Patents

Literature

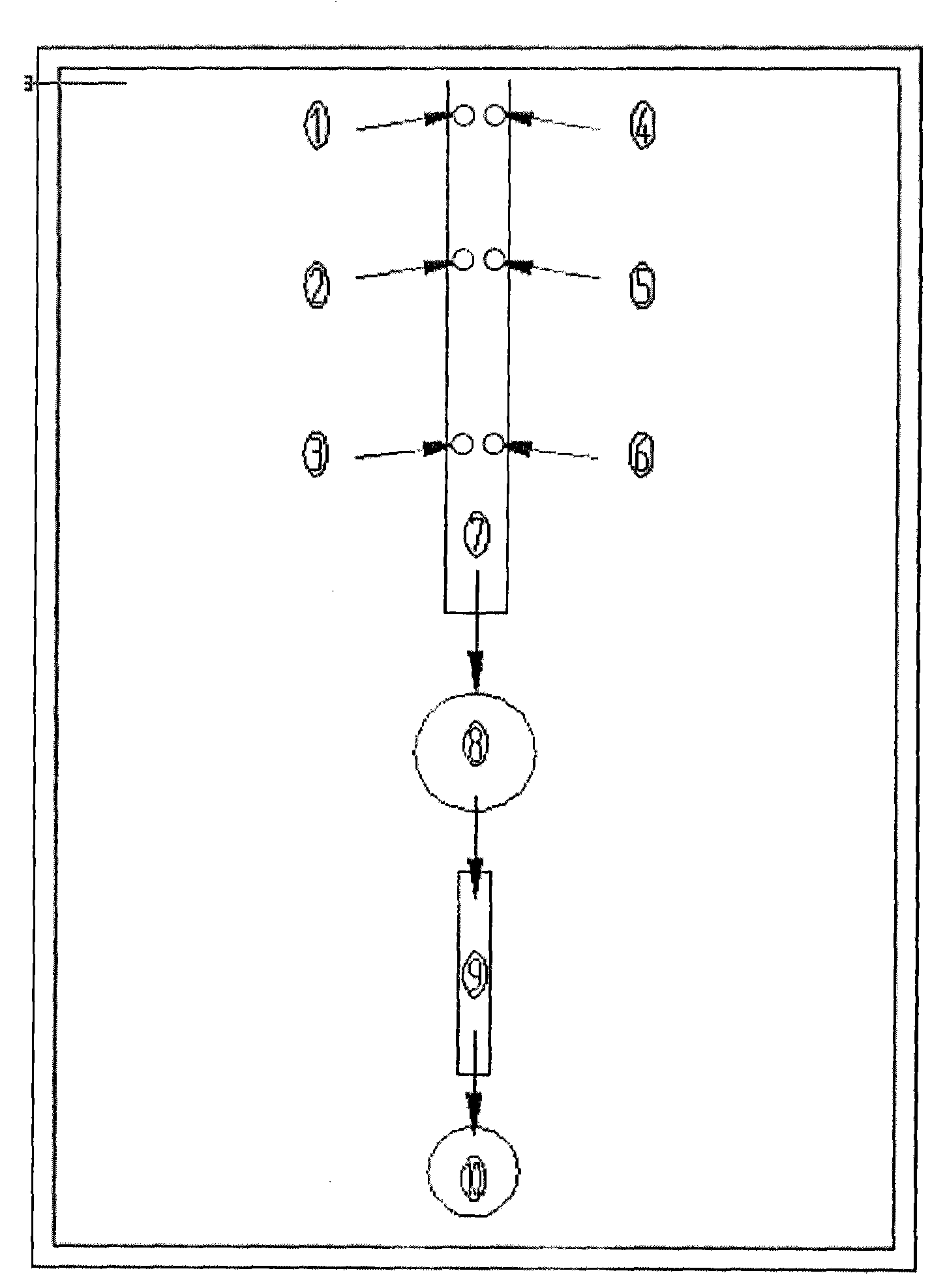

75results about How to "Crispy and delicious" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum freeze drying production method of nuts and nut product

InactiveCN103141919ALong storage timeOrganizational structure unchangedFood preparationFood treatmentFlavorAdditive ingredient

The invention provides a vacuum freeze drying production method of nuts, which comprises the following steps of quickly freezing the nuts between -35 DEG C and -55 DEG C, and conducting vacuum drying on the quickly frozen nuts for 10-15h under a vacuum environment at the medium temperature of 55-35 DEG C and the vacuum degree of 35-115Pa. The invention further provides a nut product manufactured by applying the vacuum freeze drying production method of the nuts. According to the production method and the nut product, a vacuum freeze drying mode is adopted to produce the nut product, the saving time of the nuts is prolonged, organization structures, nutritional ingredients and flavor substances of the nuts are kept unchanged, the appearances of the nuts are free from sun cracks and are not shrunk, the original shapes and colors of the nuts are maintained, and the taste is crisp and nice.

