Patents

Literature

131results about How to "Keep the color and fragrance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Camellia extraction liquid, and preparation method and application thereof

ActiveCN105997754AIncrease contentStrong antioxidantCosmetic preparationsToilet preparationsSolventBud

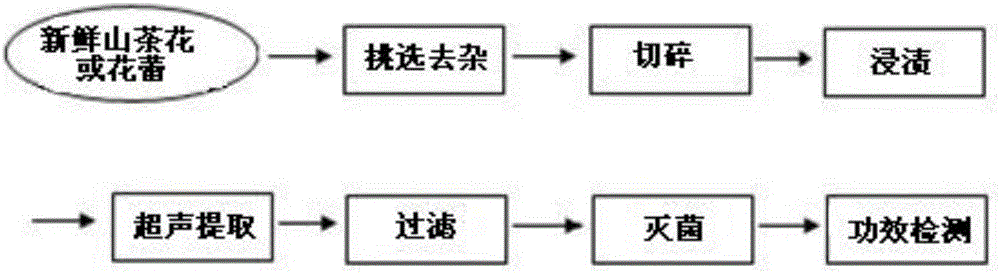

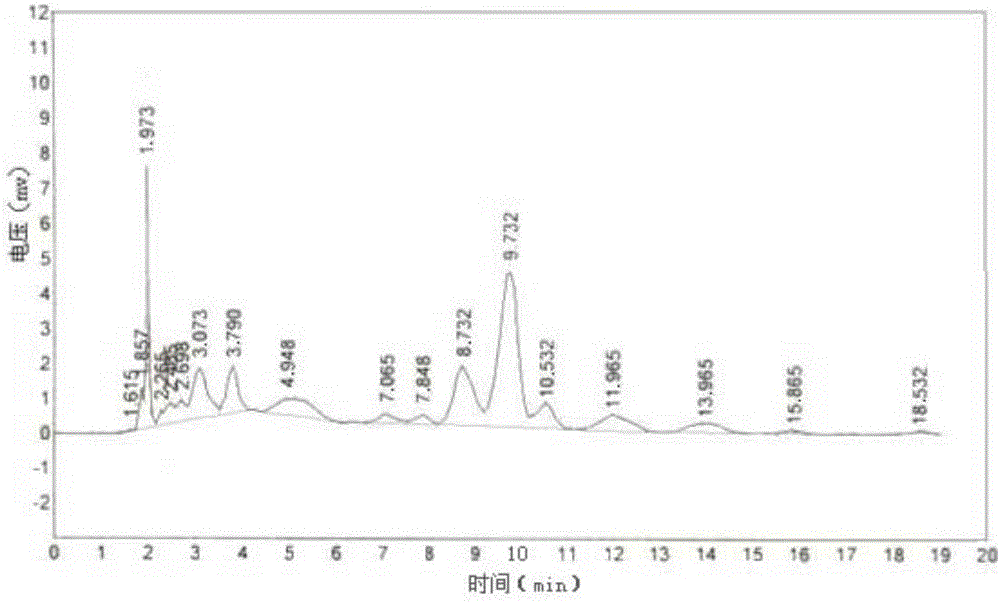

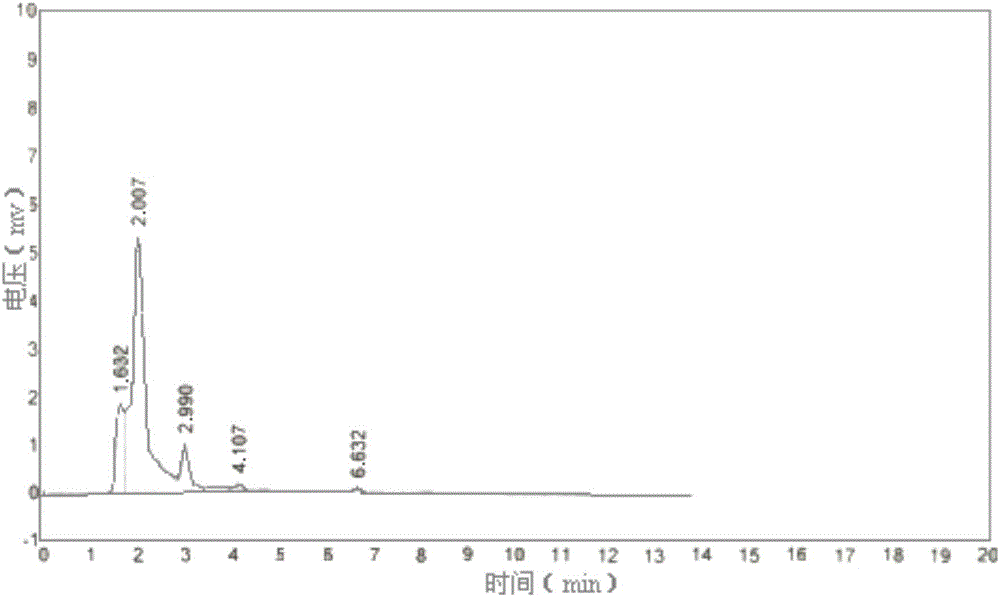

The invention provides a preparation method of camellia extraction liquid. The method comprises the following steps of 1) removing impurities of fresh camellia and / or fresh camellia buds; cutting up the fresh camellia and / or fresh camellia buds into small sections for use as raw materials; 2) taking a certain number of raw materials; putting the raw materials into an ultrasonic kettle; adding a solvent with the mass ratio being 1:(3-30); uniformly stirring the mixture; adding a certain amount of inorganic acid and / or organic acid; regulating the pH value to 1.3 to 3.0; soaking the materials for 10 to 30 min; 3) then performing ultrasonic treatment for 30 to 60min; controlling the ultrasonic frequency to be 20 to 25KHz, the ultrasonic power to be 1.0 to 2.0KW and the ultrasonic temperature to be 15 to 50 DEG C; then performing filtration, sterilization and detection to obtain camellia extraction liquid. The camellia extraction liquid maintains the color, luster, flavor and effective active ingredients of the camellia to the maximum degree; the anti-oxidation functional ingredients are overall; the contents are high; the safety and the stability are high; cosmetics prepared by using camellia extraction liquid as active ingredients have the excellent whitening, spot-reducing and anti-aging efficacies.

Owner:SHANGHAI DELTA IND

Lycium ruthenicum beverage and preparation method thereof

InactiveCN103960727AEasy to keepReduce the effects of oxidationFood ingredient functionsFood preparationFlavorLiver and kidney

The invention discloses a lycium ruthenicum beverage and a preparation method thereof and provides a beverage prepared by taking dried lycium ruthenicum fruit powder as a main raw material and a preparation method thereof. The lycium ruthenicum beverage is composed of following raw materials by weight percent: 0.1%-7% of the dried lycium ruthenicum fruit powder, 0.05%-3% of guar gum, 0.2%-7% of CMC-Na (Carboxyl Methyl Cellulose-Na), 0.05%-3% of xanthan gum, 3%-15% of erythritol, 0.006%-0.6% of stevioside, 0.01%-0.8% of citric acid, 0.01%-0.4% of sodium citrate, 0.01%-1.5% of tea polyphenol and the balance being water. The beverage is prepared by taking the dried lycium ruthenicum fruit powder as the main raw material; reasonable compatibility and synergistic effects of all the components are utilized and the color of a product is amaranth; the lycium ruthenicum beverage has a unique flavor, no astringent and mellow mouth feel, and has the effects of nourishing liver and kidney, replenishing vital essence to improve eyesight and nourishing blood, enhancing the immunity of people, beautifying, resisting oxidization, decaying aging, resisting fatigues, lowering blood pressure and lowering blood sugar.

