Patents

Literature

61 results about "Cellulosome" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

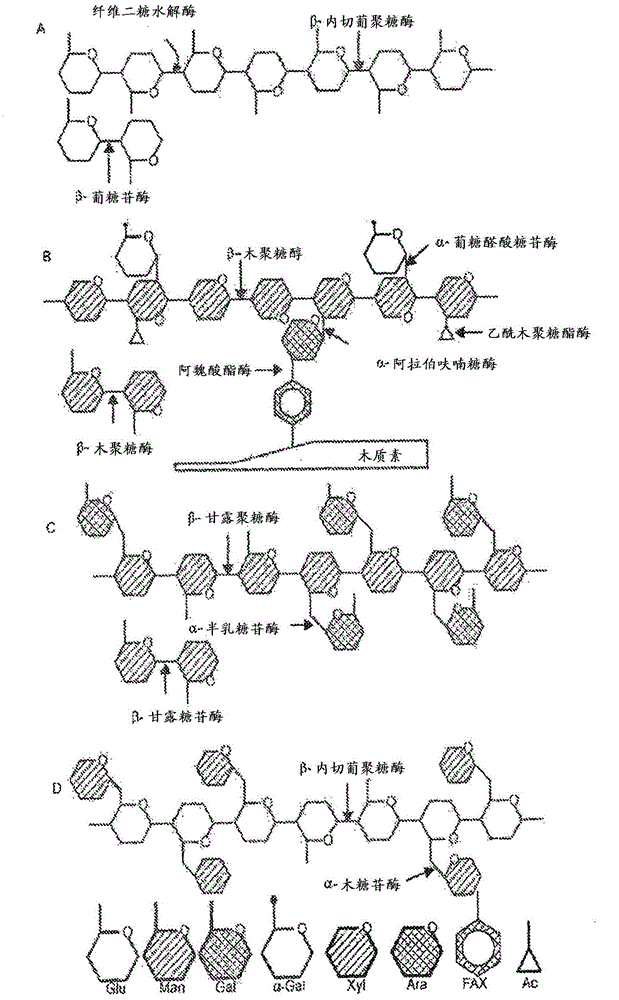

Cellulosomes are multi-enzyme complexes. Cellulosomes are associated with the cell surface and mediate cell attachment to insoluble substrates and degrade them to soluble products which are then absorbed. Cellulosome complexes are intricate, multi-enzyme machines, produced by many cellulolytic microorganisms. They are produced by microorganisms for efficient degradation of plant cell wall polysaccharides, notably cellulose, the most abundant organic polymer on Earth. The multiple subunits of cellulosomes are composed of numerous functional domains which interact with each other and with the cellulosic substrate. One of these subunits, a large glycoprotein "scaffoldin", is a distinctive class of non-catalytic scaffolding polypeptides. The scaffoldin subunit selectively integrates the various cellulases and xylanase subunits into the cohesive complex, by combining its cohesin domains with a typical dockerin domain present on each of the subunit enzymes. The scaffoldin of some cellulosomes, an example being that of Clostridium thermocellum, contains a carbohydrate-binding module that adheres cellulose to the cellulosomal complex.

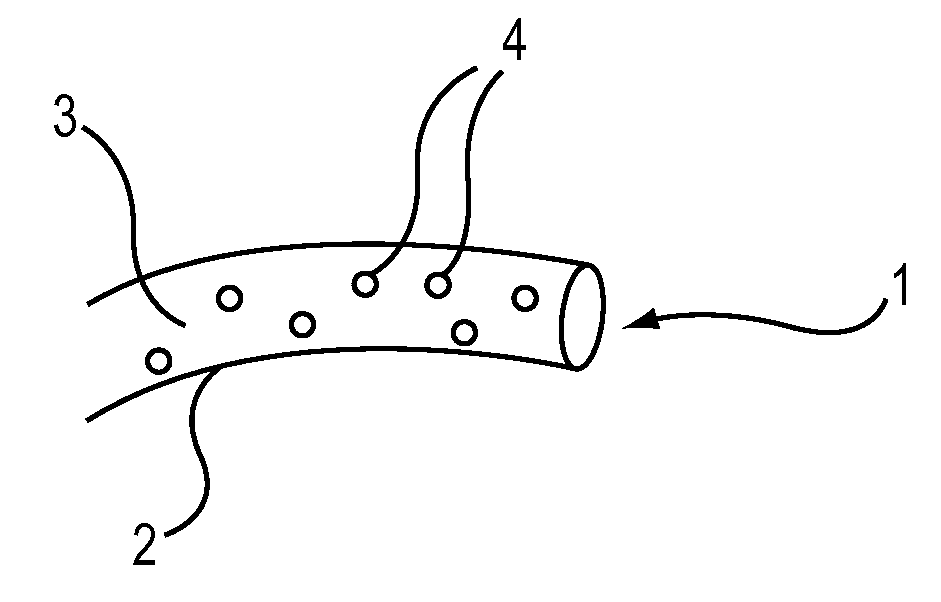

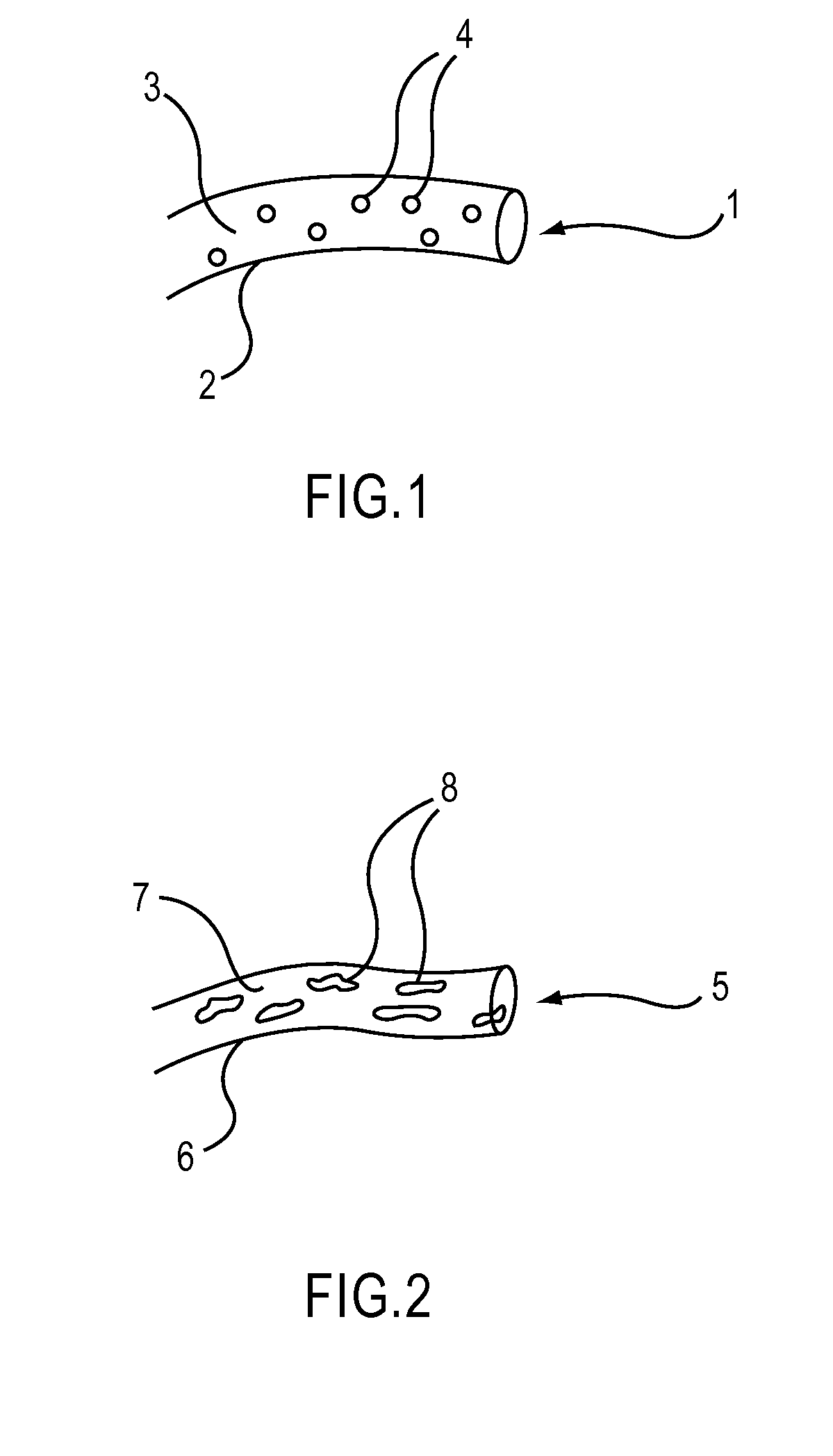

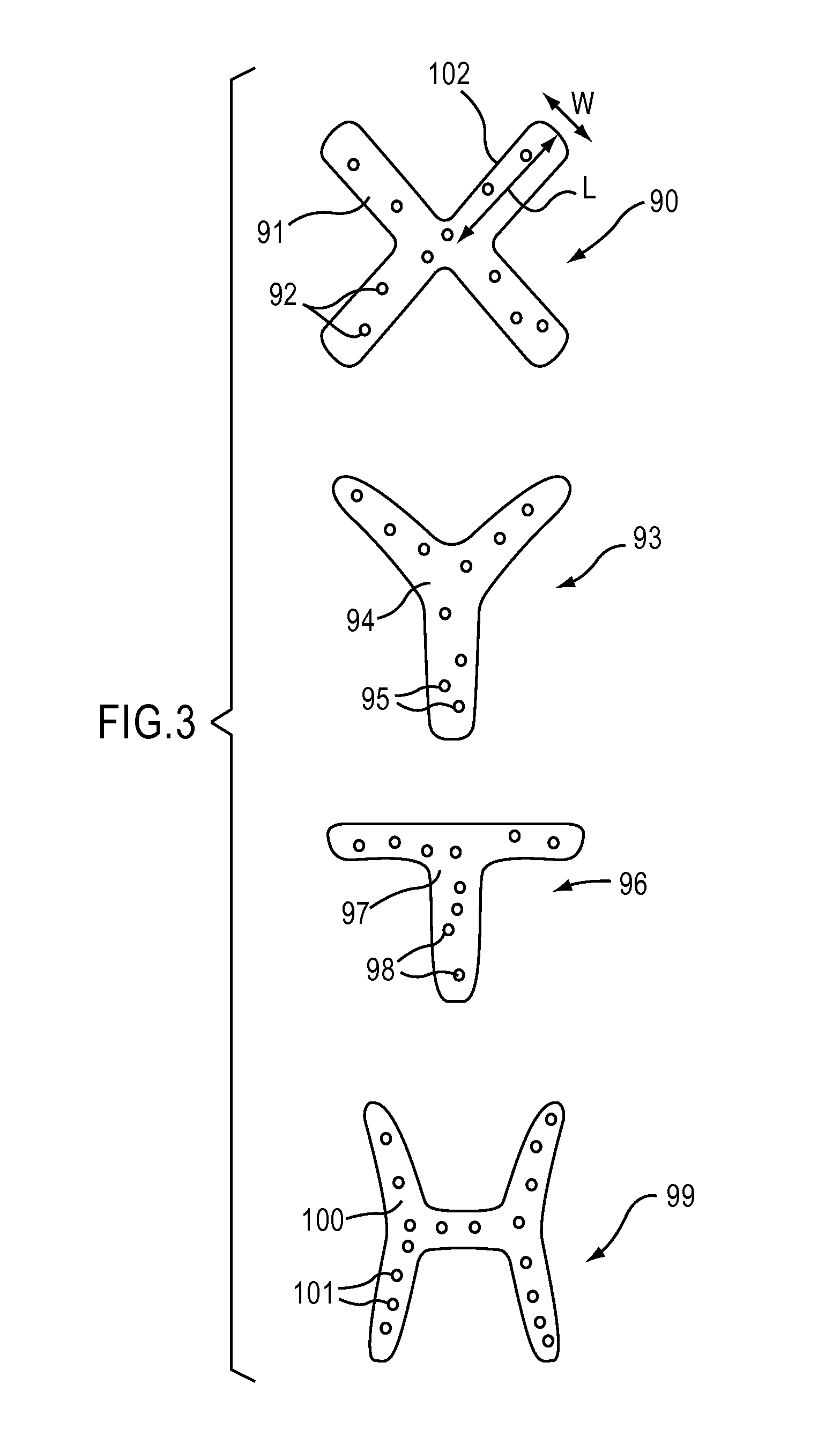

Fibers and articles having combined fire resistance and enhanced reversible thermal properties

A fabric, fiber or article comprising a plurality of fiber bodies, the plurality of fiber bodies including a first fiber material and a second fiber material, wherein the first fiber material comprises a cellulosic material and a phase change material dispersed in the cellulosic material, the phase change material forming a plurality of domains dispersed in the cellulosic material, the phase change material having a latent heat of at least 5 Joules per gram and a transition temperature in the range of 0° C. to 100° C., the phase change material providing thermal regulation based on at least one of absorption and release of the latent heat at the transition temperature. Wherein the second fiber material comprises a fire resistant material.

Owner:OUTLAST TECH LLC

Yeast expressing saccharolytic enzymes for consolidated bioprocessing using starch and cellulose

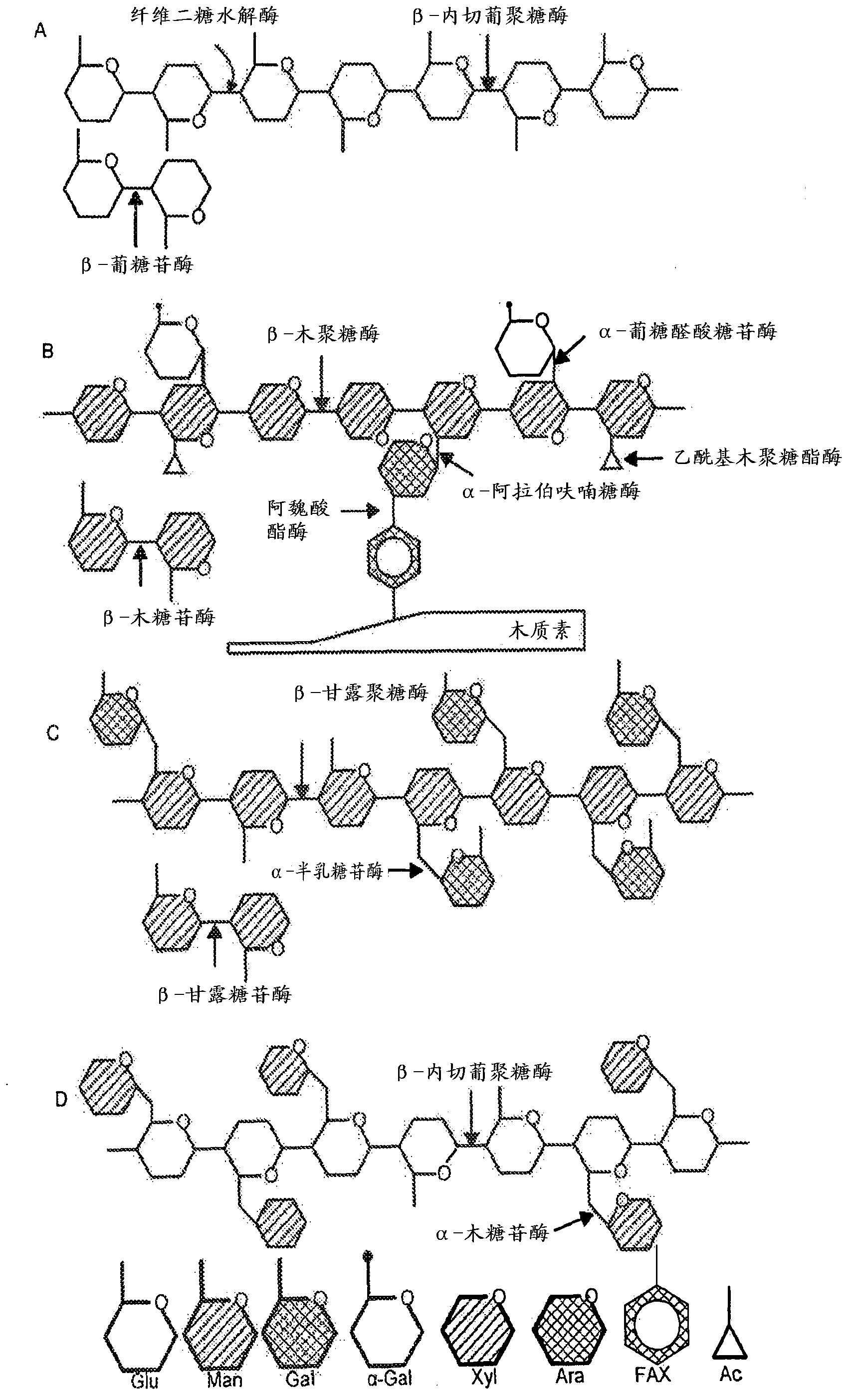

The present invention is directed to a yeast strain, or strains, secreting a full suite, or any subset of that, full suite, of enzymes to hydrolyze com starch, corn fiber, lignocellulose, (including enzymes that hydrolyze linkages in cellulose, hemicelhiiose, and between lignin and carbohydrates) and to utilize pentose sugars (xylose and arabinose). The invention is also directed to the set of proteins that are well expressed in yeast for each category of enzymatic activity. The resulting strain, or strains can be used to hydrolyze starch and cellulose simultaneously. The resulting strain, or strains can be also metabolically engineered to produce less glycerol and uptake acetate. The resulting strain, or strains can also be used to produce ethanol from granular starch without liquefaction.; The resulting strain, or strains, can be further used to reduce the amount of external enzyme needed to hydrolyze a biomass feedstock during an Simultaneous Saccharification and Fermentation (SSF) process, or to increase the yield of ethanol during SSF at current saccharolytic enzyme loadings. In addition, multiple enzymes of the present invention can be co-expressed in cells of the invention to provide synergistic digestive action on biomass feedstock. In some aspects, host cells expressing different heterologous saccharolytic enzymes can also be co-cultured togetherand used to produce ethanol from biomass feedstock.

Owner:LALLEMAND HUNGARY LIQUIDITY MANAGEMENT LLC +1

Method for saccharifying cellulose raw material

InactiveCN101851650AAvoid pollutionSave cost of saccharificationMicroorganism based processesFermentationFiberCellulose

The invention discloses a method for saccharifying a cellulose raw material. A cellulosome secreted by high-temperature thermoanaerobion can effectively reduce degrade crystalline cellulose with a complex structure. By adding low concentration acetate into a culture medium and enzyme reaction buffer solution and filling low concentration hydrogen in a fermentor thereof, the method greatly improves the enzyme reaction speed and sugar accumulation. The method can make the cellulose material which is not subjected to physical or chemical pretreatment directly fermented or subjected to enzyme treatment, and efficiently hydrolyze the cellulose material into reducing sugar.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

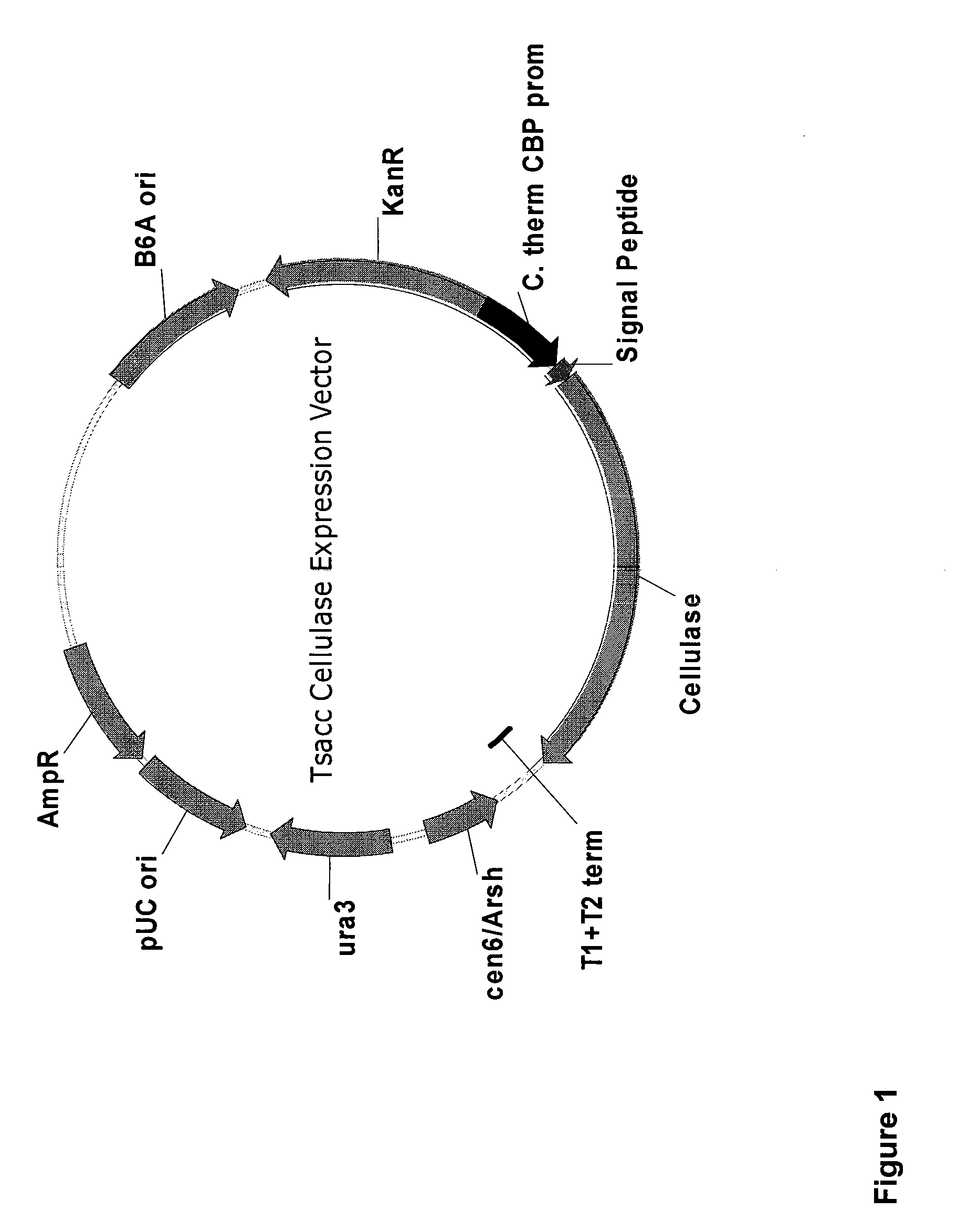

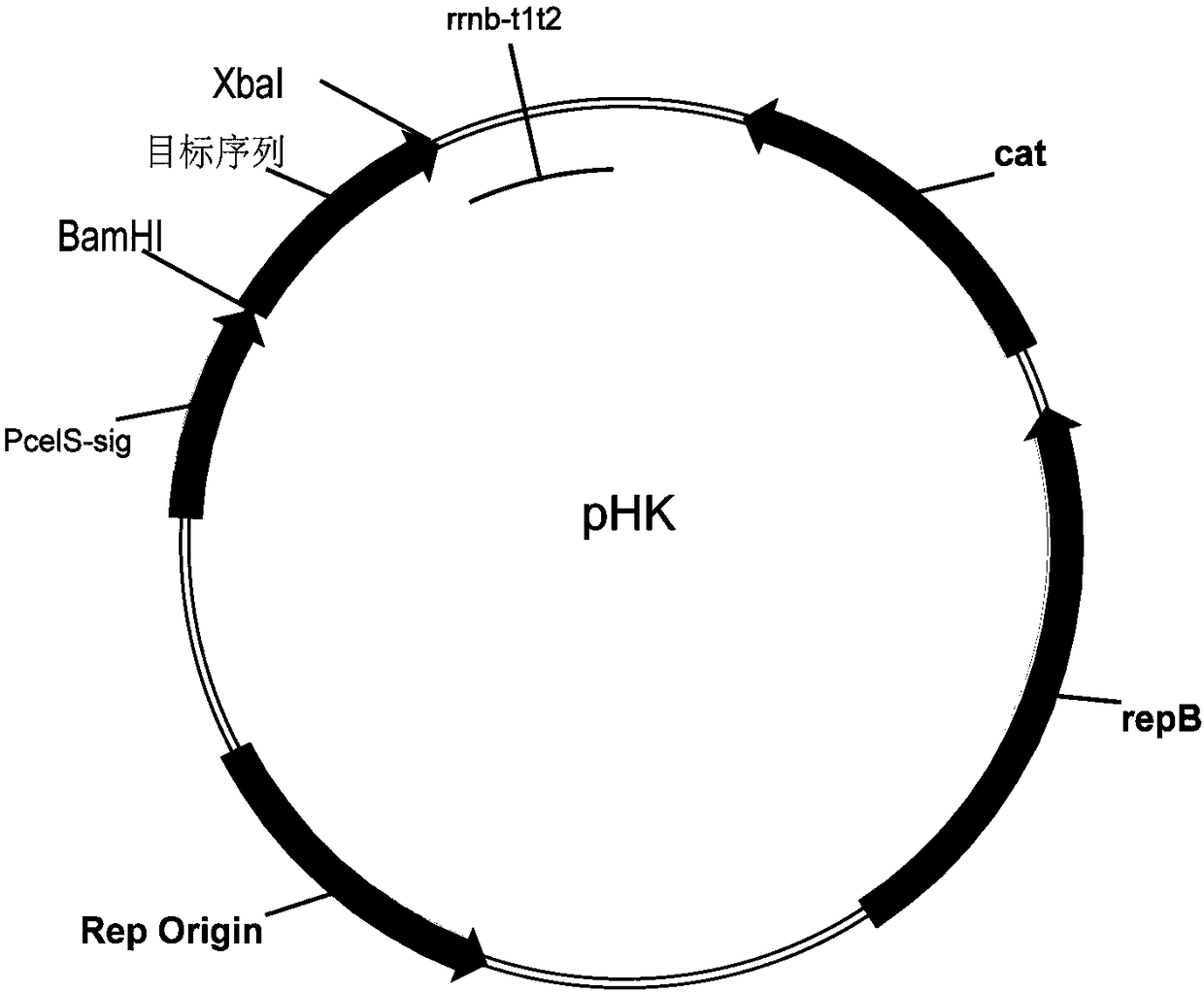

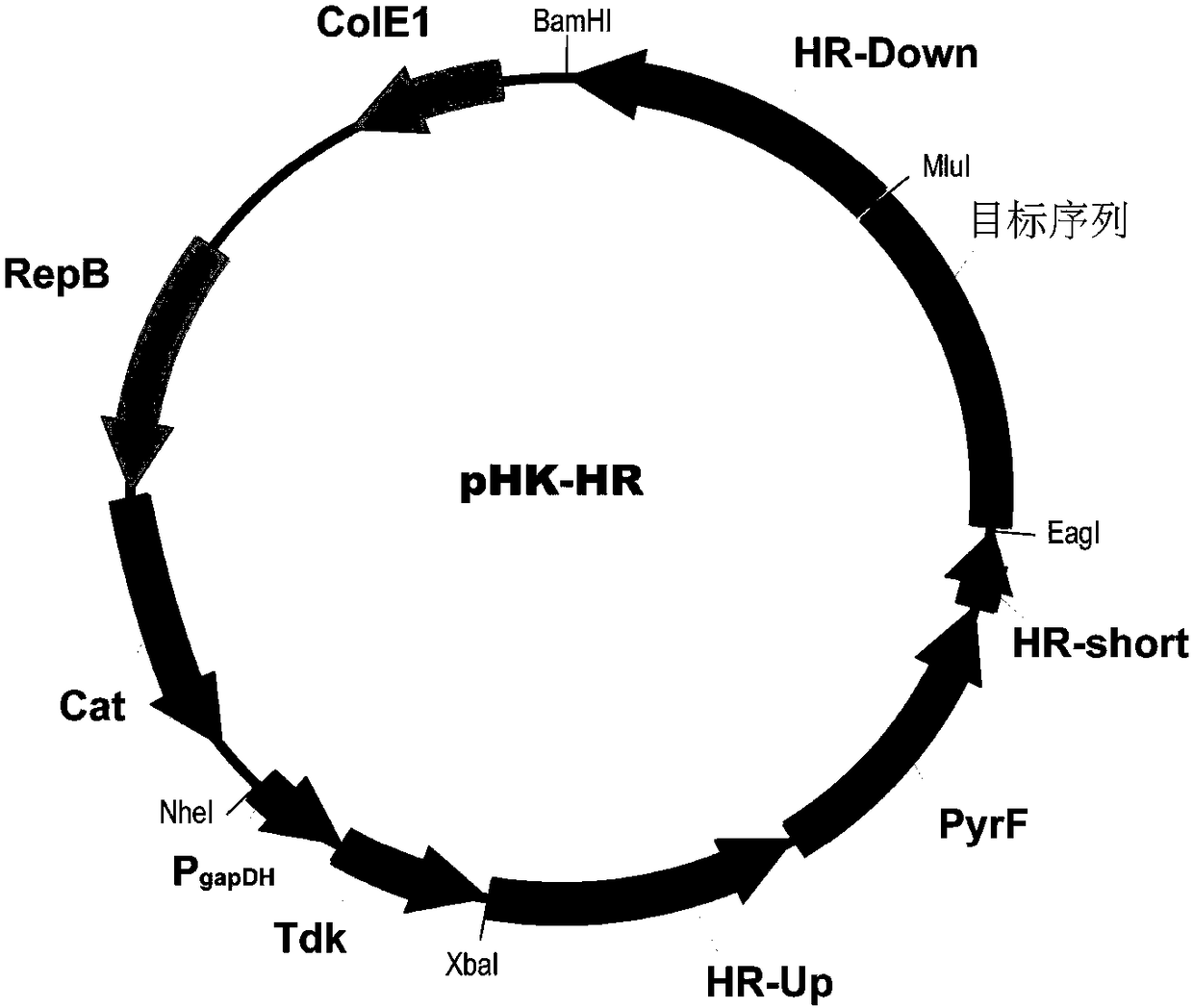

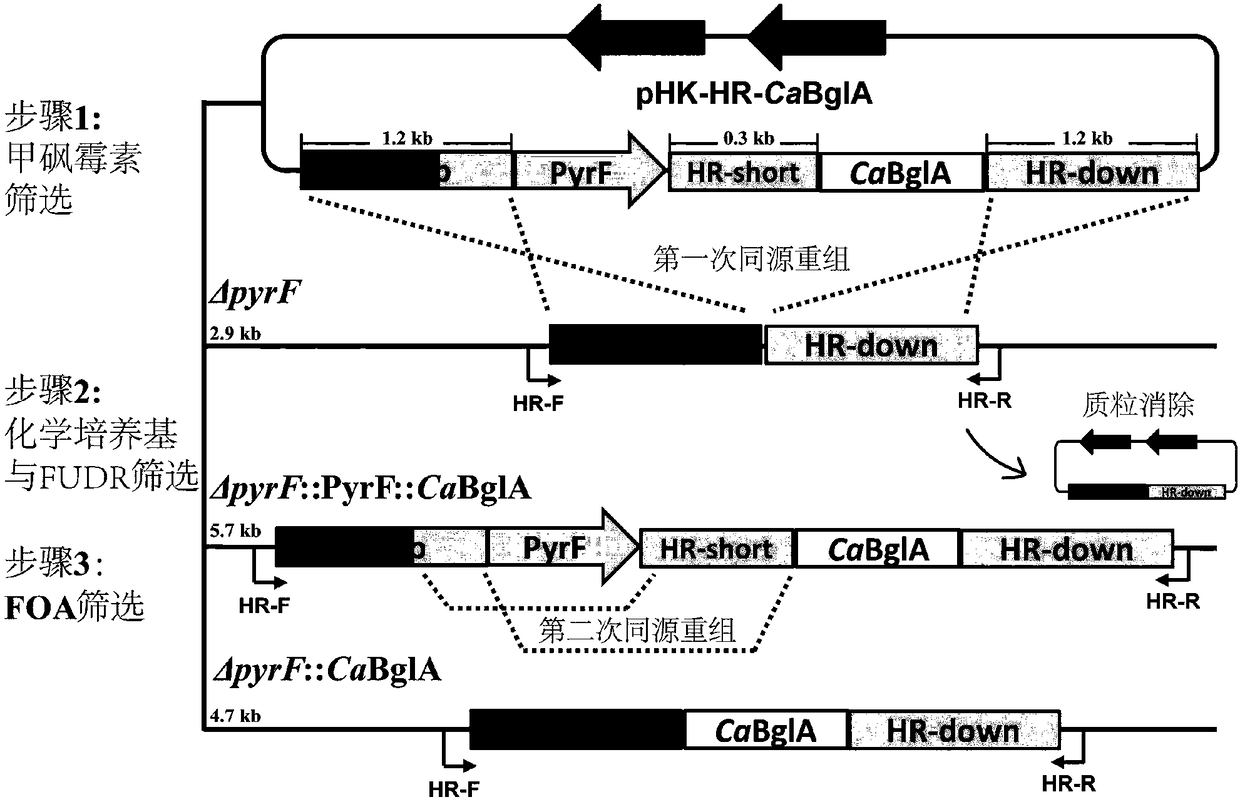

Heterologous Biomass Degrading Enzyme Expression in Thermoanaerobacterium Saccharolyticum

InactiveUS20120040409A1Increased chaperone activityDecrease protease activityBacteriaSugar derivativesThermoanaerobacterium saccharolyticumNucleotide

Thermophilic gram-positive anaerobic host cells, for example Thermoanaerobacterium saccharolyticum (“T sacch”), express heterologous biomass degrading enzymes, such as cellulases, and are able to produce useful fermentation products from cellulose. Useful fermentation products include, for example, ethanol, acetic acid, lactic acid or CO2. In order to provide maximum expression and activity levels, biomass degrading enzymes can be expressed from codon-optimized nucleotide sequences, can be expressed under the control of a high-efficiency promoter, and / or can be fused to a signal peptide. In addition, the host cell, for example, a T sacch host cell, can be genetically altered to further improve ethanol production, for example by disrupting the production of organic products other than ethanol.

