Patents

Literature

87 results about "Residual activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Herbicide resistant rice

InactiveUS6274796B1Growth inhibitionGood flexibilityBiocideMutant preparationRice plantsAcetohydroxy Acid Synthetase

Rice plants are disclosed with two separate, but synergistic mechanisms for resistance to herbicides that normally inhibit a plant's acetohydroxyacid synthase (AHAS) enzyme. The herbicide resistance of plants with both resistance mechanisms is substantially greater than one would expect from a simple combination of the two types of resistance. The first of the two resistance mechanisms is a metabolic pathway that is not fully understood, but that does not itself involve a mutant AHAS enzyme. The second resistance mechanism is a mutant AHAS enzyme, an enzyme that shows direct resistance to levels of herbicide that normally inhibit the enzyme, in both in vivo and in vitro assays. Besides controlling red rice, many AHAS-inhibiting herbicides also effectively control other weeds that are common in rice fields. Several of these herbicides have residual activity, so that a treatment controls both existing weeds as well as weeds that sprout later. No herbicide currently available for use on rice has residual activity against a broad spectrum of weeds including red rice. With effective residual activity against red rice and other weeds, rice producers now have a weed control system superior to those currently used.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Cyclodextrin glucanotransferase and its method of manufacture

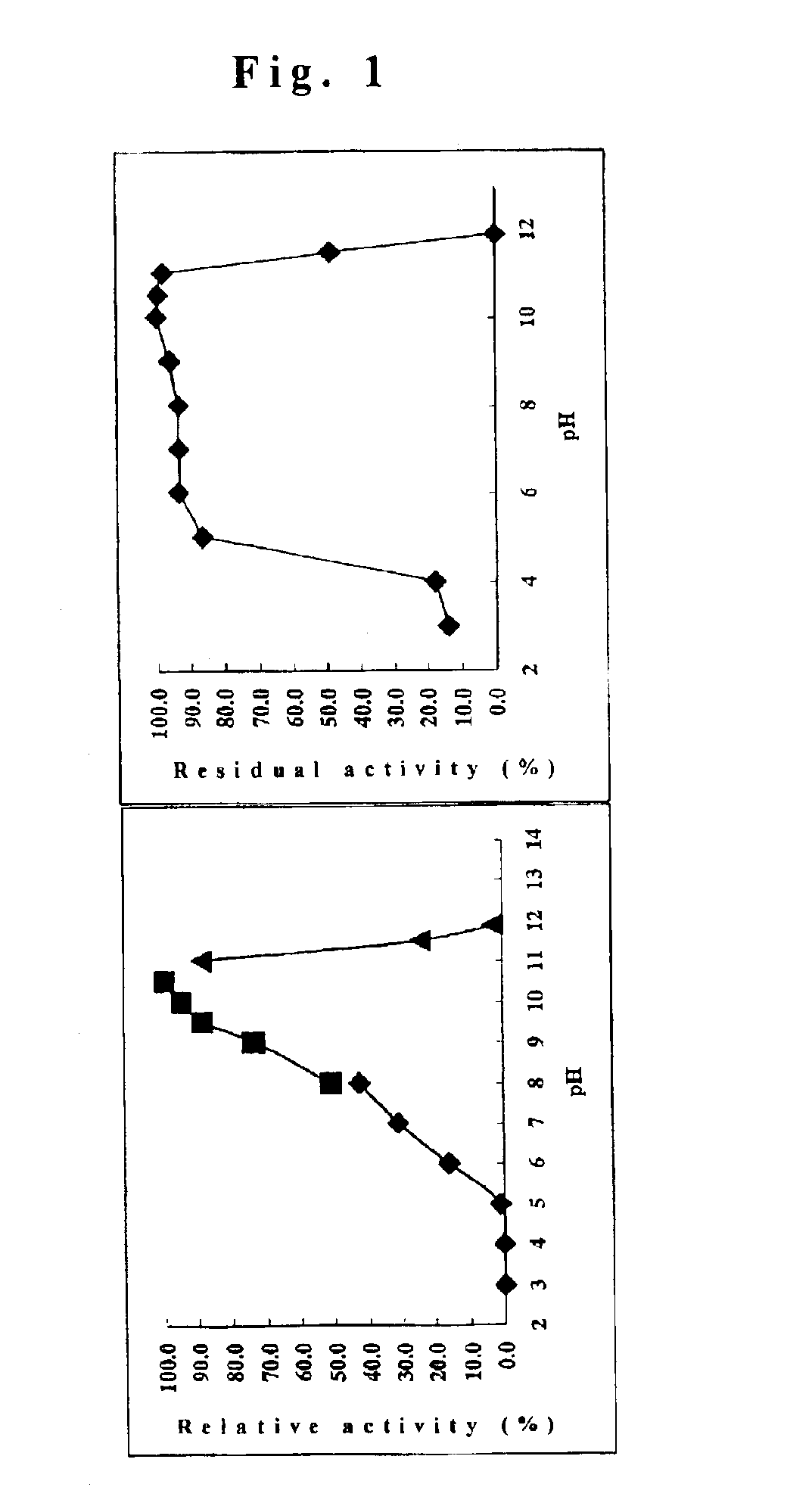

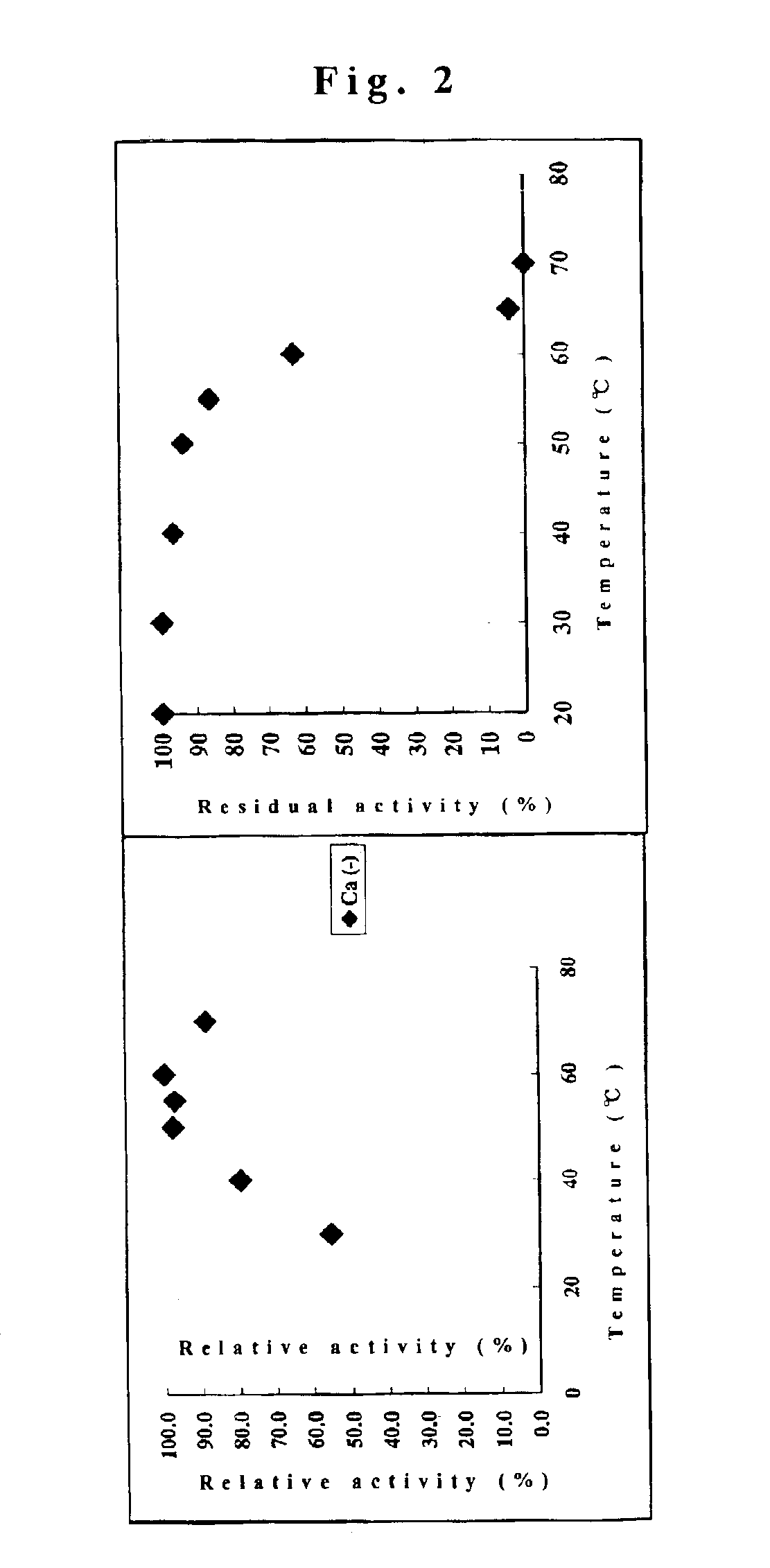

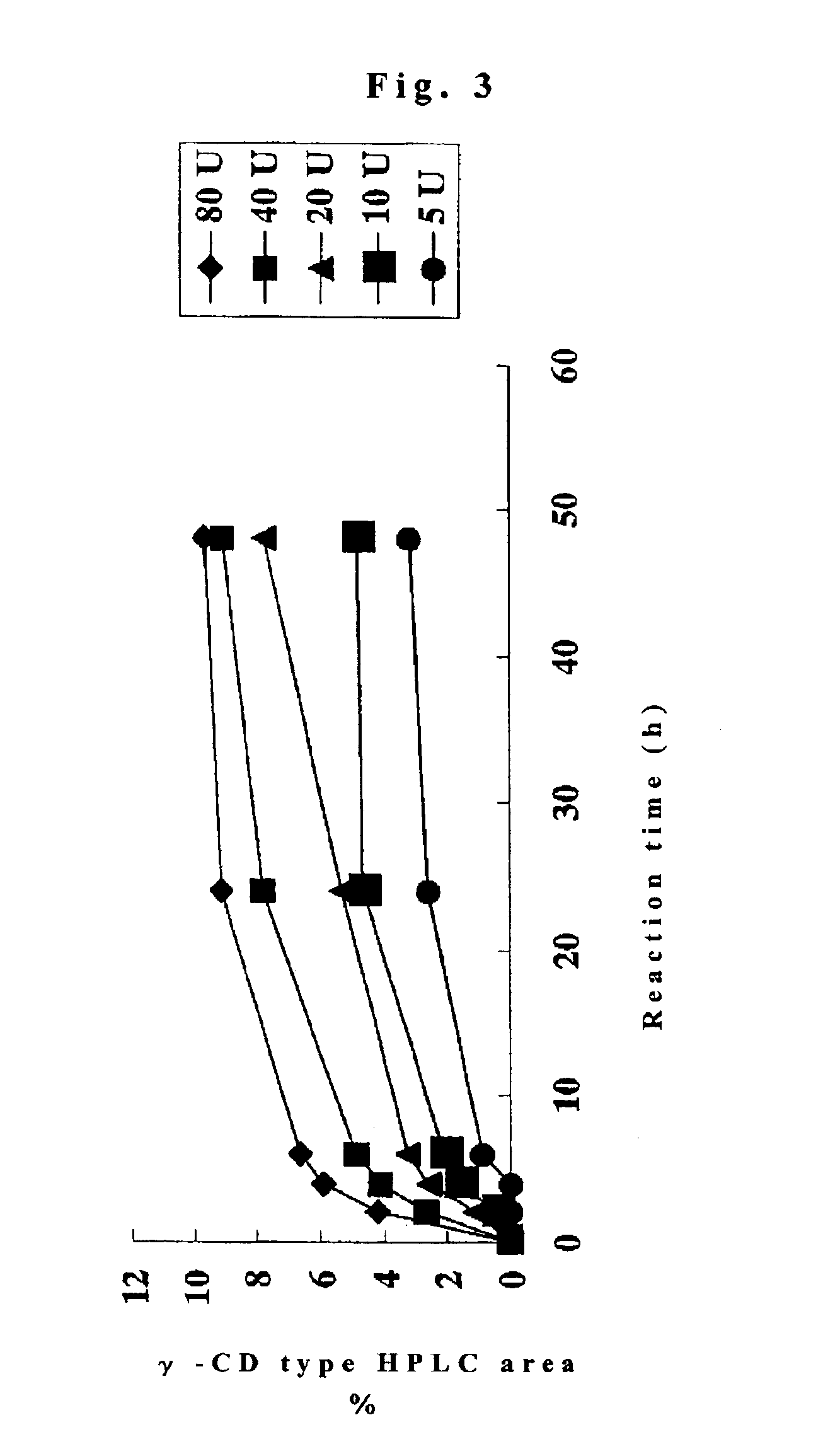

CGTase enzymatically acts on starch, dextrin, amylopectin, and amylose to produce primarily γ-CD, with quantities of β- and α-CD produced being smaller than the quantity of γ-CD produced, has an optimum pH of 10.5-11.0, an optimum temperature of about 60° C., a stable pH of 6-11, and temperature stability, exhibits residual activity of not less than 90 percent with a 15 minute-treatment at 50° C., is produced by culturing a Bacillus clarkii (for example, FERM B-7156), reacts with starch or the like to produce principally γ-cyclodextrin.

Owner:NIHON SHOKUHIN KAKO CO LTD

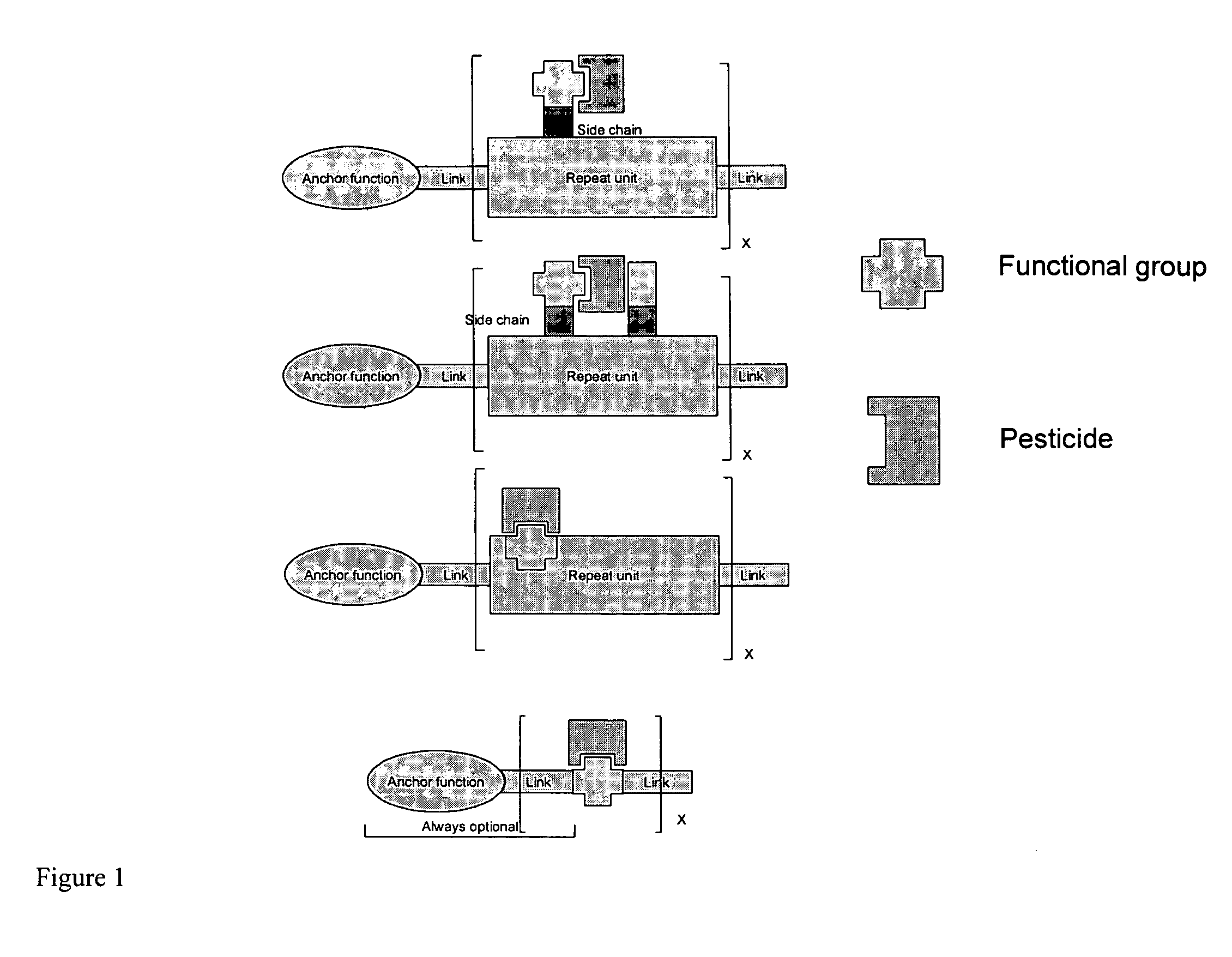

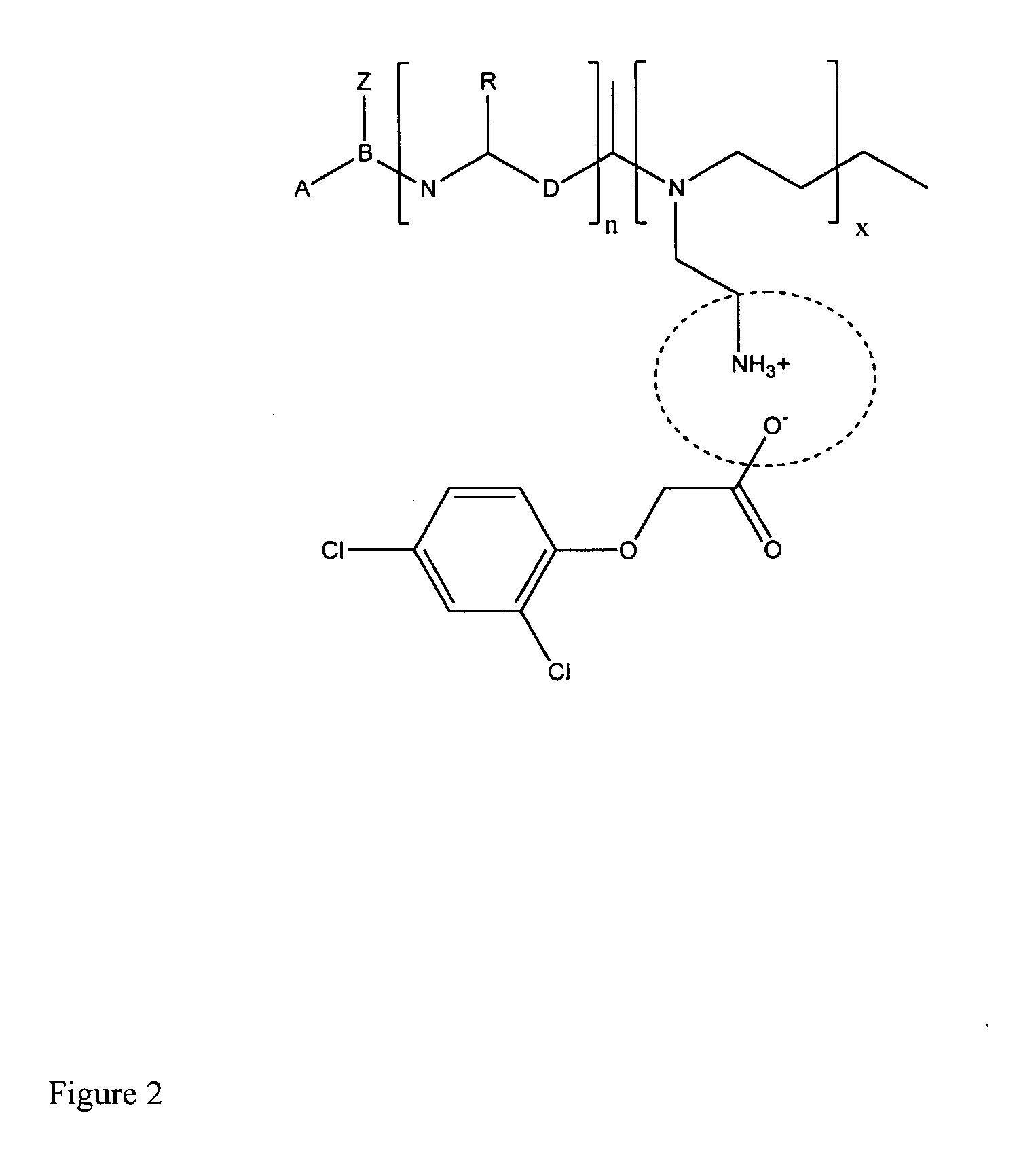

Pesticide formulations with substituted biopolymers and organic polymers for improving residual activity, droplet size, adherence and rainfastness on leaves and reduction in soil leaching

Functionalized polymers are mixed with pesticides to form semi-stable complexes with desirable field properties: reduced leaching in soil, improved leaf retention (rainfastness), selective unloading to roots and convenient packaging and application. Pesticides that may be so complexed include herbicides, insecticides (including compounds controlling non-insect arthropods and nematodes), bacteriocides, rodenticides, and fungicides. Polymers with which they may be complexed include derivatives of carbohydrates, amides, imines, alkanes, vinyls, styrenes or glycols. The polymers may be functionalized with chemical groups that exhibit ionic (amines, carboxyls), hydrophobic, complexing (e.g. metal chelating) and ligand binding interactions. The variously functionalized polymers may be mixed, grafted, or fused to obtain optimal properties. The polymer / pesticide formulations may be applied as granules, as suspensions or solutions in sprays, as foams, or as coats for seeds and fertilizers. The formulations may be applied to foliage, soil, irrigation water, construction materials (plastics, wood), seeding materials, grains, and buildings.

