Patents

Literature

138results about How to "Tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

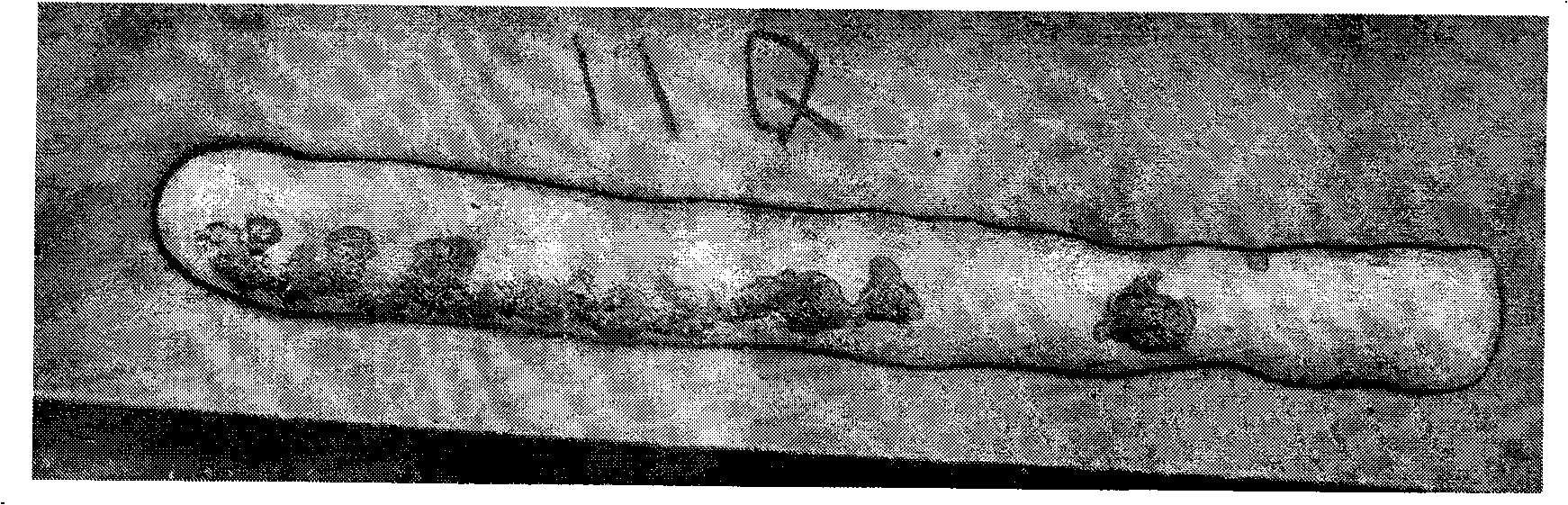

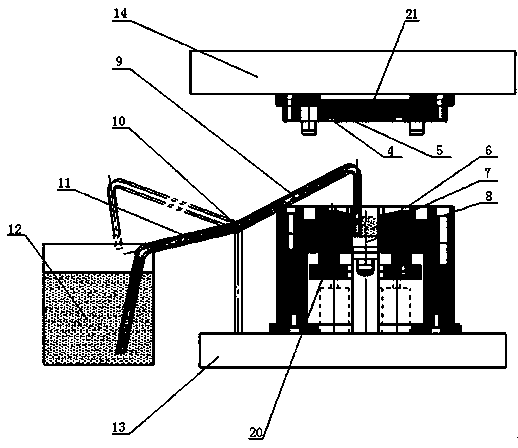

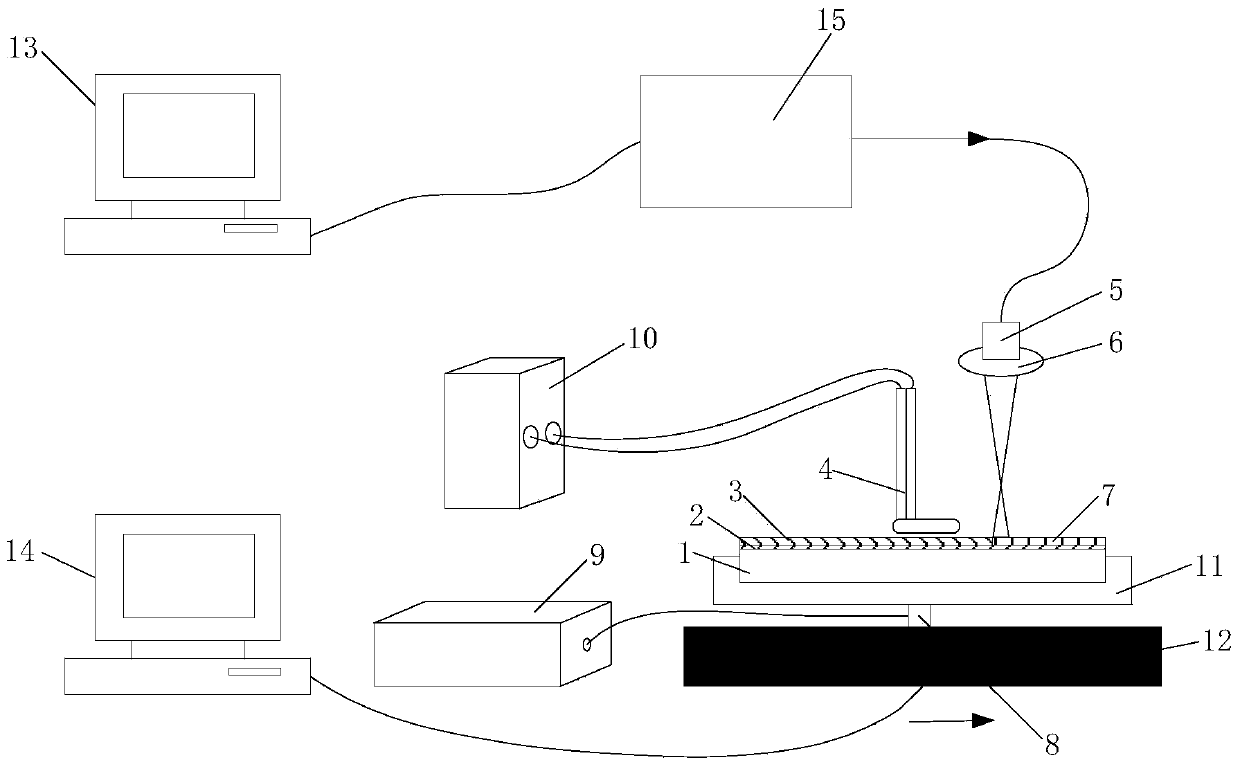

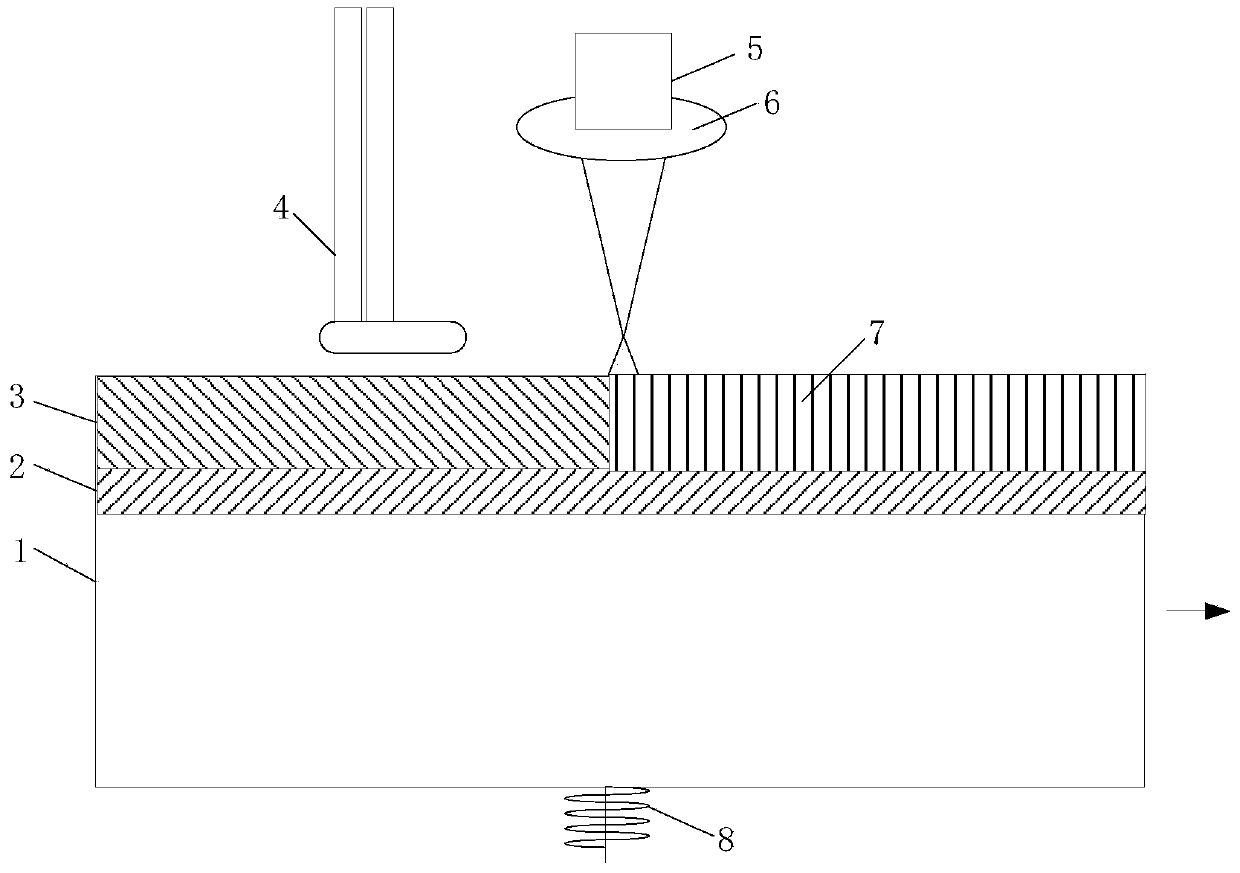

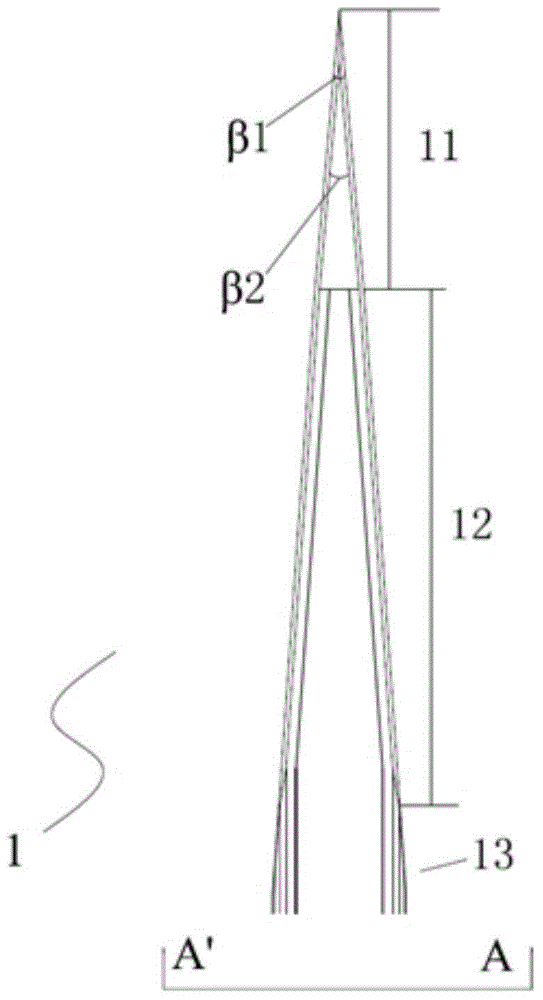

Cladding die repair technology by laser coaxial and synchronous power feeding method

ActiveCN109536955AEnergy stabilityTissueMetallic material coating processesHeat-affected zoneEngineering

