Patents

Literature

82 results about "Food extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food extrusion is a form of extrusion used in food processing. It is a process by which a set of mixed ingredients are forced through an opening in a perforated plate or die with a design specific to the food, and are then cut into a specific size by blades. The machine which forces the mix through the die is an extruder, and the mix is known as the extrudate. The extruder consists of a large, rotating screw tightly fitting within a stationary barrel, at the end of which is the die.

Method and apparatus for the manufacture of meat

InactiveUS6635301B1Proteins working-up by texturisingAnimal feeding stuffMineral bindingTemperature control

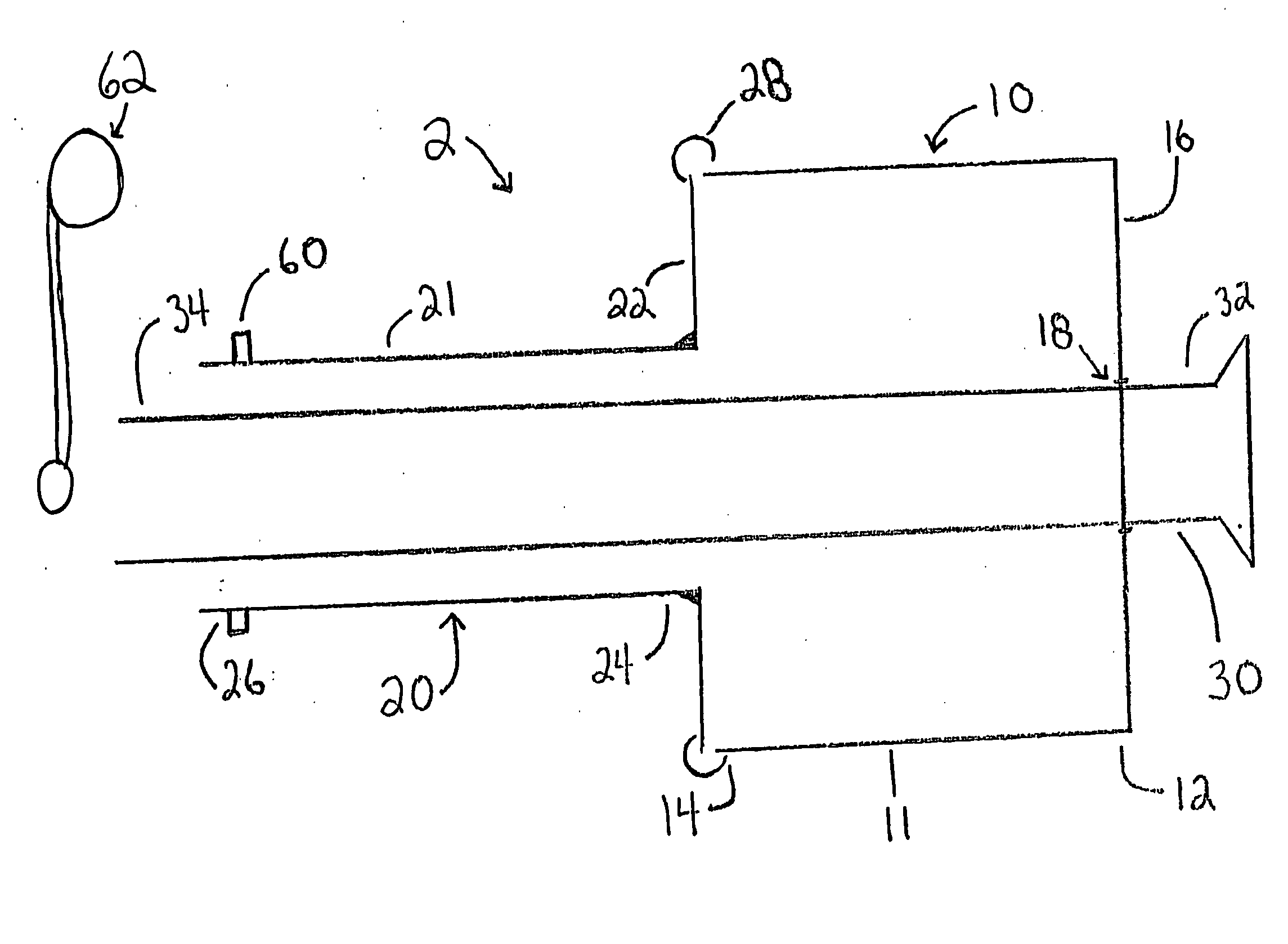

A method of manufacturing a texturised proteinaceous meat analogue product, including: subjecting, in a food extruder a mixture containing: about 40 to 95% by weight edible proteinaceous materials selected from the group of predetermined mixtures of defatted soy flour, soy meal, soy concentrate, cereal gluten in vital or starch-containing form and egg white, and up to about 7% by weight of edible mineral binding and cross-linking compounds; to mechanical pressure and added heat sufficient to convert the mixture into a hot, viscous protein lava; extruding the protein lava through and from a temperature controlled cooling die which cools and reduces the viscosity of the protein lava to obtain a cohesive, texturised, extrudate slab or ribbon in which vapour-flashing is substantially inhibited; and subjecting the solidified extrudate slab or ribbon to mechanical shredding in a hammer mill having a cage plate with a plurality of elongate discharge openings and a plurality of hammer bars hinged to discs attached to a rotating shaft, so as to obtain a plurality of extrudate shred that resemble in consistency and texture flaked or shredded meat.

Owner:MARS INC

Apparatus and method to net food products in shirred tubular casing

An apparatus and method to net shirred tubular casing, in order to create a highly-dimpled foot product. A filling horn, shir housing, and removable netting tube allow for the extrusion of food products into an edible tubular collagen film, which itself expands into a netting of a smaller diameter than that of the film. As the food product under pressure expands against the tubular film, it presses through the spaces in the netting to created a dimpled appearance. After the food product has been further processed, the netting is removed, leaving a highly-dimpled appearance.

Owner:POLY CLIP SYST

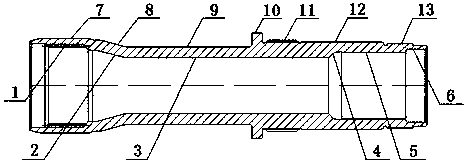

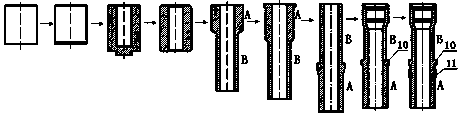

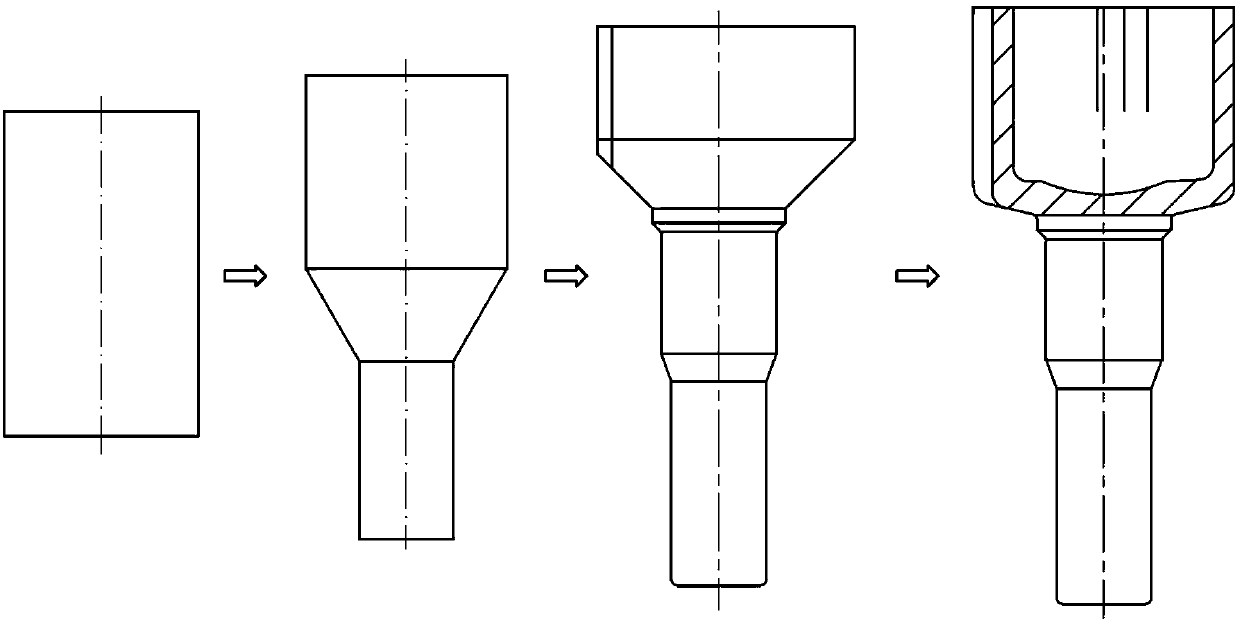

Power takeoff transmission shaft cold precision forging plastic forming process

ActiveCN103350346AMeet the precision requirementsEasy forging and demouldingOther manufacturing equipments/toolsPunchingDrive shaft

The invention discloses a power takeoff transmission shaft cold precision forging plastic forming process which comprises the following steps: a, cutting out bar materials, conducting extrusion pretreatment, b, conducting deep hole extrusion and punching, c, conducting forward extrusion, d, conducting reducing and extrusion, e, conducting plasticity chambering internal spline extrusion, f, conducting rolling extrusion, and cold forging a blank which basically conforms to the size of a transmission shaft of a power takeoff in a mold. Forging and demolding are convenient, and then the blank is machined through a machine tool. The machining method is simple, the structure is fine, the strength is high, the production efficiency is high, raw materials are saved, the requirements for product precision of the transmission shaft of the power takeoff are met, the manufacturing cost and the production cycle are reduced, and meanwhile the power takeoff transmission shaft cold precision forging plastic forming process also conforms to the tendency of the development of the present world manufacturing industry.