Owner:HI CAP FORMULATIONS

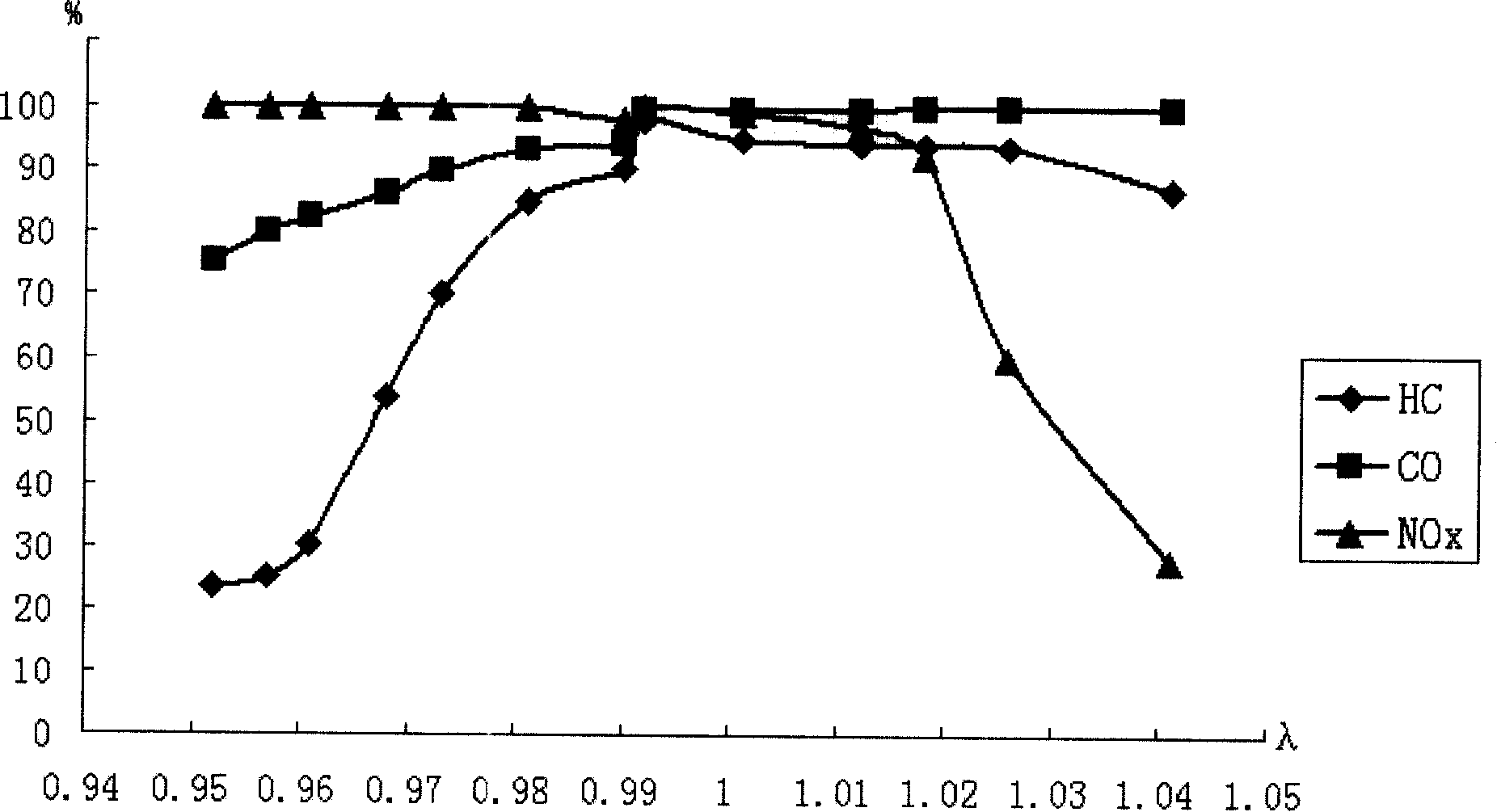

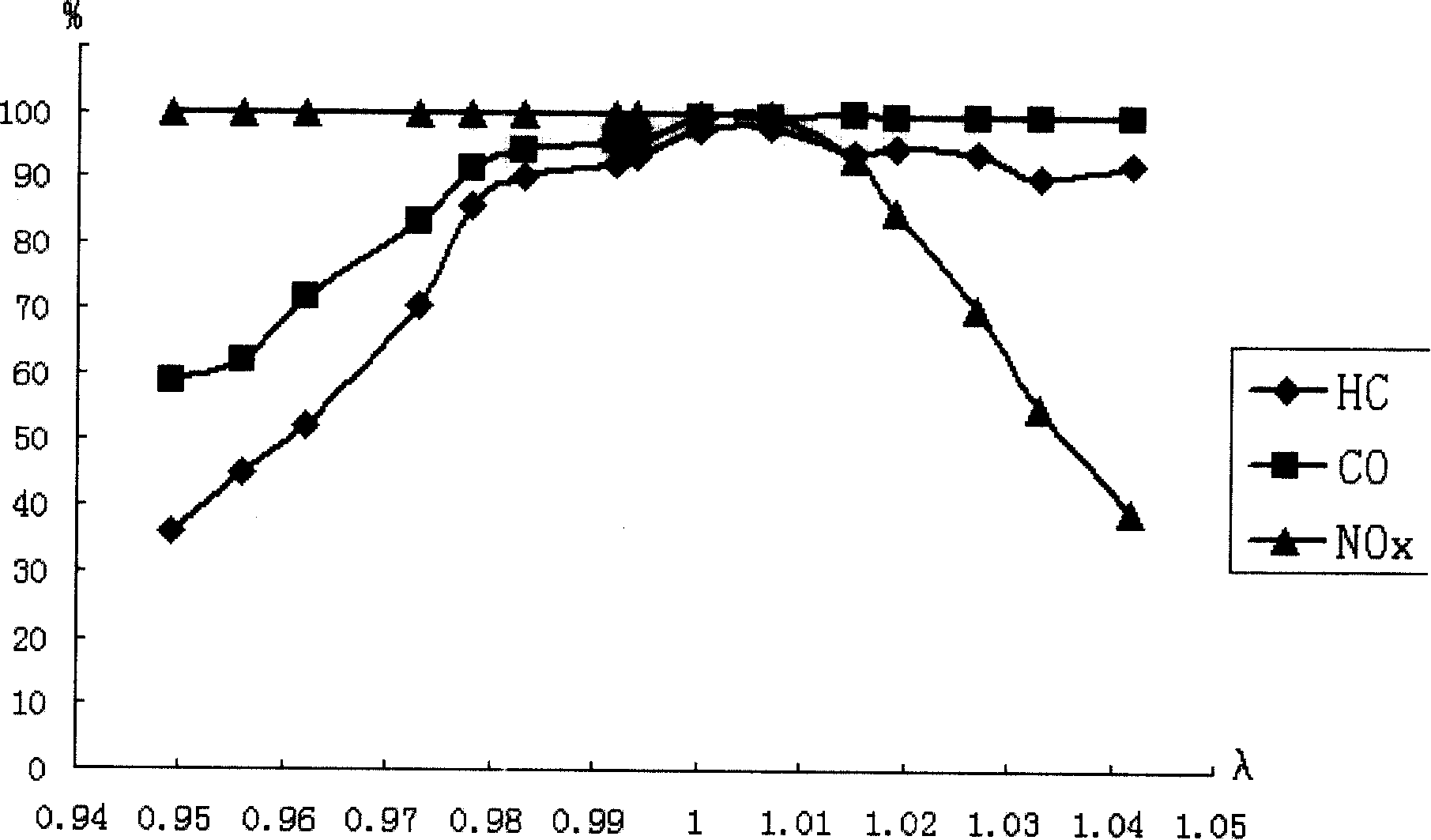

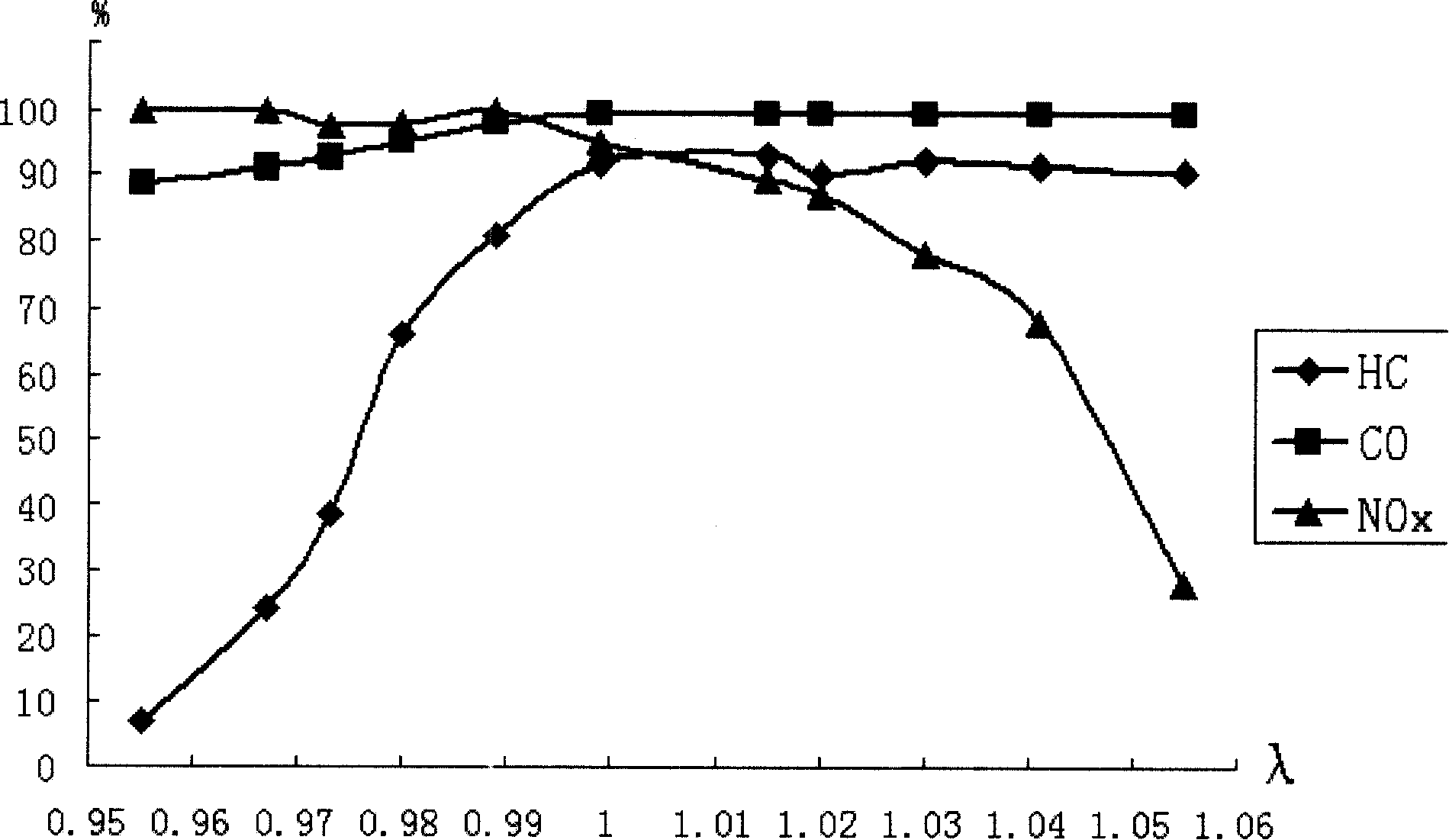

A ternary catalyst and its preparing method

The present invention relates to a three-way catalyst which is used for purifying the vehicle tail gas and can simultaneously do catalyzing and cleaning functions to CO, HC and NOx and the preparing method thereof. The first catalyzing layer is one or a mixture of a plurality of metals selected from the active aluminum oxide carrying rare earth metal and alkaline earth metal, the second catalyzing layer is alumina oxide carrying a first active noble metal which has toxin immunity and nonzero residual activity, the third catalyzing layer is a second noble metal which has catalytic activity, the fourth catalyzing layer is rare earth, alkali soil or the oxide of the transitional metal. The catalyst is composed of cordierite honeycomb ceramic substrate, the oxide aluminum layer and the active noble metal. The catalyst prepared by the method has a better catalyzing property and thermal stability, and adapts the broader air / fuel ratio scope.

Owner:BYD CO LTD

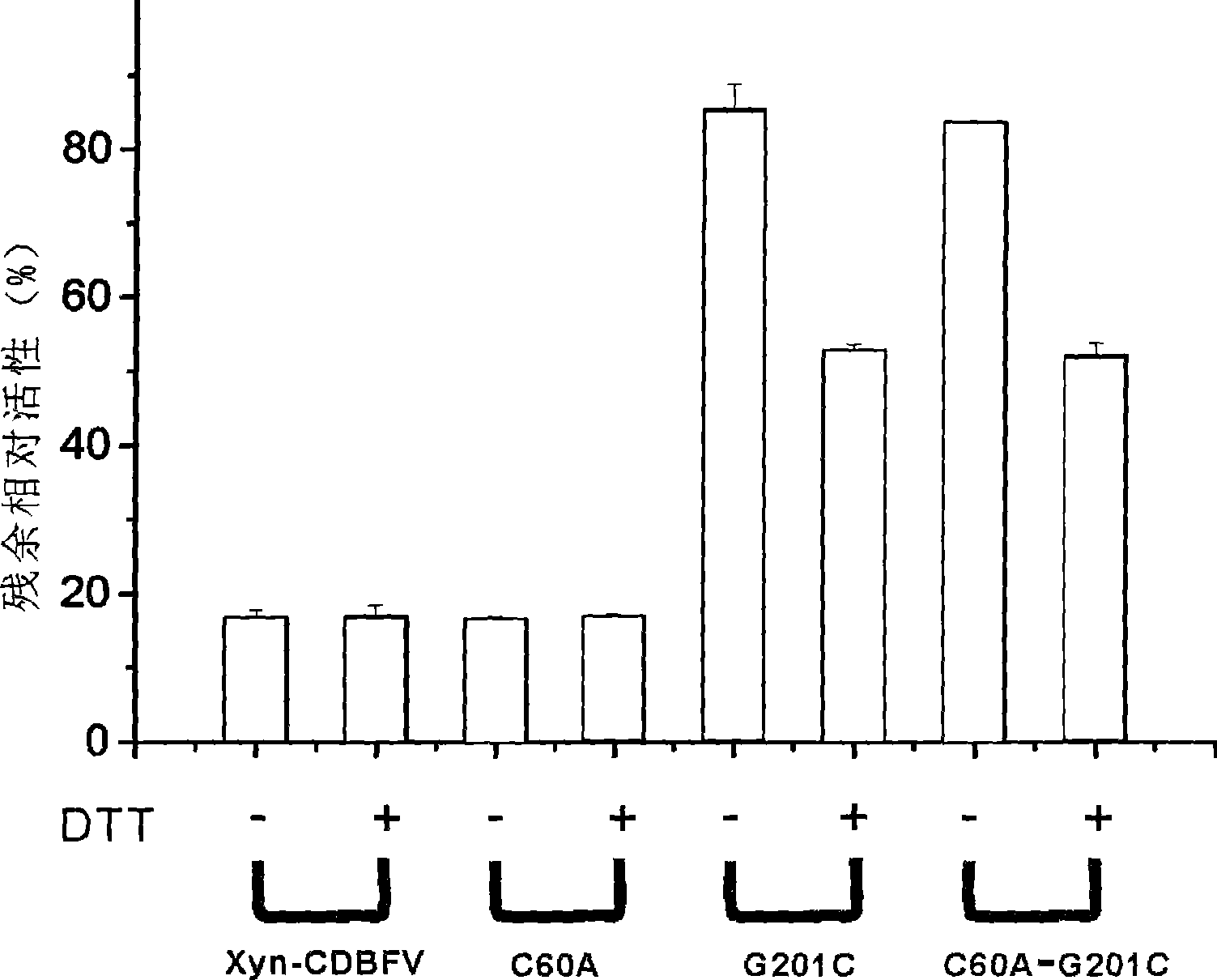

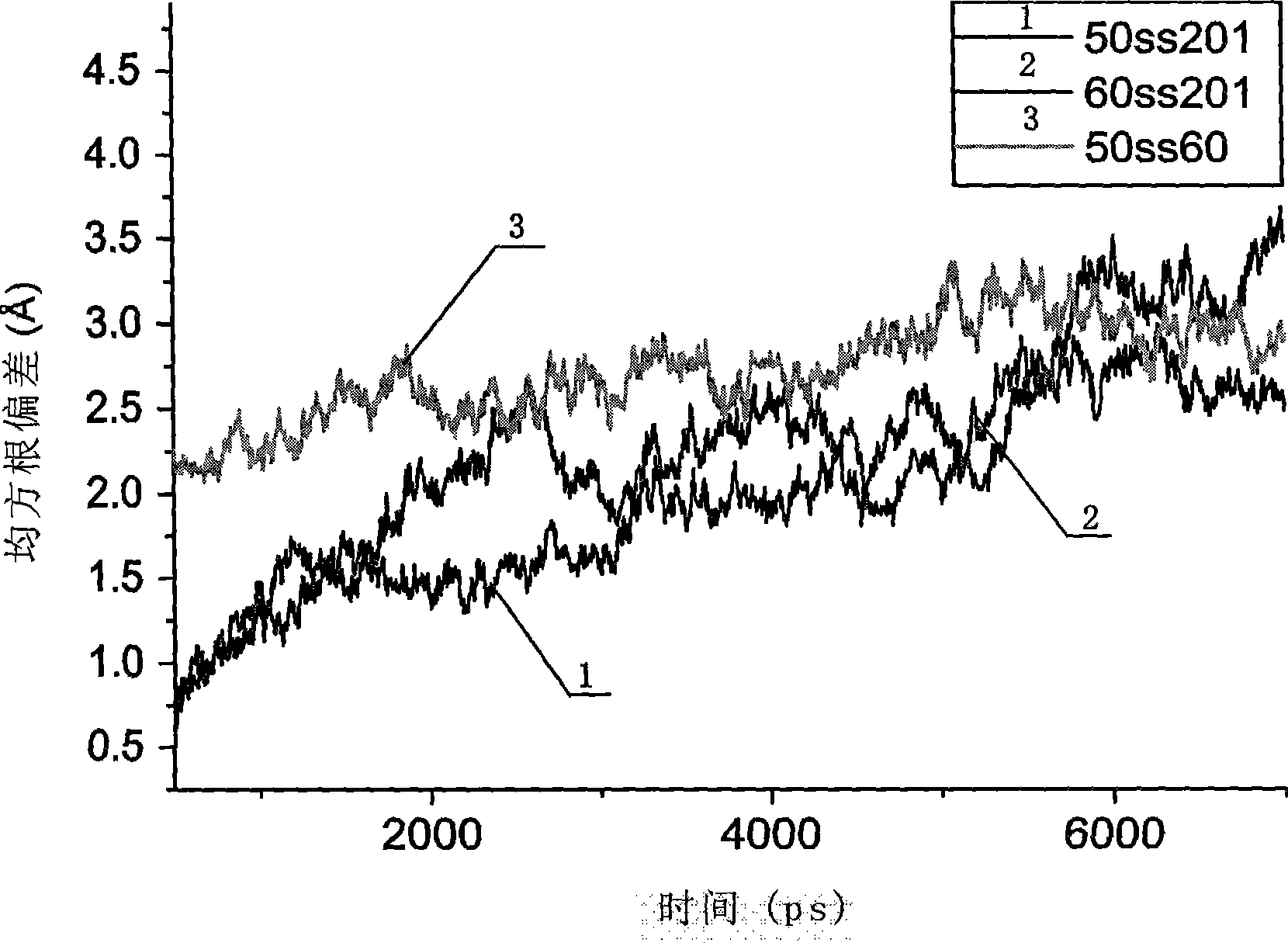

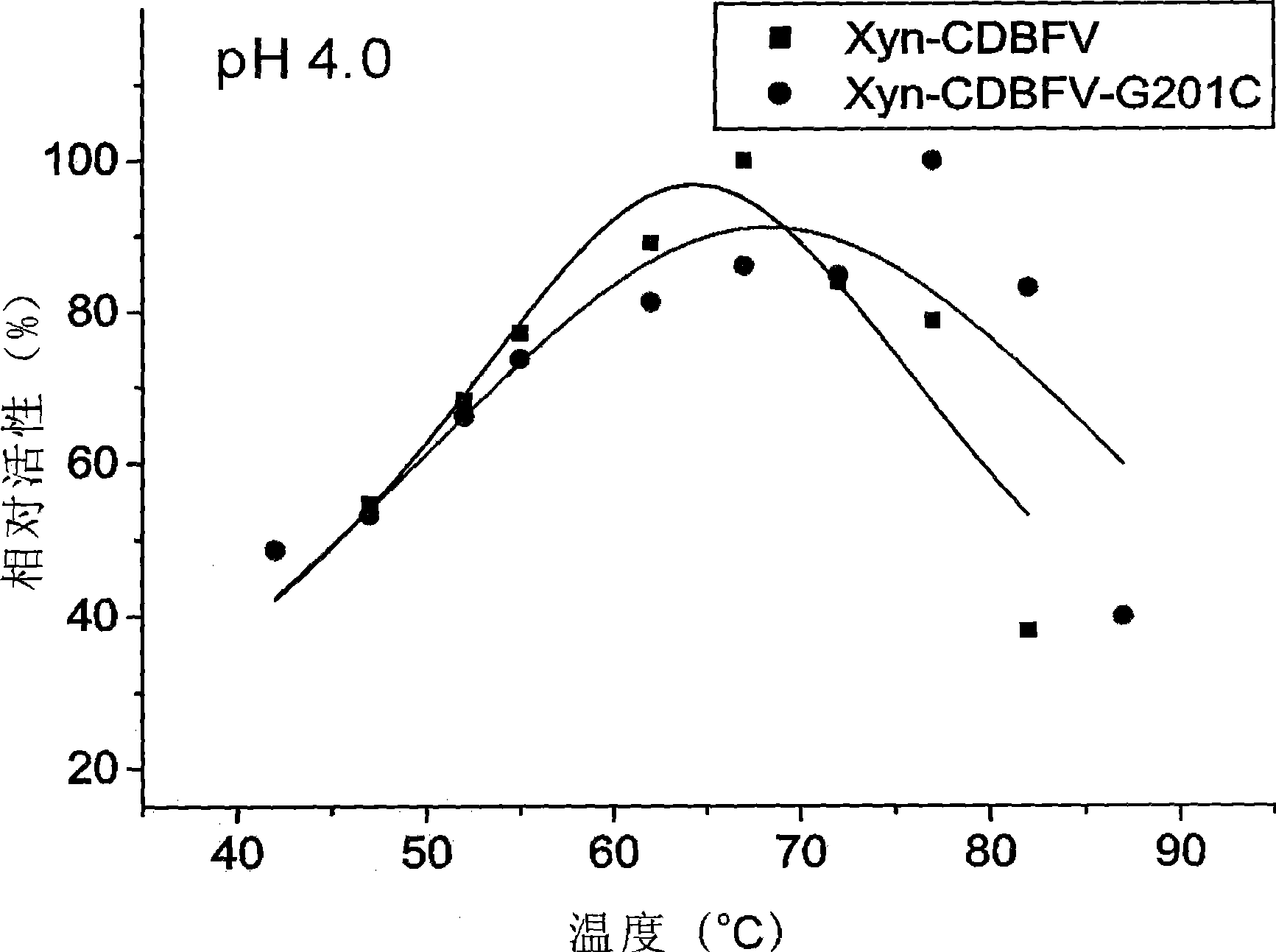

High temperature and strong alkali resistant xylanase improved gene, genetic engineering bacterial strain thereof and preparation method thereof

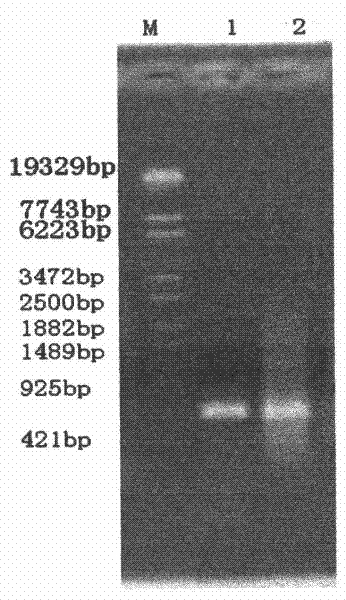

ActiveCN101392266AImprove thermal stabilityEasy extractionFungiMicroorganism based processesPichia pastorisXylanase

The invention provides a modified coding gene of xylanase that has high activity in the condition of high temperature and strong alkali, a recombinant plasmid thereof, a yeast recombination genetic engineering strain containing the gene and a preparation method of the gene. Compared with the original xylanase, the modified xylanase is mutated into cysteine from glycin of the 201 site of amino acid sequence of the original xylanase; and the modified xylanase has higher heat stability, after being processed for 10 minutes at the temperature of 75 DEG C, the residual activity of the modified xylanase reaches 80 percent, while that of the original xylanase is only 15 percent. The activity of the modified xylanase is 1.5 to 2 times of that of the original xylanase at the environment with high temperature and strong alkali and can decompose xylan for a long time at high temperature. The invention also provides the Pichia pastoris yeast recombination genetic engineering strain containing the modified gene. The modified xylanase can be widely applied to industries of paper making, feedstuff and food.

