Preparation method and application of natural material composite system immobilized bifunctional enzyme used for wine

A bifunctional enzyme, natural material technology, applied in the preparation of alcoholic beverages, biochemical equipment and methods, microorganism-based methods, etc., can solve the problems of few reports of EC degrading enzymes and no production scale, and reduce urea and urea. Effects of EC content, easy recovery, and high urea removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

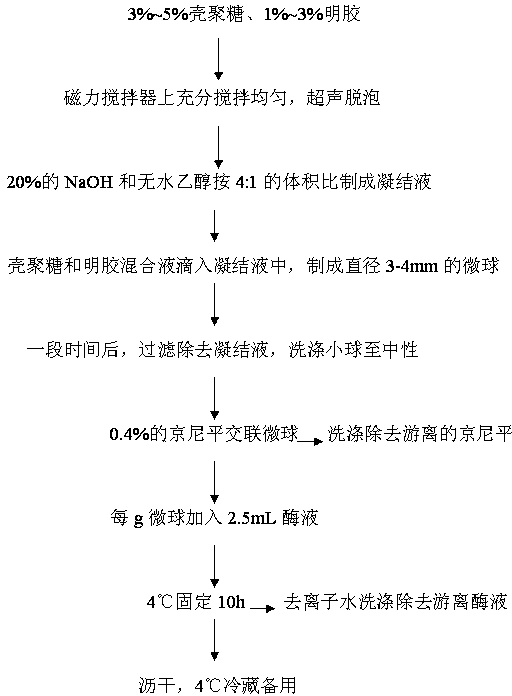

[0031] Example 1: Weighing Weigh 3~5 g of chitosan and 1~3 g of gelatin, dissolve them in 100 mL of 1% acetic acid, place them on a magnetic stirrer and stir evenly, then ultrasonically defoam. Take 20% NaOH solution and absolute ethanol and mix them uniformly at a volume ratio of 4:1 to make 200-300 mL of coagulation solution. Drop the mixed solution of chitosan and gelatin into the coagulation solution with a syringe to form microspheres with a diameter of 3-4 mm. After coagulation for a period of time, wash the chitosan microspheres with deionized water until neutral. Under the condition of shaking in a constant temperature water bath at 30°C, chitosan microspheres were crosslinked with 0.4% genipin solution, and the ratio g / mL of chitosan microspheres: genipin solution was 1:5 , the crosslinking time was 6 hours, and the free genipin solution was removed by washing; the activated microspheres and free enzyme solution were fixed in a refrigerator at 4°C for 8 hours, and 2.5...

Embodiment 2

[0032] Example 2: Put 15 g of the immobilized bifunctional enzyme for wine obtained in Example 1 (that is, the amount of enzyme added is 37.5 U / mL) into a column with an inner diameter of 3 cm and a length of 12 cm, and adjust the flow rate of the wine sample to 1 mL / mL min, 400 mL of wine samples (with a urea content of 74.94 mg / L) flowed through the reactor, and after all the wine samples passed through the column, the total urea removal rate was measured. Circulate the treatment 4 times, and measure the urea removal rate after passing through the column each time. The immobilized bifunctional enzyme for wine could remove 50.77% of urea in the wine sample for the first time, and the same rice wine sample was repeated through the column for 4 times, the urea removal rate reached 96.92%, and the final concentration of urea was reduced to 2.31 mg / L.

Embodiment 3

[0033]Example 3: Prepare 15 mL samples of yellow rice wine and simulated wine (50% ethanol) with urea additions of 25 mg / L respectively. mL, 32°C shaker at 100 rpm for 20 h, and the removal rate of urea was determined. Under two different enzyme dosage conditions, the urea removal rates of immobilized bifunctional enzymes for rice wine were 74.16% and 93.03%, respectively, and the urea removal rates of simulated wine were 95.16% and 98.01%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com