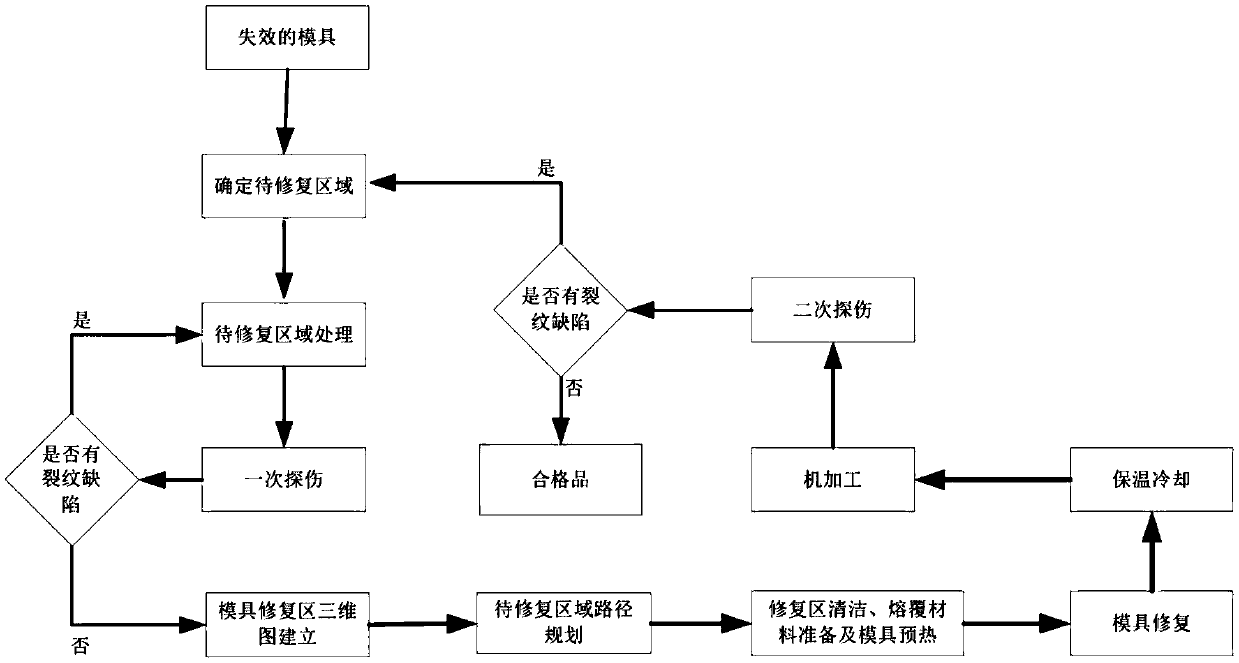

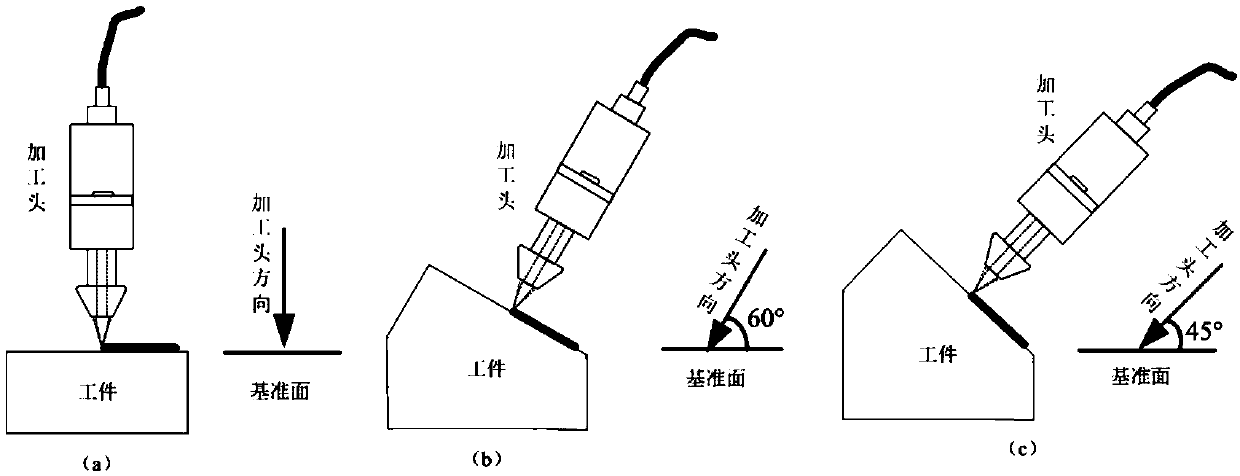

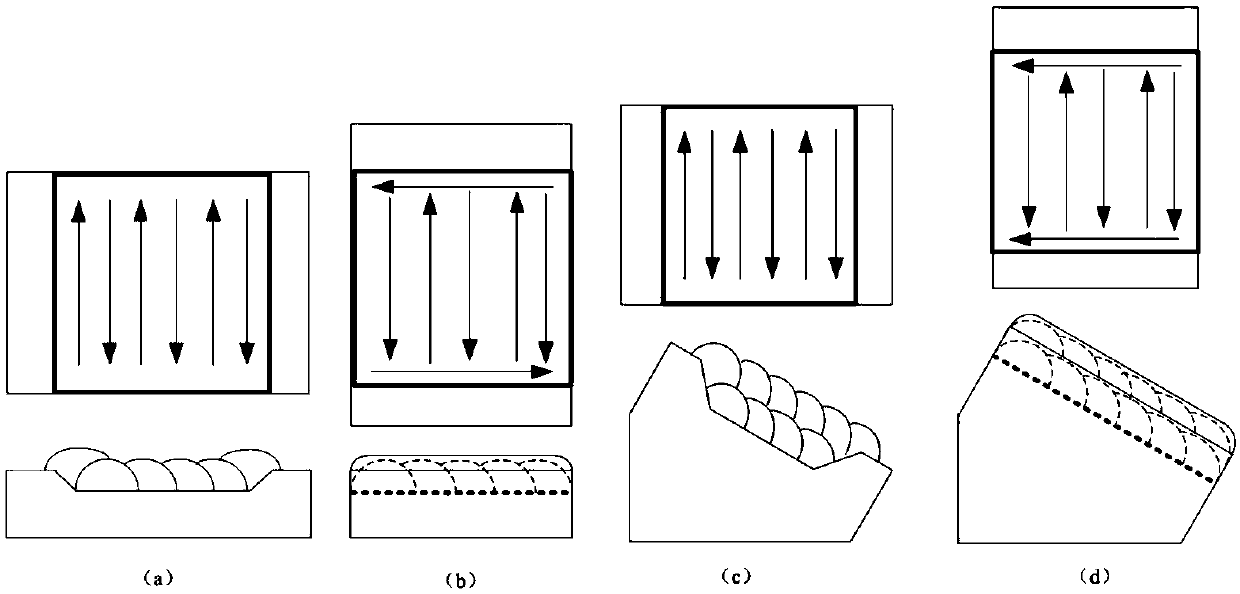

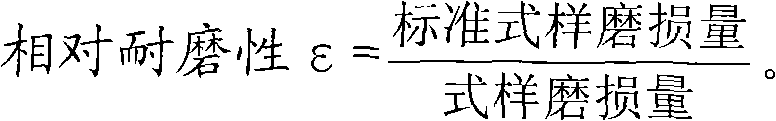

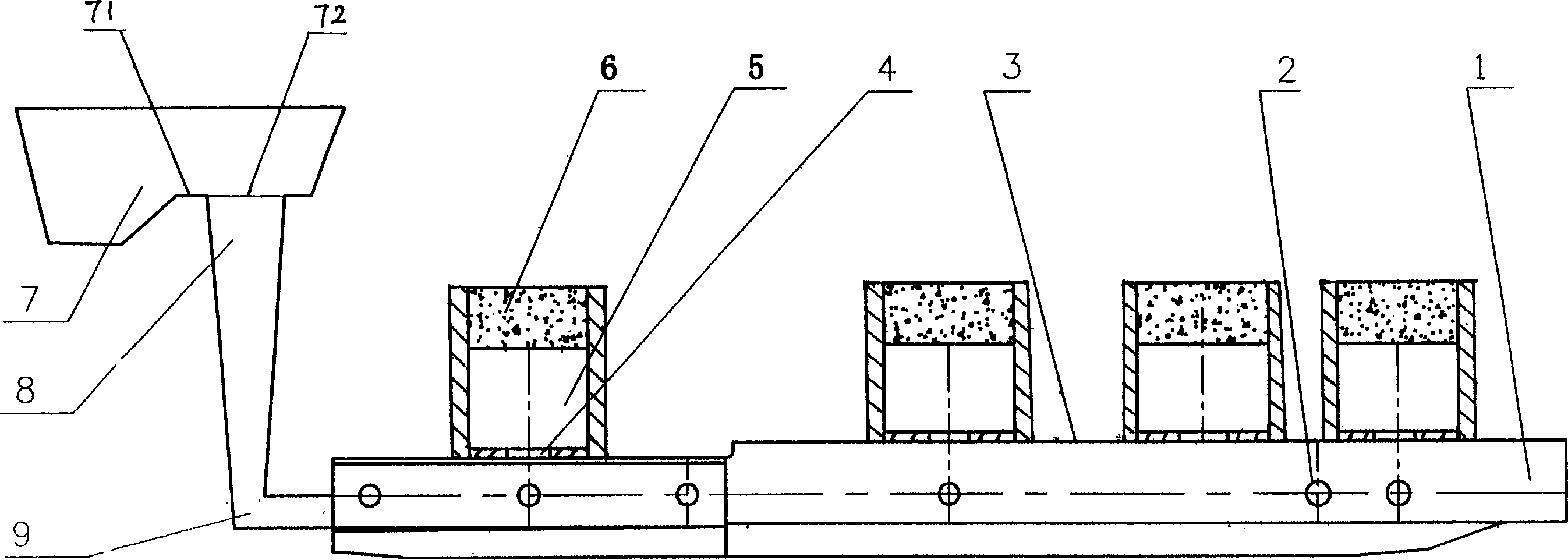

The invention discloses a cladding die repair technology by a laser coaxial and synchronous power feeding method, which is characterized in that model data of a die repair area is imported, computer programming is utilized to plan the repair path, and the way of laser coaxial and synchronous power feeding cladding is adopted to accurately repair the die, which can achieve automatic production, andthe die can be directly used after repairing; the repaired die can achieve 80% of new product performance, which greatly shortens repair cycle and reduces maintenance cost. The cladding die repair technology by the laser coaxial and synchronous power feeding method has the advantages that the energy of the laser itself is stable, the heat affected zone of the substrate is small and the technologyis clean and environmentally friendly; in addition, the microstructure of the cladding repair layer is fine, and deformation is less likely to be generated after repairing the microscopic defects oflacking parts, thereby solving the problem that many conventional methods cannot process or are difficult to process, and easy achieving automatic rapid repair of workpiece, which greatly increase production efficiency and improve processing quality.

Owner:NANJING TECH UNIV

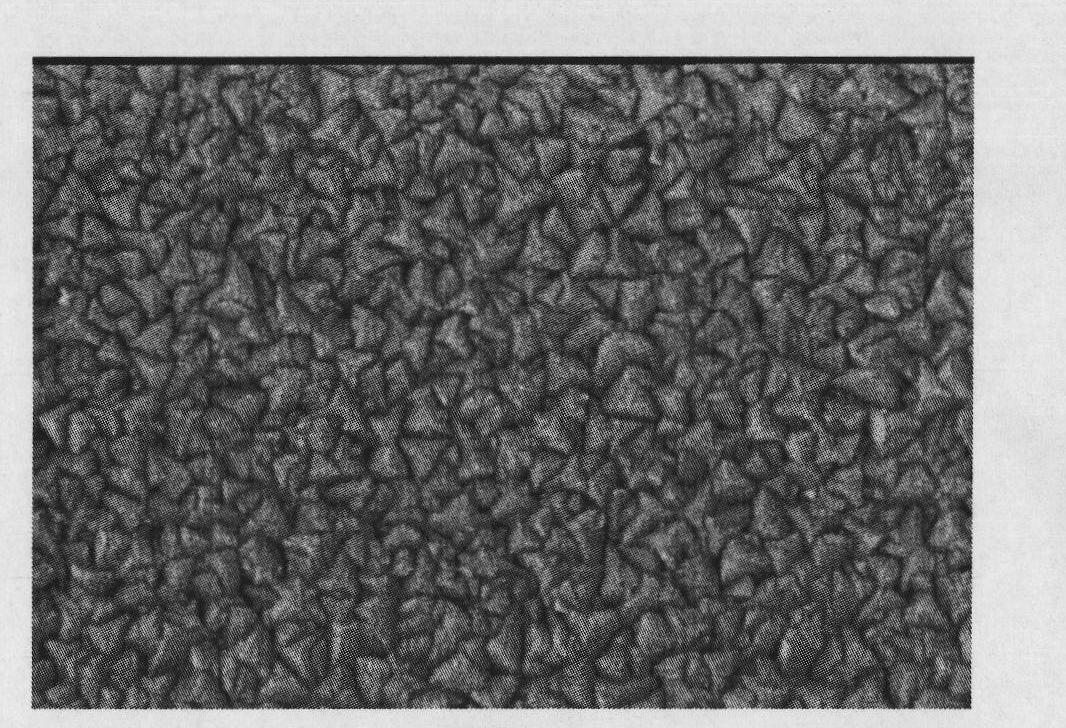

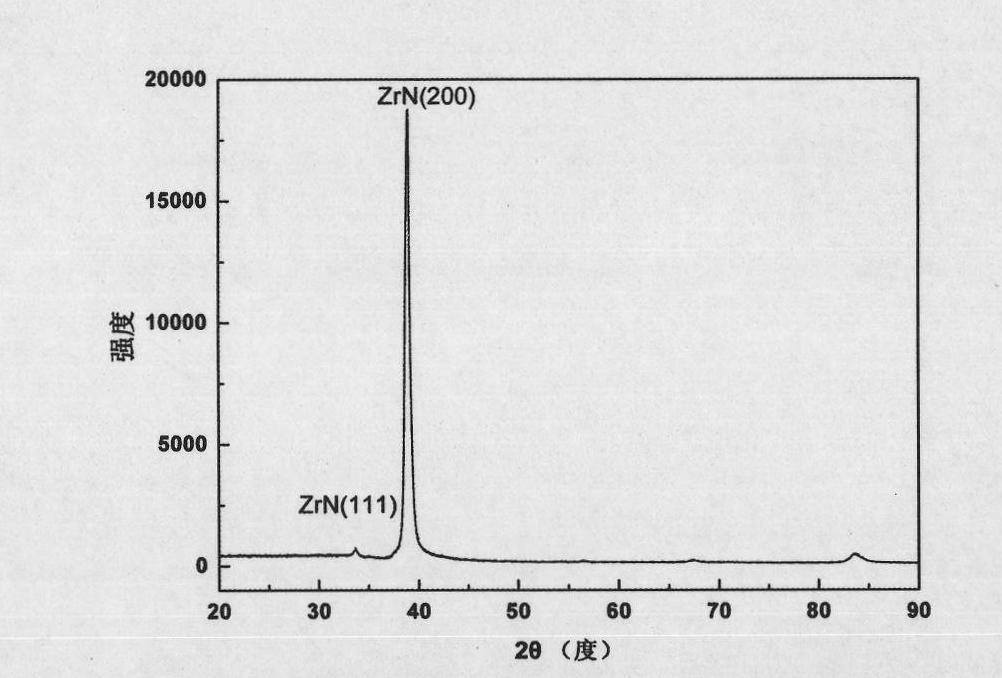

Preparation method of high hardness zirconium nitride hard coat

InactiveCN101775585AHigh hardnessHigh crystallinityVacuum evaporation coatingSputtering coatingNitrogenAlloy

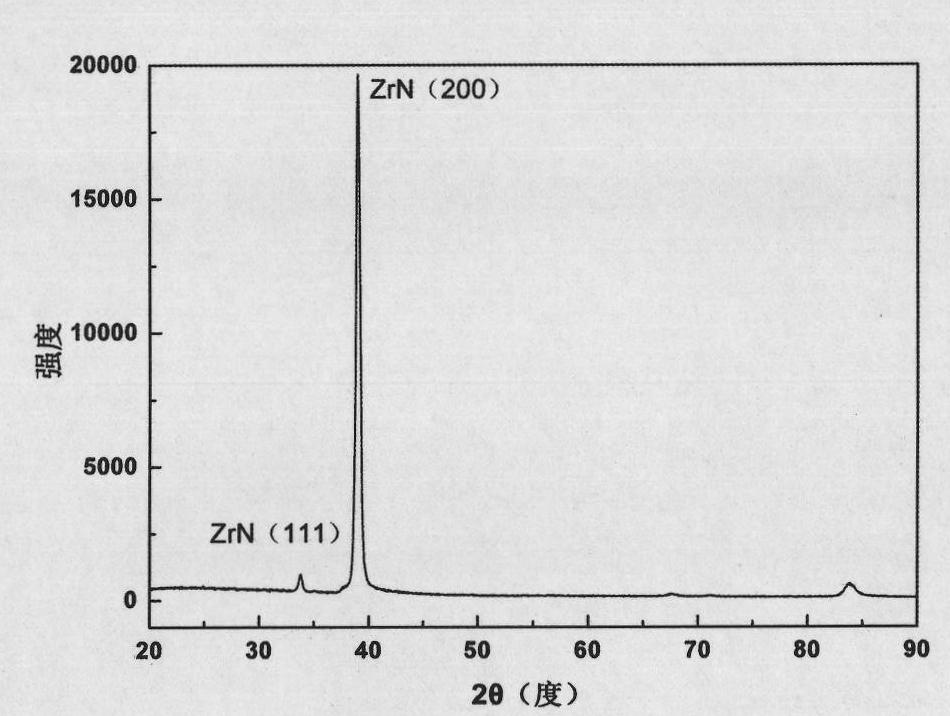

The invention discloses a preparation method of a high hardness zirconium nitride hard coat and relates to a preparation method of a hard coat, which comprises the following steps: matrix pretreatment: hard alloy matrix is washed and dried after being ground and polished; and the sputter deposition is carried out after the pre-sputtering is performed. A method by adopting magnetic control sputtering method to control the process conditions such as the atmosphere, the matrix temperature, the matrix bias and the like of the sputter deposition so as to prepare the zirconium nitride hard coat on the surface of the hard alloy matrix is adopted to improve the hardness of the zirconium nitride coat. DC power is adopted to perform the magnetic control sputter deposition on the surface of the hard alloy matrix which is mechanically polished, washed by ultrasonic and washed and processed by ion source, the total pressure is controlled at 0.3 to 0.5 Pa, the flow rate of the nitrogen is 15 to 20 percent, DC power of the Zr target is 250 to 300W, the matrix temperature is 300 to 450 DEG C, the matrix bias voltage is minus 50 to 100V, the deposition time is 90 to 120 minutes, and the coat has high hardness of more than 30 GPa.