Owner:FUDAN UNIV +1

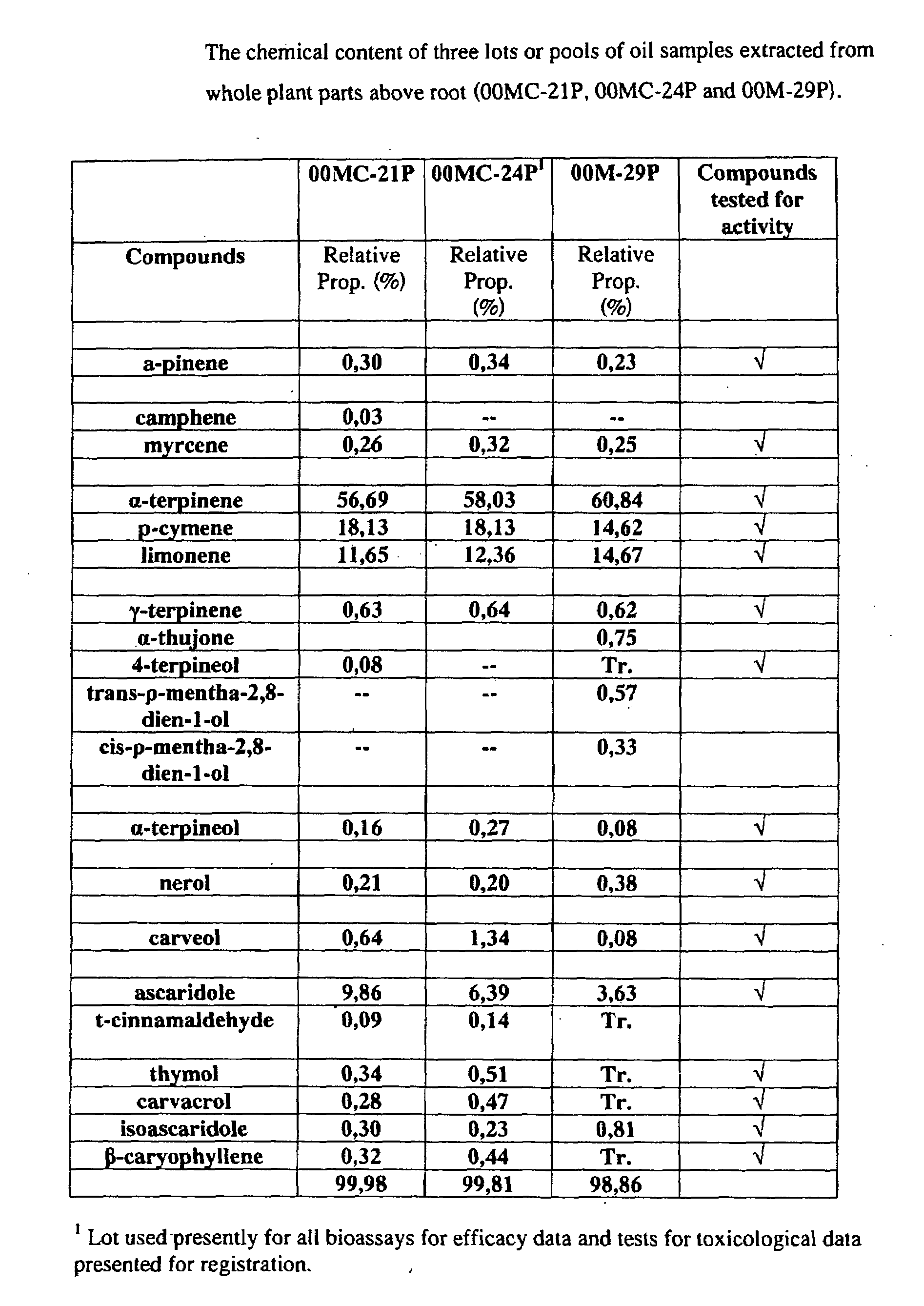

Extracts derived from chenopodium plants and uses thereof

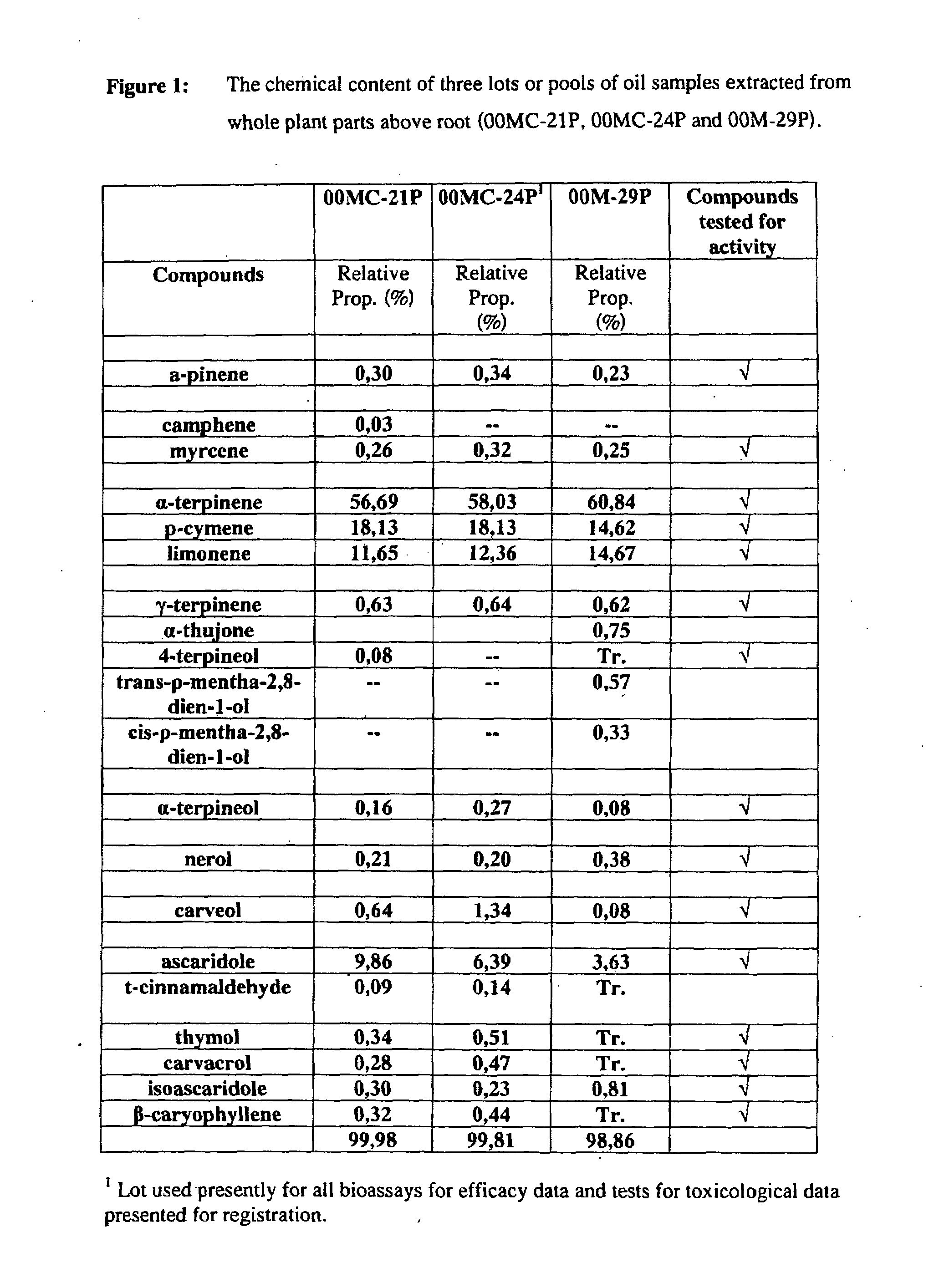

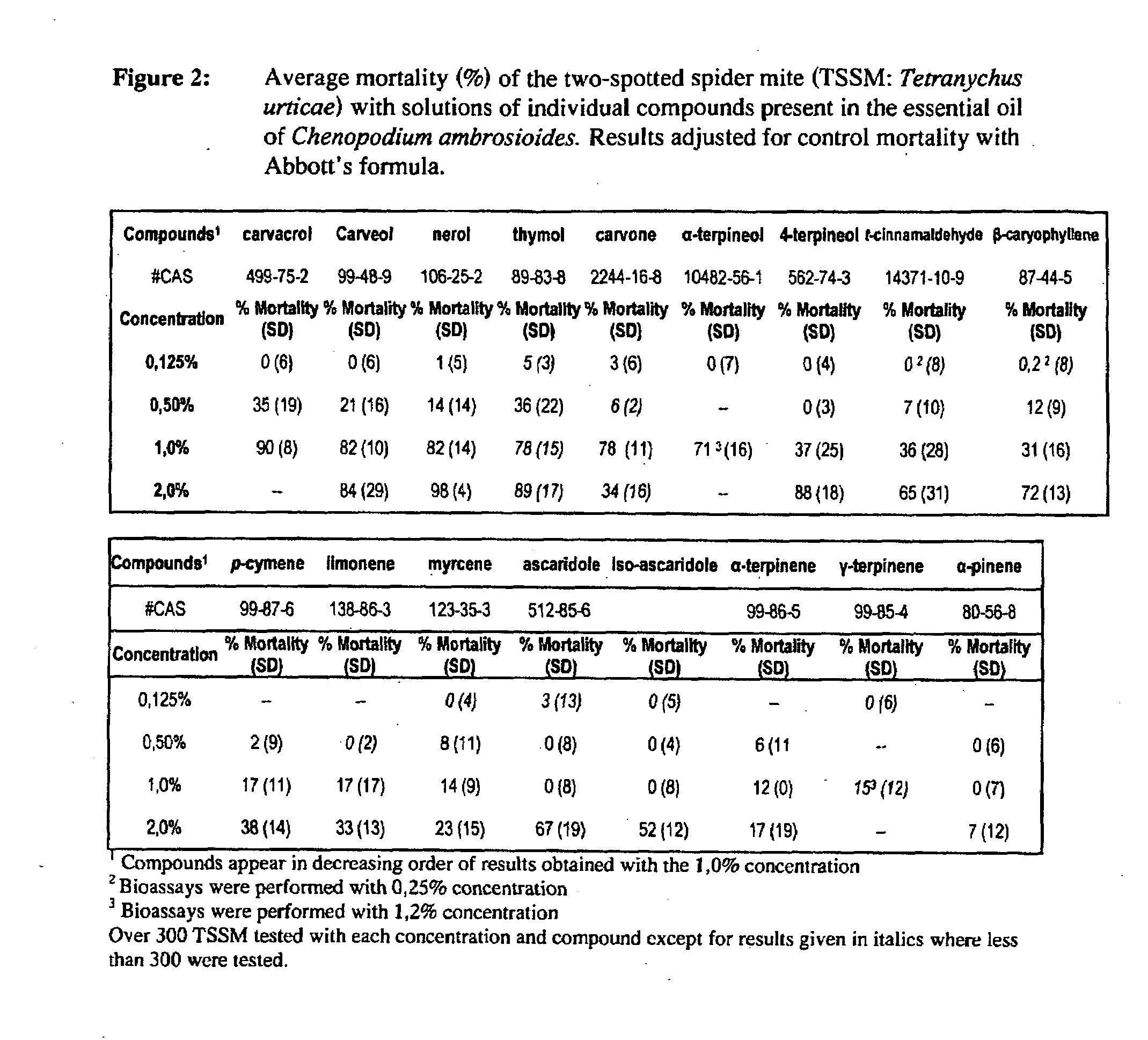

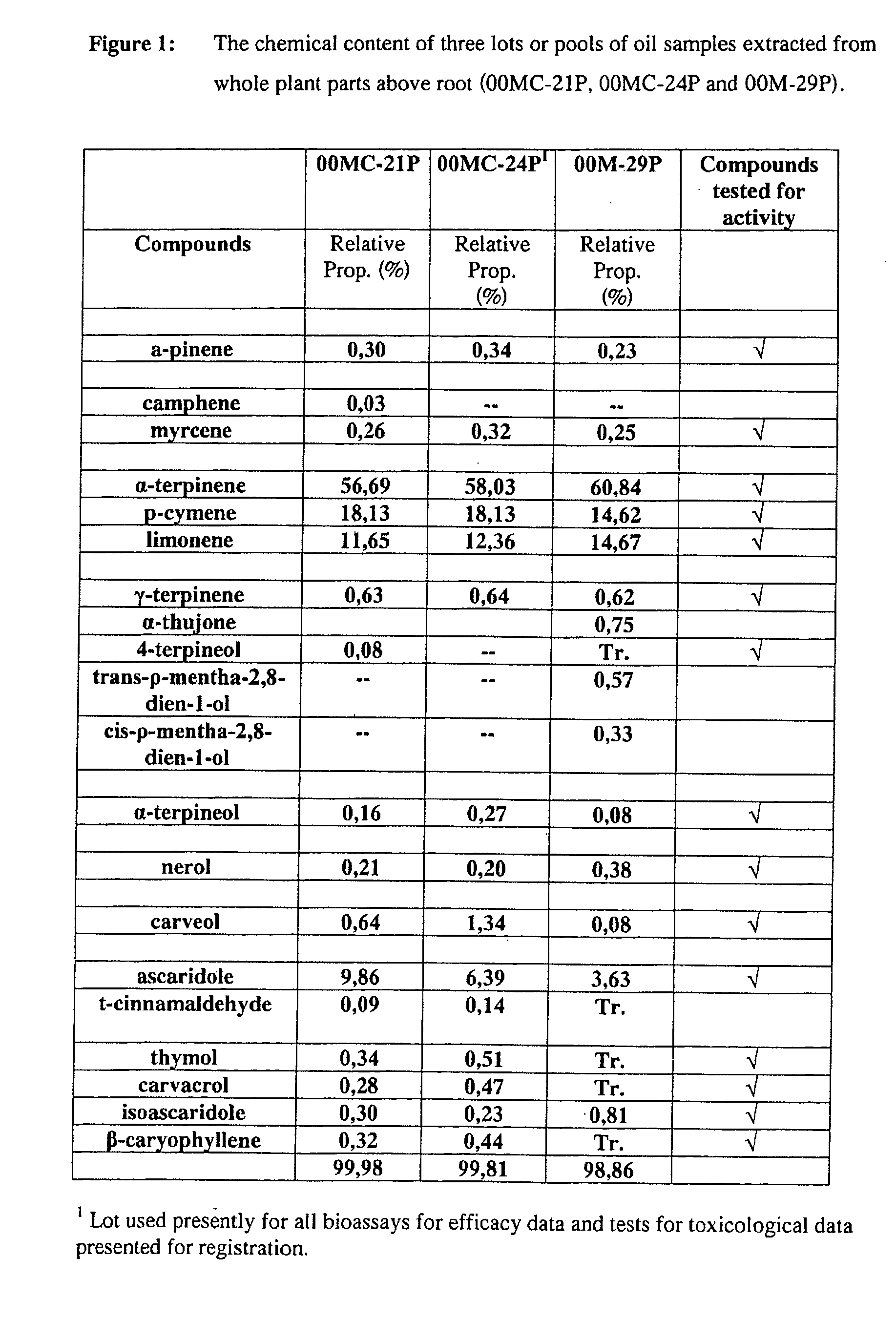

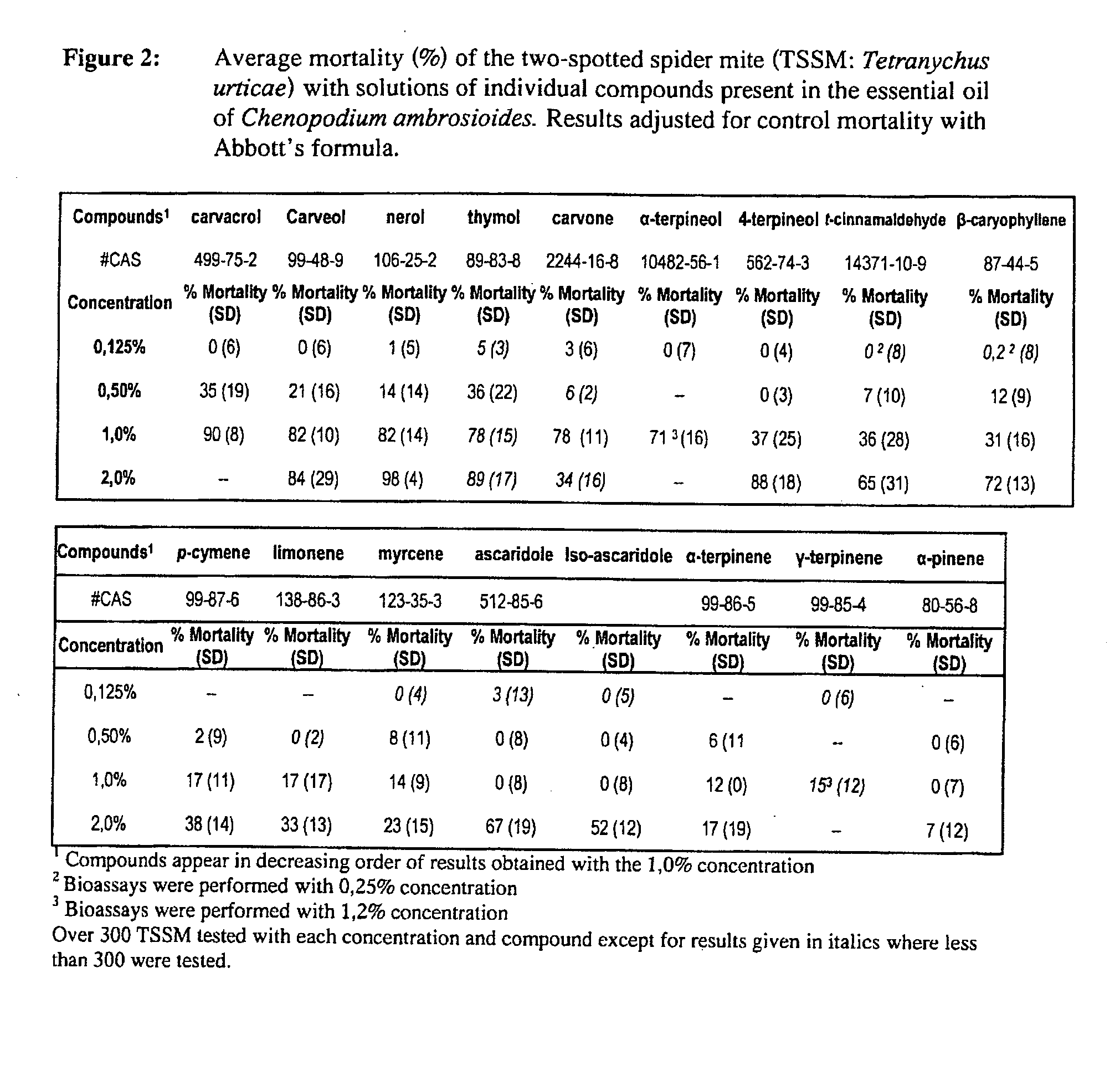

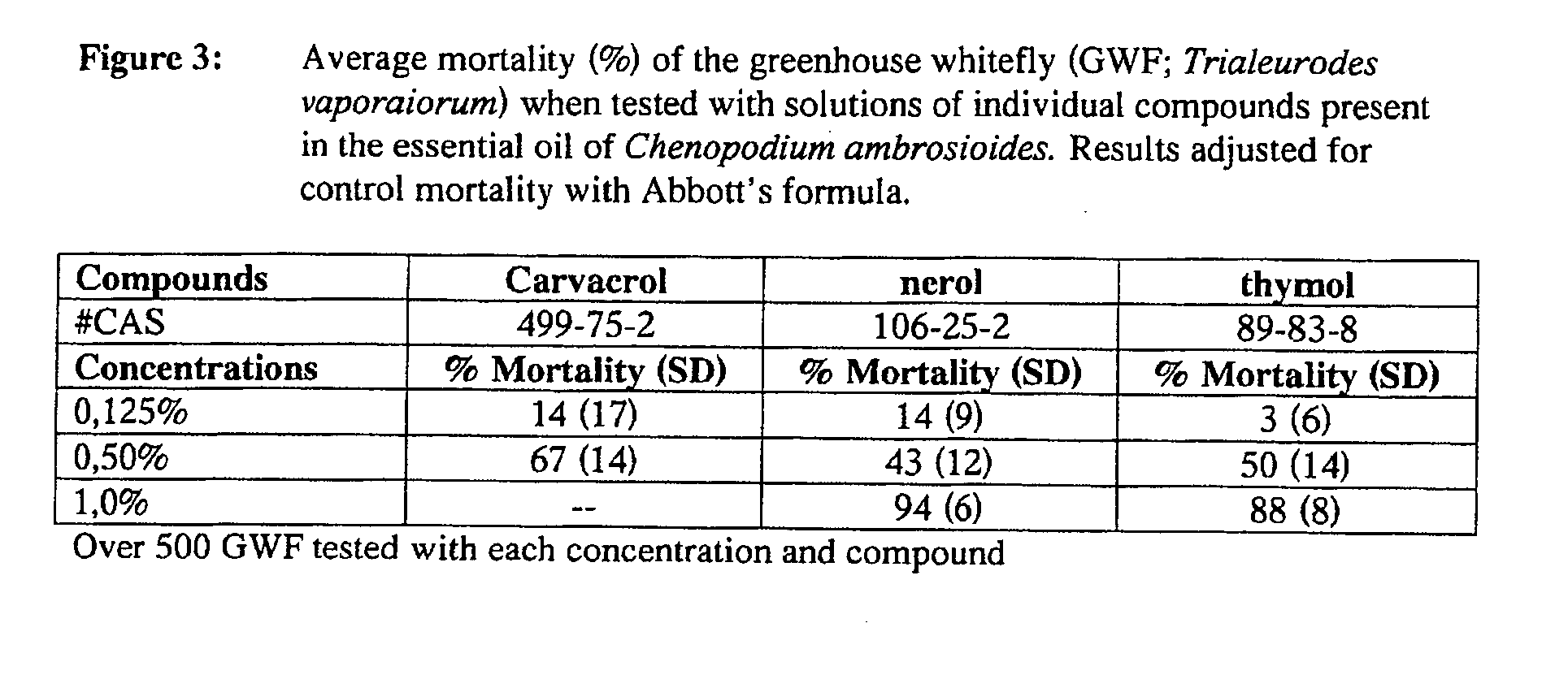

The present invention relates to pesticides. More particularly, the present invention relates to botanical pesticides. In particular, the present invention relates to compositions and methods for controlling plant-infesting pests with plant extracts and notably with compositions comprising oil extracts derived from Chenopodium sp. plant material. The invention further relates to compositions comprising such extracts as pesticidal compositions and providing the advantages of minimal development of resistance thereto, minimal toxicity to mammals, minimal residual activity and environmental compatibility. The pesticidal compositions of the present invention comprises α-terpinene, ρ-cymene, limonene, carvacrol, carveol, nerol, thymol, and carvone.

