Patents

Literature

73results about How to "Improve saccharification efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

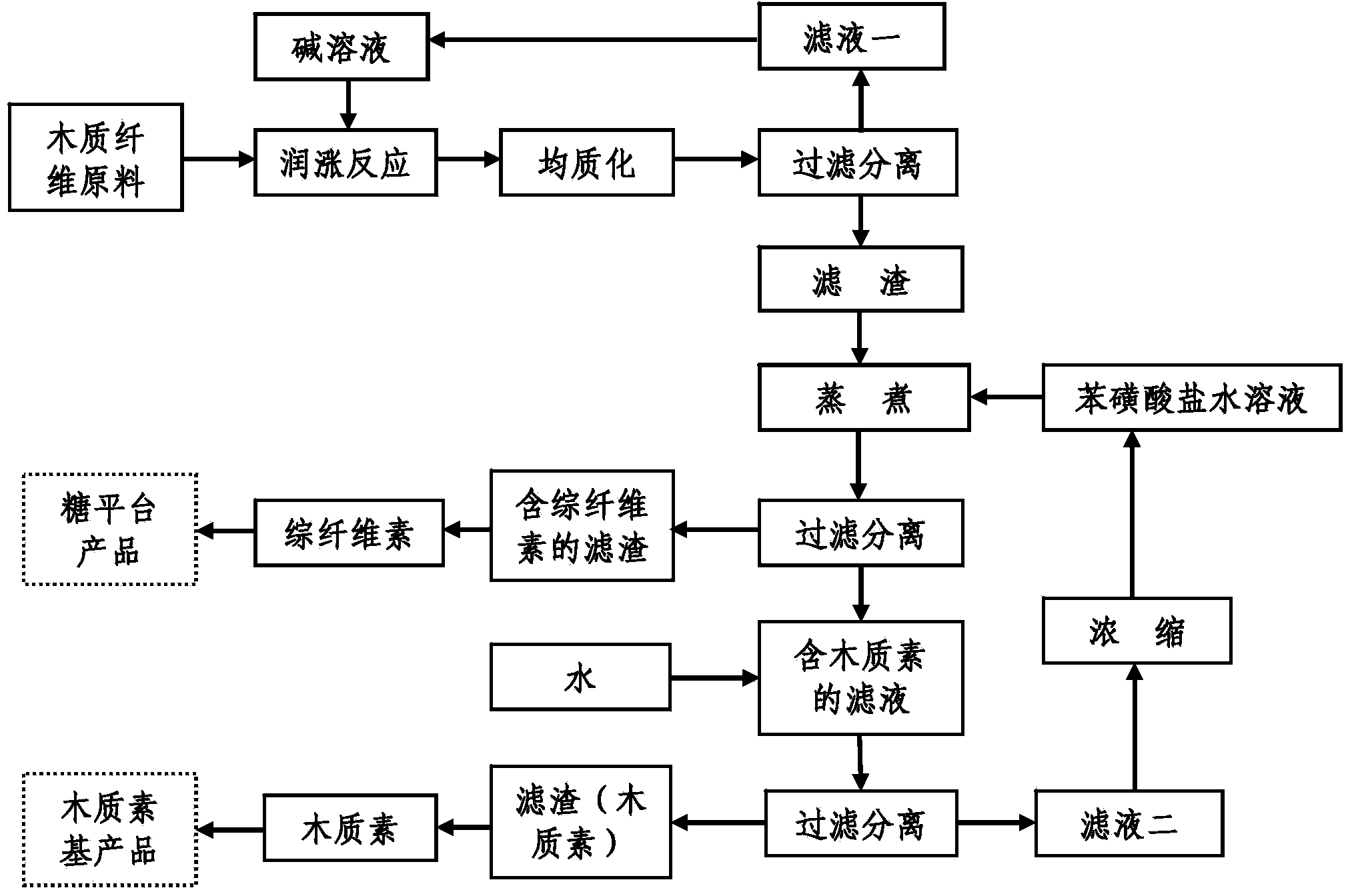

Method for separating lignin and holocellulose from wood fiber raw materials and application thereof

InactiveCN104389216AHigh extraction yieldImprove saccharification efficiencyPaper material treatmentCelluloseFiber

The invention relates to utilization and technology of agriculture and forestry biological data, in particular to a method for separating lignin and holocellulose from wood fiber raw materials. The method comprises the following steps: a, wood fiber raw materials are mixed with an alkali liquor and then soaked and moistened; b, the soaked and moistened wood fiber raw materials are homogenized and then filtered and separated to obtain solid residues and a filtrate I; c, the solid residues which are washed with water are added into a benzene sulfonate water solution for digestion, and the digested solid residues are filtered and separated to obtain residues containing holocellulose and a filtrate containing lignin; d, the residues containing holocellulose are washed to obtain holocellulose; e, water is added into the filtrate containing lignin to separate lignin, filtering is performed to obtain lignin residues and a filtrate II, and the lignin residues are washed and dried to obtain lignin. The method provided by the invention is simple and feasible in process, environment-friendly, and low in toxicity, the lignin extraction yield is high, and the saccharification efficiency of holocellulose obtained through separation is also high.

Owner:INT CENT FOR BAMBOO & RATTAN

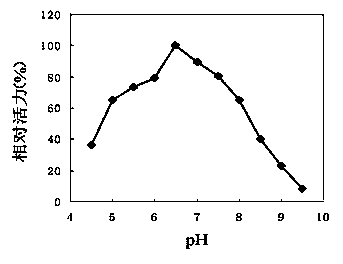

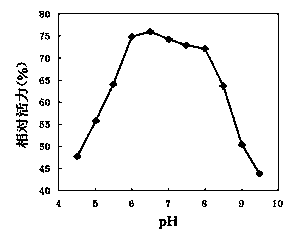

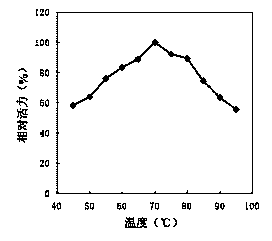

Recombinant high-temperature pullulanase and preparation method thereof

InactiveCN103834629ASmall molecular weightHigh expressionFermentationGlycosylasesAmylaseChromatographic separation

The invention relates to a recombinant high-temperature pullulanase and a preparation method thereof, belonging to the field of bioengineering technology. The invention is characterized in that a gene coding the high-temperature pullulanase is loaded on a pHsh expression vector and is then transferred to an Escherichia coli host for enlarged culture of an engineering bacterium containing the high-temperature pullulanase, then ultrasonic fragmentation and heating are carried out to remove most impurity proteins autonomously expressed by Escherichia coli, then the high-temperature pullulanase is prepared through affinity chromatographic separation and purification, and the recombinant high-temperature pullulanase has an optimal reaction temperature as high as 70 DEG C and a wide pH value application range and performs good catalytic activity at a high temperature of 70 to 80 DEG C, which enables the pullulanase to be especially suitable for cooperative usage with amylase and glucoamylase in the industry of production of sugar from starch and allows saccharification time to be reduced and saccharification efficiency to be improved. The recombinant high-temperature pullulanase provided by the invention is widely applicable to industries like food, wine brewing, feeds, medicine, papermaking and weaving.

Owner:YANGTZE UNIVERSITY

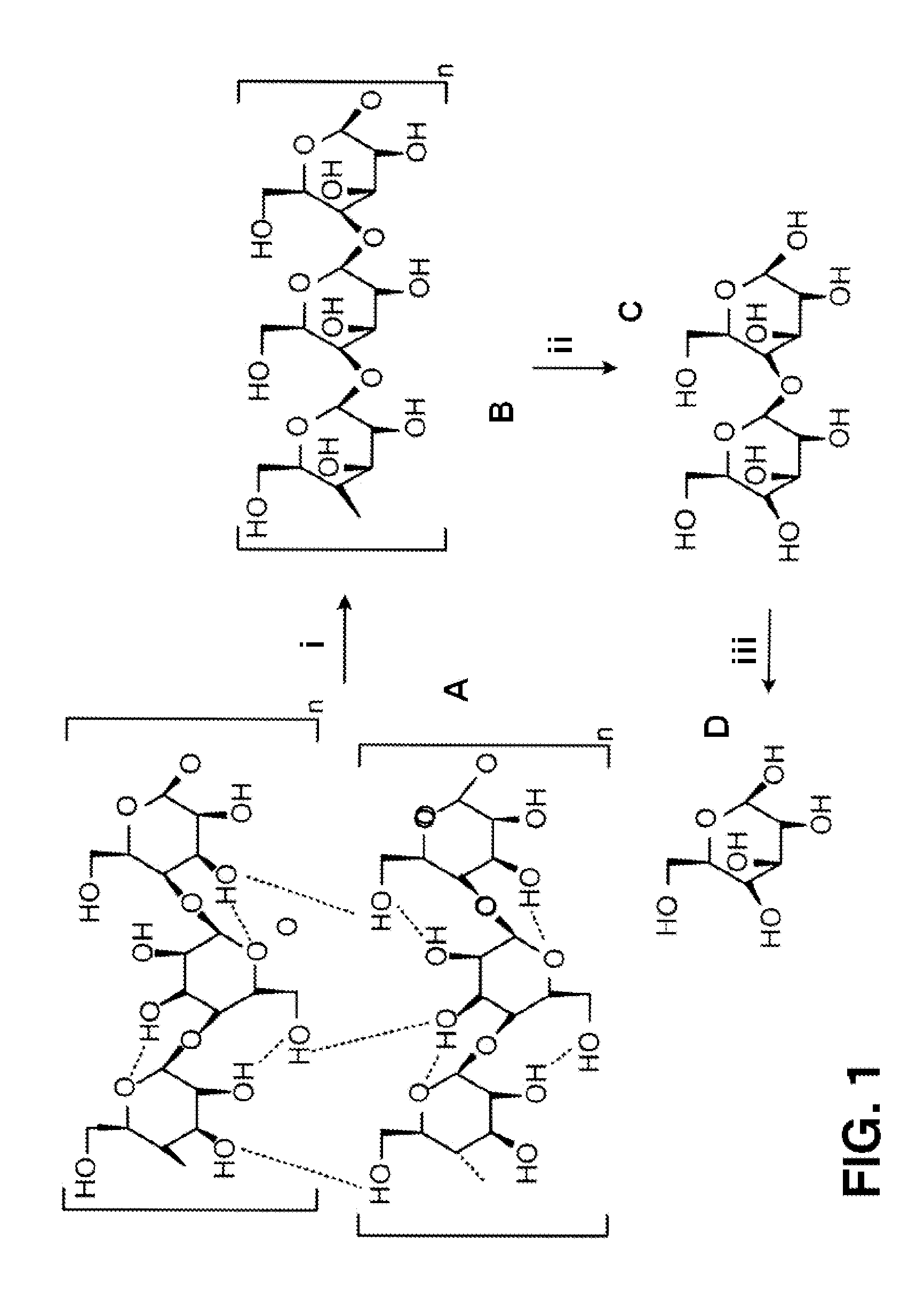

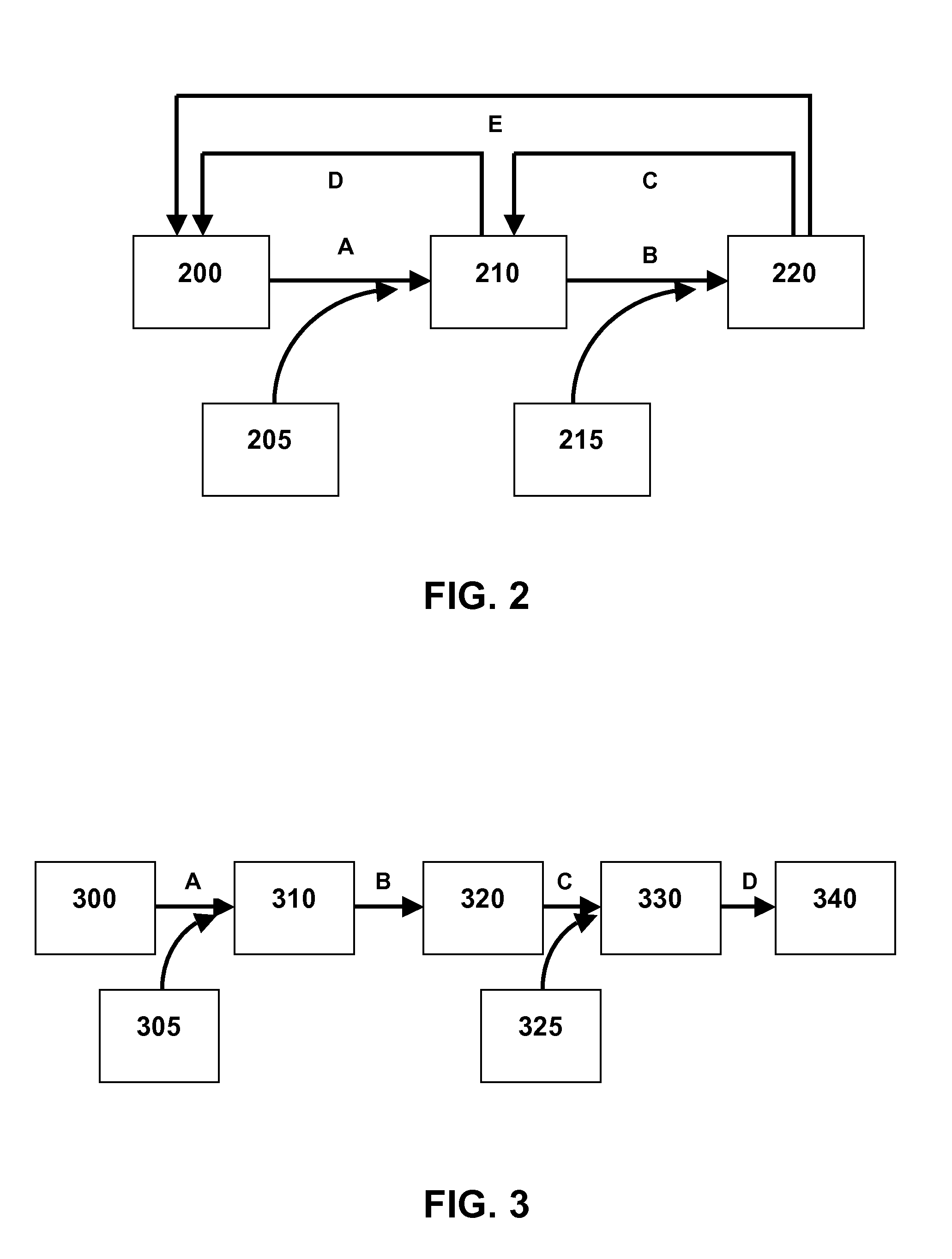

Processing biomass

InactiveUS20140004570A1Improve saccharification efficiencyAvoiding negative feedback inhibitionFungiBiofuelsFeedback inhibitionBiomass

Provided herein are methods of increasing the efficiency of biomass saccharification. In particular, the methods include ways of avoiding feedback inhibition during the production of useful products.

