organic layer at normal pressure, and carrying out reduced pressure distillation to recycle the excessive ethyl cyanoacetate, wherein the recycled solvent and ethyl cyanoacetate are used in the step 1; 3, carrying out reduced pressure distillation on the distillation tailings, adding 75-100% of ethanol for crystallizing, and filtering to obtain the etocrilene; and 4, filtering a mother solution obtained in the step 3, recycling the ethanol at normal pressure, and carrying out reduced pressure recycle on the benzophenone and the etocrilene, wherein the recycled ethanol is used in the step 3, and the recycled benzophenone and etocrilene are used in the step 1. The preparation method has the advantages of simplicity in operation, short production period, little environment pollution, low energy consumption, realization of material recycling, and the like.

Owner:ANHUI SHENGNUOBEI CHEM TECH

Heat conduction graphite flake and manufacturing process thereof

ActiveCN103787323AImprove biaxial tensile propertiesHigh thermal conductivityCarbon compoundsRadiationPolydimethylsiloxane

The invention discloses a heat conduction graphite flake, and a manufacturing process thereof. The heat conduction graphite flake comprises a polyimide film, a first coating layer and a second coating layer, wherein the first coating layer and the second coating layer are respectively arranged on the upper surface and the lower surface of the polyimide film; the first coating layer and the second coating layer are formed by sintering a graphite modifier; the graphite modifier comprises the following components in parts by weight: 20-25 parts of benzophenonetetracarboxylic dianhydride, 14-16 parts of pyromellitic dianhydride, 22-26 parts of diaminodiphenyl methane, 25-35 parts of dimethylformamide, 1.8-2.5 parts of ethylene glycol, and 2.5-3 parts of polydimethylsiloxane. According to the heat conduction graphite flake, the heat conduction performance can be improved in the vertical direction and the horizontal direction, local overheat is avoided, the uniform heat conduction performance is achieved, and the stability and reliability of radiation performance of products are improved.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