Owner:江苏威鹰机械有限公司

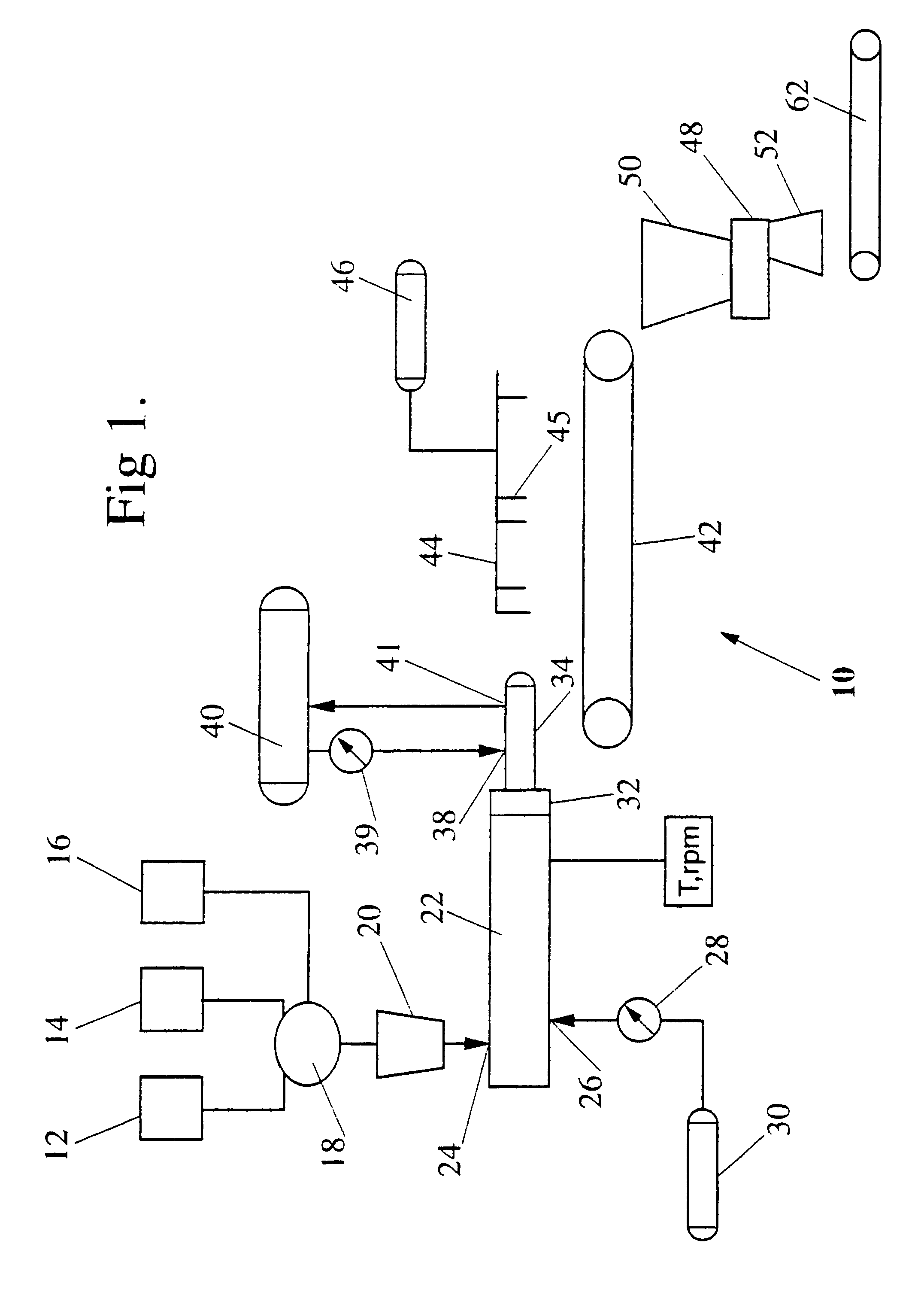

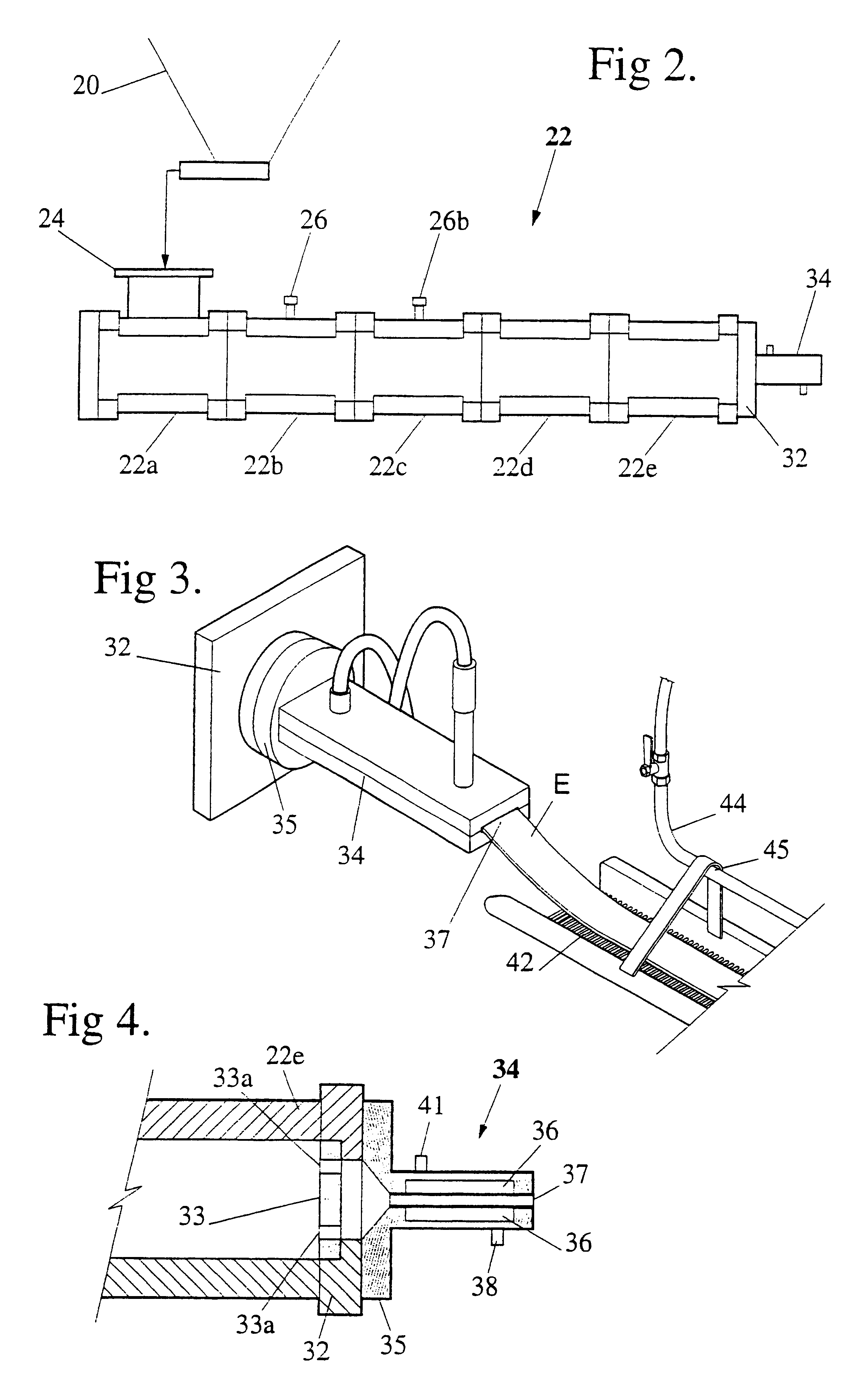

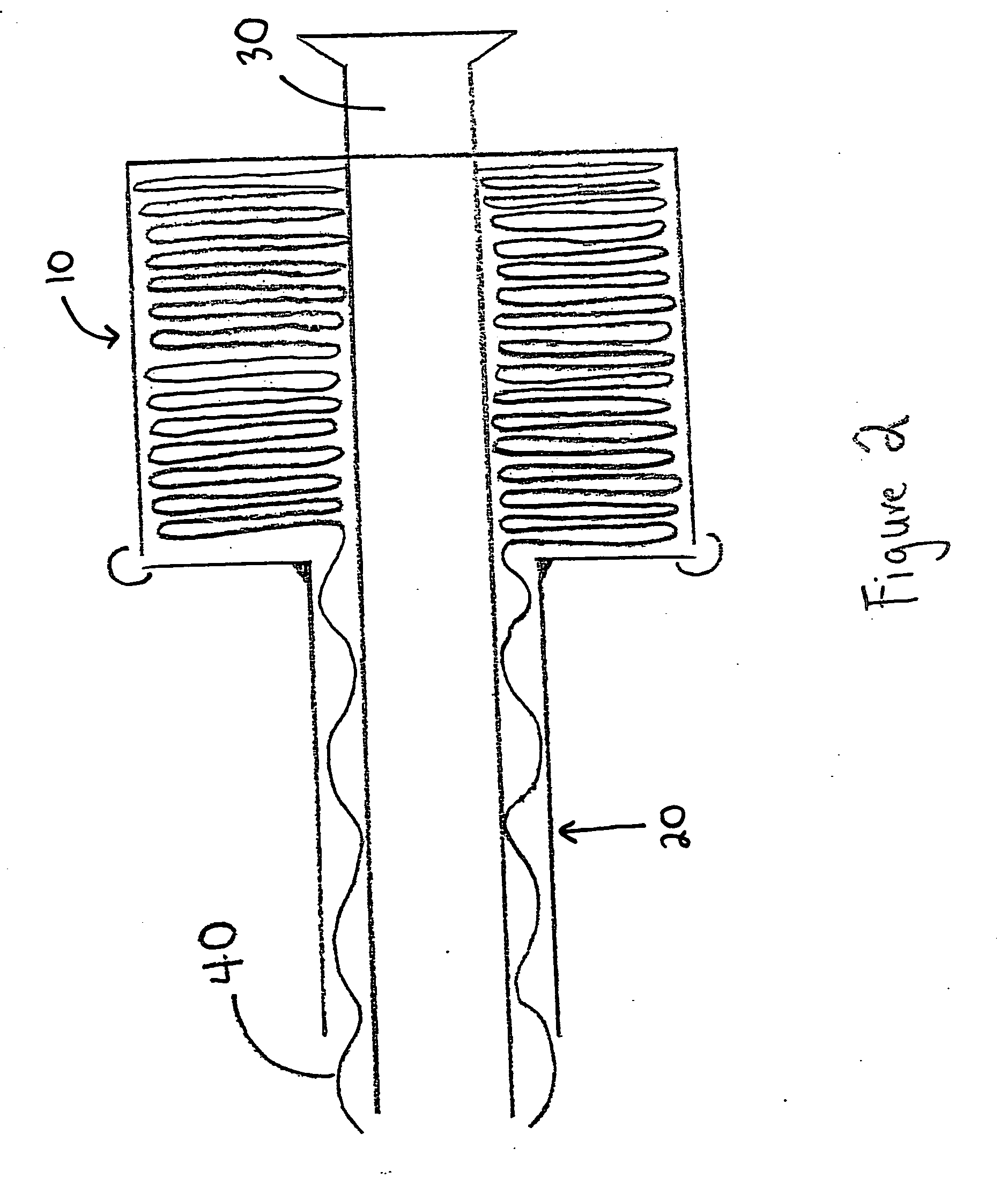

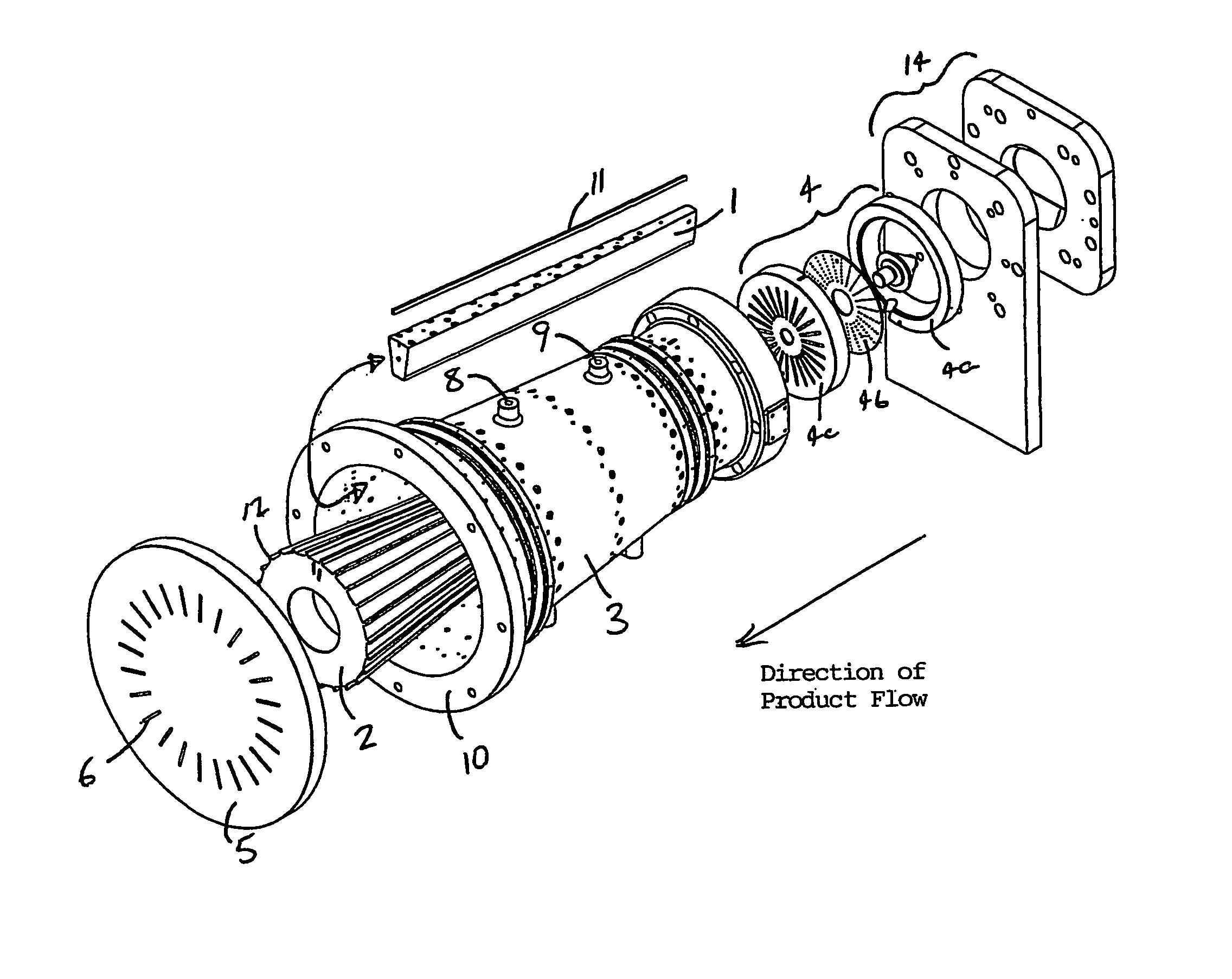

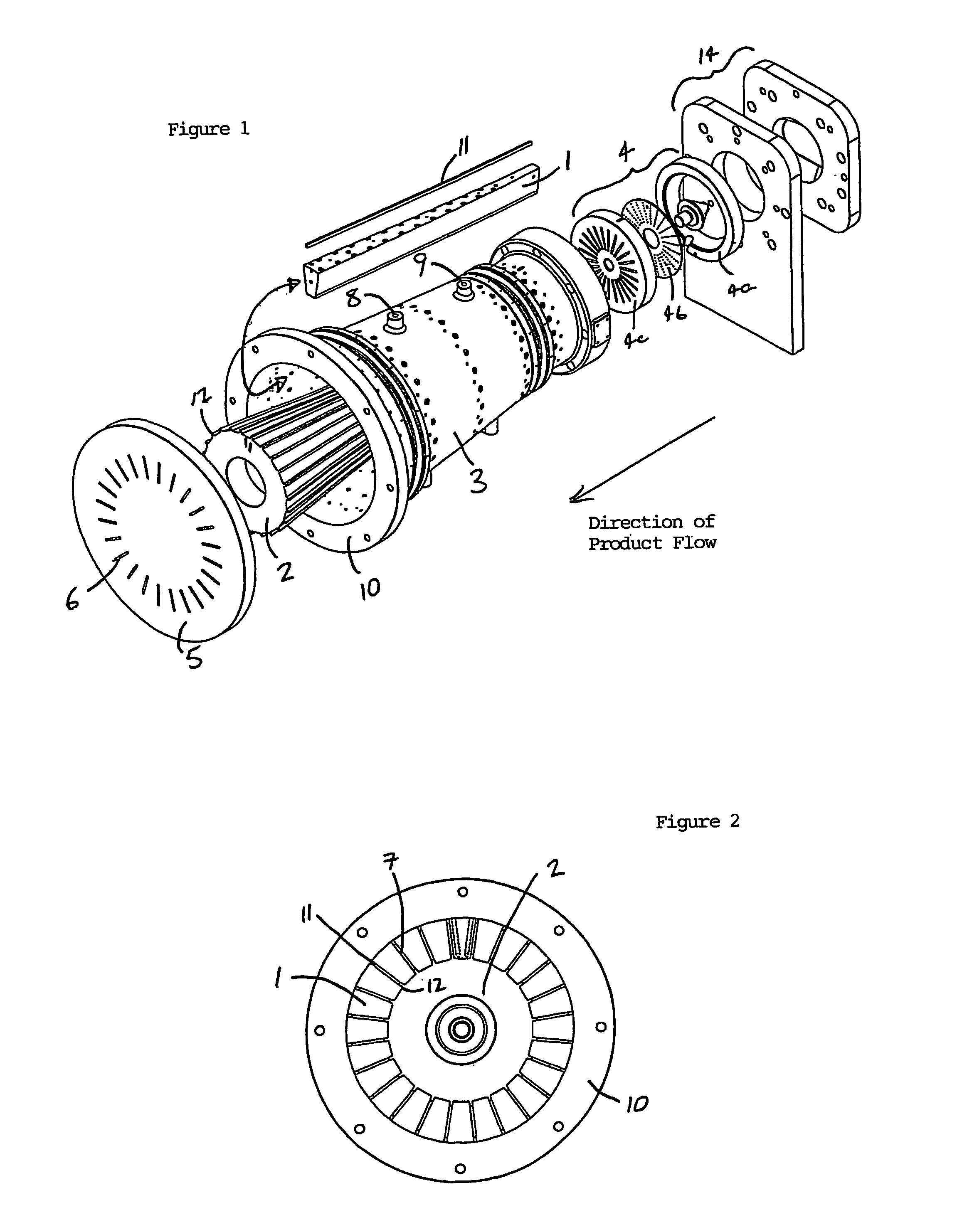

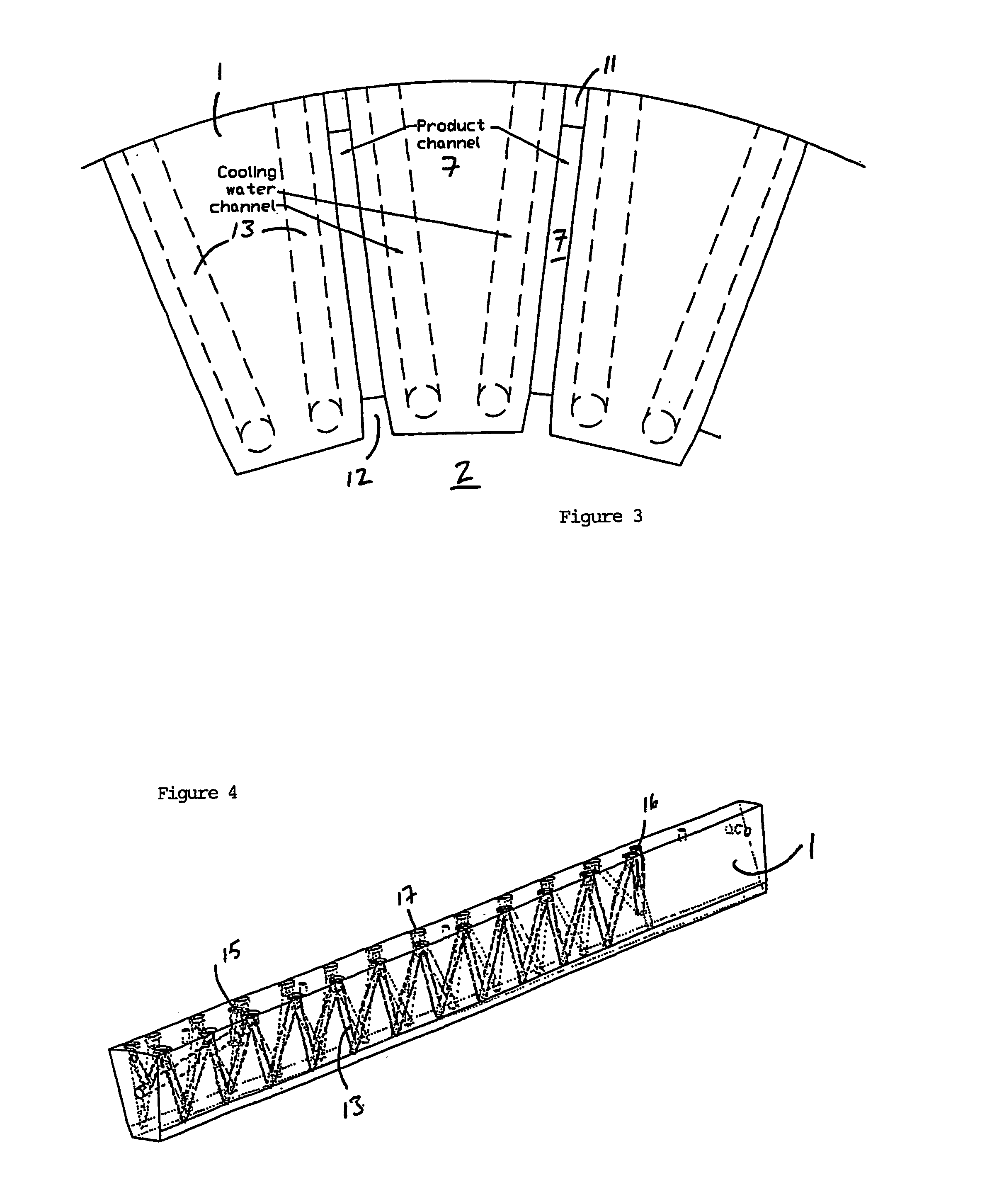

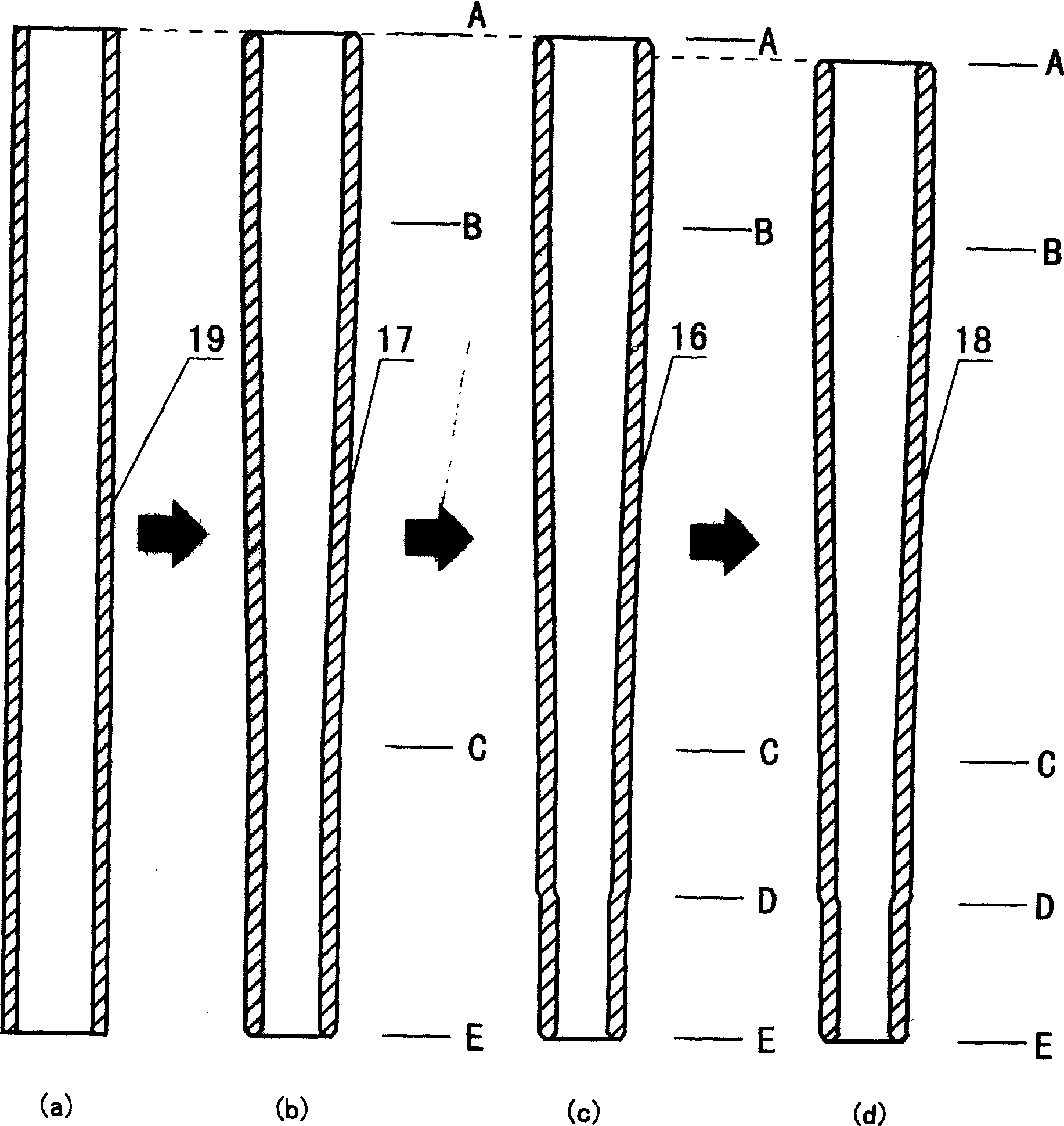

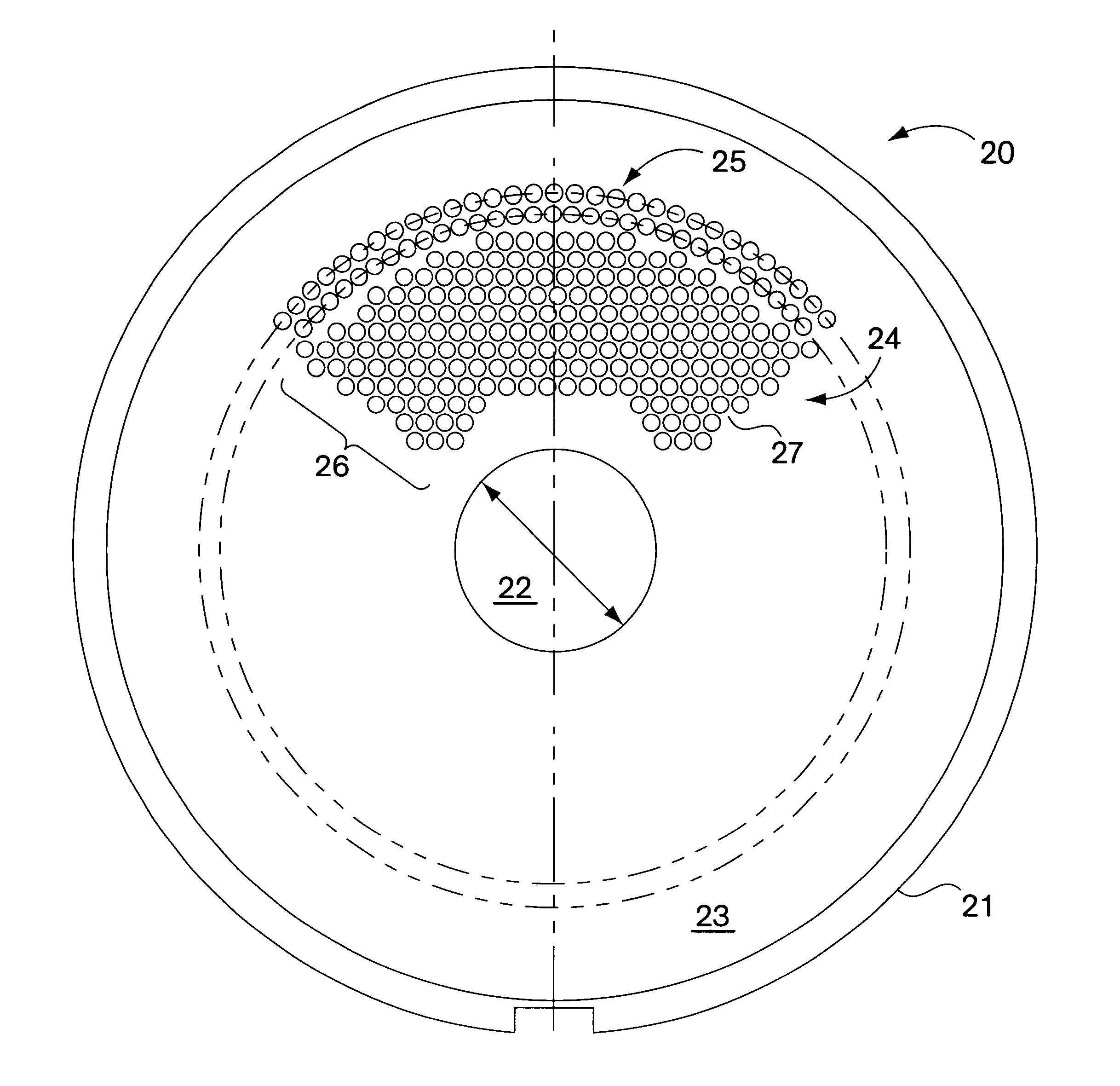

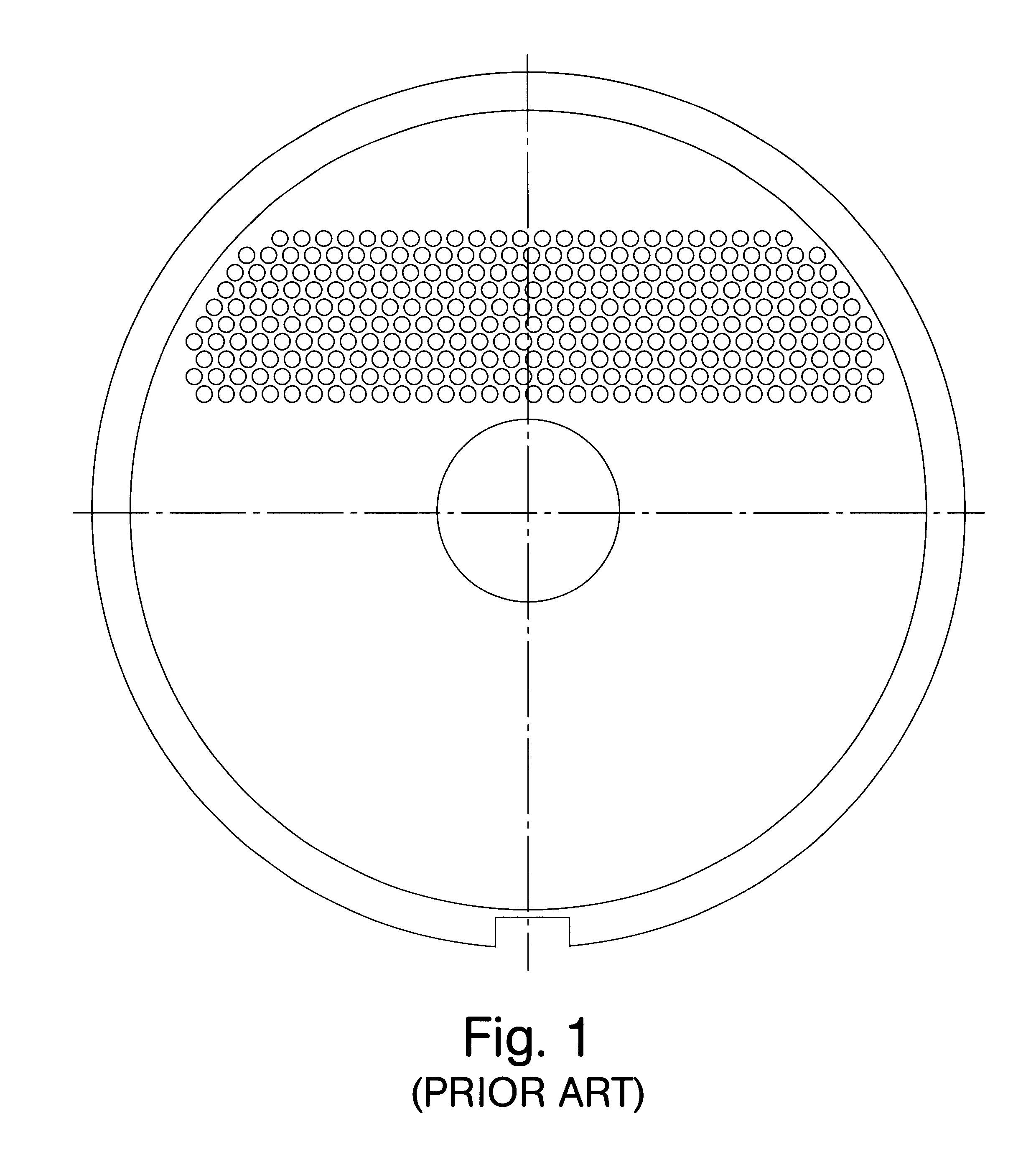

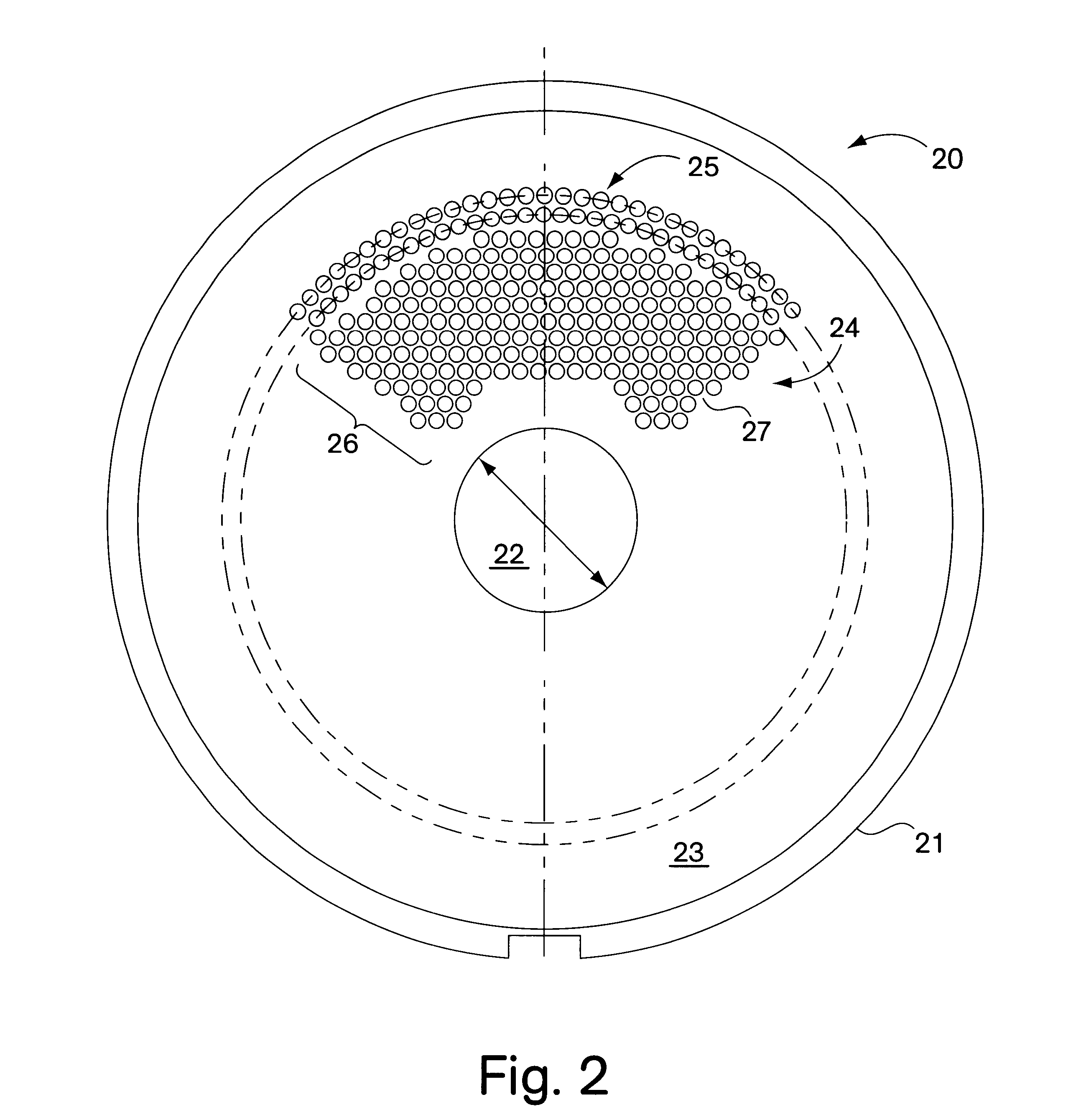

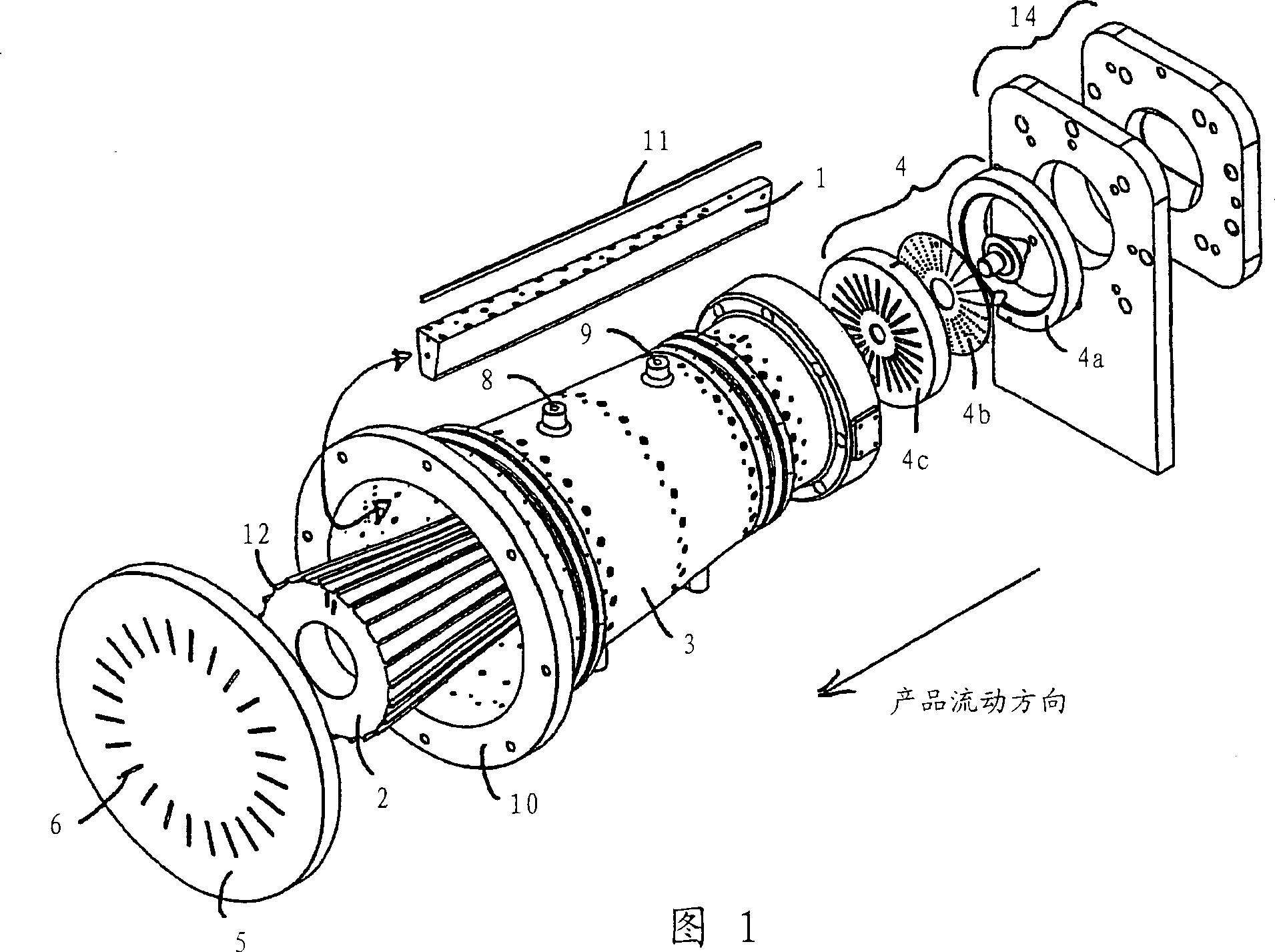

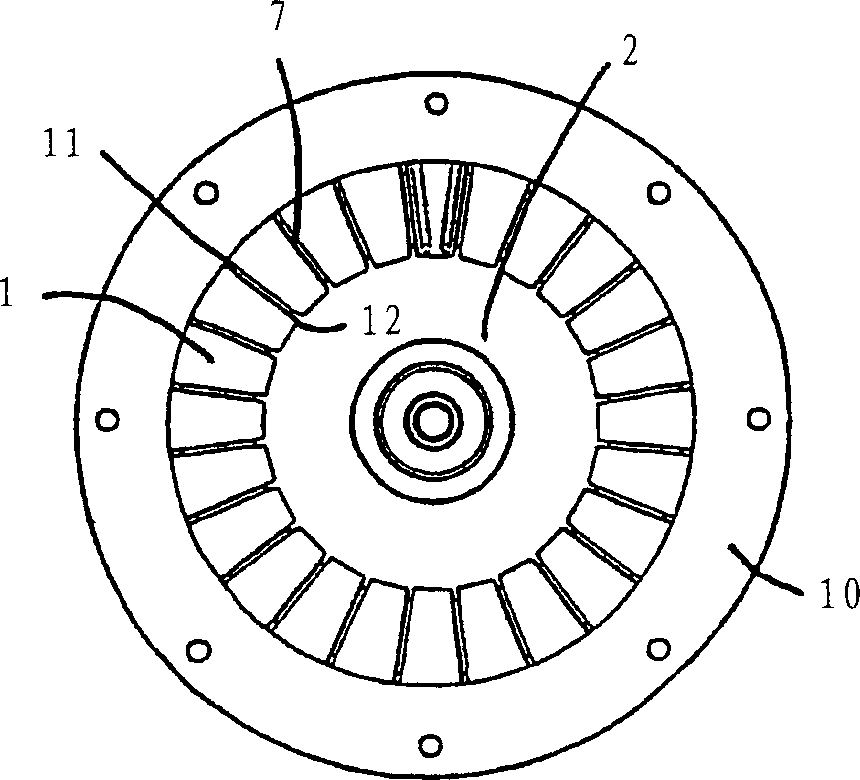

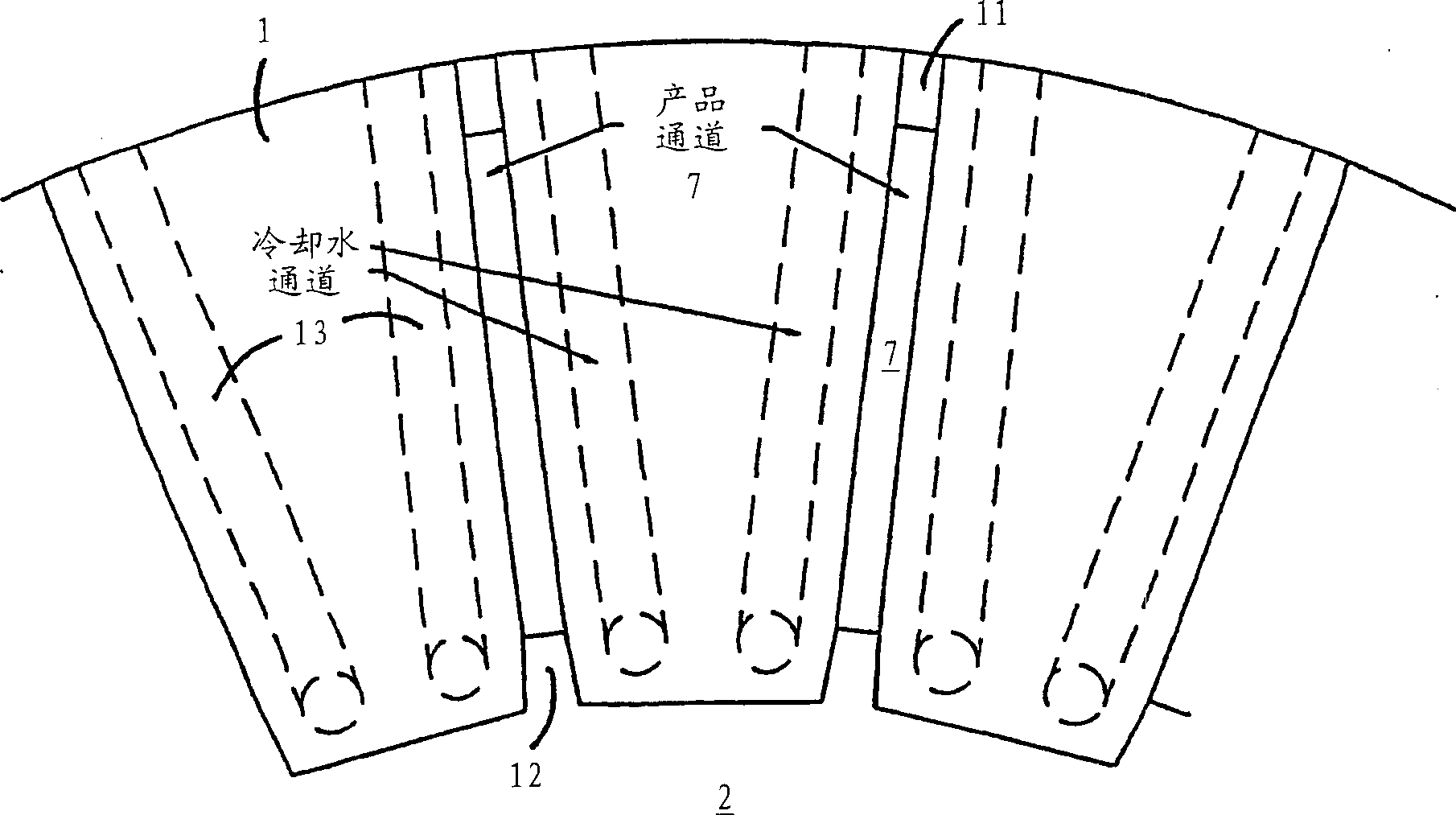

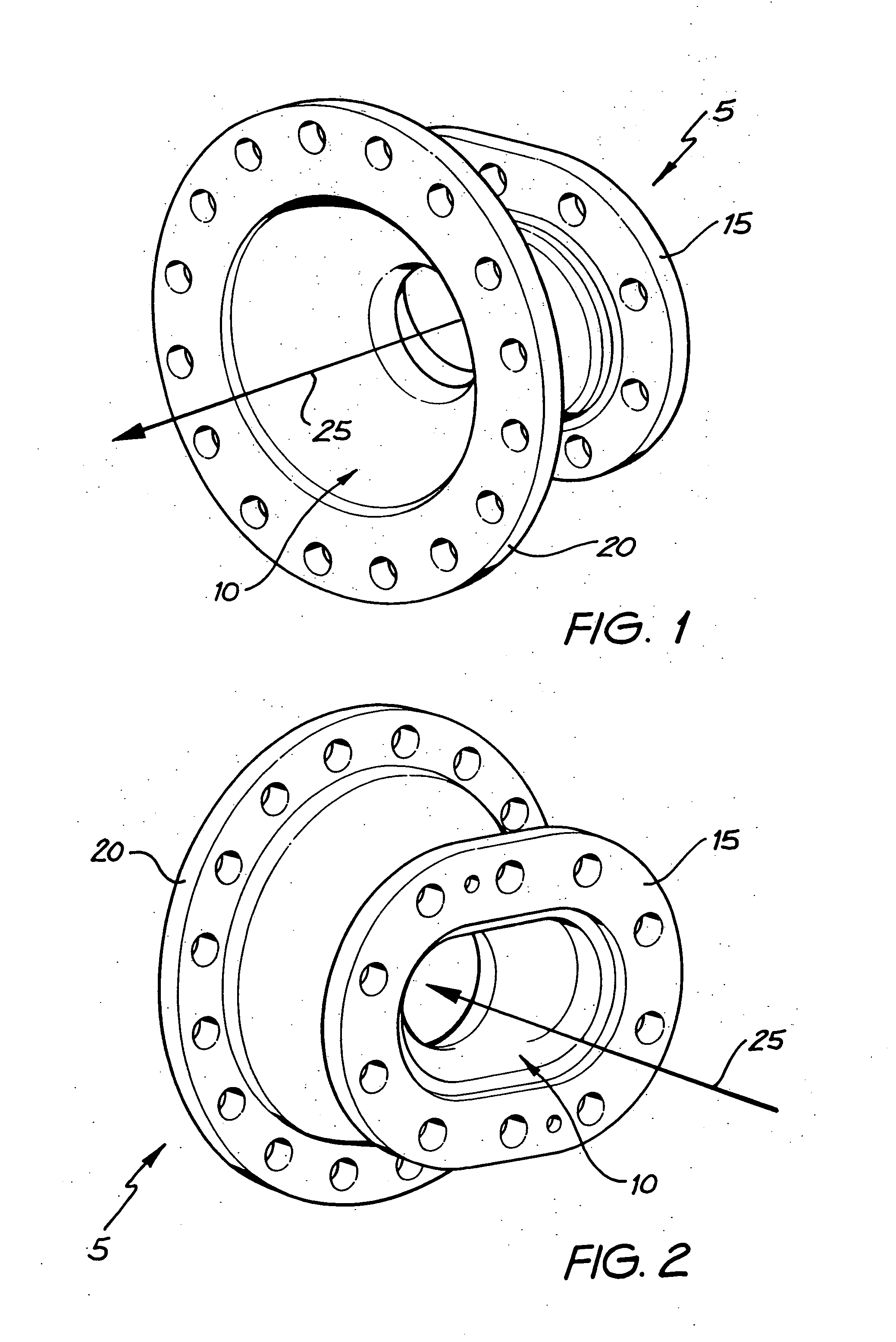

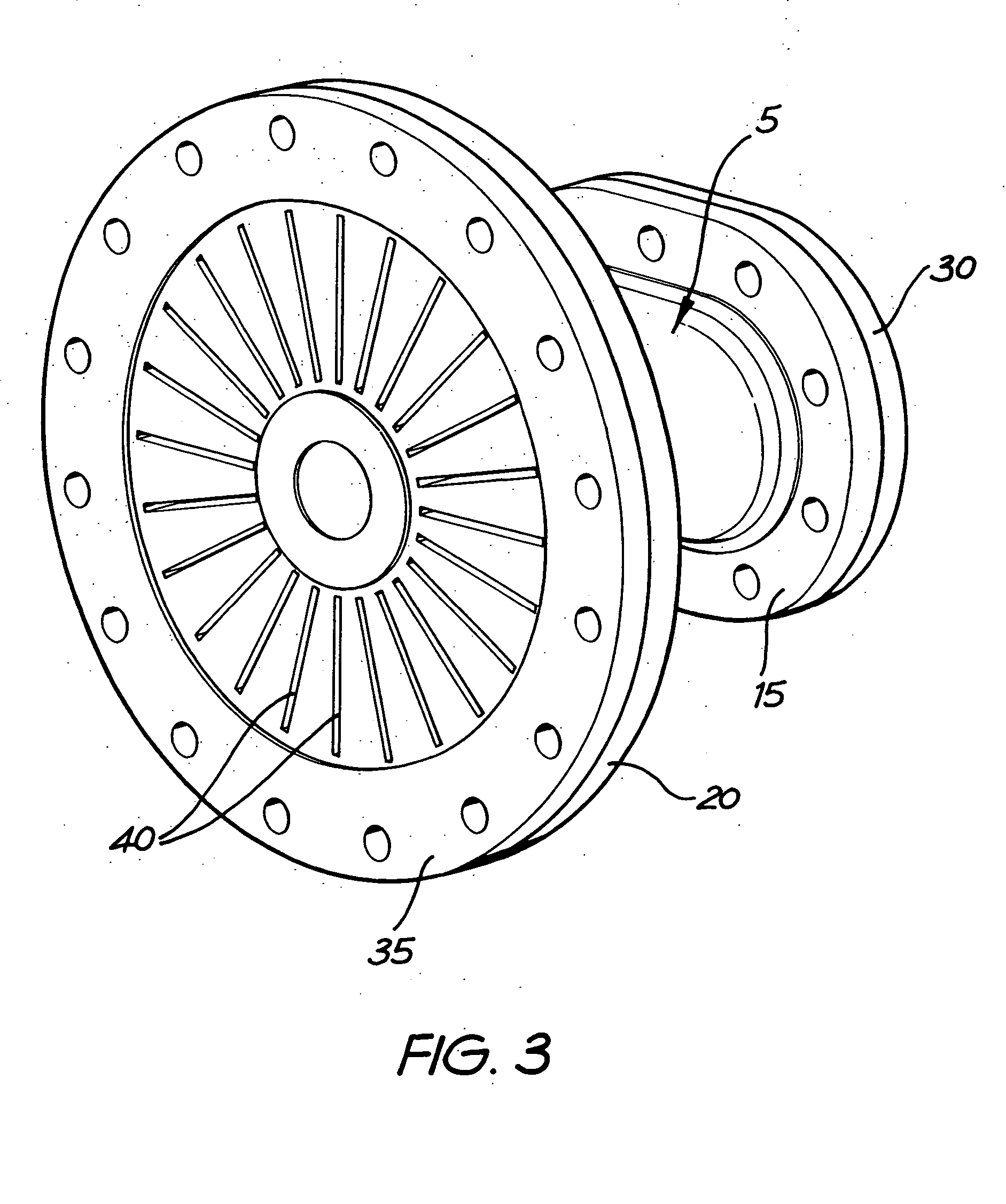

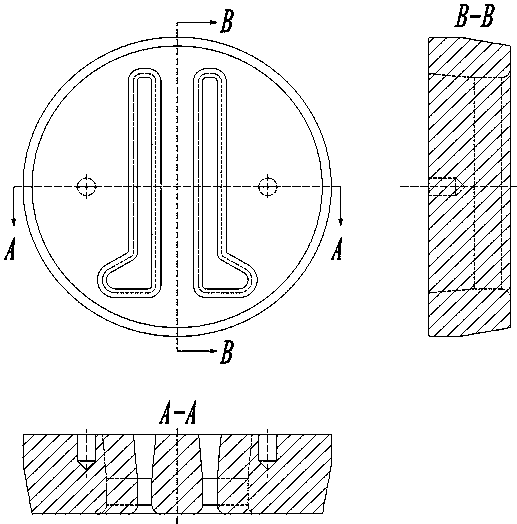

Multi-channel cooling die

InactiveUS7275927B2Reduces extrudate flow path distanceReduced operational downtimeConfectioneryMeat processingEngineeringFood extrusion

A cooling die, for use in the manufacture of extruded food products, the cooling die including: a plurality of core members forming a main body portion of the cooling die between die inlet and outlet ends and arranged about an axis of the die in neighboring relationship; a plurality of extrudate flow channels extending through the cooling die from the inlet end to the outlet end, defined by gaps between neighboring ones of said core members; at least one bore in each said core member through which coolant may flow; an enclosing structure adapted to secure the core members against radial movement relative to the die axis; means for connecting the cooling die to an outlet of a food extruder, a cooling fluid source and a cooling fluid receptacle; and extrudate flow distribution means, located adjacent the inlet end, adapted to direct extrudate from the outlet of the food extruder into selected ones of said extrudate flow channels.

Owner:MARS INC

Forging method for forming through holes of working clamping plates by hot extrusion

InactiveCN102554090AReduce usageReduce dosageForging/hammering/pressing machinesEngineeringFood extrusion