Owner:XYLECO INC

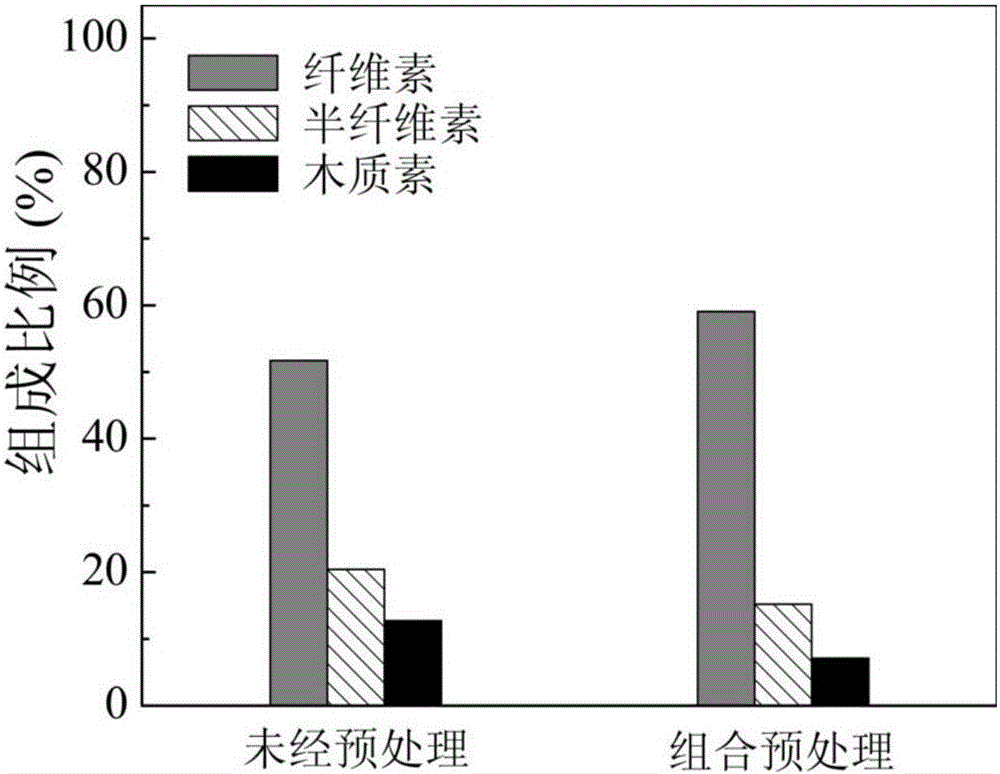

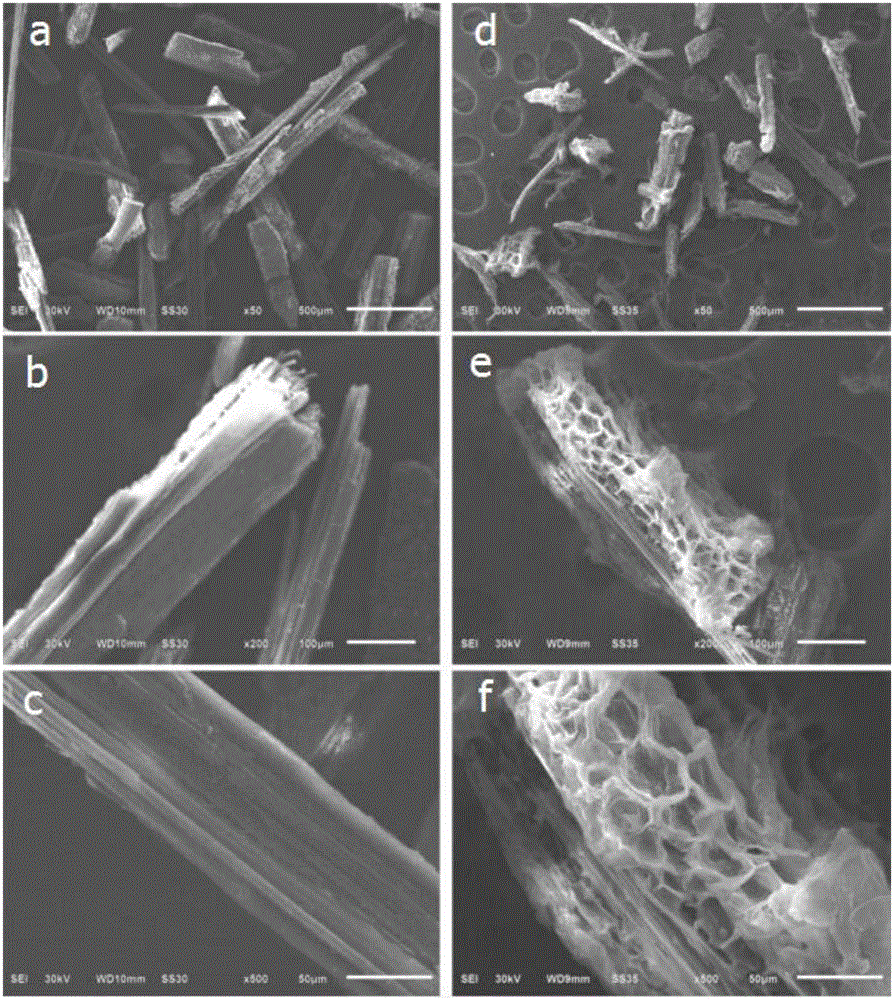

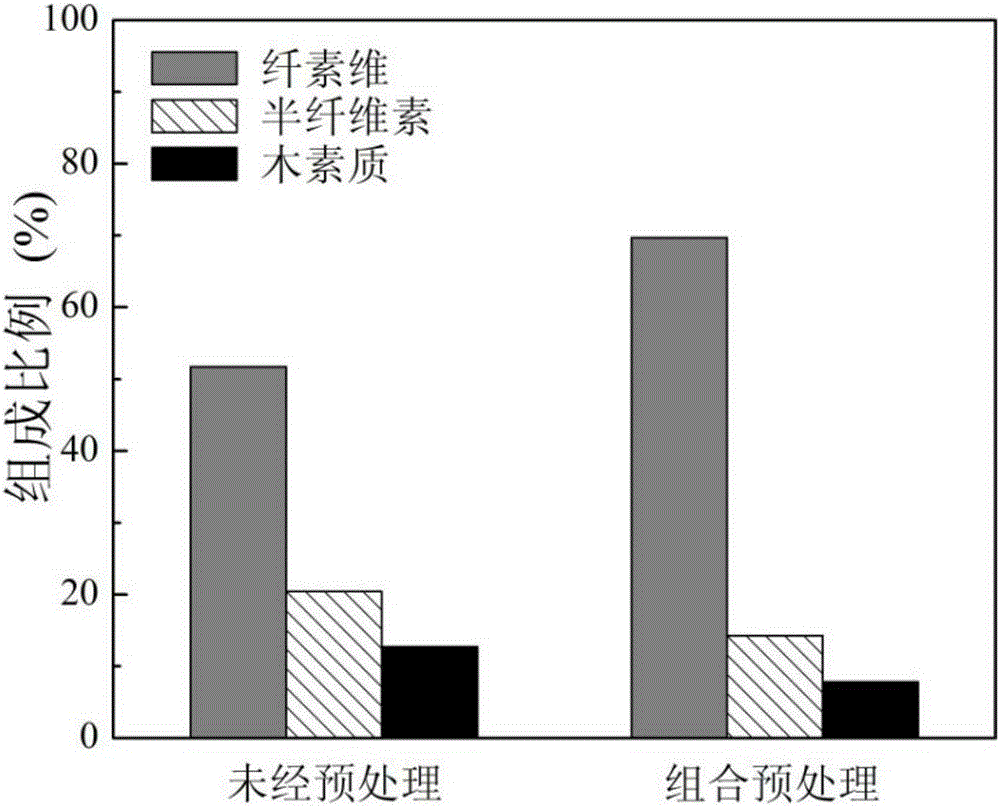

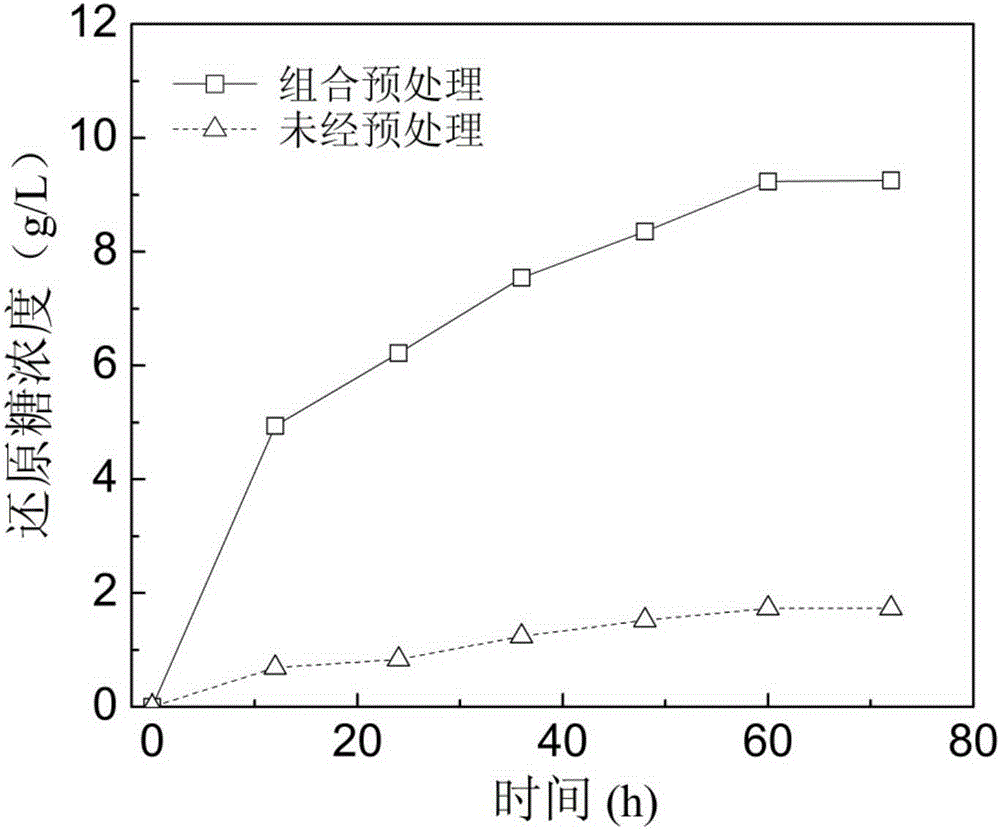

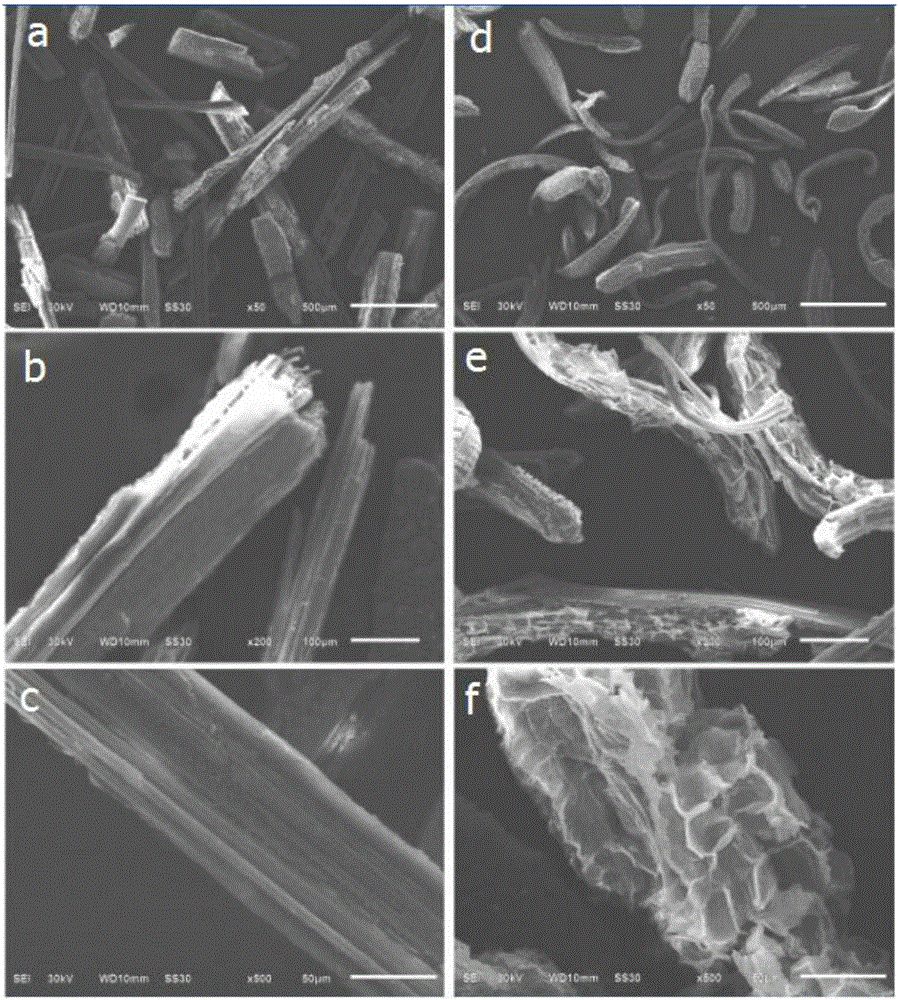

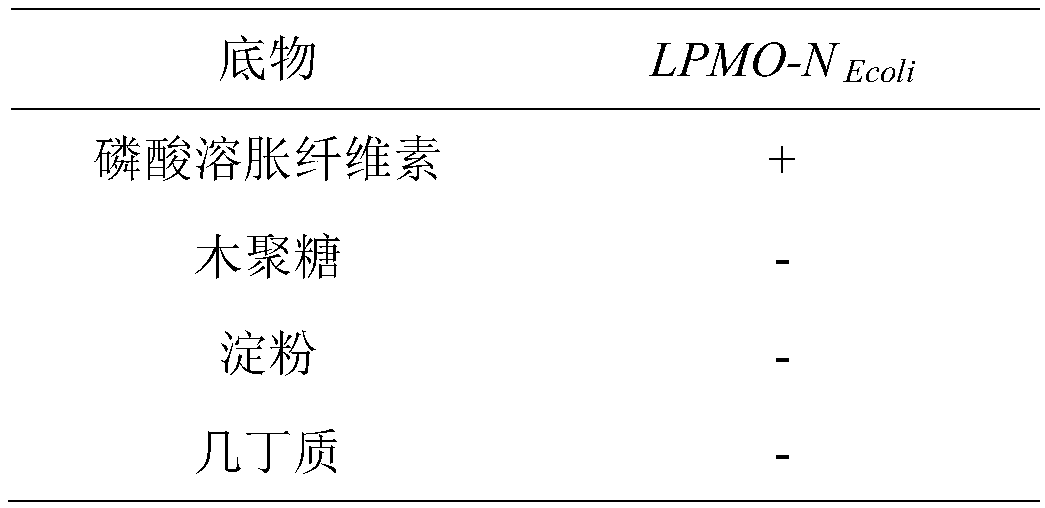

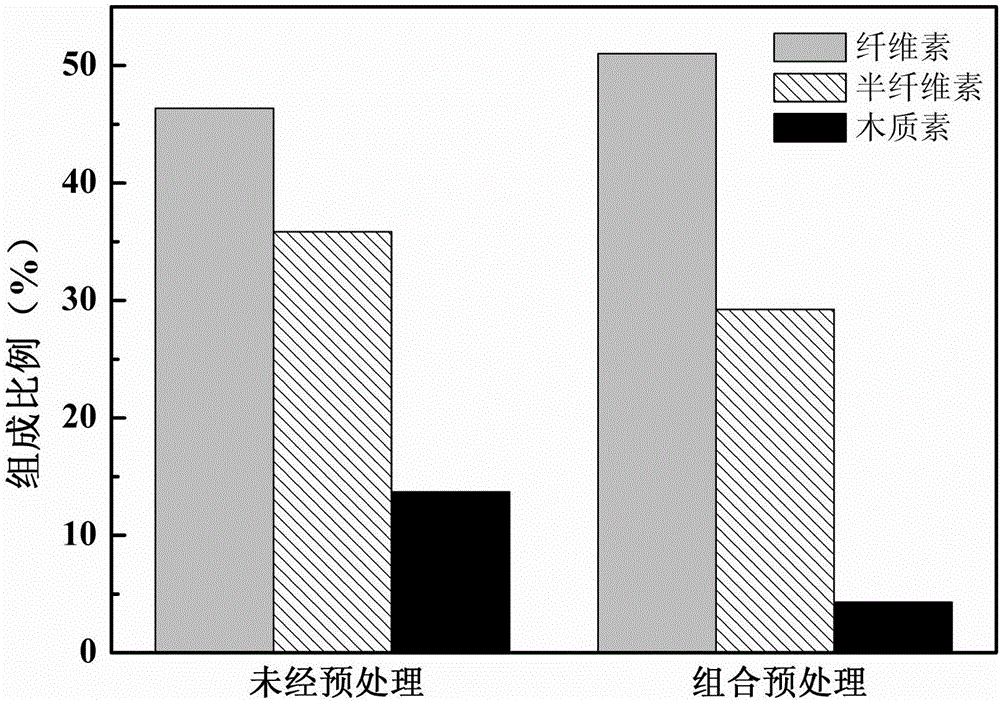

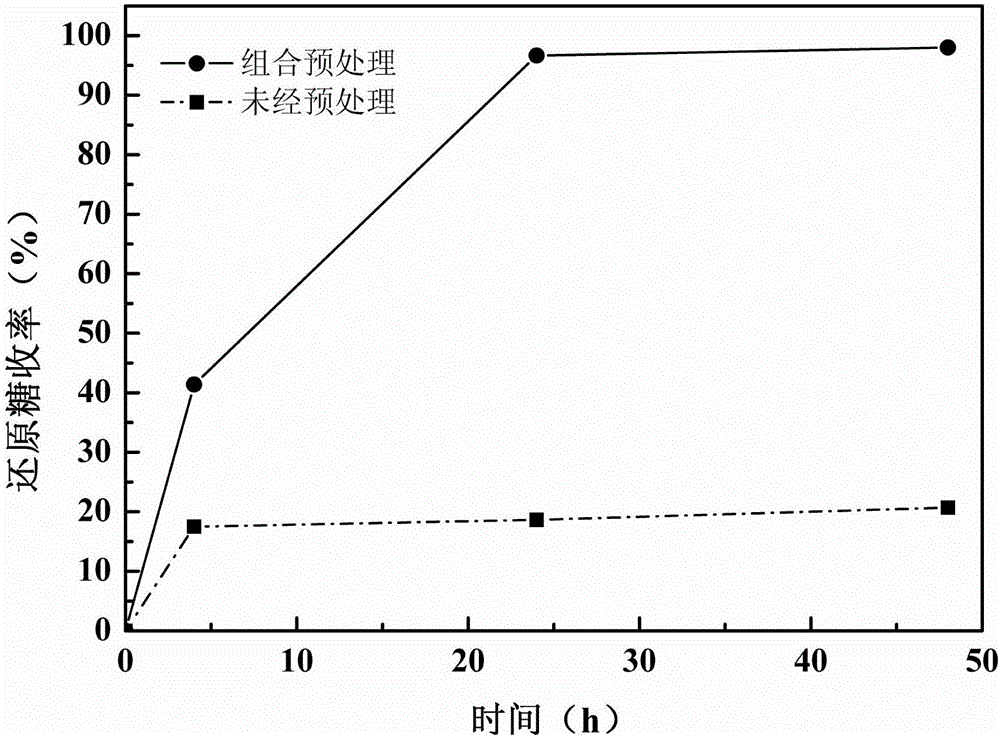

Combined pretreatment process for improving lignocellulose saccharification effect

InactiveCN105002232AShort processing timeLower requirementFermentationChemical treatmentPre treatment

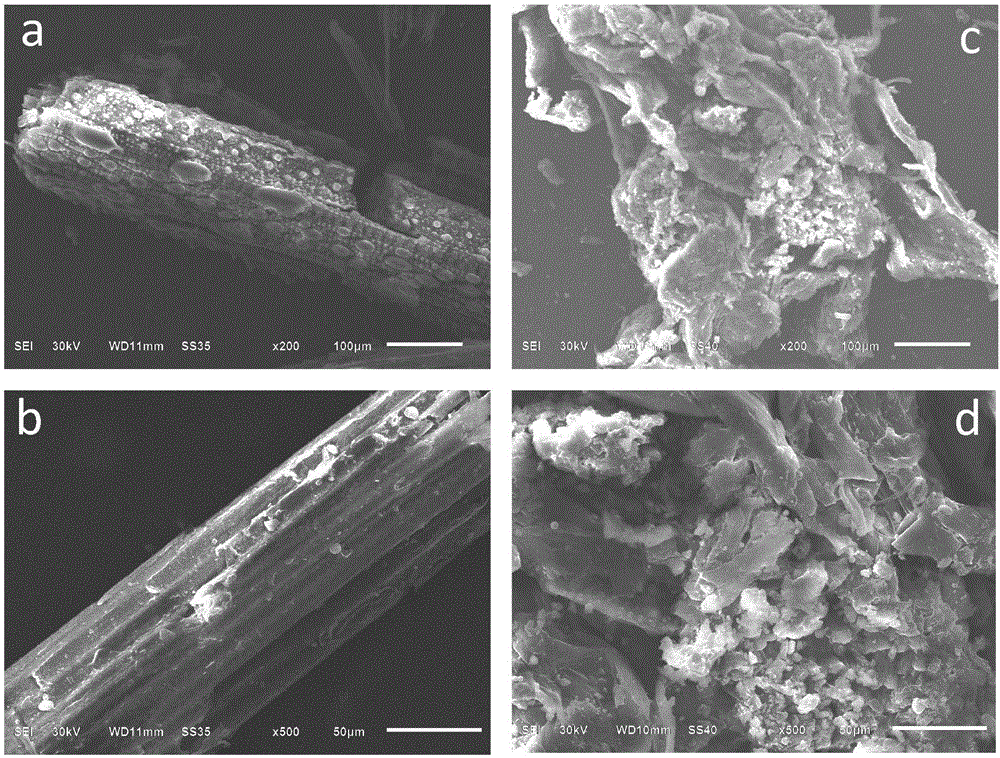

The invention provides a combined pretreatment process for improving the lignocellulose saccharification effect. According to the process, firstly, an alkali / urea solution is used for conducting first-step treatment on lignocellulose raw materials, part of lignin and hemicellulose ingredients in the lignocellulose raw materials are removed through chemical treatment, and the stable structure of lignocellulose is damaged to a certain degree; physical treatment is further conducted through ultrasonic waves, and the structure of the lignocellulose is more loosened. After pretreatment of the process, the ingredient content of the lignocellulose is obviously changed, and the proportion of cellulose is remarkably increased. In addition, the structure of the lignocellulose is remarkably changed, the raw material surface becomes rough, loosened and porous, and the accessible surface in the enzymolysis saccharification process is greatly increased. The combined pretreatment process has the advantages of being not high in equipment requirement, simple in operation, moderate in treatment condition, low in cost and the like, and can greatly improve the saccharification efficiency of the lignocellulose.

Owner:XIANGTAN UNIV

Method of selecting barley variety, barley beta-amylase gene and process for producing malt alcoholic drink