Owner:ENCHI

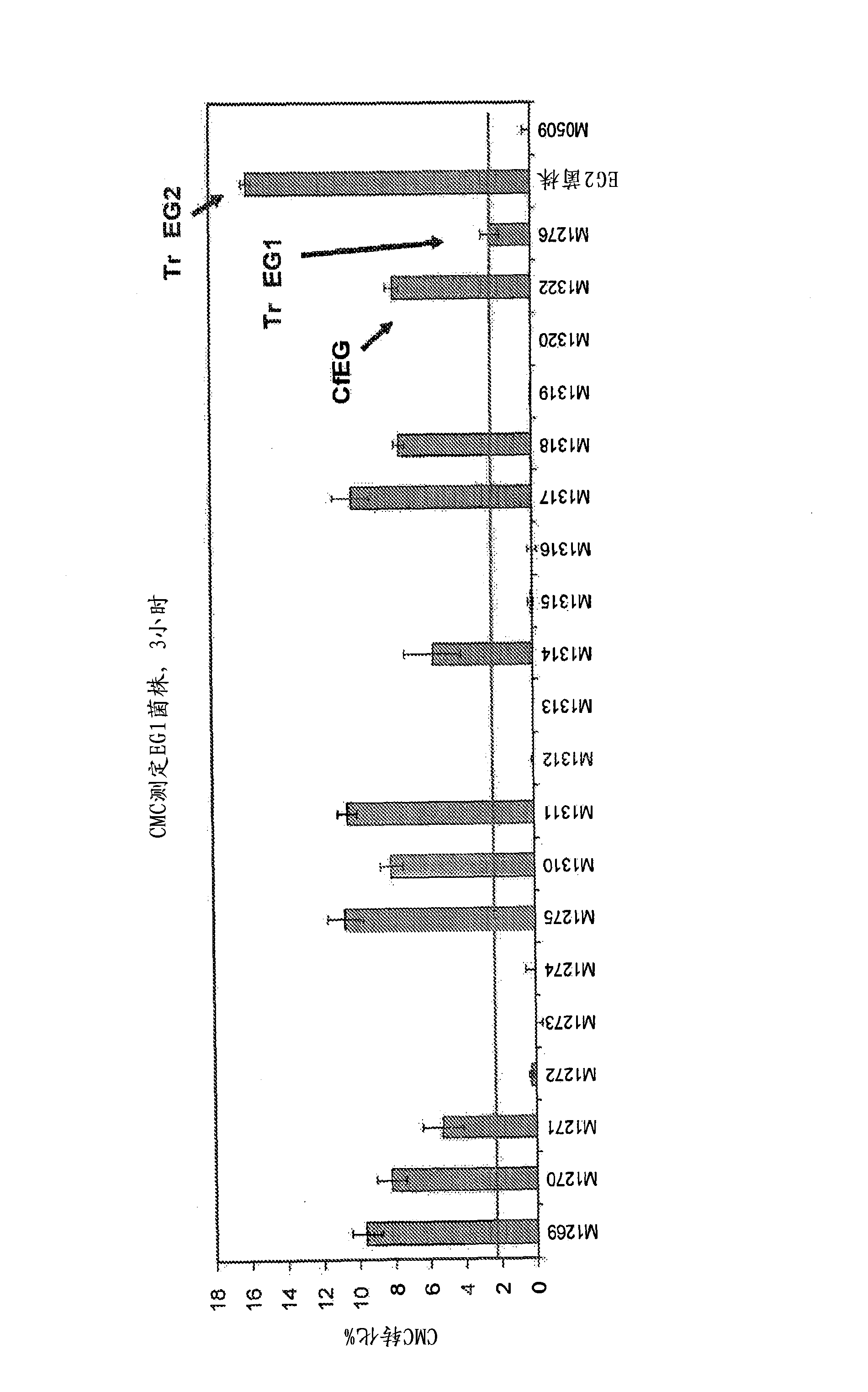

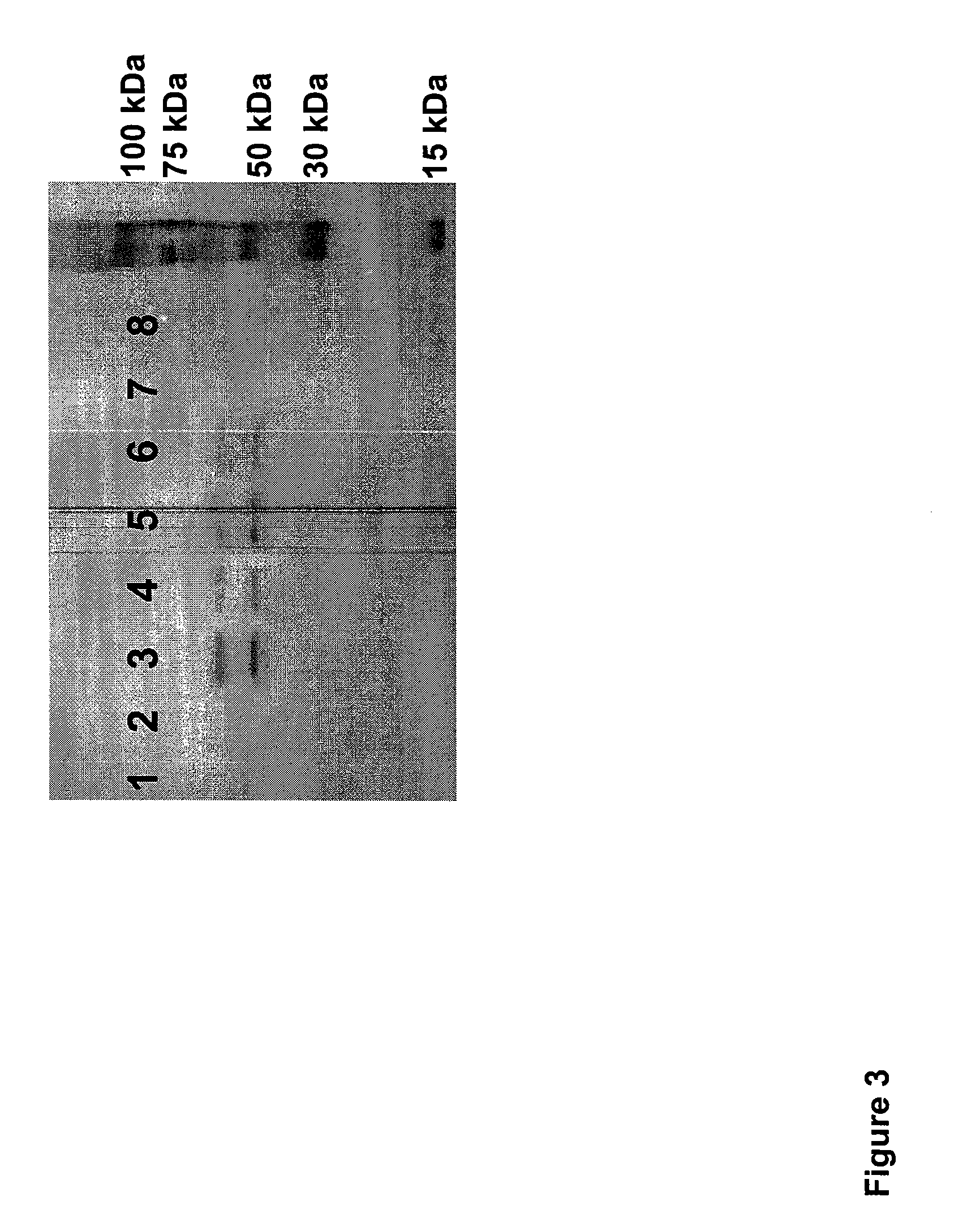

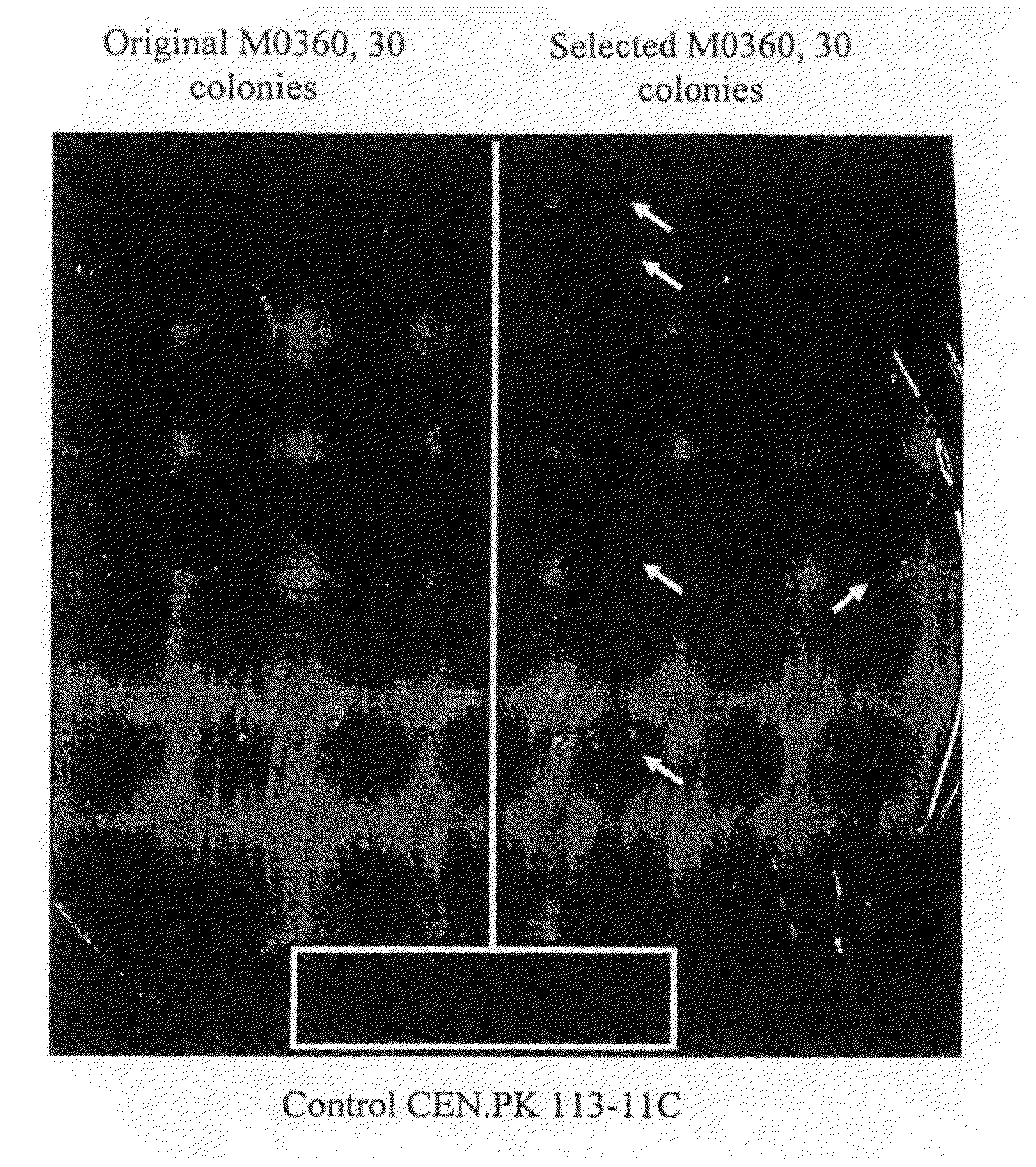

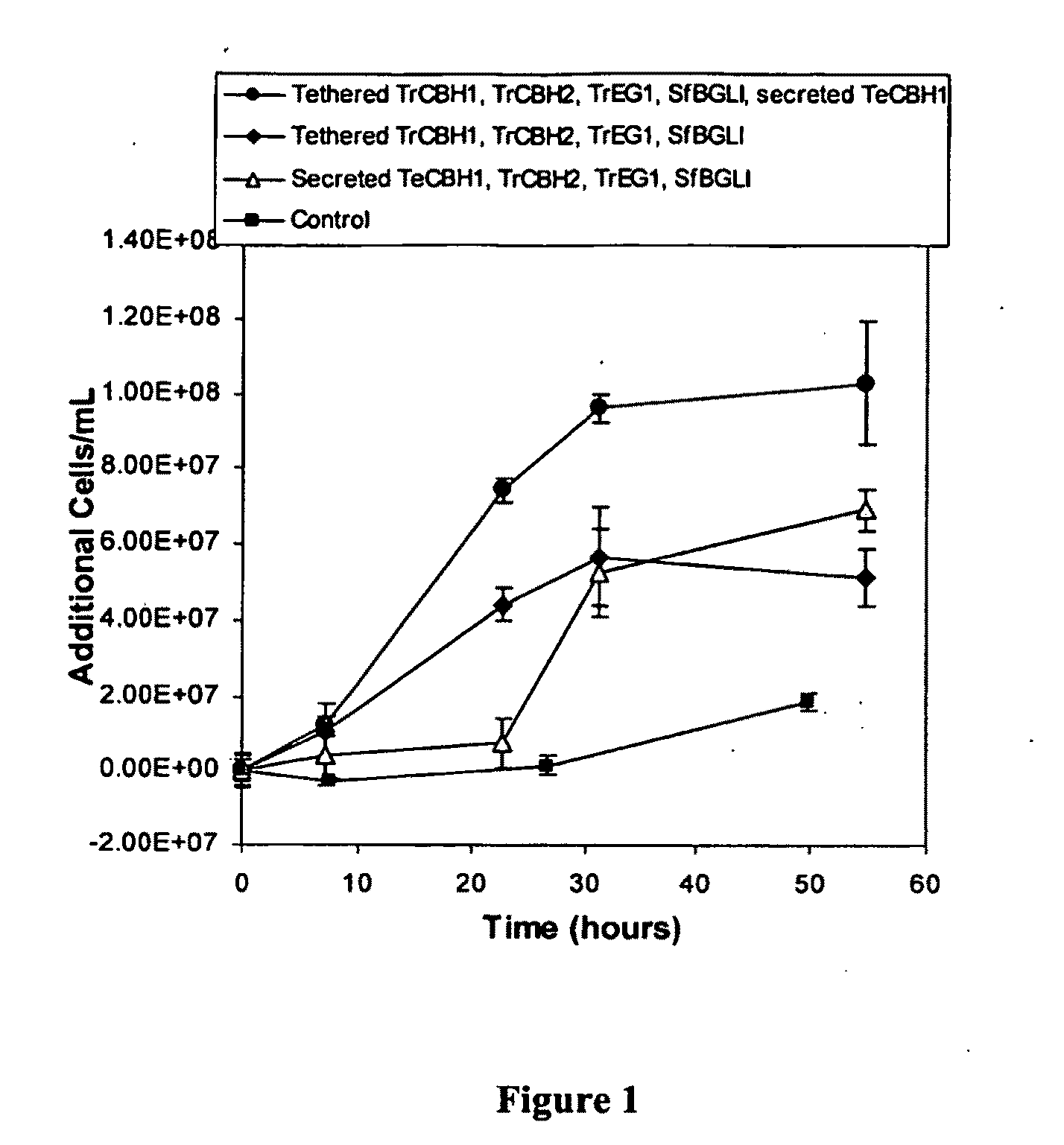

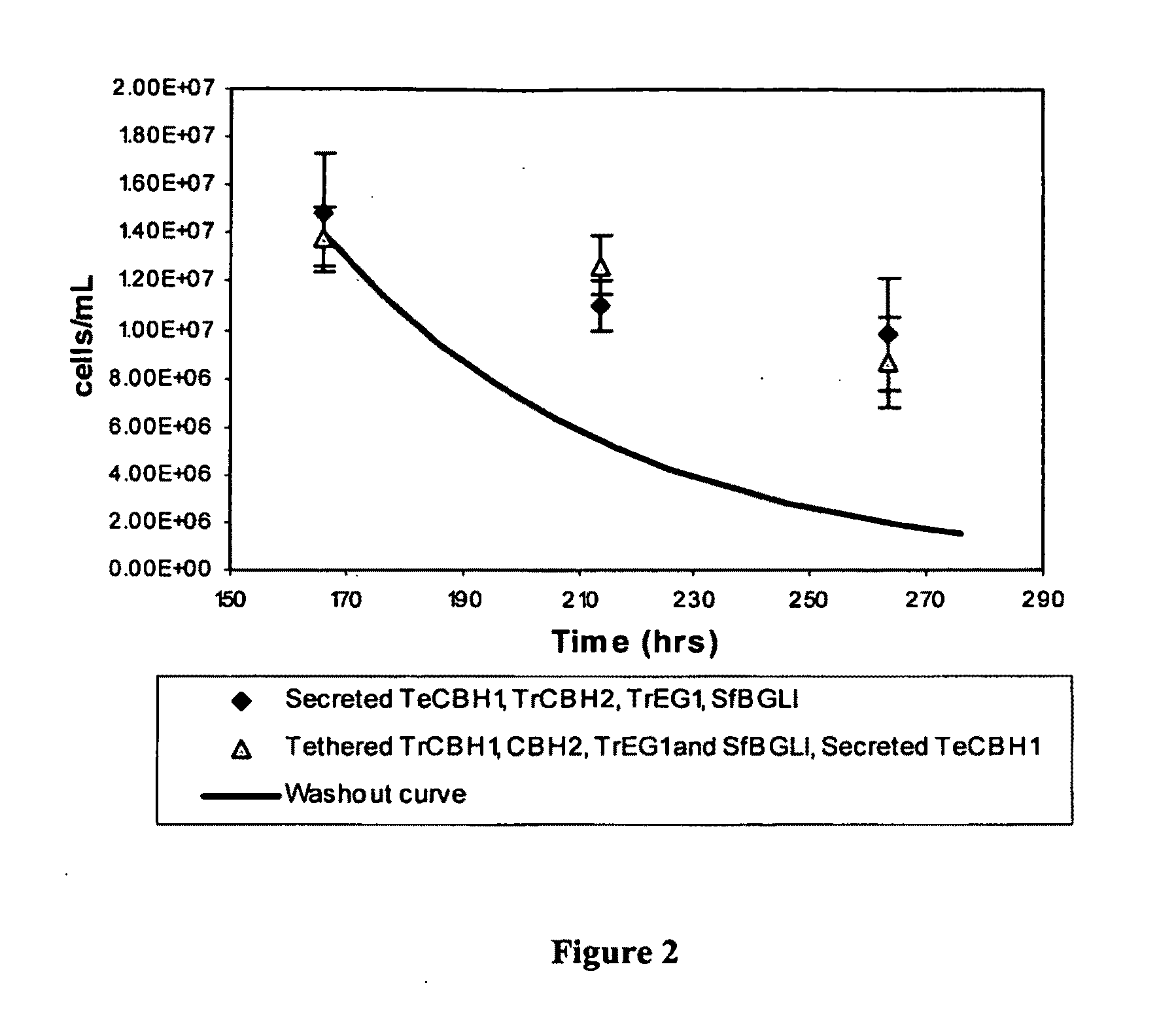

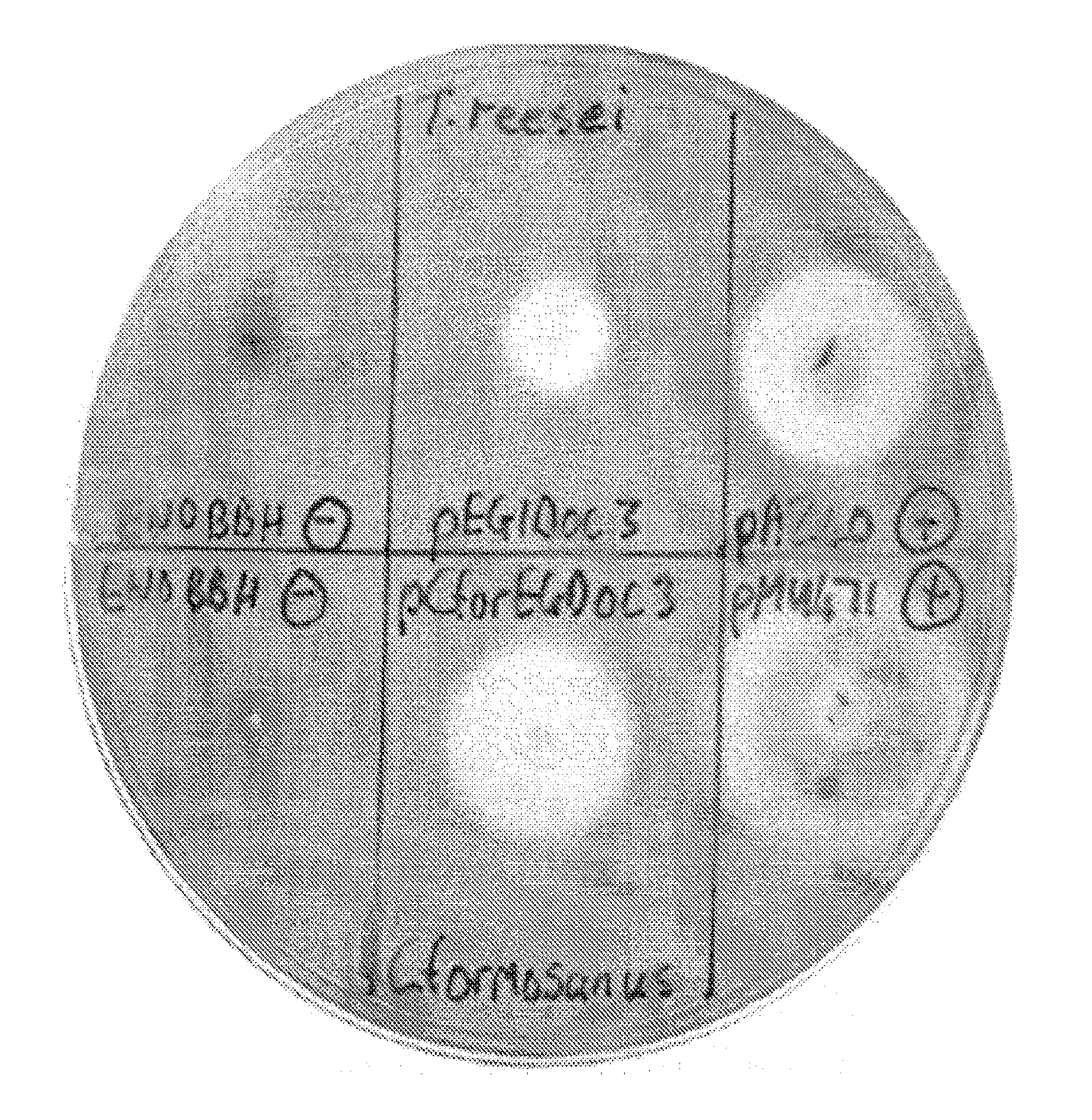

Construction of Protrophic/Celluloytic Yeast Strains Expressing Tethered and Secreted Cellulases

ActiveUS20110189744A1Improve abilitiesImprove reproductive abilityFungiAntibody mimetics/scaffoldsYeast strainMicrobiology

The present invention is directed to the construction of prototrophic, cellulo lytic strains of Saccharomyces cerevisiae with tethered and secreted cellulases and selection-based improvement of growth on cellulose by these strains. In some embodiments, host cells of the invention are able to produce ethanol using crystalline cellulose as a sole carbon source.

