Method for producing drawing protein by utilizing compound vegetable protein containing peanut and soybean

A technology of drawing protein and plant protein, which is applied in the preparation of twin-screw high-moisture plant protein texturing, the preparation of mixed plant protein texturing, and the production of drawing protein. It can solve the problems of high nutritional loss and denaturation of peanut protein, and achieve good taste. , good texture, strong fiber strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

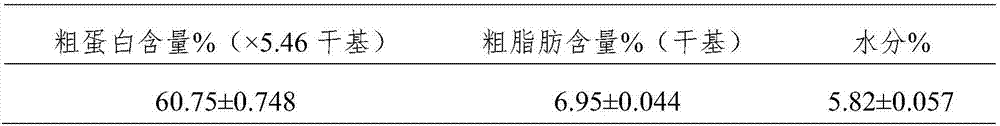

[0047] The low-temperature defatted peanut protein powder used was purchased from Qingdao Changshou Food Co., Ltd. The basic physical and chemical indicators are as follows

[0048]

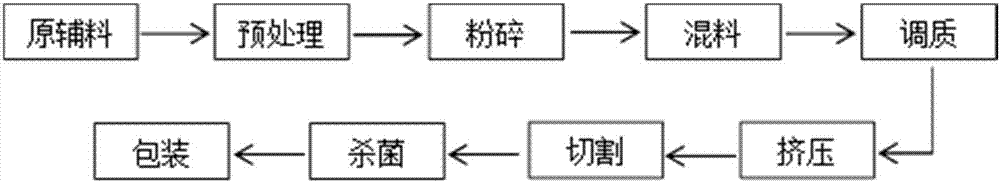

[0049] A preparation method of high-moisture peanut silk protein, comprising the steps of:

[0050] 1) Mixing and tempering: Pour the raw materials into the mixer according to the ratio, chop and mix the mixture, put it into a closed container after mixing, and balance for 24 hours;

[0051] The ratio of raw materials is: low-temperature defatted peanut protein powder 75kg, soybean protein isolate 9kg, gluten powder 6kg, wheat starch 6kg;

[0052] 2) Extrusion texture: Extrude the material obtained in step 1) with a twin-screw extruder for extrusion texture. The extrusion temperature is 58°C in the feeding zone, 90°C in the mixing zone, and 130°C in the first section of the cooking zone. The second section of the cooking zone is 133°C, the cooling zone is 110°C, and the forming zone is 95°C; ...

Embodiment 2

[0056] The low-temperature defatted peanut protein powder used was purchased from Qingdao Changshou Food Co., Ltd. The basic physical and chemical indicators are as follows

[0057]

[0058] A method for preparing high-moisture peanut silk protein, the specific operation steps are the same as in Example 1, the only difference is that in step (2), the screw speed is 240r / min, the feeding speed is 90g / min, and the extrusion die cooling temperature is 68°C; make the moisture content of the material during the extrusion process 60%. The detection results of the obtained high-moisture peanut silk protein are as follows:

[0059]

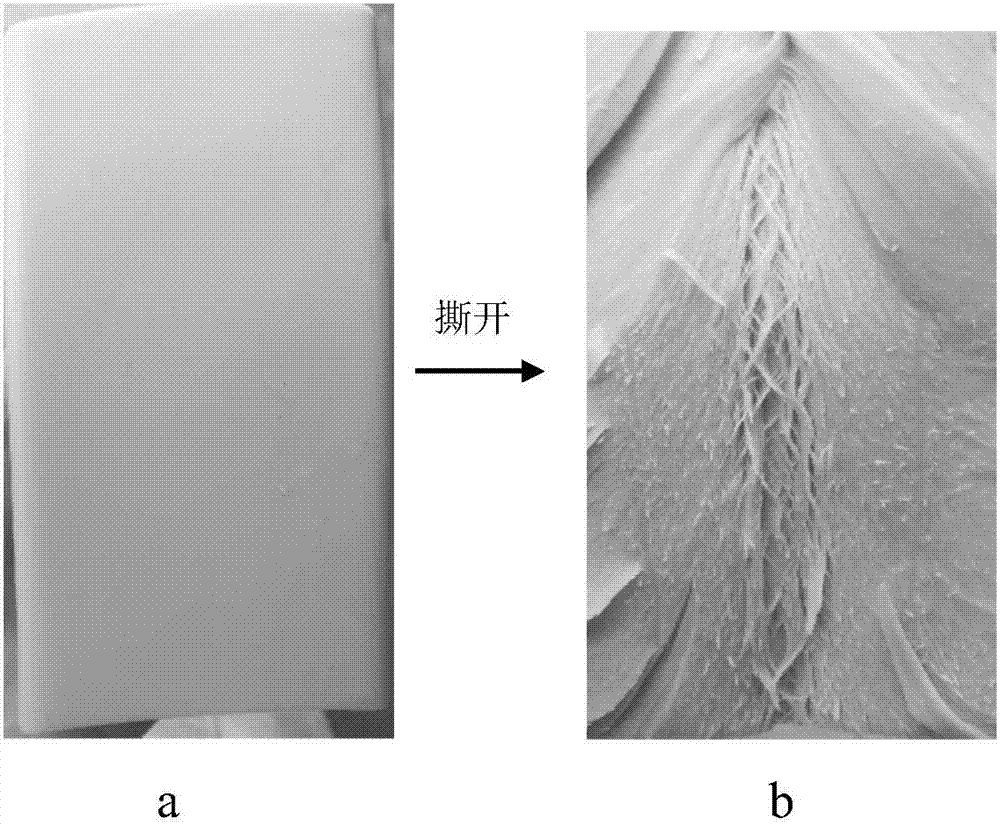

[0060] The appearance, state and internal structure of the high-moisture stretched peanut protein obtained in Example 1-2 are shown in figure 2 a and figure 2 b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com