Owner:CHIASSON HELENE

Herbicide resistant rice

InactiveUS7019196B1Seed and root treatmentMicrobiological testing/measurementRice plantsResidual activity

Rice plants are disclosed with multiple sources of resistance to herbicides that normally inhibit a plant's acetohydroxyacid synthase (AHAS) enzyme. Besides controlling red rice, many AHAS-inhibiting herbicides also effectively control other weeds that are common in rice fields. Several of these herbicides have residual activity, so that one treatment can control both existing weeds and weeds that sprout later. With effective residual activity against red rice and other weeds, rice producers now have a weed control system superior to those that are currently available commercially.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Extracts derived from chenopodium plants and uses thereof

The present invention relates to pesticides. More particularly, the present invention relates to botanical pesticides. In particular, the present invention relates to compositions and methods for controlling plant-infesting pests with plant extracts and notably with compositions comprising oil extracts derived from Chenopodium sp. plant material. The invention further relates to compositions comprising such extracts as pesticidal compositions and providing the advantages of minimal development of resistance thereto, minimal toxicity to mammals, minimal residual activity and environmental compatibility. The pesticidal compositions of the present invention comprises α-terpinene, ρ-cymene, limonene, carvacrol, carveol, nerol, thymol, and carvone.

Owner:FORAGEN TECH MANAGEMENT

Blends of micro-encapsulated pesticide formulations

The present invention is directed to micro-encapsulated formulations of soil-active pest control and agricultural chemicals such as herbicides, insecticides, nematicides and fungicides (pesticides) that combine a strong initial activity and a longer residual activity in the soil than provided by current micro-encapsulated formulations. These formulations are prepared by combining two separate suspensions of microcapsules, containing one or more pesticides, which were separately prepared under differing conditions and therefore have significantly different chemical properties and field release rates. The present invention, in particular, is useful for the herbicide clomazone, alone or in combination with other herbicides.

Owner:BAHR JAMES T

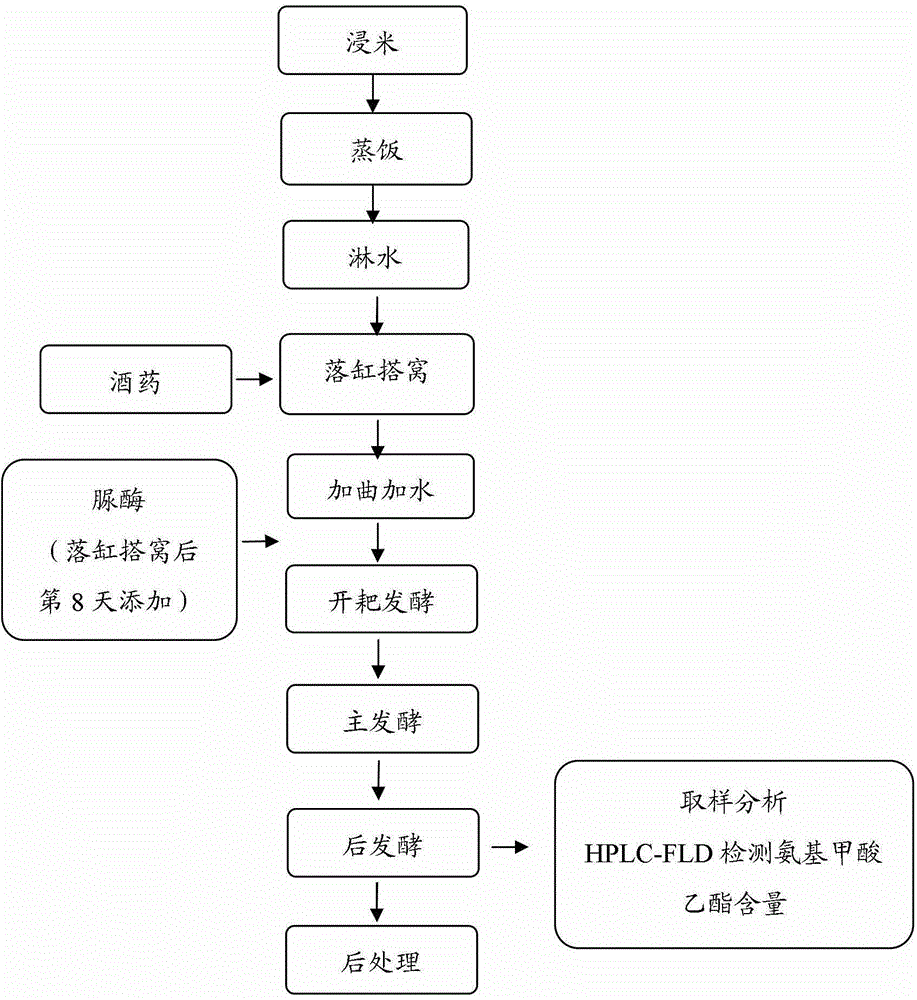

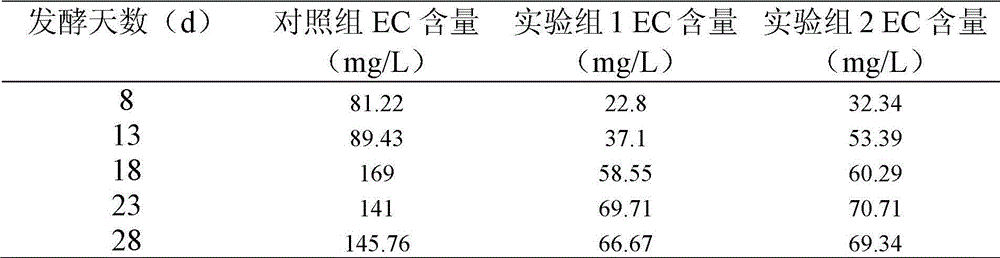

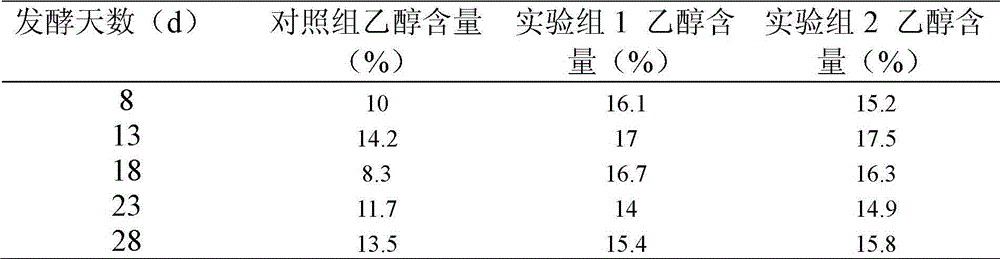

Brewing method for restraining generation of ethyl carbamate in conventional yellow rice wine

InactiveCN102978065ASuppress generationEasy to getAlcoholic beverage preparationDecompositionChemistry

The invention discloses a brewing method for restraining the generation of ethyl carbamate in conventional yellow rice wine. The brewing method comprises the steps of soaking rice, steaming the rice, spraying water, putting the obtained product into a jar and making a nest; adding wine yeast and water, fermenting and carrying out post treatment, wherein in the process of putting the obtained product into the jar and making the nest, Chinese yeast is added; and adding urase into fermented liquid after the obtained product is put into the jar and the nest is made for 5-10 days. According to the method disclosed by the invention, the urase is added into the conventional yellow rice wine fermentation stage, so that the enzymatic reaction and the fermentation process are cooperatively performed, and no additional enzymolysis technology is required, therefore, the operation is easy, and yellow rice wine is suitable for large-scale production; the urase has high efficiency in urea degradation, is persistent in activity, can effectively inhibit the generation of ethyl carbamate in the process of brewing, and can effectively reduce the accumulation of ethyl carbamate in the storage of the yellow rice wine; the urase is easy to obtain and easy to use and the dosage of the urase can be easily controlled; ammonia and carbon dioxide are generated through the decomposition of the urase, so that the urase is safe and non-toxic; and the residual activity is lost in the process of wine boiling, so that the flavor of the yellow rice wine is not affected.

Owner:ZHEJIANG UNIV

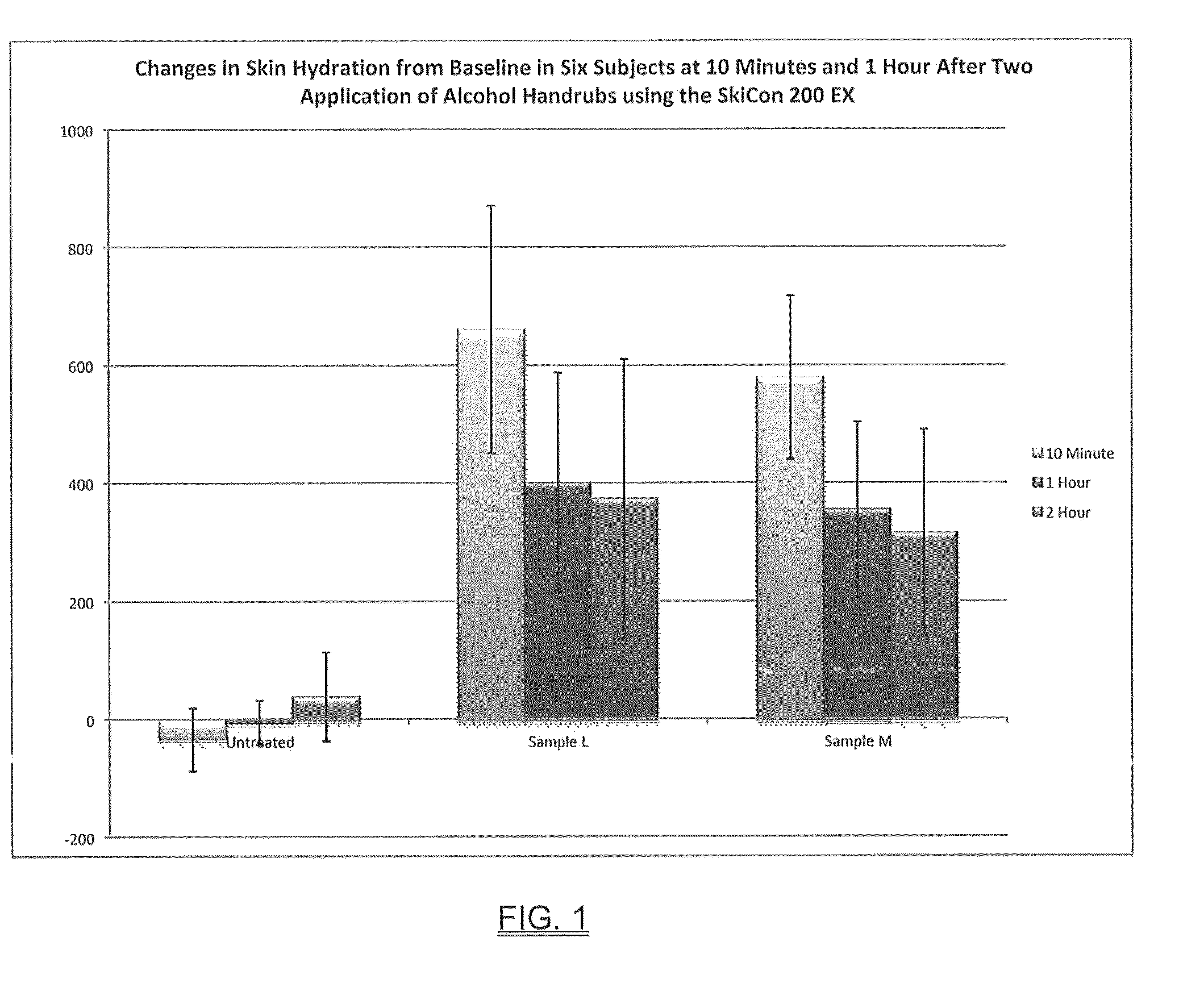

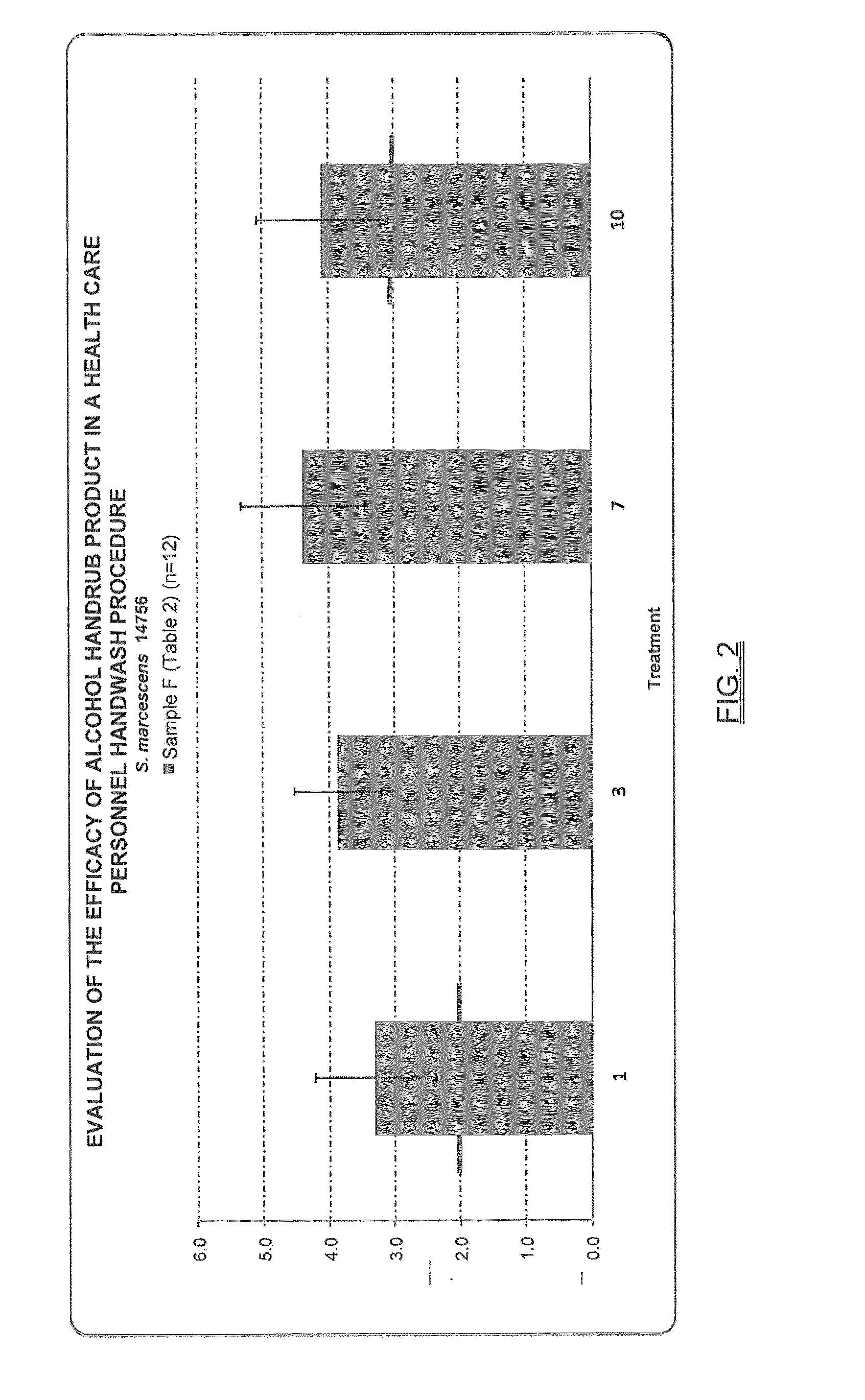

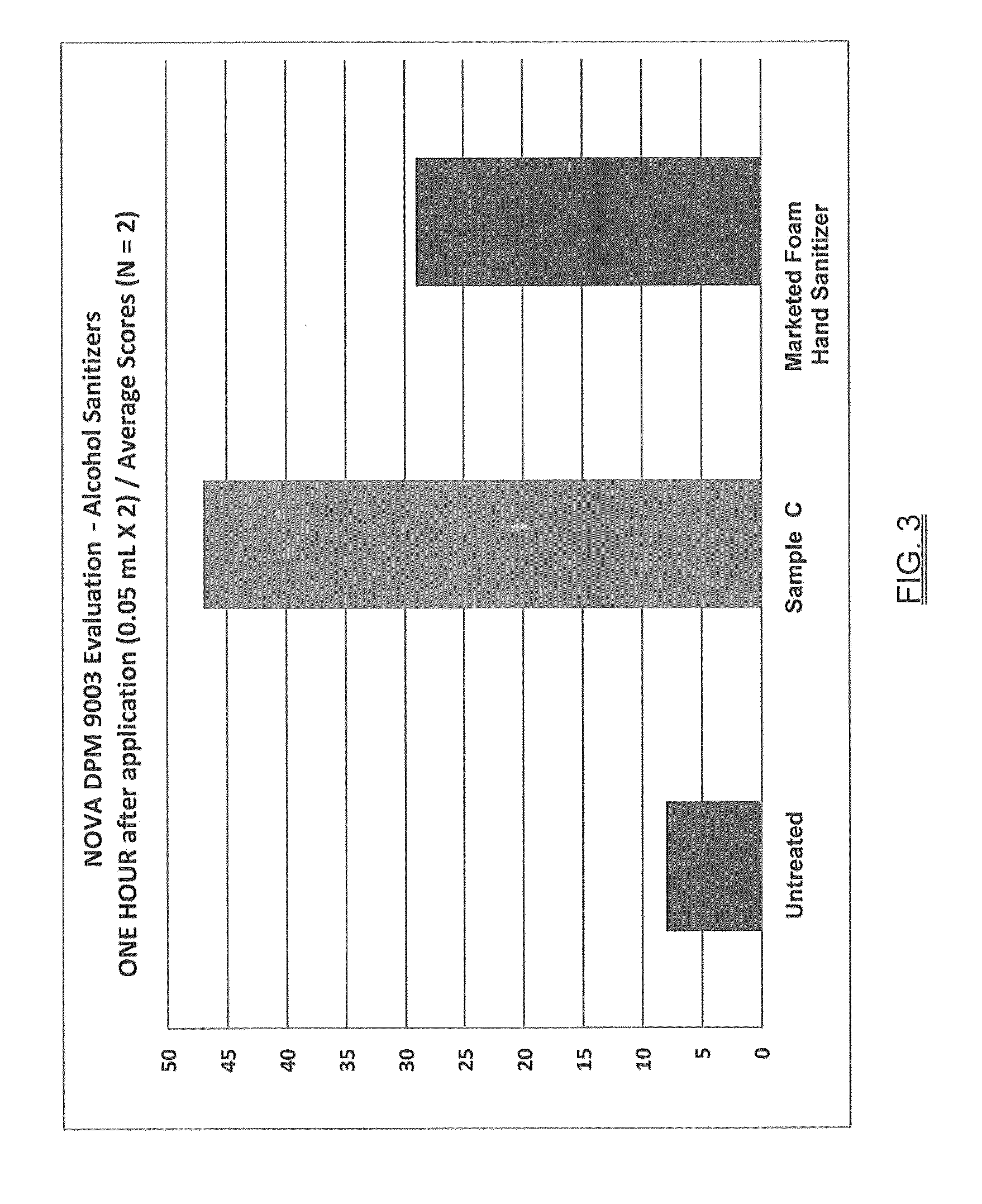

Non-aerosol foaming alcohol hand sanitizer

ActiveUS20130090380A1Aesthetically pleasingAntibacterial agentsBiocideHand sanitizerResidual activity

