Patents

Literature

111 results about "Granular starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

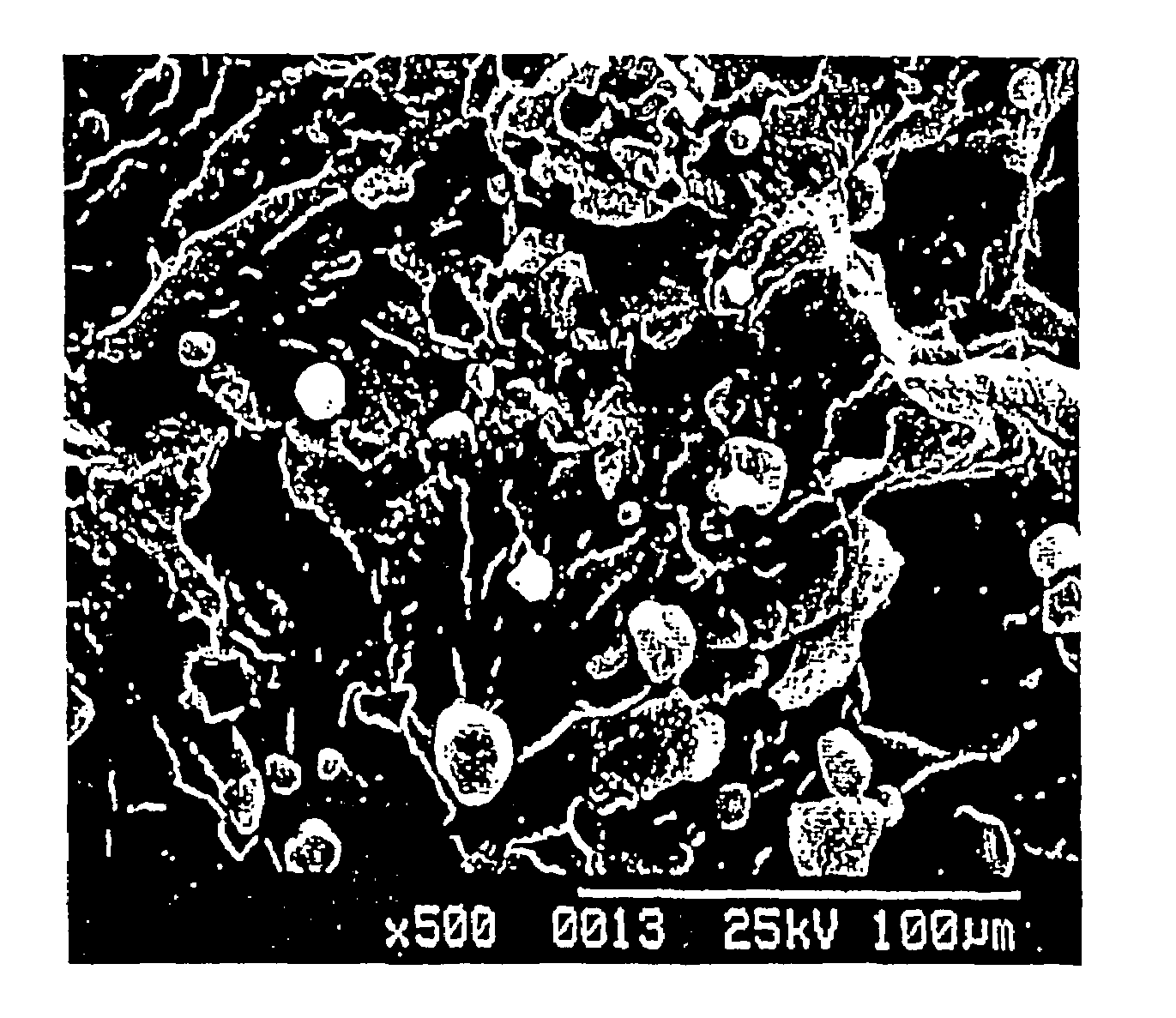

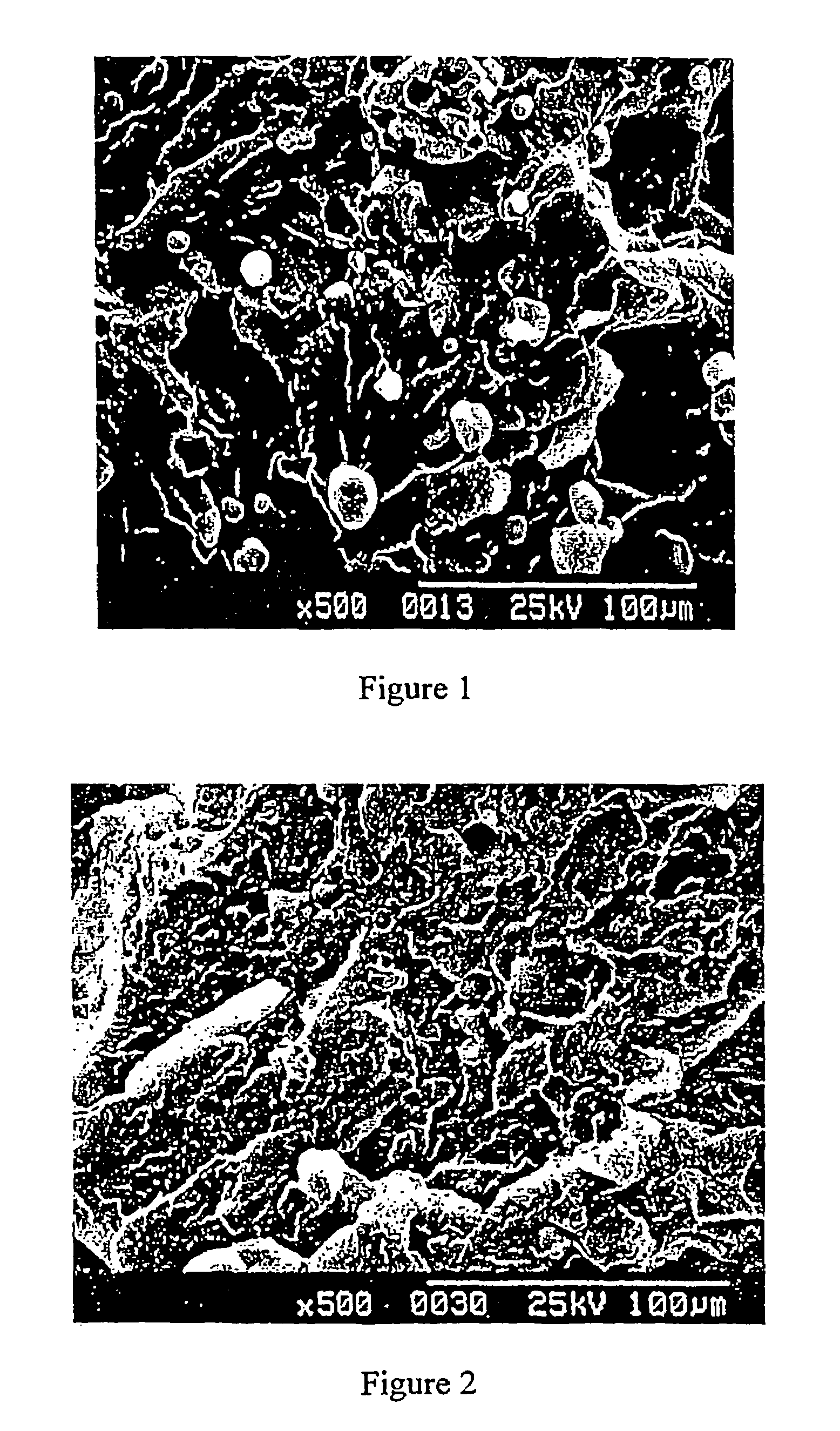

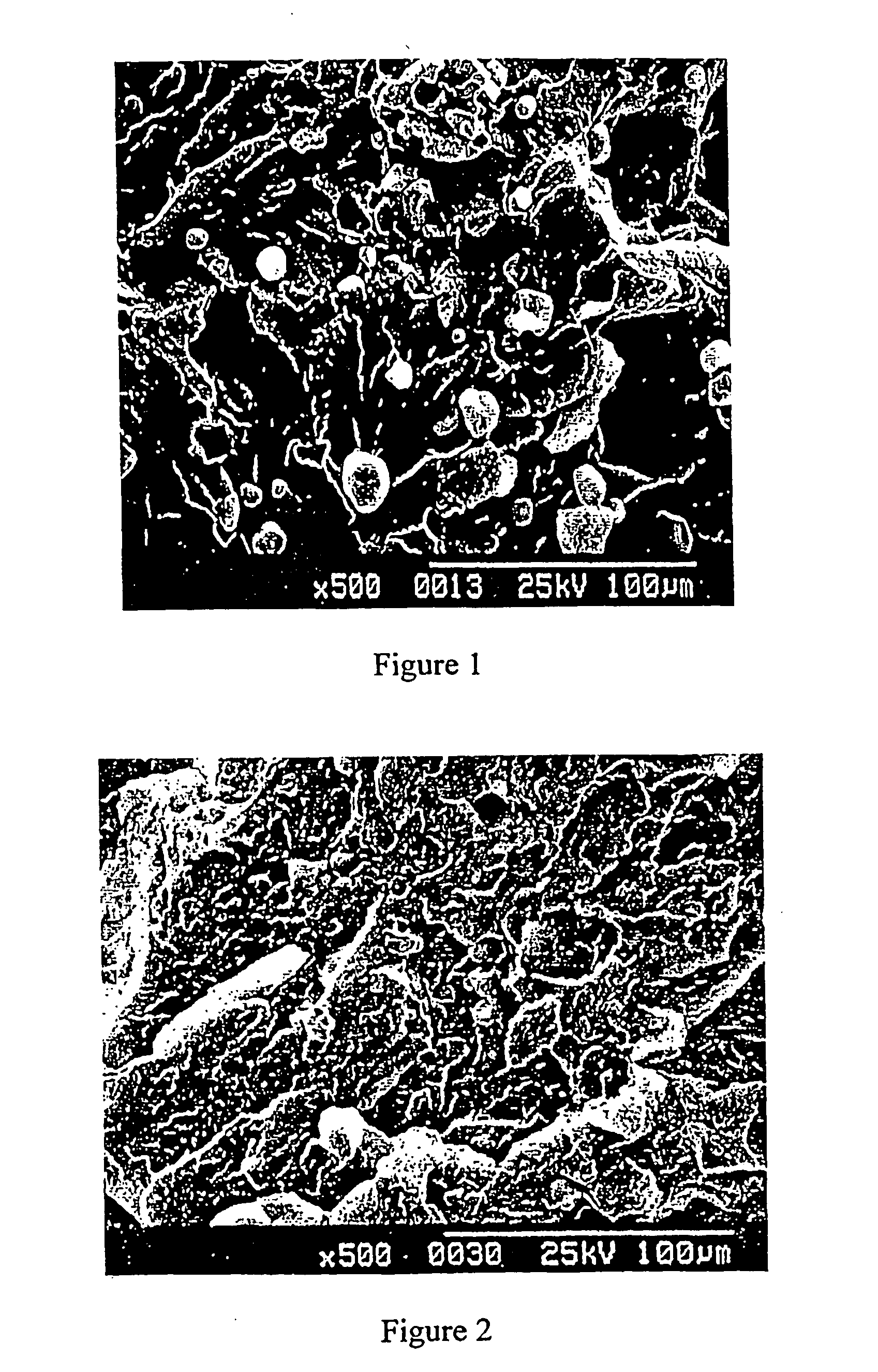

Granular starch. Granular starch is used as powder on surgical and exam gloves. These granules are commonly encountered as contaminants not only in urine sediments, but also in cytology smears of various types. They are variable in size, round to polygonal in shape, colorless, and usually have a circular or Y-shaped “dot” in the center .

Process for hydrolysis of starch

The present invention relates to a process for enzymatic hydrolysis of granular starch into a soluble starch hydrolyzate at a temperature below the initial gelatinization temperature of said granular starch.

Owner:NOVOZYMES AS

Acid fungal protease in fermentation of insoluble starch substrates

The invention is directed to methods of producing ethanol and decreasing residual starch production in a no cook fermentation comprising contacting granular starch containing substrates with a granular starch hydrolyzing enzyme, a protease, and a fermenting microorganism under suitable fermentation conditions at a temperature below the starch gelatinization temperature of the starch substrate to produce ethanol, wherein the ethanol production is increased and the amount of residual starch is decreased compared to a substantially similar method conducted without the protease.