Owner:LALLEMAND HUNGARY LIQUIDITY MANAGEMENT LLC

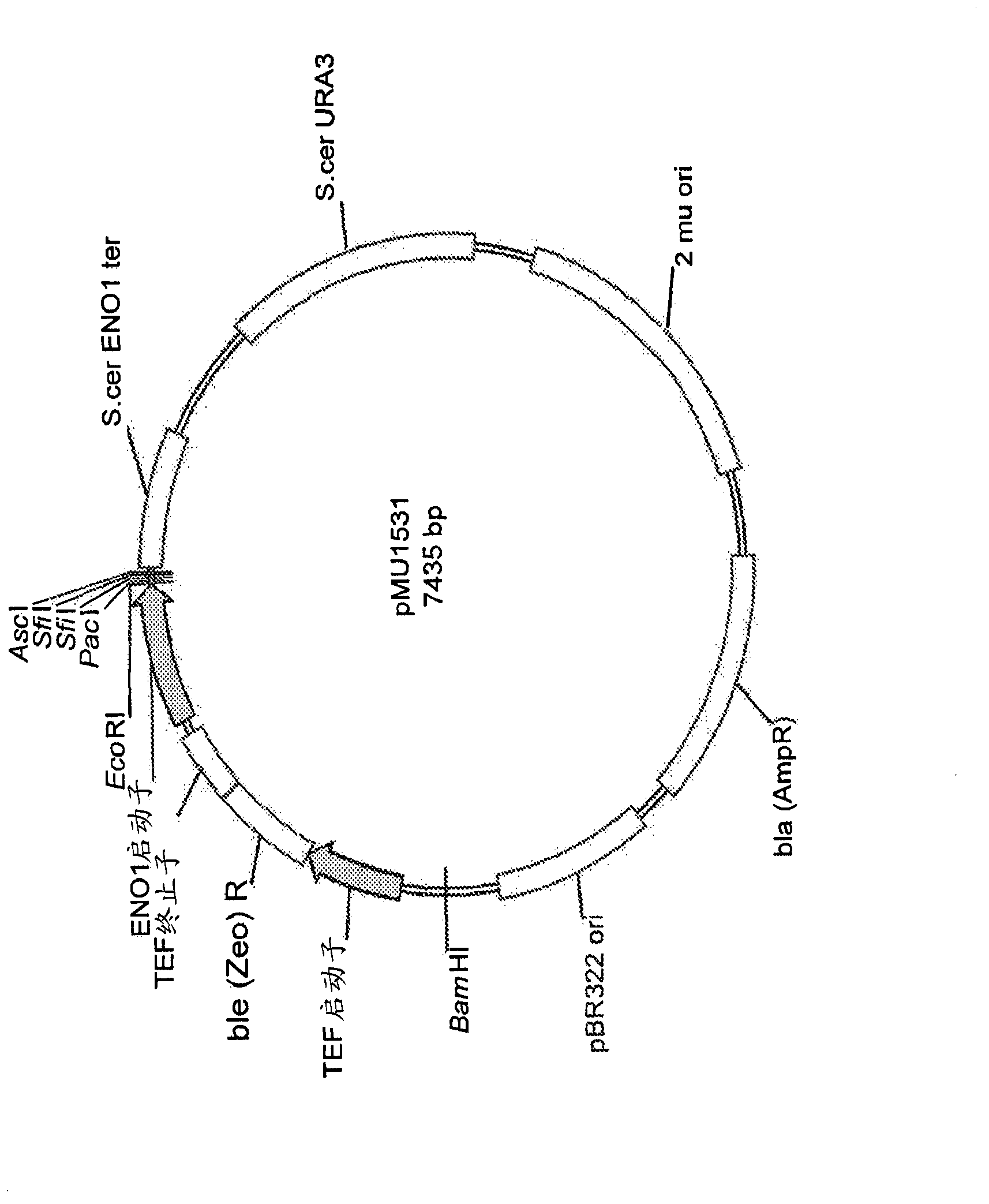

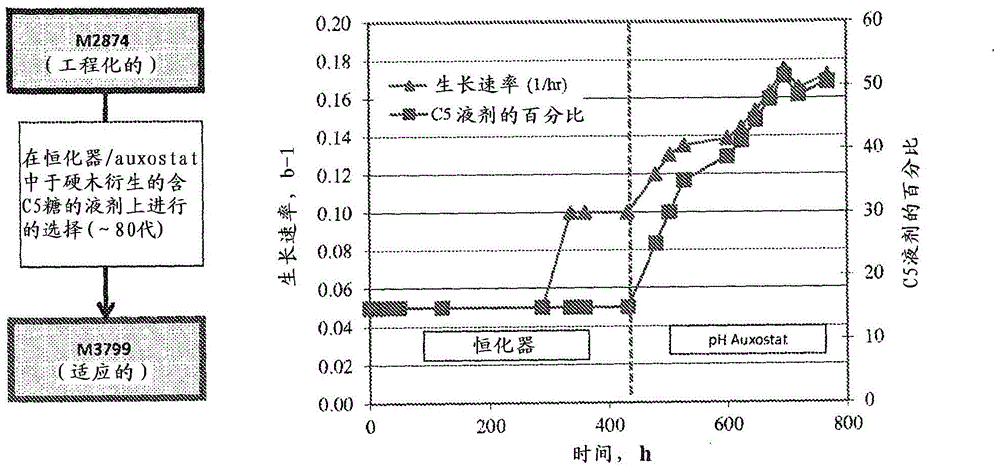

Expression cartridge for the transformation of eukaryotic cells, method for transforming eukaryotic cells, genetically modified organism, method for producing biofuels and/or biochemicals, and thus produced biofuel and/or biochemical

The present invention describes the expression cassette for transforming eukaryotic cell which comprises the peptide encoding non-natural sequence of nucleotides with xylose isomerase feature (SEQ ID NO: 1), optionally also comprising other genes of pentose phosphate route. Additionally, it is described the microorganism filed under the number DSM28739, which, in addition to the above-mentioned modifications, also present genetic modifications from adaptive evolution. The described microorganism shows efficient consumption of xylose and conversion of ethanol when compared to its correspondent without said genetic modifications and mutations from evolution. It is also described the process for producing biofuels e biochemicals, preferably ethanol, mainly from the lignocellulosic portion of the vegetal biomass. Biofuels, preferably ethanol, and biochemicals produced by the process of the invention are also described.

Owner:BIOCELERE AGROIND

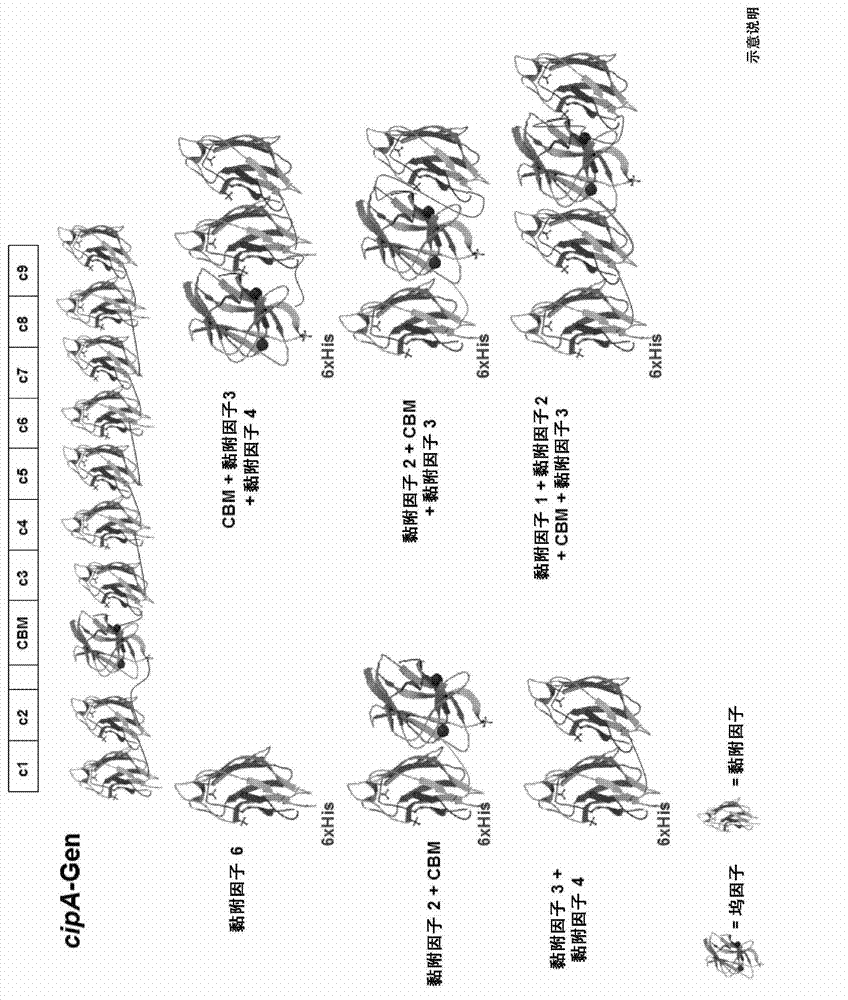

Artificial cellulosome and the use of the same for enzymatic breakdown of resilient substrates

The present invention relates to an in vitro produced, artificial cellulosome for enzymatic breakdown of resilient substrates. In particular, the present invention provides a complex having an increased activity on resilient substrates, such as crystalline cellulose. The in vitro formed complex comprises a backbone scaffold having at least four binding sites capable of binding the enzyme components, whereby at least two of the binding sites have essentially the same binding specificity; and at least three different enzyme components being randomly bound to the at least four binding sites. Method for preparing the complex and uses of the same for enzymatic breakdown of resilient substrates are also provided.

Owner:TECH UNIV MUNCHEN

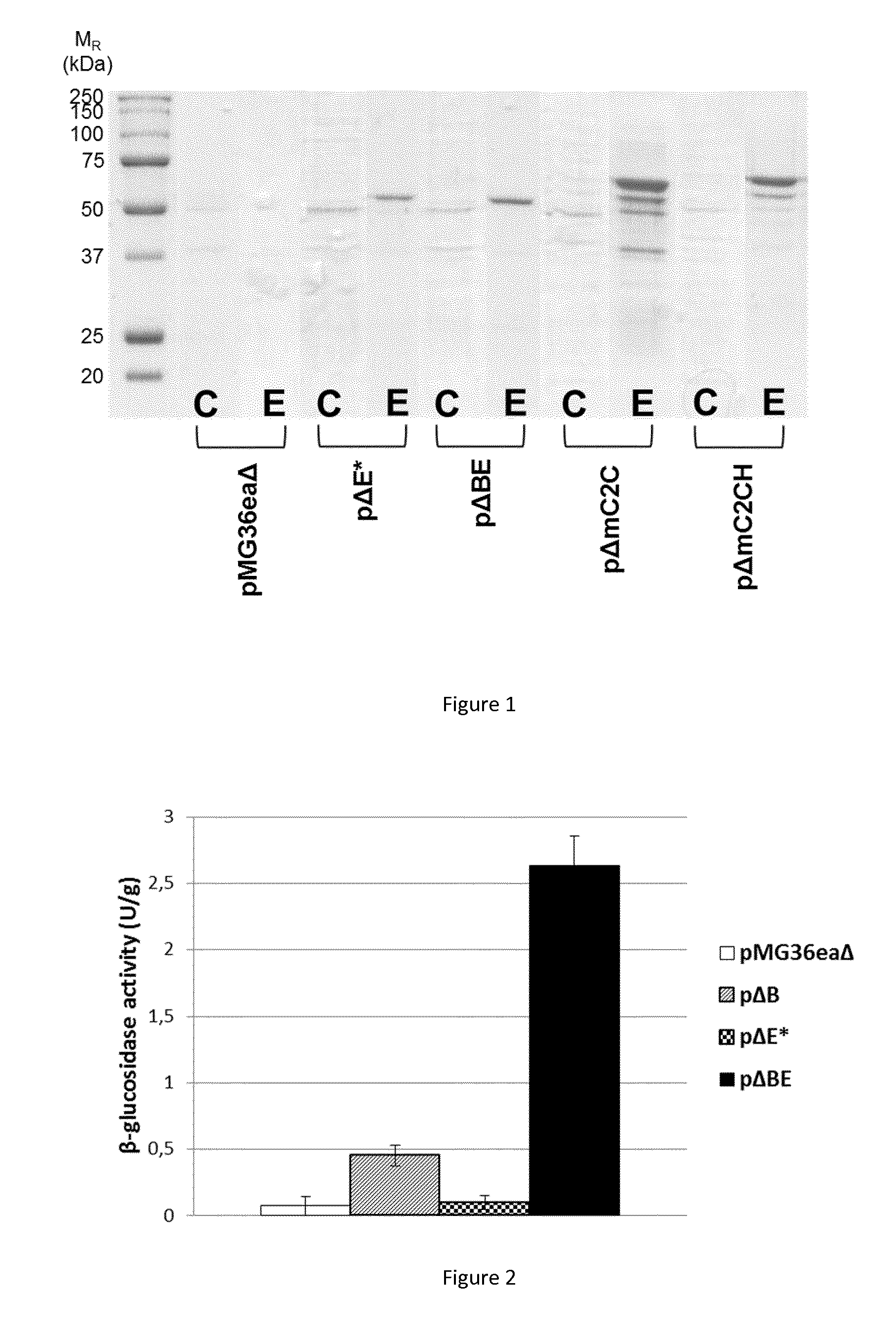

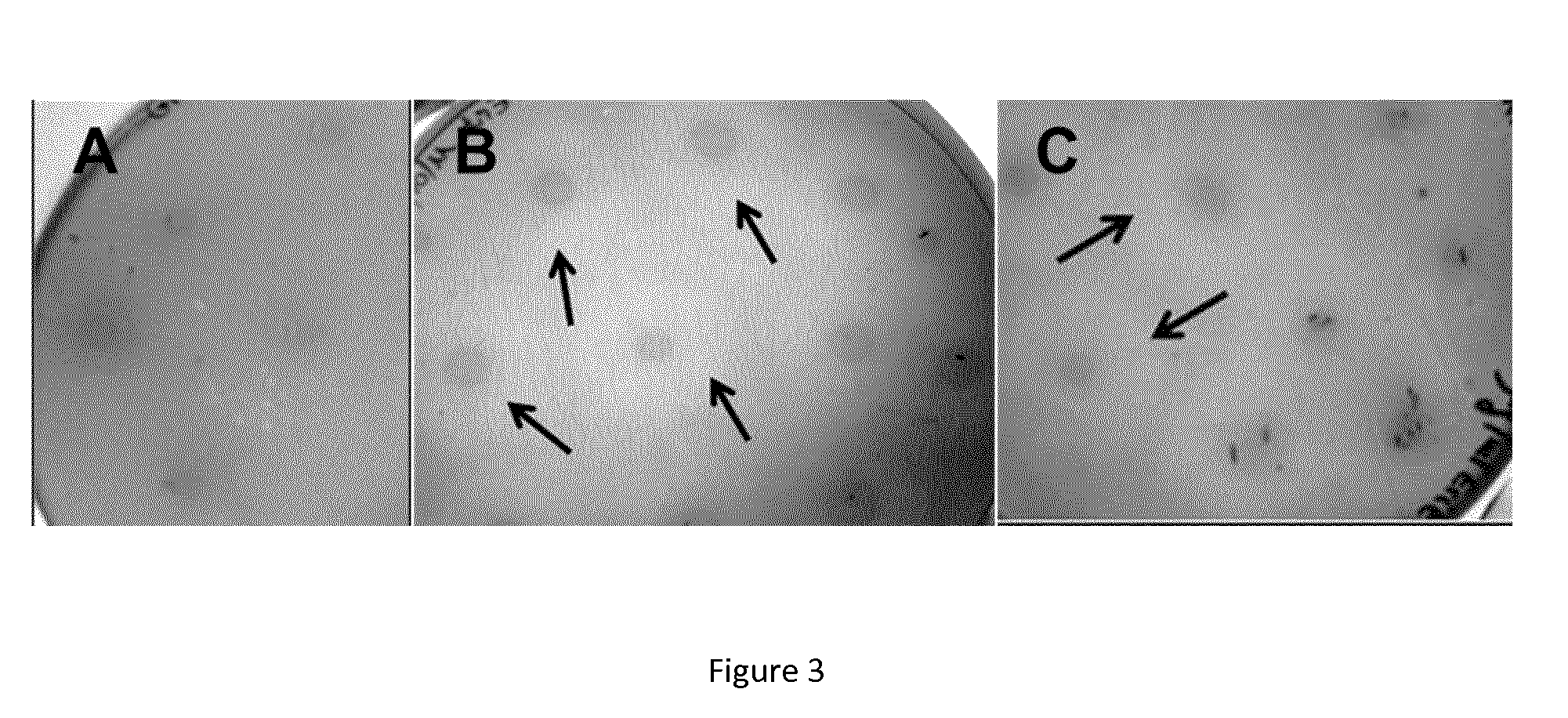

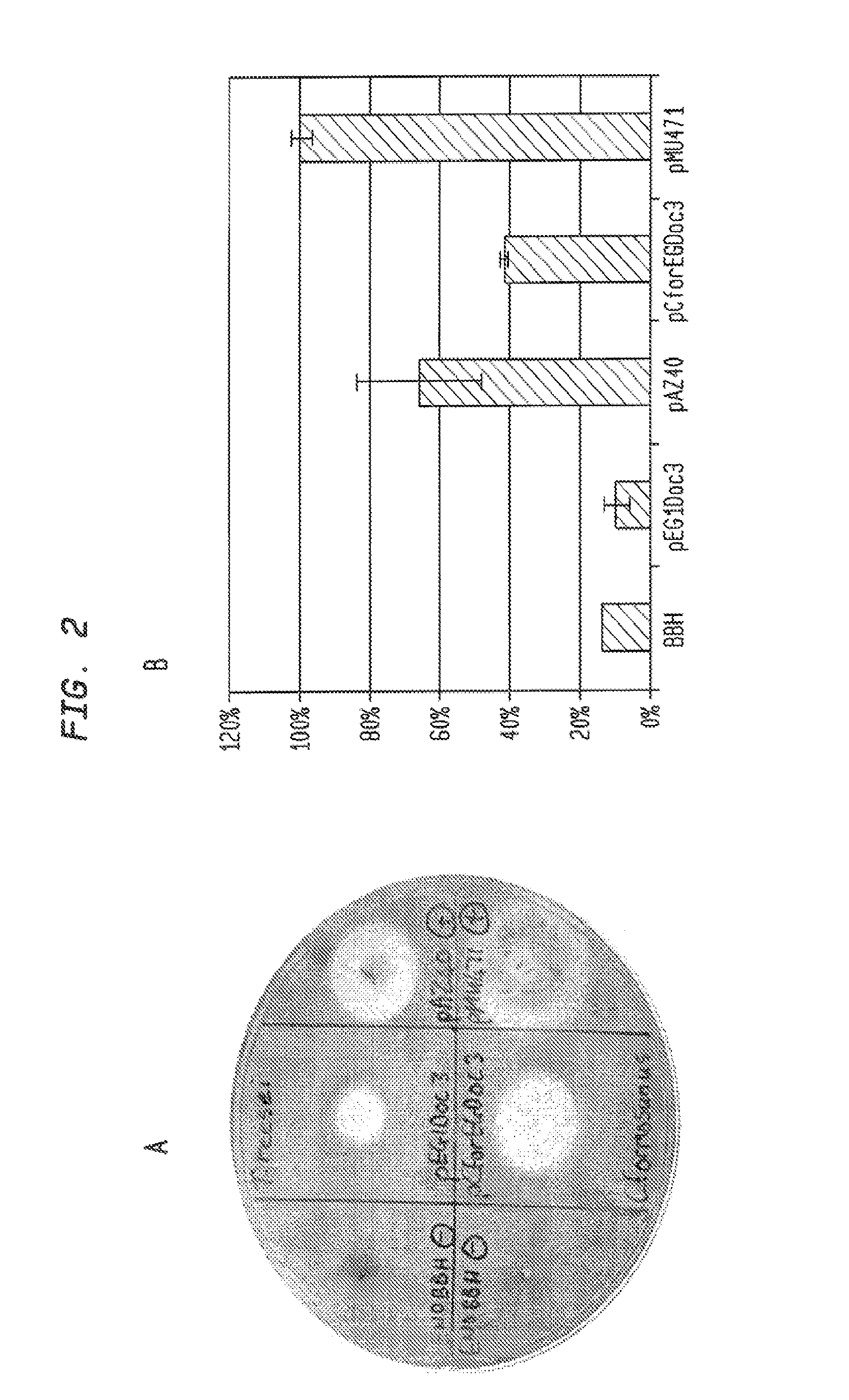

Recombinant cellulosome complex and uses thereof

ActiveUS9528132B2Degrading cellulose efficientlyEfficient degradationPolypeptide with localisation/targeting motifSugar derivativesSequence signalPleckstrin homology domain

The present invention relates to a polynucleotide encoding a recombinant scaffolding polypeptide comprising at least a signal peptide, a Cellulose Binding Domain, two cohesin domains and an S-layer Homology domain, wherein said isolated polynucleotide preferably comprises all or an active part of the nucleotide sequence as set forth in SEQ ID NO:2. The present invention further relates to vectors comprising such polynucleotides, recombinant lactic acid bacteria, and method for degrading a cellulosic biomass using such recombinant lactic acid bacteria.

Owner:CARBIOS

Gene knockout mesophilic and thermophilic organisms, and methods of use thereof

One aspect of the invention relates to a genetically modified thermophilic or mesophilic microorganism, wherein a first native gene is partially, substantially, or completely deleted, silenced, inactivated, or down-regulated, which first native gene encodes a first native enzyme involved in the metabolic production of an organic acid or a salt thereof, thereby increasing the native ability of said thermophilic or mesophilic microorganism to produce ethanol as a fermentation product. In certain embodiments, the aforementioned microorganism further comprises a first non-native gene, which first non-native gene encodes a first non-native enzyme involved in the metabolic production of ethanol. Another aspect of the invention relates to a process for converting lignocellulosic biomass to ethanol, comprising contacting lignocellulosic biomass with a genetically modified thermophilic or mesophilic microorganism.

Owner:LALLEMAND HUNGARY LIQUIDITY MANAGEMENT LLC

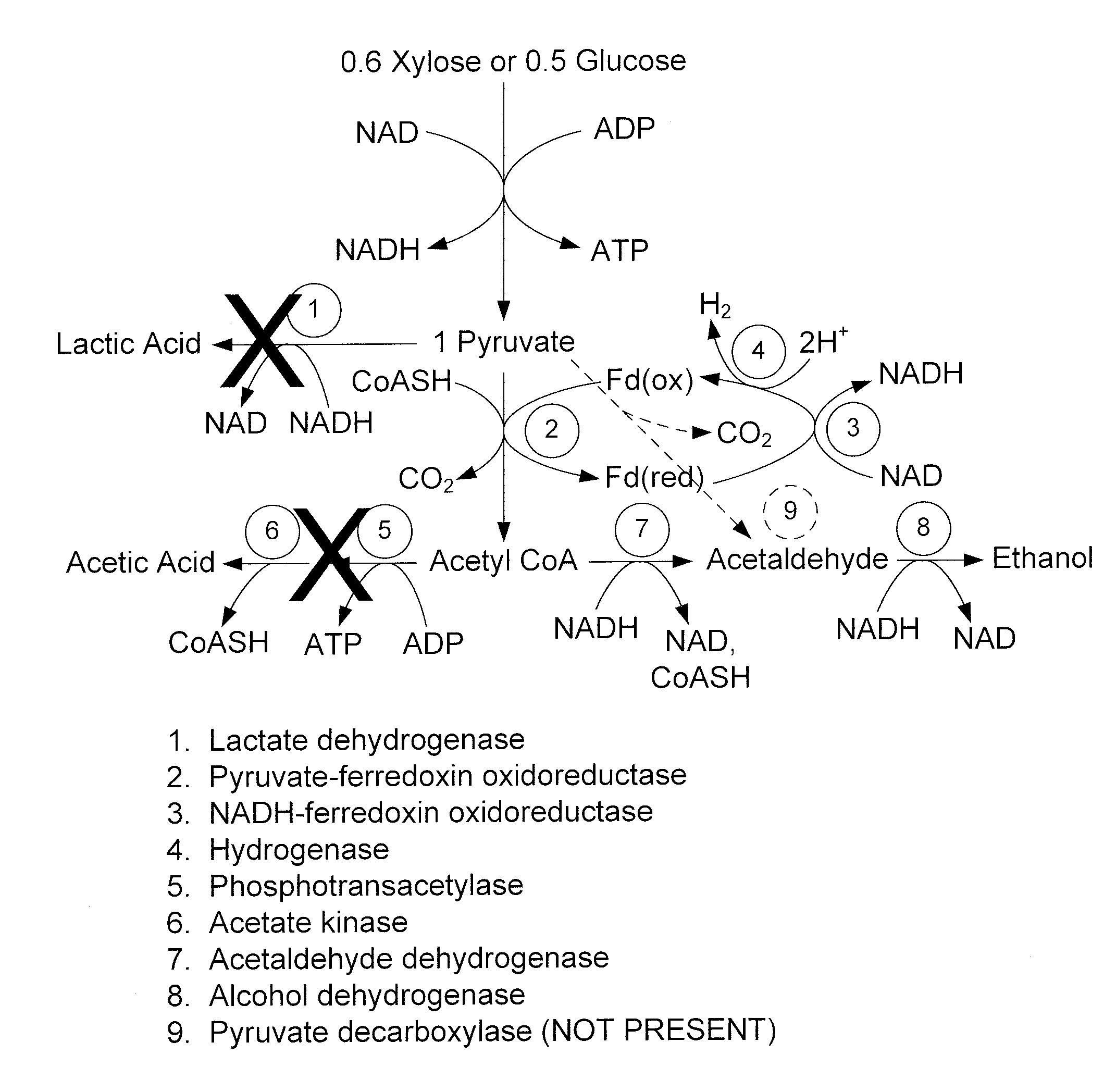

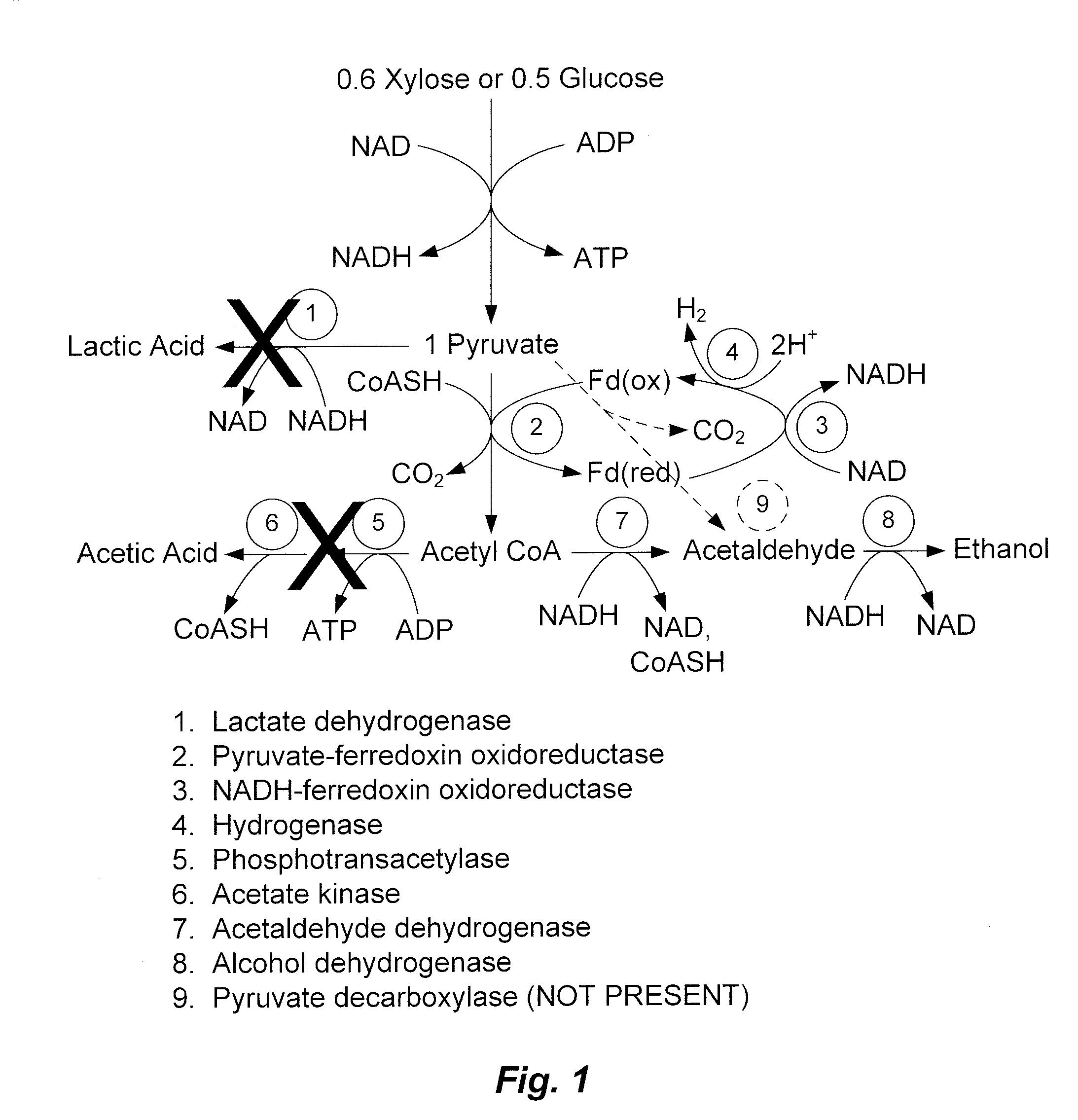

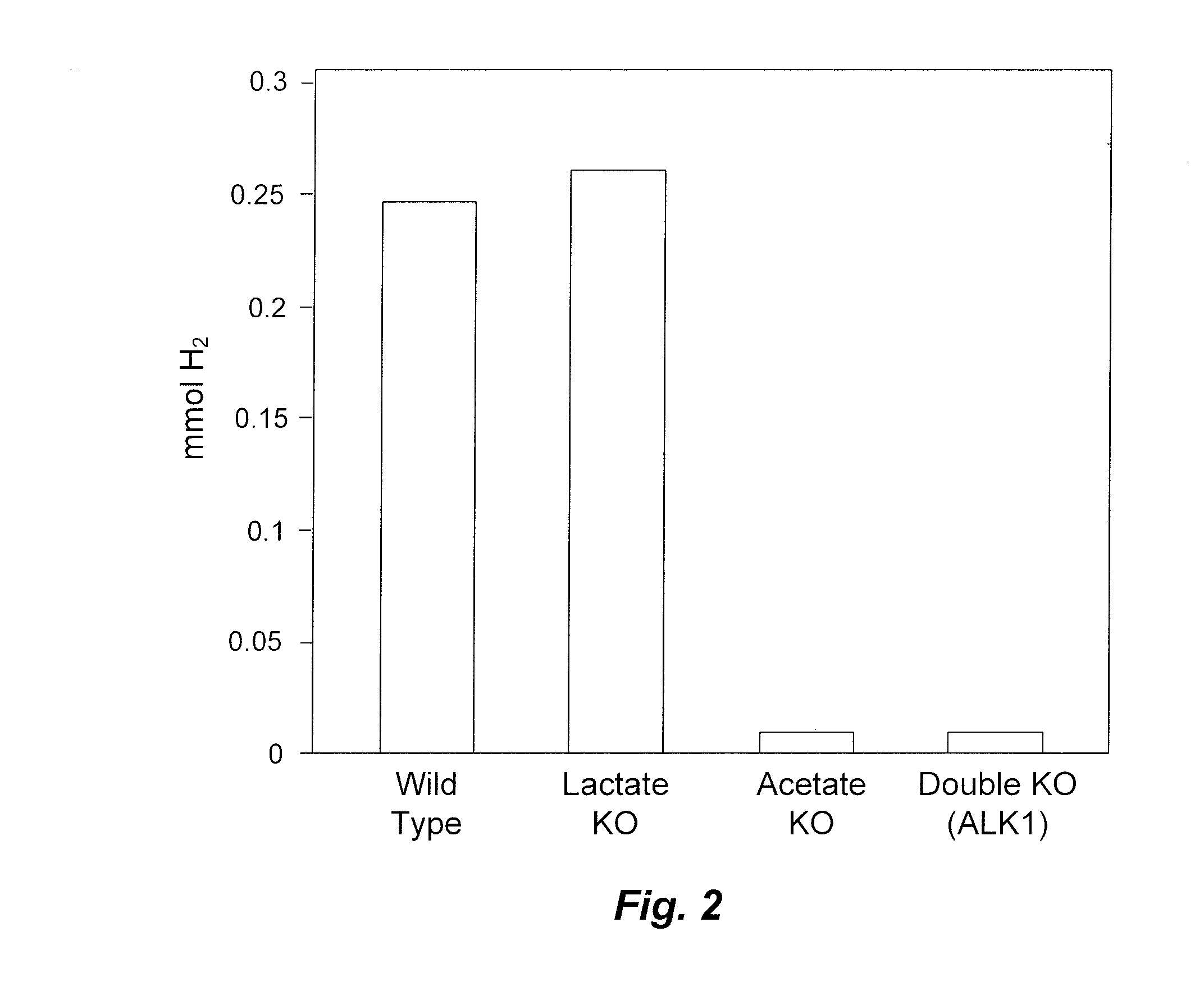

Thermophillic Organisms For Conversion Of Lignocellulosic Biomass To Ethanol

Mutant thermophilic organisms that consume a variety of biomass derived substrates are disclosed herein. Strains of Thermoanaerobacterium saccharolyticum with acetate kinase and phosphotransacetylase expression eliminated are disclosed herein. Further, strain ALK1 has been engineered by site directed homologous recombination to knockout both acetic acid and lactic acid production. Continuous culture involving a substrate concentration challenge lead to evolution of ALK1, and formation of a more robust strain designated ALK2. Both organisms produce near theoretical ethanol yields without expressing pyruvate decarboxylase

