Preparation method of folium mori nutritious protein instant powder

A production method and instant powder technology are applied in the production field of mulberry leaf nutritional protein instant powder, which can solve the problems of rough processing technology, poor solubility, poor flavor and color, and achieve low solvent consumption, ensure food safety, The effect of short operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

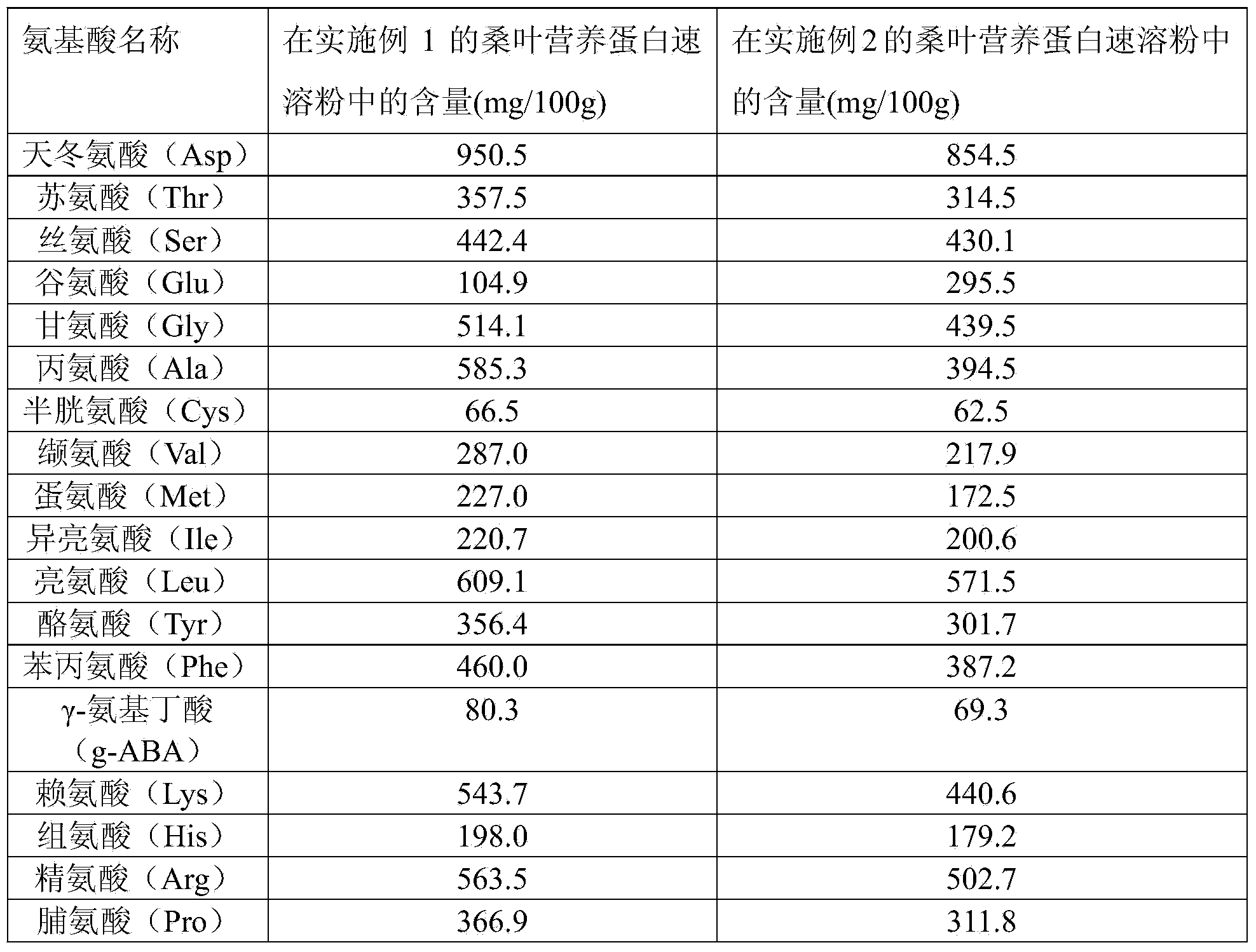

Embodiment 1

[0032] Embodiment 1, a kind of preparation method of mulberry leaf nutrient protein instant powder, carries out following steps successively:

[0033] 1) Select complete and pest-free mulberry leaves picked in Jinhua, Zhejiang Province in October, wash them with running water, dry them naturally in the shade to constant weight (moisture content ≤ 5%), and crush them through a 60-mesh sieve to obtain mulberry leaf powder.

[0034] 2) Take 100g of mulberry leaf powder, add 3000mL of NaCl aqueous solution with a mass fraction of 0.4%, ultrasonically treat at 200W for 20min, then place it at room temperature of 20-25°C for 30min (i.e. leaching for 30min); centrifuge at 3000rpm for 15min.

[0035] Take the supernatant obtained by centrifugation and adjust the pH to 4 with a concentration of 0.5mol / L HCl solution to achieve acid precipitation, centrifuge at 3000rpm for 15min, and freeze-dry the obtained precipitate (dry at -70°C for 10h) to obtain mulberry leaf protein powder (about ...

Embodiment 2

[0044] Embodiment 2 A kind of manufacturing process of mulberry leaf nutritional protein instant powder, the steps are as follows:

[0045] 1) Choose complete and pest-free mulberry leaves picked in early November in Jinhua, Zhejiang, wash them with running water, dry them naturally, and crush them with a grinder until they can pass through a 60-mesh sieve to obtain mulberry leaf powder (moisture content ≤ 5%).

[0046] 2) Take 100g of mulberry leaf powder, add 1500mL of 0.2% NaCl aqueous solution, 400W ultrasonic treatment for 10min, then put in a water bath (leaching) at 40-45℃ for 20min, and then centrifuge at 3000rpm for 15min.

[0047] The supernatant obtained by centrifugation was adjusted to pH 3 with 0.5mol / L% HCl solution to achieve acid precipitation, centrifuged at 3000rpm for 15min, and the precipitate was freeze-dried (dried at -70°C for 10h) to obtain mulberry leaf protein powder (about 20.7 g). The moisture content of this mulberry leaf protein powder is ≤5%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com