Owner:TIANJIN UNIV OF COMMERCE

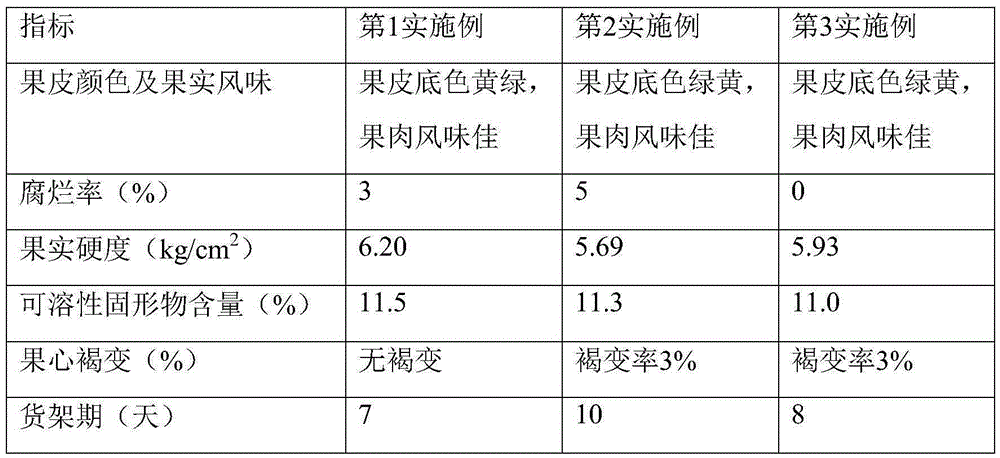

Controlled atmosphere fresh-keeping method for Yaoshan snow pears

InactiveCN102626131ARealize mass production and storageEasy to monitorFruits/vegetable preservation by freezing/coolingCold airPEAR

The invention discloses a controlled atmosphere fresh-keeping method for Yaoshan snow pears. The controlled atmosphere fresh-keeping method comprises the steps of: filling Yaoshan snow pears which are harvested duly and have no damage into plastic packaging boxes; performing fumigation treatment by using 1-MCP in an enclosed environment; ventilating and performing sterilization treatment by using ozone; filling the sterilized Yaoshan snow pears into plastic boxes or paper boxes in which PE (Polyethylene) micro-pore freshness protection packages are lined; ventilating cold air for the packaged Yaoshan snow pears for pre-cooling treatment; after the pre-cooling treatment, tightly tying the openings of the freshness protection packages; and finally carrying out controlled atmosphere storage, wherein gas parameters in a controlled atmosphere store are adjusted and controlled as follows: 2-3% by volume of O2, 3-5% by volume of CO2, and 90-95% of relative humidity. In comparison with unprocessed Yaoshan snow pears, the storage time of the Yaoshan snow pears adopting the controlled atmosphere fresh-keeping method for the Yaoshan snow pears is prolonged for three months at the same low-temperature storage condition; and in comparison with normal micro-pore controlled atmosphere, the quality of the snow pears after the same storage time is obviously better than the snow pears which are stored in the micro-pore controlled atmosphere.

Owner:江华六月香果业股份有限公司 +1

Preservation method for salt baked meat products

InactiveCN103651735AAchieve freshnessKeep the color and fragranceMeat/fish preservation using chemicalsMeat/fish preservation by irradiation/electric treatmentNutrientNutrition

The invention discloses a preservation method for salt baked meat products. The method comprises steps of smearing a preservative, dipping with the preservative, sterilizing by microwave, and sterilizing by pulsed light. According to the method, preservation by using a Chinese herbal medicine preservative, sterilization by using the microwave and sterilization by using the pulsed light, which are three preservation and sterilization technologies, are combined. The preservation method can effectively preserve the quality and prolong the shelf life of the salt baked meat products with little influence on nutrients and taste of the products. The adopted preservative is natural and nontoxic. The salt baked meat products have a unique flavor and nutritive and healthcare value. The pulsed light used for sterilization is free of toxic and side effects. The method effectively avoids disadvantages, which are caused by traditional long storage time of the salt baked meat products, of hardened meat, bad taste, high acid value caused by oxidation, and flavor change.

Owner:DOSHAN NEW STRATEGY INTPROP CULTURECO

Processing method of instant crisp fish

The invention provides a processing method of instant crisp fish. The method is performed according to the following ten steps: step one, fish selection, dissection and cleaning; step two, strip cutting; step three, salting; step four, drying; step five, aging; step six, frying; step seven, marinating; step eight, vacuum packaging; step nine, sterilizing; and step ten, cooling. Instant crisp fish processed through the method has no earthy taste, original flavors are maintained, the oil infiltration capacity during frying is small, the fish is free of greasy feelings when eaten, globular proteins in fish meet after aging are reorganized to form thread-shaped lean meat structures, the chewing feeling is good, the frying time is short, the fish is crisp and tender, tastes are good, anise and pepper are put in a leaching liquid mode to be seeped into fibers in fish meet, flavors are rich, and the appearance has no particles. According to the processing method, original flavors and nutrition values of fish meet are maintained, and the instant crisp fish is convenient to carry and eat.

Owner:SHAOXING BAIMA LAKE FOOD CO LTD +1

Skimmia japonica scented tea and making technology

ActiveCN103027142AMaximize nutritional valueGood health effectTea substituesBiotechnologyBitter taste

The invention belongs to the health care scented tea technical field, and especially relates to a skimmia japonica scented tea and making technology and a making technology, According to the making technology, 100% of pure natural Skimmia japonica is taken as a raw material, processes of acquiring fresh flower, removing the impurities, deactivating enzymes, frying to shape, drying, distilling flavor, and airing and packaging the finished product to prepare the skimmia japonica scented tea. The prepared skimmia japonica scented tea can fully perform the original natural performance of the skimmia japonica, no other compatibility component is added, the bitter taste of the skimmia japonica scented tea can be alleviated from the essence, the infused skimmia japonica scented tea has yellow tea color, aromatic flavor, good mouth feel and sweet taste and has strong health care efficacy, and the skimmia japonica scented tea is the green health care scented tea suitable for long-term drinking. The making technology of the skimmia japonica scented tea has the advantages of reasonable design, short processing time and low equipment cost.