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

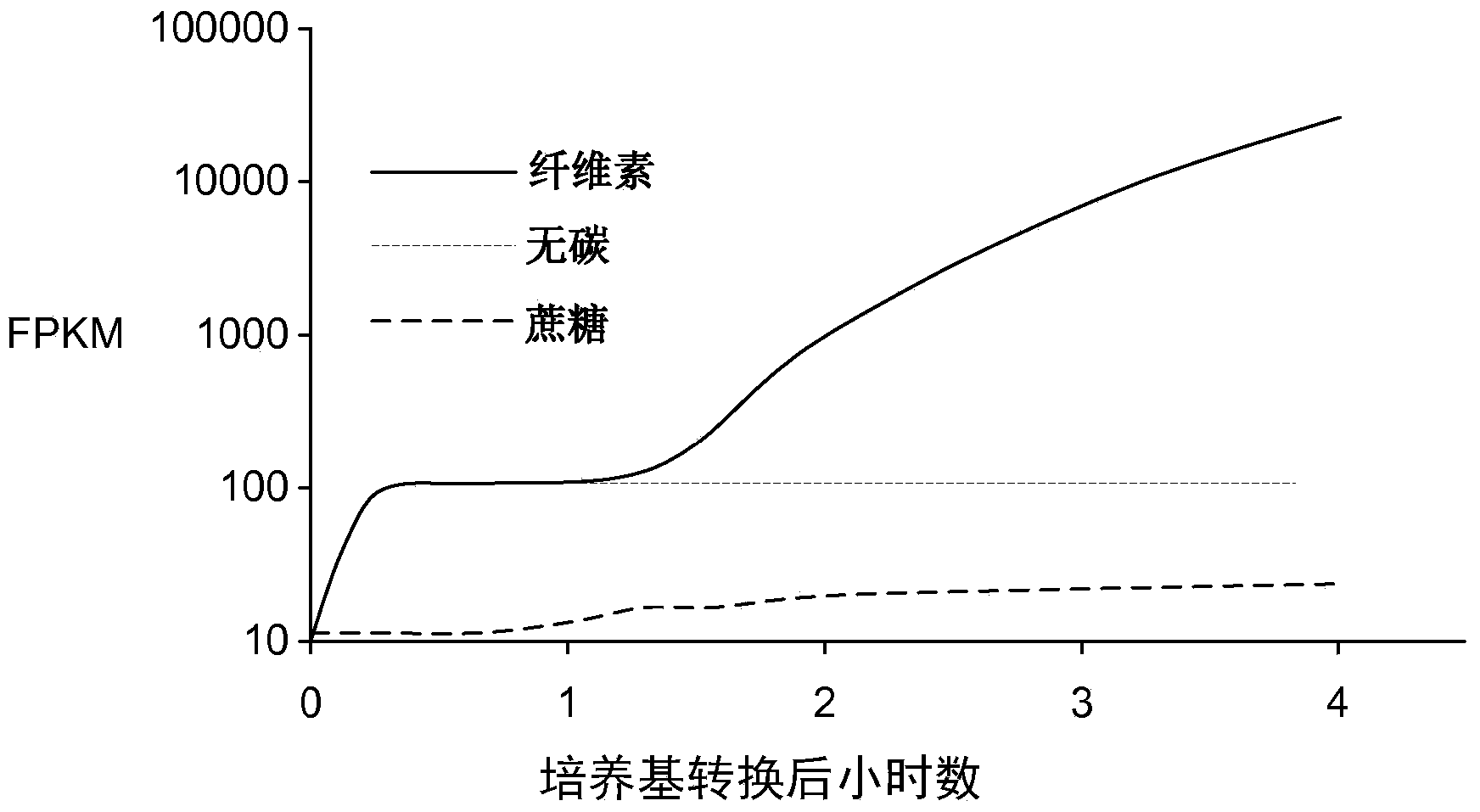

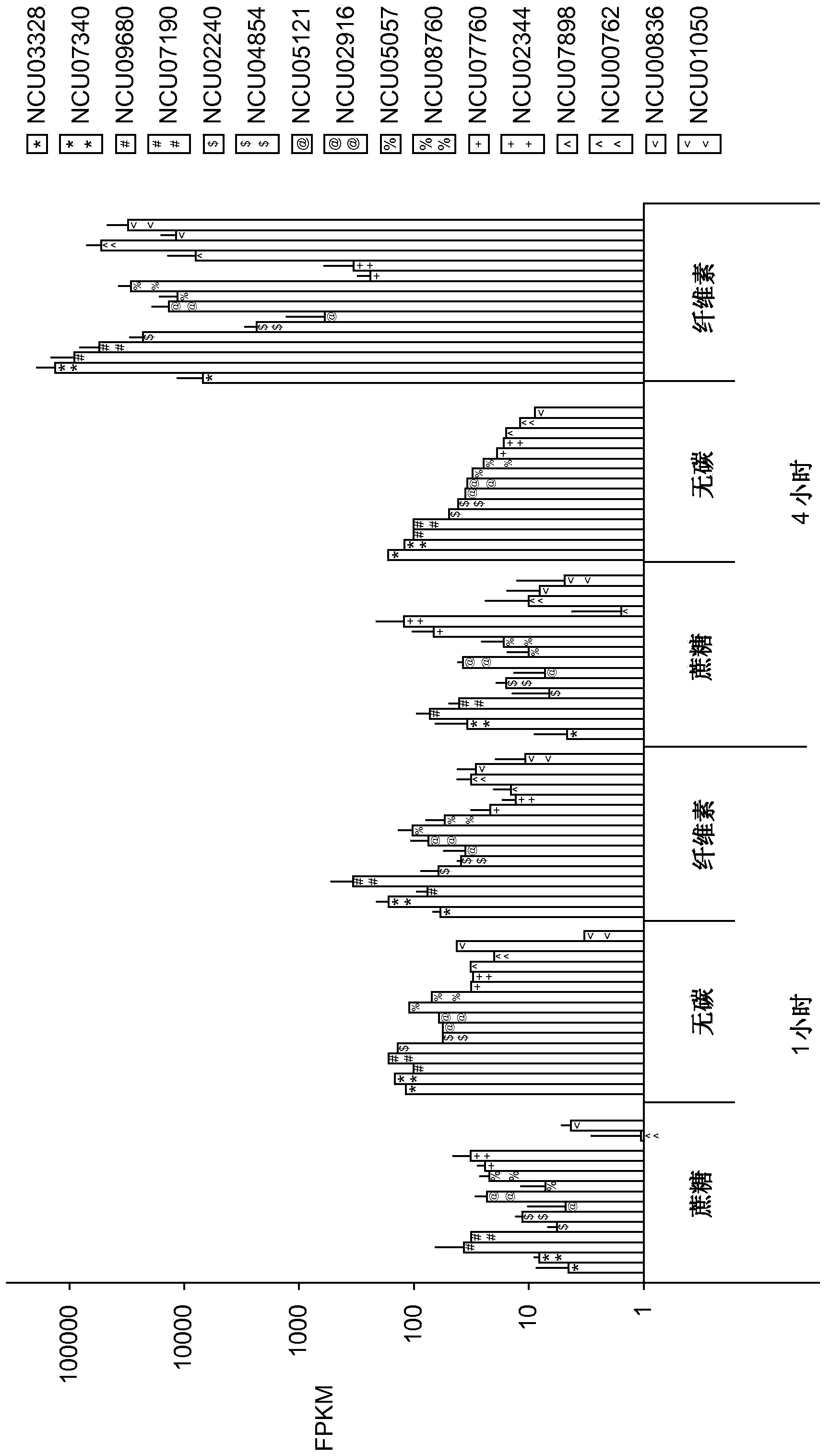

Transcription factors for the production of cellulose degrading enzymes

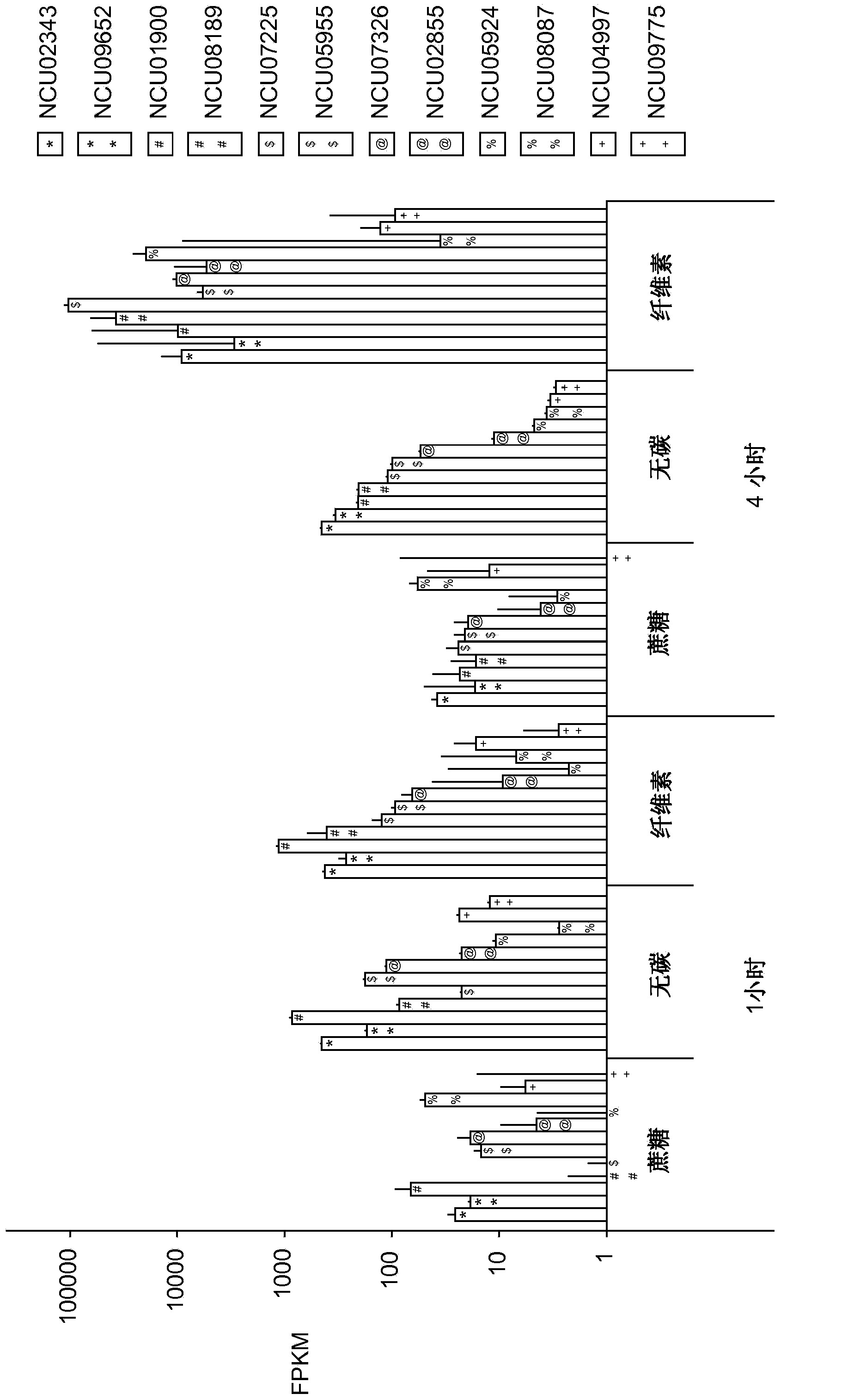

InactiveCN103917653AReduce expressionDepsipeptidesFermentationCellulose degradationSecreted substance

Provided herein are methods and compositions for increasing the production of one or more cellulases from a fungal host cell. The disclosure is based, on the surprising discovery that mis-expression of the transcriptional regulator clr-2 in a filamentous fungal cell was able to induce expression of cellulase genes under non-inducing or starvation conditions, resulting in increased secretion of cellulases from the cell. Advantageously, mis-expression of the transcription factor clr-2 in a filamentous fungal cell cultured in the absence of cellulose or cellobiose results in increased secretion of cellulases. The disclosure relates inter alia to a method of degrading cellulose-containing material, to a method of increasing the production of one or more cellulases from a fungal cell and to a method of reducing the viscosity of a pretreated biomass material, by contacting pretreated biomass material with a fungal host cell containing at least one recombinant nucleic acid encoding clr-2 or a related transcription factor.

Owner:RGT UNIV OF CALIFORNIA

Cellulase preparation and application thereof

The invention belongs to the technical field of biology, and in particular relates to a cellulase preparation for catalyzing lignocellulose saccharification, and application of the cellulase preparation. The cellulase preparation provided by the invention contains a cellulosome complex and beta-1, 4-glucosidase at the same time, wherein the beta-1, 4-glucosidase is compounded in the cellulosome complex in a way of interaction of covalent or non-covalent proteins or fusion expression with the cellulosome complex. The cellulase preparation not only can realize high-efficiency hydrolysis of a lignocellulose substrate and has high fermentable sugar yield and saccharification rate, but also has the advantages of being low in production cost, and the like.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

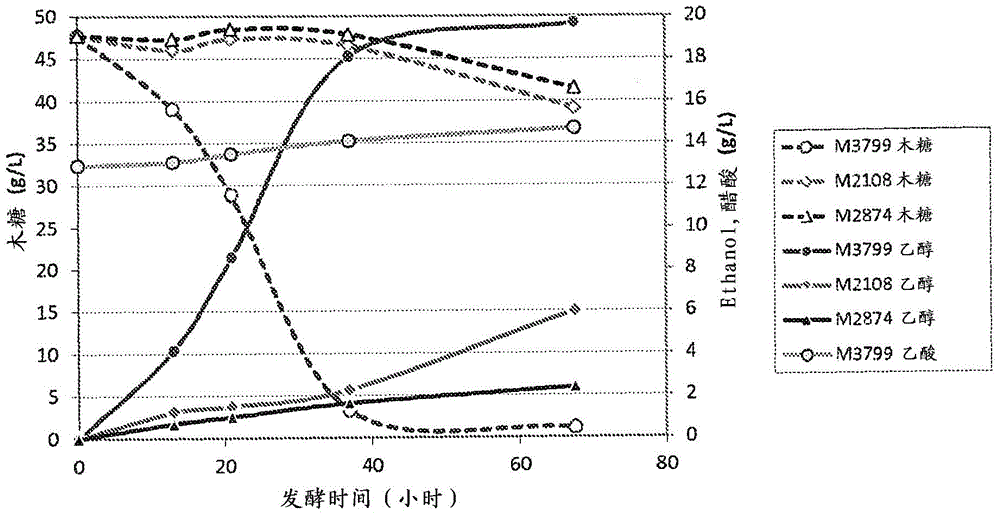

Expression of enzymes in yeast for lignocellulose derived oligomer CBP

The present invention provides a multi-component enzyme system that hydrolyzes hemicellulose oligomers from hardwood which can be expressed, for example, in yeast such as Saccharomyces cerevisiae. In some embodiments, this invention provides for the engineering of a series of biocatalysts combining the expression and secretion of components of this enzymatic system with robust, rapid xylose utilization, and ethanol fermentation under industrially relevant process conditions for consolidated bioprocessing. In some embodiments, the invention utilizes co-cultures of strains that can achieve significantly improved performance due to the incorporation of additional enzymes in the fermentation system.

Owner:LALLEMAND HUNGARY LIQUIDITY MANAGEMENT LLC

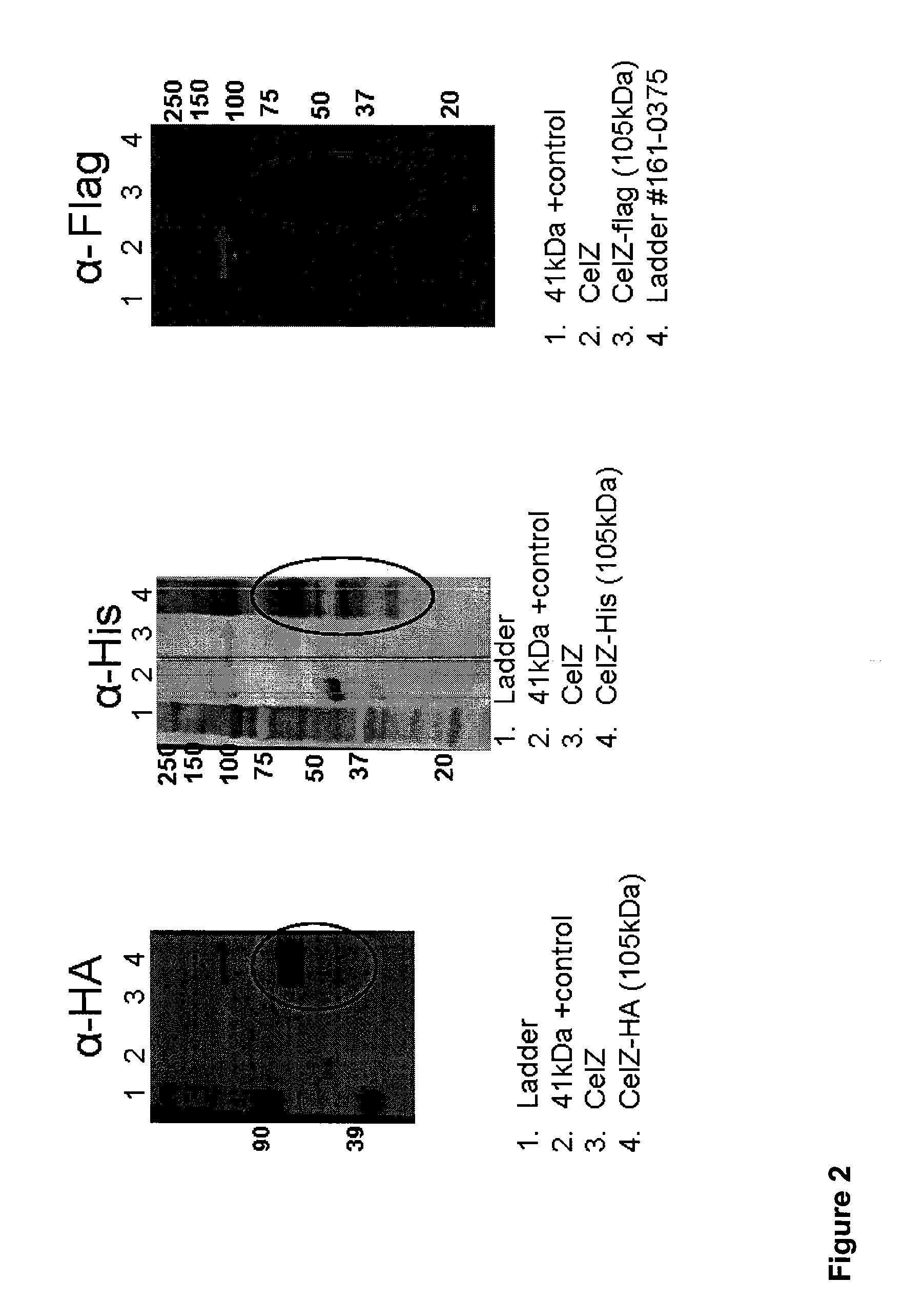

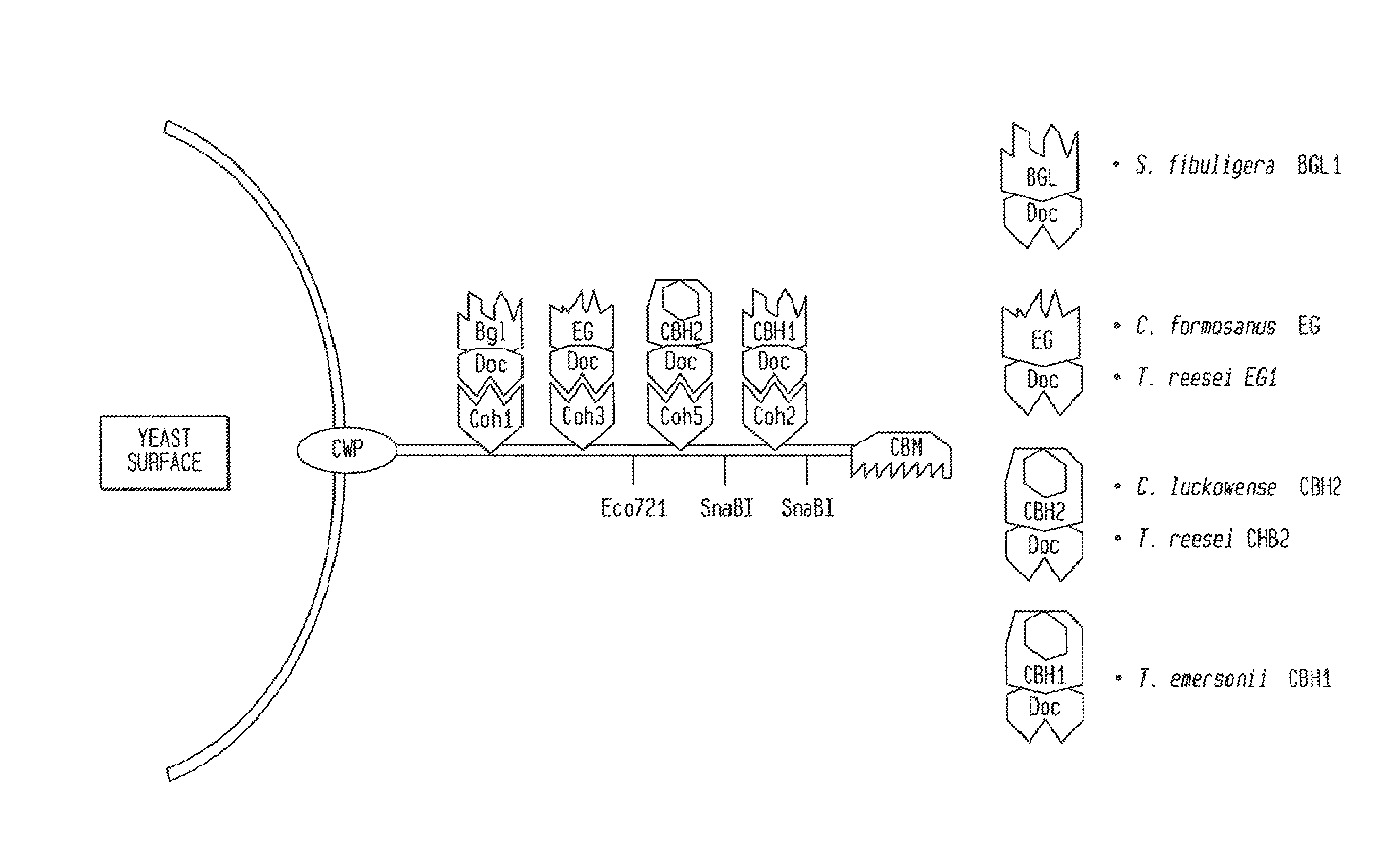

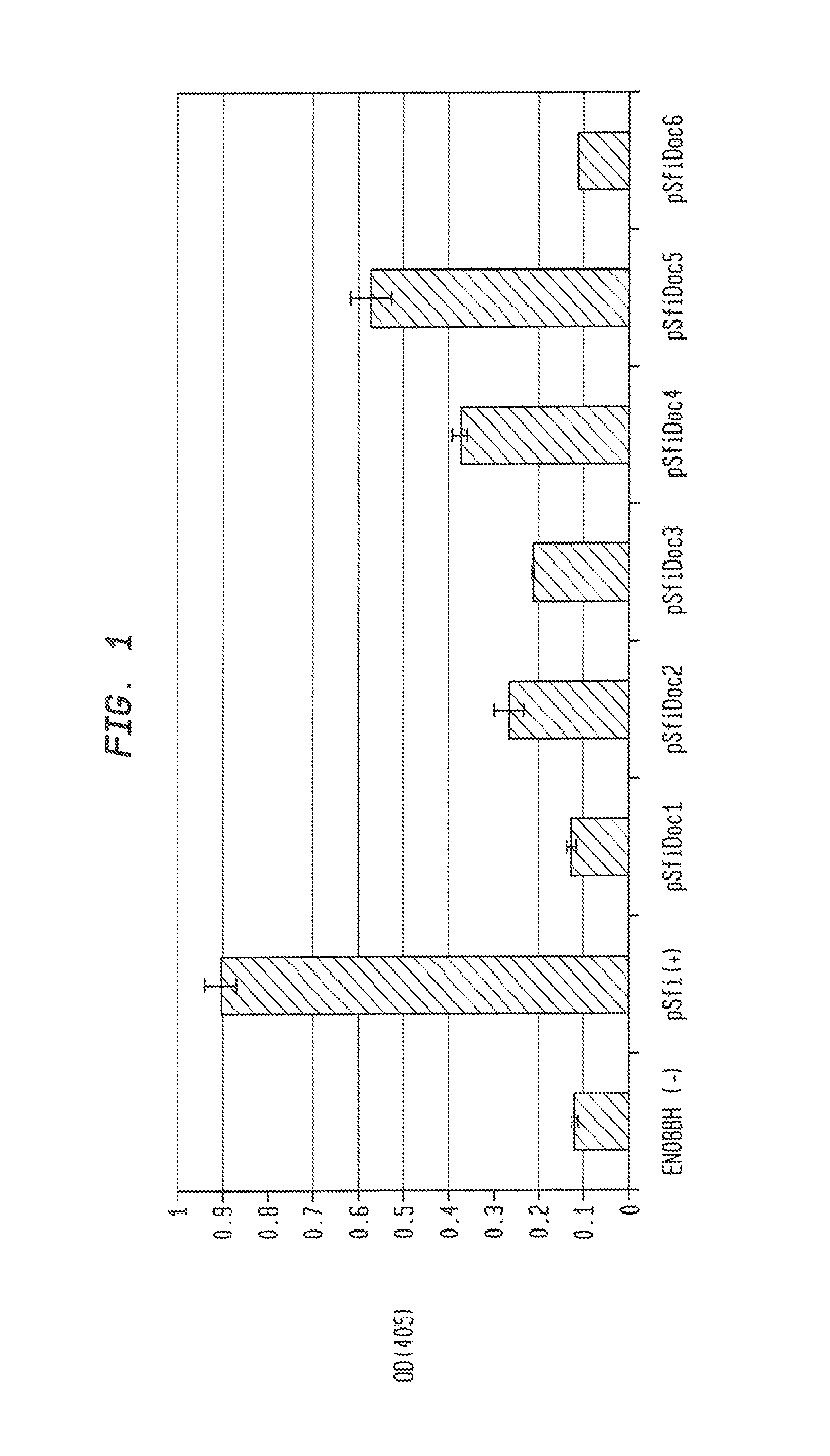

Yeast Cells Expressing An Exogenous Cellulosome And Methods of Using The Same

The present invention relates to the engineering and expression of heterologous cellulosomes in microorganisms in order to facilitate the conversion of biomass to useful products. In some embodiments, the invention relates to the expression of scaffoldin proteins which form the nucleus of a cellulosome. Cellulases or other biomass-degrading enzymes can be non-covalently linked to the scaffoldin protein by virtue of a dockerin domain-cohesin domain interaction.

