A method for extracting oligopeptide and oil from fly maggots

A fly maggot and oligopeptide technology, which is applied in the fields of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of high cost, cumbersome steps, protein damage, etc., and achieve the effect of quality improvement and good saponification value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

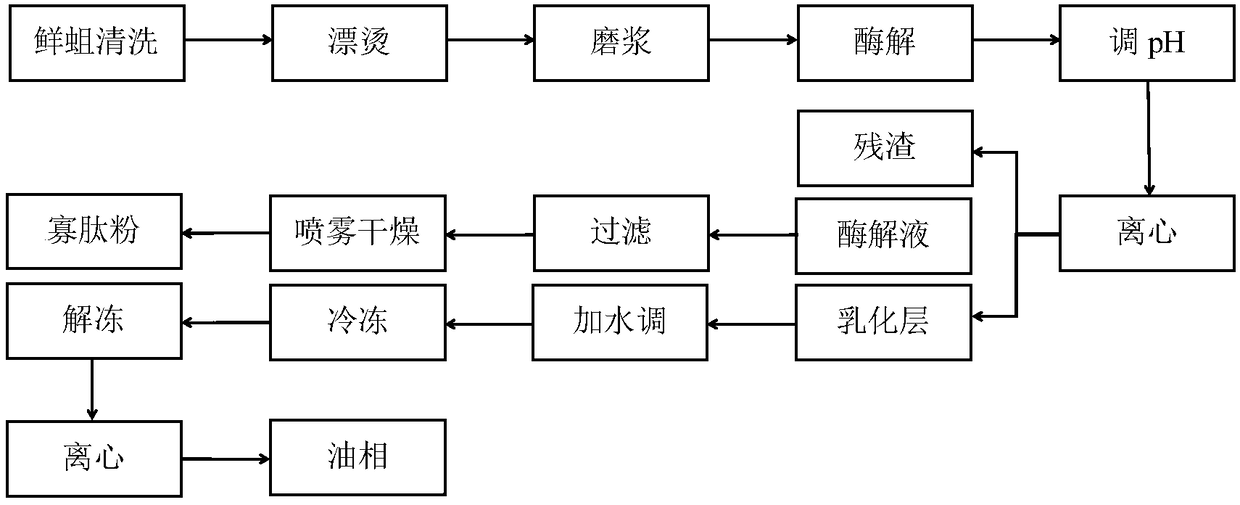

Method used

Image

Examples

Embodiment 1

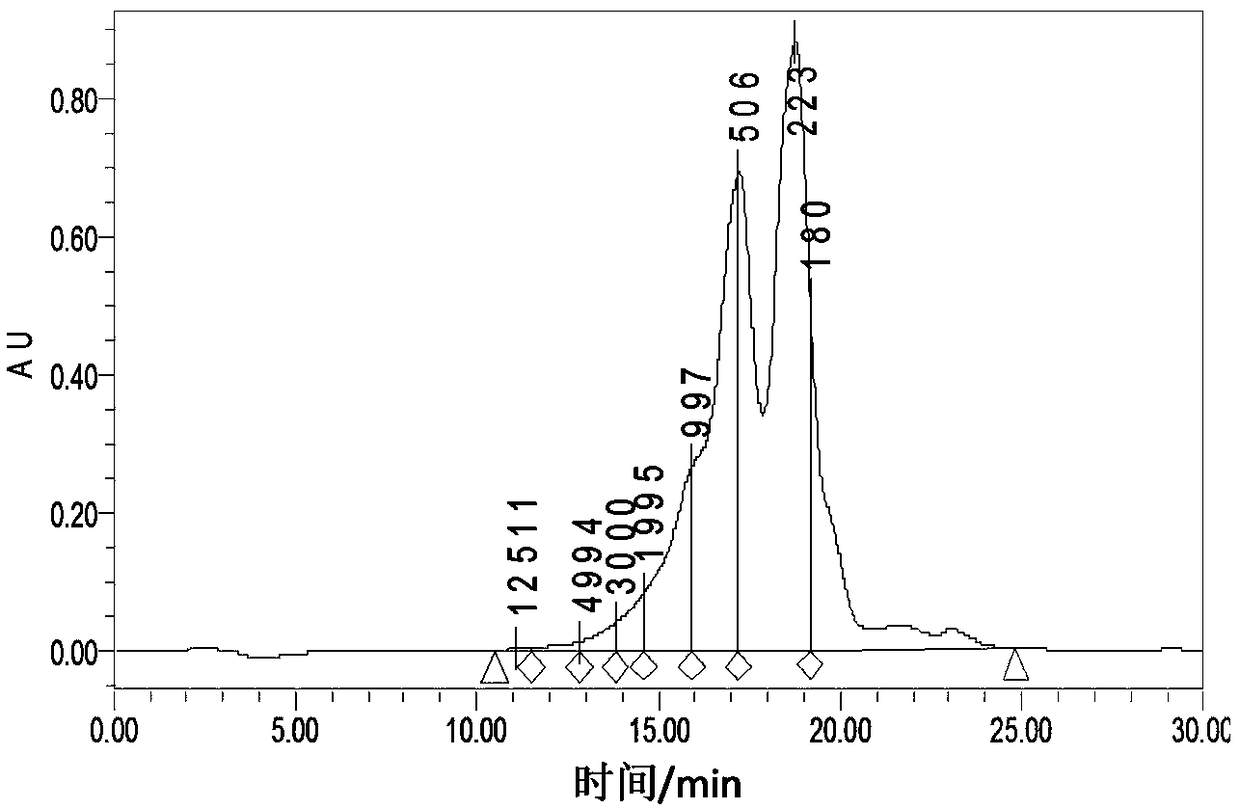

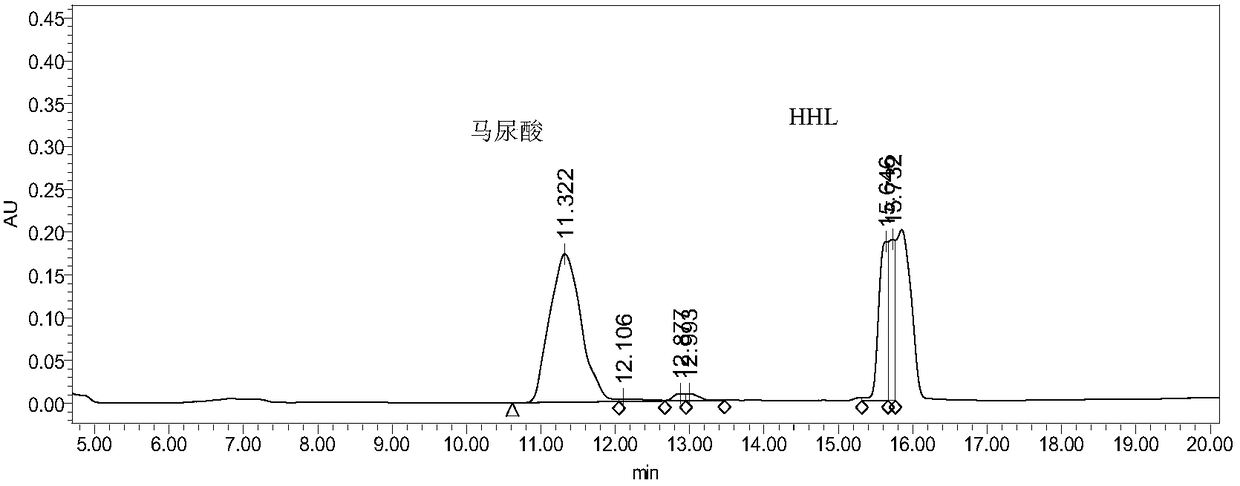

[0044] Fresh maggots are taken by weighing 200g, and after blanching, the mass ratio of fresh maggots to water is 1:1 for refining. Add deionized water to make the solid-liquid ratio 1:10, pour the mixed slurry into the enzymolysis tank, raise the temperature to 55°C, adjust the pH value to 9 with 0.5M sodium hydroxide solution, wait until the pH value is stable After transformation, the amount of Alcalase alkaline protease added is 5000U / g protein, and then the pH value is adjusted with 0.5M sodium hydroxide solution to keep the pH value stable during the enzymolysis process, and the volume of sodium hydroxide solution required is recorded. After 3 hours of enzymatic hydrolysis, the pH value was adjusted to 6 with 1M hydrochloric acid solution. Afterwards, centrifugation was carried out at a speed of 4000 rpm for 20 minutes. The emulsified layer, aqueous phase (enzymolysis solution) and residue were obtained.

[0045] Add 2 g of diatomaceous earth into the water phase, stir...

Embodiment 2