Owner:ANHUI ZHANSHI FOOD

Method for processing pitaya chips

InactiveCN103637108ACrispy and deliciousReduce oil contentFood freezingFood shearingCoatingQuick freezing

The invention discloses a method for processing pitaya chips. The method for processing pitaya chips comprises the following steps: mixing raw material (pitaya) with batter which is prepared from flour, starch, refined salt, baking powder, sugar and nutrition powder; washing; slicing up; carrying out color protectio; coating; quick-freezing; frying in vacuum for deoiling; seasoning; and packaging. The prepared pitaya chips taste crispy and delicious, are nutritious and healthy and are low-oil and low-calorie, thereby being a health-care leisure food for young and old. Also, the processing technology of pitaya chips is simple and easy to operate and the raw material sources are wide, and the economic value of pitaya can be increased; therefore, the method can be popularized favorably.

Owner:张振源

Refreshing rice cracker and making method thereof

InactiveCN103931716AComprehensive and balanced nutritionCrispy and deliciousDough treatmentBakery productsBiotechnologyNutrition

The invention discloses a refreshing rice cracker. The refreshing rice cracker is made of the following ingredients, by weight, 180-240 parts of low-gluten flour, 30-40 parts of purple rice flour, 20-30 parts of millet flour, 10-15 parts of rosemary, 10-15 parts of lemongrass, 6-8 parts of silver dishes, 15-18 parts of pomegranates, 8-10 parts of passion flowers, 6-7 parts of stevia rebaudian leaves, 1-2 parts of sanchi flowers, 4-5 parts of olives, 3-4 parts of radix ophiopogonis, 1-2 parts of fructus gardeniae, 4-5 parts of fried coffee beans, 2-3 parts of baking powder and a proper amount of icing and purple perilla seed oil. The rice cracker is made of the main ingredients of the low-gluten flour, the purple rice flour and the millet flour, is rich and balanced in nutrition and crisp and delicious in taste, the ingredients such as the rosemary, the lemongrass and the silver dishes are added to enable the rice cracker to have the effects of refreshing, appetizing, food digesting, weight loosing, cancer resistance, aging resisting and memory enhancing, honey, composite cream powder and coconut juice are made into the icing, a traditional technology is broken through, the made icing is nutritious and delicious, sweet and tasty, and therefore the health-care value is higher.

Owner:刘阿君

Preparation technology of dried mulberry fruit/mulberry powder, and product and derivative of dried mulberry fruit/mulberry powder

InactiveCN105192050AExtended shelf lifeSolid shape unchangedDough treatmentPre-extraction tea treatmentAdditive ingredientFreeze-drying

The invention discloses a preparation technology of dried mulberry fruit / mulberry powder, and a product and a derivative of the dried mulberry fruit / mulberry powder. The processing method of the dried mulberry fruit / mulberry powder adopts a vacuum freeze drying technology, so that the fresh taste, the nutritional components, the color and the fragrance of mulberries are successfully retained, and the prepared dried mulberry fruit / mulberry powder can be either directly eaten or used as a raw material for food processing. The dried mulberry fruit can be further prepared into scented tea, and the prepared scented tea tastes sour and sweet, and has mellow flavor and flower fragrance; the dried mulberry powder is further prepared into cookies; the cookies taste crispy, has a special flavor, is low in fact content and sugar content and rich in nutrition, and is favorable for the health of people.

Owner:SOUTHWEST UNIVERSITY

Tremella and peanut flaky pastries and making method thereof

ActiveCN102578187ACrispy tasteCrispy and deliciousDough treatmentBakery productsFlaky pastryTremella

The invention relates to the technical field of foods, in particular to tremella and peanut flaky pastries and a making method thereof. According to a raw material formula, the tremella and peanut flaky pastries comprise the following components in part by weight: 240 to 260 parts of self-raising flour, 170 to 190 parts of water, 140 to 160 parts of white sugar, 90 to 110 parts of peanuts, 90 to 110 parts of liquid shortening, 90 to 110 parts of eggs, 8 to 10 parts of tremella, 1 to 2 parts of cake oil and 1 to 2 parts of salt. The making method comprises the following steps of: (1) preparingmaterials; (2) crushing the tremella; (3) stirring the white sugar, the eggs, the salt and the water; (4) adding the cake oil and stirring; (5) adding flour and the crushed tremella, and stirring until the mixture is in a leavening state; (6) adding the liquid shortening and stirring; (7) molding and adding the crushed peanuts; and (8) baking. The flaky pastries have crispy mouthfeel; because thepeanuts are added, the flaky pastries have more fragrant, crispy and delicious mouthfeel; and the tremella is also added, so that the flaky pastries have nutrient components such as edible fungus protein and high dietary fiber which are not possessed by various ordinary flaky pastries, and are delicious, nutritional and healthy.

Owner:GUANGDONG YUEWEI EDIBLE FUNGI TECH

Jack fruit crispy cake and making method thereof

InactiveCN104222236AEasy to produce and processCrispy and deliciousDough treatmentFood preservationNutrientSucrose

The invention discloses a piece of jack fruit crispy cake and a making method thereof. The jack fruit crispy cake is made by wrapping a wrapper on stuffing. The wrapper is composed of 100 parts to 200 parts of wheat meal, 30 parts to 50 parts of coarse cereal flour, 0.2 part to 0.8 part of yeasts, 3 parts to 7 parts of sodium carbonate anhydrous, 1 part to 5 parts of edible salt and 5 parts to 10 parts of sesame. The stuffing is composed of 60 parts to 100 parts of jack fruit pulp, 10 parts to 20 parts of cane sugar, 15 parts to 25 parts of jack fruit powder, 6 parts to 10 parts of invert syrup, 3 parts to 7 parts of camellia oil and 0.1 part to 0.7 part of emulsifying agents. The problem that the jack fruit pulp is thin and soft and can not be easily wrapped as the stuffing is solved, and the made jack fruit crispy cake well keeps the original color, aroma and taste of jack fruit, and is rich in nutrient and crispy outside and delicious inside in taste.

