Patents

Literature

518 results about "PROTEIN S HEERLEN" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weight losing and meal replacement protein type solid beverage

ActiveCN102687750AEnhance nutritional propertiesAdd flavorMilk preparationBiotechnologyPROTEIN S HEERLEN

The invention provides a weight losing and meal replacement protein type solid beverage, which comprises ingredients including concentrated whey protein powder, soy isolate protein powder, dried skim milk, soluble dietary fiber, maltitol or erythritol, maltodextrin, fructo-oligose or fructose, soya bean lecithin, nutrose, low-fat pectin and the like. The protein in the body is effectively supplemented, the satiety is effectively prolonged, the appetite and the caloric intake are more strictly controlled, and further, the goal of losing the weight is reached. The product has the advantages that the nutrition is balanced, the mouth feeling is smooth, savoury and mellow, the carrying is convenient, the process is simple and feasible, and the solid beverage is suitable for mass production.

Owner:浙江诺特健康科技股份有限公司

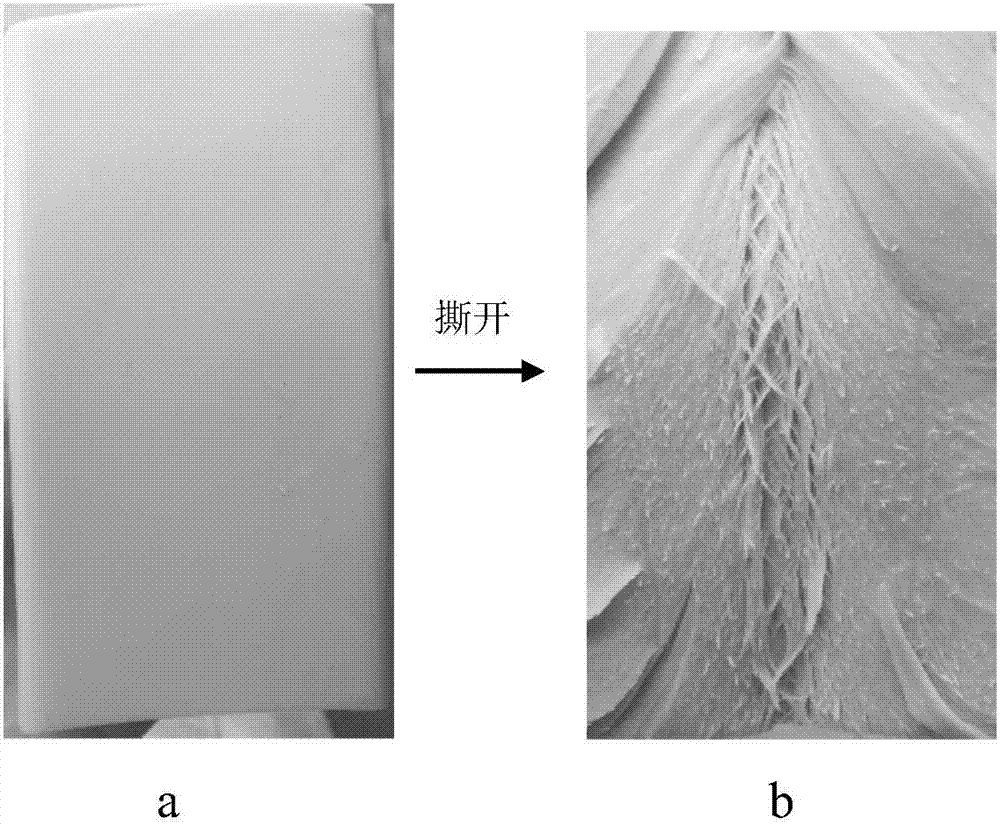

Protein cellulose viscose and preparing method thereof

ActiveCN101298708AGood protein contentImprove spinnabilityConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentSpinningPROTEIN S HEERLEN

The invention relates to a protein viscose fiber and a preparation method thereof, belonging to the textile field and aiming at solving a technical problem about how to provide a method for adopting different animal and plant proteins as materials to prepare the protein viscose fiber. The preparation method of the protein viscose fiber includes the following steps: 1. the animal and plant proteins are degreased, decolored and deodorized to obtain animal-plant protein powder; 2. alkalization: the animal-plant protein powder is dissolved in alkaline liquor to obtain protein alkaline solution; 3. cross-linker is added into the protein alkaline solution to obtain a protein spinning liquor; 4. the protein spinning liquor is blended with a glue to be spun to obtainprotein filaments; 5. the protein filaments are washed by peroxide solution and are oiled, dried and formed into cylinder form to get the protein viscose fiber. The protein viscose fiber preparation method of the invention does not adopt any acetalation treatments to the protein filaments after spinning so as to avoid the remaining of methanal, etc. harmful matters, the technique steps are simple and can be easily operated and the manufacturing can be realized with the existing viscose fiber preparation equipment.

Owner:YIBIN GRACE GROUP CO LTD

Energy rod

ActiveCN101455370AEasy to synthesizeMaintain blood sugar levelsFood preparationPhysical chemistryTriglyceride

The invention relates to an energy rod containing the following components of the weight parts of: middle chain triglyceride 2-20, protein powder 5-60, syrup 10-30 and other greases 4-10. The energy rod can provide energy rapidly, improve endurance, but can not cause obesity, is especially suitable for athletes and outdoor sporters.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

Chenopodium quinoa protein powder preparation technology

InactiveCN105076665AProteins working-up by texturisingVegetable proteins working-upBiotechnologyAmylase

The present invention discloses a chenopodium quinoa protein powder processing technology, and specifically relates to a production technology used to extract and isolate protein powder from the chenopodium quinoa. The production process includes the following steps: (1) rinsing the chenopodium quinoa, draining, then soaking in hot water and grinding into slurry; (2) conducting coarse filtration and fine filtration of the chenopodium quinoa slurry to obtain a slurry; (3) adjusting the pH of the slurry to be alkaline, keeping still, and centrifuging to obtain a primary chenopodium quinoa protein slurry; (4) adjusting the pH of the primary chenopodium quinoa protein slurry to be neutral, adding amylase and glucoamylase to conduct enzymatic hydrolysis in a warm bath; (4) increasing the temperature to inactivate the enzymes after the enzymatic hydrolysis, concentrating by ultrafiltration to remove inorganic ions and oligosaccharides; and (5) finally, conducting centrifugation and spray drying to obtain the high purity chenopodium quinoa protein powder. The chenopodium quinoa protein extracted and isolated by this technology has a yield of more than 85% and a protein purity of more than 90%.