The invention discloses a forging method for forming through holes of working clamping plates by hot extrusion, which includes steps of blanking, deburring, heating, preforging, forming, reshaping, cooling, shot blasting and the like. A male die is matched and centered with a male die bush and then is inserted into a female die to complete piercing and reshaping of a workpiece, the combining height of the male die and the female die is fixed after being regulated so as to prevent the workpiece from being eccentric and guarantee that the reshaped part meets the processing requirements, the male die and the male die bush are separated to complete stripping after the male die drives the reshaped workpiece to raise to the set position, then the workpiece can be stripped, the dies can be cooled by an automatic cooling system, and parts of the dies can be changed quickly. Compared with the prior art, the process of machining the through holes of the working clamping plates of anchors by means of die forging has the advantage that use of raw materials is saved according to the relation between the volume of the through holes of the working clamping plates and the total volume of the working clamping plates, machining procedures are simplified and cost can be saved by 20% around.

Owner:四川新筑精坯锻造有限公司

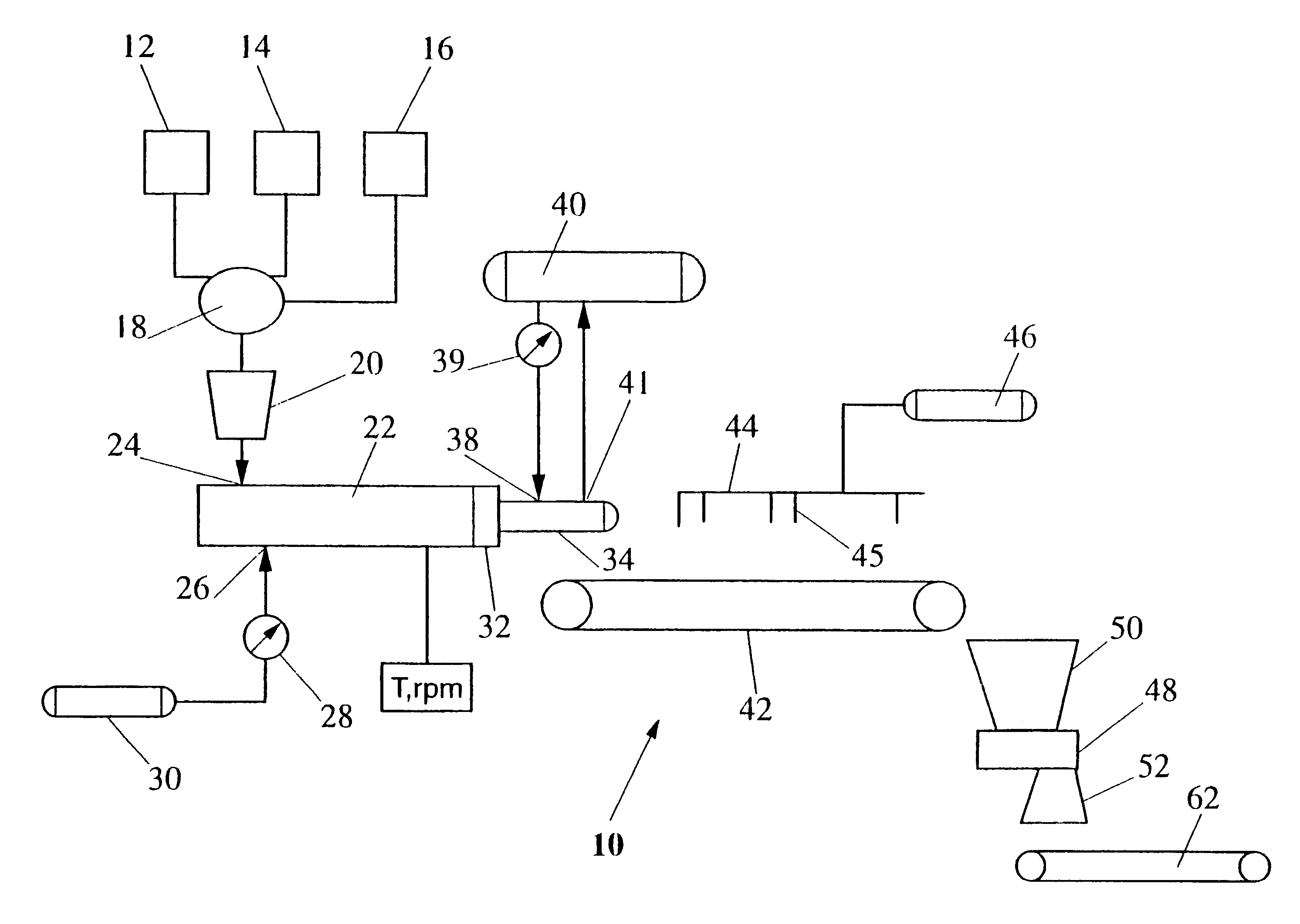

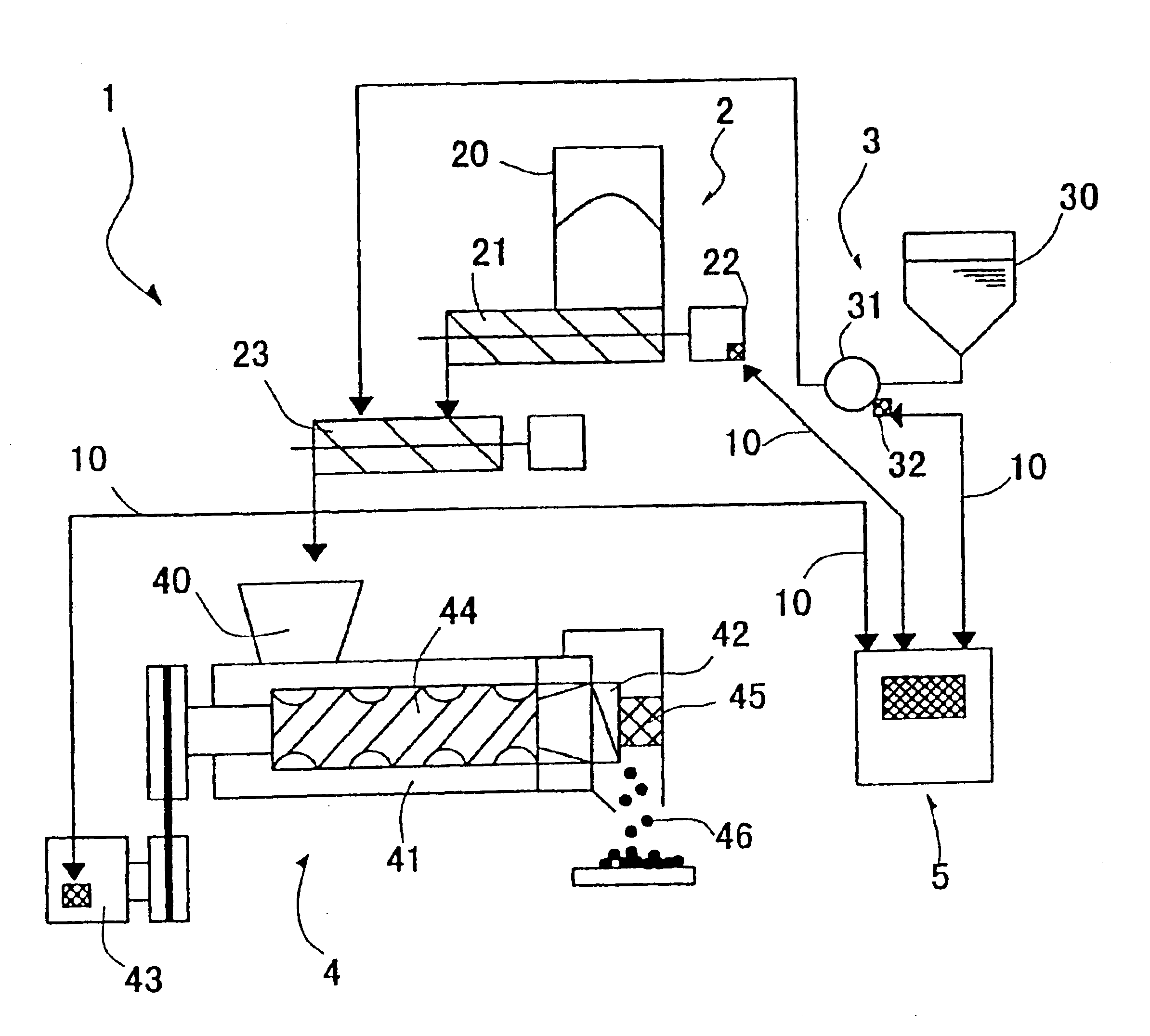

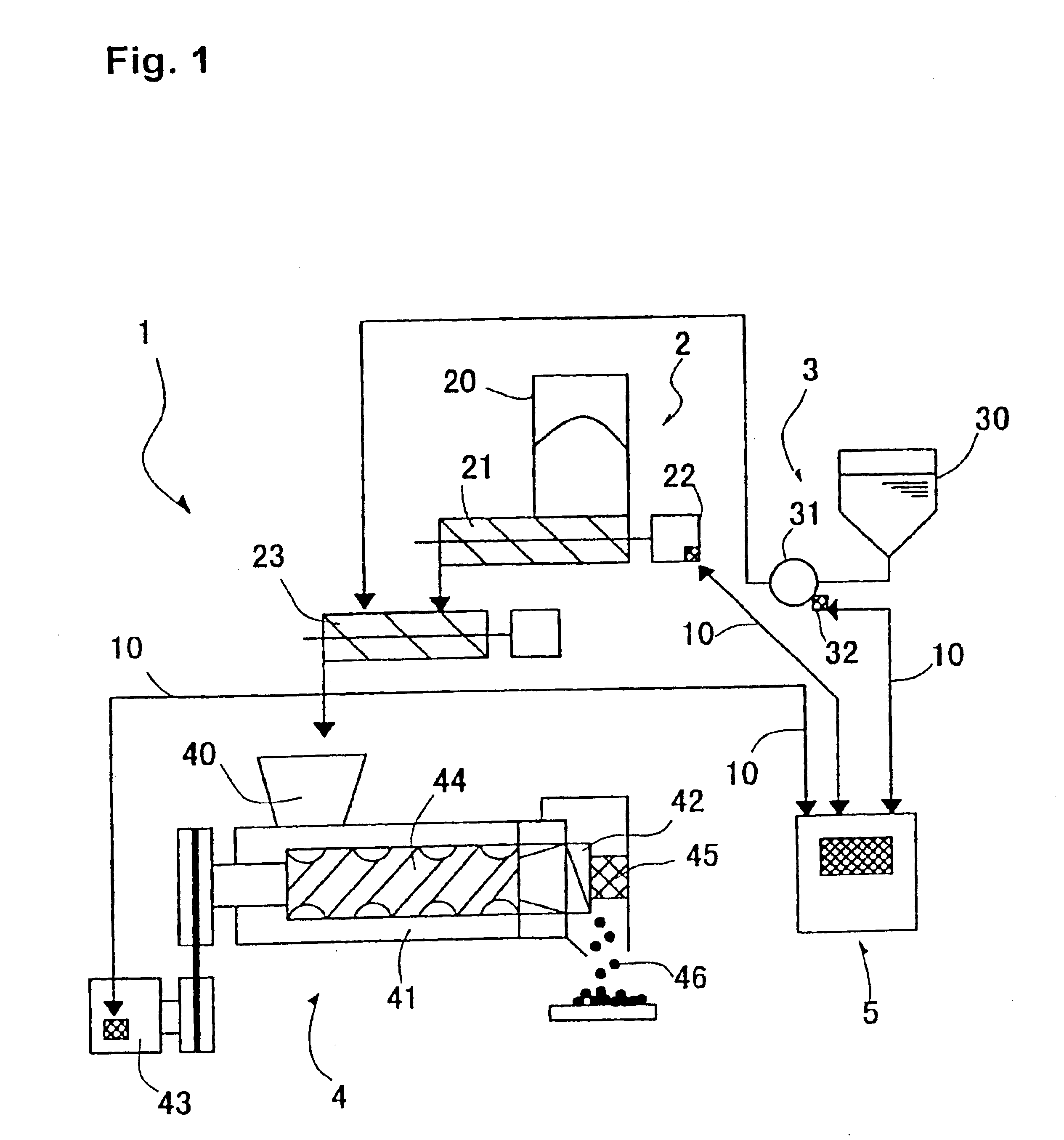

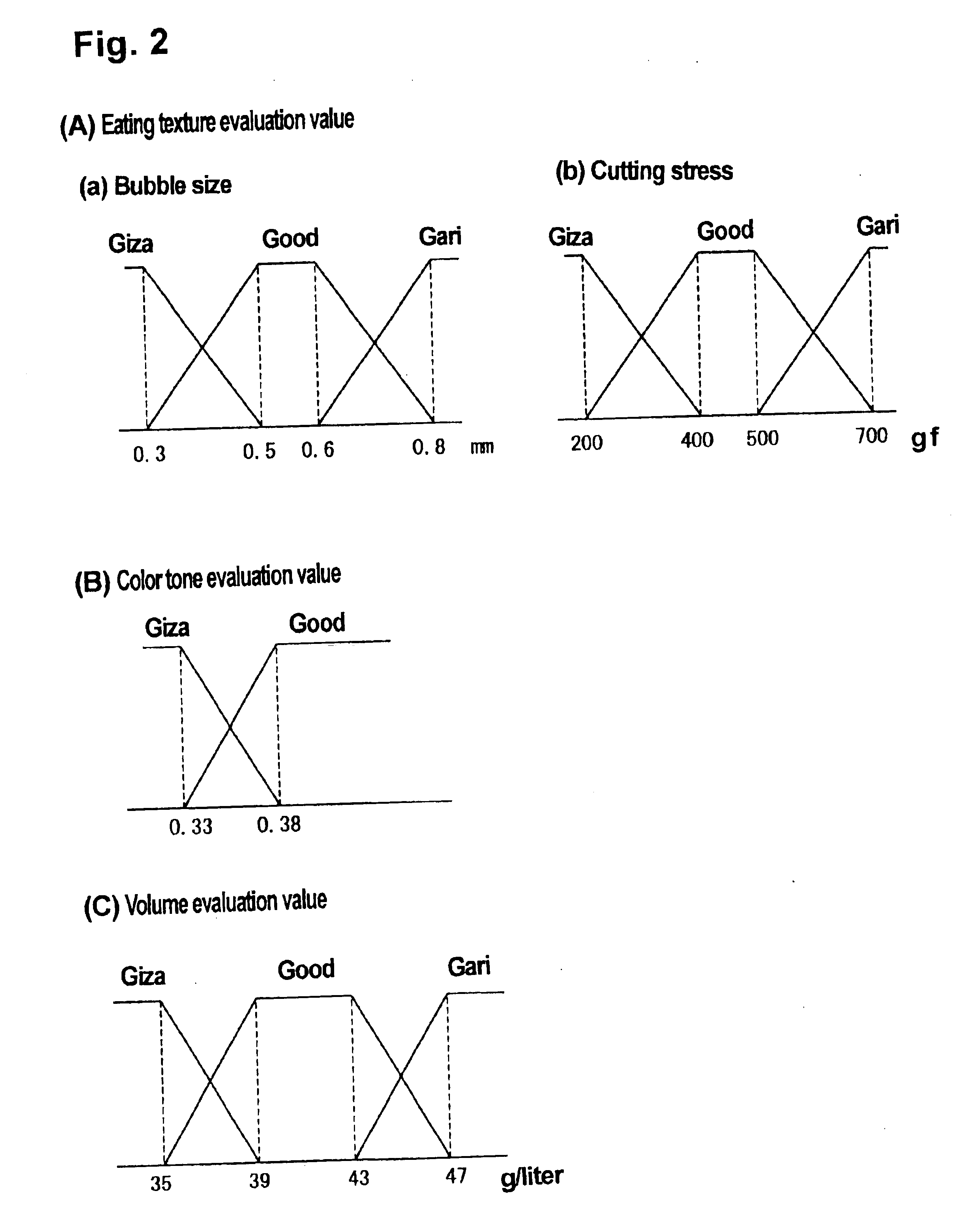

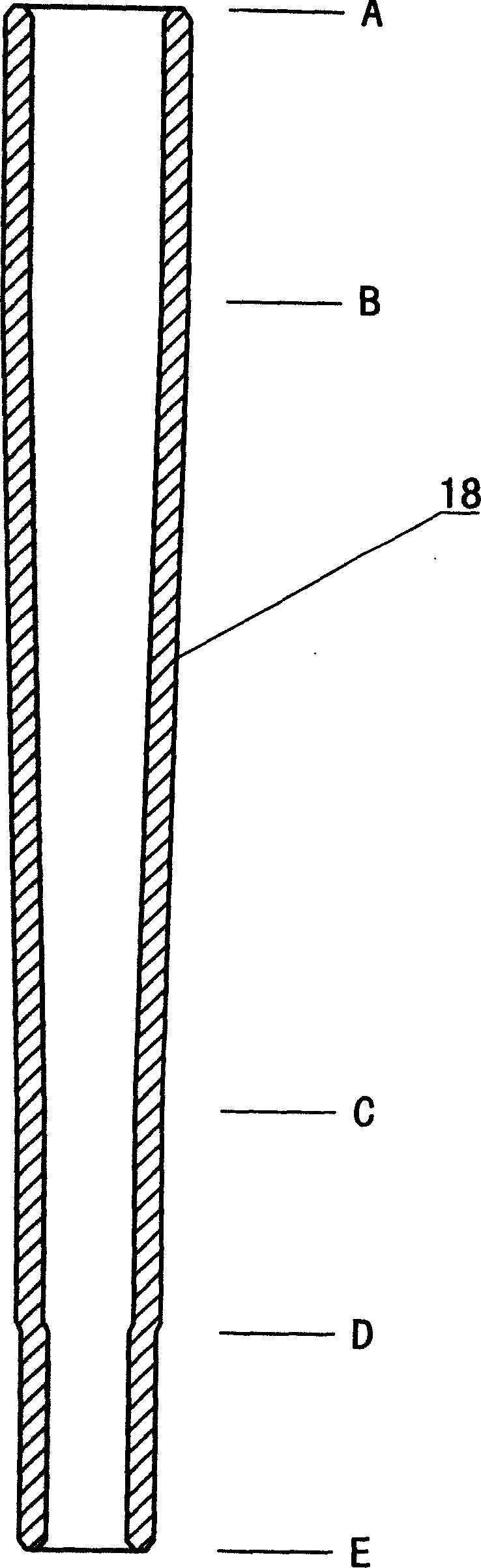

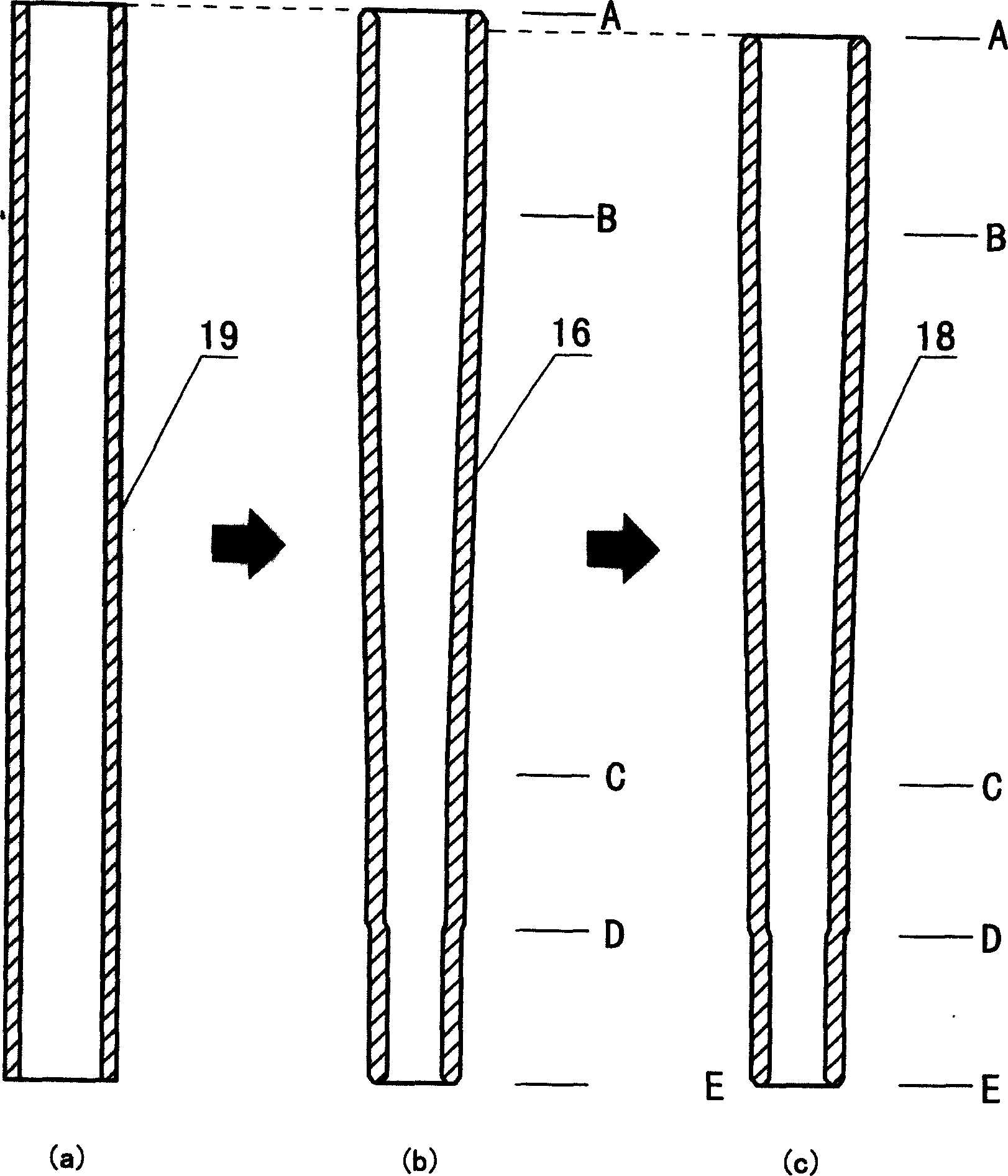

Food extruder cooking control method and cooking control system

InactiveUS6764701B1High quality expanded snackGood quality expanded snackDough treatmentFood shapingControl systemProcess engineering

A cooking control method and a cooking control system for a food extruder used for producing direct-puffed snacks includes a material supply mechanism, a hydration mechanism, a processing mechanism including an extruder, and a control computer. The control computer determines a specific power consumption value from the electric energy consumed by the extruder and the supplied amount of the dough material, at the time of producing snacks having excellent quality, to designate this value as a reference value, compares this reference value of the specific power consumption value with the actual specific power consumption value, and when the difference is small, controls the number of revolutions of the extruder, and when the difference is large, controls not only the number of revolutions of the extruder, but also the amount of water added and the feed amount of materials, to thereby stabilize the snack quality.