Owner:LALLEMAND HUNGARY LIQUIDITY MANAGEMENT LLC +1

High-density culture method of clostridium thermocellum

InactiveCN102864089AReduce manufacturing costReduce consumptionBacteriaMicroorganism based processesBiotechnologyCellulose

The invention belongs to the field of microbial fermentation engineering, and specifically relates to a high-density culture method of clostridium thermocellum. The method is characterized in that a GS-2 culture medium is used as an initial culture medium; the fermentation medium is optimized through a multivariate statistical method; and cell concentration of clostridium thermocellum is rapidly and efficiently raised. The invention has the following advantage: the invention provides a fermentation medium for rapid acquisition of large cell concentration of clostridium thermocellum, thus laying the groundwork for subsequent production of cellulosome which has high conversion efficiency of cellulose to bioethanol. Bacterial density of clostridium thermocellum is raised by 6-9 times in comparison with that of the initial culture medium. OD600 under the bottling condition reaches 8.85, and OD600 in a fermentation cylinder reaches 12.7.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

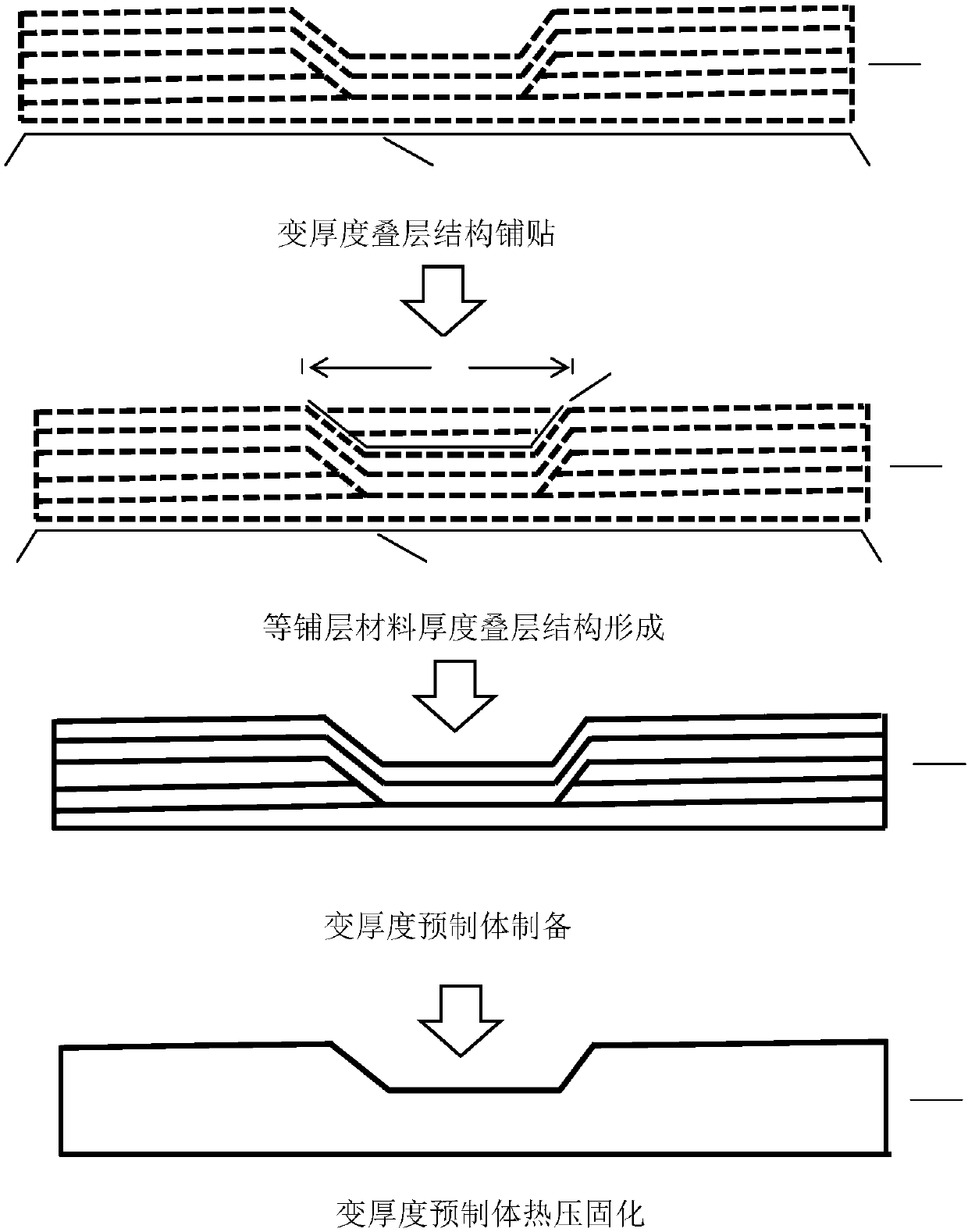

Preparation method of variable-thickness resin matrix composite structure

The invention belongs to the technical field of resin matrix composite structure molding, and relates to a preparation method of a variable-thickness resin matrix composite structure. The variable-thickness resin matrix composite structure is prepared by adopting the following steps: forming a variable-thickness perform by means of an identical ply material thickness lamination structure, and thencuring the variable-thickness perform. The variable-thickness perform eliminates a possibility of difference between pressure fields of resin flowing or difference between cellulosome distributions in the formation of the variable-thickness perform by means of the formation of the identical ply material thickness lamination structure, a high thickness precision variable-thickness perform is obtained, and when the variable-thickness perform is hot-pressed and cured again, the resin system is in a B-stage high-viscosity state, the thickness and the precision are basically set, and high thickness precision features can be maintained, so that the high thickness precision variable thickness composite structure is finally obtained.

Owner:AVIC BASIC TECH RES INST

Recombinant cellulosome complex and uses thereof

ActiveUS20150167030A1Efficient degradationBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseLactic acid bacterium

The present invention relates to a polynucleotide encoding a recombinant scaffolding polypeptide comprising at least a signal peptide, a Cellulose Binding Domain, two cohesin domains and an S-layer Homology domain, wherein said isolated polynucleotide preferably comprises all or an active part of the nucleotide sequence as set forth in SEQ ID NO:2. The present invention further relates to vectors comprising such polynucleotides, recombinant lactic acid bacteria, and method for degrading a cellulosic biomass using such recombinant lactic acid bacteria.

Owner:CARBIOS

Novel Proteins from Anaerobic Fungi and Uses Thereof

Provided herein are novel proteins and protein domains from newly discovered anaerobic fungal species. The anaerobic fungal species have unique enzymatic capabilities, including the ability to digest diverse lignocellulosic biomass feedstocks and to synthesize secondary metabolites. The scope of the invention encompasses novel engineered proteins comprising glycoside hydrolase enzymes, dockerin domains, carbohydrate binding domains, and polyketide synthase enzymes. The invention further encompasses artificial cellulosomes comprising novel proteins and domains of the invention. The scope of the invention further includes novel nucleic acid sequences coding for the engineered proteins of the invention, and methods of using such engineered organisms to degrade lignocellulosic biomass and to create polyketides.

Owner:RGT UNIV OF CALIFORNIA

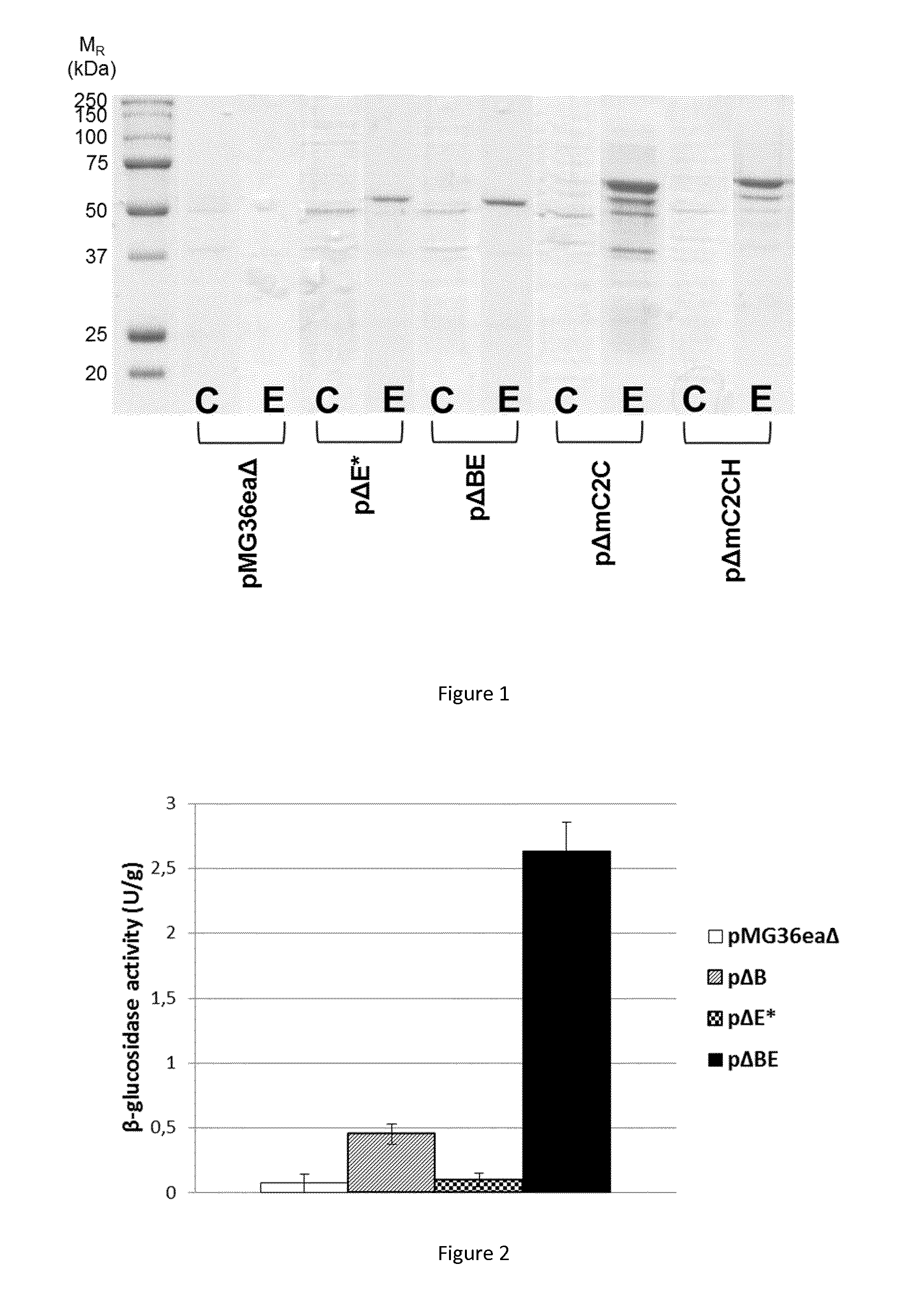

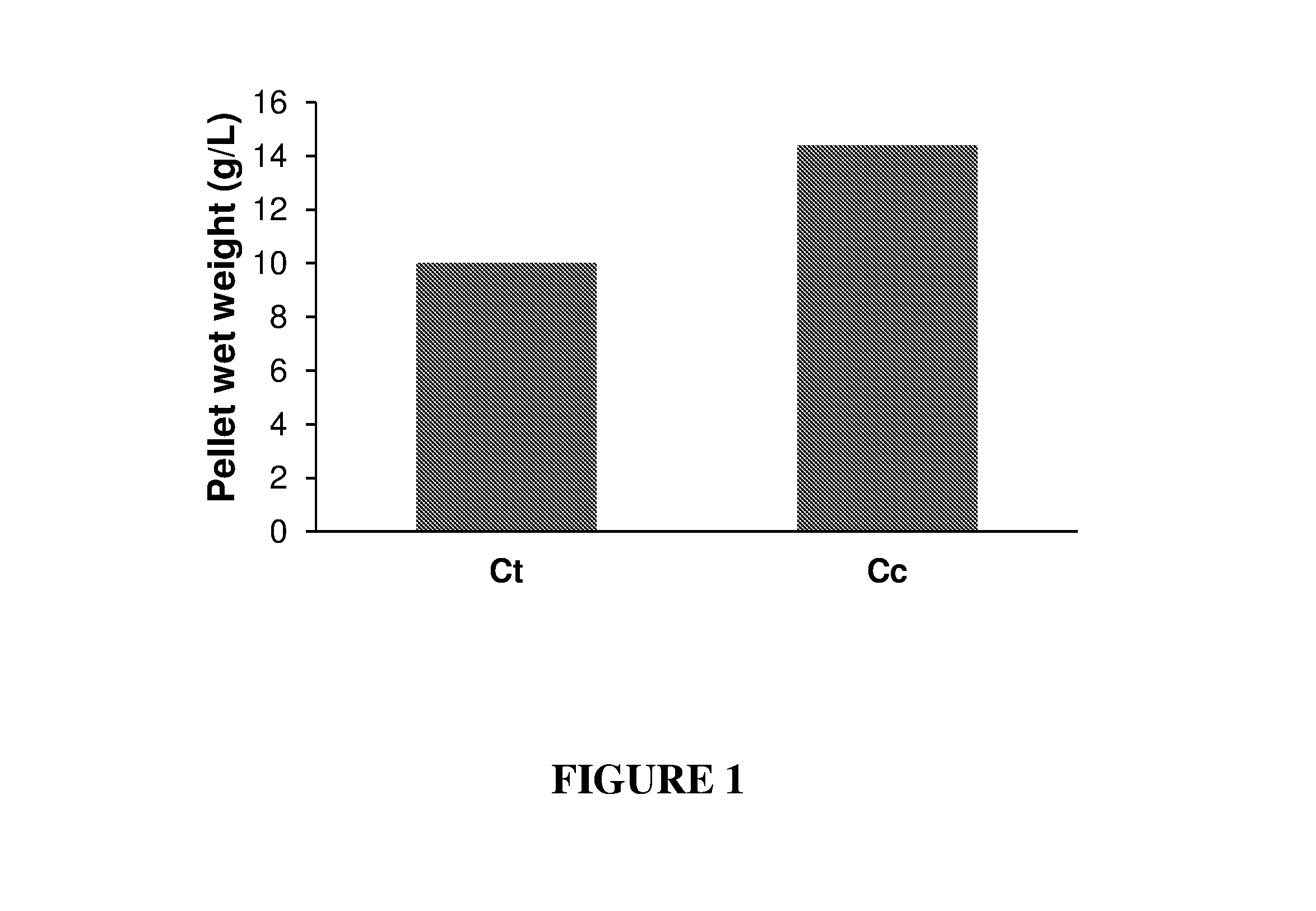

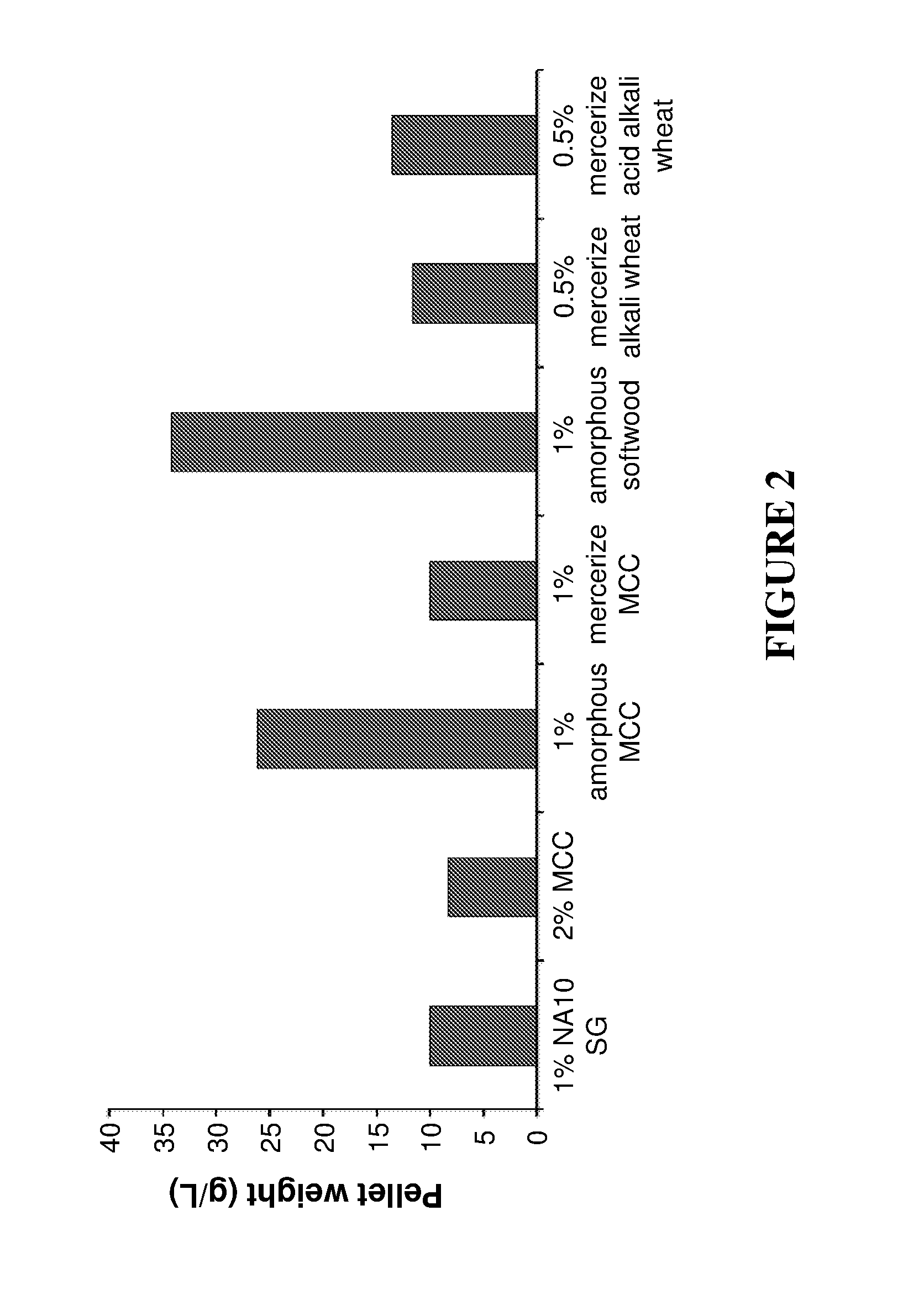

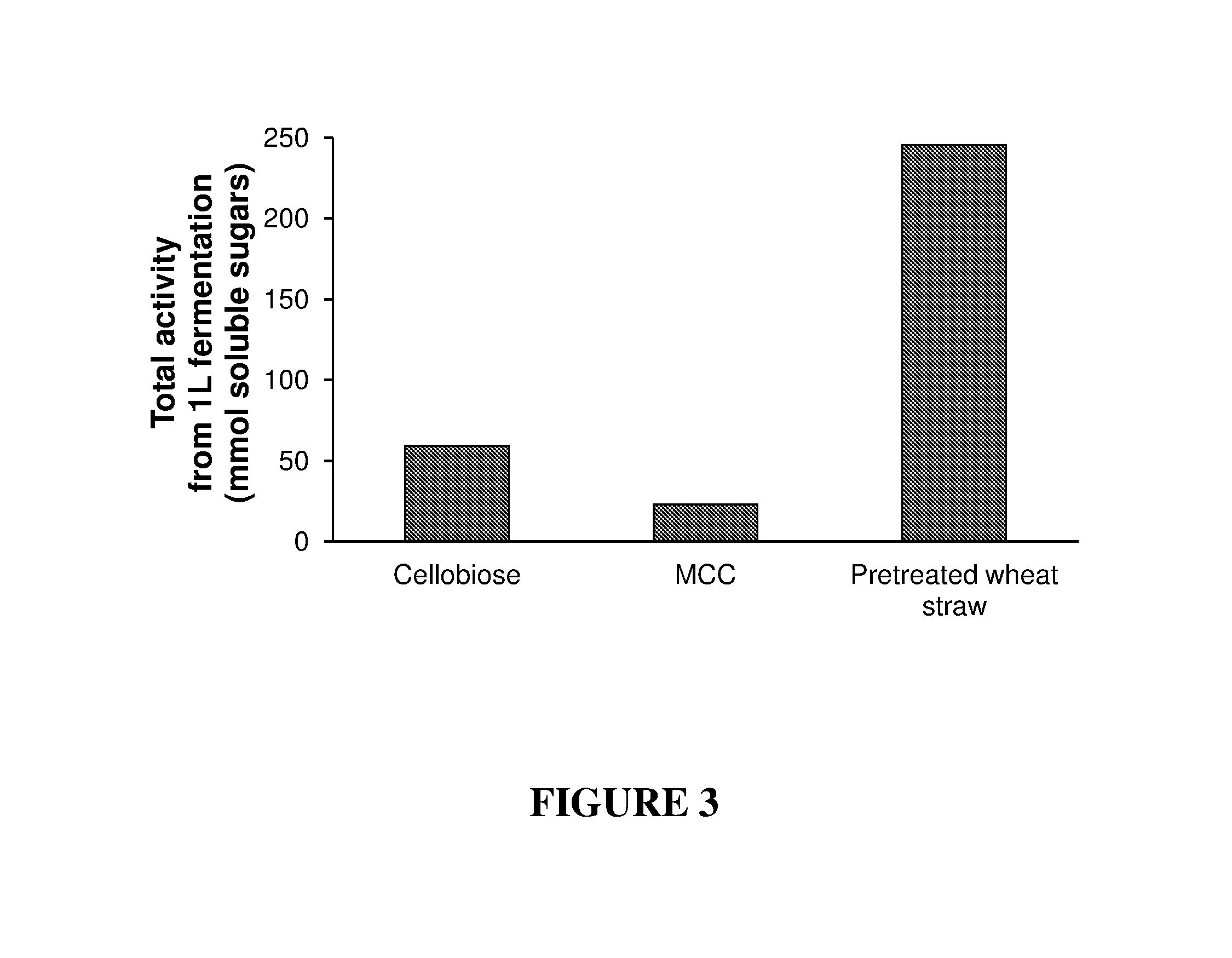

Highly potent cellulolytic enzyme preparations and processes for producing same

InactiveUS20150344867A1Increase concentrationWide rangeBiofuelsChemical recyclingCelluloseMicroorganism

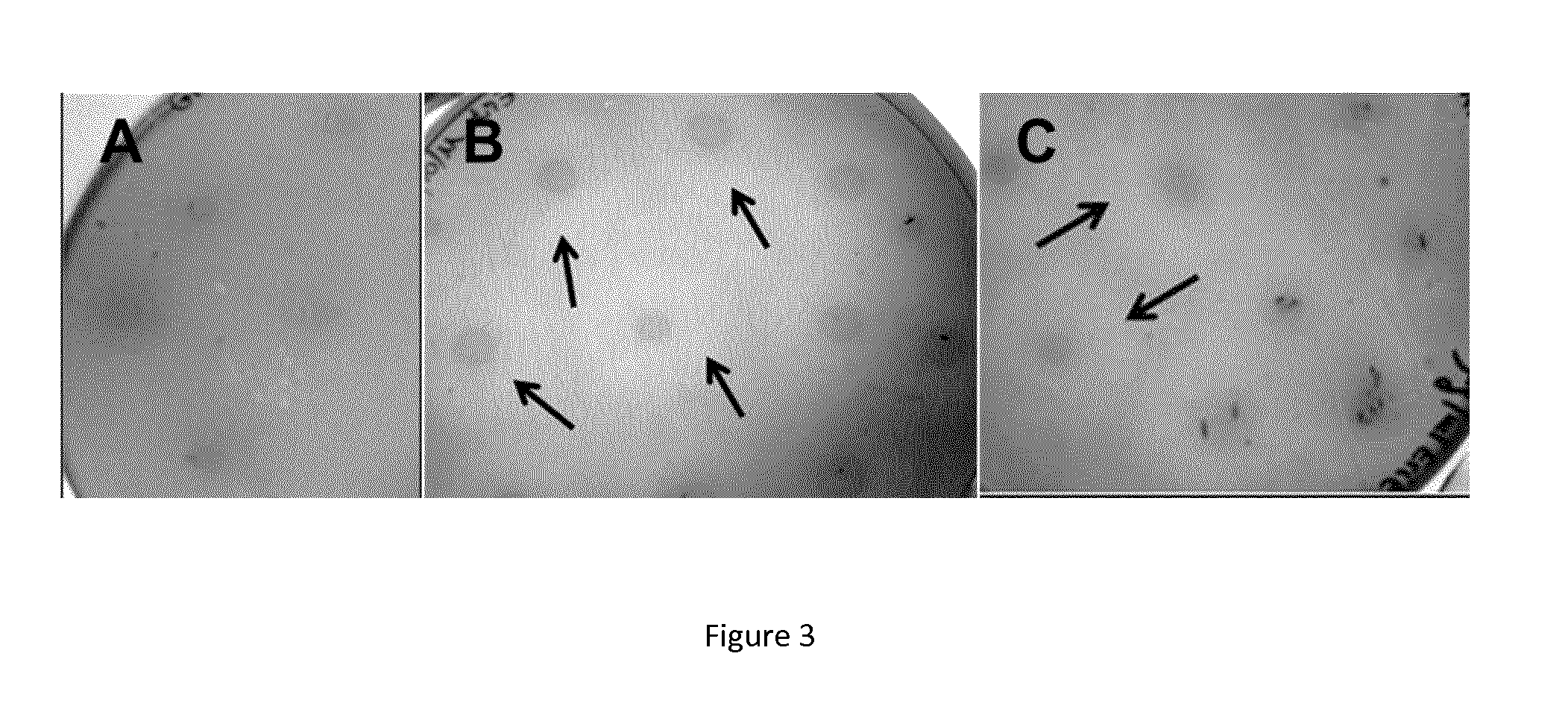

Compositions comprising unprocessed cell pellets of a cellulosome-producing microorganism grown on cellulosic biomass are provided. Further provided are methods for producing the compositions and uses thereof in hydrolysis of cellulosic substrates. In particular, the compositions advantageously contain extracellular beta-glucosidase, either expressed on the cells themselves or extrinsically added to the cell pellets.

Owner:WHITE DOG LABS INC

Manufacturing method for negative-ion cellulosome and negative-ion cellulosome manufactured by employing same

InactiveCN103866557AReduce manufacturing costEasy to useFibre treatmentTextile treatment by spraying/projectingFiberCellulosomes

A disclosed manufacturing method for negative-ion cellulosome comprises: step 1, selecting a base material, wherein the base material is a chemical fiber or cotton fiber material; step 2, preparing a nanometer tourmalinite slurry, specifically dissolving tourmalinite in water, wherein the weight ratio of tourmalinite to water is 3:5; step 3, injecting the prepared nanometer tourmalinite slurry into the base material by spraying; and step 4, drying the base material subjected to spraying injection to obtain the negative-ion cellulosome. In the step 3, the nanometer tourmalinite slurry is uniformly injected into the base material through spraying. In the step 4, air drying is employed and the drying temperature is 30-50 DEG C. The negative-ion cellulosome comprises a cellulosome body prepared from the chemical fiber or cotton fiber material, and the cellulosome body is inside provided with the nanometer tourmalinite. The beneficial effects comprise that the manufacturing method is practical, the production cost is low, the usage is convenient, and the manufactured negative-ion cellulosome is capable of effectively improving air environment around people, such as air environment in a car.