Owner:LIAOCHENG UNIV +1

Preparation method of formaldehyde-free water-resistant protein adhesive

InactiveCN103937441ALow costIncrease crosslink densityNon-macromolecular adhesive additivesProtein adhesivesPROTEIN S HEERLENProtein activation

The invention relates to a preparation method of a formaldehyde-free water-resistant protein adhesive. The main preparation steps are as follows: 1) activating a protein raw material: adding the protein-containing raw material and absolute ethanol, stirring, further adding an alkaline solution, and heating to 45-80 DEG C for reaction; cooling to room temperature and adding a reducing agent; and adjusting to neutral, and evaporating to dryness to obtain activated protein powder; and 2) preparing the protein adhesive: adding the activated protein powder prepared in the step 1, water, an acid-adjusting reagent, an enhancer and a preservative into a reactor, reacting at the temperature of 30-50 DEG C, and reducing to room temperature to obtain the protein adhesive. The preparation method is characterized in that a special protein activation process is adopted to enable proteins to expose active groups thereof and utilize a variety of active functional groups of the proteins to the greater extent; the preparation process of the adhesive is simple and has the advantages of good reproductivity, low cost, no formaldehyde and good water resistance; and a hot pressing process is the same with an existing urea-formaldehyde resin pressure plate process, on the basis of not changing and increasing the hot pressing process and equipment, the production of formaldehyde-free artificial plates can be realized, and the market prospects are greater in comparison with the existing protein adhesive in industrial production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

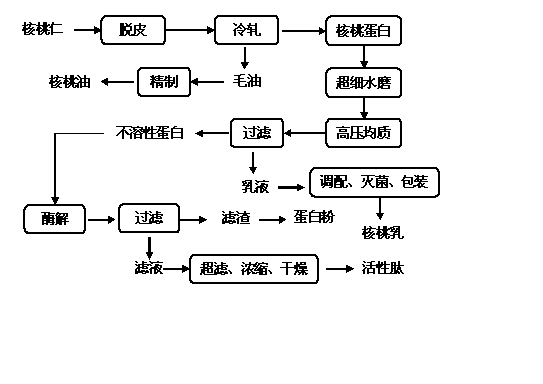

Deep processing method for preparing low-fat walnut milk, active peptide and protein powder by comprehensively utilizing walnut kernels

The invention aims at the high-value processing of walnut protein. A deep processing method comprises the following steps: firstly, separating out walnut oil by a low-temperature cold-rolling method to obtain walnut kernel protein; secondly, dissolving the soluble protein to prepare walnut milk drink through micro-grinding and homogenizing processes; thirdly, performing enzymatic hydrolysis on the insoluble walnut protein to obtain the active peptide through enzymatic degradation; and finally, developing the rest of protein residues into walnut powder so as to realize full-value utilization of the walnut protein.

Owner:JIANGNAN UNIV +1

Poly peptide protein feed and its processing method

InactiveCN1555720AIncrease payGuaranteed Bioactive IngredientsAnimal feeding stuffAquatic productOil water

A process for preparing the polypeptide-protein feed from the low-value fish and shrimp and the leftover of aquatic products includes removing impurities, steaming for defatting, oil-water separating, pulverizing, sterilizing, enzymolyzing, deactivating enzyme, concentrating and drying. The obtained feed features high contents of polypeptide and protein, and high reward rate.

Owner:韩福山

Peptide-containing low molecular plant protein milk and production method thereof

InactiveCN102640796AReduce the burden onShorten digestion timeMilk substitutesFood scienceBiotechnologyPROTEIN S HEERLEN

The invention provides a peptide-containing low molecular plant protein milk and a production method of the peptide-containing low molecular plant protein milk, belongs to food technical field, and overcome the defects of existing products, such as long digestion absorption time and low digestion rate. The production method comprises the steps of cleaning and selecting raw material soybean, drying, skinning, deactivating enzyme, coarse grinding, fine grinding, enzymatic hydrolyzing, separating pulp and residue, instantly sterilizing and deactivating enzyme under ultrahigh temperature, homogenizing, and drying to obtain powdered product with relative molecular weight not greater than 5,000. By adding enzymatic hydrolysis link in existing production process of soybean milk and instant soybean protein milk powder, the milk contains above 10% of low molecular peptide components, to relieve protein enzymolysis burden in human body after taking soybean milk or protein powder, shorten digestion time, improve digestion rate, and facilitate peptide (low molecular protein) supplementation for weak and sick population, the elderly and children through taking soybean milk or protein powder.

Owner:CHANGCHUN UNIV

Small peptide additive for fodder and preparation process thereof

InactiveCN101032280ASynthesis speedEnhance immune functionBacteriaFood processingBiotechnologyNutritional status

The present invention is one kind of small peptide feed additive with rich small peptide and probiotics matter and no anti-nutrilite. The small peptide feed additive is prepared with soybean residue, wheat bran, corn protein powder, corn starch, alcohol dreg, tropina powder, waste molasses and / or starch, and through inoculating probiotics seed and solid fermentation to eliminate anti-nutrilite and generate small peptide, lactic acid and other probiotics matters. It has total small peptide content not less than 15.0 wt%, amino nitrogen content 0.5-1.0 %, total nitrogen content not less than 8.0 %, lactic acid content not less than 3.0 %, water not more than 12.0 % and molecular weight smaller than 20,000 Dalton. The small peptide feed additive can raise the speed of synthesizing protein in animal body, appetize, raise body's immunity, promote the absorption of animal body on mineral elements, regulate physiological activity and improve nutritious condition.

Owner:BANGCHENG FORAGE SCI & TECH SHANGHAI

Inhaleable spray dried 4-helix bundle protein powders having minimized aggregation

InactiveUS20050186143A1Small sizeGood dispersionPowder deliveryPeptide/protein ingredientsPROTEIN S HEERLENInhalation

The present invention provides highly dispersible spray-dried powder compositions, and in particular, inhaleable dry powder compositions for aerosolized delivery to the lungs. The powders of the invention are produced by spray drying a 4 α-helix bundle protein under conditions which both (i) protect the protein from aggregation and (ii) provide particles suitable for inhalation (i.e., demonstrating superior aerosol performance).

Owner:NOVARTIS FARMA

Antioxidation active peptides and method for preparing same

InactiveCN101284872AGood scavenging effectInhibit peroxidation reactionMicroorganism based processesPeptide preparation methodsBacillus nattoIon exchange

The invention discloses antioxidation bioactive peptide and a method for making the same. The product is made through the following steps that: microbial bacillus natto and corn protein powder are respectively used as strain and a raw material, which undergo liquid culture; and fermentation broth is separated through ion exchange chromatography, gel chromatography, reversed phase chromatogram and electrophoresis. The molecular weight of the product is between 20,100 and 31,000 and the five amino acid sequences at an N terminal are K-V-T-Y-H with the antioxidation activity reaching to 236.68U / mL. Moreover, the product has higher antioxidation activity, and pure product can meet the requirements of structural and physical property measurements of antioxidation bioactive peptide, activity and toxicological experiments as well as large-scale application such as therapy and cultivation; because antioxidation active material has strong cleaning action on superoxide anion free radical and hydroxyl free radical and can remarkably inhibit the overoxidation reaction between red blood cell and the lipid of liver, heart and brain tissue, the product has functions such as disease prevention and aging resistance and can be further developed into additives of products such as medicine and cosmetic.

Owner:QIQIHAR UNIVERSITY

Immune type protein powder solid beverage and preparation method thereof

ActiveCN104522832AImprove absorption rateHigh purityNatural extract food ingredientsFood ingredient functionsWhey proteinGamma-Aminobutyric acid

The invention discloses an immune type protein powder solid beverage and a preparation method thereof and belongs to the field of nutritional foods. The solid beverage comprises the following components: 70-85 percent of concentrated whey protein powder, 3-8 percent of pea protein, 5-15 percent of wheat protolysate, 2-4 percent of phospholipid, 1-3 percent of an acerola cherry extract, 1-5 percent of edible essence, 0.5-1.5 percent of a yeast extract, 0.5-1.5 percent of gamma-aminobutyric acid, 0.5-1.5 percent of coconut milk powder, 0.3-0.8 percent of silicon dioxide and 0.1-0.3 percent of stevioside. The invention also discloses the preparation method of the solid beverage. The solid beverage disclosed by the invention fully meets the demands of the human body, is scientific in prescription design, reasonable in nutrition arrangement and different in taste according to different customers, and can meet the special demands of different people on taste; the solid beverage is mellow in taste, convenient to use, stable in quality, simple in preparation method, easy to operate, suitable for large-scale industrial production, free of sugar in the prescription and suitable for diabetics to eat.

