Patents

Literature

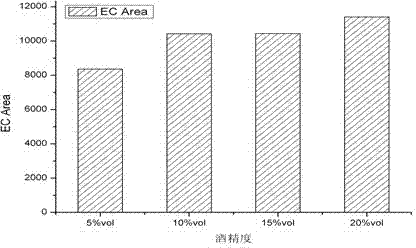

347 results about "Ethyl carbamate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl carbamate (also called urethane) is an organic compound with the formula CH₃CH₂OC(O)NH₂. It is an ester of carbamic acid. It is a white solid. Despite its name, it is not a component of polyurethanes. Because it is a carcinogen, it is little used, but has been detected in alcoholic beverages.

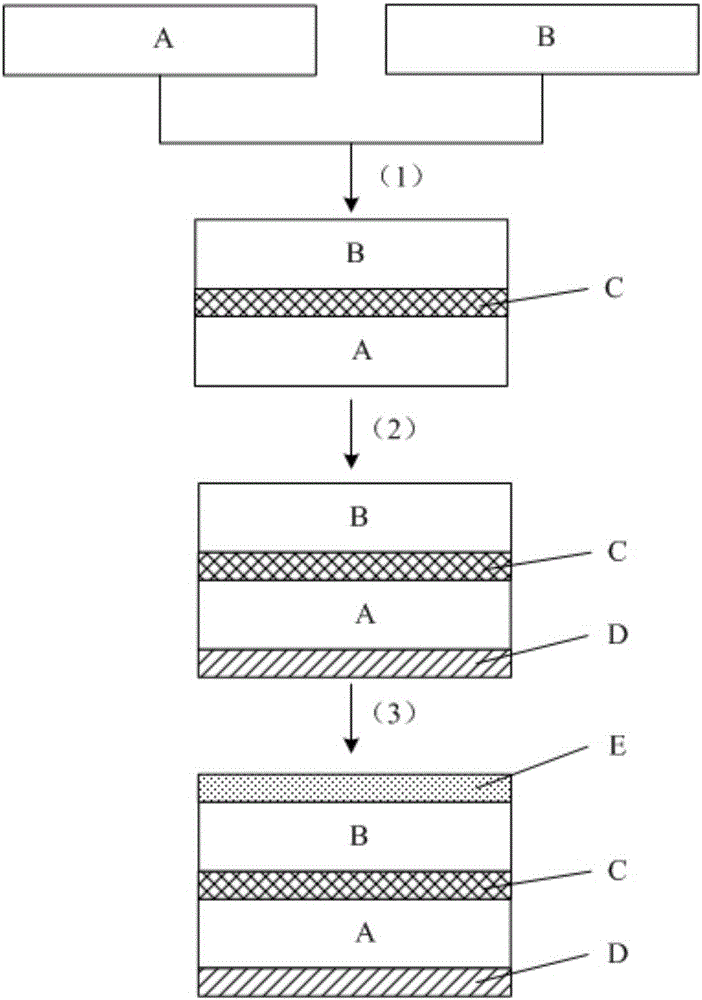

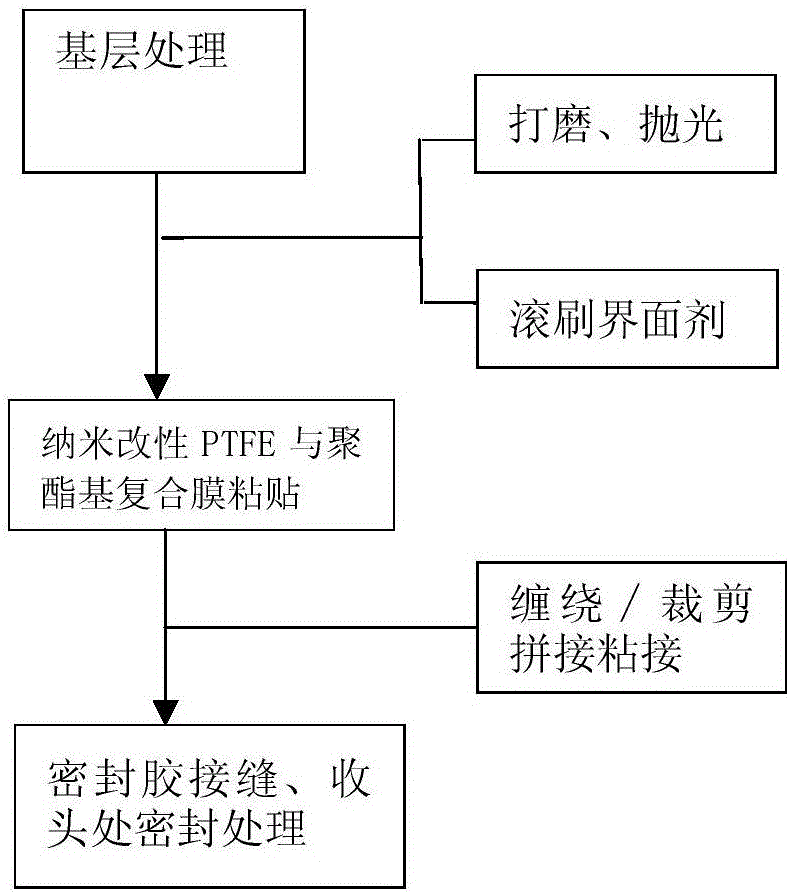

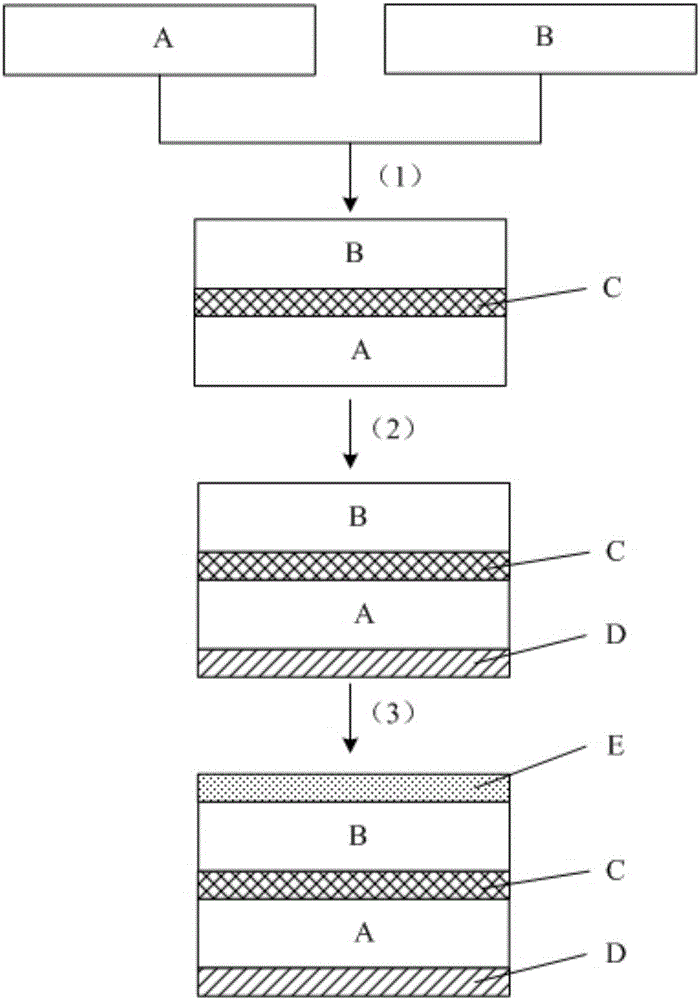

Preparation method and application of nano-modified PTFE and polyester-based composite film for preventing fan blades from icing

ActiveCN106313811ASolving non-adhesive technical problemsConvenient engineering constructionSynthetic resin layered productsLaminationPolyesterComposite film

The invention provides a preparation method and application of a nano-modified PTFE and polyester-based composite film for preventing fan blades from icing. The method includes the steps of PTFE film modification, lamination complexing and photo-crosslinked adhesive application. A modifier is prepared from antimony-doped tin oxide nano-crystals, nano-titanium dioxide, nano-silicon carbide, an organic fluorine waterproofing agent and pentaerythritol tri-(3-aziridinyl)-propionate; in lamination complexing, a bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, (2)ethoxylated bisphenol A dimethacrylate, trimethylolpropane triacrylate and benzoyl peroxide; a photo-crosslinked adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, vinyl acetate, butyl acrylate, an acrylate derivative, a photoinitiator and dimethylformamide. The method and the composite film solve the non-adhesion problem that a PTFE film can not be pasted on the surfaces of fan blades with an adhesive directly.

Owner:NANJING HAOHUI HI TECH CO LTD

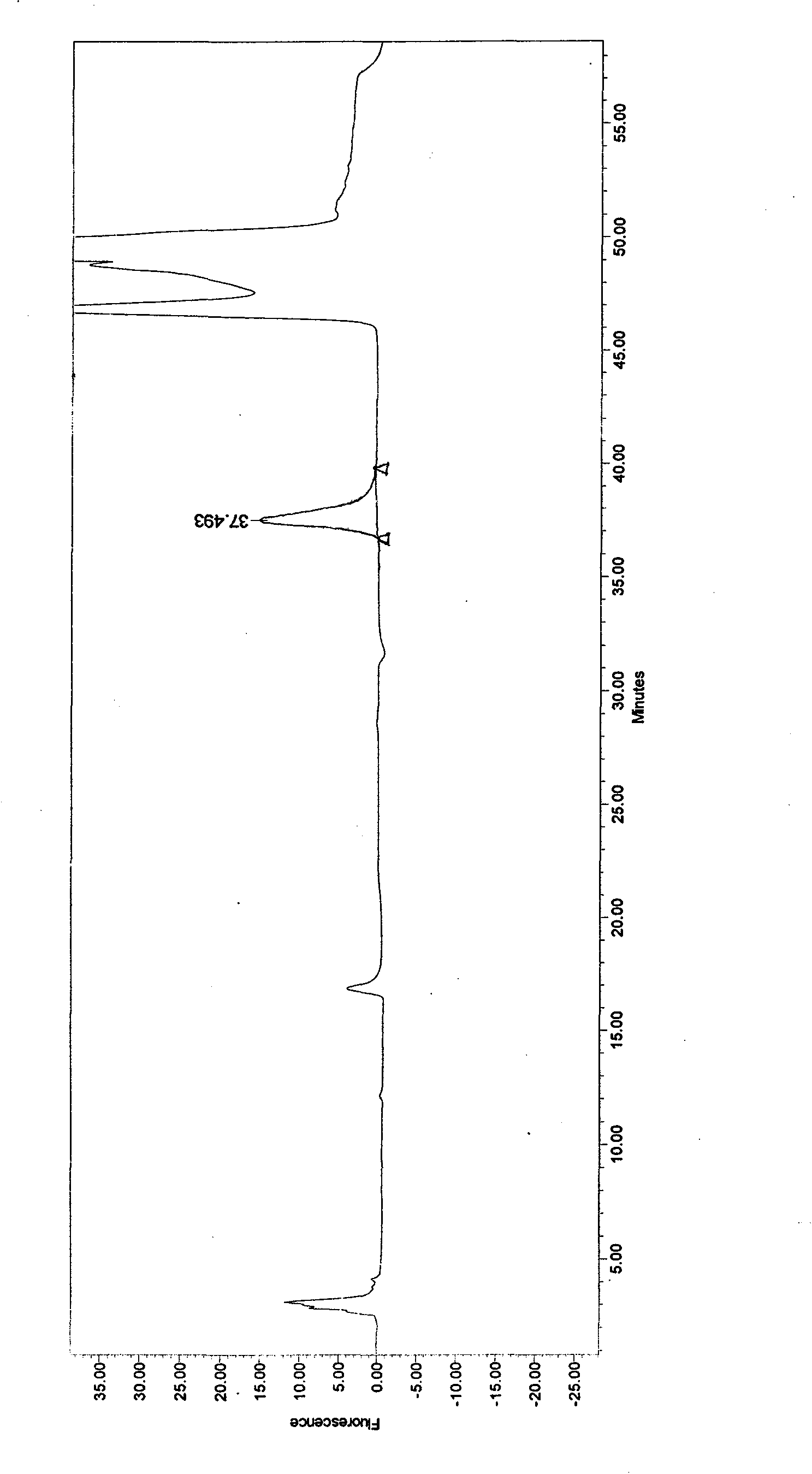

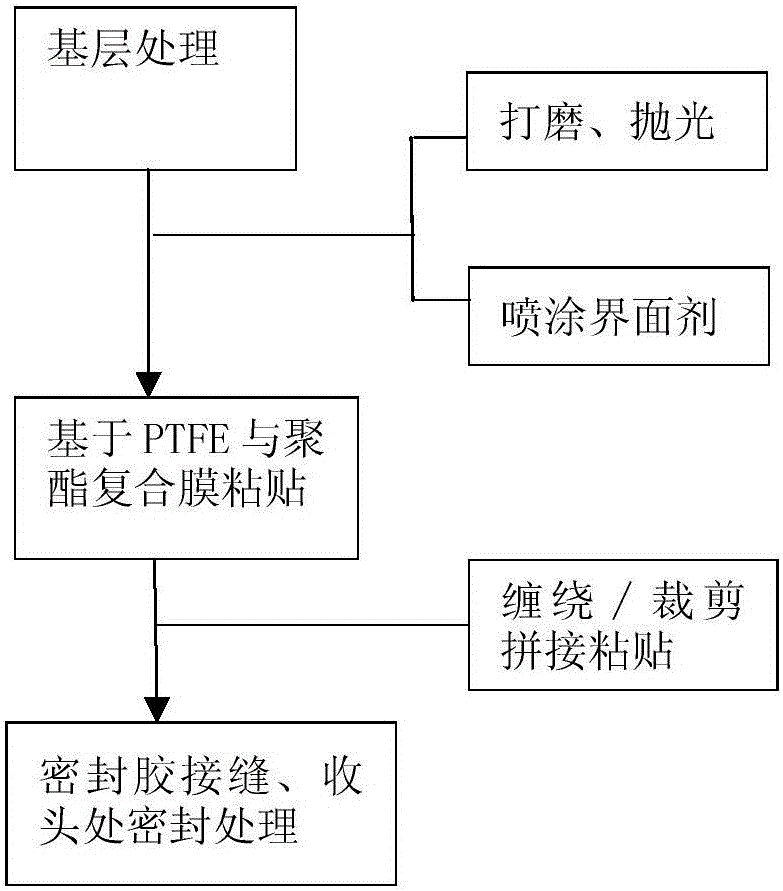

Method for detecting ethyl carbamate in yellow wine

InactiveCN101620206AAchieve separationEasy to detectComponent separationPreparing sample for investigationDistillationSolid phase extraction

The invention discloses a method for detecting ethyl carbamate in yellow wine, comprising the following steps: (1) pre-processing the yellow wine by using reduced pressure distillation so as to reduce the volume of the yellow wine to 1 / 5-1 / 10 of the initial volume; (2) mixing the pre-processed yellow wine and hydrochloric acid as well as 9-hydroxyl solutions by tons to carry out derivatizing reaction to obtain the derivatized yellow wine; and (3) carrying out component separation on the derivatized yellow wine by using an effective liquid chromatograph and calculating the content of the ethyl carbamate by using an external standard method. The method has simple operation and low detection cost, and has simpler needed apparatus, easier sample pre-processing, more convenient needed detection condition and shorter spent detection time when compared with an analysis method for solid phase extraction-gas chromatography / mass spectrometry (SPE-GC / MS).

Owner:ZHEJIANG UNIV

Bamboo weaving softening agent and preparation technique thereof

ActiveCN104493934AGood effectImprove softening effectWood treatment detailsReed/straw treatmentGlycerolStearic acid

The invention relates to a bamboo weaving softening agent and a preparation method thereof. The preparation method comprises the following steps: putting glycerol, alcohol ether glucoside, polyethenoxy ether and a surfactant into a stirring tank, stirring for 30 minutes at 80 DEG C, adding glyoxal, formaldehyde and ammonium persulfate, simultaneously adding talcum powder, limestone flour and calcium carbonate, quickly stirring at 130 DEG C for 3 minutes, finally adding stearyl alcohol, stearic acid, ethyl carbamate and paraffin, stirring for 1 hour, and cooling to normal temperature. The softening agent prepared by the method has the advantages of favorable softening effect, no corrosion and better effects, enhances the strength and toughness of the softened part, and is convenient for popularization and use.