Owner:JAPANESE RES & DEV ASSOC FOR APPLICIATION OF ELECTRONICS TECH IN FOOD OF IND THE +1

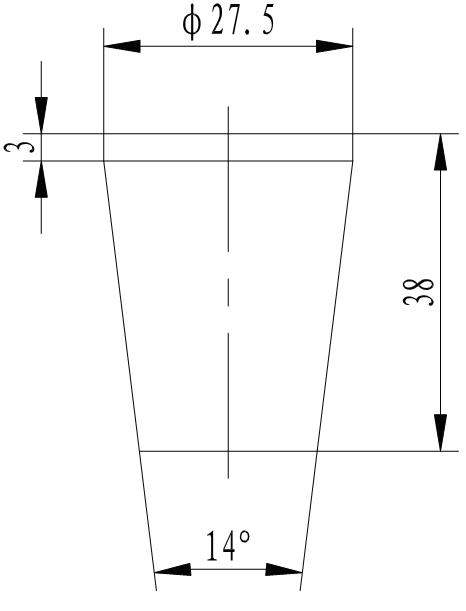

Method and equipment for producing directional vertical taper pipe in motorcycle through cold extrusion

ActiveCN1600468ASimple methodReduce processExtrusion diesExtrusion mandrelsHydraulic pumpEngineering

A cold extrusion technology for machining the vertical conic stearing tube of motorcycle includes reducing hoop, hole enlargnig and plumply shaping to obtain the target product with conic internal hole, cylindrical upper segment, and stepped cylindrical lower segment. The extrusion apparatus for reducing hoop and enlarging hole is composed of lower and upper demoulding buffer cylinders and shaping cylinder. The extrusion apparatus for plumply shaping consists of demoulding cylinder and extruding cylinder.

Owner:艾德义

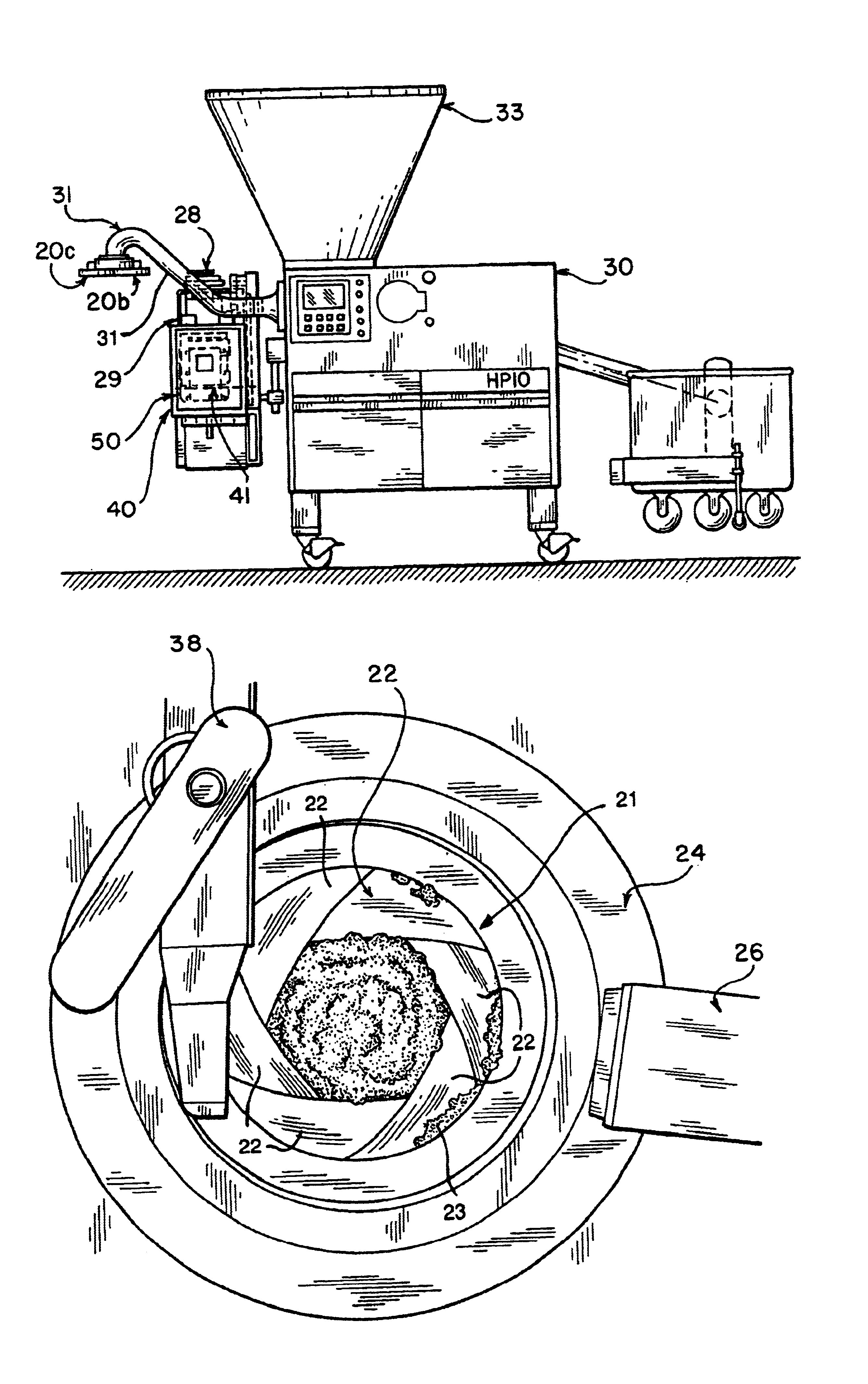

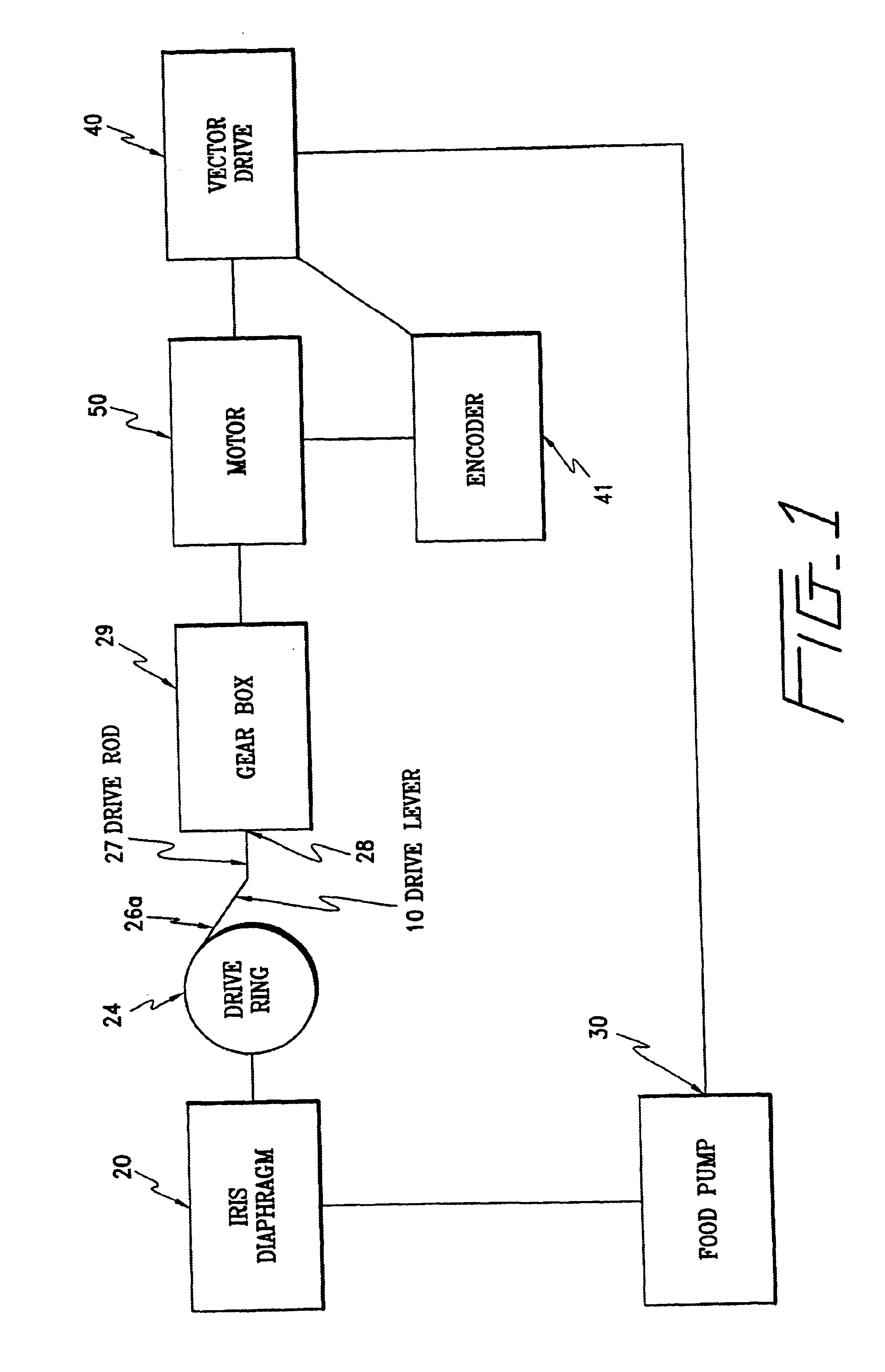

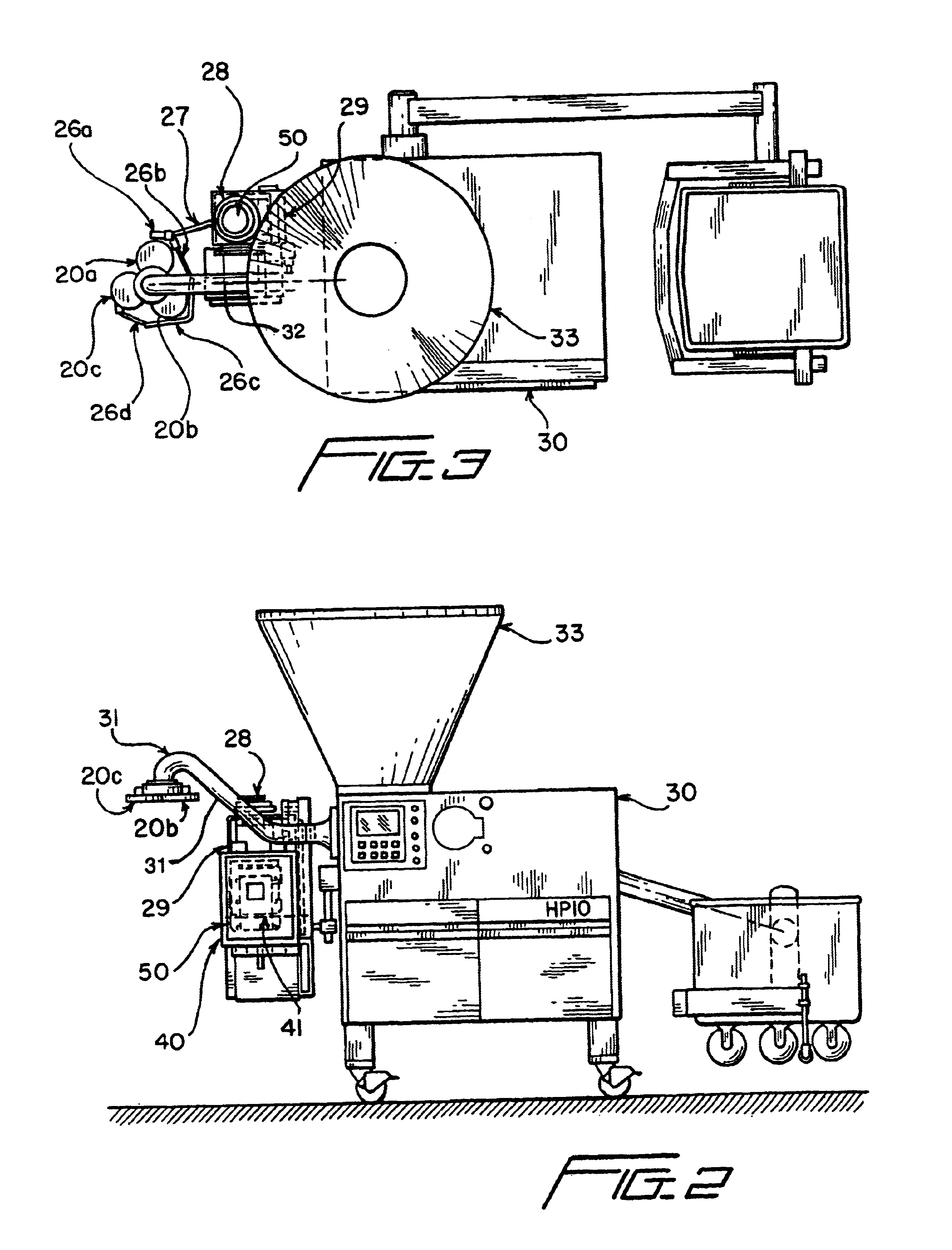

Food forming apparatus

A forming apparatus to produce nonsymmetrical three-dimensional shaped products from a food extrusion device includes a vector drive controlling an induction motor through current flux control, which selectively actuates an iris diaphragm. Food product is pumped to the diaphragm, which shapes the product in accordance with settings from an encoder. The flux drive permits variable control of the diaphragm motor in segments of a 360° revolution. Alternatively, a servo drive may be used to drive a synchronous motor to operate in accordance with instructions from an encoder-shaping product from a food pump as it is forced through the diaphragm.

Owner:ROBERT REISER

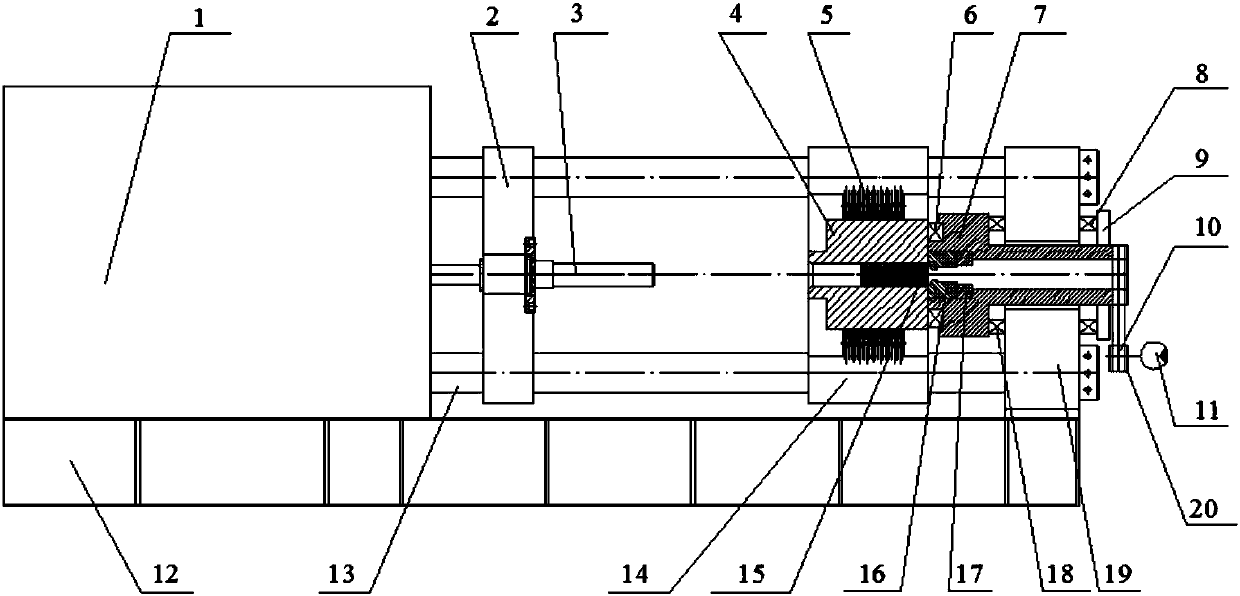

Horizontal rotary-mold extrusion forming device for improving performance of products

InactiveCN107649527AImprove mechanical propertiesGood for strong plastic deformationThrust bearingShearing deformation

The invention provides a horizontal rotary-mold extrusion forming device for improving performance of products, relates to the horizontal rotary-mold extrusion forming device for improving performanceof extruded sections, and belongs to the technical field of metal plastic-forming techniques. The horizontal rotary-mold extrusion forming device comprises a horizontal extruding machine and a rotarymold device, wherein the rotary mold device is arranged on a front cross beam and composed of a servo motor, a transmission mechanism, a rotary mold sleeve, a mold, a mold seat, a first thrust bearing, a second thrust bearing, a third thrust bearing and a locking end cover. The horizontal extruding machine, a movable platform, an extruding barrel support, the front cross beam and four extension columns are horizontally mounted on the upper surface of a machine frame. The movable platform, the extruding barrel support and the front cross beam are sequentially arranged side by side in the length direction of the machine frame, and the extruding barrel support is located between the movable platform and the front cross beam. The rotary mold device is adopted in the extruding process, throughthe rotation effect of the mold, severe shear deformation is generated in a deformation area when a product is formed by extrusion, high plastic deformation can be obtained, and thus grains are refined.

Owner:HARBIN INST OF TECH

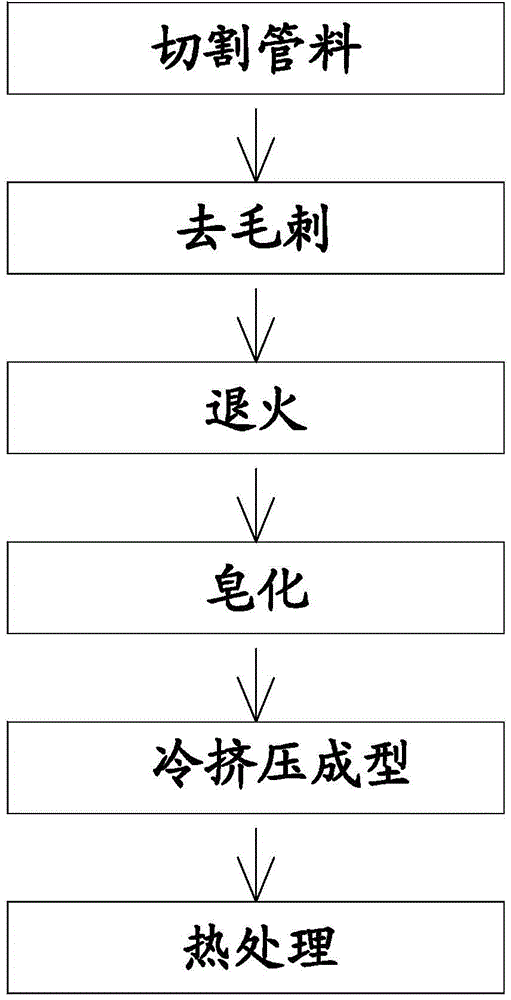

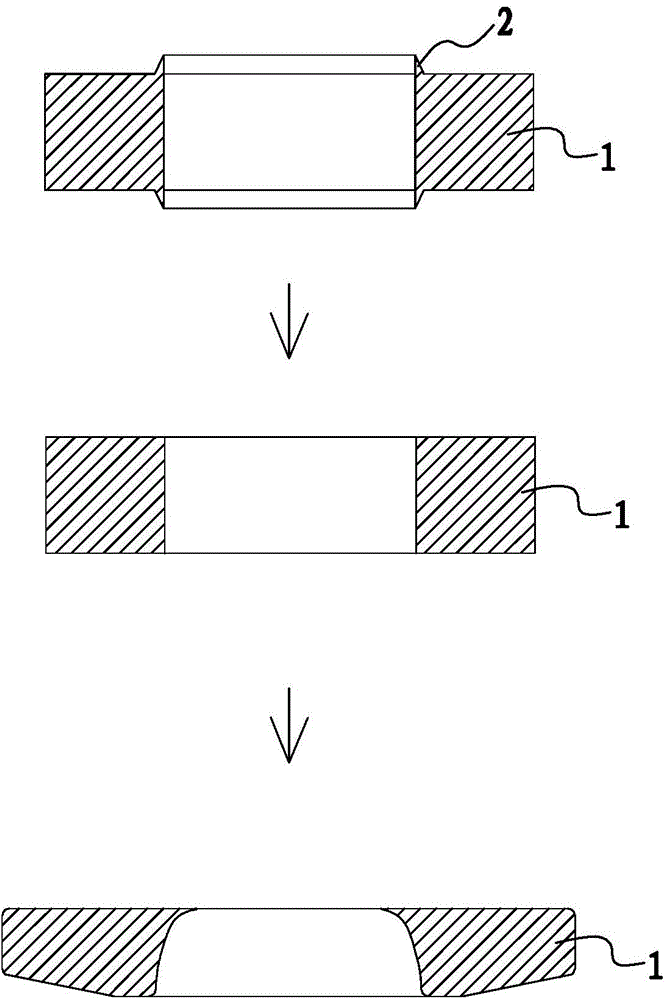

Gasket manufacturing method

ActiveCN104476145AReduce manufacturing costSimple processFurnace typesOther manufacturing equipments/toolsEngineeringFood extrusion

The invention provides a gasket manufacturing method and belongs to the technical field. According to the method, the problem that the cost of a gasket manufactured through an existing gasket manufacturing method is higher is solved. The gasket manufacturing method comprises the following steps of a, acquiring an annular workpiece, namely cutting needed length from a tubular raw material to obtain the to-be-machined annular workpiece; b, performing annealing, namely annealing the annular workpiece; c, performing cold extrusion, namely performing cold extrusion on the workpiece at one time to form a gasket in a needed shape; d, performing thermal treatment, namely performing thermal treatment on the gasket which is formed by extrusion. According to the gasket manufacturing method provided by the invention, a tube material is directly cut and is subjected to one-time cold extrusion forming, the process is simpler, and the raw material is not wasted, so that the production cost of an automobile gasket is lower.

Owner:浙江赛特机械股份有限公司

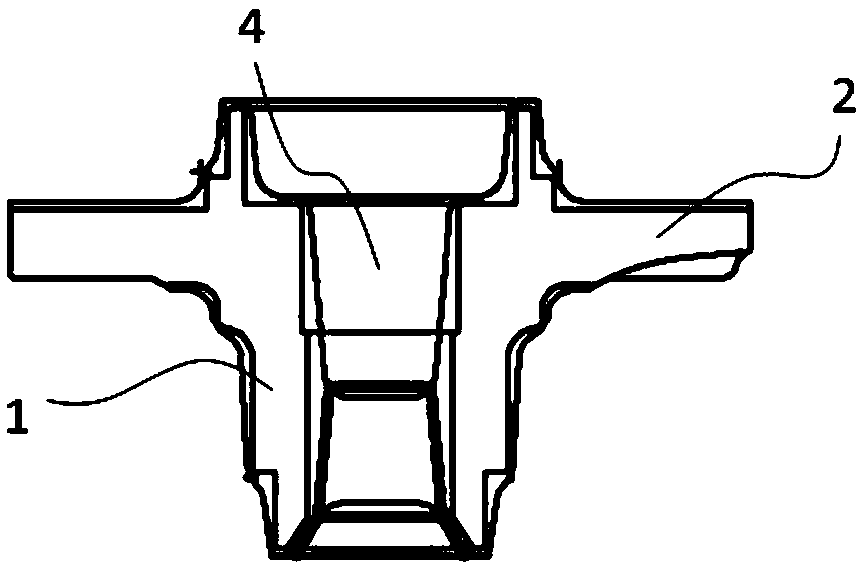

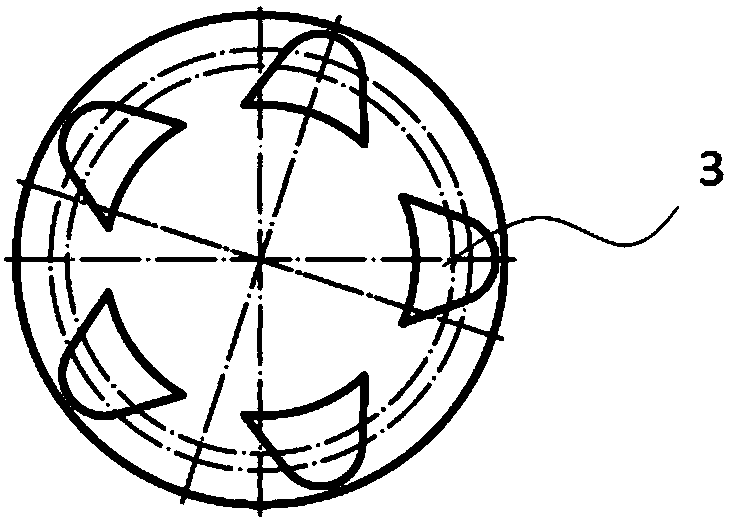

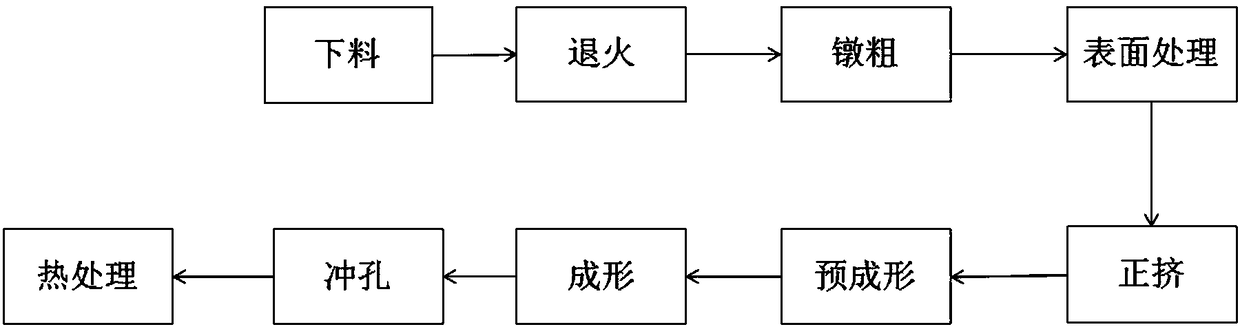

Forging process of hub unit flange plate

The invention provides a forging process of a hub unit flange plate. The process comprises flows of unloading, annealing, upsetting, surface treatment, forward extrusion, pre-molding, formation, punching and heat treatment in sequence. In the forging process of the hub unit flange plate, two extrusion procedures of forward extrusion and pre-molding are added before formation; on the one hand, fullflowing of materials can be guaranteed to improve continuity of a product production line; and on the other hand, the load of a forming mold can be reduced to prolong the service life of the formingmold.