Owner:GENENCOR INT INC

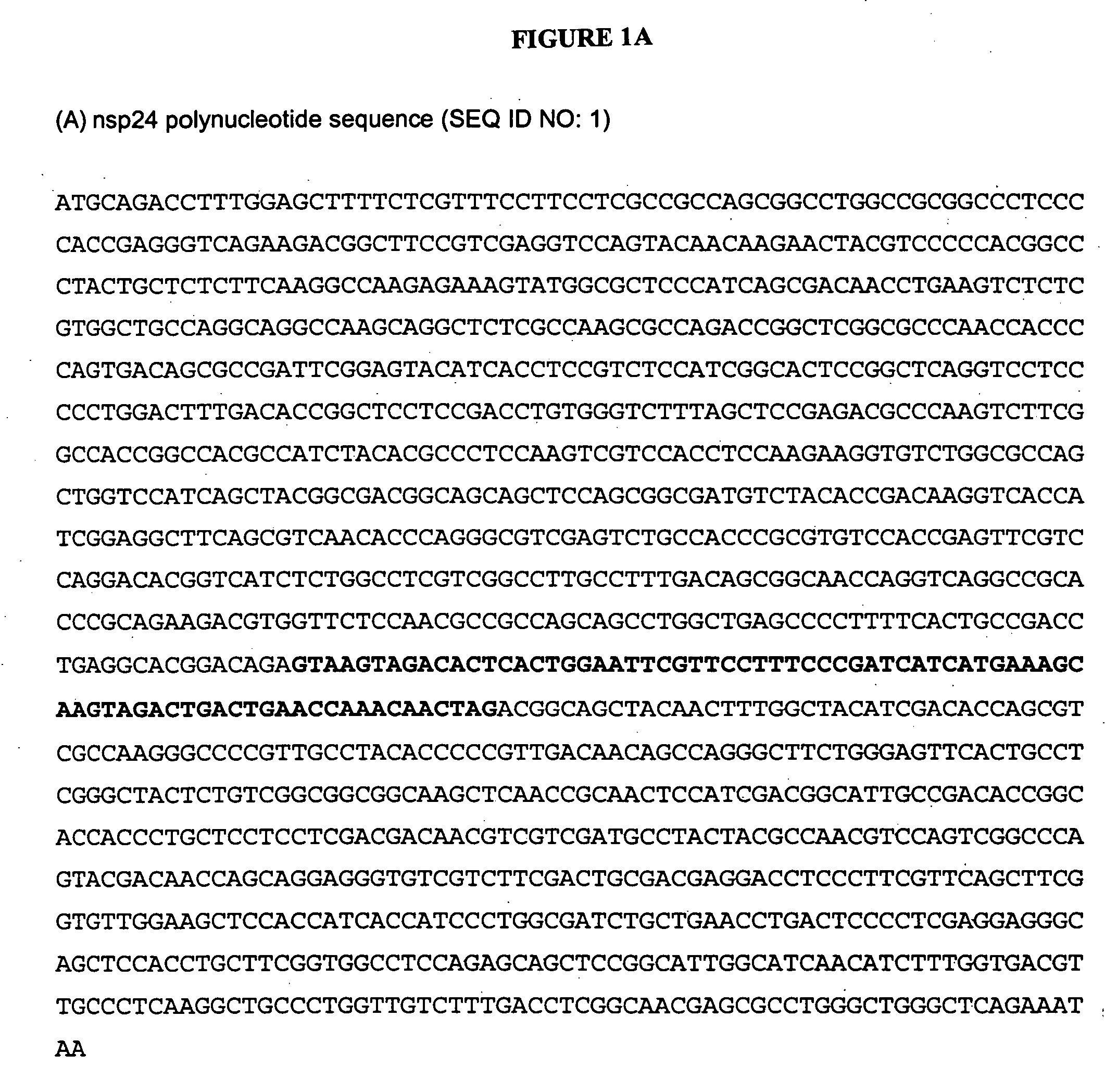

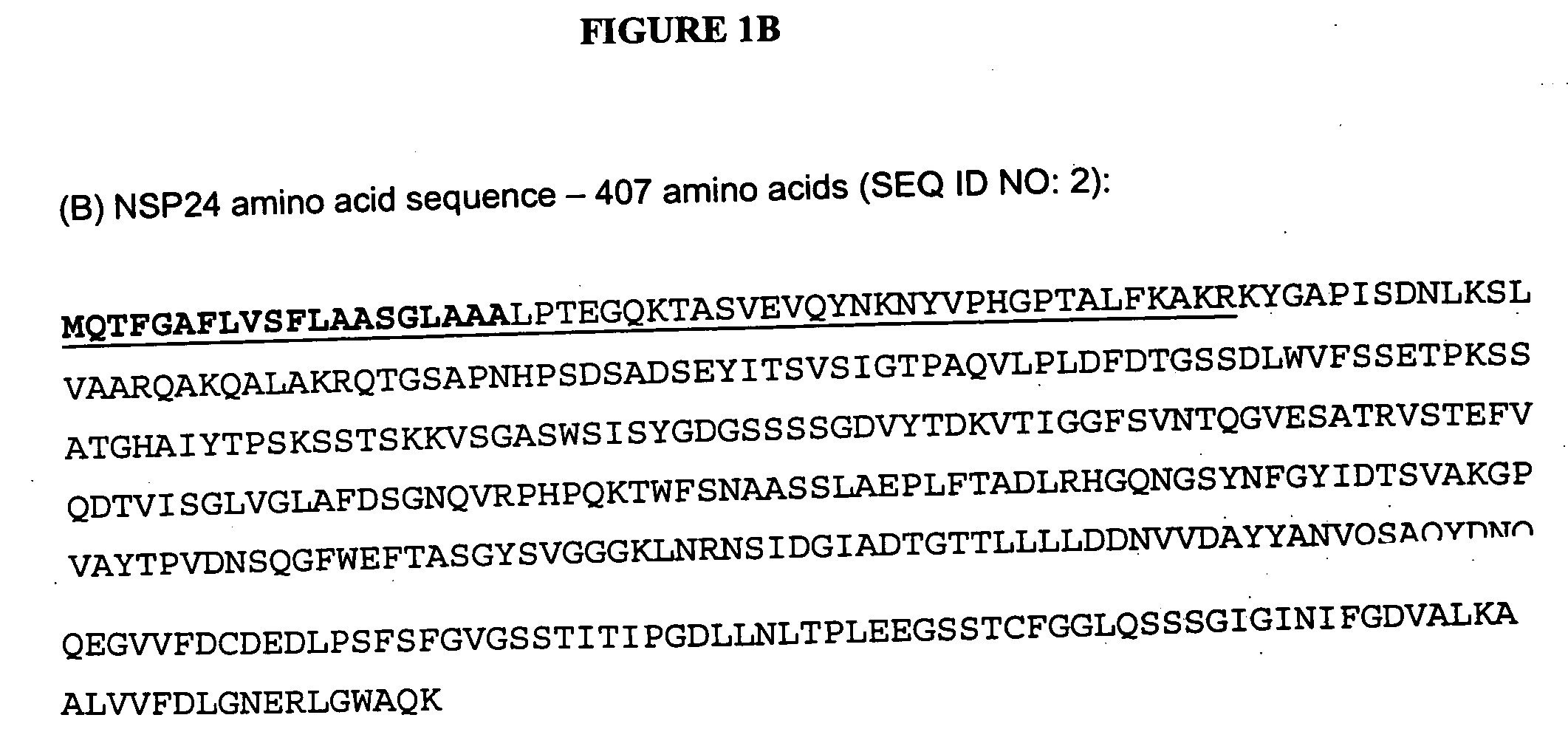

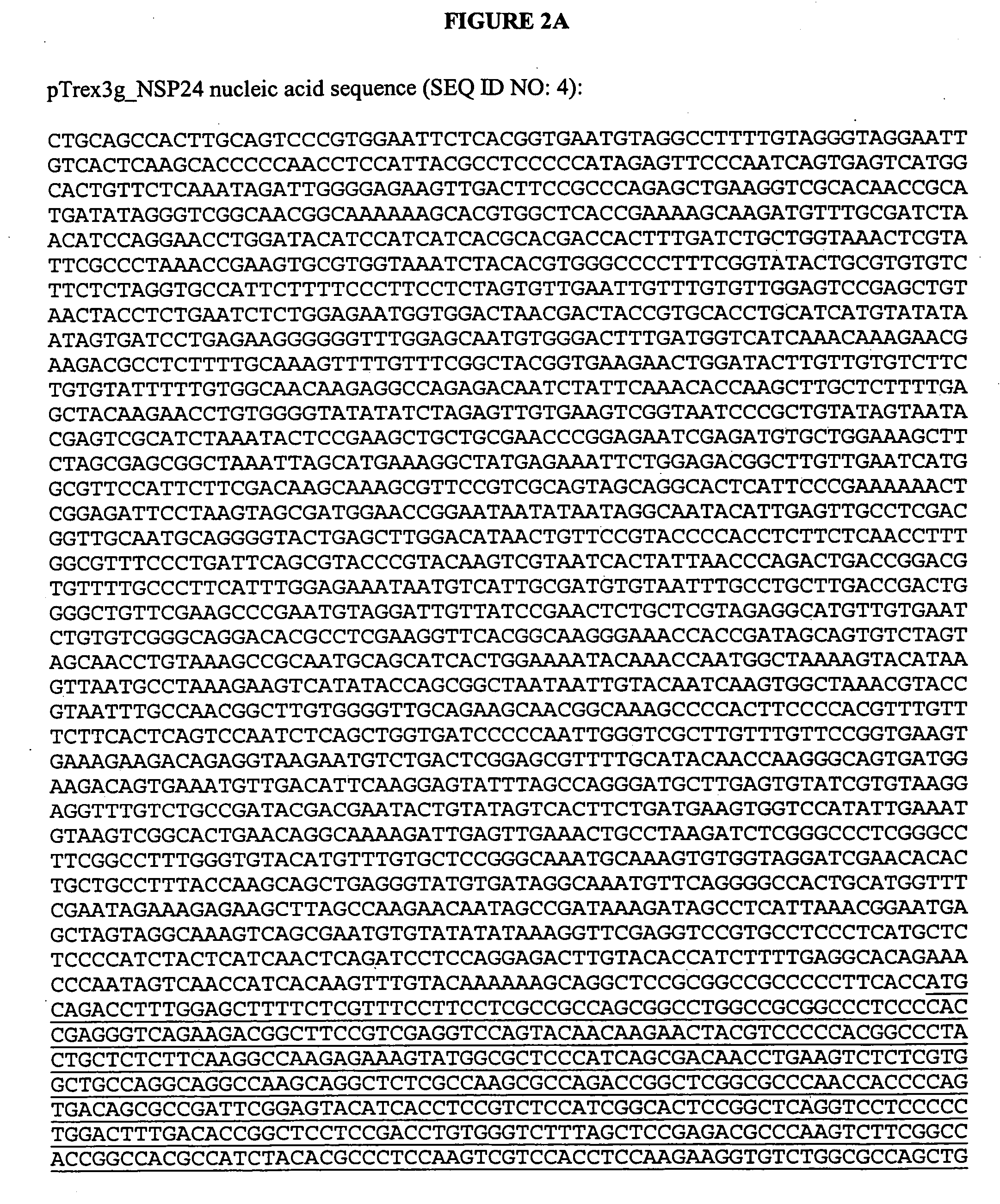

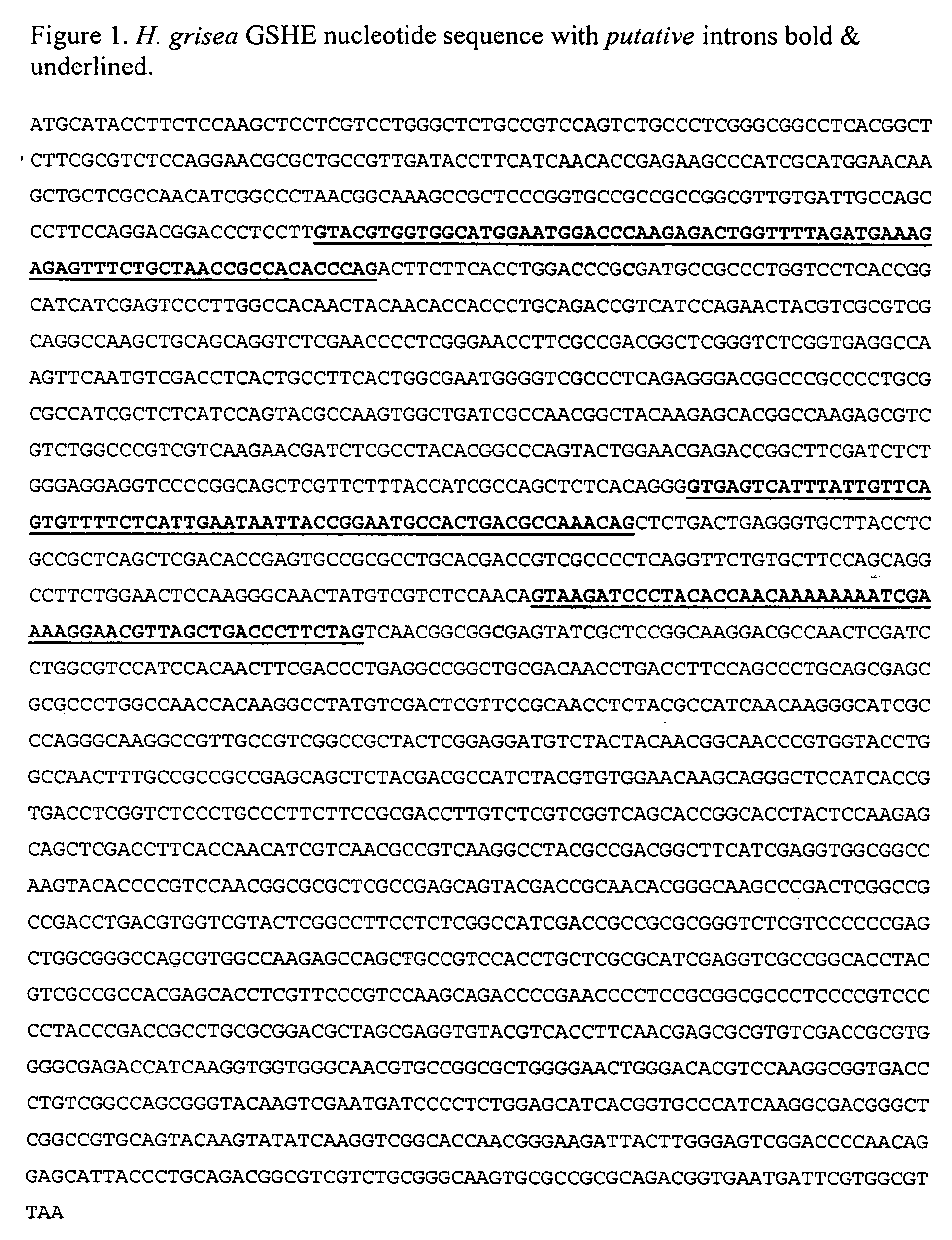

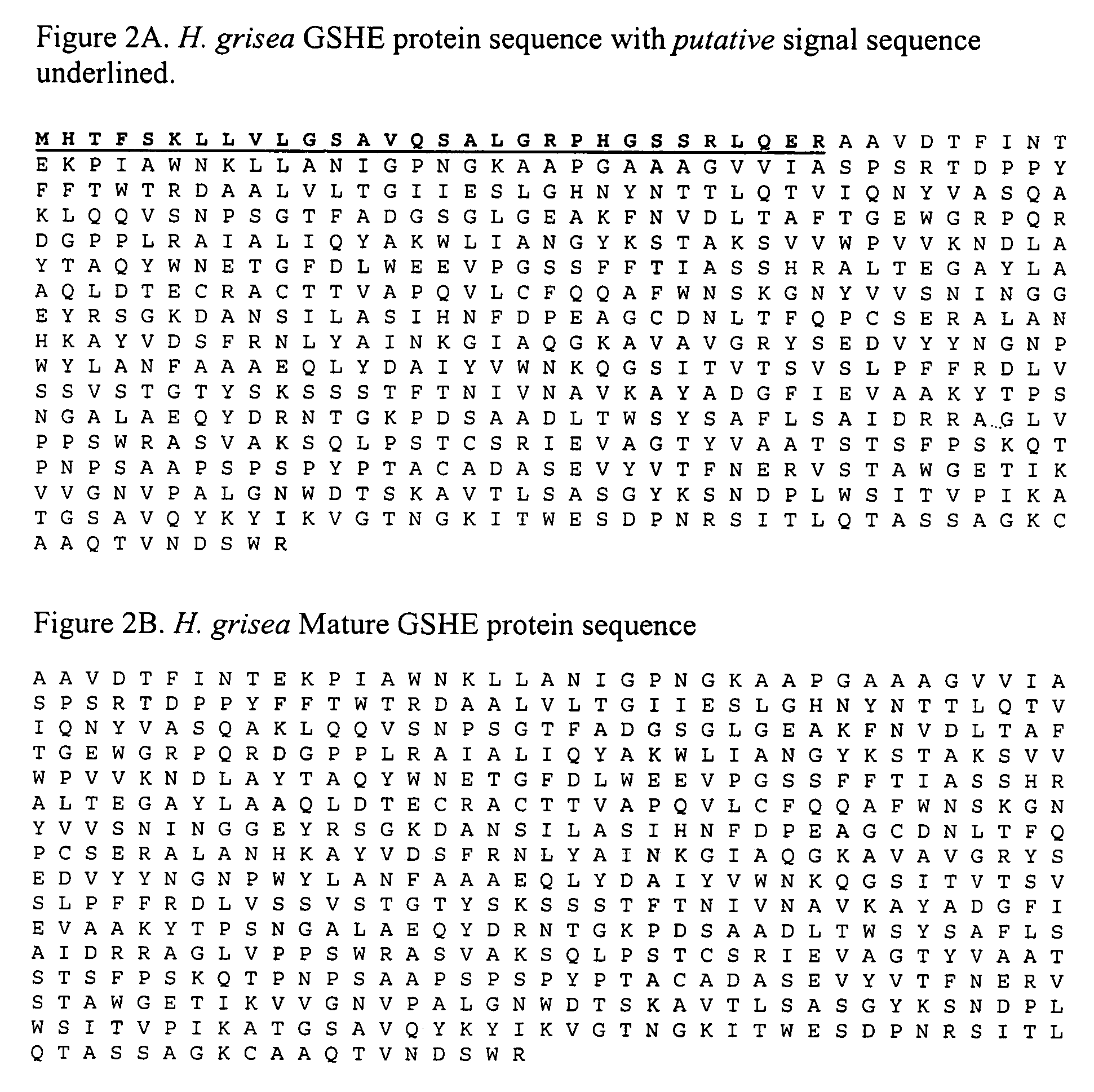

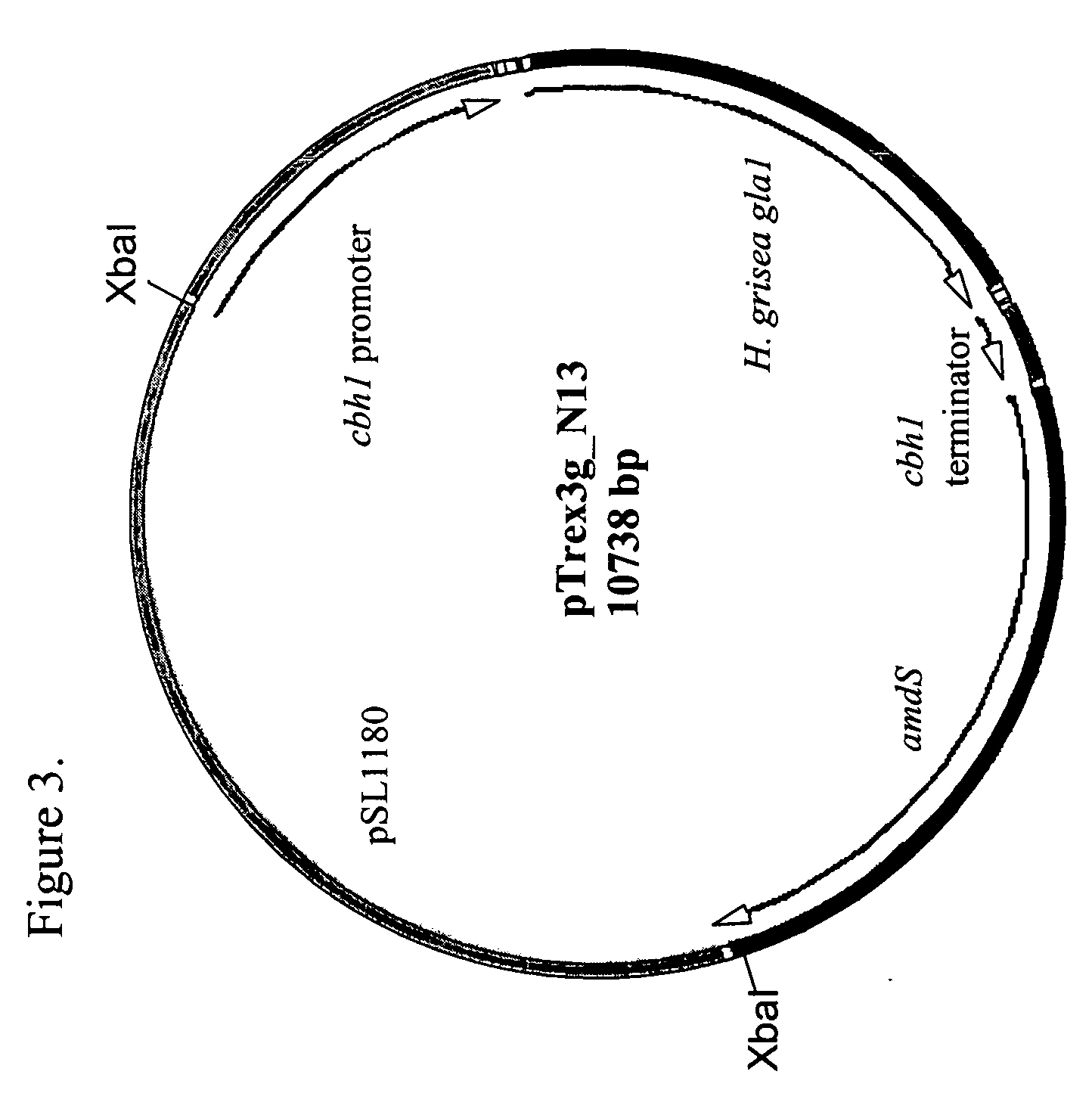

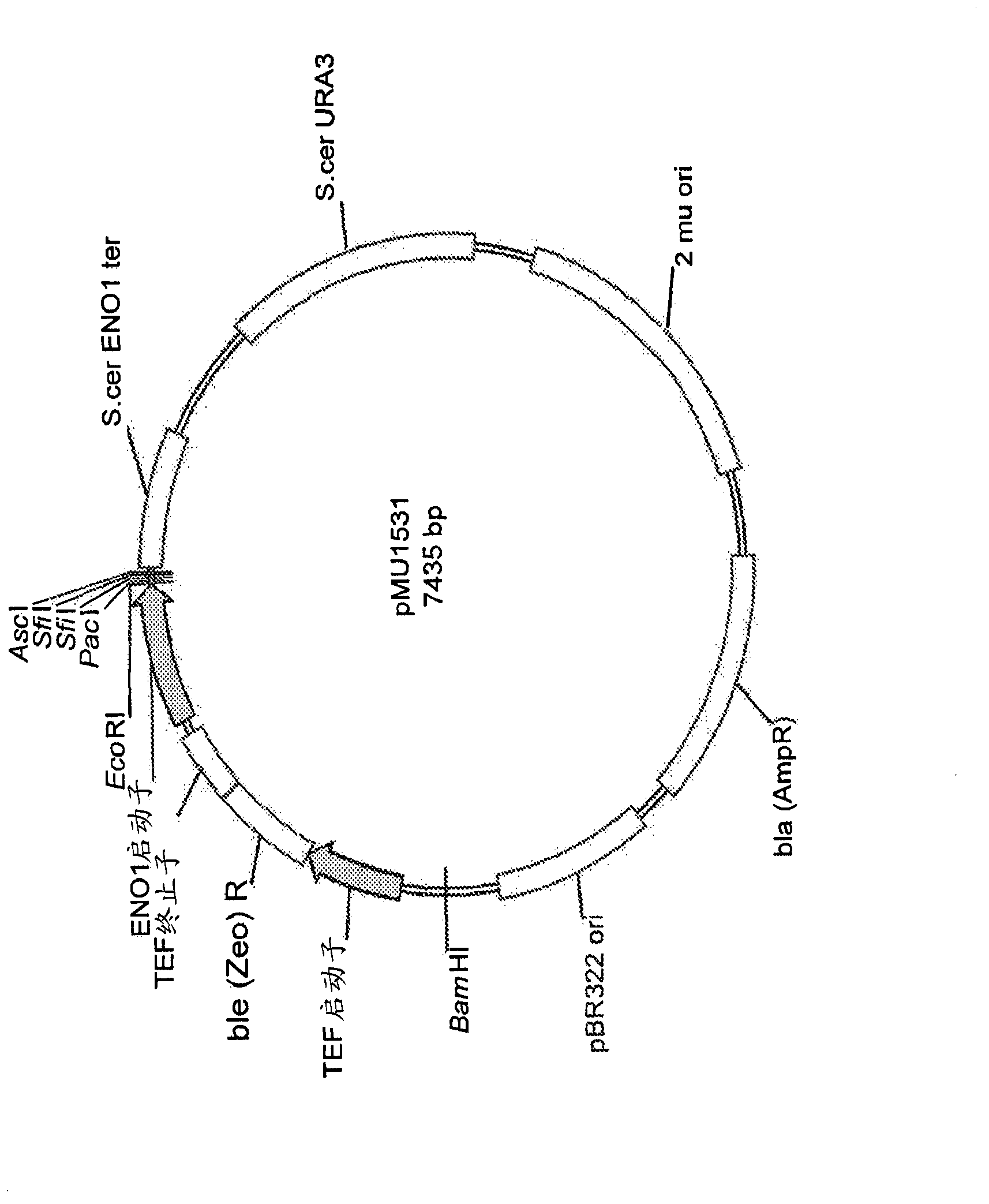

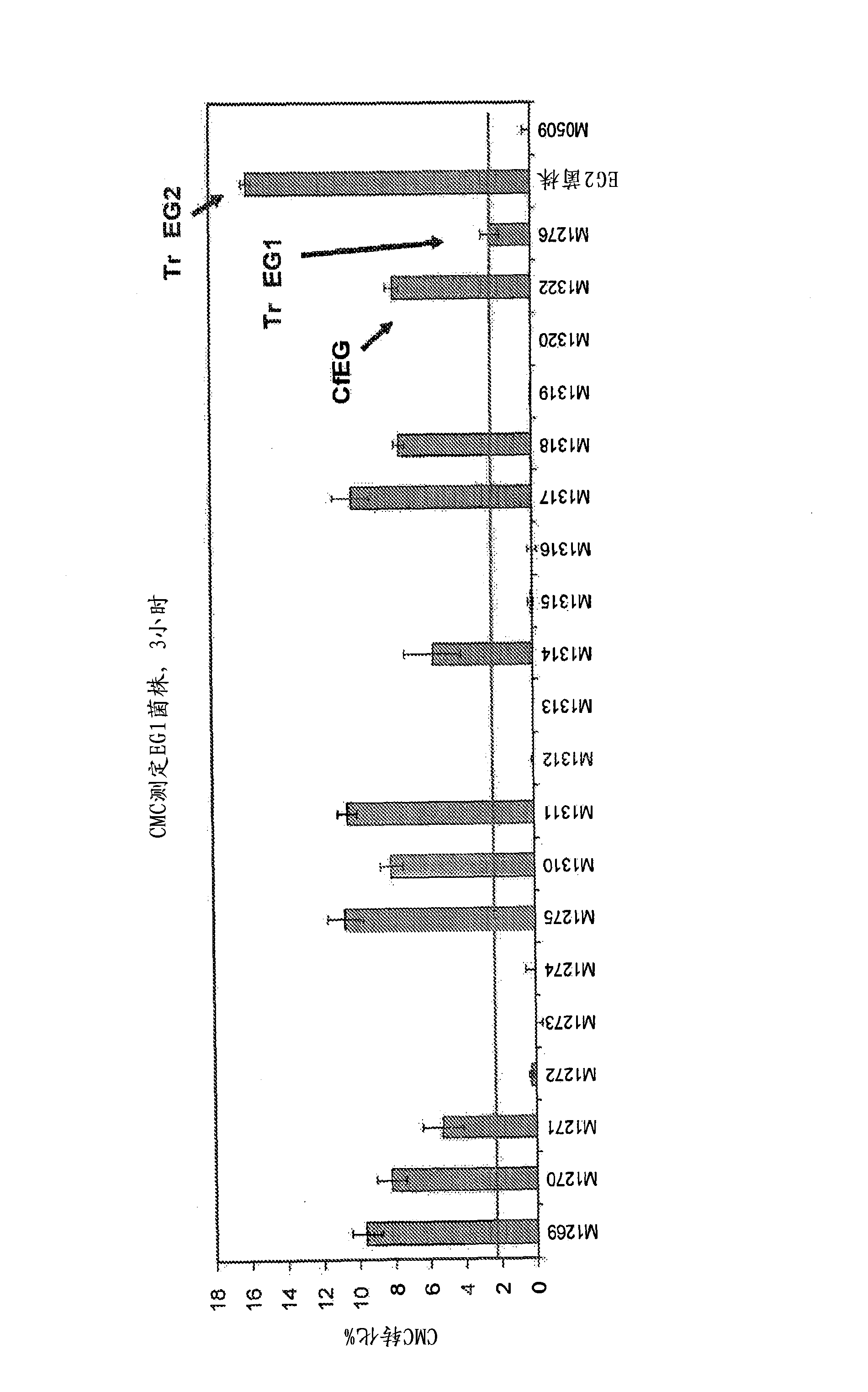

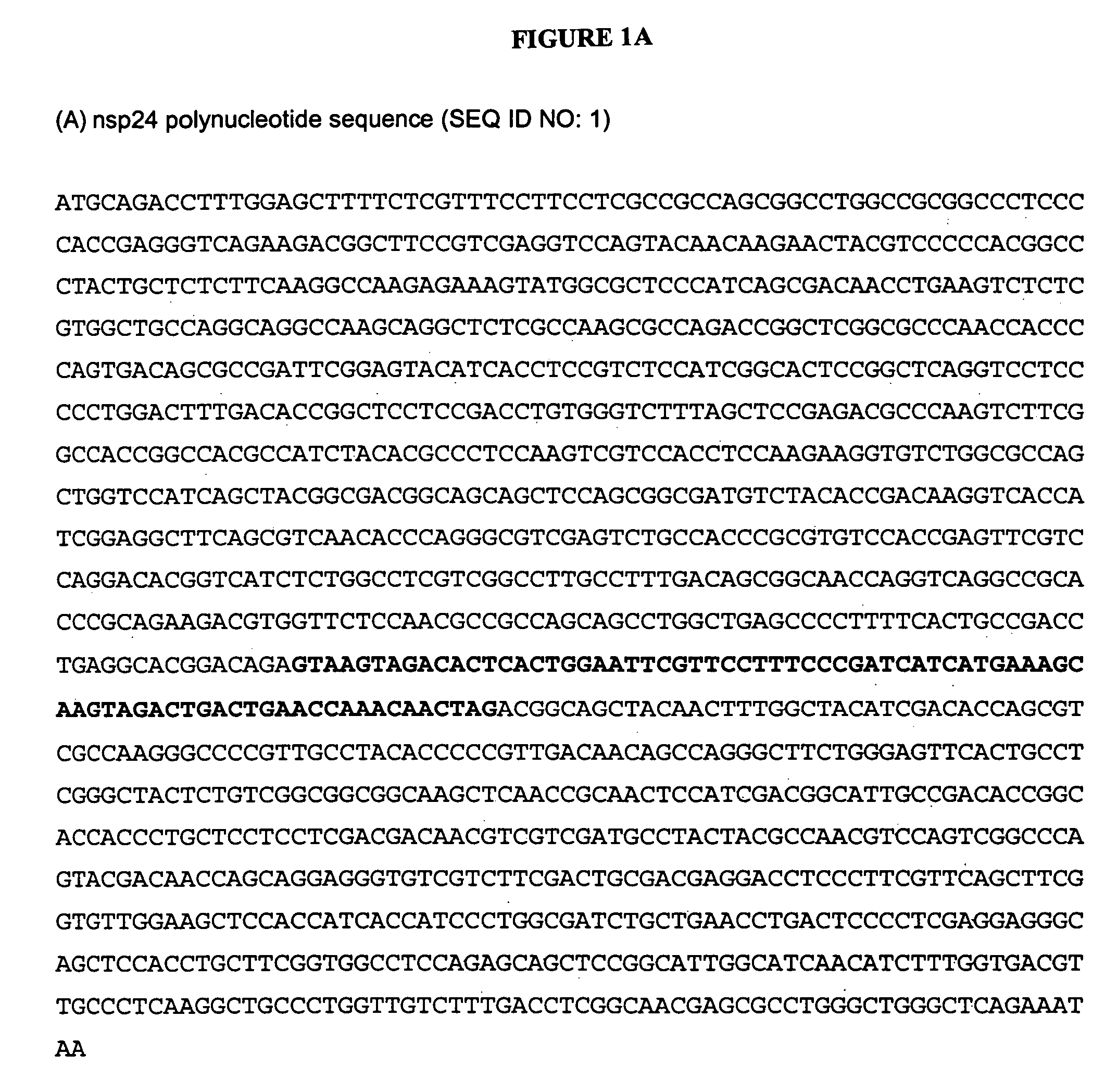

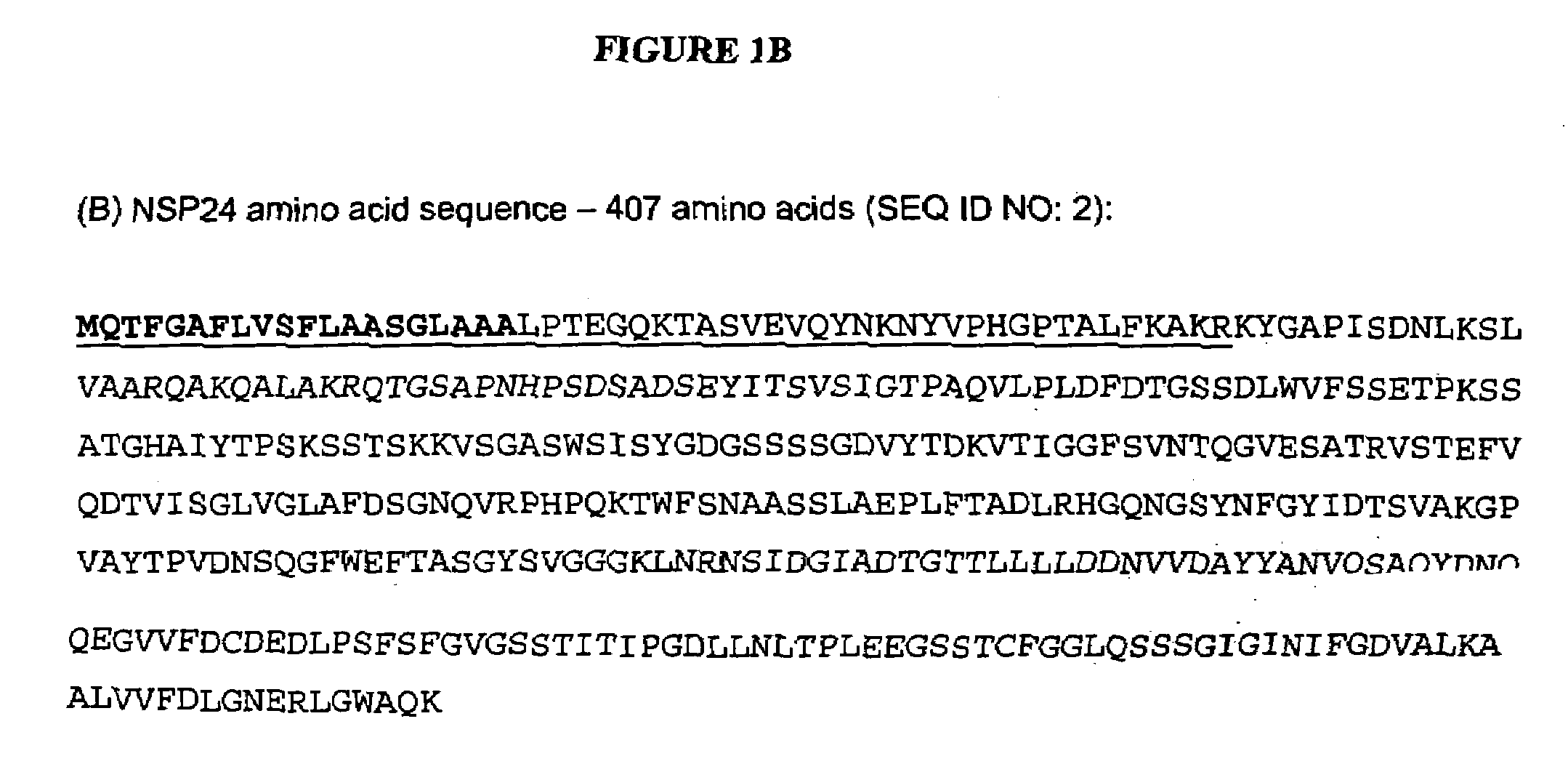

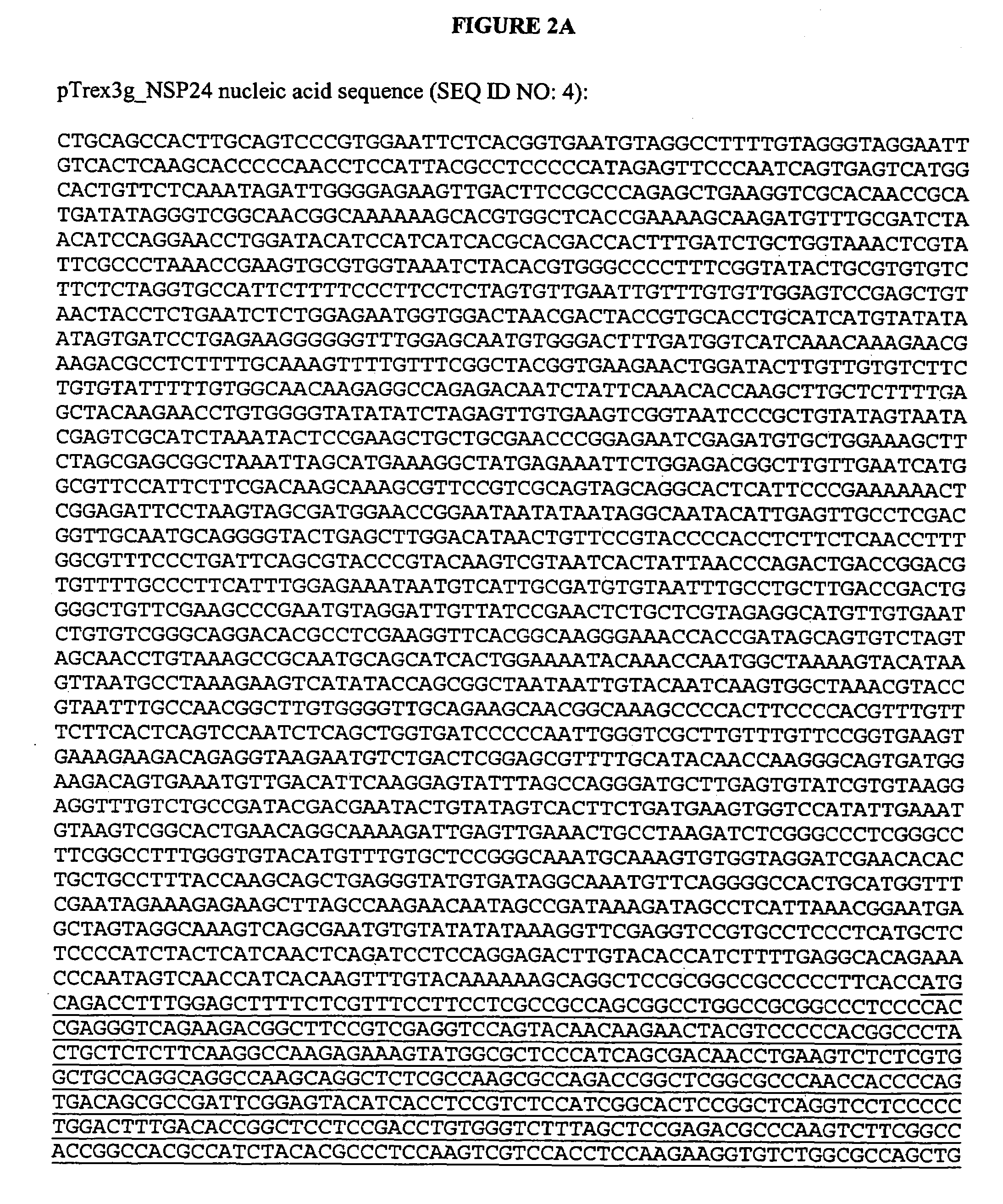

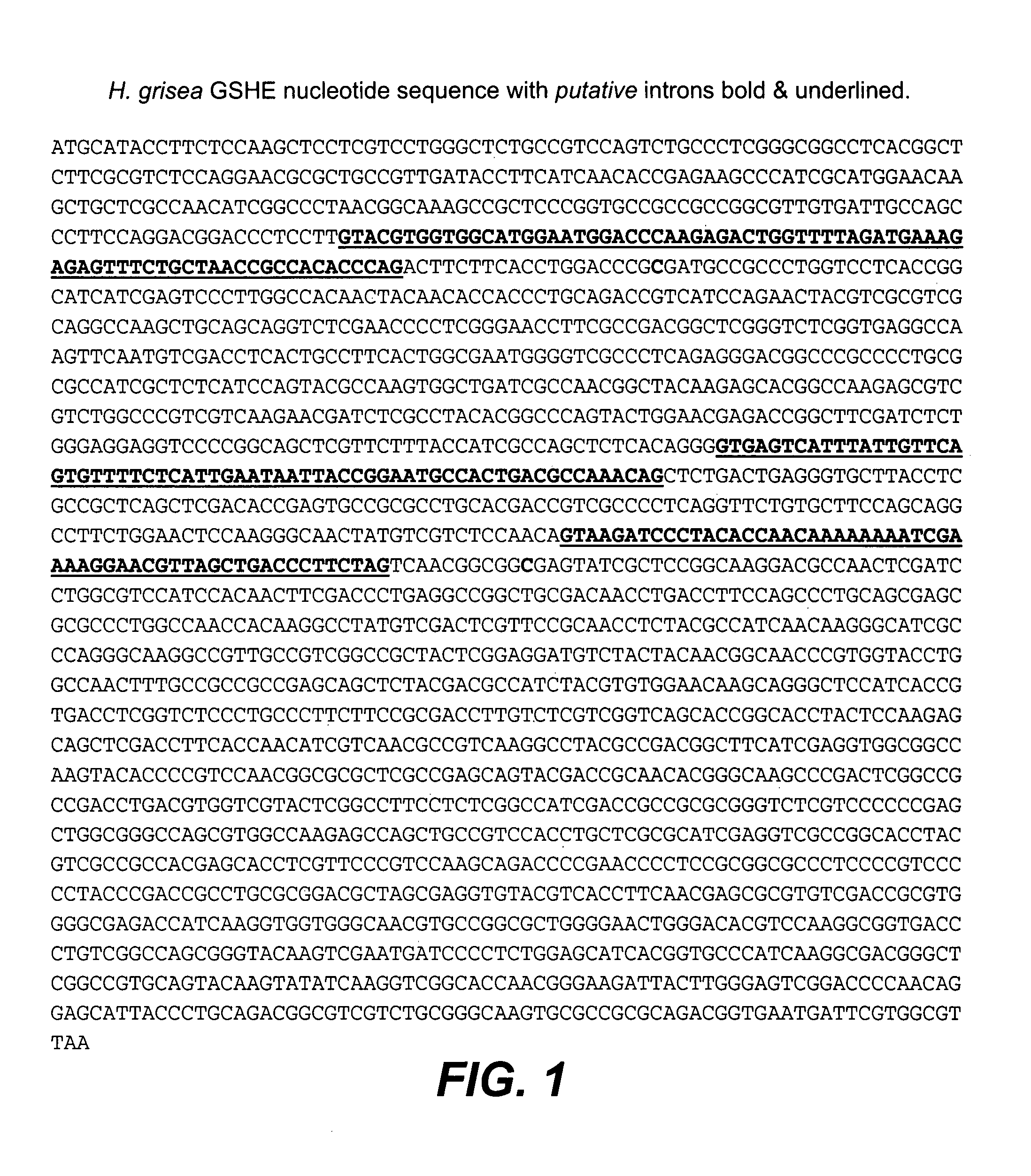

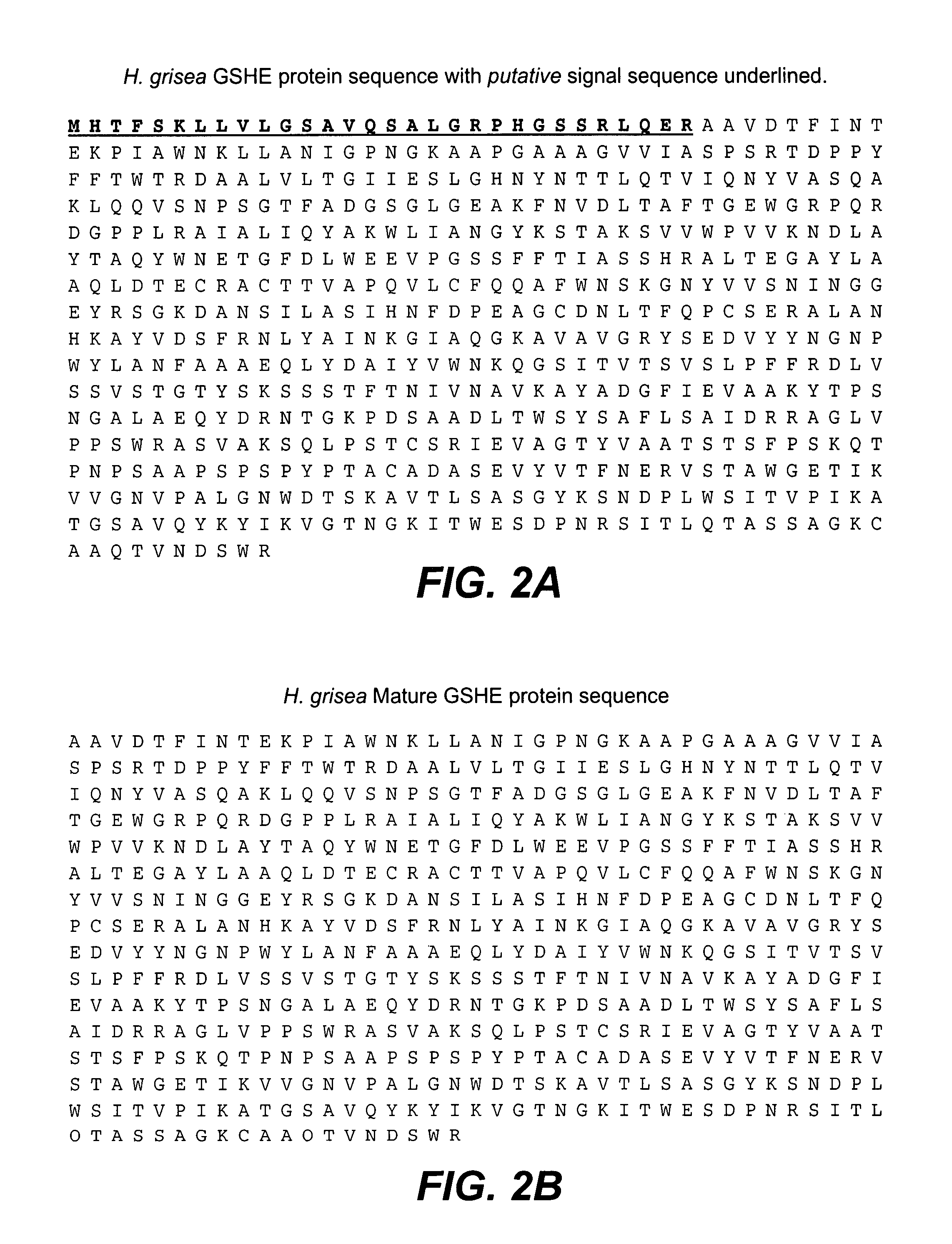

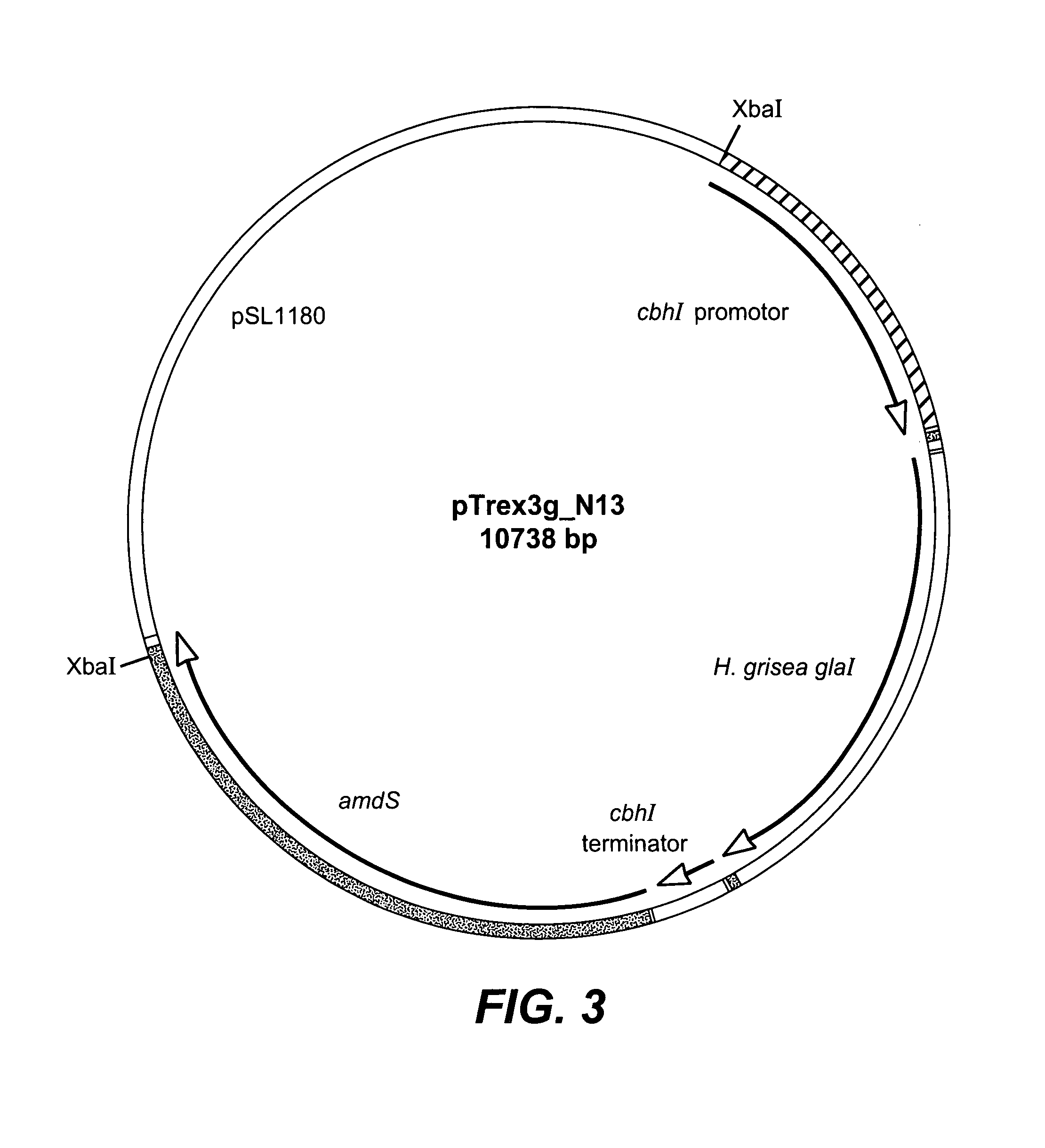

Expression of granular starch hydrolyzing enzymes in Trichoderma and process for producing glucose from granular starch substrates

InactiveUS20050136525A1Short timeHigh in sugarFungiSugar derivativesHeterologousGlucose-Fructose Syrup

The present invention relates to filamentous fungal host cells and particularly Trichoderma host cells useful for the production of heterologous granular starch hydrolyzing enzymes having glucoamylase activity (GSHE). Further the invention relates to a method for producing a glucose syrup comprising contacting a granular starch slurry obtained from a granular starch substrate simultaneously with an alpha amylase and a GSHE at a temperature equal to or below the gelatinization temperature of the granular starch to obtain a composition of a glucose syrup.