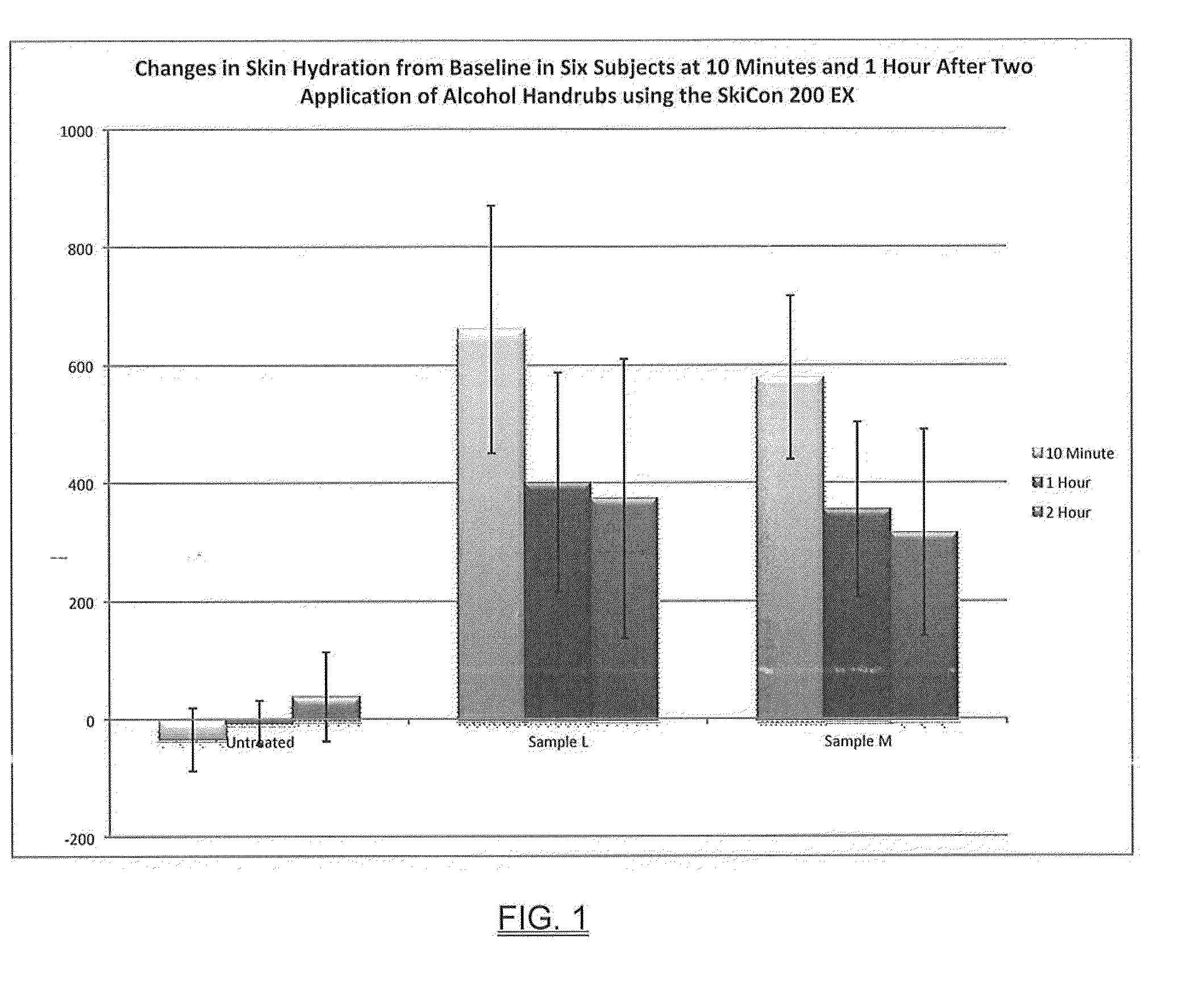

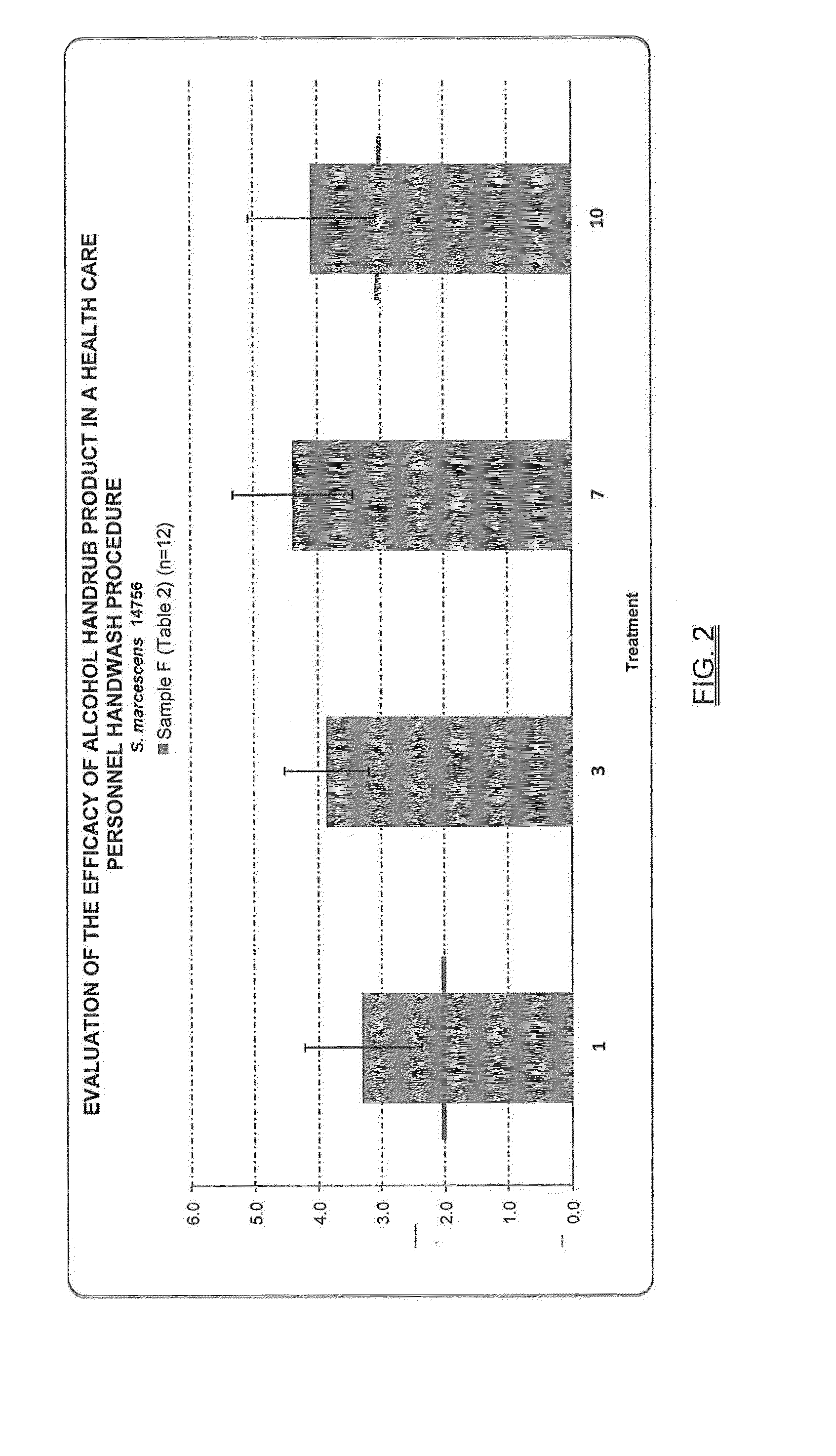

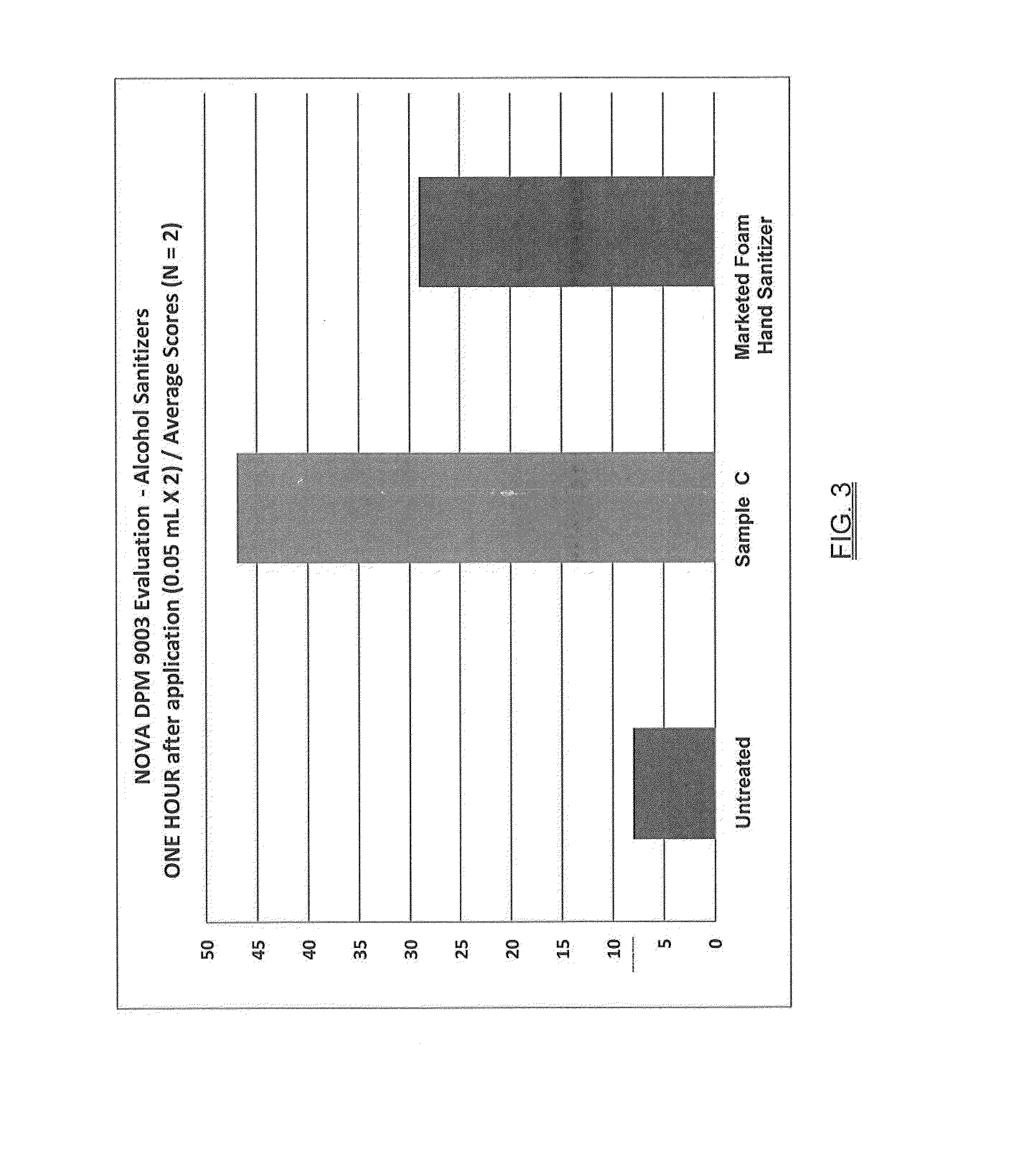

A non-aerosol, foaming high alcohol content hand sanitizer is provided which has excellent antimicrobial activity and tolerance for organic load and excellent residual activity, as well as enhanced moisturization and skin-feel properties over currently marketed alcohol-based sanitizers. The inventive composition achieves an unexpectedly large amount of quality, stable foam even in the presence of significant quantities of skin conditioning agents through the use of novel silicone surfactants and achieves enhanced and prolonged antimicrobial efficacy through the combination of high alcohol content and activity enhancing components.

Owner:SC JOHNSON & SON INC

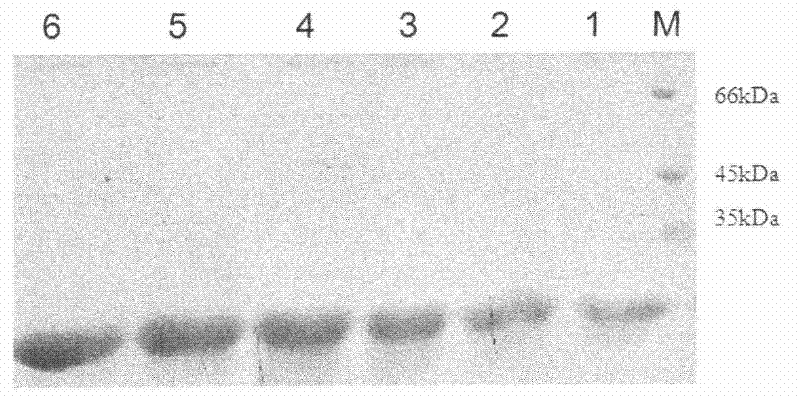

Thermostable chitosanase-producing engineered yeast strain and production method of thermostable chitosanase

ActiveCN102051369AImprove heat resistanceFungiMicroorganism based processesPichia pastorisBiotechnology

The invention provides a recombinant thermostable chitosanase-producing engineered Pichia pastoris GS115 / HBCSN and a production method of thermostable chitosanase. The invention optimizes Aspergillus fumigatus chitosanase gene (GenBank accession number AY190324) based on the codon bias of Pichia pastoris, and the optimized nucleic acid sequence shows a 70% homology to the original nucleic acid sequence. The chitosanase produced by the recombinant Pichia pastoris can be secreted out of cells in a soluble form, with expression level of 3 mg / mL, and enzyme activity of 25,000U / mL. The chitosanase after glycosylation modification in Pichia pastoris has excellent thermal stability, which is proven by that the residual activities after treating at 80DEG C for 20 min, treating at 90DEG C for 40 min and treating at 100DEG C for 20 min are 56%, 87% and 87% respectively. The inventive thermostable chitosanase is especially suitable for large-scale industrial degradation of chitosan and environmental pollution reduction.

Owner:HUBEI UNIV

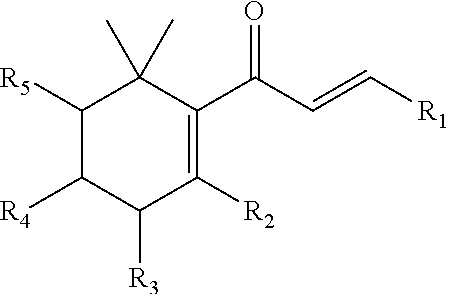

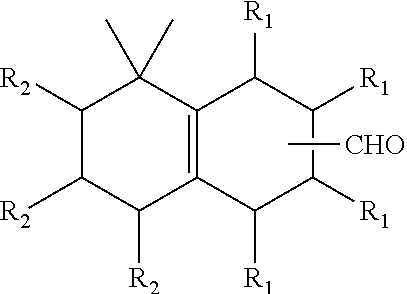

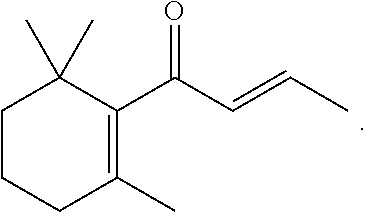

Materials and Methods for Pest Control

InactiveUS20120232160A1Reduce dosageStrong pesticidal activityBiocideKetone active ingredientsMammalian toxicityPest control

The present invention provides a novel insecticide formulation that not only demonstrates strong insecticidal and residual activity against a variety of insects, but also exhibits low mammalian toxicity.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

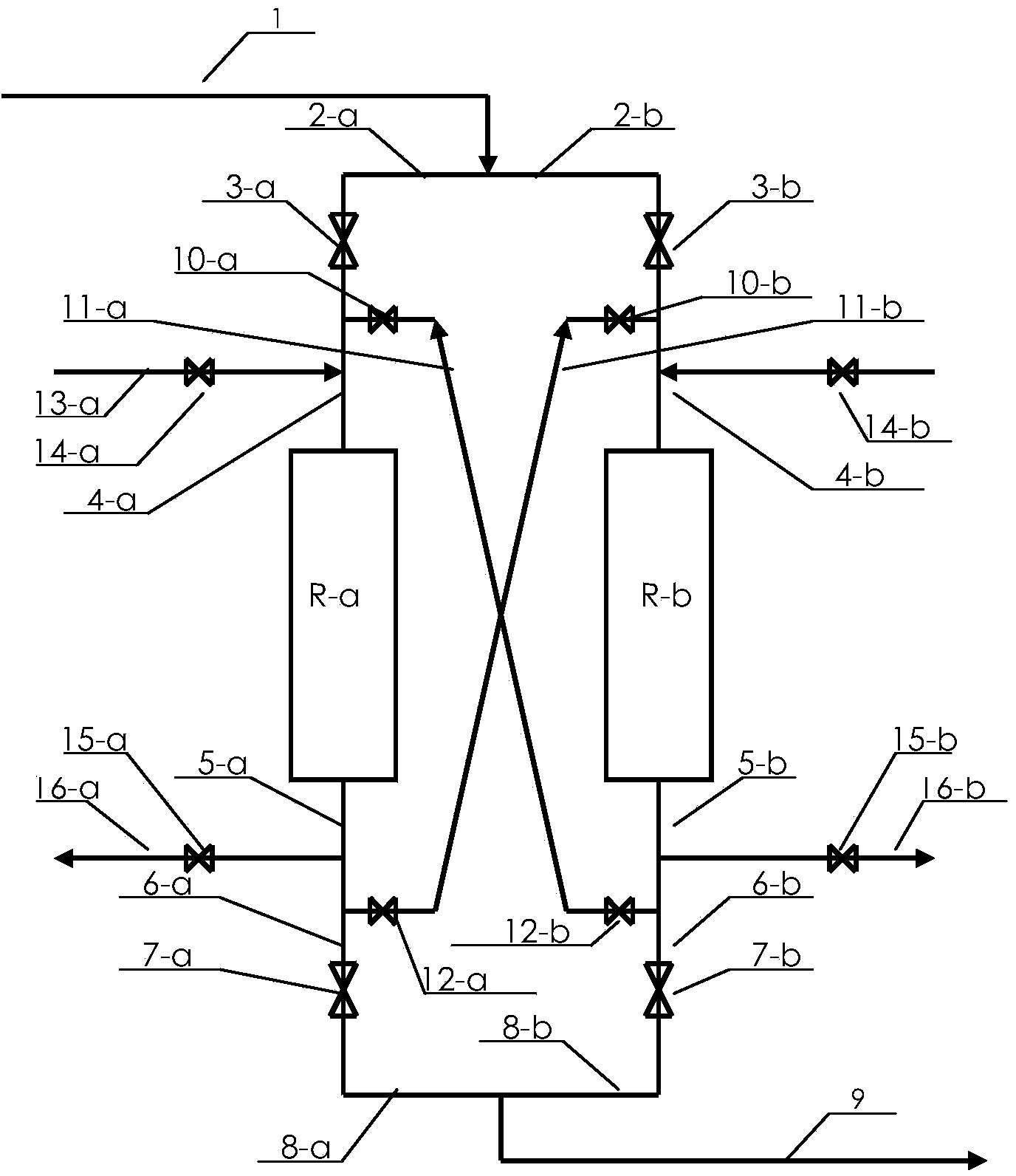

Continuous reaction and regeneration technology used for conversion of methanol to gasoline through stationary bed adiabatic reactors

ActiveCN104140839AImprove effective utilizationIncreased operating lifeLiquid hydrocarbon mixture productionBio-feedstockGasolineResidual activity

Provided is a continuous reaction and regeneration technology used for conversion of methanol to gasoline through stationary bed adiabatic reactors. The two stationary bed adiabatic reactors work independently, the first reactor carries out a reaction for conversion of methanol to gasoline independently, and the second reactor is in a standby state; when catalysts in the first reactor approach to inactivation, the two reactors can work in a series connection mode through valve switchover until residual activity of the catalysts in the first reactor is fully utilized; the two reactors are made to work in a respective independent mode through valve switchover, the second reactor completes the reaction for conversion of methanol to gasoline independently, and the first reactor finishes catalyst regeneration operation independently and gets into the standby state. The technology is repeated in that way. The technology has the advantages that operation is simple, and the utilization rate of reactivity of the catalysts in the reaction process is high.