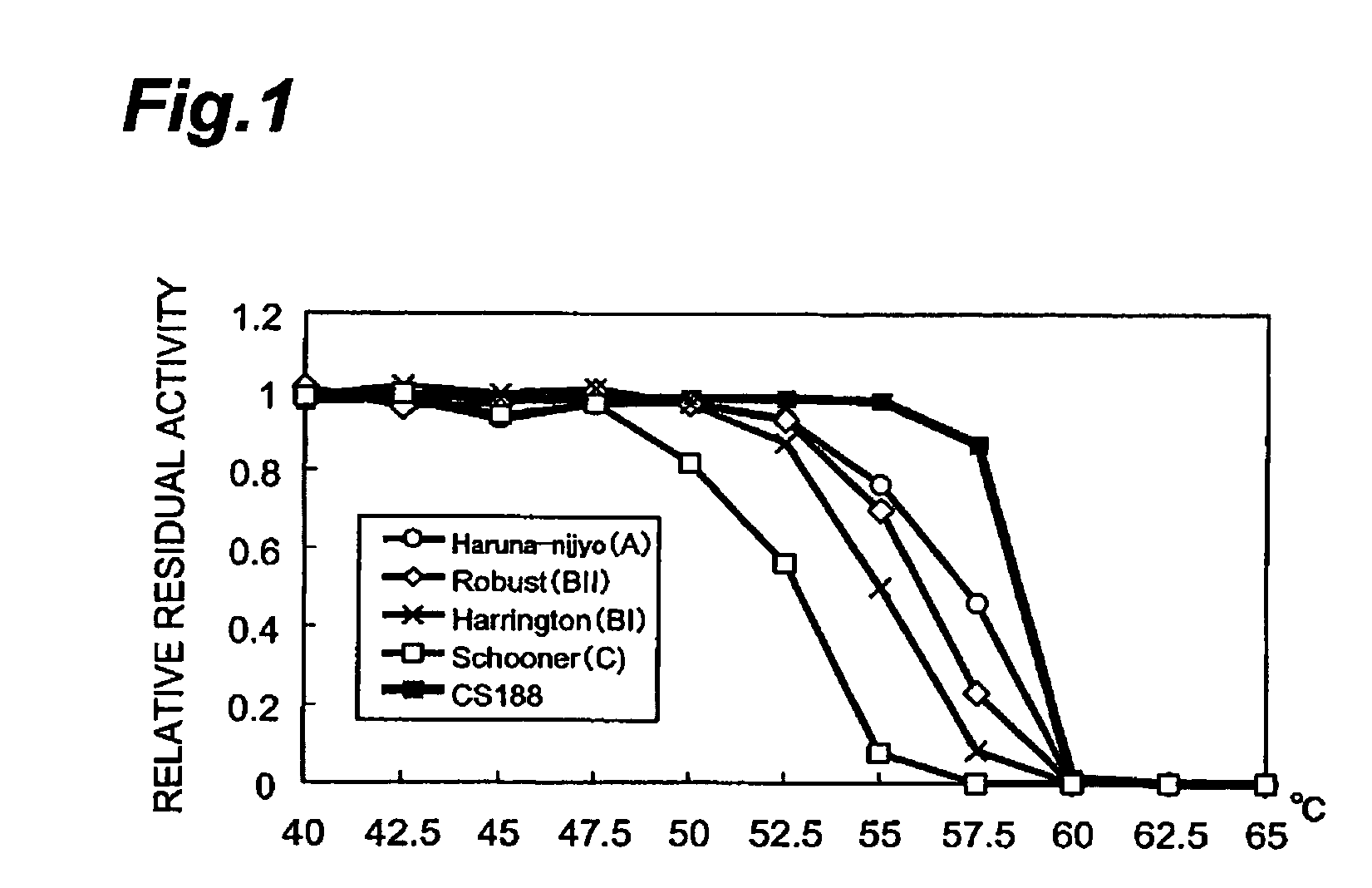

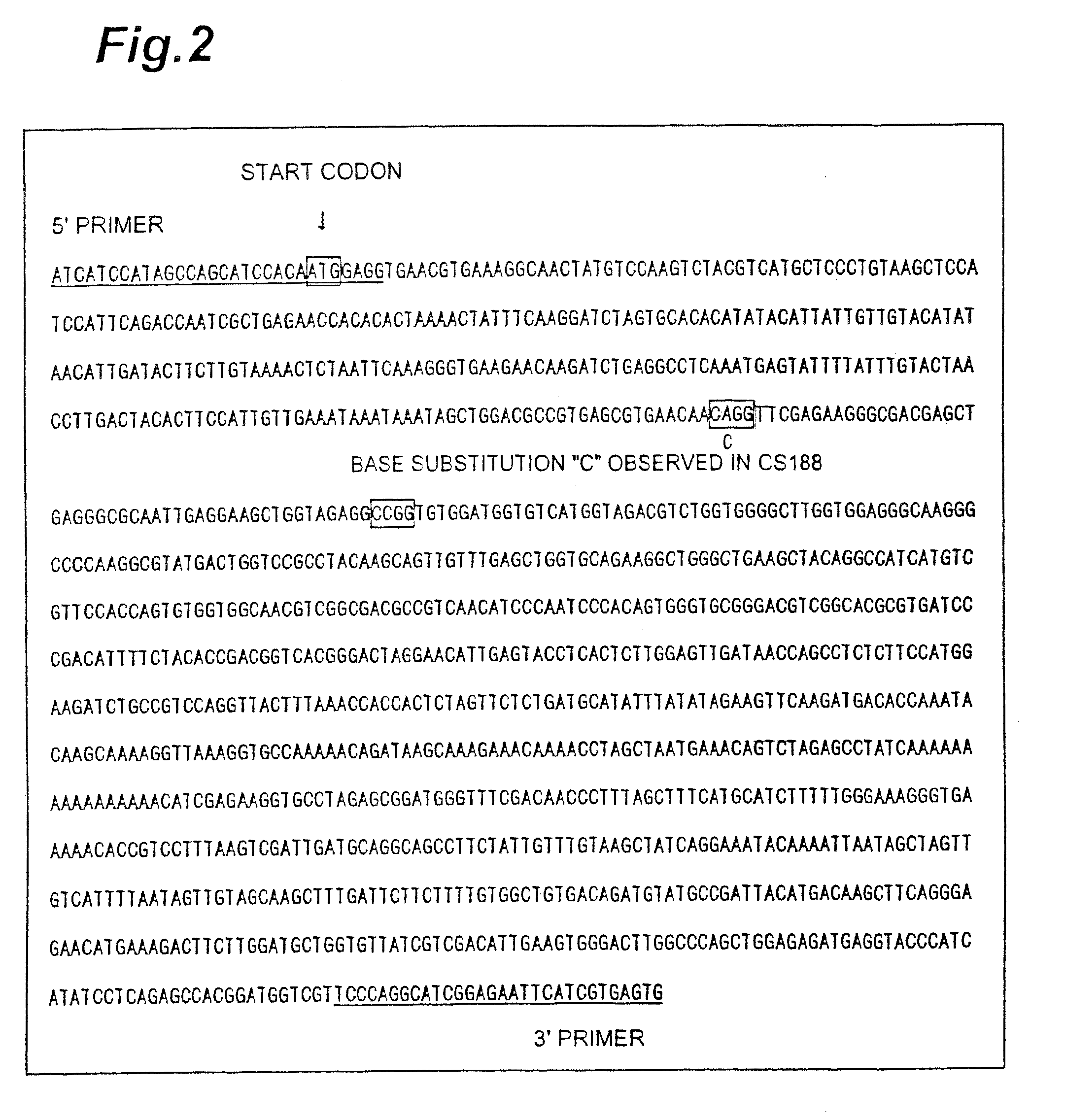

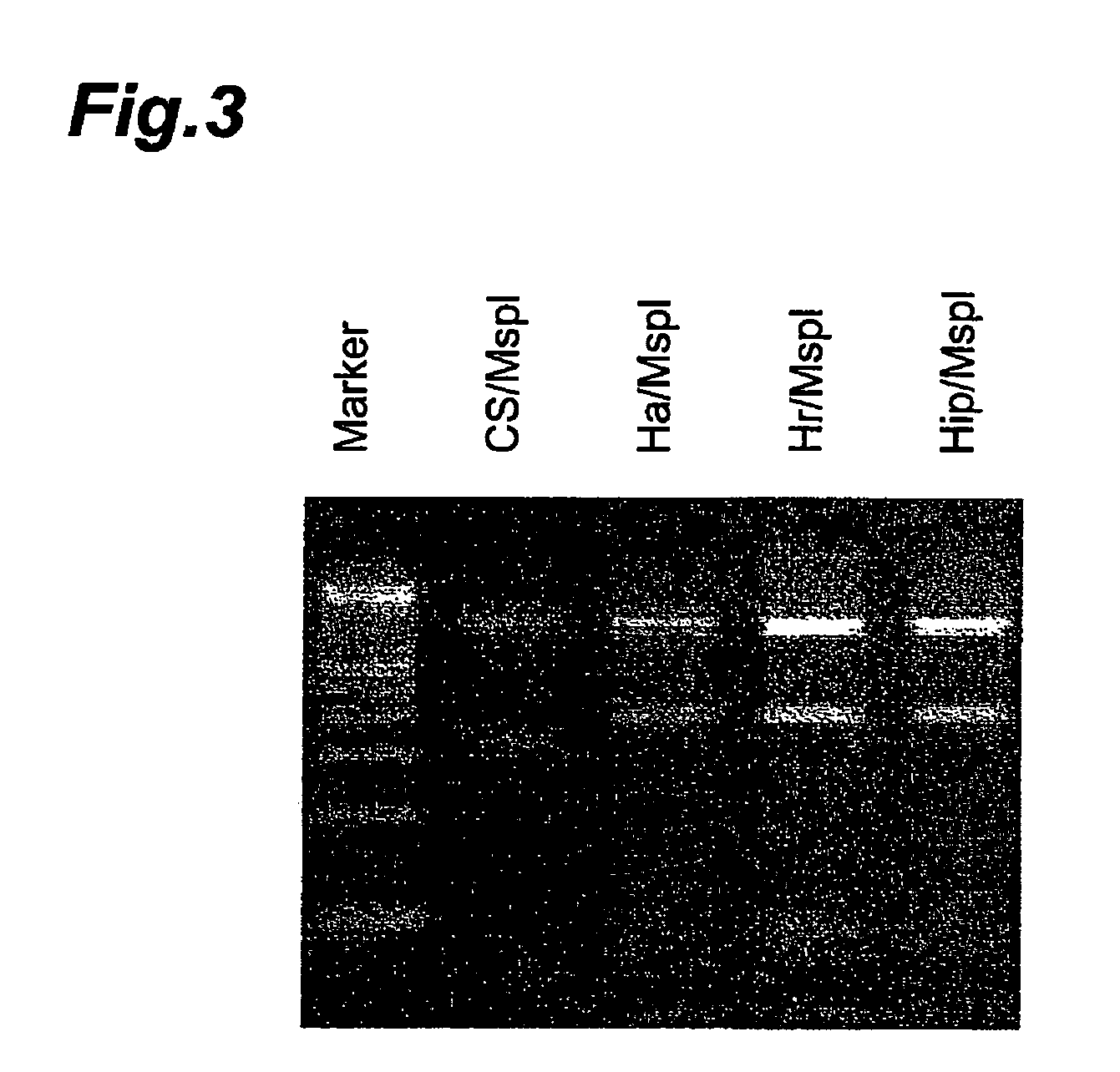

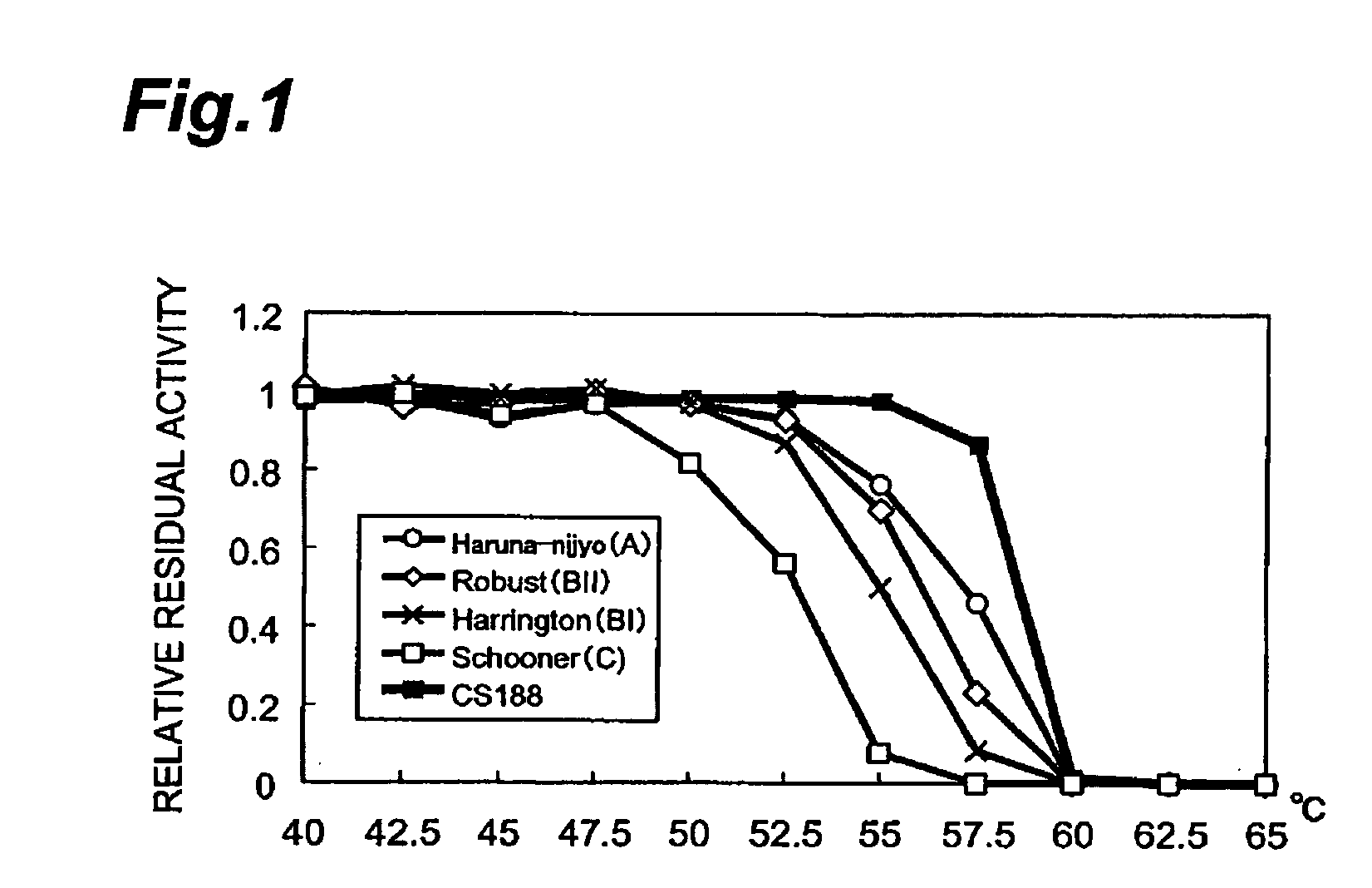

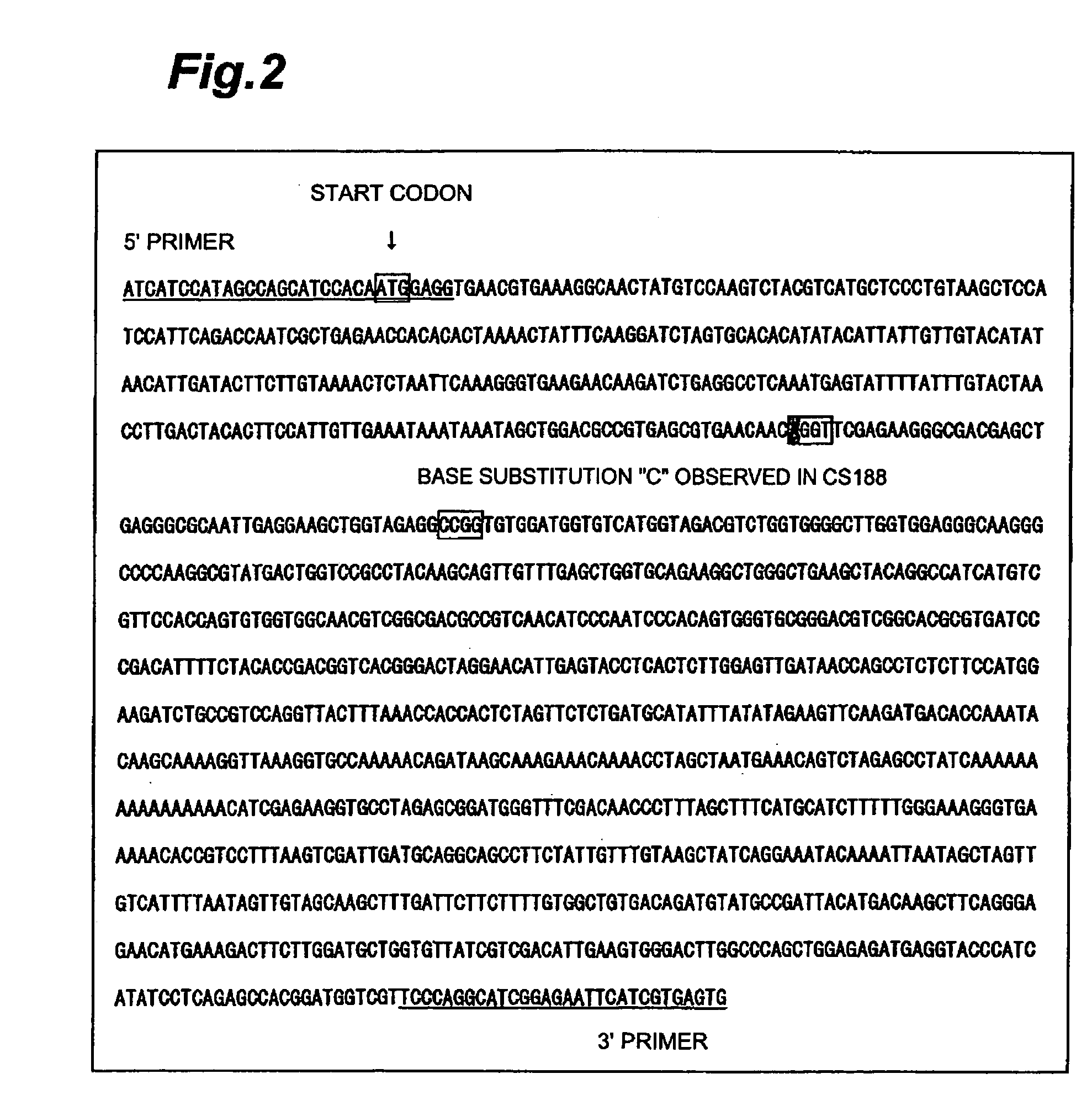

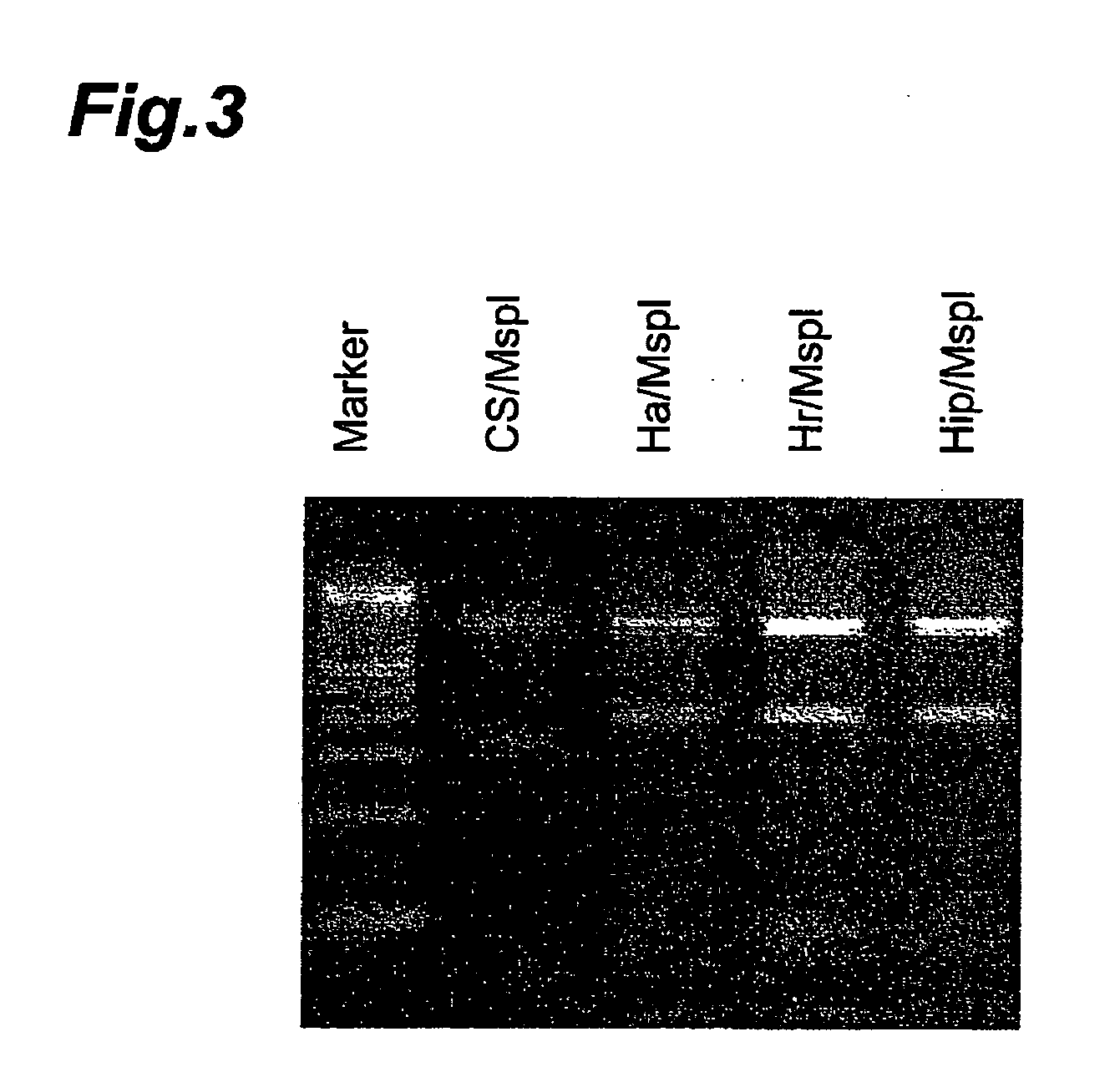

InactiveUS7465557B2Improve saccharification efficiencyImprove heat resistanceSugar derivativesMicrobiological testing/measurementAmylaseHordeum vulgare

A method of selecting a barley variety comprising: a heat treatment step of heat-treating a crude enzyme solution extracted from a seed of a barley (e.g., at 57.5° C. for 30 minutes); an activity-determining step of determining the enzyme activity of β-amylase in the crude enzyme solution heat-treated; and a selection step of selecting the barley variety containing a β-amylase having a residual activity of from 85 to 90% as a result of the activity determination.