Owner:JIANGSU SUNWAY PRECISION FORGING

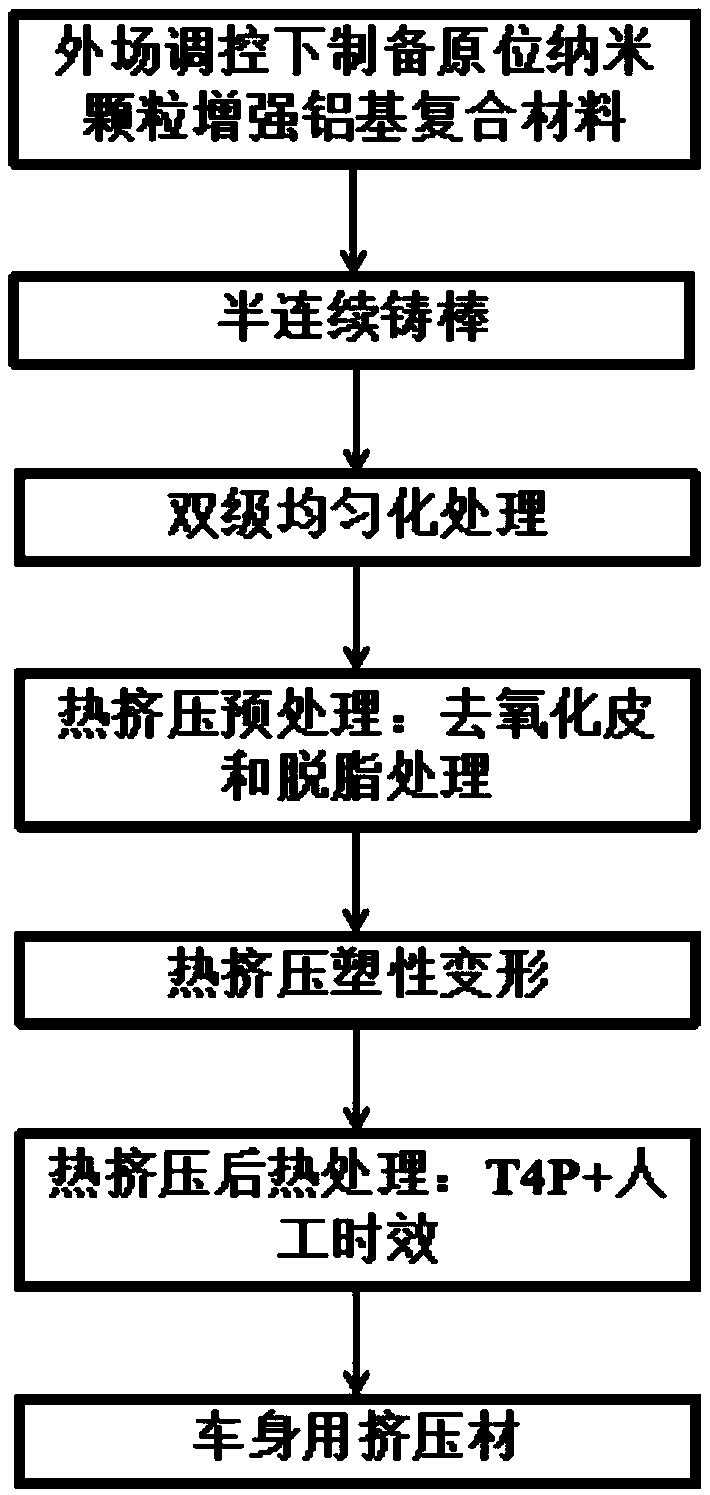

Extrusion process for vehicle body in-situ nanoparticles enhancing aluminum base composite material

ActiveCN108796404AImprove tissue performance uniformityImprove strong plasticityResearch ObjectThermal expansion

The invention relates to the field of aluminum base composite material processing, in particular to an extrusion process for a vehicle body in-situ nanoparticles enhancing aluminum base composite material. The vehicle body in-situ nanoparticles enhancing aluminum base composite material synthesized in situ under the outer field control is used as a research object, the casting defects such as holes and loosening are eliminated by adopting the hot extrusion plasticity, so that the texture is refined and dense, the extruded grains are uniform and small, and the mechanical properties are obviously improved; meanwhile, under the action of the extrusion pressure, the agglomeration particles are dispersed and dispersed in a matrix, the bonding force with the matrix is higher, a lot of dislocation is generated, a high-density dislocation mesh is formed, and dislocation enhancement is produced accordingly. The T4P+ artificial aging heat treatment of the follow-up extrusion material can eliminate the thermal residual stress caused by the different thermal expansion coefficients of nanoparticles and matrix in the process of the hot extrusion, the plasticity of the vehicle body extrusion material is further improved, and the vehicle body in-situ nanoparticles enhancing aluminum base composite material extrusion material which can replace the steel plate is obtained.