Owner:东莞市莞香园艺科技有限公司

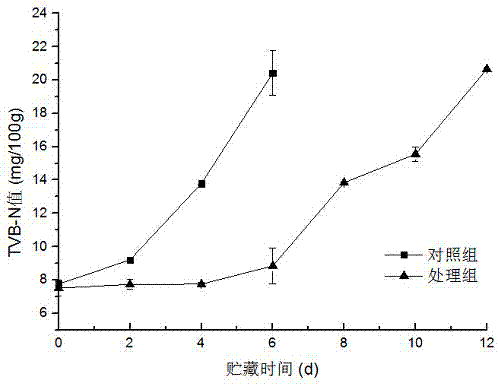

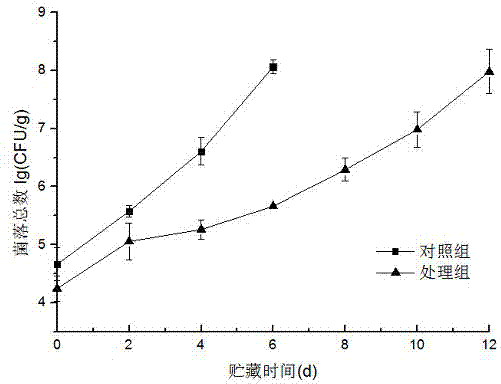

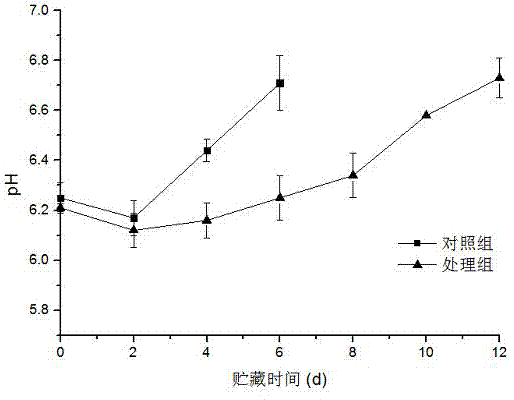

Freshness keeping method for cold fresh chicken

InactiveCN104770461AReduce spoilageFresh-keeping method is safe and reliableMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsIce waterRoom temperature

The present invention discloses a freshness keeping method for cold fresh chicken. The freshness keeping method is composed of the following steps: firstly, preparing a compound biological freshness keeping agent which contains origanum vulgare essential oil, tea polyphenols and D-sodium isoascorbate; secondly, using a heating magnetic stirrer to conduct stirring for the compound biological freshness keeping fluid; thirdly, selecting healthy chickens and conducting slaughtering, bloodletting, feather, head, claw and viscus removing, and ice water rinsing on the selected chickens; fourthly, cooling the chicken carcasses until the central temperature of the chicken carcasses drops to a temperature of 0-4 DEG C, disinfecting the cooled chicken carcasses, and washing and cleaning the disinfected chicken carcasses; fifthly, disinfecting the knife tools and cutting the fresh chicken carcasses into chicken breasts, chicken legs and chicken wings; sixthly, placing and soaking the chicken meat into the compound freshness keeping agent by class for one minute, taking out the soaked chicken meat, and draining the soaked chicken meat at room temperature; and seventhly, classifying and packaging the treated chicken meat with sterile PE bags, and storing the chicken meat in a refrigerated cabinet at 4 DEG C. Compared with the conventional cold storage, the freshness keeping method can significantly extend the shelf life of cold fresh chicken by 5-6 days, is simple and convenient to implement, is safe and reliable, and low in cost, is a good substitute for the current processing technology of cold fresh chicken, and has high market and application potential.

Owner:SHANGHAI OCEAN UNIV

Processing method of instant Chinese-chestnut

InactiveCN103653079AAchieve freshnessKeep the color and fragranceFood preservationFood preparationBiotechnologyPreservative

The invention discloses a processing method of instant Chinese-chestnut. The method comprises steps of pretreating raw materials, dipping with plant preserving liquid, rinsing, freezing rapidly, cooking, packaging and sterilizing by intense pulsed light. According to the processing method, the extract of natural plant raw materials is used to dip the Chinese chestnut kernel. By the natural sterilizing, disinfecting microbe-inhibiting effective components of the traditional Chinese medicines, preservation of the Chinese chestnut kernel is achieved, and the fragrance and tissue state of the Chinese chestnut kernel are preserved. The instant Chinese chestnut has a characteristic of long preservation time. The natural light fragrance of the Chinese chestnut is enhanced and the instant Chinese chestnut has a unique flavor. Chinese wolfberry, propolis, and other natural plant components increase the nutrition healthcare value. The processing process of the product is free of other antiseptics or chemical additives. The instant Chinese chestnut is a green and convenient leisure food.

Owner:DOSHAN NEW STRATEGY INTPROP CULTURECO

Production method of sea-buckthorn pure fruit juice primary pulp

The invention relates to a production method of fruit juice primary pulp, and specifically provides a production method of sea-buckthorn pure fruit juice primary pulp which is high in juice yield, high in soluble solid content and high in nutrition content and has no tannin bitter. The production method comprises the following processing steps of: removing fruits: shearing and selecting sea-buckthorn with branches by manpower, then quickly freezing, and after the temperature of the center of the fruit reaches (-18) DEG C, removing fruits by a fruit remover; pre-treating: removing leaves by a winnower, removing crushed branches by using a rotary fish-scale-sieve sieving machine; cleaning by using a fruit cleaner and removing sand by using sand removing equipment; immersing for 1-3min in 0 DEG C dewatering ripening solution and then draining, and unfreezing in microwave unfreezing equipment; and finally spraying by clear water at 0-5 DEG C so as to finish secondary cleaning and draining; and juice processing: breaking and pulping the sea-buckthorn, separating juice by using a juice separator, filtering impurities by using a juice primary filter, carrying out solid-liquid separation by using a horizontal spiral separator and a disc-type separator, degassing, sterilizing and sterilely filling, so as to obtain the sea-buckthorn pure fruit juice primary pulp.