Owner:JIANGSU ALAND NOURISHMENT

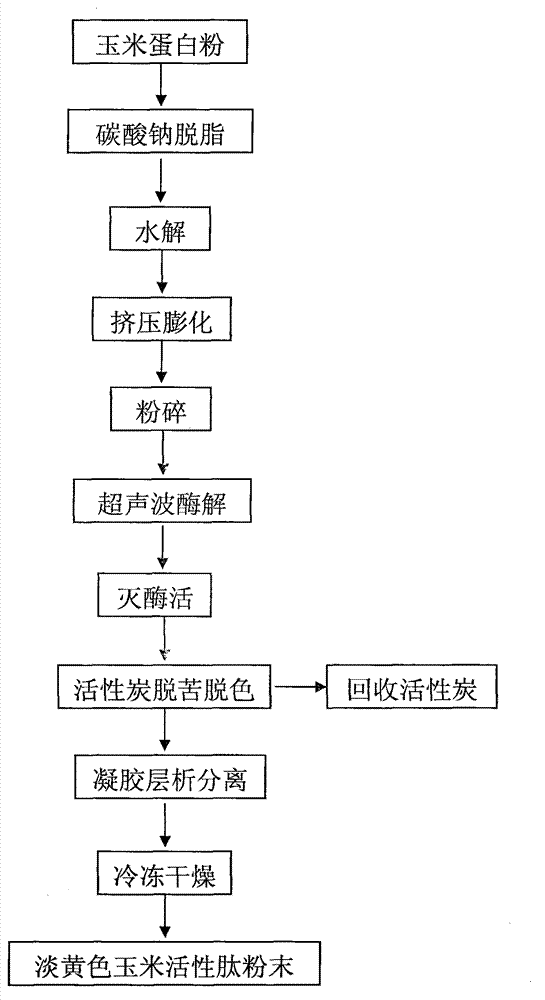

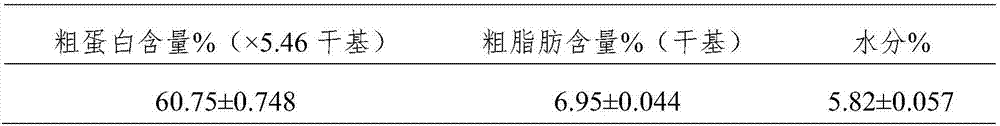

Preparation method of corn active peptides

InactiveCN102864201ALow priceImprove food safetyPeptide preparation methodsFermentationFreeze-dryingDry basis

The invention discloses a preparation method of corn active peptides. The preparation method includes subjecting corn protein powder to steps of pretreating, extrusion puffing, ultrasonic enzymolysis, enzyme deactivation, debittering, decoloring, gel chromatography, freeze-drying and the like. The preparation method is simple in process and low in cost. Content (by dry basis) of prepared corn active peptides reaches more than 85%, yield reaches more than 72%, and a feasible process for large-scale production is provided.

Owner:SHAANXI TONGZHENG TECH CO LTD

Soybean albumen powder and technique of preparing the same

InactiveCN101107967AImprove solubilityImprove stabilityVegetable proteins working-upPhosphatide foodstuff compositionsPROTEIN S HEERLENWhey protein

A soyabean protein powder is provided, which is characterized in that: the invention is made with materials as the following weight ratio: 70 pieces to 90 pieces of soy protein isolate, 5 pieces to 25 pieces of whey protein, 0.5 pieces to 2 pieces of lecithin and 0.5 pieces to 2 pieces of stabilizer. The preparation technics of the invention is that: 1, combining the soy protein isolate and the whey protein according to the proportion; 2, adding stabilizer; 3, spraying the lecithin grain granulation on a boil bed; 4, collecting the granulation production and the finished sterilizing product with the water between 3.2 per cent to 3.5 per cent and the sterilizing time of 20min to 40min. The invention has the advantages that: 1, the combination of the protein powder and the aminophenol is rational and completely and is easy for assimilation and absorbability, thus reasonably strengthening the nutriment; 2, the invention enhances the dissolvability and stability of the soy protein; 3, the boiling bed granulation technology adopted fulfills the mixing, granulation and drying in one equipment for once, thus making the production technics simple and easy.

Owner:TIANJIN YOUFUJIAN CREATURE ENG

Silk protein powder and preparation method thereof

InactiveCN103290085AHigh purityImprove biological activityPeptide preparation methodsFermentationPolymer sciencePROTEIN S HEERLEN

The invention discloses silk protein powder and a preparation method thereof. The preparation method comprises the following steps of: (1) degumming silks; (2) performing enzymolysis on silk fibroins and sericin; (3) separating and purifying silk proteins; and (4) pre-concentrating and drying a silk protein liquid. The silk protein powder disclosed by the invention comprises sericin proteins and silk fibroin proteins, has the advantages of high purity, high biological activity, proper molecular weight, white color, zero foreign smell and the like and can be used for making biological and medical materials, health protection food and the like, and the aims of pure nature, high activity, high functionality, rich nutrition and the like are fulfilled.

Owner:湖州新天丝生物技术有限公司

A method for preparing peanut antioxidant peptides by fermentation

ActiveCN102286601AInhibition of peroxidative activityInhibition of chelation abilityMicroorganism based processesFermentationBiotechnologyDPPH

The invention discloses a method for preparing peanut antioxidant peptide by fermentation, and the method comprises the following steps: adding distilled water to low-denatured degreased peanut protein powder, ultrasonically dispersing and dissolving, adjusting the pH value, sterilizing and cooling; inoculating with strain seed culture liquid, and fermenting and culturing; and carrying out ultrasonic-assisted enzymolysis, inactivating enzyme, centrifuging, and freeze-drying supernatant to obtain the peanut antioxidant peptide. The peanut antioxidant peptide prepared by the method disclosed by the invention has the antioxidant activities of scavenging hydroxyl free radical, superoxide anion free radical and DPPH (1,1-diphenyl-2-picrylhydrazyl) free radical, inhibiting hydroxyl-free-radical-mediated deoxyribose injury, inhibiting peroxidation of lipidosome, resisting oxidation of linolic acid system, resisting grease peroxidation capability and the like, and has iron reduction capability, molybdenum reduction capability, iron ion chelating capability and copper ion chelating capability; and the method is simple to operate, has mild reaction conditions and is suitable for industrial production.