Owner:GENENCOR INT INC

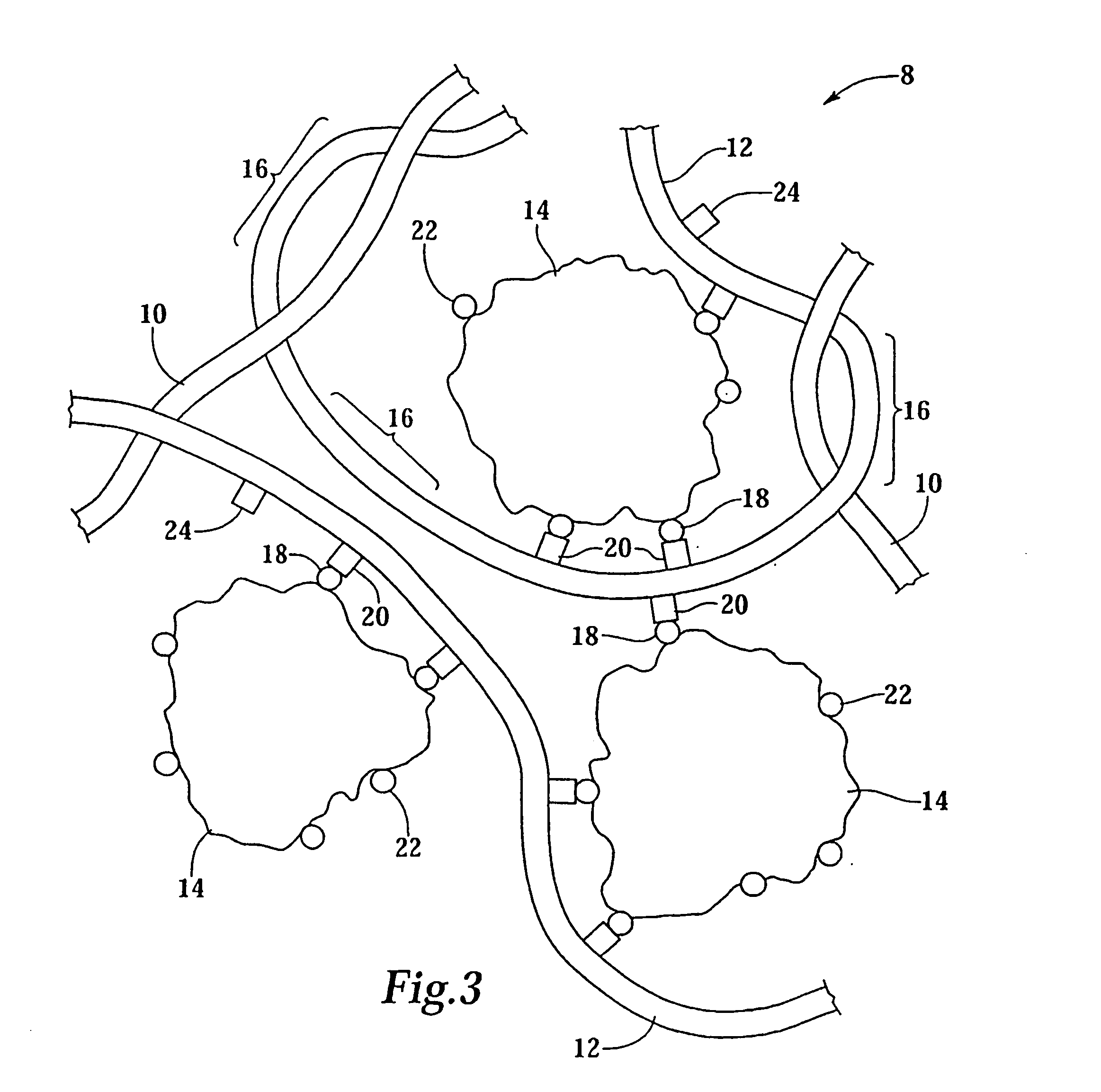

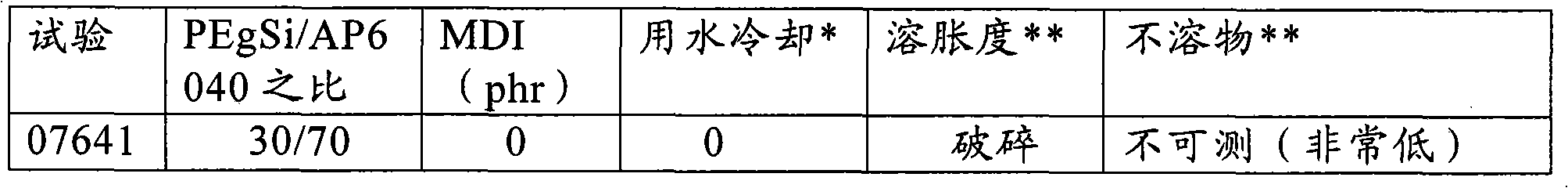

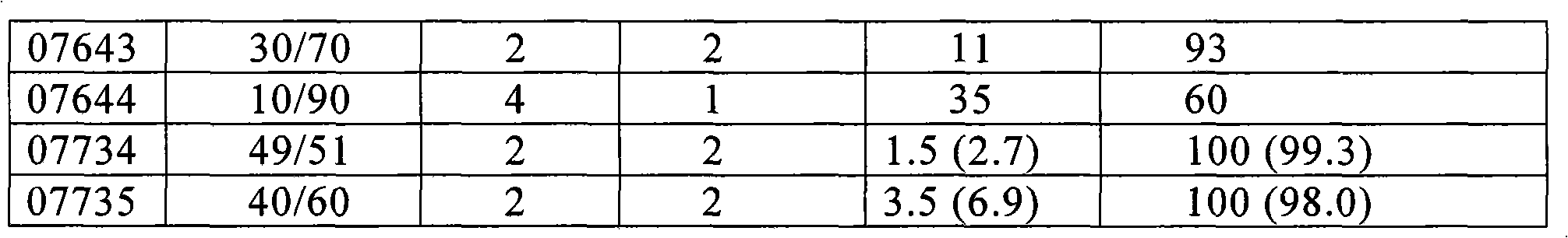

Biodegradable materials from starch-grafted polymers

Granular starch is added to a polymer in order to decrease the cost of the polymer derivative. Use of granular starch also makes the derivative more biodegradable. The polymer blend has very similar mechanical properties to pure polymer. Furthermore, unlike other starch / polyethylene mixtures, glycerol is not added to the mixture. This reduces the water absorbency of the final product. The polymer and starch are blended together in the presence of an interfacial compatibilizer that binds the two components together.

Owner:ARKANSAS UNIVESITY OF +1

Biodegradable materials from starch-grafted polymers

InactiveUS20050171249A1More biodegradableAdvantage of simplicityPaper coatingCoatingsPolymer scienceGlycerol

Granular starch is added to a polymer in order to decrease the cost of the polymer derivative. Use of granular starch also makes the derivative more biodegradable. The polymer blend has very similar mechanical properties to pure polymer. Furthermore, unlike other starch / polyethylene mixtures, glycerol is not added to the mixture. This reduces the water absorbency of the final product. The polymer and starch are blended together in the presence of an interfacial compatibilizer that binds the two components together.

Owner:ARKANSAS UNIVESITY OF +1

Cosmetic composition with soft focus properties

A cosmetic composition is provided to achieve a soft focus effect. Imperfections in skin complexion can be hidden. The composition includes a water-insoluble partially hydrated granular starch having an average particle size ranging from about 500 to about 10,000 nm, a spherical alumina having a refractive index from 1.6 to 1.9 and average particle size from about 5 to about 300 nm, an inorganic material in flat, platy form having an average particle size ranging from about 0.1 to about 30 micron and a cosmetically acceptable carrier.

Owner:CONOPCO INC D B A UNILEVER

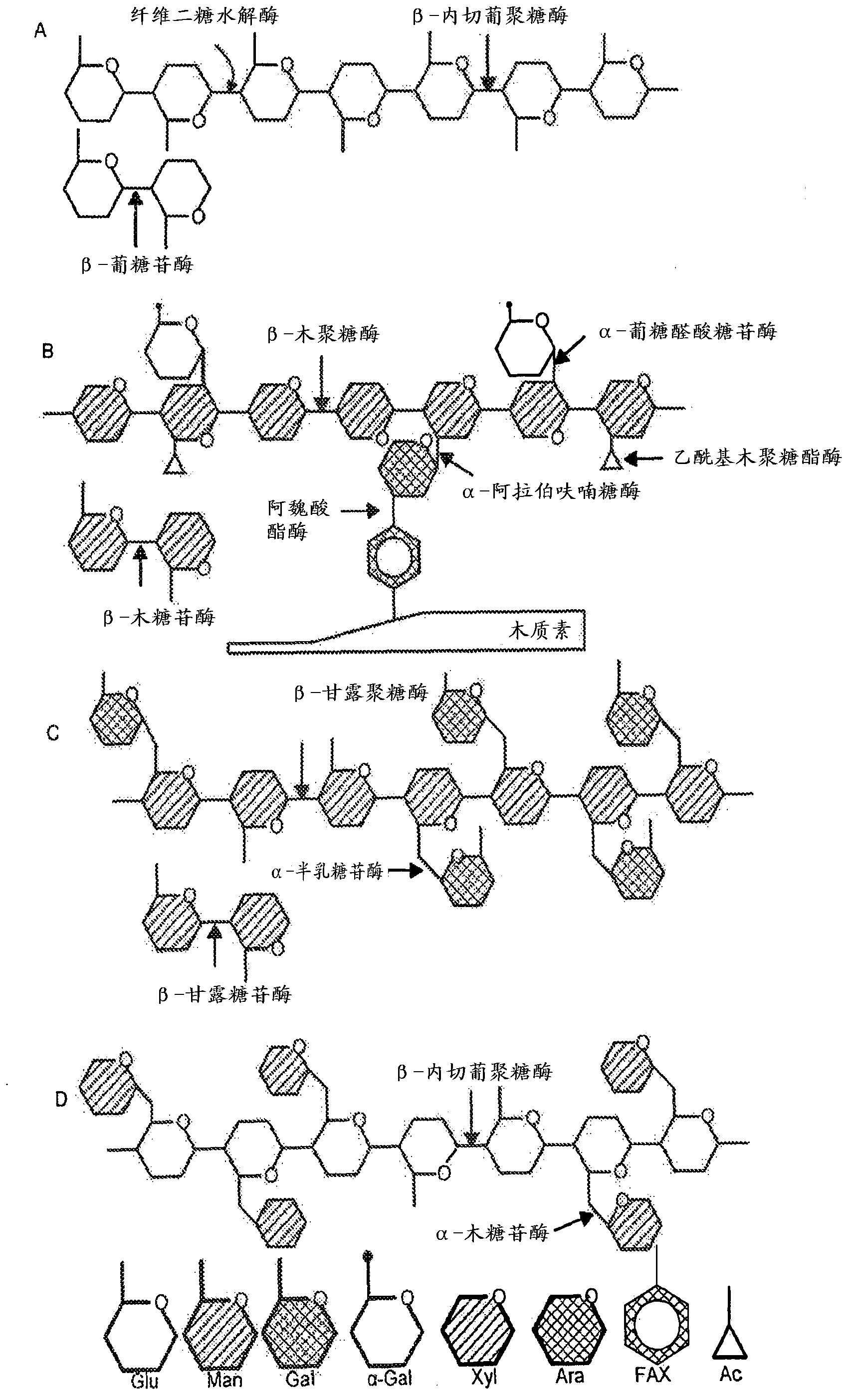

Yeast expressing saccharolytic enzymes for consolidated bioprocessing using starch and cellulose

The present invention is directed to a yeast strain, or strains, secreting a full suite, or any subset of that, full suite, of enzymes to hydrolyze com starch, corn fiber, lignocellulose, (including enzymes that hydrolyze linkages in cellulose, hemicelhiiose, and between lignin and carbohydrates) and to utilize pentose sugars (xylose and arabinose). The invention is also directed to the set of proteins that are well expressed in yeast for each category of enzymatic activity. The resulting strain, or strains can be used to hydrolyze starch and cellulose simultaneously. The resulting strain, or strains can be also metabolically engineered to produce less glycerol and uptake acetate. The resulting strain, or strains can also be used to produce ethanol from granular starch without liquefaction.; The resulting strain, or strains, can be further used to reduce the amount of external enzyme needed to hydrolyze a biomass feedstock during an Simultaneous Saccharification and Fermentation (SSF) process, or to increase the yield of ethanol during SSF at current saccharolytic enzyme loadings. In addition, multiple enzymes of the present invention can be co-expressed in cells of the invention to provide synergistic digestive action on biomass feedstock. In some aspects, host cells expressing different heterologous saccharolytic enzymes can also be co-cultured togetherand used to produce ethanol from biomass feedstock.

Owner:LALLEMAND HUNGARY LIQUIDITY MANAGEMENT LLC +1

Process for the co-manufacture of ingredients for use in foods and beverages using potatoes as starting material

InactiveUS20010041199A1Reduce the amount requiredPrevent enzymatic browningBeer fermentationAlcoholic beverage preparationBiotechnologyFruit juice

Disclosed is a process for the co-manufacture of ingredients having food and beverage applications, using potatoes as starting material. The process comprises six steps. The first step is a cutting and dipping of washed raw potatoes in an anti-oxidant solution. The second step is an extraction of undiluted juice free of starch and fibers from a purée made from the anti-oxidant-dipped raw potatoes. The third step is a concentration and enzymatic treatment of the juice. The fourth step is a heating of the juice to specific temperatures to cause precipitation of proteins and separation of precipitated protein therefrom. The fifth step is a thermal browning of the clear juice. The sixth step is an adjustment of the final pH of the juices of the fourth and fifth steps and a blending of these juices in ratios appropriate for intended use. These six steps yield products which may be used as the main flavor principle in malt-free beer, as a coffee substitute and as a flavor enhancer in savory mixes. They also yield dietary fibers, a concentrated edible protein and non-gelatinized granular starch, thereby increasing revenues derived from potato processing while minimizing liquid waste stream.

Owner:SENSICULTURE FY BIOTECH

Process for preparing inhibited non-pregelatinized granular starches

An inhibited non-pregelatinized granular starch suitable for use as a food ingredient in substitution for a chemically modified starch may be prepared by heating a non-pregelatinized granular starch in an alcoholic medium in the presence of a base and / or a salt. Steam treatment may be used to enhance the extent of inhibition.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

Concrete compositions and methods for the preparation thereof

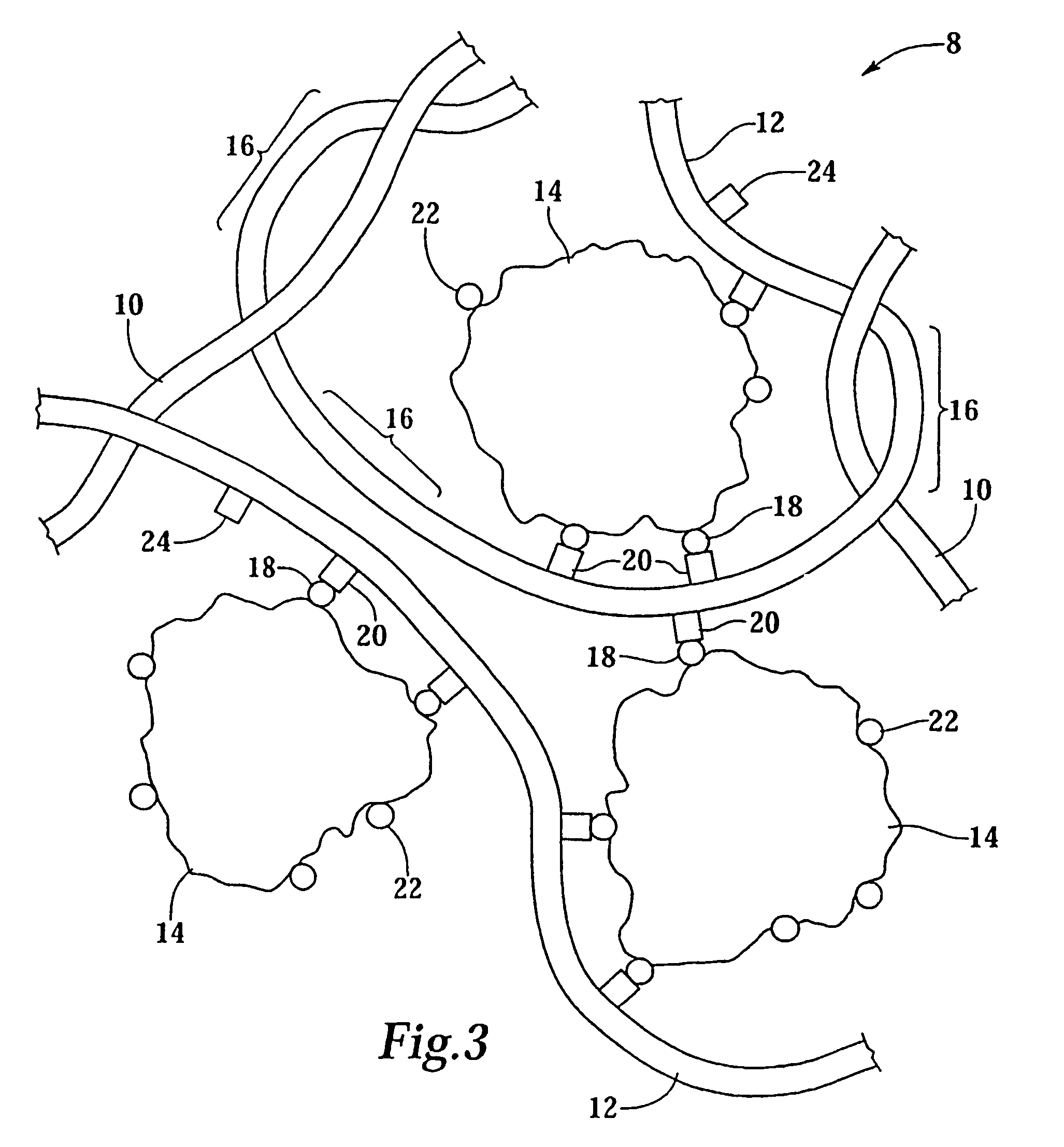

InactiveUS6387171B1Reduce the amount requiredReduce moisture contentCeramicwareGranular starchStarch granule

Disclosed is a concrete composition that comprises water, a cementitious material, and an aggregate material, the aggregate material comprising a granular starch. In accordance with preferred embodiments of the invention, the granular starch is a washed, pre-swollen starch, and is added to the composition in an amount ranging from about 1% to about 20% by weight of the cementitious material. The starch granules are swollen in the uncured composition but liberate water and shrink to their unswollen size as the concrete cures, thus providing a cured lightweight concrete. Also disclosed is a method for preparing a concrete composition. The disclosed method comprises providing starch granules, mixing the starch granules with water and a cementitious material to form an uncured concrete composition, and subsequently curing the uncured concrete composition thus formed.

Owner:GRAIN PROCESSING CORP

Process and method for hydroxyalkylation of starch and hydroxyalkyl starch prepared accordingly

InactiveUS6051700AIncreased susceptibilityEasy to disassembleFermentationGranular starchAqueous medium

Disclosed are a method and process for preparing a hydroxyalkyl starch. In accordance with the disclosed invention, the starch is treated with an enzyme under conditions to increase the susceptibility of the starch to hydroxyalkylation by a hydroxyalkylating agent. After the starch is so treated, the starch is hydroxyalkylated with a hydroxyalkylating agent. The hydroxyalkylation reaction can proceed to provide a starch having an MS greater than about 0.2, while still remaining in granular form in the aqueous suspension. The method of the invention thus provides a granular starch having a higher MS than is otherwise attainable via a reaction in aqueous media.

Owner:GRAIN PROCESSING CORP

Alcohol product processes

Owner:NOVOZYMES AS

Process Of Producing A Fermentation Product

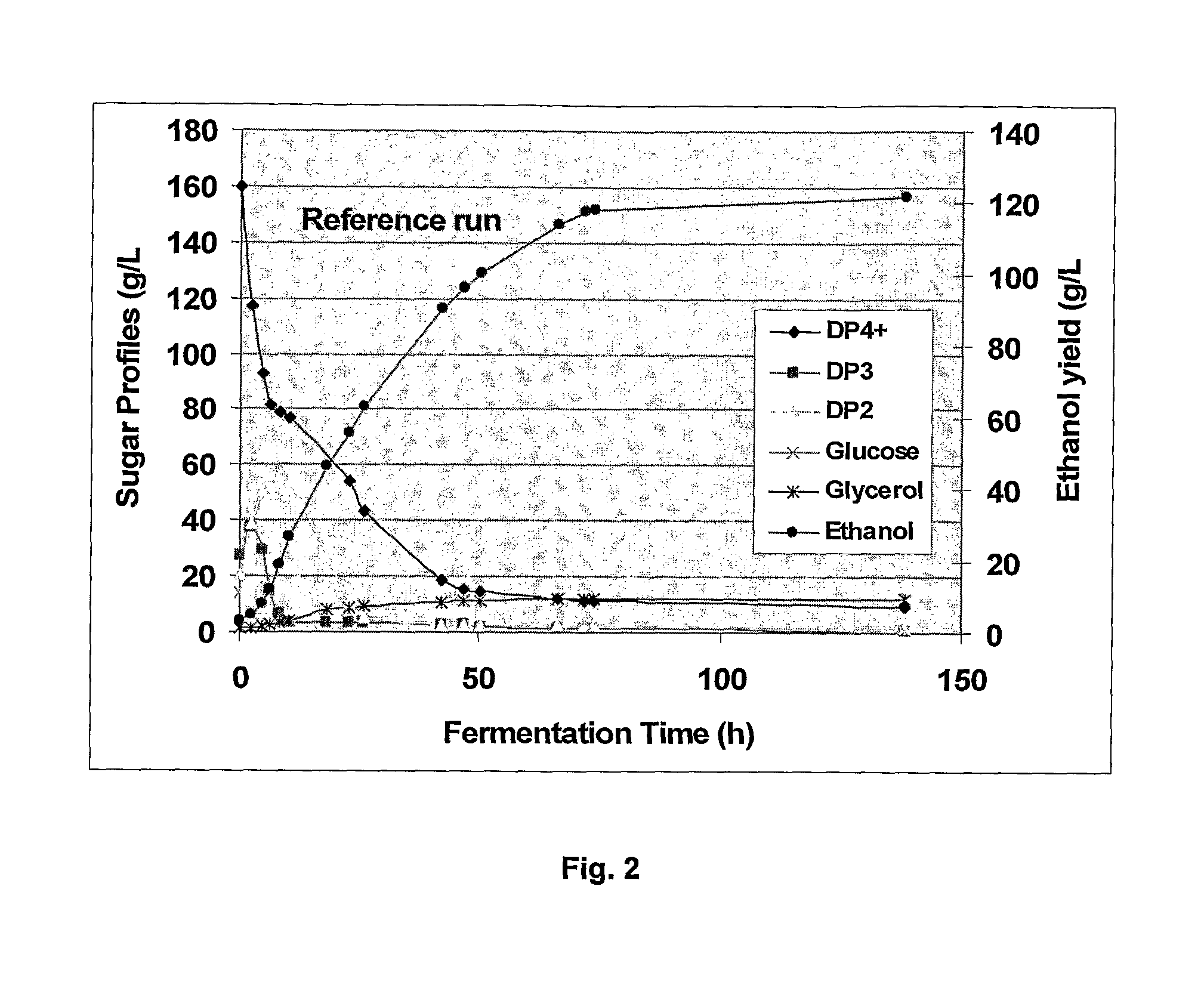

The invention relates to a process of producing a fermentation product, such as ethanol, from starch-containing material, including i) subjecting starch-containing material to an alpha-amylase, ii) subjecting the material obtained in step i) to an alpha-glucosidase and / or a maltose-generating enzyme, and iii) fermenting the material in the presence of a fermenting organism, such as yeast. Alternatively the invention relates to a process of producing a fermentation product from starch-containing material, preferably granular starch, which process comprises: a) subjecting starch-containing material to an alpha-glucosidase and optionally a glucose-generating and / or maltose-generating enzyme, and b) fermenting the material in the presence of a fermenting organism.