Owner:黄琴

Spicy bullfrog skin processing technology

ActiveCN103719929ACrispy and deliciousEasy to splitFood thermal treatmentFood shearingBrewingFood processing

The invention discloses a spicy bullfrog skin processing technology which comprises the technical steps of raw material pretreatment, brewing, slicing, blanching, rinsing, dewatering, metering and blending, casing and delivery to a warehouse. Bullfrog skins processed by the processing technology disclosed by the invention taste delicious and are rich in nutrition and convenient to store and transport; the spicy bullfrog skin processing technology belong to the frog type cooked food processing industry with a good prospect.

Owner:NANCHANG UNIV

Hard biscuits and preparation technology thereof

InactiveCN106417472ANutritional balanceFull of nutritionDough treatmentBaking processesSodium bicarbonateVegetable oil

The invention relates to the technical field of food processing, in particular to hard biscuits and a preparation technology thereof. The hard biscuits provided by the invention comprise he following components in percentage by weight: 55-65% of wheat flour, 8-13% of white granulated sugar, 5-9% of prebiotics, 1.5-4% of artificial butter, 2-5% of shortening, 2.5-5.5% of whole milk powder, 1-3% of glucose syrup, 0.3-0.8% of edible salt, 6-10% of edible vegetable oil, 0.5-1% of ammonium bicarbonate, 0.2-0.5% of sodium bicarbonate, 0.06-0.12% of calcium carbonate, 0.02-0.07% of protease, 0.02-0.05% of sodium metabisulfite, 0.02-0.05% of vanillin, 0.007-0.013% of beta-carotene, 0.03-0.07% of milk essence and 0.01-0.03% of carmel coloring. The hard biscuits disclosed by the invention are balanced in nutrients, good in flavor and good in mouth feel.

Owner:江门澳崎高质食品有限公司

Production method for continuously formed onion rings

ActiveCN103393031ASkip the quick freezing stepReduce production energy consumptionFood preparationQuick FreezeChloride

The invention discloses a production method for continuously formed onion rings. The production method comprises the following main process steps: selecting fresh white onions; peeling and cleaning the white onions; dicing the white onions by using a dicer; subjecting onion dices to water controlling or mechanical dehydration to realize raw material preprocessing; uniformly mixing the preprocessed onion dices and a binder in proportion in a mixer with stirring; carrying out forming by using a ram-type forming machine so as to obtain onion rings, each weighing 6 to 7 g; spraying a calcium chloride solution and allowing the calcium chloride solution and bonding substances in the accessory material--the binder to undergo hardening and shaping; allowing the shaped onion rings to enter into a powdering machine through a transmission network belt for automatic powdering, then into a starching machine through the transmission network belt for starching, then into a powder wrapping machine for powder wrapping and finally into a tunnel-like frying machine through the transmission network belt for pre-frying; subjecting obtained finished products to oil controlling, cooling and quick-freezing in an individual quick-freezing machine; conveying the quick-frozen onion rings to an automatic packaging machine through the transmission network belt; manually picking out defective onion rings on the transmission network belt; packaging qualified onion rings by using the packaging machine; and carrying out detection and delivery.

Owner:麦康食品(青岛)有限公司

Spiced beef sunflower seed kernel and making method thereof

InactiveCN103494272ARich sauceCrispy and deliciousFood ingredient functionsFood preparationBiotechnologyMyrrh

The invention discloses a spiced beef sunflower seed kernel and a making method thereof. The spiced beef sunflower seed kernel is composed of, by weight, 300-400 parts of sunflower seed kernels, 10-15 parts of beef powder, 4-6 parts of corn puffing powder, 5-8 parts of kelp powder, 5-8 parts of potato powder, 1-2 parts of roots of three-leaf akebia, 1-2 parts of white-flower snake bluegrass, 1-2 parts of desert cistanche, 2-3 parts of myrrh, 1-2 parts of liriope, 2-3 parts of liquorice, 2-3 parts of poria cocos and seasoning liquid in proper amount. The spiced beef sunflower seed kernel is intense in sauce flavor, and contains beef smell, thereby being crisp, delicious, spicy and refreshing in taste; traditional Chinese medicine healthcare ingredients are added in a formula, so that the spiced beef sunflower seed kernel has efficacy of promoting Qi to activate blood and strengthening the spleen and stomach, and is suitable for being eaten by various groups of people.