Owner:JIANGSU UNIV

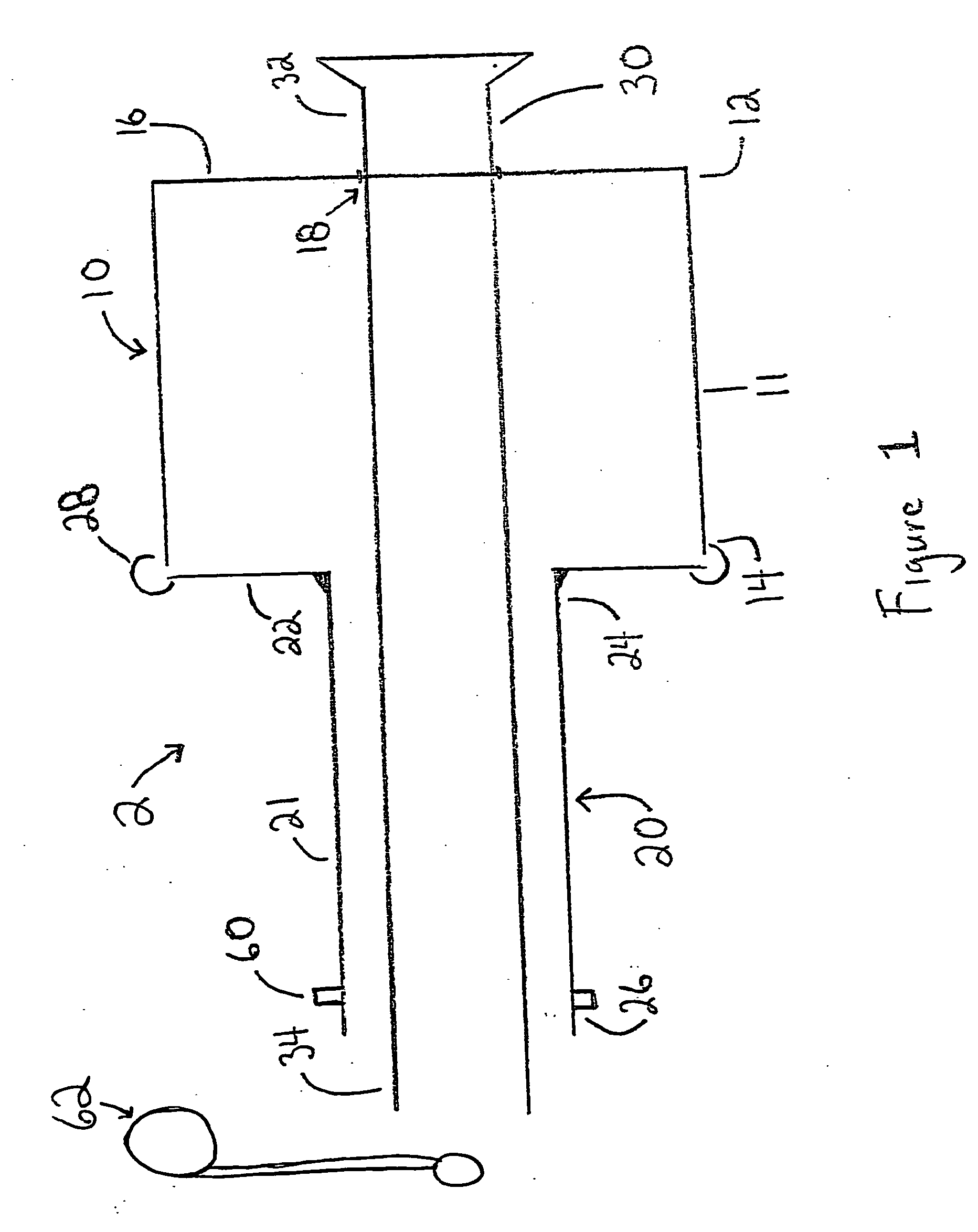

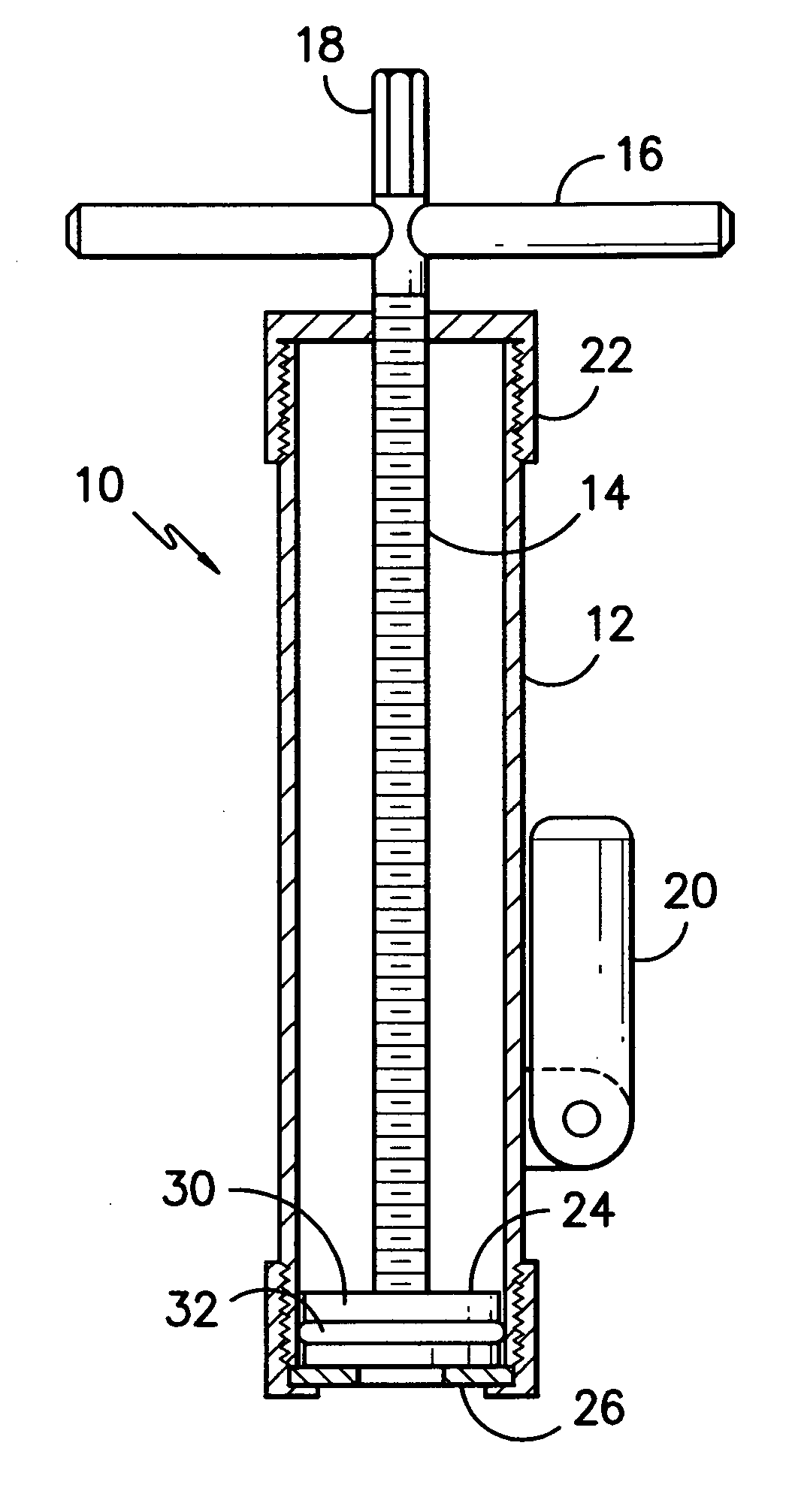

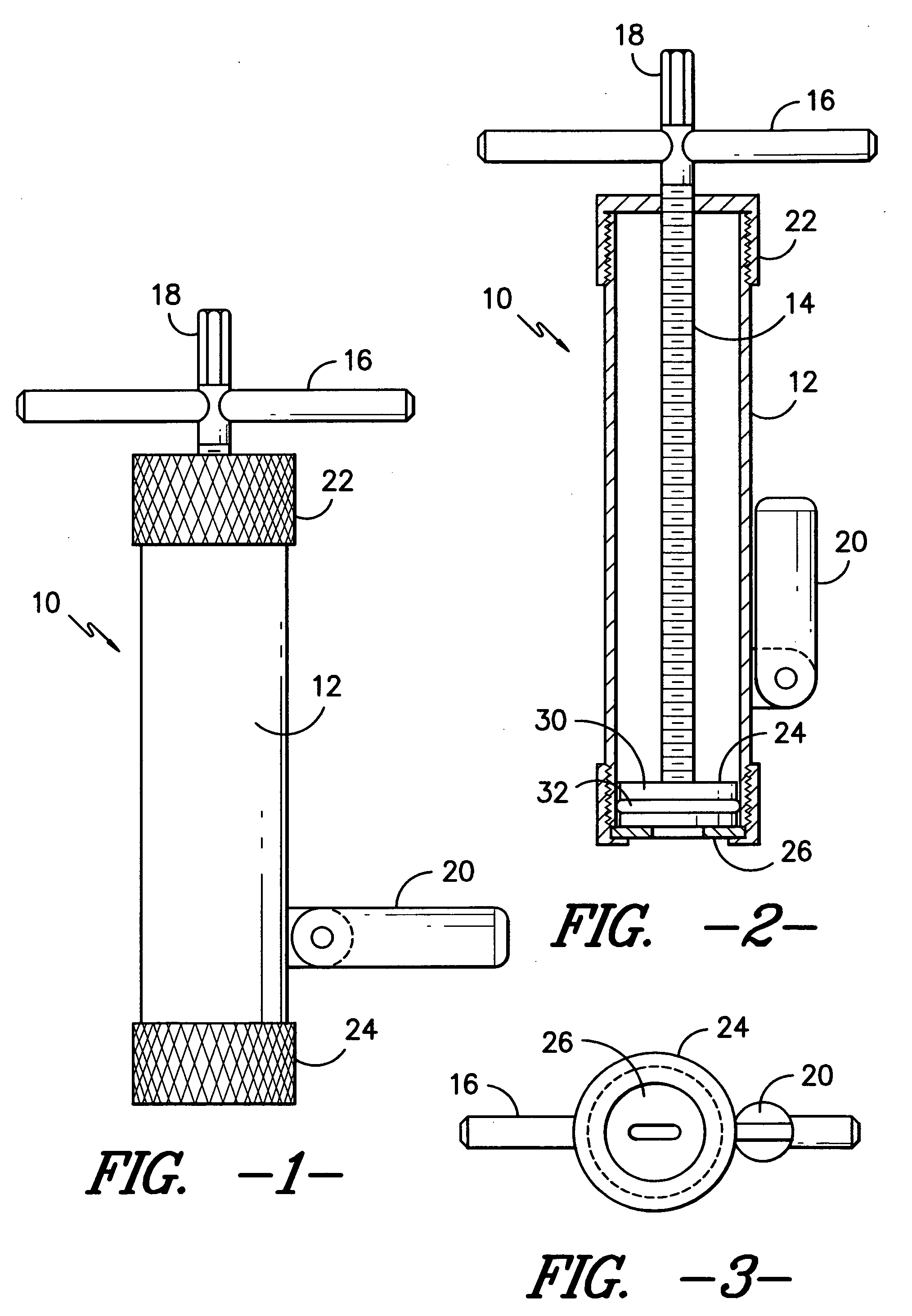

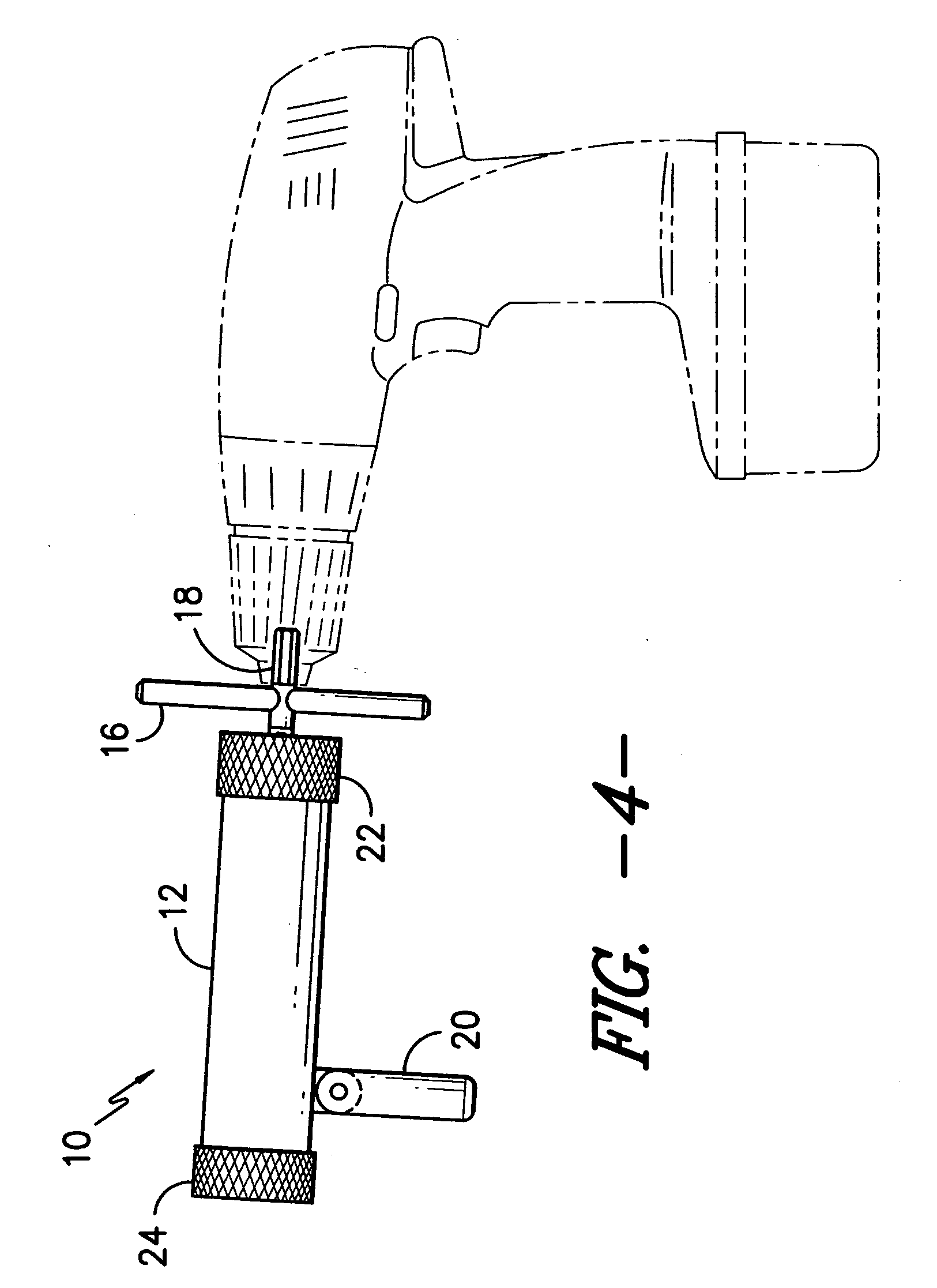

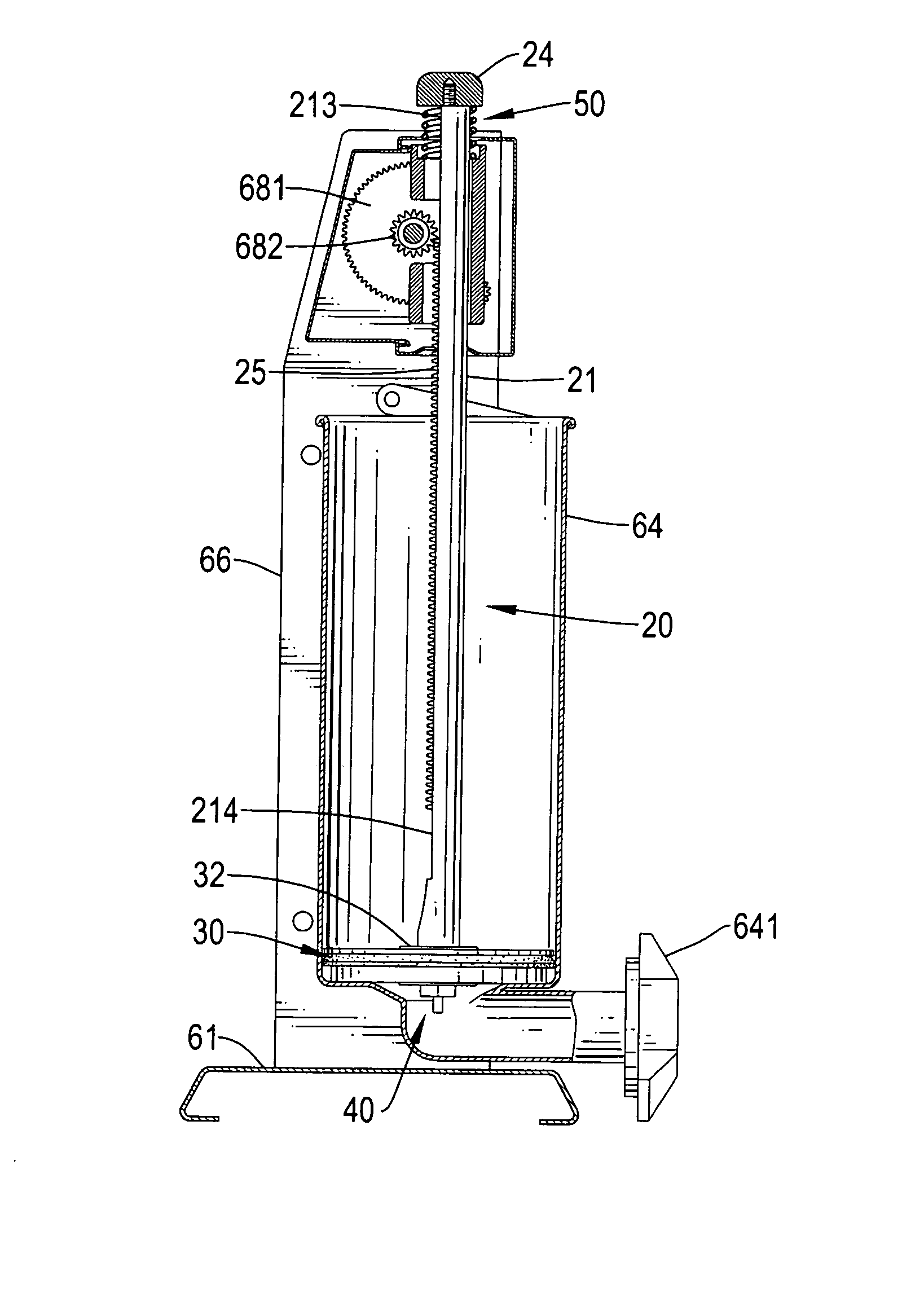

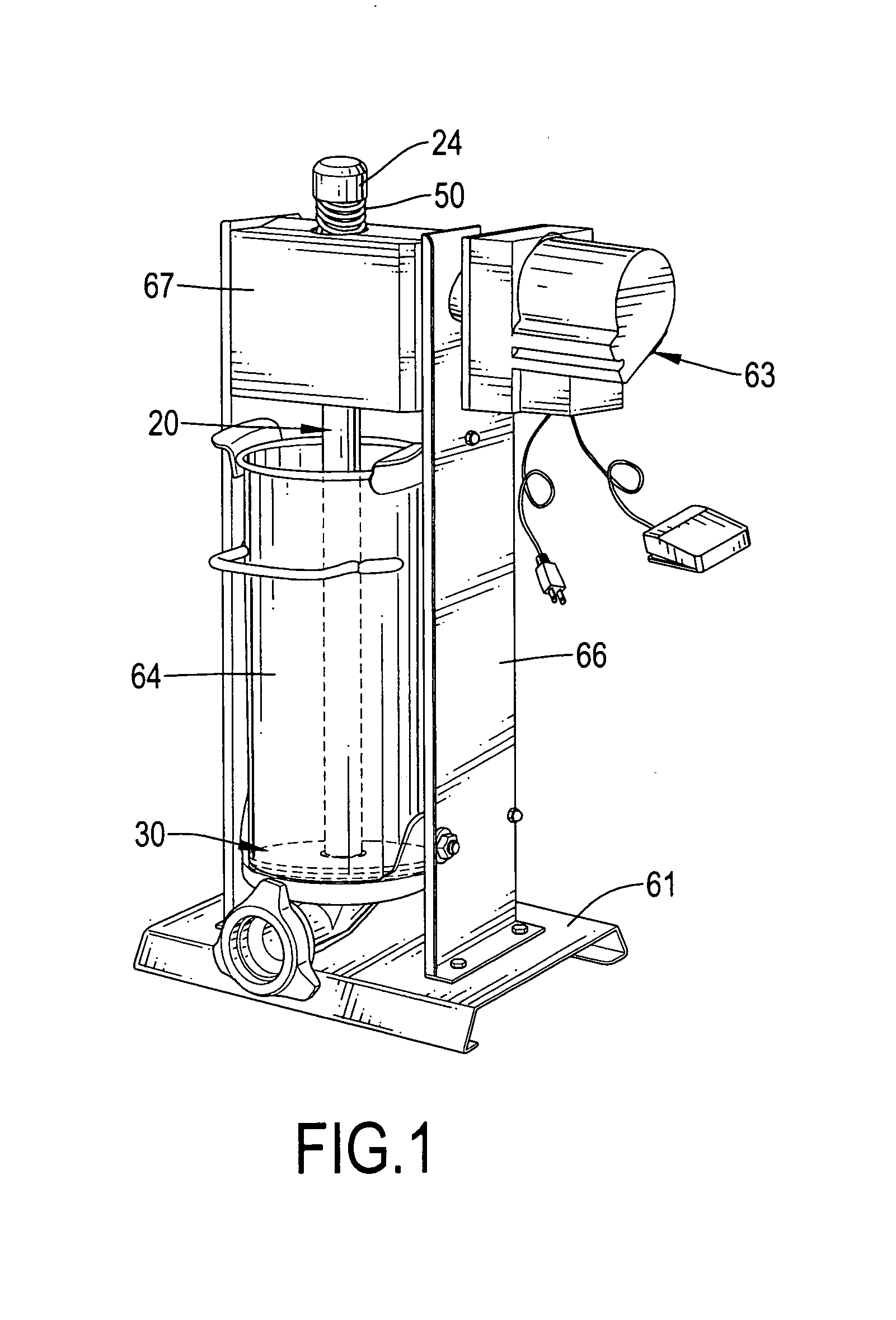

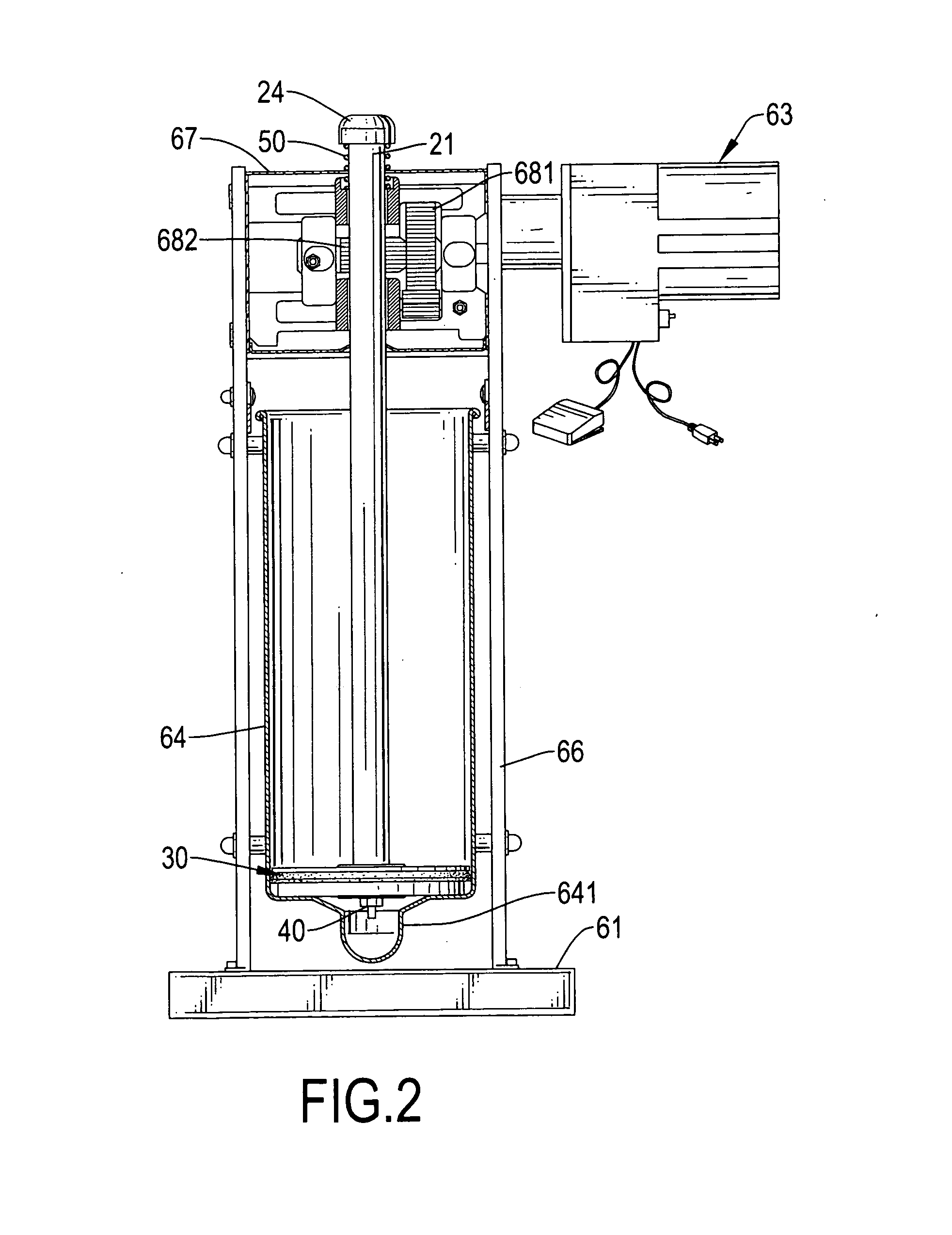

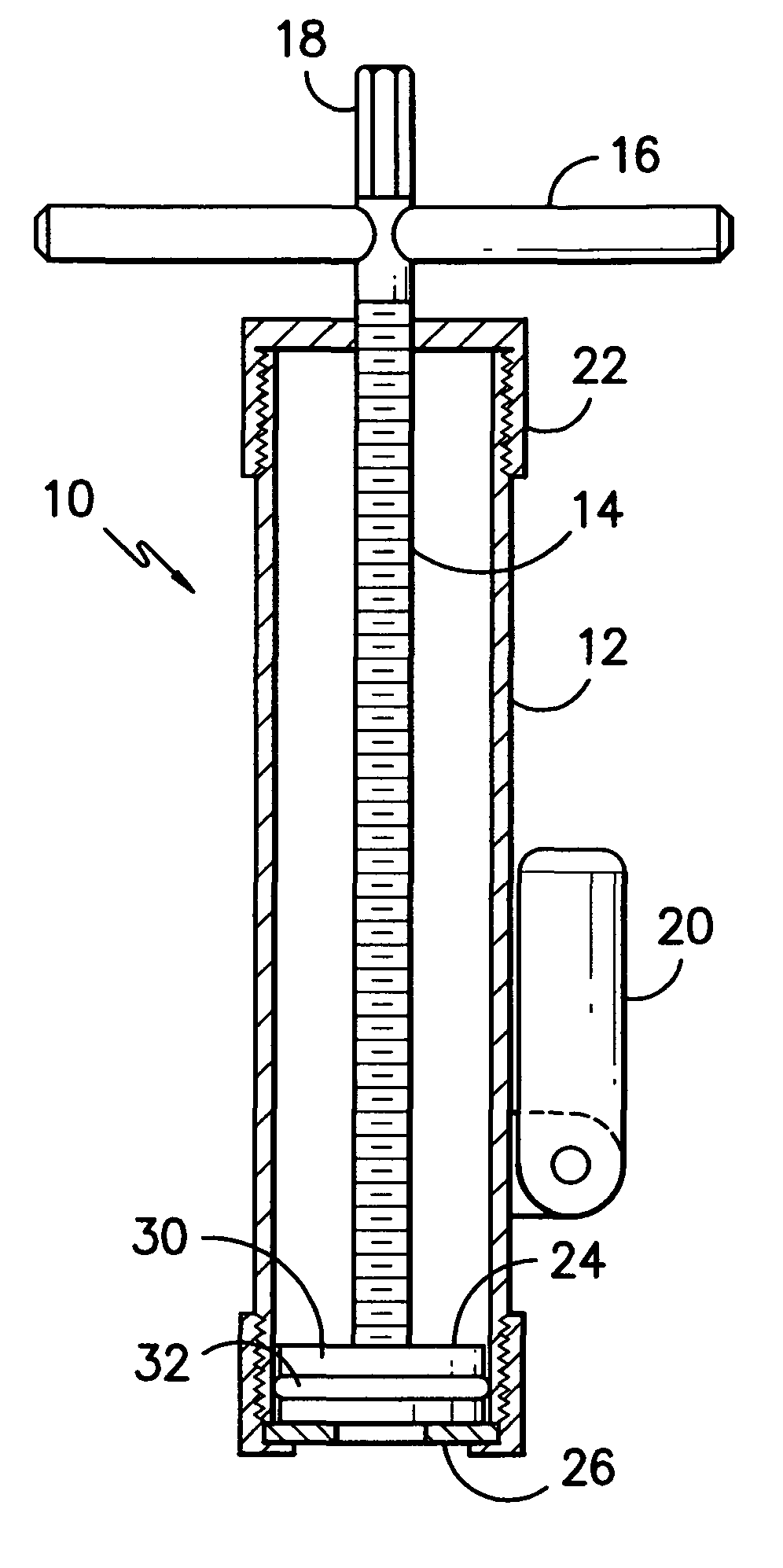

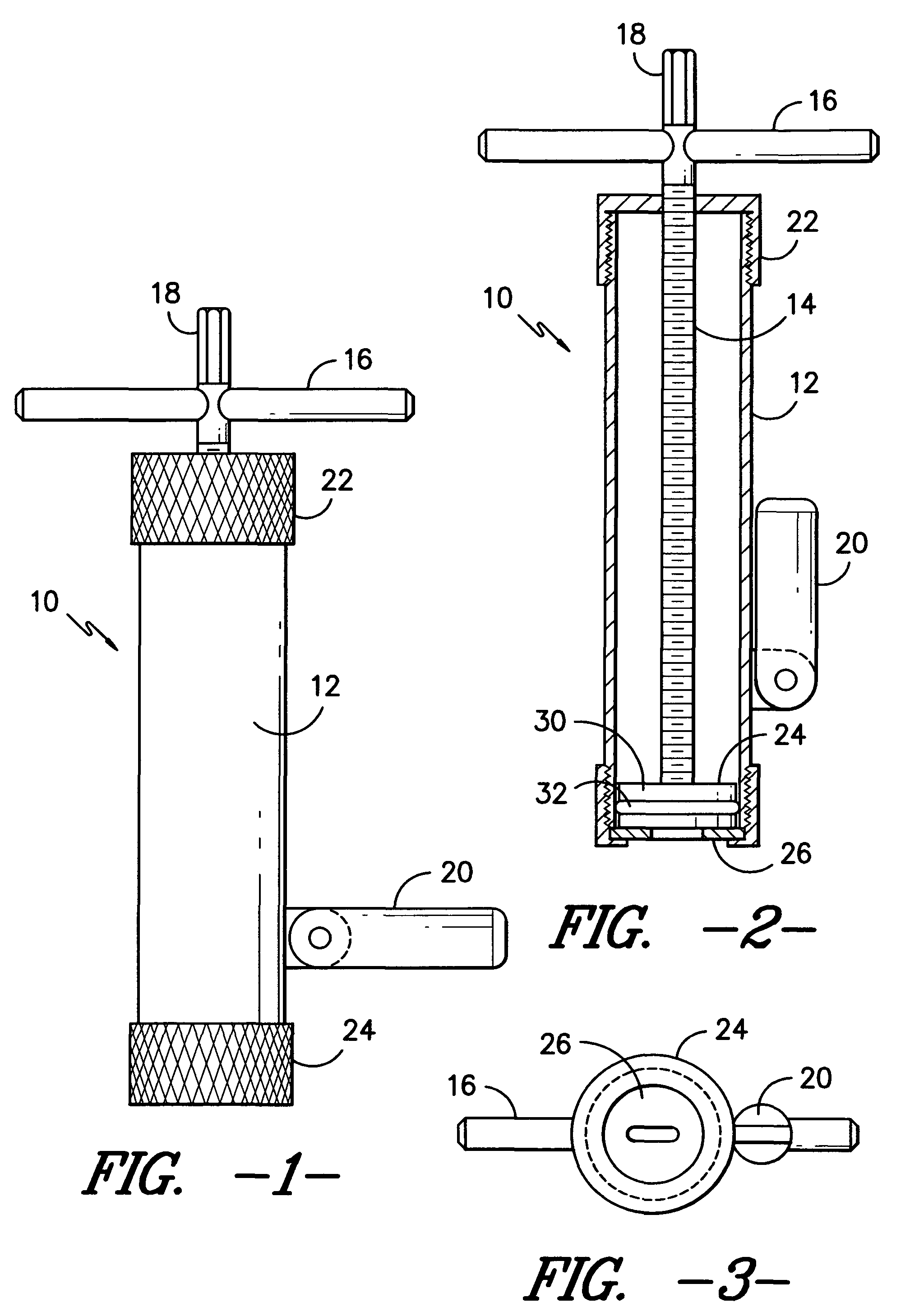

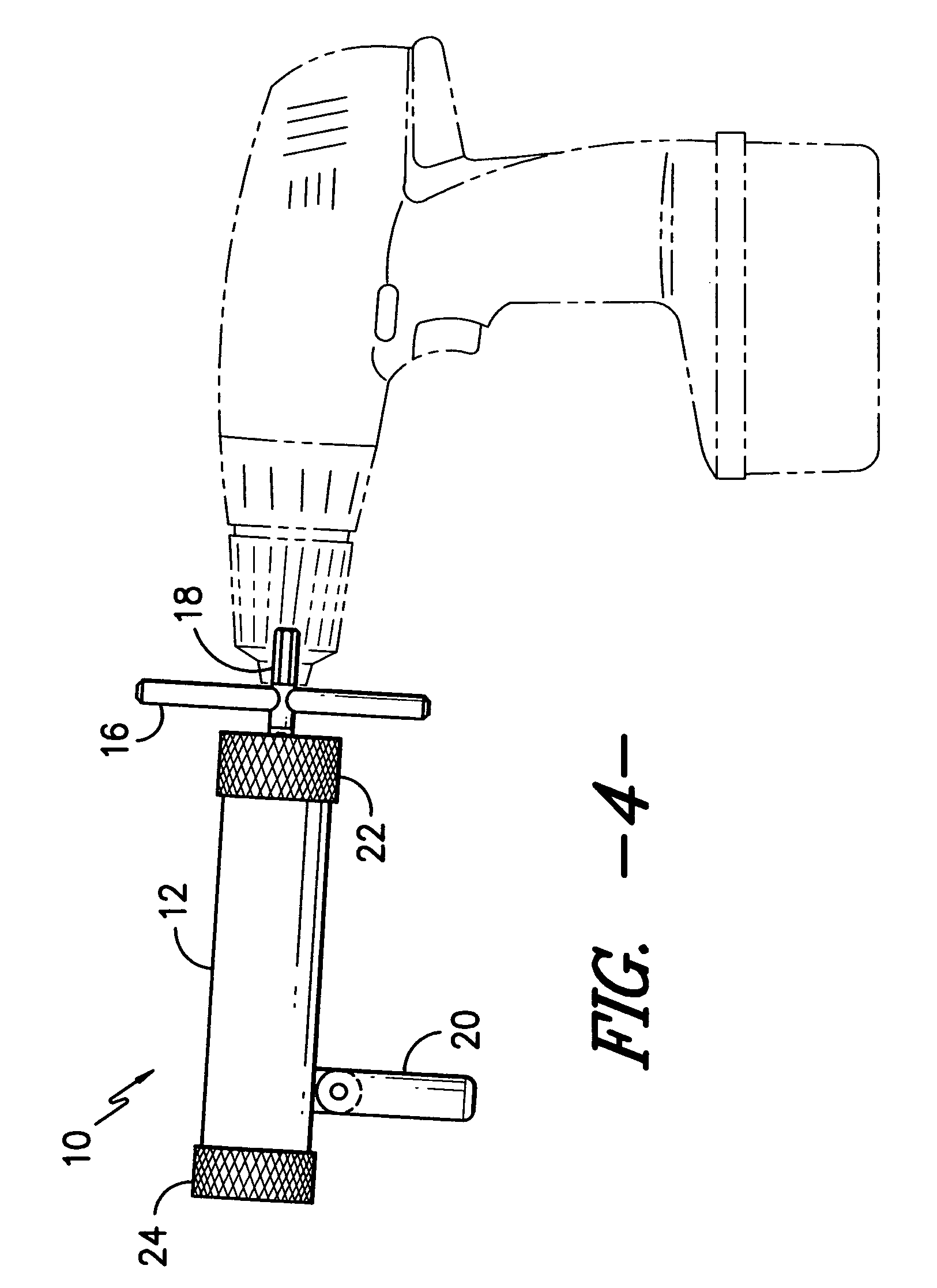

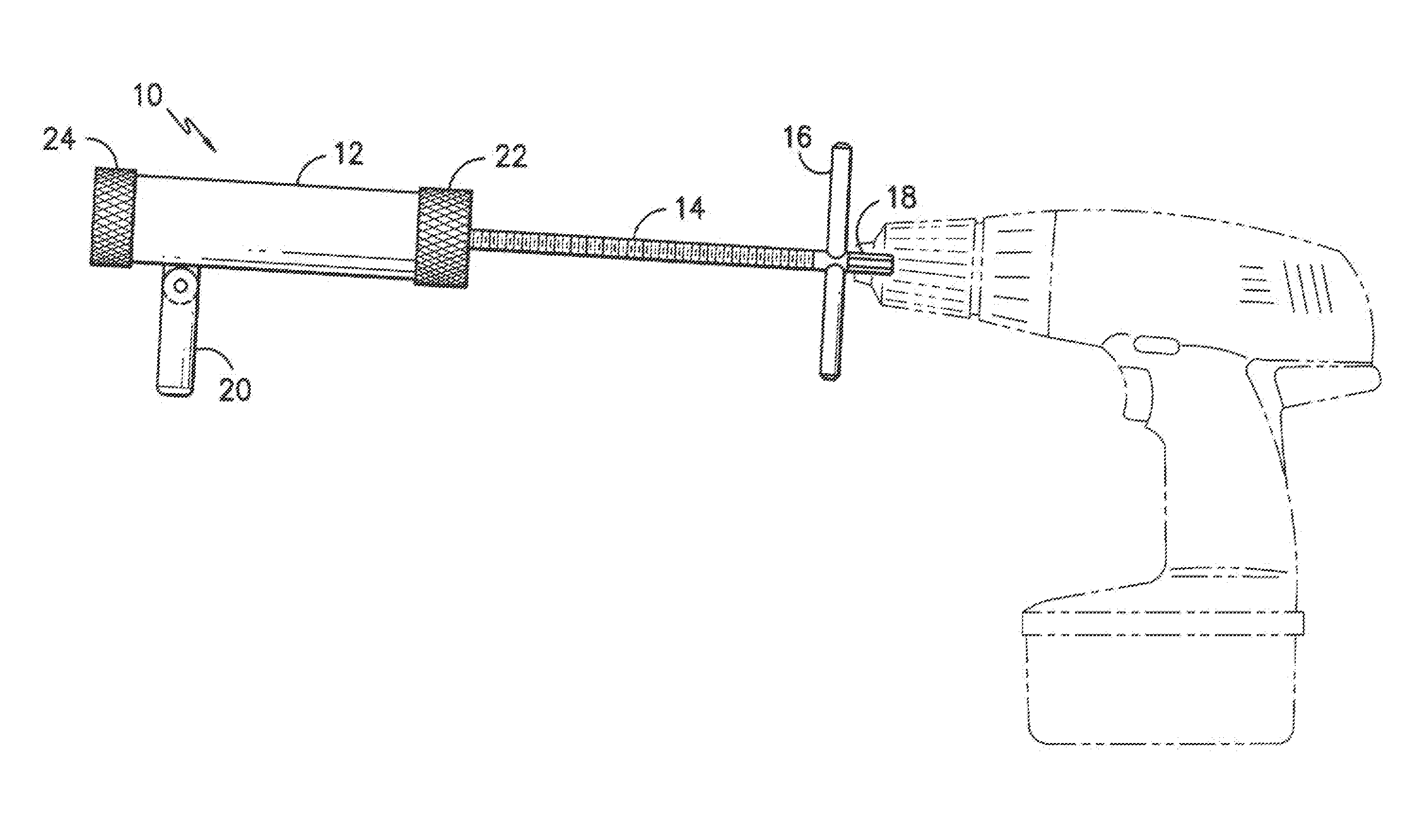

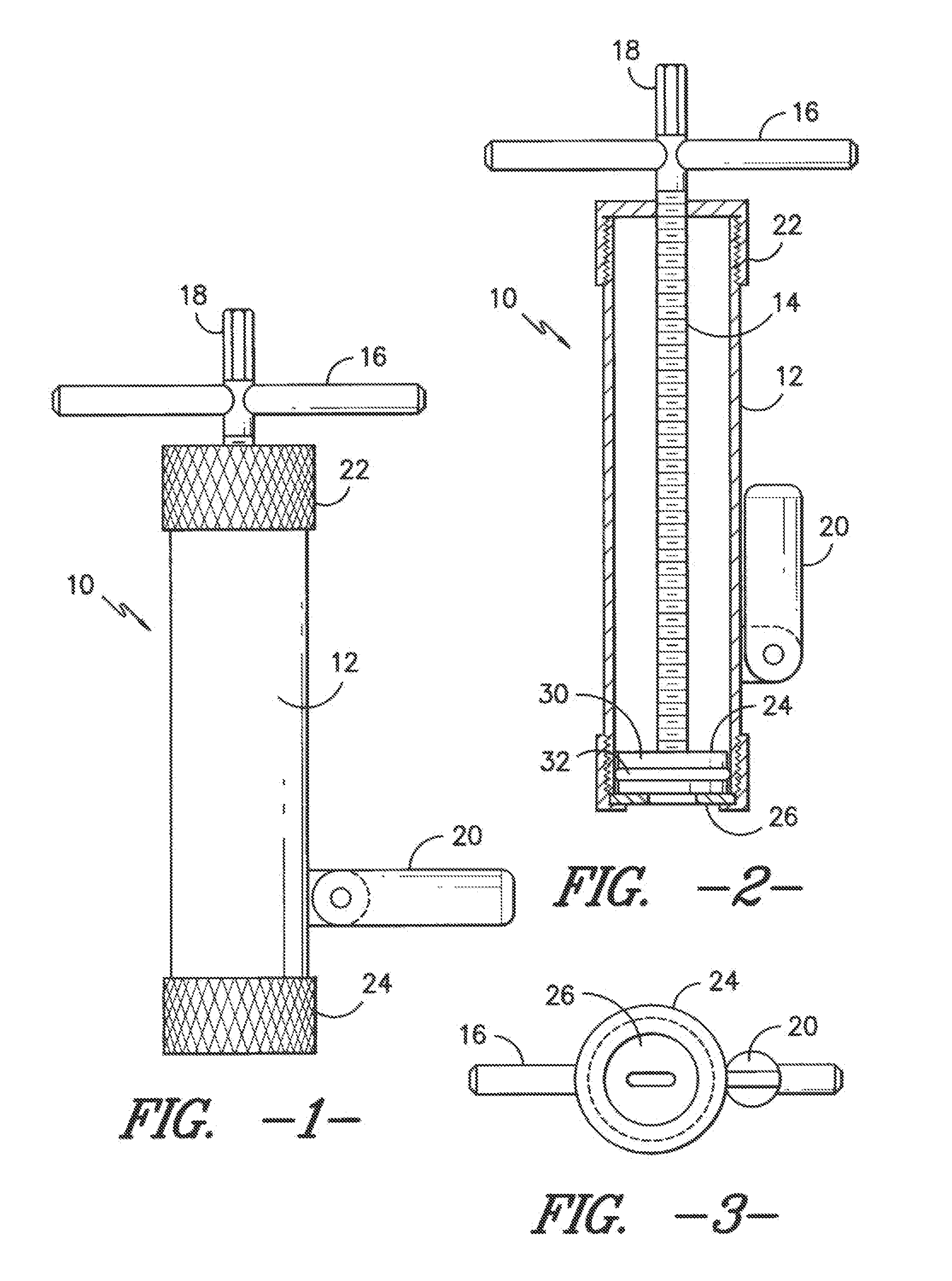

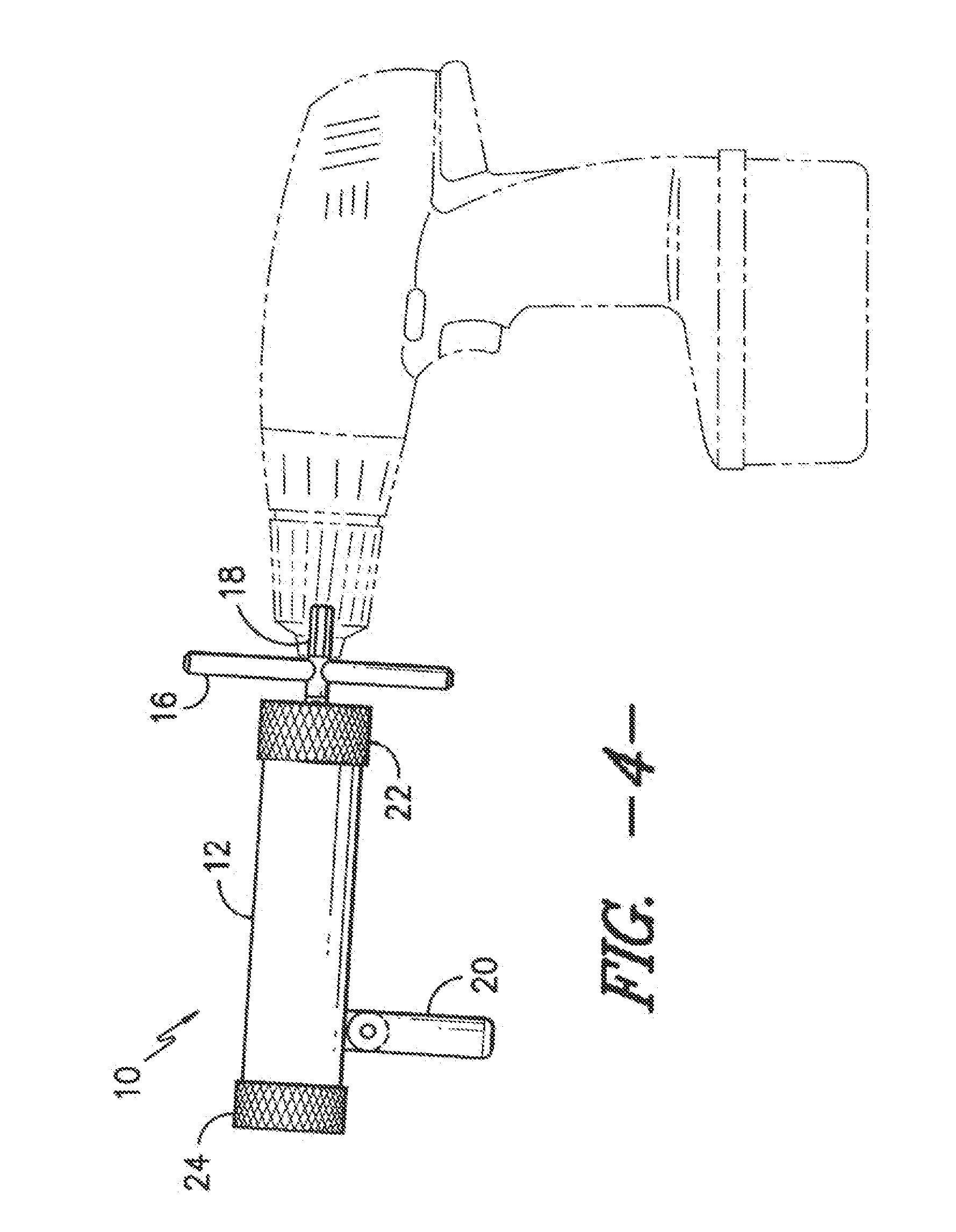

Food extruder

InactiveUS20090291158A1Easy to insertFacilitates securementConfectioneryBaked articles handlingScrew positionEngineering

A food extruder including a barrel provided at one end with an outlet from which the food substance can be extruded, a rotatable screw positioned within the barrel that is capable of being rotated and moved longitudinally within the barrel, a handle member at a top end of the rotatable screw for manual engagement, and a rod member protruding from an upper portion of the handle member for insertion into a drill chuck. The rod member, in a preferred embodiment, has a hexagonal cross section, which facilitates insertion and securement within a drill chuck, so that the drill may be used to turn the rotatable screw, rather than having to turn it manually. Additionally, a hand grip member may be attached to the barrel member at a generally right angle thereto, so that a user may grip the hand grip while using the drill to turn the rotatable screw, in order to prevent the entire extruder from rotating.

Owner:SCHNEE CHRISTINE MARIE

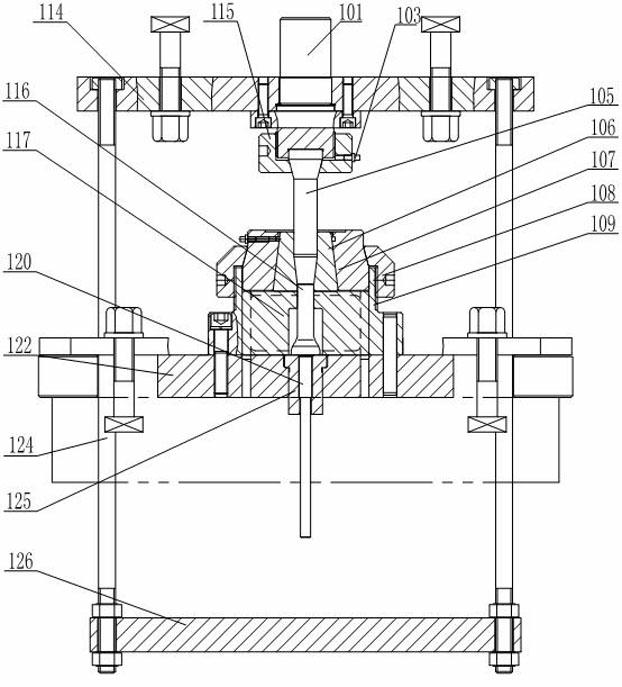

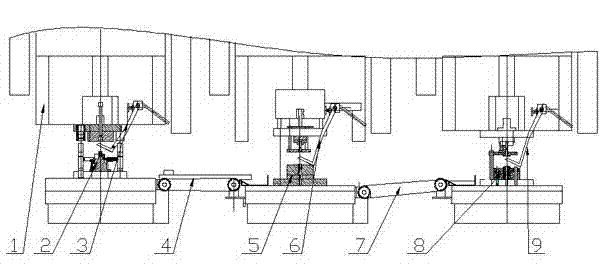

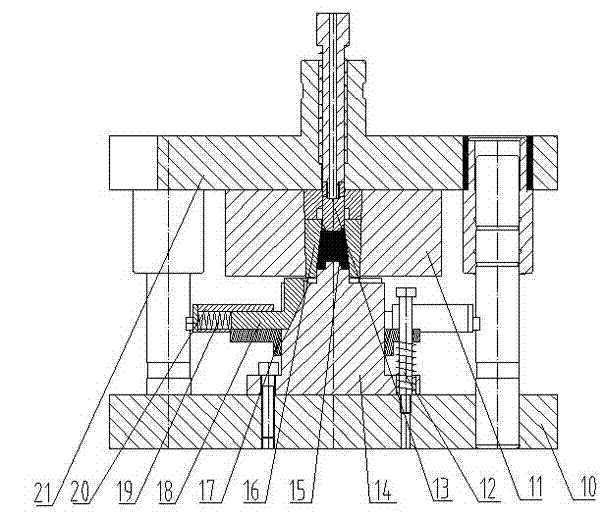

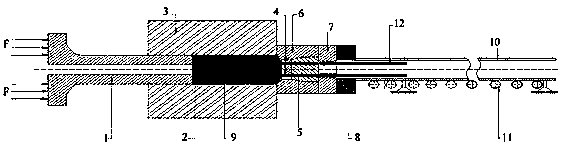

Hot-extrusion production line of prestressed anchorage device clamping piece

InactiveCN102528465AImprove extrusion lifeHigh concentricityOther manufacturing equipments/toolsProduction linePunching

The invention provides a hot-extrusion production line of a prestressed anchorage device clamping piece, and relates to the technical field of extrusion molding of metal materials. The problems such as complex working procedures, great investment and high cost in the existing machining method such as cold extrusion, warm extrusion, hot extrusion, hot forging and the like can be mainly solved. The production line consists of three working procedures such as upsetting-extruding blanking, combined extrusion and punching reshaping: (1) carrying out a upsetting-extruding blanking working procedure, namely putting a heated bar into an upsetting-extruding die to obtain a frustum with a centering hole; (2) after blanking, collecting a blank by a mechanical blank collecting hand, and transporting the blank into a combined extrusion die by virtue of a transporting chain to carry out the combined extrusion working procedure, so that a semi-finished product of which the upper part and the lower part are provided with blind holes can be obtained by means of combined extrusion; and (3) after the blank is collected by the mechanical hand, transporting the blank into a floating and positioning punching reshaping die by the transporting chain to carry out punching reshaping, so that the punching reshaping working procedure is completed, a semi-finished product of an anchorage device clamping piece is obtained; and collecting a workpiece by the mechanical hand, and transporting the workpiece into a blank storing box. The production line is fewer in working procedures, high in efficiency, less in investment, long in the service life of the die, quick in production speed, and good in the concentricity of the blank.