Owner:SHANDONG SHIJICHUN FOOD

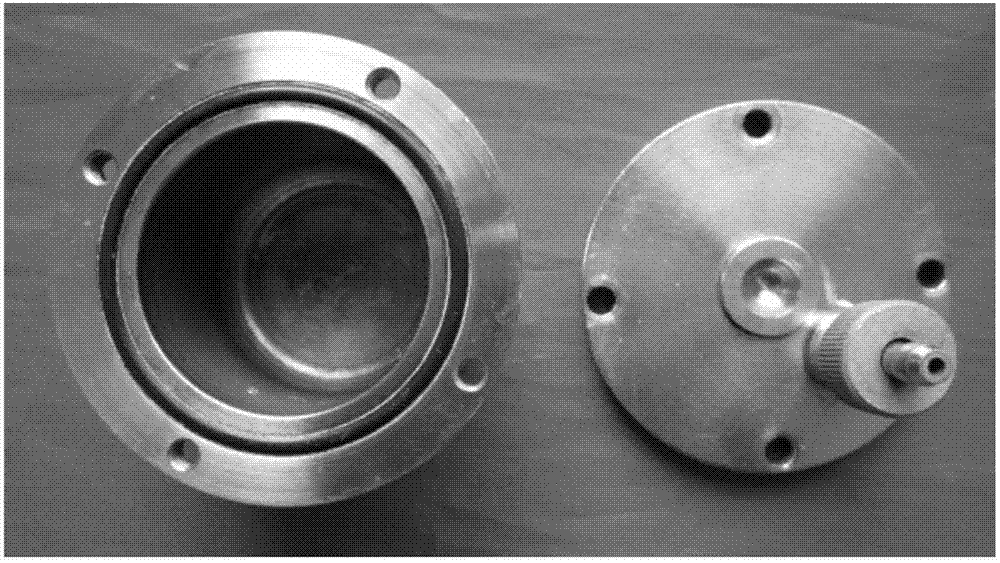

Curing and forming die for preparing foamed ceramic according to protein foaming method and preparation method of curing and forming die

ActiveCN102765126AGood molding effectOvercoming the problem of rapid water lossCeramic shaping apparatusCeramicwarePROTEIN S HEERLENSlurry

The invention discloses a curing and forming die for preparing foamed ceramic according to a protein foaming method. The curing and forming die comprises a die body and a die cover, wherein the die body is connected with the die cover in a sealing manner to form a die cavity; a pneumatic control valve is arranged on the die cover; an airflow passage is formed in the valve; and the opening and closing of the pneumatic control valve is regulated by the atmospheric pressure difference between the die cavity and the outside. The invention further discloses a method for preparing the foamed ceramic through protein foaming. The method comprises the steps as follows: raw materials are mixed, dissolved in water and ball-milled, and then albumen protein powder is added to obtain foam slurry; the foam slurry is injected into the curing and forming die and is cured in water bath to form a blank body; then the blank body is dried and heated to the protein burning-off temperature, and heat preservation is performed; and finally, heating sintering is carried out under nitrogen protection, and heat preservation is performed to obtain the foamed ceramic. The curing and forming die provided by the invention has the advantages of simple structure, low cost, easiness in control, good product quality and the like.

Owner:NAT UNIV OF DEFENSE TECH

Fodder additive having immunologic enhancement in growing and preparation method thereof

InactiveCN101032281AImprove immunityPromote growthBacteriaFood processingTotal nitrogenFeed additive

The present invention is one kind of feed additive for strengthening immunity and promoting growth. The feed additive is prepared with soybean residue, wheat bran, corn protein powder, corn starch, alcohol dreg, tropina powder, waste molasses and / or starch, and through inoculating probiotics seed and solid fermentation. It has total immune polysaccharide content not less of 0.3-1.0 %, immune energy matter content 0.3-1.0 %, lysine content not less than 4.0 %, amino nitrogen content 0.5-1.0 %, total nitrogen content not less than 10.0 %, and water not more than 12.0 %. The feed additive can raise the immunity of animal obviously, raise the speed of synthesizing protein, promote the growth of animal, appetize, promote the absorption of animal body on mineral elements, regulate physiological activity and improve nutritious condition.

Owner:上海邦成生物工程有限公司

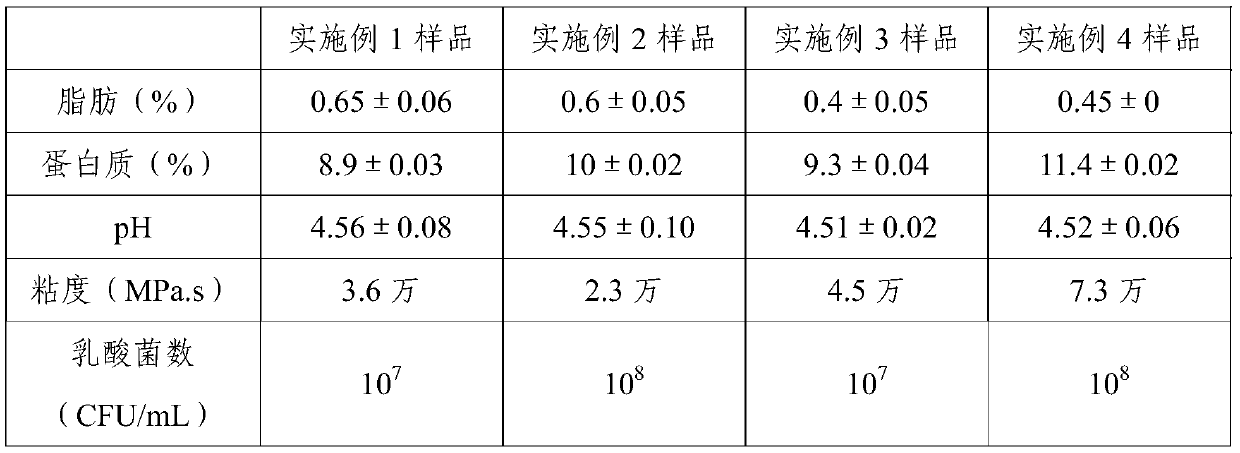

Low-fat high-protein yoghourt and preparation method thereof

The invention provides a low-fat high-protein yoghourt and a preparation method thereof. The yoghourt is prepared from, by weight, the following raw materials: 80-90 parts of low-fat milk, 8-12 partsof composite protein powder, 0.2-8.5 parts of a sweetener and a proper amount of a leavening agent, wherein the total weight is 100 parts, and the use amount of the leavening agent per 100 kg of the raw materials is 10-25U, and the composite protein powder is selected from at least two of concentrated whey protein, isolated whey protein, milk concentrated protein, casein and skimmed milk powder. By screening raw milk indexes, strains, composite protein powder and other auxiliary materials and optimizing the proportion, the problem is effectively solved that high-protein yoghourt products are prone to serious particles and poor in taste. The protein content of the product is 8% or above, and the product has the characteristics of strong fragrance, smoothness and fine taste. In addition, theprocessing method is simple and feasible, devices such as centrifugation, filtration and the like are not needed, and the cost is saved.