Owner:HEFEI ZHENTAI LAOYEYE FOOD

Process for pickling sauced white radish

The invention provides a process for pickling sauced white radish. The process comprises the following steps: washing white radish, cutting into uniform long strips, specifically, long strips which are 2-4cm in length, 0.5-1cm in width and 0.5-1cm in height, putting the long-stripy white radish into a hollow container, and shining for more than two days; heating 170-300ml of edible oil, putting 5-10g of shredded scallions, quickly frying till the fragrance is released, sequentially putting 10-15g of garlic pieces and 5-10g of shredded ginger, putting 10g of zanthoxylum bungeanum and 3g of fennel, subsequently putting 15-30g of edible salt, 20-30ml of edible vinegar and 10-15ml of soybean sauce, further adding 5-10g of white sugar, and boiling for 10-15 minutes, thereby obtaining sauce; and putting the white radish strips into the sauce, uniformly stirring, and pickling for 24 hours, thereby obtaining the sauced white radish. The process is simple in step, the sauced white radish is crispy and tasty, low in cost, appropriate in taste and applicable to people in different ages, and the taste is not degraded after the sauced white radish is preserved for a relatively long time.

Owner:茅虞

Production method of houttuynia cordata root pickles

The invention discloses a production method of houttuynia cordata root pickles. The houttuynia cordata root pickles can be produced by steps of pre-treating, pickling, mixing and seasoning, packaging, sterilizing and checking with houttuynia cordata roots as a main material, and Chinese cabbages, balsam pears, apples and red peppers as auxiliary materials, the processing cost is lower and no preservative is added in production; the product houttuynia cordata root pickles are yellow and bright, fresh and crispy, and specific in taste, and have a higher nutrition value, pesticide effect components and effects of clearing away heat and toxic materials, promoting digestion, increasing appetite, and keeping fit. The houttuynia cordata root pickles are crispy and delicious, and convenient for eating; and a new member both used as a medicine and food can be provided for a pickle family.

Owner:湖南沅味主张食品有限公司

Dried orange peel and red bean cocoa biscuit

InactiveCN105211214AUnique flavorCrispy and deliciousDough treatmentBakery productsFlavorFood additive

The invention discloses a dried orange peel and red bean cocoa biscuit which is composed of raw materials in weight of 30-40 parts of unsalted butter, 30-40 parts of white sugar, 70-80 parts of low-gluten flour, 15-25 parts of eggs, 5-8 parts of cocoa powder, 10-15 parts of dried orange peel powder, 5-8 parts of baking soda, 20-30 parts of red beans and 10-15 parts of white chocolate. The dried orange peel and red bean cocoa biscuit is unique in flavor, crispy and delicious in taste and comprehensive in nutrition, the raw materials homologous of medicine and food are finely selected for manufacturing the product, all the raw materials interact mutually, the delicious food function and the medical health care function are combined, a traditional medical concept is met, a modern health care food concept is closely met, no food additive is added, and the biscuit is suitable for both the young and the old; the production procedure is simple, manufacturing is convenient, the cost is low, the requirement of industrial production can be met, and the biscuit is convenient to carry and eat and can be eaten after bag opening and water filling.

Owner:伍玉兰

Making method of low-temperature vacuum deep-fried mushrooms

InactiveCN108433098ACrispy tasteMinimize or even avoid harmFood scienceDeep fryingMoisture absorption

The invention discloses a making method of low-temperature vacuum deep-fried mushrooms. The making method comprises the following steps of (1) performing preparation work; (2) ageing edible oil; (3) performing quick-freezing on mushrooms; (4) adding the quick-frozen mushrooms into a deep-frying jar; (5) adding oil to the deep-frying jar; (6) performing vacuum deep-frying: setting temperature in the deep-frying jar to be 70-95 DEG C, and performing vacuum deep-frying under the condition of controlling pressure to be minus 0.095-minus 0.09Mpa and time to be 25-35min; (7) recovering the edible oil: after the vacuum deep-frying in the step (6), closing a heating switch of the deep-frying jar, so that the pressure in an oil storage jar is slightly lower than the pressure in the deep-frying jarand the edible oil in the deep-frying jar to be recovered into the oil storage jar; and (8) performing high-speed deoiling: performing high-speed deoiling on the mushrooms in a deep-frying basket, after deoiling for 8-10min, closing an equipment switch, and after pressure is released, taking out products namely the low-temperature vacuum deep-fried mushrooms. Under the premise that the nurients ofhypsizygus marmoreus made by the making method disclosed by the invention are not destroyed, the processed hypsizygus marmoreus is not high in moisture absorption and oil content, good in mouth feeland better in effects than any other mushroom.

Owner:安徽蘑蘑哒食品有限公司

Formula and production method of crispy chili peppers

InactiveCN107811258ASpicy and fragrantCrispy and deliciousFood scienceStar AnisesMonosodium glutamate

The invention belongs to the technical field of foods, and especially relates to a formula and production method of crispy chili peppers . The formula of the crispy chili peppers comprises the following raw materials: chili peppers, garlic, peanut kernels, white sesame seeds, green Chinese onions, ginger, salt, monosodium glutamate, thirteen-spices, salad oil, star anises, Chinese cinnamon, and laurel leaves. Crispy chili peppers prepared by applying the technical scheme are very spicy and aromatic in flavor, as well as crispy, delicious, refreshing and sweet in taste; moreover, taste of the crispy chili peppers is kept completely unchanged even after packaging. In addition, the raw materials used for preparing the crispy chili peppers are all high-quality raw materials which are really good and reliable; and all taste is naturally produced by the food materials so that the crispy chili peppers are mellow in aroma and free of any flavoring agent, and thus, the crispy chili peppers aresafe and reliable for long-term eating, as well as suitable for people of all ages.