Owner:SHANXI FEISHI TECH +2

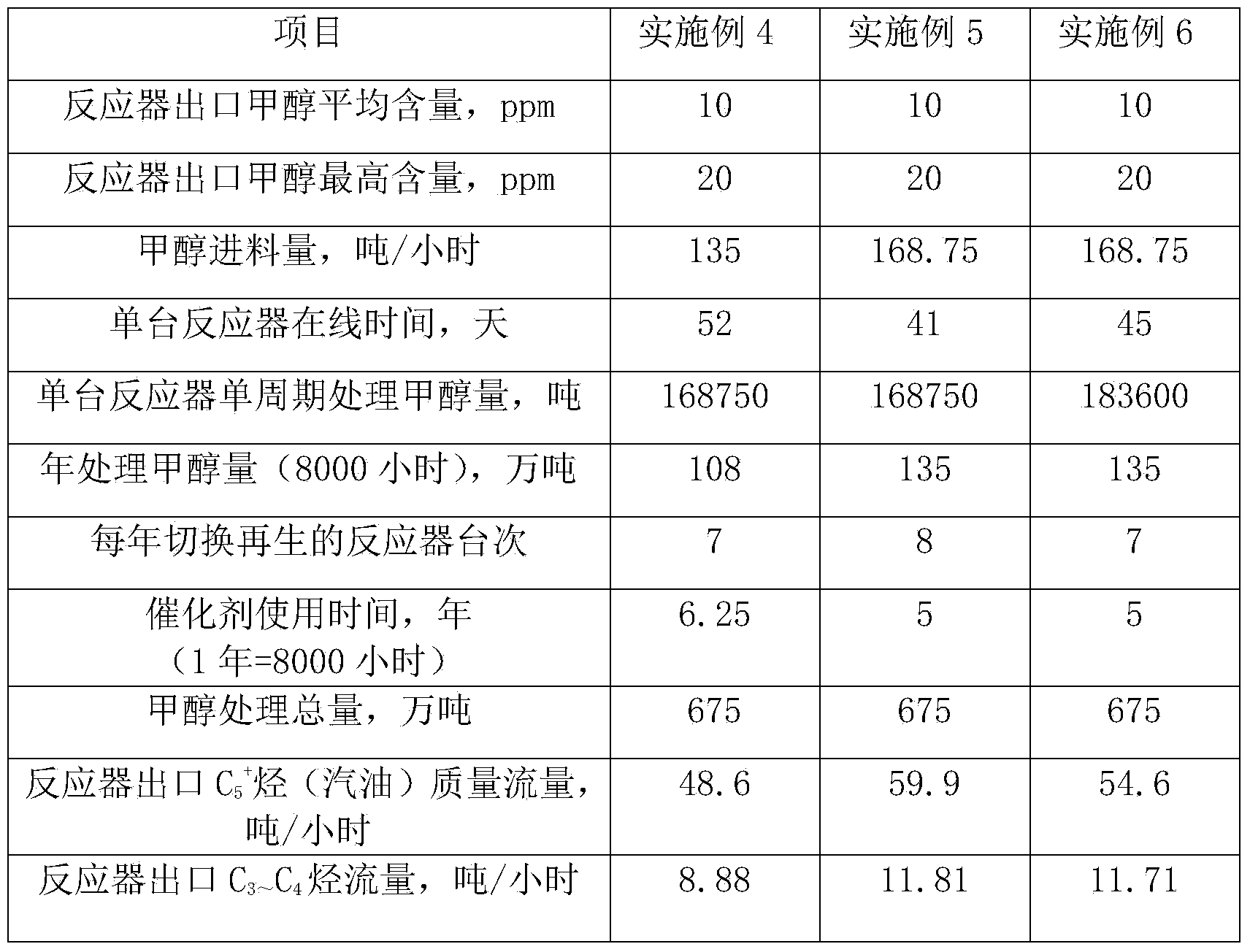

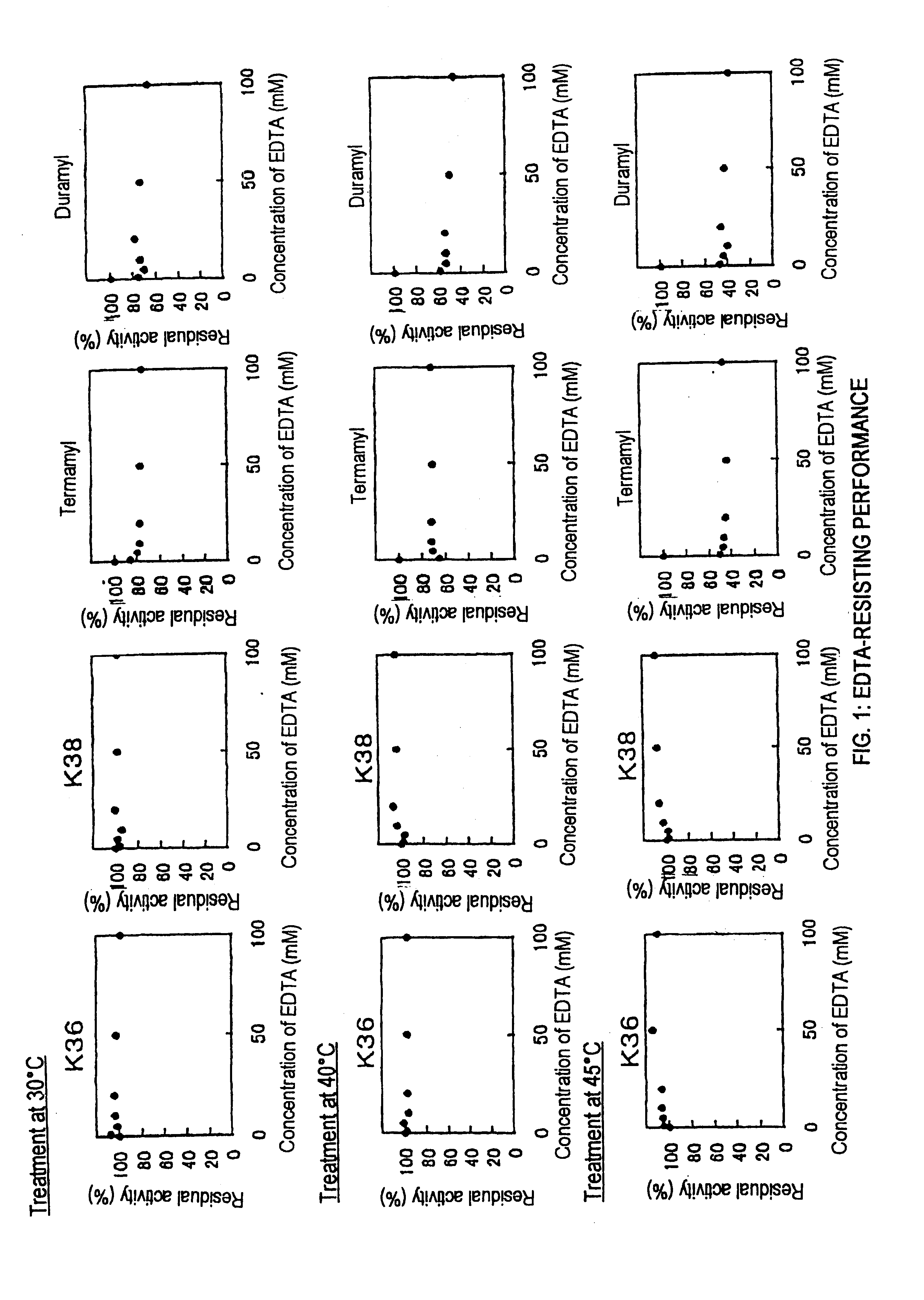

Amylases

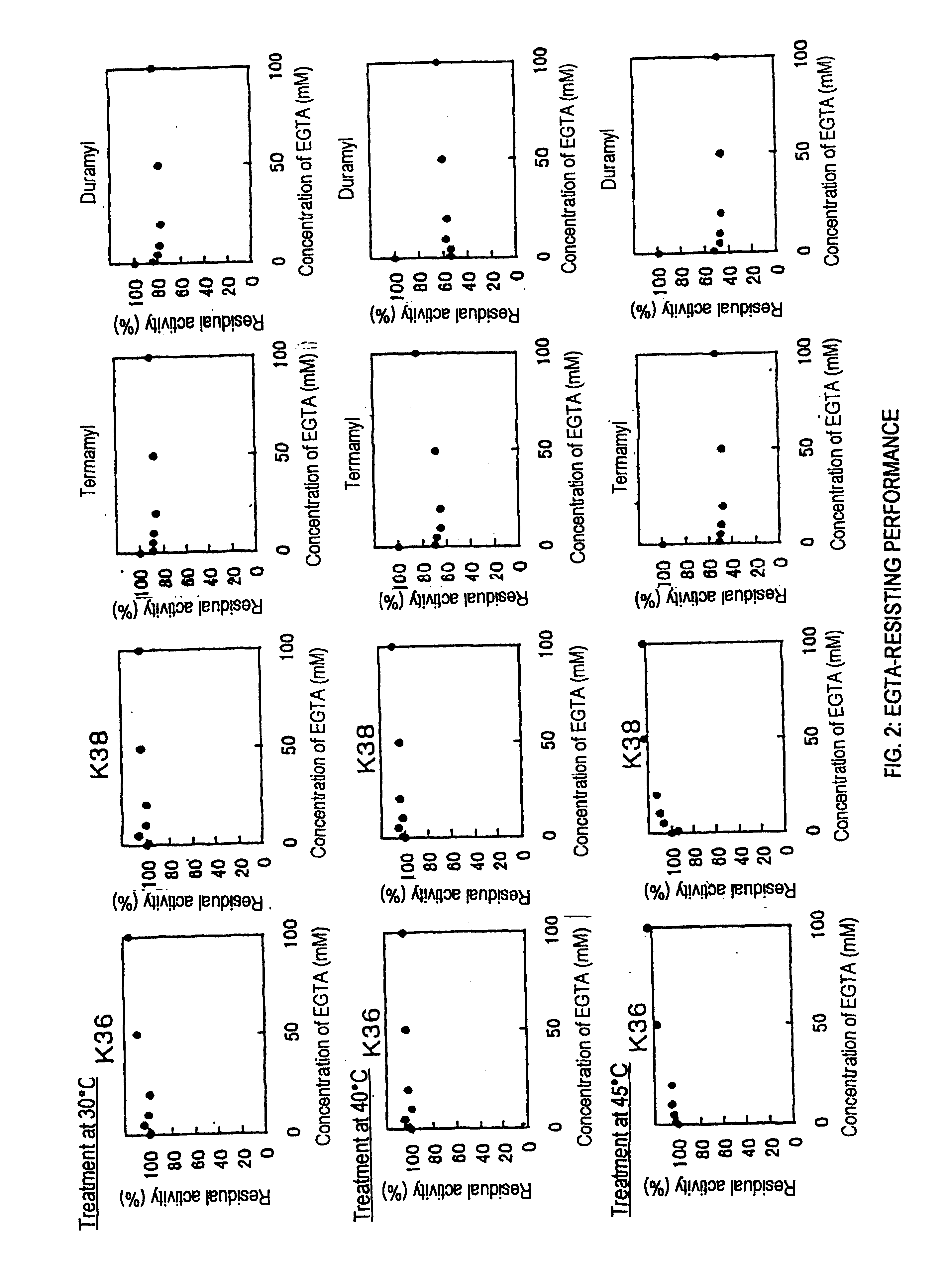

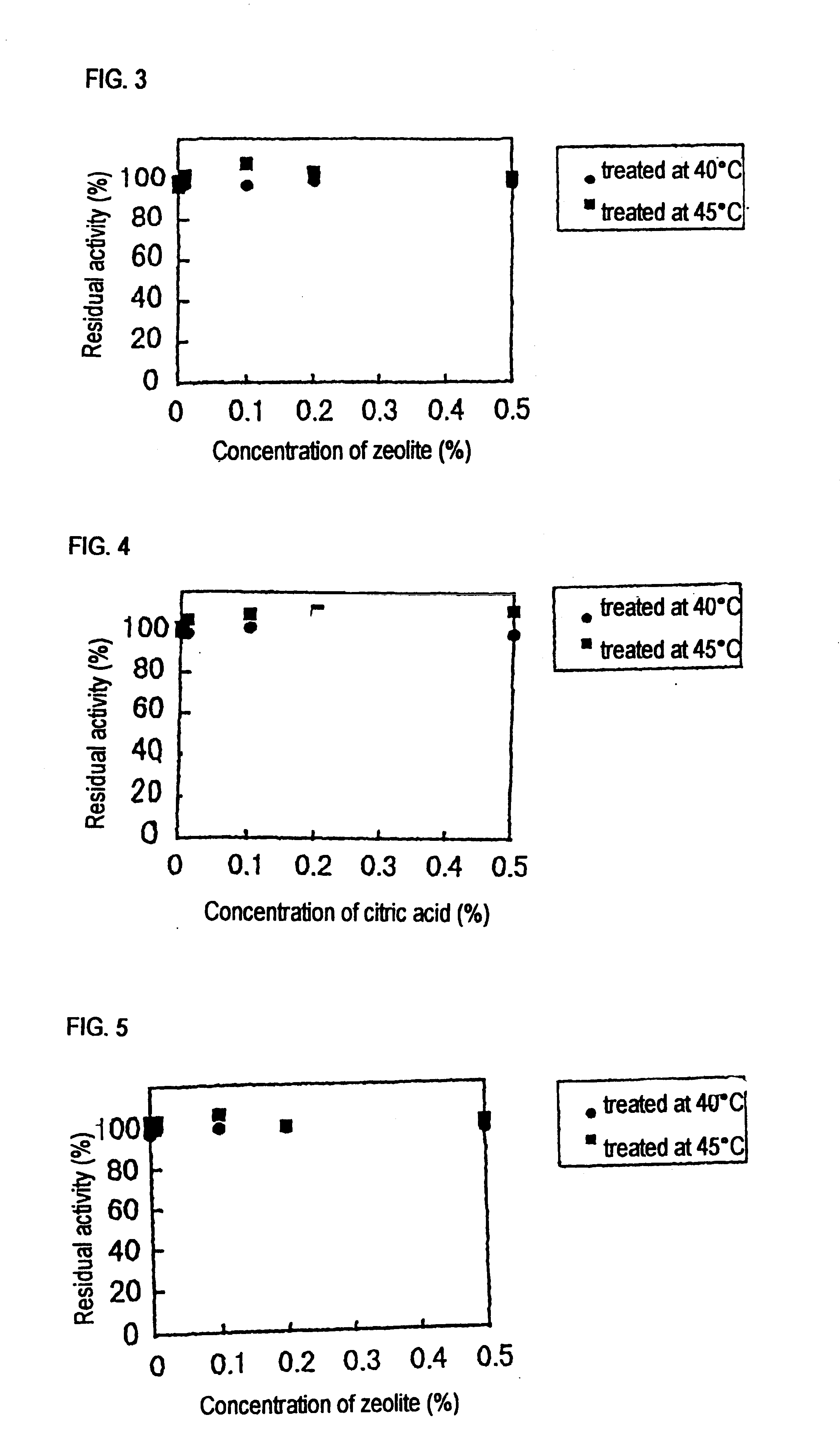

Liquefying alkaline amylases, each having residual activity not less than 70% when treated at pH 10 and 45° C. for 30 minutes in the presence of 1 to 100 mM of EDTA or EGTA, are described. Also described are detergents comprising these amylases. In comparison with conventional amylases for detergents, the liquefying alkaline amylases of this invention have a high chelating-agent resisting performance.