Owner:NOVOZYMES AS +1

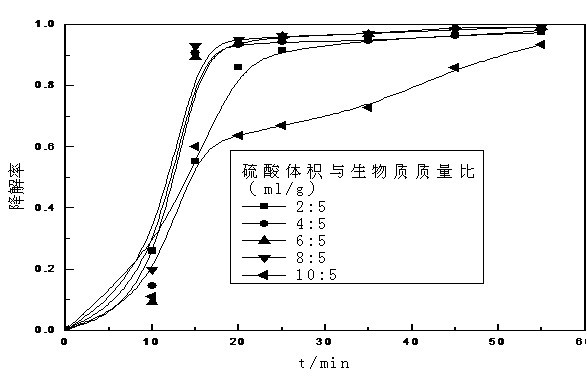

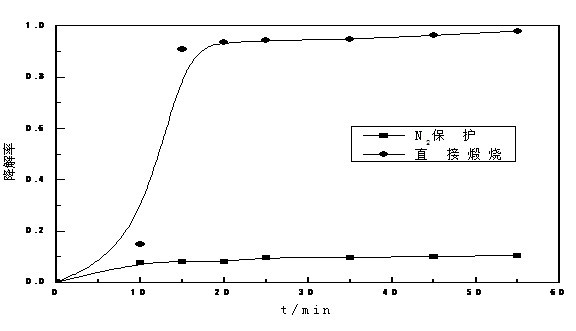

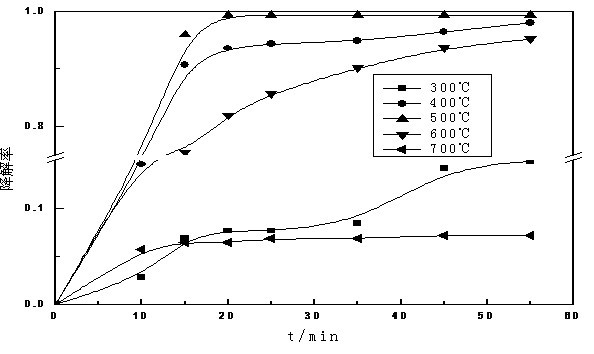

Preparation method of solid acid Fenton catalyst for processing methyl orange waste water

InactiveCN102228832AIncrease consumptionGreen and efficient degradationWaste water treatment from textile industryMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCyclodextrin

The invention discloses a preparation method of a solid acid Fenton catalyst for processing methyl orange waste water, comprising the following steps: a, using granular starch, glucose or beta-cyclodextrin as raw material, adding concentrated sulfuric acid for carbonization at the temperature of 120 DEG C; b, cooling the carbonized material to room temperature, then washing; c, drying and grinding; d, adding active components for dipping, then washing; e, drying the obtained solid for 8-10h at the temperature of 110 DEG C; and f, after drying, roasting at the temperature of 300-700 DEG C, cooling to room temperature to obtain the corresponding solid acid heterogeneous Fenton catalyst. The prepared catalyst solves the problems of loss of active components, large liquid acid consumption, low utilization rate of H2O2, equipment corrosion, environmental pollution seriously and the like in traditional heterogeneous Fenton catalytic oxidation process, and is a green and high effective organic substance degraded Fenton catalyst.

Owner:CHONGQING UNIV OF TECH

Non-crystal granular starch and its preparing process

A non-crystal granular starch is prepared from raw starch through cross-linking modification and non-crystallizing treatment. Its advantages are easy consequential processing such as separation, purification, dewatering, etc, high purity, uniformity, permeability and chemical and biological activity, easy degradation, good digestion, and wide application range.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing thermoplastic compositions based on plasticized starch and resulting compositions

InactiveCN101932647AFull mixabilitySatisfactory physical and chemical stabilityPlasticizerSubject matter

The subject matter of the present invention is a starch-based composition comprising: (a) at least 51% by weight of a plasticized amylaceous composition comprising starch and a plasticizer for said starch, obtained by thermomechanically mixing granular starch and a plasticizer for said starch, (b) at most 49% by weight of at least one non-amylaceous polymer, and (c) a bonding agent having a molecular mass of less than 5000, comprising at least two functions, at least one which is capable of reacting with the plasticizer and at least another of which is capable of reacting with the starch and / or the non-amylaceous polymer, these amounts being expressed with respect to solids and relative to the sum of (a) and (b), a method for preparing such a composition and a thermoplastic composition obtained by heating such a composition.