Owner:天津市蓟州区香满天食品有限公司

Caramel peanut crisp and preparation method thereof

InactiveCN103478203APreserve the original tasteIncrease varietyBakery productsIcing sugarGolden syrup

The invention discloses a caramel peanut crisp and a preparation method thereof. the caramel peanut crisp are made of self-raising flour, butter, powdered sugar, eggs, baking powder, butter, sugar, golden syrup, lemon juice and peanut kernel. The preparation method includes preparing a cake base, preparing peanut filling, making finished products, baking and packaging. The caramel peanut crisp is characterized in that the caramel peanut crisp is crisp, added peanut raw materials are more than the traditional peanut raw materials, original taste of peanuts can be preserved, the caramel peanut crisp tastes more crisp and delicious and nutrient-rich, varieties of peanut crisps and satiety are increased, and the caramel peanut crisp has functions to accelerate physical growth, improve anemia, lower cholesterol, slow down human aging and the like.

Owner:罗成

Korea crisp cake and production process and technology thereof

The present invention provides a Korea crisp cake and a production process and technology thereof. The Korea crisp cake contains the following components: 500 grams of pork fat, 200 grams of dried vegetables, 100 grams of white sugar, 5 grams of salt, 10 grams of monosodium glutamate, 500 grams of low-gluten flour, 550 grams of lard, 1,000 grams of medium gluten flour, and 200 grams of water. The Korea crisp cake is crisp in taste, full in color and fragrance, beautiful in appearance, and rich in nutrition.

Owner:衢州谷香人家食品有限公司

Cuttlefish puff pie

The invention discloses a cuttlefish puff pie prepared from the following raw materials in parts by weight: 150-160 parts of dried cuttlefish, 30-50 parts of onions, 150-160 parts of potatoes, 200-300 parts of puff pastries, 5-8 parts of black pepper and salt, and 20-30 parts of salt-containing cream. The cuttlefish puff pie disclosed by the invention has a unique flavor, a crispy and delicious taste and comprehensive nutrients. The cuttlefish puff pie is produced by selecting the raw material both used as medicines and foods. All the raw materials have mutual effects, and a food function and a medical health function of the foods can be combined together. Therefore, a traditional medical concept is met and the concept of modern health foods is approached. No food additive is added, so that the health and nutritional pineapple butter biscuits are suitable for people of all ages. The cuttlefish puff pie is simple in production process, convenient to produce, and relatively low in cost. Meanwhile, the requirements of industrial production can be met. The cuttlefish puff pie is convenient to carry and eat, and can be eaten after the cuttlefish puff pie is taken out of a bag and brewed with water.

Owner:蒋娜

Cinnamon, walnut and cocoa biscuits

InactiveCN105230735AUnique flavorCrispy and deliciousDough treatmentBakery productsYounger peopleBiology

The invention discloses cinnamon, walnut and cocoa biscuits. The cinnamon, walnut and cocoa biscuits consist of the following raw materials in parts by weight: 30-40 parts of unsalted butter, 30-40 parts of white sugar, 70-80 parts of low-gluten flour, 15-25 parts of eggs, 5-8 parts of cocoa powder, 10-15 parts of ground cinnamon, 5-8 parts of baking soda powder, 20-30 parts of walnuts, and 10-15 parts of white chocolates. The cinnamon, walnut and cocoa biscuits disclosed by the invention are unique in flavor, crisp and delicious in mouth feel, and comprehensive in nutrition. The cinnamon, walnut and cocoa biscuits disclosed by the invention are made by selecting medicinal and edible raw materials which interact, and the dainty function of foods and the medicinal health care function of the foods are combined together, so that the cinnamon, walnut and cocoa biscuits not only conform to a conventional medical concept, but also approach the concept of modern health care foods. No food additives are added, so that the cinnamon, walnut and cocoa biscuits are suitable for both old people and young people. The cinnamon, walnut and cocoa biscuits are simple in production working procedures, convenient to make, and low in cost, can meet the requirements of industrialized production, are convenient to carry and eat, and can be eaten when being opened and then brewed with water.

Owner:伍玉兰

Mackerel short pie

InactiveCN105580863ACrispy and deliciousNutritional diversityDough treatmentBakery productsFood additiveFlavor

The invention discloses a mackerel short pie. The mackerel short pie comprises, by weight, 150-160 parts of mackerel, 30-50 parts of onions, 150-160 parts of potatoes, 200-300 parts of short pastry, 5-8 parts of black pepper salt and 20-30 parts of salt-containing cream. The mackerel short pie is unique in flavor, crispy and tasty in taste and complete in nutrition, the medicinal-and-edible raw materials are carefully selected to make the product, all the raw materials interact with each other, the food function and the medicine healthcare function of food are combined, the mackerel short pie meets the traditional medical concept and is close to the concept of modern health food, no food additive is added, and the mackerel short pie is suitable for all ages; the production procedure is simple, making is convenient, cost is low, the requirement of industrial production can be met, carrying and eating are convenient, and the mackerel short pie can be eaten after pocket opening and water pouring.