Owner:黑龙江完达山林海液奶有限公司

Premixed feed used specially for milk cow before perinatal period and its producing method

InactiveCN101044886APromote healthEliminates loss of appetiteMetabolism disorderFood processingChemistryMagnesium sulphate heptahydrate

A pre-mixed forage for the milk cow in early perinatal period is prepared from glucose oxidase or yeast protein powder, ammonium chloride, magnesium sulfate, calcium sulfate, urea phosphate, distiller' s grains, and the mixture of copper sulfate, ferrous sulfate, manganese sulfate, Zinc sulfate, magnesium sulfate, cobalt chloride, potassium iodate, sodium selenite, VA, VD3, VE, calcium hydrogen phosphate and calcium carbonate. Its preparing process is also disclosed.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

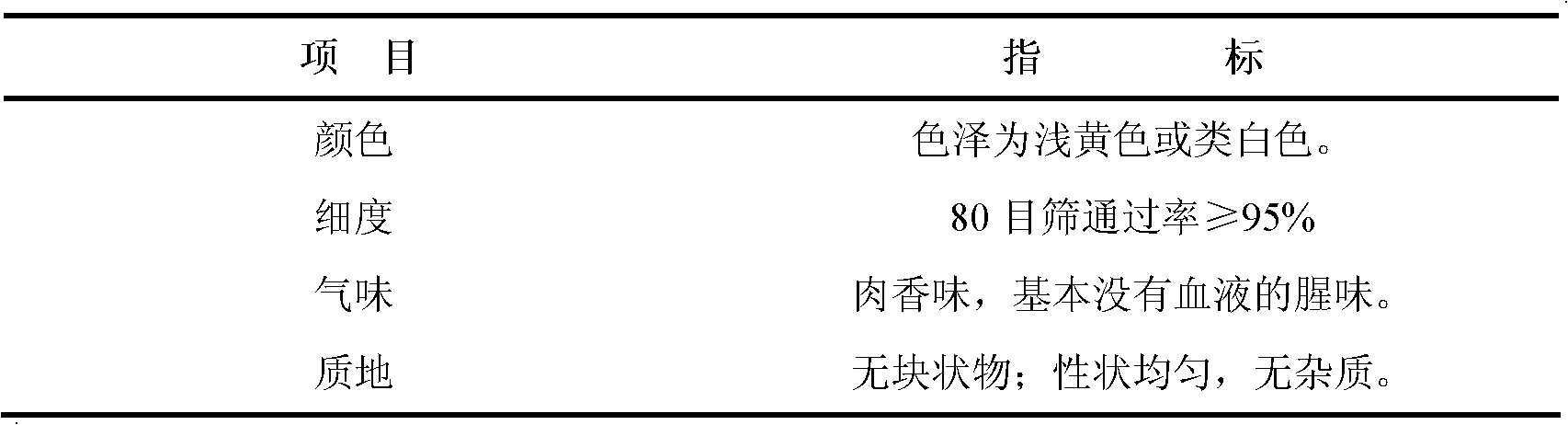

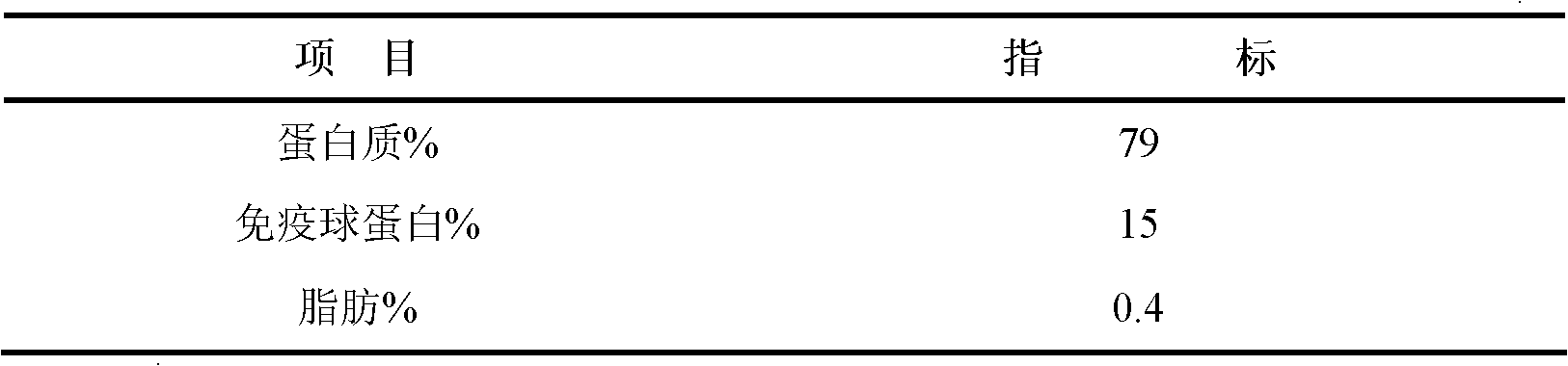

Method for preparing high-protein food-grade plasma protein powder

InactiveCN102318722ALow ashRetain physiological activityProtein composition from bloodChemical reactionDecomposition

The invention relates to a method for preparing high-protein food-grade plasma protein powder, which comprises the following steps of: sampling blood; anticoagulating; separating; refrigerating; film concentrating; spraying and drying; packing for the first time (inner packing); sterilizing with microwave; and packing for the second time (outer packing). A product prepared according to the preparation method disclosed by the invention has high protein content, high immunoglobulin content and low ash content; film concentrating equipment can be used for eliminating water and salt in plasma, reducing the ash content in the plasma protein powder and enhancing the content of protein of the plasma protein powder and immunoglobulin; the concentration process is performed at normal temperature; the protein in the plasma does not undergoes chemical reaction or phase change; other impurities cannot be brought in; decomposition and denaturation of the protein in the plasma cannot be caused; therefore, effective components in the plasma cannot be destructed; simultaneously, the method of combining a drying method in which the temperature is lower than the temperature of a spray drying inlet and a spray drying outlet with a microwave drying technology is adopted; and nutrient components with physiological activity in the plasma can be further reserved in the drying process.

Owner:天津宝迪农业科技股份有限公司

Method for preparing peptide with high antioxidant activity by utilizing rice residue protein treated by superhigh pressure

ActiveCN105010720ADoes not destroy nutrientsImproves antioxidant activityProtein foodstuffs working-upPROTEIN S HEERLENCentrifugation

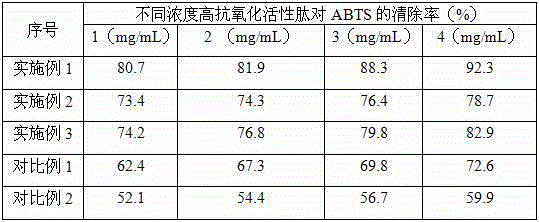

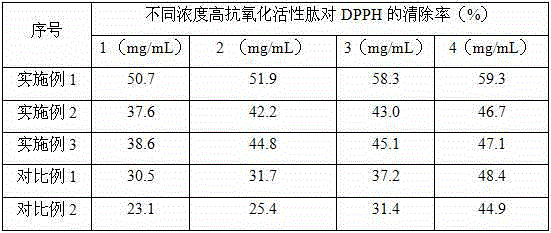

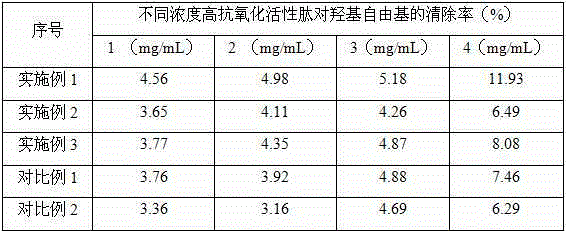

The invention relates to a method for preparing peptide with high antioxidant activity by utilizing rice residue protein treated by superhigh pressure. The method comprises the following steps: (1) pretreating rice residues so as to obtain rice residue powder; (2) extracting the rice residue protein: mixing the rice residue powder and water so as to obtain a mixture, regulating the pH value of the mixture to be 11-13, stirring the mixture for a reaction, performing centrifugation so as to collect supernatant, regulating the pH value of the supernatant to 5.0-5.8, precipitating the supernatant of which the pH value is regulated, centrifuging the precipitated supernatant and washing the centrifuged supernatant so as to obtain the rice residue protein; (3) treating the rice residue protein through superhigh pressure: treating the rice residue protein under the superhigh pressure, and freeze drying the treated rice residue protein so as to obtain superhigh-pressure rice residue protein powder; (4) performing enzymolysis: compounding the superhigh-pressure rice residue protein powder into an aqueous solution, performing enzymolysis on the aqueous solution, performing enzyme deactivation on the queous solution after enzymolysis, centrifuging the queous solution on which the enzyme deactivation is performed, and collecting supernatant; (5) performing vacuum concentration on the supernatant so as to obtain a concentrated solution; and (6) freeze drying the concentrated solution so as to obtain the peptide with high antioxidant activity. Products obtained by the method disclosed by the invention have higher antioxidant activity; compared with products which are not treated through the superhigh pressure, the clearance rate for DPPH free radicals, the clearance rate for ABTS free radicals and the clearance rate for hydroxyl free radicals in the products obtained by the method disclosed by the invention are greatly increased respectively.