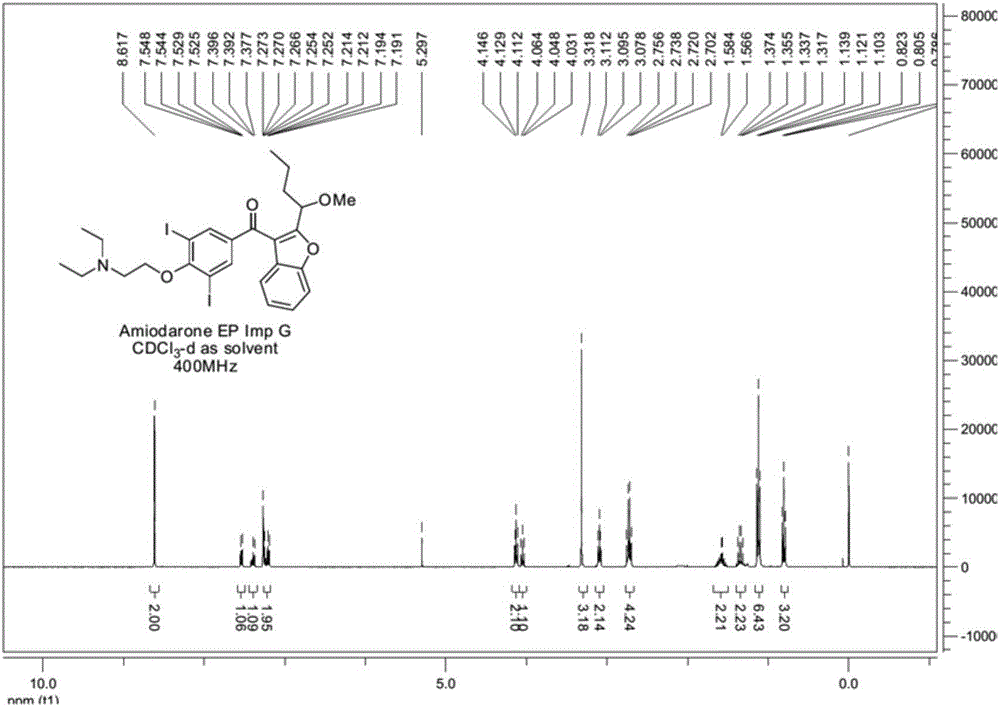

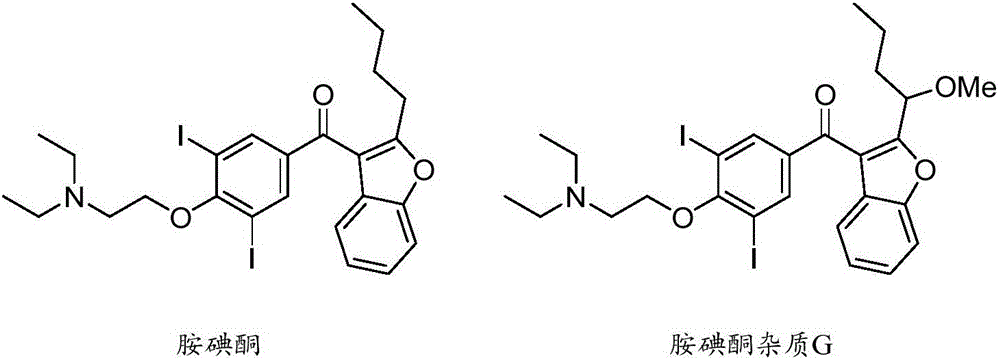

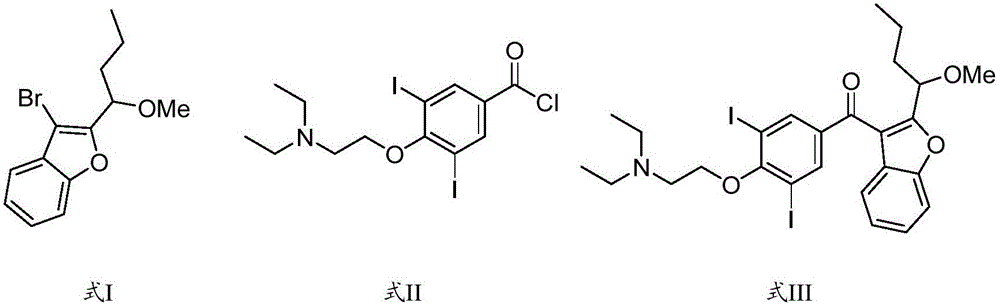

Method for synthesizing amiodarone impurity G and application of amiodarone impurity G

ActiveCN106632180APrecise structureHigh purityOrganic chemistryComponent separationChemical synthesisQuality control

The invention provides a method for synthesizing an amiodarone impurity G and application of the amiodarone impurity G, and relates to the technical field of chemical synthesis. According to the method for synthesizing the amiodarone impurity G, the amiodarone impurity G can be synthesized by one-step reaction of 3-bromo-2-(1-methoxybutyl)benzofuran and 4-(2-(diethylamino)ethoxy)-3,5-diiodobenzoyl chloride which are adopted as raw materials under protection of inert gas. The method is easy to operate and low-cost, and has certain commercial value. In addition, when the amiodarone impurity G synthesized by the method is used as an impurity reference substance, a qualified, low-cost and readily-available reference substance is provided for quality control over amiodarone, and great guiding significance is provided for safe medication.