Owner:邬汝源

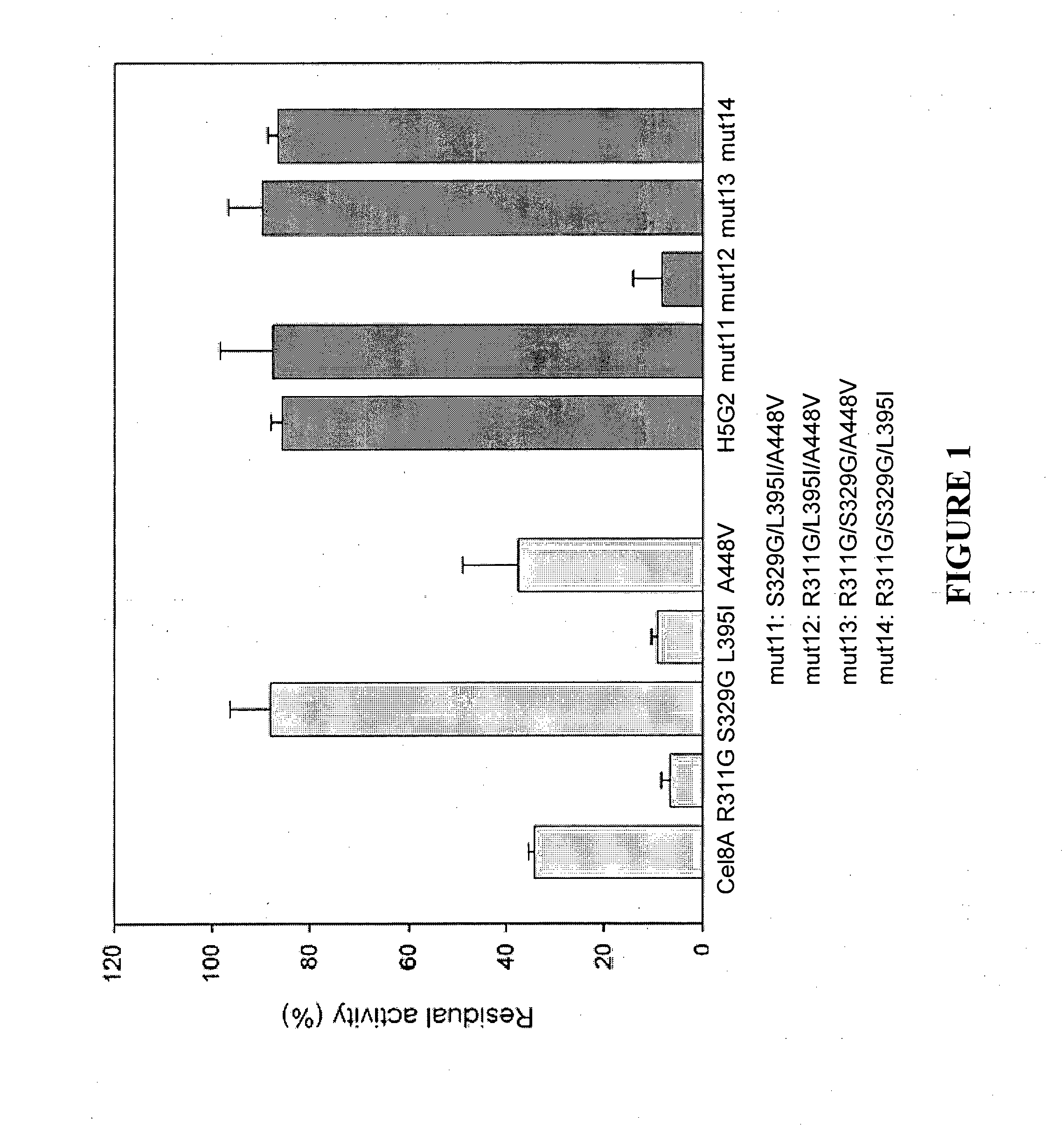

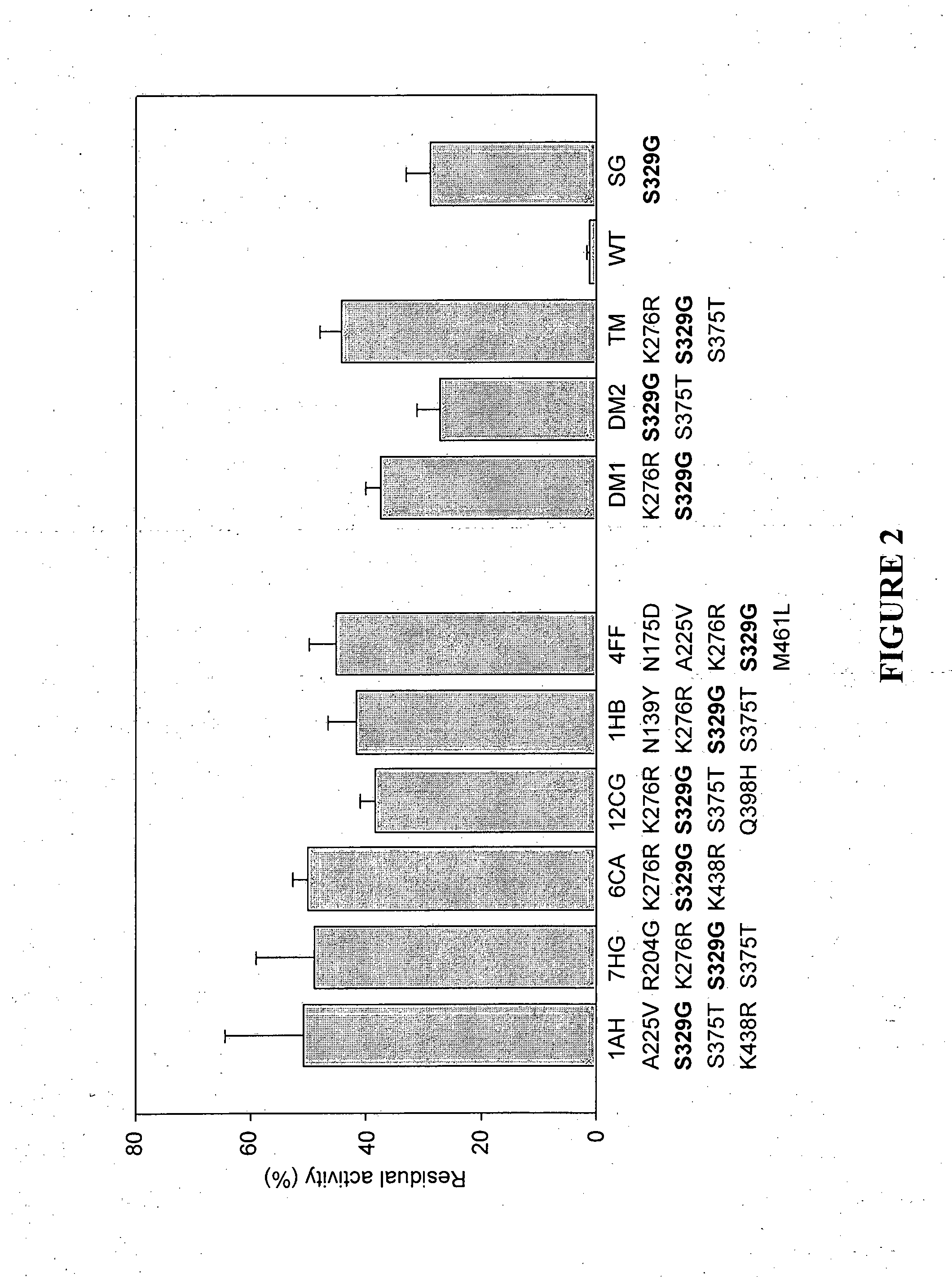

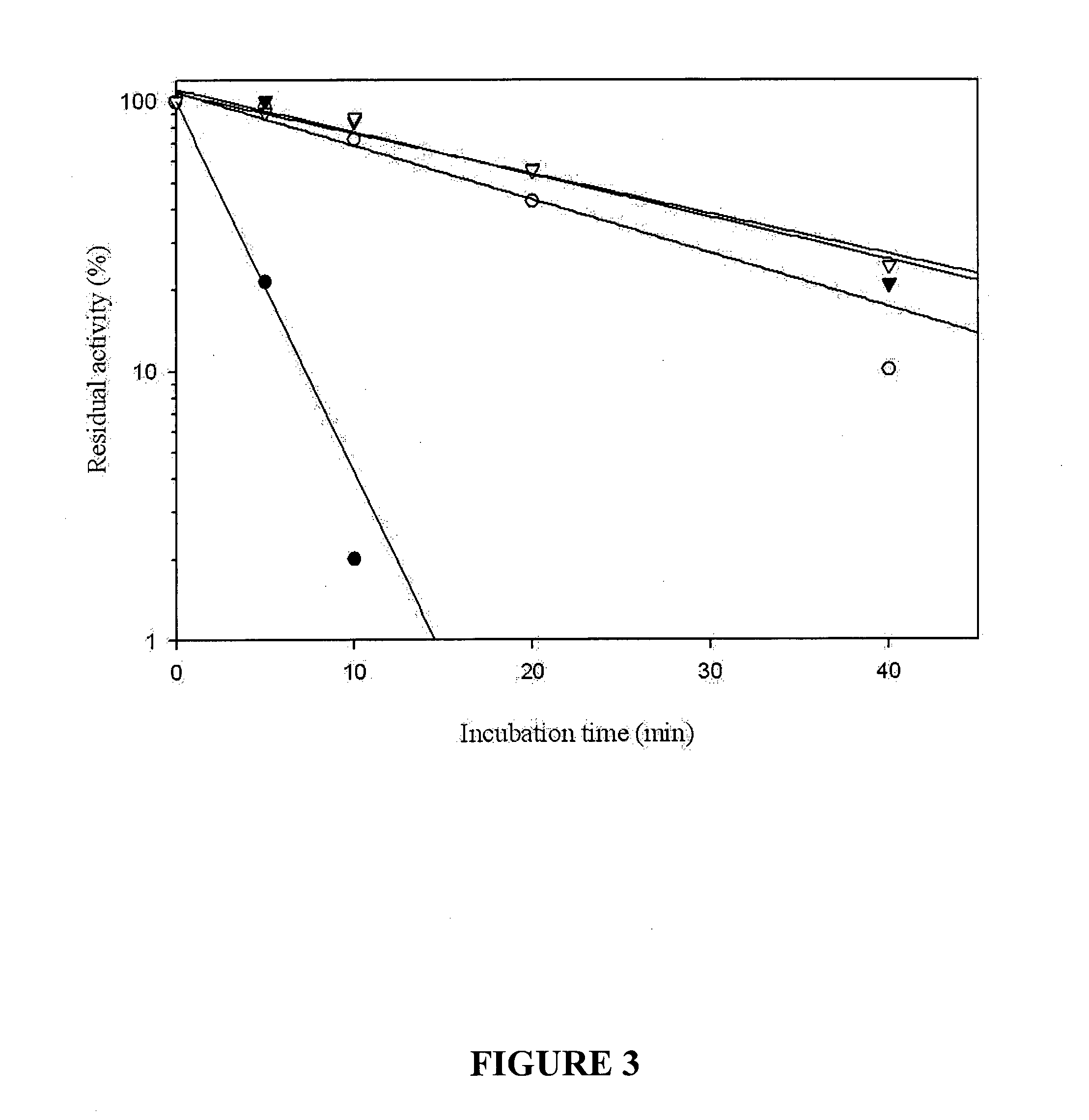

Modified cellulases with enhanced thermostability

InactiveUS20130084619A1Improve thermal stabilityHigh specific activityBacteriaSugar derivativesCellulasePolynucleotide

The present invention relates to modified family-8 cellulases that exhibit enhanced thermostability compared to the corresponding wild-type enzyme, polynucleotides encoding the modified cellulases, compositions comprising same and uses thereof. The variant family-8 cellulases are advantageous for the bioconversion process of cellulosic substrates.

Owner:YEDA RES & DEV CO LTD

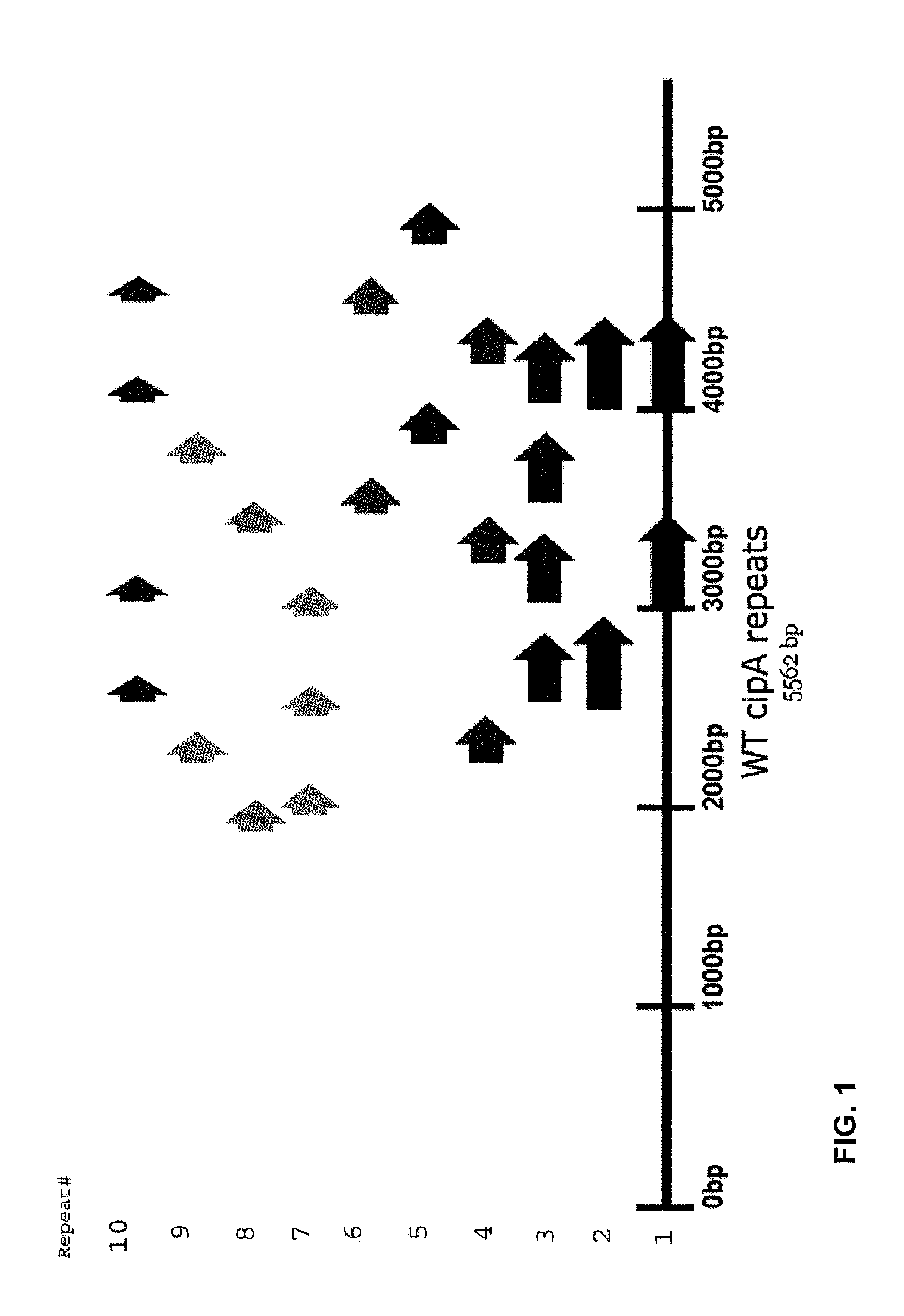

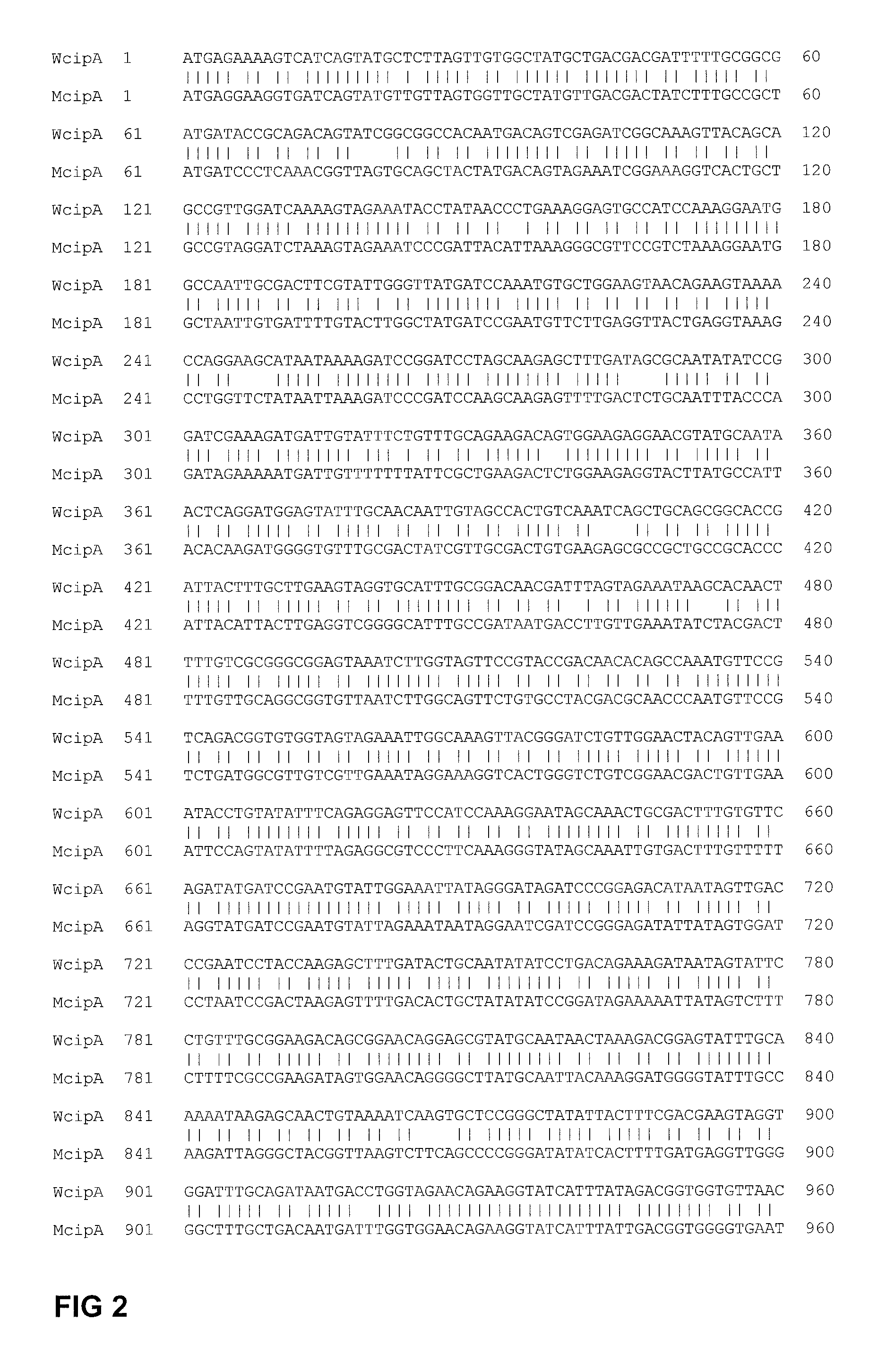

Modified CIPA Gene From Clostridium Thermocellum for Enhanced Genetic Stability

InactiveUS20120295306A1Accurate secretionAccurate translationSugar derivativesBacteriaHeterologousThermoanaerobacterium saccharolyticum

Bacteria consume a variety of biomass-derived substrates and produce ethanol. The scaffoldin gene cipA from Clostridium thermocellum is modified to generate a mutated gene with enhanced genetic stability. This mutated cipA gene can be introduced into a heterologous host, such as Thermoanaerobacterium saccharolyticum. Other cellulosome components may be introduced into the host to build a full-sized cellulosome in T. saccharolyticum. Manipulation of the scaffoldin genes provides a new approach for enhancing ethanol production by biomass-fermenting microorganisms.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

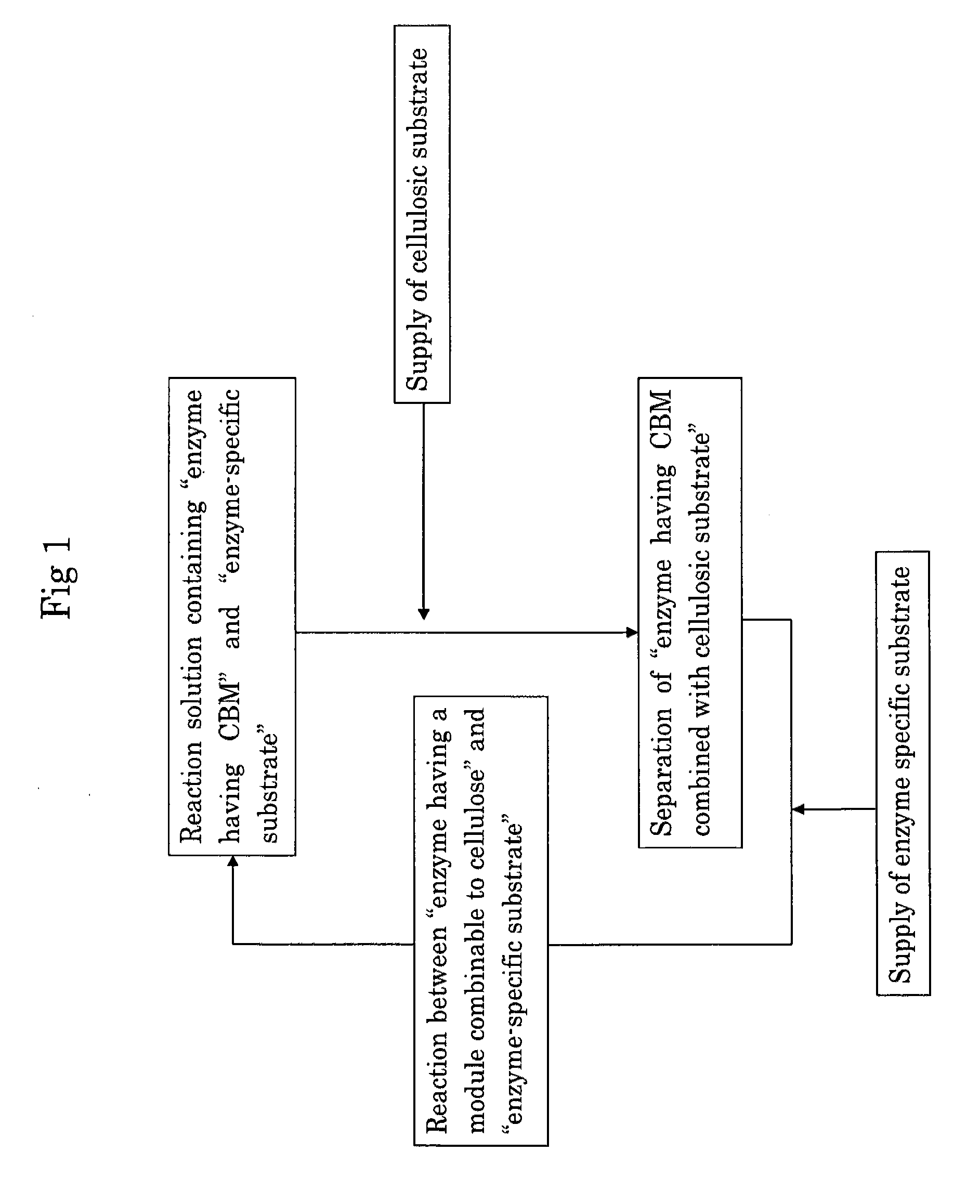

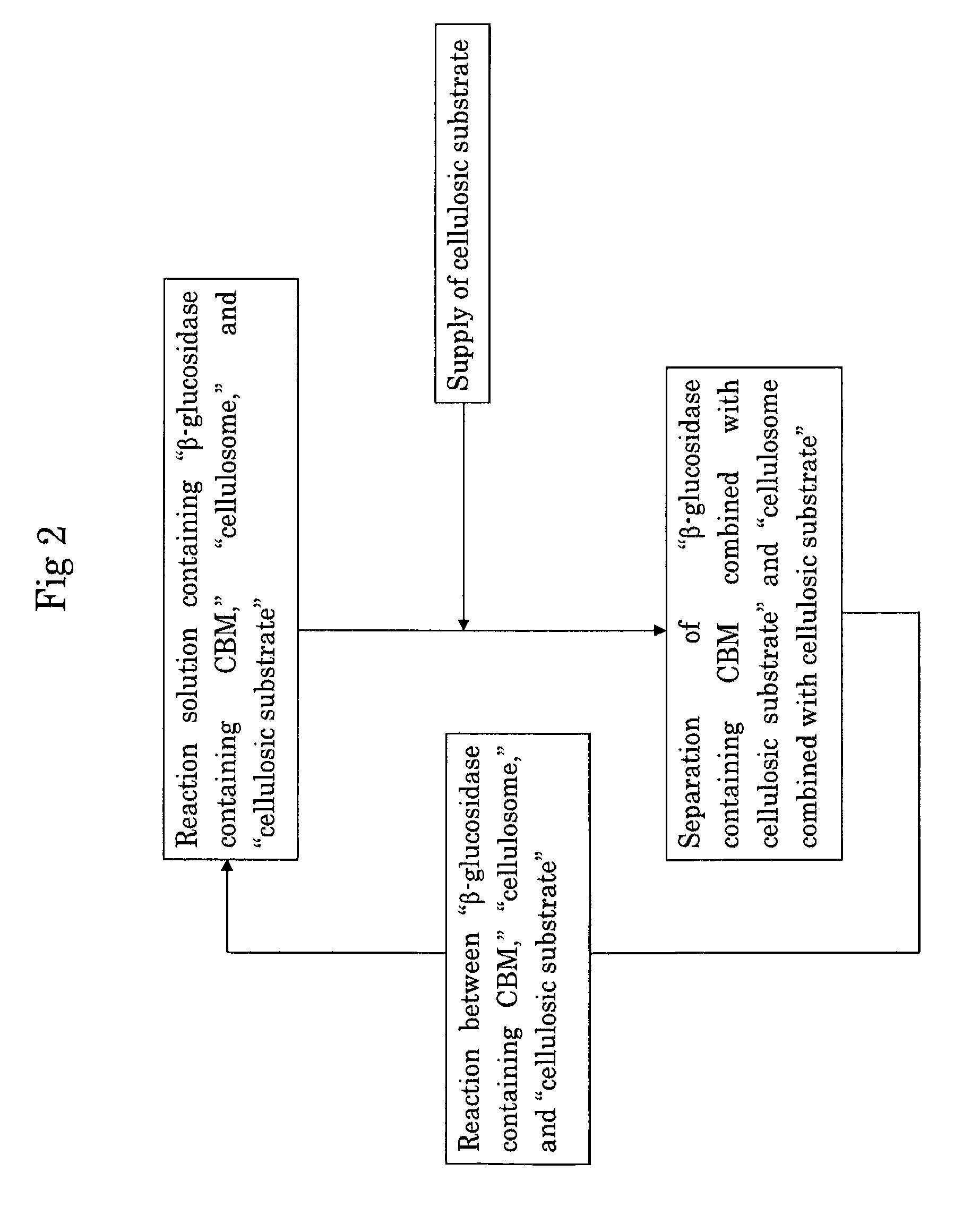

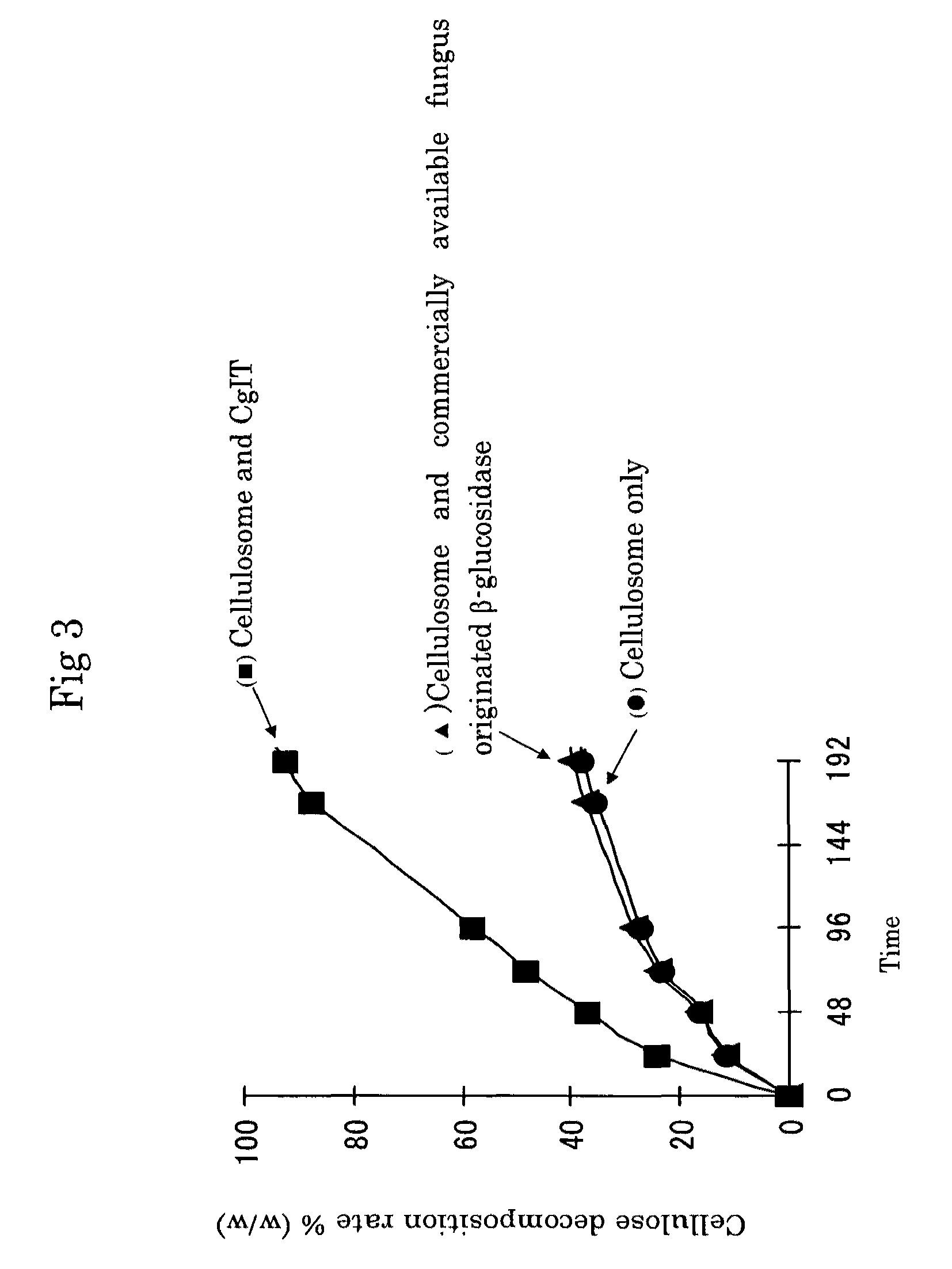

Method for recycling enzyme

InactiveUS9074200B2Efficient separationReduce usageSugar derivativesBacteriaAlgluceraseBeta-glucosidase

In saccharification of cellulose, chimeric β-glucosidase having a region exhibiting thermophilic bacteria-derived β-glucosidase activity and a module combinable to cellulose is used along with cellulosome, and at the completion of saccharification of cellulose, a cellulosic substrate is added to make the chimeric β-glucosidase and cellulosome attach to the cellulosic substrate for separation.