Owner:KAO CORP

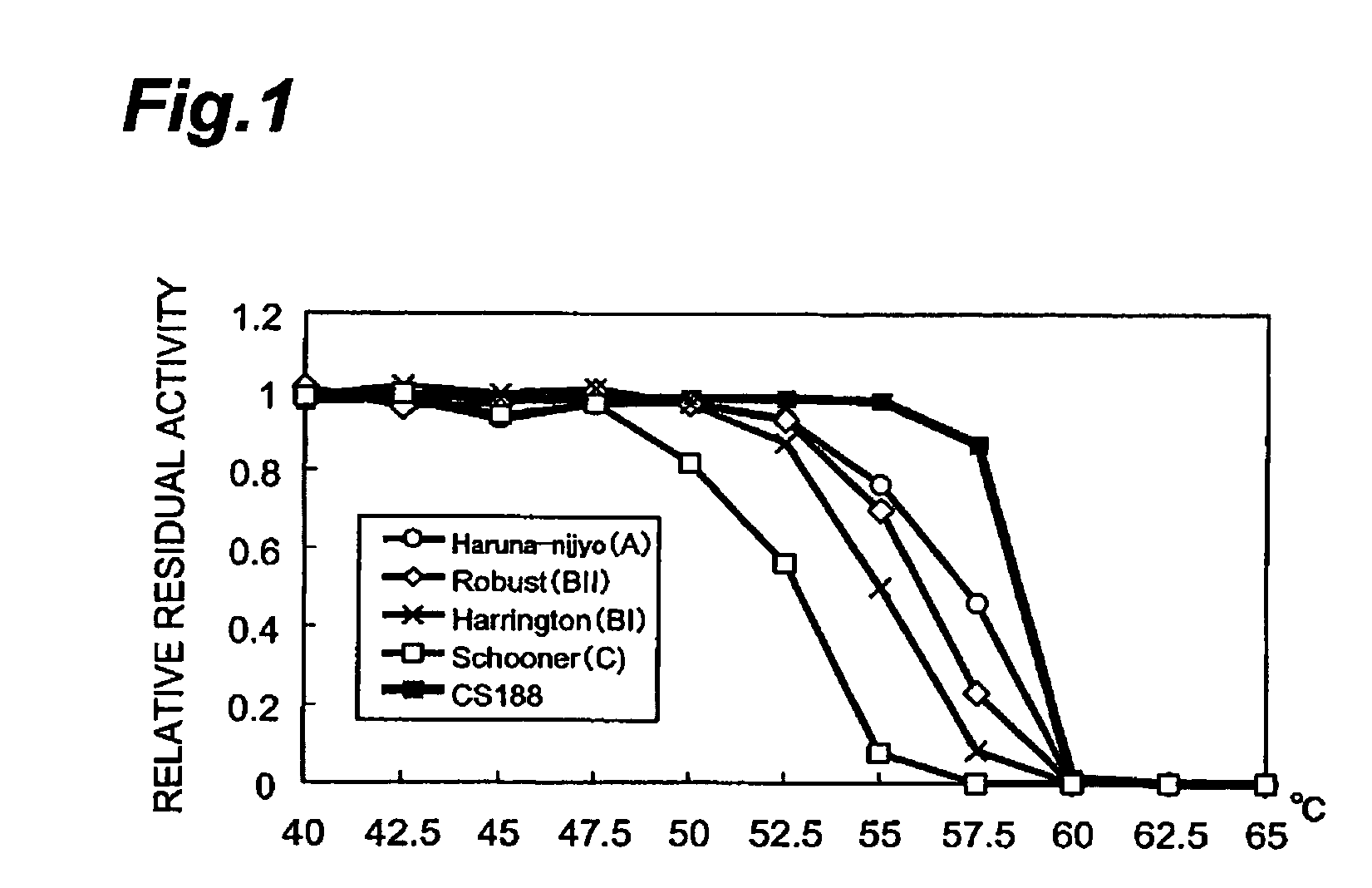

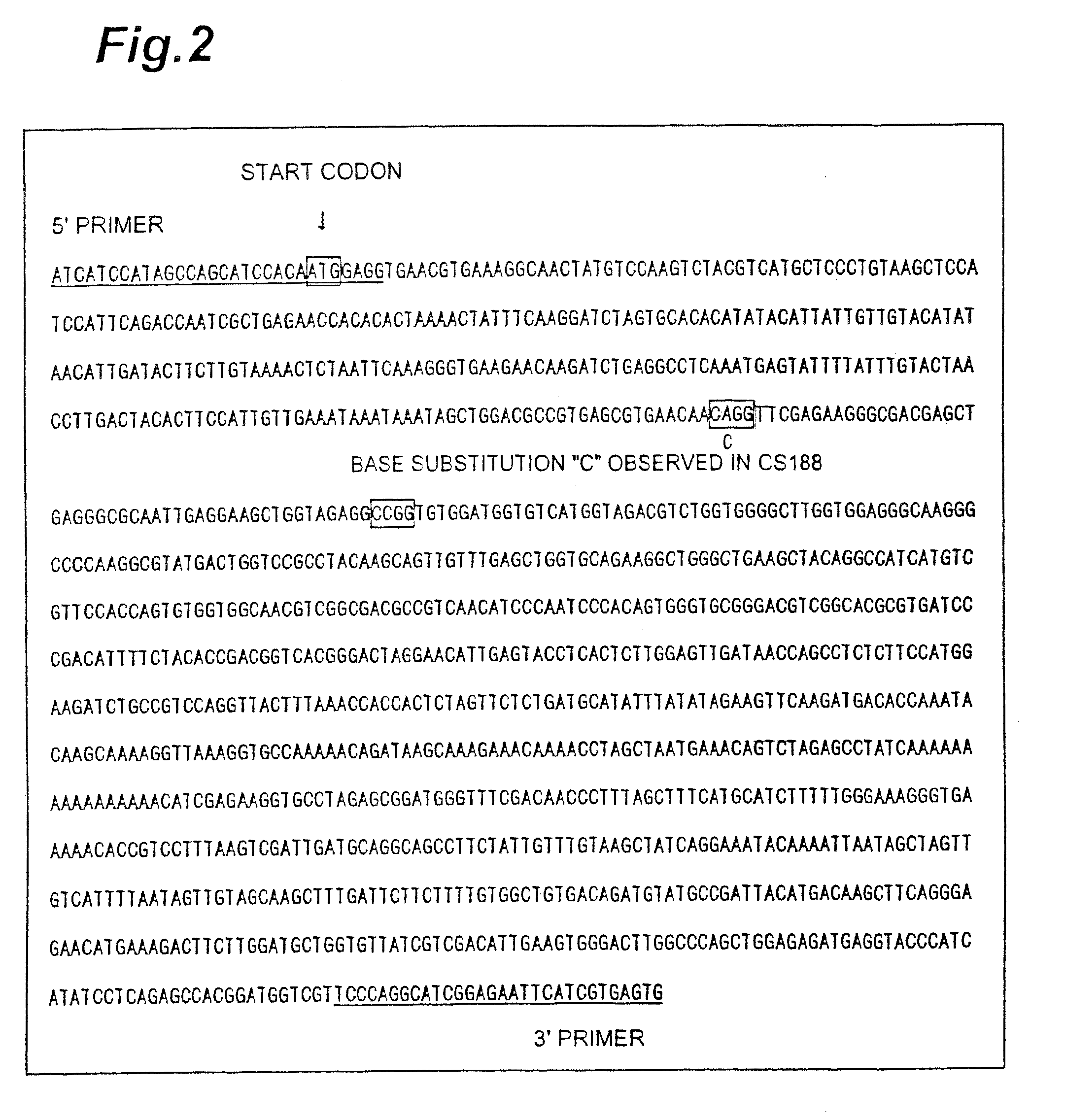

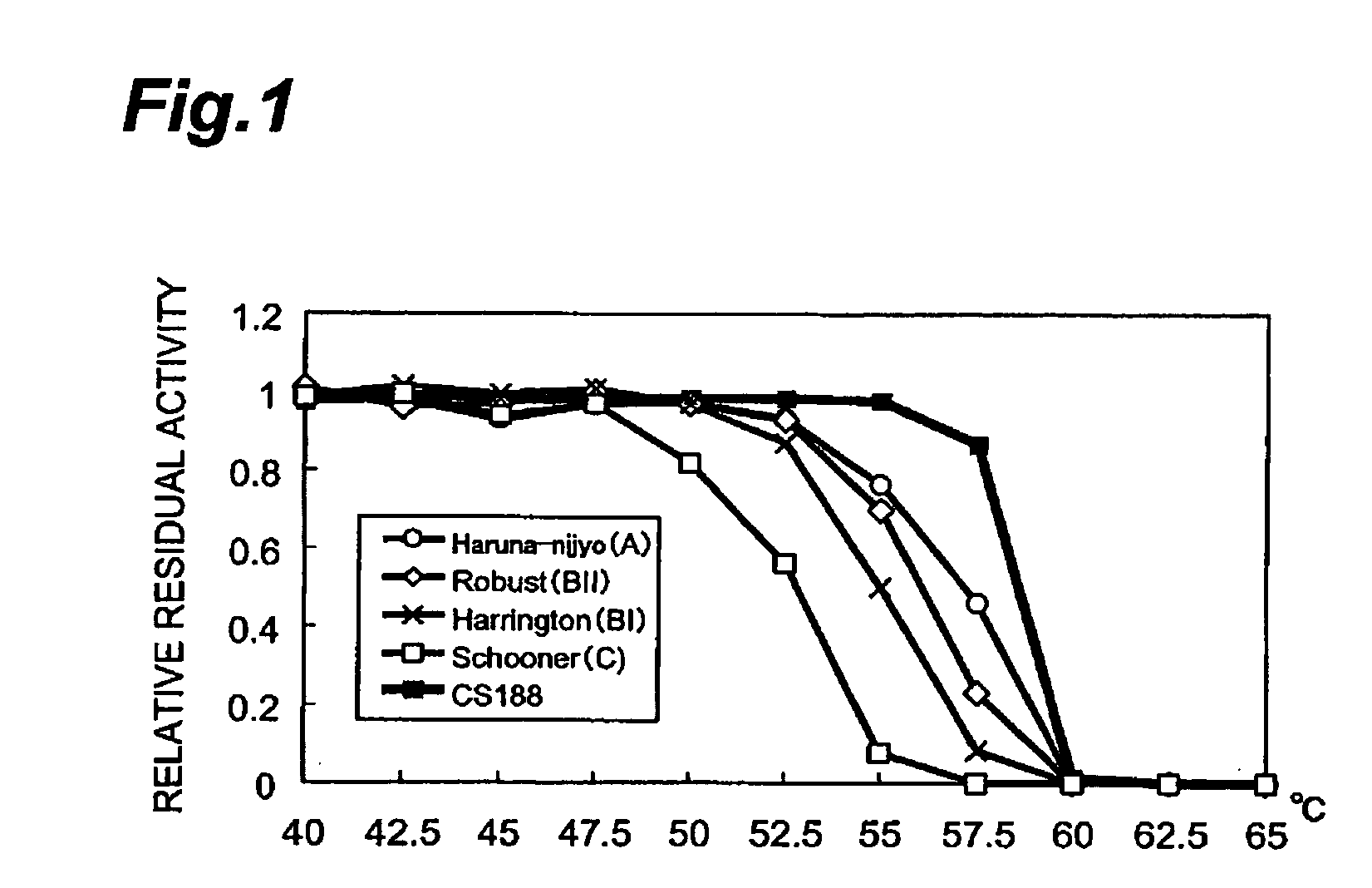

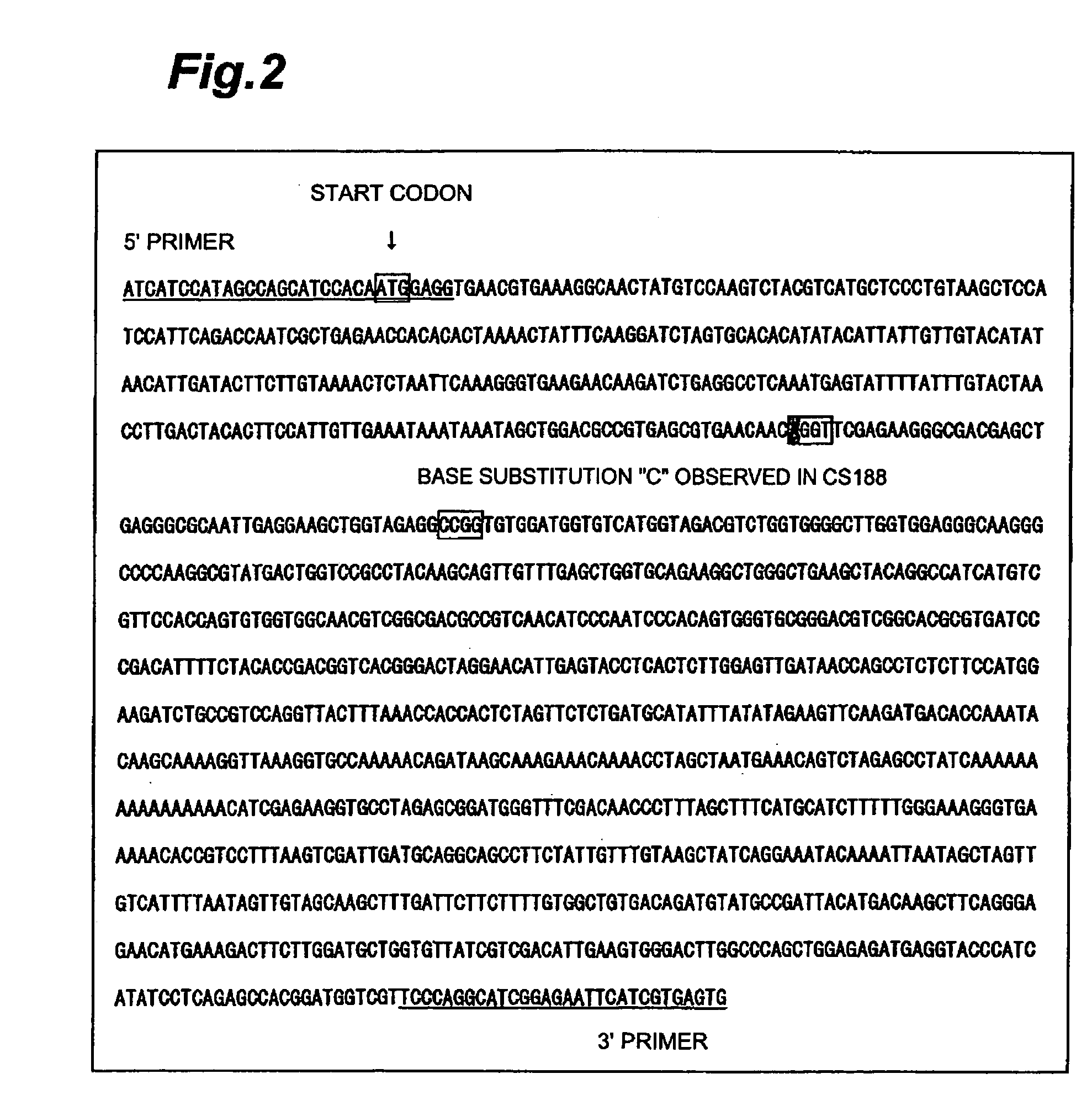

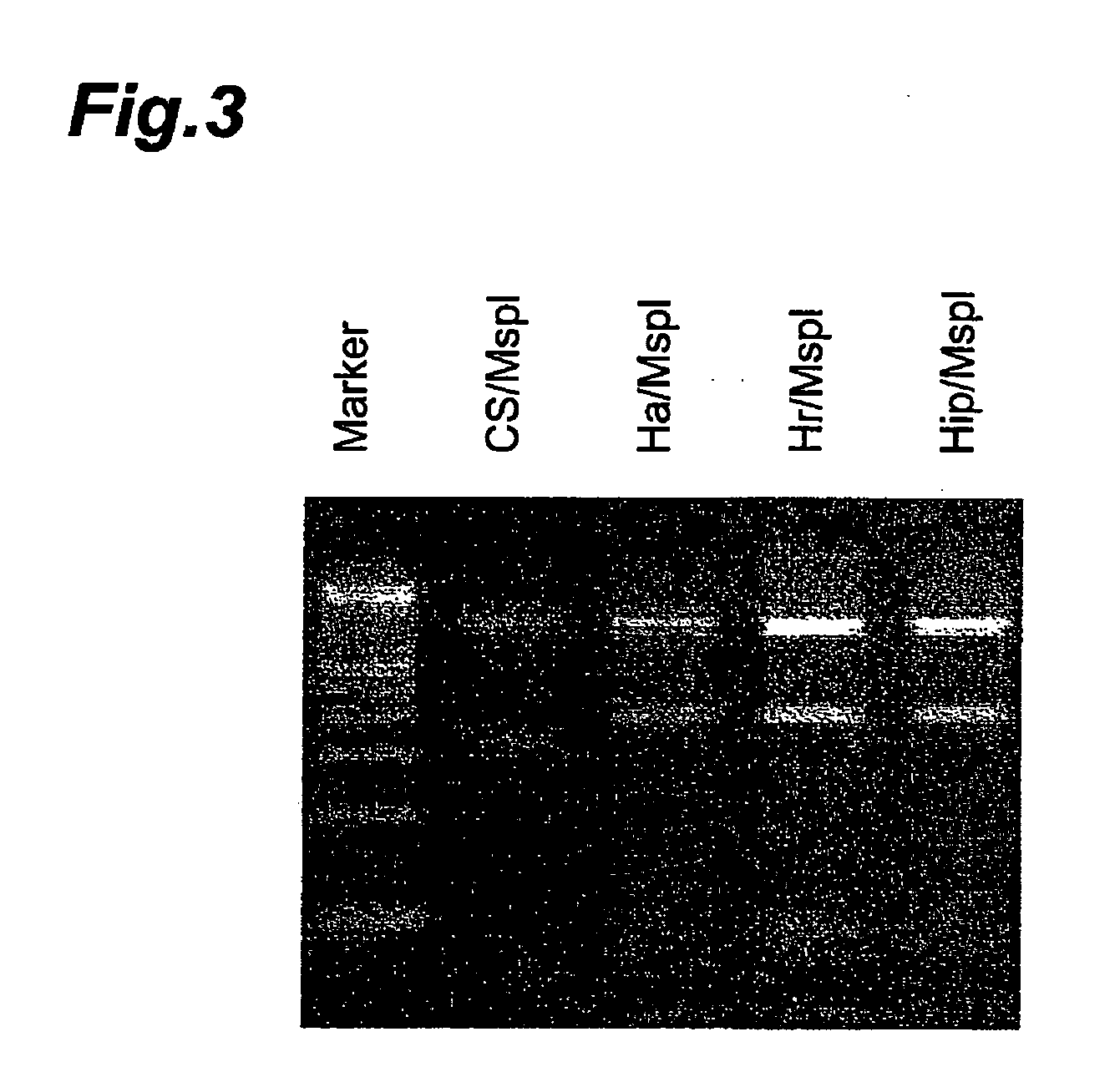

Method of selecting barley variety, barley beta-amylase gene and process for producing malt alcoholic drink

InactiveUS7465557B2Improve saccharification efficiencyImprove heat resistanceSugar derivativesMicrobiological testing/measurementAmylaseHordeum vulgare

A method of selecting a barley variety comprising: a heat treatment step of heat-treating a crude enzyme solution extracted from a seed of a barley (e.g., at 57.5° C. for 30 minutes); an activity-determining step of determining the enzyme activity of β-amylase in the crude enzyme solution heat-treated; and a selection step of selecting the barley variety containing a β-amylase having a residual activity of from 85 to 90% as a result of the activity determination.

Owner:SAPPORO BREWERIES

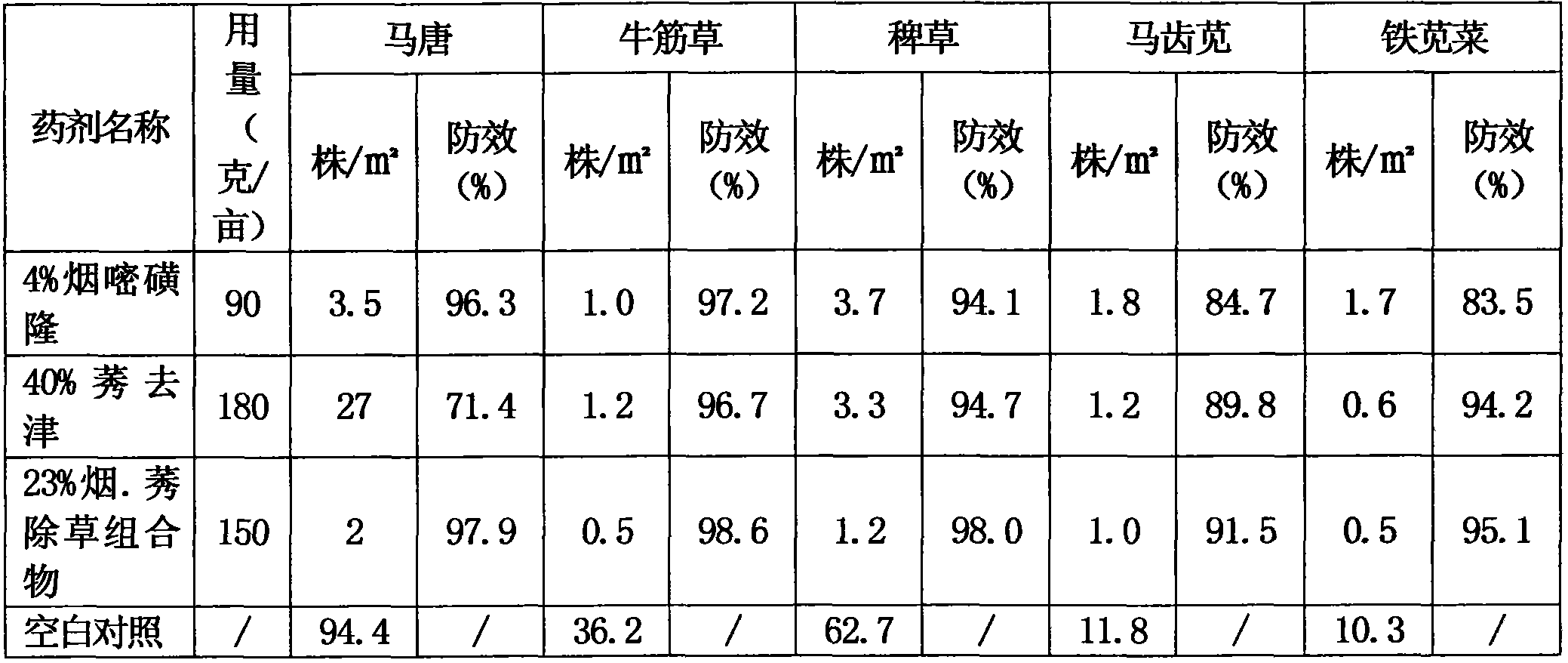

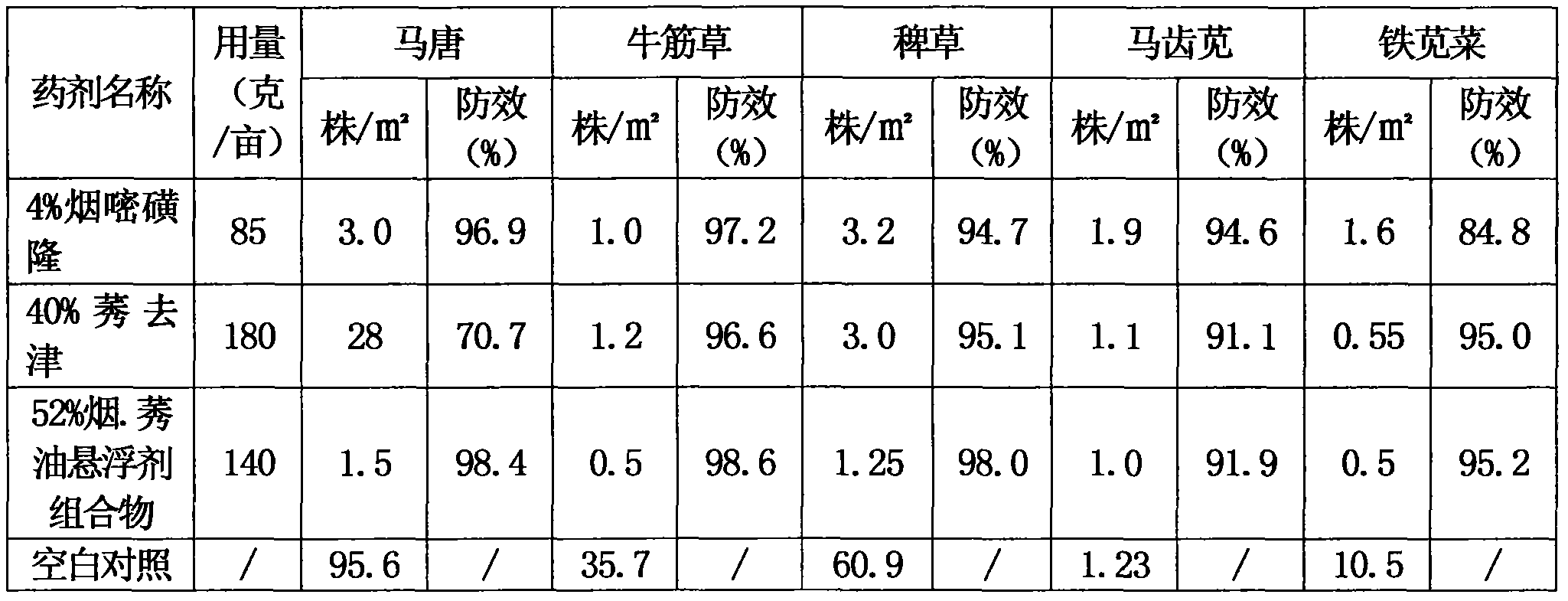

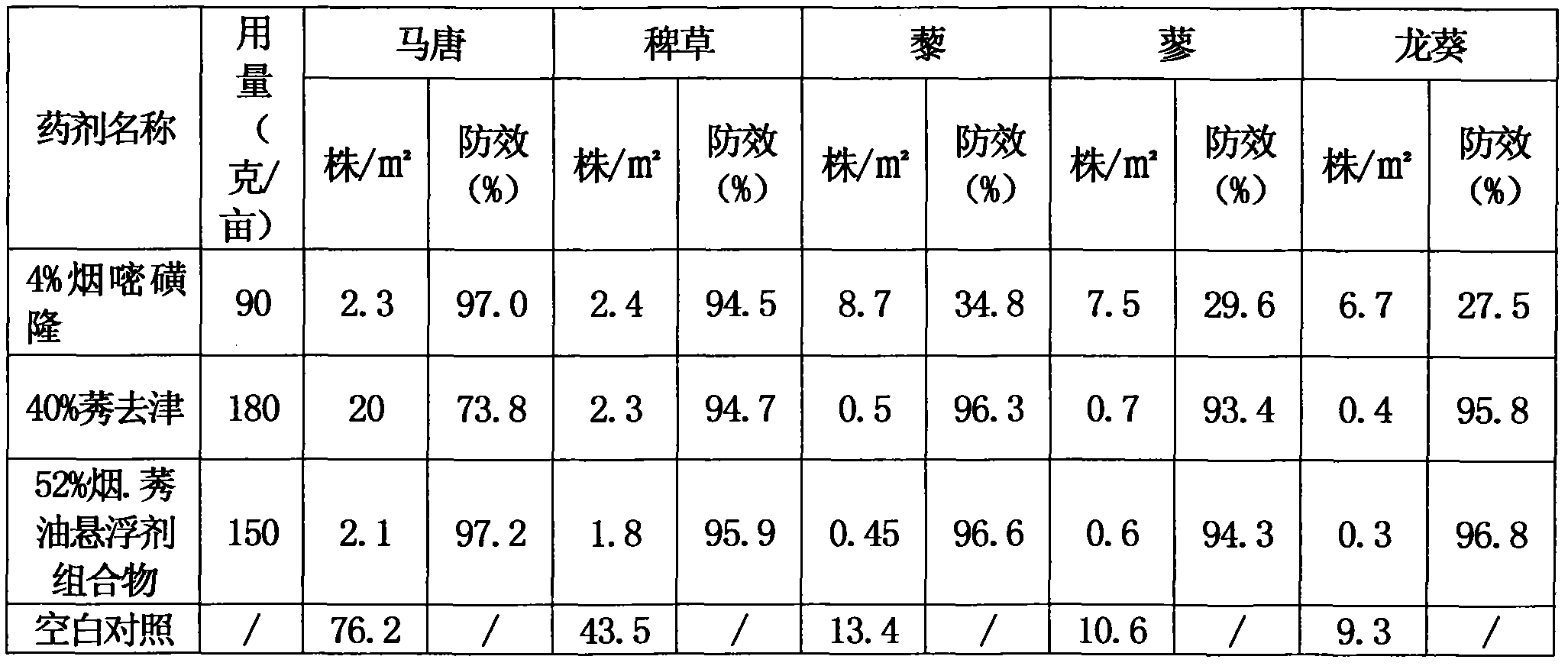

Nicosulfuron-and-atrazine-containing weeding composition

InactiveCN101999386AImprove stabilityImprove wettabilityBiocideAnimal repellantsAtrazineResidual activity

The invention relates to a nicosulfuron-and-atrazine-containing weeding composition. The composition is an oil suspending agent, which contains the following components in percentage by weight: 3 percent of nicosulfuron, 20 percent of atrazine, 10 percent of emulsifier, 20 percent of surfactant and 47 percent of oil. The weeding composition effectively combines the advantages of the nicosulfuron and the atrazine, improves the weeding effect, reduces the residual activity, reduces the herbicide damage to crops, delays the herbicide resistance of weeds and community succession, reduces the using amount of herbicides, reduces environmental pollution, is time-saving, labor-saving and money-saving and alleviates the burden on farmers.

Owner:孙雪梅

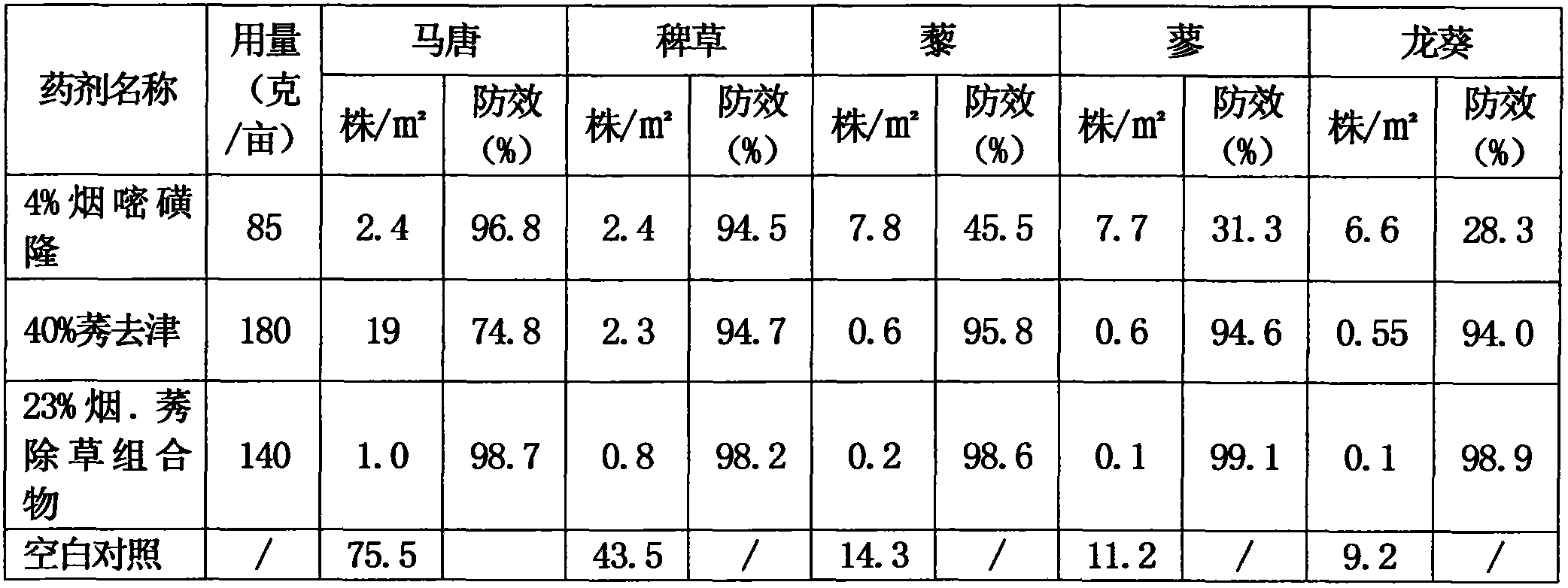

Method for detection of trace impurities in polished subsurface damage layer of optical glass

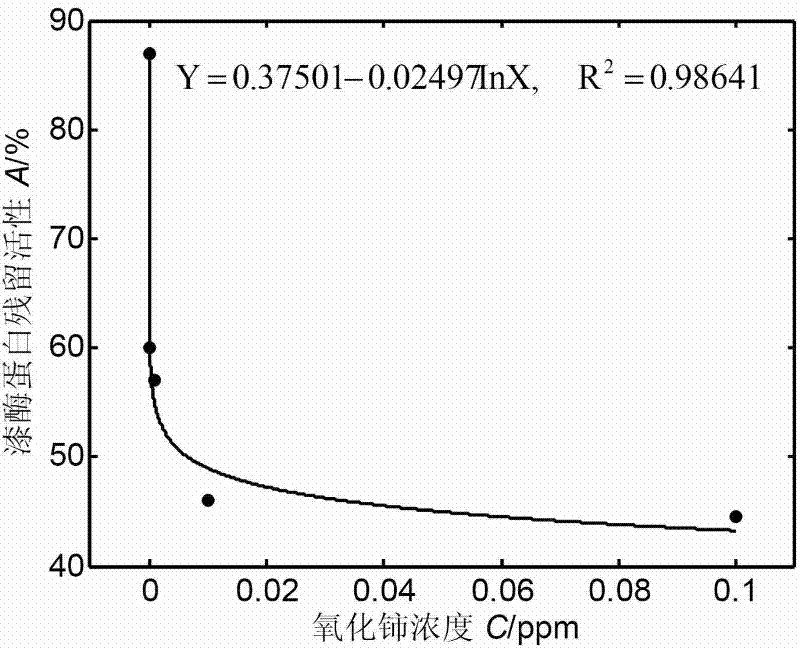

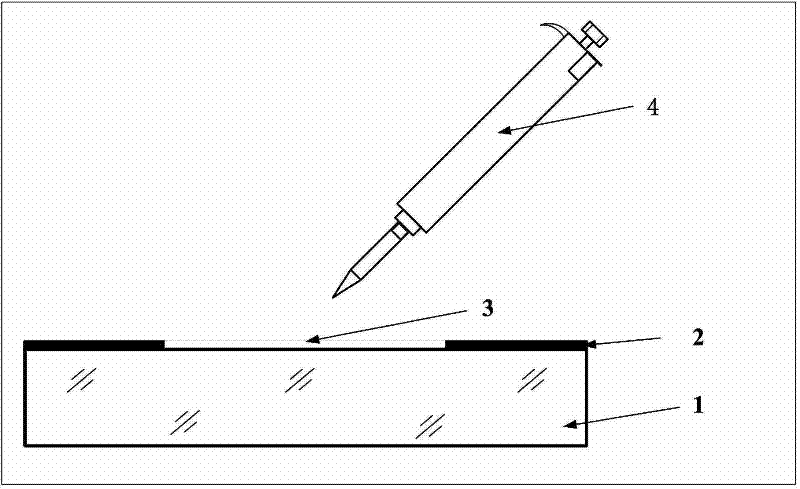

InactiveCN102288561AEnhanced inhibitory effectLayer-by-layer ablationColor/spectral properties measurementsPhysical chemistryResidual activity

The invention discloses a method for detecting a trace impurity in a damaged layer of a polished sub-surface of optical glass. The method comprises the following steps of: preparing a water solution which comprises rare-earth metal, and adjusting a pH value; mixing the water solution and a laccase solution, putting a mixed solution sample into a constant-temperature water bath, and thus obtainingthe percentage of enzyme protein residual activity of each sample by determining an enzyme protein activity value and a standard enzyme activity after reaction; according to the percentage and the concentration, corresponding to the percentage, of the rare-earth metal in each solution sample, fitting a relation curve; introducing etching liquid into a total surface of a glass sample to be detected or an unmasked local area to be detected by using a liquid-moving machine, detecting etching depth and collecting etching remained liquid after etching reaction; and adjusting the pH value of the etching remained liquid, mixing the etching remained liquid and the laccase solution, detecting the percentage of the enzyme protein residual activity in the etching remained liquid, and calculating theconcentration of the trace impurity according to the relation curve. The method has the advantages of accurate and reliable detection result and flexible and quick detection process.