Owner:成都摩尔生物医药有限公司

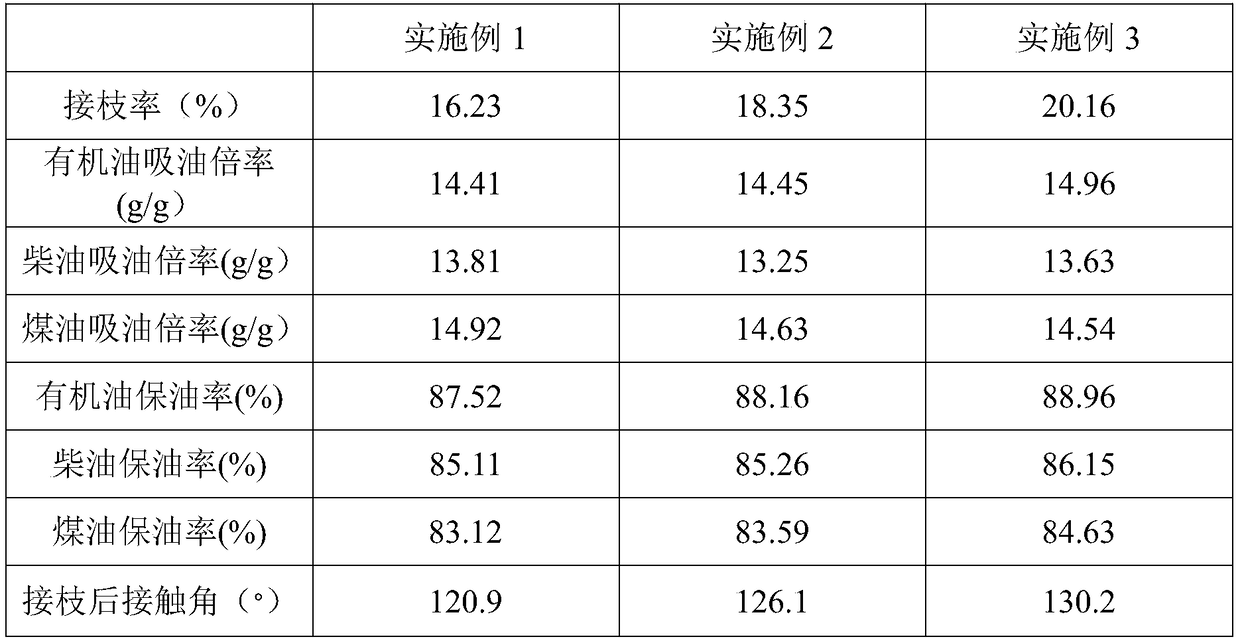

Ultraviolet compound melt-blowing polypropylene oil-absorbing non-woven fabric and its preparation method

InactiveCN109137466ALight in massLarge poresOther chemical processesUltrasonic/sonic fibre treatmentUltravioletNonwoven fabric

The invention discloses an ultraviolet compound melt-blowing polypropylene oil-absorbing non-woven fabric and its preparation method. According to the preparation method, a photosensitizer, compound monomers, solvents and melt-blowing polypropylene non-woven fabric are involved, wherein the photosensitizer relates to benzophenone, the compound monomers refer to optional two of butyl methacrylate,dodecyl methacrylate, methyl acrylate and butyl acrylate, and the solvents refer to isopropyl alcohol and deionized water. The non-woven fabric can adsorb oil substances in different type, has good oleophylic hydrophobicity, can absorb oil but water, can be reused, can also adsorb some heavy-metallic ion. Besides, as the optimum processing condition good for achieving the optimum oil absorption capacity is reached as researched, the fabric has more thorough oil absorption performance and better oil holding capacity.

Owner:JIXI YUANDAO AGRI IND TECH

Method for measuring distillate quantity of crude benzole before 180 DEG C

InactiveCN101504392AImprove efficiencyReduce work intensityComponent separationHydrogenColumn temperature