Owner:山东阳信华龙纺织科技有限公司

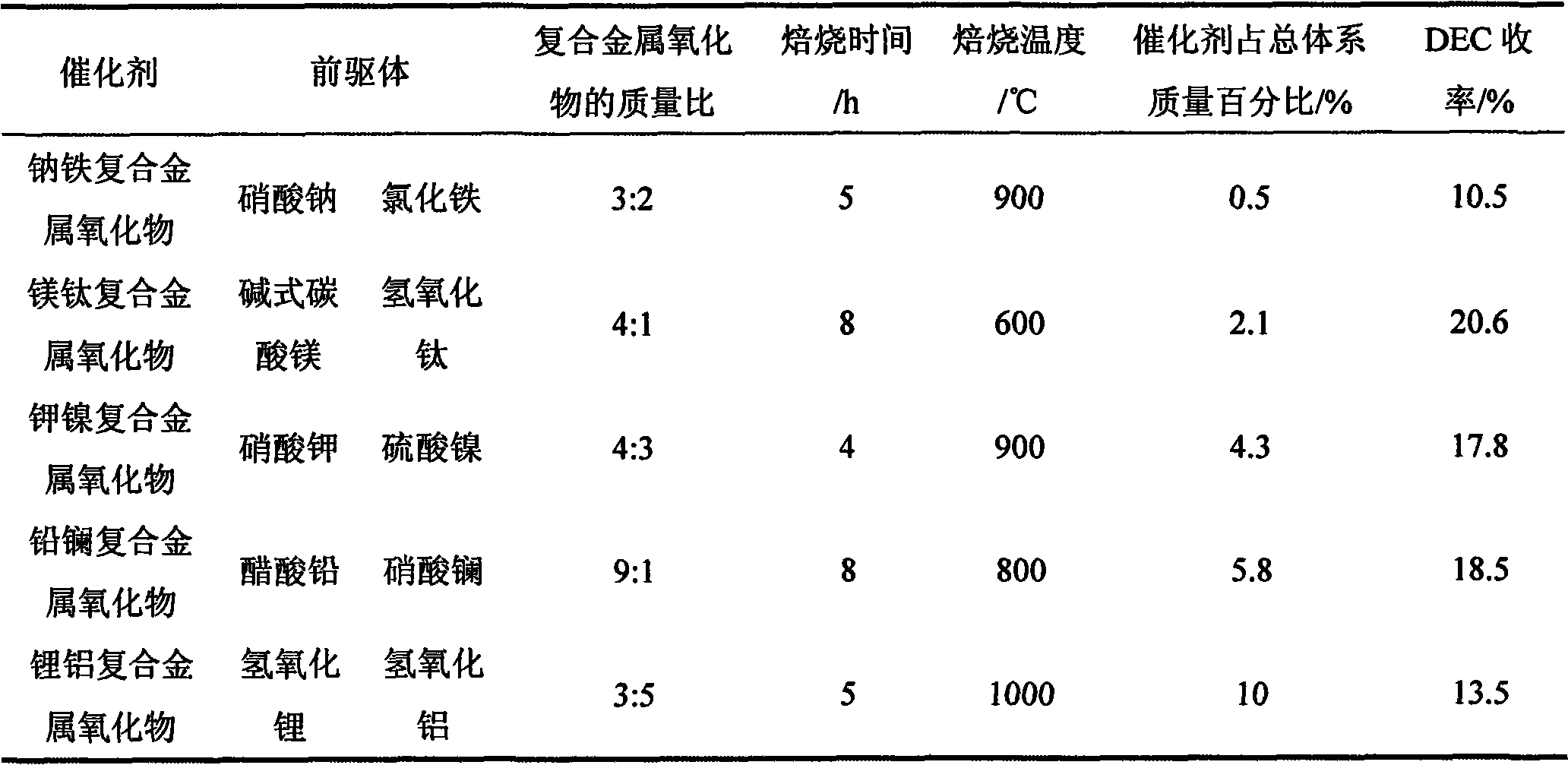

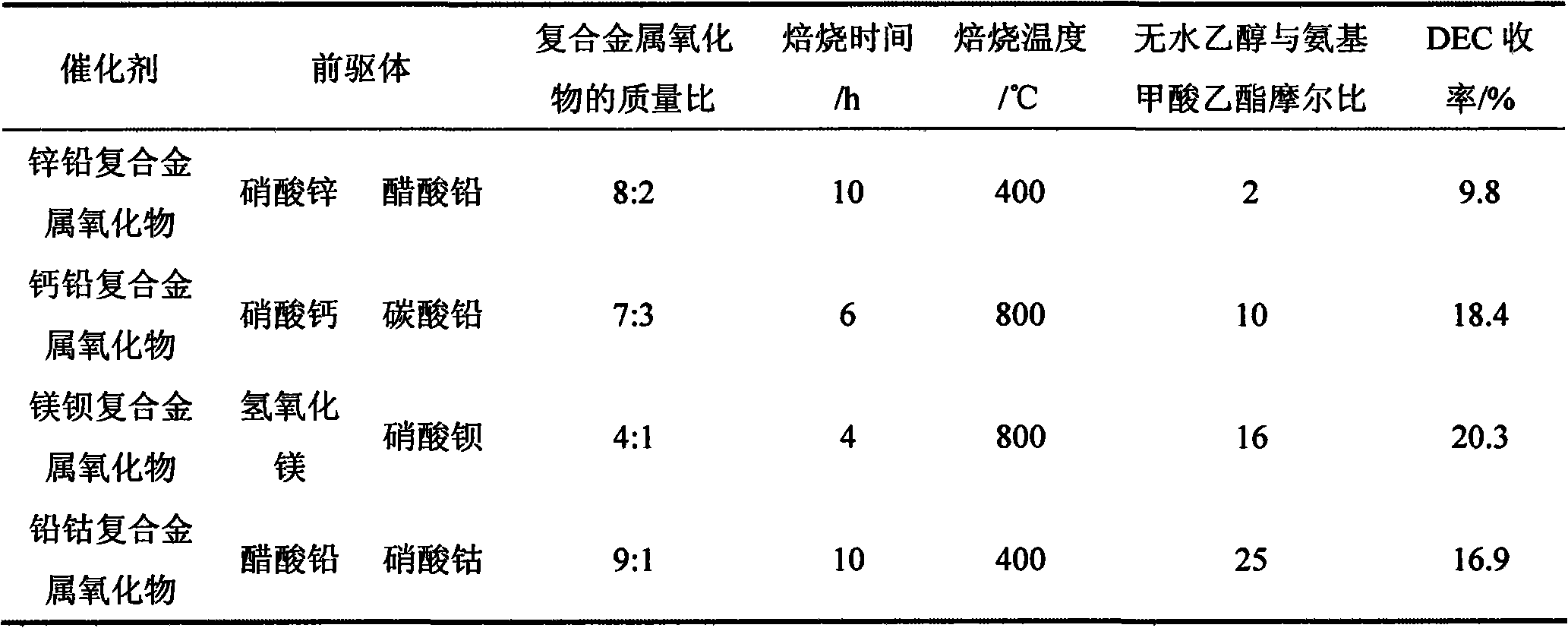

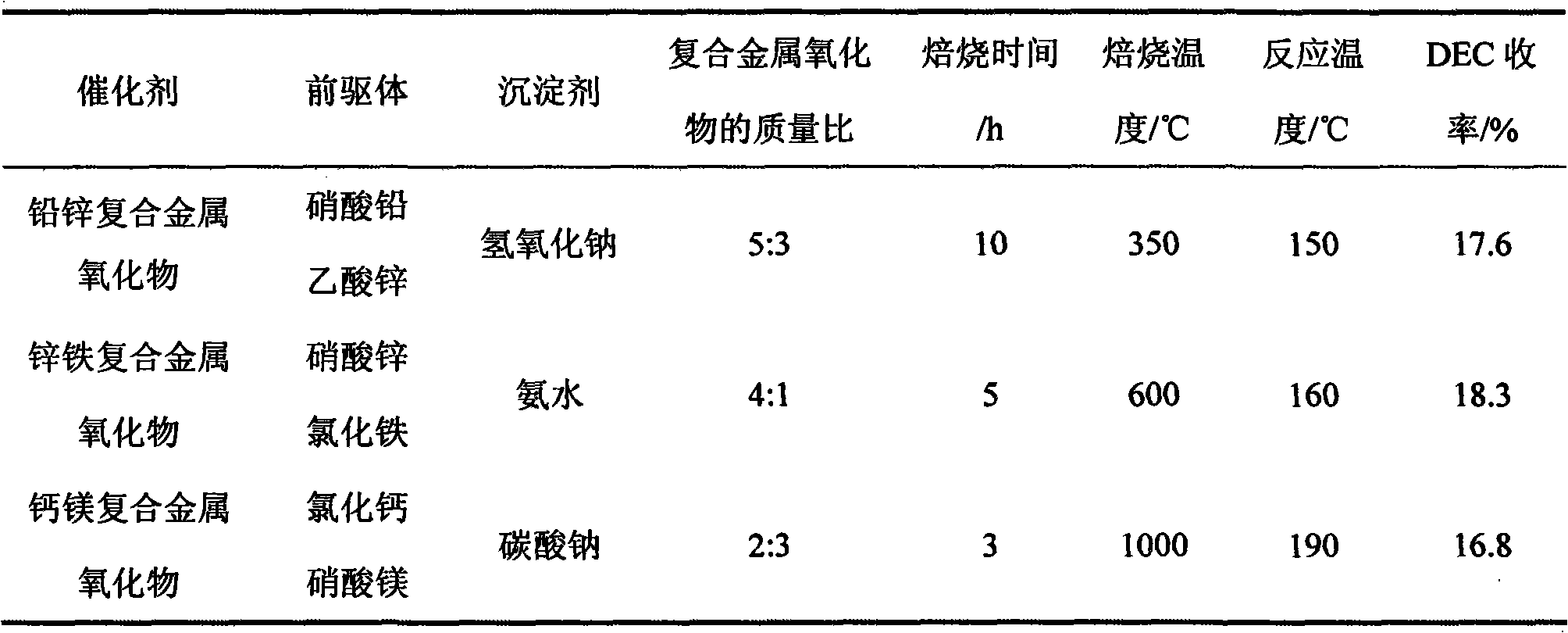

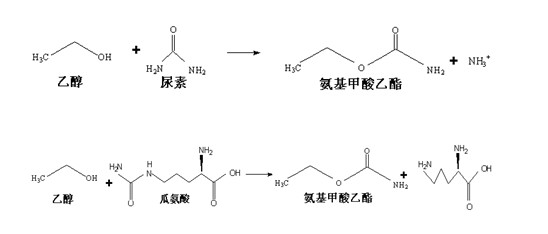

Technology of preparing diethyl carbonate by urea alcoholysis method

ActiveCN101659616AThe preparation process has no special requirementsEasy to prepareOrganic compound preparationCatalyst activation/preparationFiltrationHigh pressure

The invention belongs to the synthesis of organic carbonates and relates to a technology of synthesizing diethyl carbonate by a urea alcoholysis method. The technology comprises the steps of: adding anhydrous ethyl alcohol, ethyl carbamate and a catalyst into a high pressure reaction kettle, wherein the mole ratio of the anhydrous ethyl alcohol to the ethyl carbamate is 2 to 25, and the catalyst is combined metal oxide, and accounts for 0.5 to 10 percent of the whole system by mass percent; raising the temperature to 150 to 200 DEG C by stirring so as to carry out reaction for 1 to 15 hours; and taking out the reaction liquid after the reaction, and realizing the separation of the catalyst and the reaction liquid by simple filtration. The combined metal oxide is prepared by 2 to 3 metal oxide precursors among Li, Na, K, Ca, Mg, Ba, Sr, Al, Sn, Pb, La, Ti, W, Zr, Fe, Co, Ni, Cu and Zn through thermal decomposition method or coprecipitation method. The preparation method of the technology is simple, the catalyst activity is high, the stability is good, and the separation and recycling are easy.

Owner:HEBEI UNIV OF TECH

Preparation method and application of PTFE and polyester-based composite film for preventing wind turbine blades from icing

ActiveCN106313812AHigh peel strengthHigh bonding strengthNon-macromolecular adhesive additivesSynthetic resin layered productsPolyesterBenzoyl peroxide

The invention discloses a preparation method and application of a PTFE and polyester-based composite film for preventing wind turbine blades from icing. The method includes the steps that a bonding composite agent is adopted for lamination complexing, an interface adhesive is applied, and a pressure-sensitive adhesive is adopted for photo-initiated pressure-sensitive adhesive application. The bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, benzoyl peroxide and (4)ethoxylated bisphenol A dimethacrylate; the photo-initiated pressure-sensitive adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, butyl acrylate, (4)ethoxylated bisphenol A dimethacrylate, 4,4'-bis(diethylamino)benzophenone and dimethylformamide. The method and the composite film solve the non-adhesion technical problem that a PTFE film can not be pasted on the surfaces of wind turbine blades with an adhesive directly, the bonding peel strength is improved, and the composite film is suitable for wind turbine blades of various models.

Owner:NANJING HAOHUI HI TECH CO LTD

Method for rapidly measuring ethyl carbamate content in distilled liquor

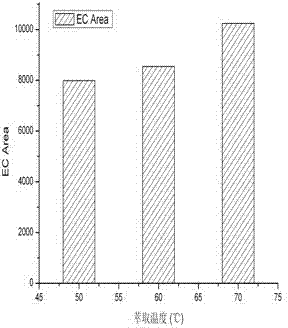

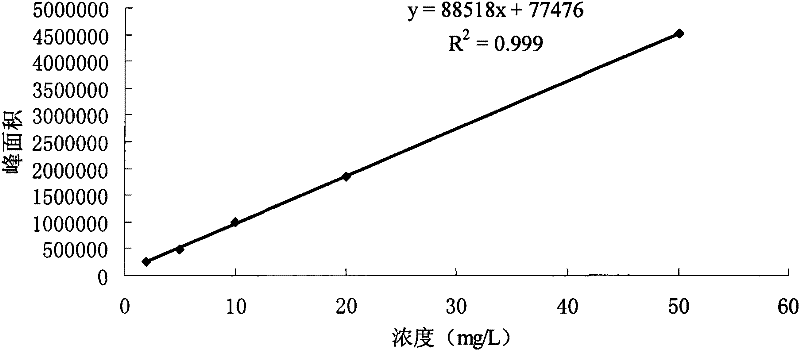

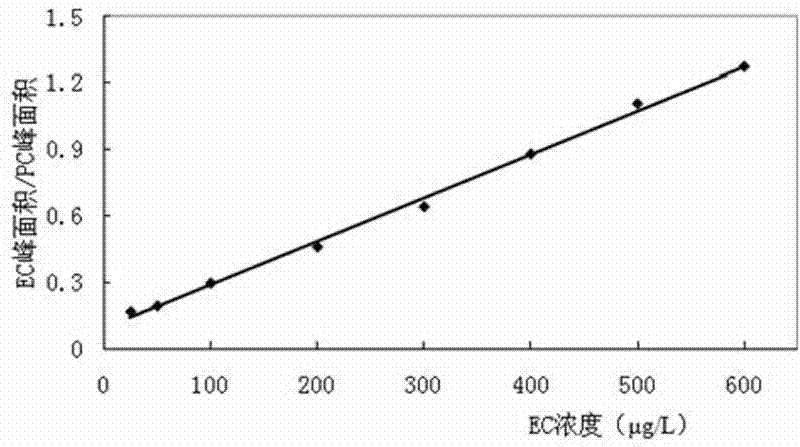

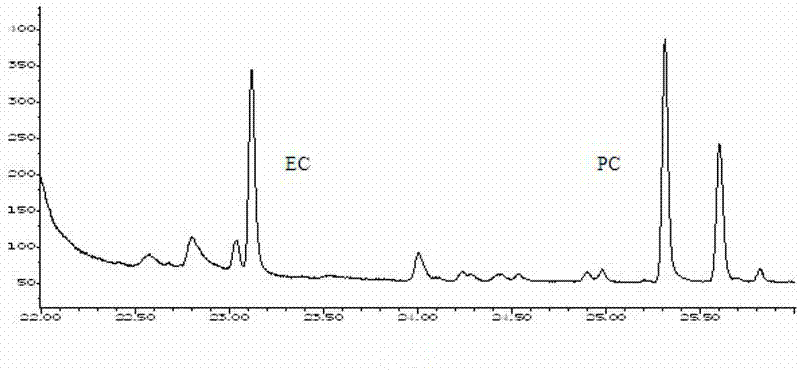

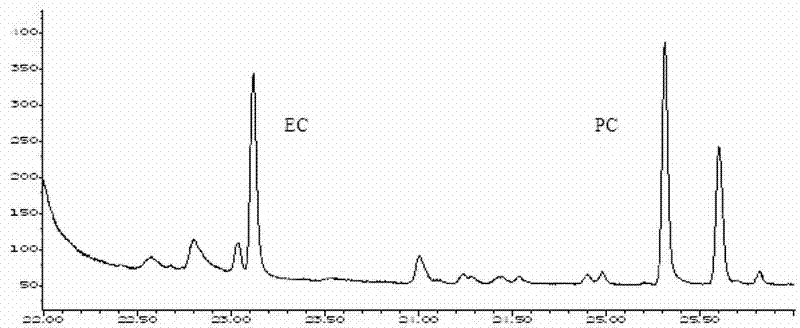

ActiveCN102393434AQuick checkRapid detection and accurate quantificationComponent separationLinear correlationSolid-phase microextraction

The invention discloses a method for rapidly measuring ethyl carbamate content in distilled liquor, belonging to the technical field of analysis measurement. In the invention, the impurities are removed by adopting rotary evaporation, the ethyl carbamate in a liquor sample is enriched by adopting headspace-solid phase microextraction technology, then gas chromatography-mass spectrum technology is adopted for conducting quantitative measurement, and the EC content in the liquor sample is calculated according to a standard curve. According to the method established in the invention, the ethyl carbamate in the distilled liquor can be detected rapidly and quantified accurately, the detection limit can be lowered to be 1.16mug / L, the linear correlation coefficient is more than 0.99, the recovery rate is 89%-119%, and the relative standard deviation is 1.26%-12.51%. In the method, a plurality of defects of in the original measuring method is overcome, the complicated pretreatment process and organic solvent are not needed, and the method is used for detection and quantitative analysis on the ethyl carbamate in the various distilled liquor with higher alcoholic strength.