Owner:SAPPORO BREWERIES

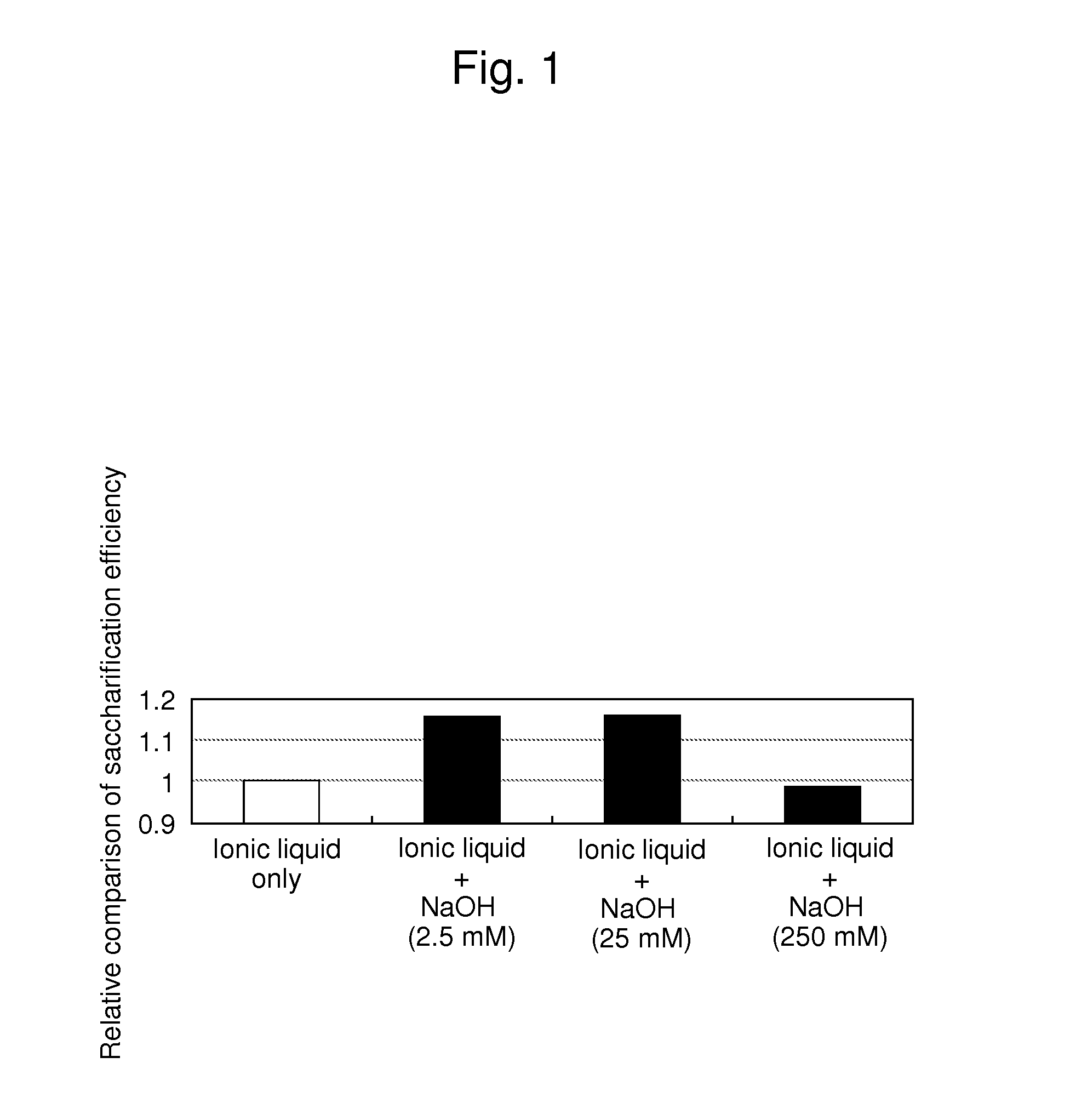

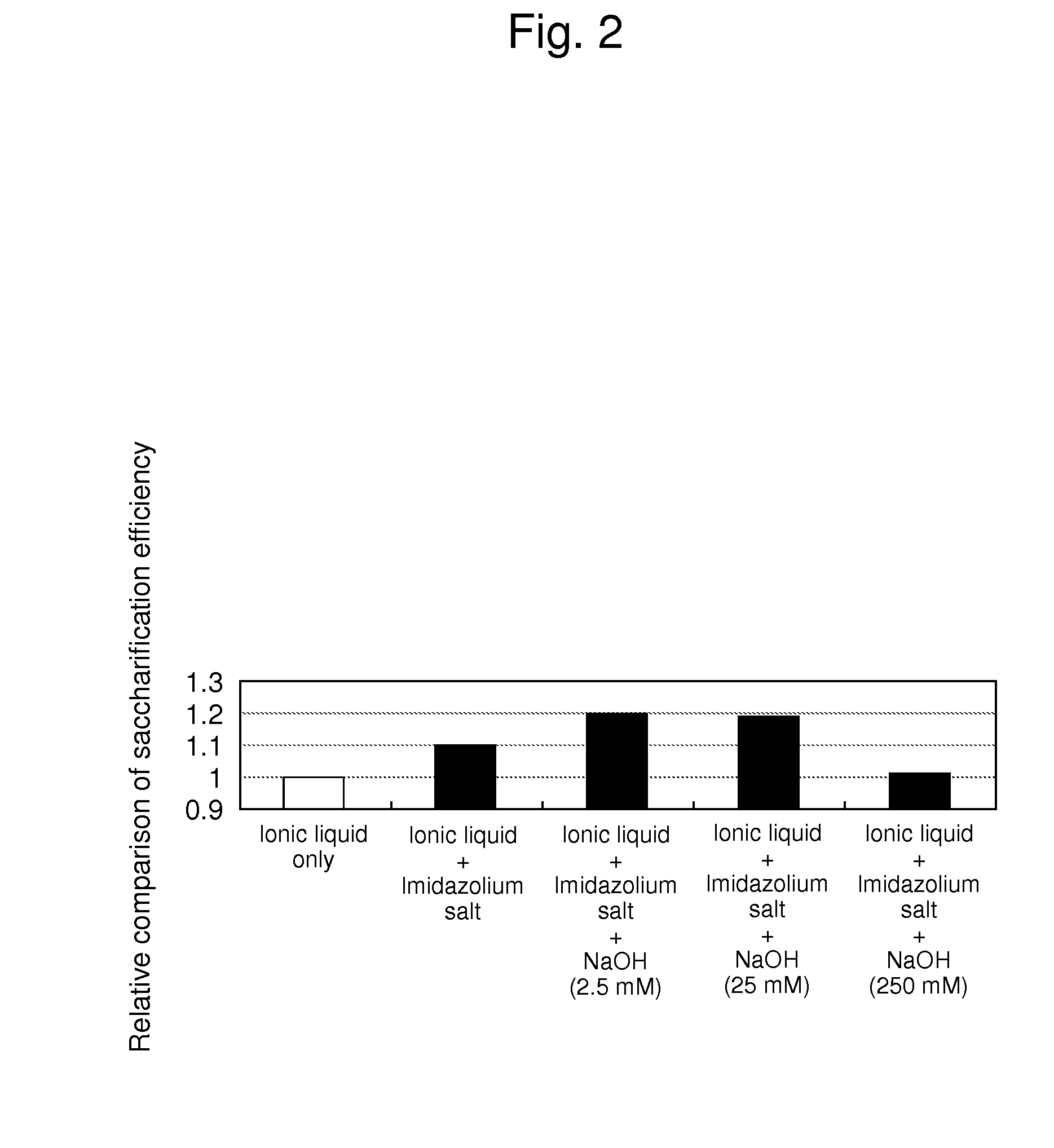

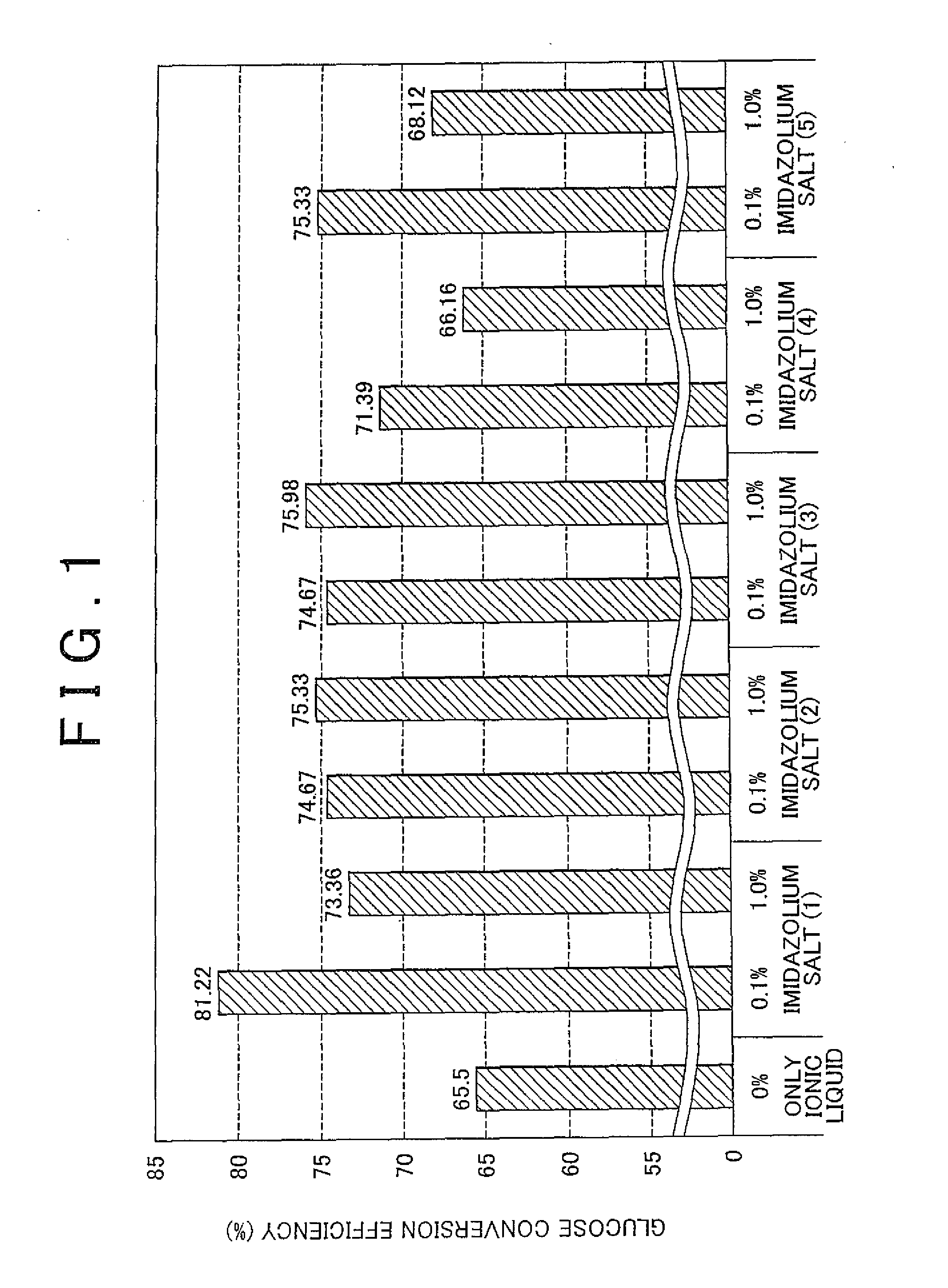

Method for treatment of cellulosic biomass and method for production of sugar, alcohol, or organic acid from cellulosic biomass

InactiveUS20130302854A1Improve saccharification efficiencyEfficient productionBiofuelsFood ingredientsOrganic acidAlcohol

This invention is intended to improve saccharification efficiency by allowing cellulose and / or hemicellulose to relax sufficiently with an ionic liquid. Cellulose and / or hemicellulose is allowed to relax sufficiently with an ionic liquid through a step of soaking cellulosic biomass in a solution containing an ionic liquid and an alkali.

Owner:TOYOTA JIDOSHA KK

Compartmentalized simultaneous saccharification and fermentation of biomass

ActiveUS20110212495A1Facilitated releaseImprove production yieldBioreactor/fermenter combinationsBiological substance pretreatmentsFermentationStereochemistry

Methods and apparatus' are disclosed for the simultaneous saccharification and fermentation of biomass providing for the compartmentalization of the saccharification process and the fermentation process resulting in decreased enzymatic end-product inhibition.

Owner:SUSTAINABLE TECH CORP

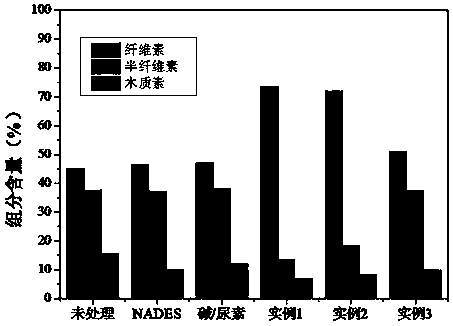

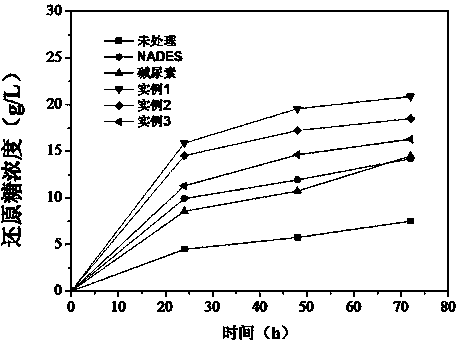

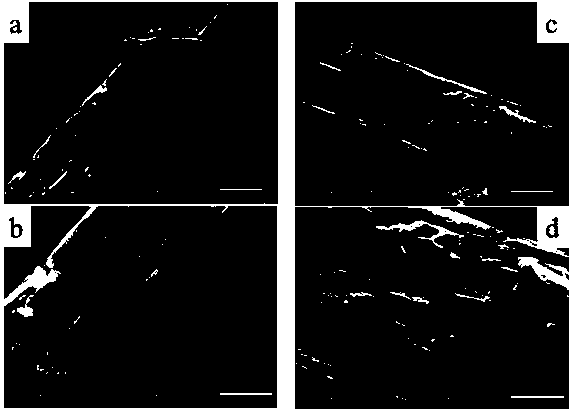

Combined pretreatment process for efficiently and environmentally friendly improving enzymolysis saccharification efficiency of lignocellulose

InactiveCN107488682AReduce crystallinityImprove saccharification efficiencyBiofuelsFermentationCellulasePre treatment

The invention relates to a process for improving enzymolysis saccharification efficiency of lignocelluloses through combined pretreatment of an NADES and NU. The process comprises the following steps: firstly, mixing choline chloride / lactic acid according to a certain ratio, and performing further treatment on a lignocelluloses raw material so as to remove a part of lignin and hemicelluloses and damage the dense structure of the lignocelluloses; further performing a second step of pretreatment on the lignocelluloses by using NU at different temperature. By adopting the process, the ratios of the lignin and the hemicelluloses can be reduced, the surfaces of the lignocelluloses are loosened and porous, the accessible areas of the lignocelluloses are increased, and the saccharification efficiency of the lignocelluloses is improved. The combined pretreatment process has the advantages of being low in equipment requirement, simple to operate, gentle in treatment condition, low in cost, environmentally friendly and the like, and the saccharification efficiency of the lignocelluloses can be greatly improved.

Owner:XIANGTAN UNIV

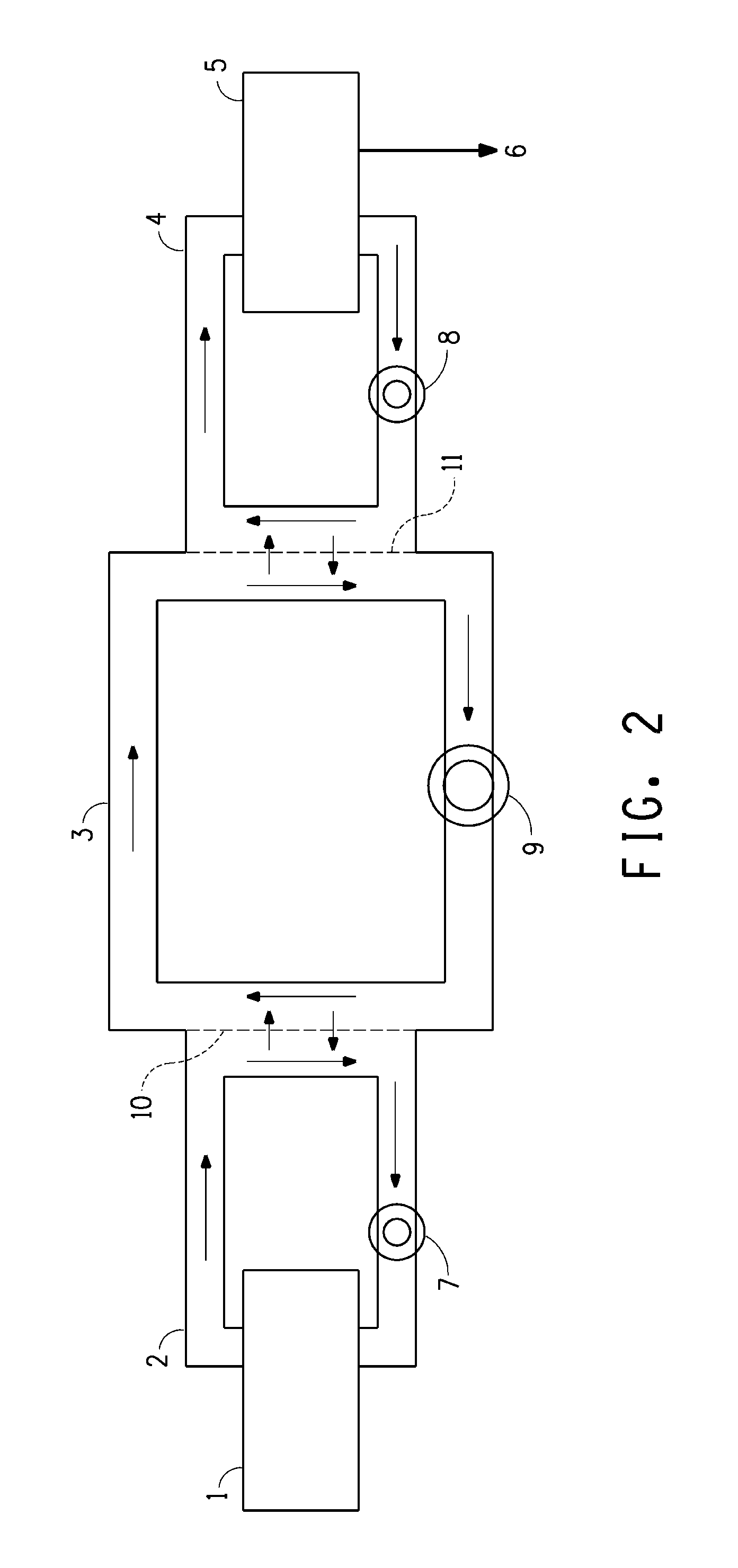

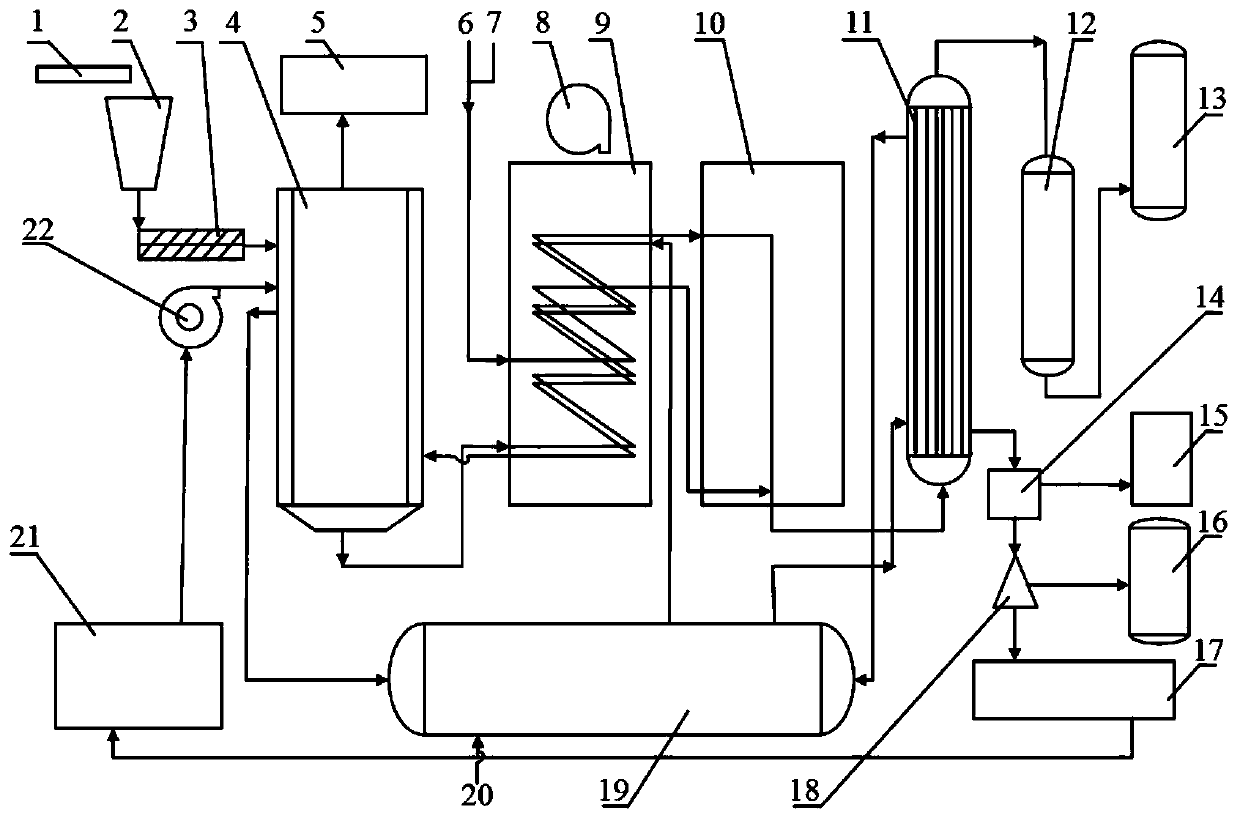

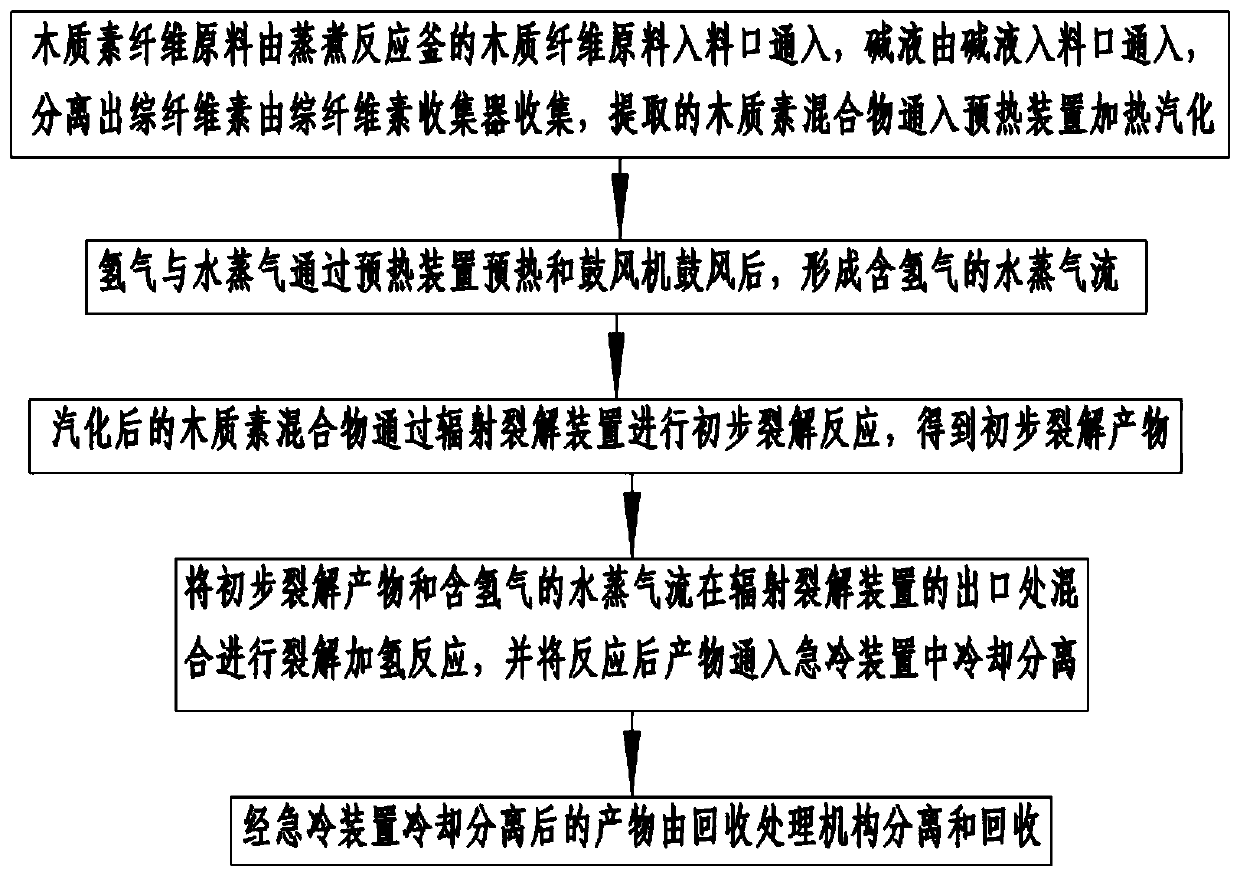

A kind of lignin separation and steam cracking system and method

ActiveCN107151560BHigh extraction recoveryImprove saccharification efficiencyLiquid hydrocarbon mixture productionHydrocarbon oils treatmentFiberQuenching

The invention relates to the technical field of agricultural and forestry biomaterial utilization, and discloses a lignin separation and steam cracking system and a method thereof. The lignin separation and steam cracking system comprises a cooking reaction kettle, a preheating device, a radiation cracking device, a quenching device and a recovery processing mechanism connected sequentially. The lignin is separated from the lignocellulosic raw materials by alkali lye and is decomposed by steam as an oxidizing agent, bio-oil and bio-gas are produced through hydrogenation reaction, residues rich in cellulose and hemicellulose have high efficiency in enzymatic saccharification, the device is simple, the whole system operating temperature is low, the cracking process is stable, the process is simple, environmentally environment-friendly and low in toxicity, the lignin extraction and recovery rate is high, holocellulose saccharification efficiency is high, and industrialization is easy to achieve.

