Vacuum low-temperature frying equipment and method

A technology of vacuum low-temperature frying and vacuum frying, which is applied in the direction of oil/fat baking, etc., can solve the problems of decreased surface tension, darkened color, increased tendency to form foam, etc., to improve quality stability, reduce operation convenience, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

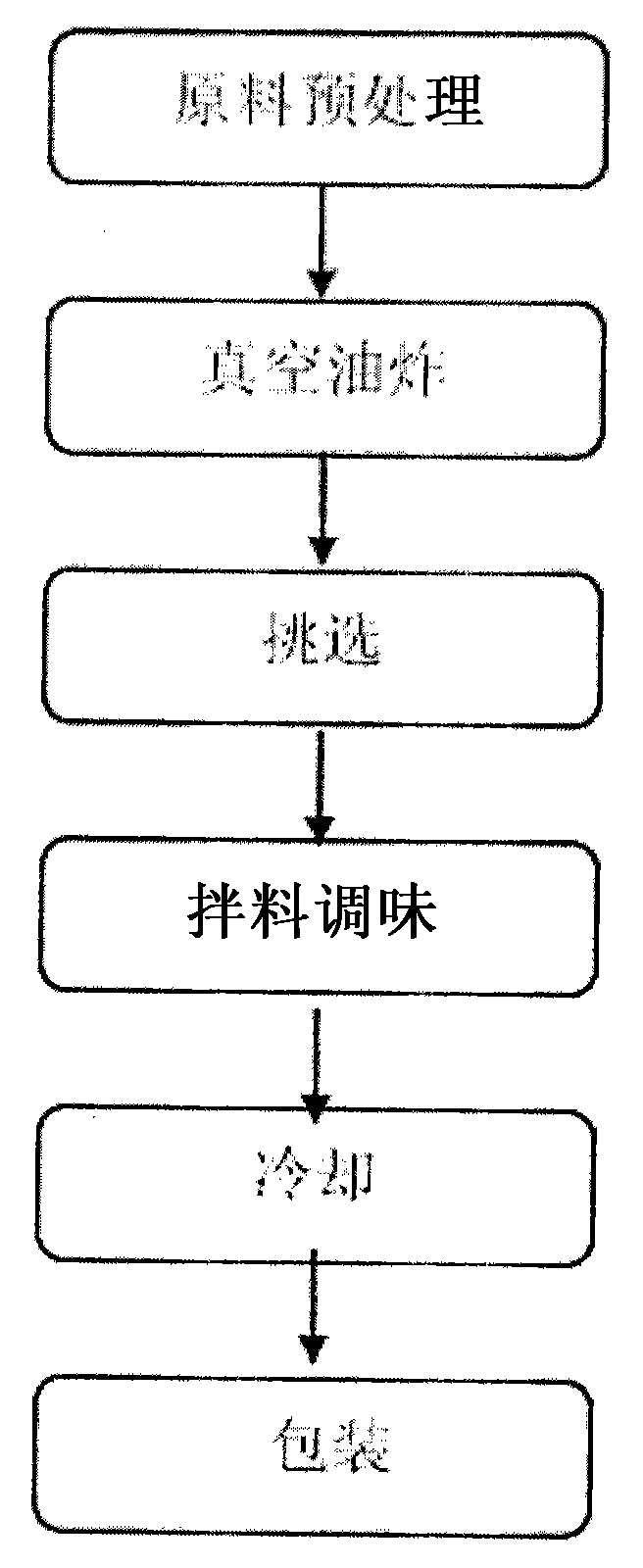

Method used

Image

Examples

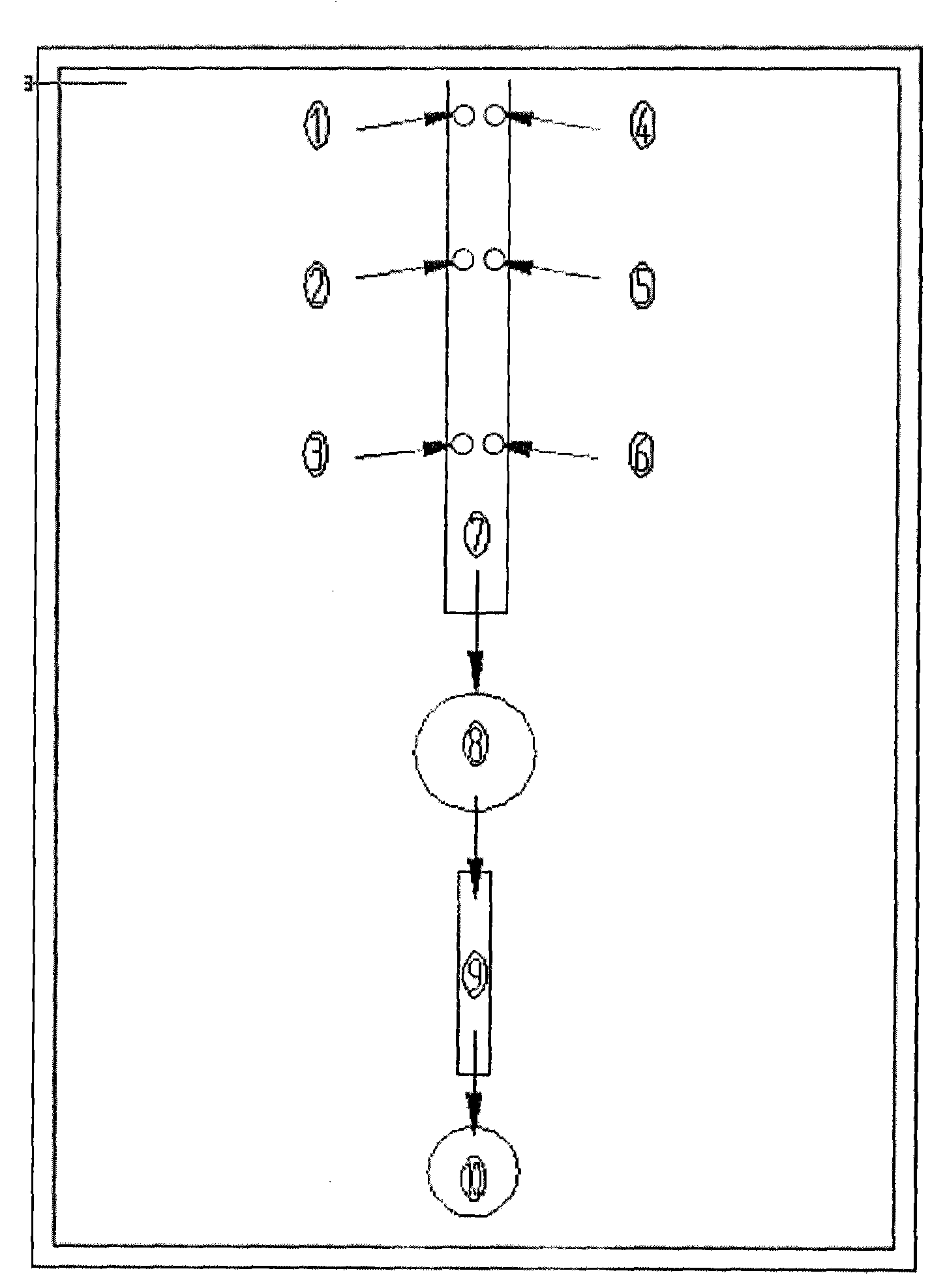

Embodiment 1

[0039] First select the new broad beans of the year, select the broad beans with full and uniform grains, and take out the rotten or immature broad beans and impurities; then use 6 vacuum fryers, use steam as the heat medium, and fry 600kg of broad beans each time , the interval time of each interval feeding is 3 minutes, each frying time is 35 minutes, the frying temperature is 95°C, the temperature is automatically controlled during the frying process, and the oil is automatically deoiled after frying. Each vacuum frying equipment is combined into one On the assembly line, the fried broad beans are poured into the collecting hopper in front of the fryer, and are conveyed to the cooling line by the frying conveying line under the collecting hopper, and the semi-finished products and impurities with poor frying effect are removed on the frying conveying line At the same time, put white sugar: 100kg, spices: 100kg, garlic powder: 50kg, beef powder: 50kg, sesame powder: 50kg, chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com