Owner:JIANGNAN UNIV

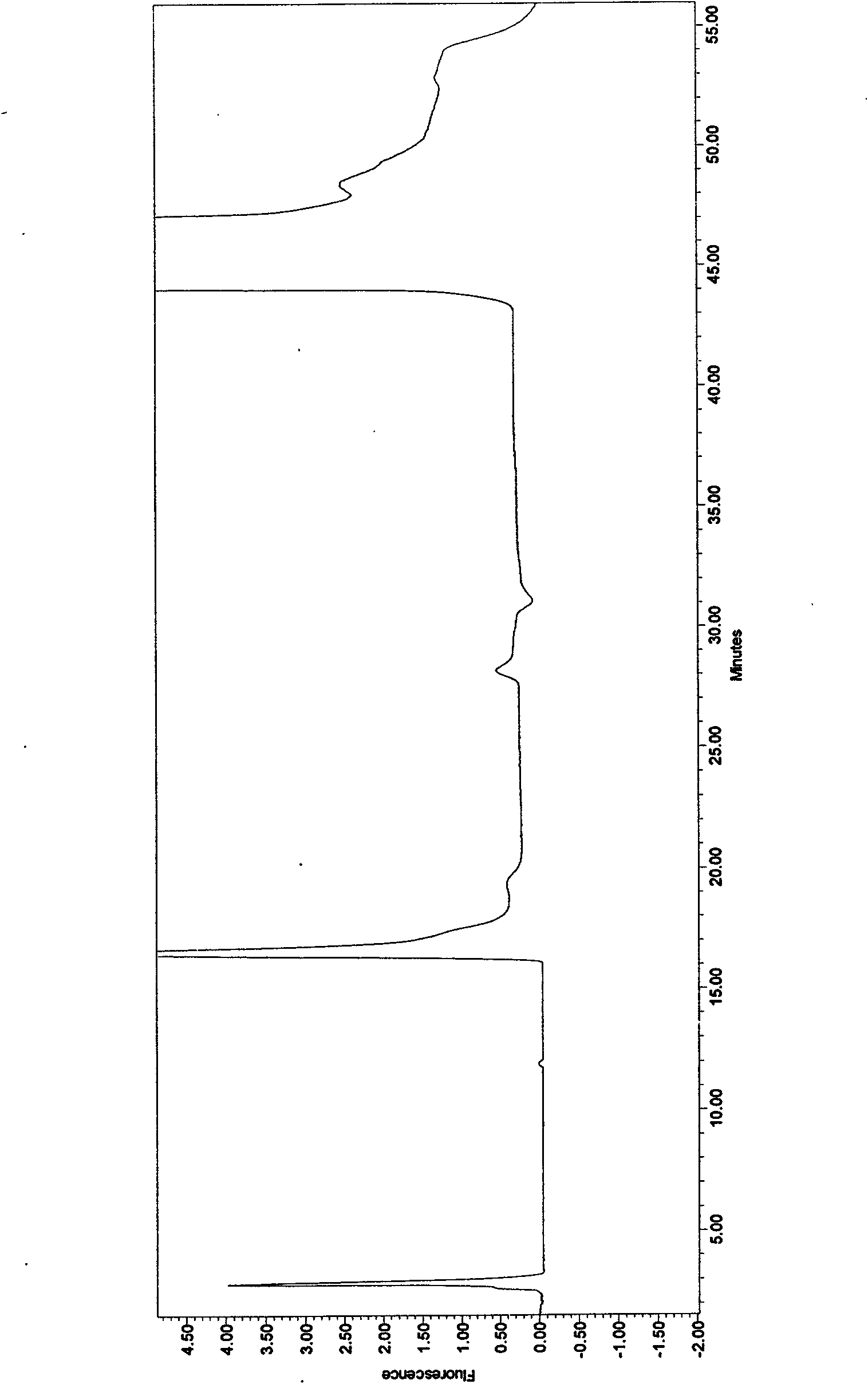

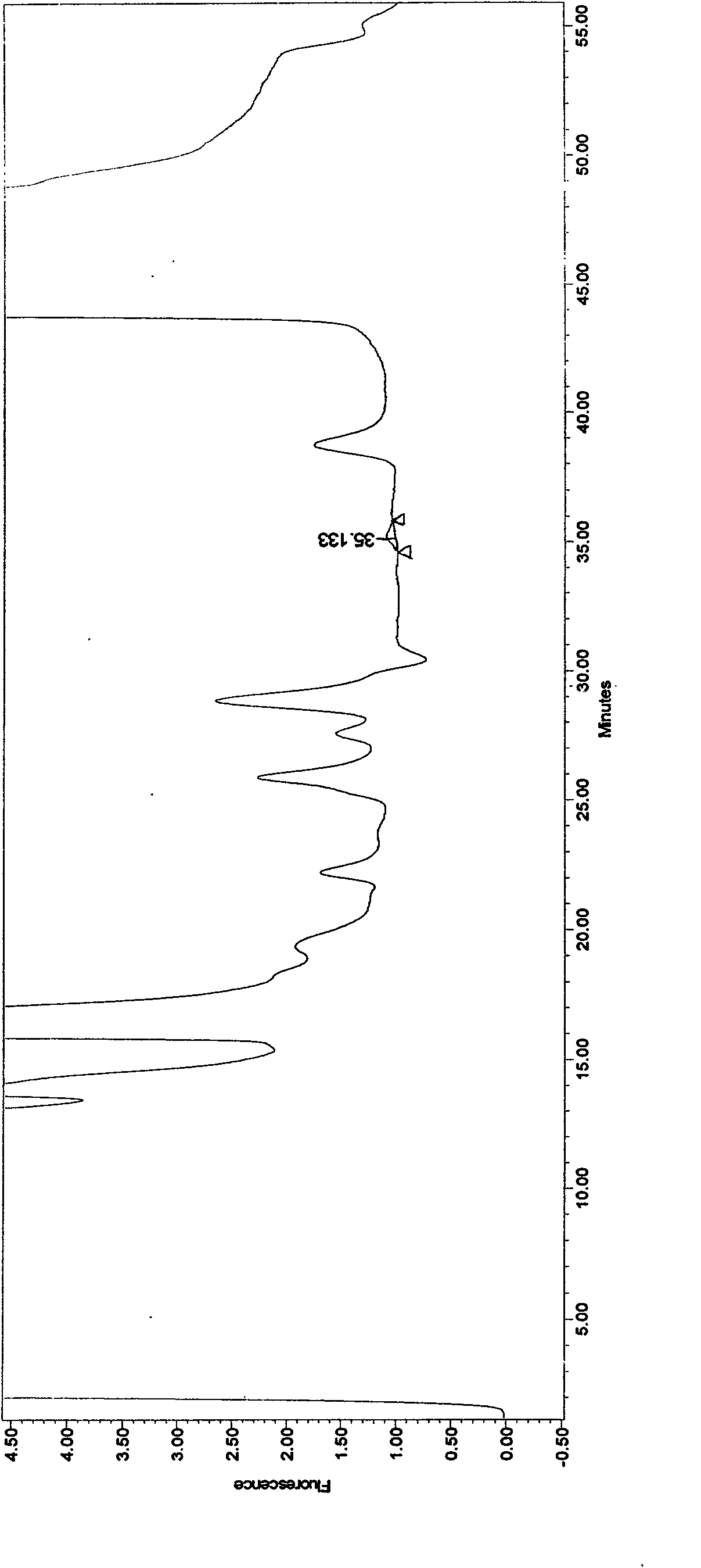

Rapid detection method for production process quality control of yellow wine

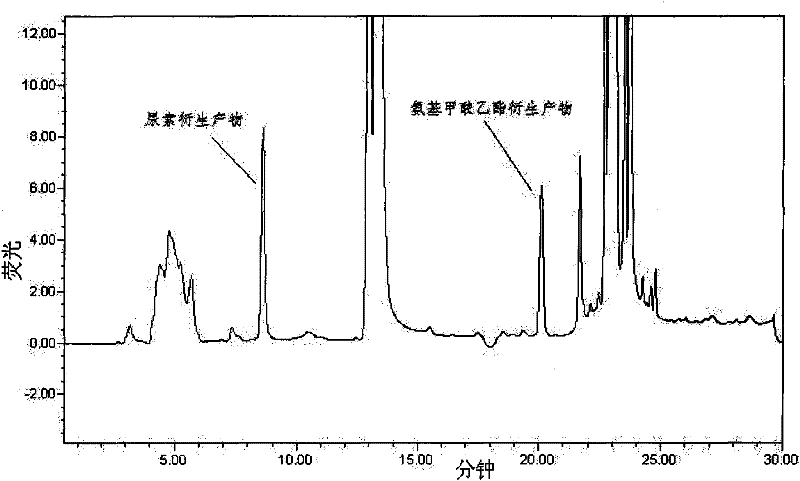

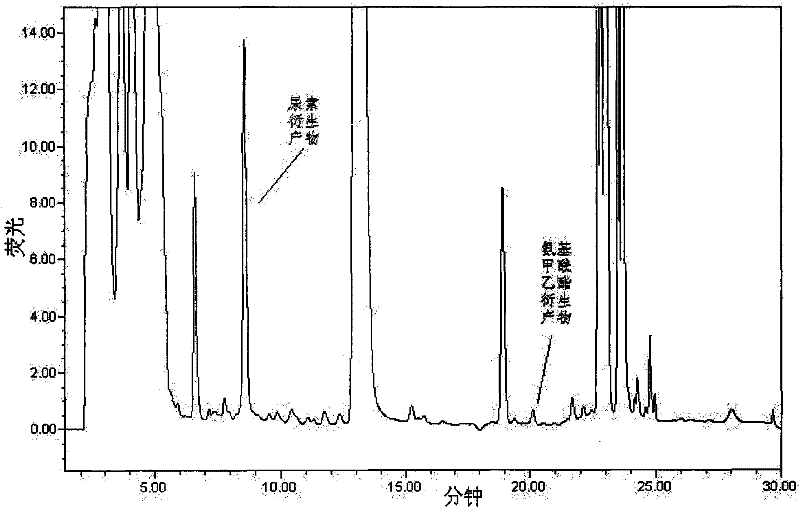

InactiveCN102353728AEasy to handleHigh precisionComponent separationFluorescence/phosphorescenceProcess qualityFluorescence

The invention discloses a rapid detection method for production process quality control of yellow wine, belonging to the technical field of food analysis and food safety, comprising the following steps: (1) carrying out dilution and determining capacity on a yellow wine sample with absolute ethyl alcohol; (2) mixing the diluted yellow wine sample with a 9-hydroxy-xanthene solution in a hydrochloric acid solution and reacting for 60 min at room temperature; and (3) carrying out component separation on the derivative yellow wine sample with high performance liquid chromatography, and calculating the content of urea and ethyl carbamate (EC) in the sample with the external standard method. According to the invention, by setting different parameters at different time periods for a fluorescence detector, the technical difficulty of simultaneously detecting the content of EC and urea in yellow wine is solved, a HPLC-FLD method for simultaneously detecting EC and urea in yellow wine is established, thus a rapid, convenient, accurate and effective monitoring method for yellow wine safety production is provided.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

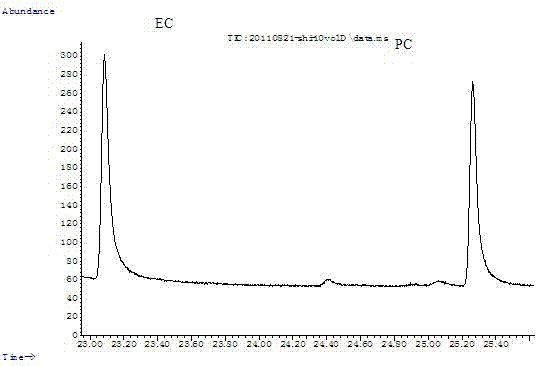

Method for quickly determining ethyl carbamate (EC) in alcoholic drink

InactiveCN102445505ARapid detection and accurate quantificationRapid quantitationComponent separationAlcohol contentAqua vitae

The invention discloses a method for quickly determining ethyl carbamate (EC) in alcoholic drink, which comprises the following steps of: diluting an alcoholic drink sample to be tested into the alcoholic drink sample with final alcoholic content of 4 percent to 20 percent (v / v) by double distilled deionized water; concentrating EC in the alcoholic drink sample through a head space solid-phase micro-extraction technology without a complex preprocessing process or organic solvent; carrying out detection and quantification analysis through a gas chromatography-mass spectrometer technology; and comparing with a standard curve to calculate the content of EC in the alcoholic drink sample. The method disclosed by the invention can be used for quickly testing and determining the EC in the alcoholic drink, the detection limit can reach as low as 1.19 mug / L, the linear correlation coefficient is larger than 0.99, the recovery rate is 90.21 percent to 99.07 percent, and the relative standard deviation is less than 10 percent. The method overcomes defects of the prior determining method, and can be used for detection and quantification analysis of the EC in the alcoholic drink.

