Power takeoff transmission shaft cold precision forging plastic forming process

A technology of plastic molding and transmission shaft, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of large investment in machining equipment, waste of raw materials, and long production cycle, so as to reduce manufacturing cost and production cycle, and meet product requirements. The effect of precision requirements and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

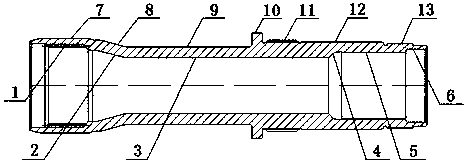

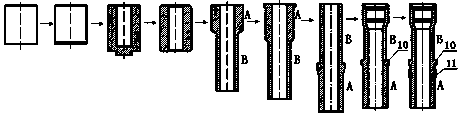

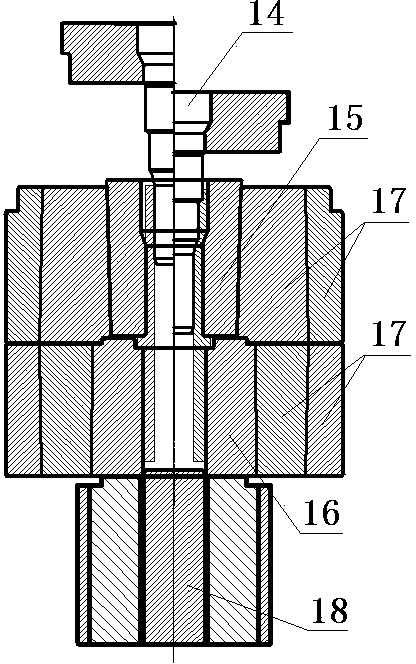

[0025] Embodiment one: see figure 1 As shown, a transmission shaft of a power take-off includes a hollow shaft body and has an inner circle and an outer circle. The inner circle has a splined inner circle surface 1, an inner diameter shrinkage transition surface 2, and a shrinkage inner circle surface 3 connected in sequence. , an inner diameter expansion transition surface 4, an expansion inner circle surface 5 and a large aperture inner circle surface 6; the outer circle has an outer circle surface 7 connected in sequence, an outer diameter contraction transition surface 8, a contraction outer circle surface 9, and an annular bump 10. The outer circular surface 11 of straight teeth, the second outer circular surface 12 and the outer diameter shrinkage thread surface 13; the inner circular surface 1 of the spline corresponding to the outer circular surface 7 is arranged on the inner circle of the hollow shaft body, and the annular convex The block 10 and the spur outer circul...

Embodiment 2

[0032] Embodiment two: same as embodiment one, the only difference is that the upper die 15 is provided with an annular groove cavity 20 on the inner wall of the joint, and the annular groove cavity 20 is connected to the outer circle of the power take-off drive shaft. The ring bump 10 matches.

Embodiment 3

[0033] Embodiment three: same as embodiment one, the only difference is that the upper die 15 and the lower die 16 are combined to be provided with an annular groove cavity 20 on the inner wall of the joint, and the annular groove cavity 20 is connected with the power take-off The annular protrusion 10 on the outer circle of the transmission shaft matches.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com