Owner:INDEPENDENT ADMINISTRATIVE INST JAPAN INT RES CENT FOR AGRI SCI

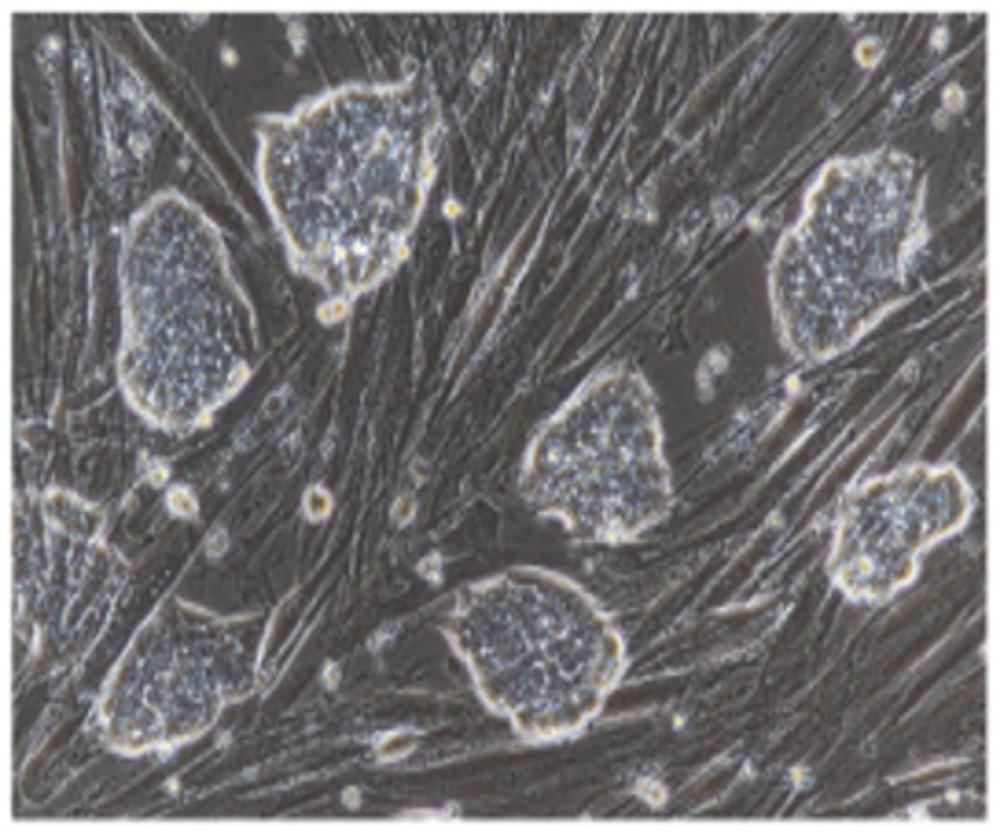

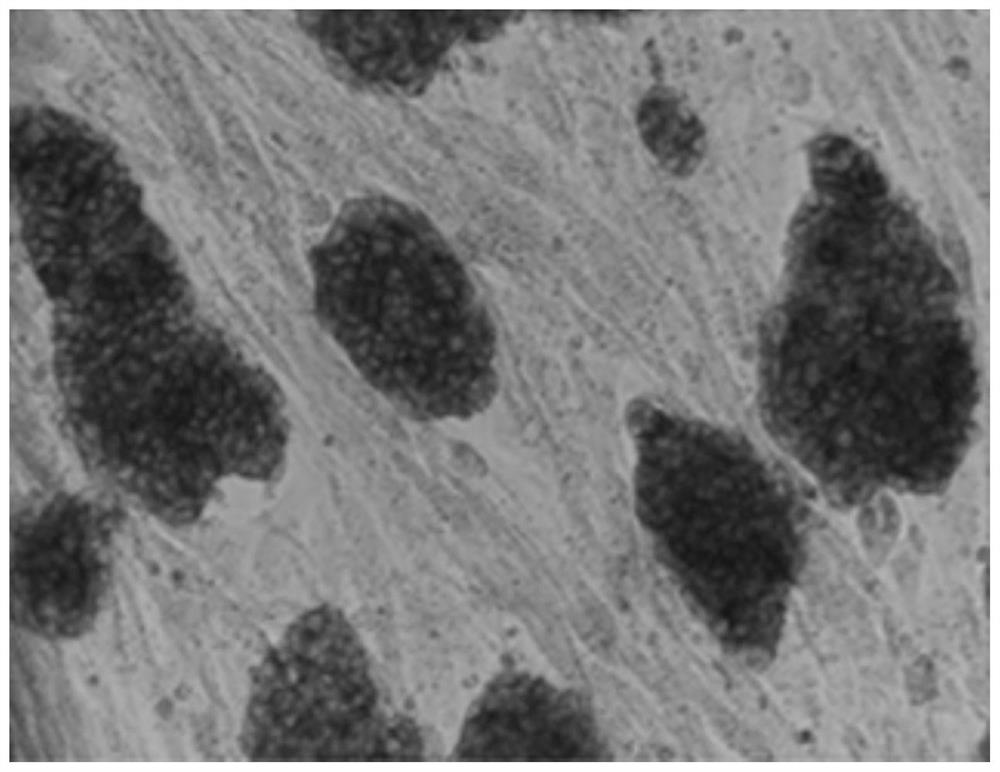

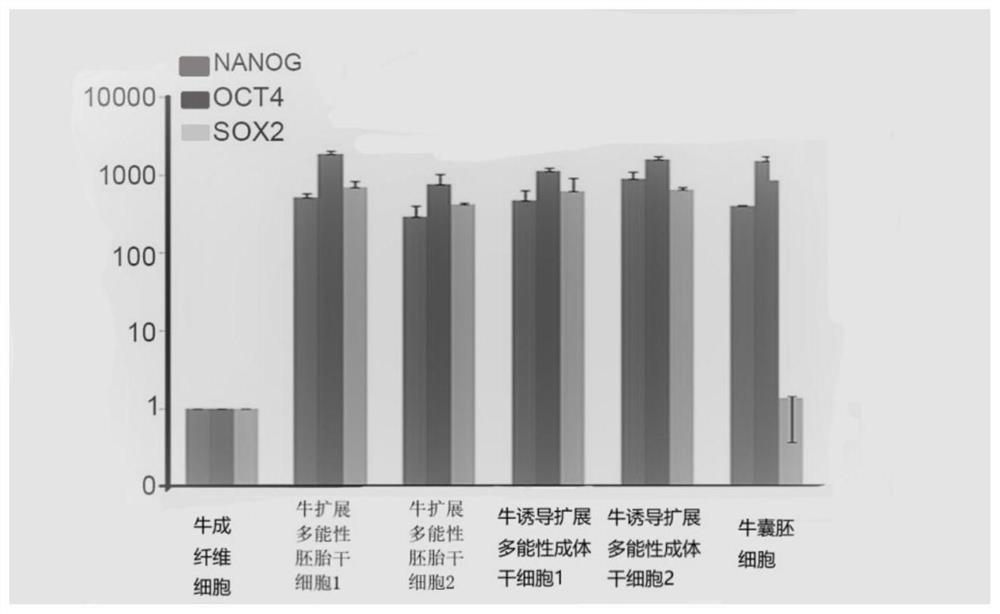

Bovine induced expansion pluripotent adult stem cells, line establishment method and culture solution

PendingCN114369577AAlmightyMaintain stabilityGenetically modified cellsCulture processTissue DifferentiationSomatic cell

The invention discloses bovine induced expansion pluripotent adult stem cells, a line establishment method and a culture solution, and the bovine induced expansion pluripotent adult stem cells are obtained by transgenosis and induced culture from bovine fibroblast cells and can be stably subcultured in vitro. The stem cell has totipotency, stability and safety, can be differentiated in an in-vivo and out-of-embryo tissue and an out-of-embryo tissue, and can be applied to various life science and medical fields such as breeding and breeding, gene editing, animal cloning, medical models, drug development carriers, induced production of bovine reproductive gametes and the like.

Owner:INNER MONGOLIA UNIVERSITY +1

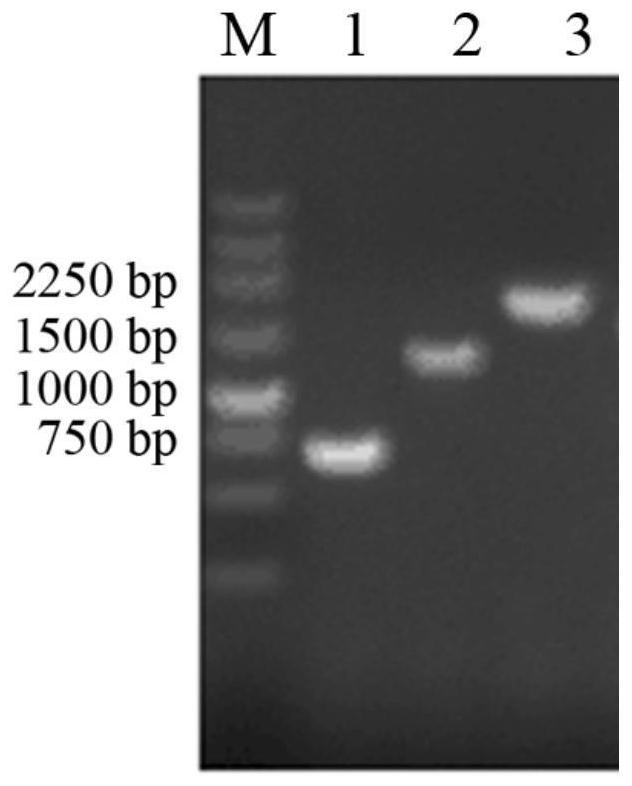

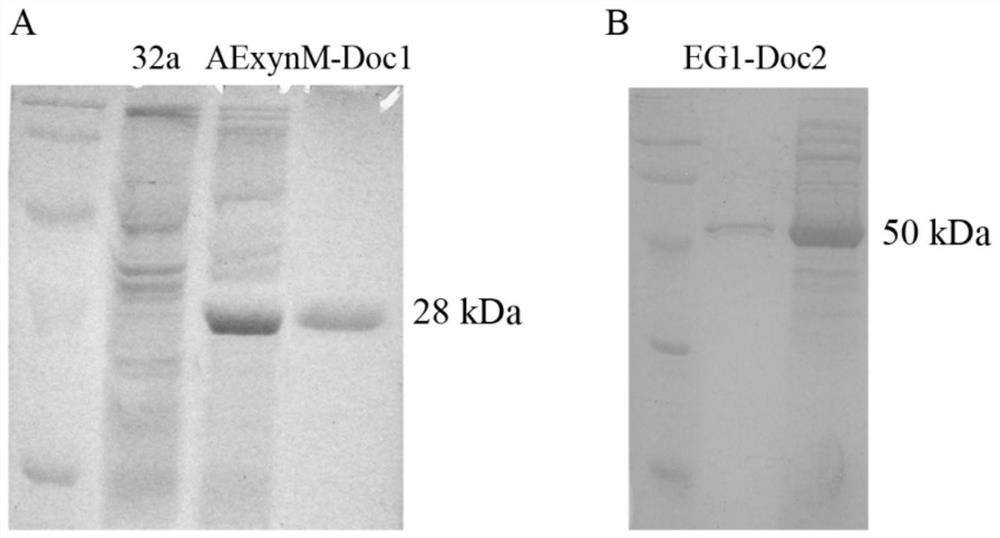

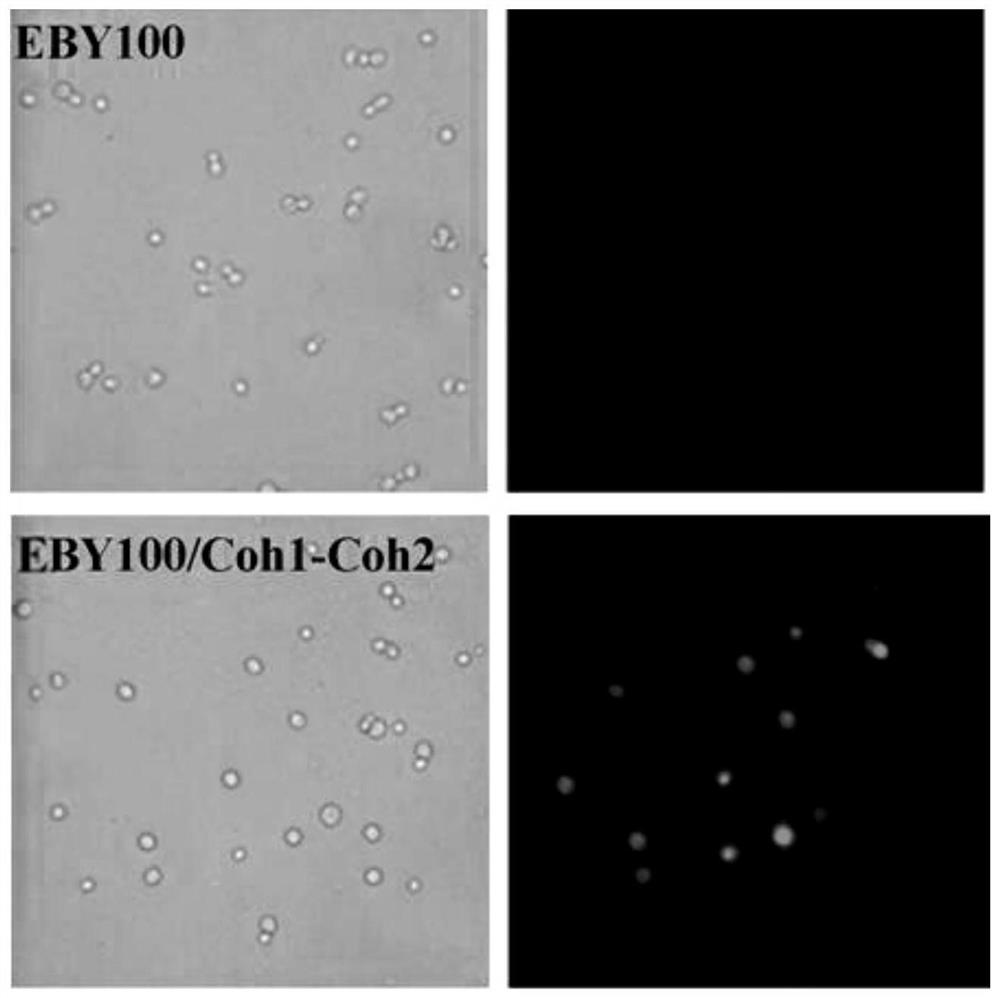

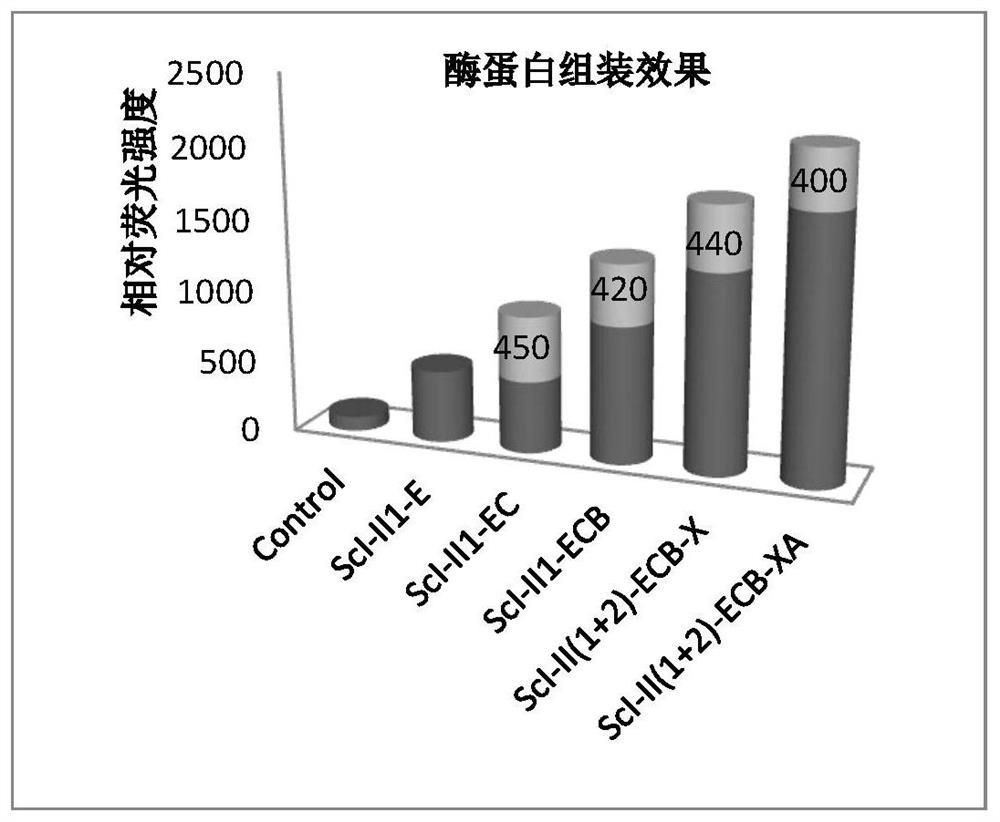

Cellulosome with improved catalytic activity and assembly method and application thereof

PendingCN112522249AHigh catalytic activityPromote synergistic catalysisPolypeptide with localisation/targeting motifMicroorganism based processesEscherichia coliCellulose

The invention discloses a cellulosome with improved catalytic activity and an assembly method and application thereof, and belongs to the technical field of biology. According to the assembly method,xylanase AExynM-Doc1 containing a docking domain and glucanase EG1-Doc2 containing a docking domain are expressed heterologously by using escherichia coli; fibronectin Coh1-Coh2 are surface-displayedby using saccharomyces cerevisiae, to obtain a recombinant yeast EBY100 / Coh1-Coh2; and the recombinant proteins AExynM-Doc1 and EG1-Doc2 are mixed with the recombinant yeast EBY100 / Coh1-Coh2, and arerespectively bound with the Coh1 and the Coh2 to finish in-vitro assembly of the cellulosome. According to the invention, the xylanase and glucanase with high catalytic activity are combined in scaffold protein of the cellosome, so that the synergistic catalytic action between the two enzymes is greatly improved, and lignocellulose can be more effectively degraded.

Owner:YANGZHOU UNIV

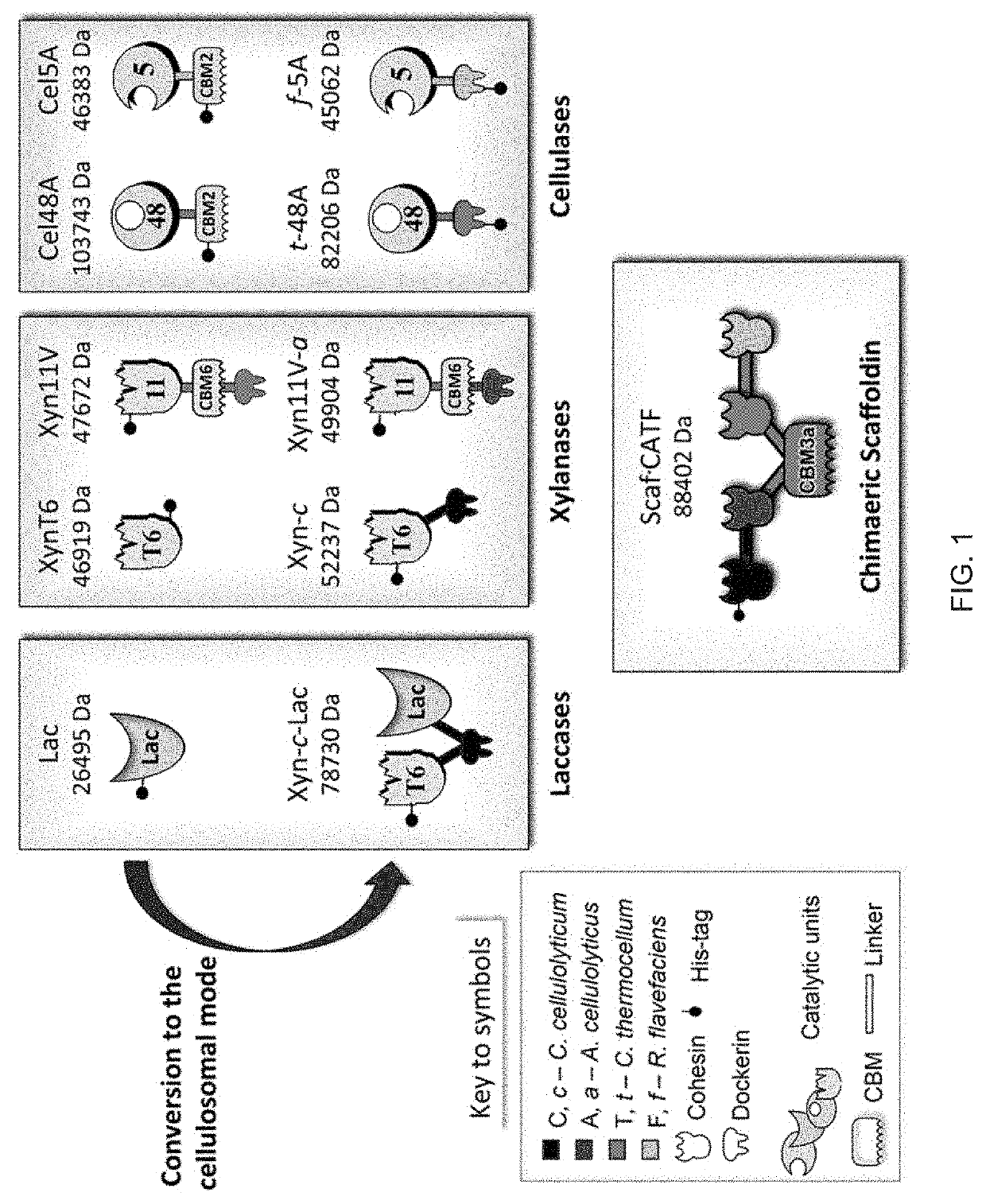

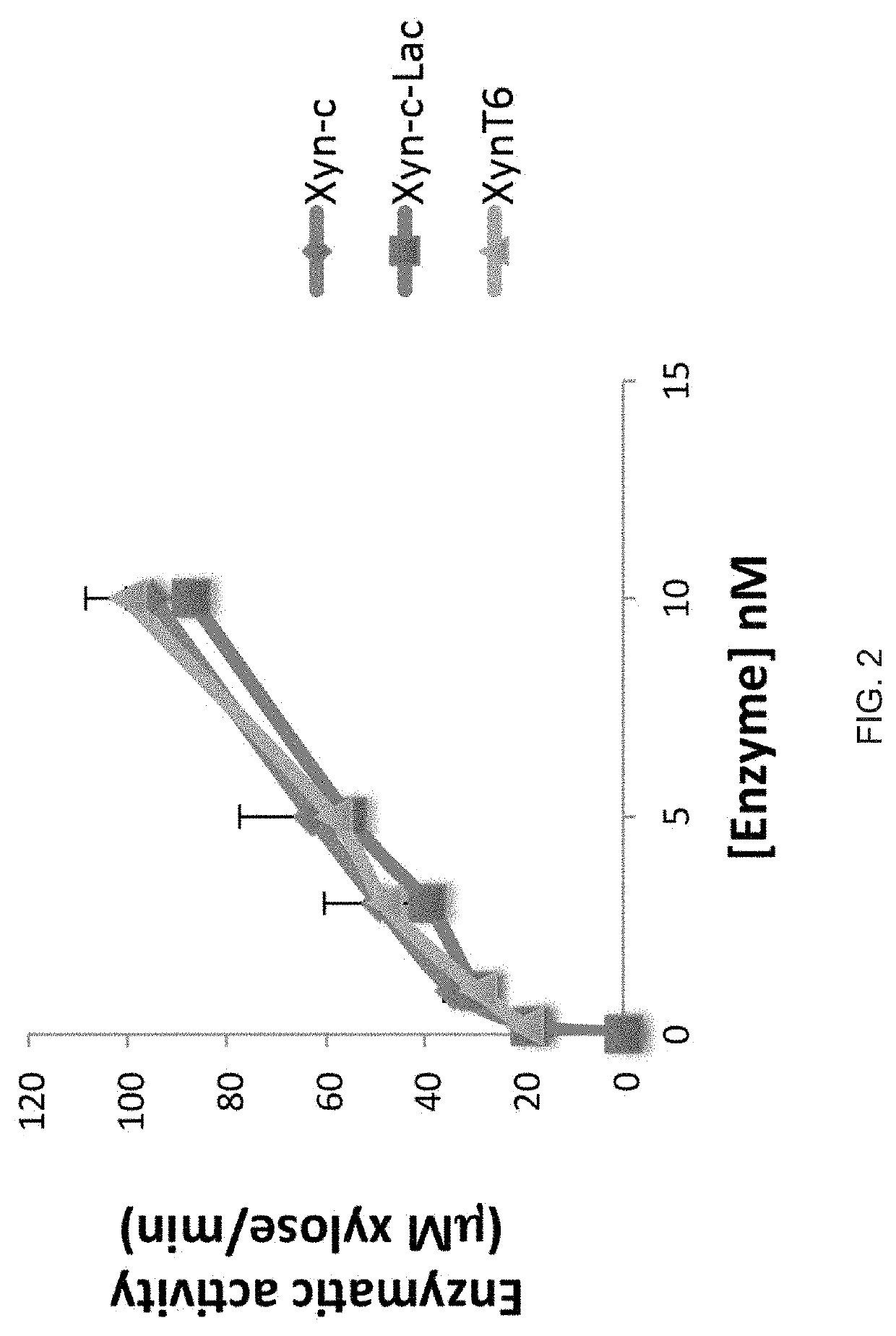

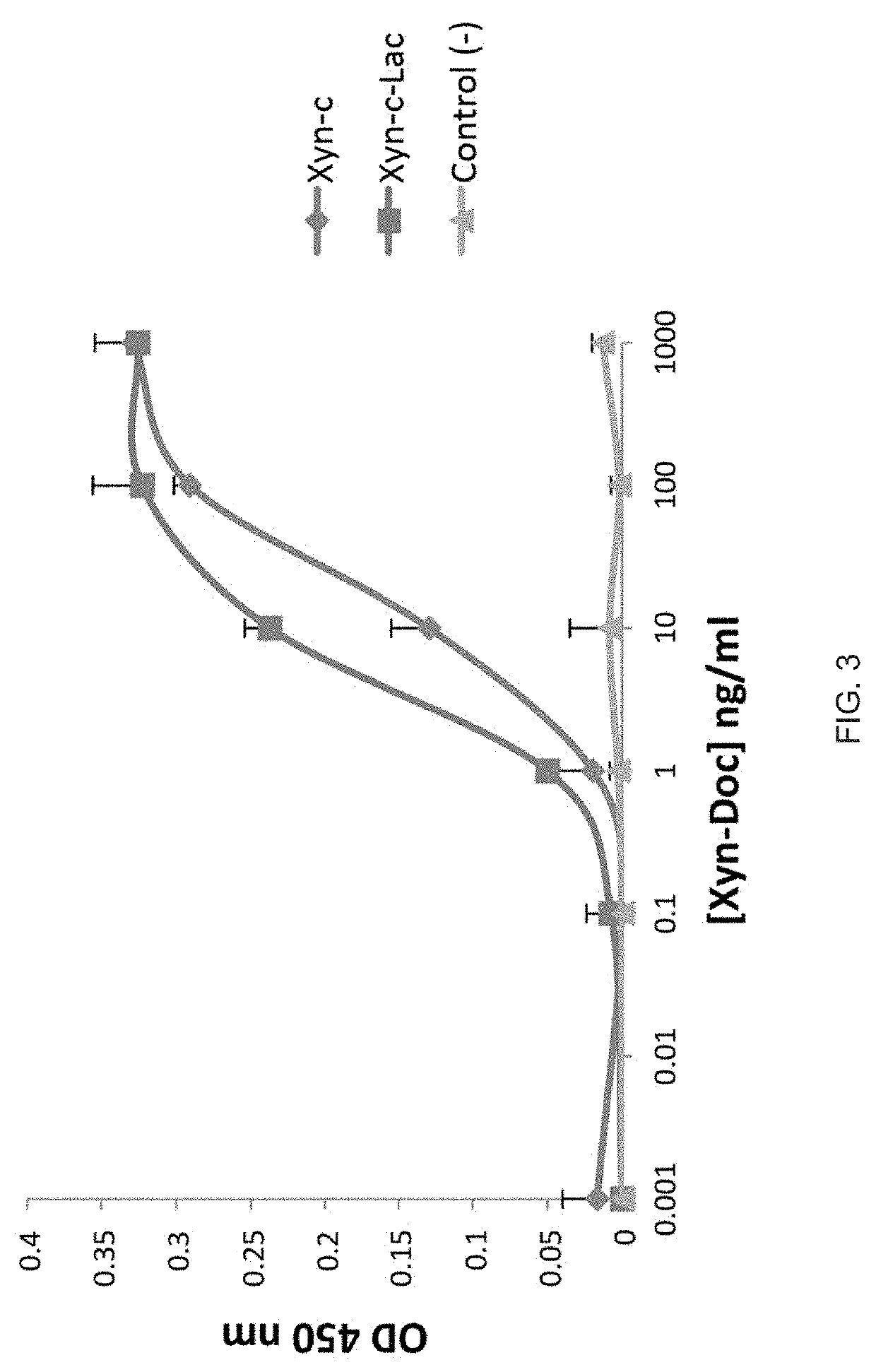

Enzyme complex for lignocellulosic material degradation

InactiveUS20190345459A1Polypeptide with localisation/targeting motifAntibody mimetics/scaffoldsMaterial DegradationMultienzyme complexes

A lignocellulolytic multi-enzyme complex in the form of a cellulosome, which includes a lignin-modifying enzyme and a carbohydrate-active enzyme, is provided herewith, as well as bifunctional chimeric enzymes having lignin and cellulose / hemicellulose degrading capacity. Also provided are methods of degrading lignocellulolytic biomass, and compositions and systems for effecting the same.