Owner:JIANGNAN UNIV

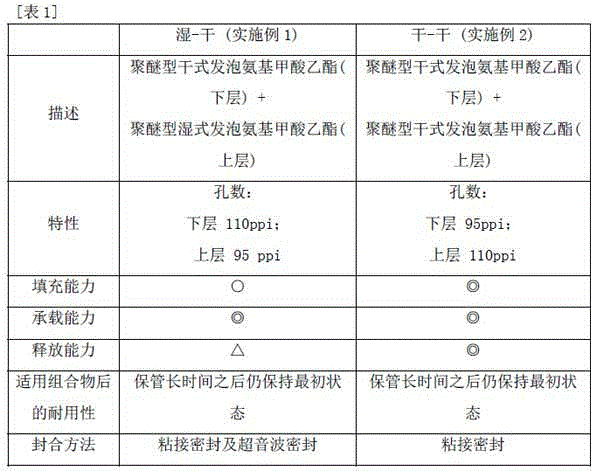

Cosmetic composition carrier containing urethane foam layer structure

ActiveCN104039196AEasy to carryIncreased durabilityCosmetic preparationsMake-upPolymer sciencePolymer chemistry

Owner:AMOREPACIFIC CORP

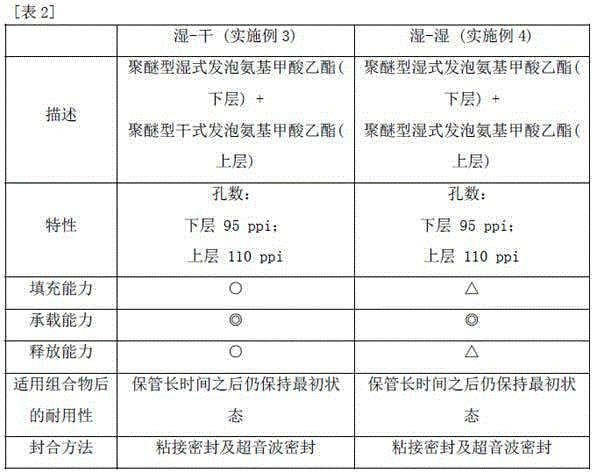

Preparing method and application of pit mud for improving flavor of baijiu in new pit

ActiveCN106085720AIncrease microbial contentPromote fermentationAlcoholic beverage preparationPeatFood flavor

The invention belongs to the field of wine brewing and particularly relates to a preparing method and application of pit mud for improving the flavor of baijiu in a new pit. The preparing method comprises the steps of preparation, and primary fermentation and secondary fermentation of raw materials. According to the preparing method, microorganisms in yellow-water-aged pit mud diluent are used for mass propagation in primary pit mud, starter microorganisms are properly added, and thus comprehensive composite pit mud function bacteria are obtained and replace a single strain to serve as a microorganism species source. Meanwhile, yellow-water-aged pit mud diluent is used for long-time soaking, a small amount of foreshot and after-run are supplemented, and thus certain organic acid and alcohol are increased, so that the original ecology of aged pit mud is simulated, and thus microorganism fermentation is better promoted. Black peat is further added to serve as humus and replace urea added by other factories as a nutrition source, and thus ethyl carbamate is avoided. On the aspect of pit mud aging, the prepared pit mud and the aged pit mud are mixed at the bottom of the pit, fermented mass fermentation is carried out for multiple turns to promote aging of the new pit mud, the circle is short, and higher practicability is achieved.

Owner:CHENGDU SHUZHIYUAN WINE

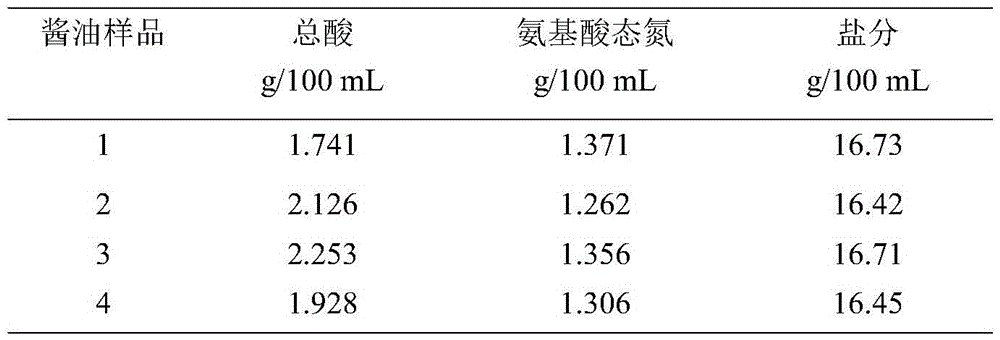

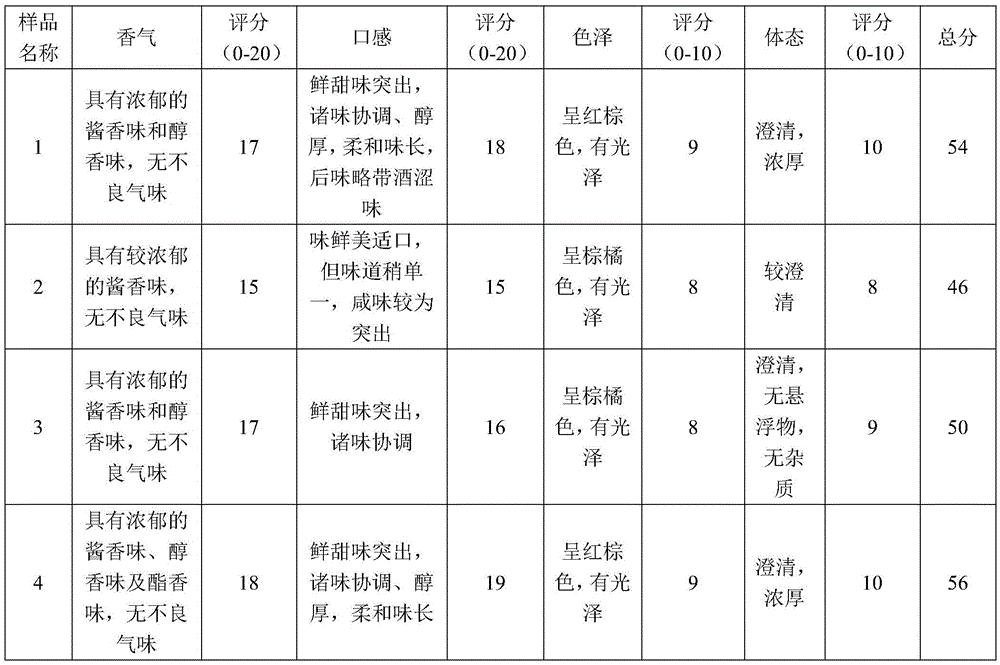

Method for applying bacillus amyloliquefaciens to soy sauce brewage

ActiveCN105639590AGreat tasteReduced urethaneFood ingredient as flavour affecting agentFood ingredient as mouthfeel improving agentBiotechnologyMicroorganism

The invention discloses a method for applying bacillus amyloliquefaciens to soy sauce brewage, and belongs to the technical field of a microorganism and food technology. The method comprises inoculating a food safe bacterium of bacillus amyloliquefaciens after prepared koji is mixed in brine and is fermented for 0-3 days during a soy sauce production process. According to the method, in the precondition of without changing main physicochemical indexes of soy sauce, flavor substances and taste of the soy sauce are improved, and an ethyl carbamate content in the soy sauce is reduced.

Owner:JIANGNAN UNIV

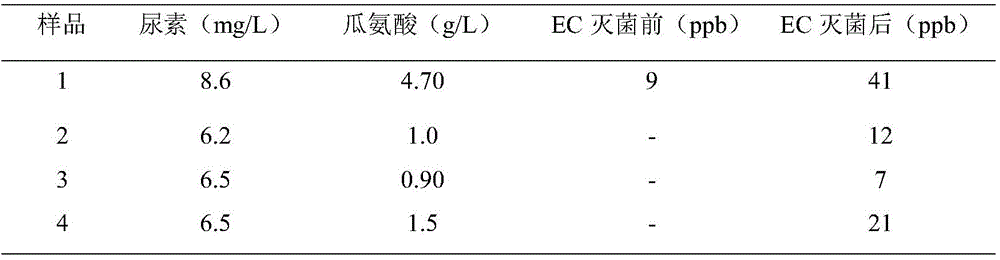

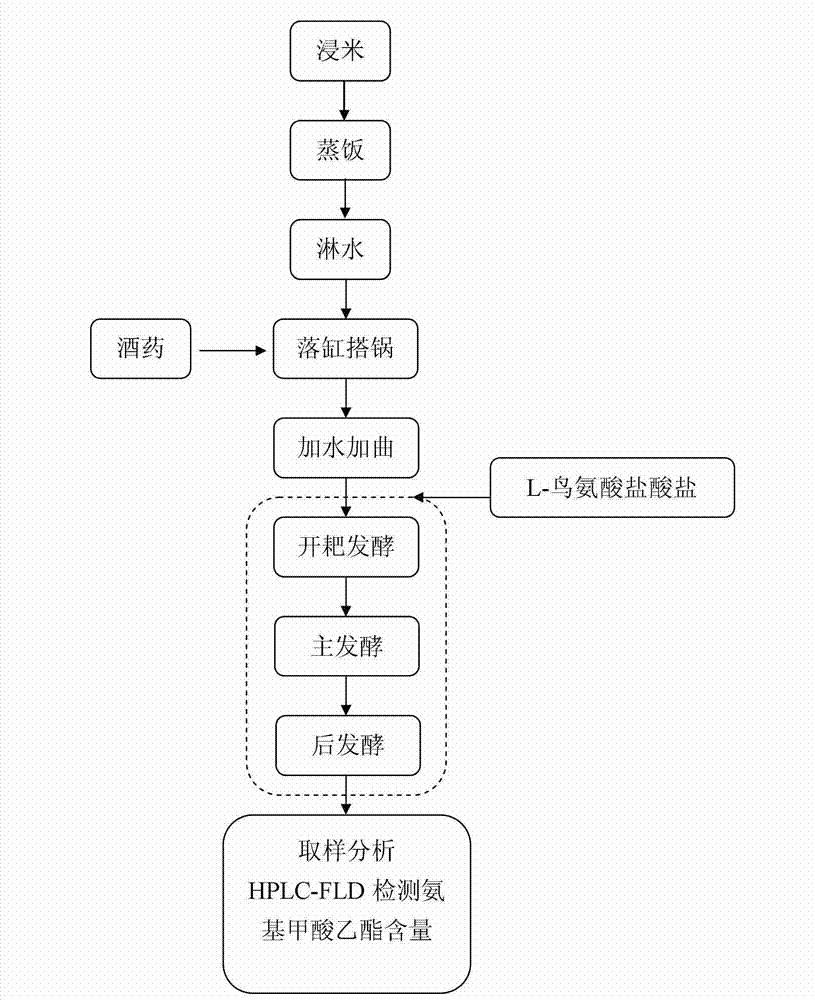

Yellow wine brewing method

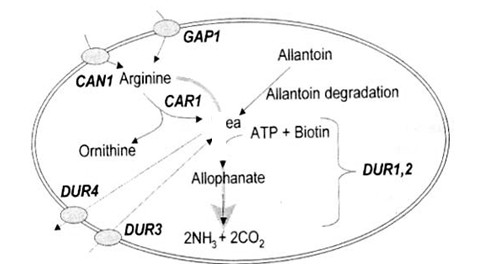

The invention belongs to a yellow wine brewing method, which comprises the steps of rice soaking, rice steaming, water spraying, jar falling and pot erecting, yeast and water addition, fermentation and post treatment, wherein L-ornithine monohydrochloride is added into fermentation liquid in the second day to the six day after the jar falling and pot erecting. The yellow wine brewing method has the advantages that the L-ornithine monohydrochloride as an inhibitor is easy to control, the inhibition efficiency is high, and the generation of ethyl carbamate can be effectively inhibited; after the L-ornithine monohydrochloride is dissolved in water, ornithine is generated and participates in uric acid circulation in vivo, no risk and no toxic and harm exist, and no environment pollution is caused; and in addition, the L-ornithine monohydrochloride is easy to obtain, the use is convenient, and the cost is low.

Owner:ZHEJIANG UNIV

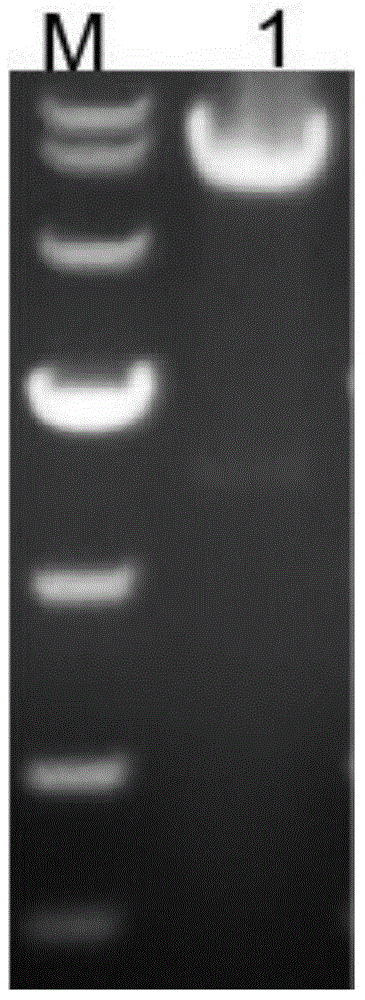

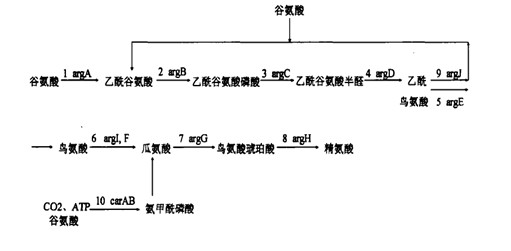

Wine yeast capable of low-yielding hydrogen sulfide and ethyl carbamate as well as screening method and application of wine yeast

InactiveCN104480029ASimple processQuality improvementFungiMicroorganism based processesScreening methodMicrobiological culture

The invention particularly relates to wine yeast capable of low-yielding hydrogen sulfide and ethyl carbamate as well as a screening method and application of the wine yeast. A strain of the wine yeast is classified and named as saccharomyces cerevisiae CECLFN524 and is preserved in China General Microbiological Culture Collection Center on November 5th, 2010, and the preservation number is CGMCC NO. 4299. The strain is separated and screened in a natural fermentation process of small seedless white grapes of Xinjiang Loulan wine plant of China. The screening method comprises the steps of: after separating and purifying the strain by virtue of a WL culture medium, feeding the strain into fermentation liquid, respectively carrying out primary screening and secondary screening on a strain capable of low-yielding hydrogen sulfide by virtue of a lead acetate test paper development method and a hydrogen sulfide detection tube method, simultaneously detecting the contents of hydrogen sulfide and ethyl carbamate in the fermentation liquid, and finally screening to obtain saccharomyces cerevisiae capable of low-yielding hydrogen sulfide and ethyl carbamate. The strain can be applied to the wine-making industries.