Owner:湖南南洲酒业有限公司

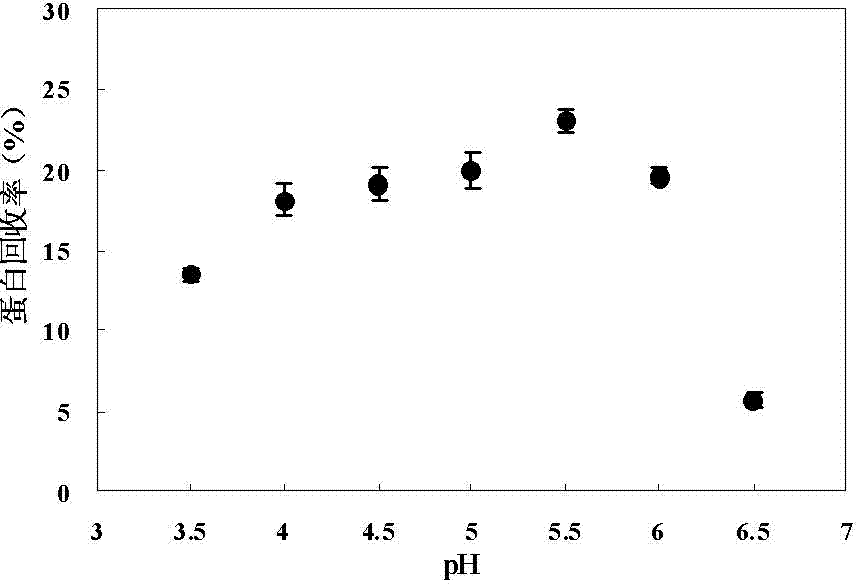

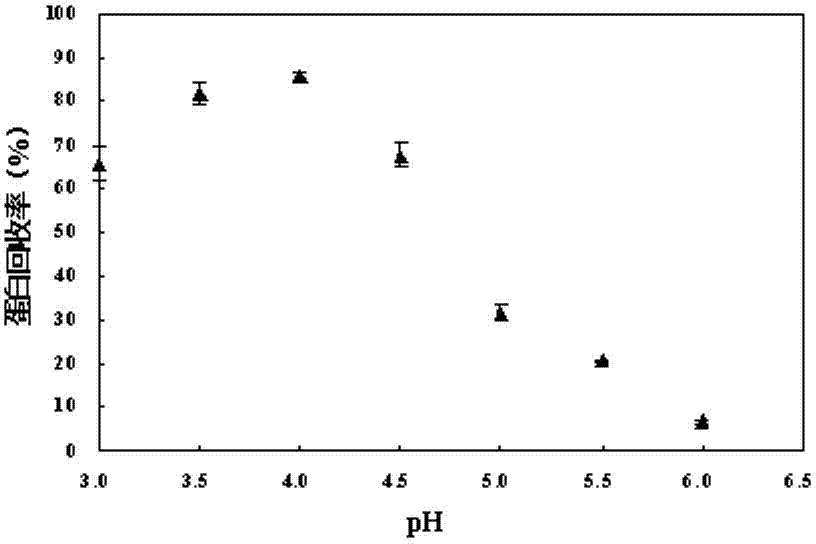

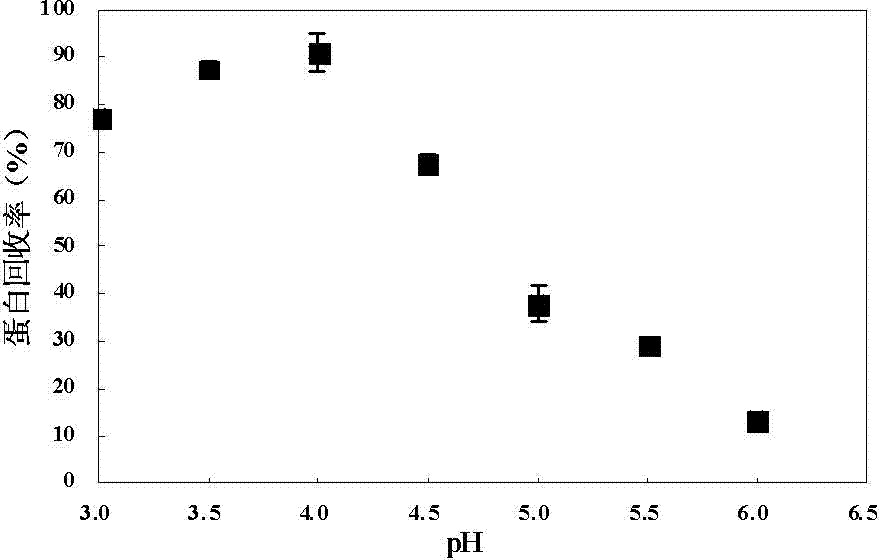

Method for recycling water-soluble proteins in minced fish rinsing water

ActiveCN102757491AIncrease ionic strengthImprove settlement performancePeptide preparation methodsAnimals/human peptidesCentrifugationEconomic benefits

The invention relates to a method for recycling water-soluble proteins in minced fish rinsing water, which is characterized by comprising the following steps: salt-process low-temperature degreasing: adding a certain amount of table salt (NaCl) into minced fish rinsing water, stirring to sufficiently dissolve the table salt, and standing until grease precipitates and floats up to the surface, wherein the temperature of the rinsing water is controlled at 10 DEG C below in the whole process; isoelectric point protein precipitation: adding acid to the obtained liquid to regulate the pH value to 4.0-5.0, and standing to sufficiently stratify; preliminary protein recycling: discharging the supernatant part of the obtained liquid out by using a pump, and collecting the understratum protein precipitation layer; and protein recycling by centrifugation. The recycled protein can be directly packaged into finished product for freezing storage, or spray-dried into protein powder. The method provided by the invention is simple and easy to implement and is efficient; and the method can greatly reduce environmental pollution caused by improper discharge of protein-rich rinsing water, enhance the economic benefit of the minced fish production enterprise, and implement efficient utilization of resources, thereby having important meaning for environment-friendly sustainable development in minced fish processing industry.