Owner:XIAMEN UNIV

Sleeve-friendly wear-resistant strip flux-cored wire

InactiveCN101524789AImprove the safety of useHigh hardnessWelding/cutting media/materialsSoldering mediaElectrolysisIron powder

A sleeve-friendly wear-resistant strip flux-cored wire belongs to the welding field of material processing project. The aim of the invention is to settle the problem of wearing on the sleeve by the wear-resistant strip. The sleeve-friendly wear-resistant strip flux-cored wire provided by the invention adopts steel strip for packaging the flux core powder which accounts for 22-37% of total weight of flux-cored wire. The flux core powder comprises the following substances by mass percent: 10-30% of high carbon ferro-chrome, 8-17% of ferroboron, 0.5-4% of ferromolybdenum, 5-10% of nickel powder, 1-3% of low carbon ferrosilicium, 2-8% of medium-carbon ferromanganese and the balance of electrolytic iron powder. The preparing method of the invention adopts the prior art. The sleeve-friendly wear-resistant strip flux-cored wire provided by the invention can effectively increase the using safety of wear-resistant strip, reduce the wearing on the sleeve and prolong the lifetime of drill pipe.

Owner:BEIJING GABBARD ENG & TECH

High manganese steel railway assembled frog centre rail casting process

A technology for casing the high-Mn steel frog of combined switch for railway features that the ferrochromium sand is used as surficial sand and core sand, the alkaline Mg sand powder paint is coated on the surfaces of moulding cavity and core, and an easily cutting plate is added under the insulating siser head. It includes such steps as applying the insulating and heat generating agent to the surface of riser head, horizontal pouring, cutting off the riser head, burying it is sand, and heat treating.

Owner:中科西王特钢有限公司

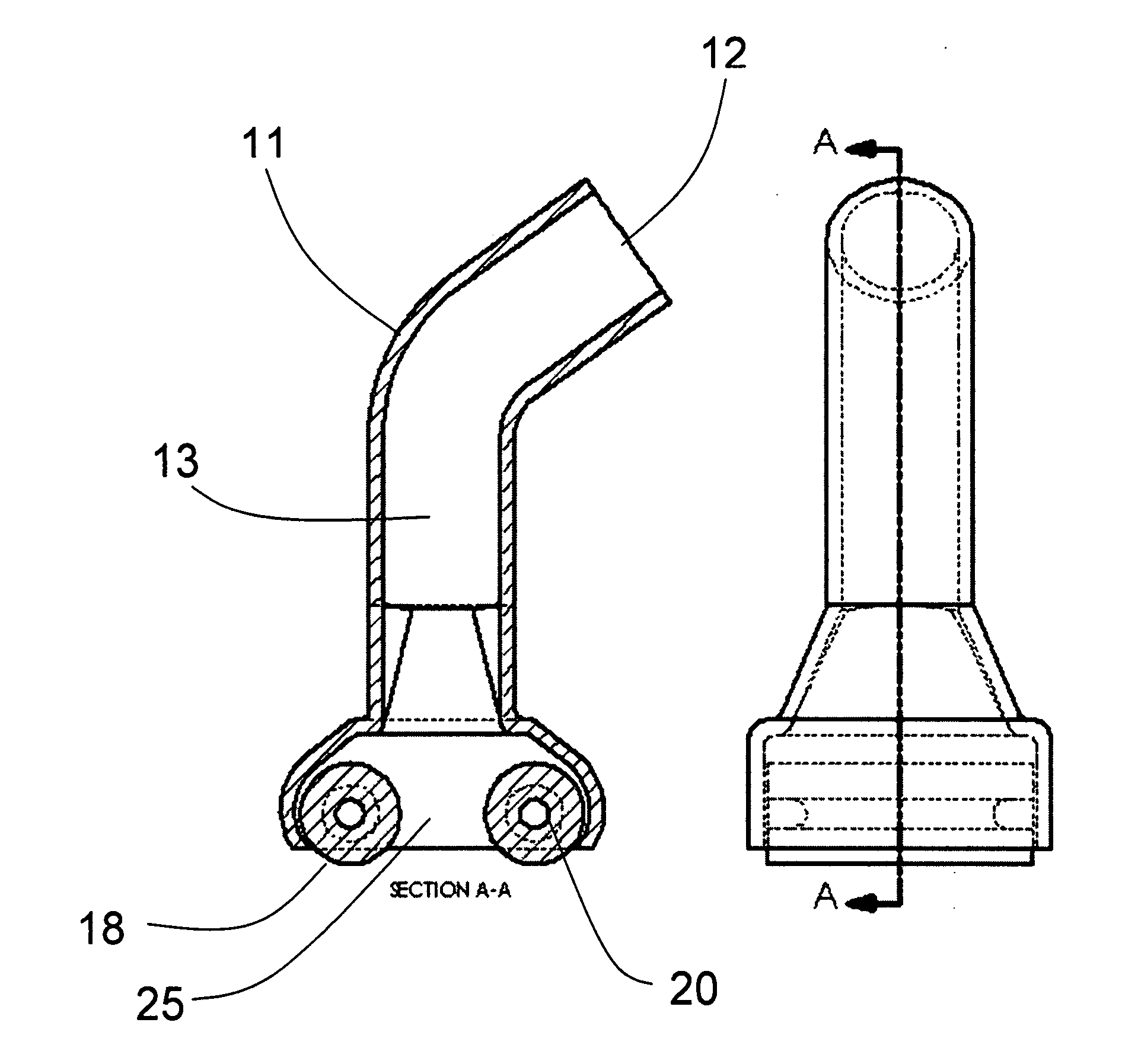

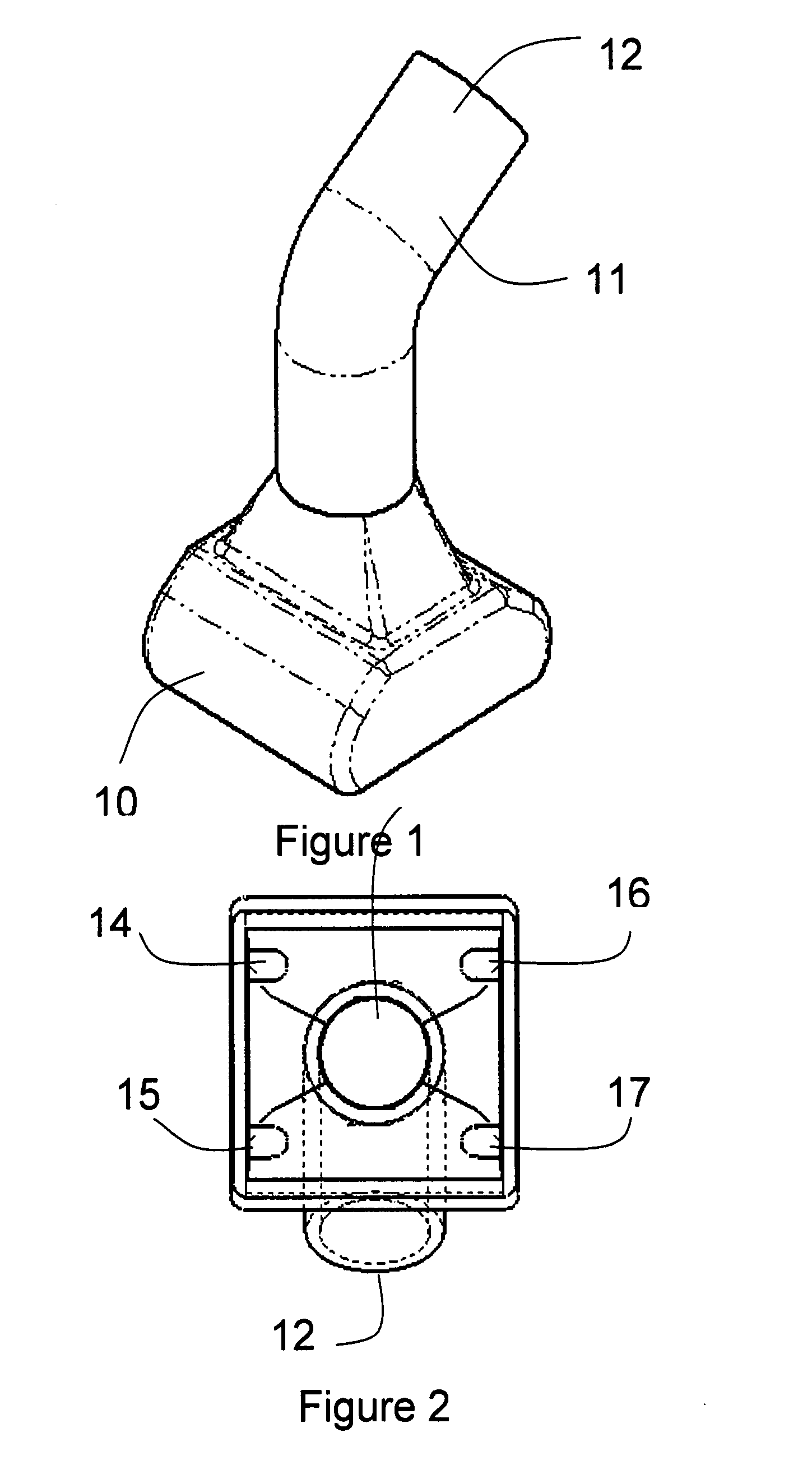

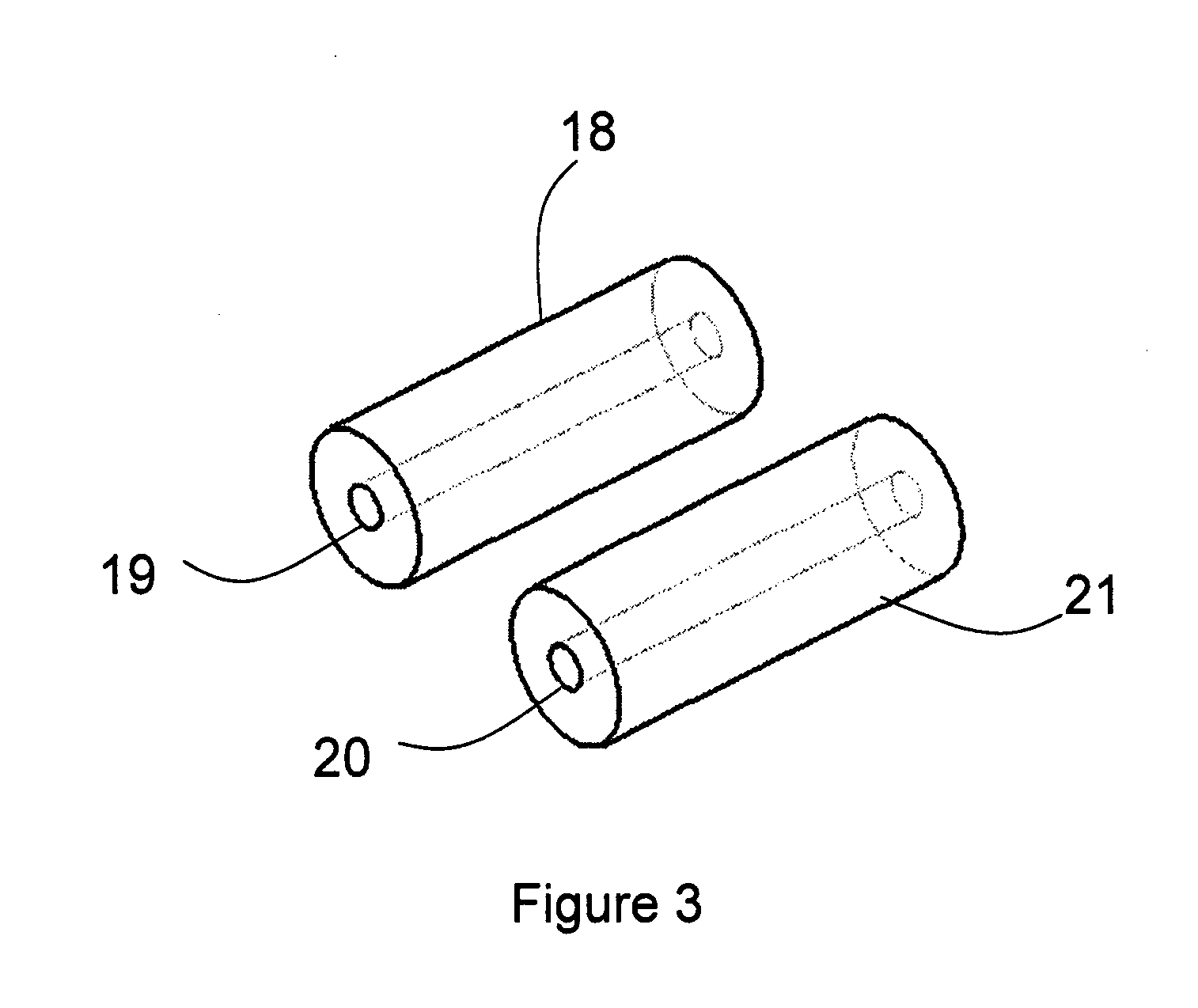

Message apparatus

InactiveUS20070225621A1Long-term useEliminate needPneumatic massageRoller massageSurgerySkin surfaces

The Invention relates to a massaging and skin suction apparatus for smoothing the skins surface caused by fat irregularities associated with cellulite fat tissues; comprising of two, stationary and distinct positioning rollers which provide massaging, while suction from a 12 Amp vacuum cleaner pulls skin between rollers; providing a push, pull and squeeze technique. This technique is allows the use of one person to perform the function of massaging.

Owner:SEBASTIAN COURTNEY +1

Healthy chili milk candy

InactiveCN105795081AAbundant raw materialsRich ingredients, rich tasteConfectionerySweetmeatsVegetable oilGalactooligosaccharide

The present invention discloses healthy chili milk candy. The healthy chili milk candy is prepared from the following raw materials in parts by weight: 42-44 parts of white granulated sugar, 35-37 parts of galactooligosaccharides, 12-14 parts of chilies, 11-13 parts of condensed milk, 3-5 parts of anhydrous cream, 3-4 parts of hydrogenated vegetable oil, 3-4 parts of skim milk, 1.6-1.8 parts of locust bean gum, 1.4-1.6 parts of chili leaves, 0.6-0.8 part of longan leaf, 1.1-1.3 parts of soybean pods, 1.1-1.3 parts of eleusine indica, 0.6-0.8 part of equisctum ramosissimum, 0.6-0.8 part of rorippa globosa, 0.4-0.6 part of gymnema sylvestre, 0.4-0.6 part of tangerine leaf, 0.4-0.6 part of betula alba juice, 0.4-0.6 part of edible salt and 0.6-0.8 part of lactobacillus delbrueckii. The provided healthy chili milk candy is crisp in texture, sweet, sour and palatable, rich in flavor, balanced in nutrition and easy to absorb, and can protect the heart and brain blood vessels, increase resistance, promote metabolism, delay aging, beautify features and lose weight.