Owner:NORTHWEST A & F UNIV

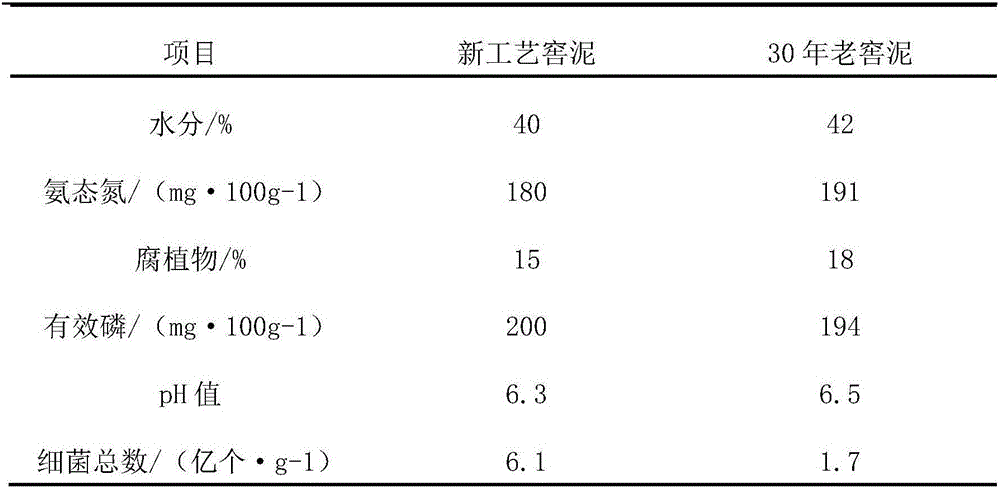

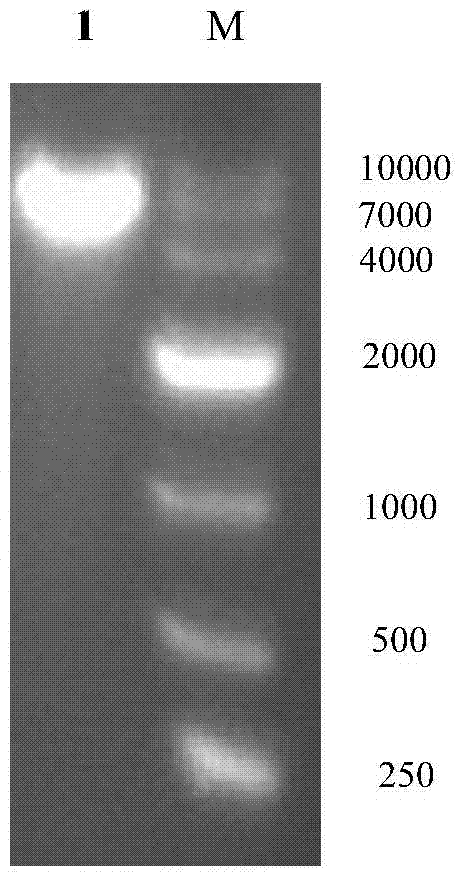

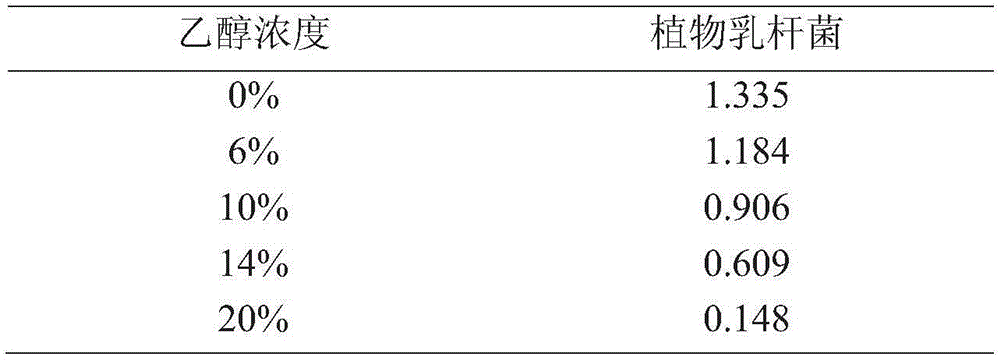

Lactic acid bacteria not generating amino acid decarboxylase high-yield urease and application of lactic acid bacteria

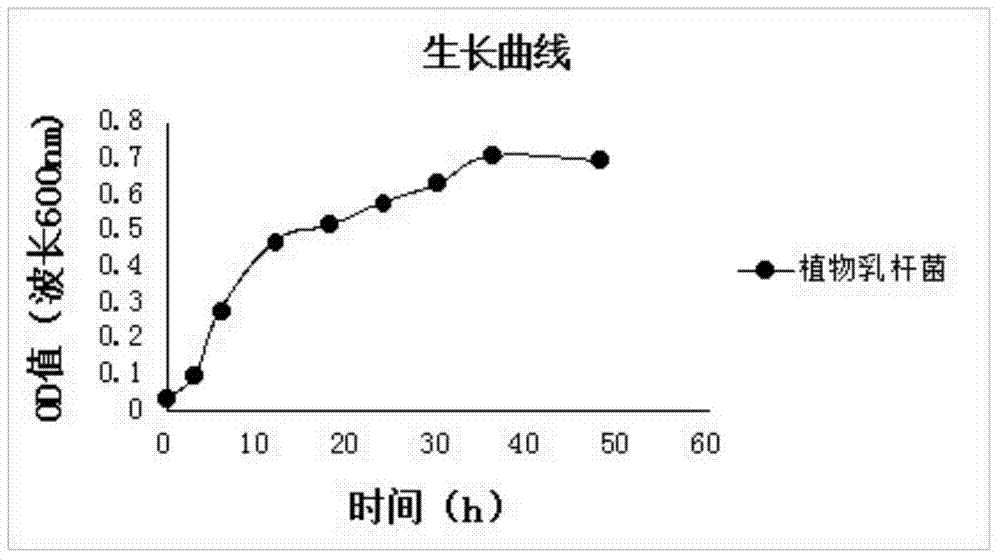

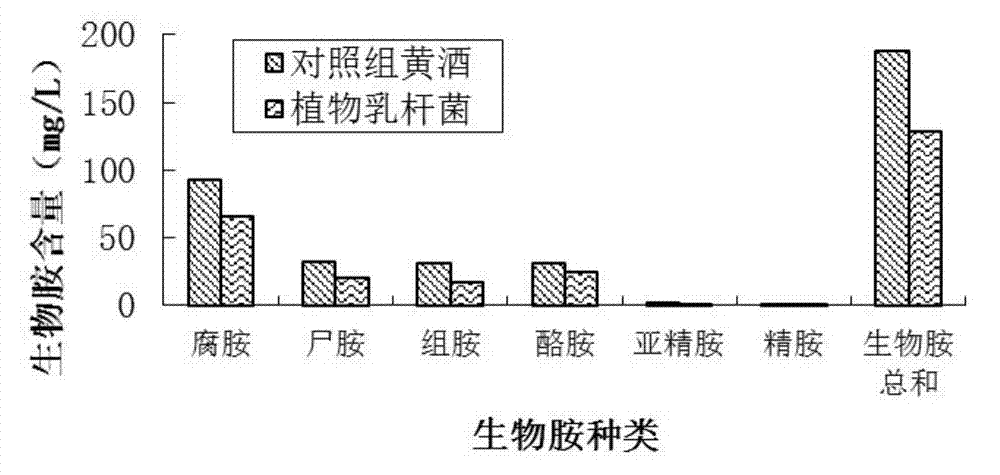

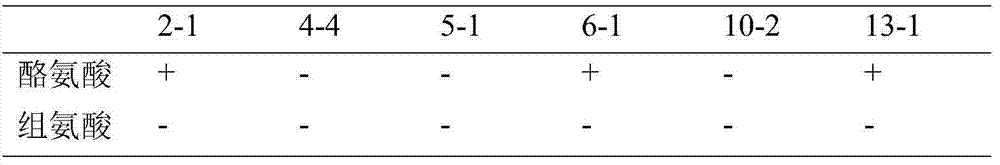

ActiveCN104762238AReduce contentReduce biogenic amine concentrationBacteriaAlcoholic beverage preparationReference sampleAmino acid

The invention discloses lactic acid bacteria not generating amino acid decarboxylase high-yield urease and application of the lactic acid bacteria, and belongs to the technical field of biological fermentation. The lactobacillus plantarum L10-2 provided by the invention is preserved in the China Center for Type Culture Collection on March 15, 2015 and has a preservation number of CCTCC No.M2015118, and the preservation address is the China Center for Type Culture Collection in Wuchang Luojiashan Wuhan University in Wuhan City of Hubei Province. At the beginning of the brewing of a rice wine, the lactobacillus plantarum, a raw material (rice), a seeding yeast and a wheat koji are added into a fermentation tank together to perform rice wine brewing, and a physical and chemical index evaluation is performed by taking a control group, namely the rice wine as a reference sample. The result shows that by adding the lactobacillus plantarum, the contents of biogenic amine and ethyl carbamate in the rice wine can be effectively reduced, and the safety of the rice wine is greatly improved.

Owner:广东至善智造科技有限公司

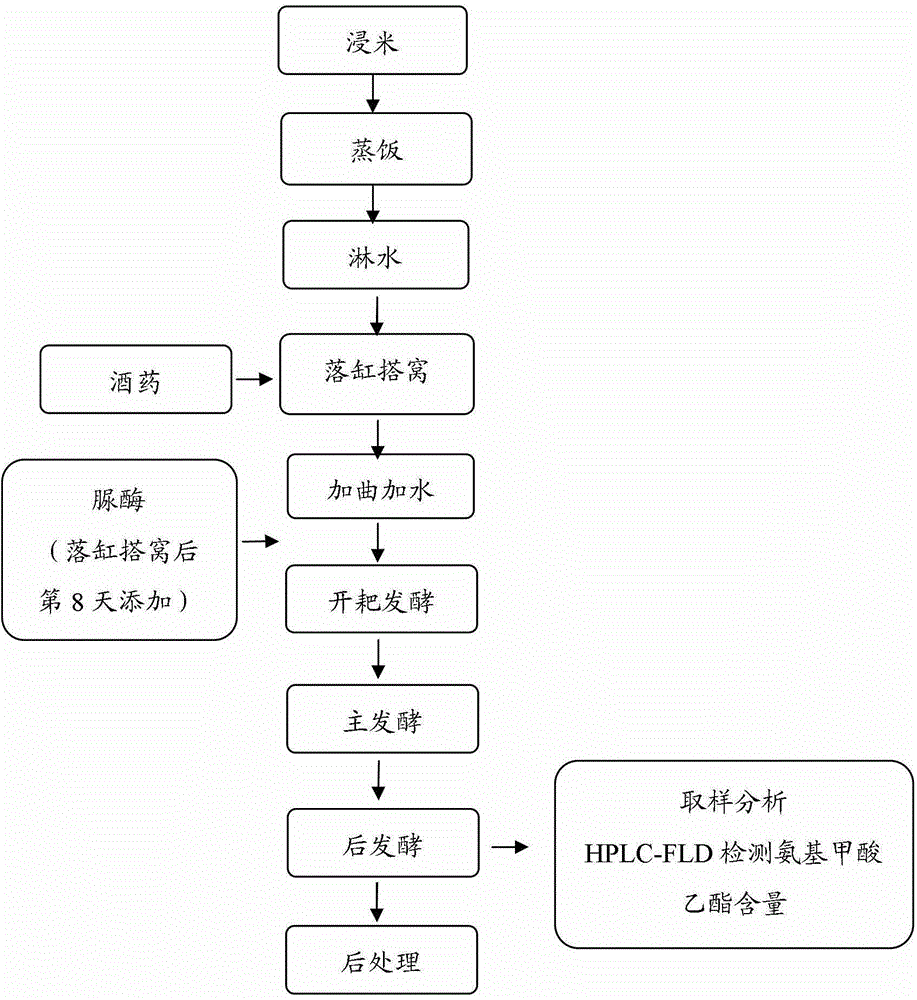

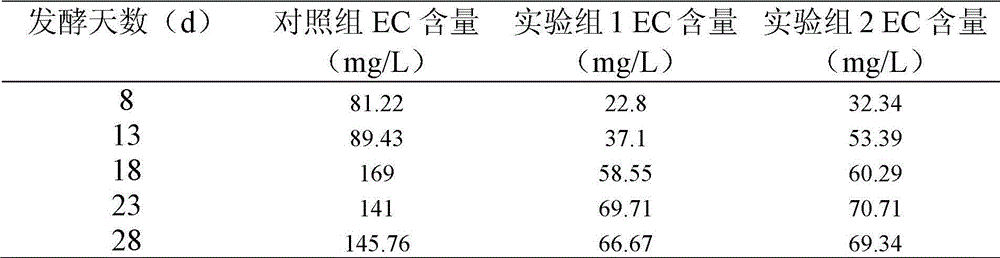

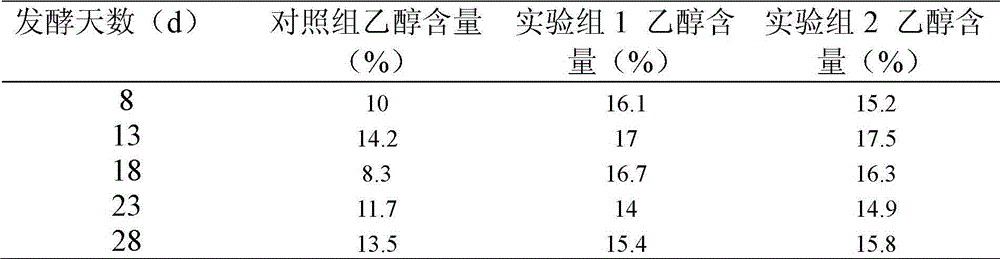

Brewing method for restraining generation of ethyl carbamate in conventional yellow rice wine

InactiveCN102978065ASuppress generationEasy to getAlcoholic beverage preparationDecompositionChemistry

The invention discloses a brewing method for restraining the generation of ethyl carbamate in conventional yellow rice wine. The brewing method comprises the steps of soaking rice, steaming the rice, spraying water, putting the obtained product into a jar and making a nest; adding wine yeast and water, fermenting and carrying out post treatment, wherein in the process of putting the obtained product into the jar and making the nest, Chinese yeast is added; and adding urase into fermented liquid after the obtained product is put into the jar and the nest is made for 5-10 days. According to the method disclosed by the invention, the urase is added into the conventional yellow rice wine fermentation stage, so that the enzymatic reaction and the fermentation process are cooperatively performed, and no additional enzymolysis technology is required, therefore, the operation is easy, and yellow rice wine is suitable for large-scale production; the urase has high efficiency in urea degradation, is persistent in activity, can effectively inhibit the generation of ethyl carbamate in the process of brewing, and can effectively reduce the accumulation of ethyl carbamate in the storage of the yellow rice wine; the urase is easy to obtain and easy to use and the dosage of the urase can be easily controlled; ammonia and carbon dioxide are generated through the decomposition of the urase, so that the urase is safe and non-toxic; and the residual activity is lost in the process of wine boiling, so that the flavor of the yellow rice wine is not affected.

Owner:ZHEJIANG UNIV

Method for improving the quality of soy sauce using Bacillus amyloliquefaciens

The present invention provides a method for improving the quality of soy sauce using Bacillus amyloliquefaciens, which relates to the field of microbiology and food technology. The method comprises inoculating Bacillus amyloliquefaciens BBE JY06 during soy sauce fermentation. With Bacillus amyloliquefaciens addition during soy sauce fermentation, the aroma and tastes of soy sauce is improved and the ethyl carbamate content in soy sauce is decreased as well.

Owner:JIANGNAN UNIV

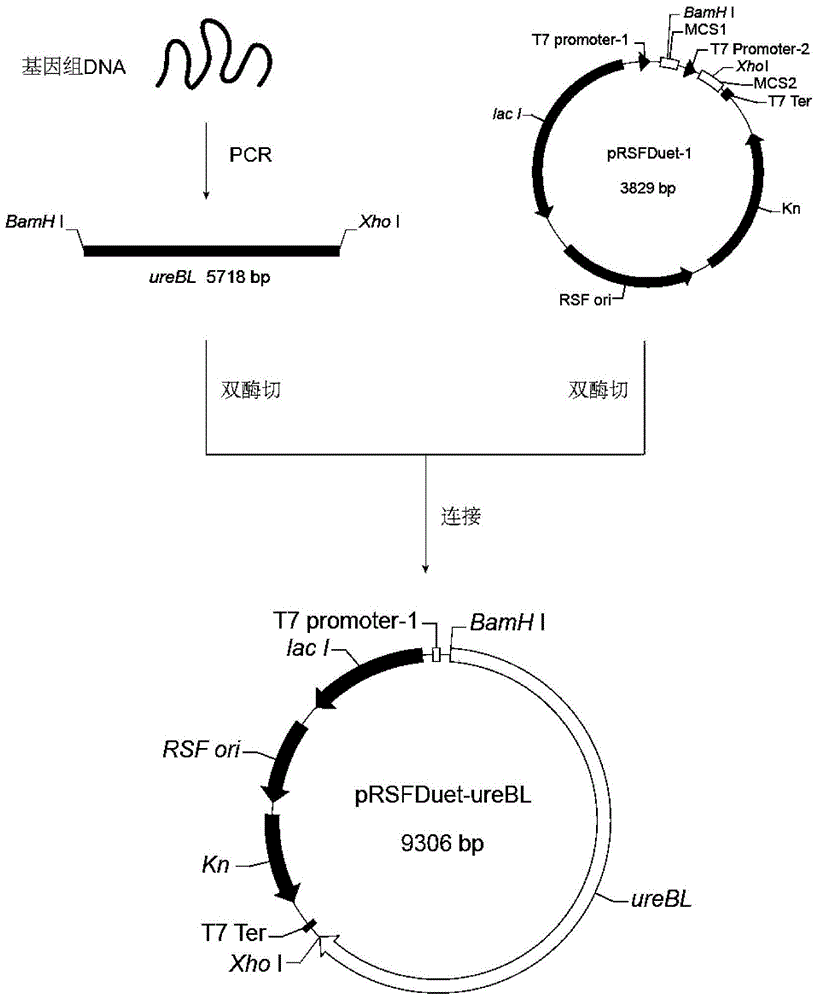

Ethanol-tolerant bifunctional enzyme capable of degrading carbamide and ethyl carbamate (EC) and application of ethanol-tolerant bifunctional enzyme

ActiveCN104818265AHigh ethanol toleranceHydrolasesAlcoholic beverage preparationHigh concentrationEscherichia coli

The invention discloses an ethanol-tolerant bifunctional enzyme capable of degrading carbamide and ethyl carbamate (EC) and application of the ethanol-tolerant bifunctional enzyme and belongs to the technical field of bioengineering. The enzyme is urease from bacillus licheniformis 9945A and is capable of tolerating high-concentration ethanol and degrading the ethyl carbamate efficiently. The ethanol-tolerant bifunctional enzyme capable of degrading the carbamide and the ethyl carbamate has the advantages that an escherichia coli expression system BL21 (DE3) / pRSFDuet-1 is adopted to achieve efficient expression of urease genes with EC urethanase, the enzyme activity reaches to 2.93U / ml when the EC serves as a zymolyte, and the enzyme activity reaches to 5.81U / ml when the carbamide serves as the zymolyte. Recombinase is retained in 20% ethyl alcohol at the temperature of 37 DEG C for 4 hours, and more than 50% of activity can be retained when the EC serves as the zymolyte. The prepared recombinase can eliminate the EC and the carbamide in yellow wine, lays the foundation for industrial production of the EC urethanase and has great economic and social benefits.