[0049]Fresh maggots are taken by weighing 200g, and after blanching, the mass ratio of fresh maggots to water is 1:1 for refining. Add deionized water to make the solid-liquid ratio 1:15, pour the mixed slurry into the enzymolysis tank, raise the temperature to 45°C, adjust the pH value to 9 with 0.5M sodium hydroxide solution, and wait until the pH value is stable. After transformation, the amount of Alcalase alkaline protease added is 5000U / g protein, and then the pH value is adjusted with 0.5M sodium hydroxide solution to keep the pH value stable during the enzymolysis process, and the volume of sodium hydroxide solution required is recorded. After 3 hours of enzymatic hydrolysis, the pH value was adjusted to 6 with 1M hydrochloric acid solution. Afterwards, centrifugation was carried out at a speed of 4000 rpm for 20 minutes. An emulsion layer, an aqueous phase and a residue are obtained.

[0050] Add 2 g of diatomaceous earth into the water phase, stir evenly, and then ...

Embodiment 3

[0054] Fresh maggots are taken by weighing 400g, and after blanching, the mass ratio of fresh maggots to water is 1:1 for defibrination. Add deionized water to make the solid-liquid ratio 1:15, pour the mixed slurry into the enzymolysis tank, raise the temperature to 55°C, adjust the pH value to 8 with 1M sodium hydroxide solution, and wait until the pH value is stable Finally, the amount of Alcalase alkaline protease added is 5000U / g protein, and then the pH value is adjusted with 1M sodium hydroxide solution to keep the pH value stable during the enzymolysis process, and the volume of sodium hydroxide solution required is recorded. After 3 hours of enzymatic hydrolysis, the pH value was adjusted to 6 with 1.5M hydrochloric acid solution. Afterwards, centrifugation was carried out at a speed of 4000 rpm for 20 minutes. An emulsion layer, an aqueous phase and a residue are obtained.

[0055] Add 4 g of diatomaceous earth into the water phase, stir evenly, and then perform su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com