Owner:华池县甘农生物科技有限公司

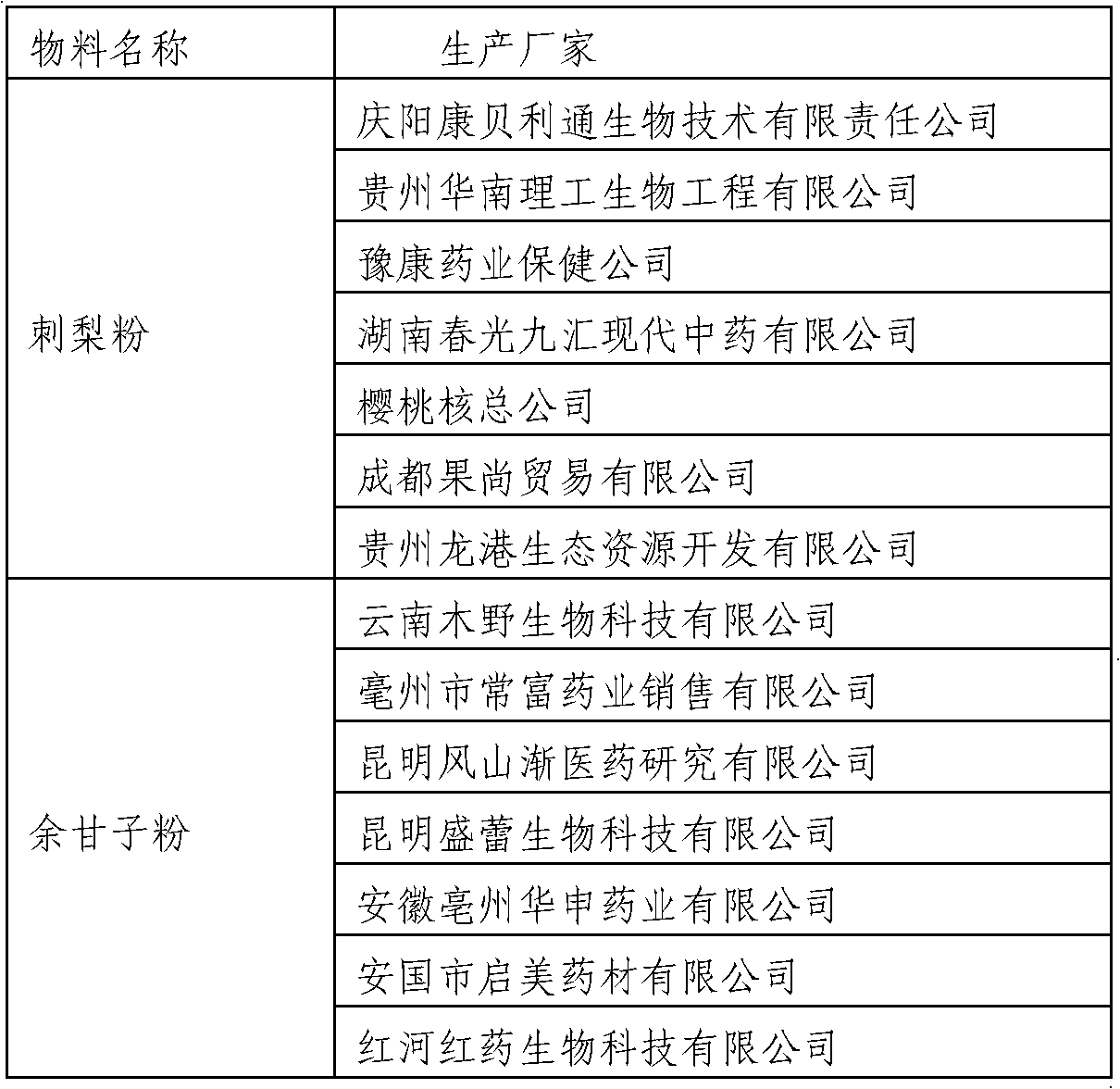

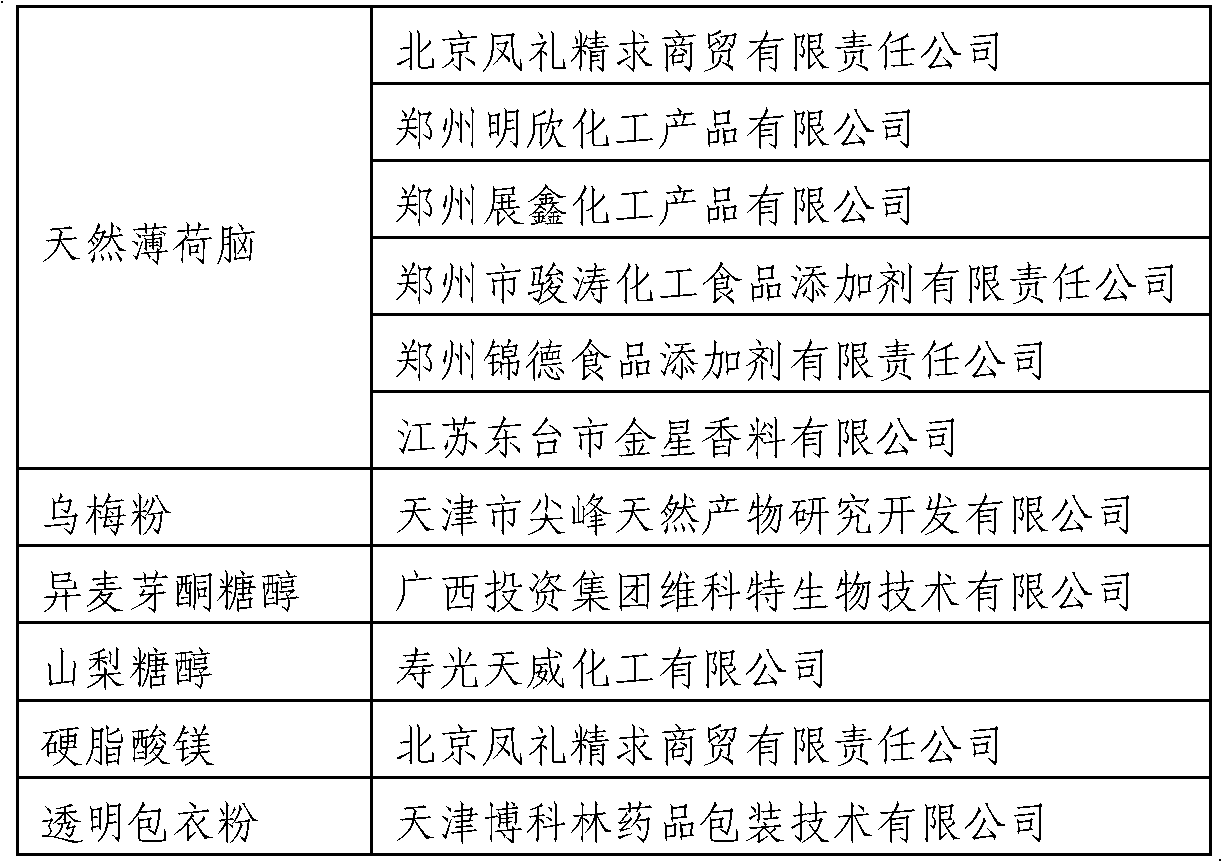

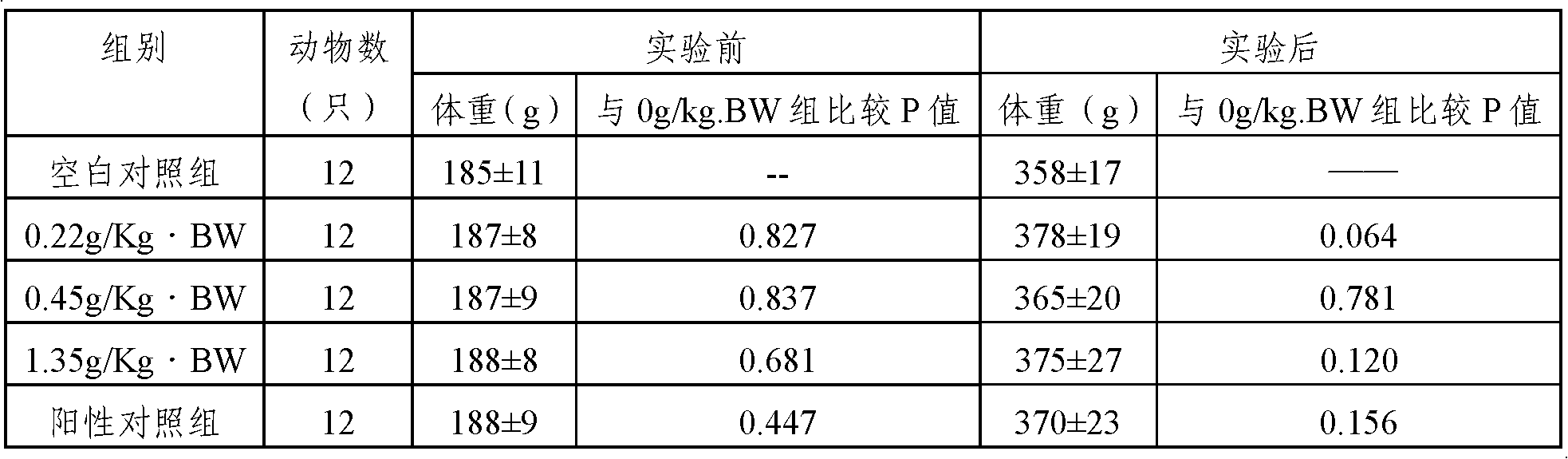

Healthcare product combination for clearing and nourishing throat and preparation method thereof

The invention relates to a healthcare product combination for clearing and nourishing the throat and a preparation method thereof. The combination comprises the following raw and auxiliary materials in parts by weight: 25-75 parts of rosa roxbughii tratt powder, 100-200 parts of phyllanthus emblica powder, 40-250 parts of sorbitol, 200-900 parts of Isomalt, 1-10 parts of stevioside and 2-18 partsof magnesium stearate. The healthcare product combination for clearing and nourishing the throat, provided by the invention, has slightly astringent taste and sweet aftertaste.