Owner:JIANGNAN UNIV

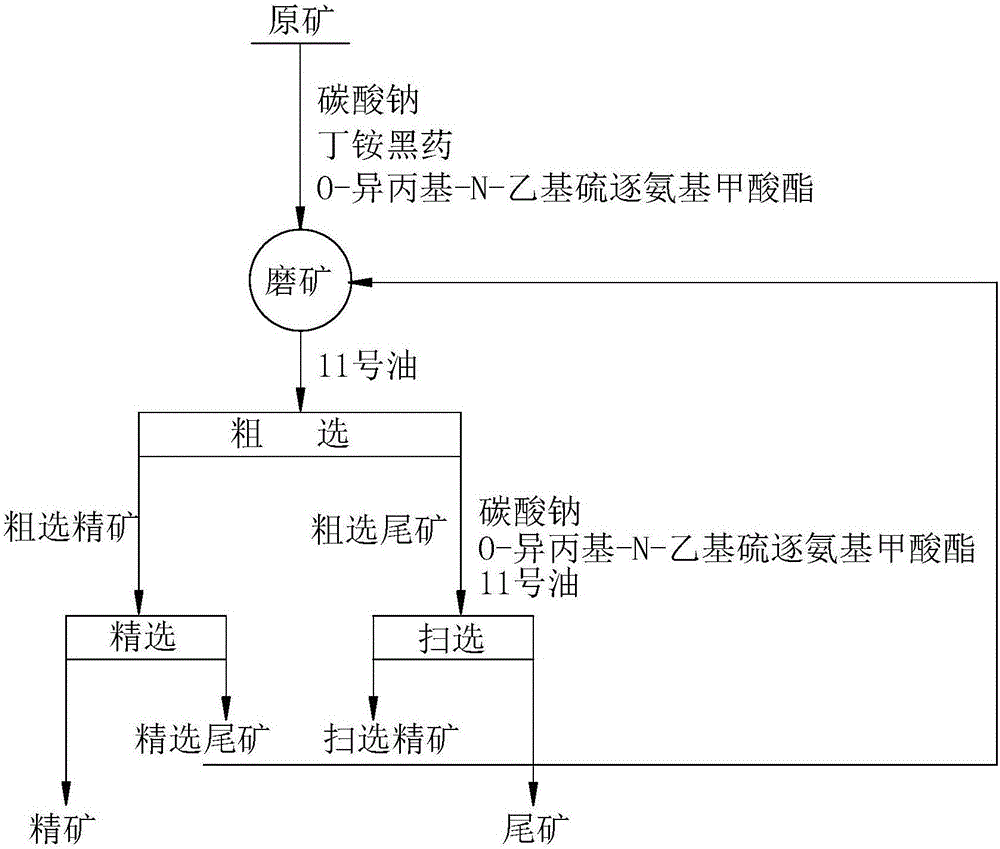

Flotation method of sulphide gold containing ores

The invention relates to a flotation method of sulphide gold containing ores. The flotation method comprises the following step: adding 1,000 to 1,200 g / t of sodium carbonate, 40 to 50 g / t of ammonium butyl aerofloat, 40 to 50 g / t of O-isopropyl-N-sulfur ethyl carbamate and the sulphide gold containing ores to be subjected to grinding and floating treatment into a ball grinding machine together for fine grinding until the particle size is -0.074 mm, wherein the particle size accounts for 90 to 95 percent by weight; and the ammonium butyl aerofloat is a collecting agent. The flotation method has the advantages that the process is simple and feasible; the use amount of the collecting agent is small, and the stirring and flotation time is short; and the resource utilization rate can be increased, and the mineral separation cost can be obviously reduced. On the premise that the closed-loop concentrate level is increased or not changed, the recycling rate of gold in the concentrates can be increased by 5 to 8 percent; the use amount of the collecting agent is reduced by 20 to 30 percent; and the stirring time is shortened by 40 to 50 percent.

Owner:GUANGXI UNIV +1

Screening method of grape wine yeast with low-yield ethyl carbamate and application thereof

InactiveCN102220252AEasy to separateImprove throughputFungiMutant preparationBiotechnologyScreening method

The invention discloses a screening method of grape wine yeast with low-yield ethyl carbamate and application of grape wine yeast in the production of grape wine. The screening method comprises the following steps of: screening out a bacterial strain with the low-yield ethyl carbamate from active dried yeast and mutant strains by adopting a structural analogue of arginine, i.e., canavanine resistance flat plate, wherein the activity dried yeast can be separated from nature or can be purchased in market, and the mutant strains are obtained through the mutagenesis of chemical mutagen. The method is designed by a yeast amino acid metabolism theory and is simple and convenient; and a target bacterial strain can be obtained through rapid separation. According to the screening method, the obtained resistance bacterial strain B1 can be numbered as F15-1-15 bacterial strain (CGMCC (China General Microbiological Culture Collection Center) NO. 4727) and is applied to the brewing of the grape wine in a small-sized fermented container; and on the basis of excellent brewing performance of the grape wine, the bacterial strain has the advantages of being capable of effectively and obviously reducing the content of the ethyl carbamate in the production of the grape wine and having the potential of industrial production and application.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Siliconstabilizers for flame retardant polyurethane- resp. polyioscyanurate rigid foams

The invention relates to a process for producing rigid polyurethane or polyisocyanurate foams by reacting an isocyanate with a polyol in the presence of urethane and / or isocyanurate catalysts, water, optionally further blowing agents, optionally flame retardants and optionally further additives (e.g. fillers, emulsifiers, purely organic stabilizers and surfactants, viscosity reducers, dyes, antioxidants, UV stabilizers, antistatics) using foam stabilizers of the general formula (I) R-Si(CH3)2-O-[-Si(CH3)2-O-]n-[-Si(CH3)R- O-]m-Si(CH3)2-R, where R=-(CH2)x-O-(CH2-CHR'-O )y- R''. -27- Claims: 1. A process for producing rigid polyurethane or polyisocyanurate foams by reacting an isocyanate with a polyol in the presence of foam stabilizers, urethane and / or isocyanurate catalysts, water, optionally further blowing agents, optionally flame retardants and optionally further additives, wherein one or more compounds of the general formula (I) R-Si(CH3)2-O-[-Si(CH3)2-O-]n-Si(CH3)R1-O-]m Si(CH3)2-R2 where the substituents and indices have the following meanings: R, R1, R2 are identical or different and are each -(CH2)x-O-(CH2-CHR'-O) y-R'', R' = H, -CH3, -CH2CH3, phenyl, R'' = H, alkyl, acyl, n+m+2 = 10 to 45, m = 0 to 4, x = 3 to 10, y = 1 to 19, are used as foam stabilizers. 2. The process for producing rigid polyurethane or polyisocyanurate foams as claimed in claim 1, wherein at least 50% of the radicals R' are H. -28- 3. The process for producing rigid polyurethane or polyisocyanurate foams as claimed in claim 1 and / or 2, wherein R'' = H. 4. The process for producing rigid polyurethane or polyisocyanurate foams as claimed in at least one of claims 1 to 3, wherein m = 0 to 2. 5. The process for producing rigid polyurethane or polyisocyanurate foams - as claimed in at least one of claims 1 to 4, wherein n+m+2 = 10 to 40. 6. The process for producing rigid polyurethane or polyisocyanurate foams as claimed in at least one of claims 1 to 5.

Owner:EVONIK OPERATIONS GMBH

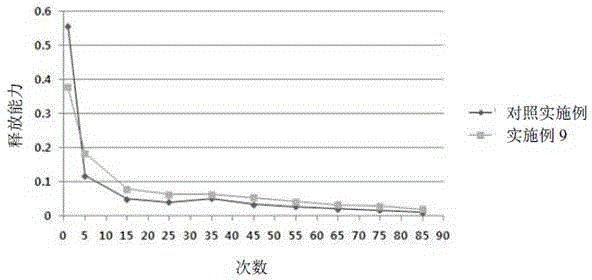

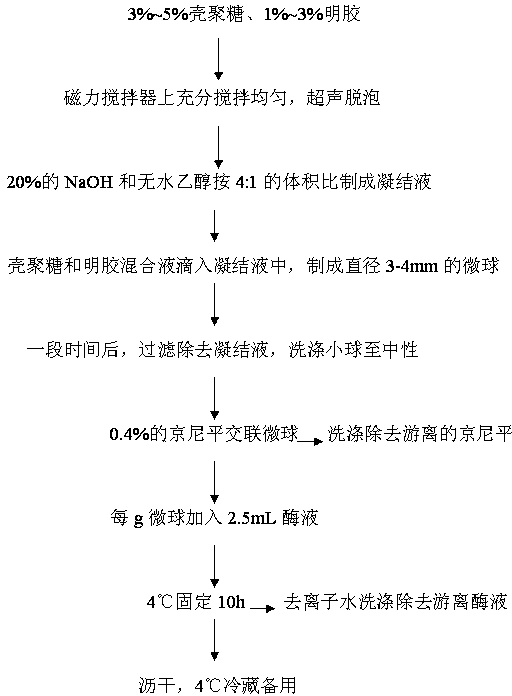

Preparation method and application of natural material composite system immobilized bifunctional enzyme used for wine

InactiveCN103525803AHigh removal rateChange flavorMicroorganism based processesAlcoholic beverage preparationFlavorHalf-life

Belonging to the technical field of enzyme preparations and wine brewing additives, the invention relates to a preparation method and application of a natural material composite system immobilized bifunctional enzyme used for wine. The preparation method includes: subjecting the free bifunctional enzyme that is extracted from Providencia sp. JNB815 and has the activity of degrading urea and ethyl carbamate (EC) to chitosan adsorption, gelatin embedding and genipin crosslinking, thus obtaining the immobilized bifunctional enzyme. When the immobilized enzyme takes urea as the substrate, the optimum temperature is 40DEG C, and the optimum pH is 4.0; when EC is adopted as the substrate, the optimum temperature is 60DEG C, and the optimum pH is 4.5. The storage half-life periods of two enzyme activity are 54d and 45d respectively. The invention also relates to application of the immobilized bifunctional enzyme, which can reach a urea removal rate of 93.03% and an EC removal rate of 56.60%. According to the invention, the process conditions of original fermented wine cannot be changed, the wine flavor is not changed, and the immobilized bifunctional enzyme can be reused, and has more advantages in the application of removing trace urea and EC from yellow wine.

Owner:JIANGNAN UNIV

Digital printing transfer paper surface coating liquid

InactiveCN105647367AHigh sun protection ratingGood mildew resistanceAntifouling/underwater paintsPaints with biocidesPolymethyl methacrylatePolyvinyl chloride

The invention relates to digital printing transfer paper surface coating liquid which is composed of, by mass, 20-24 parts of methyl etherified urea-formaldehyde resin, 22-26 parts of methyltriacetoxysilane, 18-22 parts of polyvinyl chloride resin, 16-20 parts of silicon dioxide powder, 22-26 parts of polyurethane, 18-22 parts of inorganic nanometer zirconium oxide, 16-20 parts of talcum powder, 22-26 parts of polymethyl methacrylate, 16-20 parts of chlorinated polypropylene resin, 16-20 parts of ethyl carbamate resin, 22-26 parts of chlorothalonil, 18-22 parts of polytetrafluoroethylene micro powder, 16-20 parts of fluorescent powder, 22-26 parts of permethrin, 18-22 parts of sodium tripolyphosphate, 16-20 parts of phenothiazine, 22-26 parts of zircon powder, 18-22 parts of chloroplatinic acid and 1,000-2,000 parts of water. The texture of transfer printing patterns obtained after thermal dye sublimation transfer printing is conducted on the coating liquid is clear, saturate, high in colour fastness and durable without color fading; the coating liquid has good anti-mildew and anti-bacterium performance.