Owner:ROQUETTE FRERES SA

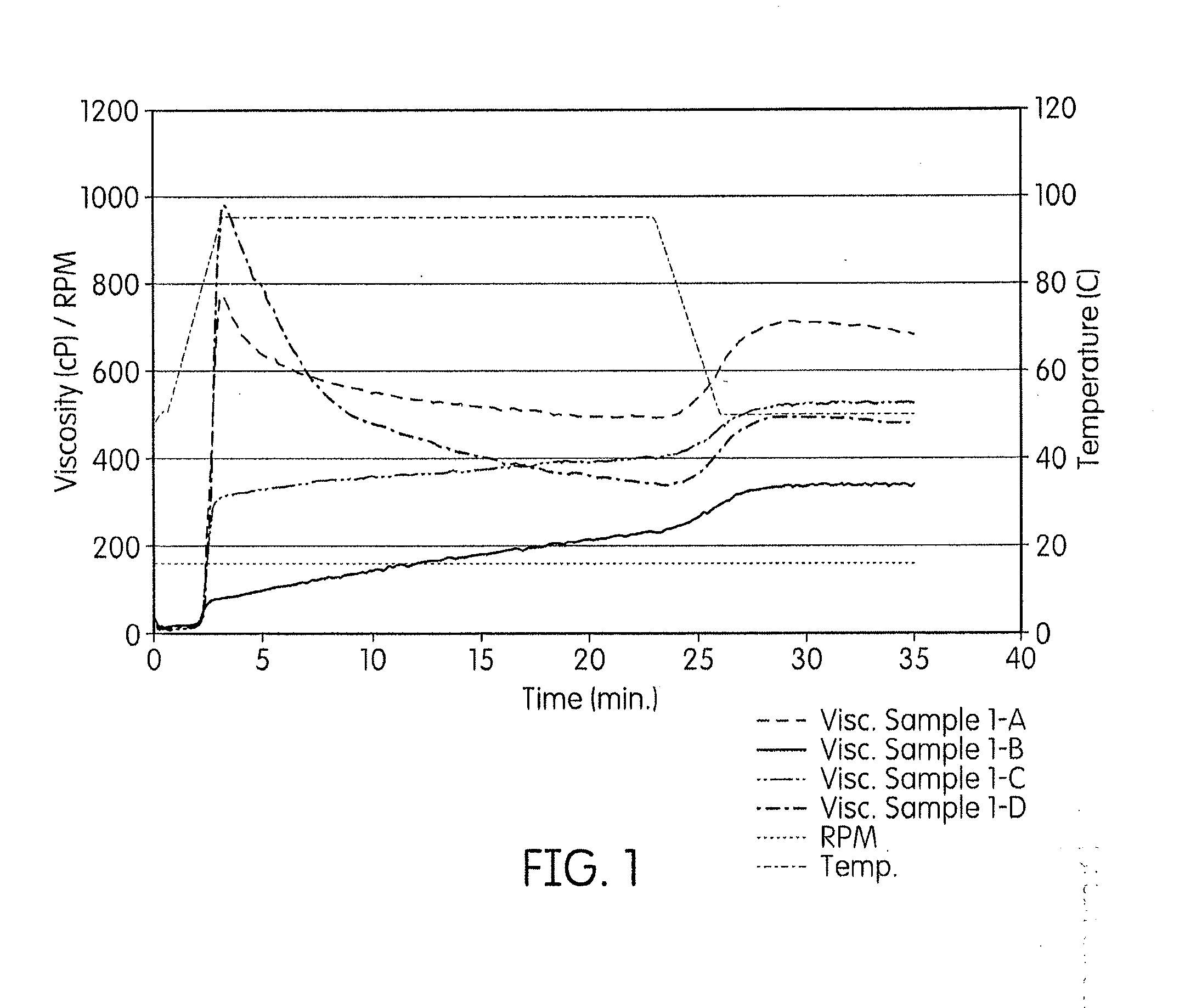

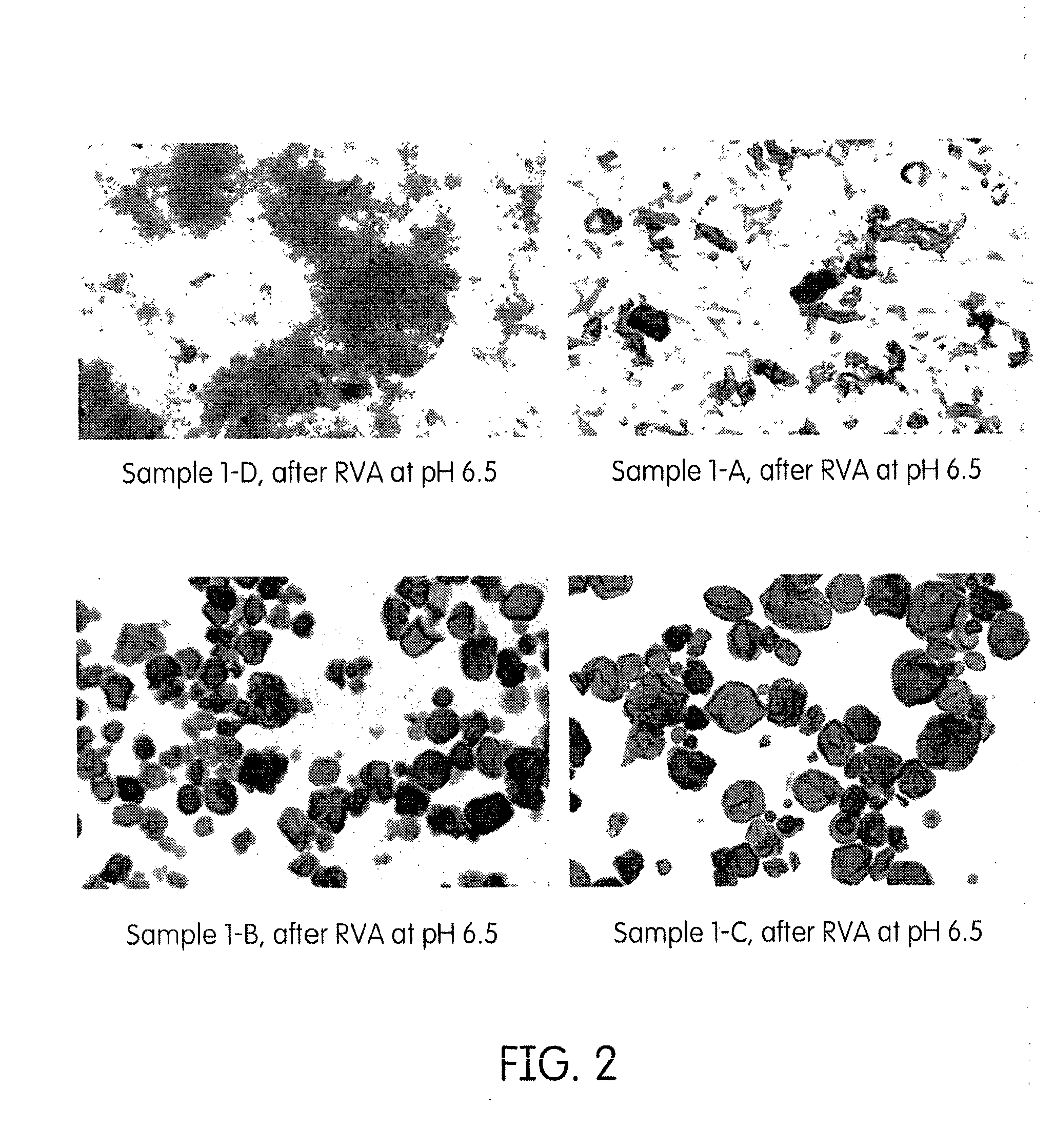

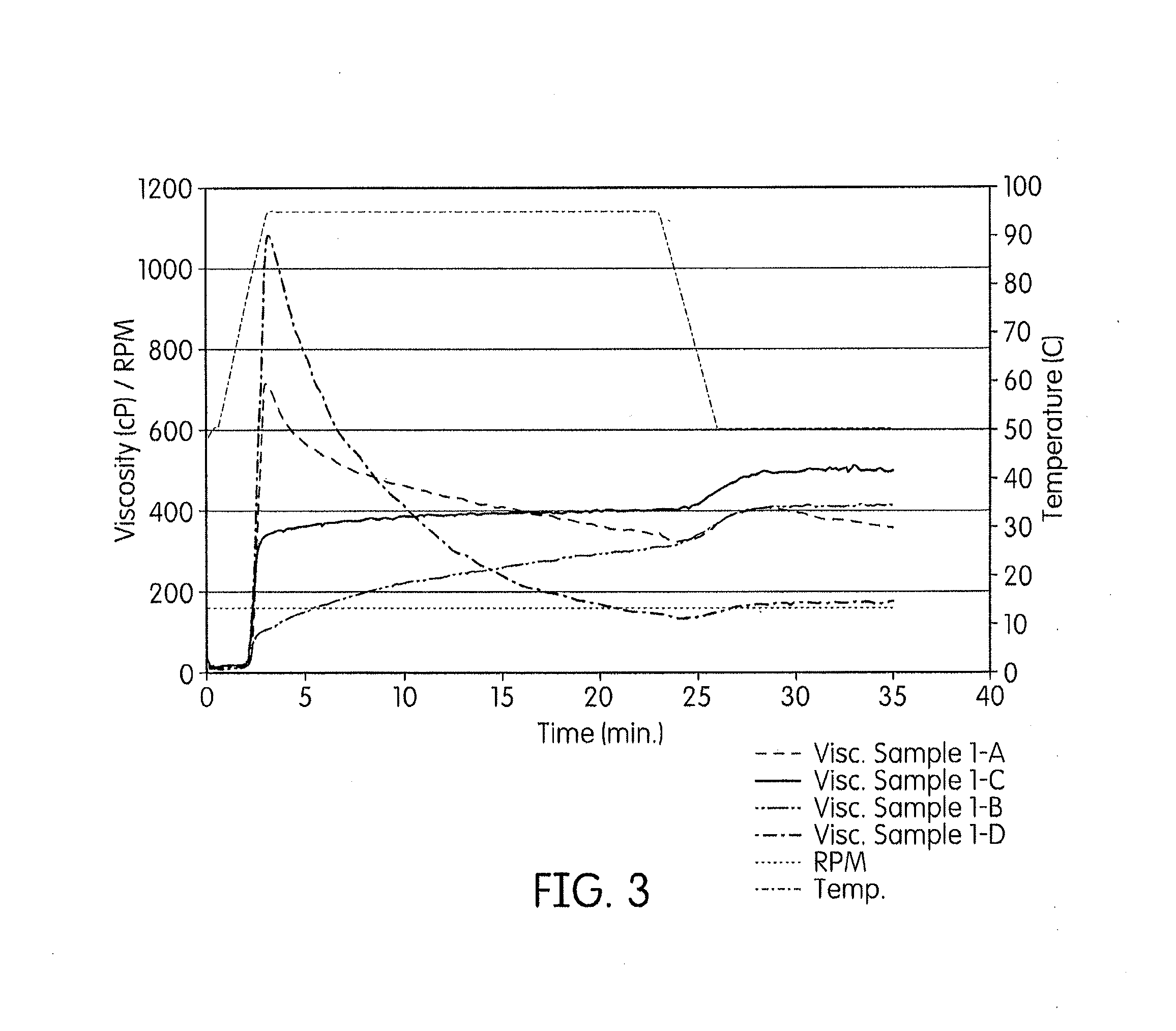

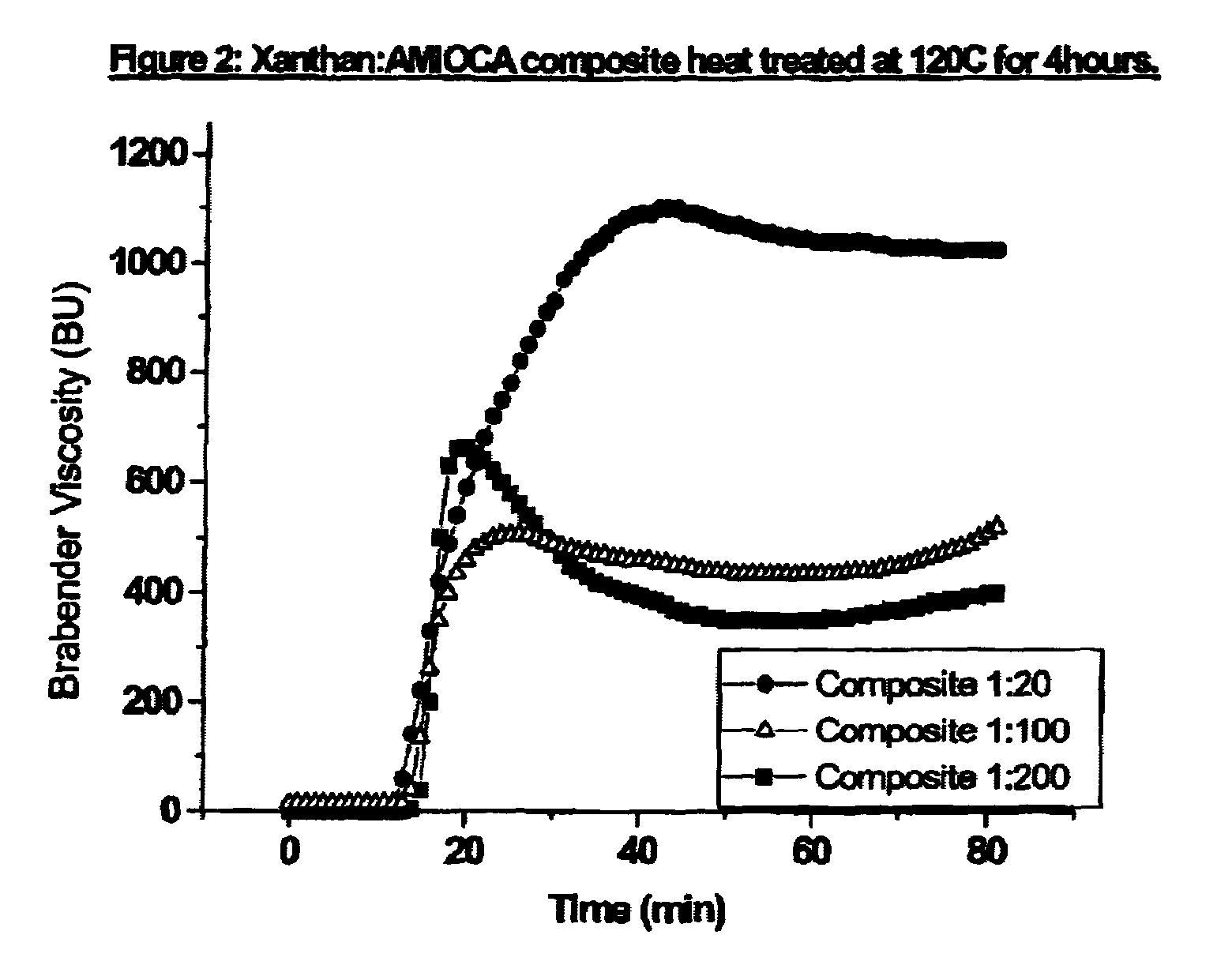

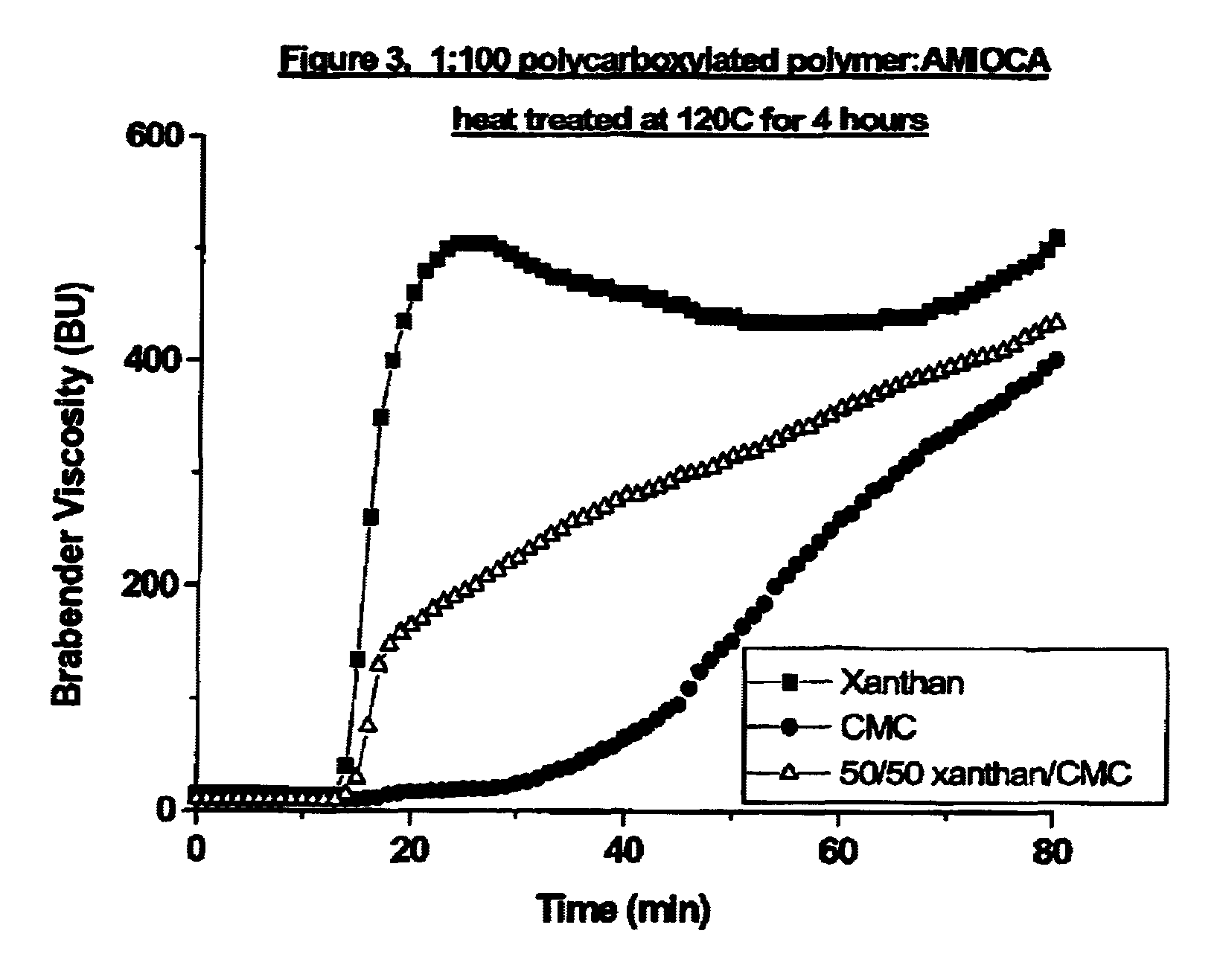

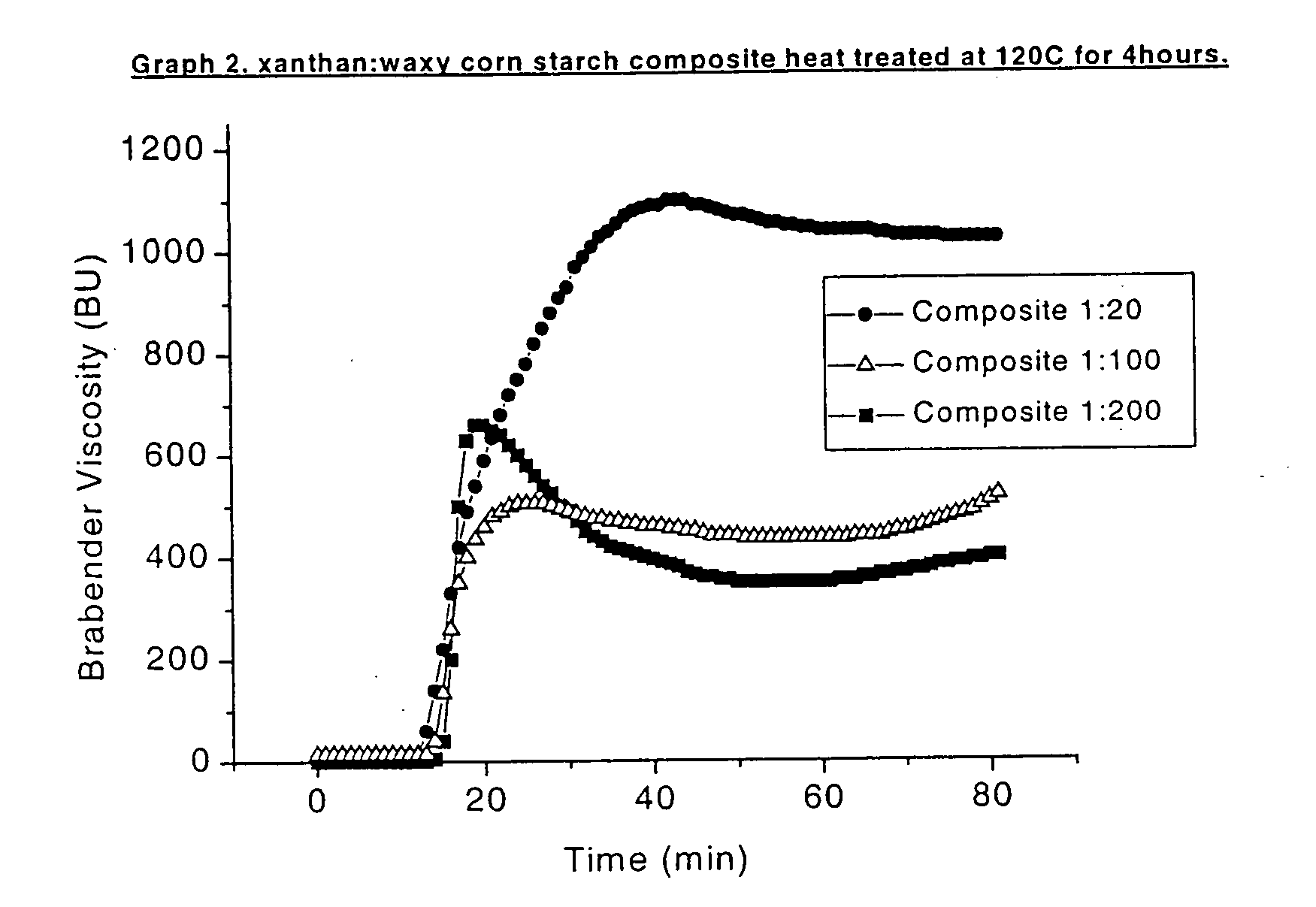

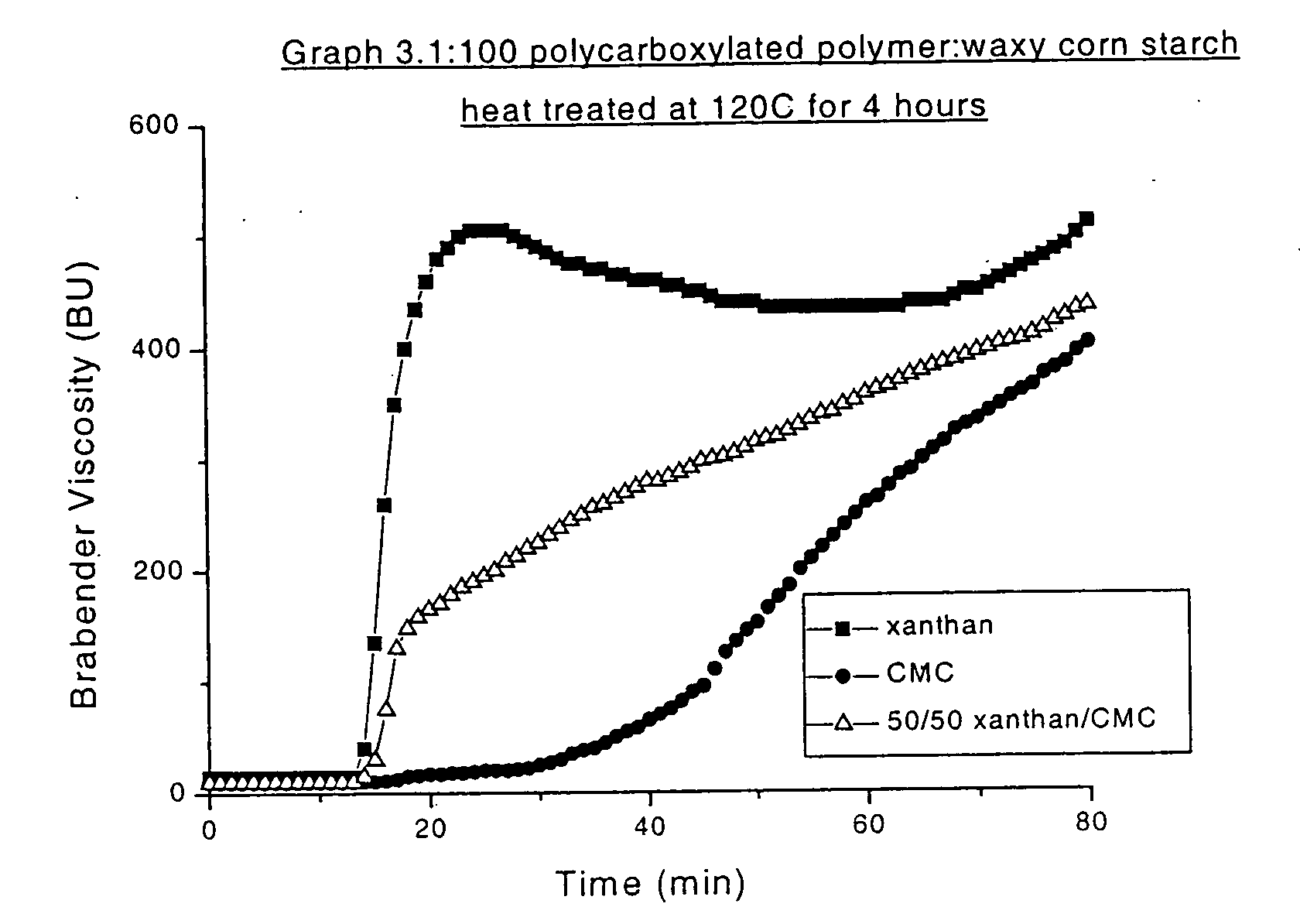

Starch/carboxylated polymer composites

InactiveUS7153904B2Short textureHigh viscosityPaper coatingFood ingredientsPolymer modifiedGranular starch

This invention relates to an inhibited non-solubilized granular starch modified by less than 5% of a carboxylated polymer. In addition, a process is provided wherein a non-solubilized, substantially granular starch is mixed with a carboxylated polymer, dried to form a starch / carboxylated polymer blend and then physically treated to form a starch / carboxylated polymer composite. Further, this invention relates to the improved industrial and food products prepared from these starch / carboxylated polymer composites.

Owner:CORN PROD DEV INC

Process of producing a fermentation product

The invention relates to a process of producing a fermentation product, such as ethanol, from starch-containing material, including i) subjecting starch-containing material to an alpha-amylase, ii) subjecting the material obtained in step i) to an alpha-glucosidase and / or a maltose-generating enzyme, and iii) fermenting the material in the presence of a fermenting organism, such as yeast. Alternatively the invention relates to a process of producing a fermentation product from starch-containing material, preferably granular starch, which process comprises: a) subjecting starch-containing material to an alpha-glucosidase and optionally a glucose-generating and / or maltose-generating enzyme, and b) fermenting the material in the presence of a fermenting organism.

Owner:NOVOZYMES NORTH AMERICA INC +1

Acid fungal protease in fermentation of insoluble starch substrates

The invention is directed to methods of producing ethanol and decreasing residual starch production in a no cook fermentation comprising contacting granular starch containing substrates with a granular starch hydrolyzing enzyme, a protease, and a fermenting microorganism under suitable fermentation conditions at a temperature below the starch gelatinization temperature of the starch substrate to produce ethanol, wherein the ethanol production is increased and the amount of residual starch is decreased compared to a substantially similar method conducted without the protease.