Owner:襄阳中铁宏吉工程技术有限公司

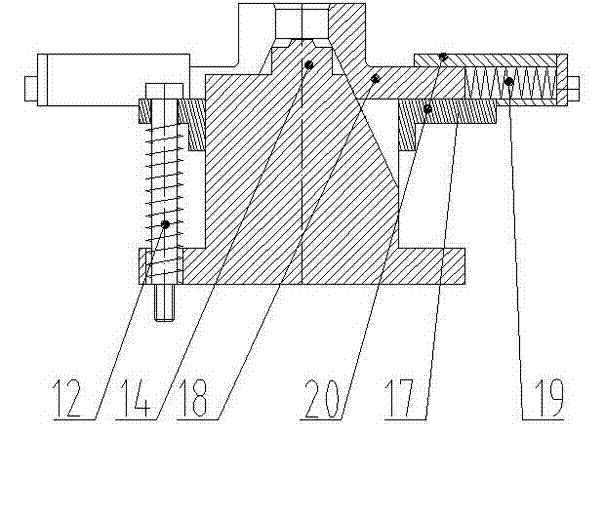

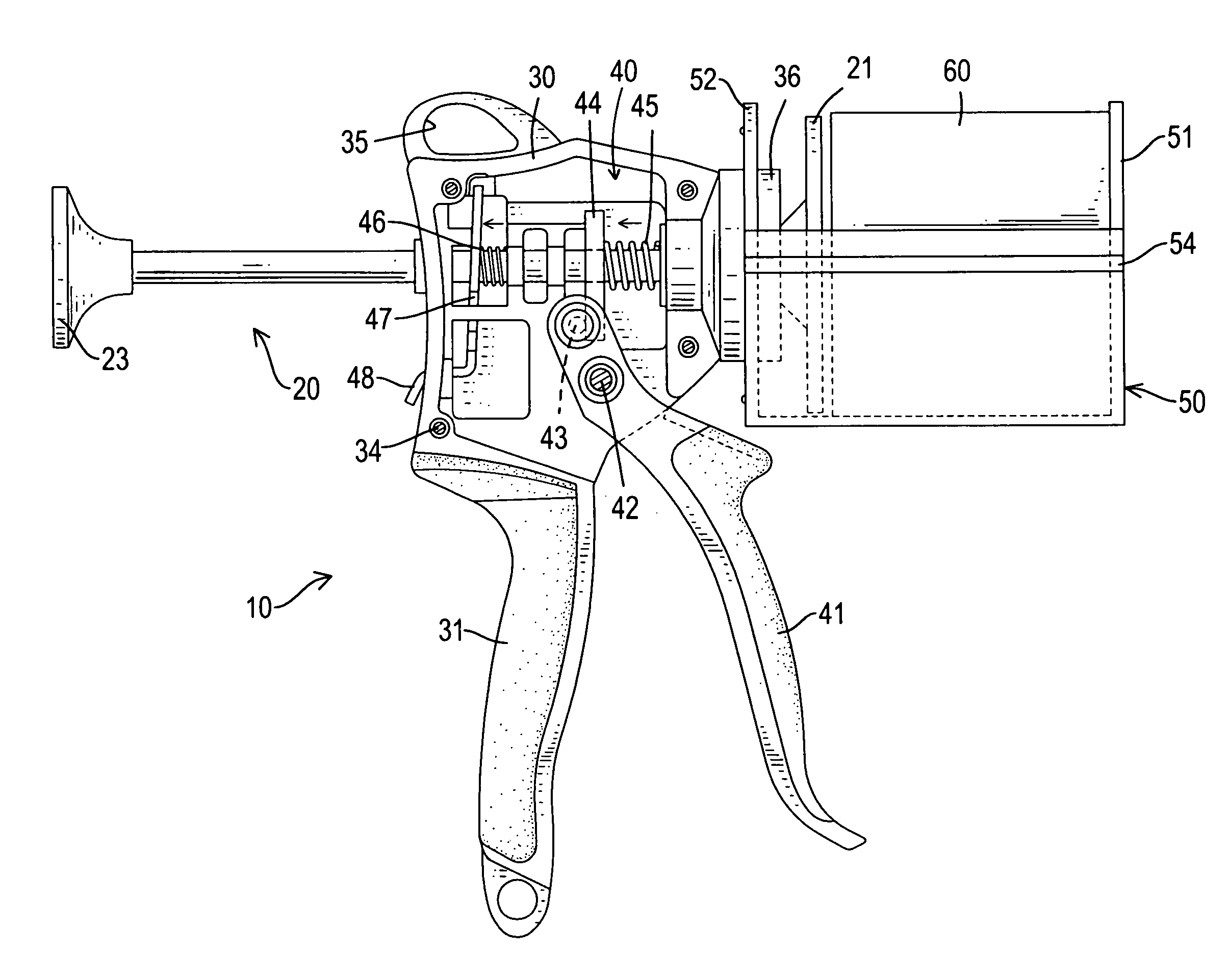

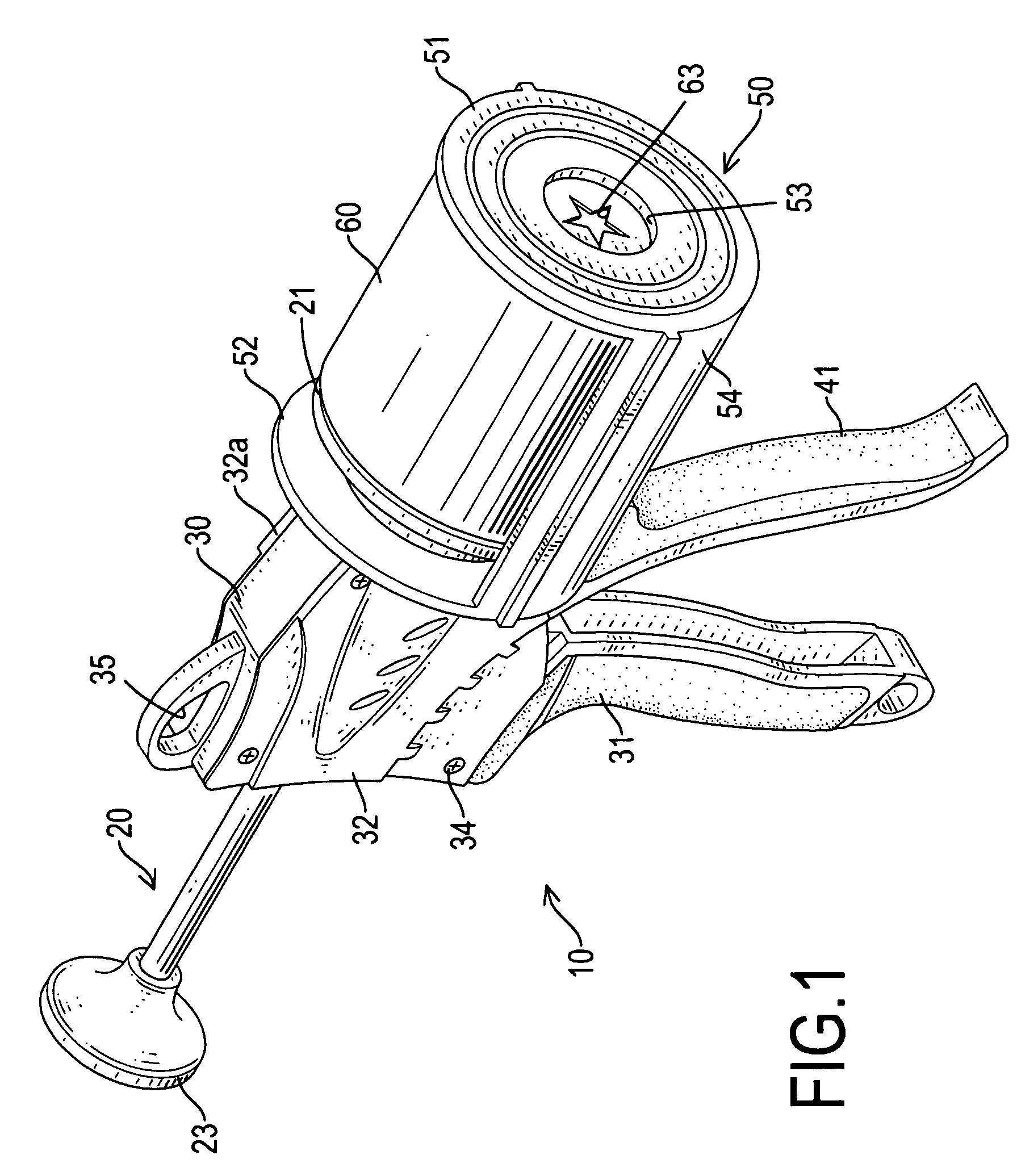

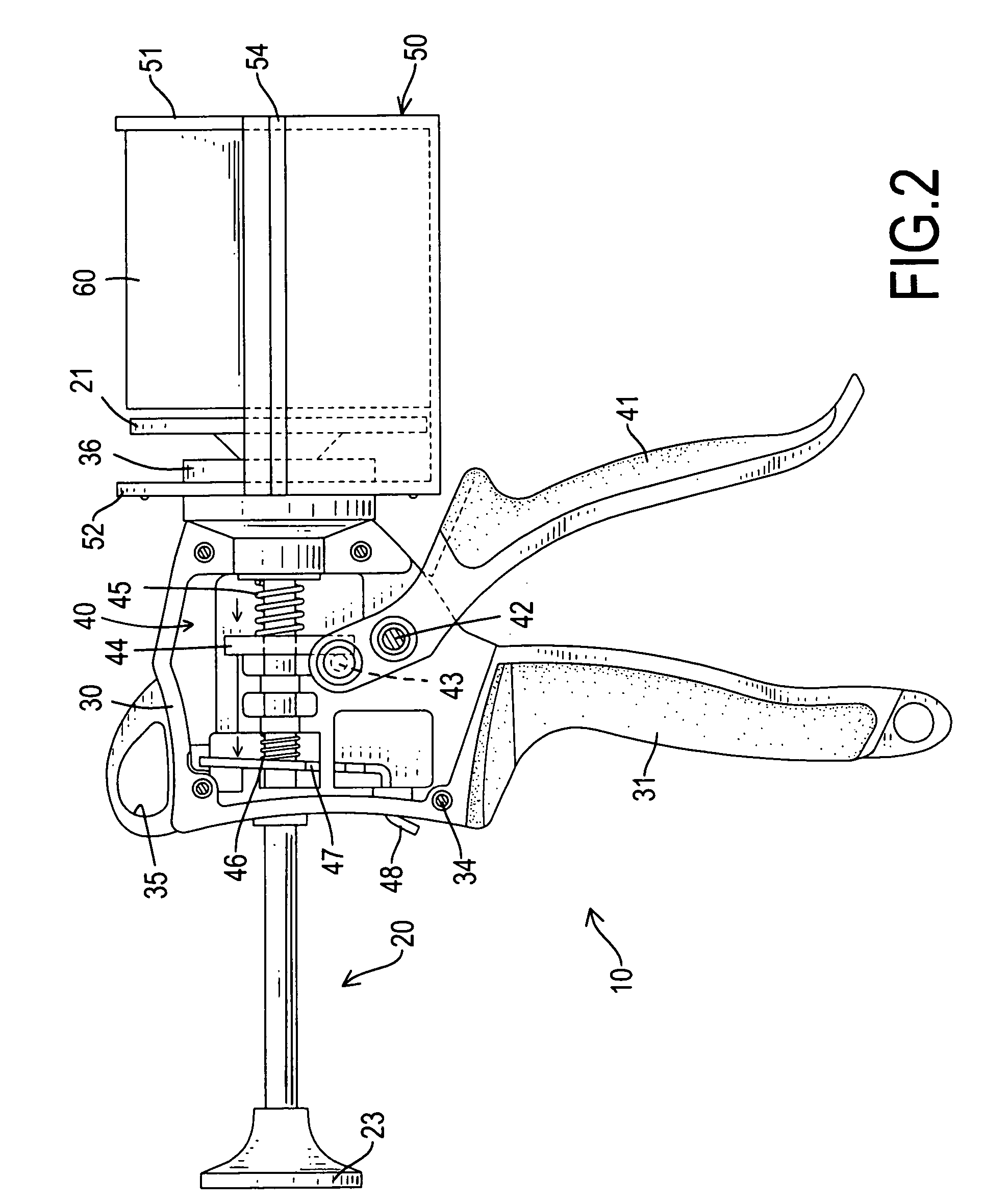

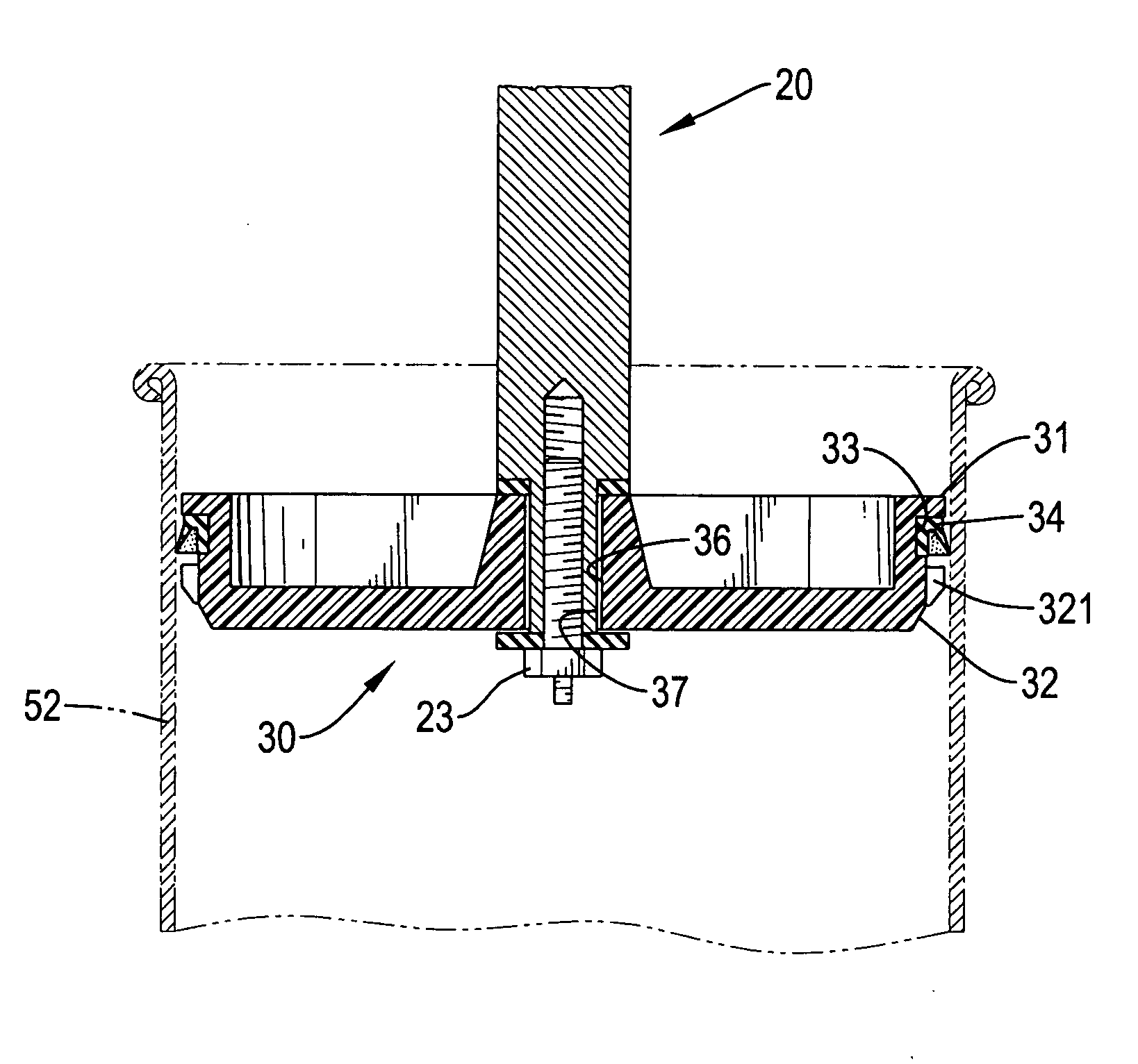

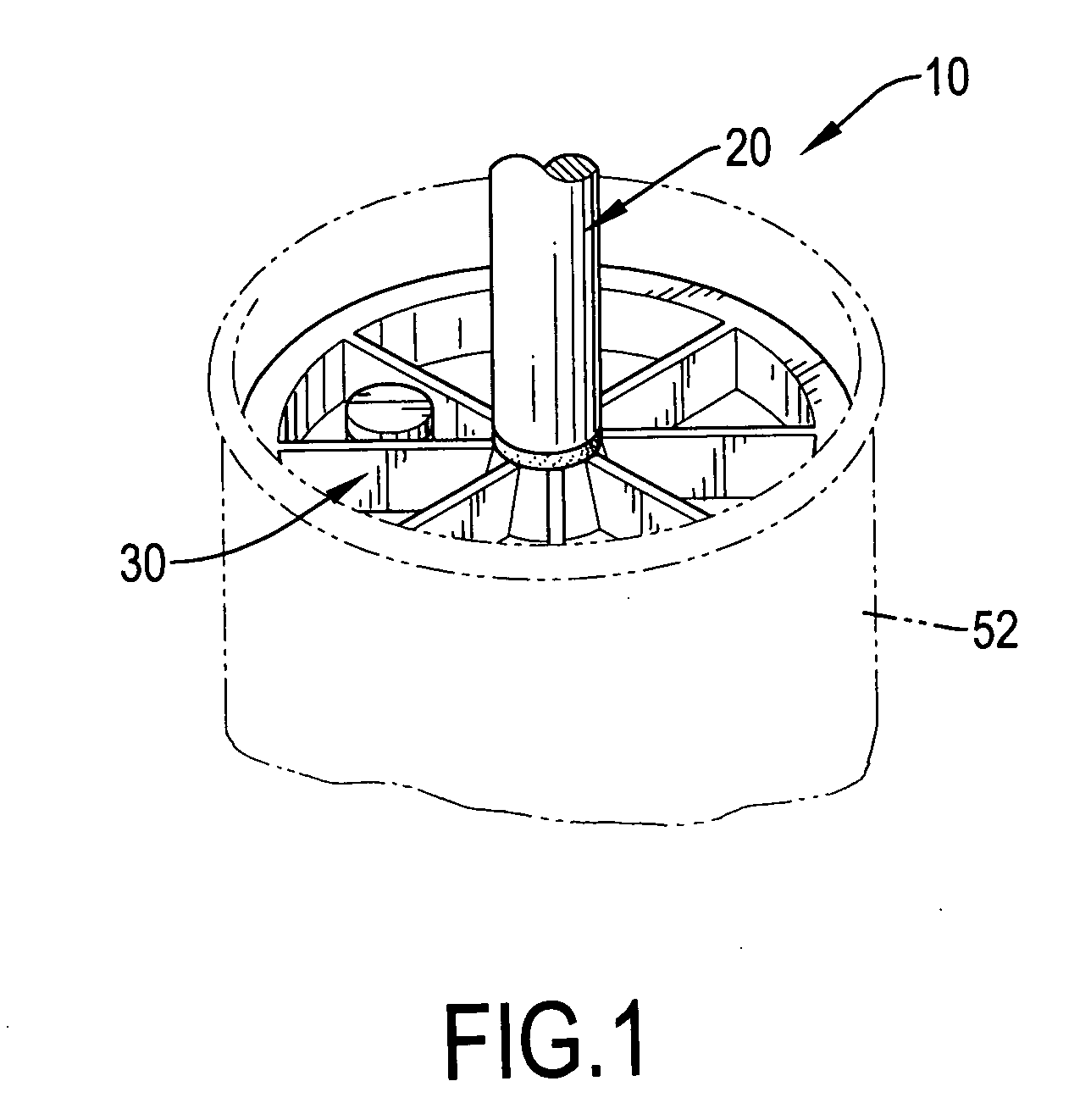

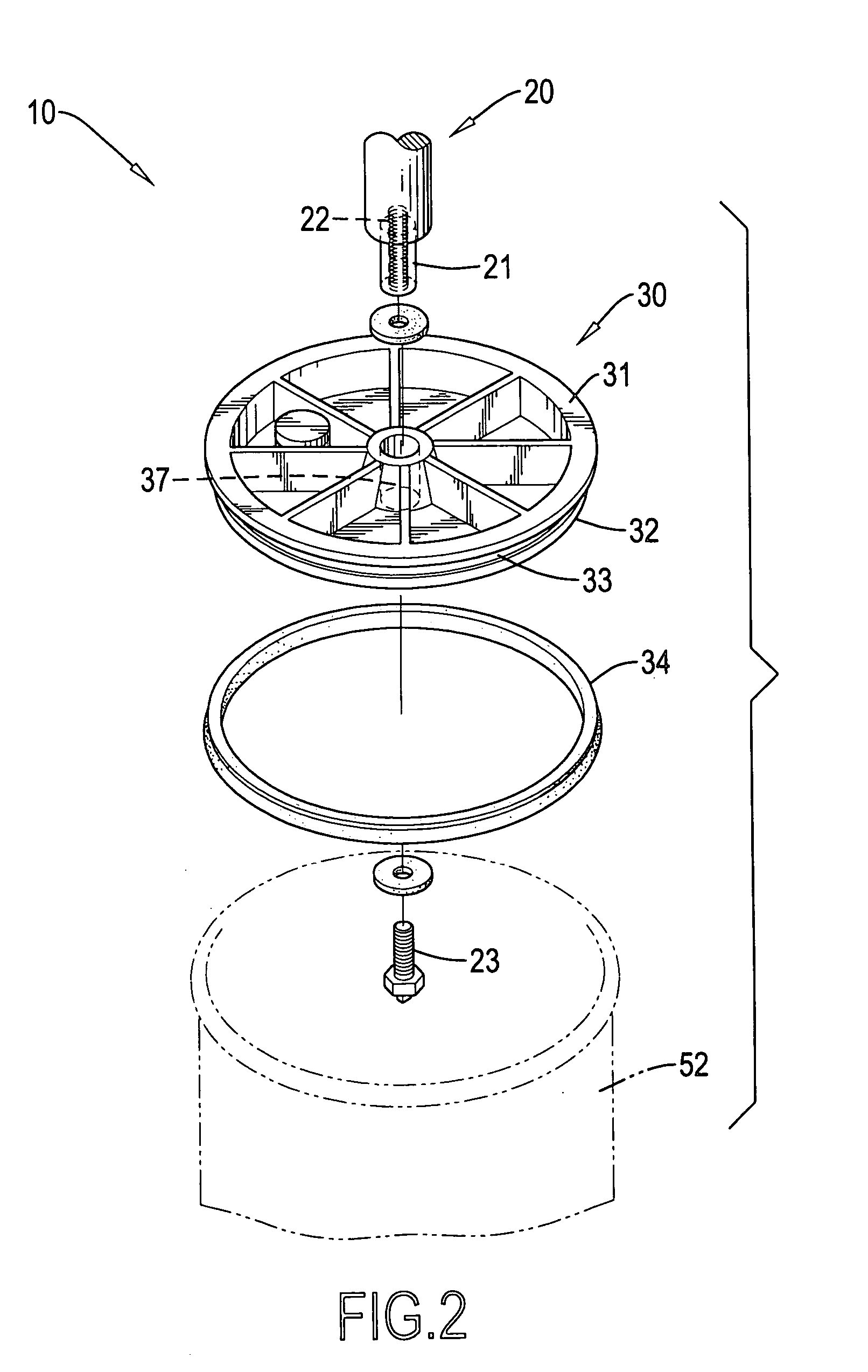

Food extrusion piston assembly

InactiveUS20070251957A1Safely and convenient to useLiquid surface applicatorsVolume measurement and fluid deliveryEngineeringFood extrusion

A food extruder has a base, a housing, a drive assembly, a food reservoir and a piston assembly. The piston assembly has a piston rod, a piston dish, a fastener and a spring. The piston rod slidably extends into the food reservoir and has a rod, and a rack. The rod has an upper and lower end and at least one flat surface formed at one or respectively at two ends of the rod. The rack is formed on the rod between the ends of the rod adjacent to the at least one flat surface. The piston dish is attached to the lower end of the piston rod and has a through hole. The fastener is extends through the through hole in the piston dish and connects to the lower end of the rod. The spring is mounted around the piston rod near the upper end of the rod.

Owner:CHEN YU CHENG

Apparatus for food extrusion

An apparatus for food extrusion is provided. The apparatus includes a substantially circular plate having a plurality of holes in an offsetting arrangement thereon. The arrangement of the holes provide food extruded through the apparatus with a shape which approximates the arrangement.

Owner:ROBERT REISER

Food extruder

InactiveUS7811074B2Facilitates insertion and securementPrevent rotationConfectioneryBaked articles handlingScrew positionEngineering

Owner:SCHNEE CHRISTINE MARIE

Food extruder

InactiveUS20110027401A1Easy to insertFacilitates securementConfectioneryBaked articles handlingScrew positionFood extrusion

A food extruder including a barrel provided at one end with an outlet from which the food substance can be extruded, a rotatable screw positioned within the barrel that is capable of being rotated and moved longitudinally within the barrel, a handle member at a top end of the rotatable screw for manual engagement, and a rod member protruding from an upper portion of the handle member for insertion into a drill chuck or other motorized means. The rod member, in a preferred embodiment, has a hexagonal cross section, which facilitates insertion and securement within a drill chuck or a receptacle for other motorized means, which may be used to turn the rotatable screw, rather than having to turn it manually. Additionally, a hand grip member may be attached to the barrel member at a generally right angle thereto, so that a user may grip the hand grip while using the drill or other motorized means to turn the rotatable screw, in order to prevent the entire extruder from rotating.

Owner:SCHNEE CHRISTINE M

Multi-channel cooling die

A cooling die, for use in the manufacture of extruded food products, the cooling die including: a plurality of core members forming a main body portion of the cooling die between die inlet and outlet ends and arranged about an axis of the die in neighboring relationship; a plurality of extrudate flow channels extending through the cooling die from the inlet end to the outlet end, defined by gaps between neighboring ones of said core members; at least one bore in each said core member through which coolant may flow; an enclosing structure adapted to secure the core members against radial movement relative to the die axis; means for connecting the cooling die to an outlet of a food extruder, a cooling fluid source and a cooling fluid receptacle; and extrudate flow distribution means, located adjacent the inlet end, adapted to direct extrudate from the outlet of the food extruder into selected ones of said extrudate flow channels.