Owner:YEDA RES & DEV CO LTD

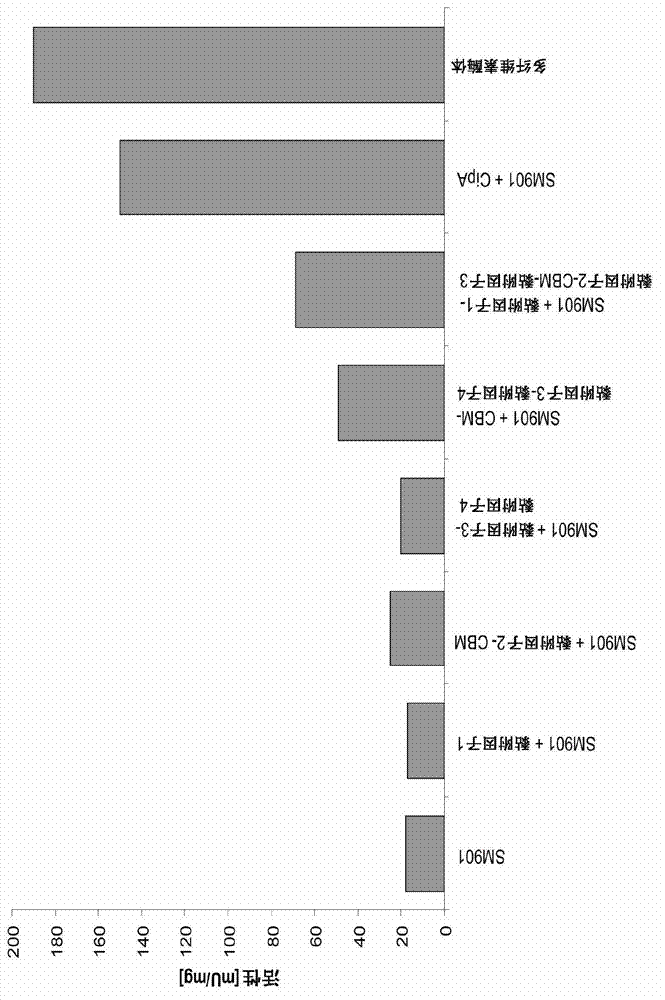

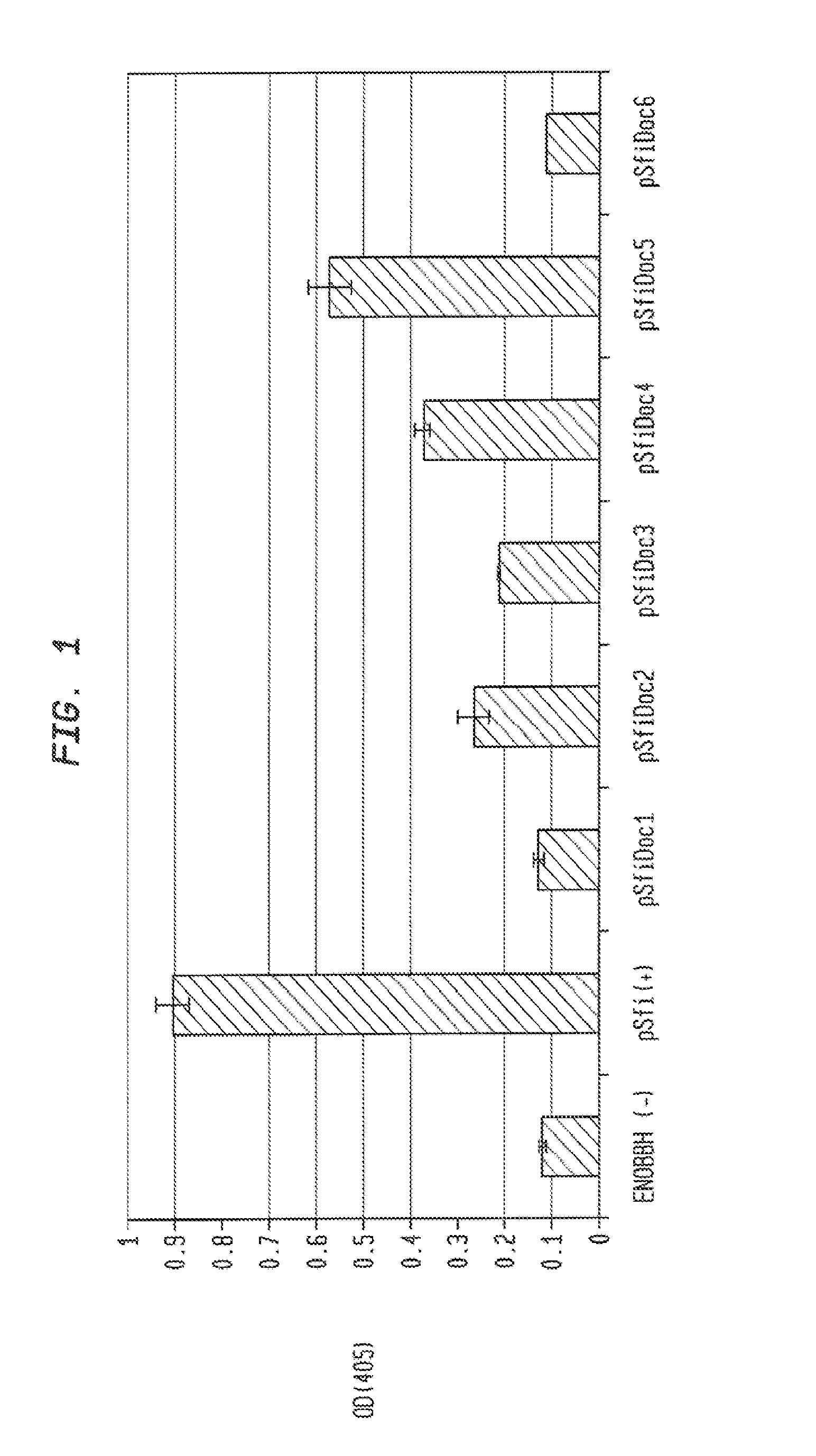

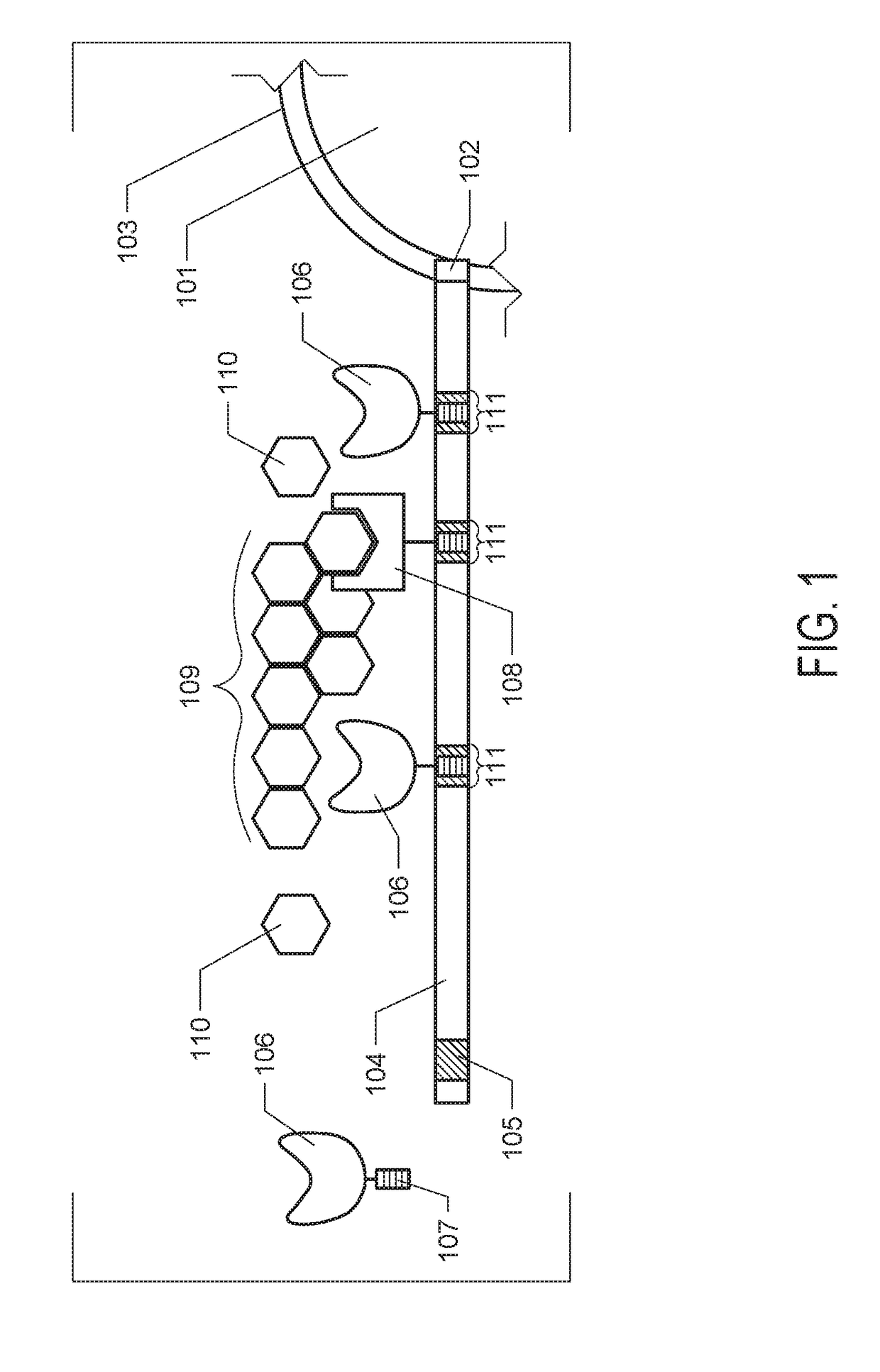

Yeast cells expressing an exogenous cellulosome and methods of using the same

The present invention relates to the engineering and expression of heterologous cellulosomes in microorganisms in order to facilitate the conversion of biomass to useful products. In some embodiments, the invention relates to the expression of scaffoldin proteins which form the nucleus of a cellulosome. Cellulases or other biomass-degrading enzymes can be non-covalently linked to the scaffoldin protein by virtue of a dockerin domain-cohesin domain interaction.

Owner:LALLEMAND HUNGARY LIQUIDITY MANAGEMENT LLC +1

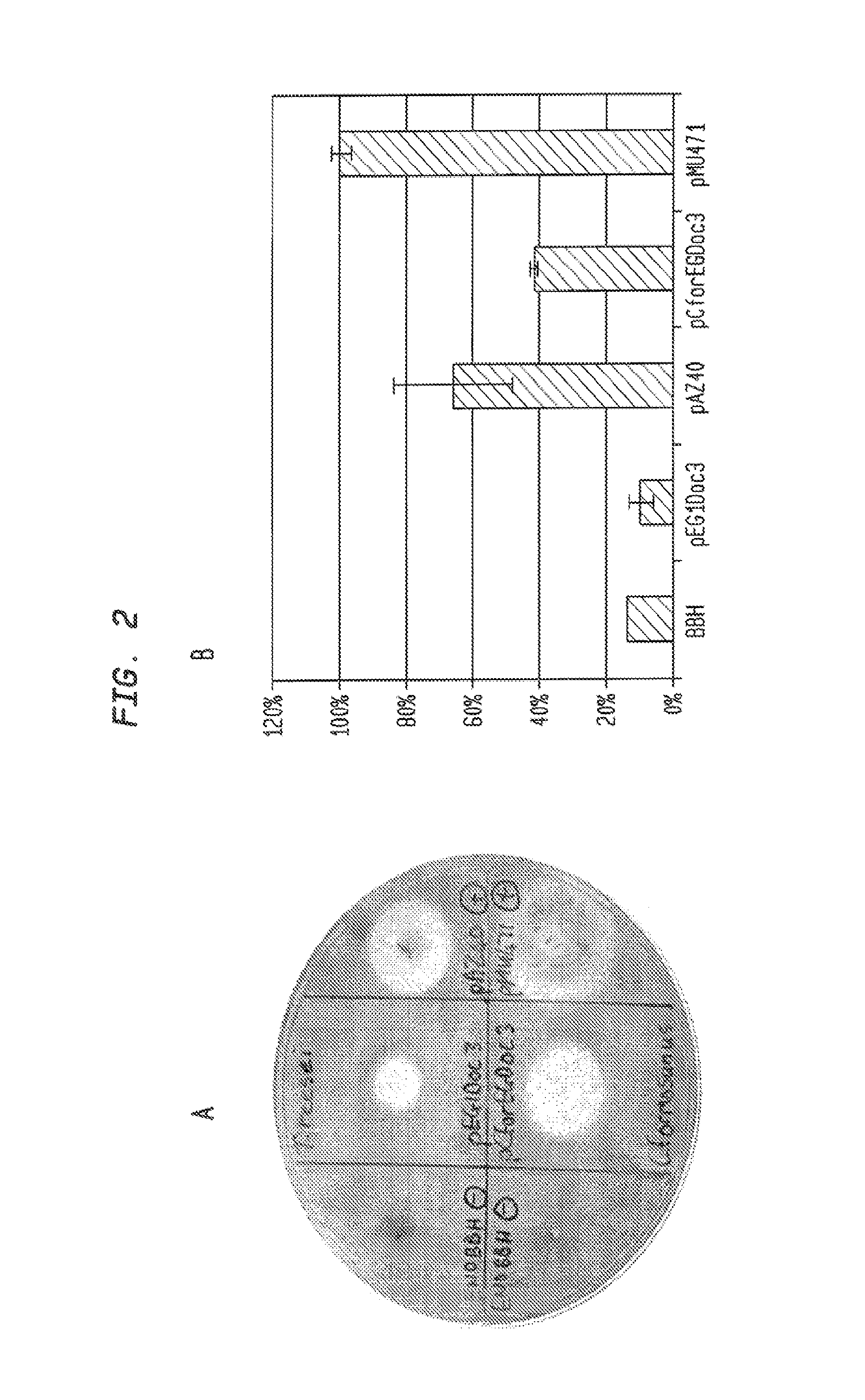

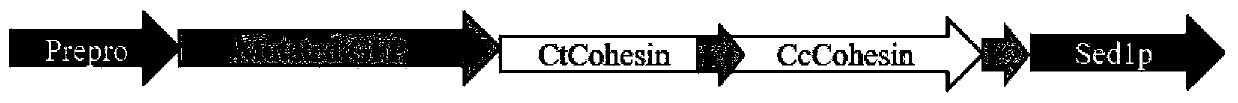

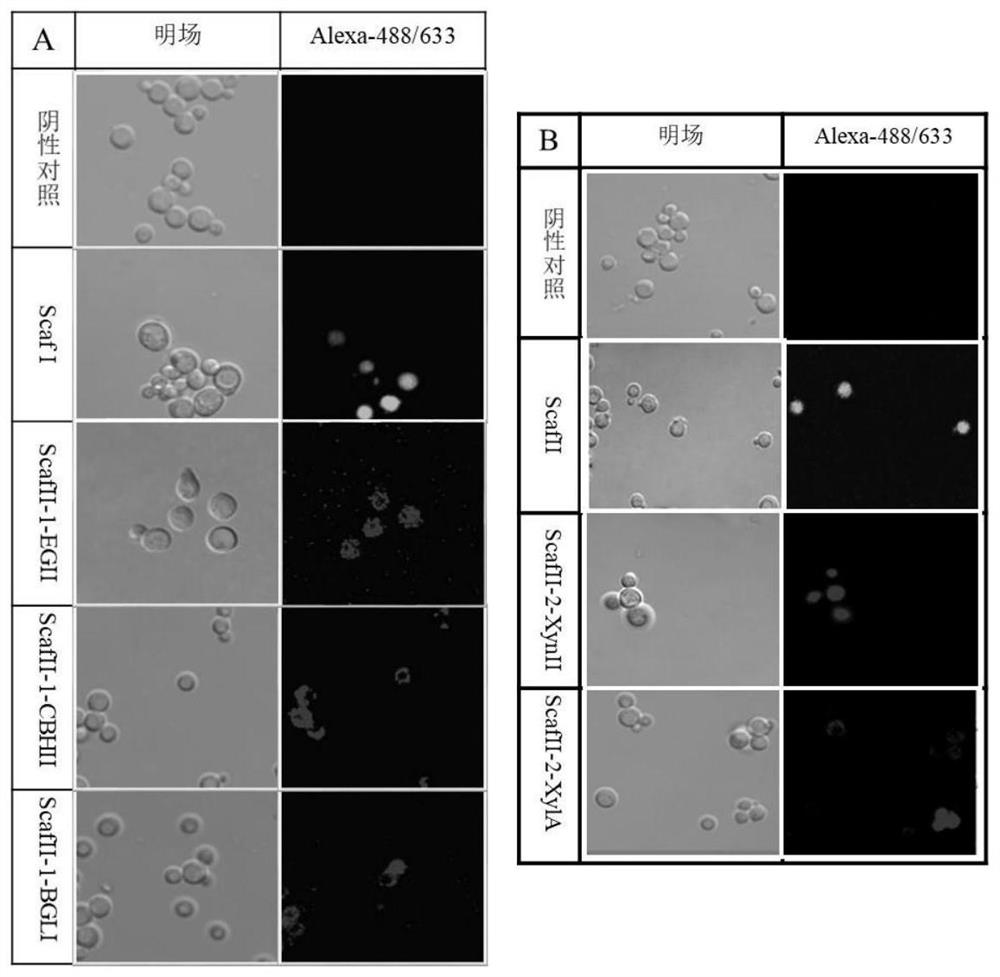

Pichia pastoris surface co-display system based on cellulosome as well as construction method and application of pichia pastoris surface co-display system

InactiveCN110229220AAchieve multi-protein co-displayReduce manufacturing costFungiBacteriaPichia pastorisCellulosomes

The invention provides a pichia pastoris surface co-display system based on cellulosome as well as a construction method and application of the pichia pastoris surface co-display system and belongs tothe technical fields of molecular biology, food and gene engineering. The system comprises anchoring protein and polyprotein display chassis protein, wherein the anchoring protein is saccharomyces cerevisiae cell wall protein Sed1p; and the polyprotein display chassis protein is artificial mini scaffold protein MixA2 of clostridium cellulosome. The pichia pastoris surface co-display system basedon cellulosome can realize polyprotein co-display on cell surfaces; heterologous protein for fusion expression of dockerin is prepared from recombinant bacteria, purification is not needed, multiple proteins can be displayed on cell surfaces by direct specific binding of dockerin on recombinant protein and cohesion on MixA2, and the preparation cost of recombinant protein can be saved effectively.

Owner:NANJING FORESTRY UNIV

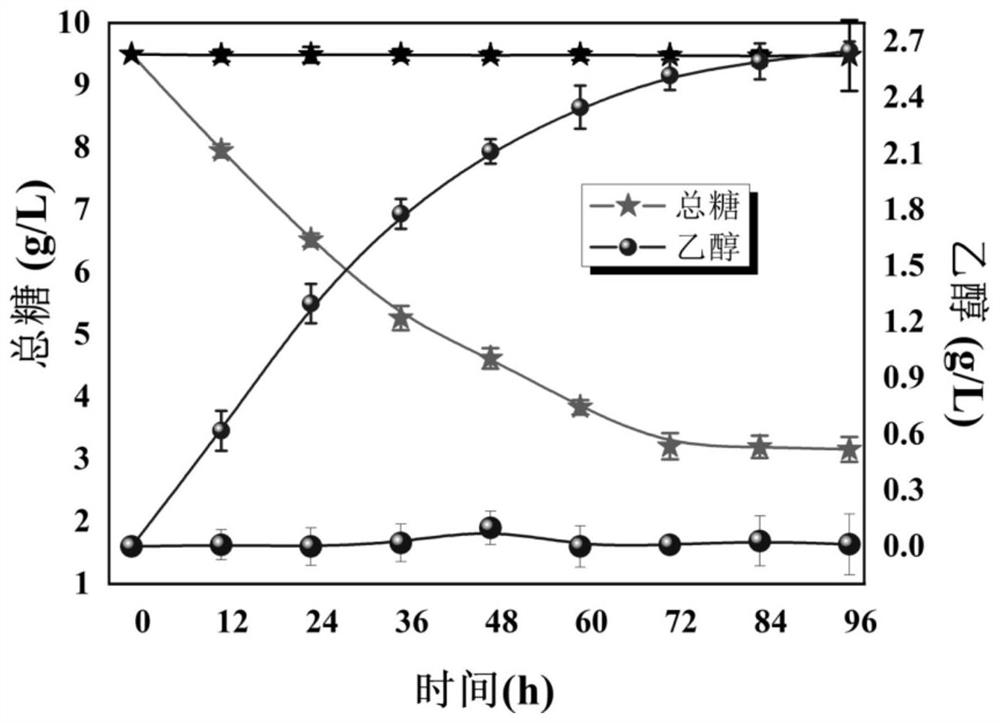

Method for producing ethanol by synchronously performing steam-exploded pennisetum alopecuroides batch feeding and saccharification fermentation

The invention discloses a method for producing ethanol by synchronously performing steam-exploded pennisetum alopecuroides batch feeding and saccharification fermentation. The method for producing theethanol by synchronously performing steam-exploded pennisetum alopecuroides batch feeding and saccharification fermentation comprises the following steps: (1) constructing recombinant yeast cells which can co-metabolize xylose and glucose and are anchored with primary scaffold protein Scaf I; (2) assembling cellulosomes derived from cellulase and hemicellulase on the surfaces of the yeast cells so as to obtain corresponding recombinant yeast cells; (3) carrying out co-culture on the recombinant yeast cells in the step (1) and the step (2), and forming recombinant yeast cells containing composite functional cellulosomes through self-assembly of the recombinant yeast cells; and (4) inoculating the recombinant yeast cells obtained in the step (3) into a fermentation culture medium, and carrying out fermenting by using steam exploded pennisetum alopecuroides as a unique carbon source according to a batch feeding method to produce the ethanol. By utilization of the method disclosed by theinvention, the concentration of the ethanol obtained by fermentation for 96 hours can reach 2.65 g / L.

Owner:CAPITAL NORMAL UNIVERSITY

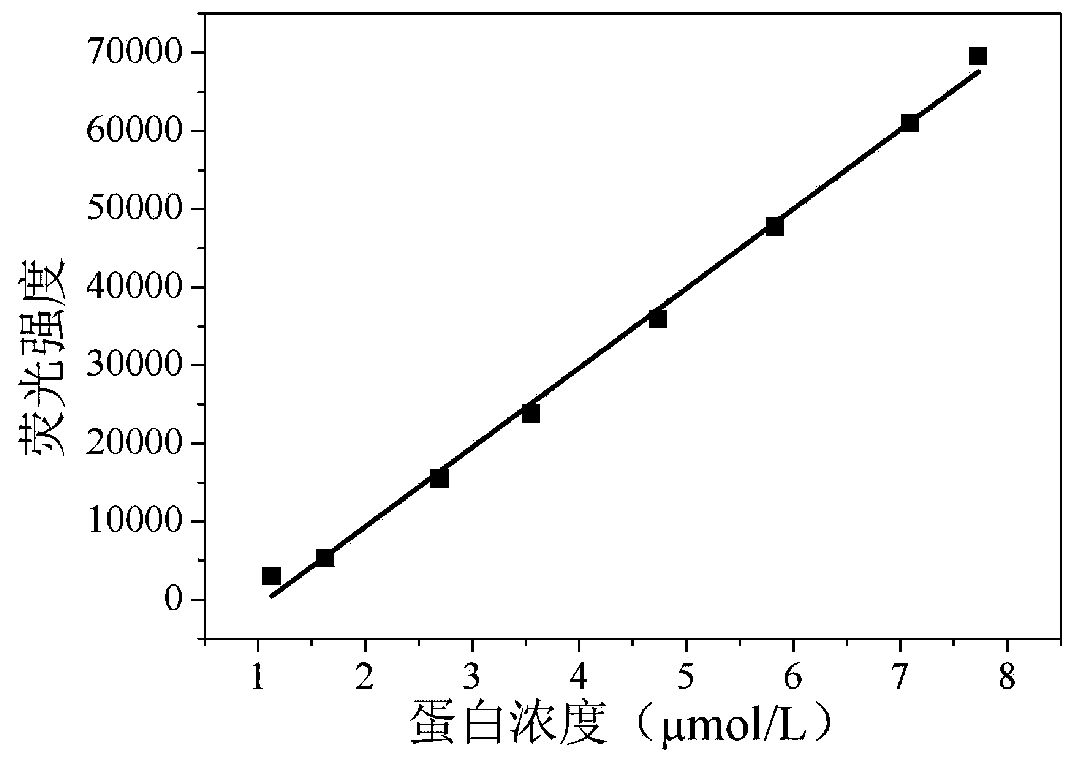

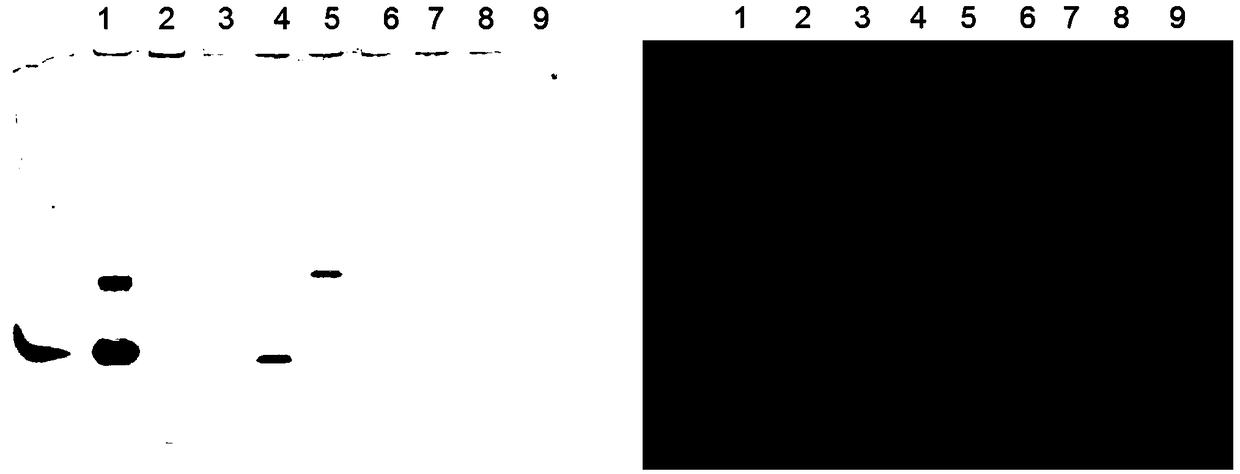

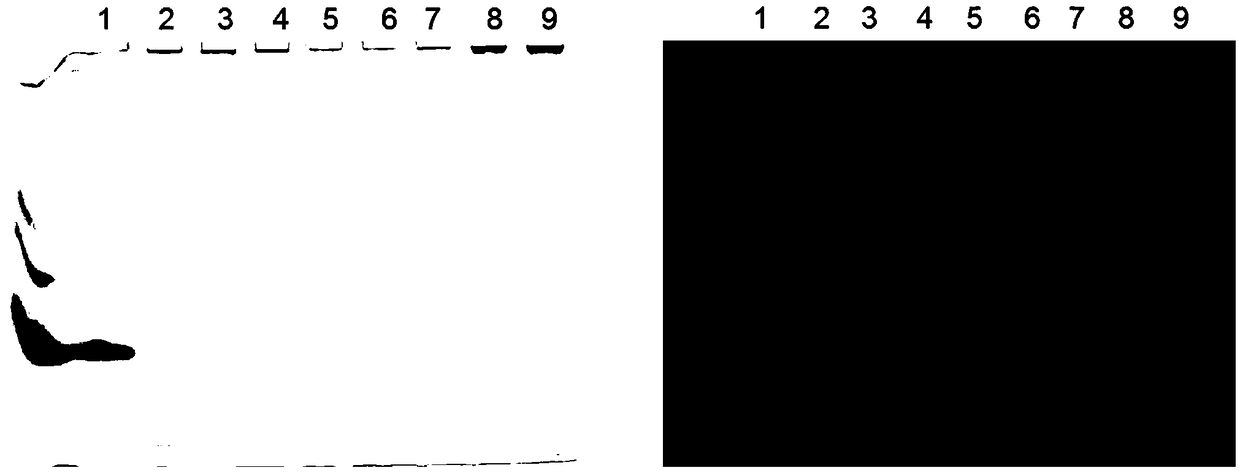

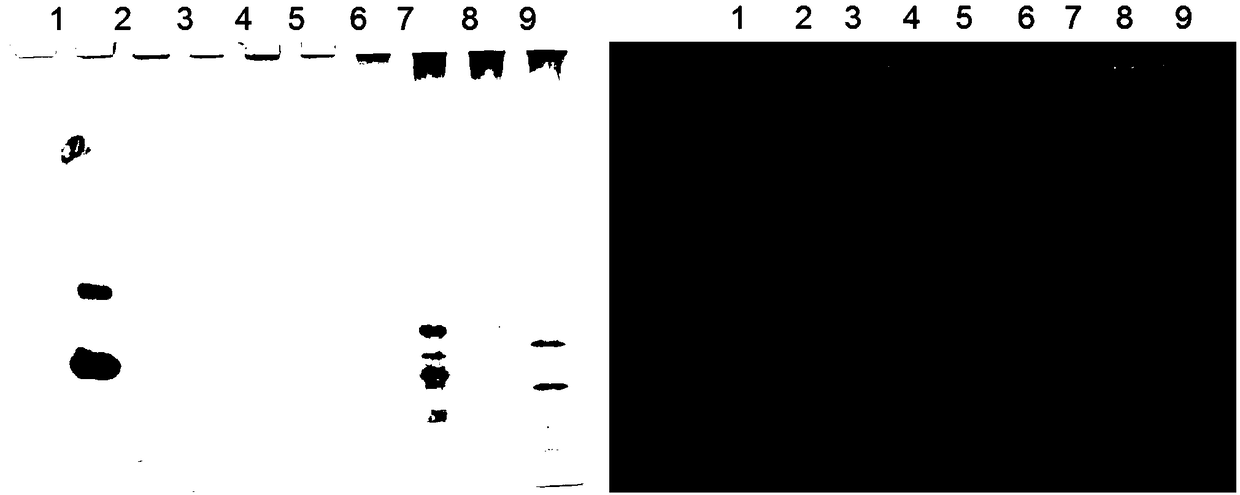

Zymogram analysis method for semi-cellulosome analogue

InactiveCN108918639AEffective judgmentMaterial analysis by electric/magnetic meansCellulosomesIndustrial biotechnology

The invention provides a zymogram analysis method for semi-cellulosome analogue and belongs to the technical field of industrial biology. The method disclosed by the invention is characterized in thatthe whole analysis process is composed of three parts: electrophoresis, zymogram analysis and proteinogram analysis. A continuous gradient non-modified gel without concentrated gel is adopted for electrophoresis; an off-on probe substrate is adopted for zymogram analysis; coomassie blue staining or silver staining is adopted for proteinogram analysis. According to the method, once electrophoresisis performed while zymogram and proteinogram information of a block of gel are collected; if multienzyme complex is generated in supernatant of microorganism fermentation liquor can be quickly and effectively judged; the zymogram analysis method is developed for screening microbial strains capable of generating cellulosome compounds and can be applied to the fields of industrial bioconversion, biological energy source, medical intermediate preparation, and the like.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com