Enzyme-deactivation stabilizing treatment method of rice bran

A technology of stabilization treatment and rice bran, which is applied in food science, food preservation, application, etc., can solve the problems of large temperature difference between inside and outside, poor uniform heating effect, fast moisture volatilization of surface materials, etc., and achieves small denaturation and overcomes microwave The effect that heating temperature control is difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

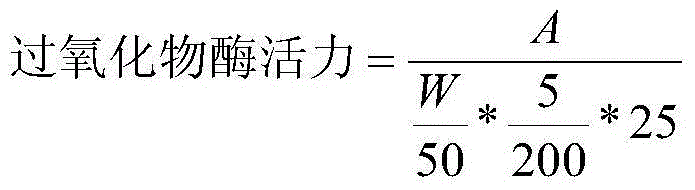

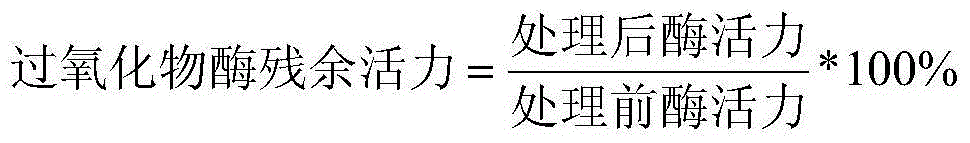

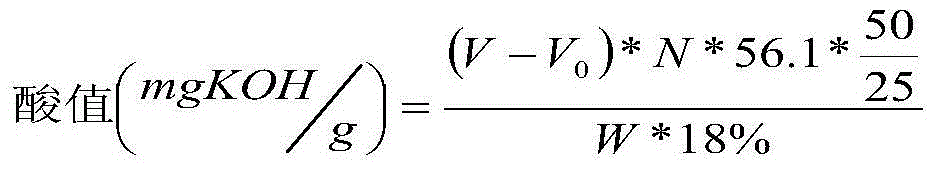

[0030] Weigh rice bran powder with a water content of 10%, pass through a sieve, and take the 40-mesh sieve, and spray clean water while stirring in a mixer at 700-1000 rpm. The amount of water sprayed makes the water content of rice bran reach 18%, continue stirring to make the rice bran evenly hydrated. Enter the microwave reactor, adjust the microwave power, and raise the temperature to the set 70°C within 60 seconds. Using a conveyor belt, the rice bran is transported to the far-infrared heating section that has been heated to 80°C, where it is heated and kept for 15 minutes. Continue to carry out the next section of microwave heater through the conveyor belt, and heat while conveying on the conveyor belt. The temperature of this section is set at 90 ° C. After heating for 200 seconds, the conveyor belt is sent to the air conveyor for transmission and cooling. Then pass through a 40-mesh sieve, and the oversize is returned to the pulverizer for re-grinding, and the unders...

Embodiment 2

[0032] Weigh rice bran powder with a water content of 10%, pass through a sieve, and take the 40-mesh sieve, and spray clean water while stirring in a mixer at 700-1000 rpm. The amount of water sprayed makes the water content of rice bran reach 30%, continue stirring to make the rice bran evenly hydrated. Enter the microwave reactor, adjust the microwave power, and raise the temperature to the set 80°C within 300 seconds. Using a conveyor belt, the rice bran is transported to the far-infrared heating section that has been heated to 90°C, where it is heated and kept for 8 minutes for reaction. Continue to carry out the next section of microwave heater through the conveyor belt, and heat while conveying on the conveyor belt. The temperature of this section is set at 100 ° C. After heating for 50 seconds, the conveyor belt is sent to the air conveyor for transmission and cooling. Then pass through a 40-mesh sieve, and the oversize is returned to the pulverizer for re-grinding, a...

Embodiment 3

[0034] Weigh rice bran powder with a water content of 10%, pass through a sieve, and take the 40-mesh sieve, and spray clean water while stirring in a mixer at 700-1000 rpm. The amount of water sprayed makes the water content of rice bran reach 25%, continue stirring to make the rice bran evenly hydrated. Enter the microwave reactor, adjust the microwave power, and raise the temperature to the set 75°C within 180 seconds. Using a conveyor belt, the rice bran is transported to the far-infrared heating section that has been heated to 86° C., where it is heated and kept for 1.5 minutes. Continue to carry out the next section of microwave heater through the conveyor belt, and heat while conveying on the conveyor belt. The temperature of this section is set at 95 ° C. After heating for 120 seconds, the conveyor belt is sent to the air conveyor for transmission and cooling. Then pass through a 40-mesh sieve, and the oversize is returned to the pulverizer for re-grinding, and the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com