Owner:NEW ERA HEALTH IND GRP +1

Processing method of instant Chinese chestnuts

InactiveCN104223204AAchieve freshnessKeep the color and fragranceFruits/vegetable preservation by irradiation/electric treatmentNatural extract food ingredientsBiotechnologyPropolis

The invention discloses a processing method of instant Chinese chestnuts. The processing method of the instant Chinese chestnuts comprises the following seven steps: pretreating raw materials, immersing the raw materials in a plant preservation solution, rinsing, quickly freezing, steaming, packaging and carrying out pulse highlight sterilization. According to the processing method, the Chinese chestnuts are immersed with an extraction solution of pure natural plant raw materials; the preservation of the Chinese chestnut kernels is realized through natural effective components with the functions of sterilizing, disinfecting and inhibiting microorganisms in Chinese herbal medicines, and the color, aroma and taste and tissue states of the Chinese chestnut kernels are kept; the light natural aroma of the Chinese chestnuts can be increased and the flavor is unique; the nutritional and health value is increased by pure natural plant components, namely medlar, propolis and the like; and other preservatives or chemical additives are not added in a processing process of the product so that the instant Chinese chestnuts are of an environmental friendly and convenient snack food.

Owner:DOSHAN NEW STRATEGY INTPROP CULTURECO

Room-temperature hot-air drying dehydration processing method for fresh bitter gourd

InactiveCN105454408AMaintain nutrientsKeep the color and fragranceFruits/vegetable preservation by dehydrationPesticide residueBitter gourd

The invention discloses a room-temperature hot-air drying dehydration processing method for a fresh bitter gourd. The method comprises the following steps: a), the fresh good-quality bitter gourd with thick flesh, moderate maturity and green skin and without mechanical damage, scabs, insect pests and standard-exceeding pesticide residues is selected; b), the bitter gourd is washed with clear water, cut in half, subjected to pulp removal, seed removal and removal of two ends, sterilized and cut into 0.5-cm thick pieces, and then the bitter gourd pieces are washed again, fished out and drained for standby application; c), the bitter gourd pieces are dispersed on a multi-layer stainless steel layered rack, the whole rack is pushed into a drying chamber of a dehydrator, and the bitter gourd pieces are subjected to dehydration drying at the hot air temperature of 30-50 DEG C for 5-6 h, cooled at the room temperature, packaged and put into storage. According to the method, soaking, color protection and high-temperature drying links are omitted, the original nutrients as well as color, aroma and taste of the bitter gourd are kept to the greatest extent, a product can be stored for a long time, the variety of bitter gourd food is enriched, the storage life and the supply period of the bitter gourd are prolonged, the demand for eating the gourd throughout the year is met, and the bitter gourd is convenient to store and eat.

Owner:杨明彰

Flavor haw cake and manufacturing method thereof

The present invention discloses a novel flavor haw jelly and a manufacturing method. The gradients and formulation (calculated with weights) are that: haw 40 to 50 kg, xylose 10 to 20 kg, white granulated sugar 15 to 20 kg and other ingredients (Osmanthus 5 to 8 kg, dried orange peel 5 to 10 kg, black tea leaves 3 to 6 kg and mint 2 to 5 kg). The present invention replaces traditional water bath stewing with micro wave curing, which can prevent the loss of nutrient substances such as the flavone and so on and prevent the damage of the pigment and shorten the curing time greatly; the adoptions of an auto casting and shaping machine and a vacuum dry drier ensure the quality of the product and improve the production efficiency and ensure traditional craft studios production to be transformed into the high-tech large scale mechanized production. The present invention needless of any gum or alum, therefore, is a natural and low sugar food which is nutrient and health. The product is not only taken as a special snack food but also taken as a pie core.

Owner:山西汉波食品股份有限公司

Potato raw slurry and starch flour used for staple foods and production process thereof

InactiveCN105901586AKeep the color and fragranceAvoid gelatinizationFood scienceBiotechnologyPotato starch

The invention discloses potato raw slurry and starch flour used for staple foods and a production process thereof. The production process of the potato raw slurry comprises the steps of selecting potatoes as a raw material, washing and peeling the potatoes, slicing and soaking the potatoes, cleaning and draining the potatoes, pulping the potatoes to obtain slurry, centrifuging the slurry, treating a filtrate, and drying the filtrate. The potato starch flour is then subjected to granulation to obtain granular whole potato starch flour. The production process of the potato starch flour and the granular starch flour can avoid gelatinization of the potato starch, can maintain the color, fragrance, taste and protein activity of the potatoes, and solves a problem of properties of potato knead in process of staple foods, and has important significance of promoting potato staple foods.

Owner:BEIJING UNION UNIVERSITY

Preservation method of salted meat product

InactiveCN104223314AExtend freshnessUnique flavorMeat/fish preservation using chemicalsFood preparationFlavorNutrition

The invention discloses a preservation method of a salted meat product. The preservation method of the salted meat product comprises the following steps: coating a preservative, immersing with the preservative, carrying out microwave sterilization and carrying out pulse illumination sterilization. The preservation method of the salted meat product combines three preservation and sterilization technologies including Chinese herbal medicine preservative preservation, microwave sterilization and pulse light sterilization, so that the quality can be effectively kept, the shelf life of the salted meat product is prolonged, and the influences on nutrition ingredients and mouth feel are very small; the preservative is pure natural and toxin-free, has a unique flavor and also has a nutrition and health value; the pulse illumination sterilization also has no toxic side effect; and by virtue of the method, the disadvantages of a traditional salted product that the meat quality is hard after the product is stored for a long time, the mouth feel is not good, the acid value is high due to oxidization and the flavor is changed are effectively avoided.

Owner:DOSHAN NEW STRATEGY INTPROP CULTURECO

Chinese chestnut snack food and processing method thereof

InactiveCN104256737AAchieve freshnessKeep the color and fragranceNatural extract food ingredientsFood preparationBiotechnologyNutritive values

The invention discloses a Chinese chestnut snack food and a processing method thereof. The Chinese chestnut snack food disclosed by the invention is a biscuit piece with crushed Chinese chestnut, which is processed by taking Chinese chestnut, henry steudnera tuber, egg wash, flour, baking powder and yeast powder as the raw materials, and pressing into various shapes by using a biscuit model. The Chinese chestnut snack food disclosed by the invention is prepared by peeling the Chinese chestnut at first, immersing selected Chinese chestnut kernels in plant extract, crushing with henry steudnera tuber after steaming to obtain powder and particles, mixing with egg wash, flour, baking powder and yeast powder to form paste, pressing into a biscuit model, and finally, steaming or baking. During processing, the Chinese chestnut kernels are immersed by the plant extract obtained by extracting honeysuckle, medlar, chrysanthemum and lophatherum gracile, so that the heavy fragrance of the Chinese chestnut can be kept; brown stain is prevented; the fresh keeping effect is achieved; simultaneously, light plant faint scent and nutritional value can be increased; and the Chinese chestnut snack food is abundant in mouth feel and high in nutritional value.