Owner:YINGSHANG HAOYUAN FOOD

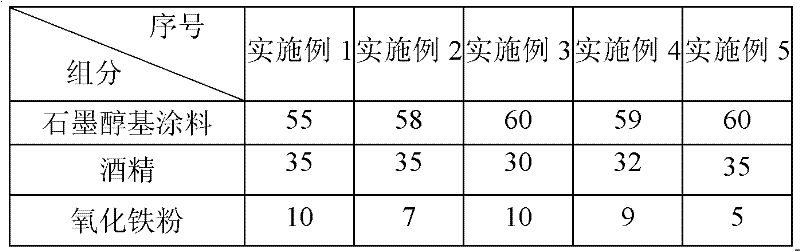

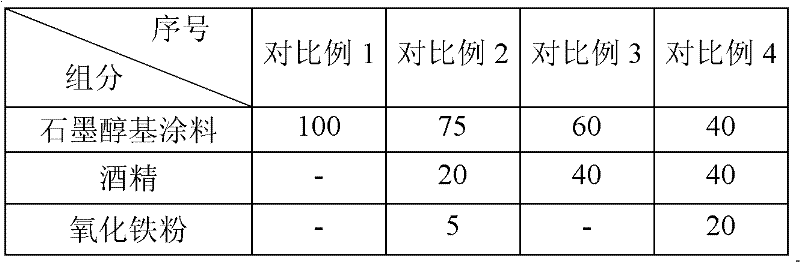

Chiller coating for molding of green-sand-casting ductile iron castings and application method thereof

ActiveCN102407280AReduce choking fireReduce the probability of chokingFoundry mouldsFoundry coresAlcoholSand casting

The invention discloses a chiller coating for the molding of green-sand-casting ductile iron castings and an application method thereof, which belong to the technical field of coatings for casting molding. The coating is prepared from the following components in percentage by mass: 55-60% of a graphite alcohol based coating, 30-35% of alcohol and 5-10% of ferric oxide powder. When in use, the coating is uniformly coated on the surface of chiller, and the coating thickness is 1-2 mm. By using the coating for the molding of green-sand-casting ductile iron castings disclosed by the invention, no harm is caused to castings, no influence is caused on the environment, and the quenching of ductile iron castings is reduced; meanwhile, because gas in a cavity is reduced, and the cooling speed is high, a casting has no pore defect, and the finished product ratio of the casting can reach 100%, therefore, the coating has a broad market prospect.

Owner:SHANDONG YUANTONG MASCH CO LTD

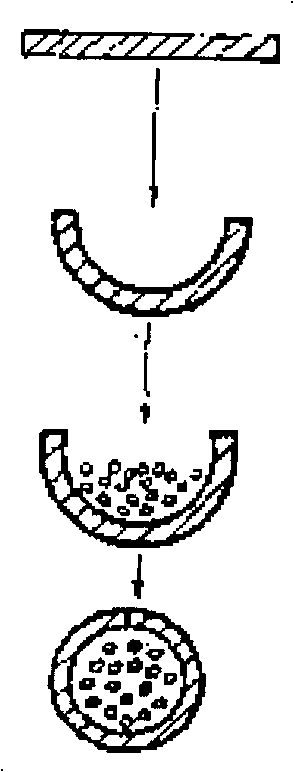

Squeeze casting preparation technology of AZ91D rare earth magnesium alloy

The invention discloses a squeeze casting preparation technology of AZ91D rare earth magnesium alloy. The technology solves the problem that the mechanical property of magnesium alloy is affected due to the fact that air holes emerge easily and die-casting of special-shaped castings is hard and cost is high in an existing preparation process of a basic phase of the magnesium alloy. The technology comprises the steps of placing AZ91D magnesium alloy in a resistance furnace, heating the resistance furnace till the temperature reaches to 180-220 DEG C, and keeping the temperature for 20 min; continuing to heat the resistance furnace till the temperature reaches to 400 DEG C and adding mixed gas of air, carbon dioxide and tetrafluoroethane with a volume ratio of 74:25:1; continuing to heat the resistance furnace till the temperature reaches to 760-800 DEG C, adding preheated Mg - 25% Y intermediate alloy, and stirring evenly with a graphite rod after the Mg - 25% Y intermediate alloy is melted, wherein the mass fraction of the Mg - 25% Y intermediate alloy in the magnesium alloy is 6-10%; carrying out filtering by spin-spraying Ar air and combining with MgO foamed ceramics, and carrying out compound purification on magnesium solution for 30 min; and cooling the resistance furnace till the temperature reaches to 715-725 DEG C, pouring the metal solution into a preheated die, extruding the blank out and cutting the blank, carrying out T4 heat treatment on the blank, wherein the preheating temperature of the die is 200-250 DEG C, the extruding force is 95-105 MPa, and the dwell time is 20-25 s. The squeeze casting preparation technology of the AZ91D rare earth magnesium alloy has the advantages that processes are simplified, usage is achievable with no need for deep processing, raw material is saved, and cost is reduced.

Owner:KANG MEI TECH DEV

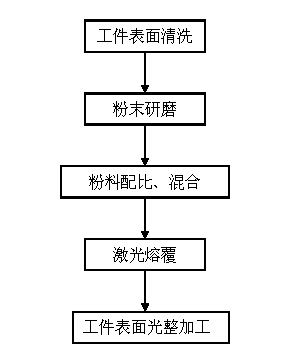

Method for preparing nano diamond composite coating by millisecond laser cladding

InactiveCN103409746AReduce cladding costsTissueMetallic material coating processesFine structureAlloy

The invention discloses a method for preparing a nano diamond composite coating by millisecond laser cladding, which comprises the following steps: adding 8-10% of fine-structure microcrystal graphite powder and 2-5% of catalyst powder into nickel-base alloy powder, putting the mixed powder in deionized water, mixing for 15-30 minutes by ultrasonic vibration, and drying; putting the nickel-base alloy workpiece in a vacuum chamber, wherein the vacuum degree is kept at 10<-3>-10<-4> Pa; and uniformly spreading the dried powder on the workpiece surface by an automatic powder delivery device to form a 0.5-2 mm preset layer, focusing a laser on the preset layer surface by a Dd:YAG laser device, and changing the position of the laser light spot relative to the workpiece to finish the cladding of the workpiece in different positions. The nano-diamond-containing composite coating prepared by the method has the advantages of compact structure, high bonding strength with the base, favorable self-lubricating property and favorable wear resistance.

Owner:JIANGSU UNIV

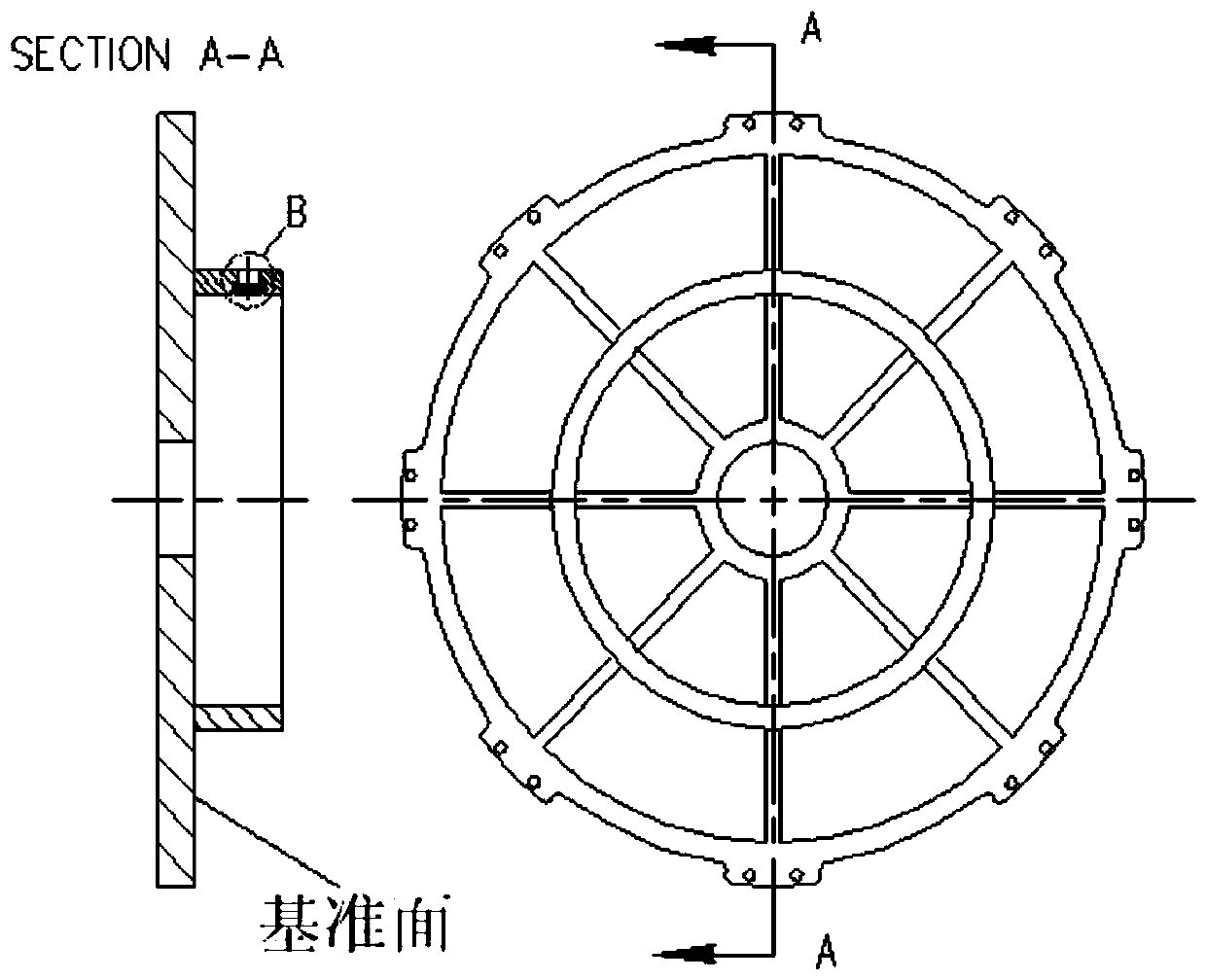

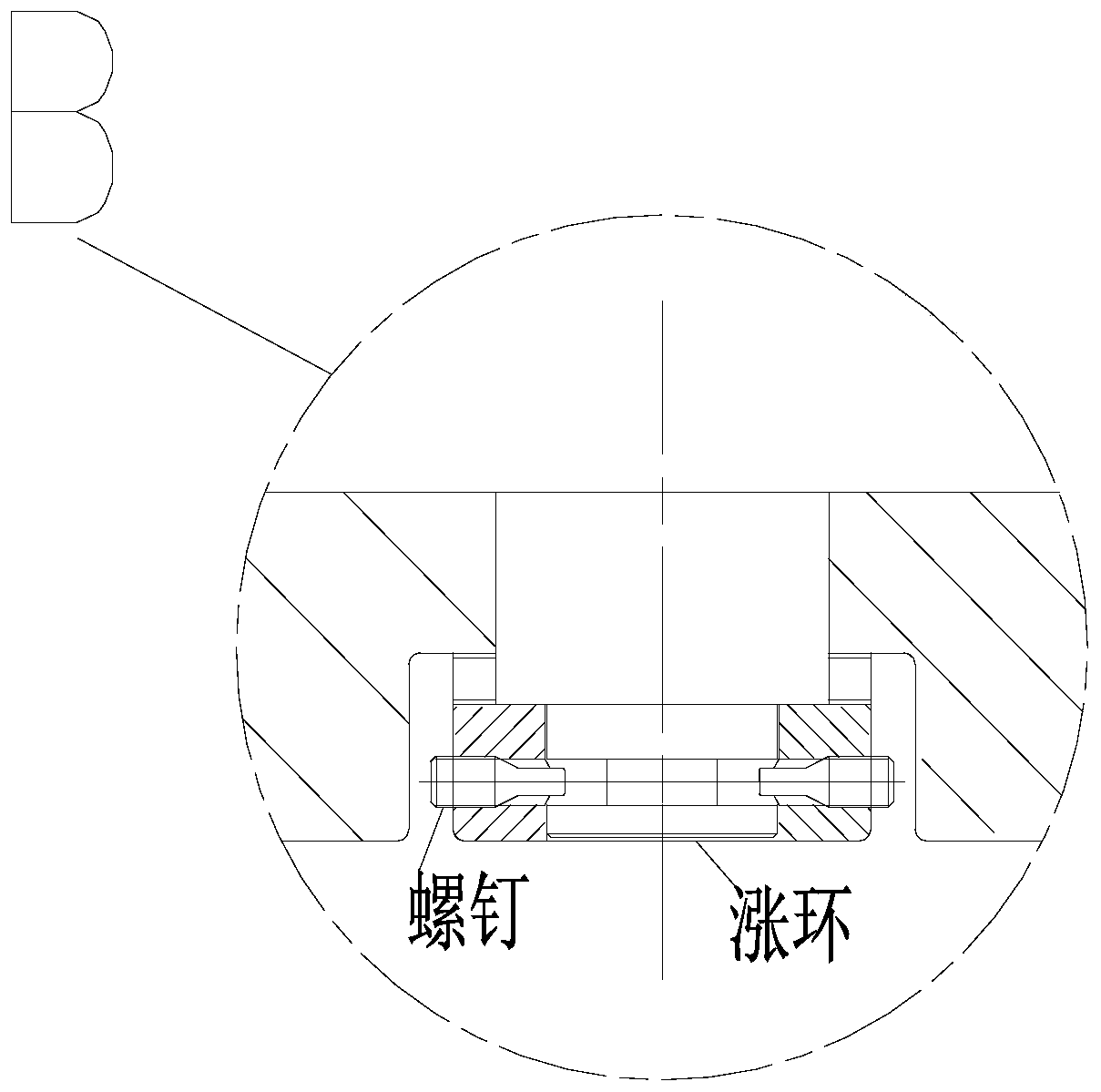

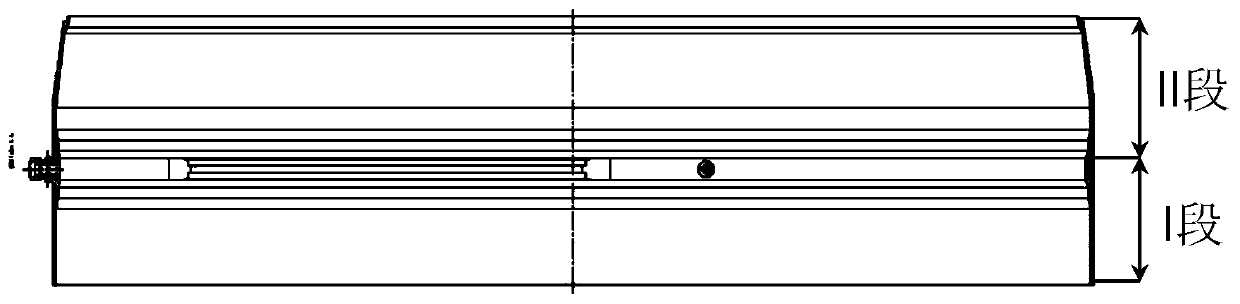

Overall manufacturing method for large-size thin-walled annular belt type oxygen-enhancing frame

ActiveCN111014668AFormed smallLess formingAdditive manufacturing apparatusFurnace typesLaser processingStress relieving

Disclosed is an overall manufacturing method for a large-size thin-walled annular belt type oxygen-enhancing frame. The overall manufacturing method comprises the following steps that a special substrate for laser melting deposition is designed; up-and-down segmentation is carried out along the wall thickness sudden changing portion of the oxygen-enhancing frame; a lower-segment part is formed byselecting a large-power large-scanning-speed laser melting deposition process parameter and a corresponding scanning strategy; laser machining program codes of all slice layers of the upper and lowersegments are obtained by utilizing slice software and are introduced into equipment to carry out laser melting deposition forming of the lower-segment portion first; stress relieving annealing is carried out after outward taking; then the lower segment end surface is taken as a substrate to complete deposition of the upper-segment portion, and heat treatment and machining are carried out to obtaina part under a final state. The overall manufacturing method solves the problems that a current forging and machining method is long in machining period, low in material utilization ratio and severein stress deformation, and the high-performance, small-deformation and small-allowance forming of the oxygen-enhancing frame part is realized.