Owner:绍兴水墨印象数码印花有限公司

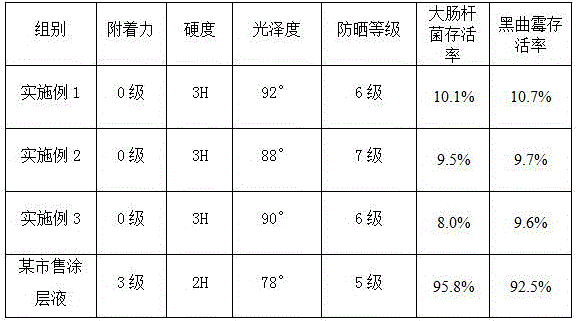

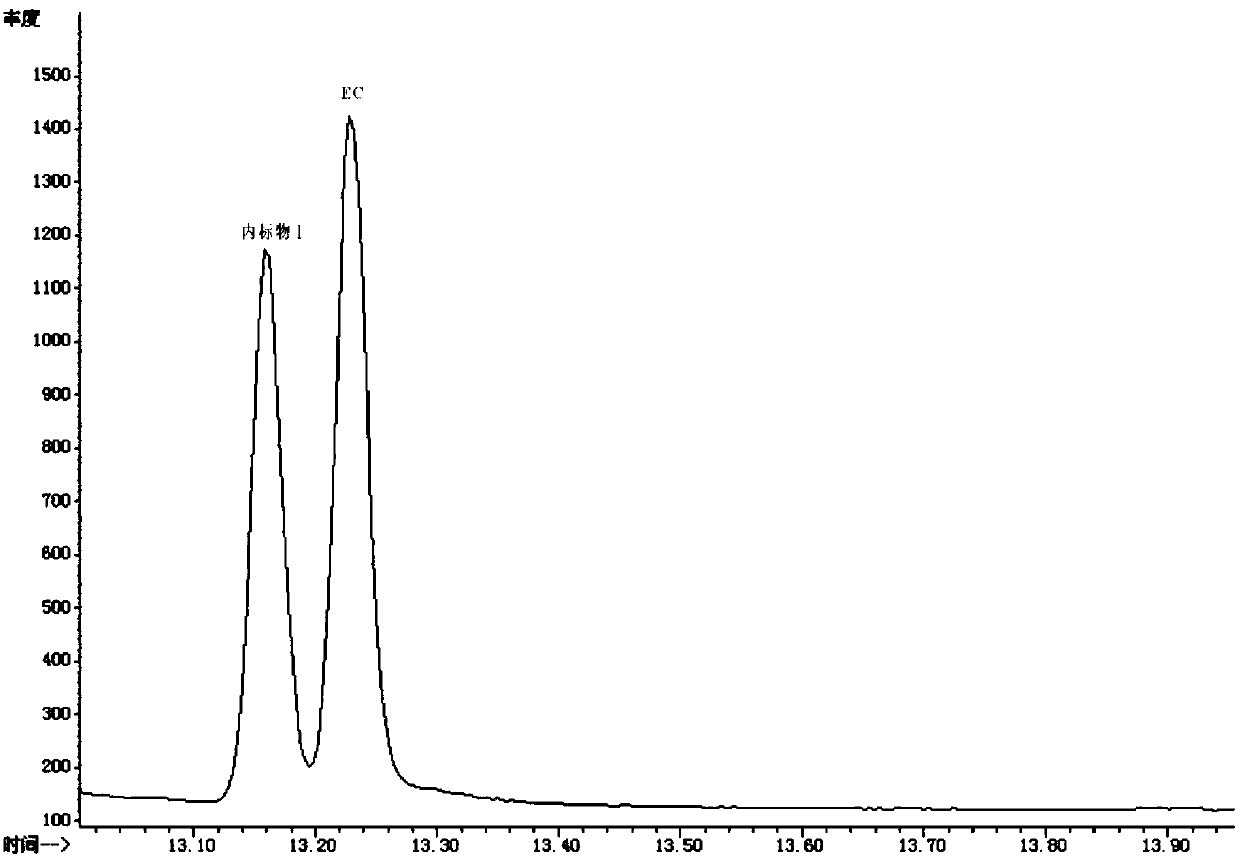

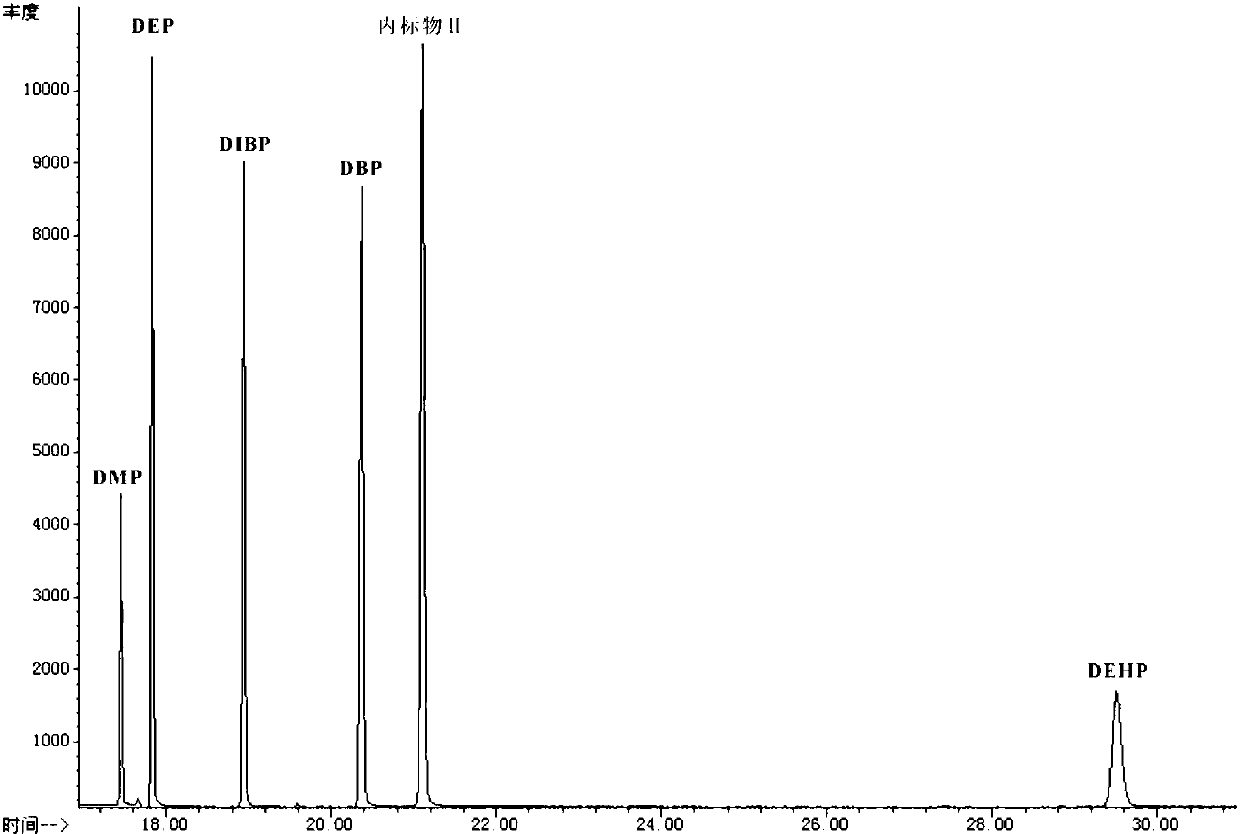

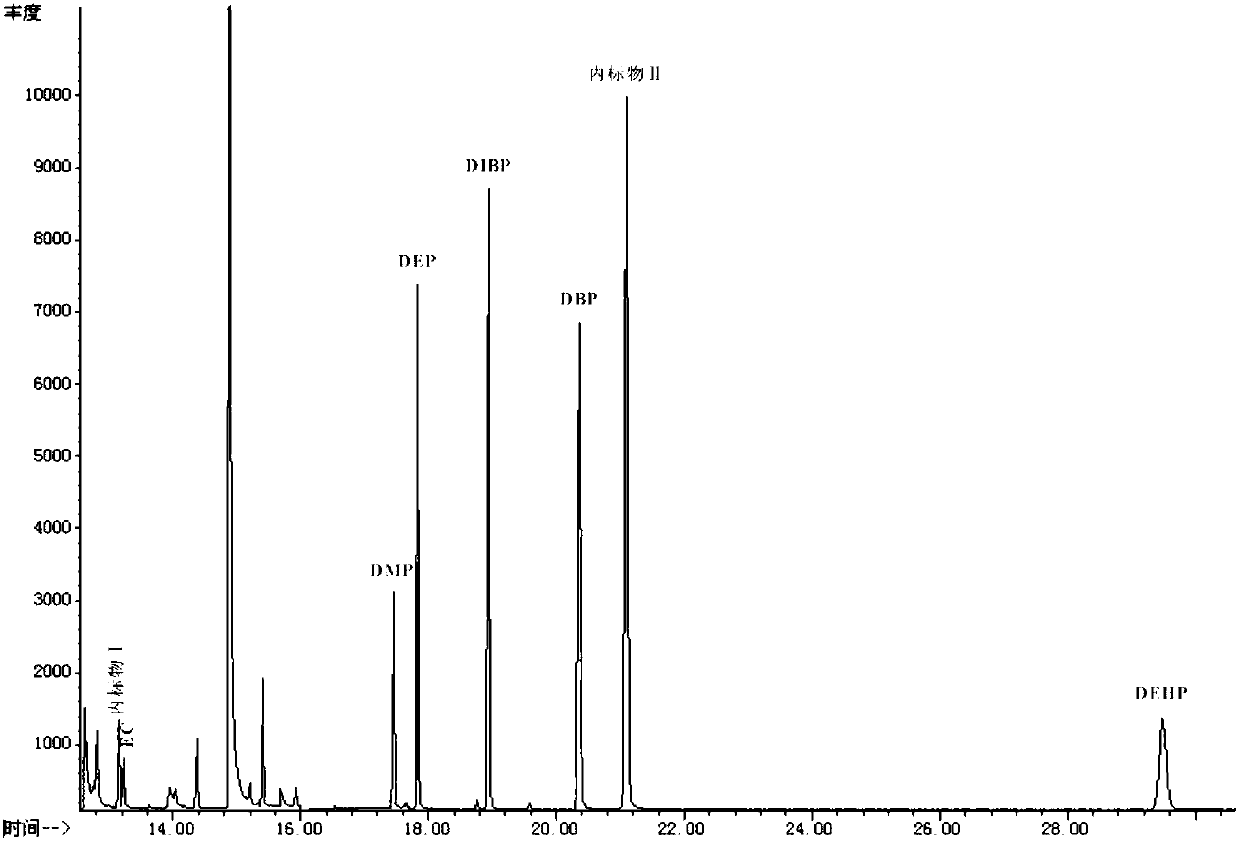

Method for simultaneously and quantitatively detecting content of ethyl carbamate and phthalate in distilled white wine

ActiveCN103344725AGood reproducibilityReduce mistakesComponent separationInternal standardEthyl ester

The invention belongs to the field of white wine detection, particularly relates to a method for simultaneously and quantitatively detecting the content of ethyl carbamate and phthalate in the distilled white wine and aims to solve the problems the existing method for detecting is complex in operation and consumes long time. The method comprises the following steps of: (a) adding an internal standard substance I and an internal standard substance II into a white-wine sample, and (b) detecting by adopting a gas chromatograph mass spectrometer, monitoring and quantitating by using selected irons, and obtaining the content of the ethyl carbamate and the phthalate in the distilled white wine by adopting the internal standard method. The method provided by the invention has good reproducibility, is accurate and is low in detection cost, thereby being easy to popularize.

Owner:SICHUAN JIANNANCHUN GRP CO LTD

Waterproof noise-reduction multifunctional woven fabric and production method thereof

InactiveCN104652016AImprove spinnabilityImprove spinning qualityWoven fabricsMonocomponent polyesters artificial filamentFiberBenzoyl peroxide

The invention discloses a waterproof noise-reduction multifunctional woven fabric which is formed by weaving warp yarns and weft yarns by an air-jet loom, wherein the warp yarns and the weft yarns are prepared from the following raw materials in parts by weight: 30 to 36 parts of isotatic polypropylene, 10 to 14 parts of polyvinyl chloride, 20 to 24 parts of cowhair, 17 to 19 parts of alpinia fiber, 22 to 26 parts of kenaf fiber, 18 to 23 parts of cotton pulp, 7 to 9 parts of liquid paraffin, 8 to 10 parts of ethyl carbamate, 7 to 11 parts of polytetramethylene glycol, 1.1 to 2.5 parts of benzoyl peroxide, 2.1 to 3.2 parts of chitosan, 0.3 to 0.5 part of magnesium acetate, 2 to 4 parts of shell powder, 1 to 3 parts of rhizoma, 2 to 5 parts of mangnolia officinalis, 85 to 95 parts of 1-butyl-3-methyl imidazole acetate, 95 to 105 parts of 1-allyl-3-methyl imidazole chloride salt, a proper amount of water and 4 to 7 parts of assistant. The woven fabric has the advantages of warmth keeping, ventilation, wear resistance, antibacterial performance and the like.

Owner:章云

Bamboo cane softener and preparation method thereof

InactiveCN104589442AGood effectImprove softening effectWood treatment detailsWood impregnation detailsAlcoholGlycerol

The invention relates to a bamboo cane softener and a preparation method thereof. The preparation method comprises the following steps: placing glycerol, alcohol ether glucoside, polyoxyethylene ether and 100-110 parts of deionized water in a stirring tank A to stir to obtain a liquid A, wherein the stirring speed is 3000r / mim; the stirring temperature is 60-65 DEG C; and the time is 5 minutes; meanwhile, placing stearic acid, ethyl carbamate and surplus deionized water in a stirring tank B and stirring for 5 minutes to obtain a liquid B; adding the liquid A and the liquid B to a stirring tank C according to a proportion of 1:(0.6-0.8), stirring for 2 minutes, adding paraffin, continuously stirring for 3 minutes, finally adding a surfactant, wherein the stirring speed is 2500r / mim; the stirring temperature is 80-90 DEG C; and the time is 10 minutes; and cooling after completing stirring. The bamboo cane softener prepared by the preparation method is good in softening effect, does not have corrosion and is good in effect and is convenient to popularize and use. By utilizing the bamboo cane softener, the strength and the tenacity of a softened part are increased.

Owner:赵俊辉

Chlorosulfonated polyethylene cable sheath material and preparation method thereof

InactiveCN103265764AImprove aging resistanceImprove heat resistancePlastic/resin/waxes insulatorsInsulated cablesPolymer scienceSilanes

The invention discloses a chlorosulfonated polyethylene cable sheath material and a preparation method thereof. The cable sheath material comprises the following raw materials: chlorosulfonated polyethylene, impact-resistant polystyrene, nano calcium carbonate, siliceous rock powder, modified zinc borate, ethyl carbamate, an accelerant CZ, a silane coupling agent KH550, epoxidized butyl stearate, thiodipropionate, alkylphenol polyoxyethylene and diisobutyl phthalate. By taking the chlorosulfonated polyethylene as a main material, the cable sheath material is excellent in aging resistance, heat resistance, low-temperature resistance, oil resistance and electrical-insulation resistance. By taking the nano calcium carbonate as a reinforcing agent and modifying the zinc borate serving as a fire retardant, the fire resistance of the cable sheath is improved greatly, so that the cable sheath is obvious in fire resistance.

Owner:ANHUI CHANGYUAN ZHIHAO ELECTRIC POWER SCI & TECH

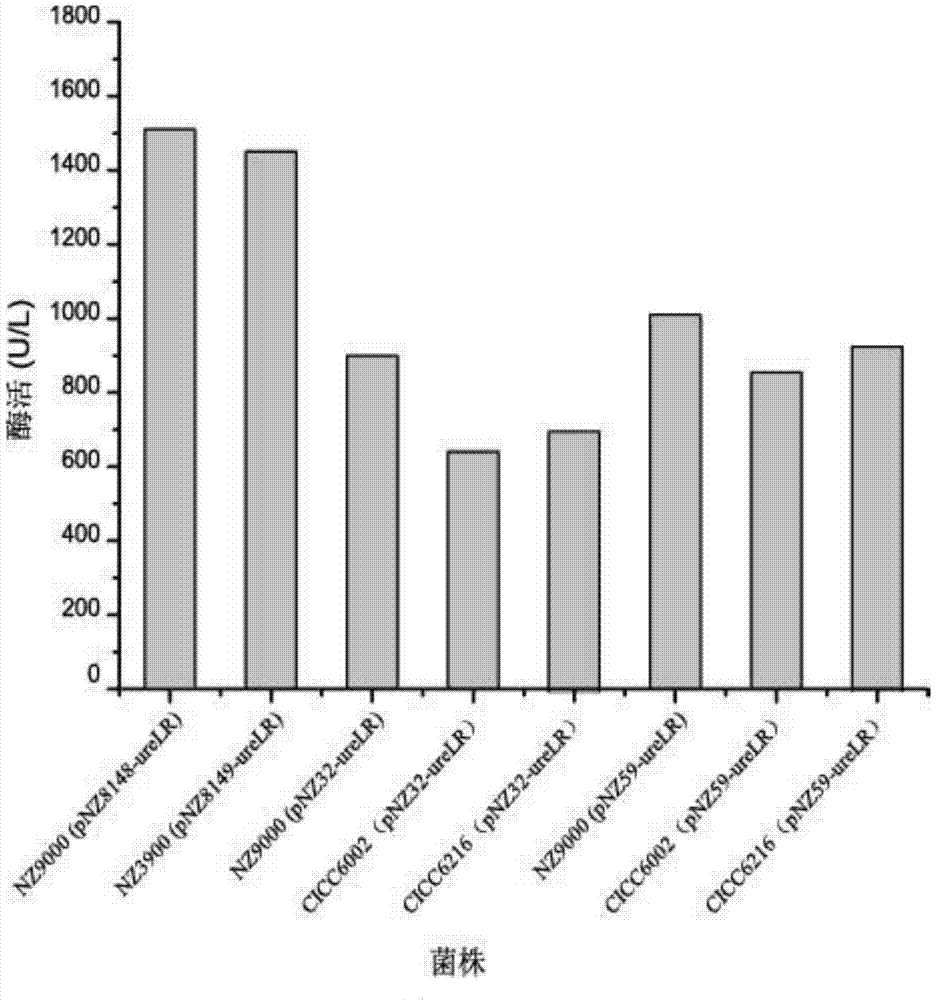

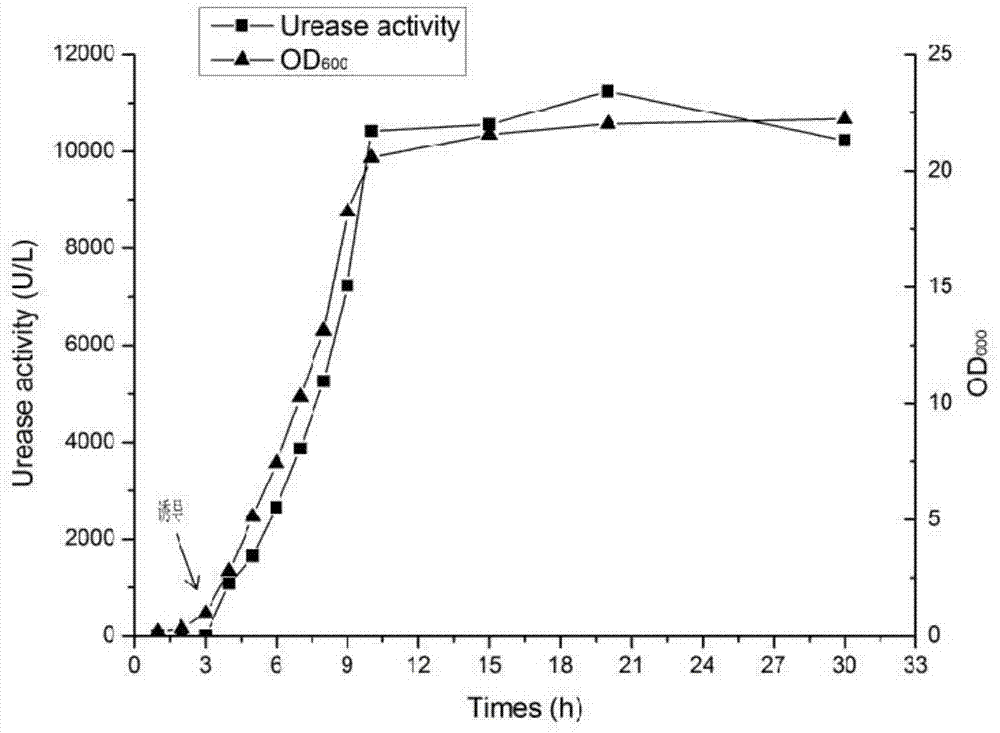

Efficient preparation method and applications of food-grade acid ureases

InactiveCN103571815AEfficient degradationSolve residual problemsHydrolasesAlcoholic beverage preparationSpecific enzymeEthyl ester