Owner:DOSHAN NEW STRATEGY INTPROP CULTURECO

Liquefied cubilose beverage and preparation method thereof

InactiveCN105661229AGreat tasteKeep the color and fragranceFood ingredient functionsFlavorNeutral protease

The invention relates to the field of cubilose products, in particular to a liquefied cubilose beverage and a preparation method thereof.The preparation method of the liquefied cubilose beverage includes steps: removing impurities of cubilose, drying, and adding water for soaking; sequentially adding neutral protease and flavor protease for enzymolysis; heating for inactivating the proteases to obtain cubilose enzymatic hydrolysate, and making the cubilose enzymatic hydrolysate into the beverage.The preparation method of the liquefied cubilose beverage has the advantages that the cubilose which is subjected to complete enzymolysis is rich in nutrient and contains abundant proteins, carbohydrates, ash, phosphorus, calcium, iron, potassium and the like; in addition, the liquefied cubilose beverage is easy for human bodies to absorb and excellent in taste, and intrinsic color, aroma and taste of cubilose can be effectively protected under the enzymolysis condition and well kept by the enzymatic hydrolysate.

Owner:ZHONGYATIANCHENG XIAMEN BIOTECH CO LTD

Method for preparing lucid ganoderma polysaccharides

The invention discloses a method for preparing lucid ganoderma polysaccharides. The method comprises the following steps: using lucid ganoderma as a raw material; after overflow circulation ultrasonic shattering and extracting, separating a supernatant through high-speed centrifuging, removing proteins from the supernatant through circular current foam separation, and carrying out microwave vacuum drying to obtain lucid ganoderma polysaccharide powder. Due to the adoption of overflow circulation ultrasonic shattering and extracting, the shattering efficiency of the lucid ganoderma can be increased, the extracting rate of the lucid ganoderma active polysaccharides is increased, and automation operation can be conveniently carried out. The preparing method has the advantages of simplicity, low energy consumption, short time and capability of well preserving the natural activity of the lucid ganoderma polysaccharides and is suitable for industrial production. The obtained lucid ganoderma polysaccharides can be used for preparing different types of food, health food or drugs.

Owner:福建省神六保健食品有限公司

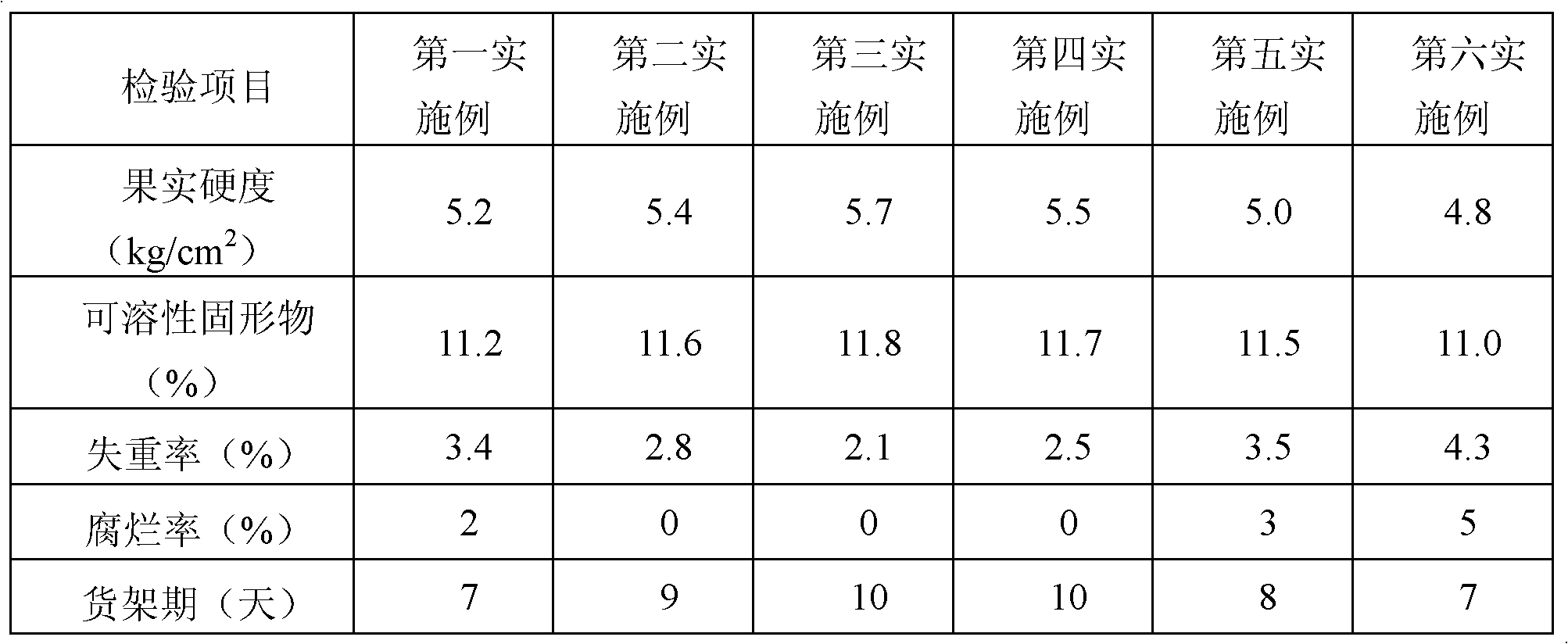

Red fragrant pear storage fresh-keeping method

InactiveCN105341142AKeep the color and fragranceReduce decay rateFruits/vegetable preservation by freezing/coolingChlorine dioxideOxygen

The invention relates to a fruit preservation method, and concretely provides a red fragrant pear storage fresh-keeping method. Harvested red fragrant pear fruits are immersed in a chlorine dioxide solution and then are subjected to ventilation, air drying, packaging and precooling; the 1-MCP sustained release agent and a potassium permanganate ethene remover are added, mixed gases of oxygen, carbon dioxide and nitrogen are inputted into an air regulating box, and air regulating storage is carried out. The red fragrant pear storage fresh-keeping method combines physical and chemical methods, air regulating fresh-keeping storage of red fragrant pear fruits is carried out, fresh-keeping red fragrant pear fruits are stored for 8-10 months, color and fragrance of fruits at harvest are kept basically within 10 shelf days after warehouse-out, yellowing of pericarp is delayed obviously, the fruit rotting rate is lowered, and quality and flavor of fruits are kept.