Owner:JIMEI UNIV

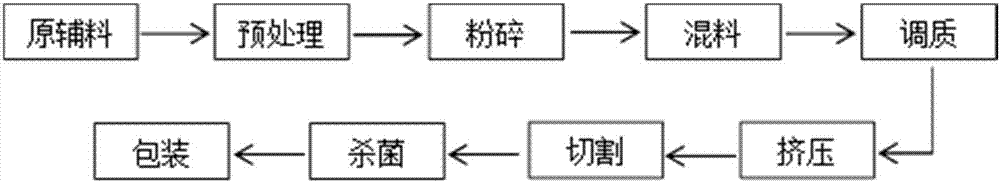

Method for producing drawing protein by utilizing compound vegetable protein containing peanut and soybean

The invention discloses a method for producing a drawing protein by utilizing a compound vegetable protein containing peanut and soybean. The method comprises the following steps: mixing and tempering 73-85 parts of low-temperature degreased peanut protein powder, 5-15 parts of soy isolate protein, 1-15 parts of vital gluten and 1-15 parts of starch at the ratio of raw materials and then performing extruding tissue treatment under the conditions of extruding temperature of 60-160 DEG C, screw speed of 180-240r / min, feeding rate of 80-140g / min, cooling temperature of extruding mold of 62-75 DEG C and moisture content of materials in the extruding process of 50%-62%. High-moisture peanut drawing protein prepared according to the invention can overcome the difficulty in preparing the high-moisture drawing protein by taking peanut protein as the raw material; the acquired product requires no rehydration, has uniform and bright color and is free from bean flavor; compared with a tissue product taking a single protein as the raw material, the product has the advantage of rich nutrition.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Production method of deodorized silver carp protein powder

ActiveCN103330046APromote dissolutionHigh extraction rateProtein composition from fishBiotechnologyPROTEIN S HEERLEN

The invention discloses a production method of deodorized silver carp protein powder, which comprises the steps of taking a low-value freshwater fish, namely a silver carp, as a raw material, preparing surimi pulp, degreasing and deodorizing with saccharomycete fermentation liquid, extracting by an acid method, condensing, and drying to obtain the silver carp protein powder. According to the method, surimi and the rosin saccharomycete fermentation liquid are incubated together, saccharomycete fermentation and active ingredients in the fermentation liquid are used for deodorization, and hydrolysis of an endogenous histenzyme of fish is used to promote protein dissolution. With the adoption of the ultrasonic aided acid method for extraction, the protein extraction rate of the silver carp is increased significantly, and acetic acid can be utilized to deodorize a protein extract effectively. Endogenous enzyme hydrolysis and yeast fermentation liquid deodorization as well as acid method extraction and acetic acid deodorization are performed simultaneously during the whole production process, a bio-enzyme is not required to be added, the technological operation is simple, the cost is low, and the protein powder product is green, safe and good in water solubility.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