Owner:MARS INC

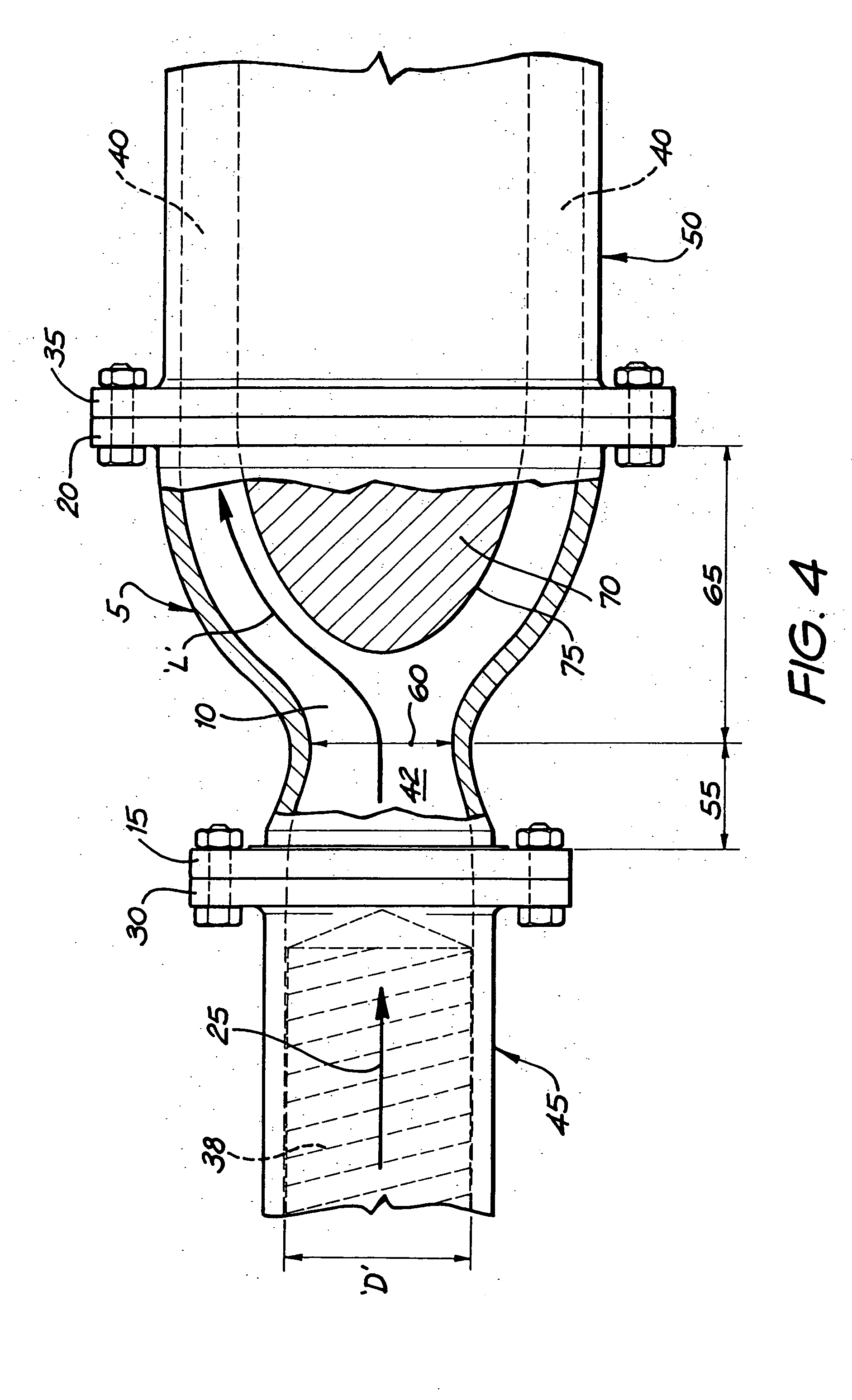

Flow distributor device for an extruder

InactiveUS20050048178A1Increase the lengthIncrease volumeProteins working-up by texturisingCocoaEngineeringFood extrusion

An extruder exit flow distribution device, for use in the transfer of high-moisture food extrudate material from an extruder, said extruder having one or more extrusion screws, to the inlet of a multi-channel cooling die, said flow distribution device having an internal extrudate passage which defines a flow path for any given element of extrudate passing from the extruder exit to the entrance of said cooling die.

Owner:MARS INC

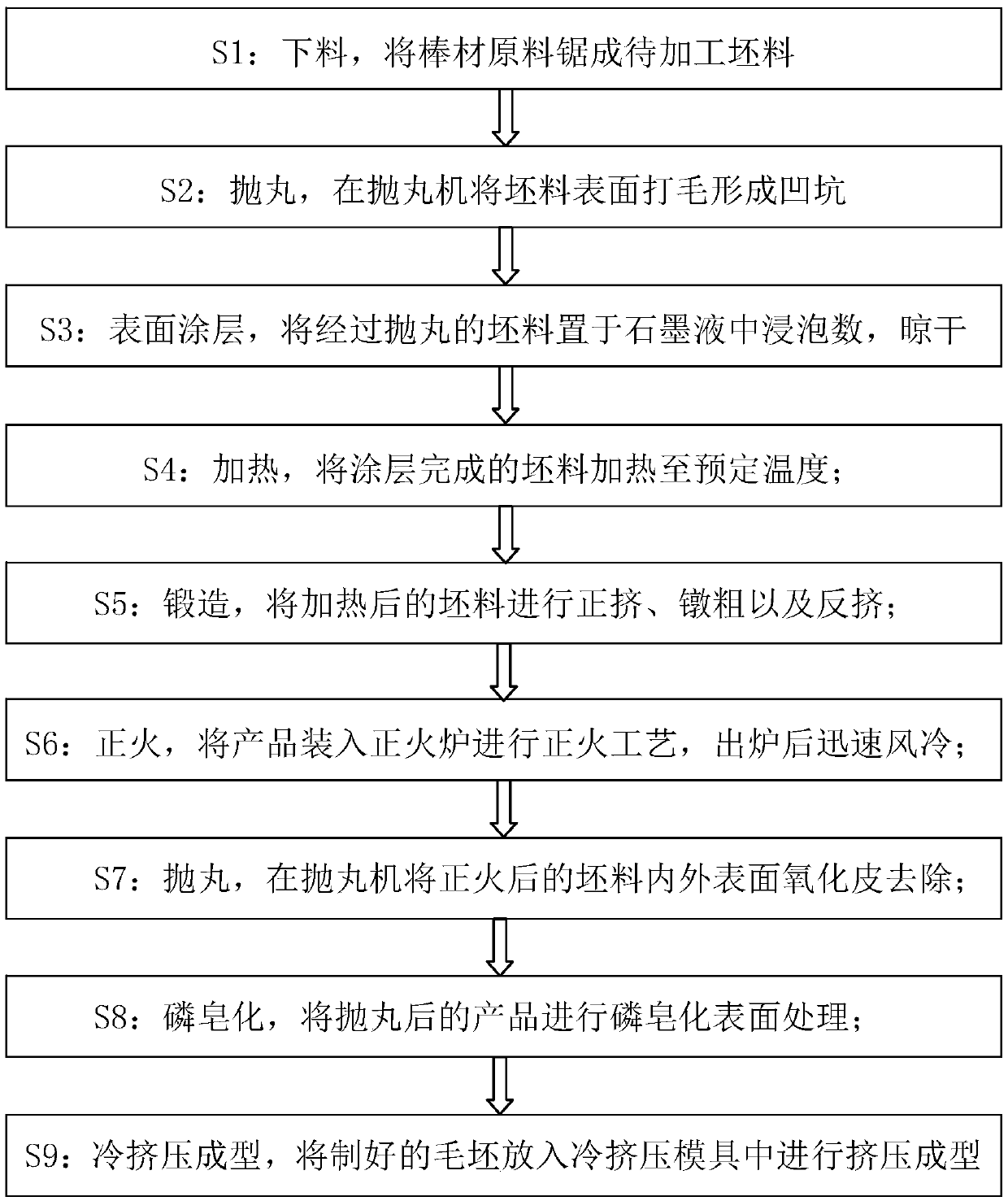

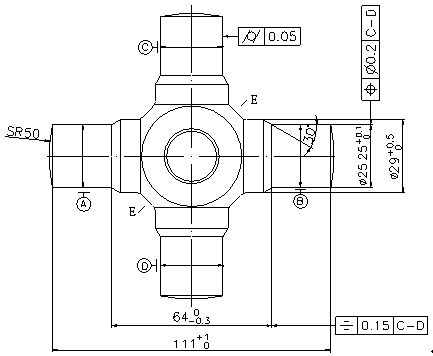

Processing method of universal joint precision forging with R arc end faces

InactiveCN107716839ASimple processing technologyHigh strengthEngine componentsUniversal jointFood extrusion

The invention provides a processing method of a universal joint precision forging with R arc end faces. The processing method comprises the steps of blanking, shot blasting, surface coating, blank heating, forging, quick air cooling after normalizing, shot blasting, phosphorus saponification and cold extrusion forming. Circular arc cold extrusion forming structures are arranged at the parts, corresponding to R arcs of the end faces of the universal joint, of a cold extrusion forming mold. According to the processing method of the universal joint precision forging with the R arc end faces, an original processing technology is improved, during final universal joint cold extrusion forming, circular arc cold extrusion forming surfaces are arranged at the parts, corresponding to the R arcs of the end faces of the universal joint, of the cold extrusion forming mold, and besides, two rods of the universal joint are formed at a time in a forward extrusion mode by virtue of the extrusion mold,so that the metal streamline distribution situation of the forging is excellent, quality of the forging is higher, follow-up machining is not required, and a prepared product is high in strength and excellent in anti-twisting property.

Owner:JIANGSU HAIYU MACHINERY

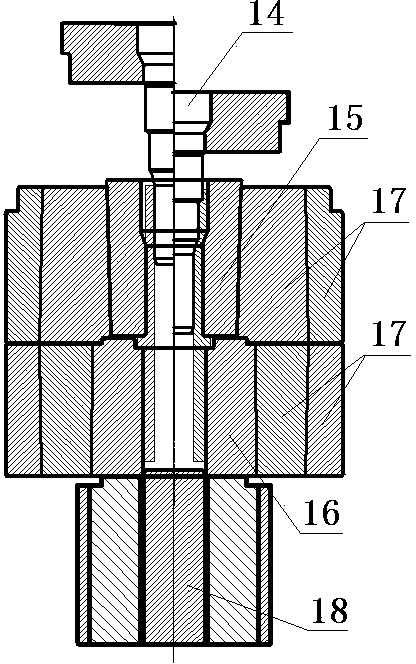

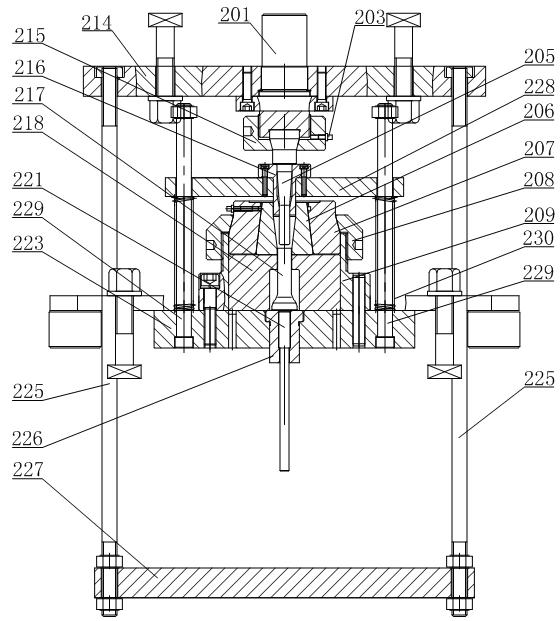

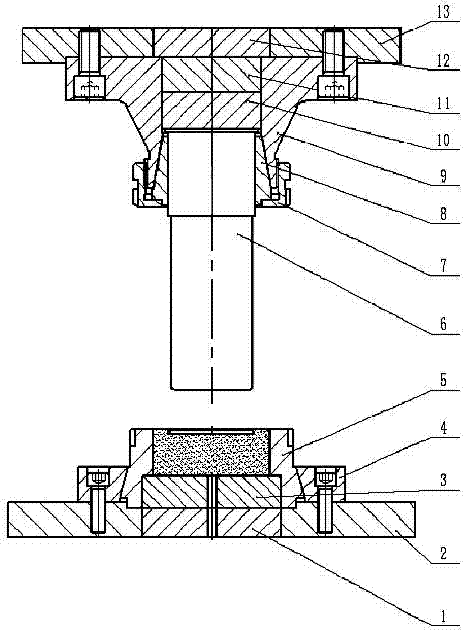

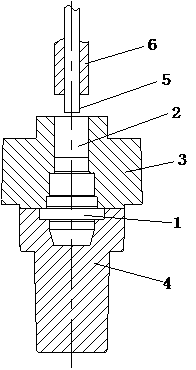

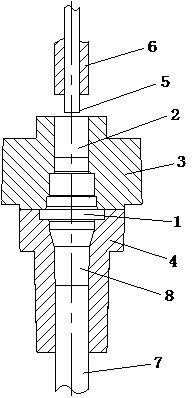

Cold extrusion forming die fixture and cold extrusion forming method for aluminum rear covers of cellphones

InactiveCN104841834AGood metal effectSimple internal structureForging/hammering/pressing machinesPunchingEconomic benefits

The invention discloses a cold extrusion forming die fixture for aluminum rear covers of cellphones. The cold extrusion forming die fixture comprises a female die and a male die. The female die comprises a female die body, a compression ring, a female die plate, a cushion block A, a cushion block B and the like. The male die comprises a male die body, a compression ring, a male die base, a nut, a cushion block C, a cushion block D, a cushion block E, a die base plate and the like. The invention further discloses a cold extrusion forming method for the aluminum rear covers of the cellphones. The cold extrusion forming die fixture and the cold extrusion forming method have the advantages that a vertical multi-connecting-rod toggle rod type cold forging press machine is used technologically for performing one-time cold extrusion forming on square aluminum blanks to enable the blanks to have shapes and sizes required by the aluminum rear covers of the cellphones after coating the blanks with graphite or lubricant powder, so that products acquired from cold extrusion forming have fine grains and compact textures, production efficiency is improved, product weight is reduced, and raw materials and manpower are saved; original methods such as punching, milling, engraving and digging are replaced, so that effects of chipless forming, energy conservation and environment protection are achieved, production cost is reduced remarkably and economic benefit is improved greatly.

Owner:江苏启力锻压机床有限公司

Food extruder

Owner:KAE CHIH ENTERPRISE

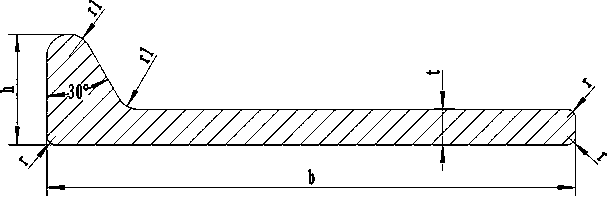

Ball flat steel double hole die extrusion molding method

ActiveCN108421839AReduce curvatureNo distortionExtrusion diesExtrusion containersFood extrusionBearing surface

The invention discloses a ball flat steel double hole die extrusion molding method. The hot extrusion process includes the operation procedures of mold design and production, billet processing, billetheating including annular furnace preheating plus induction furnace heating, hot extrusion and straightening. The ball flat steel double hole die extrusion molding method has the advantages that withtwo ball flat steel die holes designed on an extrusion die bearing surface, distortion or bending are reduced, extruded ball flat steel is ensured not to collide with discharge equipment facilities,and a discharge guide tube is added; an finite element simulation method is used to optimize the design of the extrusion die and extrusion process, and extrusion load is predicted; ball flat steel manufactured by the above-mentioned method satisfies the surface and size requirements of 'hot-rolled ball flat steel' of GB / T 9945-2001, and a more reasonable hot extrusion method in addition to the hotrolling method is explored.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

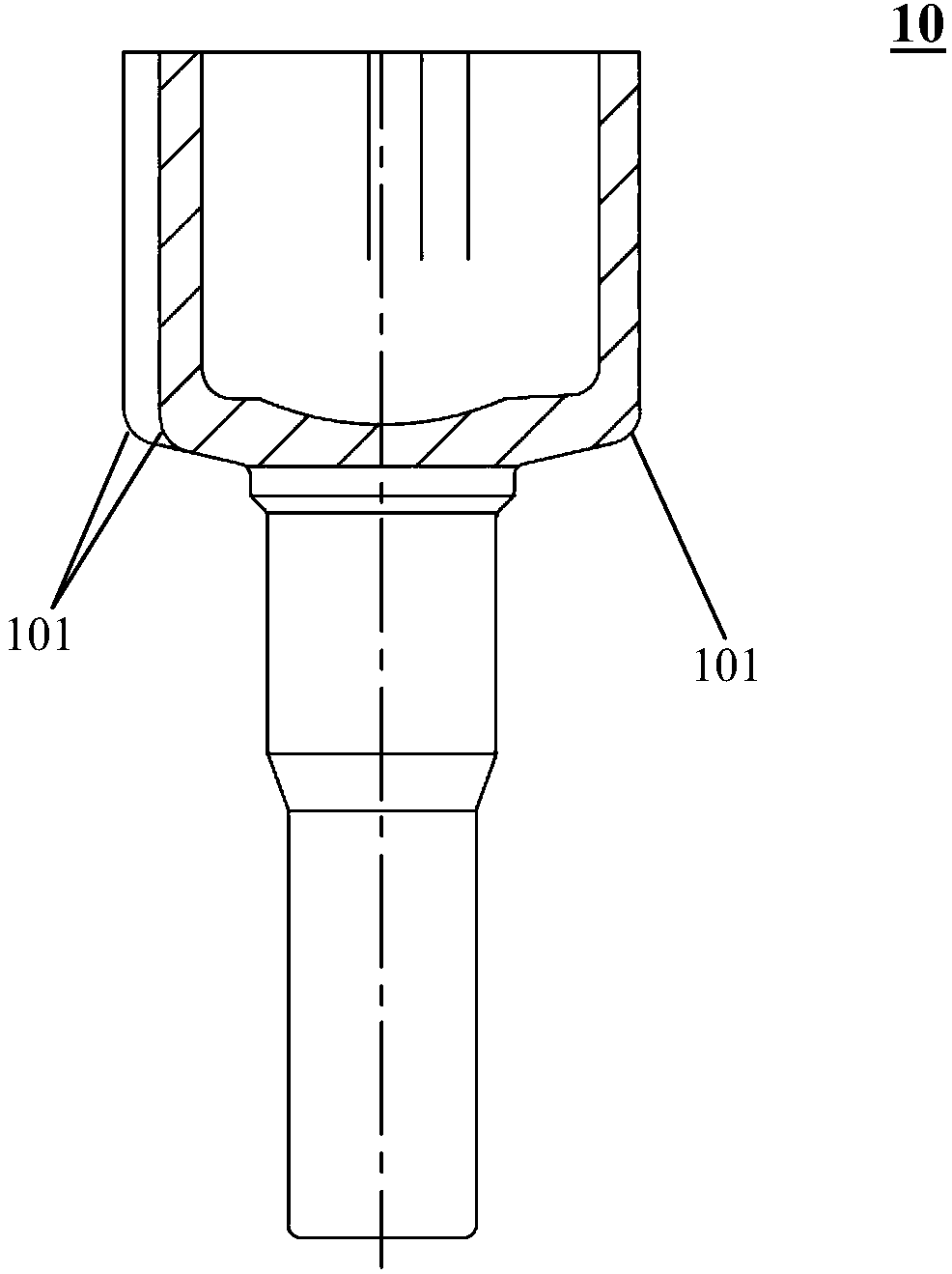

Piston assembly for a food extruder

A piston assembly for a food extruder having a food reservoir with a chamber and an inner surface, a piston rod and a piston dish. The piston rod slidably extends into the chamber of the food reservoir. The piston dish is attached loosely to the piston rod and has a lower segment, an upper segment, an annular groove and a sealing ring. The lower segment has an outer surface with an inclined bottom edge. The upper segment is hollow and is formed with the lower segment. The annular groove is formed in the outer surface of the lower segment adjacent to the upper segment. The sealing ring is mounted in the annular groove and slidably presses against the inner surface of the food reservoir to form an airtight seal.

Owner:CHEN YU CHENG

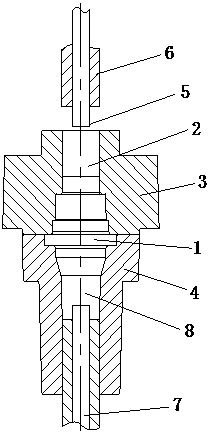

Semi-cured food extrusion machine

InactiveCN103251120AAchieve extrusionRealize half-cooked extrusion processingFood shapingGear wheelEngineering

The invention provides a semi-cured food extrusion machine. The semi-cured food extrusion machine comprises an engine base (1), a gear box (2) and an extrusion device (3), wherein the extrusion device (3) comprises screw rods (4) and an extrusion sleeve (5); the screw rods (4) are connected with the gear box (2) in a matched manner; the screw rods (4) are mounted in the extrusion sleeve (5); and a feeding opening (8) is formed in the rear end of the extrusion sleeve (5). The semi-cured food extrusion machine is characterized in that the screw rods (4) are double screws; each screw rod (4) is connected with a corresponding gear in the gear box (2) through a spline housing; the extrusion sleeve (5) is externally provided with a plurality of temperature-controllable water tanks (10); different temperature regions are respectively formed by extrusion cavity regions surrounded by each temperature-controllable water tank (1); and each temperature-controllable water tank (10) is provided with a water inlet pipe (16) and a water outlet pipe (17). According to the semi-cured food extrusion machine disclosed by the invention, the temperature of each section of the extrusion cavity can be controlled, semi-cured extrusion machining of materials can be effectively realized and the loss of effective components can be reduced to the greatest extent; and the semi-cured food extrusion machine is particularly suitable for curing and extrusion machining of kudzu vine root starch.

Owner:李时令

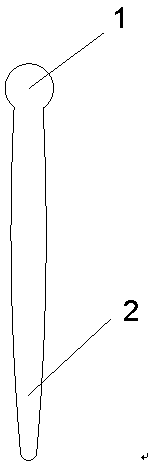

Universal joint crossing shaft blank cold extrusion processing technology

ActiveCN108284304AAvoid exposureIncrease profitLubricant compositionChemical treatmentUniversal joint

The invention provides a universal joint crossing shaft blank cold extrusion processing technology. The universal joint crossing shaft blank cold extrusion processing technology comprises the following steps that (1) raw materials are cut into material sections, the surfaces are ground by a center-less grinder, the qualified material sections are subjected to spraying and drying of a lubricant; (2) first time annealing heat treatment is performed, specifically, the material sections are heated to 850+ / -5 DEG C and held for 10 hours, cooled to 340+10 DEG C, and cooled to the room temperature; (3) the material sections are subjected to shot blasting and then phosphating and saponifying; (4) the material sections are placed on a hydraulic machine for cold extrusion, and a cross-shaped round bar blank is obtained in a mold; (5) circular arc-shaped burrs of the cross-shaped round bar blank is subjected to hammer grinding by using a low-carbon steel bar to form an outer convex bulge; and (6)the outer convex bulge on the surface of the cross-shaped round bar blank is ground away by using a sandpaper. According to the universal joint crossing shaft blank cold extrusion processing technology, sharp edges caused by the cutter cutting are avoided, the exposure of interior materials on the surface without the chemical treatment is avoided, and the defects of cracks, crusting, folding andthe sharp edges visible to naked eyes of an existing blank after the surface treatment are effectively solved.

Owner:HANGZHOU NEW CENTURY UNIVERSAL JOINT

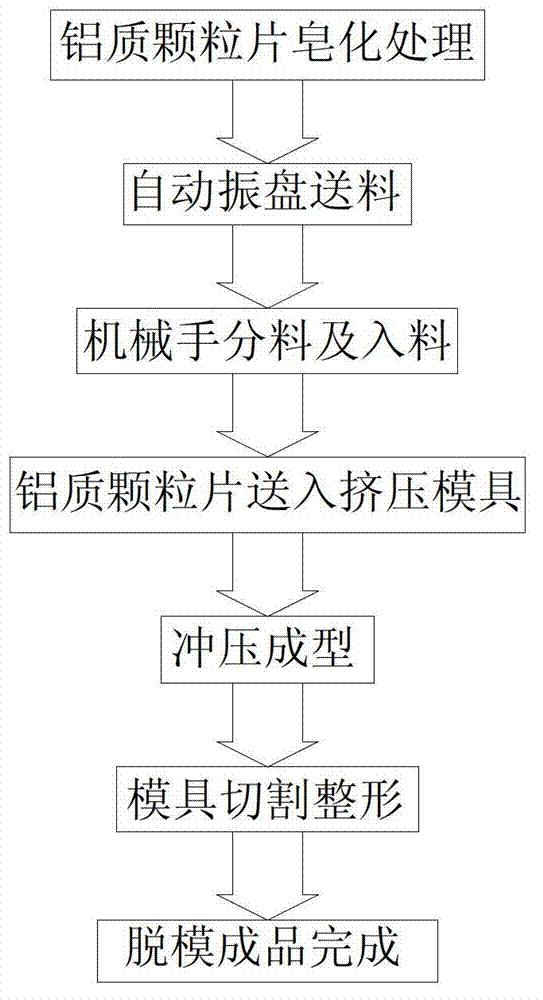

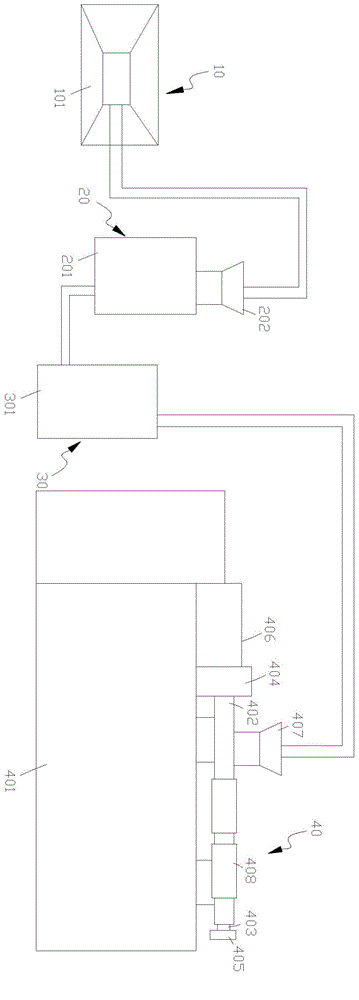

Metal earphone shell production process

The invention discloses a metal earphone shell production process, which comprises the following steps of: a, preparing a material, i.e., conveying machined metal particle sheets to an inlet end of cold extrusion equipment by using an automatic feeding system; b, performing cold extrusion forming, i.e., dropping the metal particle sheets into an extrusion mould for cold extrusion forming through the automatic feeding system; and c, shaping and demolding, i.e., cutting and shaping the edge of a port part of an earphone shell formed by cold extrusion molding through a convex die of the cold extrusion equipment after the extrusion is finished and demolding. Compared with the prior art, the production process has the advantages of simple structure, convenience in operation, low raw material cost, high finished product accuracy, no surface post-processing, one-time forming, less steps, less waste material, automatic production in the full process, high production efficiency, low energy consumption, low manufacturing cost and the like; and the earphone shell is formed at one time, the dimensional accuracy is high, close fit butting production is adopted during assembly of the earphone finished product, a gluing step in the manufacturing process is saved, the cost can be reduced and the efficiency can be increased, and the production process is an innovation development the earphone production.

Owner:刘天镐

Bean food biologicalization full nutrition intelligent preparation system

ActiveCN104621268AChange the way of manual loading and unloadingImprove work efficiencyInduction heatingCheese manufactureEngineeringFood extrusion

The invention relates to a bean food biologicalization full nutrition intelligent preparation system which comprises a biologicalization system, a grinding system, a storage system and a forming system, wherein the biologicalization system mainly comprises a biologicalization tank which is used for performing biologicalization treatment to beans; the grinding system mainly comprises a fine wet powder machine, a feed inlet of the fine wet powder machine is connected with the biologicalization tank through an adsorption pump and an adsorption pipeline, so as to pump the biologicalized bean raw materials in the biologicalization tank into the fine wet powder machine for grinding; the storage system mainly comprises a storage pot which is used for storing soybean milk products ground by the fine wet powder machine, and then sending the soybean milk products into the forming system; and the forming system mainly comprises a food extruding and forming machine which is used for curing and carrying out extrusion-forming on the soybean milk products; biologicalization treatment is implemented to soybeans by adopting the biologicalization pretreatment mode, so that grease substances are converted into protein without generation of soybean residues. The nutrients of the prepared finished product is easily absorbed and the fat content is low.

Owner:安徽省丰龙机械科技股份有限公司

Metal plastic swaging forming method

ActiveCN104226871AImprove internal structural performanceAvoid the problem of not being able to fully enter the mold cavityMetal-working apparatusEngineeringSwaging

The invention discloses a metal plastic swaging forming method. The metal plastic swaging forming method comprises the steps of swaging forming equipment preparation, feeding and hole extrusion, forming and discharging. By adopting hoe extrusion, avoidance and swaging in a closed cavity, a workpiece blank is plastically deformed in two steps to obtain a formed workpiece. The metal plastic swaging forming method has the advantages that the needed swaging force is small, the forming is easy, the energy consumption is low, the working efficiency is high, the requirements on equipment parts and a power system are low, the swaging forming difficulty can be reduced, the internal property and quality of the formed workpiece are improved and the like.

Owner:ZHUZHOU WENJIA IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com