Owner:XIAN SPACE ENGINE CO LTD

Cake with cayenne pepper and poria cocos

InactiveCN105851159AAbundant raw materialsSweet and sour tasteDough treatmentBakery productsCayenne pepperWolfiporia cocos

The invention discloses a cake with cayenne pepper and poria cocos. The cake is prepared from the following raw materials in parts by weight: 36-40 parts of egg liquid, 30-33 parts of flour, 2-3 parts of cayenne pepper, 11-13 parts of poria cocos, 2-3 parts of lotus seeds, 1.2-1.8 parts of longan, 1.5-2.2 parts of notoginseng flos, 1.3-2.3 parts of orange peel, 1.3-1.5 parts of marsdenia tenacissima, 1.3-1.5 parts of ramulus mori, 2.2-2.8 parts of milk, 2-3 parts of galactooligosaccharide, 0.6-0.8 part of lactic acid bacteria, 0.4-0.6 part of sesame oil, 0.3-0.8 part of honey, 0.3-0.6 part of salt and 0.2-0.3 part of edible essence. The cake with cayenne pepper and poria cocos is rich in raw materials, sweet and sour in taste, rich in fragrance, balanced in nutrition, easy to absorb, low in fat and low in sugar, is capable of enhancing immunity, enhancing metabolism and delaying senescence, is free of chemical preservatives, and is highly popular to a large number of consumers.

Owner:ANHUI JIHONG FOOD

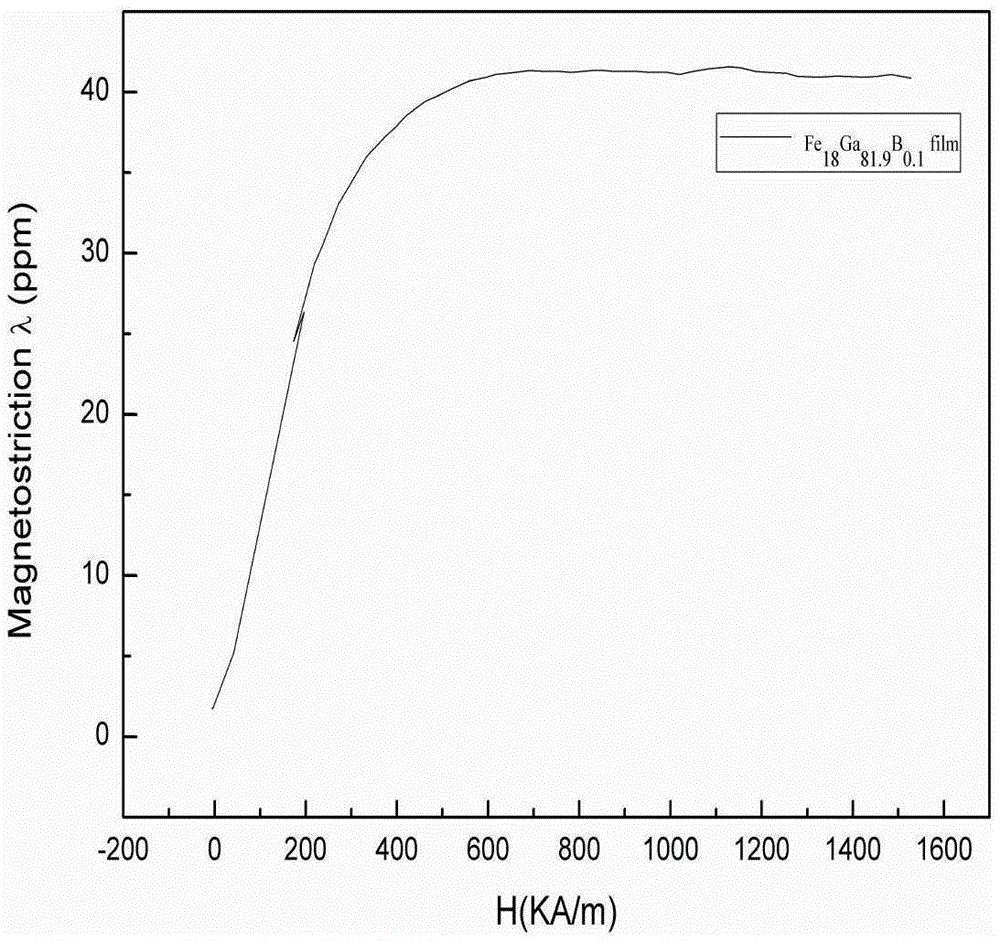

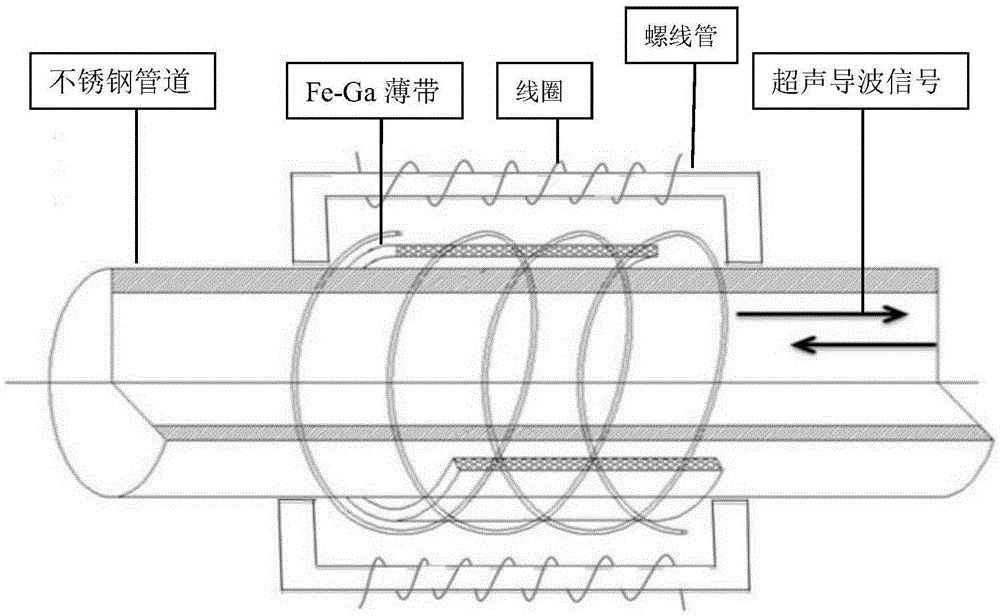

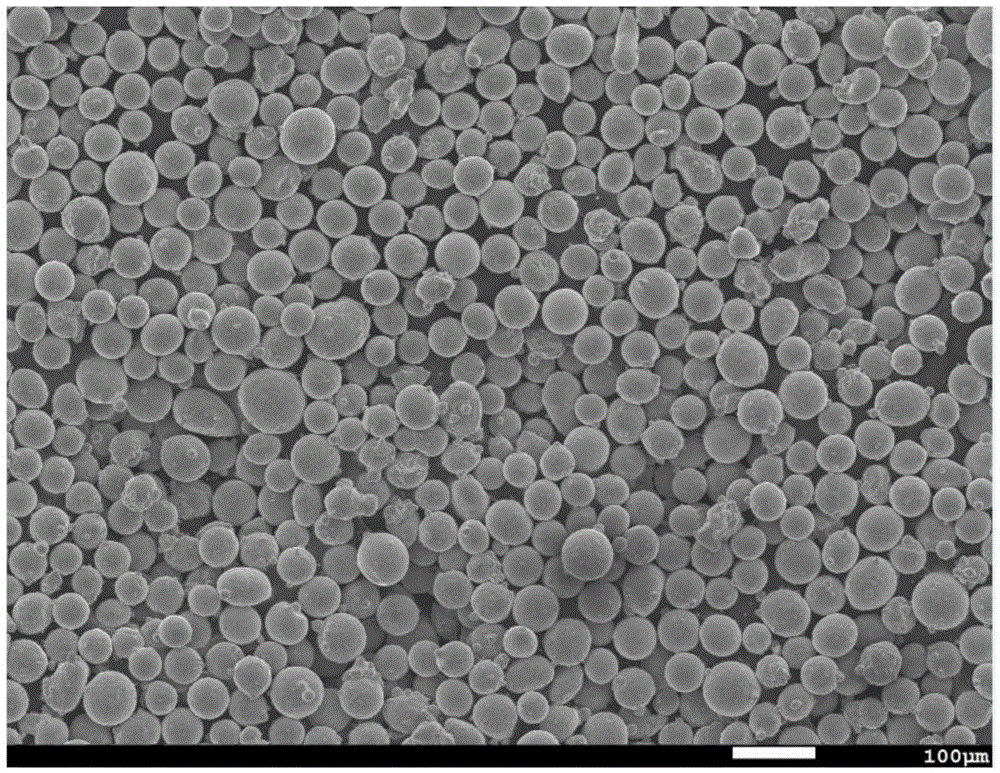

Method for manufacturing iron-based magnetostrictive coating through thermal spraying technology

ActiveCN105252011AHigh magnetostriction coefficientNot easily oxidizedMolten spray coatingPorosityThermal spraying

The invention provides a method for manufacturing an iron-based magnetostrictive coating through the thermal spraying technology and belongs to the field of magnetic materials. An iron-based magnetostrictive material is manufactured into spherical gasified and atomized powder, a metal material serves as a substrate, the spherical gasified and atomized powder is sprayed to the metal substrate in a plasma spraying manner, and the iron-based magnetostrictive coating is manufactured. The method includes the specific steps that the iron-based magnetostrictive material is smelted into a cast ingot in a vacuum smelting furnace, oxide skin on the surface is removed in a machining manner, the cast ingot is then conveyed to a high-pressure atomization powder making device, and molten alloy flow is crushed into small drops through high-speed argon flow and then condensed into powder. Plasma spraying is adopted in the thermal spraying technology, plasma gas is mainly nitrogen, hydrogen is auxiliary gas, the iron-based magnetostrictive gasified and atomized powder is conveyed into a plasma chamber, and through heating, smelting, flight, base body impact, cooling and solidification, the coating is formed. The method has the beneficial effects that the coating combination strength is high, the structure is dense, the porosity is low, and included oxide slag is reduced due to the addition of alloy elements.

Owner:UNIV OF SCI & TECH BEIJING

Nutrient cake and making method thereof

InactiveCN105994530ANutritional balanceNutrition and healthDough treatmentBakery productsBiotechnologyNutrition

The invention provides a nutrient cake and a making method thereof. The nutrient cake is prepared from, by mass, 100-120 parts of egg liquid, 60-80 parts of white granulated sugar, 50-70 parts of low-gluten flour, 45-55 parts of edible oil, 25-35 parts of dried meat floss, 10-15 parts of yolk powder, 8-12 parts of honey, 6-8 parts of d-sorbitol solution, 6-8 parts of trehalose, 5-7 parts of compound baking powder, 5-7 parts of cake emulsifier, 1-2 parts of edible salt, 0.1-0.2 part of potassium sorbate, 0.05-0.1 part of sodium dehydroacetate and 8-10 parts of water. The nutrient cake is prepared through stirring, leavening, filling, capping, baking, decapping, demolding, cooling, sterilization, nitrogen introduction and packaging. The product is golden in color, properly salty and sweet, fine and dense in texture, thick in egg flavor, balanced in nutrition, capable of achieving healthcare including digestion promotion and immunity enhancement, capable of being absorbed by the body easily, and capable of reducing the consumption of preservative and prolonging shelf life.

