Preparation method and application of PTFE and polyester-based composite film for preventing wind turbine blades from icing

A technology of polyester composite film and wind power blades, which is applied in the direction of chemical instruments and methods, adhesive additives, synthetic resin layered products, etc., can solve the problems that PTFE films cannot be firmly bonded to wind power blades, and achieve excellent UV resistance and complex The performance of the climate, the expansion of the selection range, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

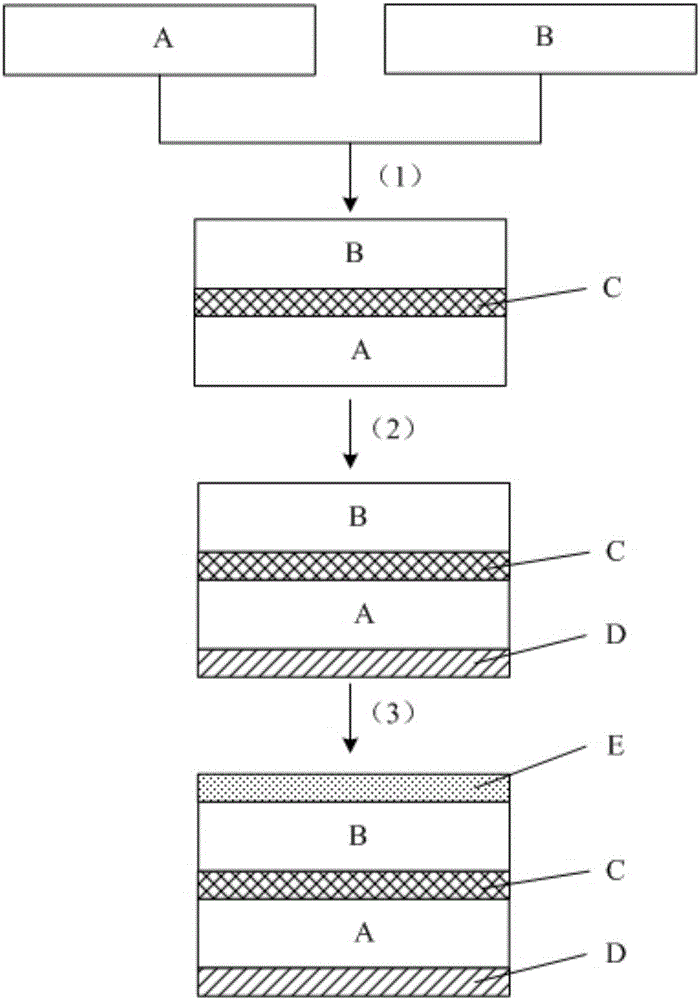

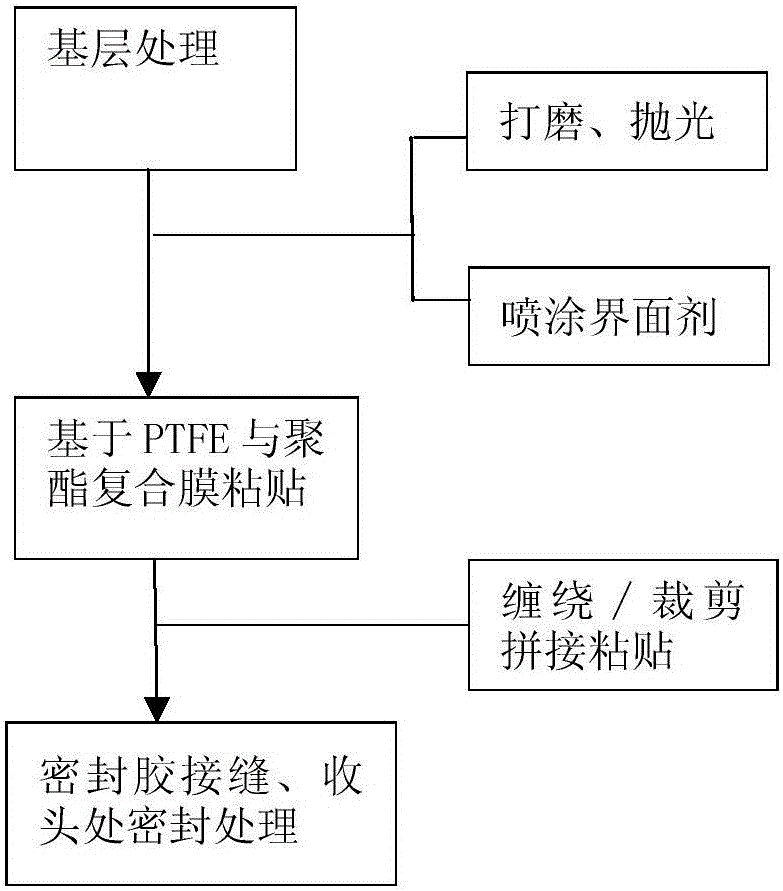

[0052] This embodiment is a preparation method for anti-icing of wind power blades based on PTFE and polyester composite film. The process is as follows figure 1 shown, including the following steps:

[0053] On the hot-press laminating machine, the polyester fabric B is coated with the adhesive compound C, and then hot-pressed and laminated with the PTFE-based film A at the same time. mm. The bonding compound consists of 45.0 Kg 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, 5.0 Kg urethane, 5.0 Kg α-linolenic acid, 2.0 Kg (4) ethoxylated bisphenol A dimethacrylate, 1.5 Kg benzoyl peroxide and 41.5 Kg vinyl acetate are composed, stirred evenly at room temperature. A composite membrane based on PTFE membrane / polyester fabric was prepared.

[0054] Then, on the PTFE-based membrane based on the PTFE membrane / polyester fabric composite material, the interface glue D was sprayed, and after spraying, it was dried at 100°C to obtain the [interface glue-based on PTFE mem...

Embodiment 2

[0057] This embodiment is a preparation method for anti-icing of wind power blades based on PTFE and polyester composite film. The process is as follows figure 1 shown, including the following steps:

[0058] On the hot-press laminating machine, the polyester fabric B is coated with the adhesive compound C, and then hot-pressed and laminated with the PTFE film A at the same time. The hot-press laminating temperature is 170°C, the time is 1.2min, and the line pressure is 1.0 Kg / mm . Adhesive compound 55.0 Kg 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, 8.0 Kg urethane, 3.0 Kg α-linolenic acid, 4.0 Kg (4) ethoxylated bisphenol A dimethacrylate, 2.0 Kg of benzoyl peroxide and 28.0 Kg of vinyl acetate, stirred evenly at room temperature. A PTFE membrane / polyester fabric composite membrane was prepared.

[0059]Then, on the PTFE-based membrane based on the PTFE membrane / polyester fabric composite material, the interface glue D was sprayed, and after spraying, it was ...

Embodiment 3

[0062] This embodiment is a preparation method for anti-icing of wind power blades based on PTFE and polyester composite film. The process is as follows figure 1 shown, including the following steps:

[0063] On the hot-press laminating machine, the polyester fabric B is coated with the adhesive compound C, and then hot-pressed and laminated with the PTFE-based film A at the same time. mm. The bonding compound consists of 50.0 Kg 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, 6.5 Kg urethane, 4.0 Kg α-linolenic acid, 3.0Kg (4) ethoxylated bis Phenol A dimethacrylate, 1.6 Kg benzoyl peroxide, 34.9 Kg vinyl acetate, stirred evenly at room temperature. A composite membrane based on PTFE membrane / polyester fabric was prepared.

[0064] Then, on the PTFE-based membrane based on the PTFE membrane / polyester fabric composite material, spray the interface glue D, and dry it at 95°C after spraying to prepare the [interface glue-based on PTFE membrane-polyester fabric] compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com