Owner:FRUIT TREE INST OF CHINESE ACAD OF AGRI SCI

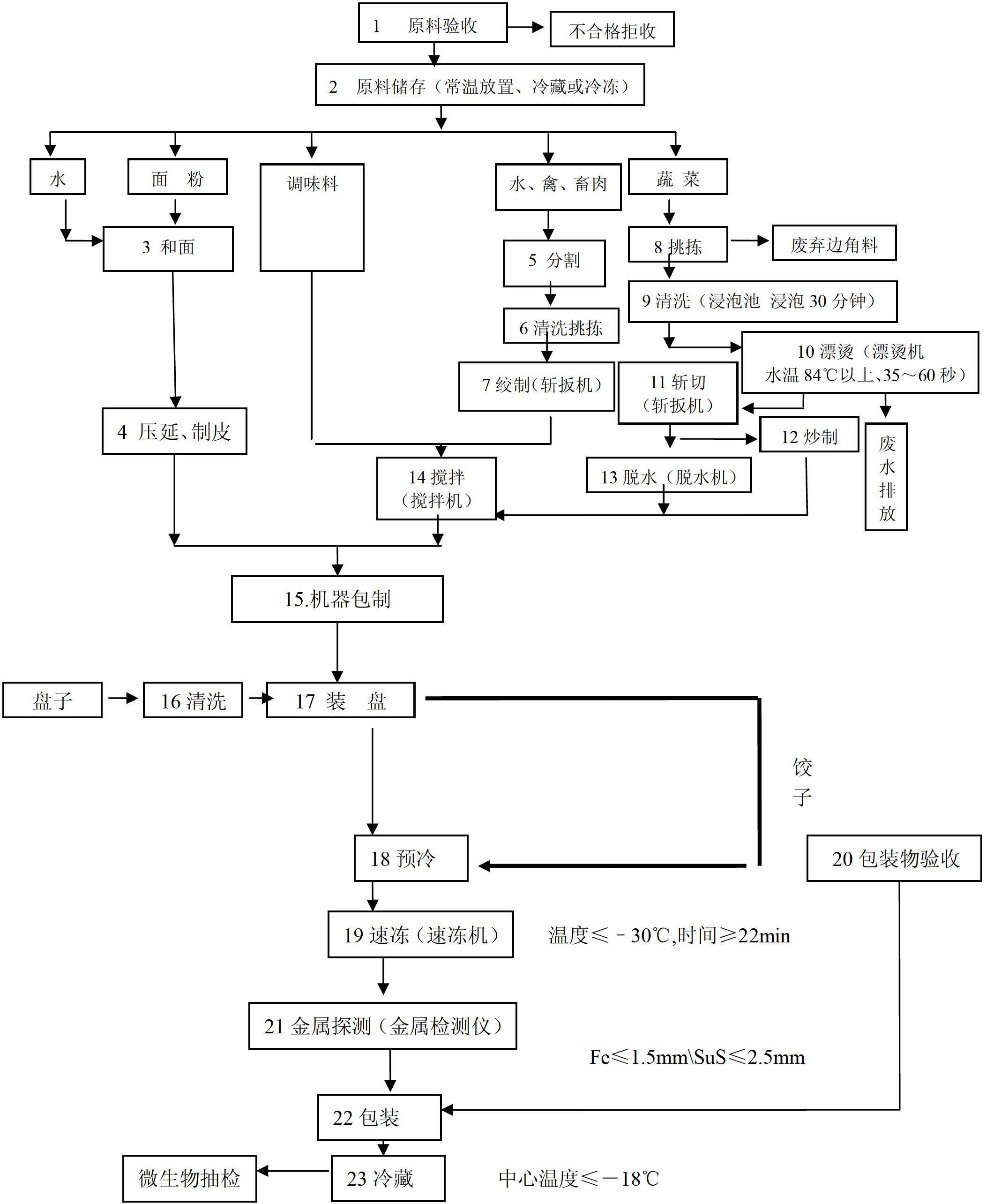

Production process of microwave-cooked dumplings

The invention provides a production process of microwave-cooked dumplings. The production process of the microwave-cooked dumplings includes the steps of firstly, using a vacuum dough mixer to make dough; secondly, mixing vegetable, minced meat, condiments and drinking water to make stuffing; thirdly, using a miniature dumpling maker to make crust and make the dumplings; fourthly, precooling the made dumplings; fifthly, quick-freezing the precooled dumplings; and sixthly, packaging the dumplings. The production process has the advantages of simple process, easiness to operate and low production cost, the dumplings can be cooked by microwave heating, complex procedures of steaming and cooking are avoided, and the dumplings are more convenient for eating and have broad market prospect and fine economic and social benefits.

Owner:DANIANG DUMPLINGS DINING GROUP

Seasoner containing edible mushrooms and preparation method thereof

The invention discloses a seasoner containing edible mushrooms. The seasoner is prepared from the following materials in parts by weight: 5 to 20 parts of agrocybe cylindracea, 1 to 10 parts of pleurotus eryngii, 1 to 10 parts of pholiota nameko, 1 to 10 parts of abalone mushrooms, 1 to 5 parts of bolete, 5 to 20 parts of lentinula edodes, 1 to 10 parts of wild portobello, 0.1 to 2 parts of cordyceps flowers, 1 to 10 parts of fresh ginger, 10 to 30 parts of scallion oil, 40 to 60 parts of vegetable oil, 5 to 20 parts of red camphor oil, 1 to 10 parts of aginomoto, 1 to 5 parts of white spirit and 0.1 to 1 part of a fungus flavoring agent. Meanwhile, the invention also discloses a preparation method of the seasoner. The seasoner provided by the invention comprises various edible mushrooms, is special in flavor, intense and rich in mouthfeel, long in aftertaste, thick in taste, delicious and mellow, natural in color, and suitable for all seasons and all groups of people.

Owner:SICHUAN WUDOUMI FOOD DEV

Dual-rose emblic leafflower fruit juice beverage and preparation method thereof

InactiveCN106616137AKeep the color and fragranceRich color and fragranceFood scienceFruit juiceLiquorices

The invention discloses dual-rose emblic leafflower fruit juice beverage and a preparation method thereof. The preparation method mainly comprises the steps of fresh emblic leafflower fruit astringency removing treatment: blanching fresh emblic leafflower fruits in light salt brine; mother solution preparation: decocting dry roselle calyx, liquorice root and the emblic leafflower fruits and filtering to obtain mother solution; dual-rose emblic leafflower fruit juice beverage preparation: mixing and stirring the mother solution, rose flower normal juice, crystal sugar, honey and edible salt, completely dissolving, filtering, subpackaging and sterilizing to obtain the dual-rose emblic leafflower fruit juice beverage. The dual-rose emblic leafflower fruit juice beverage prepared through the method has the characteristics of having rich nutrients, soft color and luster and pure fragrance, being sour, sweet and tasty, being sweet after bitter and having an effect of wetting throat; the dual-rose emblic leafflower fruit juice beverage is green, well-being and pure-natural flower and fruit mixed beverage; the dual-rose emblic leafflower fruit juice beverage also has the advantages of simple production operation, low production cost and easiness in industrial production.

Owner:RES INST OF TROPICAL ECO AGRI SCI YUNAN ACAD OF AGRI SCI

Peanut freshness preservation processing method

InactiveCN104432276APrevent aroma lossFast heat dissipationSeed preservation by heatingFood preparationArachis hypogaeaNitrogen

The invention provides a peanut freshness preservation processing method. The method includes the steps that peanuts are cleaned and immersed in water, soil and sand are cleaned away, the peanuts are placed in a salt solution, immersed at the indoor temperature and then taken out, and water on the surfaces of the peanuts is drained off; the peanuts are placed in a high-temperature retort pouch or an aluminum foil bag, the retort pouch or the aluminum foil bag is vacuumized, inflated with nitrogen and sealed for high-temperature high-pressure sterilization, the peanuts can be delivered out of a pot and naturally cooled, and therefore the peanuts processed by freshness preservation can be obtained. Compared with the traditional technology, the steps of heating conducted multiple times are simplified, the peanuts can be cooked and freshness of the peanuts can be preserved after high-temperature high-pressure operation is conducted once, and a chemical reagent and an antiseptic do not need to be added in the whole process. The processed peanuts taste glutinous, soft, fragrant and mellow and are delicious and rich in nutrition. The quality of the processed peanuts can be guaranteed at the normal temperature for more than one year, the surfaces of the peanuts are free of obvious water, and glutinous liquid and mildew can not be generated.