Owner:新疆八一钢铁股份有限公司炼钢厂

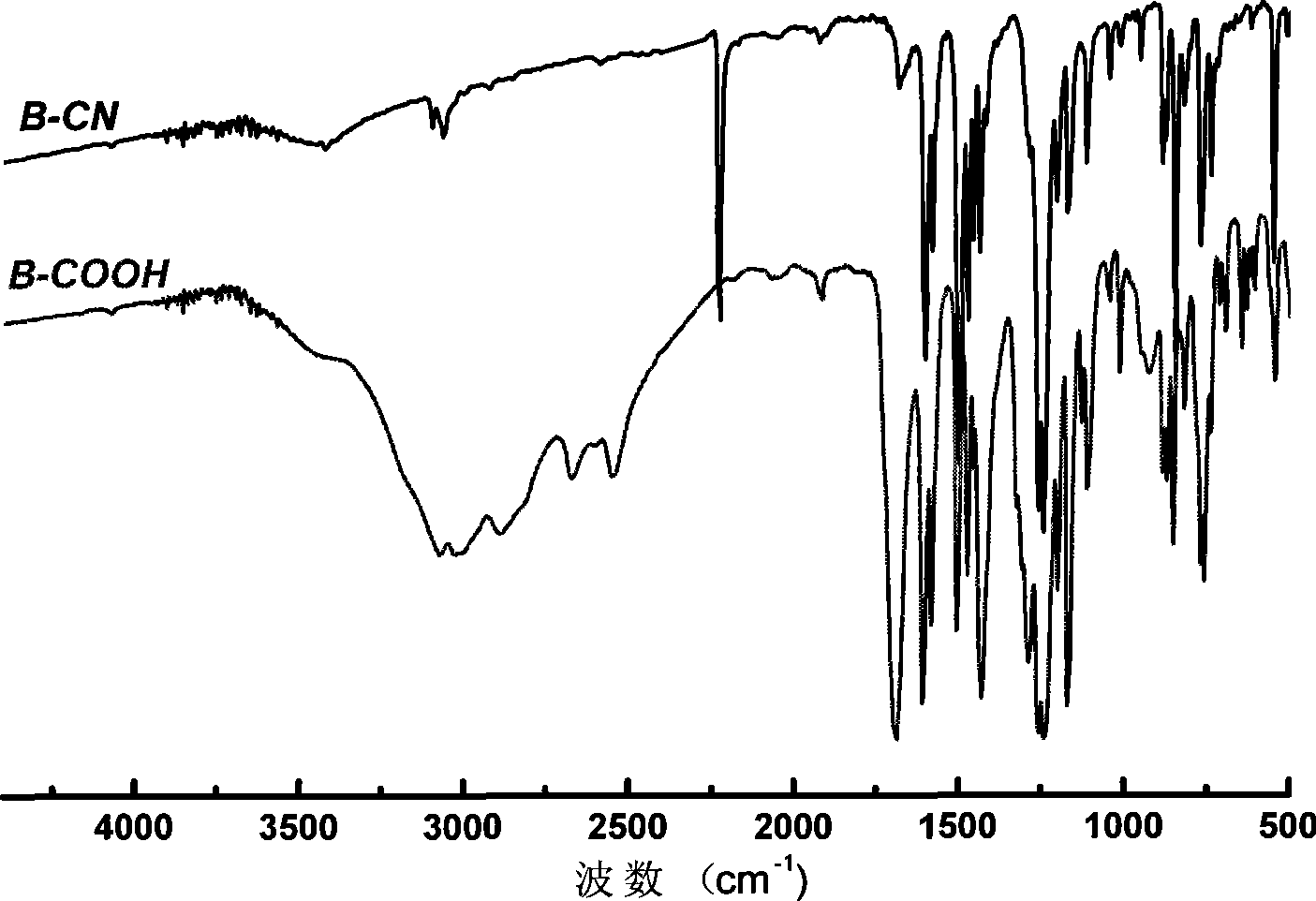

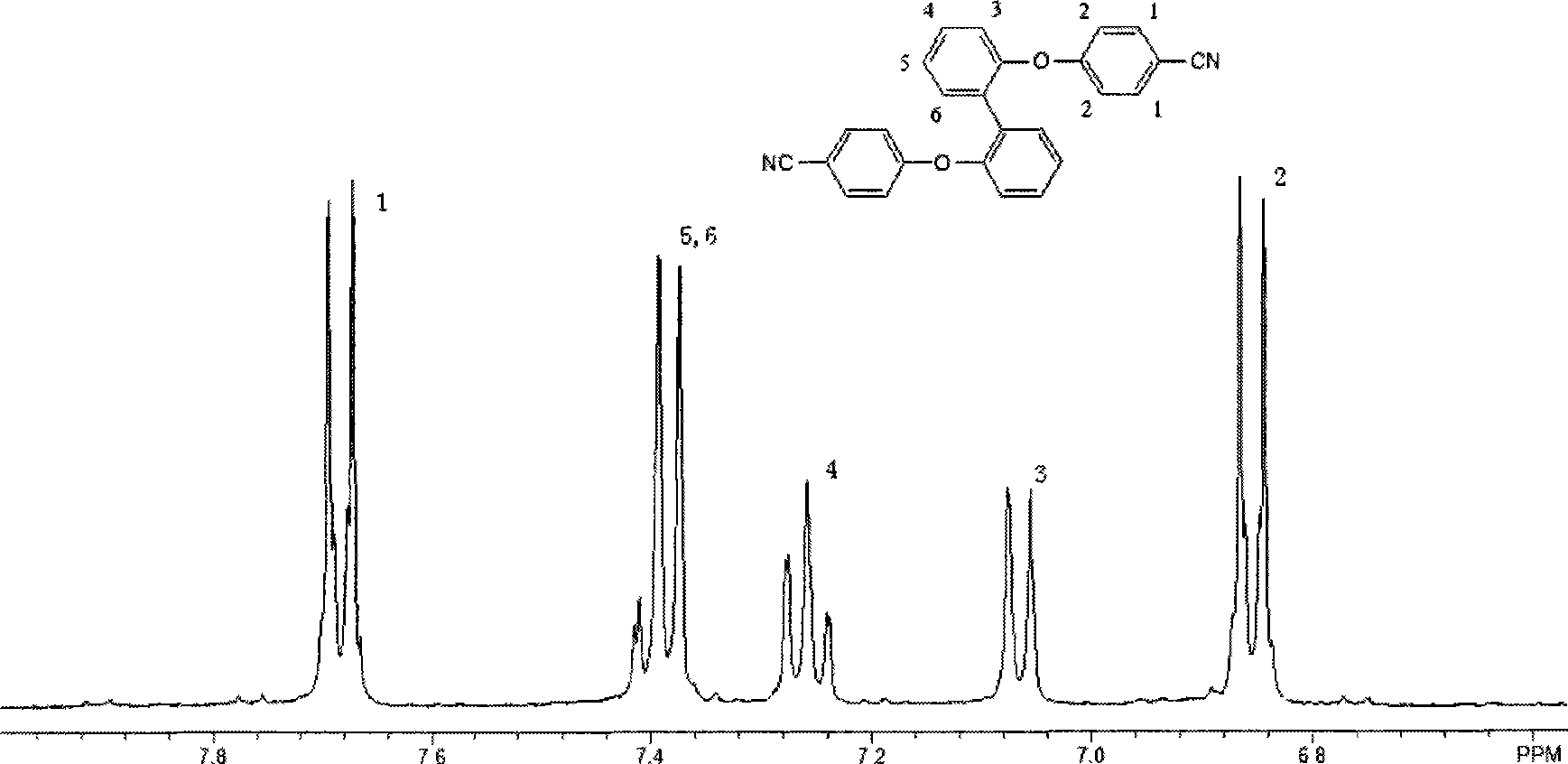

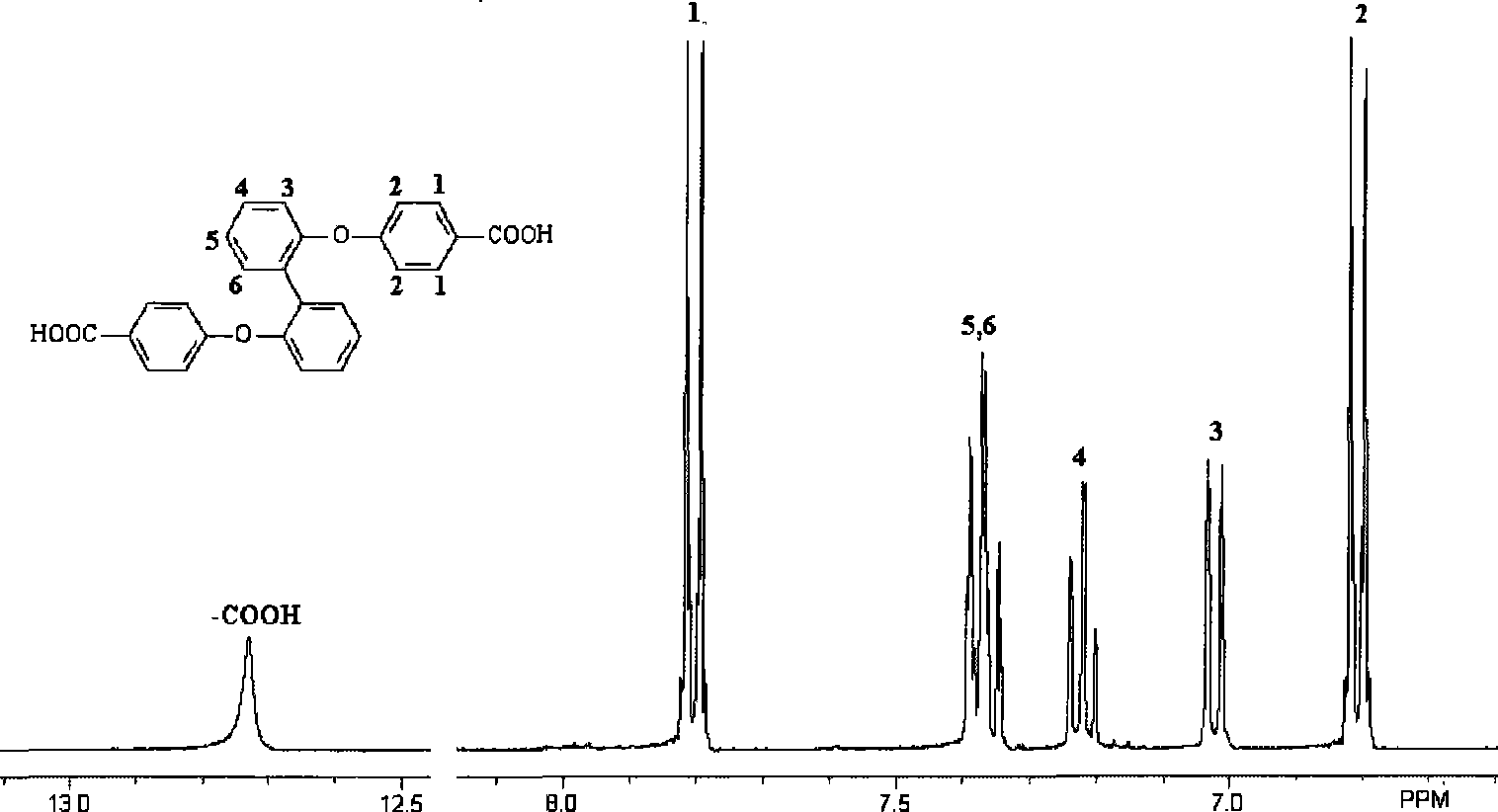

Sulfonated aromatic dicarboxilic acid and preparation method thereof

InactiveCN101381329AGood mechanical propertiesImprove heat resistanceSulfonic acid preparationPolyamideCarboxylic acid

The invention discloses sulfonated aromatic dicarboxylic acid and a preparation method thereof. The sulfonated aromatic dicarboxylic acid is prepared by the following steps: 2, 2'-biphenol or 4, 4'-biphenol and 4-halogen benzonitrile are taken as raw materials to synthesize dicyanoarylene first, the dicyanoarylene is hydrolyzed to produce aromatic diacid, and then the aromatic diacid is sulfonated to obtain the sulfonated aromatic dicarboxylic acid. The sulfonated aromatic dicarboxylic acid can prepare sulfonated polyamide by reacting with diamine, and can prepare sulfonated polybenzimidazole by reacting with tetraarylamine or hexamine. Sulfonated polyamide and sulfonated polybenzimidazole crosslinking membranes have excellent mechanical properties, heat resistance, and solvent resistance, and are widely applied to aspects such as proton conducting membranes and separation membranes for fuel cells, ion exchange membranes for chlor-alkali industry and so on.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com