Owner:蒋娜

Bitter gourd pickles and preparation method thereof

InactiveCN103637135AReasonable collocationCrispy and deliciousFood preparationGreen yellowIllicium verum

The invention discloses bitter gourd pickles and a preparation method thereof. The bitter gourd pickles are prepared from the following raw materials: bitter gourds, salt, fresh pimiento, garlic, white sugar, soy sauce, spirit, white vinegar and anise. The preparation method of the bitter gourd pickles comprises the following steps: raw material selection, insolation, continuous insolation for preparing bitter gourd particles, immersion and drying, pickling, secondary pickling, vacuum packaging, sterilization, inspection and storage. The bitter gourd pickles and the preparation method thereof have the characteristics that the ratios of the raw materials are reasonable; the product is green-yellow, tastes crisp and delicious, is salty and bitter and is refreshing and delicious; if the bitter gourd pickles are eaten together with rice or bread, the effects of stimulating the appetite, tonifying the spleen and promoting the appetite can be achieved; the bitter gourd pickles can be stored for a long time without any preservative; all the raw materials are true-color natural high-quality raw materials, and the product is a healthy, safe and green food which can be eaten together with rice or bread. The bitter gourd pickles are novel pickle products which have the effects of clearing heat, detoxifying, relieving summer heat, cooling down, tonifying kidney, moisturizing spleen, improving the immunity, reducing the blood fat and the like; the preparation technology is simple, is convenient in processing, is suitable for factory production and can easily form the pickles and meet requirements of the market; the market of the bitter gourds is developed.

Owner:邓江莲

Potato semi hard biscuit and making method thereof

ActiveCN103891850BCrispy and deliciousBright colorDough treatmentBakery productsSodium bicarbonateCooking & baking

The invention provides a potato semi hard biscuit, and belongs to the technical field of food and processing method thereof. The potato semi hard biscuit mainly resolves the technical problems that an existing coarse cereal biscuit has bed mouth feel, a dim color and a complex making method. According to the technical scheme, potato starch, wheat flour, white granulated sugar, vegetable oil, edible salt, sesame, distarch phosphate, sodium bicarbonate, calcium carbonate, ammonium bicarbonate, ammonium bicarbonate, disodium dihydrogen pyrophosphate, protease, baking chicken powder and water are adopted as raw materials; weighing, mixing, forming, baking and other technologies are conducted. The potato semi hard biscuit has crisp and tasty mouth feel, a bright color, and a simple manufacturing method.

Owner:晋城市古陵山食品有限公司

Puffed crisp jujube and making method thereof

InactiveCN103932078AReduce hardnessCrispy and deliciousFood freezingFood thermal treatmentPressure decreaseNutrient content

A making method of a puffed crisp jujube comprises the following steps: 1, carefully choosing winter jujubes; 2, red promotion: blanching with 80-100DEG C hot water until the jujubes are completely red; 3, quick freezing: quickly freezing to -18 - -30DEG C; 4, pre-drying: pre-drying at 45-55DEG C for 24-36h; 5, adding the pre-dried jujubes to a sealed tank, and rewetting at 0-4DEG C for 12h; 6, vacuum puffing: adding the rewetted jujubes in a vacuum puffing machine, heating, carrying out heat insulation for 30min when the temperature rises to 45-60DEG C, rapidly reducing the pressure to -0.08 - -0.15MPa, carrying out evacuation drying for 4-8h, stopping the evacuation, stopping heating, and reducing the temperature to 20-30DEG C when the pressure decreases to 0MPa in order to obtain the finished crisp jujube; 7, sterilizing; and 8, cooling, examining, and packaging. The puffed crisp jujube has the advantages of small hardness, crisp and tasty mouthfeel, and reservation of the nutritional components of fresh jujubes as possible.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Process for pickling sauced cucumber

The invention provides a process for pickling sauced cucumber. The process comprises the following steps: washing cucumber, cutting into uniform long strips, specifically, long strips which are 2-4cm in length, 0.5-1cm in width and 0.5-1cm in height, uniformly scattering 15-30g of edible salt on the long-stripy cucumber, uniformly stirring, putting the long-stripy cucumber into a hollow container, and shining for 1-3 days; heating 170-300ml of edible oil, putting in 5-10g of shredded scallions, quickly frying till the fragrance is released, sequentially putting in 10-15g of garlic pieces and 5-10g of shredded ginger, putting in 10g of zanthoxylum bungeanum and 3g of fennel, subsequently putting in 20-30ml of edible vinegar and 10-15ml of soybean sauce, further adding 5-10g of white sugar, and boiling for 10-15 minutes, thereby obtaining sauce; and putting the cucumber strips into the sauce, uniformly stirring, and pickling for 3 hours, thereby obtaining the sauced cucumber. The process is simple in step, the sauced cucumber is crispy and tasty, low in cost, appropriate in taste and applicable to people in different ages, and the taste is not degraded after the pickled sauced cucumber is preserved for a relatively long time.