Owner:YOUCHEN FUJIAN FOOD

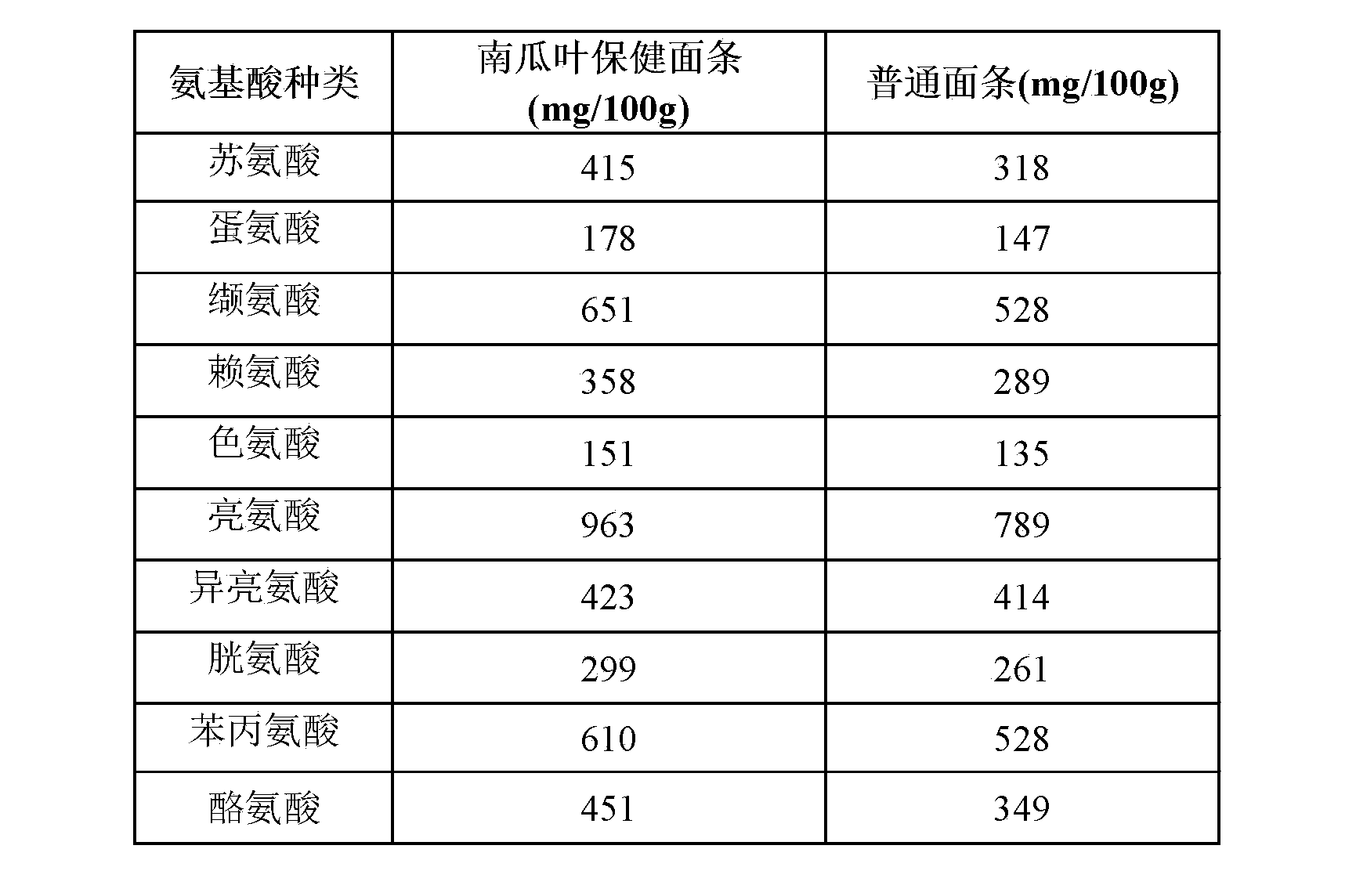

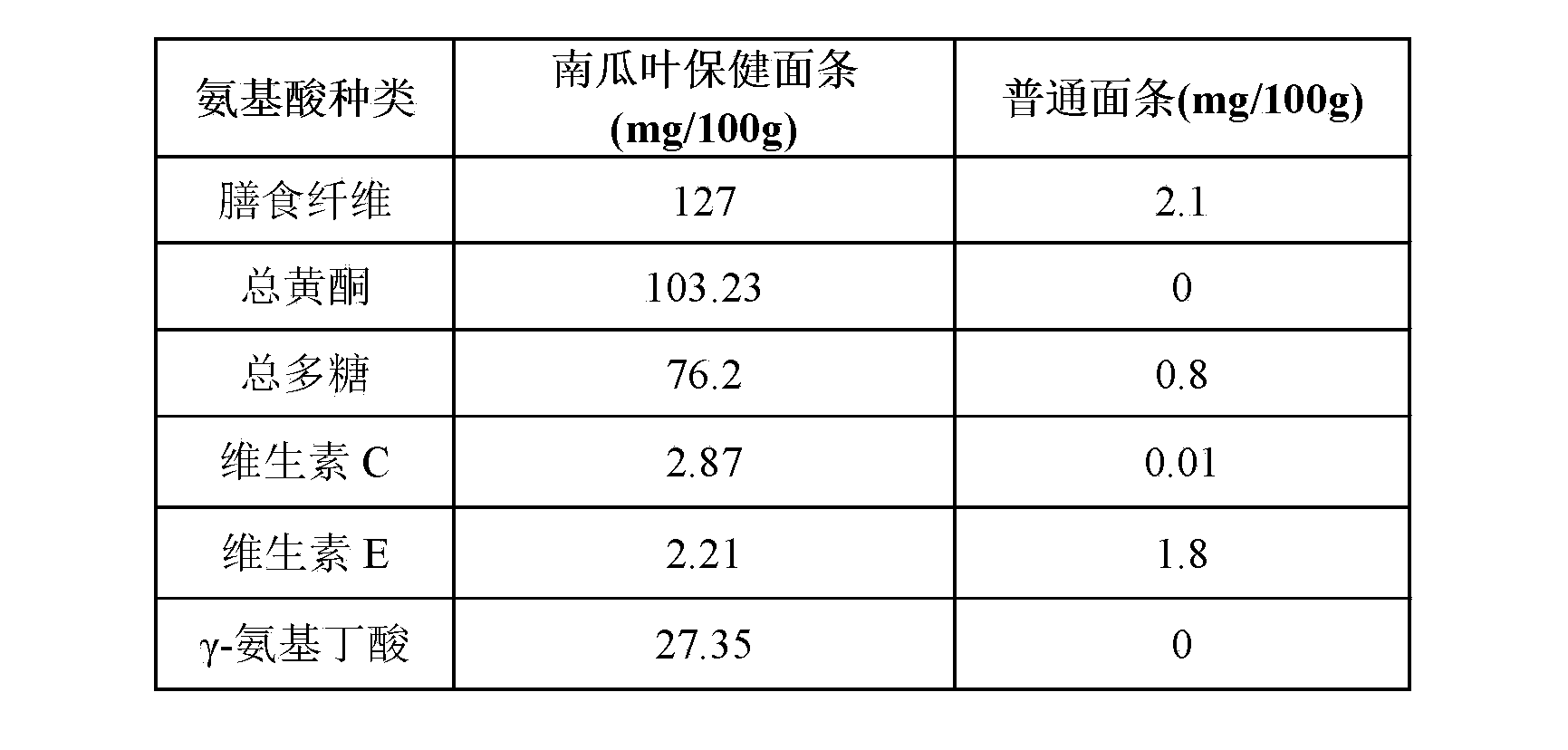

Pumpkin leaf healthcare noodles and processing method thereof

InactiveCN103445071AClears the stomach and invigorates the spleenHypoglycemicFood preparationPotato starchGrape seed

The invention provides pumpkin leaf healthcare noodles. The pumpkin leaf healthcare noodles are processed from the following raw materials in parts by weight: 20 to 25 parts of pumpkin leaves, 5 to 6 parts of hawthorn, 10 to 12 parts of longan leaves, 4 to 6 parts of kohlrabi leaves, 10 to 15 parts of corn stigma, 2 to 3 parts of grape seed powder, 1 to 2 parts of moringa seeds, 1 to 2 parts of mulberry fruit powder, 1 to 2 parts of kudzu vine powder, 4 to 6 parts of potato starch, 1 to 3 parts of corn starch, and 75 to 85 parts of flour. A processing method of the final healthcare noodles comprises the steps of washing the leafy materials, grinding the washed materials into pulp, then mixing the pulp with the powder materials, curing, slicing, and drying. Compared with common noodles on the market, the pumpkin leaf healthcare noodles produced by the method have high dietary fiber content, and contain active substances, such as gamma-aminobutyric acid, total flavonoids and polysaccharide, in the pumpkin leaves; the noodles are convenient to eat and long in shelf life, do not have any preservative, and can protect gastric mucosa, promote digestion and absorption, enhance human immunity and achieve the effects of clearing stomach, tonifying spleen, reducing blood glucose and blood pressure and losing weight after long-term consumption.

Owner:安徽稼仙金佳粮集团股份有限公司

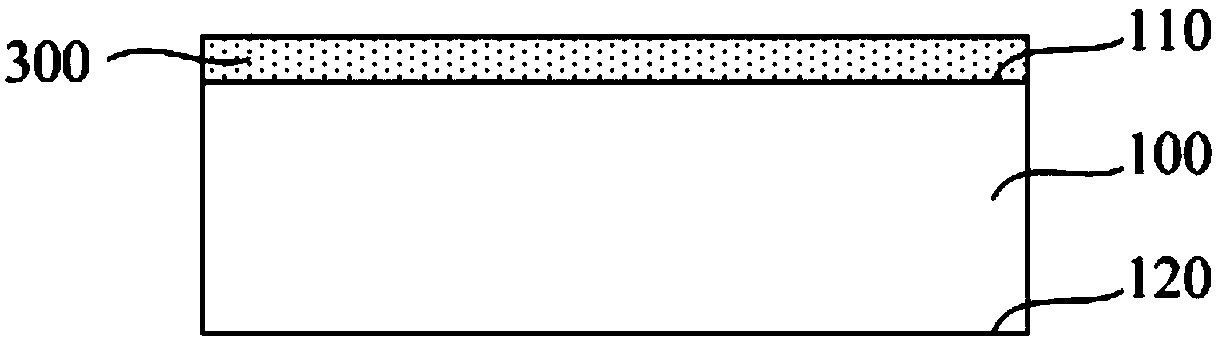

Target material assembly forming method

InactiveCN110937911ASmall difference in coefficient of thermal expansionReduce thermal stressWelding/cutting media/materialsSoldering mediaComposite materialWeld strength

The invention relates to a target material assembly forming method, which comprises: providing a ceramic target material, wherein the ceramic target material is provided with a target material weldingsurface; providing a metal back plate, wherein the metal back plate is provided with a back plate welding surface; plating nickel on the welding surface of the target material to form a nickel plating layer; placing a solder on the surface of the nickel plating layer and the welding surface of the back plate, and welding the ceramic target material and the metal back plate to form the target material assembly. According to the invention, the welding strength between the ceramic target material and the metal back plate can be improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method for manufacturing automobile control arm body blank

The invention discloses a method for manufacturing an automobile control arm body blank. The method comprises the steps of 1) melting an alloy melt, namely taking waste mixed aluminum alloy as a raw material, preparing an Al-Si-Mg cast aluminum alloy, and after the chemical components, the temperature and the purity are satisfied, transferring into a heat preserving furnace for preserving heat for later use, 2) pouring the aluminum alloy liquid under a low pressure, namely exerting pressure to the cast aluminum alloy liquid in the heat-preserving furnace and pouring the aluminum alloy liquid into the central pressure chamber of a metal die by a set height by use of a delivery pipe, 3) performing pressured filling on the die cavity, namely fully charging the aluminum alloy liquid in the pressure chamber into the die cavity by pressurizing, 4) pressurizing for feeding and solidifying for molding under constant pressure, namely increasing the pressure for feeding and solidifying for molding, and 5) opening the die to take out the blank and performing heat treatment, namely opening the die to take out the blank and performing T6 heat treatment. The method for manufacturing the automobile control arm body blank has the advantages that the material utilization rate reaches up to 80%, the obtained blank is fine in internal structure without shrinkage cavity and shrinkage porosity defects, and excellent in mechanical properties, and can be applied to take the place of a forged aluminum alloy control arm and a steel control arm to realize light weight of the automobile.

Owner:吉林金城铸锻有限责任公司 +1

Preparation method of aluminum boron intermediate alloy wire for electrician aluminum melt purification

The invention discloses a preparation method of an aluminum boron intermediate alloy wire for electrician aluminum melt purification, and relates to a preparation method of an alloy wire. The method comprises the following process: (1) after industrial pure aluminum with a purity higher than 99.7% is heated to melt in a heating furnace, 2-3 batches of KBF4 powder are added in the molten pure aluminum melt; (2) when the temperature of a molten alloy reaches 780 DEG C, N2 with a purity of 99.95% is filled in the alloy melt to degas and refine the melt; and (3) when the refined alloy melt is at 720-780 DEG C, AL and B in the alloy melt in aluminum boron are prevented from forming a netty structure under continuous stirring of a stirrer with a rotating speed of 220 RPM to prepare an aluminum boron intermediate alloy wire with a diameter of 9.5 mm; and the wire is continuously wound to a coil after cooling. When liquid-state metal is crystallized, the method is high in cooling strength, dense in structure, uniform in grain distribution and stable and reliable in product quality; and a continuous casting extrusion process of the aluminum boron intermediate alloy wire is advanced.

Owner:江苏和拓铝线有限公司

Extruding and die-casting process for electric steering shell with high strength and low porosity

The invention relates to an extruding and die-casting process for an electric steering shell with high strength and low porosity. The die-casting method comprises the following steps: melting materials, fixing a mold with a local extruding device to a die-casting machine, carrying out extrusion and die casting when the materials are semi-solidified, and carrying out final die casting to obtain a product. The extruding and die-casting process has the advantages that in structure design of the mold, the local extruding device is adopted, so as to extrude the connecting parts (parts where the die casting pressure cannot be transferred) between holes with thicker walls; a special mold is adopted for designing the structure, when mixed materials are filled into a cavity and then take on a semi-solidified state, an extruding pin is pushed by an oil cylinder to extrude the connecting parts between the holes with thicker walls tightly, so that the defect of hole shrinkage is avoided, and the porosity can be controlled within 3%; the internal structure of a die-casting part is finer, so that the strength of the product is greatly improved.

Owner:TAICANG HAIJIA VEHICLE FITTINGS

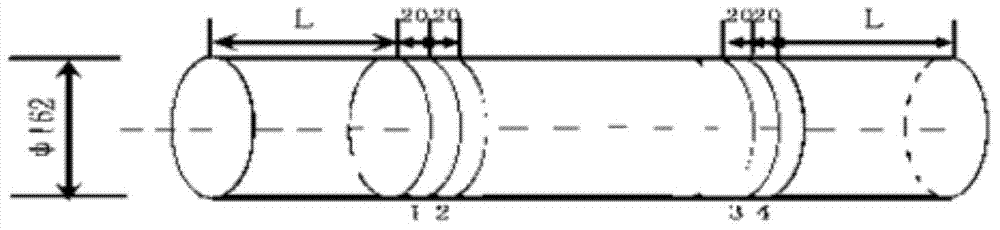

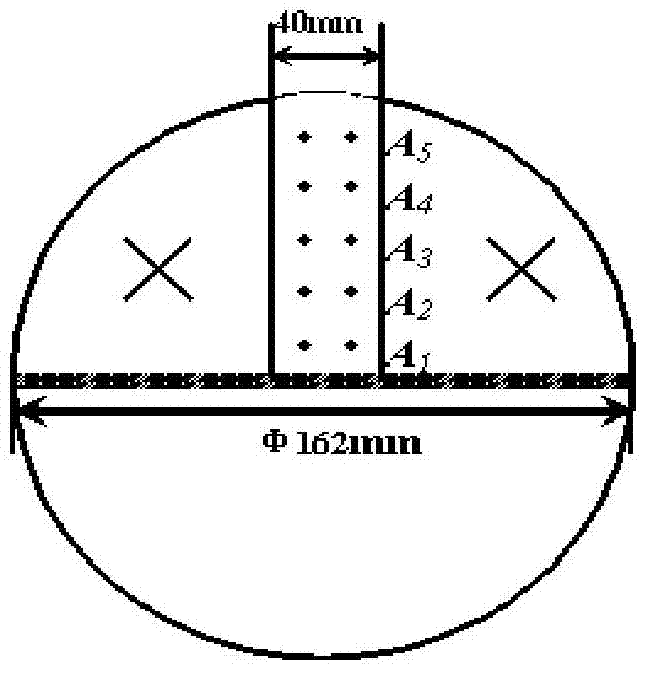

Processing technology of chromium-zirconium-copper contact wire for high-speed electrified railway

ActiveCN111799035AIncrease profitReduce energy consumptionApparatus for heat treatmentConductive materialElectric conductanceMachining process