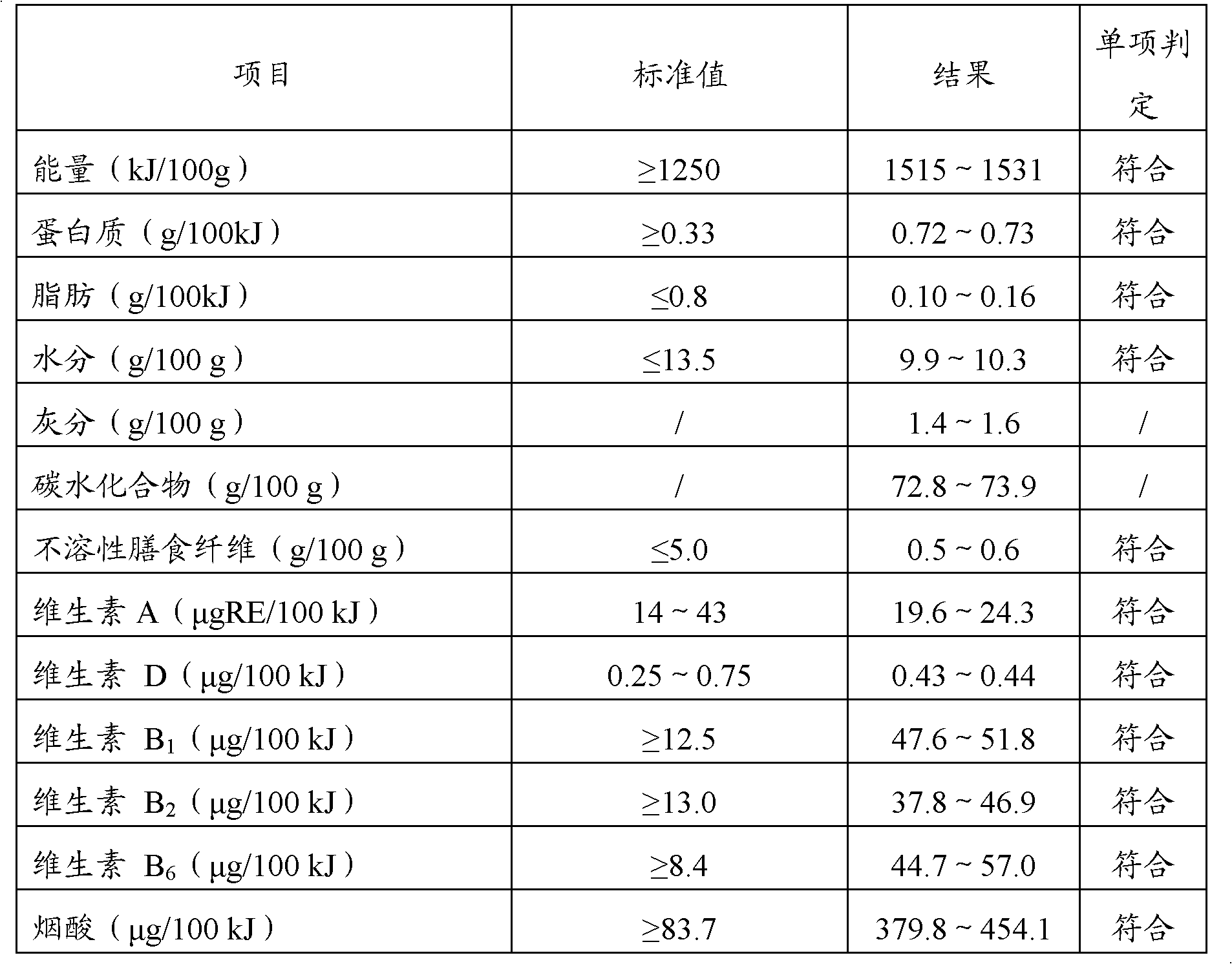

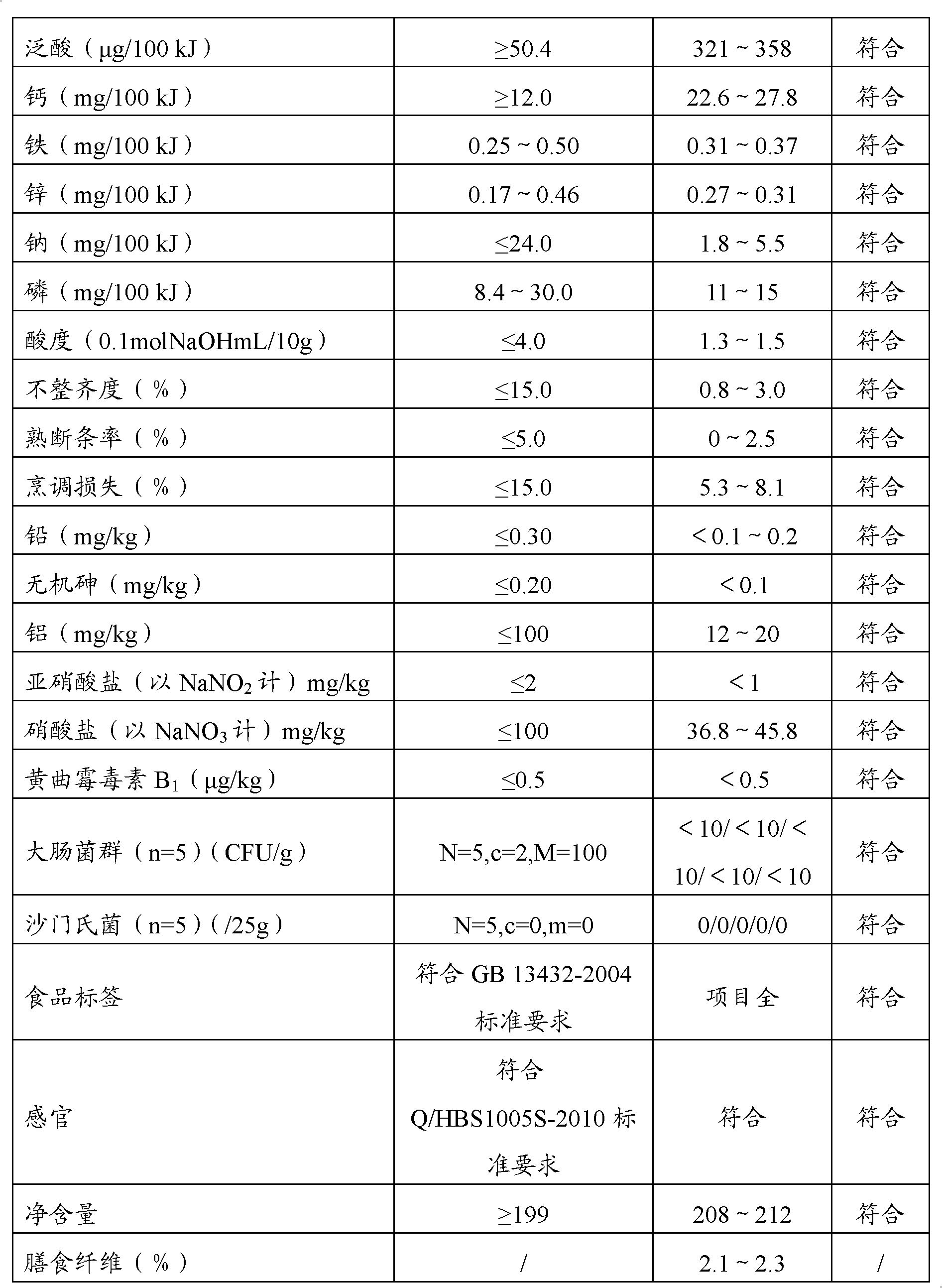

Baby nutrition noodles and preparation method thereof

ActiveCN103169006AIncrease profitHigh nutritional valueDough treatmentFood preparationNutritive valuesWhey protein powder

The invention relates to the field of processing of infant foods, and particularly relates to baby nutrition noodles and a preparation method of the baby nutrition noodles. The preparation method takes excellent wheatmeal and concentrated whey protein powder as main materials, fully improves the utilization rate and nutrition value of protein, and strengthens fructo-oligose, galactooligosaccharide, vitamine and mineral substance at the same, wherein the ratio of amino acid is very close to that needed by the human body. The low-temperature moisturizing drying process is adopted to produce the high-quality baby nutrition noodles suitable for eating of infants.

Owner:贝因美(杭州)食品研究院有限公司

Preparation method of folium mori nutritious protein instant powder

The invention discloses a preparation method of folium mori nutritious protein instant powder. The preparation method comprises the following steps of 1) cleaning folium mori through running water, naturally drying in the shade, and crushing; 2) adding a 0.2 to 1.0% by mass NaCl aqueous solution to folium mori powder, ultrasonically processing at 200 to 500W for 10 to 40 minutes, digesting at 20 to 45 DEG C for 10 to 50 minutes, centrifuging, collecting centrifuged supernate, adjusting pH (Potential of Hydrogen) to 1 to 4.5 to realize acid precipitation, centrifuging, freezing and drying the obtained precipitate to obtain folium mori protein powder; 3) adding beta-cyclodextrin and neutral protein powder to the folium mori protein powder, adding water to dissolve; heating at 35 to 50 DEG C for 10 to 50 minutes, and filtering or centrifuging to obtain a folium mori nutritious protein powder solution; and 4) performing rotary distillation, concentrating and spray drying on the folium mori nutritious protein powder solution to obtain the folium mori nutritious protein instant powder.

Owner:ZHEJIANG NORMAL UNIVERSITY

Composite protein powder

InactiveCN105146512ALow costHigh nutritional valueFood ingredient functionsFood preparationPROTEIN S HEERLENGalactooligosaccharide

The invention relates to composite protein powder. The composite protein powder is characterized by consisting of the following raw materials in parts by weight: 20-40 parts of soybean protein powder, 10-30 parts of organic rice flour, 10-15 parts of galactooligosaccharide and 30-50 parts of fresh milk powder. The composite protein powder is lower in cost, is suitable for old people and young people, does not contain any side effects, and can improve constitutions and immunity after being eaten for a long term.

Owner:曹峥峥

Method for extracting heparin sodium from small intestine of pig and co-producing protein powder

ActiveCN103665192AIncrease added valueExtraction rate is not affectedFermentationPROTEIN S HEERLENMedicine

The invention relates to a method for extracting heparin sodium, and particularly relates to a method for extracting heparin sodium from a small intestine of a pig and co-producing protein powder. The method comprises steps of (1) carrying out enzymolysis and salt hydration; (2) separating protein powder out; and (3) extracting heparin sodium: adsorbing, eluting, precipitating and drying. The method improves the yield of heparin sodium, furthermore, the equipment for co-production has higher usage rate than single producing equipment, saves resources, and can lower the production cost of heparin sodium and protein powder. The small intestine of the pig is fully used and is improved in additional value, furthermore, the pollution of waste liquid and waste residue containing protein to environment is reduced, and the waste liquid and waste residue are turned into wealth.

Owner:SHIFANG LELI FUYANG BIOLOGY CO LTD

High-protein, low-sugar and high-lipid ketogenic meal replacement cake and manufacturing method thereof

PendingCN110679620APromote catabolismReduce cholesterolDough treatmentBiotechnologyPROTEIN S HEERLEN

The invention discloses a high-protein, low-sugar and high-lipid ketogenic meal replacement cake and a manufacturing method thereof. The formula comprises the following by mass parts: 16-35 parts of almond powder, 0-8 parts of flaxseed powder, 16-25 parts of protein powder, 10-25 parts of edible oil, 8-16 parts of dietary fiber, and 6-15 parts of erythritol. The formula of the invention is not only suitable for obese people and hyperglycemic people, but can also regulate the gastrointestinal health of the human body, and can increase the muscle mass of the body and improve the health of the user. Grease, erythritol and cream are mixed firstly, and then eggs and dietary fiber are added, and finally the mixed solid powdery material is added. The method can completely dissolve the dietary fiber, so that the produced cakes have delicate texture without obvious rough feelings.

Owner:杭州赛能医药科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com