Owner:INT CENT FOR BAMBOO & RATTAN

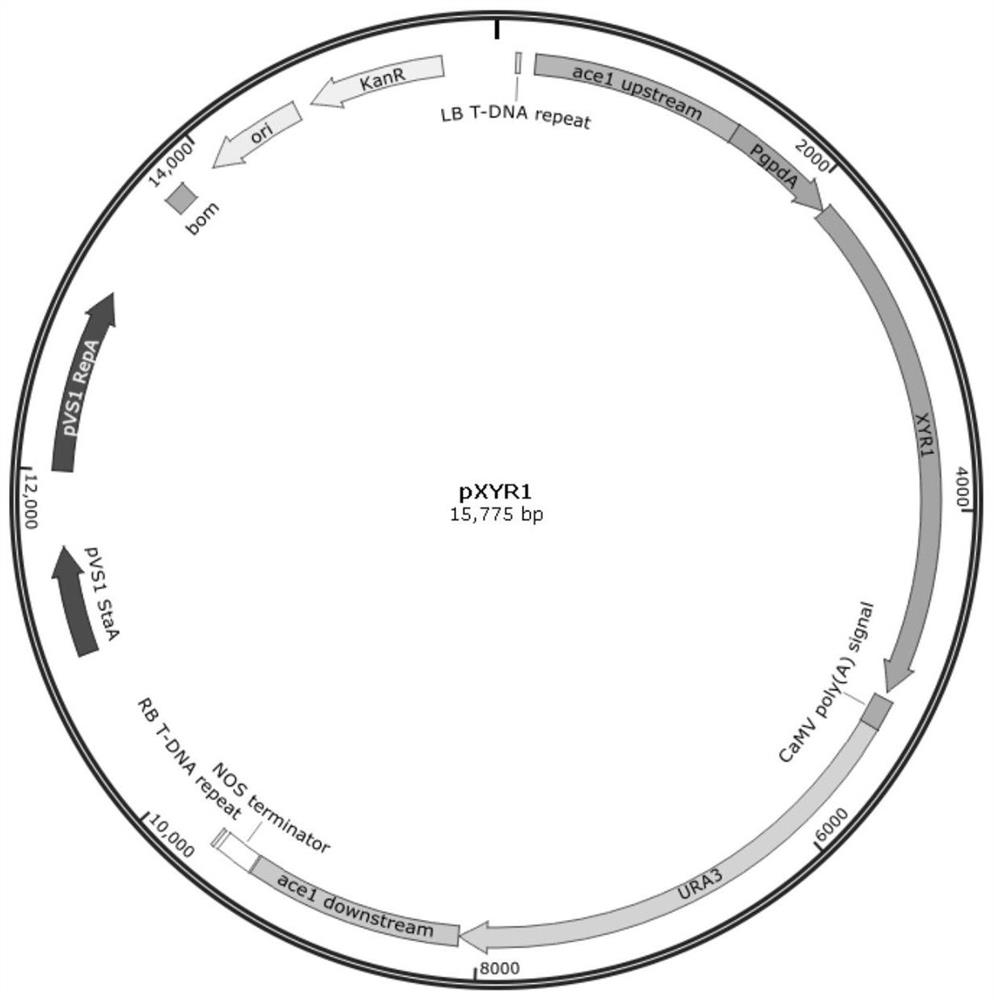

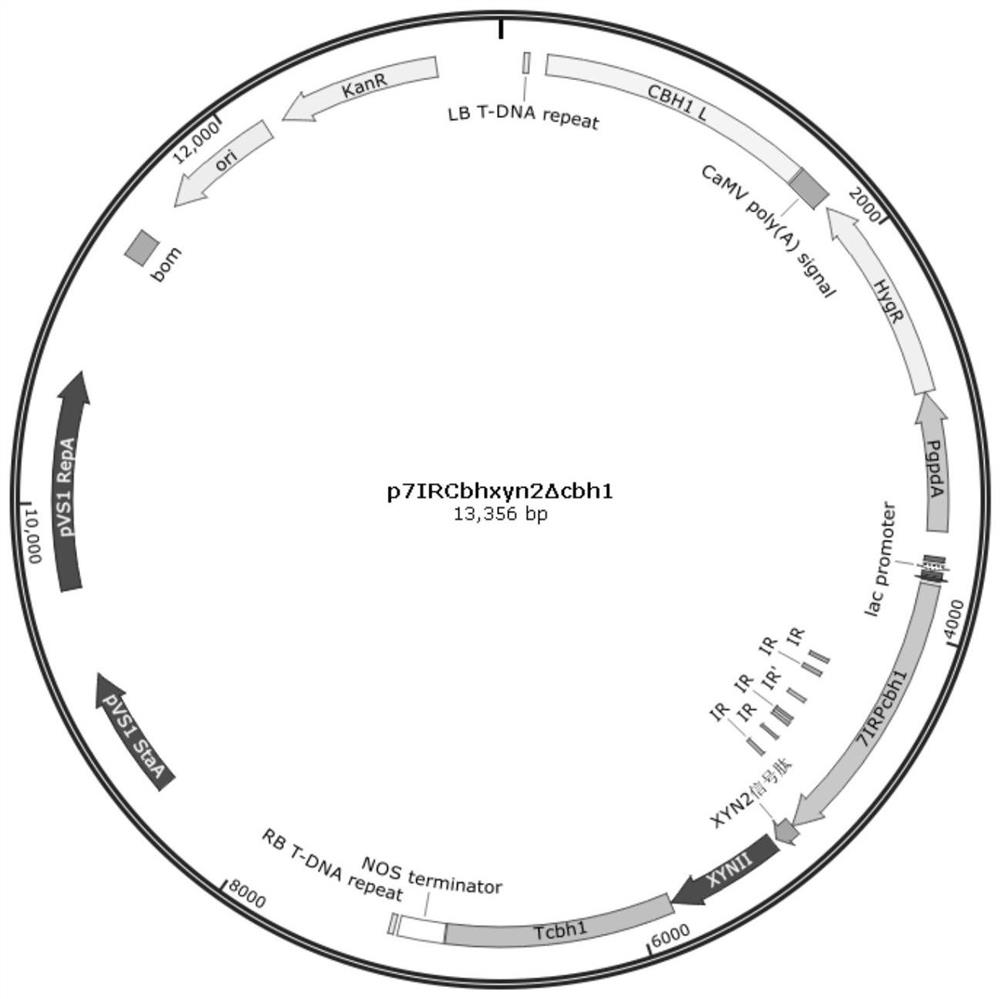

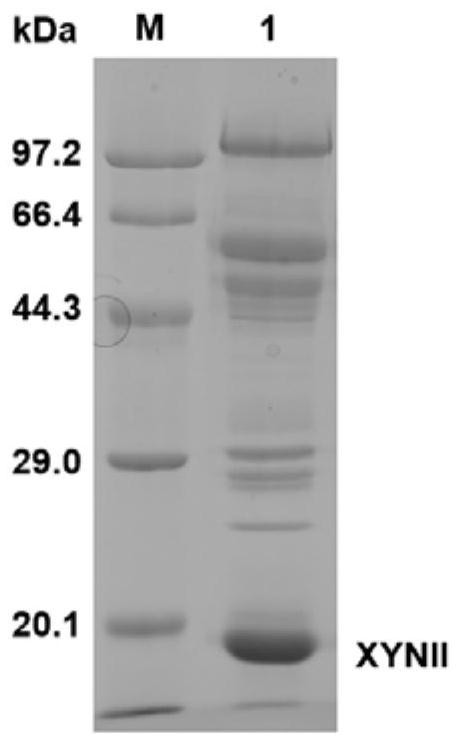

Method for producing xylanase at high yield from trichoderma reesei and application of xylanase

The invention discloses a method for producing xylanase at high yield from trichoderma reesei and application of the xylanase, and belongs to the technical field of bioengineering. According to the invention, a transcription activator XYR1 is expressed to enhance the xylan degrading enzyme expression ability, and a transcription factor binding site on a promoter Pcbh1 is designed, so that XYR1 of constitutive expression can further activate the artificial promoter Pcbh1, and the artificial promoter Pcbh1 is used for expressing homologous xylanase XYNII to obtain recombinant trichoderma reesei. Under the cellulose induction condition, the expression quantity of the recombinant strain xylanase reaches 6410U / mL, which is 9.28 times higher than that of a parent; meanwhile, the activity of xylosidase is improved by 1.93 times and reaches 9.08 U / mL; and the recombinant strain can relieve carbon metabolism repression, soluble cheap carbon sources glucose and lactose are used as fermentation carbon sources, the activity of the extracellular xylanase of 2514 U / mL and the activity of the extracellular xylanase of 3446 U / mL can also be obtained, and meanwhile, the yield of the xylosidase is increased by 9.3 times and 2.3 times compared with that of the parent. Meanwhile, the xylanase produced with the method cooperates with commercial cellulose to perform straw saccharification, so that the saccharification efficiency can be improved by 35%.

Owner:JIANGNAN UNIV

Biological-chemical combined treatment process for improving saccharifying effect of lignocellulose

ActiveCN105177055ALower requirementReduce investmentBiofuelsMicroorganism based processesChemical treatmentMicroorganism

The invention discloses a biological-chemical combined treatment process for improving saccharifying effect of lignocellulose. According to the process, a lignocellulose raw material is subjected to biological treatment by virtue of an efficient lignocelluloses degrading bacterium sphingobacterium sp. LD-1 (preservation number is CGMCC No.10920), so as to remove partial lignin and hemicellulose components in the lignocellulose raw material with the action of microorganisms, and to damage the stable structure of the lignocellulose to a certain degree; and furthermore, the lignocellulose undergoes chemical treatment at low temperature by virtue of alkali / urea, so that the lignocellulose is more loose in structure. The lignocellulose, which is preprocessed by the process disclosed by the invention, achieves significant change in component content and obvious increase in proportion of cellulose; in addition, the structure of the lignocellulose is significantly changed as well, and the surface of the raw material becomes rough, loose and porous, so as to greatly increase an accessible surface during enzymolysis saccharifying. The combined pretreatment process disclosed by the invention has the advantages of being not high in requirement on equipment, simple in operation, mild in processing condition, low in cost and the like, and the saccharifying efficiency of the lignocellulose is greatly improved.

Owner:湖南中森环境科技有限公司

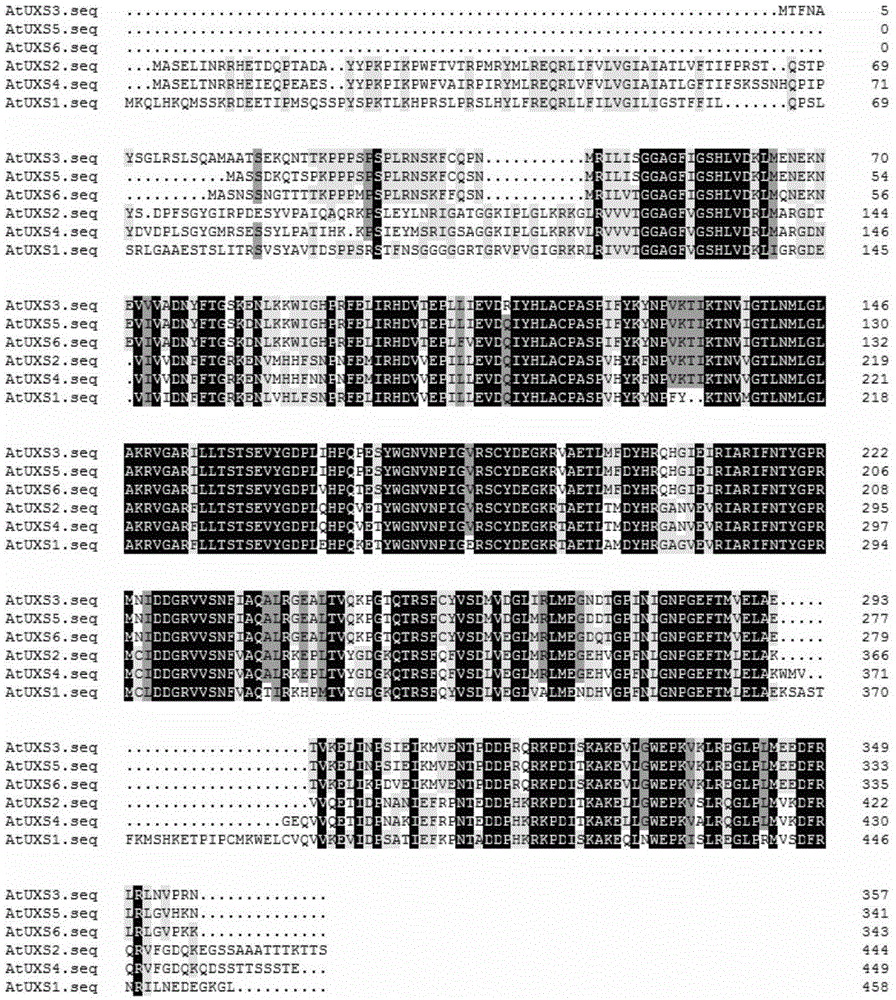

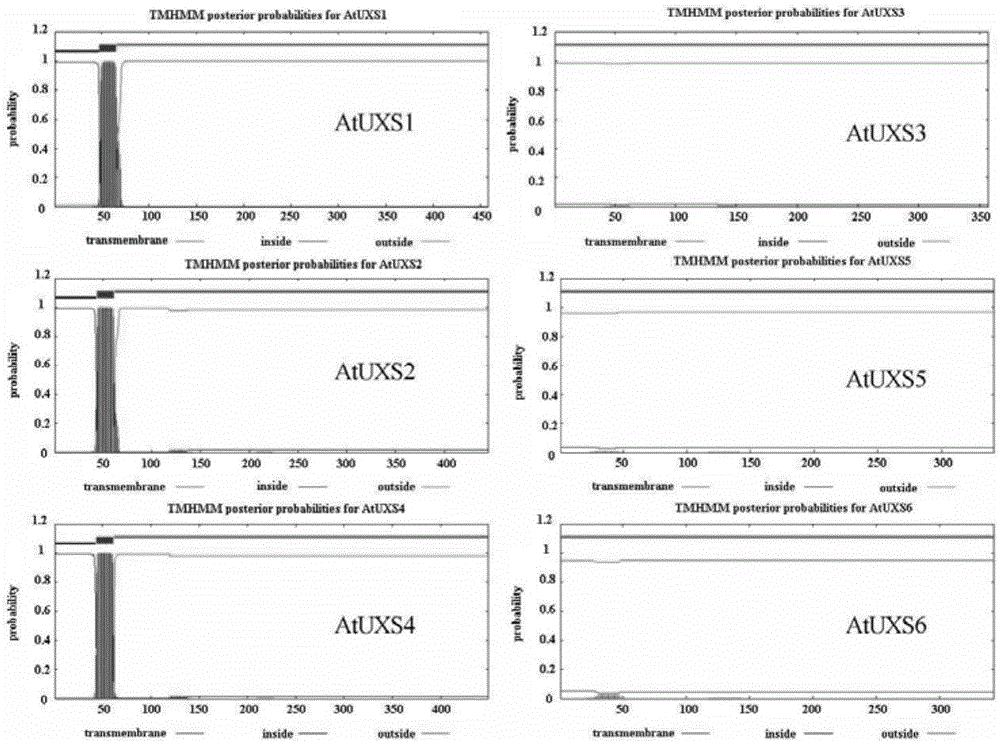

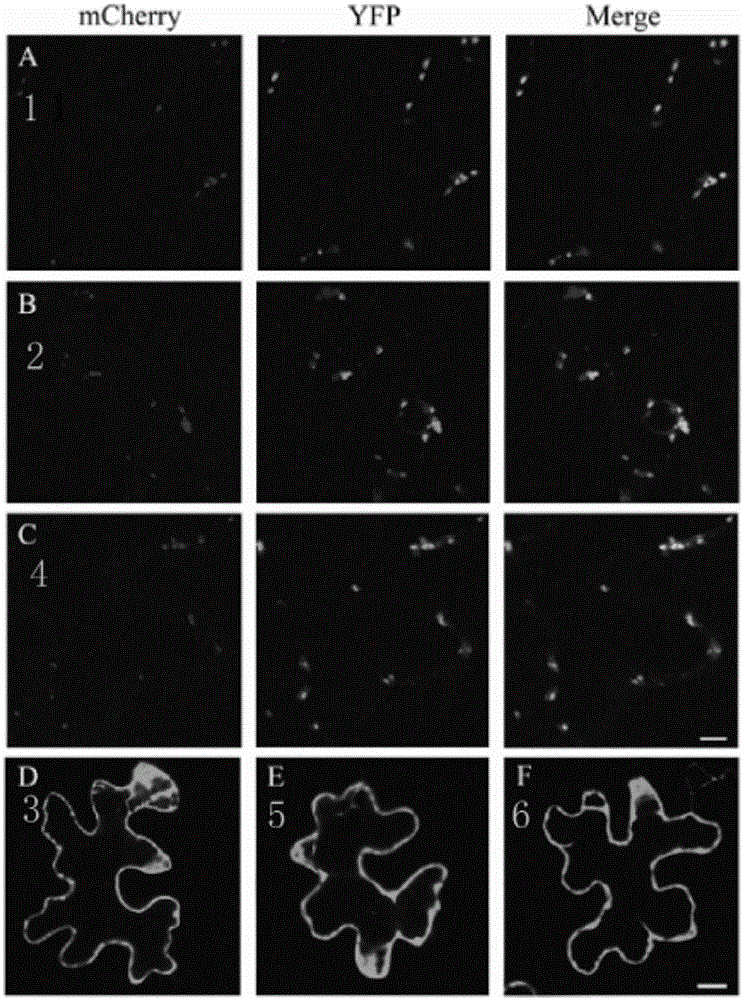

Method for improving plant saccharification efficiency and application of method

ActiveCN105112439AImprove utilization efficiencyIncrease available ingredientsVector-based foreign material introductionAngiosperms/flowering plantsCellulosePaper manufacturing

The invention discloses a method for improving plant saccharification efficiency and application of the method, and belongs to the field of biomass energy. The plant saccharification efficiency is improved by mutation or lowering of UXS genes of plants. By the method, the content of xylose is reduced, relative content of cellulose is increased correspondingly, the saccharification efficiency of a mutant material can be improved owing to reduction of the content of the xylose, and the material treatment cost is reduced. Therefore, biomass characteristics of the material are changed fundamentally, the saccharification efficiency is improved fundamentally, energy can be saved, and labor intensity is reduced. Materials obtained by the method can be used in biomass conversion, pulp and paper manufacturing industry.

Owner:SOUTH CHINA AGRI UNIV

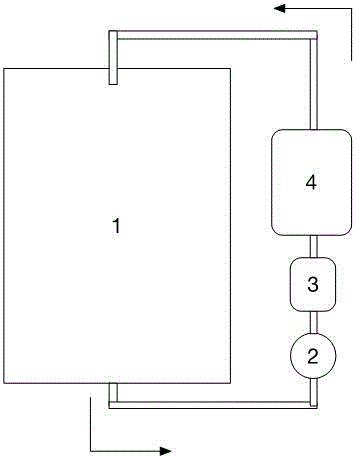

Beer brewing saccharifying heating device and beer brewing saccharifying heating method

InactiveCN105886180ALiquid temperature difference is smallHeating fastWort preparationMalt GrainTemperature difference

The invention relates to a beer brewing saccharifying heating device and a beer brewing saccharifying heating method. The beer brewing saccharifying heating device comprises a saccharifying container, a water pump and a heating module. The saccharifying container is used for accommodating malt and comprises a first opening and a second opening; the first opening is connected with the second opening by the water pump and the heating module, the heating module comprises pipes and electric heating elements, and the electric heating elements are positioned on the outer sides of the pipes. According to the technical scheme, the beer brewing saccharifying heating device and the beer brewing saccharifying heating method have the advantages that the beer brewing saccharifying heating device and the beer brewing saccharifying heating method are high in heating speed, and liquid in the integral saccharifying container is low in temperature difference; the beer brewing saccharifying heating device and the beer brewing saccharifying heating method are easy to implement, the beer brewing saccharifying heating device is small in occupied space, electricity can be saved, the temperatures can be accurately controlled, and more importantly, the beer brewing saccharifying heating device and the beer brewing saccharifying heating method are high in malt saccharifying efficiency.

Owner:爱咕噜(上海)智能科技有限公司

Method of selecting barley variety, barley beta-amylase gene and process for producing malt alcoholic drink

InactiveUS20050053934A1Increases starch-decomposing efficiencyRaise saccharization temperatureMicrobiological testing/measurementGenetic engineeringAmylaseMalt Grain

A method of selecting a barley variety comprising: a heat treatment step of heat-treating a crude enzyme solution extracted from a seed of a barley (e.g., at 57.5° C. for 30 minutes); an activity-determining step of determining the enzyme activity of β-amylase in the crude enzyme solution heat-treated; and a selection step of selecting the barley variety containing a β-amylase having a residual activity of from 85 to 90% as a result of the activity determination.

Owner:SAPPORO BREWERIES

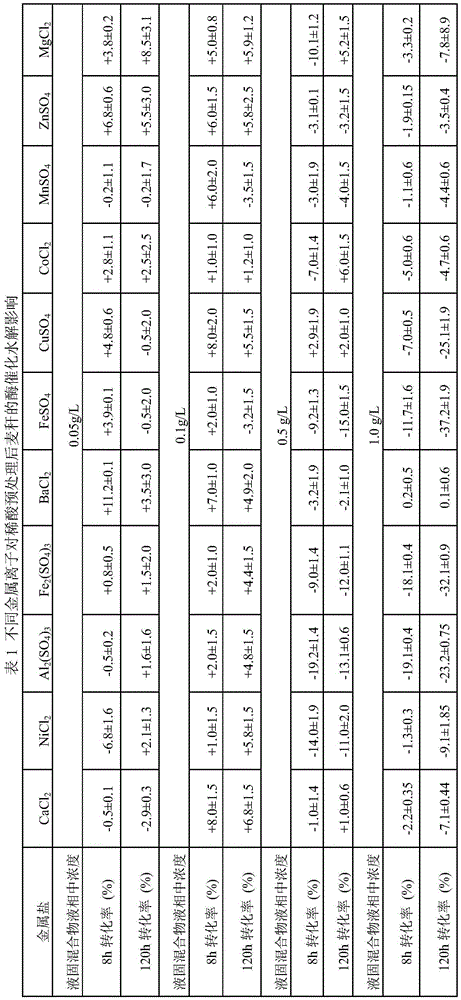

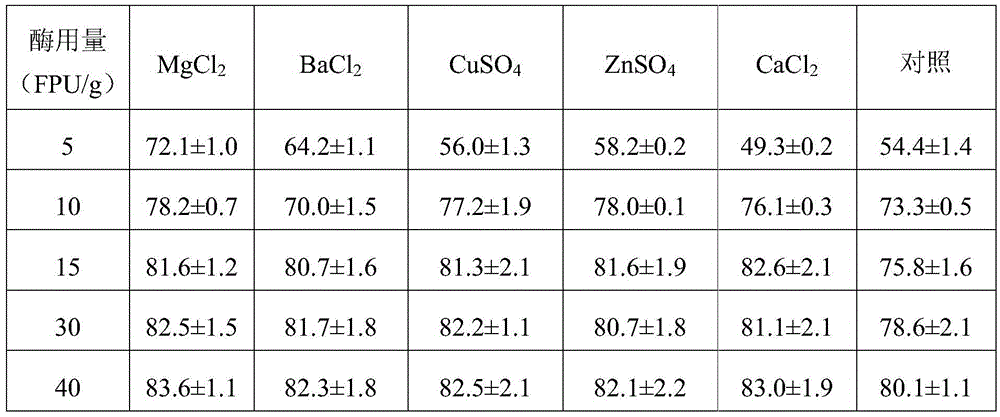

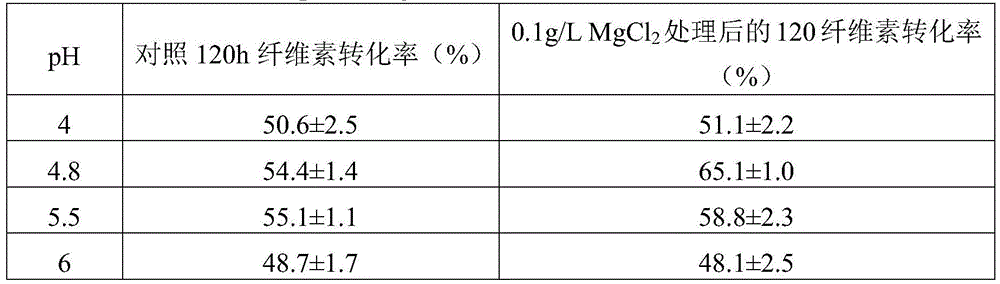

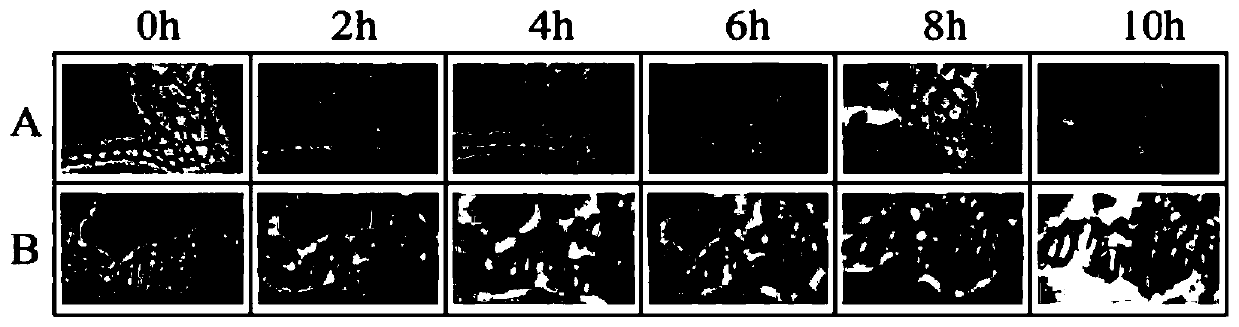

Method for promoting enzymatic hydrolysis of lignocellulose

InactiveCN105524959AReduce invalid adsorptionImprove saccharification efficiencyFermentationEnzymatic hydrolysisPh regulation

The invention discloses a method for promoting enzymatic hydrolysis of lignocellulose. The method comprises the following steps: (1) mixing lignocellulose and a pH regulation solution for obtaining a first liquid-solid mixture, wherein the lignocellulose is subjected to pretreatment in advance, and the pH value of the pH regulation solution is 4.0-10.0; (2) adding a metal salt solution to the first liquid-solid mixture, and reacting for preset time to obtain a second liquid-solid mixture; (3) separating the second liquid-solid mixture to obtain a solid; and (4) enabling the solid to be subjected to enzymatic hydrolysis by utilizing cellulose. With the adoption of the method, the invalid adsorption of lignin for the cellulose can be effectively reduced, the enzymatic hydrolysis of the lignocellulose is promoted, and the saccharifying efficiency of the cellulose is improved; and the method is low in cost, and easy for popularization and use.