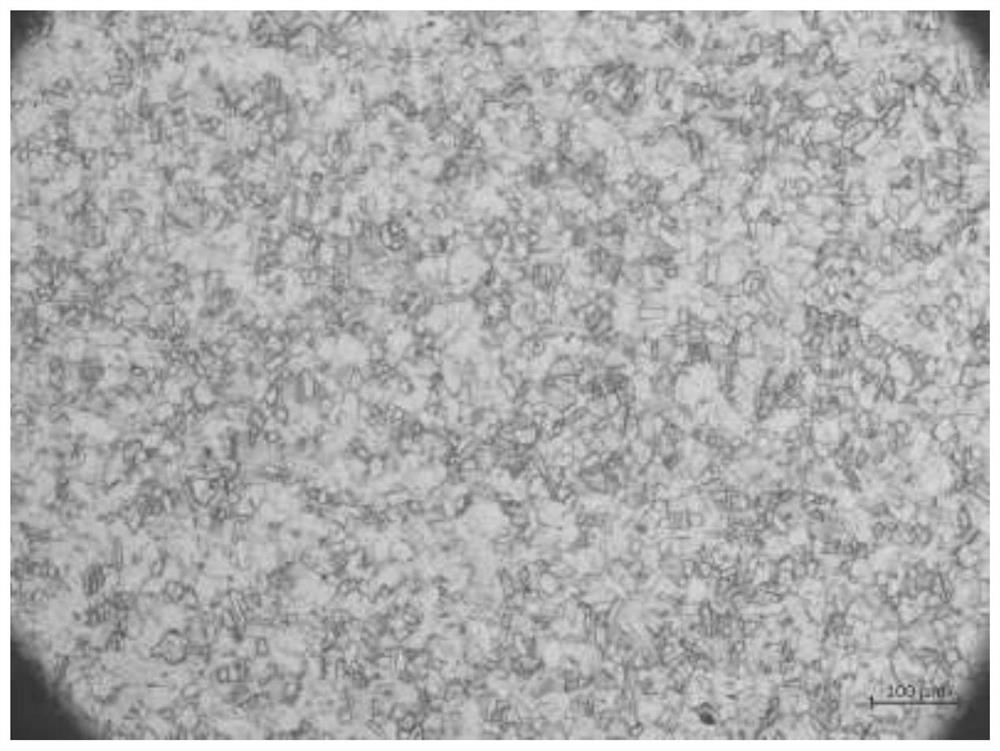

The invention discloses a processing technology of a chromium-zirconium-copper contact wire for a high-speed electrified railway. The method specifically comprises the following steps: upward continuous casting of a chromium-zirconium-copper rod blank, continuous extrusion, solid solution heat treatment, continuous rolling, aging heat treatment, peeling and drawing to obtain a finished product. According to the process, large-length and large-piece-weight industrial production of the chromium-zirconium-copper contact line of the high-speed railway is realized. The product performance is more excellent. The material structure is further refined and uniform through continuous extrusion and rolling. The average grain size is 10-50 [mu]m, the mechanical performance of the material is further improved, the tensile strength Rm reaches 600 Mpa or above, the conductivity is 80% IACS or above, the advantages of being stable and excellent in quality, high in material utilization rate and the like are achieved, a new way is provided for domestication of the chromium-zirconium-copper contact wire, and the method is suitable for wide popularization.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Heat resistant, high-strength and wear resistant ball with high hardness for ball grinder

InactiveCN104099532AEliminate internal stressReduce internal stressFurnace typesMetallic material coating processesWear resistantBall mill

The invention discloses a heat resistant, high-strength and wear resistant ball with high hardness for a ball grinder. The heat resistant, high-strength and wear resistant ball comprises the following components: C, Mn, Si, Ni, Cr, Mo, V, Nb, Ca, Zr, Cu, S, P, balance of Fe and inevitable impurities; the ultrasonic auxiliary laser-cladding technology is adopted to modify the surface of the wear resistant ball, wherein parameters of the ultrasonic auxiliary laser-cladding technology are as follows: a laser is a CO2 laser, the power is 1450-1650 W, the powder feeding rate is 0.4-0.5 g / min; the scanning speed is 3-5 mm / s, the layering thickness is 0.4-0.6 mm, the overlapping rate is 20-28%, the supersonic frequency is 17-19 kHz, the ultrasonic power supply current is 0.02-0.08 A and the applied cladding powder comprises 20-30 parts of WO3 powder, 30-50 parts of V2O5 powder, 50-80 parts of C powder, and 300-500 parts of Ni 60 self-melting powder. The wear resistant ball provided by the invention has excellent impact strength, hardness, heat resistance and wearing resistance.

Owner:宁国市宁武新材料科技有限公司

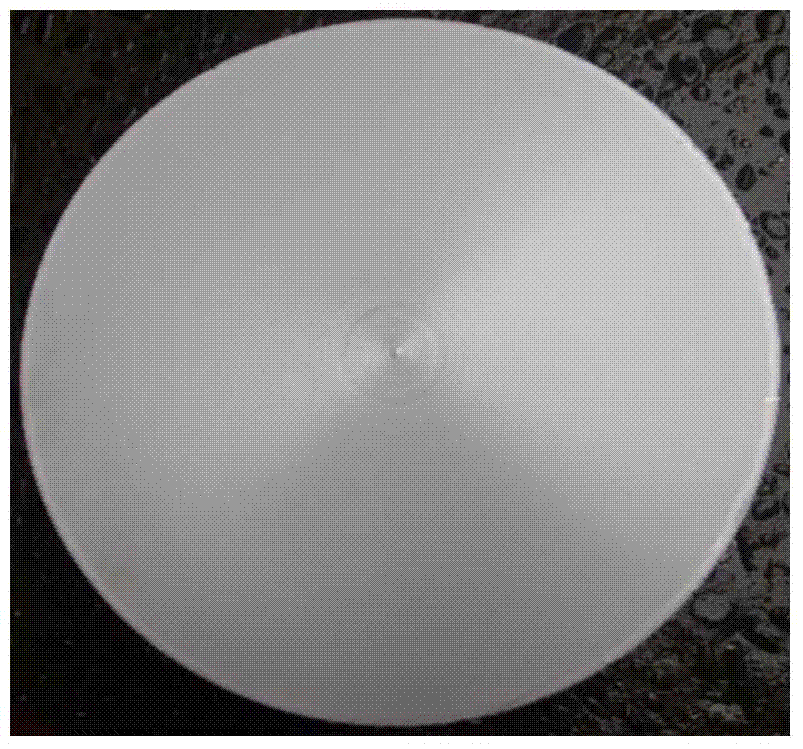

Aluminum alloy 62Sn spectral standard sample and preparation method thereof

InactiveCN103698181AIncrease productivityImprove product qualityPreparing sample for investigationColor/spectral properties measurementsSpectral analysisStandard samples

The invention discloses an aluminum alloy 62Sn spectral standard sample and a preparation method thereof. The aluminum alloy 62Sn spectral standard sample provided by the invention comprises Bi and Sn, so that production and development of the aluminum alloy 62Sn can be satisfied, i.e., the aluminum alloy 62Sn spectral standard sample can be applied to stokehold spectral analysis in the aluminum alloy 62Sn production and the spectral analysis of an aluminum alloy 62Sn product, and therefore, production efficiency and the product quality of the aluminum alloy 62Sn are improved.

Owner:SOUTHWEST ALUMINUM GRP

Preparation process of densely-arranged columnar crystal ceramic coating based on laser remelting technology

InactiveCN103993313AFast heatingReduce thermal stressMetallic material coating processesThermal barrier coatingHigh frequency

The invention discloses a preparation process of a densely-arranged columnar crystal ceramic coating based on a laser remelting technology. The preparation process comprises the steps of improving the remelting quality by using high frequency induction heating and ultrasonic vibration assisted processes while carrying out laser remelting on a nickel-based high-temperature alloy piece with a thermal barrier coating by using laser, wherein the thermal stress generated in a remelting process can be reduced and a large number of cracks generated when a ceramic layer is deeply remolten by using laser can be avoided through high frequency induction heating in the remelting process; and refining grains of the ceramic layer through ultrasonic vibration to obtain a densely-arranged columnar crystal. Due to the introduction of the two high frequency induction heating and ultrasonic vibration assisted processes, the ceramic coating with a densely-arranged columnar crystal structure can be obtained, the laser remolten ceramic coating is fewer in cracks as well as uniform and dense in columnar crystal tissues, and the width of the densely-arranged columnar crystal is 1-5mu m.

Owner:XI AN JIAOTONG UNIV

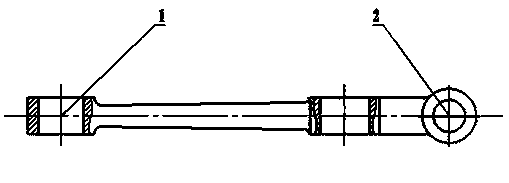

Precise forming method for automobile engine hollow valve blank with core bar

ActiveCN104924028AIncrease productivityGood shape consistencyMachines/enginesLift valveSpherical shapedGrain structure

The invention belongs to the technical field of metal plastic forming, and particularly provides a method for transverse rolling forming of an engine hollow valve blank. The transverse rolling method is used for symmetrically machining the hollow blank of a hollow valve; a conical table and a spherical table are formed on the machined hollow blank, and then a disc portion of the hollow valve is formed through die forging. Compared with the traditional solid valve drilling and backward extrusion process, the transverse rolling process is used for producing the automobile engine hollow valve blank, and the method has the advantages that production efficiency is high, and 6-12 blanks can be manufactured every minute through one machine; the material utilization rate is improved; the overall streamline distribution in the valve is reasonable, and the tissue is fine; all parts of the blank deform, a refined and even grain structure can be obtained, and the overall mechanical property of the valve can be conveniently improved.

Owner:UNIV OF SCI & TECH BEIJING +1

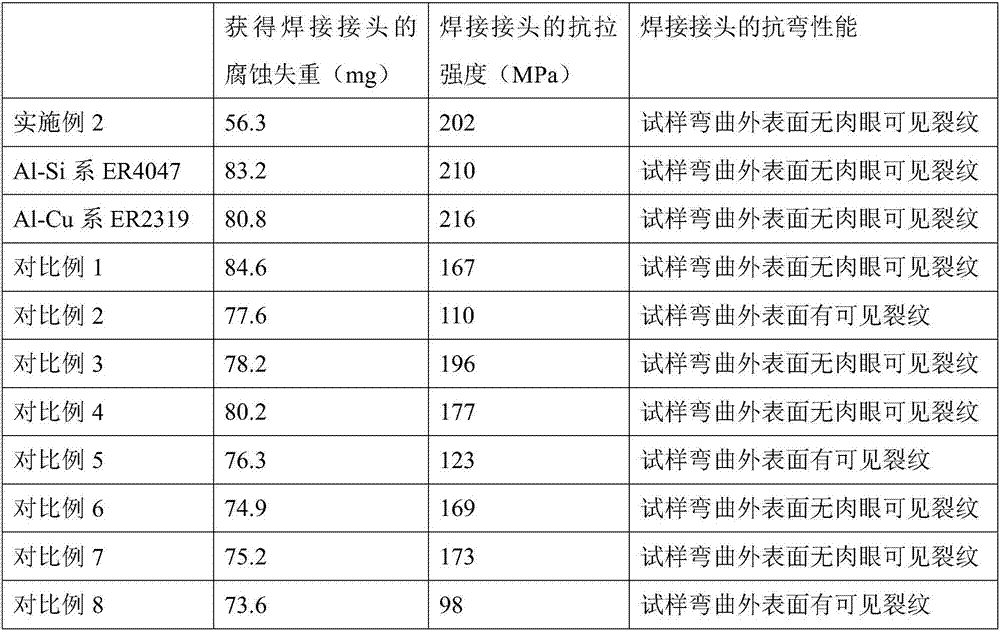

Aluminum-copper alloy grounding material welding wire and preparation method thereof

ActiveCN106862796AReduce compositional differencesGood resistance to soil corrosionWelding/cutting media/materialsSoldering mediaPotential differenceRare earth

The invention discloses an aluminum-copper alloy grounding material welding wire and a preparation method thereof. The aluminum-copper alloy grounding material welding wire comprises, by mass, 1%-3% of silicon, 1%-3% of copper, 0-0.3% of iron, 0.001%-0.05% of zirconium, 0.001%-0.5% of rare earth, and the balance aluminum. The aluminum-copper alloy grounding material welding wire can achieve welding of an aluminum-copper alloy grounding material, the structure of a weld zone is fine, the components are similar to those of parent metal, the potential difference is small, and the soil corrosion resistance is good.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