Owner:茅虞

Fruit and vegetable potato chips

The invention discloses fruit and vegetable potato chips. The fruit and vegetable potato chips consist of the following raw materials in parts by weight: 70-120 parts of potatoes, 30-40 parts of honey, 30-40 parts of carrots, 20-40 parts of white gourds, 20-30 parts of bitter gourds, 20-30 parts of lemons, 10-20 parts of oranges, 8-10 parts of pomelos, 6-8 parts of dried orange peel, 2-4 parts of table salt and 160-200 parts of water. According to the fruit and vegetable potato chips disclosed by the invention, the vegetables and the fruits including the carrots, the lemons and the like are added, so that the fruit and vegetable potato chips have the effects of promoting the production of body fluid to relieve thirst, maintaining beauty, keeping young, moistening the lung for relieving a cough, clearing summerheat and quenching thirst.

Owner:刘毅

Crisp and high-tenacity double-layer composite biscuits and making method thereof

ActiveCN103891849BCrispy and deliciousBright colorDough treatmentBakery productsSodium bicarbonateVegetable oil

The invention discloses crisp and high-tenacity double-layer composite biscuits and a making method of the crisp and high-tenacity double-layer composite biscuits, and belongs to the technical field of foods and food processing methods. The crisp and high-tenacity double-layer composite biscuits and the making method of the crisp and high-tenacity double-layer composite biscuits mainly solve the technical problem that existing biscuits made of coarse cereals taste rough, look pale and are complex to make. According to the technical scheme, with wheat flour, white granulated sugar, vegetable oil, potato flakes, purple potato flakes, margarine, edible salt, sodium bicarbonate, ammonium bicarbonate, roasted chicken powder, calcium hydrogen phosphate, soyabean lecithin, disodium dihydrogen pyrophosphate, water and the like serving as raw materials, the crisp and high-tenacity double-layer composite biscuits are made through the processes of weighing, mixing, forming, baking and the like. The crisp and high-tenacity double-layer composite biscuits made through the making method taste crisp and delicious, look bright and are easy to make.