Owner:TSINGHUA UNIV +1

Full bacteria saccharification method for lignocellulose

InactiveCN109055459AShort cycleLow costMicroorganism based processesFermentationCarbon sourceCellulose

The invention provides a full bacteria saccharification method for lignocellulose. The full bacteria saccharification method comprises the following steps of (1) optimizing of a seed solution under the anaerobic condition, performing passage domestication on a cellulosome-producing strain on a culture medium using glucose as a unique carbon source; then, inoculating into a glucose culture medium added with the pretreated lignocellulose raw material, and performing inducing domestication; (2) pre-impregnating of raw materials: uniformly mixing the pretreated lignocellulose raw material and a culture medium solution; (3) full bacteria saccharification: inoculating the optimized seed solution of full bacteria saccharification in step (1) into a reaction system after pre-impregnating, and performing saccharification reaction, so as to obtain the solution containing the glucose. The full bacteria saccharification method has the advantages that the cycle in the seed culture phase is greatlyshortened, the cost of the seed solution is reduced, the full bacteria saccharification cycle is shortened, and a foundation is laid for the industrialization process.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Method for improving lignocellulose saccharification efficiency

PendingCN110669804AImprove accessibilityImprove saccharification efficiencyPulping with acid salts/anhydridesPulping with organic solventsBiologyPolymer chemistry

The invention relates to the field of biotransformation, in particular to a method for improving lignocellulose saccharification efficiency. The invention relates to the method for improving lignocellulose saccharification efficiency, which comprises the following steps: (1) pretreating a lignocellulose material: pretreating the lignocellulose material to obtain a pretreated product, and pulverizing the pretreated product into powder; (2) performing enzymolysis: adding cellulase, an enzymolysis additive and a solvent into the pretreated product to carry out enzymatic saccharification reaction;and (3) obtaining a lignocellulose saccharification product: after an enzymatic saccharification reaction is finished, obtaining a centrifuged supernate which is the lignocellulose saccharification product. According to the method, the accessibility of hydrolysis factors to cellulose is improved by pretreating the lignocellulose material and adding an enzymolysis additive, so that the saccharification efficiency of the lignocellulose is improved.

Owner:HUBEI UNIV

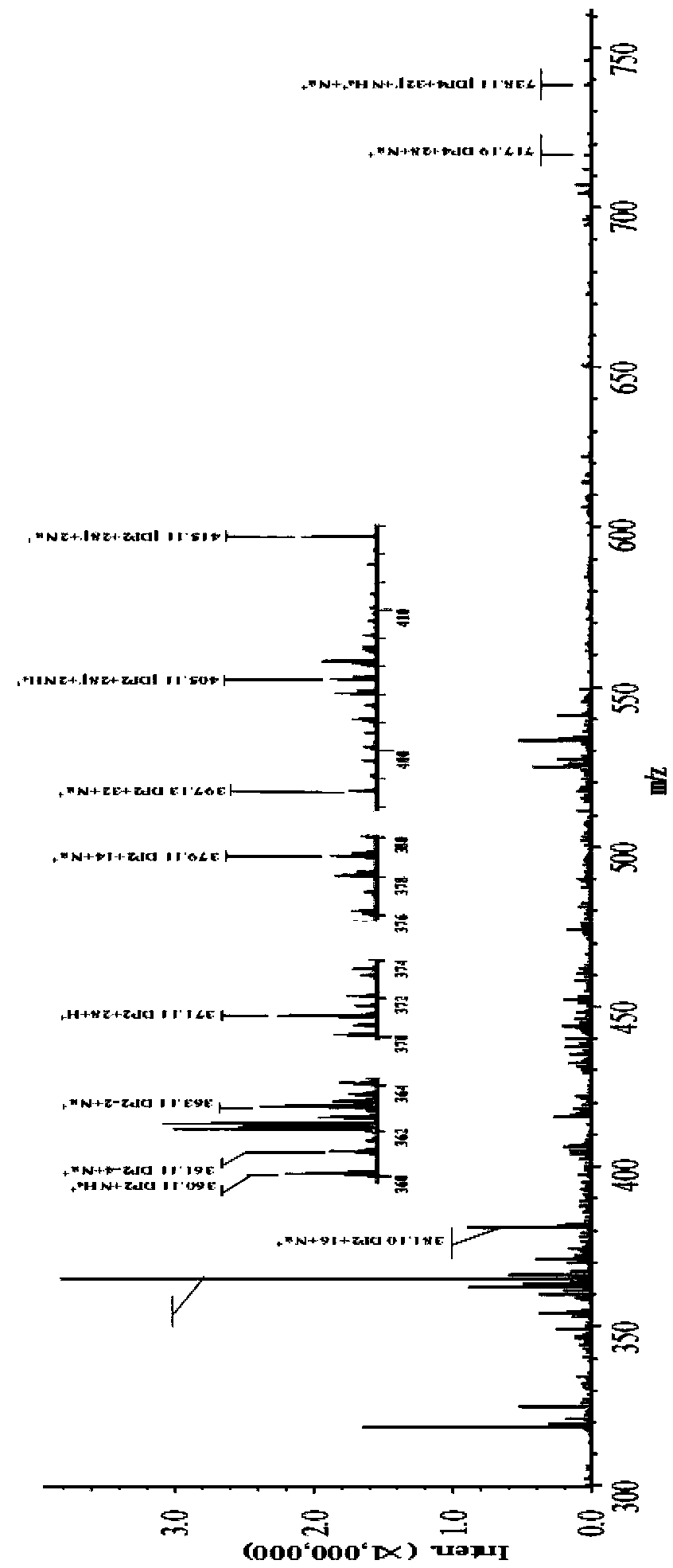

Polypeptides having cellulolytic degradation enhancing activity and application thereof

ActiveCN109554355AImprove saccharification efficiencyImprove utilization efficiencyFungiBiofuelsChemistryAmino acid

The present disclosure relates to polypeptides having cellulolytic degradation enhancing activity and application thereof, and provides application of polypeptides with an amino acid sequence shonw asa SEQ ID NO.1 in the preparation of a thermostable auxiliary active enzyme having cellulolytic degradation enhancing activity. The polypeptides can effectively degrade cellulose, and can be combinedwith other cellulose degrading enzymes to improve the saccharification efficiency of cellulose-containing raw materials; and the polypeptides can be further applied to industrial fermentation production of ethanol by using lignocellulose such as straw, thereby increasing the utilization efficiency of the lignocellulose such as straw.

Owner:SHANDONG HENGLU BIOTECH CO LTD

Biological-ionic liquid combined pretreatment method of lignocellulose

InactiveCN106086115AShorten biological pretreatment cyclePreserve Fiber ContentMicroorganism based processesFermentationPretreatment methodCellulase

The invention relates to a method for improving the lignocellulose saccharification efficiency by means of bacterium and ionic liquid combined pretreatment. The method comprises the steps that biological treatment is conducted on the lignocellulose raw materials by means of an efficient lignin degradation bacterium Sphingobacterium sp.LD-1 of which the preservation number is CGMCC No.10920, partial lignin and hemicellulose are removed, and the dense structure of the lignin is destroyed to a certain extent; pretreatment is conducted on the lignocellulose at a certain temperature for a certain period of time by means of an ionic liquid. According to the method for improving the lignocellulose saccharification efficiency by means of bacterium and ionic liquid combined pretreatment, the proportions of the lignin and the hemicellulose can be reduced, the degree of crystallinity of the lignocellulose is obviously decreased, the accessible surface of cellulase is enlarged, and the saccharification efficiency of the lignocellulose is improved. The method for improving the lignocellulose saccharification efficiency by means of bacterium and ionic liquid combined pretreatment has the advantages of being low in requirement of equipment on compression resistance and corrosion resistance, easy to operate, environmentally friendly and the like.

Owner:XIANGTAN UNIV

Method of treating plant biomass

InactiveUS20130130328A1Efficient degradationEfficiently obtainedBiofuelsWaste based fuelCellulaseSolvent

Plant biomass is immersed in a solution that contains a polar solvent and an imidazolium salt that has a melting point of at least 100° C. As a result, the cellulose and hemicellulose present in the plant biomass are relaxed (decrystallized and depolymerized) and brought into an easy-to-degrade state. Reacting the immersed plant biomass with a cellulase produces saccharide at a high conversion efficiency.

Owner:TOYOTA JIDOSHA KK

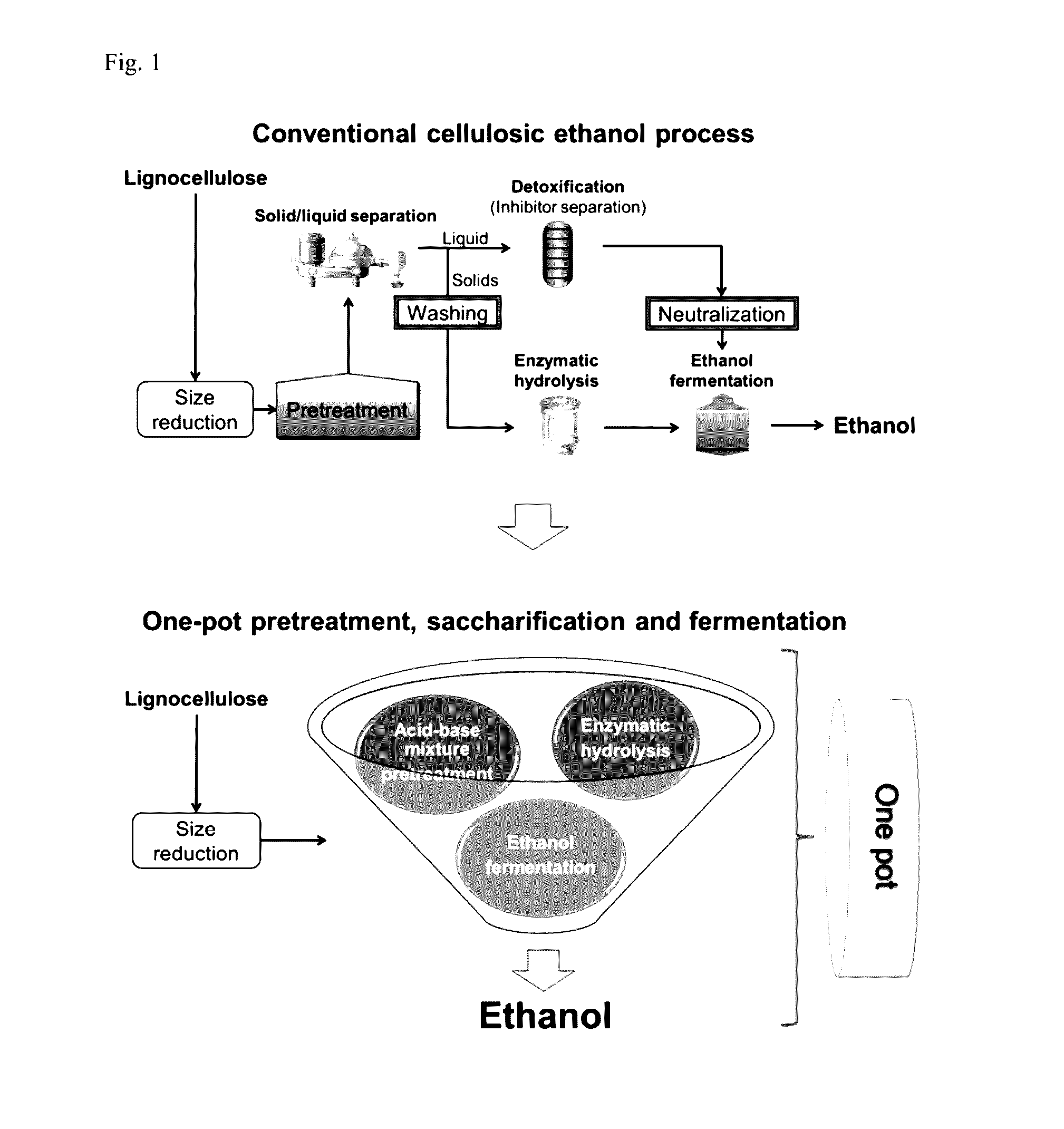

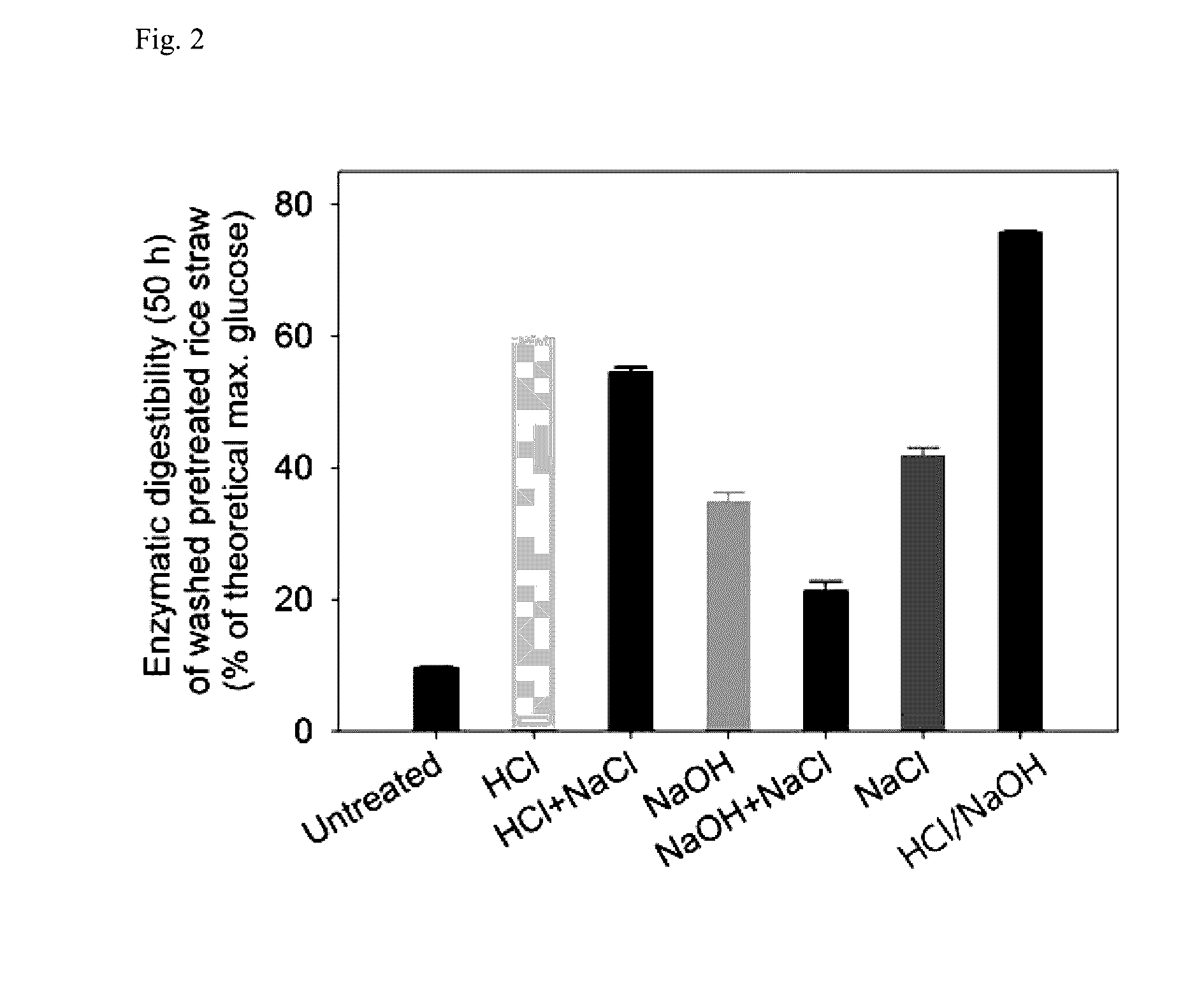

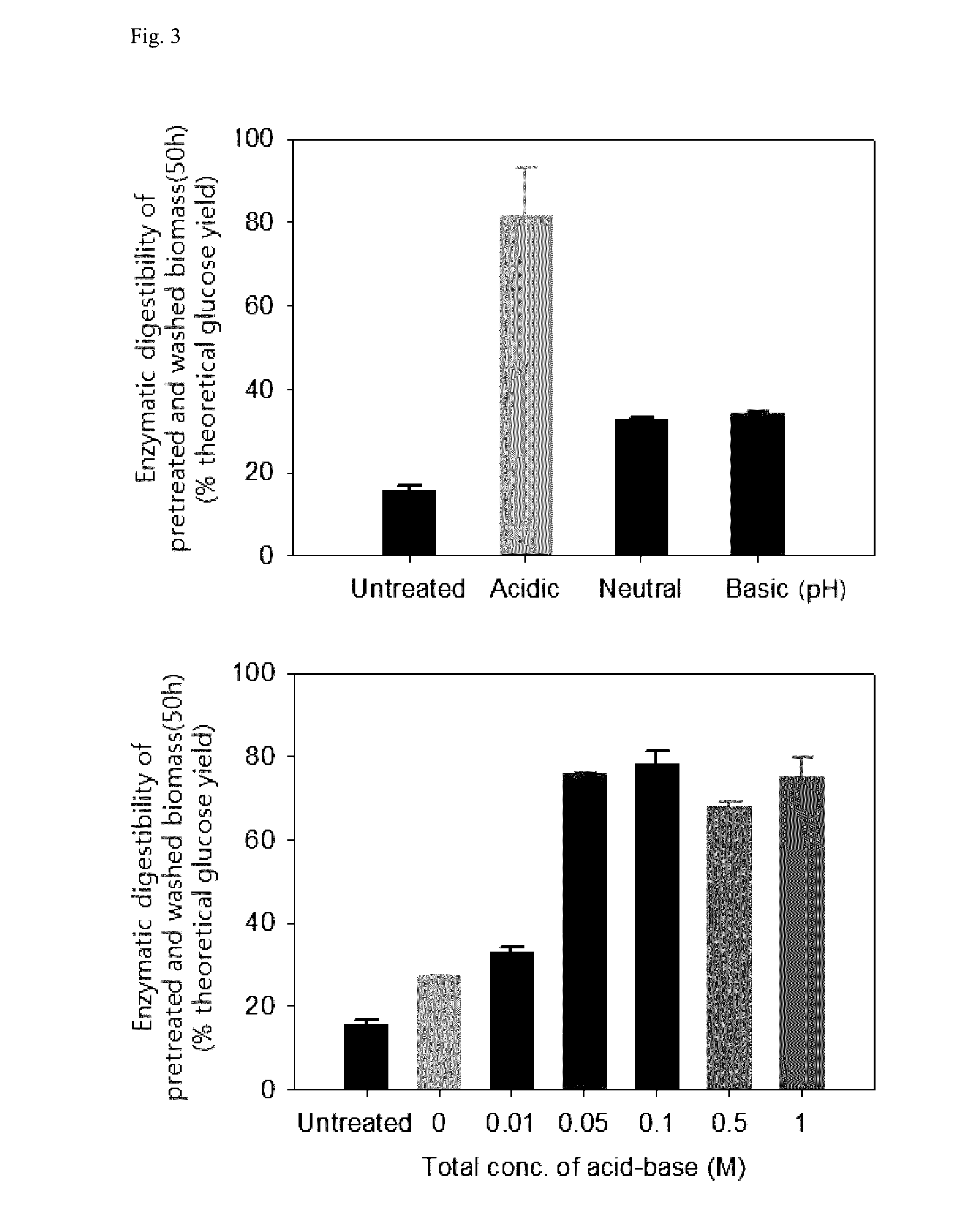

Method for pretreating lignocellulose by using acid-base mixture catalyst

ActiveUS20170044329A1Improve production yieldImprove saccharification efficiencyBiofuelsFermentationCelluloseLignocellulosic biomass

The present invention relates to a method for pretreating lignocellulose by using an acid-base mixture catalyst. The method pretreats lignocellulose, by using a mixture catalyst of an acid and a base, so as not to pass through additional neutralization steps, and carries out pretreatment and simultaneous saccharification and fermentation through an identical single reactor process, thereby having an effect of producing ethanol in an excellent production yield from lignocellulosic biomass while simplifying the total process and reducing equipment costs and total processing costs.