Owner:GENENCOR INT INC

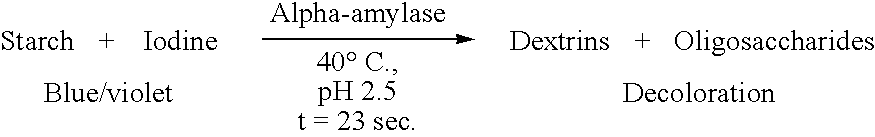

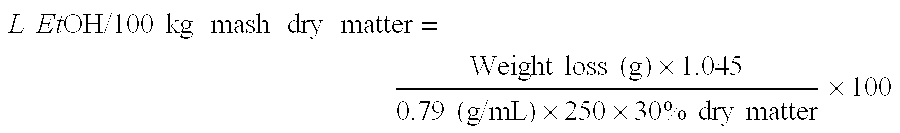

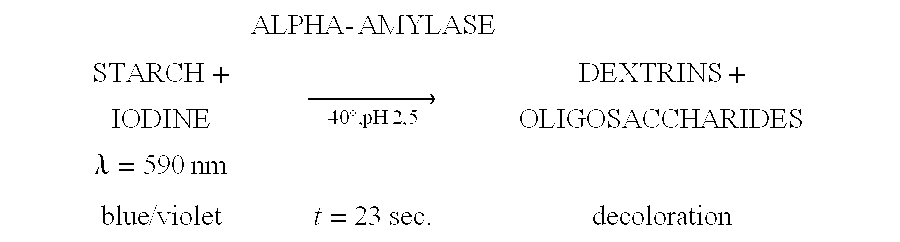

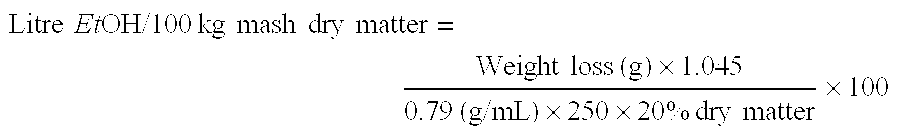

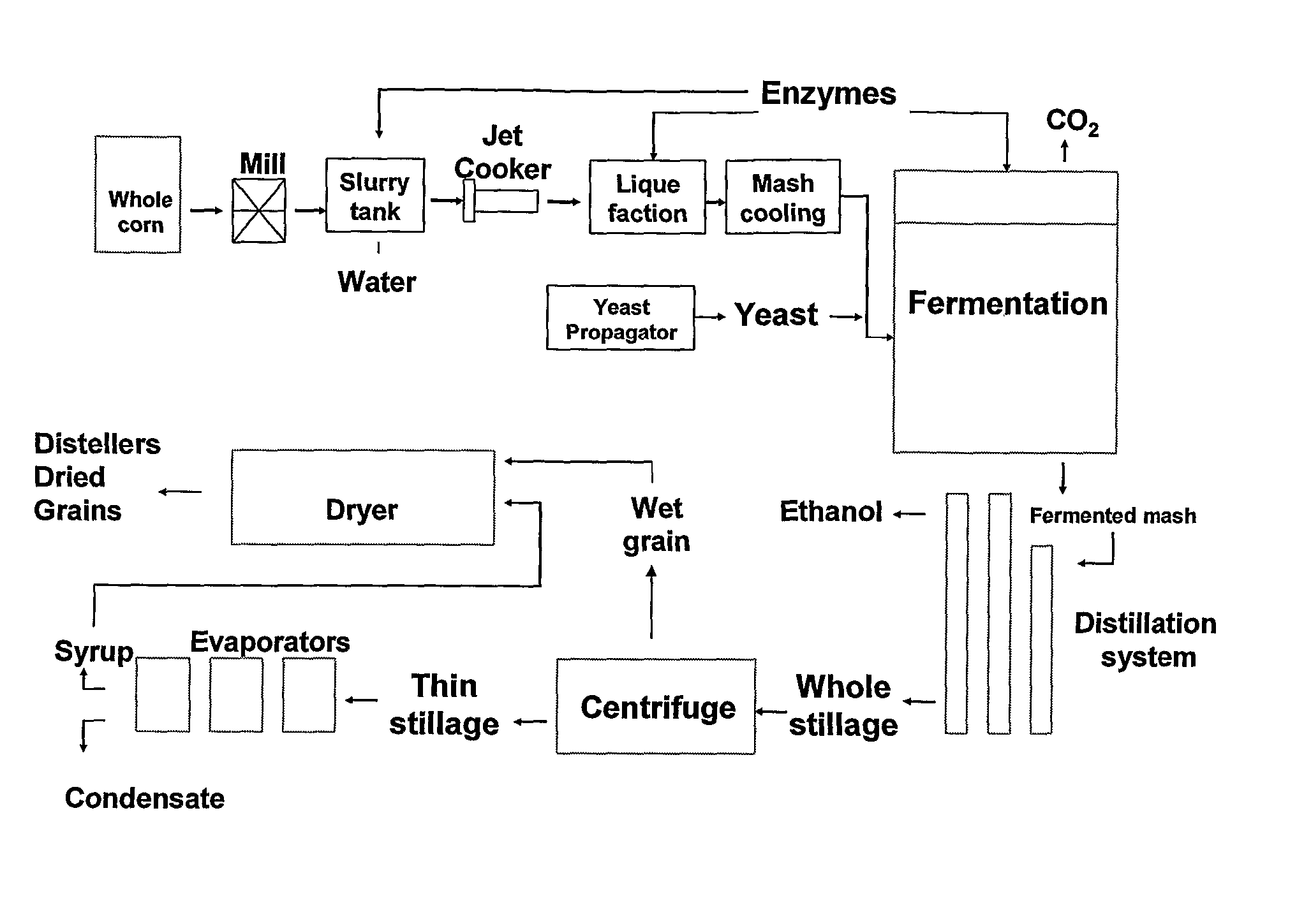

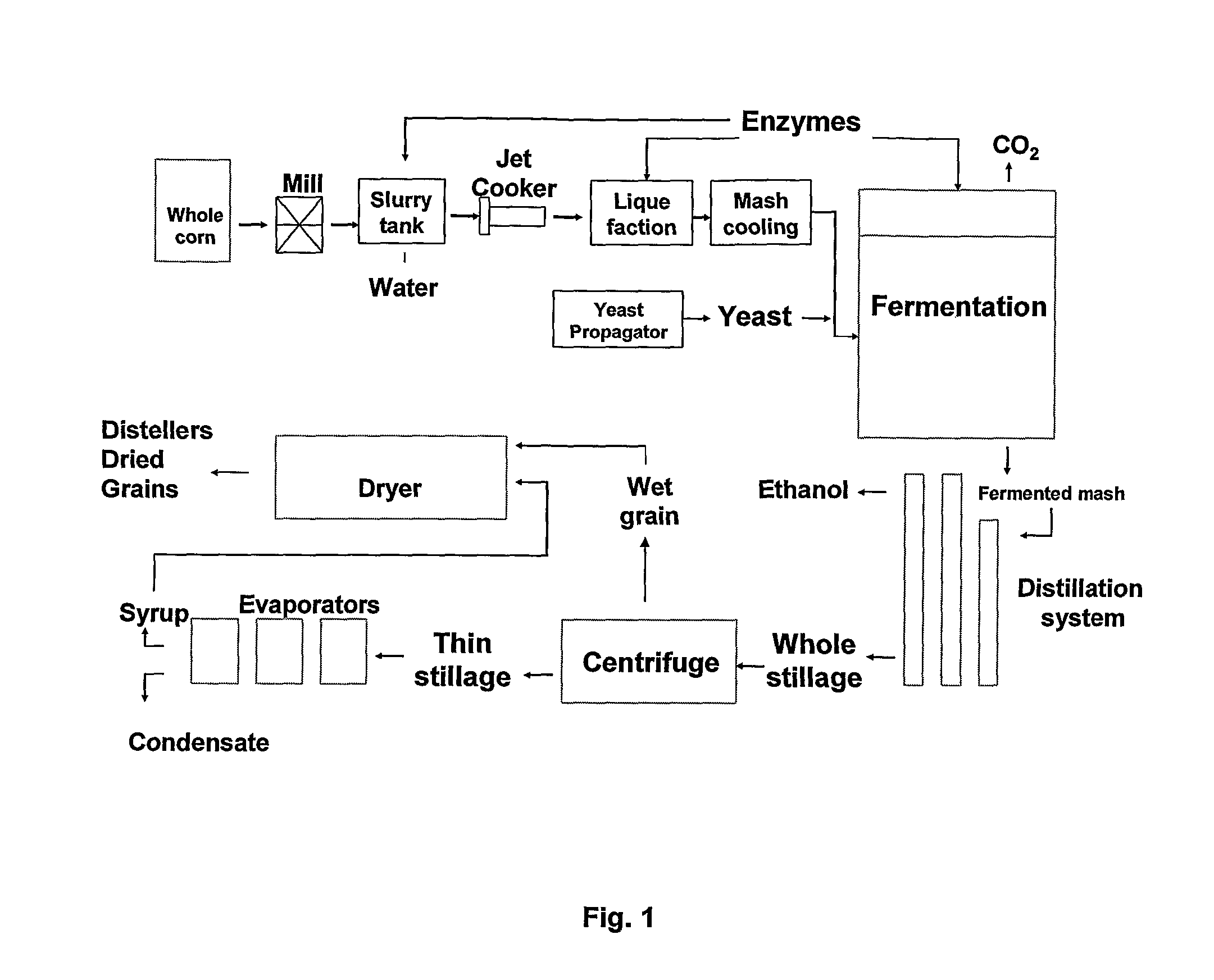

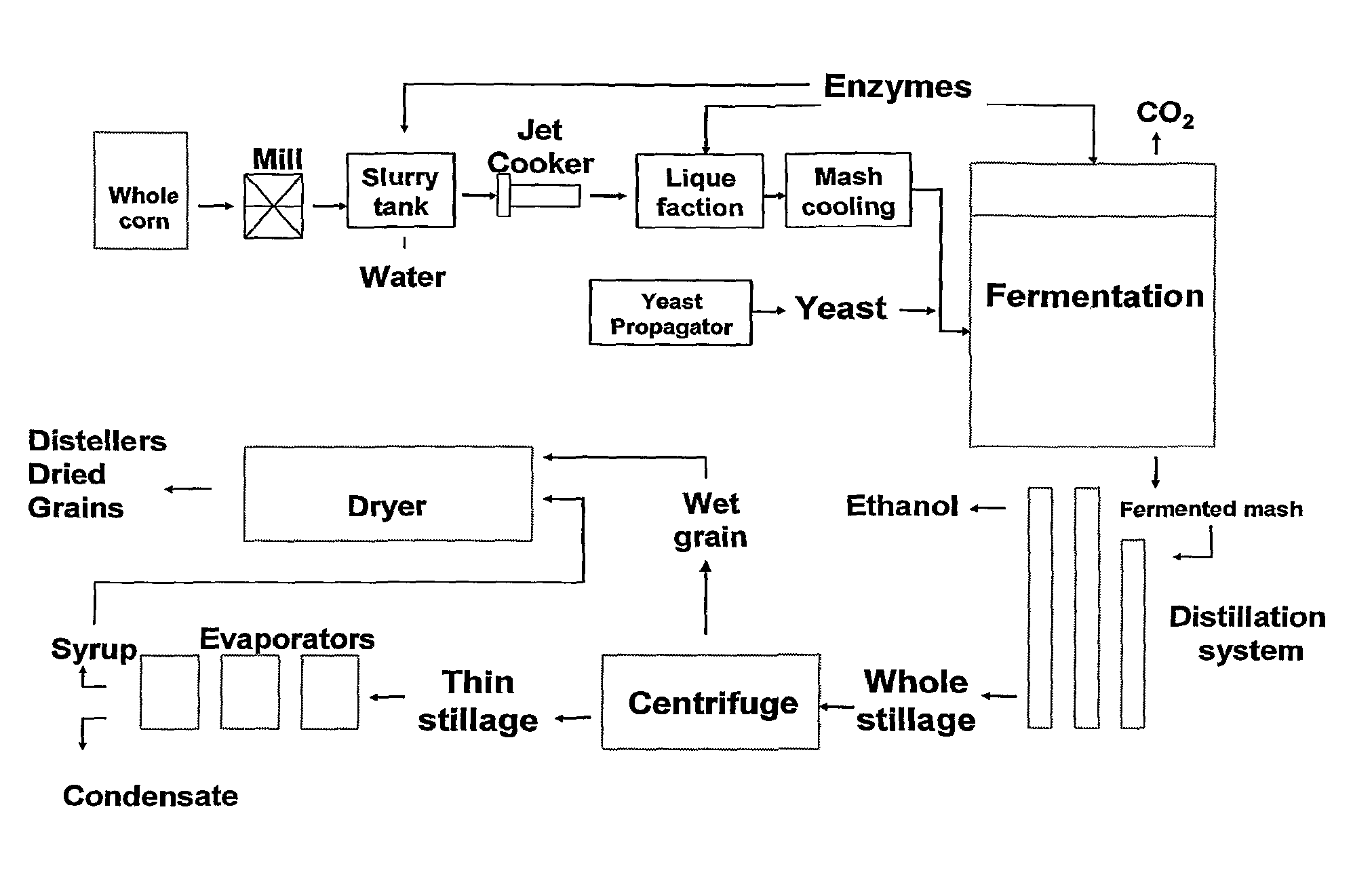

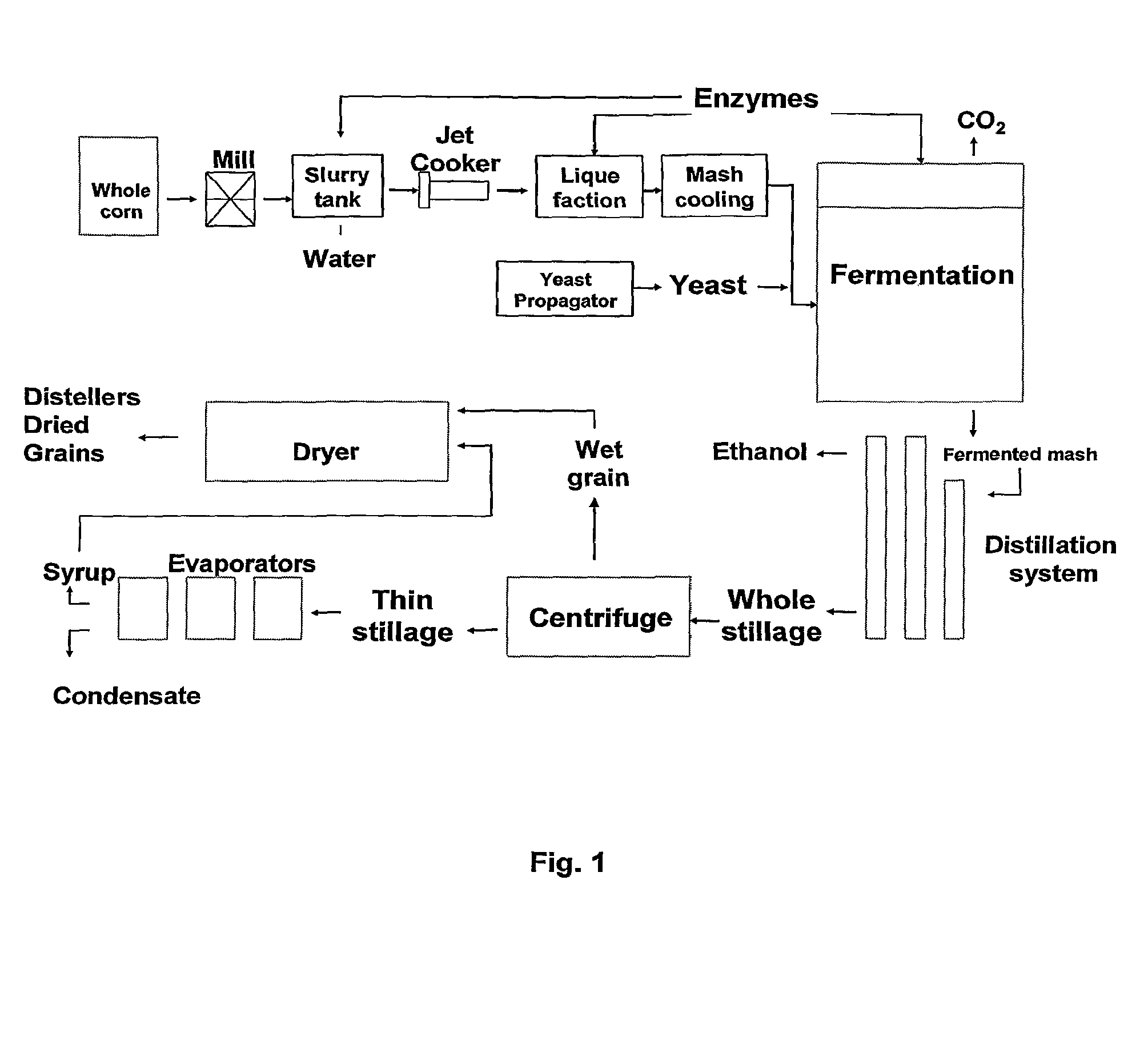

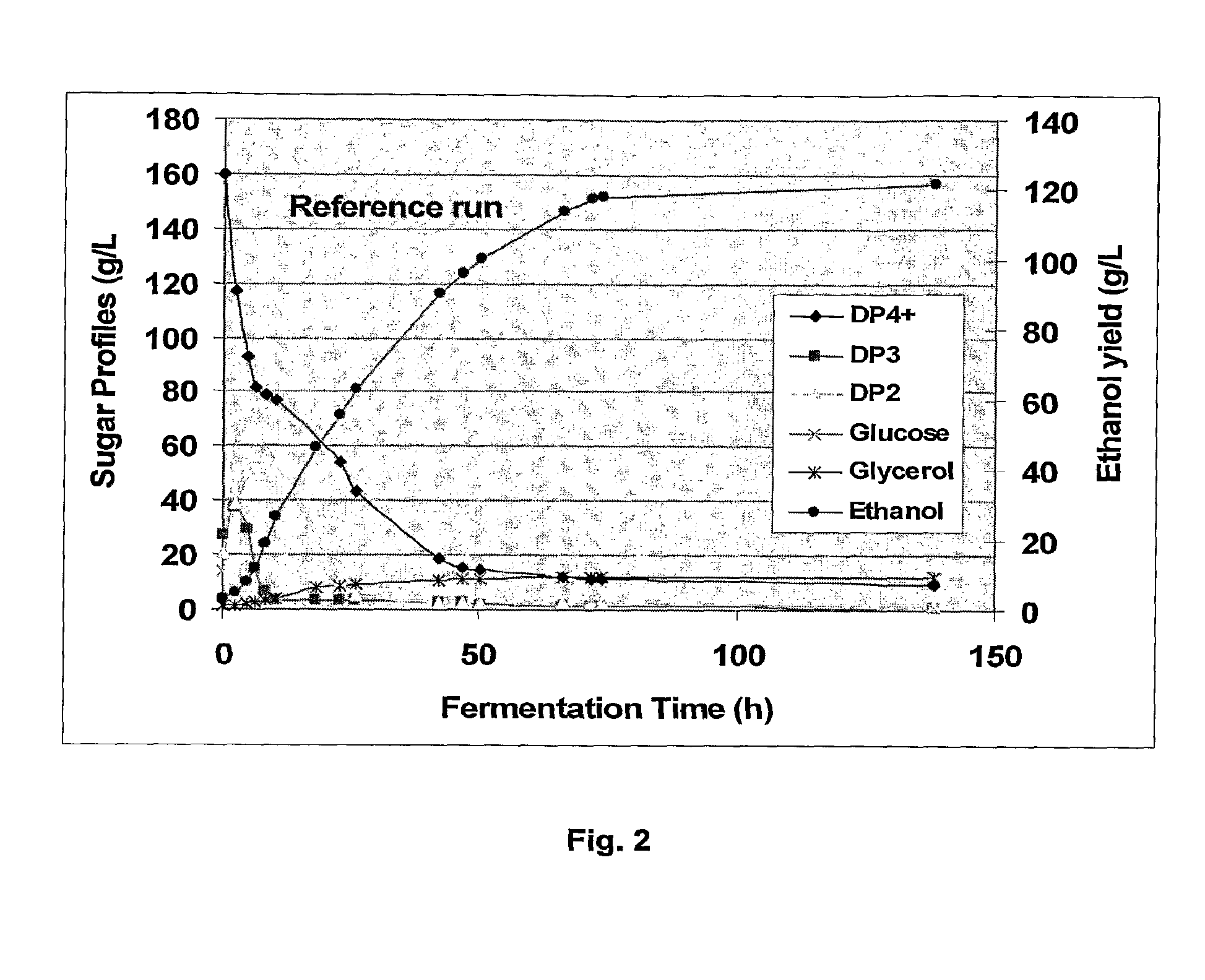

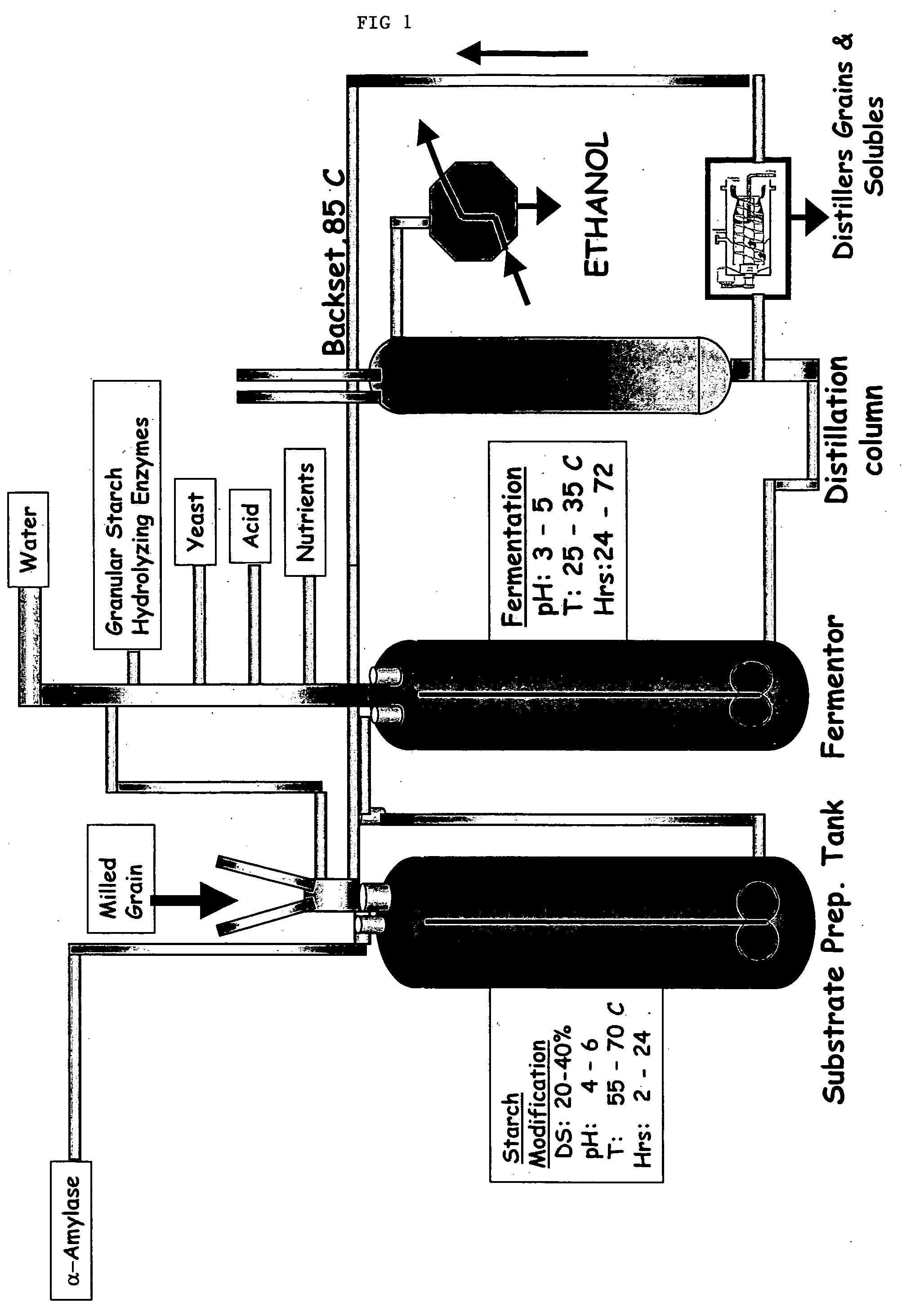

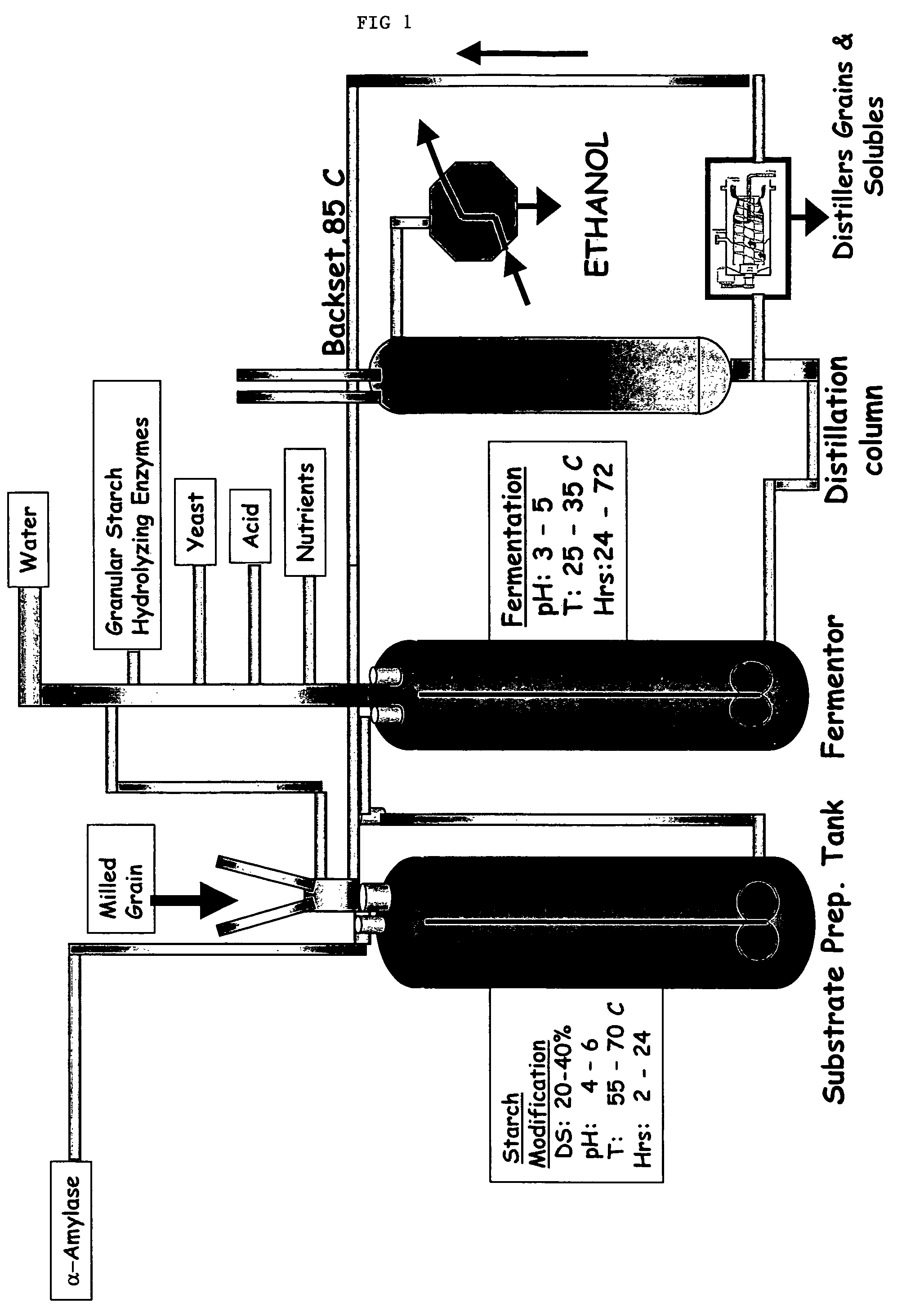

Process for conversion of granular starch to ethanol

InactiveUS20070281344A1Microbiological testing/measurementBiofuelsStarch gelatinizationAlpha-amylase

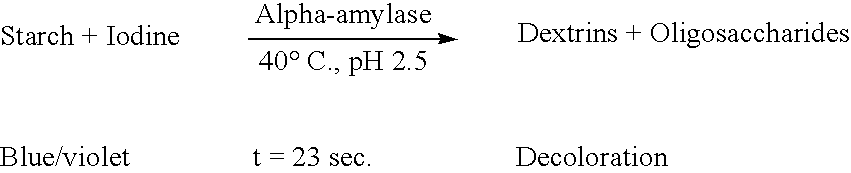

The present invention concerns a method of producing glucose from a granular starch substrate comprising, contacting a slurry comprising granular starch obtained from plant material with an alpha-amylase at a temperature below the starch gelatinization temperature of the granular starch to produce oligosaccharides and hydrolyzing the oligosaccharides to produce a mash comprising at least 20% glucose and further comprising fermenting the mash to obtain ethanol.

Owner:GENENCOR INT INC

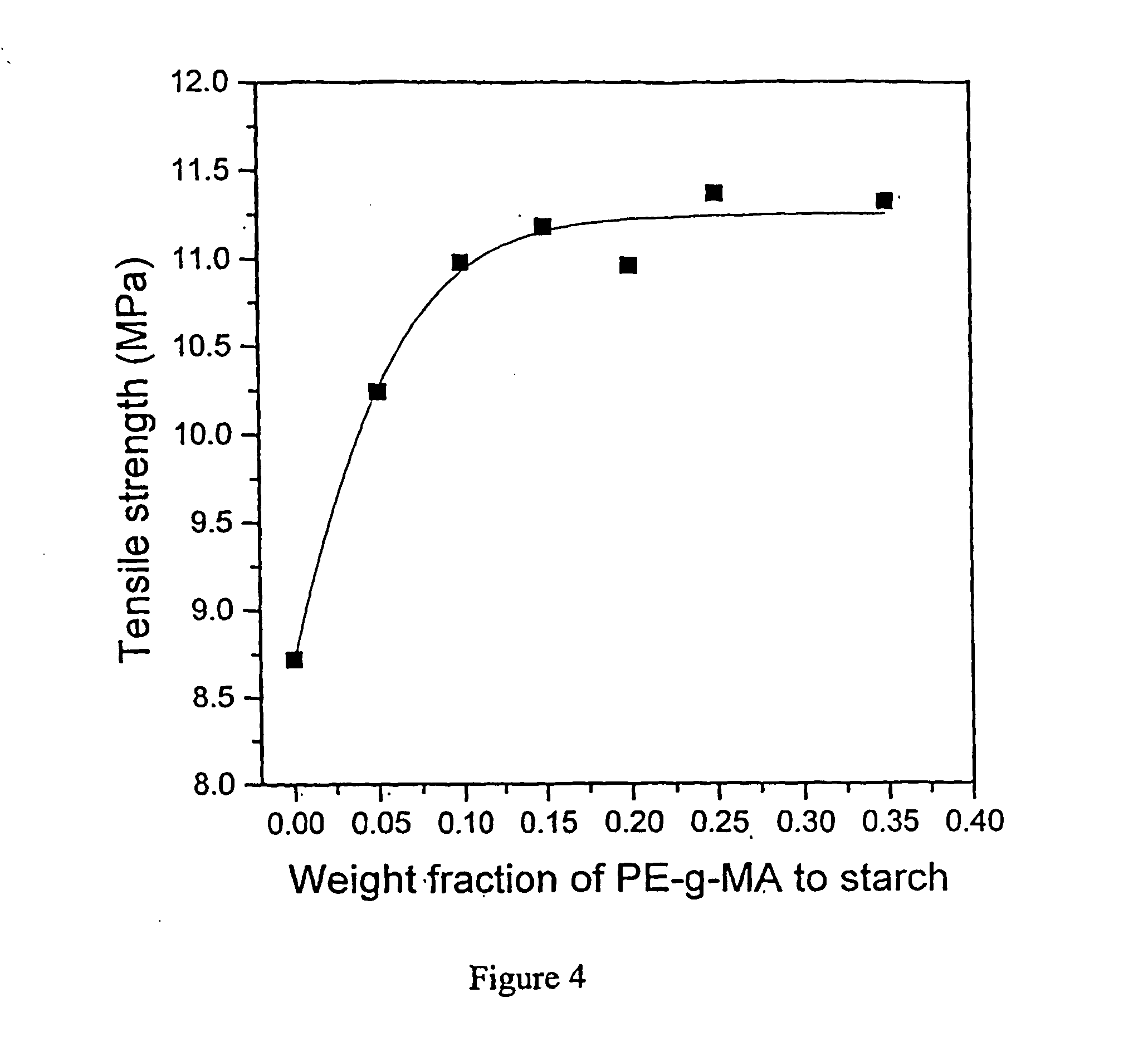

Starch-polyolefin composites with improved performance

InactiveUS20080249212A1Improve mechanical stiffnessHigh strengthFibre treatmentPaper coatingPolyolefinGranular starch

A composition is disclosed that comprises:(A) from about 65 wt % to about 10 wt % of a polyolefin resin:(B) from greater than 30 wt % up to about 90 wt % of a granular starch; and(C) from about 0.1 wt % to about 10 wt % of a functionalized polyolefm coupling agent, which agent improves the mechanical stiffness and strength of the polyolefin / granulated starch composites.