Owner:晋城市古陵山食品有限公司

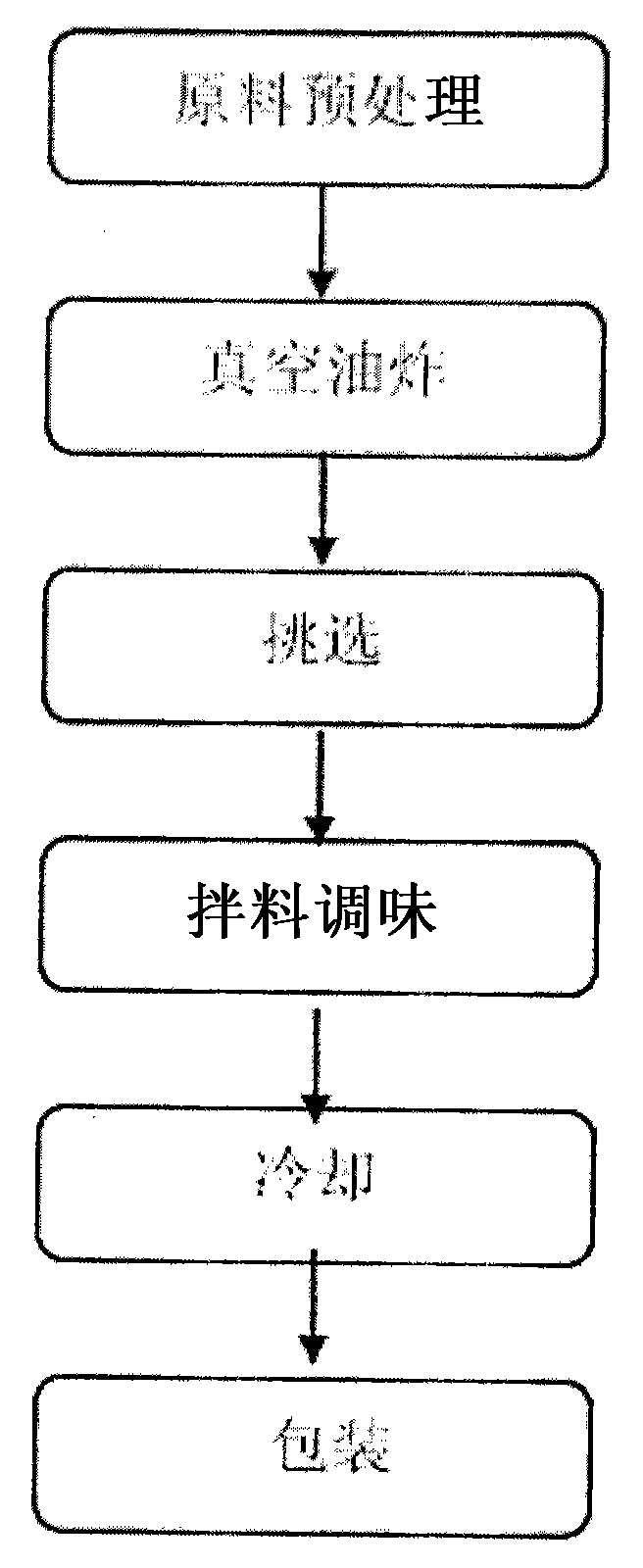

Vacuum low-temperature frying equipment and method

The invention relates to vacuum low-temperature frying equipment and method, and aims at providing vacuum low-temperature frying equipment and method with the advantages that the operation is continuous, the operation is simple and convenient, the labor cost is reduced, and the mouth feel of fried food is good. The method comprises the following steps of sending to-be-fried material into a vacuum frying pot for frying, maintaining the process temperature to 80-110 DEG C and the frying time to 30-40 minutes, automatically controlling the temperature in the frying process, and automatically removing oil after frying; putting the fried food into a collection hopper, and removing defective semi-finished products and impurities on a frying conveying line; stirring the material by a stirrer in a rolling way, and uniformly mixing the sorted fried semi-finished products and the auxiliary materials; conveying the semi-finished products to a cooling line for cooling, and maintaining the temperature to 20-30 DEG C by adjusting, increasing and reducing the number of cooling fans; conveying the seasoned fried semi-products to a package table, and packaging.

Owner:SUZHOU KOUSHUIWA FOOD

Manufacturing method for flat peach cake

InactiveCN104472640ACrispy and deliciousUniform crunchinessBakery productsEngineeringProcess engineering

The invention discloses a manufacturing method for a flat peach cake. The manufacturing method is characterized by comprising the following steps: firstly, decocting 4 to 6 parts of white granulated sugar and 3 to 5 parts of maltose into sticky syrup by heating; secondly, cooling the prepared syrup into a dough shape, and drawing the syrup; thirdly, frying flour, placing the flour into a low-temperature room, and cooling the fried flour to 15 to 20 DEG C; fourthly, wrapping sugar tows with the flour, twisting the sugar tows into fried dough twists, connecting the fried dough twists end to end to form a circular ring, and cooling the circular ring to the room temperature to form a finished product. Preferably, the fried flour in the third step is cooled to 17 DEG C. The flat peach cake manufactured by the method comprises the following components in parts by mass: 5 parts of the white granulated sugar, 4 parts of the maltose, and 0.5 part of flour. The flat peach cake manufactured by the method is crisp and sweet and is not greasy, few varieties of raw materials are required, and a manufacturing process comprises few steps, so that the manufacturing method is suitable for large-scale production and low in cost.

Owner:文吉道

Broad bean sauce and processing technology thereof

The invention discloses broad bean sauce. The broad bean sauce comprises raw materials of preparation components in parts by weight as follows: 200-300 parts of shelled broad beans, 500-600 parts of flour, 20-30 parts of plant oil, 50-80 parts of peanuts, 20-30 parts of edible salt, 3.5-4 parts of largehead atractylodes rhizomes, 4-5 parts of leonurus, 10-20 parts of wild celery, 50-60 parts of honey, 60-80 parts of beef, 40-60 parts of perilla leaf powder, 20-30 parts of bitter gourds, 10-13 parts of ground seaweed, 3-5 parts of South dodder seeds, 4-6 parts of gordon euryale seeds, 4-6 parts of phyllanthus emblica, 3-4 parts of cowpea leaves, 3-5 parts of lilies, 8-11 parts of Hierochloe alpine, 15-19 parts of mulberry leaf powder, 13-18 parts of hairy holly leaf powder, 14-17 parts of ginger, 32-55 parts of edible salt, 1.5-2.5 parts of sodium citrate, 2.3-2.5 parts of ground pepper, 14-16 parts of skim milk powder, 12-15 parts of allspice powder, 12-13 parts of dried red chilies, 15-18 parts of orange peels, 25-27 parts of rice wine and aspergillus oryzae, wherein the weight of aspergillus oryzae is 0.3%-0.5% of the total weight of the broad beans and the flour. People cannot suffer from excessive internal heat after eating the broad bean sauce, the technical problem of high probability of excessive internal heat due to eating of conventional broad bean sauce is solved, and the broad bean sauce can stimulate assimilation of the stomach to food after being eaten, and the appetite is promoted.

Owner:赵兰

Aquatic products pet food (cookies series) and production method thereof

InactiveCN101396062ASatisfy curiosityIncrease curiosityAnimal feeding stuffAccessory food factorsAquatic animalAnimal protein

The invention relates to an aquatic pet food (biscuit series) and a preparation method thereof; the preparation method is characterized in that aquatic animal and starch are used as raw material and flavoring agent is added in the raw material to prepare the aquatic pet food; the flavoring agent is natural fermented seafood condiment, sodium erythorbate, seaweed, compound vitamin and mineral; the preparation method comprises the steps as follows: raw material disposing, compounding, forming, baking and packaging and the like; the preparation method sufficiently uses the advantages that the aquatic animal has high protein content and low fat content, the proportion of the indispensable fatty acid Omega3 and Omega6 contained by the aquatic pet food is most beneficial for the growth and development of pet body, the aquatic pet food has various shapes and delicious tastes and balanced and healthy nutrition; the aquatic pet food can attract the eyes of the pet, meet the curiosity of the pet and improve the appetite of pet, meanwhile, the aquatic pet food reinforces the immunity of the pet, and also has the advantages of grinding and cleaning the teeth and cleaning the peculiar smell in nonnasality of the pet; furthermore, the added natural fermented seaweed condiment can attract the appetite of the pet more.

Owner:威海同仁食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com