Owner:KOREA UNIV RES & BUSINESS FOUND

Brewing method of Japanese Peristrophe Herb health red koji wine

InactiveCN105524783AHeat-clearing and detoxifyingLiver-protectiveAlcoholic beverage preparationMicroorganism based processesBrewingHorticulture

The invention relates to a brewing method of Japanese Peristrophe Herb health red koji wine. The method comprises the following steps: taking fresh stems, flowers and leaves of Japanese Peristrophe Herb, boiling the stems, flowers and leaves, taking the obtained detection, immersing glutinous rice-indica rice mixed uncooked rice, and boiling the mixed uncooked rice to form cooked rice; and inoculating a monascus seed liquid, saccharifying, mixing with wine koji and sweet wine koji, pre-fermenting, adding high-alcohol rice wine, and fermenting and ageing to obtain the Japanese Peristrophe Herb health red koji wine. The Japanese Peristrophe Herb health red koji wine has the characteristics of abundant active substances, red and brilliant color, soft smell and fragrance, and mellow and full mouthfeel, and is a health wine with heat clearing, detoxifying, liver protecting, blood fat conditioning and other physiologically active functions.

Owner:HEZHOU UNIV

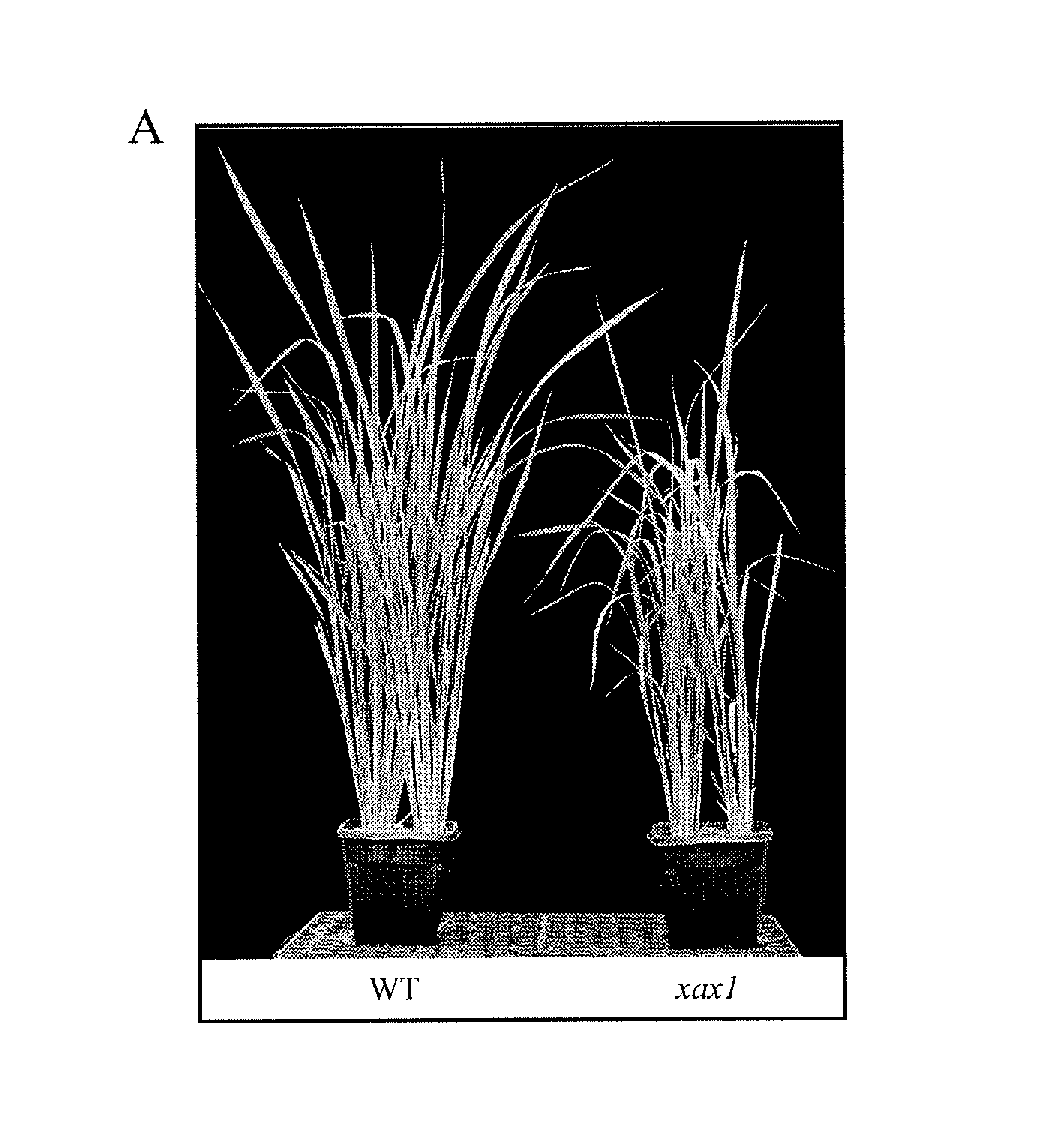

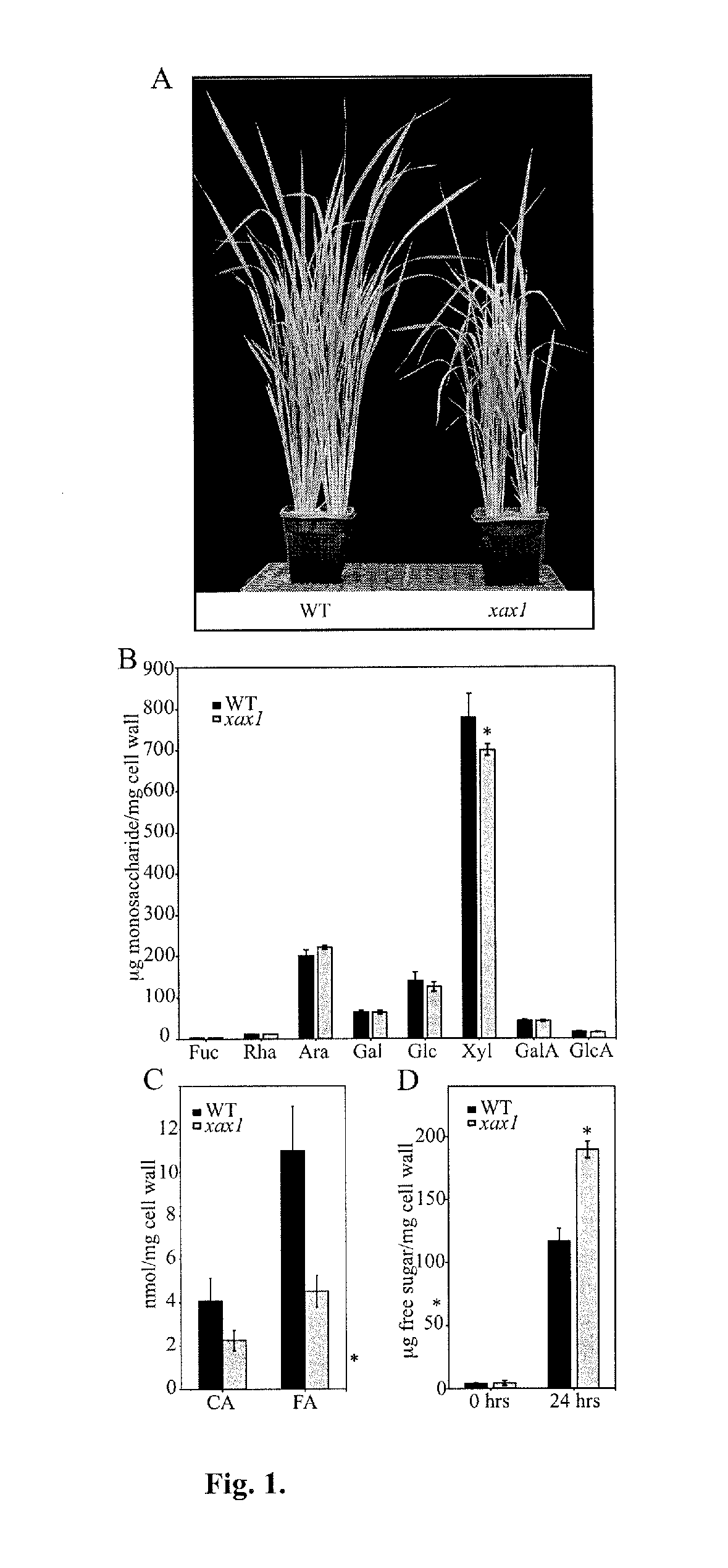

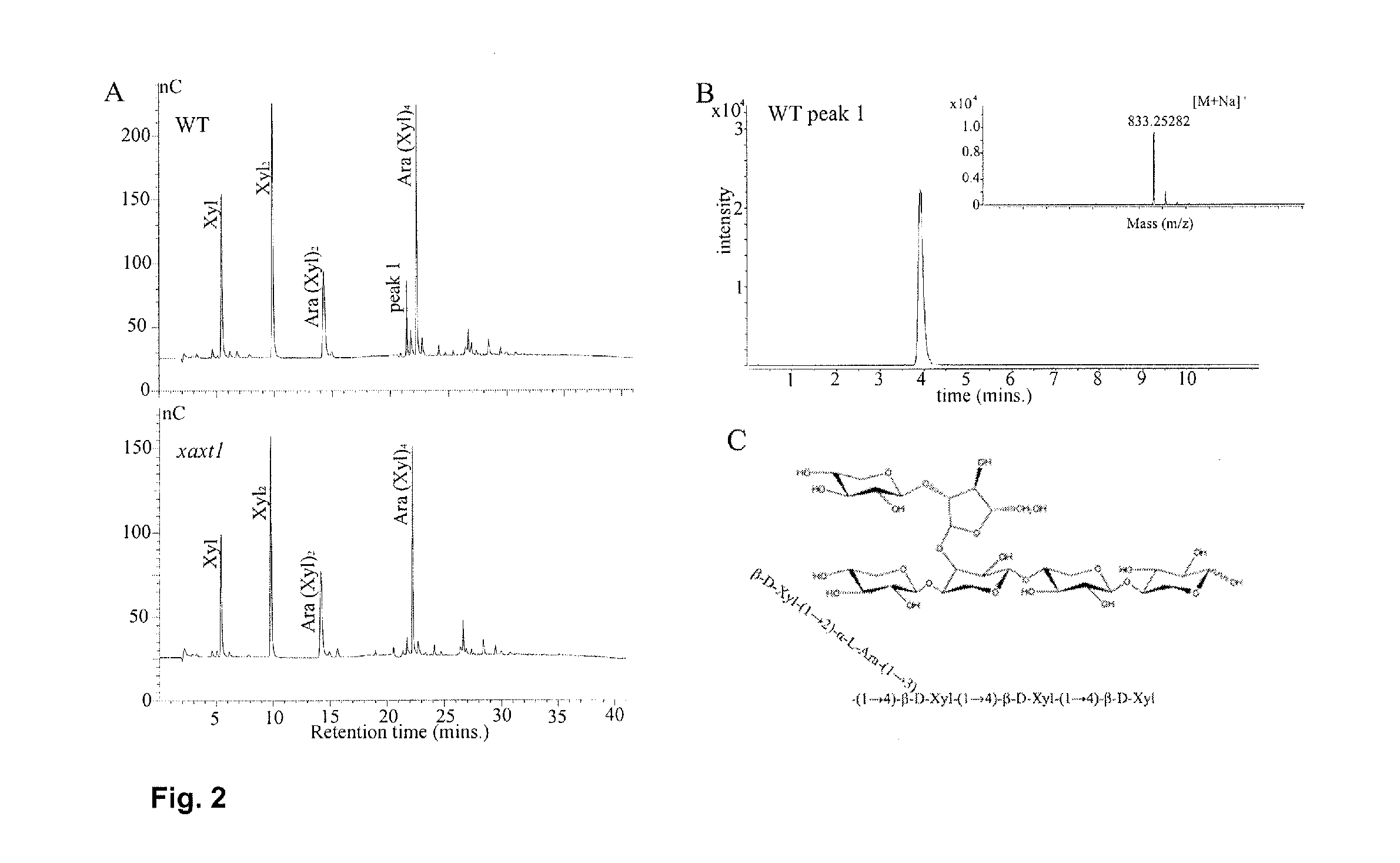

Inhibition of a Xylosyltransferase to Improve Saccharification Efficiency

ActiveUS20140033365A1Increase volumeExcellent extractabilityOther foreign material introduction processesFermentationXylosyltransferaseBiotechnology

Owner:RGT UNIV OF CALIFORNIA

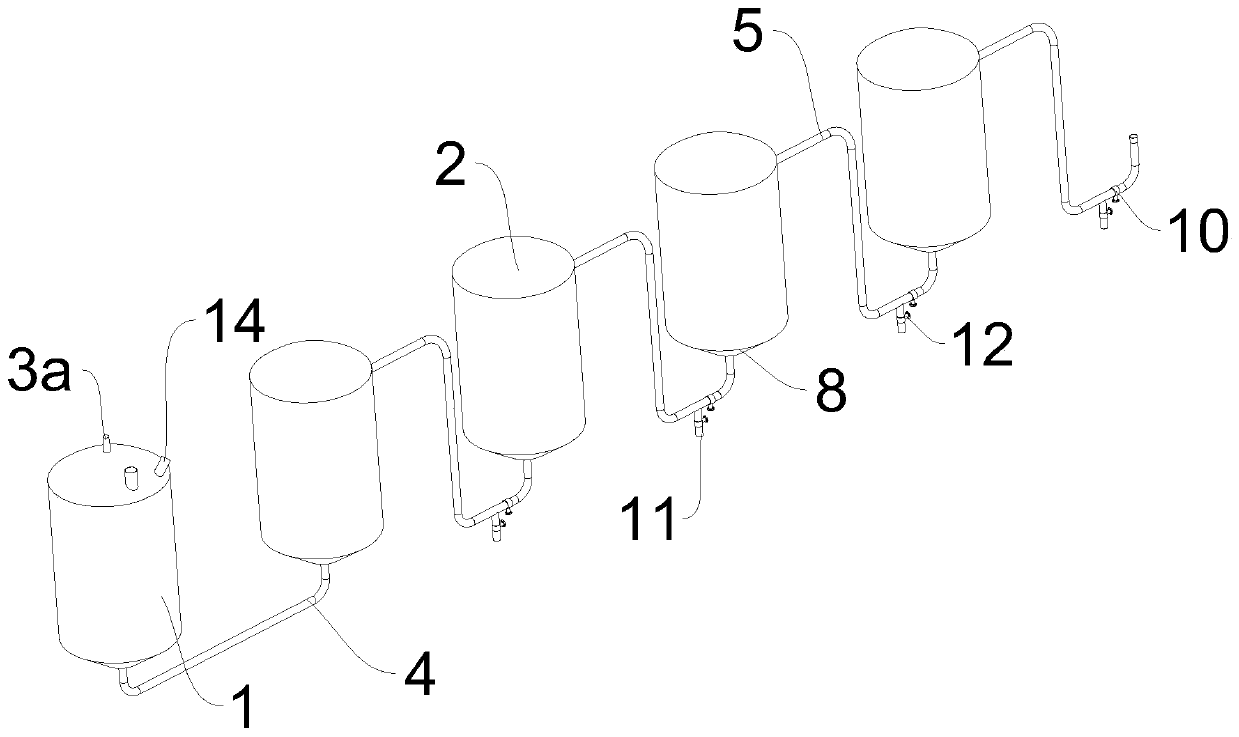

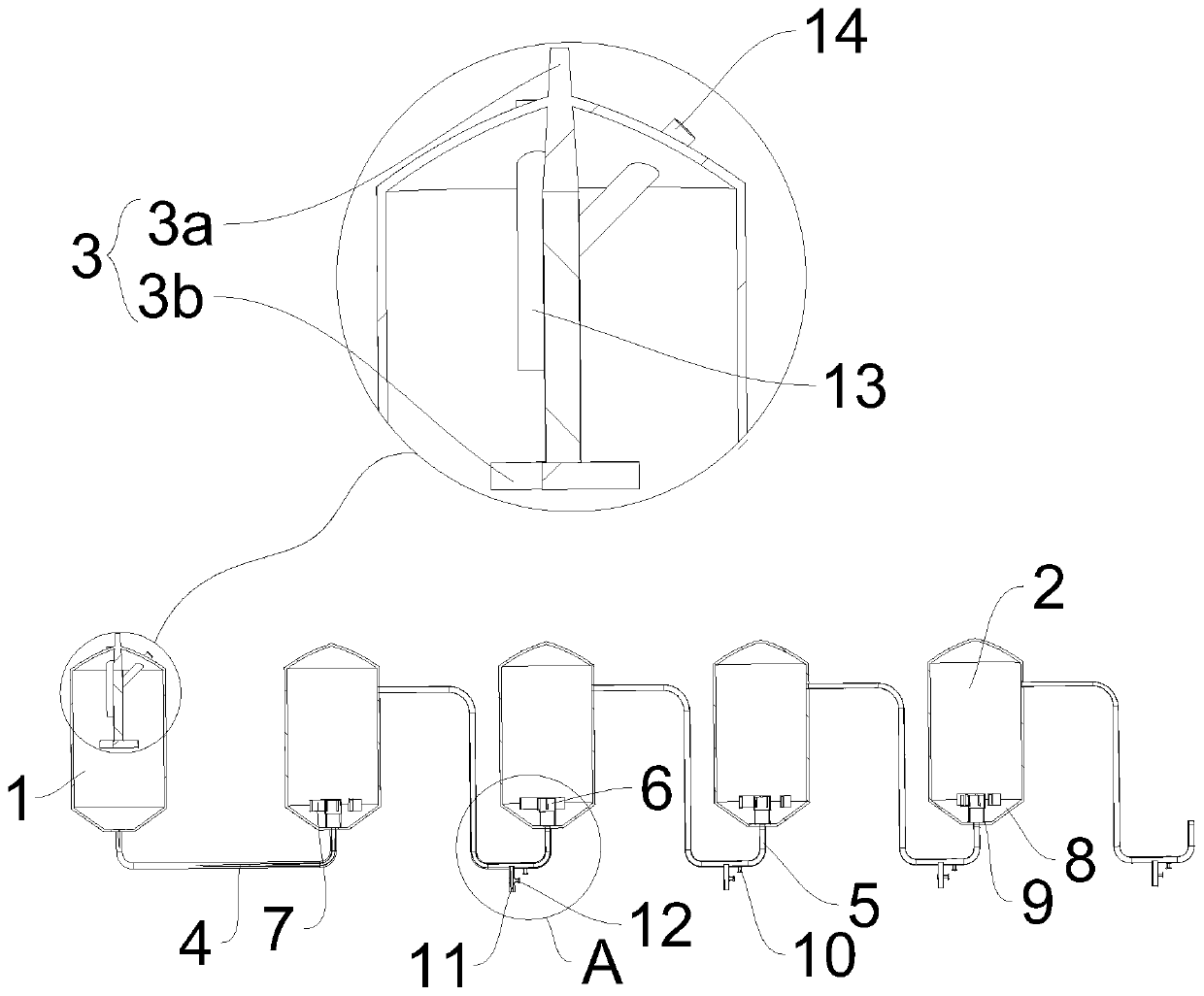

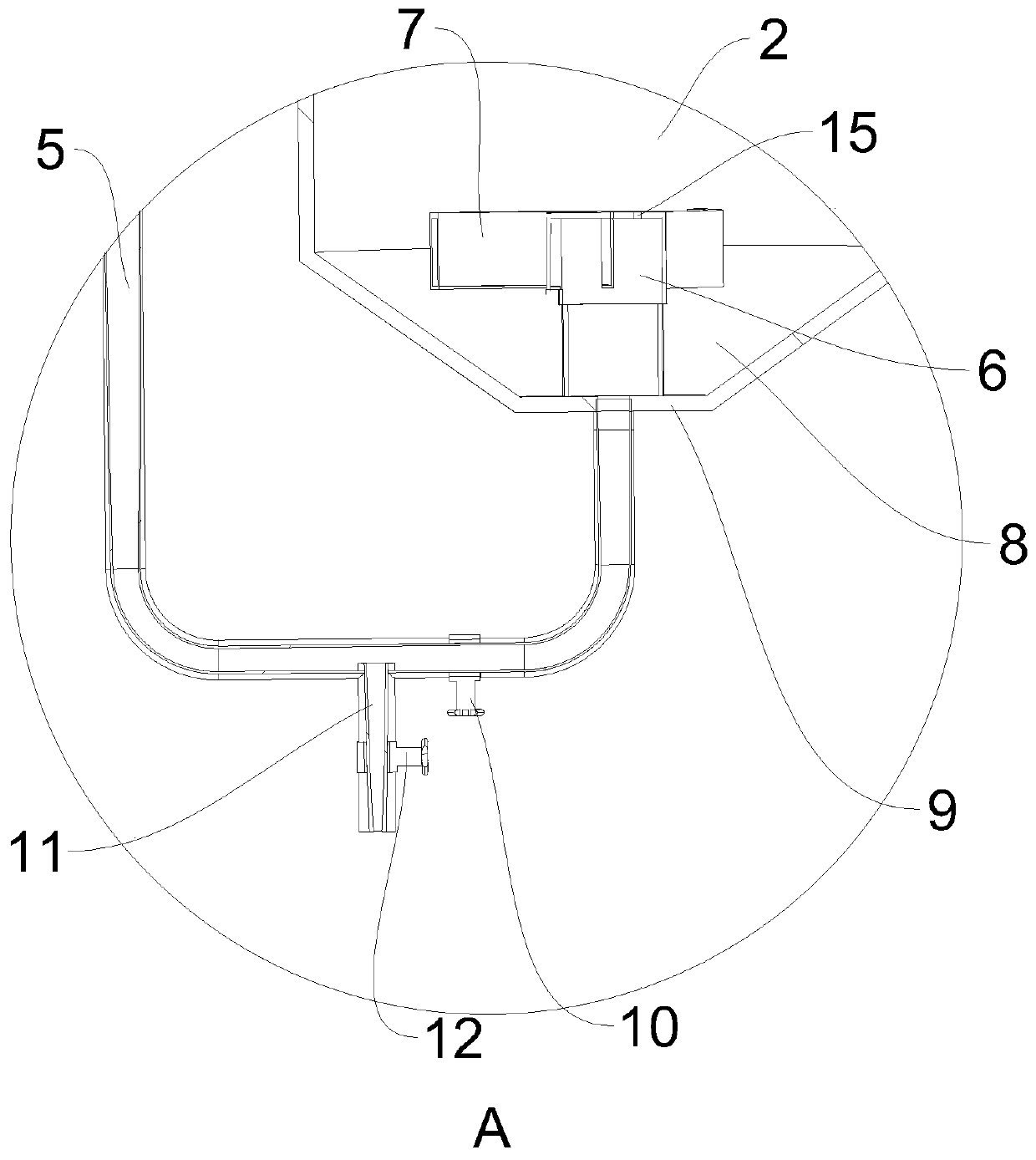

Saccharification system and method for starch sugar

PendingCN110117536AWell mixedFast saccharificationBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSugar

The invention relates to the technical field of starch sugar processing, and discloses a saccharification system of starch sugar. The system comprises a feeding tank and a plurality of saccharification tanks communicated with the feeding tank in sequence, wherein the top end of the feeding tank is provided with a stirring unit and a feeding tube, the bottom end of the feeding tank is provided witha transfer tube, the transfer tube is connected to the bottom end of the saccharification tank closest to the feeding tank, a guide tube is arranged between every two adjacent saccharification tanks,one end of the corresponding guide tube is connected to the top of one of the corresponding saccharification tanks, the other end of the corresponding guide tube is connected to the bottom of the other saccharification tank, the inner walls of the bottoms of the saccharification tanks are rotatably provided with cover-shaped material conveying parts, the peripheries of the material conveying parts are provided with arc-shaped material conveying bodies, the material conveying parts and the material conveying bodies are both of hollow structures, the guide tubes are communicated with the saccharification tanks through the material conveying parts and the material conveying bodies in sequence, the material conveying bodies are hollow, the two ends of the material conveying bodies are both ofopened structures, the openings of one ends of the material conveying bodies are communicated with the material conveying parts, and the openings of the other ends are formed in the ends, away from the material conveying parts, of the material conveying bodies. The saccharification system of the starch sugar improves the saccharification efficiency.