The invention discloses an efficient preparation method and applications of food-grade acid ureases, belonging to the technical field of biological engineering. The efficient expression and preparation methods and applications of acid ureases are realized successfully by using food-grade lactococcus lactis expression system, the enzyme activity of the acid ureases reaches 10200 U / L, and the enzyme activity of purified acid ureases is 325.6 U / mg. The specific enzyme activity of purified enzymes to an urethane substrate reaches 243.4 U / mg, and food-grade acid ureases which are prepared by using the method disclosed by the invention and added in a yellow rice or millet wine can efficiently degrade urea (the degradation rate per two days is 100%) and urethane (the degradation rate per three days is 72% %). Recombined acid ureases prepared by using the method disclosed by the invention can be applied to the removal of urea and urethane in fermented food, so that the residue problem of urethane in fermented food can be efficiently solved. The efficient preparation method and applications of food-grade acid ureases disclosed by the invention lay a foundation for the implementation of the industrialized production of food-grade acid ureases.

Owner:JIANGNAN UNIV

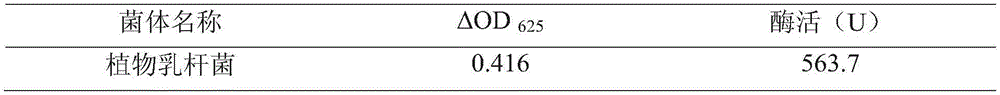

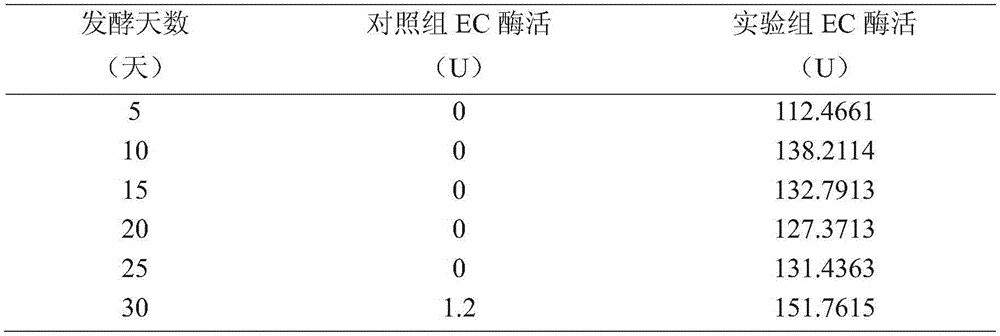

Rice wine brewing method using lactobacillus plantarum to degrade ethyl carbamate (EC)

The invention discloses a rice wine brewing method using lactobacillus plantarum to degrade ethyl carbamate (EC). The method comprises the following steps: soaking rice, steaming the rice, spraying water, dropping a cylinder to put up a boiler, adding leavens and water, fermenting, and performing after-treatment, wherein in the 5th-20th days after fermentation, the lactobacillus plantarum ACCCl0171 is inoculated into fermentation liquid. According to the method disclosed by the invention, the lactobacillus plantarum ACCCl0171 capable of producing an EC degrading enzyme is added to degrade EC generated during wine brewing. The lactobacillus plantarum ACCCl0171 belongs to lactic acid bacteria, the addition of the lactobacillus plantarum ACCCl0171 cannot introduce genes to transform strains, and follow-up treatment processes are not needed, so that the defects of two ways of degrading EC at present can be effectively overcome.

Owner:ZHEJIANG UNIV

Low-ethyl carbamate Hakka mother wine and production method thereof

ActiveCN103074191AContent does not affectReduced urethane contentAlcoholic beverage preparationYeastAlcohol content

The invention discloses a low-ethyl carbamate Hakka mother wine and a production method thereof. The method comprises the steps as follows: soaking sticky rice with clear water at first; steaming the soaked sticky rice with steam until the centers of rice grains are not white; cooling; adding wheat yeast which is equivalently 0.2-0.5% of the sticky rice, red yeast which is equivalently 3-8% of the sticky rice and wine yeast which is equivalently 0.2-0.5% of the sticky rice; uniformly stirring and feeding into a vat; pre-fermenting at the temperature of 32-38 DEG C, adding lactic acid bacteria and uniformly mixing; fermenting for two days in a sealed way; adding white wine with the alcohol content of 40-50 degrees for post-fermenting; and taking out after one month, adjusting the pH value, adding acid urease, treating for 48-60 h, adding acid urease again, stirring for 48-60 h, and finally clearing, decocting, ageing, blending, sterilizing and filtering to obtain the Hakka mother wine as a finished product. The low-ethyl carbamate Hakka mother wine is red brown, glittering, translucent, sweet, mellow, rich in fragrance, fresh, tasty, long in aftertaste and high in drinking safety.

Owner:ZHONGKAI UNIV OF AGRI & ENG

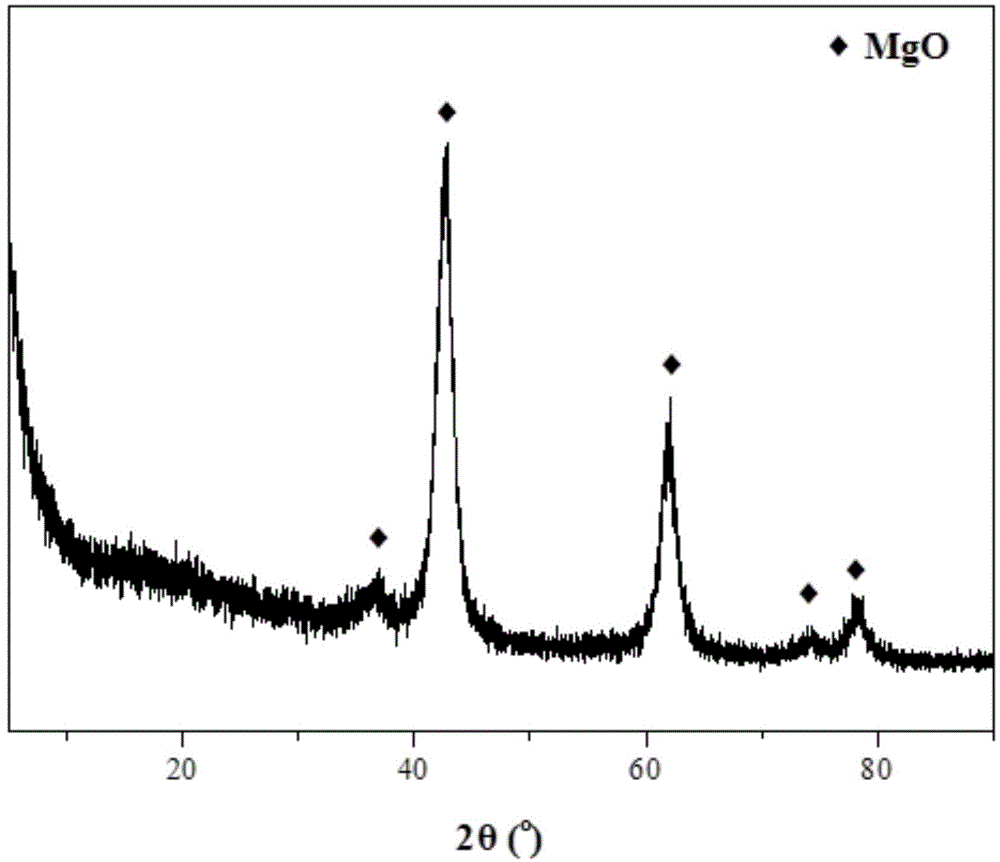

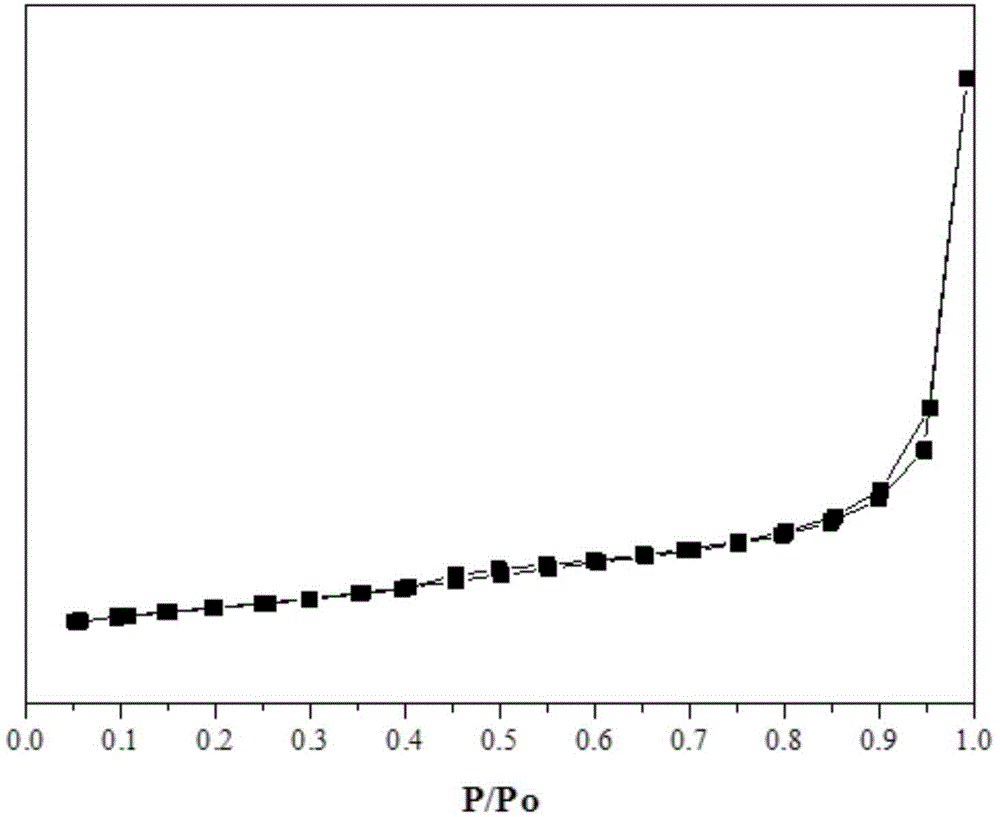

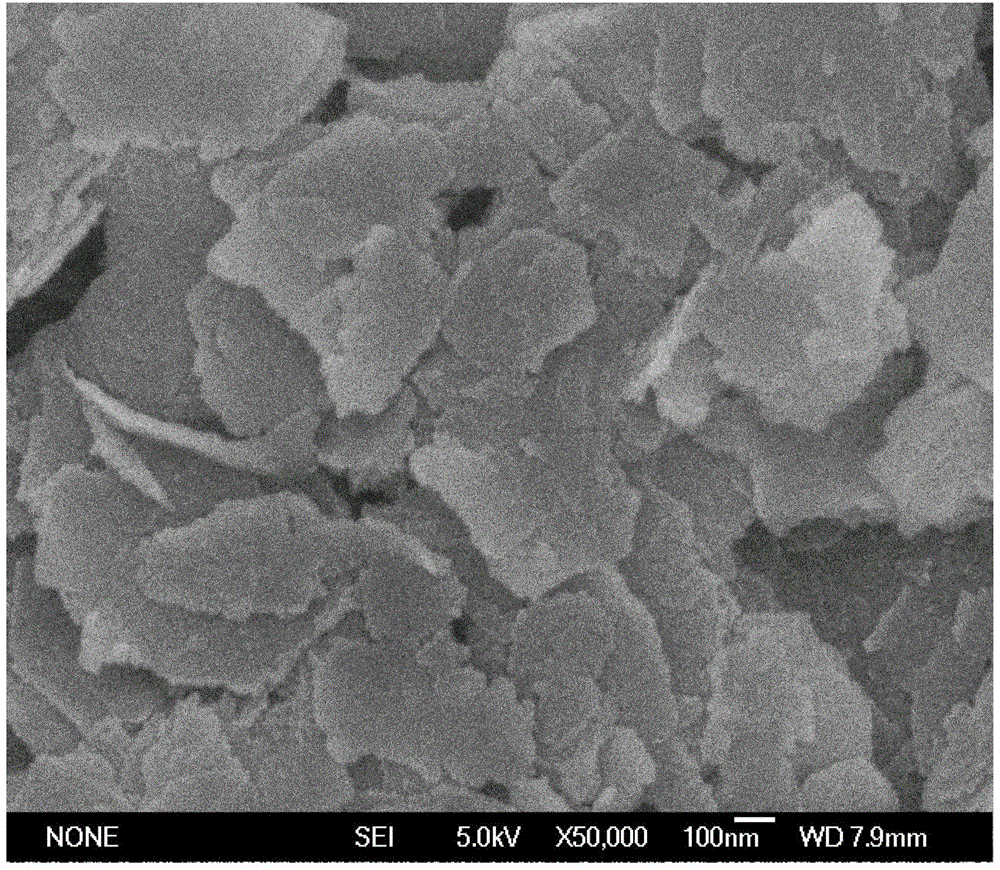

Preparation method of nanosheet magnesium oxide catalyst and method for preparing diethyl carbonate by adopting catalyst

InactiveCN104923201ARich in basic sitesEasy to manufacturePhysical/chemical process catalystsOrganic compound preparationSaline waterAlcohol

The invention discloses a preparation method of nanosheet magnesium oxide catalyst and a method for preparing diethyl carbonate by adopting the catalyst. The preparation method of the magnesium oxide catalyst comprises the following steps: (1) mixing 0.1 to 2 mol / L magnesium salt aqueous solution and 0.1 to 12 mol / L metal salt aqueous solution precipitating agent, wherein the precipitation temperature is 20 to 80 DEG C, the pH value in the precipitation process is 9 to 12, and precipitating insoluble metal salt mixture; (2) after the precipitation is ended, continuously stirring for 0.1 to 3 hours at the temperature of 40 to 80 DEG C; (3) then hydrothermally aging for 10 to 20 hours, filtering and washing precipitates to be neutral, and drying the precipitates at the temperature of 100 to 120 DEG C for 6 to 24 hours; (4) then roasting the precipitates for 0.2 to 6 hours, and obtaining white magnesium oxide powder. The average thickness of nanosheet magnesium oxide is 20nm to 50nm, and the specific surface area is 200 to 500 m<2> / g. The catalyst is used for preparing diethyl carbonate by virtue of alcoholysis of ethyl carbamate and ethanol, the product yield is 80 percent or more, and the selectivity is 99 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com