Owner:CHEMTURA CORP

Expression of granular starch hydrolyzing enzymes in Trichoderma and process for producing glucose from granular starch substrates

InactiveUS7303899B2Short timeHigh glucose syrupFungiSugar derivativesHeterologousGlucoamylase activity

The present invention relates to filamentous fungal host cells and particularly Trichoderma host cells useful for the production of heterologous granular starch hydrolyzing enzymes having glucoamylase activity (GSHE). Further the invention relates to a method for producing a glucose syrup comprising contacting a granular starch slurry obtained from a granular starch substrate simultaneously with an alpha amylase and a GSHE at a temperature equal to or below the gelatinization temperature of the granular starch to obtain a composition of a glucose syrup.

Owner:GENENCOR INT INC

Pregelatinized starches as carrier materials for liquid components

InactiveUS20100330369A1Cosmetic preparationsLiquid surface applicatorsGranular starchPersonal Care Product

The present invention provides a liquid-loaded starch material comprising a solid carrier material consisting of pregelatinized, non-granular starch material which consists of flake-shaped starch particles, wherein the size distribution of the starch particles is such that at least 50% by weight of the starch particles have a particle size of between 100 and 375 μm, and wherein the BET specific surface area is less than or equal to 0.5 m2 / g and one or more liquid components. There is also provided the use in food and animal feed products, pharmaceuticals, nutraceuticals, agrochemicals, and cosmetic or personal care products. In addition, the present invention provides a process for preparing said powdered liquid-loaded starch material.

Owner:CARGILL INC

Starch process

The present invention relates to a process for enzymatic hydrolysis of granular starch into a soluble starch hydrolysate at a temperature below the initial gelatinization temperature of said granular starch.

Owner:NOVOZYMES AS

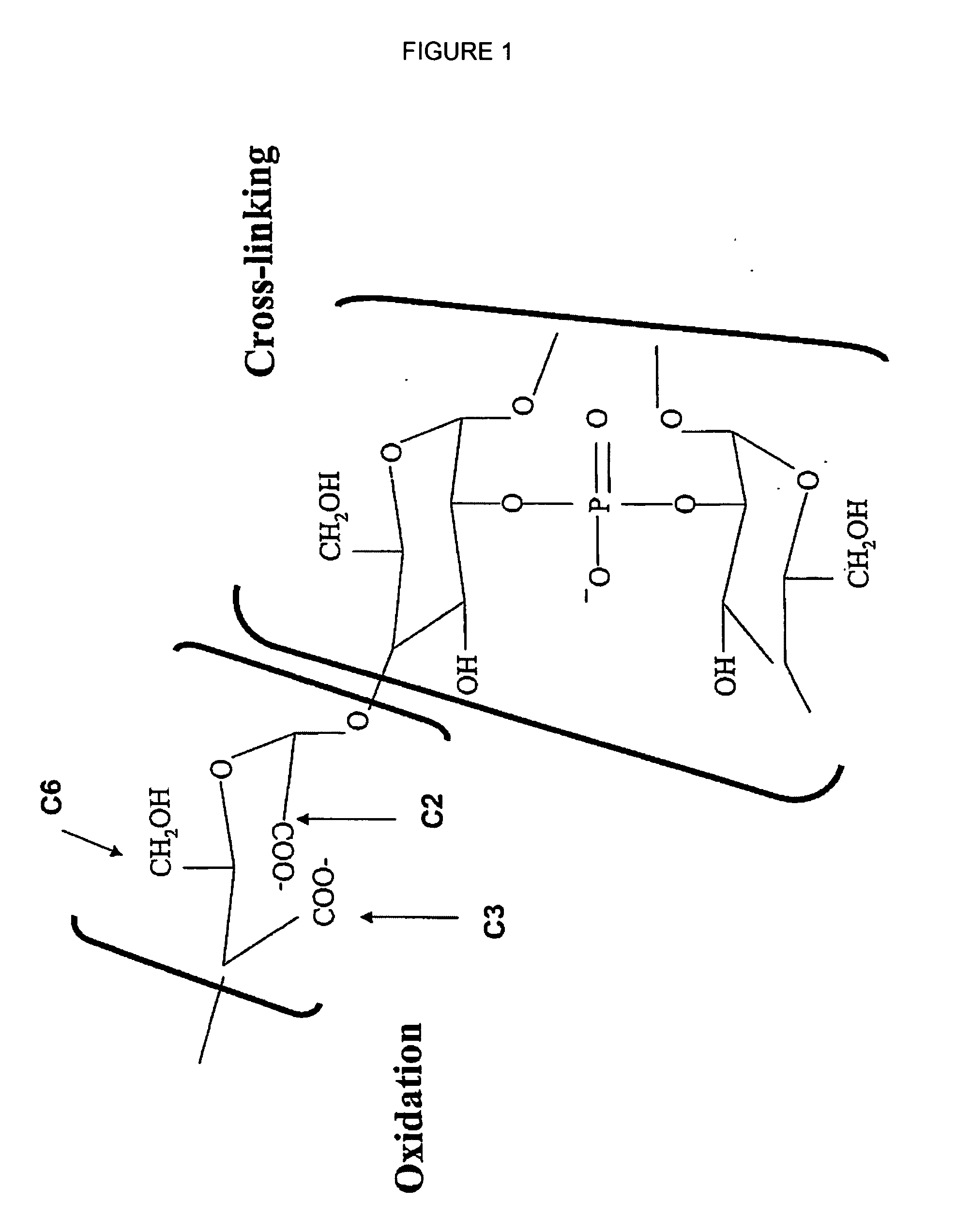

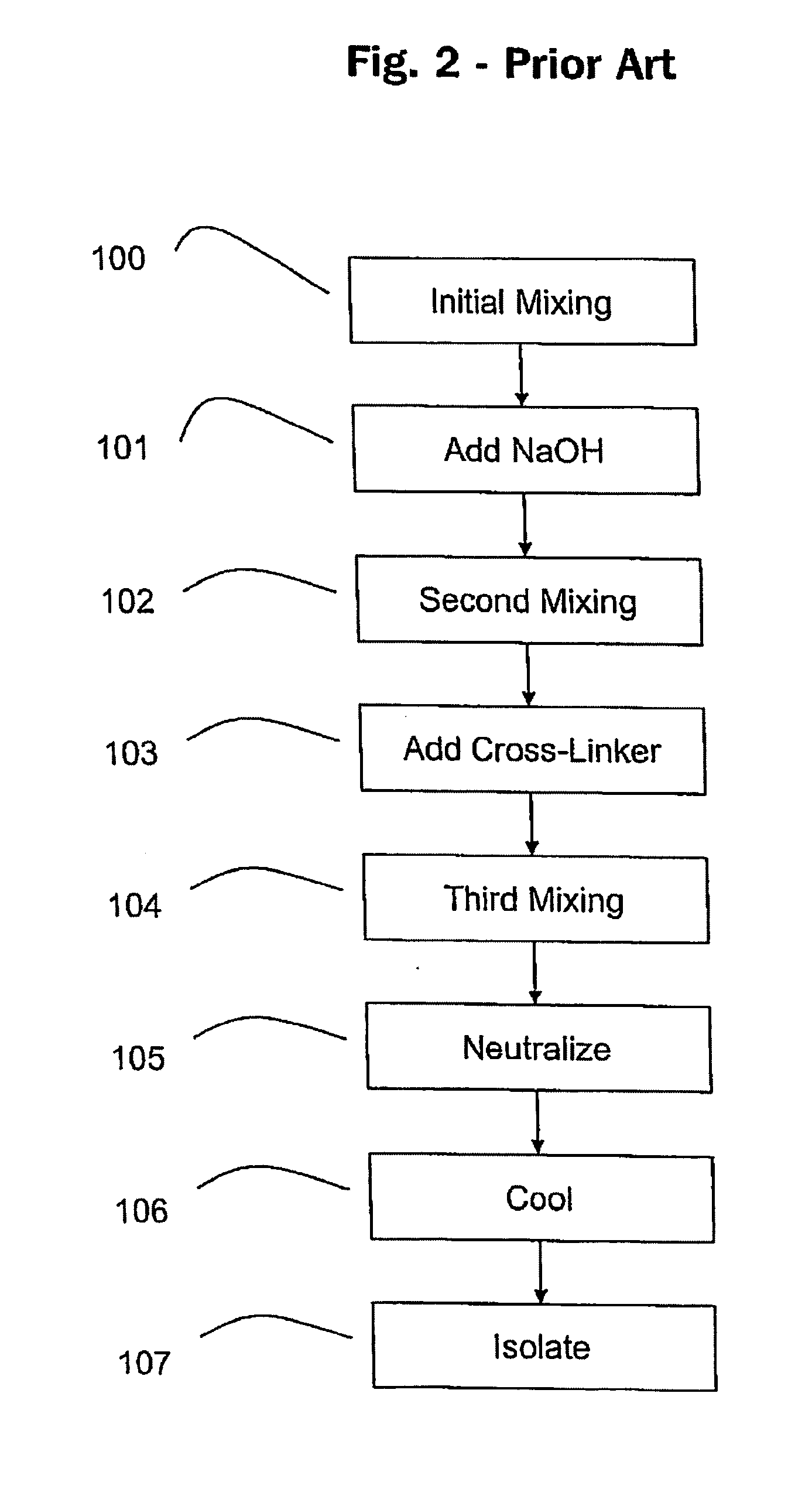

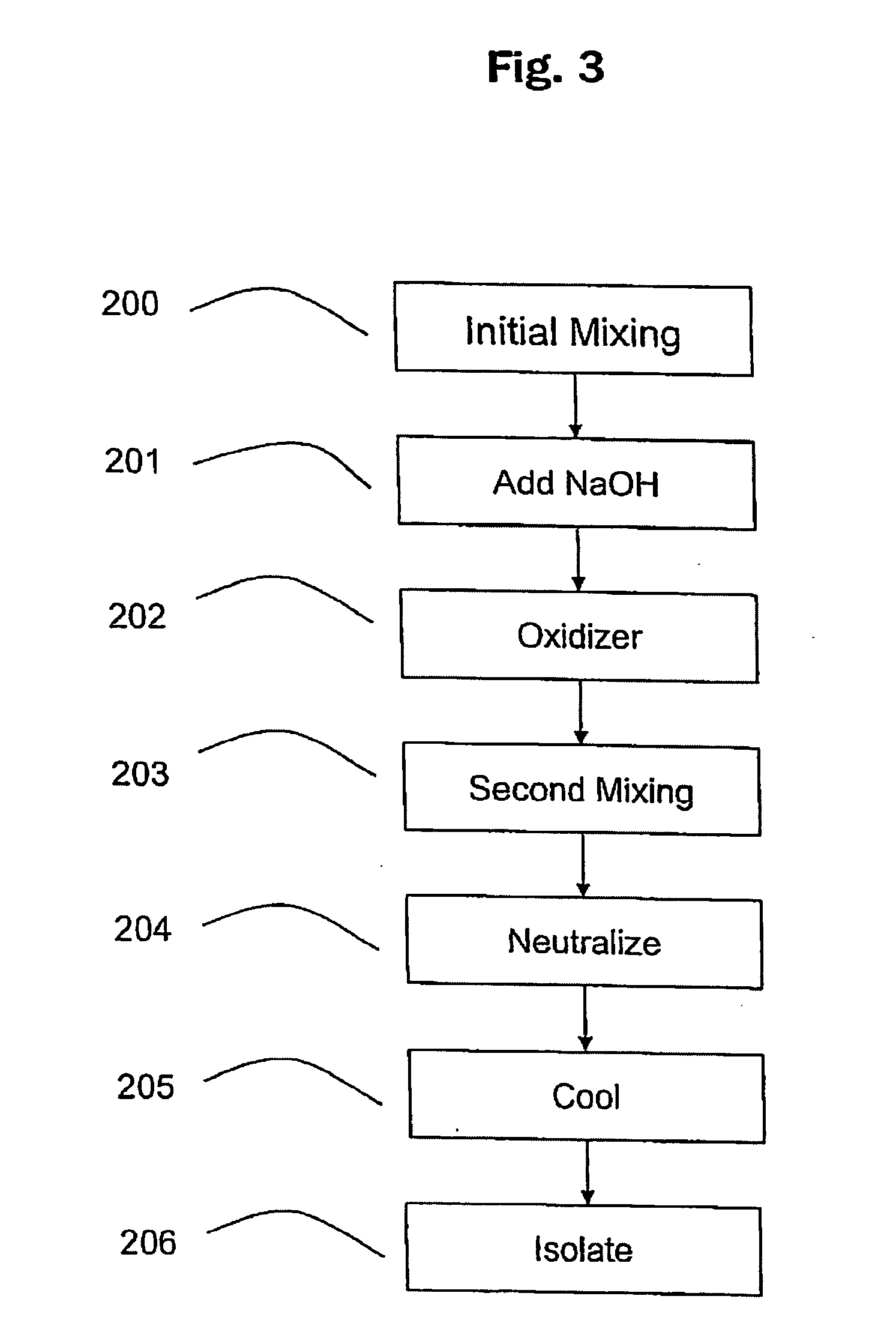

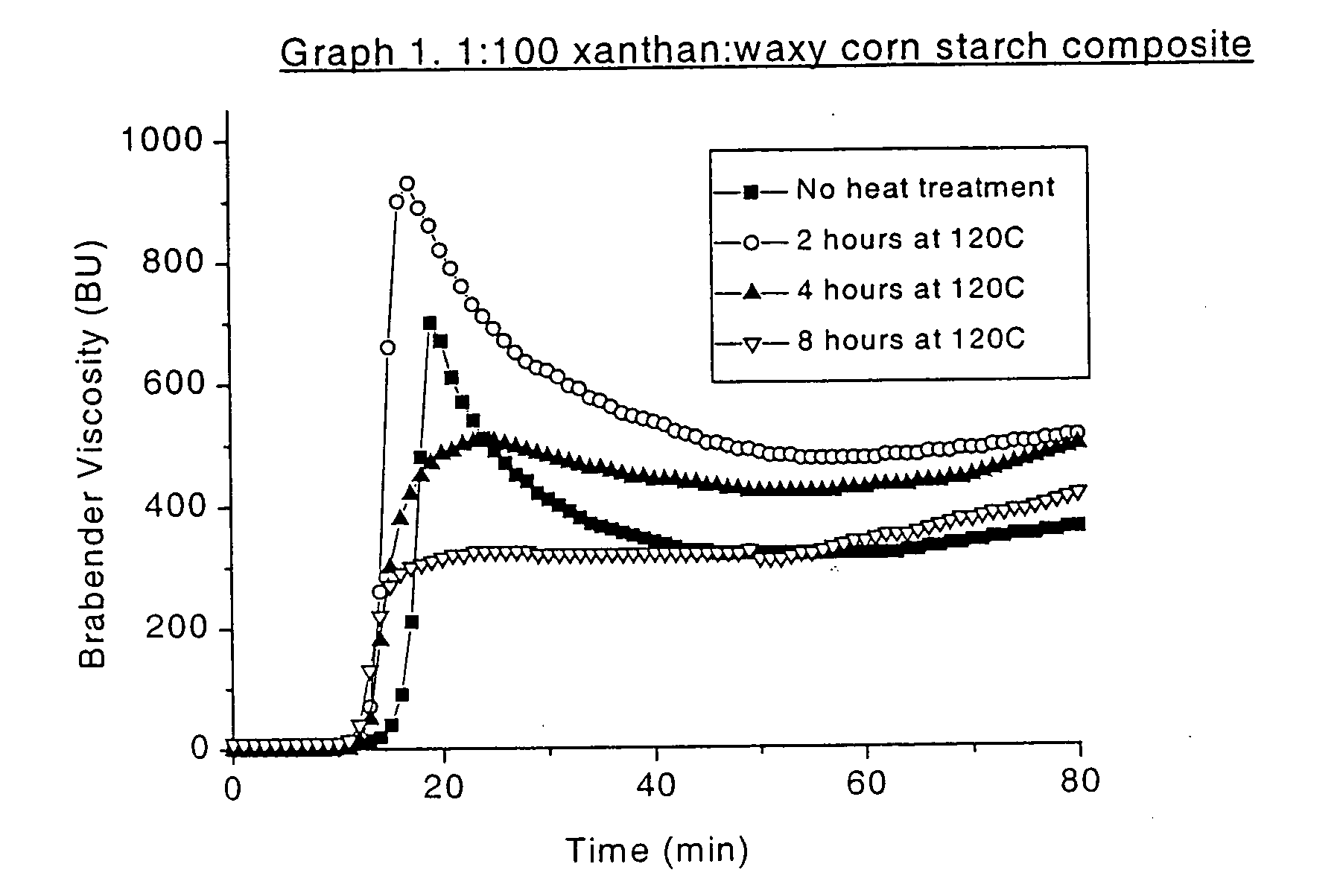

Oxidized reversibly swelling granular starch products

A rapidly-hydratable oxidized resistant starch having a cold-water hydration at least 20% greater than the resistant starch before oxidation, makeable by oxidation with an oxidizing agent selected from the group consisting of periodate, chromic acid, permanganate, nitrogen dioxide, and alkali metal hypochlorites. The starch may be made by a process for preparing a rapidly-hydratable resistant starch comprising the steps of swelling starch granules in the presence of alkali and / or heat, dispersing at least one cross-linking agent, mixing said dispersion, adding an oxidizing agent to said dispersion, and agitating said dispersion.

Owner:MGP INGREDIENTS

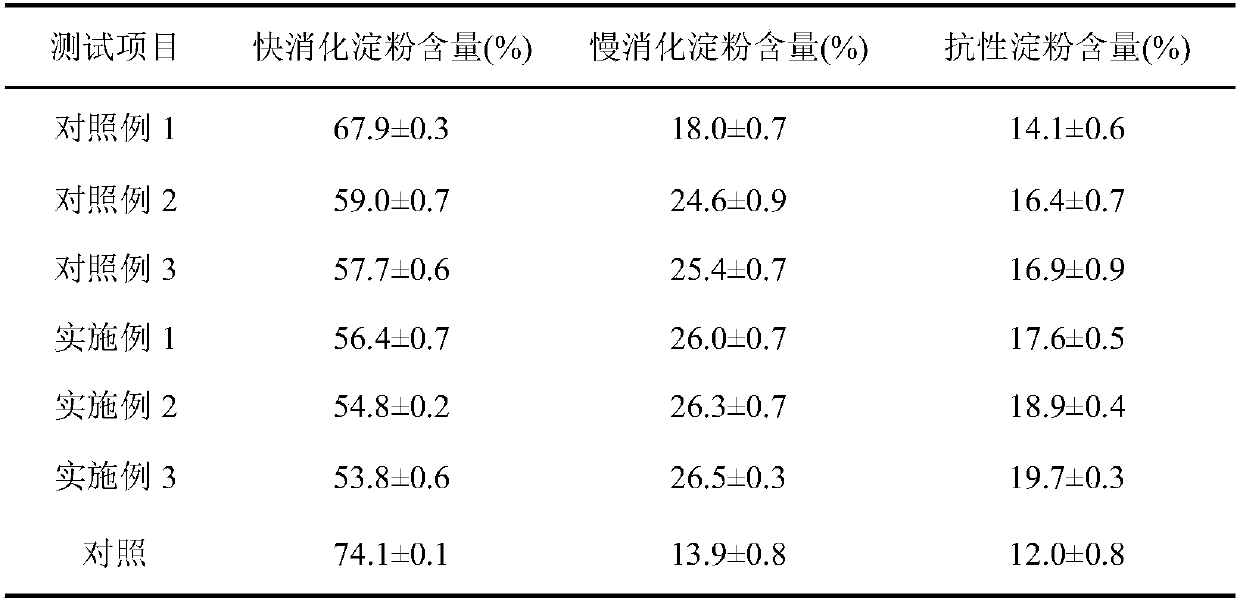

Modification method for improving slow digestion performance of starch

InactiveCN108047340AReduced rate of digestionGood modification effectFermentationDigestionGranular starch

The invention discloses a modification method for improving slow digestion performance of starch, and belongs to the field of biological modified starch. According to the modification method disclosedby the invention, spindly starch molecules can be converted into a pyknic branch structure of which the structure is more compact by utilizing starch branching enzyme, so that the digestion rate of the starch is slowed down; by controlling a modification substrate, two-stage treatment of carrying out gelatinized starch modification after granular starch modification is adopted, so that the purpose of enhancing a modification effect of the starch branching enzyme is achieved, the content of slow digestion raw starch in modified starch is further increased, the digestion rate of the starch is reduced, and a thought is provided for preparing the slow digestion starch for biological modification.

Owner:JIANGNAN UNIV

Potato raw slurry and starch flour used for staple foods and production process thereof

InactiveCN105901586AKeep the color and fragranceAvoid gelatinizationFood scienceBiotechnologyPotato starch

The invention discloses potato raw slurry and starch flour used for staple foods and a production process thereof. The production process of the potato raw slurry comprises the steps of selecting potatoes as a raw material, washing and peeling the potatoes, slicing and soaking the potatoes, cleaning and draining the potatoes, pulping the potatoes to obtain slurry, centrifuging the slurry, treating a filtrate, and drying the filtrate. The potato starch flour is then subjected to granulation to obtain granular whole potato starch flour. The production process of the potato starch flour and the granular starch flour can avoid gelatinization of the potato starch, can maintain the color, fragrance, taste and protein activity of the potatoes, and solves a problem of properties of potato knead in process of staple foods, and has important significance of promoting potato staple foods.

Owner:BEIJING UNION UNIVERSITY

Mashing process

The present invention provides processes for production of wort and beer from a granular starch adjunct grist mashed-in at a temperature below the gelatinization temperature of said starch.

Owner:NOVOZYMES AS

Process for conversion of granular starch to ethanol

A method is disclosed for producing glucose from a granular starch substrate including, contacting a slurry comprising granular starch obtained from plant material with an alpha-amylase at a temperature below the starch gelatinization temperature of the granular starch to produce oligosaccharides and hydrolyzing the oligosaccharides to produce a mash comprising at least 20% glucose and further comprising fermenting the mash to obtain ethanol.

Owner:GENENCOR INT INC

Starch/carboxylated polymer composites

InactiveUS20060276569A1Short textureHigh viscosityPaper coatingFood ingredientsPolymer scienceGranular starch

This invention relates to an inhibited non-solubilized granular starch modified by less than 5% of a carboxylated polymer. In addition, a process is provided wherein a non-solubilized, substantially granular starch is mixed with a carboxylated polymer, dried to form a starch / carboxylated polymer blend and then physically treated to form a starch / carboxylated polymer composite. Further, this invention relates to the improved industrial and food products prepared from these starch / carboxylated polymer composites.

Owner:BRUNOB II BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com