Owner:NAT UNIV OF DEFENSE TECH

Herbicid resistant rice

Rice plants are disclosed with multiple sources of resistance to herbicides that normally inhibit a plant's acetohydroxyacid synthase (AHAS) enzyme. Besides controlling red rice, many AHAS-inhibiting herbicides also effectively control other weeds that are common in rice fields. Several of these herbicides have residual activity, so that one treatment can control both existing weeds and weeds that sprout later. With effective residual activity against red rice and other weeds, rice producers now have a weed control system superior to those that are currently available commercially.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Method for extracting rice bran oil through three-phase separation aqueous enzymatic method

InactiveCN108342247AKeep active ingredientsReduce residual activityFatty-oils/fats productionOil and greaseRice Bran Extract

The invention discloses a method for extracting rice bran oil through a three-phase separation aqueous enzymatic method. By adopting a near infrared heating technology for stabilizing fresh rice brans, partial lipase and lipoxidase in rice bran are damaged, so that rice bran proteins cannot be excessively denatured; then through supercritical CO2 wall-breaking treatment, the residual activity of the lipoxidase and the like in the rice bran is further reduced, and meanwhile, a remarkable breaking effect on rice bran cell walls is achieved; contact sites with a complex enzyme are increased during an enzymolysis technology step, and interval type high-pressure pulse treatment is simultaneously carried out during an enzymolysis process, so that the effect of carrying out enzymolysis and demulsification simultaneously is achieved, the grease release and the oil drop gathering are facilitated, the dissolving of grease is accelerated, and the oil yield is improved; then through three-phase method separation, the grease and proteins are separated and extracted.

Owner:安徽德运粮油有限公司

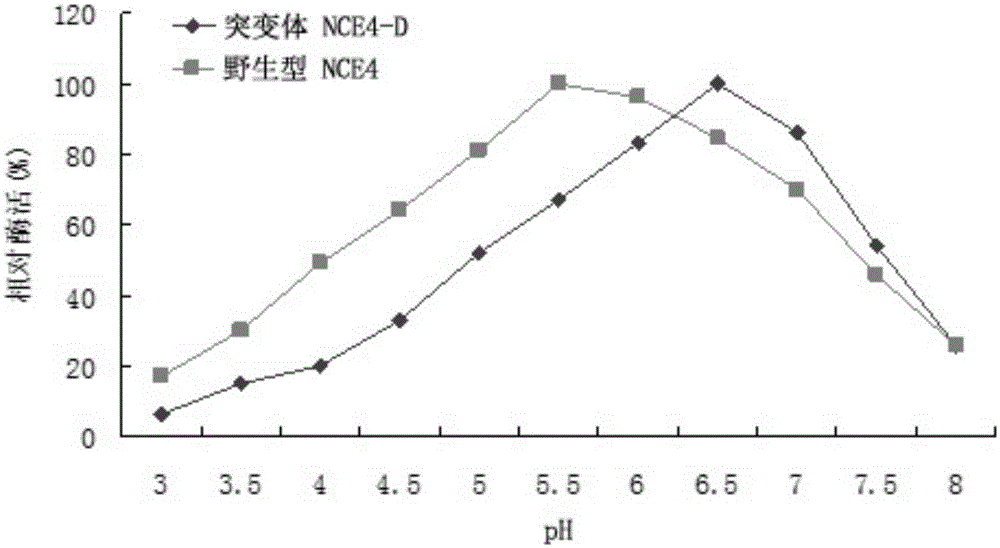

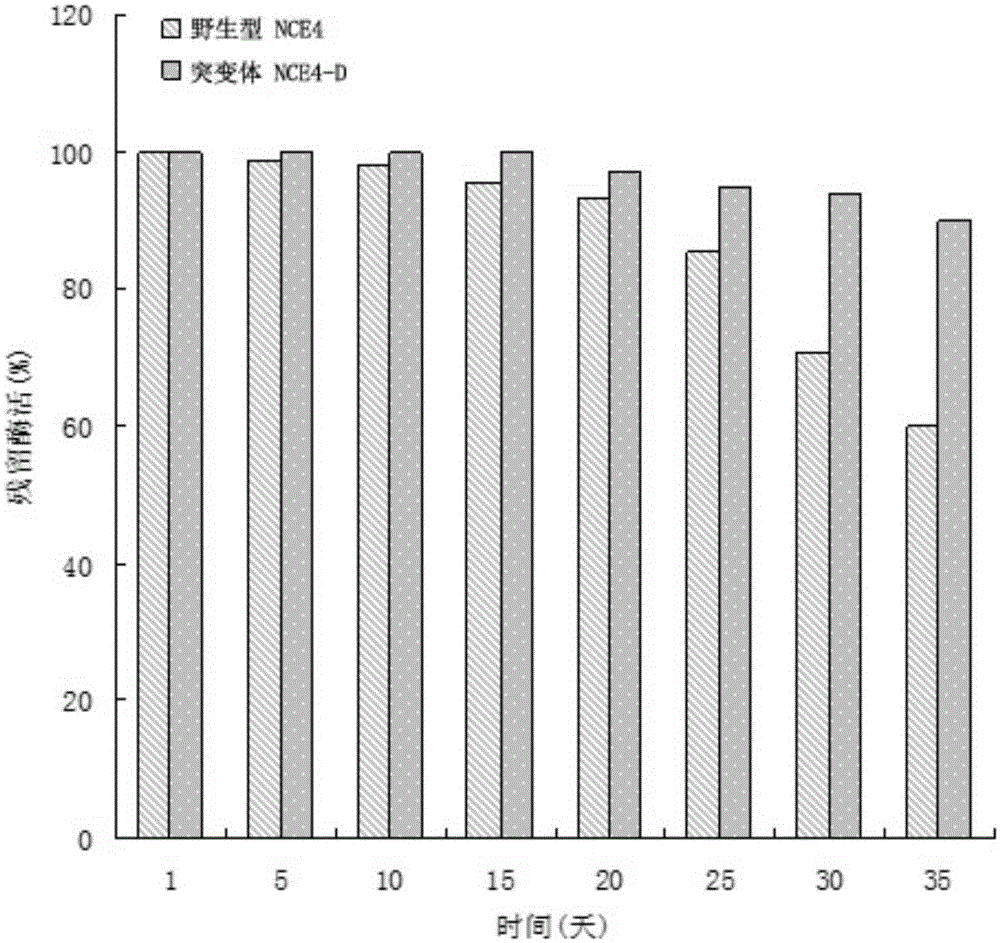

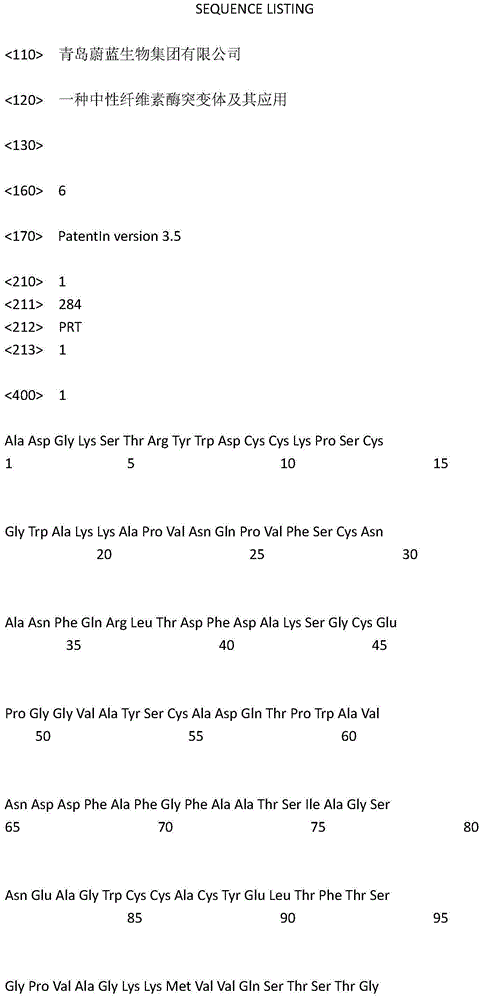

Neutral cellulase mutant and application thereof

ActiveCN105039288AImprove heat resistanceImprove stabilityFungiMicroorganism based processesHeat resistanceWild type

The invention aims to provide a neutral cellulase mutant. The amino acid sequence of the neutral cellulase mutant is shown in SEQ ID NO: 5. The optimum action temperature of the cellulase mutant is 60 DEG C, the optimum action pH of the cellulase mutant is 6.5, and an enzyme activity level above 80% can be kept within the pH range from 6.0 to 7.0; however, the optimum action pH of wild cellulase is 5.5, and enzyme activity above 80% is kept within the pH range from 5.0 to 6.5. Compared with the wild cellulose, the pH range of the cellulase mutant is more suitable for the neutrality condition, and therefore the cellulase mutant has a broader application range. In addition, the heat resistance and stability of the cellulase mutant are significantly improved, and residual activity above 90% still can be kept after the cellulase mutant is stored for 35 days at 42 DEG C; however, a residual rate lower than 60% of the wild cellulase only can be kept under the condition.

Owner:QINGDAO VLAND BIOTECH GRP

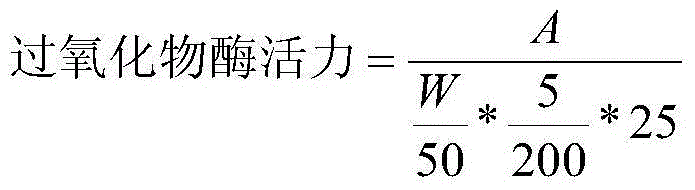

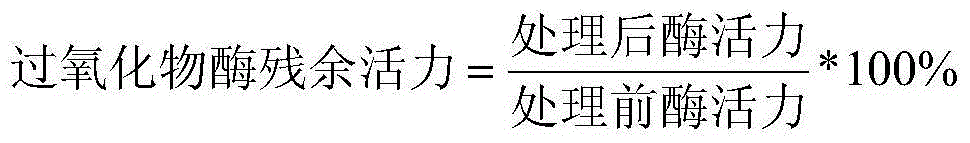

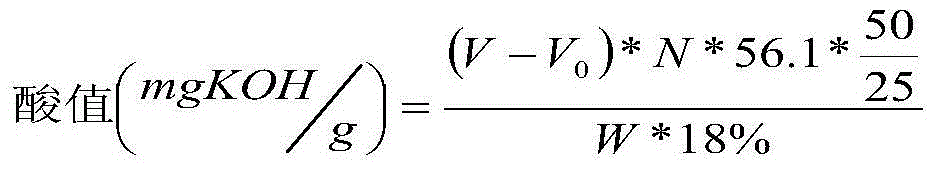

Enzyme-deactivation stabilizing treatment method of rice bran

InactiveCN104939266ALittle change in colorLow denaturationFood processingFood preservationTemperature controlMicrowave

The invention discloses an enzyme-deactivation stabilizing treatment method of rice bran. According to the stabilizing treatment method, by combining a rapid microwave heating manner with an efficient far-infrared temperature control manner, the disadvantage that although the temperature increase is rapid, the temperature is difficult to stabilize and control in a microwave heating manner is overcome, and microwave and far-infrared heating energy-saving techniques are truly applied to the production field of enzyme deactivation of rice bran. According to the stabilizing treatment method, the residual activity of peroxidase of rice bran which is subjected to enzyme-deactivation stabilization is 1.1%, and after the rice bran is cultured in a constant-temperature incubator at 37 DEG C for 60 days, the free fatty acid value of the stabilized rice bran is always stabilized at 140mgKOH / 100g-170mgKOH / 100g; the microwave heating technique and the far-infrared heating technique are two excellent energy-saving heating techniques and are applied to the industrial production of stabilization of rice bran, so that the purposes of high efficiency, energy saving, emission reduction and consumption reduction are achieved; by combining the microwave heating technique and the far-infrared heating technique, the disadvantages of the single microwave heating manner that the temperature is difficult to control, and the product quality is instable are overcome.

Owner:SOUTHWEST UNIVERSITY

Nicosulfuron-atrazine mixed herbicide

InactiveCN103053575ABroad herbicidal spectrumDelay drug resistanceBiocideAnimal repellantsPhytotoxicityAtrazine

The invention relates to a nicosulfuron-atrazine mixed herbicide, which contains the following effective ingredients: 2% (weight) of nicosulfuron and 20% (weight) of atrazine. The effective ingredients and known assistants can be compounded into conventional dosage forms including powder, wettable powder, suspension emulsions, missible oil and granules. With a wide weed control spectrum, the nicosulfuron-atrazine mixed herbicide can prevent and remove weeds in corn fields, and also can kill weeds in other crop fields. With outstanding advantages in the aspects of improving the weeding effect, reducing pesticide residual activity, lowering phytotoxicity, delaying the drug resistance occurrence of weeds and community succession, lowering drug consumption, and reducing environmental pollution, the mixed herbicide also saves time, labor and money simultaneously, thus being more easily acceptable to farmers.

Owner:孙雪梅

Composition for weeding

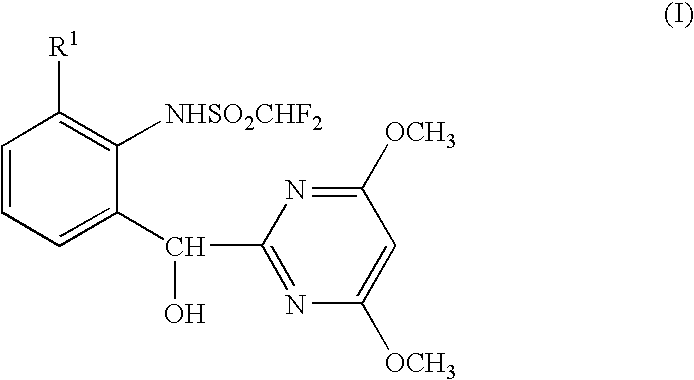

A mixed composition for weeding useful as a herbicide which is effective against a wide spectrum of weeds, is highly active, has excellent residual activity, and is highly safe for useful plants. It is characterized by containing as an active ingredient a combination of (A) a compound selected among a difluoromethanesulfonylanilide compound represented by the general formula (I):(wherein R1 is hydrogen, C1-6 alkyl, or C2-6 alkoxyalkyl) and salts of the compound and (B) at least one member selected among herbicidal aromatic-ring-containing compounds, e.g., indanofan, and herbicidal nitrogenous heterocyclic compounds, e.g., TH-547, nicosulfuron, Flutiacet-methyl, and atrazine.

Owner:KUMIAI CHEM IND CO LTD

Selenium-rich biological agent for improving activity of microbes in soil and preparation method of selenium-rich biological agent

InactiveCN105367307AImprove efficiencyLow costCalcareous fertilisersMagnesium fertilisersActivated sludgeMonopotassium phosphate

The invention relates to a selenium-rich biological agent for improving the activity of microbes in soil. The selenium-rich biological agent comprises the following raw materials: 8-15 parts of sodium selenite, 5-15 parts of compound trace elements, 8-20 parts of monopotassium phosphate, 10-25 parts of urea, 8-20 parts of peptone, 4-10 parts of yeast powder, 8-20 parts of NaCl, 8-15 parts of NaOH, 4-10 parts of NaNO3, 10-25 parts of NaCl, 4-10 parts of NH4Cl, 8-20 parts of K2HPO4, 4-10 parts of a beef extract, 10-25 parts of glucose, 10-25 parts of starch, 8-20 parts of calcium carbonate, 10-25 parts of amino acid, 2-6 parts of potassium nitrate, 2-6 parts of ferrous sulfate, 10-25 parts of magnesium sulfate, 25-40 parts of trisodium citrate, 10-25 parts of enzymes and 800-896 parts of excess activated sludge. The selenium-rich biological agent adopts excess activated sludge produced by treatment of domestic sewage, so that not only is the fermentation speed of the selenium-rich biological agent increased, but also the particle diameters of selenium nano-particles are more uniform, and absorption of the selenium-rich biological agent by plants is benefitted.

Owner:SHANDONG UNIV

Nicosulfuron and atrazine oil suspending agent composition

InactiveCN101971846AReduce drug damageReduce pollutionBiocideAnimal repellantsAtrazineSuspending Agents

The invention relates to a nicosulfuron and atrazine oil suspending agent composition. The composition is an oil suspending agent and comprises the following components in percentage by weight: 4 percent of nicosulfuron, 48 percent of atrazine, 10 percent of emulsifying agent, 15 percent of surfactant and 23 percent of oil. A weed control composition has the advantages of effectively combining the advantages of the nicosulfuron and the atrazine, enhancing weed control effect, lowering residual activity, reducing chemical injury to crops, delaying the occurrence of medicament resistance of weeds and community succession, reducing the using amount of a medicament, reducing environmental pollution, saving time, labor and money and lightening burden on farmers.

Owner:孙雪梅

Non-aerosol foaming alcohol hand sanitizer

A non-aerosol, foaming high alcohol content hand sanitizer is provided which has excellent antimicrobial activity and tolerance for organic load and excellent residual activity, as well as enhanced moisturization and skin-feel properties over currently marketed alcohol-based sanitizers. The inventive composition achieves an unexpectedly large amount of quality, stable foam even in the presence of significant quantities of skin conditioning agents through the use of novel silicone surfactants and achieves enhanced and prolonged antimicrobial efficacy through the combination of high alcohol content and activity enhancing components.

Owner:SC JOHNSON & SON INC

Method of selecting barley variety, barley beta-amylase gene and process for producing malt alcoholic drink

InactiveUS20050053934A1Increases starch-decomposing efficiencyRaise saccharization temperatureMicrobiological testing/measurementGenetic engineeringAmylaseMalt Grain

A method of selecting a barley variety comprising: a heat treatment step of heat-treating a crude enzyme solution extracted from a seed of a barley (e.g., at 57.5° C. for 30 minutes); an activity-determining step of determining the enzyme activity of β-amylase in the crude enzyme solution heat-treated; and a selection step of selecting the barley variety containing a β-amylase having a residual activity of from 85 to 90% as a result of the activity determination.

Owner:SAPPORO BREWERIES

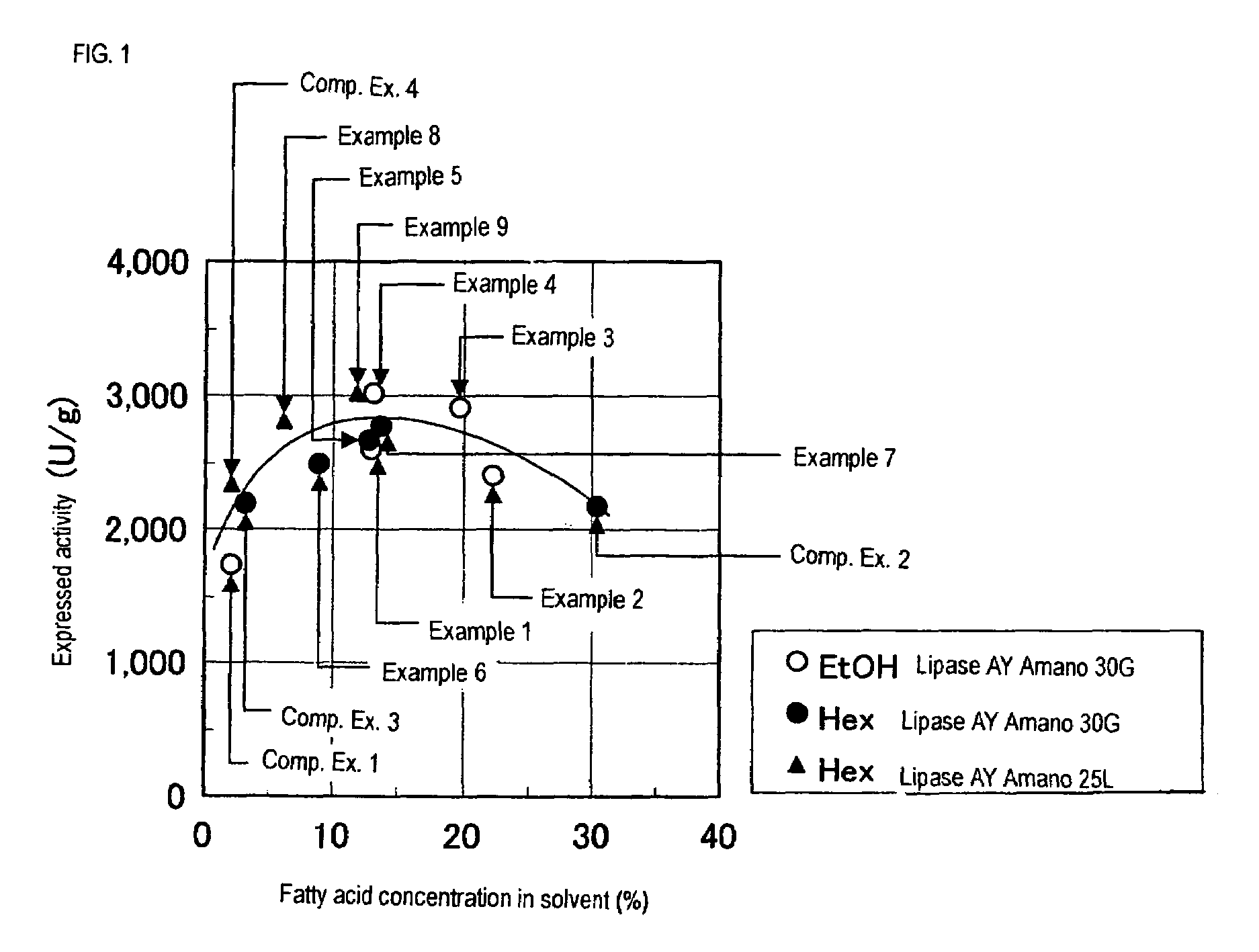

Regenerating method of immobilized enzyme

Provided is a method for regenerating an immobilized enzyme for lipolysis which has been used for lipolysis, thereby exhibiting a reduced activity, which includes washing the immobilized enzyme with a solvent; controlling an equilibrium concentration of fatty acids in the solvent; removing the washed immobilized enzyme therefrom, and contacting the resulting immobilized enzyme with a fresh enzyme, wherein the fresh enzyme adsorbs onto the immobilized enzyme. According to the preferred methods of the present invention, it is possible to make effective use of the residual activity of an immobilized enzyme spent for lipolysis and regenerate the spent immobilized enzyme to have a performance similar to that before the lipolysis at a low cost using less amount of liquid waste.

Owner:KAO CORP

High-efficient pesticide combination containing chlorpyrifos

InactiveCN103371172AReduce releaseLower resistanceBiocideAnimal repellantsChlorpyrifosSuspending Agents

The invention discloses a high-efficient pesticide combination containing chlorpyrifos. The combination is mainly characterized by comprising active ingredients A and chlorpyrifos, wherein the active ingredients A are selected from thiamethoxam and thiacloprid, the weight ratio of the active ingredients A to the chlorpyrifos is (1:1)-(1:15), and the combination can be prepared into suspoemulsion, a microcapsule suspending agent and microcapsule suspension. The combination provided by the invention can be used for preventing and treating various insect pests, has an obvious synergistic effect, expands a preventing and treating spectrum, has high activity on the insect pests on cereal crops, ornamental plants, tea trees, vegetables, cottons and fruit trees, has a slow release function, reduces the using amount of the pesticide, is safe to human and livestock, is free of chemical injury, and has good environment compatibility; the preparation has enhanced binding performance, is resistant to rain wash, has long residual activity and the like.

Owner:陕西亿田丰作物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com