Owner:纳来创硕湖北生物科技有限公司

Method for preparing cellulosic ethanol through simultaneous saccharification and fermentation

ActiveCN109355347AIncrease concentrationReduce dosageBiofuelsMicroorganism based processesUltrafiltrationFermentation

The invention relates to a method for preparing cellulosic ethanol through simultaneous saccharification and fermentation. The method comprises the following steps of partitioning the interior of a container into a first accommodating cavity and a second accommodating cavity in advance through a nanofiltration membrane or an ultrafiltration membrane, wherein the first accommodating cavity is filled with a first solvent system of enzymolysis fermentation solvents, and the second accommodating cavity is filled with a second solvent system of fermentation solvents; adding pretreated lignocellulose into the first solvent system of the first accommodating cavity, and after the first solvent system and the second solvent system are stirred for 12-60 h separately, simultaneously obtaining cellulosic ethanol after fermentation and saccharification in the two accommodating cavities respectively. According to the method, lignocellulose serves as a raw material, carboxylate zwitterionic liquid and water are regarded as a mixed solvent, and cellulose is added; meanwhile, the mixed solvent is connected with a solvent system formed by co-fermentation yeast of a non-ionic surfactant and C5 and C6through the nanofiltration membrane to achieve the purposes of high saccharification and high fermentation.

Owner:ZHEJIANG HUAKANG PHARMA +1

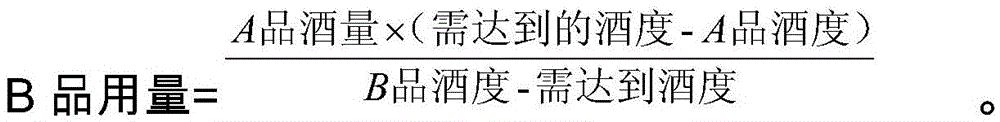

Brewing method of Japanese Peristrophe Herb raw material health red koji wine

InactiveCN105524781AImprove saccharification efficiencyImprove food utilizationMicroorganism based processesAlcoholic beverage preparationHorticultureBioactive substance

The invention relates to a brewing method of a Japanese Peristrophe Herb raw material health red koji wine. The Japanese Peristrophe Herb raw material health red koji wine is prepared through combining a three-step fermentation technology with a blending technology by adopting glutinous rice-indica rice mixed uncooked rice as a fermentation raw material and by extracting active substances in fresh Japanese Peristrophe Herb with edible alcohol, so boiling energy consumption is reduced, the starch saccharification efficiency is greatly improved, and the grain utilization rate is improved; marrow of a wine brewing technology is selected, so the kinds and the contents of the active substances in the wine are further enriched, and the health efficacy is strong; and a low temperature extraction mode is in favor of maintaining the bioactivity and the physiologic activity of the Japanese Peristrophe Herb, so the retention rate of natural fragrance is high. The Japanese Peristrophe Herb raw material health red koji wine has the advantages of brilliant color, delicate fragrance and tastiness, high raw material utilization rate, production cost reduction, abundant bioactive substances, and strong liver protection and health efficacy.

Owner:HEZHOU UNIV

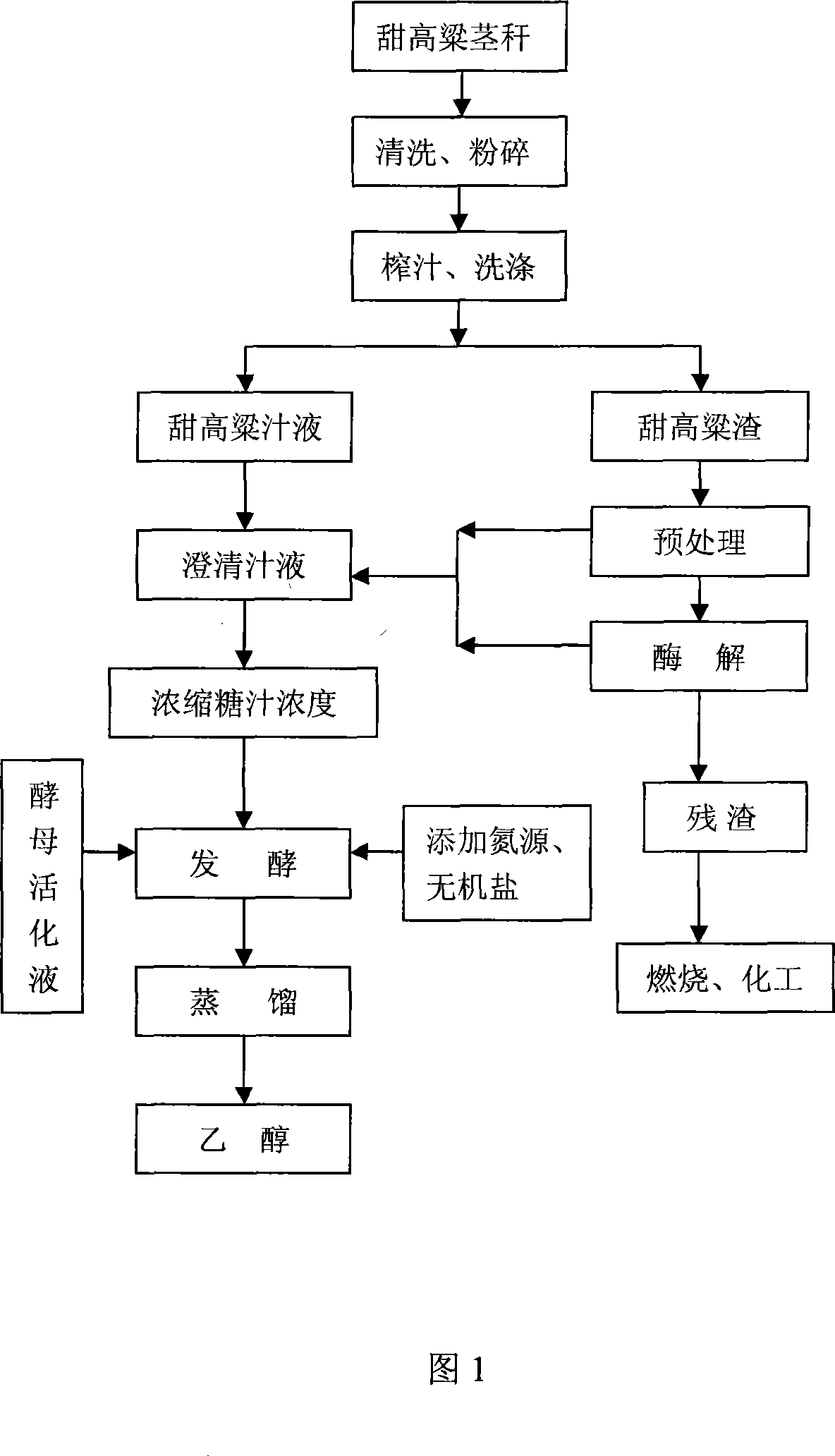

Method for producing ethyl alcohol by using sorgo stalk

InactiveCN101220379BIncrease profitTake advantage ofBiofuelsMicroorganism based processesAlcoholFermentable sugar

The invention discloses an ethanol production method by utilizing sweet sorghum stalks, which pertains to the field of plant fuel. The invention includes the following steps that: the juice and the residue of the sweet sorghum stalks are separated, then the sweet sorghum residue is treated with diluted acid explosion pretreatment, fermentable sugar is obtained by the enzymolysis of a cellulase , then the sweet sorghum juice and the sorghum residue are processed to obtain the fermented sugar liquid, concentration and regulation of the fermented sugar liquid are carried out, and finally the ethanol is prepared by using the brewing yeast for fermentation. The method of the invention can make full use of the sweet sorghum stalks and has the advantages of short fermentation time, high enzymolysis efficiency of the cellulose, high ethanol yield, etc.

Owner:CHINA AGRI UNIV

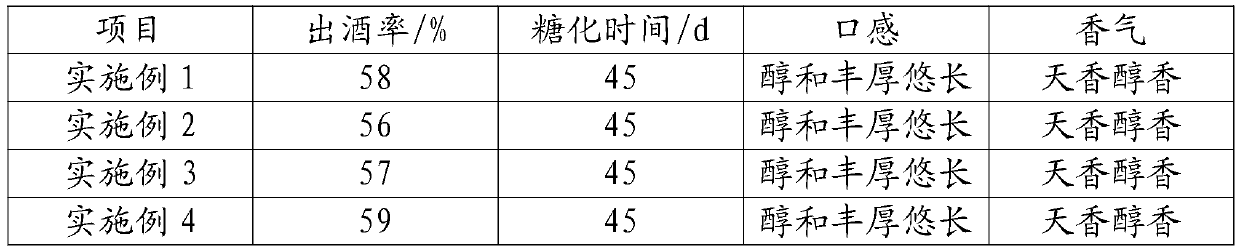

Agilawood-type aromatic liquor and preparation method thereof

InactiveCN111154586AHigh yieldAccelerated saccharificationAlcoholic beverage preparationMicroorganism based processesBiotechnologyYield (wine)

The invention discloses agilawood-type aromatic liquor and a preparation method thereof. Raw materials of koji include barley, wheat and agilawood powder. Liquor-making raw materials comprise sorghum,wheat, corn and glutinous rice. The preparation method comprises steps of preparing the koji with the agilawood, processing the raw materials, and conducting fermentation, distillation and blending.In preparation process, agilawood powder is added as a raw material for making the koji to change microorganisms and flavour of the koji. By traditional fermentation for strong aromatic liquor, the liquor body is rich in flavour of the agilawood. Meanwhile, rhizopus and mucor are added to accelerate saccharification and improve yield of the liquor during saccharification. According to the invention, by changing koji-making process and saccharification process, the aroma of agilawood is added to the wine body, thereby enriching flavour of traditional strong aromatic liquor without losing flavour of original strong aromatic liquor, and improving yield of the liquor.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

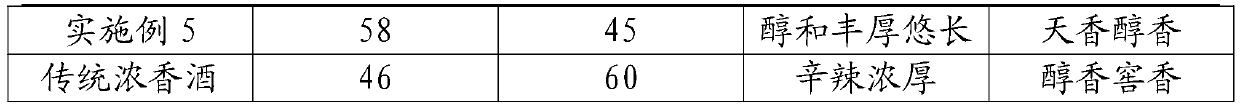

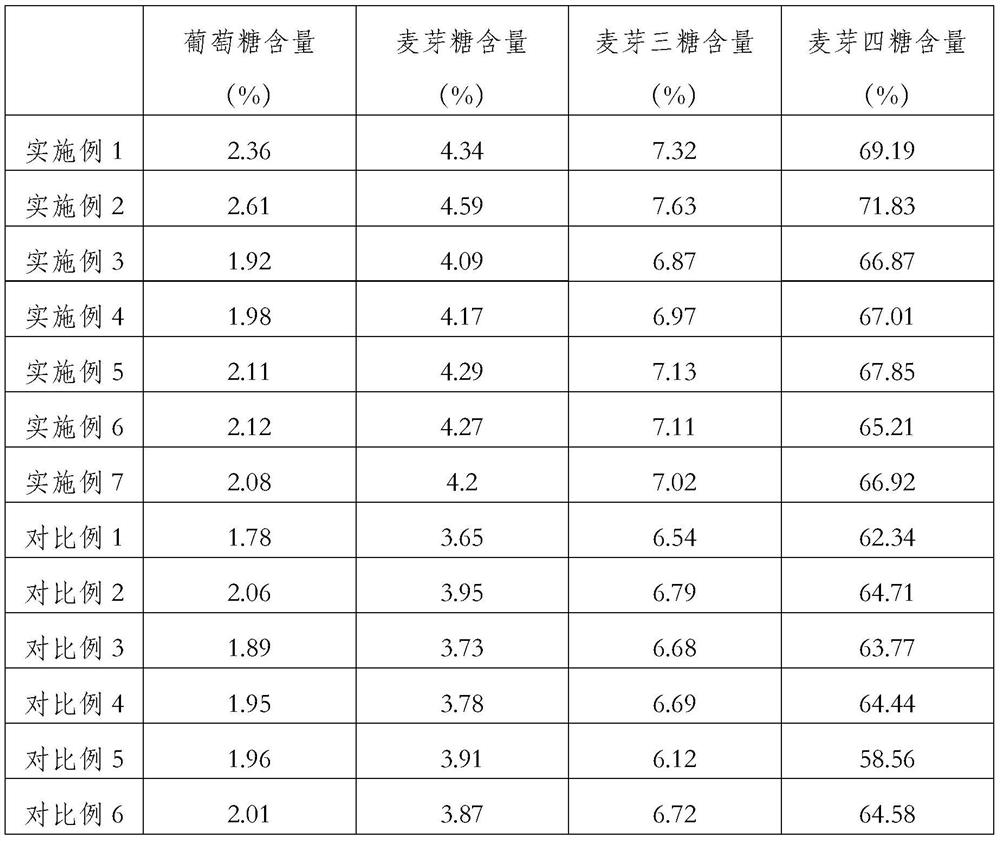

Preparation process of maltooligosaccharide syrup with high maltotetraose content

The invention discloses a preparation process of maltooligosaccharide syrup with high maltotetraose content. The preparation process comprises the following steps of adding water into starch to prepare starch slurry, and adjusting the pH value of the starch slurry to 5.8-6.0; adding high-temperature-resistant alpha-amylase into the starch slurry, and performing primary spray liquefaction, laminar flow tank heat preservation and secondary spray liquefaction to obtain liquefied liquid; when the liquefied liquid is rapidly cooled to 55-65 DEG C, adding pullulanase and maltotetraose enzyme sequentially for a saccharification reaction, and after the saccharification reaction is conducted for 5-18 h, obtaining reaction liquid; and enabling the reaction liquid to be subjected to activated carbon decoloration, ion exchange and concentration, and obtaining the maltooligosaccharide syrup. After liquefaction is finished, the temperature is rapidly reduced to the saccharification temperature by adopting a flash heat exchanger, the problems of starch aging and retrogradation in the cooling process are avoided, saccharification is performed by adopting a two-step enzyme adding method of firstly adding pullulanase and then adding maltotetraose enzyme, the conversion rate of maltotetraose is increased, the technological process is simplified, and the maltooligosaccharide syrup with maltotetraose content of more than or equal to 65% is prepared.

Owner:无锡秋可生物科技有限公司

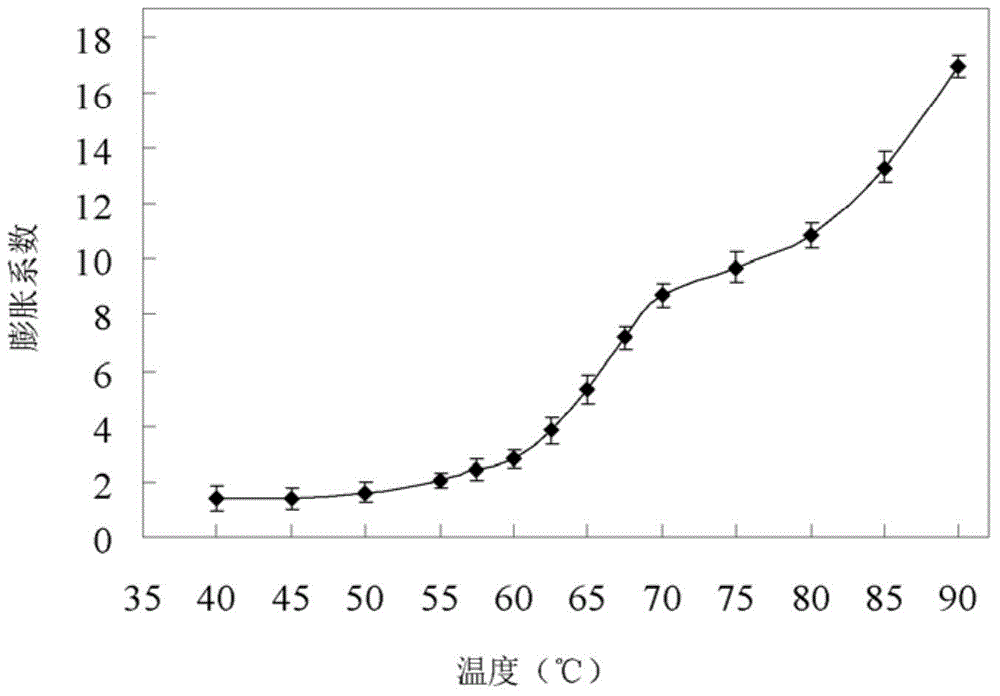

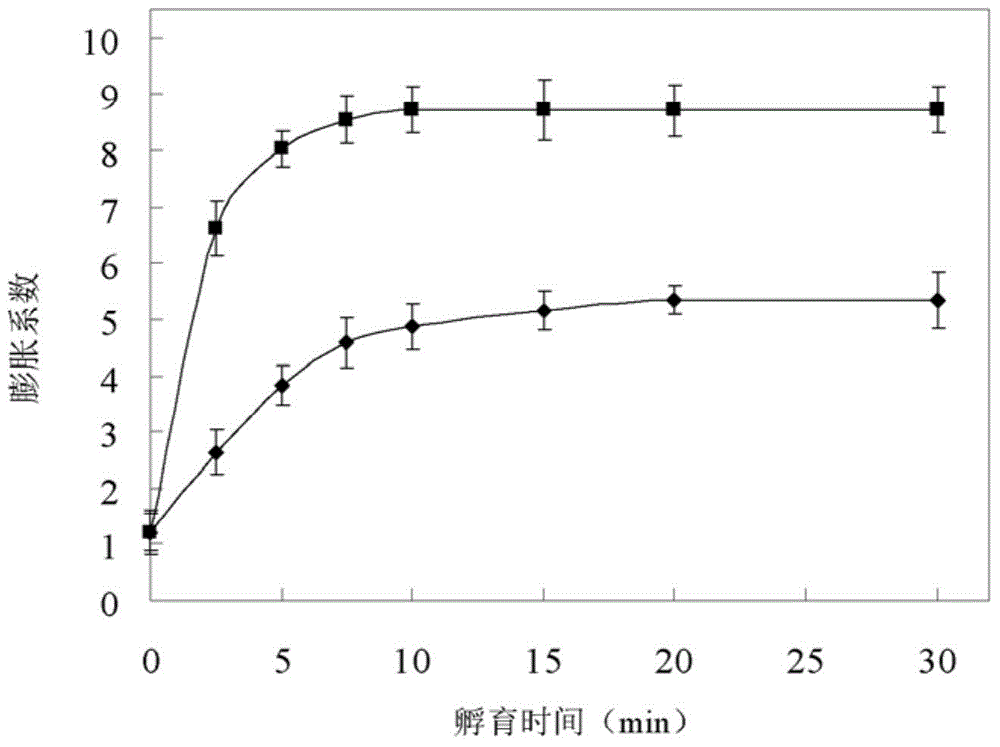

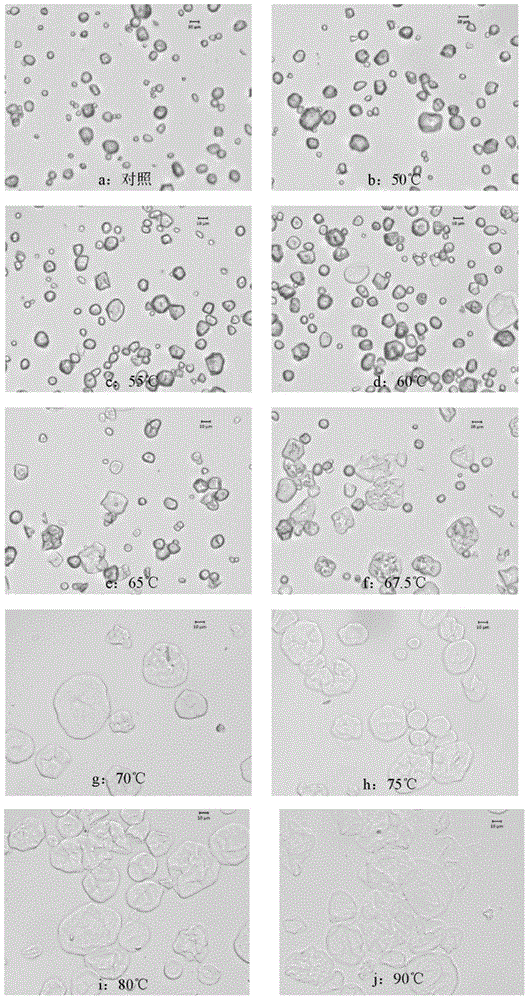

Raw starch expansion treatment and enzyme glycosylation method

The invention provides a raw starch expansion treatment and enzyme glycosylation method comprising the following steps: mixing water with raw starch so as to make starch slurry; carrying out hot process for the starch slurry under 40-90 DEG C so as to expand raw starch particles; the invention also provides a raw starch enzyme glycosylation method; the method makes the expanded raw starch to contact with enzyme, thus greatly reducing raw starch enzyme usage amount, and greatly reducing alcohol production cost. In an enzymatic reaction early stage, the hot process can obviously promote starch particles to convert to glucose, thus promoting yeasty fermentation in an alcohol production process; therefore, in a raw starch enzyme glycosylation process, the proper hot process for the starch particles has vast potential for diastatic fermentation alcohol industry.

Owner:史永成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com