Owner:KUNMING CITY YILIANG DIANWANG FOOD

Jack fruit crispy cake and making method thereof

InactiveCN104222236AEasy to produce and processCrispy and deliciousDough treatmentFood preservationNutrientSucrose

The invention discloses a piece of jack fruit crispy cake and a making method thereof. The jack fruit crispy cake is made by wrapping a wrapper on stuffing. The wrapper is composed of 100 parts to 200 parts of wheat meal, 30 parts to 50 parts of coarse cereal flour, 0.2 part to 0.8 part of yeasts, 3 parts to 7 parts of sodium carbonate anhydrous, 1 part to 5 parts of edible salt and 5 parts to 10 parts of sesame. The stuffing is composed of 60 parts to 100 parts of jack fruit pulp, 10 parts to 20 parts of cane sugar, 15 parts to 25 parts of jack fruit powder, 6 parts to 10 parts of invert syrup, 3 parts to 7 parts of camellia oil and 0.1 part to 0.7 part of emulsifying agents. The problem that the jack fruit pulp is thin and soft and can not be easily wrapped as the stuffing is solved, and the made jack fruit crispy cake well keeps the original color, aroma and taste of jack fruit, and is rich in nutrient and crispy outside and delicious inside in taste.

Owner:黄琴

Process for extracting polysaccharide from milkvetch roots

The invention discloses a process for extracting polysaccharide from milkvetch roots. The process is characterized by including the following steps of step a, using a dry milkvetch root powder as a raw material, placing the dry milkvetch root powder in a reaction vessel, and adding a mixed solvent to the reaction vessel; step b, heating a solution obtained after the mixing reaction in the step a, and adding a multienzyme complex to the mixed solution, wherein the multienzyme complex comprises cellulose and pectinase with the weight ratio of 1:1; step c, cooling the mixed solution obtained after enzymolysis reaction, and removing lower layer precipitates after the cooling to obtain supernatant; step d, concentrating the supernatant obtained from the step c to be paste, adding ethanol for precipitation, and performing filtering to obtain a milkvetch root polysaccharide crude product; and step e, refining the milkvetch root polysaccharide crude product to obtain a milkvetch root polysaccharide refined product. The process for extracting the polysaccharide from the milkvetch roots has the advantages of being simple in operation, conditions are easy to achieve, the yield rate of the polysaccharide is high, and the purity is high.

Owner:NANTONG SIHAI PLANT EXTRACTS

Cranberry milky tea and preparing technology thereof

InactiveCN105994645AImprove constipationKeep the color and fragranceMilk preparationPre-extraction tea treatmentAmerican cranberryFreeze-drying

The invention discloses a cranberry milky tea and a preparing technology thereof. The cranberry milky tea is prepared from freeze-dried cranberry fruits and milky tea powder. Cranberry fruits are subjected to dehydration treatment with the vacuum freeze drying technology so that the cranberry fruits can be still in the shape of fresh fruits and have the flavor of fresh fruits in experience after the milky tea is brewed with water, and the nutrition value of cranberry fruits can be preserved while the flavor and the sour sweetness of the cranberry fruits are maintained; according to the milky powder, modified milky powder is used for replacing vegetable fat powder, cream powder and whole milk powder are supplemented and added to improve the aroma, and thus the milk aroma, the milk sense and the tea flavor of the milky tea are harmoniously blended. The preparing technology is easy and convenient to implement and suitable for industrial mass production.

Owner:阳江喜之郎果冻制造有限公司

Refreshing fruit and vegetable crisp chip and production technology thereof

PendingCN107616447AKeep the color and fragranceCrispy tasteFood scienceAdditive ingredientFreeze-drying

The invention discloses a refreshing fruit and vegetable crisp chip and a production technology thereof. The production technology comprises the steps as follows: (1) cleaning and slicing; (2) blanching; (3) freeze drying; (4) vacuum low-temperature deep-frying; (5) oil removing; and (6) natural cooling to room temperature. The production technology of the refreshing fruit and vegetable crisp chipis simple, the product cost can be well controlled, the product is nutritious, and the drying and puffing temperature is decreased; besides, the refreshing fruit and vegetable crisp chip tastes crisp, contains rich nutritional ingredients and can better reserve original colors, fragrances and tastes of fruits and vegetables.

Owner:绍兴市果哥食品科技有限公司

Low-temperature mulberry drying treatment process

InactiveCN105192051ARetain nutrientsKeep the color and fragranceFruit and vegetables preservationFlavorAdditive ingredient

The invention discloses a low-temperature mulberry drying treatment process. The low-temperature mulberry drying treatment process comprises the following steps: (1) pre-treating mulberries: cleanly washing the fresh mulberries and putting the fresh mulberries into ozone water to be immersed for 10-15 minutes; (2) pre-freezing: putting the mulberries into a freezing chamber; reducing the temperature of the freezing chamber to be in a range from -15 DEG C to -5 DEG C and keeping for 1-2 hours; (3) drying in vacuum: putting the mulberries which are subjected to pre-freezing treatment into a vacuum drying chamber to be subjected to sublimation drying, wherein the vacuum degree of the vacuum drying chamber is 100-200pa; controlling the temperature to be 20-30 DEG C and keeping for 2-4 hours; and (4) cooling and carrying out water balance: putting the dried mulberries into an environment with the temperature of 10-15 DEG C and the relative humidity of 10-20% for 1-5 hours, and then cooling and carrying out the water balance until the moisture content of the mulberries is 1-5%. According to the low-temperature mulberry drying treatment process disclosed by the invention, the mulberries are frozen and then are subjected to the sublimation drying of ice in vacuum to remove surplus moisture, so that nutritional ingredients of the mulberries are kept to the greatest extent, color, aroma and flavor of the mulberries are kept, and the mulberries are easy to store and convenient to carry.

Owner:安徽韵沣农业发展股份有限公司

Student nutrition diet and its producing method

InactiveCN104161283ARich varietyImprove digestibilityFood preparationThermal insulationNutritional composition

The invention relates to a student nutrition diet and its producing method. The student nutrition diet comprises a staple food and three dishes, wherein the staple food is rice, the three dishes are celery with smoked bean curd, fried?eggs?withtomatoes and spicy diced chicken with peanuts respectively, so that the celery, tomato, cucumber, smoked bean curd, eggs, chicken breast and rice in certain parts by weight are pre-processed and cooked with various seasonings in a certain way, and during the cooking process, the sensory quality such as color and taste is improved and the nutritional?ingredients are retained; the staple food and the dishes are placed into a four-part fast food box, the fast food box is covered and then thermally insulated in a thermal insulation box, and then the fast food boxes are uniformly transferred to schools by a thermal insulation car. The student nutrition diet has features of scientific and reasonable match and balanced nutrition and is very suitable for students. The producing method has features of reasonable method and simple process and is suitable for factory production.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Raw fish processing method

InactiveCN101731307ANo longer limitedGreat tasteMeat/fish preservation by freezing/coolingAquatic productAmomum aromaticum

The invention belongs to the field of aquatic product processing, and particularly discloses a raw fish processing method. The method comprises the following steps: dissecting and cleaning fish, cutting, and putting in a bag; adding curcuma, clove, pepper, Chinese anise, amomum aromaticum, cassia bark, myrcia and table salt; and sealing the packaging bag, and deep-freezing to obtain the product. The invention maintains the original color and taste of fish, is convenient to eat, can be stored for a long time, has a simple processing technique and is beneficial for realizing industrial production.

Owner:王韵棠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com