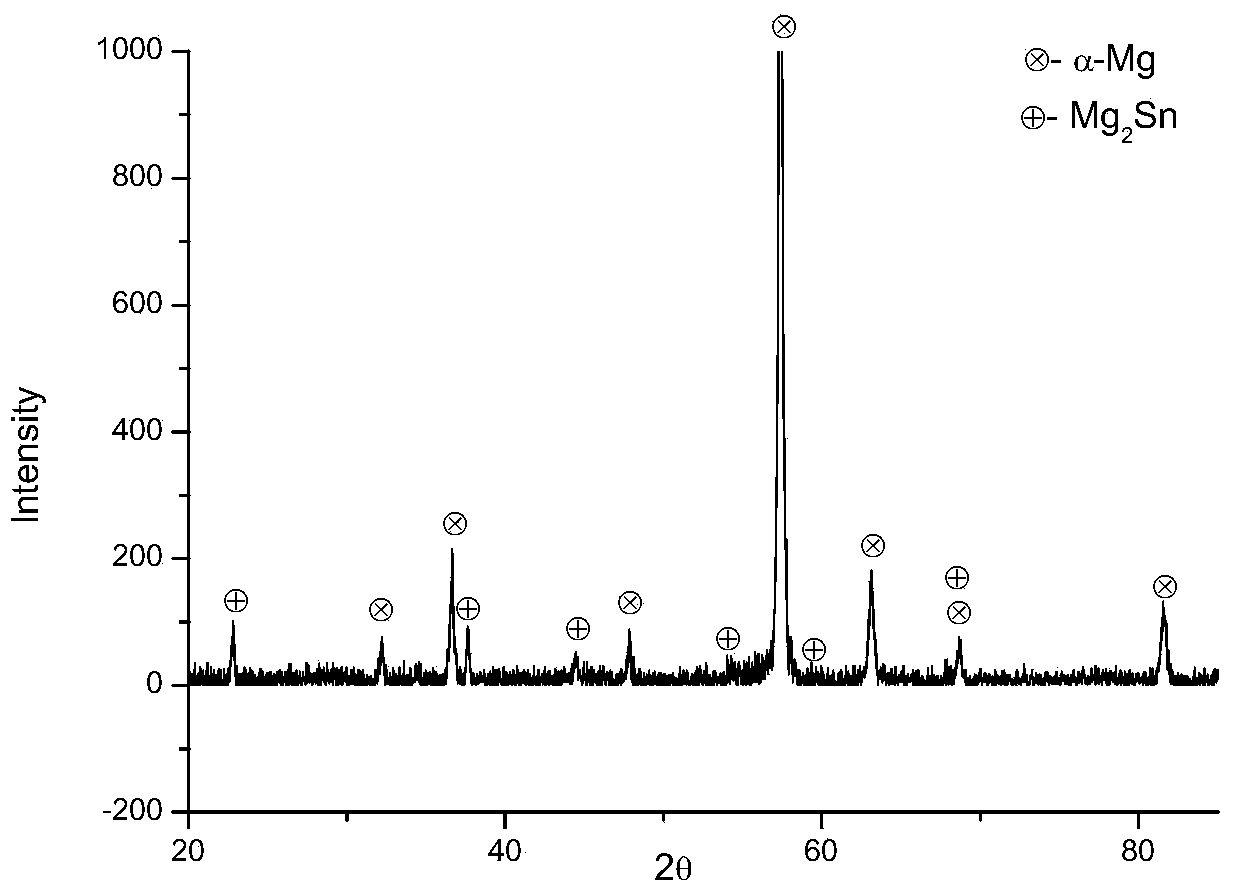

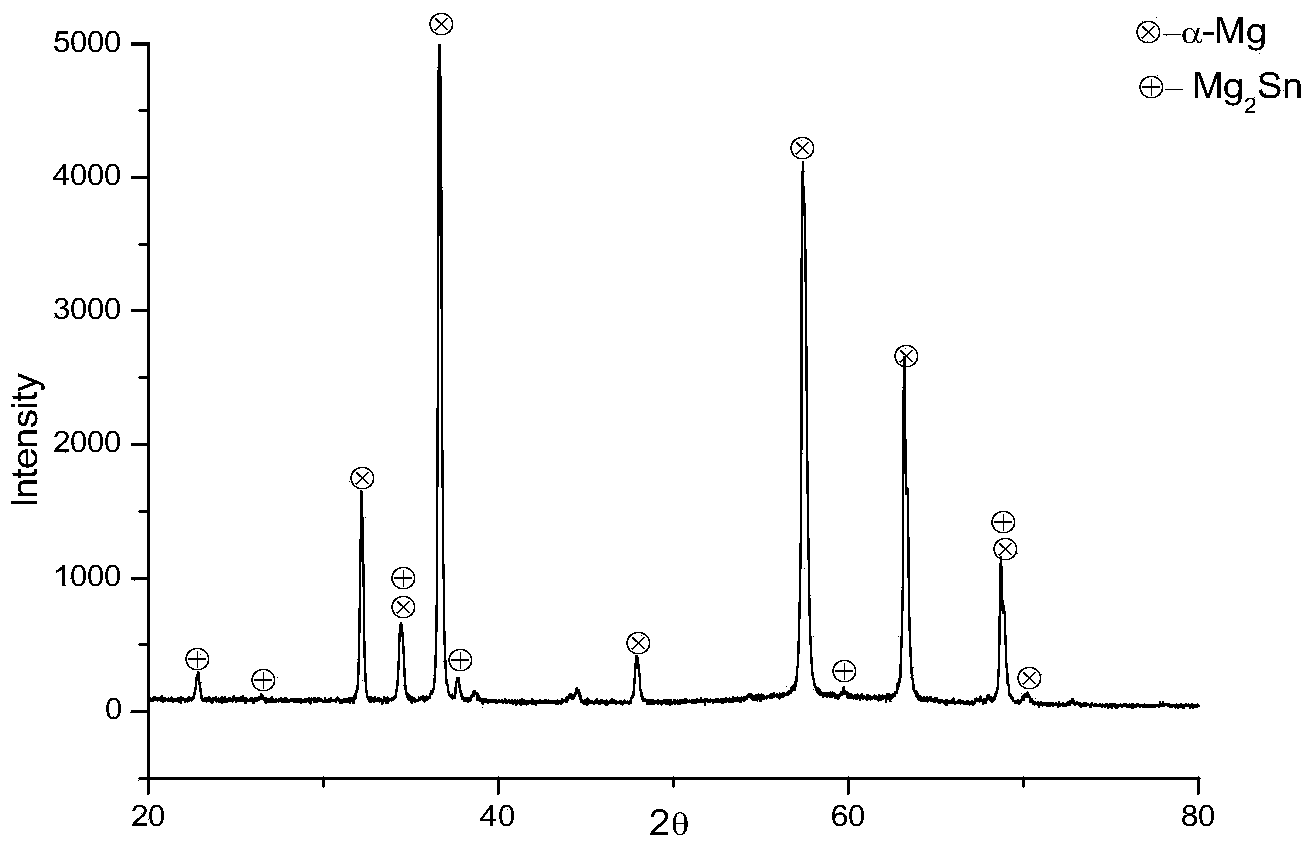

Magnesium-stannum-zinc-aluminum wrought magnesium alloy suitable for being extruded

The invention relates to a magnesium-stannum-zinc-aluminum wrought magnesium alloy suitable for being extruded. The wrought magnesium alloy comprises the following components in percentage by mass: 3-5% of Sn, 1% of Al, 0.5-2.0% of Zn, less than or equal to 0.10% of inevitable impurities and the balance of Mg. According to the alloy provided by the invention, the Mg-Sn magnesium alloy is subjected to modification treatment by adopting Zn and Al, so that the grains can be refined and the alloy tissue can be improved. Meanwhile, the tensile strength and the ductility of the alloy are improved to facilitate processing and moulding in the later period. The wrought magnesium alloy provided by the invention is simple in preparation method, relatively low in equipment cost and easy to implement.

Owner:CHONGQING UNIV

Rare-earth multi-element alloy coating and hot-dip galvanizing method thereof

The invention discloses a rare-earth multi-element alloy coating and a hot-dip galvanizing method thereof. The rare-earth multi-element alloy coating comprises the following main components: rare earth, aluminum, nickel, magnesium and zinc. The hot-dip galvanizing method comprises the following steps: (1) mix-melting intermediate alloys, namely Al-RE-Mg and Zn-Ni; (2) mix-melting a multi-element rare-earth alloy; (3) dredging slag; (4) casting; and (5) applying. The rare-earth multi-element alloy coating and the hot-dip galvanizing method thereof have the advantages that: firstly, difficulty of directly adding multiple elements with different melting points into a zinc liquid to melt and the impossibility problem of adding high-melting-point elemental metal elements into the zinc liquid to melt are solved; secondly, the multiple elements can be completely and quickly molten and dispersed, so that the hot-dop galvanizing method is easy to operate and control in a practical production process; thirdly, the dilution capability, the dispersive capacity, the mobility and the uniformity of the zinc liquid are strengthened, so that the zinc consumption is reduced by 5%-15%, the cost is reduced and the benefits are increased; and fourthly, the corrosion resistance of the rare-earth multi-element alloy coating is doubled in comparison with that of a conventional hot dip galvanized coating.

Owner:江苏中远稀土新材料有限公司

Wheat-flavor self-rising flour and production technology thereof

The invention discloses wheat-flavor self-rising flour which comprises the following raw materials, by weight, 98.2-98.5% of wheat flour, 1.2-1.5% of dried yeast and 0-0.6% of a food leavening agent. The wheat flour is processed by using flour with the following parameters: 28-30% of gluten; unit weight is 750-850; unsound grain is less than or equal to 5%; water absorption is 55-60; stabilization time is 6-8 min; softening degree is less than 60; and extensibility is greater than 150. The invention also discloses a production technology of the wheat-flavor self-rising flour. The production technology comprises flour blending process. The method comprises the following steps: firstly, flour, yeast and the food leavening agent are added in batches into a mixer; and a circle-vibrating sieve with larger sieve pore than a minor sifter is used to sieve the mixture after mixing is finished. By selecting specific wheat-processed flour, steamed buns have rich wheat flavor, bright color, fine texture and fine and smooth mouthfeel. As the circle-vibrating sieve with larger sieve pore is used to replace a traditional minor sifter during the flour blending process, blending uniformity of the self-rising flour is greatly raised.

Owner:COFCO CHENGDU GRAIN & OIL IND

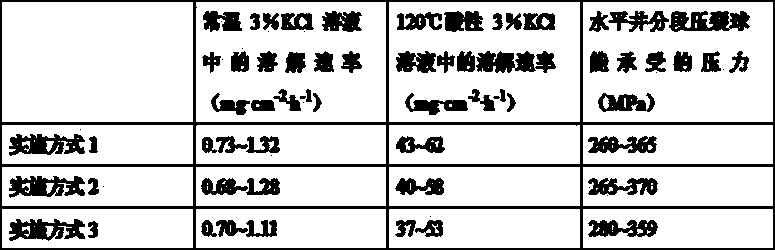

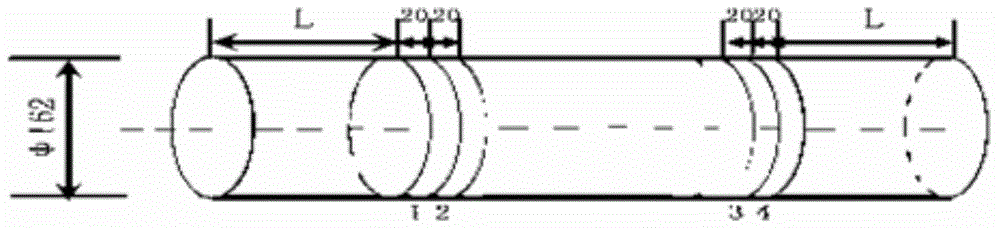

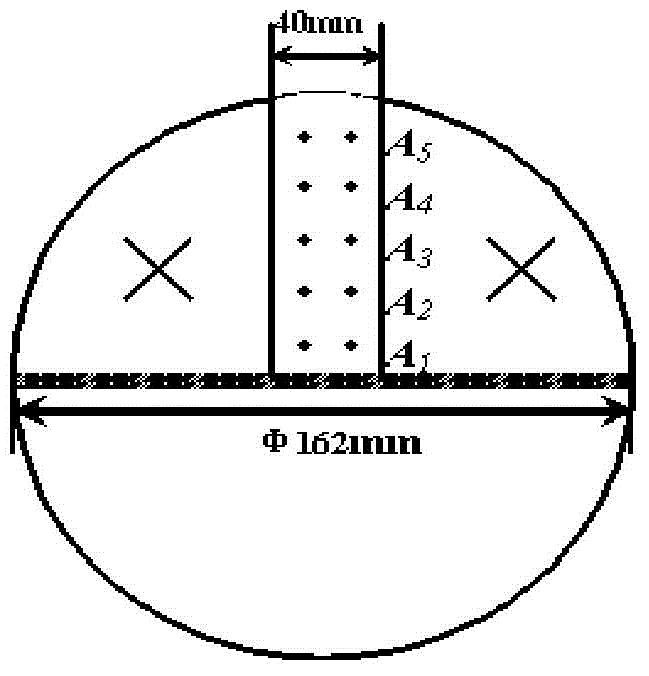

Magnesium alloy for staged fracturing of petroleum exploitation and preparation method of magnesium alloy

The invention relates to the field of metal smelting, and discloses magnesium alloy for staged fracturing of petroleum exploitation and a preparation method of magnesium alloy. The soluble magnesium-based alloy is prepared from the following components in percentage by weight: 5%-10% of Gd, 3%-7% of Al, 0.5%-4% of Zn, 1%-3% of Y, 0.1%-0.5% of Ca and the balance of Mg. Compared with the prior art,fracturing balls prepared from the magnesium-based alloy which is prepared by the method have high toughness, good plasticity and high pressure bearing capacity, and meet the requirement of dissolution rate in an electrolyte solution; and thus, the problems that the fracturing balls made of metal or nonmetal cannot be dissolved and are less likely to flow back in the prior art are solved.

Owner:江苏奇纳新材料科技有限公司 +1

Preparation method of 6082 aluminum alloy spectral standard sample

InactiveCN104458379AUniform chemical compositionImprove stabilityPreparing sample for investigationStandard samplesMaterials science

The invention belongs to the field of aluminum alloys, and particularly relates to a preparation method of a 6082 aluminum alloy spectral standard sample. The preparation method provided by the invention comprises the following steps: a) carrying out melt-blending of an aluminum source, a silicon source, an iron source, a copper source, a manganese source, a magnesium source, a chrome source, a nickel source, a zinc source and a titanium source, so as to obtain aluminum alloy melt, wherein the aluminum alloy melt comprises the following raw materials in percentage by weight: 1.0wt%-1.3wt% of Si, 0.2wt%-0.5wt% of Fe, 0.04wt%-0.05wt% of Cu, 0.7wt%-1.0wt%of Mn, 1.0wt%-1.2wt% of Mg, 0.1wt%-0.25wt% of Cr, 0.05wt-0.06wt% of Ni, 0.1wt%-0.2wt% of Zn, 0.04wt%-0.06wt% of Ti and the balance of Al; and b) sequentially carrying out casting, homogenizing heat treatment and extrusion on the aluminum alloy melt, so as to obtain the 6082 aluminum alloy spectral standard sample. A to-be-detected 6082 aluminum alloy sample is subjected to component analysis by adopting a standard spectral line intensity curve of atomic emission spectroscopy corrected by the 6082 aluminum alloy standard sample prepared by the method, and the result accords with the result of component analysis based on a chemical analysis method.

Owner:SOUTHWEST ALUMINUM GRP

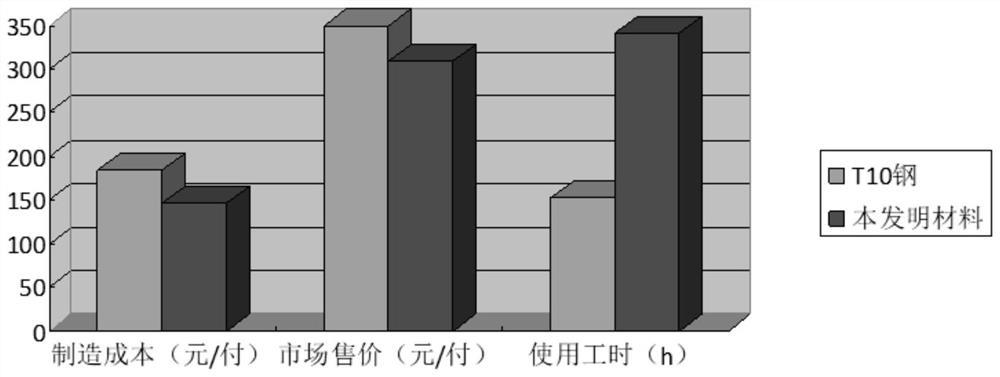

Self-hardening iron-based material for shear blade and preparation method of shear blade

InactiveCN112210715AImprove impact toughnessHigh impact strengthFurnace typesHeat treatment furnacesCarbon layerWear resistance

The invention discloses a self-hardening iron-based material for a shear blade. The self-hardening iron-based material is prepared from the following raw material components in percentage by mass: 3.0%-4.0% of C, 2.0%-3.5% of Si, 0.1%-0.6% of Mn, not more than 0.06% of P, not more than 0.02% of S, not more than 0.05% of Re, not more than 0.04% of Mg and the balance of Fe. The self-hardening iron-based material solves the problem that the prior carbon steel and alloy steel blade loses wear resistance and fatigue resistance due to movement or loss of the carbon layer and the hardening layer. Thepreparation method of the shear blade is simple in process, the manufacturing and processing cost of the material is greatly reduced, and the preparation method has good practical value.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com